Patents

Literature

224results about How to "Realize waste heat utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder

InactiveCN101851071AF-CaO content decreasedAchieve stabilizationCalcium/strontium/barium carbonatesGas treatmentSlagResource utilization

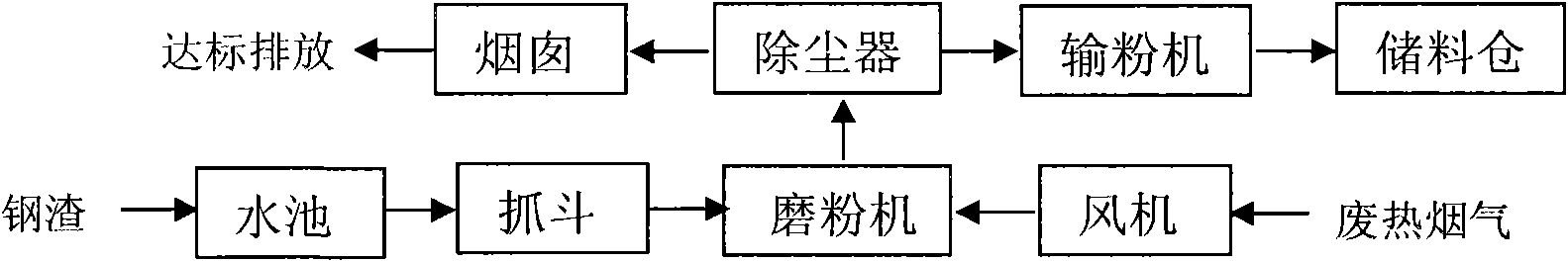

The invention relates to a method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder, which belongs to the technical field of the carbon dioxide reduction and the industrial solid waste resource utilization. Converter steel slag is soaked in water, then the steel slag after being soaked in the water is added into a grinding machine, at the same time, waste heat smoke gas containing carbon dioxide is introduced into the grinding machine with the steel slag to carry out the stabilization reaction, and the steel slag is ground and dried; the waste heat smoke gas brings out the steel slag micro powder after being ground and dried from the tail section of the grinding machine to enter a power collection device, and the steel slag micro powder is discharged from the bottom part of the powder collection device; and the temperature of the waste heat smoke gas is 150 to 180 DEG C. The method has the advantages that: carbon dioxide in the waste smoke gas is used for chemically modifying the steel slag micro powder, so the content of the f-CaO is reduced, the chemical stability of the steel slag micro powder is improved, and technical requirements of the national standard GB / T 20491 - 2006 of steel slag powder for cement and concrete can be reached. The carbon dioxide also can be cured, so the exhaustion of the greenhouse gas can be reduced, and the environment-friendly carbon cycling mode can be realized.

Owner:SHOUGANG CORPORATION

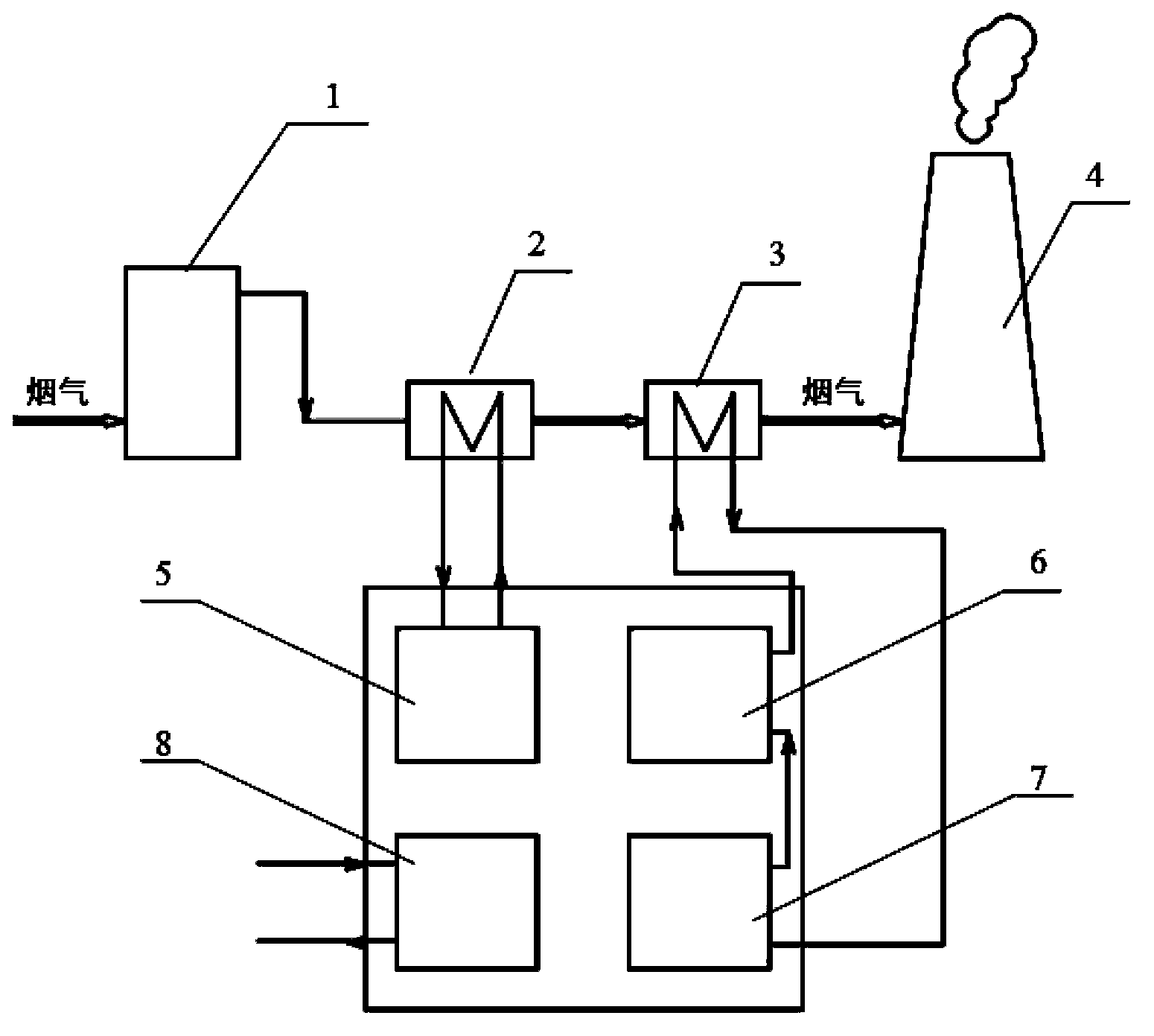

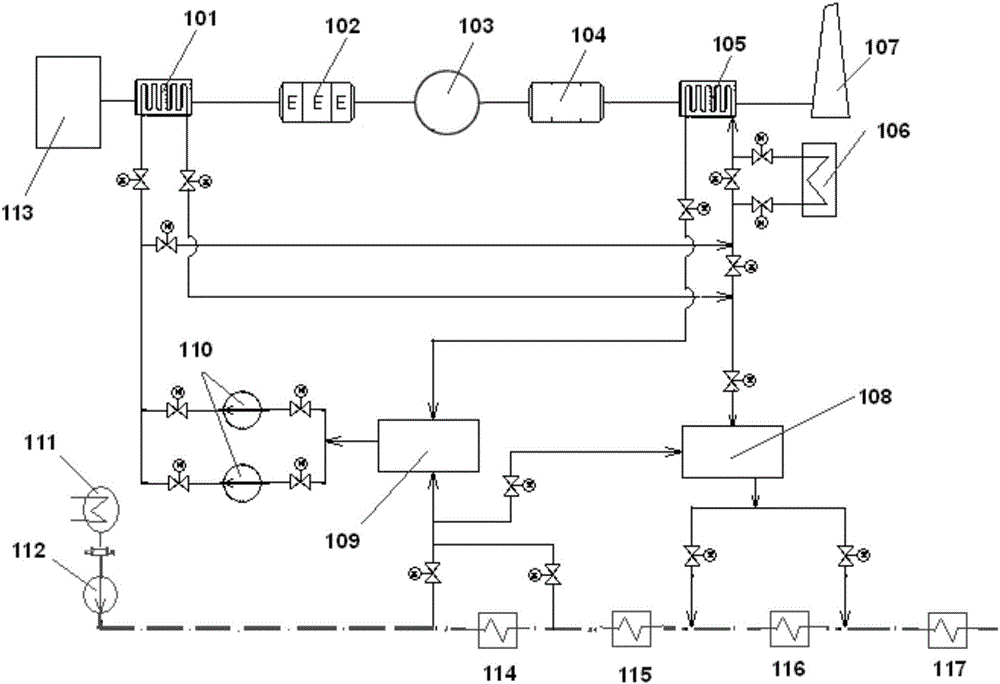

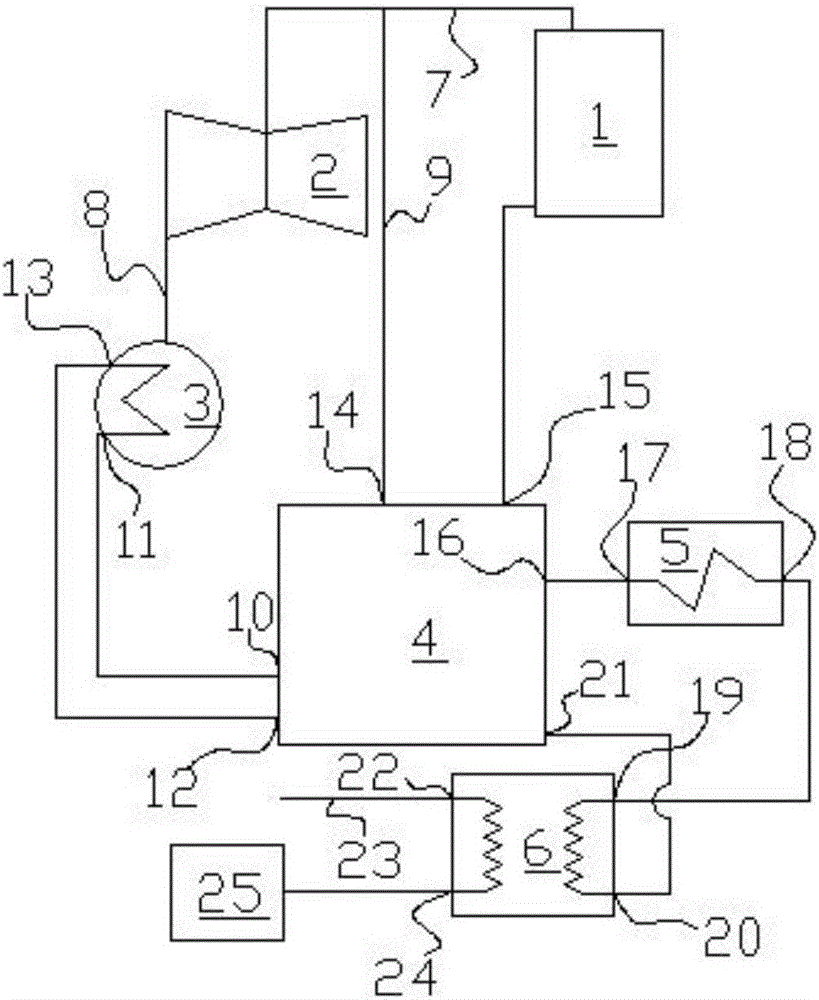

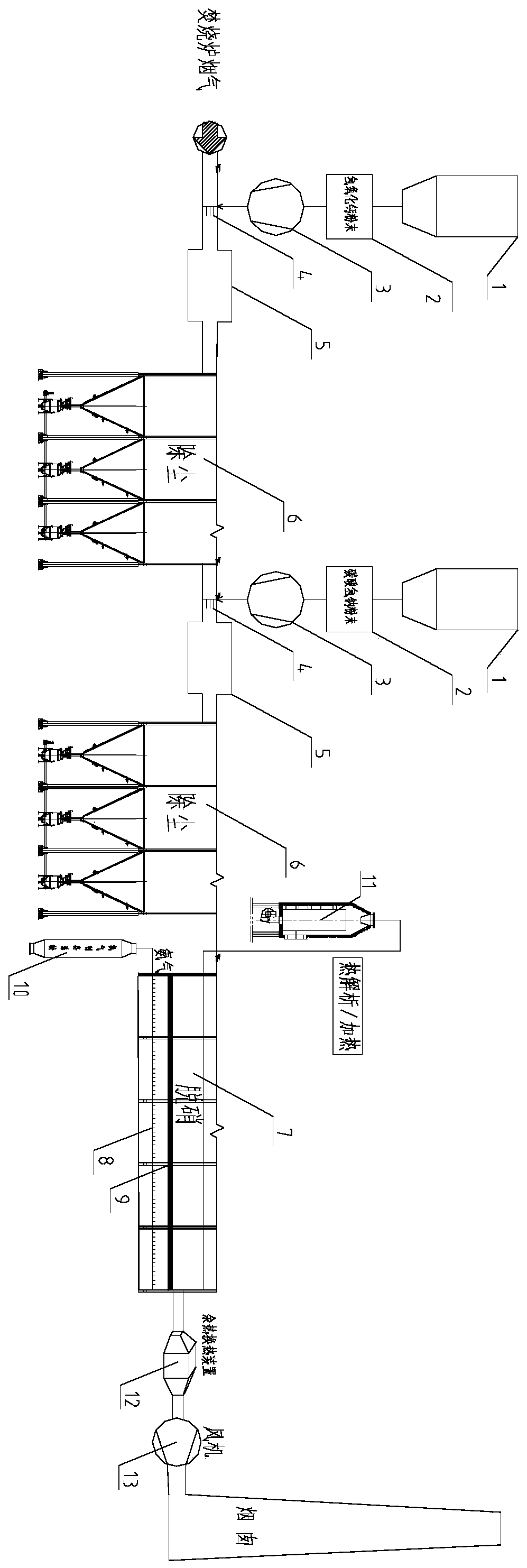

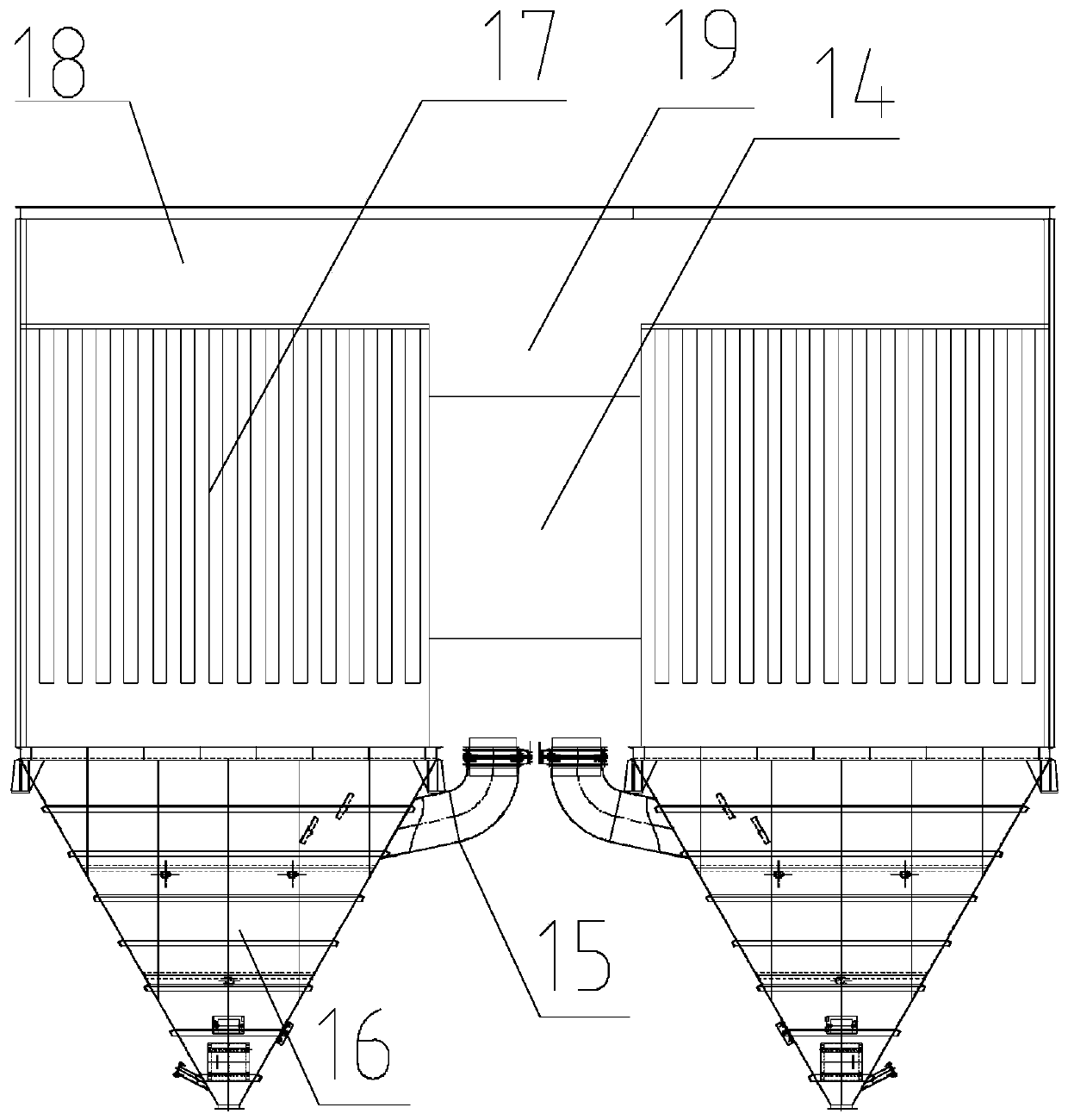

Flue gas circulation system and method for sintering machine flue gas recirculation denitration

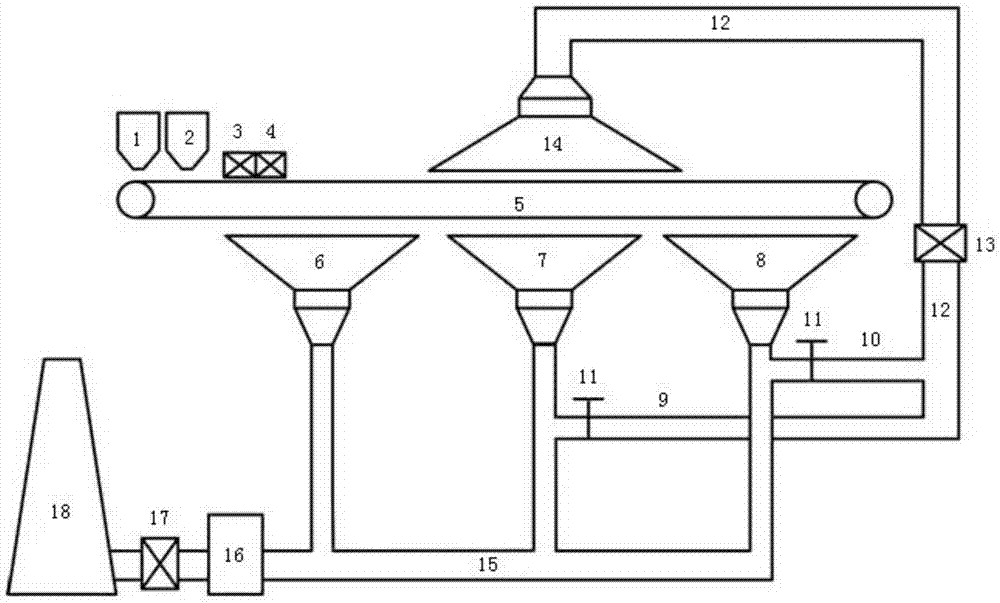

The invention discloses a flue gas circulation system and method for sintering machine flue gas recirculation denitration. The flue gas circulation system is composed of a sintering machine, a branch pipe I, a branch pipe II, regulating valves, a recirculation flue, a recirculation draught fan and a top-suspended flue gas hood. The method comprises the steps that the recirculation draught fan is utilized to extract flue gas in the middle section and the rear section of a wind box of the sintering machine, recirculation flue gas enters the recirculation flue through the branch pipe I and the branch pipe II, enters the top-suspended flue gas hood, and enters a high-temperature combustion zone of a trolley again from the top of the sintering machine, NOx in the flue gas is restored to be N2 through coke, and the NOx is removed. According to the flue gas circulation system and method for the sintering machine flue gas recirculation denitration, on the premise that the combustion mode of the sintering machine and the sinter quality are not changed, the NOx is removed efficiently, the changes to a system are less, the operating cost is low, the operation is simple, convenient and flexible, and the denitration efficiency is high; the flue gas circulation system and method for the sintering machine flue gas recirculation denitration have wide application prospect in the field of sintering machine flue gas denitration.

