Large-span flexible arch skew back joining construction method

A large-span, flexible technology, applied in the field of bridge steel structure, to achieve the effect of technical feasibility, simple operation and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

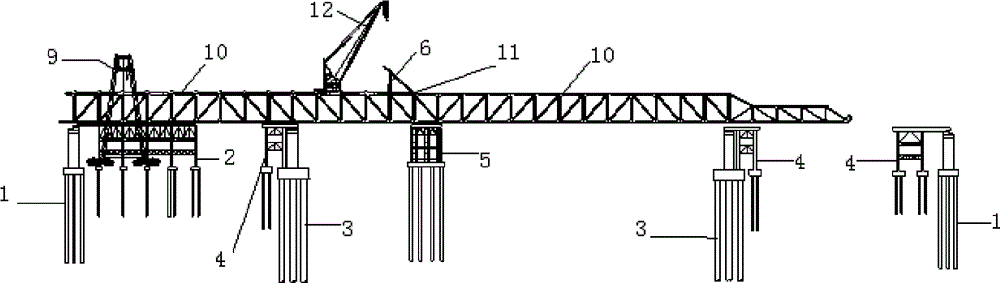

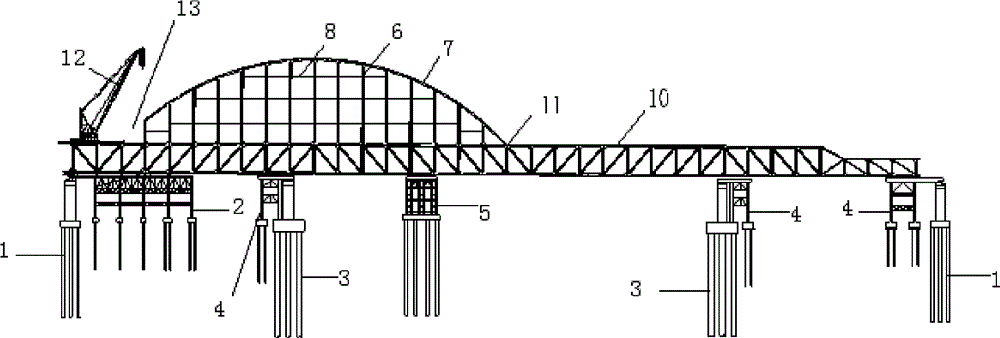

[0027] Referring to the accompanying drawings, a construction method of large-span flexible arch-arch foot closure includes the following construction steps:

[0028] (1) When the arch foot of the steel truss beam is pushed to the top of the temporary pier support, a beam crane is installed on the upper chord of the steel truss beam;

[0029] (2) After the installation and commissioning of the beam erecting crane, drive to the arch foot position by itself, and start erecting the flexible arch rod. The beam erecting crane adopts a one-way step-back method. The erection sequence of the arch ribs;

[0030] (3), repeat step (2), until the flexible arch is erected to the last remaining arch section, reserve the arch foot closing mouth;

[0031] (4) Using finite element analysis software to simulate and calculate the state of Helongkou, the software analysis results are basically consistent with the actual measurement results of Helongkou, but there are still vertical deviations, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com