Patents

Literature

56results about How to "No fog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet-cured stripping protective material and preparation method and application thereof

ActiveCN103627313AHigh elongationEasy to dryPolyurea/polyurethane coatingsPolyethylene terephthalate glycolUltraviolet lights

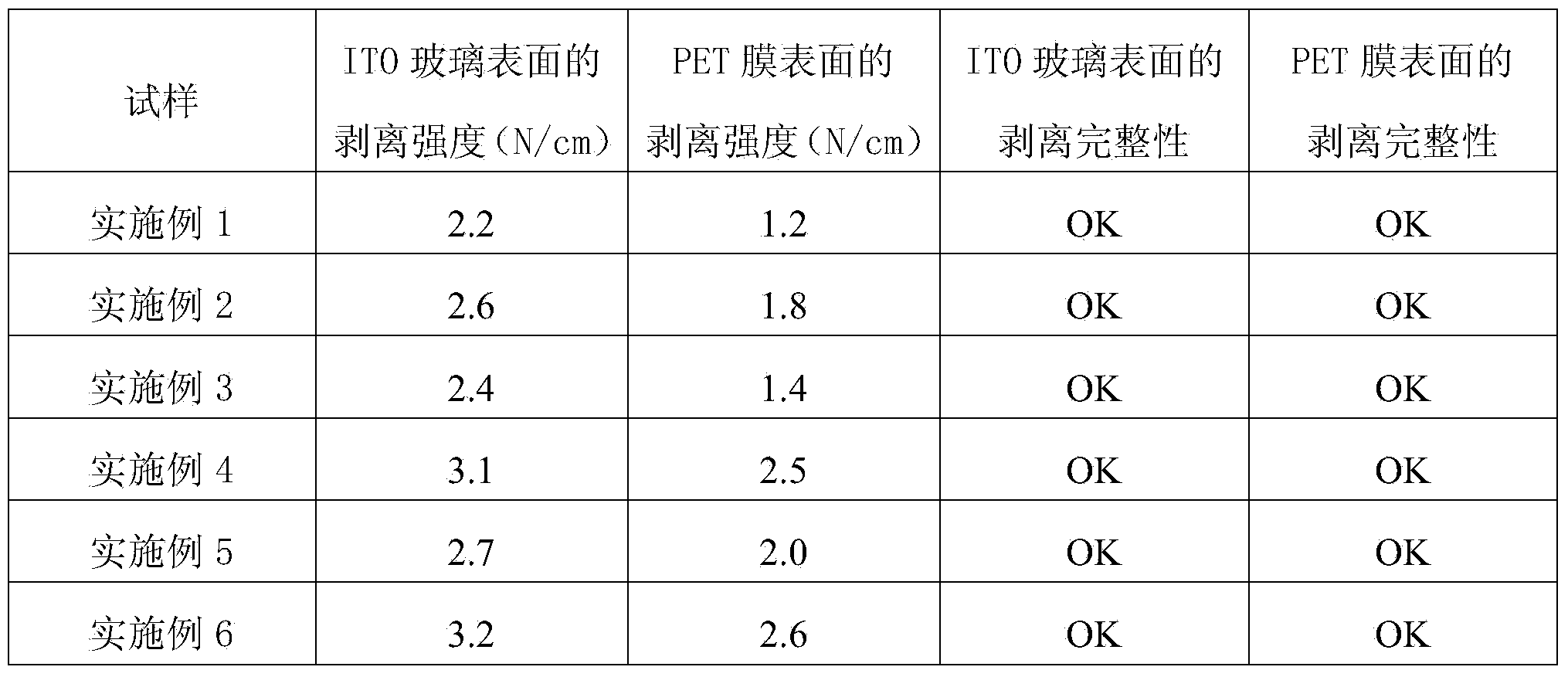

The invention belongs to the technical field of surface protective materials, and discloses an ultraviolet-cured stripping protective material and a preparation method and application thereof. The stripping protective material comprises the following components in parts by weight: 50-90% of polyurethane modified acrylic ester, 5-35% of acrylics reactive diluent, 1-8% of photoinitiator, 1-15% of filler, and 0-10% of additive. According to the ultraviolet-cured stripping protective material, the ultraviolet light is used for triggering a chained polymerization, the time for curing is short, generally 1-5 seconds, and the production efficiency is high; not any organic gas is released, so that the preparation method is more environment-friendly; the use and operation process is simple and convenient, the surface of the material is not affected due to overheating curing, mist is generated after stripping; the integral protective material can be better stripped, is not sticky, has no mist, and is applicable to protecting surfaces of ITO (indium tin oxide) glass, ITO membranes and PET (polyethylene terephthalate) membranes.

Owner:GUANGZHOU MECHANICAL ENG RES INST

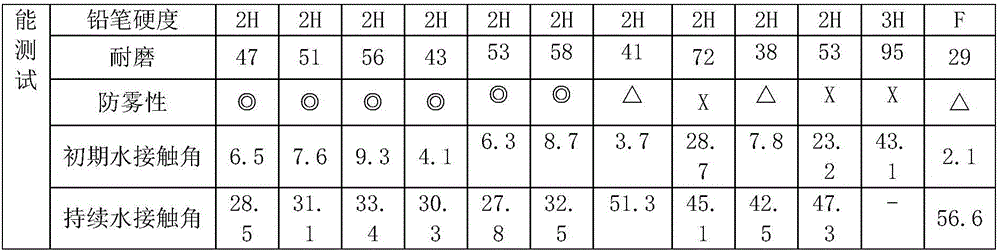

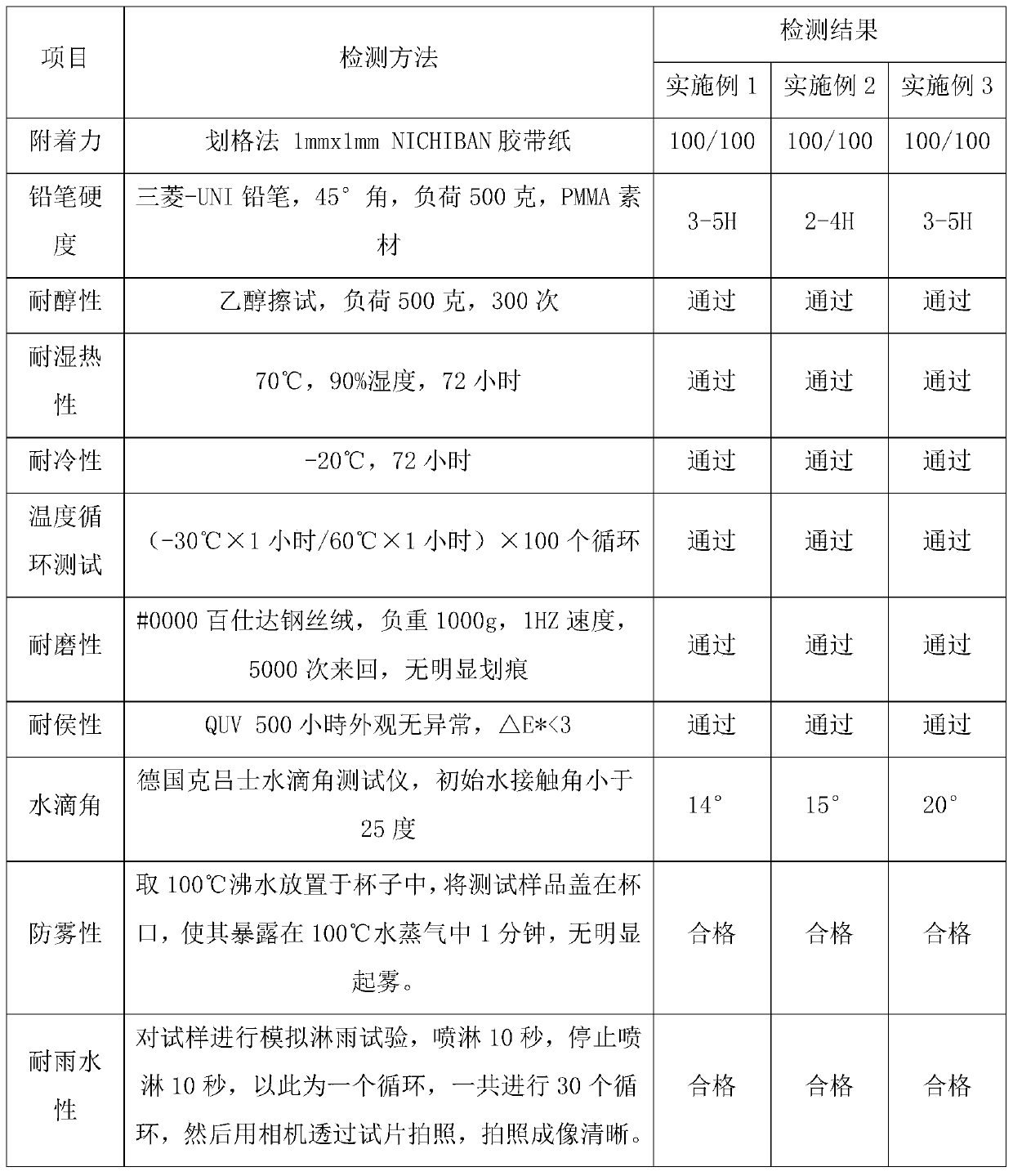

UV curable antifogging paint composition and preparation method thereof

InactiveCN106243983AExcellent hardness and wear resistanceIncrease crosslink densityPolyurea/polyurethane coatingsSolventChemistry

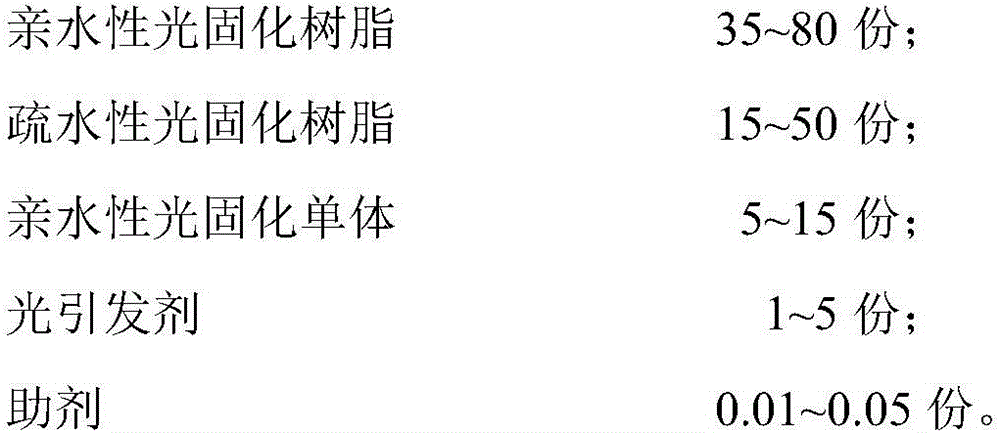

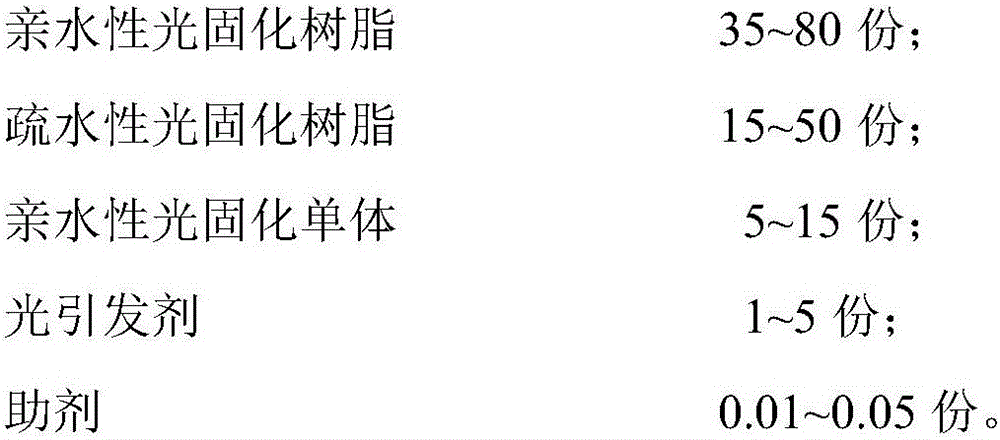

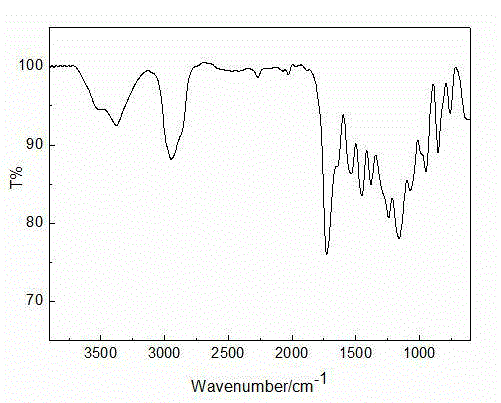

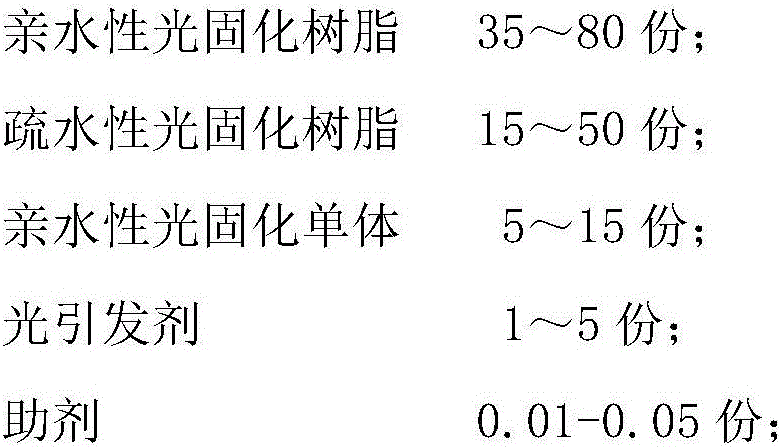

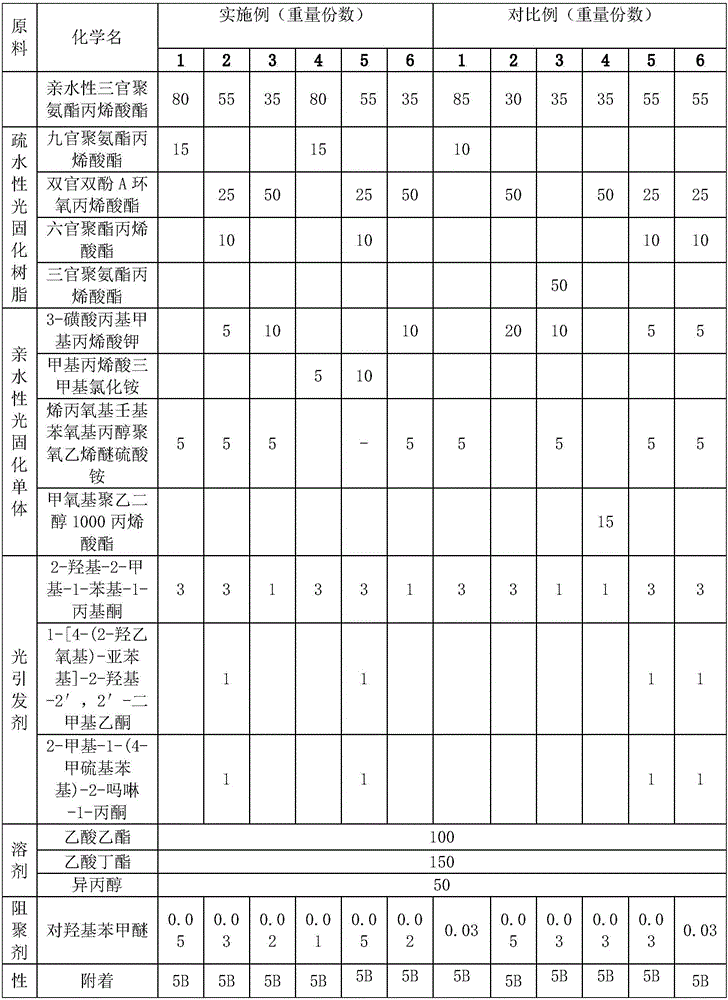

The invention provides a UV curable antifogging paint composition and a preparation method thereof. The paint composition comprises the following components: hydrophilic light cured resin, hydrophobic light cured resin, a hydrophilic light cured monomer, a photoinitiator, a solvent and an assistant. According to the invention, through use of the hyperbranched light cured resin with excellent hydrophility and the polymerizable surfactant, and cooperation with the high functionality hydrophobic light cured resin, a hydrophilicity and hydrophobicity partially cross-linked net structure can be formed after photocuring. Specifically, the hydrophilic part has excellent hydrophilic properties, so that water droplets can be easily spread on the coating to form a water film without fogging, and the hydrophobic part plays an anchorage point role in the coating, and the crosslinking density is increased, thus ensuring that the coating cannot be dissolved due to swelling in the circumstance of a large amount of water.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

Resin for UV-cured strippable protection film, preparation method and applications thereof

The invention discloses a resin for UV-cured strippable protection film, a preparation method and applications thereof. The preparation method comprises the following steps: adding the following monomers: methyl methacrylate, butyl acrylate, acrylic acid, hydroxypropyl acrylate, isooctyl methacrylate, and azodiisobutyronitrile into an organic solvent, evenly mixing to obtain a mixed solution, introducing nitrogen gas into the mixed solution; adding part of the mixed solution into a four-mouth flask, carrying out reactions; dropwise adding the rest mixed solution and lauryl mercaptan, keeping on reactions; dissolving azodiisobutyronitrile by an organic solvent, then dropwise adding into the four-mouth flask, carrying out reactions; cooling the solution, dropwise adding diisocyanate, heating to carry out reactions; after cooling, dropwise adding a mixed solution of hydroxy acrylate and a polymerization inhibitor, heating; adding monohydric alcohol, cooling, and discharging the product. The provided resin can be easily peeled off from the surface of steel or glass. Furthermore, the UV curing system is more environment-friendly, the resin is nontoxic and harmless, the curing time is short, the resin can be cured within 10 seconds to form a film, and the production efficiency is largely improved.

