Patents

Literature

423results about "Oven air-treatment devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

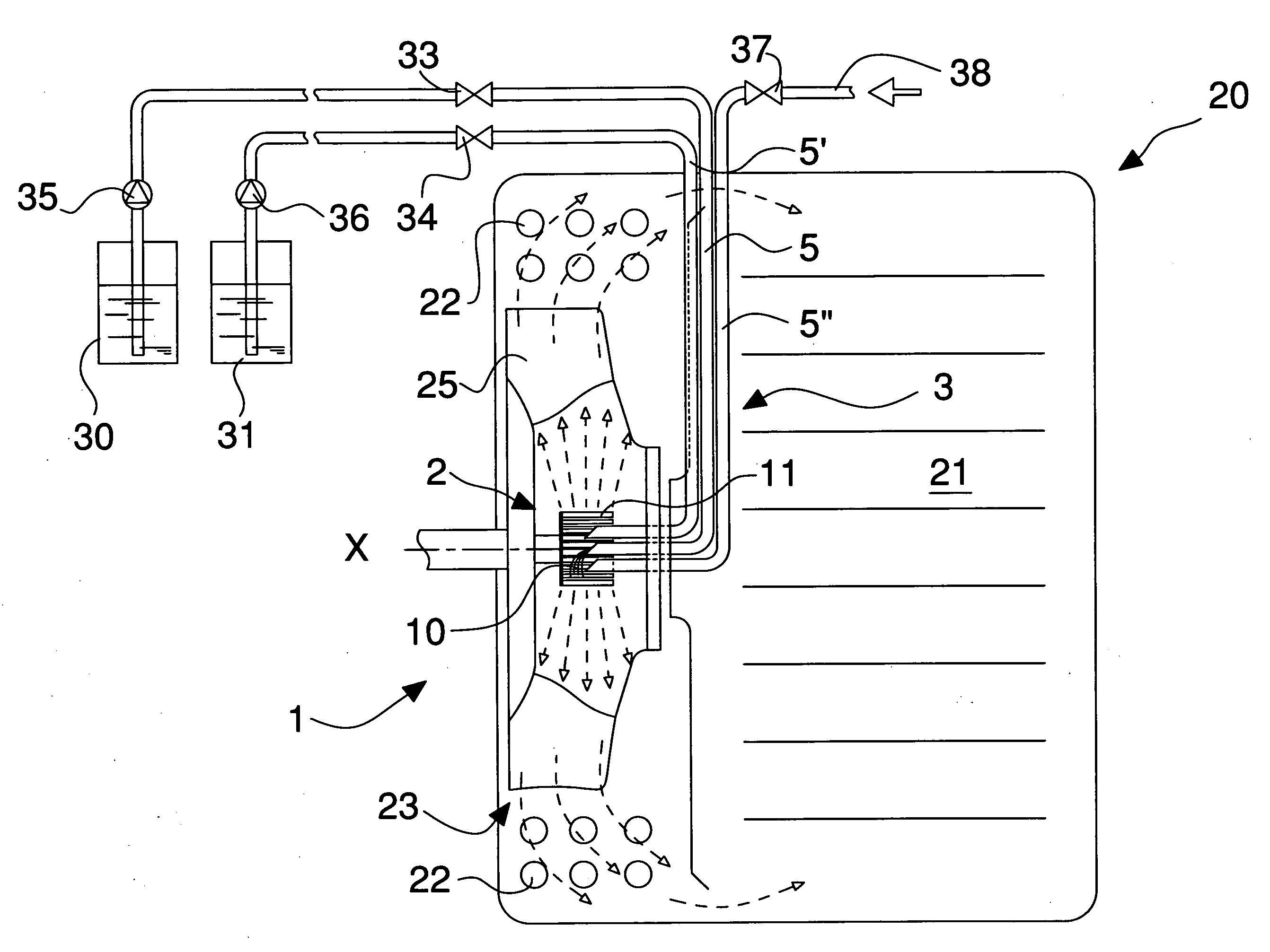

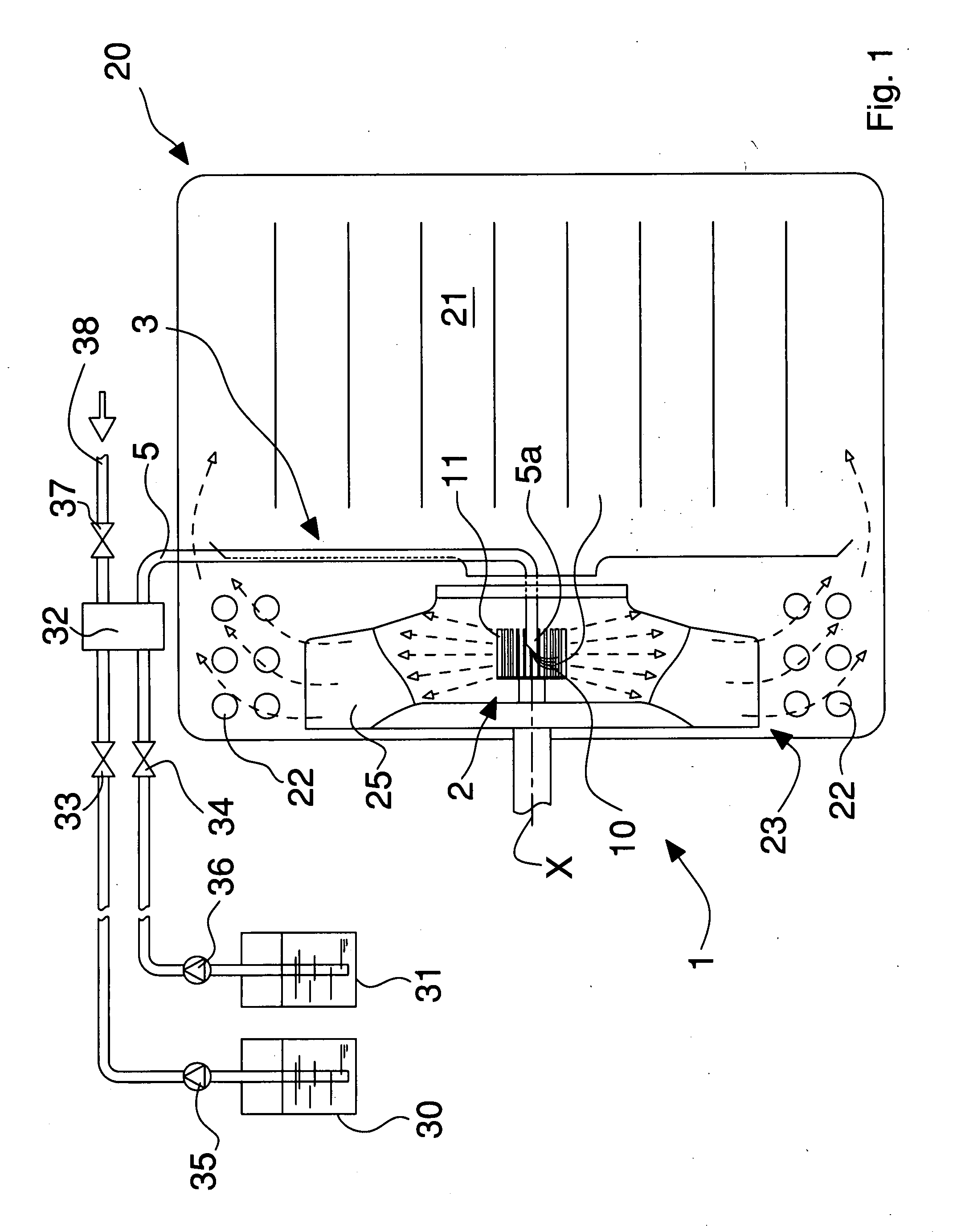

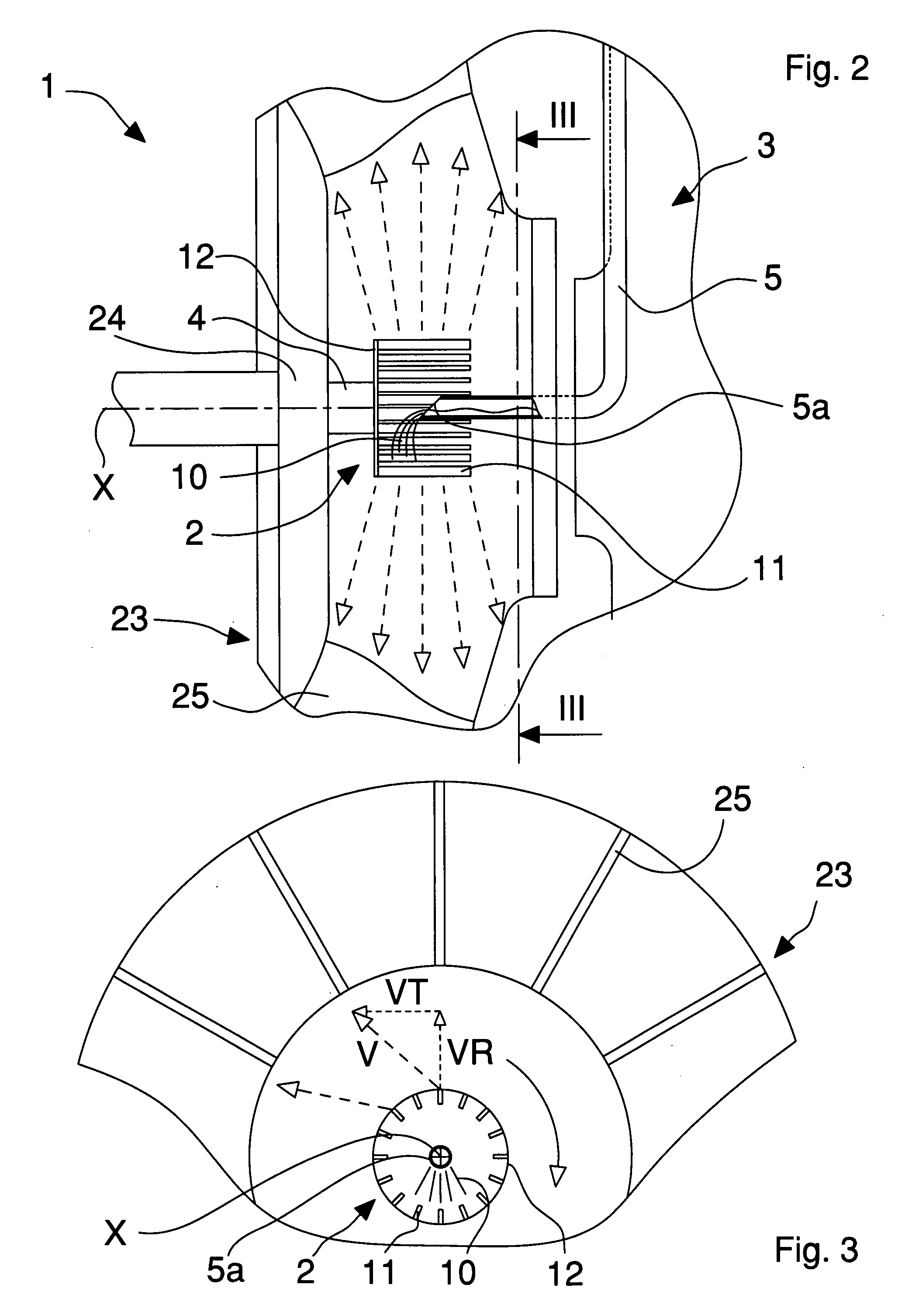

Nebulizing device for oven

InactiveUS20080078371A1Stable and reliableImprove efficiencySelf-cleaning stoves/rangesOven air-treatment devicesEngineeringMechanical engineering

Owner:ANGELO PO GRANDI CUCINE

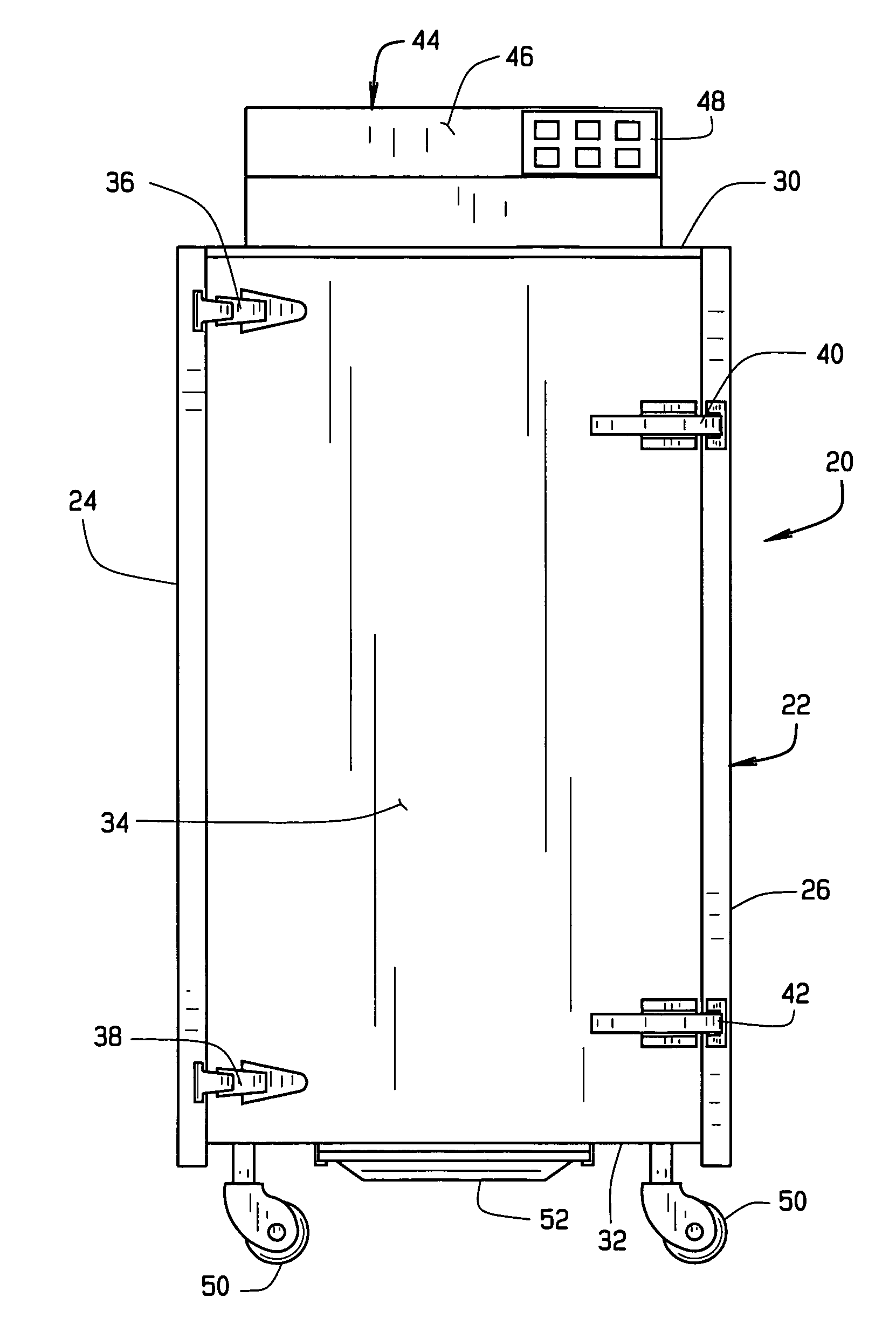

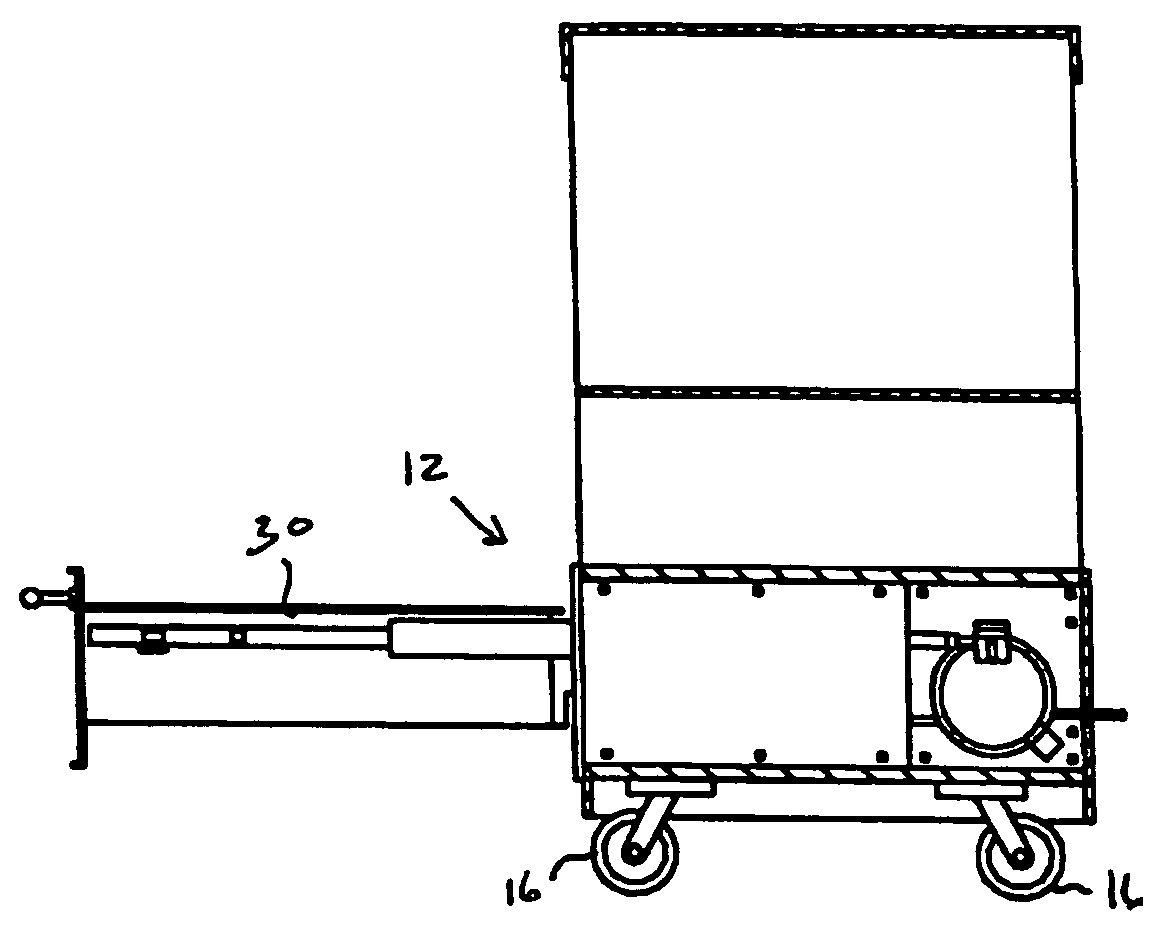

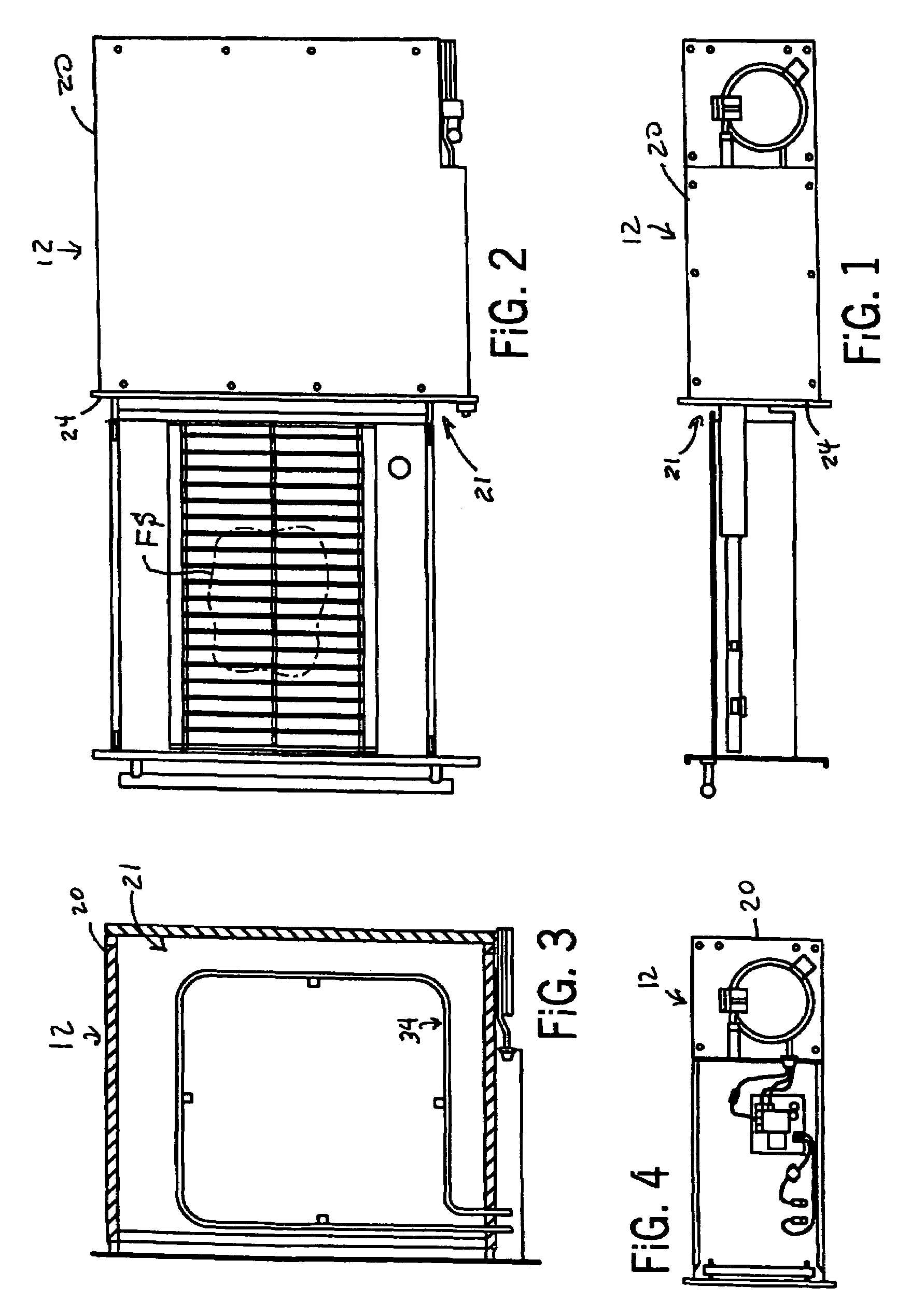

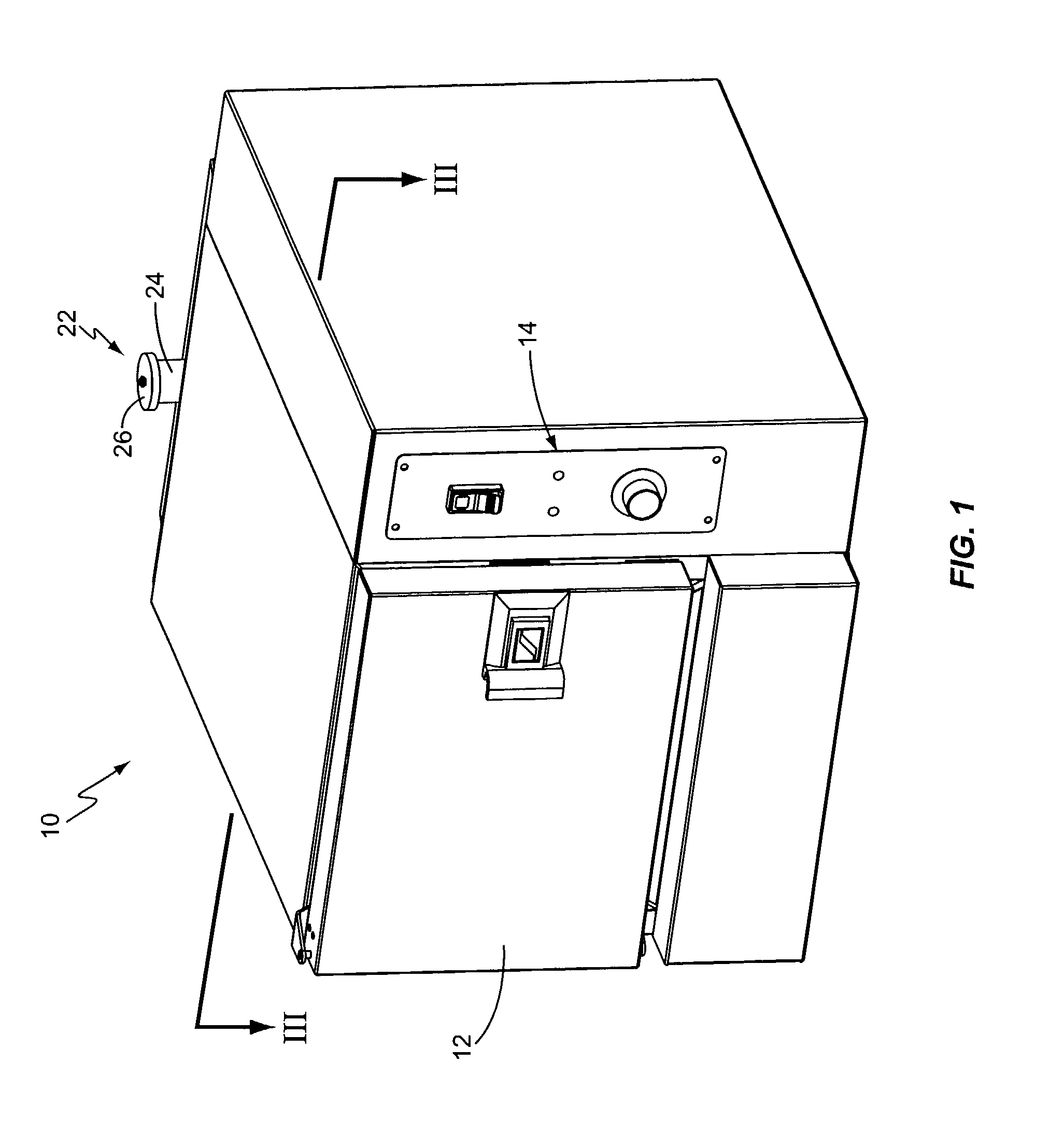

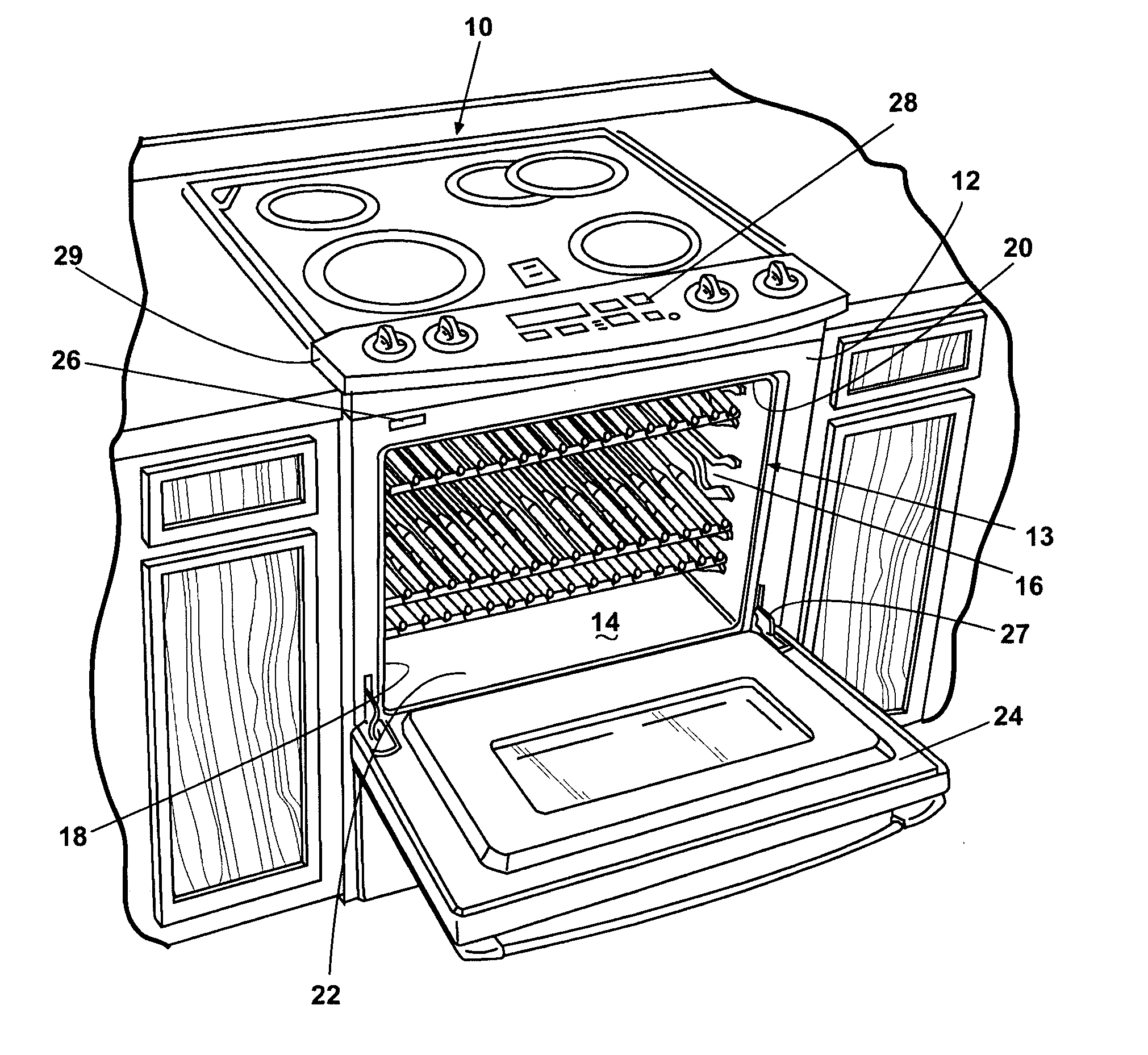

No waste cooking oven with multiple cooking functions

A multifunctional cooking oven for the preparation of food products including a cooking chamber, racks within the cooking chamber to support products to be prepared in the oven and a primary convection heat source. There is a drainable collection pan positioned below the racks to collect by-products rendered from the food products during preparation for later use. A steam source is positioned below the collection pan as well as a flavored smoke generator at the bottom of the preparation chamber. Airflow paths within the preparation chamber allow for the circulation of heat, steam and flavored smoke around the racks. The oven includes a programmable controller to control the primary heat source, the steam source and the flavored smoke generator that is programmed to operate any one of the heat source, the steam source and the flavor generator in any predetermined sequence, and for any predetermined duration of time to provide optimum preparation and flavoring of the products.

