Patents

Literature

228 results about "Decompression chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

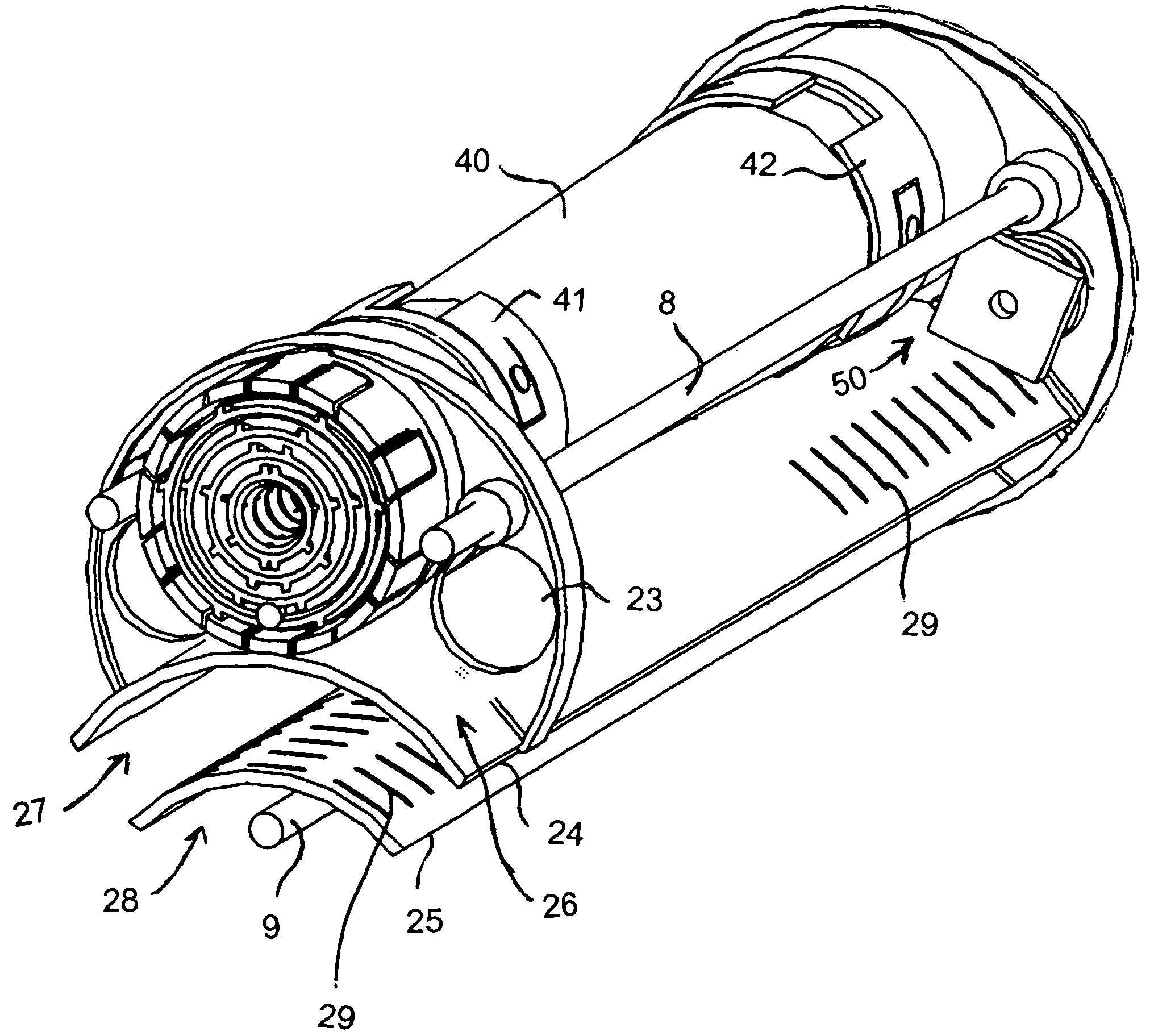

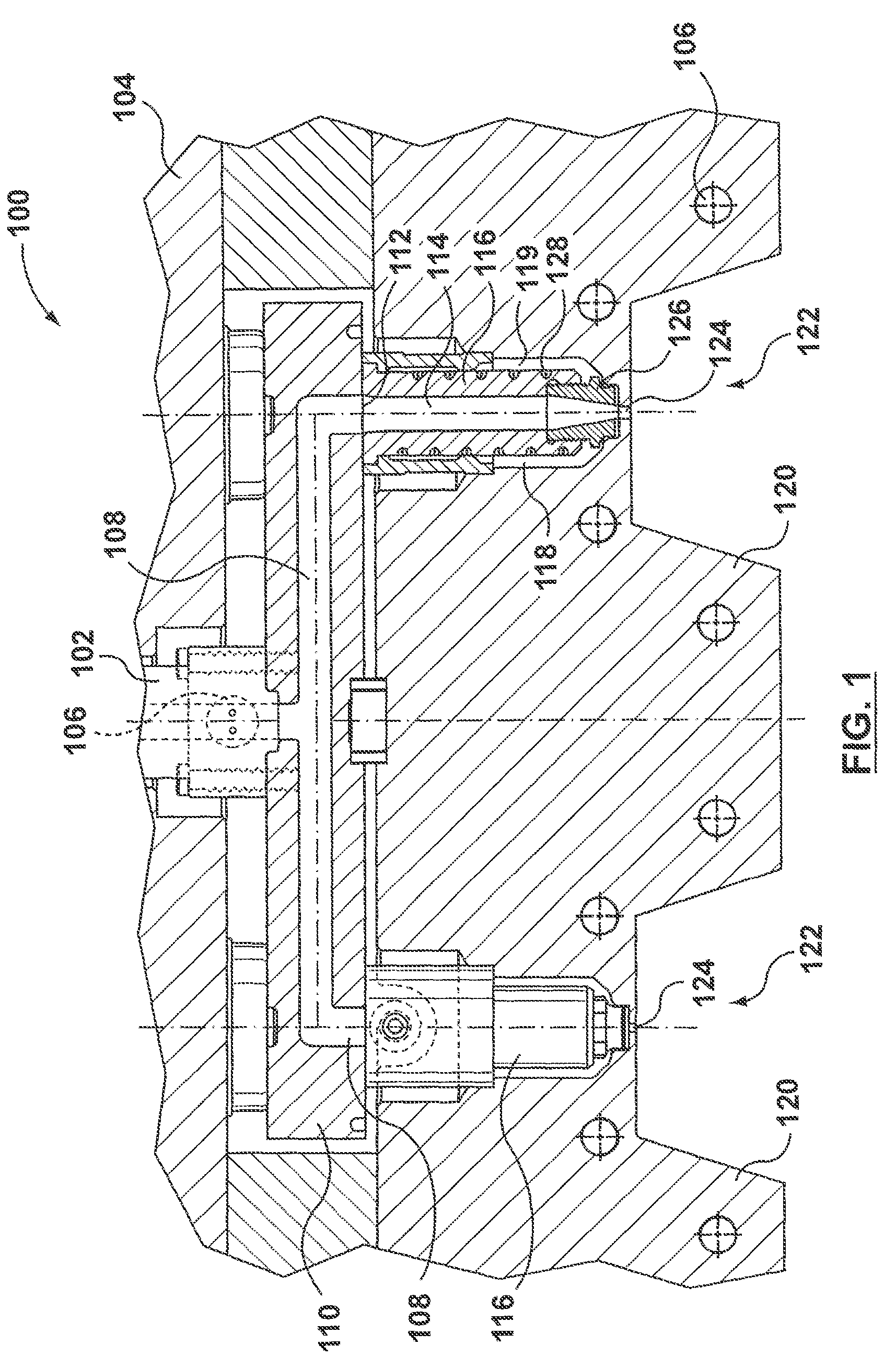

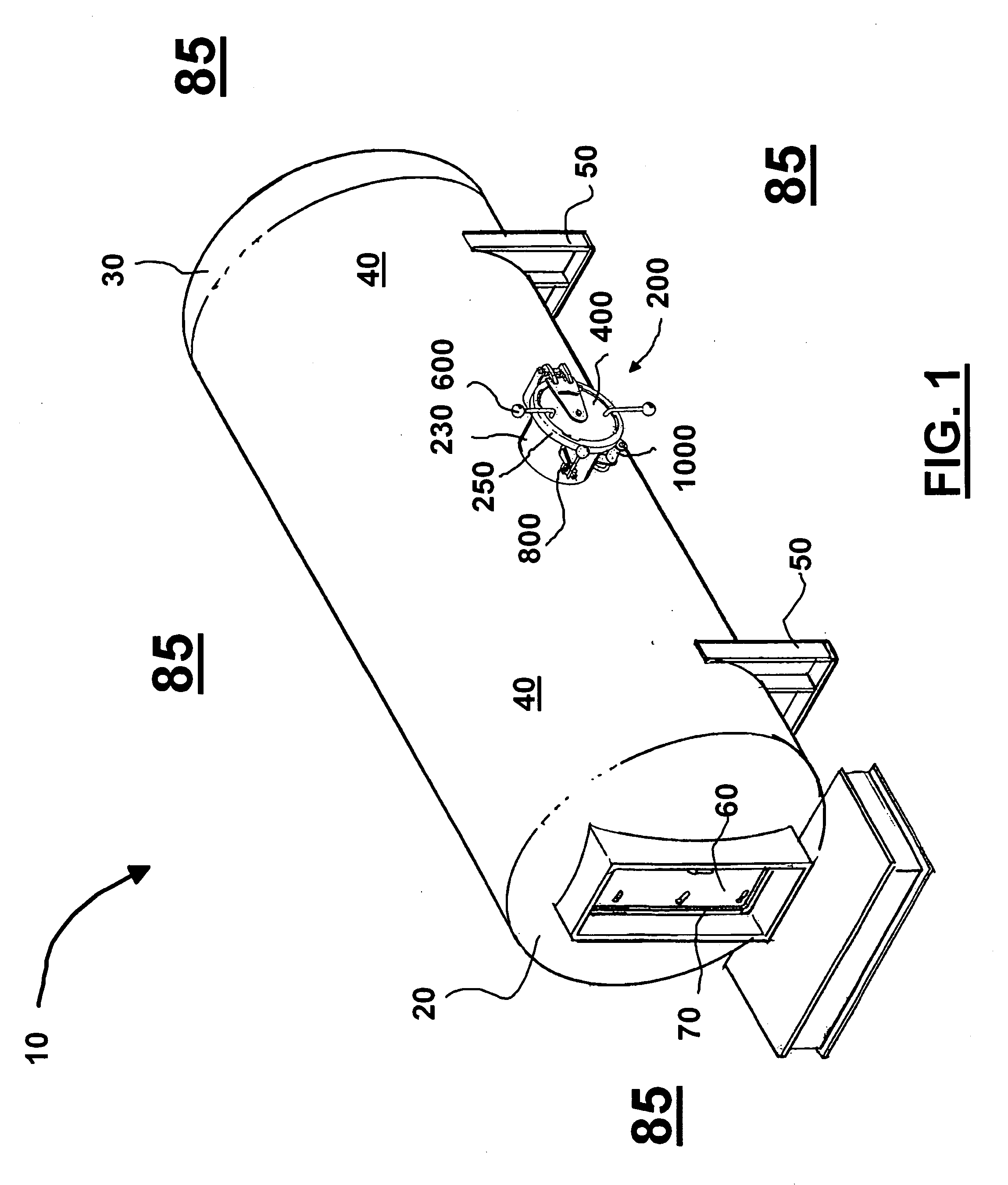

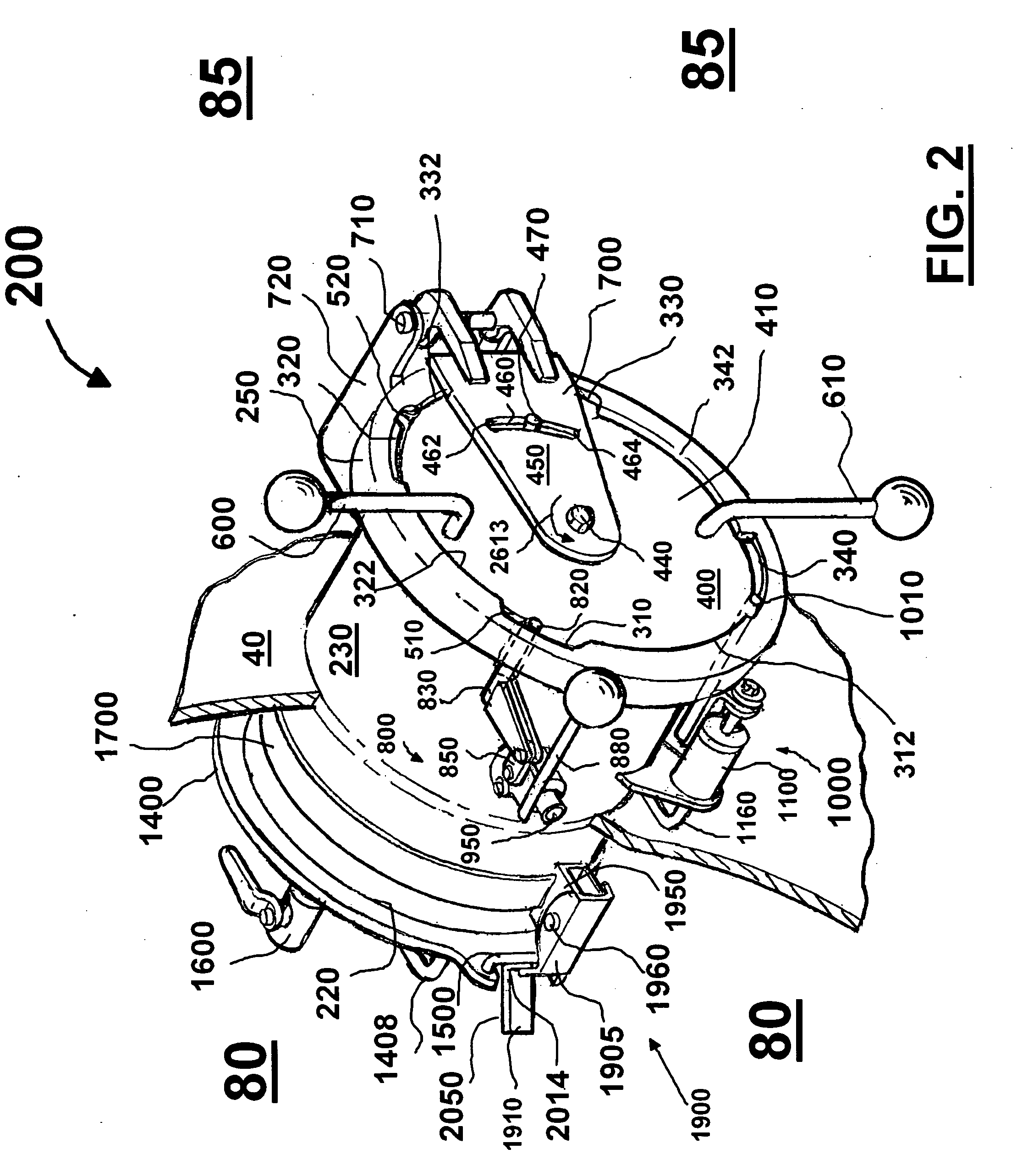

Firearm suppressor, mounting system and mounting method

InactiveUS20080148928A1Reduce impactOvercome disadvantagesMuzzle attachmentSuppressorAtmospheric air

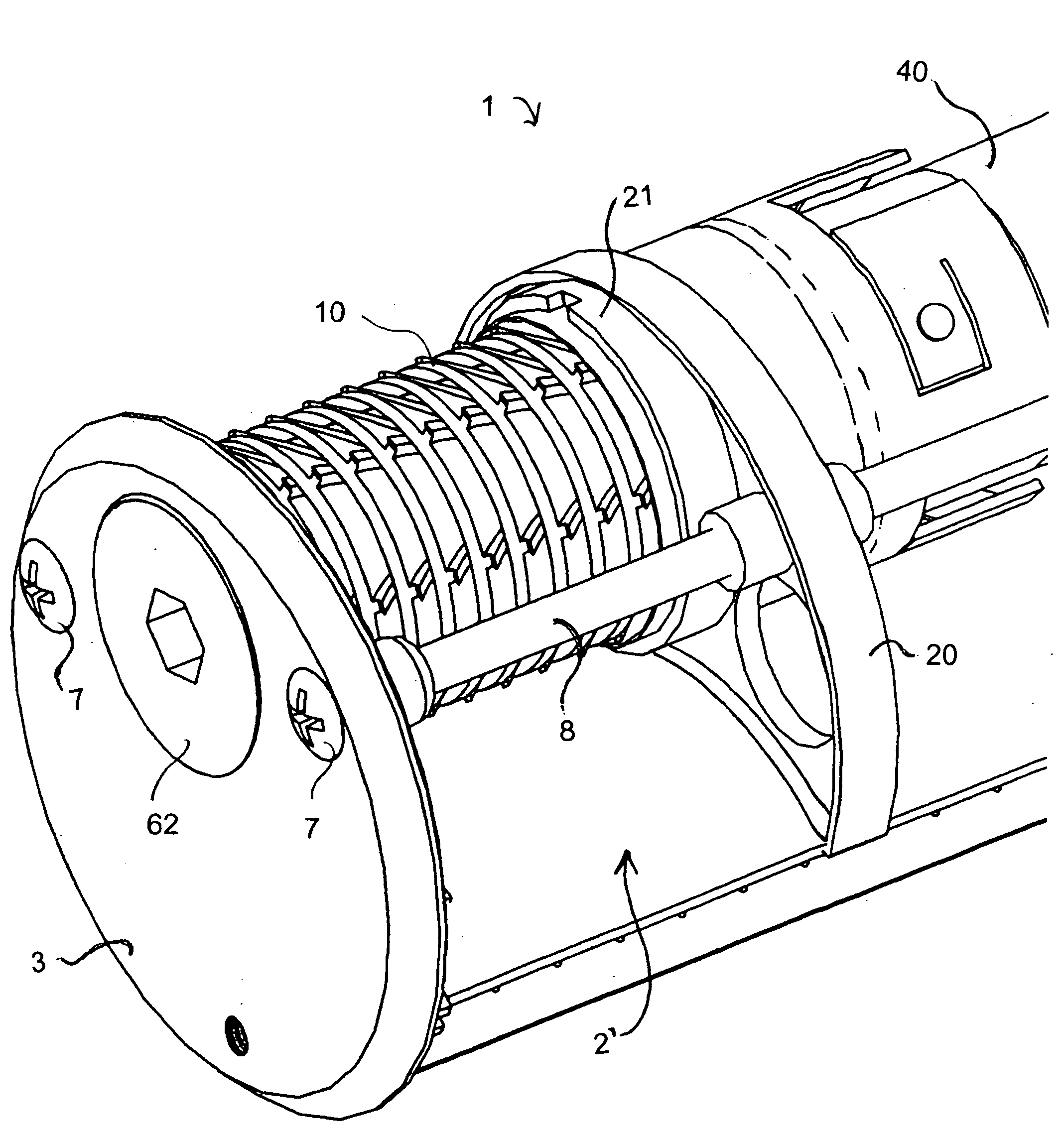

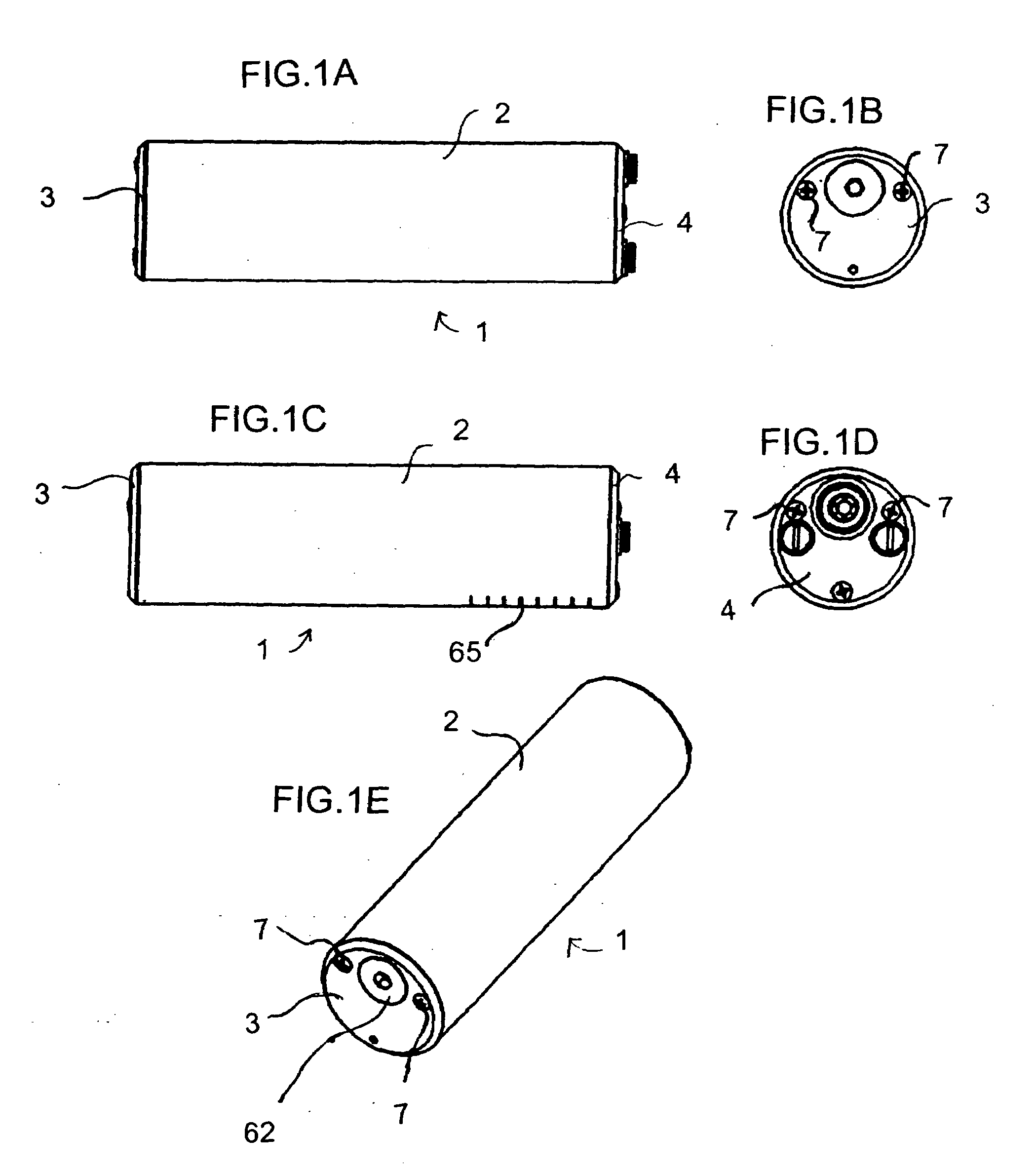

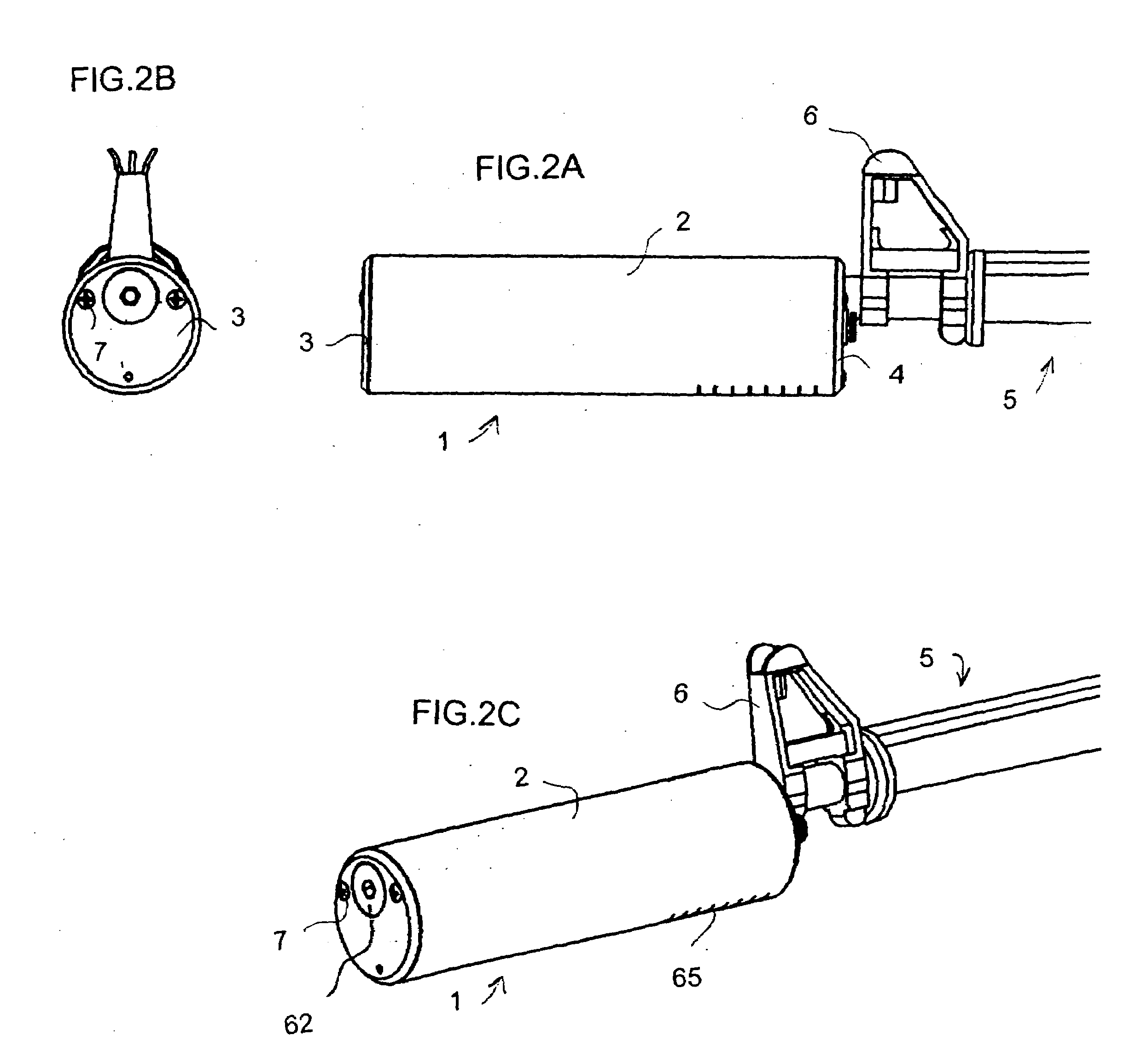

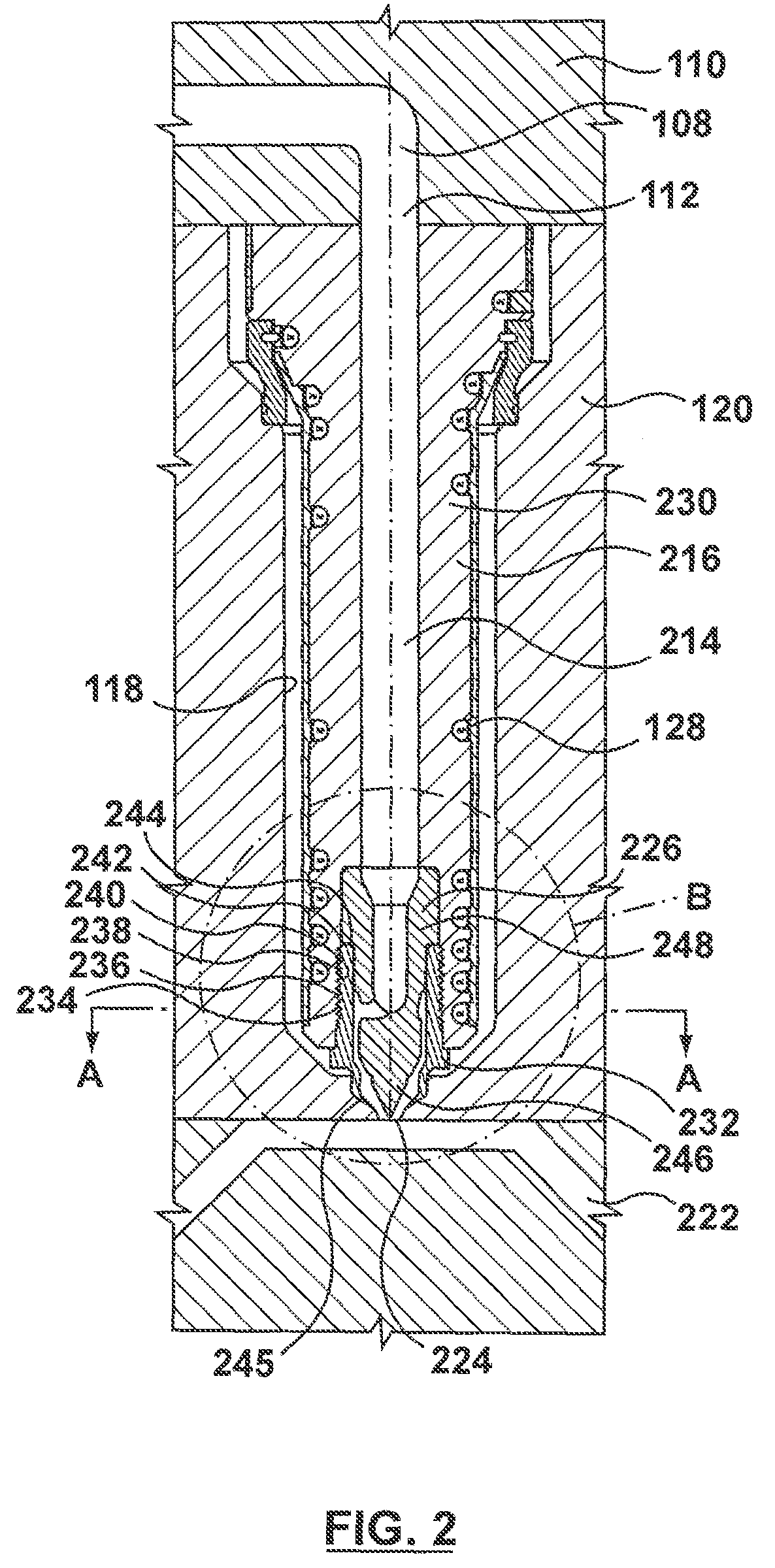

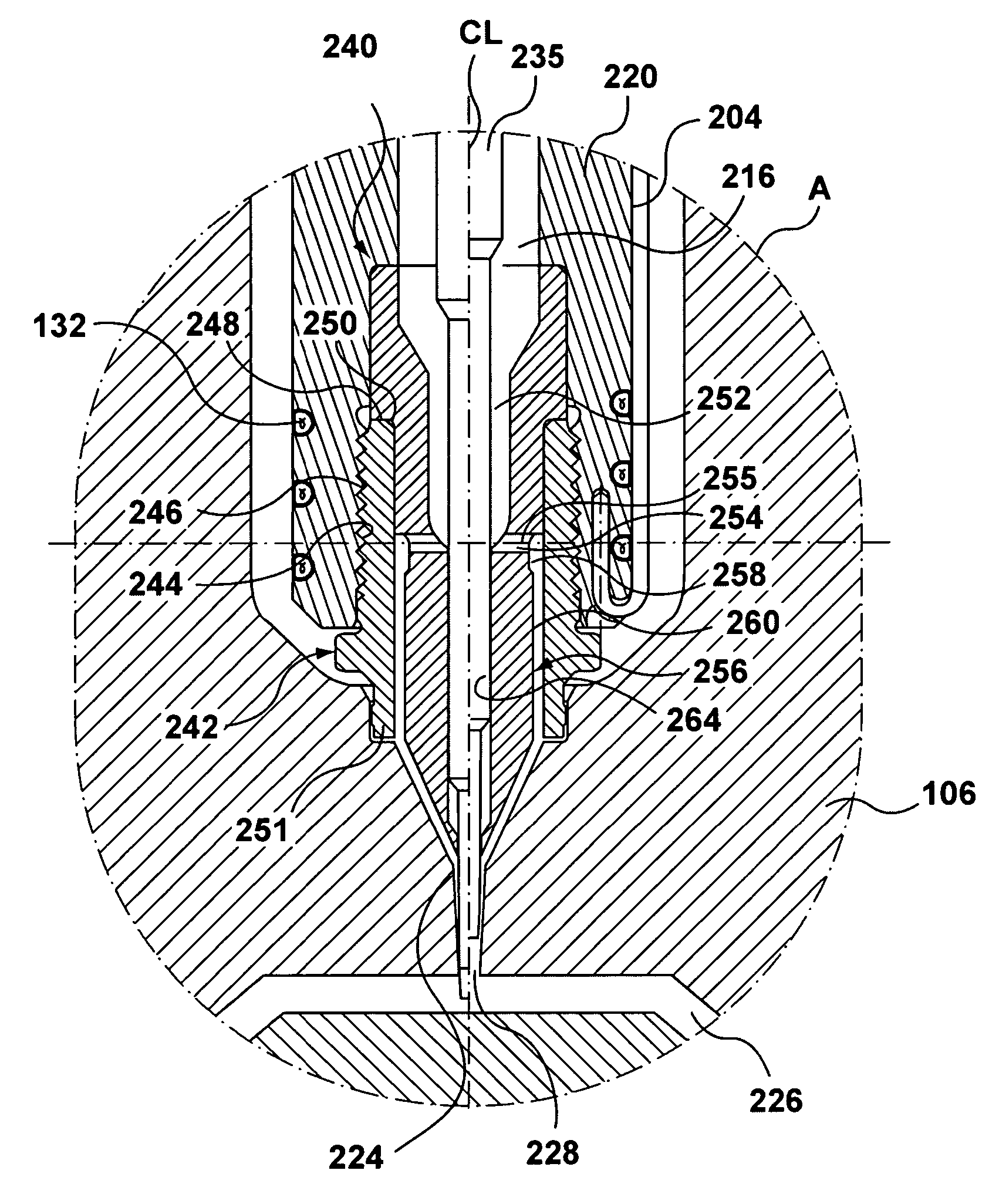

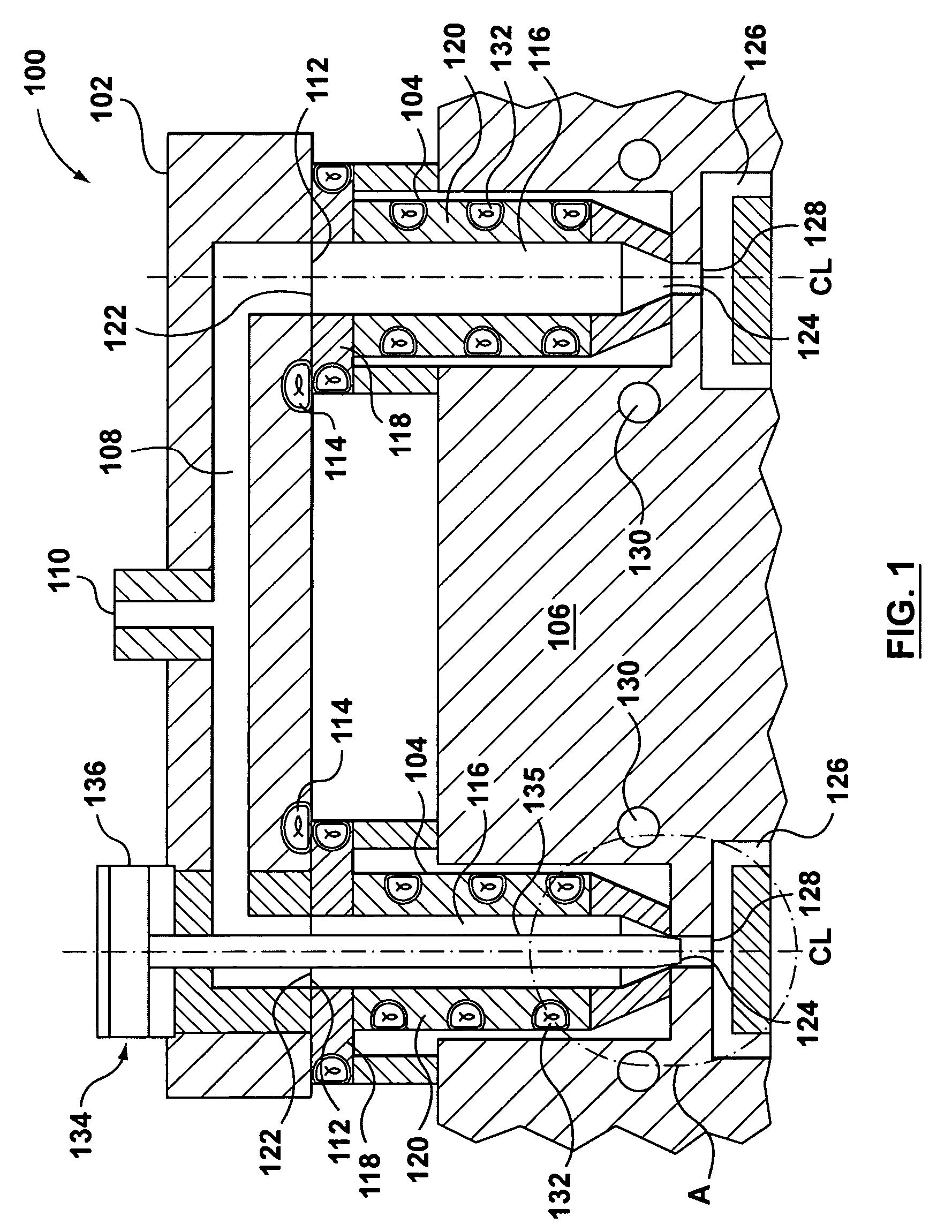

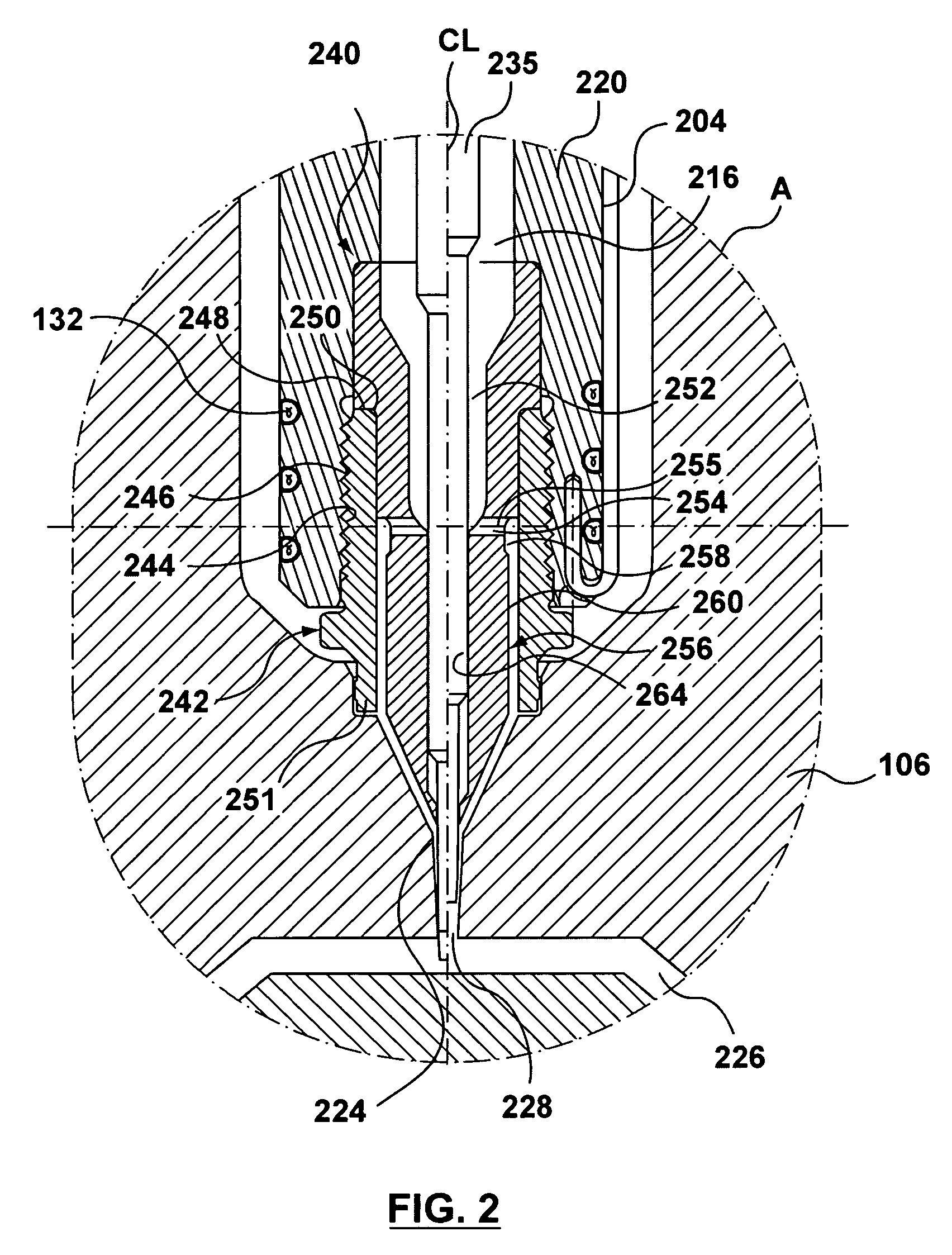

A firearm suppressor includes a housing to be mounted to a firearm. The housing defines a lumen therein for receiving gases from the firearm. At least one stripper member is disposed in the lumen for engaging and deflecting the gases. At least one one-way flow element is disposed downstream of the at least one stripper member in gas flow direction for permitting a one-way flow of the gases. At least one decompression chamber is disposed downstream of the at least one one-way flow element for reducing energy in the gases. At least one vent valve is disposed downstream of the at least one decompression chamber for expelling the gases into the atmosphere. A mounting system and a mounting method are also provided.