Owner:SOUTH CHINA UNIV OF TECH

UV photo-cured anti-fog paint composition

InactiveCN106085203AAct as an anchor pointWon't dissolvePolyurea/polyurethane coatingsEpoxy resin coatingsHardnessSolvent

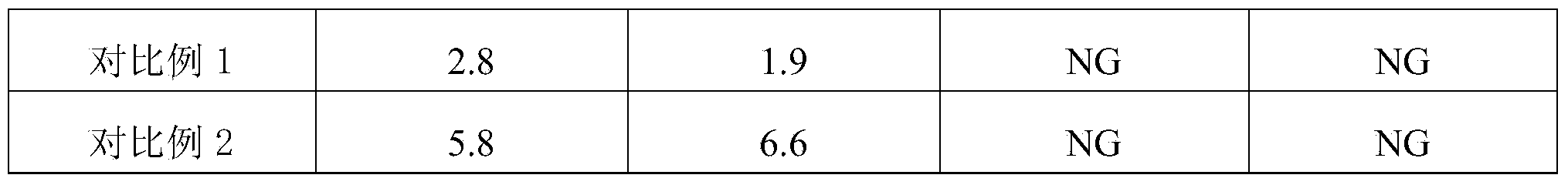

The invention provides a UV photo-cured anti-fog paint composition. The composition is prepared from, by weight, 35-80 parts of hydrophilic photo-cured resin, 15-50 parts of hydrophobic photo-cured resin, 5-15 parts of hydrophilic photo-cured monomers, 1-5 parts of photoinitiator and 0.01-0.05 part of auxiliaries. The composition further comprises a solvent. The weight of the solvent is 2-4 times of the total weight of the other components. After UV anti-fog paint is photo-cured by UV, the water resistance of a paint film is improved, durable anti-fog performance is achieved, the hardness of the paint film is high, and scrubbing resistance is good.

Owner:SHANGHAI WEIKAI CHEM +2

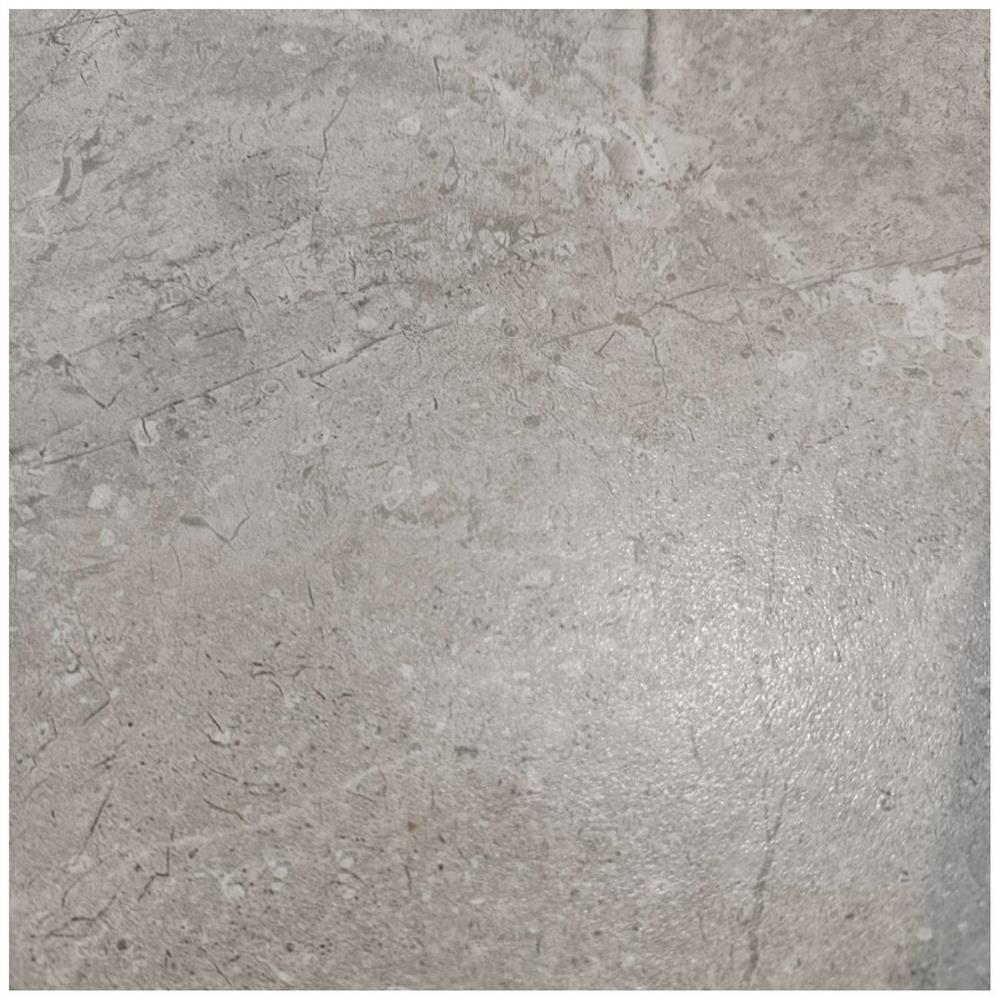

Fine concave-convex surface matte ceramic tile and preparation method thereof

ActiveCN113799531AHigh mechanical strengthGood flexibilityDecorative surface effectsSpecial ornamental structuresGlazeSuspending Agents

The invention provides a fine concave-convex surface matte ceramic tile and a preparation method thereof, wherein the ceramic tile comprises a green body layer with a concave-convex texture, a cover coat composed of feldspar calcium glaze is arranged on the green body layer, a pattern layer is arranged on the cover coat, and a dry granular glaze layer is arranged on the pattern layer, wherein according to the parts by mass, a glaze material of the dry granular glaze layer comprises the following components including, 20-50 parts of low-temperature glaze slip, 10-50 parts of high-temperature dry granules, 50-100 parts of medium-temperature dry granules, 30-50 parts of high-temperature matte powder and 200-400 parts of a dry granular suspending agent, wherein the specific gravity of the low-temperature glaze slip is 1.85-1.95 g / ml. According to the ceramic tile, the composition proportioning scheme of the components of the dry granular glaze layer and cover glaze is originally provided; and in the technological process of the matte ceramic tile, the manufacturing processes of fine molds, fine dry granular glaze pouring and brushing and polishing are adopted, the matte ceramic tile is further matte, the ceramic tile which is good in stereoscopic impression and layering sense, obvious in glimmer and matt contrast, smooth and fine is obtained, and the comfort of the whole decoration space is improved.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

Mirror-surface nanometer spraying solution and spraying method

ActiveCN104120415AGuaranteed lifeGuaranteed stabilityLiquid/solution decomposition chemical coatingMass ratioGlucose polymers

A mirror-surface nanometer spraying solution and a spraying method are disclosed. The spraying solution comprises following three separated solutions: an A solution containing silver nitrate, a B solution containing glucose and an S solution containing sodium hydroxide, wherein the mass ratio of the sodium hydroxide to the silver nitrate in the A solution is 0.5-6:1. The spraying method is to separately spray the three solutions at the same time by adopting three spraying guns. The sodium hydroxide solution used for adjusting the pH value is not added into the A solution or the B solution, thus guaranteeing the lifetime and stability of the A solution and the B solution. The concentration of the sodium hydroxide is 2-6 times of the sodium hydroxide concentration in the prior art, thus largely increasing the speed of the silver mirror reaction, increasing the reduction efficiency and reducing the production cost. At a low temperature of 0 DEG C, the reaction speed can be high, and a silver layer is bright and white and free of fog. Normal production can be performed at 0-40 DEG C without the use of thermostatic equipment and silver layers with high quality can be deposited. The silver layers can be sprayed for many times and can be thick. The spraying solution and the spraying method are suitable for spraying of oversized workpieces.

Owner:陈徐丰

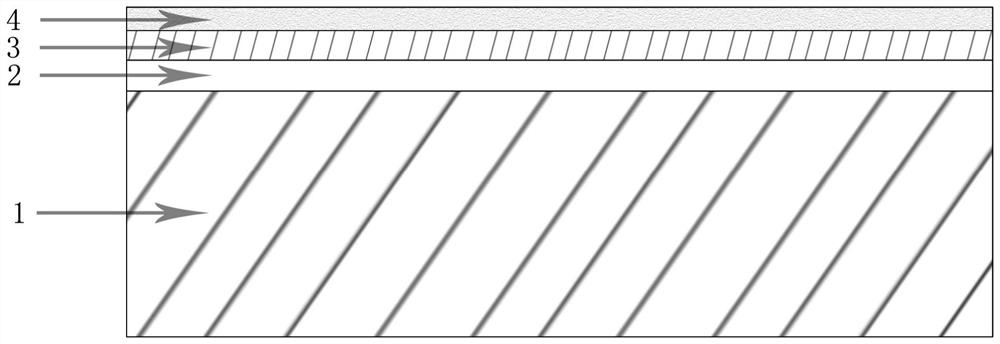

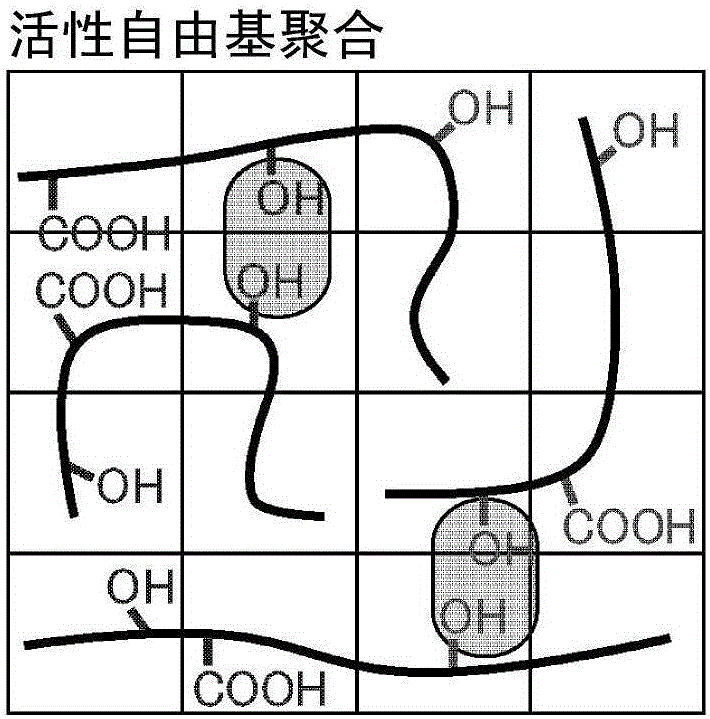

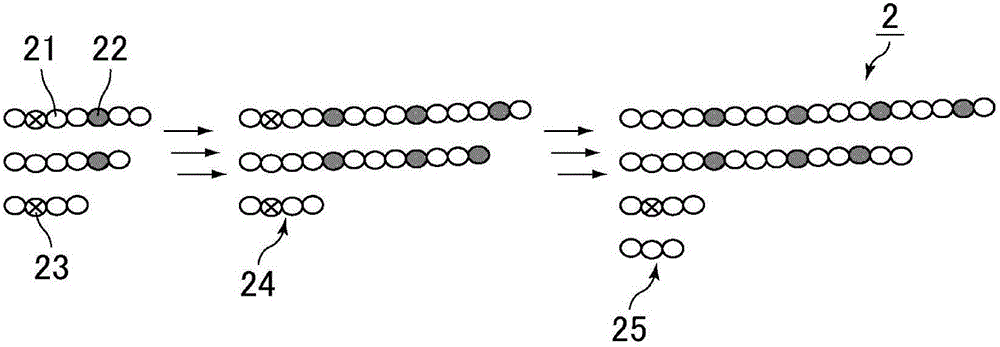

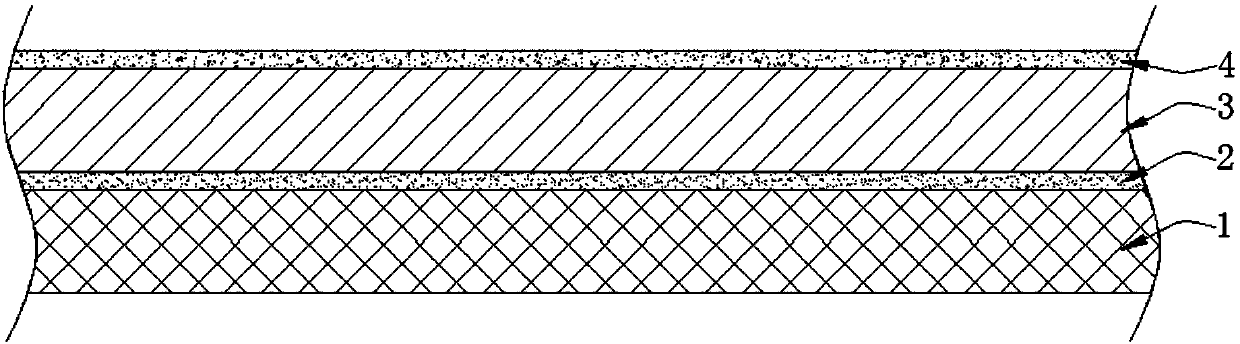

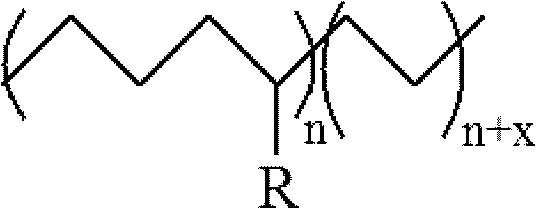

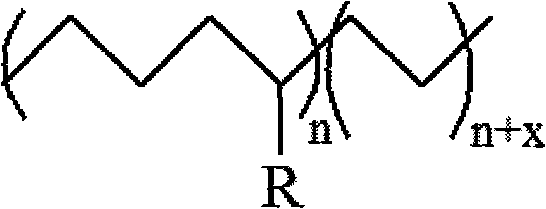

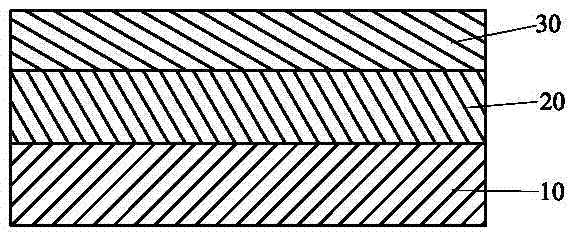

Optical adhesive, optical adhesive tape, and layered body

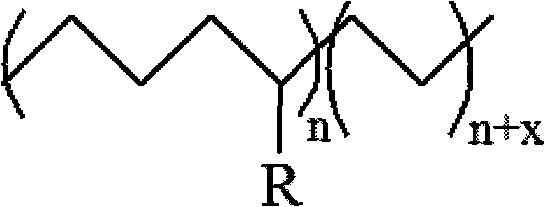

InactiveCN105683324ANo fogExcellent foam resistanceFilm/foil adhesivesAdhesive articlesMeth-Adhesive

The present invention provides an optical adhesive which does not become clouded even when exposed to high temperature and humidity, which also has excellent antifoaming properties or workability, and which does not degrade a transparent electrode such as one comprising ITO. Another purpose of the present invention is to provide an optical adhesive tape and a layered body manufactured using the optical adhesive. The present invention is an optical adhesive containing: a (meth)acrylic polymer having a molecular weight distribution (Mw / Mn) of 1.05-2.5 obtained by copolymerization by living radical polymerization of a monomer mixture including a) 60-95 parts by weight of alkyl (meth)acrylate having a C1-14 alkyl group, b) 0.1-1 part by weight of a monomer containing a carboxyl group, and c) 10-30 parts by weight of a monomer containing a hydroxyl group, an amino group, or an amide group; and a crosslinking agent; the alkyl (meth)acrylate a) having a C1-14 alkyl group including (meth)acrylate having a bicyclo ring structure.

