Patents

Literature

116results about How to "Uniform stomata" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

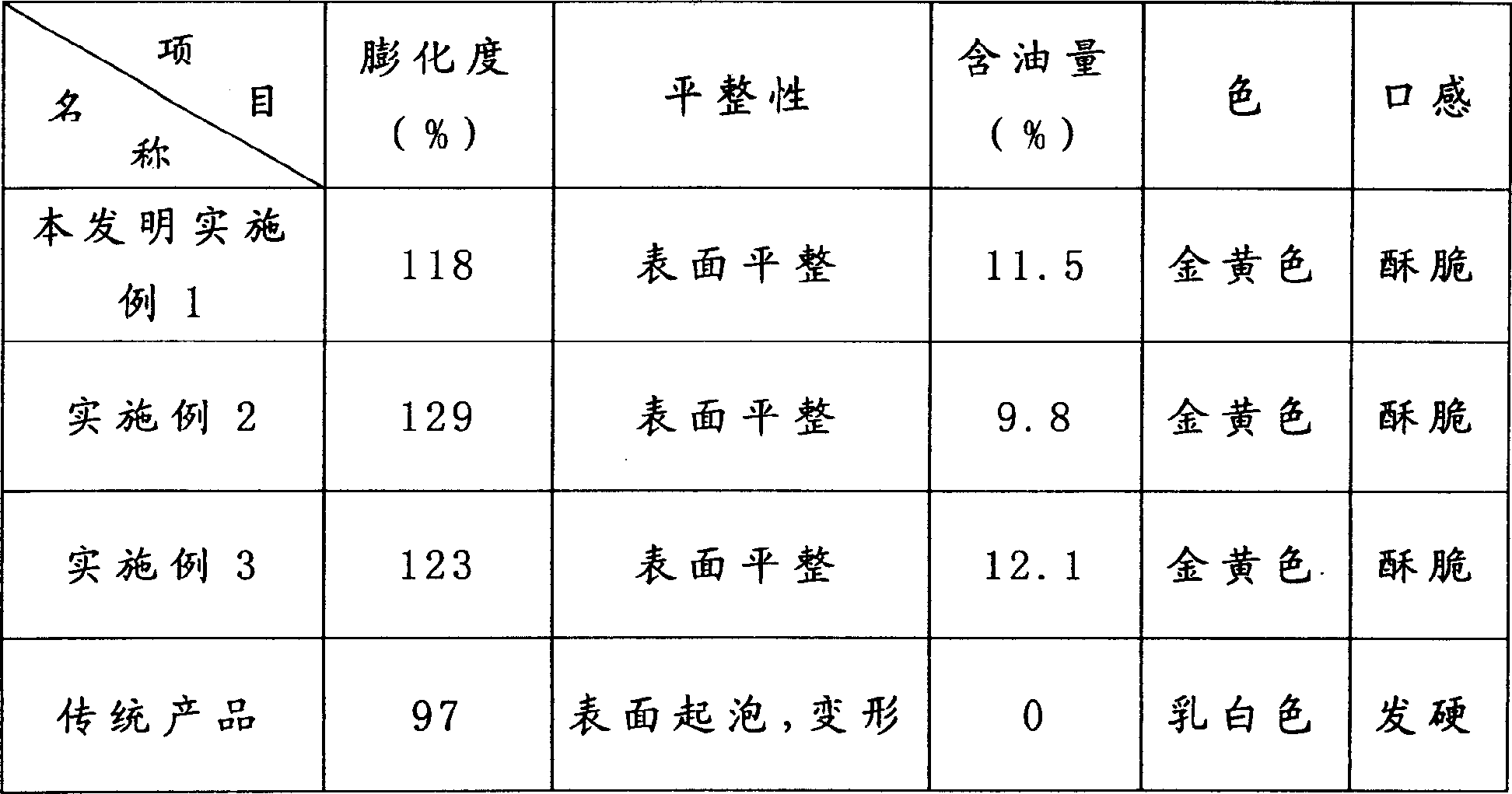

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

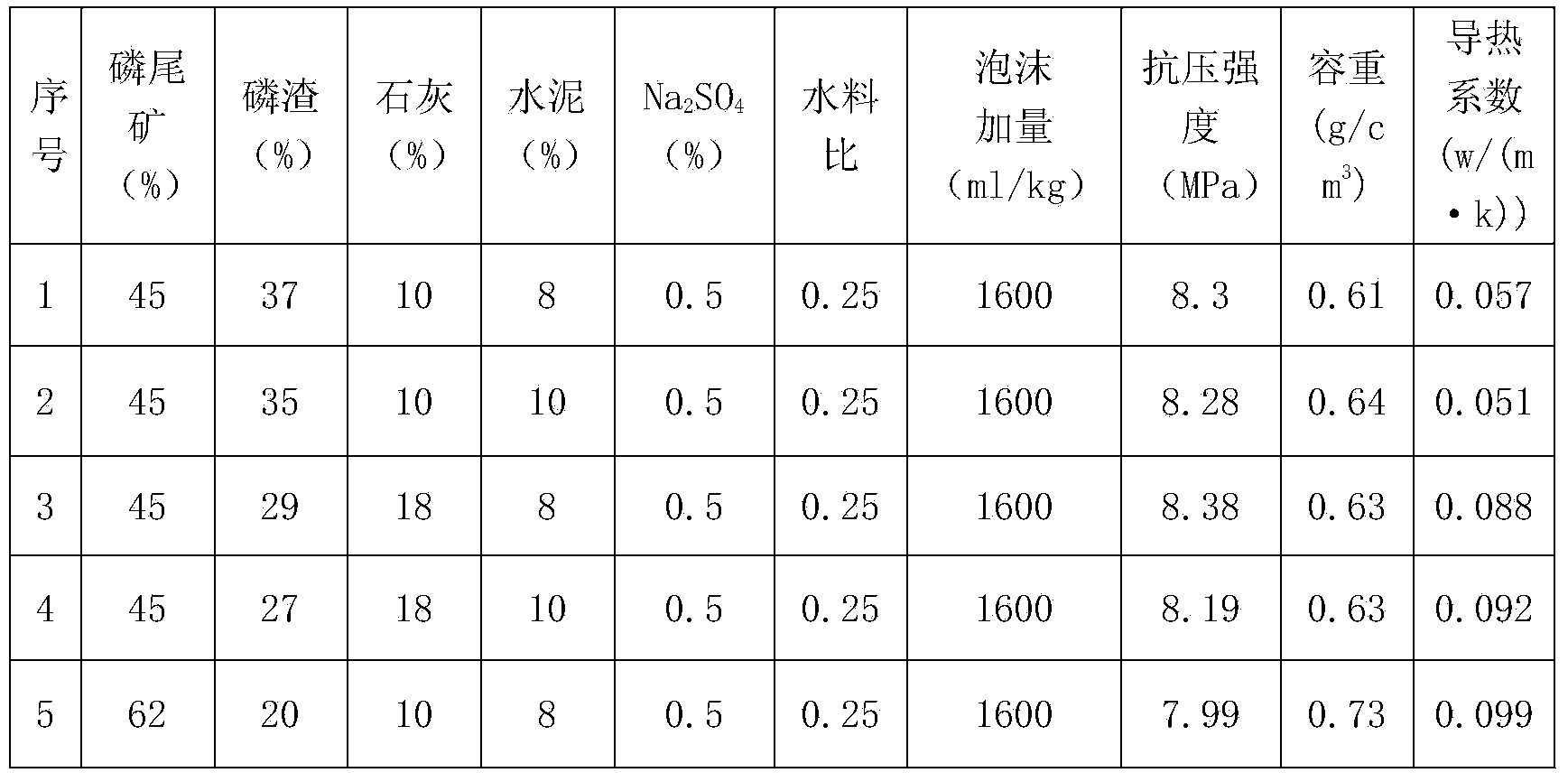

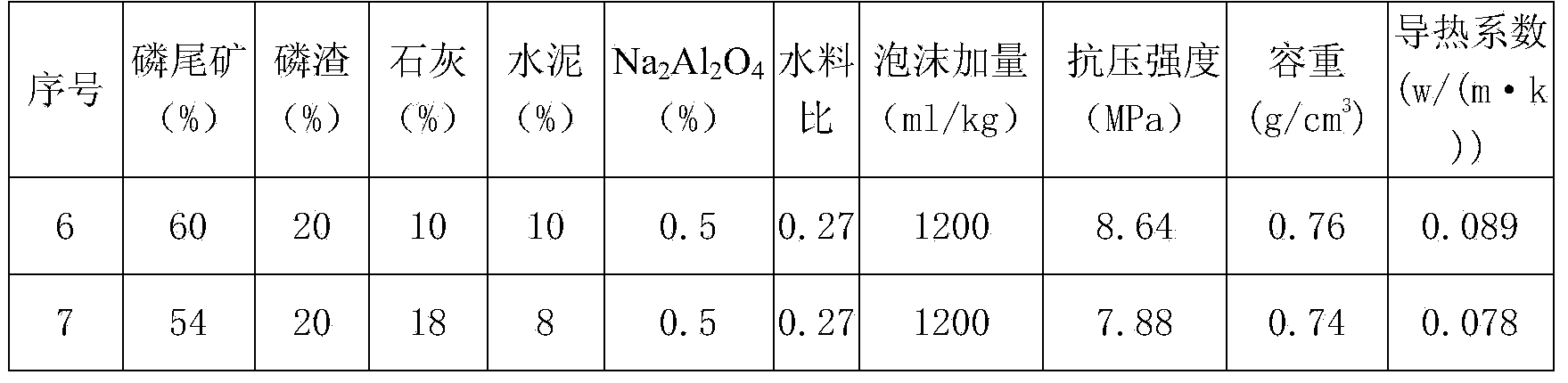

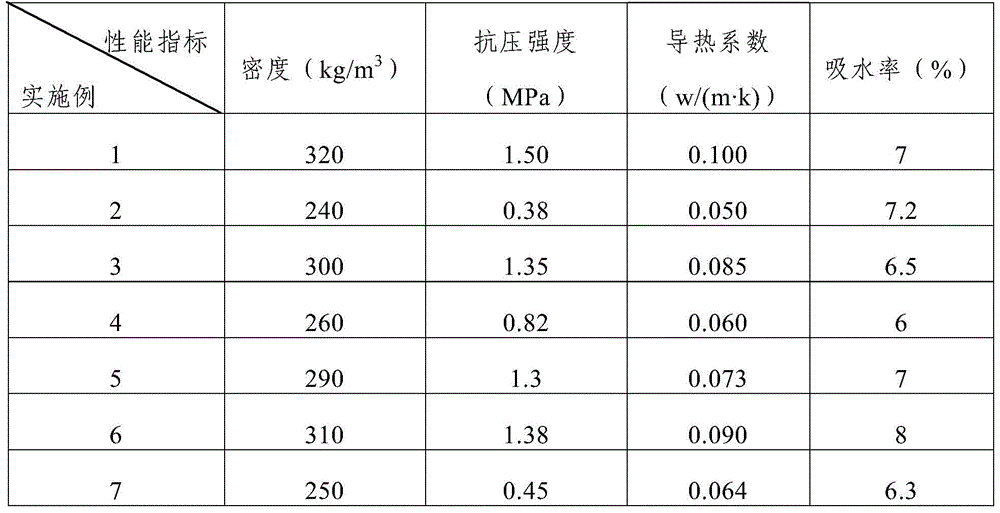

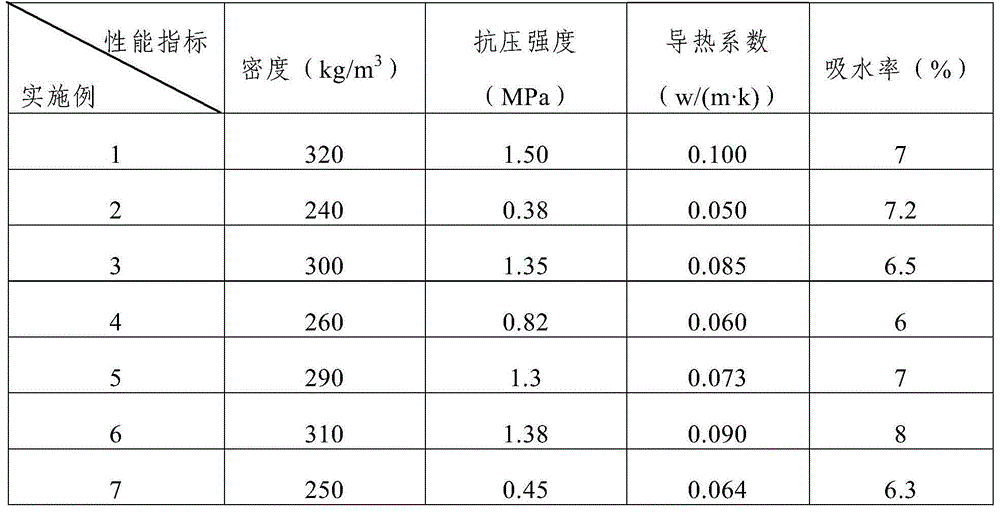

Phosphorus slag-phosphate tailing foam concrete block and making method thereof

InactiveCN103588451AReduce environmental stressLow costSolid waste managementCeramicwareFoam concretePolymer science

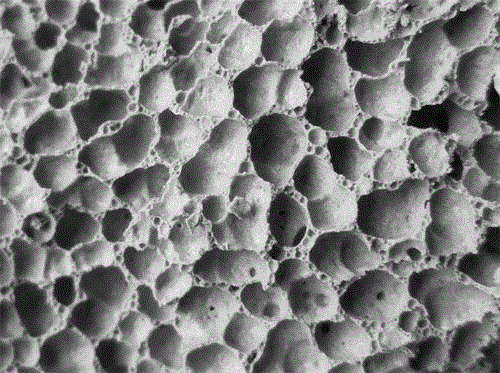

The invention belongs to the waste recycle application field, and relates to a phosphorus slag-phosphate tailing foam concrete block and a making method thereof. The phosphorus slag-phosphate tailing foam concrete block is made by using a base material, an additive, water and foam, the base material comprises, by mass, 45-62% of a phosphate tailing, 20-37% of phosphorus slag, 10-18% of lime and 8-10% of cement, and the additive is one or more of sodium sulfate, sodium aluminate and sodium silicate. The phosphorus slag-phosphate tailing foam concrete block is produced in a foam addition mode, the consumption of cement is controlled within 10%, the utilization rate of each of the phosphate tailing and the phosphorus slag is not lower than 72%, and the made foam concrete block has uniform pores, has a heat conduction coefficient of below 0.1w / (m.k), has good heat and sound insulation effects, a high strength and a small weight, and accords with Foam Concrete JGT266-2011 Standard.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Method for preparing geopolymer adsorption material by using Bayer process red mud

ActiveCN103920457AUniform stomataHigh strengthOther chemical processesAluminium silicatesSoluble glassKaolin clay

The invention discloses a method for preparing geopolymer adsorption material by using Bayer process red mud. According to the invention, kaolin and red mud are respectively dried, kaolin is calcined after ball milling, then red mud and calcined kaolin are mixed according to mass ratio of 3: 7-6: 4, placed in a stirring pan, a soluble glass solution with 1.5 of modulus is added for uniformly stirring until the sodium oxide mass in the soluble glass solution accounts for 8% of total mass of a mixture of