Ultraviolet-cured stripping protective material and preparation method and application thereof

A protection material, ultraviolet light technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of wasting energy, poor thermal stability, long curing time, etc., and achieves simple operation process, convenient transportation and storage, and short curing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

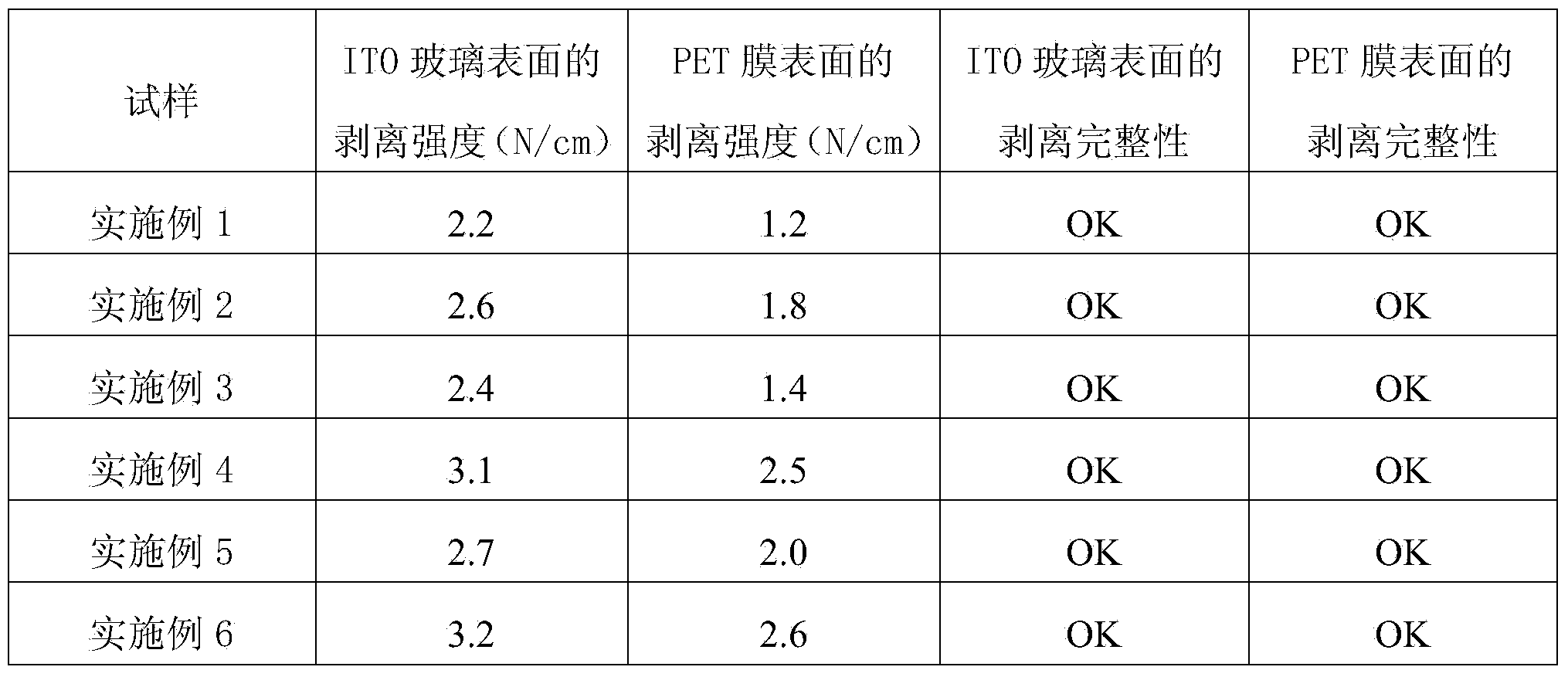

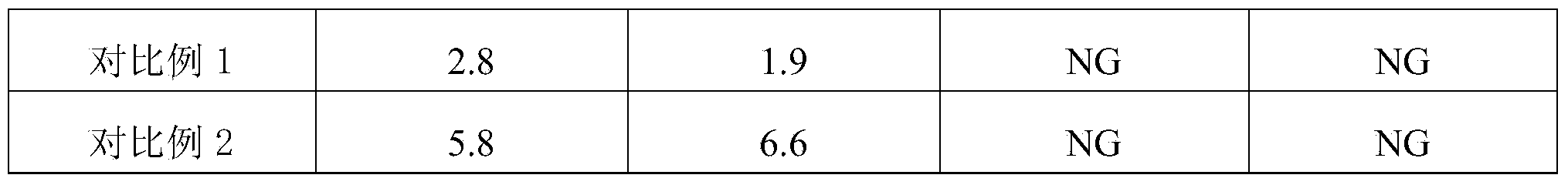

Examples

Embodiment 1

[0045] Example 1: Preparation of UV-cured peelable protective material

[0046] In a 500 ml glass four-neck flask equipped with a stirrer and a condenser, first take 145 grams of polyether polyols with a molecular weight between 2000 and 2500, an average functionality of 2, and an ether chain of ethylene oxide. Vacuumize and remove water for 3 hours at ℃, then cool it down to 45℃, stop vacuuming, add 16.4 grams of methane dicyclohexyl diisocyanate, stir rapidly, after the temperature is stable, slowly raise the temperature and control the temperature to 80℃ for reaction After 2.5 hours, cool down to 45°C after the reaction is complete, add 5.3 grams of hydroxyethyl acrylate, and add 0.05 grams of hydroquinone as a polymerization inhibitor, slowly raise the temperature to 75°C for 2.5 hours, and vacuum degas for 0.5 hours after the reaction is complete. hour, get the material to obtain polyurethane modified acrylate, and seal it away from light for future use. The tensile stre...

Embodiment 2

[0048] Example 2: Preparation of UV-cured peelable protective material