Owner:MCCLELLAN W THOMAS

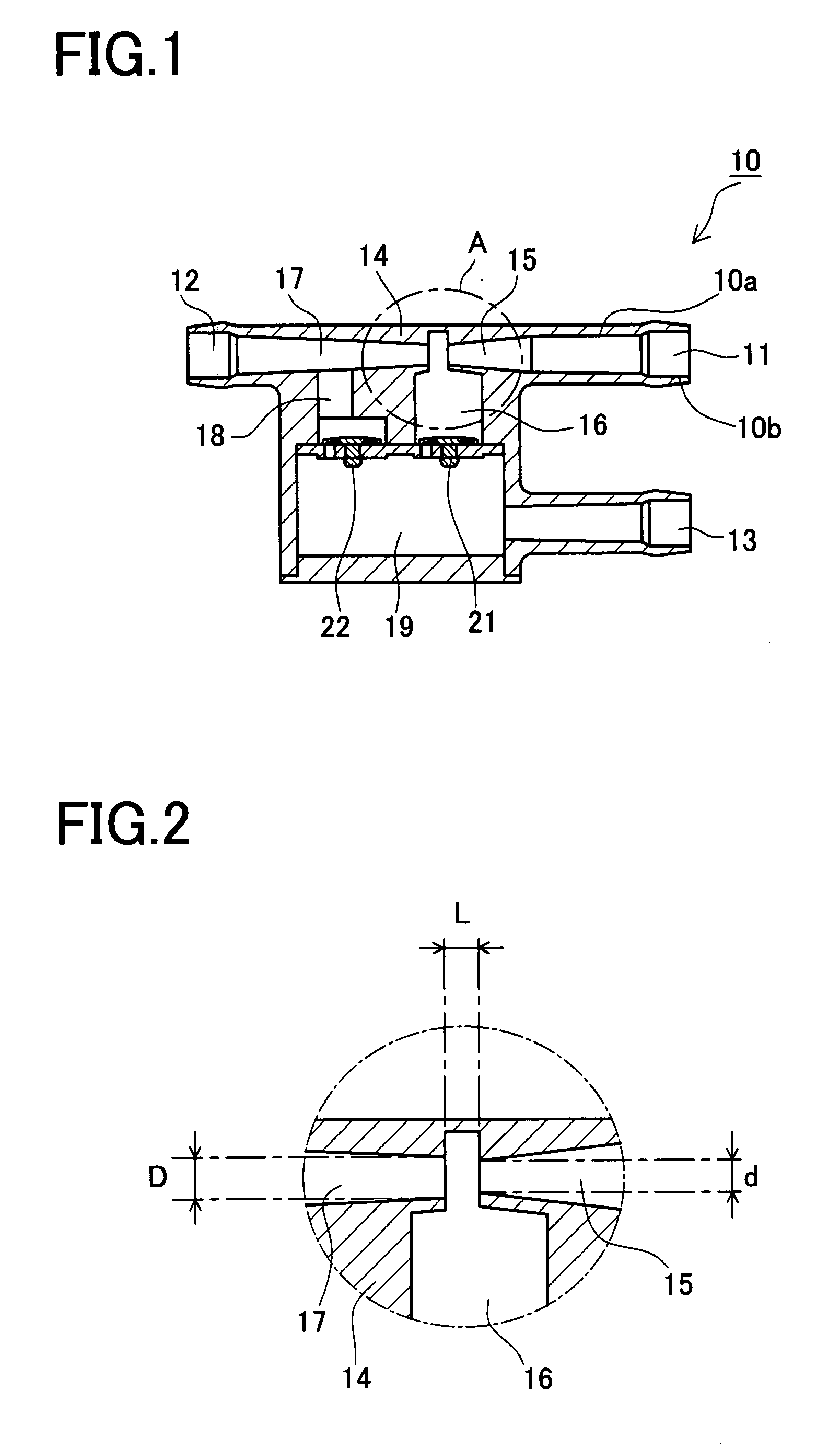

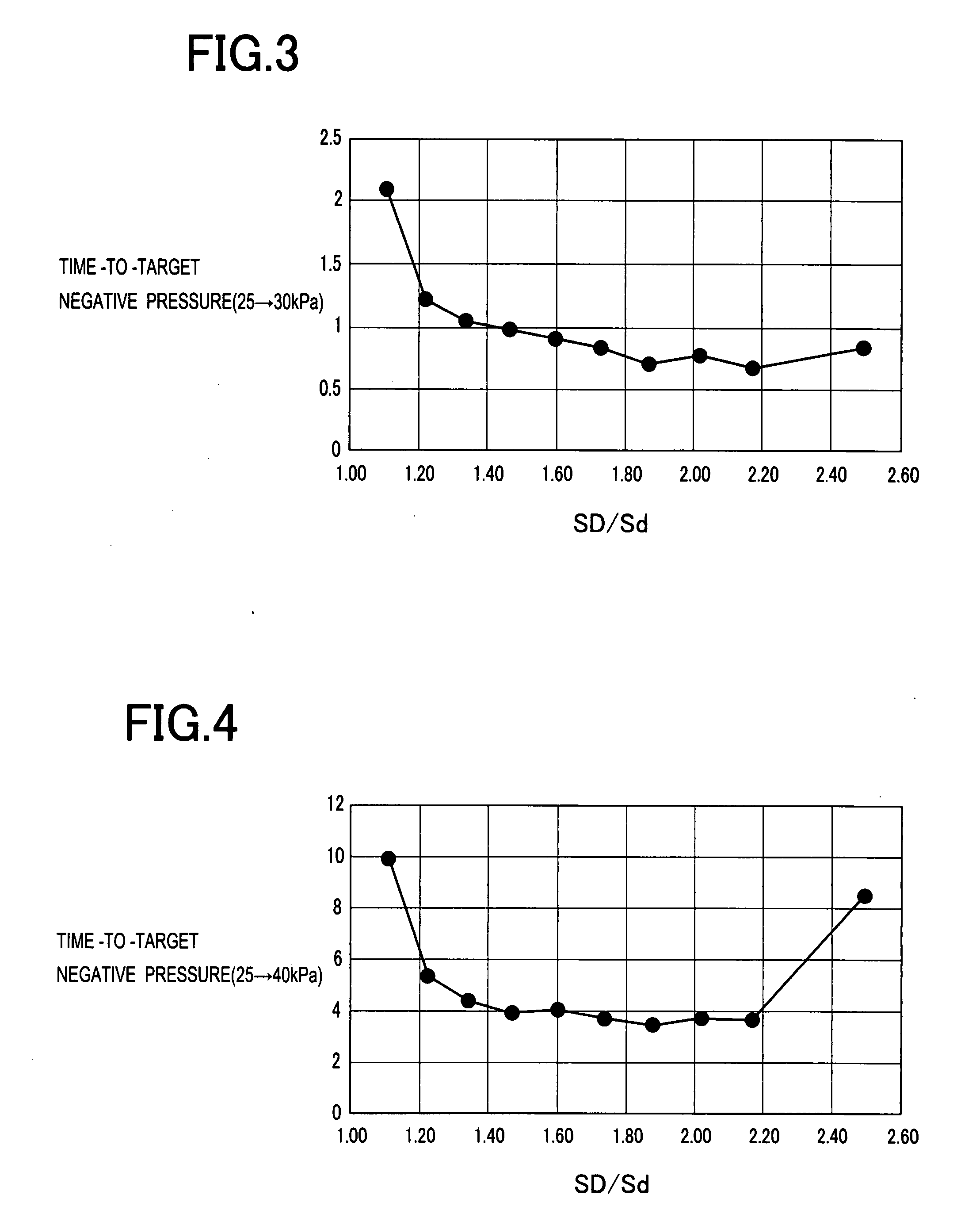

Ejector and negative pressure supply apparatus for brake booster using the ejector

InactiveUS20080121480A1Short operating timeBraking action transmissionPump/compressor arrangementsDecompression chamberEngineering

An ejector including a nozzle communicating with a fluid inlet, a diffuser communicating with a fluid outlet, and a decompression chamber placed between the nozzle and he diffuser. The ejector is arranged to generate a negative pressure in the decompression chamber by a fluid ejected from the nozzle. A target negative pressure P in the decompression chamber is set in a range of “40 kPa<P≦50 kPa”. A SD / Sd ratio between a sectional area SD of an inlet of the diffuser and a sectional area Sd of an outlet of the nozzle is determined to meet a relation:“1.20≦SD / Sd≦4.08−0.047P”.

Owner:AISAN IND CO LTD

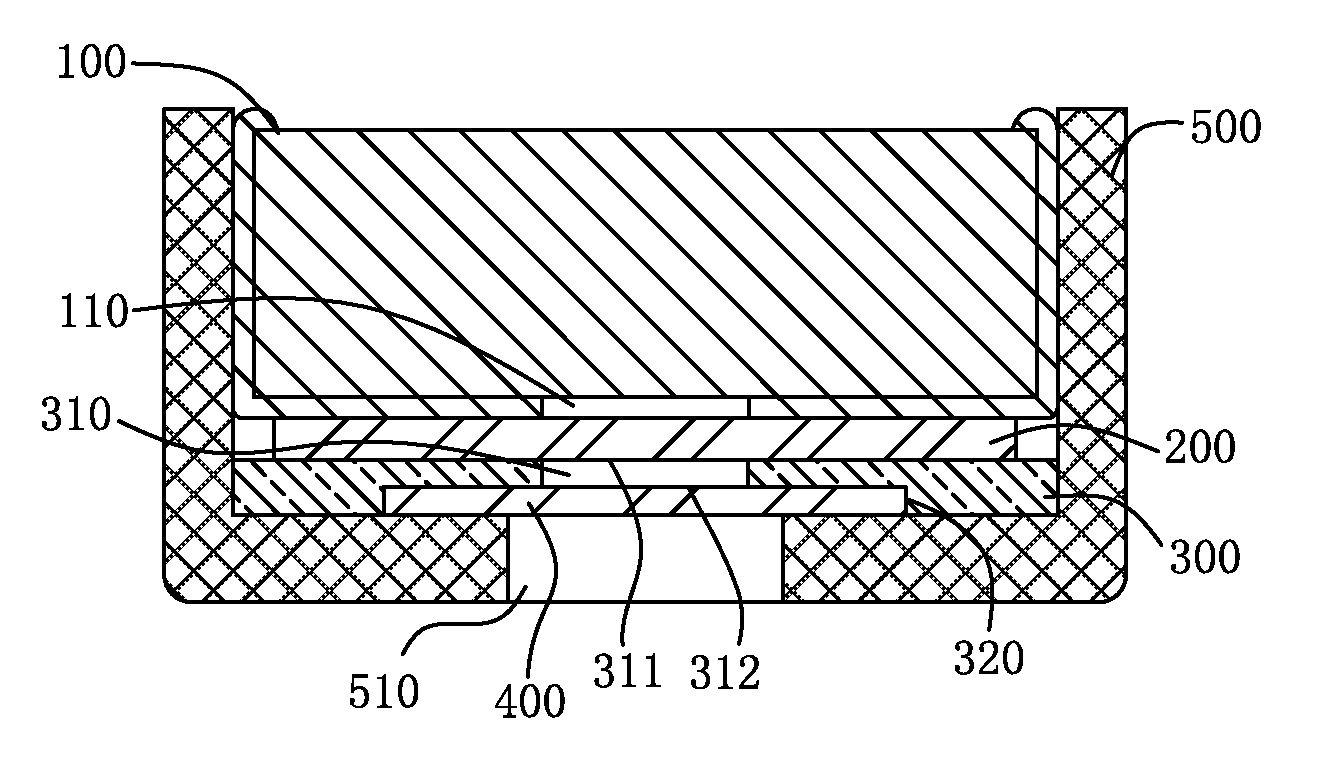

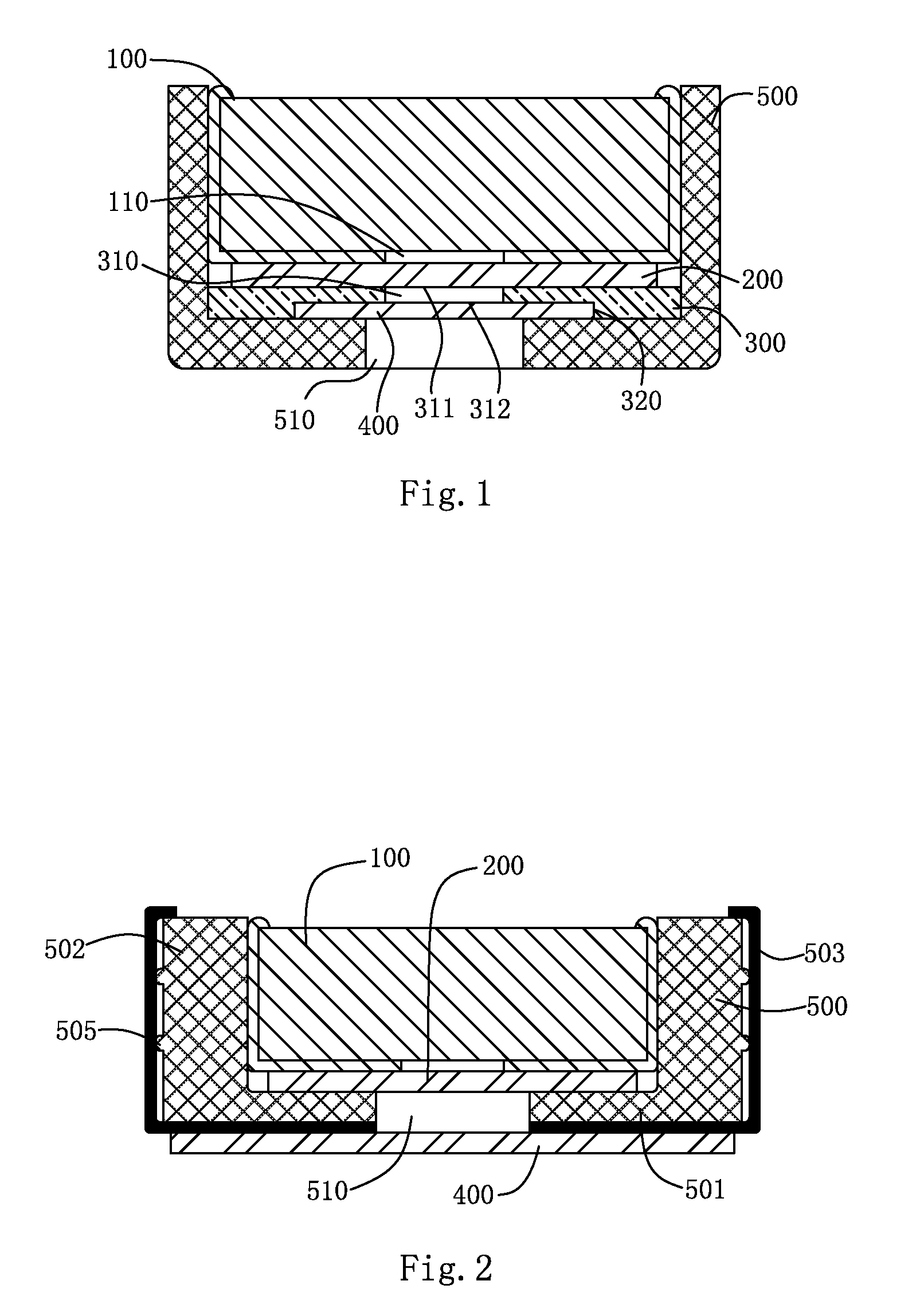

Waterproof microphone

InactiveUS20110013799A1Piezoelectric/electrostrictive microphonesTransducer detailsDecompression chamberTransducer

A waterproof microphone includes a transducer unit defining a sound receiving opening, a first waterproof layer fully covering the sound receiving opening, and a second waterproof layer spaced from the first waterproof layer for forming a closed decompression chamber.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

Degasifier

InactiveUS20070240569A1Prevents deterioration in sealing propertySemi-permeable membranesDispersed particle filtrationDecompression chamberEngineering

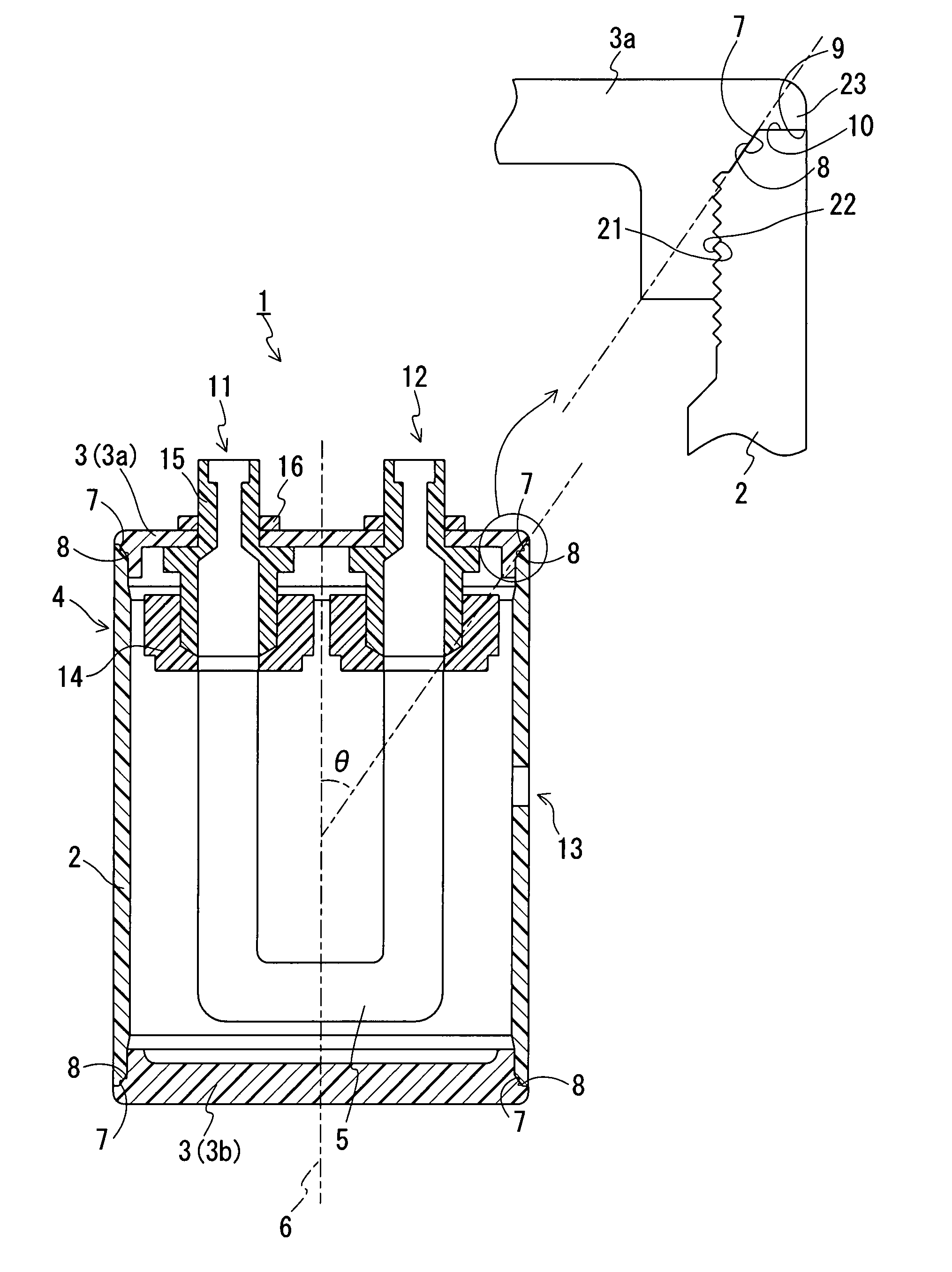

A degasifier is provided in which the deterioration in sealing property (deterioration in airtightness) is prevented while sealing members to be placed between a container and covers that compose a decompression chamber can be omitted. A degasifier includes a decompression chamber provided with a container and covers, and a gas-permeable tube. The container is a tubular body extending along the central axis. The covers seal the openings of the ends of the tubular body. The gas-permeable tube is contained in the decompression chamber in such a manner that a liquid to be degassed that has entered from the outside of the decompression chamber flows therethrough and the liquid to be degassed that has flowed therethrough flows out of the decompression chamber. The inner circumference surfaces in the vicinities of the openings of the container each are provided with a first slope that is formed to be tilted at a predetermined angle θ with respect to the central axis and to extend away from the central axis toward the opening side of the container. A portion of each of the covers that is in contact with the container is provided with a second slope that is formed to be tilted at the angle θ with respect to the central axis and to extend to approach the central axis toward the inner side of the decompression chamber, with the openings being sealed. The openings are sealed with the container and the covers being joined to each other in the state where the first slopes and the second slopes are in contact with each other, respectively.

Owner:NITTO DENKO CORP

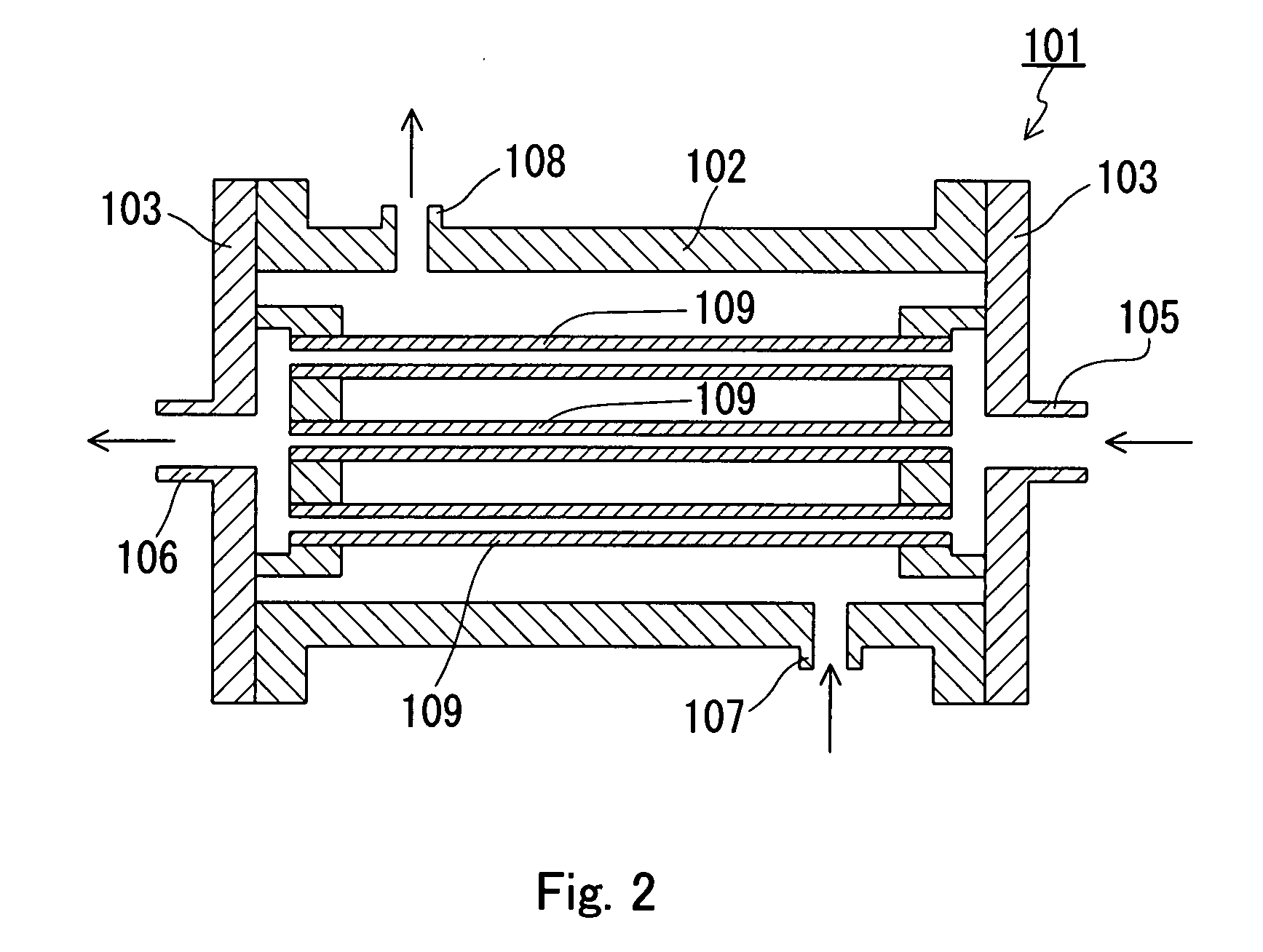

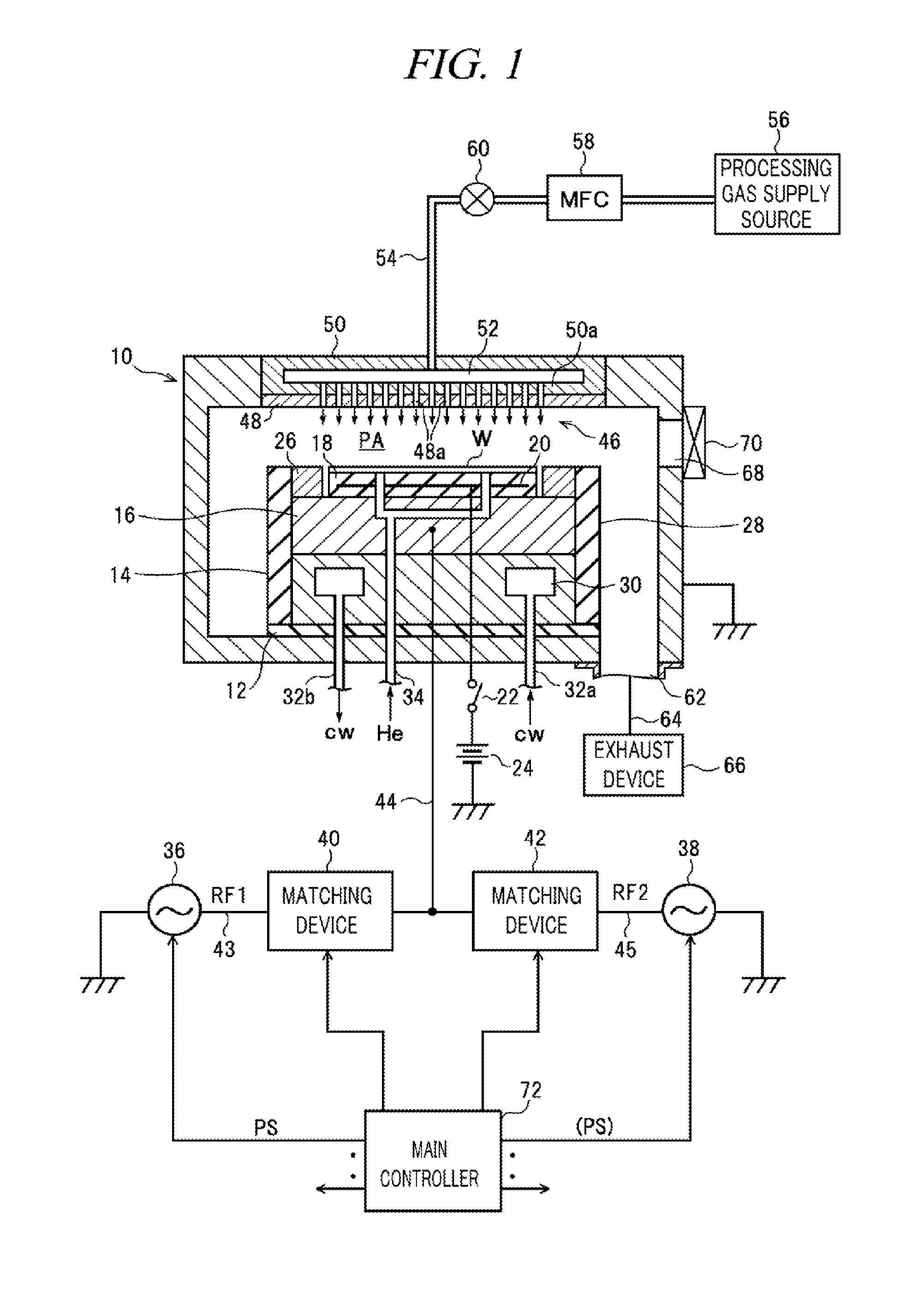

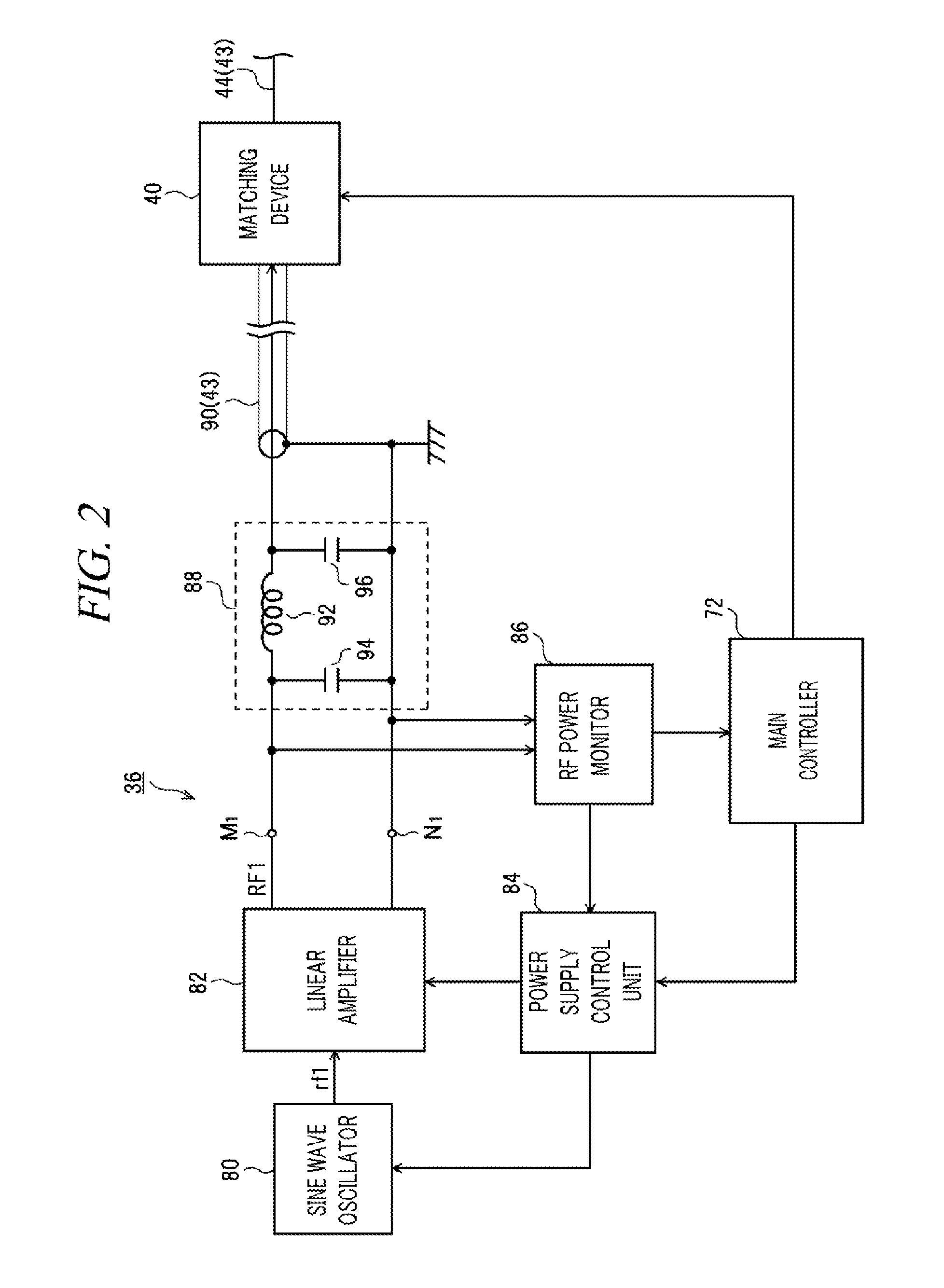

Plasma processing apparatus

ActiveUS9355822B2Suppress powerElectric discharge tubesChemical vapor deposition coatingCapacitanceSusceptor

In a capacitively coupled plasma processing apparatus, a susceptor (lower electrode) 16 within a decompression chamber 10 faces an upper electrode 46 serving as a shower head. The susceptor 16 is electrically connected with a first high frequency power supply 36 and a second high frequency power supply 38 via matching devices 40 and 42, respectively. The first high frequency power supply 36 is formed of a linear amplifier type high frequency power supply and outputs a first high frequency power RF1 for plasma generation. The second high frequency power supply 38 is formed of a switching type high frequency power supply and outputs a second high frequency power RF2 for ion attraction. A residual high frequency power removing unit 74 is connected to a high frequency power supply line 45 on a side of the second high frequency power supply 38.

