Patents

Literature

1959 results about "Laboratory oven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laboratory ovens are ovens for high-forced volume thermal convection applications. These ovens generally provide uniform temperatures throughout. Process applications for laboratory ovens can be for annealing, die-bond curing, drying, Polyimide baking, sterilizing, and other industrial laboratory functions. Typical sizes are from one cubic foot to 0.9 cubic metres (32 cu ft) with temperatures that can be over 340 degrees Celsius.

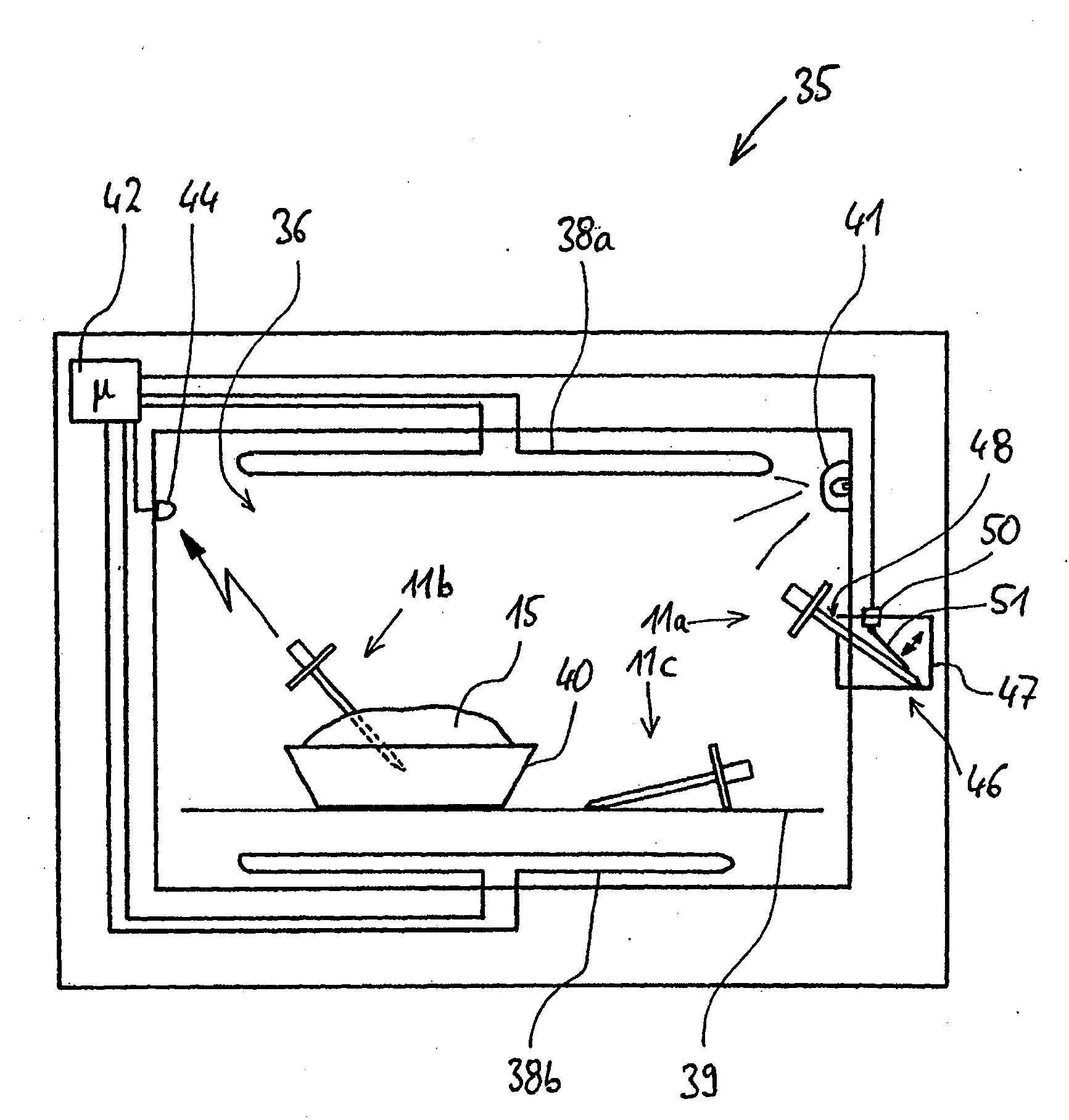

Oven for heating and frying food

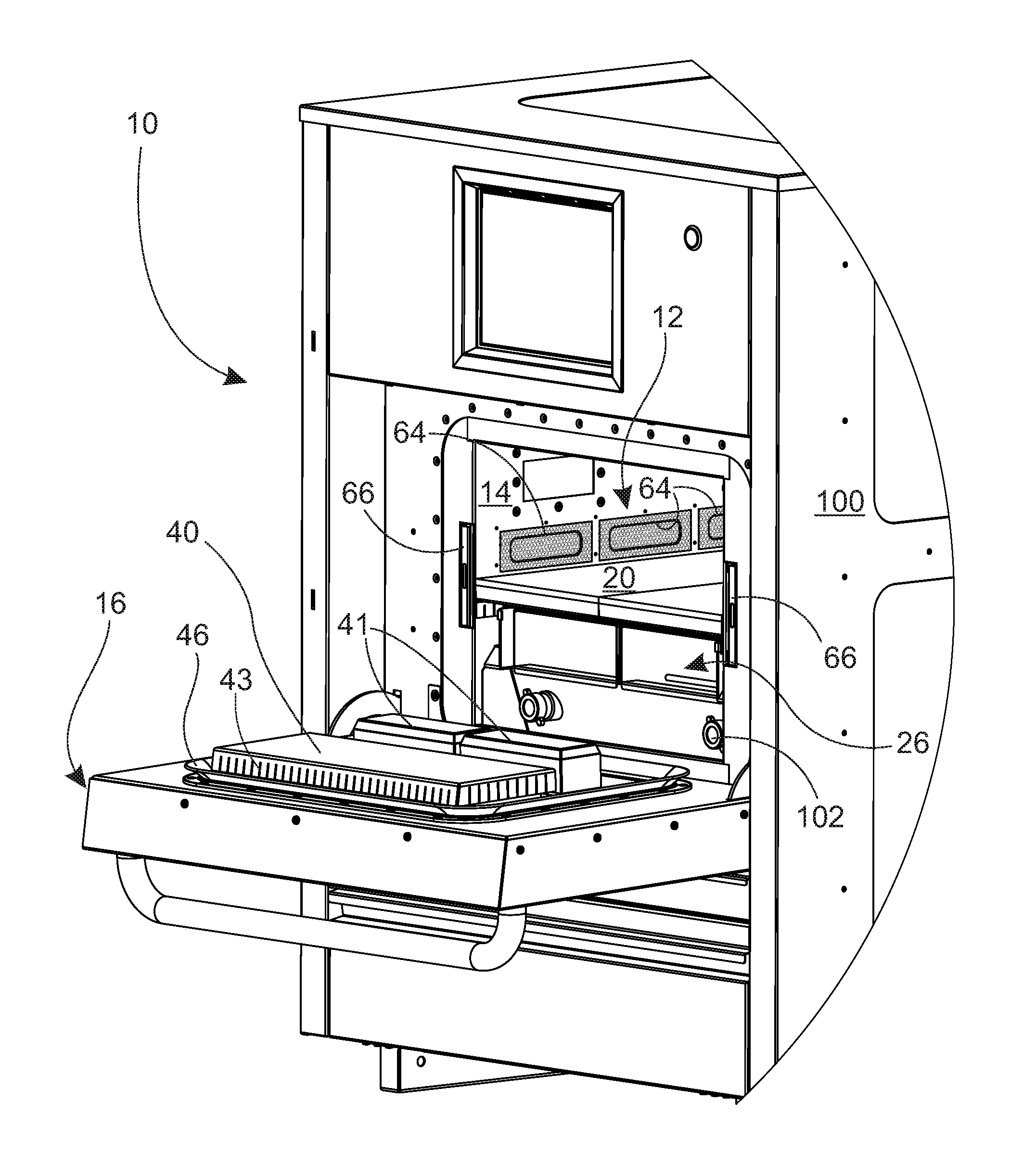

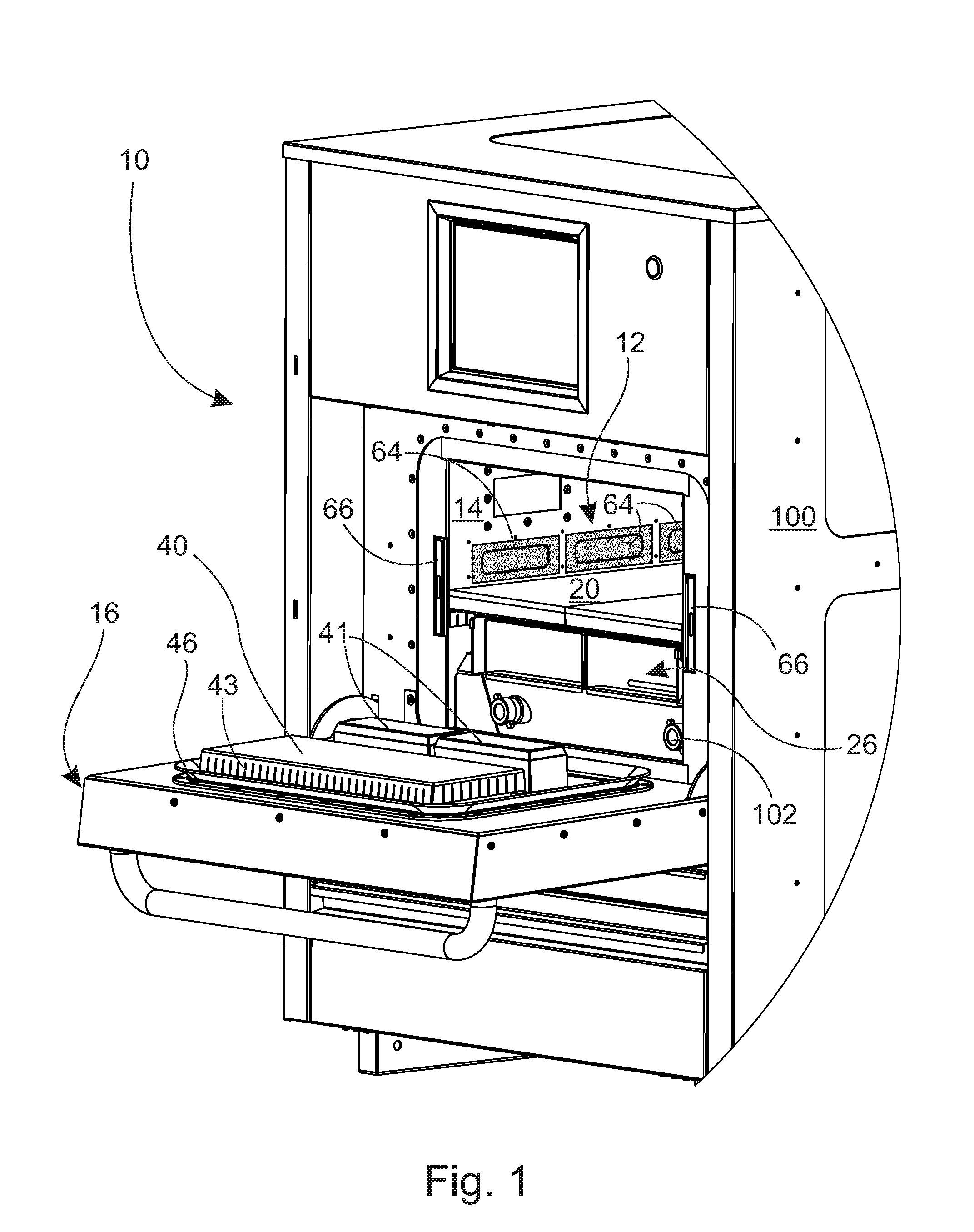

ActiveUS20160316525A1Guarantee product qualityTime of keeping in accurateDomestic stoves or rangesLighting and heating apparatusMicrowaveThermal insulation

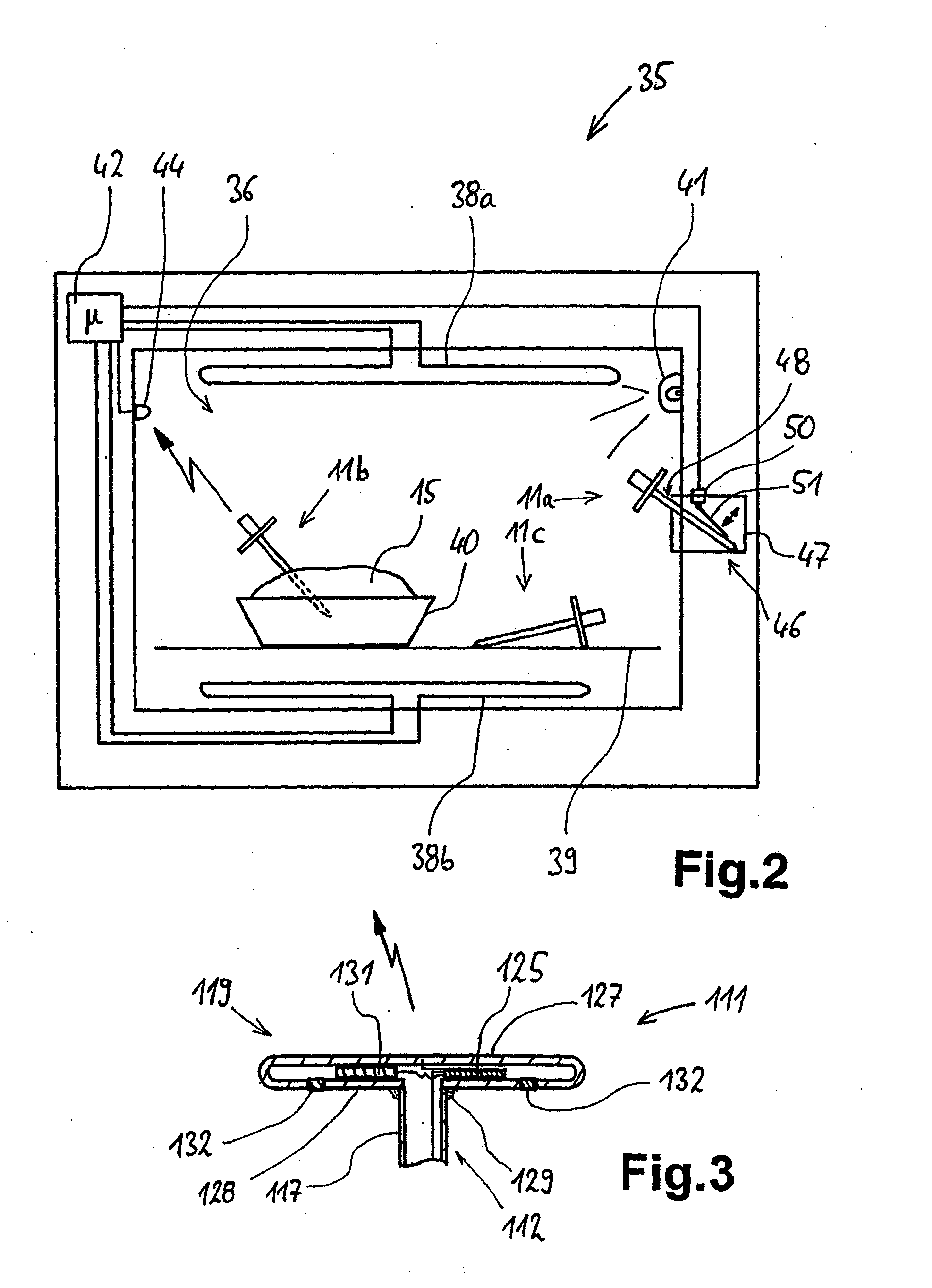

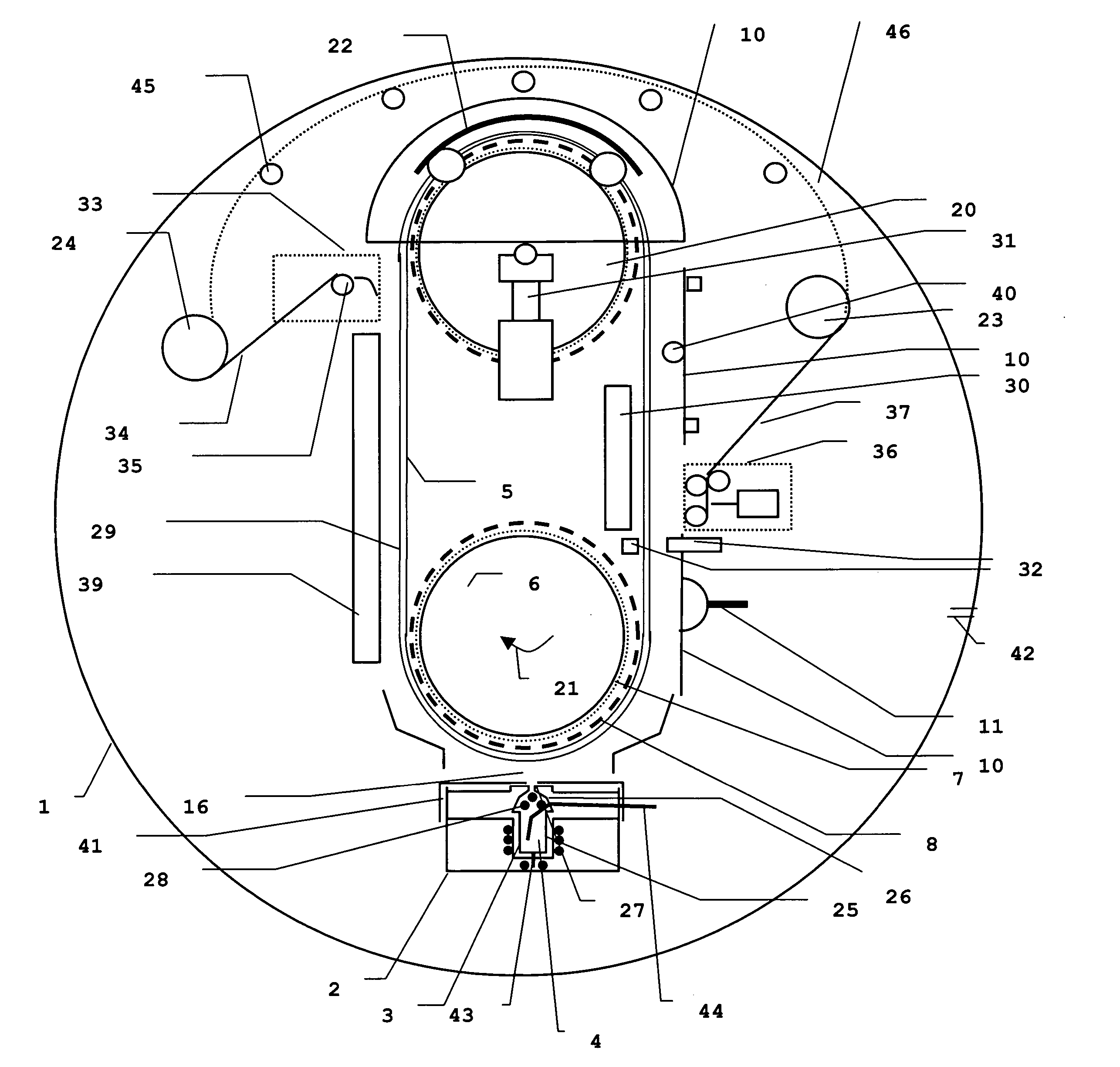

An oven for heating and frying food, particularly a rapid cook oven, includes walls and an openable oven door delimiting an oven space and heaters to heat food in the oven space. Such heaters including: microwave radiation devices, a frying plate having an undersurface, and heat circulating-air devices comprising a flow duct for removing circulating air from the oven space and leading it back into the oven space after cleaning, and a fan installed in the flow duct for creating a circulating-air flow in the said flow duct. The oven additionally includes structure delimiting a cooker space, thermal insulation between the oven space and the cooker space and a heater comprising a cooker situated in the cooker space.

Owner:R MENU

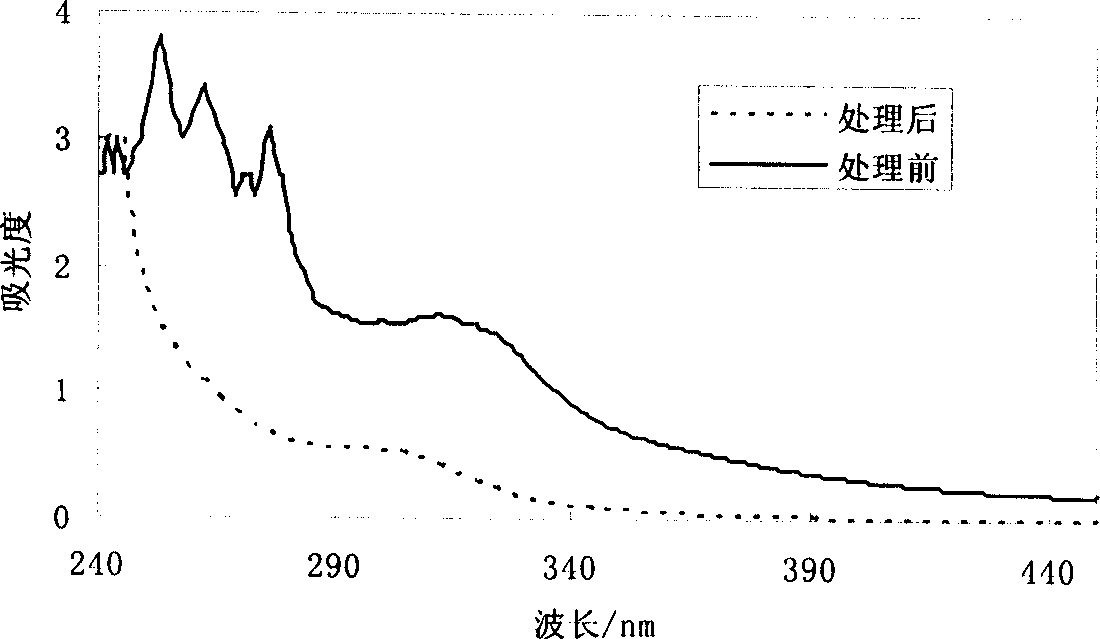

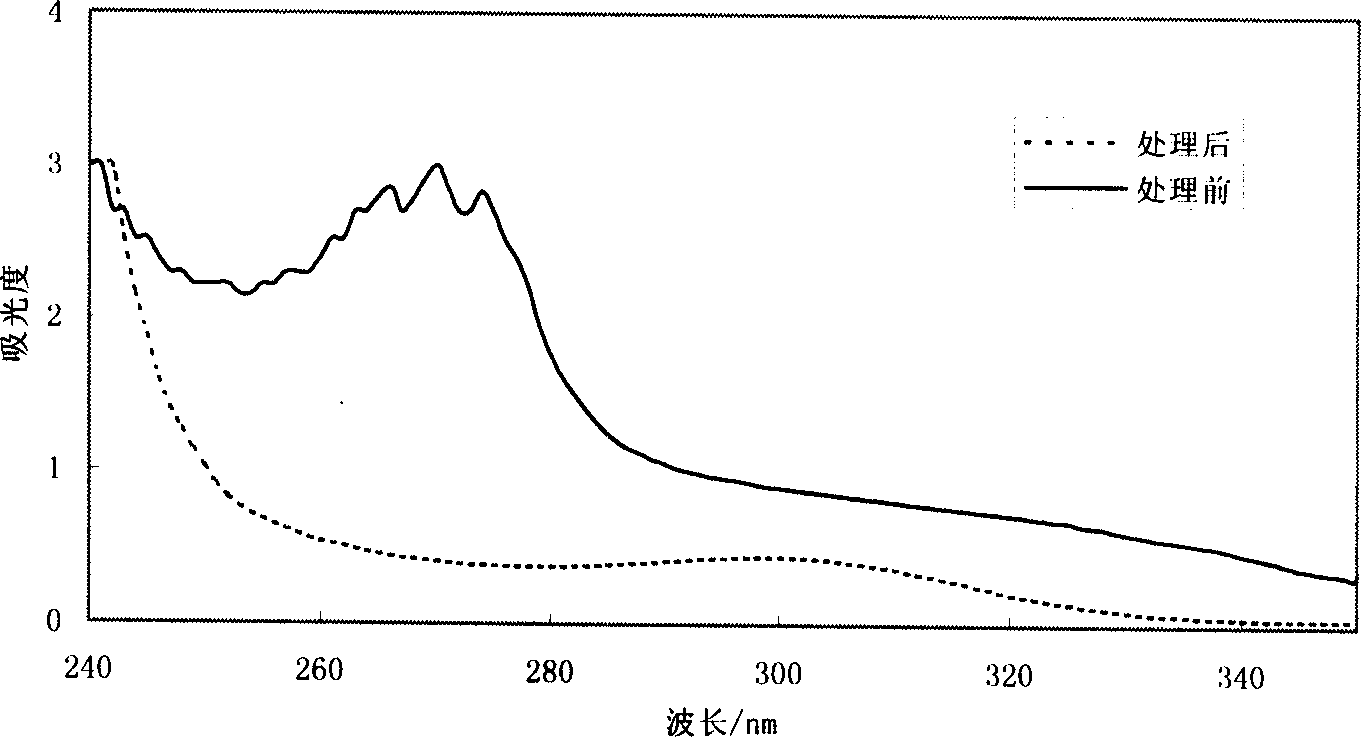

Activated charcoal carried copper oxide catalyst and process for preparing same

InactiveCN1876232AEasy to prepareLow priceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationActivated carbonWastewater

The related preparation method for a CuO catalyst contained 1.0-5.0% active carbon carrier comprises: dipping the active carbon in 10% NaOH solution / HNO3 solution for 24h to filter and clean with deionized water till neutrality in turns, drying in oven at 100-110Deg, adding 0.2-0.3mol / L Cu(NO3)2 solution to stir and drop 20% NaHCO3 till much deposition, slaking 24h, filtering, cleaning with deionized water till no separation of metal ion, drying in oven at 100-110Deg, and activating the obtained solid for 2.5h at 270-280Deg.