Owner:ROBERTSON MICHAEL L

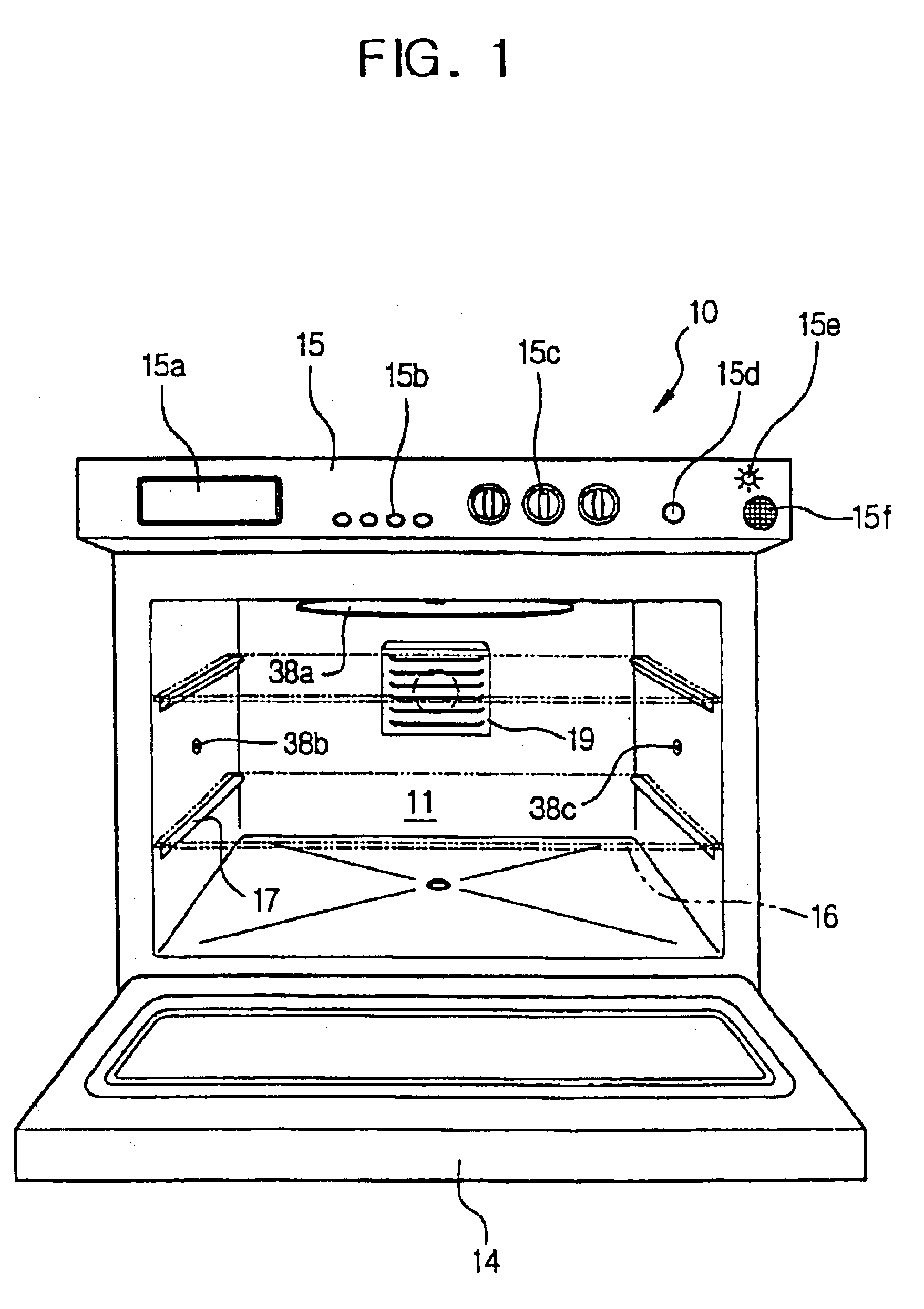

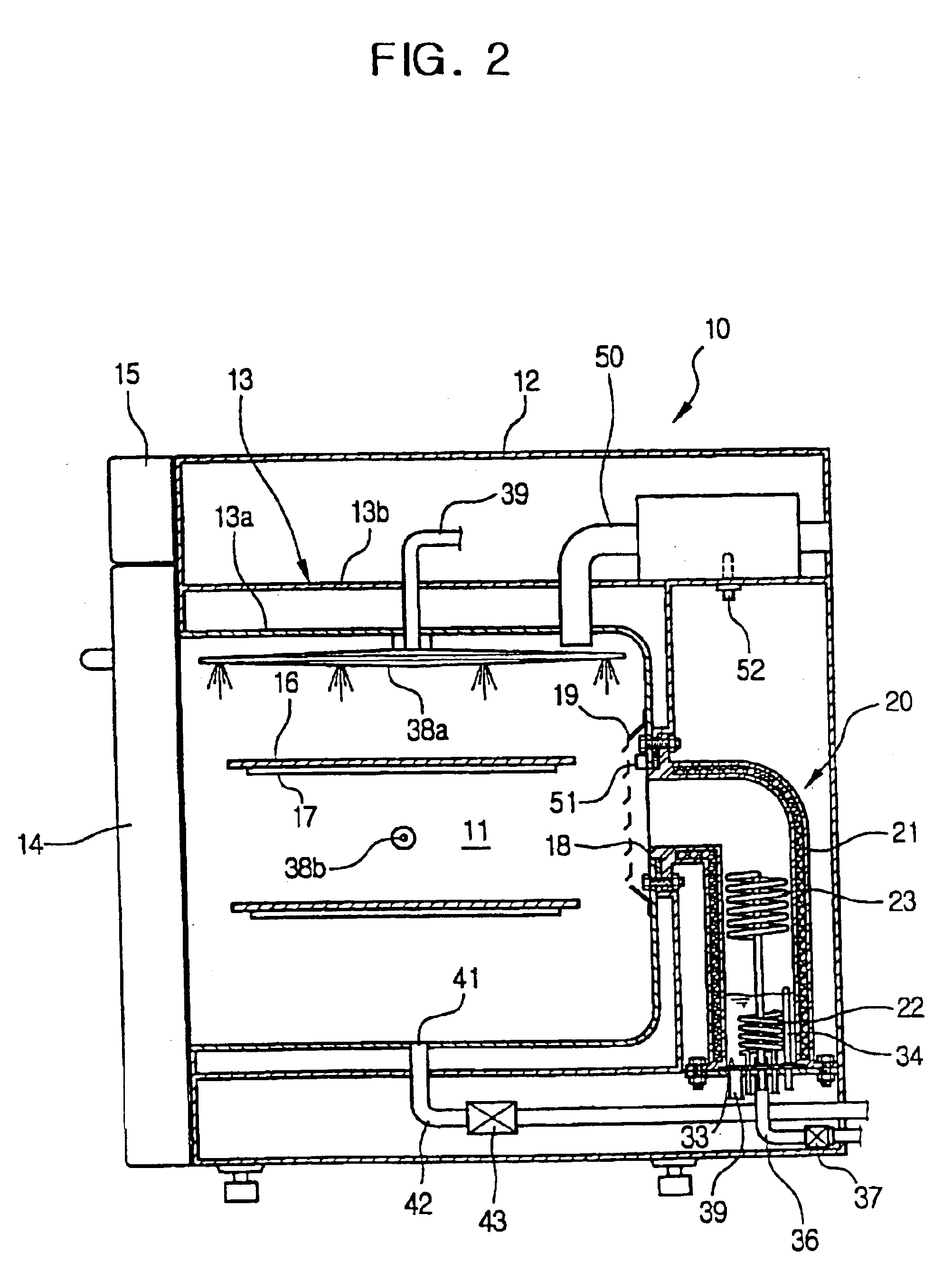

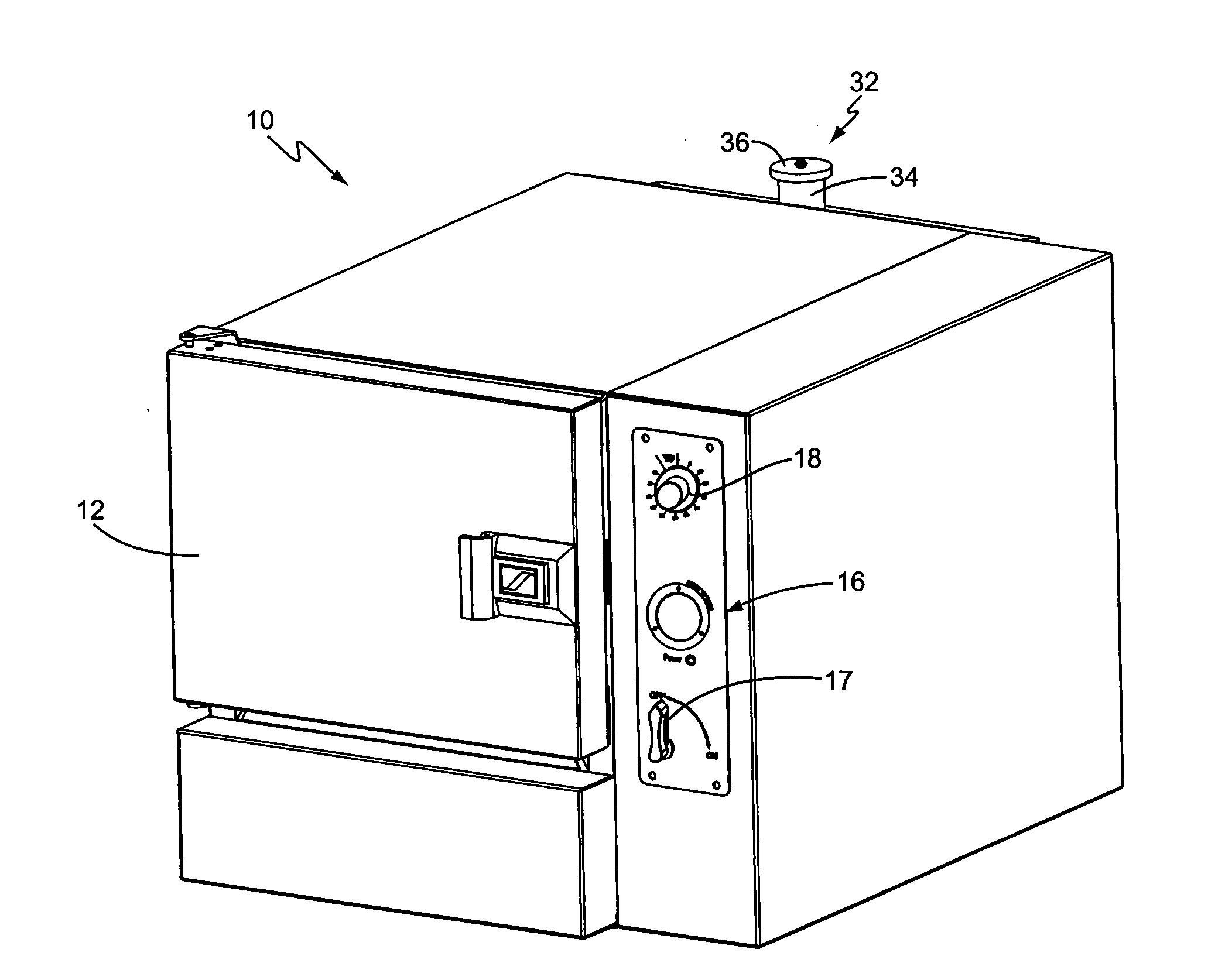

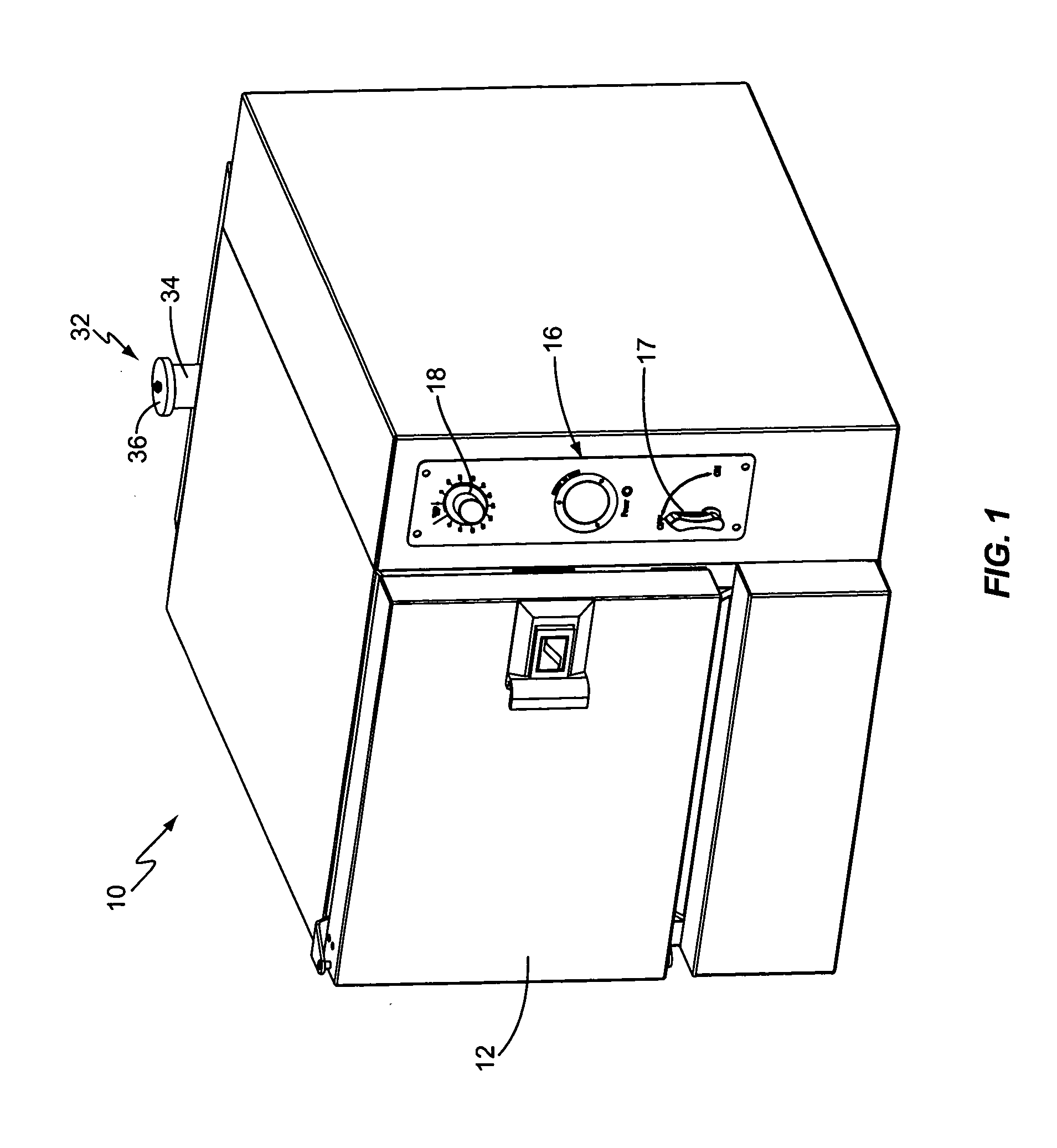

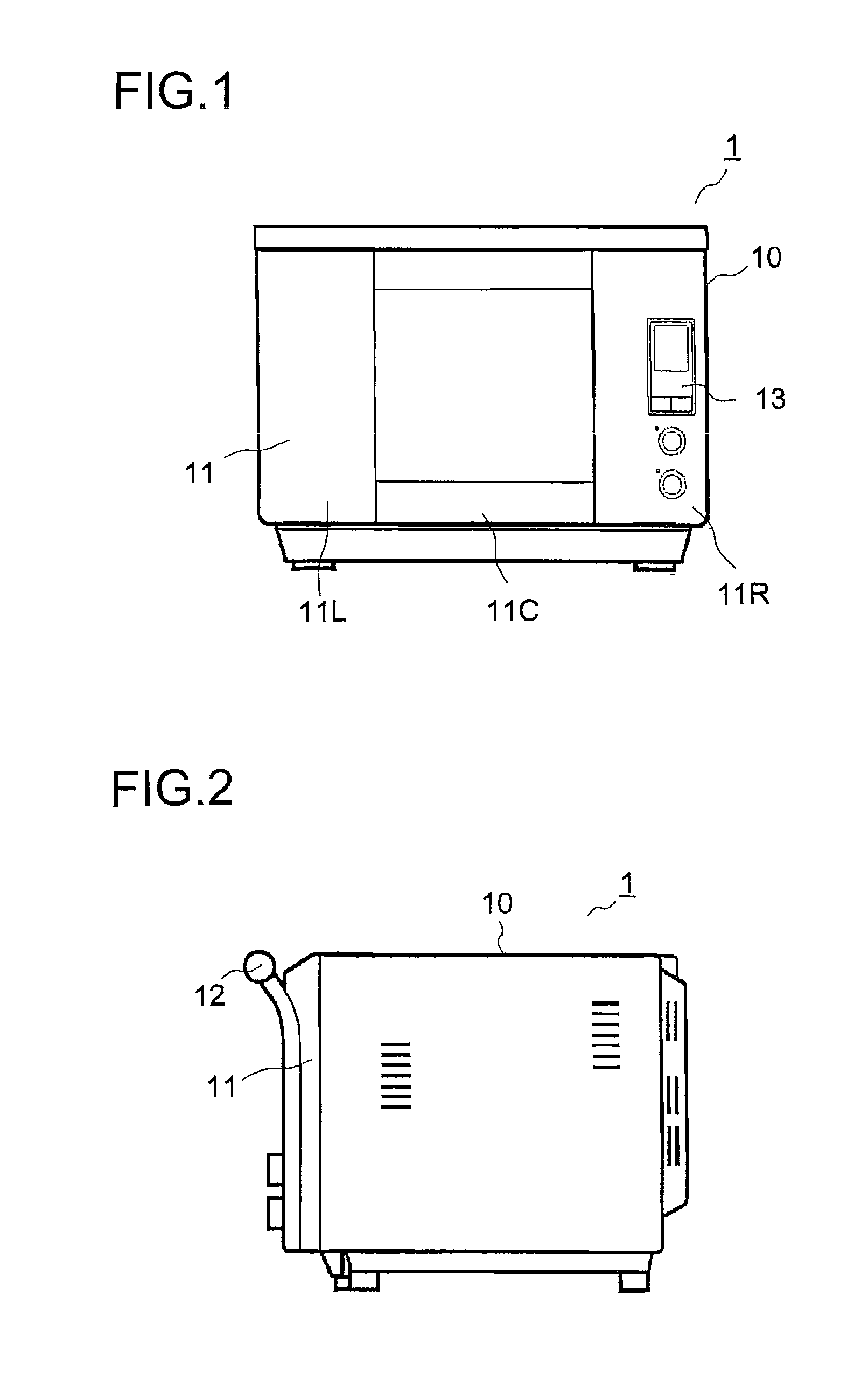

Combination heat and steam oven

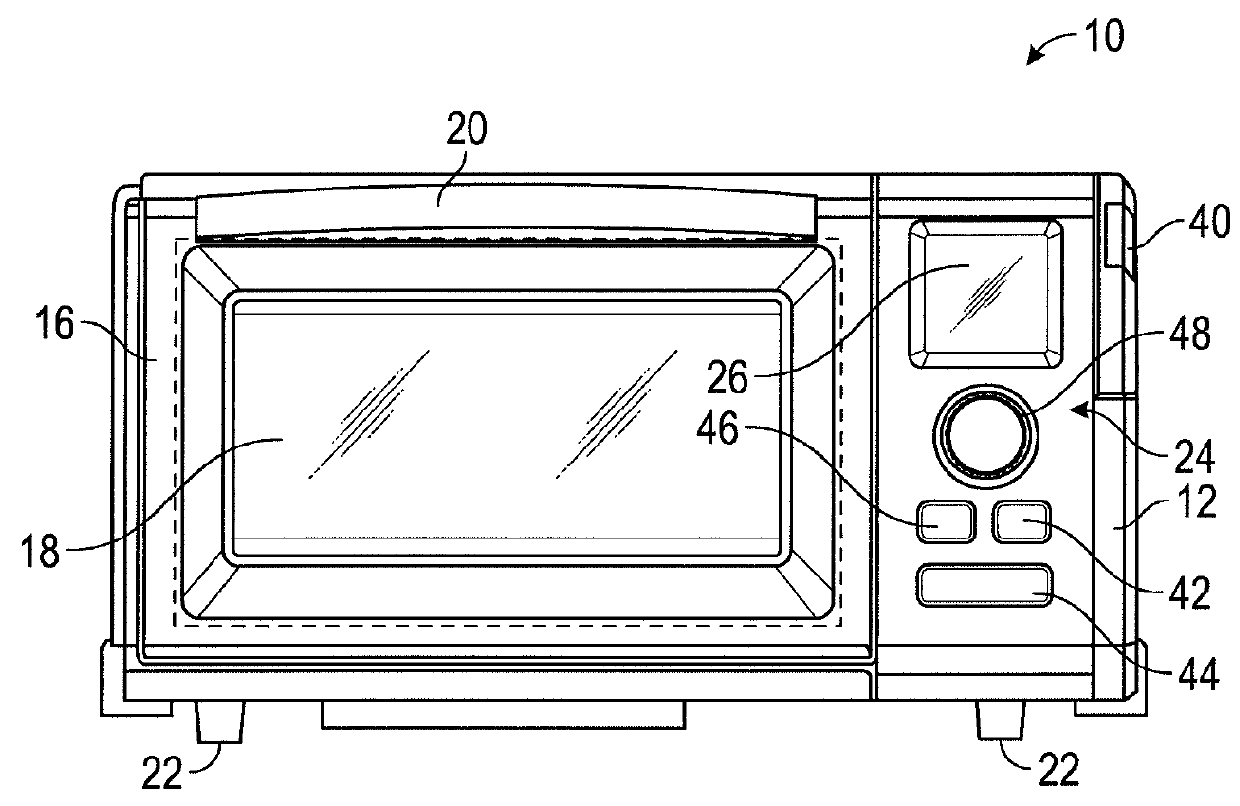

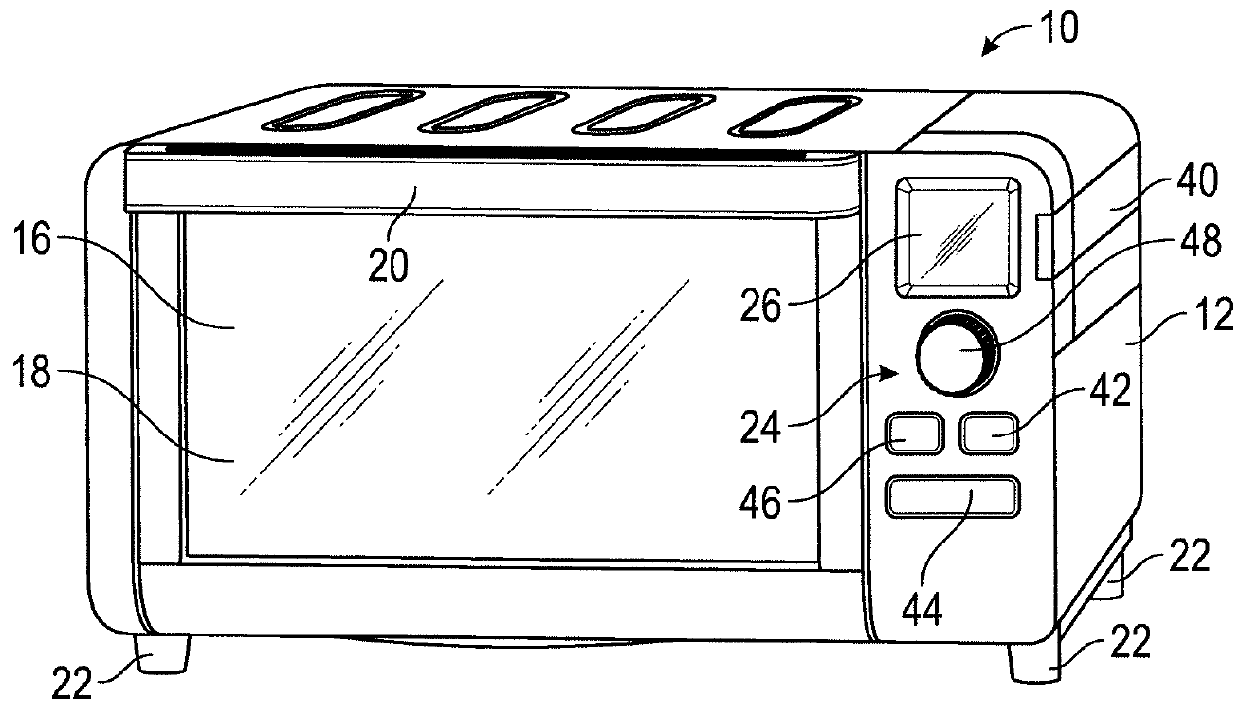

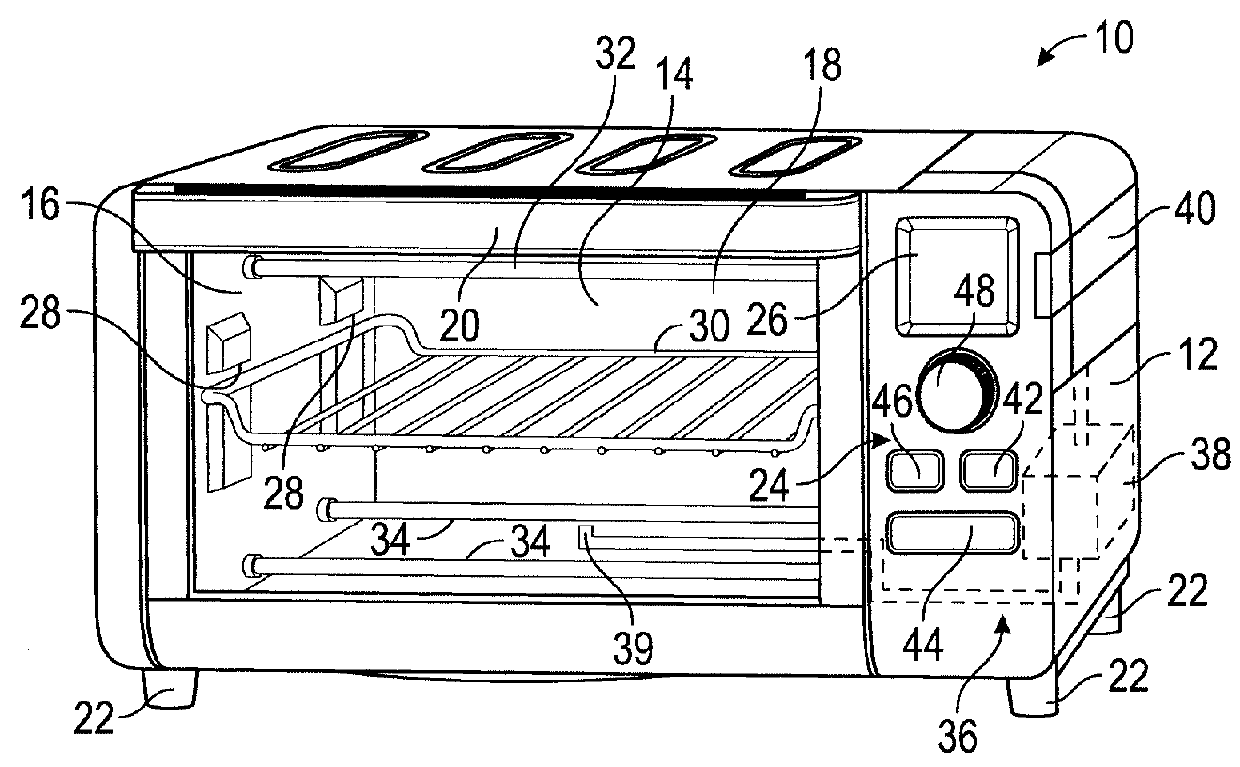

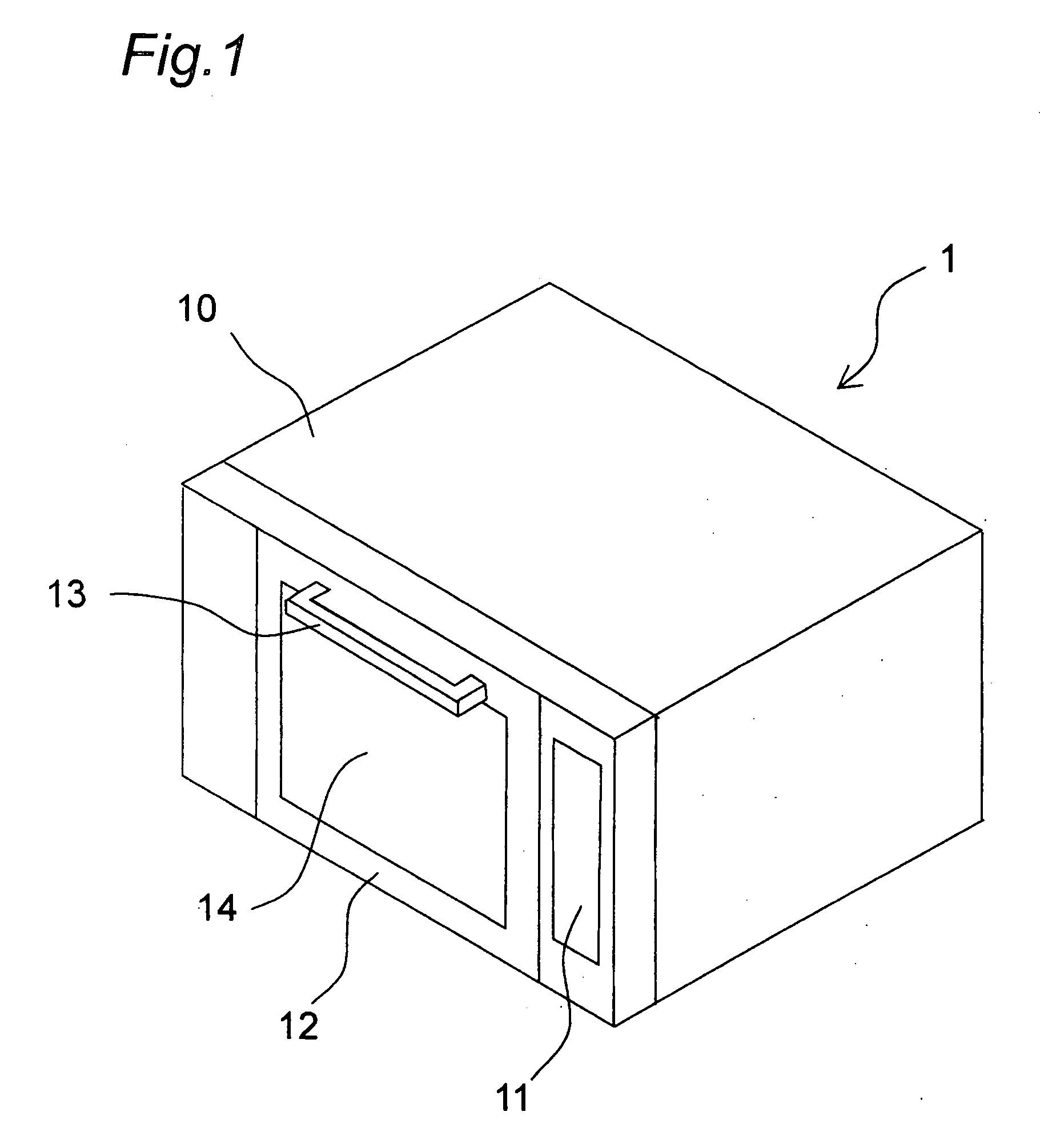

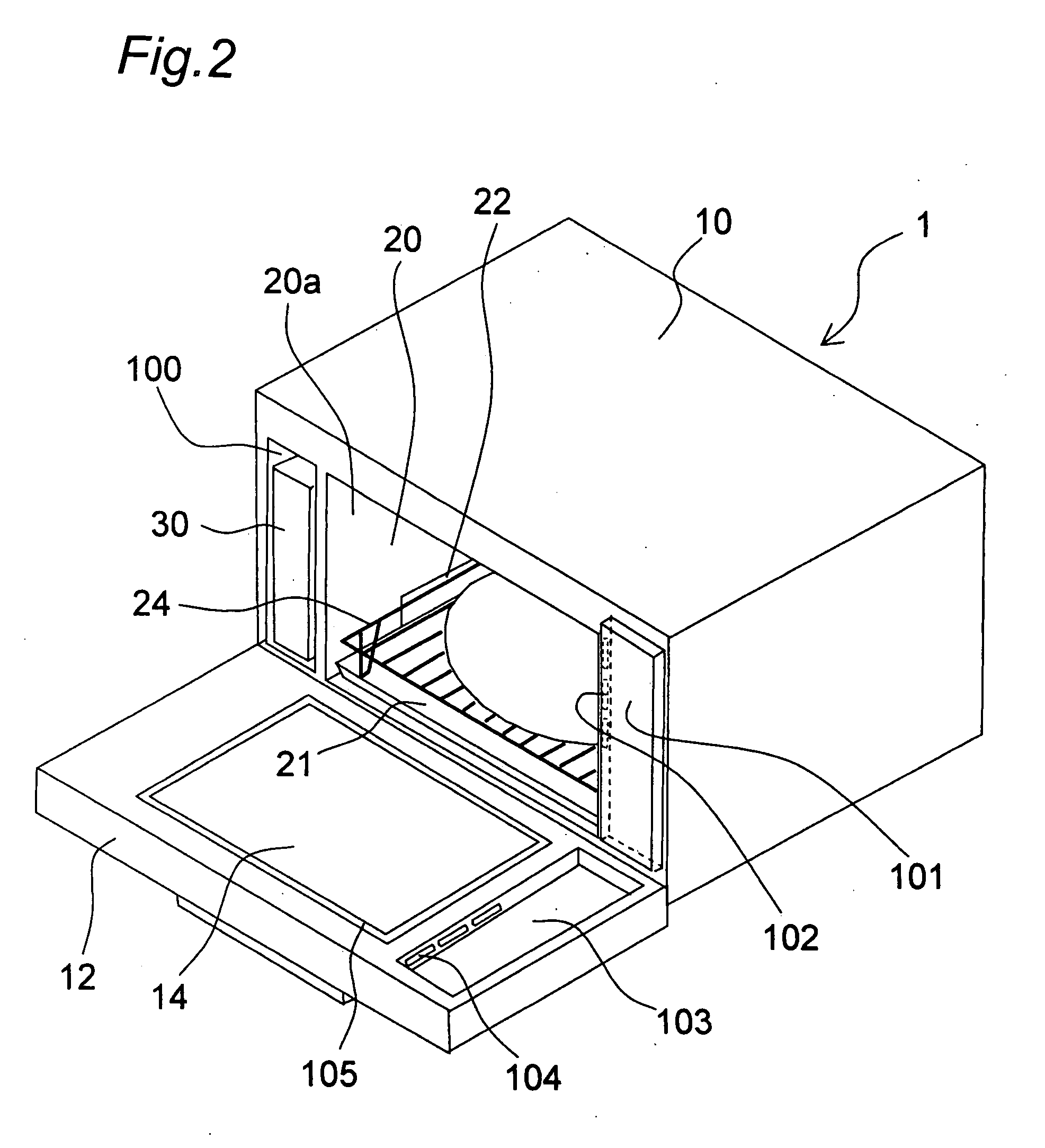

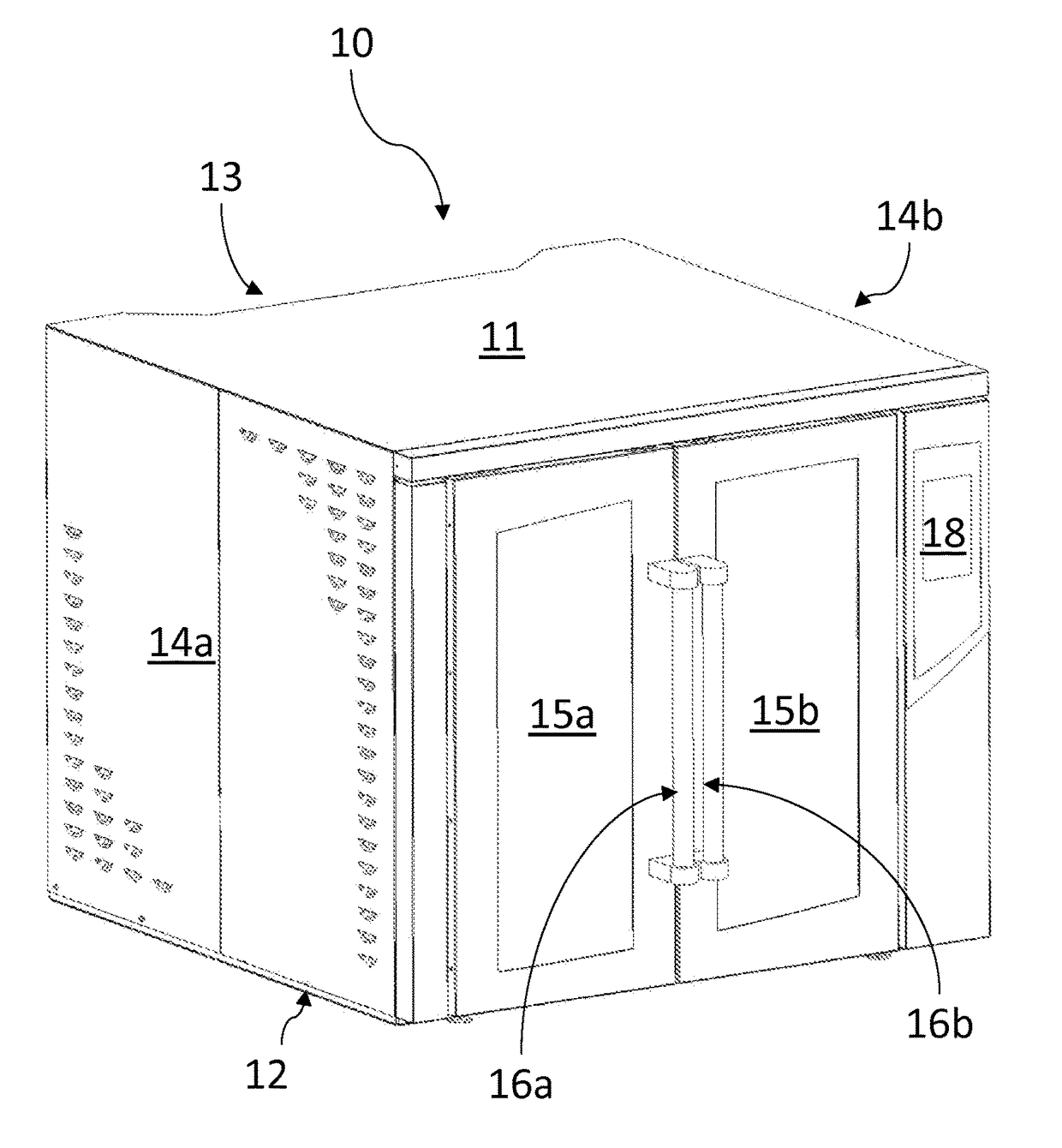

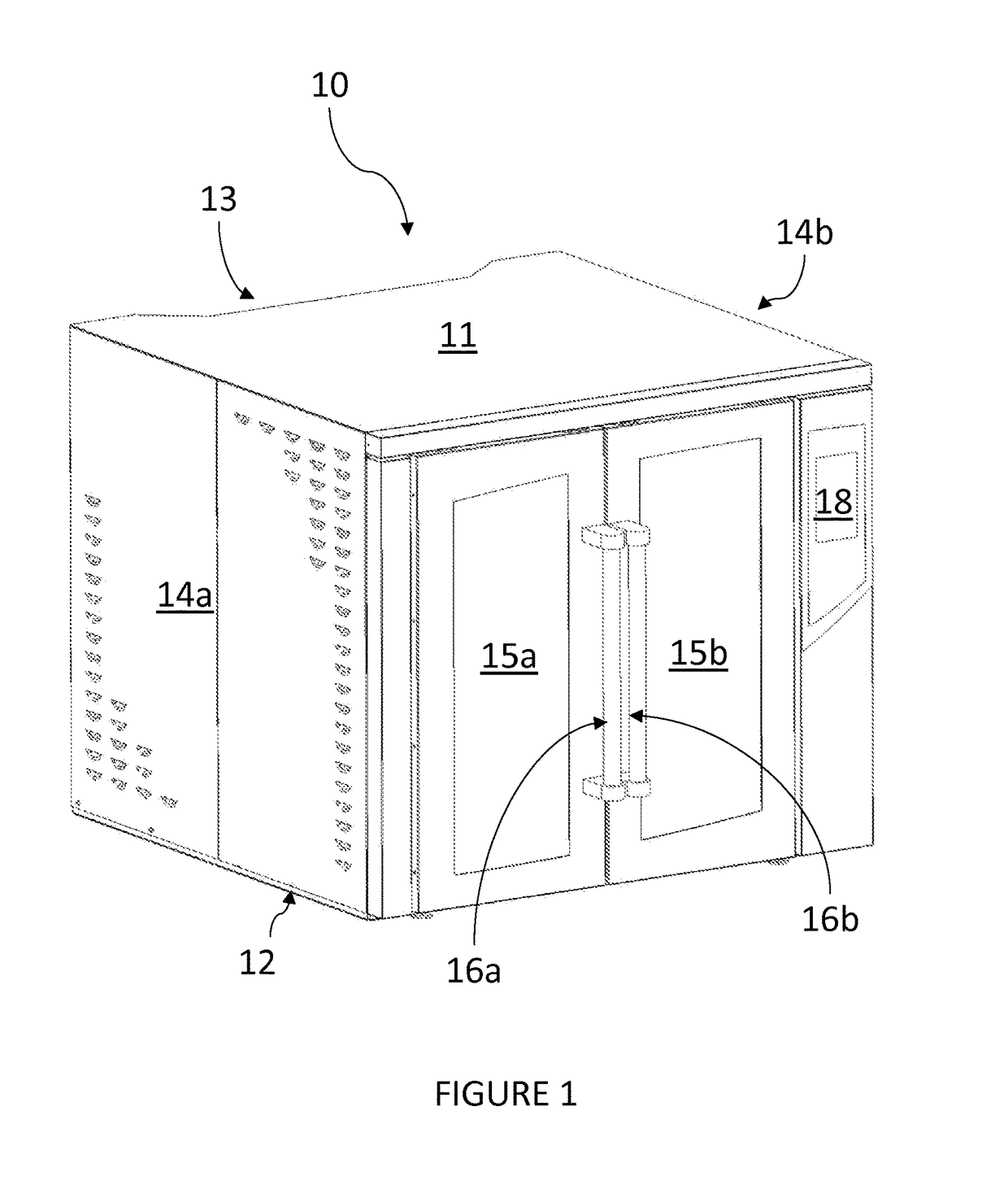

PendingUS20160033141A1Self-cleaning stoves/rangesOven air-treatment devicesProcess engineeringEngineering

A combination heat and steam oven according to the present invention includes a housing having an internal heating compartment, at least one dry heating element disposed within the heating compartment, a steam generating unit configured to produce steam for injection into the heating compartment, and a user interface. The user interface is configured for selectively controlling operation of the at least one dry heating element and the steam generating unit, so that the steam generating unit and the at least one dry heating element may be operated alone or simultaneously with the other of the steam generating unit and the at least one dry heating element.

Owner:CONAIR CORP

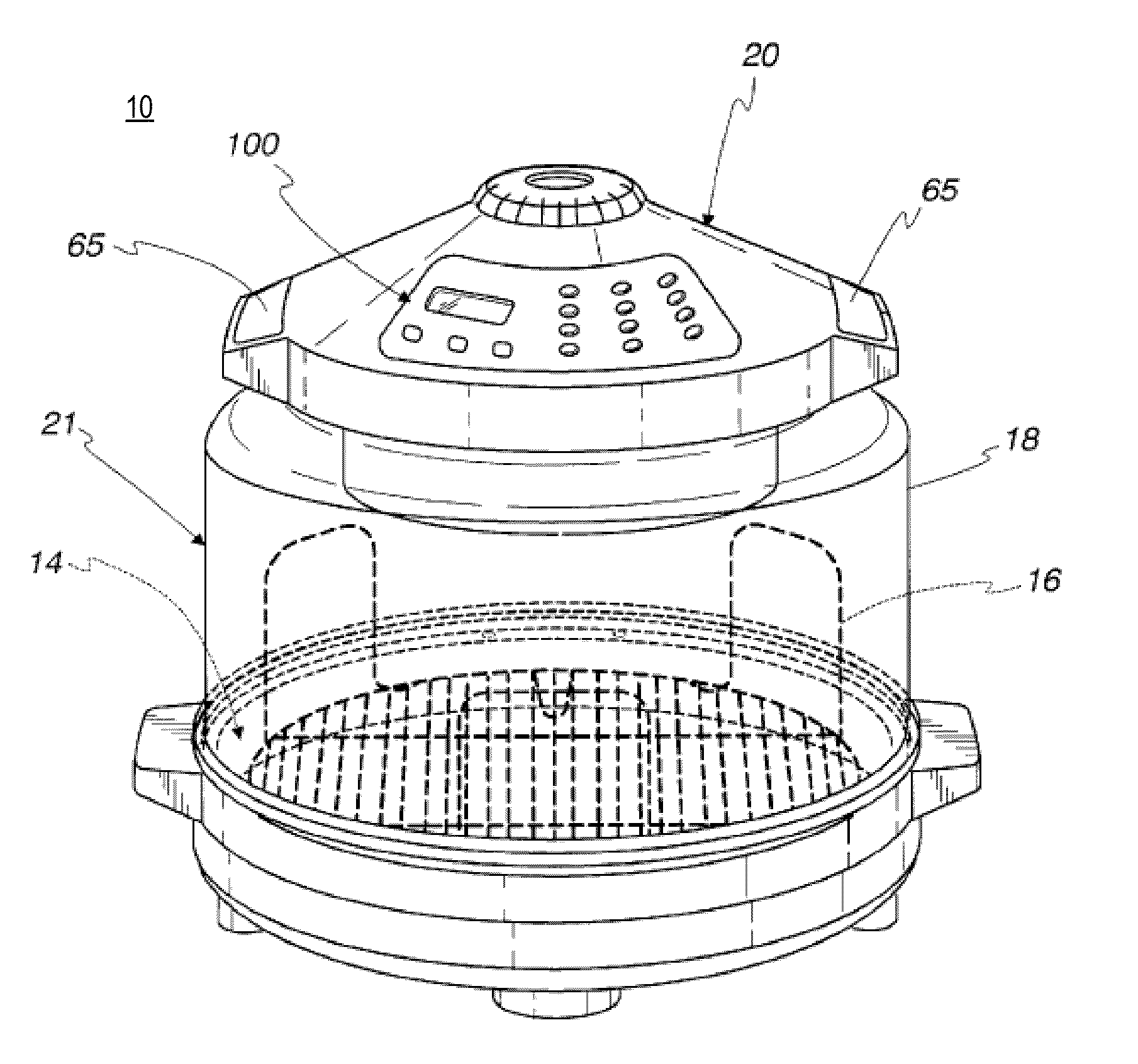

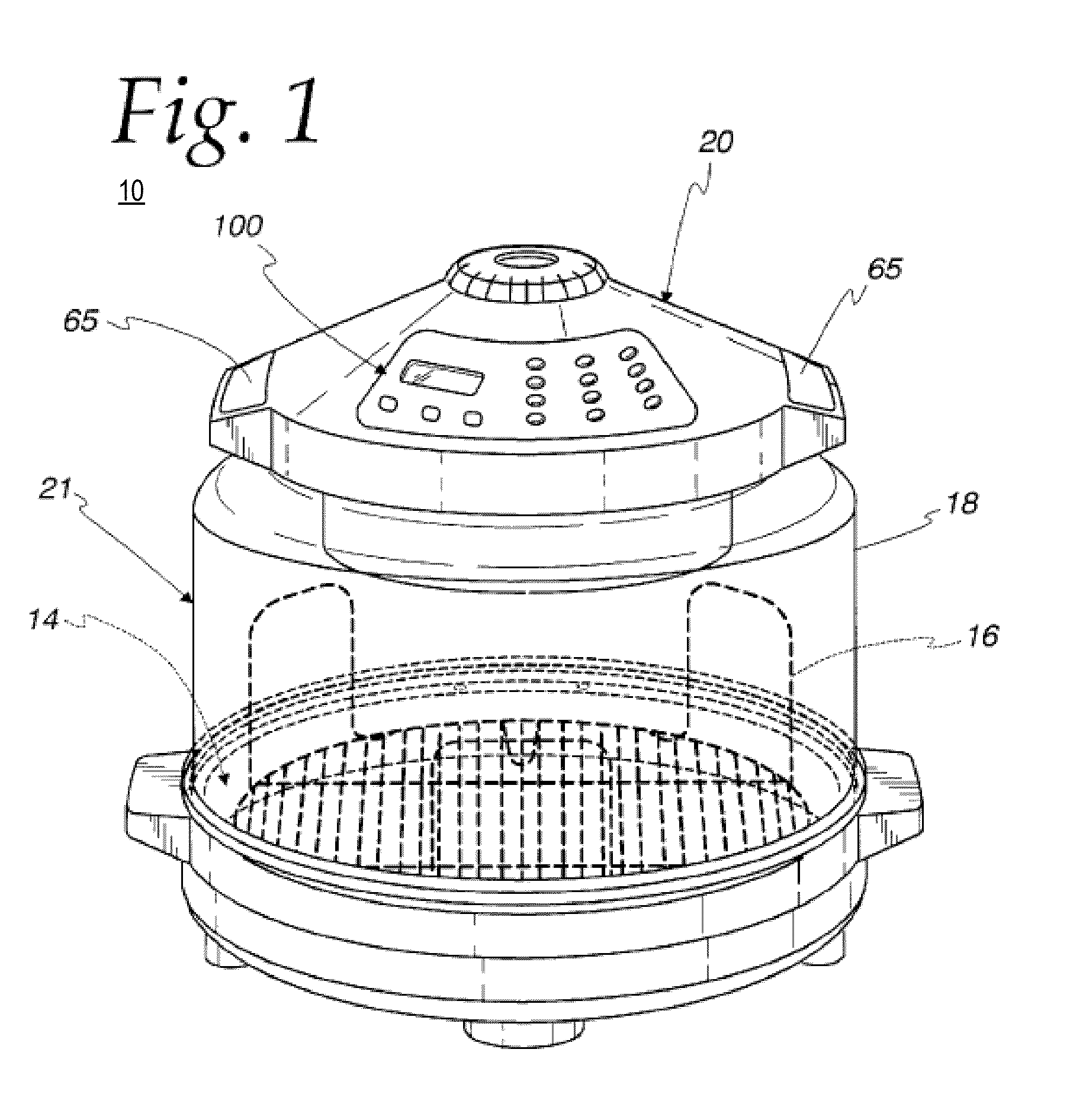

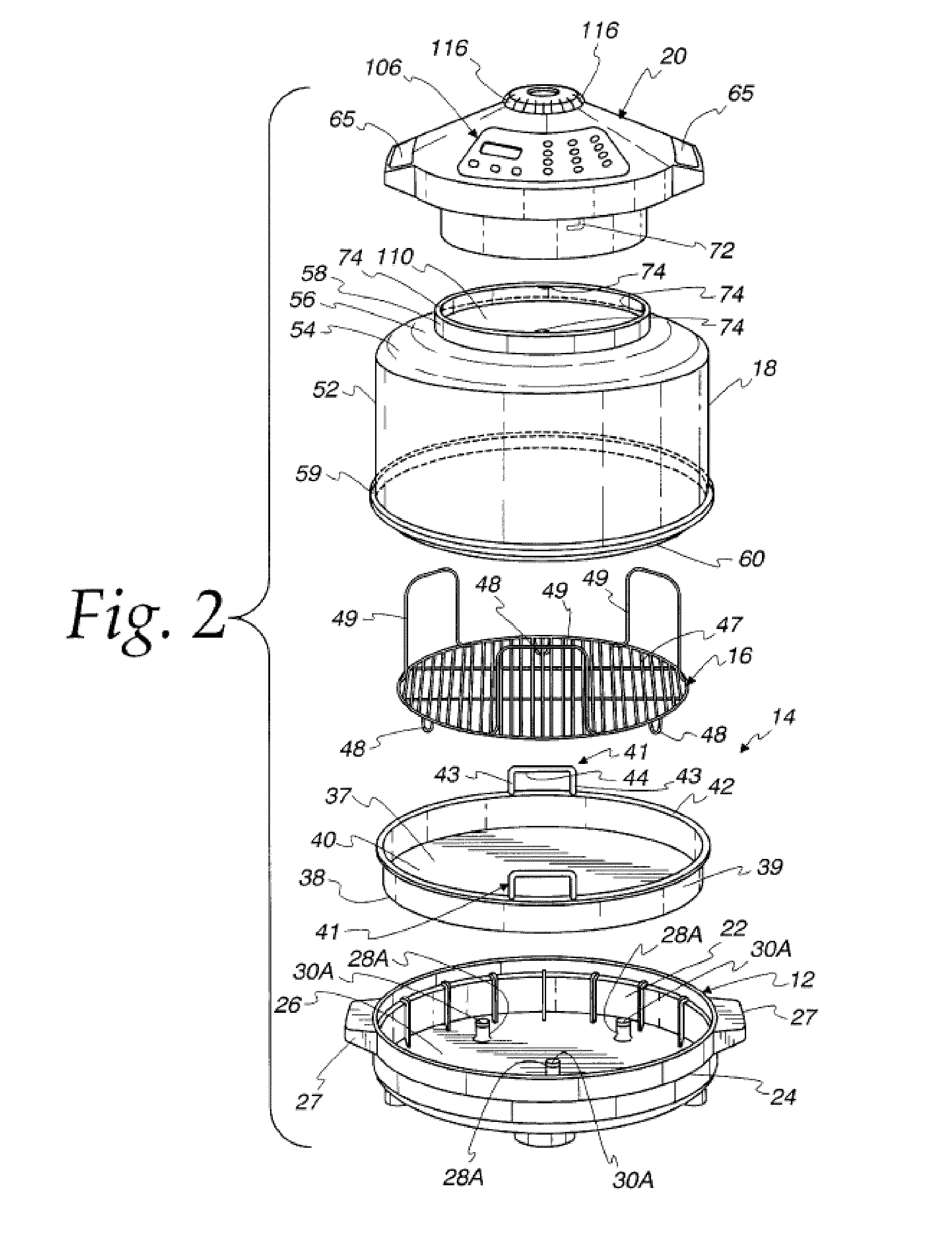

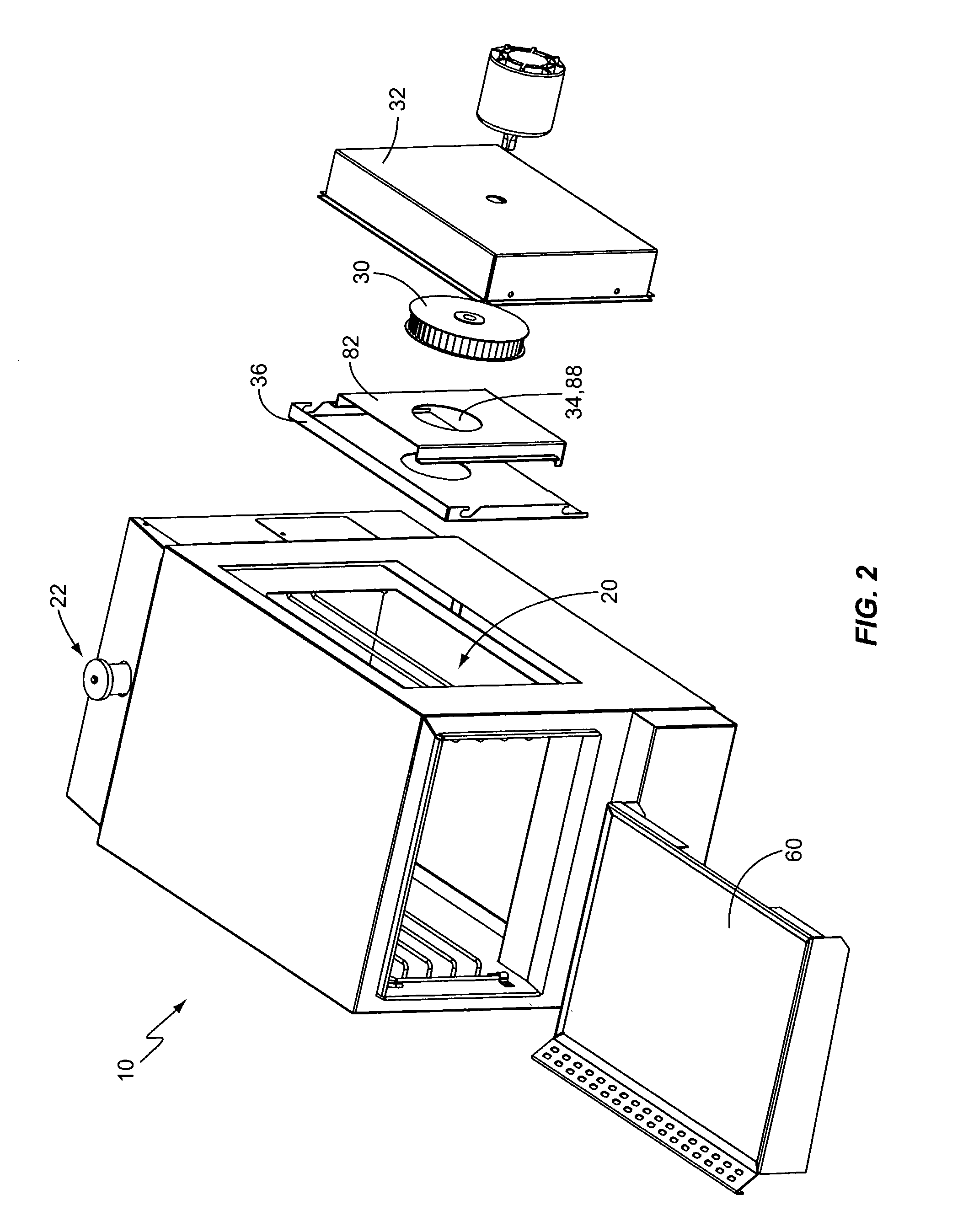

System and Method for a Programmable Counter-top Electric Oven and Dehydrator

A system and method directed to a countertop oven comprising a powerhead or power unit, a dome, and a base, which may include a stainless steel pan, and / or a plastic base, adaptable to receive a dehydrating adapter, base, and / or one or more dehydrator trays. According to exemplary embodiment, the powerhead may include a sensor to detect when the powerhead has been inserted in the dehydrator adapter, according to an exemplary embodiment. The power unit may be detachably connectable to the dehydrating enclosure and a cooking enclosure dome. The power unit and the cooking enclosure may collectively combine into a multi-stage counter-top electric oven. The power unit and the dehydrating enclosure may also collectively combine into a dehydrator. The dehydrating enclosure may include a plurality of stackable dehydrating trays through which dehydrating air is circulated from the power unit.

