Patents

Literature

294results about How to "Dry in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

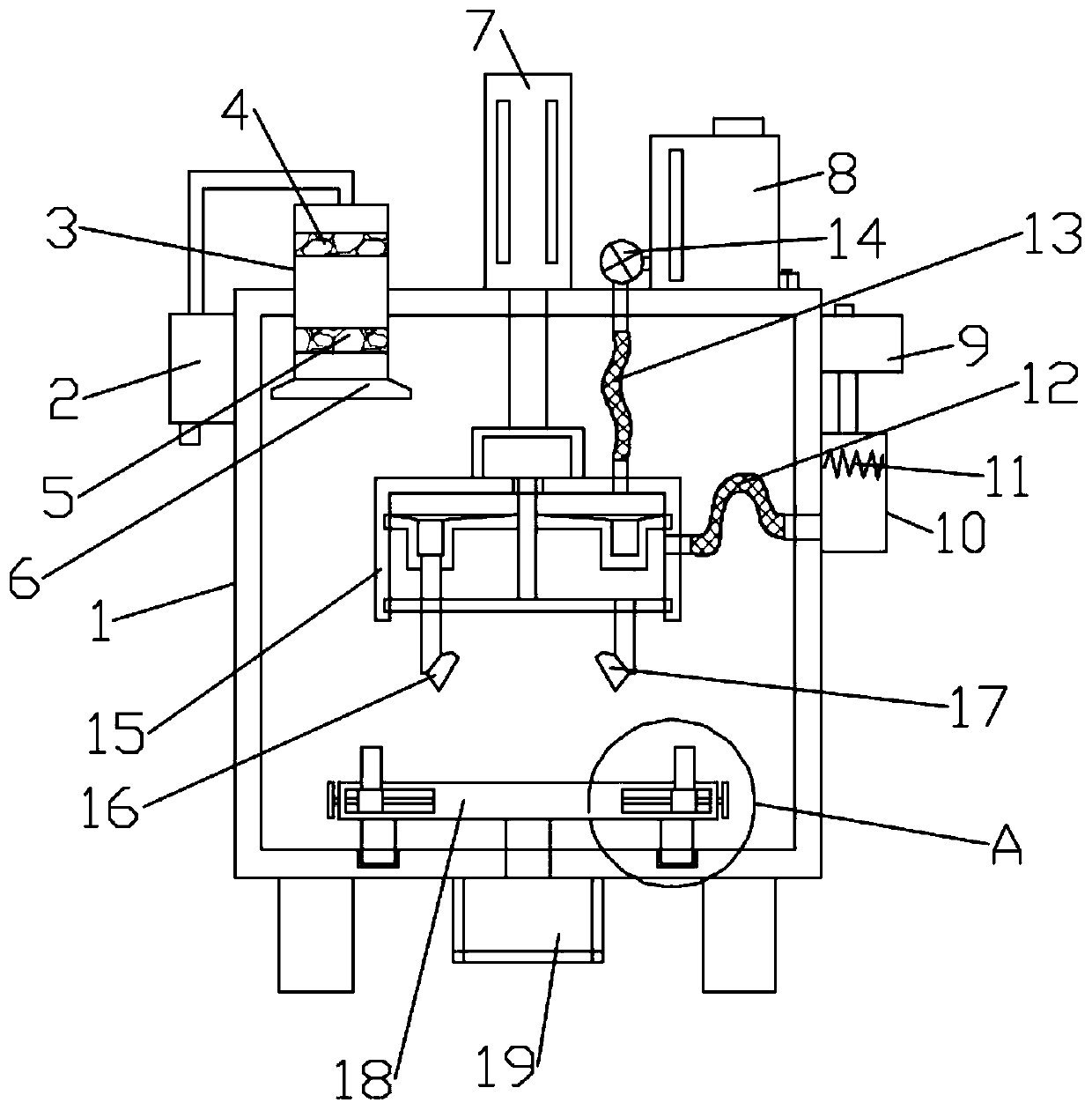

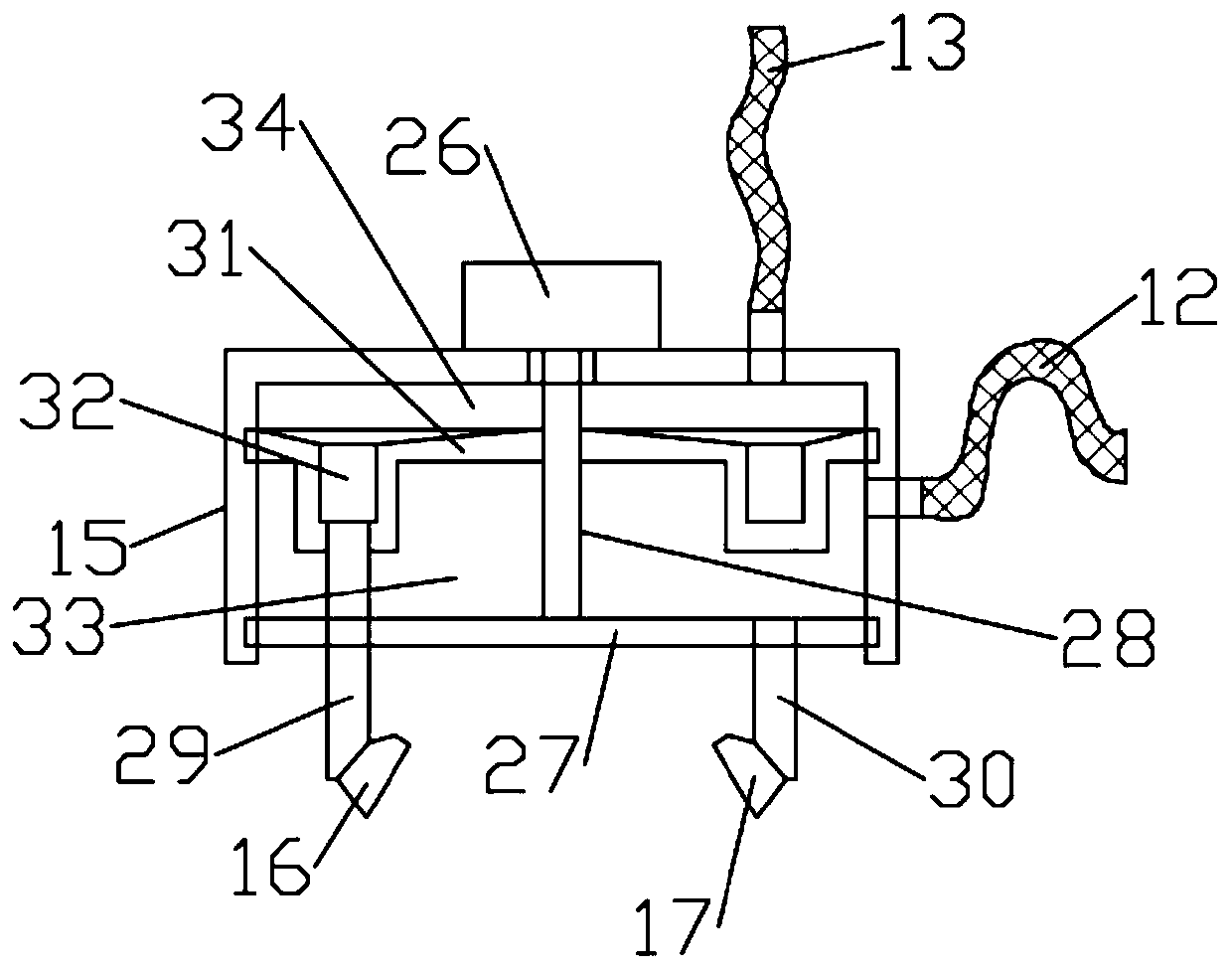

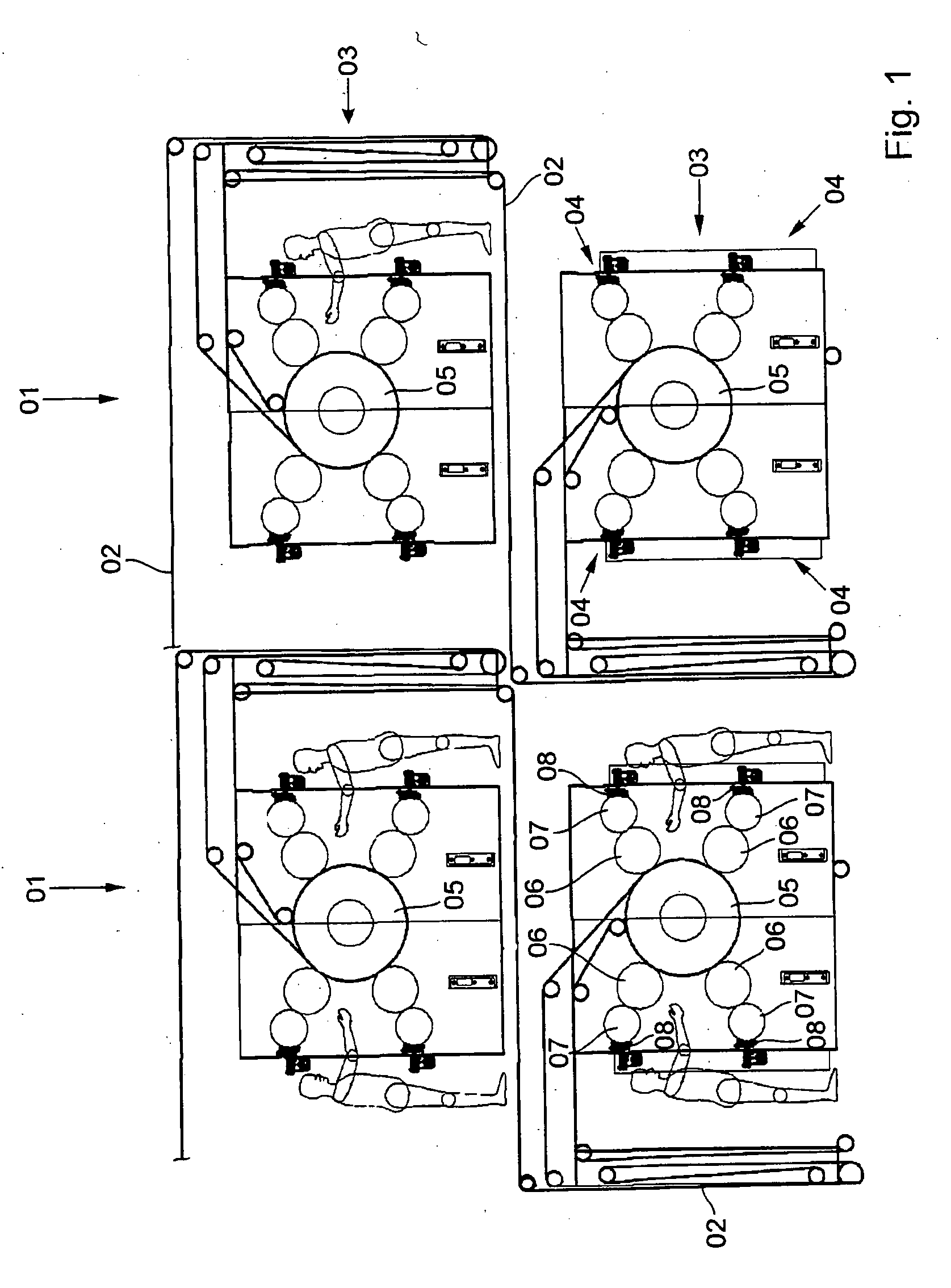

Production method for two-monolayer paper supporting to print and process into stickers

InactiveCN101054010ARealize printingSimultaneous printingLamination plant layoutStampsPulp and paper industryPlastic film

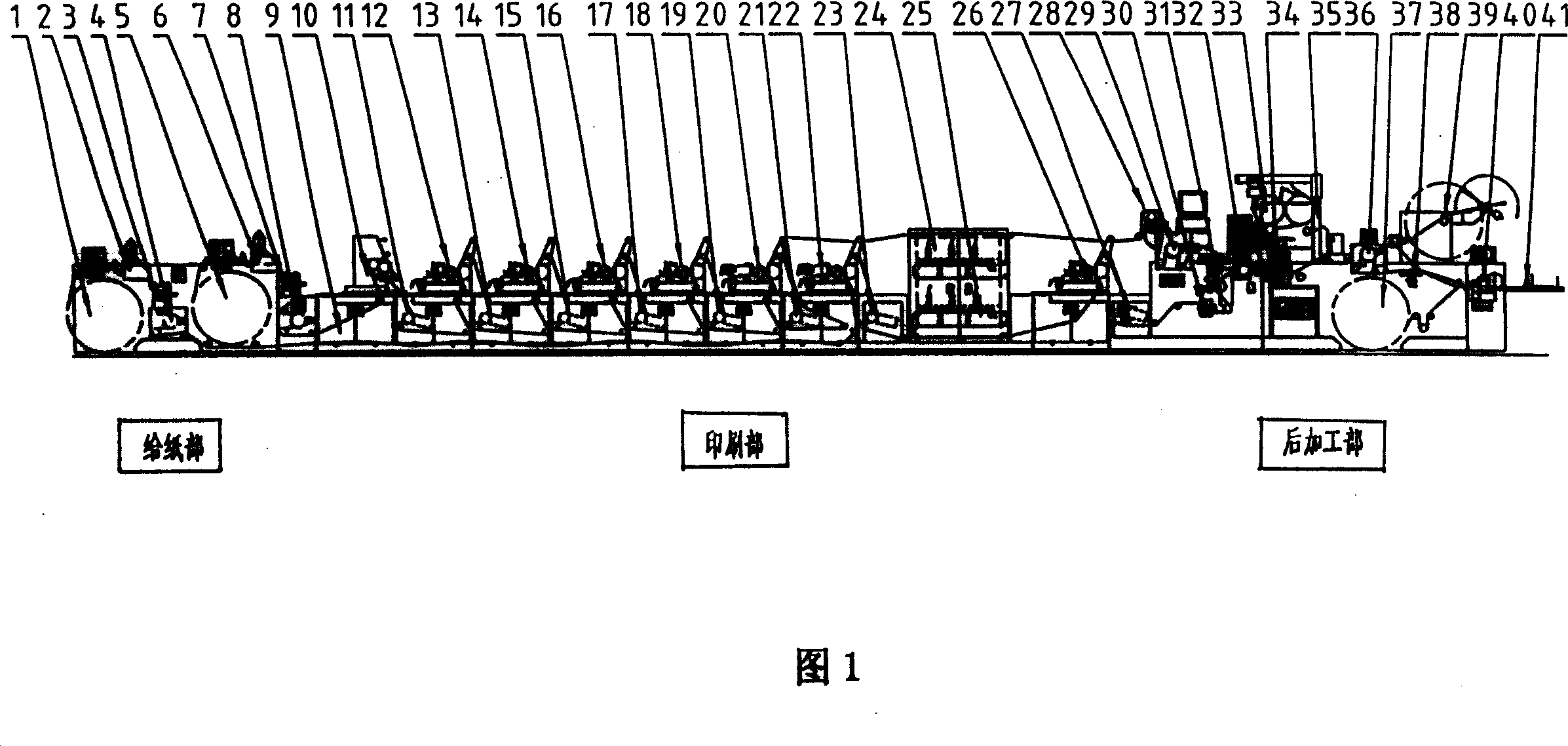

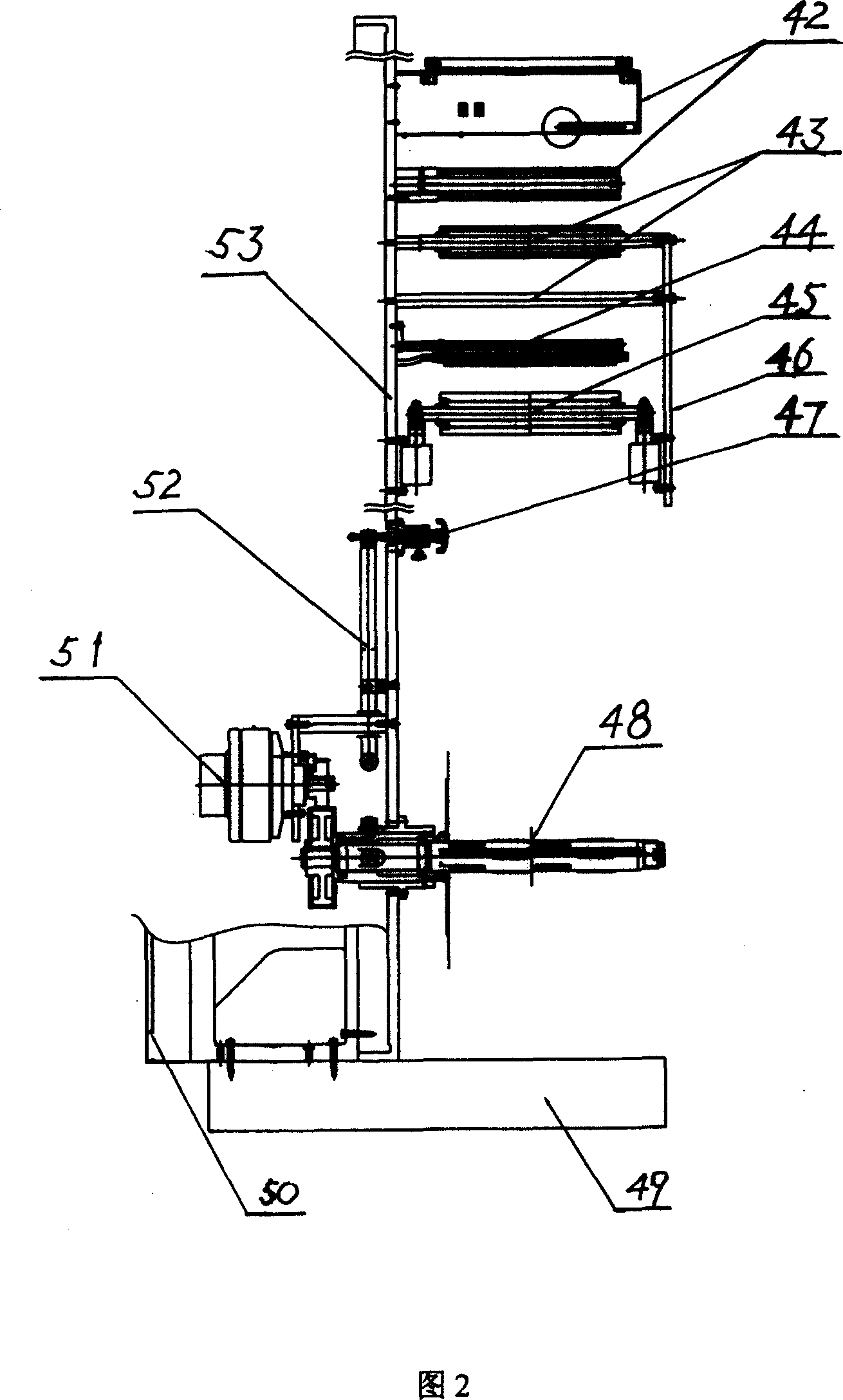

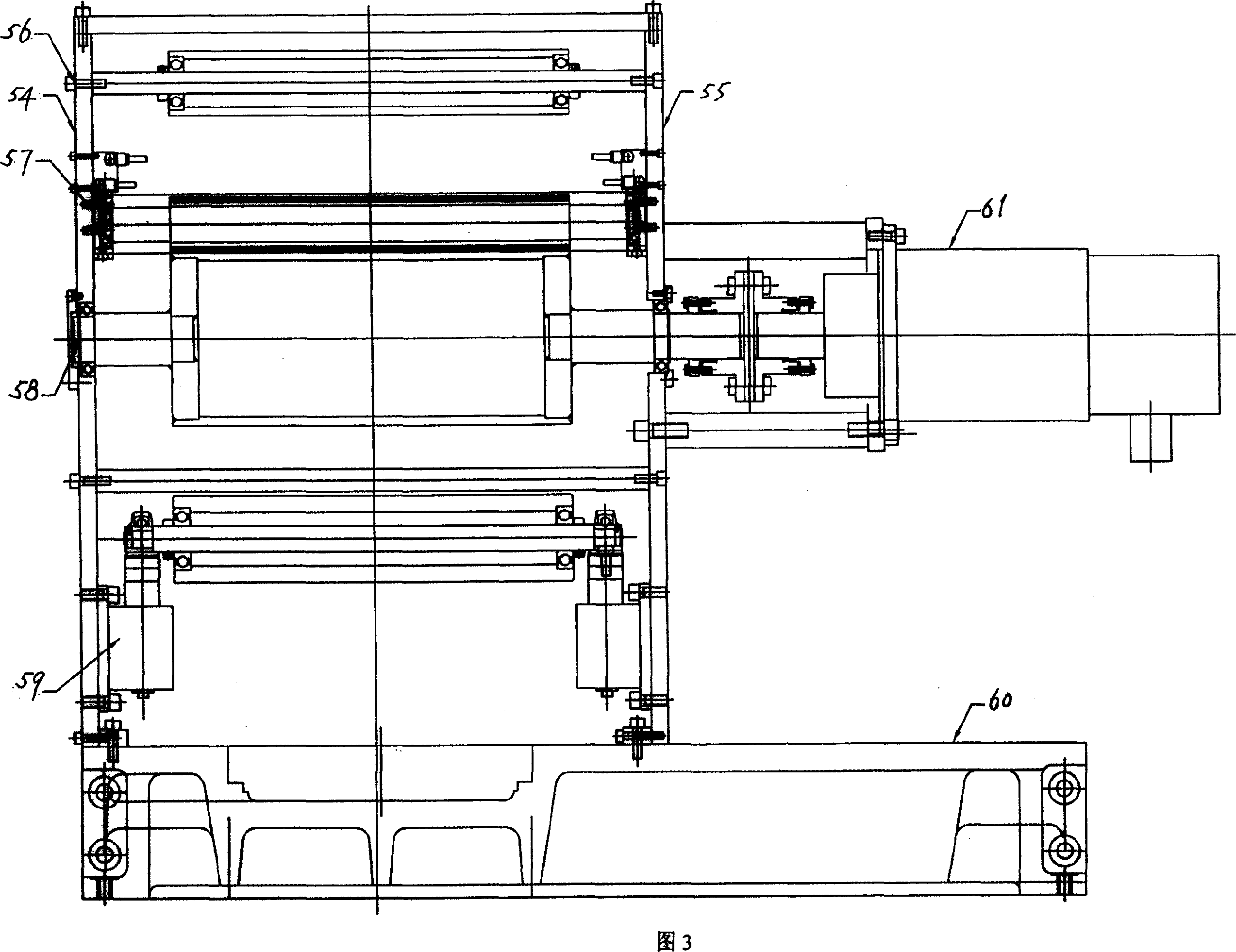

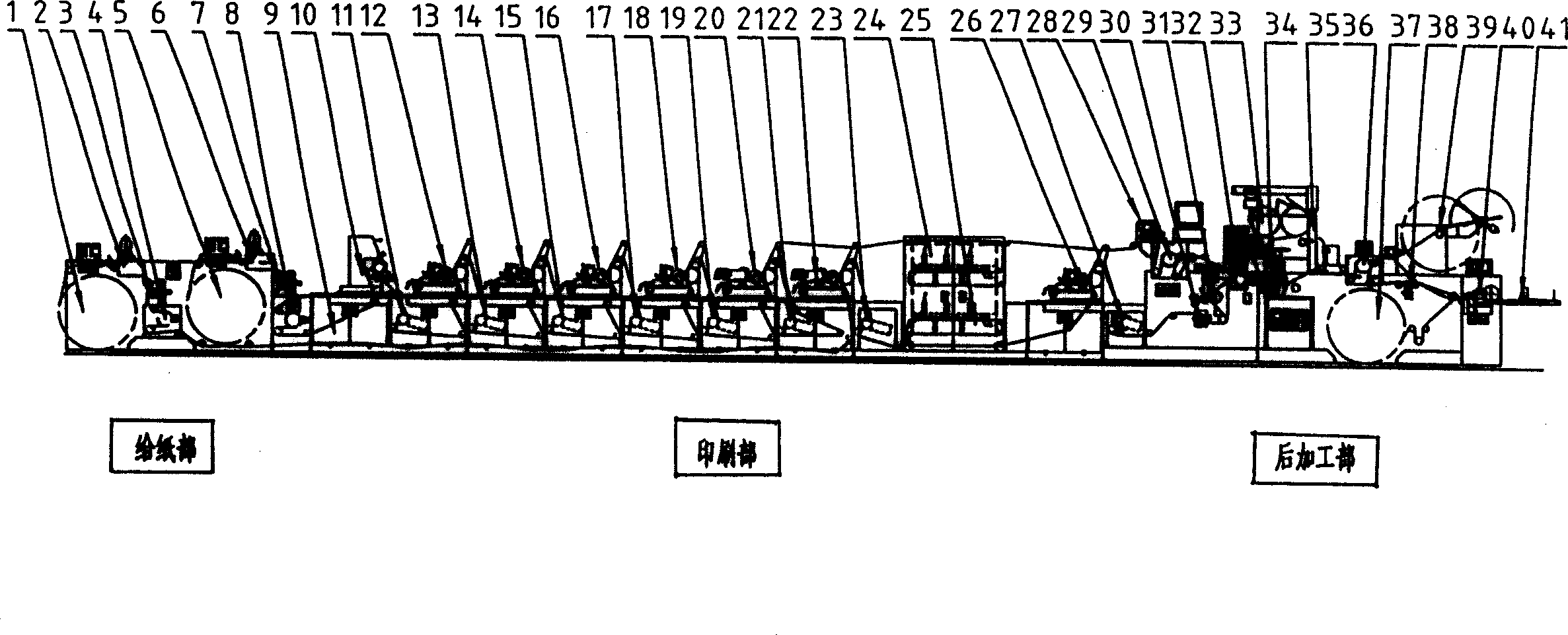

The invention relates to a method which feeds single layer paper or double layer paper to respectively print and then processes the paper into non-drying glue label. The method is characterized in that: the label is made of single layer or double layer web and film and is printed, gelatinized, hinged, post-processed on same non-drying glue rotary printing. The method includes following steps: the single layer or double layer web and film are respectively arranged on two paper feeding portions of the non-drying glue rotary printing; printing color class is selected, and the single layer or double layer web and film respectively penetrate corresponding printing station and following stations such as gelatinization, joint, mould cutting and so on; the surfaces of the single layer or double layer web and film is printed simultaneously; the single layer or double layer web and film, whose surface has been coated by hot melting glue, arranged on the lower paper feeding portion joints with the back side of the film arranged on the upper paper feeding portion; and a transparent plastic film is coated on the surface of the joint non-drying glue paper, and the mould cutting device cuts the part needing to be cut and reserves base paper.

