Patents

Literature

6819results about How to "Easy to dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

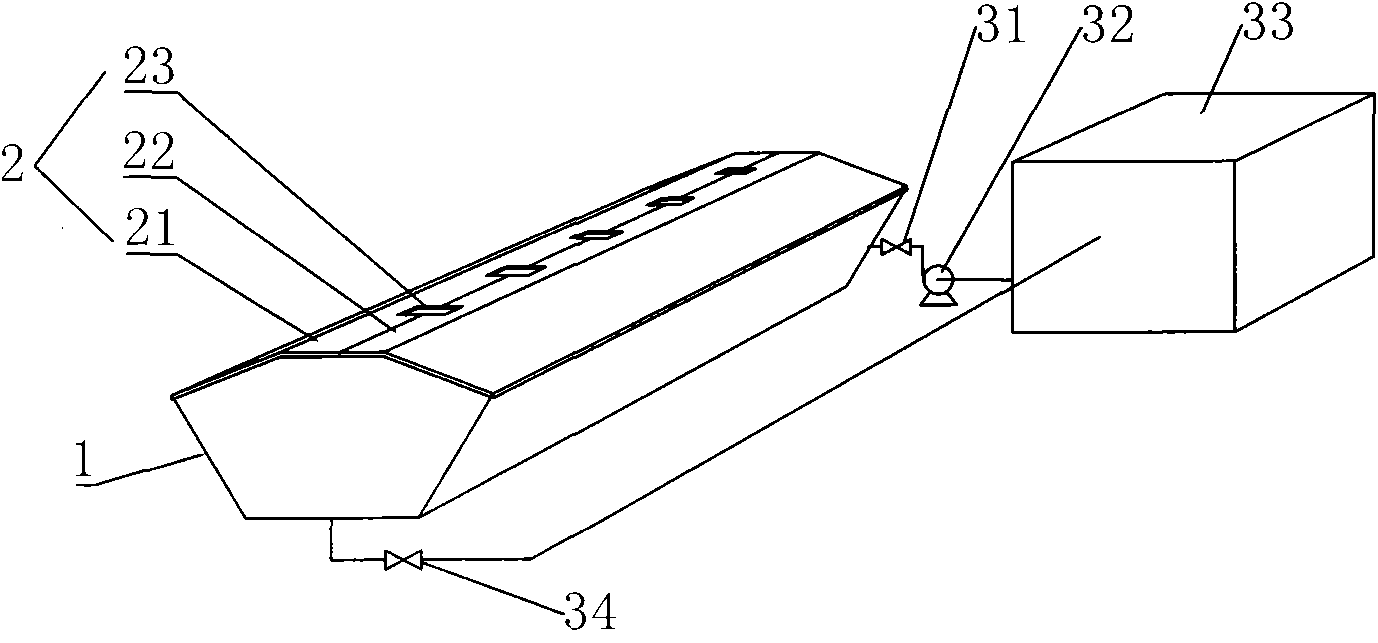

Multifunctional matrix soilless culture method and device

InactiveCN102210254ASuitable for growthPromote absorptionAgriculture gas emission reductionCultivating equipmentsNutrient solutionPlant growth

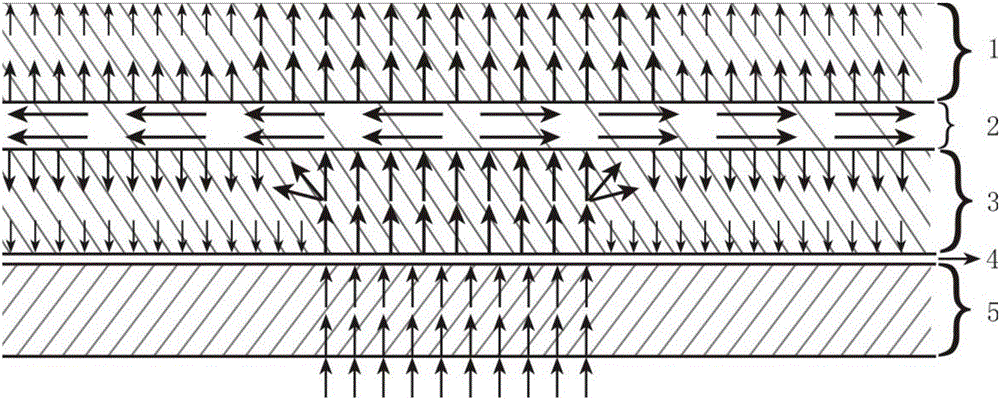

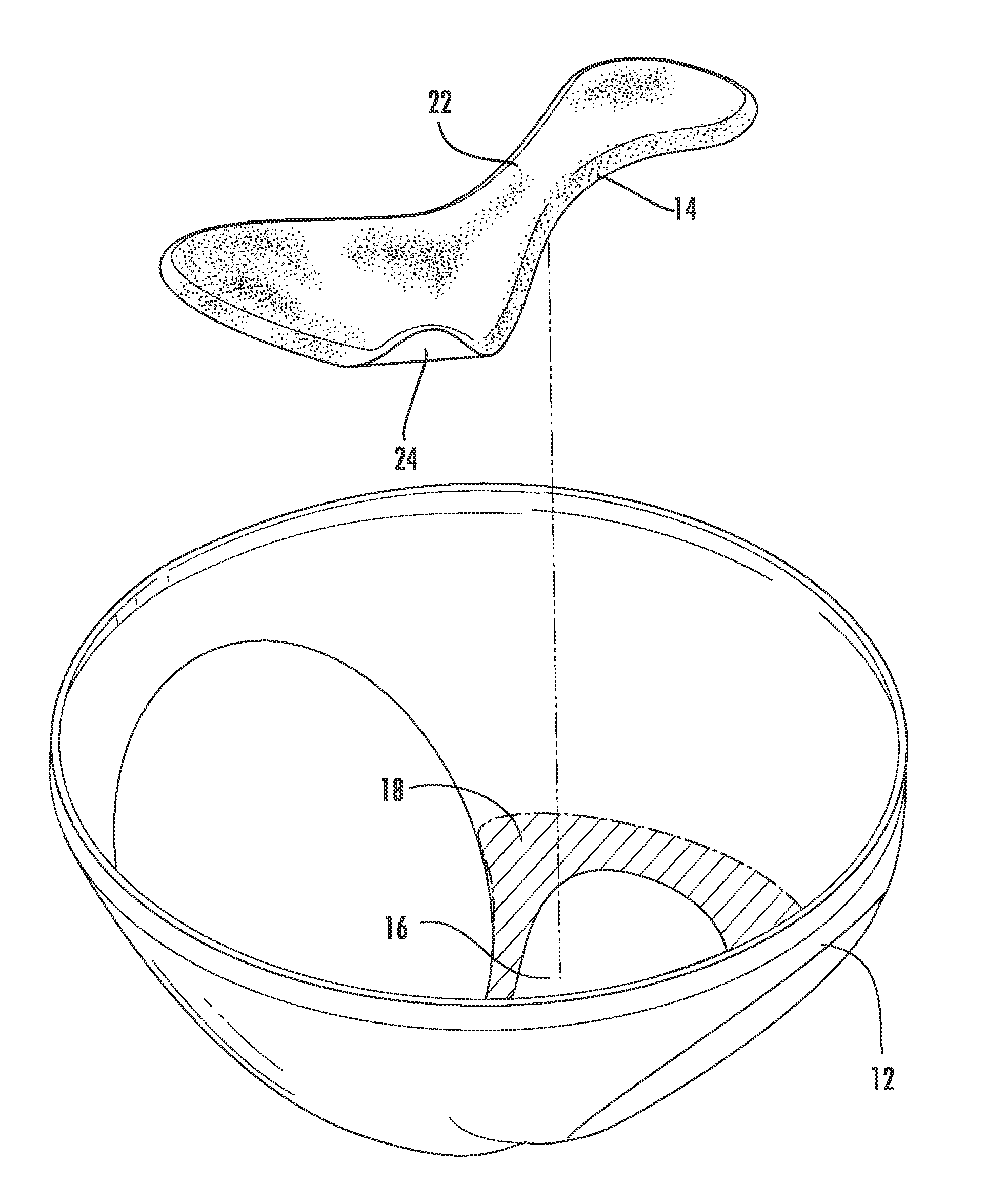

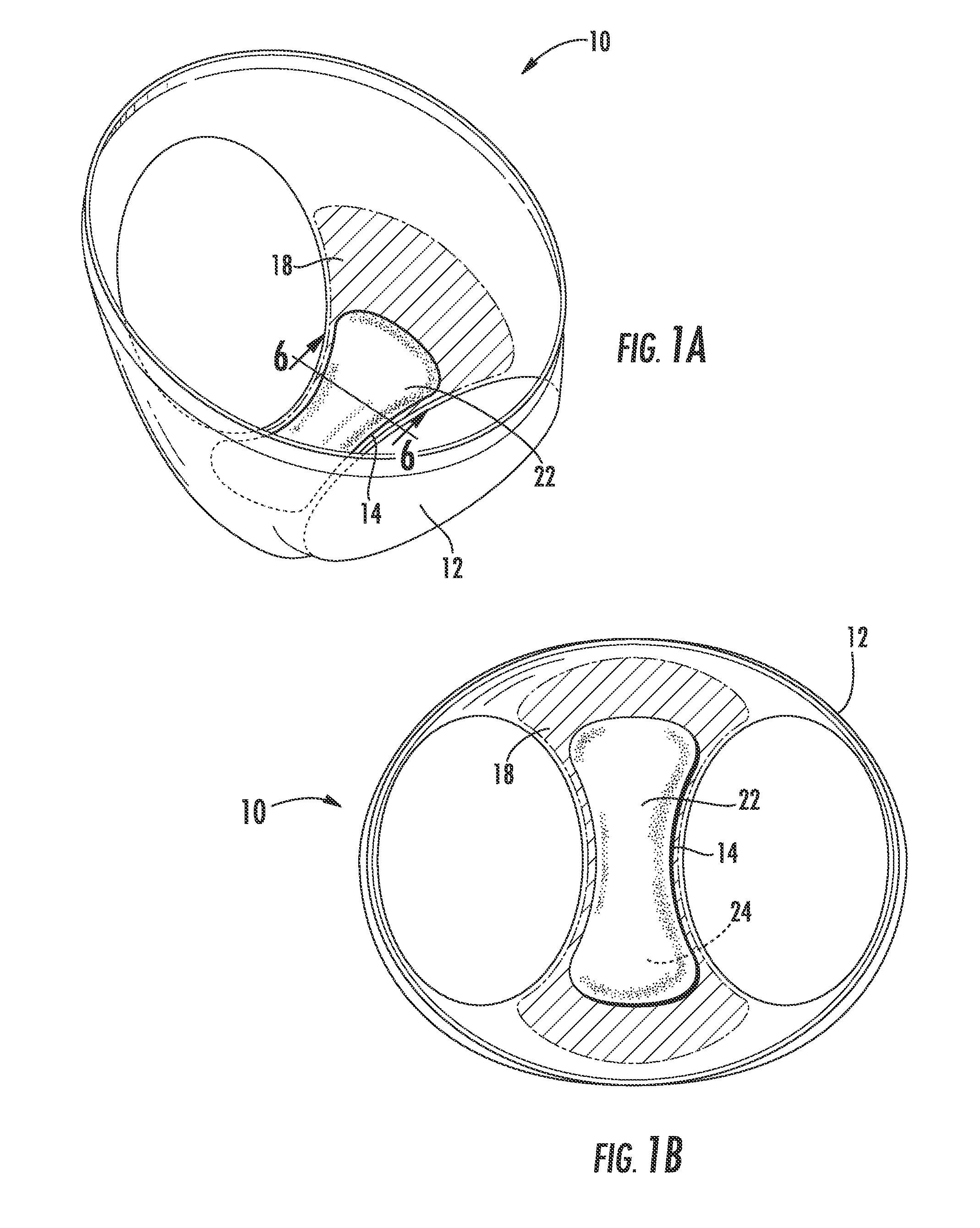

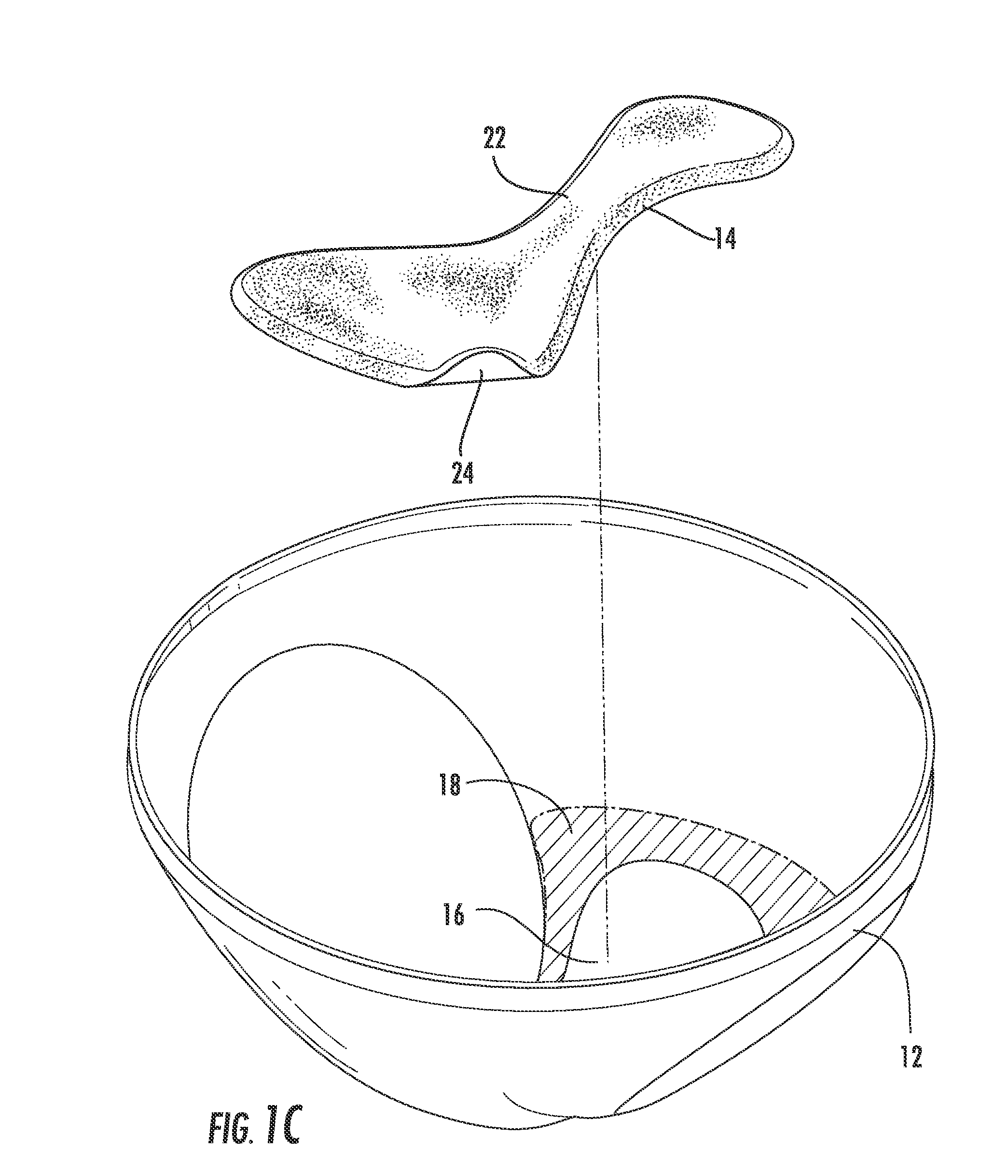

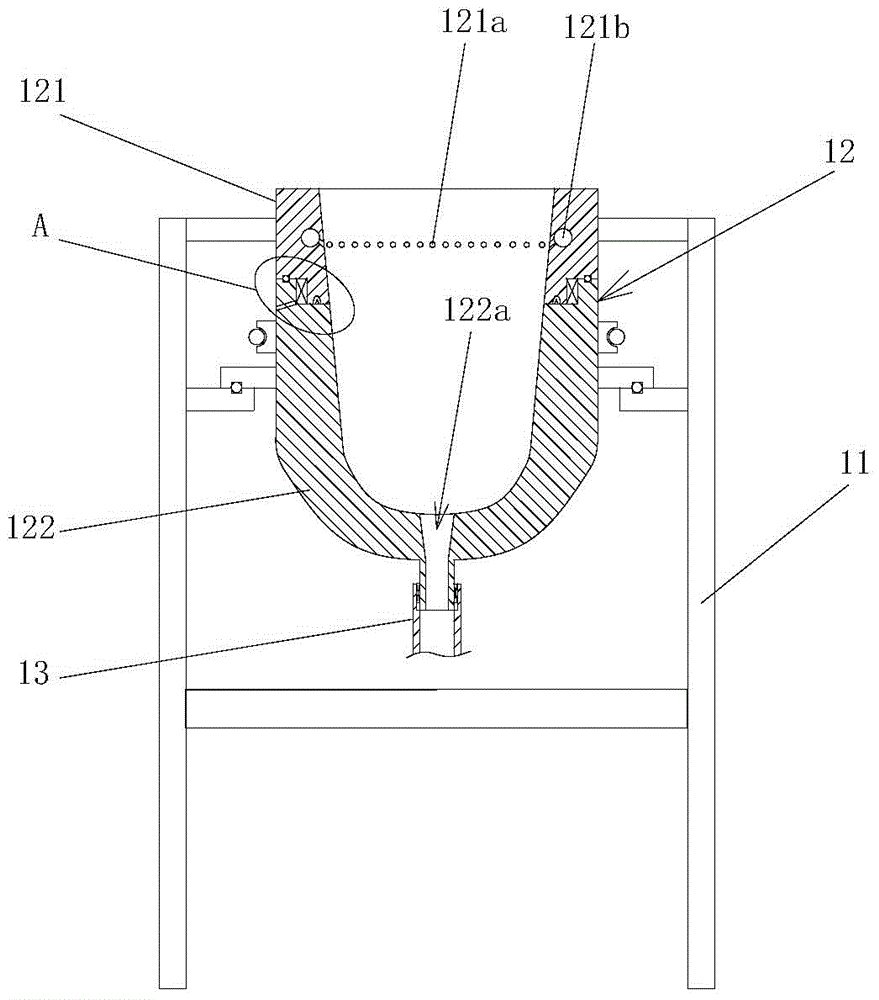

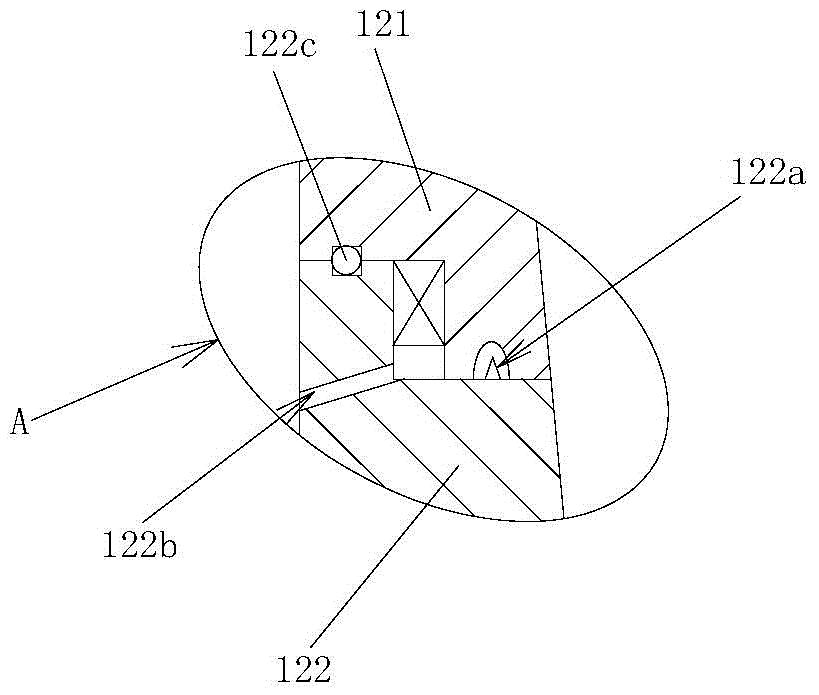

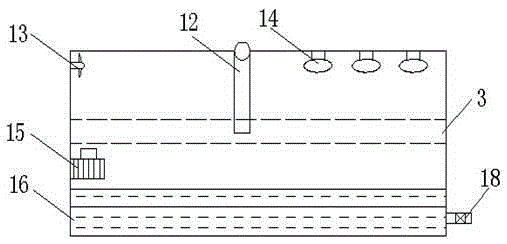

The invention discloses a multifunctional matrix soilless culture method and device. The method comprises the following steps of: filling culture matrix into a porous culture container; placing the porous culture container filled with the culture matrix into a culture bed groove; reserving gaps between the inner wall of the culture bed groove and the porous culture container to form a root exogenous space; planting plants on the porous culture container with the culture matrix; covering the upper opening of the culture bed groove with a covering substance; reserving a plant fixing hole or growth port at the position, wherein the plant is planted, on the covering substance, so that a heat-preserving, a humidity-preserving and black environment is formed in the culture bed groove; and supplying water or nutrient solution to the culture matrix in the porous culture container, wherein in the growth process of the plant, the root grows to permeate the gaps of the porous gap culture container to grow into and out of the culture container and in the space in the bed groove. By the soilless culture method and the soilless culture device, good growth environment and balanced supply of nutrients and water of the root can be guaranteed; and different irrigation modes are suitable, such as the soilless culture method for culturing various crops, the matrix culture method and the matrix and water composite culture method.

