Environment-friendly waterborne adhesive spray gun

A water-based adhesive, environmentally friendly technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of complex structure and poor spraying effect, and achieve the effect of uniform spraying and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

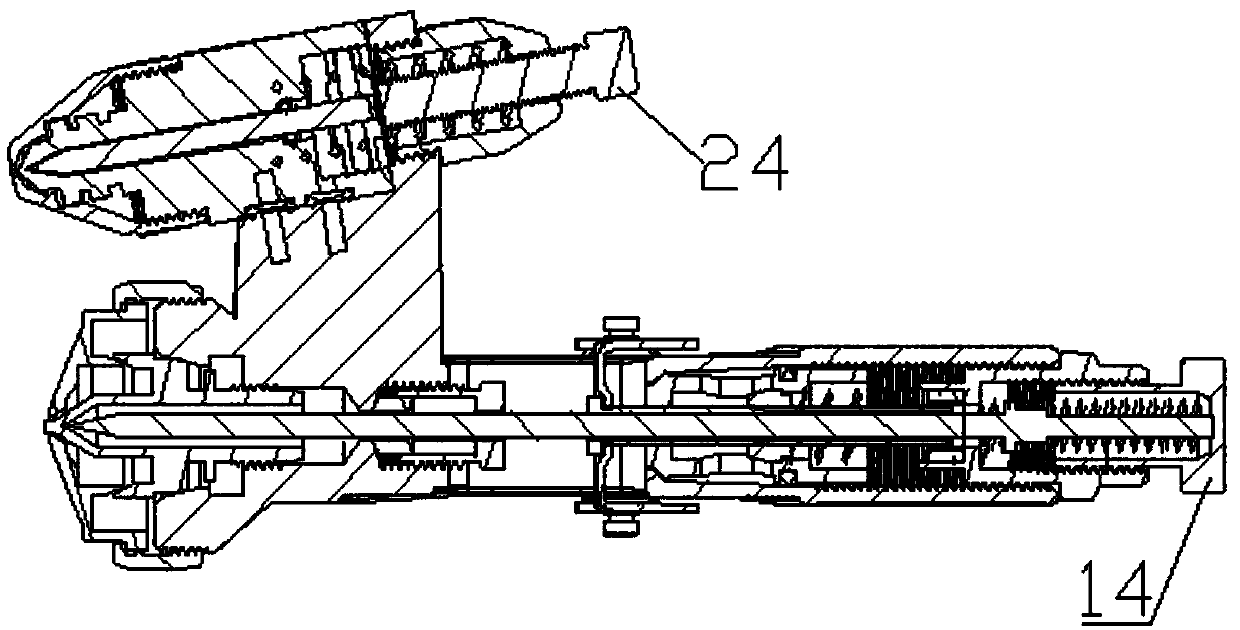

[0016] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are attached with accompanying drawings in detail as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention , without limitation of any form, size or proportion.