Owner:SHANGHAI XINMIN TAIYO KIKAI

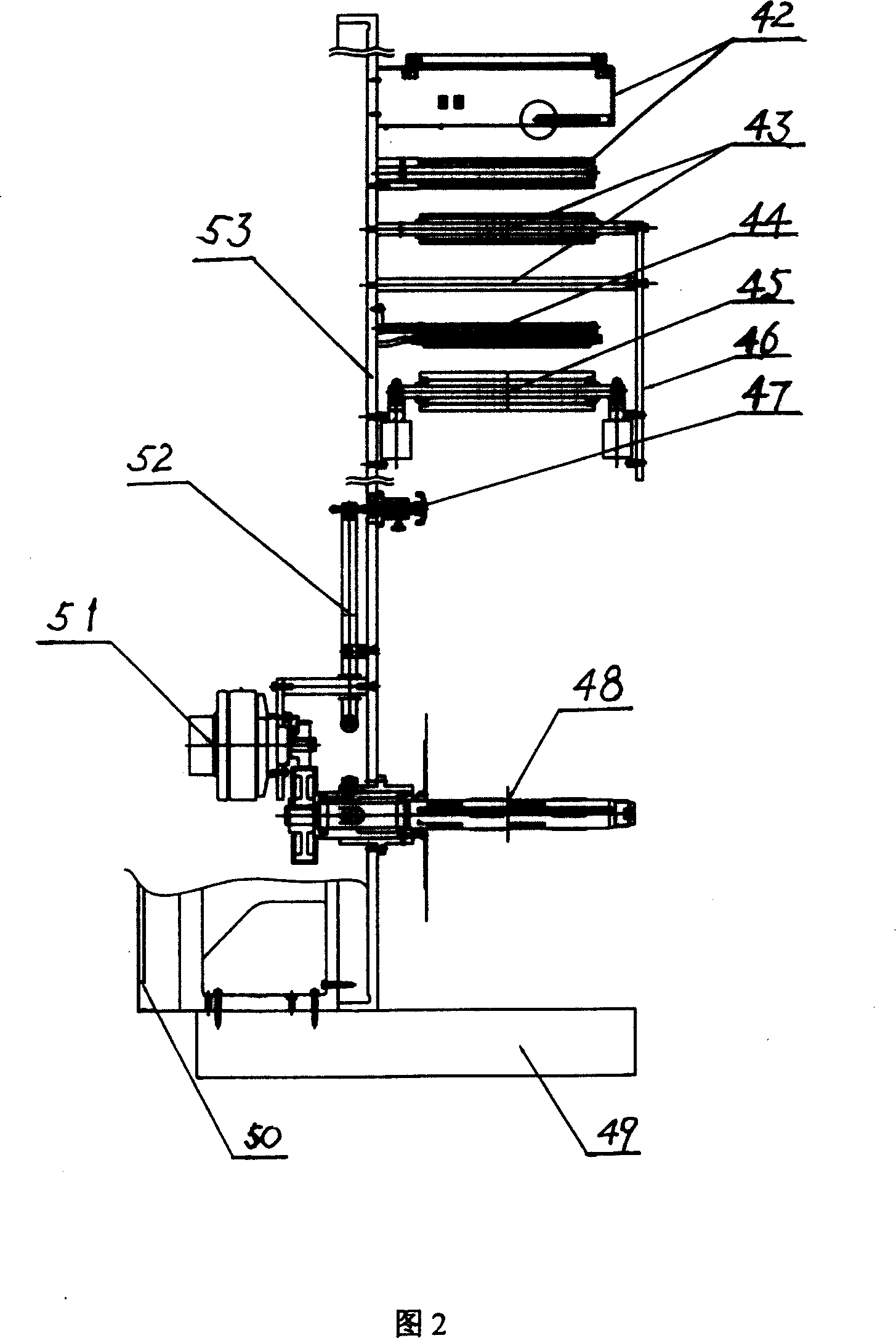

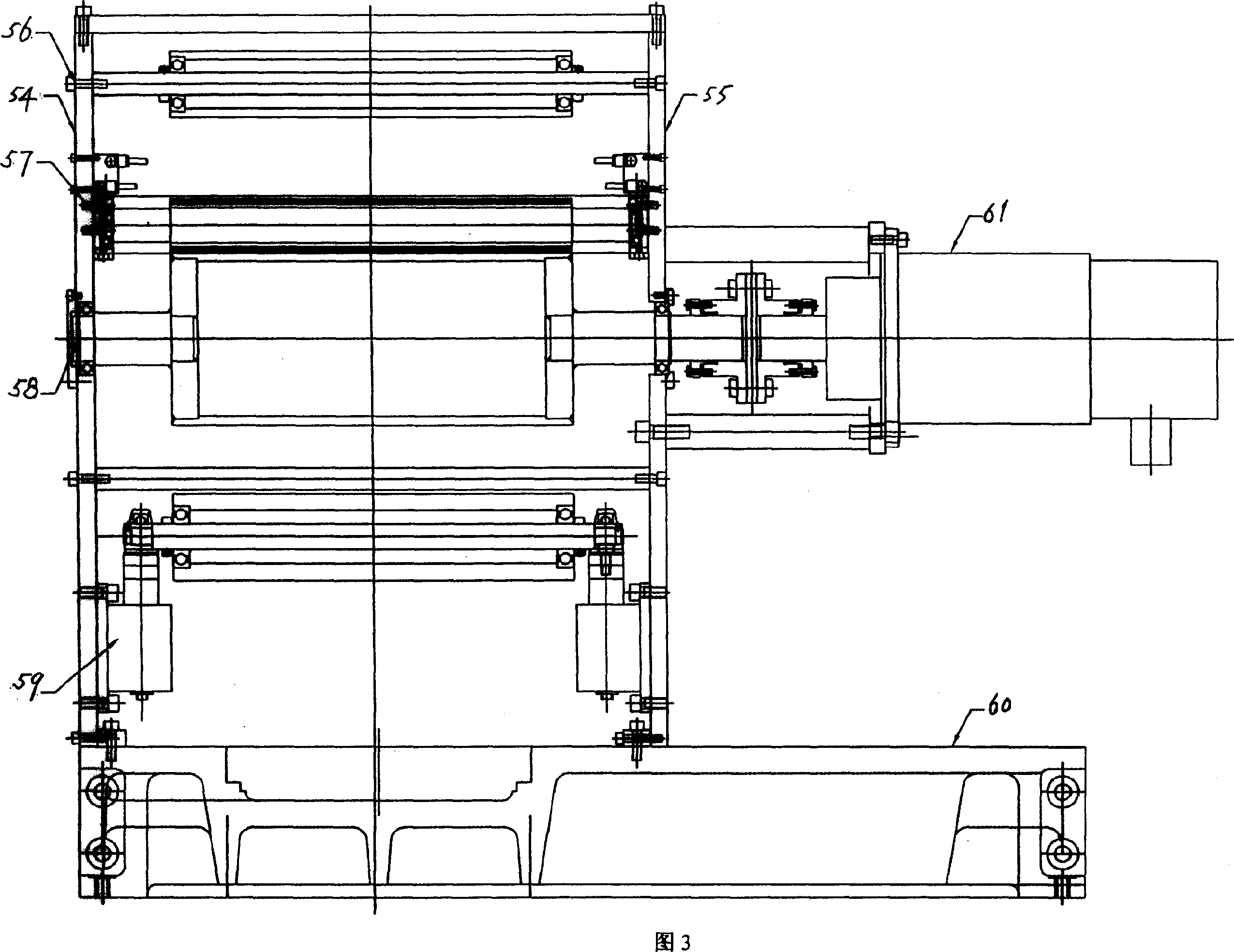

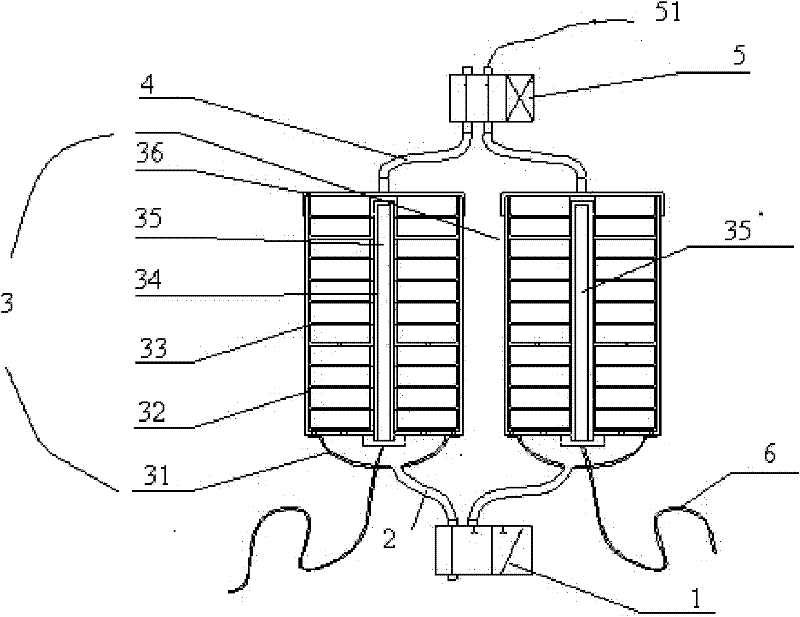

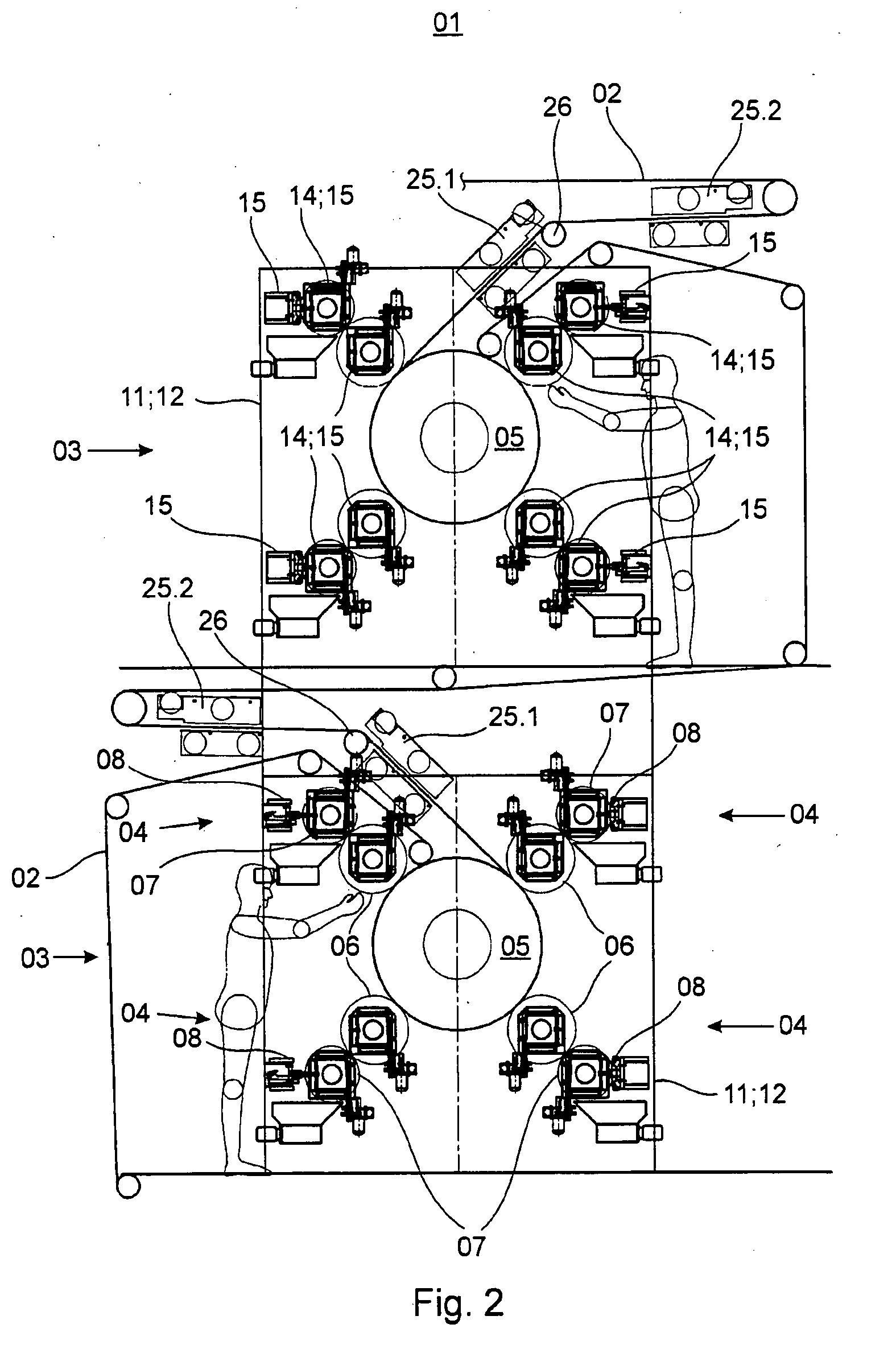

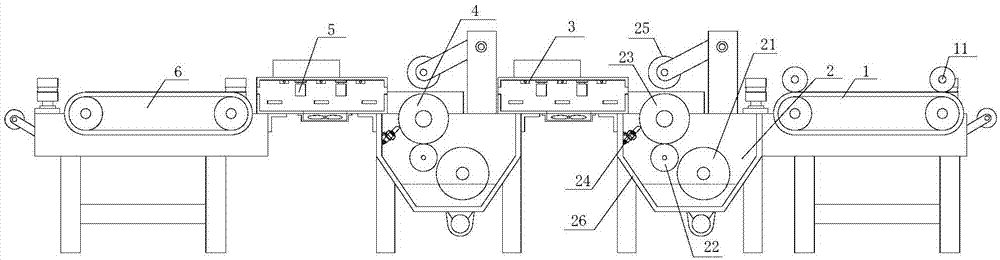

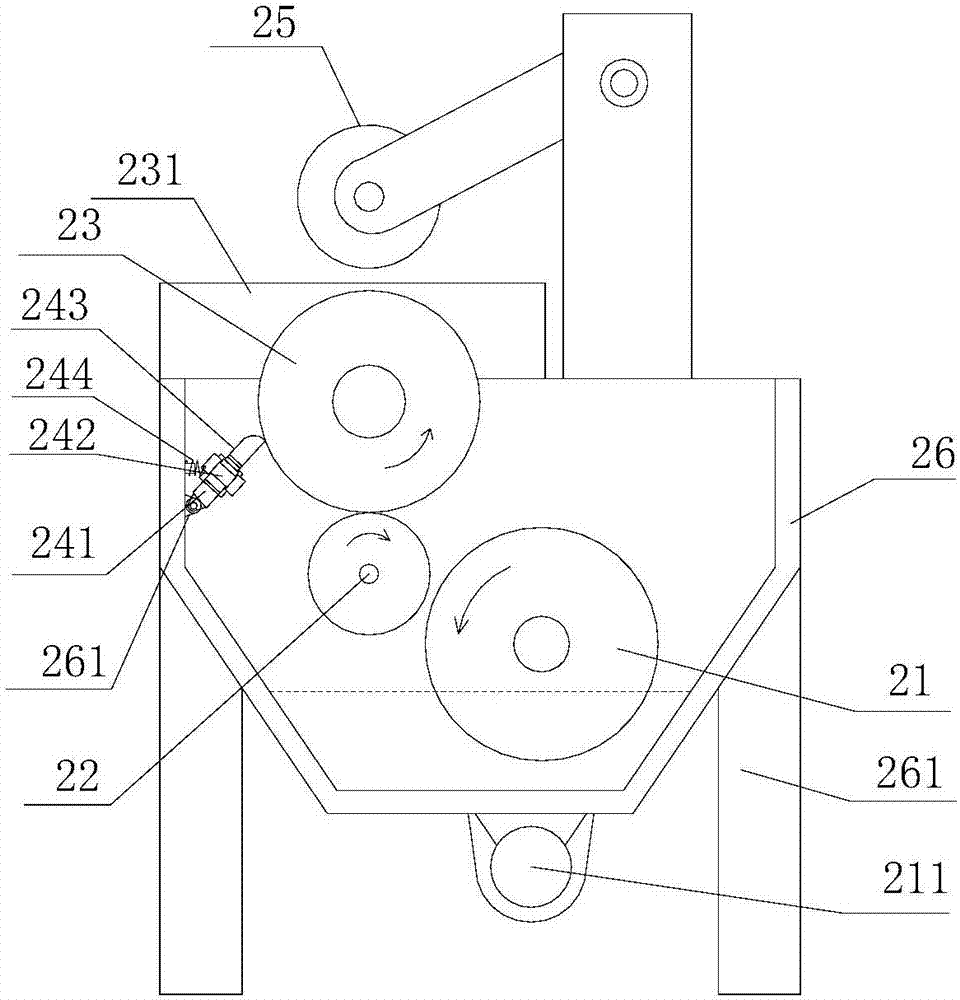

Label wheel rotary printing machine

InactiveCN101054011AImprove matchDry in timeLamination plant layoutStampsPlastics industryEngineering

The invention relates to a label rotary printing which is characterized by that: it is mainly comprised by paper feeding device, printing section, post-process portion, and can be linked with relief printing, flexographic printing, offset printing, and can be further linked with code spray, silicon oil coating, hot melting glue coating to make multi-layer anti-counterfeiting label, and two paper feeding portions can simultaneously print two rolls of stocks, and coats hot melting glue between the two rolls of stocks, and compounds them to obtain the non-drying glue label, and the invention is applicable in plastic industry for plastic film printing, and can be also used in printing commercial table and printing non-carbon impact paper; because the invention has five flexo printing color classes, it can be regarded as a pure five-color rotary flexo printing used in commercial packing printing field. The advantage of the invention is that: the invention can print single roll of stock as well as two rolls of stocks and can compound the two rolls of stocks, multi-layer non-drying glue label can be processed by multiple printings and ink jet printing on same device.

Owner:SHANGHAI XINMIN TAIYO KIKAI

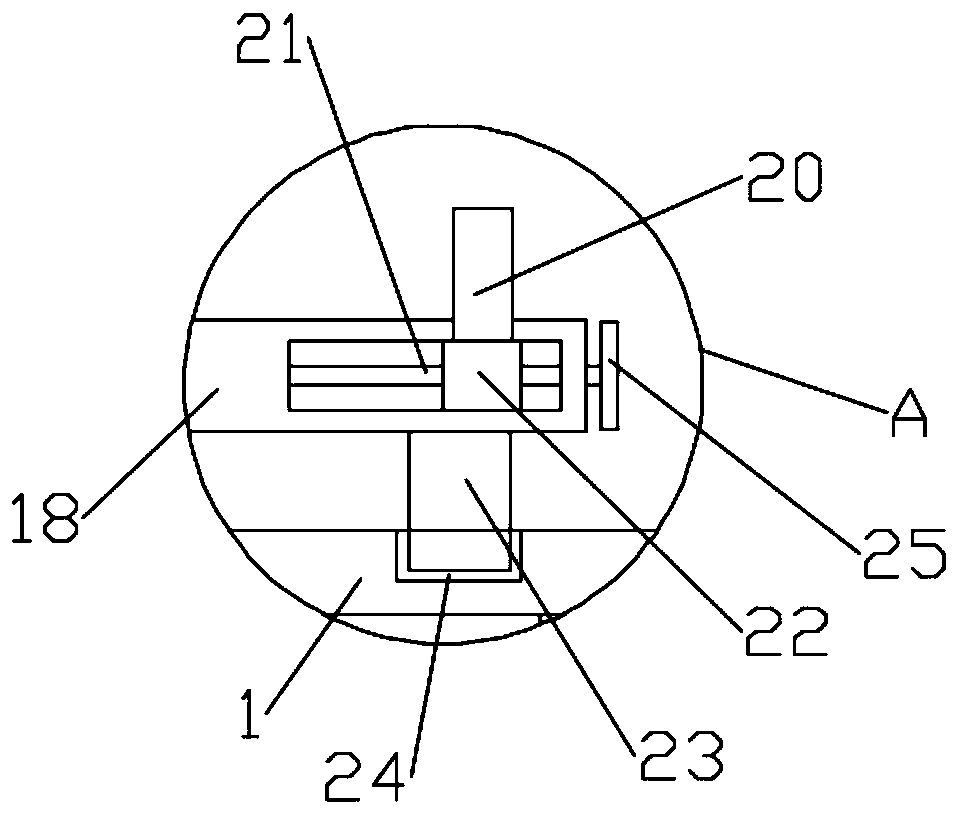

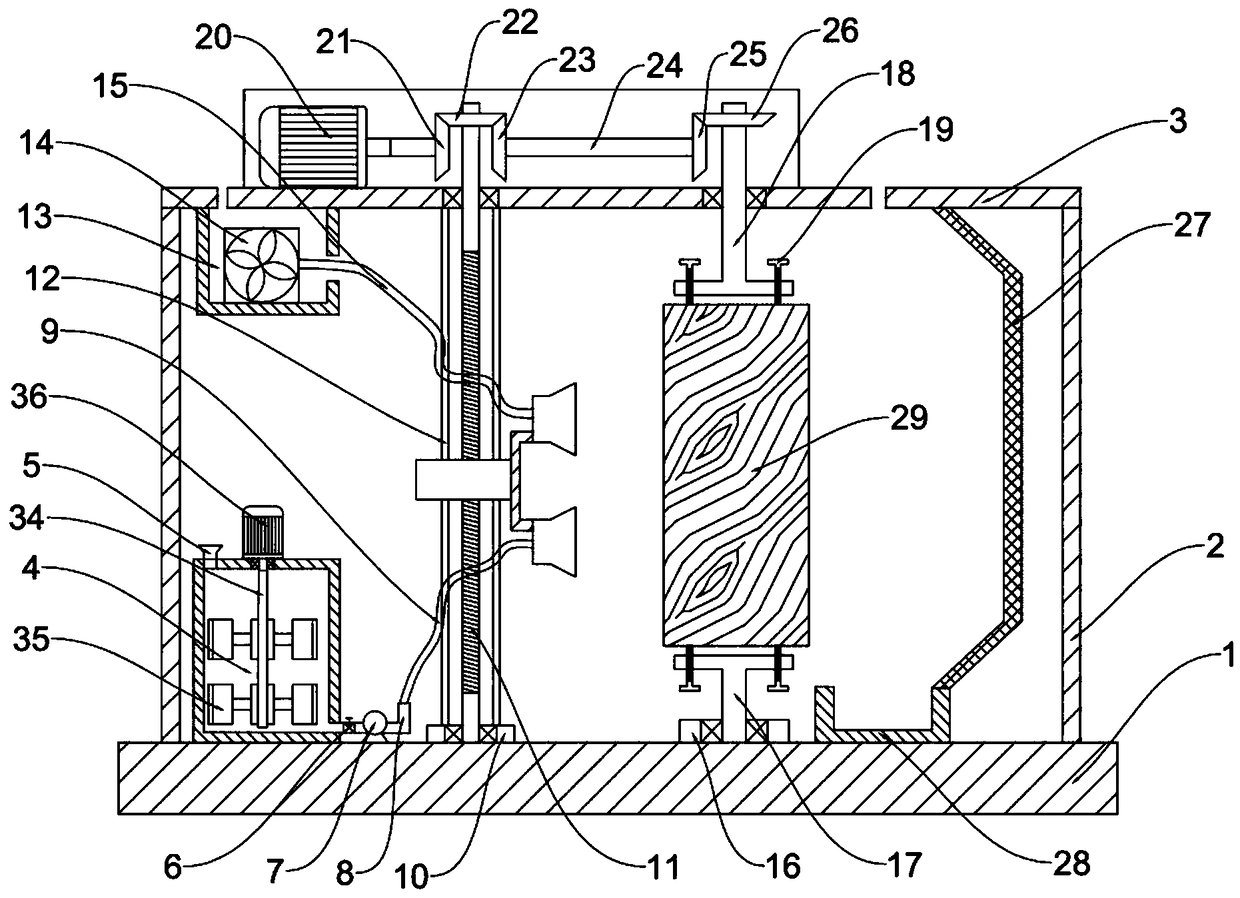

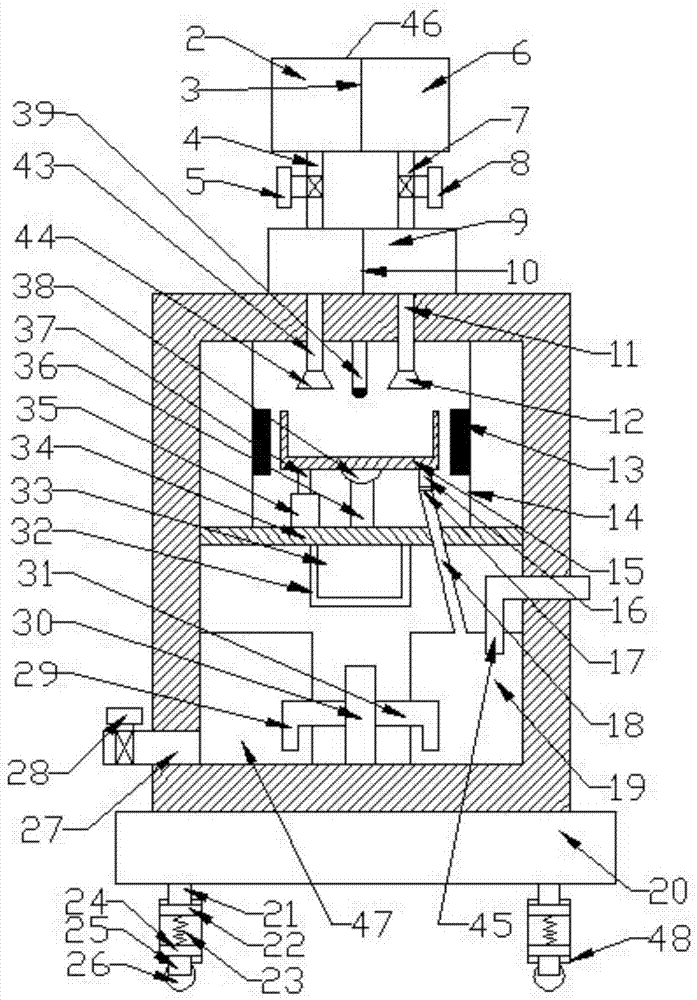

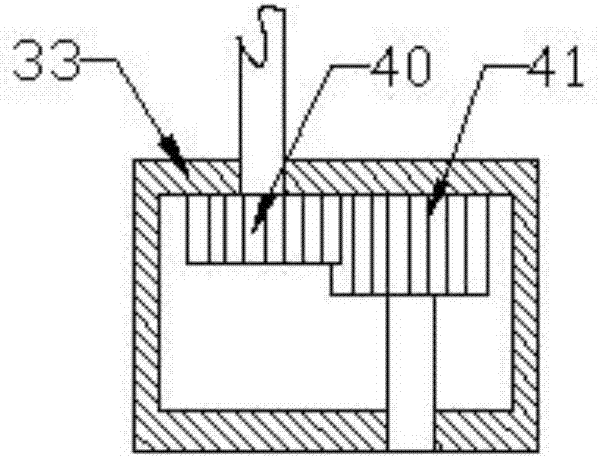

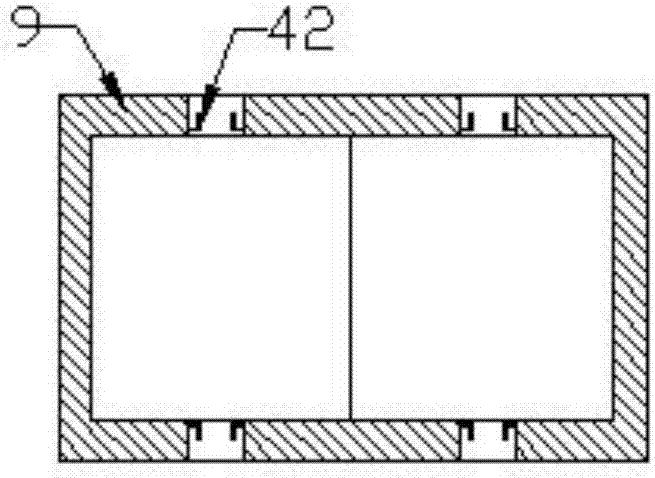

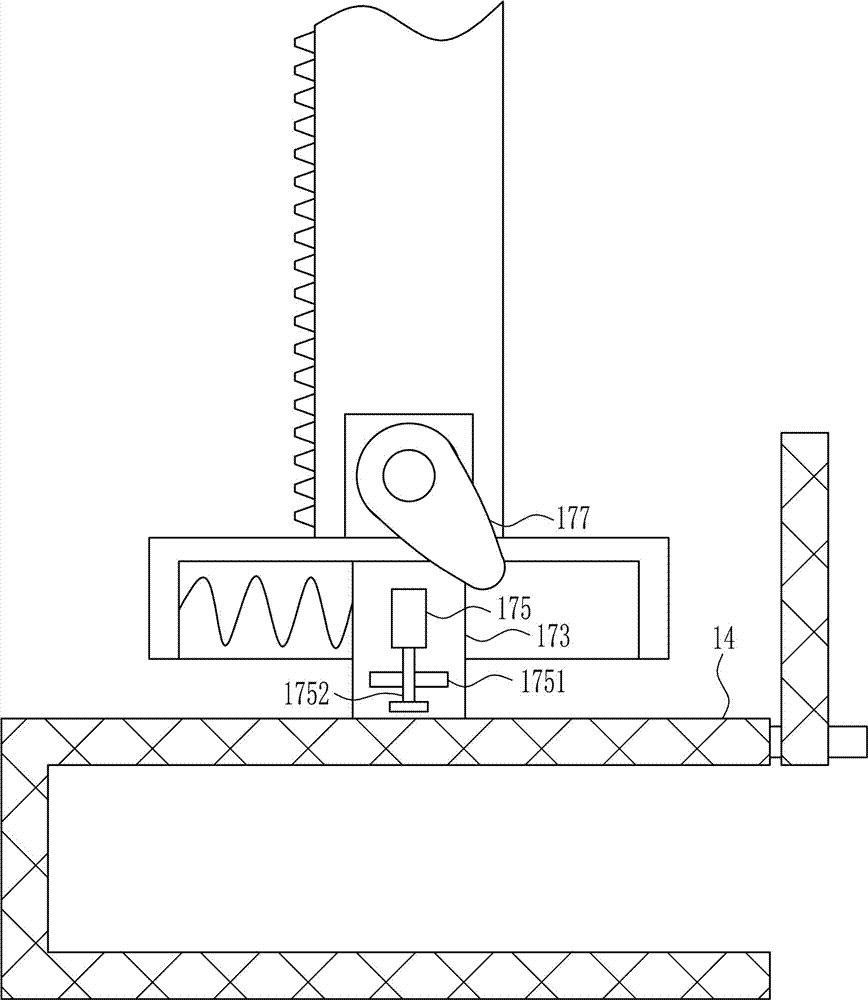

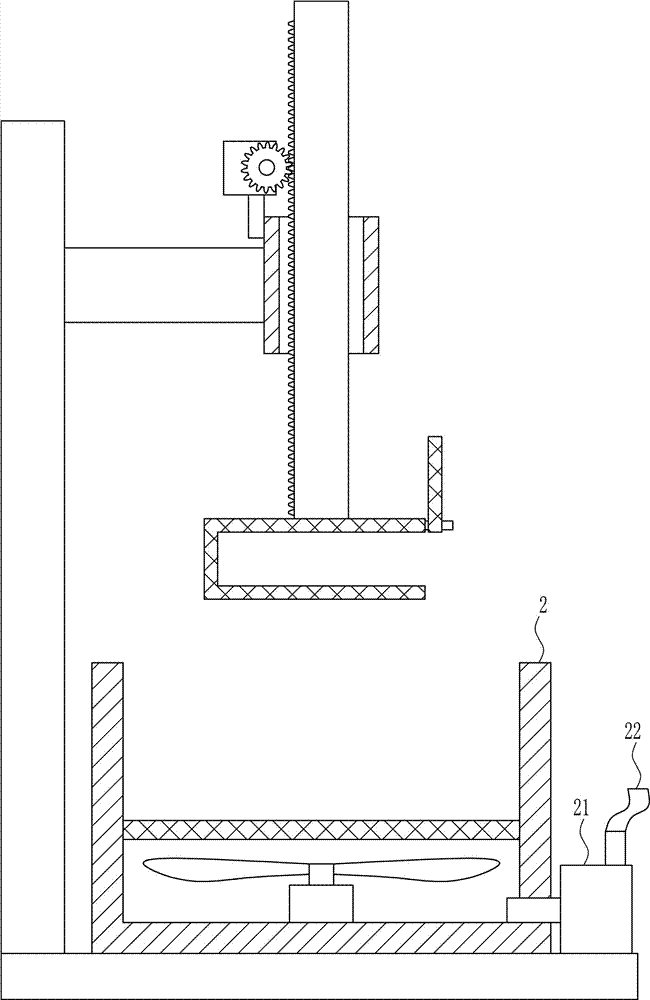

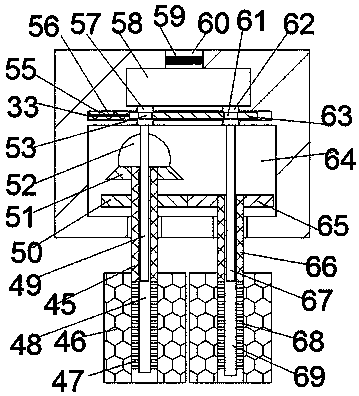

Multi-angle automatic paint spray equipment for machining mechanical part

ActiveCN110773365ADry evenlyGood effectPretreated surfacesLiquid spraying apparatusHot blastTelescopic cylinder

The invention relates to the field of automatic machining equipment and particularly discloses multi-angle automatic paint spray equipment for machining a mechanical part. The multi-angle automatic paint spray equipment comprises a box body; a supporting cylinder realizing height adjustment by virtue of a telescopic cylinder is arranged inside the box body; a rotating partition plate and a rotating plate are arranged in a synchronous rotation manner inside the supporting cylinder; an inner chamber of the supporting cylinder is divided into an upper chamber and a lower chamber, namely a paint liquid chamber and a hot air chamber by virtue of the rotating partition plate and the rotating plate; an air pipe used for exhausting hot air out of the hot air chamber is fixedly installed at one side of the rotating plate; a hot air nozzle is arranged at the bottom end of the air pipe; a paint liquid pipe used for discharging paint liquid inside the paint liquid chamber is fixedly installed at the other side of the rotating partition plate; and a paint mist sprayer used for atomizing the paint liquid is arranged at the bottom end of the paint liquid pipe which extends to a position below therotating plate. The multi-angle automatic paint spray equipment provided by the embodiment of the invention can effectively widen the paint spraying range, guarantees the uniformity of paint spraying, can also guarantee timely drying of the paint liquid at the surface of the part, and also realizes uniform drying and a good effect.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

