Patents

Literature

1006results about "Casting cleaning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

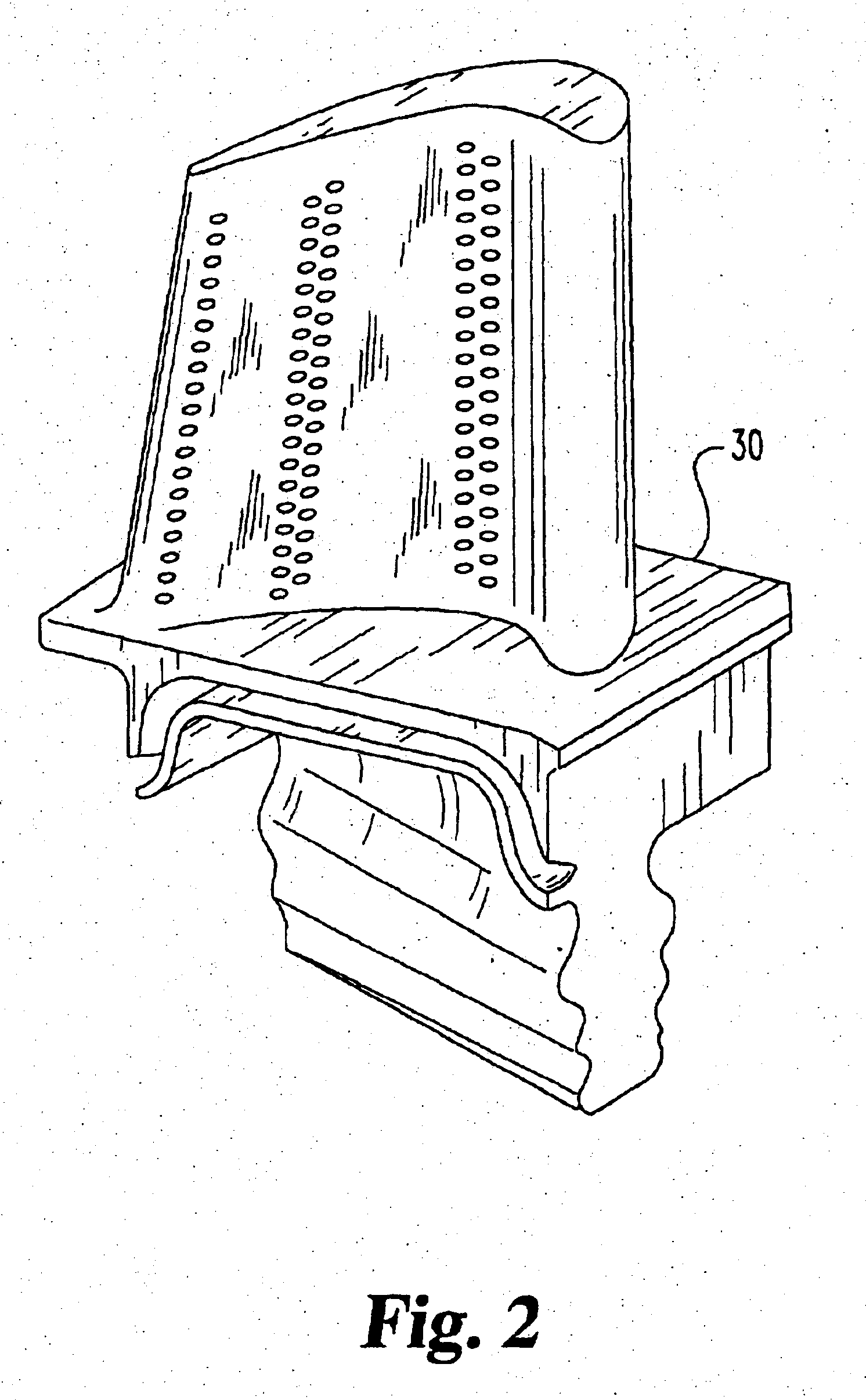

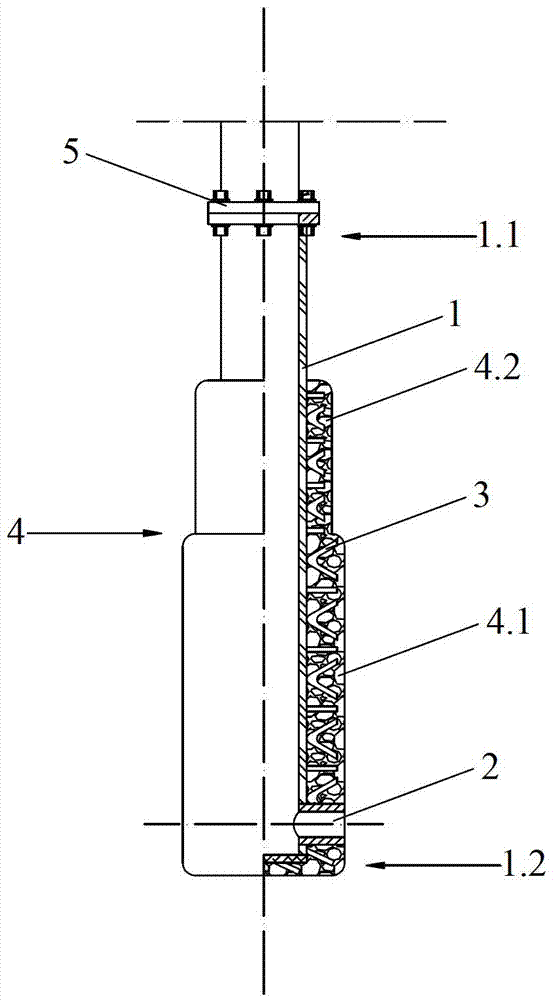

Bonded particle filters

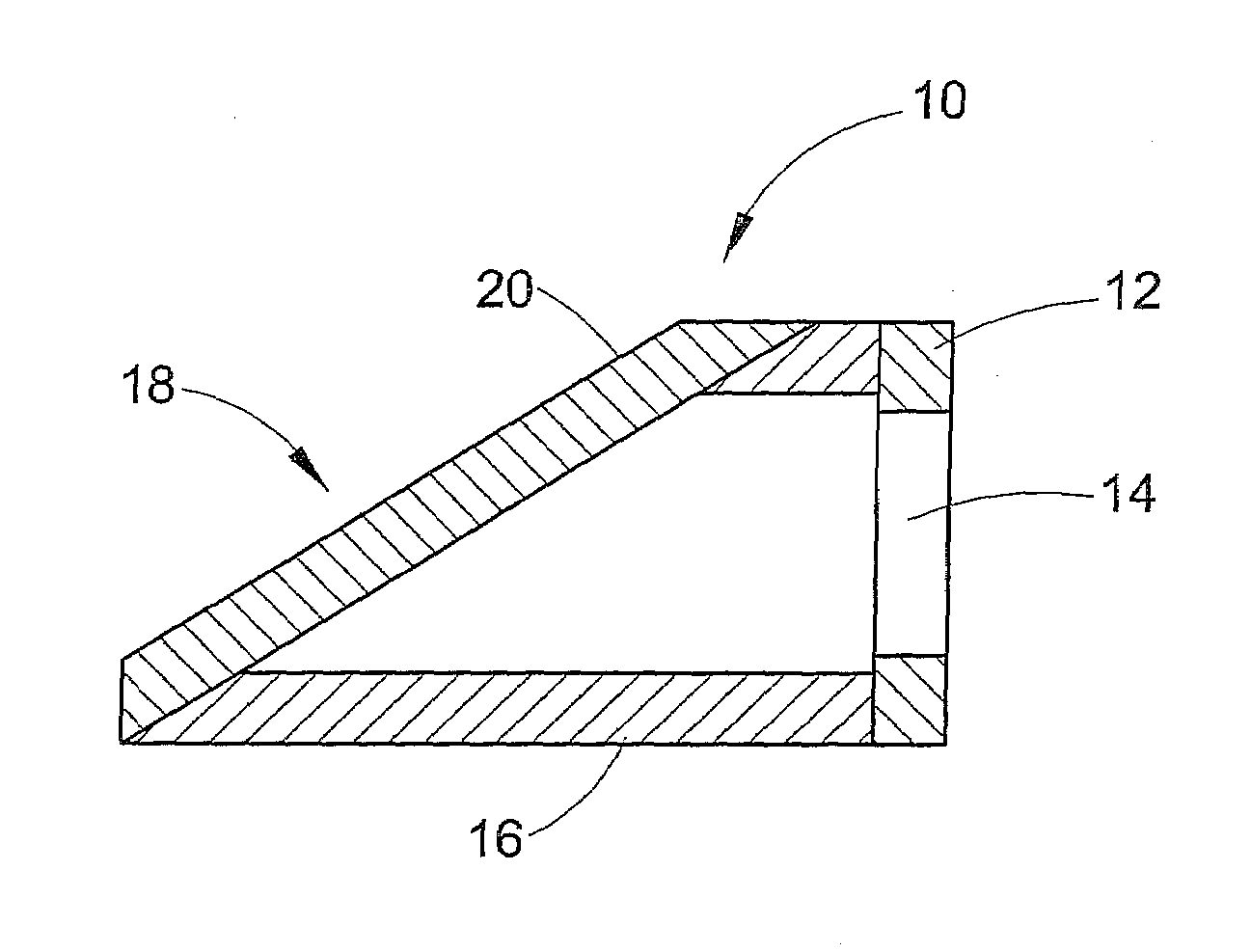

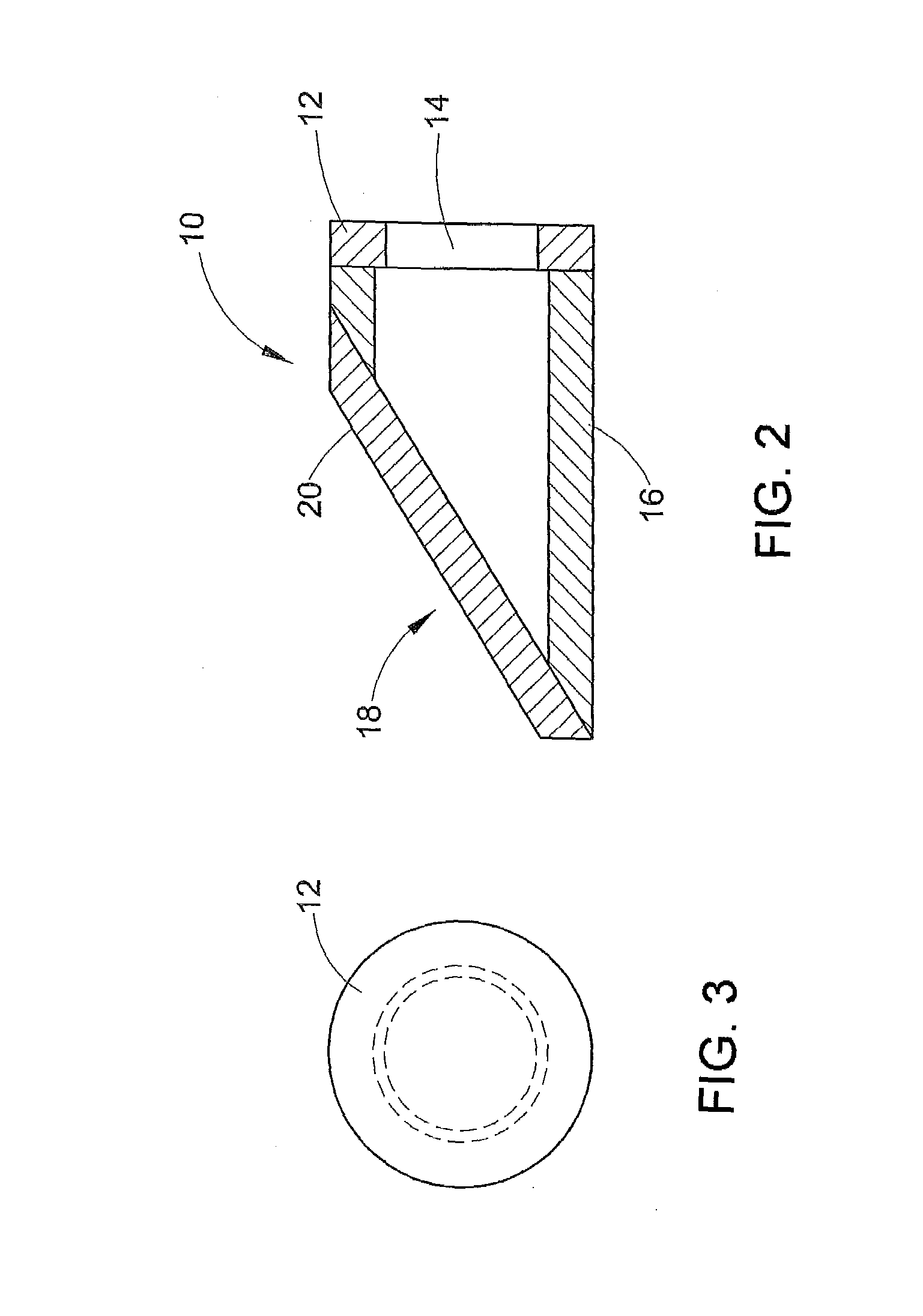

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

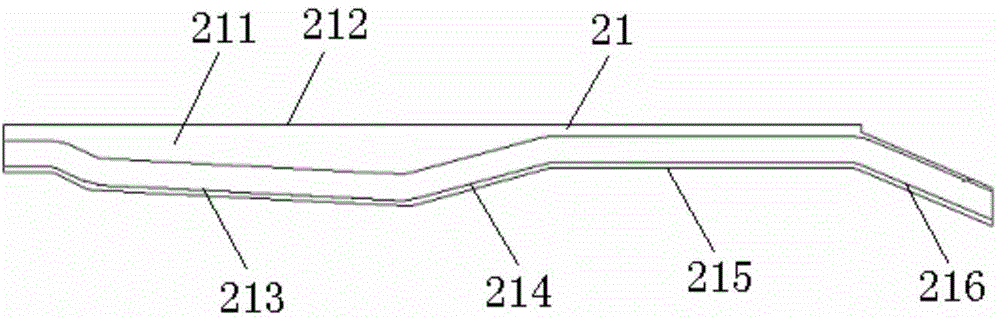

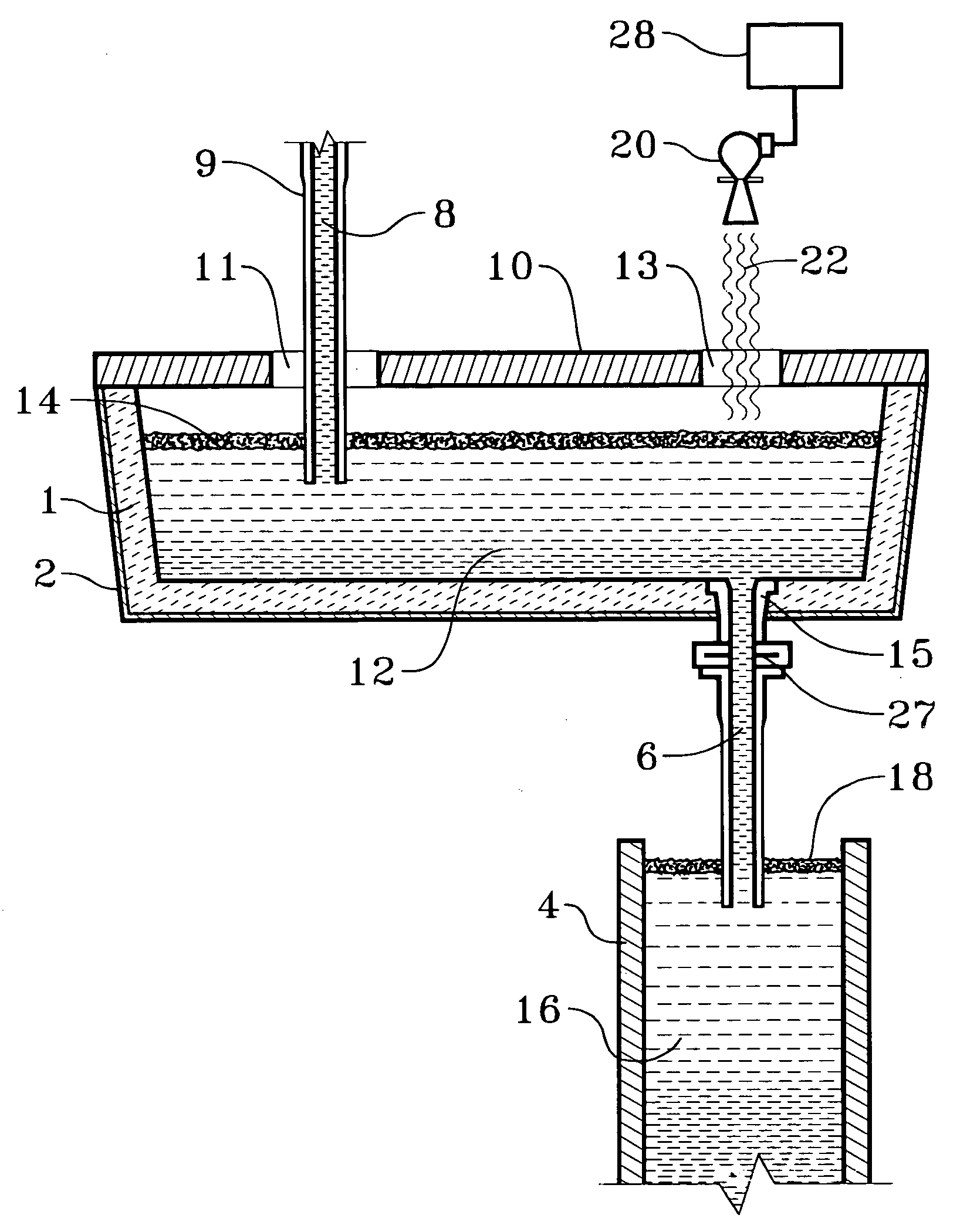

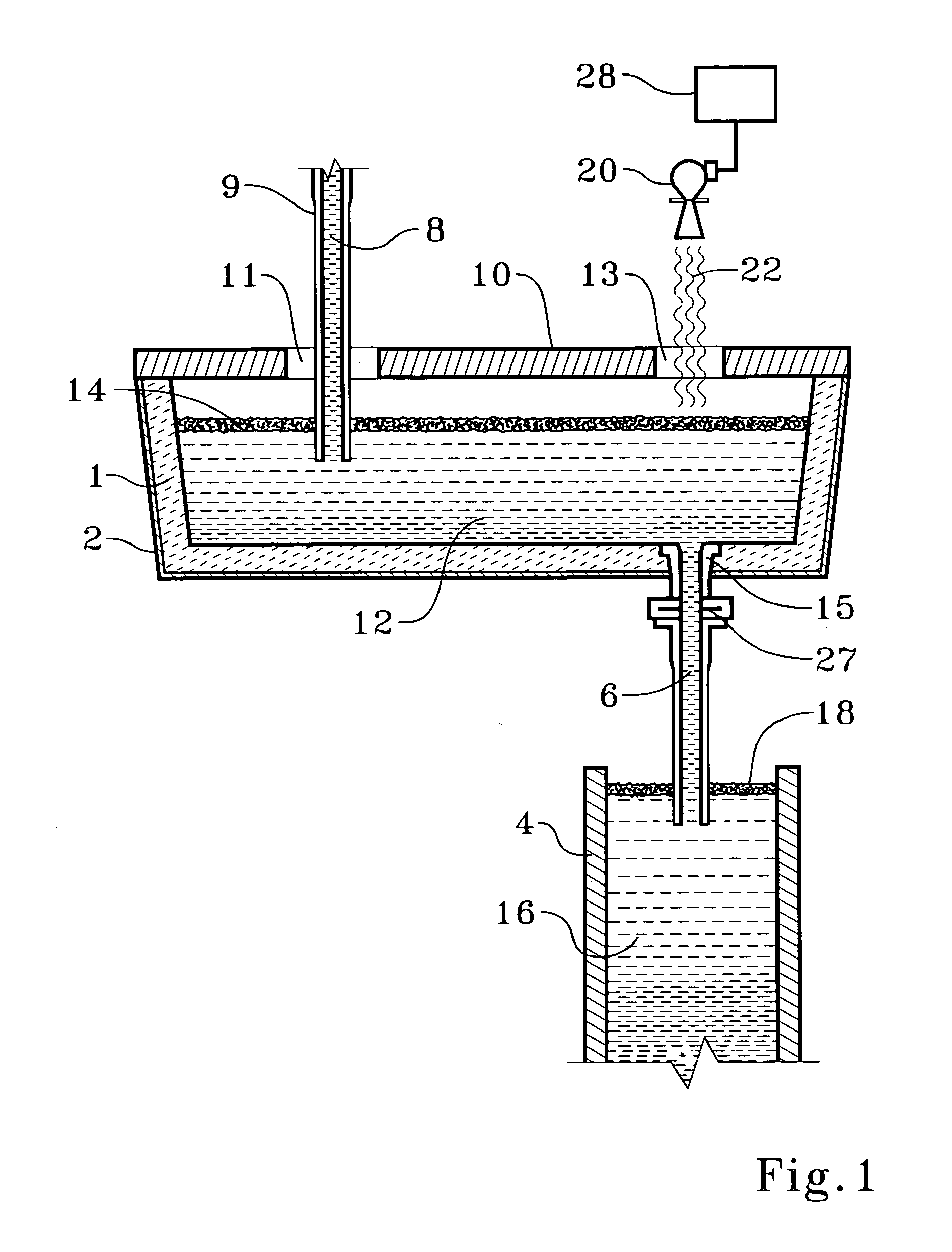

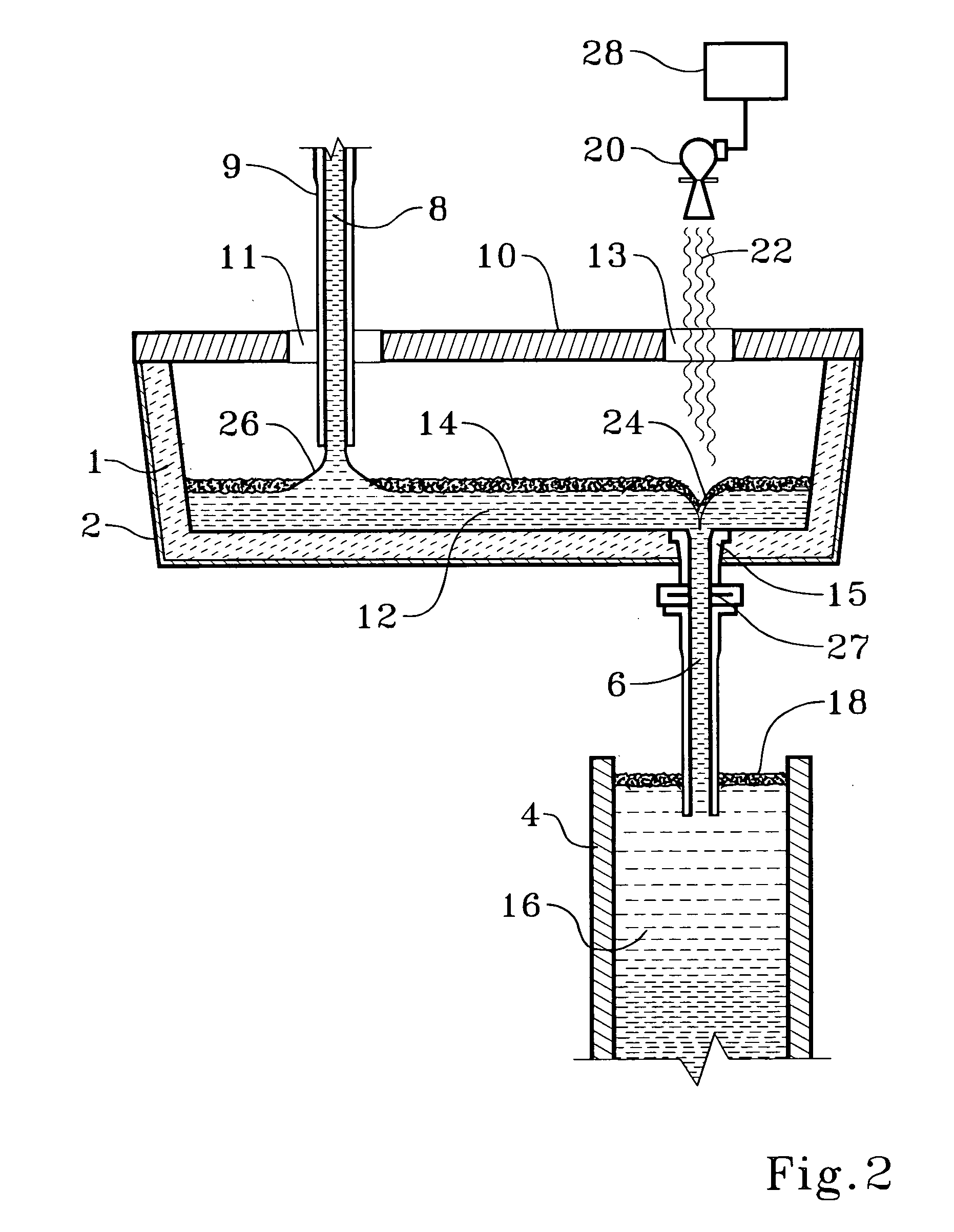

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