Owner:北京绿东国创农业科技有限公司

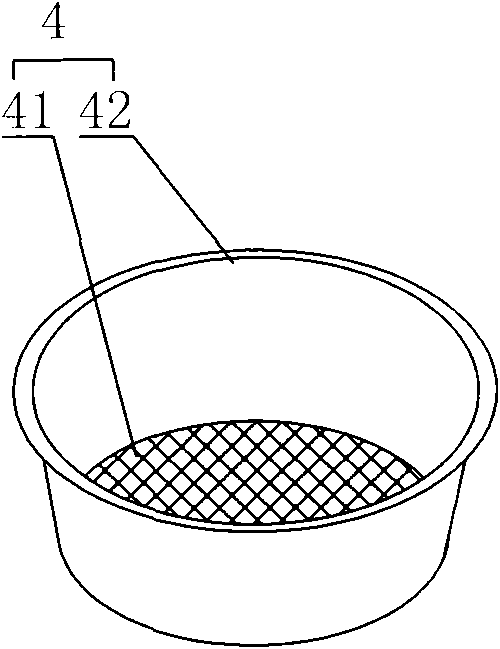

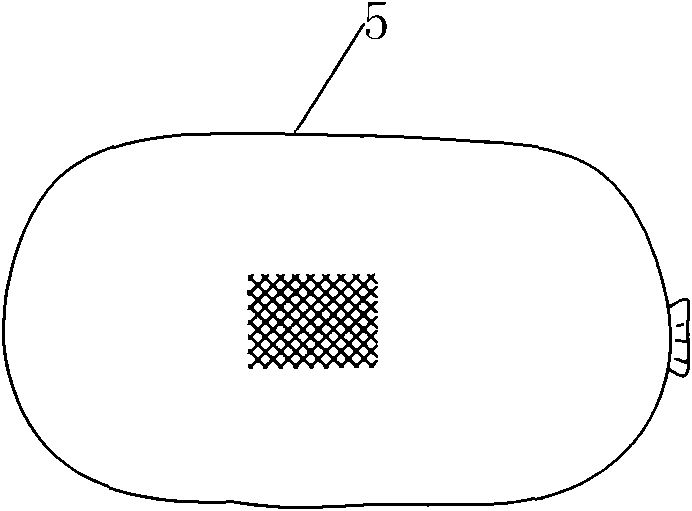

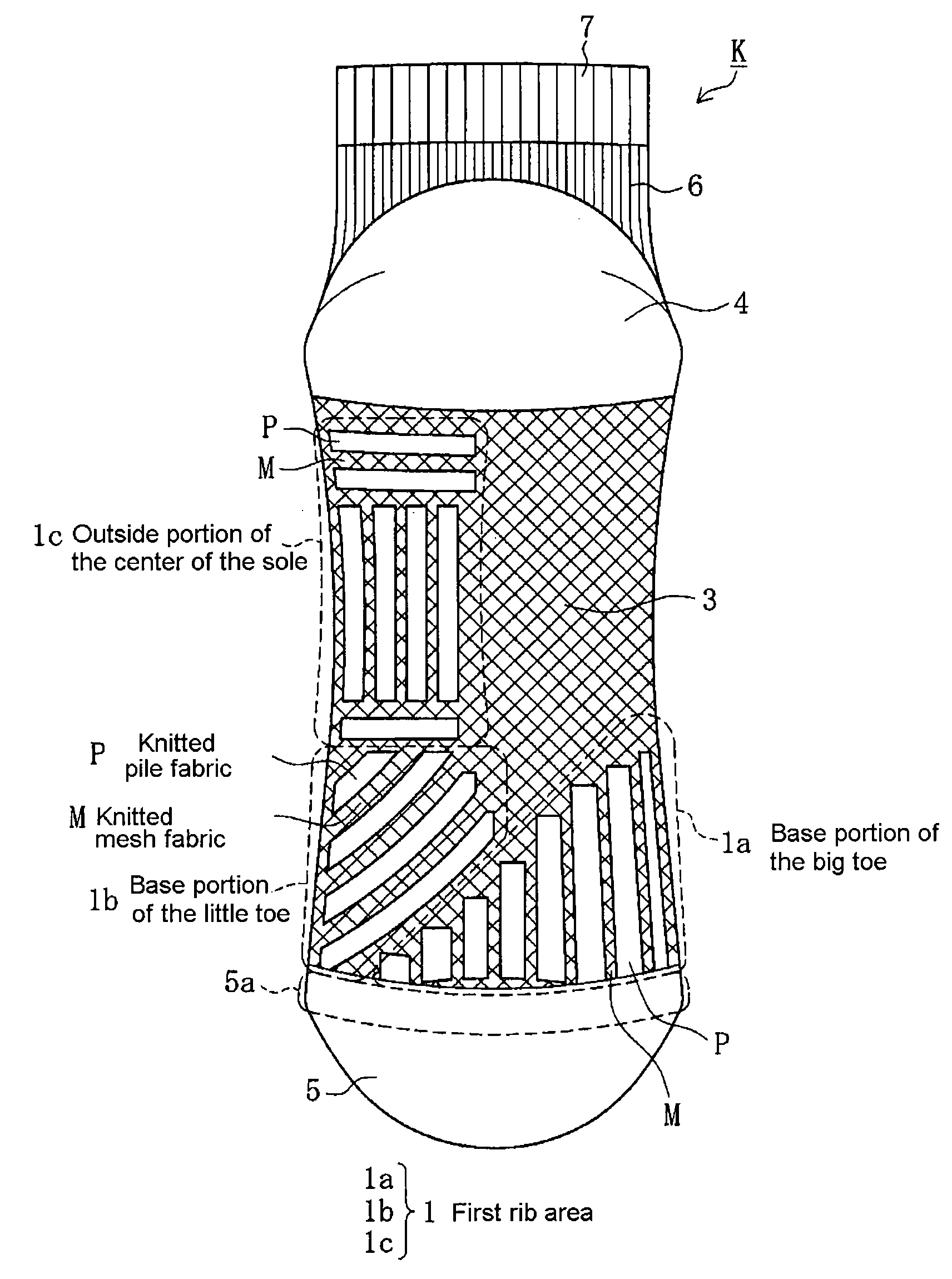

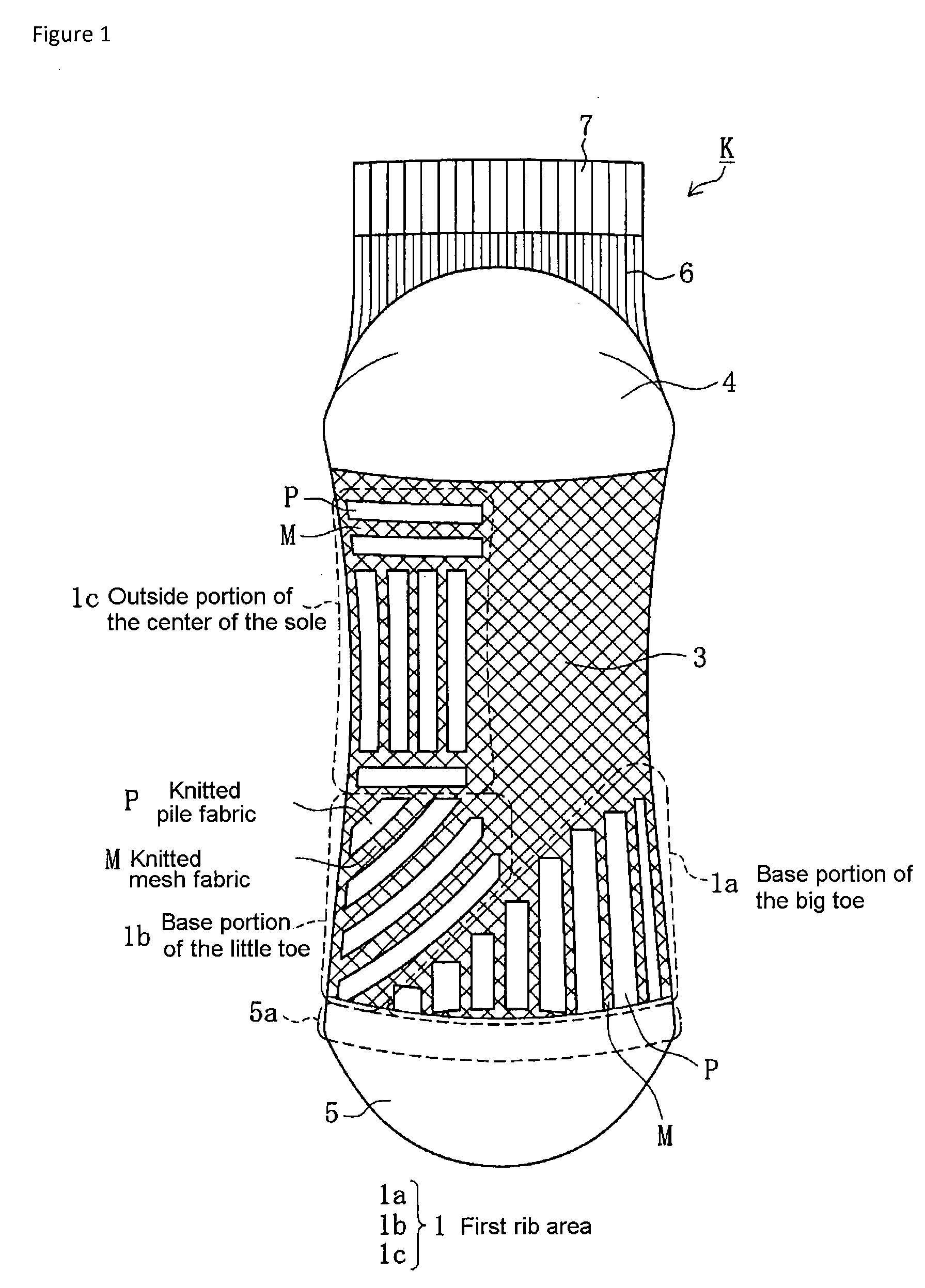

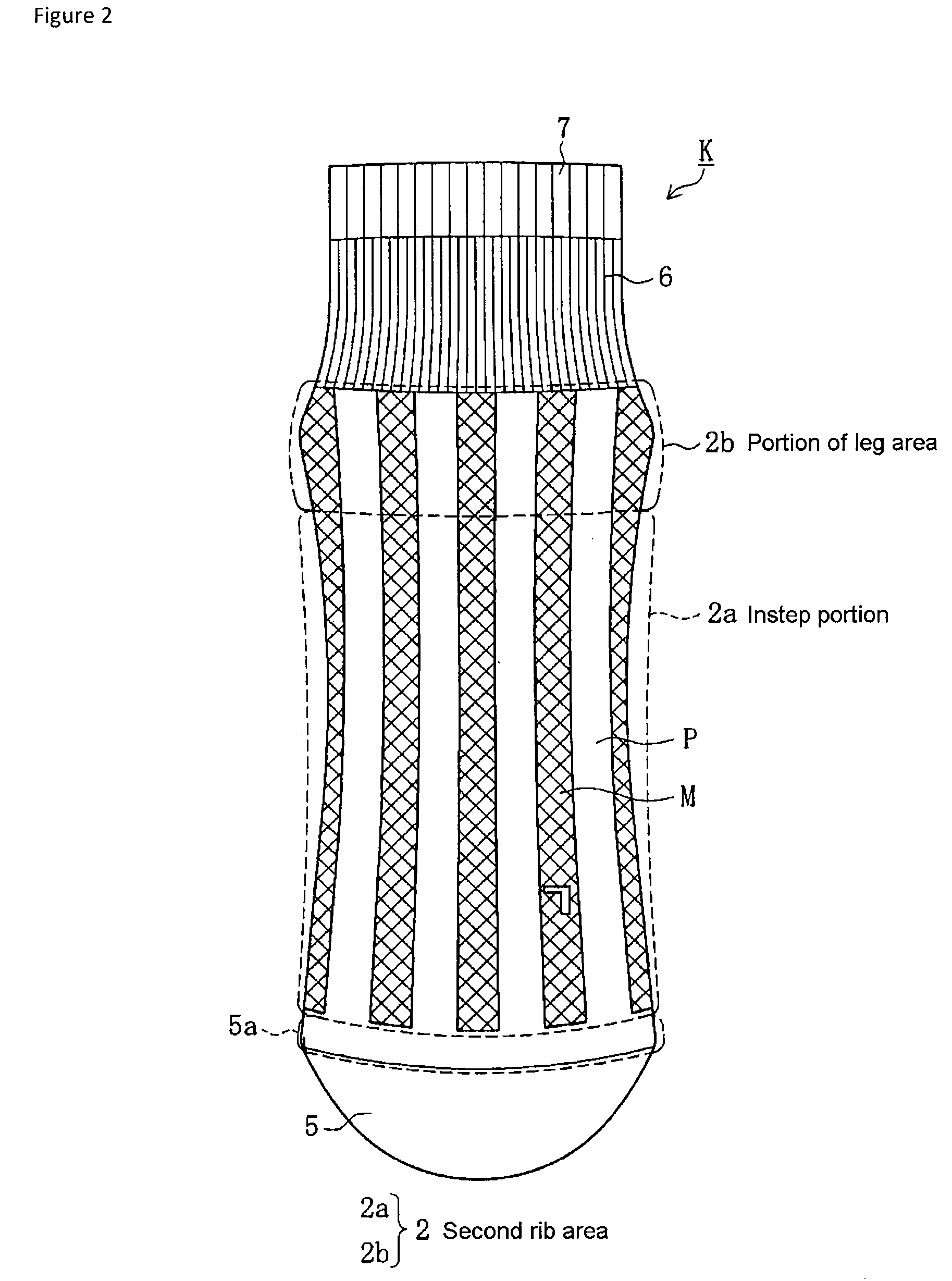

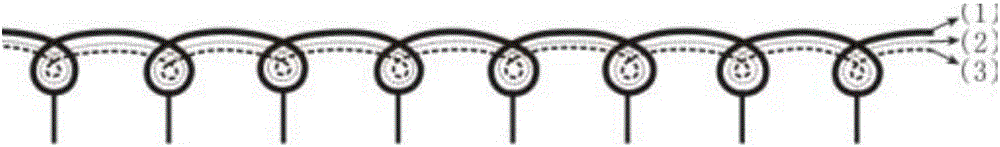

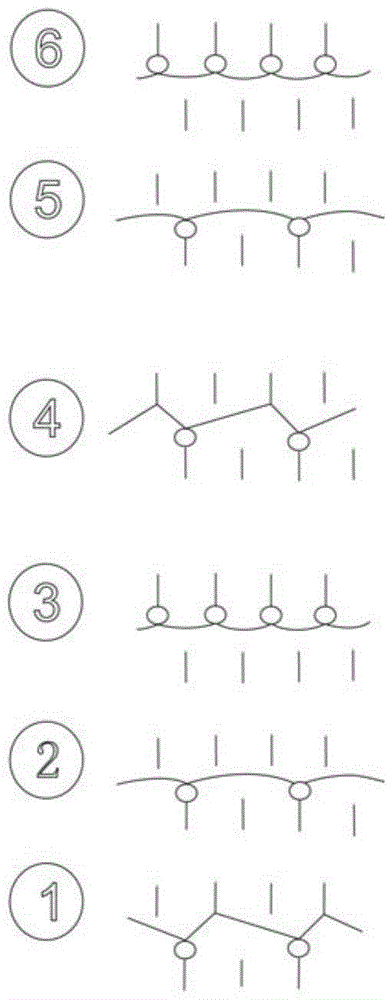

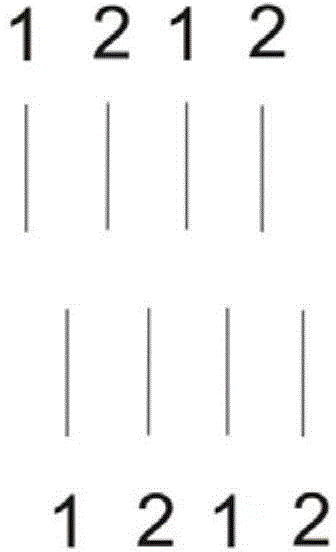

Sock

A sock includes an air escape route that allows humid air to be expelled to the outside of a shoe. The sock may include a first rib area provided in a ground-touching area of a sole portion of the sock, the ribs being formed in a desired direction. A second rib area, in which ribs are formed in a wale direction, may also be provided in an instep portion of the sock. The ribs of the first and second rib areas may be knitted with alternating knitted pile and knitted mesh fabric. Humid air collecting in areas that do not touch the ground passes through the concave portions of the ribs of the first rib area, and is impelled toward the instep side. Air flowing to the instep side of the sock via the first rib area is expelled to the outside of the shoe via the second rib area.