the calcined kaolin and red mud, the water cement ratio of the slurry is 0.35-0.38; a proper amount of aluminum powder and powdered soap are placed in a few water, and uniformly dispersed and then added in the obtained slurry, uniformly stirred; after waiting for 3-5 minutes, the expanded slurry is filled in a die, and the expanded slurry is placed in a baking oven with the die or placed in the baking oven without die for maintenance, so that the geopolymer adsorption material is prepared. The method has the advantages of simple equipment, low cost, easy popularization and little environmental influence, the prepared geopolymer adsorption material has the advantages of uniform pore and high strength, and can be reused after being processed by an acid solution.

Owner:徐州星皓乐器有限公司

Process for producing aerated concrete from calcium carbide waste slag

InactiveCN101353266AThick slurryUniform stomataSolid waste managementCeramic materials productionSlagSlurry

The invention discloses a process for producing aerated concrete by waste residue of calcium carbide, which can change waste into valuable and decrease the cost. The concrete steps of the process are as follows: the first step, according to the mixture ratio of materials (volume ratio), 60-80% of quartz sand (quartz voetail), 10-30% of the waste residue of the calcium carbide and 8-15% waste residue of citric acid (gypsum) are mixed to prepare slurry, and then the slurry is ground; the second step, according to the content mixture ratio of the concrete block (weight ratio), 2,300-2,700kg of the slurry material, 180-250kg of cement, 350-450kg of quick lime powder, 1.3-1.6kg of aluminum powder and residual amount of water are poured, precured, cut, steamed, removed from a kettle and stacked. The process has the advantages that the waste residue of the calcium carbide is chosen as the raw material in the process of manufacturing the aerated concrete, by mixing and grinding the waste residue of the calcium carbide, the prepared slurry is denser, the pores of the product are even, the whiteness is increased and the strength is also improved. The practice proves that the recycle of the waste residue of the calcium carbide regarded as waste can change the waste into valuable and the production cost is greatly reduced. The process is widely applied to the manufacturing field of concrete.