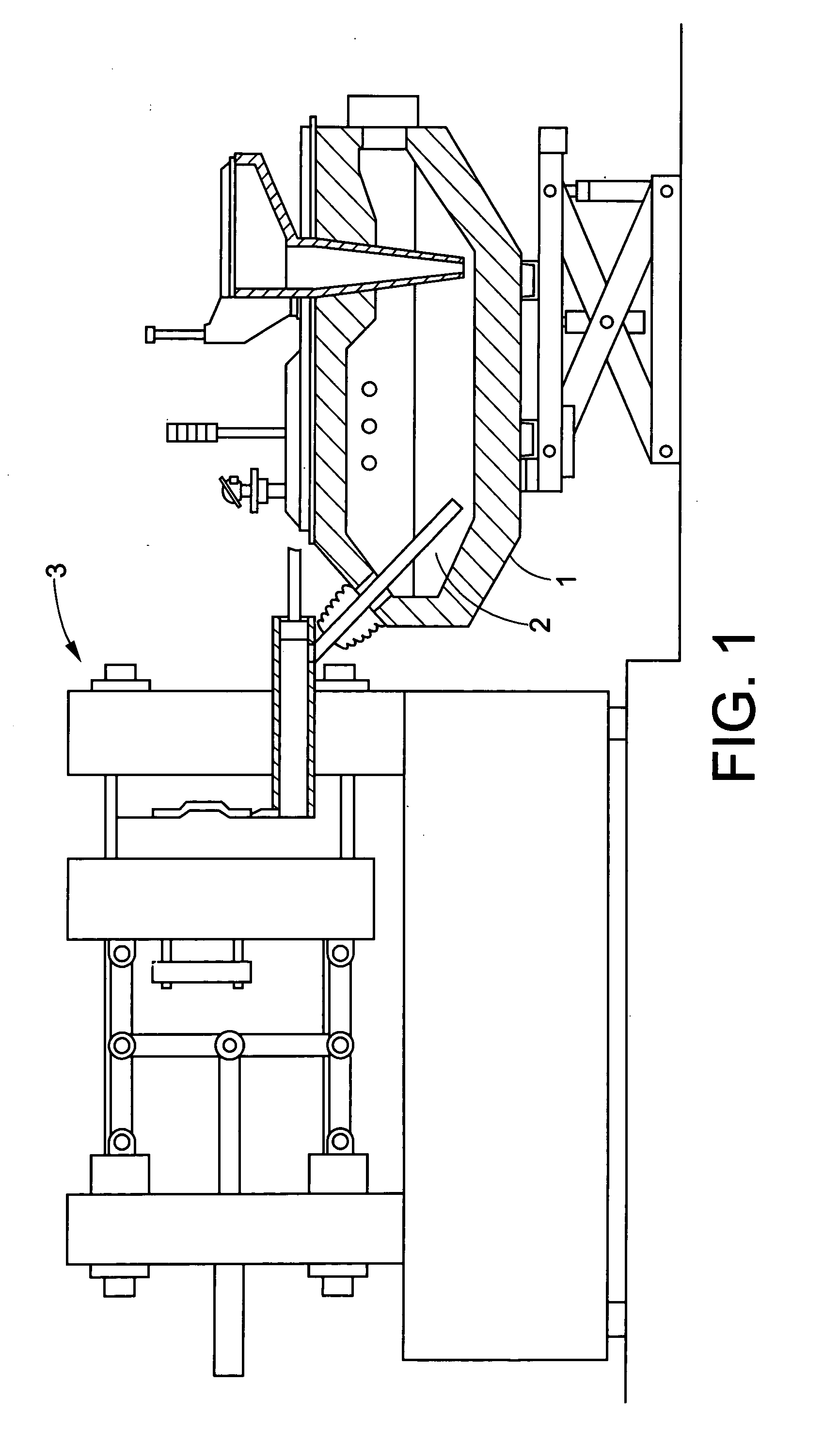

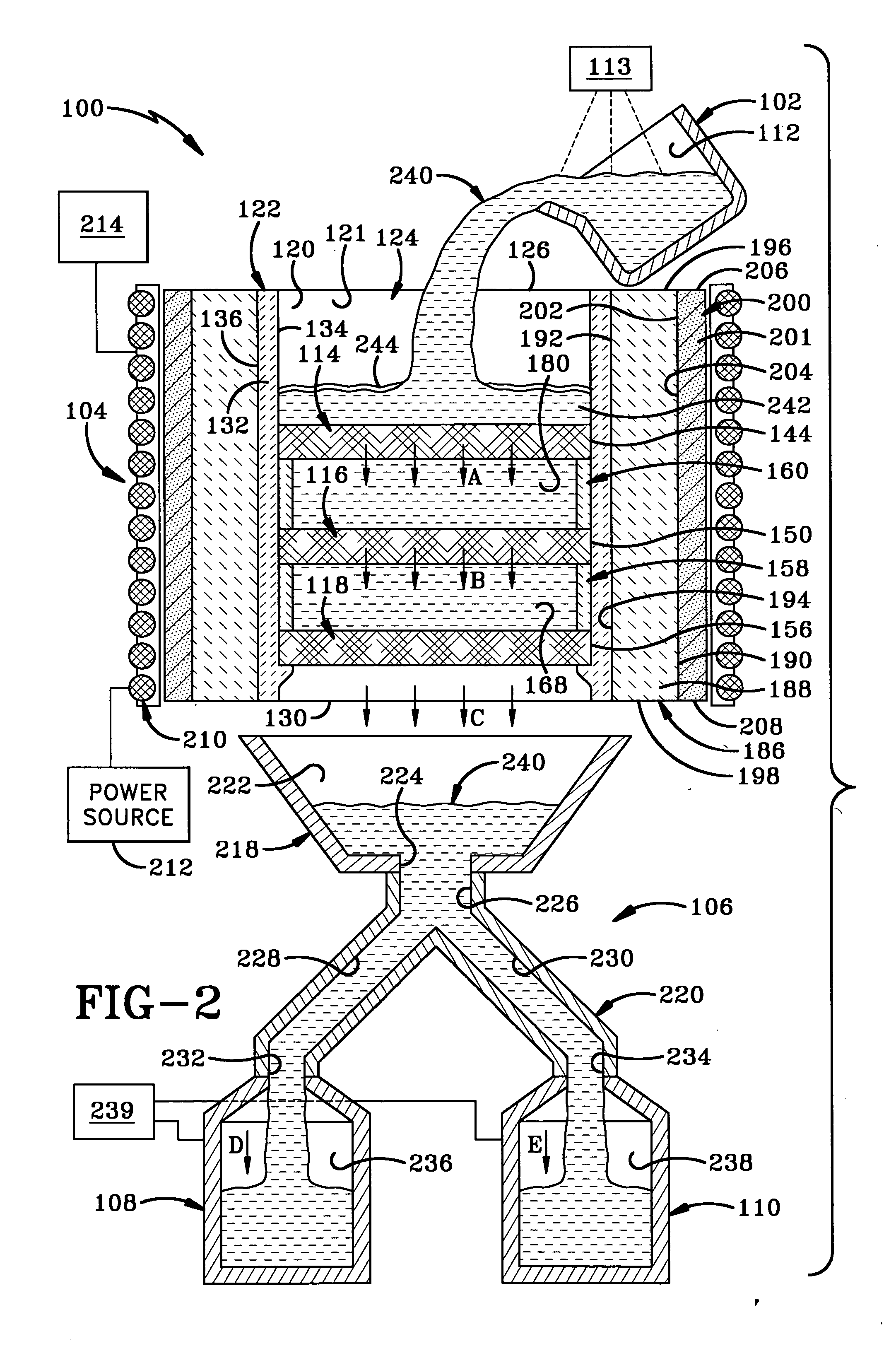

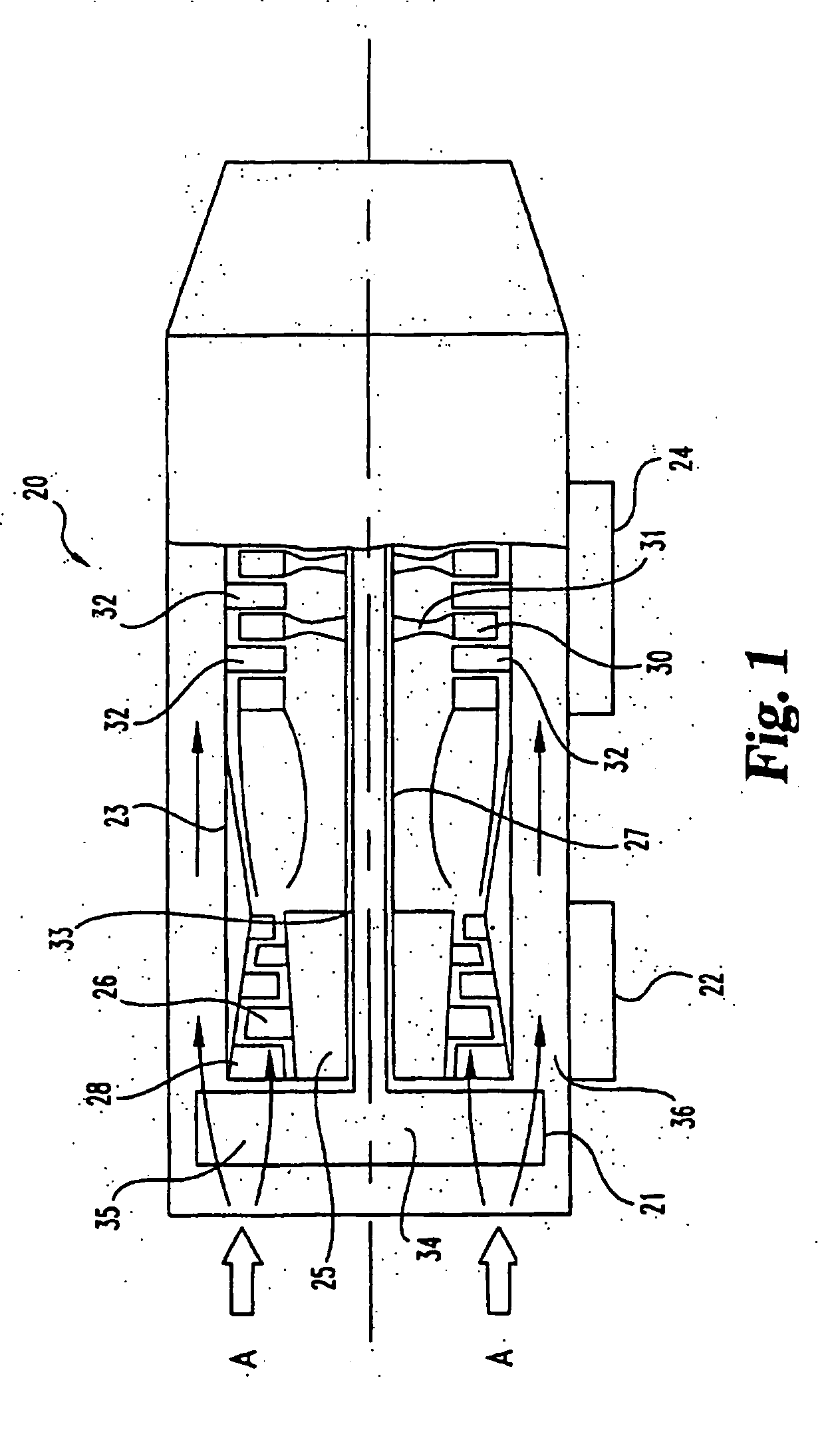

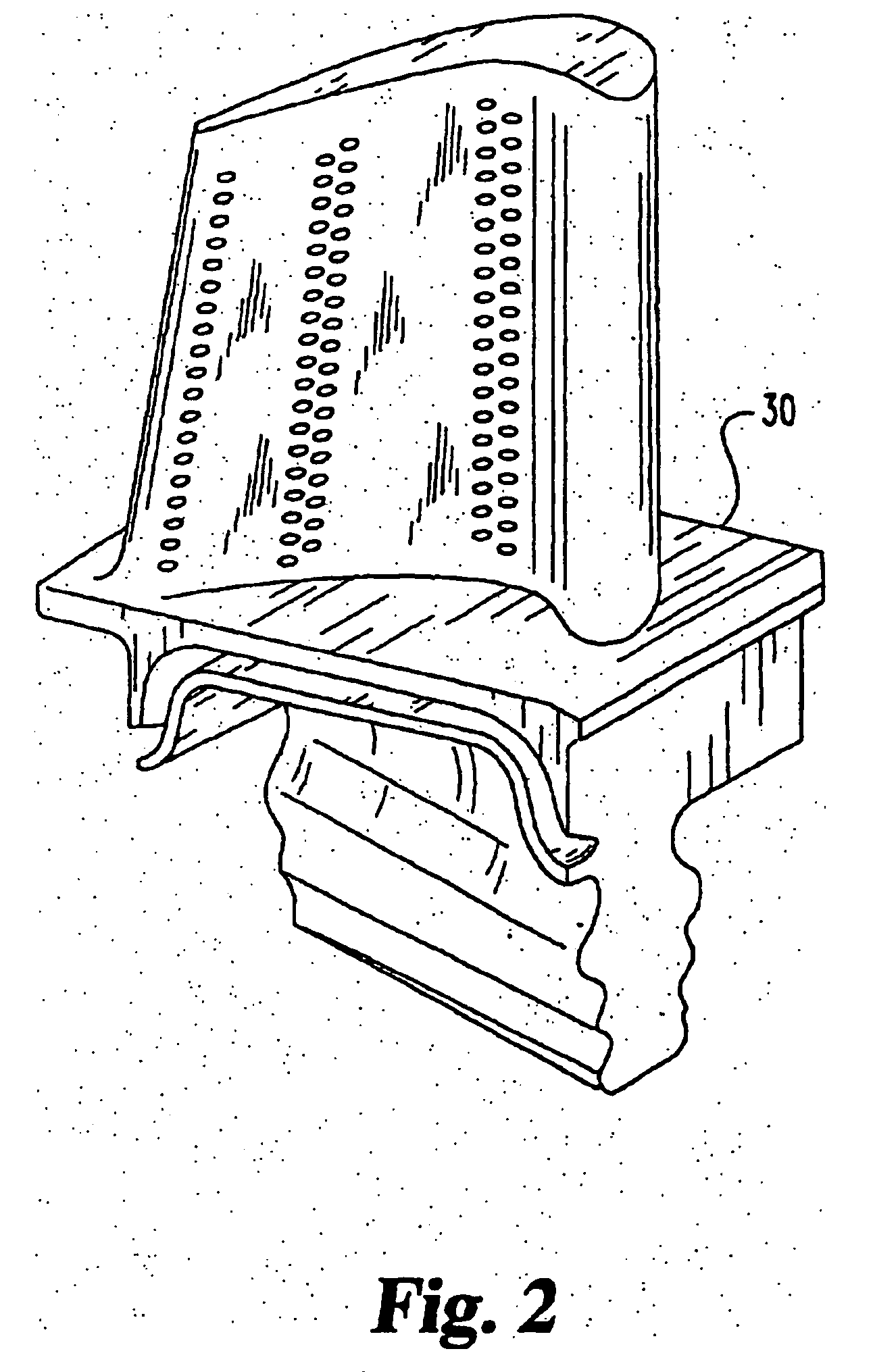

Method and apparatus for production of a cast component

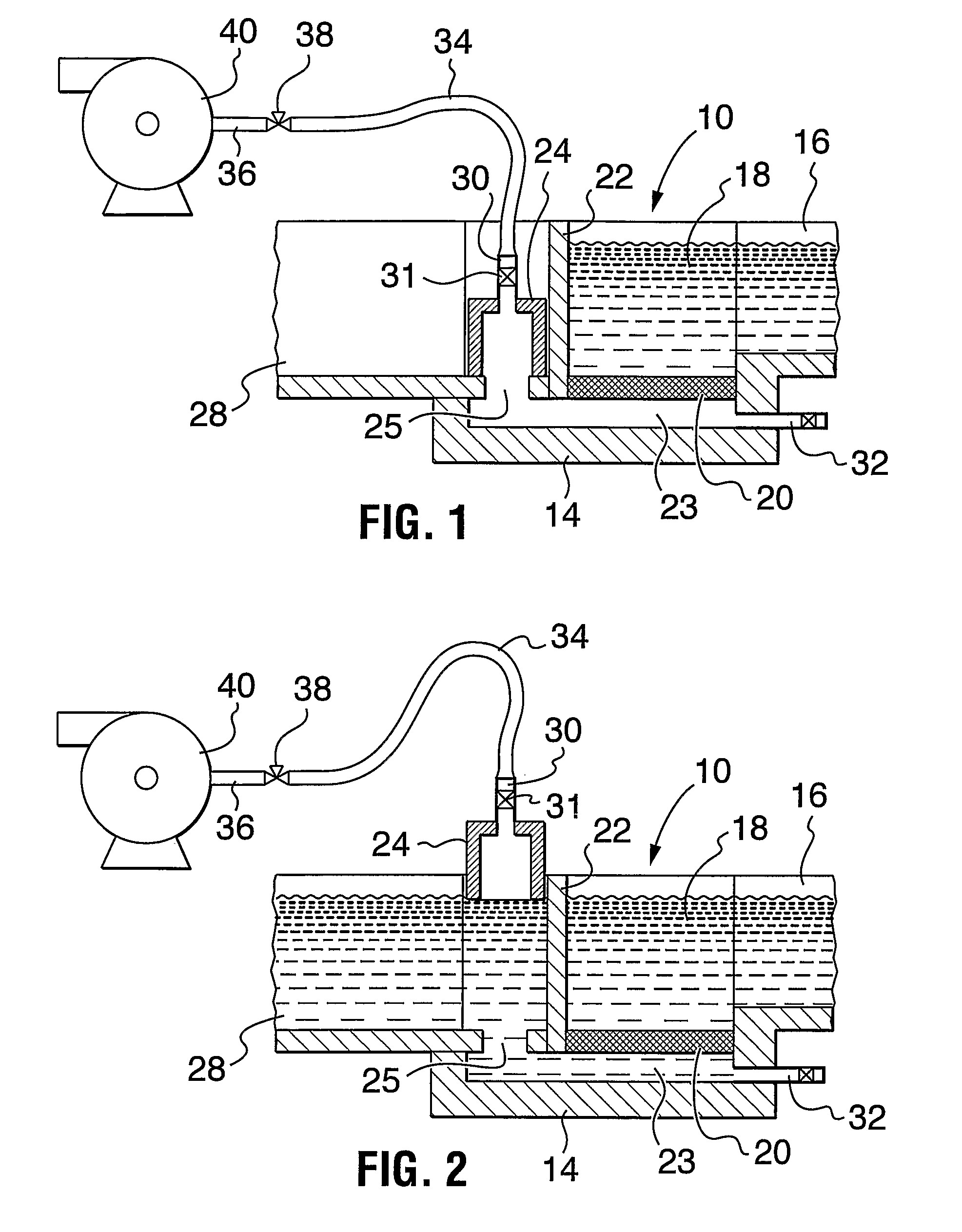

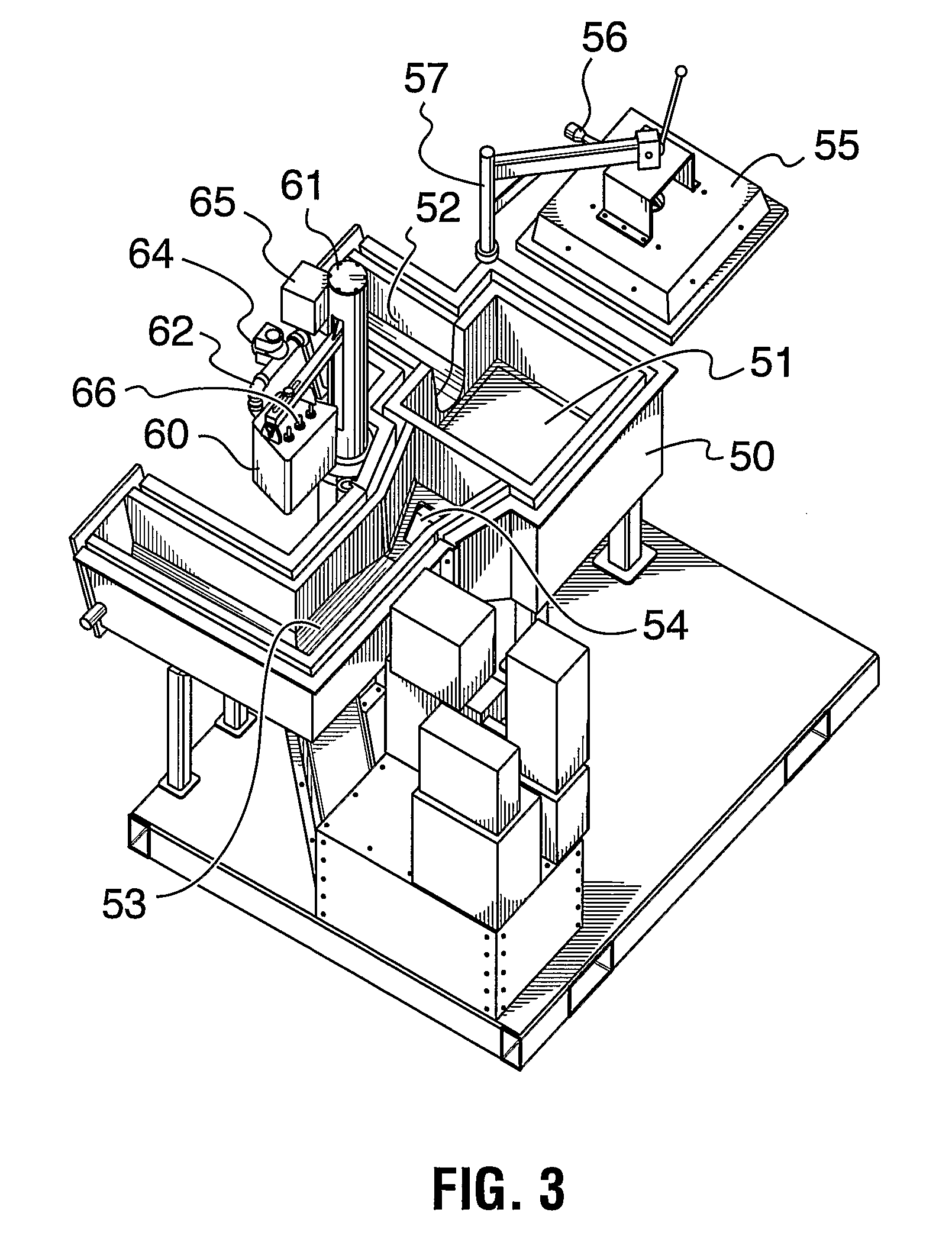

InactiveUS6932145B2Minimize transmission of heatGas turbine plantsFrom frozen solutionsCasting moldMolten metal

A system for producing cast components from molten metal. One form of the present invention includes a system for the precision pouring of molten metal within a casting mold.