Owner:OKAMOTO INDS

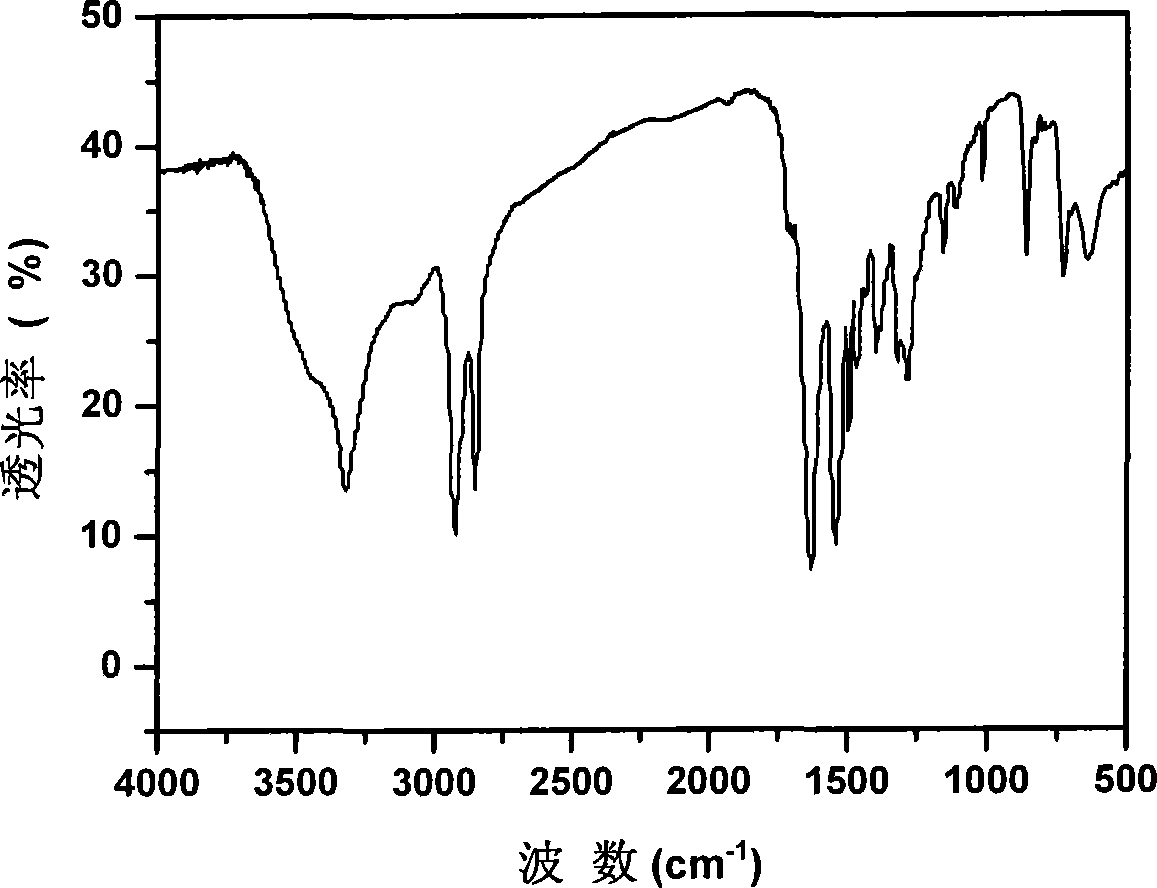

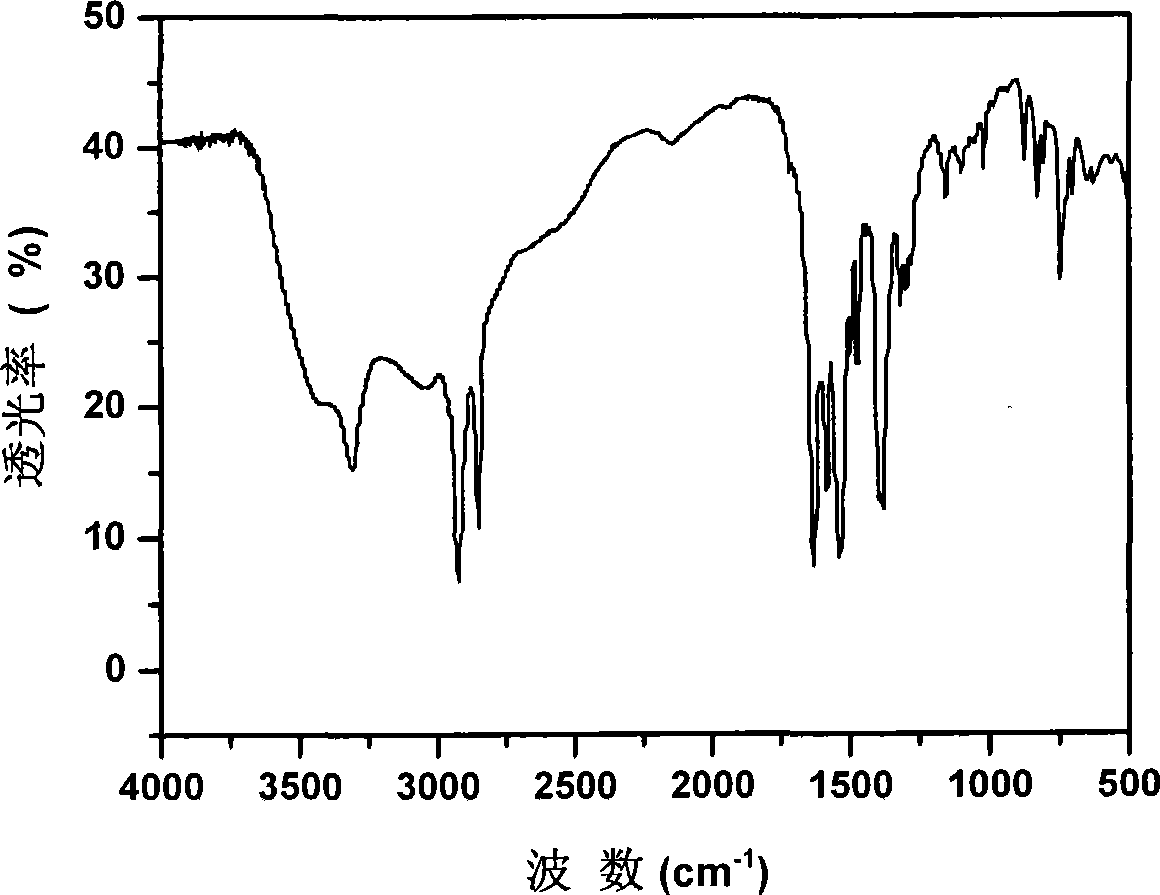

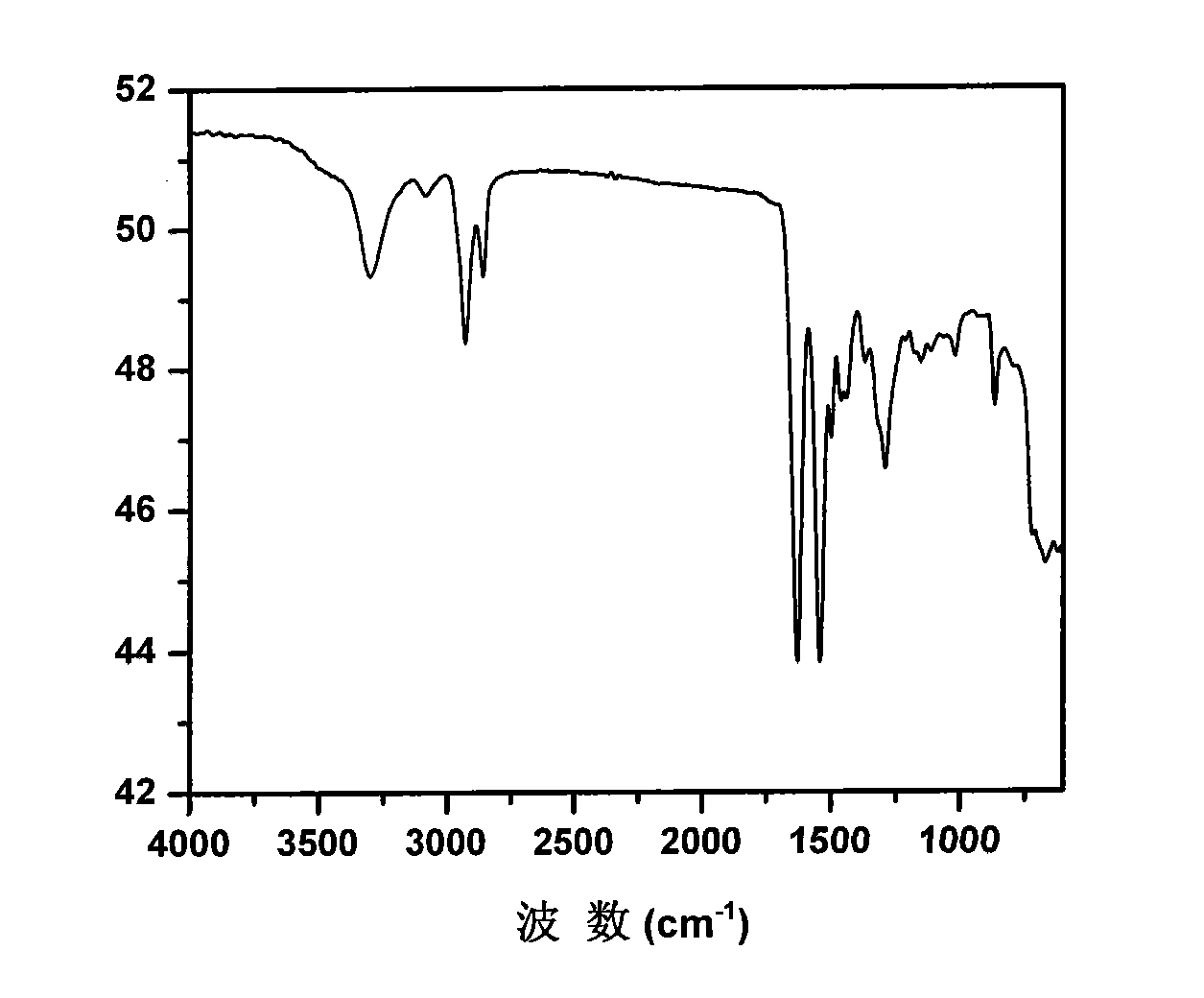

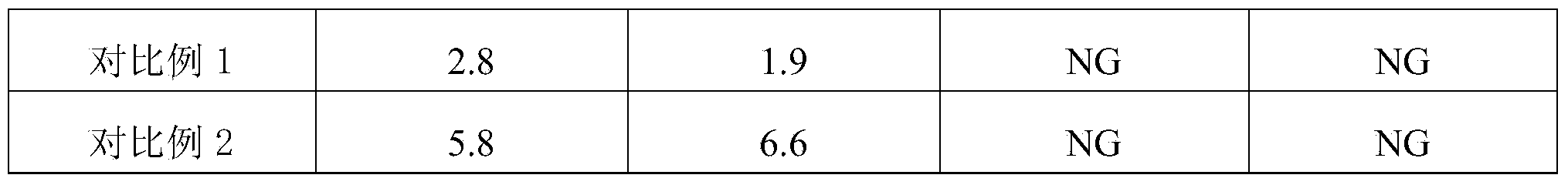

Method for preparing semi-aromatic nylon

The invention discloses a method for preparing semi-aromatic nylon and belongs to the technical field of macromolecular material synthesis. The method comprises the following steps: (1) uniformly mixing aliphatic diamine and water of which the weight is two to ten times that of the aliphatic diamine, heating the mixture to the temperature of between 50 and 90 DEG C, adding aromatic diacid into the mixture with stirring till a pH value of the solution reaches 7.0-7.7, continuously stirring for 1 to 5 hours, cooling the solution to room temperature, continuously stirring the solution for 1 to 5 hours again, and filtering and drying to obtain nylon salt for later use; and (2) adding the prepared nylon salt and a solvent to a polymerization kettle in a certain mixture ratio (0.5 to 3.0 g / mL), raising the temperature to between 190 and 230 DEG C under the protection of inert gas, keeping the pressure in the kettle between 2.0 and 3.0 MPa, discharging gas after 1 to 5 hours to make the pressure in the kettle reduced to normal pressure within 1 to 5 hours, raising the temperature to between 210 and 270 DEG C, and continuing to react for 1 to 5 hours, and discharging to obtain a powdery semi-aromatic nylon product. The method has mild reaction condition and low energy consumption; the product is easy to mold and machine; and the method solves the difficult problem of difficult discharging of the semi-aromatic nylon, and is applicable to industrialized production.

Owner:青岛智库生物技术有限公司

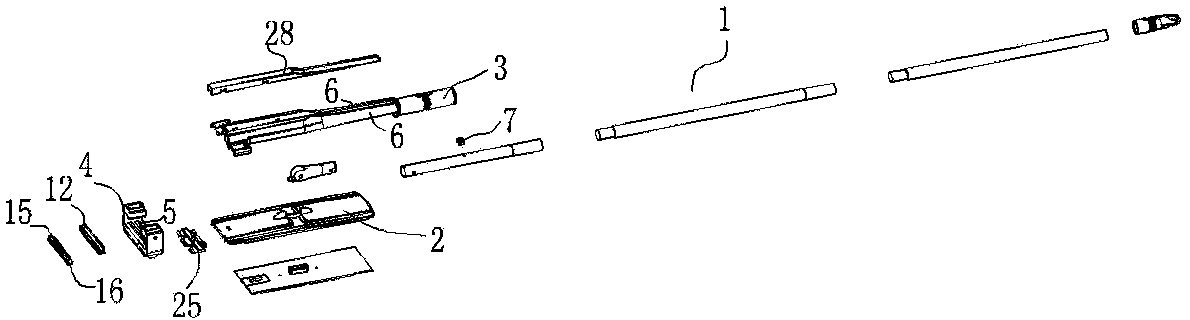

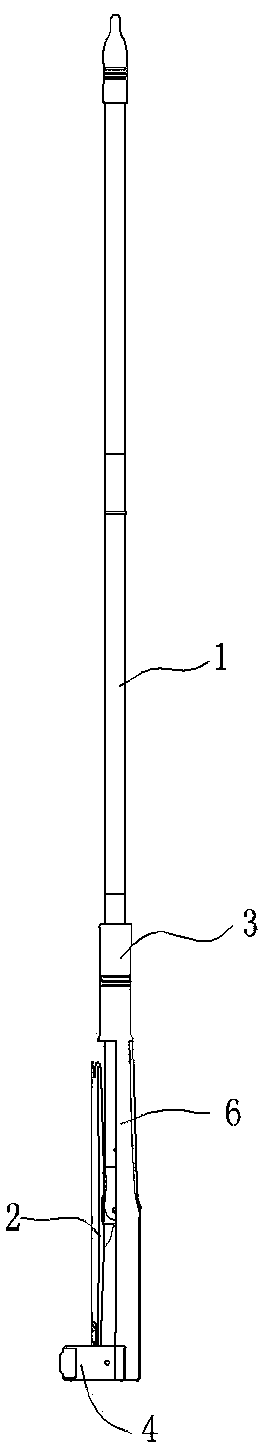

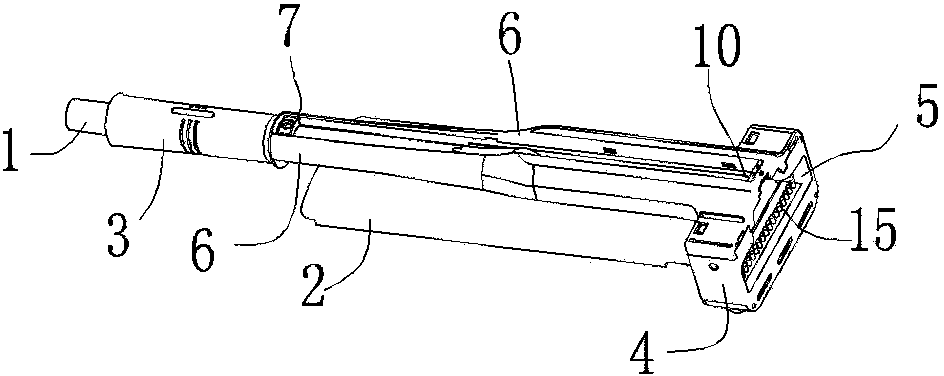

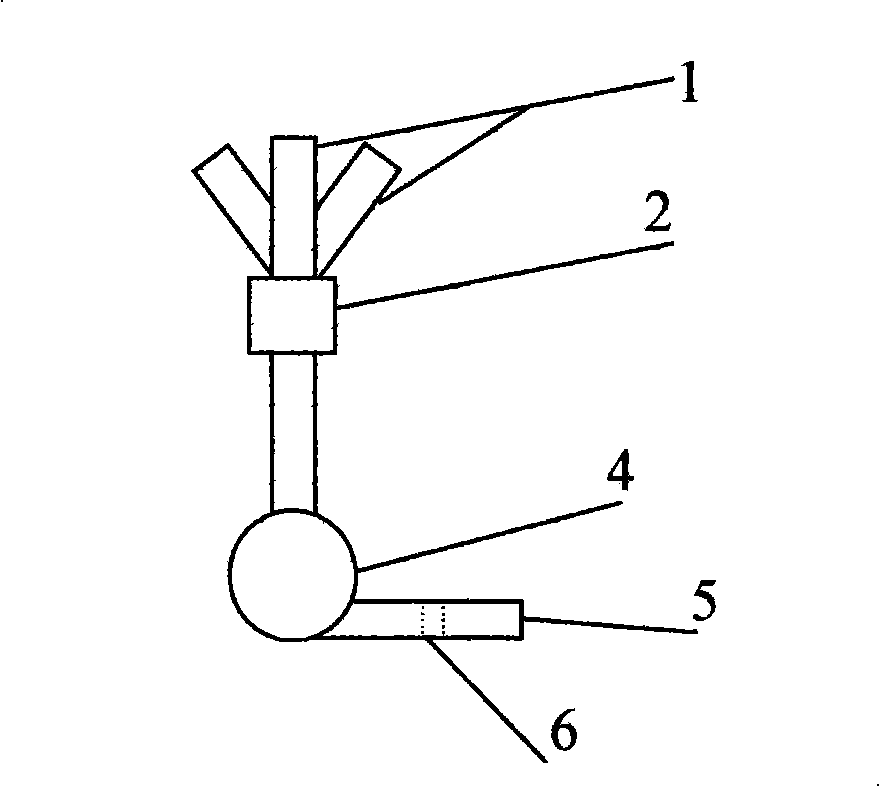

Self-wringing flat plate mop

The invention discloses a self-wringing flat plate mop, which comprises a mop rod and a flat plate mop head, wherein mop cloth can be arranged on the back surface of the flat plate mop head; a smoothing sleeve capable of sliding up and down is arranged on the mop rod in a sleeving way; a smoothing head is arranged at the lower end of the smoothing sleeve, and is provided with a penetration opening; a wringing mechanism is arranged on the bottom surface of the penetration opening; the flat plate mop head can be inserted into the penetration opening after rotating to be parallel to the mop rod; when the smoothing head is at a high position, the flat plate mop head is separated from the penetration opening, and when the smoothing head is at a low position, the lower end of the flat plate mop head is inserted into the penetration opening; when the smoothing sleeve is upwards pulled, the mop cloth on the back surface of the flat plate mop head is wrung through the wringing mechanism; the smoothing head transversely extends, so that the smoothing head also serves as a base when being at the low position, the lower end of the flat plate mop head parallel to the mop rod is inserted into the penetration opening, and the mop can be vertically arranged. According to the self-wringing flat plate mop, the whole mop (comprising the flat plate mop head) can be vertically arranged after being wrung, so that the mop cloth on the flat plate mop head is conveniently air-dried, and is prevented from being in contact with the ground again and getting dirty.

