Patents

Literature

4977 results about "Contact type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, more precisely in symplectic geometry, a hypersurface of a symplectic manifold is said to be of contact type if there is 1-form such that and is a contact manifold, where is the natural inclusion. The terminology was first coined by Alan Weinstein.

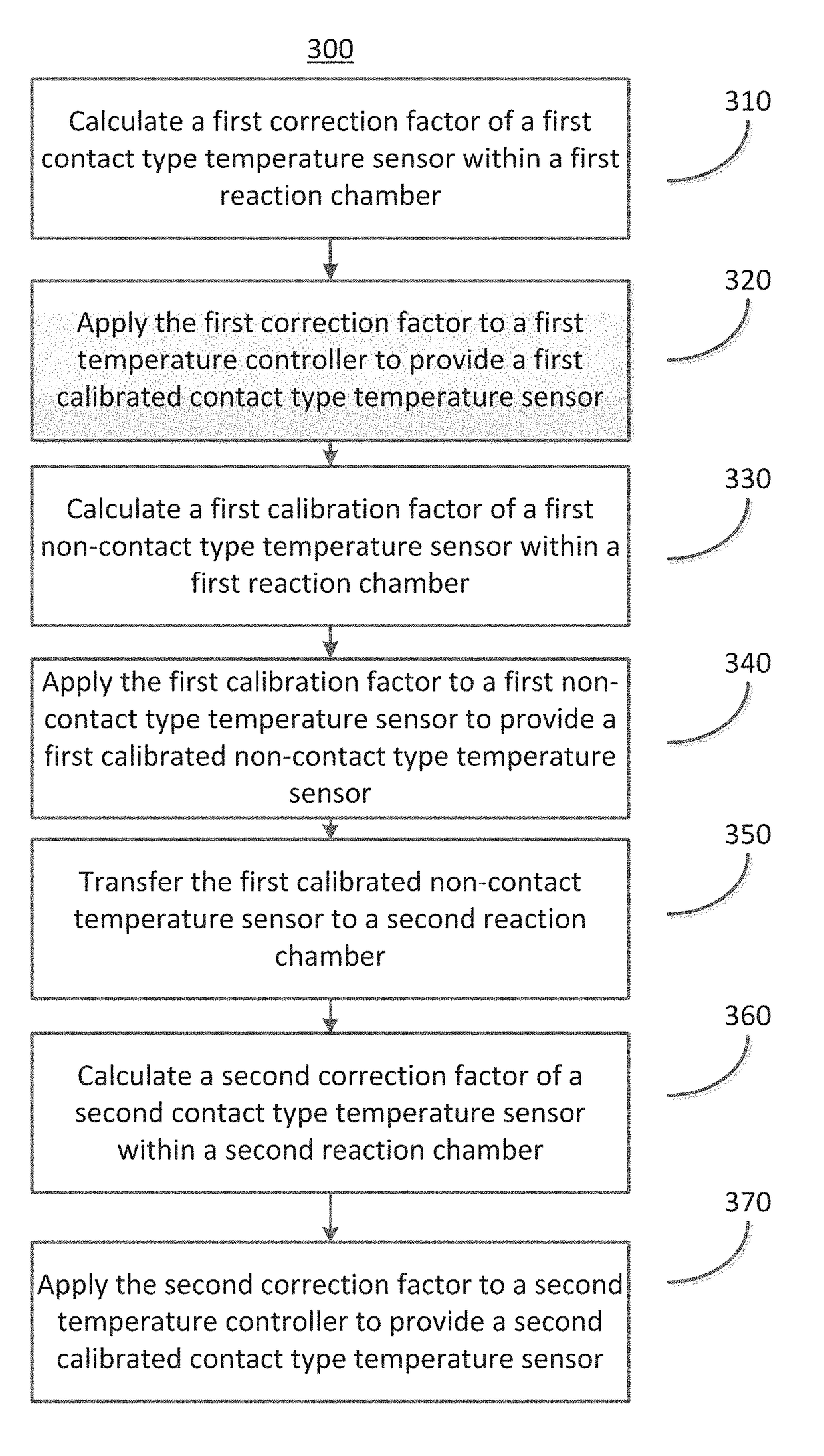

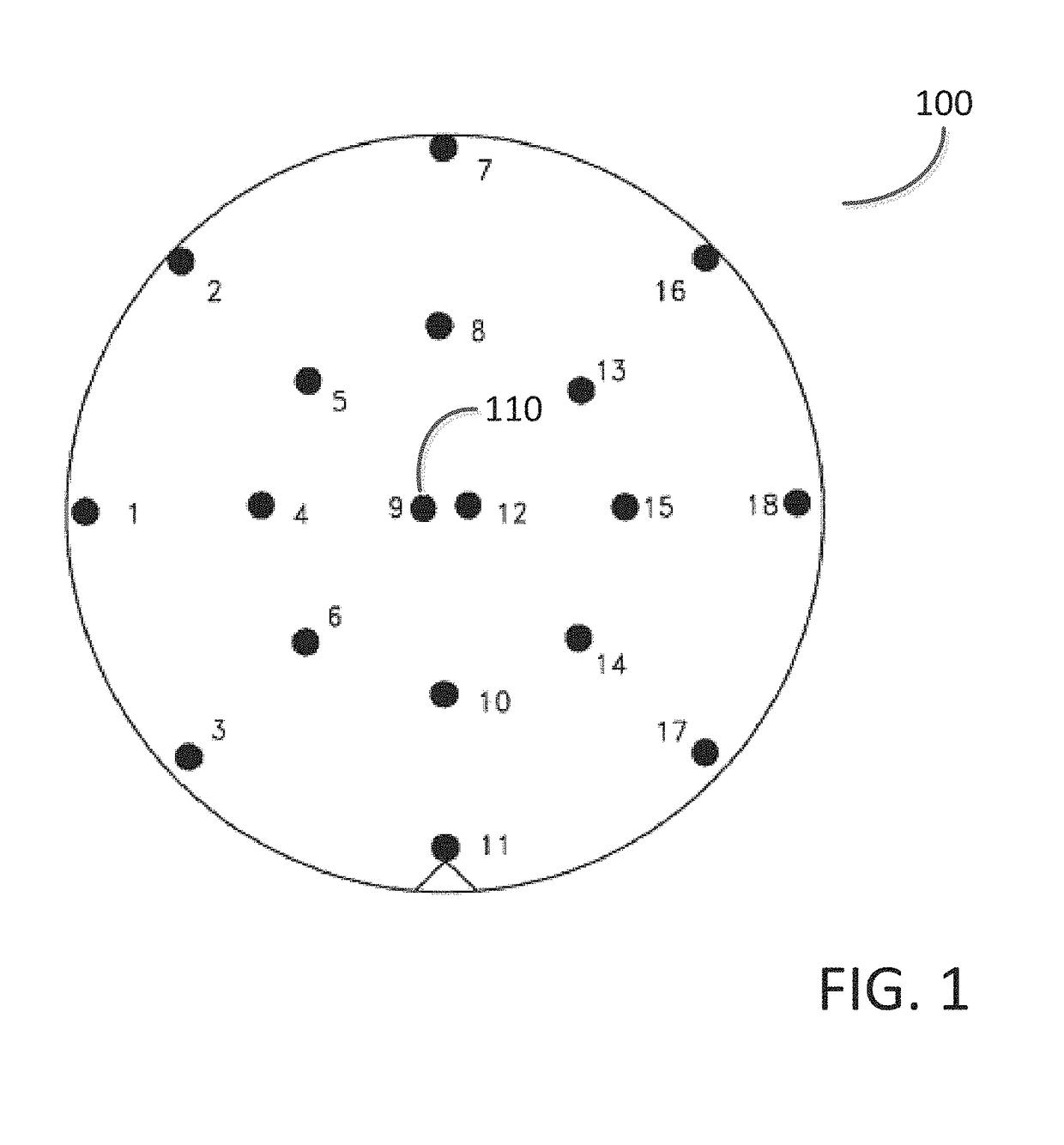

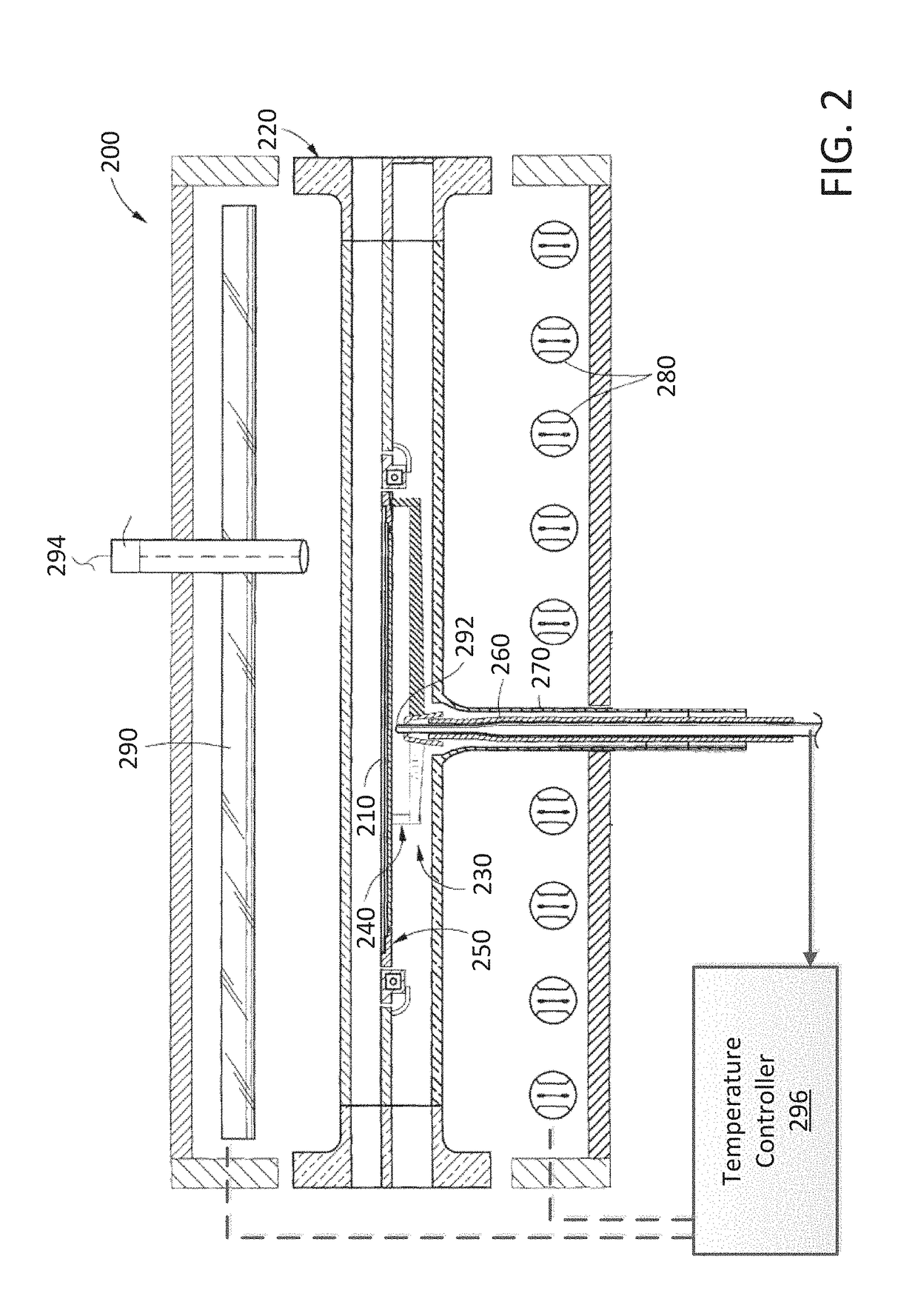

Methods for thermally calibrating reaction chambers

Methods for thermally calibrating reaction chambers are provided. In some embodiments, methods may include calculating a first correction factor of a first contact type temperature sensor within a first reaction chamber utilizing a first temperature sensor and applying the first correction factor to a first temperature controller to provide a first calibrated contact type temperature sensor. Embodiments may also include calculating a first calibration factor of a first non-contact type temperature sensor within the first reaction chamber utilizing the first calibrated contact type temperature sensor and applying the first calibration factor to the first non-contact type temperature sensor to provide a first calibrated non-contact type temperature sensor.