Owner:SUZHOU BAIGAO NEW CONSTR MATERIALS

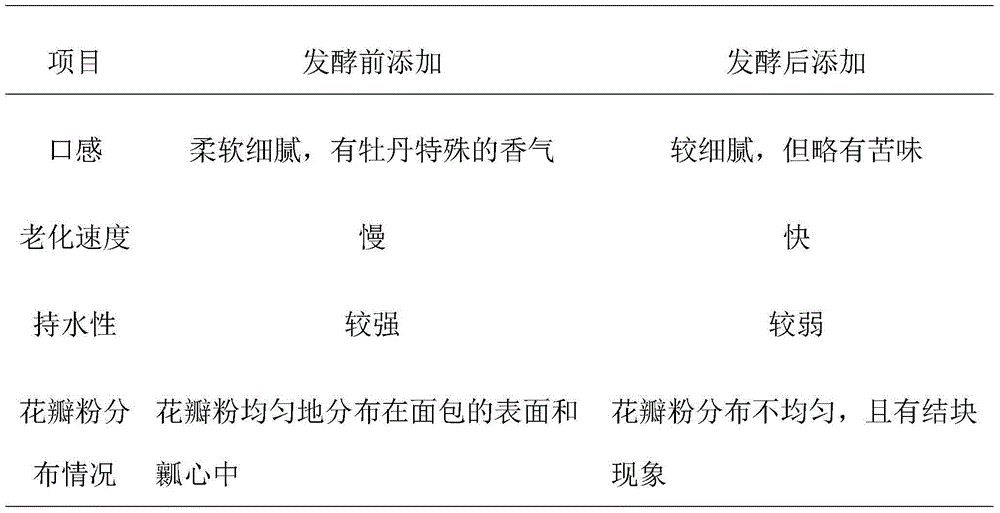

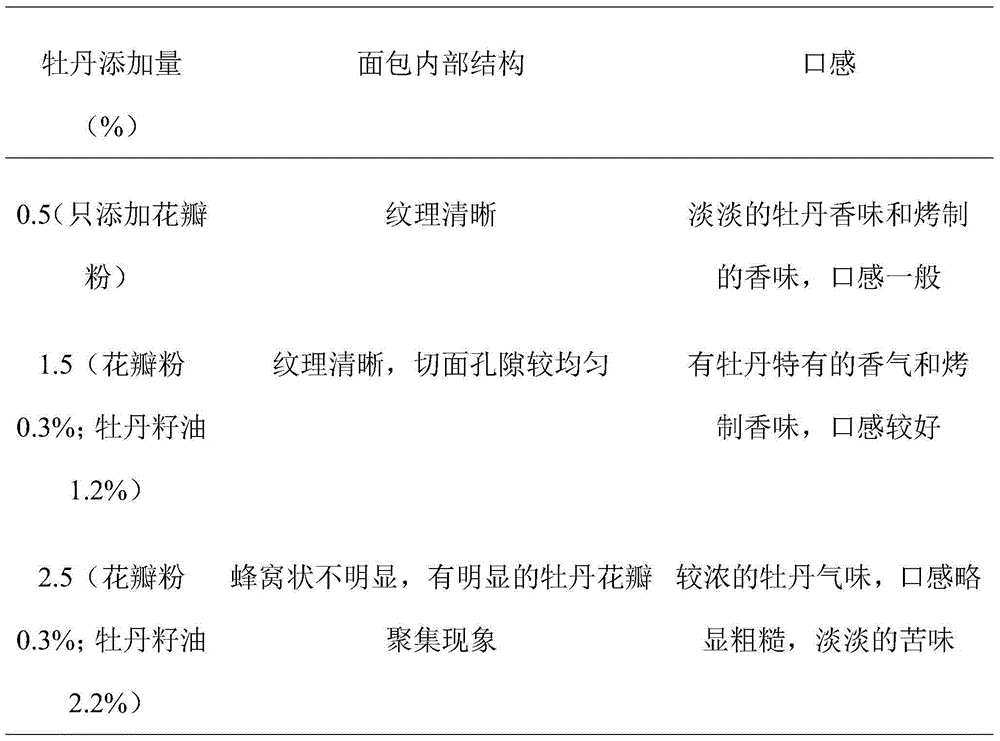

Bread and processing technology thereof

ActiveCN104957215AHigh nutritional valueGreat tasteDough treatmentBakery productsBiotechnologyNutritive values

The invention relates to bread and a processing technology thereof. Flour is used as a main material, and peony petals for oil, yeast, eggs, a bread modifier, white sugar, table salt, milk and peony seed oil for the oil are used as auxiliary materials. The processing technology comprises the following steps: firstly, making the peony petals for the oil into petal powder, activating the yeast, mixing the flour with water, fermenting dough, shaping the fermented dough, fermenting the shaped bread, and baking the fermented bread so as to obtain the bread. The bread and the processing technology thereof, disclosed by the invention, have the benefits that the peony petals for the oil and the peony seed oil for the oil are added to the flour to prepare the peony bread, so that the nutrient value of the bread is increased, and different flavors and medical-care functions are given to the bread; the mouth feel of the bread is improved through the processing technology, the water retention property of the bread is improved, and the quality of the bread is improved; the surface of the bread presents golden, the color of the bread is uniform and consonant, the bread has rich baking fragrance and special fragrance of peonies, and the mouth feel of the bread is soft and palatable.

Owner:ZHENGZHOU NORMAL UNIV

Bamboo charcoal-polyvinyl formal biological carrier and preparation thereof

InactiveCN101428901AImprove toughnessHigh strengthSustainable biological treatmentBiological water/sewage treatmentPolyvinyl alcoholEconomic benefits

The invention provides a bamboo carbon-polyvinyl formal biological carrier for water treatment and a process for preparing the same. The bamboo carbon-polyvinyl formal biological carrier is designed for solving the technical problems of high price, high abrasion ratio, large density, easy fragile, and difficult cleaning and replacement in the prior biological carrier active carbon and the inorganic carrier, and is produced by using polyvinyl formal as the organic polymer carrier, and adding filler such as bamboo-carbon for foaming treatment of calcium carbonate and citric acid. The prepared product has the characteristics of communication pore, multiple pores, micro pores, has large specific surface and biological compatibility, facilitates bacteria laminating and carries a large amount of bacteria, can fully meet the application requirements of suspended filler for water treatment, has great scientific and social significance, and can create good environmental, social and economic benefits if being popularized and applied.

Owner:SHENYANG NORMAL UNIV

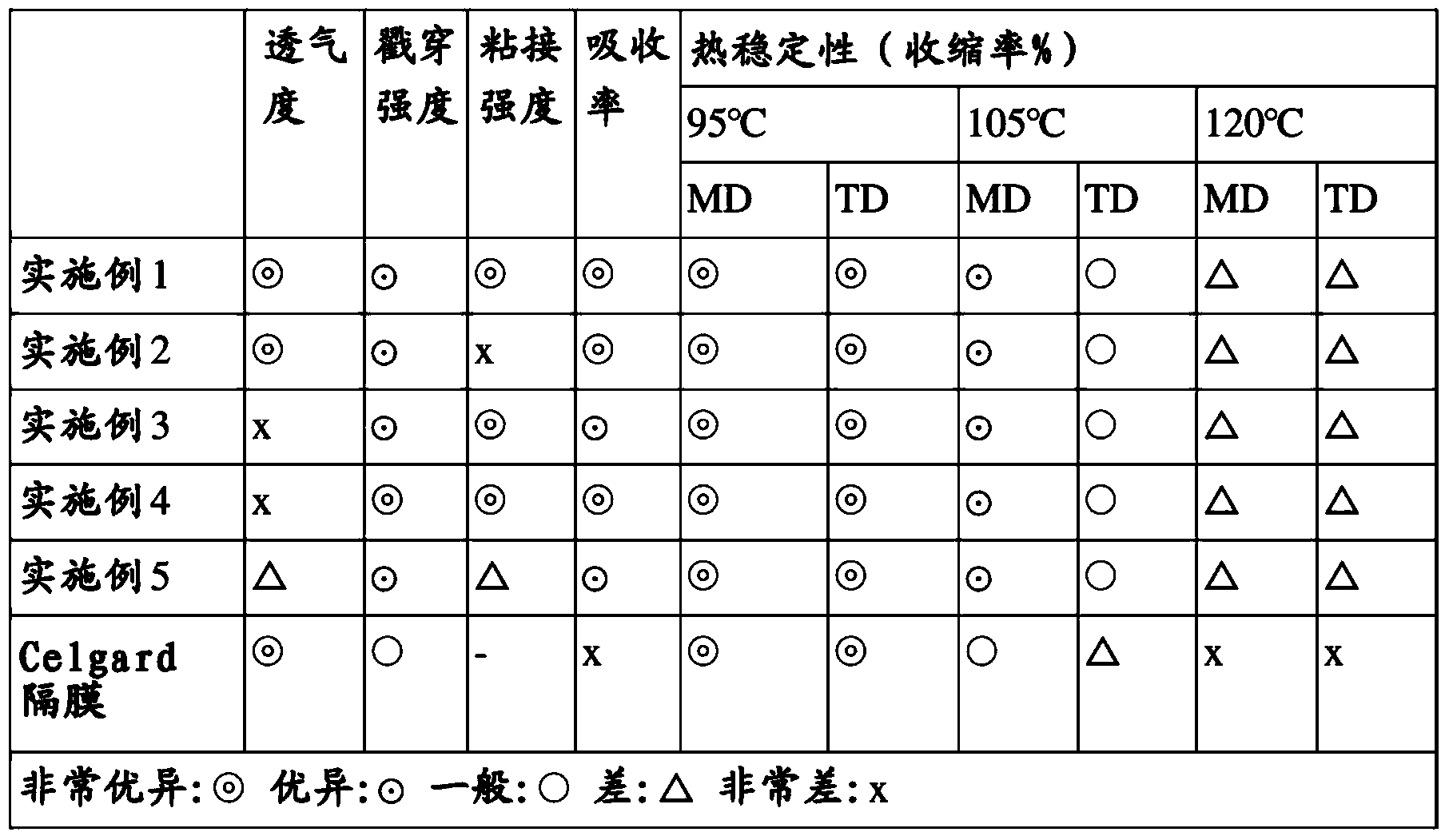

Separator for secondary battery having excellent electrolyte wettability and method for manufacturing same

InactiveCN104081557AUniform stomataUniform porositySynthetic resin layered productsElectrical equipmentPorosityPolyolefin

The present invention relates to a highly wettable separator for a secondary battery, and provides a highly wettable separator for a secondary battery, the separator comprising: a polyolefin-based substrate; a hot melt nanofiber layer formed on one surface or both surfaces of the substrate; and a nanofiber layer with high electrolyte wettability, the nanofiber layer being formed on the hot melt nanofiber layer, wherein the coating amount of the hot melt nanofiber layer is 0.05-2.5 g / m2 and the layer with high electrolyte wettability has a porosity of 55-89%. The separator according to the present invention can exhibit a shutdown function while having excellent heat resistance and high mechanical strength, and can exhibit excellent ion conductivity and prevent deterioration in battery performance by having excellent pore size and porosity.

Owner:TOPTEC HNS

Premixed coarse cereals flour for fried bread sticks and manufacturing method thereof

InactiveCN104222201AReduced gluten contentMuscular weaknessDough treatmentBaking mixturesCelluloseTriticum turgidum

The invention discloses premixed coarse cereals flour for fried bread sticks. The premixed coarse cereals flour is made of the following raw materials, by weight part, of 40-70 parts of wheat flour, 8-15 parts of wheat protein powder, 30-50 parts of coarse cereals powder, 2-4 parts of aluminum-free fried bread stick swelling agents, 1 part- 3 parts of konjaku flour, 0.3-0.8 parts of xanthan gum, 0.2-0.6 part of guar gum, 5-15ppm of glucose oxidase and 3-10ppm of cellulose. The manufacturing method comprises the following steps of weighing raw materials according to the formula proportion, mixing the raw material for 20 minutes in a mixing machine and weighing and packing the raw materials in an automatic flour packing machine. The wheat protein powder in the formula can overcome the defect that the elasticity is reduced due to coarse cereals, the dough strength is improved, the konjaku flour, the xanthan gum and the guar gum can be favorable for formation of a wheat gluten network and have an elasticity improving function, the glucose oxidase can improve the tissue structure of the wheat gluten network, and the cellulose has an enzymolysis function on a part of cellulose in the premixed flour to be favorable for formation of the wheat gluten. According to the premixed flour, the coarse cereals and the refined grains are matched with each other. Thus, the nutrition balance is achieved.