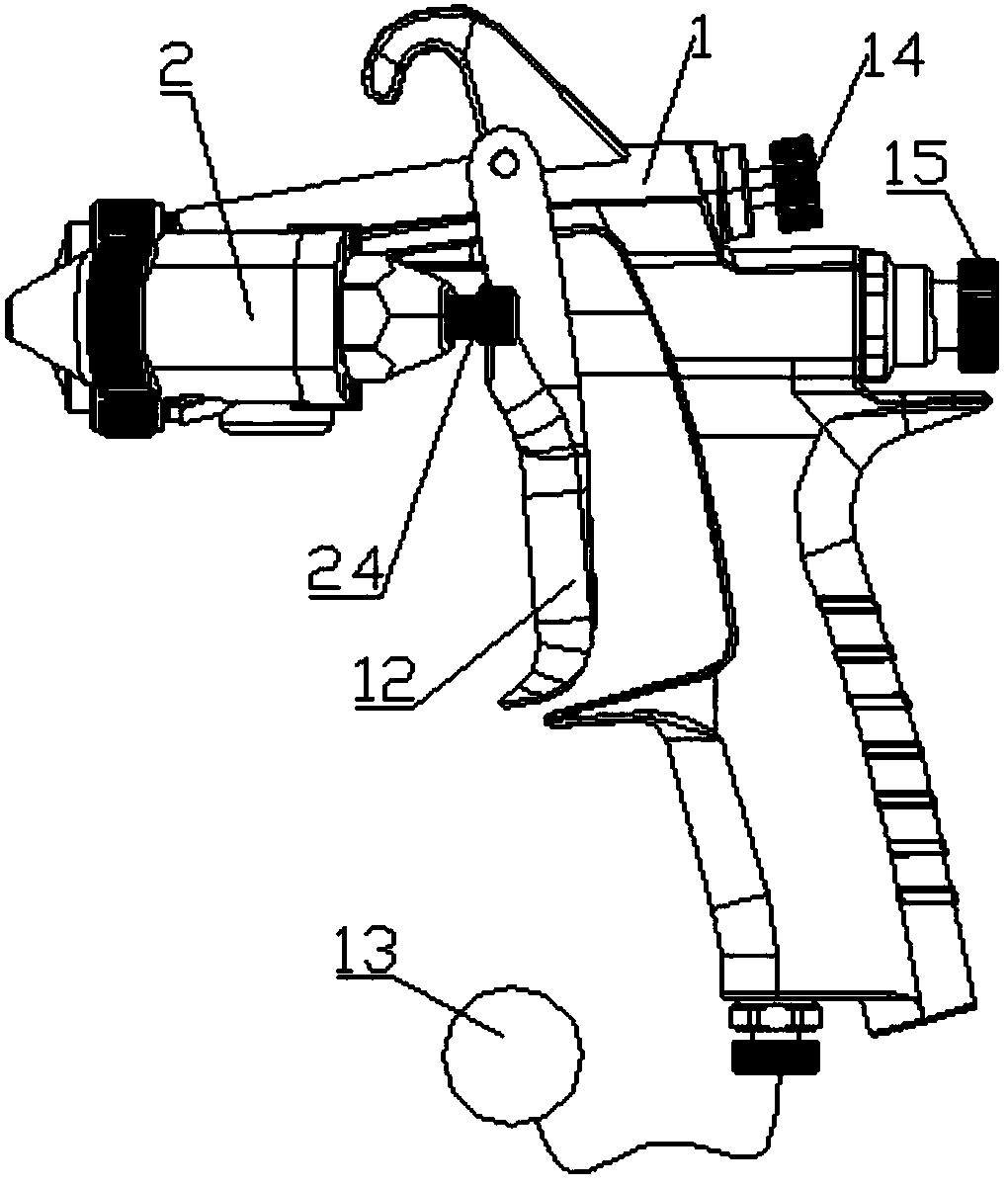

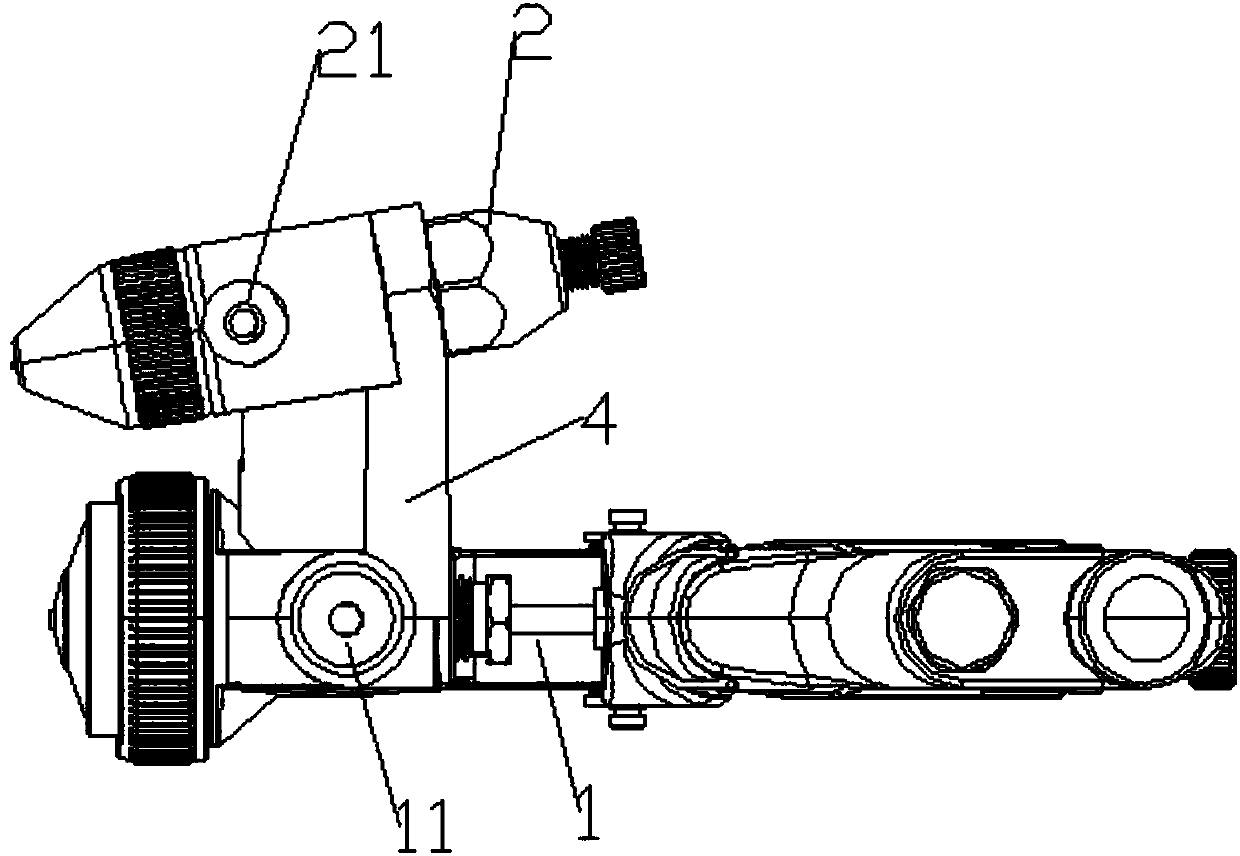

[0017] Such as figure 1 , figure 2 As shown, the present invention provides an environmentally friendly water-based adhesive spray gun, which includes an A gun 1 that sprays A material outward and a B gun 2 that sprays B material outward.

[0018] The front end of A gun 1 is connected with the A material pipe 11 that delivers A material to A gun 1, and the rear end of A gun 1 is connected with an air pump mechanism 13 that helps push A material to spray outward through a trigger mechanism 12. The internal air pressure of the air pump mechanism 13 is at 121- 128kPa; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com