Metal thin plate double roller acynchronous casting and rolling mill

A metal thin plate, casting and rolling machine technology, applied in metal processing equipment, mechanical cleaning, casting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Aluminum and its alloys

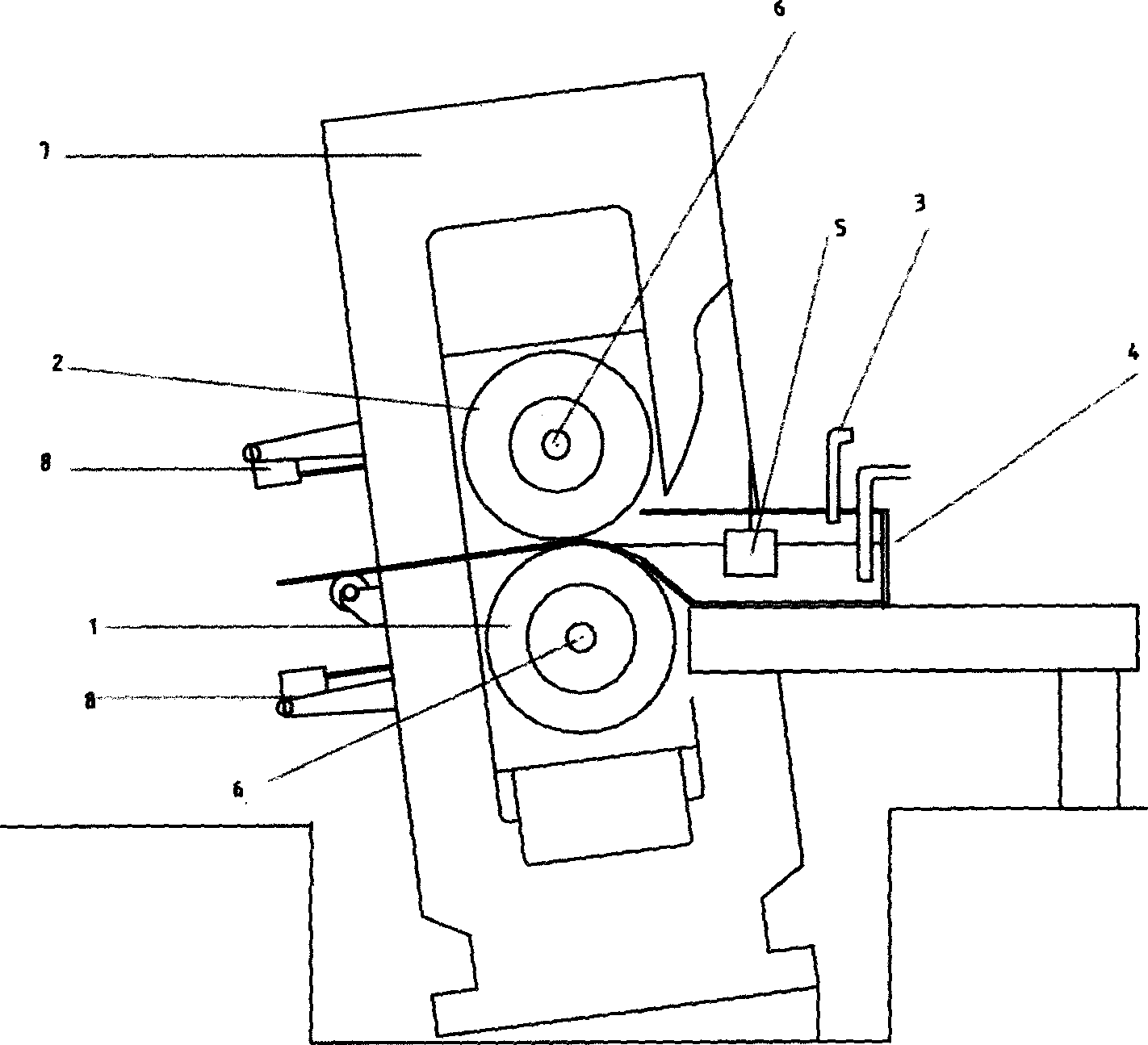

[0023] The coagulation roll (1) and the forming roll (2) are made of gun steel with good performance. In order to increase the cooling rate, aluminum oxide dispersion-strengthened copper can be used. The diameter of the roll is 600 mm, and there is a water-cooling tank inside. The linear speed of the roll rotation surface is 10-100 m / min, which is continuously adjustable, so that one machine can produce various types of aluminum and its alloy strips.

[0024] The feeding of integrated front box flow lip (4) is set on the side of the coagulation roller, the frame (7) is inclined 15° to the moving direction of the plate, and the molten metal is dragged by the coagulation roller (1) when it rotates; the thickness of the strip can be It is determined by adjusting the rotating speed of the roll, the heat conduction speed of the roll, the depth of the liquid in the flow lip (4), and the roll gap between the two rolls. The depth of the liquid metal a...

Embodiment 2

[0028] Magnesium and its alloys

[0029] The coagulation roll (1) and the forming roll (2) are made of gun steel with good performance. In order to increase the cooling rate, aluminum oxide dispersion-strengthened copper can be used. The diameter of the roll is 600 mm, and there is a water-cooling tank inside. The linear speed of the roll rotating surface is 20-120 m / min, which is continuously adjustable, so that one machine can produce magnesium and various alloy strips.

[0030] The feeding of integrated front box flow lip (4) is set on the side of the coagulation roller, the frame (7) is inclined 15° to the moving direction of the plate, and the molten metal is dragged by the coagulation roller (1) when it rotates, and the thickness of the strip can be adjusted. It is determined by adjusting the rotational speed of the roll, the heat conduction speed of the roll, the depth of the liquid in the flow lip (4), and the roll gap between the two rolls, and good results can be obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com