Owner:ASM IP HLDG BV

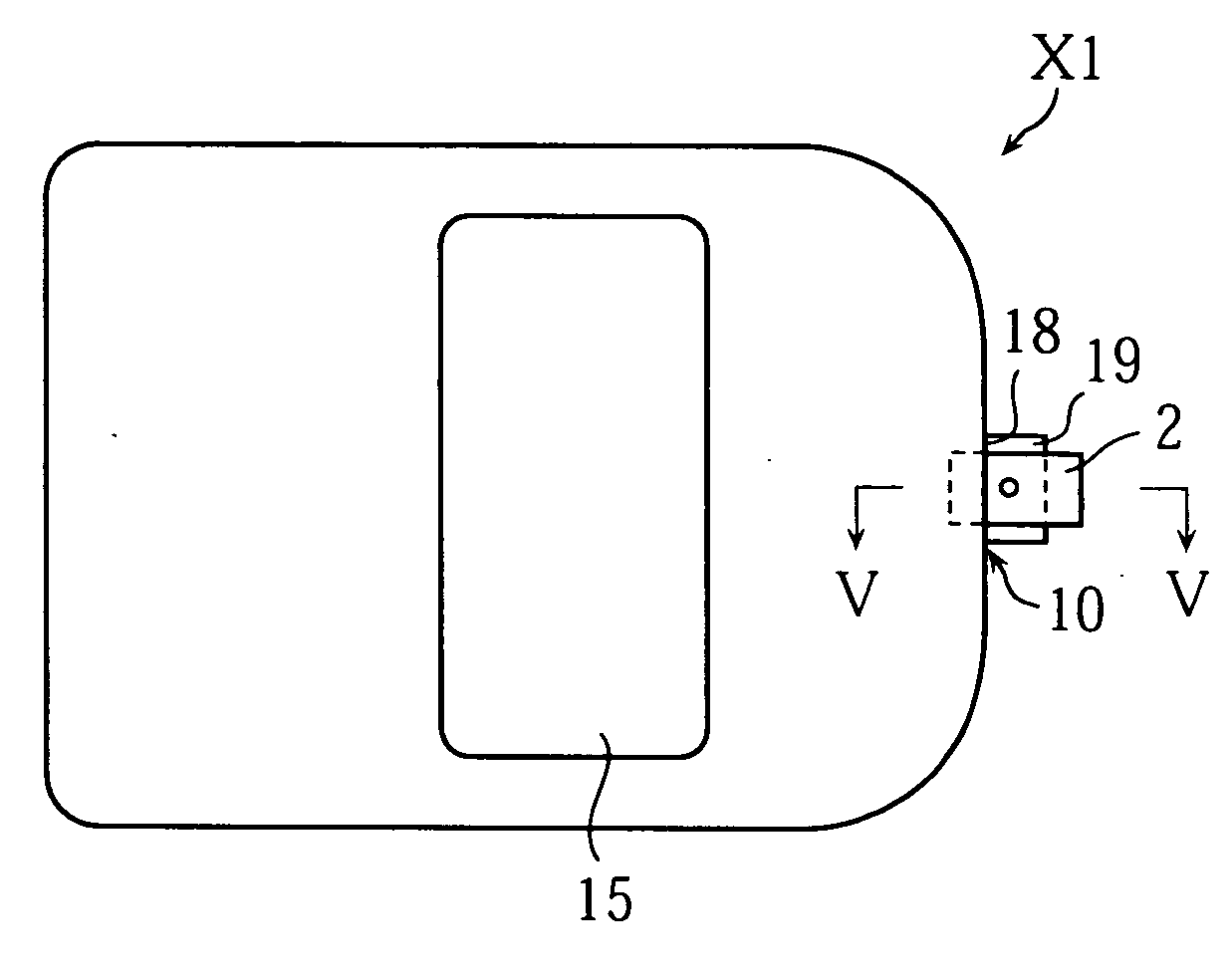

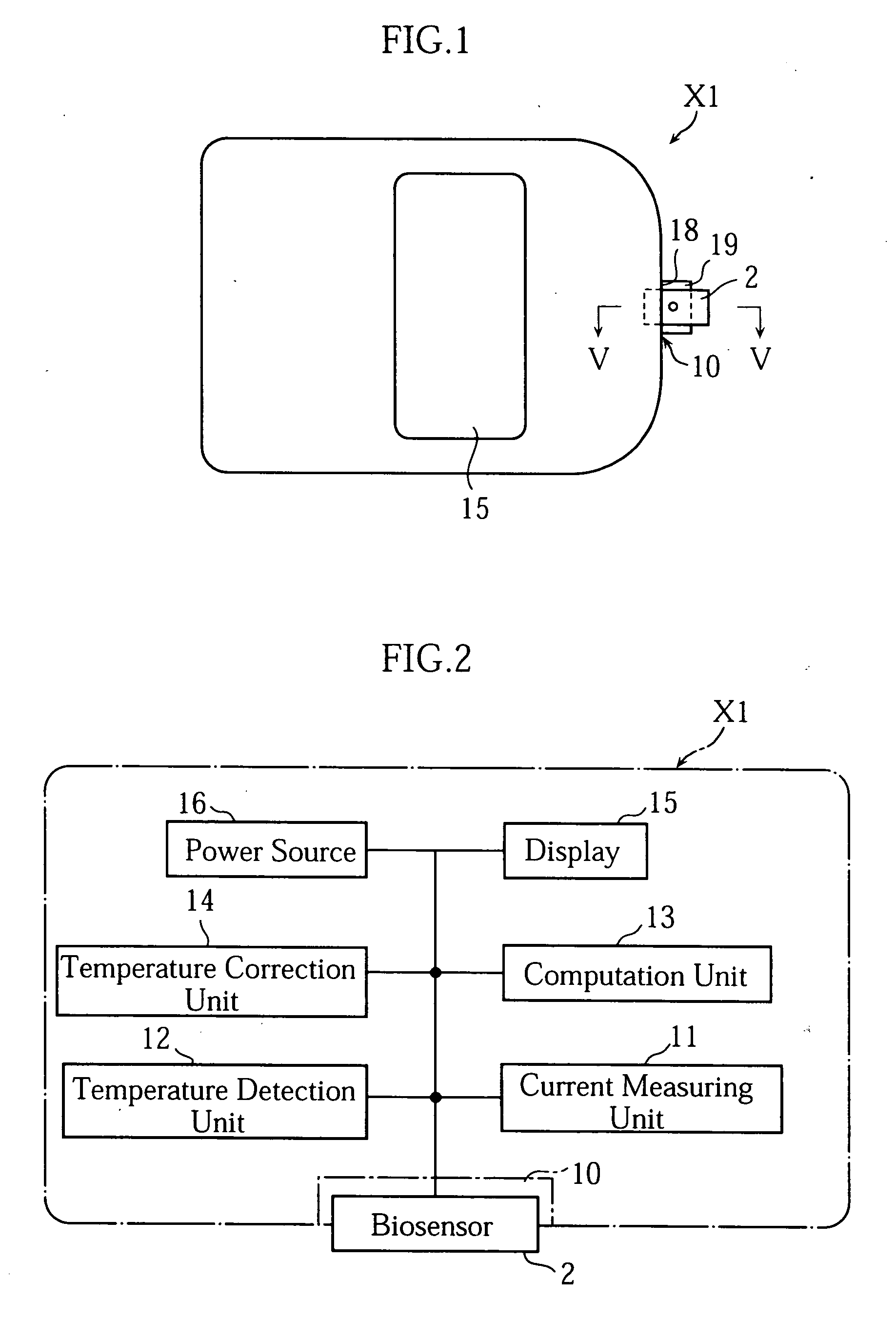

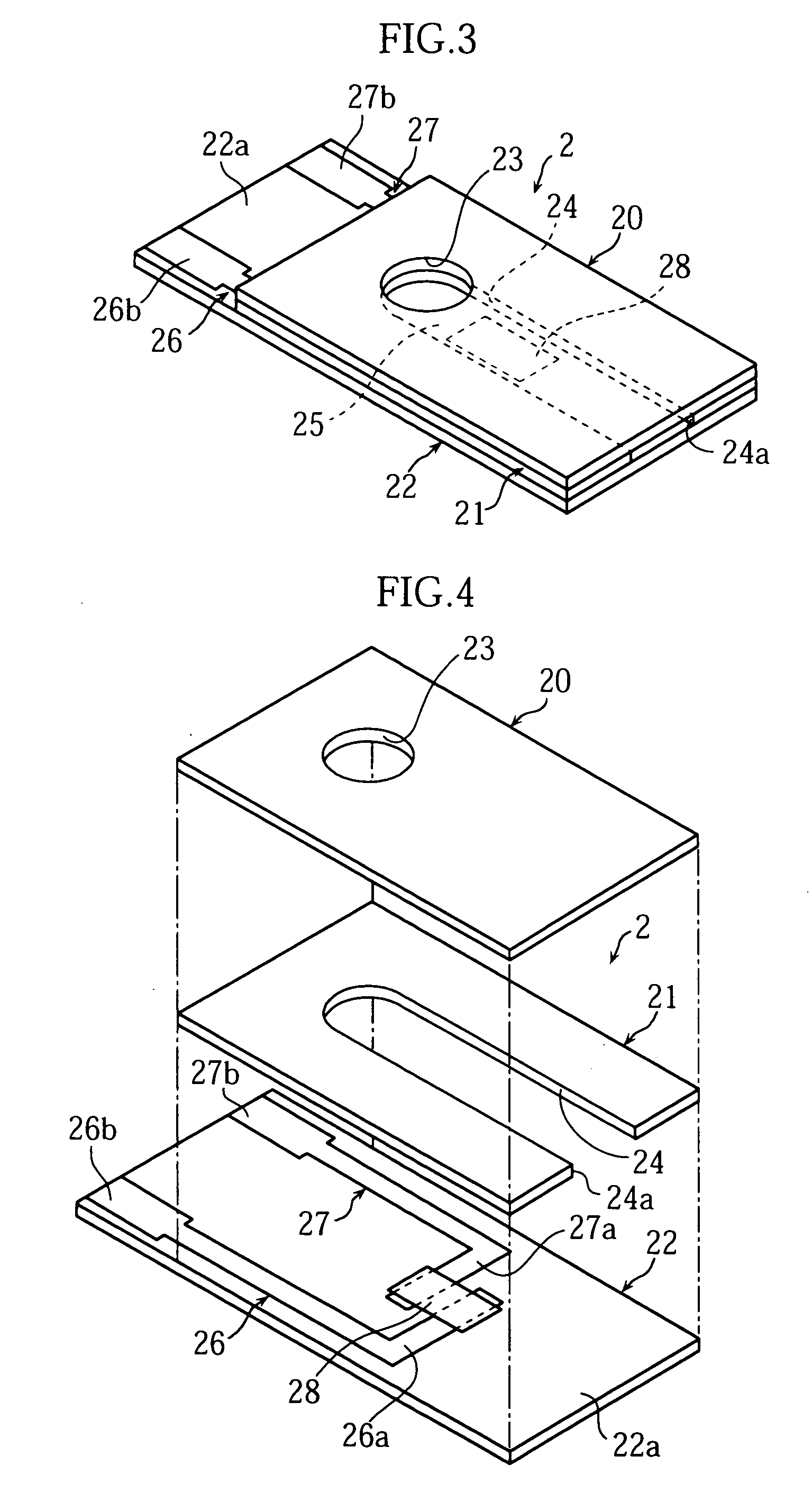

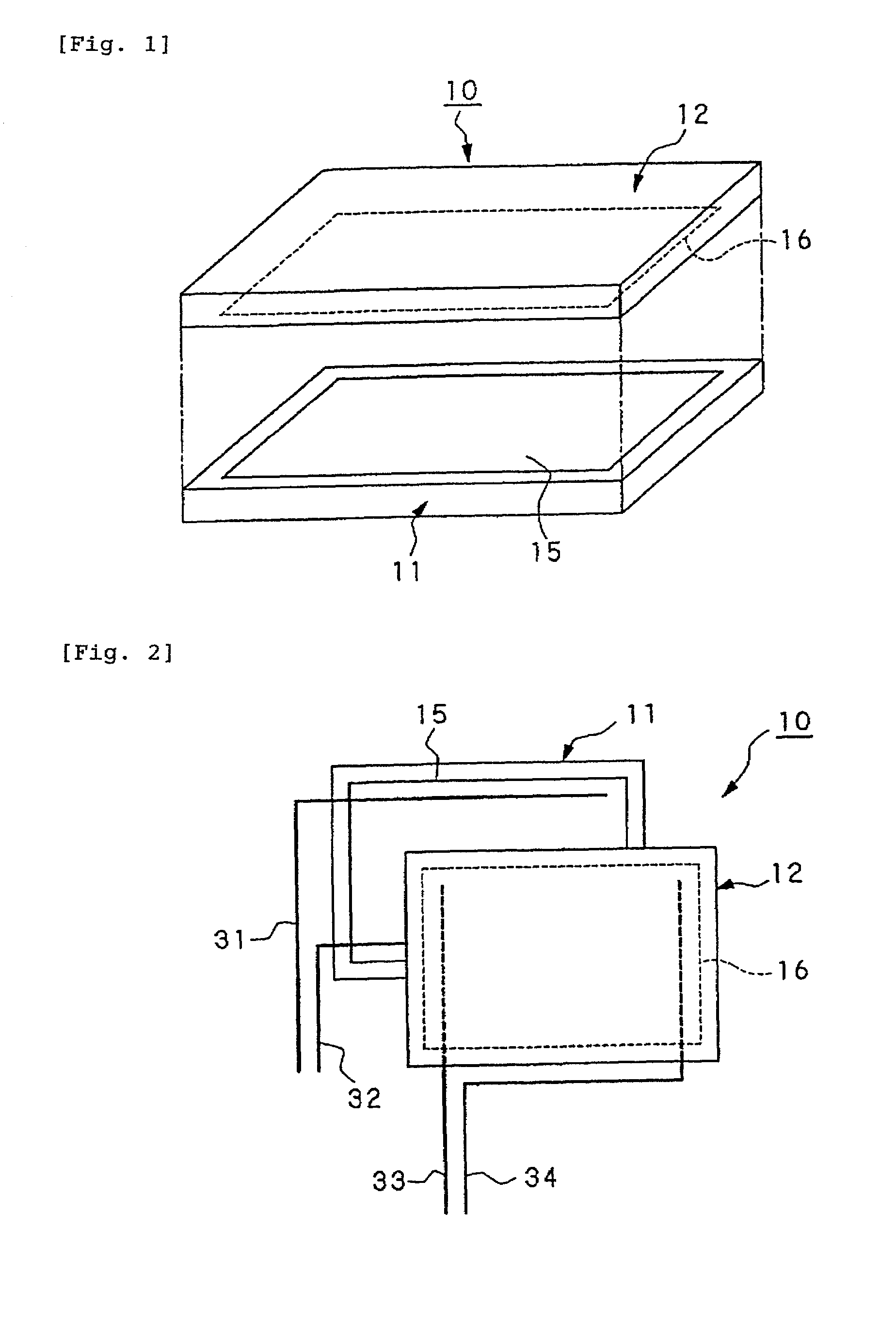

Analyzer having temperature sensor

The present invention relates to an analytical device (X1) including a mounting portion (10) for mounting an analytical tool (2) capable of outputting information for computation, a computation unit for conducting computation for analyzing a sample based on the information for computation, and a temperature detection unit (12) for outputting the temperature information. The temperature detection unit (12) is disposed in the mounting portion (10). The analytical device (X1) preferably further includes a temperature correction unit for correcting the computation results obtained in the computation unit, based on the temperature information. The temperature detection unit (12) includes, for example, a contact type temperature sensor (12A). In this case, the contact type temperature detection unit (12) may include a thermally conductive portion (12B) having a contact surface (12b) to be brought into contact with the temperature sensor (12A) and the analytical tool (2).

Owner:ARKRAY INC

Reprogrammable circuit board with alignment-insensitive support for multiple component contact types

InactiveUS20080143379A1Semiconductor/solid-state device testing/measurementWave amplification devicesSignal conditioningContact type

The present invention is directed to a system that programmably interconnects integrated circuit chips and other components at near-intra-chip density. The system's contact structure allows it to adapt to components with a wide variety of contact spacings and interconnection requirements, the use of releasable attachment means allows component placement to be modified as needed, the system identifies the contacts and the components to facilitate specifying the inter-component connections, and the system provides signal conditioning and retiming to minimize issues with signal integrity and signal skew.