Owner:SEKISUI CHEM CO LTD

Light transmitting coating layer for window curtain and application method thereof

The invention discloses a light transmitting coating layer for a window curtain. The light transmitting coating layer comprises components of mixed liquid and thickener, wherein the weight ratio of the mixed liquid to the thickener is 100: 1.5-4; the mixed liquid comprises the following components in percentage by weight: 10-20% of polystyrene, and 80-90% of polyethylene; the polystyrene is CU-620A pure acrylic emulsion; and the polyethylene is CU-621 pure acrylic emulsion. An application method of the light transmitting coating layer comprises the steps of: (1) mixing, (2) starching, (3) drying, and (4) rolling. Compared with the prior art, the light transmitting coating layer has the characteristics of fewer components, simple process, higher flatness, higher yield and lower cost.

Owner:NINGBO GRAND HOME FURNISHING

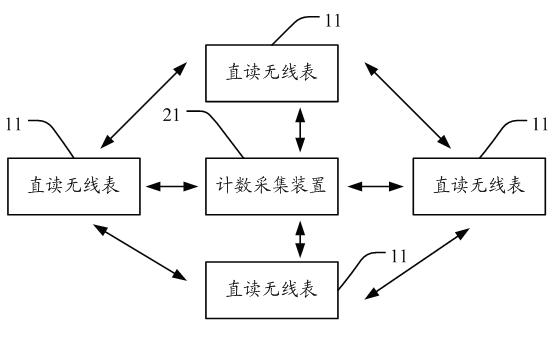

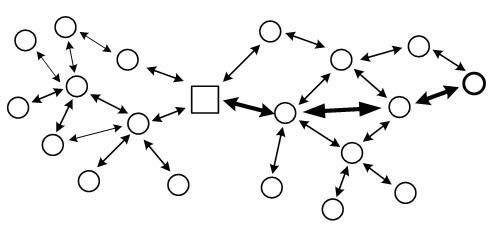

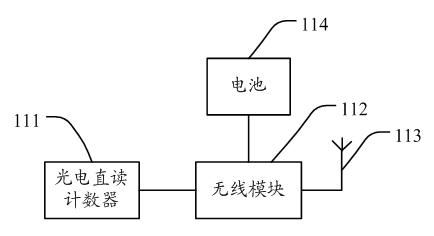

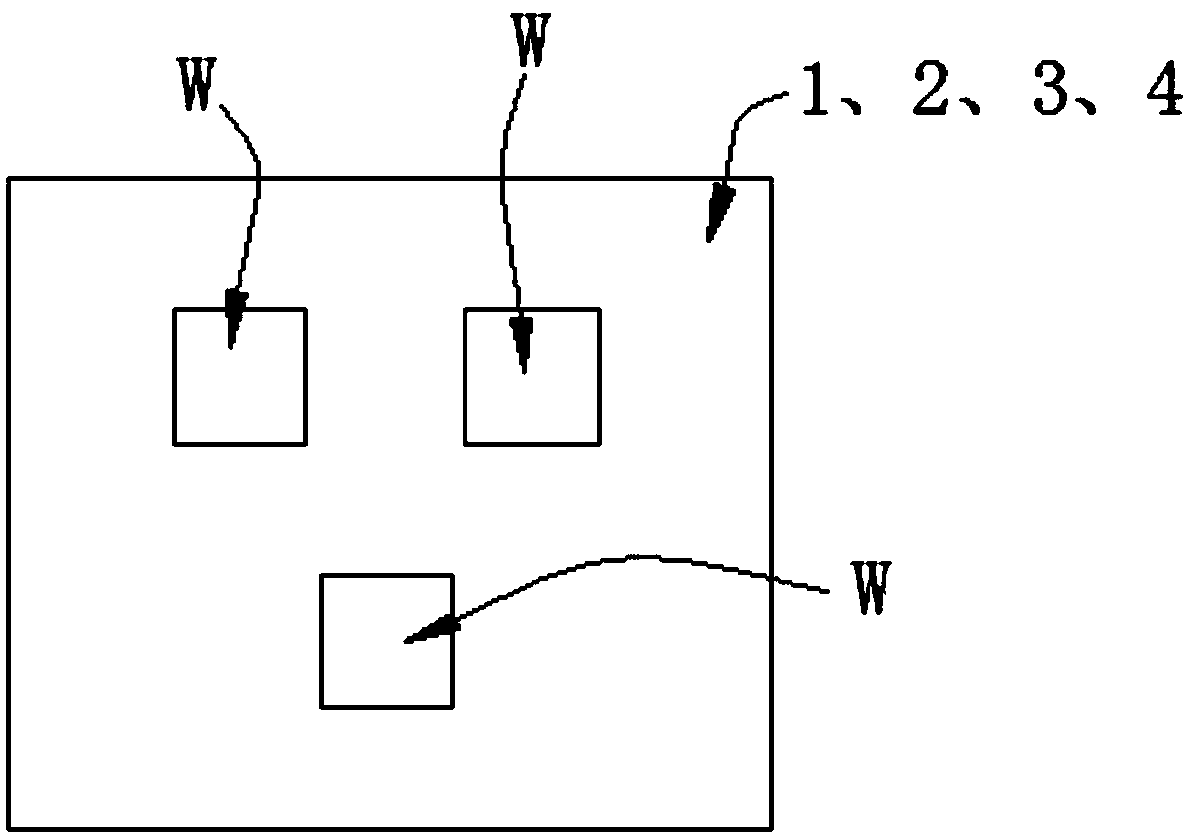

Gas wireless meter reading system

ActiveCN102142188AReliable transmissionEasy maintenanceTransmission systemsVolume indication and recording devicesReliable transmissionSystem maintenance

The invention discloses a gas wireless meter reading system which comprises direct reading wireless meters and a counting and acquisition device, wherein the direct reading wireless meters are used for acquiring counting data of gas and transmitting the counting data to the counting and acquisition device in a wireless manner; the counting and acquisition device is used for acquiring the counting data; the direct reading wireless meters are wirelessly connected with the counting and acquisition device; the number of the direct reading wireless meters are at least two; all the direct reading wireless meters are connected with one another in a wireless manner; and the direct reading wireless meters are also used for receiving the counting data acquired by the adjacent direct reading wireless meters and transmitting the counting data to the counting and acquisition device in a wireless manner. In the gas wireless meter reading system, the direct reading wireless meters are used for acquiring the counting data of the gas and transmitting the counting data to the counting and acquisition device in a wireless manner; the direct reading wireless meters can be automatically networked in the system, so that the reliable transmission of multi-level data is achieved through more than one pair of data transmission, and the reliability of the system is improved; and moreover, the wiring is not required when the data is transmitted in a wireless manner, so that the installation construction and the system maintenance are simple.

Owner:深圳资江实业有限公司

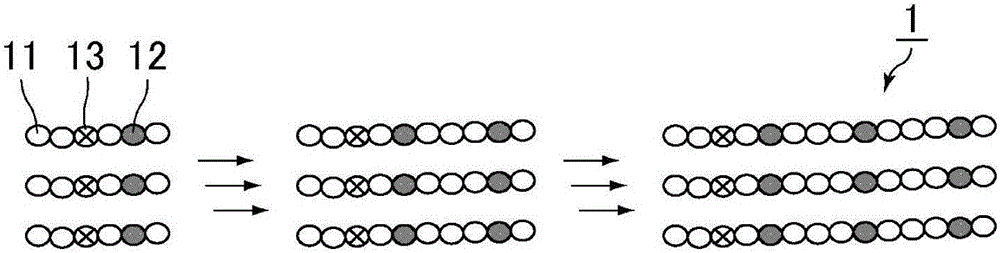

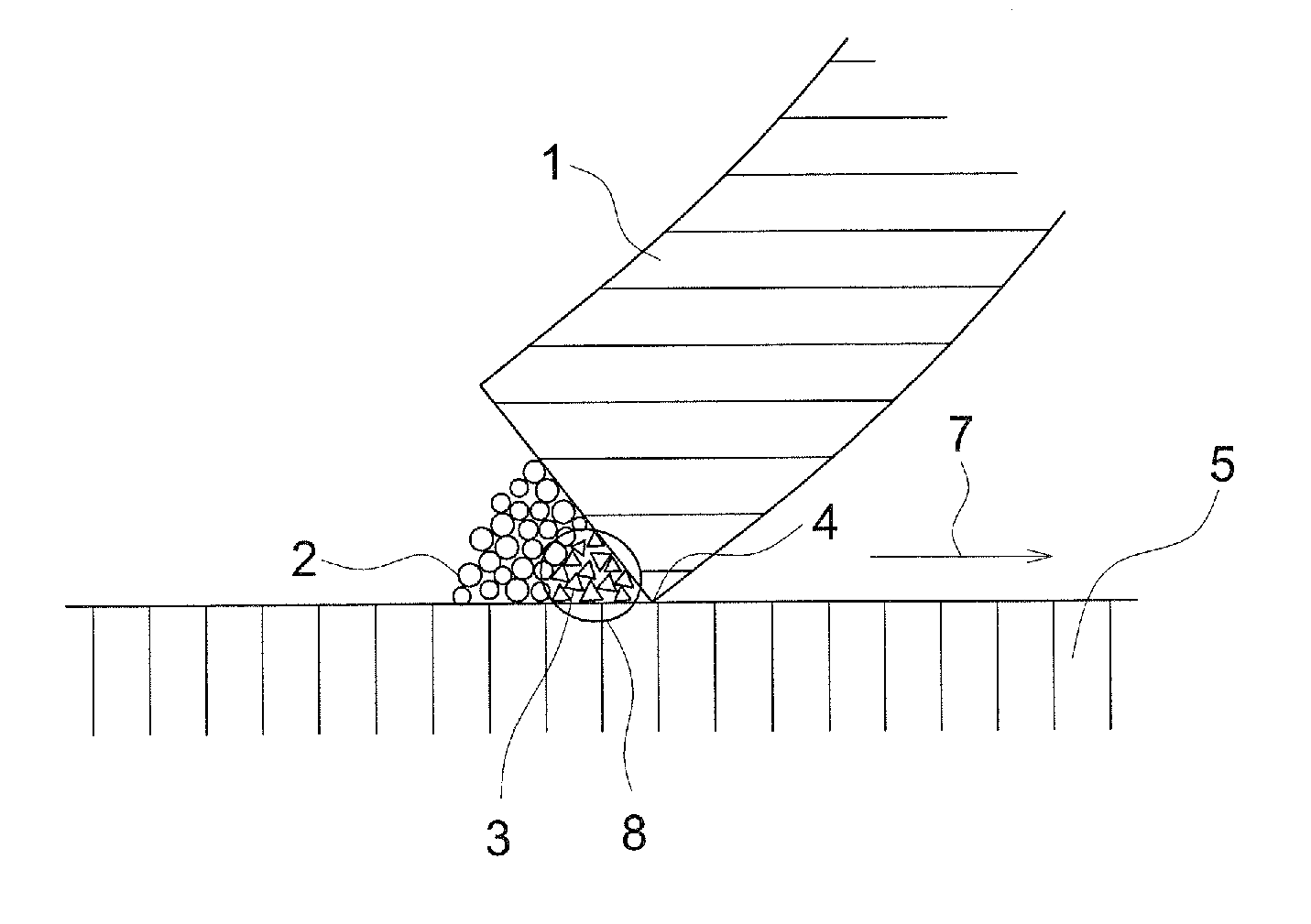

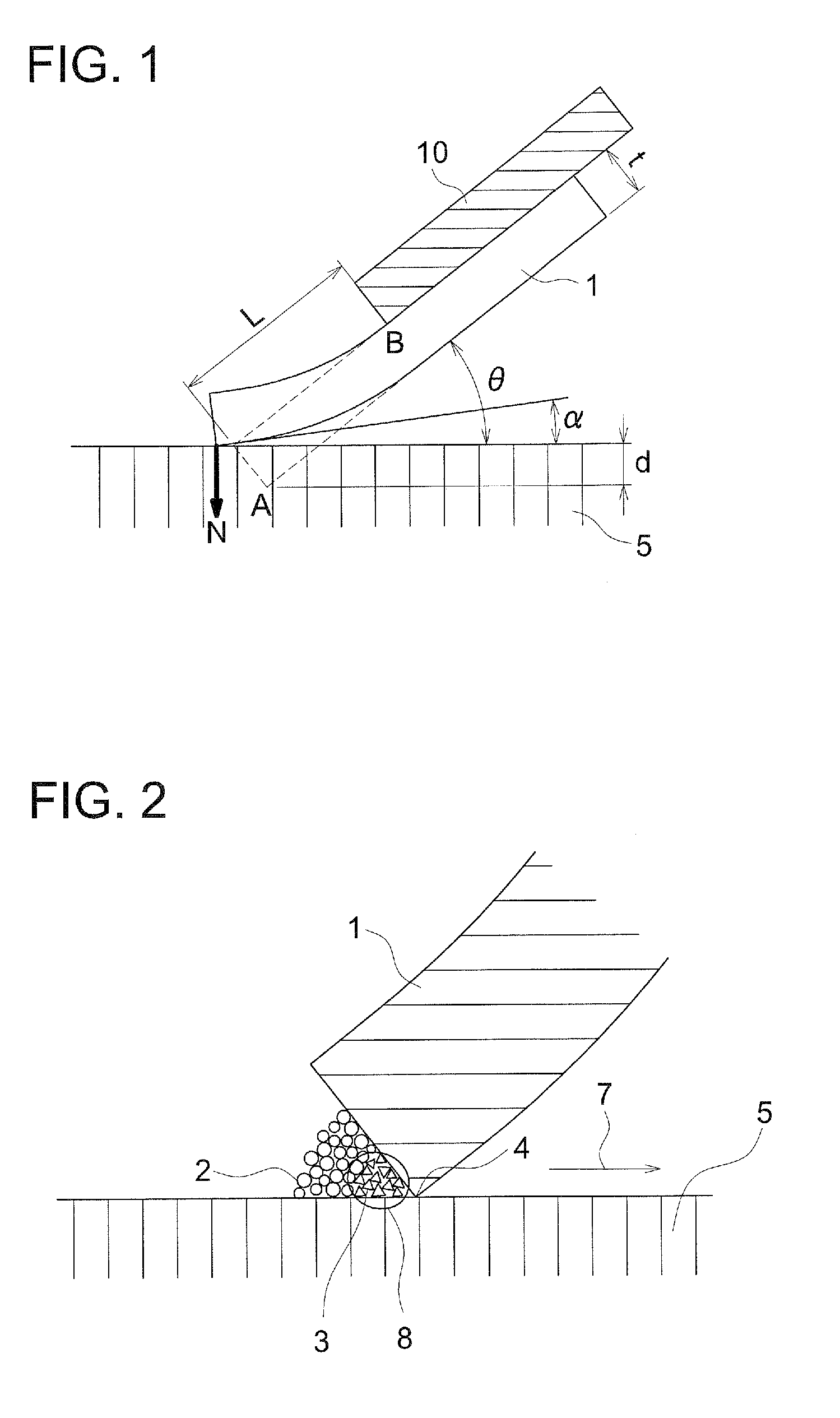

Toner

Disclosed is toner in which is used in an image formation process comprising the steps of transferring an image of toner formed on a photoreceptor onto a recording sheet, and removing any residual toner remaining on any of the photoreceptor, an intermediate transfer member and a secondary transfer member with a cleaning blade, the toner containing at least toner particles (A) and small particles (B), wherein the toner particles (A) have an average circularity of from 0.93 to 0.99 and a number-based median diameter (D50) of from 3.0 to 8.0 μm, the small particles (B) have an average circularity of from 0.70 to 0.92 and a number-based median diameter (D50) of from 0.15 to 0.60 times that of the toner particles (A), and the surface energy of the toner particles (A) is different from that of the small particles (B).