Owner:BEIJING JIAOTONG UNIV

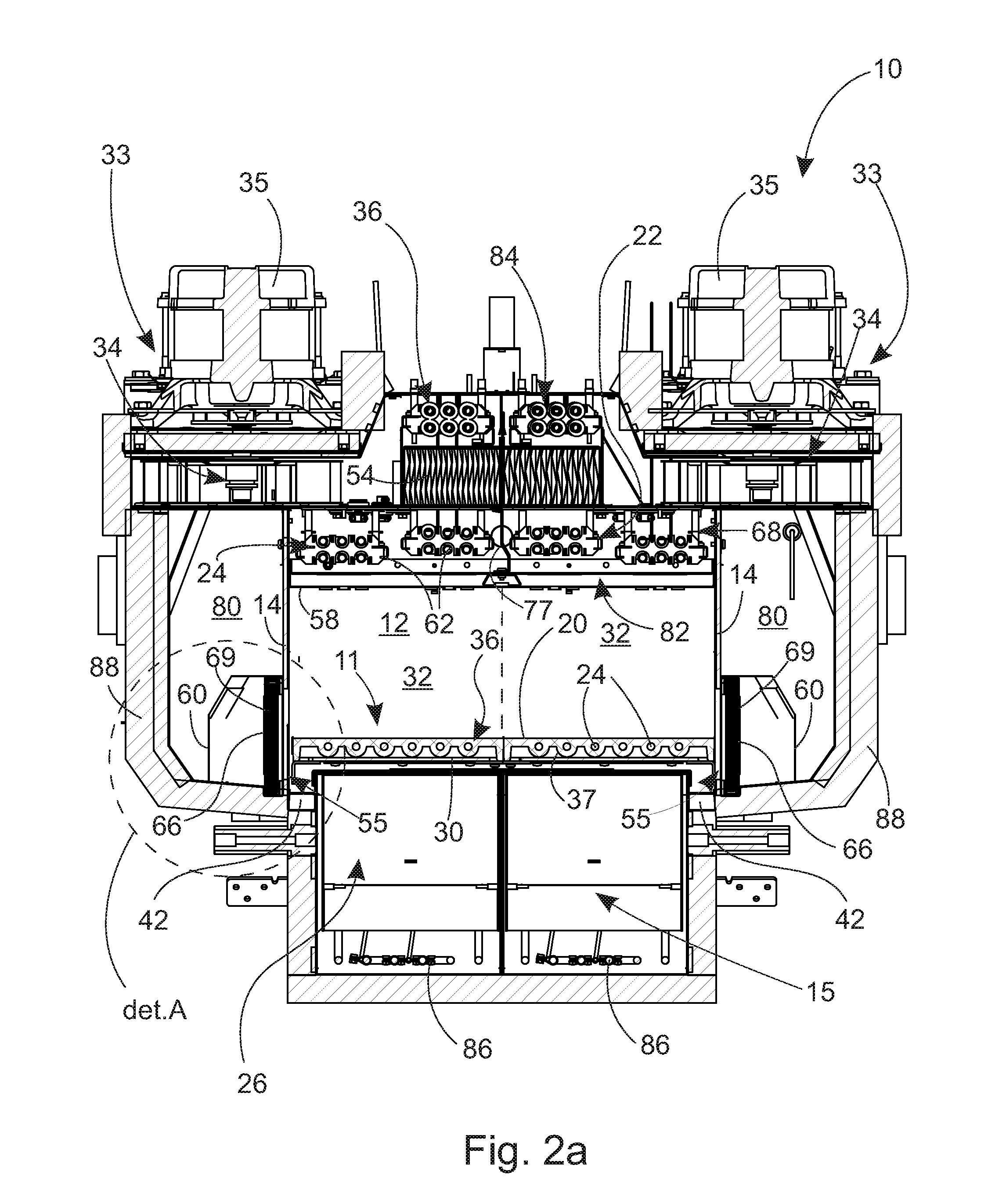

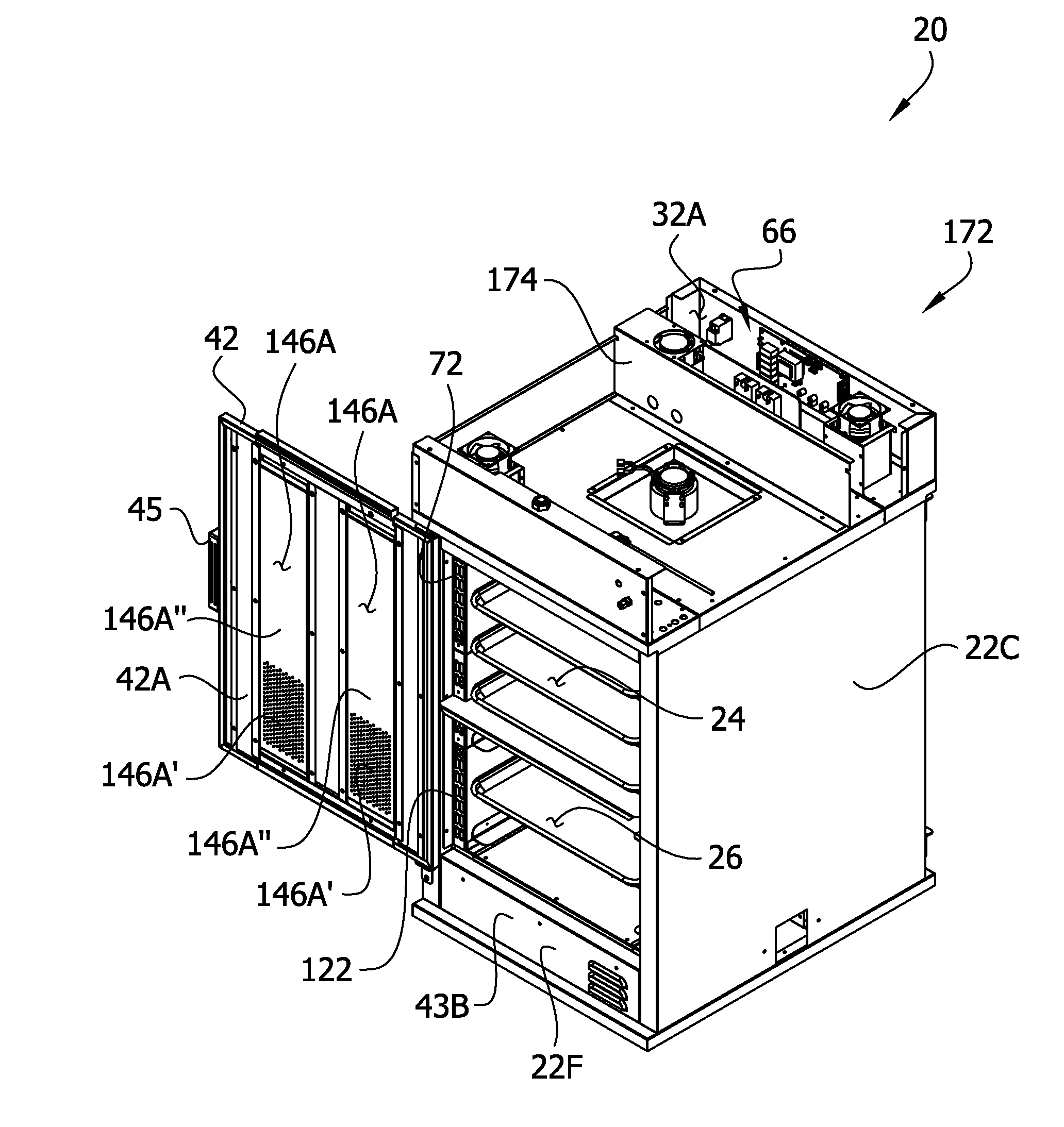

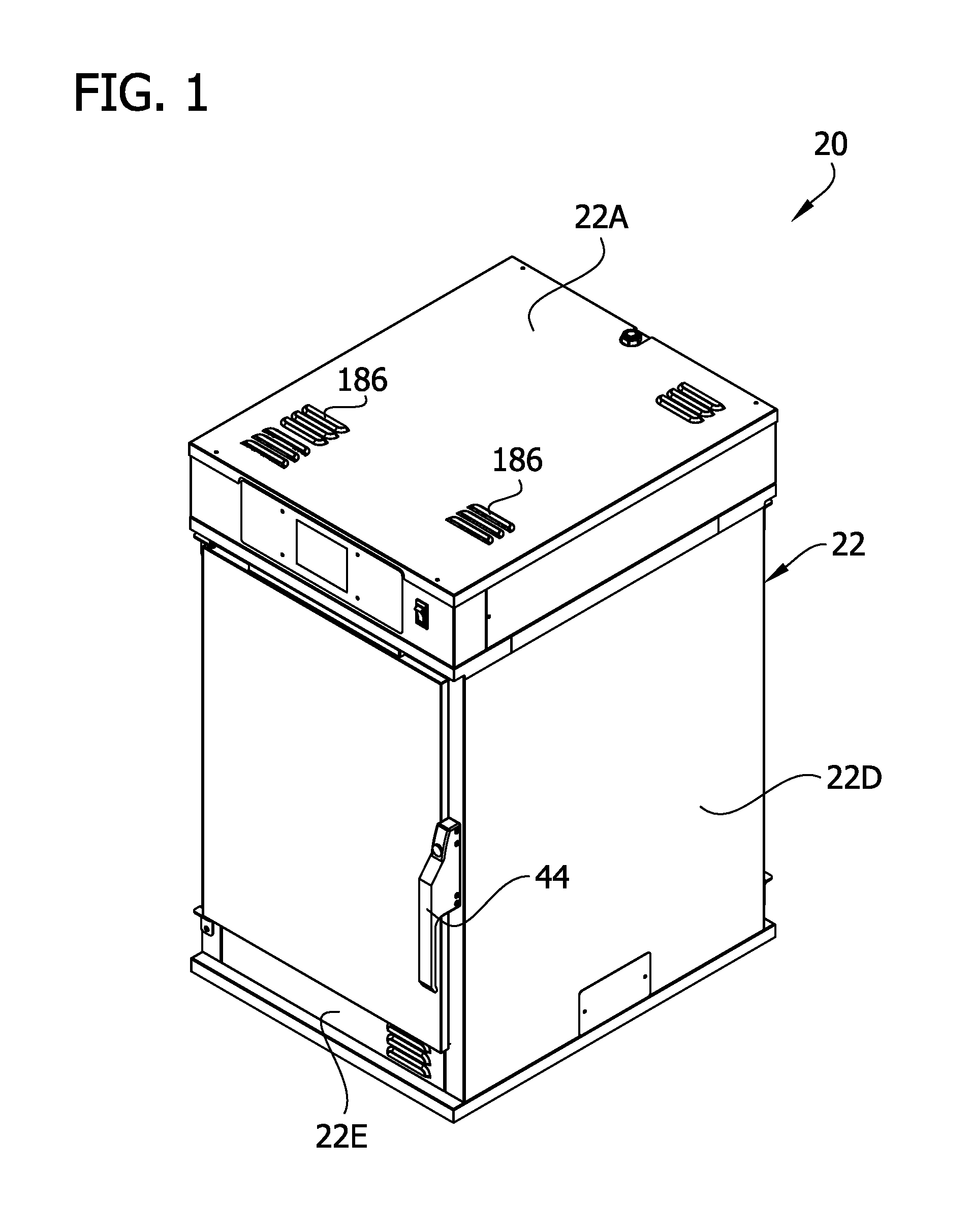

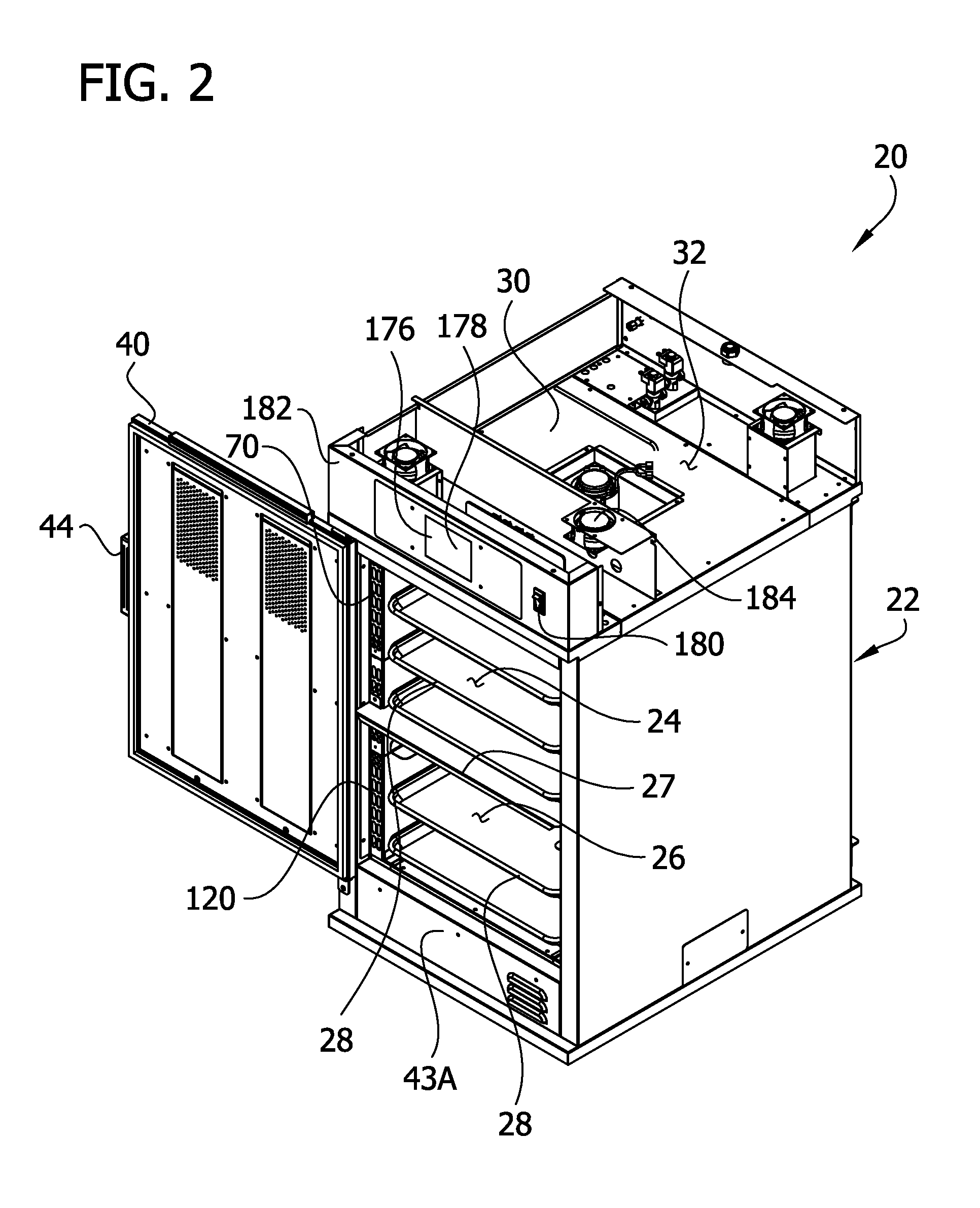

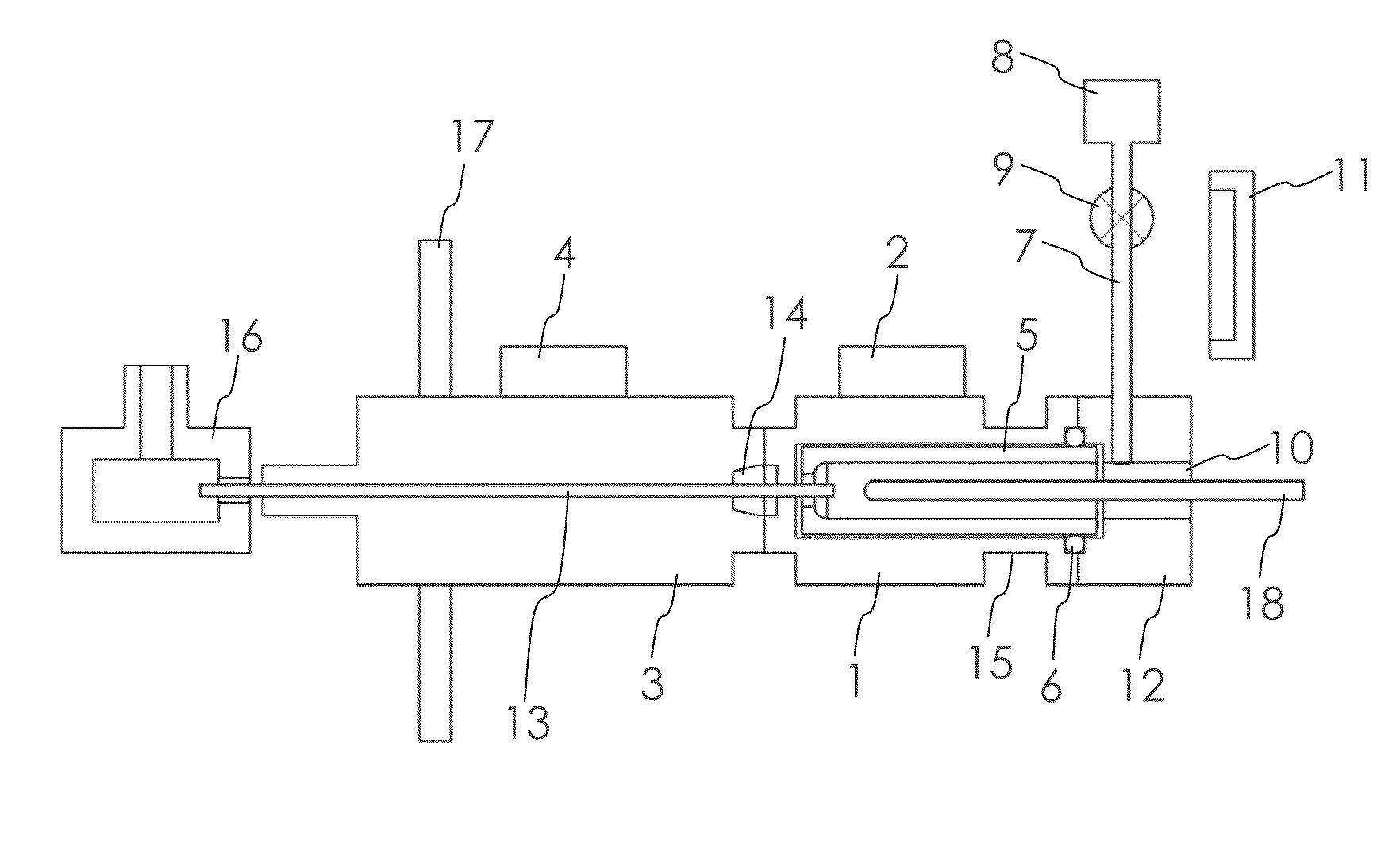

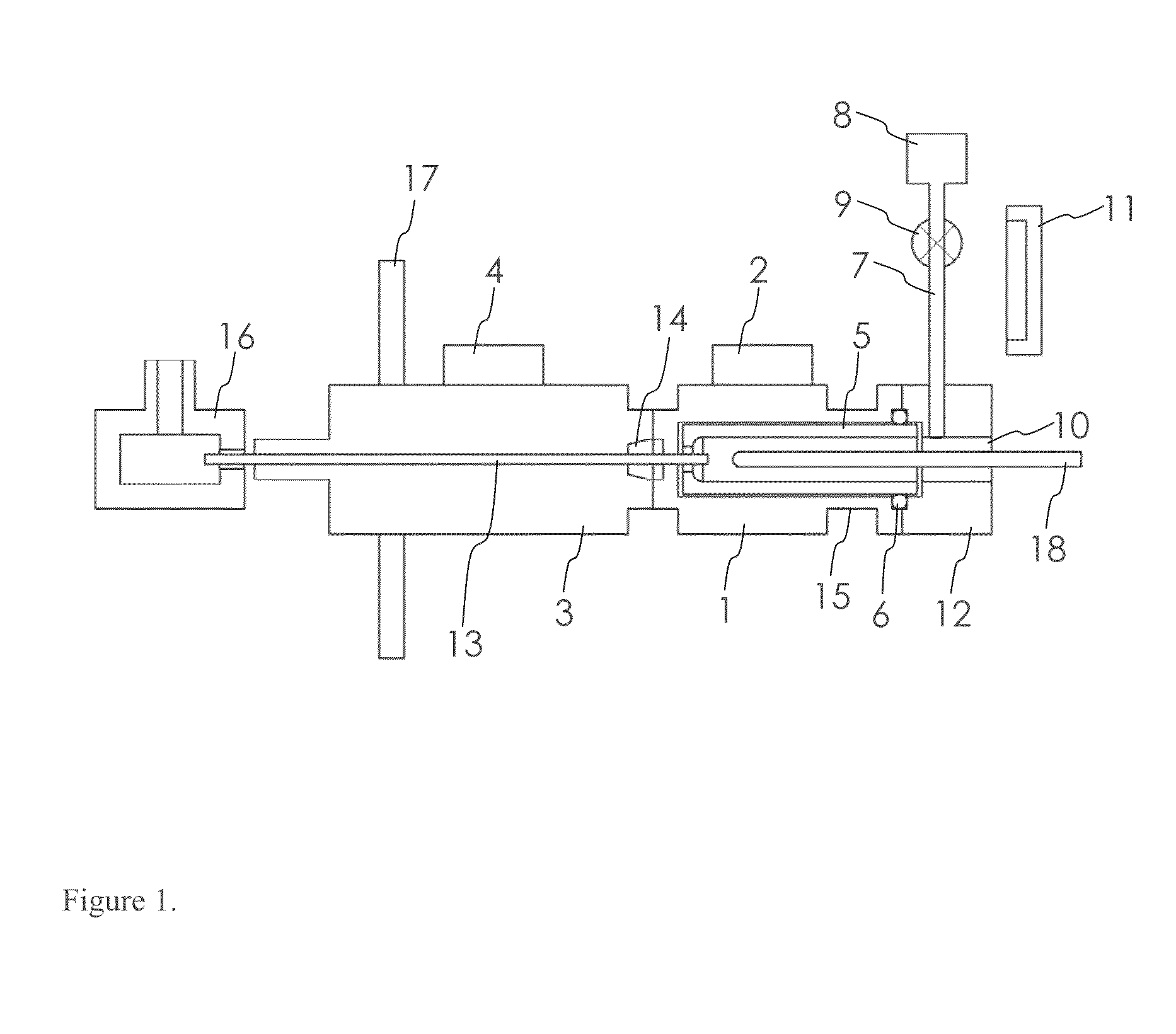

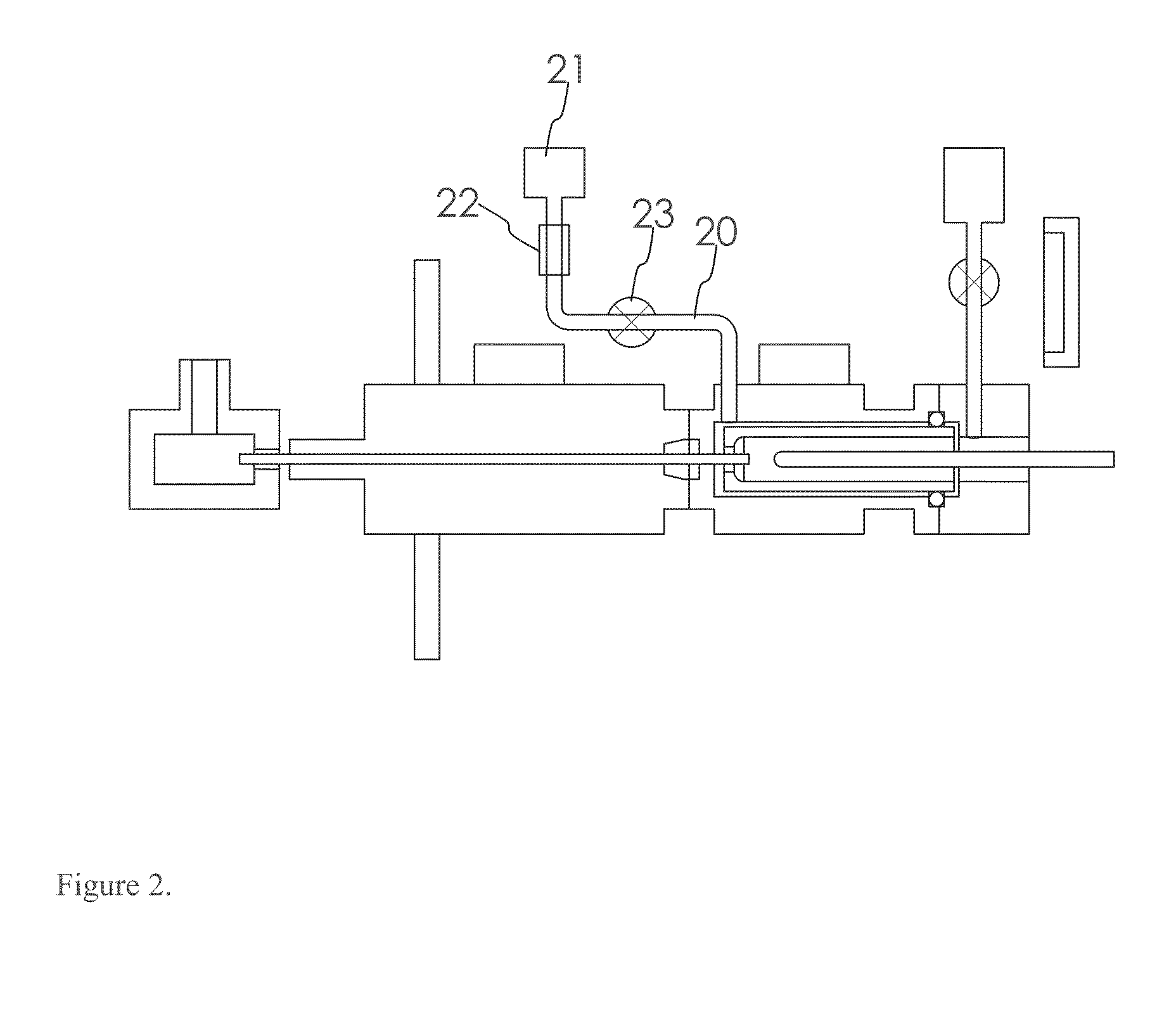

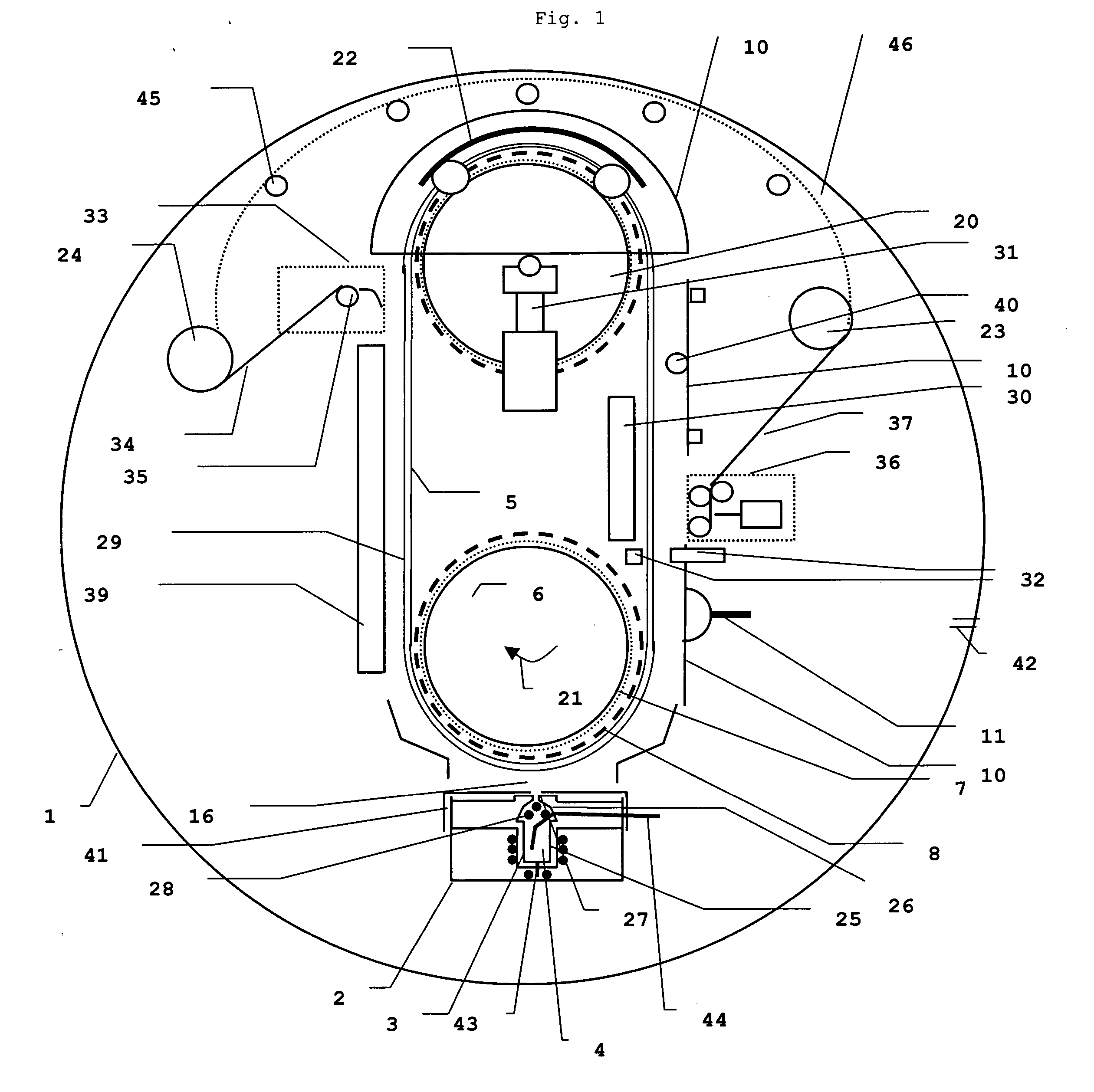

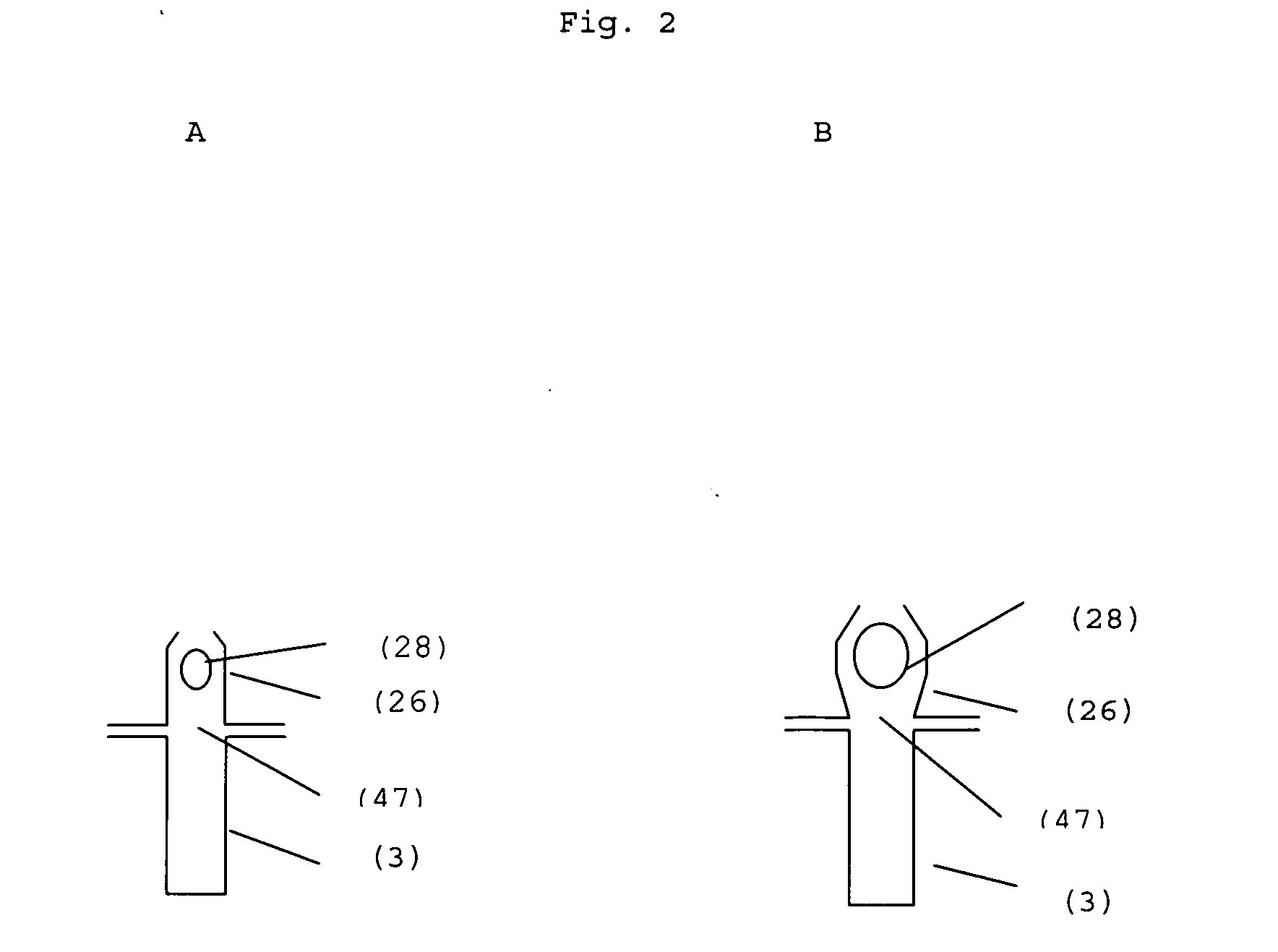

Holding oven

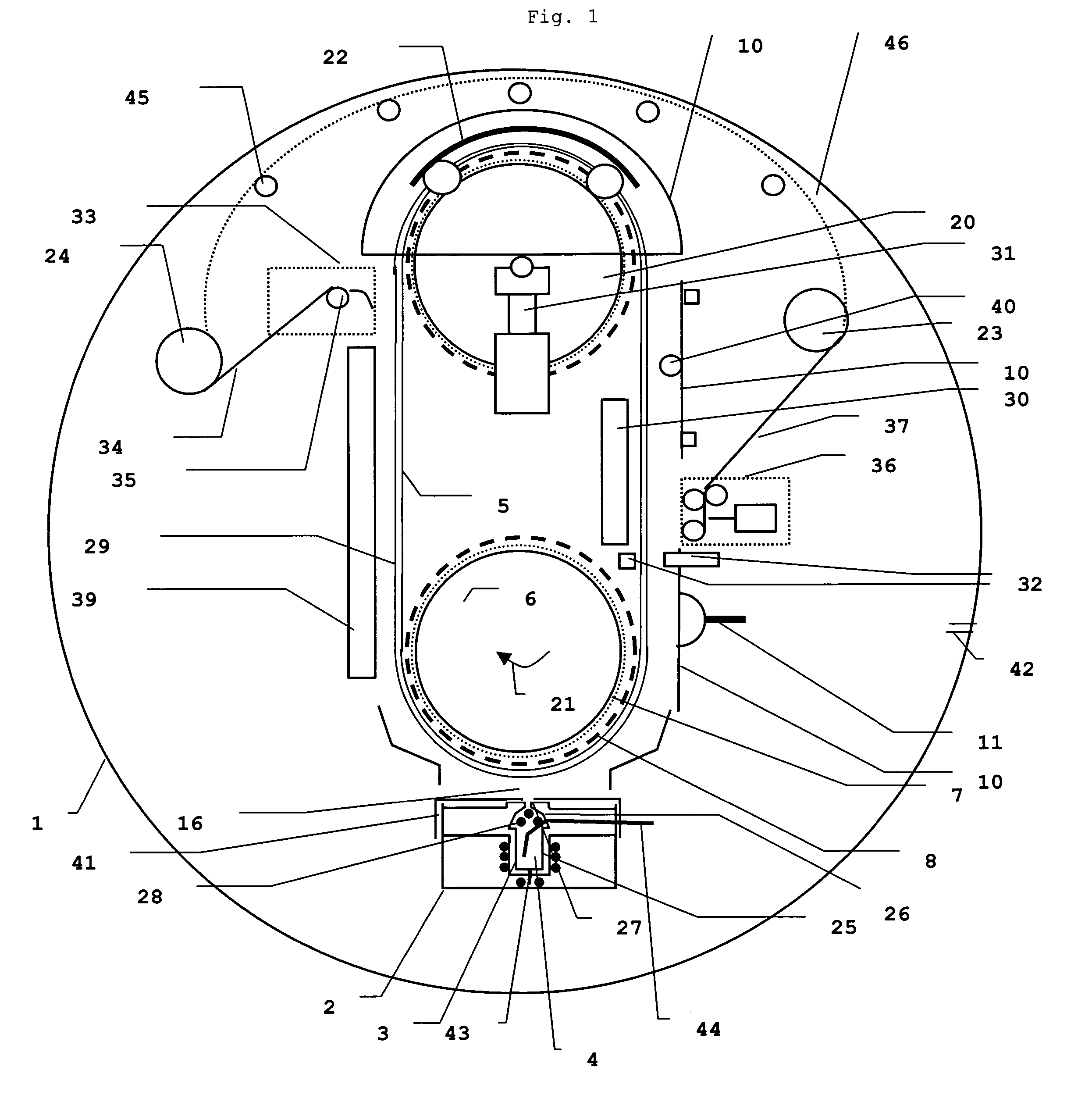

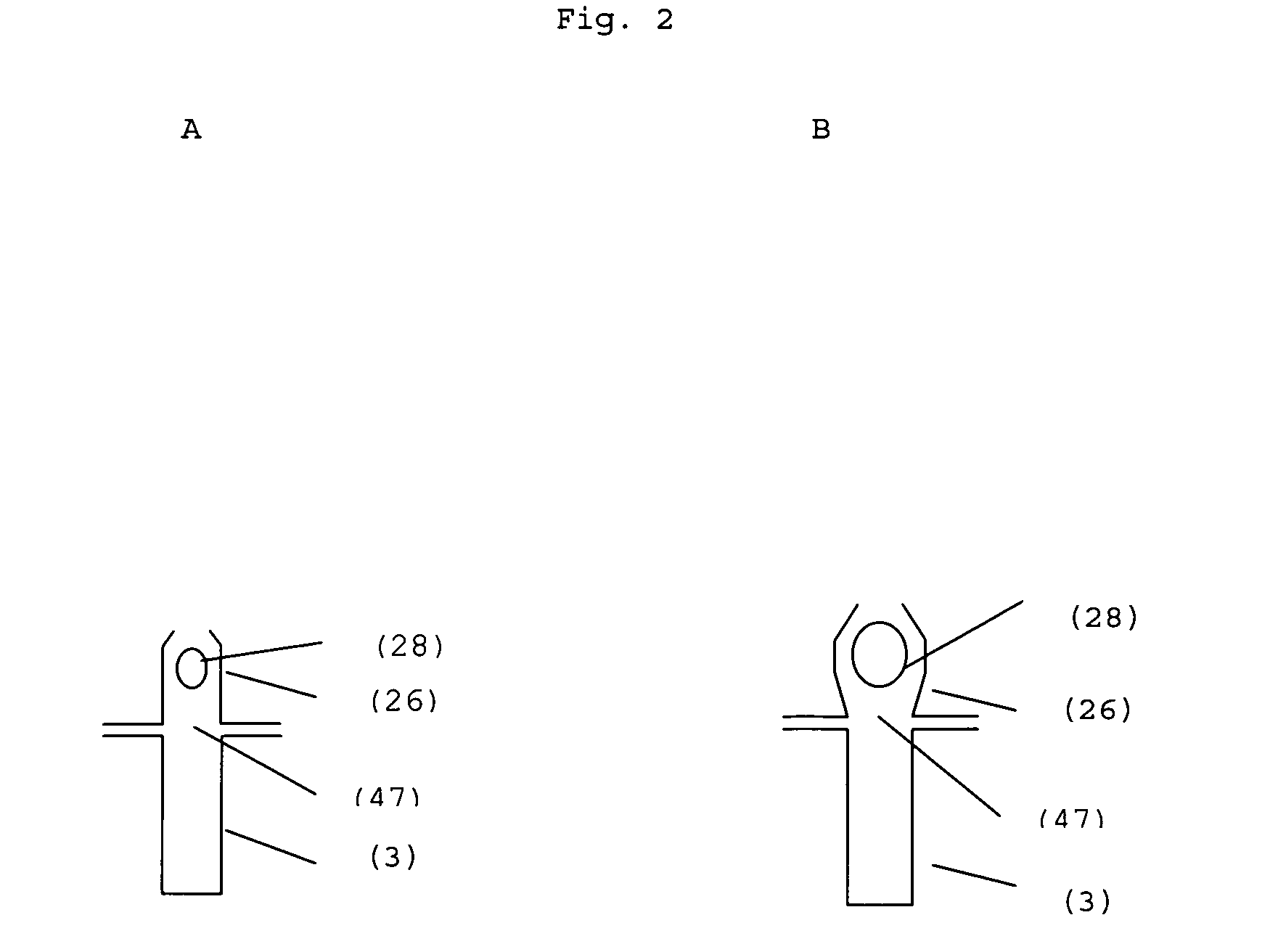

ActiveUS20140083309A1Maintain qualityQuick buildDomestic stoves or rangesOven air-treatment devicesWater vaporLaboratory oven

Methods, ovens, and associated apparatus. Ovens and methods are adapted for maintaining the quality of a pre-cooked food product. Rapid temperature and / or relative humidity restoration may be used. Ovens may include a partition movable to vary sizes of oven cavities. Ovens may include removable interior panels. Humidification mechanisms are adapted for generating water vapor which may be used to maintain the quality of a pre-cooked food product.

Owner:DUKE MANUFACTURING COMPANY

Open probe method and device for sample introduction for mass spectrometry analysis

An open probe method for sample introduction into a mass spectrometer is disclosed, comprising the steps of: loading a sample holder with sample compounds to be analyzed; heating a probe oven; introducing said sample compounds in said sample holder into said heated probe oven; flowing inert gas into said heated probe oven; vaporizing said sample in said heated probe oven by the combined effect of oven temperature and inert gas flow; entraining said vaporized sample in said inert gas; and, transferring said vaporized sample in inert gas into an ion source of a mass spectrometer; wherein said heated probe oven remains open to the ambient atmosphere during sample introduction and analysis; said inert gas is flowing in said heated probe oven in two directions of a transfer line to a mass spectrometer ion source and to the oven opening; said vaporized sample in inert gas is transferred through a heated transfer line directly into the ionization chamber of an ion source of a mass spectrometer. An apparatus for this method of sample introduction is also disclosed. The primary advantage of this method and apparatus is that the heated probe oven remains open to the ambient atmosphere during sample introduction and analysis thereby enabling faster sample analysis.

Owner:AMIRAV AVIV

Temperature probe for an oven, oven and method for operating an oven

InactiveUS20100012645A1Easy and handlingRequired emitting powerThermometer detailsTemperature measurement in household appliancesTemperature differenceCore temperature