Owner:HENAN AGRICULTURAL UNIVERSITY

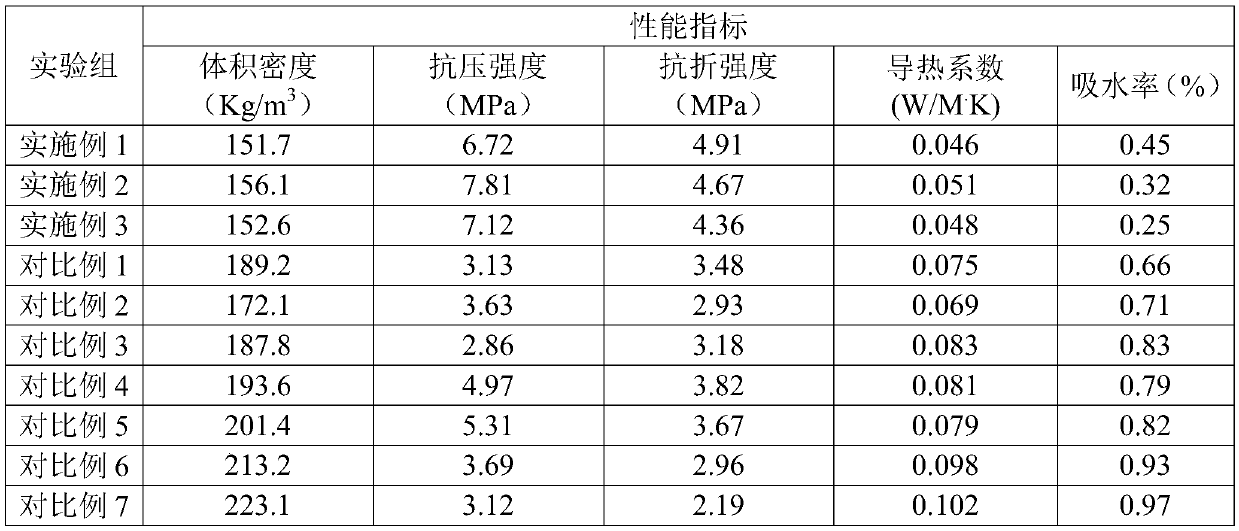

High-doping-amount furnace slag aerated concrete building block and preparation method thereof

The invention relates to a wall concrete material, particularly a high-doping-amount furnace slag aerated concrete building block and a preparation method thereof. The high-doping-amount furnace slag aerated concrete building block is composed of the following components in parts by weight: 125-140 parts of furnace slag, 30-46 parts of quicklime, 10-15 parts of cement, 4-7 parts of slaked lime, 1-3 parts of desulfurized gypsum, 0.2-0.3 part of aluminum powder paste, 0.005-0.01 part of thickener, 0.03-0.08 part of foam stabilizer and 175-225 parts of water. The furnace slag comprises 20-35% of SiO2, 40-50% of Al2O3, 12-17% of Fe2O3, 3-5% of CaO and at most 2.0% of MgO. The PAI index of the furnace slag is greater than 55%. The high-doping-amount furnace slag aerated concrete building block prepared by the method has the advantages of low cost and favorable properties.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

Inflaming retarding heat preservation plate and production technology thereof

InactiveCN103253897AUniform stomataExcellent flame retardant and heat resistanceCeramicwareTemperature resistanceCorrosion

The invention provides an inflaming retarding heat preservation plate and a production technology thereof. The inflaming retarding heat preservation plate is prepared by feeding, mixing, and stirring a foaming agent, cement R, a foam stabilization enhancement agent, anti-cracking fibers and a water prevention agent, performing injection molding on the materials, foaming the materials, performing preliminary maintenance, demolding the materials, cutting the materials, maintaining a finished product and the like. No combustible substance is added into the inflaming retarding heat preservation plate from manufacturing to mounting; the inflaming retarding and heat resistance performance of a product is high; the inflaming retarding heat preservation plate has the outstanding characteristics of damp resistance, corrosion resistance, high temperature resistance, ageing resistance and the like; potential quality hazards such as swelling, cracking, falling and permeation in application of conventional engineering construction are avoided; furthermore, the problems that an outer layer is easy to crack and the like because of a poor fireproof inflaming retarding effect and contraction and deformation of a large area of heat preservation layer at high temperature are solved; and the later maintenance cost and the comprehensive cost are greatly reduced.

Owner:髙吉才

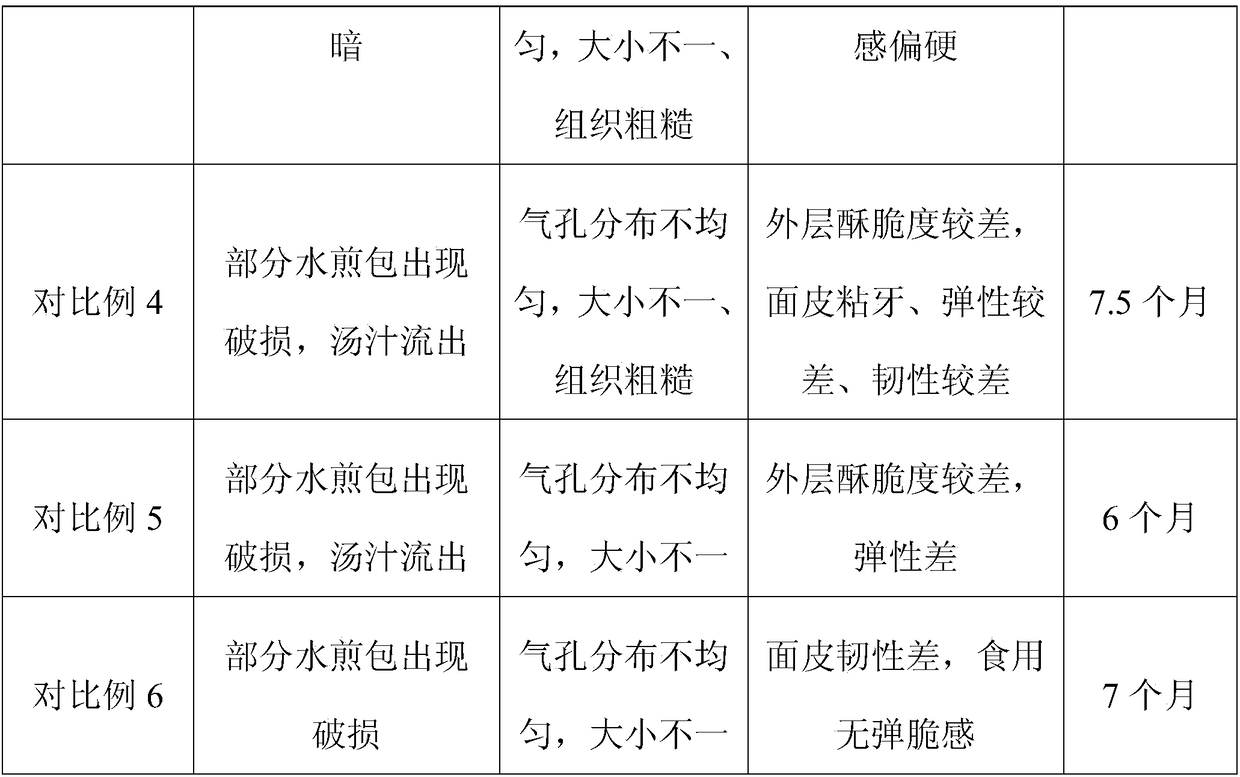

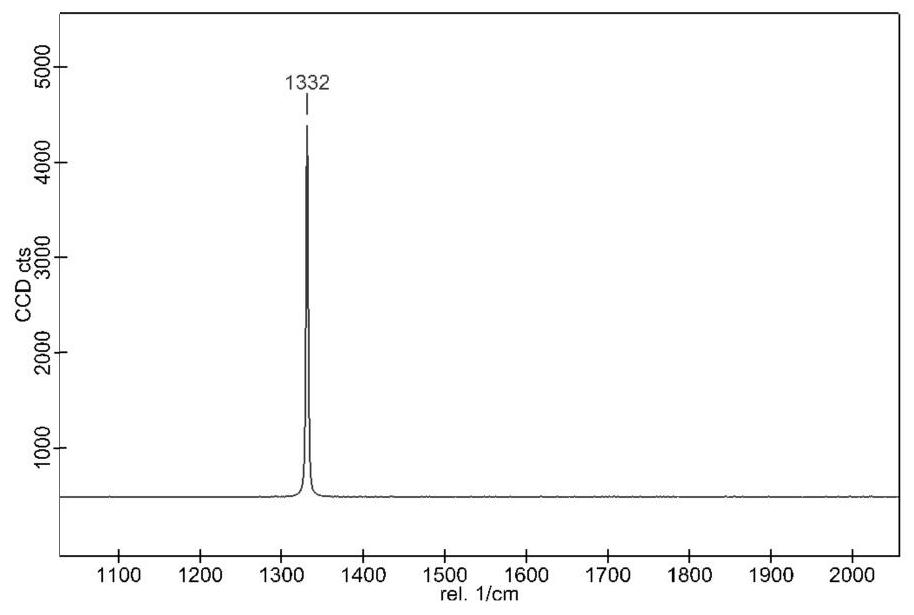

Preparation method for ceramic binder used for rapid synthesis of CBN abrasive tools by microwave method