Owner:ROLLS ROYCE CORP

Gas-blowing and slag-removing device and slag-removing method

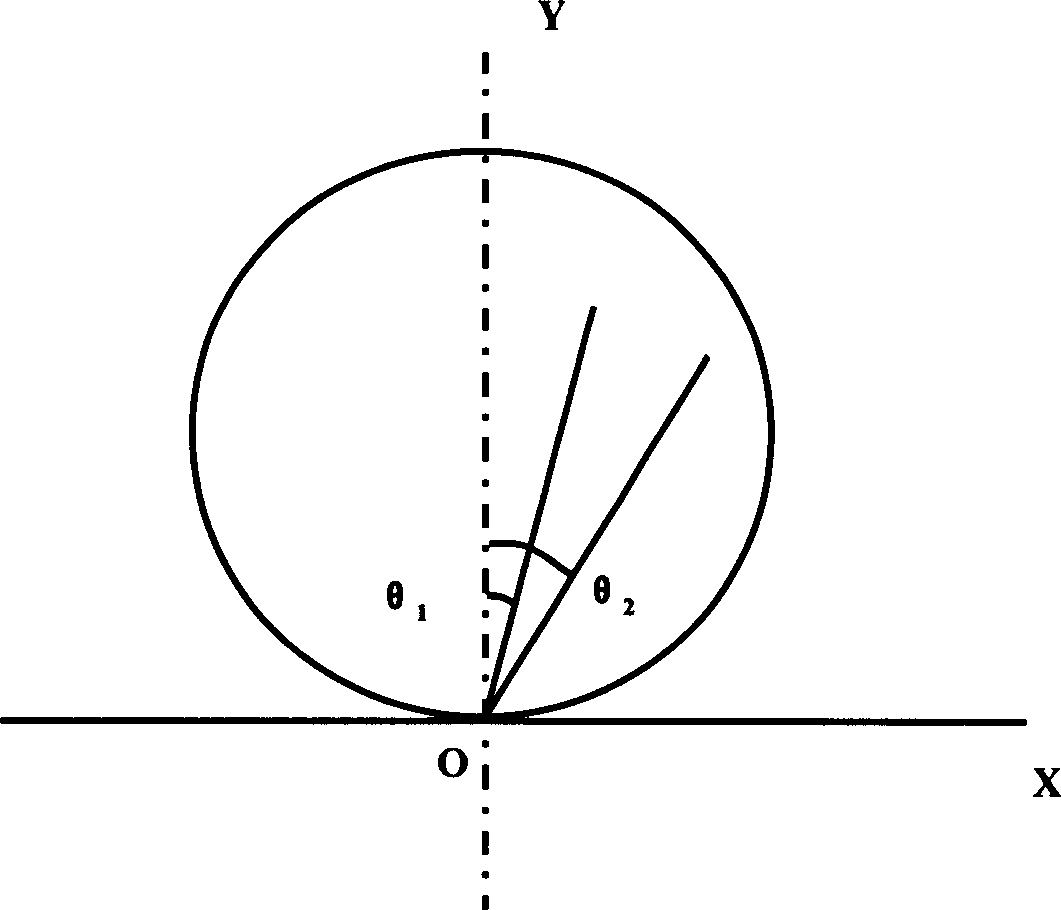

The invention relates to a gas-blowing and slag-removing device and a process, mainly solving the technical problems that the slag removing is difficult to realize and the slag-removing effect is poor in the existing slag-removing device. The technical scheme of the invention is as follows: the gas-blowing and slag-removing device comprises a gas-blowing mechanism, a hot-iron ladle and a slag-skimming machine, and is characterized in that the gas-blowing mechanism is fixed at one side of a supporting platform by a hinge base and comprises an oblique rail frame which is provided with a rail chain; the gas-blowing and slag-removing device also comprises a bracket which is level to the upper surface of the rail frame and is provided with a speed-changing machine; an output shaft of the speed-changing machine is provided with a first chain wheel matched with the rail chain; the rail frame is also provided with a clamping trolley which forms a moving pair with the rail frame; the clamping trolley is provided with a second chain wheel which is fixed together with the rail chain; a connecting rod positioned in the middle of the rail frame is clamped and fixed in the middle of the clamping trolley, and is equidirectional with the rail frame; and the lower end of the connecting rod is provided with a connector and is connected with a gas-blowing and slag-removing gun by a connecting flange. The invention is mainly used for removing the slag on the surface of hot iron in the hot-iron ladle.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

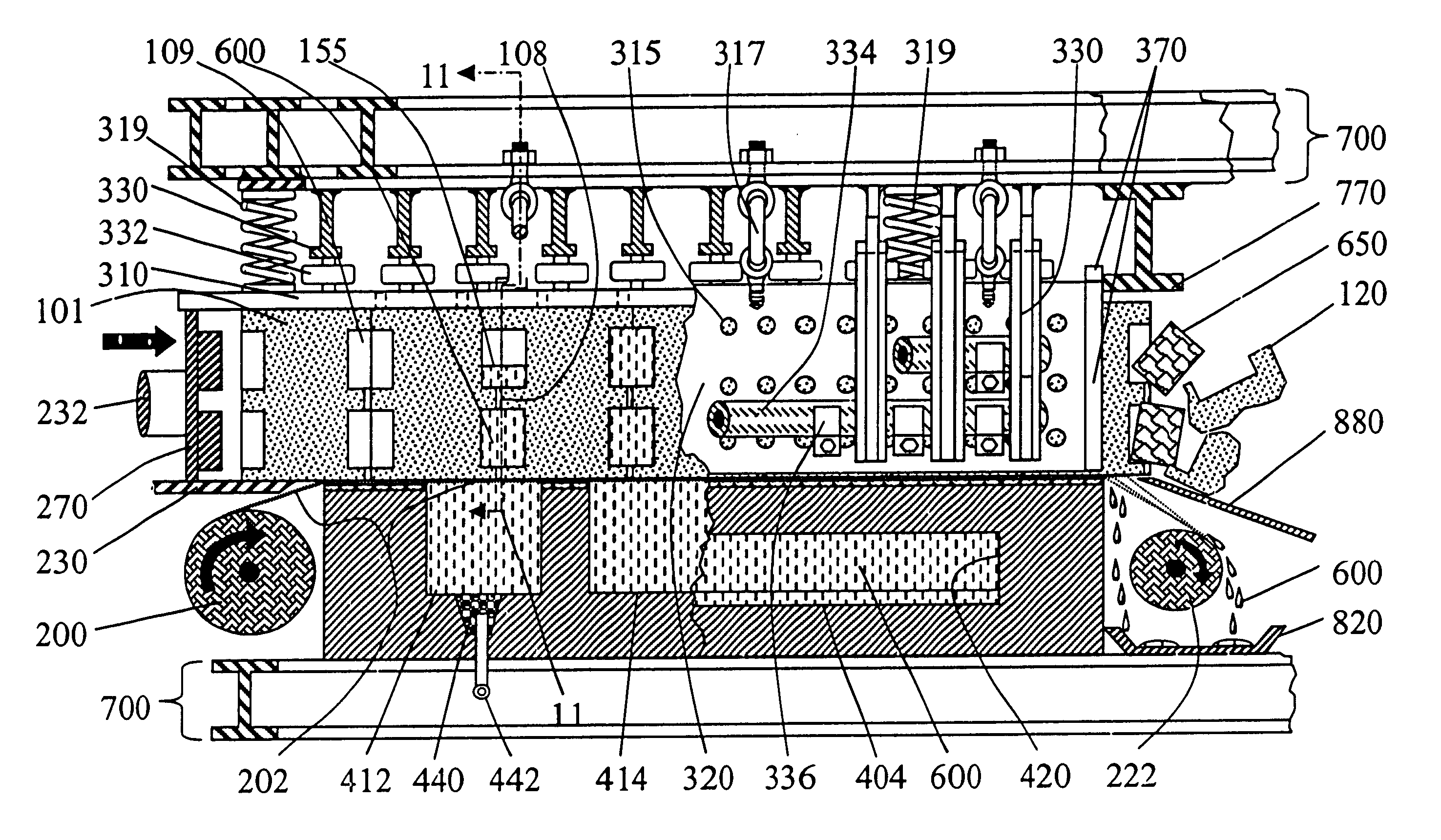

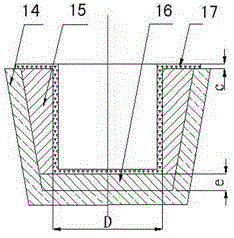

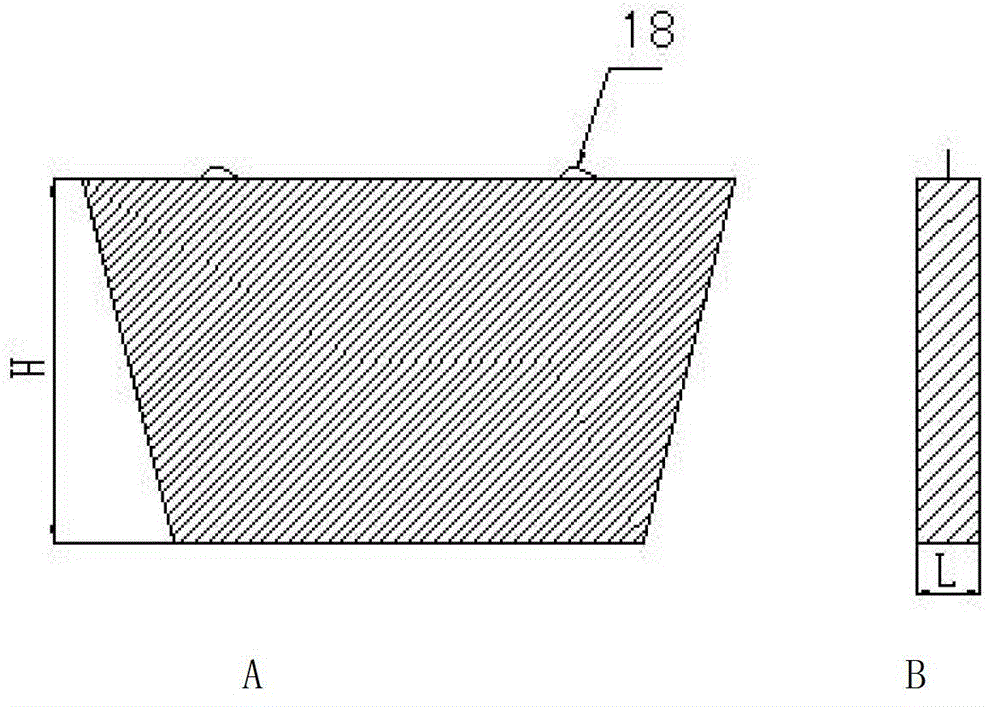

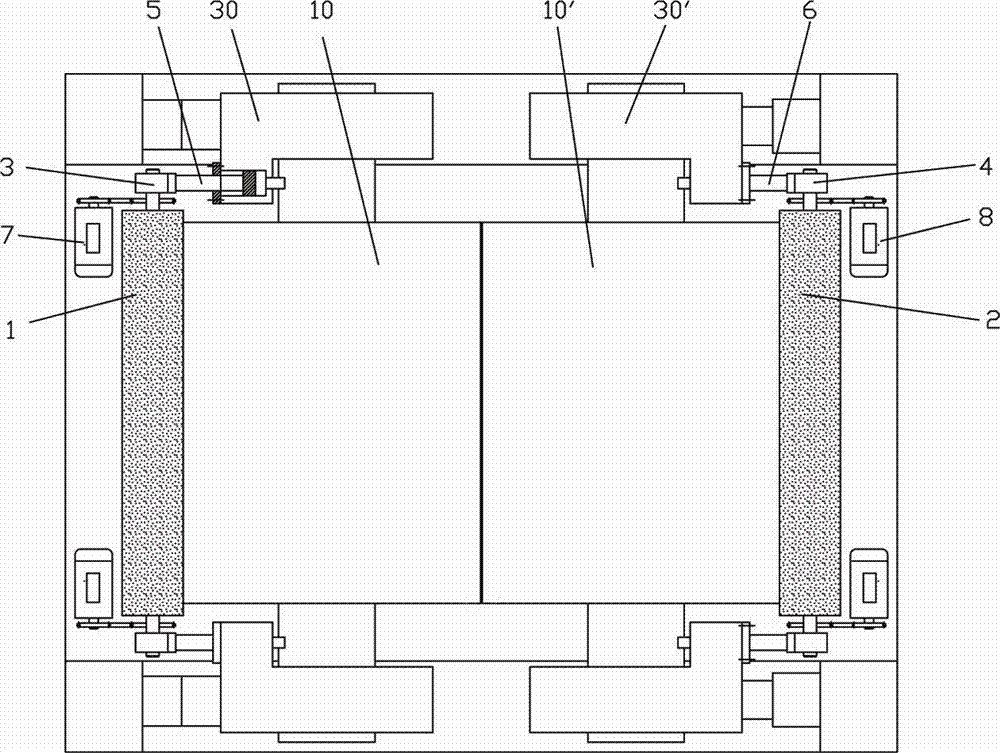

Tundish flow control device for slab casting machine, preparation method thereof and slagging method using tundish flow control device

ActiveCN102744393AReduce the balanceImprove erosion resistanceMelt-holding vesselsCasting cleaning apparatusSlab casterSlag

The invention relates to a tundish flow control device for a slab casting machine, a preparation method of the tundish flow control device and a slagging method using the tundish flow control device, and belongs to the technical field of the ferrous metallurgy slab casting tundish technology. The tundish flow control device for the slab casting machine comprises a turbulence controller, a slag blockage weir and a slag blockage dam, and is characterized in that the upper edge of the slag blockage weir (5) is higher than the highest liquid level (10) of molten steel normally poured by the tundish, but is lower than the working face of tundish overflow port coating (1); the slag blockage weir (5) and the slag blockage dam (6) are vertically staggered; two ends of the slag blockage dam (6) are respectively provided with a through hole; a center distance a between the slag blockage weir (5) and the turbulence controller (4) is 400-600mm; and a center distance b between the slag blockage weir (5) and the slag blockage dam (6) is 300-400mm. After the tundish flow control device for the slab casting machine is adopted, slab tundish injection residue can be reduced by more than 25%, the service life of the flow control device is improved by one time and is above 14 hours, and the production cost of continuous casting refractory material is lowered by more than 30%.