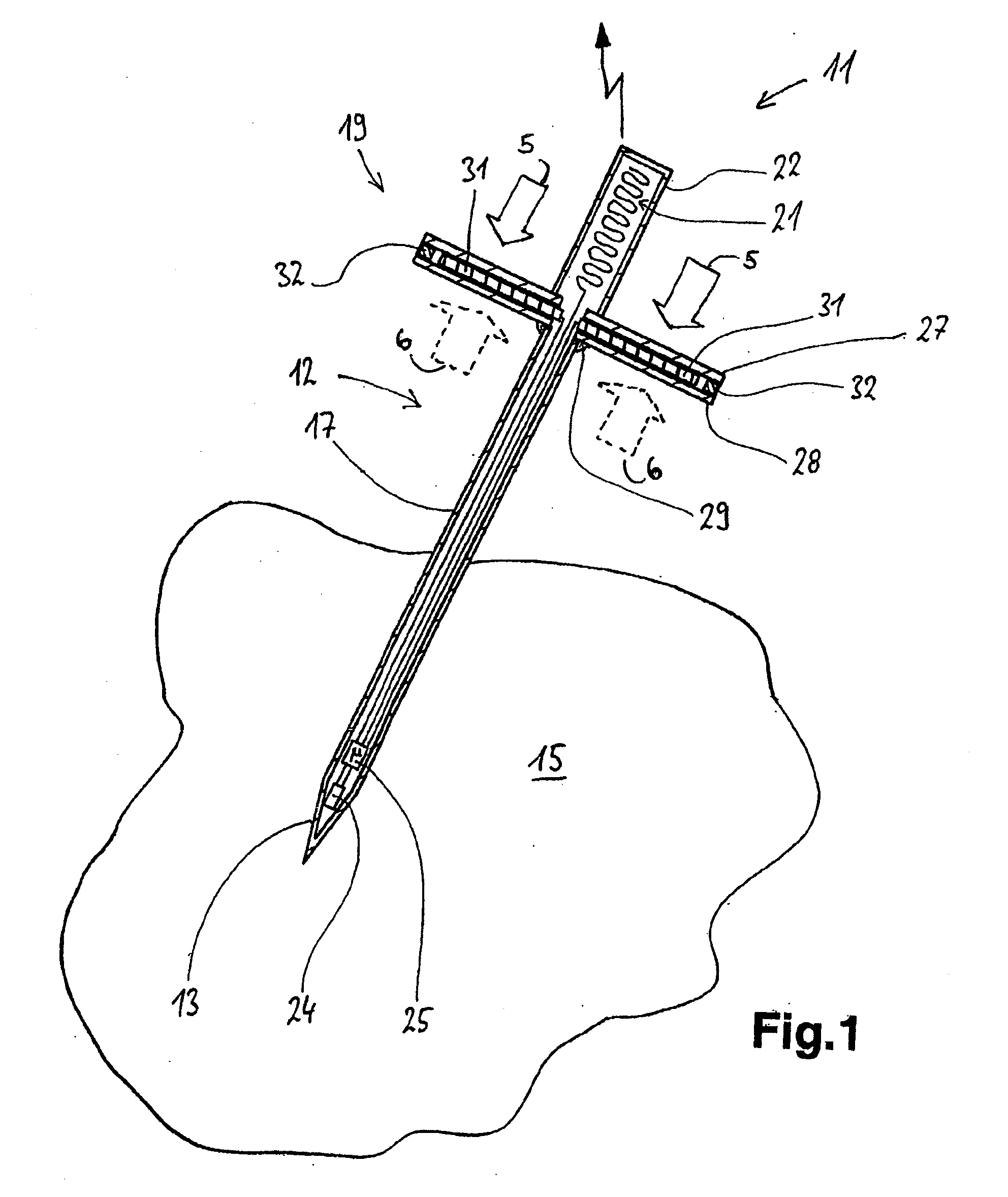

The invention relates to a temperature probe for an oven, comprising in one embodiment a longitudinal housing in the form of a spit. A temperature sensor and an electronic unit are arranged in a tip and are connected at the other end to emitting means. The temperature probe comprises a thermogenerator for producing energy. The thermogenerator uses a temperature difference between a higher temperature inside the oven and a lower core temperature in a food product, such as roast, in which the temperature probe is inserted, for producing energy for operating the emitting means.

Owner:E G O ELEKTRO GERAETEBAU GMBH

Method for adsorption and removal of heavy metals and dye of waste water by garlic waste

InactiveCN102557181AReasonable designEasy to operateOther chemical processesWater contaminantsSorbentPhysical chemistry

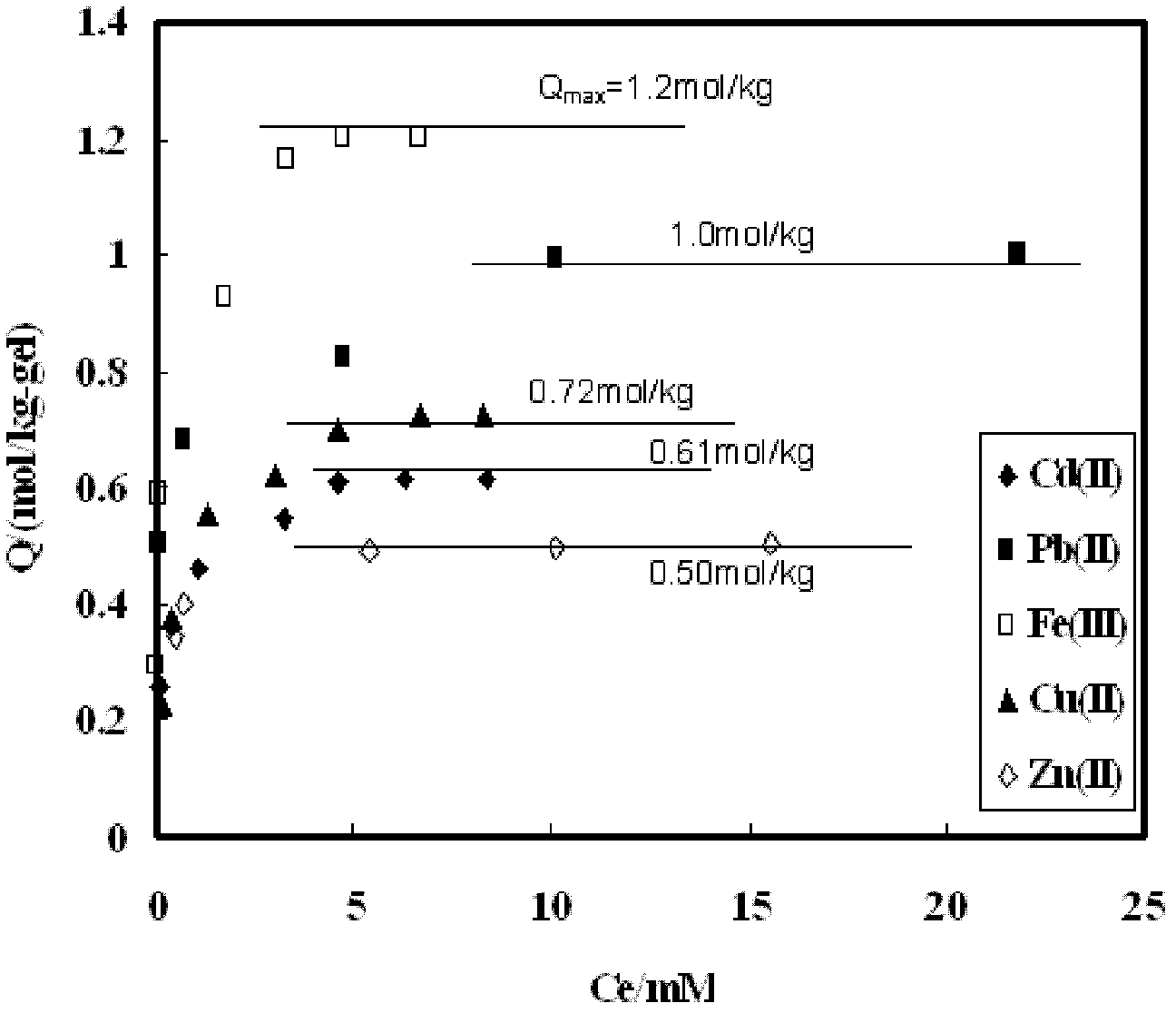

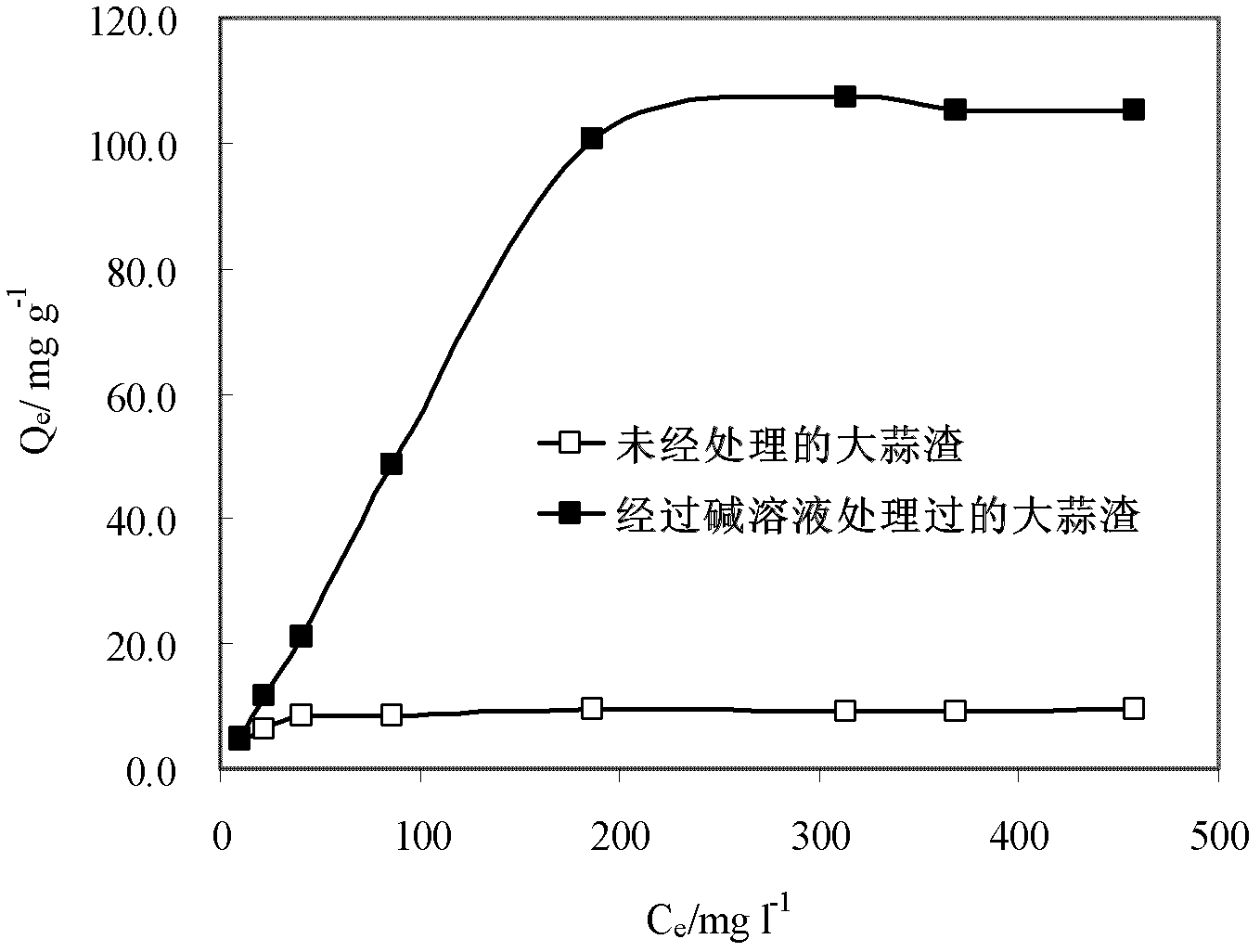

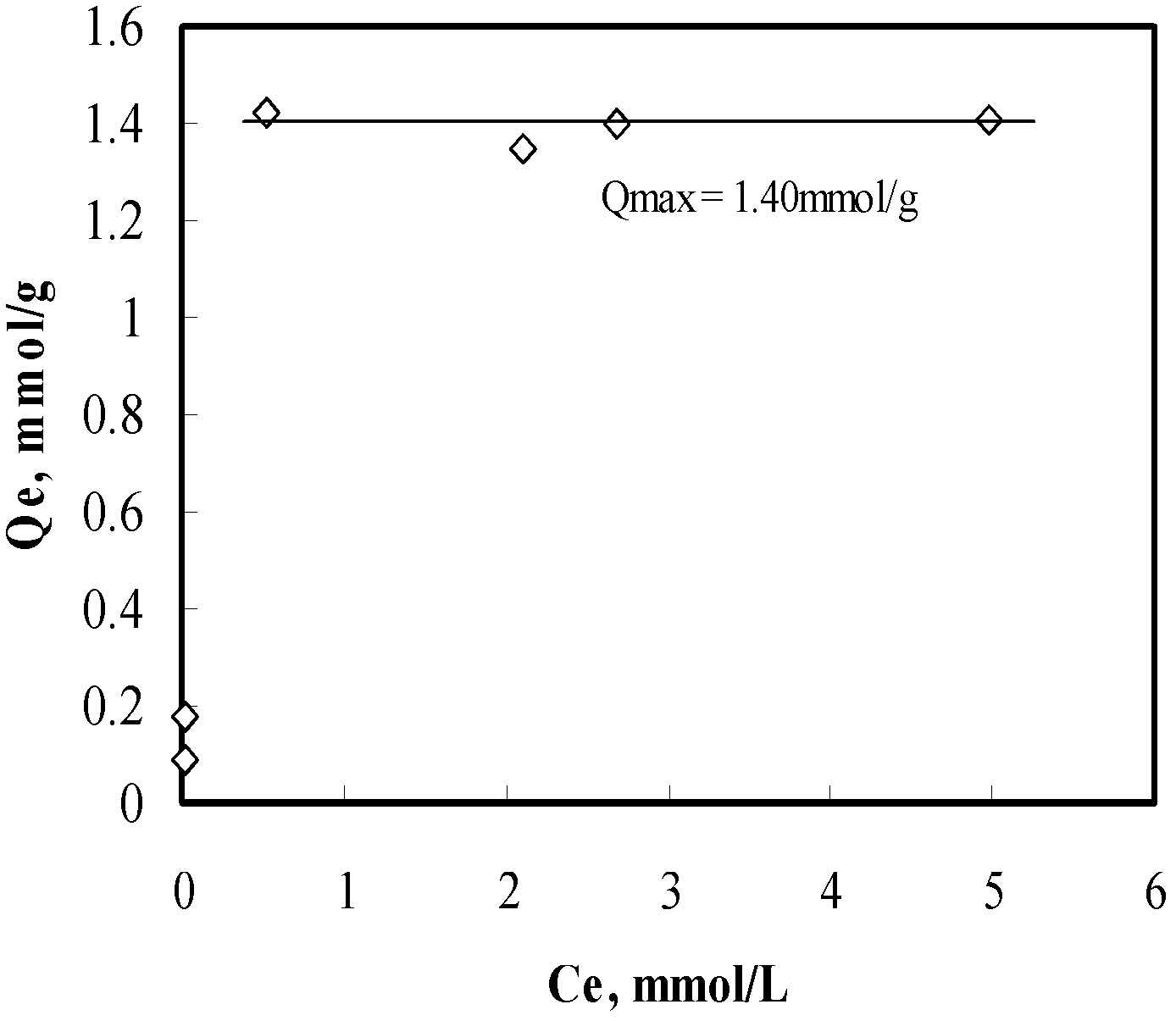

The invention discloses a method for adsorption and removal of heavy metals and dye of waste water by garlic waste. The method provided by the invention comprises the following steps of washing a certain amount of garlic waste by water; mixing the washed garlic waste, one or more alkalis and water by stirring for 12 to 24 hours according to a mass ratio of 1: (0.05 to 0.2): (0.5 to 2) for a reaction, filtering to obtain a solid product, washing the solid product by water until the solid product has a pH value of 7, feeding the washed solid product into a vacuum baking oven, drying at a temperature of 60 to 120 DEG C, carrying out fragmentation and screening, collecting particles below 40 meshes, wherein the particles below 40 meshes are utilized as adsorbents, preparing a heavy metal ion or dye molecule aqueous solution having concentration of 0.1 to 10mmol / L, adding a certain amount of the adsorbents into the heavy metal ion or dye molecule aqueous solution according to a volume ratio of 0.5 to 10g / L, and shaking the mixed solution obtained by the previous step at a room temperature for 0.5 to 24 hours so that the adsorbents can fully adsorb heavy metal ions or dye molecules of the heavy metal ion or dye molecule aqueous solution. The method provided by the invention has a reasonable design and simple processes, realizes obvious effects, greatly reduces a treatment cost, wherein the treatment cost of the method is 10 to 15% of that of the traditional treatment method, greatly shortens a treatment period, does not produce secondary pollution after adsorption treatment, andcan be operated and popularized easily.