Owner:TOKYO ELECTRON LTD +1

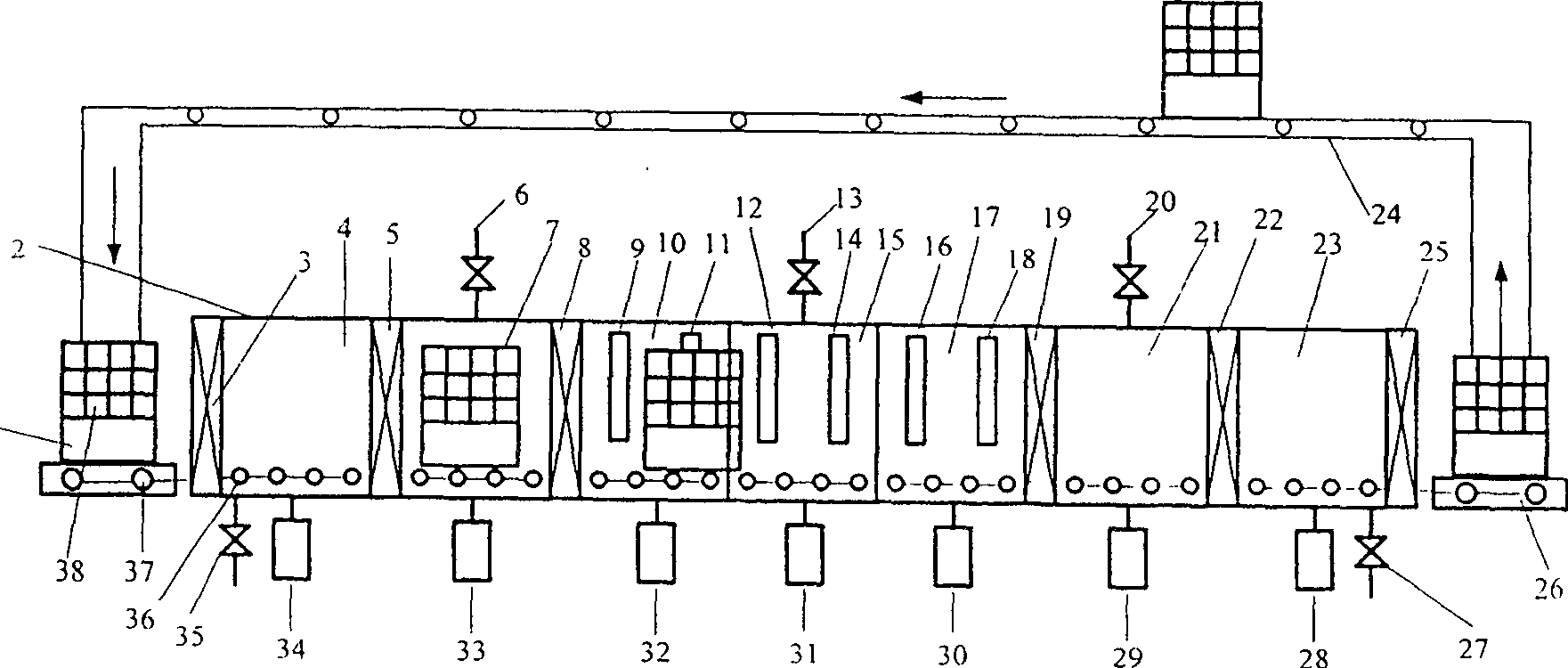

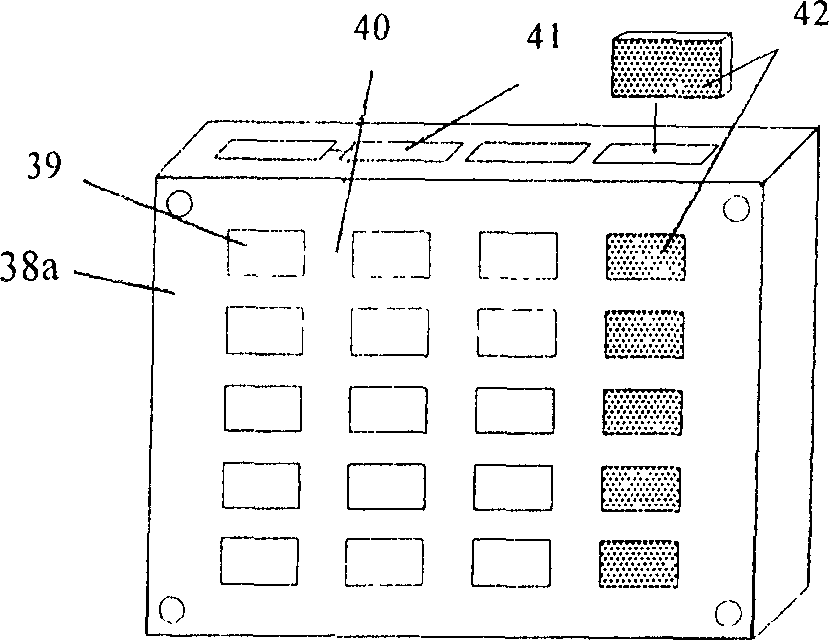

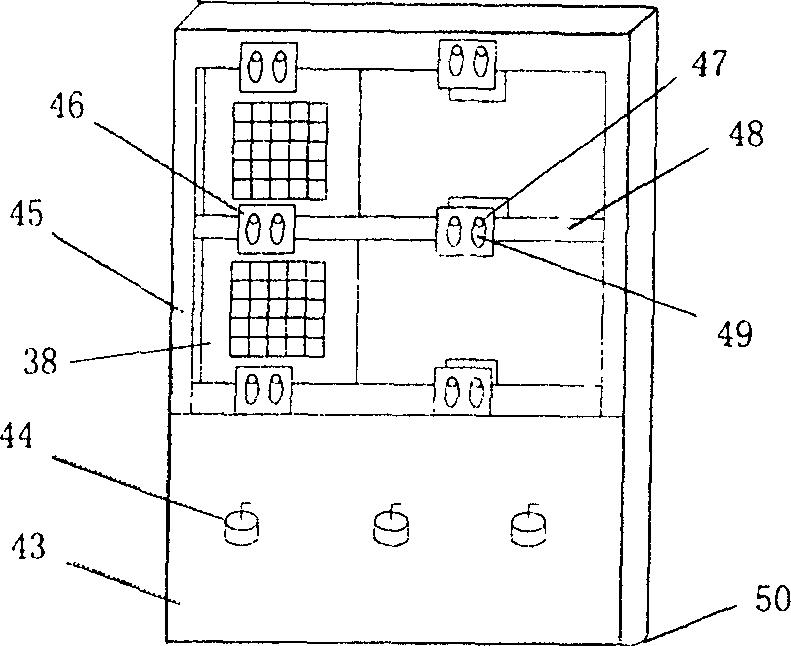

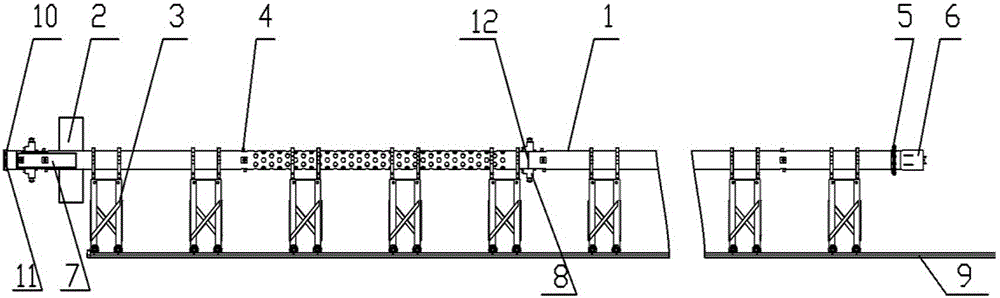

Electronic ceramic continuous sputtering coating equipment

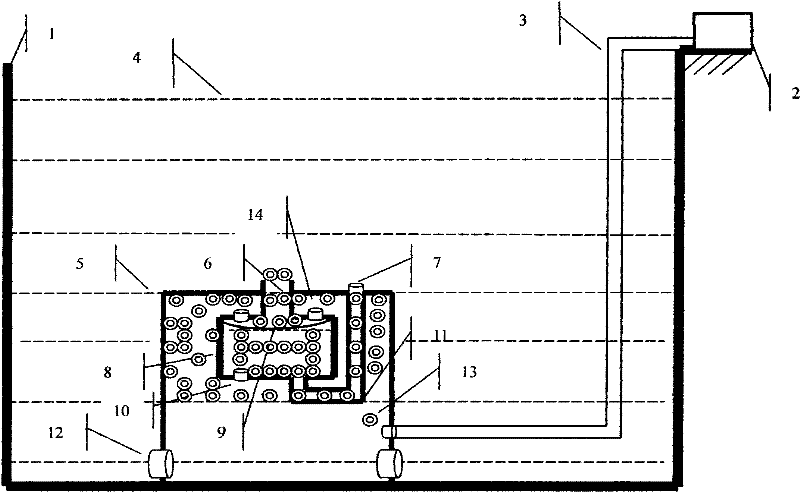

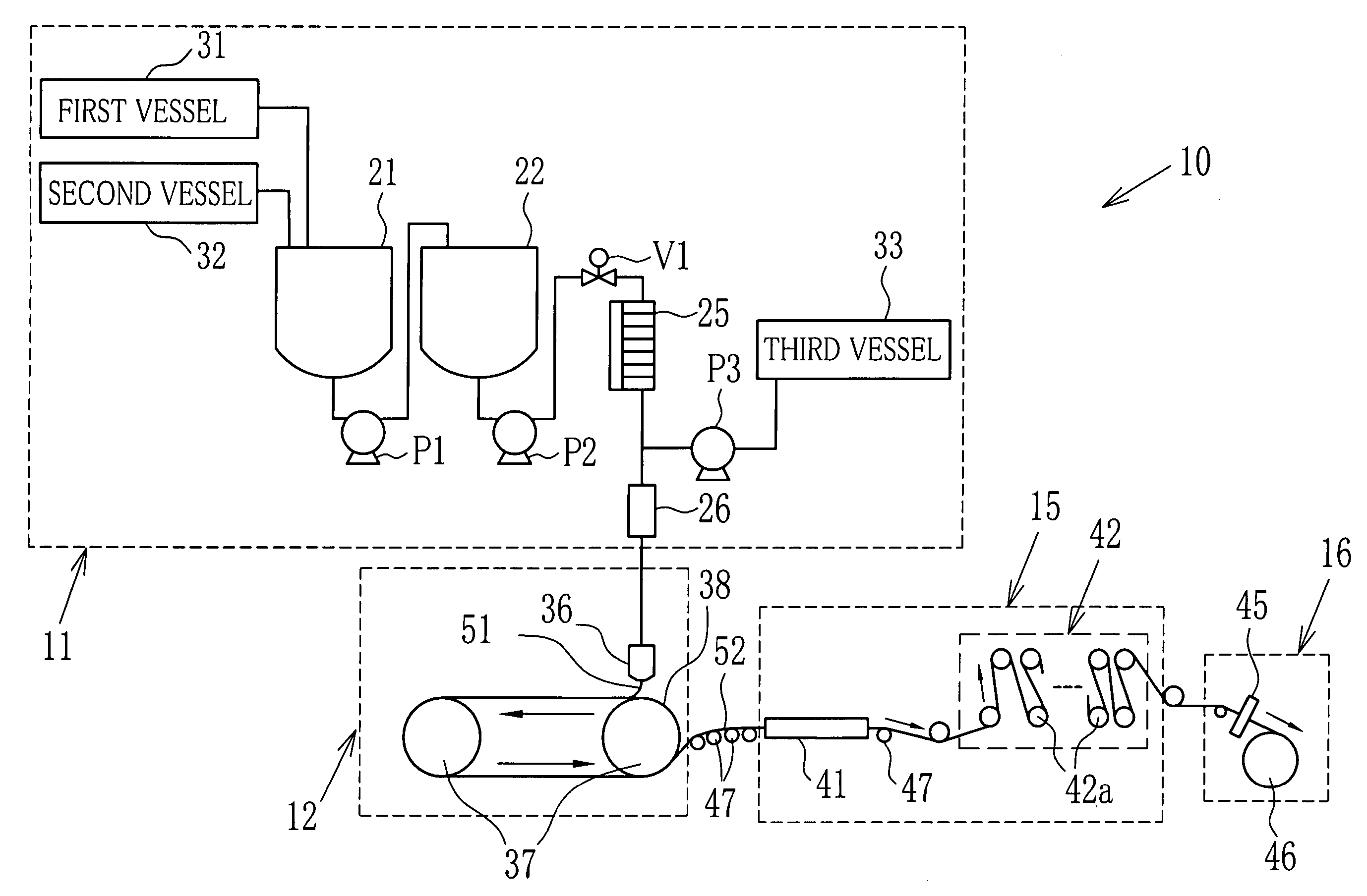

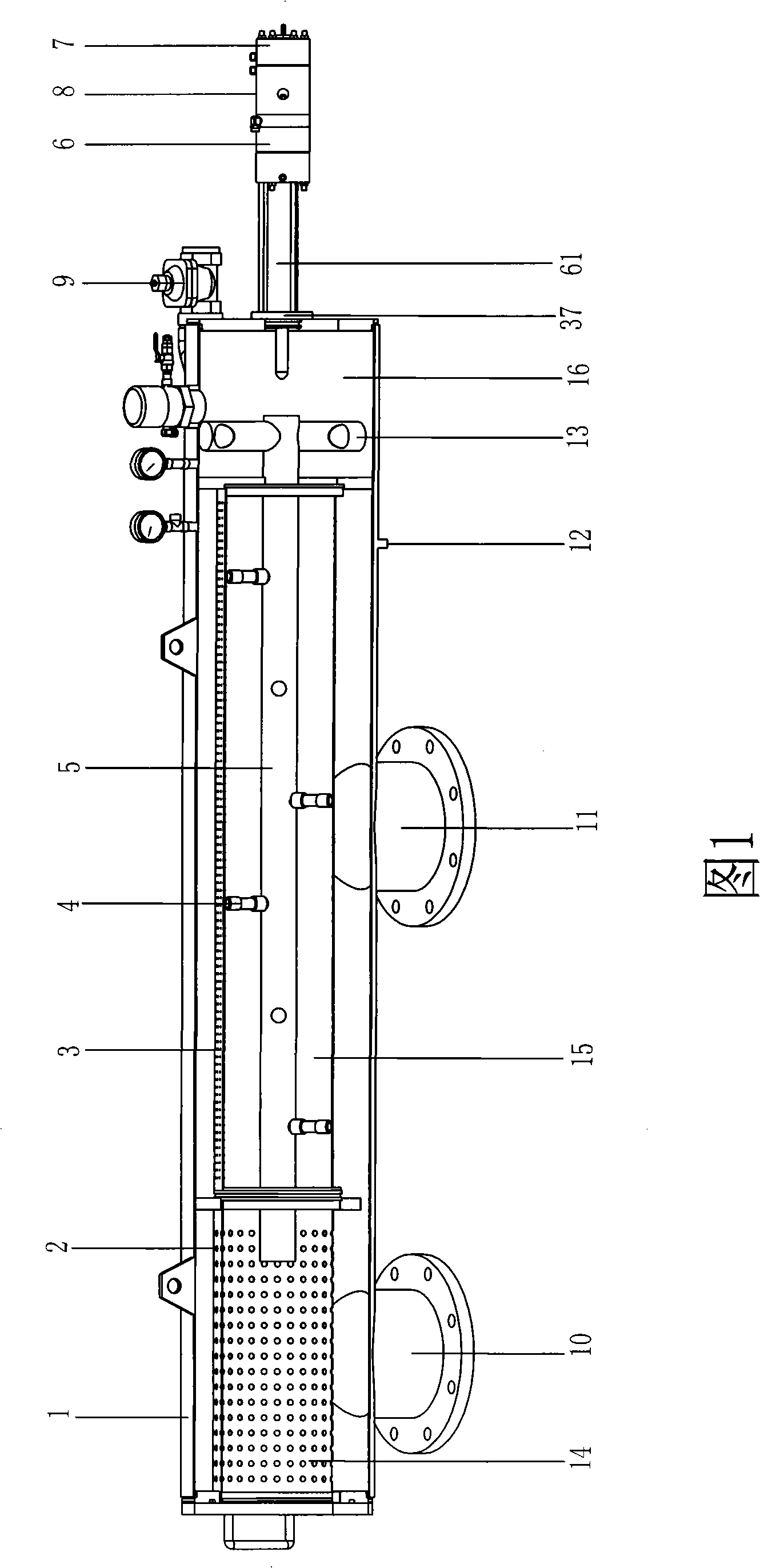

InactiveCN1804112AImprove uniformityImprove consistencyVacuum evaporation coatingSputtering coatingIsolation valveVacuum extraction

The electronic ceramic continual sputter plating device comprises: a vacuum extraction device; and a body with five near vacuum chambers mutual connected insulating valves as the pre-pump chamber, front transition chamber, sputtering chamber with metal sputtering targets on mutual disposition, back transition chamber and the decompression chamber. Wherein, arranging a fitting friction piece transfer device and a piece frame can be convened to five chambers and outside by the transfer device; arranging a feeding table, an out-feeding table and a back mechanism all and said transfer device connected to a continual loop transfer line. This invention has large yield with low cost, strong bonding force and resistance to high temperature and corrosion.

Owner:ZHEJIANG UNIV

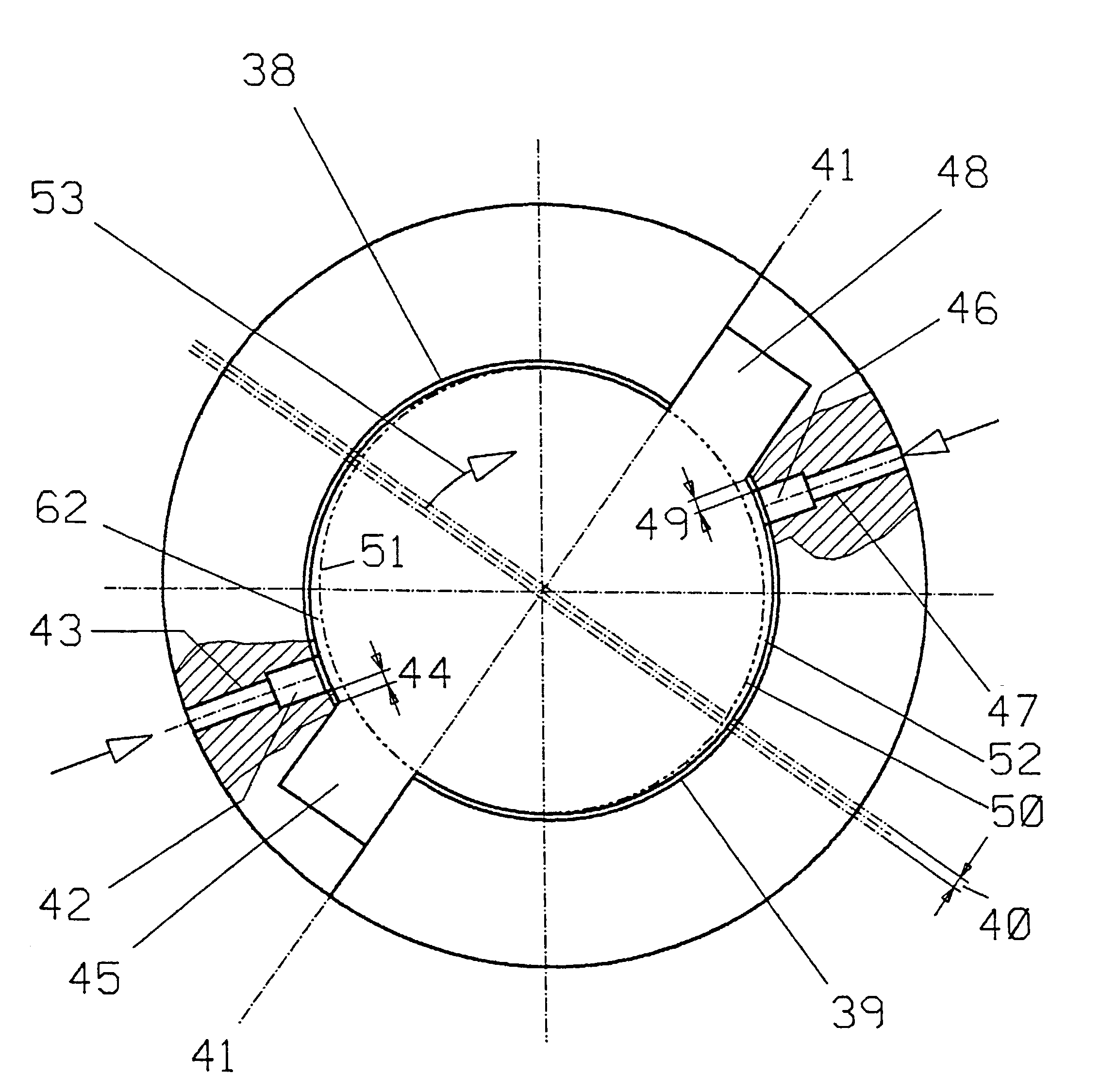

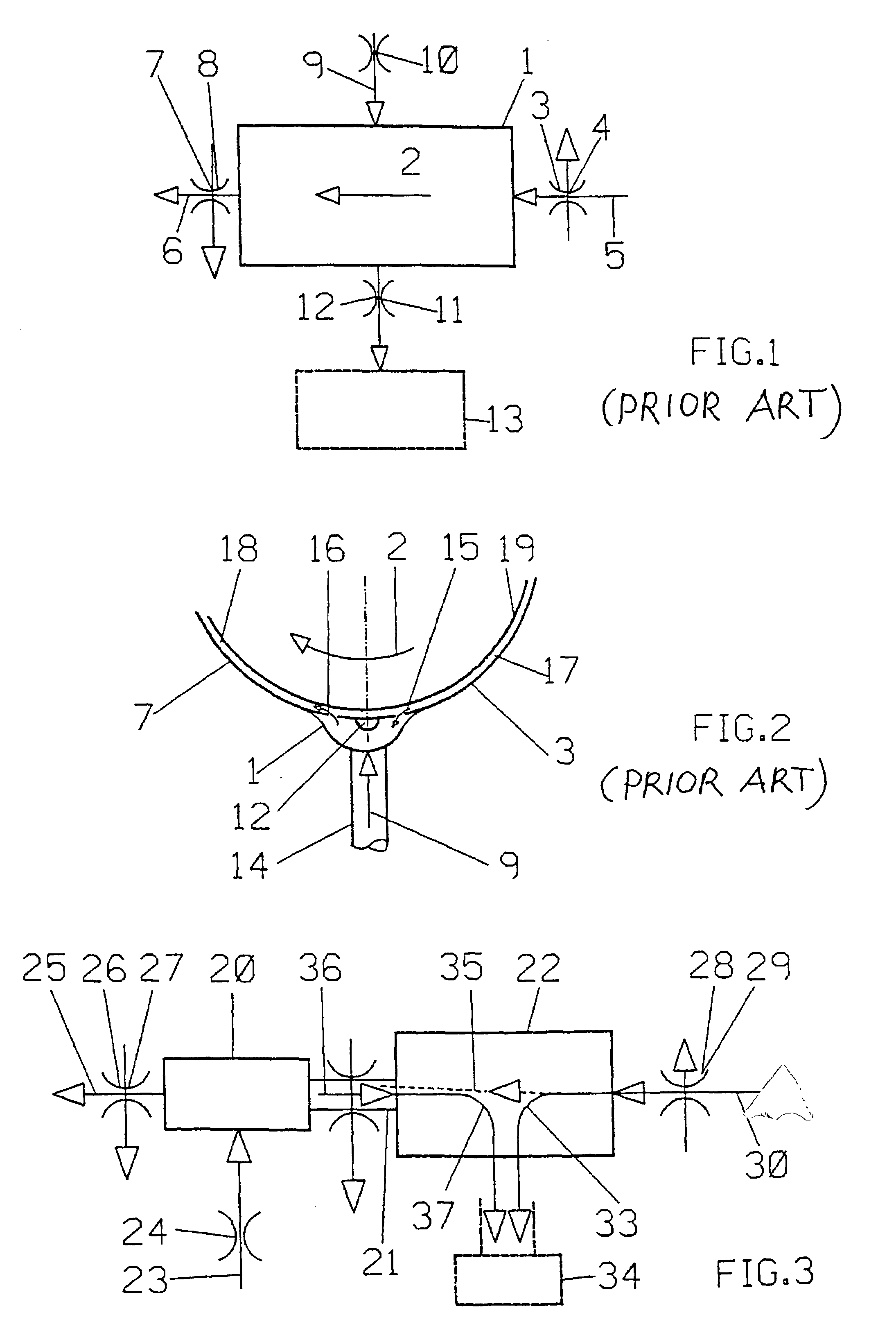

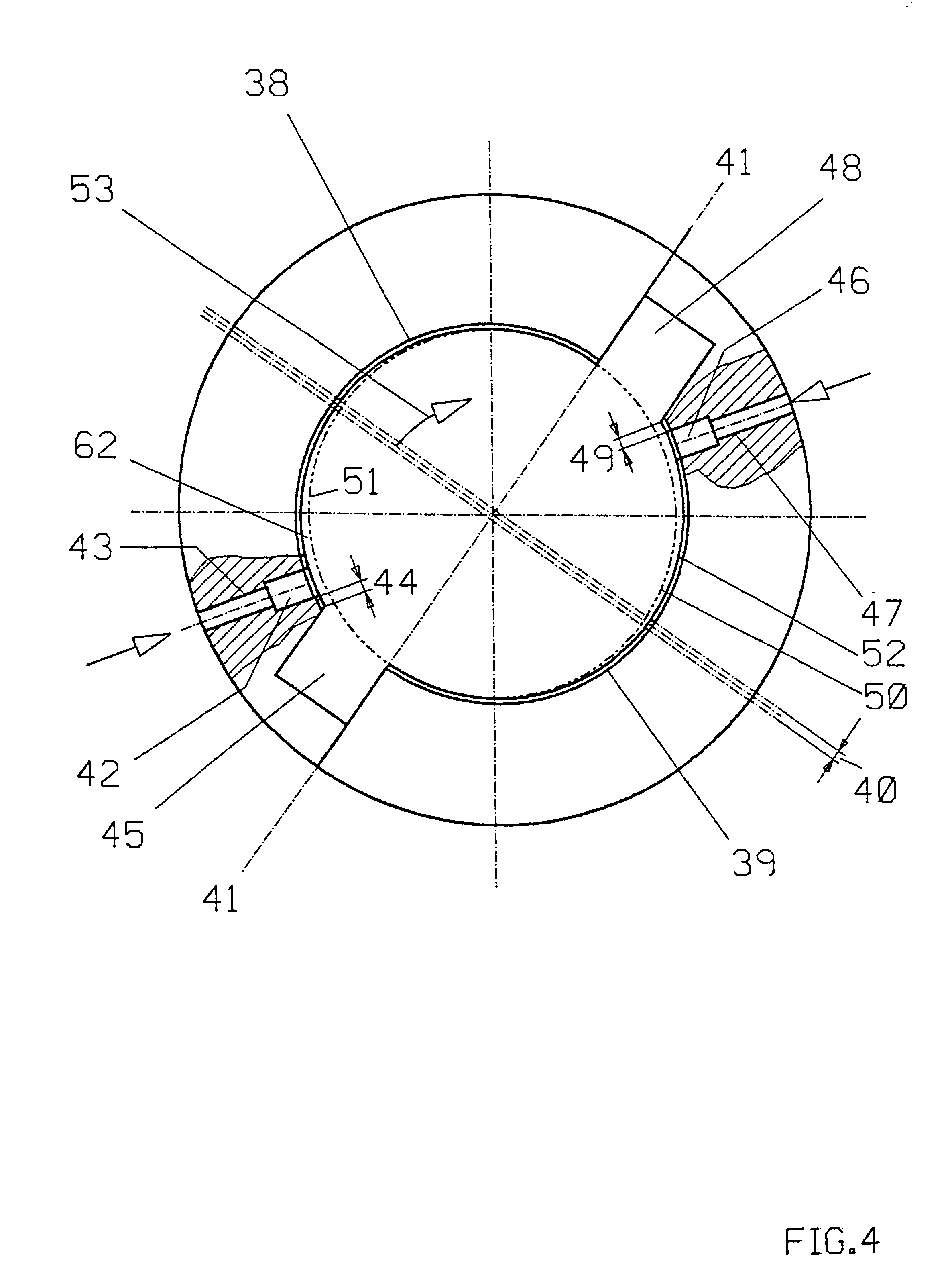

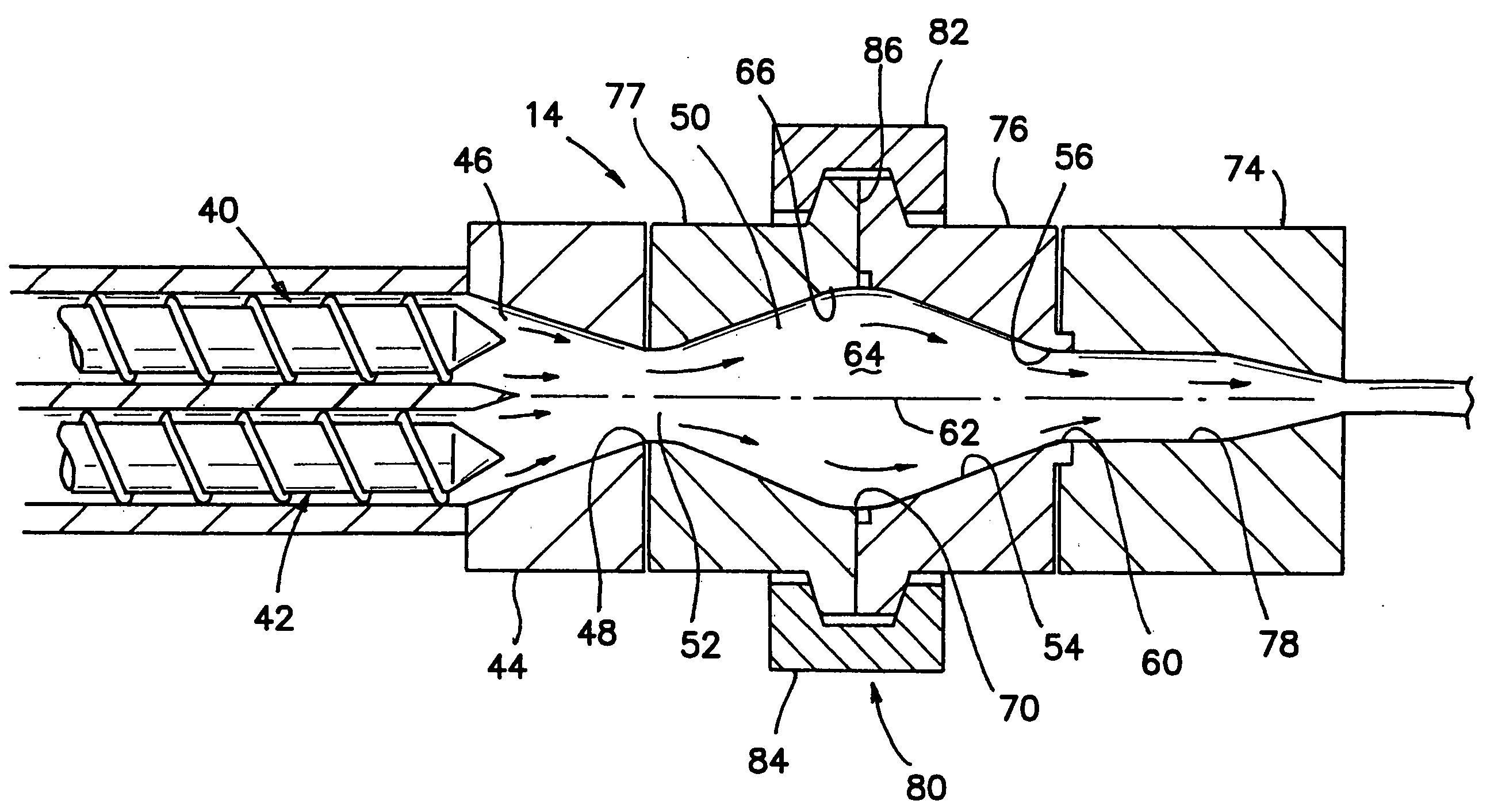

Firearm suppressor, mounting system and mounting method

A firearm suppressor includes a housing to be mounted to a firearm. The housing defines a lumen therein for receiving gases from the firearm. At least one stripper member is disposed in the lumen for engaging and deflecting the gases. At least one one-way flow element is disposed downstream of the at least one stripper member in gas flow direction for permitting a one-way flow of the gases. At least one decompression chamber is disposed downstream of the at least one one-way flow element for reducing energy in the gases. At least one vent valve is disposed downstream of the at least one decompression chamber for expelling the gases into the atmosphere. A mounting system and a mounting method are also provided.

