Phosphorus slag-phosphate tailing foam concrete block and making method thereof

A foamed concrete and phosphorus tailings technology is applied in the application field of waste recycling, which can solve the problems of high production cost, low utilization rate of industrial waste, large amount of cement and aggregate, etc., and achieves low cost, thermal insulation and sound insulation effect. Good, reduce the effect of environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

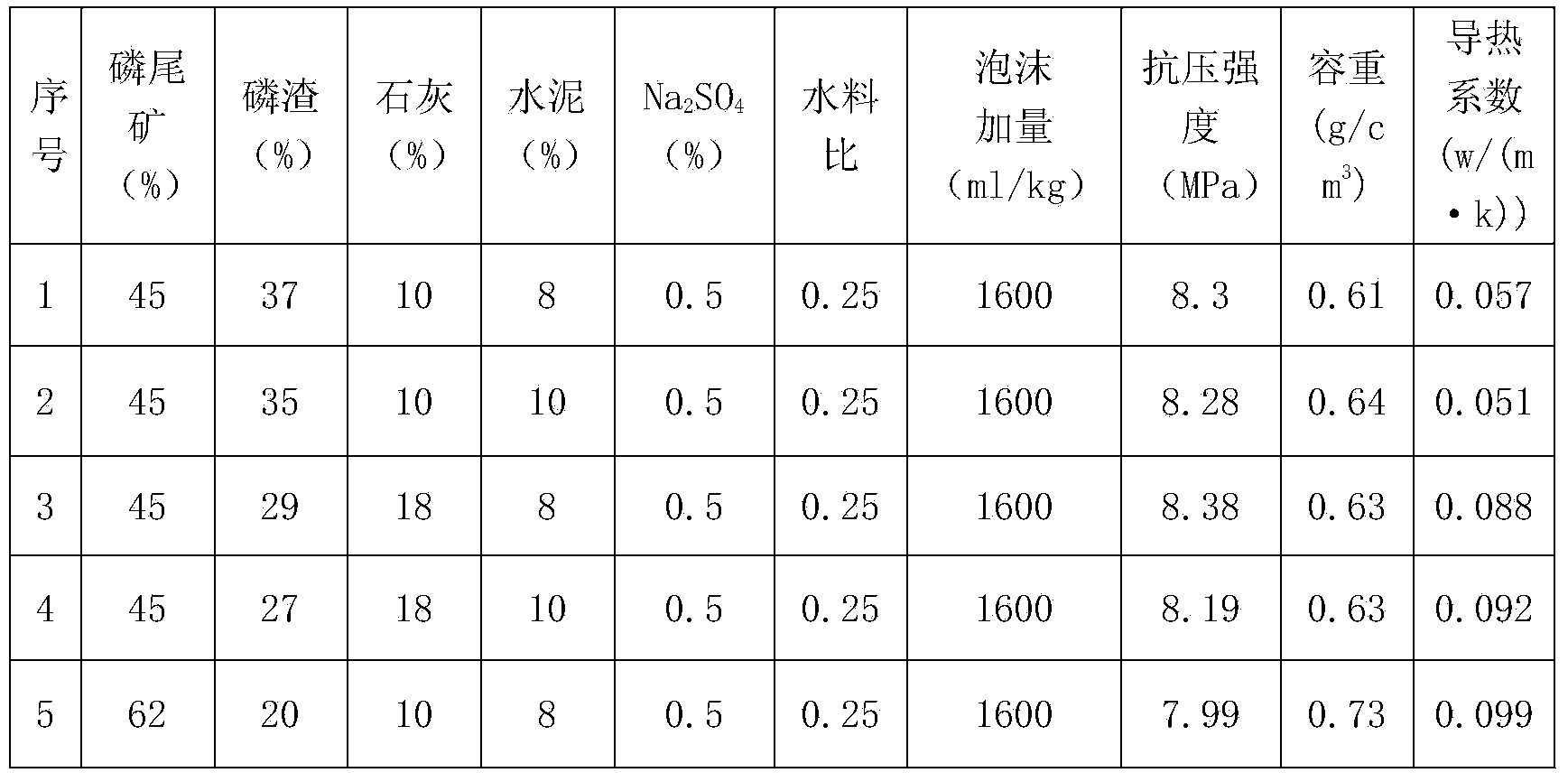

Embodiment 1~5

[0026] The phosphorus slag-phosphorus tailings foamed concrete blocks of Examples 1 to 5 are prepared by mixing base material, admixture, water and foam. The distribution ratio of each component is shown in Table 1. The base material is composed of phosphorus tailings, Composed of phosphorus slag, lime and cement, the admixture is sodium sulfate (Na 2 SO 4 ), the amount of the admixture is 0.5% of the mass of the base material, the amount of the water is 0.25 of the mass of the dry material composed of the base material and the admixture (the ratio of water to material is 0.25), the Foam is measured by volume, and the ratio of the amount of foam to the total mass of other components (the total mass of base material, admixture and water) is 1600ml / kg.

[0027] The preparation method of phosphorus slag-phosphorus tailings foam concrete block in the embodiment 1~5, comprises the following steps:

[0028] (1) According to the distribution ratio of each component in Table 1, weig...