Owner:LAIWU IRON & STEEL GRP

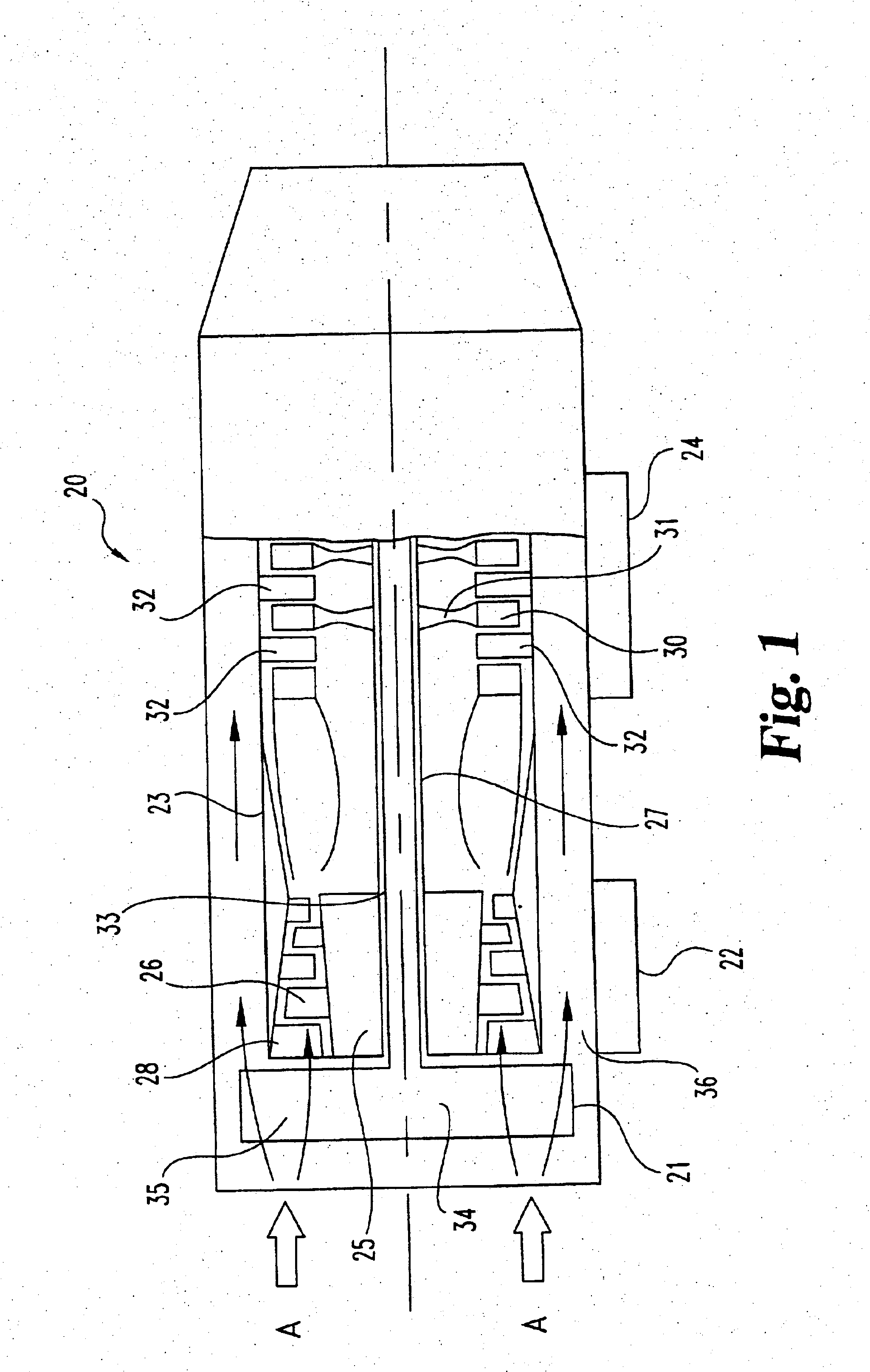

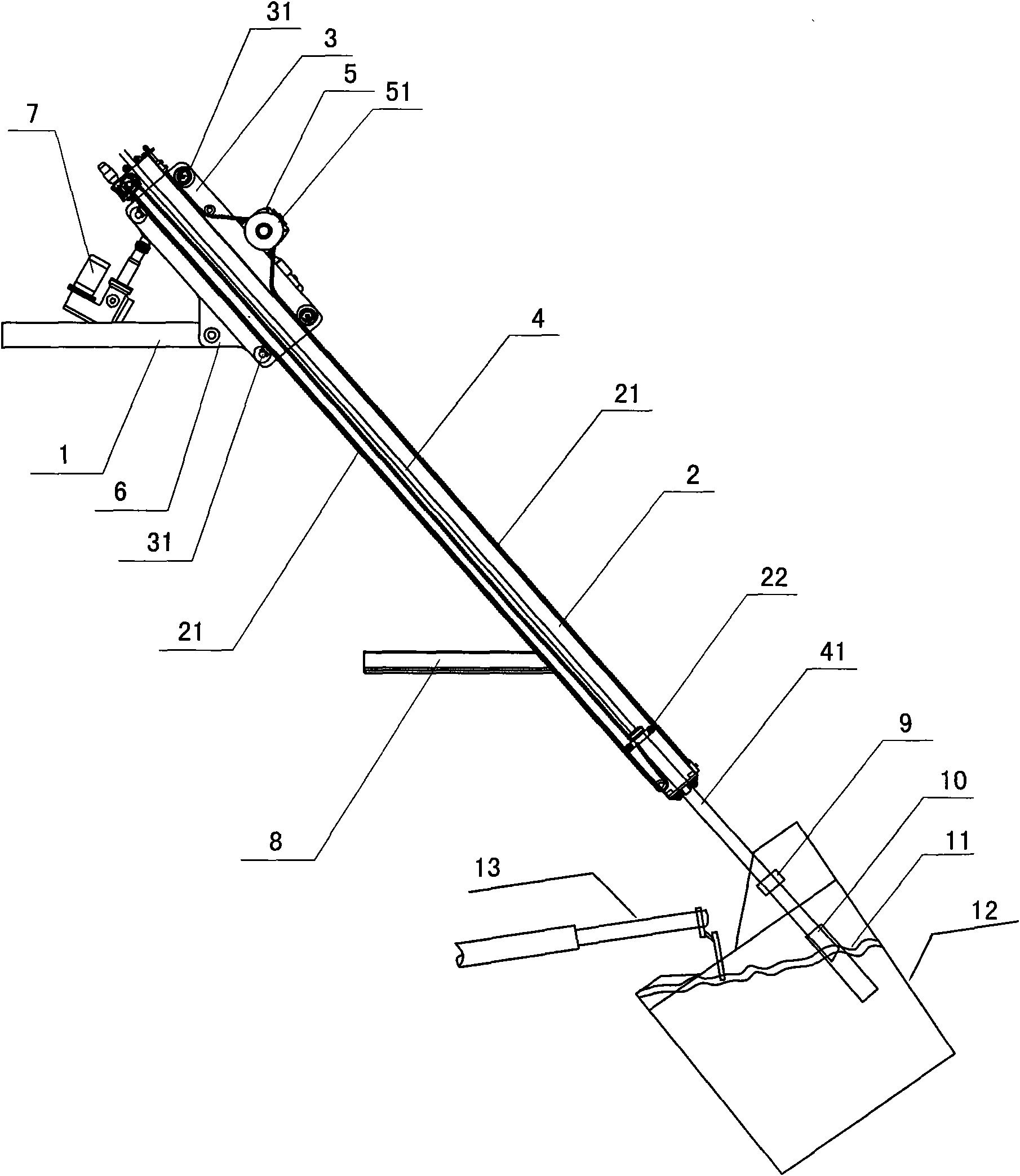

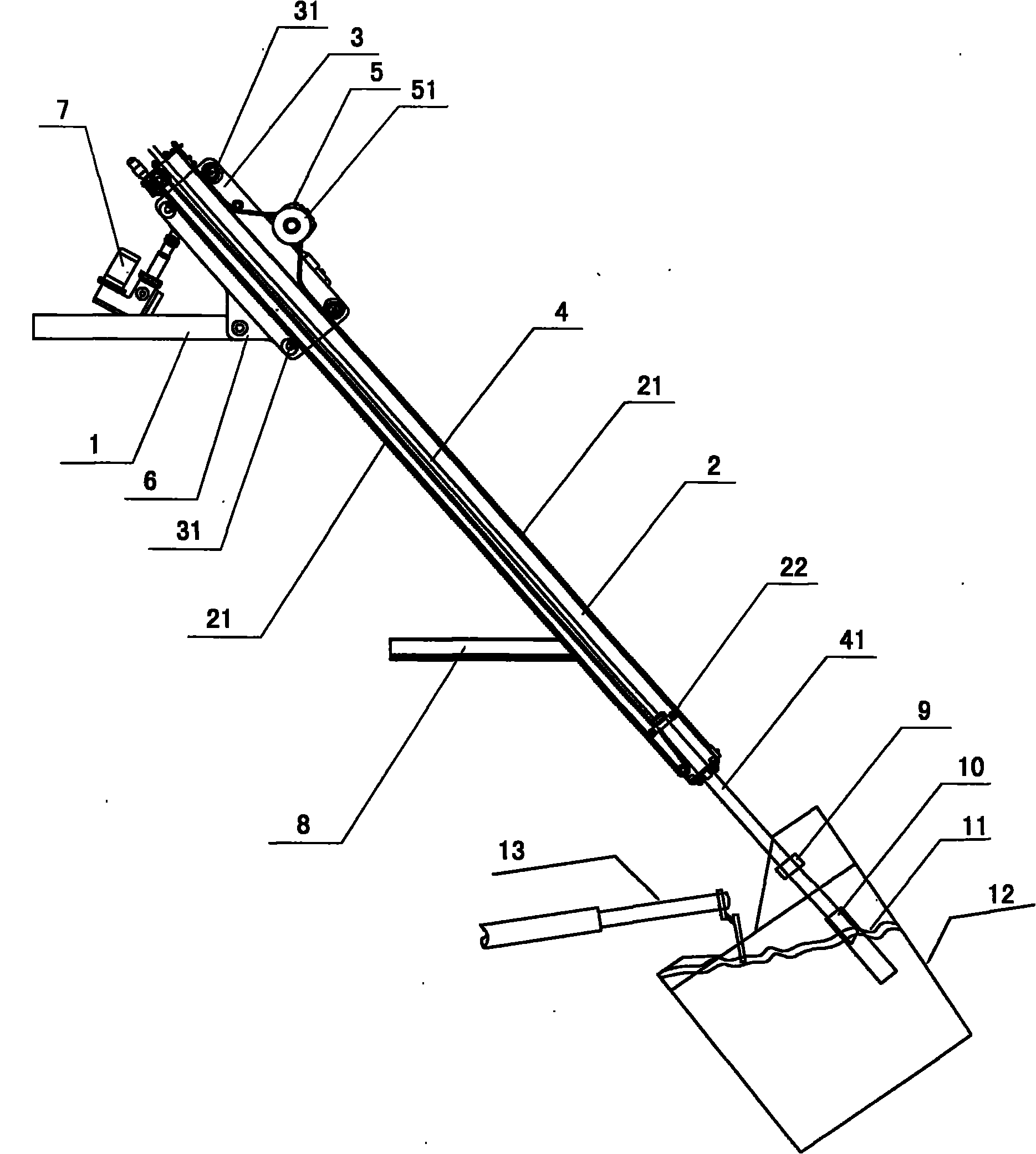

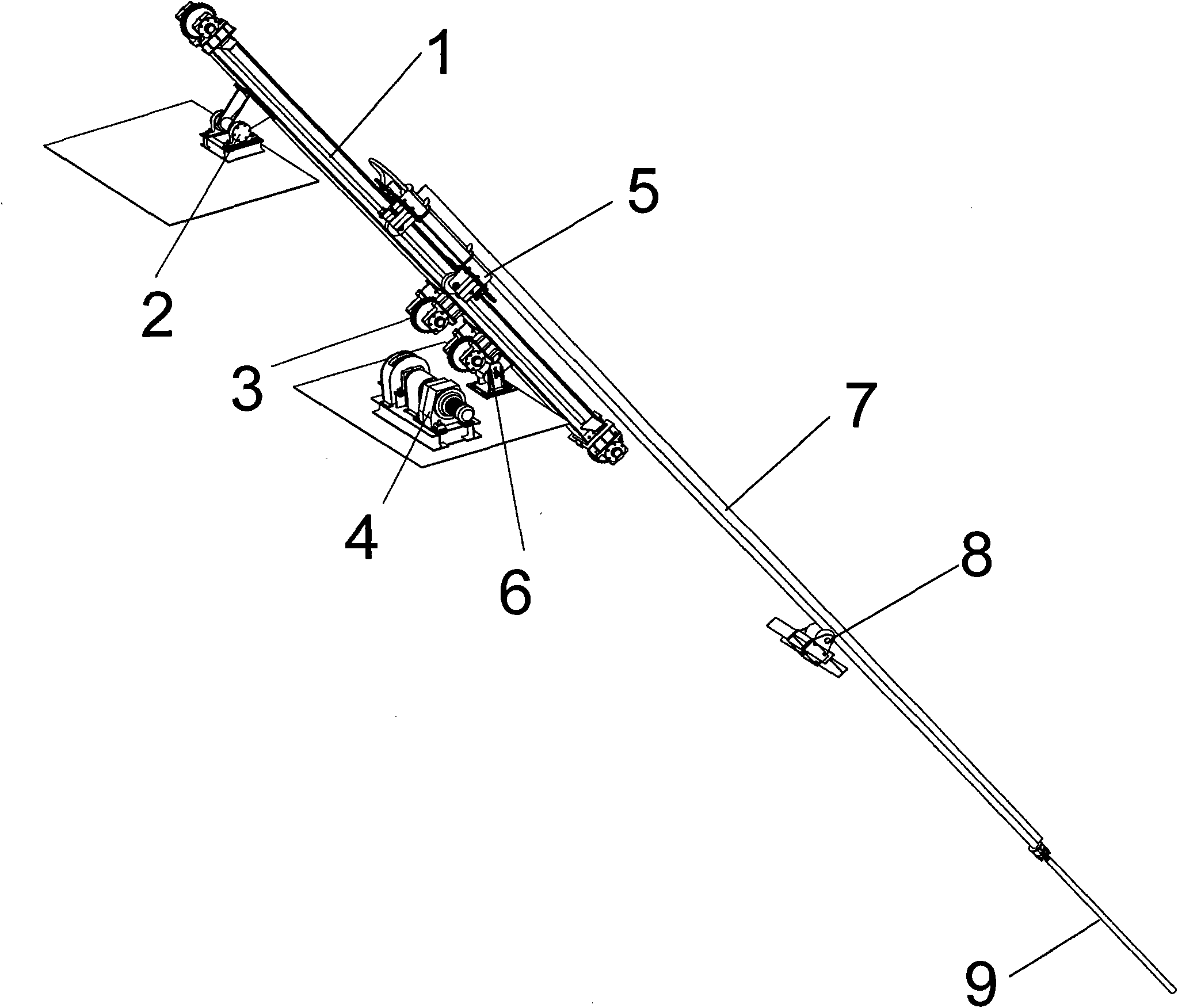

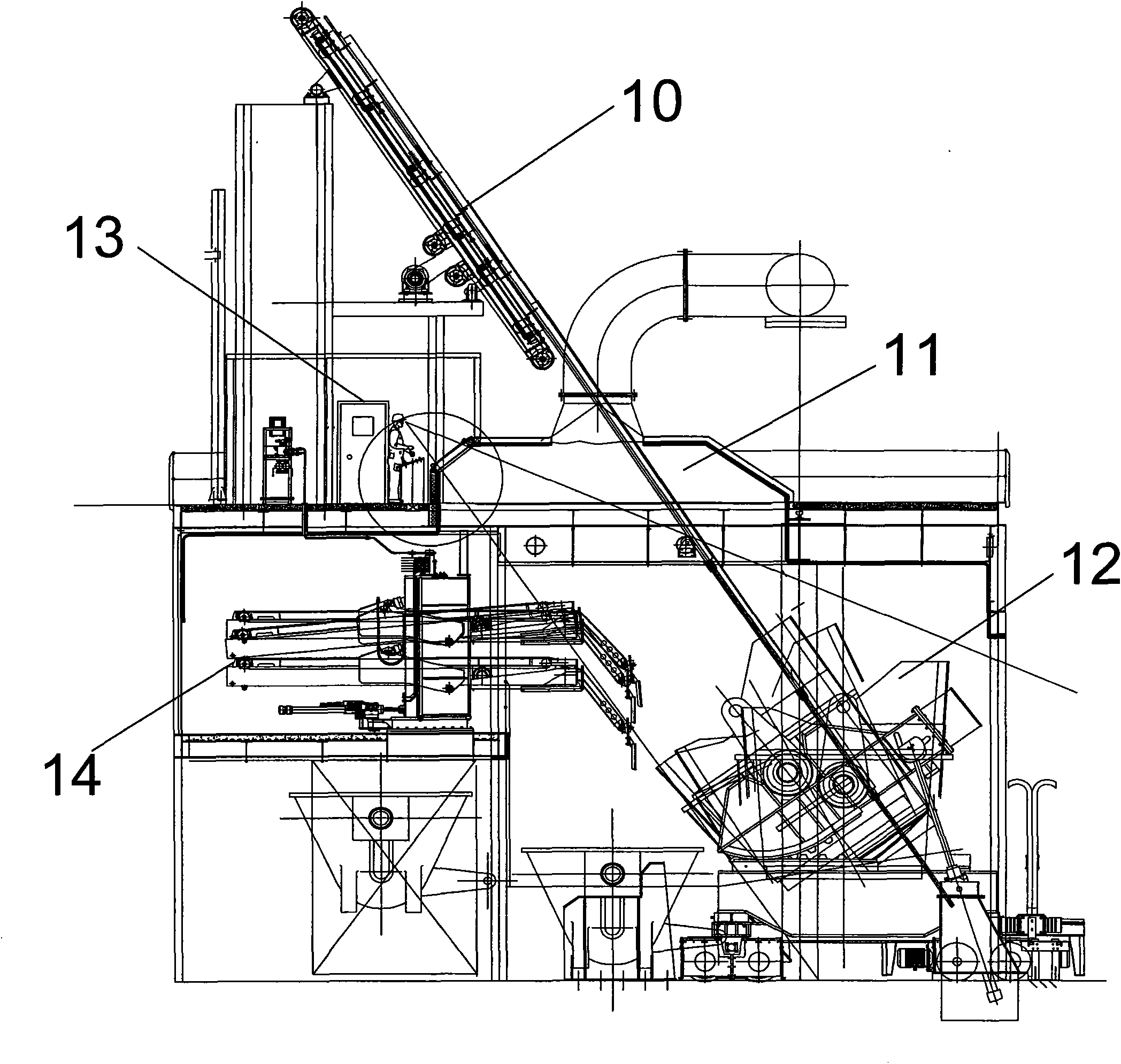

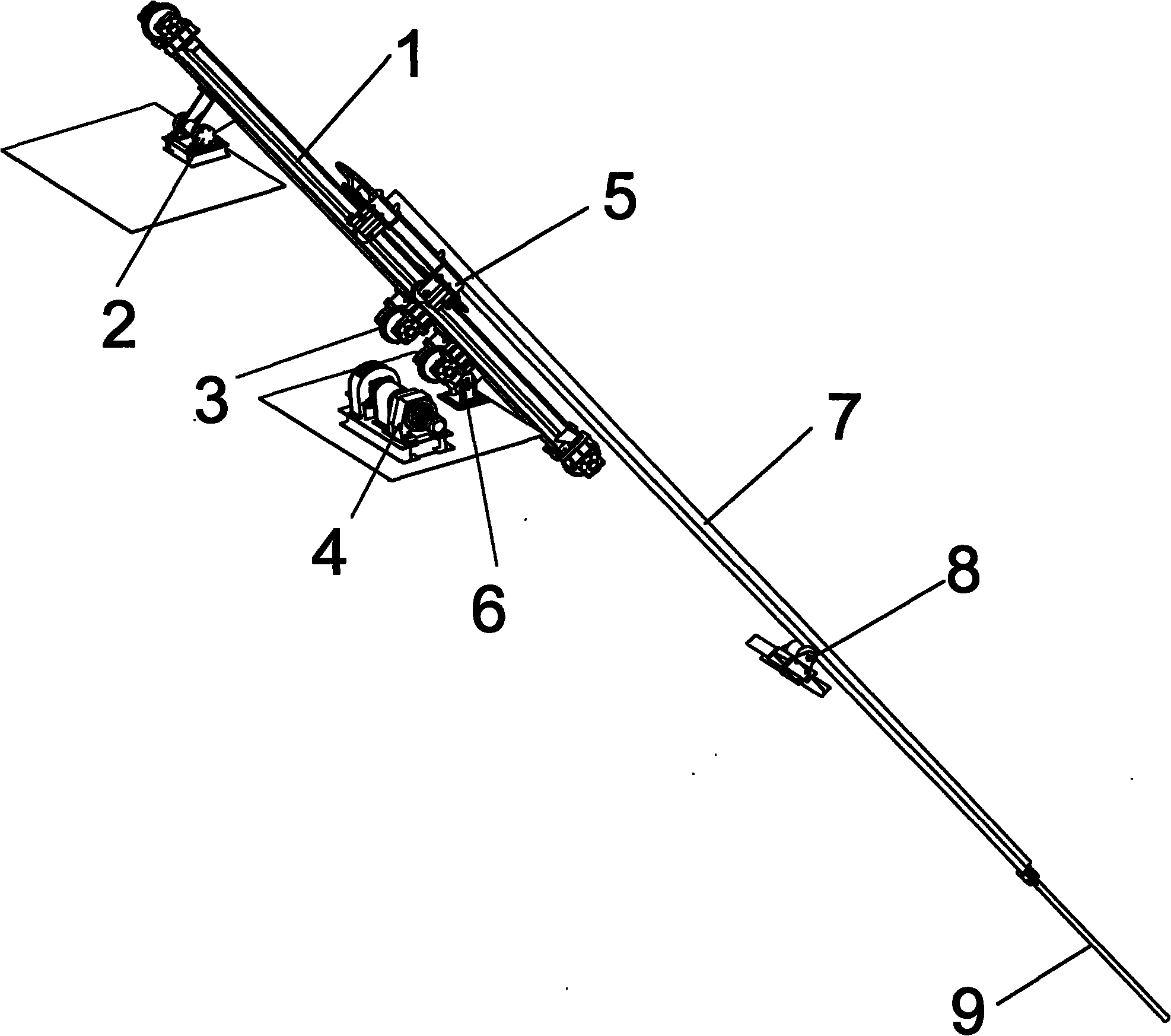

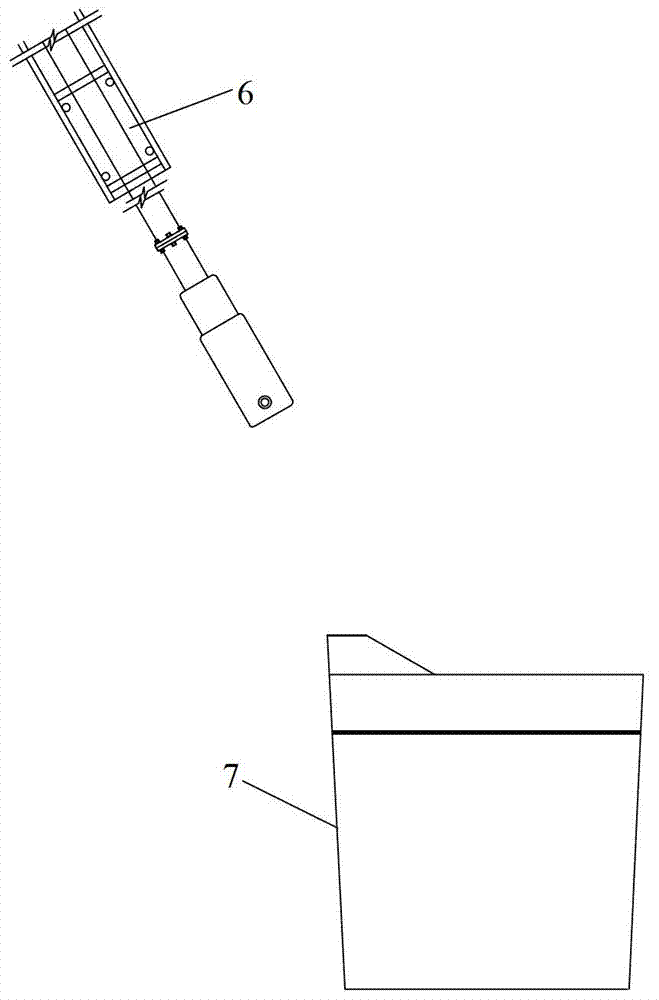

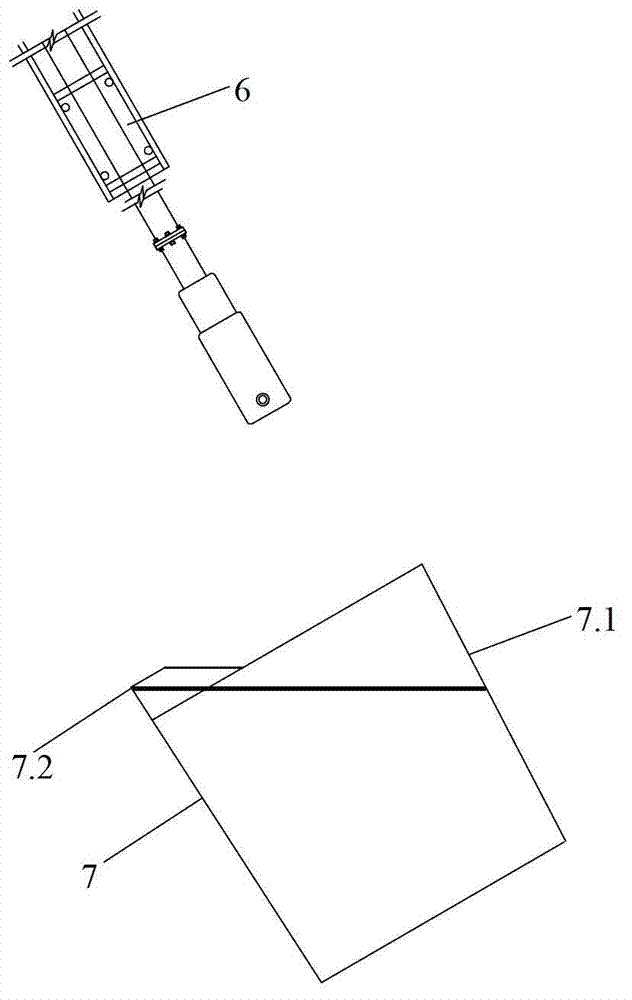

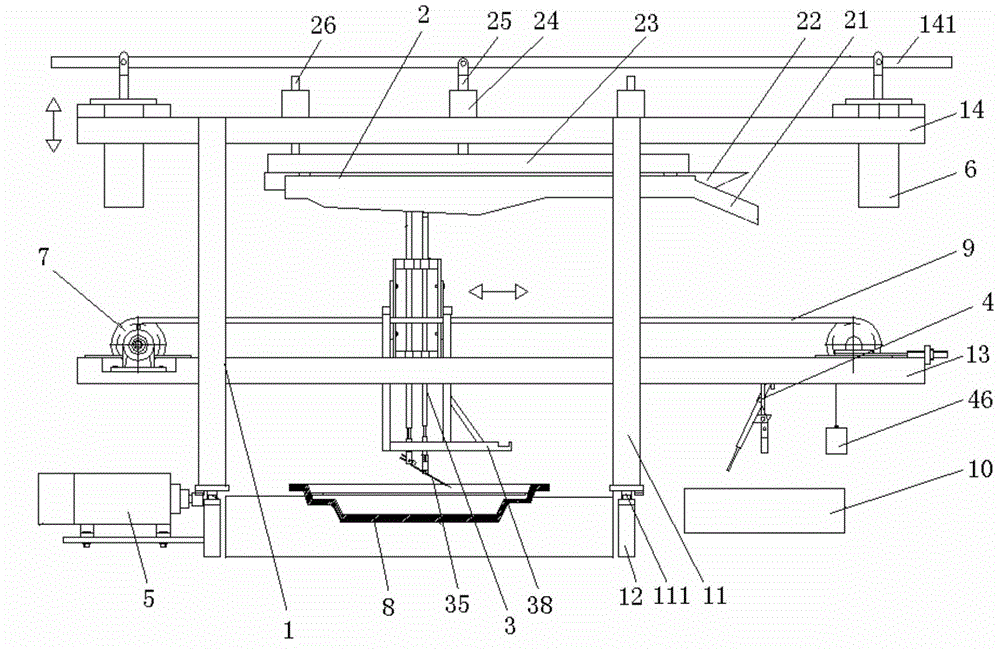

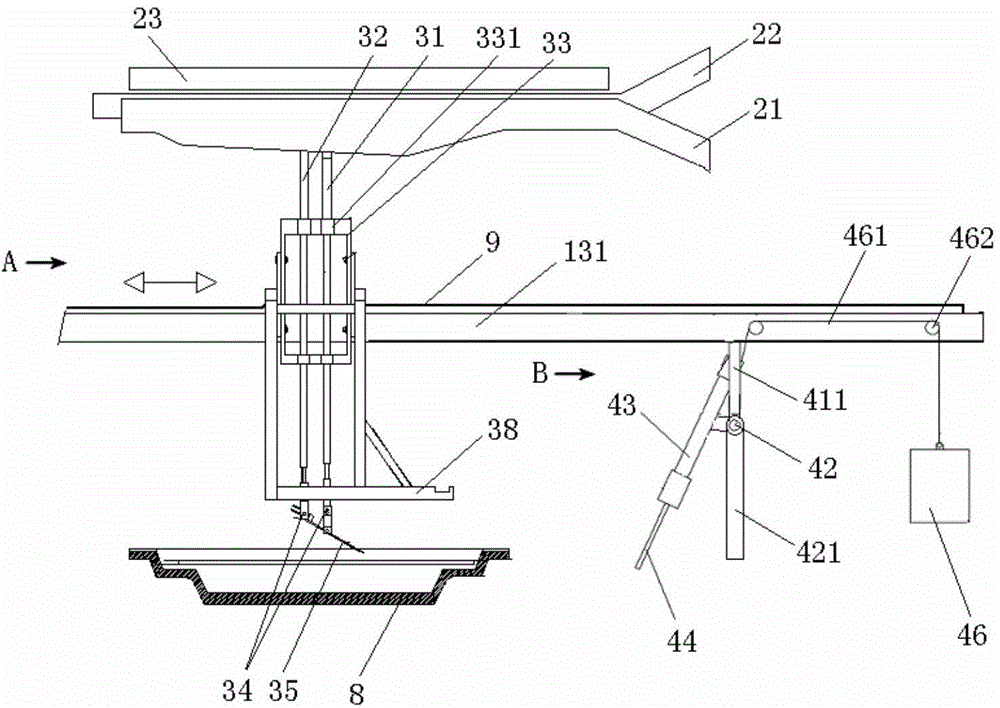

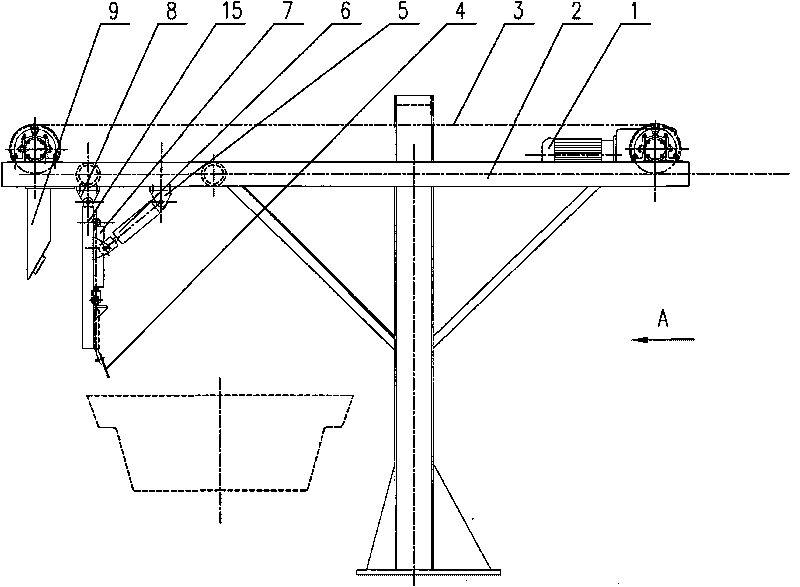

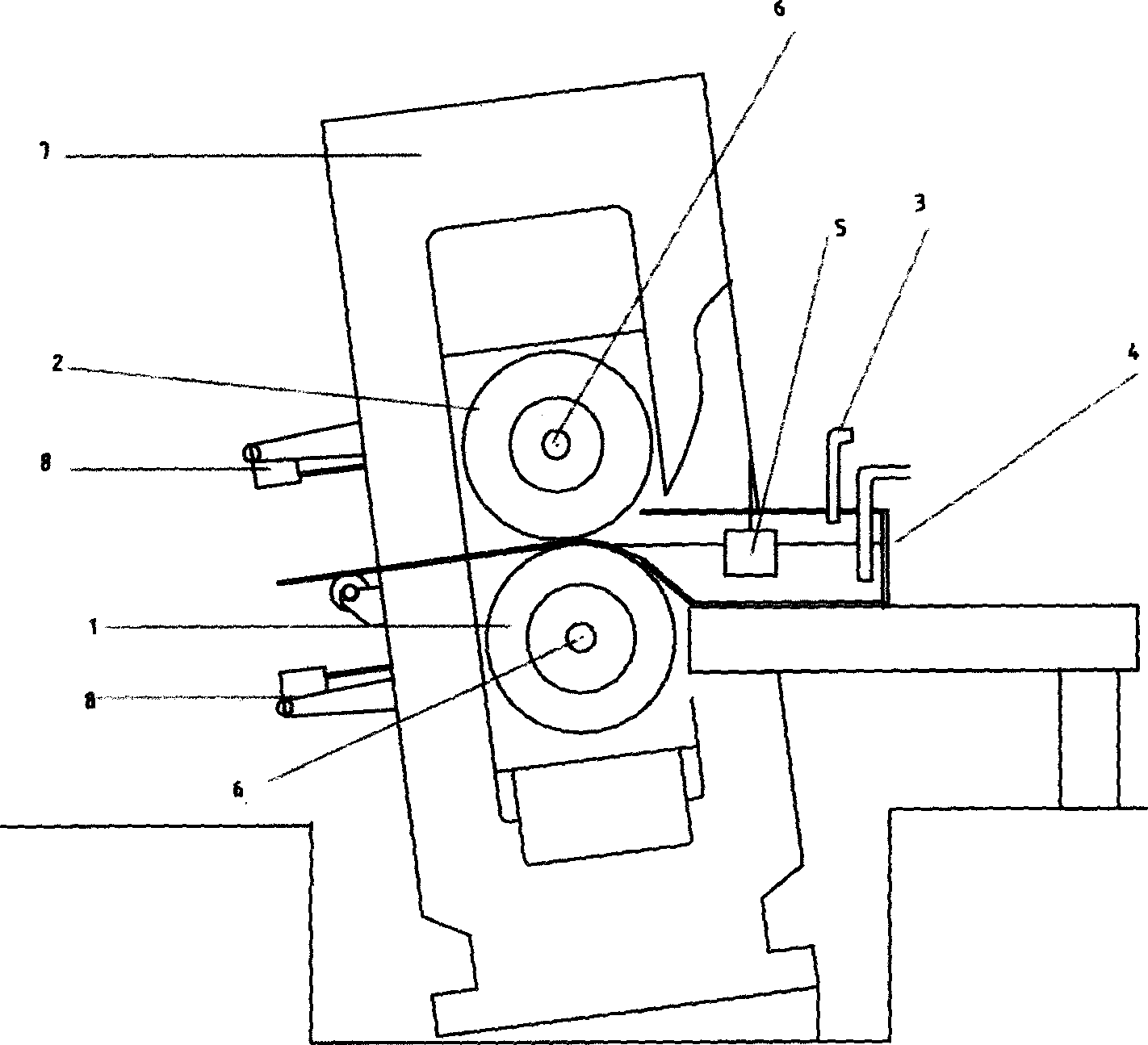

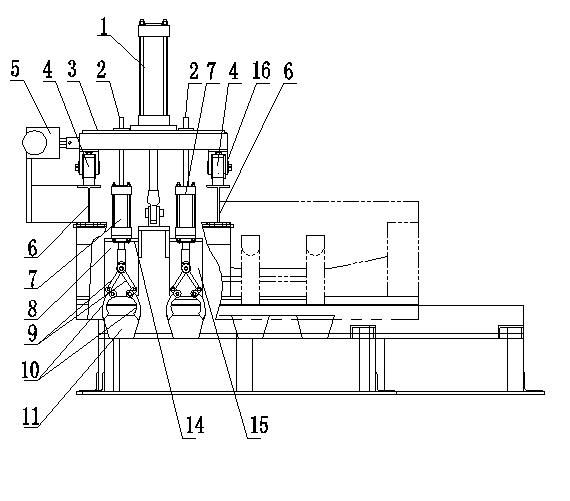

Blowing slag-removing equipment for molten iron pretreatment

ActiveCN101928801AShorten the slag removal timeReduce iron lossCasting cleaning apparatusSlagNitrogen

The invention relates to blowing slag-removing equipment for molten iron pretreatment, which is arranged on a platform of a slag-raking machine of a molten iron tank. The blowing slag-removing equipment comprises a guide rail, a rotary bearing, an adjustable bearing, a guide roll, a guide chain wheel, an elevating drive unit, an elevating trolley, a blowing rod and a refractory material section, wherein, the guide rail is arranged slantwise above the molten iron tank; the elevating trolley is arranged on the guide rail; the elevating drive unit drives the elevating trolley to move up and down along the guide rail through the guide chain wheel; the rotary bearing is connected with the upper part of the guide rail, the adjustable bearing is connected with the middle part of the guide rail, and the guide roll is arranged at the lower part of the guide rail; the rotary bearing and the adjustable bearing are fixed on the platform of the slag-raking machine; and the blowing rod is arranged on the elevating trolley and the refractory material section is connected with the lower part of the blowing rod. When the slag-raking machine runs, the blowing rod is inserted in ladle for blowing nitrogen; and during the slag-removing process, the slag quantity is continuously reduced and an exposed surface of molten iron is increasingly enlarged until the slag is almost entirely removed. The blowing slag-removing equipment can shorten the slag-removing time by 2 minutes, lower the iron loss by over 20% and achieve better economic benefit.