Owner:NORMAN RICHARD

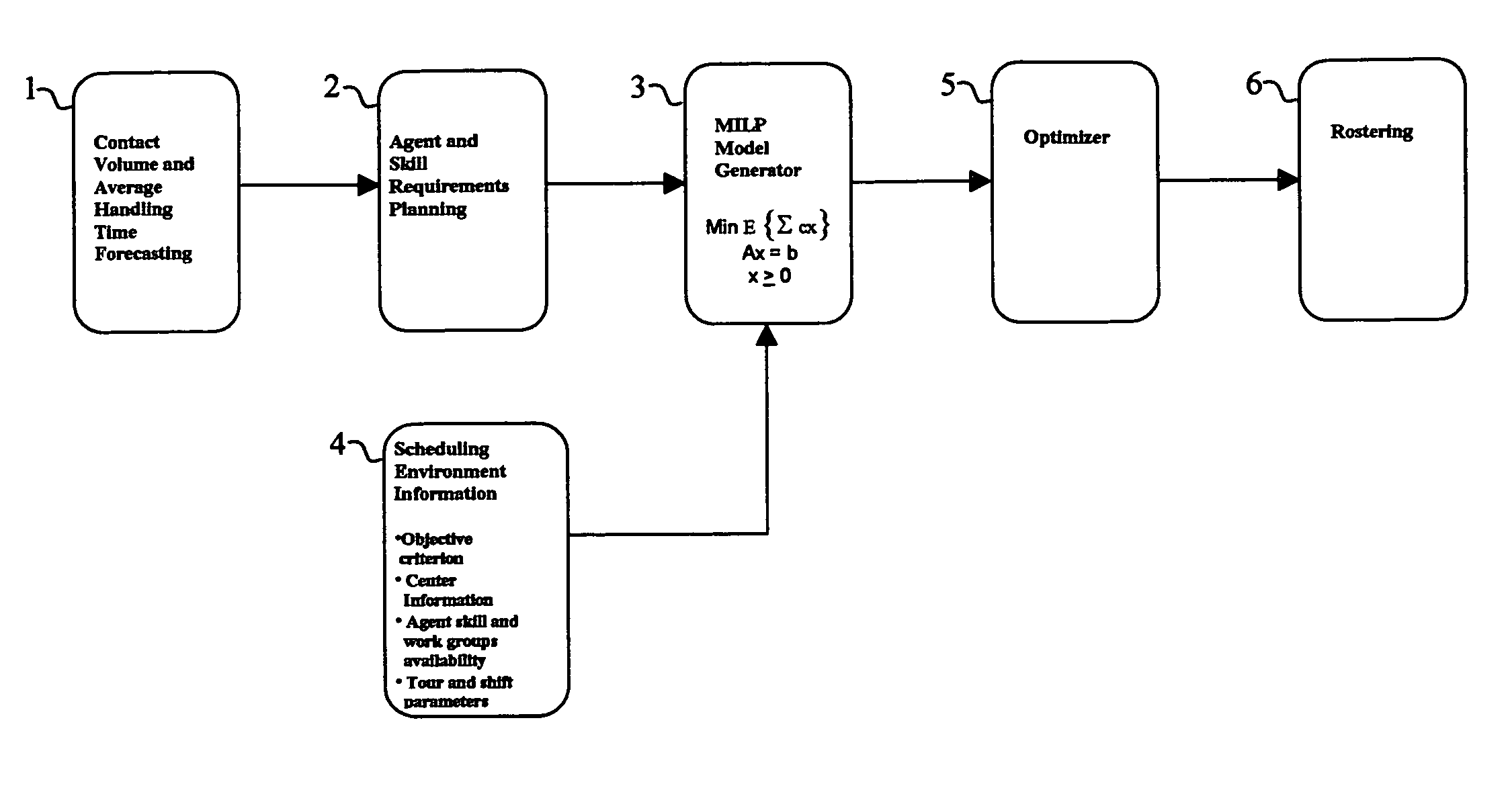

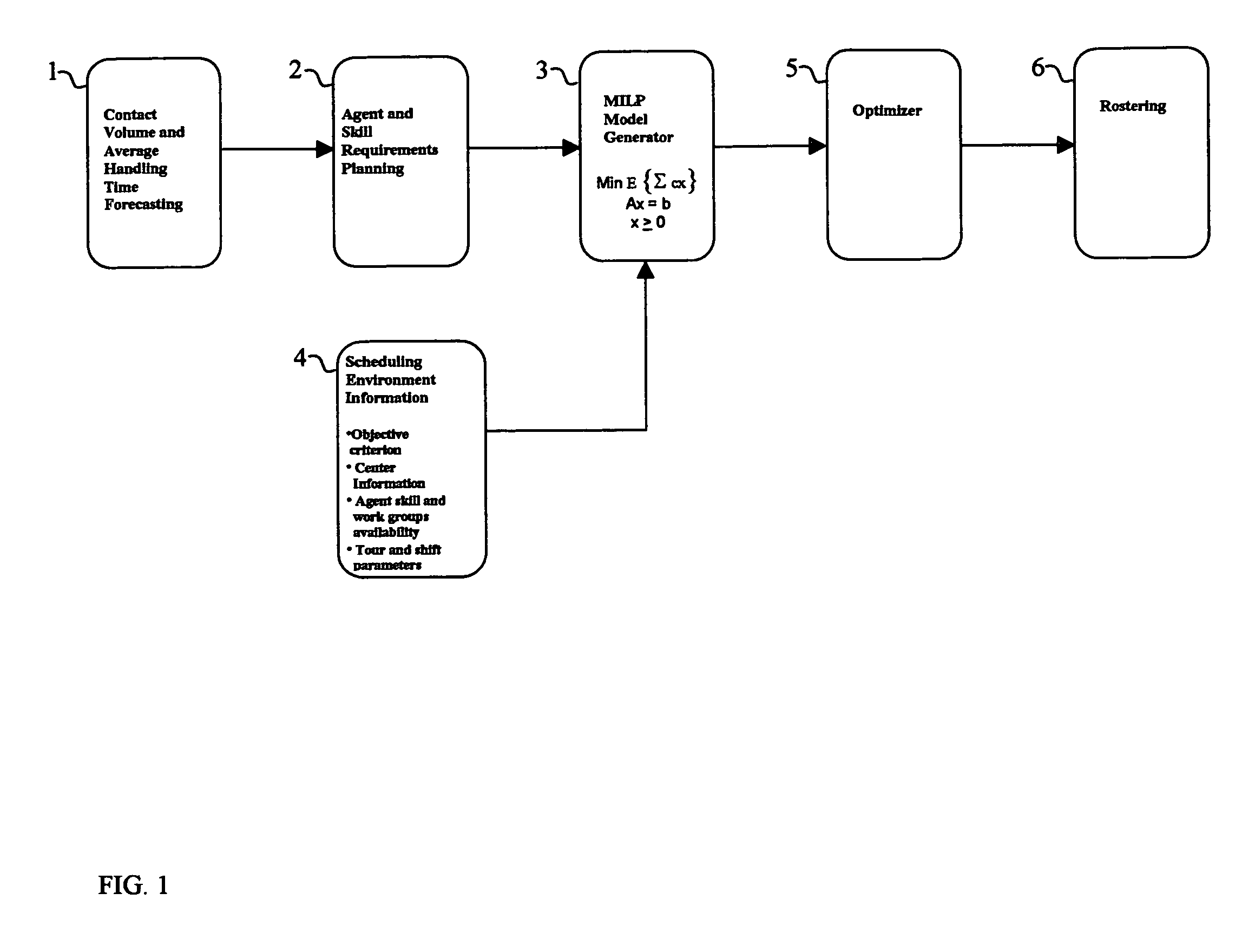

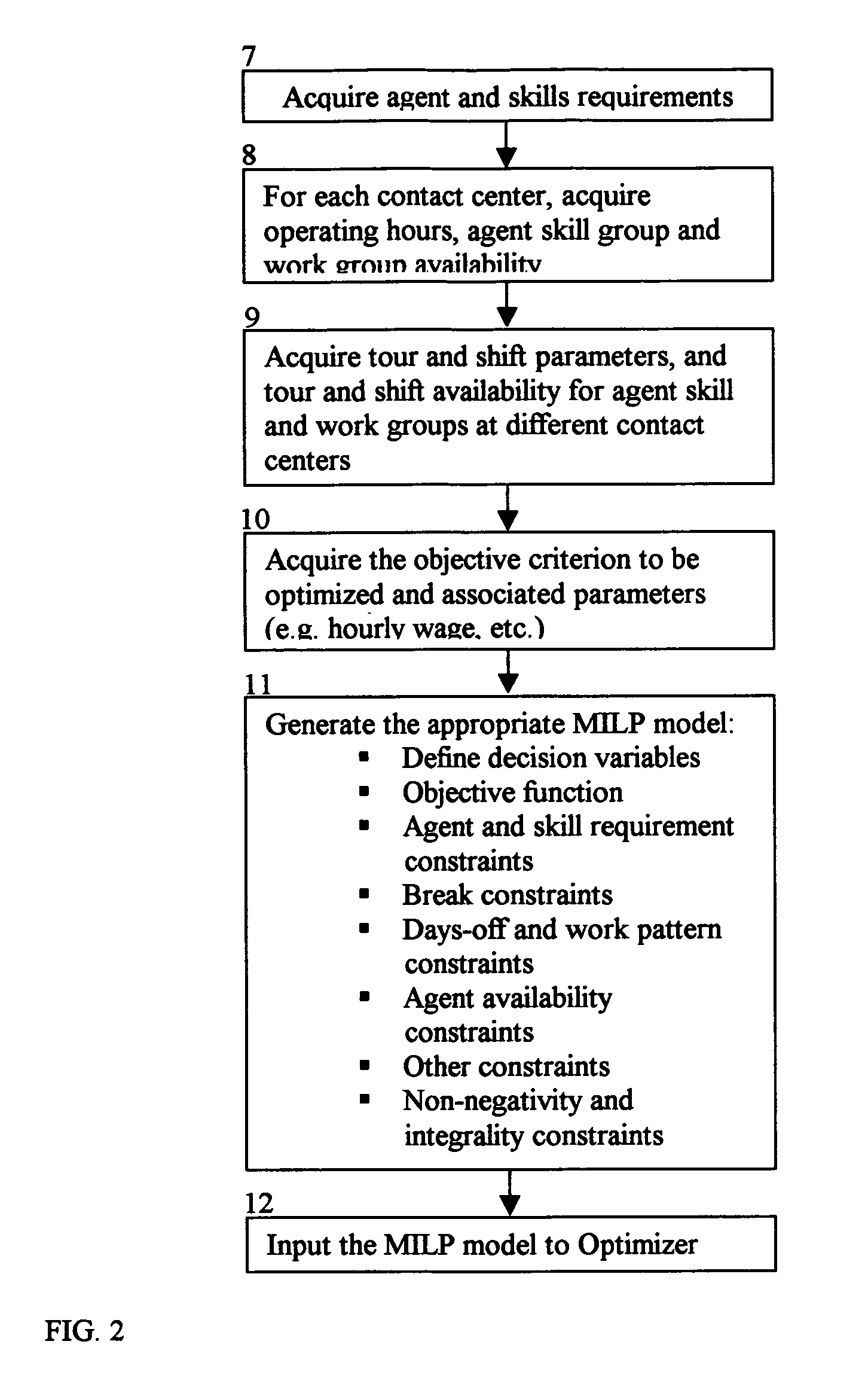

Contact center scheduling using integer programming

ActiveUS7725339B1Easy to solveFavorable objective valueOffice automationSpecial data processing applicationsContact centerWorkforce scheduling

The present invention relates to a method for workforce scheduling in which workload and workload types vary during scheduling period. The method acquires agent and skill requirements for all periods and contact types; acquires the contact center information including agent skill groups, agent work groups, tour and shift scheduling rules, agent availability, objective criterion to be optimized and its parameters; develops a Mixed Integer Linear Programming (MILP) model for the scheduling environment; applied an optimization algorithm that uses the Branch and Bound algorithm with a Rounding Algorithm to improve performance; and locates a globally optimal or near optimal workforce schedule in total cost or paid time or agent satisfaction. Detailed schedules may be developed by assigning daily shifts to work patterns, and breaks scheduled to daily shifts.