Owner:NUWAVE

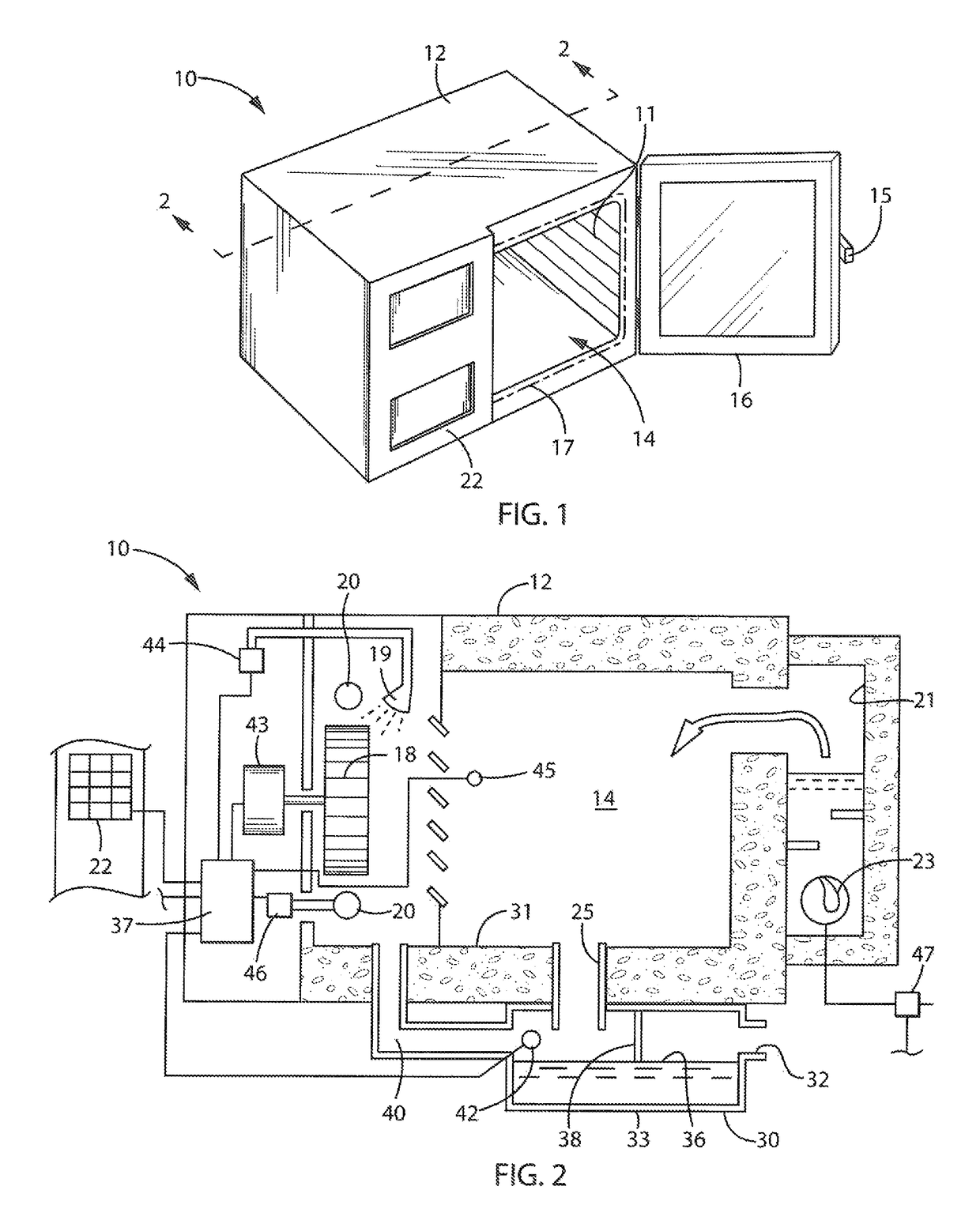

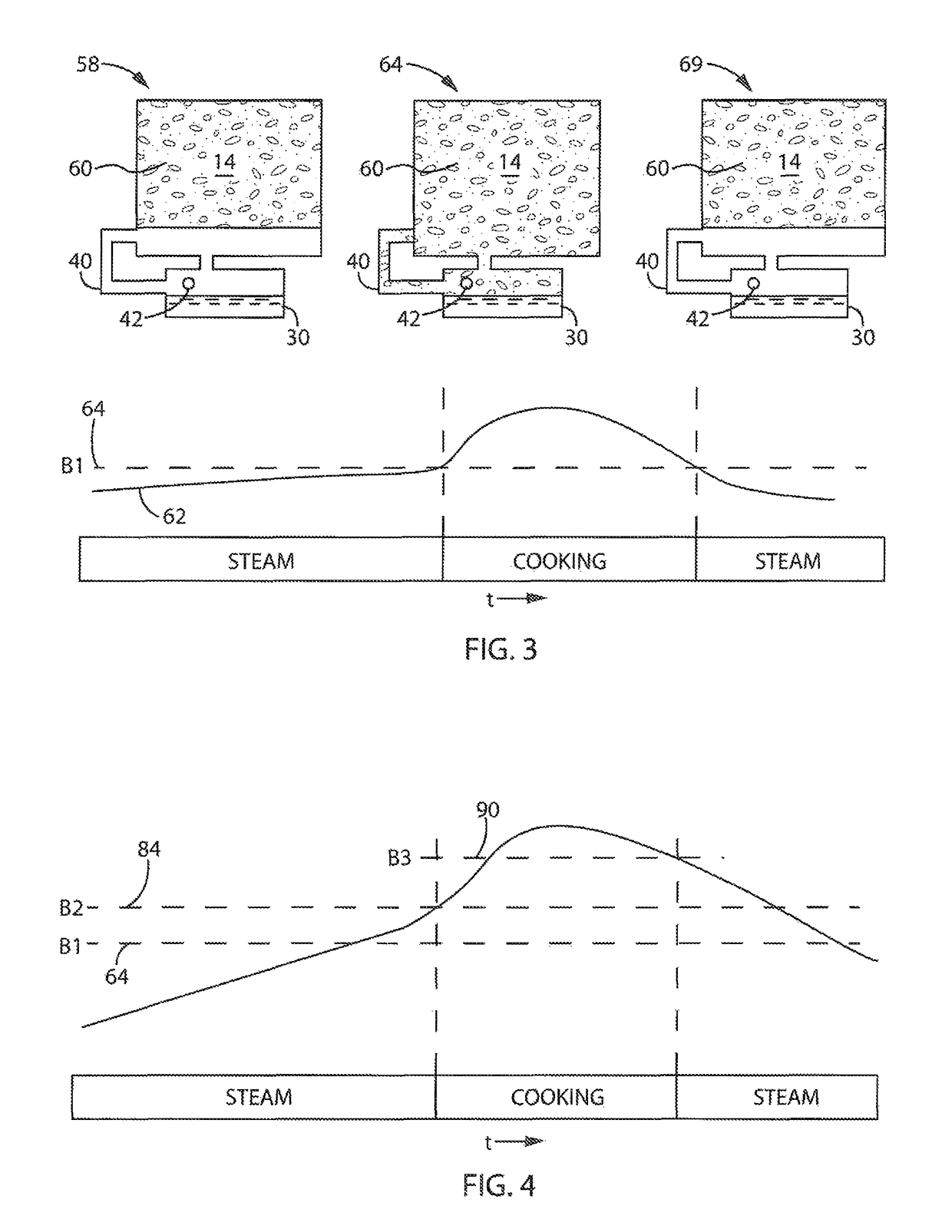

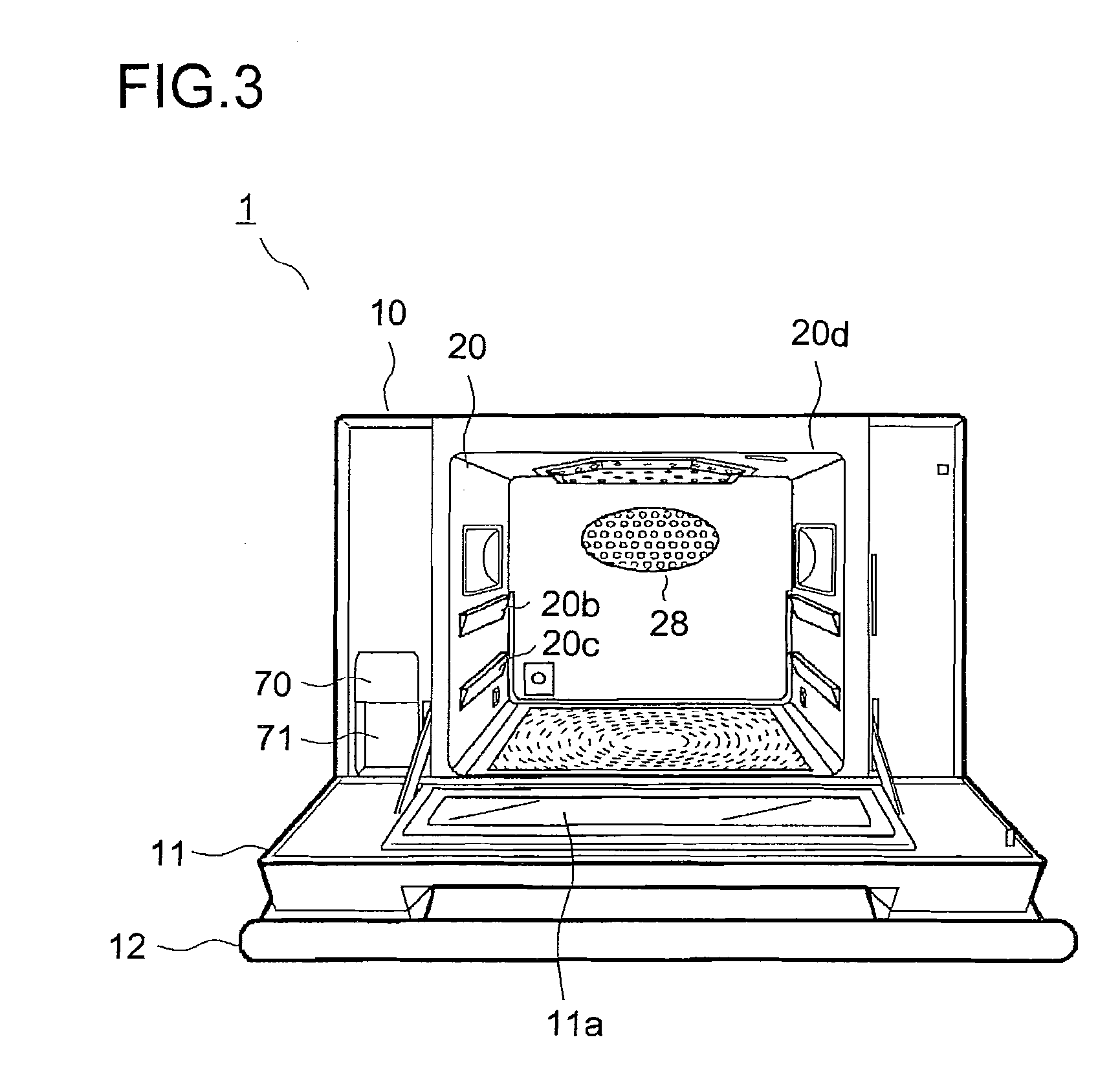

Apparatus and method for preparing food

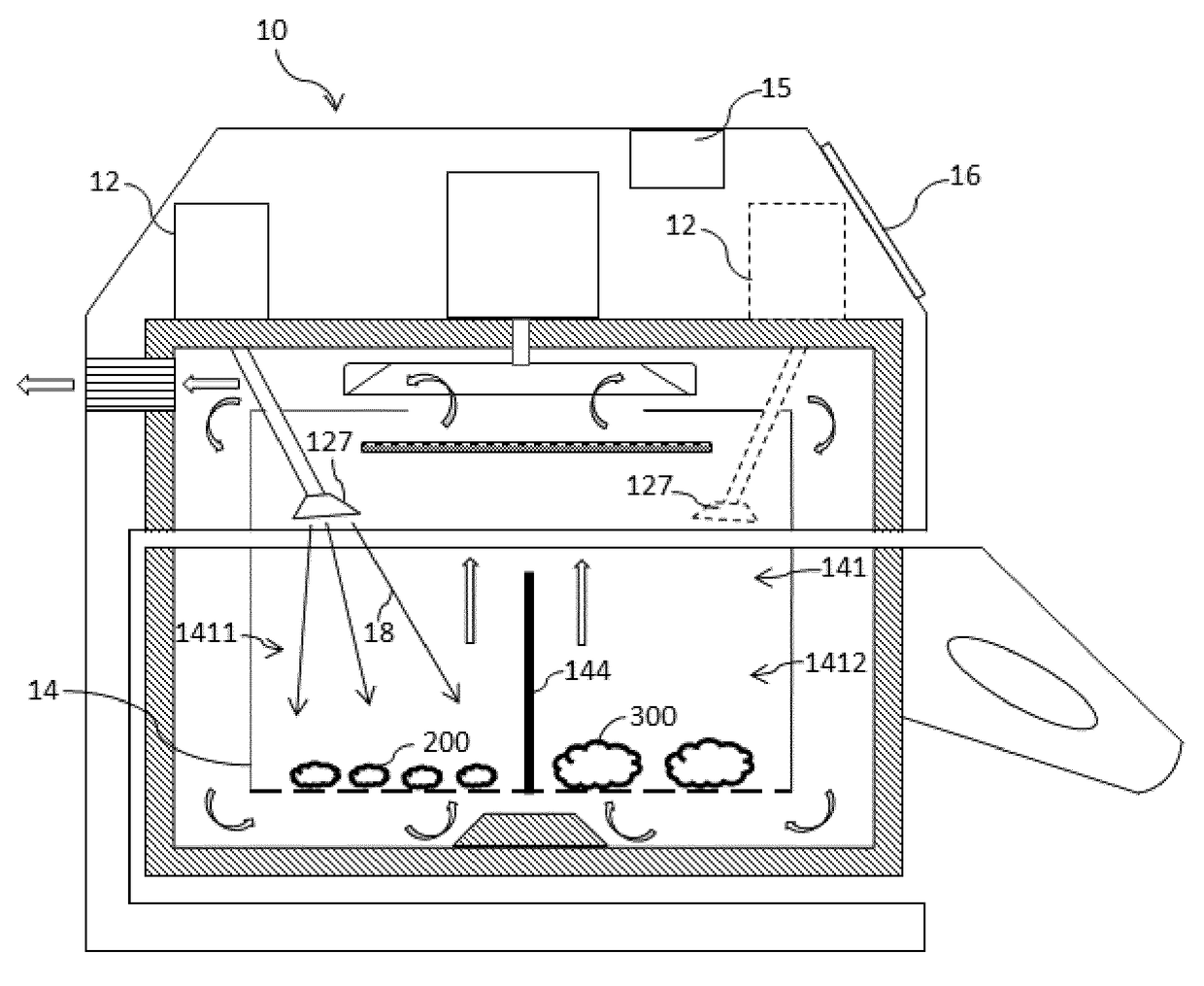

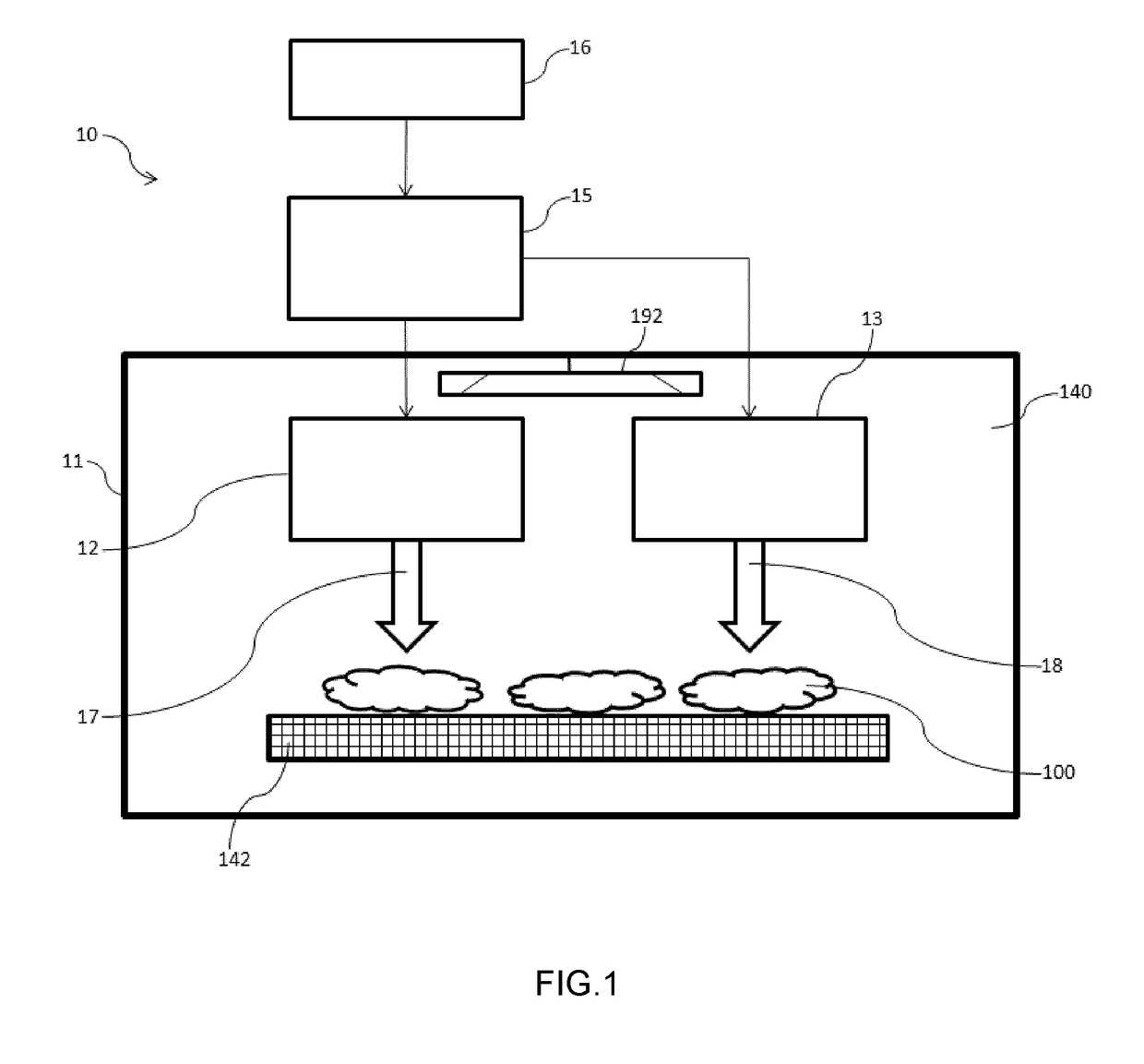

ActiveUS20170245683A1Reduce surface moisture contentImprove propertiesDomestic stoves or rangesOven air-treatment devicesAir heaterEngineering

The present invention relates to an air-based flyer (10) apparatus comprising a food preparation chamber (140) comprising an outer wall (11), an inner wall (14) defining a food receiving space (141) with an air inlet (142) and an air discharge opening (145), and a circulation channel (113) defined between the outer wall (11) and the inner wall (14). The apparatus also comprises an air heater (13) for heating air in the food preparation chamber (140), a fan (192) for moving a flow of hot air successively through the air inlet (142), the food receiving space (141), the discharge opening (145), and the channel (113). The apparatus also comprises a steam generator (12) comprising at least one nozzle (127) extending into the food receiving space (141) for spraying temperature-controlled steam (18) onto the food; and a controller (15) adapted to control the steam generator to spray steam to food placed in the food receiving space (141) for a first predetermined period, and to control the air heater (13) and the fan (192) to circulate hot air to the food for a subsequent second predetermined period. This apparatus allows keeping the tenderness or crunchiness of the food during subsequent hot air cooking.

Owner:KONINKLJIJKE PHILIPS NV

Combination oven with peak power control

ActiveUS9841261B2Highly integratedEasy to controlDomestic stoves or rangesOven air-treatment devicesPower modeSteam cooking

A commercial oven, such as a combination oven providing steam and convection heating, may provide for two different peak power modes and for steam cooking. A temperature sensor sampling temperature from a region of the oven may be used to detect a complete filling of the oven with steam. The temperature of the temperature sensor is compared against different temperature thresholds depending on the selected peak power so that temperature may be used to discriminate steam filling for different peak power levels.

Owner:ALTO SHAAM

Factory preset temperature warming appliance

ActiveUS7235762B2Domestic stoves or rangesDomestic cooling apparatusTemperature controlInterior space