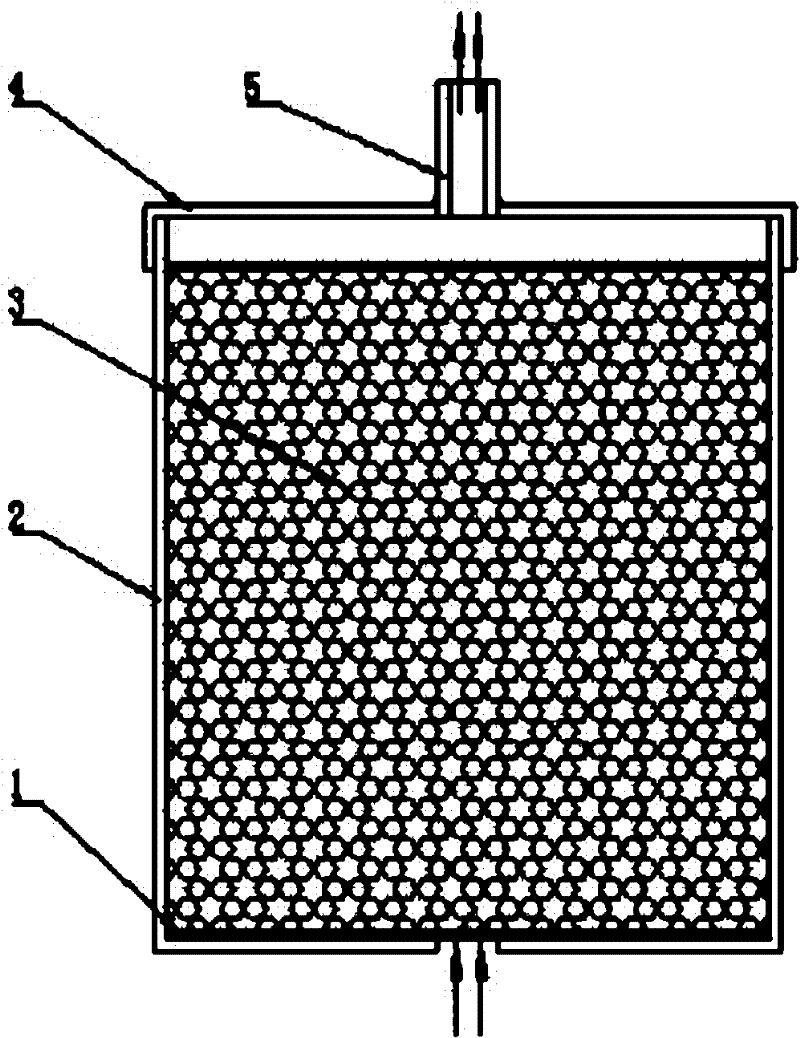

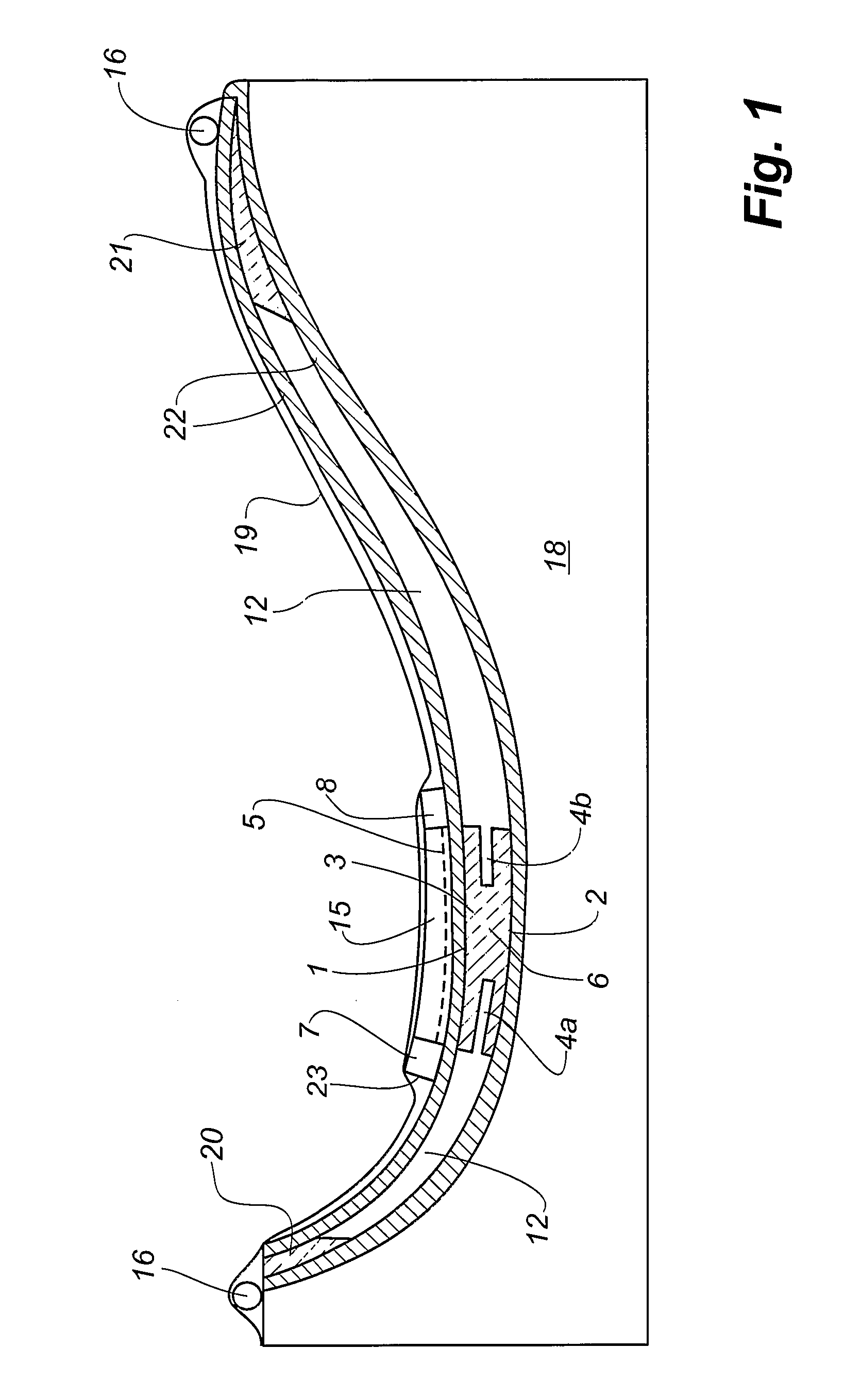

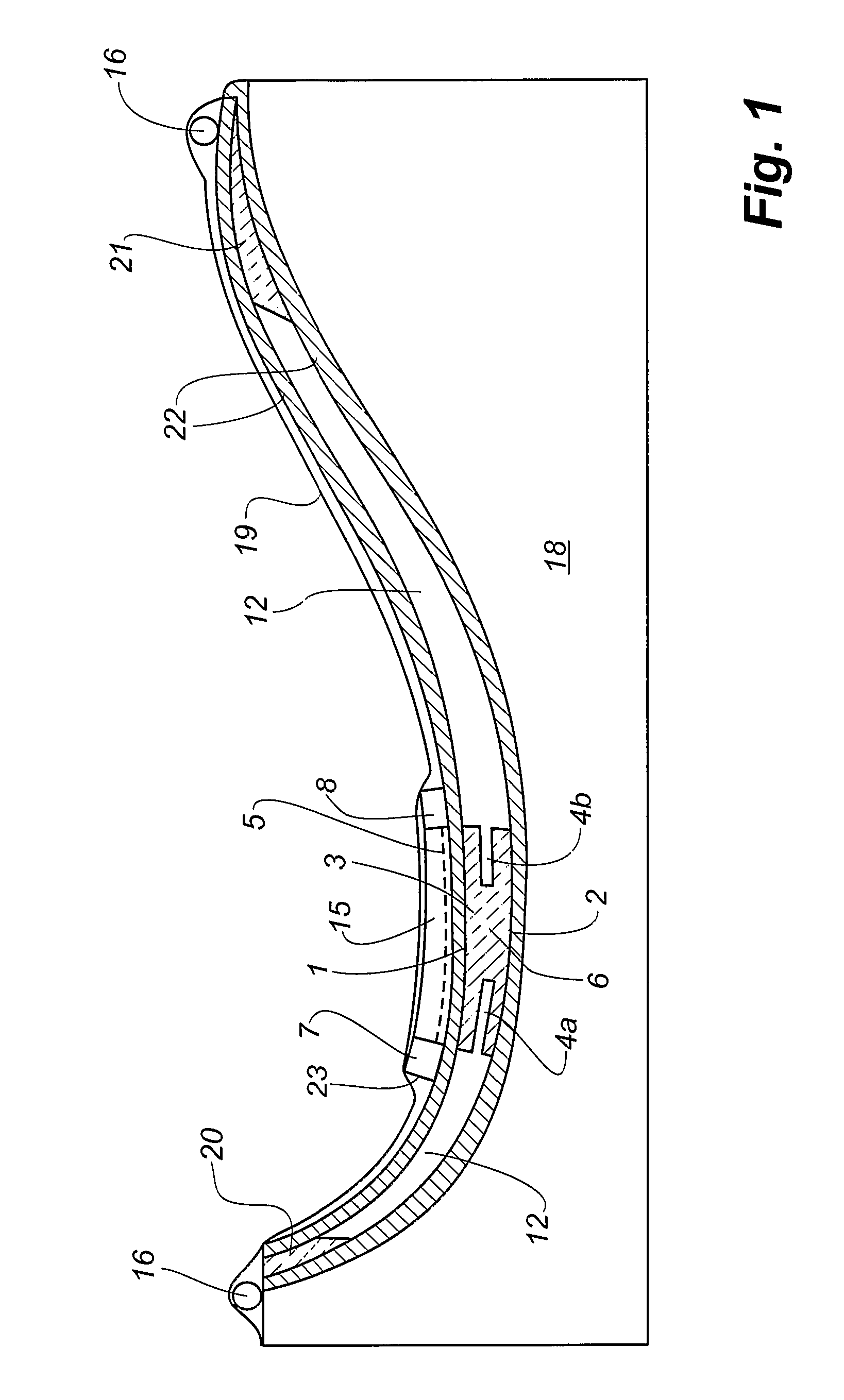

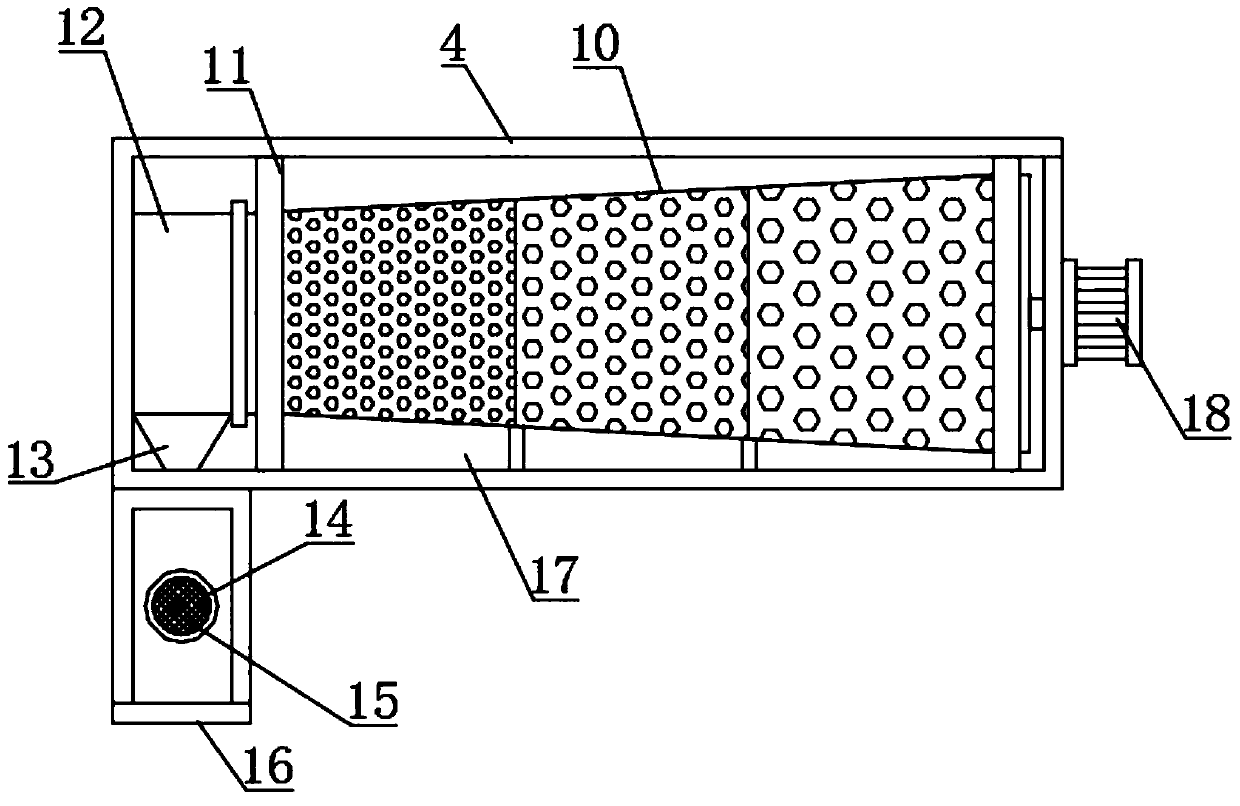

Method and Apparatus for Providing polymer to be Used at Vacuum Infusion

ActiveUS20090051076A1Time for filling the mould,Risk of dryFinal product manufactureLaminationInlet channelLiquid state

The invention relates to a method of producing a shell member of fibre composite material by means of vacuum infusion, where the fibre material is impregnated with liquid polymer, and applying a mould (18) with a mould cavity. In the mould cavity a lower distribution layer (11) is placed. A fibre insertion (1) including a plurality of fibre layers is placed above the lower distribution layer (11). A first upper distribution layer (9) and a second upper distribution layer (10) are placed at a transverse distance of each other above the fibre insertion, so that at least a part of the first distribution layer overlaps a first zone (2) of the fibre insertion (1), and at least a part of the second distribution layer overlaps a second zone (3) of the fibre insertion (1), the first zone (2) and the second zone (3) being separated by an intermediate zone (6) neither overlapping the first nor the second distribution layer (9, 10). A first inlet channel (7) is placed above the first distribution layer (9), and a second inlet channel (8) is placed on top of the second distribution layer (10). Above the intermediate zone (6) of the fibre insertion (1) a semi-permeable membrane (5) is placed, which may expand overlappingly over the first distribution layer (9) and / or the second distribution layer (10), and which is permeable to gasses and substantially impermeable to liquid polymer, said semi-permeable membrane (5) communicating with a vacuum source. Finally, in a manner known per se, a vacuum bag (19) is placed on top of the mould (18), which is evacuated of air by means of the vacuum source, and polymer is directed into the mould via the first and the second inlet channels (7, 8). The invention also relates to an apparatus for providing polymer for use with the method.