Owner:JIAXING JACKSON TRAVEL PROD CO LTD

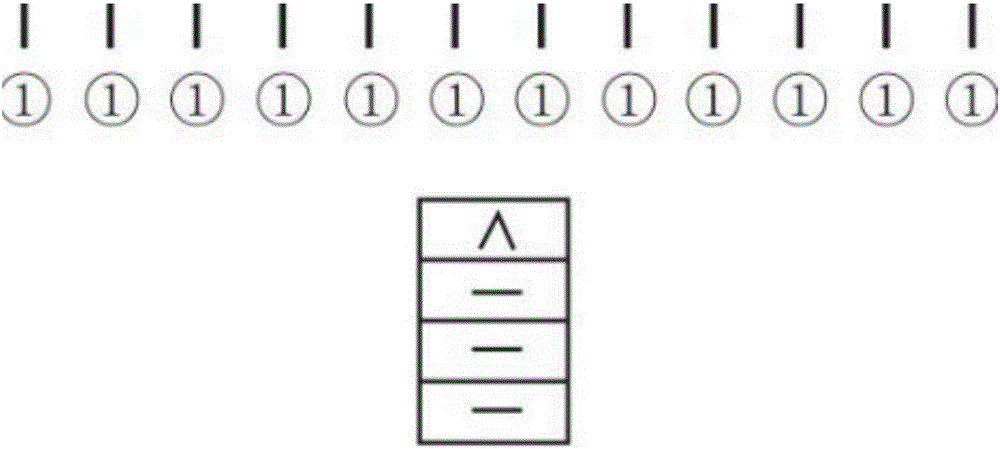

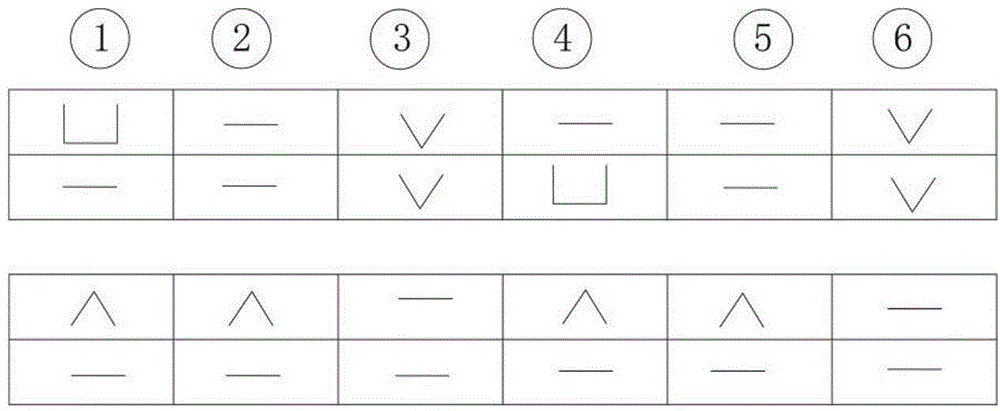

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

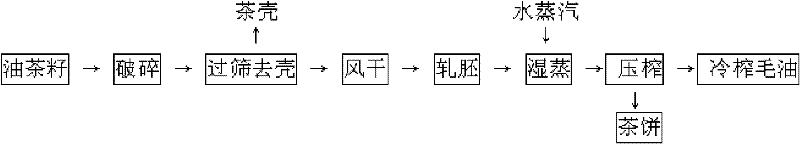

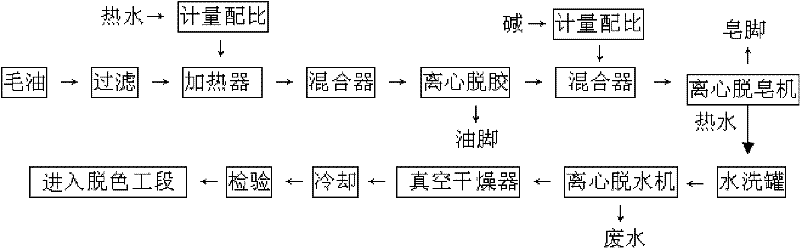

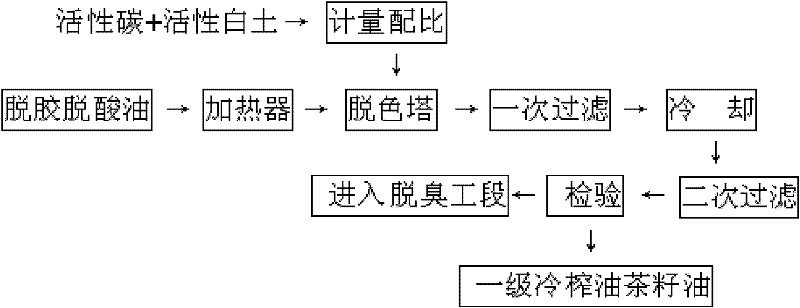

Low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil

InactiveCN102329690AAvoid it happening againEasy to dryFatty-oils/fats refiningFatty-oils/fats productionSocial benefitsActivated carbon

The invention discloses a low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil, which mainly comprises the following technical steps of squeezing, leaching, degumming, deacidifying, decoloring, deodorizing, winterizing, dewaxing and the like. In the method, the technology of low-temperature drying and low-temperature squeezing and the bivariate mixed decoloring technology of activated carbon and activated clay are adopted to adsorb and decolor oil, thereby preventing from generating harmful substances, such as benzopyrene, coking objects, carbide and the like, and improving the quality and the grade of the product. The method has good economic benefit and social benefit.

Owner:贵州大龙健康油脂有限公司

Silane modified polyurethane glass primer and preparation method thereof

ActiveCN102516921AFast film formationIncrease the density of crosslinksNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventChemistry

The invention discloses a silane modified polyurethane glass primer and a preparation method thereof. The glass primer is prepared from the following raw materials by weight: 20 to 60 parts of silane-terminated polyurethane perpolymer, 30 to 65 parts of a solvent, 1 to 3 parts of a water-removing additive, 2 to 10 parts of carbon black, 1 to 2 parts of an anti-settling agent, 2 to 5 parts of a cross-linking promoter and 0.05 to 0.2 part of a catalyst A, wherein, raw materials for the silane-terminated polyurethane perpolymer comprise, by weight, 15 to 25 parts of polyether polyol, 12 to 24 parts of diisocyanate, 0.01 to 0.05 part of dibutyltin dilaurate or stannous octoate, 30 to 60 parts of ethyl acetate and 12 to 22 parts of an end-capping reagent. According to the invention, disadvantages of the prior art are overcome; when the silane modified polyurethane glass primer is used at normal temperature for 40 min in the air, the phenomenon of obvious thickening does not appear, and a film is not formed on the surface of the glass primer; the glass primer facilitates construction and is simple to use, and when used, the glass primer is directly poured into a container and then is directly used for brush coating within 40 min.

Owner:SHANDONG NORTH MODERN CHEM IND

Window multifunction guard rail and manufacturing method and application thereof

InactiveCN101270631AWill not affect daylightingNice appearanceFixed grillesBurglar alarm mechanical actuationSOCKSElectronic switch

The invention relates to a multi-function window guardrail and a manufacturing method and application, which belongs to the anti-creep, burglary-prevention and protecting device of the wall, the balcony and the window of a building. The invention comprises a fender bracket that is characterized in that the fender bracket is provided with a setting spring and an electronic switch. The electronic switch is connected with an alarm. The fender bracket is a mobile part. When external force acts, the fender bracket rotates to an angle and the electronic switch is turned on. Meanwhile, the alarm gives warning and the external force is lost. With the aid of the spring, the fender bracket is reset and the alarm stops giving warning. The multi-function window guardrail is installed outside the balcony and the window to be used for guarding against being climbed and theft, giving shoes and socks an airing and actively giving the warning. In addition, the multi-function window guardrail is also used for guarding against the creeper and the theft and protection for the pipes of the building and wall.

Owner:张朝峰

Method for surface modification of carbon nanotube and its dispersion method in epoxy resin

This invention relates to a carbon nanometer pipe surface modification and its disperse method in epoxy resin. The method includes (a) carbon nanometer pipe that is passivated to 0.5~500nm pipe diameter, 200nm~40ª–m and coupling agent is agitated with organic solvent to react for 10~20 minutes. (b) Certain dispersant and organic solvent are added into the uniform compound, then it is proposed for 20~40 minutes. (c) the solution said above is mixed with certain epoxy resin for 10~20 minutes. The carbon nanometer in this system is easy to disperse, and the system is stable.

Owner:DAQING PETROLEUM ADMINISTRATION

Environment-friendly starch adhesive for cementing corrugated boards at low temperature and preparation method of environment-friendly starch adhesive

InactiveCN106085289ALess glueFacilitates quick dryingNon-macromolecular adhesive additivesStarch derivtive adhesivesChemistryAdhesive

The invention relates to an environment-friendly starch adhesive for cementing corrugated boards at a low temperature and a preparation method of the environment-friendly starch adhesive. The starch adhesive is prepared from the following raw materials in parts by weight: 15 to 30 parts of starch, 60 to 80 parts of water, 0.2 to 1 part of sodium hydroxide, 0.05 to 0.2 part of oxidizing agent, 0.1 to 0.5 part of cross-linking agent, 0.1 to 0.5 part of stabilizing agent, 2 to 10 parts of drier, 1 to 5 parts of reinforcing agent and 0.1 to 1 part of penetrating agent. Under the oxidation of the oxidizing agent, besides hydroxyl, groups such as carboxyl and carbonyl are added on molecular chains of the starch, so that the initial adhesion of the adhesive is improved, the cementing quantity is reduced, and the rapidness in drying is facilitated; by adding the penetrating agent, the adhesive can rapidly penetrate through paper and destroy fibers; by adding the cross-linking agent and the reinforcing agent, the adhesive can be instantaneously cross-linked to form a mass structure, the rapid dryness of the adhesive is facilitated, and the adhesive can also be cross-linked with groups on the paper fibers so as to increase the cementing strength and the water resistance of paper boards; and by adding the drier, the drying speed of the starch adhesive can be increased, so that the steam pressure of a paper machine is reduced.

Owner:明辉大秦(上海)环保科技股份有限公司

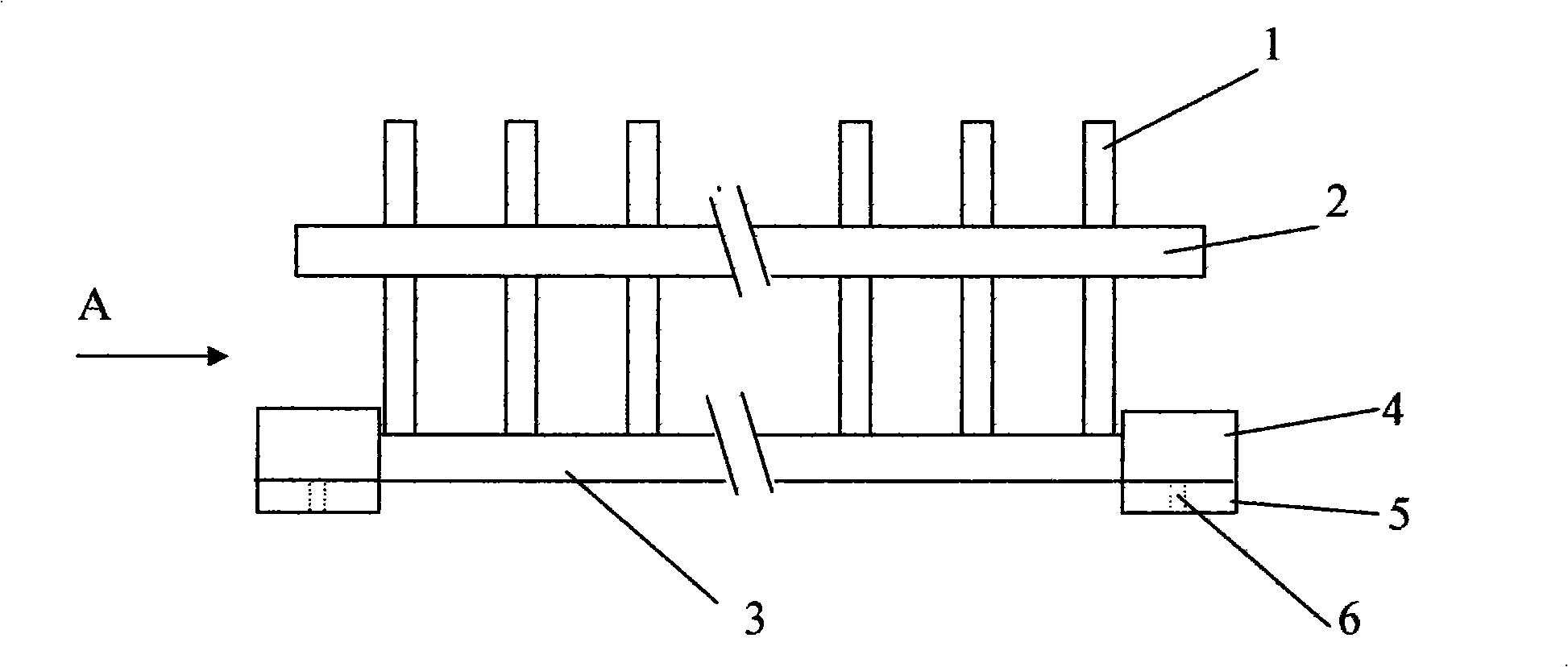

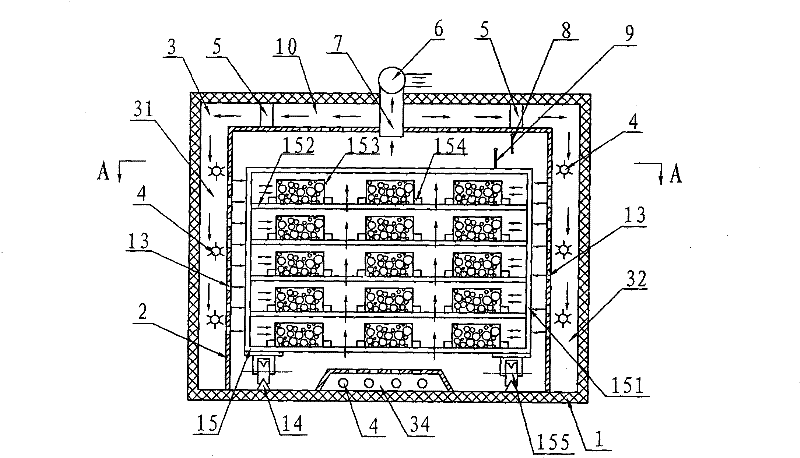

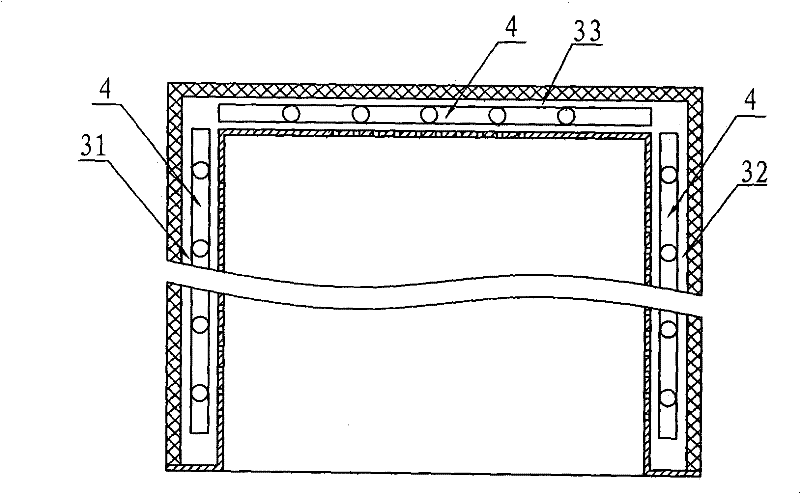

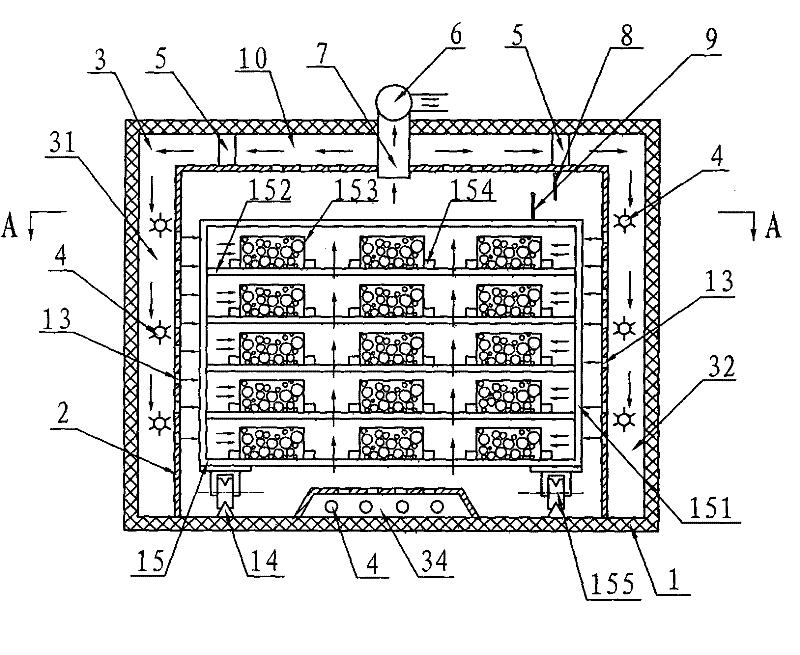

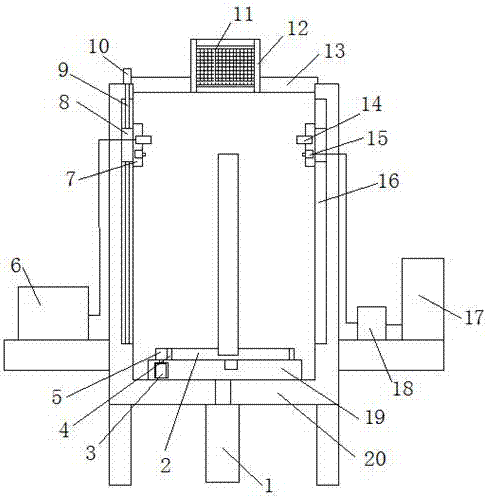

Special baking oven and special movable material rack thereof for silicon material

InactiveCN101749928AEasy loading and unloadingFully contactedDrying solid materials with heatDrying gas arrangementsThermal insulationProcess engineering

The invention relates to a special baking oven and a special material rack thereof for silicon material. The baking oven comprises a thermal insulation shell, an inner container, a high temperature air cavity, a hot air duct, a heater, a circulating fan, a dehumidifier, a dehumidification pipe, a humidity sensor, a temperature sensor, a frame body, idler wheels and a silicon material box, wherein the high temperature air cavity is arranged on top of the inner container, the hot air duct is arranged around the inner container, the heater is arranged in the baking oven, the circulating fan is arranged between the high temperature air cavity and the hot air duct, the dehumidifier is communicated with the inner chamber of the inner container, and the humidity sensor and the temperature sensor are arranged to realize automation control of the baking oven. The movable baking shelf thereof can facilitate loading / unloading and in / out of silicon material, save baking preparation time, and has the advantages of high baking efficiency and low energy consumption. The whole silicon material box can be directly moved in the baking oven for baking, thereby greatly shortening technology preparation time and reducing labor strength of operators.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