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

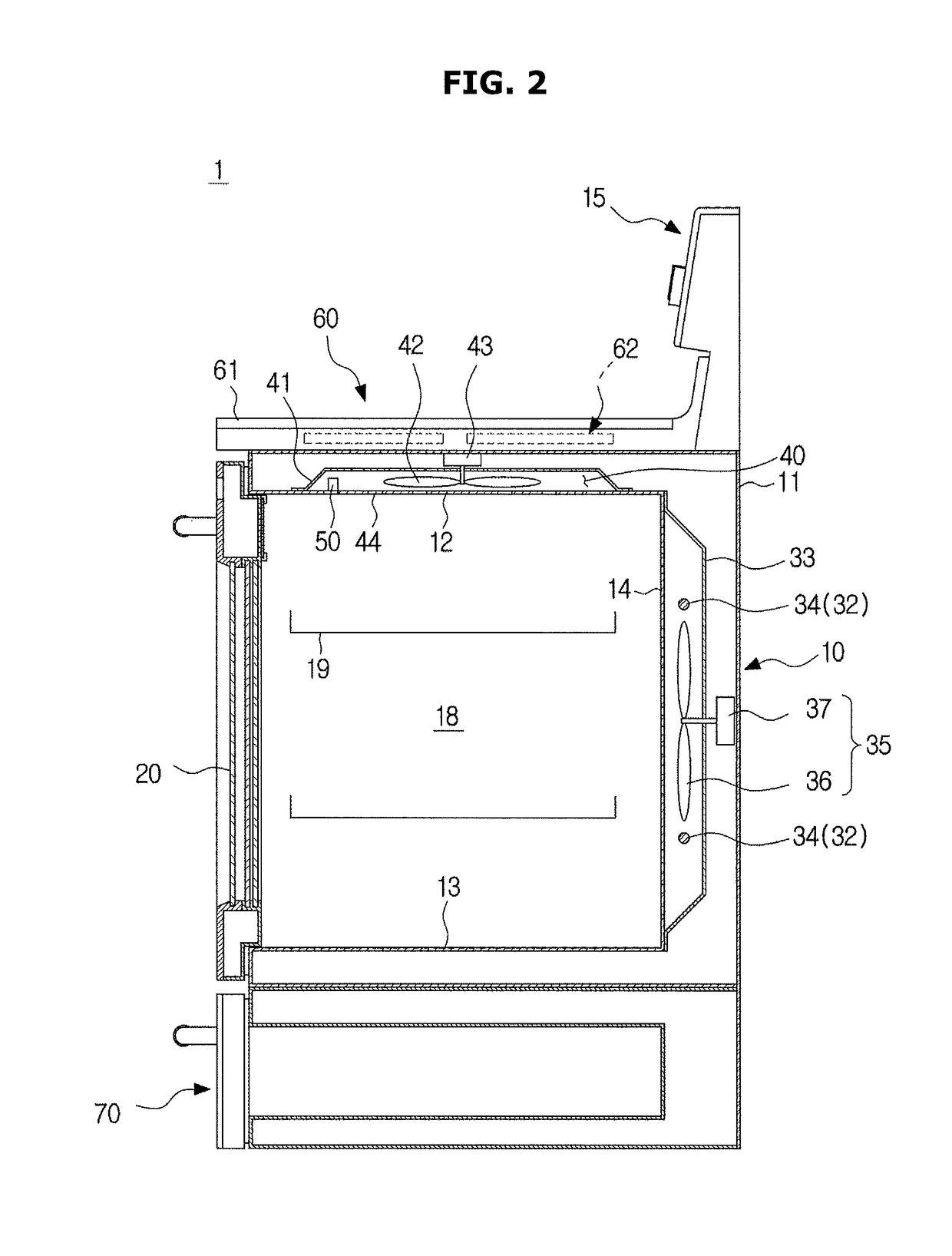

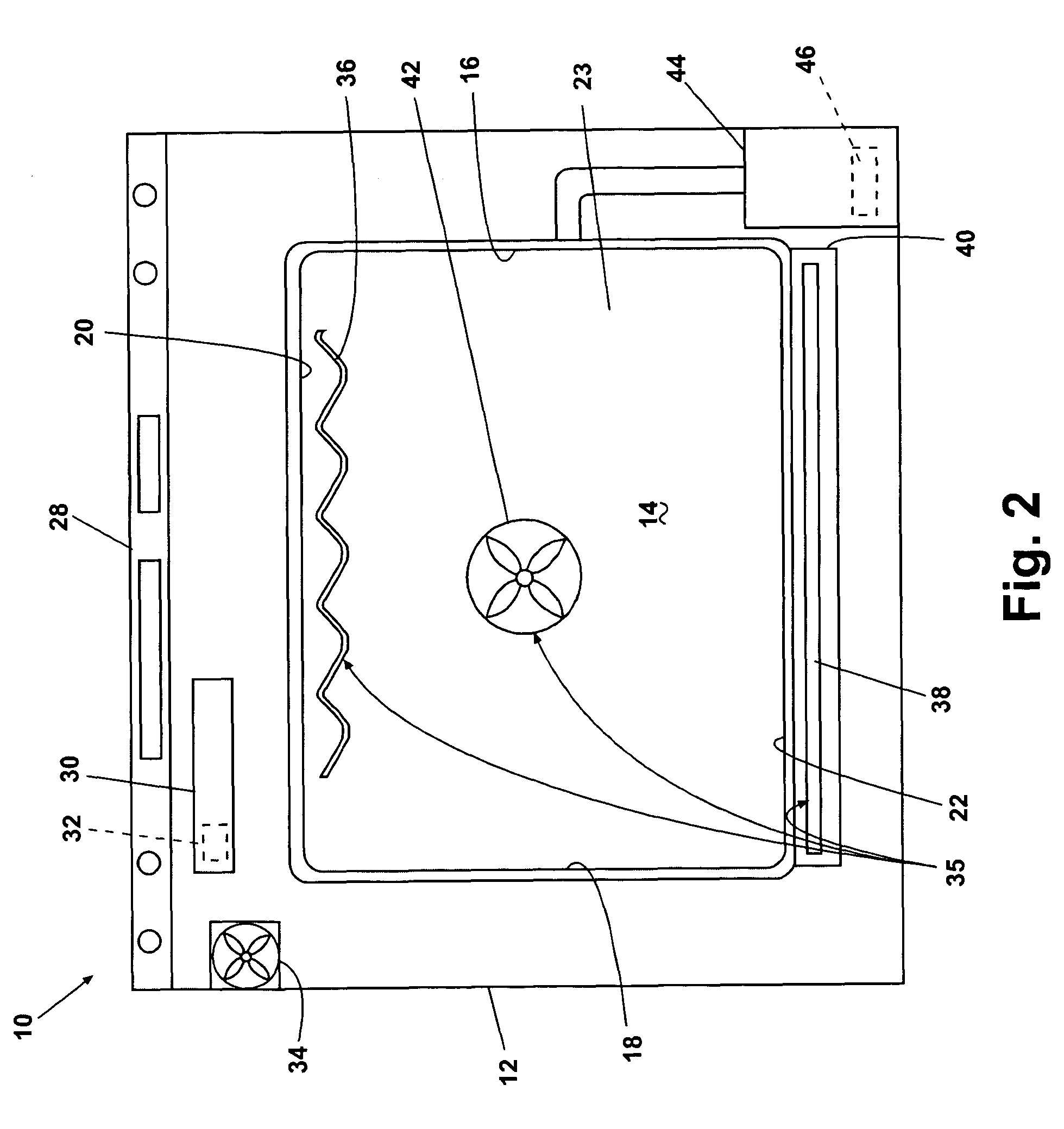

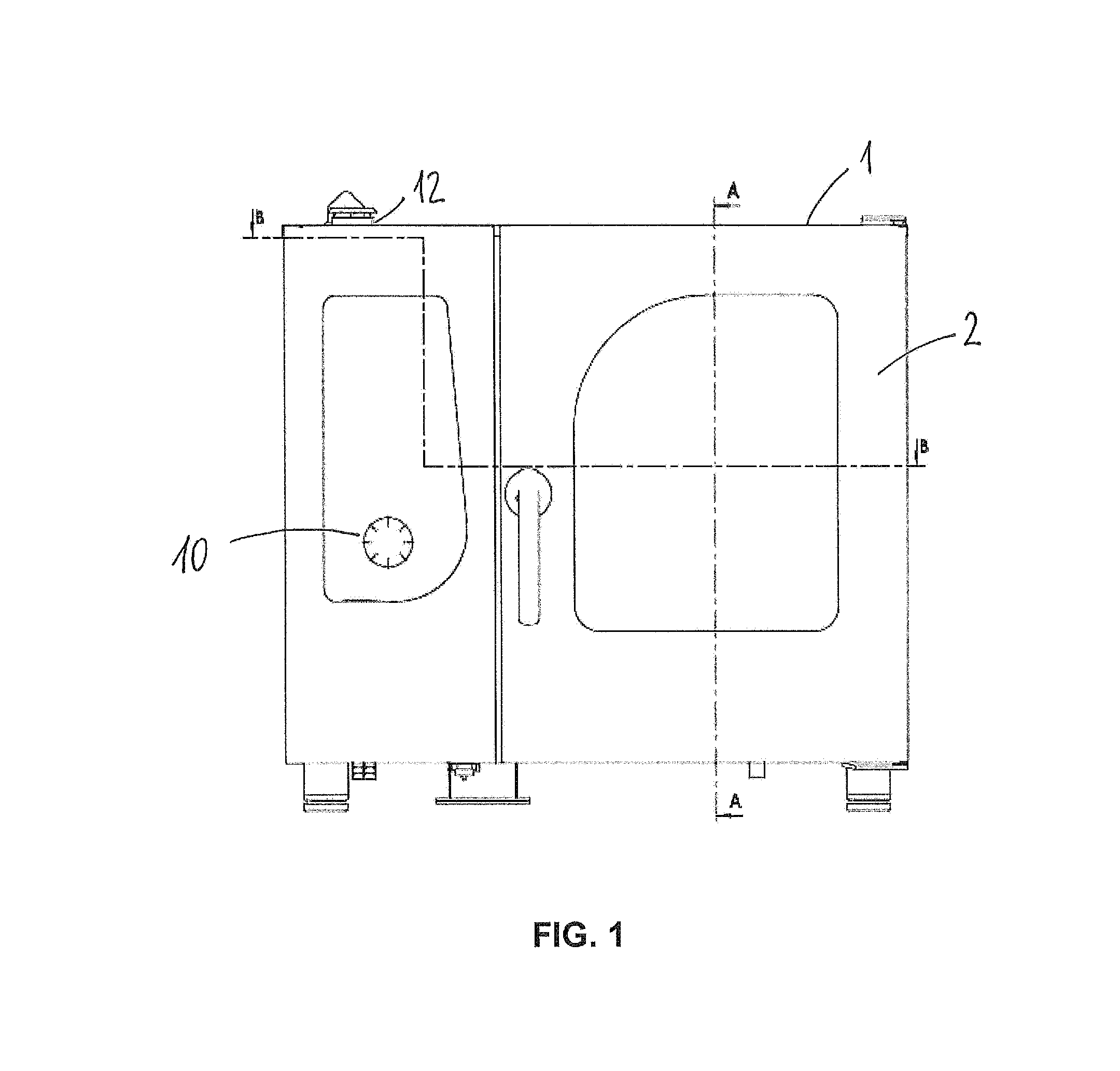

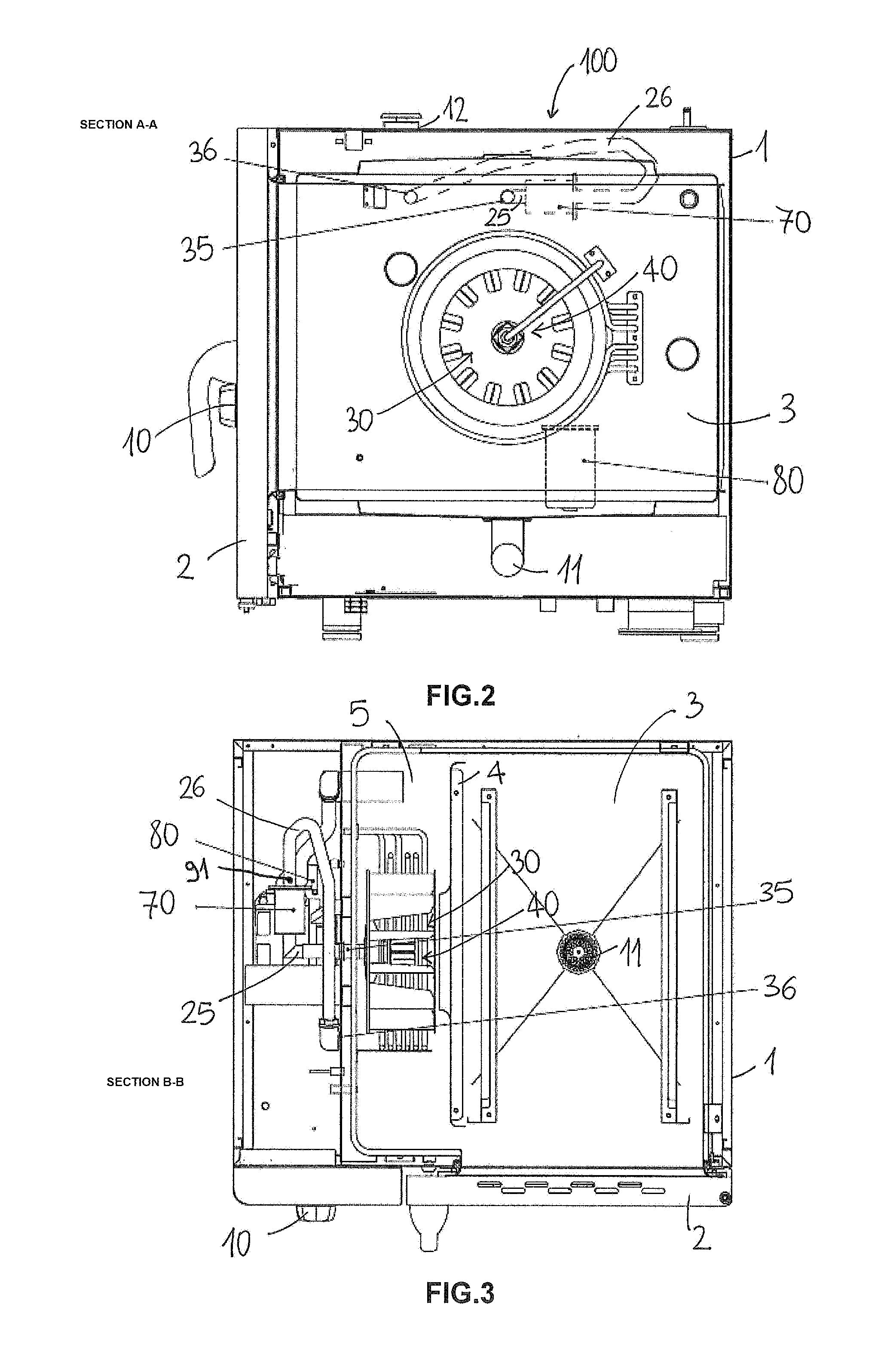

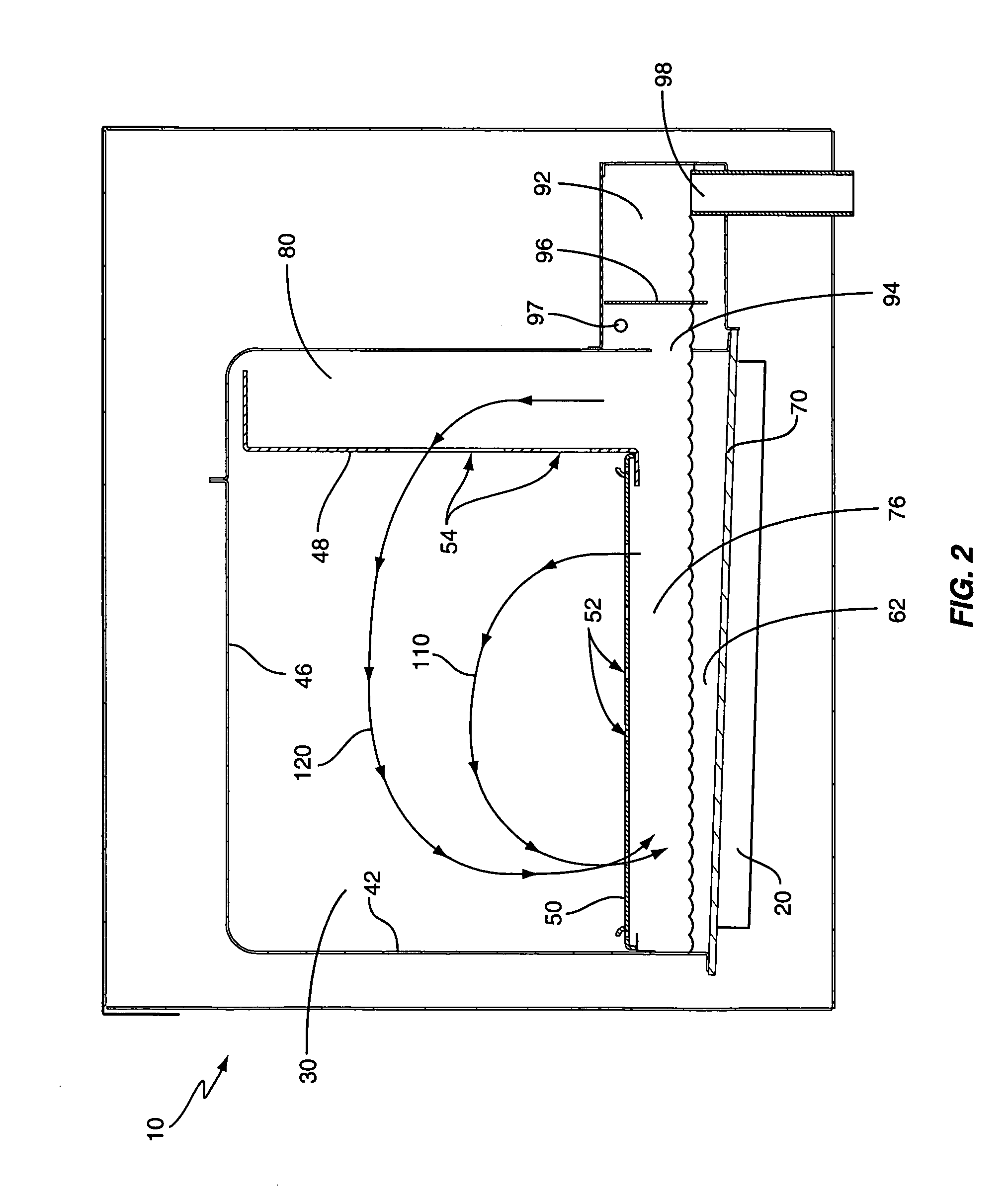

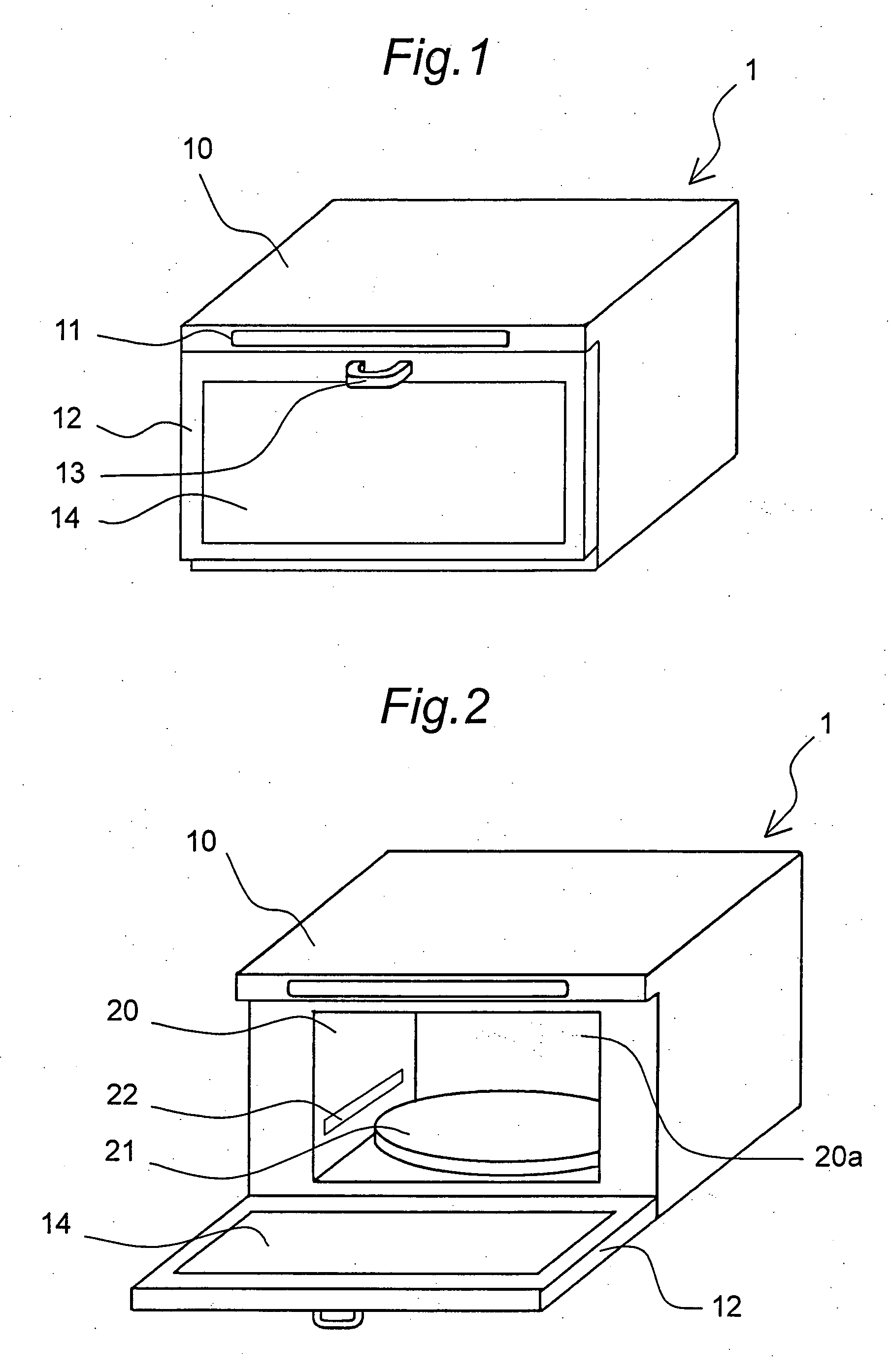

Apparatus for preparing food

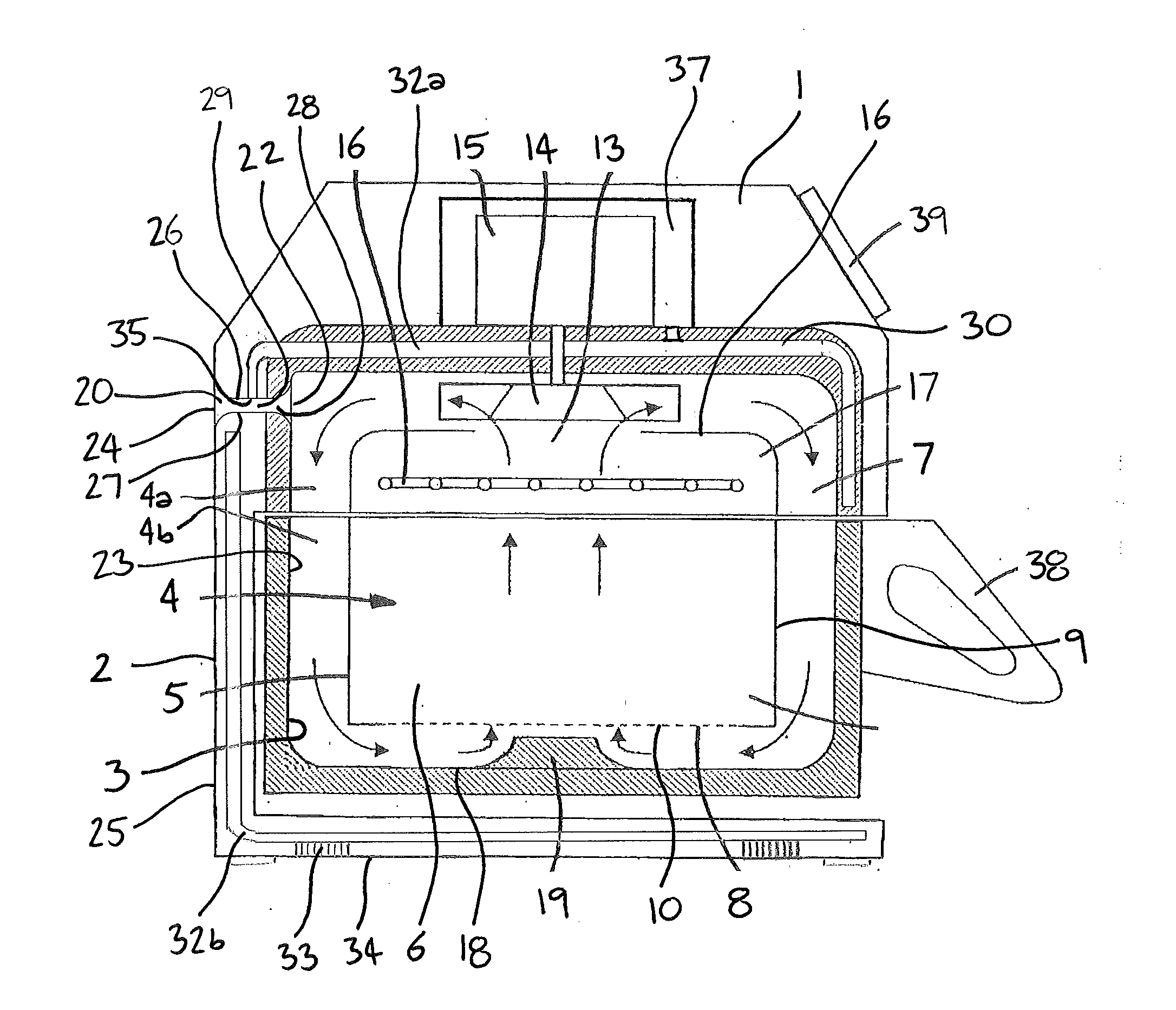

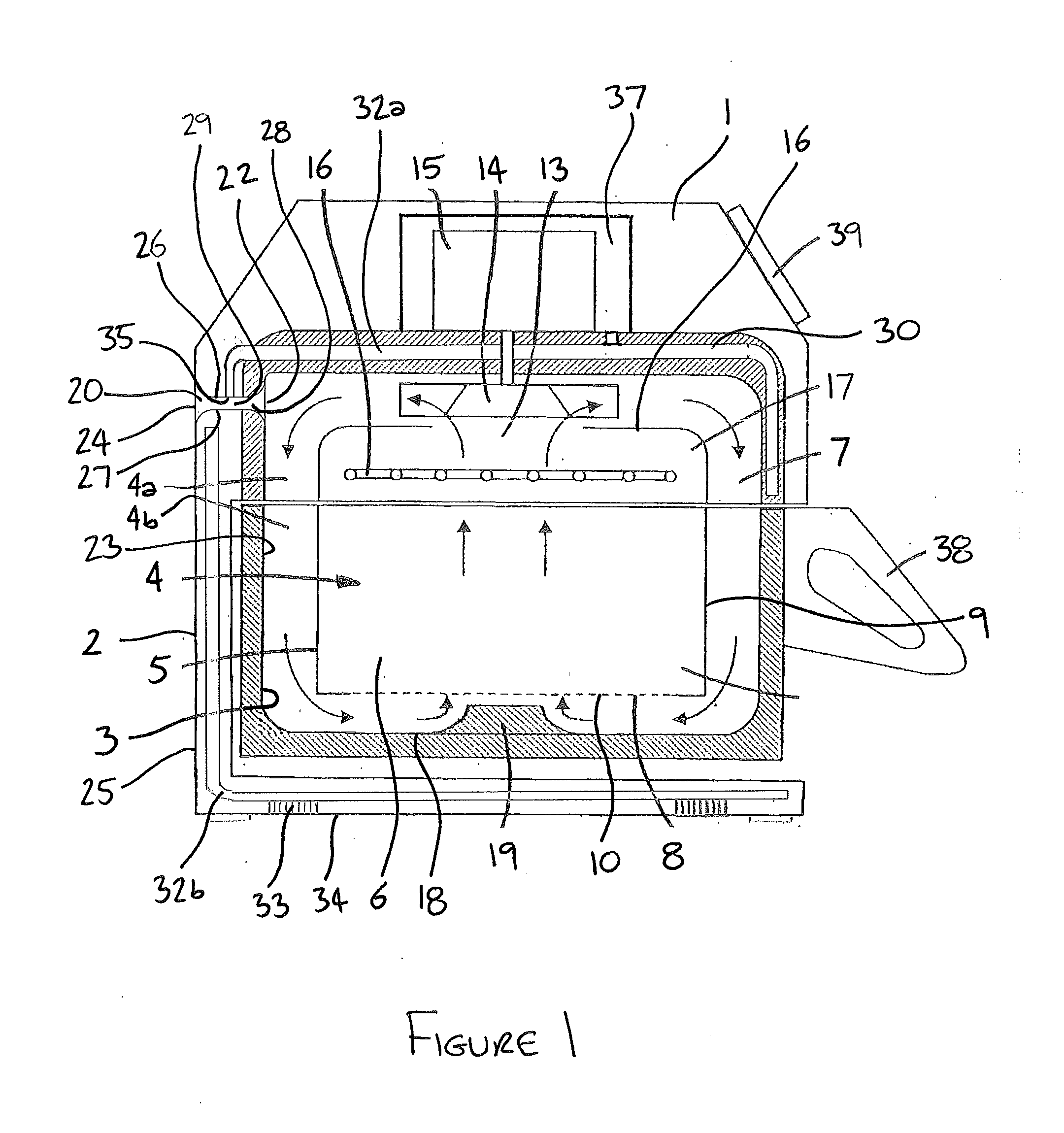

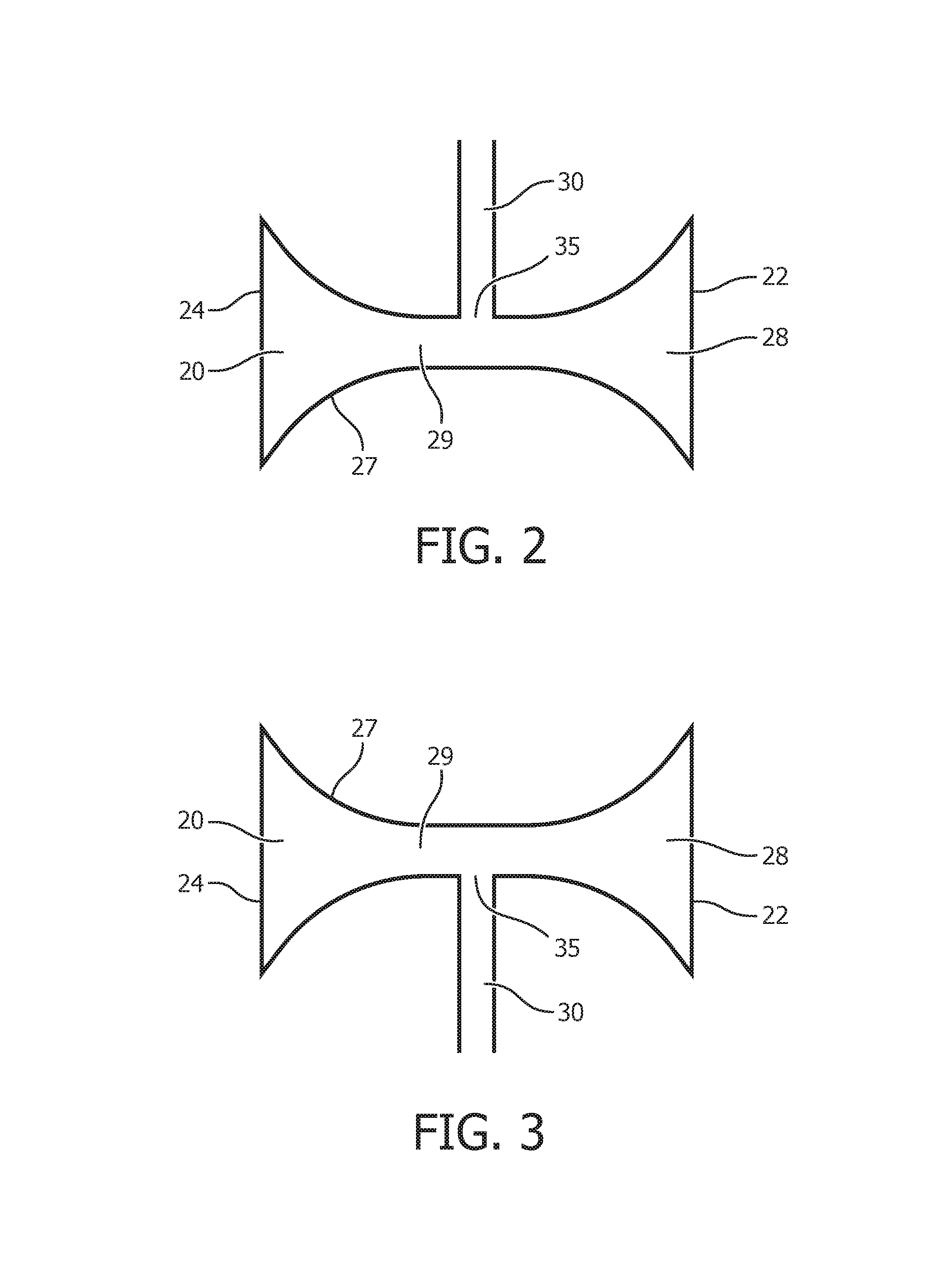

ActiveUS20140083992A1Improve cooling reliabilityImprove reliabilityDomestic stoves or rangesOven air-treatment devicesEngineeringFood preparation

The application relates to an apparatus for preparing food. The apparatus includes a housing (1), a food preparation chamber (4) in the housing (1) having an inner wall (5) defining a food receiving space (6) with an air entry aperture (10) and an air discharge aperture (13), a fan (14) for moving a flow of hot air successively through the air entry aperture (10), the food receiving space (6) and the air discharge aperture (13), and an air guide passage (7) for returning the flow of air from the air discharge aperture (13) towards the air entry aperture (10) separate from the food receiving space (6). The housing (1) comprising a cooling air channel (30) and a hot air vent (20) for exhausting the flow of hot air from the food preparation chamber (4) to outside the housing (1) with a constricted section (29) having a reduced cross-sectional area such that a venturi effect is generated in the hot air vent (20). An outlet (35) to the cooling air channel (30) communicates with the hot air vent (20) at the constricted section (29) such that a region of low pressure is formed at the outlet (35) and a flow of cooling air is drawn along the cooling air channel (30) and into the hot air vent (20).

Owner:KONINKLJIJKE PHILIPS NV

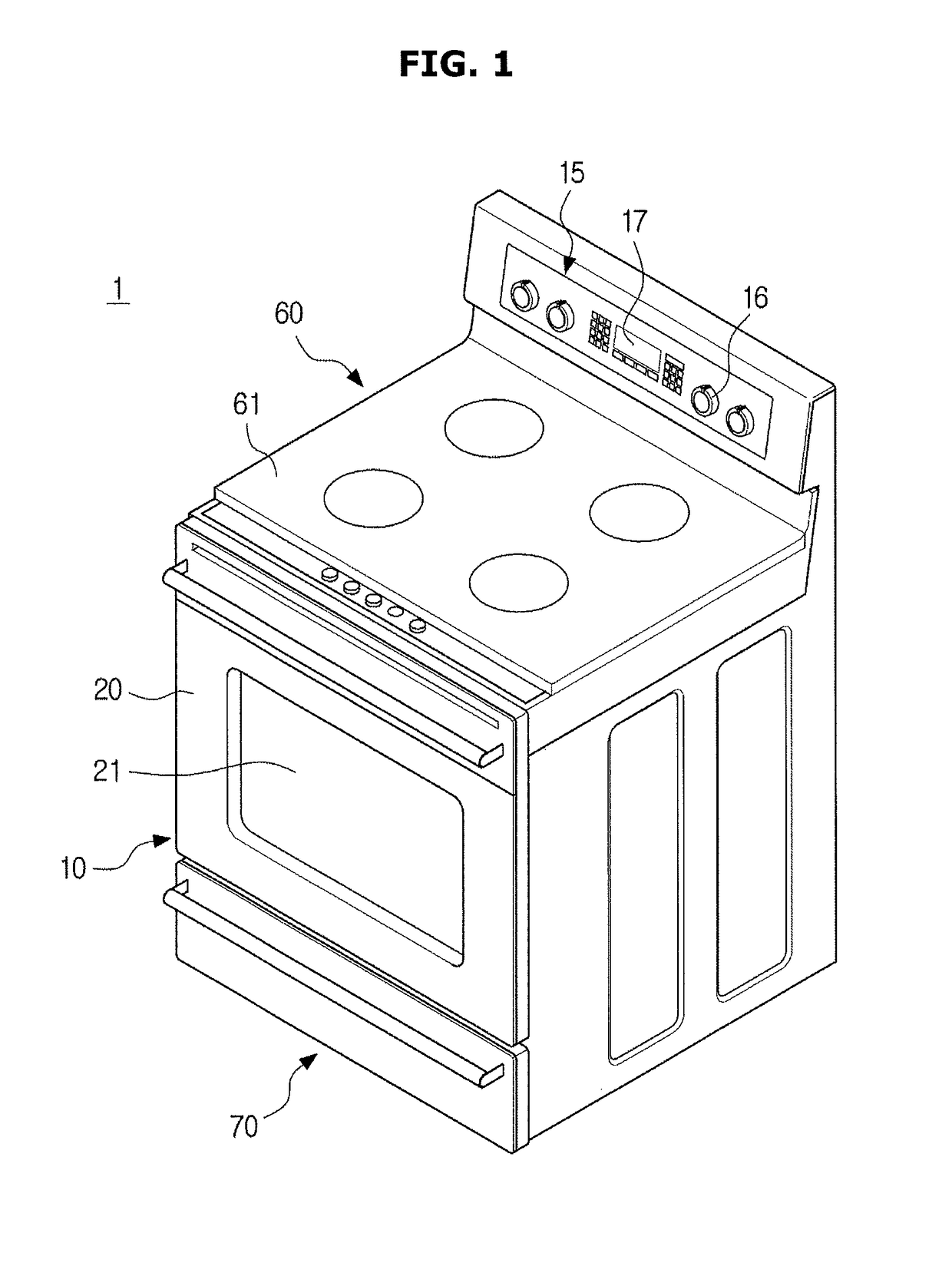

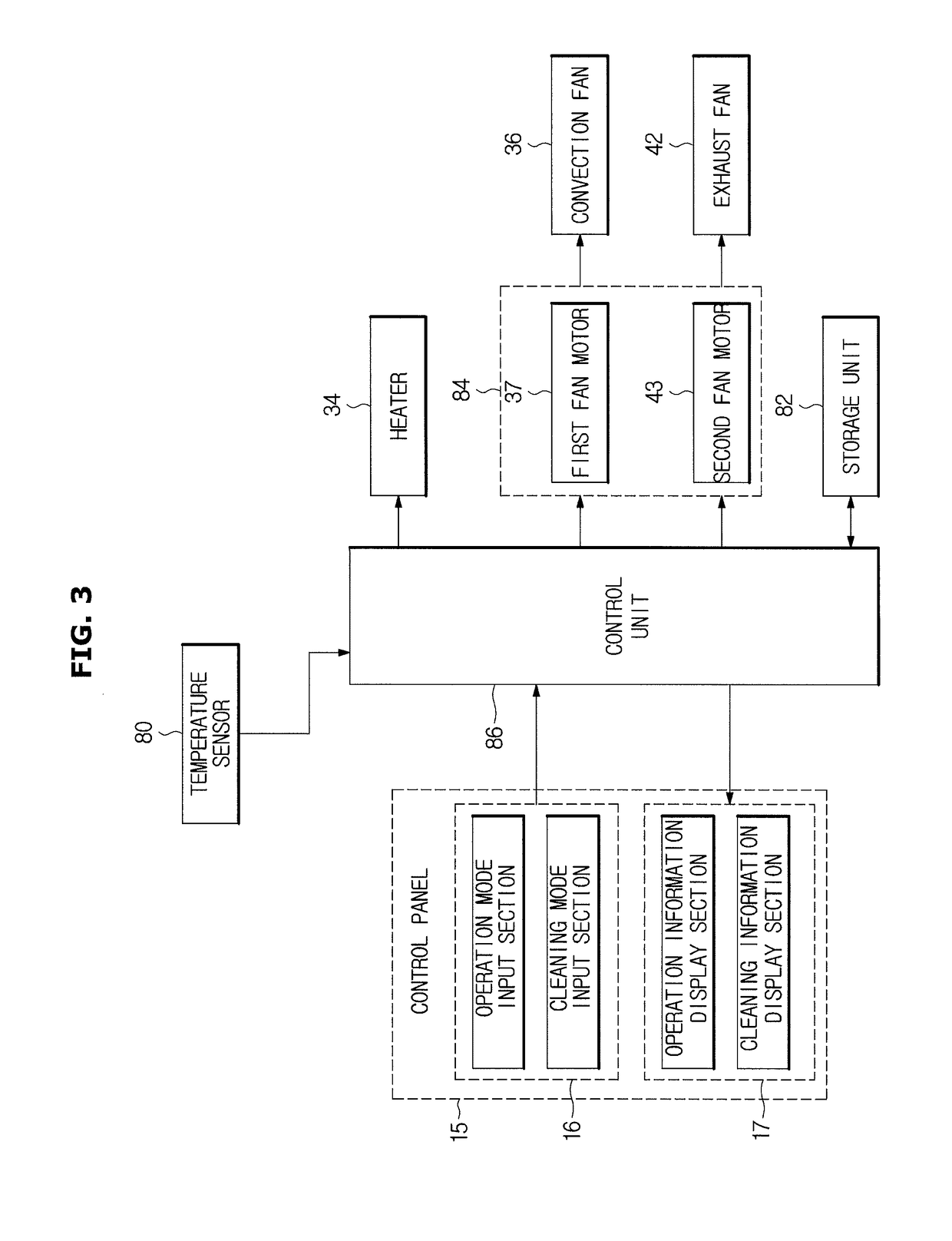

Cooking apparatus and method of controlling the same

ActiveUS10060632B2Self-cleaning stoves/rangesOven air-treatment devicesProcess engineeringMetal sheet

A cooking apparatus including a filter which may efficiently collect gas and smoke generated in a pyro-cleaning process, and a method of controlling the same. The cooking apparatus includes a main body having a cooking chamber formed therein, a vent unit configured to discharge gas in the cooking chamber to the outside of the main body, and a filter installed in at least one of the cooking chamber and the vent unit to collect gas or smoke generated in the cooking chamber. The filter includes a metal sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

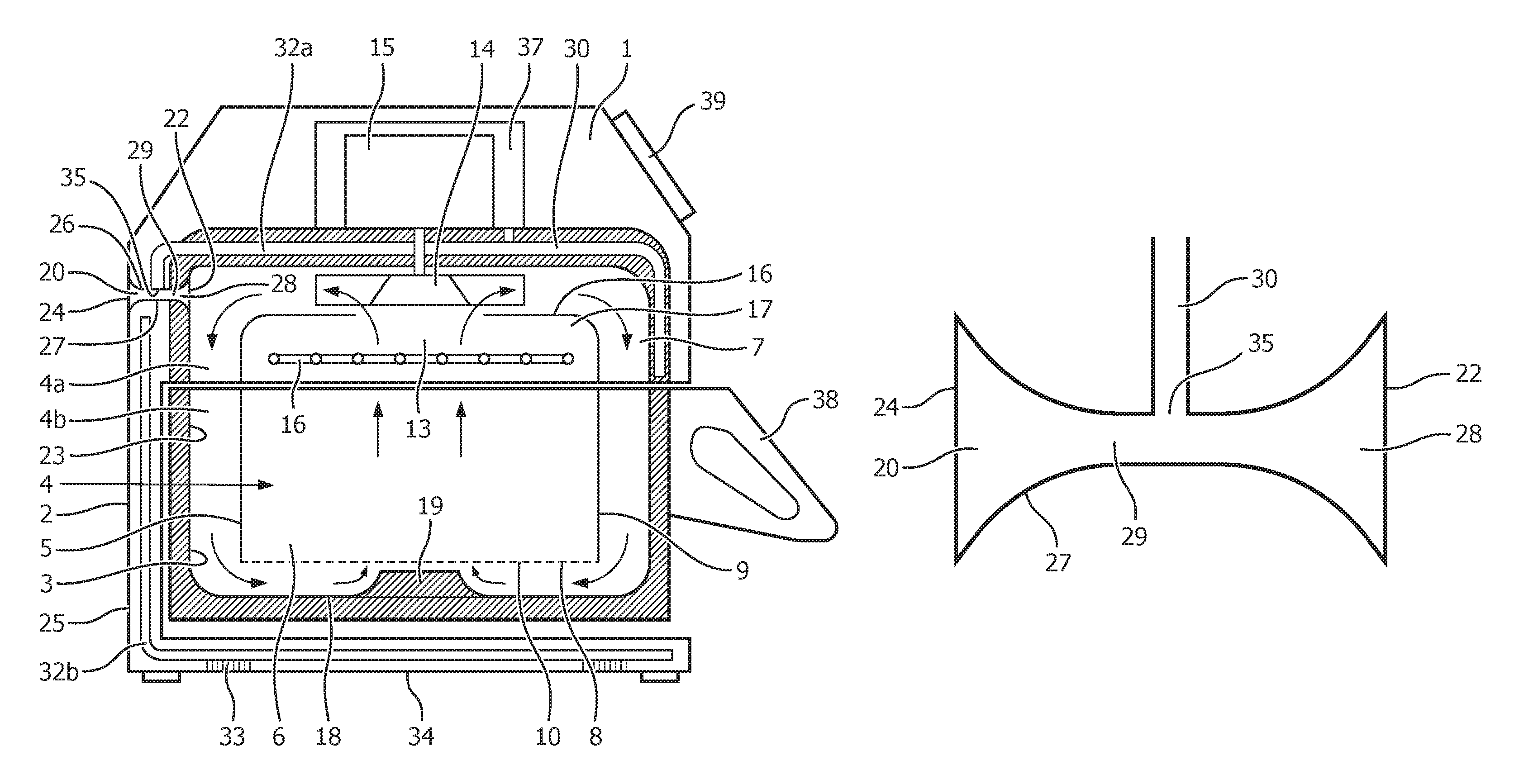

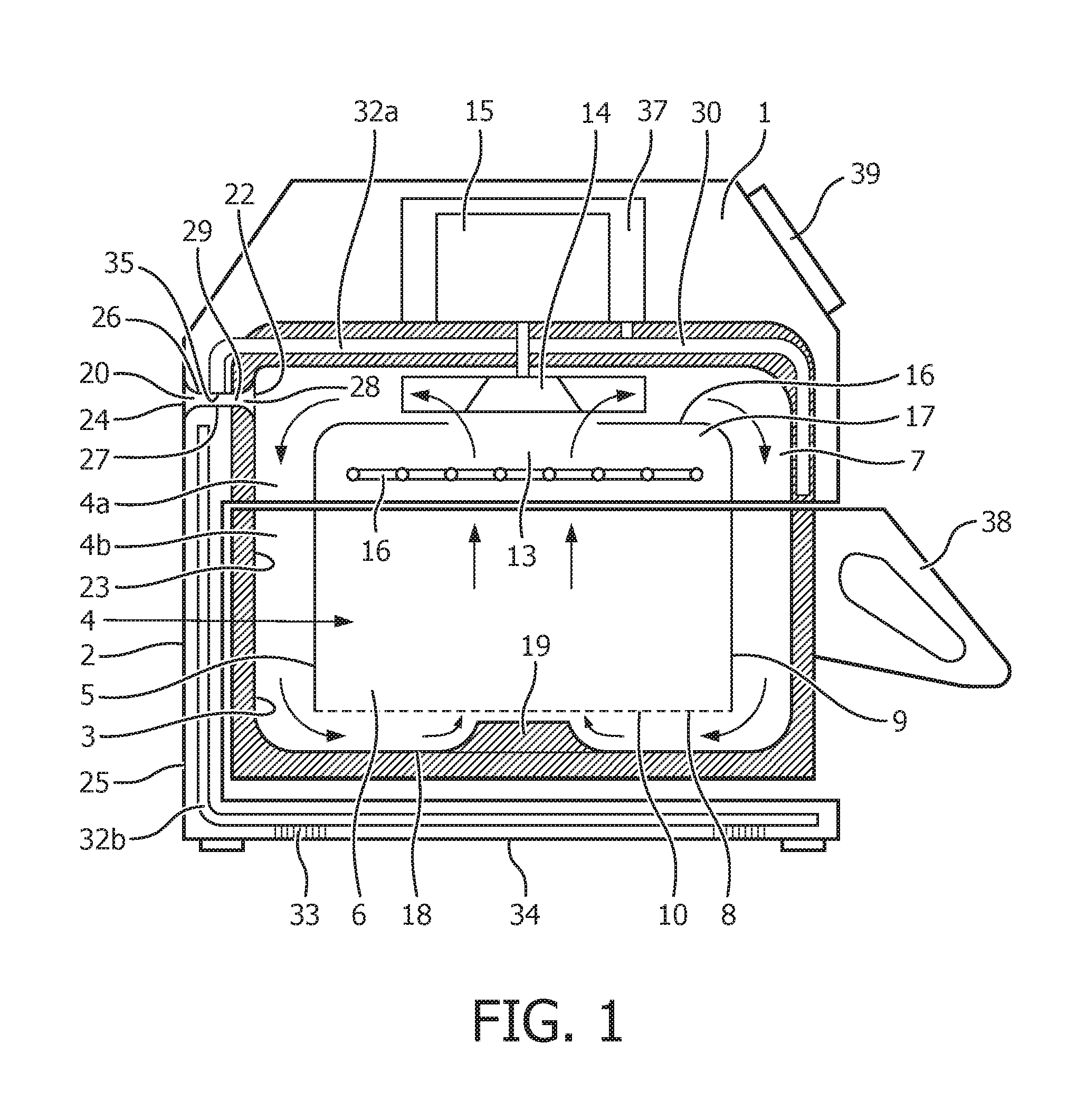

Apparatus for preparing food

ActiveUS9353954B2Reduce the cross-sectional areaImprove cooling reliabilityDomestic stoves or rangesOven air-treatment devicesEngineeringMechanical engineering

The application relates to an apparatus for preparing food. The apparatus includes a housing (1), a food preparation chamber (4) in the housing (1) having an inner wall (5) defining a food receiving space (6) with an air entry aperture (10) and an air discharge aperture (13), a fan (14) for moving a flow of hot air successively through the air entry aperture (10), the food receiving space (6) and the air discharge aperture (13), and an air guide passage (7) for returning the flow of air from the air discharge aperture (13) towards the air entry aperture (10) separate from the food receiving space (6). The housing (1) comprising a cooling air channel (30) and a hot air vent (20) for exhausting the flow of hot air from the food preparation chamber (4) to outside the housing (1) with a constricted section (29) having a reduced cross-sectional area such that a venturi effect is generated in the hot air vent (20). An outlet (35) to the cooling air channel (30) communicates with the hot air vent (20) at the constricted section (29) such that a region of low pressure is formed at the outlet (35) and a flow of cooling air is drawn along the cooling air channel (30) and into the hot air vent (20).

Owner:VERSUNI HLDG BV

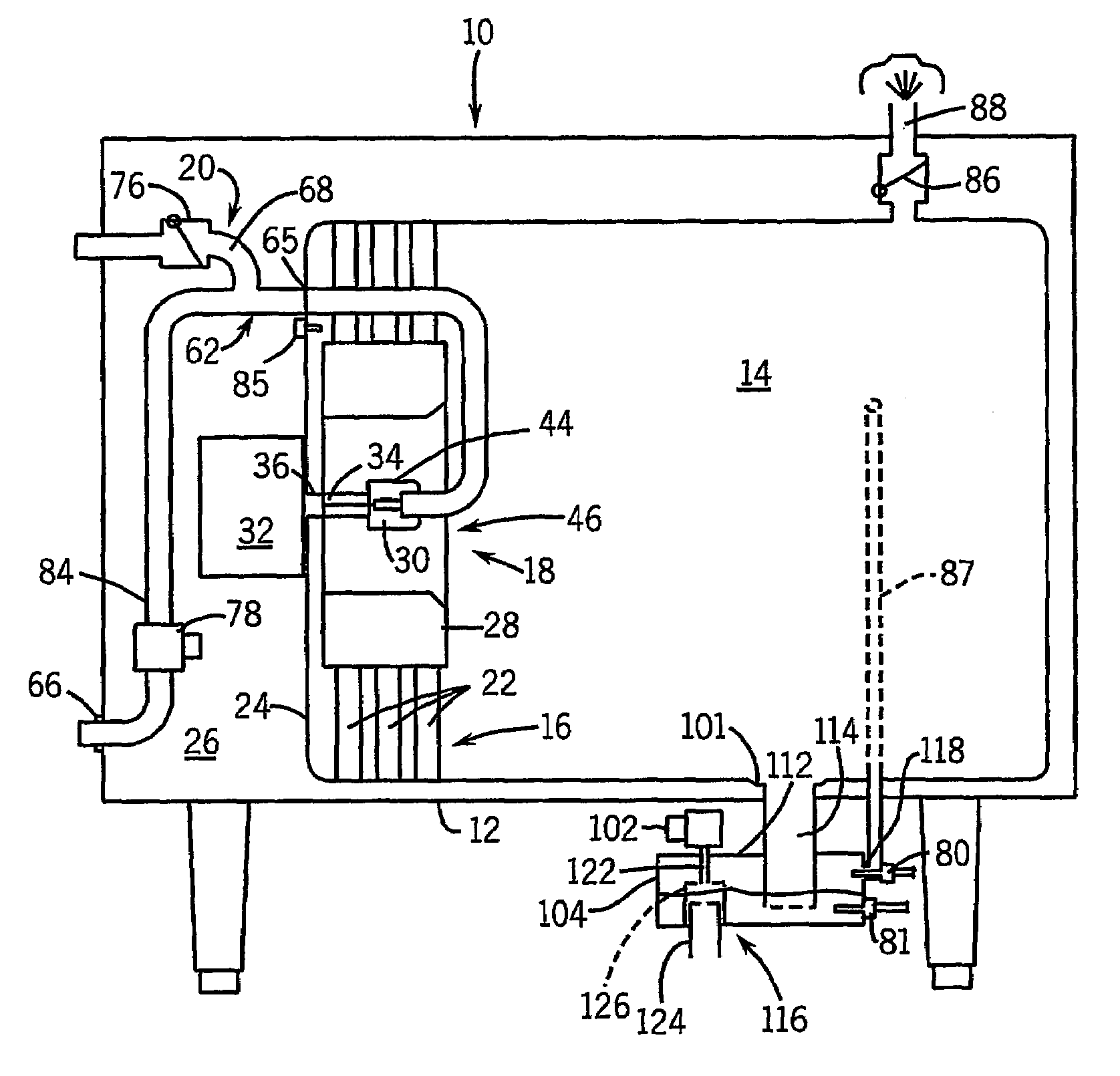

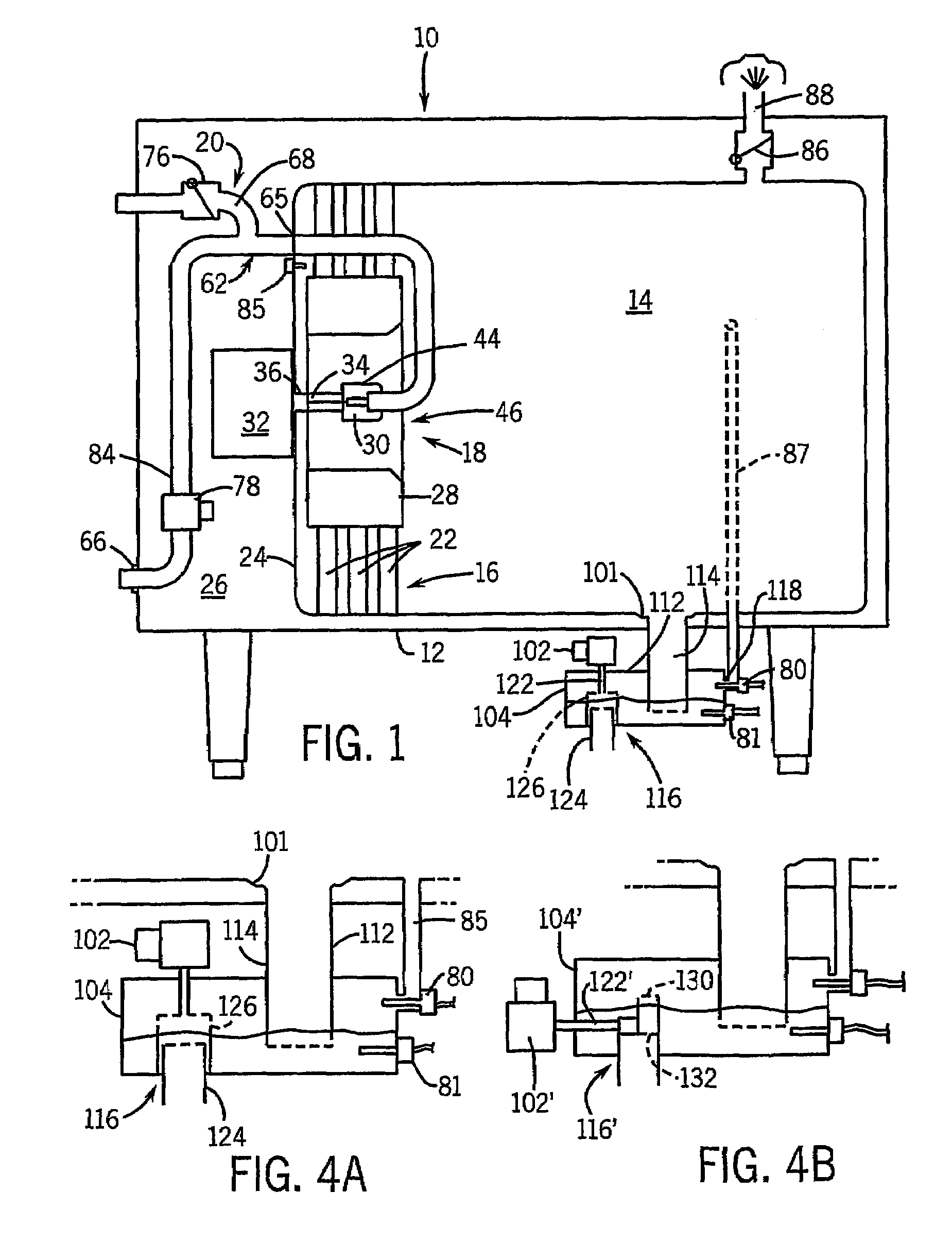

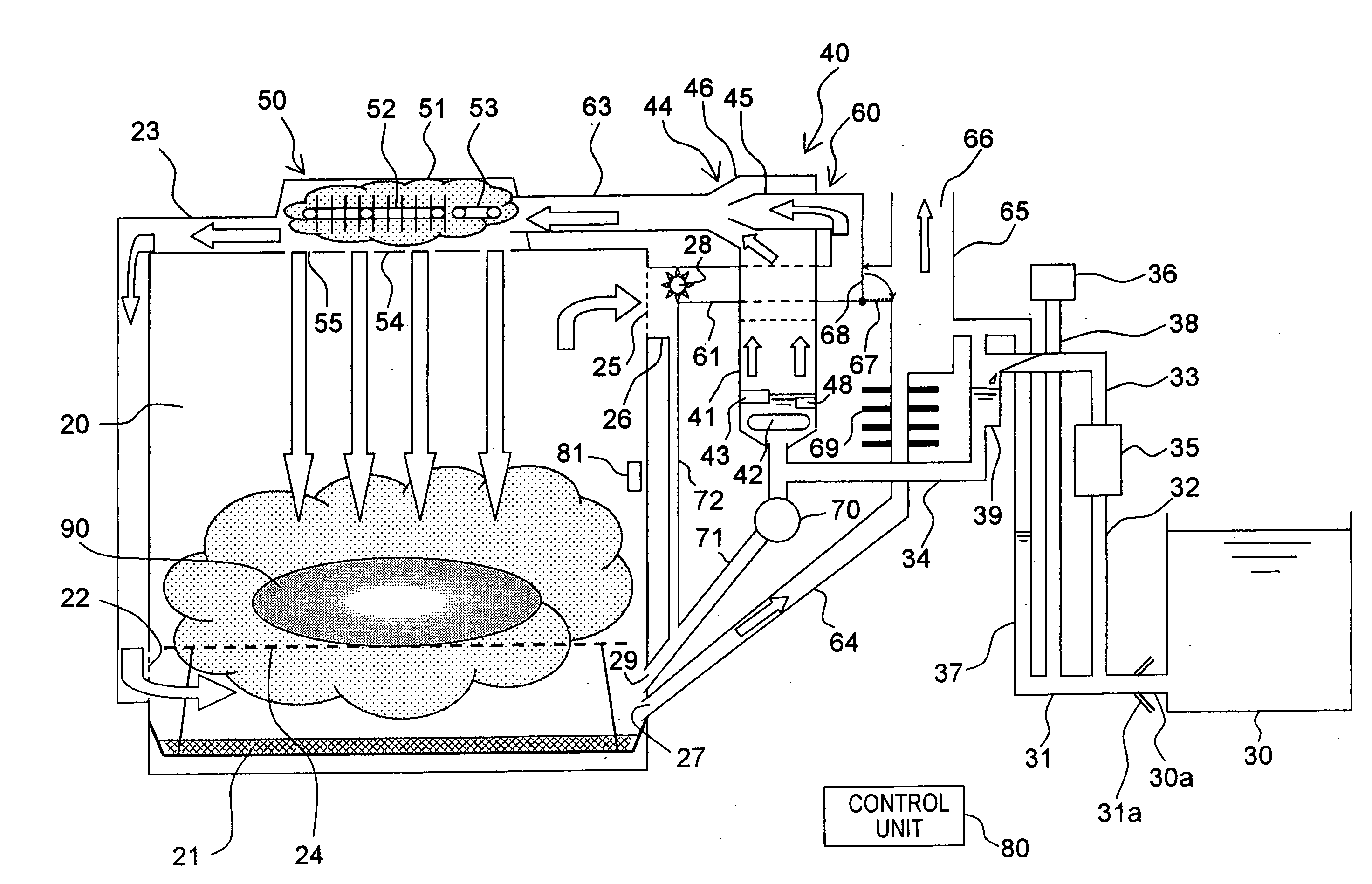

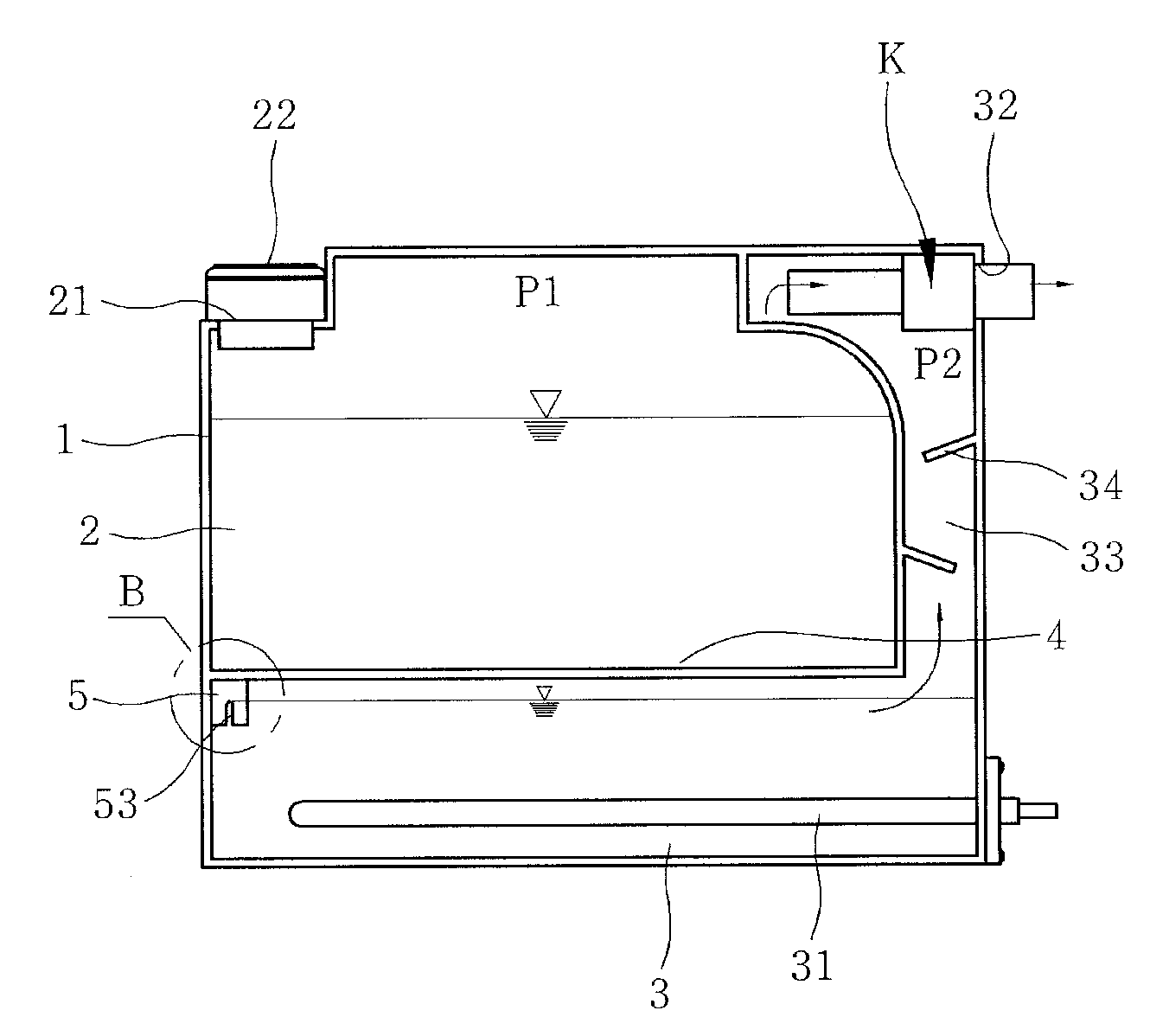

Humidity control system for combination oven

InactiveUS6987246B2Increase surface areaImprove thermal efficiencyDomestic stoves or rangesMilk treatmentSteam cookingControl system

A combination oven for the preparation of food has a cooking chamber containing heating elements, a fan and an atomizer for radiant, convective or steam cooking. The humidity within the cooking chamber is controlled by a water valve and either by forcing dry air into the cooking chamber and venting the humid air or by using a pressure box. Without any moving parts, the pressure box controls air exchange of the cooking chamber according to the level of water within the pressure box and the pressure in the cooking chamber. The oven has a condensate tank to collect condensation drained from the cooking chamber. The pressure box and condensate tanks form water barriers effectively isolating the cooking chamber from the vent and drain during cooking until venting is required.