Owner:LM GLASSFIBER

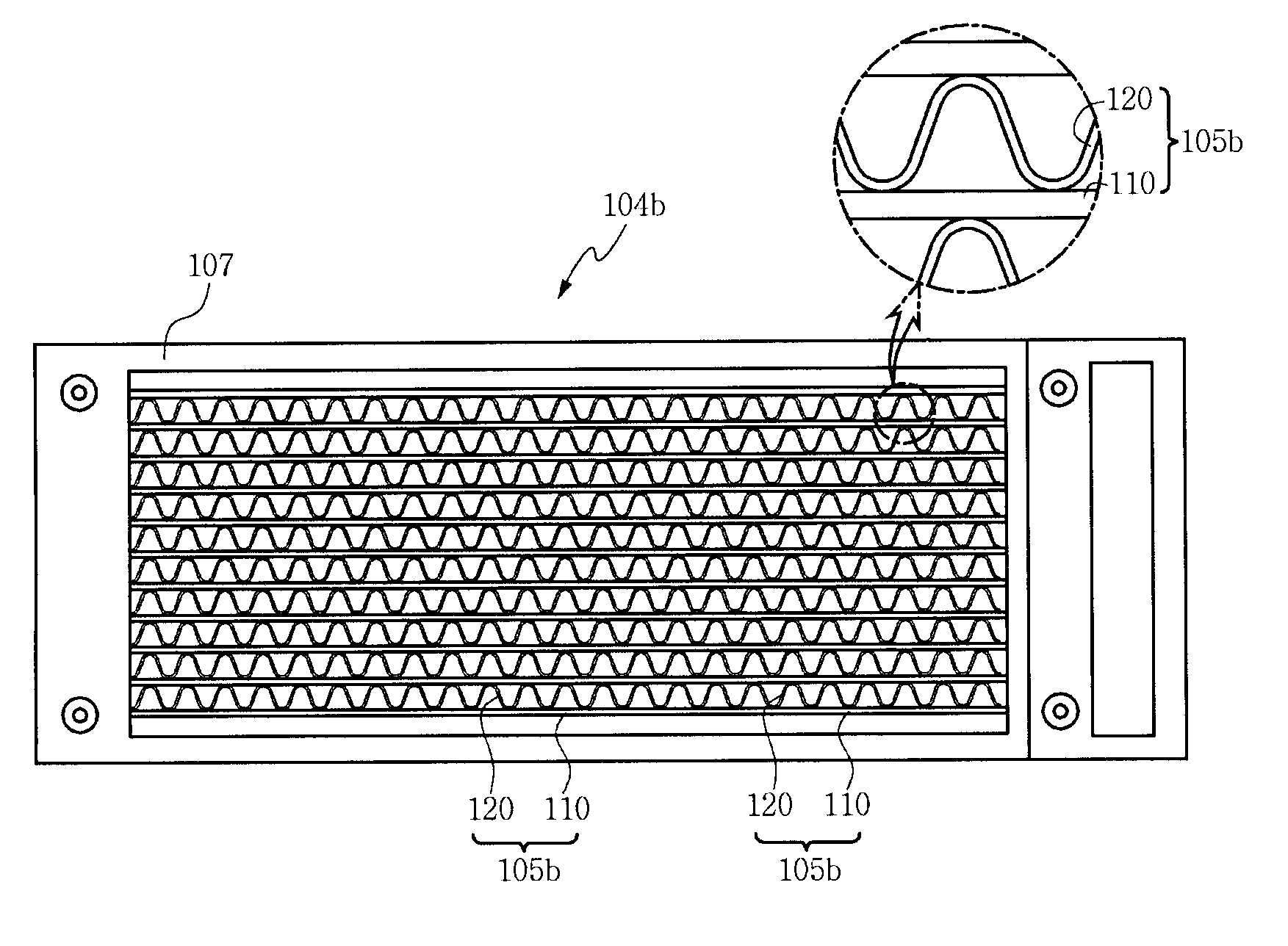

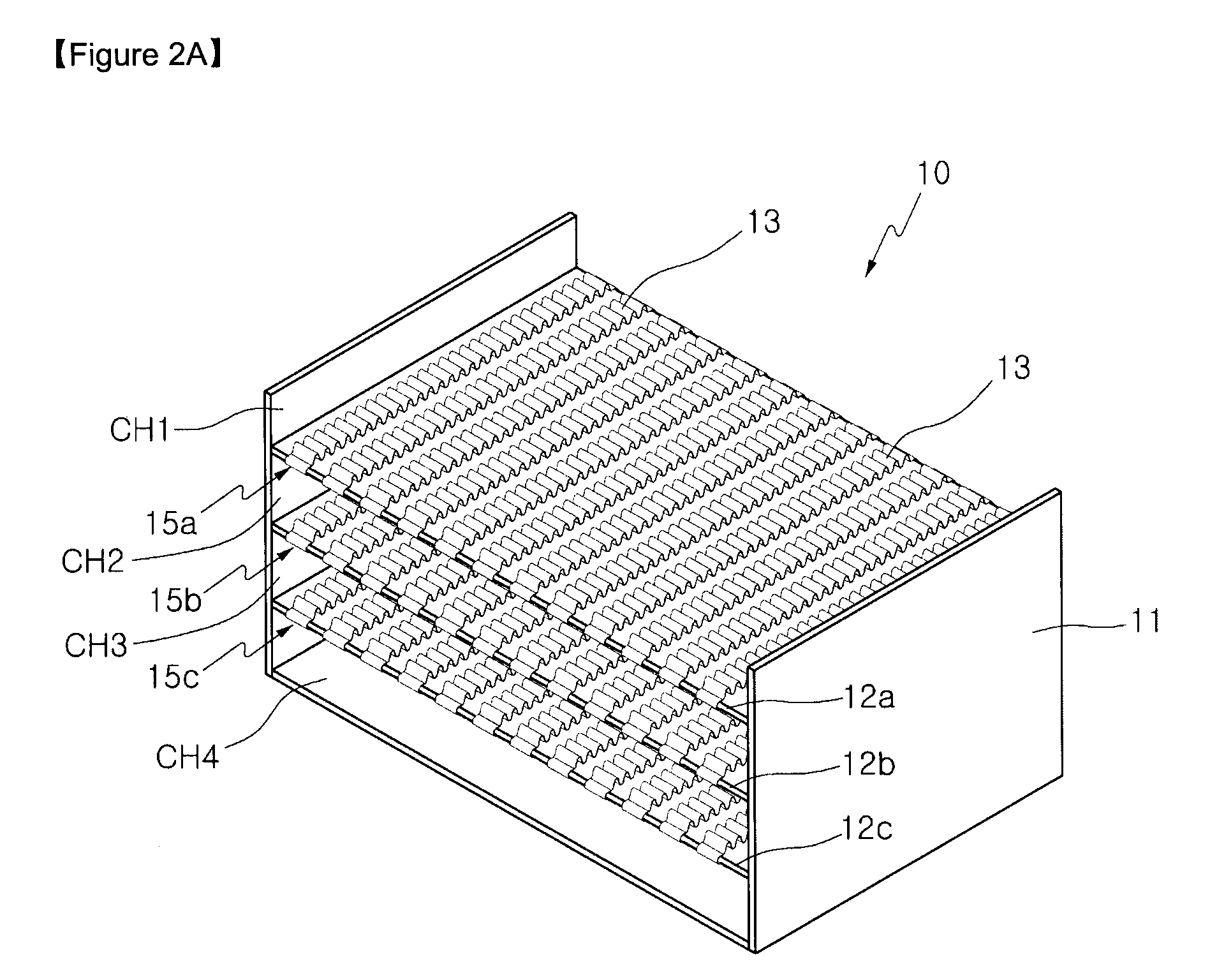

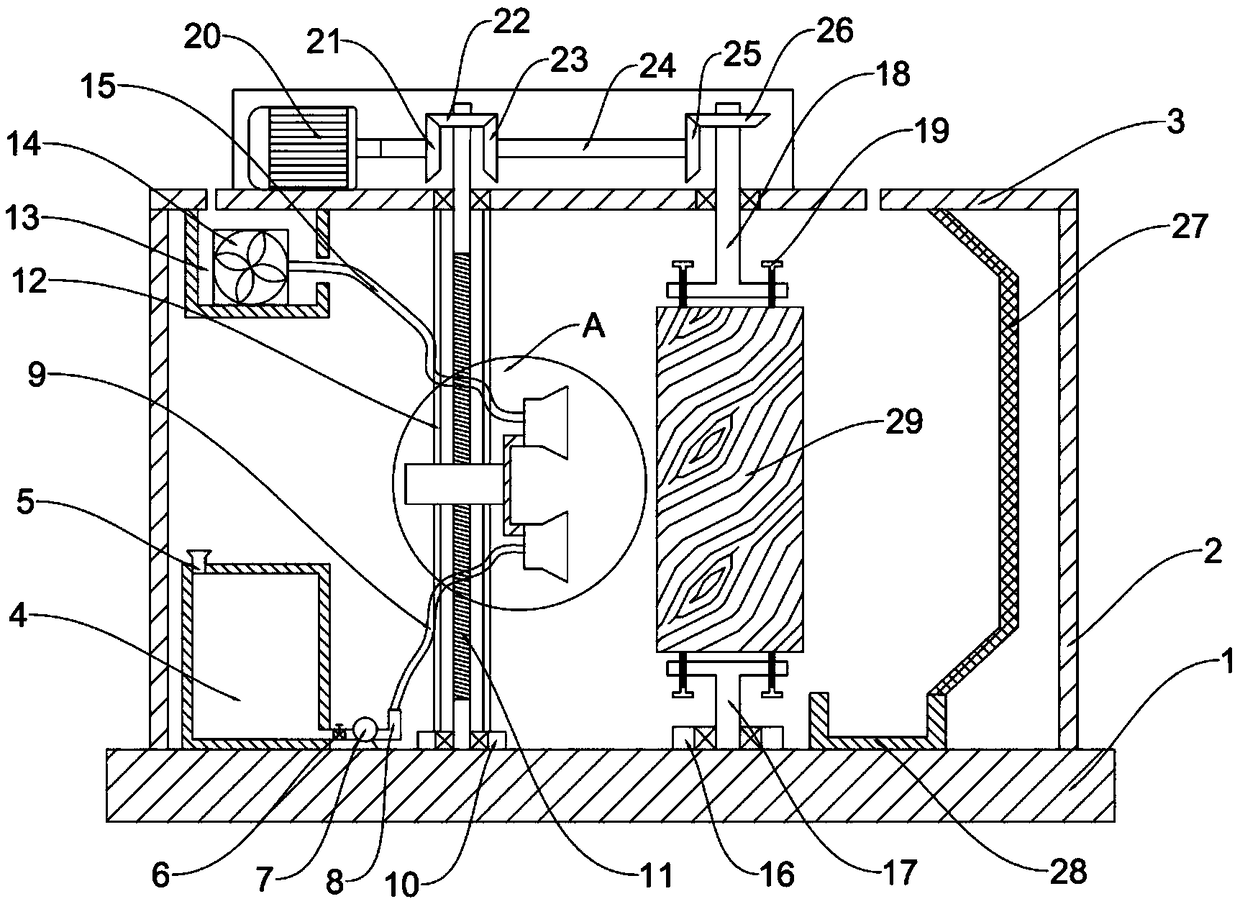

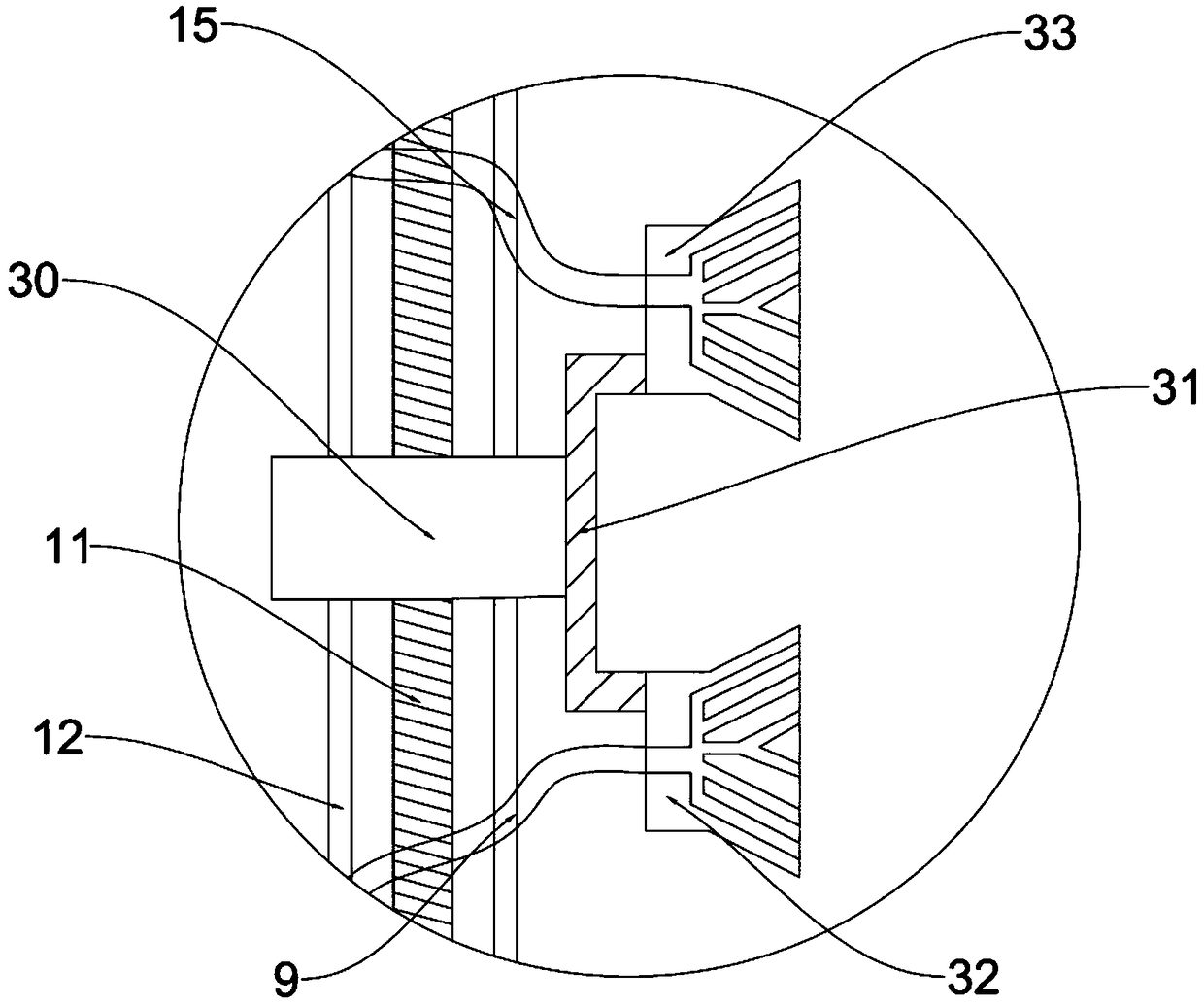

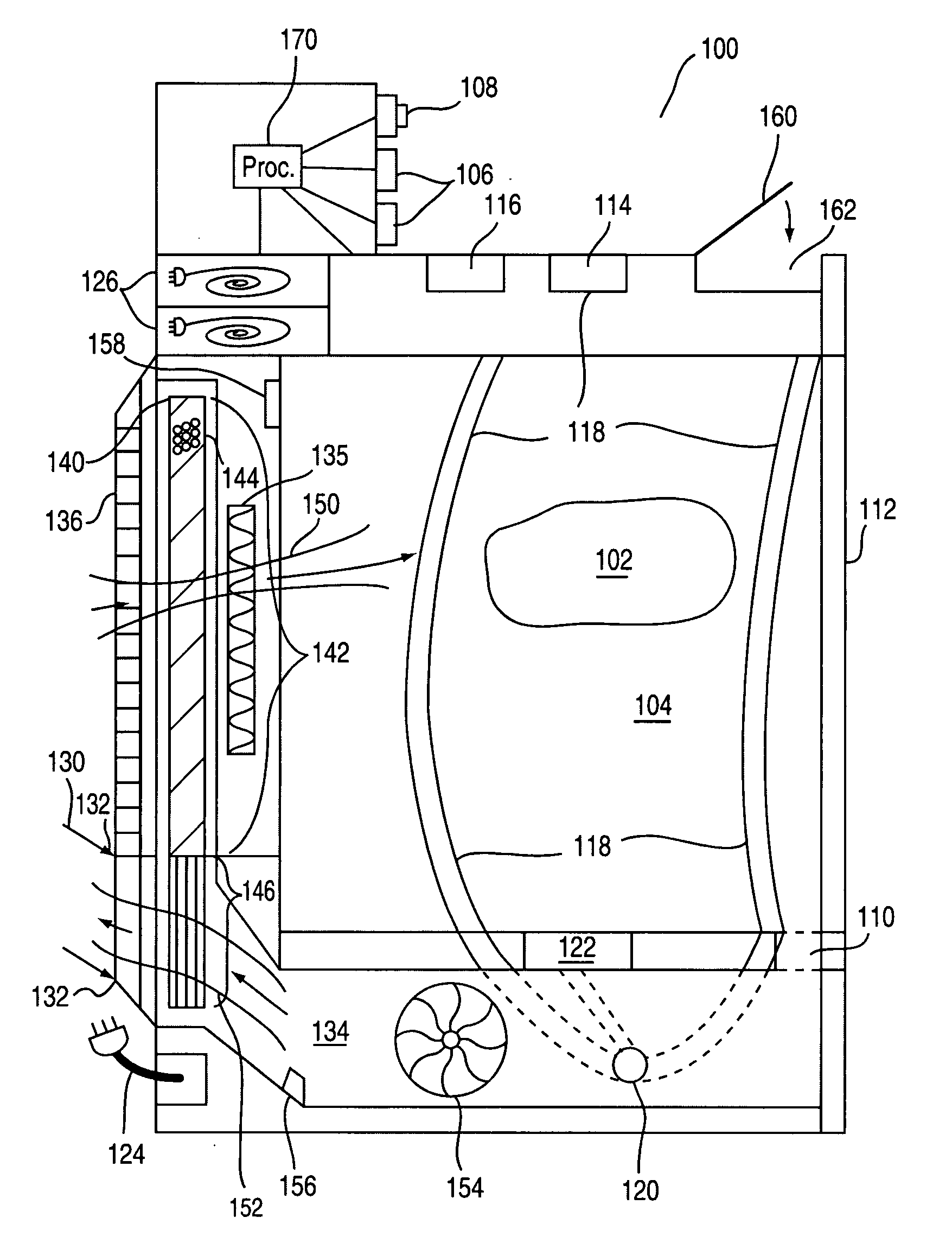

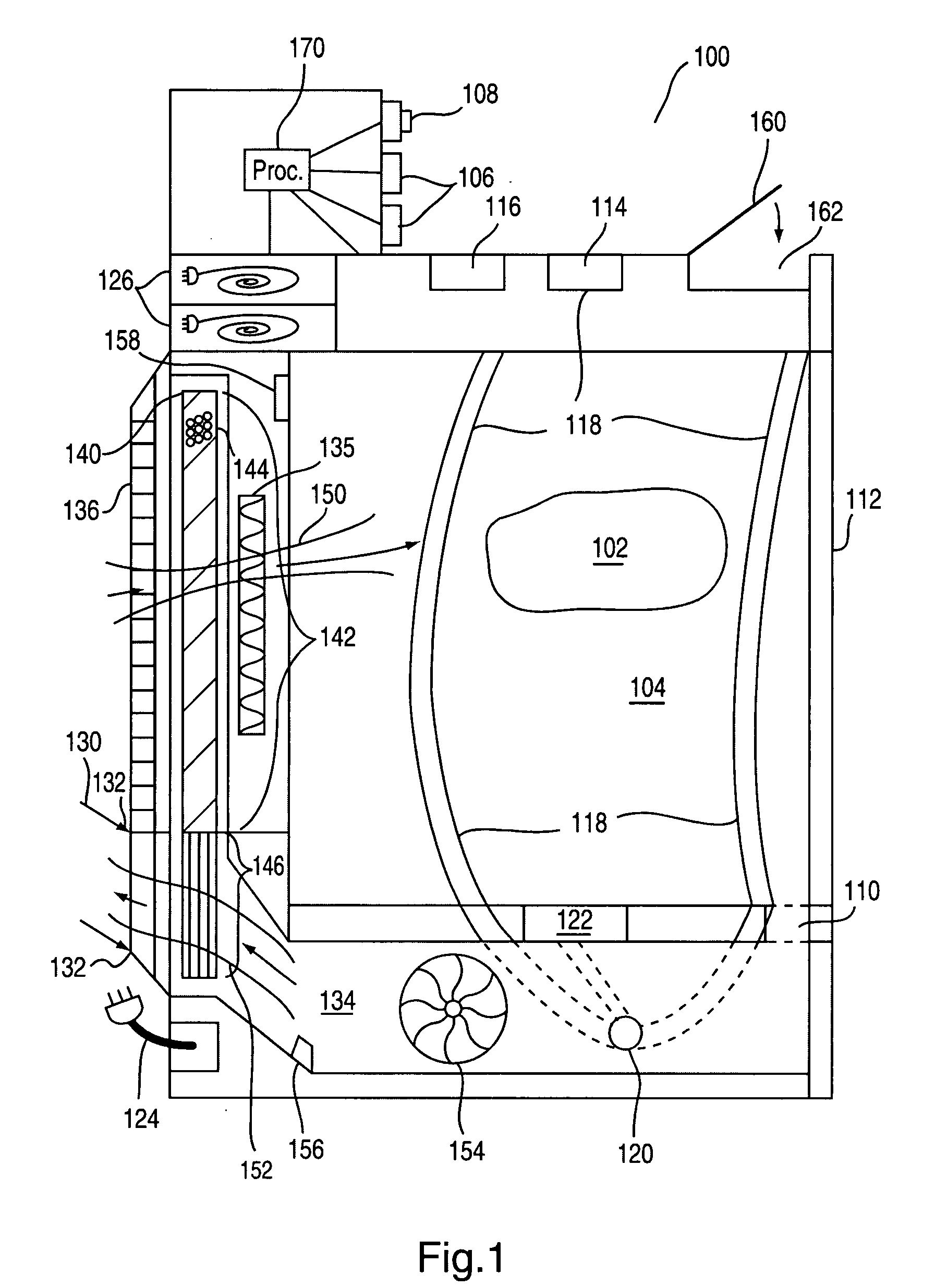

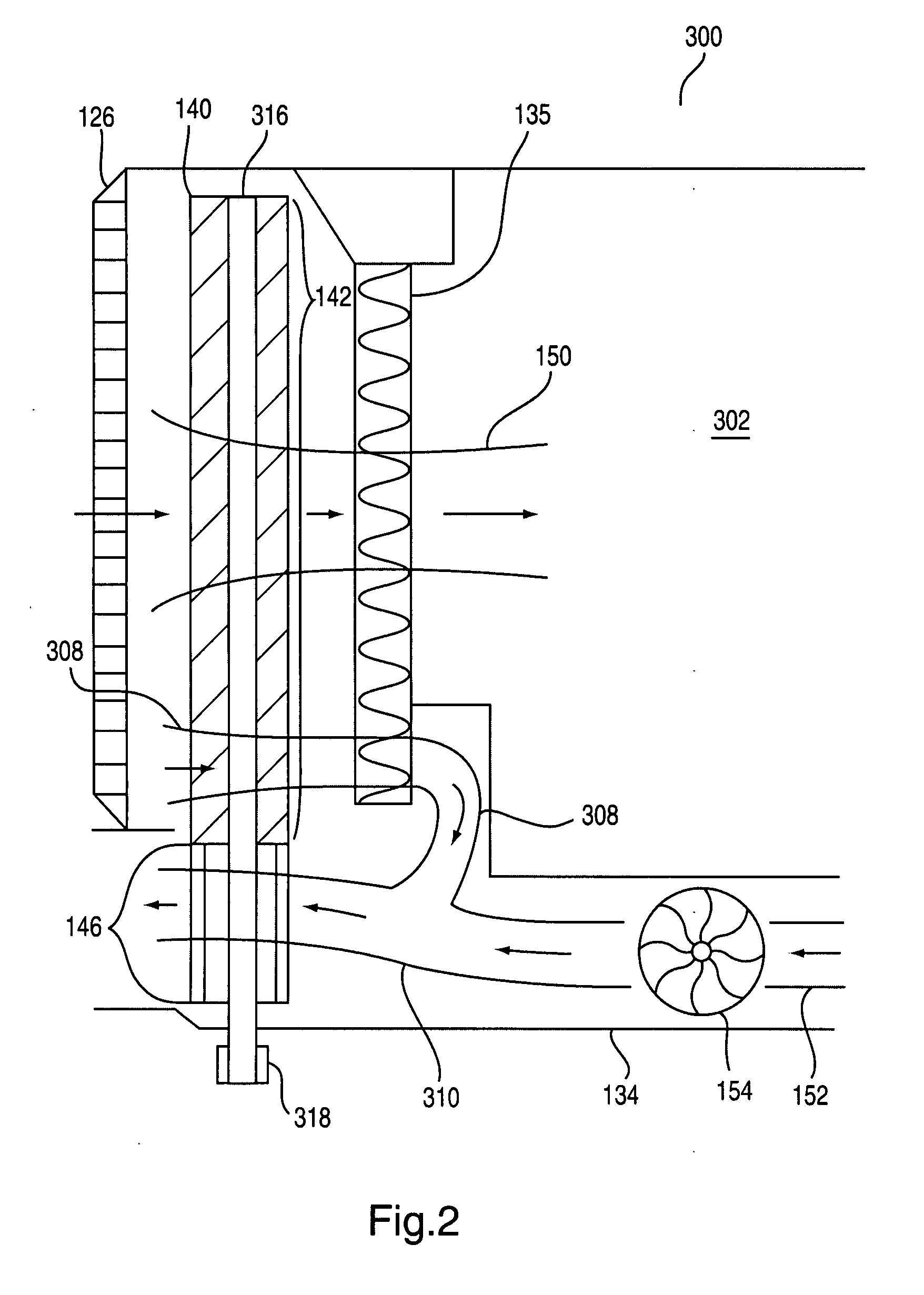

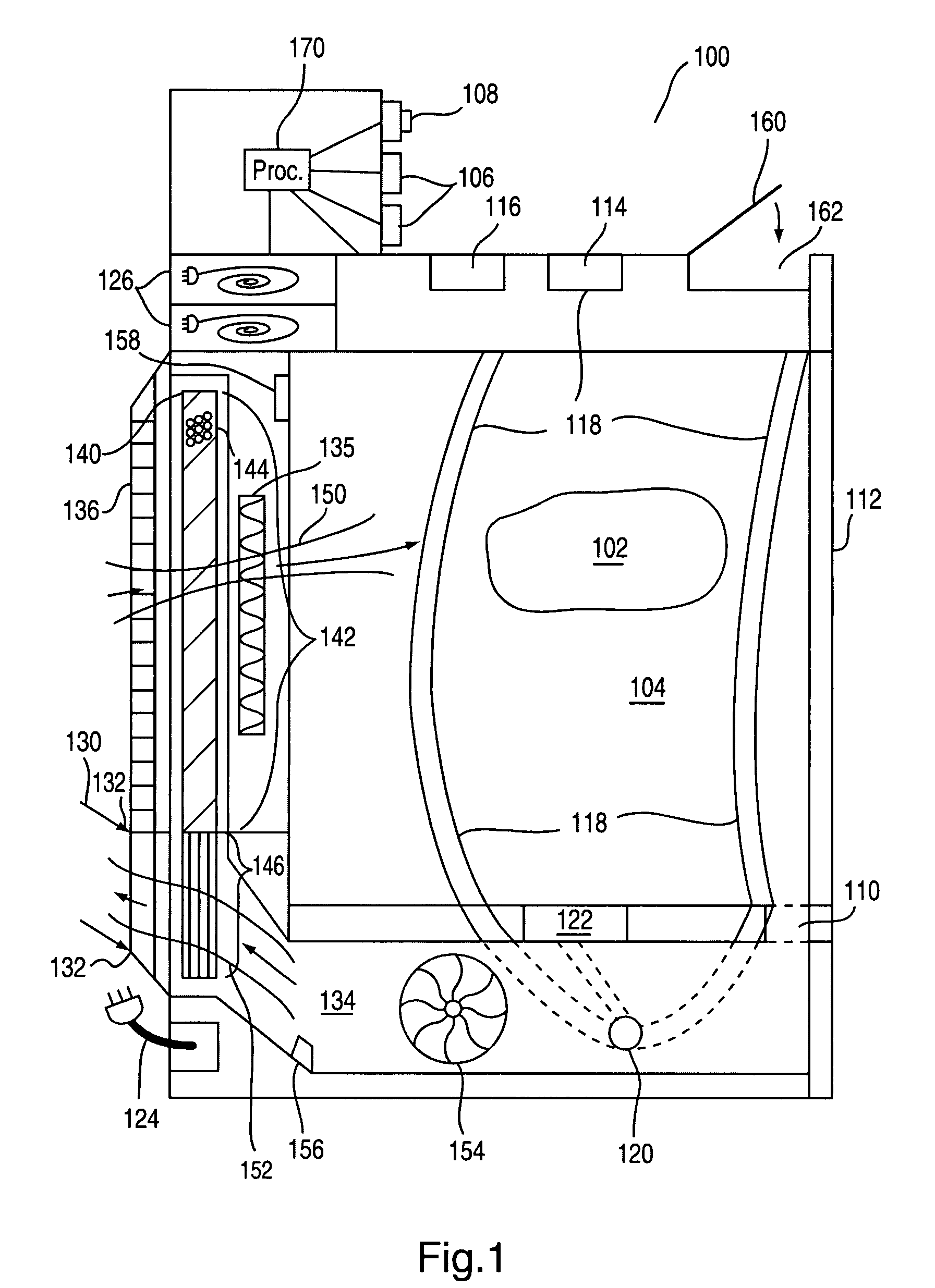

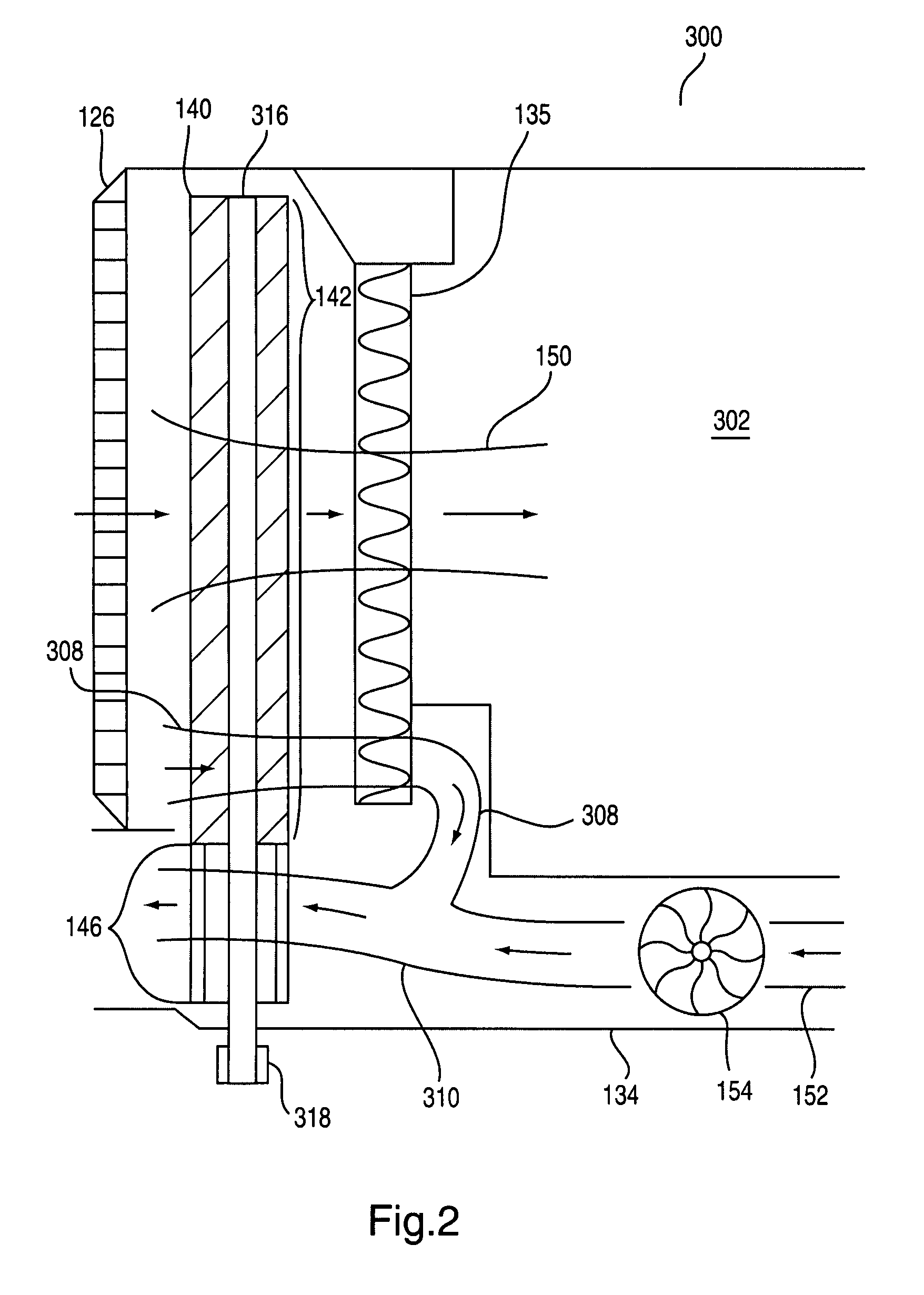

Drying heater, heating unit for drying laundry using the same, drying control system and control method thereof

InactiveUS20110062145A1Improve heat transfer efficiencyReduce the amount requiredOhmic-resistance heating detailsTextiles and paperControl systemMetal sheet

Provided is a drying heater, a heating unit for drying laundry using the same, a drying control system and control method thereof that reduces electric power consumption of the drying heater to supply high temperature dry air to the inside of a drum in a washing machine or a laundry drying machine, to thus simplify structure of the drying heater and reduce a manufacturing cost. The drying control method includes the step of applying a first electric power from a first drive power supply to a drying heater when a drum internal temperature is lower than a preset temperature, and applying a second electric power from a second drive power supply which is relatively smaller than the first electric power to the drying heater when the drum internal temperature is higher than the preset temperature. The drying heater includes a surface-shaped heat generation member made of a low thermal density strip style metal thin plate.

Owner:AMO GMBH

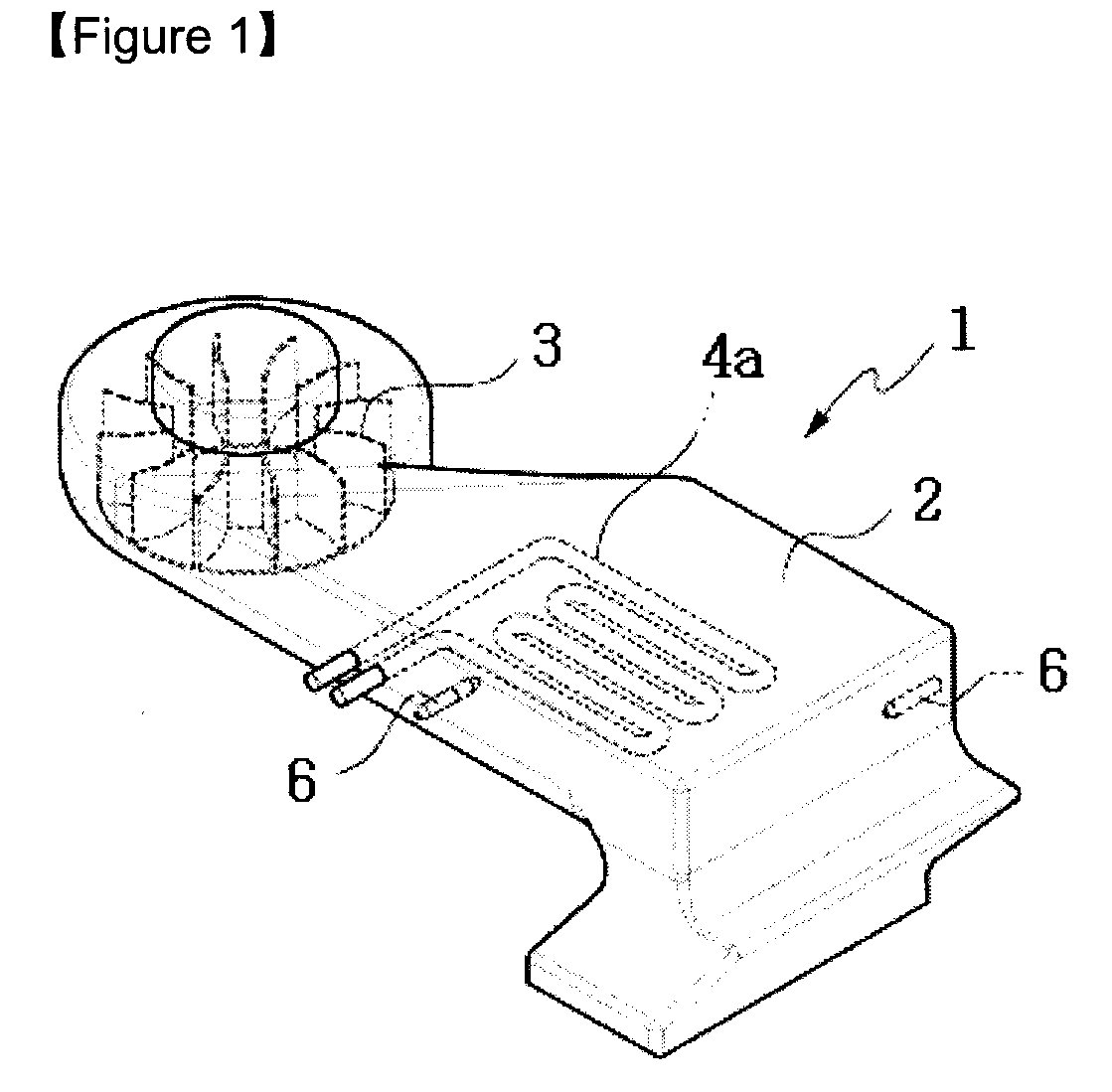

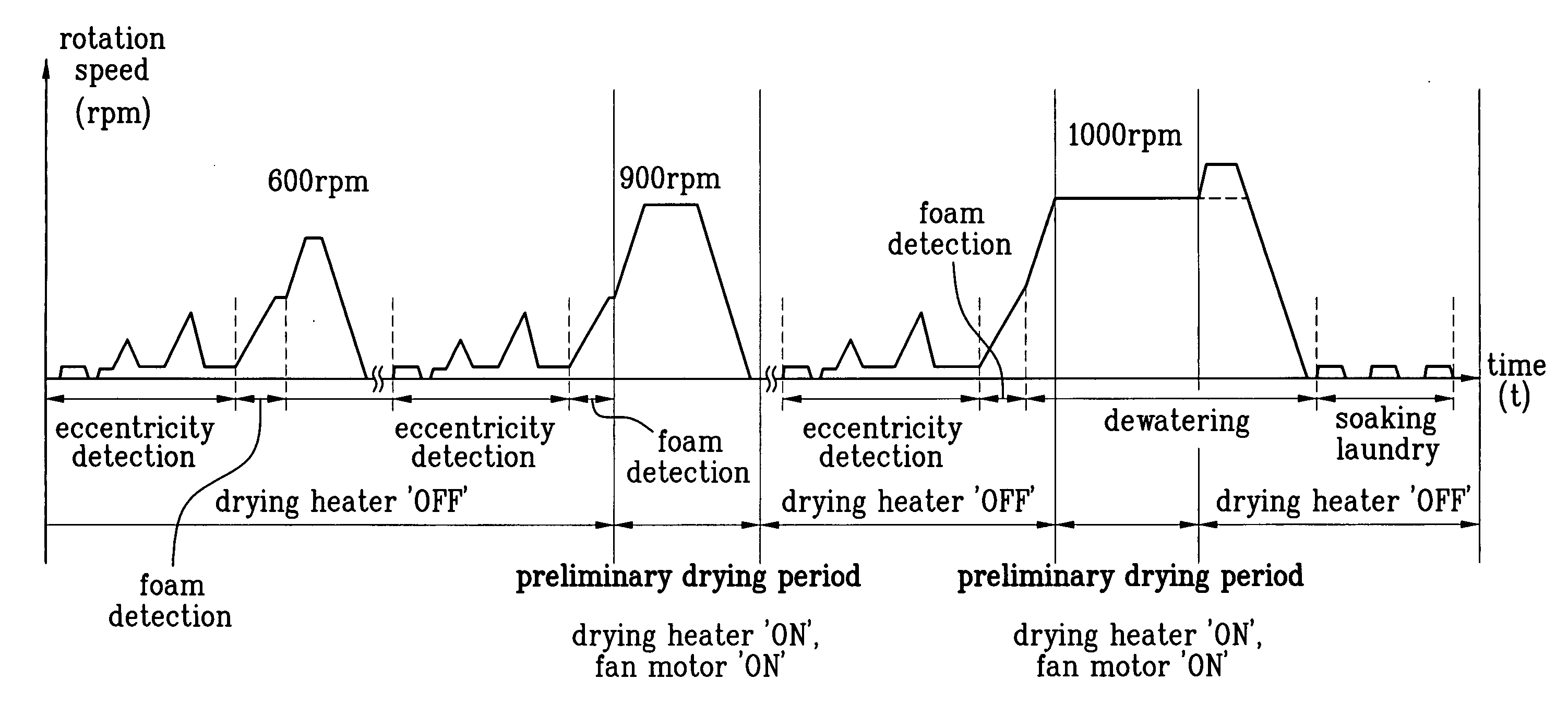

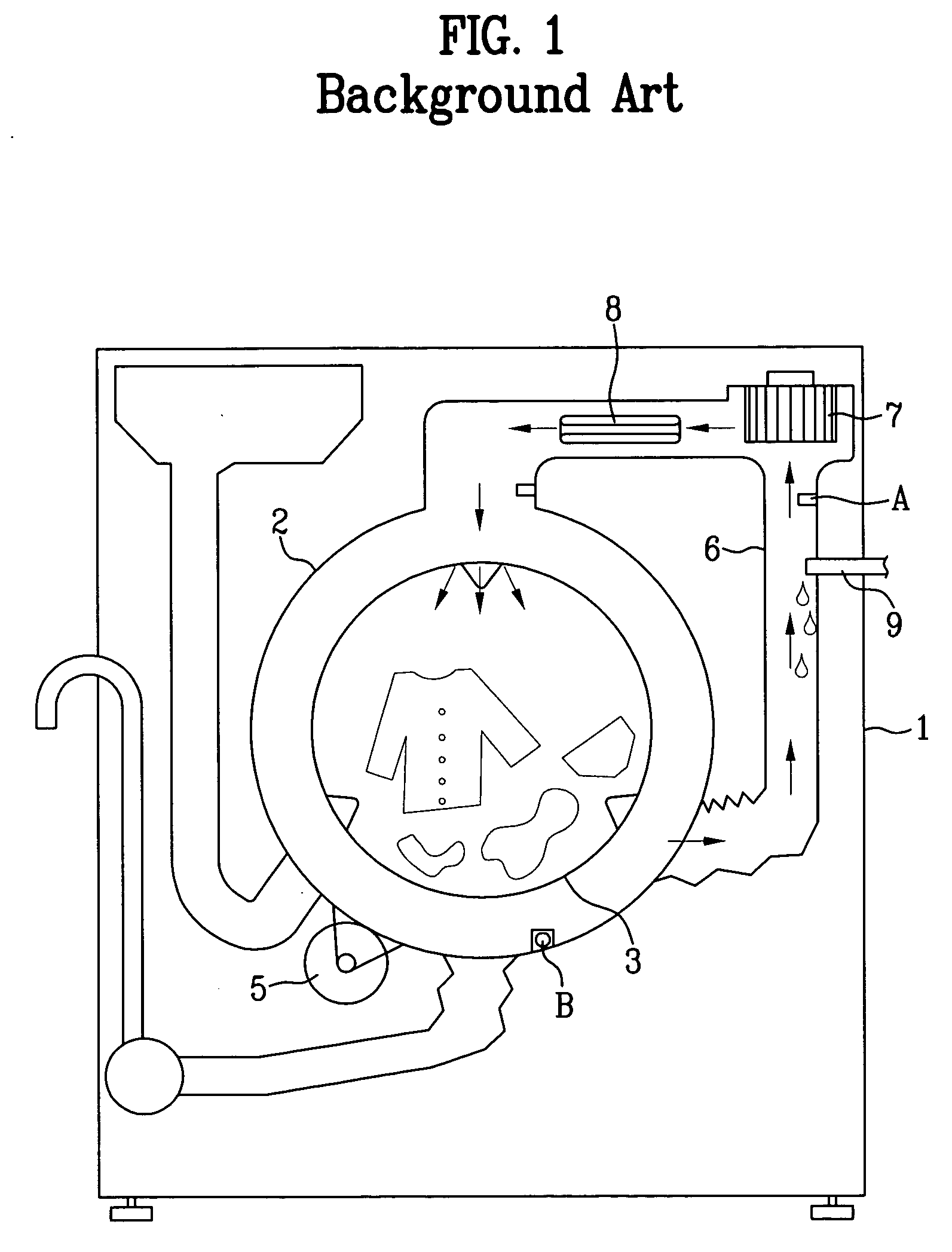

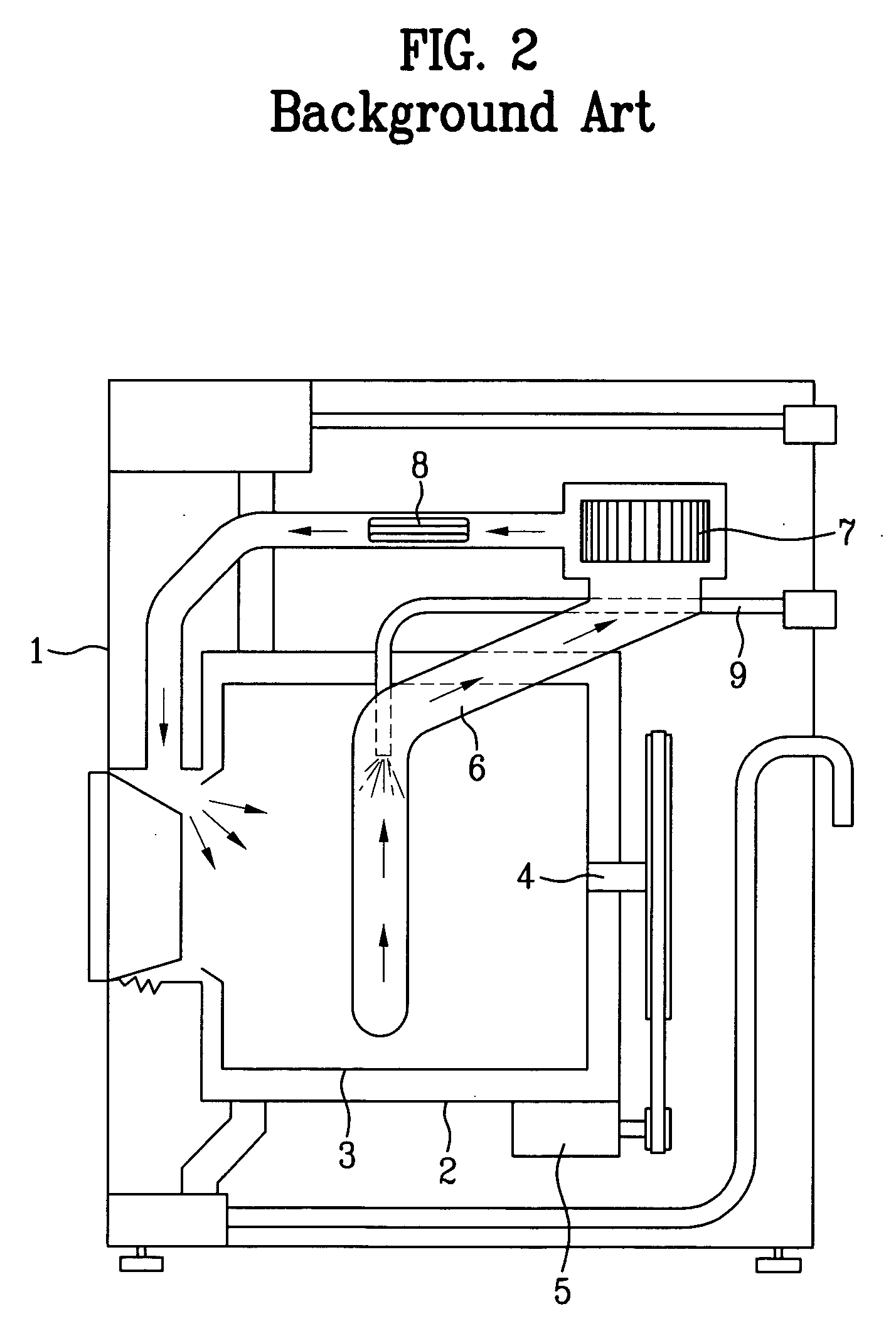

Washing machine and control method thereof

InactiveUS20050081308A1Efficient dryingDrying cycle timeDrying solid materials without heatOther washing machinesPulp and paper industryCycle time

The present invention provides a washing machine and control method thereof, by which a laundry can be dried more effectively, by which a drying cycle time can be shortened, and by which stability and reliance can be enhanced. The present invention includes the step of performing dewatering and preliminary drying simultaneously during a dewatering cycle. And, The present invention supplies cooling water for condensing hot and humid air during the dewatering cycle.

Owner:LG ELECTRONICS INC

Efficient and uniform wooden product paint spraying equipment

The invention discloses efficient and uniform wooden product paint spraying equipment, and belongs to the field of wooden product machining equipment. The device comprises a base, supporting columns,a top plate, a paint spraying and drying device, a fixing device and a recycling device; the paint spraying and drying device comprises a threaded rod, a positive and negative rotating motor, a threaded sleeve, a paint spraying mechanism and a drying mechanism; an installing rack is fixedly connected to the right end of the threaded sleeve; the paint spraying mechanism comprises a paint box, a paint pump and paint sprayers; the drying mechanism comprises a hot air chamber, a hot air blower and air nozzles; the paint sprayers are fixedly installed at one end of the installing rack; and the airnozzles are fixedly installed at the other end of the installing rack. According to the efficient and uniform wooden product paint spraying equipment, efficient, uniform and comprehensive paint spraying and drying operation can be conducted on wooden products, redundant paint in the paint spraying process can be recycled, and unnecessary waste can be reduced.