Owner:河北强久自行车配件集团有限公司

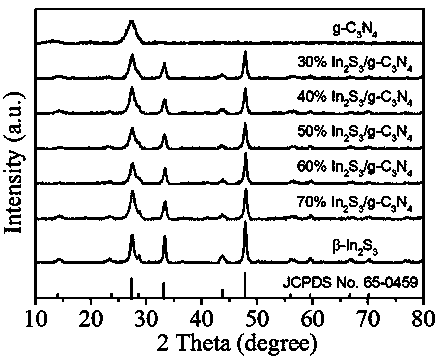

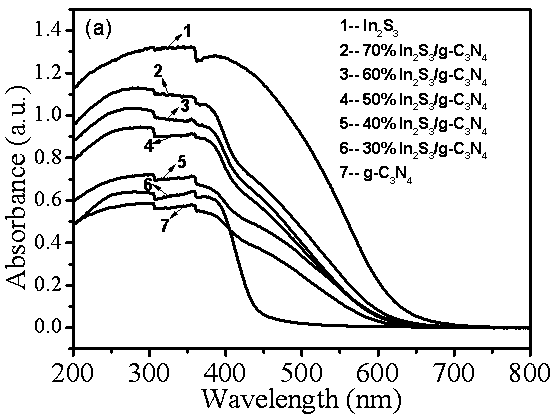

Preparation method of indium sulfide/carbon nitride composite nano material

The invention relates to a photocatalytic material, and particularly relates to a preparation method of an indium sulfide / carbon nitride composite nano material. The preparation method of the indium sulfide / carbon nitride composite nano material comprises the following steps: weighing g-C3N3 powder, dissolving into purified water, carrying out ultrasonic dispersion uniformly, then adding In(NO3)3.4.5H2O, carrying out magnetic stirring until dissolving completely, dropwise adding the prepared C2H5NS solution, carrying out magnetic stirring, transferring into a reaction kettle with an inner liner made of Teflon, putting into a baking oven, and carrying out hydrothermal reaction; and cleaning and drying to obtain the indium sulfide / carbon nitride composite nano material. The method protects the environment, is efficient, simple, convenient and feasible, and the prepared In2S3 / g-C3N4 composite material has a favorable application prospect in the fields of photocatalysis and the like.

Owner:江苏良基集团有限公司

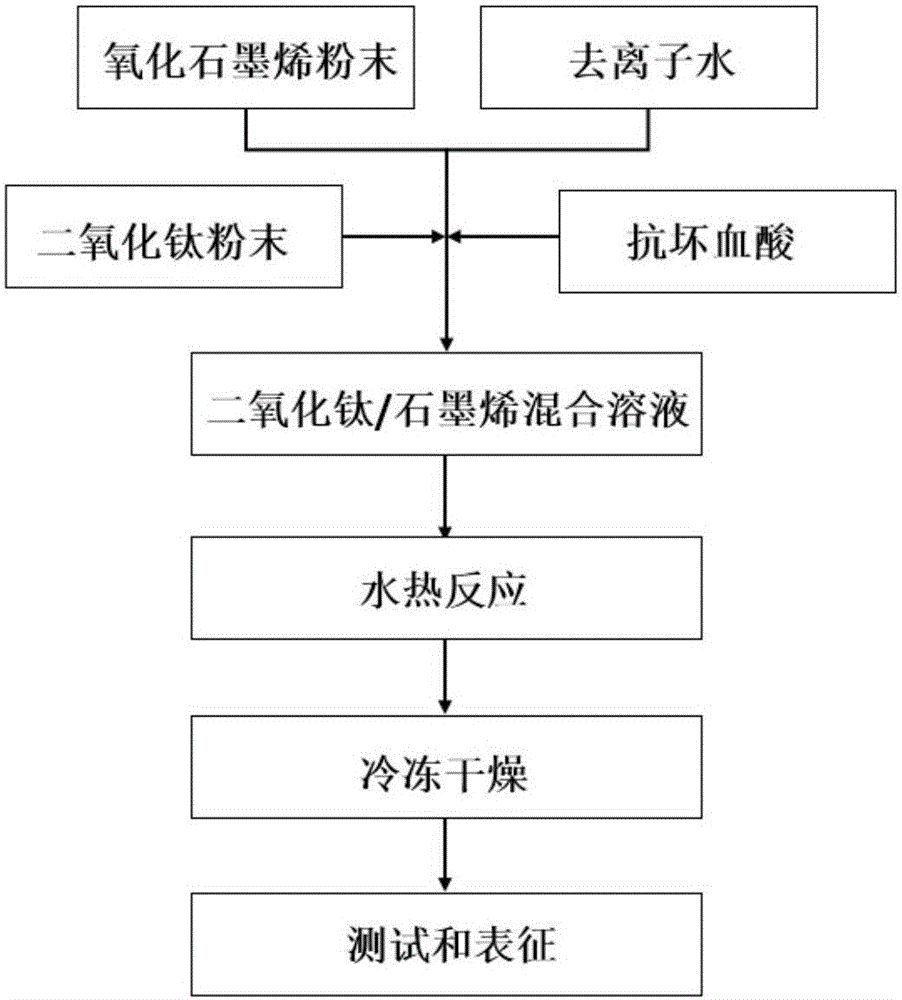

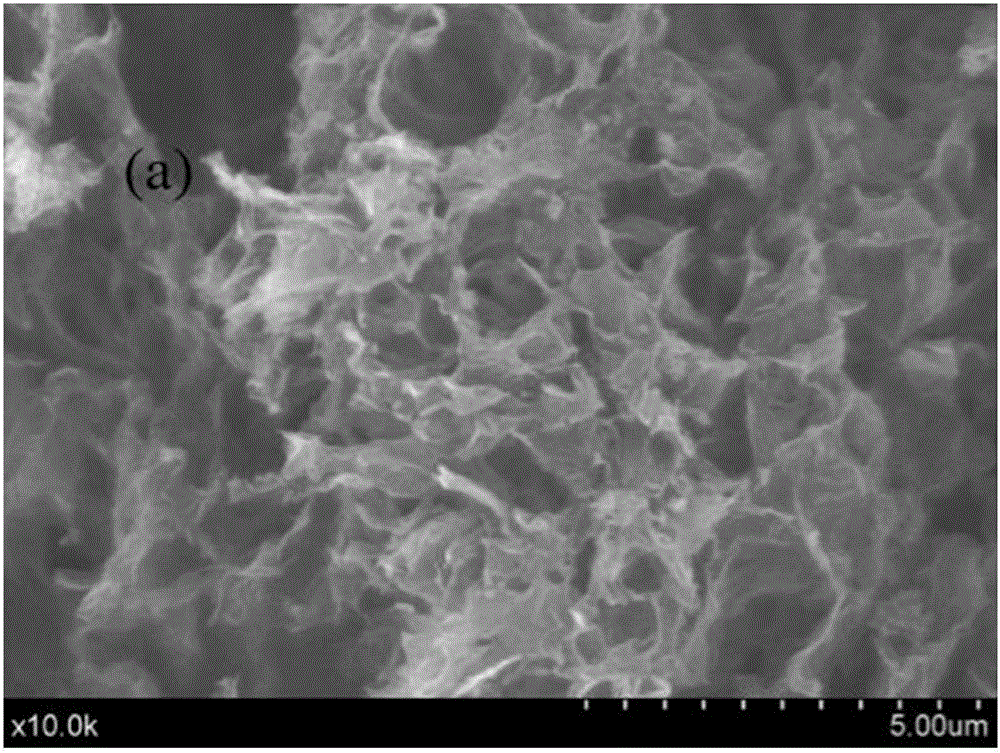

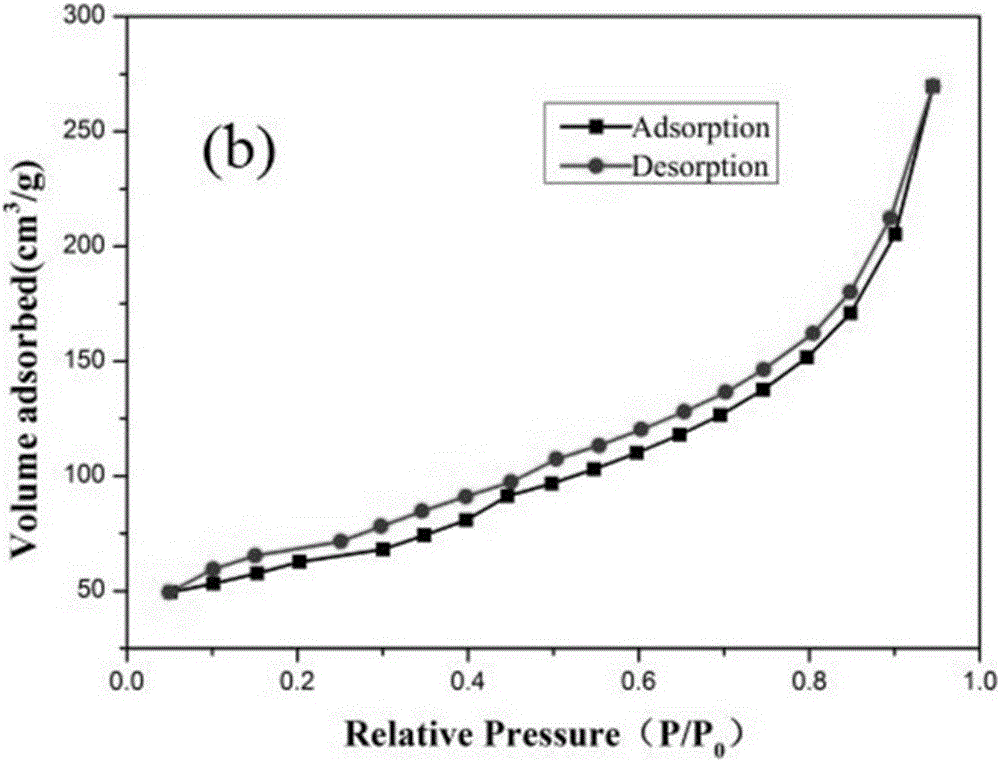

Preparation method for titanium dioxide/graphene aerogel with high specific surface area

InactiveCN105854860ALow densityLarge specific surface areaCatalyst carriersWater/sewage treatment by irradiationFreeze-dryingOperability

The invention relates to a preparation method for titanium dioxide / graphene aerogel with a high specific surface area, belonging to the technical field of energy and catalysis. The preparation method comprises the following steps: mixing graphene oxide powder with deionized water and carrying out ultrasonic dispersion and mechanical stirring so as to obtain a stable aqueous graphene oxide solution with good dispersibility; adding titanium dioxide powder into the aqueous graphene oxide solution, adding a reducing agent at the same time and carrying out ultrasonic dispersion and mechanical stirring until a stable titanium dioxide / graphene mixed solution is formed; and putting the prepared mixed solution into a baking oven, preparing three-dimensional titanium dioxide / graphene hydrogel by using a constant-temperature hydrothermal method and subjecting the titanium dioxide / graphene hydrogel to freeze drying to remove a solvent so as to obtain the titanium dioxide / graphene aerogel with a high specific surface area. The method provided by the invention is simple in process, good in operability, low in energy consumption, free of pollution and high in the specific surface area and has great application prospects in the fields of energy and catalysis.

Owner:JIANGSU UNIV

Vapor deposition apparatus

InactiveUS7070658B2Easy to implementImprove sharpnessX-ray/infra-red processesVacuum evaporation coatingGas phaseCrucible

Owner:T2PHARMA GMBH

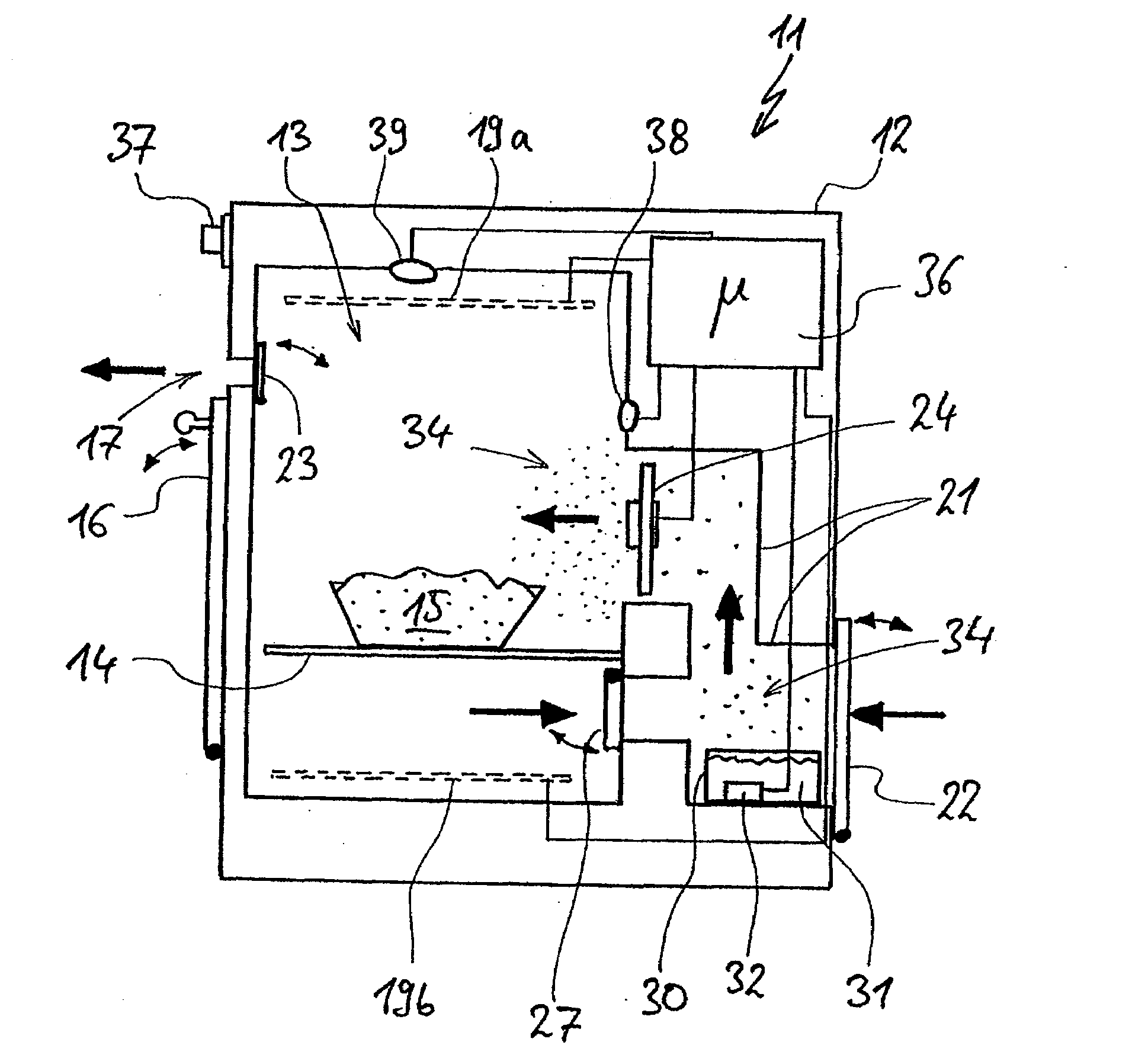

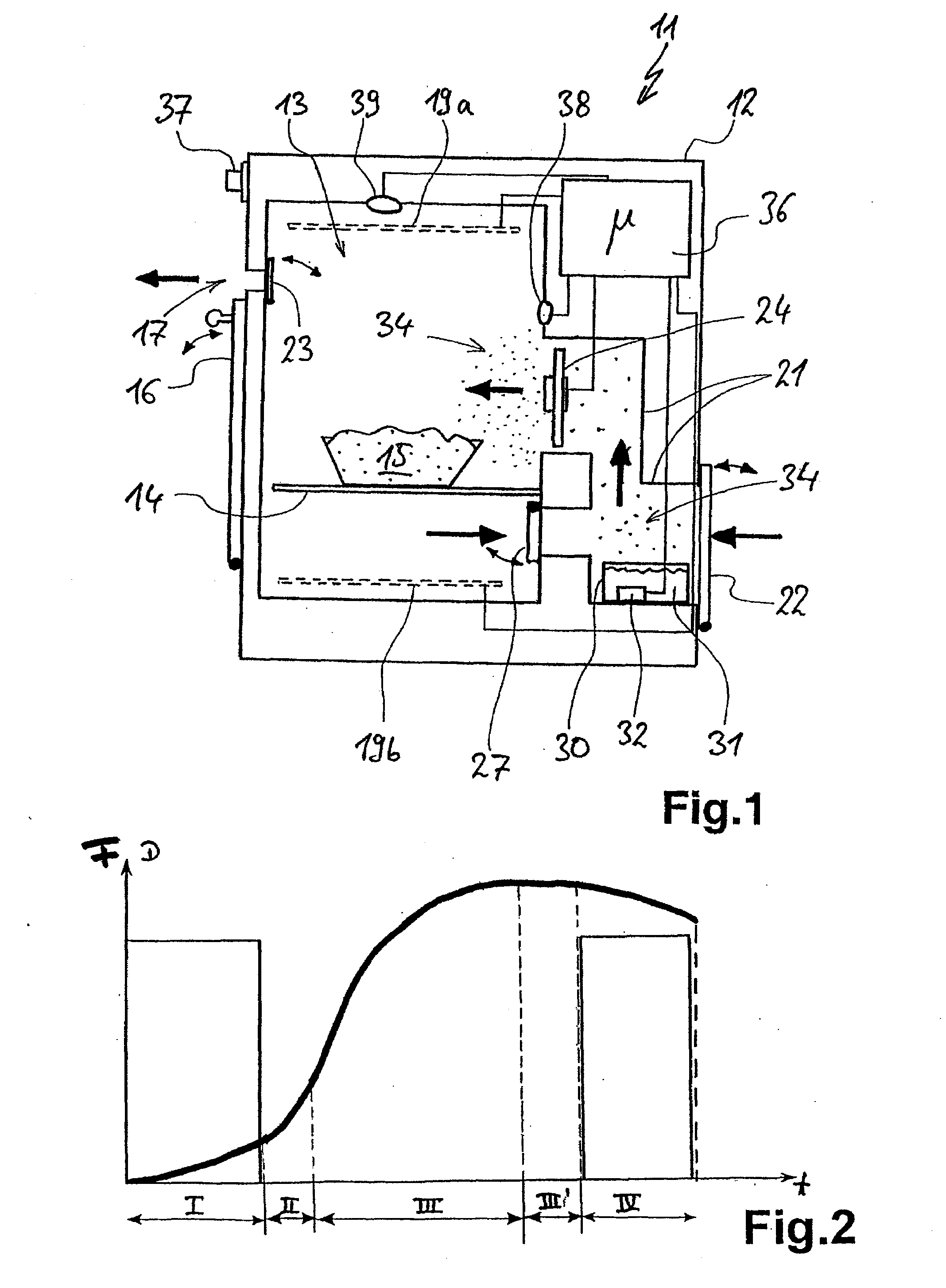

Method and steam cooking apparatus for regulating cooking processes in an oven

ActiveUS20080236404A1Domestic stoves or rangesElectrical heating fuelSteam cookingProcess engineering

A method for regulating a cooking process of a cooking product in an oven of a steamer, during which the moisture in the oven coming from the cooking product is at least periodically determined over time by a moisture sensor. During a measuring phase there is no introduction of steam into the steam oven and the moisture sensor is evaluated. For a given cooking process with fixed times for the supply of steam, on the basis of the moisture sensor evaluation during the measuring phase, the end of cooking is determined. Prior to the measuring phase and during a steam phase, steam is introduced into the oven, the steam supply being terminated following the steam phase and prior to the measuring phase during a ventilating phase. During the ventilating phase the steam concentration in the oven is greatly reduced.

Owner:E G O ELEKTRO GERAETEBAU GMBH

Test method of sulphate content of desulfurization gypsum

InactiveCN101625300ASimple methodFast analysisWeighing by removing componentCooking & bakingWater content

The invention provides a test method of the sulphate content of desulfurization gypsum, comprising the following steps: 3-5 grams of gypsum samples are taken to be heated and dried for 30-60 minutes in a baking oven with the temperature of 42-48 DEG C and then placed into a drier to be cooled to room temperature and weighed by a 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W (g) of the gypsum samples is recorded; the gypsum samples are placed back to the baking oven to be heated and dried for 30-60 minutes under the temperature of 350-370 DEG C and then placed into the drier to be cooled to the room temperature and weighed by the 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W1 (g) of the gypsum samples is recorded; the computation of the crystallization water content of the gypsum samples is as follows: the crystallization water content X(%)=(W-W1)*100 / W, and the computation of the sulphate content of the gypsum samples is as follows: the sulphate content is indicated by calcium sulphate dehydrate content, CaSO4.2H2O(%)=X*100 / 20.9275. The method is simple, convenient and fast; and in addition, compared with the prior art, the invention greatly enhances the analysis speed, simplifies the analysis steps and decreases the experimental apparatus.

Owner:HEBEI ELECTRIC POWER RES INST

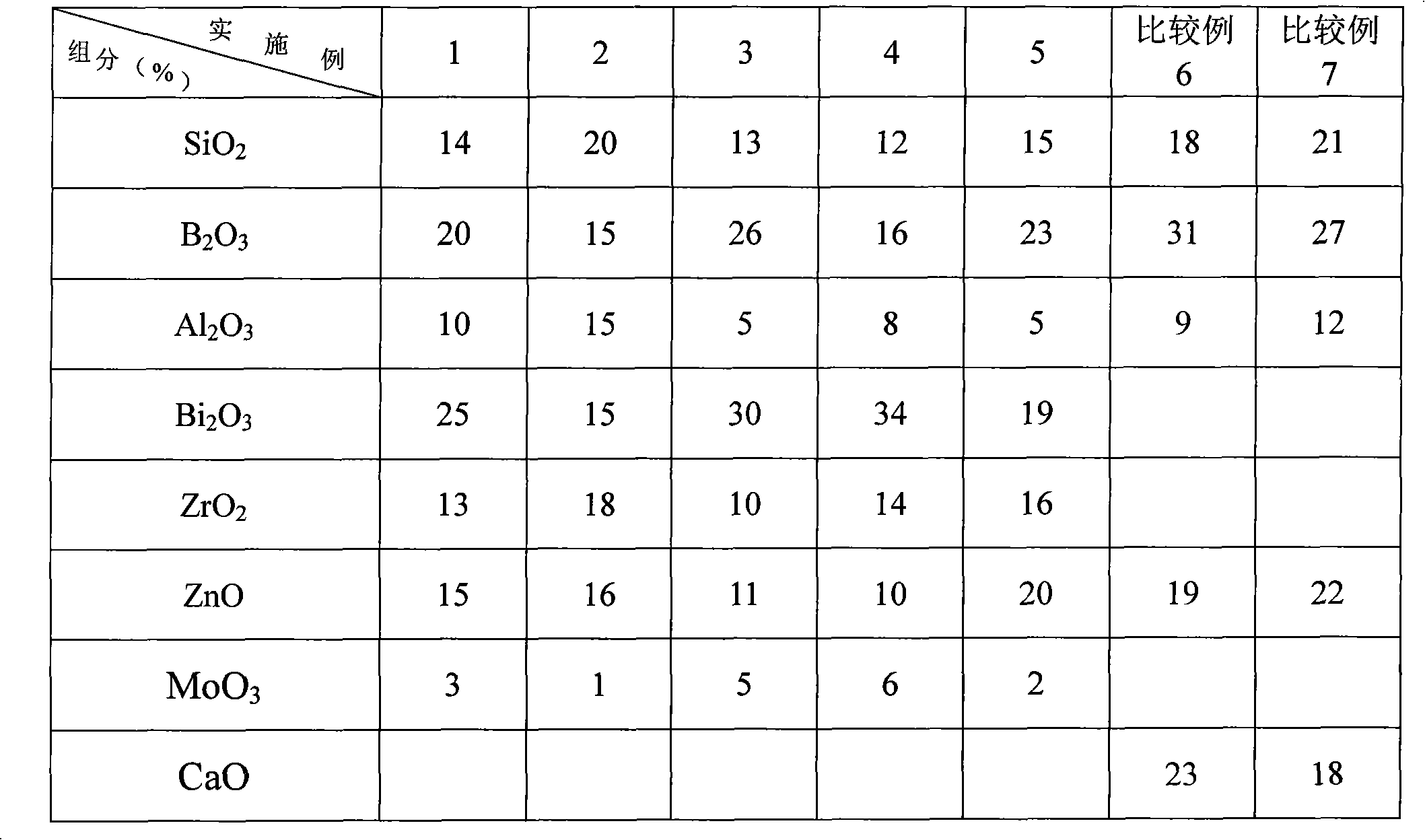

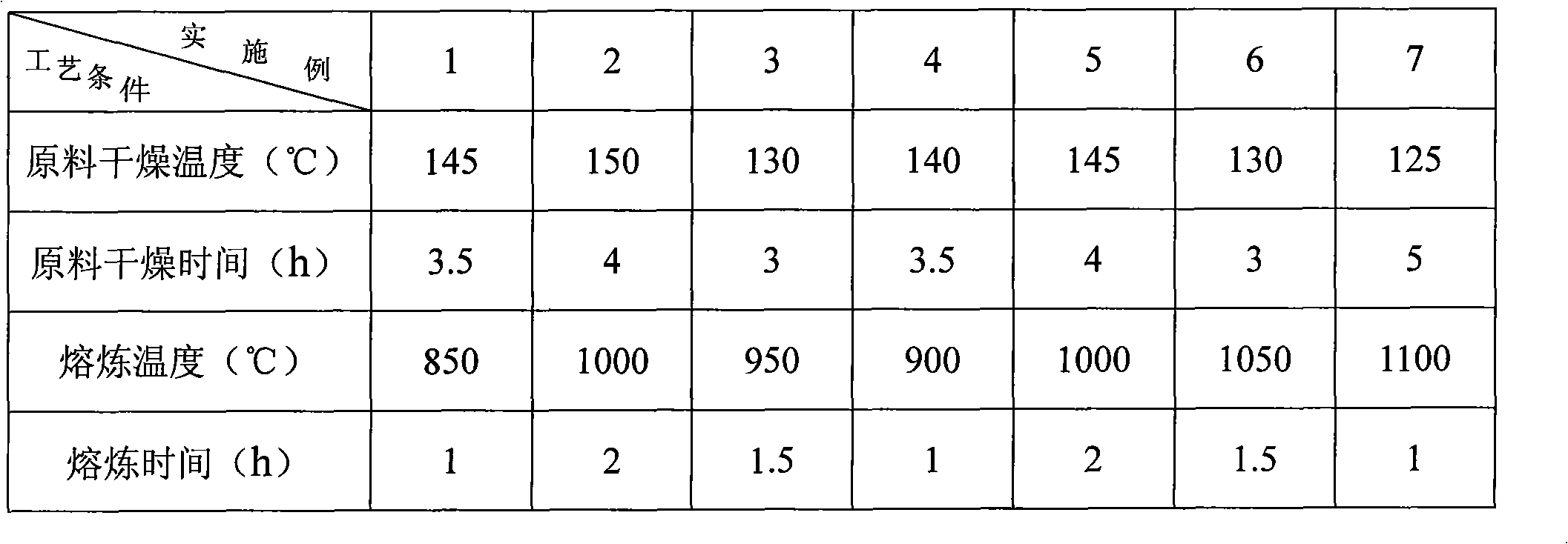

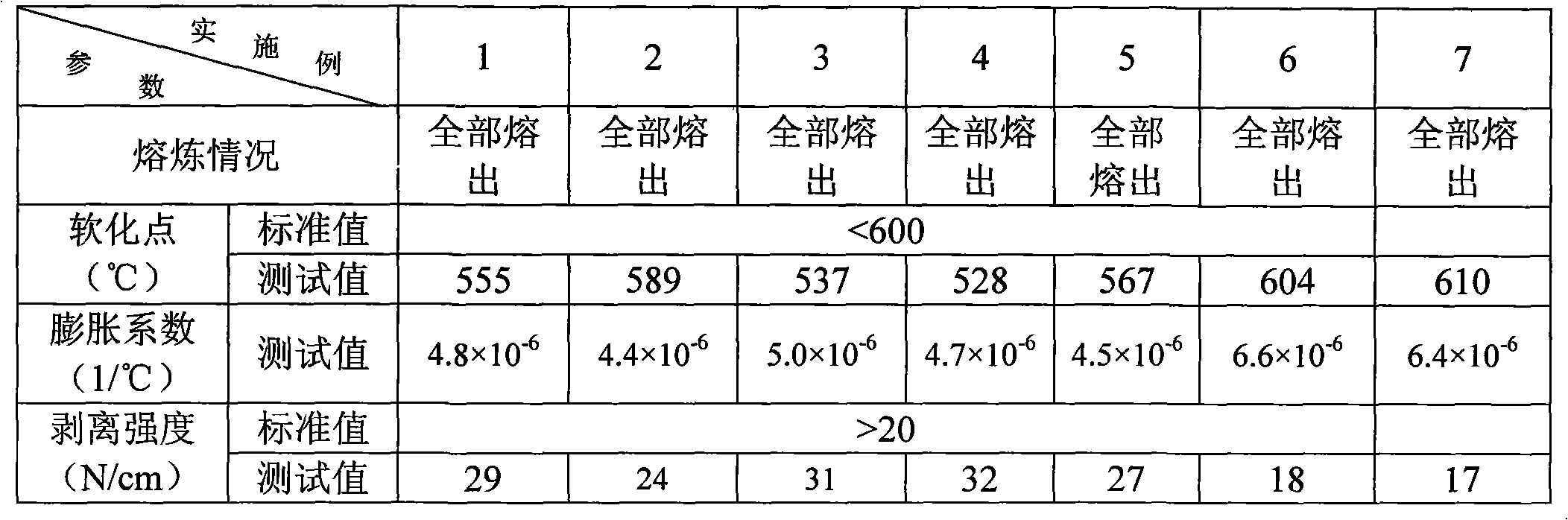

Inorganic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555388ASmall expansion coefficientLess bendingFinal product manufactureInorganic adhesivesAdhesiveSilicon solar cell