The invention relates to a preparation method for a ceramic binder used for rapid synthesis of CBN abrasive tools by a microwave method, belonging to the field of preparation of binders. The preparation method comprises the following steps: a, by mass, weighing 45 to 70% of silica acid or silicon dioxide, 3 to 10% of aluminium hydroxide or aluminium oxide, 5 to 15% of anhydrous sodium carbonate or sodium oxide and 5 to 20% of boric acid or diboron trioxide, carrying out uniform mixing and grinding, and carrying out sieving with a 200-to-300-mesh sieve so as to prepare a mixed material; b, melting the mixed material prepared in the step a and then carrying out water quenching, wherein melting conditions are as follows: carrying out heating to 1300 to 1500 DEG C with a rate of 10 DEG C / min and then carrying out melting for 2 to 5 h; c, drying a product prepared in the step b at 100 to 150 DEG C for 4 to 8 h, then carrying out grinding, and carrying out sieving with the 200-to-300-mesh sieve so as to prepare a basic ceramic binder; and d, subjecting the basic ceramic binder prepared in the step c to pressing molding into a blank with a presser, and carrying out sintering with a microwave sintering furnace so as to prepare the ceramic binder. The method provided by the invention has the characteristics of low reaction temperature, short reaction time, low production cost, energy conservation, etc., and is easy to realize industrial production.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

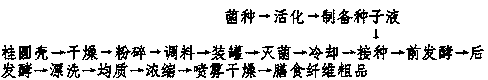

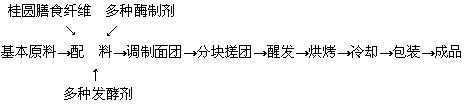

Making method of longan dietary fiber bread

The invention belongs to the technical field of food processing, in particular to a making method of bread having a special healthcare function. The making method specifically comprises the following steps: firstly, weighing a certain amount of longan dietary fiber, yeast, lactic acid bacteria, sweet distiller yeast, glucose oxidase, cellulase, xylanase and materials required by the traditional bread; then, preparing dough, putting the well weighed materials into a mixing cylinder, stirring to mix the materials uniformly, and the like. With adoption of the making method, the problems that the bread made according to the prior art has peculiar smell, rougher taste, darker color, smaller size, non-even pores, insufficient softness and elasticity as the fermenting property and the baking property of the dough are changed due to the addition of the dietary fiber are solved. The bread prepared according to the method provided by the invention is smooth in bread crust, has no cracks, is brownish yellow, good in inside glossiness, fine and even in pores, soft in the bread body, and high in elasticity, contains rich longan dietary fiber, has strong fermentation fragrance and wheat fragrance, and delays the aging of the bread.

Owner:四川川科食品开发有限公司

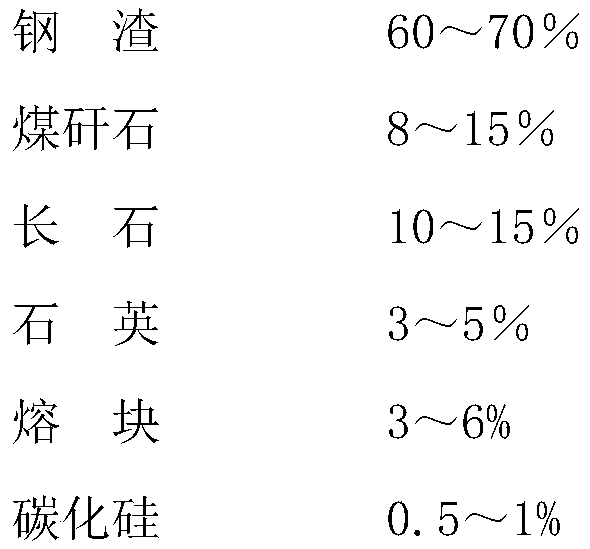

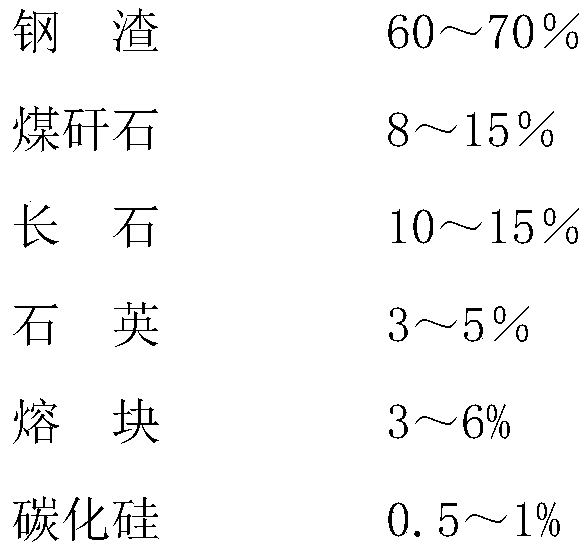

Method for preparing foam ceramic heat-insulation board by utilizing gold ore tailings

InactiveCN106699217AReduce manufacturing costWide variety of sourcesCeramic materials productionCeramicwareFoaming agentPore diameter

The invention belongs to the field of building materials and discloses a method for preparing a foam ceramic heat-insulation board by utilizing gold ore tailings. The foam ceramic heat-insulation board is characterized by being prepared from the following components in parts by weight: 25 weight percent to 70 weight percent of the gold ore tailings, 0 to 15 weight percent of pottery stone, 5 weight percent to 20 weight percent of feldspar, 0 to 25 weight percent of clay, 0 to 15 weight percent of sandstone, 5 weight percent to 10 weight percent of coal gangue, 0.3 weight percent to 1.5 weight percent of additional SiC, 0.5 weight percent to 2.0 weight percent of additional Fe2O3 and 0.5 weight percent to 1.5 weight of an additional grinding aid. The method takes the gold ore tailings as a main raw material and takes the SiC, the coal gangue and the Fe2O3 as a compound foaming agent; the prepared foam ceramic heat-insulation board has a uniform and controllable pore diameter and low cost and a process is simple.

Owner:UNIV OF JINAN

Porous aluminum-magnesium alloy preparation method

The invention relates to a porous aluminum-magnesium alloy preparation method, which comprises: adopting an aluminum-magnesium alloy prepared according to a mass ratio of aluminum to magnesium of 2:8 as a matrix material, carrying out surface cleaning air-drying, heating and melting the aluminum-magnesium alloy, adding a foaming agent, uniformly stirring the aluminum-magnesium alloy, adding a binder, uniformly stirring, pouring the stirred mixture into a foaming tank, conveying into a foaming furnace to foam, taking out, and carrying out a cooling treatment. According to the present invention, the process of the technical scheme is simple, the production cost is low, the preparation method is suitable for large-scale industrial production, and the porous magnesium-aluminum alloy is suitable for advanced furniture production.

Owner:DALIAN FEIMA OFFICE FURNITURE

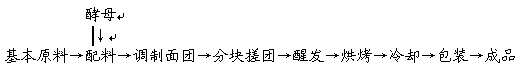

Technology adopting secondary fermentation method for making bread

InactiveCN105028568AComplete formPlumpPre-baking dough treatmentBakery productsDough fermentationRaw material

The invention discloses a technology adopting a secondary fermentation method for making bread, and relates to the technical field of bread making. The technology mainly comprises the steps that raw materials are prepared and weighed, seed dough is made through mixing and fermented, main dough is made through mixing and fermented, the dough is divided and rubbed to be round and stands, formed dough is fermented and baked, and then a baked product is taken out of an oven to be placed on an airing frame, cooled at indoor temperature and then packaged. The defects in the prior art can be overcome, the technology for making the bread is simple, by the adoption of the secondary fermentation method, the made bread is complete in form, plump, free of black foams or obvious burned dots, even and normal in surface color and luster, fine, smooth and elastic in internal tissue, even in pore, clear in grain, slow in aging, softer and more agreeable to the taste, and is in a sponge shape, and a stuffing membrane is thin.

Owner:金怀蕊

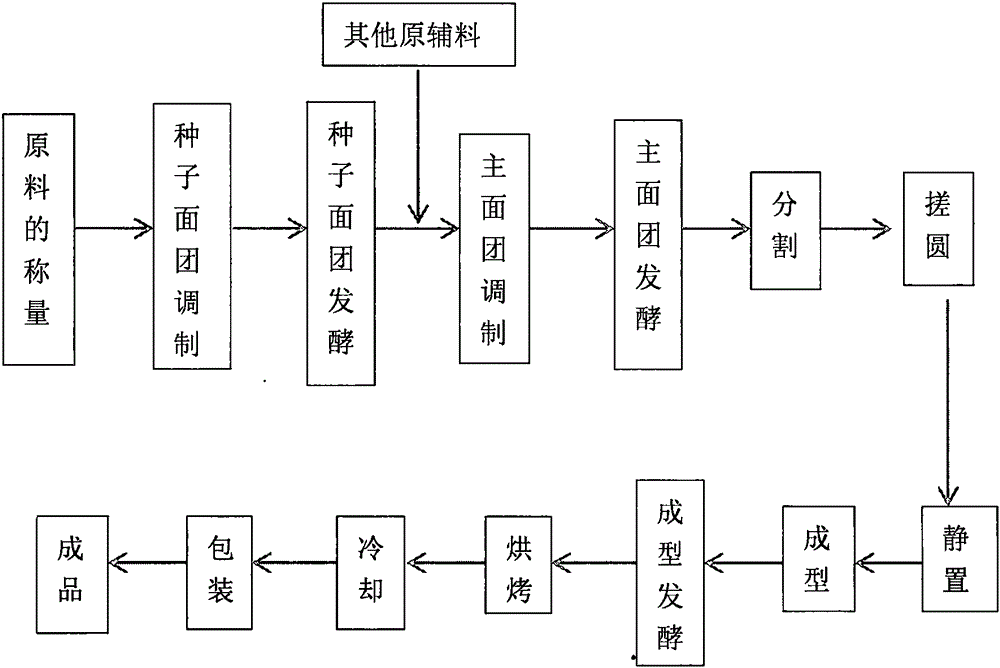

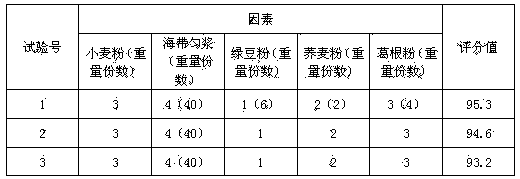

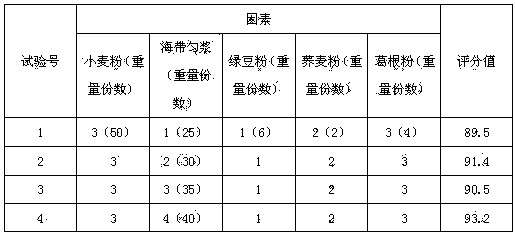

Kelp and mung bean healthcare steamed bun and preparation method thereof

ActiveCN103859290AGuaranteed tasteGuaranteed flavorNatural extract food ingredientsFood ingredient functionsBiotechnologyPolygonum fagopyrum