Owner:INCONTACT

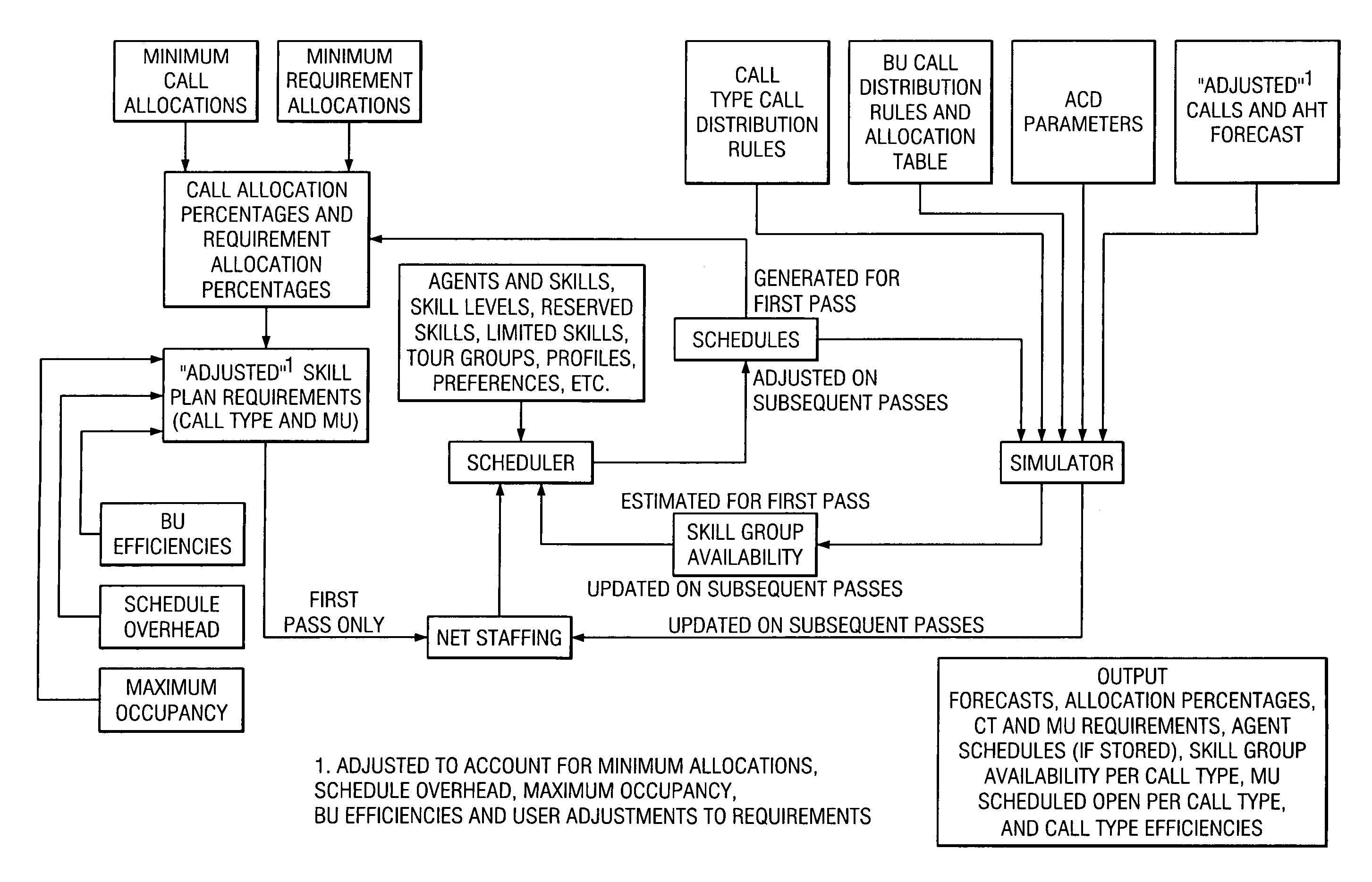

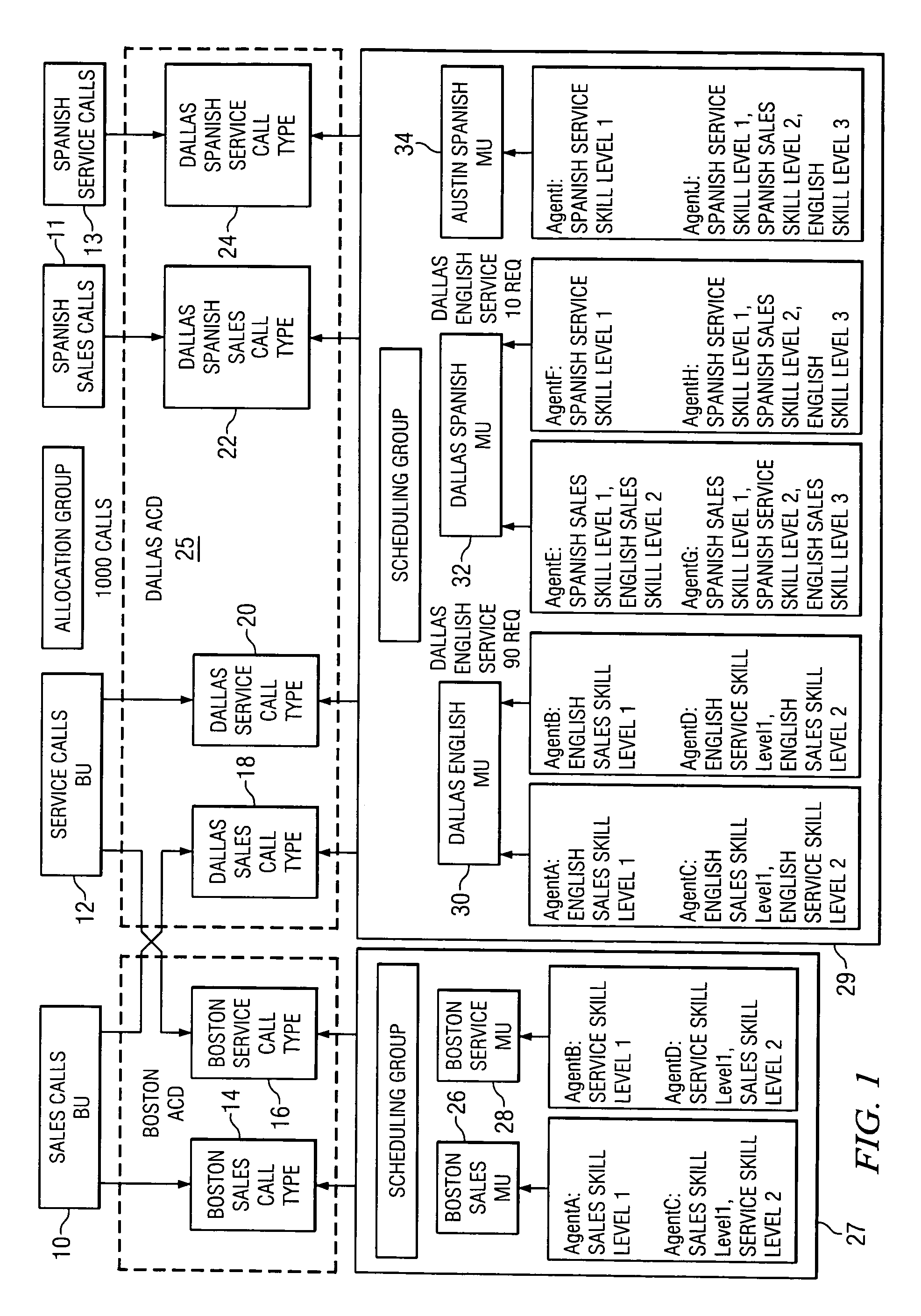

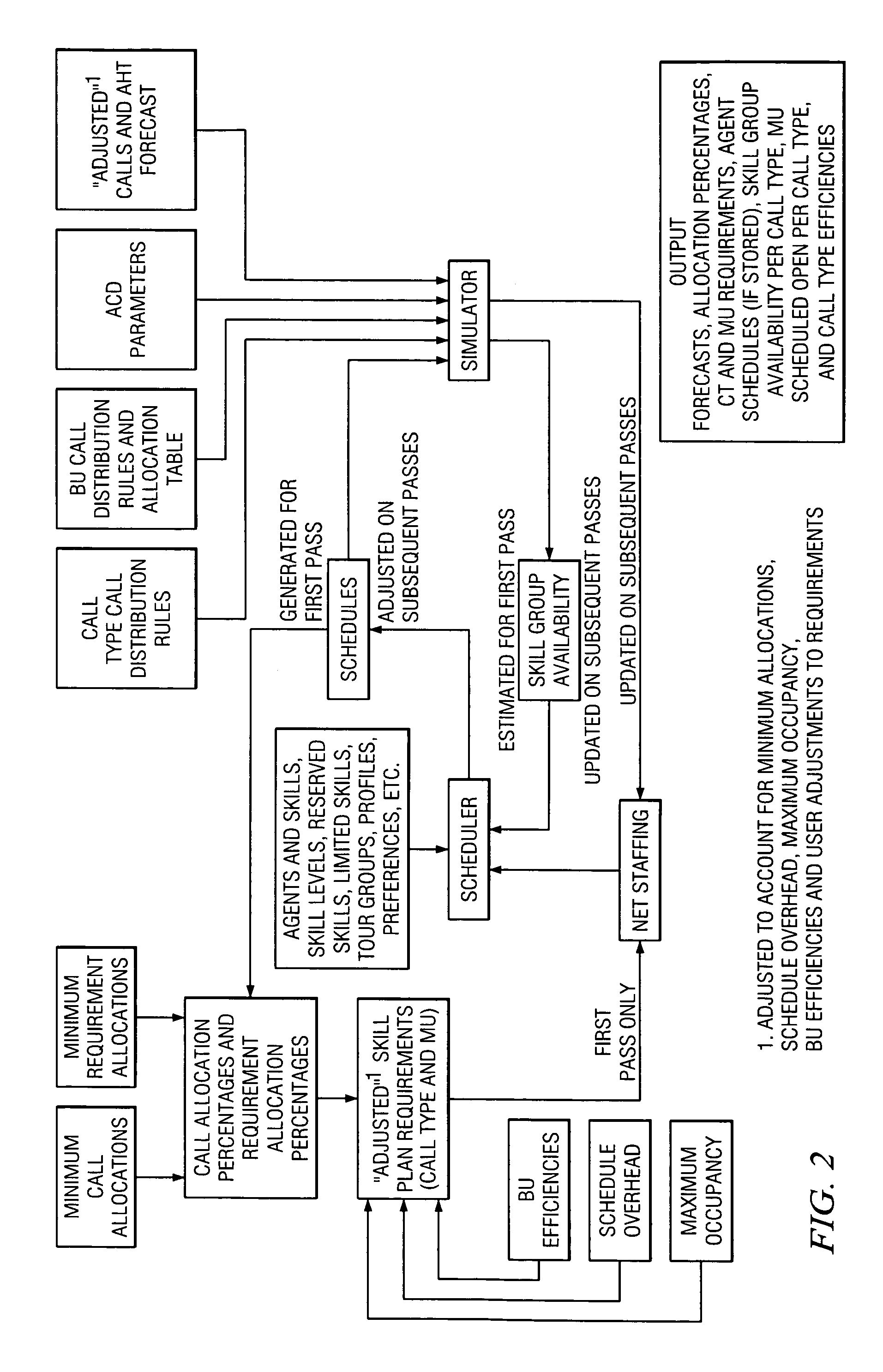

Method and system for skills-based planning and scheduling in a workforce contact center environment

InactiveUS6970829B1Minimum level of skill coverageImprove fitSpecial service provision for substationMultiplex system selection arrangementsMulti siteManagement unit

A method of forecasting, allocating and scheduling in a single or multi-site skills-based contact or call center environment organized into a hierarchy of zero or more business units at a first, upper level, one or more contact types at a second, intermediate level, and one or more management units at a third, lower level. A user creates (a) a set of given contact allocations that define how contacts are distributed from a given business unit to multiple contact types, and (b) a set of given requirement allocations that define how agent requirements are distributed from a contact type to one or more management units. Agent availability by contact type is then predicted to generate agent availability data. Thereafter, forecasted contacts and forecasted agent requirements are allocated based on the given contact and requirement allocations as well as the agent availability data. Preferably, the agent availability data is predicted using a schedule simulator and is characterized by contact type for agents in the same skill group.