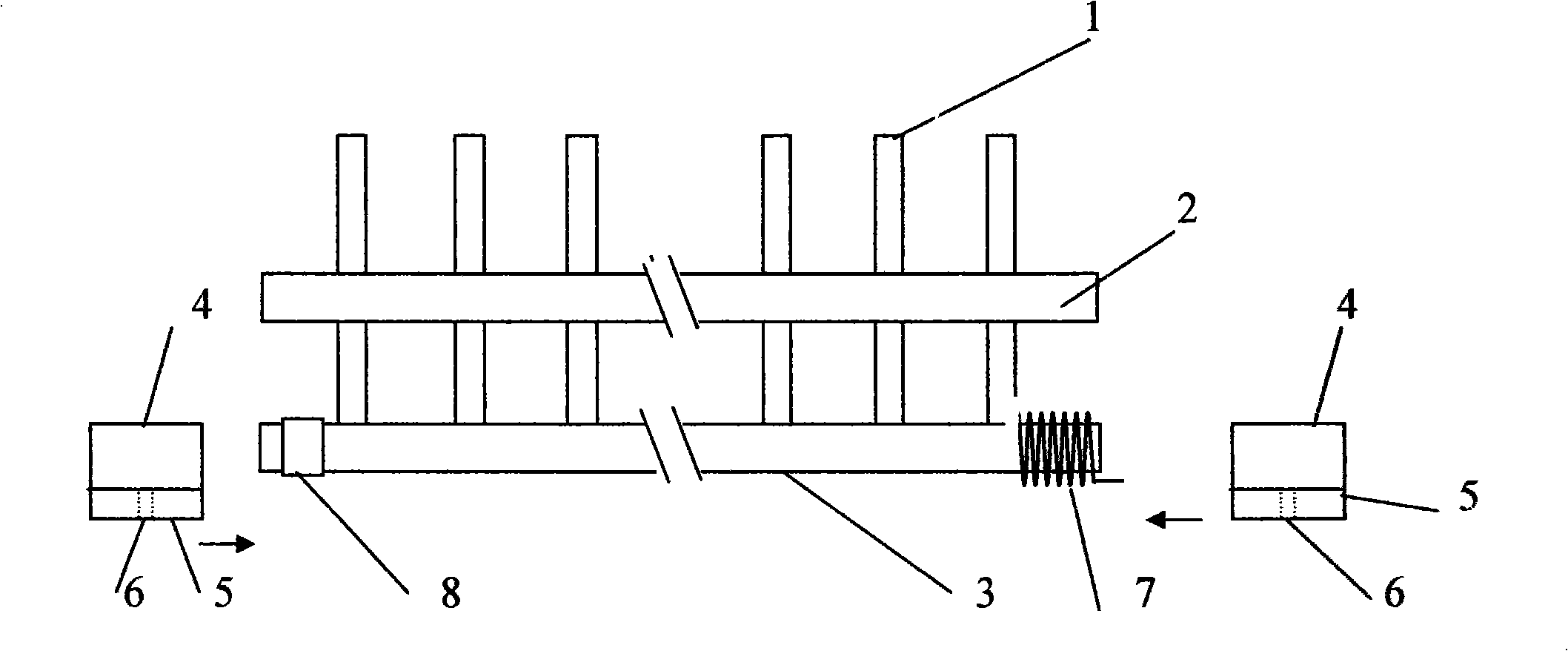

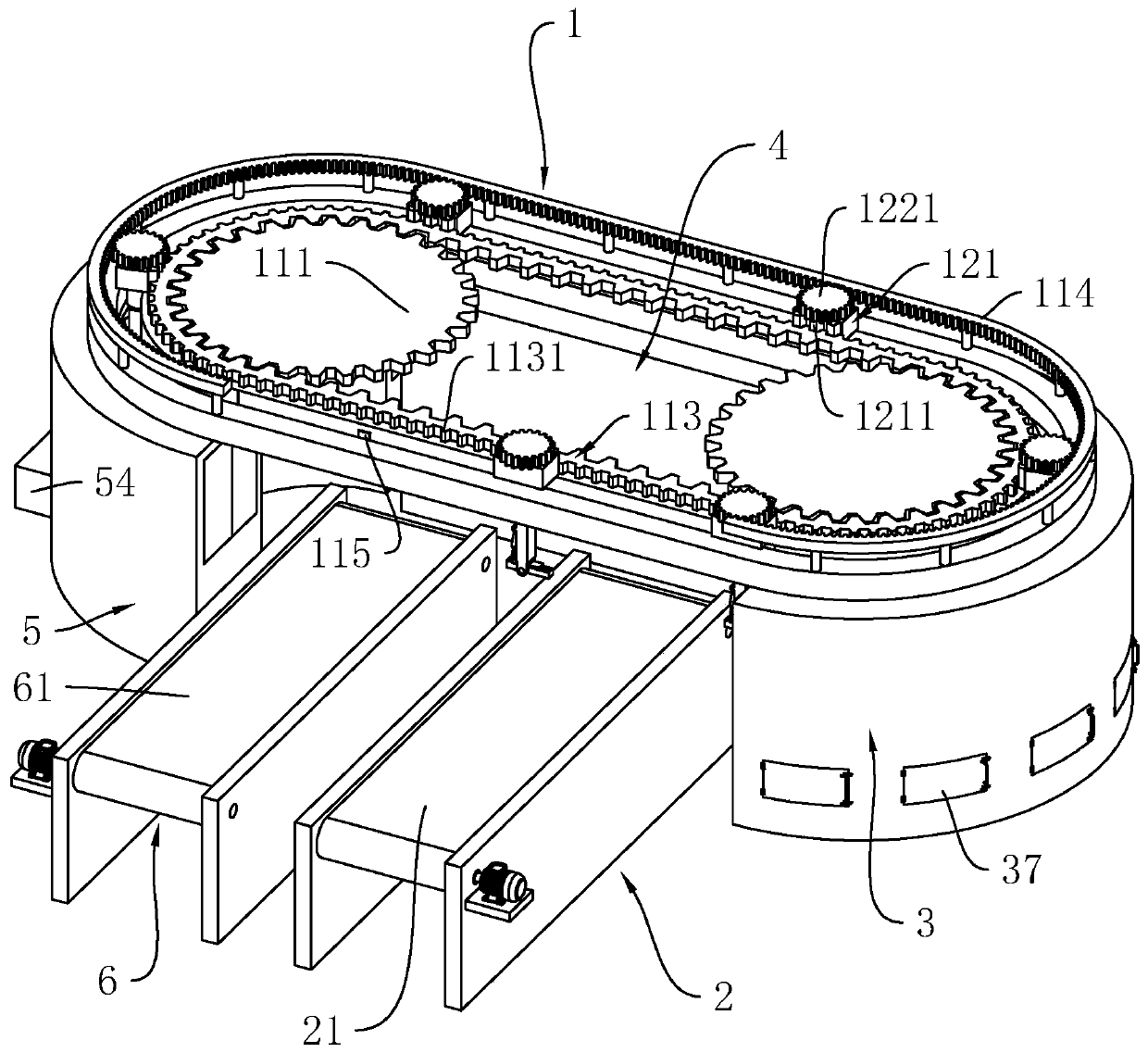

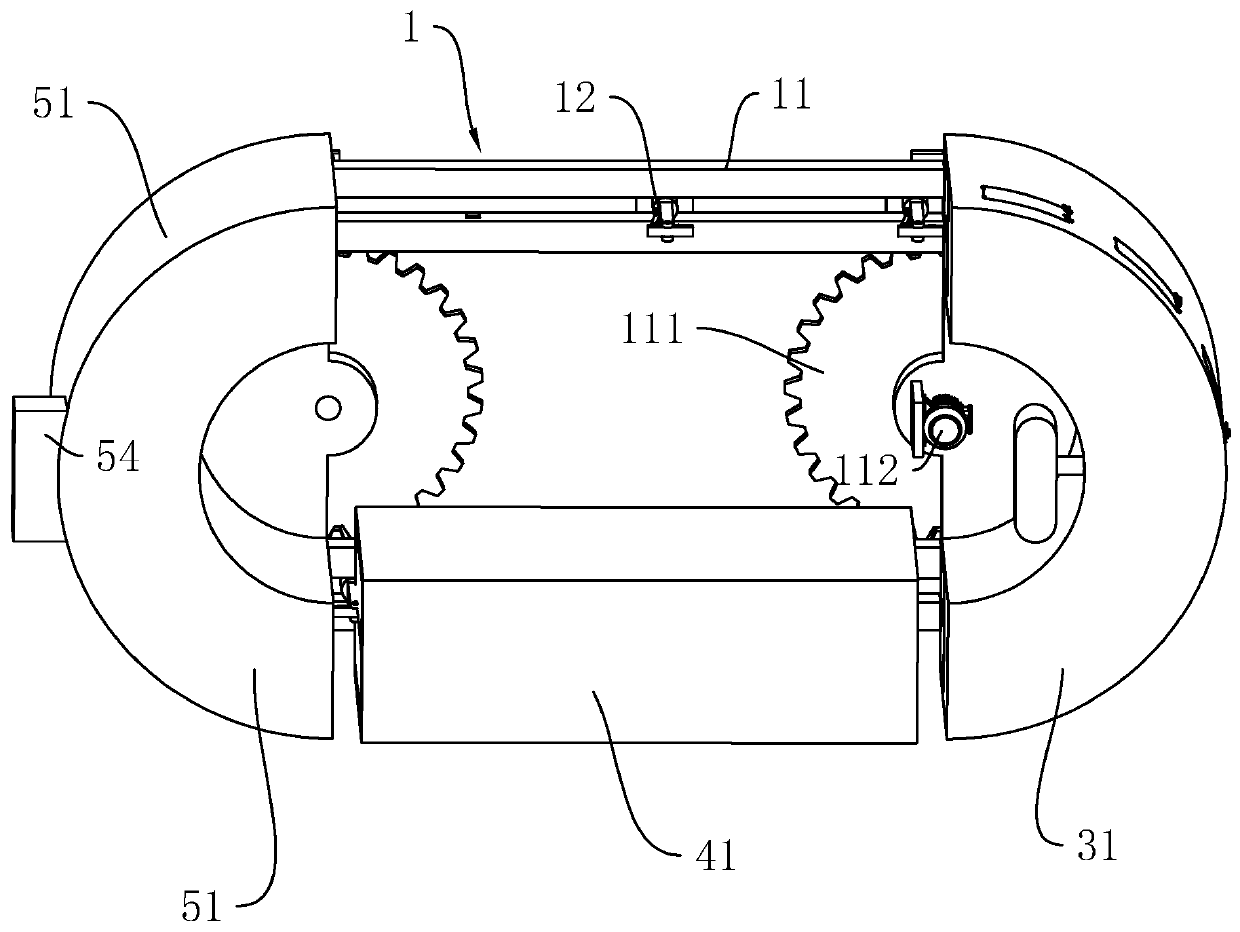

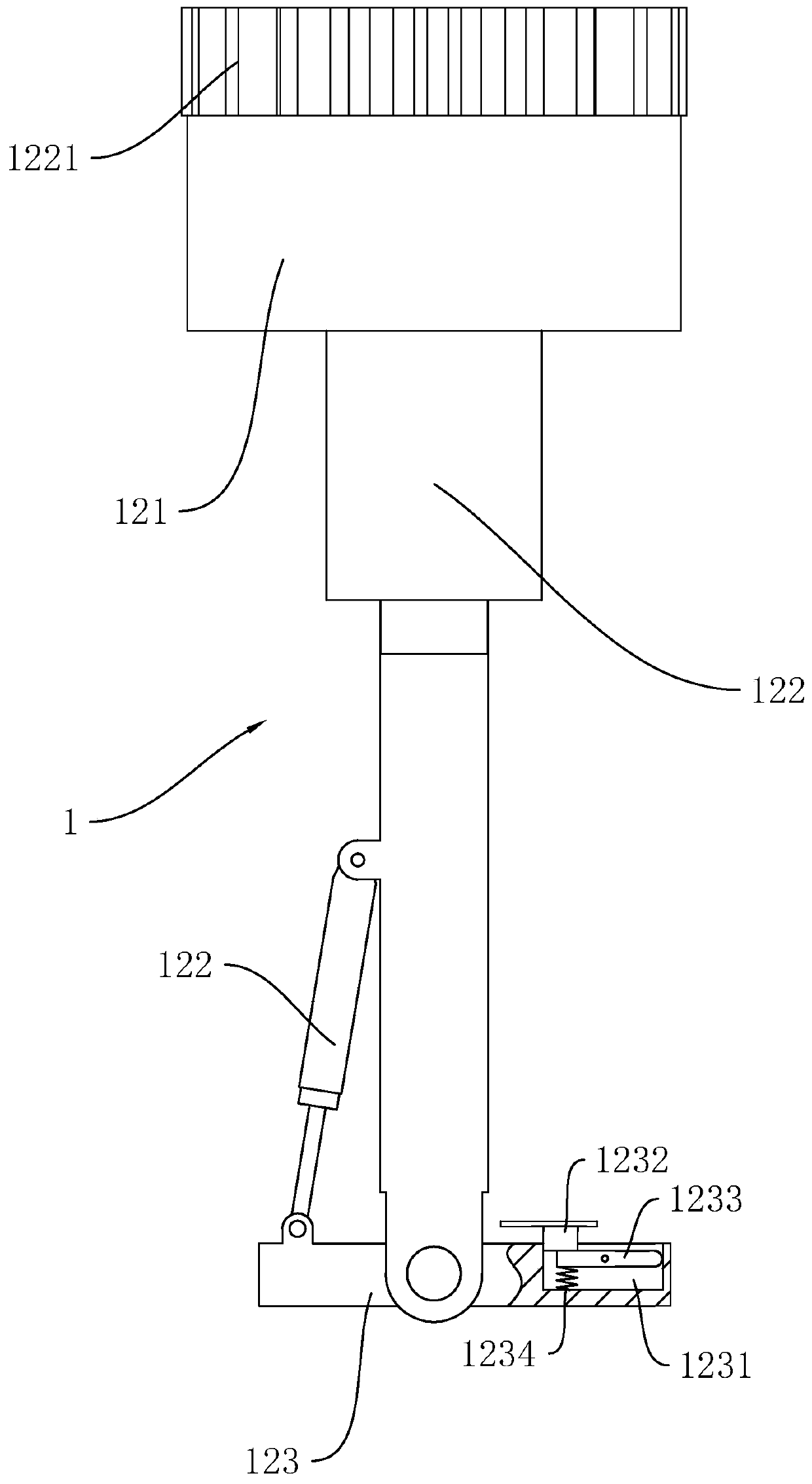

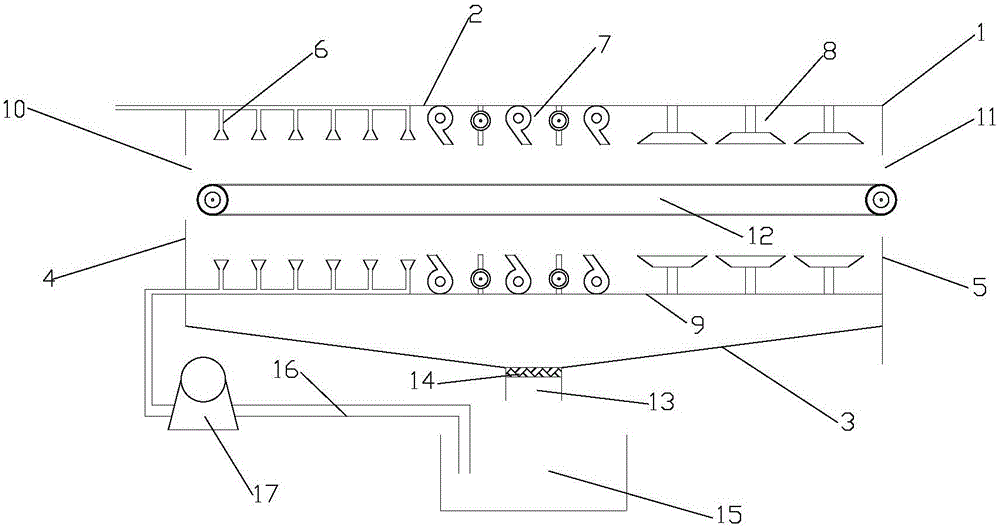

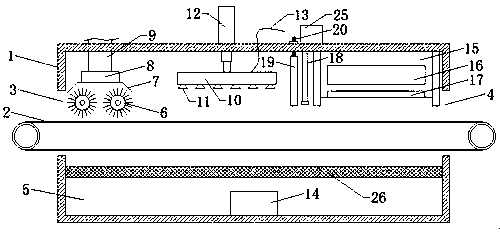

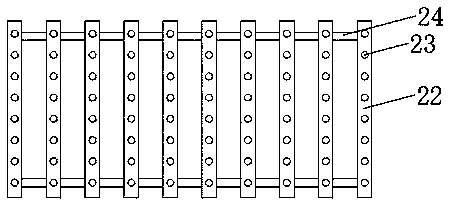

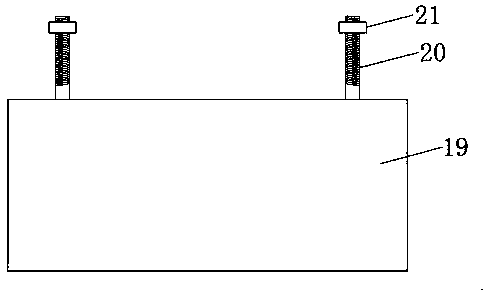

Workpiece lifting spraying production line

The invention relates to a workpiece lifting spraying production line which comprises a lifting conveying device, a feeding station, a spray cleaning station, a spraying station, a drying station anda discharging station. The lifting conveying device comprises a conveying rail in the shape of a kidney-shaped ring, and multiple lifting frames arranged on the lower side of the conveying rail. The spray cleaning station comprises a spray cleaning box, and a first through groove for the lower ends of the lifting frames to be inserted into the spray cleaning box conveniently is formed in the upperside of the spray cleaning box. Multiple gas spraying guns capable of spraying gases to workpieces are arranged at the positions, corresponding to the lifting frame conveying track, of the two sidesof the spray cleaning box. A blanking groove is fixedly connected to the position, corresponding to the lower side of the lifting frame, of the spray cleaning box along the movement track of the lifting frame, and a cloth bag dust collecting bag with an opening formed in the upper end is arranged on the lower side of the blanking groove. A draught fan is fixedly connected to the position, corresponding to the lower side of the cloth bag dust collecting bag, of the spray cleaning box. First flexible dust blocking curtains are further fixedly connected to the two ends of the spray cleaning box.The workpiece lifting spraying production line has the beneficial effects that the workpieces can be automatically cleaned, the labor intensity is lowered, and the work efficiency is improved.