Owner:MCCLELLAN W THOMAS

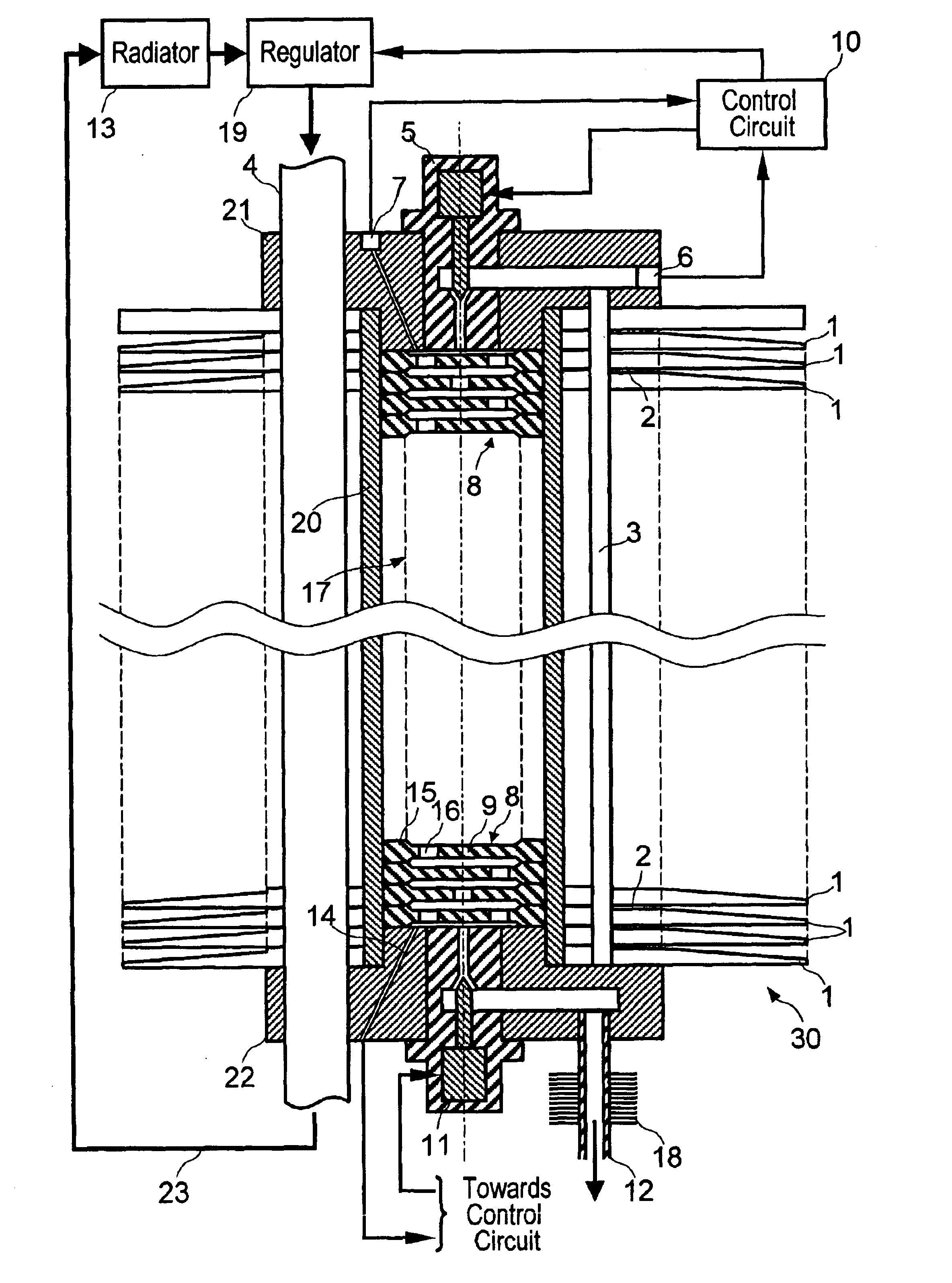

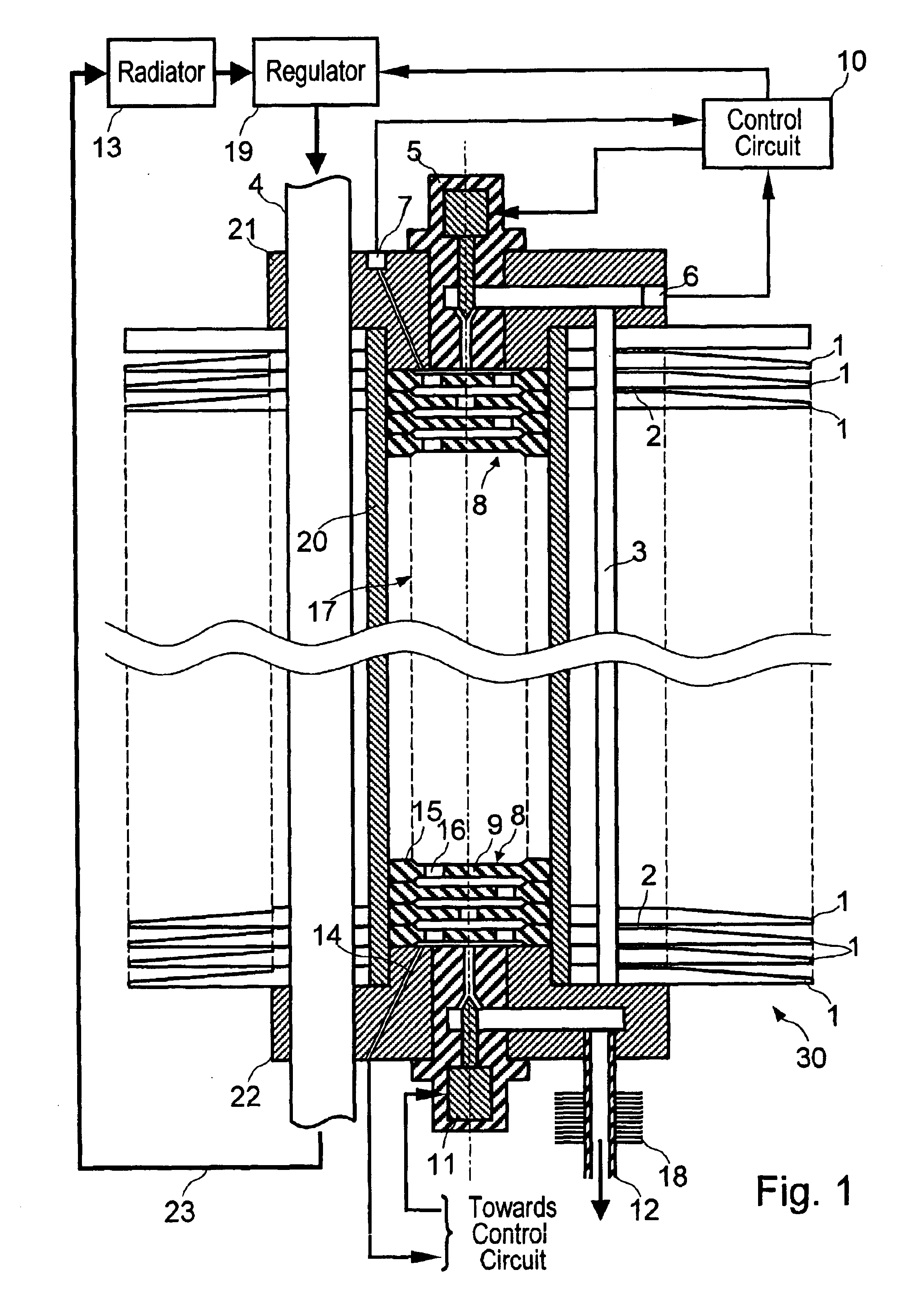

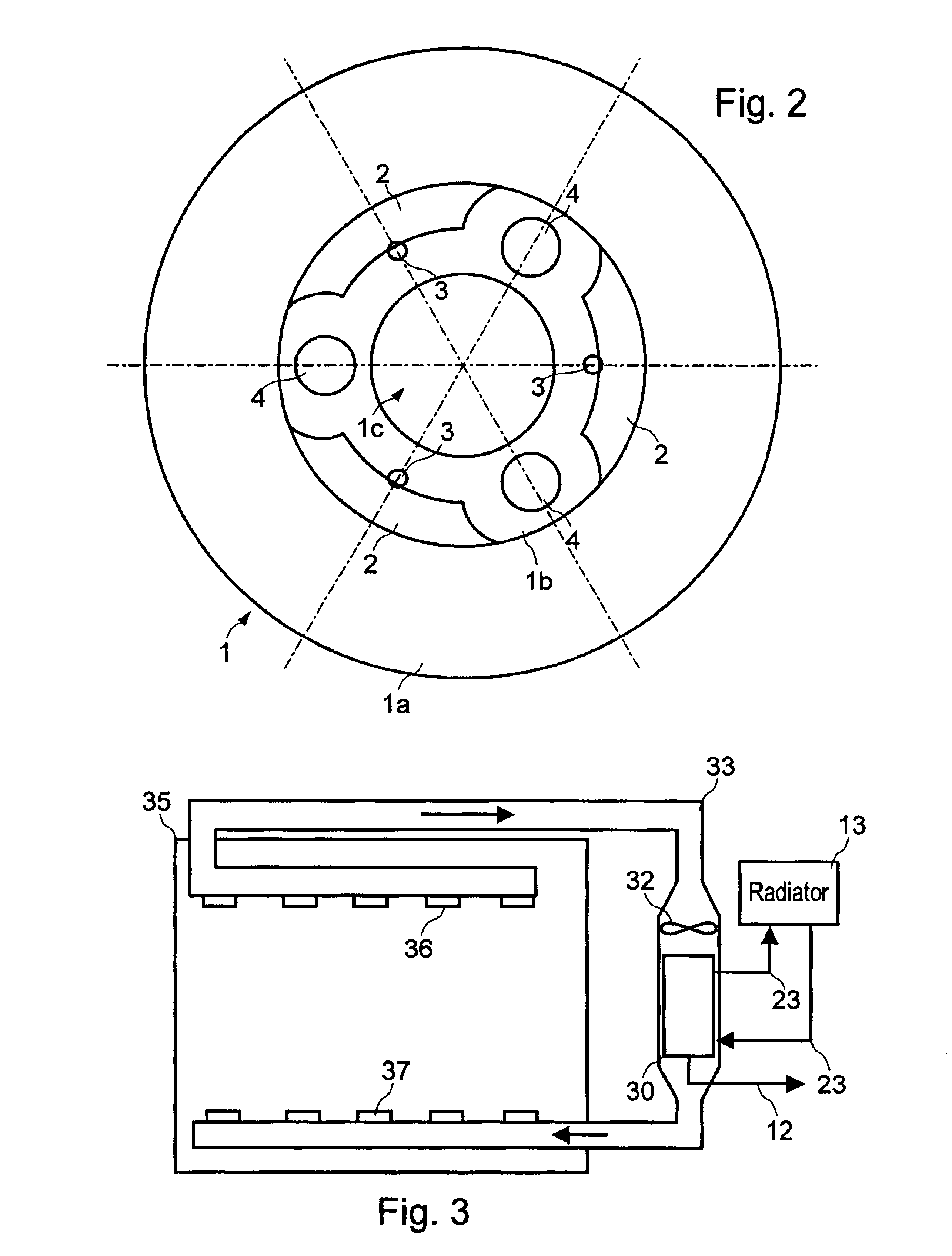

Hydrodynamic plain bearing and method of lubricating and cooling the bearing

InactiveUS6966700B2Reduce lossReduce consumptionCrankshaftsCrossheadsSlider bearingDecompression chamber

A method of lubricating and cooling a hydrodynamic plain bearing for a rotating element comprises the steps of supplying fresh, cold lubricant under pressure from a pressure chamber arranged upstream of a fixed gliding plane to a lubricating gap between the fixed gliding plane and the rotating element, the supply of fresh, cold lubricant being so controlled that an effective lubricating wedge is formed between the rotating element and the fixed gliding plane. The pressure chamber is connected to a decompression chamber predominantly filled with gas and arranged upstream of the pressure chamber by a mixing conduit, used, hot lubricant adhering to the rotating element is moved to the decompression chamber, and a portion of the used, hot lubricant is removed from the decompression chamber while the remaining portion of the used, hot lubricant flows from the decompression chamber into the mixing conduit and is mixed with fresh, cold lubricant flowing countercurrently in the mixing conduit whence the mixture is pressed into the decompression chamber.

Owner:GLEITLAGERTECHN WEISSBACHER

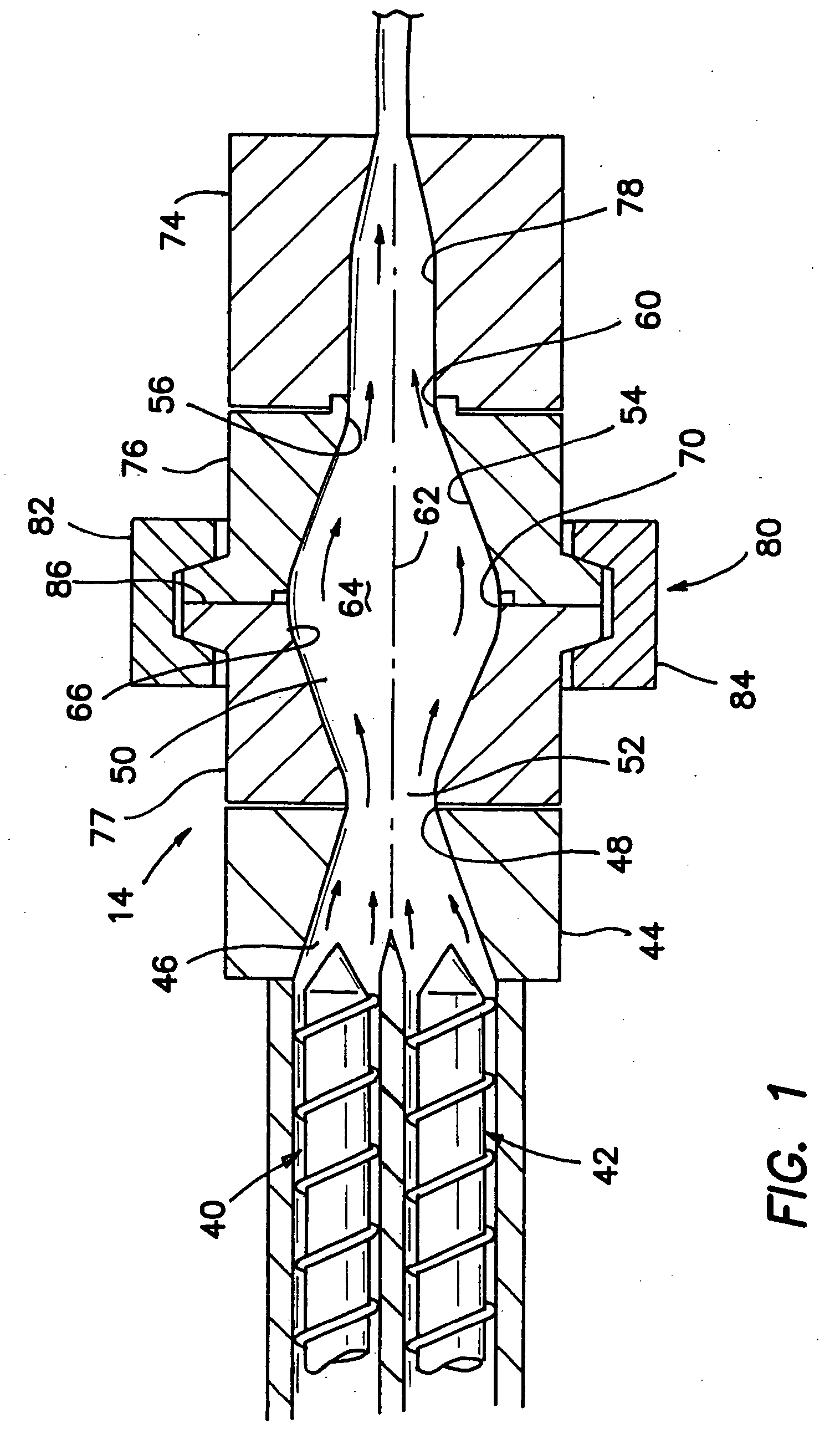

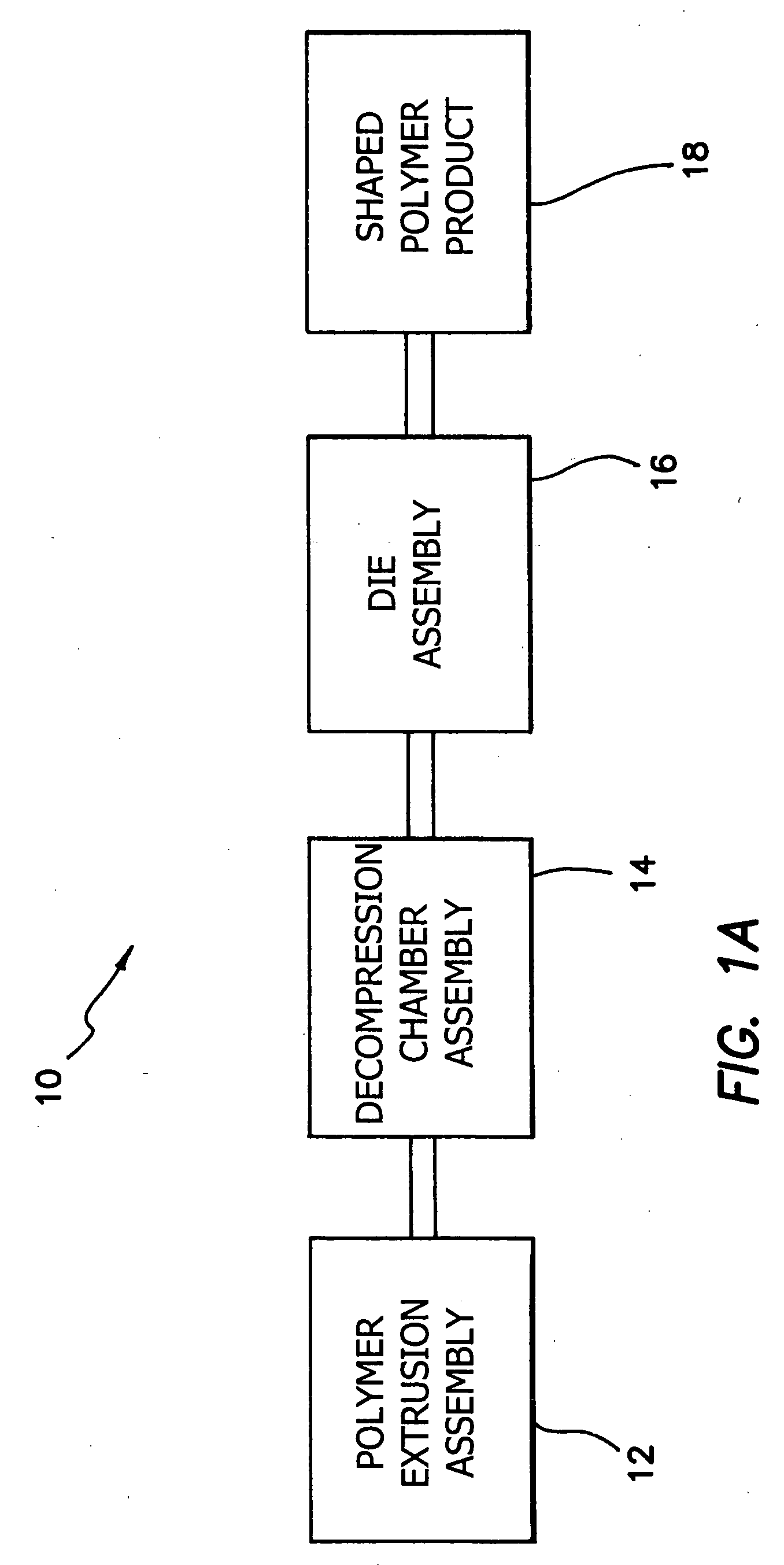

Polymer processing system including compression chamber and method for using same

InactiveUS20060105072A1Efficient extrusionReduce productivityConfectionerySweetmeatsDecompression chamberEngineering

Polymer processing systems are provided including an extrusion assembly, a specially configured decompression chamber assembly, and a die assembly. Such systems are effective to provide shaped polymer products having reduced extrusion markings. Methods of using such systems are also provided.

Owner:EXTRUTECH INT

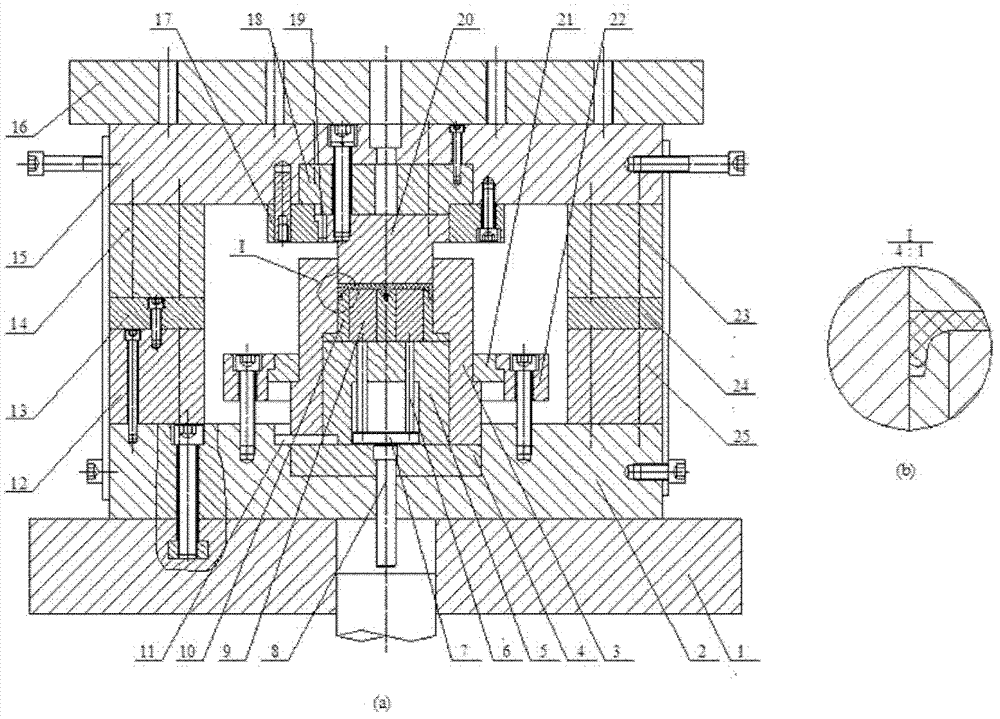

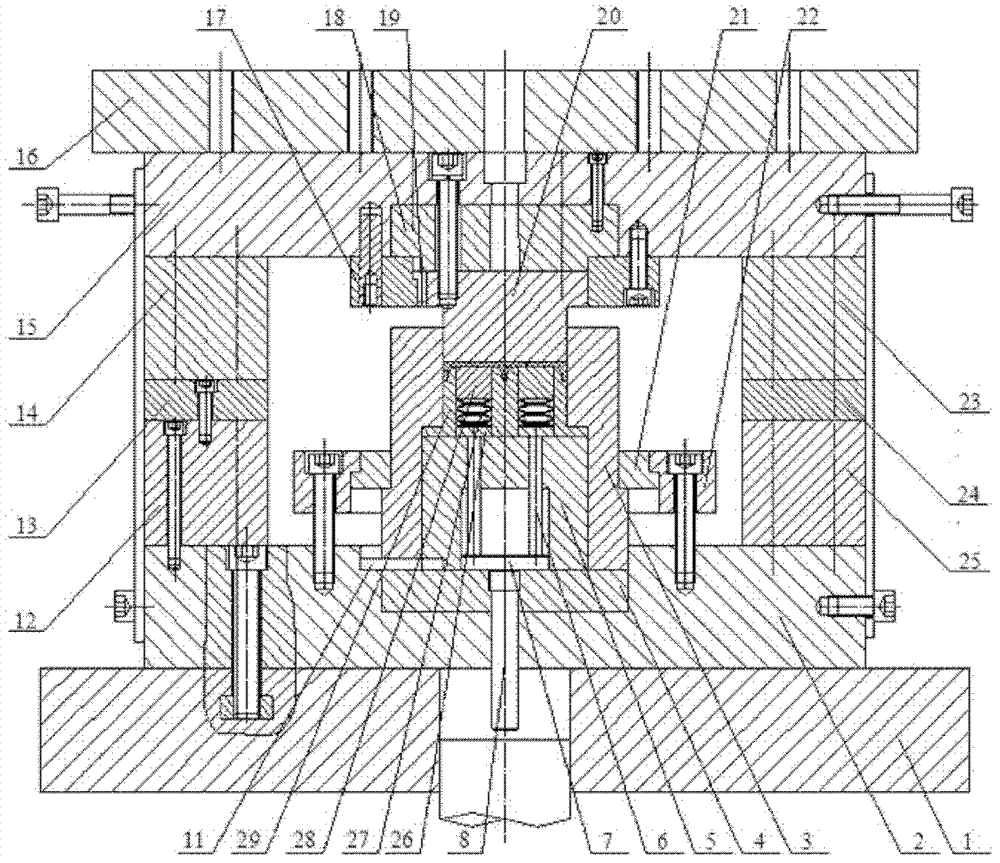

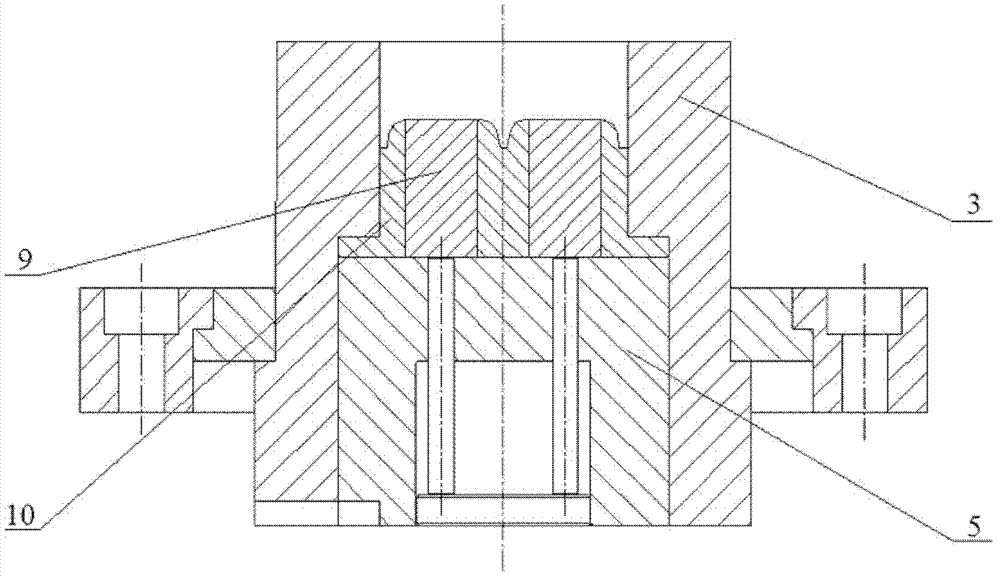

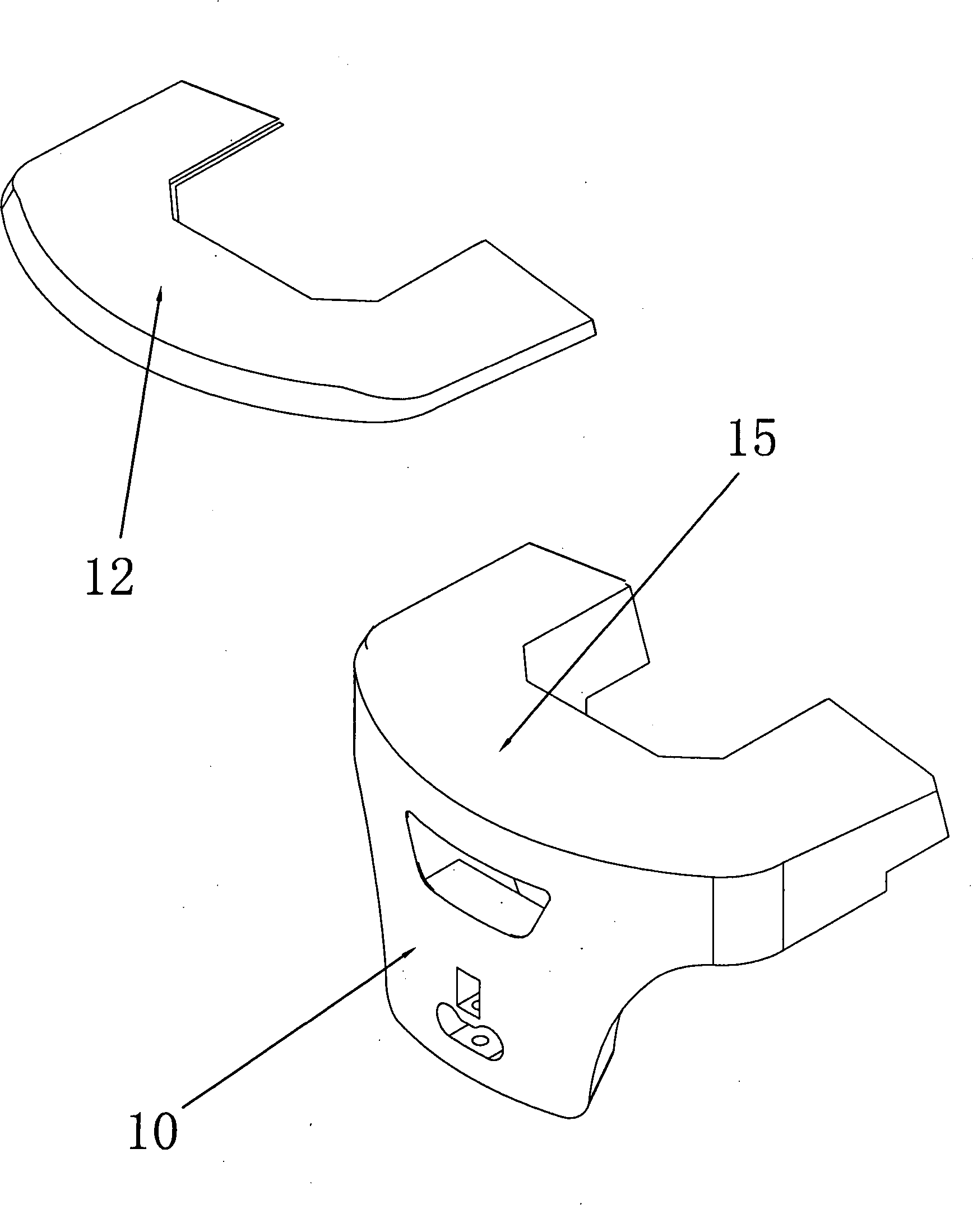

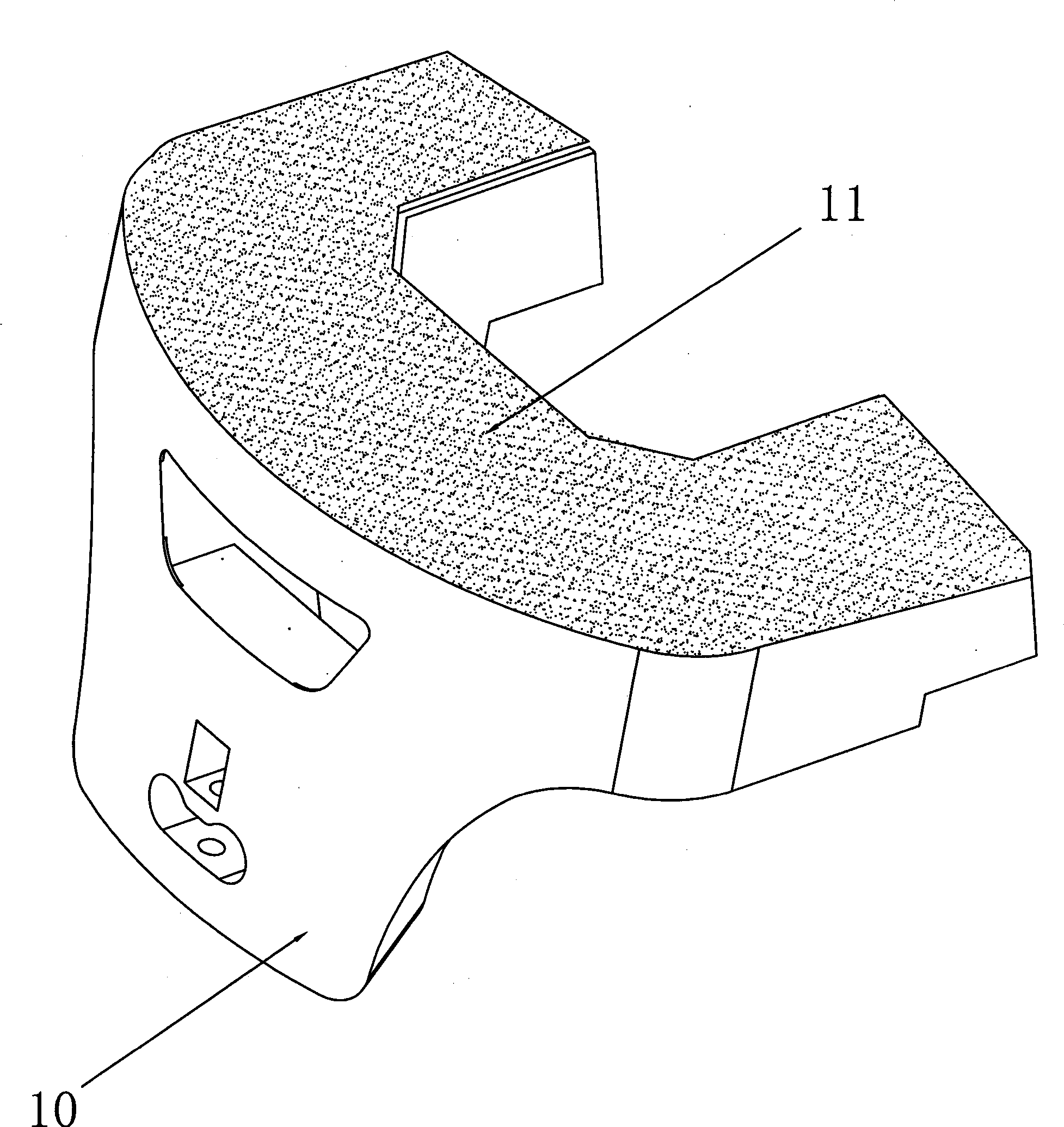

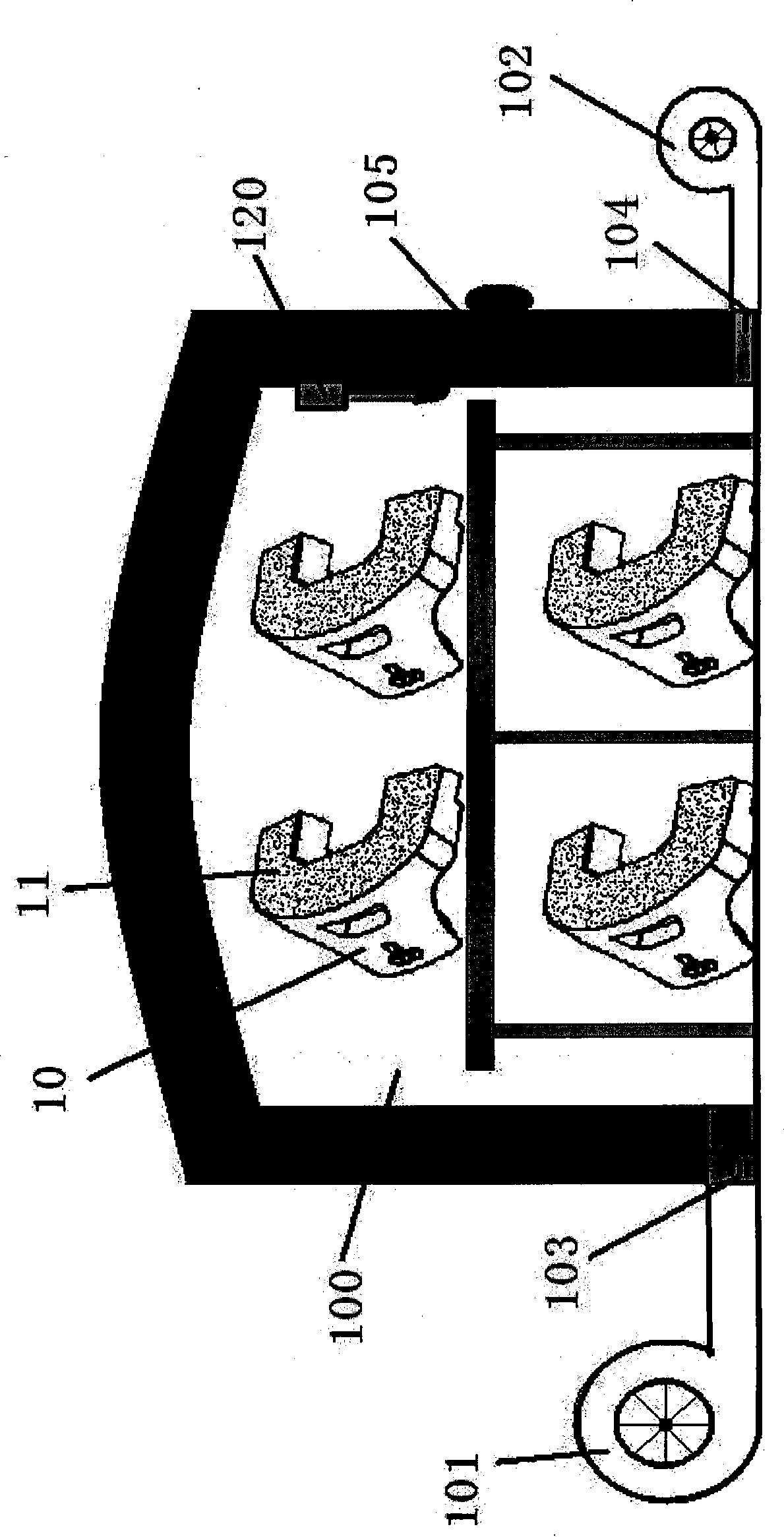

Damping type flow control forming process and die for aluminium-alloy rib-plate forging

ActiveCN103357804ASmall forming forceEffective control of flow directionForging/hammering/pressing machinesDecompression chamberEngineering

The invention provides a damping type flow control forming process for an aluminium-alloy rib-plate forging. The process comprises two forming steps of pre-forging and finish-forging, a forming load is reduced through a decompression chamber during pre-forging, and the damping force is applied to a web portion of the forging during finish-forging, so that the web portion is prevented from plastic deformation, and deformation only occurs in rib portions. The invention also provides a die for implementing the method. A damper is arranged inside a concave die to apply the acting force to the web portion of the forging. According to the process and the die, metal flow is controlled through the damping force, so that metal distribution is adjusted reasonably during forming, and the forming load is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