The invention provides inorganic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The inorganic adhesive comprises the following components by the weight part: 10% to 20% of SiO2, 15% to 30% of B2O3, 5% to 15% of Al2O3, 15% to 35% of Bi2O3, 10% to 18% of ZrO2, 10% to 25% of ZnO and 1% to 8% of MoO with the total amount being 100%. The preparation method comprises the following steps: putting the components forming the inorganic solvent into a mixer to mix the components uniformly; loading the mixed components into a porcelain crucible and placing the porcelain crucible into a baking oven to be dried at the temperature of 120 to 150 DEG C for 3 to 5 hours; then, placing the porcelain crucible into a high-temperature furnace to melt at the temperature of 800 to 1,100 DEG C for melting for 1 to 2 hours; carrying out water-quenching and oven-drying; milling the components with a planetary ball mill until the particle size is lower than 10 mum; and oven-drying the components to obtain the final product of the inorganic adhesive. The glass powder has lower softening temperature and high adhesion when the aluminum paste prepared from the inorganic solvent is used for sintering, so that the aluminum powder layer can be firmly adhered to silicon chips; the expansion coefficient is lower after sintering; the bending degree of cell chips is lower; and the breakage rate is reduced.

Owner:WUXI RUXING TECH DEV +1

Method for reducing content of reducing sugar in reconstituted tobacco

ActiveCN103948163ASimple reaction conditionsReduced reducing sugar contentTobacco preparationTobacco treatmentEthylene diamineCooking & baking

The invention relates to the field of reconstituted tobacco preparation, in particular to a method for reducing the content of reducing sugar in reconstituted tobacco, and an application of the method. The method comprises the following steps: adding a mixture material of tobacco stems, tobacco waste and tobacco pieces into hot water of 60-70 DEG C, keeping the temperature, performing solid-liquid separation, and preparing to obtain a tobacco extract liquid; respectively adding EDTA (Ethylene Diamine Tetraacetic Acid), proline, lysine, diammonium hydrogen phosphate and a catalyst into the obtained extract liquid, adjusting the pH value of the reaction liquid till the reaction liquid is faintly acid, stirring for more than 2 hours at the constant temperature of 70-80 DEG C, subsequently performing vacuum concentration, and uniformly applying the concentrated extract liquid onto the front and back sides of a paper substrate; putting the obtained product into a baking oven for baking under the condition of ventilation till the moisture content is 11.5-13.5%, and obtaining a finished reconstituted tobacco product. Compared with that of a thin piece which is not treated by using the technical method, the content of the reducing sugar is reduced by 10-20% on premise that the sensory quality of the product is not affected.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Vapor deposition apparatus

InactiveUS20050000448A1Good effectEasy to implementX-ray/infra-red processesVacuum evaporation coatingGas phasePhosphor

A vapor deposition apparatus, developed in particular for on-line deposition of phosphor or scintillator material, wherein said vapor deposition apparatus comprises a crucible containing a mixture of raw materials, a chimney having at least one inlet in communication with the said crucible and a linear slot outlet, one or more lineair heating elements, contained within said chimney, an oven surrounding said crucible, wherein said oven contains heating elements, shielding elements and cooling elements.

Owner:T2PHARMA GMBH

Method for processing plastic floor material by utilizing PVC waste material

The invention relates to a method for processing plastic floor material by utilizing PVC waste material, including: (1) PVC waste material is cleaned, dried and smashed and is subject to extrusion filtering at 130-150 DEG C by virtue of an extrusion machine, so that impurities are removed, and plasticizer is added, so as to form membrane feed back; (2) PVC resin, plasticizer, stabilizer, foaming agent and filler are added into the membrane feed back, mixing is carried out to obtain mixture, the mixture is subject to banburying at 140-160 DEG C for 150-220s, then is subject to milling at 140-160 DEG C for 3min and then is subject to extrusion filtering at 140-160 DEG C by virtue of the extrusion machine, and the working speed of the extrusion machine is 300r / min, film is made by virtue of a calendaring machine, and film pressing temperature is 130-160 DEG C; (3) the film is compounded onto a surface course coated with wear layer at 170-190 DEG C, heating foaming plasticizing and drying are carried out at 200-220 DEG C by virtue of a baking oven, and then cooling, trimming and crimping are carried out, thus forming the product. The invention utilizes PVC waste material to produce film, the produced film substitutes the blade coating foaming layer in plastic floor production process, production cost is reduced, recycling of waste PVC material is realized, and plentiful natural resources are saved.

Owner:赵如勇

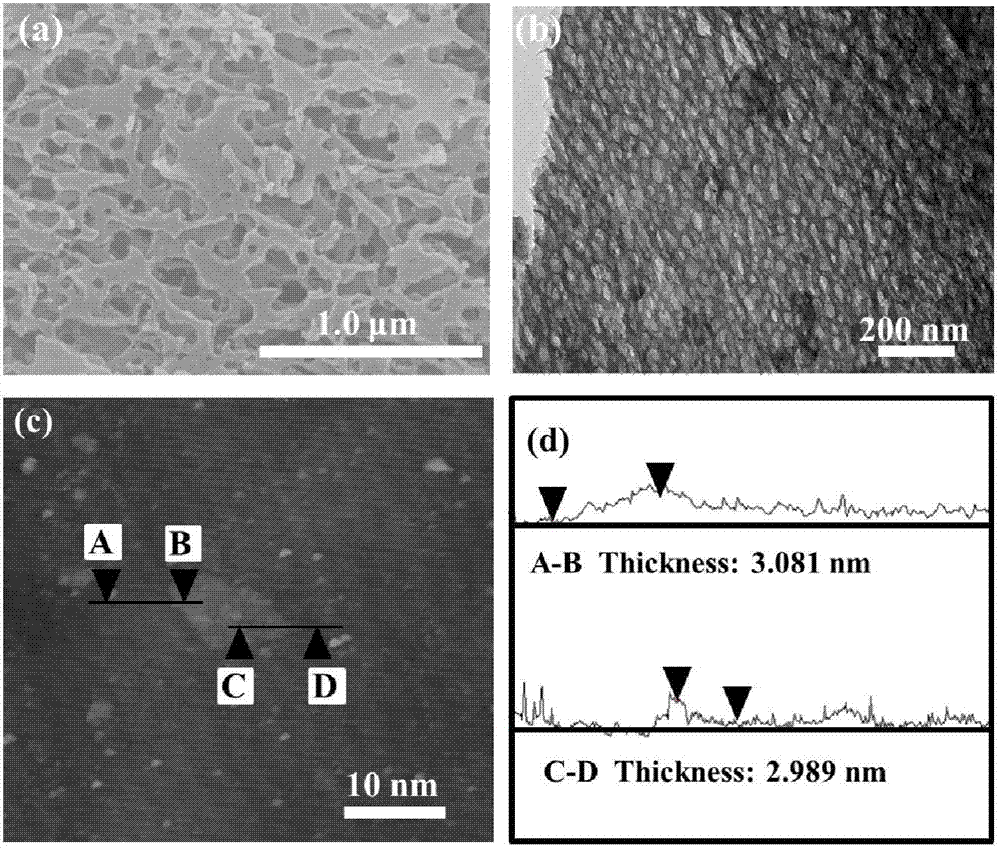

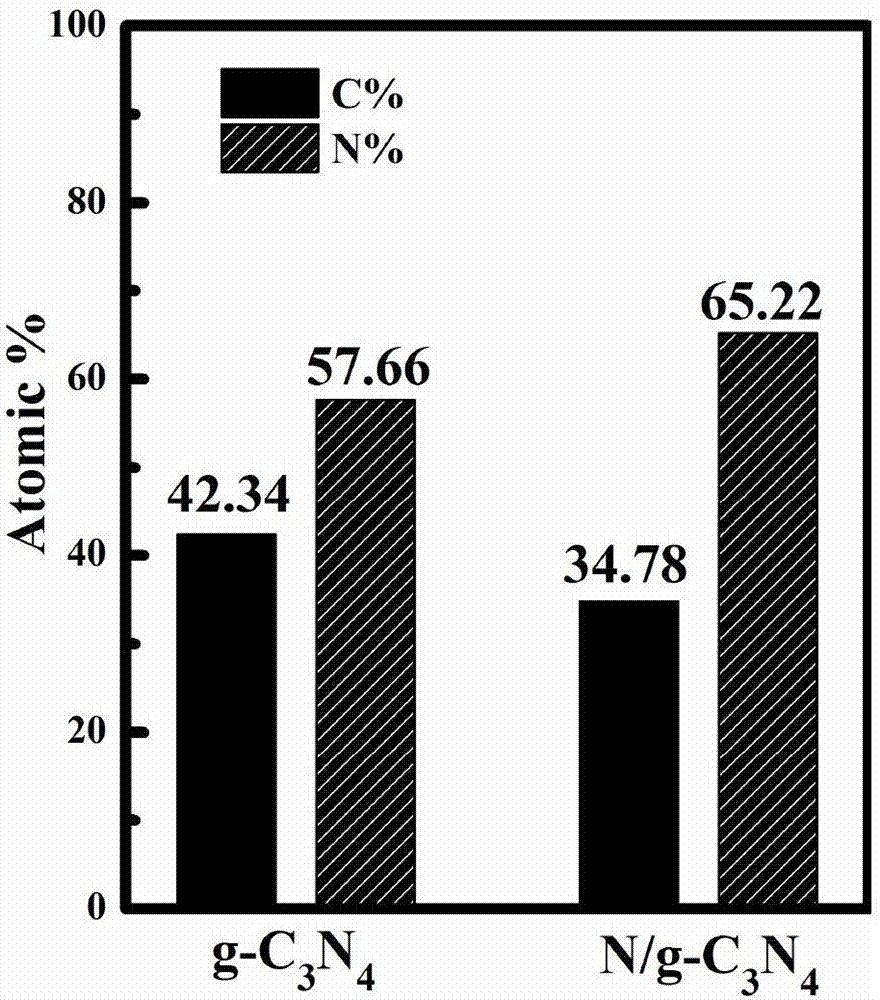

Ultrathin porous N doped g-C3N4 photocatalyst and preparation method thereof

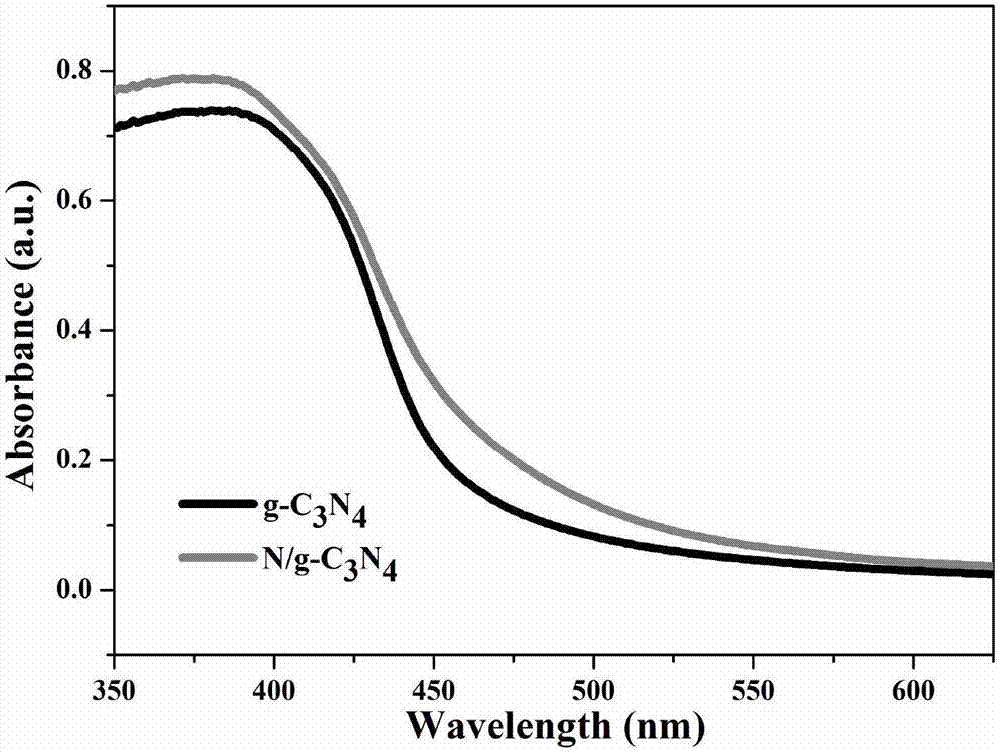

InactiveCN107469851ALow costThe preparation process is green and simplePhysical/chemical process catalystsPretreatment methodMuffle furnace

The invention relates to a preparation method of ultrathin porous N doped g-C3N4 photocatalyst, and an experiment employs hydro-thermal pretreatment and calcination for preparation. The method concretely comprises the following steps: (1) urea and melamine are added into 50ml of distilled water according to a mol ratio 3:1, stirring is carried out on a constant temperature magnetic stirrer for 30 minutes, a solution is transferred to a 100ml hydrothermal reactor, and the reactor is placed in a baking oven at 180 DEG C and insulation is carried out for 24 hours. (2) natural cooling is carried out to a room temperature, a white substance in the reactor is washed with distilled water for 3-5 times, and drying is carried out (60 DEG C for 10 hours). The dried white substance is grinded and placed in a crucible, and the crucible is placed in a muffle furnace and calcination is carried out at 520 DEG C for 4 hours. The N doped g-C3N4 with an ultrathin porous structure has good photocatalytic hydrogen production, NO gas degradation, and pollutant degradation performance, and oxidation and reductibility are greatly improved; compared with the prior art, N / g-C3N4 with high specific surface area is obtained by using the hydrothermal pretreatment method, raw materials are cheap, the process is simple and green, and the method is suitable for industrialized production of large batch with wide application prospects.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for detecting microdefects of quasi monocrystalline silicon sheets

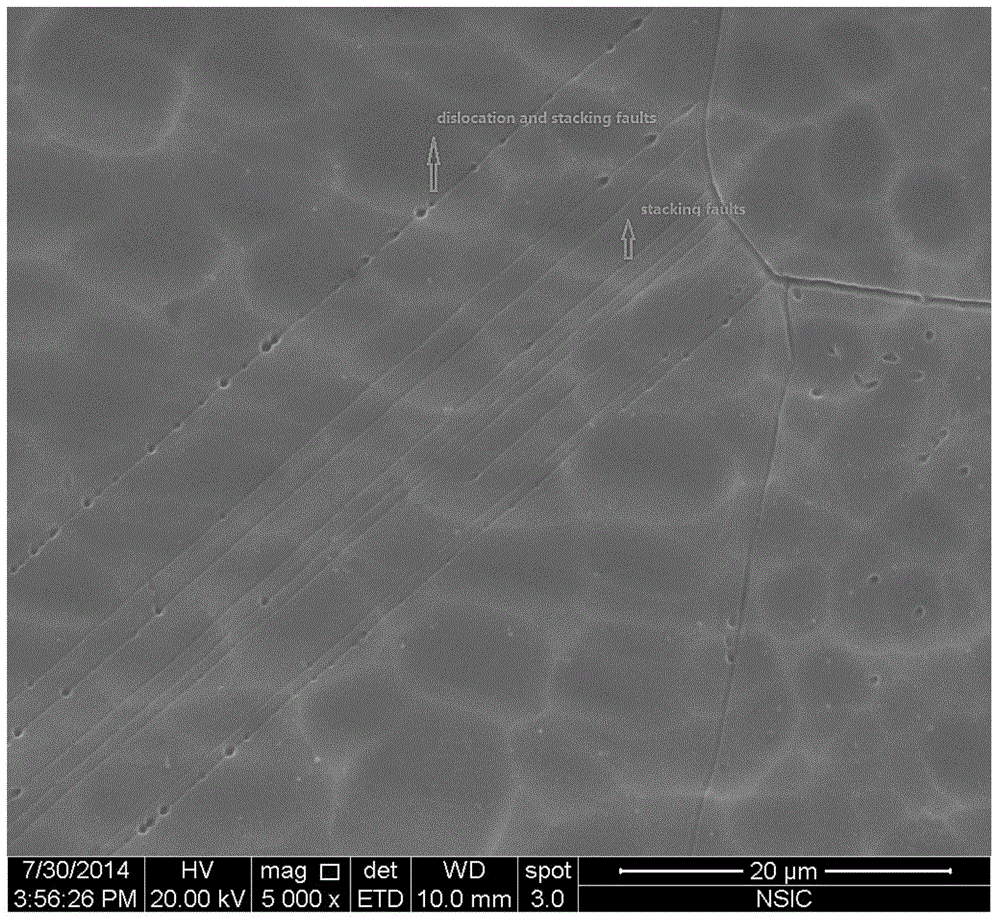

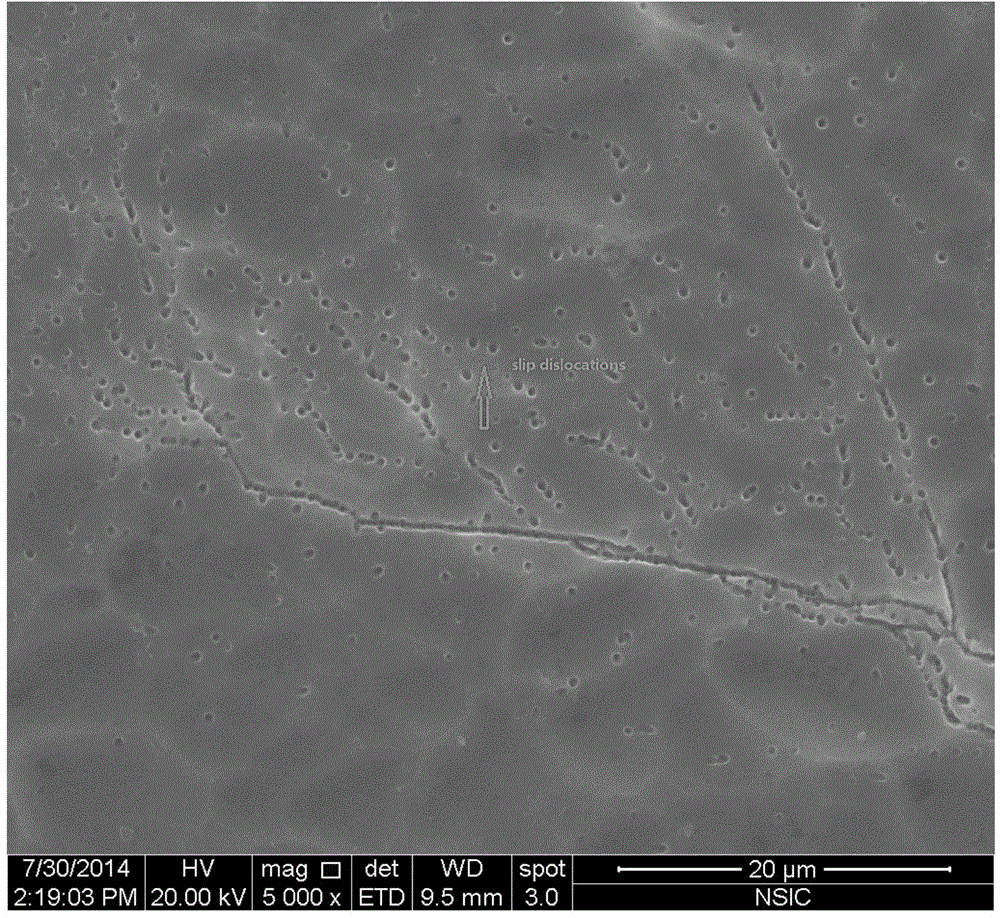

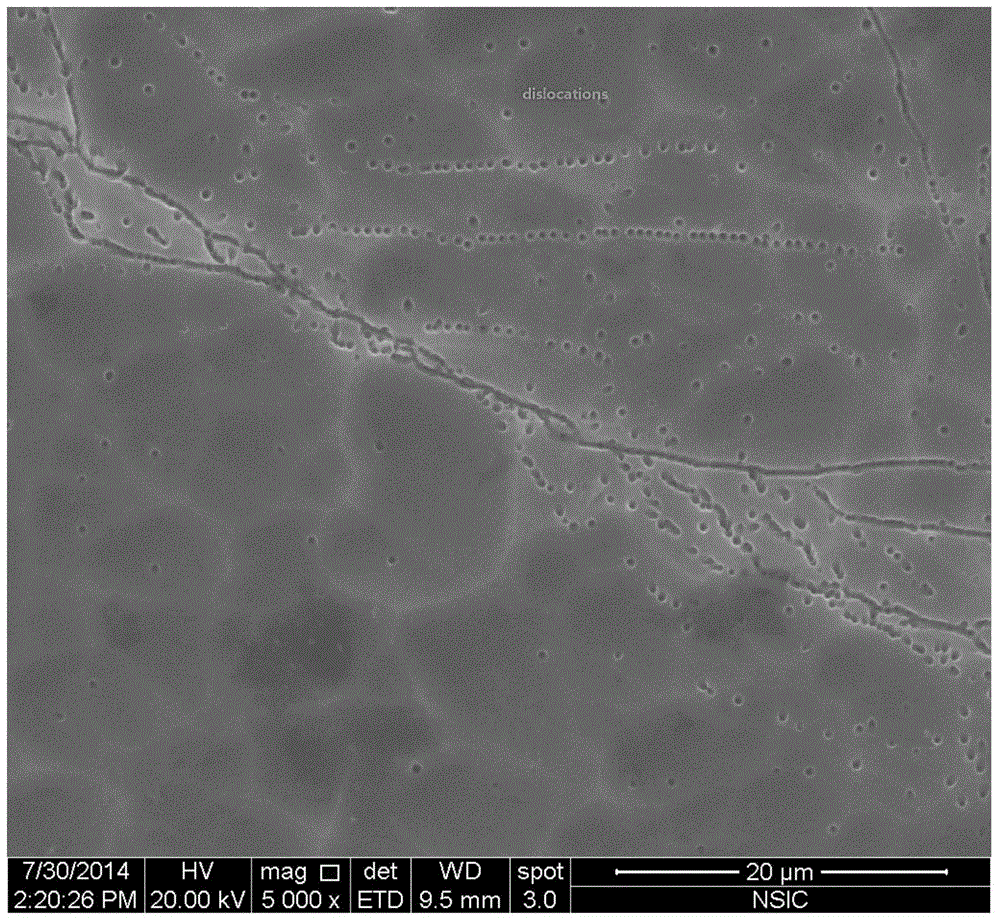

InactiveCN104900758AGood casting processImprove conversion efficiencyFinal product manufactureSemiconductor devicesCooking & bakingMicroscopic observation

The invention discloses a method for detecting microdefects of quasi monocrystalline silicon sheets. The method includes a manually and mechanically polishing step of manually and mechanically polishing aquasi monocrystalline silicon sheet to be etched and flushing the quasi monocrystalline silicon sheet with deionized water; a chemical etch polishing step of chemically etching and polishing the silicon sheet subjected to the mechanical polishing and rinsing the silicon sheet with deionized water; a preferential microdefect etching step of carrying out preferential microdefect etching on the silicon sheet subjected to the chemically etching and polishing, rinsing the silicon sheet with deionized water and drying the silicon sheet in a baking oven; and a microdefect observation process of carrying out minority carrier lifetime and iron-boron opposite scanning for the etched silicon chip, observing the minority carrier lifetime scanning color distribution by a metallographic microscope, accurately positioning the microdefect positions, classifying the defect types, positioning and cutting the silicon chip into pieces, and marking the pieces. The method is rapid, accurate, energy-saving, environmental-friendly, pollution-free and highly practical.