Owner:ALTO SHAAM

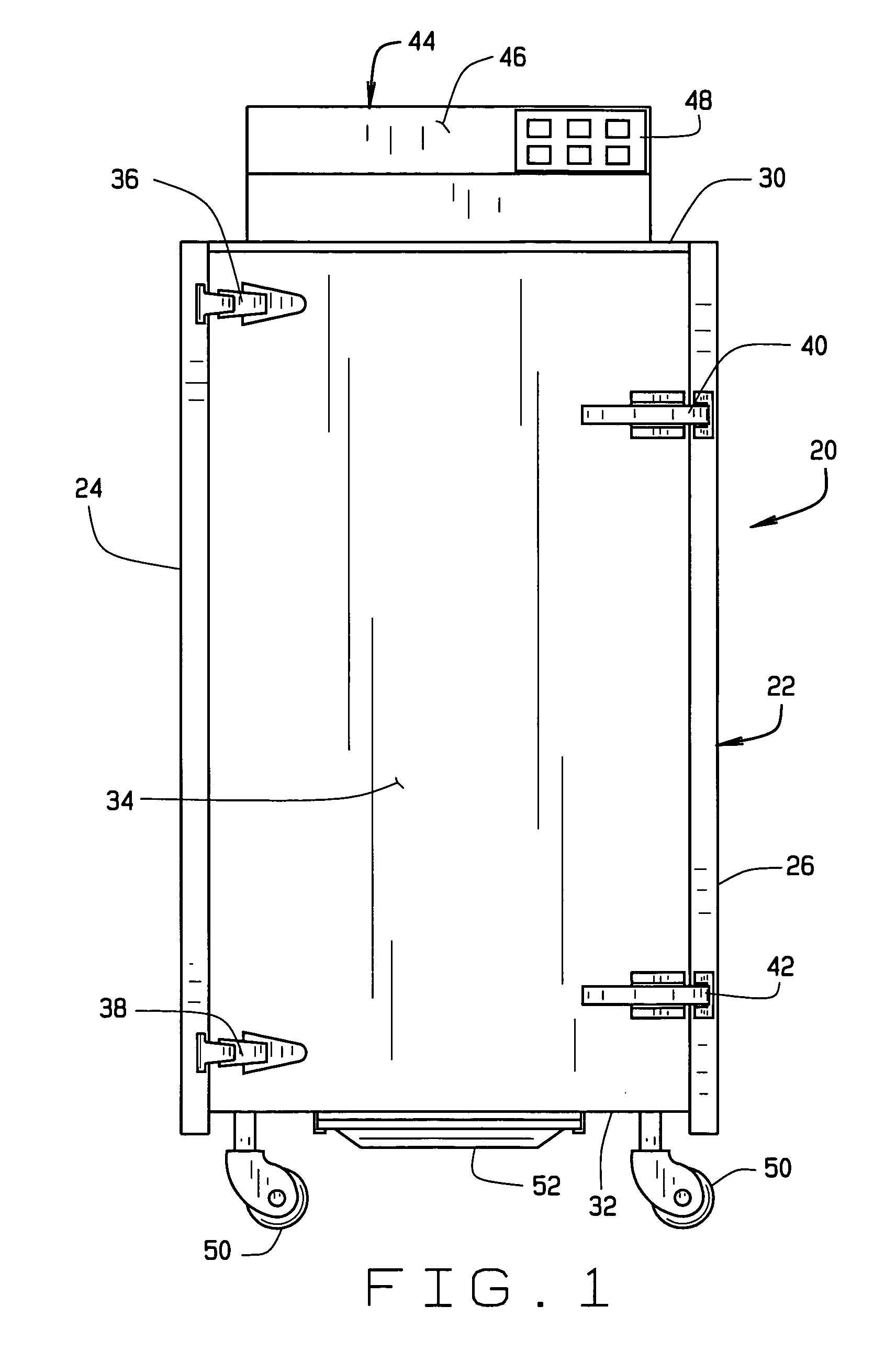

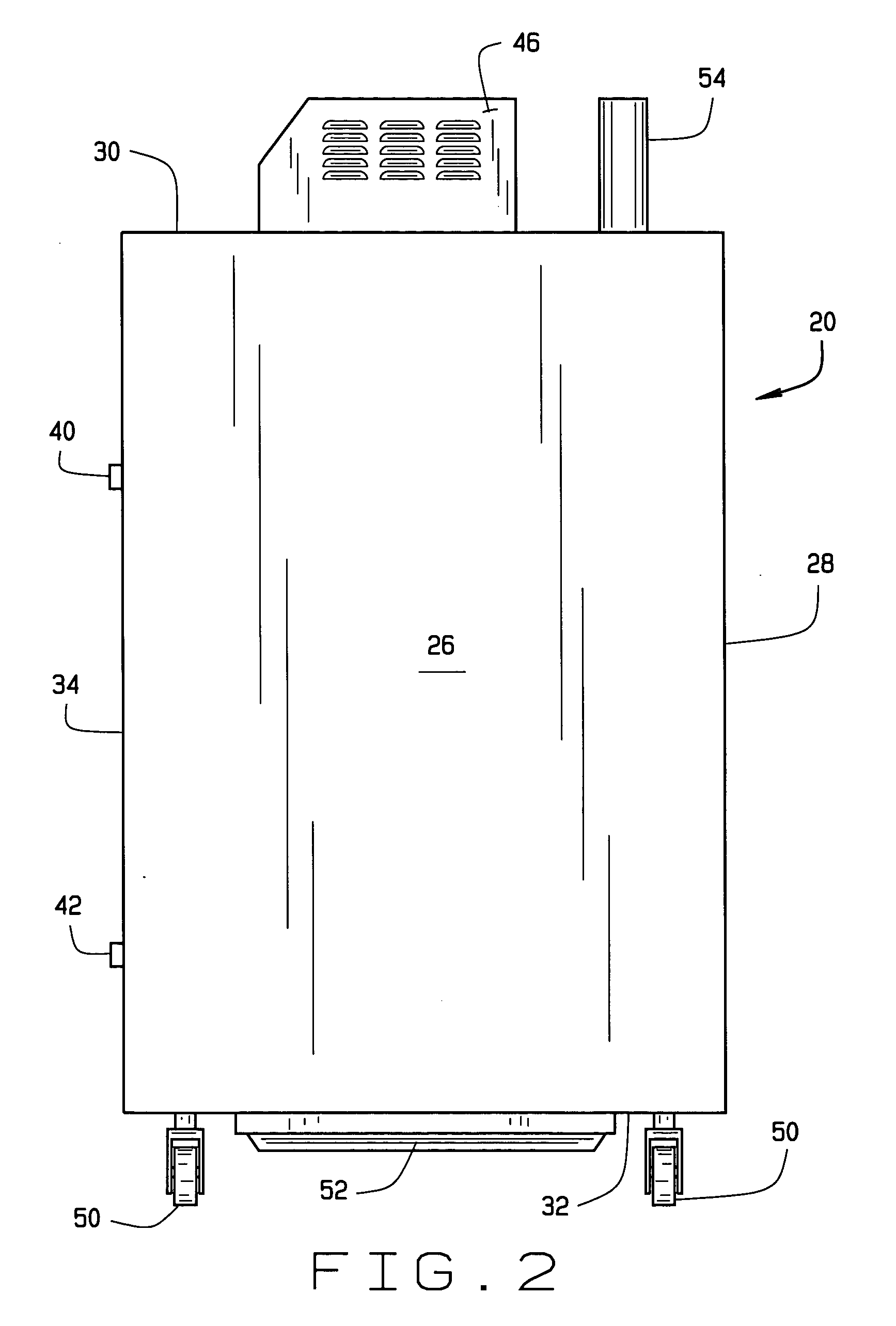

Holding oven

ActiveUS20140083309A1Maintain qualityQuick buildDomestic stoves or rangesOven air-treatment devicesWater vaporLaboratory oven

Methods, ovens, and associated apparatus. Ovens and methods are adapted for maintaining the quality of a pre-cooked food product. Rapid temperature and / or relative humidity restoration may be used. Ovens may include a partition movable to vary sizes of oven cavities. Ovens may include removable interior panels. Humidification mechanisms are adapted for generating water vapor which may be used to maintain the quality of a pre-cooked food product.

Owner:DUKE MANUFACTURING COMPANY

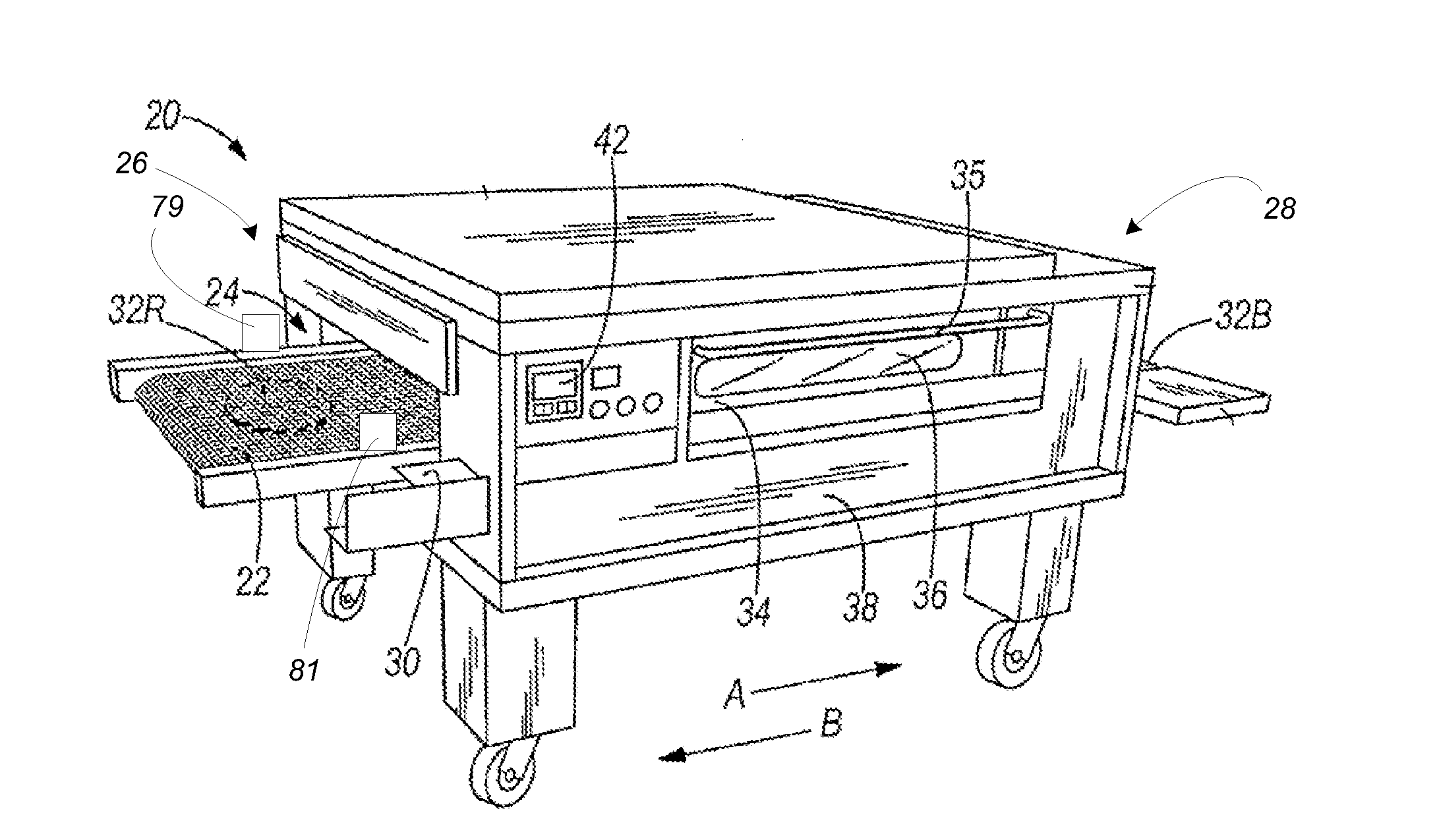

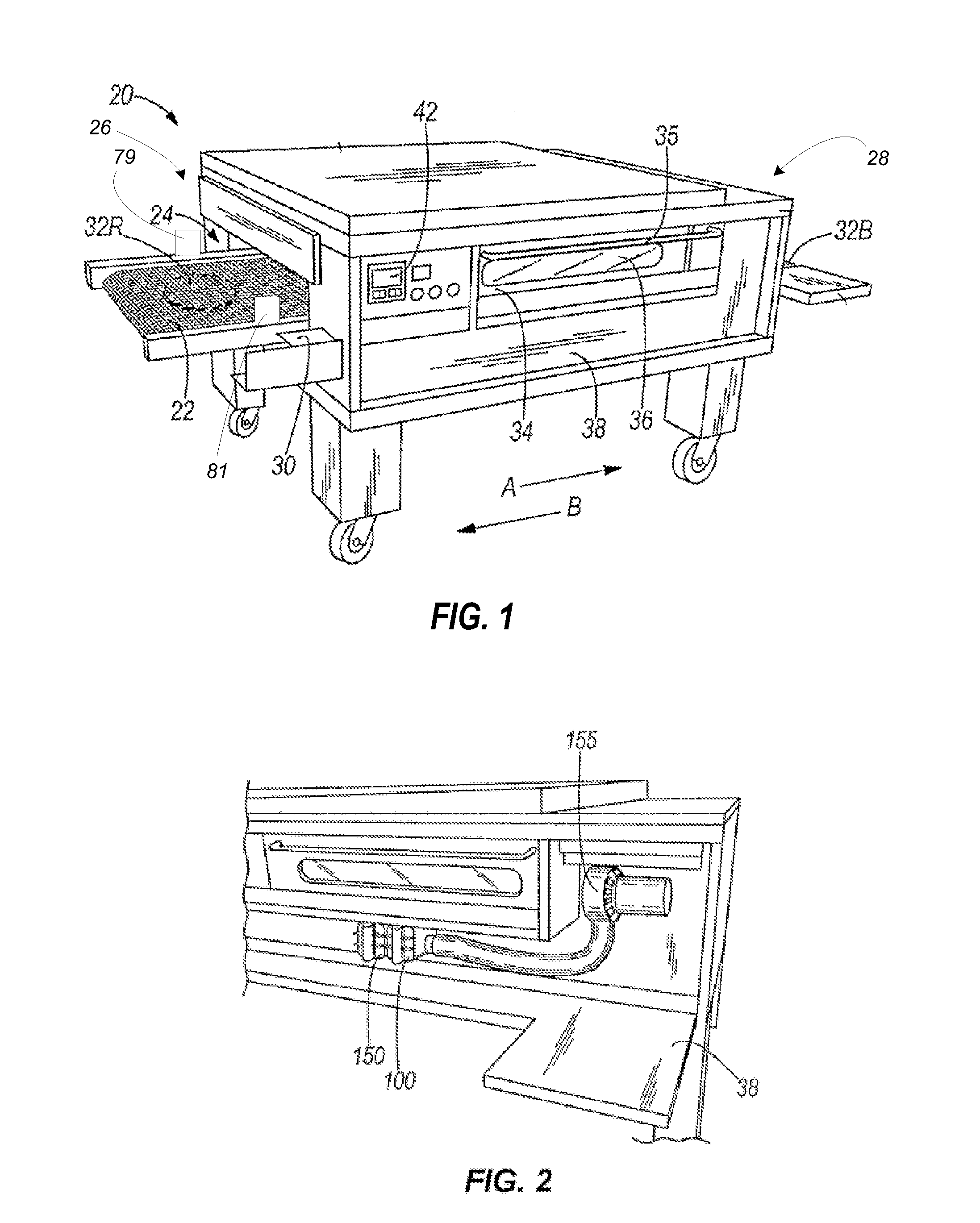

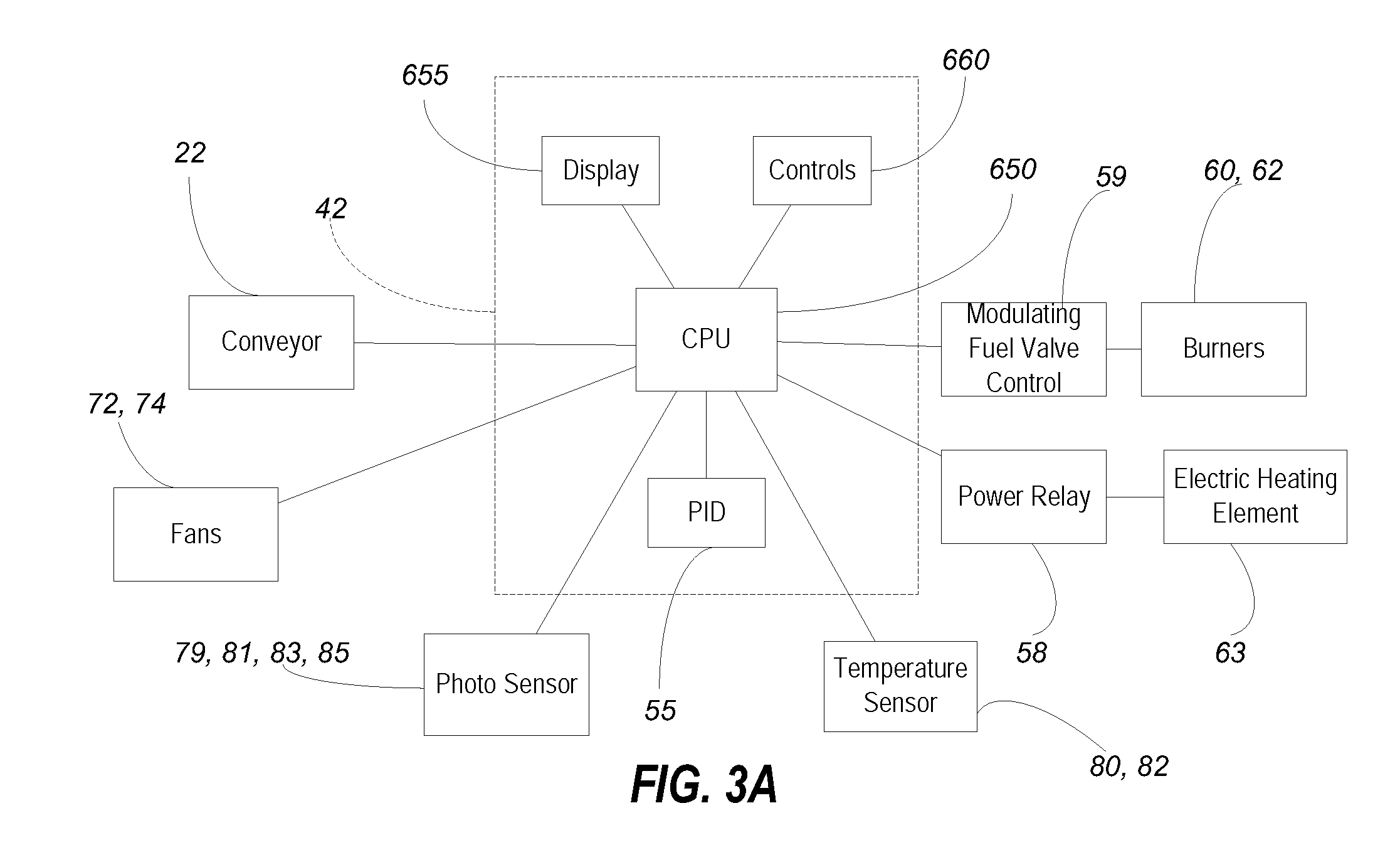

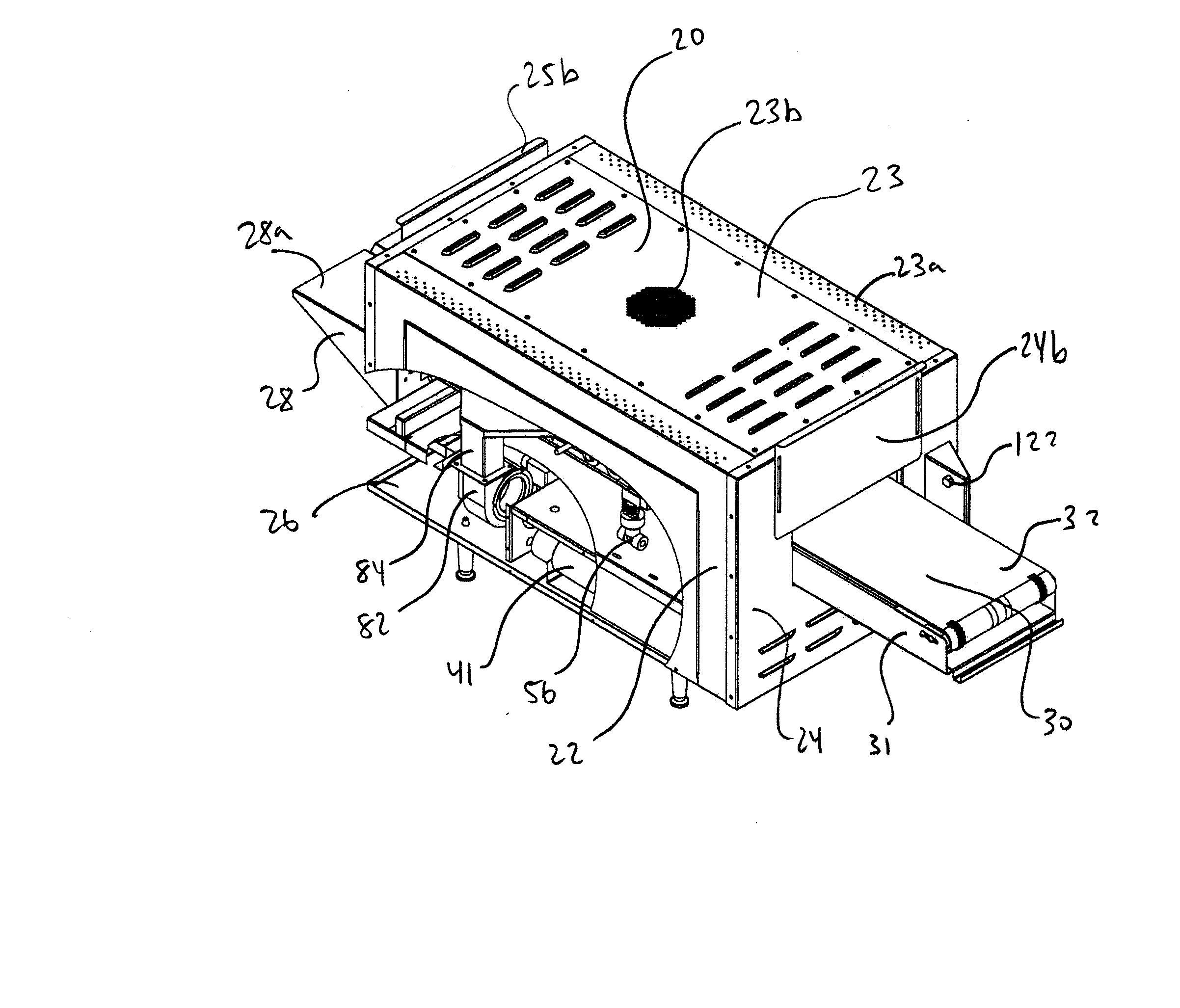

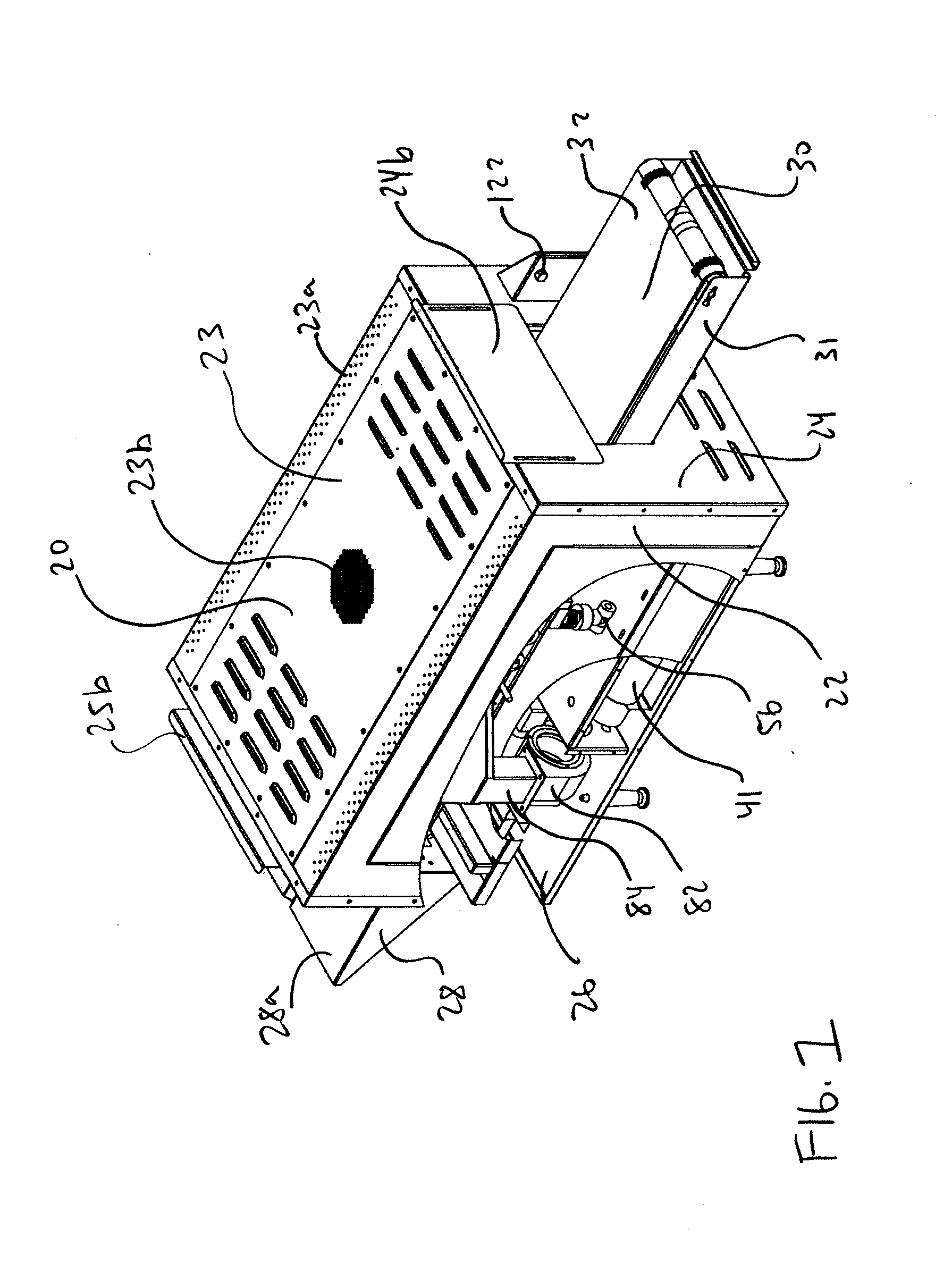

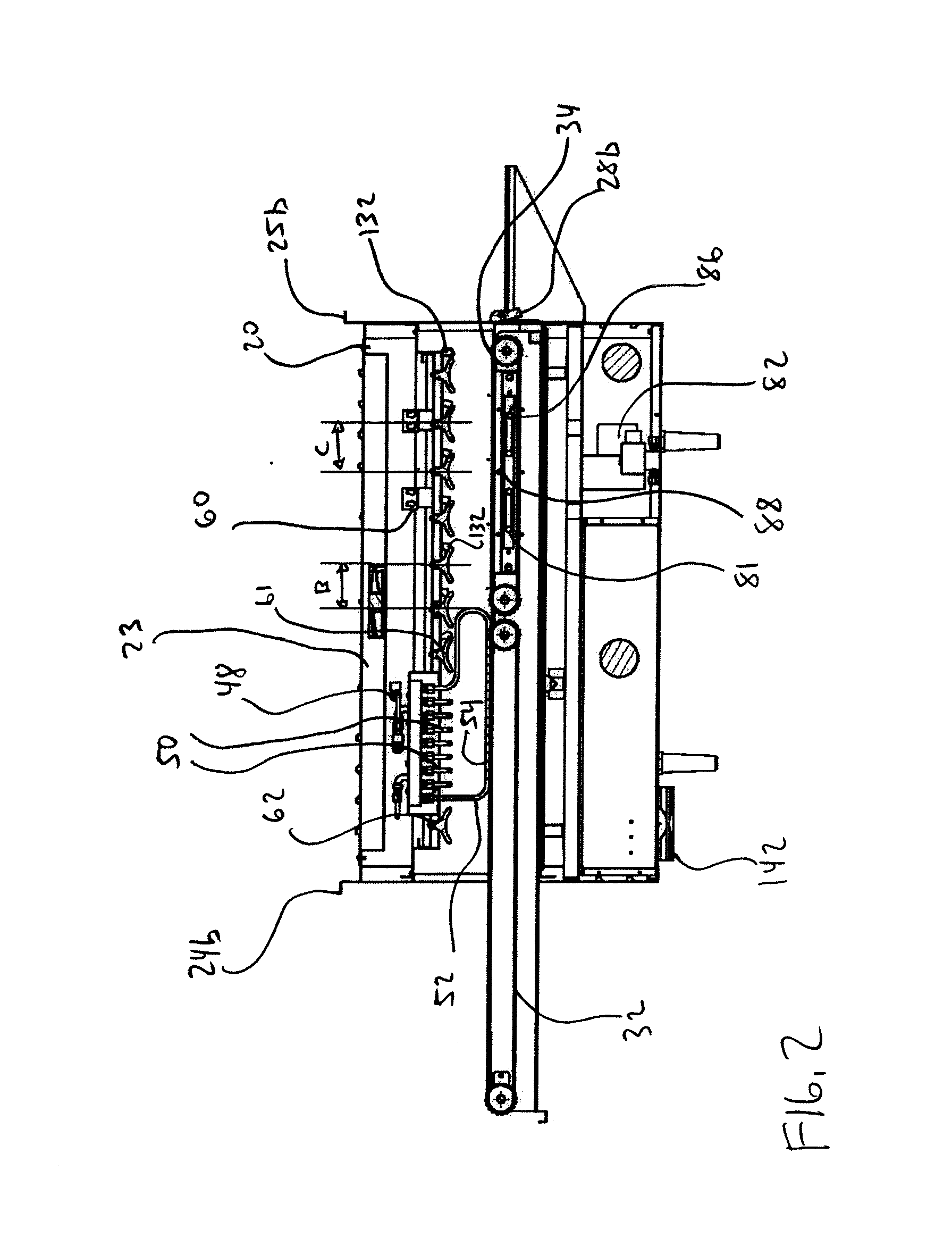

Conveyor oven apparatus and method

ActiveUS20110269085A1Increase productionReduce internal temperatureStoves/ranges foundationsDomestic stoves or rangesEngineeringInternal temperature

An oven with a sensor positioned to detect an event that will cause a decrease in the internal temperature of a tunnel. The oven includes a controller configured to increase the thermal output of a heating element in anticipation of the upcoming decrease in the internal temperature. In some embodiments, the oven is a conveyor over and the sensor is positioned to detect a food item approach the tunnel on a conveyor. In some embodiments, the amount of current provided to an electric heating element is increased by increasing the target temperature. In some embodiments, the amount of current provided to the electric heating element is increased by a predetermined offset.