Owner:KONICA MINOLTA BUSINESS TECH INC

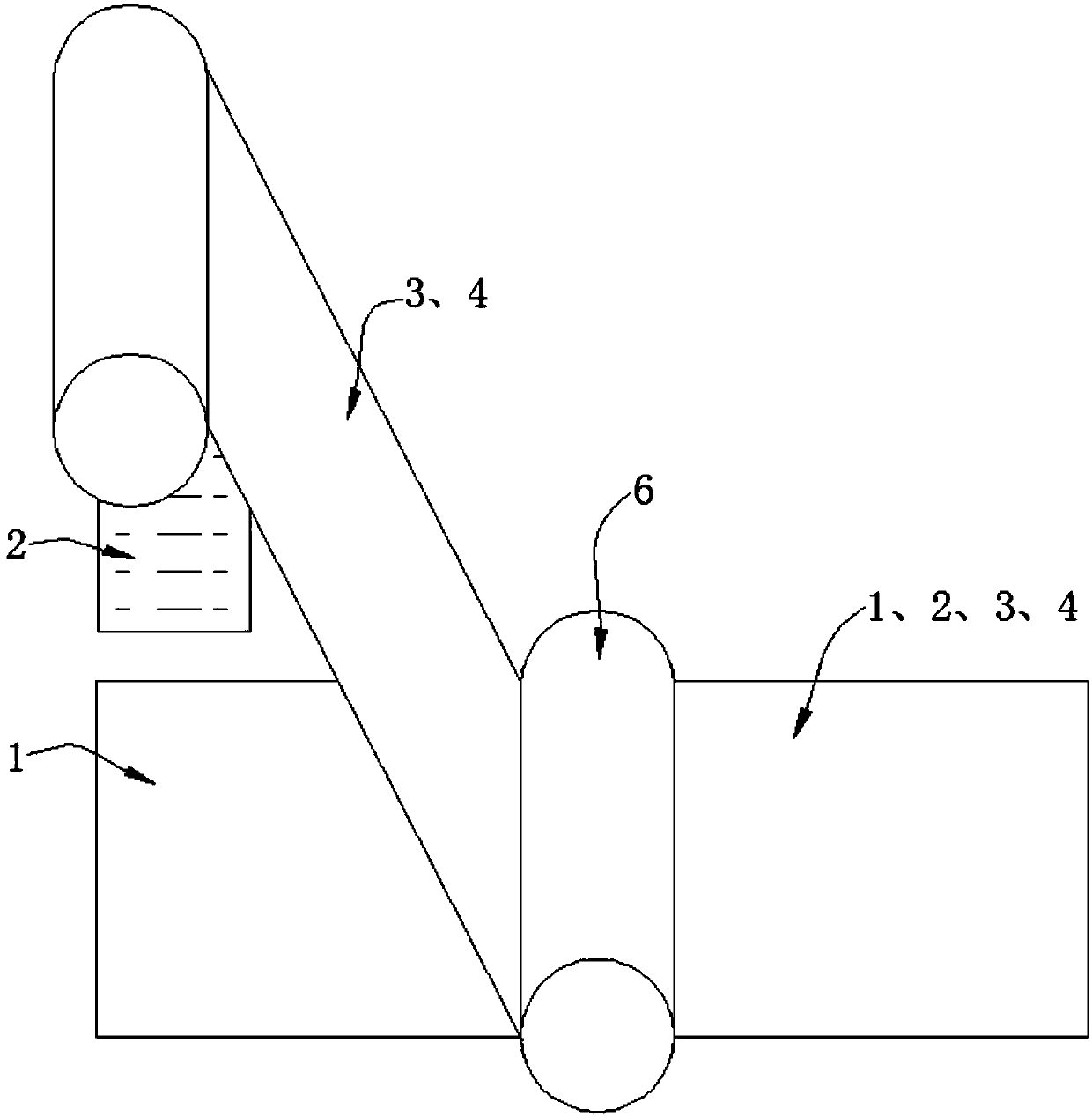

Metal welding flat tempered low altitude glass and manufacturing method thereof

InactiveCN102976591ARelieve pressureReduce oxidationGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention provides a flat tempered low altitude glass, which comprises an upper glass and a lower glass, wherein the upper glass and the lower glass are flat tempered glasses, the peripheries of the welding surface of the upper glass and the lower glass have edge sealing strip frames, the peripheries of the upper glass and the lower glass are integratedly welded through a low temperature welding material, the low temperature welding material is a low melting-point metal or an alloy melding material, a sealed low altitude layer is formed between the upper glass and the lower glass, and a supporting matter aligned in a point lattice manner is arranged inside the low altitude layer. According to the present invention, the process of the low altitude glass manufacturing method is simple, disadvantages in the prior art can be overcome with the manufactured tempered low altitude glass, and mass production can be achieved.

Owner:戴长虹

Anti-fog urethane acrylate coating as well as preparation method and use method thereof

InactiveCN110903754AGood film-forming performancePreserves hydrophilicity and adhesionPretreated surfacesPolyurea/polyurethane coatingsPhotoinitiatorCarboxylic group

The invention discloses an anti-fog urethane acrylate coating as well as a preparation method and a use method thereof. The invention relates to the technical field of urethane acrylate coatings. Thecoating comprises the following raw materials in parts by weight: 30-50 parts of urethane acrylate, 15-40 parts of acrylic resin, 10-15 parts of a carboxylated graphene dispersion liquid, 40-60 partsof a solvent, 1-5 parts of a photoinitiator and 0.1-1 part of a catalyst. According to the invention, hydrophilic pure acrylic resin is matched with hydrophobic urethane acrylate, and a hydrophilic and hydrophobic partially cross-linked network structure is formed after photocuring; meanwhile, the carboxylated graphene dispersion liquid has hydrophilicity, so that water drops are easy to spread onthe coating to form a water film without fogging; meanwhile, graphene is introduced, so that various film-forming properties of the prepared ultraviolet curing anti-fog coating are excellent, and hydrophilicity and adhesive force of carboxylated graphene can be reserved.

Owner:上海翰飞新材料科技有限公司

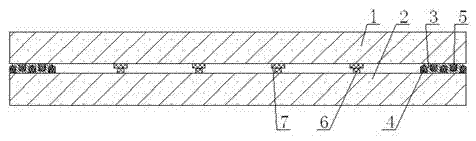

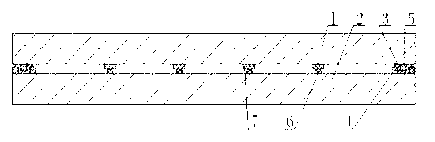

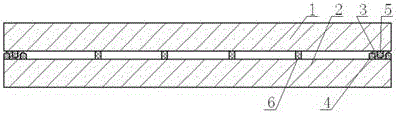

Flat low-altitude glass and manufacturing method thereof

ActiveCN102951799ARelieve pressureReduce oxidationGlass reforming apparatusGlass productionFlat glassEngineering

The invention provides flat low-altitude glass comprising upper glass and lower glass which are sheet glass, wherein edge sealing strip frames are arranged at the peripheries of the welding surface of the upper glass and the lower glass, the peripheries of the upper glass and the lower glass are welded together by low-temperature solders, a closed low-altitude layer is formed between the upper glass and the lower glass, and supports arranged in a dot matrix manner are arranged in the low-altitude layer. According to a manufacturing method of the low-altitude glass provided by the invention, the manufactured low-altitude glass can overcome the defects in the prior art, and can be produced in batch.