Owner:青岛欧轩机械有限公司

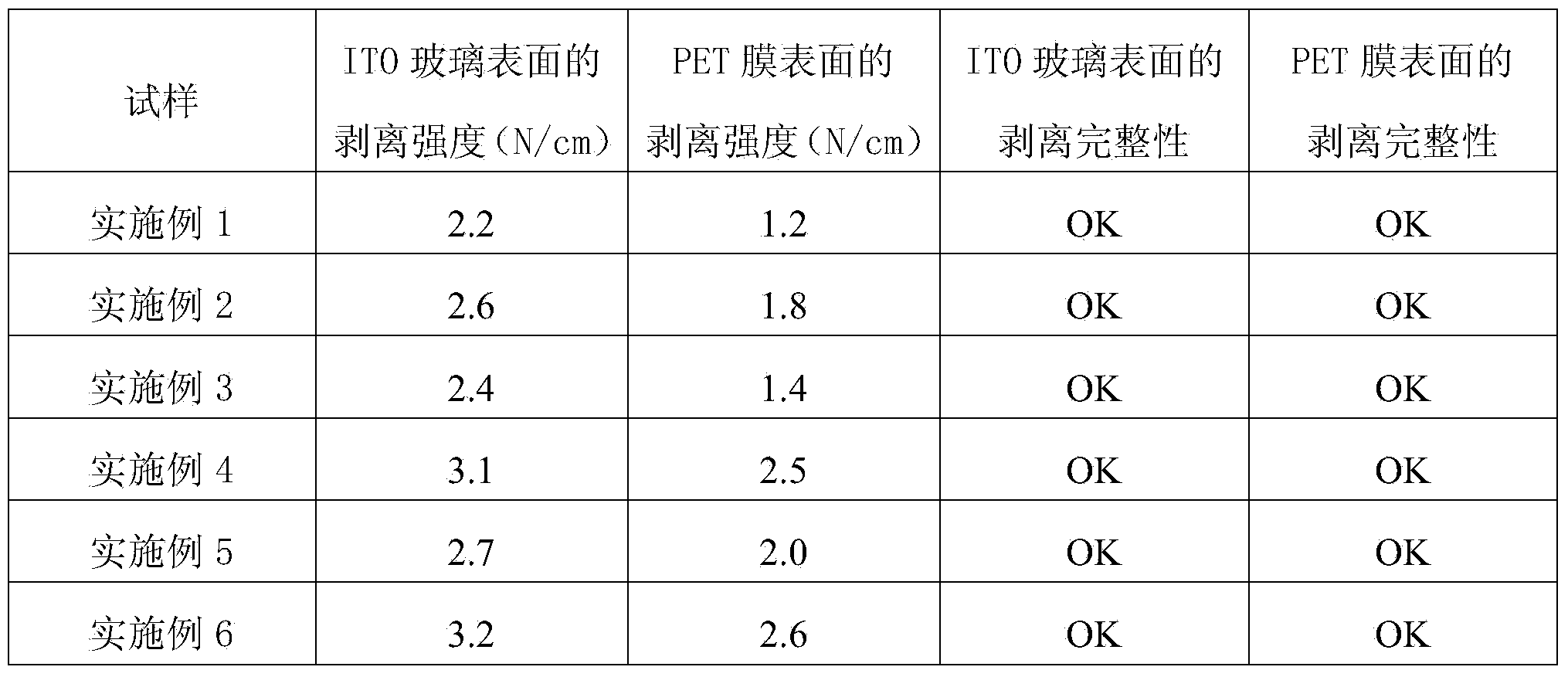

Ultraviolet-cured stripping protective material and preparation method and application thereof

ActiveCN103627313AHigh elongationEasy to dryPolyurea/polyurethane coatingsPolyethylene terephthalate glycolUltraviolet lights

The invention belongs to the technical field of surface protective materials, and discloses an ultraviolet-cured stripping protective material and a preparation method and application thereof. The stripping protective material comprises the following components in parts by weight: 50-90% of polyurethane modified acrylic ester, 5-35% of acrylics reactive diluent, 1-8% of photoinitiator, 1-15% of filler, and 0-10% of additive. According to the ultraviolet-cured stripping protective material, the ultraviolet light is used for triggering a chained polymerization, the time for curing is short, generally 1-5 seconds, and the production efficiency is high; not any organic gas is released, so that the preparation method is more environment-friendly; the use and operation process is simple and convenient, the surface of the material is not affected due to overheating curing, mist is generated after stripping; the integral protective material can be better stripped, is not sticky, has no mist, and is applicable to protecting surfaces of ITO (indium tin oxide) glass, ITO membranes and PET (polyethylene terephthalate) membranes.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

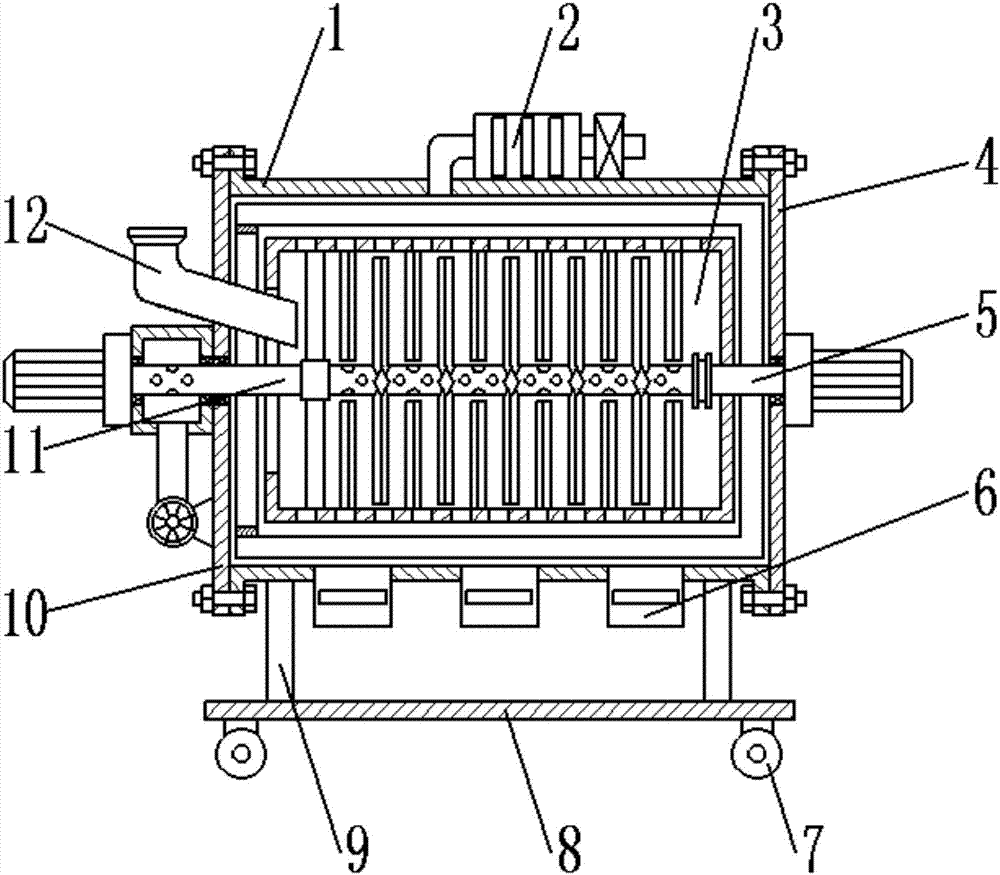

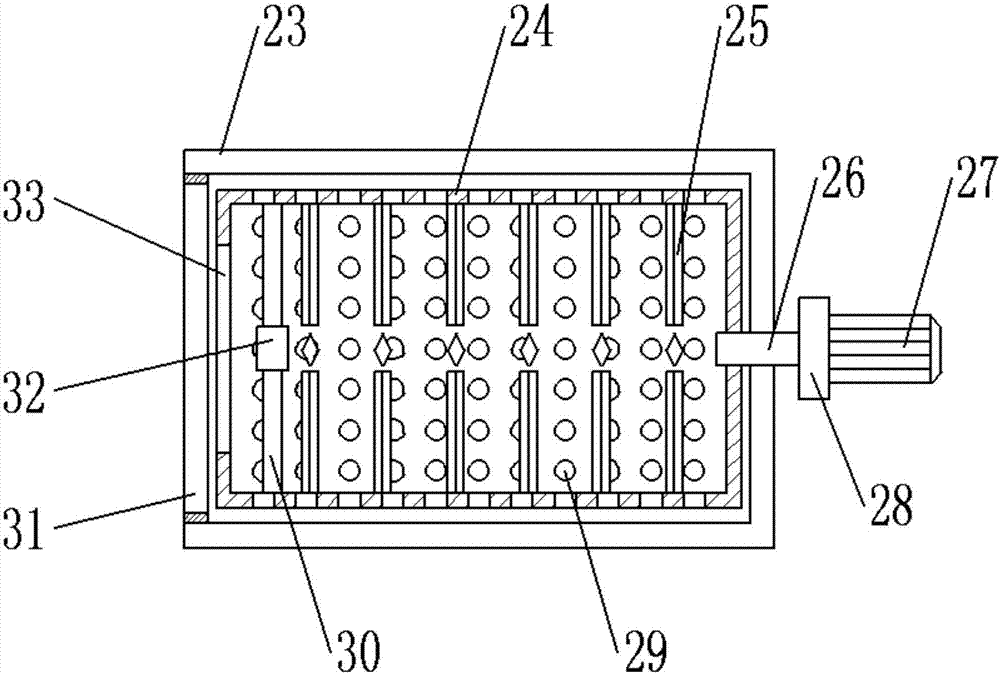

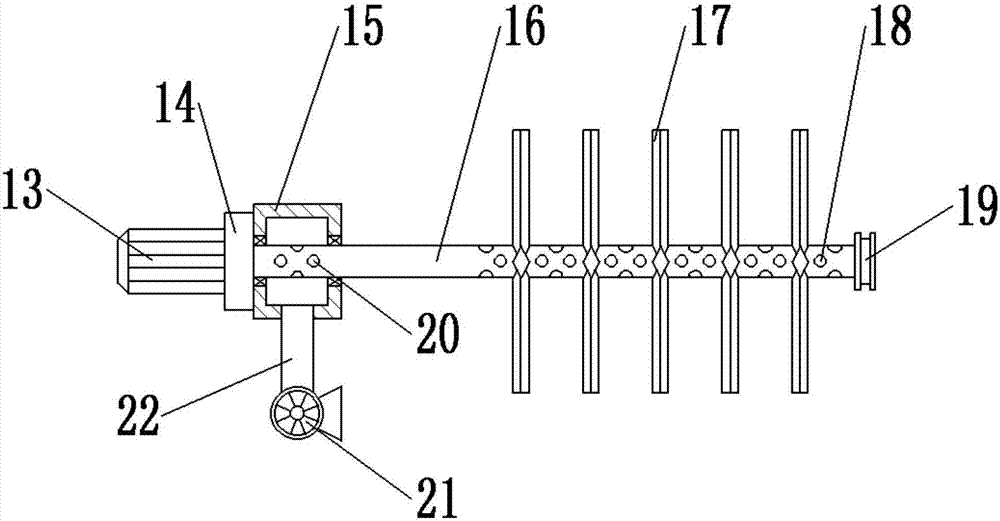

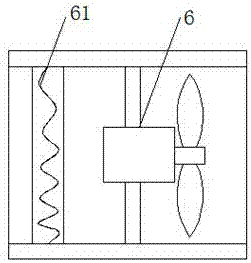

Raw material crushing and drying integrated equipment for chemical industry production

The invention provides raw material crushing and drying integrated equipment for chemical industry production. The raw material crushing and drying integrated equipment comprises a tank body; the tank body is arranged to be a hollow cylinder with the two ends communicating with each other, and the tank body is horizontally arranged; an opening in the left end of the tank body is provided with a left end cover, and an opening in the right end of the tank body is provided with a right end cover; the middle upper portion of the left end cover is fixedly provided with a feeding pipe in a welded manner; the top face of the tank body is provided with a dehumidification device; the outer wall of the tank body is fixed to a bottom plate through supporting plates in a welded manner; the tank body is internally provided with a processing cavity; and the processing cavity is internally provided with a first crushing and material-turning-over device and a second crushing and drying device. Through the arrangement of the first crushing and material-turning-over device and the second crushing and drying device, materials are sheared and crushed through second rotary crushing blades in cooperation with first crushing blades, hot air blown in by a warm air machine is uniformly distributed through air injection holes uniformly distributed in the surface of a second rotary shaft, the distribution area of the hot air is expanded, and the raw materials are fully dried conveniently.

Owner:合肥多智科技开发有限公司

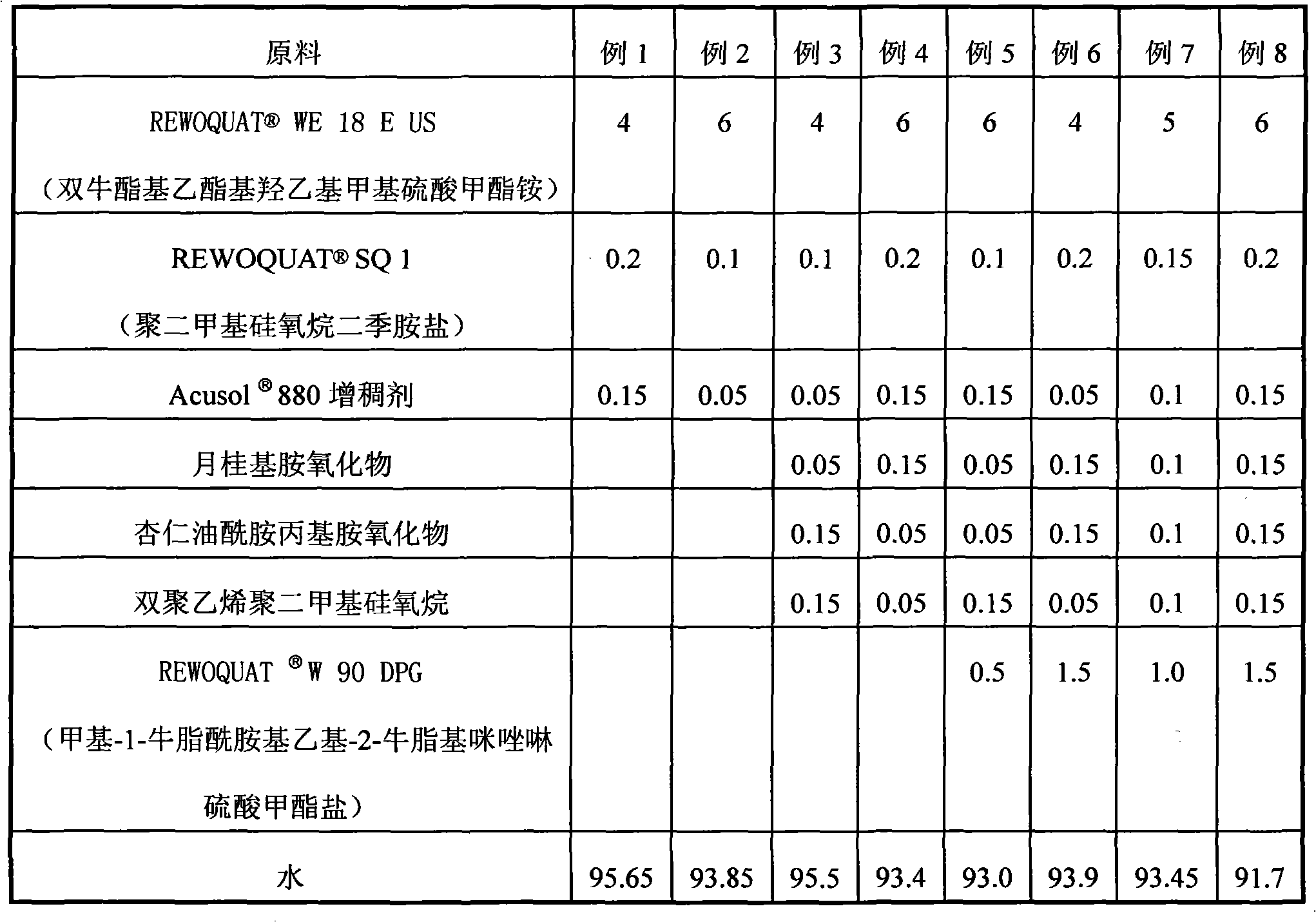

Clothes softener

Owner:SHANGHAI SOAP FACTORY

Paint spraying device with dust removal and drying functions

InactiveCN105562258ASimple structureReasonable designPretreated surfacesCoatingsElectrostatic precipitatorEngineering

The invention discloses a paint spraying device with dust removal and drying functions. The paint spraying device comprises a supporting plate and a cover plate. A supporting column is fixedly connected to the bottom of the supporting plate. The cover plate is fixedly mounted at the top of the supporting plate. A dust removal chamber, a paint spraying chamber and a drying chamber are sequentially arranged in the interval between the supporting plate and cover plate from left to right. An electrostatic dust removal device is fixedly mounted in the dust removal chamber. A paint cylinder is arranged above the paint spraying chamber. The bottom of the paint cylinder is fixedly connected with the top of an air pump through a first connecting pipe. The bottom of the air pump is fixedly connected with one end of a second connecting pipe. A draught fan is fixedly mounted above the drying chamber. The paint spraying device with the dust removal and drying functions is simple in structure, reasonable in design, capable of conducting electrostatic dust removal on the surface of a workpiece before paint spraying to remove dust on the surface of the workpiece and avoiding the situation of uneven paint spraying and capable of quickly drying the painted workpiece and avoiding paint respraying caused by scratches on wet oil paint.

Owner:WUXI YONGYI PRECISION CASTING

Preparation process for fine denier and superfine denier polypropylene fibers

InactiveCN101736416AReduce consumptionSave dyeing energyMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAbnormal shaped

The invention mainly discloses a preparation process for fine denier and superfine denier polypropylene fibers, which comprises the following steps of: adopting a spinning special material of which the melting point is between 165 and 175 DEG C; in a spinning device, extruding and melting the spinning special material by a single screw extruder, wherein a melt flows evenly; performing spinning through a round or abnormal spinneret orifice of a spinneret plate of a spinning box, wherein the spinning speed is 2,200 miters per minute; cooling and oiling tows; and then performing hot drawing and winding to finally obtain the fine denier and superfine denier polypropylene fibers of 0.5 to 2 deniers, wherein the hot drawing temperature is between 45 and 105 DEG C, the drawing multiple is 1.5 to 4 times, and the winding speed is 80 meters per minute for overfeeding. The preparation process is a nuisanceless, environment-friendly, energy-saving and innovative process, and the finally obtained product has the advantages of light in texture, high strength, good abrasion resistance and elastic resilience, small static electricity, small coefficient of heat conductivity and good electrical insulating property.

Owner:绍兴前瞻化纤有限公司

Aluminum profile cooling device

The invention provides an aluminum profile cooling device. The device comprises a cooling box. The cooling box comprises a top plate, a bottom plate, a left side plate and a right side plate. The top plate of the cooling box is sequentially provided with a spraying device, an air blowing device and a drying device from left to right. The bottom plate is of a concave structure and is provided with a bottom plate support. The bottom plate support is provided with a spraying device, an air blowing device and a drying device which are the same as those of the top plate. The aluminum profile cooling device has the advantages that aluminum profiles can be quickly cooled through the spraying devices, water can be blown off or dried quickly through the air blowing devices, water left on the aluminum profiles can be dried quickly through the drying devices, a filter screen is disposed on a drainage port, impurities in recycled spraying water can be filtered out so that the water can be used again, the spraying device on the bottom plate is connected with a water storage pond, the water can be recycled and a large amount of cost is reduced.

Owner:TIANJIN SHENGFA IND & TRADE

Automatic paint spraying device for metal castings

PendingCN107214035AEasy to installEasy to unloadLiquid surface applicatorsLiquid spraying apparatusPiston rodSpray painting

The invention discloses an automatic paint spraying device for metal castings. The automatic paint spraying device comprises a paint spraying barrel with an opening in the top end. Support columns are correspondingly mounted on the four corners of the bottom end of the paint spraying barrel. An air cylinder vertically arranged is fixedly arranged on the side wall of the bottom end of the paint spraying barrel through bolts. A movable plate is welded to a piston rod of the air cylinder. The movable plate is located on the inner wall of the bottom end of the paint spraying barrel. The top end of the movable plate is rotationally connected with a mounting plate horizontally arranged. A first electric motor is embedded into the movable plate. An output shaft of the first electric motor is connected with a gear. The gear is located on one side of the mounting plate. Tooth mouths distributed in an array manner are mounted on the side walls of the periphery of the mounting plate. The tooth mouths are engaged with the gear. A fixing ring is slidably connected into the paint spraying barrel. An annular air outlet pipe and a liquid spraying pipe are mounted on the inner wall of the fixing ring. The air outlet pipe is located above the liquid spraying pipe. By the adoption of the automatic paint spraying device, the multi-angle paint spraying of the metal castings can be achieved, the paint spraying effect is good, the quick mounting and discharging of the metal castings are achieved, and the air pollution is reduced.