Owner:BAOSTEEL ENG & TECH GRP

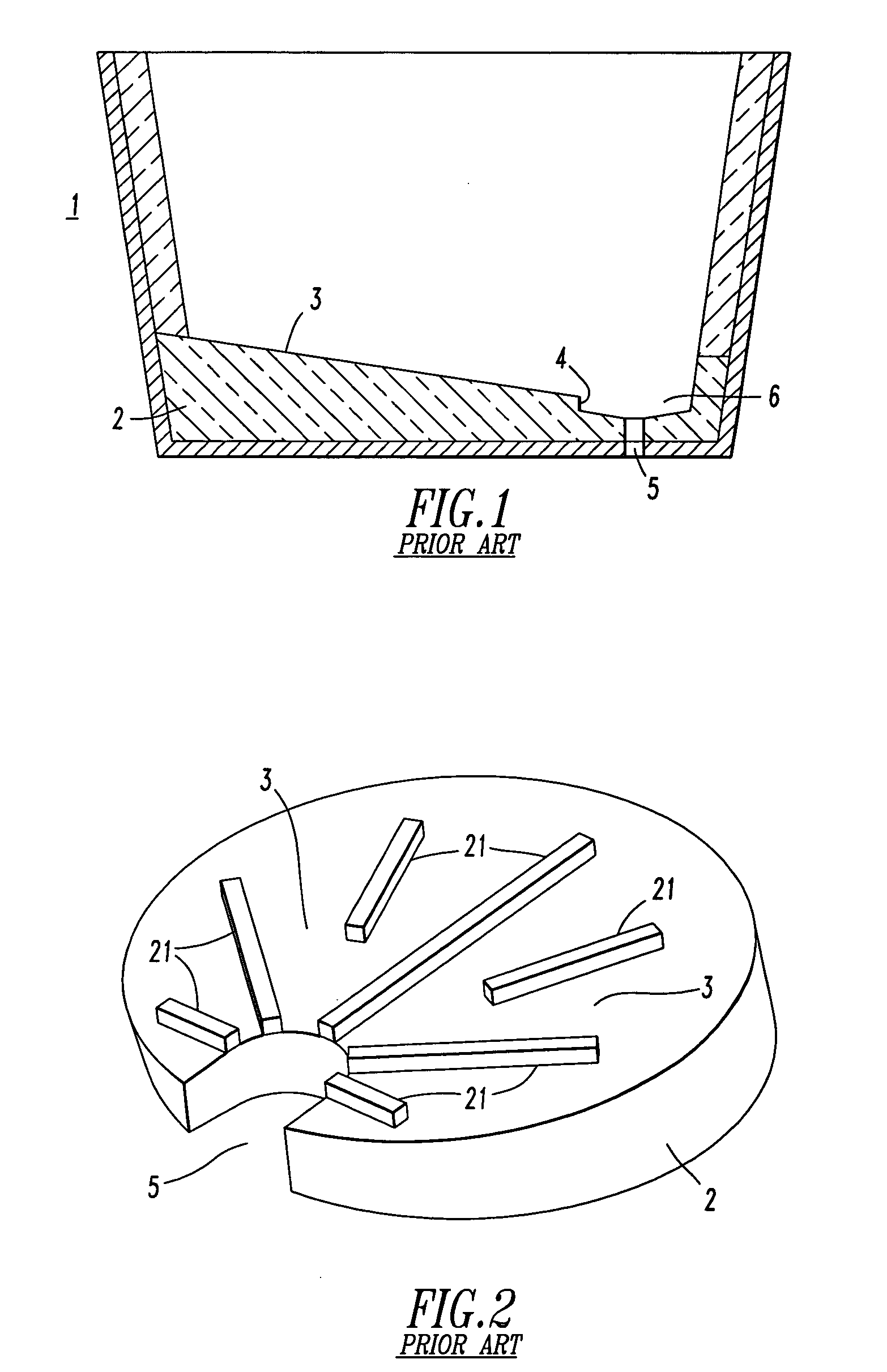

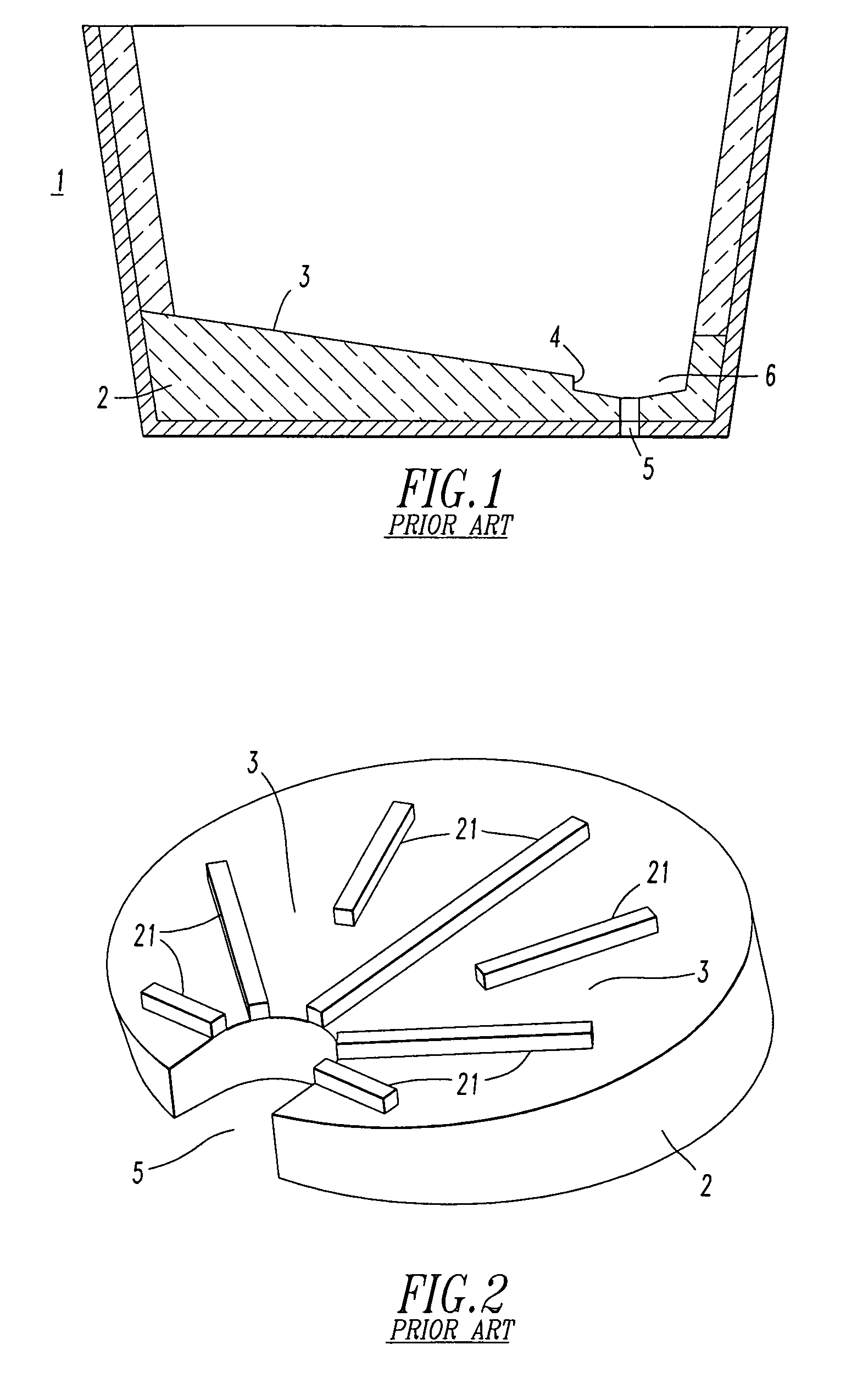

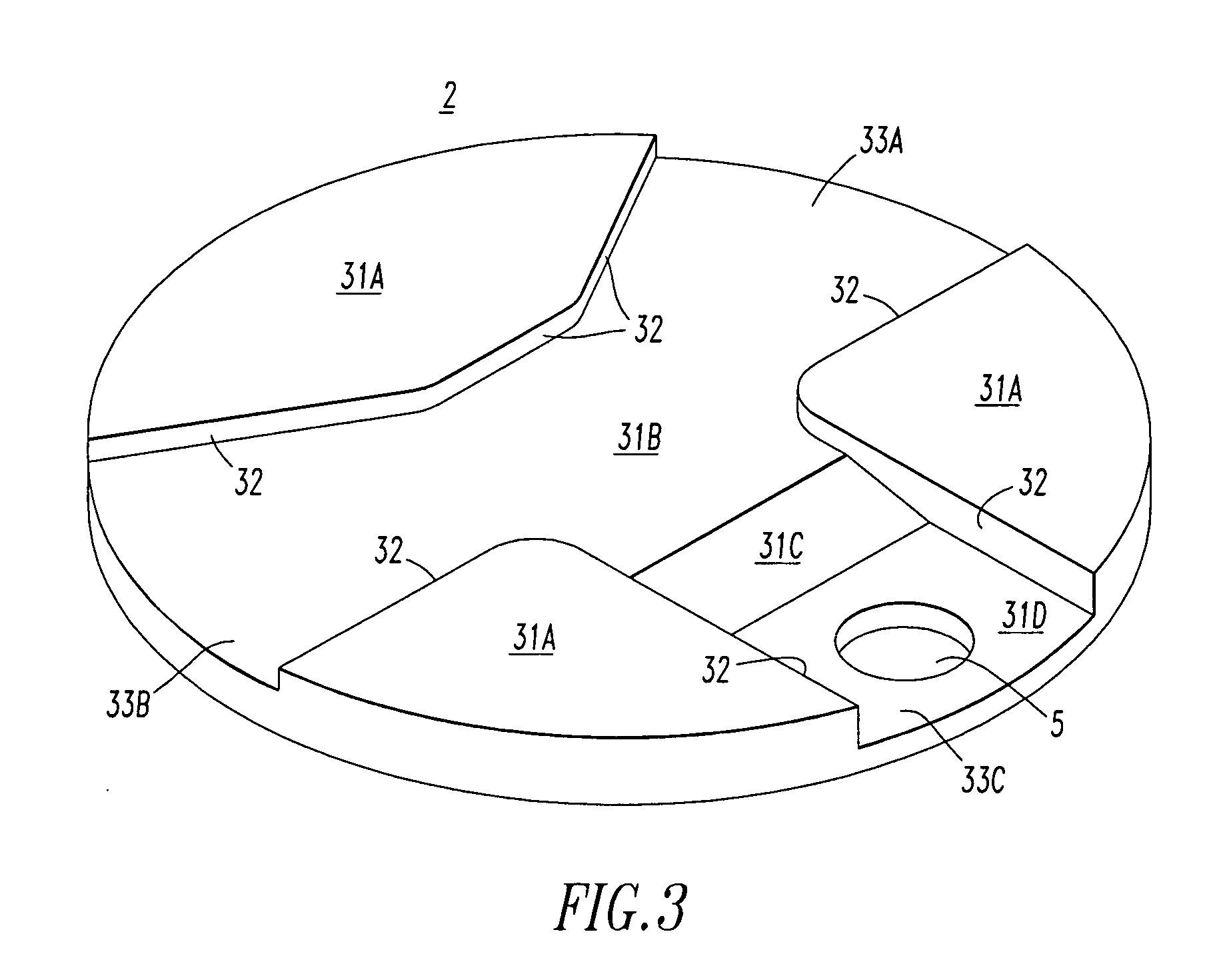

Ladle bottom

InactiveUS20050127582A1Improve efficiencyReduce the amount requiredMelt-holding vesselsCasting cleaning apparatusMolten slagMolten metal

The present invention relates to a metallurgical ladle and more particularly to the bottom of the ladle having an outlet through which the molten metal can drain. An object of the present invention is to increase the efficiency of a ladle draining operation, including reducing the amount of discarded metal, avoiding the premature flow of slag through the outlet, and reducing the contamination of slag in the molten metal effluent. The ladle bottom comprises a plurality of terraces and flow channels, ultimately directing the stream of molten metal to an outlet of the ladle. The terraces are described as capturing slag and the channels permit molten metal to flow preferentially through the outlet.

Owner:VESUVIUS USA CORP

Ceramic filter containing graphene for molten metal

The invention provides a ceramic filter containing graphene for molten metal. The ceramic filter containing graphene comprises main preparation raw materials, including a refractory material, an adhesive and the graphene, wherein the refractory material at least comprises a part of ceramic material. Due to introduction of graphene, the mechanical strength and the thermal shock resistance of the filter are improved.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

Molten iron slagging-off method

The invention relates to the field of molten iron pretreatment technologies, in particular to a molten iron slagging off method which is characterized in that an inert gas is continuously blown into a liquid iron tank at the farthest end on the slagging-off side at the later period of slagging off. The method comprises the following steps of: (1) carrying out slagging off by using a slagging off machine after iron is molten until the thickness of a slag layer is smaller than 50 mm; (2) stretching a slag blowing pipe 300-400 mm below the level of the molten iron at the farthest end on the slagging off side, and controlling air pressure at 0.6-0.8 MPa and air flow at 15-30 Nm3 / h; and (3) stopping blowing the gas after slagging off is completed. The gas is nitrogen, and the purity is greater than 98%. The invention has the advantages that slag is discharged to the slagging off side and gathered through gas churning, the slagging off time can be obviously shortened and is controlled within 10 min, the sulfur moisture content of a deeply-desulfurized steel grade can be well satisfied, the resulfurization of the melting process is reduced, and simultaneously, the slagging off iron content is reduced.

Owner:ANGANG STEEL CO LTD

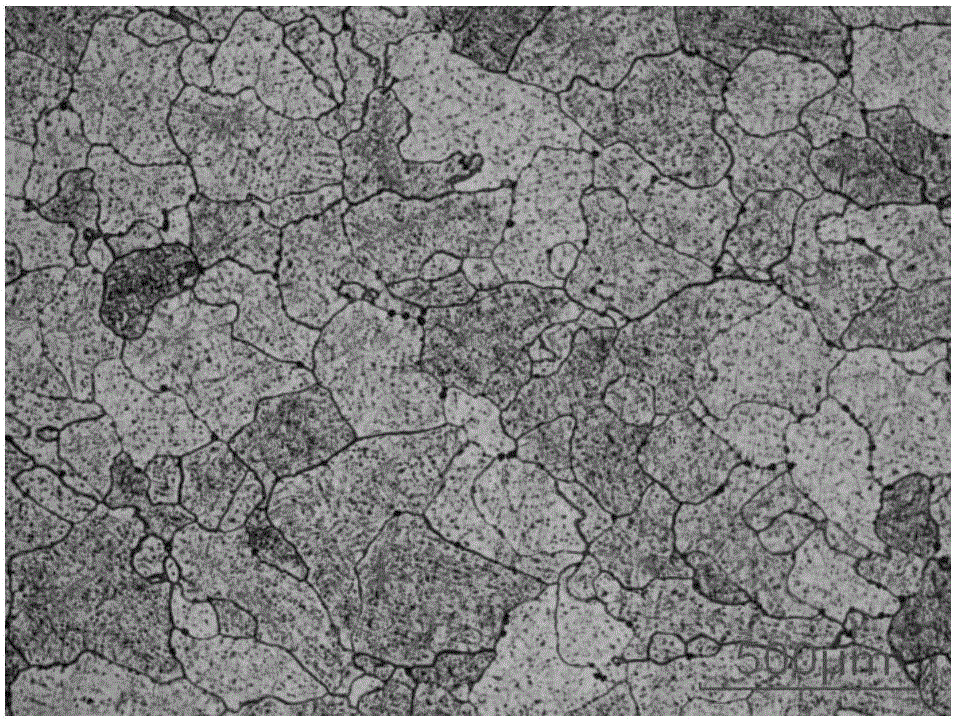

Production technology for 1070A alloy aluminum foil with ultrahigh strength and high elongation for lithium battery

InactiveCN106929713AImprove mechanical performance indexImprove inner qualityCasting cleaning apparatusNon-aqueous electrolyte accumulator electrodesPerformance indexAlloy

The invention relates to a production technology for 1070A alloy aluminum foil with the ultrahigh strength and the high elongation for a lithium battery. The aluminum foil for the lithium battery comprises, by mass percentage, less than or equal to 0.2% of Fe; less than or equal to 0.1% of Si, less than or equal to 0.1% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.03% of Mg, less than or equal to 0.03% of Zn, less than or equal to 0.04% of Ti, and greater than or equal to 99% of Al. The preparation method comprises the steps of (1) smelting, and cast rolling; (2) cold rolling; and (3) aluminum foil rolling, specifically, cutting a aluminum foil coil to obtain the finished aluminum foil for the lithium battery. The production technology has the beneficial effects that a newly improved 1070A alloy is adopted, the proportion is reasonable, an electrolytic aluminum liquid with the high purity is adopted, a novel tubular filter box is adopted for production in the cast rolling process, the technology is scientific, the mechanical performance indexes of products can be improved, the tensile strength and the elongation of the products are higher than those of similar products in China, and the use requirements of customers can be met.

Owner:ZOUPING DELI TECH

Skimming tool

InactiveCN1944343AImprove erosion resistanceImprove antioxidant capacityBlast furnace componentsBlast furnace detailsSlagSilicon

The skimming tool is made with dense corundum or brown corundum 43-48 wt%, silicon carbide 29-33 wt%, pelleted pitch 2-3 wt%, calcium aluminate cement 2.5-3 wt%, fine alpha-Al2O3 powder 8-10 wt%, fine uf-SiO2 powder 2-2.5 wt%, metal aluminum powder 0.5-1.5 wt%, metal silicon powder 1-3 wt%, composite additive 0.3-0.5 wt%, and water 3.5-5.5 wt%. The skimming tool of the present invention has excellent washing, oxidizing and slag erosion resisting performance and long service life.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

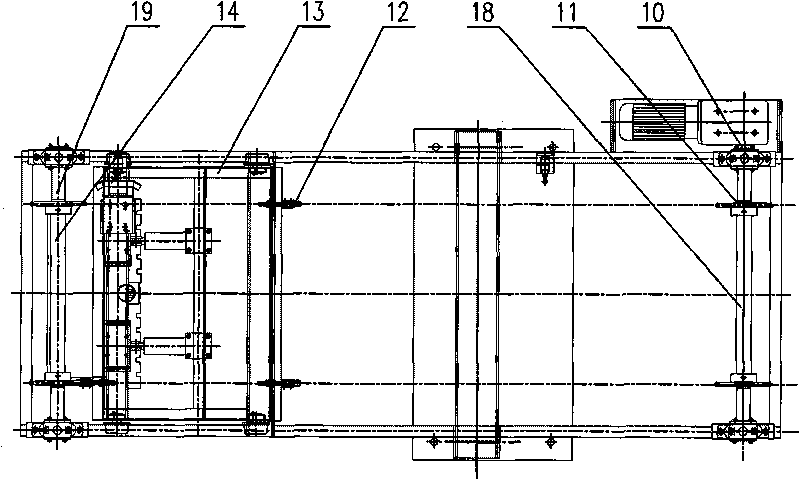

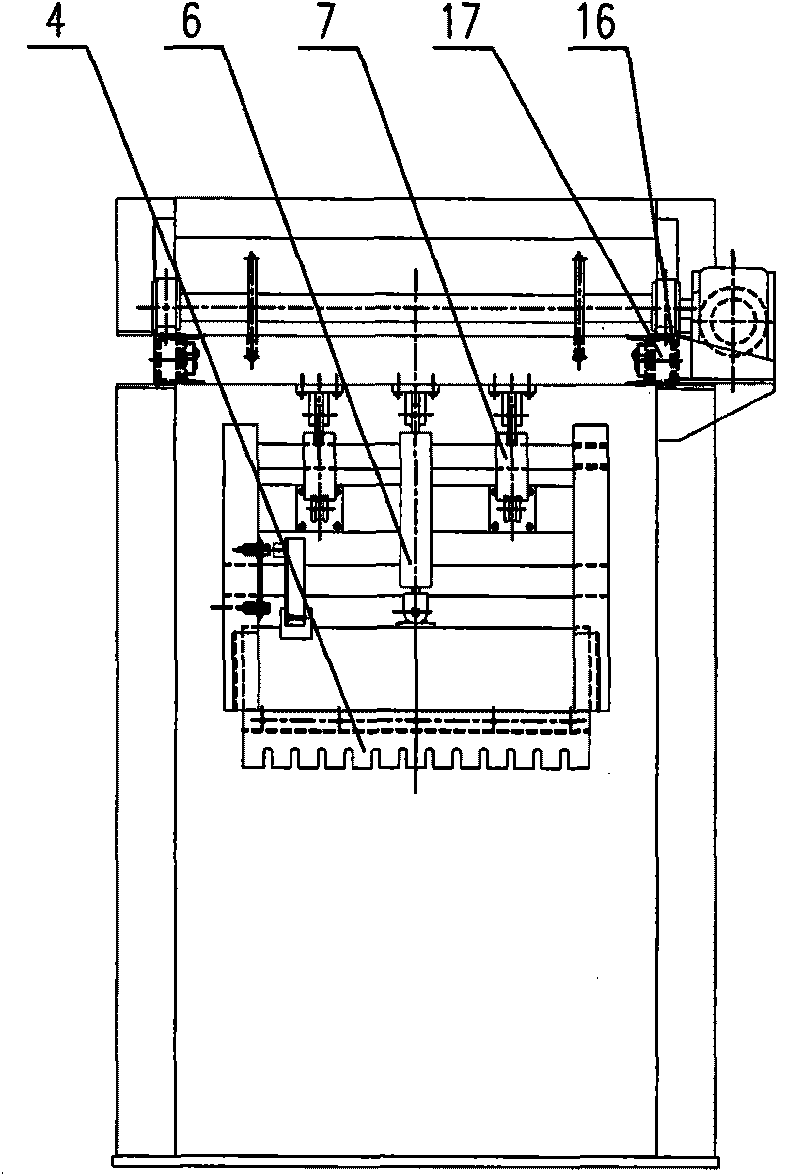

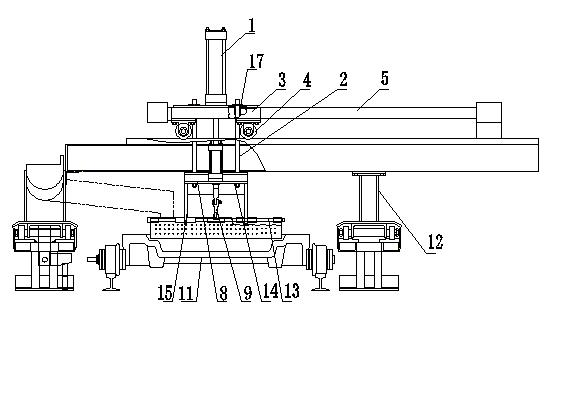

Automatic slag removal machine for ingot casting

ActiveCN104923774AReduce labor intensityIncrease productivityIngot casting plantsCasting cleaning apparatusSlagIngot casting

The invention provides an automatic slag removal machine for ingot casting. The automatic slag removal machine is characterized in that the machine comprises a cart mechanism, a lifting guide rail on the upper portion of the cart mechanism and slagging-off mechanisms on the lower portion of the cart mechanism, the cart mechanism and a continuous casting machine move synchronously and longitudinally, and the upper ends of the slagging-off mechanisms are arranged on the lifting guide rail. Longitudinal movement, ascending and descending and transverse movement are achieved through driving of a power machine, a series of movements such as slag fishing, slag lifting, deslagging and slag scraping can be automatically finished through the design of the simple special-shaped lifting guide rail, no more power machines or more complex structures are needed, and therefore manual slag removal is completely and thoroughly replaced, the slag removal movements are safe, flexible and reliable, the structure is simple, cost is low, labor intensity is lowered, production efficiency is improved, and safe production is guaranteed.

Owner:YUNNAN RUNXIN ALUMINUM

Tundish control

InactiveUS20050133192A1Facilitate low-level tundish operationQuality improvementCasting cleaning apparatusLevel indicatorsReal-time dataSlag

Microwave transmission and reception, and analysis thereof, are used to monitor the level of molten metal, paradigmatically steel, in a tundish receiving molten metal (steel) from a ladle or other vessel and passing it to the head of a continuous caster, while the steel in the tundish is covered with slag. The control factors may include level, weight or volume limits in the tundish derived from historical or real-time data, including data representing a predictable or developing vortex in the well feeding the continuous caster. The system is particularly useful in minimizing transition mix during change from one metal specification or grade to another.