[0049] In a 500 ml glass four-neck flask equipped with a stirrer and a condenser, first take 218 grams of polyether polyols with a molecular weight between 3000 and 4000, an average functionality of 2.5, and an ether chain of butylene oxide. Vacuumize and remove water for 2 hours at ℃, then cool it down to 40℃, stop vacuuming, add 21.1 grams of methane dicyclohexyl diisocyanate, stir rapidly, after the temperature is stable, slowly raise the temperature and control the temperature to 75℃ for reaction After 3 hours, cool down to 40°C after the reaction is complete, add 6.4 grams of hydroxyethyl methacrylate and 5.0 grams of hydroxypropyl acrylate, and add 0.08 grams of polymerization inhibitor p-hydroxyanisole, slowly heat up to 70°C for reaction After 3 hours, after the reaction is complete, vacuum degassing for 0.5 hours, the material is obtained to obtain polyurethane-modified acrylate, which is sealed ...

Embodiment 3

[0051] Embodiment 3: Preparation of UV-cured peelable protective material

[0052] In a 500 ml glass four-neck flask equipped with a stirrer and a condenser, first take 283 grams of polyether polyols with a molecular weight between 2500 and 3000, an average functionality of 3, and an ether chain of propylene oxide. Vacuum down to remove water for 4 hours, then cool it down to 50°C, stop vacuuming, add 23.7 grams of methane dicyclohexyl diisocyanate, stir quickly, after the temperature is stable, slowly raise the temperature and control the temperature to 85°C Reaction 2 Hours, after the reaction is complete, cool down to 50°C, add 4.3 grams of hydroxyethyl acrylate, 2.5 grams of hydroxypropyl methacrylate and 5.7 grams of hydroxypropyl acrylate, and add 0.09 grams of polymerization inhibitor p-hydroxyanisole , slowly raised the temperature to 80°C for 2 hours, and after the reaction was complete, vacuum degassed for 0.5 hours, and obtained the polyurethane-modified acrylate, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com