Owner:JIANGSU SUGAO FLUID MACHINERY

Low-profile washable garments for capturing bodily fluids

InactiveUS20120010582A1Promote wearer comfortPromote hygieneTrousersBrassieresBiomedical engineeringBody fluid

Embodiments of the present invention provide an improved garment for capturing bodily fluids. In particular, embodiments of the present invention provide a garment including a main garment body configured to be worn by a wearer and a capturing panel having a receiving surface configured to receive bodily fluids excreted from the wearer attached to the main garment body such that the capturing panel covers at least a first portion of said main garment body. The capturing panel is made out of a natural material, has a thickness no greater than approximately 4 mm, and is configured to transfer bodily fluid received from the wearer away from the receiving surface. A fluid resistant treatment may be applied to at least a second portion of the main garment body, which second portion may be identical to the first portion. A odor-neutralizing treatment may be applied at least a portion of the capturing panel.

Owner:ANGLE ENTERPRISES

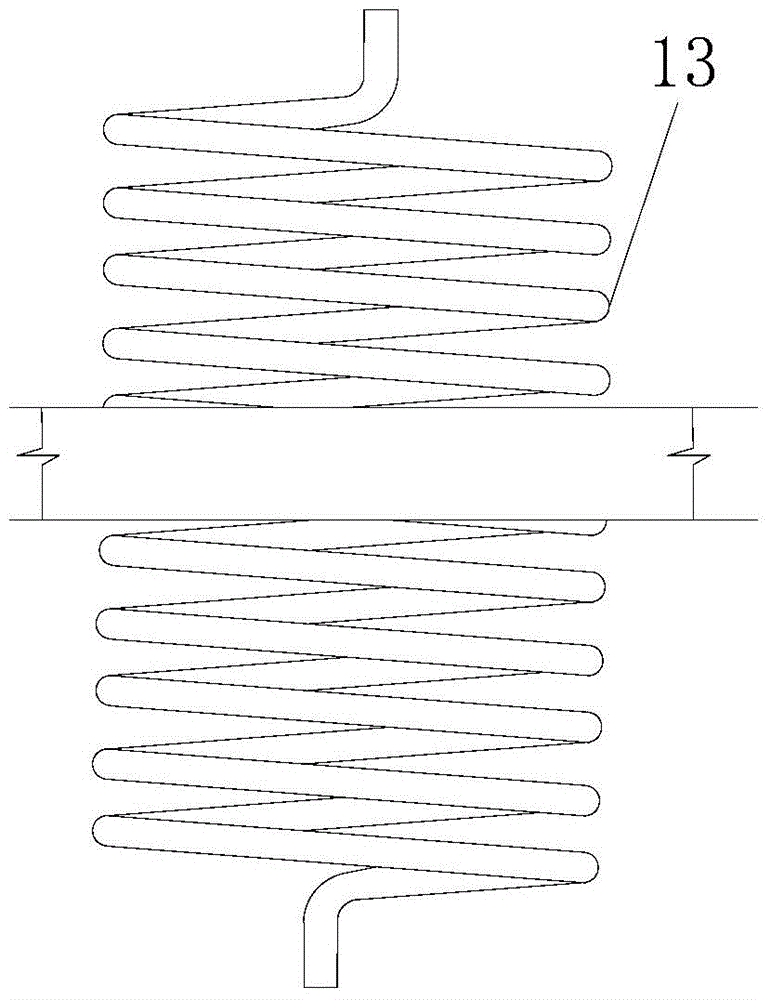

System for producing selenized tea

The invention discloses a system for producing selenized tea, which comprises a heating device, a drying device, a first fixation pan, a second fixation pan, a preparing gill machine, a first drying cage, a cool sharing device, a second drying cage, a refrigeration device, a fragment enhancer and a vacuum package machine which are orderly front and back connected, wherein the heating device is used to heat tea, the dying device is used to dry the tea, the first and the second fixation pans are used to fix the tea, the preparing gill machine is used to prepare gills, the first drying cage is used to primarily dry and process the tea, the cool sharing device is used to cool the tea which are primarily dried and processed and sprays organic selenium solution to the surface of the tea, the second drying cage is used to secondarily dry and process the tea, the refrigeration device is used to refrigerate and cure the tea, and the fragment enhancer is used to enhance fragment for the tea. The tea and hot water flow out from a discharge interface to enter a heating conveyer pipe in a spiral shape by being put into a hopper, and each tea blade is enclosed in the heating conveyor pipe to be uniformly heated in the hot water, thereby improving heating effect and reducing heating time.

Owner:ANQING WANCAO QIANMU AGRI TECH

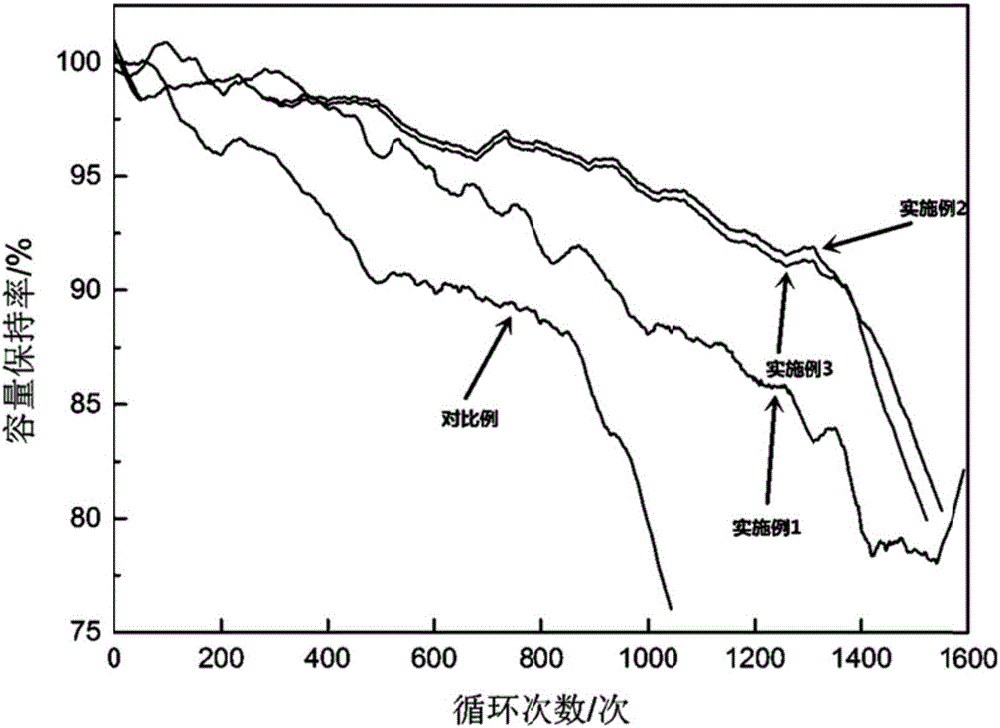

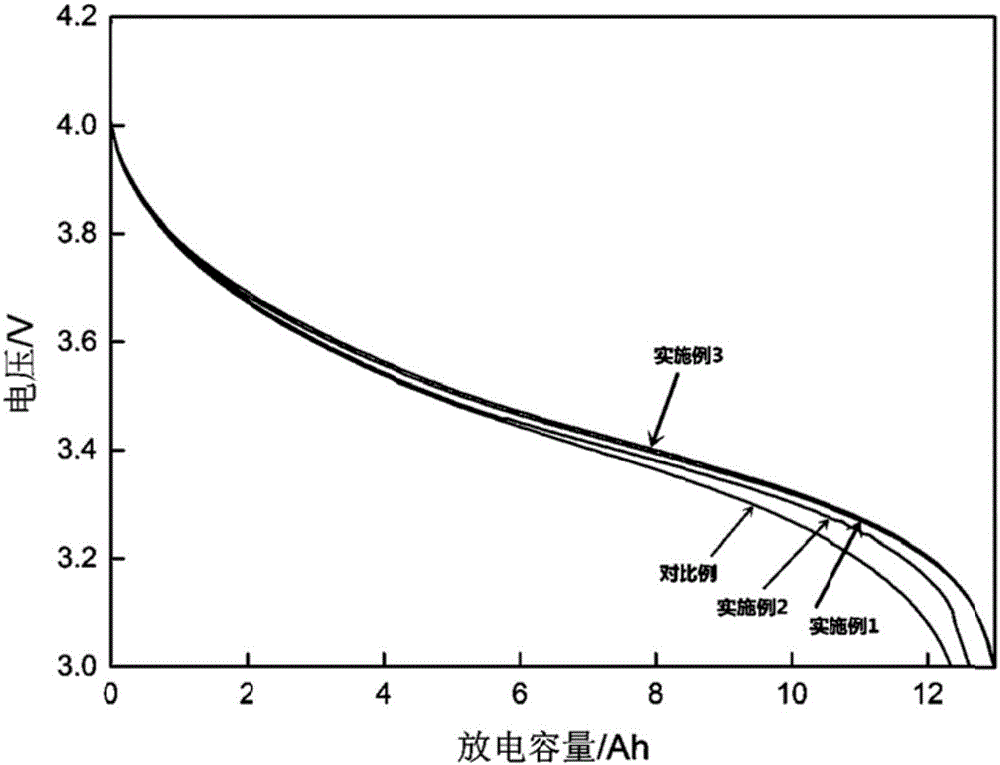

Slurry-homogenizing process for positive electrode slurry of lithium ion battery, positive electrode plate and lithium ion battery

ActiveCN106654166AImprove uniformity and stabilityReduce evaporationSecondary cellsNon-aqueous electrolyte accumulator electrodesCurrent collectorLithium electrode

The invention discloses a slurry-homogenizing process for positive electrode slurry of a lithium ion battery, a positive electrode plate and the lithium ion battery, and belongs to the technical field of manufacturing of the lithium ion battery. The slurry-homogenizing process for the positive electrode slurry of the lithium ion battery comprises the steps of preparing an adhesive solution, stirring by a V-shaped stirrer, performing pre-mixing and stirring, performing high-speed stirring, performing viscosity adjustment, performing vacuum defoaming and the like; the positive electrode plate of the lithium ion battery comprises a positive electrode current collector and the positive electrode slurry for coating the positive electrode current collector; the positive electrode current collector adopts an aluminum foil; the positive electrode slurry is prepared by the slurry-homogenizing process for the positive electrode slurry of the lithium ion battery; and the lithium ion battery adopts the positive electrode plate of the lithium ion battery prepared by the method. By adoption of the slurry-homogenizing process, the solid content of the slurry is increased, so that solid granule friction in stirring can be improved, and the uniformity and the stability of the slurry can be improved; and by lowering a baking temperature in a drying oven in coating and drying, gaps formed between active material granules, conducive carbon granules and a binder can be reduced, thereby enhancing an adhesive effect and improving the performance of the lithium ion battery.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

Paint-spraying device with desusting and drying integrated structure

InactiveCN109261416AGuaranteed long-term useSolving Recycling ProblemsPretreated surfacesLiquid spraying apparatusSprayerEngineering

The invention relates to the field of paint spraying, and particularly discloses a paint-spraying device with a desusting and drying integrated structure. The paint-spraying device comprises a shell,a conveying belt, a feeding inlet, a discharging outlet and a paint collection tank, wherein a dust suction hood, an installation support and a drying cavity are arranged / formed above the conveying belt from left to right in sequence; a plurality of brush rollers are arranged below the dust suction hood, the dust suction hood is communicated with a dust suction blower, and the installation supportis fixedly connected with an electrical telescoping rod which stretches and retracts in the vertical direction; a vertical hot air suction pipe is arranged on the outer portion on the left side of the drying cavity, and a wind deflector with adjustable height is arranged on the left side of the hot air suction pipe. By means of the drying cavity, the paint on the surface of wood can be quickly dried, meanwhile, hot air overflows outwards can be recycled, the hot air is prevented from flowing to the position of a paint sprayer, the paint is prevented from being dried in the sprayer, it is ensured that the paint sprayer is used for a long time, and the service life is prolonged.

Owner:湖南匡沐环保科技有限公司

Charcoal fertilizer as well as preparation method and application thereof

InactiveCN105753546AImprove carbonization rateImprove the carbonization effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdjuvantCarbonization

The invention discloses a charcoal fertilizer, prepared from the following raw materials in percentage by weight: 10-50% of charcoal powder, 20-70% of compound fertilizer and 5-30% of adjuvant, wherein the charcoal powder is obtained by putting straws in a carbonization furnace for dehydration and deoxygenation treatment and smashing the straws to a particle size of not more than 0.5mm after high-temperature carbonization. A preparation method of the charcoal fertilizer comprises the following steps: feeding the straws into the carbonization furnace; performing the dehydration and deoxygenation treatment for 1-2 hours at a temperature of 100-250 DEG C; carbonizing the straws at a high temperature of 600-700 DEG C for 30-240min; cooling the carbonized product and then smashing the carbonized product to form the charcoal powder with the particle size of not more than 0.5mm; uniformly mixing the charcoal powder, the compound fertilizer and the adjuvant in proportion to obtain a mixture and then pelleting the mixture to obtain pellets; cooling and screening the pellets to a particle size of 1.5-4.75mm; packing the screened pellets. The charcoal fertilizer disclosed by the invention has the advantages of an extensive source of the raw material straws, a good carbonization effect, high carbon content, conformity with the concept of environmental protection, simplicity in preparation technique, low energy consumption, high product strength and capability of processing the raw materials in a centralized manner and obviously increasing the utilization rate and quality stability of the fertilizer. The invention further discloses an application of the charcoal fertilizer in crop growth.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Fast-curing one-component polyurethane sealant and preparation method thereof

InactiveCN101818040AFast curingEasy to dryNon-macromolecular adhesive additivesOther chemical processesAntioxidantPolystyrene

The invention relates to a sealant, in particular to a fast-curing one-component polyurethane sealant and a preparation method thereof. The fast-curing one-component polyurethane sealant is characterized by comprising 30%-60% of prepolymer containing silyl-terminated polyurethane, 0.2%-5% of silane coupling adhesion promoter, 0.301%-0.35% of catalyst, 10%-40% of plasticizer, 10%-60% of filler and 0.05-1% of antioxidant, wherein the content of each component is represented by the weight percent. The fast-curing one-component polyurethane sealant has the advantages of fast surface drying, fast curing speed, avoidance of impacts caused by the environmental temperature and the humidity, high cross-linking density, high elongation ratio, good adhesion strength, no solvent, environmental protection and excellent adhesive performance to base materials, such as metal, ceramics, glass, silica PVC, ABC, polystyrene, polyacrylate and the like.