Owner:MIDDLEBY CORPORATION

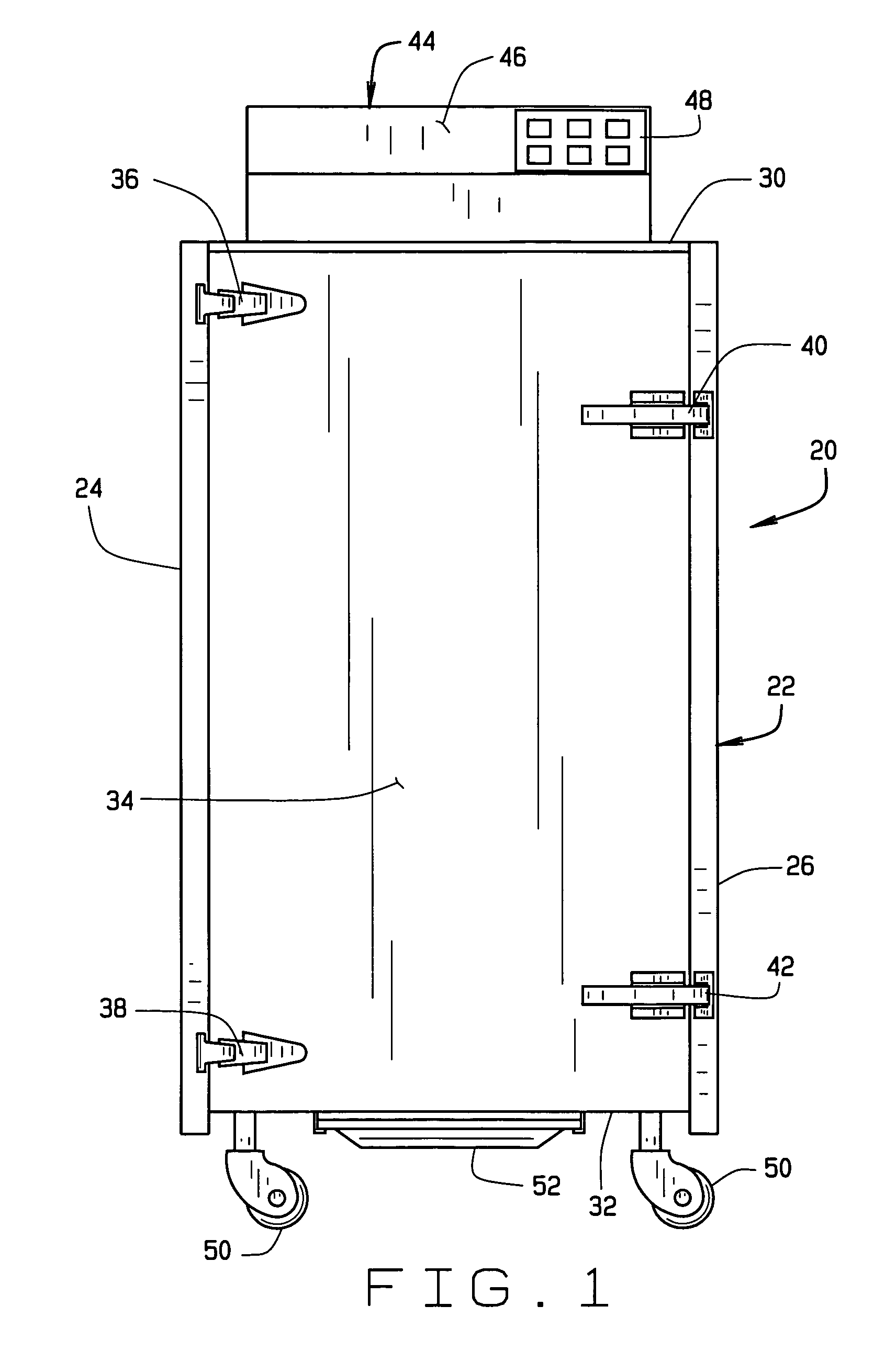

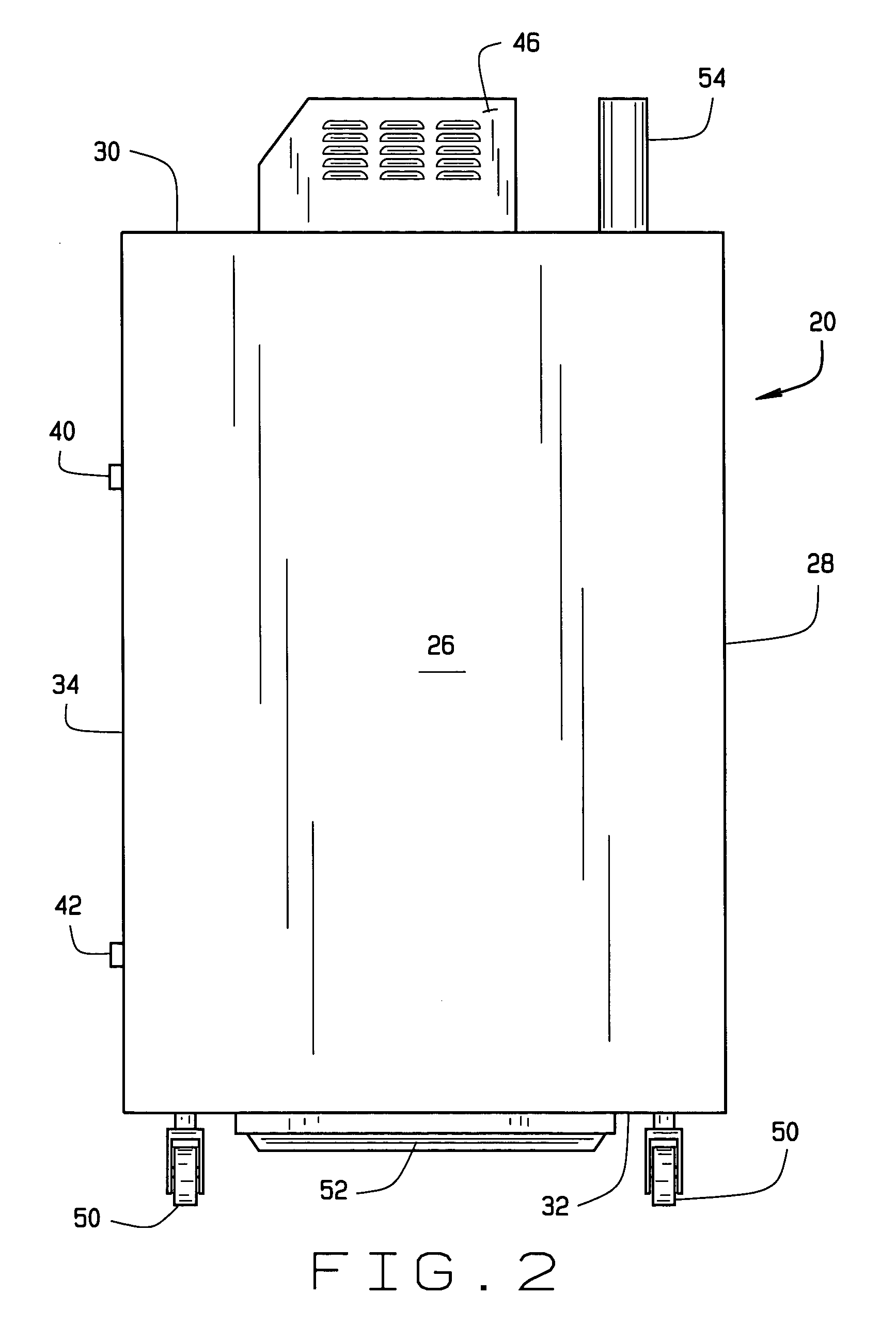

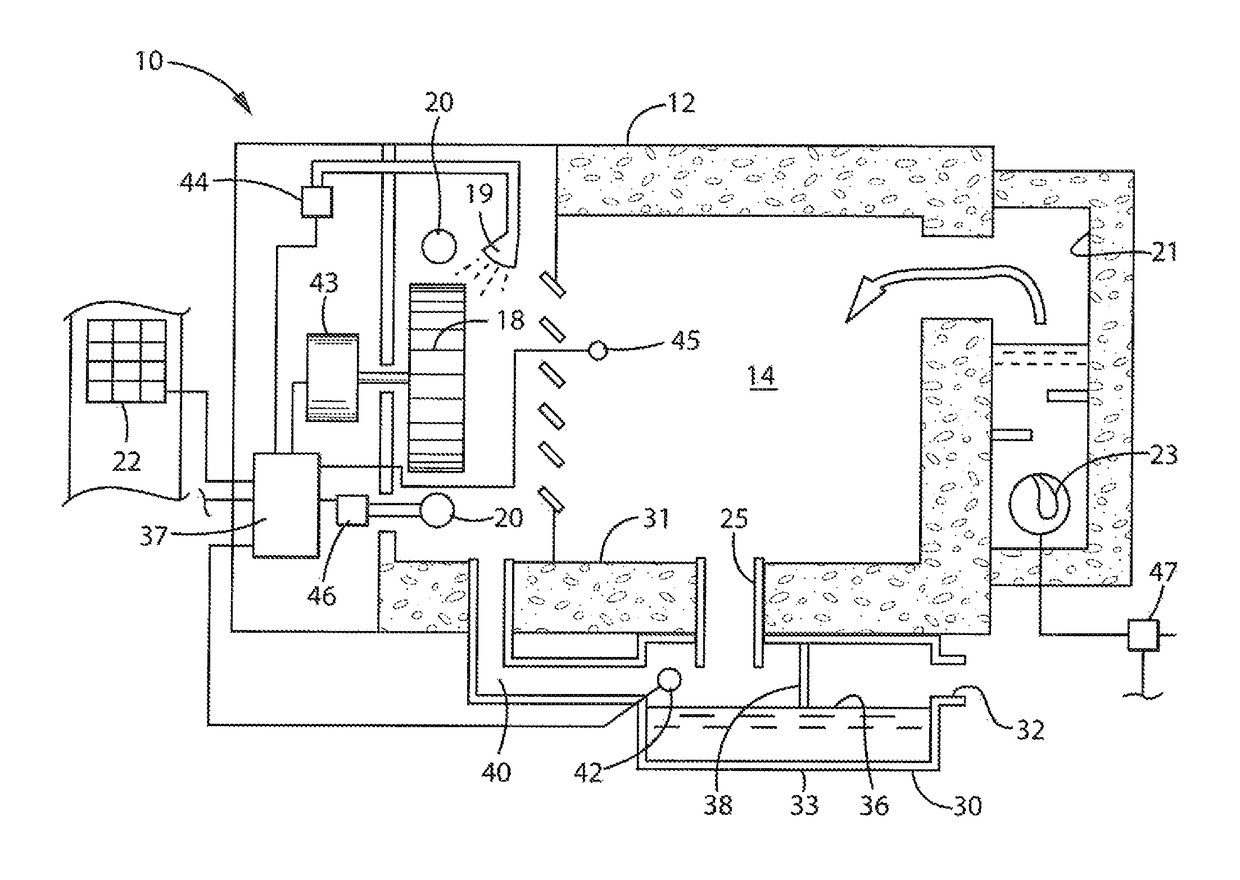

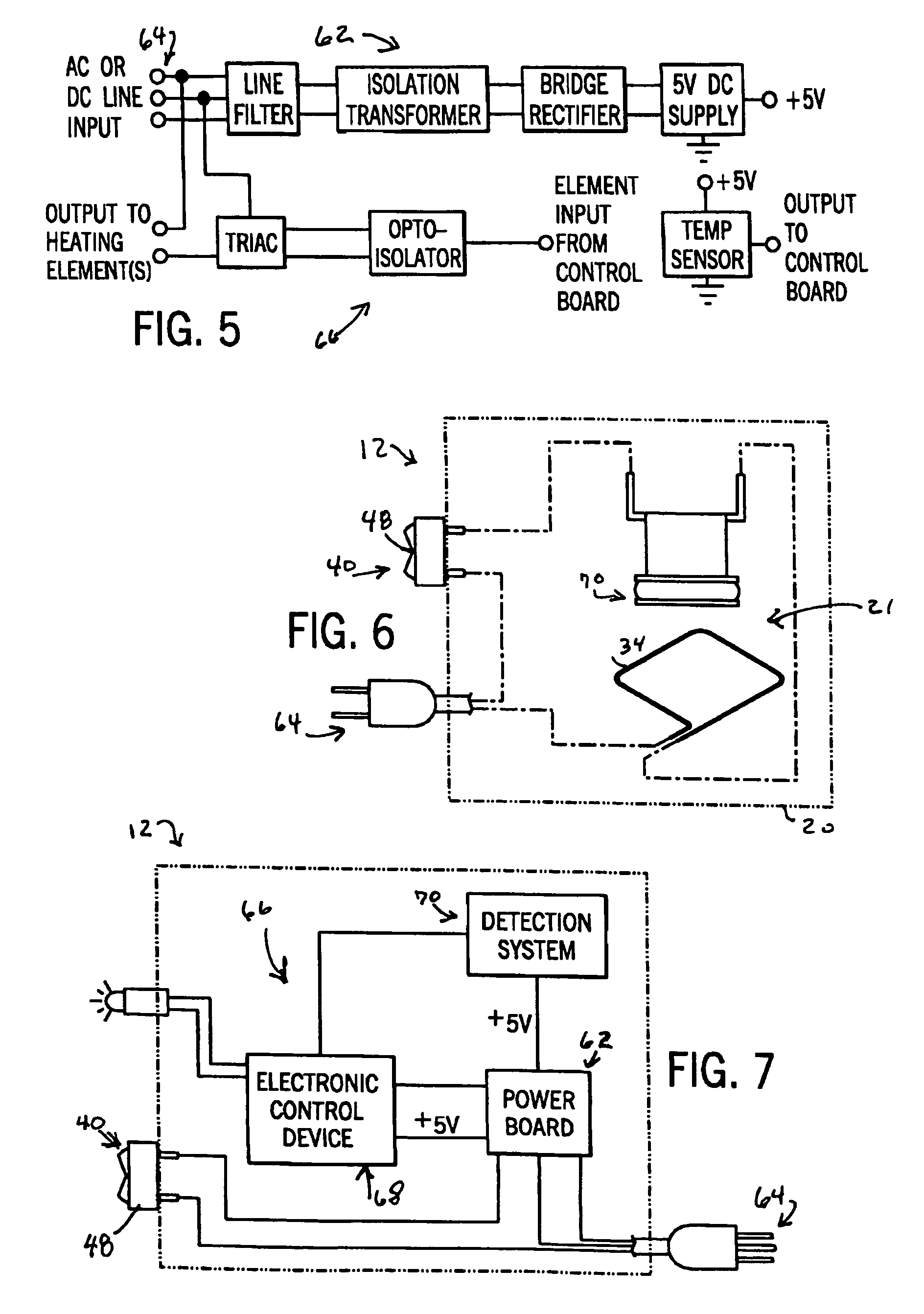

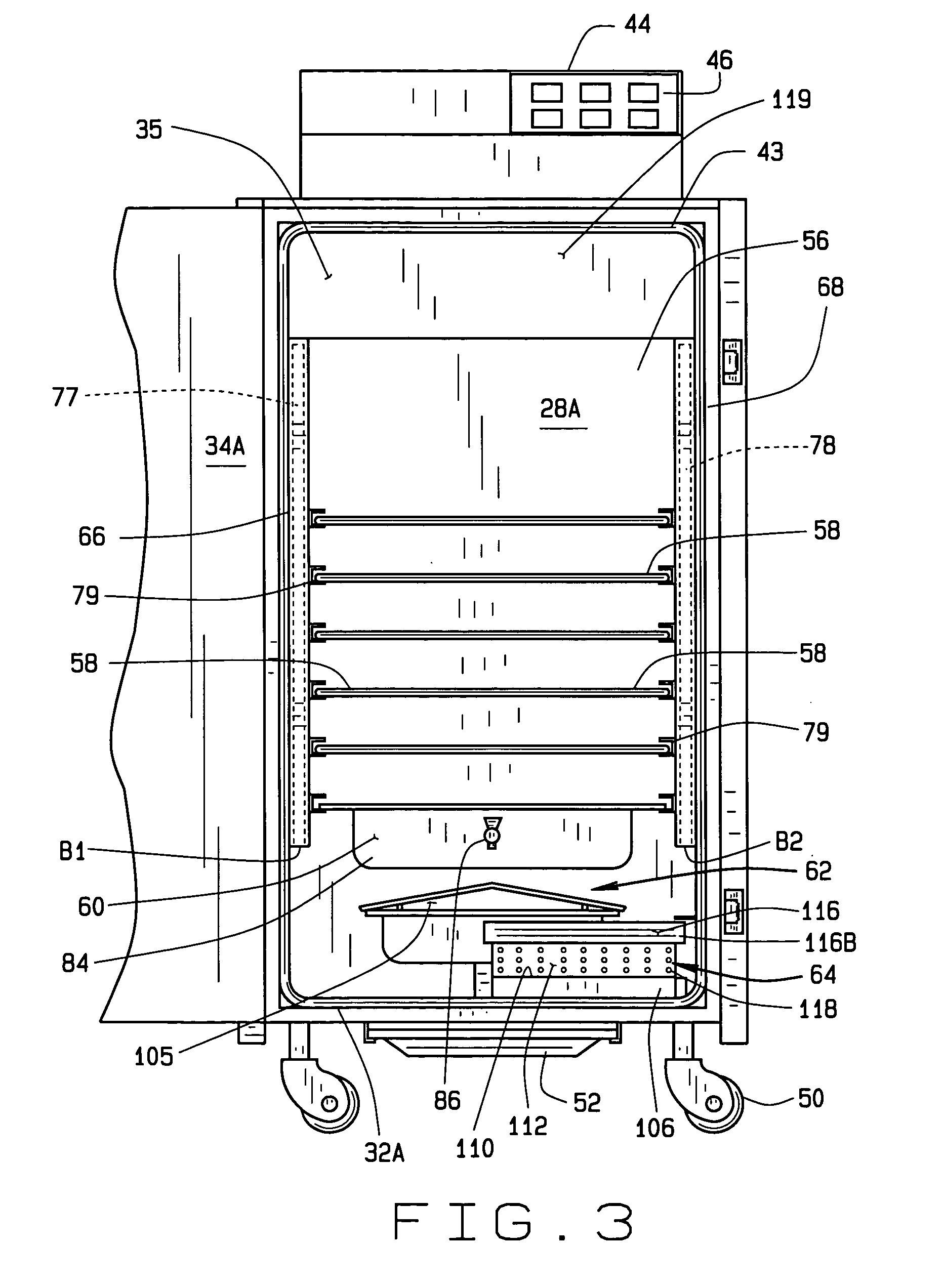

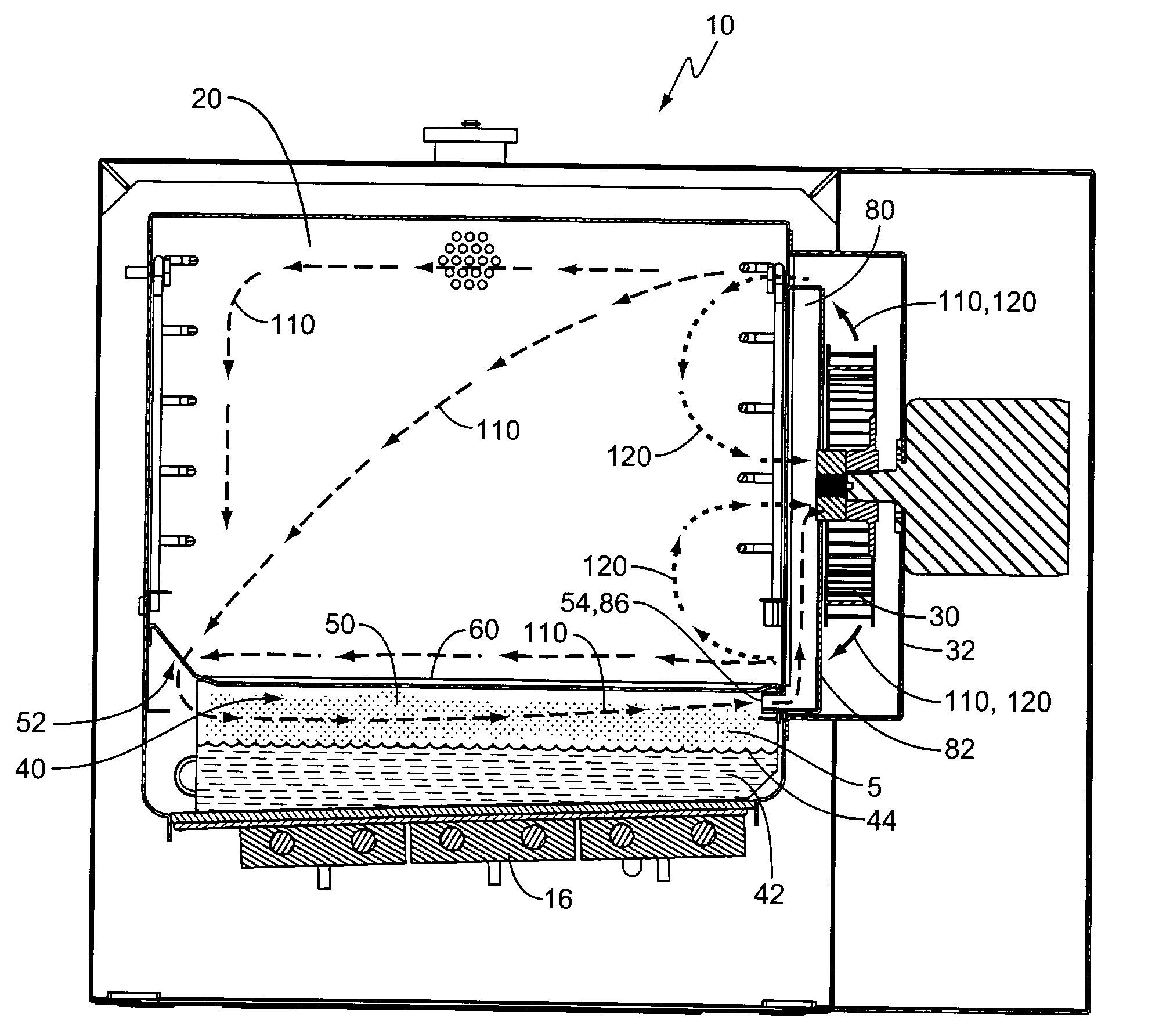

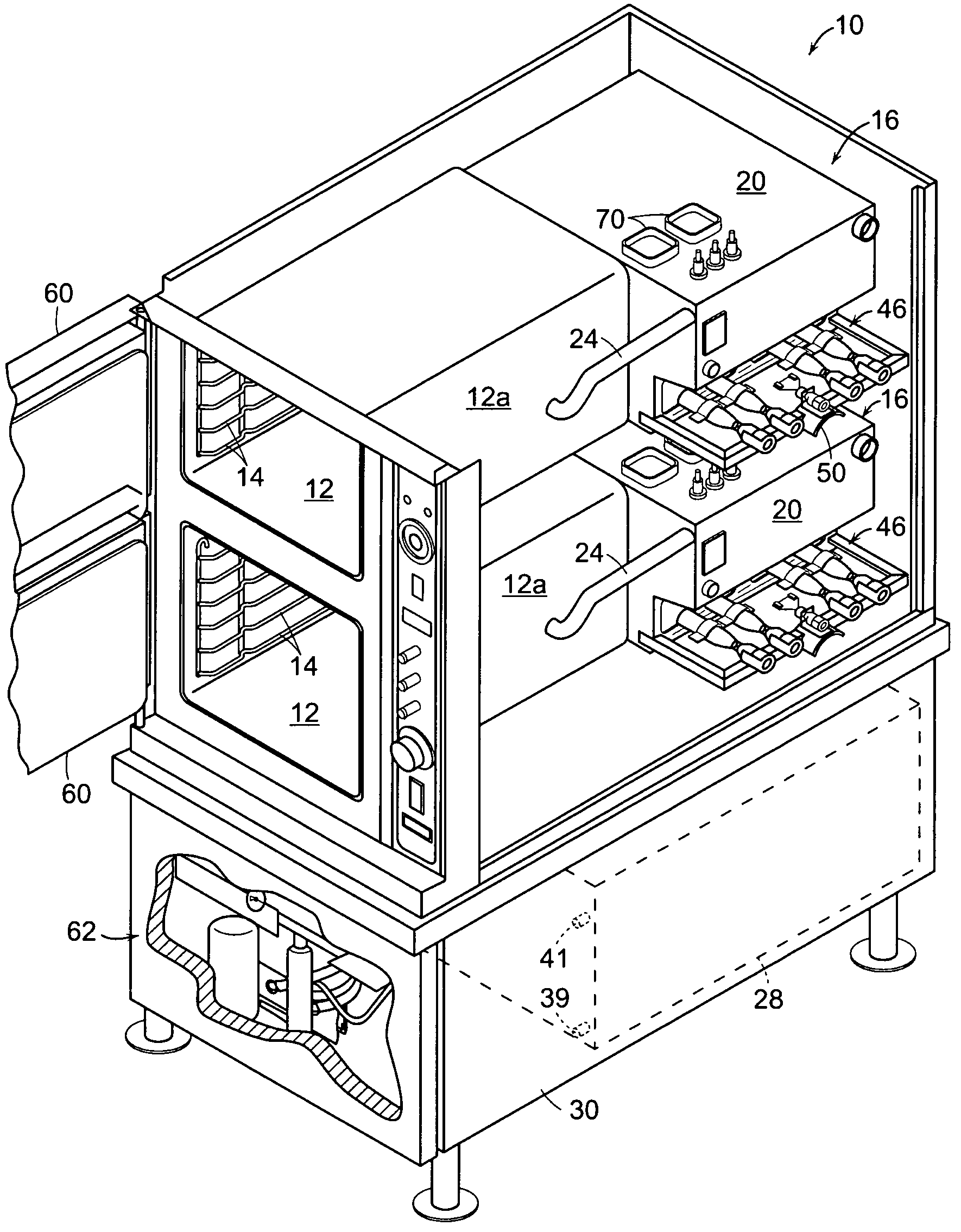

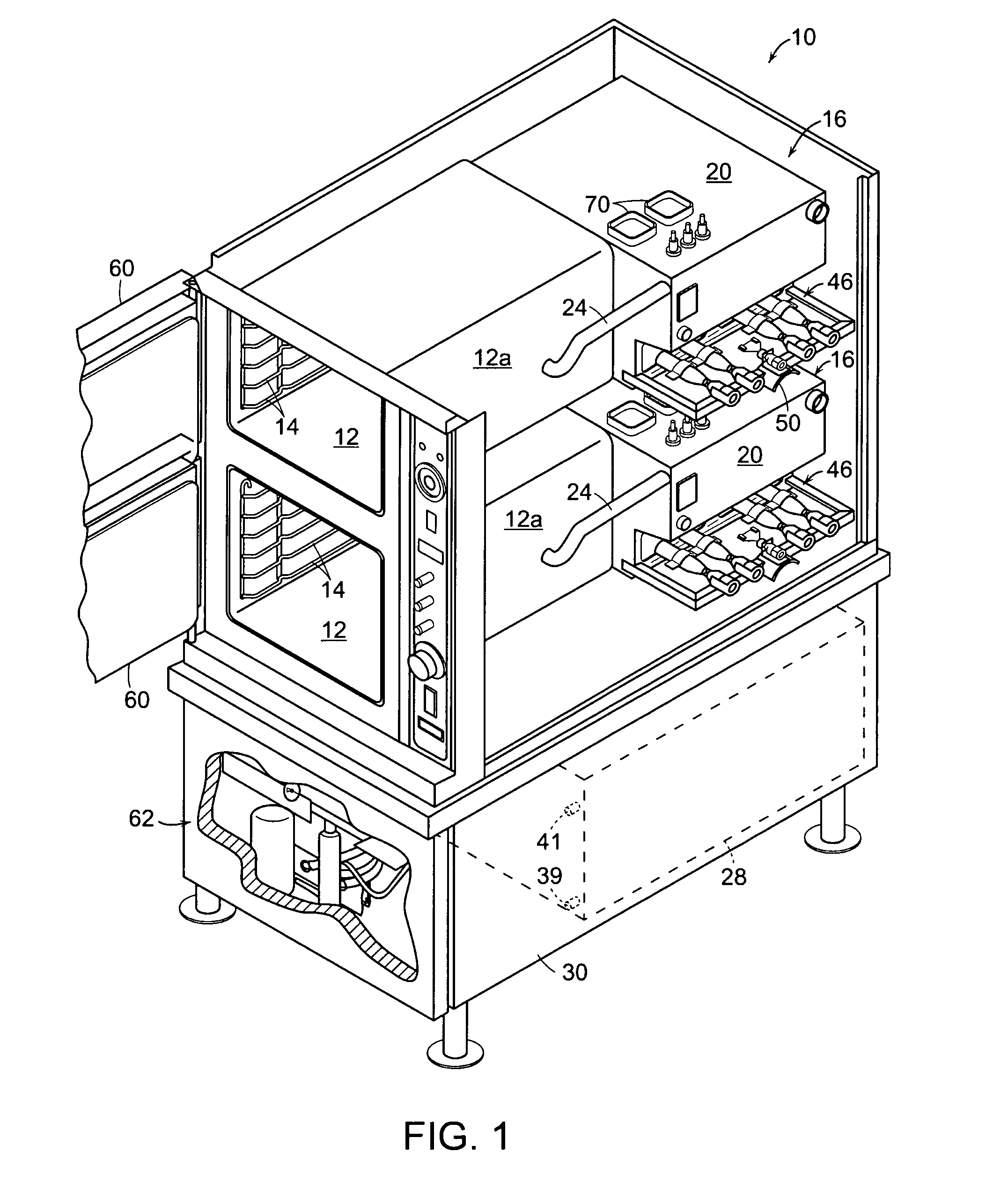

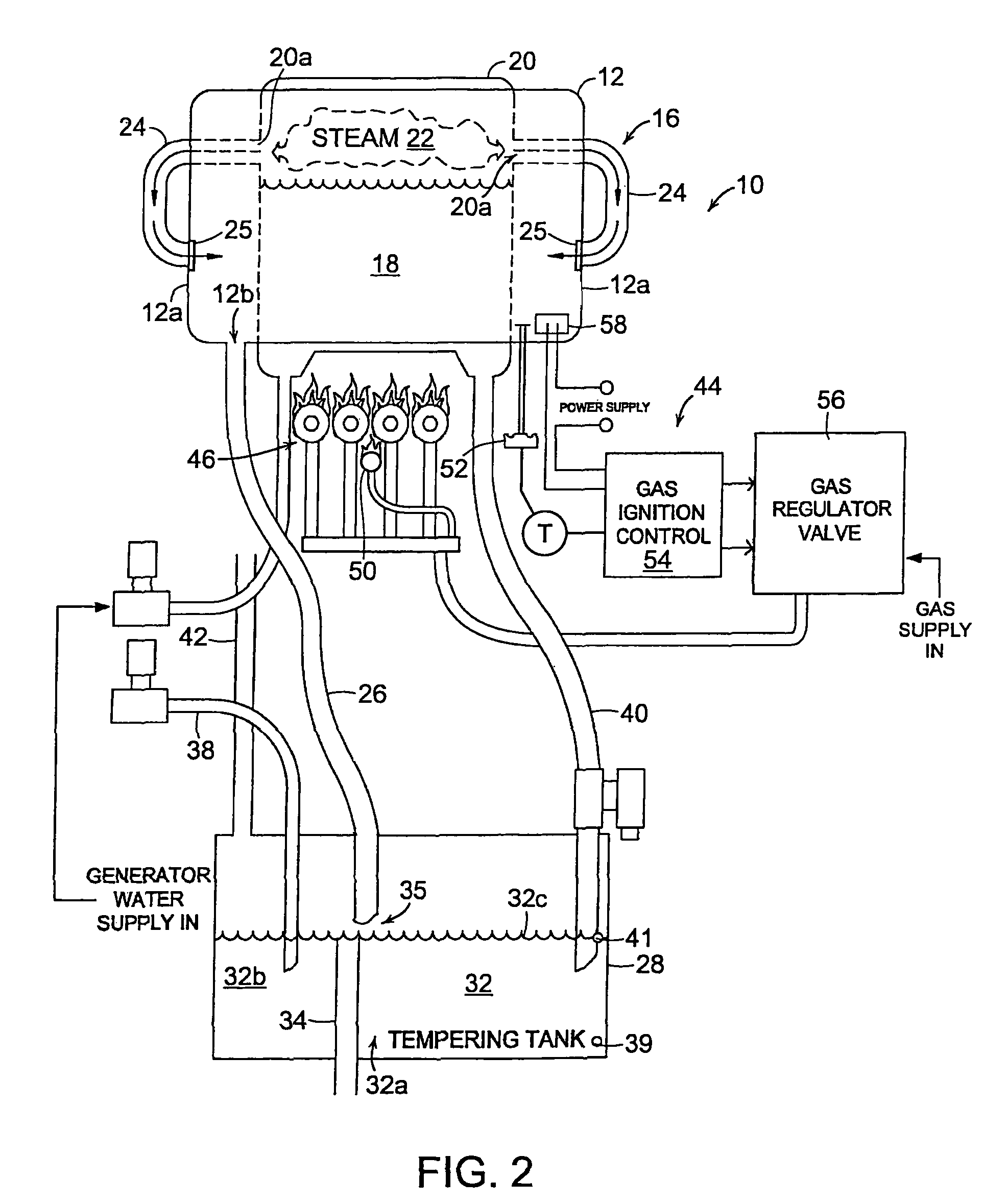

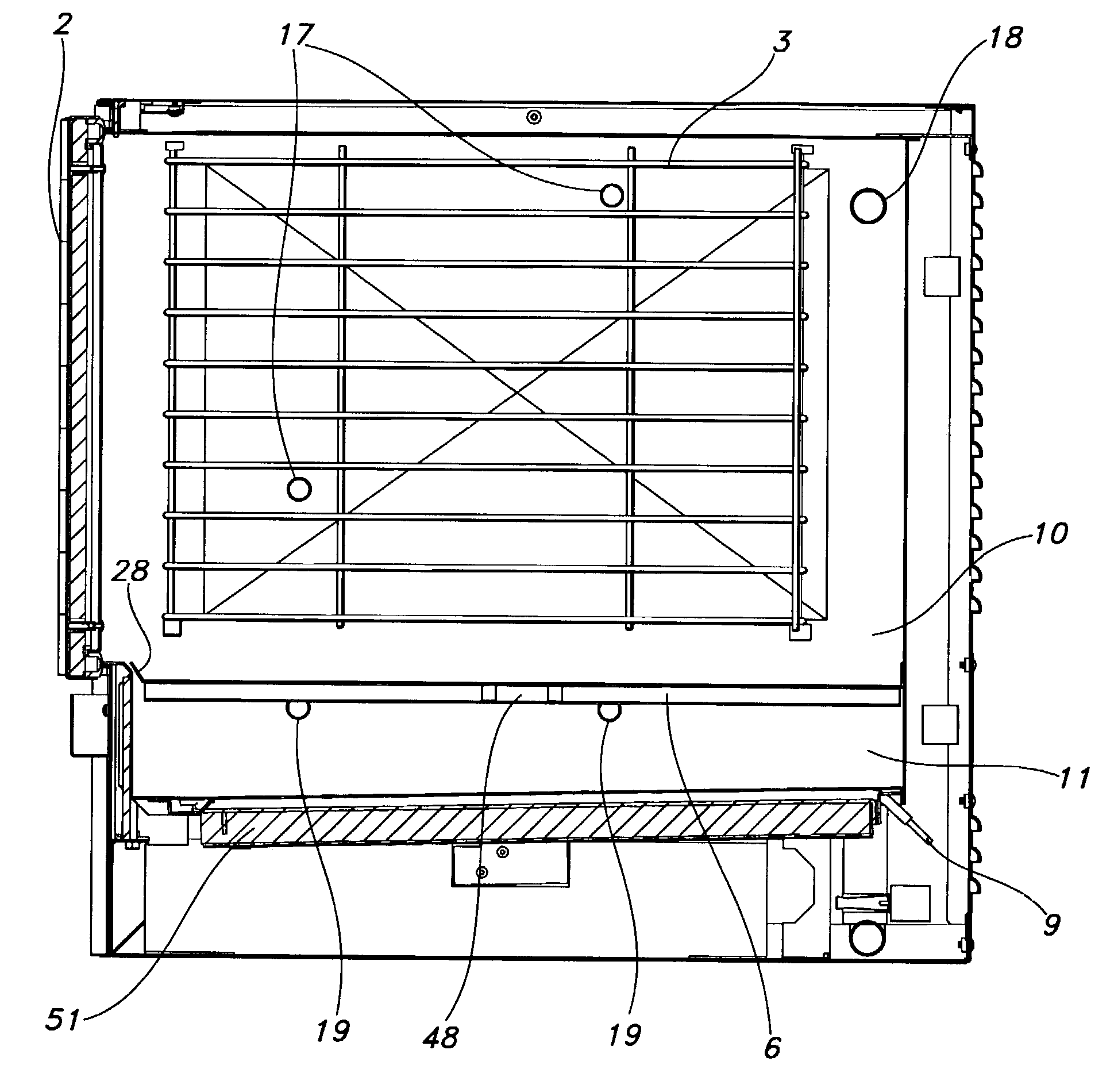

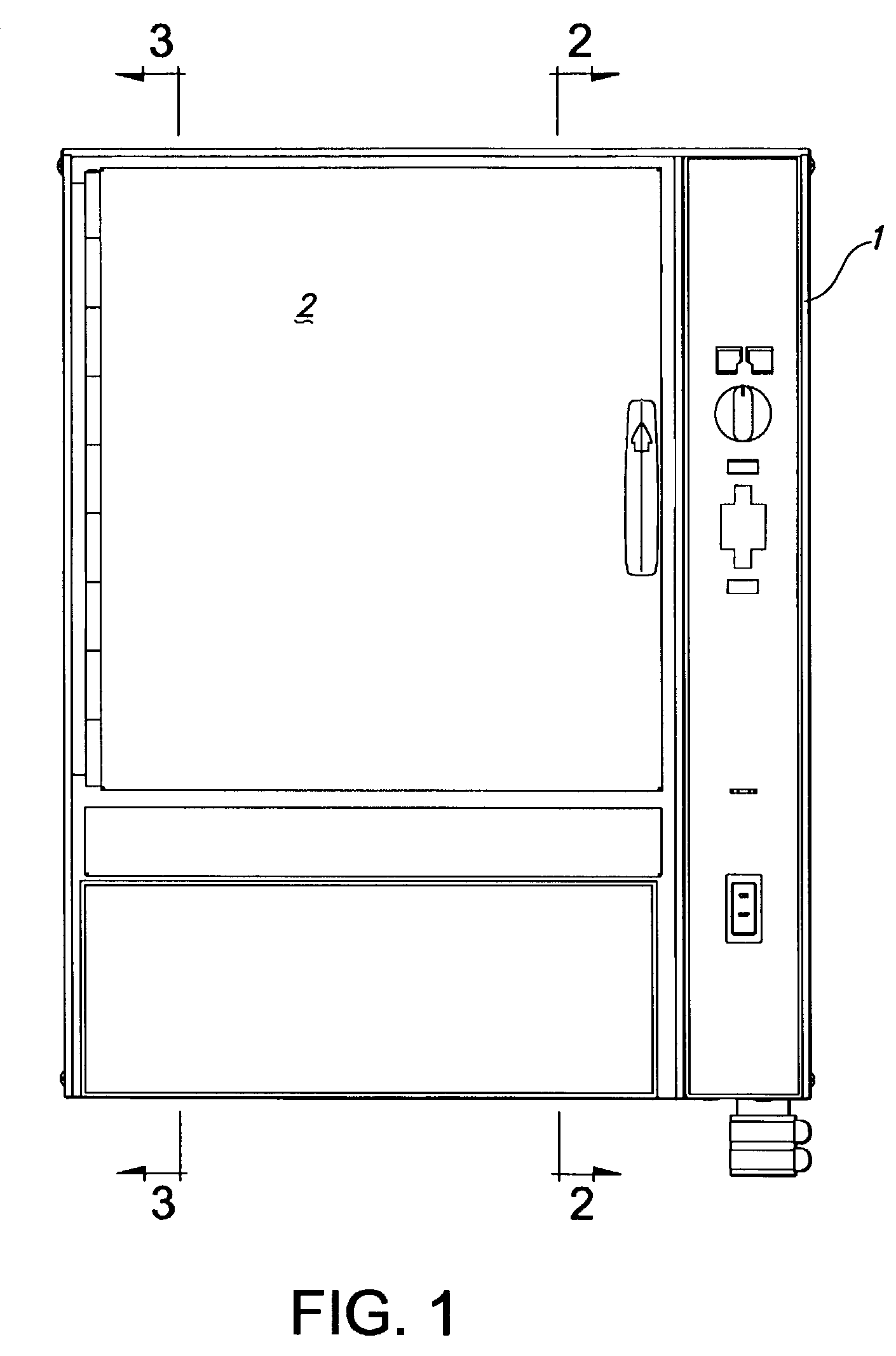

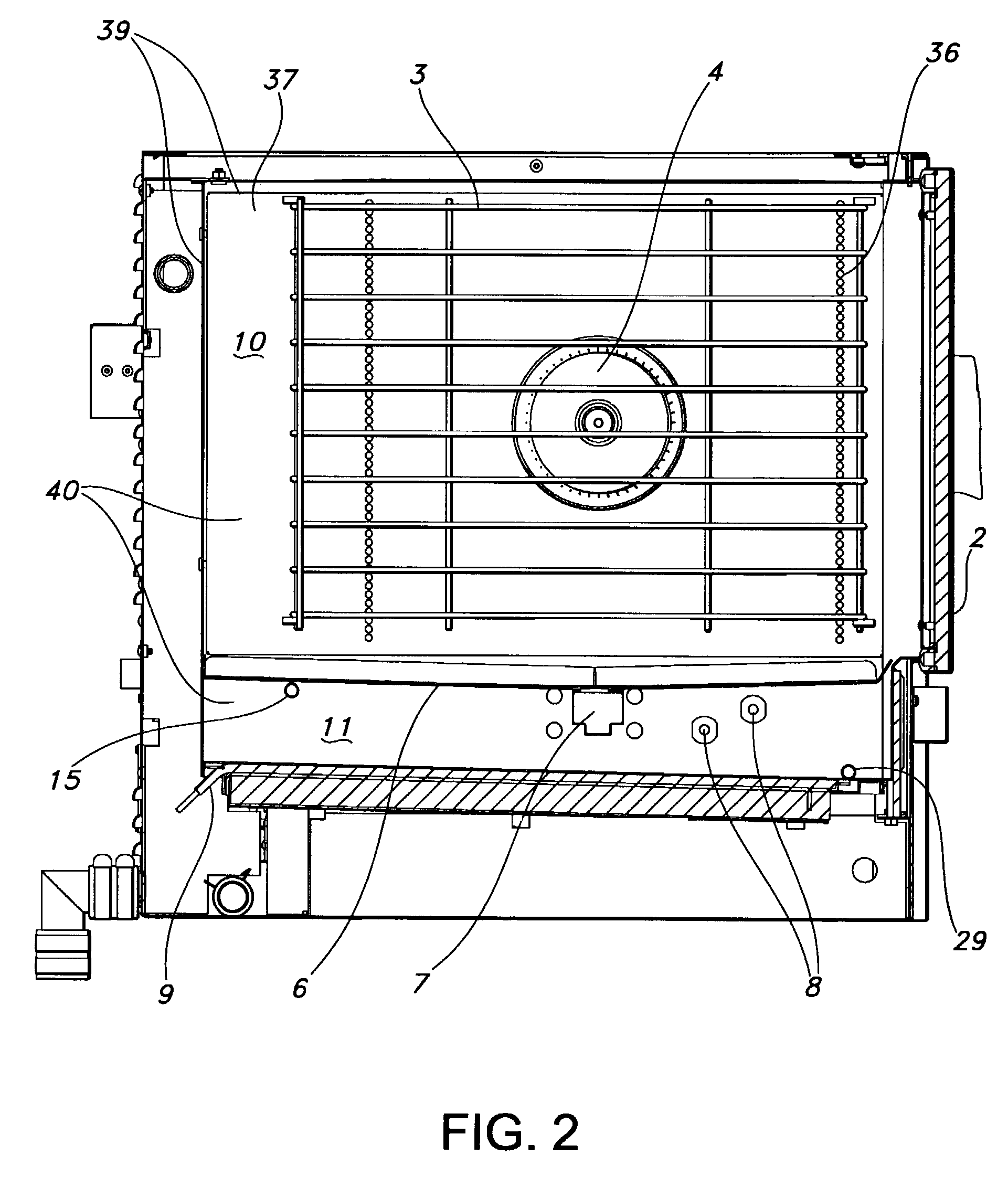

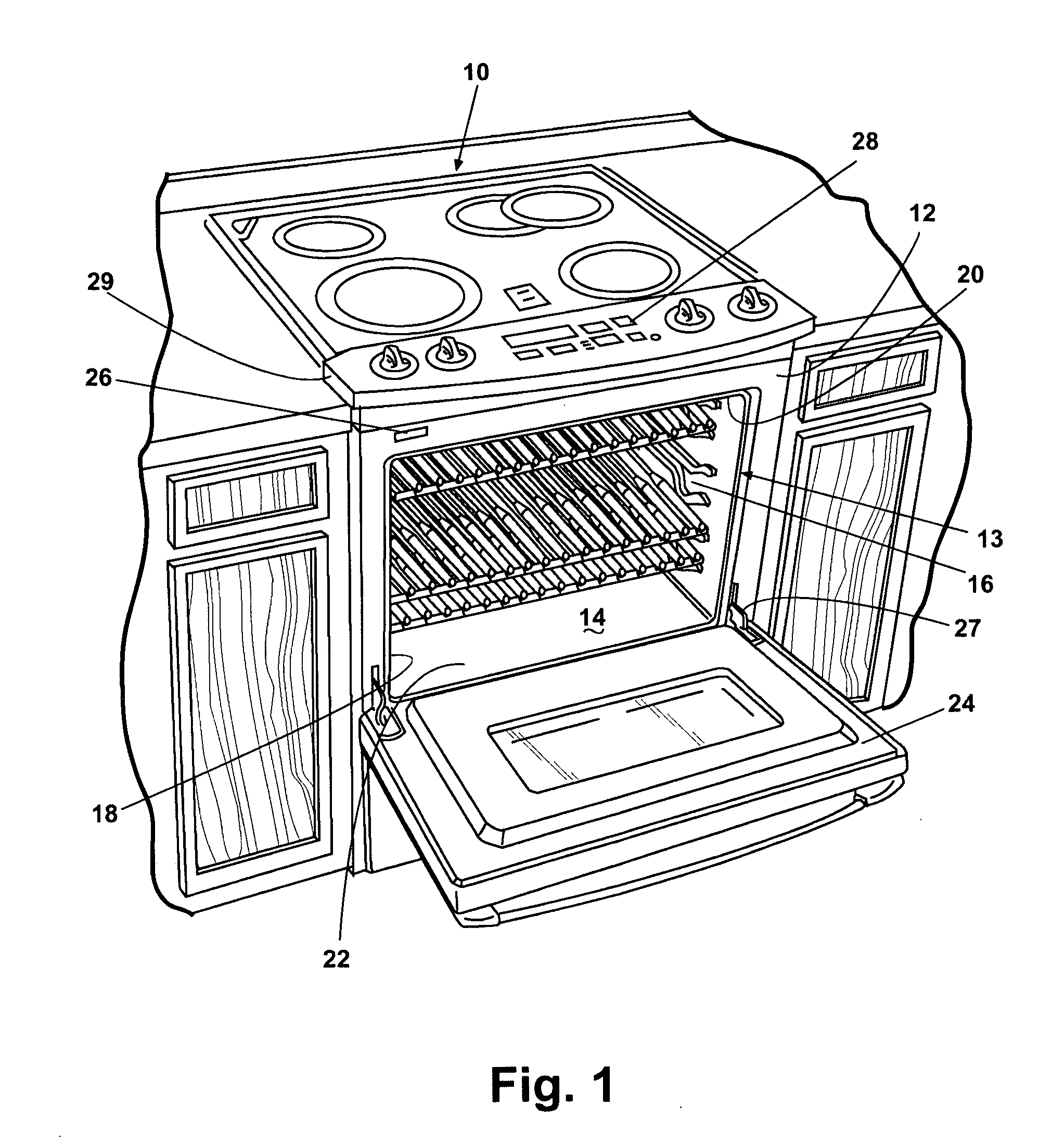

No waste cooking oven with multiple cooking functions

A multifunctional cooking oven for the preparation of food products including a cooking chamber, racks within the cooking chamber to support products to be prepared in the oven and a primary convection heat source. There is a drainable collection pan positioned below the racks to collect by-products rendered from the food products during preparation for later use. A steam source is positioned below the collection pan as well as a flavored smoke generator at the bottom of the preparation chamber. Airflow paths within the preparation chamber allow for the circulation of heat, steam and flavored smoke around the racks. The oven includes a programmable controller to control the primary heat source, the steam source and the flavored smoke generator that is programmed to operate any one of the heat source, the steam source and the flavor generator in any predetermined sequence, and for any predetermined duration of time to provide optimum preparation and flavoring of the products.

