Hot-working die steel plate and preparation method thereof

A hot work die and steel plate technology, applied in the field of hot work die steel and its preparation, can solve the problems of difficult expansion of production scale, difficult control, poor quality of steel plate core, etc., and achieve good comprehensive mechanical properties, strong crack sensitivity, Good production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

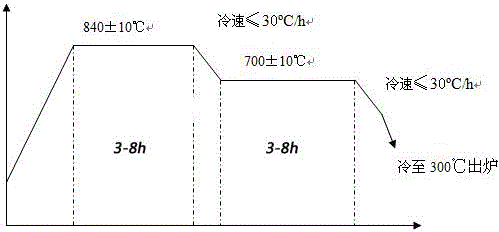

[0035] A production process of hot work die steel plate, the production process adopts appropriate composition design, belongs to medium carbon high alloy steel, the chemical composition of the steel plate is C: 0.45-0.55, Si: 0.20-0.80, Mn: 0.50 ~0.80, Cr: 3.00~3.50, Mo: 1.30~1.80, V: 0.05~0.20, Nb: 0.02~0.10, Als: 0.01~0.04, P≤0.015, S≤0.005, and the rest are Fe and unavoidable impurities.

[0036] Specific steps are as follows:

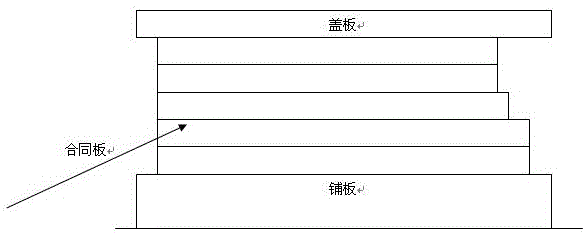

[0037] 1) Smelting: Select high-quality scrap steel for electric furnace smelting, adopt lime spreading operation on the bottom of the furnace, slagging operation in advance, foam slag smelting in front of the furnace, and operation of leaving steel and slag to obtain low-P molten steel; molten steel is subjected to LF deoxidation operation, strictly controlled Refining time, and wire feeding operation; VD vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com