The invention discloses a kelp and mung bean healthcare steamed bun and a preparation method of the kelp and mung bean healthcare steamed bun. The kelp and mung bean healthcare steamed bun comprises the following ingredients in parts by weight: 40 to 55 parts of wheat flour, 6 to 9 parts of mung bean powder, 2 to 5 parts of radix puerariae powder, 1 to 4 parts of buckwheat flour, 25 to 40 parts of kelp pulp, 1 to 3 parts of hawthorn, 2 to 5 parts of milk, 5 to 9 parts of eggs and 0.5 to 1.5 parts of active dry yeast. The raw materials are pretreated, mixed, fermented, kneaded, molded, fermented, steamed and cooled to obtain the healthcare steamed bun. The healthcare steamed bun is good in taste, rich and balanced in nutrients, good in healthcare effect, toxic-free, wide in raw material source, low in price and simple and convenient to prepare. The prepared kelp and mung bean healthcare steamed bun is suitable for diabetes and hypertensive to eat.

Owner:LANGFANG NORMAL UNIV

Preparation method for sodium carboxymethylcellulose degradation product and purpose of working as frozen dough modifier

ActiveCN107041399AControl growth rateReduce sizeDough treatmentPre-baking dough treatmentBiotechnologyFood additive

The invention discloses a preparation method for sodium carboxymethylcellulose degradation products and belongs to the field of food additives. Sodium carboxymethylcellulosewith substitute degree of 0.9 to 1.5 and then dissolved into phosphate buffer with a pH value of 5.0 to prepare a sodium carboxymethylcellulose solution with weight concentration of 2%; and then cellulose is added for degradation and a sodium carboxymethylcellulose degradation product with viscosity of 100 to 700mPa.s can be achieved. The degradation product is applied for a frozen dough modifier and the addition amount is 0.3 to 1% of the flour; the dough structure can be protected during the refrigeration by the use of the degradation product; content of water capable of being frozen can be reduced for the dough; a finished product volume can be increased and a tissue structure can be improved; and bread taste and flavor can be improved.

Owner:HUAZHONG AGRI UNIV

Selenium enriched fruit Switzerland sugar

InactiveCN105580950AFormulation ScienceReasonable ratio of oil to waterFlexible coversWrappersNutritionOligosaccharide

The present invention discloses a selenium enriched fruit Switzerland sugar which consists of the following raw materials: granulated sugar, fructooligosaccharides, soy oligosaccharides, lactitol, water, fruits, cream, hydrogenated coconut oil, selenium-enriched yeast powder, selenium-enriched malt powder, corn starch, gellan gum, konjac gum, citric acid, compound vitamins and lysozyme. The product is scientific in recipe, good in thermal stability, sweet, sour and tasty, fragrant and delicate, and rich in organic selenium, helps digestion and absorption, and has functions of preventing oxidation and aging, enhancing immunity, expelling toxins, preventing against cancers, improving eyesight, preventing cardiovascular and cerebrovascular diseases, protecting liver, and promoting gastrointestinal function. Fruit juice is used to increase the flavor of the Switzerland sugar, and the Switzerland sugar is natural and healthy, and rich in nutrition. The sugar is melted, filtered and boiled in stages, the corn and edible gel are added, so that the obtained sugar body is delicate, soft and not sticky to teeth. After the sugar is boiled and the temperature is lowered, the vitamins and lysozyme are added, nutrients and flavors are maintained, and the Switzerland sugar is subjected to natural sterilization. The Switzerland sugar is long in shelf life, free of preservative, and safe and healthy.

Owner:ANHUI BAOZHITANG PHARMA

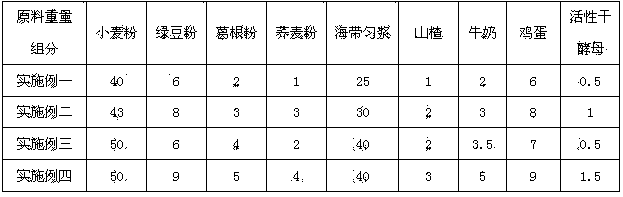

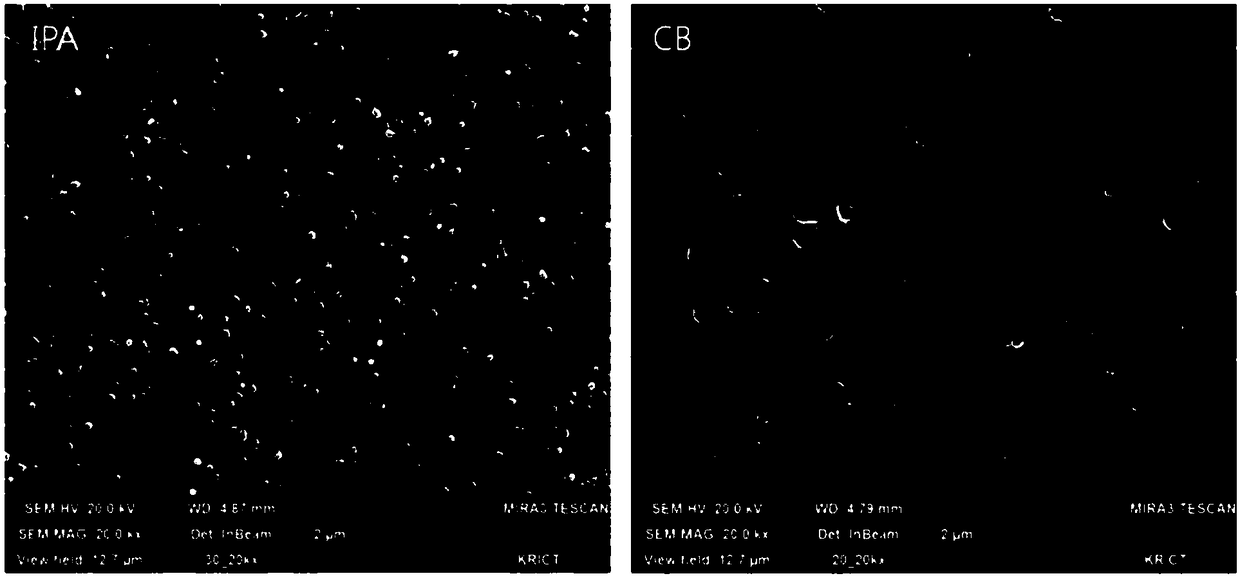

Porous metal halide film, fabrication method thereof, and fabrication method of organometal halide having perovskite structure using the same

InactiveCN108569719AUniform stomataIncrease production capacitySolid-state devicesLead halidesCrystallographyK-alpha

Provided are a porous metal halide film that reacts with an organic halide to be converted into an organometal halide having a perovskite structure, thereby fabricating the organometal halide, a fabrication method thereof, and a fabrication method of an organometal halide having a perovskite structure using the same, and specifically, the porous metal halide film according to the present disclosure satisfies Relational Expression 1 below: I (101) / I (001)>=0.5 in Relational Expression 1, 1(101) is a diffraction intensity of a (101) plane in X-ray diffraction pattern using a Cu K alpha line ofthe porous metal halide film, and I(001) is a diffraction intensity of the (001) plane in the same X-ray diffraction pattern.

Owner:KOREA RES INST OF CHEM TECH +1

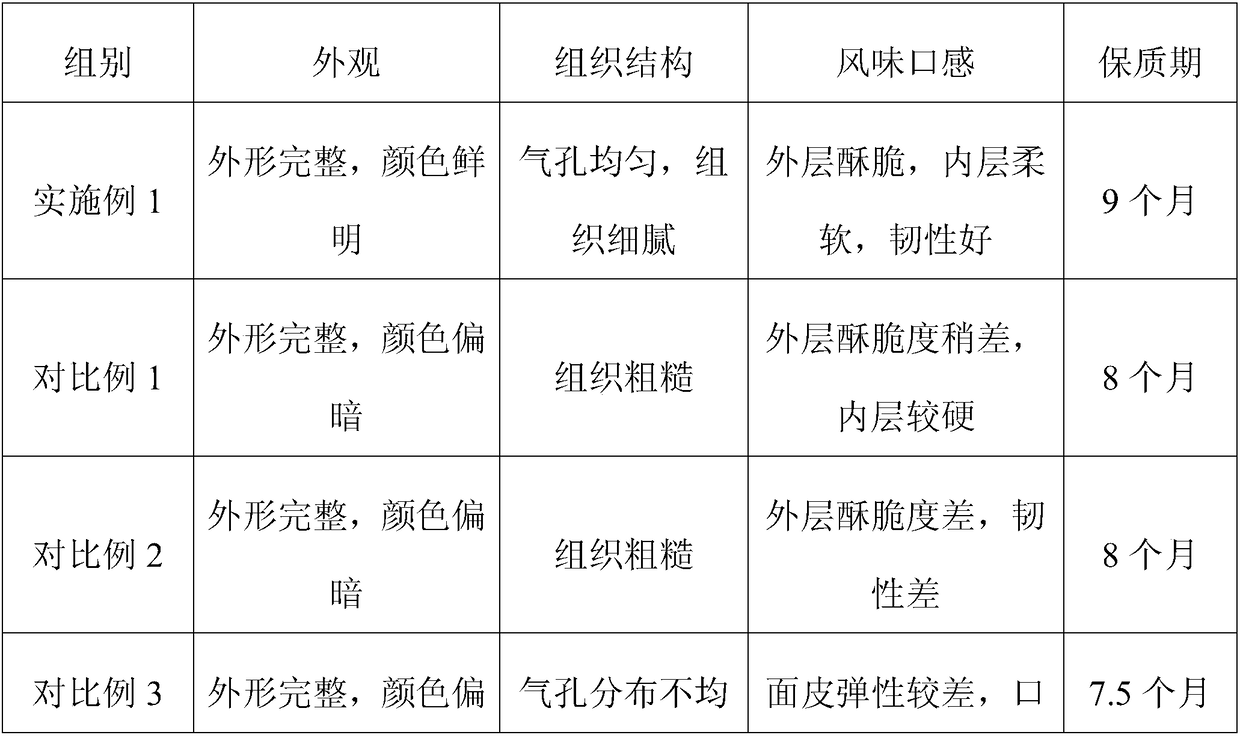

Quick-frozen pan-fried pork buns and making method thereof

InactiveCN109480184AIncrease surface areaCrispy tasteFood freezingYeast food ingredientsGlutenBaking powder

