PC/PMMA alloy material for LED lampshade and preparation method of PC/PMMA alloy material

A technology for LED lampshades and alloy materials, applied in the field of alloy materials, can solve the problems of complex processing procedures, uncontrollable processing processes, production costs, low toughness, and limited application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a kind of preparation method of PC / PMMA alloy material for LED lampshade, comprising the following steps:

[0051]S1: Mix transparent PC, transparent PMMA, MBS, SMA and silicone light diffusing agent through a high mixing pot at a mixing temperature lower than 50°C for 5-8 minutes. If the mixing time is too low, the dispersion and mixing will be uneven. If the time is too long or the mixing temperature is too high, defects such as melting and sticking of low-melting point additives will be caused; the above components are the main ingredients, and their additions are all higher than 1%, and they are all in the state of solid particles. By first mixing the main ingredients , to make it easier to mix the materials evenly, and judge whether the mixing is uniform by visually observing the degree of dispersion of the materials. When the various component materials are fully dispersed among each other, the mixing is complete; then add antiox...

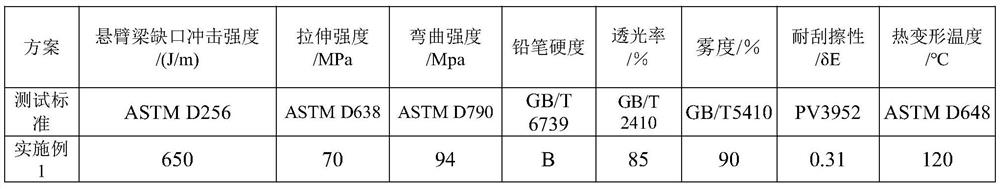

Embodiment 1

[0056] A PC / PMMA alloy material for an LED lampshade, consisting of the following materials in parts by mass:

[0057] PC (refractive index is 1.491): 74 parts;

[0058] PMMA (refractive index 1.495): 9 parts;

[0059] MBS (particle size 220nm-320nm): 6 parts;

[0060] SMA: 6 copies;

[0061] Silicone light diffusing agent: 3 parts;

[0062] Antioxidant: 0.2 parts;

[0063] Light stabilizer: 0.2 parts;

[0064] Lubricant: 0.5 parts;

[0065] UV absorber: 0.2 parts.

[0066] The embodiment of the present invention provides the preparation method of the PC / PMMA alloy material for the LED lampshade, comprising the following steps:

[0067] S1: Mix transparent PC, transparent PMMA, MBS, SMA and silicone light diffusing agent through a high-mixing pot at room temperature for 5-8 minutes. After observing that the mixture is uniform, add antioxidants, light stabilizers, UV absorbers and lubricants again well mixed;

[0068] S2: The materials mixed in step S1 are blended and ...

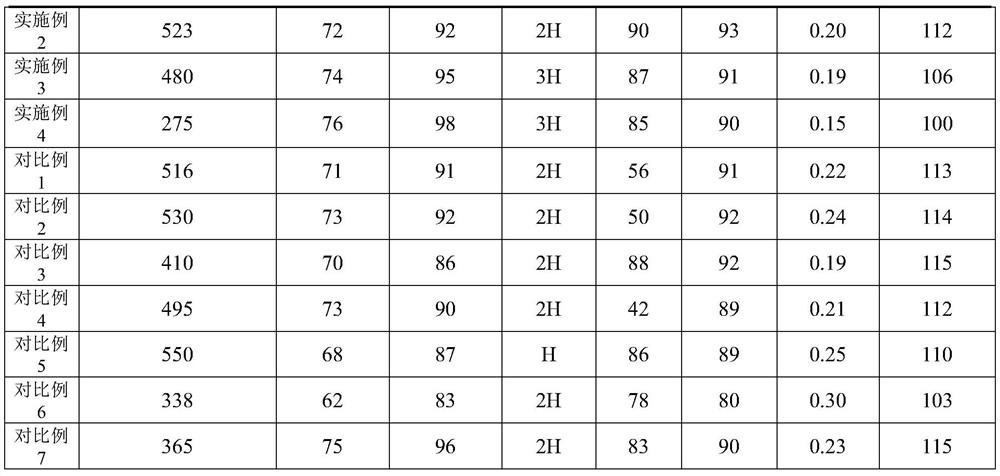

Embodiment 2

[0071] The preparation method and steps are consistent with Example 1, except that:

[0072] A PC / PMMA alloy material for an LED lampshade, consisting of the following materials in parts by mass:

[0073] PC (refractive index is 1.496): 68 parts;

[0074] PMMA (refractive index 1.498): 17 parts;

[0075] MBS (particle size 220nm-320nm): 6 parts;

[0076] SMA: 6 copies;

[0077] Silicone light diffusing agent: 3 parts;

[0078] Antioxidant: 0.2 parts;

[0079] Light stabilizer: 0.2 parts;

[0080] Lubricant: 0.5 parts;

[0081] UV absorber: 0.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com