Owner:安徽菌仙菇农业开发有限公司

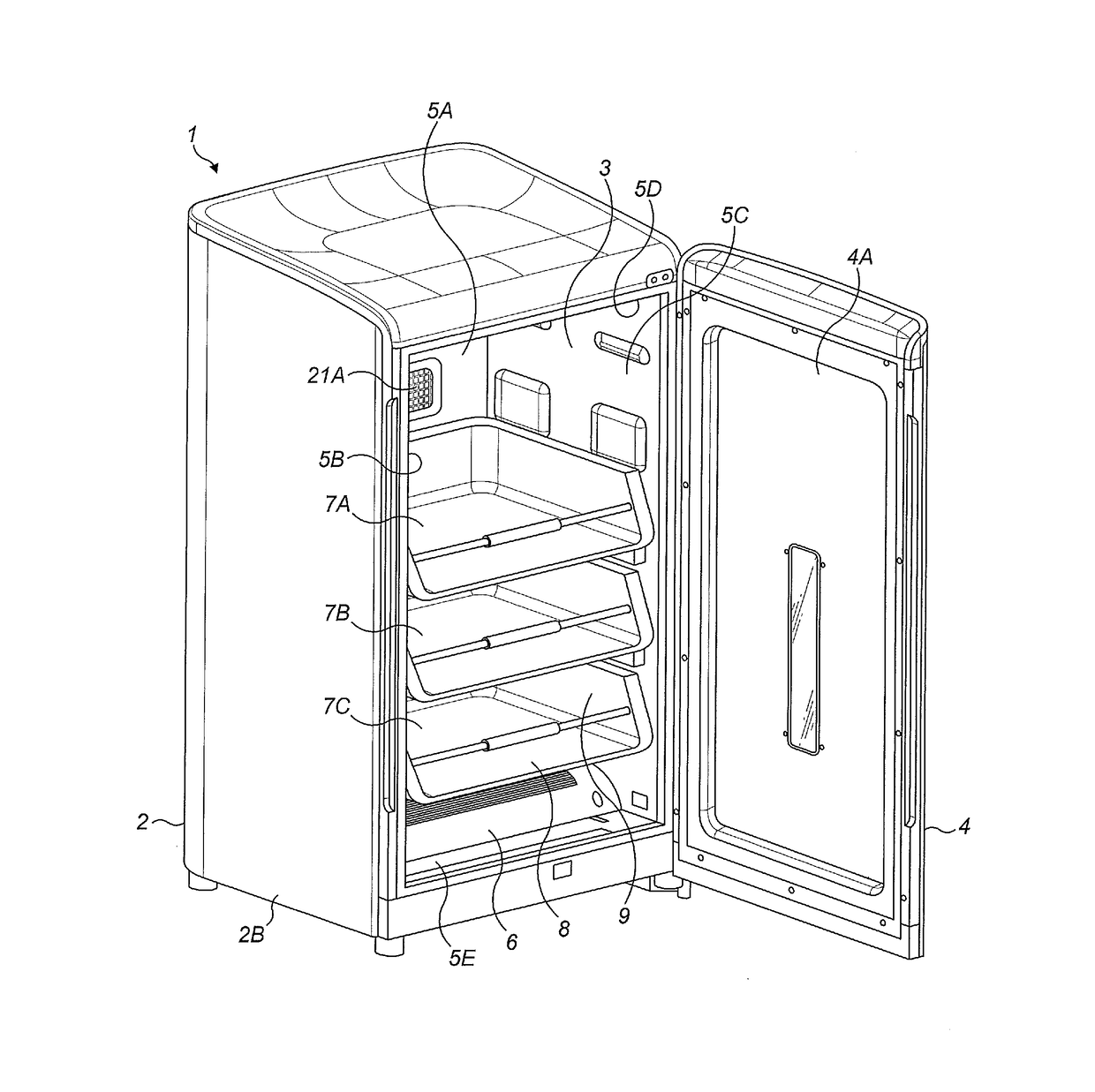

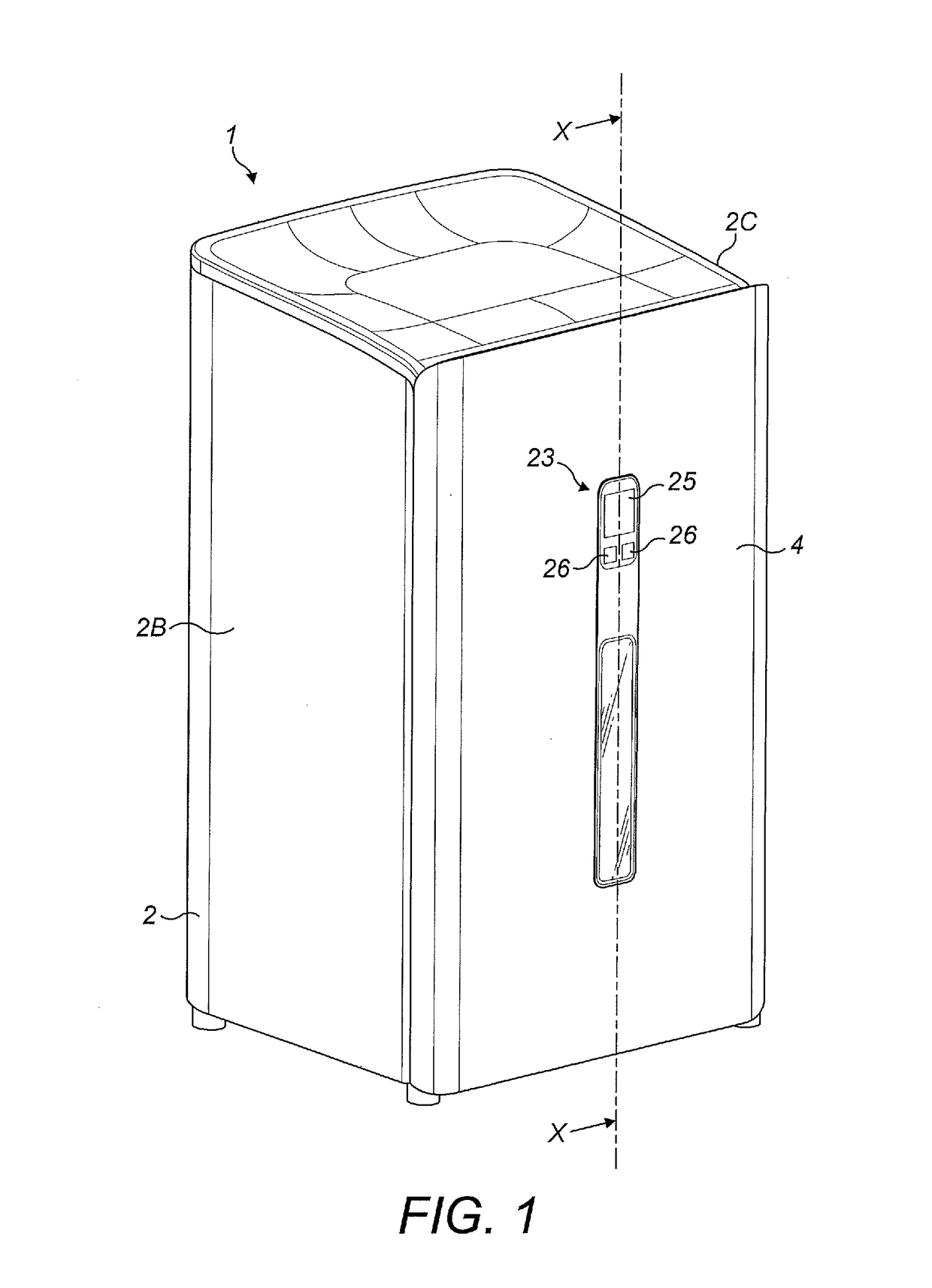

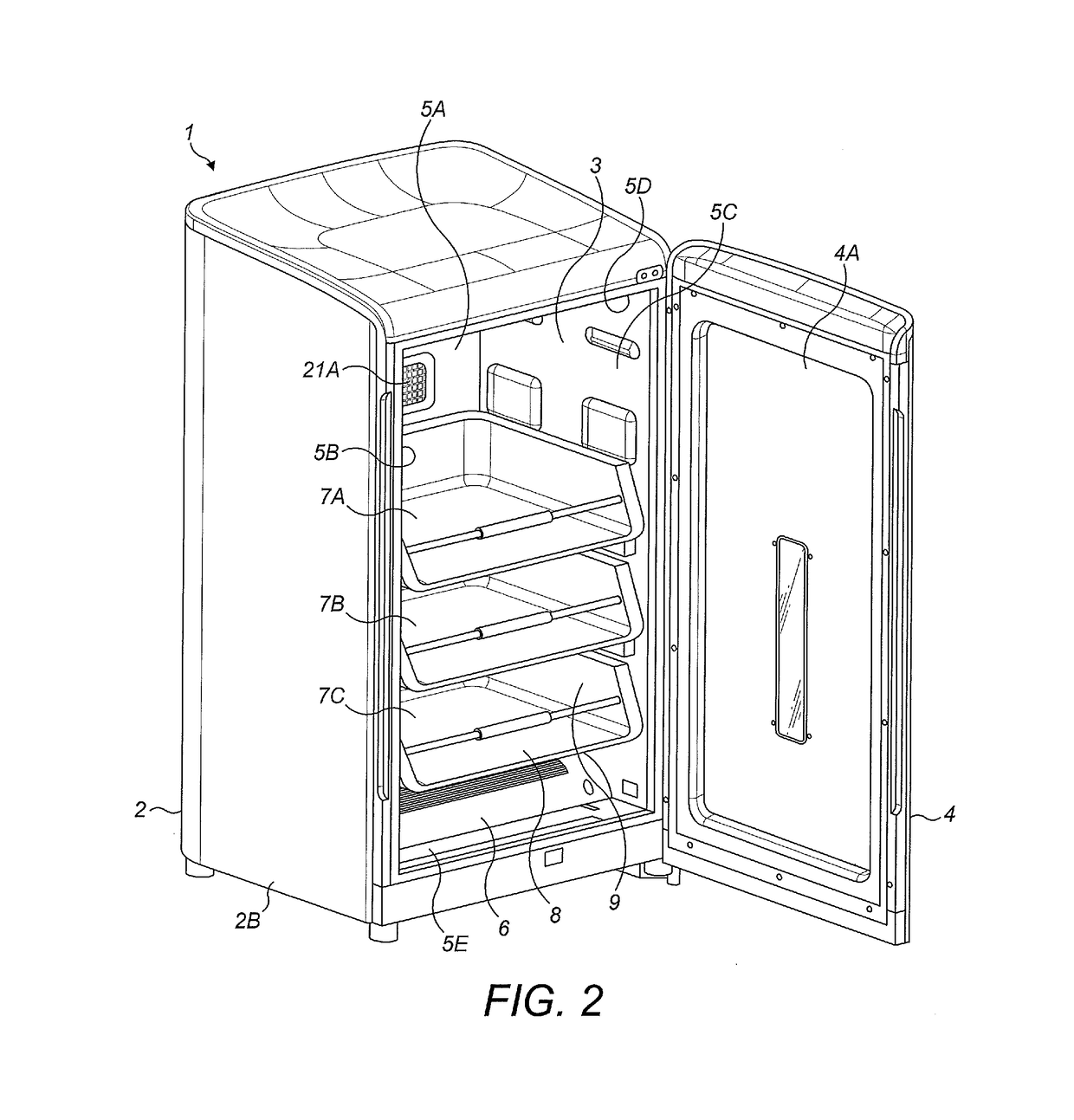

A garment care device for drying and sanitizing garments

InactiveUS20170260681A1Reduce timeSanitize garmentTextiles and paperLaundry driersAirflowEngineering

The present application relates to a garment care device (1) comprising a housing (2) and a chamber (5) within the housing (2) to receive at least one garment. The chamber (5) comprises an air inlet (17) and an air outlet (18). An air channel (15) links the air inlet (17) and the air outlet (18). The garment care device (1) further comprises a fan (19) for circulating an air flow between the chamber (5), the air outlet (18), the air channel (15) and the air inlet (17), and a heater (14) for heating the air flow. The air inlet (17) is configured such that air entering the chamber (5) flows along a first direction (A1, A2). The air outlet (18) is configured to draw the air in the chamber (5) along a second direction (B) transverse to the first direction (A1, A2).The garment care device further comprises a second fan (32) and an extraction channel (31) linking the chamber (5) with the second fan (32). The second fan (32) is configured to selectively draw an air flow out of the chamber (5) and into the extraction channel (31). The garment care device (1) allows improving the drying and sanitizing of garments.

Owner:KONINKLJIJKE PHILIPS NV

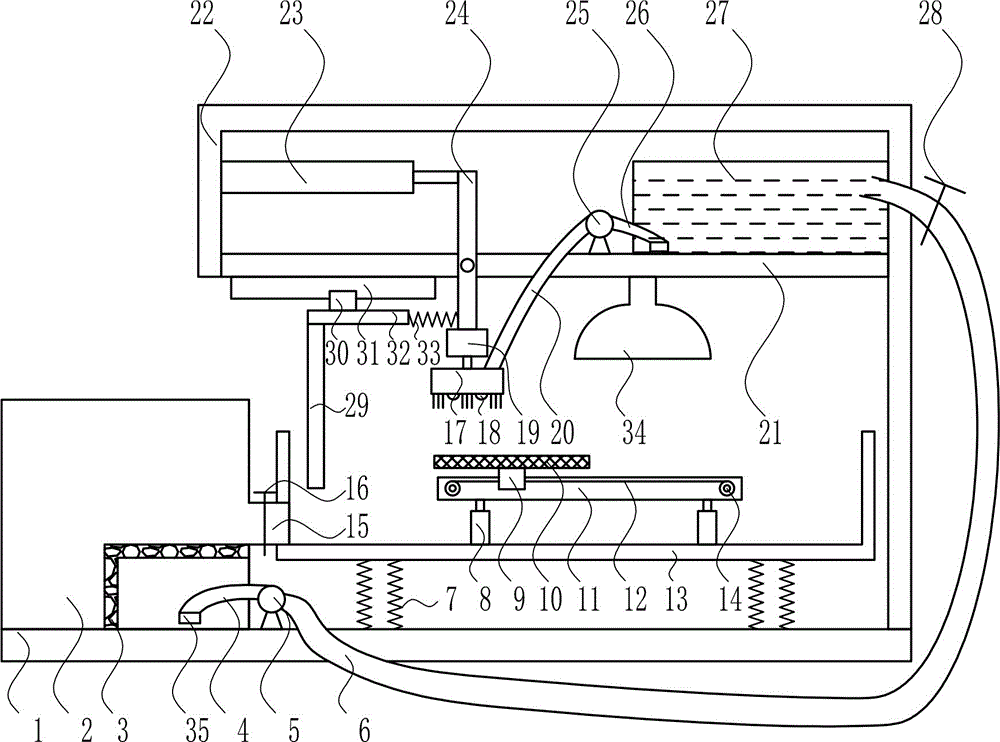

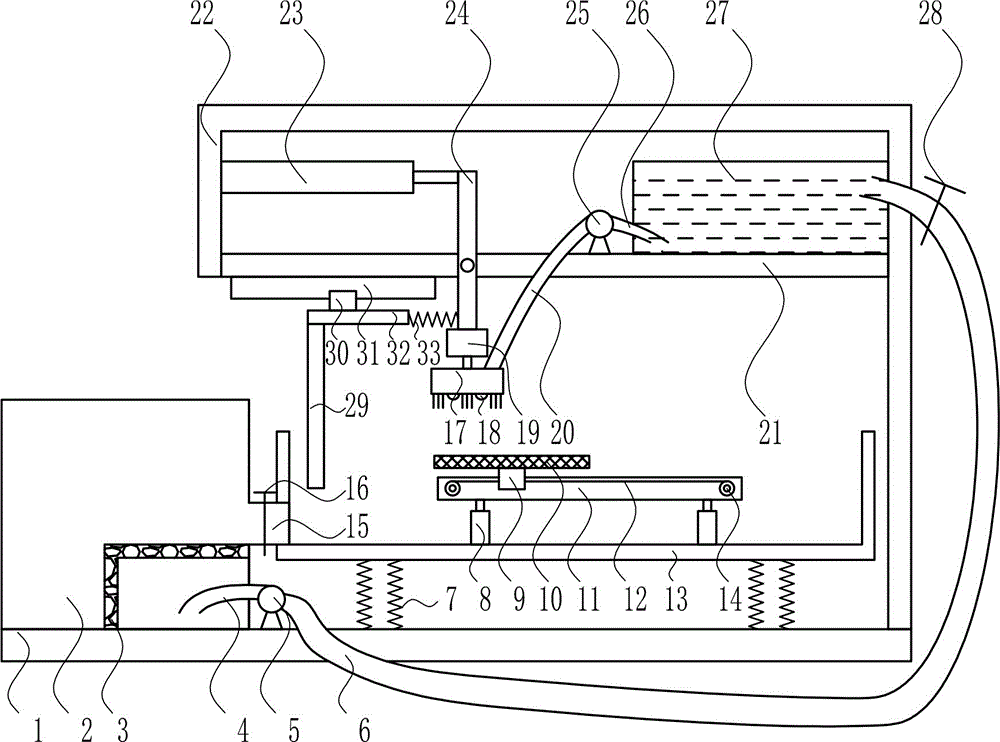

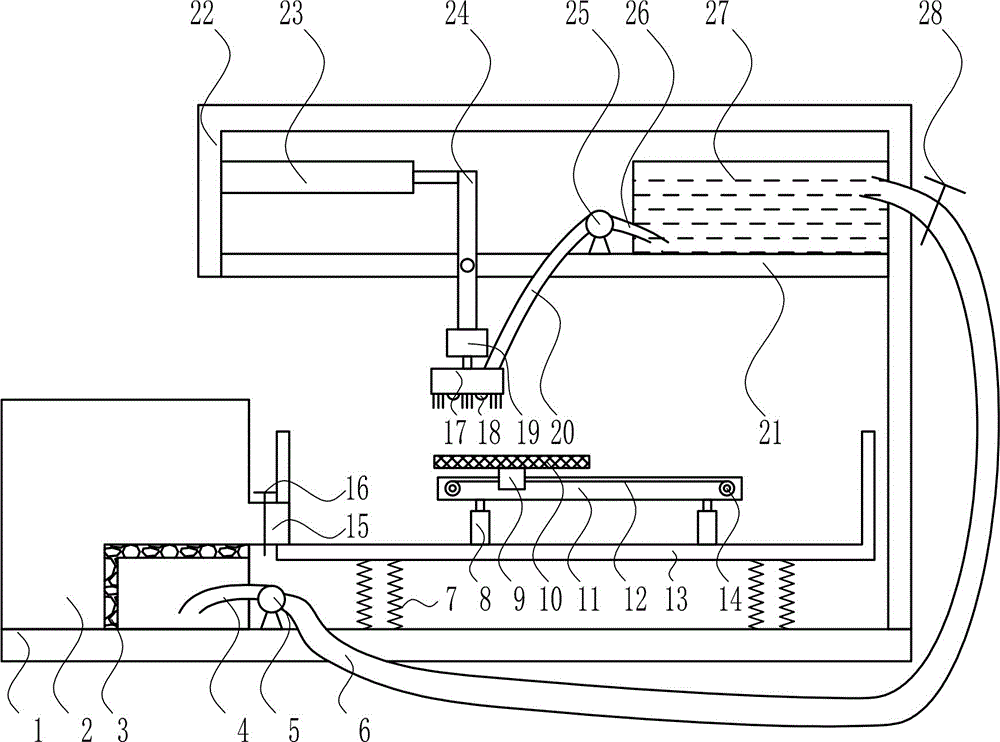

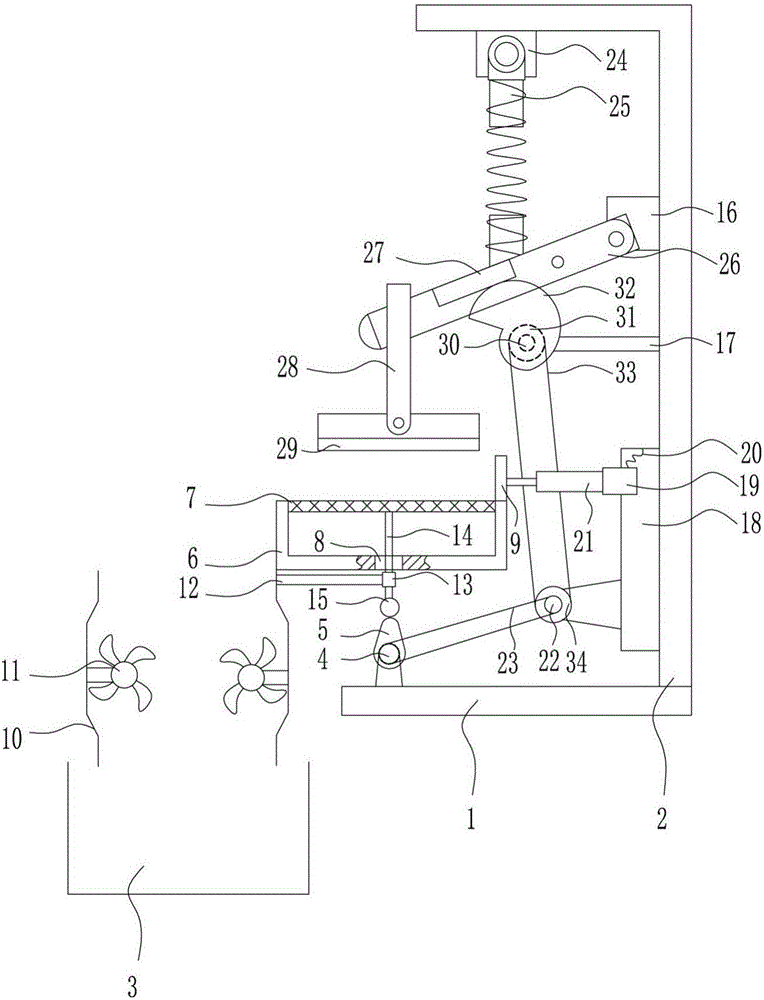

Quick cleaning device for cloth shoes

InactiveCN106264415AReduce laborWash thoroughlyCleaning using toolsCleaning using liquidsActivated carbonEngineering

The invention relates to a cleaning device and in particular relates to a quick cleaning device for cloth shoes. The technical problem to be solved by the invention is to provide a quick cleaning device for cloths, which is small in amount of labor, is thorough in cleaning and can achieve a timely drying effect. The quick cleaning device for cloth shoes comprises a bottom plate, a first water tank, an activated carbon layer, a first hose, a first water pump, a second hose, first springs, second electric push rods, a first slider, a screen, and the like, wherein the first water tank, the first water pump, the first springs and a support are arranged at the top of the bottom plate from left to right in sequence; the activated carbon layer is arranged in the first water tank; a water outlet is formed in the right side of the first water tank; a first electronic control valve is arranged on the water outlet. The device has the beneficial effects that the device achieves the effects of small amount of labor, thorough cleaning and capability of timely drying; in addition, the device can drain dirty water after cleaning so that the interior of the device can be kept clean and does not need to be wiped again.

Owner:杨娇仔

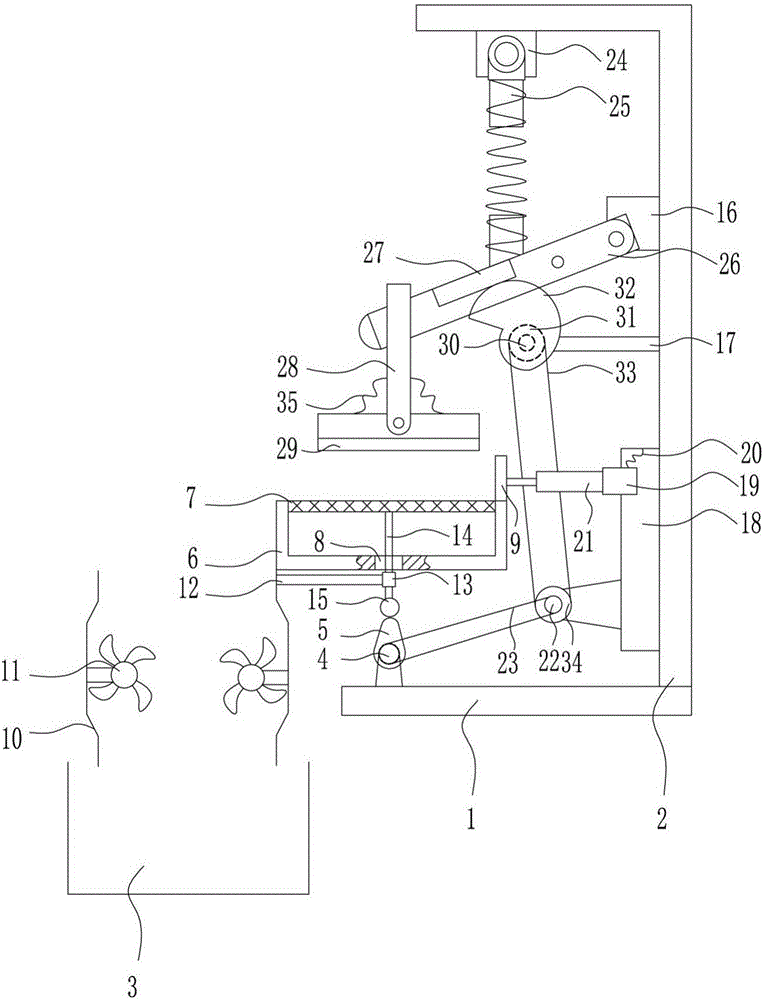

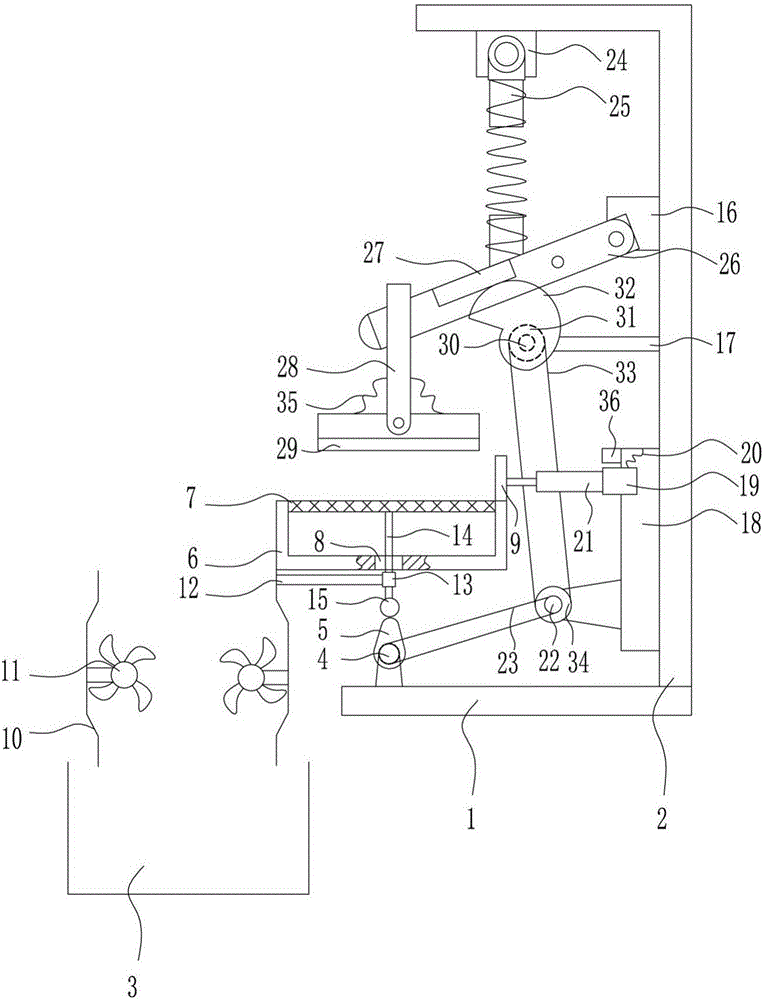

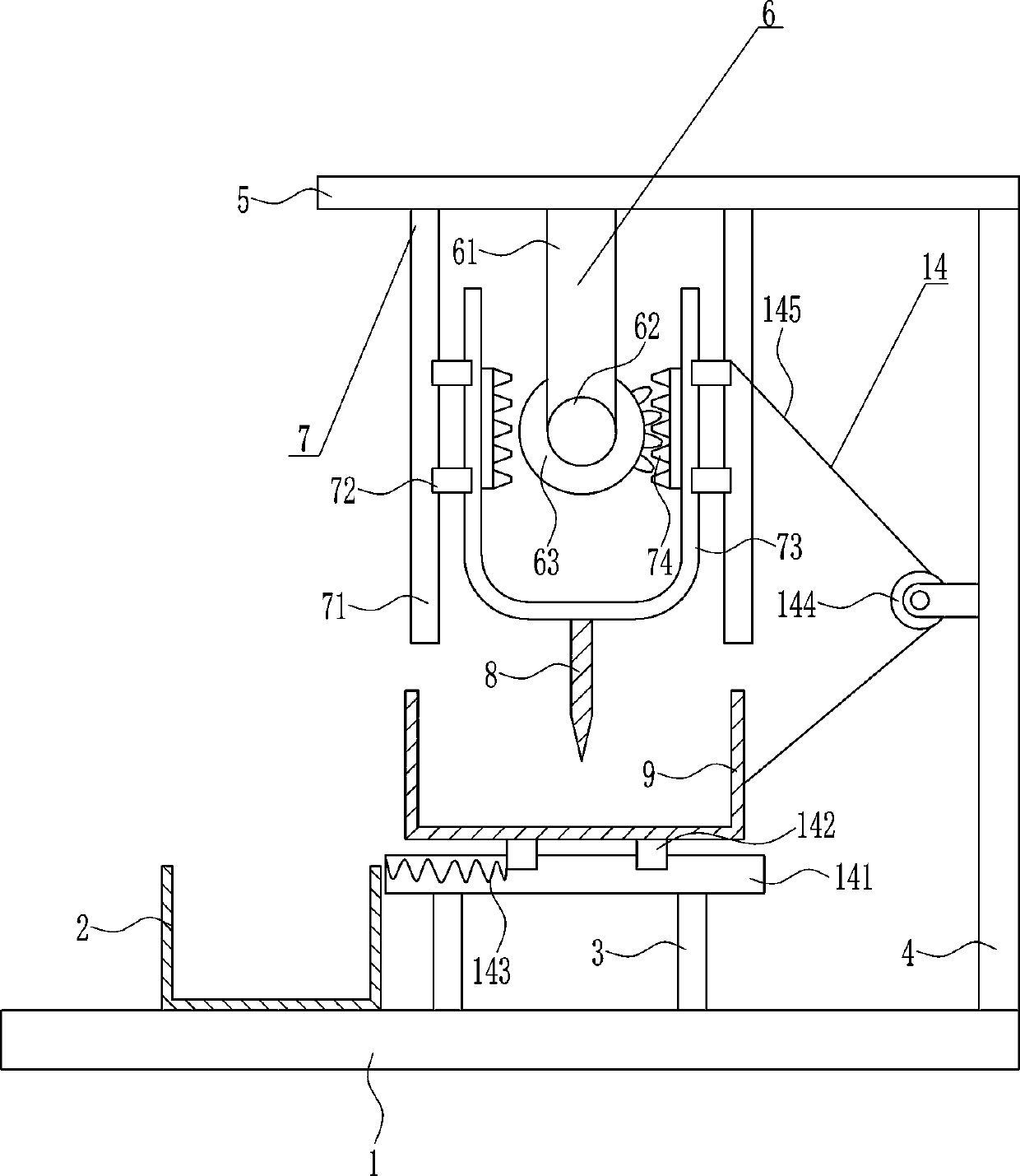

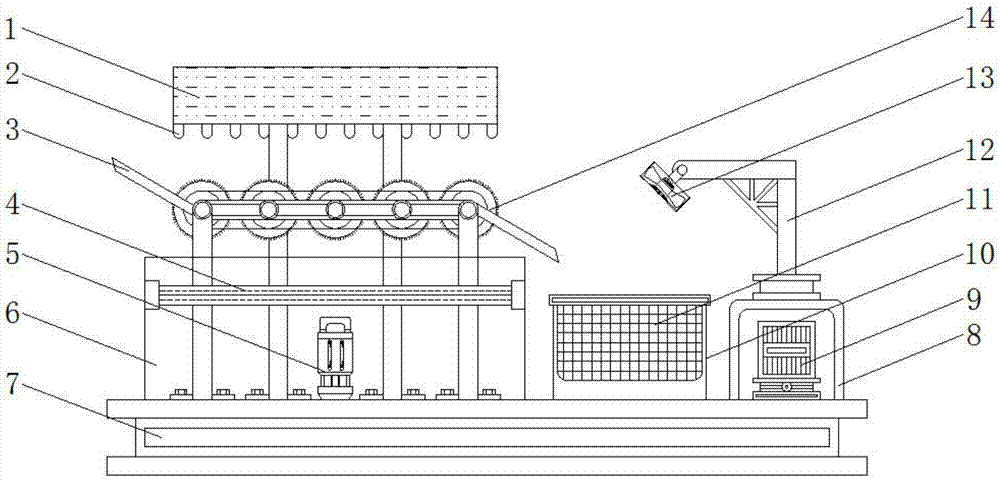

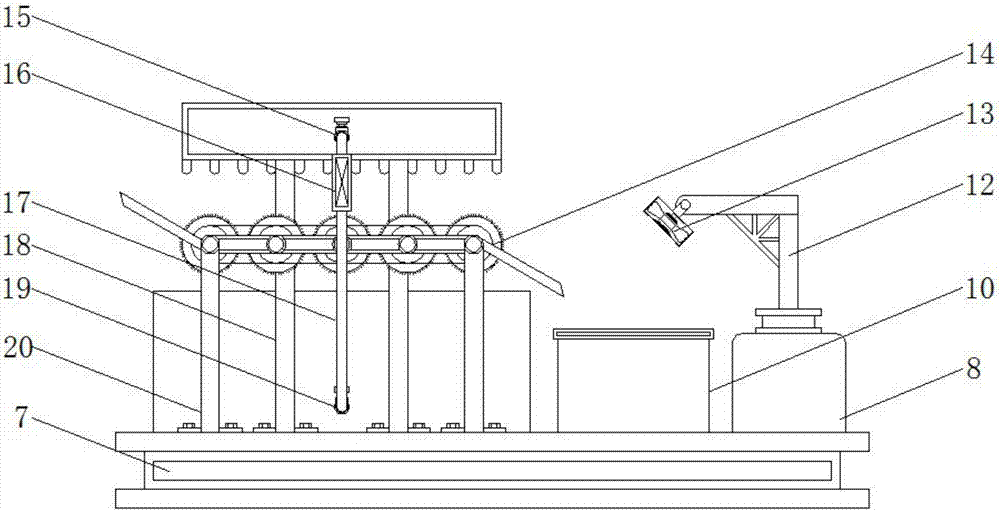

Grass cutting device used in animal husbandry

The invention relates to a grass cutting device, in particular to a grass cutting device used in animal husbandry. The technical problem to be solved by the invention is to provide the grass cutting device used in animal husbandry, which can perform air drying on cut grass in time, cuts grass uniformly and can separate grass cuttings with the grass. In order to solve the technical problem, the grass cutting device used in animal husbandry comprises a base plate, a 7-shaped rack, a collecting frame, a first belt pulley, a small cam, a cutting box, a screen, a push plate, a fan, a guide rod, a guide sleeve, a connecting rod, a sliding rail, a sliding block, a first spring, a cylinder, a fixed seat, an elastic piece, an oscillating rod, a first baffle block, a connection rod, a blade, a motor, a large flat belt, a fourth belt pulley and the like, wherein the first belt pulley and the 7-shaped rack are arranged on the base plate. According to the grass cutting device used in animal husbandry, by using the manner that the up-and-down motion of the blade works together with the up-and-down motion of the screen, the grass on the screen is uniformly cut, and the grass cuttings fall into the bottom inside the cutting box through the screen.