The invention discloses quick-frozen pan-fried pork buns. The wrappers of the pan-fried pork buns comprise the following raw materials in parts by weight of 95-105 parts of medium-gluten flour, 0.15-0.35 part of yeast, 0.8-1.3 parts of white sugar, 0.3-0.5 part of baking powder, 0.8-1.3 parts of emulsified oil, 2-5 parts of lard, 0.2-0.4 part of a wrapper modifier and 51-54 parts of water. The wrapper modifier is added to the wrappers, so that the mouth feel of the wrappers can be notably improved, the stability can be improved, and the quality guarantee period can be prolonged. The inventionalso provides a making method of the quick-frozen pan-fried pork buns. Dough leavening is performed in a freezer, fermentation is performed in the freezer of 0-5 DEG C for one night, on the next day,the effect of half-leavened dough can be achieved, and the wrappers of the pan-fried pork buns can be tenacious and cannot retract; and dough is put in a pork bun making machine for shaping, secondaryleavening is not used, the pan-fried pork buns are directly put in a tunnel for quick-freezing, the technology is simplified and controllable, and the production efficiency is greatly improved.

Owner:河南创新研霖食品科技有限公司

Slurry direct writing forming method of diamond tool

ActiveCN112723902APromote self-sharpeningUniform stomataAdditive manufacturing apparatusAbrasion apparatusPolymethyl methacrylateNanoceramic

The invention discloses a slurry direct writing forming method of a diamond tool, which comprises the following steps: (1) fully mixing nano ceramic powder, PMMA (polymethyl methacrylate) and diamond microparticles to obtain mixed powder; (2) fully dispersing xanthan gum in deionized water to obtain a xanthan gum solution; (3) uniformly mixing the mixed powder prepared in the step (1) with the xanthan gum solution obtained in the step (2) to obtain slurry; (4) adding the slurry prepared in the step (3) into a needle cylinder of slurry direct writing forming equipment, and printing into a designed shape in a layer-by-layer overlapping manner to obtain a green body; and (5) drying the green body prepared in the step (4) to constant weight, and then sintering to obtain the diamond tool. The diamond tool with a complex structure can be manufactured at a time through slurry direct writing forming, and the diamond tool has high consistency, proper mechanical property, controllable porosity and high shape precision.

Owner:HUAQIAO UNIVERSITY

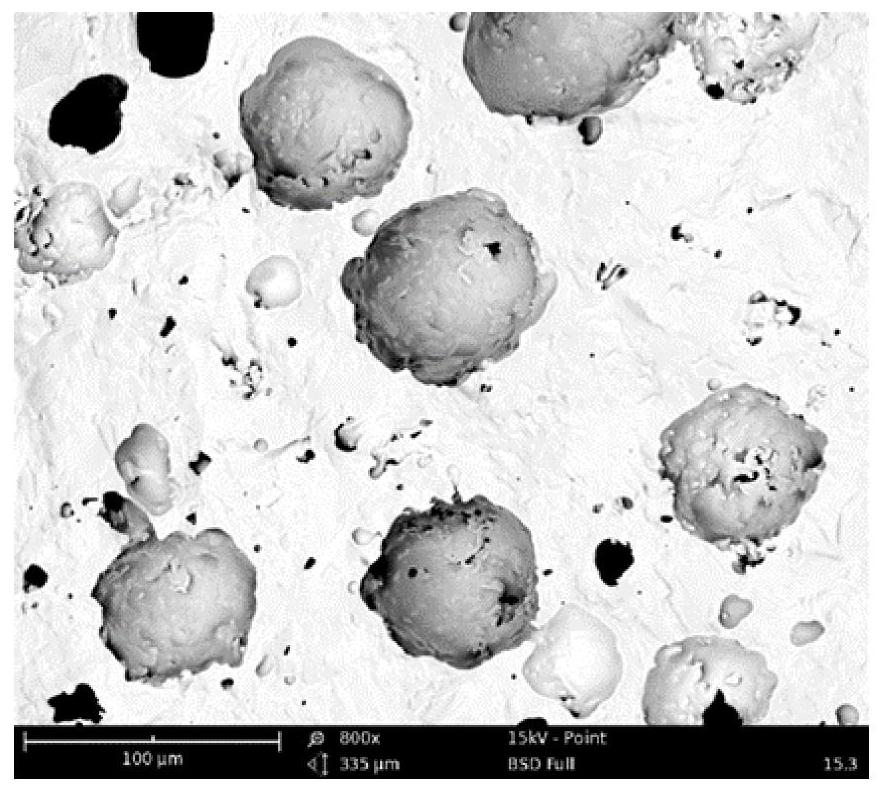

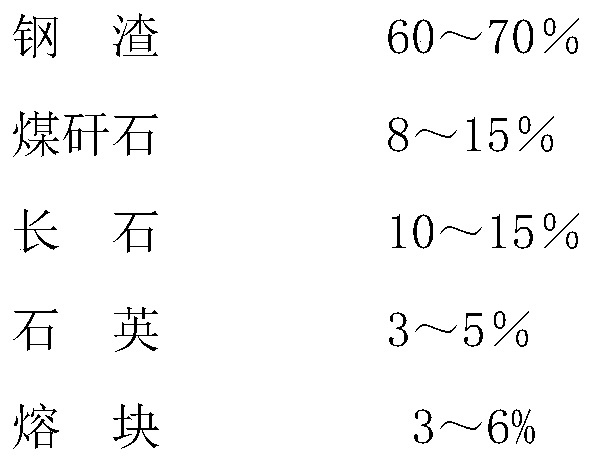

Method for preparing foamed ceramic from metallurgical high-temperature flow-state steel slag

InactiveCN111517819ARemarkable effect of energy saving and consumption reductionEliminate evaporationCeramic materials productionCeramicwareSteelmakingMolten state

The invention relates to a method for preparing foamed ceramic from metallurgical high-temperature flow-state steel slag, and belongs to the technical field of building materials. According to the method, the waste steel slag serves as a main raw material, physical heat in the metallurgical production process is utilized, the steel slag does not need to be sintered after being subjected to the processes of cooling, crushing, mixing and the like, and thus the remarkable energy-saving and consumption-reducing effects are achieved in the product preparation process. In addition, the steel slag at the temperature of 1100-1400 DEG C in the steelmaking process is directly used in the high-temperature molten state without supercooling, and the steel slag does not need to be treated by a water splashing method or a hot stuffy method so that evaporation of hot fugitive white water vapor is completely eliminated, the environment is improved, and the environment-friendly'white removal 'requirement is met. The foamed ceramic prepared by the method is stable in phase and uniform in pores, foamed ceramic parts with different complex shapes can be manufactured according to different requirementsof product usability, and the foamed ceramic has good social benefits and economic benefits and wide application prospects.

Owner:唐山庄信科技有限公司

Old dough yeast and preparation method thereof

The invention discloses an old dough yeast and a preparation method thereof. The old dough yeast comprises flour and mixed liquid, wherein the mixed liquid comprises the ingredients of bread yeast milk, wine yeast milk, rosin yeast milk, lactic acid bacteria milk, trehalose, edible glycerol and food-grade calcium carbonate through mixing. The preparation method of the old dough yeast comprises the following steps of: (1) preparing the bread yeast milk; (2) preparing the wine yeast milk; (3) preparing the rosin yeast milk; (4) preparing the lactic acid bacteria milk; (5) weighing the bread yeast milk, the wine yeast milk, the rosin yeast milk, the lactic acid bacteria milk, the trehalose, the edible glycerol and the food-grade calcium carbonate and evenly mixing the ingredients to prepare the mixed liquid; (6) evenly mixing the flour and the mixed liquid, extruding and granulating; and (7) drying and dewatering the granules. The old dough yeast prepared by the method provided by the invention remains the advantages of high leavening speed of steamed bread by bread yeast. The finished products of steamed bread are white and soft, the pores of steamed bread are arranged evenly and the steamed bread has the sweet smell of old dough steamed bread.