Owner:海宁市袁花镇工业投资有限公司

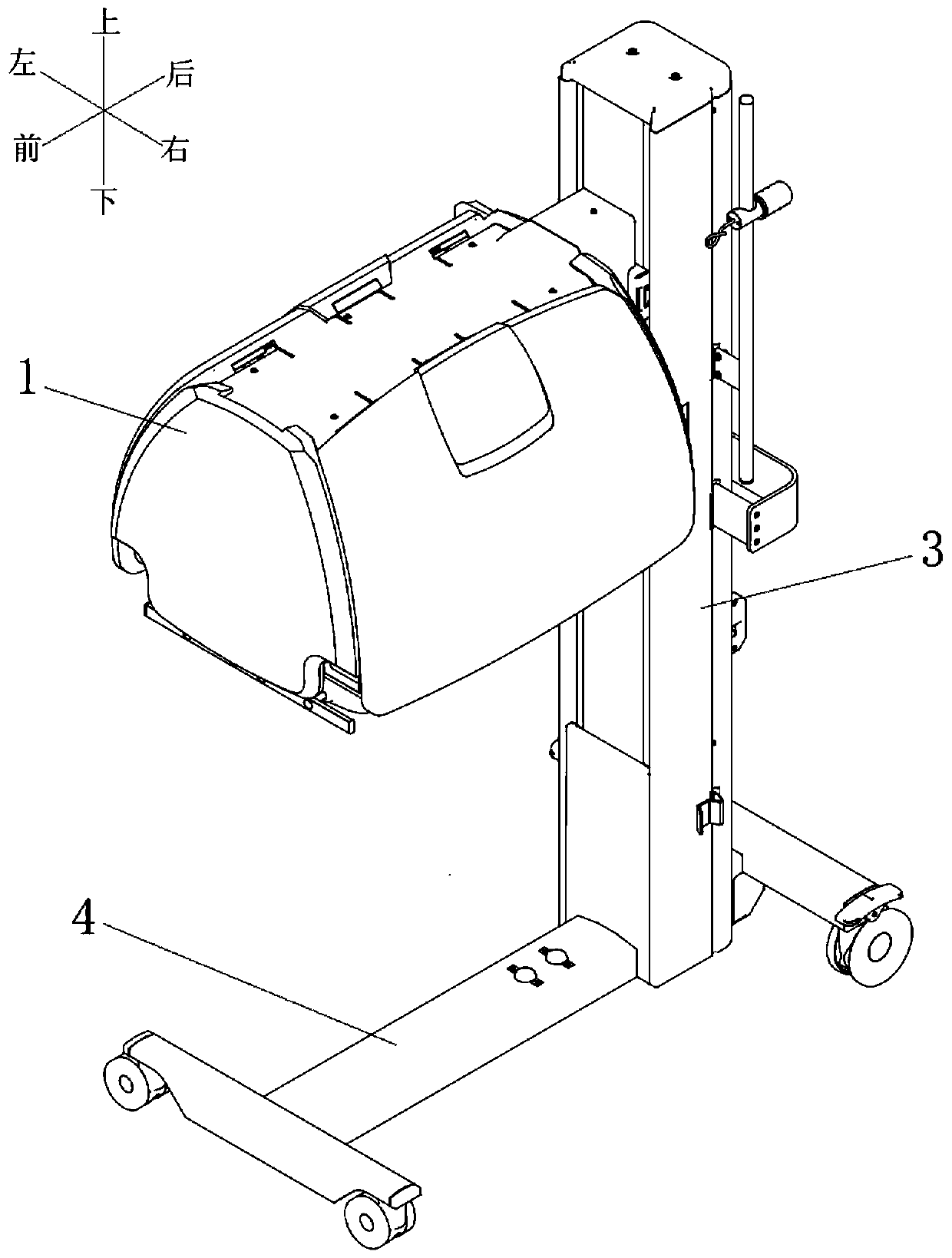

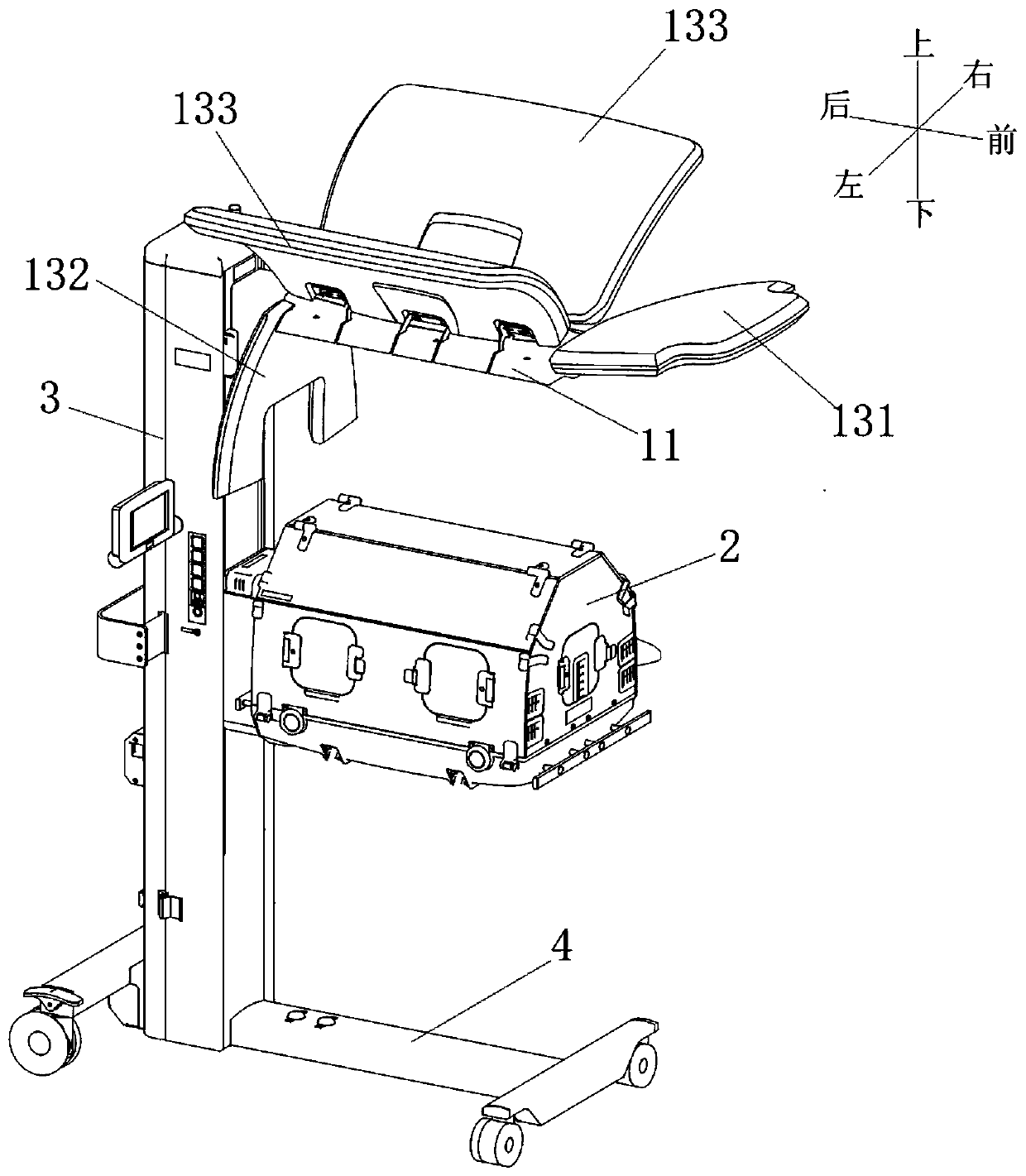

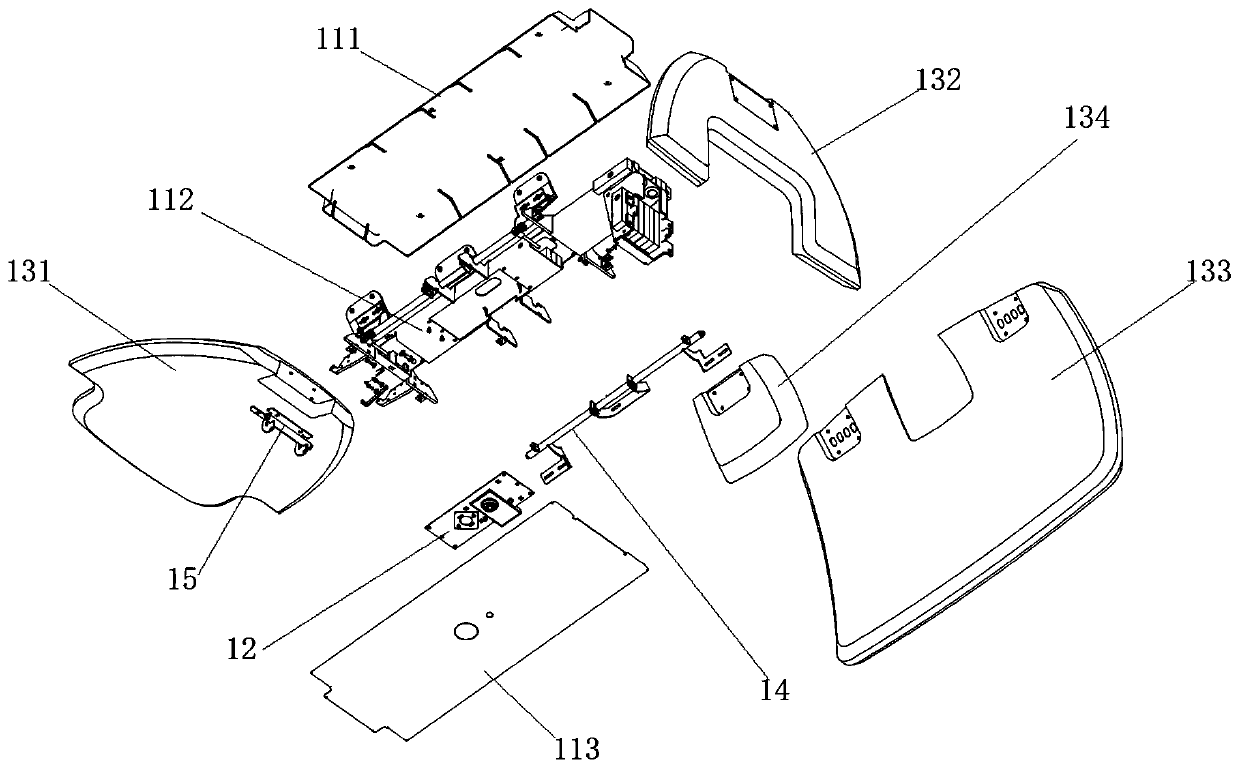

Infant culture device with box cover

PendingCN110368234AReduce heat exchangeLess power consumptionBaby-incubatorsMedical transportEngineeringNoise reduction

The invention provides an infant culture device with a box cover. The infant culture device comprises an infant box and the box cover, wherein the box cover comprises a top plate assembly and a baffleplate assembly arranged around the top plate assembly, and the box cover can integrally cover the outer portion of the infant box. Compared with the prior art, the infant culture device is provided with the box cover capable of integrally covering the outer portion of the infant box, the box cover can have effects of light shading, heat preservation, noise reduction and the like when covering theinfant box, so that the environment in the infant box is more comfortable; the box cover can reduce the heat exchange between the infant box and the external environment, so that fogging cannot occuron the surface of the infant box, and power consumption of temperature and humidity adjusting equipment is reduced.

Owner:NINGBO DAVID MEDICAL DEVICE CO LTD

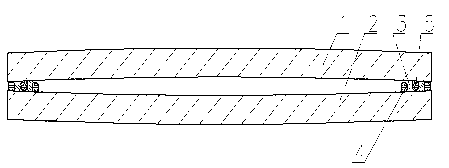

Edge sealing method with metal solders for low-altitude glass and product of method

ActiveCN102951796AEasy edge bandingExtend your lifeGlass reforming apparatusGlass productionLow altitudeHot Temperature

The invention discloses an edge sealing method for low-altitude glass. The method is used for sealing the peripheries of the low-altitude glass by edge sealing strip frames and metal solders at a high temperature. The peripheries of upper and lower glass of the low-altitude glass are provided with the edge sealing strip frames, so that the edge sealing of the low-altitude glass is simpler and more convenient to implement, and a sealing effect of the upper and lower glass is ensured by the embedding combination of the upper and lower edge sealing strip frames. The method provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and can be used for manufacturing not only common low-altitude glass but also tempered low-altitude glass.

Owner:海宁市袁花镇工业投资有限公司

Window lamination method for paper

InactiveCN107599598ARealize window coatingBonded firmlyLamination ancillary operationsLaminationWork in processEngineering

The invention discloses a window lamination method for paper. The window lamination method comprises the following steps: step 1, a two-sided corona film with one side pre-coated with hot melt glue isadopted, the other side of the two-sided corona film is bonded with the surface of the paper to be subjected to window lamination, full lamination of the two-sided corona film on the paper is realized, and an early semi-finished product is obtained; step 2, windowing is performed on the early semi-finished product, that is, a window is die-cut in a predetermined position of the early semi-finished product, scraps produced in die cutting are removed, and an intermediate semi-finished product is obtained; step 3, a heat seal film provided with co-polypropylene on at least one side is adopted, hot melt glue of the intermediate semi-finished product is covered with the side, provided with co-polypropylene, of the heat seal film, the heat seal film and the intermediate semi-finished product are bonded together through hot pressing by a hot pressing roller, and a finished paper product subjected to window lamination is obtained. The window lamination method has the advantages that the process difficulty is low, the effect of the window lamination finished product is good and the production efficiency is high.

Owner:广州市恒远彩印有限公司

Preparation method of environment-friendly benzene-free ketone-free white printing ink

The invention provides a preparation method of an environment-friendly benzene-free ketone-free white printing ink. The preparation method comprises the following steps: equipment is selected; the formulation of the white printing ink comprises the following components by weight percent: 35% of titanium dioxide, 30% of a resin, 1.5% of a wetter, 2% of a dispersing agent, 1.5% of an anti-settling agent and 30% of a mixed solvent; the components of the formulation are placed in a printing ink tank; operation is conducted to prepare the white printing ink; after the fineness and viscosity are qualified, the densities of toluene and butanone in the white printing ink are tested by a gas chromatograph so as to ensure the contents of the toluene and butanone in the white printing ink are lower than 0.03%; the white printing ink is filtered, weighed and packaged. The white printing ink prepared through the preparation method has the benefits as follows: the contents of the toluene and butanone in the white printing ink are lower than 0.03%, so that health of operating personnel is ensured; the white printing ink is stable in quality and good in performance; as the prepared white printing ink is free from the phenomenon of thickening or insoluble precipitate, the guarantee period can be above 1 year; phenomena such as fuzzy printing and cut lines in the printing process of the white printing ink are avoided; the production efficiency is high; the printing stability is ensured for users.

Owner:TIANJIN ANGEL CHEM GRP

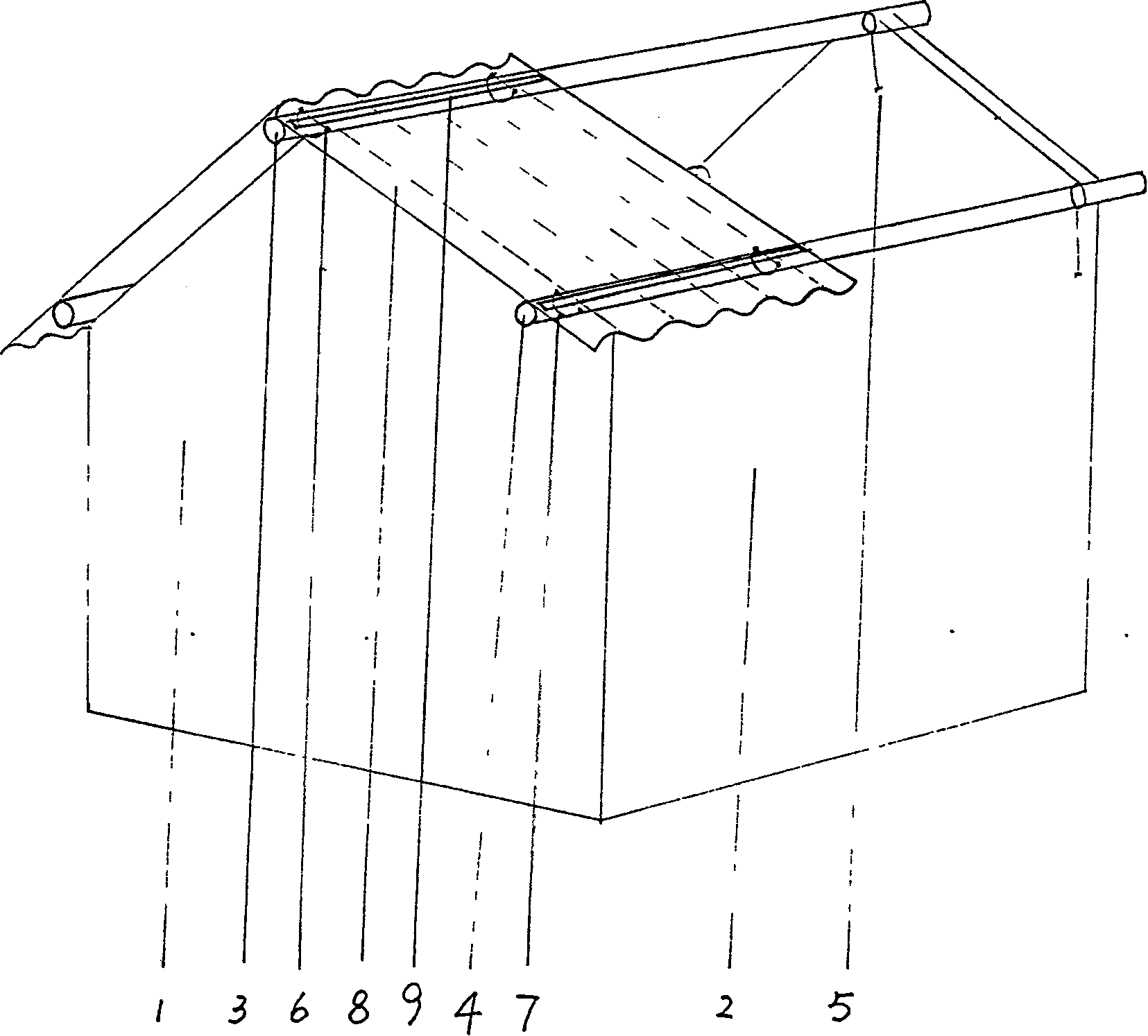

Binding-type asbestos shingle cover spiking method

InactiveCN101191362ASolve technical problems in constructionAvoid consumptionRoof covering using slabs/sheetsRural areaEcological environment

The present invention relates to a colligation type asbestic tile bamboo beam covering and nailing method and is characterized in covering and nailing points of a centre sill (3) and a circular beam (4) of an asbestic tiles (8) are bored (6) and pressed with treadle bars (9), then colligated and fixed by iron wires (7); the centre sill (3) and the circular beam (4) are also colligated, pulled and nailed on a wall to fix by the iron wires (5). The colligation type asbestic tile bamboo beam covering and nailing method of the invention overcomes the disadvantage that when bamboo is used to make beams, the bamboo can not be stably nailed and also solves the difficult problems that when the asbestic tile is covered and the nails are nailed and the screws are arranged on the beam and the girder by the prior art; the construction is so difficult that the asbestic tile is nailed unstably, easy to damage, high in cost, inconvenient to dismantle and easy to blow off by wind. The wind resisting effect of the present invention is three to five times of the wind resisting effect of the method by nailing the nails and screwing the screws; no stone blocks are needed to pressurize, thereby solving the difficult problem of firm covering and nailing. The invention is widely popularized to the rural areas to replace Han tiles (clay tiles) and save the beam and rafter which are the carriers of the Han tiles (clay tiles), thereby radically restraining timber consumption, and protecting forest ecological environment.