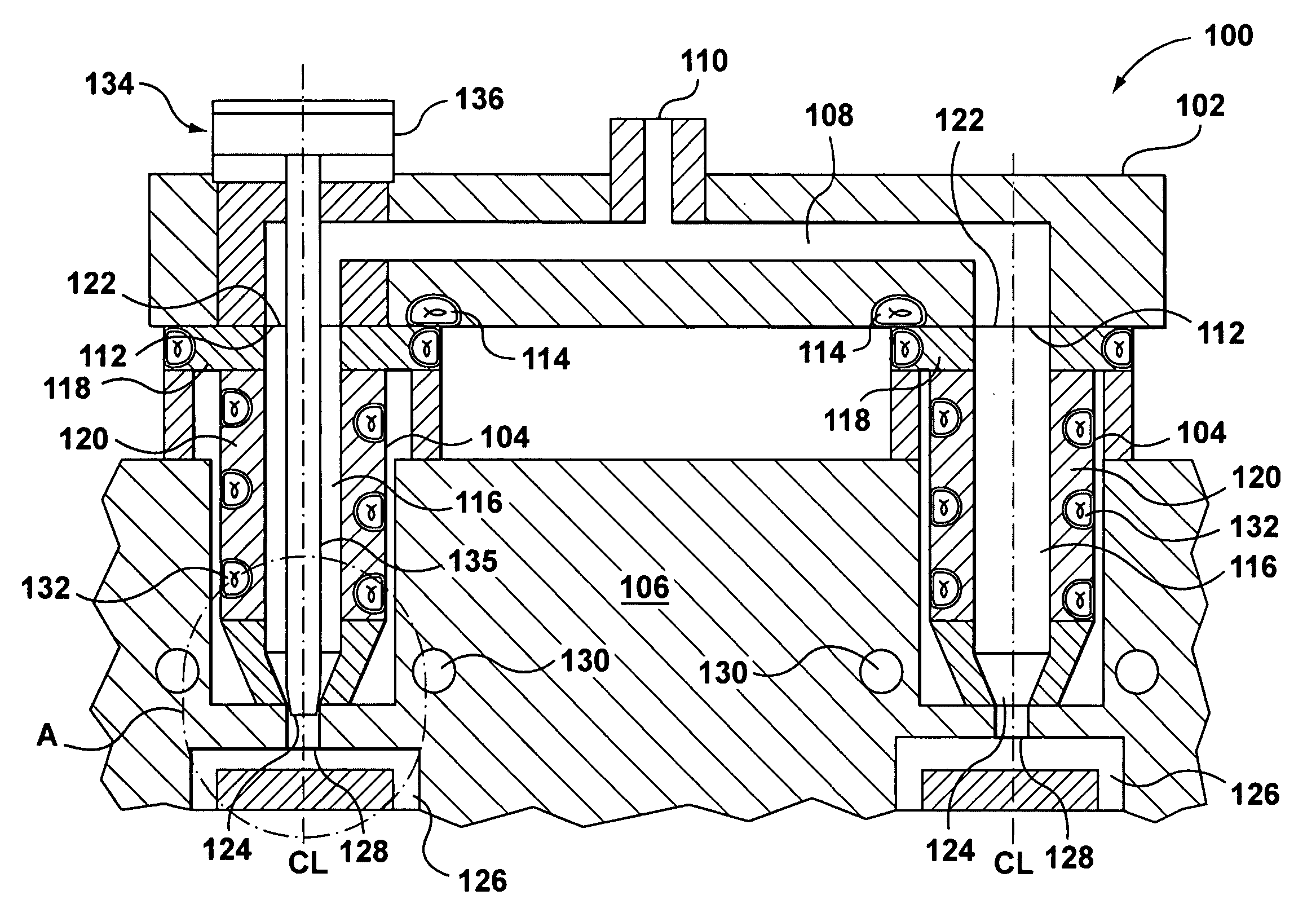

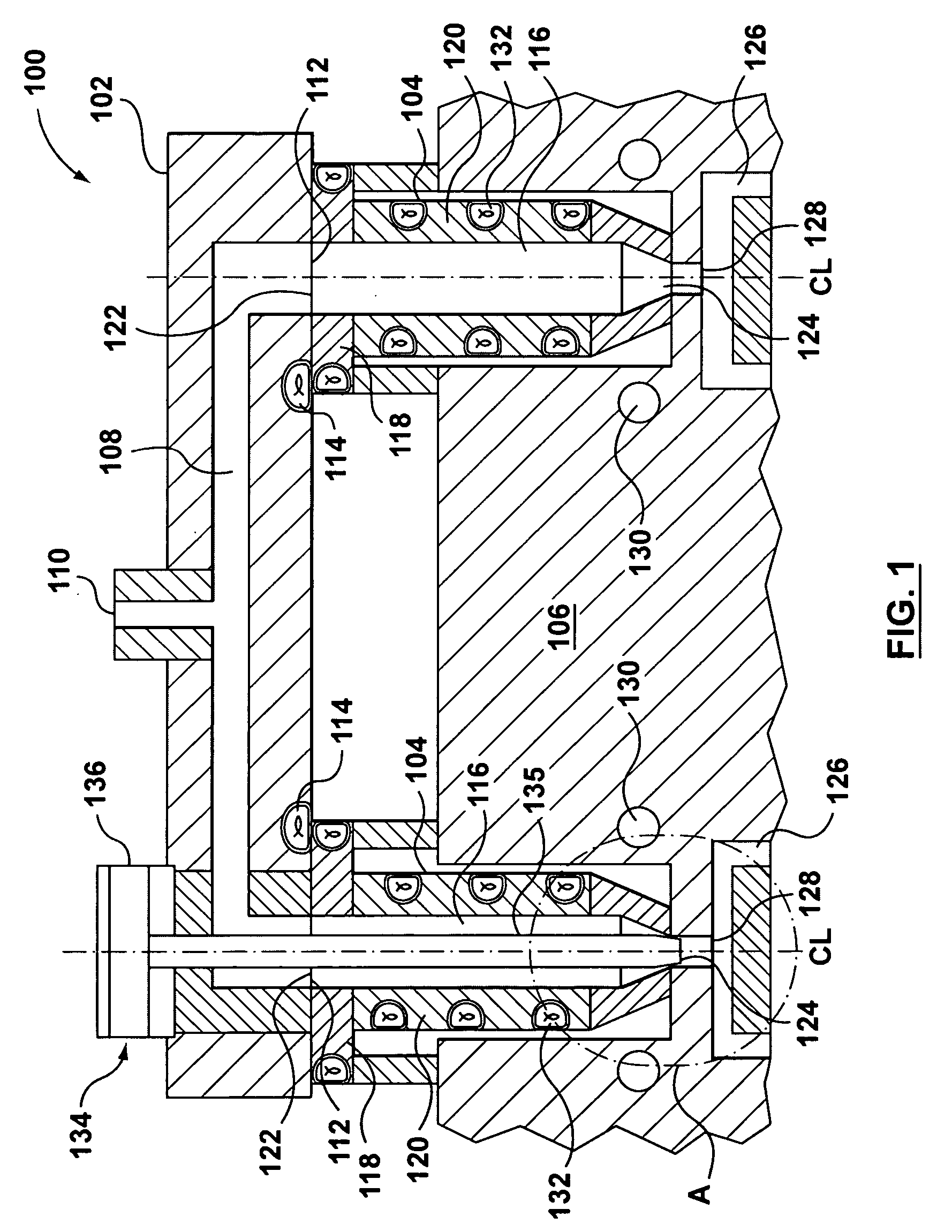

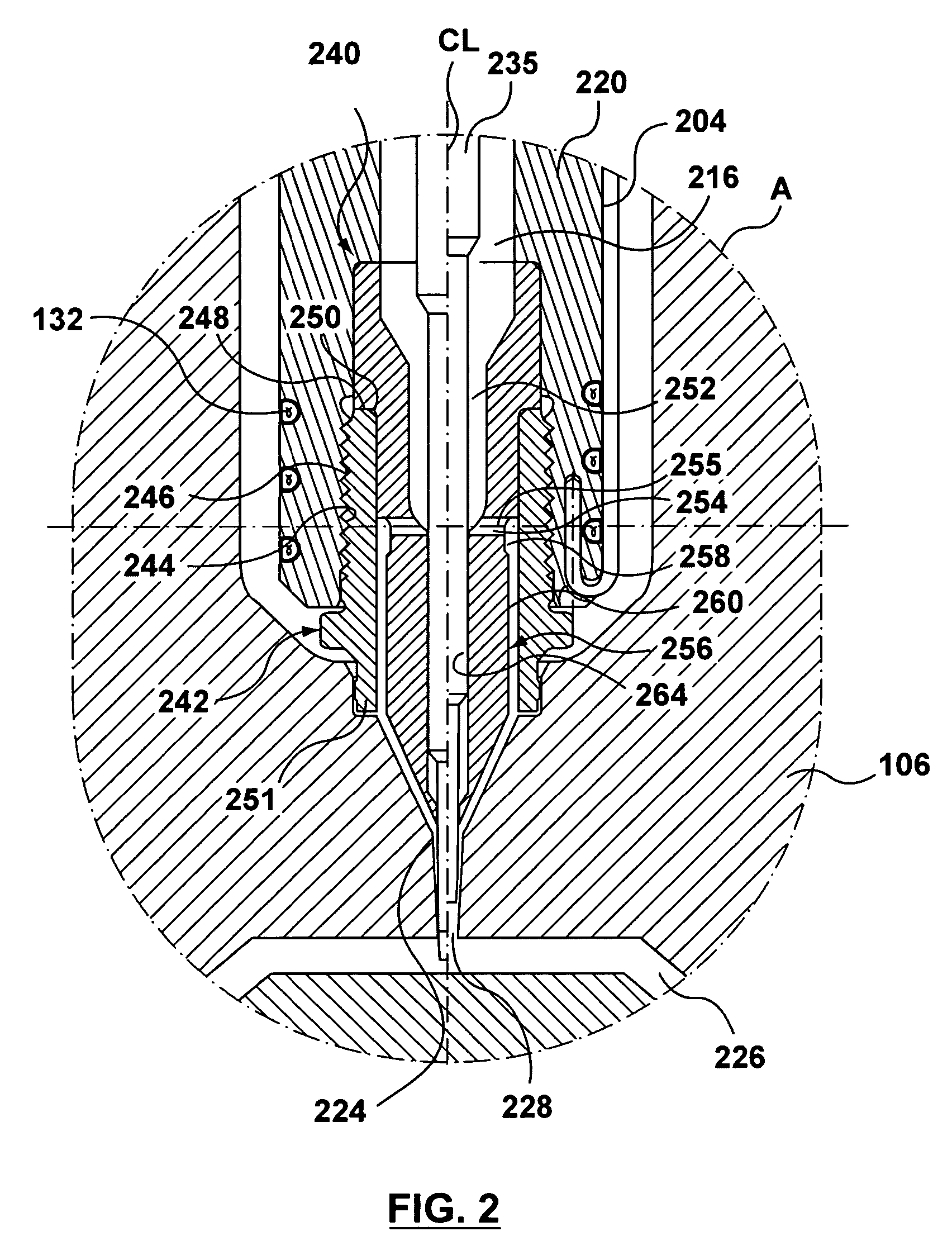

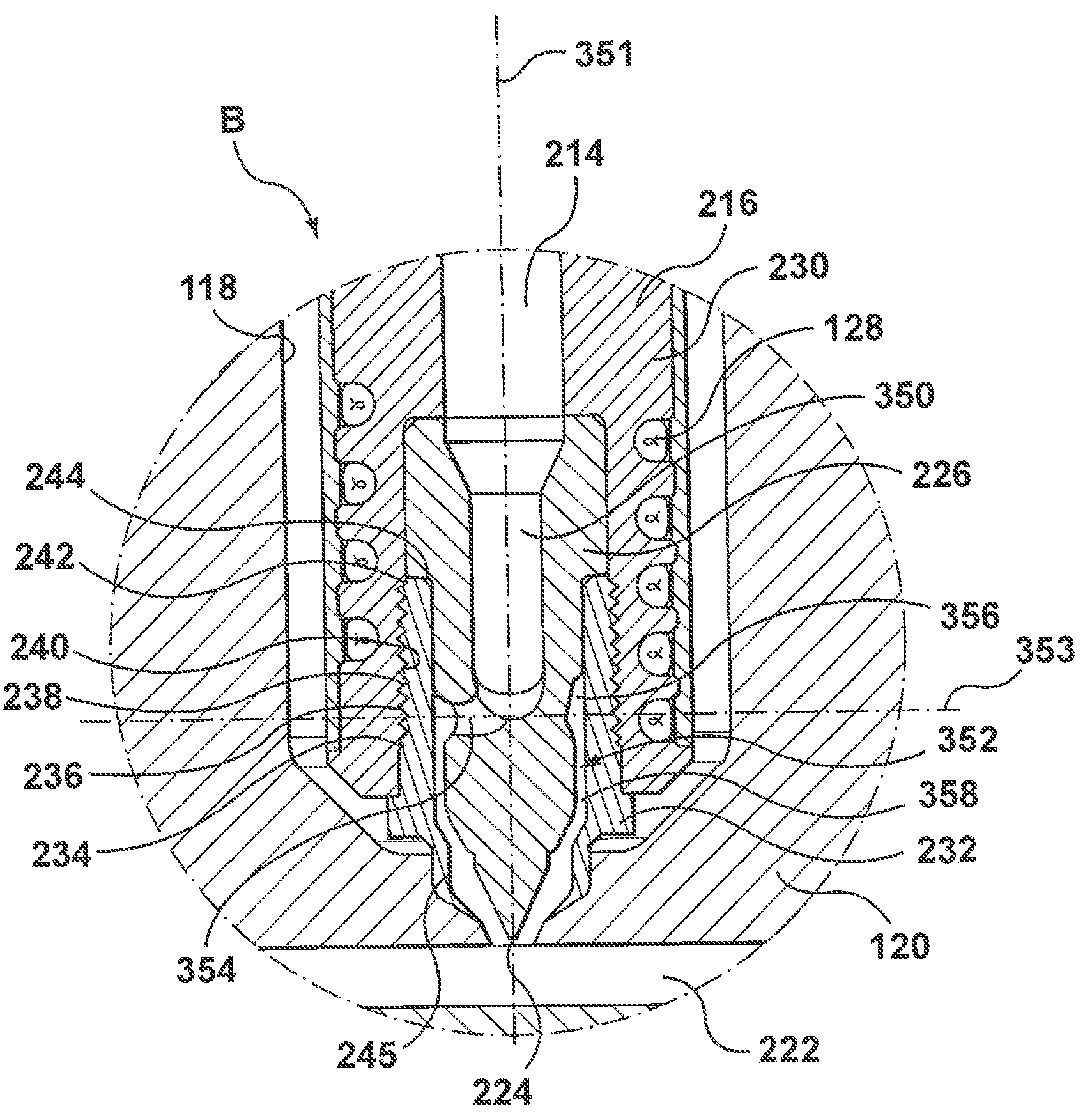

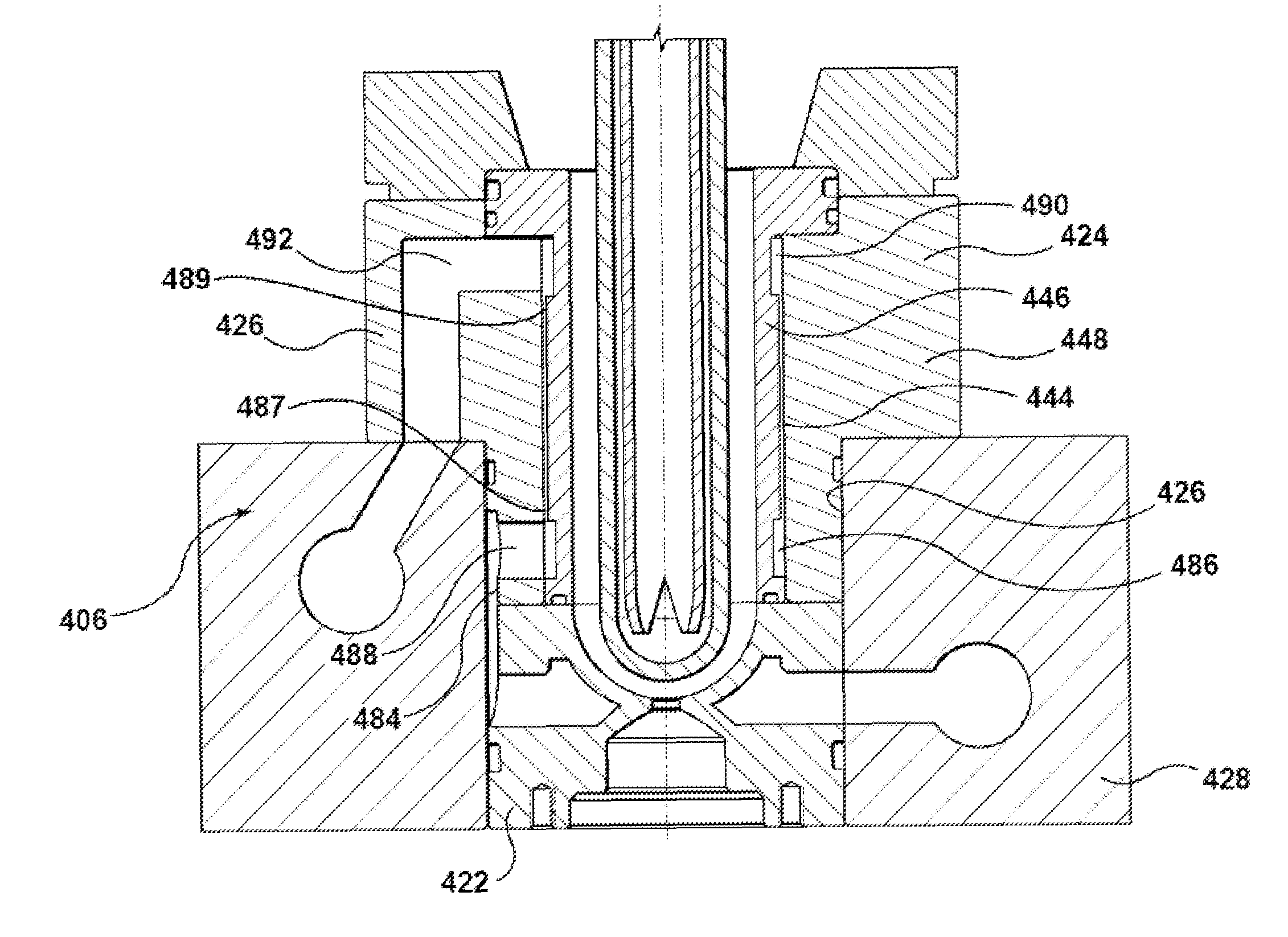

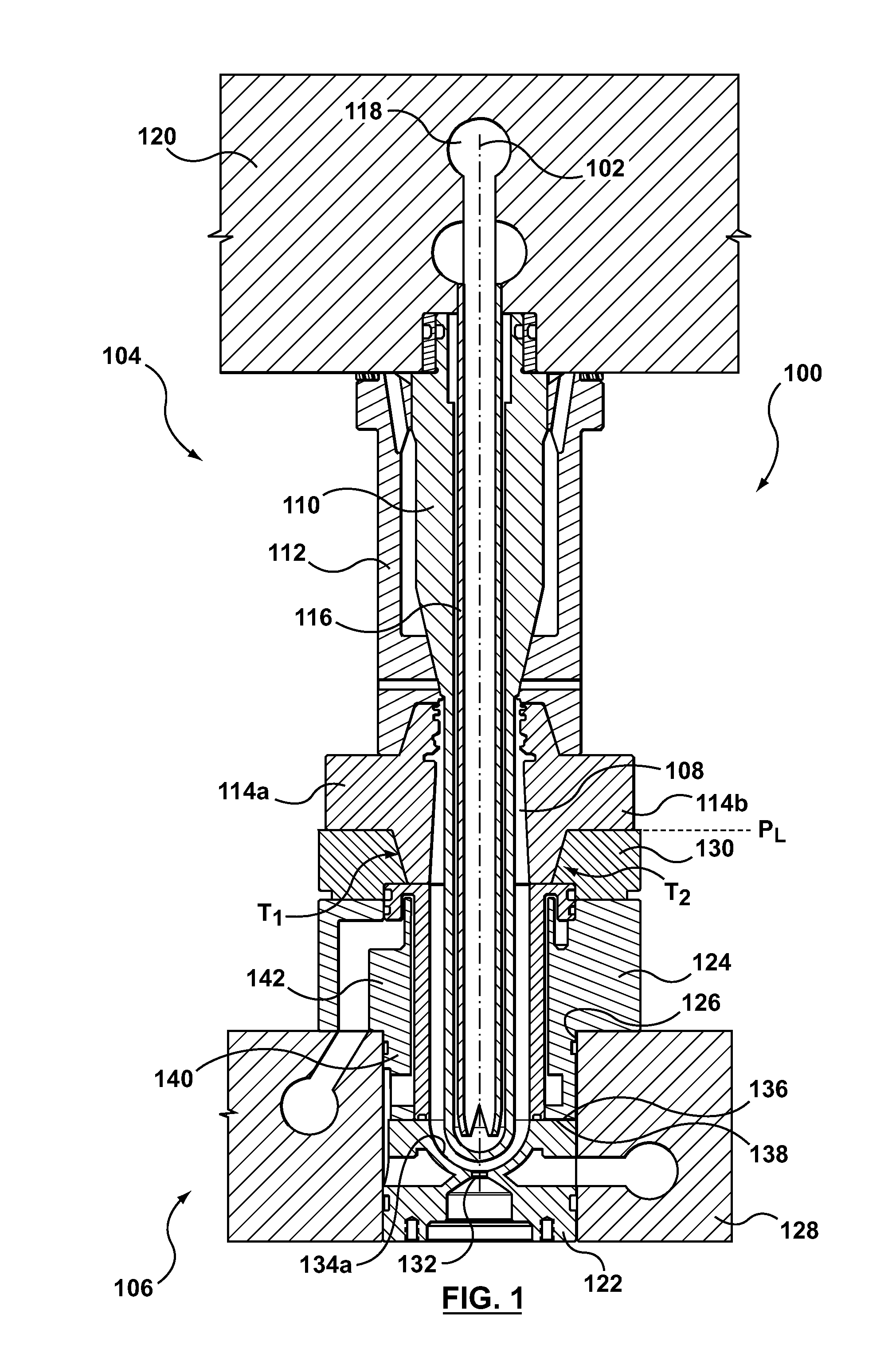

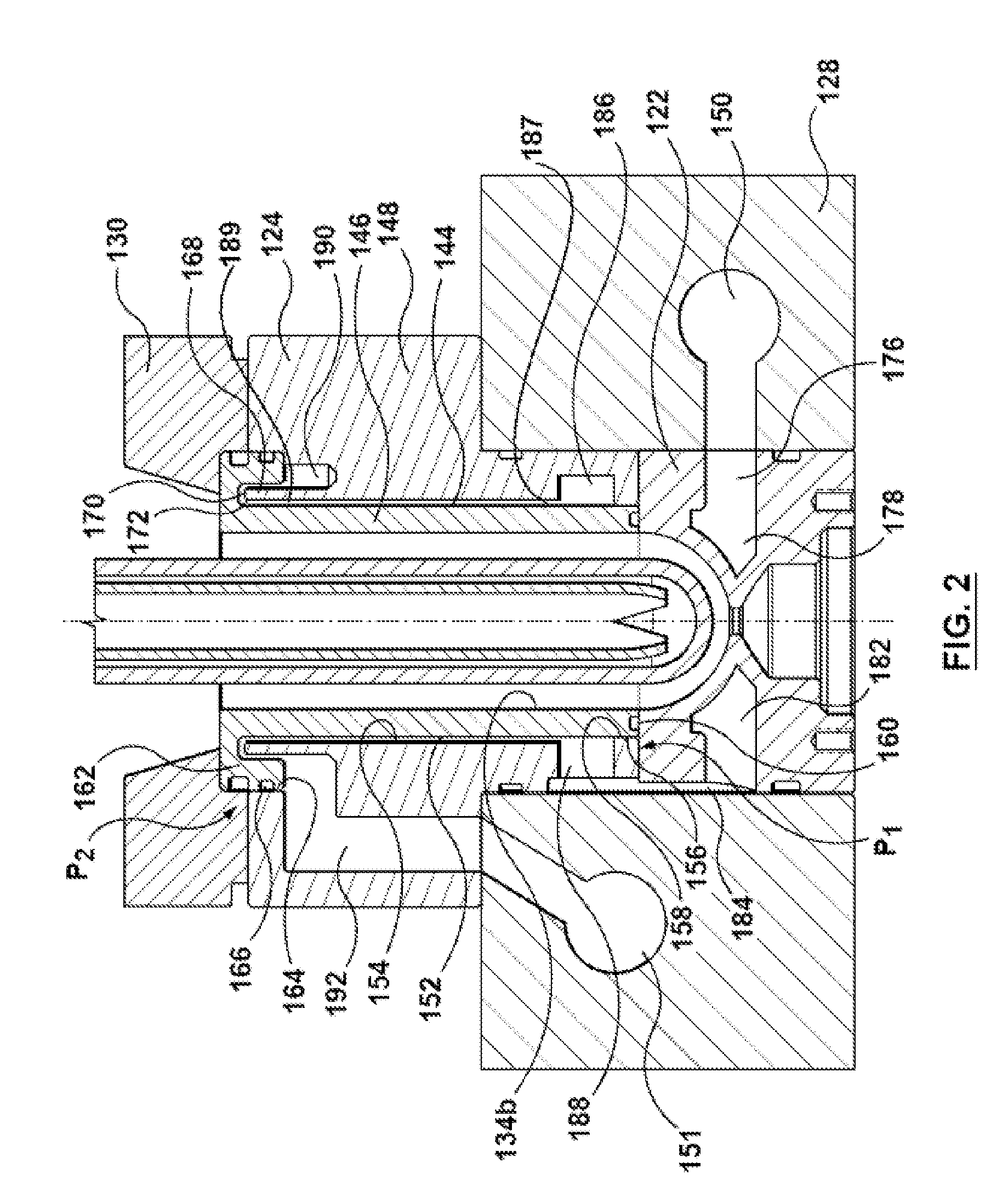

Valve-gated injection moding nozzle having an annular flow

A valve-gated nozzle in an injection molding machine allows for smooth, blended melt flow into a mold cavity. In one example, this is accomplished through use of a valve-gated nozzle having a nozzle body with a nozzle melt channel in fluid communication with a manifold melt channel and a nozzle tip. The nozzle tip includes a first melt channel in fluid communication with the nozzle melt channel and a plurality of release melt channels between the first melt channel and an annular melt channel. The annular melt channel is formed between a retaining device and the nozzle tip. The annular melt channel includes a decompression chamber in fluid communication with respective ones of the release melt channels and a compression chamber between the decompression chamber and a mold. A pressure difference formed between the respective release melt channels and the decompression chamber and between the decompression chamber and the compression chamber blends the molten material to even and balance flow into the mold cavity.

Owner:MOLD MASTERS 2007

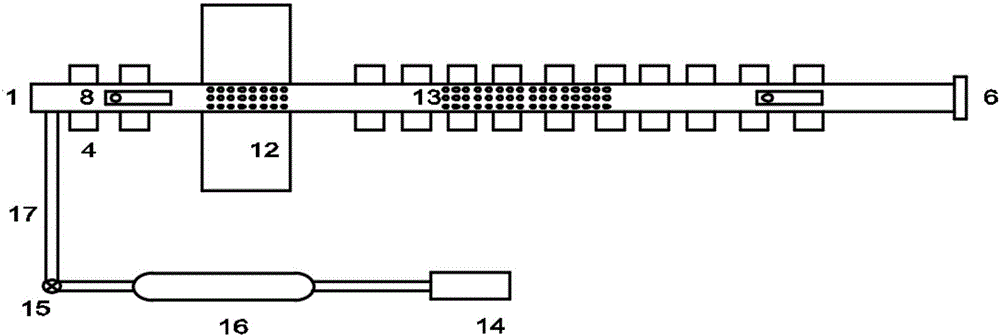

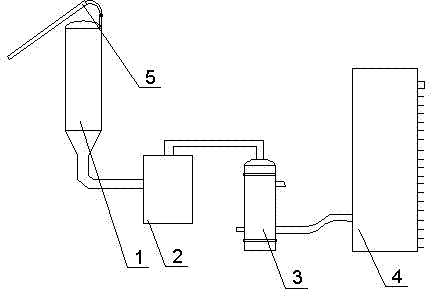

Emission and recovery integrated air cannon experiment apparatus

InactiveCN105758442AThe principle is simpleFew partsMeasurement devicesSolenoid valveDecompression chamber

The invention provides an emission-recovery integrated air cannon experiment apparatus. The air cannon experiment apparatus triggers a bullet by using air expansion to do work so as to better simulate the overload environment when the bullet is blasted, which can truly reflect the overload condition of the bullet. The air cannon experiment apparatus is mainly composed of an air cannon barrel, an annular precompressed chamber, an air cannon bracing frame, a measuring bulkhead, a decompression valve gun port, a spring decompression chamber, a test engine, a fastener, a slide rail, a clamping ring, a rupture of membranes sheet, a pressure relief aperture, a solenoid valve and an air cushion cover. A certain amount of air is fed into an air cylinder by using an air compressor, and at the same time the test engine is locked by using the fastener. When pressure inside an auxiliary segment is sufficiently enough to overcome a fastening force, the test engine is launched, and the air cannon is accelerated, evenly decelerated, and even stopped, so as to achieve soft recovery by using air. The apparatus of the invention is characterized by few movable members, simple and reliable structure, easy mounting and dismantling, and rapid decompression.

Owner:NANJING UNIV OF SCI & TECH

Injection molding nozzle having an annular flow tip

A nozzle in an injection molding machine allows for smooth, blended melt flow into a mold cavity. In one example, this is accomplished through use of a nozzle having a nozzle body with a nozzle melt channel in fluid communication with a manifold melt channel and a nozzle tip. The nozzle tip includes a first melt channel in fluid communication with the nozzle melt channel and a plurality of release melt channels between the first melt channel and an annular melt channel. The annular melt channel is formed between a retaining device and the nozzle tip. The annular melt channel includes a decompression chamber in fluid communication with respective ones of the release melt channels and a compression chamber between the decompression chamber and a mold. A pressure difference formed between the respective release melt channels and the decompression chamber and between the decompression chamber and the compression chamber blends the molten material to even and balance flow into the mold cavity.