Owner:JINAN RUIFENG BIO ENG

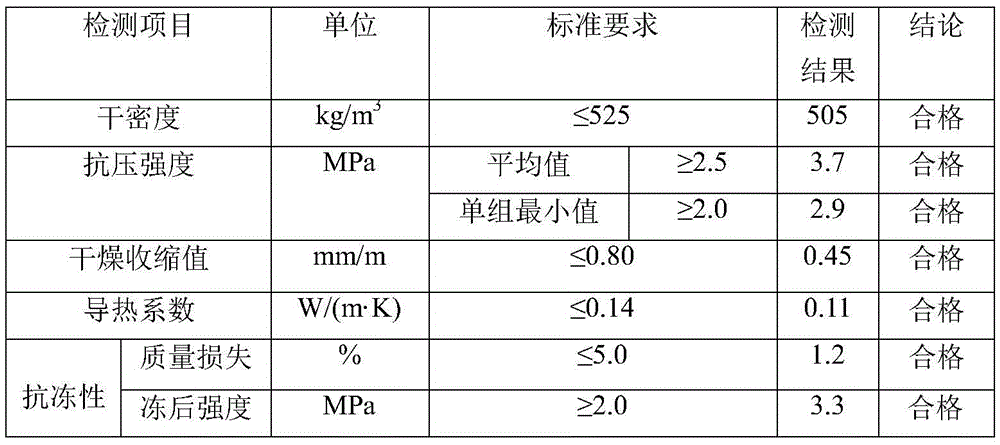

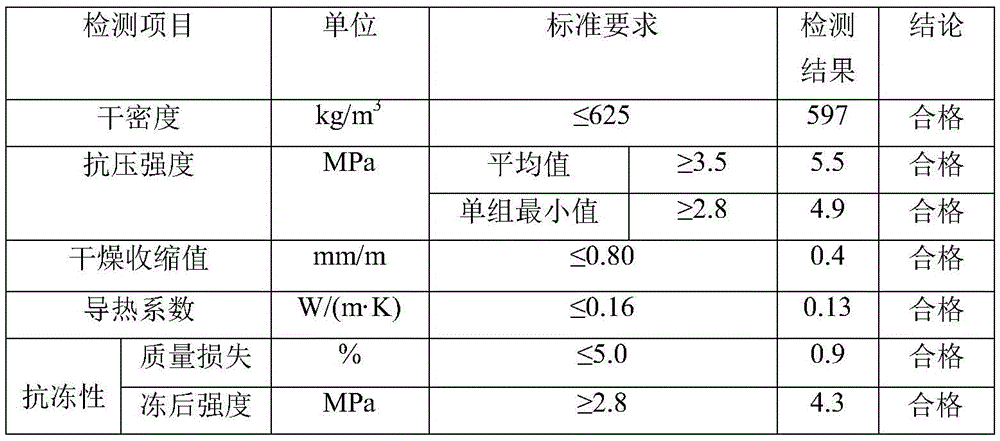

Molybdenum-tailings microcrystal foaming material and preparation method thereof

ActiveCN109626829AHigh chemical composition requirementsOvercome strengthFreeze thawingFoaming agent

The invention belongs to the field of building materials and particularly relates to a molybdenum-tailings microcrystal foaming material and a preparation method thereof. The raw materials comprise molybdenum tailings, a foaming agent and an ingredient. The application amount of the molybdenum tailings is above 90%, and the utilization rate of the molybdenum tailings is greatly increased; the preparation method of the material is simple, and through simple pretreatment, granulation, distribution and sintering technologies, the raw materials can be processed into the finished products. The prepared molybdenum-tailings microcrystal foaming material can be applied to the building industry and has excellent performance such as low weight, high strength, low heat conduction coefficient and freeze thawing resistance, and the quality of the foaming material is greatly improved.

Owner:河北恒钏建筑材料有限公司 +1

Nourishing lung-moistening Swiss sugar

InactiveCN105594964AFormulation ScienceReasonable ratio of oil to waterConfectionerySweetmeatsIsomaltooligosaccharideFruit juice

The invention discloses nourishing lung-moistening Swiss sugar comprising the following ingredients: granulated sugar, xylooligosaccharide, isomaltooligosaccharide, gentiooligosaccharide, water, persimmon, lily, pears, duck eggs, traditional Chinese medicines, cream, hydrogenated palm oil, corn starch, gellan gum, konjac gum, citric acid and lysozyme. The product is scientific in formula, good in thermal stability, fragrant, fine, smooth and rich in a variety of nourishing lung-moistening food ingredients and traditional Chinese medicines, is conducive to digestion and absorption, antioxidant and anti-aging, can enhance immunity, is anti-cancer, and can clear lung, reduce phlegm, dispel diseases and relieve cough; juice increases the taste of the Swiss sugar, the Swiss sugar is free of essence and additives, natural and healthy; the nourishing lung-moistening Swiss sugar is obtained by dissolving the sugar, filtering, and decocting in different stages and then adding edible gum, the obtained Swiss sugar is fine, smooth and soft, and does not stick teeth, the obtained Swiss sugar is uniform, fine and close in pores and good in chewiness due to vacuum freeze-drying, work efficiency is improved, and by addition of the lysozyme for natural sterilization and corrosion prevention, the obtained Swiss sugar is long in shelf life, does not contain preservatives, and is safe and healthy.

Owner:界首市奥源食品有限责任公司

A water-resistant foamed gypsum insulation material and its preparation method

The invention discloses a water-resistant foamed gypsum thermal-insulation material which is prepared from the following raw materials in parts by weight: 100 parts of modified desulfurized building gypsum powder, 5-10 parts of polymer composite emulsion, 0.1-0.5 part of polyvinyl alcohol fiber and 40-60 parts of mixing water. The modified desulfurized building gypsum powder is prepared by mixing the following raw materials in parts by weight and grinding in a ball mill for 0.5-1 hour: 100 parts of building desulfurized gypsum powder, 2-10 parts of sodium aluminate, 1-5 parts of natural base, 1-3 parts of sodium citrate, 5-20 parts of rice hull ash and 1-3 parts of trisodium phosphate. Besides, the invention also discloses a preparation method of the water-resistant foamed gypsum thermal-insulation material. The water-resistant foamed gypsum thermal-insulation material has the advantages of light weight, high strength, thermal insulation, fire resistance, water resistance, short manufacturing period, low cost and the like, can be directly used for internal wall thermal insulation and external wall thermal insulation of a building, and has certain carrying capacity.

Owner:CHANGAN UNIV

Water-resistant foamed gypsum thermal-insulation material and preparation method thereof

The invention discloses a water-resistant foamed gypsum thermal-insulation material which is prepared from the following raw materials in parts by weight: 100 parts of modified desulfurized building gypsum powder, 5-10 parts of polymer composite emulsion, 0.1-0.5 part of polyvinyl alcohol fiber and 40-60 parts of mixing water. The modified desulfurized building gypsum powder is prepared by mixing the following raw materials in parts by weight and grinding in a ball mill for 0.5-1 hour: 100 parts of building desulfurized gypsum powder, 2-10 parts of sodium aluminate, 1-5 parts of natural base, 1-3 parts of sodium citrate, 5-20 parts of rice hull ash and 1-3 parts of trisodium phosphate. Besides, the invention also discloses a preparation method of the water-resistant foamed gypsum thermal-insulation material. The water-resistant foamed gypsum thermal-insulation material has the advantages of light weight, high strength, thermal insulation, fire resistance, water resistance, short manufacturing period, low cost and the like, can be directly used for internal wall thermal insulation and external wall thermal insulation of a building, and has certain carrying capacity.

Owner:CHANGAN UNIV

Low-cost solar heat-absorbing ceramic material and preparation method thereof

ActiveCN107010962AGood high temperature oxidation resistanceImprove thermal shock resistanceCeramicwareBoron nitrideThermal shock

The invention discloses a low-cost solar heat-absorbing ceramic material. The low-cost solar heat-absorbing ceramic material contains the following components in parts by weight: 15-40 parts of silicon nitride, 15-40 parts of boron nitride, 5-15 parts of titanium silicide, 5-15 parts of nickel carbide, 5-12 parts of chromium oxide, 5-12 parts of aluminum oxide, 2-7 parts of sodium silicate, 2-5 parts of boron oxide and 2-3 parts of manganese monoxide. The heat-absorbing ceramic material with good high-temperature oxidation resistance and thermal shock resistance, a three-dimensional network structure, a high specific surface area and high thermal conductivity is prepared by virtue of an organic foam dipping process and is particularly suitable for tower type solar thermal power generation heat-absorbing bodies.

Owner:泾县凡泽科技服务有限公司

Hybridized aramid silicone aerogel modified flame-retardant polypropylene foaming plate and preparation method thereof

The invention discloses a hybridized aramid silicone aerogel modified flame-retardant polypropylene foaming plate and a preparation method thereof. A hybridized aramid silicone aerogel filler in foaming materials is obtained by mixing an aramid pulp solution with a silica sol system, an aerogel compound with a porous network structure and high in toughness, heat resistance and flame retardant is finally obtained. Melt strength can be effectively increased by adding the aerogel compound into a resin system, effects of reinforcement, flame retardance, nucleation and the like are achieved, usage amount of a traditional flame retardant is reduced, porosity of the system can be effectively increased, resin foaming is facilitated, traditional flame retardant materials of molybdenum disulfide, diethyl phosphonate aluminum and the like are combined, and the lightweight polypropylene foaming composite material with good flame-retardant effect is finally prepared; the composite material is even in porosity, crush and heat resistant, resistant to wear corrosion, economic and durable and quite promising in application.

Owner:阜阳市三郁包装材料有限公司

High-temperature good-strength quartz-based expendable pattern paint modified by mica powder and preparation method of high-temperature good-strength quartz-based expendable pattern paint

InactiveCN105855459AImprove dispersion stabilityImprove crack resistanceFoundry mouldsFoundry coresAluminiumPlastic foam

The invention discloses high-temperature good-strength quartz-based expendable pattern paint modified by mica powder. The high-temperature good-strength quartz-based expendable pattern paint is prepared from the following raw materials in parts by weight: 100-102 parts of quartz powder, 0.9-1.1 parts of modified starch, 0.9-1.1 parts of carboxymethyl cellulose, 2.4-2.6 parts of sodium bentonite, 0.9-1 part of mica powder, 0.8-0.9 part of tetrapod ZnO whiskers, 0.9-1.1 parts of silicasol, 10-13 parts of ethanol, an appropriate amount of water, 0.5-0.6 part of aluminum sol, 1.1-1.3 parts of nonionic boronates and 0.2-0.3 part of tea tree essential oil. The aluminum sol, the nonionic boronates and the tea tree essential oil are used, so that the bentonite is modified, the lipophilicity of the bentonite is improved, and the cohesiveness and the sagging resistance of the paint to plastic foams are improved; therefore, coatings are uniform and compact, molten steel is prevented from penetrating, the fissility is improved, and the aluminum sol and the nonionic boronates can form heat-resistant oxide after being heated, so that the high temperature strength of the coatings is improved.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com