Binding-type asbestos shingle cover spiking method

A technology of binding and asbestos tiles, which is applied to roof coverings, roofs, and roofs using flat/curved panels, etc., can solve the problems of hindering the enthusiasm of asbestos tiles, difficulty in dismantling and disassembly, and easy damage by wind, so as to promote Understand the effects of utilization and planting, curbing illegal logging, and improving wind and earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

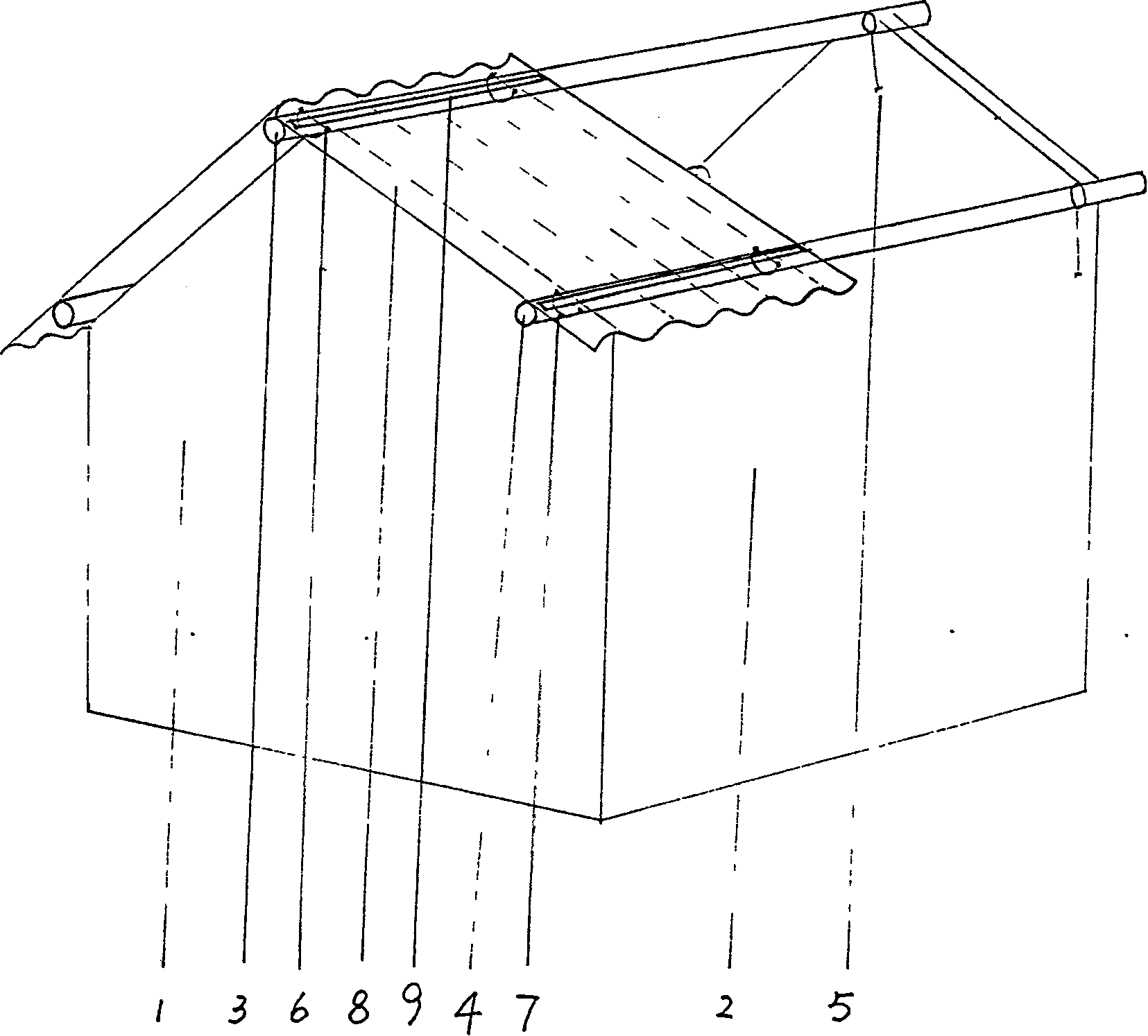

[0016] According to the binding method of asbestos tile bamboo beam cover of the present invention, the gable 1 and the back wall 2 are built, and the middle beam 3 and the original beam 4 are loaded and calibrated, and iron wires are used to bind and pull the girder and the inner wall of the gable. After the next section is fixed on the wall and fixed 5 is completed, asbestos tiles 8 are put on, each threading eye 6 is punched at the two ends of the beam top position, the beading 9 is installed, and the iron wire is tied and tightened 7, and the construction is carried out one by one in this way.

[0017] This binding and covering method can also be used for the construction of beams of various textures, wood angle steel, etc., and the fixing and covering of various tiles, such as asbestos tiles, iron sheets, color steel tiles, glass fiber tiles, glass fiber reinforced plastic arch tiles, lighting tiles, etc. Strong wind resistance and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com