Owner:连云港市产品质量监督检验中心

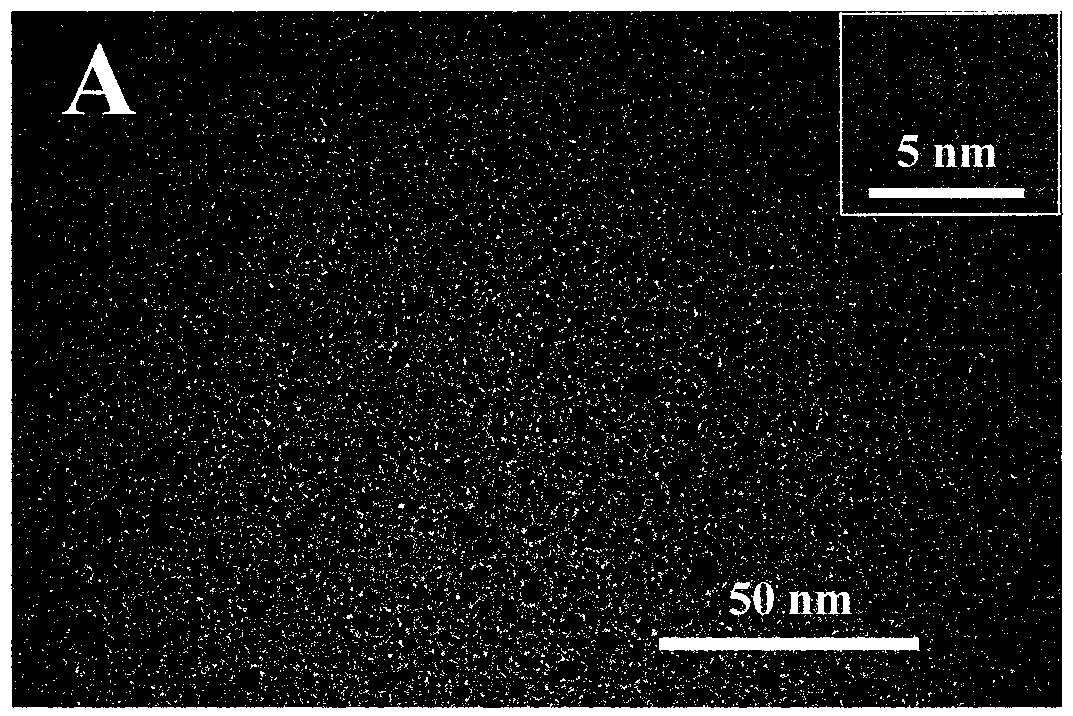

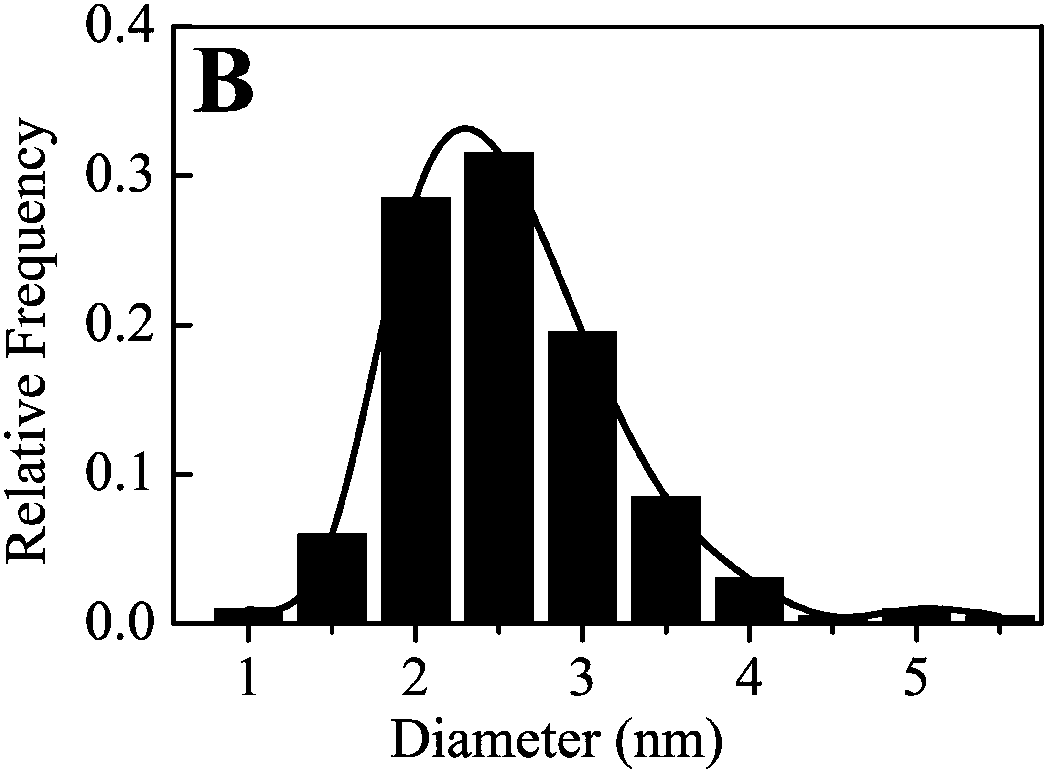

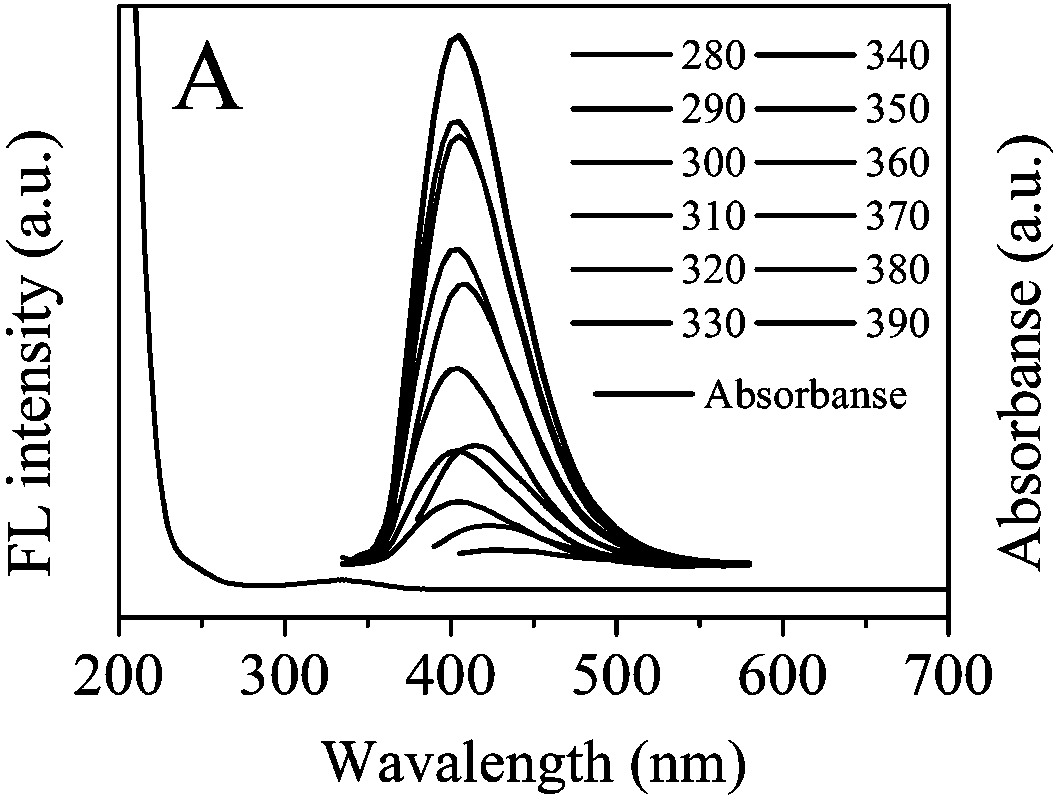

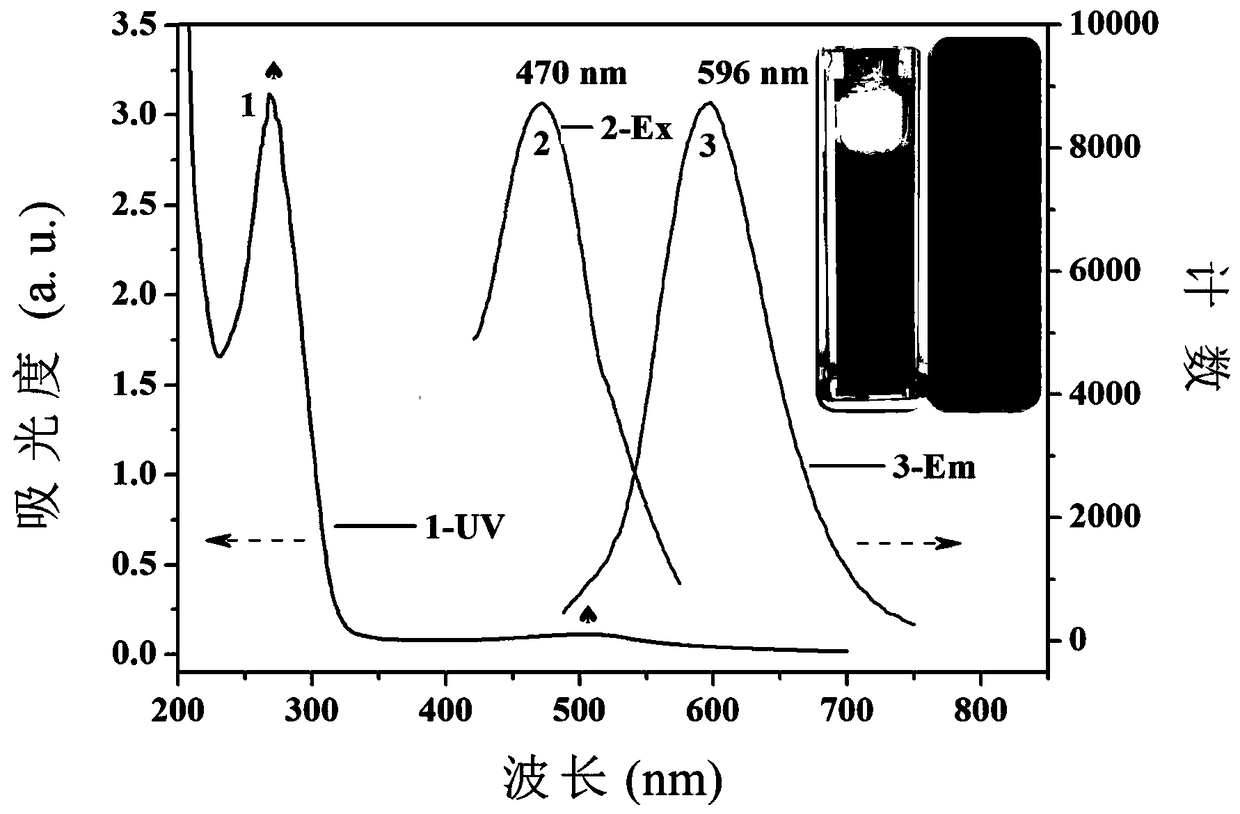

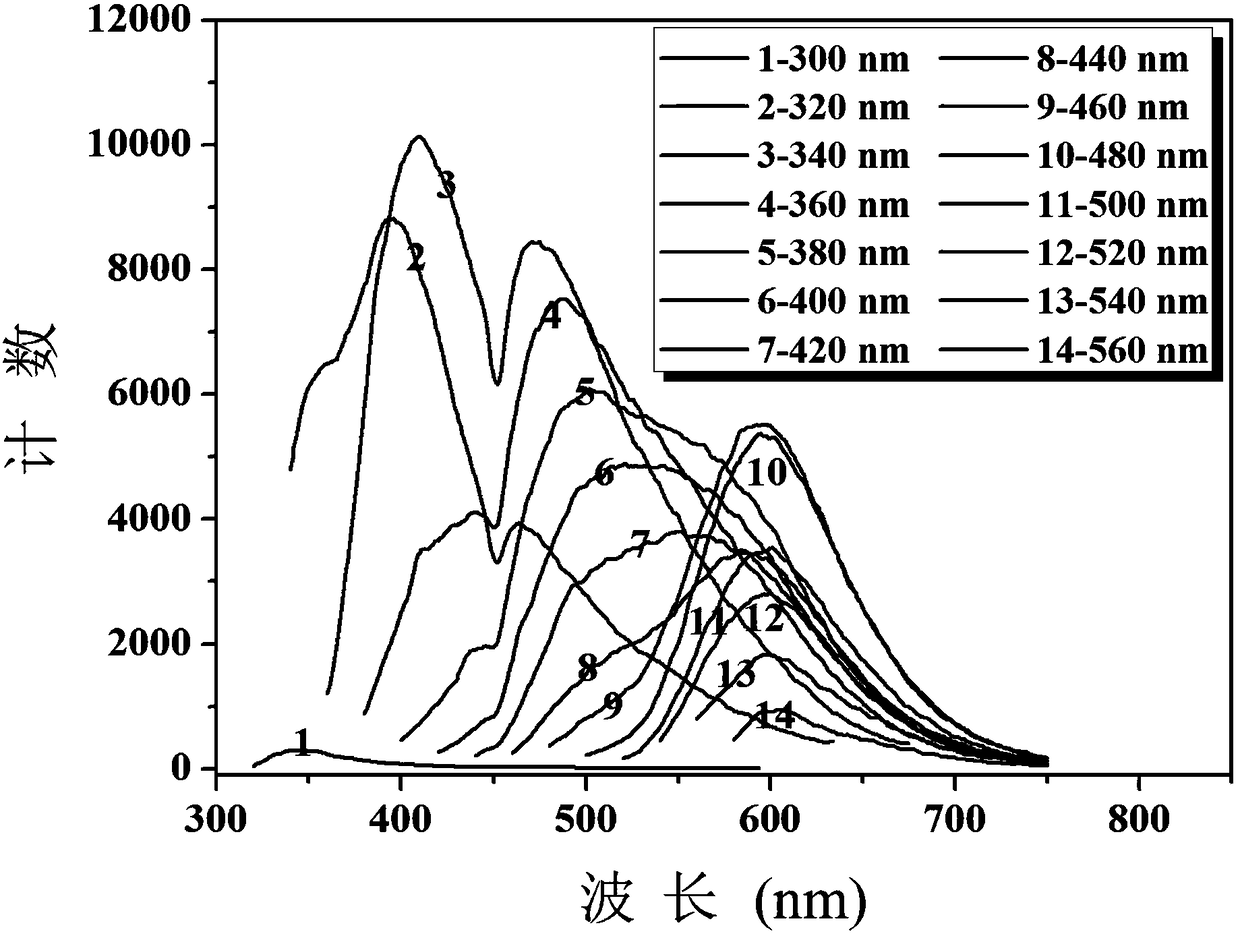

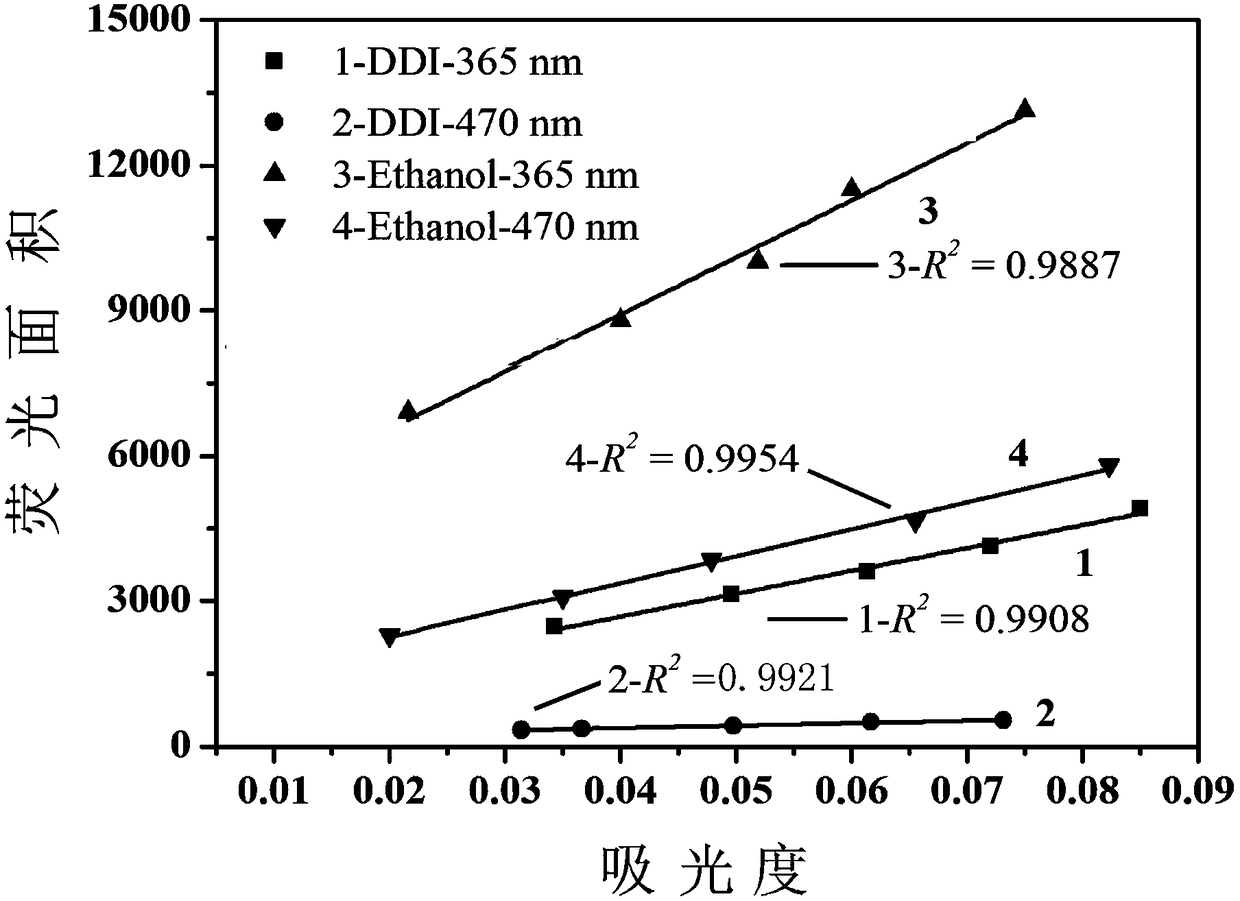

Preparation method of high-fluorescent fluorescence carbon quantum dots and application of high-fluorescent fluorescence carbon quantum dots in Cr (VI) detection

The invention discloses a preparation method of high fluorescent fluorescence carbon quantum dots. The preparation method comprises the following specific steps: A, dissolving 0.1 to 10g of citric acid and 0.1 to 10g of glycine into 1 to 20mL of water; B, putting a high pressure reactor into a baking oven, heating for several hours under the condition of high temperature and then carrying out natural cooling to room temperature, thus obtaining dark brown suspension containing the fluorescence carbon quantum dots; C, centrifuging the obtained dark brown suspension to remove large particles, using the means of adsorption with macroporous resin, size exclusion chromatography gel or dialysis, purifying a coarse product by using water as eluant and purifying the fluorescence carbon quantum dots; D, concentrating the purified product by using a rotary evaporator at the temperature of 45 DEG C and carrying out freeze-drying to obtain purified fluorescence carbon quantum dots which are white powder. The preparation method of the high fluorescent fluorescence carbon quantum dots, disclosed by the invention, has the advantages of low cost, simple and controllable preparation process, simpleand convenient operation, high sensitivity and selectivity, intuitive detection results and capability of realizing quantitative detection; the obtained carbon quantum dots have the advantages of highquantum yield, long fluorescence life as well as higher detection sensitivity and stability.

Owner:DALIAN POLYTECHNIC UNIVERSITY

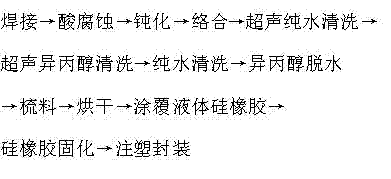

A plastic-encapsulated power diode and its manufacturing process

InactiveCN102263140AAvoid shockRelieve heat stressSemiconductor/solid-state device manufacturingSemiconductor devicesEpoxyManufacturing technology

The invention discloses a plastic-encapsulated power diode and a manufacturing process thereof, and relates to the technical field of semiconductor discrete devices. Its manufacturing process does not adopt the cleaning and dehydration process of organic solvents such as isopropanol and absolute ethanol in the prior art, and the water washing and dehydration process after cleaning with organic solvents is omitted; the chip connected with the wire is put into a heated oven Baking in medium temperature for 4-10 hours, the oven temperature is 200-250°C, and the hydrogen-nitrogen mixed gas or clean air is passed through the oven; put the chip coated with liquid epoxy resin or liquid silicone rubber into the oven at 150±10°C to cure the glue for 10 -60 minutes. Compared with the prior art, the product of the invention has excellent high-temperature characteristics, consistency and reliability.

Owner:SHANDONG YIGUANG ELECTRONICS

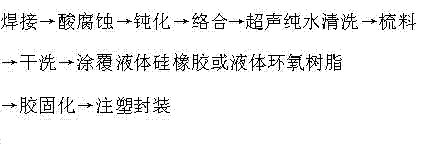

System and method for manufacturing flocking wall hangings

ActiveCN101439321AThe pattern is clear and completeReduce intensityLiquid spraying plantsPretreated surfacesGlass fiberElectronic spin

The invention discloses a manufacturing system of pile coating wall cloth and a method thereof; the system sequentially comprises an unreeling device, a roller guide, a rotary screen gumming machine, an electronics spinning device, a baking oven, a wrap-up device, an unreeling position correcting device and a gumming position correcting device; wherein, the unreeling position correcting device is arranged between the unreeling device and the roller guide, and the gumming position correcting device is positioned between the rotary screen gumming machine and the electronics spinning device. The method comprises: towing force is applied on glass fiber base cloth which is inlaid with colored thread at one side to lead a wound roll of the glass fiber base cloth arranged on an unreeling frame to rotate correspondingly to the unreeling device for unreeling, and then the glass fiber base cloth sequentially passes through an unreeling color control patch sensor of the unreeling position correcting device, the roller guide, the rotary screen gumming machine, a gumming color control patch sensor of the gumming position correcting device, the electronics spinning device and the baking oven to obtain the pile coating wall cloth when moving towards the rear direction; after that, the unreeling operation is carried out on the glass fiber base cloth by the unreeling device. The pile coating wall cloth manufactured by the invention has clear and complete pattern and is in accordance with higher environmental protection requirements.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Method for producing automotive sound-insulating pad

ActiveCN101987511AReduce weightMeet the requirements of lightweight designDomestic articlesFlat articlesThermoplasticEngineering

The invention relates to a method for producing an automotive sound-insulating pad. The method for producing the automotive sound-insulating pad comprises the following steps of: a, laying a raw material, namely laying a thermoplastic felt material on the network chain of an oven; b, baking and softening, namely feeding the thermoplastic felt material into the oven through the network chain of the oven for baking and softening, wherein the temperature of an upper heating zone in the oven is between 230 and 250 DEG C, the temperature of a lower heating zone is between 310 and 330 DEG C, and the baking time is 255 to 285 s; c, performing compression molding, namely performing compression and cooling on the baked and softened thermoplastic felt material to be a semi-finished product, wherein during the compression and cooling molding, the molding pressure is 16 to 17 MPa, the molding time is 90 to 110 s, and the cooling temperature is between 20 and 30 DEG C; d, performing water jet cutting, namely positioning the semi-finished product subjected to the compression cooling, and performing water jet cutting to obtain the required sound-insulating pad, wherein the cutting water pressure is 40,000 to 50,000 psi, and the cutting air pressure is 0.6 to 0.8 MPa; and e, inspecting, namely inspecting the sound-insulating pad, and packing and warehousing. The method for producing the automotive sound-insulating pad is simplified, energy-saving and environment-friendly, the automotive sound-insulating pad has high strength, the production efficiency of the method is high, and the method can reduce labor intensity.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