Owner:杨国锋

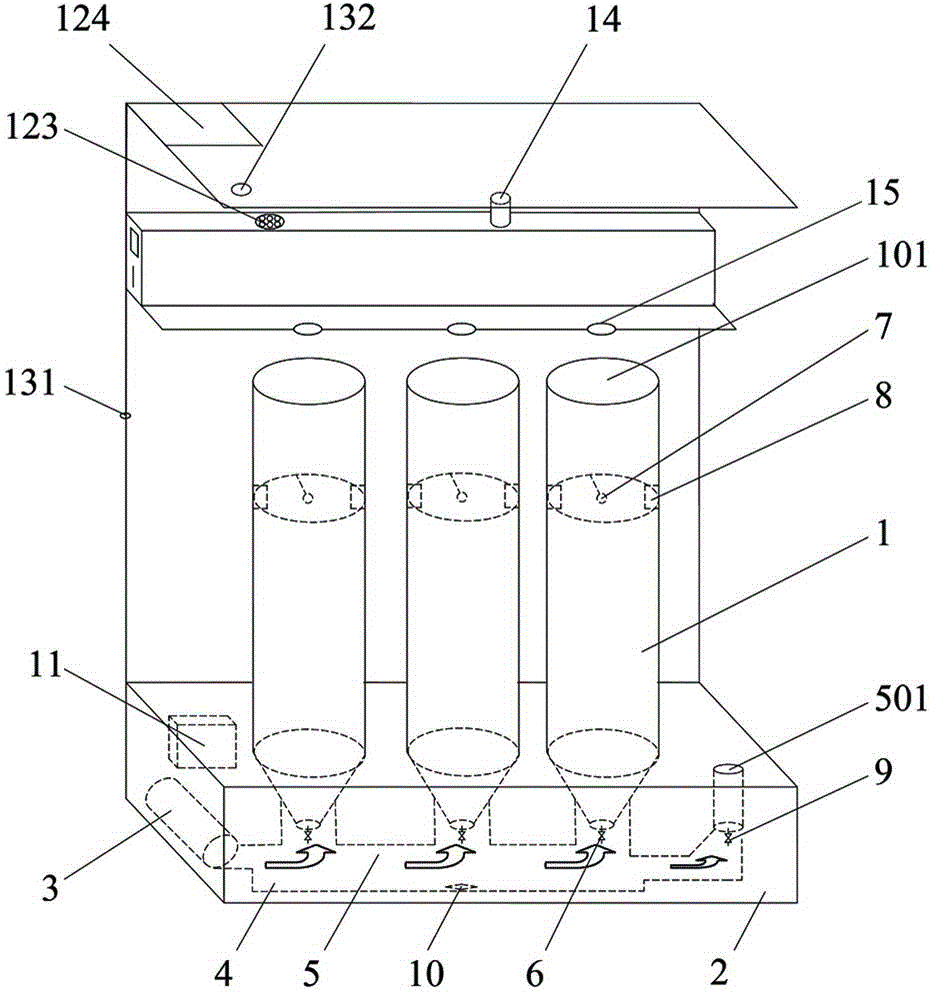

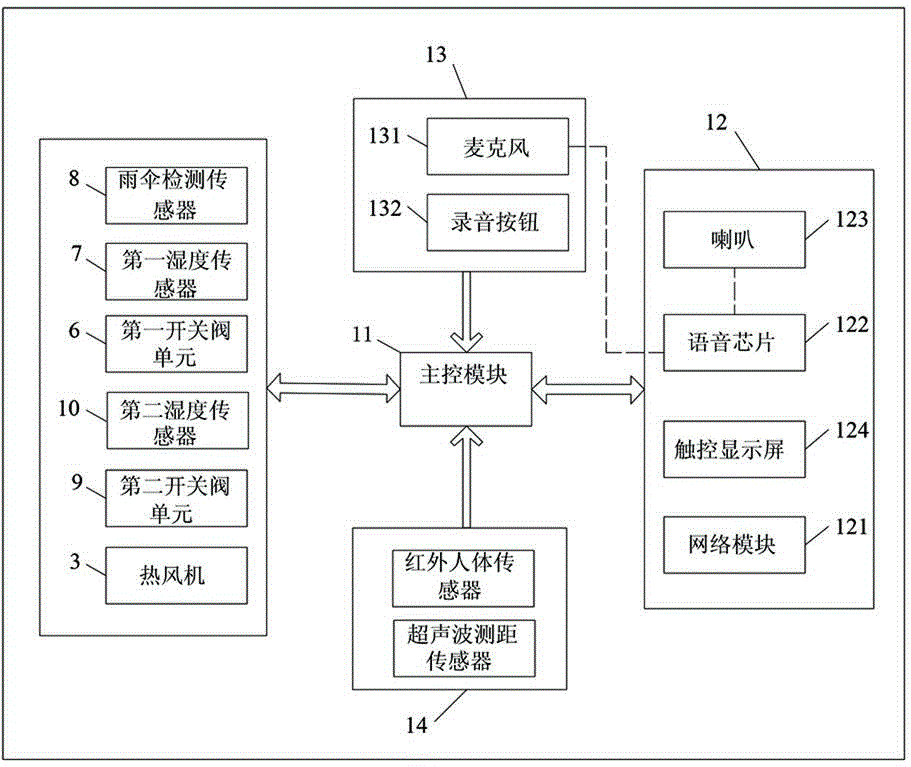

Intelligent umbrella stand

The invention discloses an intelligent umbrella stand which comprises a base, a hot-air blower and more than one drying cylinder. The hot-air output end of the hot-air blower is communicated with the inner cavity of the drying cylinder. The intelligent umbrella stand further comprises an air guide cavity communicated with the bottom of the drying cylinder. The air guide cavity is provided with more than one ventilation openings, one end of the air guide cavity is communicated with the hot-air output end of the hot-air blower, and the hot air output by the hot-air blower removes water accumulated in the air guide cavity and is discharged through the ventilation openings. The intelligent umbrella stand further comprises a smart weather voice reminder display assembly, a record message assembly and a human body detection assembly. The intelligent umbrella stand is simple and compact in structure and convenient and flexible to operate, can dry an umbrella timely, can keep and remove the rainwater dropped from the umbrella, can initiatively broadcast weather conditions and display the weather conditions in real time, has the voice message reminder function, brings convenience to life and meanwhile makes life more interesting.

Owner:刘权

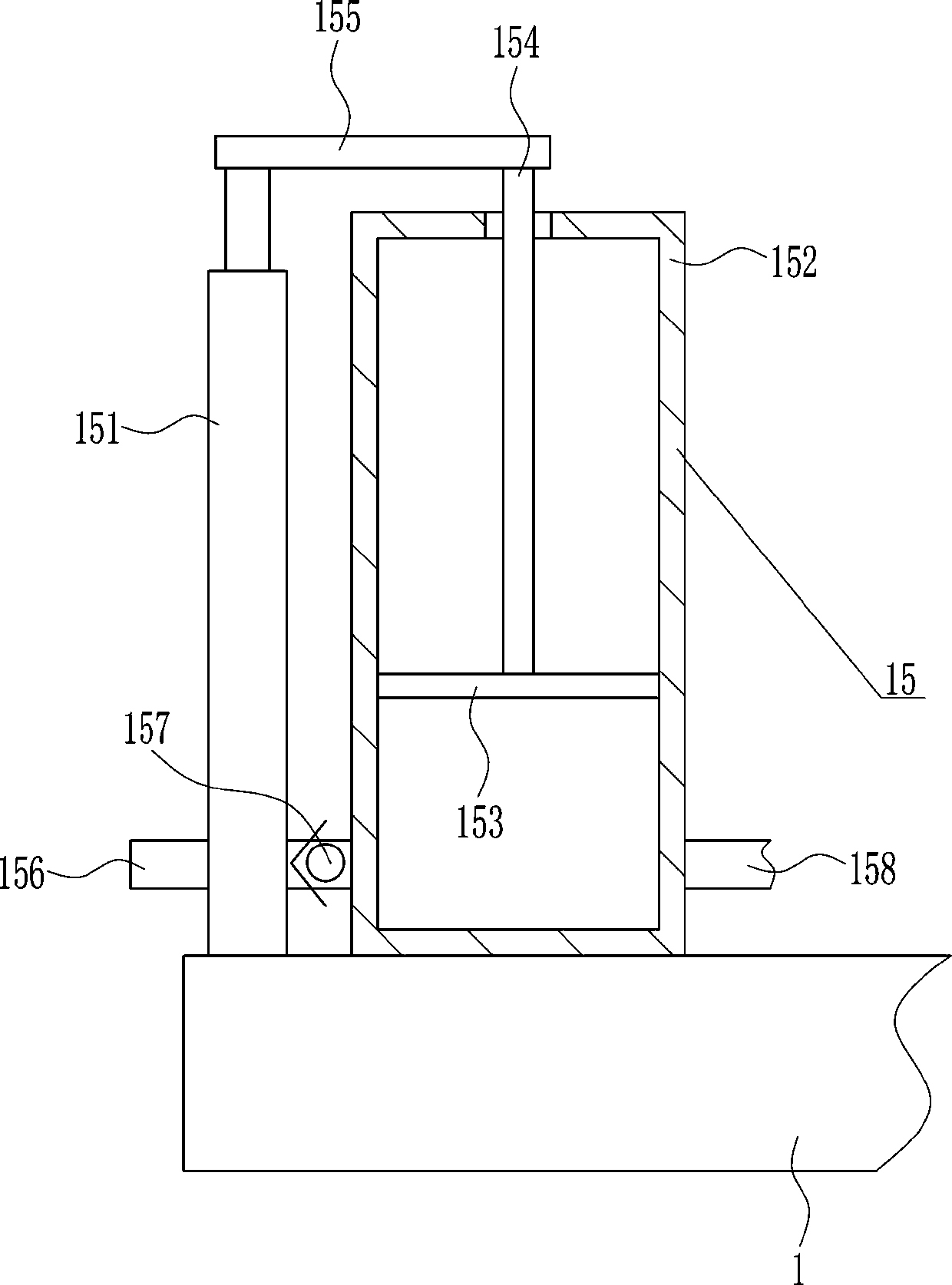

Medical device cleaning and disinfecting integrated device

InactiveCN107570462APrevent leakageAvoid pollutionCleaning using liquidsChemicalsWater pipeEngineering

The invention provides a medical device cleaning and disinfecting integrated device and belongs to the technical field of medical device cleaning and disinfecting. The medical device cleaning and disinfecting integrated device comprises a box body, a liquid storage box, a sealing box, a bottom plate, a damping device and castors. The liquid storage box is divided into a left cavity and a right cavity through a first partition plate in the middle. Fresh water is contained in the left cavity, and disinfecting liquid is contained in the right cavity. A water inlet pipe is arranged on the lower portion of the left cavity, a first valve is arranged on the water inlet pipe, and a lower end opening of the water inlet pipe leads to the sealing box. By arranging the sealing box, the loss and unnecessary pollution caused by liquid leakage can be effectively prevented; a transmission device drives a tray to make small amplitude rotating movement, and thus the purposes of cleaning and disinfectingare achieved; the tray is made to tilt rightwards through a hydraulic cylinder and a telescopic rod, and thus discharging of the liquid in the tray is facilitated; heating sheets are arranged so thata medical device can be dried in time; and waste liquid after use is purified through a reaction and then discharged, so that pollution to the environment is prevented.

Owner:郑州莉迪亚医药科技有限公司

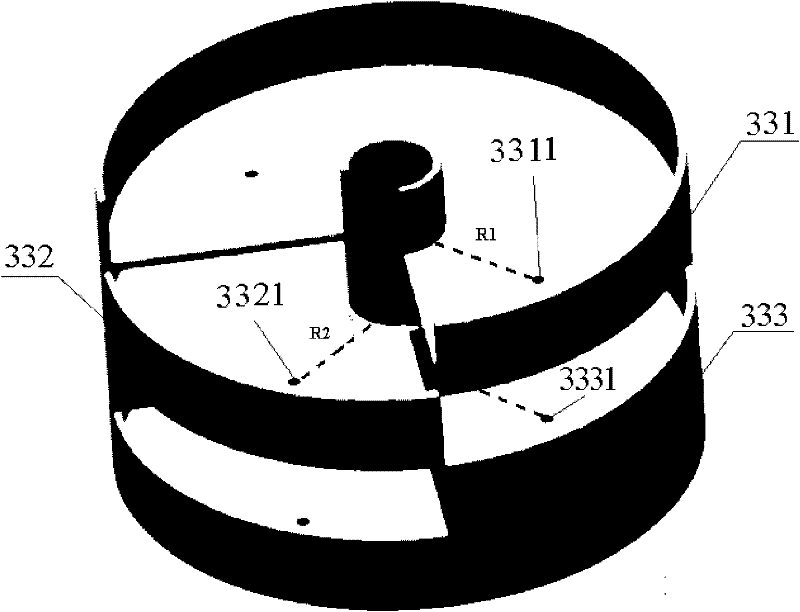

Multi-channel switchable electric heating dryer

InactiveCN102290199AExtended service lifeDry in timeTransformers/inductances coolingHeater elementsTransformerEngineering

The invention relates to a multi-passage switchable electric heating dryer, which comprise a first passage switcher, a plurality of moisture-absorbing barrels and a second passage switcher; one end of the first passage switcher is connected with the inlets of the moisture-absorbing barrels, the other end of the first passage switcher communicates with the atmosphere, and the first passage switcher is used for switching passages between the moisture-absorbing barrels and the atmosphere, so that part of the moisture-absorbing barrels can communicate with the atmosphere and the rest of the moisture-absorbing barrels cannot communicate with the atmosphere; one end of the second passage switcher is connected with the outlets of the moisture-absorbing barrels, the other end of the second passage switcher respectively communicates with the atmosphere and a drying destination, and the second passage switcher is used for switching passages between the moisture-absorbing barrels and the atmosphere as well as the drying destination, so that part of the moisture-absorbing barrels can communicate with the atmosphere and the rest of the moisture-absorbing barrels can communicate with the dryingdestination; and a barrel body of each moisture-absorbing barrel is provided with a heating part for drying the moisture-absorbing barrel. The multi-passage switchable electric heating dryer can dry the silica gel and the air in the dryer in a switching manner, thus prolonging the service life of the silica gel, solving the problem of complex process switching and enhancing the safety stability of a transformer.

Owner:EAST CHINA UNIV OF SCI & TECH

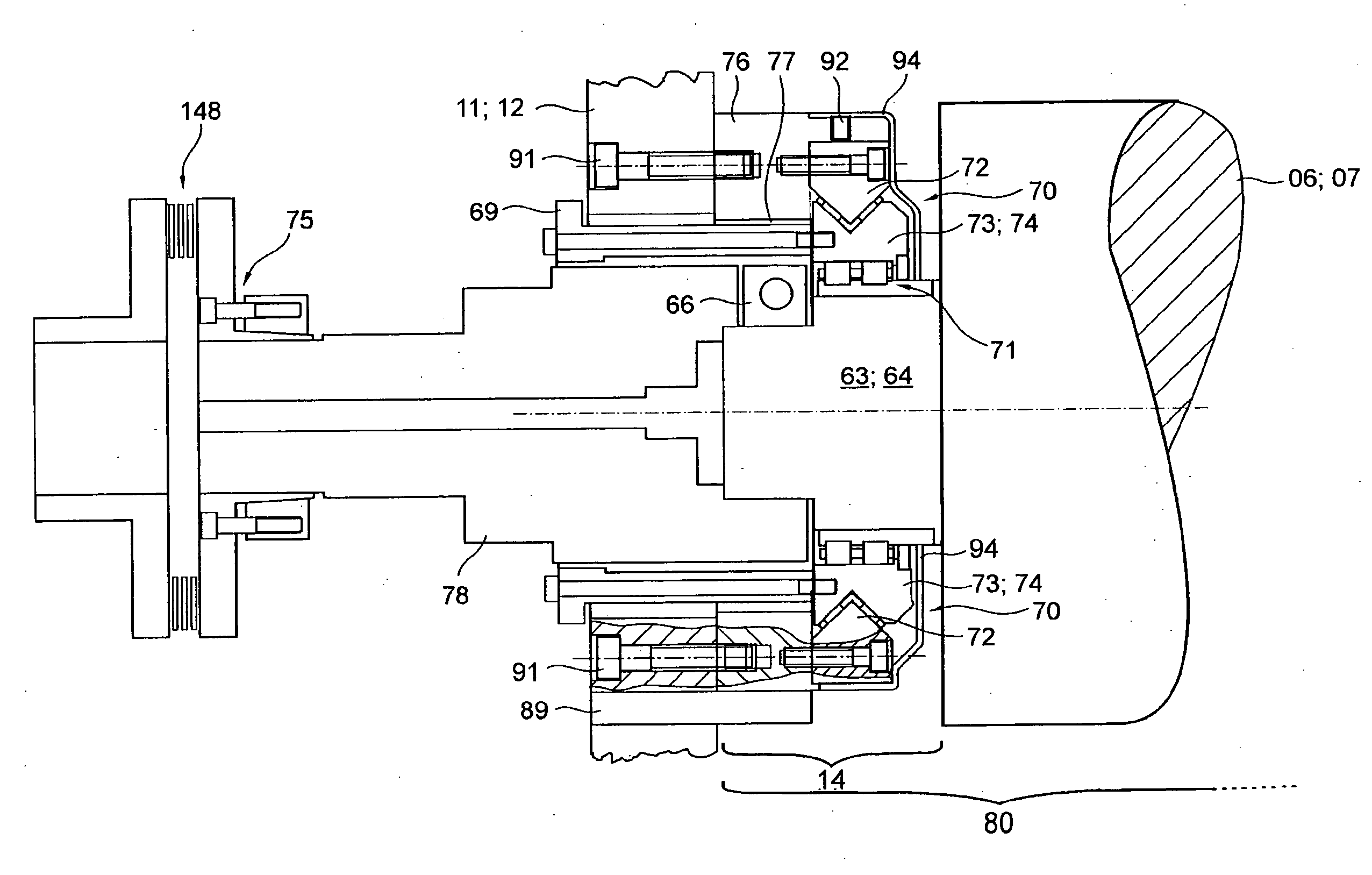

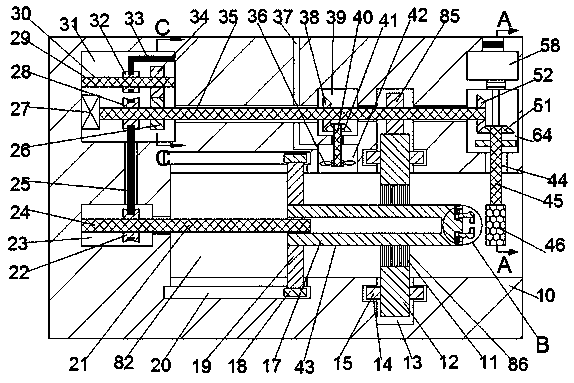

Flexographic Printing Press

InactiveUS20090078134A1Simple and yet strong drive mechanismDry in timeStructural associationMechanical energy handlingSynchronous motorElectric machinery

A flexographic printing press is comprised of at least four printing cylinders which are each driven by a respective drive motor. These at least four printing cylinders cooperate directly with a common satellite cylinder during the printing of a web of material. Each of these printing cylinders supports at least one flexographic printing plate. Each end journal of such printing cylinder is mounted in at least one linear bearing that is located on a lateral frame, and which can be moved perpendicularly to the axis of rotation of the respective cylinder. A stator of each driving motor can be moved along with the associated linear bearing, or along with the printing cylinder. Each such drive motor is configured as a synchronous motor which is excited by a permanent magnet. An independent hydraulic actuator is assigned to each printing cylinder, to change the position of that printing cylinder. At least one linear bearing is arranged in a bearing unit which is placed on the interior wall of the respective lateral frame. The journals of each printing cylinder do not penetrate the lateral frames.

