Recycling treatment system and recycling treatment method of dewatered sludge

A dewatered sludge and treatment method technology, which is applied in the directions of dehydration/drying/concentrated sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of poor treatment effect, inability to effectively prevent secondary pollution, cost High-level problems, to achieve the effect of reducing energy waste, efficient removal and biodegradable characteristics, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

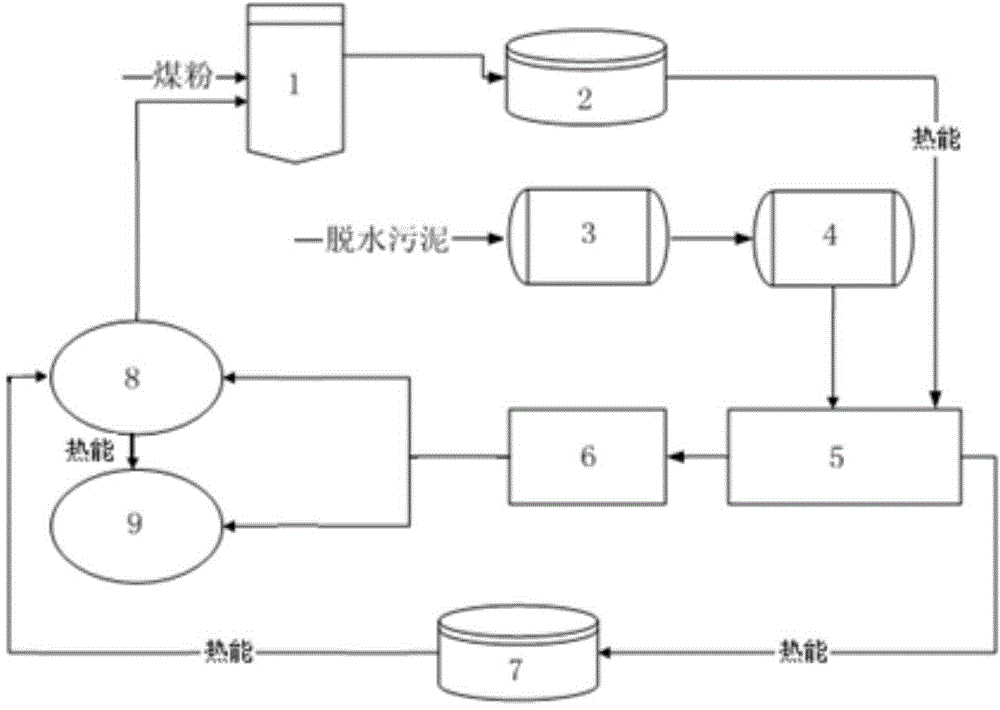

[0030] A resourceful treatment method for dewatered sludge, which is carried out according to the following steps: after the dewatered sludge is poured into the sludge storage tank 3, it is transported to the alkali conditioning chamber 4 through a screw pump conveying device, and limestone and the mass of the solid content of the sludge are added. The ratio is 0.25, that is, 37.5kg of limestone is added to 1t of dewatered sludge (water content 85%), and the alkali conditioning time is 2 days; the sludge after alkali conditioning is transported to the thermal cracking chamber 5 through an anti-corrosion pump delivery device, and The heat energy of the incineration boiler 1 is thermally decomposed, and the heat energy of the incineration boiler 1 is transported to the serpentine steam coil in the thermal decompression chamber 5 through the first flue gas waste heat exchanger 2, and the hot steam passes through the serpentine steam coil to decompose the material in the tank. Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com