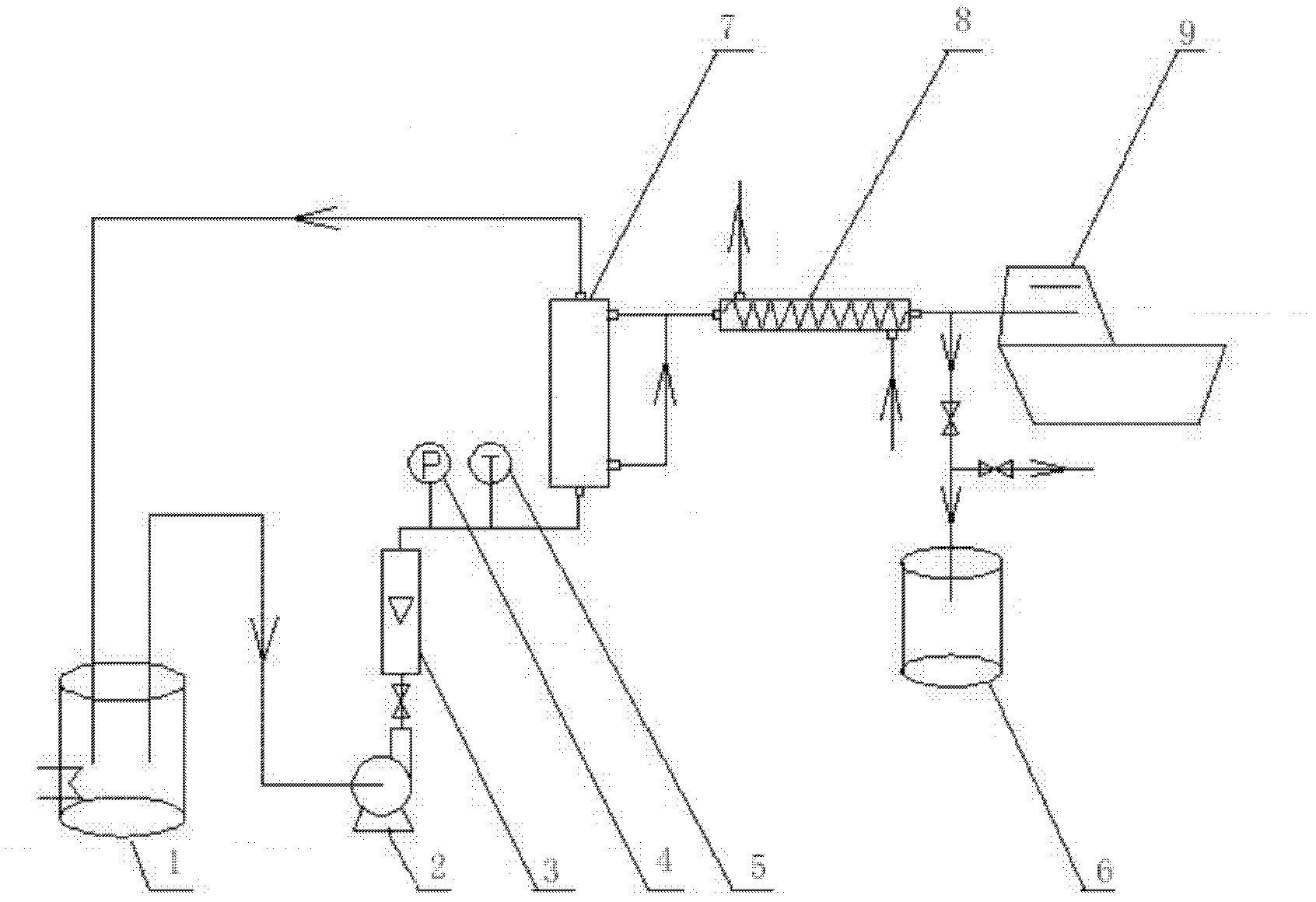

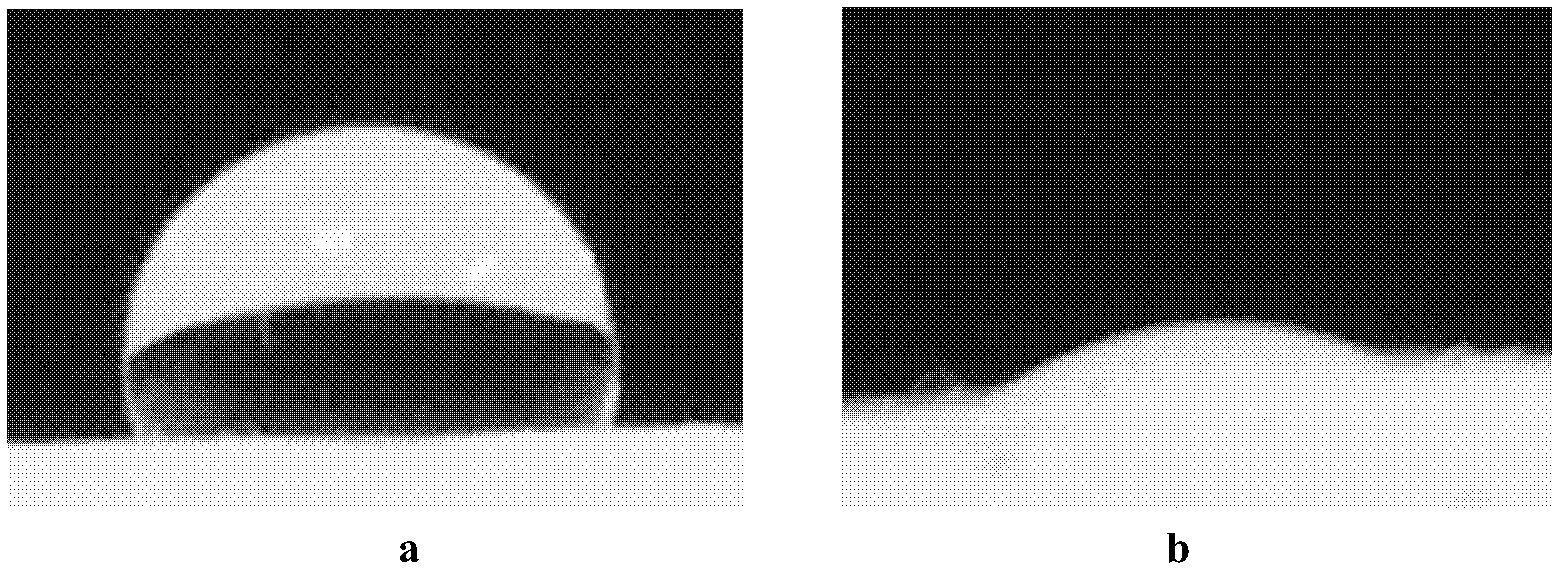

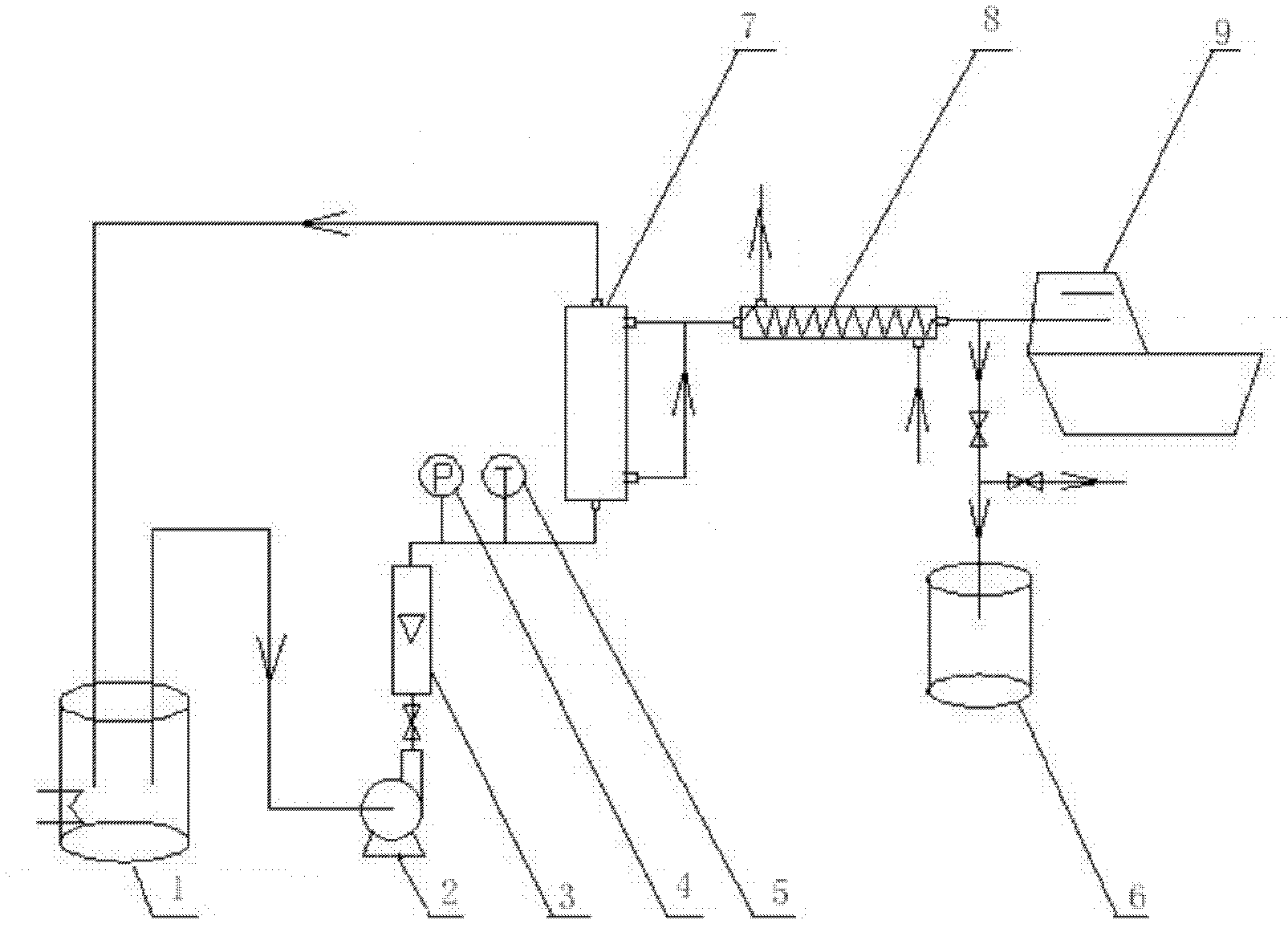

Method for modifying hydrophobicity of ceramic membrane, its application and its apparatus

InactiveCN102423641ASimple processEasy to modifyDistillationMembrane distillationTemperature resistance

The invention relates to a method for modifying hydrophobicity of a ceramic membrane, its application and its apparatus. The method comprises the following steps: 1) selecting an organic precursor; 2) preparing a modification solution; 3) pretreating the Al2O3 ceramic membrane, immersing for 8-12 minutes in a NaOH solution (3mol / L), washing by chloroform and deionized water, placing in a baking oven at the temperature of 140-160 DEG C for 0.75-1.25 hours, and cooling to the room temperature; 4) carrying out grafting reaction on the surface of the Al2O3 ceramic membrane; 5) performing heat treatment on the modified Al2O3 ceramic membrane, washing the modification solution on the surface of the modified Al2O3 ceramic membrane by deionized water, and placing in the baking oven of 95-105 DEG C for 11-13 hours to obtain the hydrophobic modified ceramic membrane. One of the greatest use of the membrane is an application in membrane distillation. The invention has the advantages of simple technology, good chemical stability, acid resistance, alkali resistance, organic solvent resistance, large mechanical strength, easy flushing, strong antimicrobial capability, high temperature resistance, narrow aperture distribution, high separation efficiency and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing geopolymer adsorption material by using Bayer process red mud

ActiveCN103920457AUniform stomataHigh strengthOther chemical processesAluminium silicatesSoluble glassKaolin clay

The invention discloses a method for preparing geopolymer adsorption material by using Bayer process red mud. According to the invention, kaolin and red mud are respectively dried, kaolin is calcined after ball milling, then red mud and calcined kaolin are mixed according to mass ratio of 3: 7-6: 4, placed in a stirring pan, a soluble glass solution with 1.5 of modulus is added for uniformly stirring until the sodium oxide mass in the soluble glass solution accounts for 8% of total mass of a mixture of the calcined kaolin and red mud, the water cement ratio of the slurry is 0.35-0.38; a proper amount of aluminum powder and powdered soap are placed in a few water, and uniformly dispersed and then added in the obtained slurry, uniformly stirred; after waiting for 3-5 minutes, the expanded slurry is filled in a die, and the expanded slurry is placed in a baking oven with the die or placed in the baking oven without die for maintenance, so that the geopolymer adsorption material is prepared. The method has the advantages of simple equipment, low cost, easy popularization and little environmental influence, the prepared geopolymer adsorption material has the advantages of uniform pore and high strength, and can be reused after being processed by an acid solution.

Owner:徐州星皓乐器有限公司

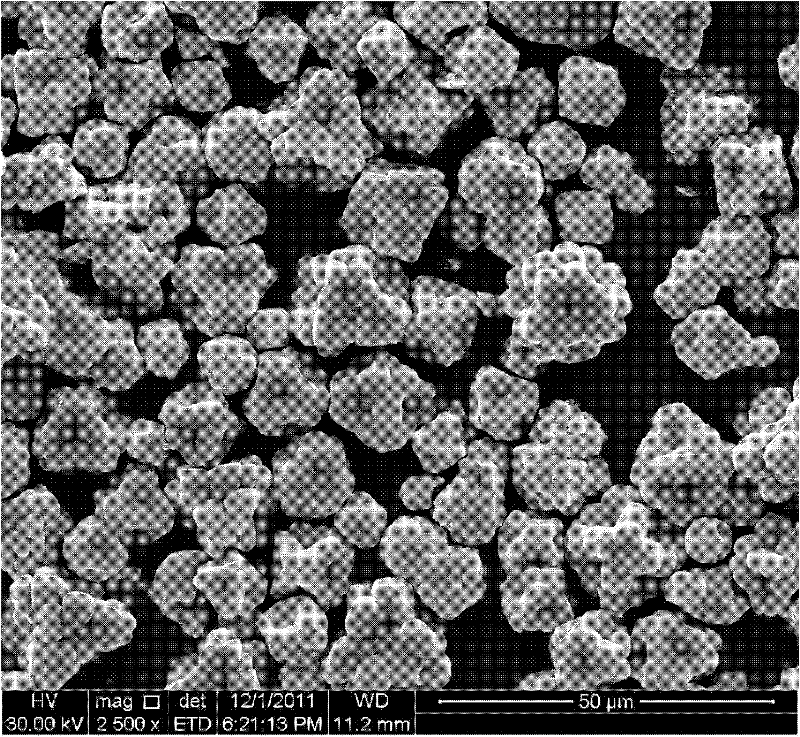

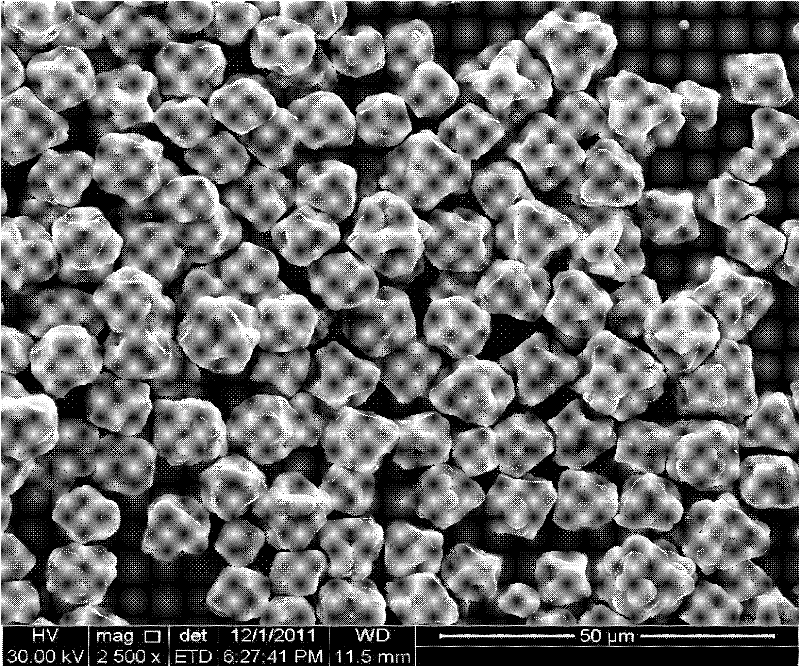

Preparation method for cuprous oxide micron/nano crystal with controllable morphology

InactiveCN102583499AGood dispersionControl growth characteristicsNanotechnologyCopper oxides/halidesMicro nanoWatch glass

The invention relates to a preparation method for cuprous oxide micron / nano crystal with controllable morphology, relating to the preparation method for the cuprous oxide micron / nano crystal. The invention mainly solves the technical problems of high cost and environmental pollution in the preparation process of the micron / nano cuprous oxide. The method comprises the following steps of: 1, dissolving copper salt into ultrapure water, pouring lactic acid, continuously stirring, regulating a pH value, cooling to the temperature of 25 DEG C, keeping constant volume, measuring the pH value, and obtaining solution A; 2, moving the solution A to a hydrothermal reaction kettle, sealing the reaction kettle, putting the hydrothermal reaction kettle into a drying oven, keeping the temperature, naturally cooling to a room temperature, centrifugally washing by using the ultrapure water, centrifugally washing by using anhydrous ethanol, transferring the reaction kettle onto watch glass, and drying the reaction kettle in the drying oven; and thus obtaining the cuprous oxide micron / nano crystal. The preparation method for the cuprous oxide micron / nano crystal with the controllable morphology has the advantage of simpleness and practicability, simple equipment operation, low raw material price, easy synthesis, less pollution to environment and high synthetic concentration, the problem of the cost of the morphology control and industrialized large-scale synthesis in the prior art is solved, and the industrial production is facilitated.

Owner:HARBIN INST OF TECH

Method for calibrating drying box for determining tobacco moisture and method for determining tobacco moisture

ActiveCN101126693AAccurate measurementConsistent resultWeighing by removing componentCalibration apparatusProduction lineMoisture

The utility model relates to a calibration method for the oven which is used for measuring water in the tobacco and a method for measuring the water in the tobacco; wherein the calibration method for the oven which is used for measuring water in the tobacco is as follows: a standard sample with known water content is put into the oven to be calibrated to do the test on a prescriptive environmental condition, then the difference between the determination result and the standard value is calculated, then the fan velocity and the heating curve of the oven are adjusted until the determination result and the standard value are uniform according to the difference. The utility model can guarantee the product quality stability and consistency of the same brand tobacco produced by different production lines and different manufacturing sites by calibrating any oven as the tool for calibrating the on-line water determinative instrument.

Owner:CHINA TOBACCO HUNAN INDAL CORP

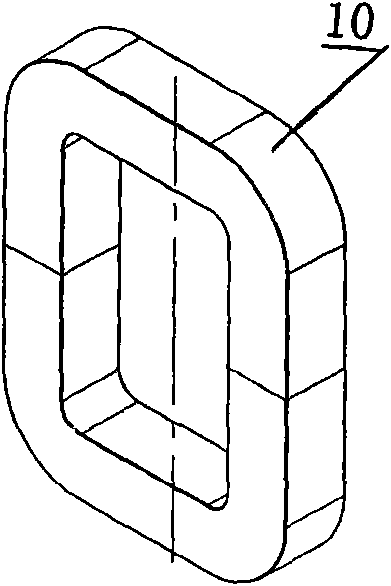

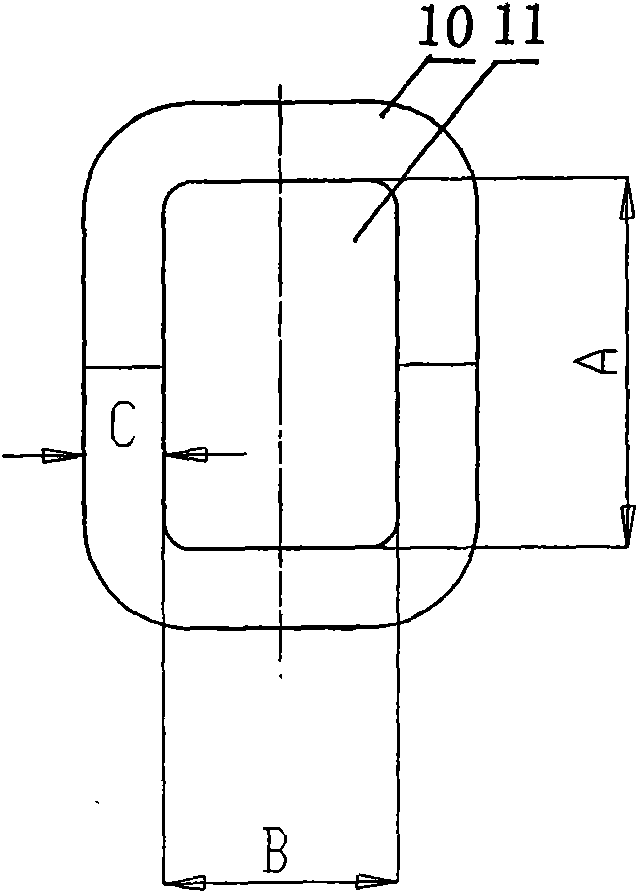

Ultracrystalline transformer core manufacturing method and special mould therefor

InactiveCN101572182ATransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerFirming agent

The invention relates to an ultracrystalline transformer core manufacturing method and a special mould therefor. The method comprises that: ultracrystalline laminar strips are overlapped and wound on a circular mould to form a circular blank, an internal mould of a square mould is inserted into a circular inner window of a circular core blank to make the inner window deformed into the square window, and a square external mould encloses and clamps on the outside of the core to form a square core blank; the square core blank and the square mould are put into a high frequency heating furnace together, subjected to heat treatment for four hours at a temperature of between 550 and 570 DEG C and temperature reduction at a rate of between 95 and 105 DEG C per minute to 80 DEG C, and injected with modified epoxy resin containing firming agent, and then put into an oven for curing and sizing for 8 hours at a temperature of between 80 and 110+ / -5 DEG C; and the square core blank and the square mould are taken out for demoulding, naturally cooled, and divided into two U-shaped ultracrystalline transformer cores. The method and the special mould adopted make the ultracrystalline strips or blanks stressed evenly in various processes such as winding, heat treatment and the like and avoid breakage and damage. The core has good electromagnetic characteristic and frequency characteristic, and low power consumption and temperature rise, and can be made into transformer cores for a high-power high-frequency high-voltage power supply.

Owner:NANJING GUODIAN ENVIRONMENTAL PROTECTION TECH

Impregnation formula, impregnation production method and impregnation technology for high temperature resistant conveyer belt

ActiveCN102220699AExtended service lifeGood high temperature aging performanceFibre typesLaboratory ovenDry heat

The invention discloses an impregnation formula, an impregnation production method and an impregnation technology for a high temperature resistant conveyer belt. The impregnation technology comprise the following steps that: a impregnation machine contains 5 drying heat treatment baking oven and is equipped with far-infrared predrying; after put on the machine, canvas is unwound with a unwinding tension force of 100kg, and passes through a cloth storage rack with a cloth storage tension force of 160kg; the canvas is impregnated through a impregnation station with a impregnation compression roller pressure of 1000kg; after the impregnation residual slurries are sucked through a vacuum suction with a degree of vacuum of 20MPa; after suction, the canvas enters into far-infrared preheat baking ovens with baking oven temperature preset to 65 DEG C. An impregnation speed is 5m / min; the unwinding tension force is 100kg / m; a dipping adhesive amount of a first bath is 0.7%; a first bath drying temperature is 150-160 DEG C, and a first bath heat treatment temperature is 210 DEG C; a second dipping adhesive amount is 4-6%; a second bath predrying temperature is 90 DEG C; a second bath predrying temperature is 150 DEG C; and a second bath heat treatment temperature is 210 DEG C.