Owner:TSINGHUA UNIV

Method for producing silicate cement by using silico-calcium dregs and carbide dregs

InactiveCN101591150AReduce contentMeet the requirements of alkali contentCement productionCalcinationMaterials science

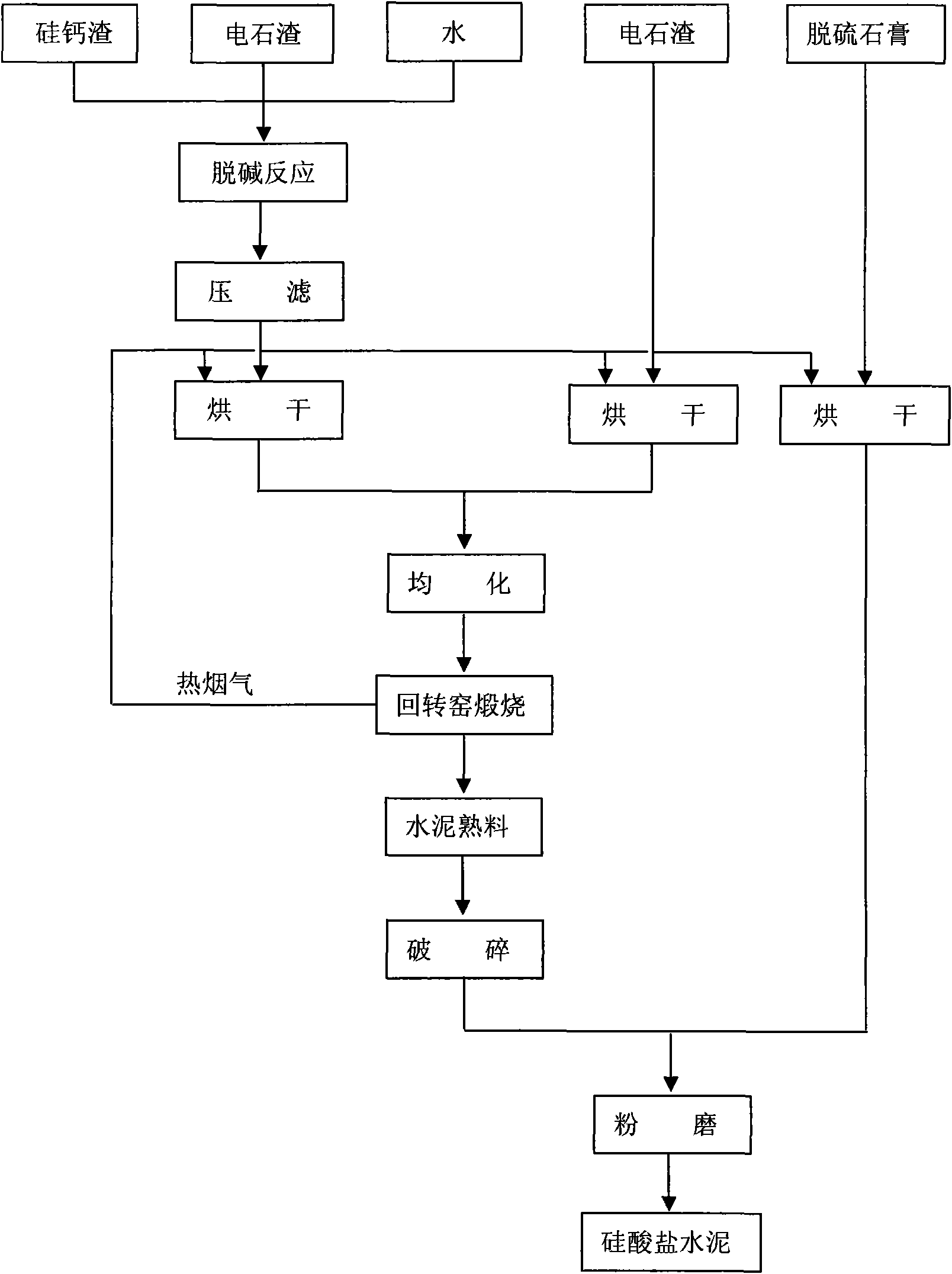

The invention provides a method for producing silicate cement by using silico-calcium dregs and carbide dregs, relating to the technical field of building materials. The method has the following steps: 1. adding carbide dregs and water into silico-calcium dregs followed by dealkalization and carrying out pressure filtering and drying on the dealkalized silico-calcium dregs if the alkali content in the silico-calcium dregs is high, or directly drying the silico-calcium dregs if the alkali content in the silico-calcium dregs is low; and drying the carbide dregs and desulfurated plaster respectively; 2. dosing and homogenizing the dealkalized silico-calcium dregs and carbide dregs after drying; 3. sending the homogenized crude materials into a rotary kiln for high temperature calcinations and obtaining the cement clinker after cooling; and 4. smashing the cement clinker and sending the smashed cement clinker and the dried desulfurated plaster into a cement grinding mill for grinding to prepare the silicate cement. Compared with the prior art, the method of the invention is simple in process, low in investment, low in production cost, low in energy consumption, and stable in the prepared silicate cement performance.

Owner:TONGFANG ENVIRONMENT

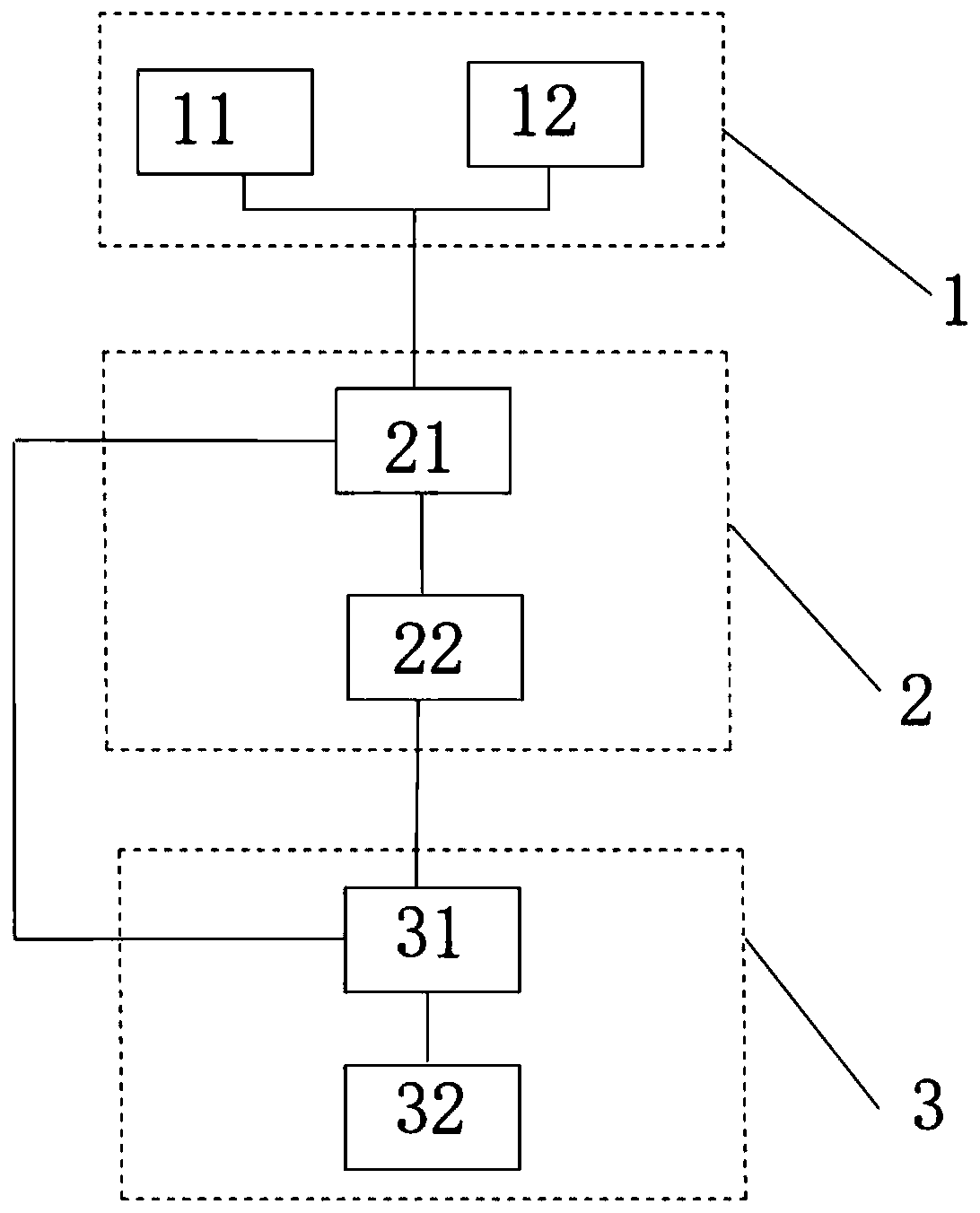

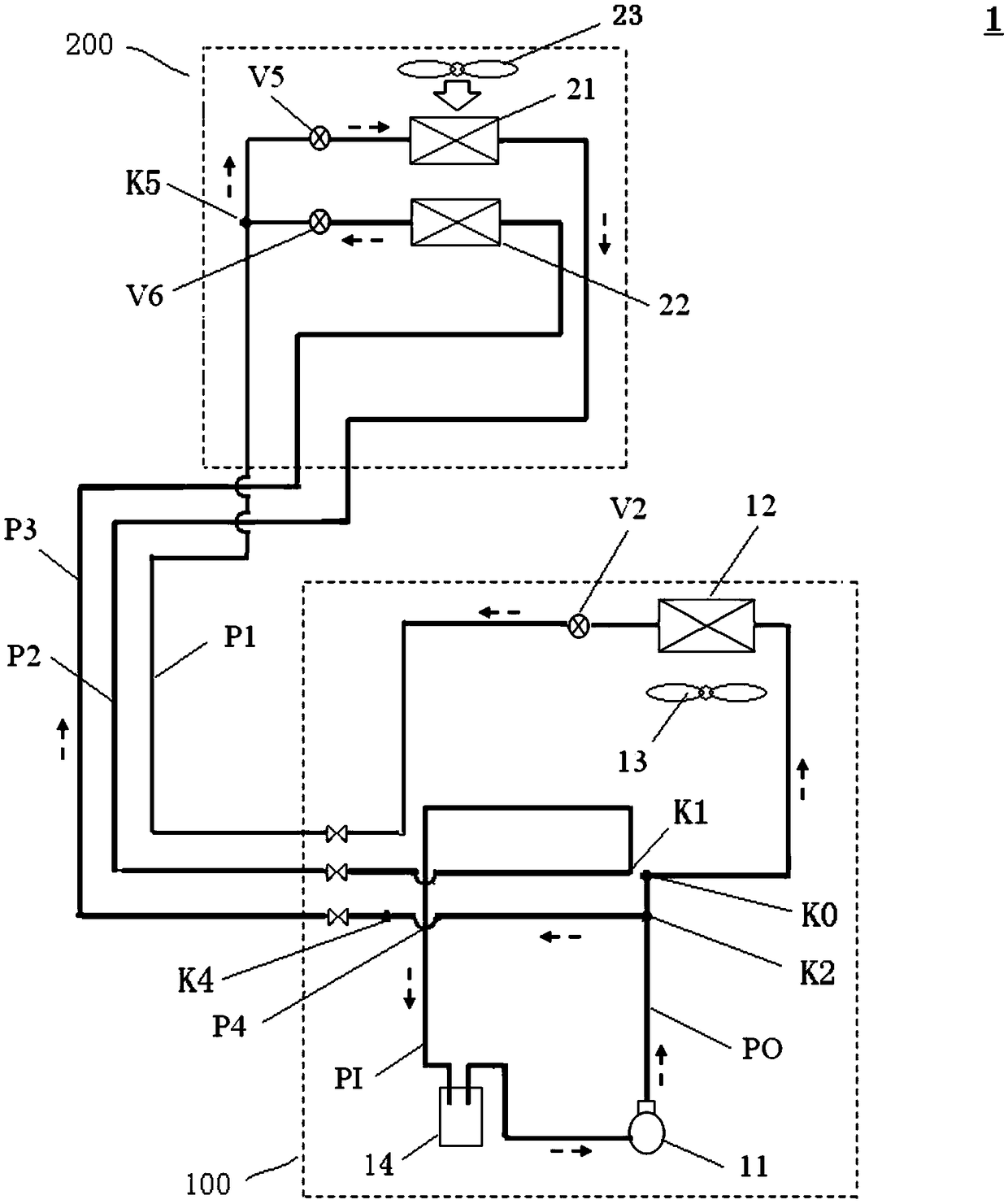

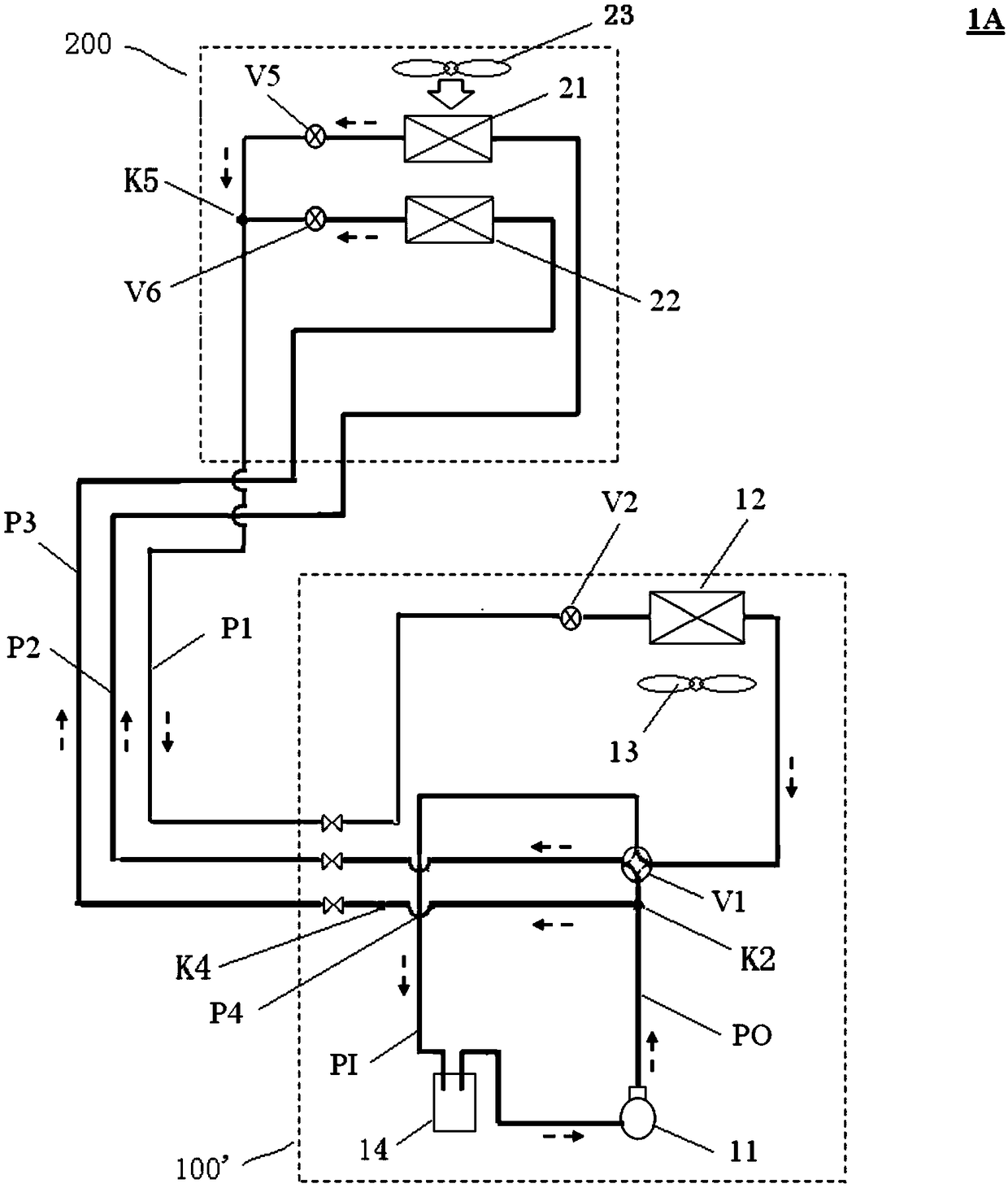

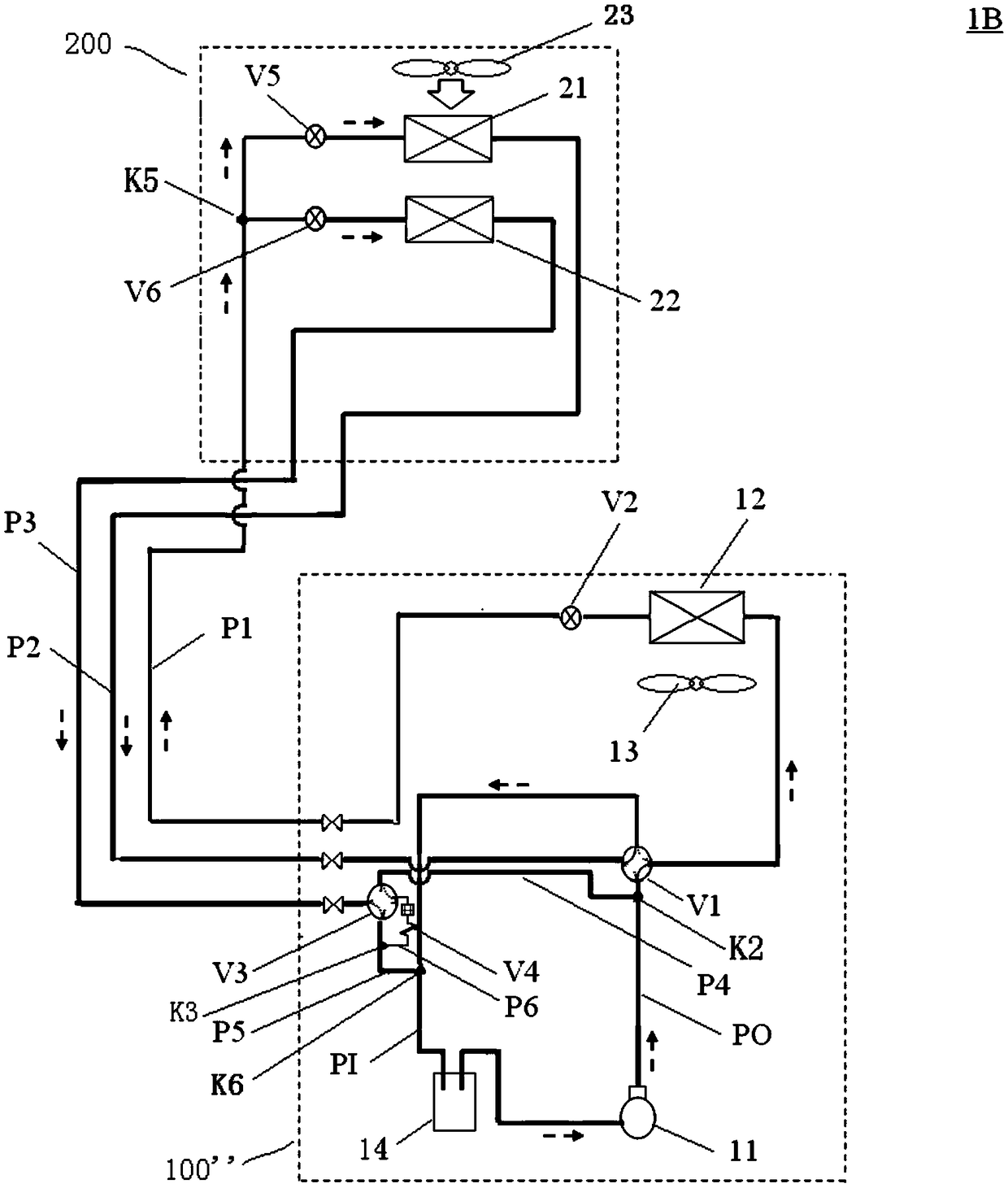

Flue gas moisture recovery system and method

ActiveCN104235864ARealize waste heat utilizationReduce water consumptionLighting and heating apparatusWater vaporLiquid water

The invention discloses a flue gas moisture recovery system and method. Flue gas discharged by a boiler sequentially passes a desulfurization tower (1), a first heat exchanger (2) and a second heat exchanger (3), enters a chimney (4) and is discharged, the flue gas passing the desulfurization tower (1) is cooled by the first heat exchanger (2), water vapor in the flue gas is coagulated into liquid water, and the flue gas is heated by the second heat exchanger (3). The desulfurized flue gas is cooled and dewatered by the aid of an absorption heat pump and then heated, flue gas moisture can be recovered, chimney output is improved, 'gypsum rain' and 'white smoke' discharging are relieved, and contaminant can be diffused towards high altitude.

