Flue gas circulation system and method for sintering machine flue gas recirculation denitration

A flue gas recirculation and sintering machine technology, which is applied in the field of air pollutant control in the iron and steel industry, achieves the effects of small changes, low operating costs, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

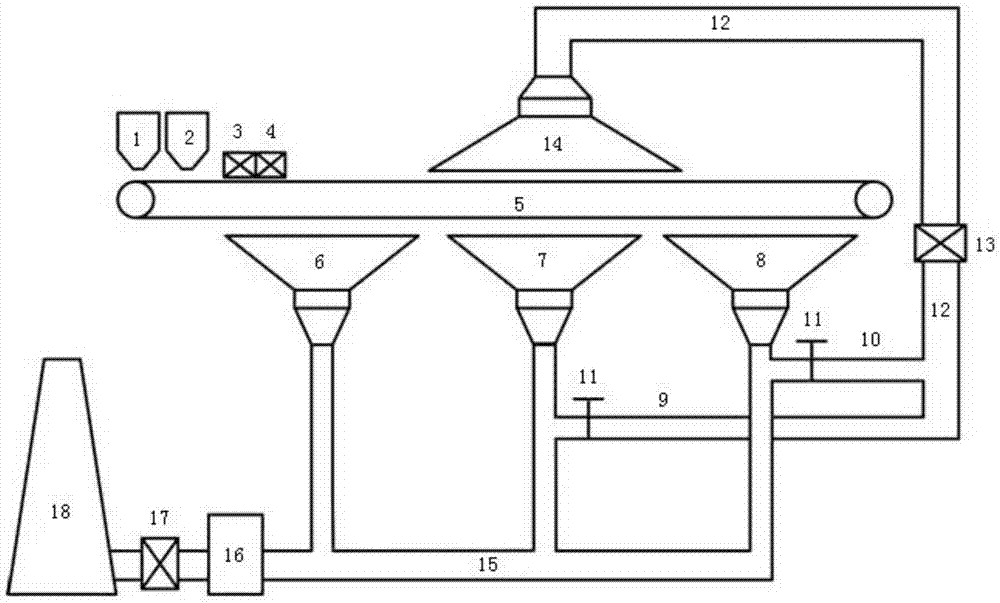

[0029] A sintering machine flue gas recirculation denitrification method using the flue gas circulation system, implemented in a 360m 2 Belt sintering machine. The denitrification process is as follows: the base material and the mixed material are respectively laid on the trolley 5 by the base material tank 1 and the mixed material tank 2, and are burned on the trolley 5 after being ignited by the ignition furnace 3 and kept warm by the holding furnace 4; Enter the front bellows 6, the middle bellows 7 and the rear bellows 8 respectively; part of the flue gas in the middle bellows 7 (the temperature of the flue gas is about 150°C) and the rear bellows 8 (the temperature of the flue gas is about 400°C) enters the large flue 15. Part of it is extracted by the recirculation fan 13 and enters the recirculation flue 12 from the first branch pipe 9 and the second branch pipe 10. The flow rate of the recirculation flue gas is controlled by the regulating valve 11, and the circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com