Owner:MOLD MASTERS 2007

Valve-gated injection molding nozzle having an annular flow

Owner:MOLD MASTERS 2007

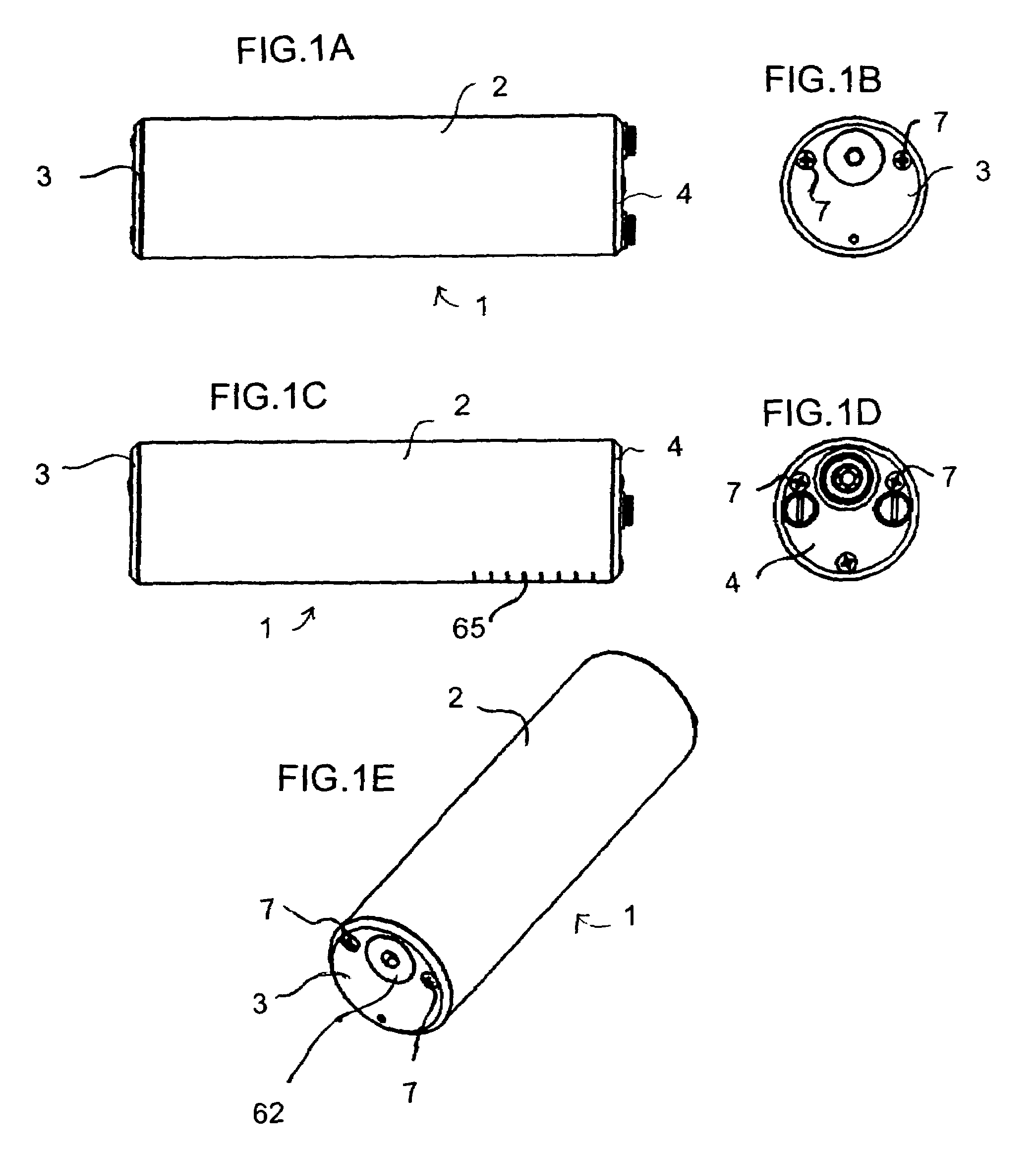

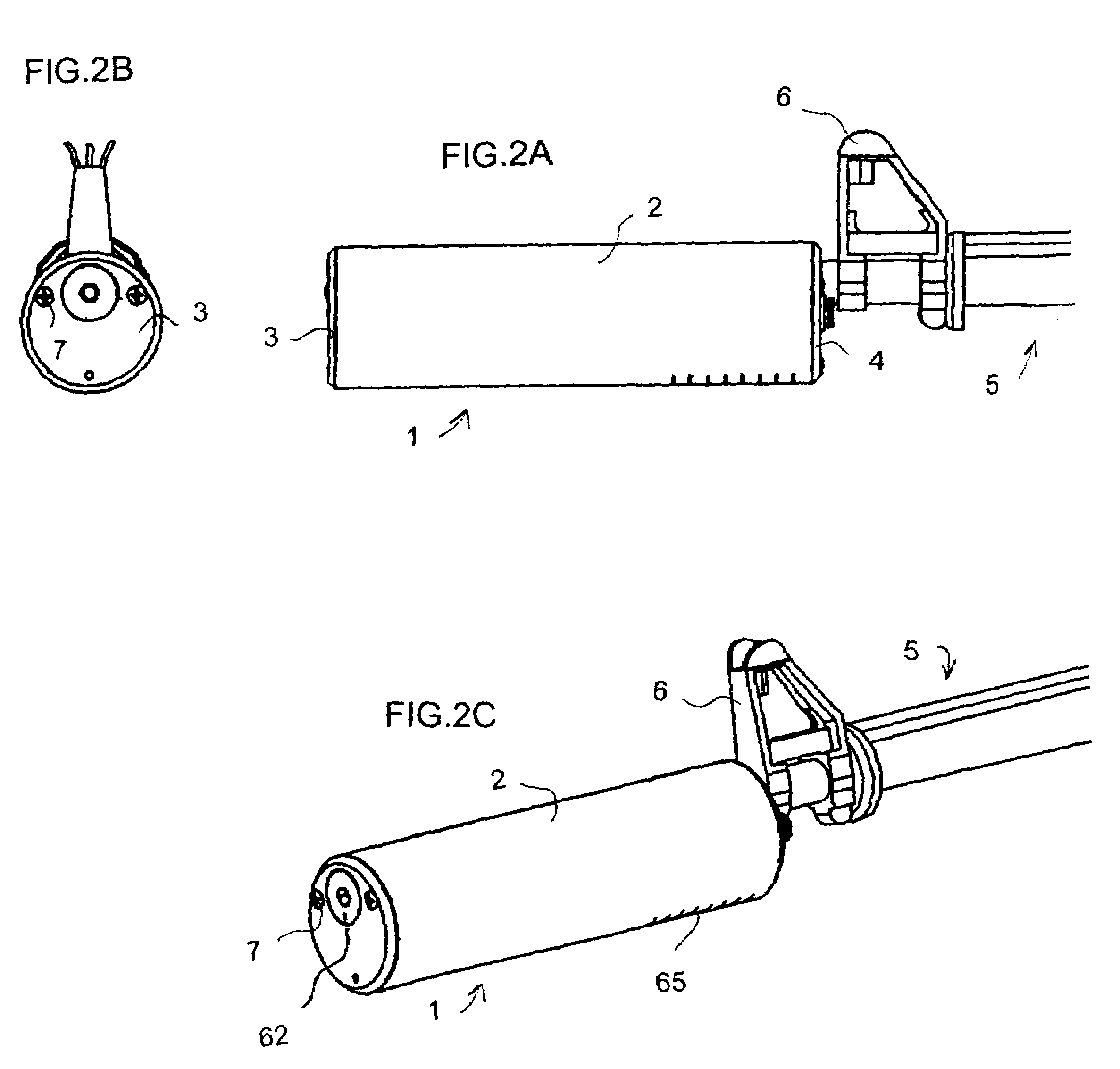

Gas removal device

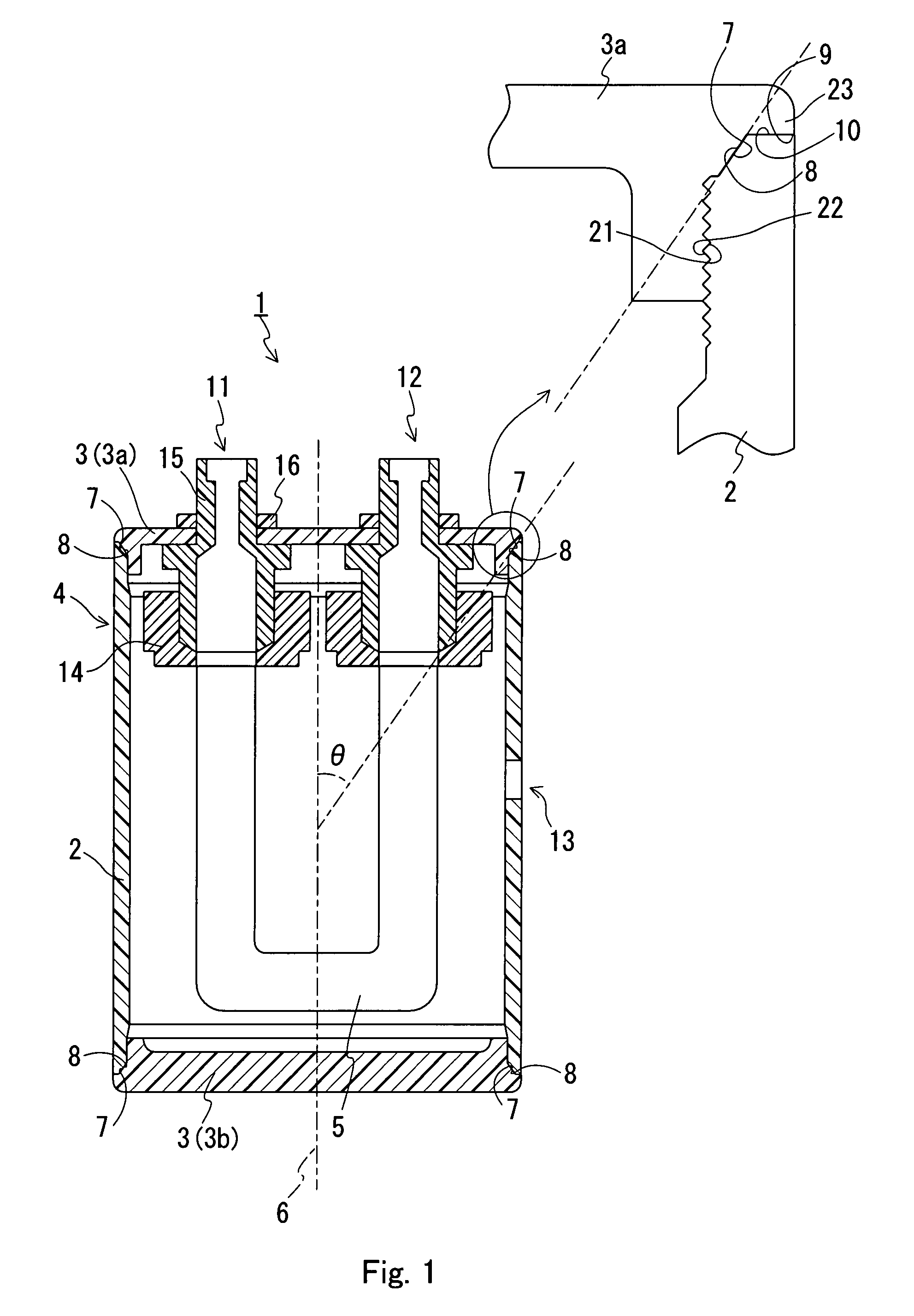

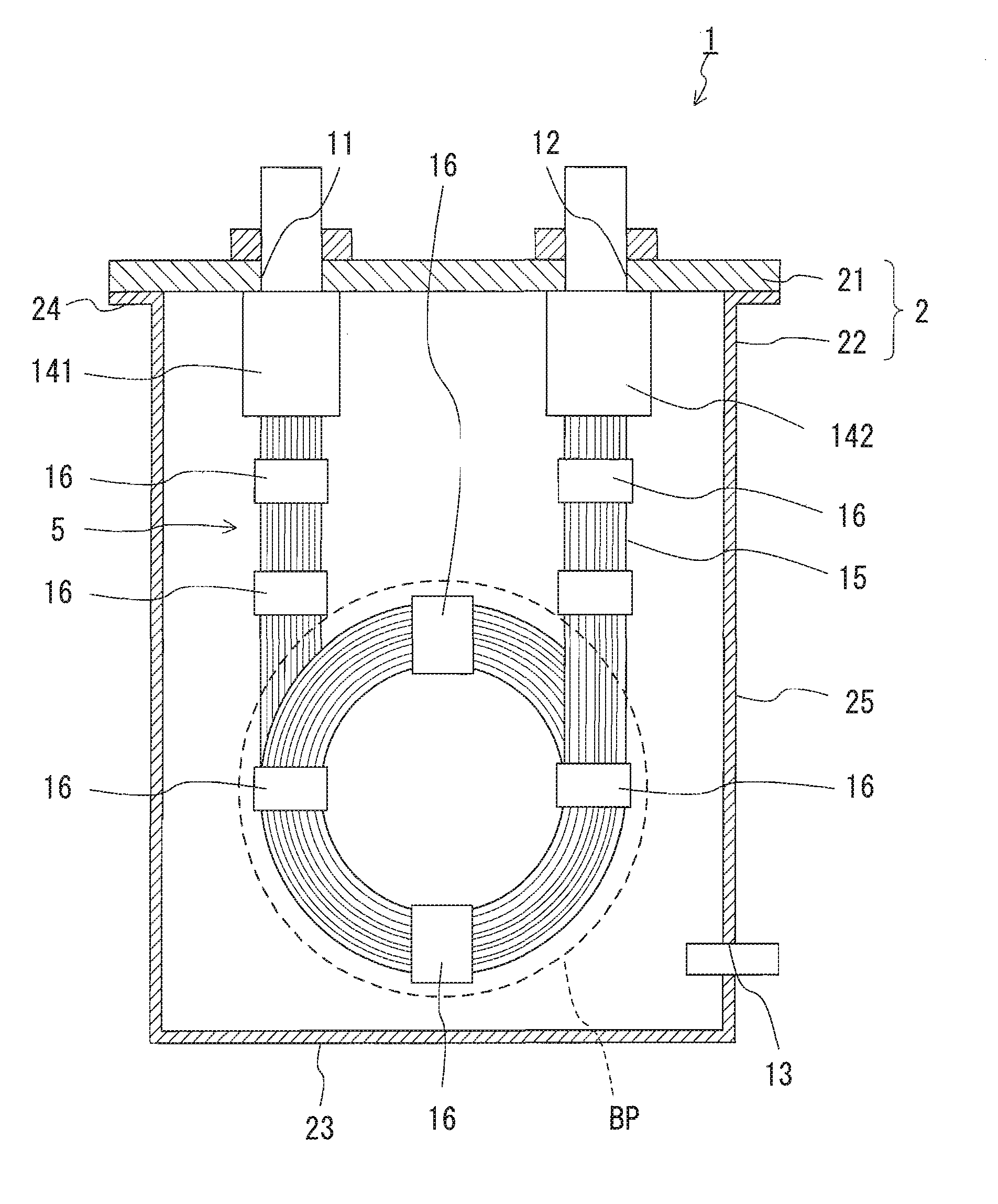

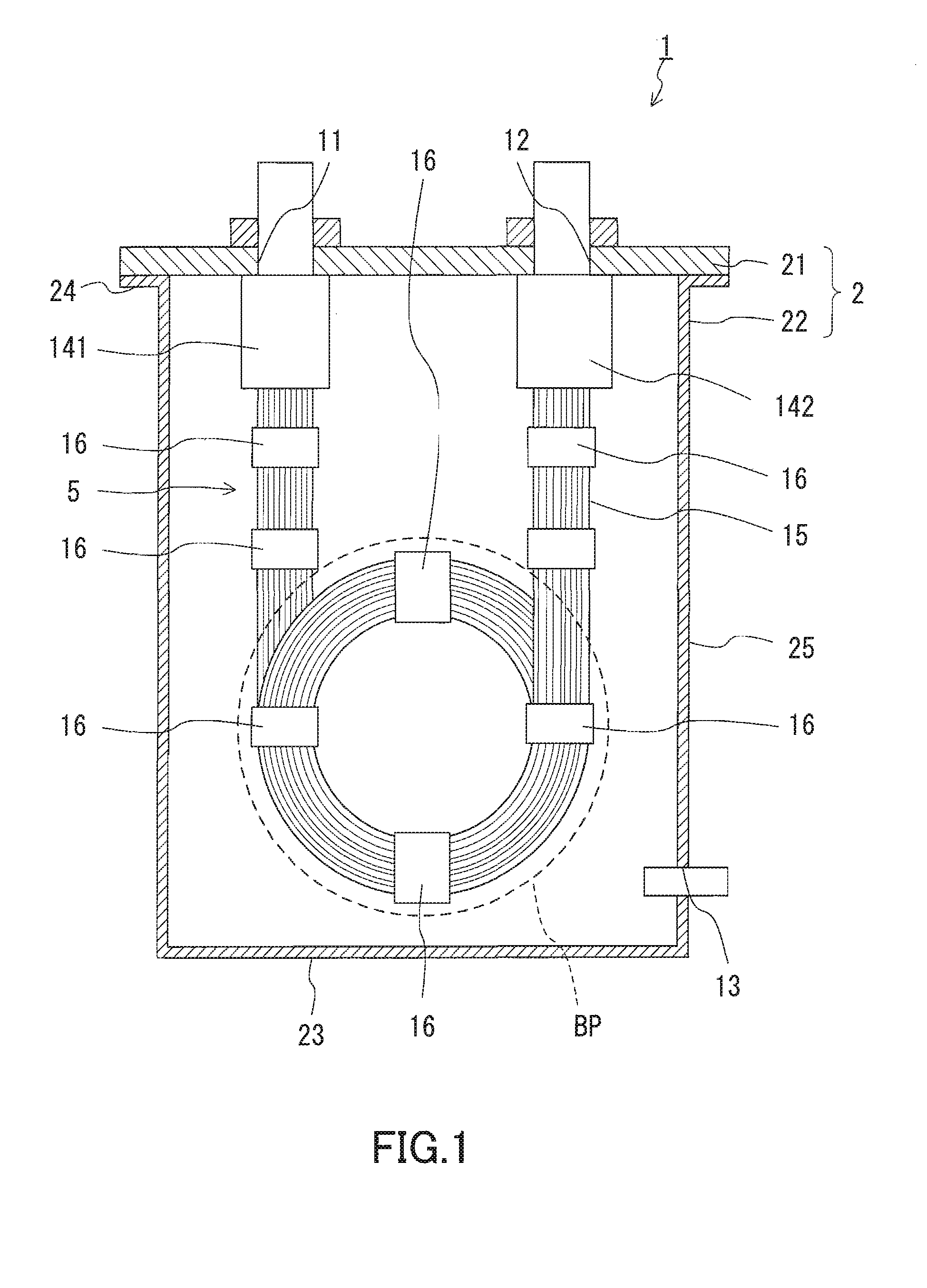

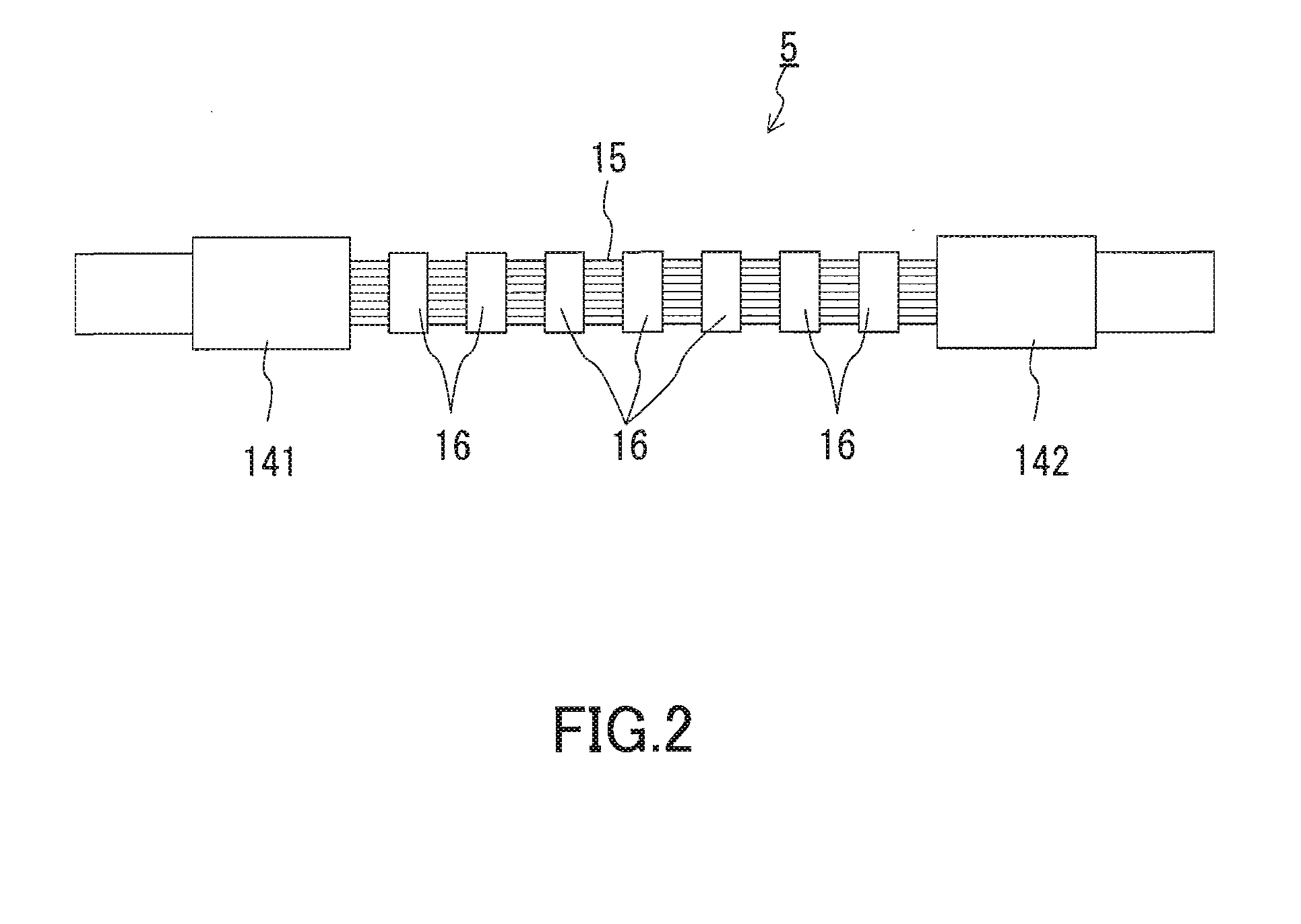

InactiveUS20090301306A1Improve degassing effectRelieve pressureSemi-permeable membranesMembranesDecompression chamberEngineering

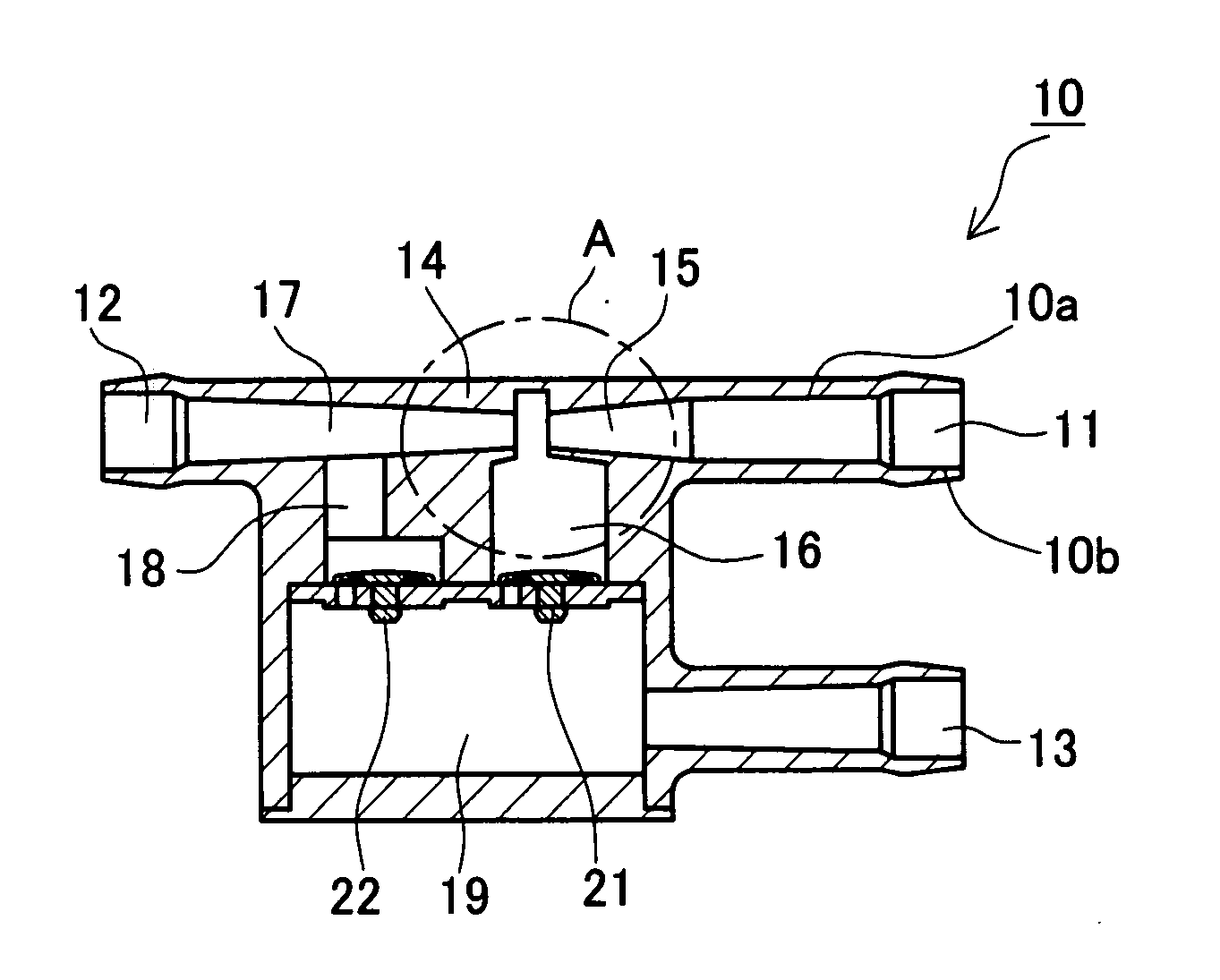

A gas removal device 1 includes a decompression chamber 2 with an inlet 11 and an outlet 12 through which a liquid to be degassed flows therein and thereout, and a degassing element 5 that is accommodated in the decompression chamber 2 while having one end connected to the inlet 11 and another end connected to the outlet 12, and that allows the liquid to be degassed entering into the inlet 11 to pass through the degassing element 5. The degassing element 5 includes a tube bundle 15 composed of a plurality of flexible gas-permeable tubes 151, and a tying member 16 tying the plurality of gas-permeable tubes 151 to form the tube bundle 15. The tube bundle 15 is bent in a shape of coil with multiple turns in such a manner that a portion tied by the tying member 16 is included in a bent portion BP.