Owner:IEX CORP

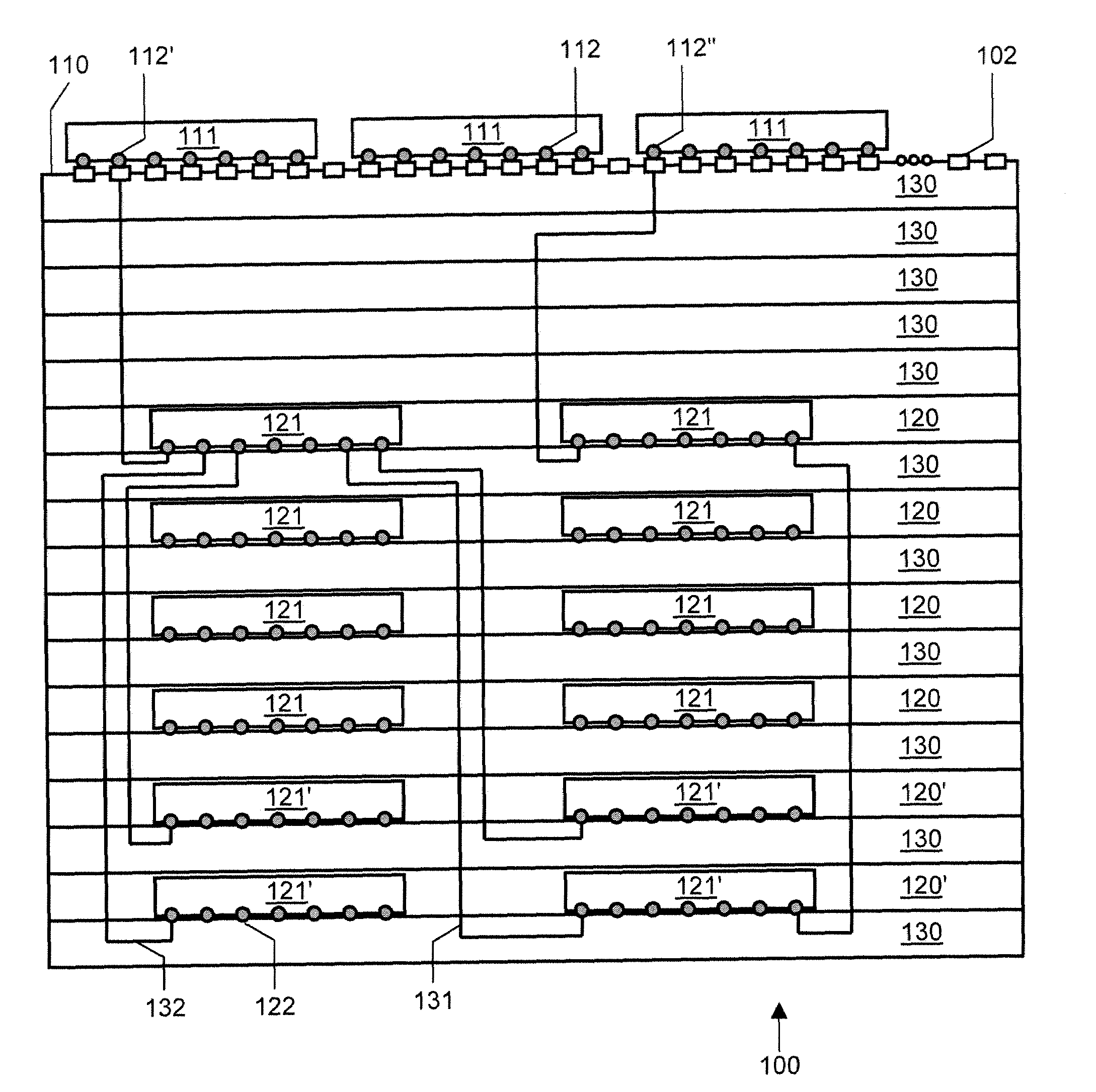

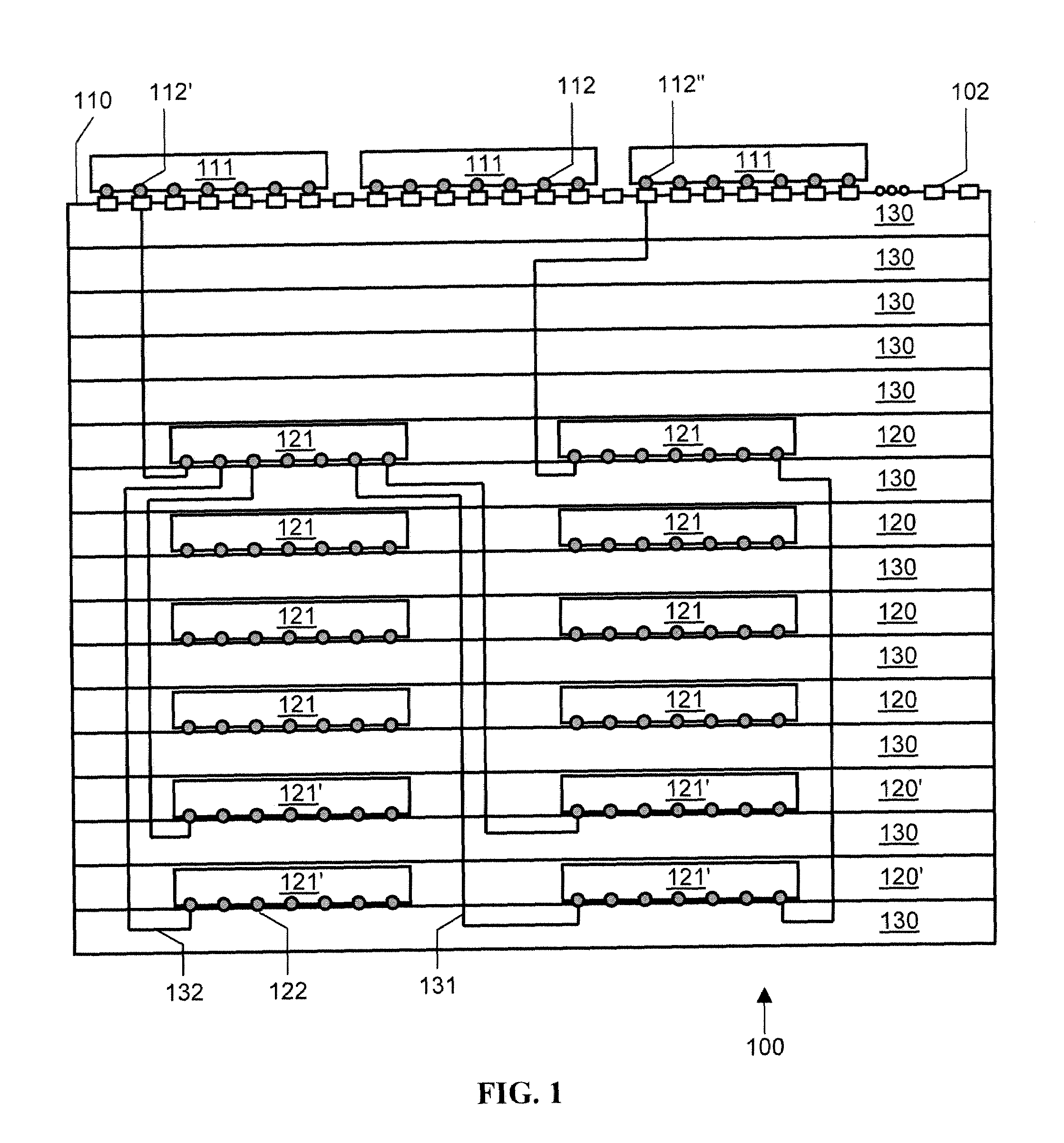

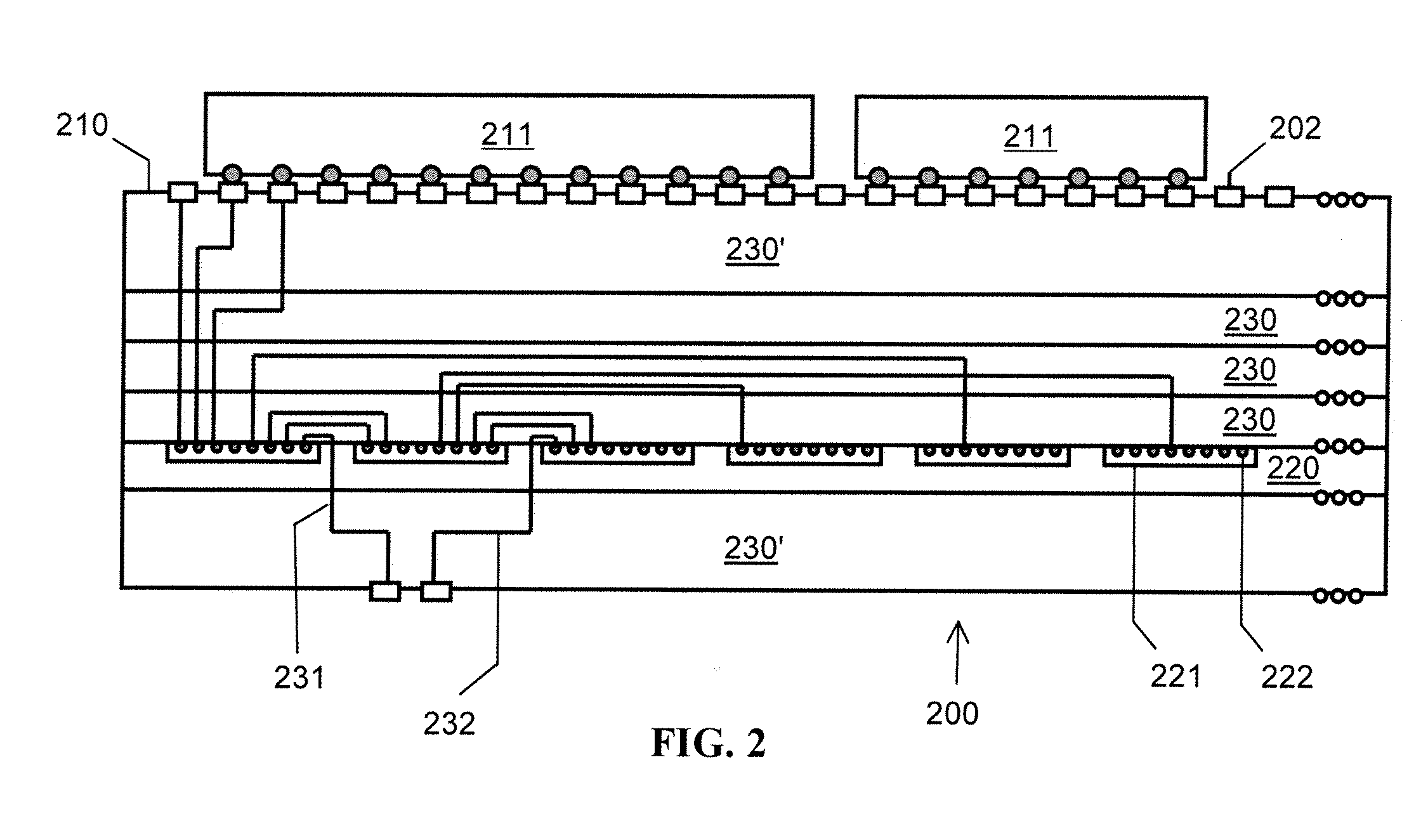

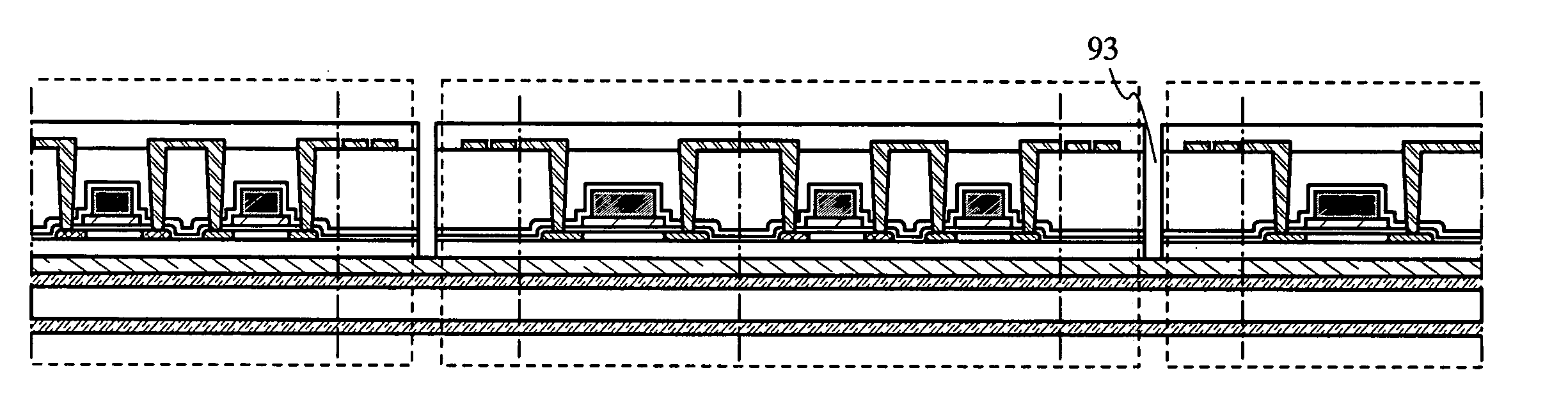

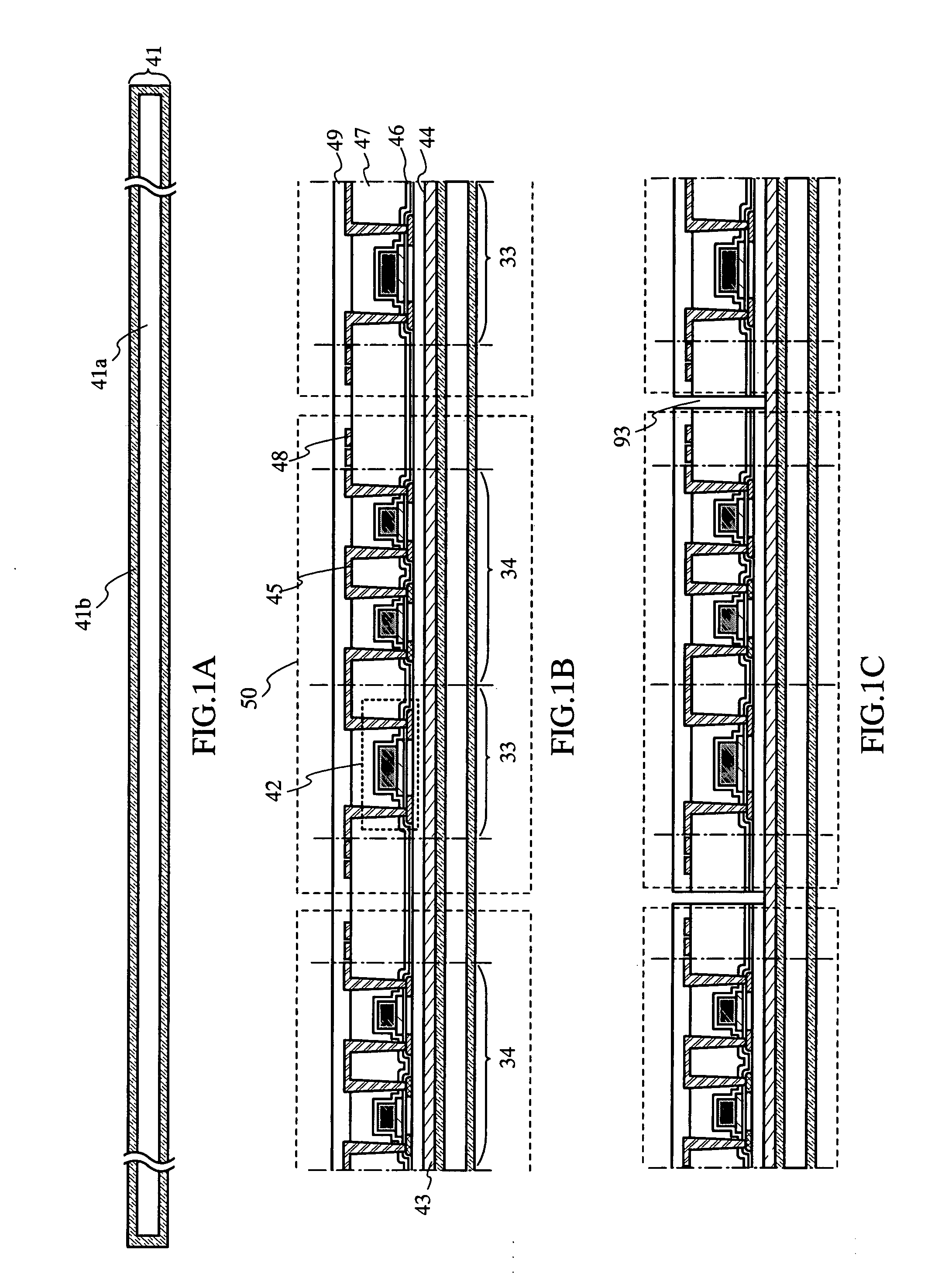

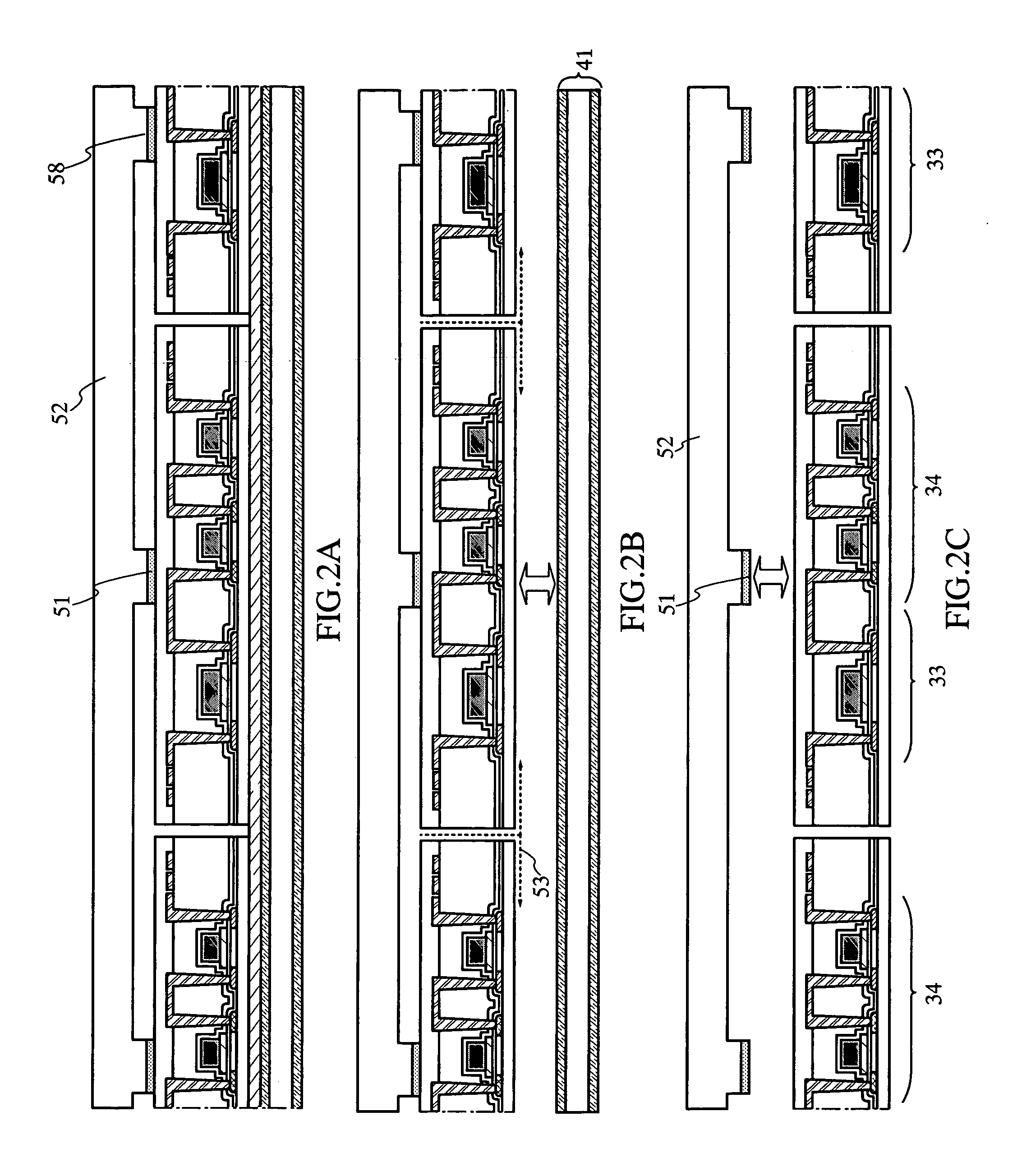

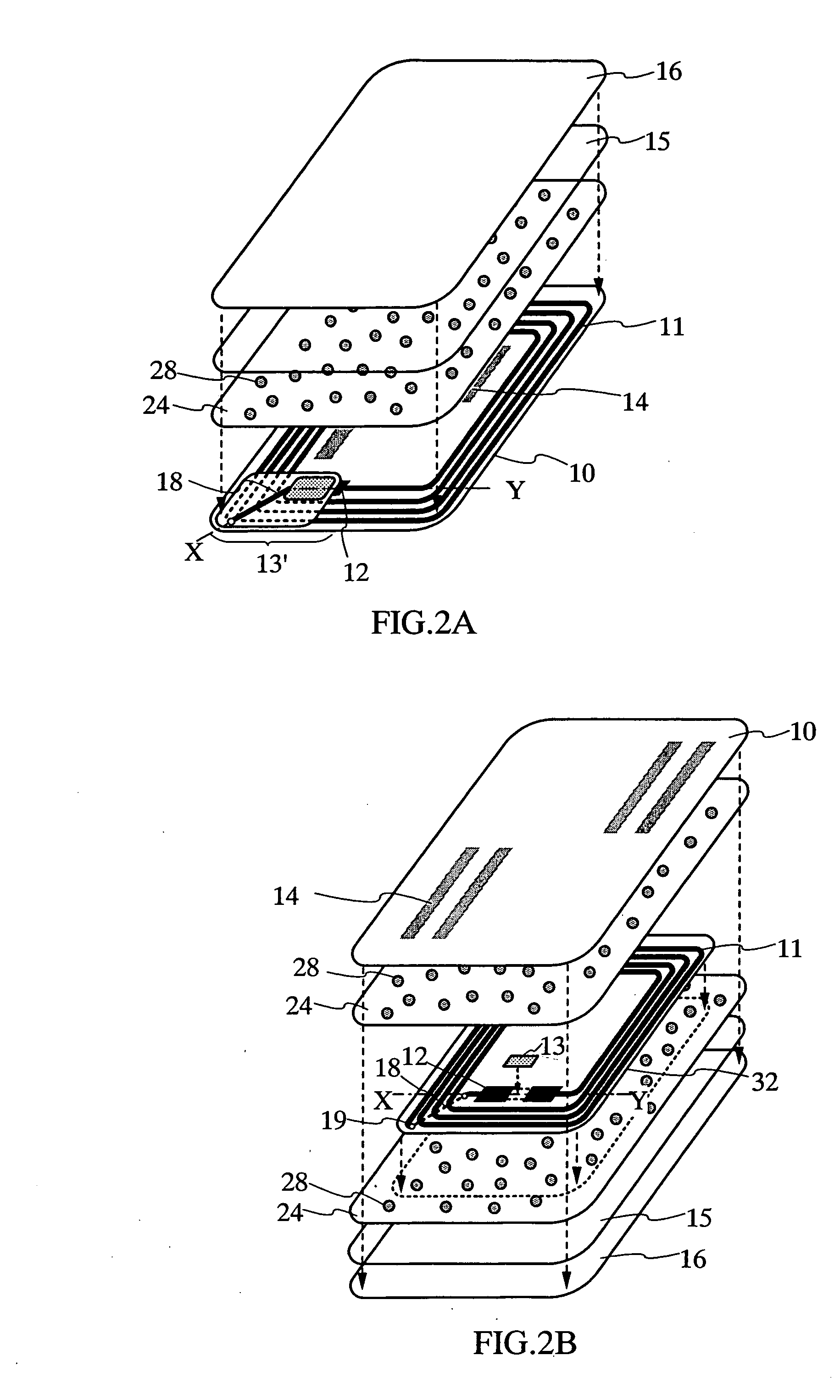

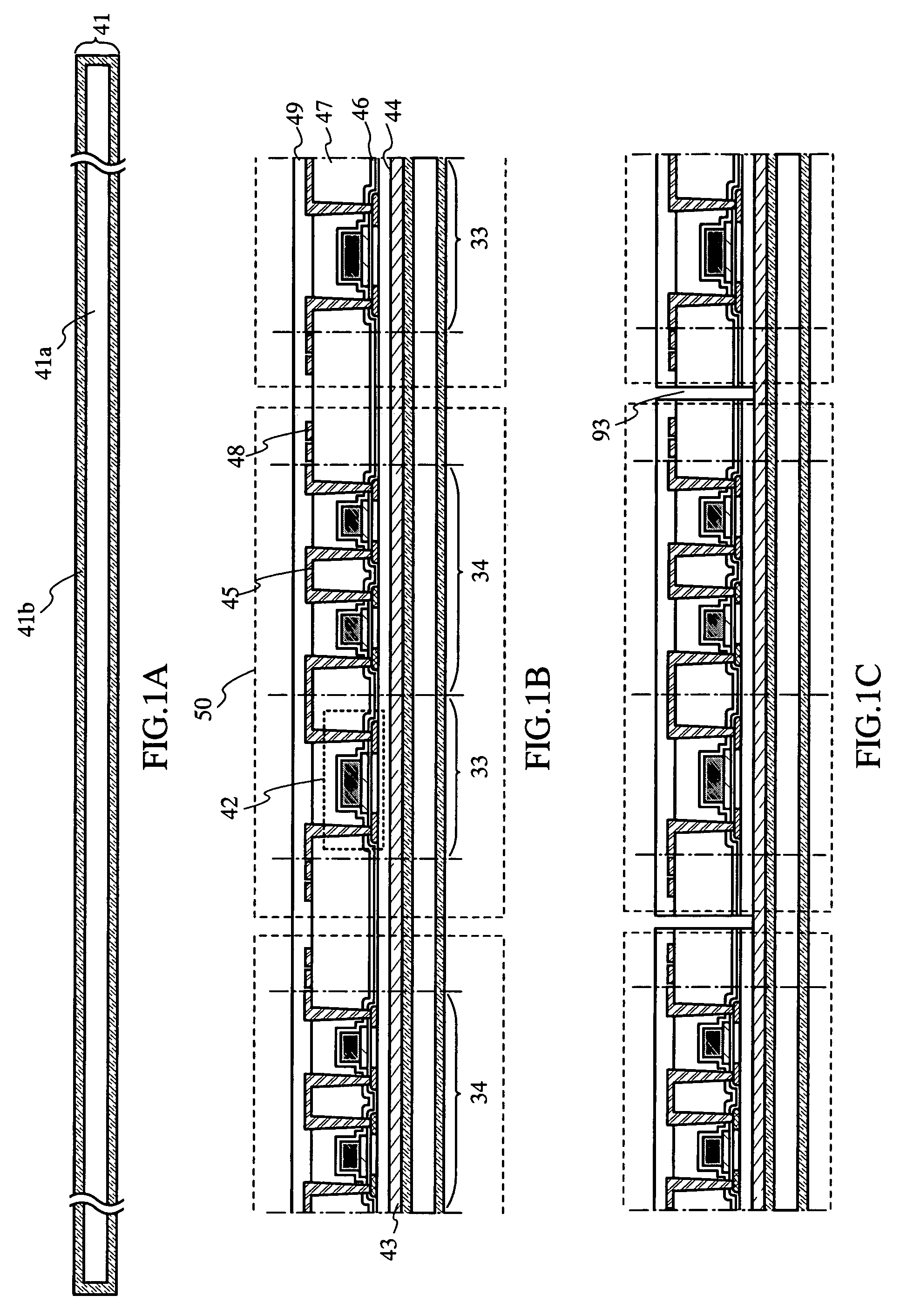

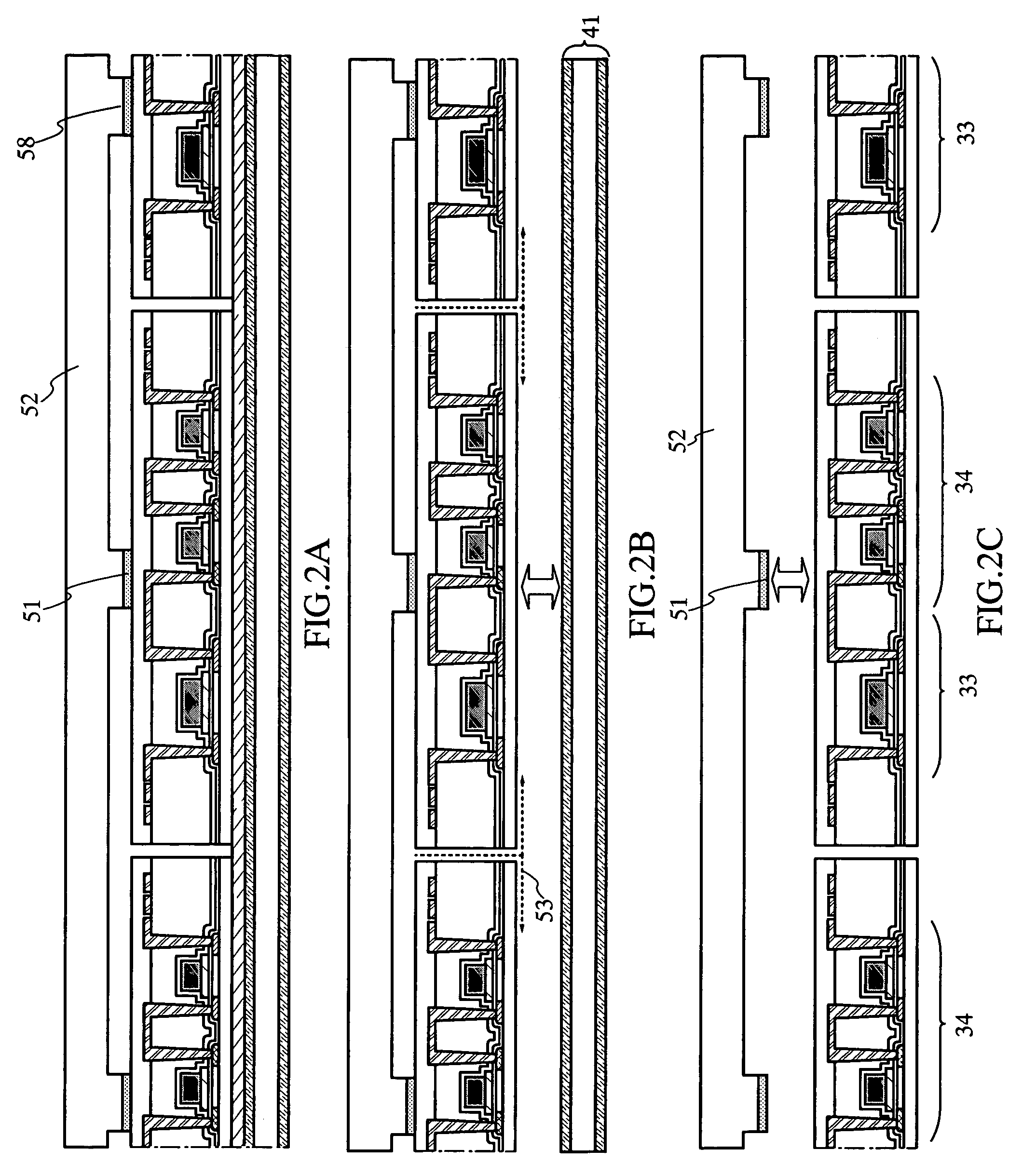

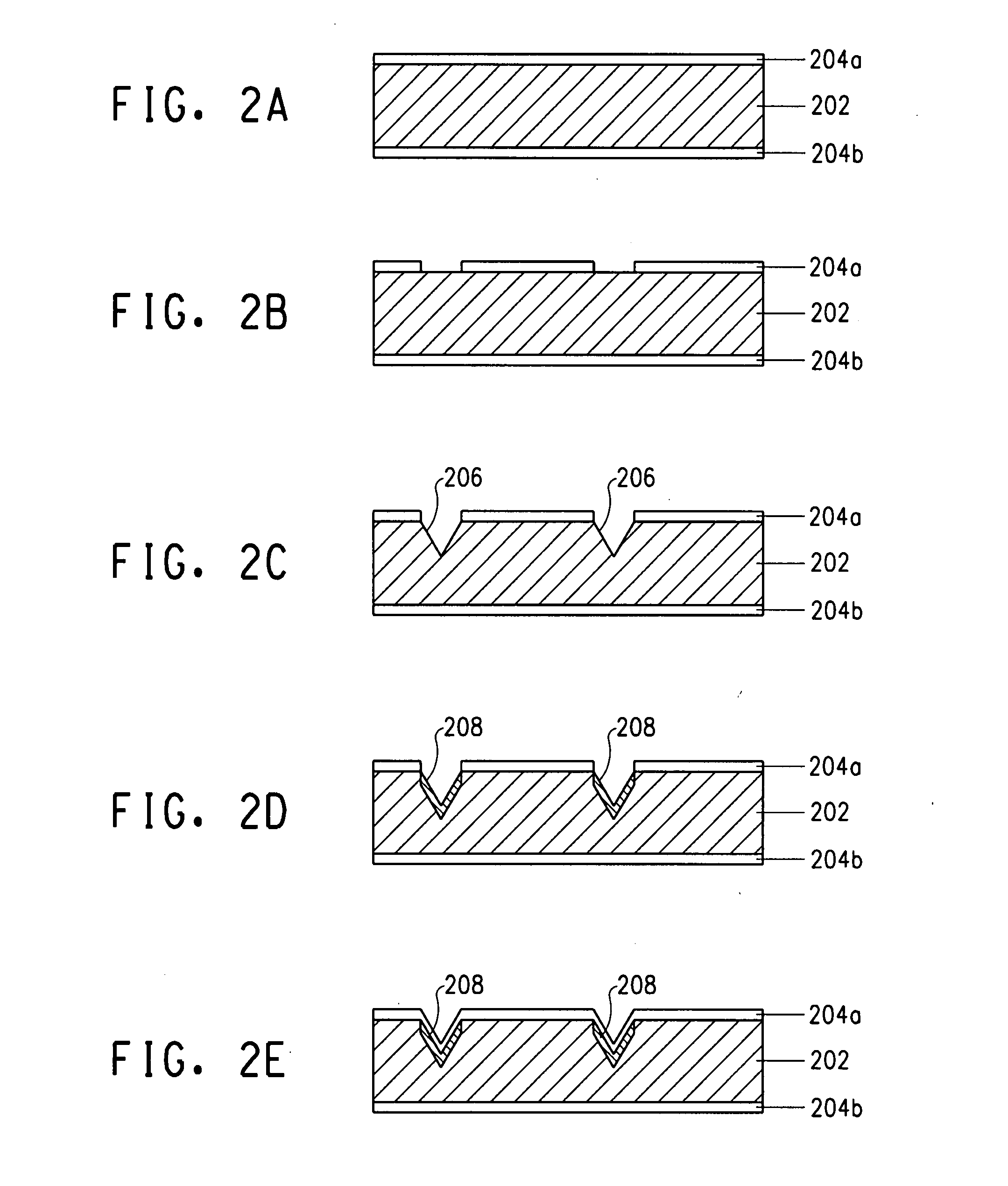