Owner:USX CORP

Aluminum liquid submerged slag conveyor and slag conveying method

InactiveCN101745633AReduce labor intensityReduce pollutionCasting cleaning apparatusSlagPulp and paper industry

The invention discloses a submerged slag conveyor and a slag conveying method, in particular to a submerged conveyor and a slag conveying method used for casting large aluminium ingots.The aluminum liquid submerged slag conveyor is composed of the following structure: a machine frame is provided with an actuating device and a track, the track is internally provided with roller wheels which are arranged on a movable cart, the actuating device and the movable cart are fixed, the movable cart is connected with a movable frame on which a NO.2 cylinder is arranged, a NO.1 cylinder is fixed on the movable cart, a piston rod of the NO.1 cylinder is fixed at the lower part of the movable frame, the piston rod of the NO.2 cylinder is fixedly connected with a slag conveying plate.The invention has the following advantages and beneficial effects: the structure is simple, slag conveying effect is good, the cost is low, mechanical automation is realized, labor intensity is lowered and pollution to the environment is reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

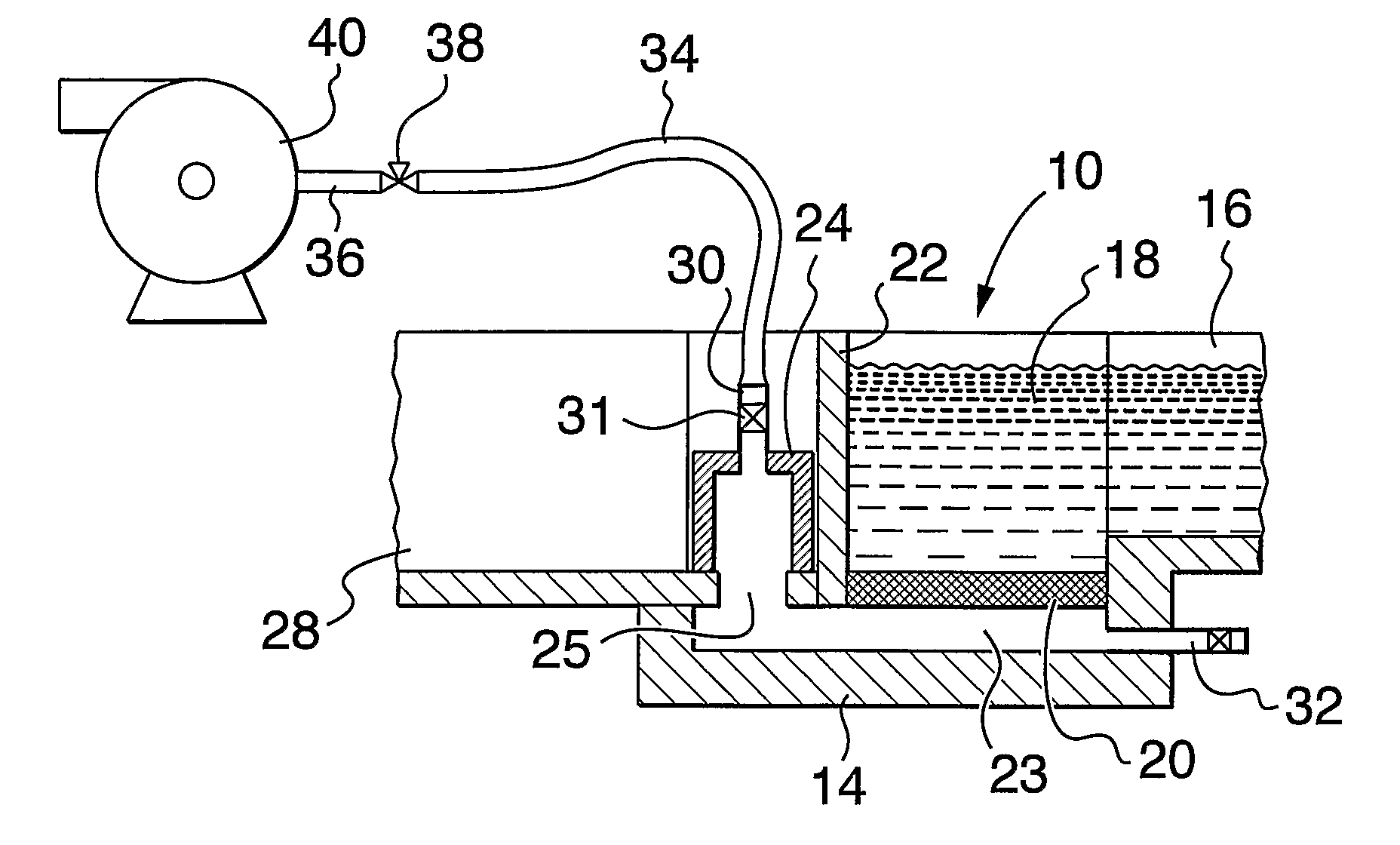

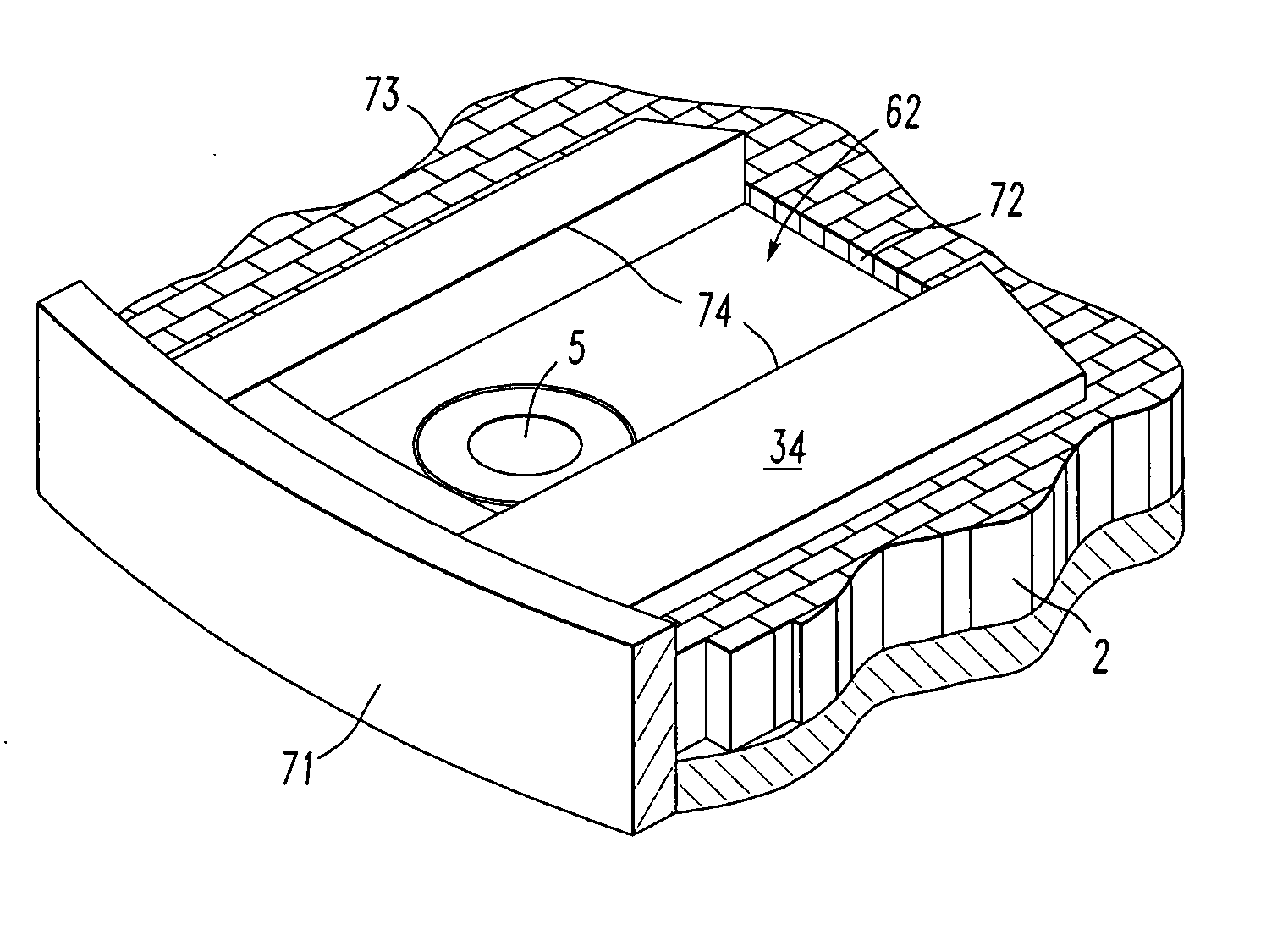

Method of priming filter for molten metal

ActiveUS7666248B2Quickly release withoutLevel of vacuumBlast furnace detailsCasting cleaning apparatusFiltrationPorous ceramics

A method is described for priming an in-line molten metal filtration unit having a porous ceramic or refractory filter mounted substantially horizontally in a filter box. This filter box has an inlet for molten metal and an outlet for molten metal, the outlet being a closeable outlet in an exit well connecting to the downstream side of the filter. The method of the invention comprises the steps of adding a molten metal to the filter box sufficient to entirely cover the upstream side of the filter with a depth of molten metal and temporarily sealing the outlet in the exit well. A steadily increasing vacuum is then applied to the closed exit well at a rate between 0.1 and 10 kPa per second by withdrawing a stream of air from the exit well by means of a fan or air venturi until molten metal begins to flow through the filter. At that point the vacuum is quickly released and the molten metal outlet is opened. Once the filter has been primed in this manner, flow of metal through the filter continues while requiring only a relatively low head of molten metal on the inlet side of the filter.

Owner:ALCAN INT LTD

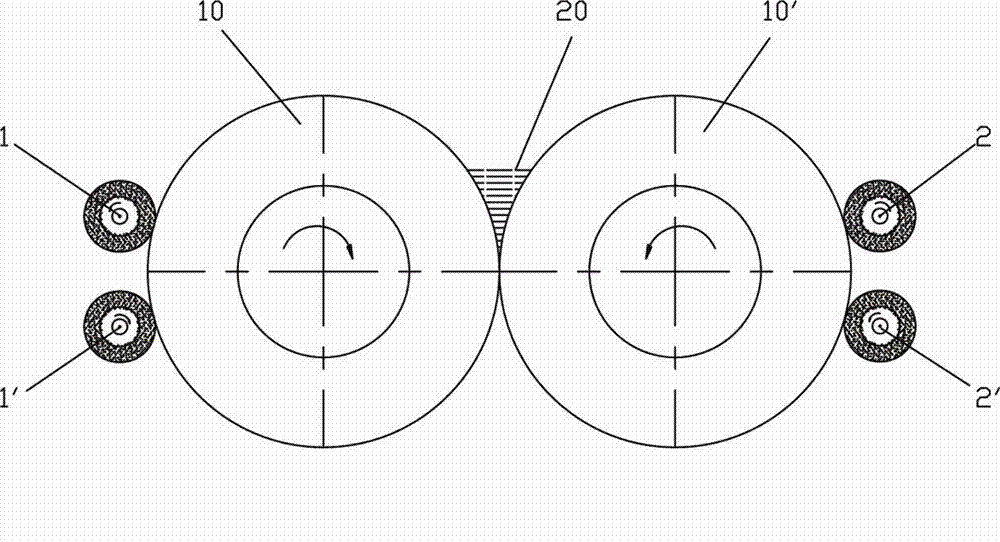

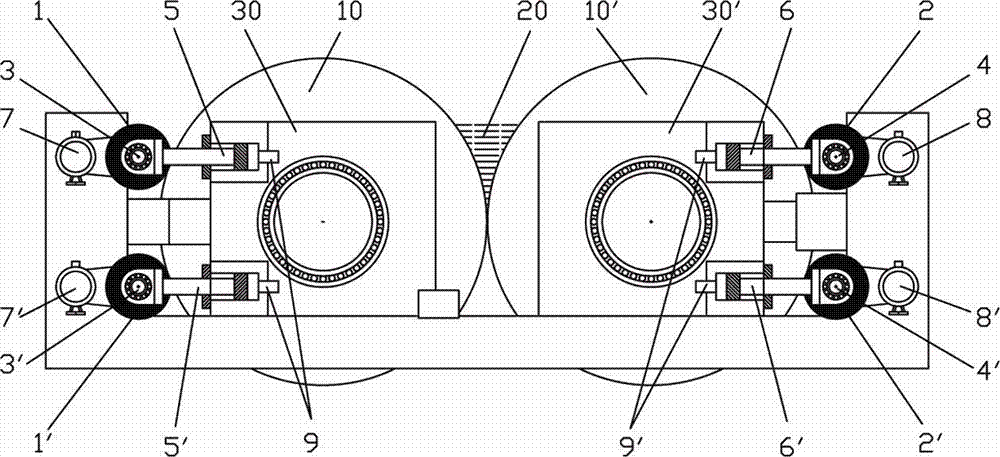

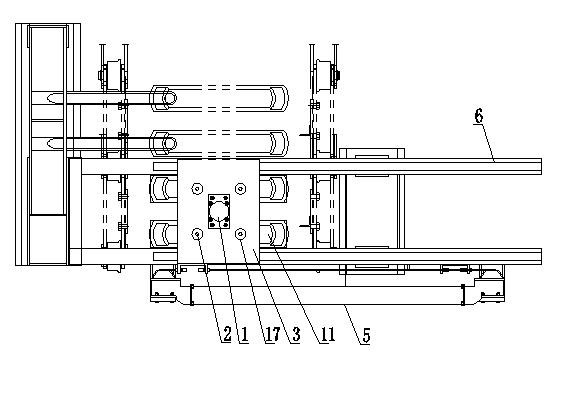

Method and device for cleaning surface of dual-roller thin-strip casting roll

ActiveCN102950276AEasy to cleanImprove cleaning qualityCasting cleaning apparatusHydraulic cylinderMetallurgy

The invention relates to a method and device for cleaning the surface of a dual-roller thin-strip casting roll. The surface of each casting roll of a dual-roller thin-strip continuous casting machine is cleaned by adopting two brush rolls arranged up and down, wherein the rotation direction of at least one brush roll is the same as that of each casting roll; the linear speed of each casting roll is constant and is more than the rotating speed of the casting roll, the device for cleaning the surfaces of the rolls controls the distance or pressure between the brush rolls and the casting rolls through a hydraulic cylinder fixed on a casting roll bearing seat; and the efficiency of cleaning the surfaces of the rolls is ensured through controlling the flattening quantity to be less than the average pit depth of the surfaces of the textured casting rolls by 1-10 times. According to the invention, in a process of casting the dual-roller thin-strip continuous casting process, the cleaning effect of the thin-strip continuous casting rolls can be improved, the heat conduction coefficient of the surfaces of the rolls is uniform, and the casting strip quality is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

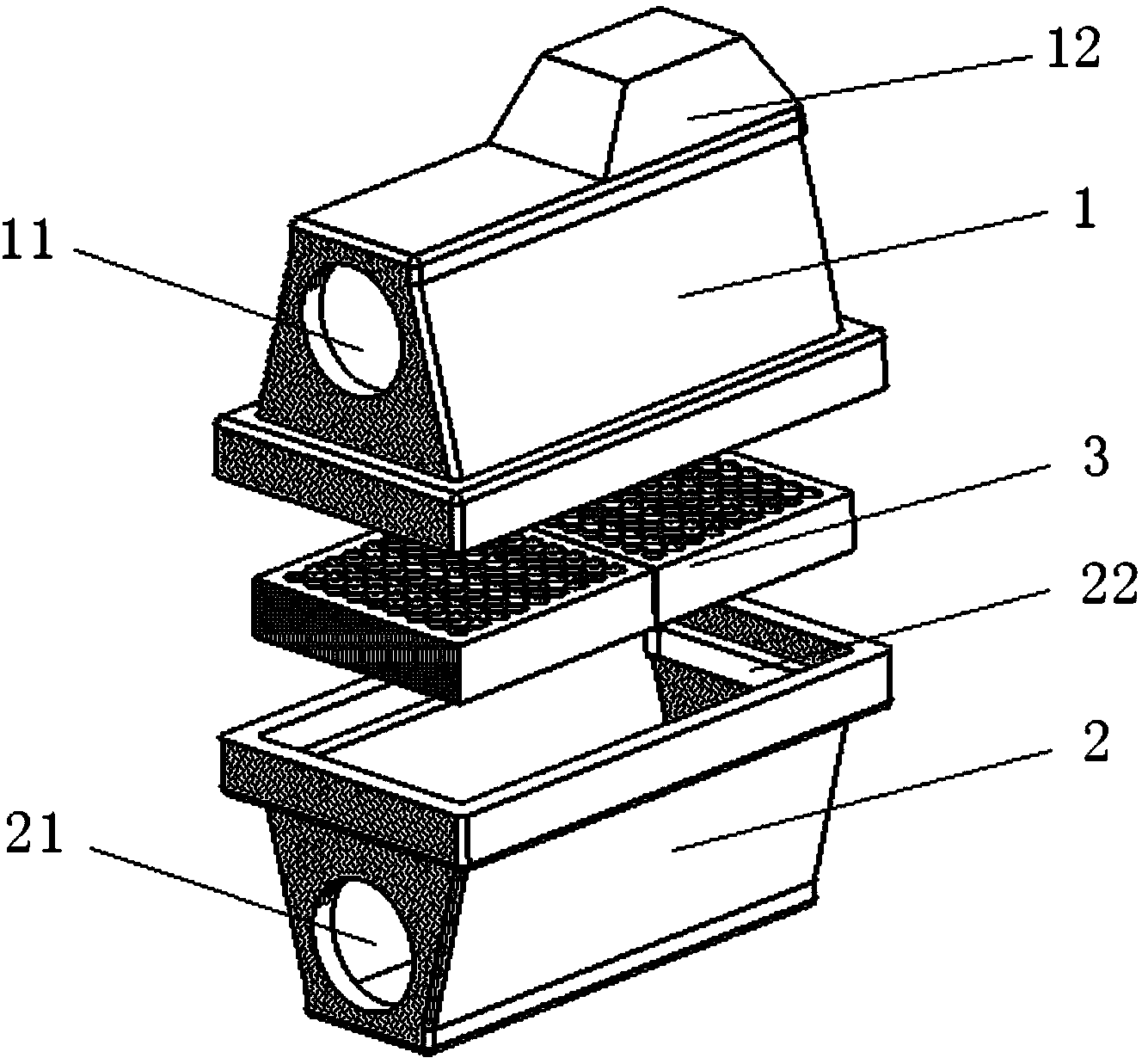

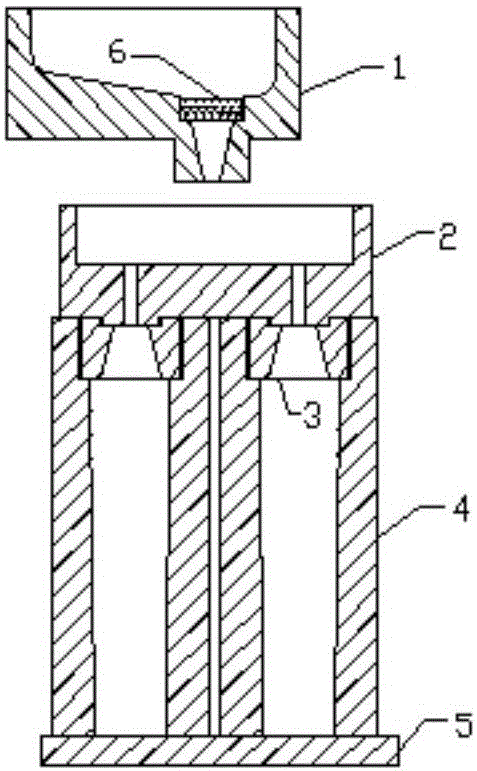

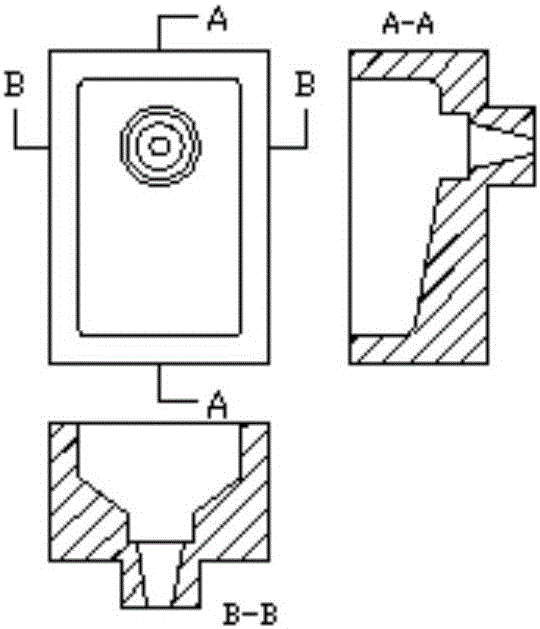

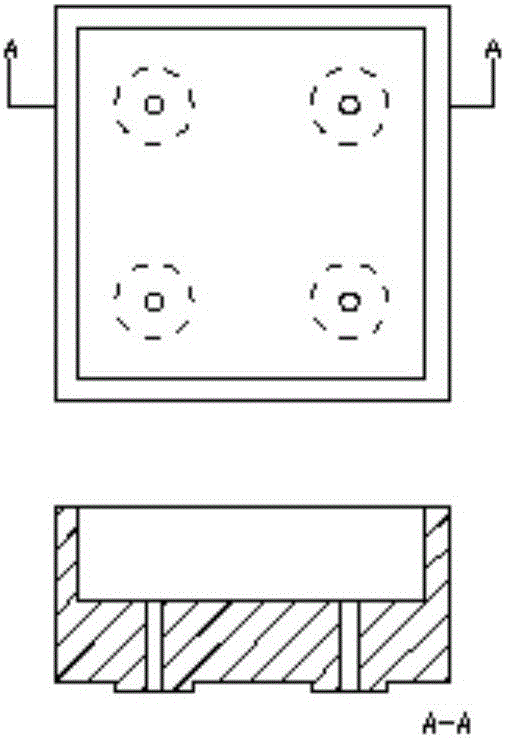

Molten metal filtering device

InactiveCN104128599AImprove filtering effectAvoid risk of breakageCasting cleaning apparatusFiltration separationMolten metal

The invention relates to a molten metal filtering device. The molten metal filtering device comprises a liquid inlet bin, a liquid outlet bin and multiple filters, wherein the liquid inlet bin is located on the upper portion of the filtering device and provided with a liquid inlet, and the liquid inlet is formed in the wall of the liquid inlet bin; the liquid outlet bin is located on the lower portion of the filtering device and provided with a liquid outlet; the multiple filters are arranged between the liquid inlet bin and the liquid outlet bin in parallel. The molten metal filtering device is suitable for casting of heavy castings and easy to manufacture.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