Owner:易美春

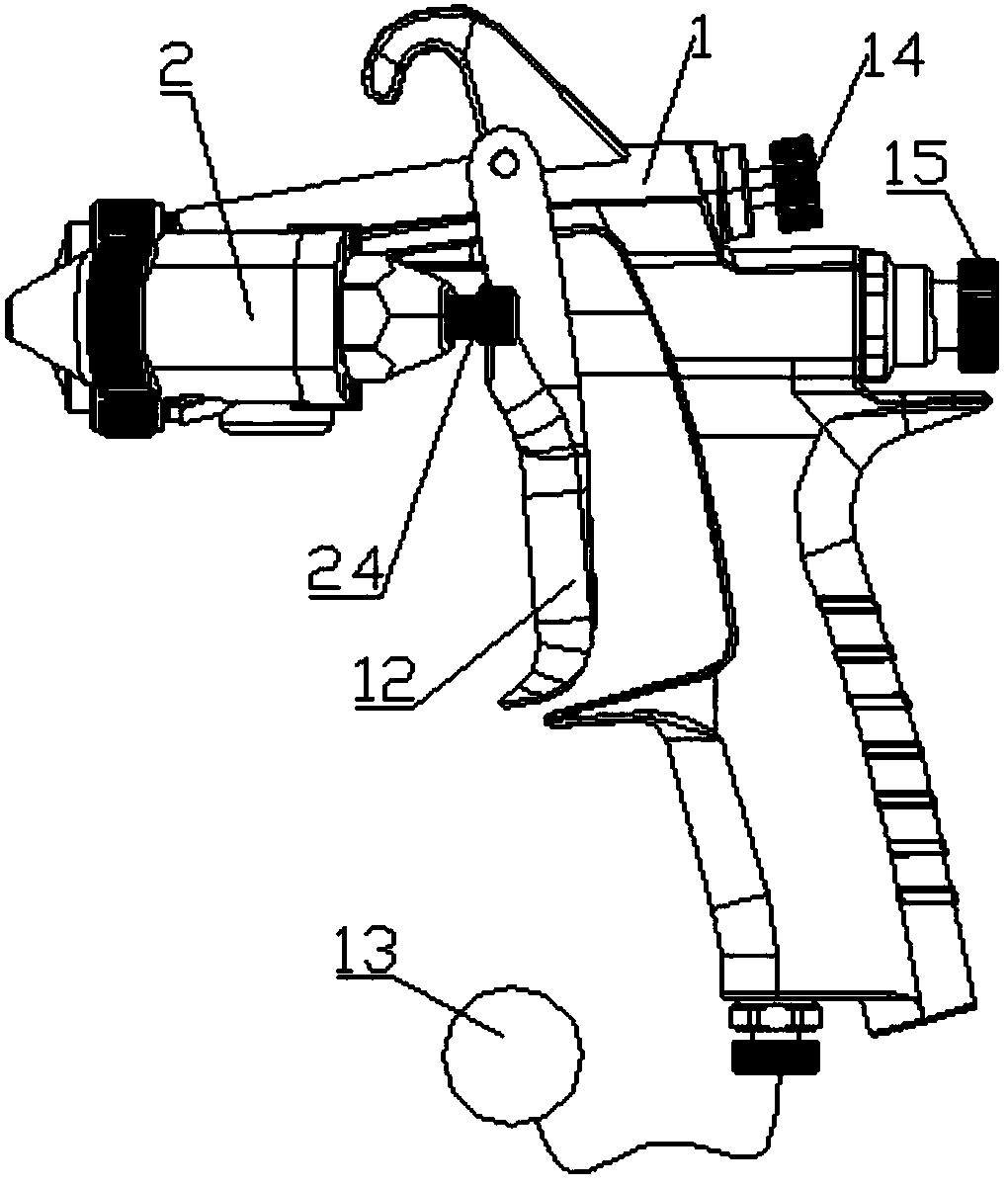

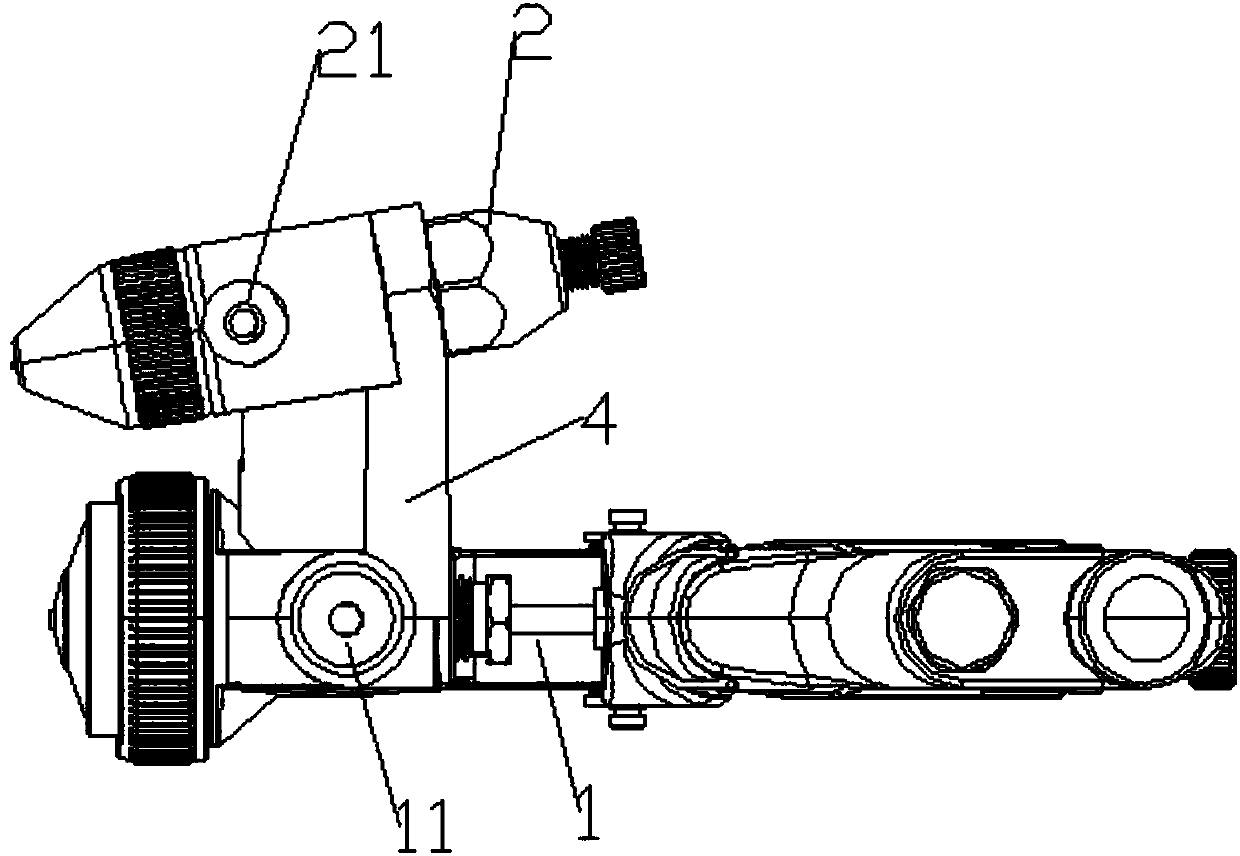

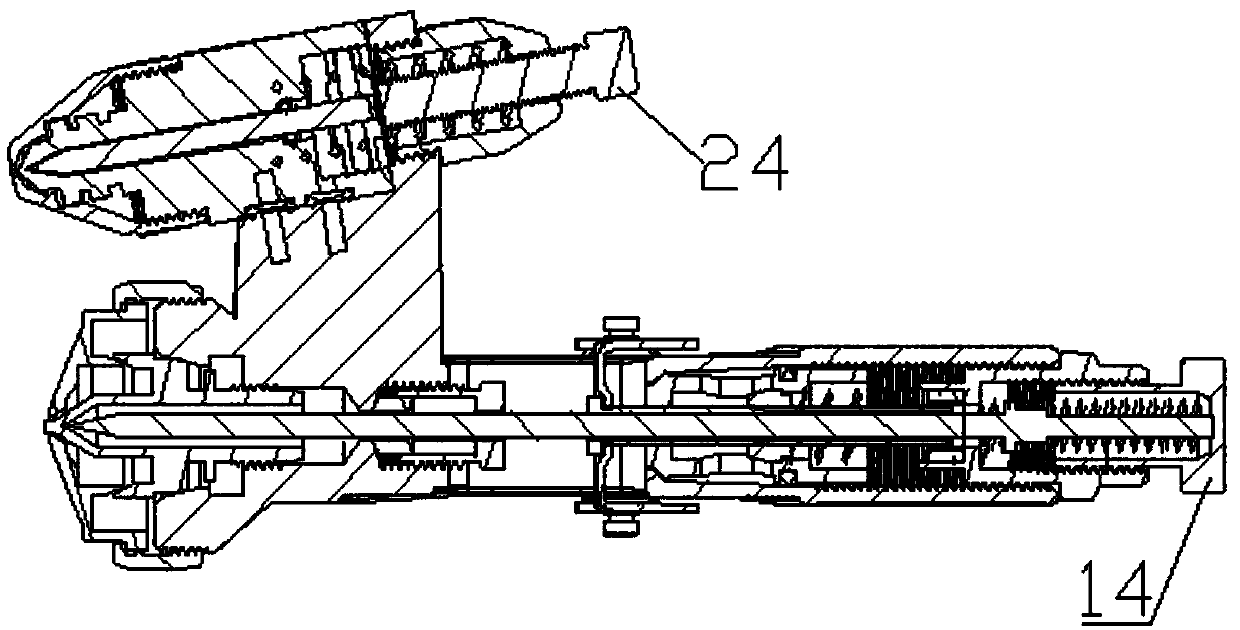

Environment-friendly waterborne adhesive spray gun

The invention provides an environment-friendly waterborne adhesive spray gun which comprises a gun A spraying a material A outwards and a gun B spraying a material B outwards. A material pipe A used for conveying the material A towards the gun A is connected to the front end of the gun A, and an air pump structure used for assisting in pushing of the material A and making the material A sprayed outwards is connected to the rear end of the gun A through a trigger mechanism. A material pipe B used for conveying the material B towards the gun B is connected to the front end of the gun B. The rearend of the gun B is connected to the trigger mechanism, and the gun B and the gun A share the same air pump mechanism so that when a trigger is pulled, the gun A and the gun B can spray coatings outwards at the same time, and a spraying layer formed by mixing the material A and the material B can be formed on the outer surface of a workpiece. The environment-friendly waterborne adhesive spray gunis simple in structure and uniform in spraying and cannot generate fog.

Owner:东莞市星东升实业有限公司

High-surface gloss glass fiber reinforced flame retardant polycarbonate composition and preparation method thereof

The invention relates to a high-surface gloss glass fiber reinforced flame retardant polycarbonate composition and a preparation method thereof. The composition comprises the following components by weight parts: 50-95 parts of polycarbonate, 5-50 parts of glass fiber, 0.1-5 parts of surface modifier, 0.01-0.2 part of flame retardant agent and 0.05-2 parts of anti-dripping agents. The preparationmethod comprises the steps of: adding the polycarbonate, the surface modifier, the flame retardant agent and the anti-dripping agents in a high-speed mixer in the proportions; stirring and mixing in uniformity; delivering the mixture in a twin-screw extruder through a main feeder; adding the glass fiber in the extruder through a side feeder; extruding and cutting into grains to obtain the high-surface gloss glass fiber reinforced flame retardant polycarbonate composition. Compared with the prior art, the high-surface gloss glass fiber reinforced flame retardant polycarbonate composition has the characteristics of high surface gloss, high rigidity, no welding line, no fogging, and the like. The high-surface gloss glass fiber reinforced flame retardant polycarbonate composition can be directly used as a structure and appearance integrated component, and can be used as a component integrating a face frame, a base and an inner structure of a display.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Toner

Disclosed is toner in which is used in an image formation process comprising the steps of transferring an image of toner formed on a photoreceptor onto a recording sheet, and removing any residual toner remaining on any of the photoreceptor, an intermediate transfer member and a secondary transfer member with a cleaning blade, the toner containing at least toner particles (A) and small particles (B), wherein the toner particles (A) have an average circularity of from 0.93 to 0.99 and a number-based median diameter (D50) of from 3.0 to 8.0 μm, the small particles (B) have an average circularity of from 0.70 to 0.92 and a number-based median diameter (D50) of from 0.15 to 0.60 times that of the toner particles (A), and the surface energy of the toner particles (A) is different from that of the small particles (B).

Owner:KONICA MINOLTA BUSINESS TECH INC

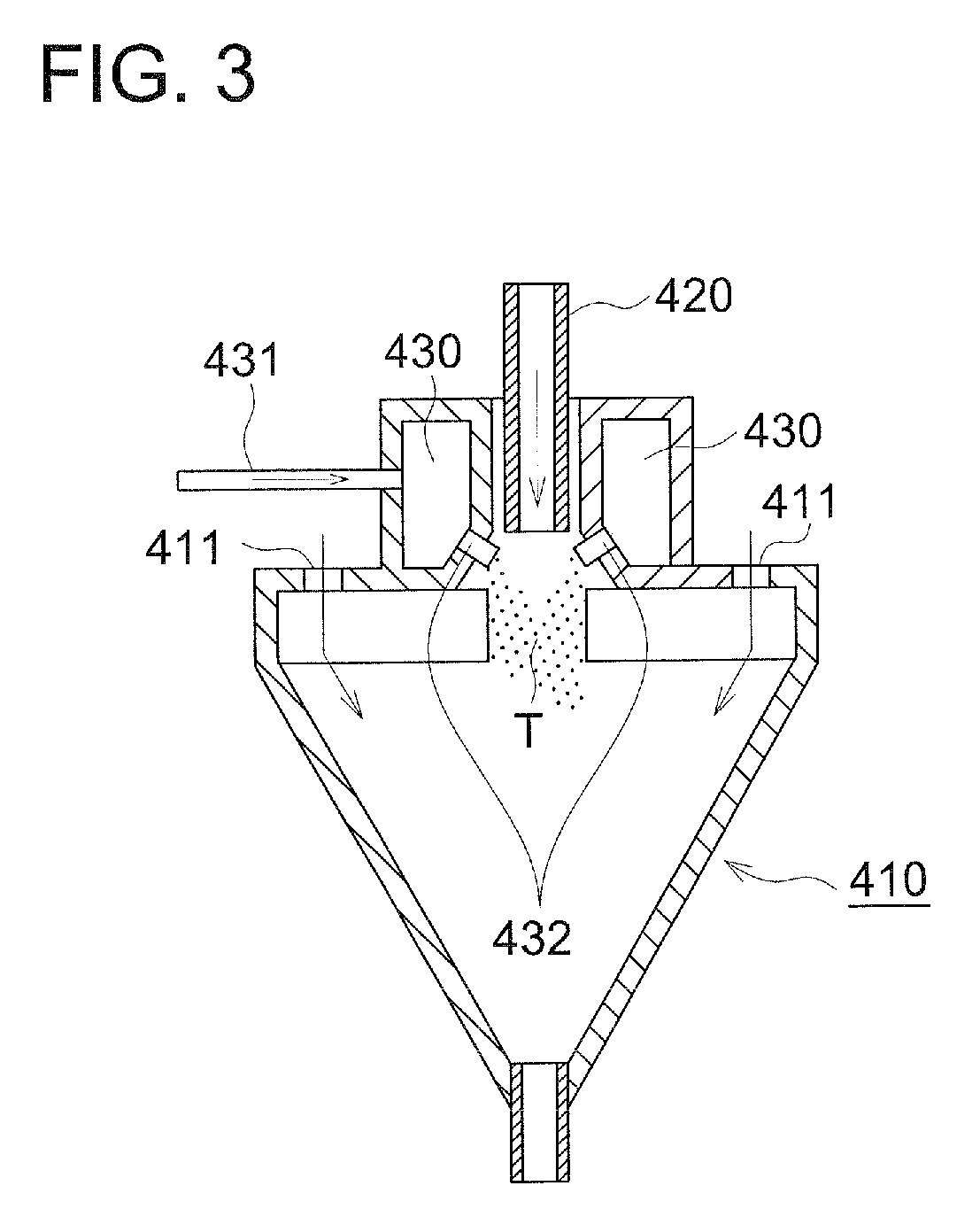

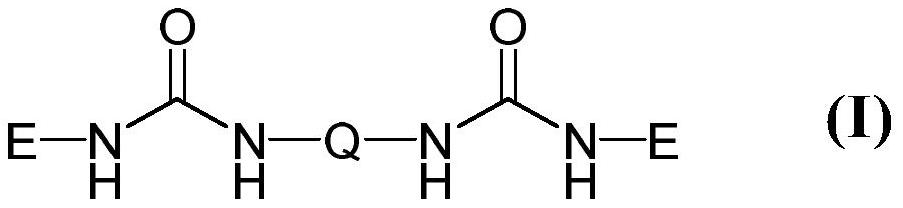

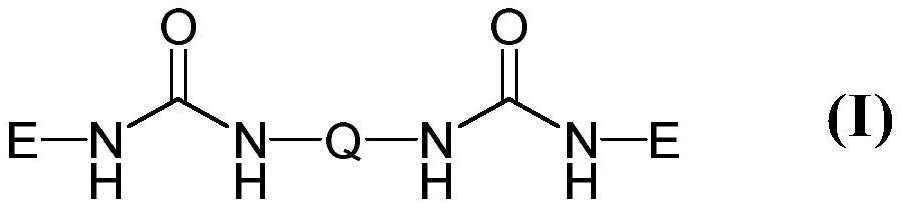

Thixotropic agent for curable compositions

ActiveCN112955485AEasy to processIncrease yield pointUrea derivatives preparationOther chemical processesPolymer scienceAdhesive