Owner:YANTAI LONGYUAN POWER TECH

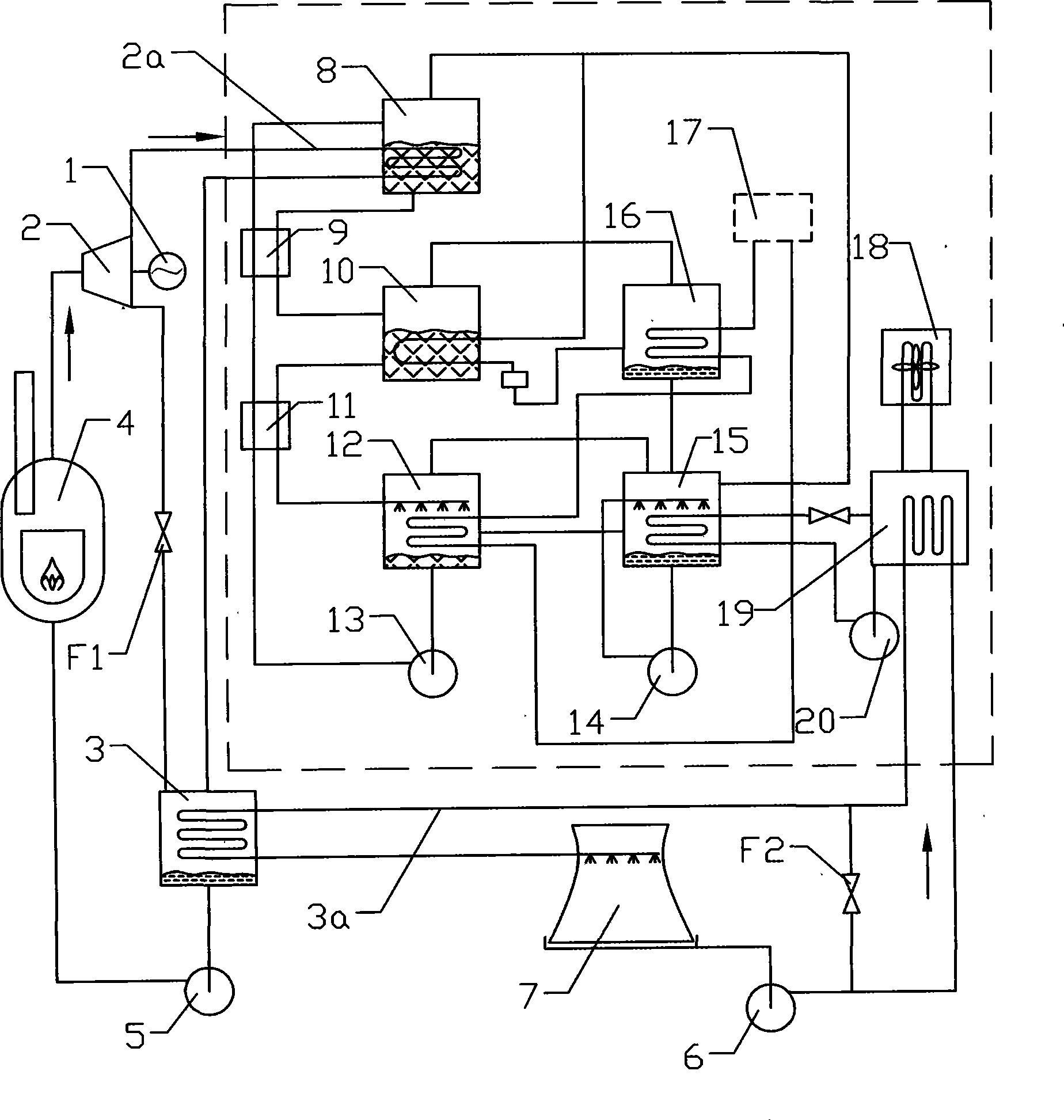

Electric power plant cooling system for enhancing cooling efficiency by utilizing residual heat refrigeration manner

InactiveCN101509716AFlexible adjustmentRealize waste heat utilizationClimate change adaptationSteam useLithium bromideCentral air conditioning

The invention relates to a power plant cooling system which improves the cooling efficiency by a residual heat refrigeration way, in particular to a cooling system which is used for the power plant, carries out the refrigeration by the residual heat of a steam turbine and utilizes the prepared cold water to cool the circular cooling water of the steam turbine further. The cooling system comprises a steam condensed water circulation consisting of a steam turbine, a steam condenser, a condensed water circulation pump and a combustion boiler, and a steam cooled water circulation consisting of a steam condenser, a cooling tower and a cooled water circulation pump. The cooling system is characterized in that a lithium bromide refrigeration unit is added; a high pressure generator of the lithium bromide refrigeration unit is arranged between the steam turbine and the steam condenser so as to lead the steam to become the heat source of the unit; the unit also comprises a refrigerant water tank which can store the cold energy; furthermore, the refrigerant water tank is connected with all air conditioners of the central air conditioning by pipelines; and the refrigerant water tank is arranged between the steam condenser and the cooling water circulation pump so that the refrigerant water is used for supplying the coldness to the central air conditioning or further cooling the circular cooling water of the steam turbine. The cooling system solves the problem that the residual heat of the power plant is cooled and wasted and has the advantages of high cooling efficiency, saving energy, being capable of supplying the cold source for the central air conditioning and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

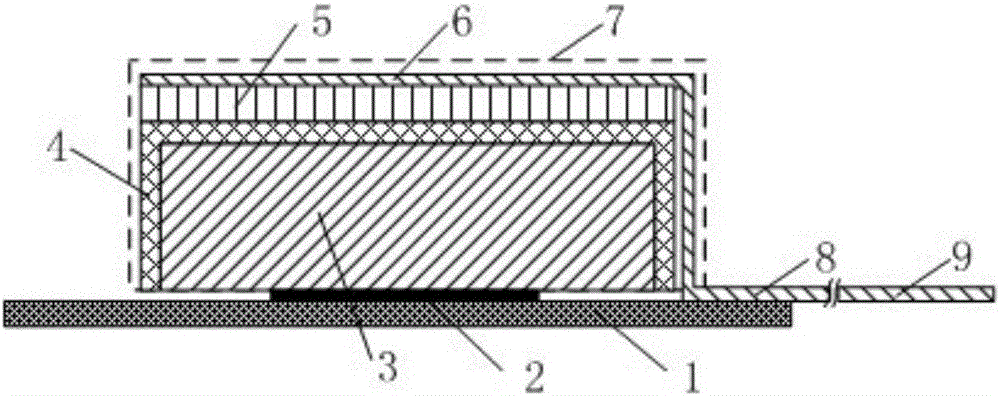

Radiating apparatus for variable high-power device of spacecraft

InactiveCN105702641ALow costReduce consumptionSemiconductor/solid-state device detailsSolid-state devicesTemperature controlThermal insulation

The invention discloses a radiating apparatus for a variable high-power device of a spacecraft, belongs to the field of the spaceflight thermal control technology, and solves the problem of single radiating method and high compensation heating power consumption of the spacecraft device in the prior art. The radiating apparatus provided by the invention mainly comprises a mounting plate, a thermal insulation cushion, a phase-changing box, a thermal pipe hot end, a multi-layer thermal insulation assembly, a thermal pipe middle section and a thermal pipe cold end, wherein the thermal insulation cushion is arranged between the mounting plate and the device; the phase-changing box comprises a main body and a sealing cover; the inner surface of the main body is fixed on the outer surface of the device; staggered rib plates are arranged on the outer surface of the main body; the sealing cover is fixed on the outer surface of the main body in a sealing manner; the space between the main body and the sealing cover is filled with a phase-changing material; the thermal pipe hot end is fixed on the surface of the sealing cover; and the thermal pipe cold end is fixed on a radiating surface or a position needing to be radiated. The radiating apparatus does not require a quite large radiating surface or compensating heat; meanwhile, the energy saving efficiency can reach greater than 90%; and in addition, afterheat utilization and accurate temperature control can be realized as well.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI +1