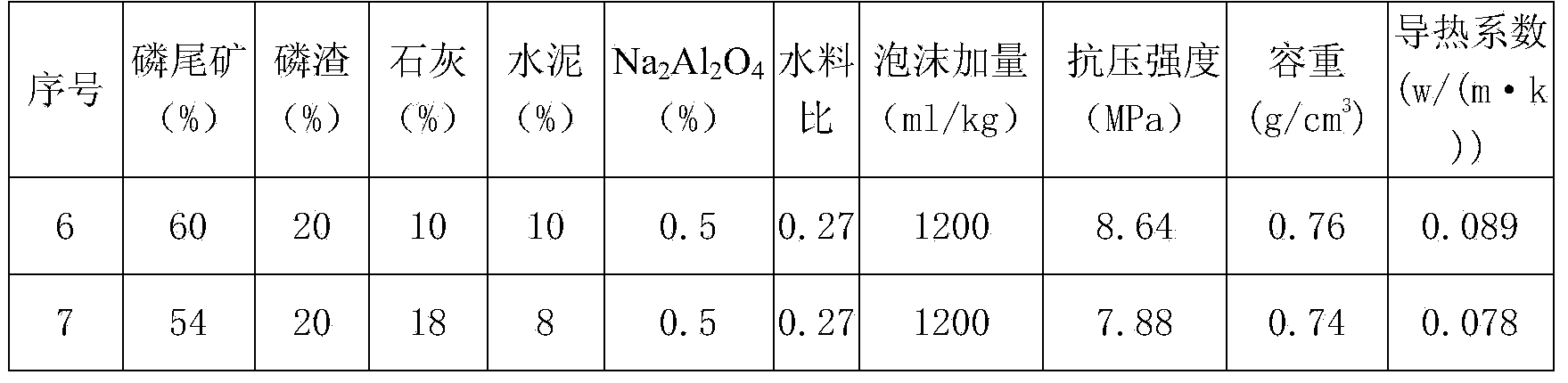

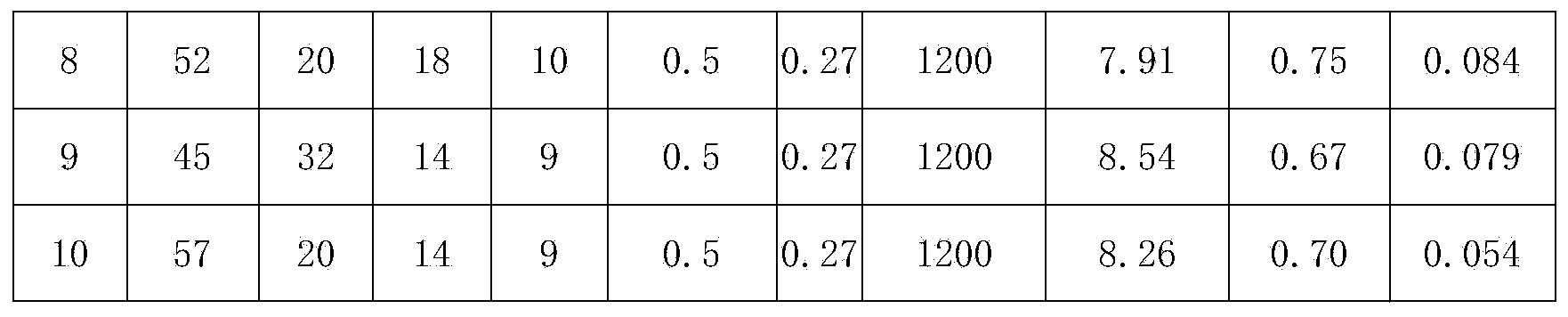

Embodiment 6~10

[0035] The distribution ratio of each component of the phosphorus slag-phosphorus tailings foam concrete block in Examples 6-10 is shown in Table 2. The base material is composed of phosphorus tailings, phosphorus slag, lime and cement, and the admixture is sodium aluminate (Na 2 Al2 o 4 ), the amount of the admixture is 0.5% of the mass of the base material, the amount of the water is 0.27 of the mass of the dry material composed of the base material and the admixture (the ratio of water to material is 0.27), the Foam is measured by volume, and the ratio of the amount of foam to the total mass of other components (the total mass of base material, admixture and water) is 1200ml / kg.

[0036] In Examples 6-10, the preparation method of the phosphorous slag-phosphorus tailings foam concrete block is roughly the same as that of Examples 1-5, the difference is that the curing in step (3) is under natural conditions for 24 hours, and the cured After demolding the completed test bl...

Embodiment 11~15

[0043] The distribution ratio of each component of the phosphorous slag-phosphorus tailings foam concrete block in Examples 11 to 15 is shown in Table 3. The base material is composed of phosphorous tailings, phosphorous slag, lime and cement, and the admixture is sodium silicate (Na 2 SiO 3 ), the amount of the admixture is 0.5% of the mass of the base material, the amount of the water is 0.3 of the mass of the dry material composed of the base material and the admixture (the ratio of water to material is 0.3), the Foam is measured by volume, and the ratio of the amount of foam to the total mass of other components (total mass of base material, admixture and water) is 1000ml / kg.

[0044] In Examples 11 to 15, the preparation method of the phosphorus slag-phosphorus tailings foam concrete block is roughly the same as that of Examples 1 to 5, the difference is that in step (3), after demoulding the cured test block, place Steamed in an autoclave with a steam pressure of 0.8Mp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com