Owner:ROBERTSON MICHAEL L

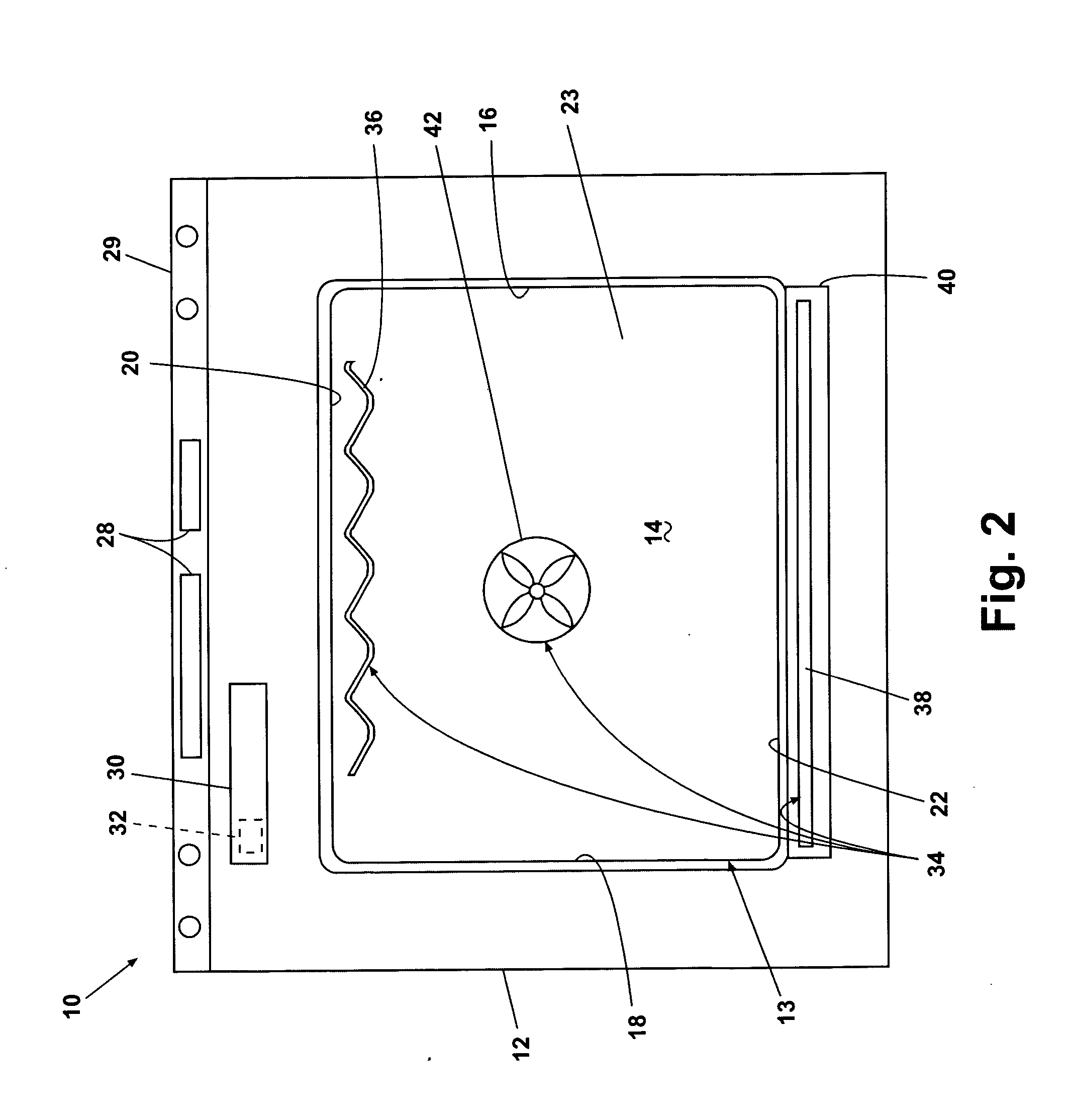

Self-cleaning convection oven

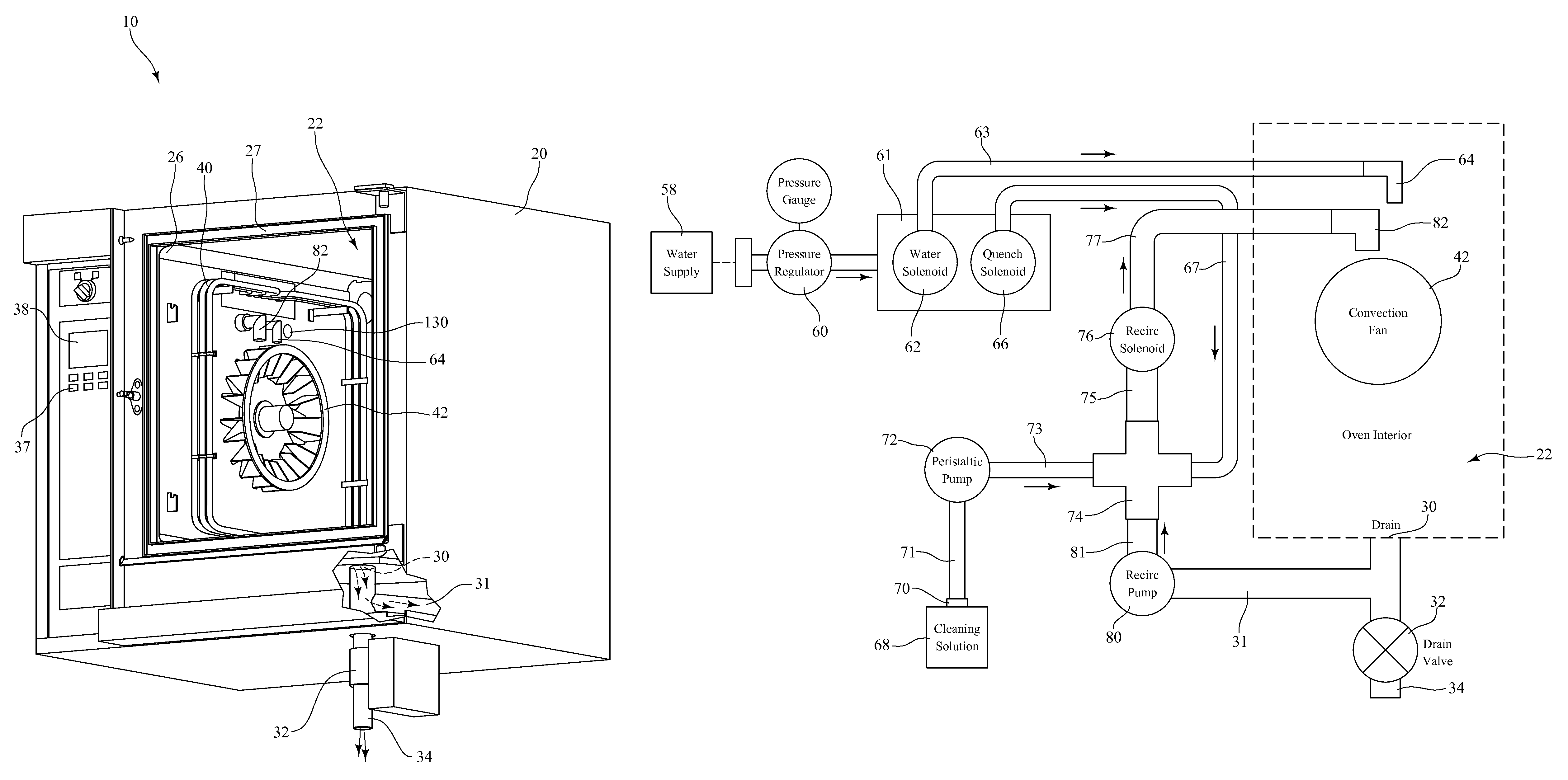

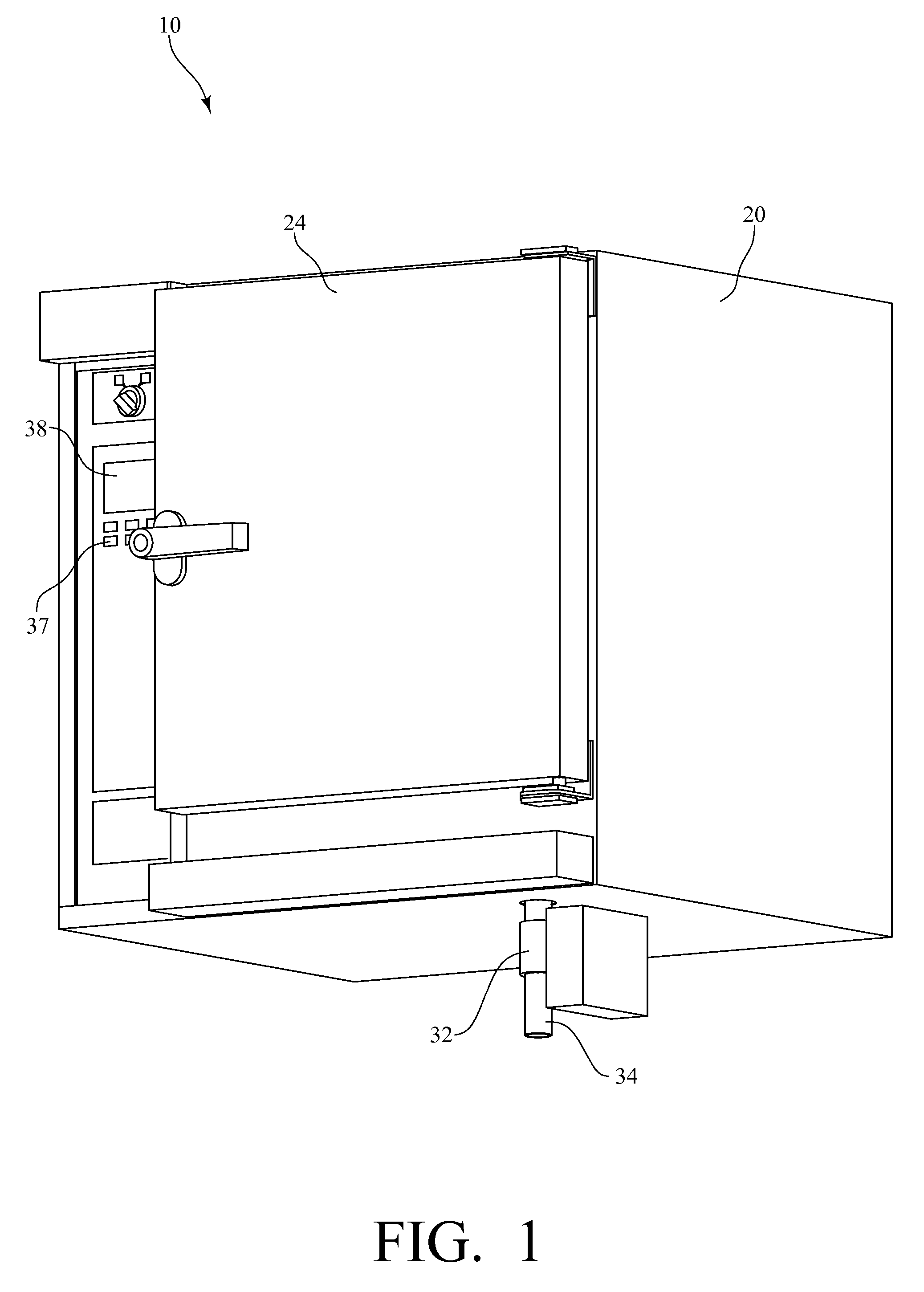

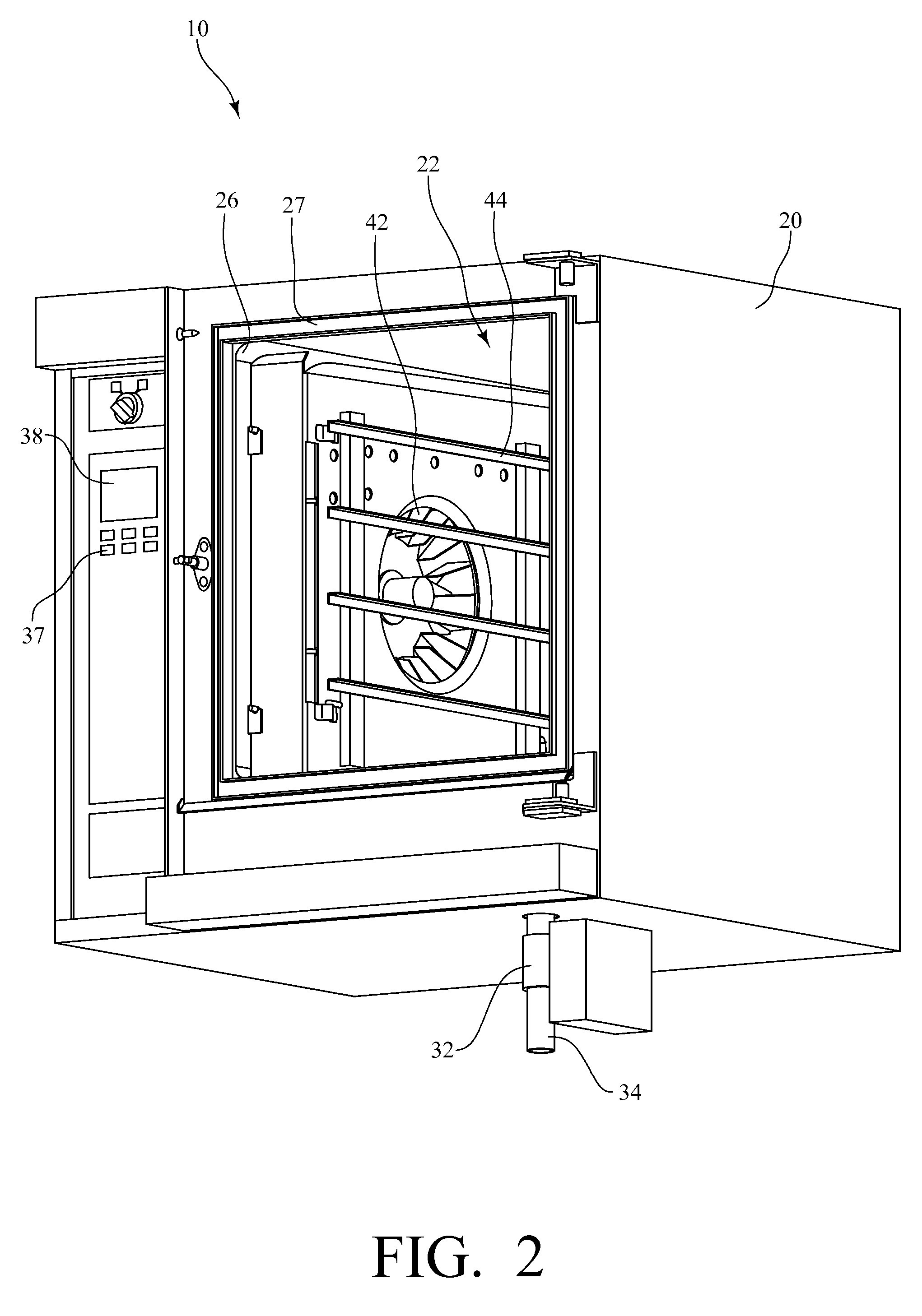

InactiveUS8193470B1Self-cleaning stoves/rangesOven air-treatment devicesEngineeringMechanical engineering

A self-cleaning convection oven includes a cabinet defining an interior cavity for cooking a food product; a door moveable between an open position and a closed position for allowing access to the interior cavity; one or more heating elements positioned in the interior cavity for delivering heat to the interior cavity; a fan positioned within the interior cavity; and a plumbing system operably connected to a water supply for delivering water into the interior cavity of the oven through a first nozzle positioned near the fan. The plumbing system of the self-cleaning convection oven further also delivers a cleaning solution into the interior cavity of the oven.

Owner:KFC CORP

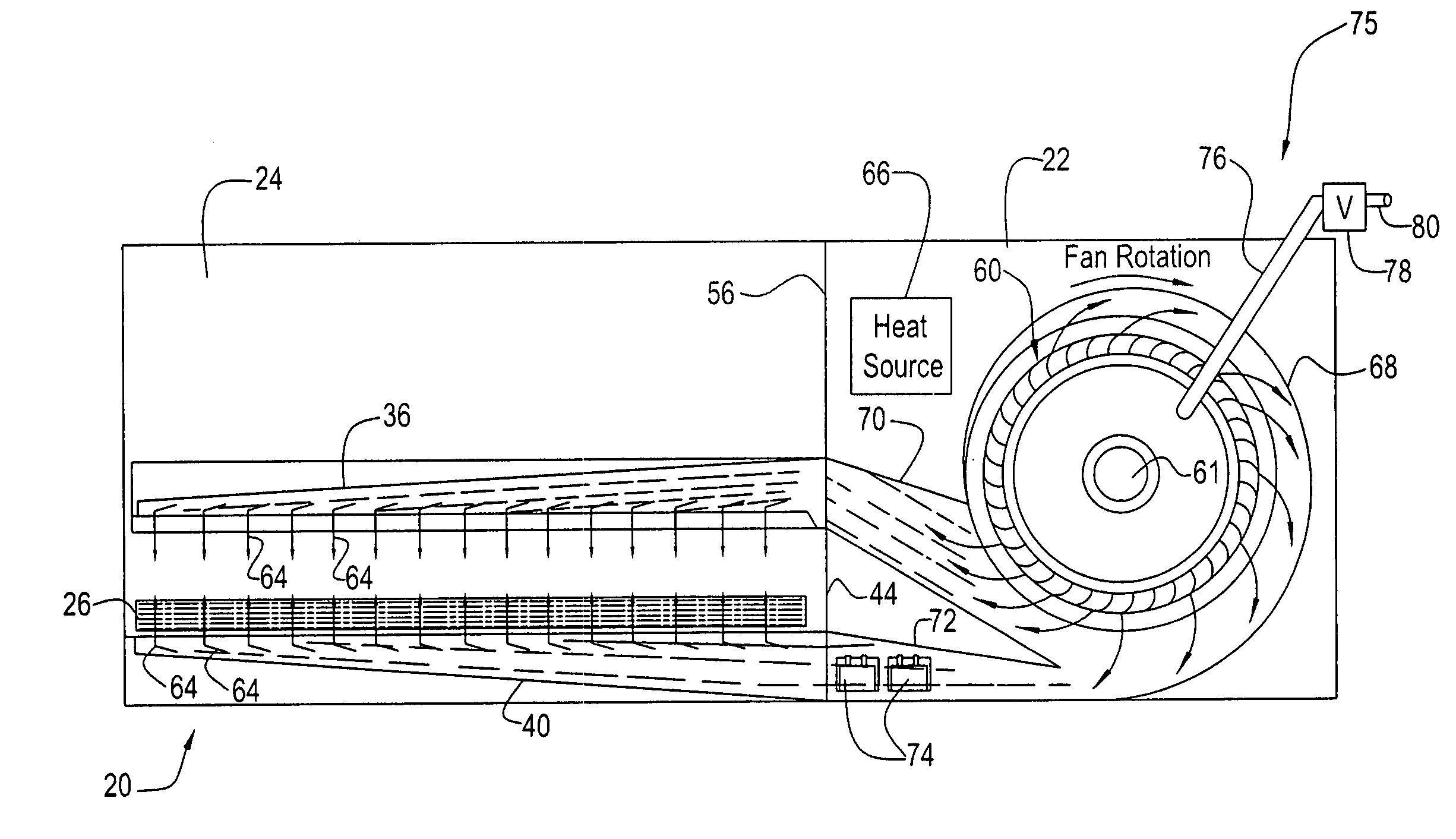

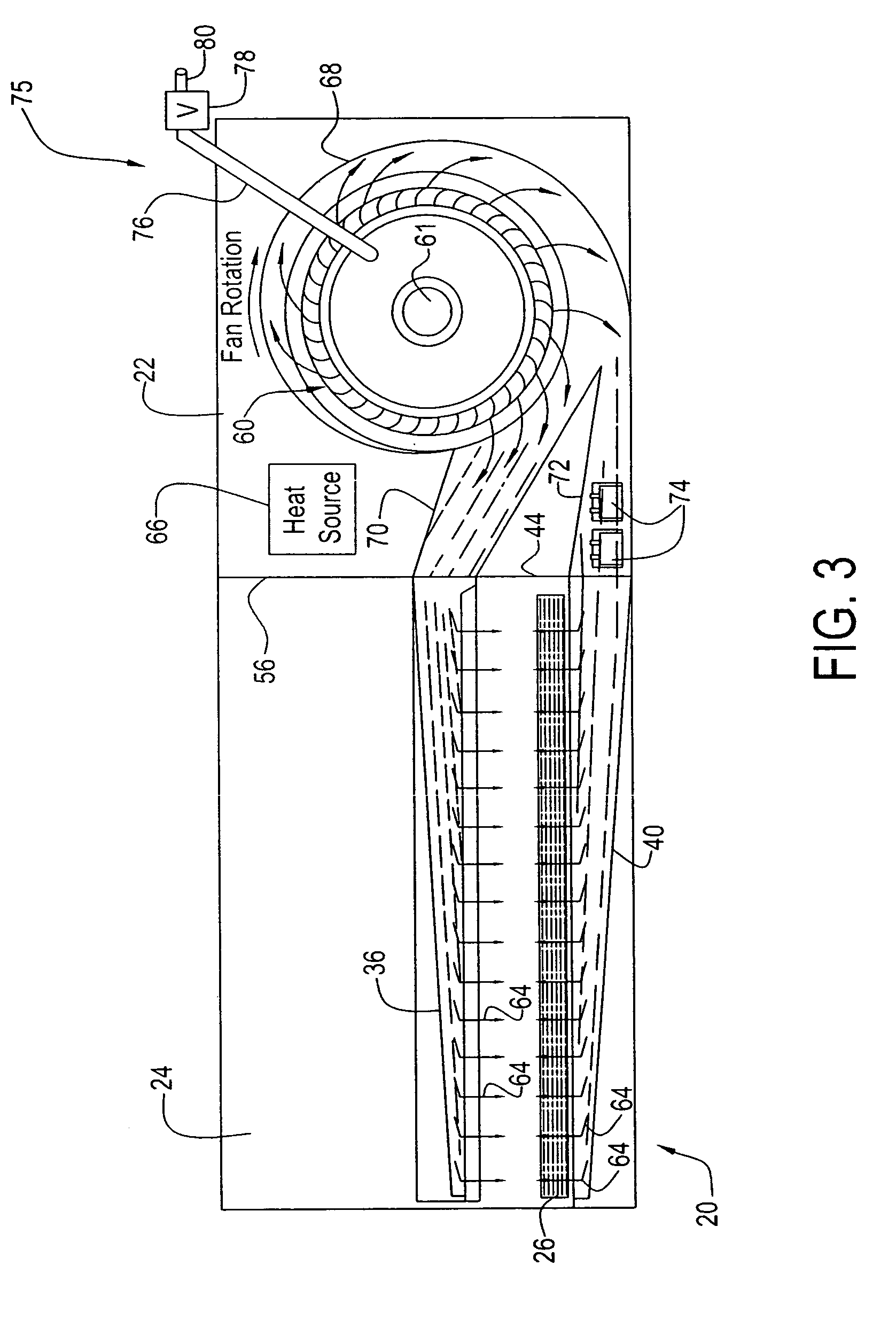

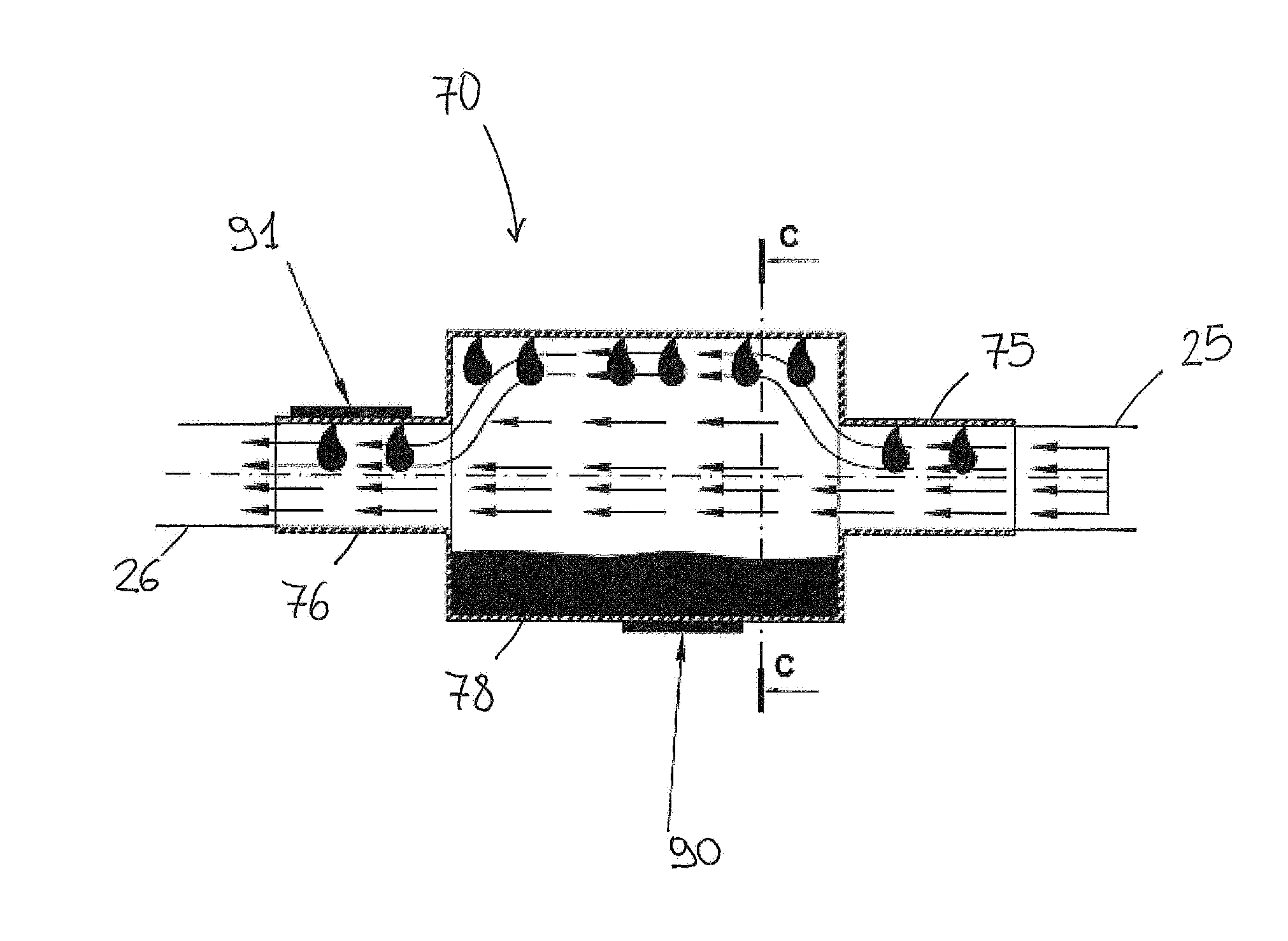

Conveyorized oven with moisture laden air impingement and method

A conveyor oven having a heating chamber and an oven chamber. A conveyor is disposed in the oven chamber to convey food products between an entry port and an exit port. An air impingement assembly is disposed to provide jets of impingement air toward the food product. A fan blower, a heater and a moisture delivery device are arranged to provide heat and moisture to an airflow to the air impingement assembly so that the jets of air are heated and laden with moisture and provide as a blanket-like mixture of air and moisture at the surface of the food product.

Owner:ENODIS

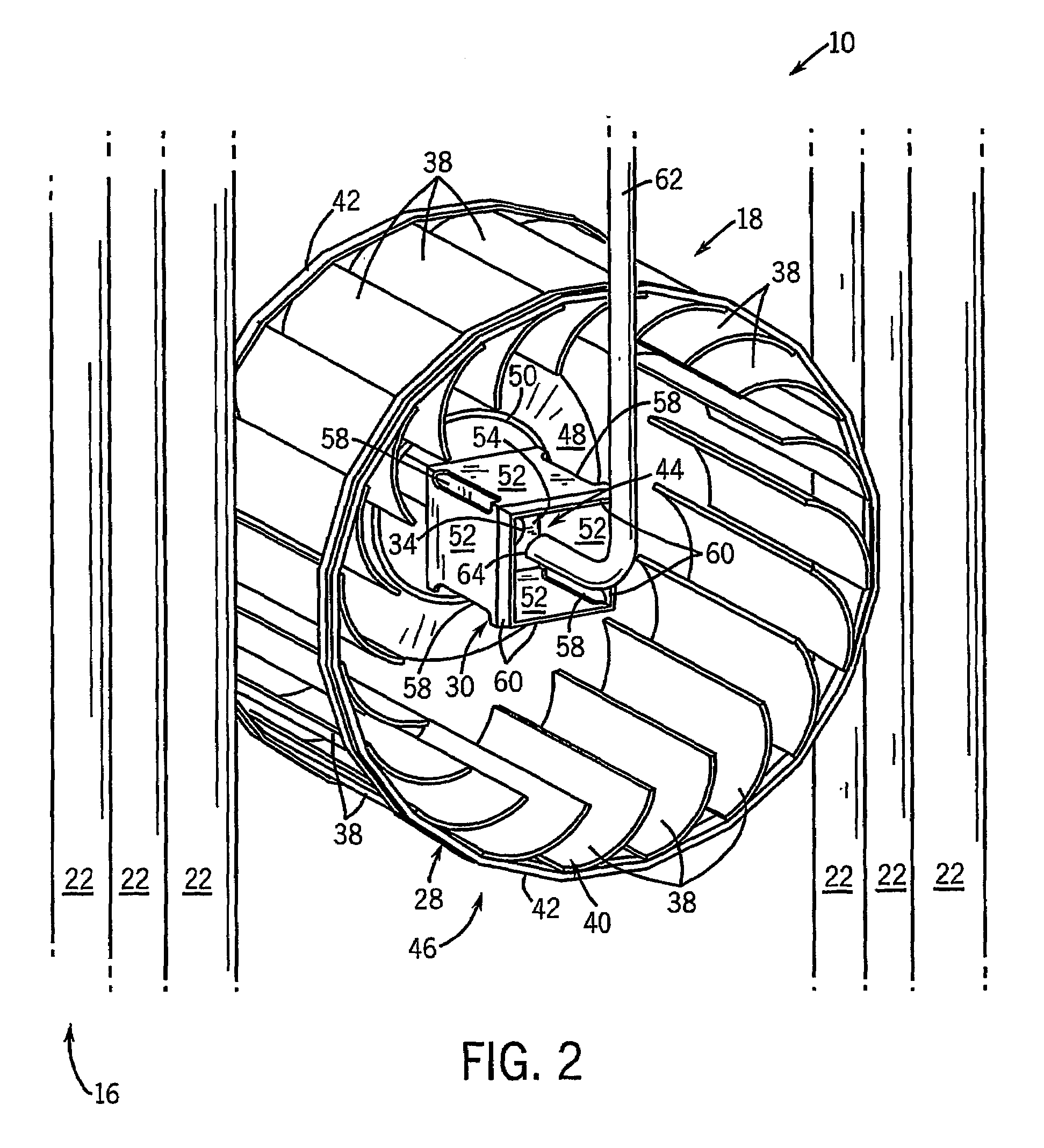

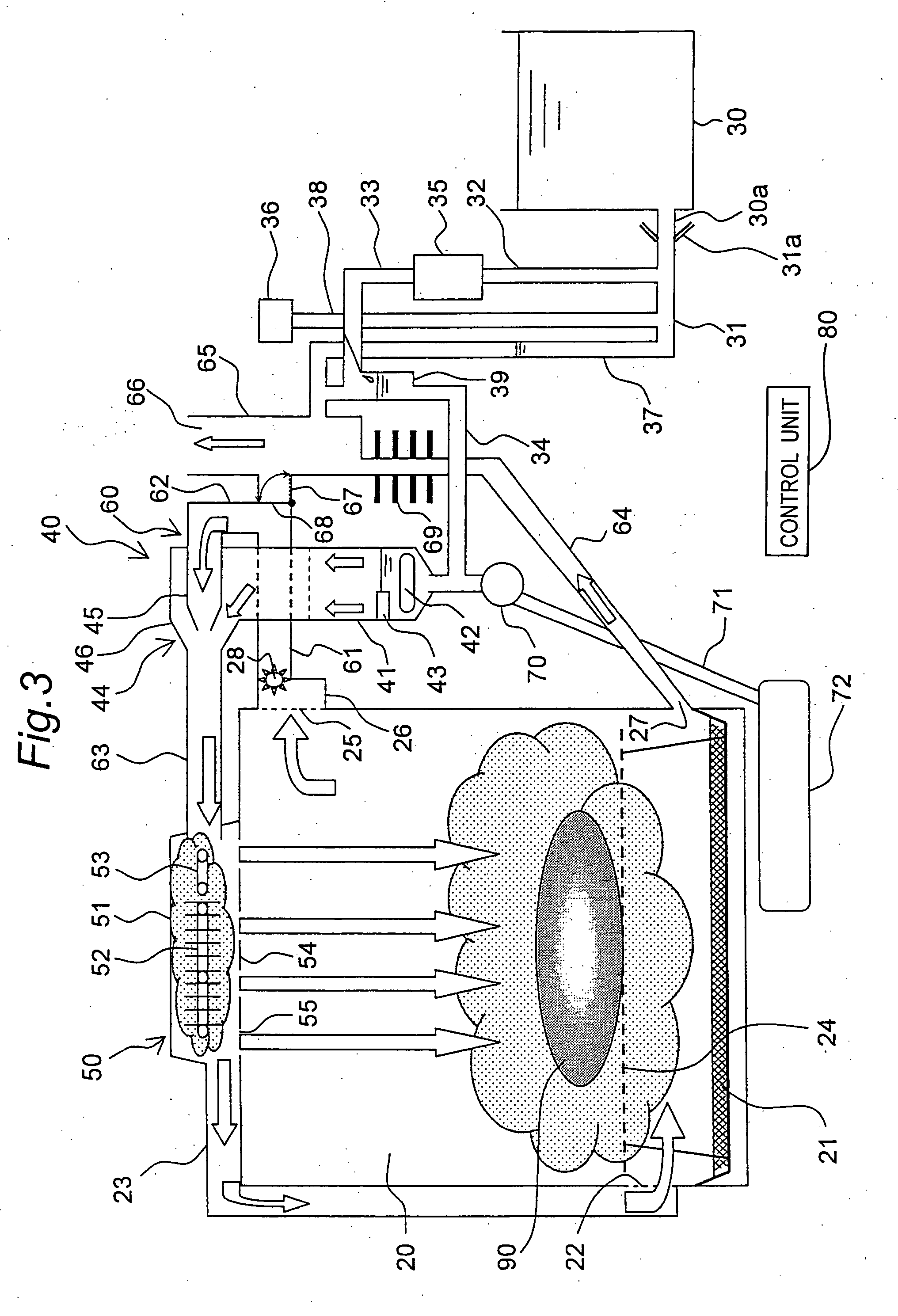

Convection steamer with forced recirculation through steam bath

InactiveUS6904903B1Efficient cookingSelf-cleaning stoves/rangesOven air-treatment devicesSteam cookingEngineering

A convection steam cooking device utilizes forced recirculation of gases along a primary recirculation path that extends through a steam chamber so that gases from the cooking cavity flow through the steam chamber and are subjected to a “steam bath” that alters the gases by adding heat and / or moisture. The cooking device includes a cooking cavity, a fan, a steam chamber disposed beneath the cooking cavity with a lower pool area for holding water and an upper steam collecting area disposed directly above the pool area, and a removable baffle disposed between the cooking cavity and the steam chamber with a perforated section remote from the fan and disposed at an upward angle. The primary forced recirculation path extends from the main cooking cavity, through the baffle, substantially across the steam collecting area, through a duct to the fan, and back to the main cavity.

Owner:MIDDLEBY MARSHALL

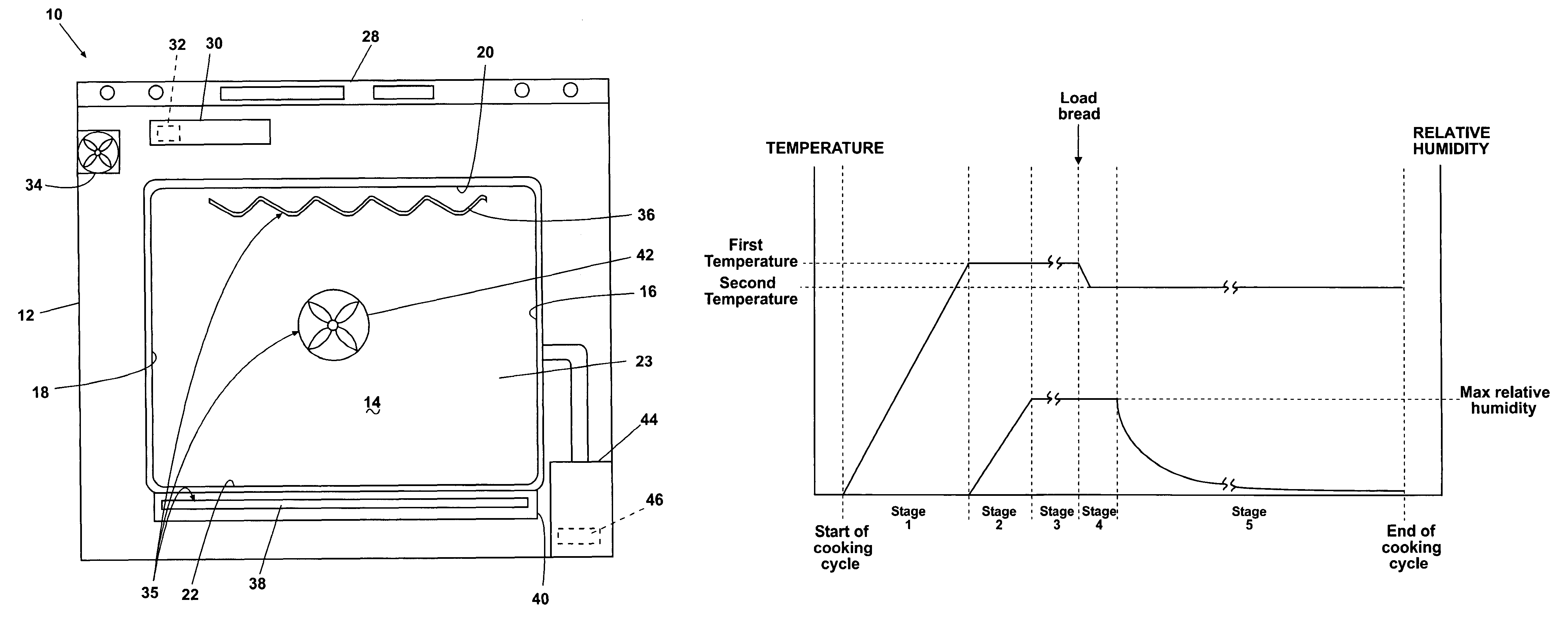

Method for baking bread using steam

A method of baking bread using steam in an automated household oven with a cooking cavity and a steam system for introducing steam into the cooking cavity comprises determining a presence of bread in the cooking cavity and introducing steam into the cooking cavity upon a positive determination of the presence of bread. After the positive determination, the steam is introduced into the cavity to maintain a desired relative humidity in the cavity for a predetermined period of time to aid in formation of a moist, flexible crust on the bread, and the amount of steam introduced into the cavity decreases after the predetermined period of time. The cavity can be preheated and prehumidified prior to the determining of the presence of the bread in the cooking cavity.

Owner:WHIRLPOOL CORP

Combination Conveyor Oven

InactiveUS20080032018A1Save energyReduce the amount requiredOven air-treatment devicesDielectric heating circuitsProcess engineeringPartial closure

An oven for heating a product is provided. The oven includes a partially enclosed housing with an inlet opening and an outlet opening and a conveyor to move a product through the housing. The oven additionally includes a steam system for boiling liquid with an associated steam pipe and a heating element provided within the housing.

Owner:NU VU FOOD SERVICE SYST

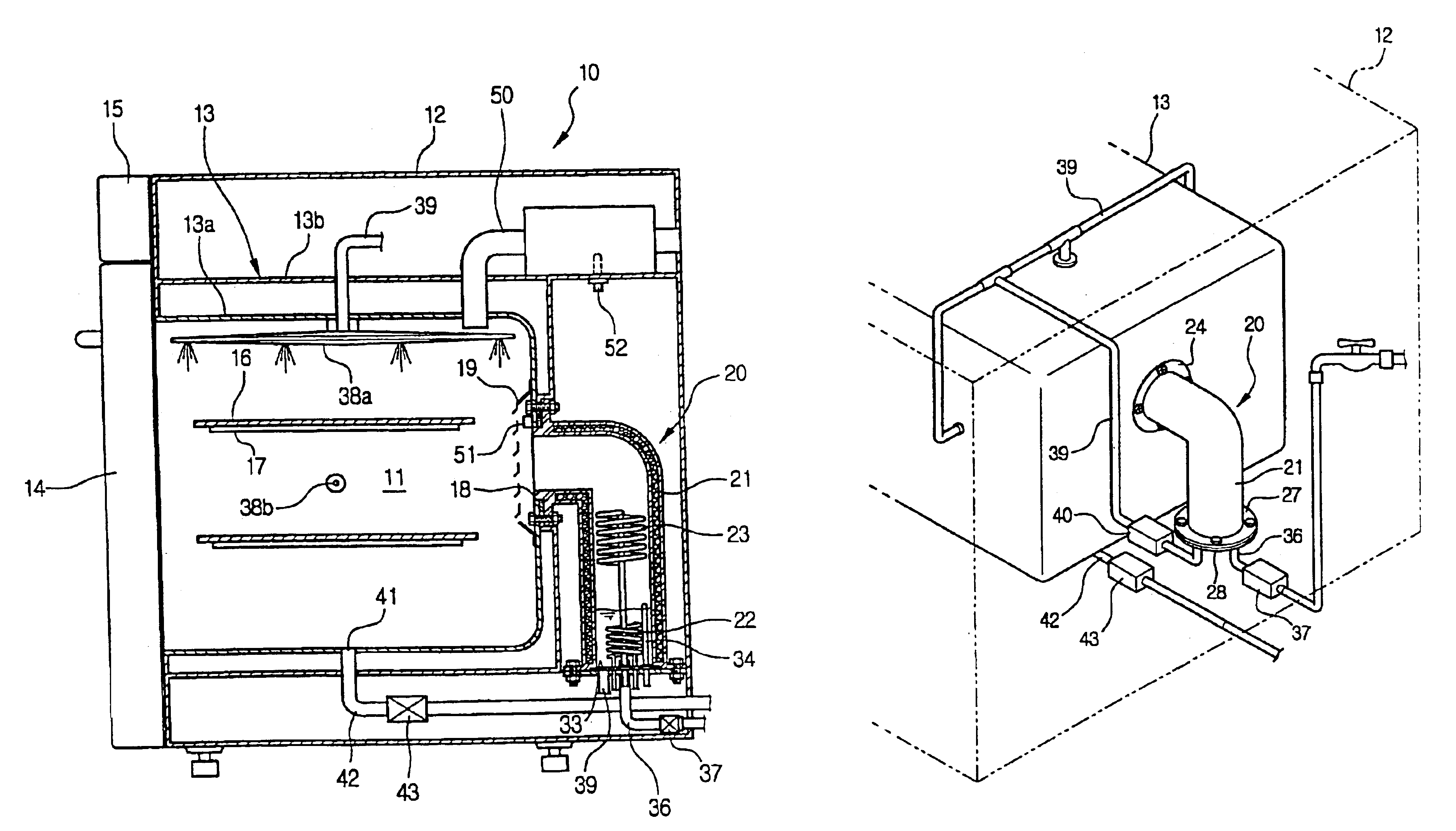

High efficiency atmospheric steamer

ActiveUS7810488B2Temperature control without auxillary powerDomestic stoves or rangesSteam pressureFiltration

A pressureless or atmospheric steamer for cooking food with a high cooking efficiency has a cooking compartment with an outlet for steam and condensate that feeds to a tempering tank via an outlet conduit. The outlet conduit is spaced closely from the controlled water level in the tempering tank, and is in fluid communication with the atmospheric vent to create an open steam cooker. A steam generator is adjacent the cooking compartment and has a water reservoir, a heat exchanger secured within the reservoir in a heat-transferring relationship at an exterior surface of the heat exchanger with the water held in the reservoir, and a heater that supplies heat to the interior of the heat exchanger. The tempering tank has a drain and level controls for a water supply held in the tempering tank. A pressure-sensitive device is disposed to measure the steam pressure in the cooking compartment and to generate electrical output signals indicative of minimum and maximum pressure values to control the operation of the heater to maintain the steam pressure in the cooking compartment within that operating range. The steamer has an in-built water filtration system for water supplied to the water reservoir.

Owner:MARKET FORGE INDS

Overheated steam oven and method of controlling the same

InactiveUS6909071B2Self-cleaning stoves/rangesOven air-treatment devicesProcess engineeringSuperheated steam

An overheated steam oven which cleans an interior of a cooking cavity of the overheated steam oven using hot water and overheated steam, and executes a cooking operation using the overheated steam. The overheated steam oven includes a cabinet to define the cooking cavity therein, an overheated steam generator to supply overheated steam into the cooking cavity, and a cleaning unit to spray water from an interior of the overheated steam generator into the cooking cavity to clean the interior of the cooking cavity. A control method of the overheated steam oven includes spraying the water into the cooking cavity by use of the cleaning unit in response to a cleaning start signal, thus cleaning the interior of the cooking cavity, and supplying the overheated steam from the overheated steam generator into the cooking cavity after the cooking cavity is cleaned, thus drying the interior of the cooking cavity.