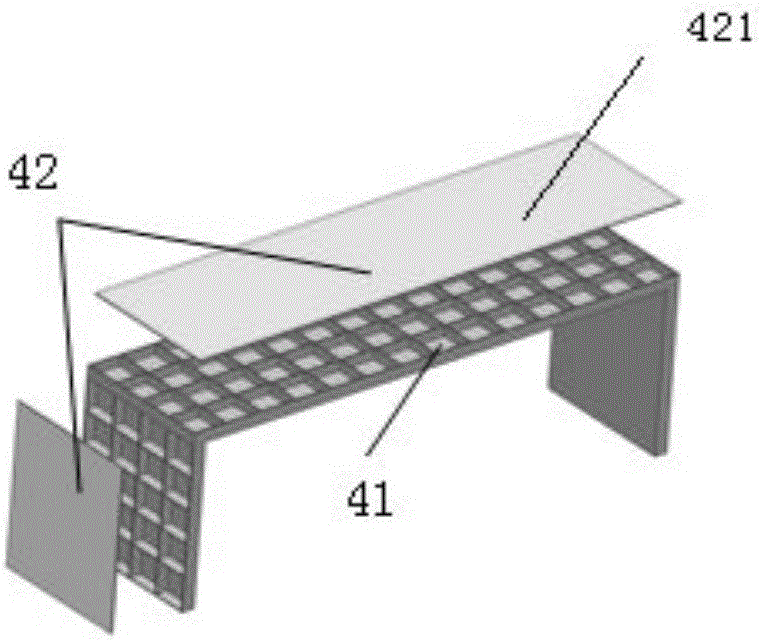

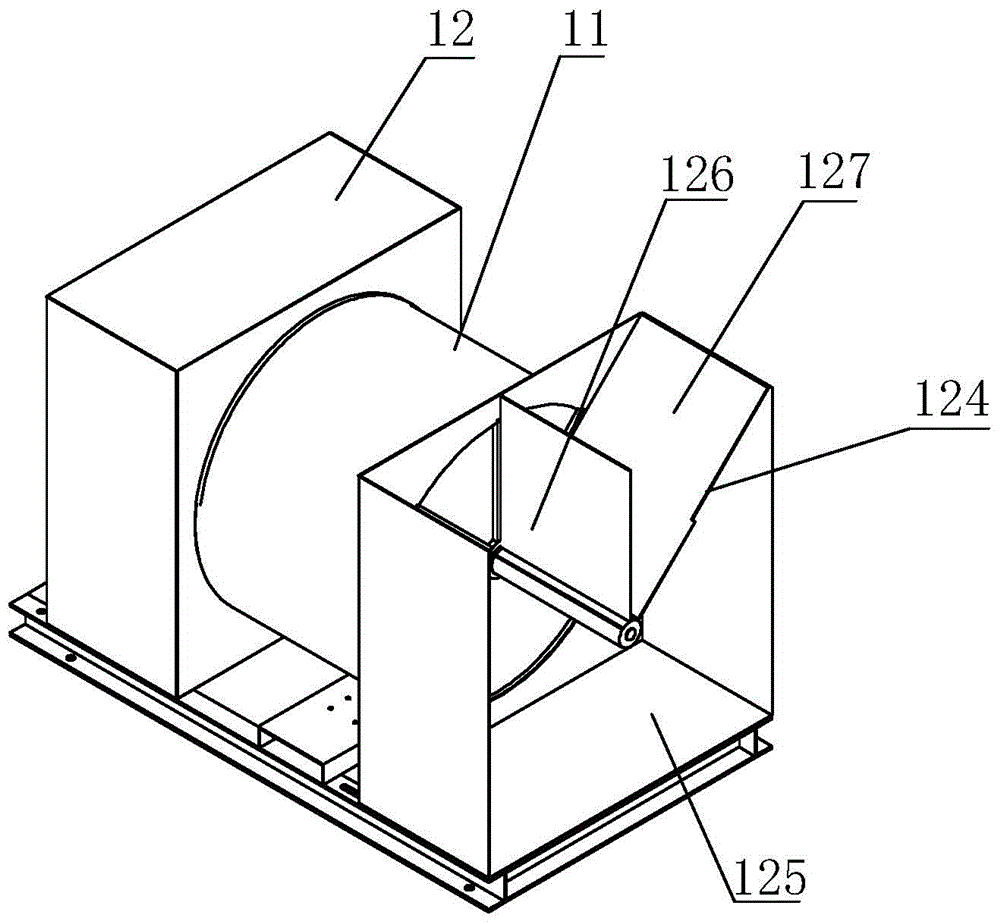

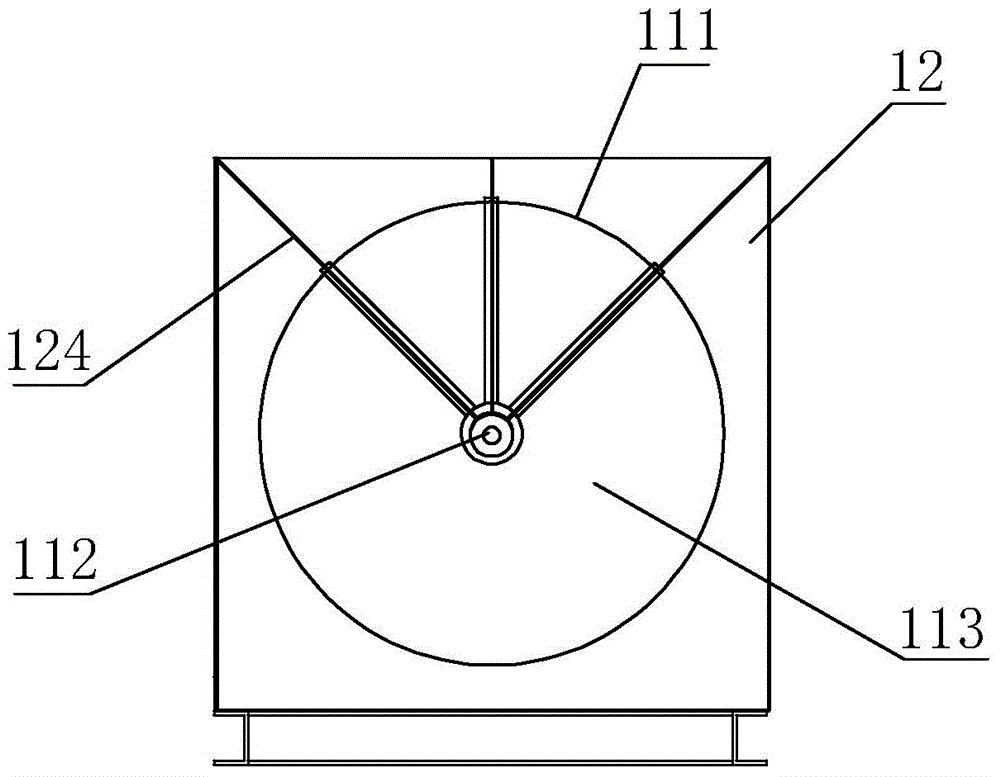

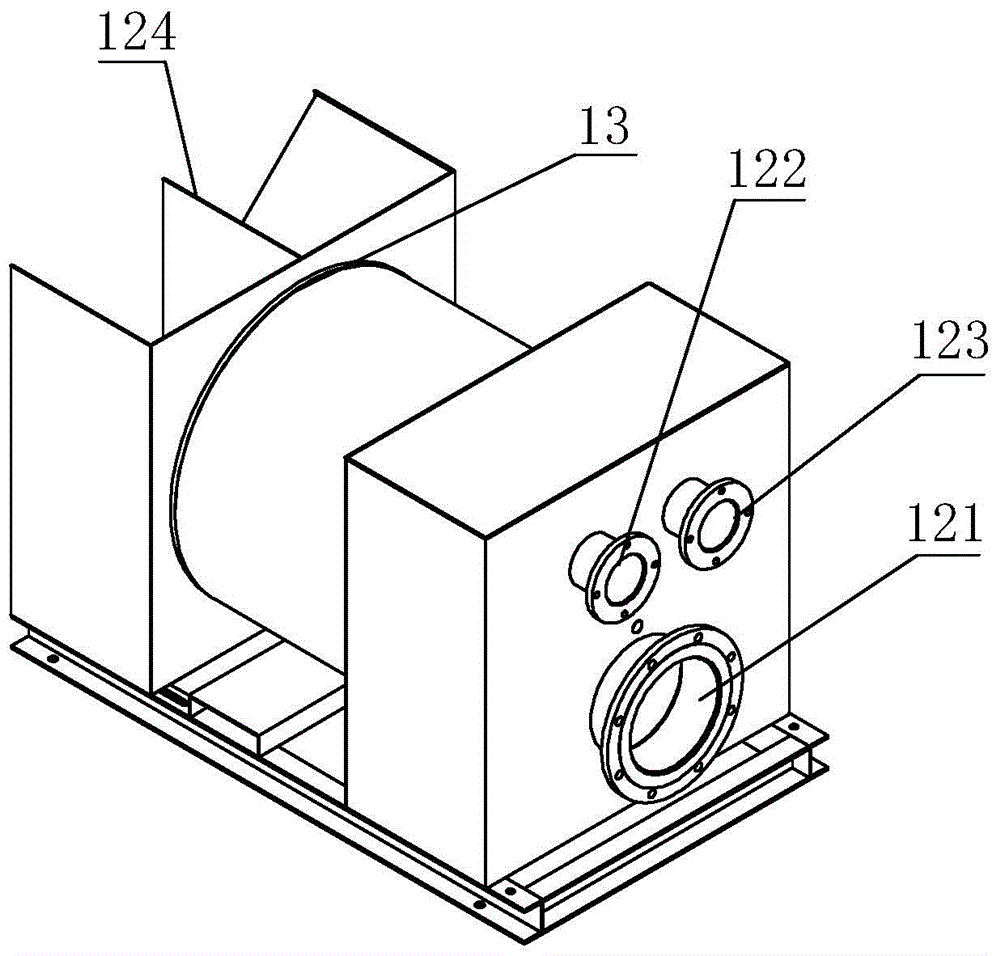

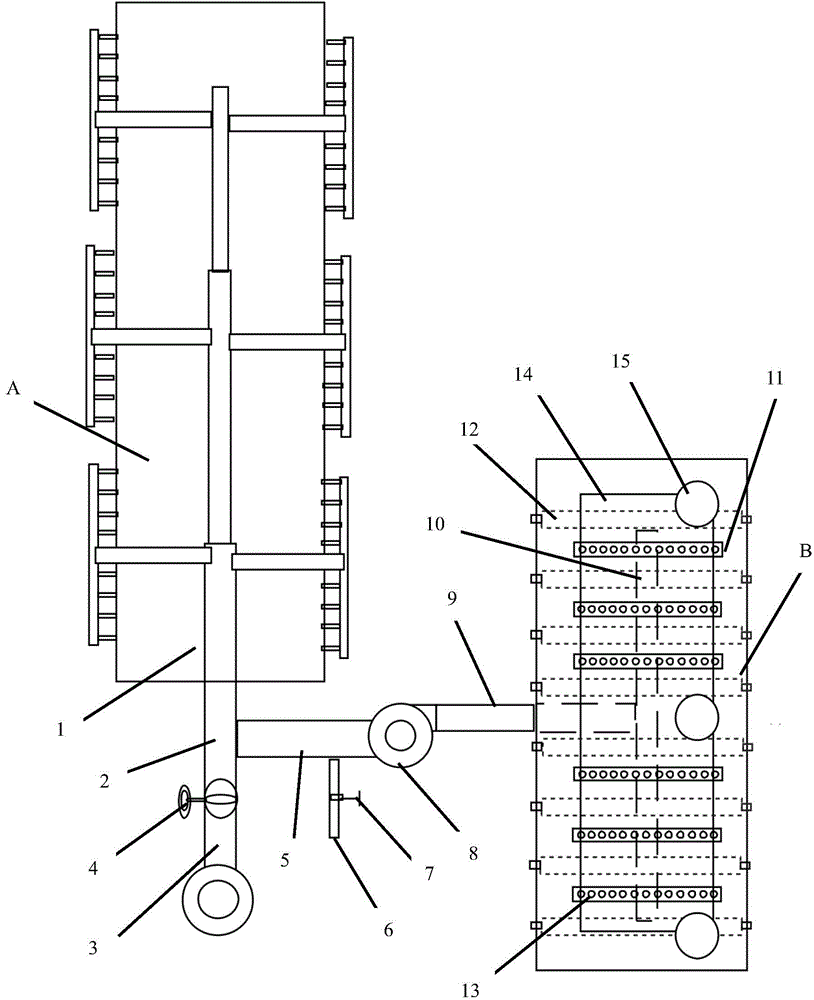

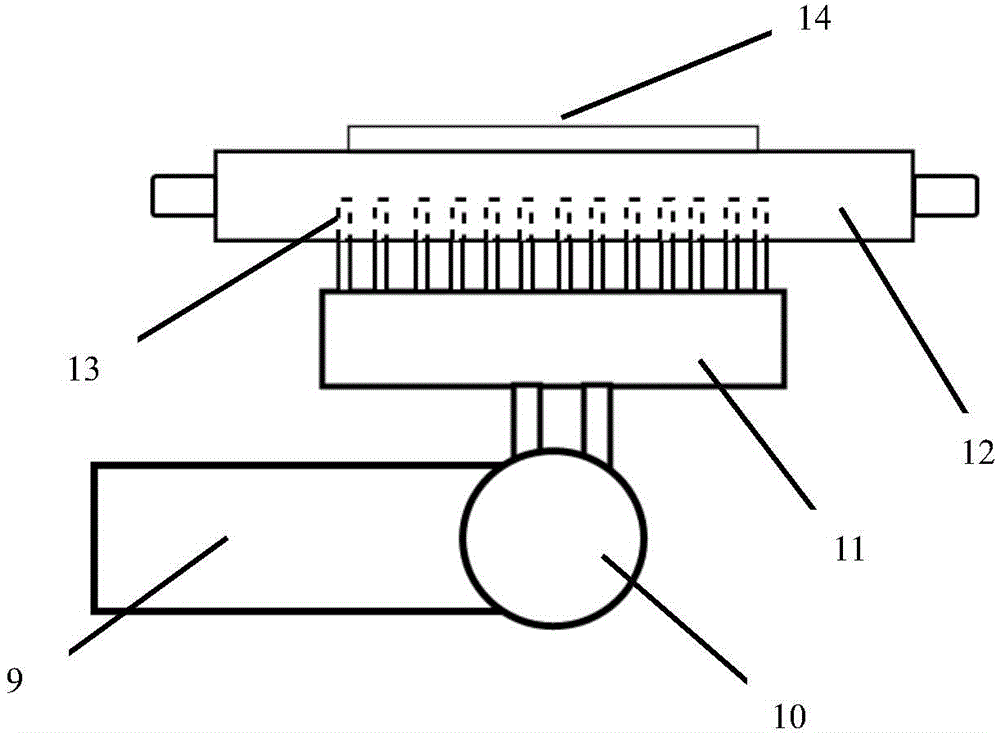

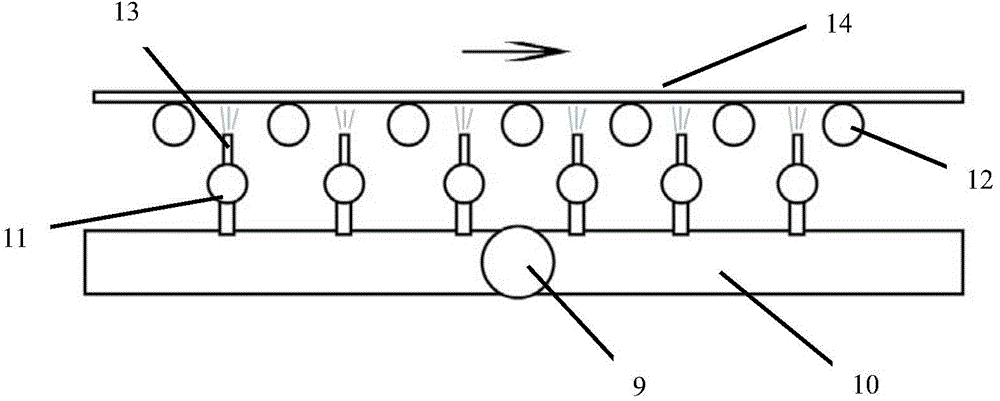

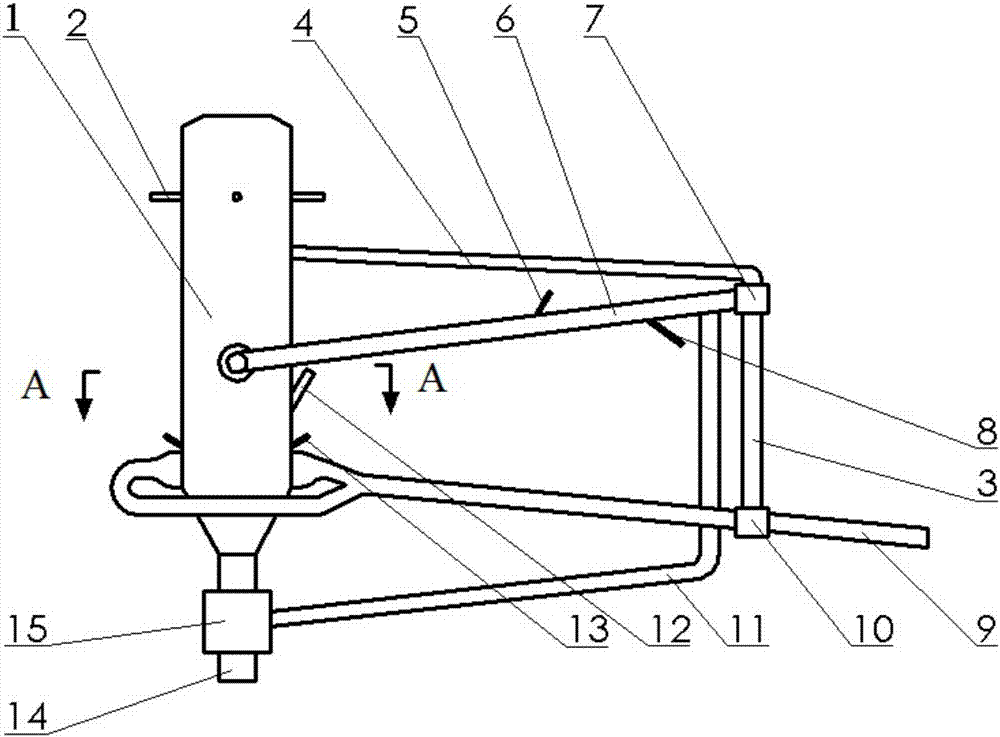

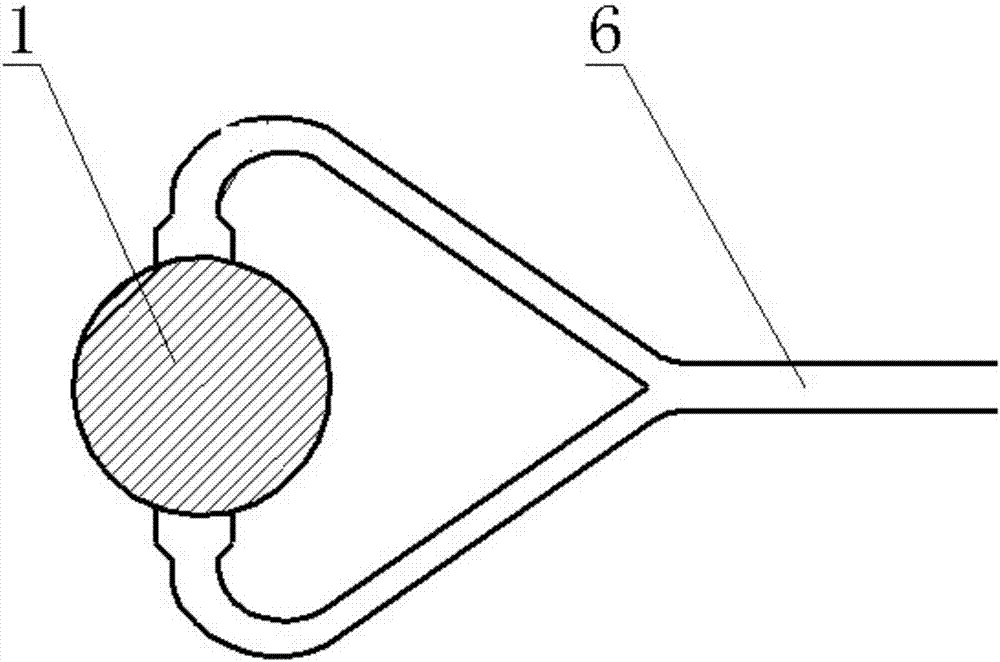

Absorption type rotating wheel gas purifying device

ActiveCN103599676AImprove adsorption efficiencyImprove adsorption utilizationDispersed particle separationActivated carbonDesorption

The invention discloses an absorption type rotating wheel gas purifying device. The absorption type rotating wheel gas purifying device comprises a rotating wheel and two gas partitioning boxes, wherein the rotating wheel comprises a shell, a core shaft, a partitioning leaves and honeycomb active-carbon modules, wherein the shell rotates around the core shaft by virtue of mechanical driving; the shell is averagely divided into a plurality of areas by virtue of the partitioning leaves; a plurality of layers of small active-carbon honeycomb bodies are respectively embedded into each area; gas channels on the active-carbon honeycomb bodies are distributed along the length direction of the active-carbon honeycomb bodies; two gas partitioning boxes are respectively arranged at the two sides of the rotating wheel; each gas partitioning box comprises a box body; one side of the box body is connected with a gas inlet and outlet pipeline, and the other side of the box body is provided with a round opening with the diameter equal to that of the shell of the rotating wheel; the box body is internally divided into 6 areas (an absorbing area, a desorbing area, a cooling area and three isolating areas without being adjacent) by virtue of partitioning plates; the end surface, which is contacted with the rotating wheel, of each isolating area is sealed. The absorption type rotating wheel gas purifying device disclosed by the invention has the advantages that the absorption and the desorption can be finished simultaneously, the problem that the adsorbability of active carbon is reduced along with the accumulation of the absorbing amount is avoided, the volume is small, the weight is light and the structure is compact.

Owner:青岛纳博科环保科技有限公司

Two-stage type hot water direct-fired single-double effect composite lithium bromide absorption refrigeration unit

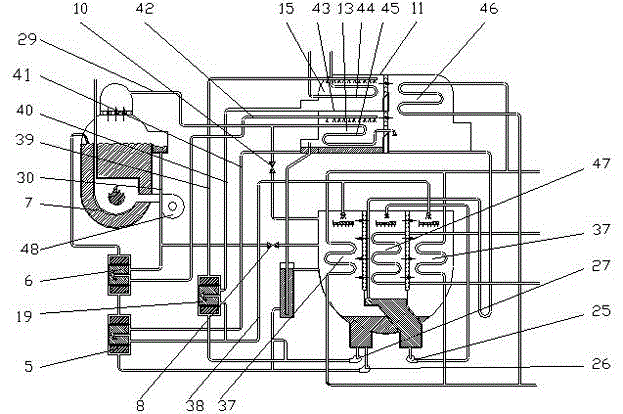

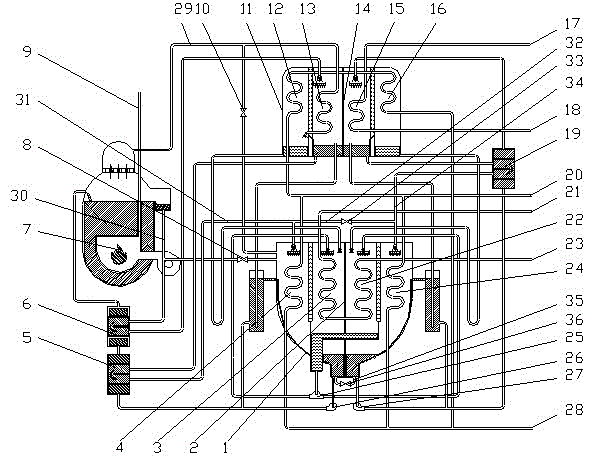

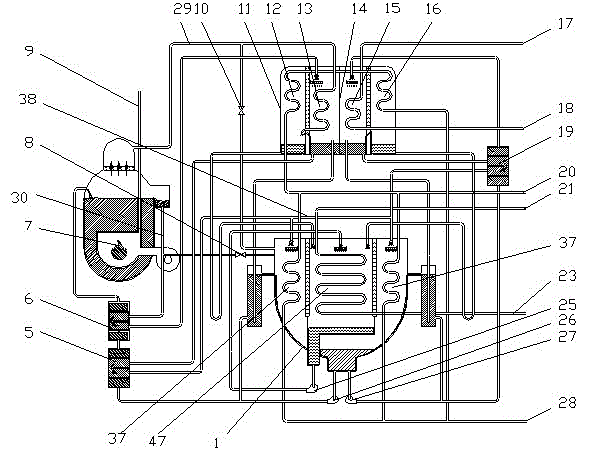

InactiveCN102914079ARelieve stressReduce the temperatureEnergy efficient heating/coolingClimate change adaptationWater flowLithium bromide

The invention relates to a two-stage type hot water direct-fired single-double effect composite lithium bromide absorption refrigeration unit. The absorption refrigeration unit comprises a direct-fired high pressure generator (7), an evaporator, an absorber, a steam generator (13), a hot water generator (15), a condenser, a solution heat exchanger, a solution pump and a refrigerant pump and is characterized by comprising a single effect condenser (16) and a double effect condenser (12); the heat exchange tube bundle of the hot water generator (15) and the heat exchange tube bundle of the single effect condenser (16) are arranged in a cavity; the heat exchange tube bundle of the steam generator (13) and the heat exchange tube bundle of the double effect condenser (12) are arranged in another cavity; the cooling water flow paths of the single effect condenser (16) and the double effect condenser (12) adopt series connection flow paths; and cooling water gets into the single effect condenser (16) and gets out of the double effect condenser (12). The two-stage type hot water direct-fired single-double effect composite lithium bromide absorption refrigeration unit can be used for reducing the generation pressure of the hot water generator and the concentration of a dilute solution for hot water single effect circulation.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

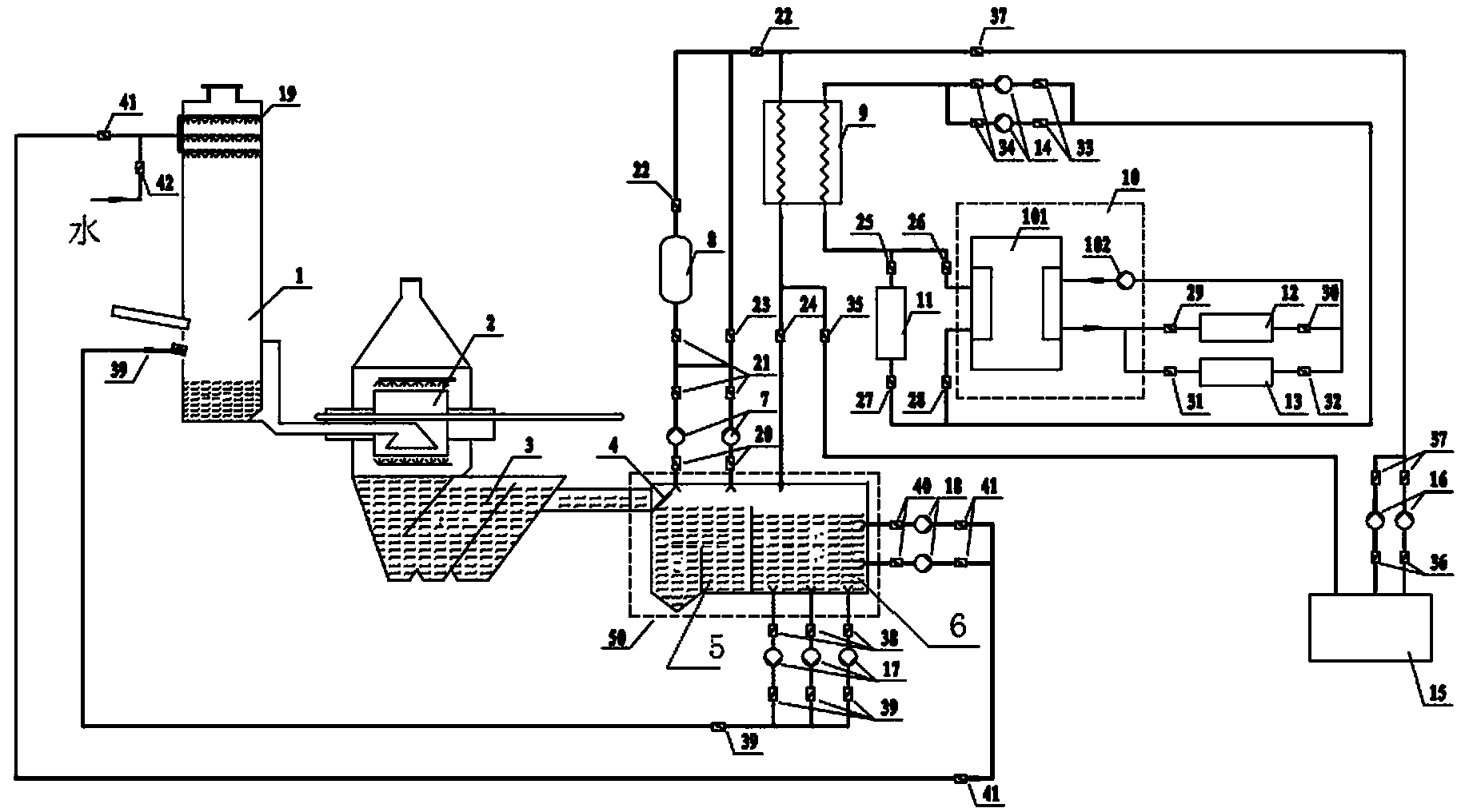

Method and system for cooperatively treating sludge through grate furnace waste incineration

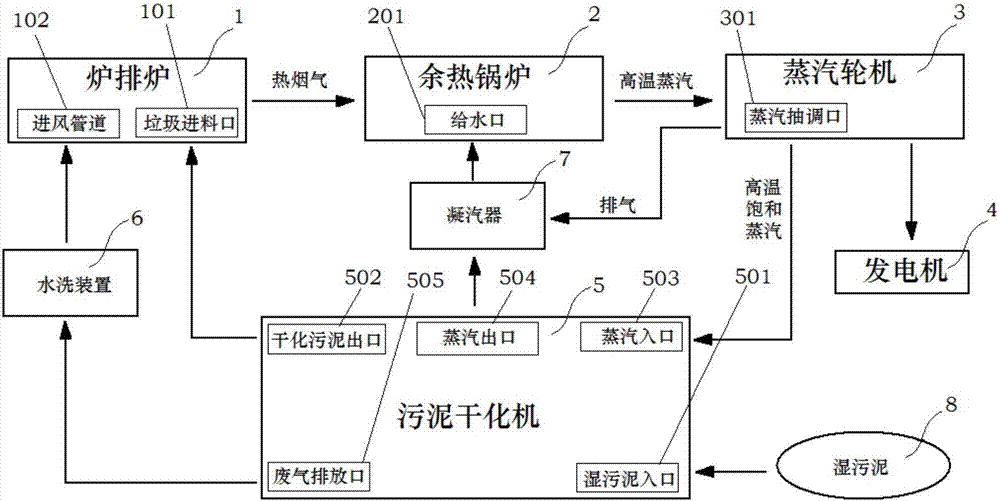

PendingCN107013928AEasy to handleTechnically feasibleSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention discloses a method and system for cooperatively treating sludge through grate furnace waste incineration, and belongs to the field of sludge treatment. Steam generated by grate furnace waste incineration is firstly utilized for carrying out indirect heat exchange drying on the sludge, and then the sludge dried to a certain degree and in-furnace waste are mixed and incinerated in a grate furnace according to a certain proportion. According to the method and system, the existing and mature grate furnace waste incineration technology is utilized for achieving effective drying and cooperative incineration on the sludge, the sludge independent drying cost and the building and operating cost of an incineration treatment project can be greatly reduced, and harmlessness, reduction and recycling of sludge treatment are achieved.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