Owner:浙江尤夫科技工业有限公司

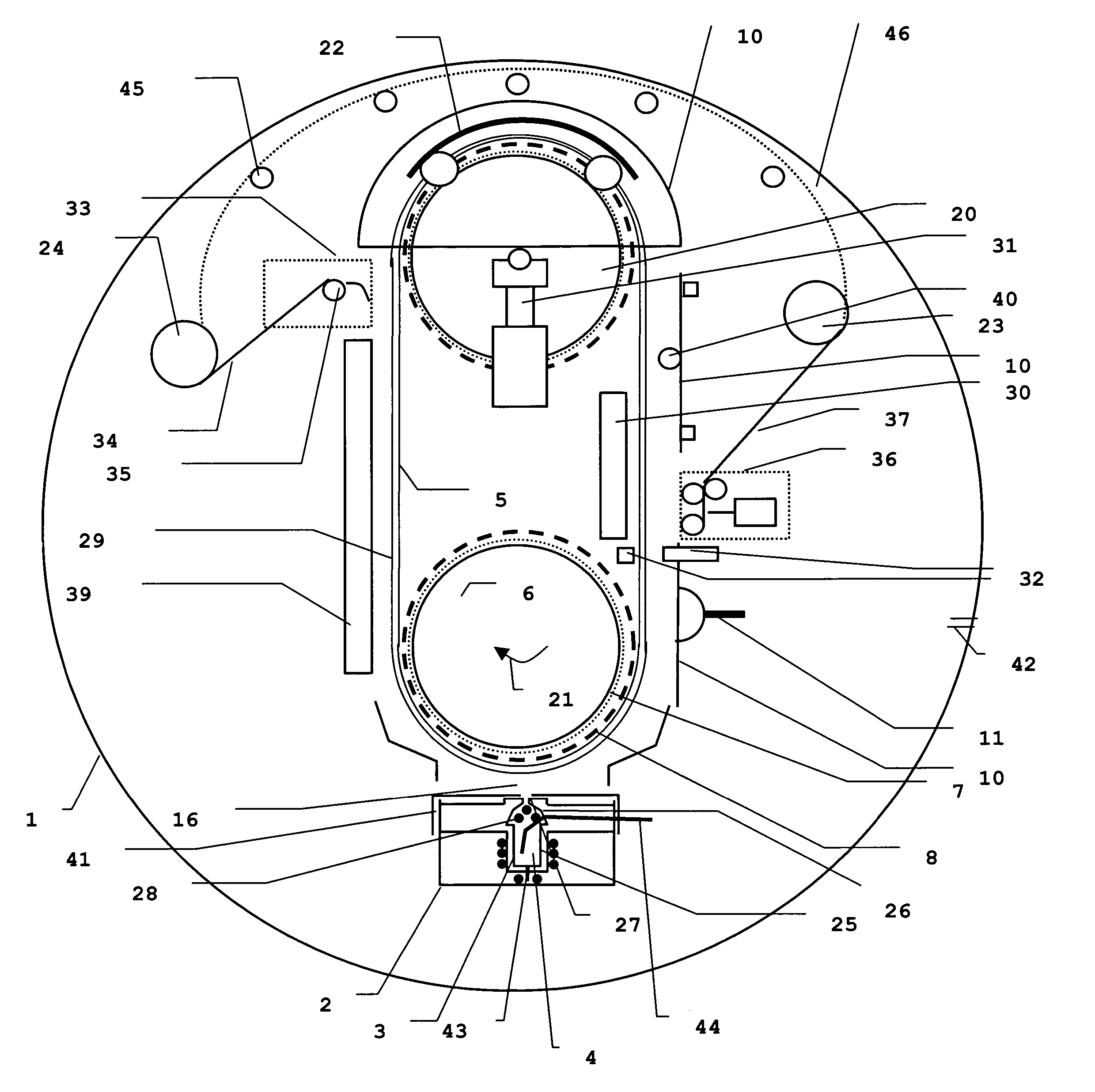

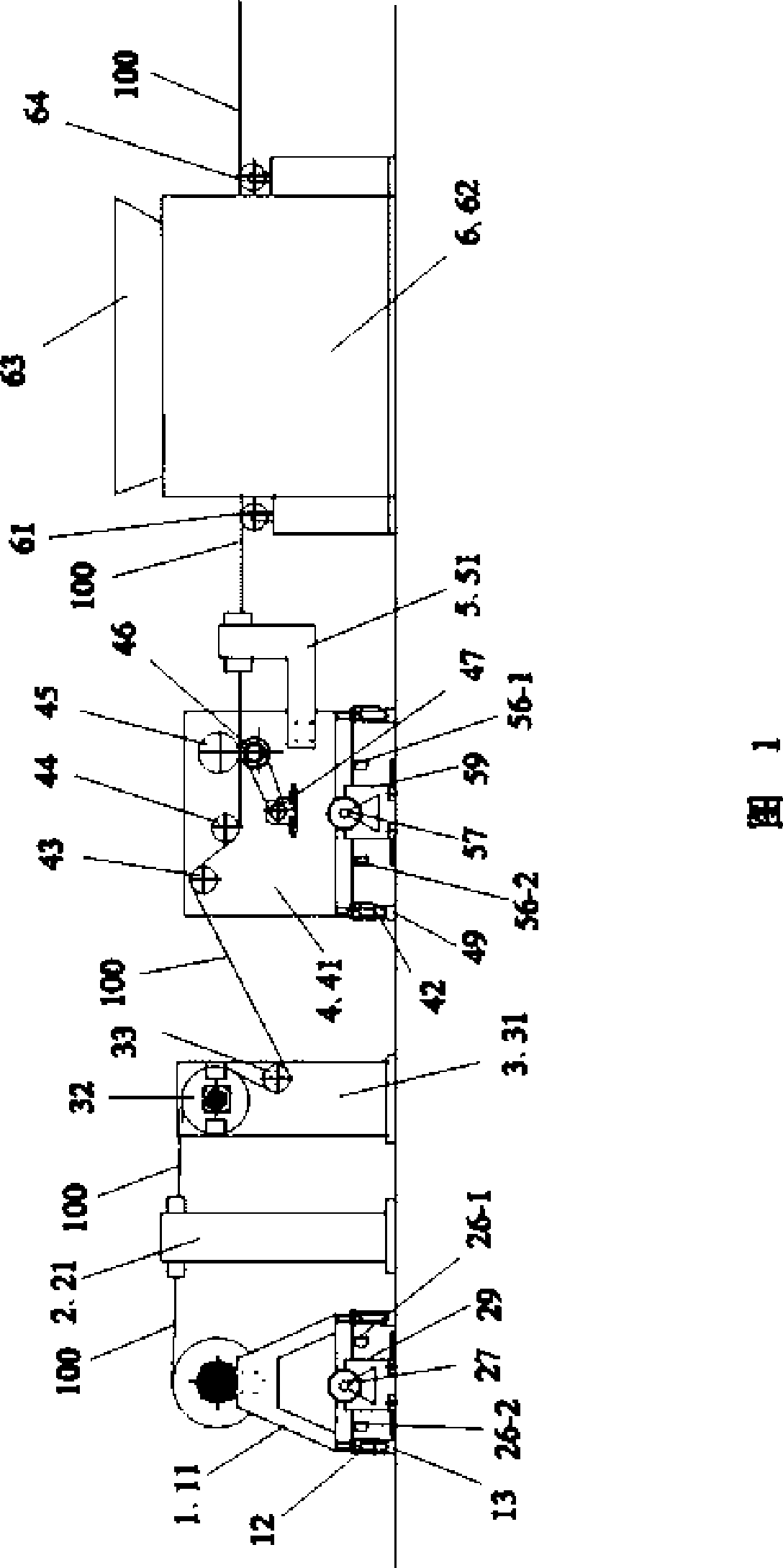

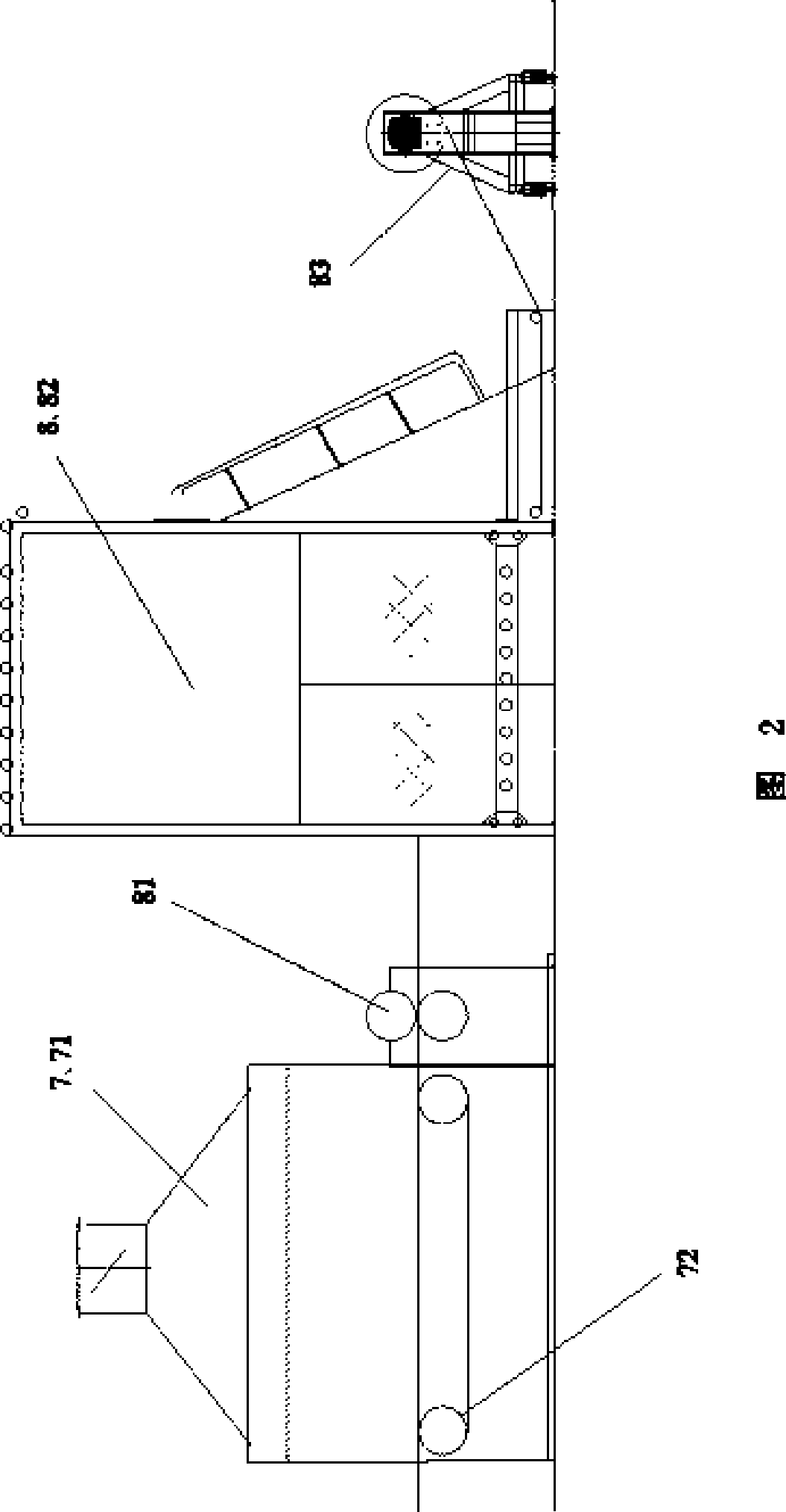

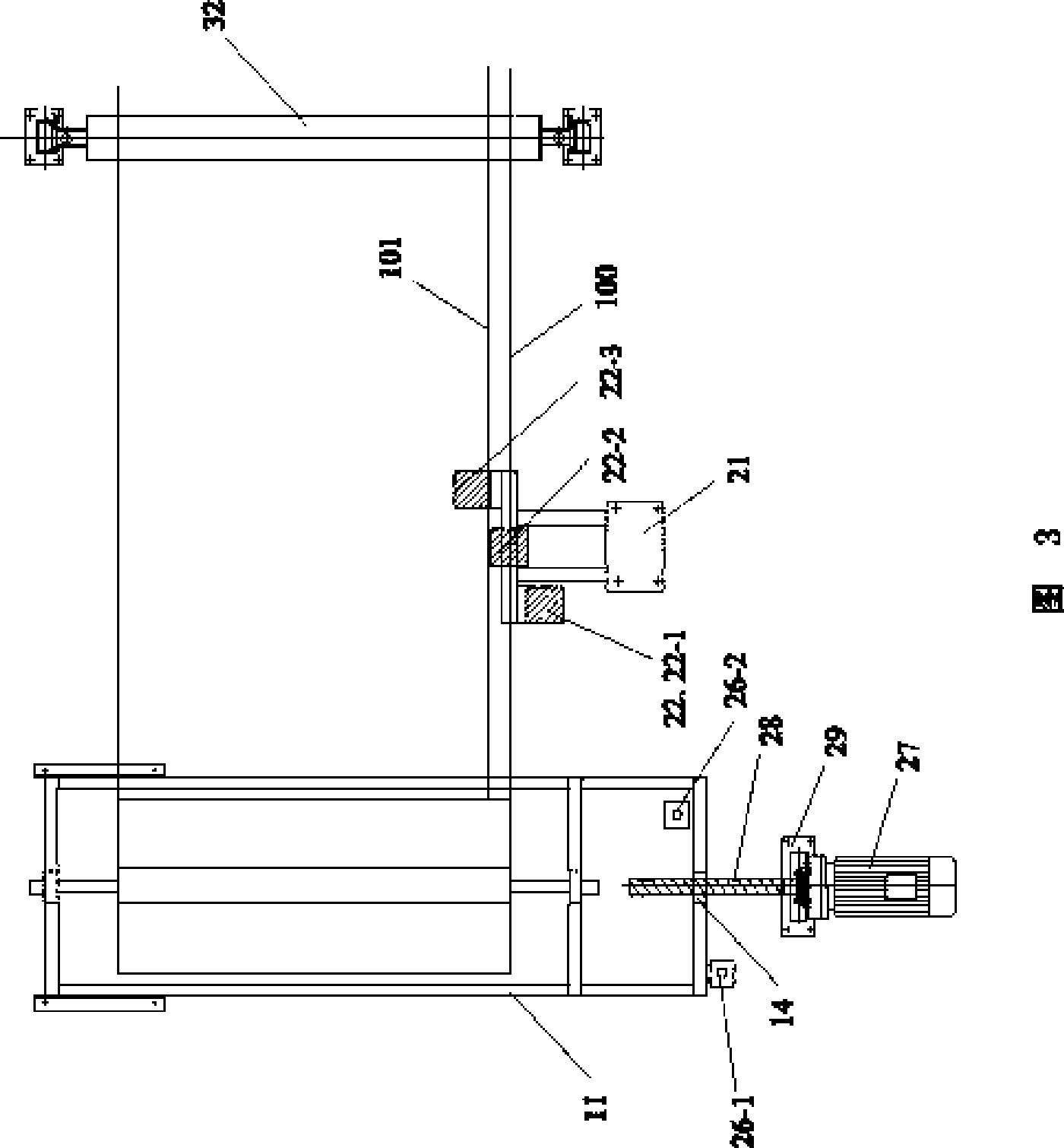

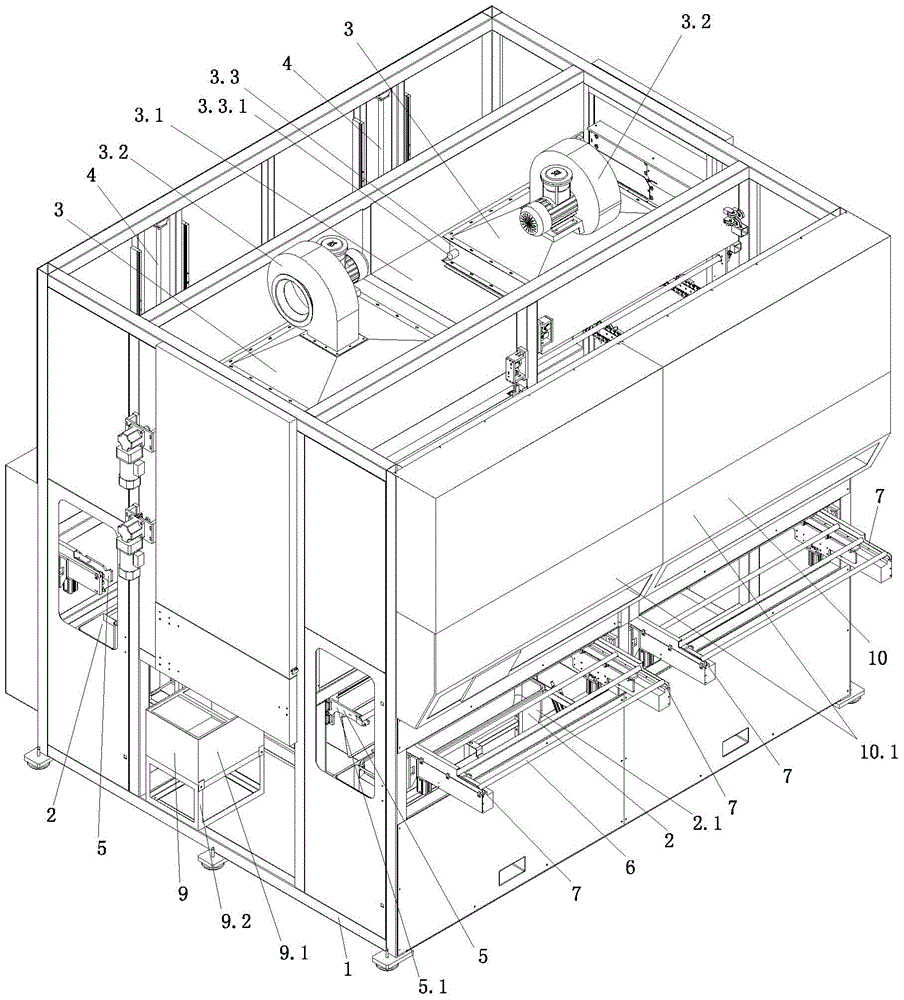

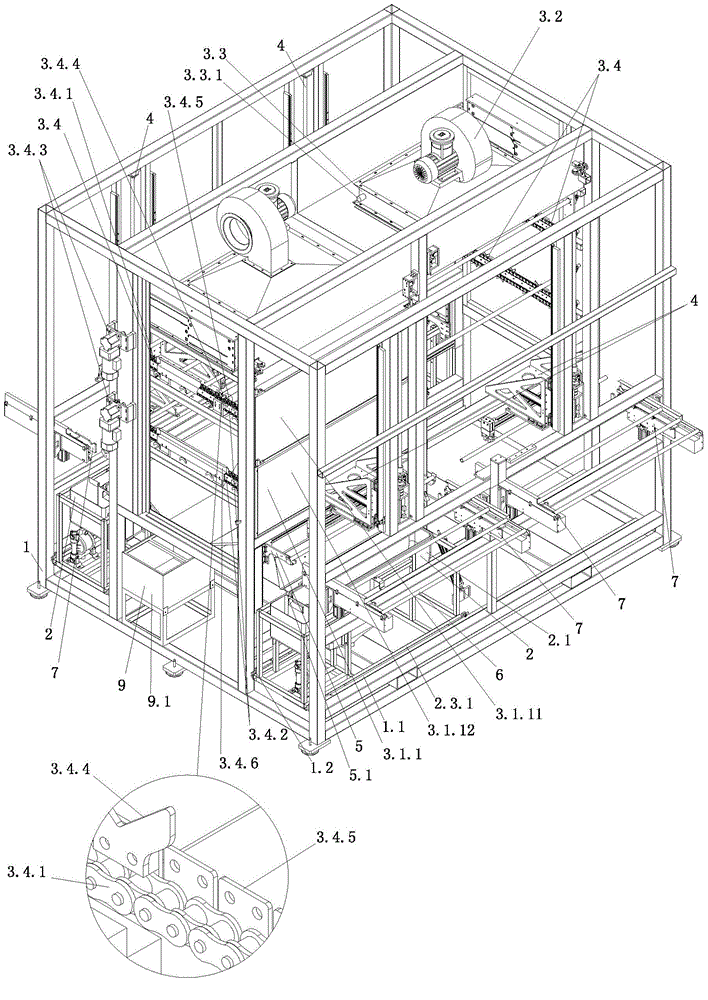

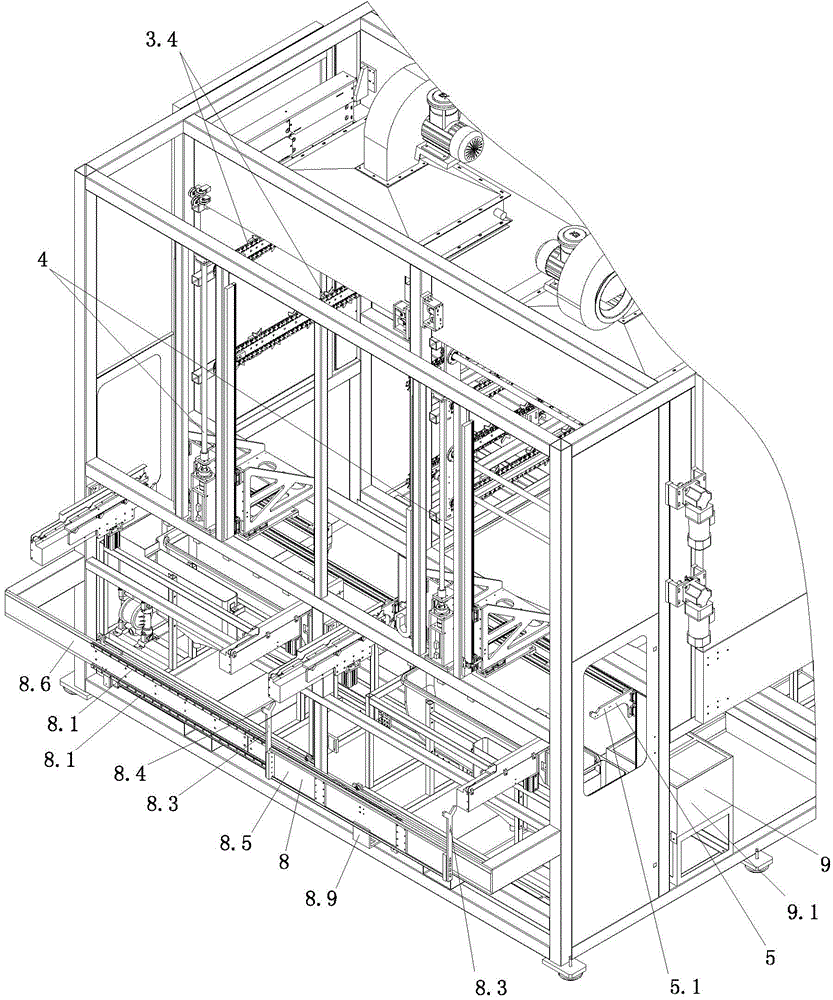

Glue dipping machine and glue dipping process

A glue dipping machine comprises a machine frame, three glue dipping tank assemblies, two drying oven assemblies, four transfer mechanical hand assemblies, three pairs of glue dipping mechanical hand assemblies, and a plurality of workpiece hanging rods. The workpiece hanging rods are each provided with a plurality of hanging points for hanging workpieces; the drying oven assemblies each comprise a drying oven body, a circulation fan and a heat exchanger, the front side and the rear side of each drying oven body are each provided with a upper-and-down moving oven door, and each drying oven body is internally provided with a hanging rod box internal support moving mechanism in front-to-rear direction; parts, at the left side and the right side outside each of the oven doors of the front side and the rear side of each of two drying oven bodies, of the machine frame are each provided with a hanging rod intermittent support moving mechanism in front-to-rear direction. The glue dipping machine is applicable to automatic glue dipping operation of the workpieces, and has high working efficiency. The glue dipping process comprises that the workpieces are successively subjected to three times of glue dipping in the three glue dipping tank assemblies, and drying is carried out for one time respectively after completion of the first time glue dipping and the third glue dipping. The glue dipping process can obtain good glue dipping effect.

Owner:NINGBO BEILUN LEIAO AUTOMATION EQUIP

One-step rapid controllable preparation method of full-emission fluorescence carbon quantum dots

ActiveCN108998010AHigh fluorescence quantum efficiencyWide variety of sourcesNanoopticsLuminescent compositionsSolubilityReaction temperature

The invention belongs to the technical field of a light-emitting nanometer material and provides a one-step rapid controllable preparation method of full-emission fluorescence carbon quantum dots so as to solve the problems that the existing fluorescence carbon dots are single in wavelength and uncontrollable in preparation and the fluorescence quantum efficiency of the carbon quantum dots is low.The method comprises the following steps: modifying any two of amino, carboxyl and hydroxyl on a benzene ring, mixing with absolute ethanol and dissolving ultrasonically and completely to obtain a mixed solution; transferring the mixed solution to a high-pressure reaction kettle and performing high-temperature reaction in a drying oven to obtain a claybank or black solution, namely a full-emission fluorescence carbon quantum dot solution; and flexibly adjusting the type and the proportion of a reaction precursor, the reaction temperature and the reaction time and performing one-step rapid control to obtain the full-emission fluorescence carbon quantum dots. The raw materials are wide in source and low in price, the production equipment is cheap and the universality is high. The prepared full-emission fluorescence carbon quantum dots have high solubility and dispersibility in an aqueous solution and an organic solvent, have high fluorescence quantum efficiency and can be applied to cell marking and imaging.

Owner:SHANXI UNIV

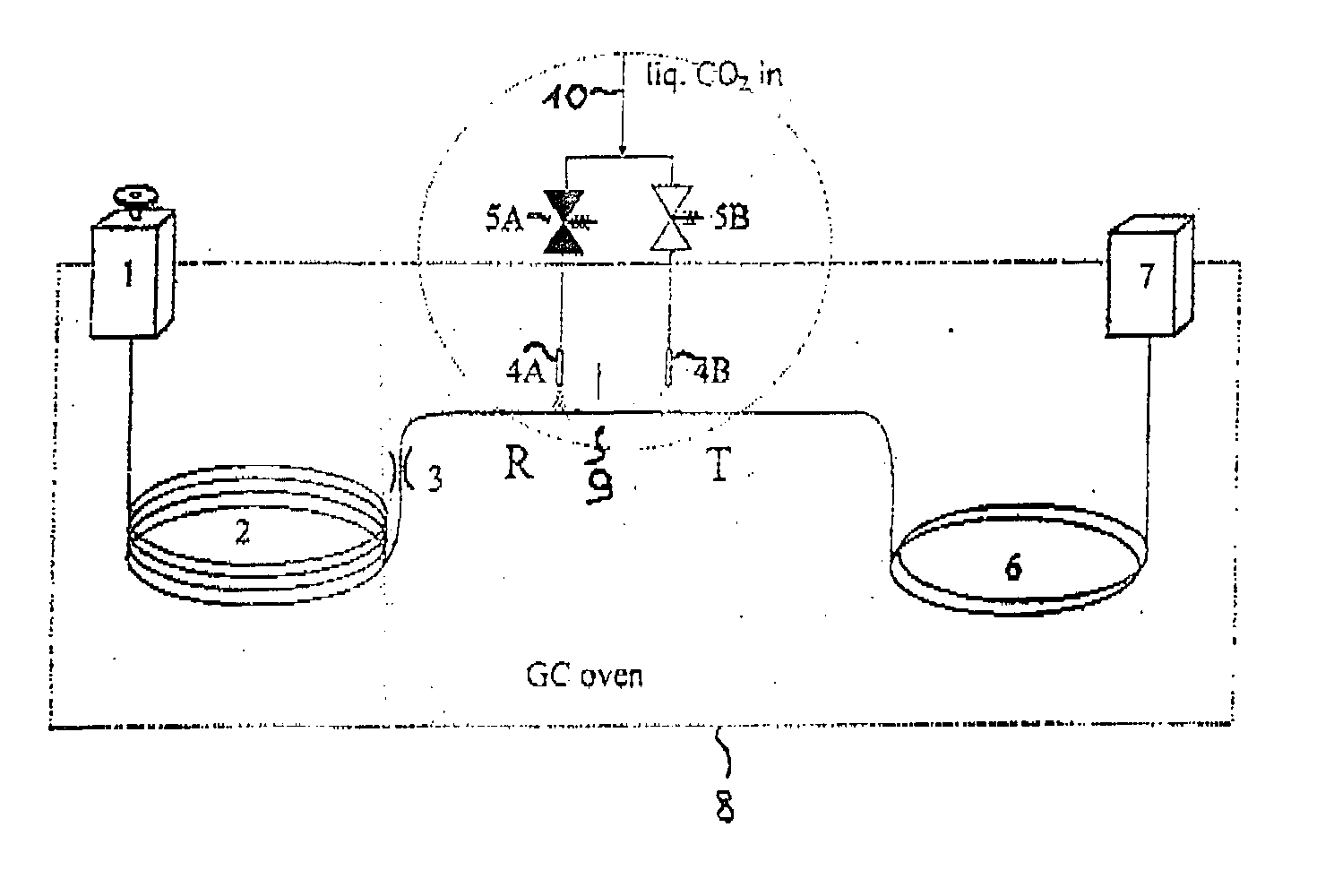

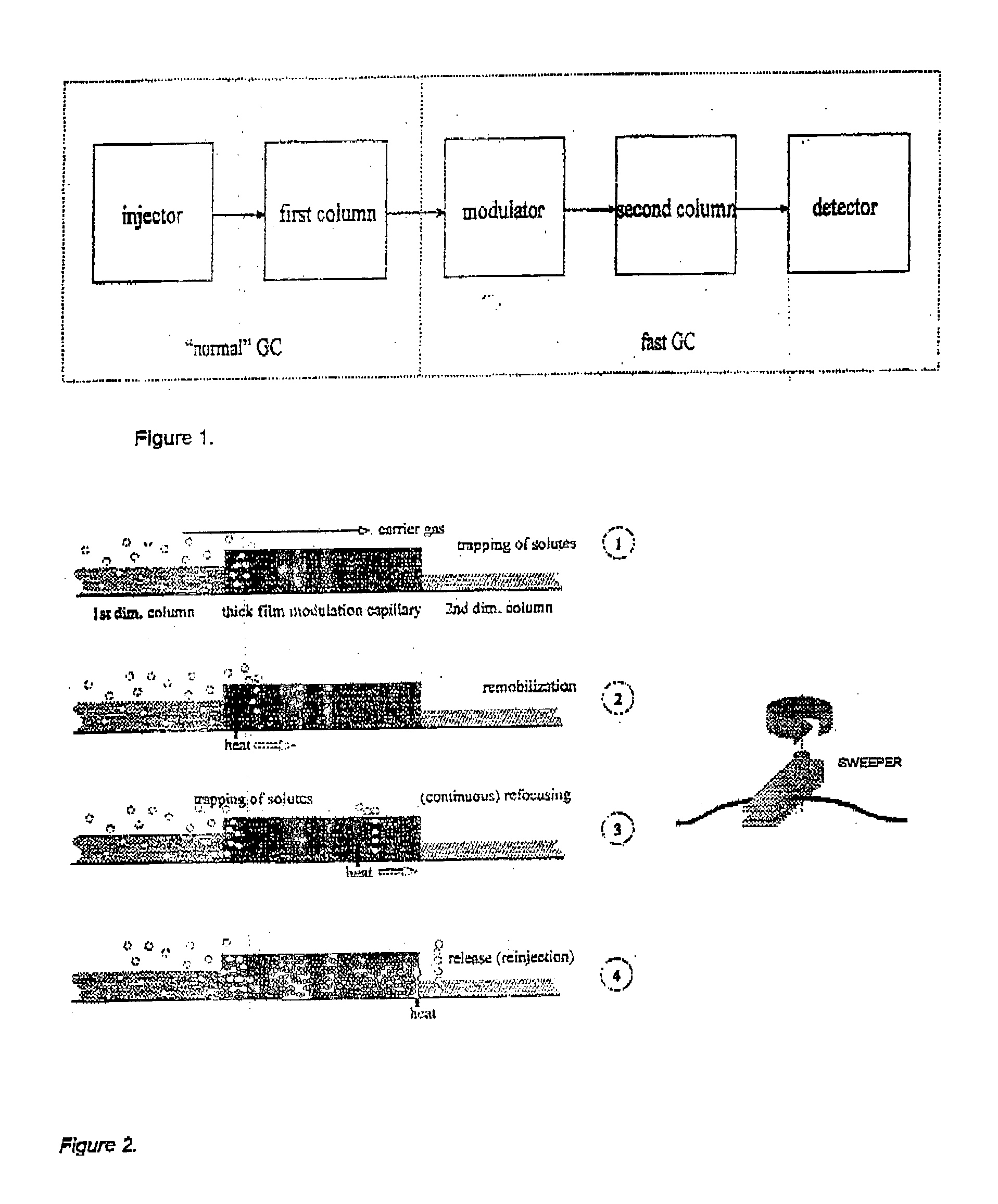

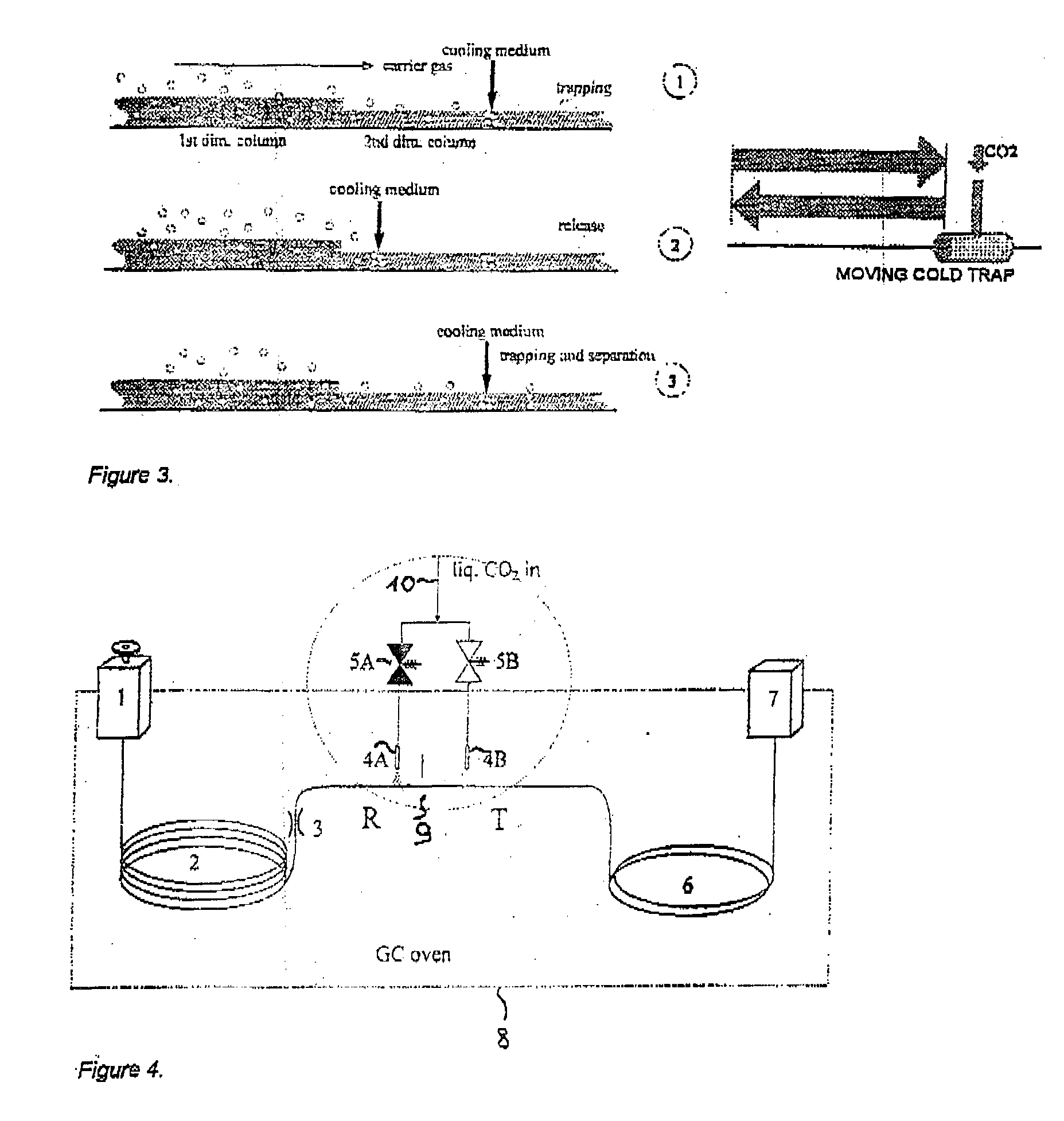

Modulator for gas chromatography

This invention relates to a modulator for use in gas chromatographic analysis, adopted for alternatively trapping and releasing fractions of solutes in a length of a capillary column within a chromatographic oven, characterized in that it comprises at least one nozzle placed to spray at least one jet in at least one corresponding place along said capillary column length, said nozzle(s) being connected each to a source of liquid CO2 via a related valve, and means for alternatively opening said valve(s) for a predetermined time, to cause a jet of liquid CO2 to impinge for said predetermined time on said column place and to leave the oven atmosphere to heat said column place after said predetermined time. The modulator can be used in a conventional GC system or in a two dimensional GC system, for modulating the analytes fed to the second capillary column.

Owner:THERMO ELECTON

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com