Owner:KOENIG & BAUER AG

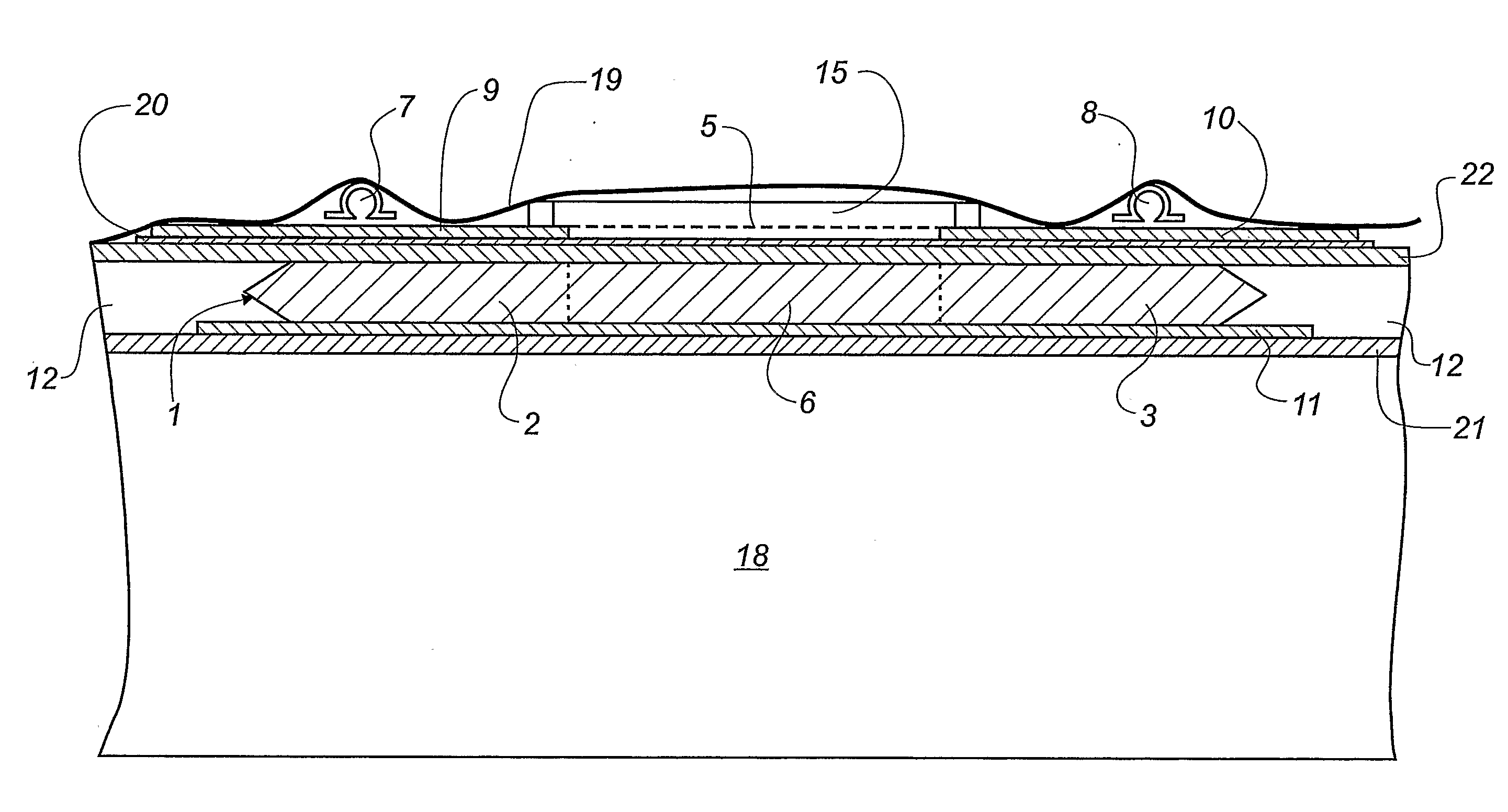

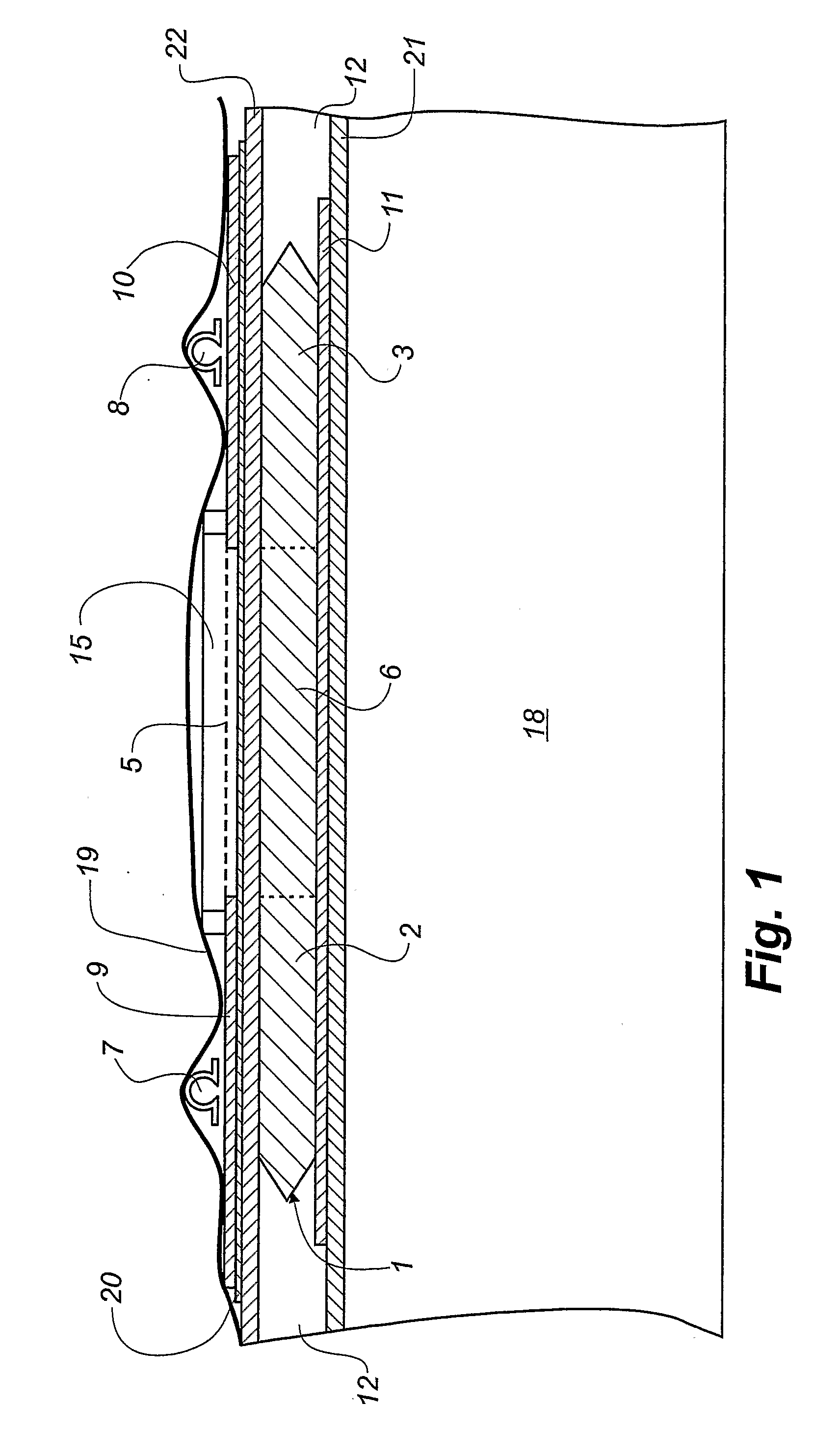

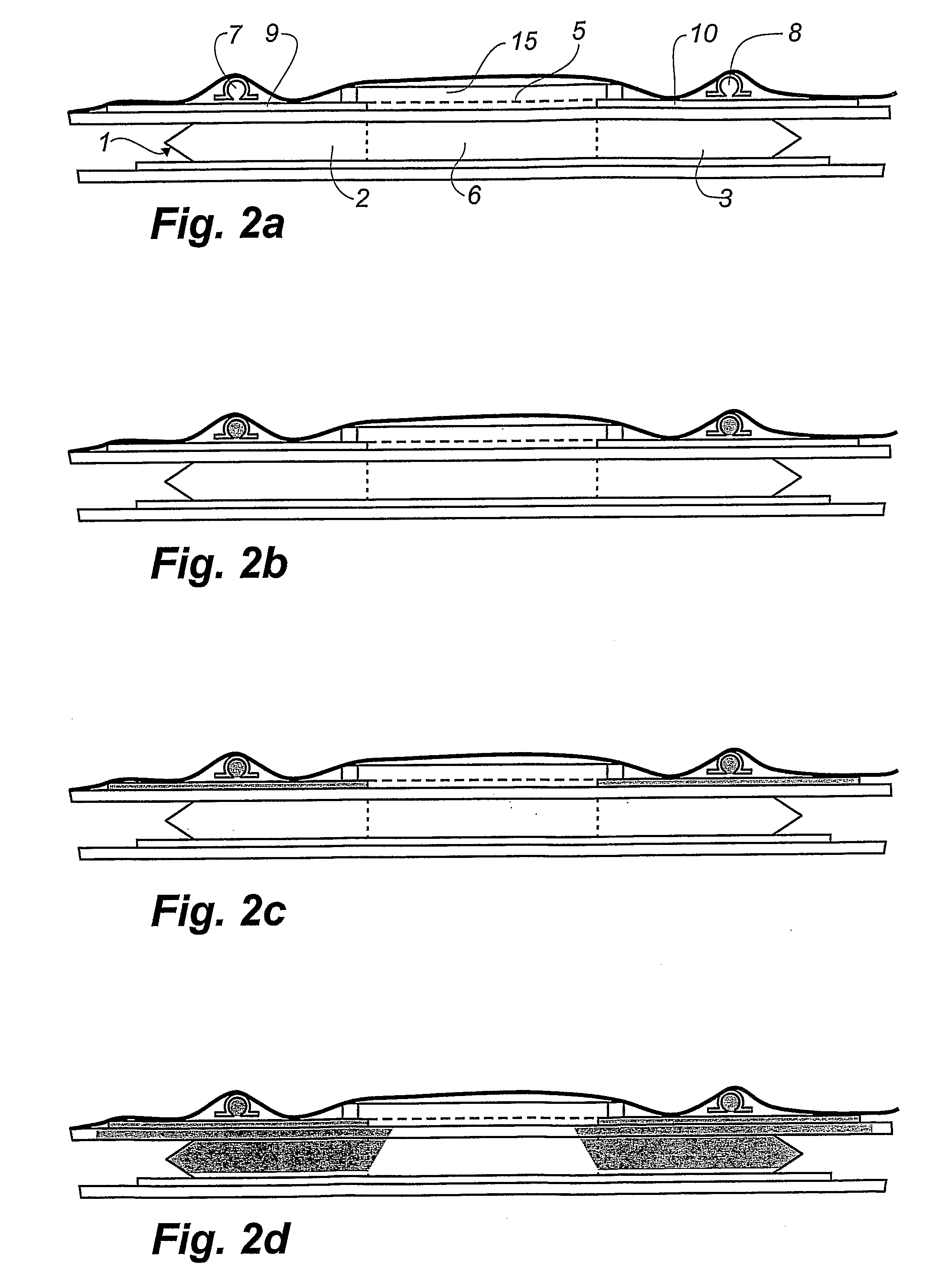

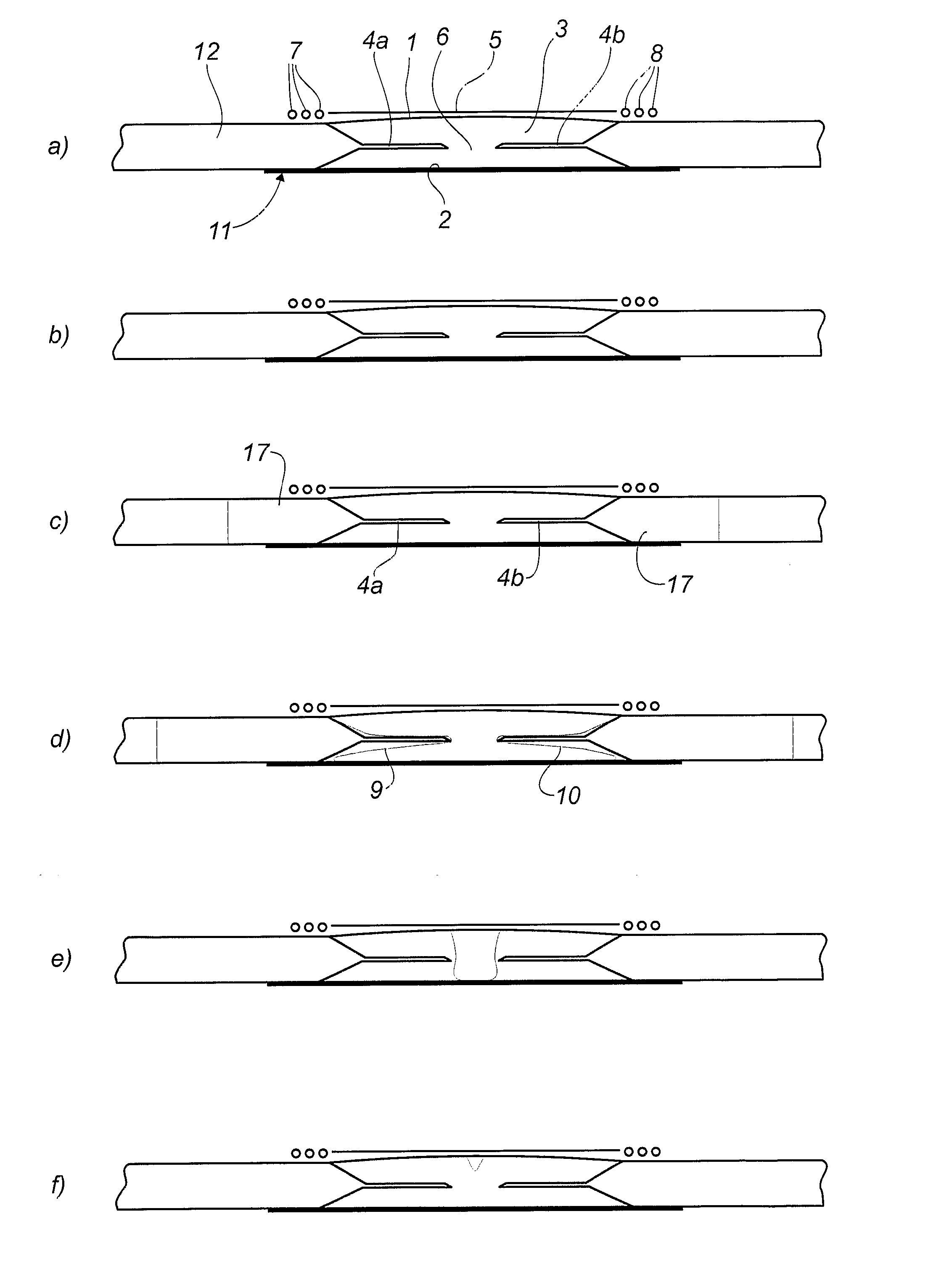

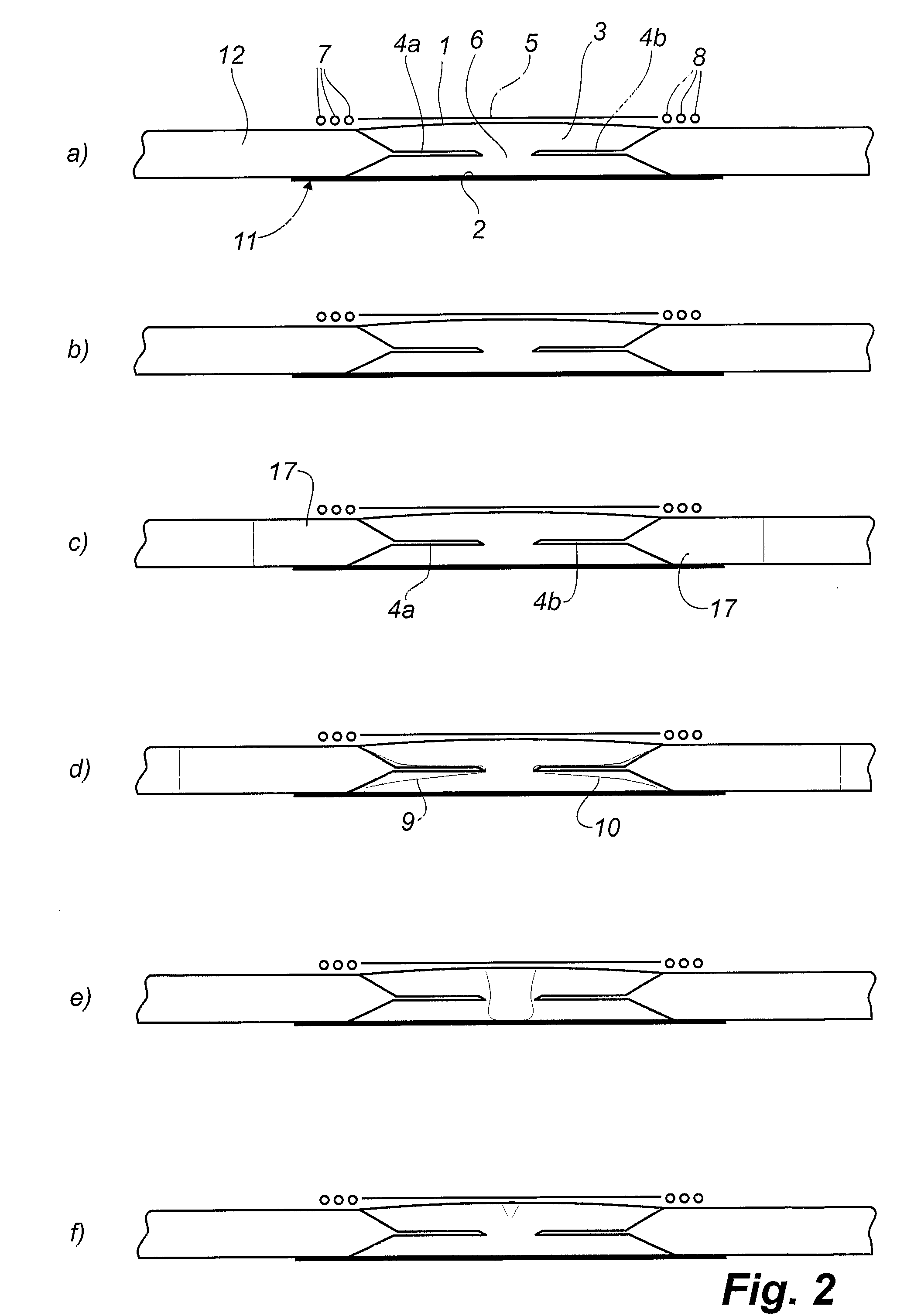

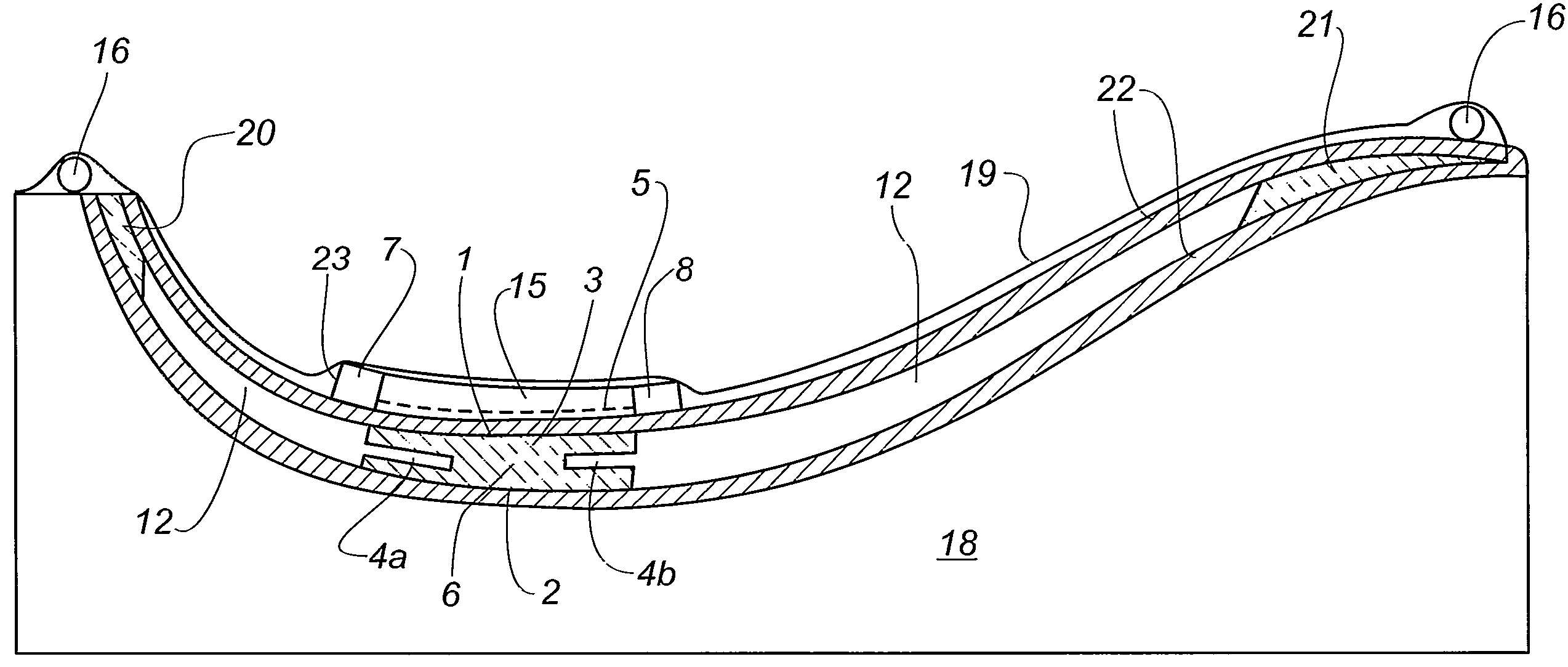

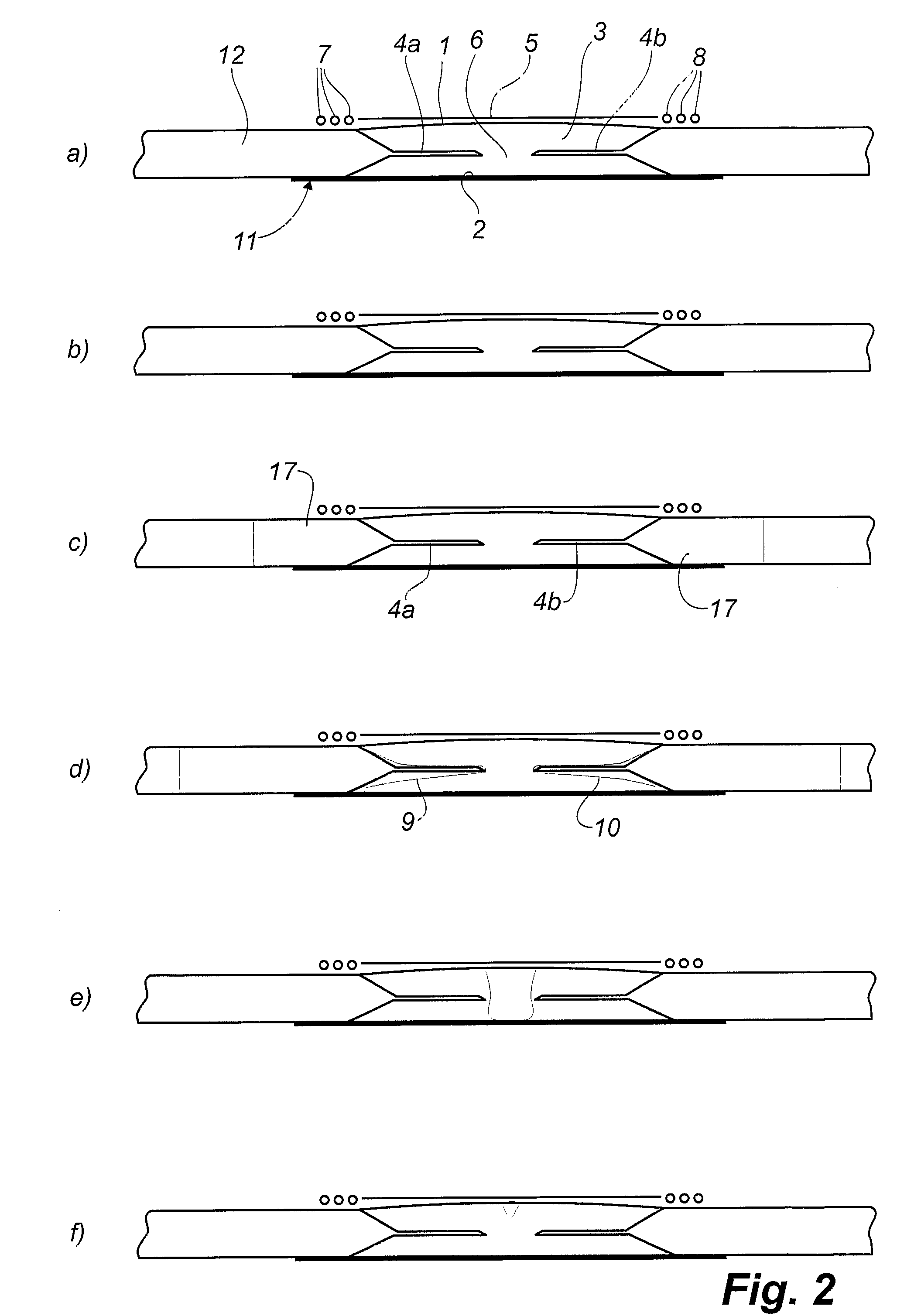

Vacuum Infusion by Means of a Semi-Permeable Membrane

ActiveUS20080093761A1Speed up the flowShorten the timeLaminationLamination apparatusMembrane methodInlet channel

Method of producing an oblong shell member made of fibre composite material by means of vacuum infusion, where the fibre material is impregnated with liquid polymer. A mould is applied with a mould cavity, in which a fibre insertion (3) with a first lateral face (1) and a second lateral face (2) is placed, and where said fibre insertion includes a plurality of fibre layers and a distribution layer (4), said distribution layer allowing a higher rate of flow for the liquid polymer than the fibre layers. A semi-permeable membrane (5) is placed opposite the first lateral face (1) of the fibre insertion, said semi-permeable membrane being substantially permeable to gasses and substantially impermeable to liquid polymer and further communicating with a vacuum source The distribution layer (4) is placed inside the fibre insertion (3) with fibre layers on both sides and is interrupted by a zone (6) opposite the semi-permeable membrane (5) Liquid polymer is directed via inlet channels (7, 8) to the distribution layer (4), thus creating a flow front (9, 10) between the distribution layer (4) and the second lateral face (2), said flow front moving through the central zone (6) towards the semi-permeable membrane (5)

Owner:LM GLASSFIBER

Cutting device used for pasture grass for feeding livestock in animal husbandry

The invention relates to a pasture grass cutting device, and particularly relates to a cutting device used for pasture grass for feeding livestock in animal husbandry. The technical problem to be solved by the invention is to provide a cutting device with which manpower and time can be saved, overall cutting can be achieved, air drying can be carried out in time after cutting, and economic loss can be reduced, wherein the cutting device is used for feeding the livestock in animal husbandry. In order to solve the technical problems, the invention provides the cutting device for the pasture grass for feeding the livestock in animal husbandry. The cutting device comprises a bottom plate, a lifting device and the like; the top part of the bottom plate is connected with a collecting frame, support rods and a support frame through a connecting way by bolts in sequence from left to right; and both the support rods and the support frame are vertically arranged. According to the cutting device,a first motor is adopted as a drive, so that a cutter moves up and down ceaselessly to cut the pasture grass; meanwhile a placing frame moves left and right to overall cut the pasture grass, so thatthe following effects that the manpower and the time can be saved, the whole cutting can be achieved, air drying can be carried out in time after cutting, and the economic loss can be reduced are achieved.

Owner:皮强义

Vacuum infusion by means of a semi-permeable membrane

Method of producing an oblong shell member made of fiber composite material by means of vacuum infusion, where the fiber material is impregnated with liquid polymer. A mould is applied with a mould cavity, in which a fiber insertion (3) with a first lateral face (1) and a second lateral face (2) is placed, and where said fiber insertion includes a plurality of fiber layers and a distribution layer (4), said distribution layer allowing a higher rate of flow for the liquid polymer than the fiber layers. A semi-permeable membrane (5) is placed opposite the first lateral face (1) of the fiber insertion, said semi-permeable membrane being substantially permeable to gasses and substantially impermeable to liquid polymer and further communicating with a vacuum source The distribution layer (4) is placed inside the fiber insertion (3) with fiber layers on both sides and is interrupted by a zone (6) opposite the semi-permeable membrane (5) Liquid polymer is directed via inlet channels (7, 8) to the distribution layer (4), thus creating a flow front (9, 10) between the distribution layer (4) and the second lateral face (2), said flow front moving through the central zone (6) towards the semi-permeable membrane (5)

Owner:LM GLASSFIBER

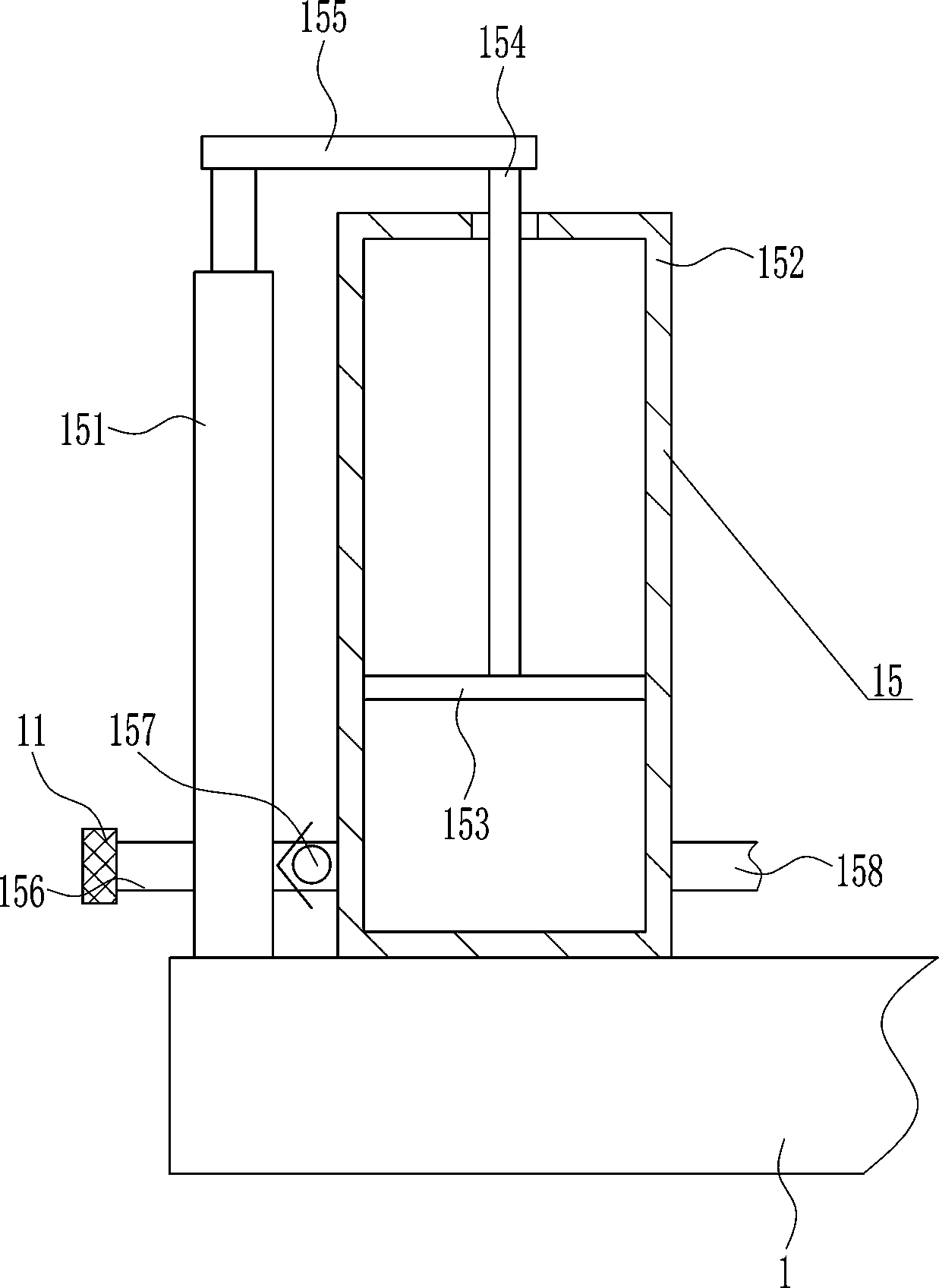

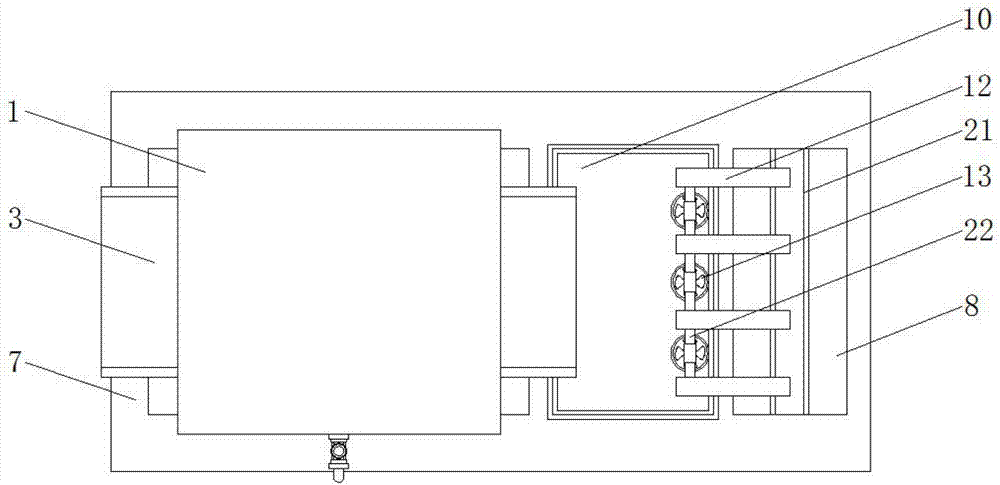

Rapid washing and drying equipment for medical surgical instruments

The invention particularly relates to rapid washing and drying equipment for medical surgical instruments. In order to achieve the technical aims, the rapid washing and drying equipment for medical surgical instruments does not cause secondary pollution by transportation after washing is finished and can perform drying in time after washing is finished. The rapid washing and drying equipment for medical surgical instruments comprises a bottom board, a washing tank, a first motor, stirring blades, a first filtering board, a supporting rod, a connection rod, a guide sleeve, a guide rail, a rack, a connection block, a second motor and the like. The bottom board is provided with the washing tank in a bolt connection mode; and the first motor is installed on the lower side wall inside the washing tank in a bolt connection mode. The rapid washing and drying equipment for medical surgical instruments achieves the effects that secondary pollution caused by transportation after washing is finished is avoided, and drying can be performed in time after washing is finished.

Owner:赖富山

High temperature investment material and method for making solid investment molds

An improved phosphate-type refractory investment material and method for making solid investment molds especially useful for casting high melting point metals and alloys, such as platinum and the like. The material consists essentially of one or more phosphate salts, a water soluble acidic constituent, and refractory powder. The material can be prepared as a dry powder blend which is easily shipped to the user and mixed with water at the time of investing the flask. Alternatively, the salt and / or acidic constituent can be combined with the refractory powder at the time of mixing with water.

Owner:AVALON PRECISION CASTING CO LLC

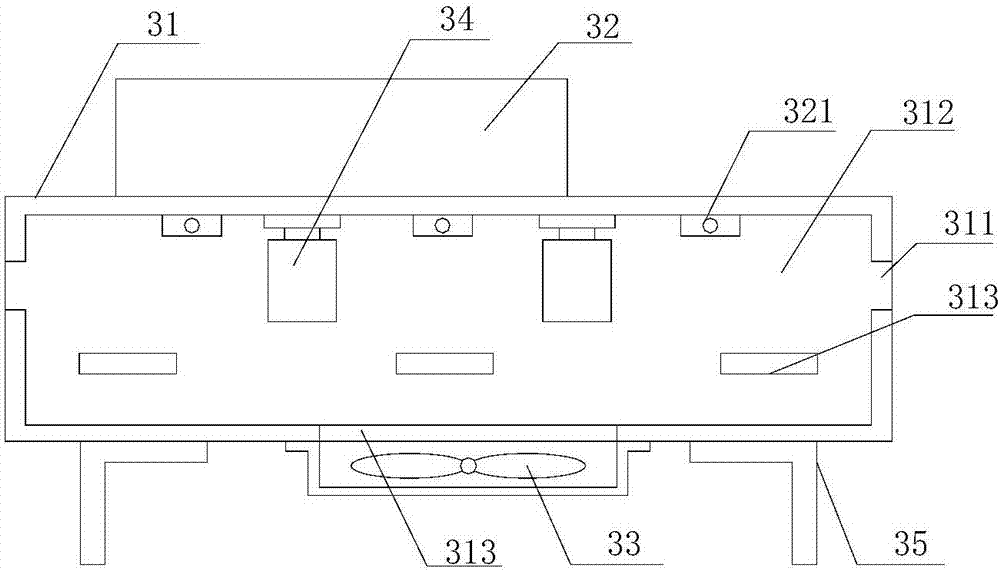

Gradation roller coating device of aluminum plate

PendingCN107321568ARoller evenlyIncrease productivityLiquid surface applicatorsCoatingsSurface coverBellows

The invention provides a gradation roller coating device of an aluminum plate. The gradation roller coating device comprises a material conveying conveyer belt device, a primary roller coating device, a first drying air box, a secondary roller coating device, a second drying air box and a material discharging conveyer belt device, wherein the output end of the material conveying conveyer belt device is provided with the primary roller coating device; a material charging coating roller mechanism, a transition coating roller mechanism, a roller coating roller mechanism and a scraper device are arranged in the primary roller coating device; the first drying air box is arranged between the primary roller coating device and the second roller coating device; an air blower is arranged below the first drying air box; a plurality of heating pipes are arranged above the first drying air box; a second drying air box is arranged between the secondary roller coating device and the material discharging conveying device; material feeding is realized for the roller coating roller mechanism through the transition coating roller mechanism, so that paint with uniform thickness can be smeared on the surface of the roller coating roller; roller coating is performed in a grading manner using the two roller coating devices; besides, drying is separately performed after roller coating; uniform roller coating of the aluminum plate is ensured; and production efficiency is improved.

Owner:嘉兴亿豪新材料股份有限公司

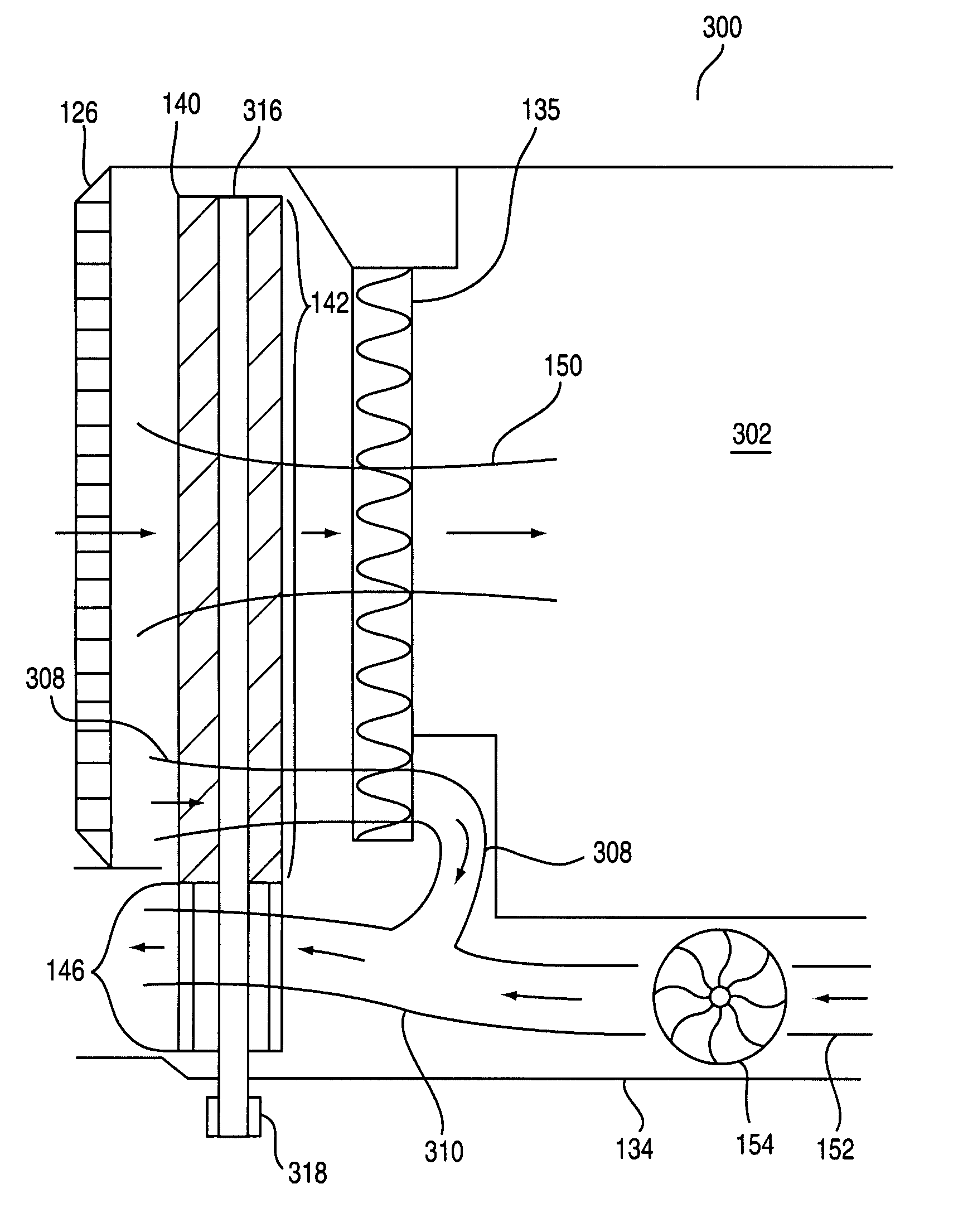

Dryer and drying apparatus with enhanced moisture removal

InactiveUS20080276802A1Improve drying efficiencyReduce amountDrying gas arrangementsIsotope separationDesiccantMoisture

A dryer and a drying apparatus attachable to a dryer are disclosed. A wheel having desiccant material is located in line and in close proximity with a heating element. The wheel includes a first portion positioned in an inlet air path and a second portion positioned in an outlet air path. The desiccant material removes water molecules from air within the inlet air path, and lowers the vapor pressure of the incoming air. In the outlet air path, heated air flows through the second portion to transfer energy to the desiccant material. The wheel rotates to change the desiccant material within the portions.