Owner:PUYANG CITY WANQUAN CHEM

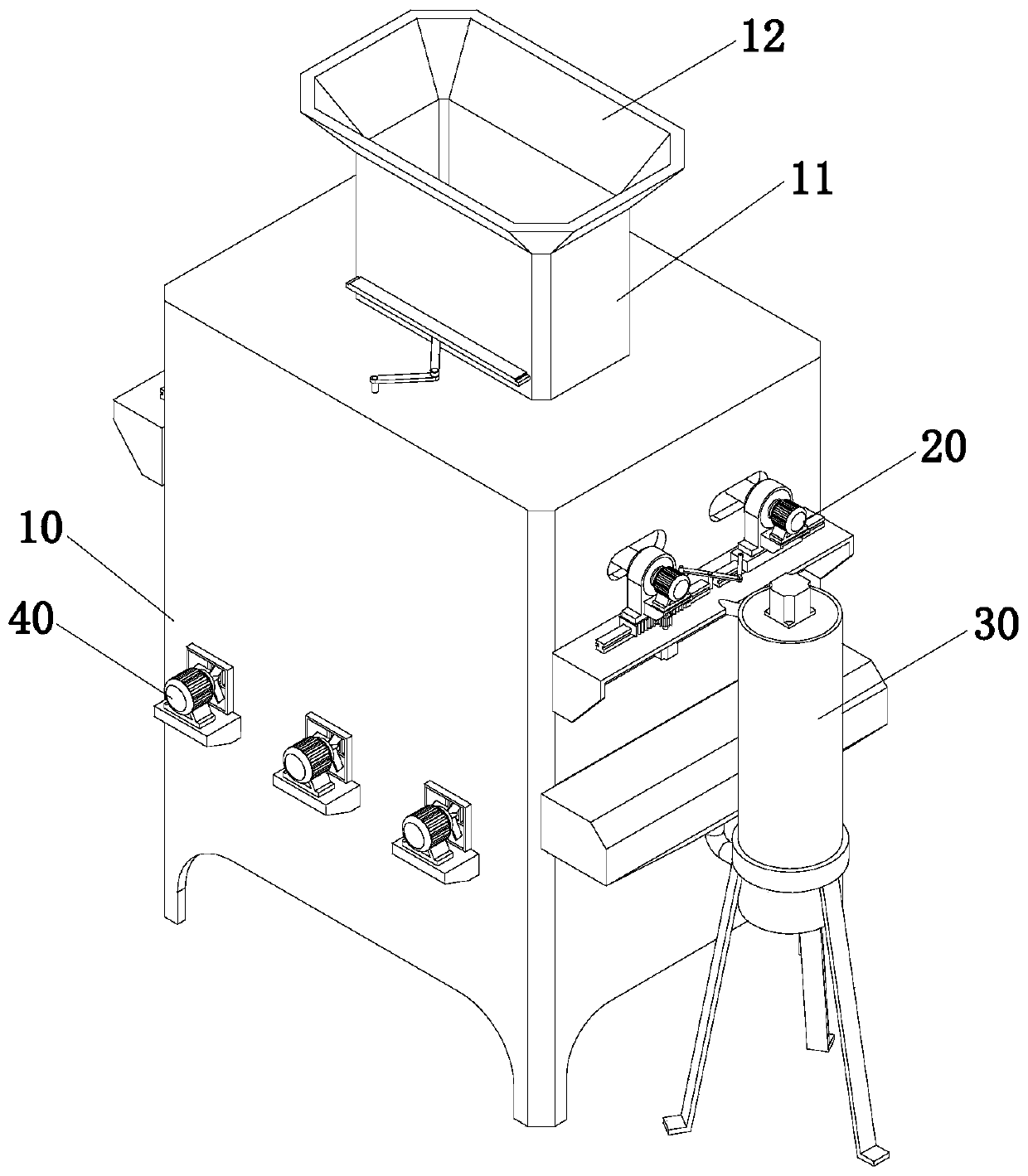

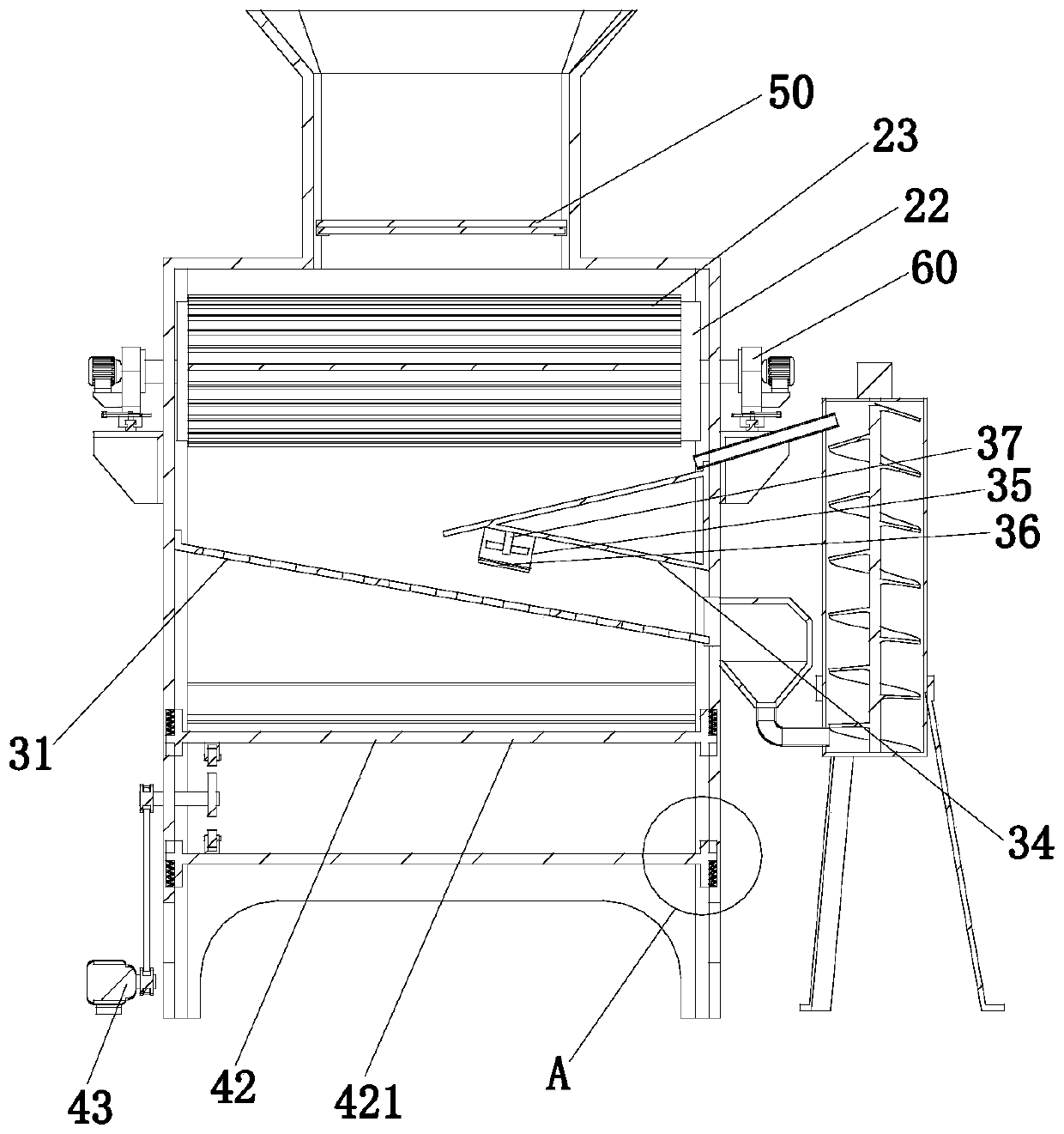

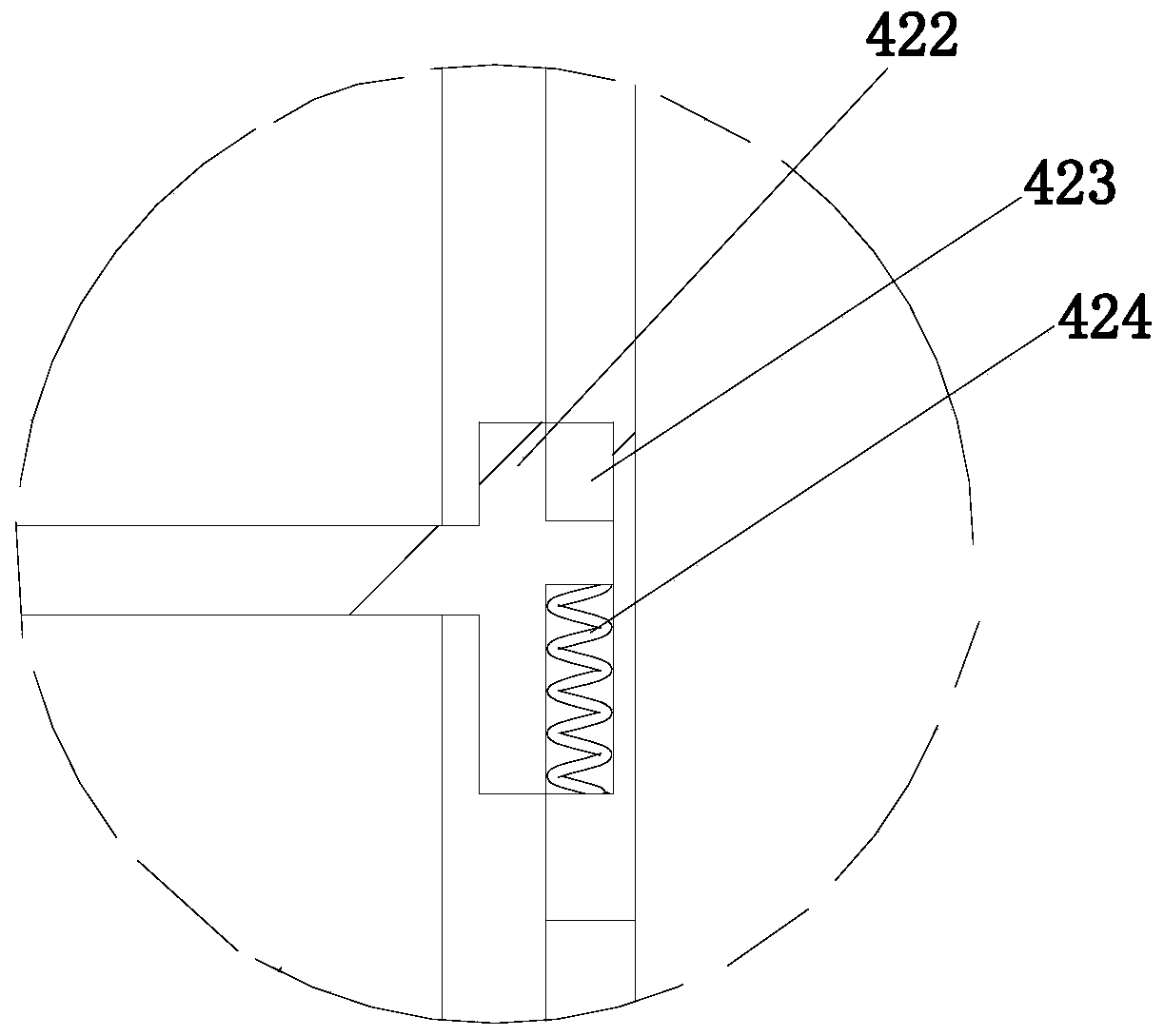

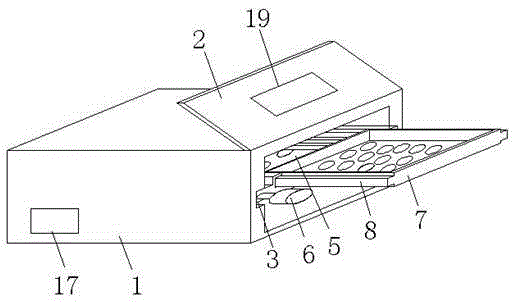

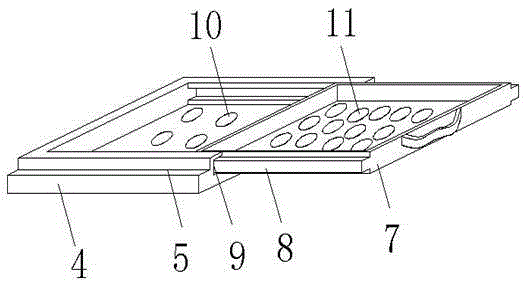

Rice screening and husking device

ActiveCN110152763ARealize separation workReduce laborSievingGrain huskingAgricultural engineeringMechanical devices

The invention discloses a rice screening and husking device, and belongs to the technical field of agricultural machinery and equipment. The rice screening and husking device comprises a husking cabinet. An extrusion husking mechanism, a drying and adhesion resisting mechanism and a screening and separating mechanism are arranged in the husking cabinet. A feed box is arranged at the top of the husking cabinet. A leakproof hopper is arranged at the top of the feed box. A flow control component is arranged on the lower section of the feed box. The extrusion husking mechanism comprises a spacingadjustment component and two mounting shafts. Each mounting shaft is sleeved with a rotating drum. The spacing adjustment component comprises two spacing adjustment members. Each spacing adjustment member comprises a support frame, a moving piece, a left bearing block and a right bearing block. The rice screening and husking device has the advantages that rice in the feed box can be fed for multiple times through the flow control component, the drying and adhesion resisting mechanism can dry the rice to prevent adhesion, and the extrusion force for husking can be adjusted by the extrusion husking mechanism to meet demands of different users.

Owner:ANHUI SCI & TECH UNIV

Chopstick cleaning box

InactiveCN105411500AClean upEasy to placeTableware washing/rinsing machine detailsHigh intensityEngineering

The invention discloses a chopstick cleaning box, which comprises a box body, a bearing plate and a cleaning basket, wherein a box cover is hinged at one end of the box body; first sliding grooves, which are mutually parallel, are formed in two side faces of an inner cavity of the box body; the bearing plate is movably clamped on the inner cavity of the box body by virtue of a first sliding block and the first sliding grooves on the side faces, and the first sliding block is connected to the rotating shaft of a linear motor on the side face of the box body; a holding groove is formed in the surface of the bearing plate; first water passing holes are formed in the bottom of an inner cavity of the holding groove, and second sliding grooves, which are mutually parallel, are formed in two side faces of the inner cavity of the holding groove; the cleaning basket is movably clamped inside the holding groove by virtue of a second sliding block and the second sliding grooves on the side faces; and second water passing holes are formed in the bottom of an inner cavity of the cleaning basket. The chopstick cleaning box can achieve integration and automation of chopstick cleaning, drying and disinfecting, so as to reduce the high labor intensity of people and to facilitate use.

Owner:陈玲

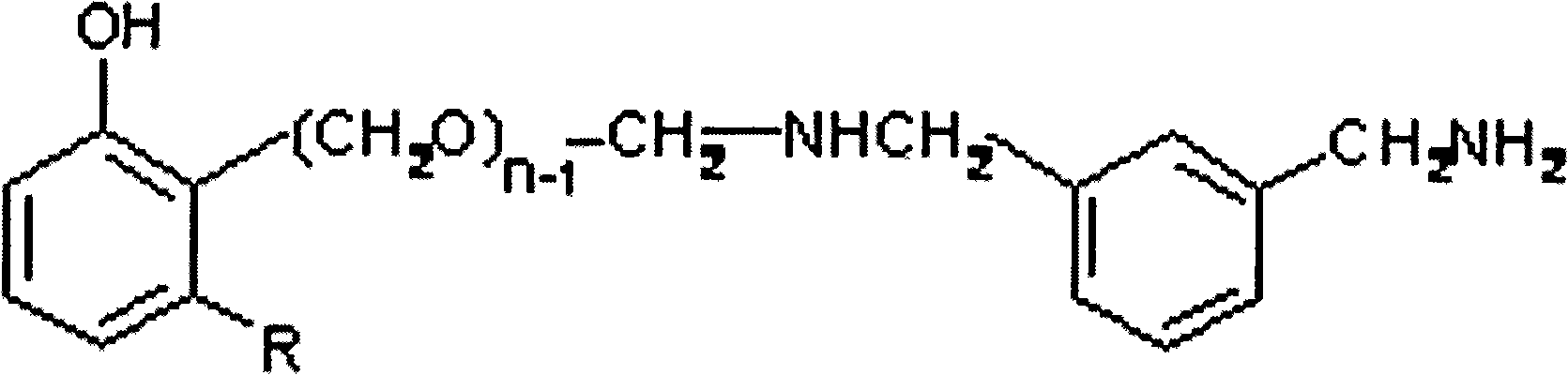

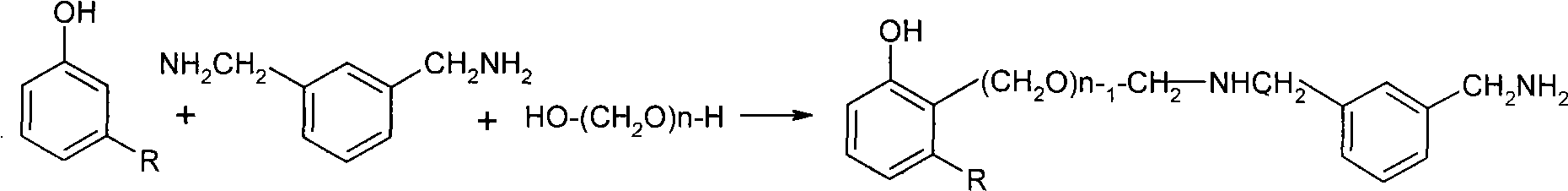

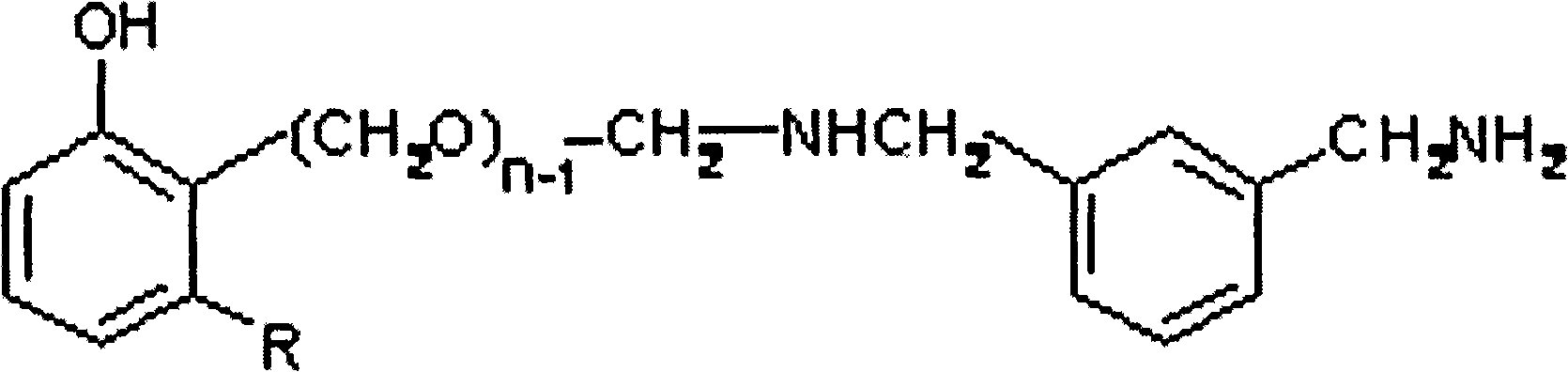

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

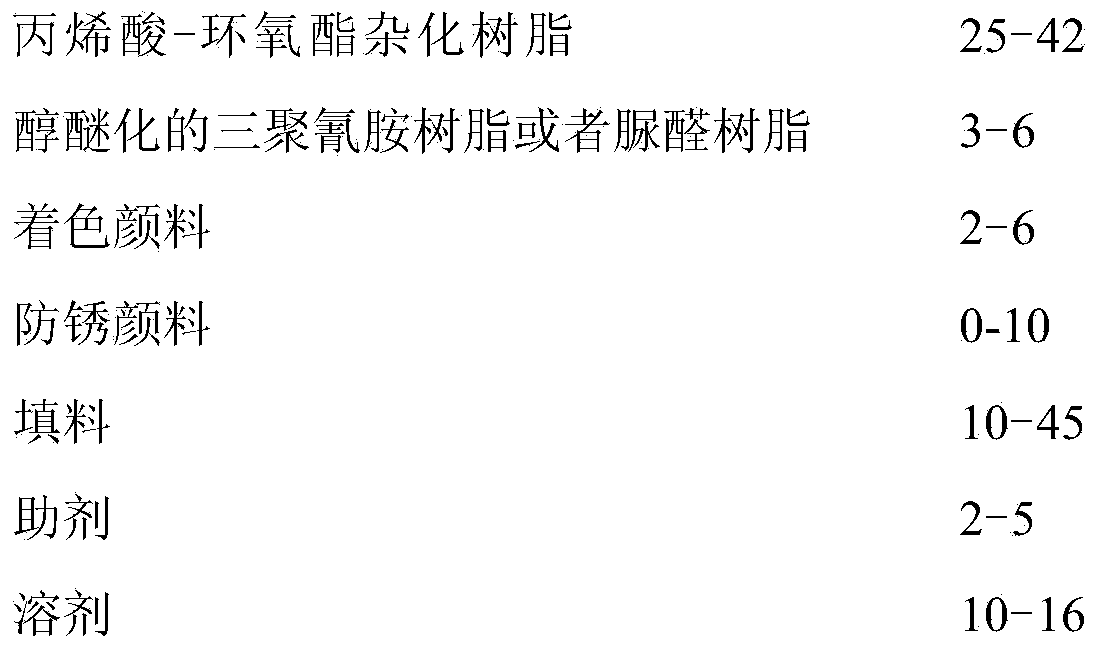

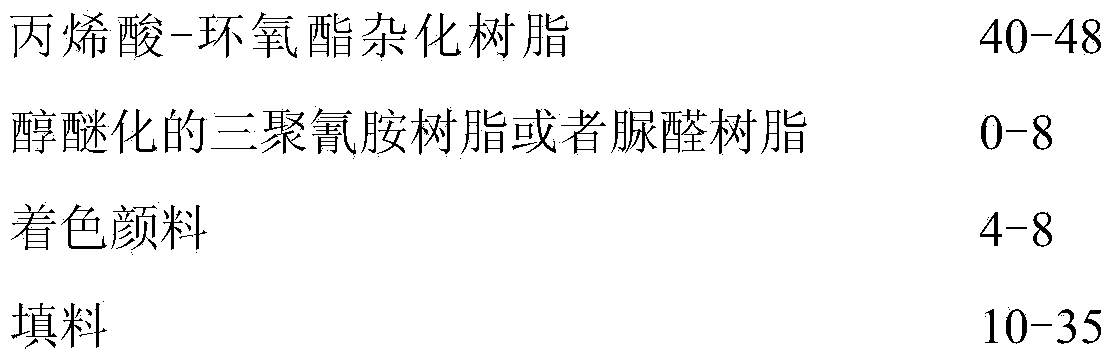

Acrylic acid-epoxy ester hybrid resin and coatings thereof

The invention provides an acrylic acid-epoxy ester hybrid resin. The acrylic acid-epoxy ester hybrid resin is prepared by reacting an epoxy resin and aliphatic acid under the action of a catalyst so as to prepare epoxy ester and then adding acrylic monomers and an initiator under certain conditions. A self-drying type antirust coating can be prepared with the acrylic acid-epoxy ester hybrid resin provided by the invention as a main film forming substance; a dried anticorrosive coating can also be prepared, especially coatings for curtain spraying sliver-coated mirrors, color films and aluminum mirrors; the coatings can meet coating process requirements of a wide-curtain spraying and coating production line with a maximum length of 3 m and are completely dried when baked at a temperature of 130 to 150 DEG C for 5 to 3 min, a film obtained after complete drying has excellent anticorrosion performance, can resist CASS, dampness, dryness and water with a temperature of 60 DEG C for more than 240 h, satisfy requirements of edging and texturing process of a downstream client and do not suffer from edge blackening and corrosion of clad layers.

Owner:常州市弘可利办公用品有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com