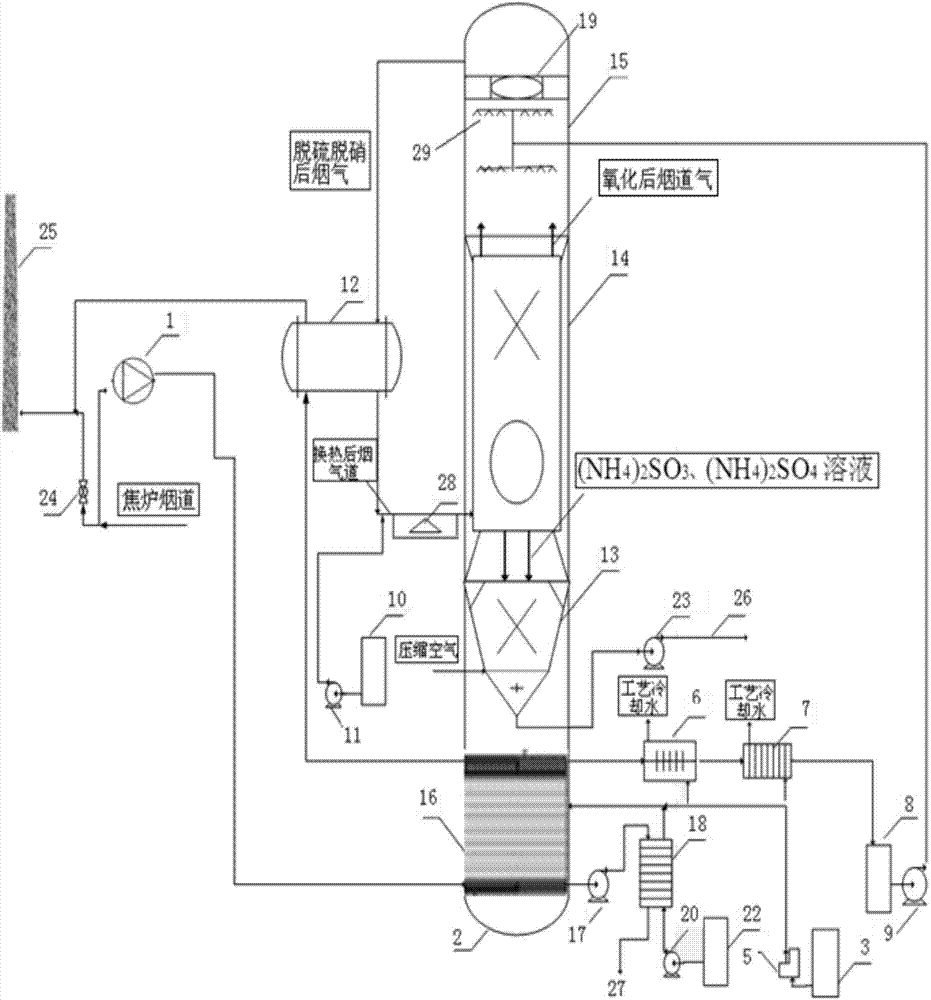

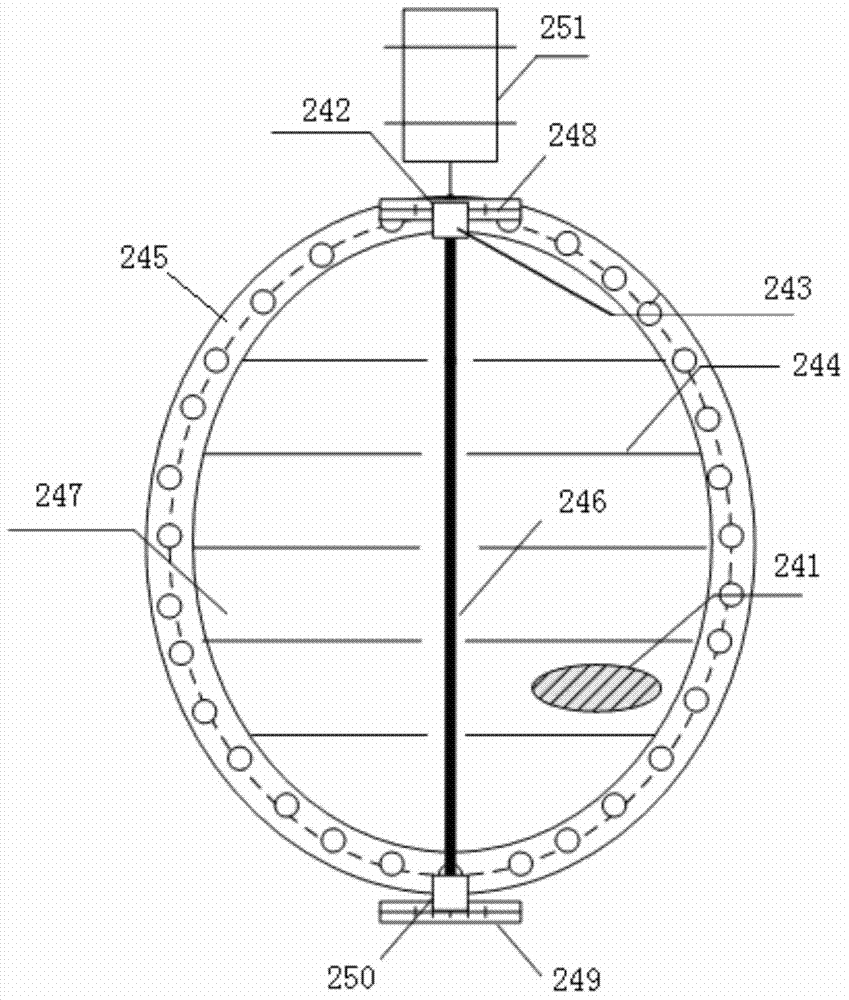

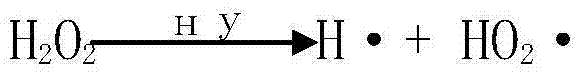

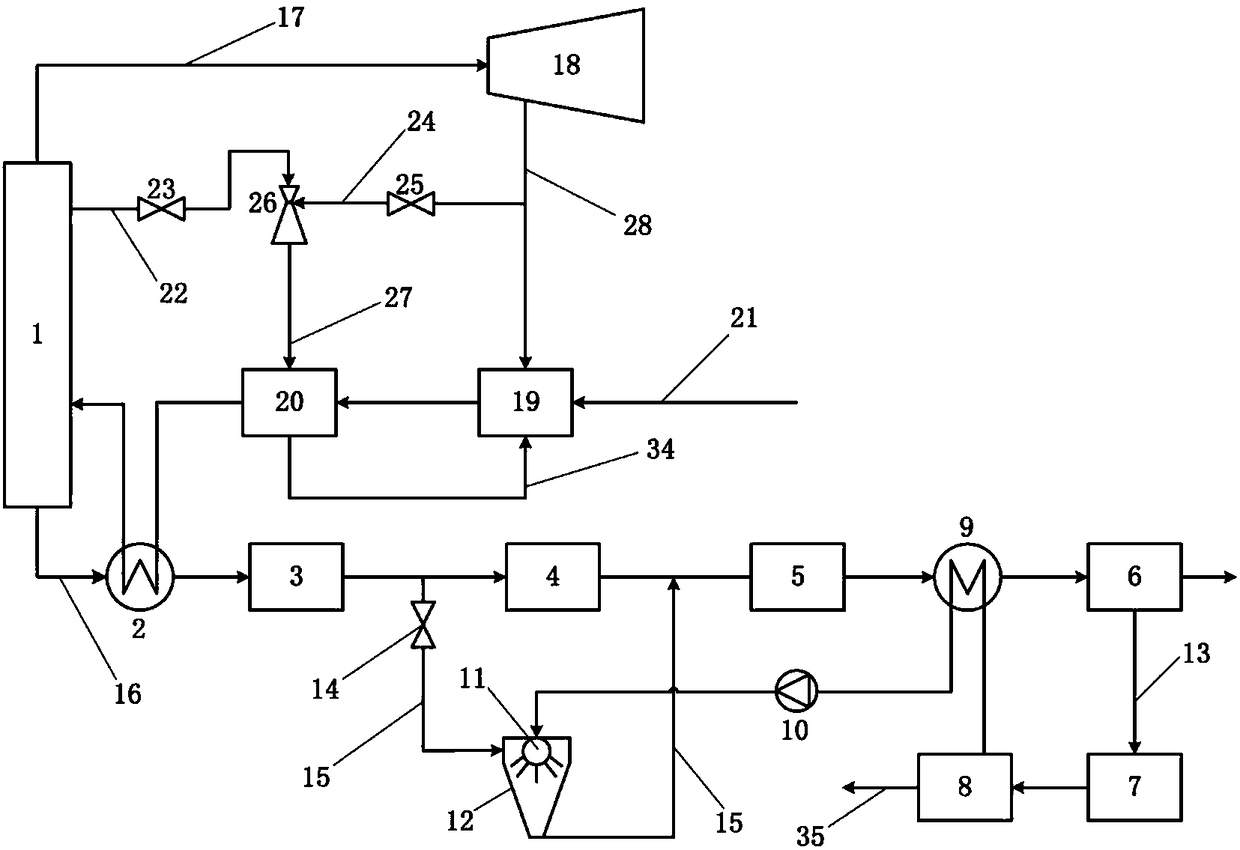

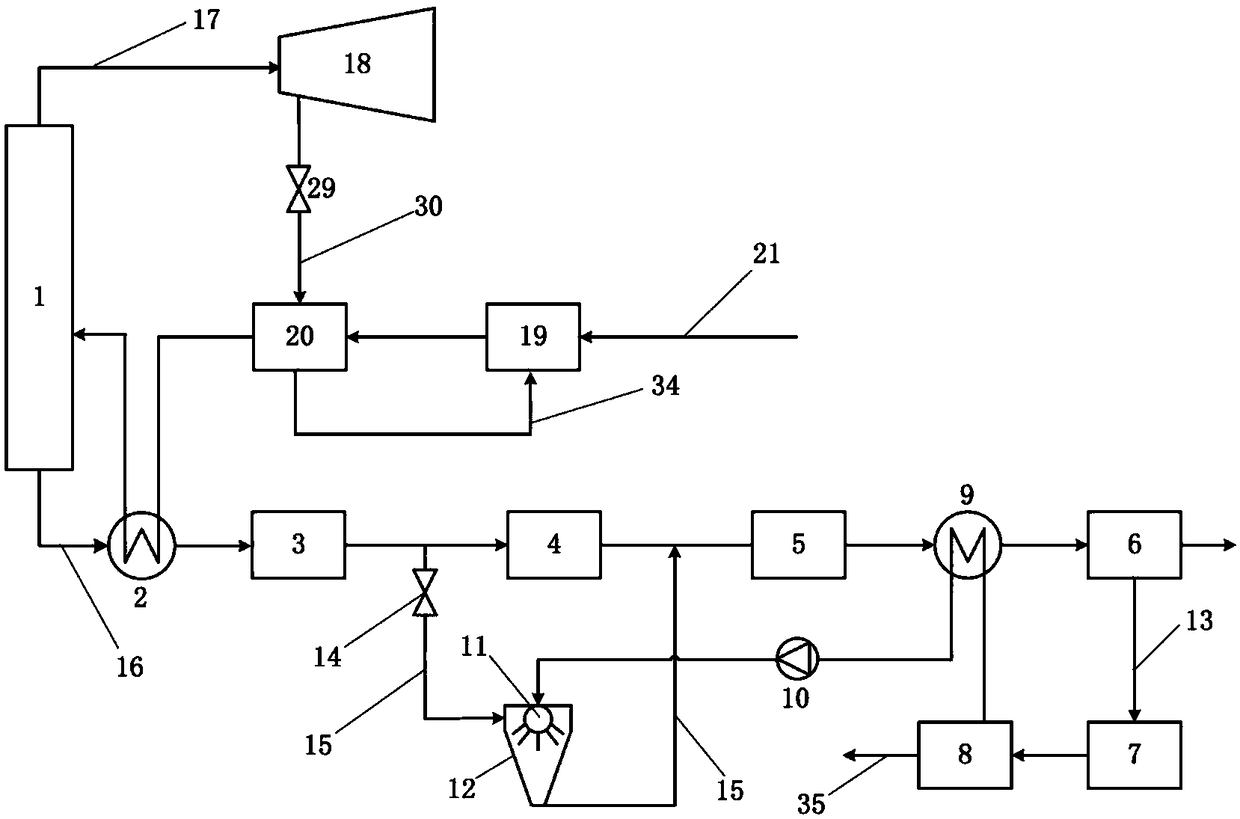

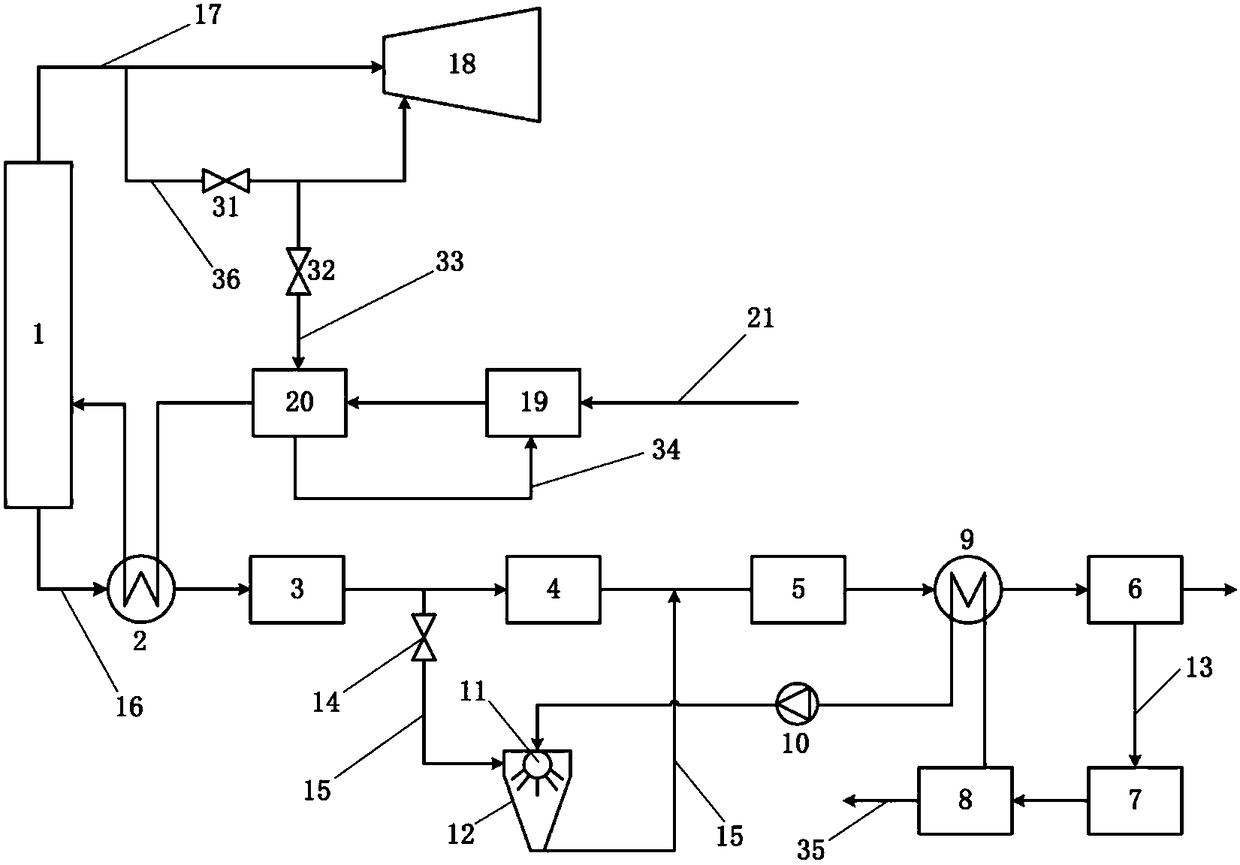

Residual heat utilization and simultaneous desulfurization and denitrification system for tower type coke oven flue gas

ActiveCN104707454AReduce waste heat utilizationRealize waste heat utilizationAmmonium nitratesDispersed particle separationEvaporationAmmonium sulfate

The invention discloses a residual heat utilization and simultaneous desulfurization and denitrification system for tower type coke oven flue gas. The residual heat utilization and simultaneous desulfurization and denitrification system comprises a draught fan and a flue gas purification tower, wherein the draught fan is connected with a coke oven flue and the flue gas purification tower; the flue gas purification tower comprises a hot pipe type wastewater evaporator, a crystallization tank, a flue gas oxidization reactor and a flue gas washing tower; the hot pipe type wastewater evaporator is connected with a wastewater circulating pump and a waste water tank; the hot pipe type wastewater evaporator is connected with an ammonia evaporation wastewater pump and a wastewater heat exchanger; the hot pipe type wastewater evaporator is connected with an alkali liquid metering pump and a complete condenser; the complete condenser is connected with an ammonia water cooler, an ammonia water cooler and an ammonia water pump; the ammonia water pump is connected with the flue gas washing tower; the complete condenser and the ammonia water cooler are connected with technical cooling water; the hot pipe type wastewater evaporator is connected with a flue gas heat exchanger and a light generator; the light generator is connected with the flue gas oxidization reactor; flue gas is subjected to heat exchange by the flue gas heat exchanger and then enters a main flue to be evacuated by a chimney; and the crystallization tank lifts a crystallization pump to be connected with a coke oven coal gas ammonium sulfate production system.

Owner:SHANDONG IRON & STEEL CO LTD

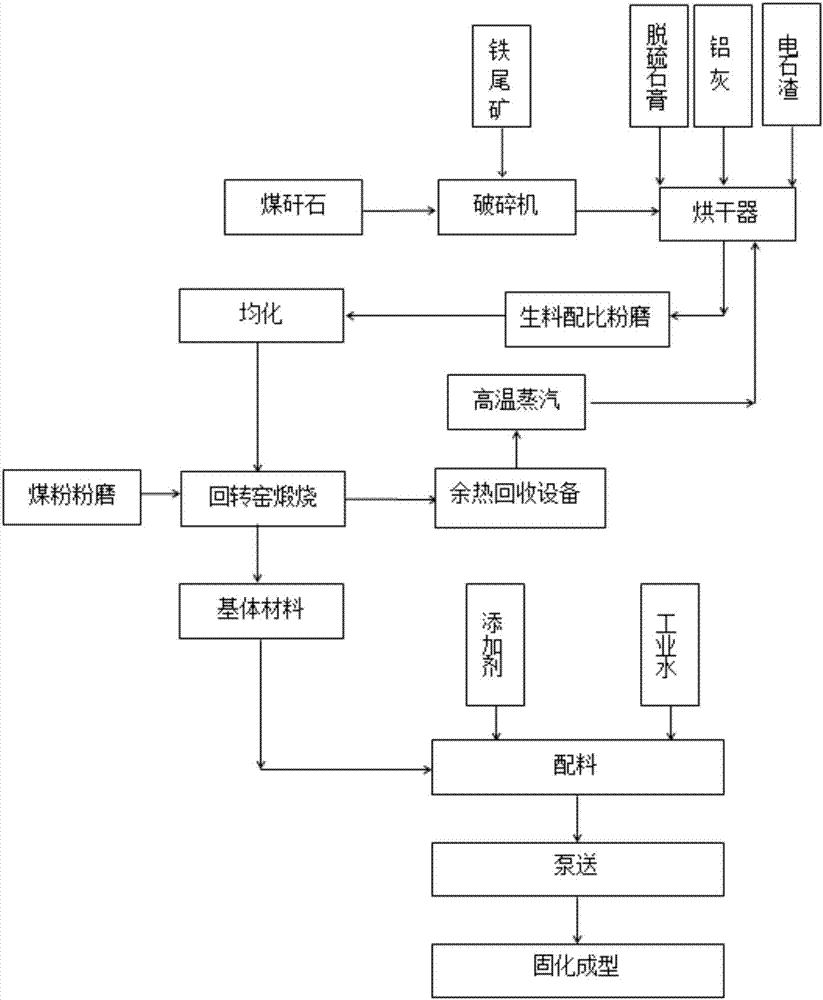

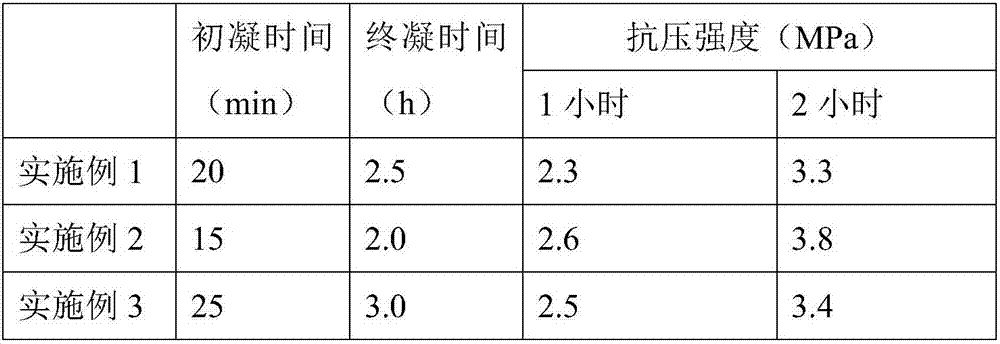

System for preparing sulphoaluminate superhigh water filling material by using industrial solid waste and method thereof

ActiveCN106915938AAvoid wastingRealize waste heat utilizationClinker productionMineral SourcesSulfate

The invention discloses a system for preparing a sulphoaluminate superhigh water filling material by using industrial solid waste and a method thereof, and relates to a method for producing the superhigh water filling material by using a matrix material. According to the invention, ferro-silico-aluminum based solid waste such as gangue and calcium sulfate based solid waste such as desulfurized gypsum are taken as the raw materials, the above raw materials are subjected to grinding, homogenizing, sintering and clinker grinding, and the matrix material is prepared. The matrix material is taken as a core material, a specific additive is taken as an auxiliary material, through a certain construction technology, and the superhigh water filling material with highest water content of 97% can be used for backfill of a goaf such as coal mine. In the invention, complementation and utilization of a plurality of large industrial solid and waste can be realized, the produced superhigh water filling material has high cost performance, can substitute the high-quality mineral product resource, and can greatly increase the added value of the large industrial solid waste regeneration products.

Owner:SHANDONG UNIV

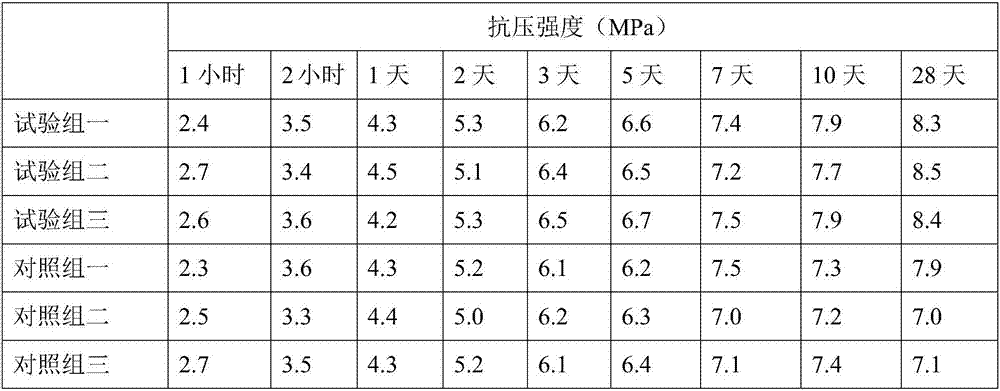

Two stage treatment method for distillation concentration and incineration of diffusion liquid from refuse burying site

InactiveCN1278963CAchieve unified processingAvoid wasteful situationsSludge treatment by oxidationByproduct vaporizationCombustion chamberDistillation

The method's fuel is gas and or other business fuel. It worked by technology of immerge burning and distilling. The distilled burning include stair evaporator and ambipolar evaporator. The two evaportor are comprise of a fuel burning room and a distilling room. The function of stair evaportor is to distill the volatile organism in order to burning out; the ambipolar evaportor is to distill water and concentrate the fluid. The smog of volatile organism produced by stair evaporator, is burned out by the ambipolar evaportor.

Owner:TSINGHUA UNIV

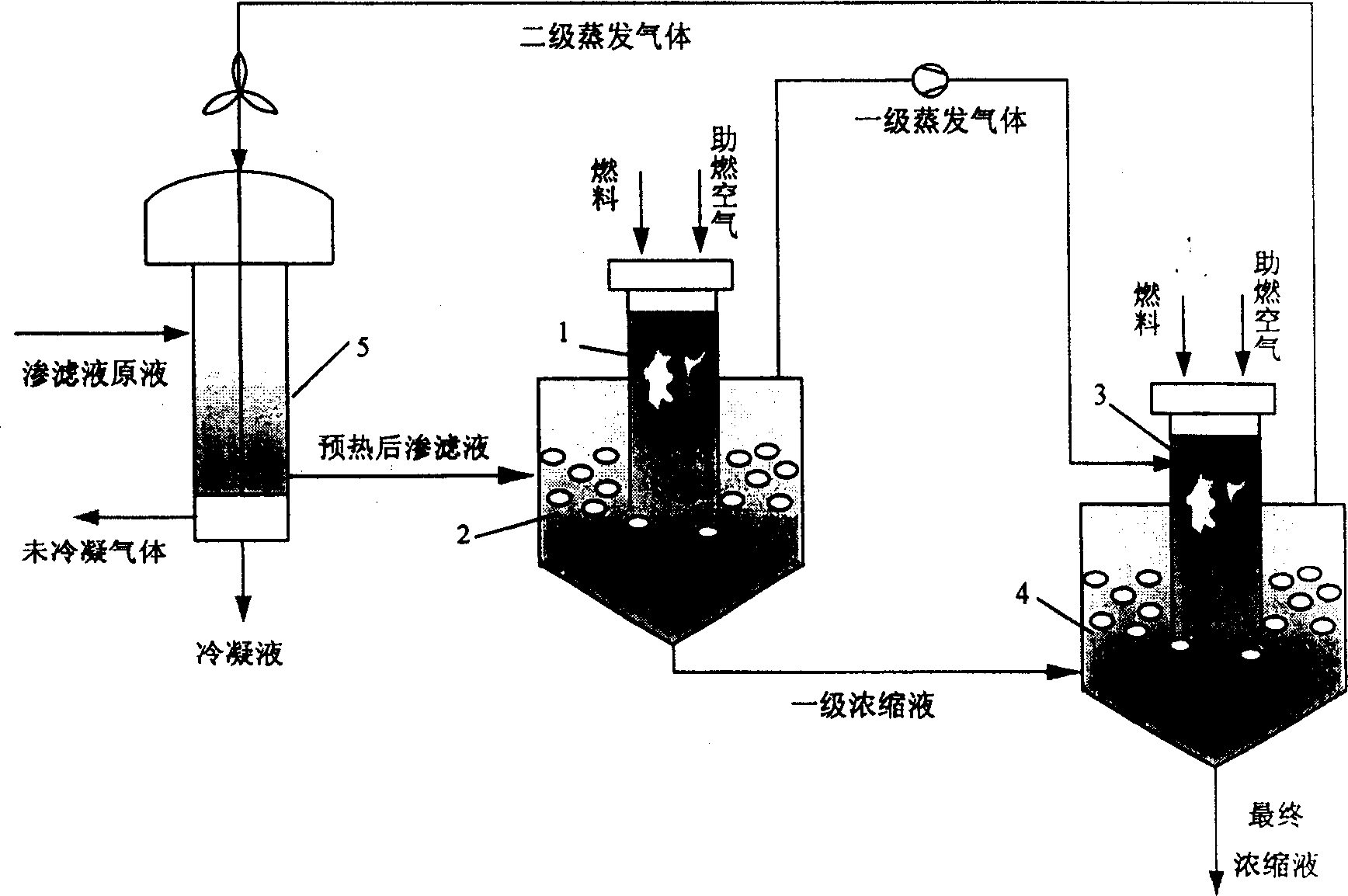

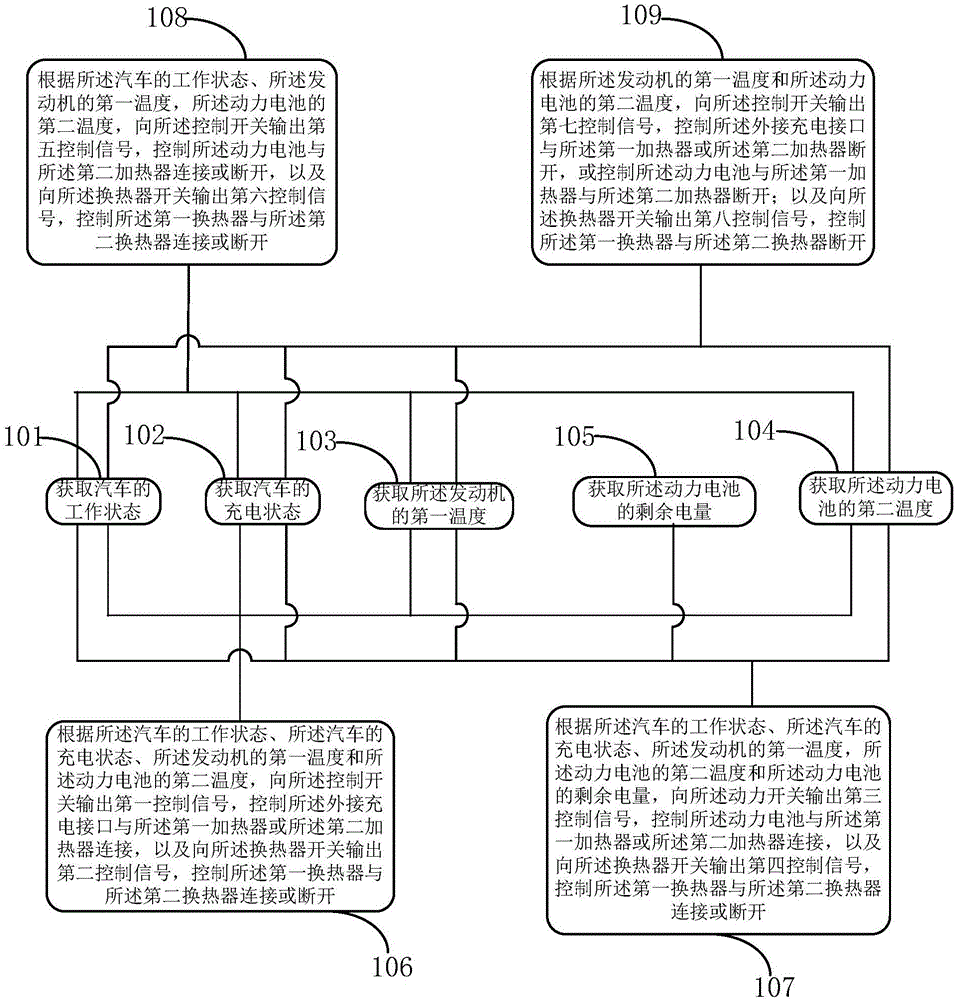

Heat exchange system for engine and power cell, control method and automobile

ActiveCN106401833ARealize waste heat utilizationReduce energy consumptionSecondary cellsMachines/enginesFuel cellsEngineering

The invention provides a heat exchange system for an engine and a power cell, a control method and an automobile. The heat exchange system for the engine and the power cell comprises an external charging connector, a second heater, a second heat exchanger, a first heat exchanger, a first heater, a control switch and a controller. The second heater and the second heat exchanger are attached to the power cell. The first heat exchanger is connected with the engine through a pipeline and connected with the second heat exchanger through a pipeline. A heat exchanger switch is arranged between the first heat exchanger and the second heat exchanger. The first heater is attached to the first heat exchanger. The control switch is connected with the external charging connector, the power cell, the first heater and the second heater. The controller judges whether the engine and the power cell need to be heated or not according to the temperature of the engine and the temperature of the power cell, a power supply device for heating the engine and the power cell is selected according to the working state of the automobile, waste heat utilization of the engine is achieved, and meanwhile mutual heating of the engine and the fuel cell is achieved.