Owner:NITTO DENKO CORP

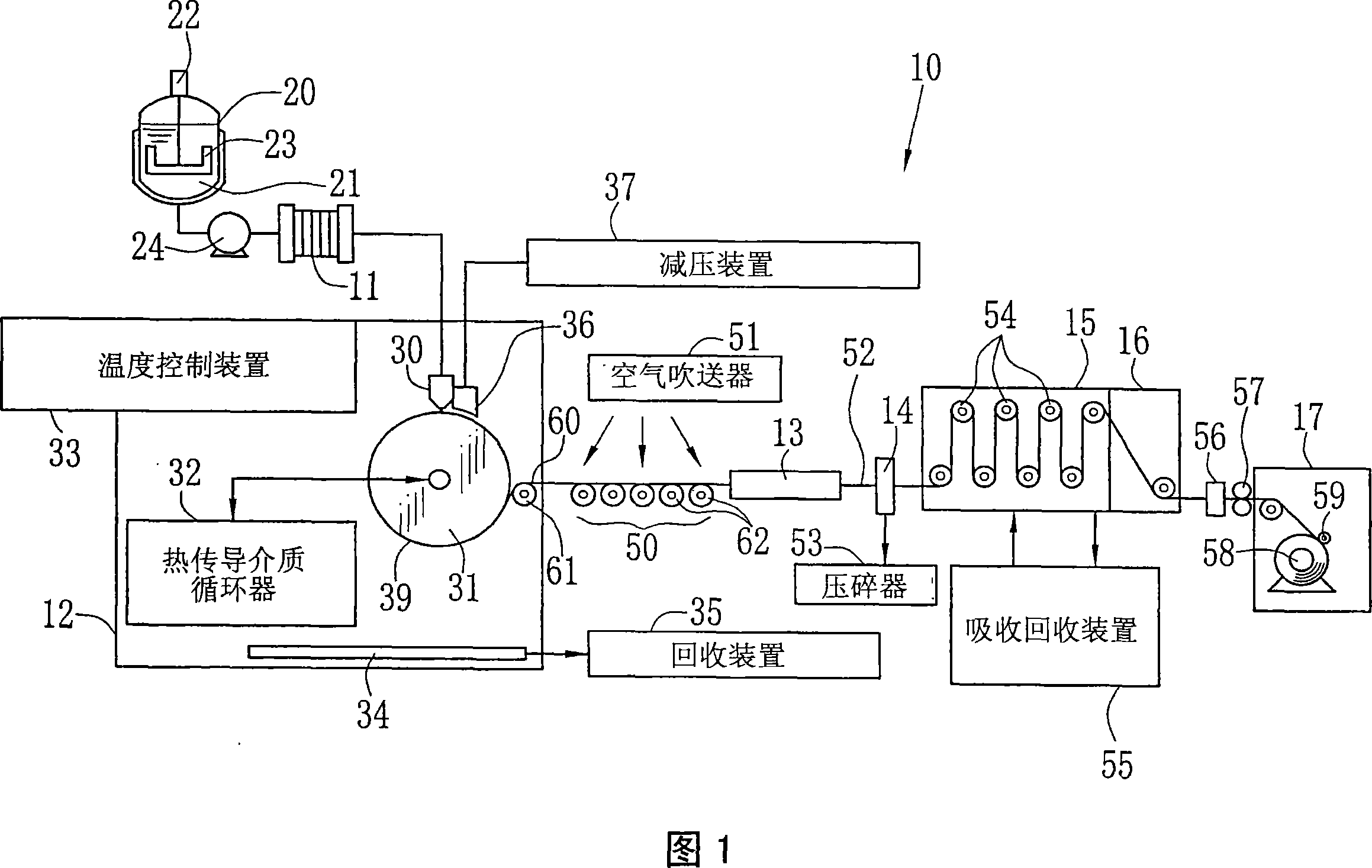

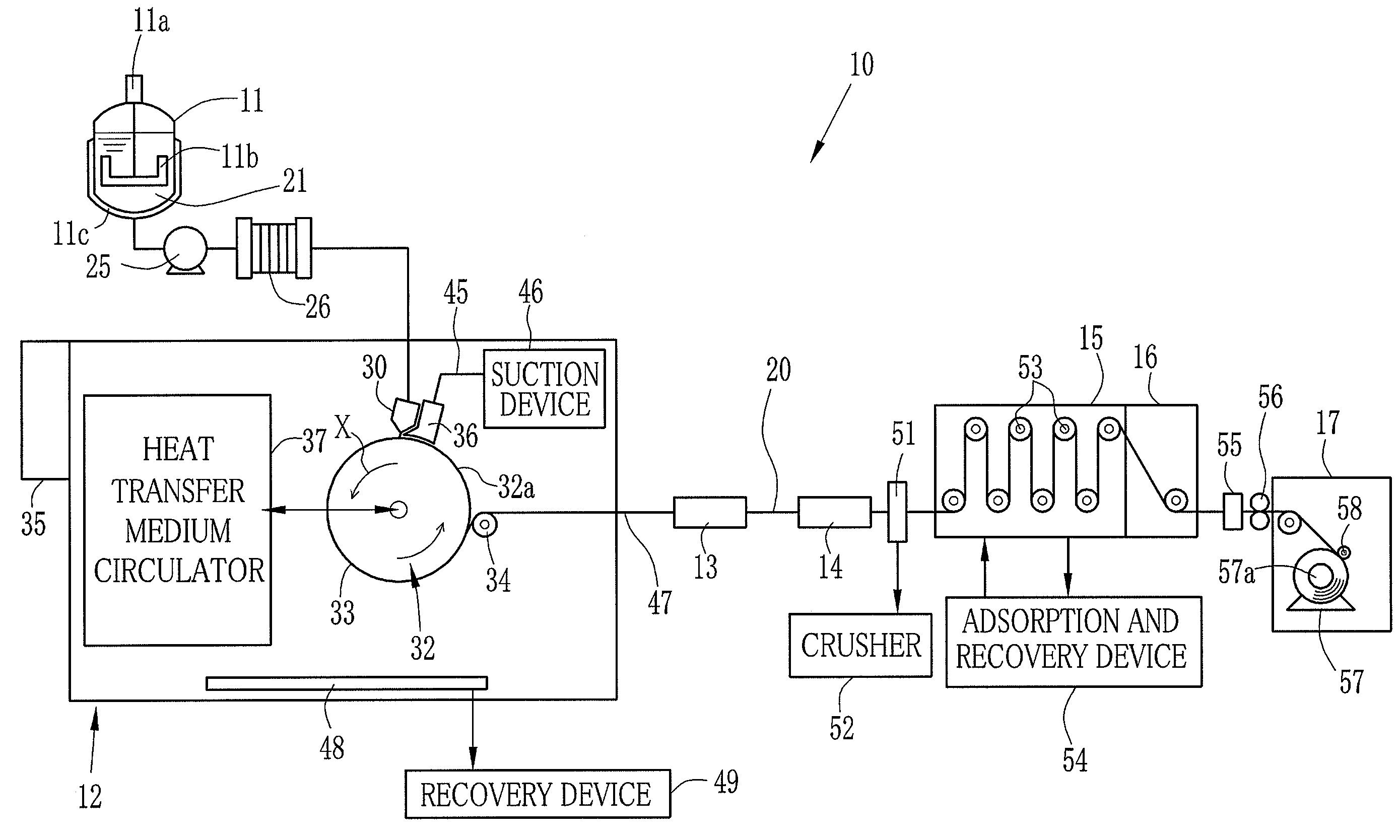

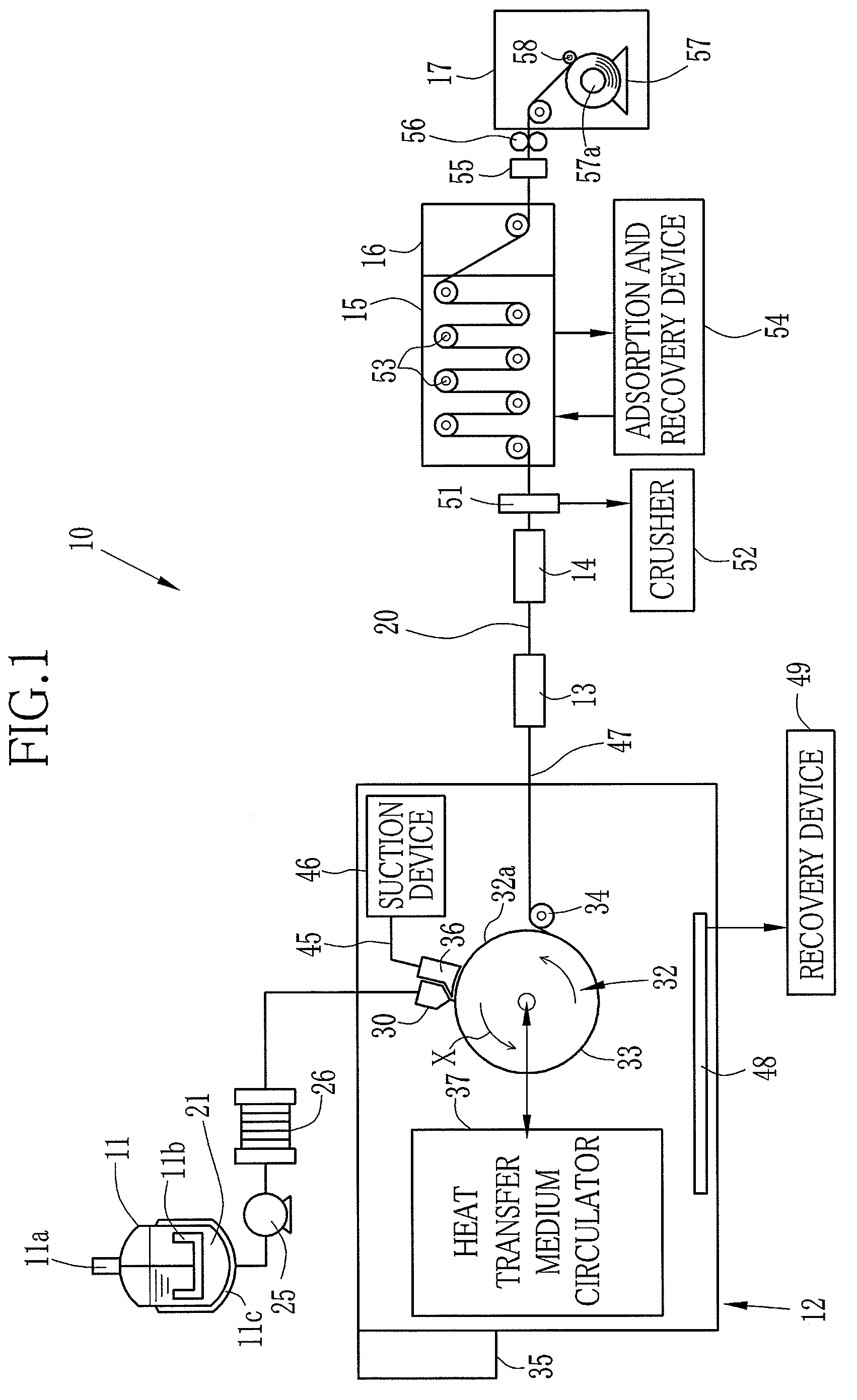

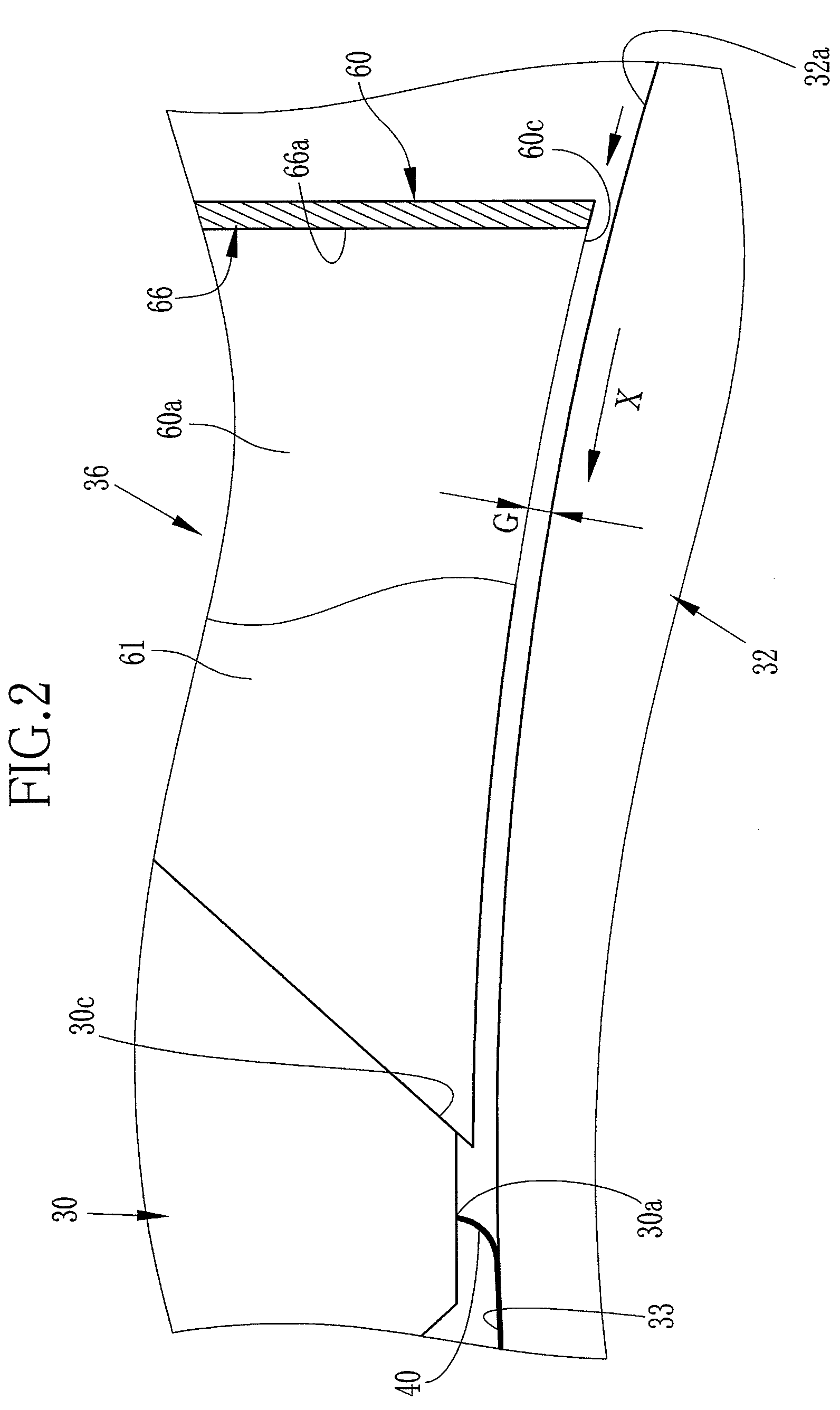

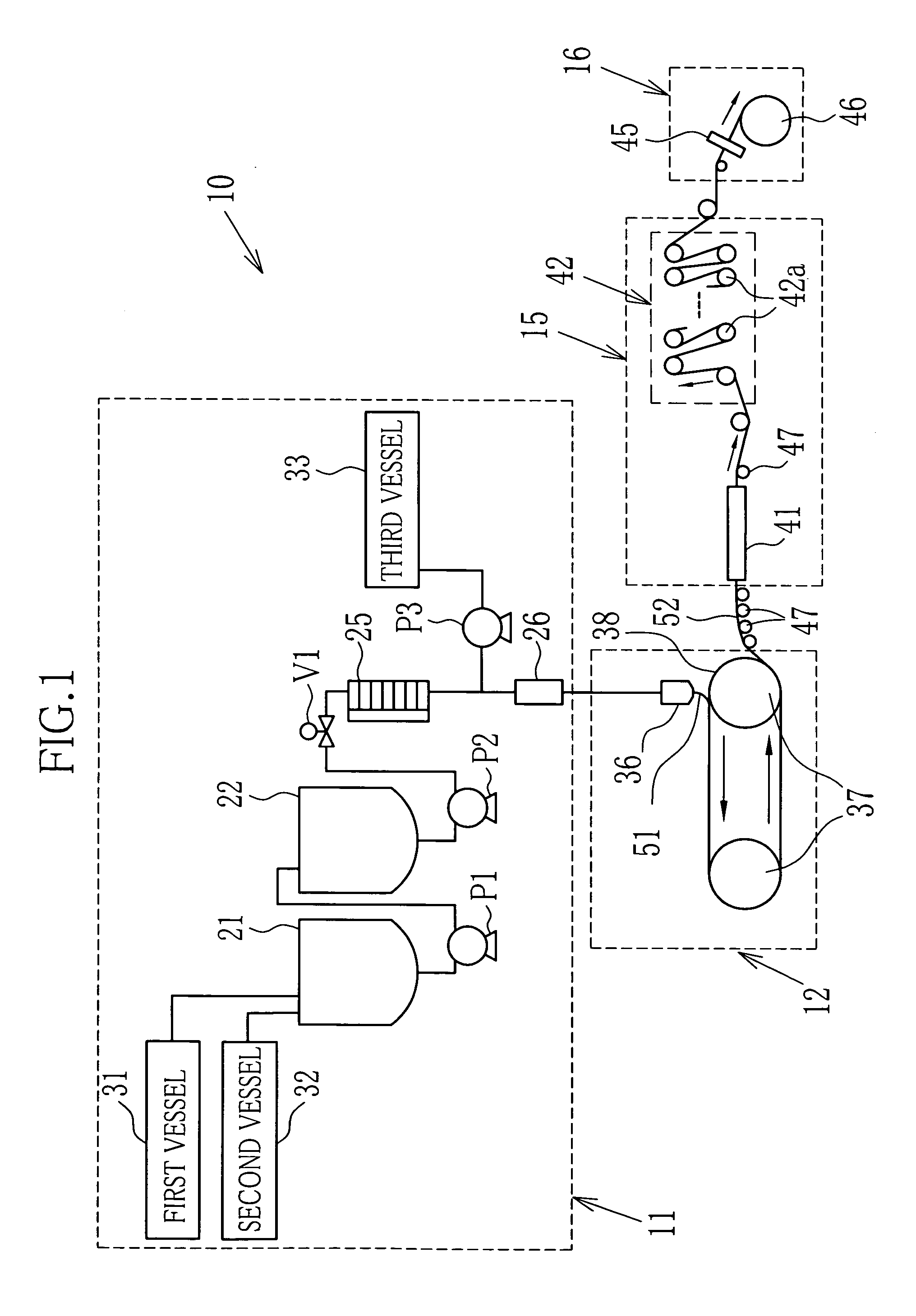

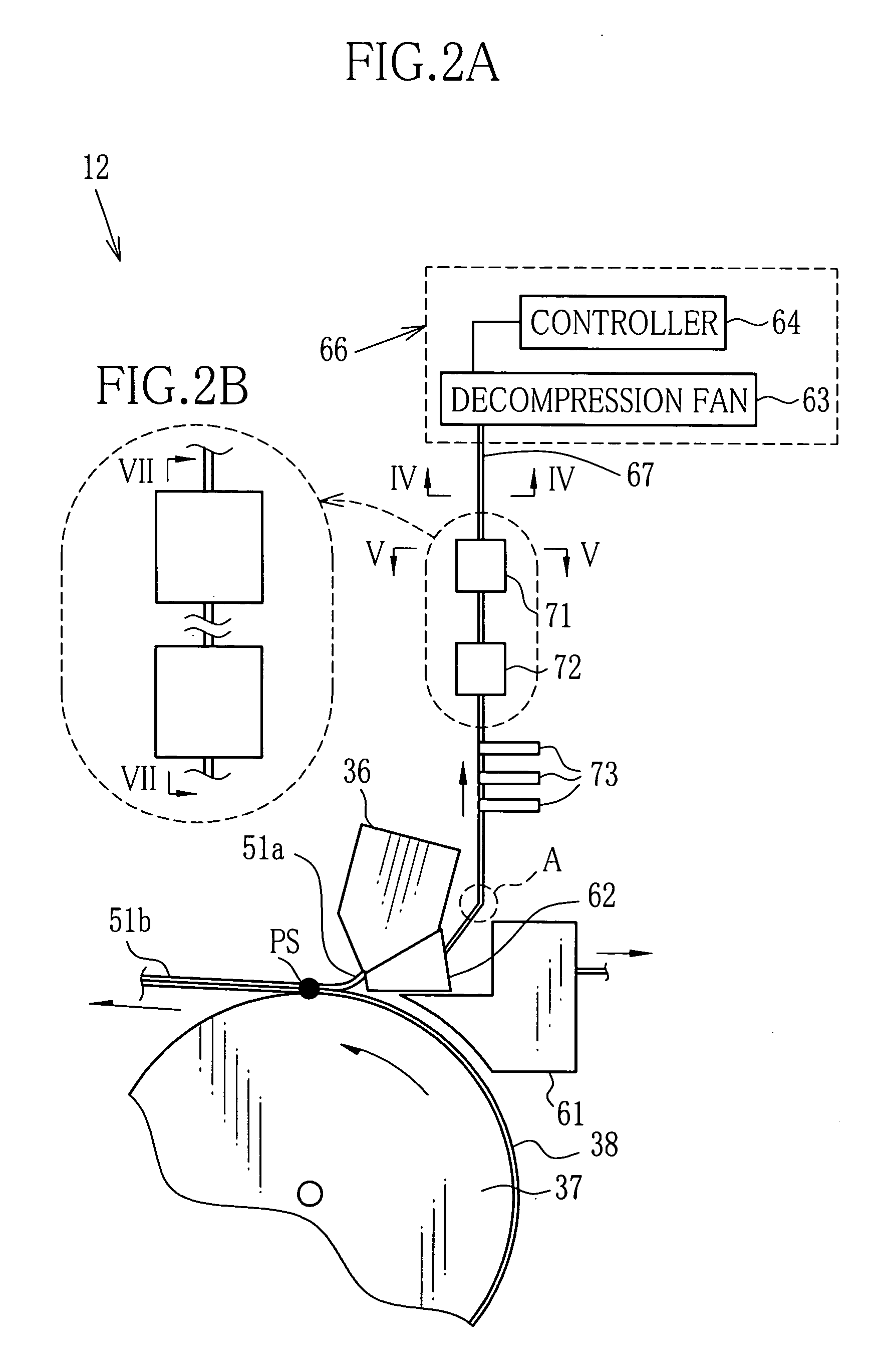

Solution casting method of film

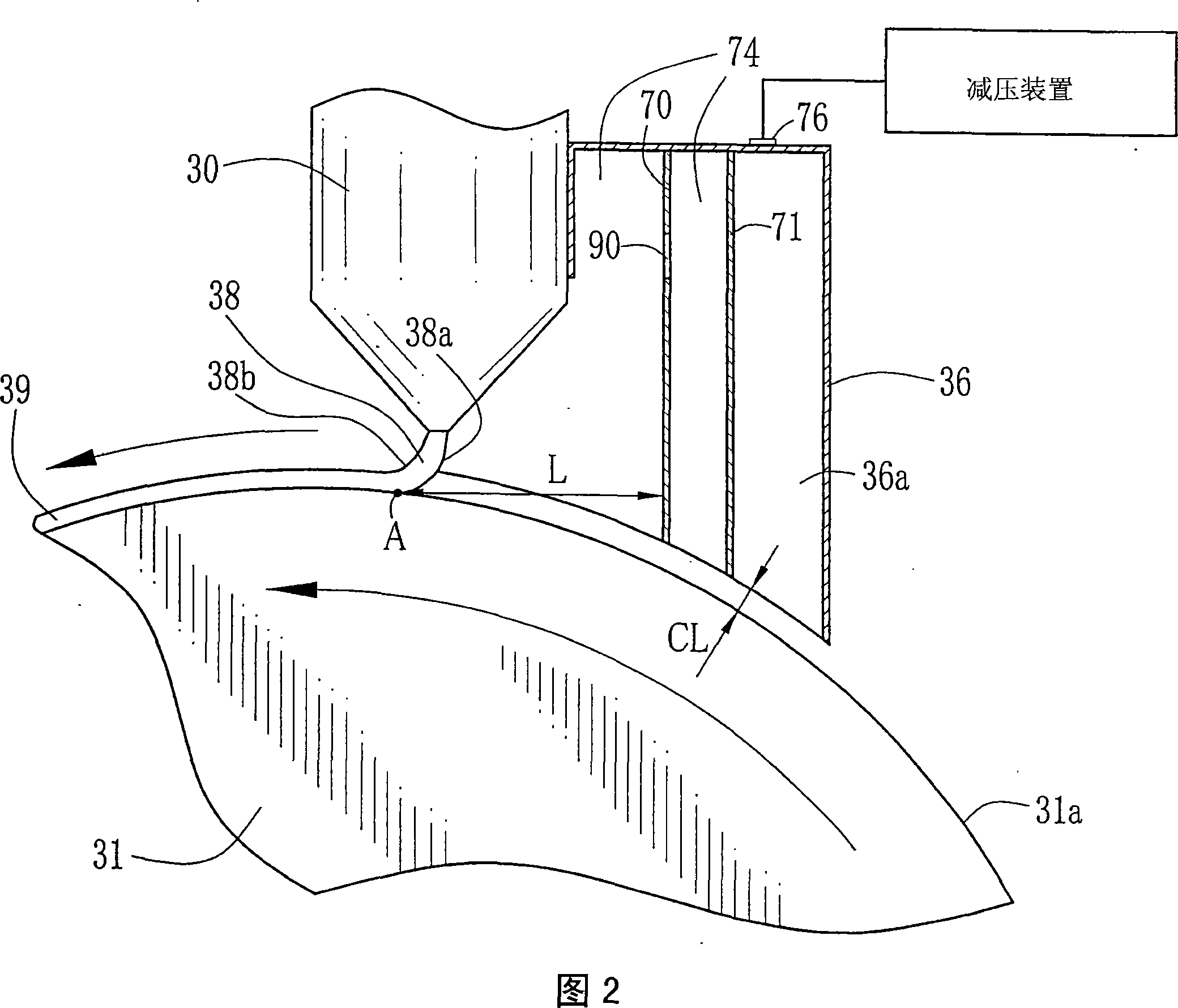

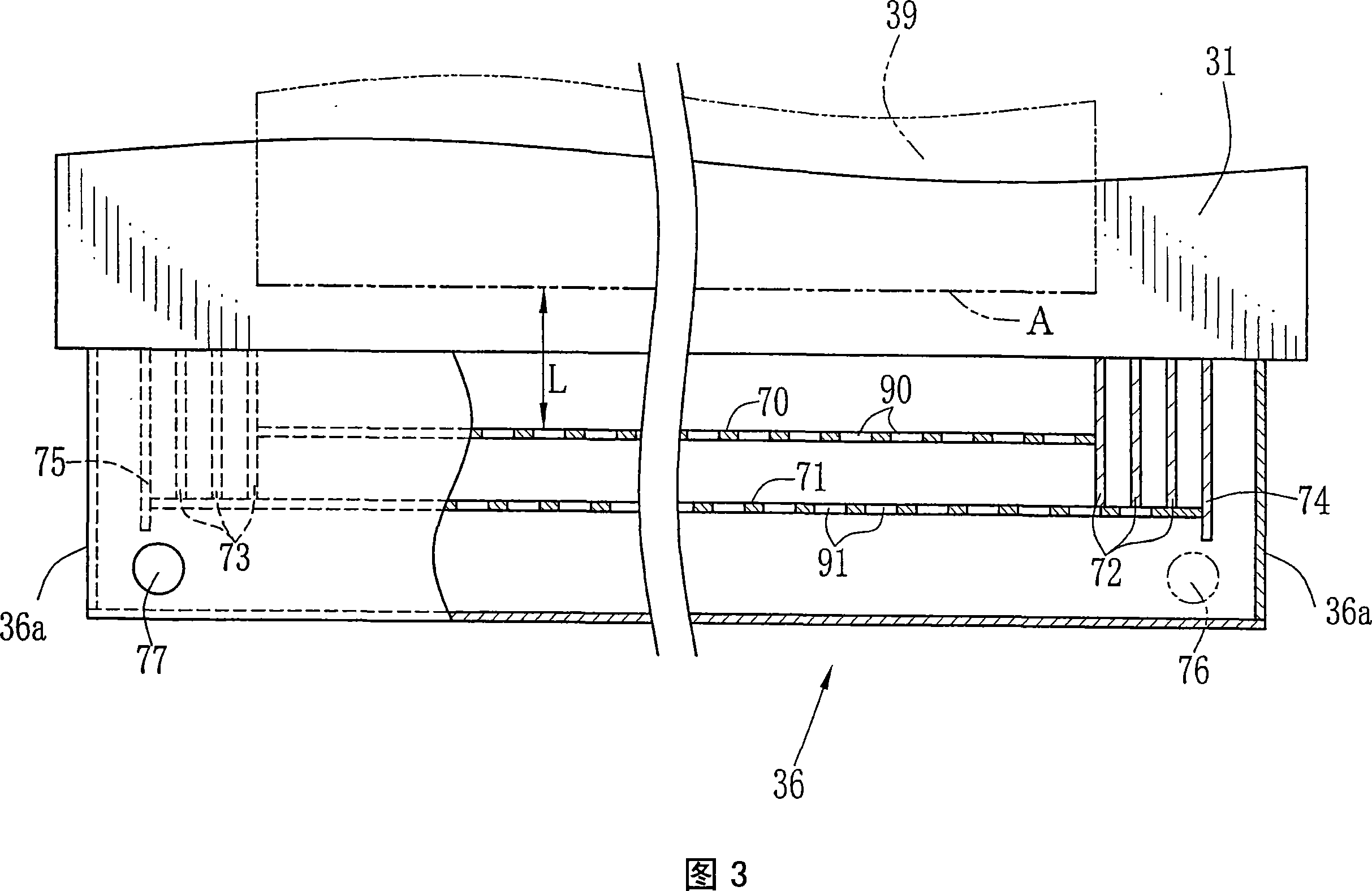

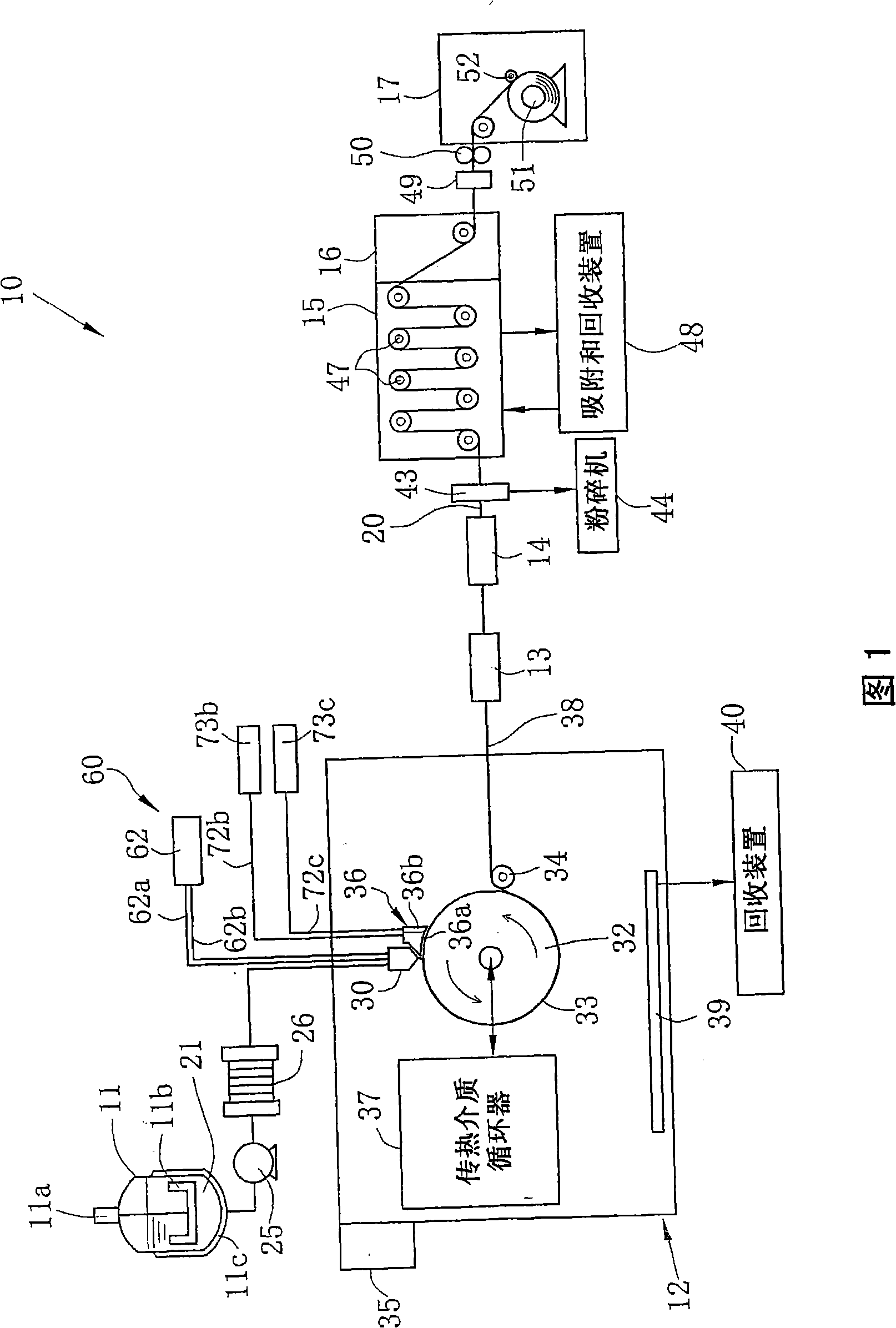

Dope including a polymer and a solvent is discharged from a casting die (30) to a casting drum (31) while forming a casting bead (38). An upstream side (38a) area of the casting bead (38) is decompressed by a decompression chamber (36) to (atmospheric pressure - 300) Pa. Air shielding plates (70, 71) are provided inside the decompression chamber (36). Openings (90) are respectively formed in upper half portions of the air shielding plates (70, 71). Adistance L (mm) between a contact position A of the casting bead (38) and the air shielding plate (70) is set in the range of 20 mm to 100 mm. After the casting bead (38) forms a casting film (39) on the casting drum (31) , the casting film (39) is peeled and dried to obtain a TAC film.

Owner:FUJIFILM CORP

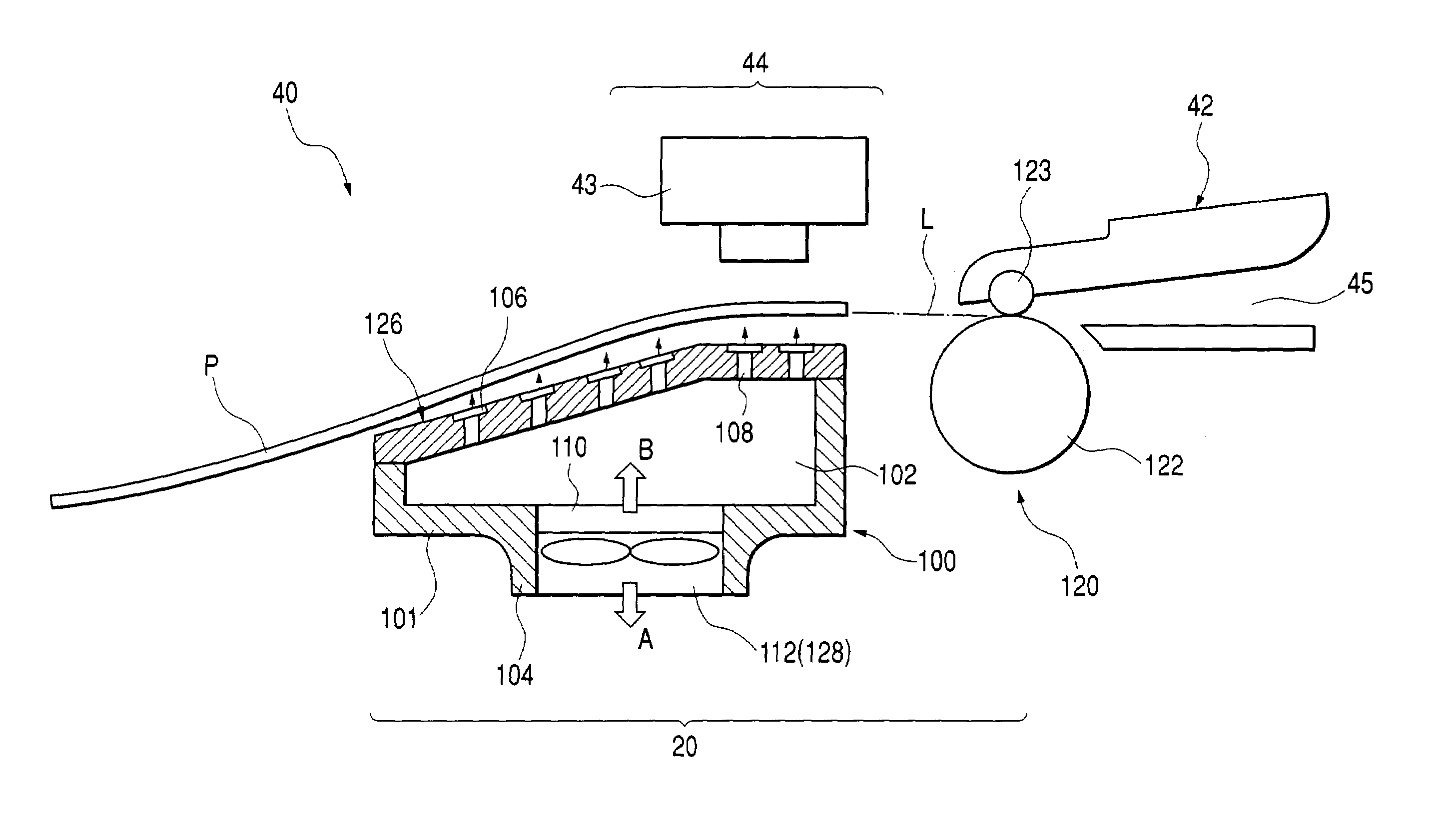

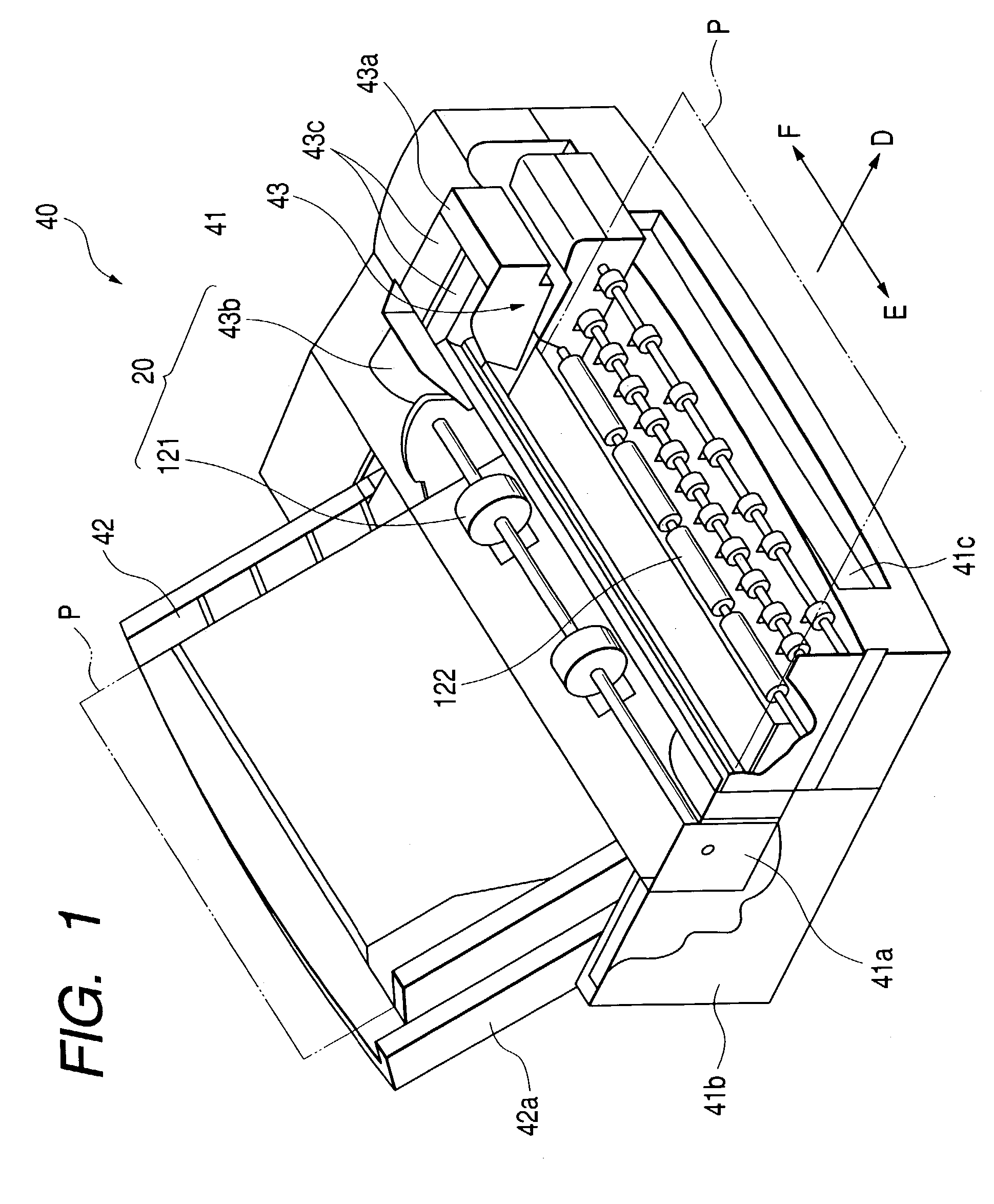

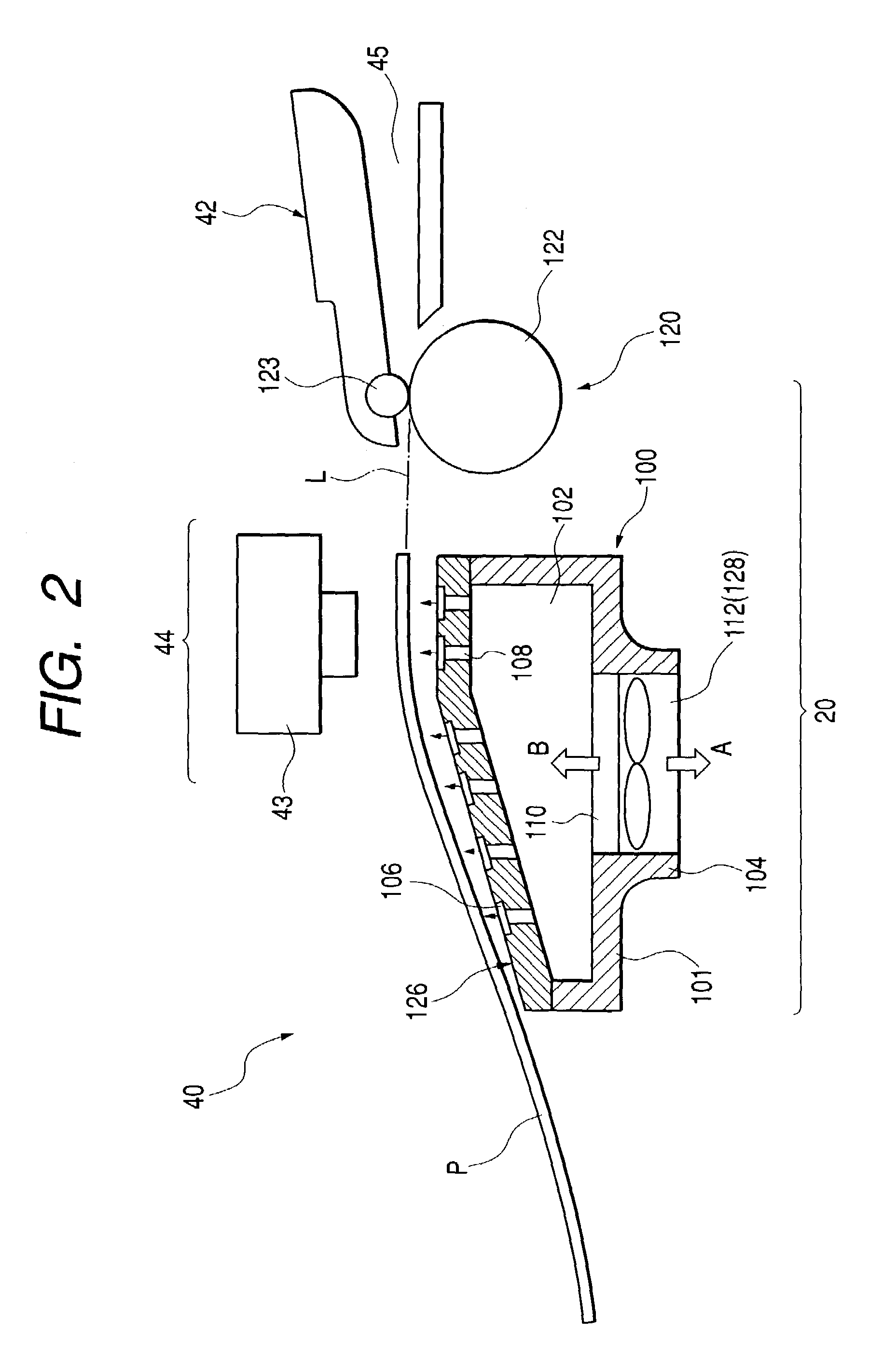

Solution casting method and apparatus

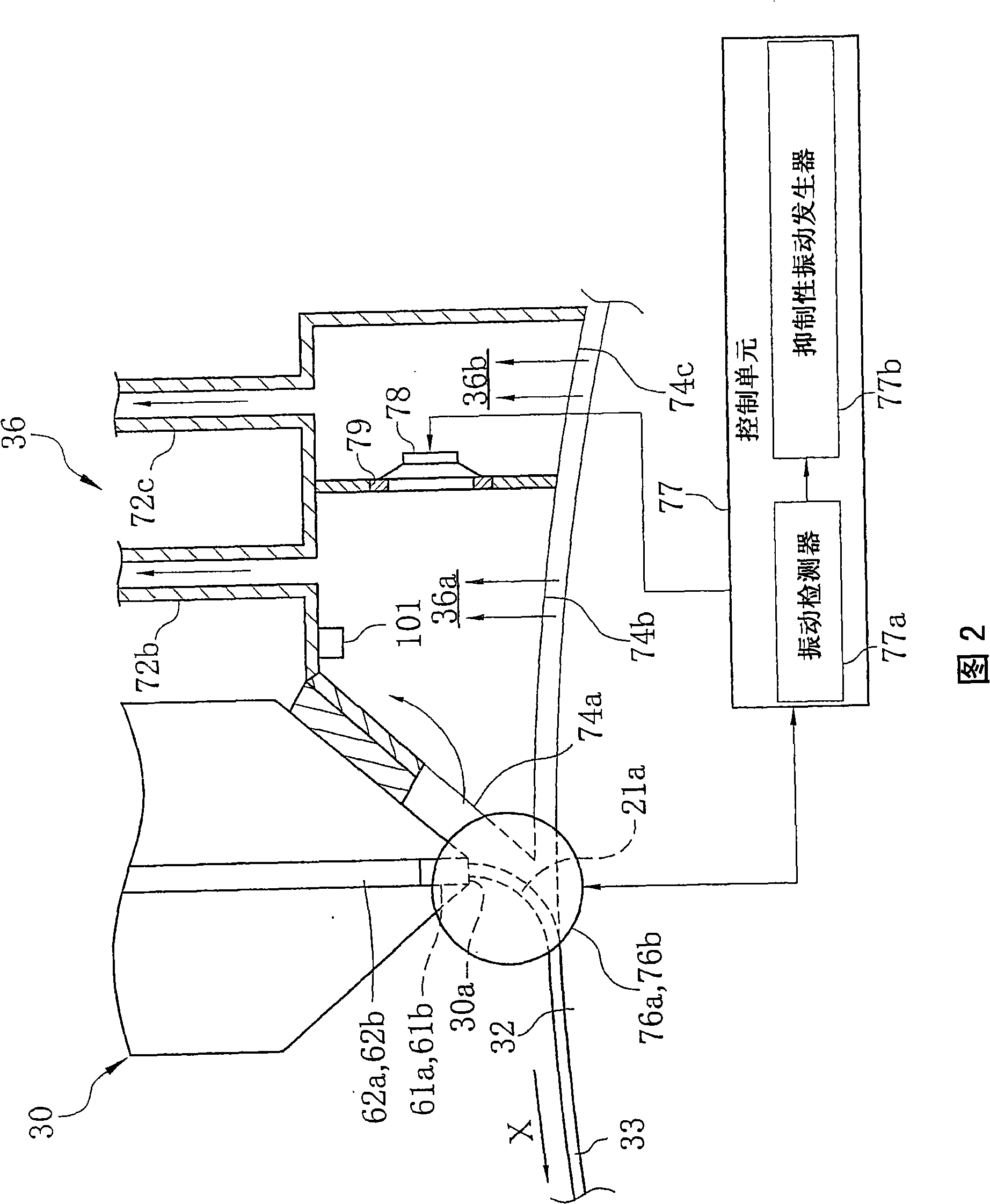

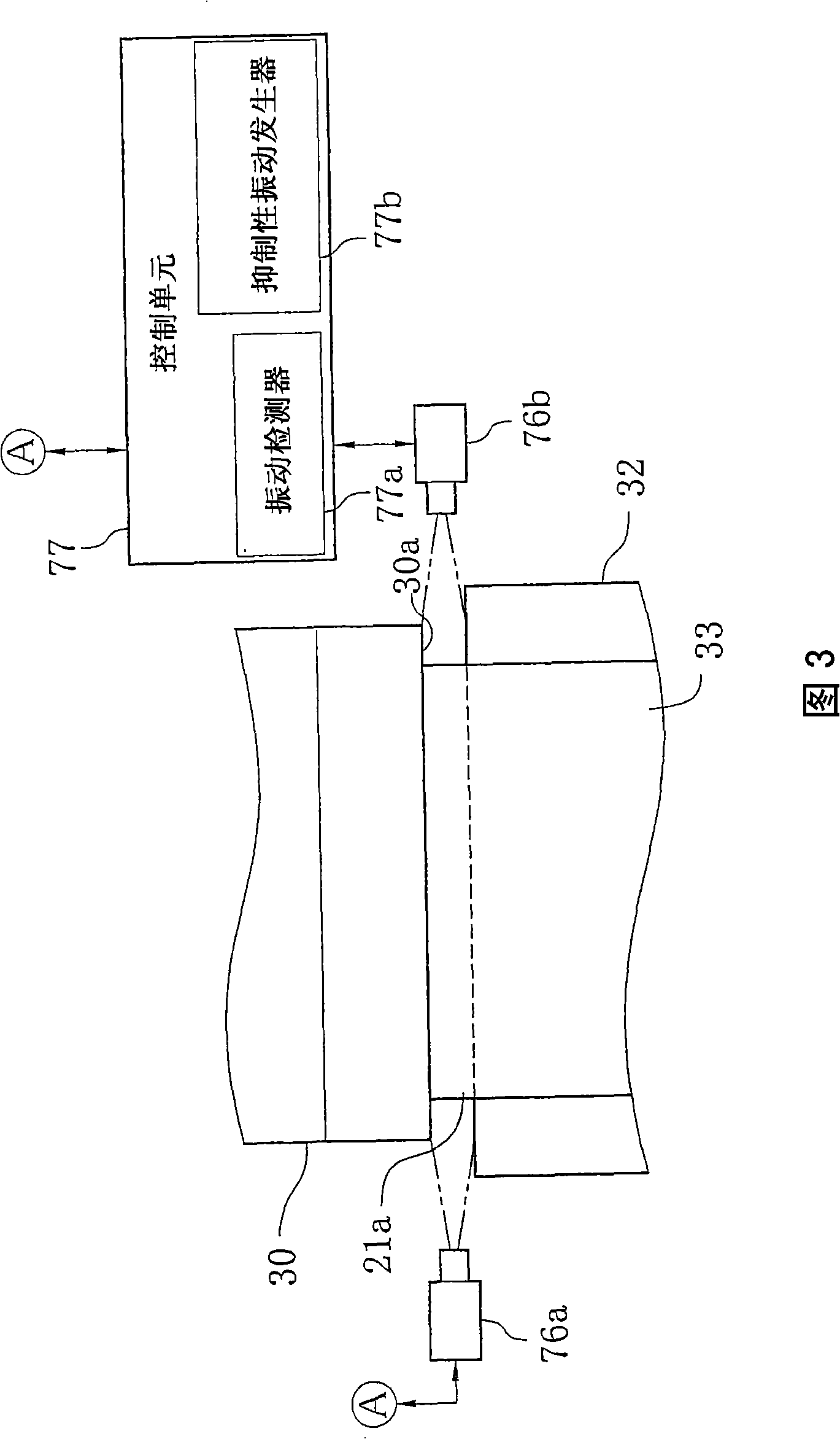

A camera for capturing a casting bead is provided at each side end of a discharge port in a width direction thereof. Plural speakers are provided at the vicinity of an opening of a decompression chamber. The camera continuously captures the casting bead, and outputs image data thereof to a control unit. The control unit includes a vibration detector and a suppressing vibration generator. The vibration detector detects vibration of the casting bead based on the plural image data. The suppressing vibration generator generates suppressing vibration signal representing the phase and amplitude of the suppressing vibration for suppressing the vibration generated in the thickness direction of the casting bead. The control unit controls the speakers based on the suppressing vibration signal to output sound wave. Thereby, the suppressing vibration is applied to the casting bead.

Owner:FUJIFILM CORP

Fixed material transportation apparatus, fixed material discharging apparatus, method for discharging the fixed material, and liquid fixing apparatus

InactiveUS7093931B2Smooth materialShort working hoursOther printing apparatusDecompression chamberWaste management

The present invention involves a sucking device having a fixed material transportation surface including plural sucking holes, a decompression chamber connecting to the plural sucking holes, and a sucking device sucking air in the decompression chamber. The fixed material is fed on the fixed material transportation surface of the sucking device by the delivering device, and is stuck on the fixed material transportation surface through the sucking holes by the sucking device. The fixed material is fixed by a fixing head at the state of being stuck and is transported gradually to a downstream side by the delivering device on the fixed material transportation surface. When fixing is finished, the fixed material separates from the surface of the fixed material transportation surface and rises slightly by blowing air from the sucking holes by a blowing device so as to move to a discharging direction.

Owner:SEIKO EPSON CORP

Cavity insert film flow cooling

A cavity insert for a mold stack is disclosed, the cavity insert being dimensioned to define a continuous annular cavity insert cooling chamber. The cavity insert also provides a first and second decompression chamber in fluid communication with each end of the cavity insert cooling chamber. Also disclosed is a chamber extension feature in fluid communication with the cavity insert cooling chamber to promote cooling in the downstream region of the cavity insert.

Owner:MOLD MASTERS 2007

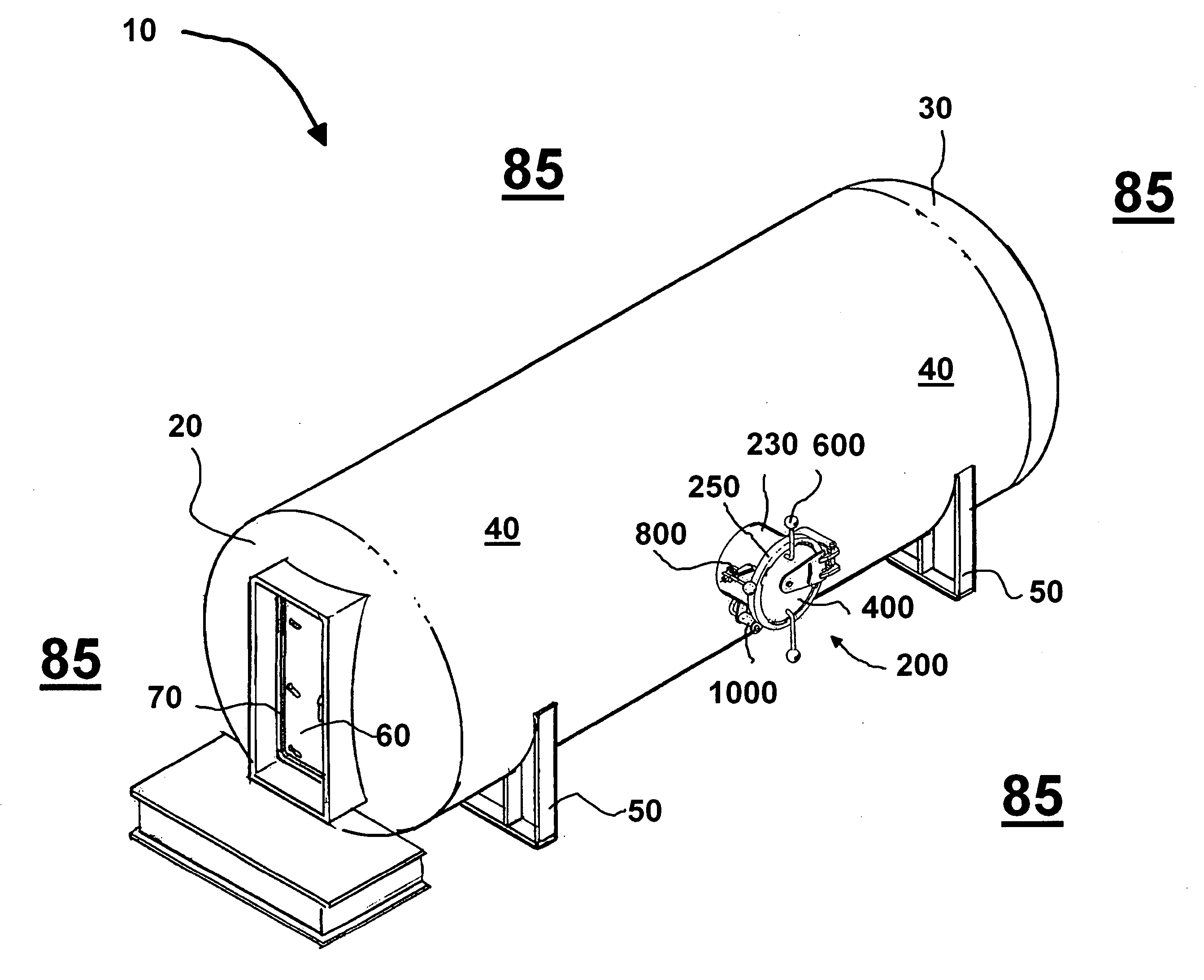

Interlock vessel for hyperbaric transfer system

InactiveUS20100037892A1Close safeTighter engagementBreathing protectionTreatment roomsInterlockDecompression chamber

An interlock vessel having an air-tight body with opposing ends. A portion of the body is designed to fit into a decompression (hyperbaric) chamber, wherein a diver or a patient undergoing a decompression treatment is positioned. The opposing ends are closed by pivotally moveable doors and locking assemblies that retain the doors in a closed position until the pressure inside the decompression chamber and the exterior of the chamber can be equalized. The outer door has two locking systems: (a) an interlock system and (b) a safety / delay locking system. Both locking assemblies are manually operated.