Owner:PROTEGE ENTERPRISES

Automatic traditional Chinese medicine bletilla striata cleaning and collecting device

InactiveCN107377482ADry in timeSave waterDrying gas arrangementsCleaning using toolsBristleBletilla striata

The invention relates to an automatic traditional Chinese medicine bletilla striata cleaning and collecting device which comprises a spraying water tank, a water collecting tank, a supporting base, a collecting box and a cleaning roller. A motor case is installed on one side of the top end of the supporting base, a motor is installed at the bottom end in the motor case, a fixing base is installed at the middle position of the top end of the motor case, a fixing rack is installed at the top end of the fixing base, a fixing rod is transversely installed at the end, away from the fixing base, of the fixing rack, fans are uniformly installed on the fixing rod, the spraying water tank is installed on the other side of the top end of the supporting base through a first supporting rod, and spray heads are uniformly arranged at the bottom end of the spraying water tank. The water in the spraying water tank is pressurized by a booster pump and then is sprayed out from the spray heads to clean bletilla striata roots by installing the booster pump, the spraying water tank, the spray heads, a cleaning support, the cleaning roller and a rotary shaft, and a soft bristle brush on the cleaning roller washes off sludge.

Owner:胡小爱

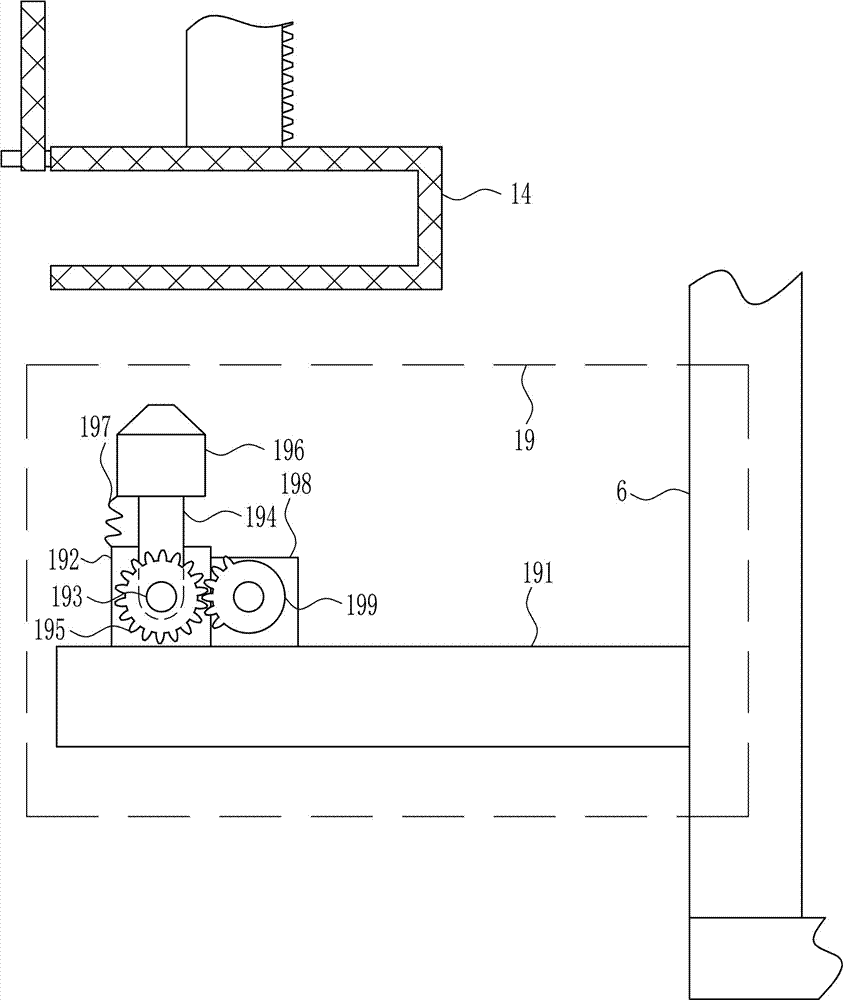

Mobile phone data cable efficient cleaning device

InactiveCN110813806ASimple structureEasy to operateLiquid surface applicatorsDrying gas arrangementsEngineeringMechanical engineering

The invention discloses a mobile phone data cable efficient cleaning device. The mobile phone data cable efficient cleaning device comprises a machine shell, a transmission cavity is formed in the left end in the machine shell, a conveying cavity with a rightward opening is formed in the right end in the machine shell, a transmission mechanism for providing power for the device is arranged in thetransmission cavity, a smearing and cleaning mechanism for smearing cleaning liquid for a data cable and cleaning the data cable is arranged on the right end in the conveying cavity, and a conveying and drying mechanism for fixing the data cable and drying the data cable is arranged on the left end in the conveying cavity. During work, cleaning liquid smearing, data cable wiping and data cable drying are integrated, the cleaning time is greatly shortened, the cleaning efficiency can be improved, the rotary cleaning manner is adopted for carrying out comprehensive cleaning and in-time drying onthe data cable, and the cleaning effect is improved.

Owner:SHANGHAI WENQI COMP CO LTD

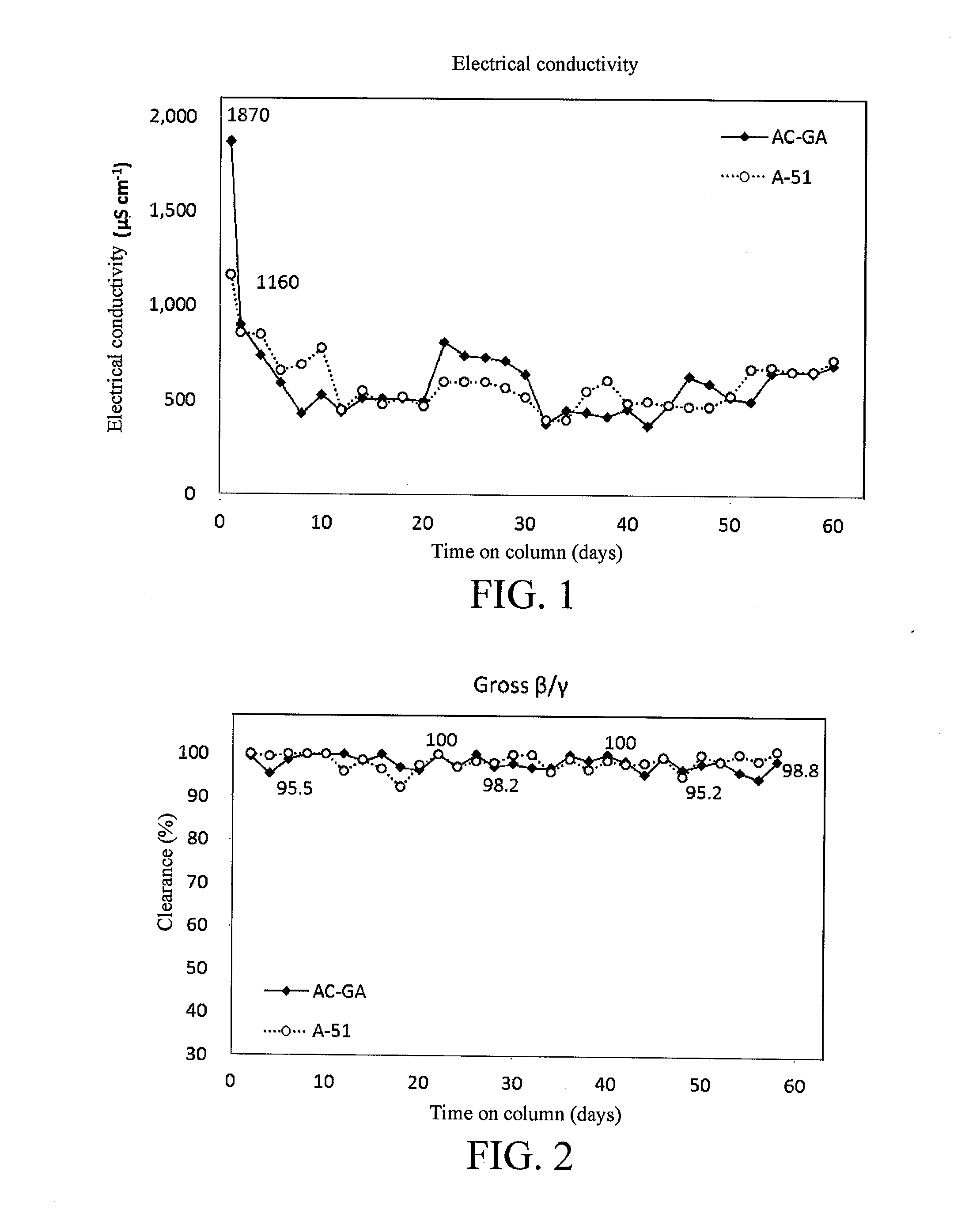

Method for granulation of absorbent and adsorbent granules prepared by the same

ActiveUS20150238932A1Dry in timeAvoid separationIon-exchange process apparatusOther chemical processesSodium metasilicatePrill

The present invention relates to a method for granulation of an absorbent and adsorbent granules prepared by the same. The method comprises the steps of blending sodium metasilicate, metakaoline and an inorganic ion exchange material in water to form a slurry; decanting the resulted slurry onto a nylon cloth of 300 to 400 meshes and natural drying at ambient temperature to solidification; then breaking the solidified final product and sieving it by a screen having a mesh size of from 0.2 to 2.5 mm to provide the absorbent granules having excellent absorbability.

Owner:INST NUCLEAR ENERGY RES ROCAEC

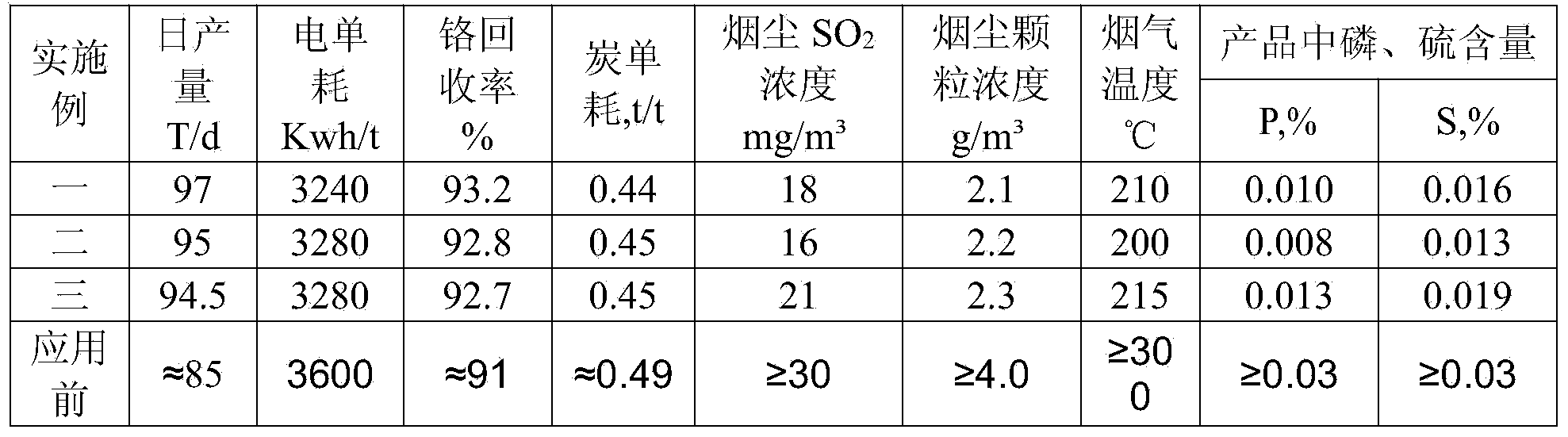

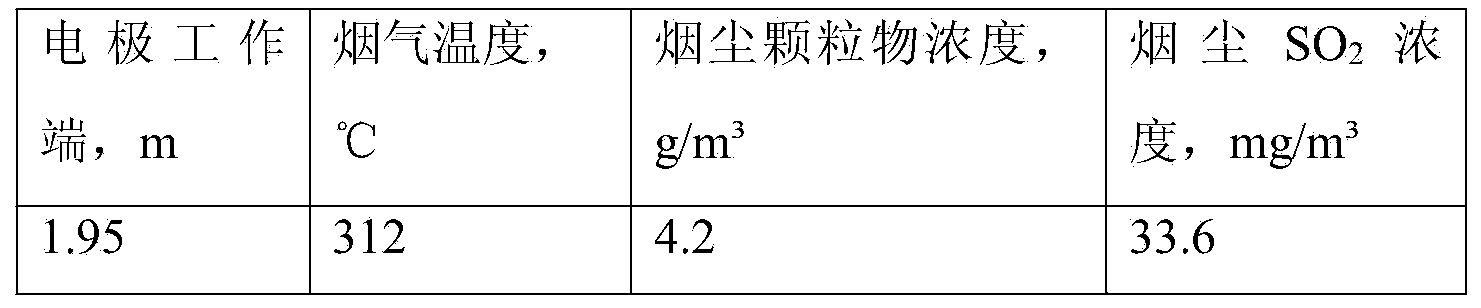

Production method for smelting high carbon chromium iron by using carbonaceous combination reducing agent

The invention discloses a production method for smelting high carbon chromium iron, belonging to the technical field of ferroalloy smelting. By adopting the production method, the consumption and comprehensive energy consumption of a carbonaceous reducing agent can be reduced. The production method is characterized in that the particle size, moisture and volatile matters are controlled by pretreatment measures through the reasonable matching of semi-coke, anthracite and metallurgical coke; the air permeability of furnace charge is ensured through the agglomeration treatment of ores so as to provide conditions for the matching of lots of semi-coke and coal; the uniformity is improved through batch-wise quantity control burdening and two-times mixing; the burdening error is reduced; the thickness of feed is controlled so as to ensure that the thickness of an in-furnace raw material layer is within 600mm, and the air permeability of the material layer is ensured; meanwhile, moisture in raw materials added to a furnace is timely dried under the effect of the high temperature of a charge level, the raw materials are preheated very well, and the air permeability of the furnace charge is further improved by pricking holes on the charge level. According to the production method, the carbonaceous combination reducing agent can be used for the smelting of slag-process high carbon chromium iron through the comprehensive measures, meanwhile, the consumption cost of the reducing cost is reduced, and the power consumption is reduced.

Owner:青海金广镍铬材料有限公司

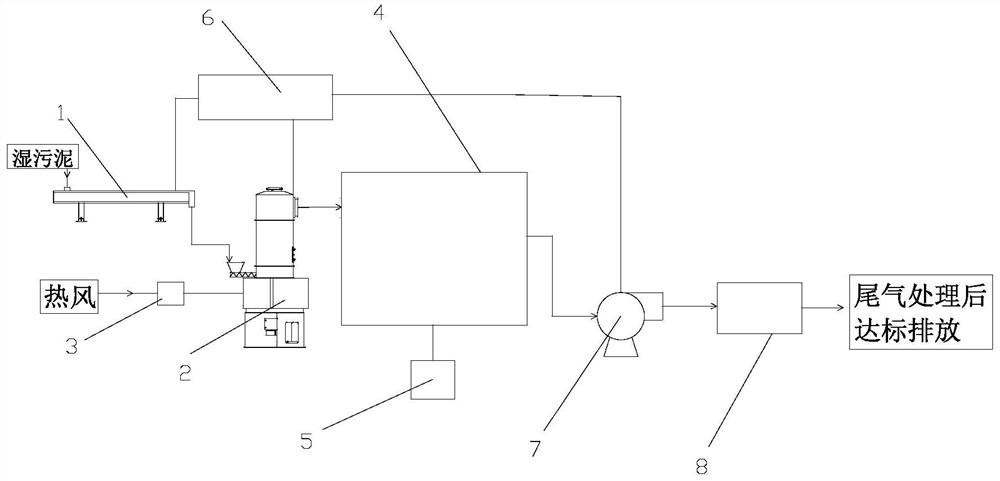

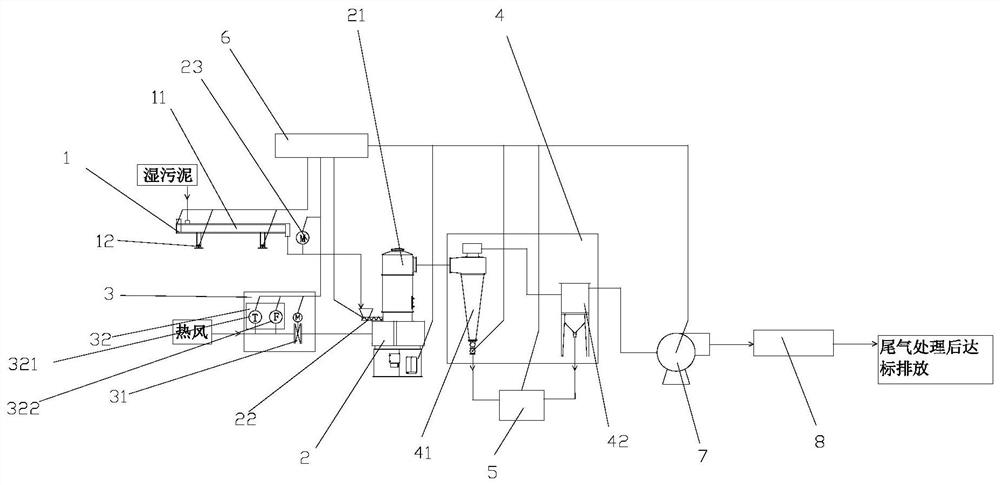

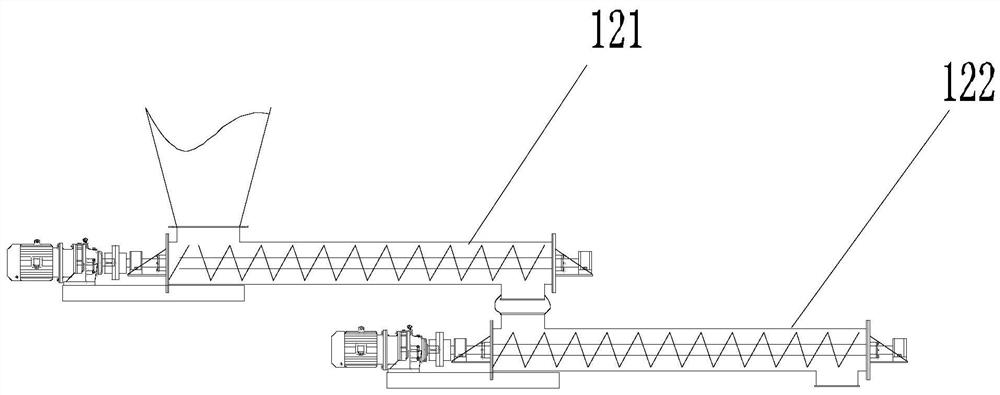

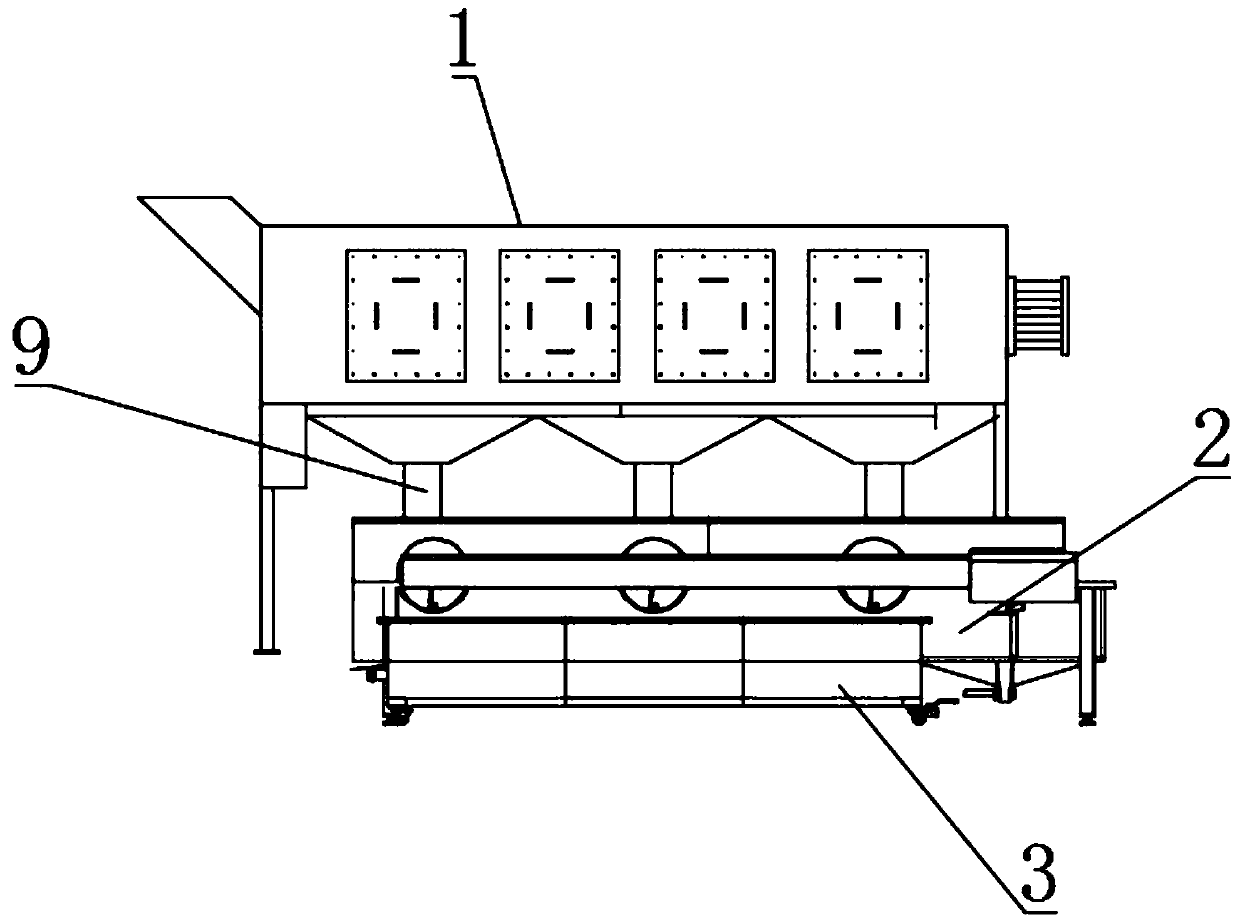

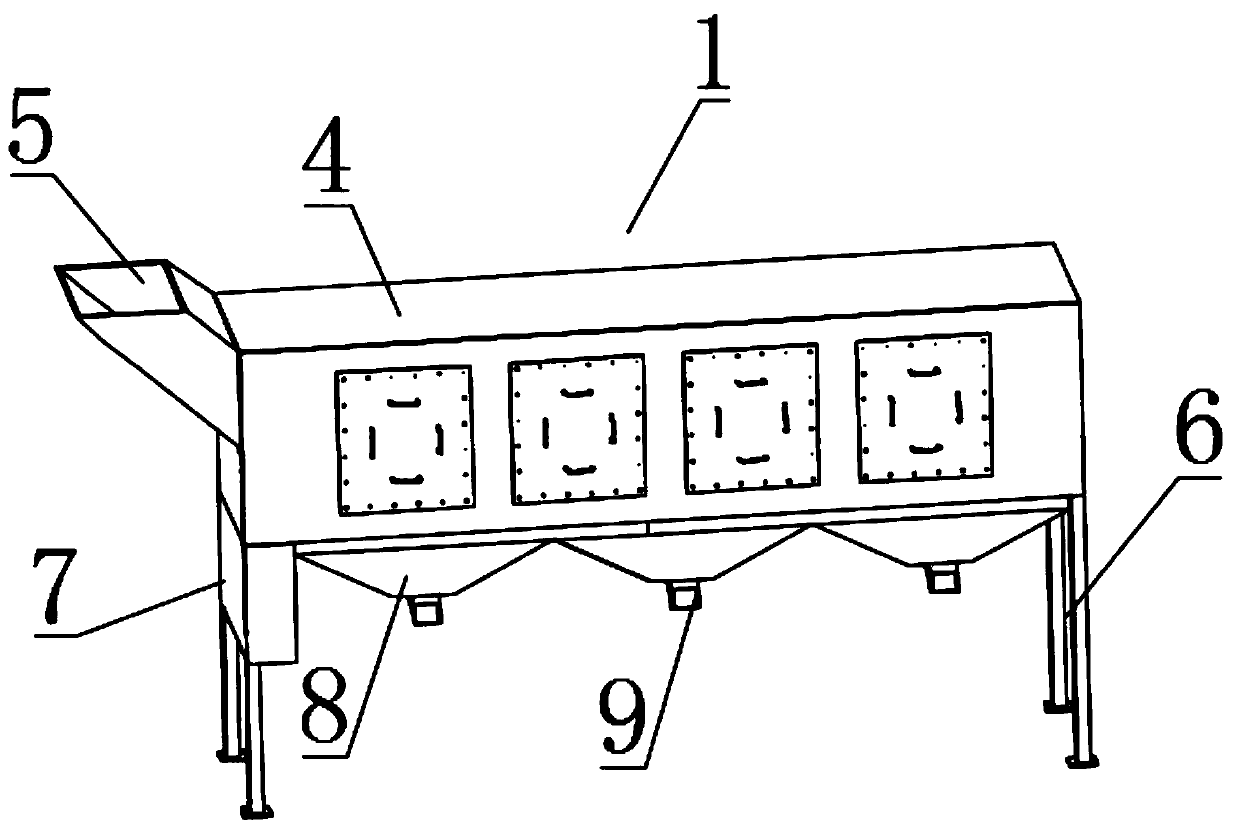

Full-automatic hot-air sludge drying equipment and drying method thereof

PendingCN111675478ARealize measurementEasy to calculateCombination devicesSludge treatment by de-watering/drying/thickeningControl systemSludge

The invention discloses full-automatic hot-air sludge drying equipment and a drying method thereof. The full-automatic hot-air sludge drying equipment comprises a continuous weighing system, an automatic air distribution system, a solid-gas separation system, a main control system and a discharging system. The continuous weighing system is used for detecting a sludge feeding amount and the moisture content of wet sludge; the automatic air distribution system is used for detecting hot air temperature and air inflow quantity; the continuous weighing system and the automatic air distribution system feed data back to the main control system; the main control system calculates the total heat required by sludge drying according to the wet sludge feeding amount, the moisture content of the wet sludge, the moisture content of dry sludge, the hot air inflow quantity and the hot air temperature and then controls the opening degree of a valve in the automatic air distribution system to adjust anair inflow amount, thereby achieveing stable operation of equipment. The full-automatic hot-air sludge drying equipment effectively reduces the workload of manual operation, reduces manual misoperation, prevents a drying tower from being blocked due to insufficient heat in the drying process, and has the advantages of being stable in operation and high in drying efficiency.

Owner:杭州守道环境科技有限公司

Dryer and drying apparatus with enhanced moisture removal

InactiveUS7785398B2Improve drying efficiencyShorten the timeDrying gas arrangementsIsotope separationDesiccantMoisture

A dryer and a drying apparatus attachable to a dryer are disclosed. A wheel having desiccant material is located in line and in close proximity with a heating element. The wheel includes a first portion positioned in an inlet air path and a second portion positioned in an outlet air path. The desiccant material removes water molecules from air within the inlet air path, and lowers the vapor pressure of the incoming air. In the outlet air path, heated air flows through the second portion to transfer energy to the desiccant material. The wheel rotates to change the desiccant material within the portions.

Owner:PROTEGE ENTERPRISES

Screening and cleaning device for food processing and application method thereof

InactiveCN111266286ALess cleaning and handlingSimple structureSievingScreeningProcess engineeringFood material

The invention discloses a screening and cleaning device for food processing. The screening and cleaning device comprises a screening mechanism, a cleaning mechanism and a material receiving mechanism.The screening mechanism is mounted on a supporting frame. The cleaning mechanism is mounted on a supporting seat. The cleaning mechanism is located in front of the screening mechanism. The discharging end of the screening mechanism communicates with the feeding end of the cleaning mechanism through a communicating pipe. The material receiving mechanism is located in front of the cleaning mechanism. The screening mechanism comprises a screening box, a feed pipe, a dust suction pipe, a dust suction assembly and a screening assembly. The screening box is mounted on the supporting frame, and thefeed pipe is arranged on one side of the screening box and is arranged obliquely. The screening assembly is mounted in the screening box. The dust suction box is arranged at the bottom of the side, close to the feed pipe, of the screening box. The dust suction assembly is mounted in the dust suction box. According to the screening and cleaning device, screening, graded cleaning, graded collectionand drying are integrated, and the efficiency of processing food raw materials is greatly improved.

Owner:耿言华

Method for preparing catalysts for partial oxidation of propylene and iso-butylene

ActiveUS20050165252A1High propyleneHigh isobutylene conversion rateOrganic compound preparationHeterogenous catalyst chemical elementsOrganic acidPartial oxidation

The present invention relates to a process for preparing a catalyst for partial oxidation of propylene and iso-butylene, and more particularly to a process for preparing a catalyst for partial oxidation of propylene and iso-butylene that can stably prepare a catalyst that shows high activity for conversion of propylene and iso-butylene to obtain acrolein and methacrolein with a high yield, by dissolving salts of metals acting as a catalyst in a nitric acid aqueous solution or in an organic acid solution to prepare a catalyst suspension, drying the catalyst solution in a microwave oven, and then pulverizing and molding the dried catalyst, and calcining the catalyst.

Owner:LG CHEM LTD

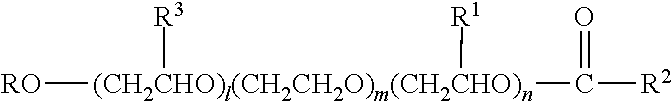

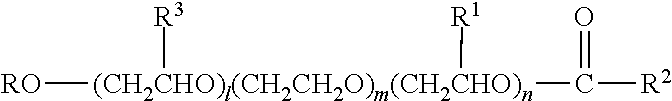

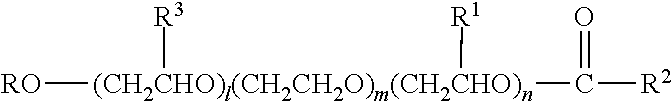

Detergent composition

InactiveUS20110143986A1Easy to cleanPositively impactingSurface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsAlcoholHydrogen

Automatic dishwashing detergent composition for use in the main wash of a dishwasher to provide drying wherein the detergent comprises an esterified alkyl alkoxylated surfactant of general formula (I)whereR is a branched or unbranched alkyl radical having 8 to 16 carbon atoms;R3, R1 independently of one another, are hydrogen or a branched or unbranched alkyl radical having 1 to 5 carbon atoms;R2 is an unbranched alkyl radical having 5 to 17 carbon atoms;l, n independently of one another, are a number from 1 to 5 andm is a number from 13 to 35; andan alcohol alkoxylated surfactant.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com