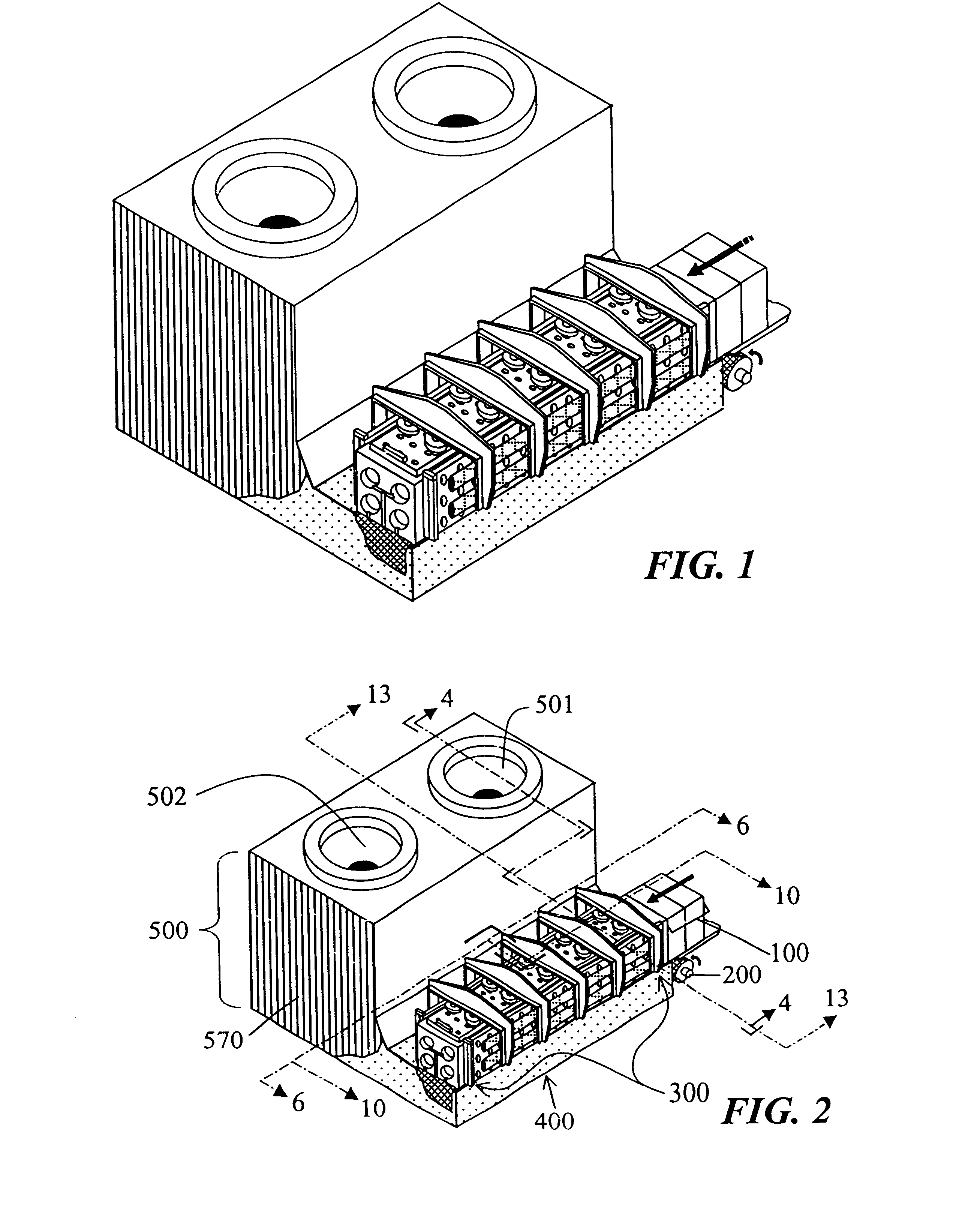

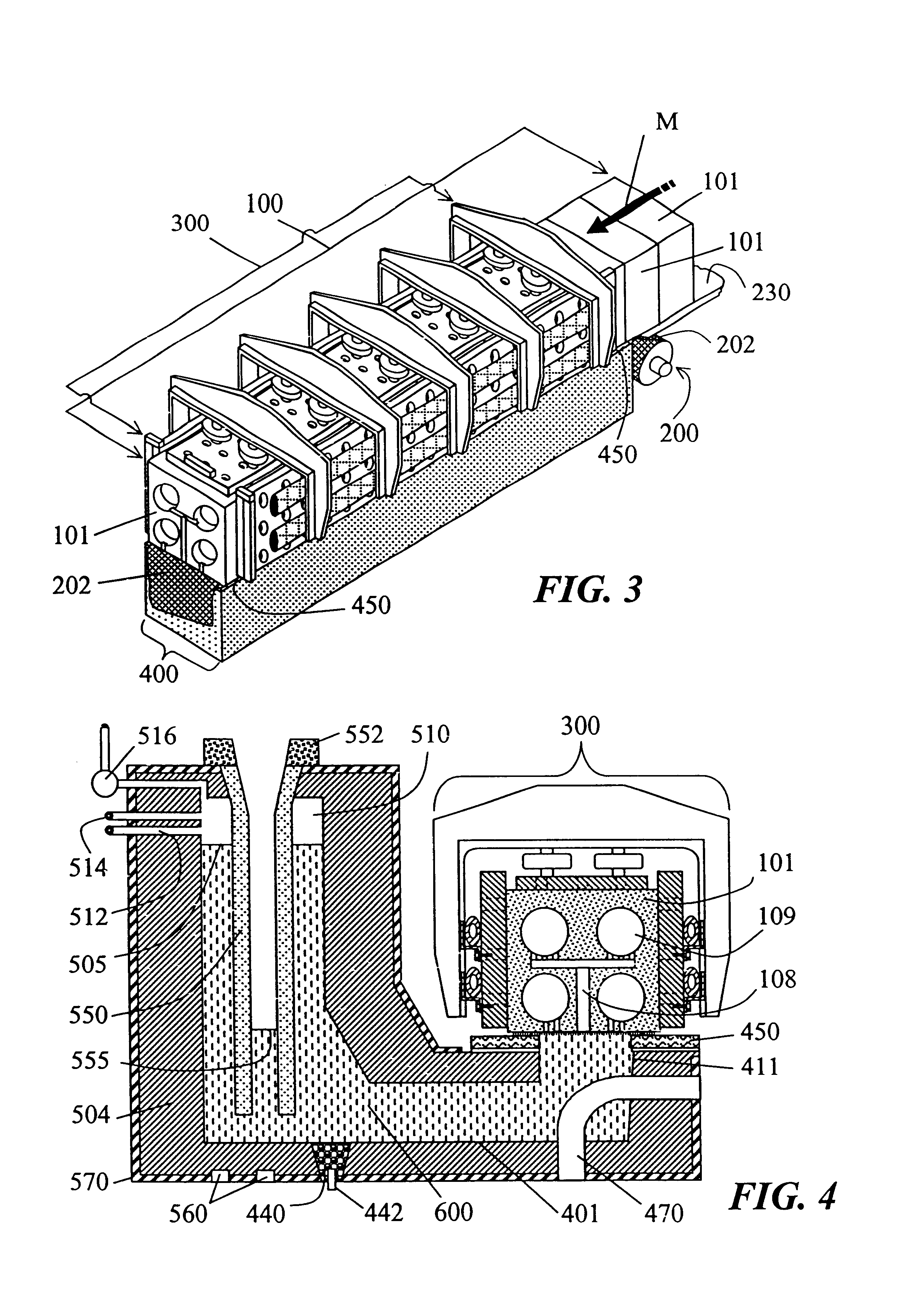

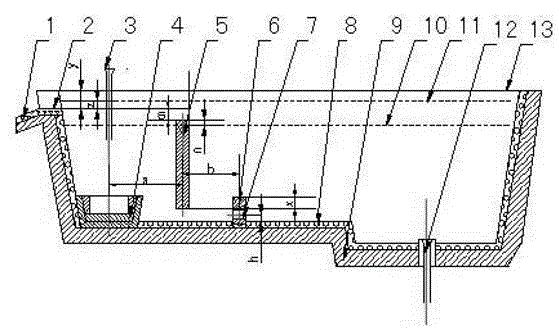

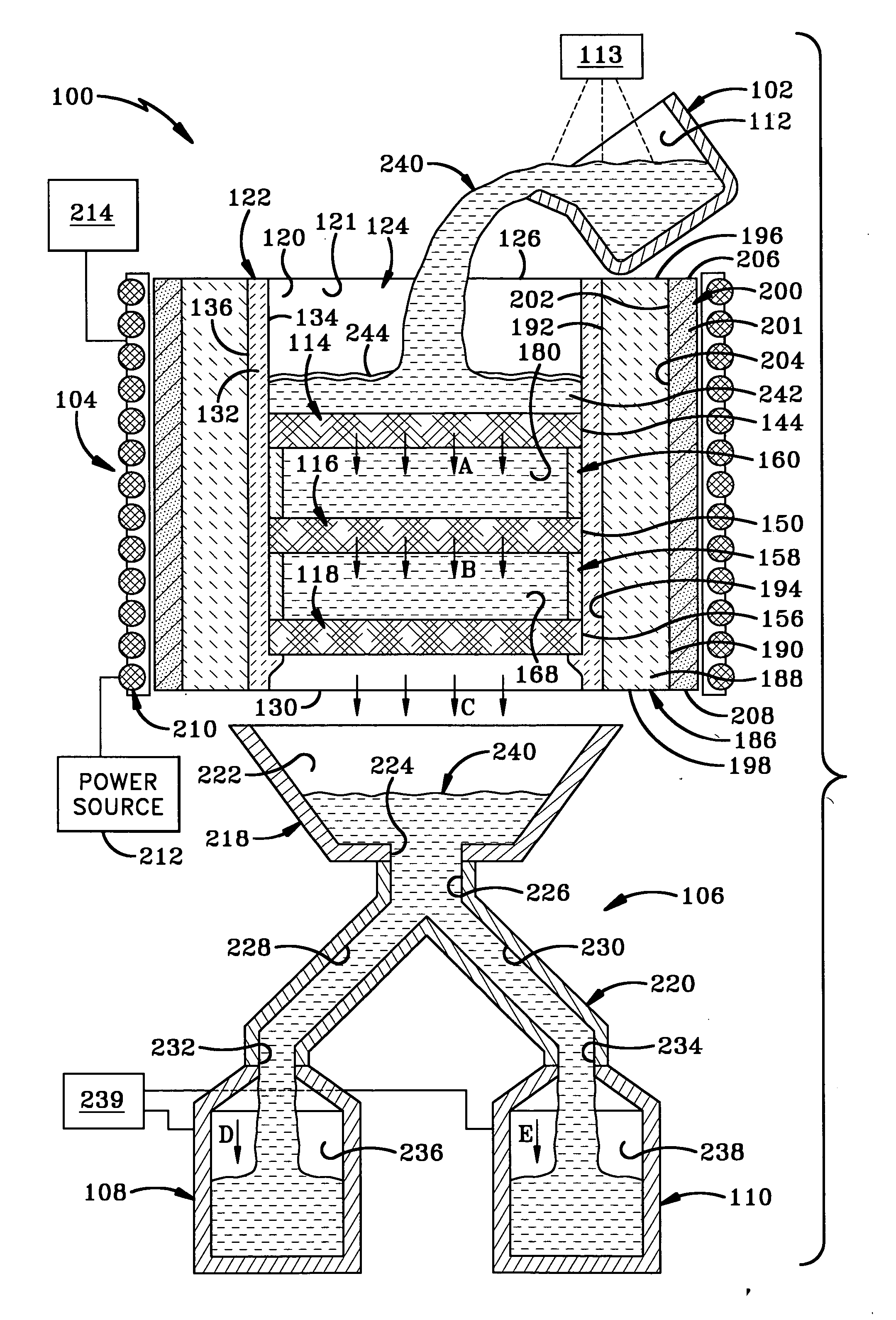

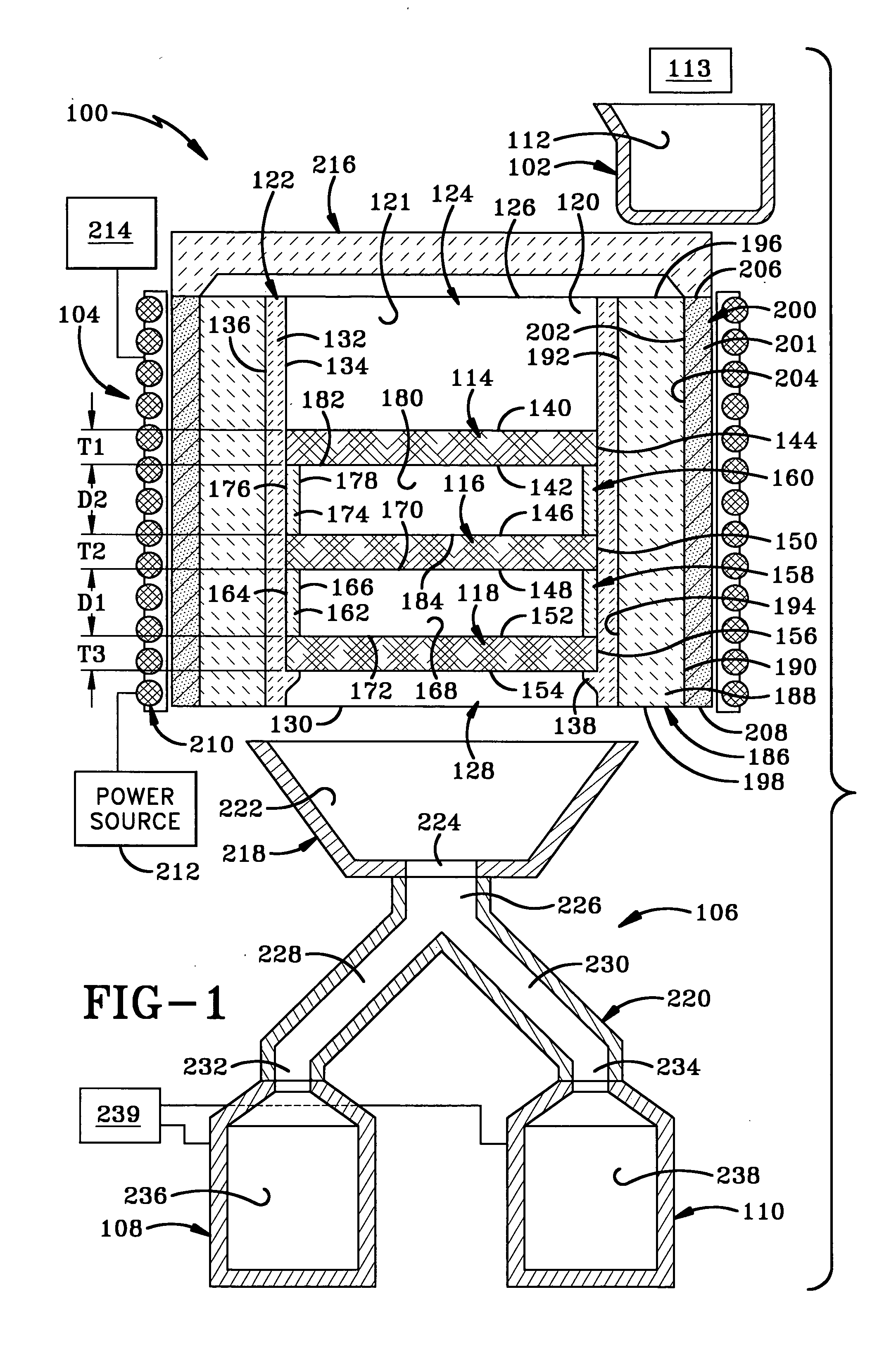

Direct casting utilizing stack filtration

InactiveUS20070022841A1Avoid breakingPrevent thermal shockCasting cleaning apparatusProcess efficiency improvementFiltrationThermal shock

A casting system includes a filtration assembly including a filter vessel housing spaced filters pre-heated to a temperature approximating a pouring temperature of molten material to be filtered to prevent breakage of the filter due to thermal shock from contact with the molten material. Preferably, an induction coil is used to inductively heat a susceptor adjacent the filter vessel or inductively heat filters which themselves serve as susceptors. Typically, the filter vessel is disposed below a pouring vessel and above a mold, pour cup and any sprue system used and is heated independently from the same. The filters are heated during pouring to facilitate flow of the molten material therethrough whereby very fine filters may be used. Spacing of the filters enhances flow control and allows a head of molten material to form whereby dross floats to the top of the head to prevent its entry into the mold.

Owner:AJAX MAGNETHERMIC CORP

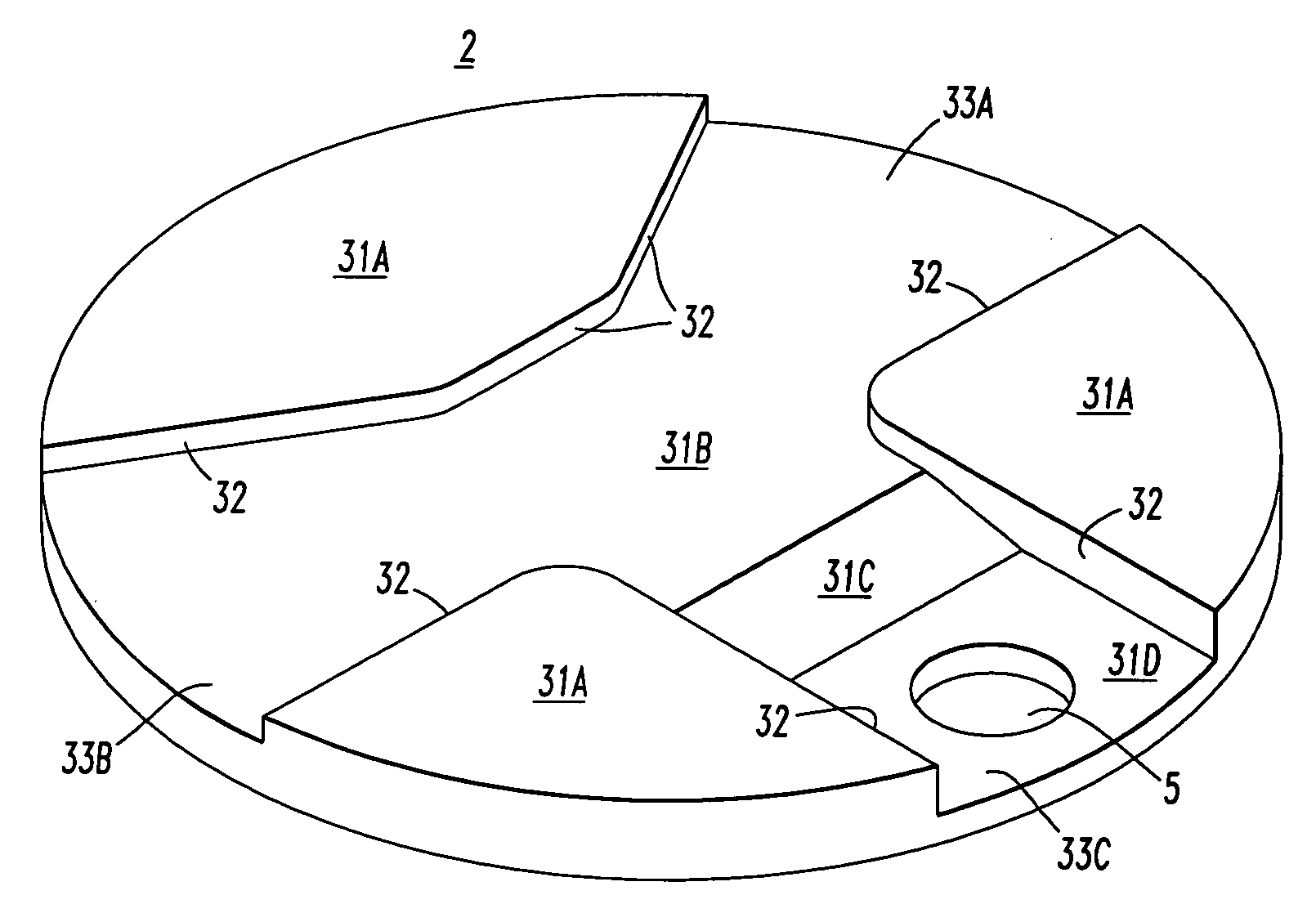

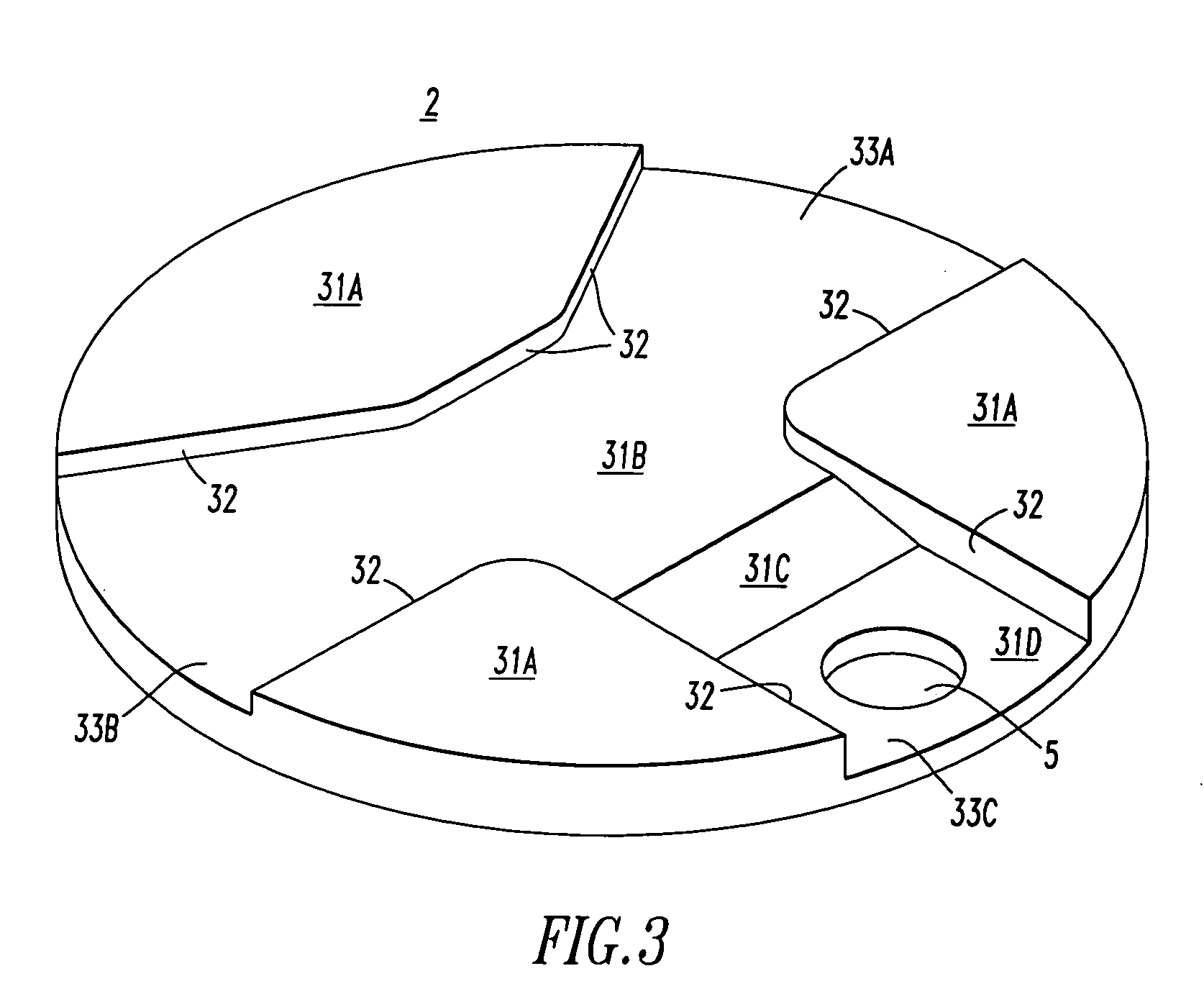

Ladle bottom

InactiveUS20070029708A1Increase fractionImprove efficiencyMelt-holding vesselsBlast furnace detailsMolten slagMaterials science

The present invention relates to a ladle block for use in a bottom of a molten metal ladle. The ladle block reduces the amount of contaminants, particularly slag, exiting the ladle during casting operations. The ladle block includes a floor defining an outlet and sidewalls substantially orthogonal to the floor. The floor and sidewalls define a channel having dimensions of length, width and height. Channel dimensions are determined from the Froude number, which is based at least partially on the casting flow rate.

Owner:VESUVIUS USA CORP

Slag conglomerating and skimming method and device

The invention relates to the field of molten iron pretreatment desulfurization processes, in particular to a slag conglomerating and skimming method and a device. The slag conglomerating and skimming method sets a traveling wave magnetic field; the phase of the magnetic field is controlled to enable the moving direction of molten iron driven by the traveling wave magnetic field to point to a ladle port; the traveling wave magnetic field enables the molten iron to flow to the ladle port under the effect of electromagnetic force, so that molten iron slag is conglomerated in the ladle port; and when the conglomerated molten iron slag is higher than the ladle port, the molten iron slag can overflow a ladle to enter a slag receiving tank so as to realize the ladle slag skimming. The slag conglomerating and skimming device comprises an electromagnetic winding and the slag receiving tank; the electromagnetic winding is arranged above the ladle; the magnetic force line of a magnetic field generated by the electromagnetic winding is pointed to an area of the ladle port; and the slag receiving tank is arranged below the ladle port. The slag conglomerating and skimming process is finished under non-contact conditions without generating the molten iron oscillation phenomenon; the molten iron nearly has no loss; the precise slag conglomerating and skimming operation is realized without polluting the molten iron; and the ton steel energy consumption can be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

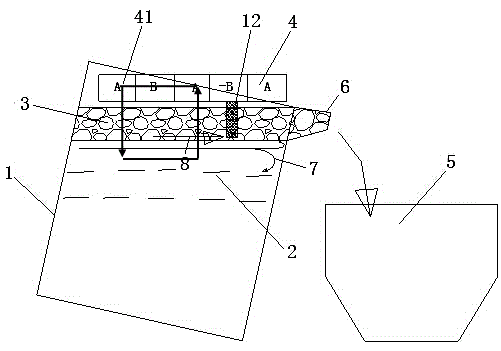

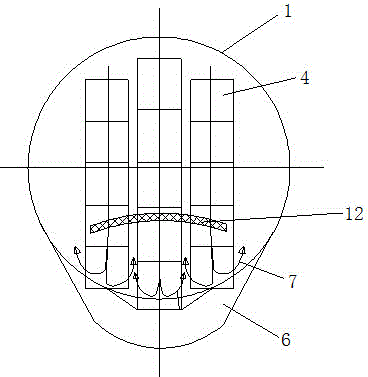

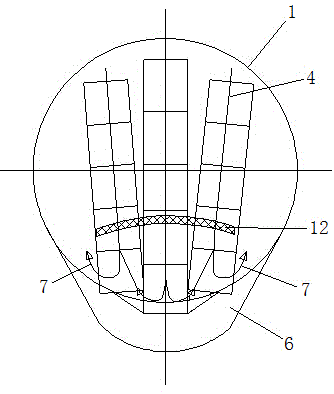

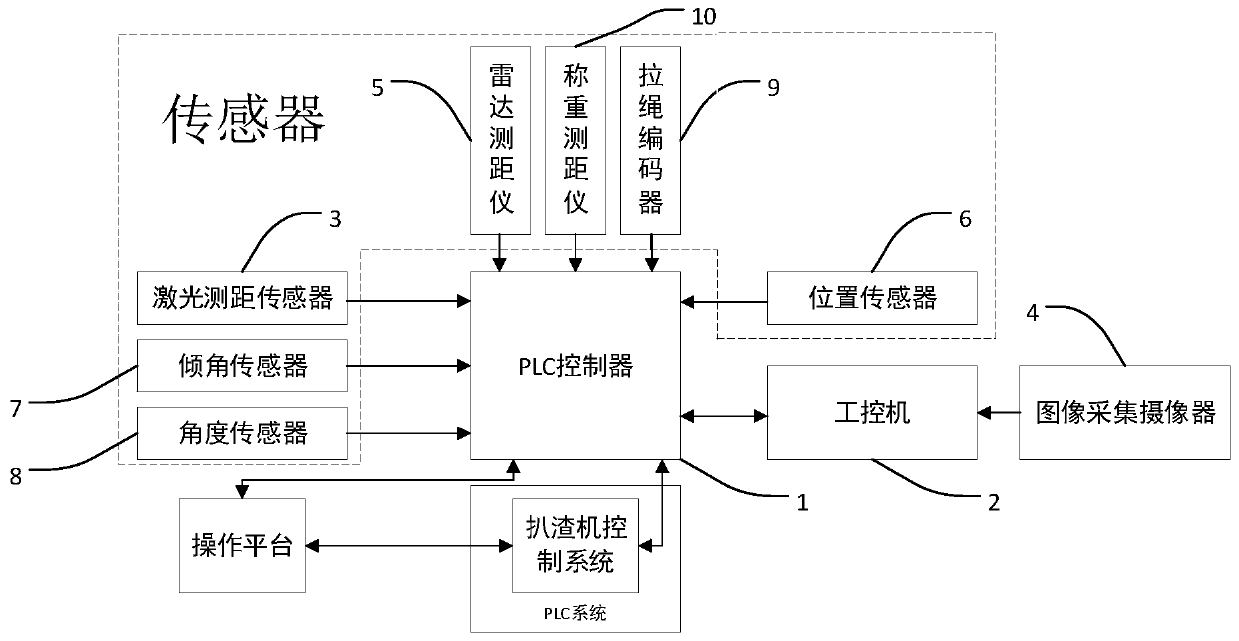

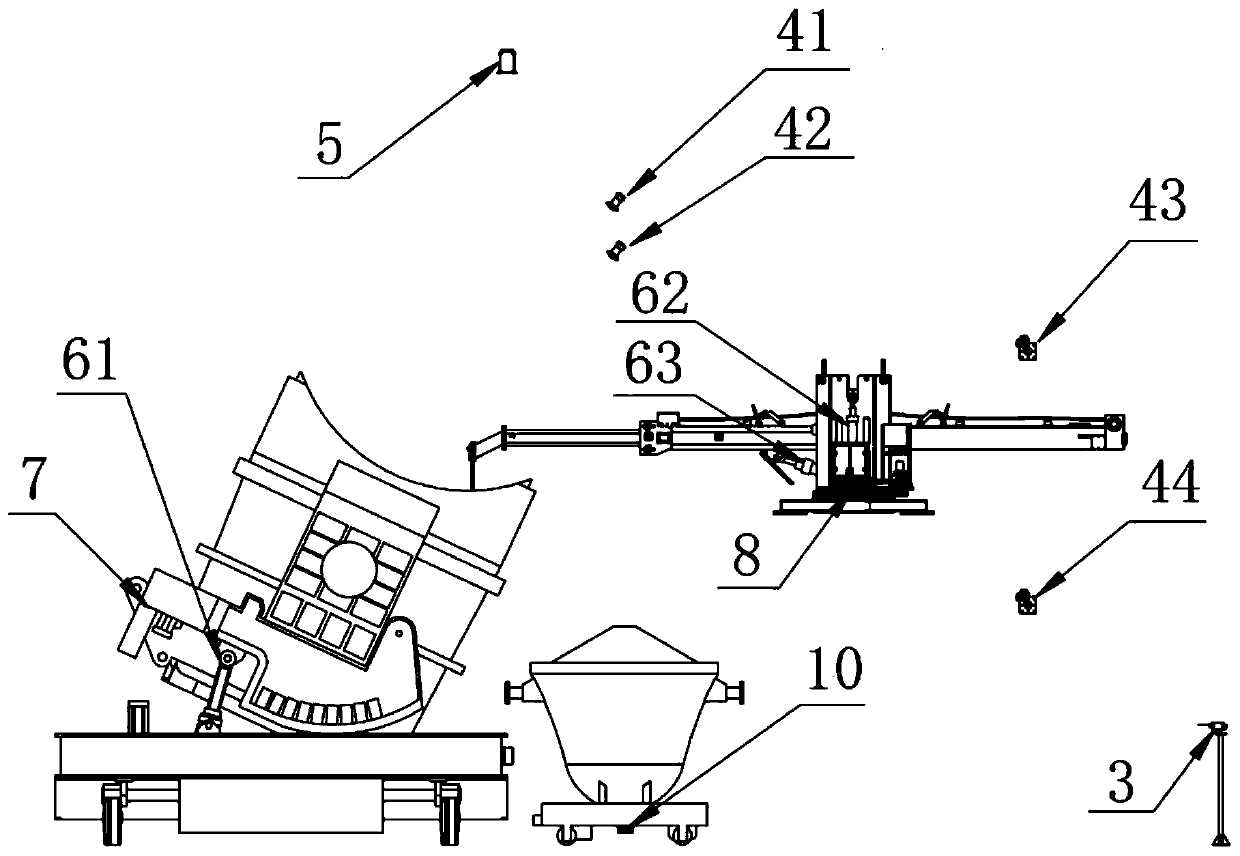

Hot metal ladle slagging-off control system, slagging-off machine and hot metal ladle automatic slagging-off control method

InactiveCN111349753AImprove pick-up rateReduce sulfur contentCasting safety devicesCasting cleaning apparatusLaser rangingControl system

The invention provides a hot metal ladle slagging-off control system. The hot metal ladle slagging-off control system comprises a laser distance measuring sensor, an image acquisition camera, a radardistance measuring instrument, a first position sensor, a tilt angle sensor, a pull rope encoder, a angle sensor, a second position sensor, a first weighing sensor, a first image acquisition camera, asecond image acquisition camera, a second weighing sensor, a cabinet and automatic slagging-off control software, wherein the laser distance measuring sensor is arranged on one side of a running track of a hot metal ladle car and is connected with a PLC, the image acquisition camera is arranged on the front surface of a dust hood above a hot metal ladle, the radar distance measuring instrument isarranged on the back surface of the dust hood above the hot metal ladle and is connected with the PLC, the first position sensor is mounted in an oil cylinder for controlling tilting action of the hot metal ladle and is in control connection with the PLC, the tilt angle sensor is mounted on the hot metal ladle car and is connected with the PLC, the pull rope encoder, the angle sensor and the second position sensor are mounted on a slagging-off machine and are connected with the PLC, the second position sensor can control the oil cylinder, the first weighing sensor is installed at the bottom of a slag basin transport vehicle and is connected with the PLC, the first image acquisition camera is installed on a platform of the slagging-off machine, the second image acquisition camera is installed above a slag receiving position of a slag basin, the second weighing sensor is installed at the bottom of the slag basin, and the cabinet comprises the PLC and an industrial personal computer.