Owner:BARTLETT ROBERT D

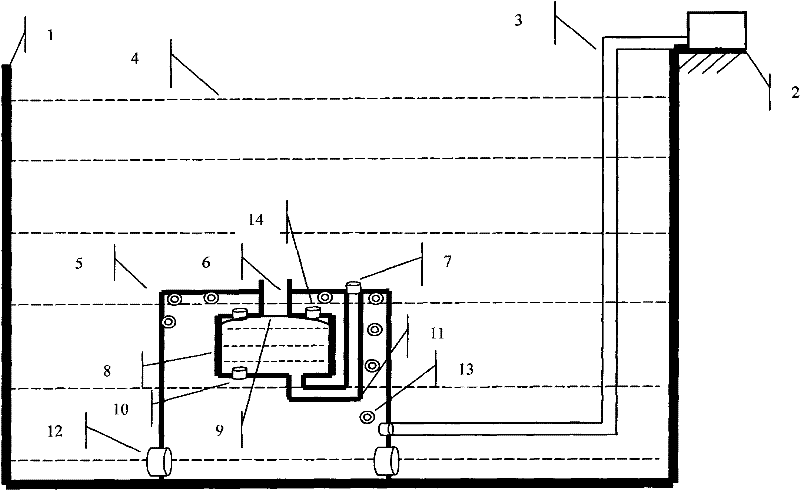

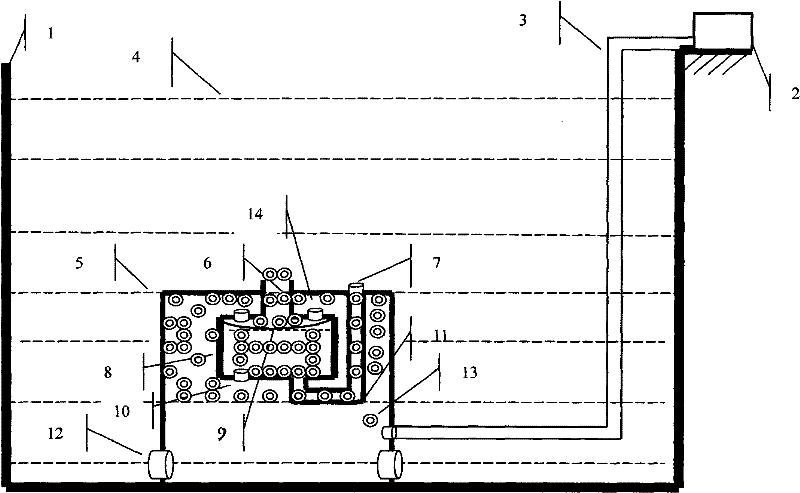

Air-blast water oxygenation device

InactiveCN102241442ASimple structureLow construction costWater aerationSustainable biological treatmentSludgeHazardous substance

The invention provides an air-blast water oxygenation device. The device is characterized in that an air collector is fixed on the bottom of a pool; then an air compressor is started to collecting air and air bubbles are accumulated continuously in the air compressor; when the accumulated air bubbles reach to a certain volume, a built-in decompression chamber can examine out this condition automatically and open automatically an air gate, and a large bubble rushes to the water surface and pushes a large area of water out the water surface; water rushed out falls back under the water surface to form an explosion-like shape and produce a strong pushing force to produce water waves radiating around the water bubble as the center; and because of the water waves, a negative pressure is formed in water thus fresh air enters into the water and gas in the water is exchanged with air thus a purpose of water oxygenation is realized. Because air bubbles rush upwards, the device does not stir sludge in a pool thereby releasing harmful substances in the sludge.

Owner:佘伟强

Casting device, solution casting apparatus, and casting method

InactiveUS20090218721A1Easy to adjust the widthEfficient productionFilament/thread formingFlat articlesMaterials scienceDecompression chamber

A casting drum is rotated around a shaft. A peripheral surface of the casting drum moves in an X direction. A dope is discharged through a casting die onto the peripheral surface such that a casting bead is formed so as to extend from a discharge port of the casting die to the peripheral surface. A decompression chamber decompresses an upstream side from the casting bead in a moving direction of the casting drum. The decompression chamber is provided with a sensor unit for detecting a width of the casting bead in a Y direction as width data. A control section shifts outer side seal plates in the Y direction based on the width data detected by the sensor unit such that the outer side seal plates are located in an upstream side from side ends of the casting bead in the X direction. Upon formation of a casting bead having a new width, the control section shifts the outer side seal plates in the Y direction based on the width data of the casting bead having the new width such that the outer side seal plates are located in the upstream side from the side ends of the casting bead having the new width in the X direction.

Owner:FUJIFILM CORP

Steam explosion straw material collection and energy utilization technology

InactiveCN103045656AIncrease temperatureReduce contentBiofuelsFermentationDecompression chamberWastewater

The invention belongs to the technical field of cellulosic ethanol production process steam explosion pretreatment, and discloses a steam explosion straw material collection and energy utilization technology, comprising the concrete steps of: (1) feeding the crushed straw into a blasting vessel by mechanical means; (2) feeding high pressure steam with a pressure of 1.2-4.0 MPa into the blasting vessel; (3) keeping pressure for the blasting vessel for 10-120 min; (4) opening the blasting vessel to eject the material to achieve separation of the material and the steam; (5) feeding the steam from the step (4) into a decompression chamber, and discharging organic molecule containing steam from the top of the decompression chamber and into the a condenser; (6) feeding a liquid formed by the steam of the step (5) through the condenser to the wastewater treatment process, and feeding the exhaust gas into an absorption tower for subsequent exhaust absorption. The technology enables steam explosion byproducts to be scientifically collected and used, makes fully use of exhaust heat, and is easy to promote and use.

Owner:河南天冠纤维乙醇有限公司

Method and system for extracting and disposing of water vapor contained in the air of a space vehicle

InactiveUS6910339B2Eliminate disadvantagesMinimizes amount of airCosmonautic environmental control arrangementLiquid degasificationWater vaporDecompression chamber

A system for extracting including a cooled condenser apparatus in contact with the volume of pressurized air being dehumidified, the condensed water being transferred into collection areas by means of capillary attraction; an evaporation chamber in thermal contact with the condenser apparatus having an inlet connected to the collection areas by means of a first valve device and an outlet connected by means of a second valve device to a space wherein the pressure is lower than that of the volume of pressurized air; and a control device for controlling the valve devices in order to carry out a control cycle with a first phase for placing the evaporation chamber under negative pressure in relation to the volume of pressurized air, and a second phase for suctioning the condensed water in the collection areas towards the decompression chamber, until the pressure in the decompression chamber reaches a predefined threshold.

Owner:EUROPEAN SPACE AGENCY

Weight clump manufacturing method

The invention discloses a method for manufacturing a non-casting balancing weight, which comprises: firstly welding a plurality of metal plates into a shell, reserving a feeding port on the shell, filling core materials such as waste metal, gravel and waste residues into the shell, putting the balancing weight filled with the core materials into a decompression chamber for drying, pumping wet air in the decompression chamber by an extraction pump and simultaneously blowing dry air into the decompression chamber in the drying process, and sealing the feeding port after drying of the balancing weight to manufacture the balancing weight; or firstly sealing the feeding port before executing the drying step, and in the process of executing the drying step, utilizing the shell of the balancing weight to replace the decompression chamber, configuring an extract opening and an air inlet port on the shell, respectively connecting the extract opening and the air inlet port to the extraction pump and a dry air source, pumping the wet air in the shell of the balancing weight by the extraction pump while filling the dry air into the shell, and using less energy consumption to achieve better drying effect.

Owner:青岛地恩地材料科技有限公司

Method and equipment for producing polymer-film

InactiveUS20050062194A1Good optical performanceSmall pressure changeConfectionerySweetmeatsLiquid-crystal displayOptical property

A dope is discharged from a casting die toward a belt to form a film-like material above the belt. Thereby a range near the film-like materials is decompressed by first and second decompression chambers. A pipe connecting each decompression chamber to a pressure controller has an inner diameter from 70 mm to 700 mm, and a length of the pipe is at most 30 m. Further the pipe is provided with a first expansion silencer of expansion silencer and a second expansion silencer of resonance silencer, and a sectional dimension ratio of the first expansion silencer to the pipe is from 5 to 500. Thus a pressure fluctuation in the second decompression chamber and the pipe is reduced and the film-like material becomes uniform. Thus the obtained film has no thickness unevenness, and used for producing a polarizing filter excellent in optical properties and a liquid crystal display.

Owner:FUJIFILM CORP

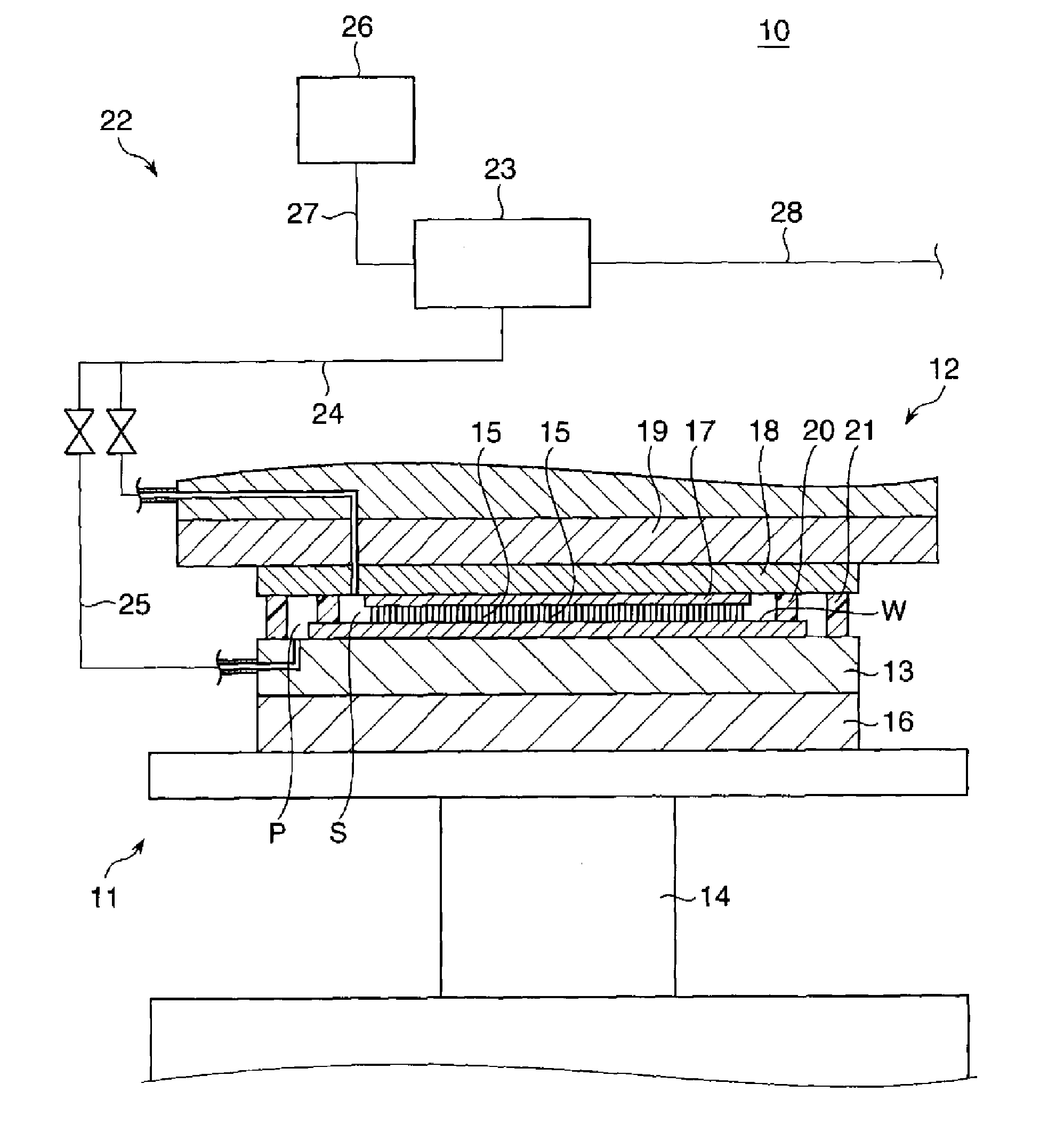

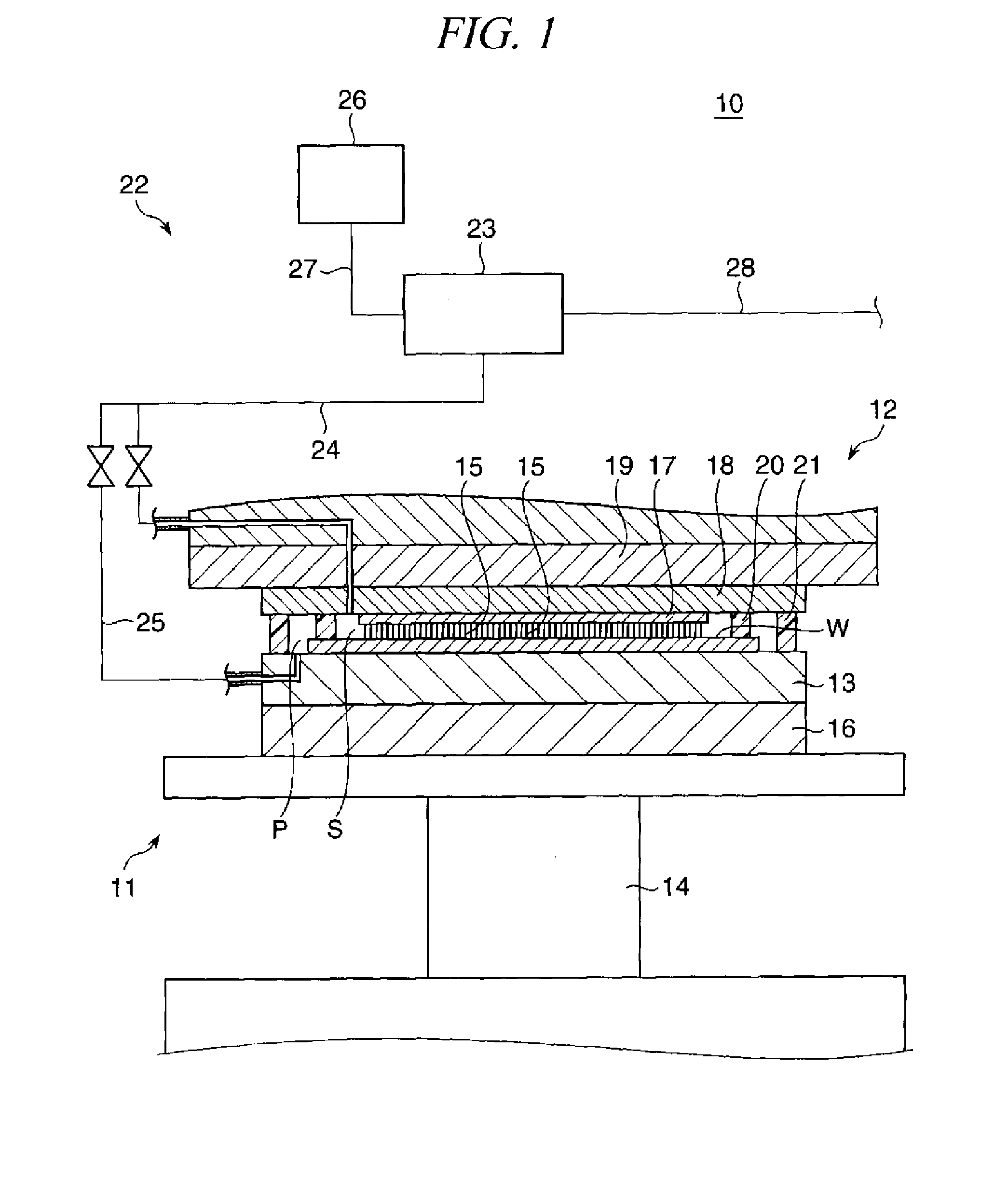

Substrate inspection apparatus

InactiveUS20150130489A1Strong contactSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardDecompression chamber

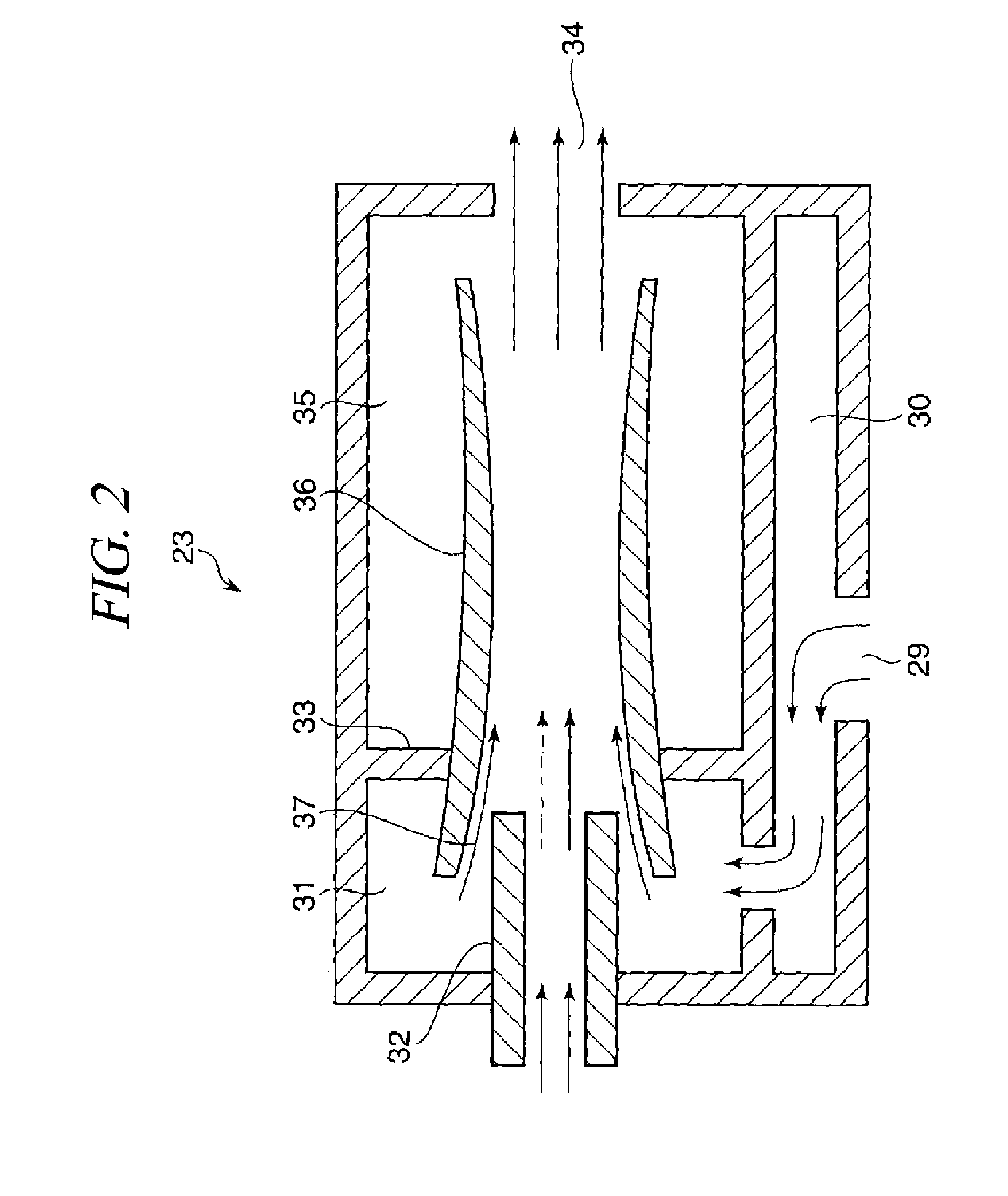

A probe apparatus 10 that maintains a contact state between each of probes 15 of a probe card 17 and each of corresponding electrodes of semiconductor devices formed on a wafer W by maintaining a decompressed state of a sealed space S between the wafer W and the probe card 17 includes an ejector 23 configured to decompress the sealed space S. Further, the ejector 23 includes a suction port 29; a decompression chamber 31 communicating with the suction port 29; an exhaust port 34 communicating with the decompression chamber 31; and a nozzle 32 through which air is discharged toward the decompression chamber 31 at a high velocity. Furthermore, the nozzle 32 is configured to directly confront the exhaust port 34, and the suction port 29 communicates with the sealed space S.

Owner:TOKYO ELECTRON LTD

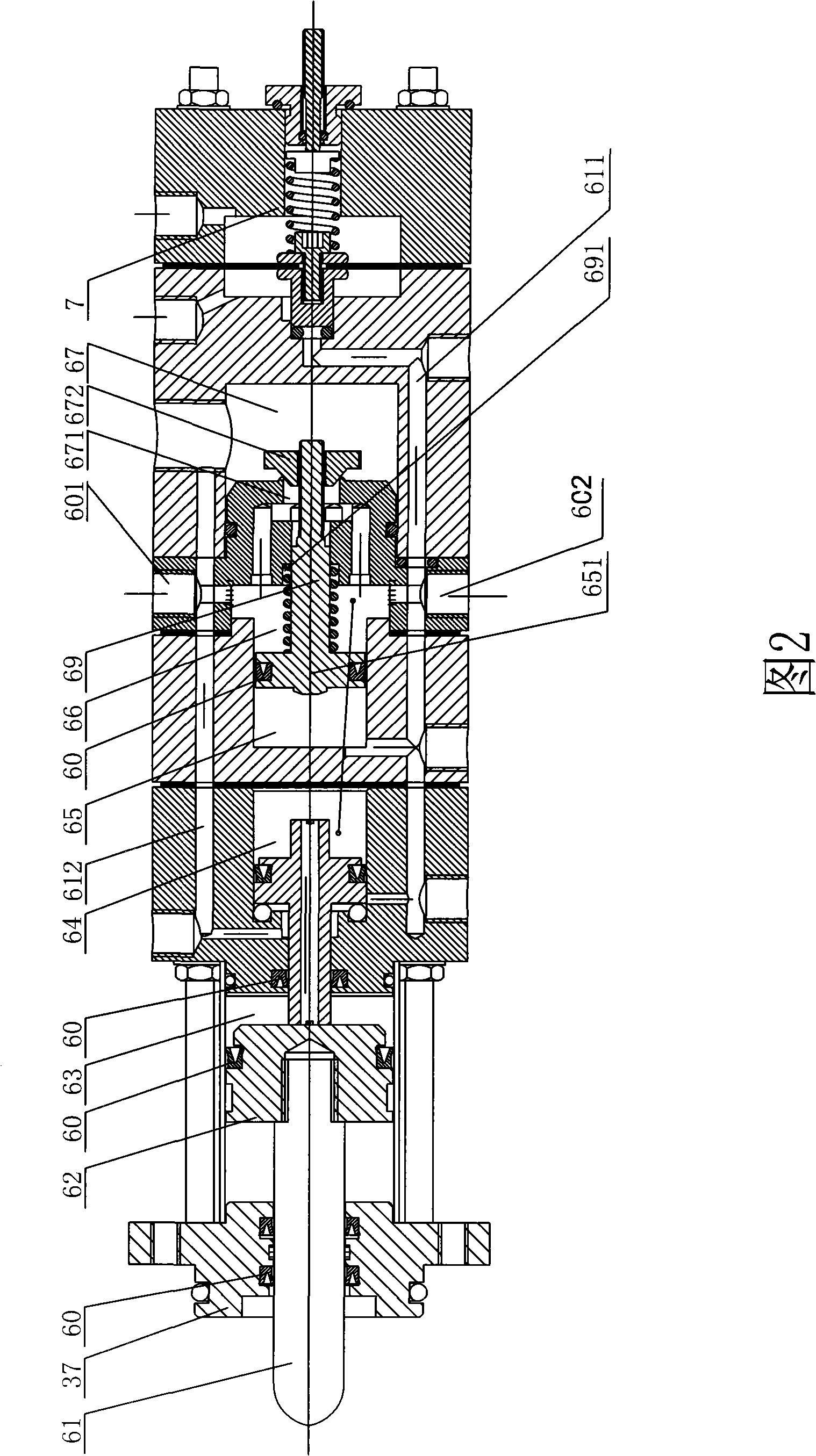

Cleaning driver of self-cleaning mechanical type filter

The invention discloses a cleaning driver for a self-cleaning mechanical filter, comprising a piston mandril and a piston which are always linked with a sewage absorber along the axial direction, and a backbone pressure chamber, a triggering chamber, a driving chamber and a decompression chamber which are arranged outside a piston chamber in parallel from the interior to the exterior, wherein, the triggering chamber and the driving chamber are sealed and separated by a movable rigid wall liquid, and when the rigid wall receives triggering signals in the triggering chamber, the rigid wall moves towards the driving chamber, thus causing the driving chamber to communicate with the decompression chamber for decompression and causing the piston to drive the sewage absorber to make the axial movement. As the rigid walls adopted by the cleaning driver can bear great pressure, the filter can work under extremely high water pressure of raw water.

Owner:黄庆

Aviation-simulated rapid decompression chamber

InactiveCN103241395AReduce or avoid damageReduce or avoid casualtiesCosmonautic condition simulationsExperimental researchElectricity

The invention belongs to the technical field of pressure chamber structures, and relates to a decompression chamber, in particular to an aviation-simulated rapid decompression chamber. The aviation-simulated rapid decompression chamber is characterized by comprising a main chamber, wherein the main chamber is connected with an auxiliary chamber by a quick-open chamber door, and is an environmental experiment chamber used for simulating and creating environments in different height and at different temperatures, and the auxiliary chamber is a rapid decompression chamber used for simulating and creating an environment in a cabin or a cockpit. The aviation-simulated rapid decompression chamber is provided with a one-chamber and two-room structure, so that the required pressure and temperature environments are achieved by adjusting pressure and temperature adjustment equipment in the chamber; when rapid decompression is required to be simulated, the quick-open door is controlled by controlling and operating an electric permanent magnet between the two chambers through an electric signal; a course of environment change when the cabin is damaged and a cockpit drops during a high-altitude flight of an airplane is simulated truly; and experimental researches such as various aeromedical researches, equipment experiment testing and the like are carried out during the course, so that the purposes of reducing or avoiding casualties and equipment damages are achieved.

Owner:烟台宏远氧业股份有限公司

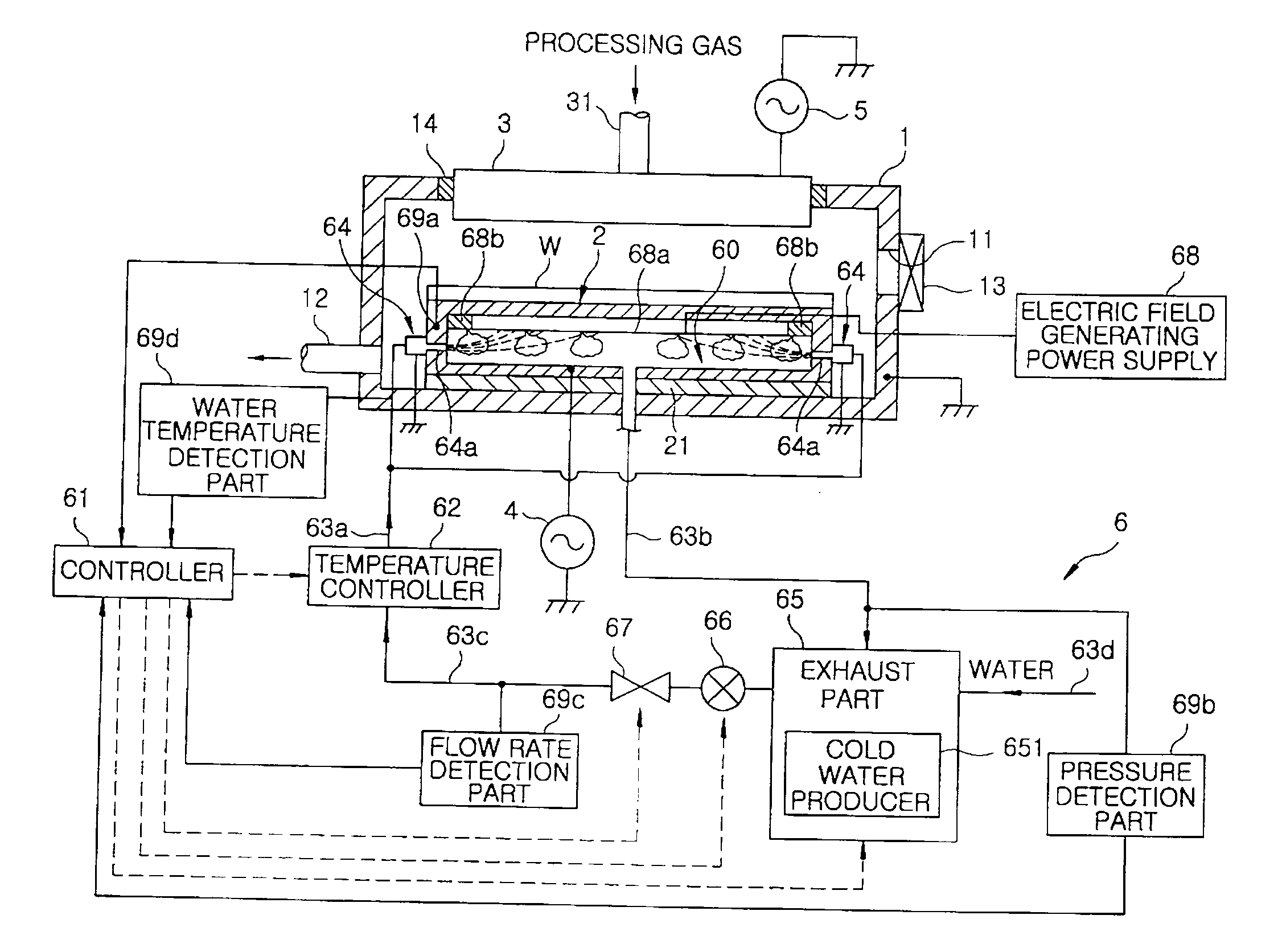

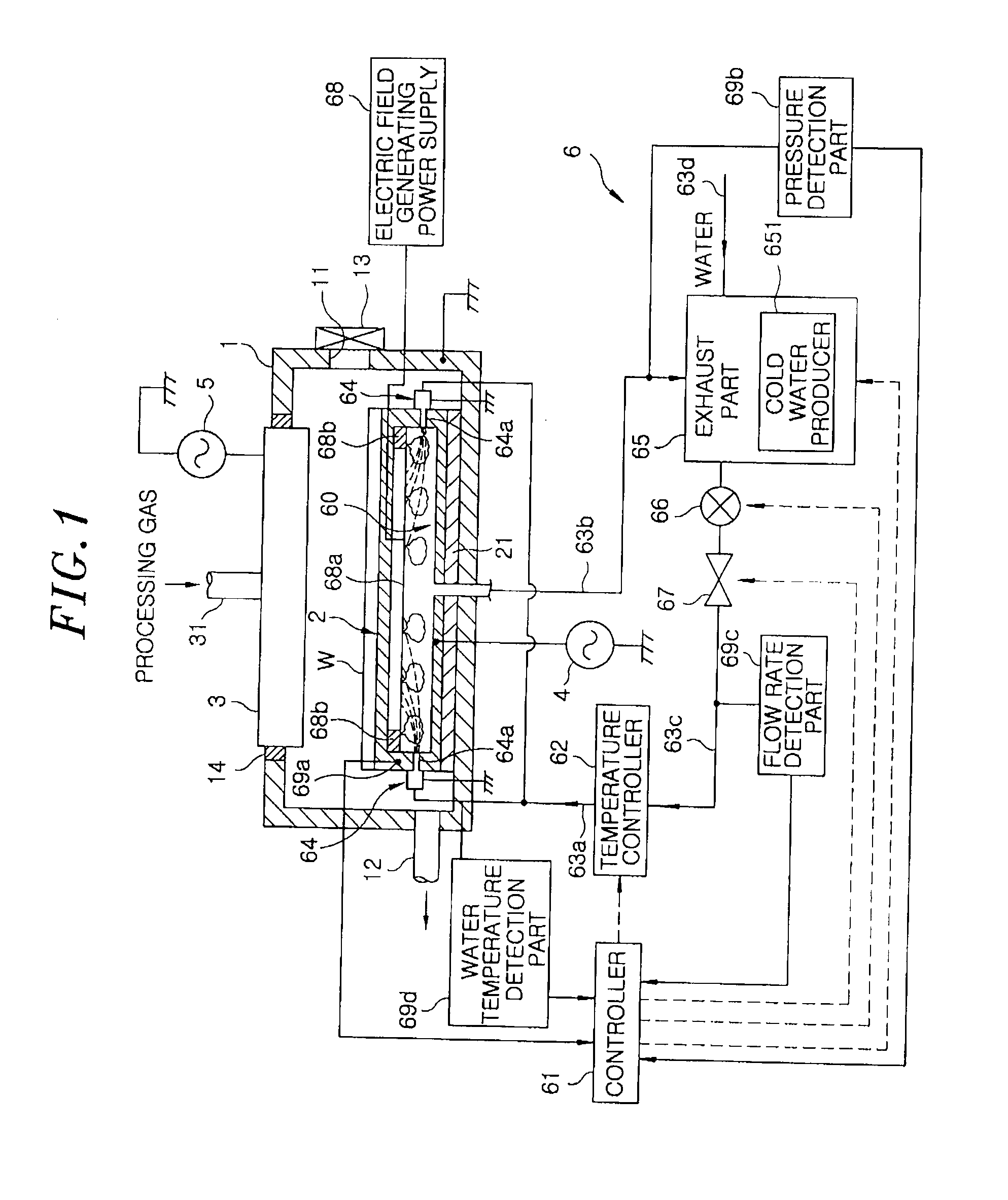

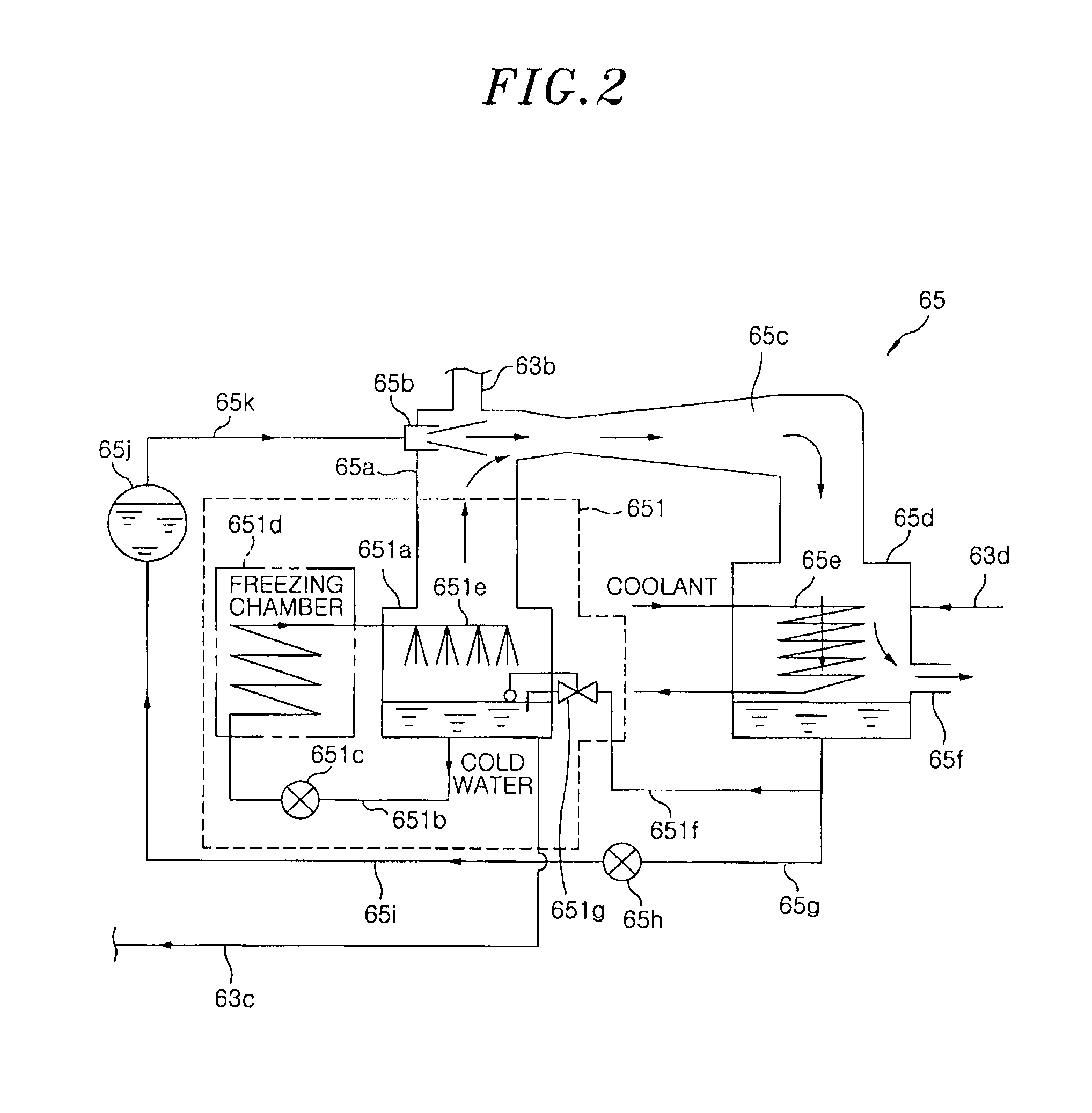

Cooling unit, processing chamber, part in the processing chamber, and cooling method

InactiveUS20120204576A1Reduce heatImprove efficiencySemiconductor/solid-state device manufacturingMachines using electric/magnetic effectsDecompression chamberEngineering

A cooling unit for cooling a target object to a target temperature includes a decompression chamber thermally connected to the target object; a spraying part which sprays a liquid heat medium having a temperature equal to or lower than the target temperature to an inner surface of the decompression chamber; and an electric field generator which generates an electric field such that the heat medium sprayed from the spraying part is attached to the inner surface of the decompression chamber. The cooling unit further includes an exhaust part which evacuates the decompression chamber such that a pressure in the decompression chamber is equal to or lower than a saturated vapor pressure of the heat medium at the target temperature.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com