Efficient and uniform wooden product paint spraying equipment

A technology for spraying equipment and wood products, which is applied in the direction of spraying booths, spraying devices, etc., can solve the problems of spraying paint pollution, waste, and impracticality of drying mechanisms, achieve comprehensive painting and drying operations, facilitate discharge, and prevent precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

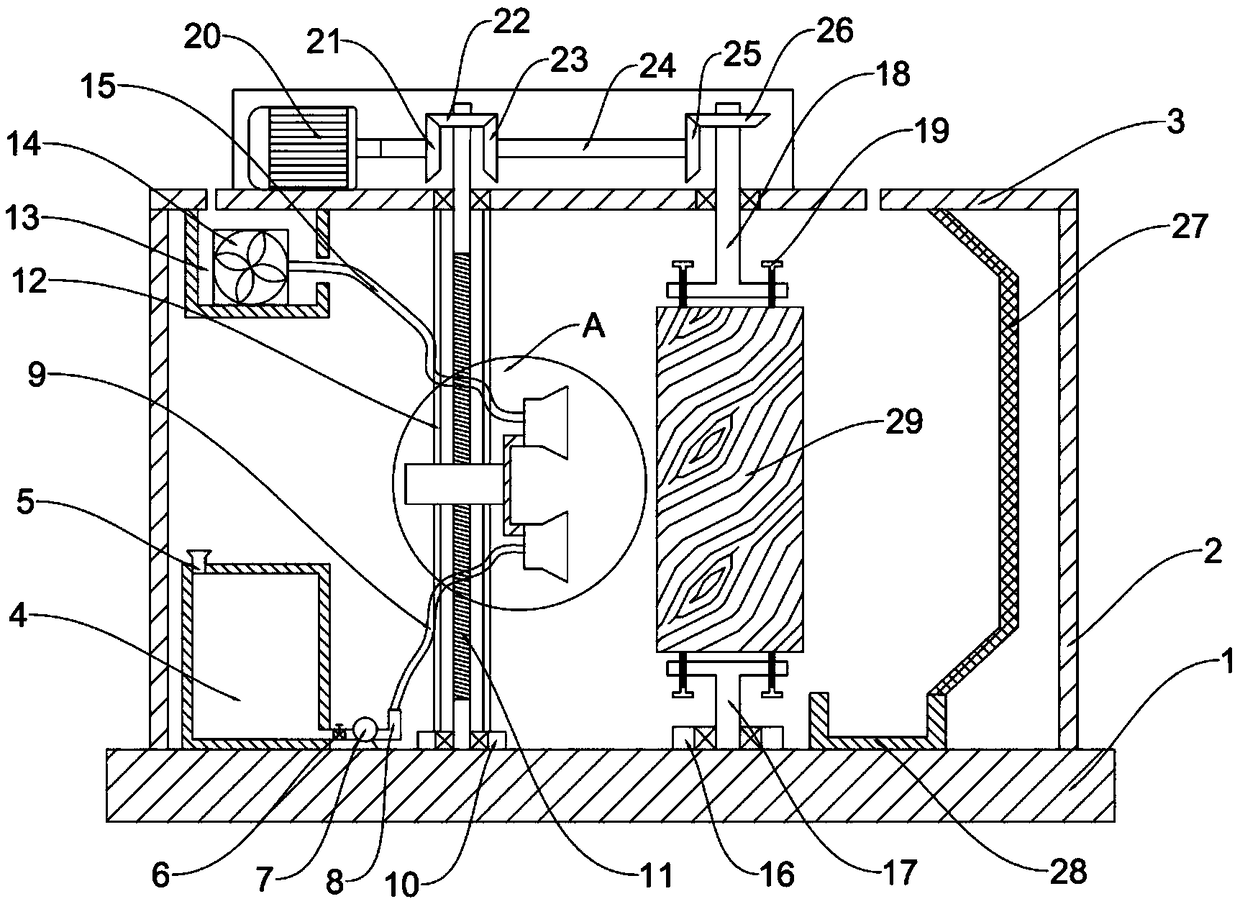

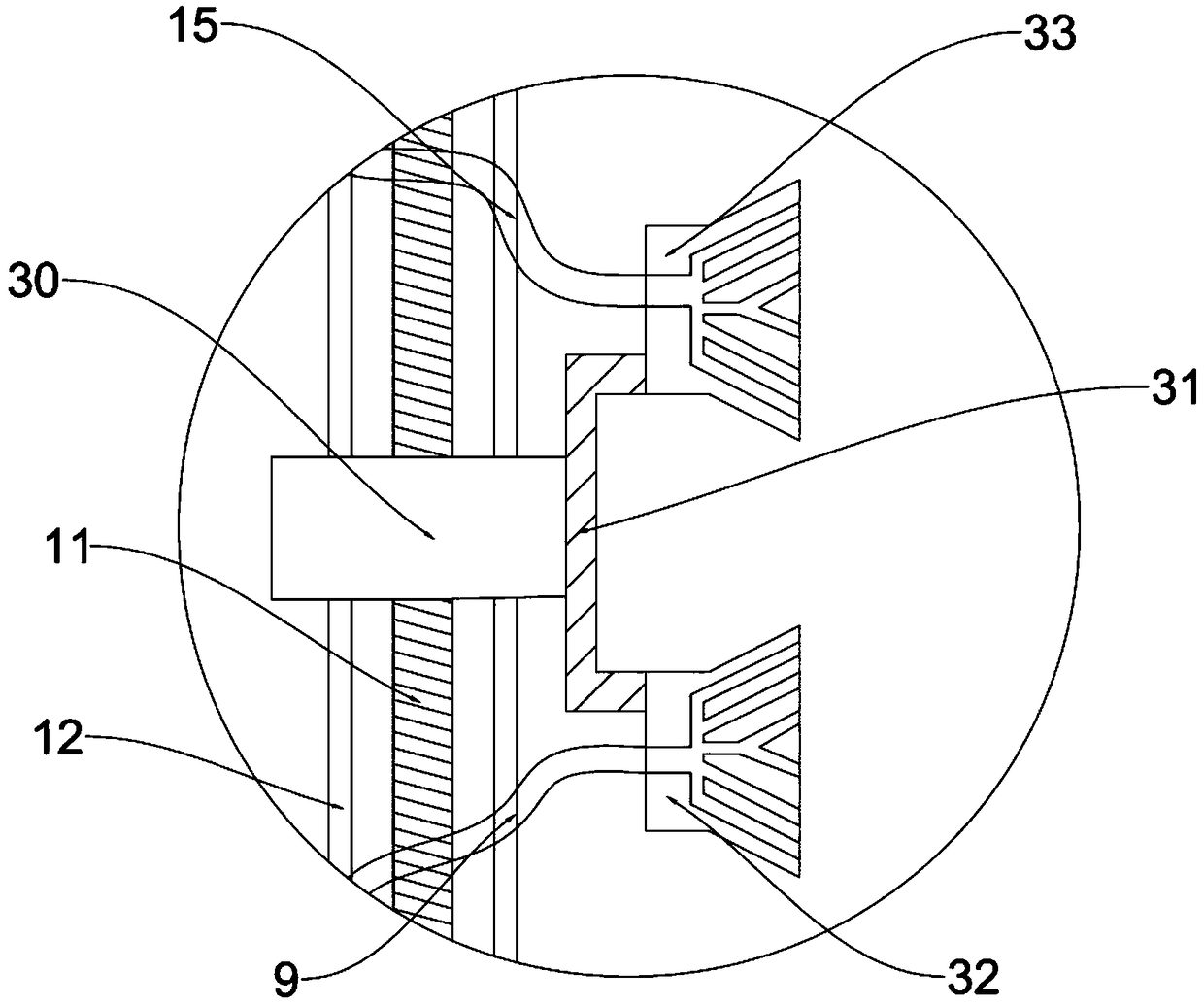

[0030] Refer to attached Figure 1-2 , a high-efficiency and uniform spray painting equipment for wood products, including a base 1, a support column 2, a top plate 3, a paint drying device, a fixing device and a recovery device, the support column 2 is fixedly installed on the base 1, and the top plate 3 is fixedly installed on the support column 2 above; wherein, the paint spraying and drying device includes a screw rod 11, a forward and reverse motor 20, a threaded sleeve 30, a paint spraying mechanism and a drying mechanism; the lower end of the screw rod 11 is rotationally connected with the first mounting plate 10 through a bearing, and the upper end Pass through the top plate 3, and be rotationally connected with the top plate 3 through bearings; the first mounting plate 10 is fixedly mounted on the base 1; the top of the screw rod 11 is connected with the first driven bevel gear 22, and the The forward and reverse motor 20 can carry out positive and negative rotation, ...