Owner:SIKA TECH AG

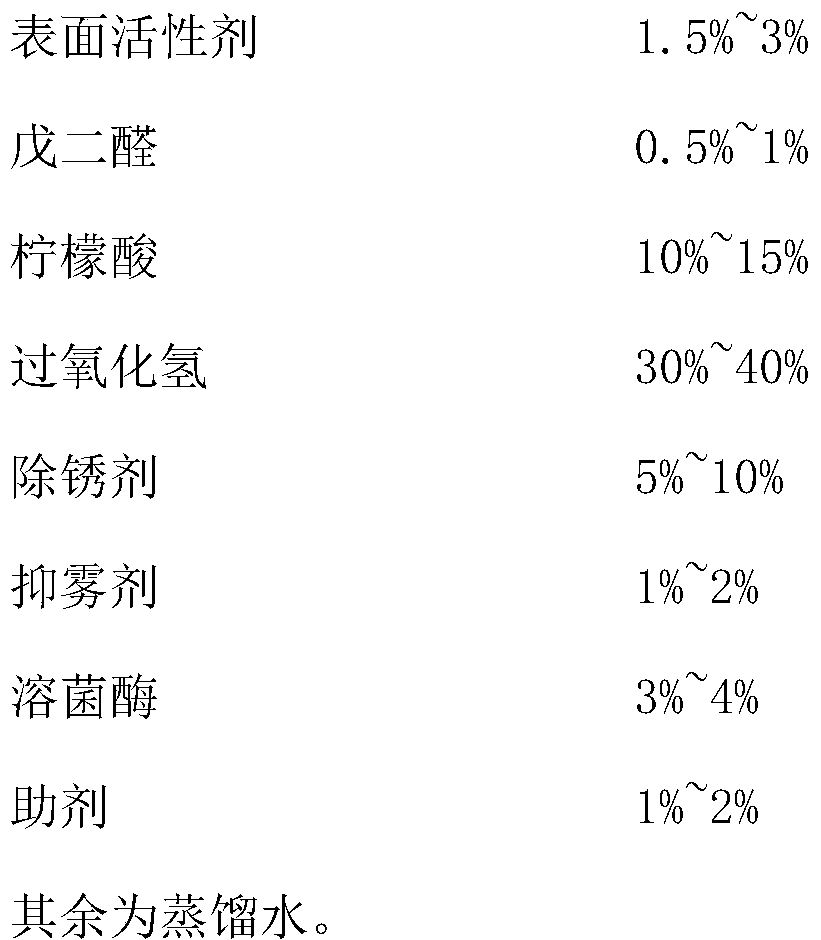

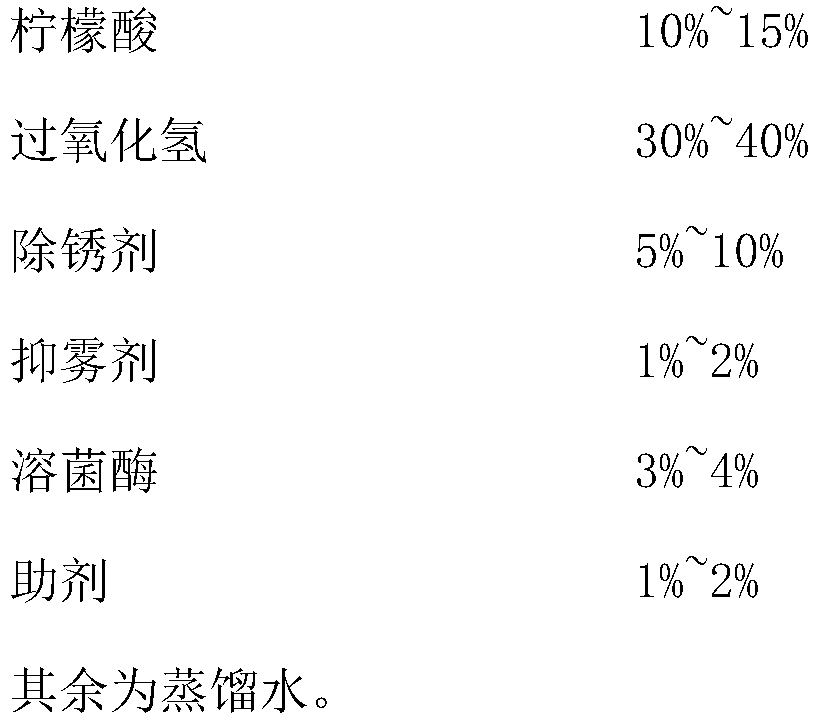

Bactericide for medical instruments

The invention provides a bactericide for medical instruments. The bactericide for the medical instruments is prepared from the following components, by weight, 1.5%-3% of a surfactant, 0.5%-1% of glutaraldehyde, 10%-15% of citric acid, 30%-40% of hydrogen peroxide, 5%-10% of a rust remover, 1%-2% of a fog inhibitor, 3%-4% of lysozyme, 1%-2% of auxiliaries, and the balance being distilled water. The cationic surface active agent is one of chlorhexidine or benzalkonium bromide; the cationic surfactant and water form a solution; the ratio of the cationic surfactant to the water is 1: 1. 50-55; the coco fatty acid diethanolamide and the water form a solution, the ratio of the coco fatty acid diethanolamide to the water is 1: 55-60; the surfactant comprises a mixture of a cationic surfactant and the coco fatty acid diethanolamide, and the mixing ratio of the cationic surfactant to the coco fatty acid diethanolamide is 1: 0.5-0.8.

Owner:沈小燕

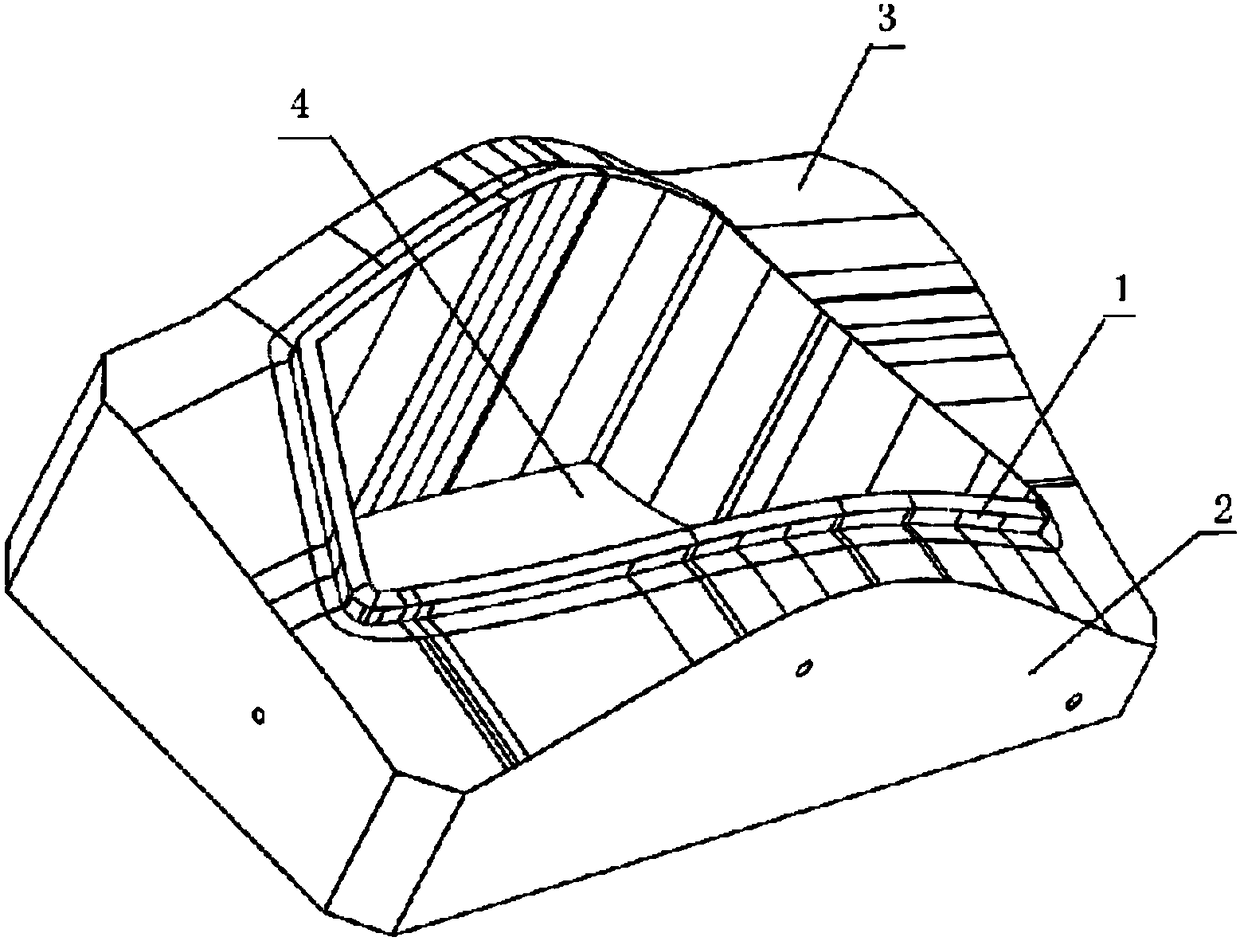

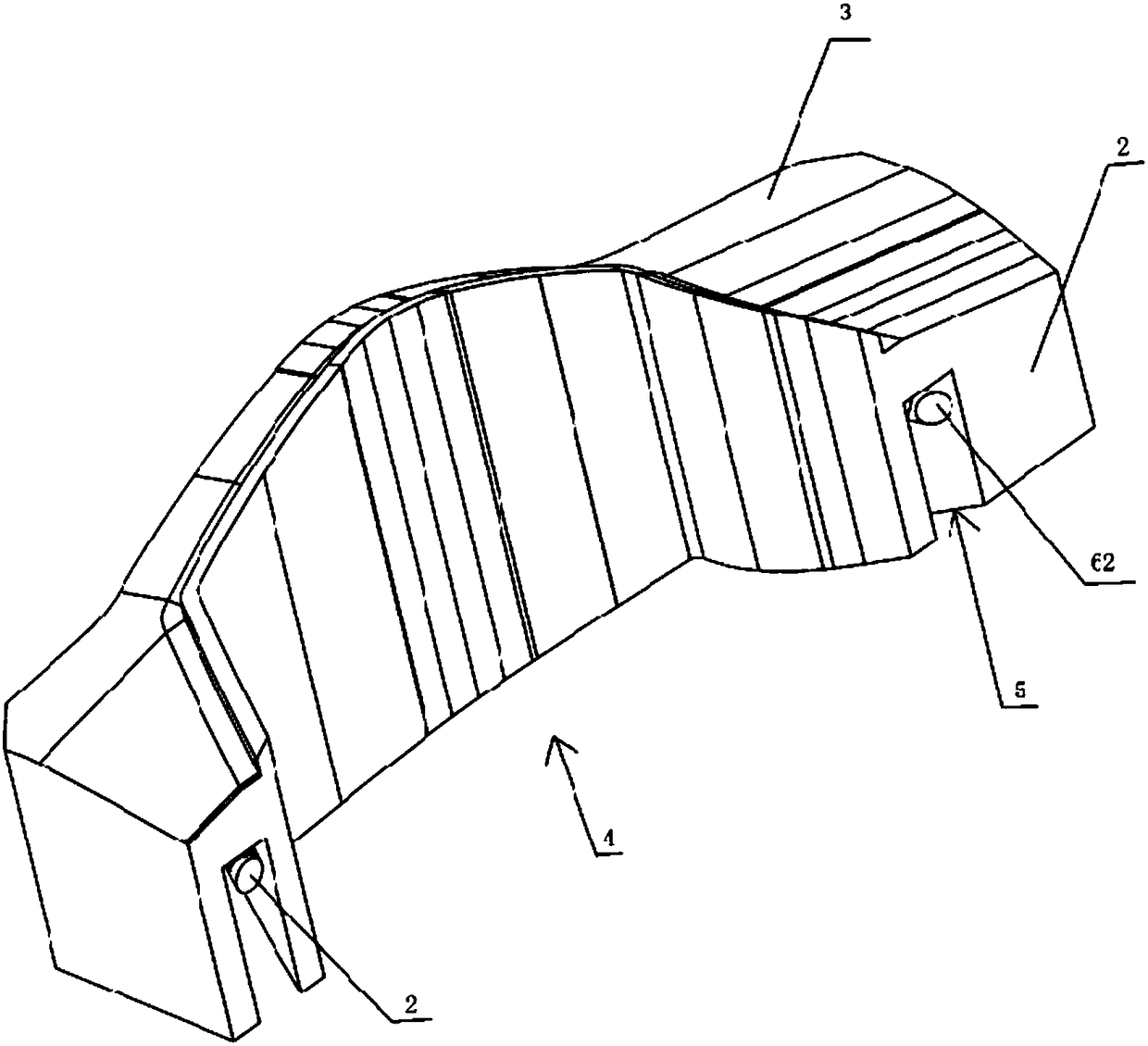

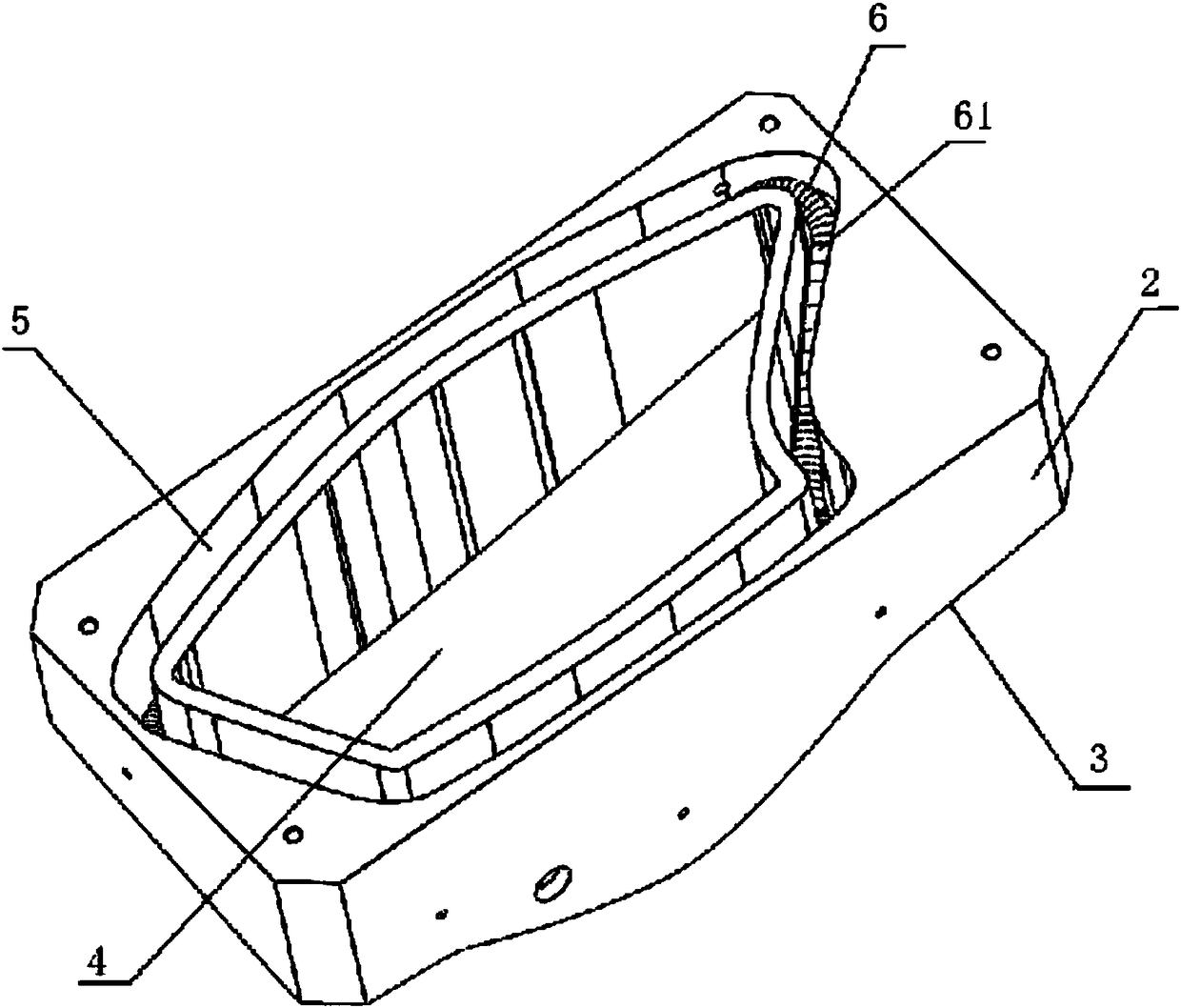

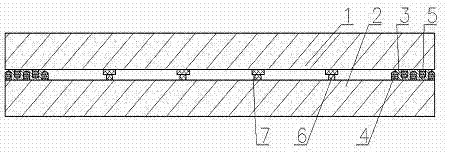

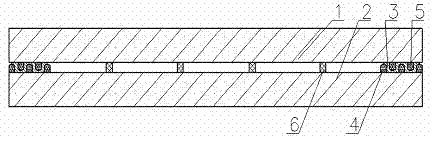

Hot plate mold for automobile lamp housing manufacturing equipment

The invention relates to the field of mechanical equipment, in particular to a hot plate mold for automobile lamp housing manufacturing equipment. The hot plate mold for automobile lamp housing manufacturing equipment comprises a mold base, the upper surface of which is a working face of a shape corresponding to a to-be-processed workpiece, wherein a heating device is arranged in the mold base; aheating groove for placing the heating device is formed in a mounting face of the mold base; the heating groove corresponds to the contour of the outer edge of a welding rib used for processing the workpiece; and a hollow cavity is formed in the contour range of the heating groove in the middle of the mold base, so that the upper surface and the lower surface of the mold base are connected through. The mold provided by the invention has the advantages of being simple to operate, low in manufacturing cost and good in using effect.