Owner:BEIJING ELECTRIC VEHICLE

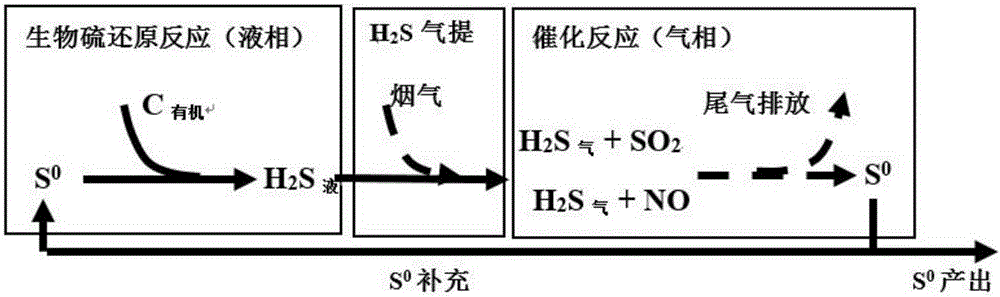

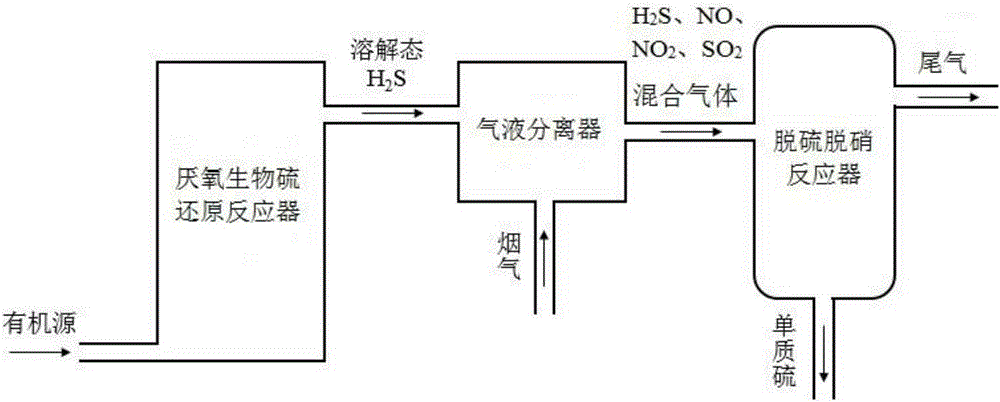

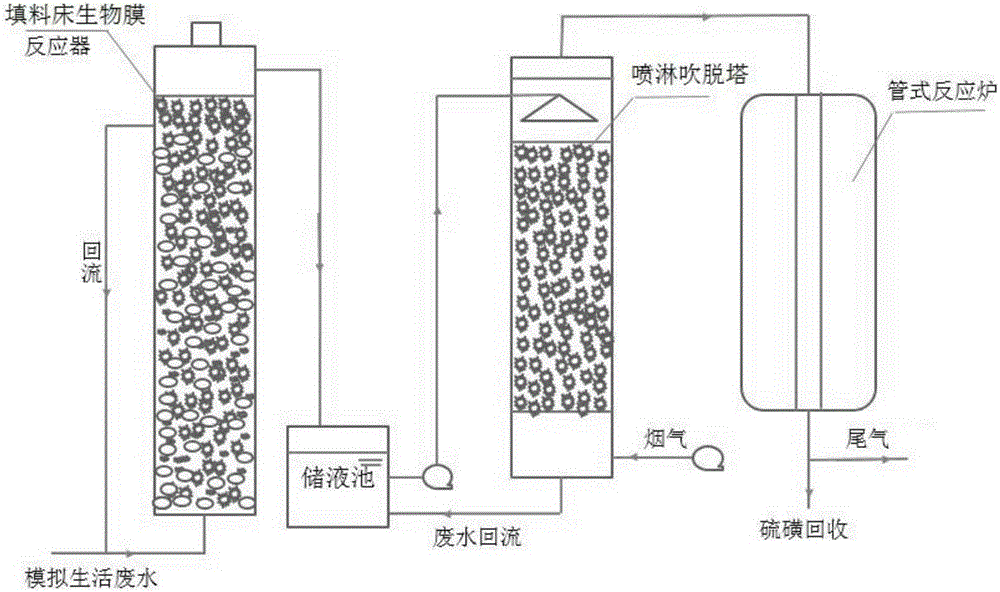

Synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as reducing agent

InactiveCN105214495ARealize integrationHigh outputUsing liquid separation agentSulfur preparation/purificationFlue gasEnvironmental engineering

The invention discloses synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as a reducing agent. The technology comprises the following steps: 1) preparation of dissolved H2S; 2) preparation of a mixed gas of H2S, NO, NO2, and SO2; and 3) synchronous desulfurization and denitrification. According to the technology, integration of a desulfurization and denitrification device is authentically realized. NO and NO2 in the coal-fired flue gas are converted into N2 and water; SO2 and H2S are converted to high-purity elemental sulfur; and organic matters in waste water are further removed, so that treatment of wastes with other wastes is realized. Elemental sulfur is recycled through the technology; one part of elemental sulfur is cycled and utilized to maintain equipment operation; and the other part of elemental sulfur is output as a product. The reducing agent of H2S in the technology is prepared from an in-situ product of elemental sulfur through reduction, can be prepared when used, and does not need to be bought outside. Therefore, cost of purchase, transportation, and storage and potential security risk are avoided. Compared with a mainstream device, the desulfurization and denitrification device is significantly lower with respect to land occupation, construction cost, operation cost, and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

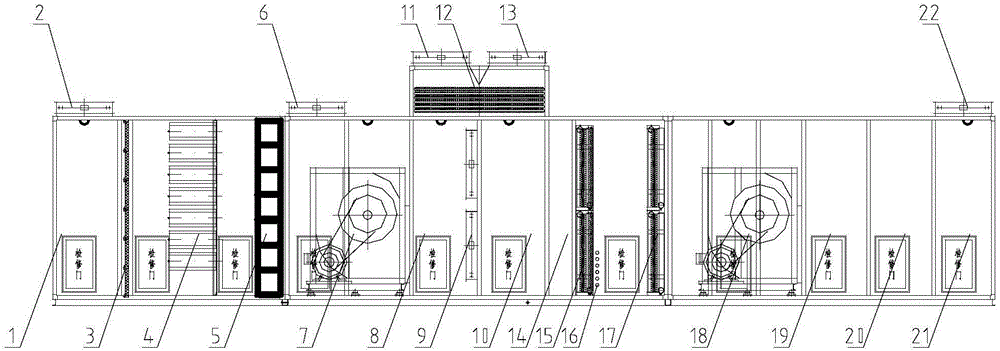

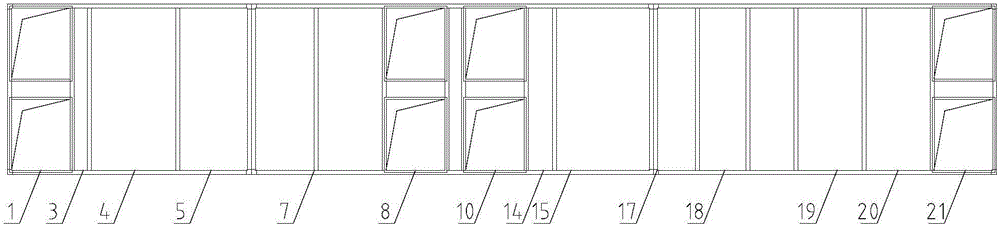

Combined oil mist purifying unit of air conditioner

InactiveCN105698297ARealize cooling and dehumidificationRealize isohumidity heatingEnergy recovery in ventilation and heatingMechanical apparatusExhaust valveAir volume

The invention discloses a combined oil mist purifying unit of an air conditioner. The combined oil mist purifying unit comprises an air return filtering part and a fresh air conveying part, wherein the oil return filtering part is used for performing suction filtering on air in a workshop and filtering oil mist particles and comprises an air return section, an oil mist filtering section, a peculiar smell purifying section, an air return fan section and an exhaust regulating section which communicate in sequence; the fresh air conveying part is used for feeding clean fresh air into the workshop and regulating the temperature of the air, and comprises a fresh air regulating section, an air filtering section, a temperature adjusting section, an air feeder section and an air feeding section which communicate in sequence; the exhaust regulating section and the fresh air regulating section communicate by an air mixing valve; and an exhaust valve and a fresh air valve are jointly arranged on a thermal recovery section. According to the combined oil mist purifying unit disclosed by the invention, by organically combining oil mist purification and the air conditioner, exhausting and thermal recovery can be realized; in addition, no cross contamination exists in the fresh air and the exhausted air; and the temperature and the air volume can be adjusted according to the technological requirements. The combined oil mist purifying unit has the functions of utilizing waste heat of the unit and purifying waste gases, and has the advantages of safety, reliability, reduction of pollution, convenience in technological operation and high degree of automation.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

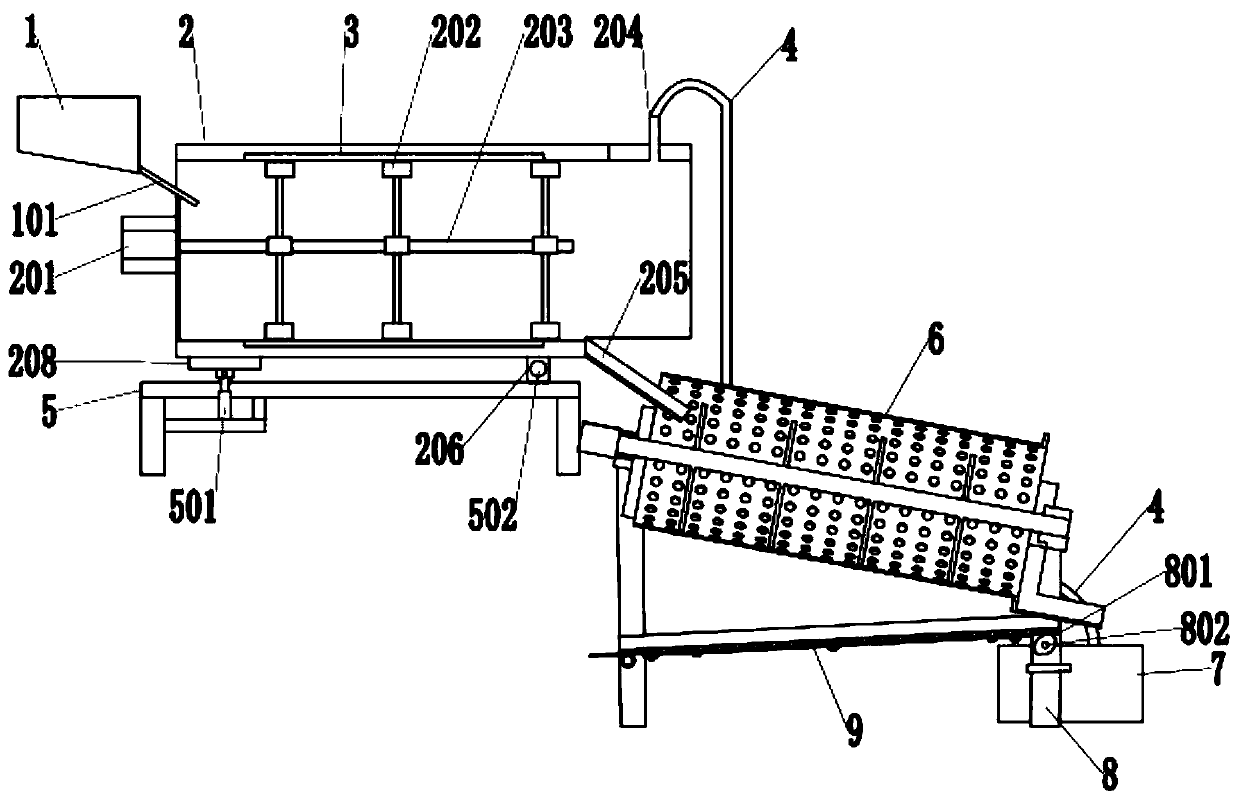

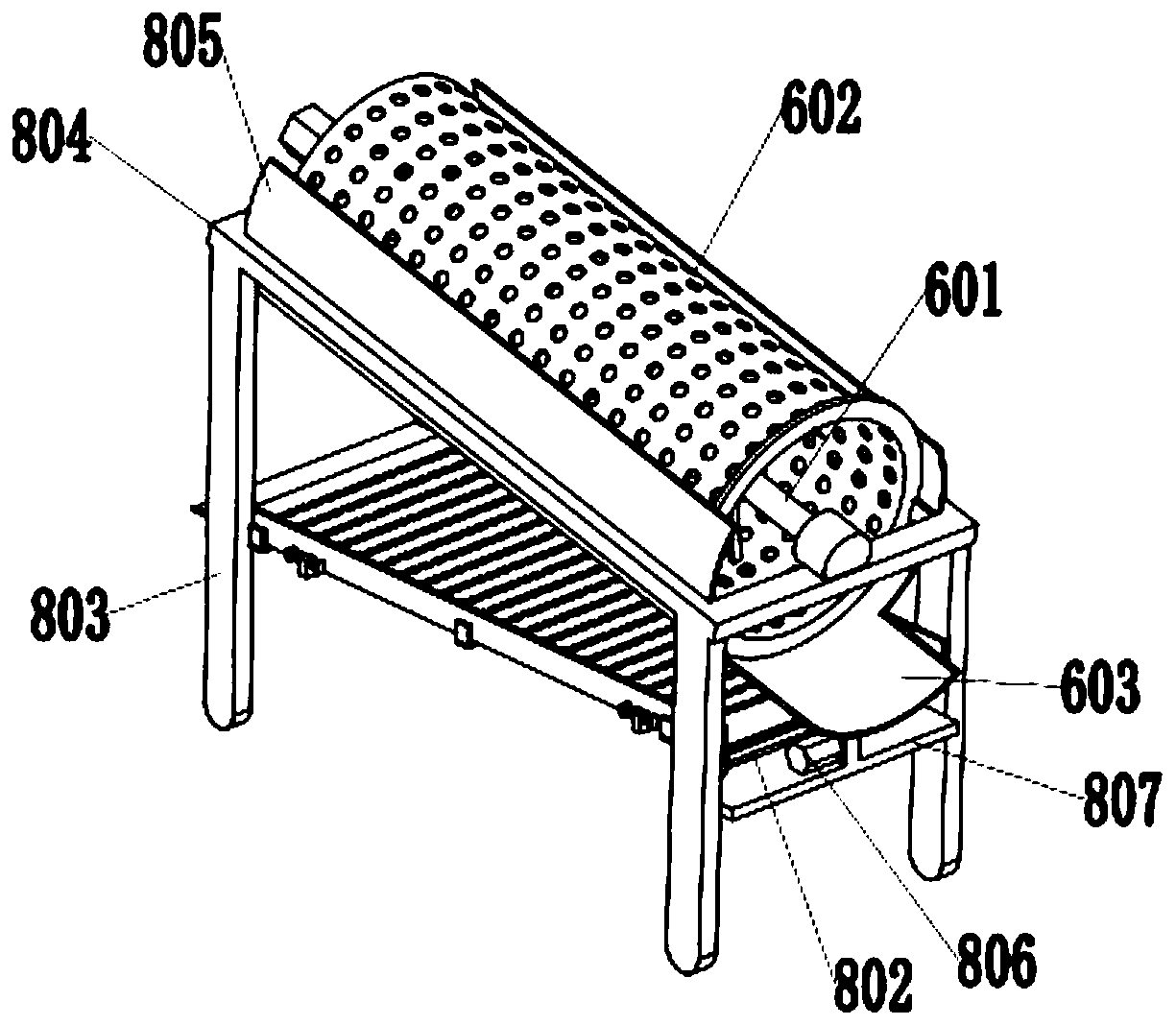

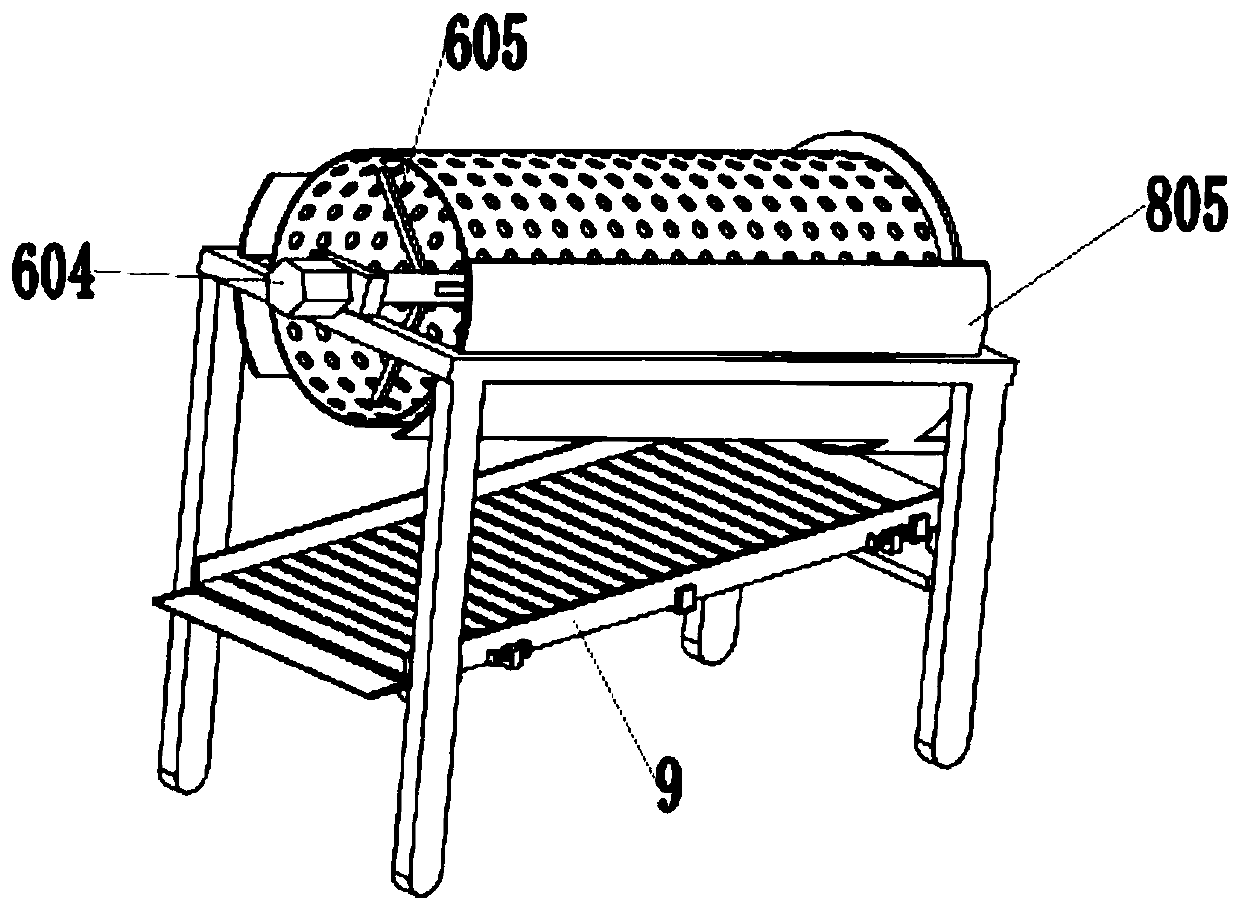

River sand screening device for construction

ActiveCN111054631ASmooth slidingIncrease profitSievingSand dryingEnvironmental engineeringSand filter

The invention discloses a river sand screening device for construction. The sand screening device comprises a sand feeding hopper, a drying cylinder, a primary screening device and a secondary sand screening device, the drying cylinder is mounted at the upper end of a bracket; the drying cylinder is of a double-layer hollow structure, a heating block is arranged between the outer cylinder wall andthe inner cylinder wall of the drying cylinder; one end of the drying cylinder is connected with a sand inlet hopper; the other end of the drying cylinder is communicated with the primary screening device; the primary screening device is a sand screening barrel; the sand screening barrel is installed on a supporting frame, first screening holes are formed in the side wall of the sand screening barrel, the second-stage sand screening device comprises a swing frame and a sand filtering plate, a sand screening plate is fixed to the upper end of a swing frame, second screening holes are formed inthe sand screening plate, the swing frame is connected with the supporting frame and located below the sand screening barrel, and the sand screening plate and the sand screening barrel are opposite in inclination direction. The problem that wet sands with small particles are mutually adhered is solved, the working efficiency is improved, the screening effect is improved, the utilization rate of the sand is increased, waste is avoided, and the construction cost is reduced.

