Cement-based material spraying and building device and spraying and building method

A cement-based material and spray construction technology, which is applied in water supply devices, spray devices, and devices for coating liquid on surfaces, etc. Improve uniformity, improve the effect of spraying, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

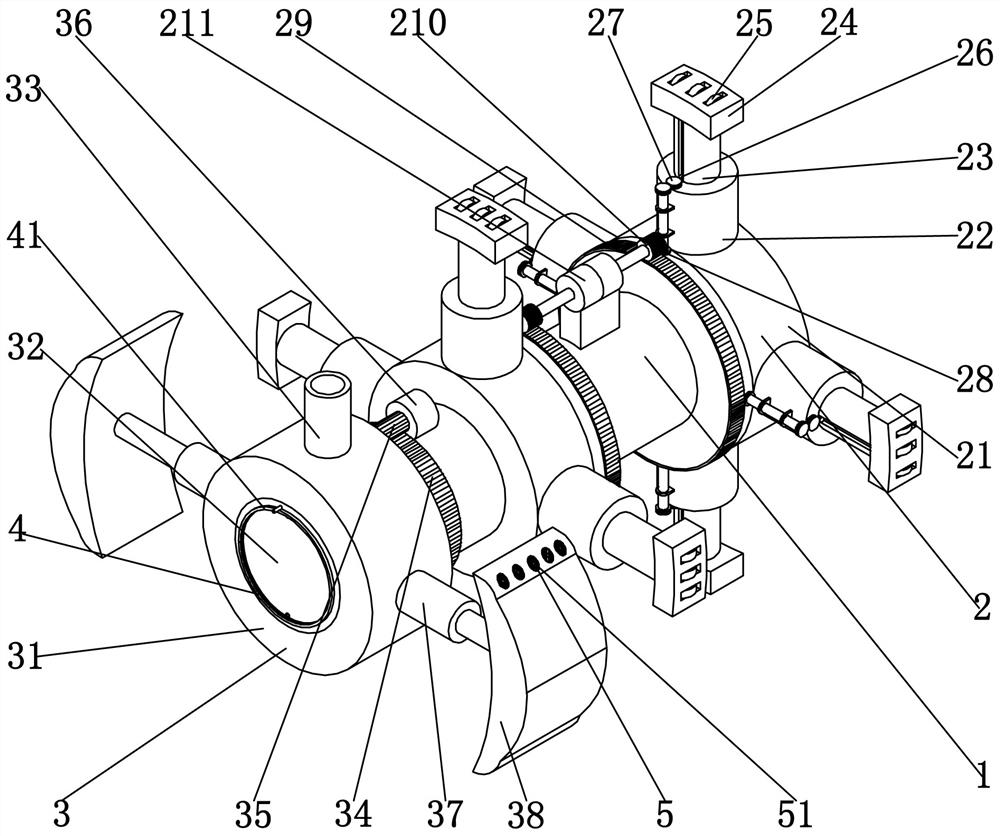

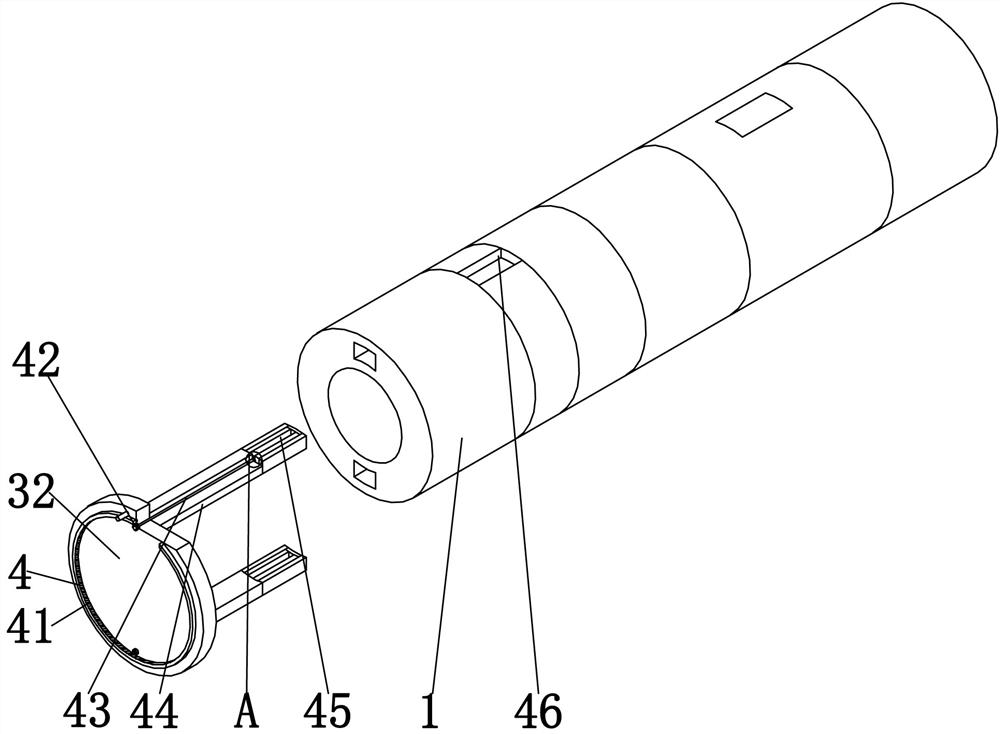

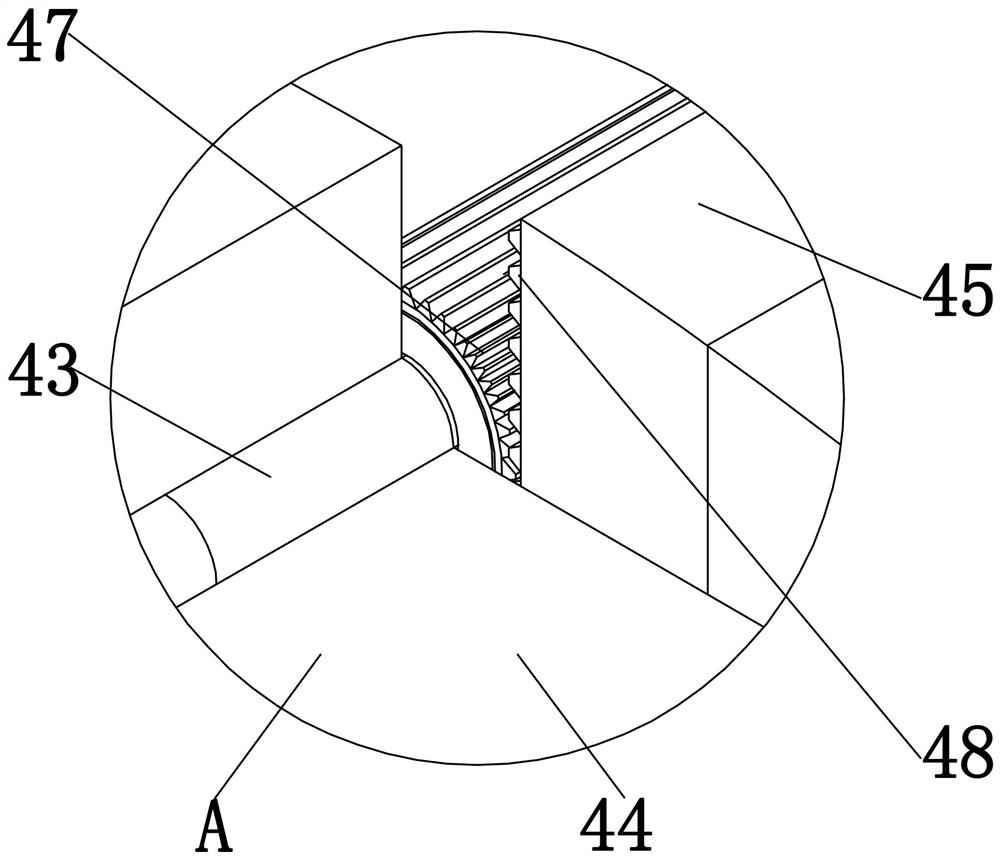

[0032] see Figure 1-5 , the present invention provides a technical solution: a cement-based material spraying device and a spraying method, including a main nozzle 1, one side outside the main nozzle 1 is provided with an adjustment support structure 2, and the other outside the main nozzle 1 One side is provided with a sprayed structure 3, the inner side of the sprayed structure 3 is provided with an installation structure 4, and one end of the sprayed structure 3 is provided with a drying mechanism 5;

[0033] Wherein, the spray construction structure 3 comprises a rotary spray head 31, the middle part of one end of the rotary spray head 31 is provided with a monitor mounting plate 32, the middle part of the upper and lower ends of the rotary spray head 31 is fixedly connected with a spray construction pipe 33, and the middle part of one side of the rotary spray head 31 is fixedly connected with a Driving gear ring 34, the middle part of driving gear ring 34 tops is meshed ...

Embodiment 2

[0044] The method for spraying with a cement-based material spraying device comprises the following steps:

[0045] Step 1: Install the device on the connected spraying pipe. According to the width of the inner wall of the pipe to be sprayed, the electric telescopic rod provided on the inside of the support rod first drives the telescopic rod to stretch and drives the support block to move outward. When the telescopic rod moves to the first When the three auxiliary gears mesh with the first auxiliary gear, the double-headed motor drives the adjusting gear ring meshed with the adjusting gear to rotate through the adjusting gear, thereby driving the I-shape gear lever meshing with one side of the adjusting gear ring to rotate , the second auxiliary gear is driven to rotate through the rotating I-shaped gear rod, the first auxiliary gear meshed with the second auxiliary gear is driven to rotate through the second auxiliary gear, and the third auxiliary gear meshed with the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com