Embodiment 2

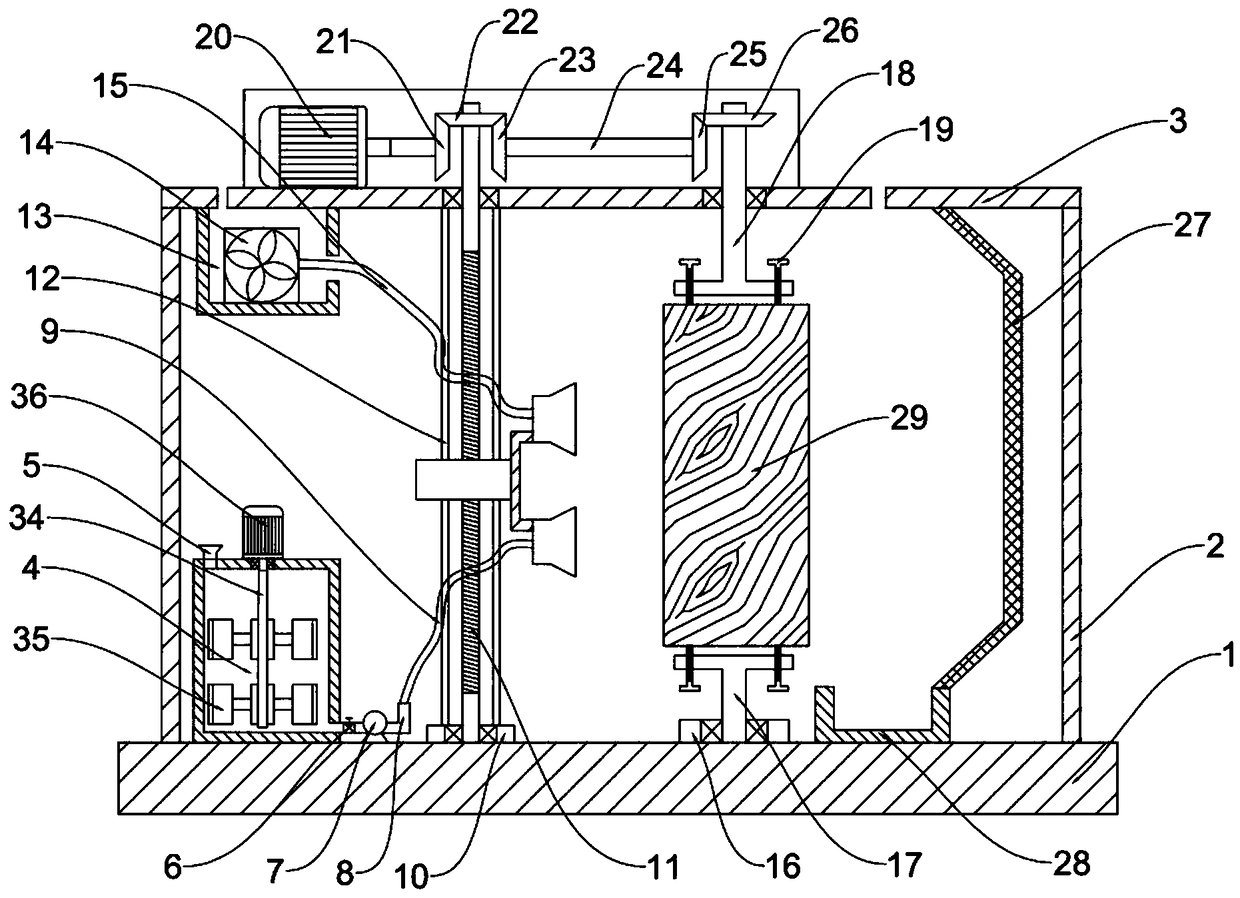

[0037] Refer to attached Figure 2-4 , the present embodiment is improved on the basis of embodiment 1; wherein, a stirring device is also provided in the described painting mechanism; the stirring device includes a stirring shaft 34, a stirring blade 35 and a stirring motor 36, and the Stirring motor 36 can be selected deceleration motor, and concrete model can be obtained from prior art, and it is fixed on the top of paint case 4; The bearings are connected in rotation; the stirring blades 35 are installed on the stirring shaft 34, at least one set is provided, and its structure is a backward curved blade disc turbine structure. By starting the stirring motor 36, the stirring shaft 34 can be driven to rotate, thereby driving the stirring blade 35 to rotate, which can stir and disperse the spray paint in the paint box 4, and facilitate the discharge of the spray paint.

[0038] The working principle of this device: when preparing to spray paint, first fix the wooden product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com