Owner:SAMSUNG ELECTRONICS CO LTD

Convection and steam oven comprising a humidity detection and regulation system

ActiveUS8993934B2Suitable for useDomestic stoves or rangesOven air-treatment devicesEngineeringAtmosphere

A convection and steam oven includes an outer supporting casing, which contains a cooking chamber to contain food, a heating element for heating the atmosphere in said cooking chamber, a steam generator, a steam vent, and a cooking chamber humidity detection and regulation system. The humidity detection and regulation system includes at least first and second temperature probes, said humidity detection and regulation system being adapted to operate the steam generator and the steam vent in response to the temperature values detected by said first and second temperature sensing probes.

Owner:GIORIK

Natural convection steam cooking device

InactiveUS20060081592A1Domestic stoves or rangesOven air-treatment devicesSteam cookingNatural convection

A natural convection steam cooking device with a cooking cavity having a floor defining a lower boundary thereof and a sidewall defining a side boundary thereof, the floor having a plurality of first holes therein, the sidewall having a plurality of second holes therein; a steam chamber disposed below the cooking cavity and along the sidewall, the steam chamber having a pool disposed below the floor; wherein the steam enters the cooking cavity from the steam chamber via both the first holes and the second holes; and wherein the steam circulates within the device in an unforced manner by natural convection. The first holes and the second holes may have a ratio of cross-sectional areas of approximately 2:3. And method(s) of providing steam to, and design of steam flow for, a cooking cavity of a commercial steam cooking device.

Owner:MIDDLEBY MARSHALL

Boilerless steamer apparatus

InactiveUS7024104B2Easy accessEasy to cleanOven air-treatment devicesGaseous substancesProcess engineeringSteam generation

Owner:UNIFIED BRANDS

Steam cooker

InactiveUS20090007798A1Improve workabilityReduce cooking timeDomestic stoves or rangesBoiling over preventionSuperheaterEngineering

After a preheating operation is performed to raise an inner temperature of a heating chamber to a target preheating temperature (first specified temperature) by a first steam superheater of a steam temperature-raising device, a cooking operation is performed to raise, by the first steam superheater of the temperature-raising device, a temperature of steam obtained by heating of water in a steam generator by heaters 42A, 42B of the steam generator and then supply the steam to the heating chamber. In this process, when inner temperature of the heating chamber detected by an inner temperature sensor 81 during the preheating operation has come to or beyond a steam generation start temperature (second specified temperature) which is lower than a target preheating temperature, a control unit 80 decides that a steam generation start condition has been satisfied, and heats water in the steam generator by the heaters of the steam generator.

Owner:SHARP KK

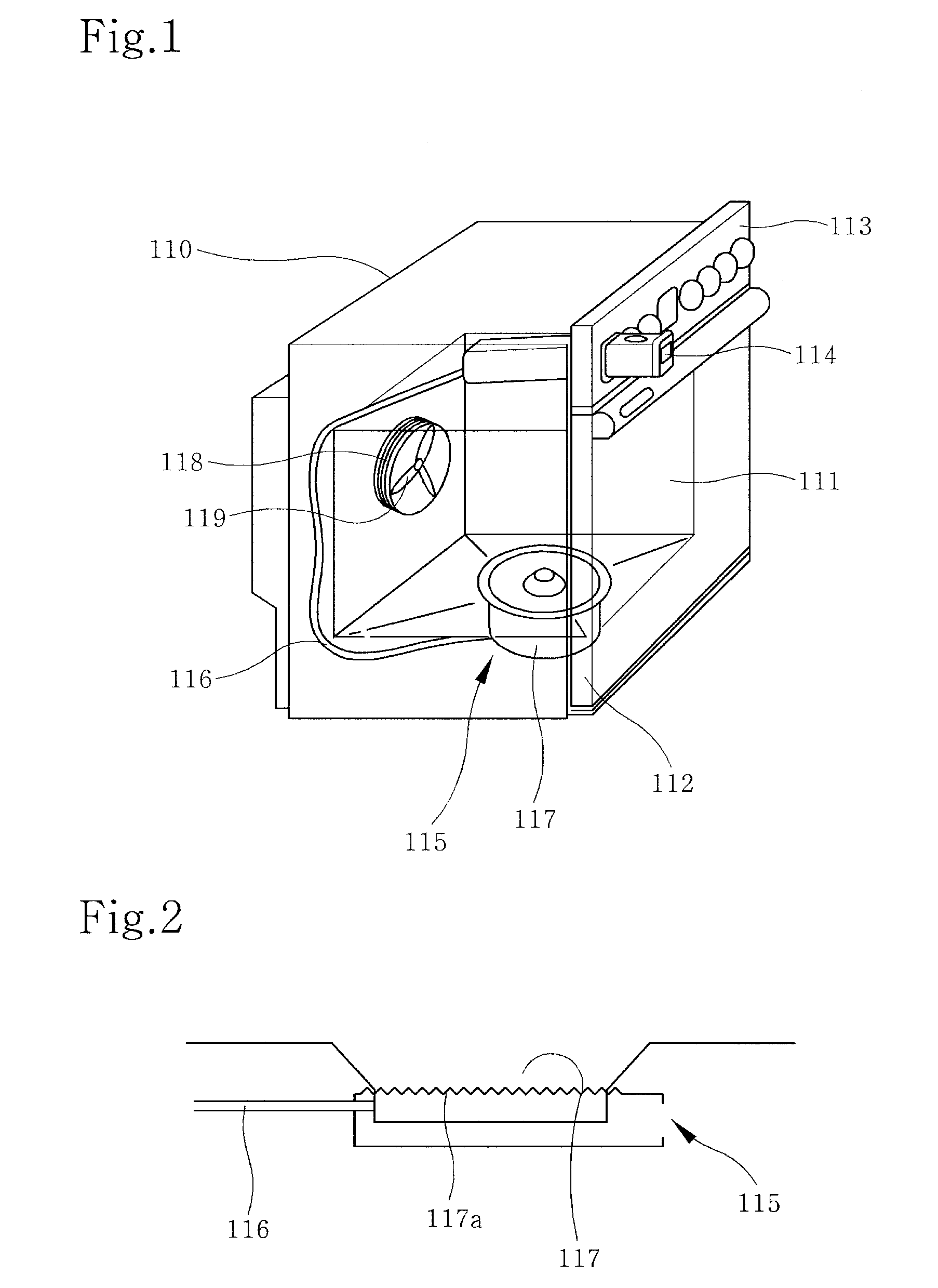

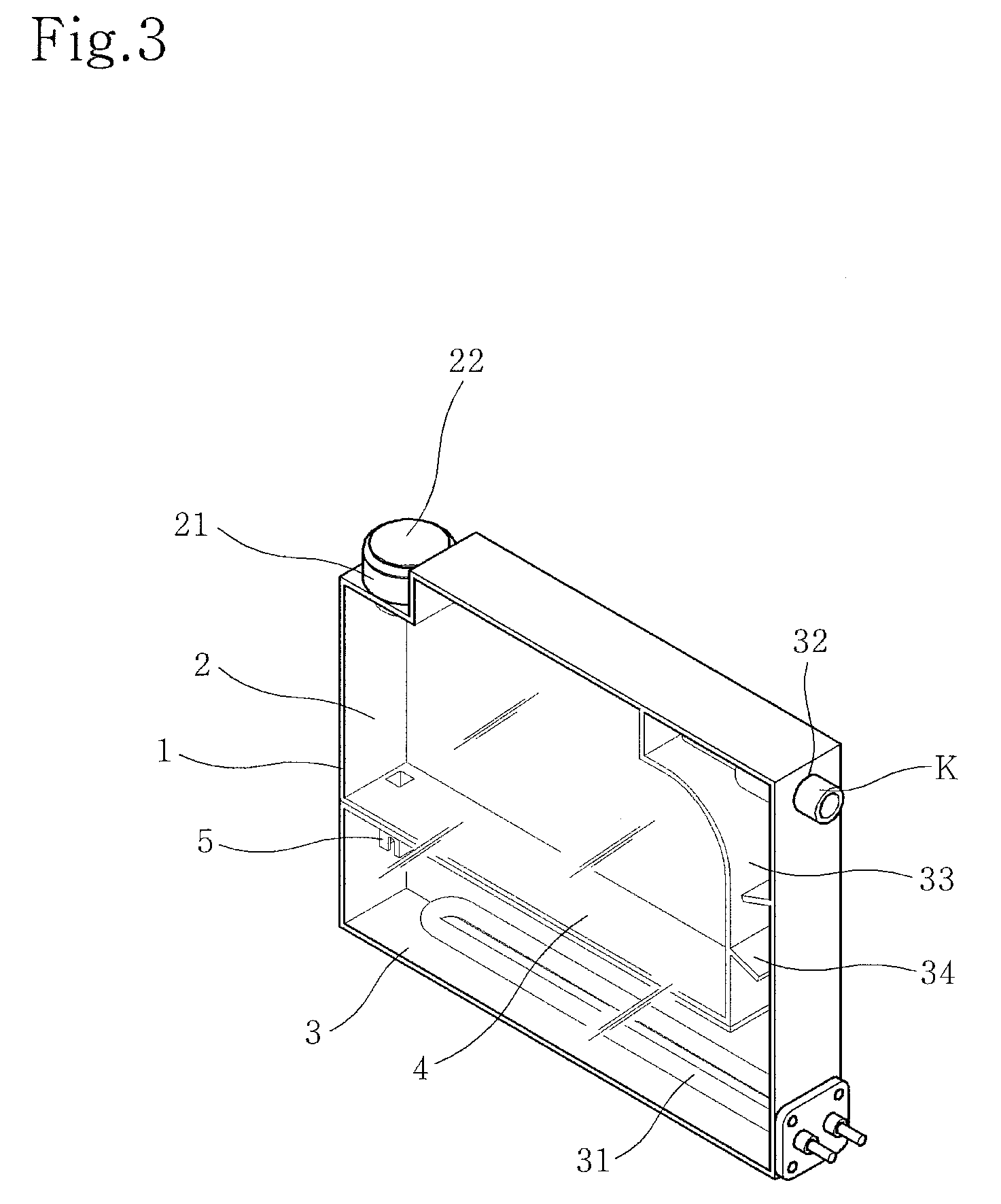

Steam generator of steam oven

ActiveUS8369695B2Simplify device configurationEasy to cleanDomestic stoves or rangesOven air-treatment devicesManufacturing cost reductionInterior space

Disclosed is a steam oven to cook food in a cooking chamber by use of steam. More particularly, disclosed is a steam generator of a steam oven, which can simplify the configuration of a device required to generate steam and is detachably attached to a cabinet to assure easy cleaning and washing thereof. The steam generator includes a single body having an inner space divided into a water supply compartment and a boiler compartment by a partition, the water supply compartment having a water pouring hole, and the boiler compartment having a heater and a steam discharge hole. Also, a water supply passage is defined between the water supply compartment and the boiler compartment. This configuration has the effects of achieving improved workability and reduced manufacturing costs of the steam generator and also, of overcoming a limit in the inner volume of a cooking chamber of the steam oven.

Owner:LG ELECTRONICS INC

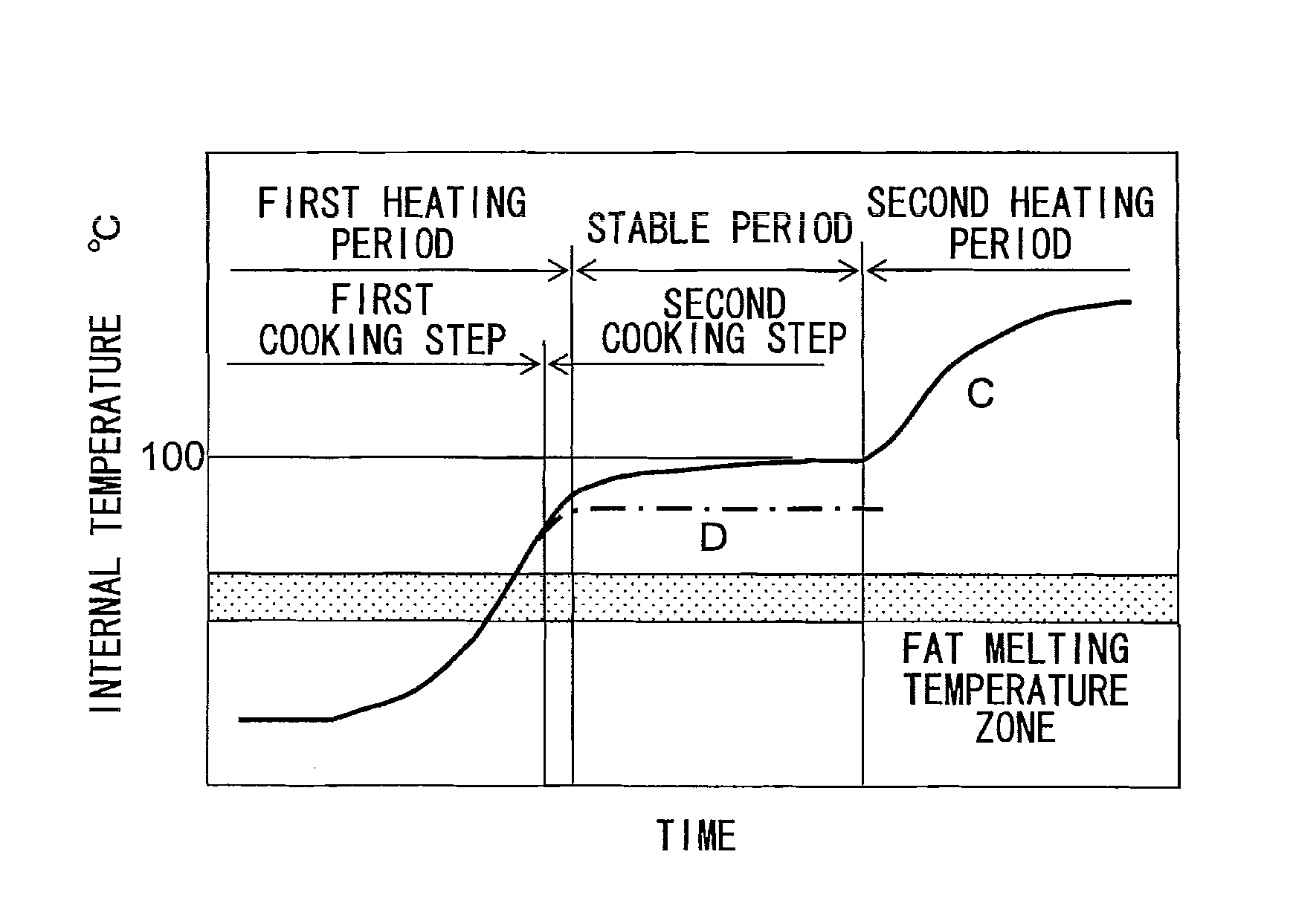

Vapor cooker

ActiveUS8420983B2Increase temperatureKeep for a long timeOven air-treatment devicesElectric heating for furnacesEngineeringSuperheated steam

A steam cooker 1 has: a steam generation heater 52 generating steam; and a steam heating heater 41 heating the steam generated by the steam generation heater 52 to generate overheated steam and heating steam in a heating chamber 20 through circulation, an-article-to-be-heated F being cooked by use of steam fed into the heating chamber 20. The steam cooker 1 has: a first cooking step in which the article-to-be-heated F is cooked with supply of electric power to the steam generation heater 52 being larger than that to the steam heating heater 41; and a second cooking step in which the article-to-be-heated F is cooked with supply of electric power to the steam generation heater 52 being smaller than that to the steam heating heater 41. When the temperature of the article-to-be-heated F exceeds the fat melting temperature zone but is less than or equal to 100° C., the first cooking step is switched to the second cooking step.

Owner:SHARP KK

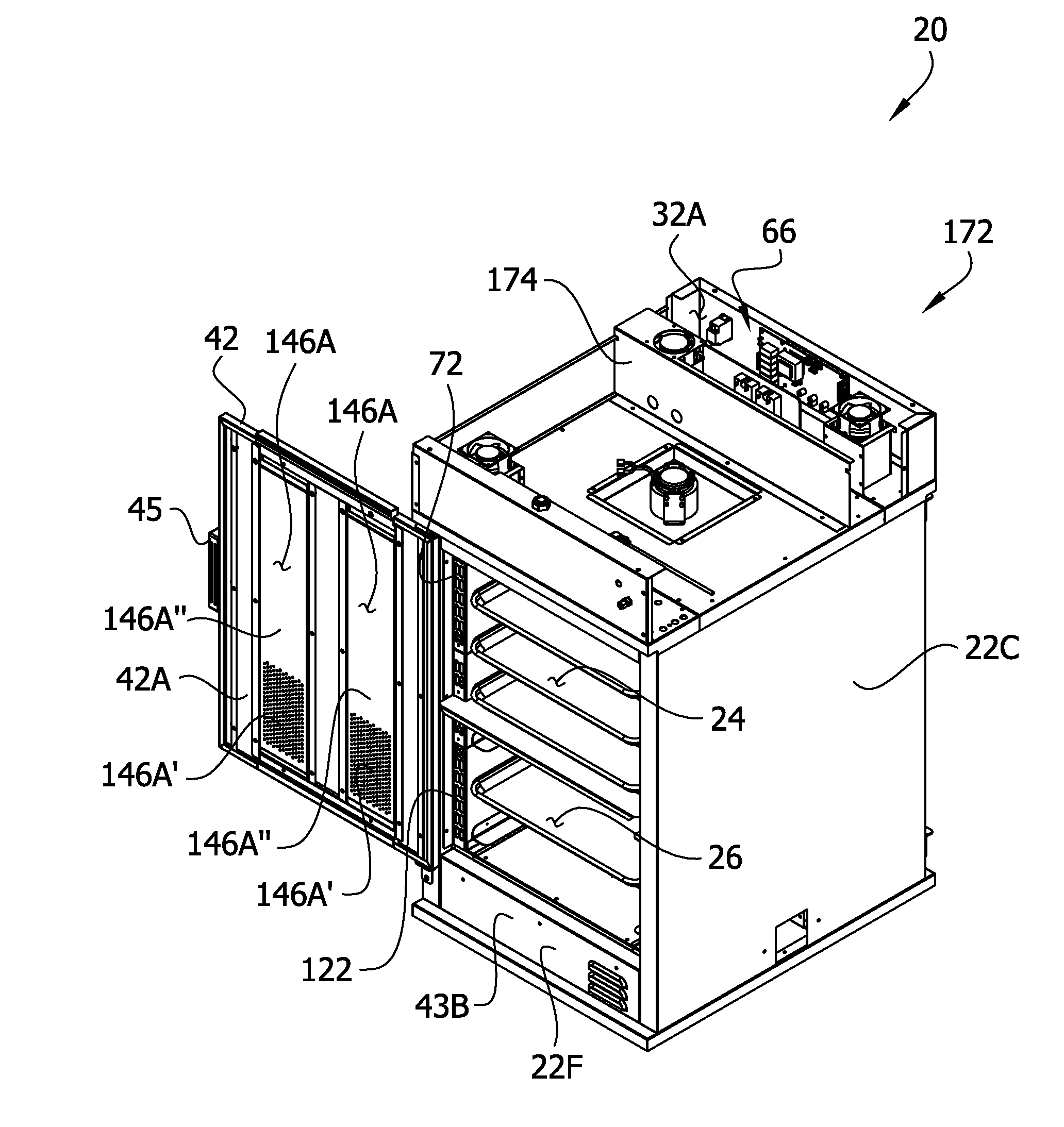

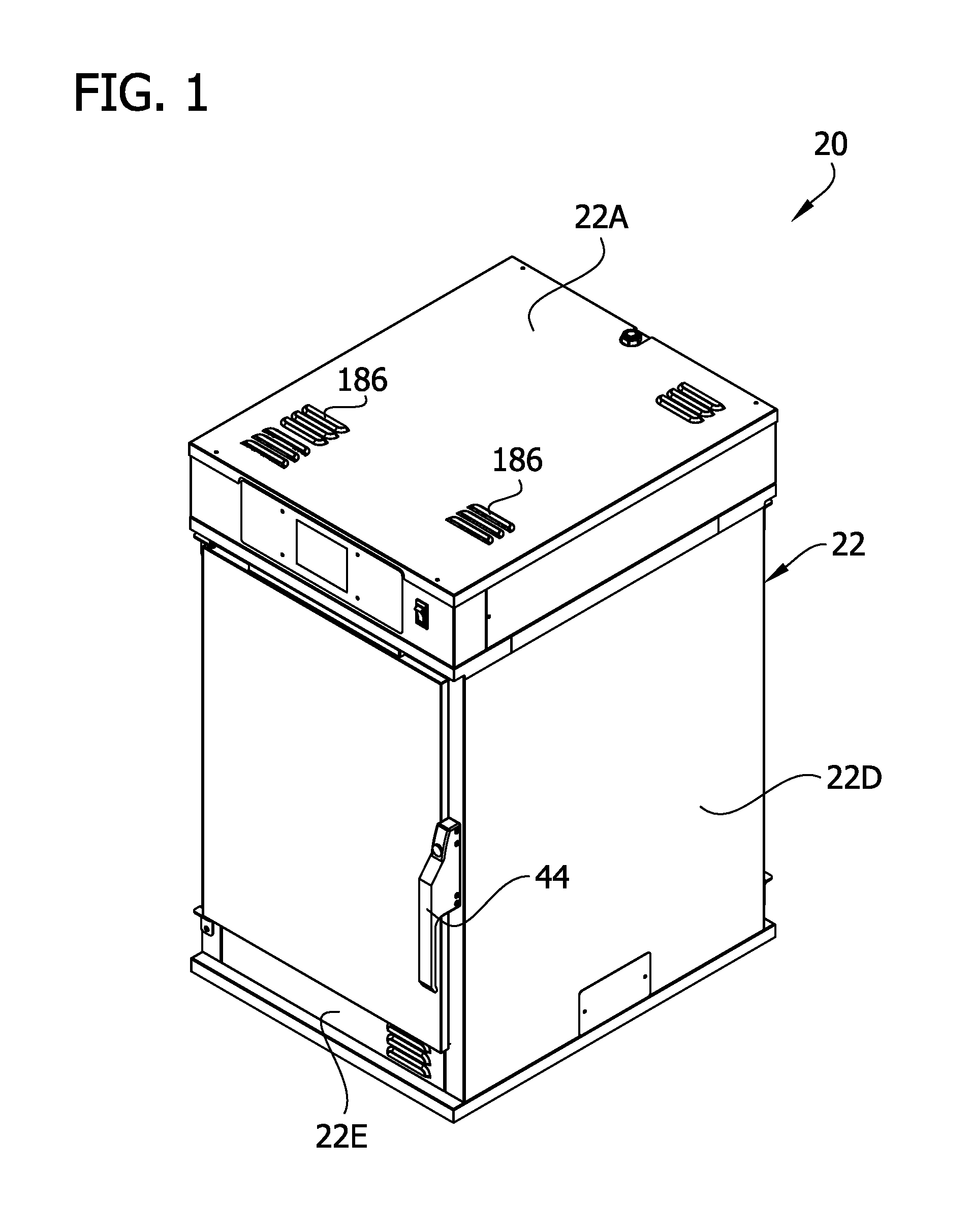

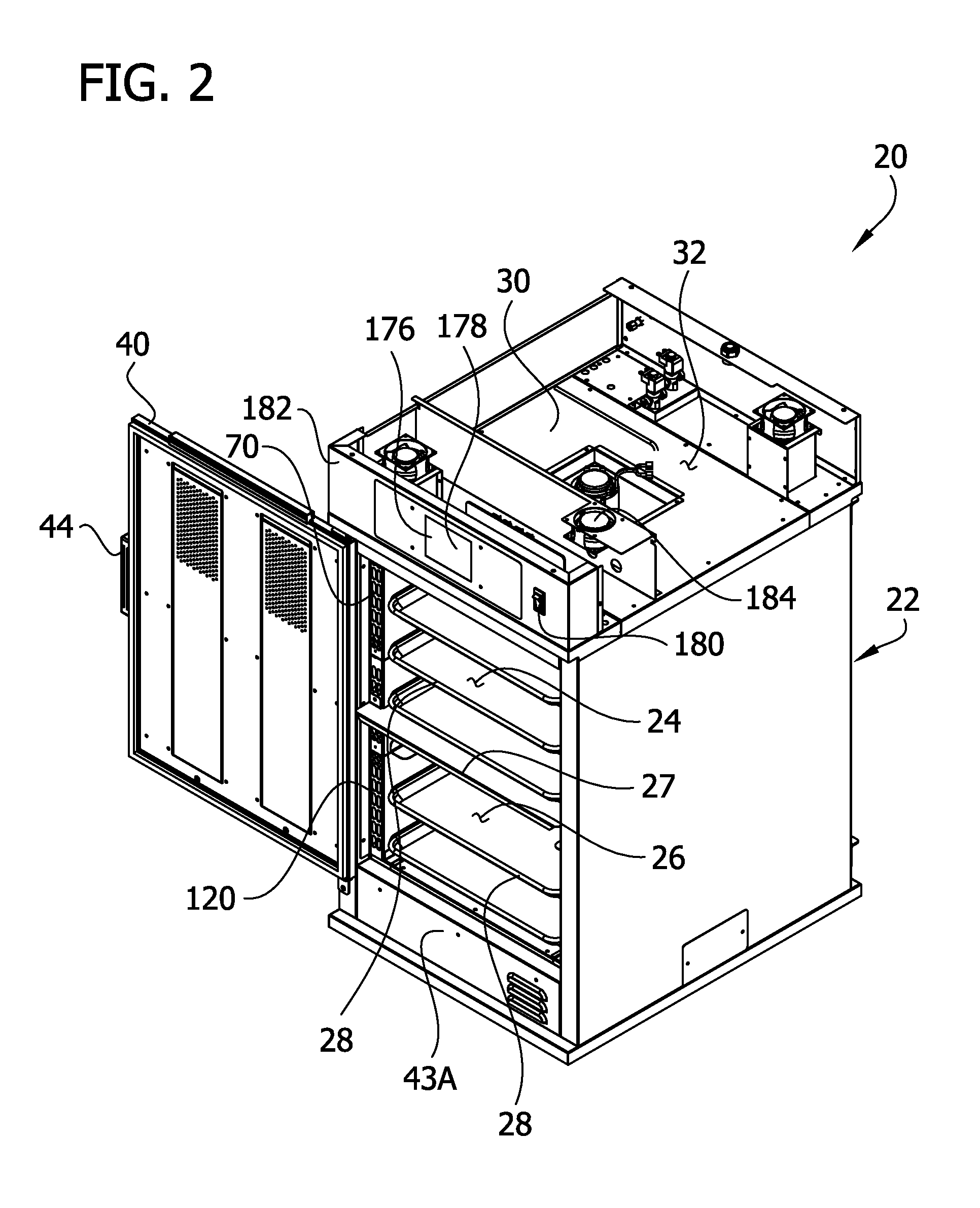

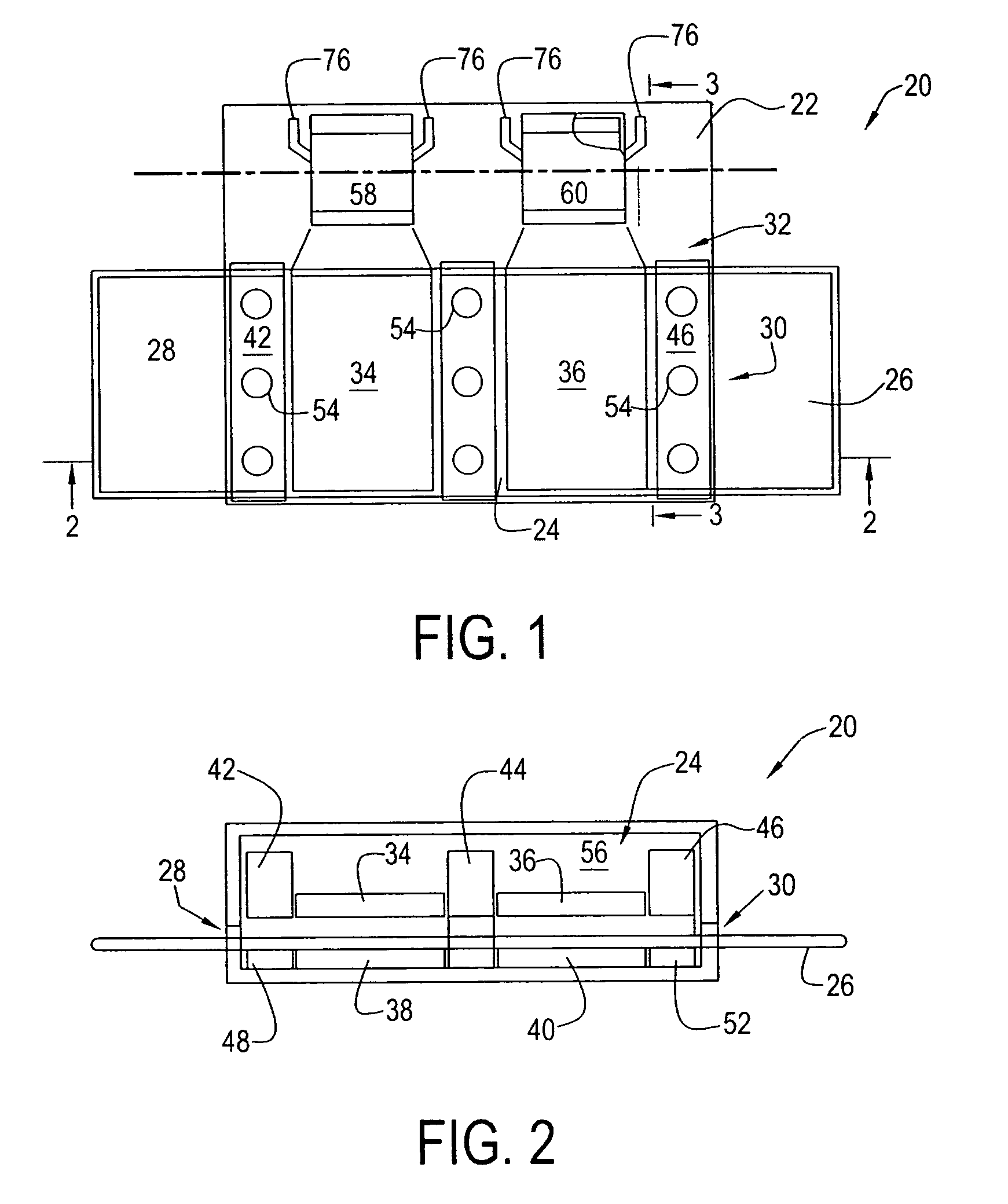

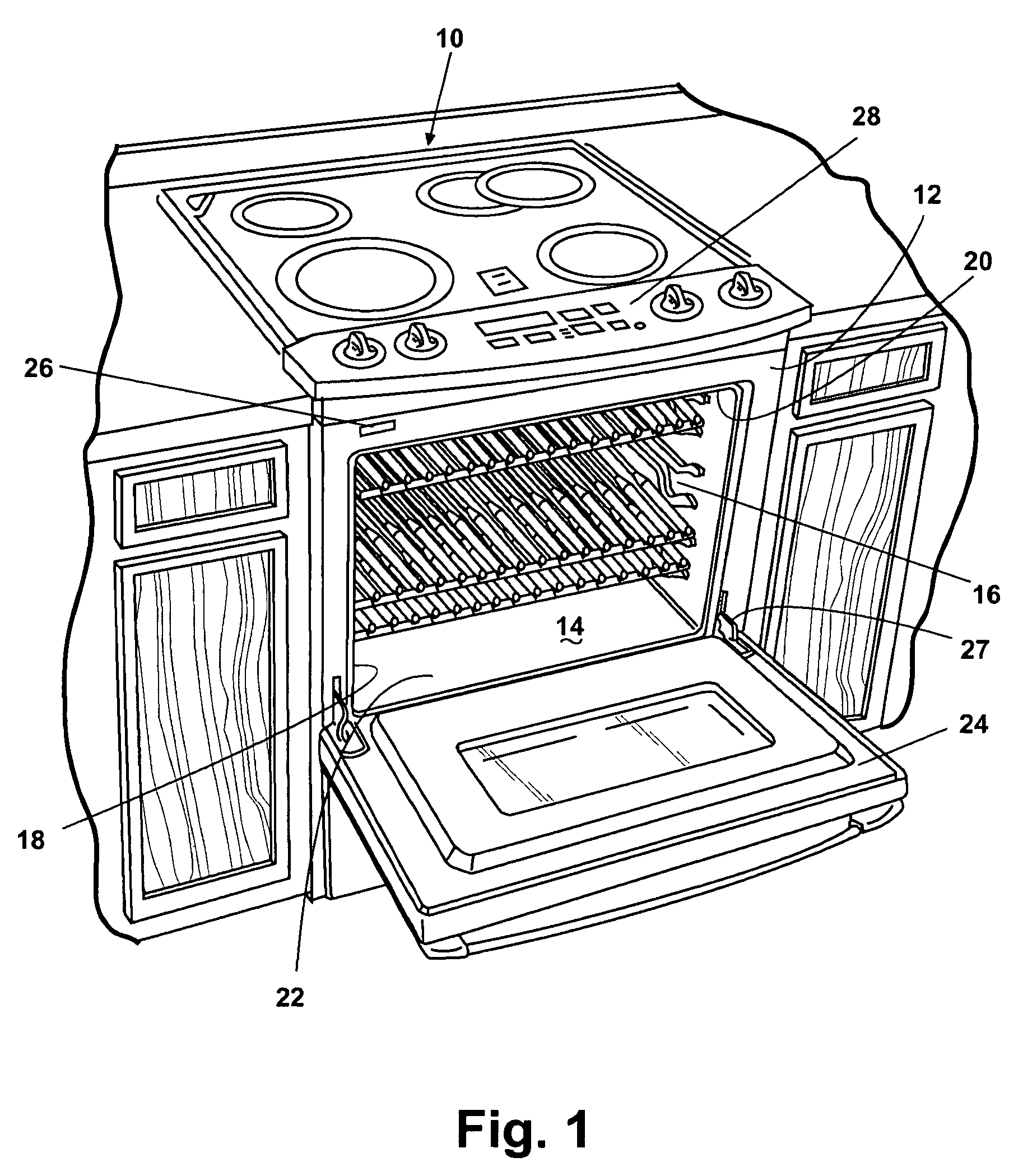

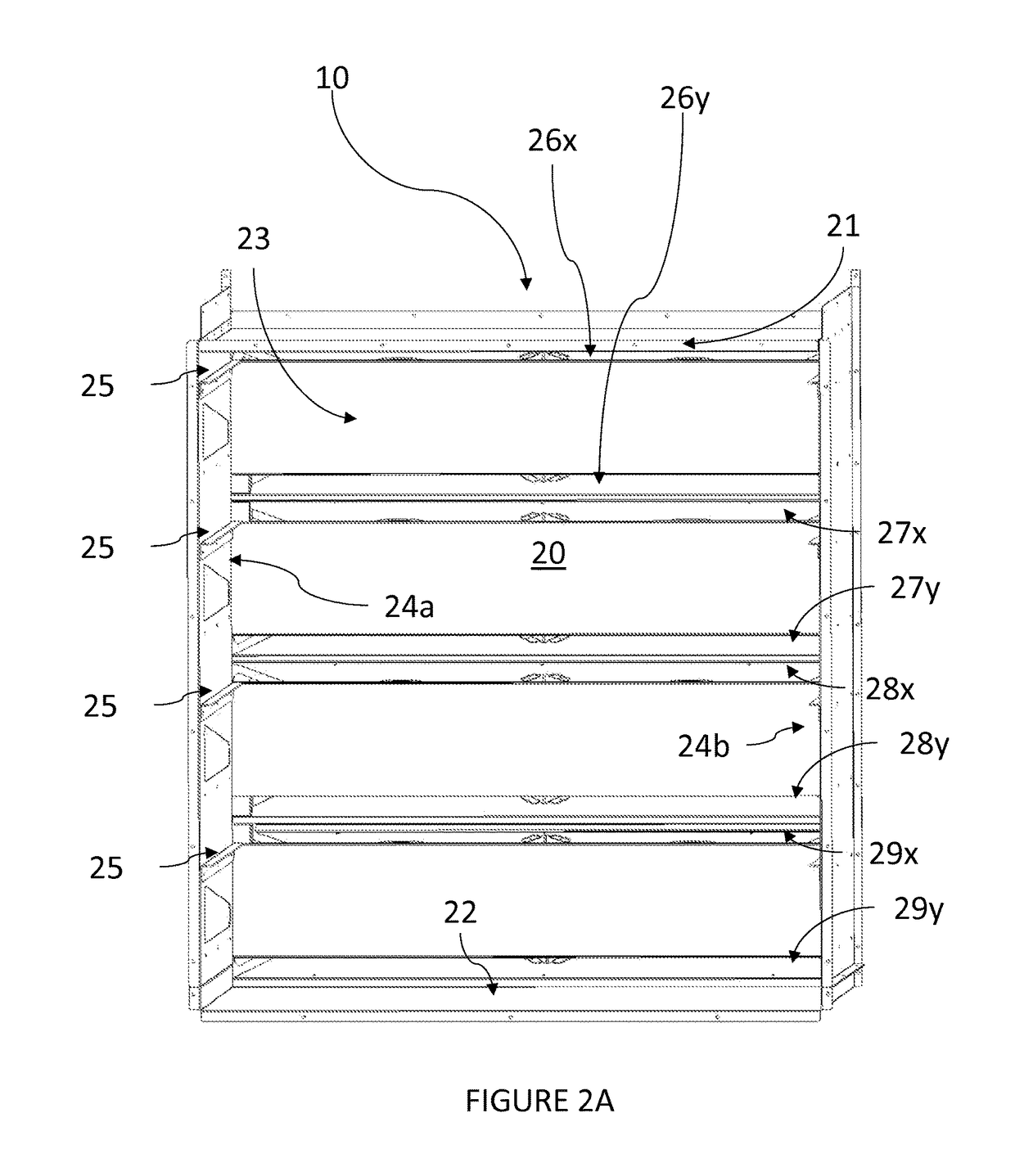

Multi-zone oven with variable cavity sizes

ActiveUS9677774B2Extended cooking timeDomestic stoves or rangesOven air-treatment devicesCavity sizeAir blower

A convection oven is disclosed. The convection oven comprises a housing having an oven cavity and an oven door for access to the oven cavity, at least one air blower for generating heated air, one or more air channels for directing the heated air from the air blower toward the oven cavity, and one or more removable air plenums, wherein each removable air plenum is connected to one of the one or more air channels, comprises an air intake edge for receiving the heated air from the air channel, defines the top or the bottom of a cooking chamber within the oven cavity, and comprises a plurality of air vents for directing the heated air into the cooking chamber. The convection oven may further comprise a control panel for separately and independently controlling each of the cooking chambers defined by the removable air plenums.

Owner:ALTO SHAAM

Oven with a system for generating steam

Owner:WHIRLPOOL CORP

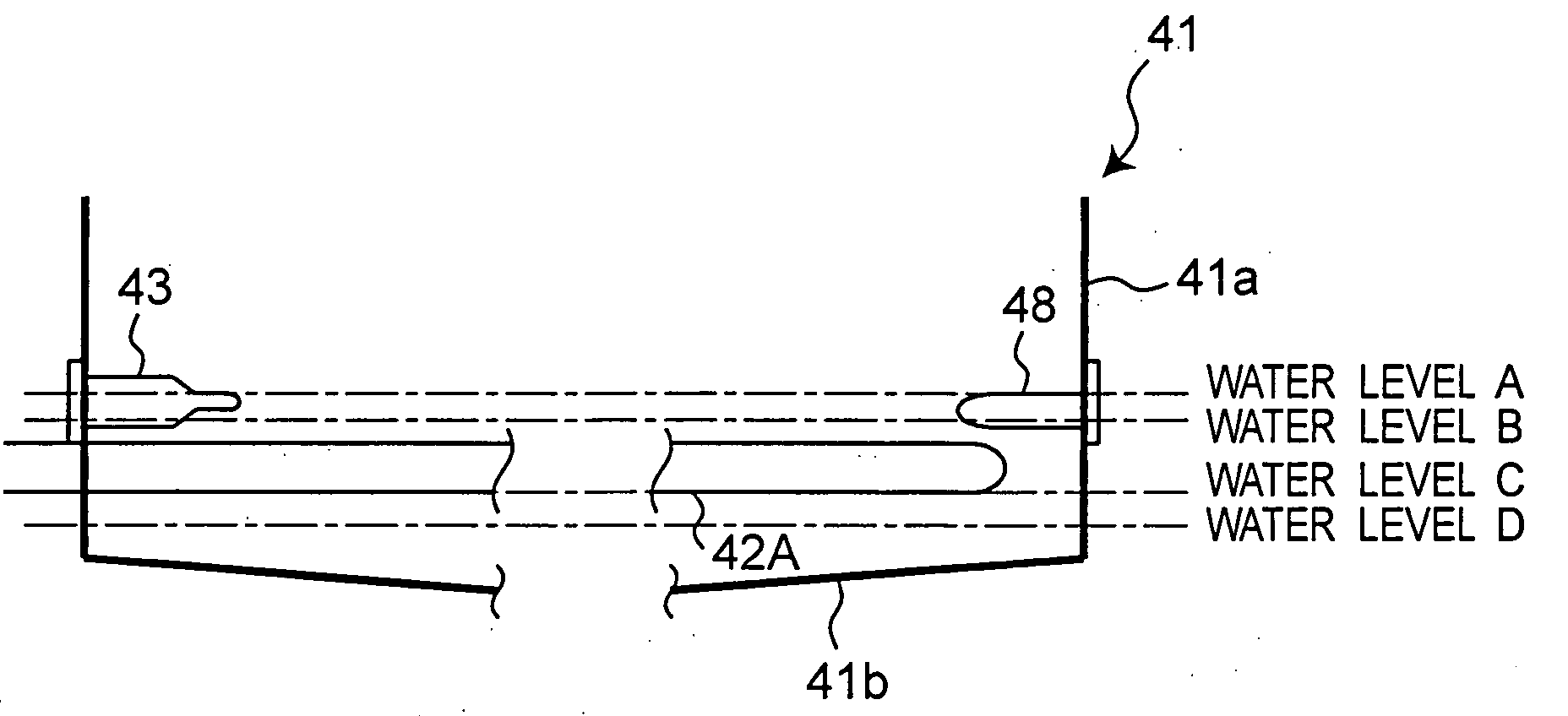

Steam cooker

InactiveUS20090007797A1Steam generation heating methodsDomestic stoves or rangesElectrical resistance and conductanceHeat sensitive

A controller monitors water temperature in a pot (41) through a water temperature thermistor in a temperature sensor (48) while a water level sensor is detecting the water level in the pot. When the water temperature in the pot exceeds 110° C., the controller determines that the water level thermistor in the water level sensor (43) cannot perform normal detection, and drives the pump (35) to supply water. When water supply based on the temperature detected by the water temperature thermistor is carried out more than three times, the controller determines that scale has deposited on the water level sensor (43), and notifies a user of a scale cleaning request. In this manner, in the case of detection failure of the water level thermistor, it is possible to notify a scale cleaning request at an appropriate time by determining whether or not the detection failure is attributable to scale deposits.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com