Owner:济南工程职业技术学院

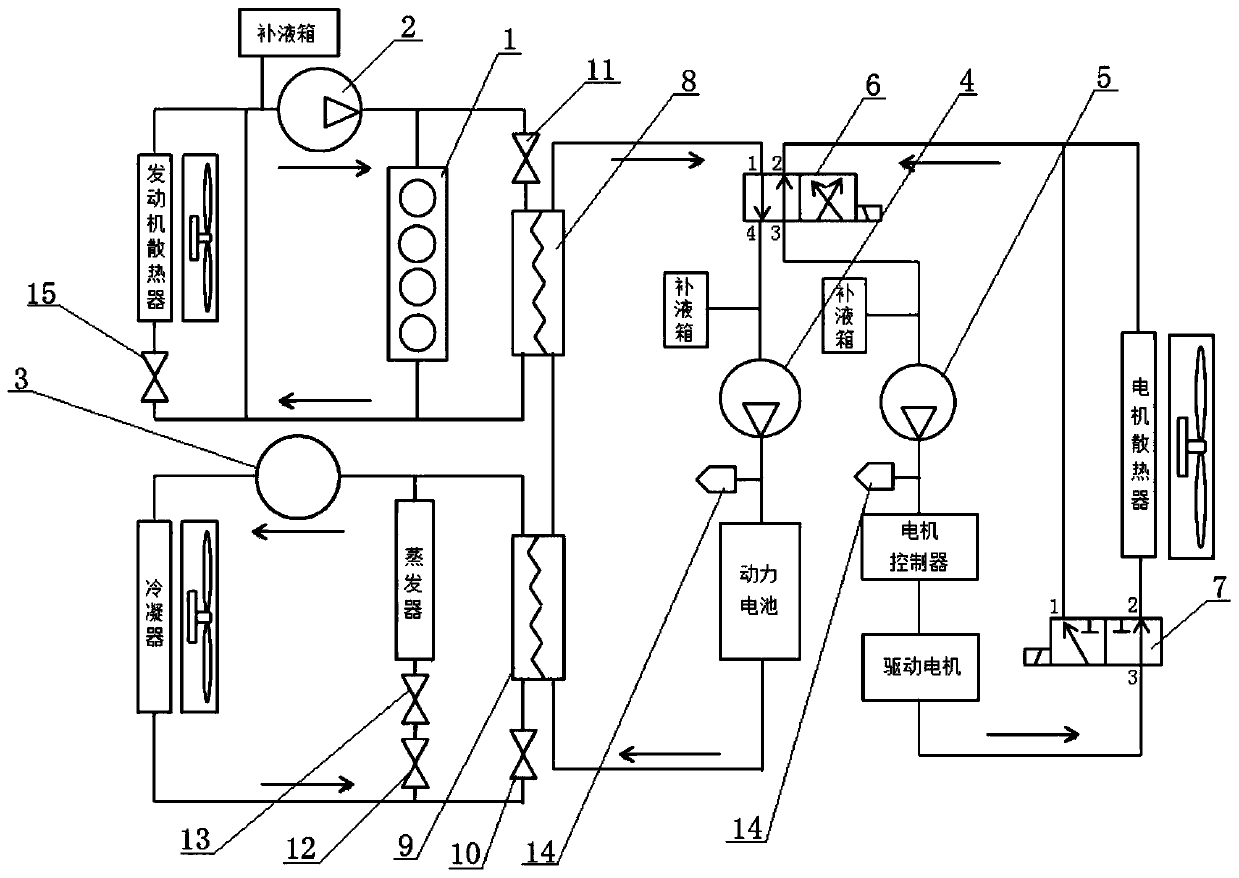

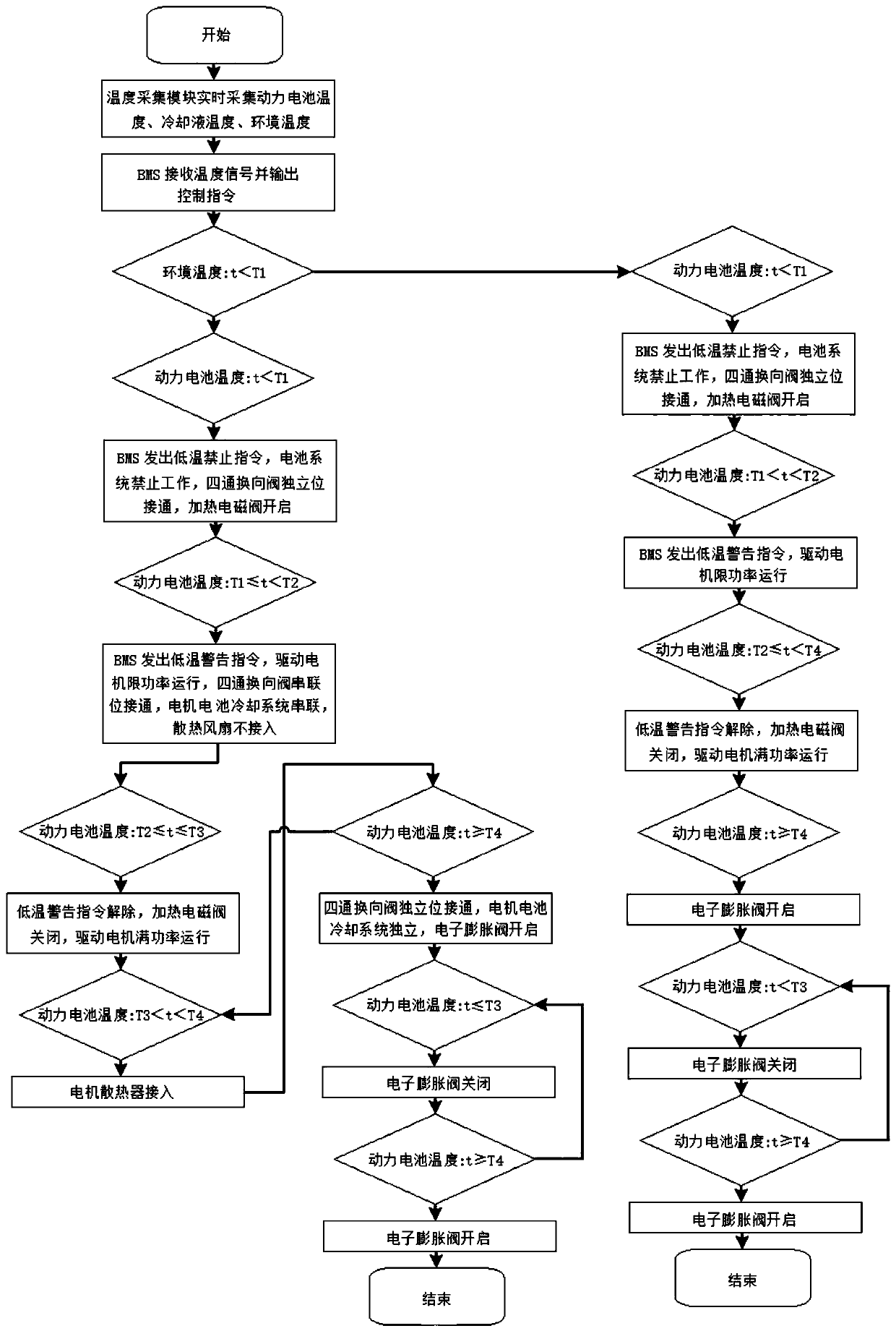

Integrated type heat management system for hybrid power car and control method thereof

ActiveCN110422082AReduce energy consumptionRealize waste heat utilizationVehicular energy storageBattery/fuel cell control arrangementPower batteryHeat management

The invention provides an integrated type heat management system for a hybrid power car and a control method thereof. The system comprises an engine heat dissipater, an air-conditioner for the car, acondenser, an evaporator, a power battery, a drive motor, a motor controller, a motor heat dissipater, a four-way reversing valve and a three-way reversing valve. According to the control method, temperature values T1, T2, T3 and T4 are set, wherein T1 is smaller than T2, T2 is smaller than T3, and T3 is smaller than T4; when the environment temperature is below T1, if the temperature of the powerbattery is smaller than T1, a heater heats the power battery; when the temperature of the power battery surpasses T1, battery cooling liquid heats the power battery; when the temperature of the powerstorage surpasses T4, the motor heat dissipater dissipates the heat; and when the environment temperature is over T1, the drive motor utilizes the motor heat dissipater for dissipating the heat, andthe power battery utilizes a refrigerating device for dissipating the heat. The drive motor, a power battery temperature controlling system, the air-conditioner for the car and the engine heat management system are controlled in an integrated manner, all the systems coordinate mutually, and the energy consumption of the whole car is reduced.

Owner:DONGFENG COMML VEHICLE CO LTD

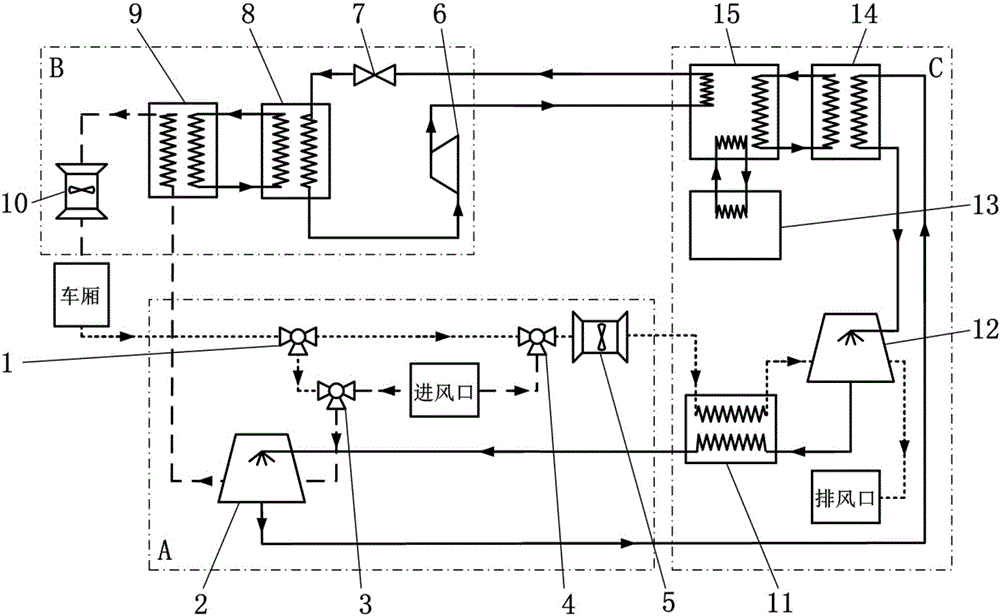

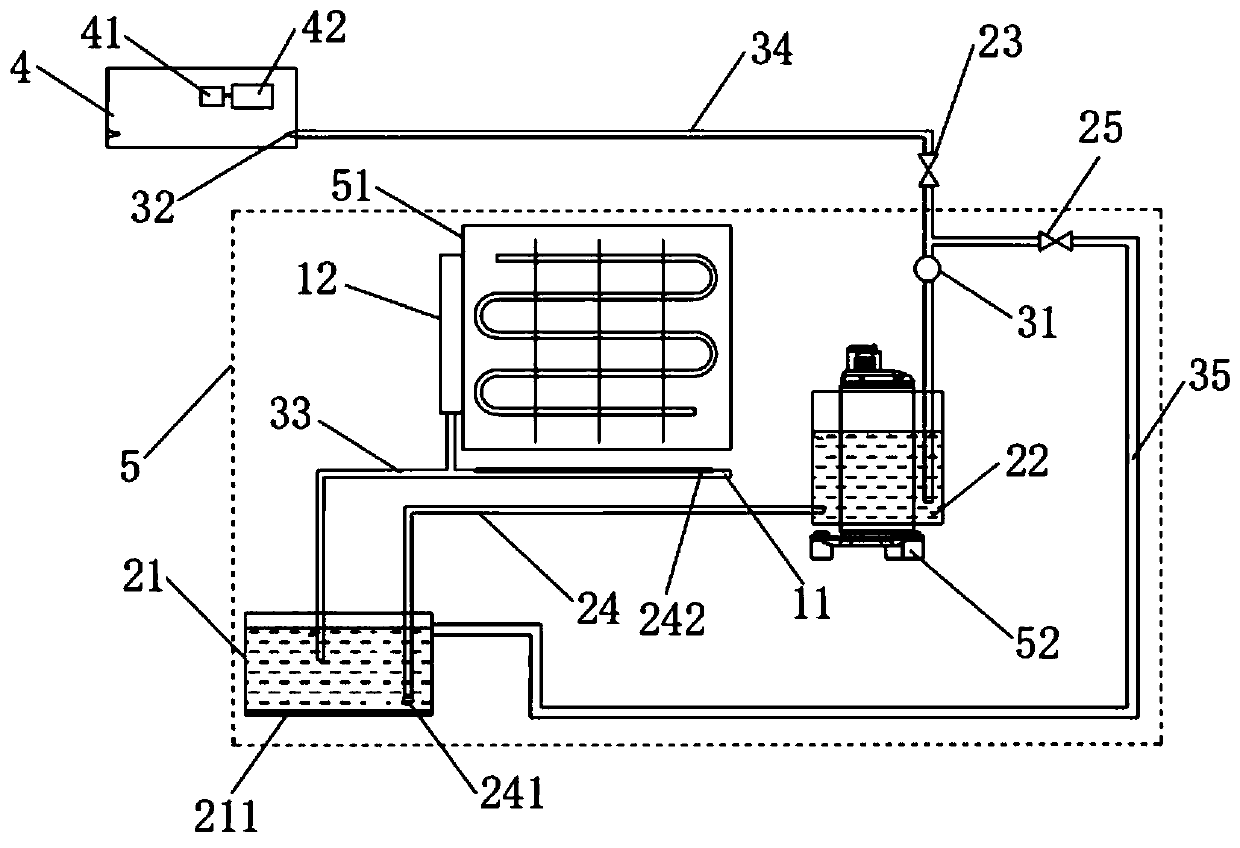

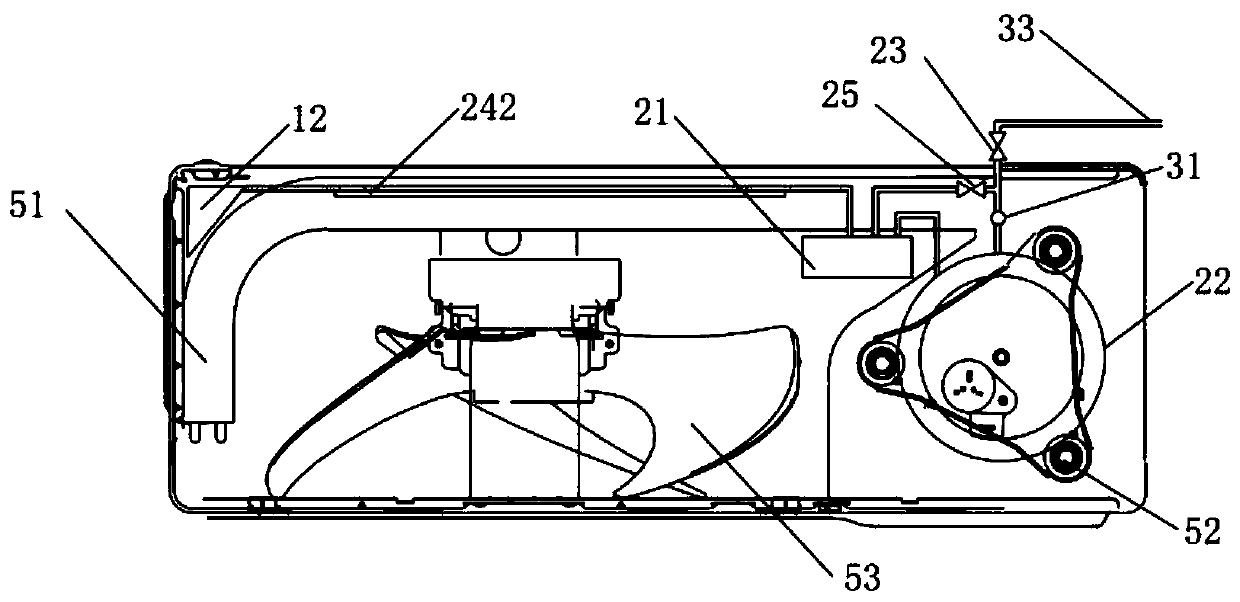

New energy electric vehicle waste heat energy storage type air-conditioning system based on solution dehumidification and method thereof

ActiveCN105774468AImprove cooling effectTemperature controlAir-treating devicesVehicle heating/cooling devicesAutomotive batteryNew energy

The invention discloses a new energy electric vehicle waste heat energy storage type air-conditioning system based on solution dehumidification and a method thereof. The air-conditioning system comprises a primary return air solution dehumidification system, an air-conditioning refrigerant circulation system and a waste heat energy storage solution regeneration system. Heat dissipated by batteries of an electric vehicle is absorbed by a phase-change material, and thus the heat dissipation effect of the batteries can be improved, and the temperature of the battery pack can be effectively controlled. By means of the phase-change energy storage technology, heat of condensation and the heat dissipated by the batteries can be efficiently recycled and controllably output, waste heat utilization is achieved, and the overall energy consumption of the electric vehicle is reduced. Through the solution dehumidification technology, separation between a dehumidification link and a temperature control link is achieved, dehumidification is conducted without the need for decreasing the temperature of air to the dew point temperature or below, and the temperature control load of the air-conditioning system is greatly reduced. Through a primary return air mode, fresh air and return air are mixed, so that air quality is guaranteed, and the temperature control load of the air-conditioning system is reduced. Meanwhile, a dehumidification solution can be regenerated repeatedly, and the service life is long.

Owner:ZHEJIANG UNIV

Open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit

PendingCN106765265AAvoid condensationAvoid Low Temperature CorrosionFeed water supplyCombustion technology mitigationGas heaterGas cooler

The invention discloses an open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit, and relates to a steady controllable open MGGH system. A water outlet of a gas cooler is communicated with a gas-gas heater and a water inlet of waste heat recovery hot water mixer through pipeline systems with valves respectively, and the water inlet pipeline of the gas-gas heater is also provided with an auxiliary steam heater; the water outlet of the gas-gas heater is communicated with the water inlet of the gas cooler through a circulating water and make-up water mixer, a variable frequency booster pump and the pipeline systems with the valves; the water inlet of the circulating water and make-up water mixer is also communicated with a condensation water pipeline, and the water outlet of the waste heat recovery hot water mixer is communicated with a low-temperature heating system pipeline through at least two pipelines with the valves. In the invention, the problems that the inlet gas temperature of an electrostatic precipitator and chimney inlet gas temperature are difficult to control, the low-temperature heating adjustment of the unit is difficult to control and the disturbance is severe due to poor heat exchange effect of a plate heat exchanger in the existing MGGH technology are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Air conditioner water circulation system, control method and air conditioner

ActiveCN111486506AAchieve self-sufficiencySufficient water sourceMechanical apparatusCondensate preventionWater storageWater storage tank

The invention provides an air conditioner water circulation system, a control method and an air conditioner. The air conditioner comprises an indoor unit and an outdoor unit. The air conditioner watercirculation system comprises a condensed water collecting component, a water storage component and a humidifying component which are sequentially connected. The water storage component comprises a water storage tank and a compressor water tank which are connected. Water collected in the water storage tank enters the compressor water tank for heat exchange and then indoor air is humidified throughthe humidifying component. According to the water circulation system, in a heating mode, the water circulation system is intelligently adjusted based on the relationship of values of indoor temperature and humidity and preset values, so that the indoor air humidity is increased, and the comfort of a human body is improved.