Owner:HENGYANG RAMON SCI & TECH CO LTD

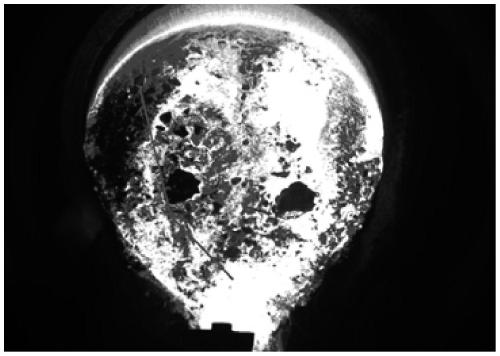

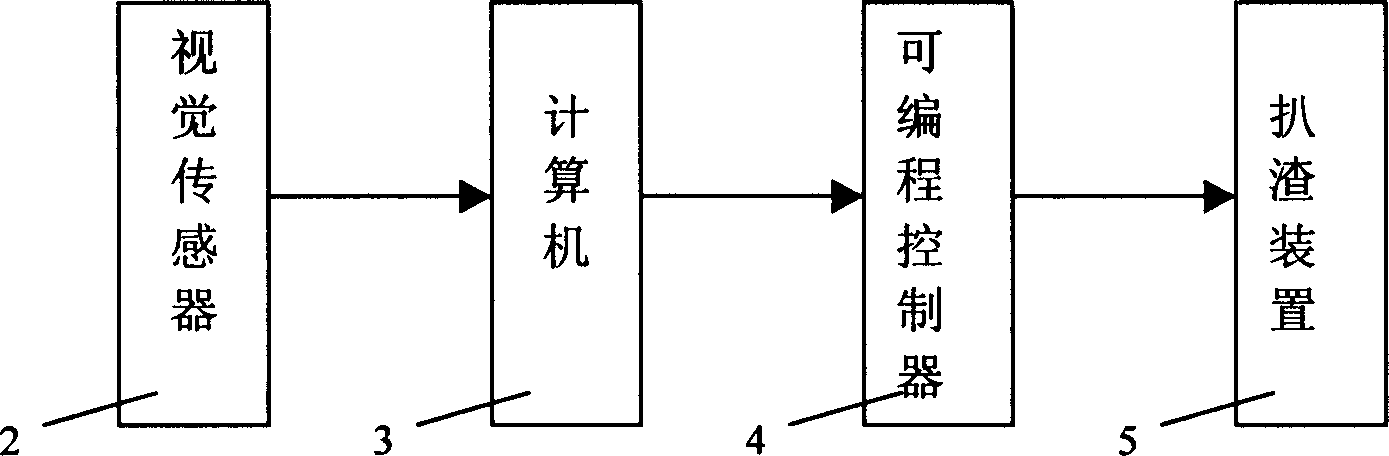

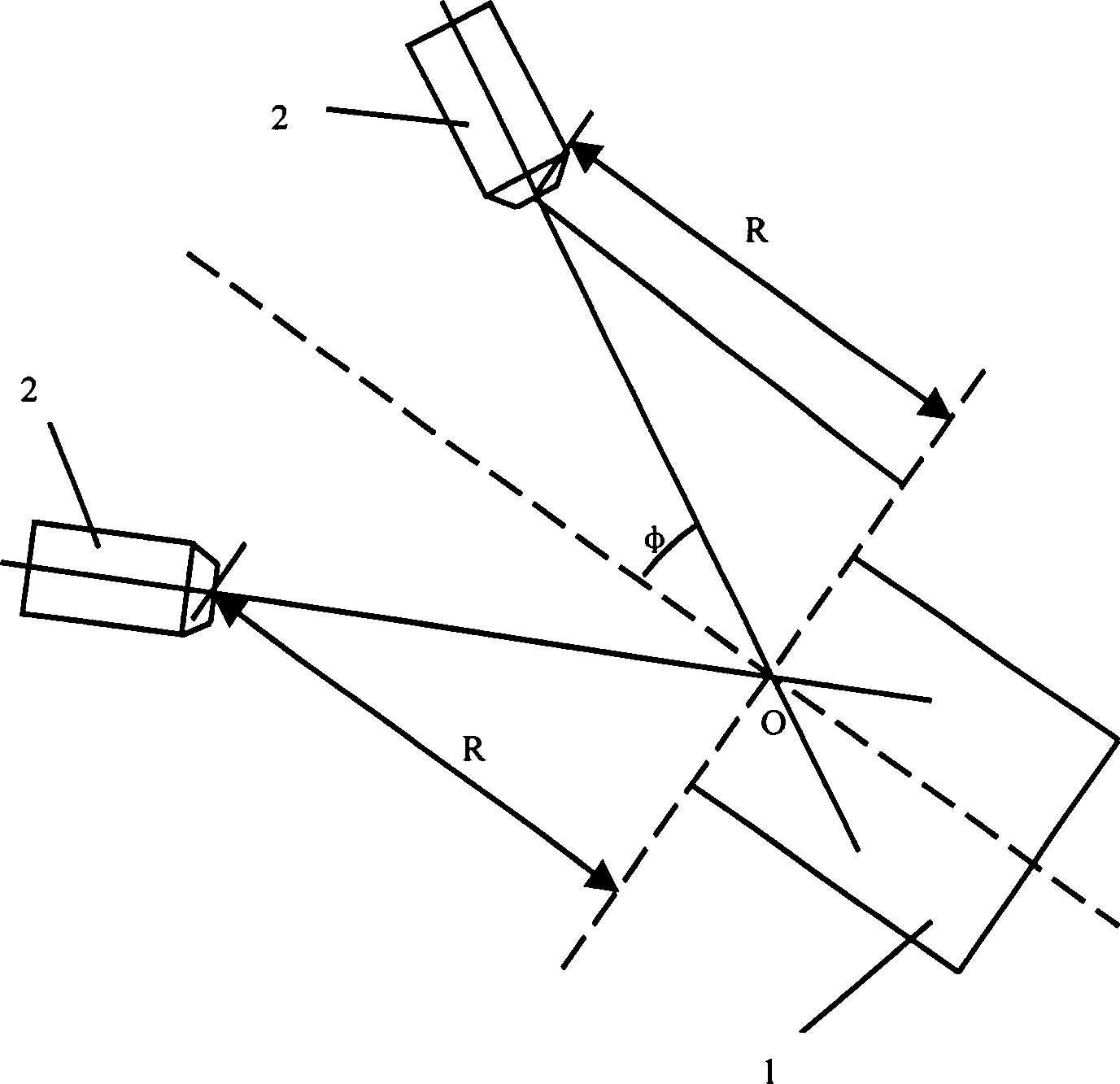

Automatic skimming method and apparatus

The present invention relates to a skimming method for auxiliary equipment in steel-smelting technique and an automatic skimming machine. It is characterized by that a visual sensor is mounted over the ladle, said visual sensor can be used for detecting steel slag on the surface of ladle, then the detected image can be inputted into computer, after having been processed by computer a signal can be outputted by computer and transferred into programmable controlled to control manipulator of skimming machine to implement skimming operation.

Owner:BAOSHAN IRON & STEEL CO LTD

Metal thin plate double roller acynchronous casting and rolling mill

The continuous metal sheet casting and rolling production apparatus consists of mainly solidifying roller, forming roller, asynchronous double roller driving mechanism, integral front box flow lip, liquid surface regulator and circulating water cooler. The present invention features that liquid metal is converted directly into sheet with homogeneous crystal grain structure in certain plastic deformation characteristic. The metal sheet has its solidification and formation completed separately in the position of the solidifying roller and the forming roller in different speed, which results in one increased kneading deformation to promote the formation of the sheet with plastic deformation structure characteristic. The present invention is suitable for production of metal sheet of different thickness and different kinds.

Owner:FUJIAN HUAMEI NEW TECH DEV

Submerged chain conveyor

InactiveCN102151807AAutomate operationsSolve the problems of high labor intensity, low work efficiency and low safetyIngot casting plantsCasting cleaning apparatusIngot castingSlag

The invention discloses a submerged chain conveyor which comprises a main cylinder, wherein the main cylinder is fixed on a platform which is provided with a plurality of guide sleeves, the bottom of the platform is provided with a plurality of idler wheel supports, idler wheels are arranged on the idler wheel supports and movably connected with two guide rails, one side of the platform is connected with a rodless cylinder, the rodless cylinder is fixed at two ends of the guide rails; a piston rod of the main cylinder is hinged with a support frame, the support frame is provided with two flat plates which are respectively used for mixing a lifting cylinder, a piston rod of the lifting cylinder is coaxially hinged with two connecting rods, each connecting rod is hinged with a hinge arm of a slag rake through a pin roll, the pin roll is movably connected with two supporting plates of the support frame; and the two flat plates of the support frame are fixedly provided with a plurality of guide columns, and the guide columns are movably connected with the guide sleeves on the platform. The invention overcomes the defects of large labor intensity and low working efficiency when workers drag for the slag under a high-temperature environment, difficulty in ensuring product quality, low safety and easiness in generating lead poisoning in the prior art, and is suitable for being matched with a lead alloy ingot casting unit or similar equipment for use.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

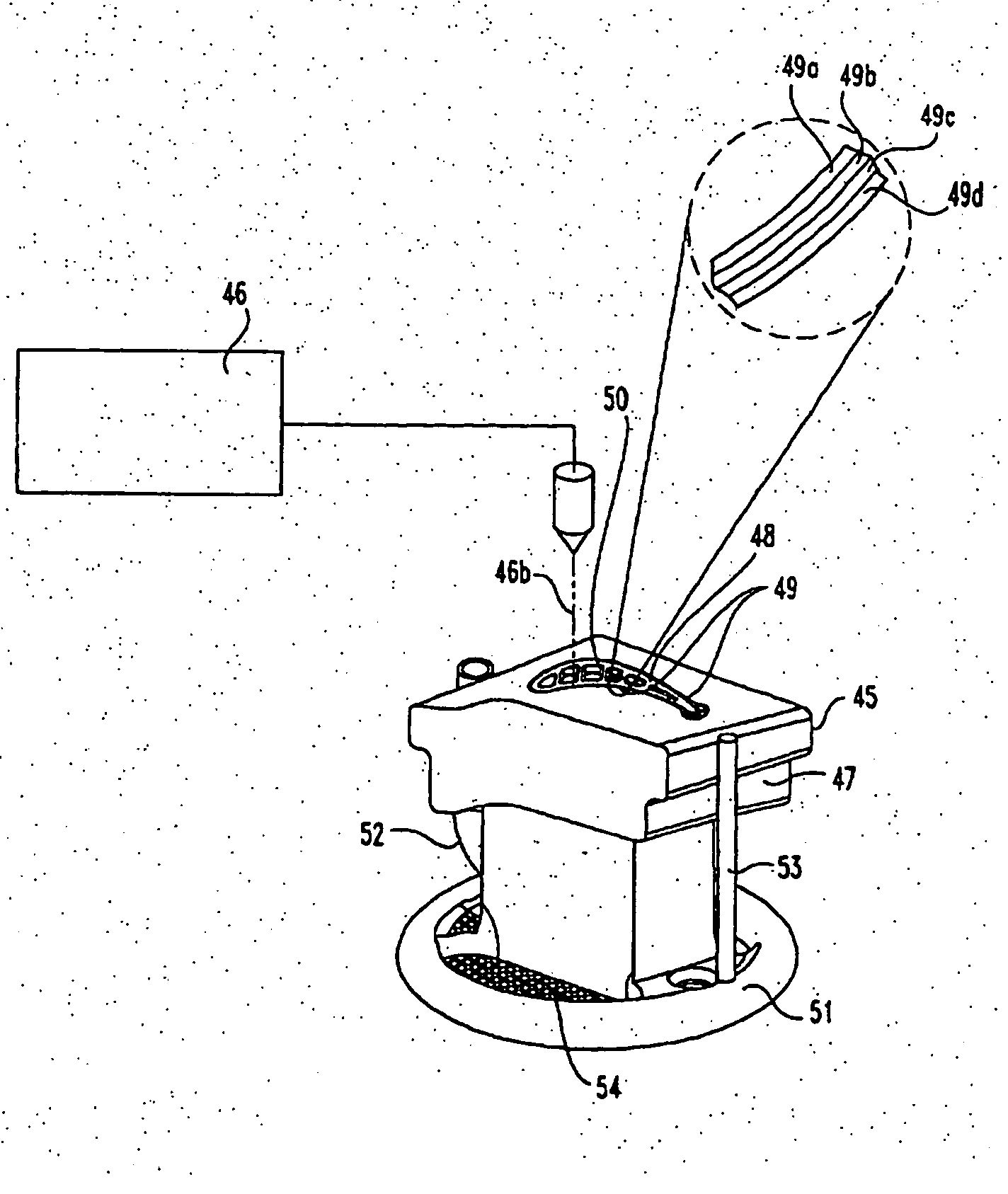

Method and apparatus for production of a cast component

InactiveUS20060118266A1Minimize transmission of heatGas turbine plantsFrom frozen solutionsCasting moldMolten metal

A system for producing cast components from molten metal. One form of the present invention includes a system for the precision pouring of molten metal within a casting mold.

Owner:ROLLS ROYCE CORP

Small-capacity master alloy casting system

InactiveCN105750515AExtend the floating timeTo promote floatingMelt-holding vesselsIngot casting plantsPorosityRefractory

The invention discloses a small-capacity master alloy casting system.The whole system is mainly composed of a prefabricated tundish, a square four-hole diverter, an embedded exothermic riser, an ingot mold and a refractory bottom plate, wherein the prefabricated tundish is provided with a zirconium oxide filter and internally provided with three oblique faces and one vertical face.The square four-hole diverter is connected with the embedded exothermic riser through refractory mortar, and the embedded exothermic riser is connected with the ingot mold through the refractory mortar.The three faces, away from a water gap, inside the prefabricated tundish are the oblique faces, the face, close to the water gap, inside the prefabricated tundish is the vertical face, and the porosity of the zirconium oxide filter in the tundish is 10 ppi.An inner hole of the ingot mold has taper, and the taper is about 3 degrees.According to the casting system, a single-station casting mode is adopted, and the diameter of produced master alloy is 80-90 mm.The casting system can be used for master alloy round bar production with testing or small-lot production as the purpose, produced master alloy round bars are free of shrinkage cavities, and the quality of products is good.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

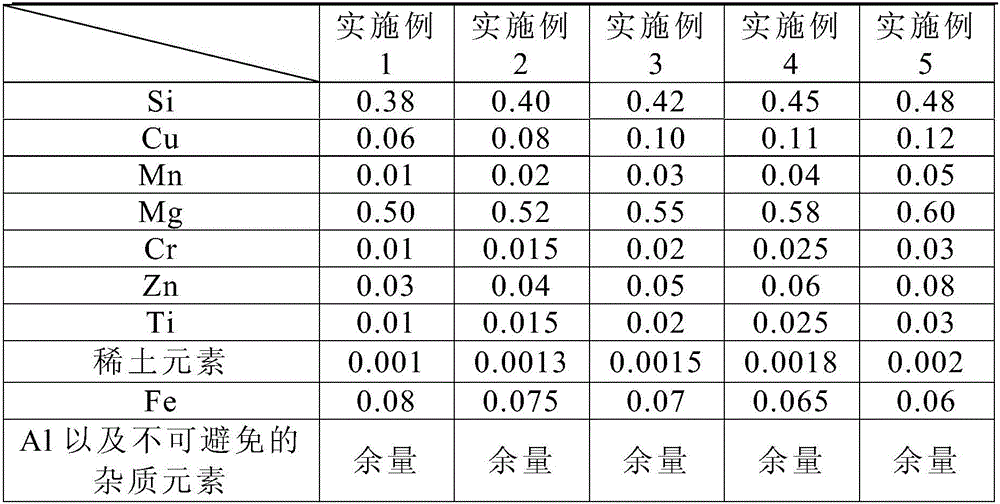

6042 aluminum alloy and preparation method thereof

InactiveCN105838942AHigh standardControl contentCasting cleaning apparatusRare-earth elementCrack resistance

The invention relates to a 6042 aluminum alloy and a preparation method thereof. The 6042 aluminum alloy is composed of the following components in mass percentage: Si: 0.38-0.48%, Cu: 0.06-0.12%, Mn: 0.01-0.05%, Mg: 0.50-0.60 %, Cr: 0.01‑0.03%, Zn: 0.03‑0.08%, Ti: 0.01‑0.03%, Fe≤0.08%, rare earth elements: 0.001‑0.002%, the balance is Al and unavoidable impurity elements, of which, a single The content of impurity elements is ≤0.02%, and the content of total impurity elements is ≤0.15%. The structure of the 6042 aluminum alloy of the present invention is better, and it can suppress or eliminate defects such as white lines, pitting and color difference when used in bright anodic oxidation production. The glossiness is 350-450, and it has better appearance quality, corrosion resistance and high temperature resistance. Crackability and other properties.

Owner:HUAIAN HETONG AUTOMOTIVE COMPONENTS CO LTD

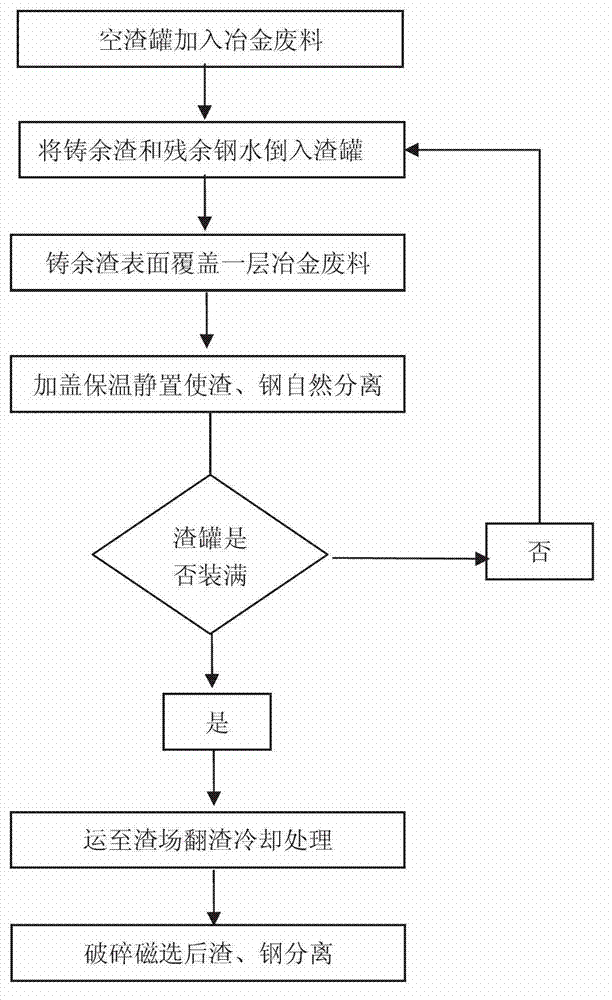

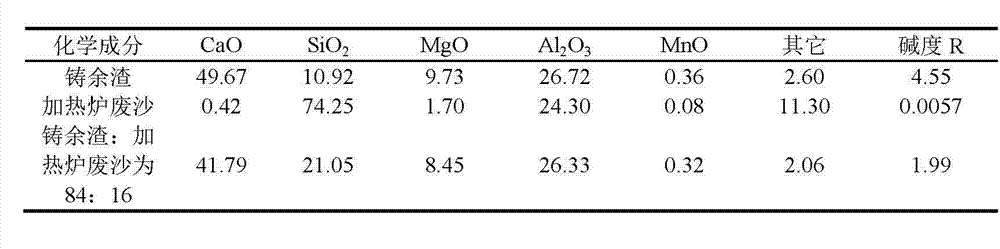

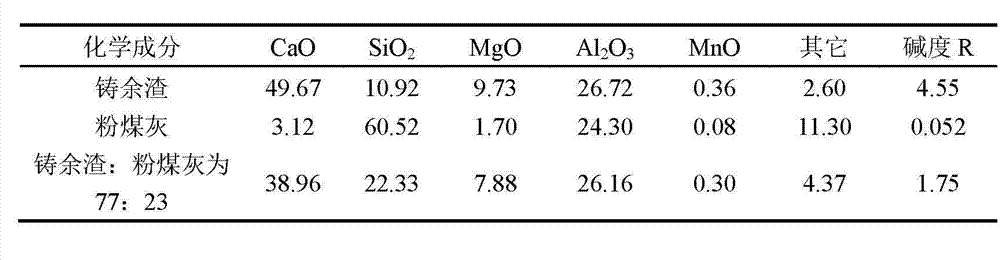

Method for separating and recycling casting residues

ActiveCN102896310ALow melting pointImprove liquidityCasting cleaning apparatusRecycling and recovery technologiesMolten steelFerric

The invention discloses a method for separating and recycling casting residues, which comprises the following steps: paving acidic metallurgy wastes being 13%-15% of primary casting residues into an empty residue tank; pouring the casting residues and residual molten steel into the residue tank; coating by adding 16%-30% of metallurgy wastes to the liquid level of the residue tank; standing by and waiting for the pouring of the casting residues and residual molten steel in the next residue tank; transporting the residue tank to a residue field for turning the residues and cooling, after the residue tank is full; naturally layering the residues and irons after cooling; separating the residues from the steel after crushing and magnetically separating; and respectively applying the residues and the steel to the subsequent technologies. The method has the advantages that: the present equipment and the low-cost wastes are utilized; the technology is simple; the separating efficiency of the residues and residual steel is obviously increased after the method is applied; the residue and steel separation can be realized in continuous casting intermission; the cost of the separating technology of the residues and the residual steel is greatly reduced; the occupied area and the environmental pollution are reduced; the use level and value of the waste steel in the residual steel are increased; and the method has higher popularizing and applying value in the industry.

Owner:ANGANG STEEL CO LTD

3004 aluminum foil and preparing method and application thereof

The invention discloses 3004 aluminum foil and a preparing method and application thereof. The aluminum foil comprises chemical elements: by mass, 0.15-0.25% of Si, smaller than or equal to 0.55% of Fe, 0.14-0.2% of Cu, 1.02-1.15% of Mn, 0.95-1.1% of Mg, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.15% of Zn, 0.015-0.025% of Ti, smaller than 0.1% of other chemical elements andthe balance Al. The 3004 aluminum foil is obtained by performing 3004 aluminum alloy smelting, refining, standing, online degassing and deslagging, casting, face-milling, uniform heating treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing. With the combination of the various elements and the preparing process, the prepared aluminum foil has high strength and toughness, the thickness is greatly reduced when the aluminum foil is used as a container, use is convenient, and the consumption of the raw materials is reduced; and waste ring-pull cans can be adopted as a raw material, the consumption of the raw material is reduced, resources are reutilized, the source of the raw materials for preparing the aluminum foil is widened, meanwhile the burdens on the environment are avoided, the production cost is reduced, and the 3004 aluminum foil has quite good social economic benefits.

Owner:河南明泰科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com