Owner:JIANGSU YEDI AUTOMOTIVE LIGHTING SYST

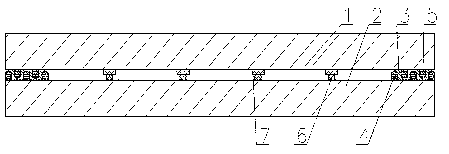

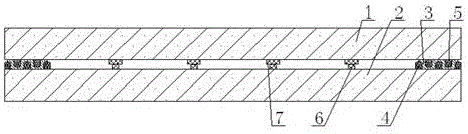

Flat tempered low-altitude glass with glass welding and manufacturing method of glass

ActiveCN102951798ARelieve pressureReduce oxidationGlass reforming apparatusGlass productionLow altitudeWelding

The invention provides flat tempered low-altitude glass. The glass comprises upper glass and lower glass, which are flat tempered glass, wherein edge sealing strip frames are arranged on the peripheries of the welding surfaces of the upper and lower glass; the peripheries of the upper and lower glass are welded together through low-temperature glass solders; and a closed low-altitude layer is formed between the upper glass and the lower glass and is internally provided with supports which are arranged in a lattice manner. A manufacturing method of the low-altitude glass provided by the invention is simple in process; and the manufactured tempered low-altitude glass can overcome defects in the prior art and can be subjected to mass production.

Owner:海宁市袁花镇工业投资有限公司

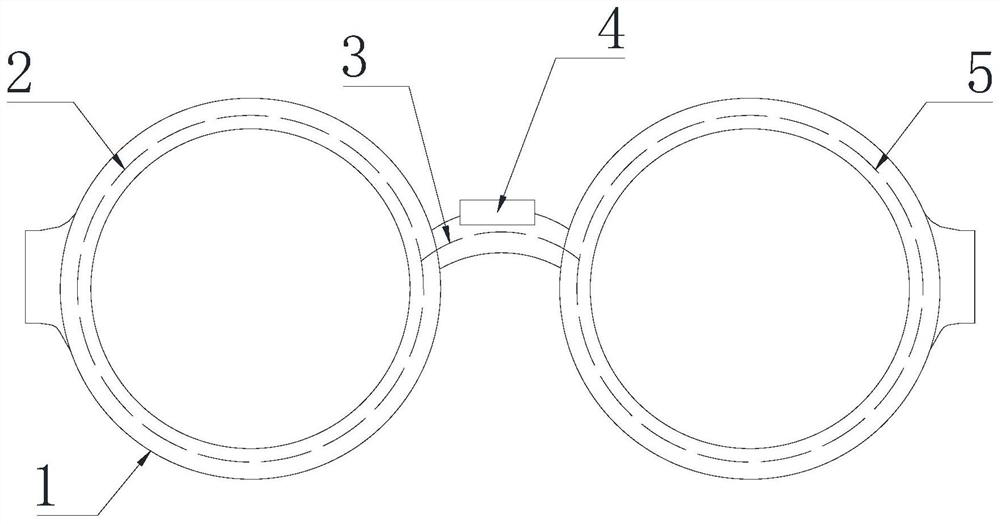

Defogging glasses

The invention discloses a pair of defogging glasses. The pair of defogging glasses comprises a glasses body, lens frames which are in bilateral symmetry are arranged on the glasses body, a first electric heating wire and a second electric heating wire are arranged in the two lens frames respectively, a nose pad is arranged between the two lens frames, a wire and a heating mechanism are arranged inthe nose pad, and the heating mechanism is electrically connected to the first electric heating wire and the second electric heating wire through the wire respectively. The surrounding environment ofthe lenses of the defogging glasses can be heated to avoid fogging.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

PU protective film adhesive tape capable of automatically changing color and preparation method of adhesive tape

InactiveCN107384234AEye protection effectEliminate reflections and other phenomenaFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membranePolyurethane adhesive

The invention discloses a PU protective film adhesive tape capable of automatically changing color and a preparation method of the adhesive tape. The PU protective film adhesive tape comprises a transparent base film, a color-changeable polyurethane adhesive layer and a one-sided release film, wherein the color-changeable polyurethane adhesive layer is coated on the surface of the transparent base film; the one-sided release film is laminated on the surface of the color-changeable polyurethane adhesive layer; the color-changeable polyurethane adhesive layer contains the following components in percentage by weight: 80-93% of a polyurethane adhesive, 2-8% of a curing additive and 3-12% of a coloring additive. The color-changeable polyurethane adhesive layer is prepared by proportioning specific components, so that the adhesive tape absorbs ultraviolet light or sunshine to produce color change while being subjected to ultraviolet light or sunshine irradiation; and moreover, when ultraviolet light or sunshine irradiation is lost, the adhesive tape returns to the original color, the product capable of automatically changing the color effectively prevents sight stimulation of the sunshine on a user, and the comfortableness and visual effect of the sight of the user are effectively ensured. The product is suitable for surface protection of glass lenses of electronic products, panels, touch screen module and other parts.

Owner:东莞市古川胶带有限公司

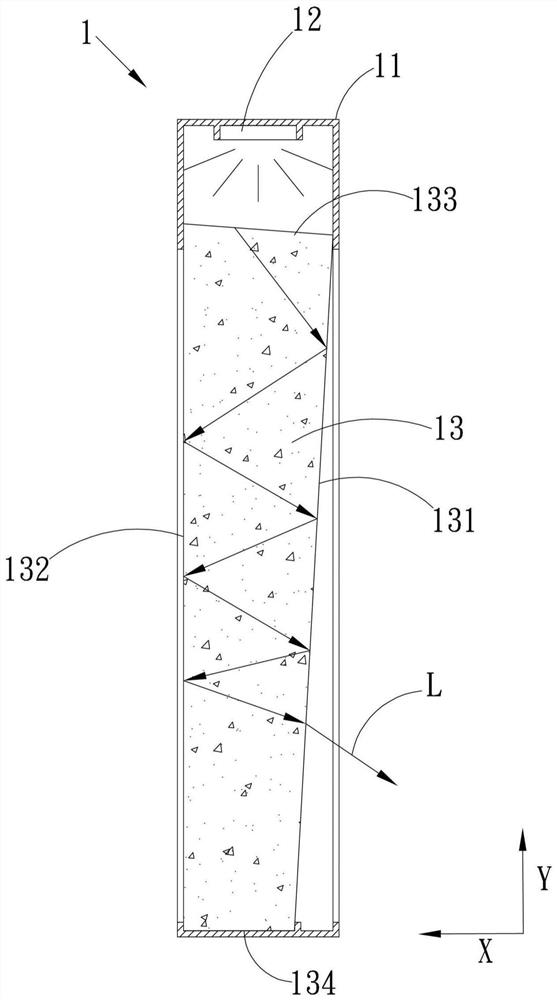

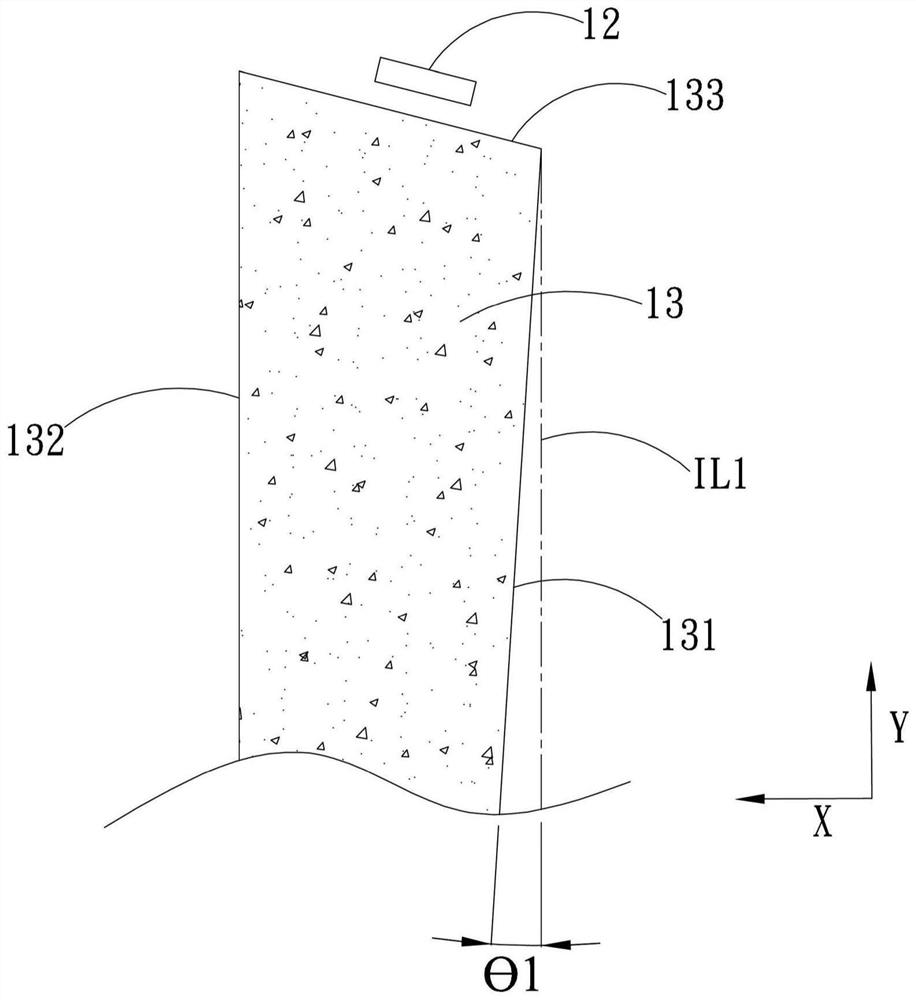

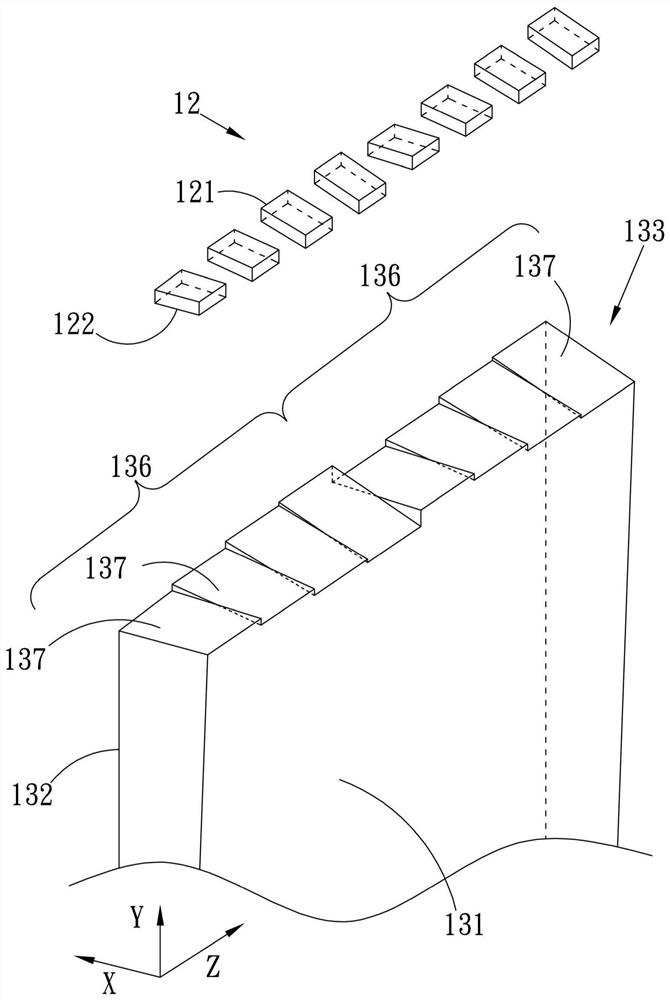

Lighting device and window light simulation system

ActiveCN111102498BSimulated exposureEasy to irradiateMechanical apparatusLight guides detailsLight guideFixed frame

The invention discloses a light emitting device and a window light simulation system. Wherein, the light emitting device includes a fixed frame, a light source module and a light guide. Wherein, the light source module and the light guide are arranged on the fixed frame. The light source module is configured to emit light, and the light guide is located on one side of the light source module; the light guide has a non-parallel first surface, a second surface and a light incident end between the first surface and the second surface. The light incident end is opposite to the light source module to receive light, and the light leaves the light guide at least from the first surface. Wherein, the light incident end has a specific structure for receiving light. Thereby, the present invention can maintain the transparency of the light guide and achieve a good effect of simulating sunlight.

Owner:AU OPTRONICS CORP

Flat low-altitude glass and preparation method thereof

ActiveCN102951799BReduced service lifeExtended service lifeGlass reforming apparatusGlass productionFlat glassMaterials science

The invention provides a flat low-altitude glass, which includes: upper and lower glasses, the upper and lower glasses are flat glass, and the edges of the welding surfaces of the upper glass and the lower glass are provided with edge sealing strips, so The peripheries of the upper glass and the lower glass are welded together by low-temperature solder, and a closed lower space layer is formed between the upper glass and the lower glass, and there are supports arranged in a lattice in the lower space layer. The manufacturing method of the low-altitude glass of the present invention has a simple process, and the prepared low-altitude glass can overcome the deficiencies in the prior art, and can realize batch production.

Owner:海宁市袁花镇工业投资有限公司

Tempered, semi-tempered low-altitude glass and manufacturing method thereof

ActiveCN102951797BRelieve pressureReduce oxidationGlass reforming apparatusGlass productionToughened glassCeramic materials

The invention provides tempered and semi-tempered low-altitude glass. The glass comprises upper glass and lower glass, wherein the upper and lower glass are flat tempered and semi-tempered glass; edge sealing strip frames are arranged on the peripheries of the welding surfaces of the upper and lower glass; the peripheries of the upper and lower glass are welded together through low-temperature solders; and a closed low-altitude layer is formed between the upper glass and the lower glass and is internally provided with supports which are arranged in a lattice manner. A manufacturing method of the low-altitude glass provided by the invention is simple in process; and the manufactured tempered low-altitude glass can overcome the defects in the prior art and can be subjected to mass production.

Owner:海宁市袁花镇工业投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com