Owner:NINGBO AUX ELECTRIC +1

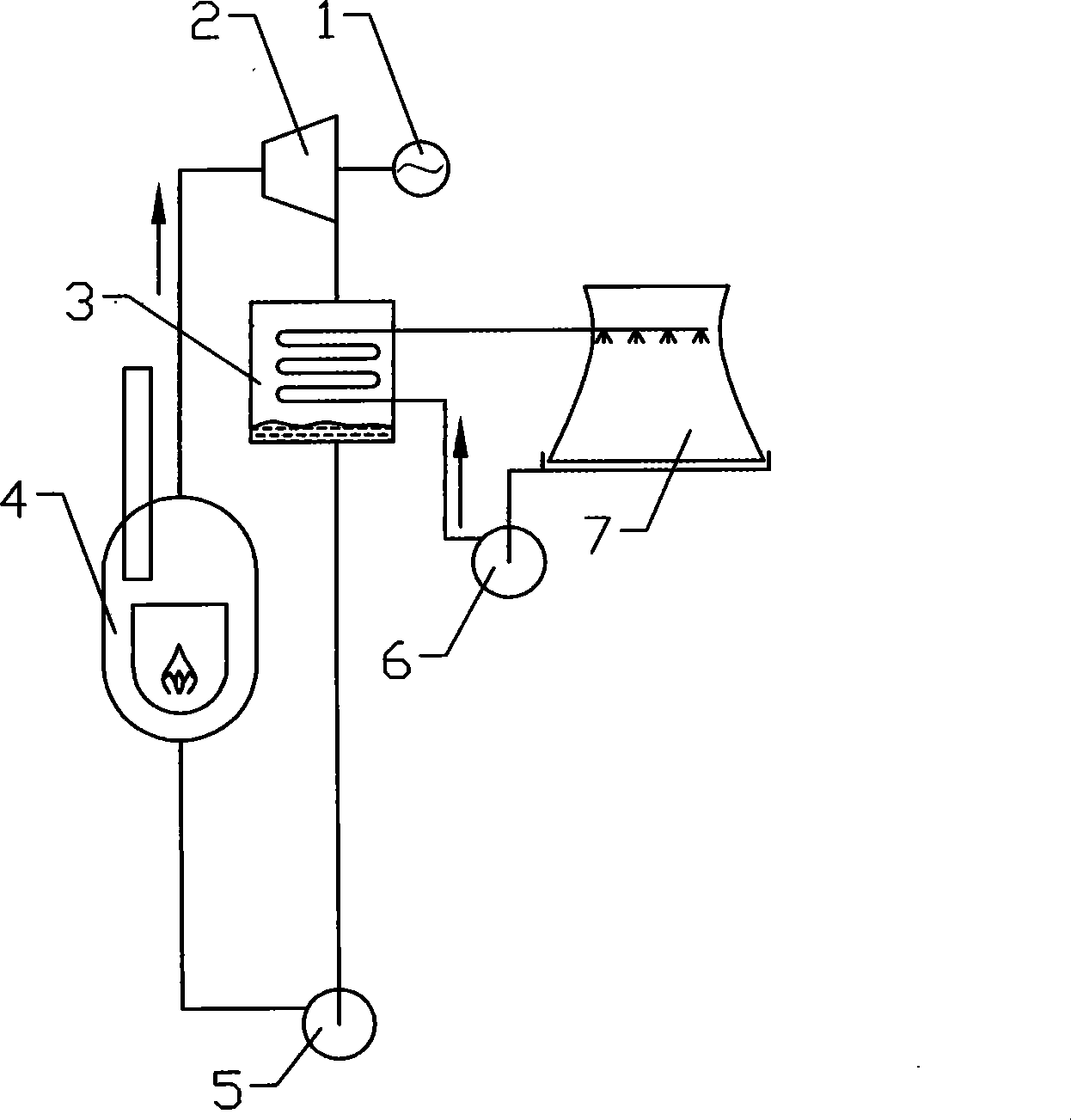

Utilization system of dead steam heat of power plant

The invention relates to a utilization system of dead steam heat of a power plant. The utilization system comprises a boiler, a steam turbine, a condenser, a heat pump, a peak load calorifier and a secondary heat exchange station, wherein the steam turbine is connected with the condenser through an exhaust pipe; a steam extraction pipe is arranged on an air inlet pipe of the steam turbine; a low temperature heat source inlet of the heat pump is connected with a water outlet of the condenser; a lower temperature heat source outlet of the heat pump is connected with a water return port of the condenser; a driving heat source inlet of the heat pump is connected with the steam extraction pipe; a condensate outlet of the heat pump is connected to the boiler; a water supply outlet of the heat pump is connected with a water inlet of the peak load calorifier; a water outlet of the peak load calorifier is connected with a heat source inlet of the secondary heat exchange station through a pipeline; a heat source outlet of the secondary heat exchange station is connected with a water supply inlet of the heat pump; a water inlet of the secondary heat exchange station is connected with a water supply source; and a water outlet of the secondary heat exchange station is connected with a heat utilization device. The utilization system can well adapt to an existing power plant heat supply unit and can utilize dead steam waste heat of the steam turbine, thereby achieving the purposes of energy conservation and consumption reduction.

Owner:中国大唐集团科学技术研究总院有限公司

System and method for realizing zero emission of desulfurization waste water by denitrifying wide negative charges and utilizing waste heat

PendingCN108128956ARaise the exhaust gas temperatureAchieving zero emissionsDispersed particle separationScale removal and water softeningAir preheaterLow load

The invention relates to a system and a method for realizing zero emission of desulfurization waste water by denitrifying wide charges and utilizing waste heat, and belongs to the fields of energy conservation and emission reduction of thermal power generation. The system comprises a boiler, a coal economizer, an SCR denitrification device, an air preheater, an electric dust remover and a desulfurization tower which are connected sequentially through a main flue; a steam turbine is connected with the boiler through a main steam pipeline; a No.1 high-pressure heater and a No.0 high-pressure heater are arranged on a water supply pipeline sequentially; and the system also comprises a water supply backheating subsystem and an air preheater bypass flue evaporation subsystem. The invention alsorelates to a method for realizing zero emission of the desulfurization waste water by denitrifying the wide negative charges and utilizing the waste heat based on the system for realizing zero emission of the desulfurization waste water. Denitrification effect improvement, zero emission of desulfurization waste water and utilization of flue gas waste heat can be realized simultaneously by increasing the smoke discharge temperature of the boiler under various low-load working conditions of a machine unit.

Owner:DATANG ENVIRONMENT IND GRP

Triple-generation system for utilizing slag-washing water afterheat by using blast furnace drum method

ActiveCN103866058ADoes not affect operationIncrease savingsIncreasing energy efficiencyRecycling and recovery technologiesSlagWater quality

The invention relates to a triple-generation system for utilizing slag-washing water afterheat by using a blast furnace drum method. The system comprises a graining tower, wherein the graining tower is sequentially communicated with a drum, a hot water tank and a heat storage regulating reservoir; the heat storage regulating reservoir comprises a precipitating heat storage tank and a graining impounding reservoir; the precipitating heat storage tank is connected with a first inlet of a heat exchange device through an afterheat water supply pump group; a first outlet of the heat exchange device is communicated with the graining impounding reservoir; a second inlet of the heat exchange device is respectively connected with a heating user and the first outlet of a refrigeration mechanism through a heating water supply pump group; the heating user and the first inlet of the refrigeration mechanism are communicated with the second outlet of the heat exchange device; the second inlet of the refrigeration mechanism is communicated with an indoor refrigeration user and a dehumidified blast user; the indoor refrigeration user and the dehumidified blast user are communicated with the second outlet of the refrigeration mechanism; and the graining impounding reservoir is communicated with the graining tower through a graining water supply pump group. The system is applied to triple-generation of heating, refrigerating or dehumidified blasting of a blast furnace, and is high in thermal efficiency and stable in water quality.

Owner:WISDRI ENG & RES INC LTD

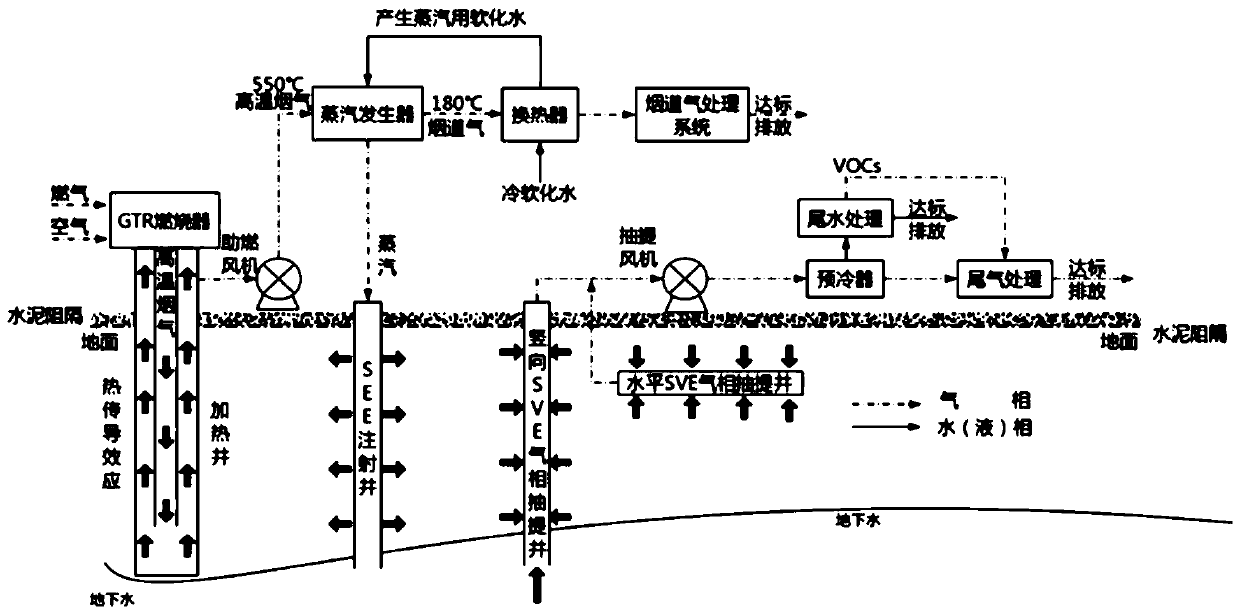

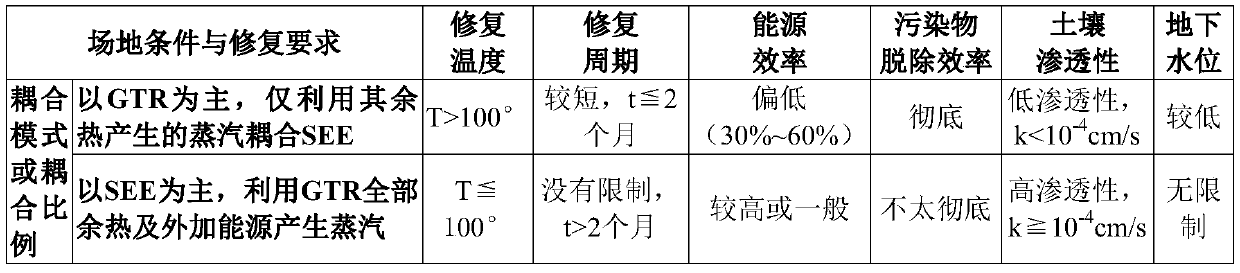

Fuel gas thermal desorption-steam enhanced vapor extraction in-situ coupling repair method for composite organic contaminated site

InactiveCN111250524AAchieve intrinsic couplingRealize waste heat utilizationContaminated soil reclamationHalohydrocarbonSoftened water

The invention discloses a fuel gas thermal desorption-steam enhanced vapor extraction in-situ coupling repair method for a composite organic contaminated site. A high-temperature flue gas heating well, a steam injection well and a vapor extraction well are included. High-temperature flue gas generated by a combustor is subjected to heat transfer through the high-temperature flue gas heating well for soil remediation; flue gas returned from the high-temperature flue gas heating well is introduced into the steam generator, softened water for generating steam is introduced into the steam generator at the same time, and steam generated by heat of the flue gas is injected into the steam injection well and used for steam enhanced vapor extraction. High-temperature flue gas generated by thermal desorption of fuel gas and steam generated by external softened water are used for steam injection of steam enhanced vapor extraction, internal coupling of GTR and SEE is truly achieved, waste heat ofhigh-temperature flue gas is recovered, waste heat utilization is achieved, remediation efficiency is greatly improved, and the method is particularly suitable for benzene series, petroleum hydrocarbon, polycyclic aromatic hydrocarbon and halogenated hydrocarbon composite organic contaminated sites.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Quenching furnace flue gas reusing device and reusing method based on quenching furnace flue gas reusing device

ActiveCN105420458AFlexible to meet secondary utilization needsMeet the needs of secondary usePreheating chargesQuenching devicesFlue gasQuenching

The invention discloses a quenching furnace flue gas reusing device and a reusing method based on the quenching furnace flue gas reusing device. The device comprises a quenching furnace and a tempering furnace which are arranged side by side; a flue gas pipeline is mounted in the quenching furnace; a transverse flue gas main pipe is disposed at the bottom of the tempering furnace and extends towards the outside of the tempering furnace; a three-way pipe is disposed at one end of the flue gas pipeline and provided with a quenching furnace chimney and a connecting pipeline; an air mixing pipe is disposed in the middle of the connecting pipeline; a high-temperature suction fan is disposed at the end of the connecting pipeline; the high-temperature suction fan is communicated with one end of the transverse flue gas main pipe. The quenching furnace flue gas reusing device and the reusing method based on the quenching furnace flue gas reusing device have the beneficial effects that large part of waste heat of original exhausted wasted quenching furnace flue gas can be reused economically and efficiently in the low-temperature tempering furnace so that a low-temperature steel plate entering the furnace can be pre-heated and extra energy consumption caused by burning of coal gas which is needed to generate heat to heat the steel plate when the low-temperature furnace does not have external flue gas to pre-heat the steel plate can be omitted.

Owner:BAOSHAN IRON & STEEL CO LTD

Air conditioner

ActiveCN109386886AImprove comfortReduce energy consumptionEnergy recovery in ventilation and heatingMechanical apparatusEngineeringRefrigerant

An air conditioner includes an outdoor unit and a dehumidifying and reheating indoor unit, is capable of avoiding non-uniform temperature distribution of airflow supplied to the indoor by the dehumidifying and reheating indoor unit, and gives full play to the functions of a dehumidifying heat exchanger and reheating heat exchanger of the dehumidifying and reheating indoor unit. According to the air conditioner, the outdoor unit includes a compression mechanism and an outdoor heat exchanger, the dehumidifying and reheating indoor unit includes a dehumidifying heat exchanger and a first indoor refrigerant regulating device, the air conditioner utilizes a suction pipe, a discharge pipe, a first matched pipe and a second matched pipe to connect the compression mechanism, the outdoor heat exchanger, the first indoor refrigerant regulating device and the dehumidifying heat exchanger, the air conditioner also comprises a reheating heat exchanger, a second indoor refrigerant regulating device,a third matched pipe and a branch pipe, the third matched pipe sequentially connects a first junction portion of the first matched pipe, between the first indoor refrigerant regulating device and theoutdoor heat exchanger, the second indoor refrigerant regulating device, the reheating heat exchanger, and the branch pipe.

Owner:DAIKIN IND LTD

Coal gasification and reburning efficient denitrification system for cement decomposing furnace by high-temperature triple air

ActiveCN107099336AReduce dosageReduce ammonia slipGas treatmentDispersed particle separationProduct gasCombustion

The invention discloses a coal gasification and reburning efficient denitrification system for a cement decomposing furnace by high-temperature triple air. The coal gasification and reburning efficient denitrification system comprises a decomposing furnace and a high-temperature triple air duct, wherein the decomposing furnace is provided with a main combustion zone coal-injection duct and a cement raw material discharging pipe; the high-temperature triple air duct communicates with a main combustion zone of the decomposing furnace for providing combustion-supporting wind; a branched pipe extending to the upper part is connected onto the high-temperature triple air duct; a coal gasifying pipe and a burnout air duct which communicate with a reburning zone and a burnout zone of the decomposing furnace are respectively educed from the unconnected end of the branched pipe; a first high-temperature adjusting valve is arranged at a connecting part of the branched pipe and the high-temperature triple air duct; a second high-temperature adjusting valve is arranged at the unconnected end of the branched pipe; a coal gasification coal-injection pipe and a water steam spraying-in pipe are respectively connected onto the gas gasifying pipe. Large-sized equipment does not be refitted if the coal gasification and reburning efficient denitrification system is adopted, so that investment is less; by using gas as a reburning fuel, the efficient denitrification system has high denitrification efficiency and the characteristics of economy and high efficiency.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

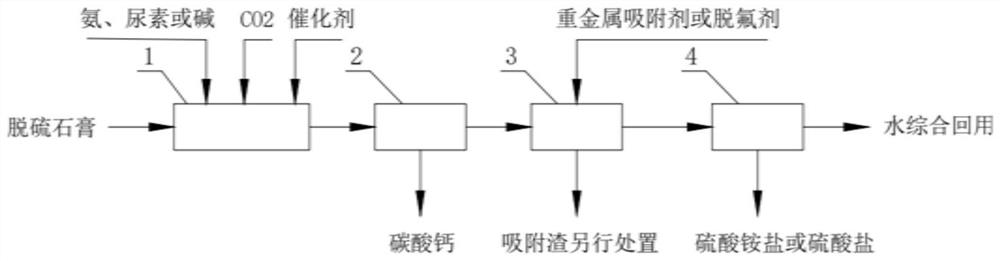

Method for preparing calcium carbonate and co-producing sulfate by utilizing industrial desulfurization gypsum

PendingCN113149055ARealize resource utilizationResource utilization hasCalcium/strontium/barium carbonatesUrea derivatives preparationChemical industrySulfate sulfur

The invention discloses a method for preparing calcium carbonate and co-producing sulfate by utilizing industrial desulfurization gypsum, and the method comprises the following steps: carrying out size mixing treatment on the desulfurization gypsum to obtain gypsum slurry, adjusting the gypsum slurry to be alkaline by adopting an alkaline compound, introducing carbon dioxide gas for reaction, and after the reaction is finished, carrying out solid-liquid separation, and obtaining a calcium carbonate product and a sulfate solution; carrying out impurity removal treatment on the sulfate solution, and concentrating and crystallizing to obtain a sulfate product. According to the method, the maximum resource comprehensive utilization of the desulfurized gypsum can be realized, a high-purity calcium carbonate product can be obtained and can be returned to the flue gas desulfurization process of enterprises in the electric power industry, the fluorine chemical industry and the metal smelting industry, and byproducts such as sulfate (ammonium sulfate) can be obtained and can be used as fertilizers or industrial raw materials for agricultural production; virtuous cycle of the whole production and manufacturing process is realized, comprehensive utilization of sulfur and calcium resources and emission reduction of carbon are promoted, and large-scale popularization and application are facilitated.

Owner:湖南西林环保材料有限公司

Incinerator flue gas multi-pollutant dry-type purification process and device

PendingCN111282419AAchieving processing powerRealize waste heat utilizationHuman health protectionGas treatmentThermal desorptionDust collector

The invention relates to an incinerator flue gas multi-pollutant dry-type purification process and device. The device comprises a first-stage desulfurization system and a second-stage desulfurizationsystem which are arranged in sequence, wherein the desulfurization system in each stage comprises a desulfurizing agent powder bin, a desulfurizing agent pulverizer, a Roots blower, a desulfurizing agent adding device, a desulfurizing tower and a bag-type dust collector which are arranged in sequence; a medium-low temperature SCR reactor, a waste heat exchange device and an induced draft fan are sequentially arranged at the lower part of the second-stage desulfurization system; an ammonia spraying grid and a static mixer are arranged in the medium-low temperature SCR reactor, and the ammonia spraying grid is arranged in an air inlet pipeline of the medium-low temperature SCR denitration reactor; the medium-low temperature SCR reactor is connected with an ammonia gas preparation system anda thermal desorption / heating system; the bag-type dust collector comprises a gas inlet flue, an ash bucket arranged at the bottom of the dust collector, a filter bag arranged in the dust collector, agas purification chamber and a gas outlet flue, and a flue gas uniform distribution device is arranged on the side of the ash bucket.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

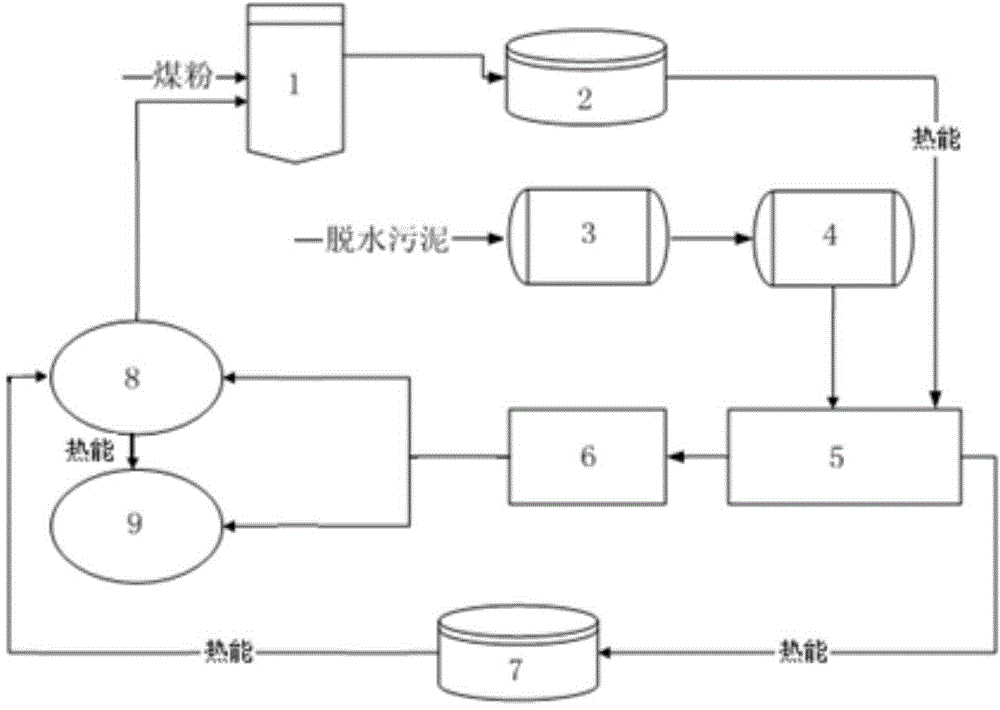

Recycling treatment system and recycling treatment method of dewatered sludge

InactiveCN104649529AEfficient resource utilizationGood removal effectSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlue gasFermentation

The invention relates to a recycling treatment system and a recycling treatment method of dewatered sludge. The recycling treatment system is composed of an incineration boiler, a first flue gas waste heat exchanger, a sludge storage pool, an alkaline conditioning chamber, a thermal cracking chamber, a dewatering chamber, a second flue gas waste heat exchanger, a waste heat drying chamber and an anaerobic fermentation tank. The recycling treatment method comprises the following steps: firstly, performing alkaline conditioning and thermal cracking on the dewatered sludge and then dewatering to obtain a solid phase and a liquid phase, performing drying treatment on the solid phase with thermal cracking flue gas waste heat as a heat source to obtain the dried sludge, and producing biogas from the liquid phase with drying flue gas waste heat as the heat source. The recycling treatment method realizes the removal of easily removable moisture in the sludge and also realizes sludge stabilization; meanwhile, the recycling treatment method is capable of promoting further efficient removal and biochemical degradation of the moisture content in the sludge; and as a result, the problems of low drying efficiency, easy binding and easy explosion are solved, and efficient recycling utilization of the sludge based on phase separation is realized.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com