Casting device, solution casting apparatus, and casting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Hereinafter, preferred embodiments of the present invention are described in detail. However, the present invention is not limited thereto.

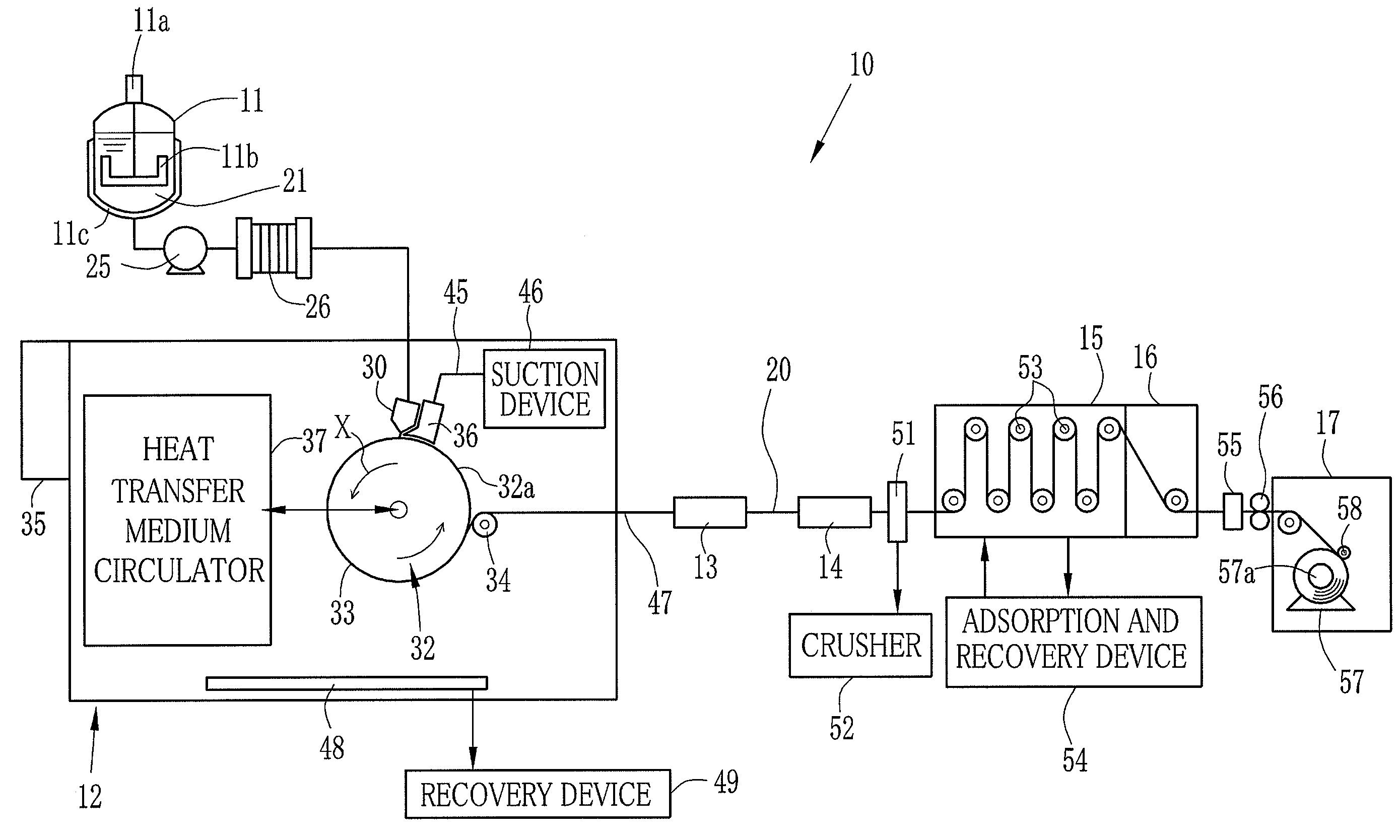

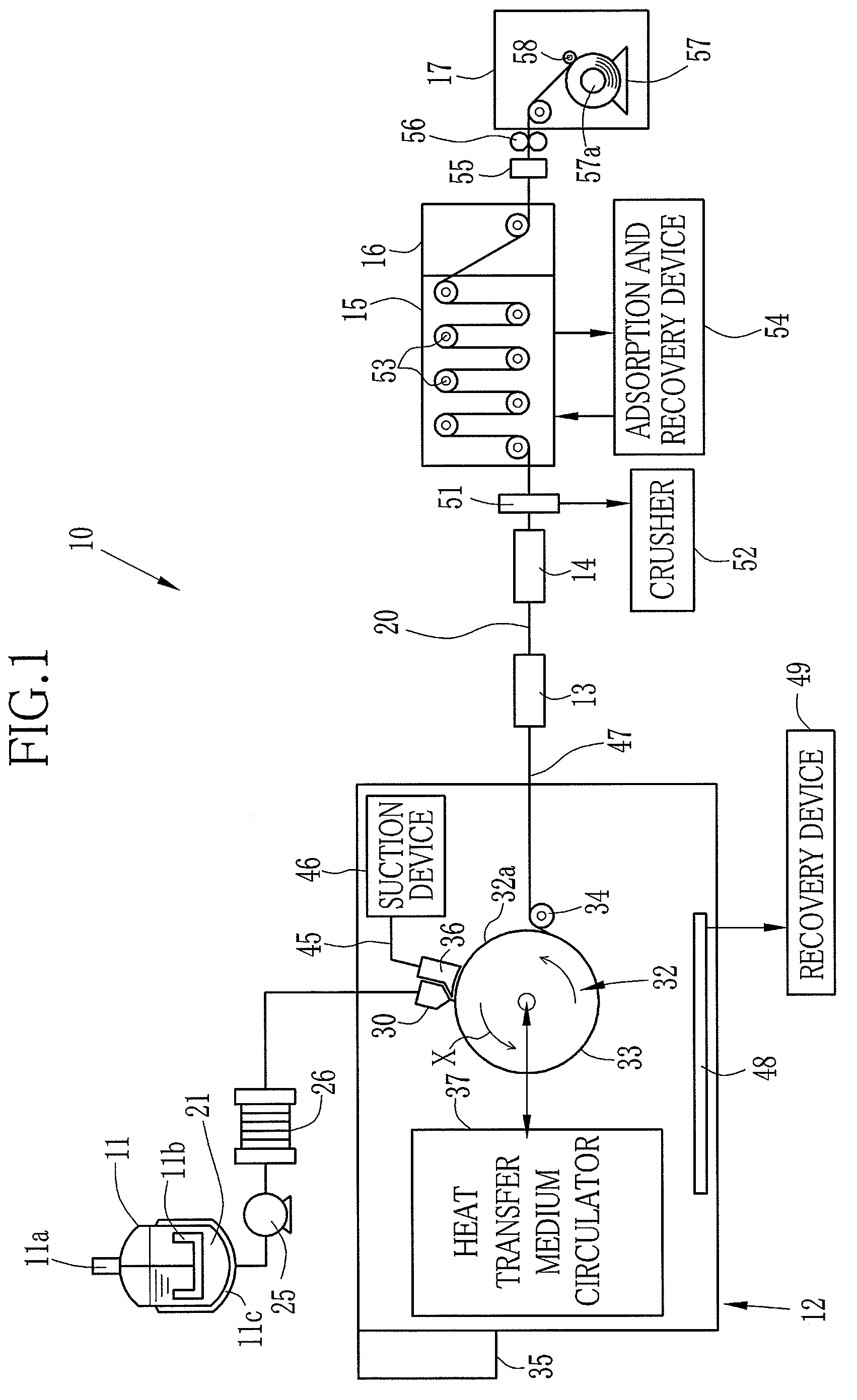

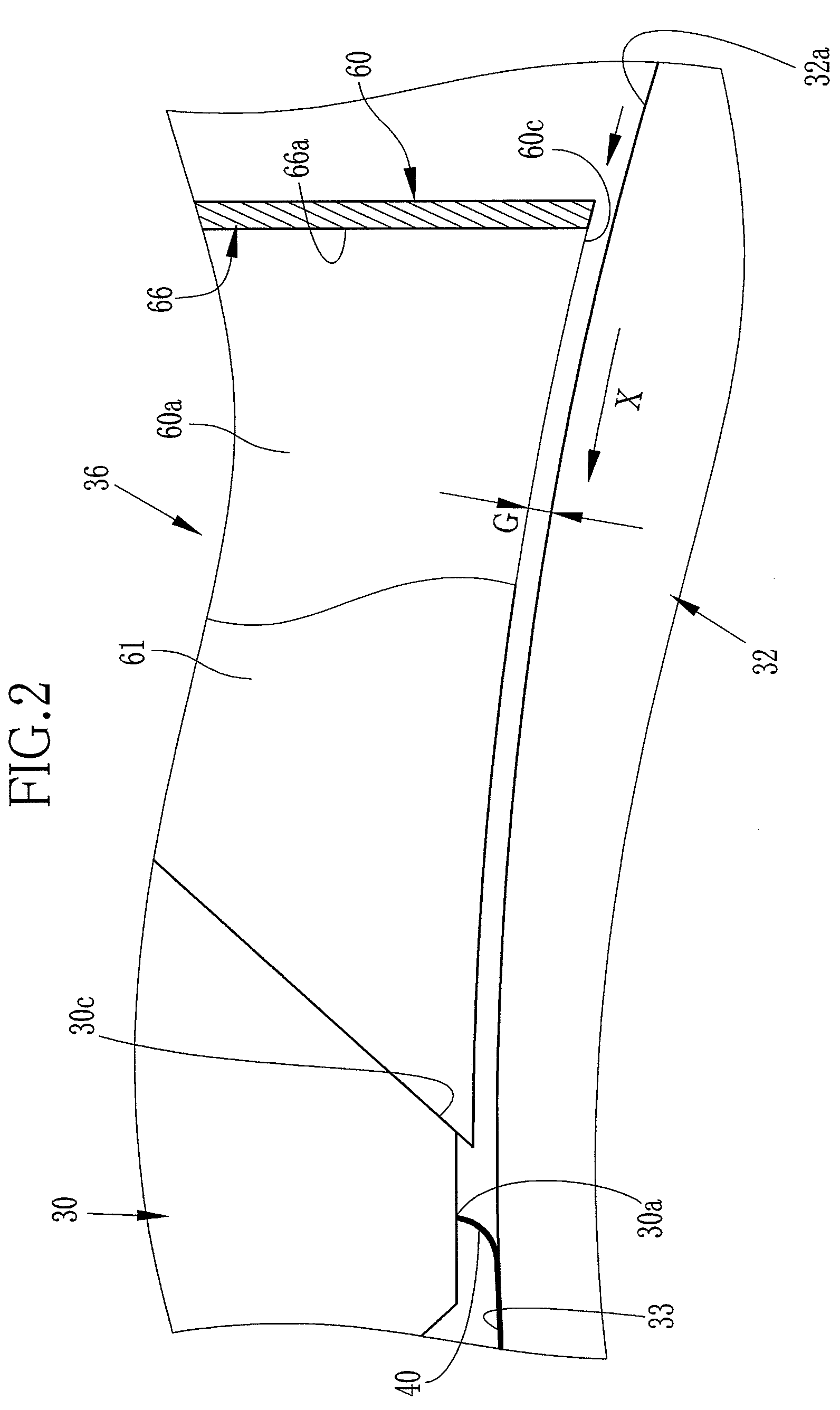

[0032]As shown in FIG. 1, a film production line 10 includes a stock tank 11, a casting chamber 12, a pin tenter 13, a clip tenter 14, a drying chamber 15, a cooling chamber 16, and a winding chamber 17.

[0033]The stock tank 11 is provided with a stirrer blade 11b rotated by a motor 11a and a jacket 11c. Inside the stock tank 11 is stored a dope 21 as a raw material for a film 20. A heat transfer medium flows inside the jacket 11c of the stock tank 11 such that a temperature of the dope 21 is adjusted to be within the range of 25° C. to 35° C. Since the stirrer blade 11b is rotated by the motor 11a in the stock tank 11, it is possible to keep the dope 21 in a constant state while preventing aggregation of a polymer and the like.

[0034]A pump 25 and a filtration device 26 are disposed in a downstream side from the stock tank 11. An adequate am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com