Manufacturing method of thin film integrated circuit device and manufacturing method of non-contact type thin film integrated circuit device

InactiveUS20050148121A1Easy to disassembleEfficient use ofSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyContact type

With non-contact and contact IC chips becoming common, it is necessary to mass-produce enormous amount of IC chips, which are utilizable for human beings, animals and plants, commercial products, banknotes, and the like, at low cost. For example, it is necessary to manufacture IC chips to be applied to commercial products, banknotes, and the like at a cost of 1 to several yen per IC chip, preferably, at a cost less than 1 yen, and it is desired to realize a structure of an IC chip that can be mass-produced at low cost and a manufacturing process of the IC chip. A method of-manufacturing a thin film integrated circuit device according to the present invention includes steps of forming a peel-off layer over a thermally oxidized silicon substrate, forming a plurality of thin film integrated circuit devices over the peel-off layer with a base film interposed therebetween, forming a groove between the plurality of thin film integrated circuit devices, and separating the plurality of thin film integrated circuit devices by introducing one of a gas and a liquid including halogen fluoride into the groove to remove the peel-off layer.

Owner:SEMICON ENERGY LAB CO LTD

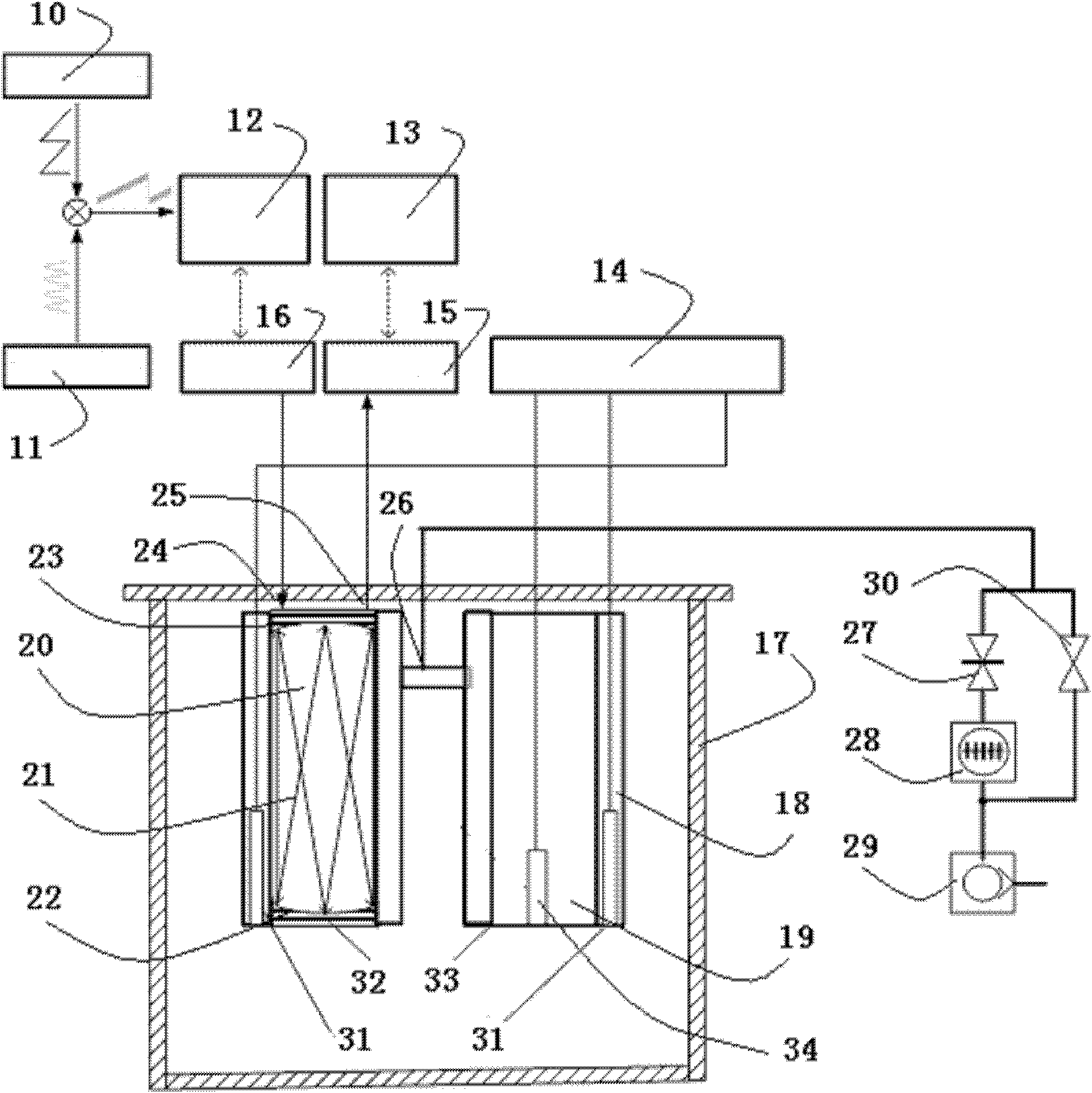

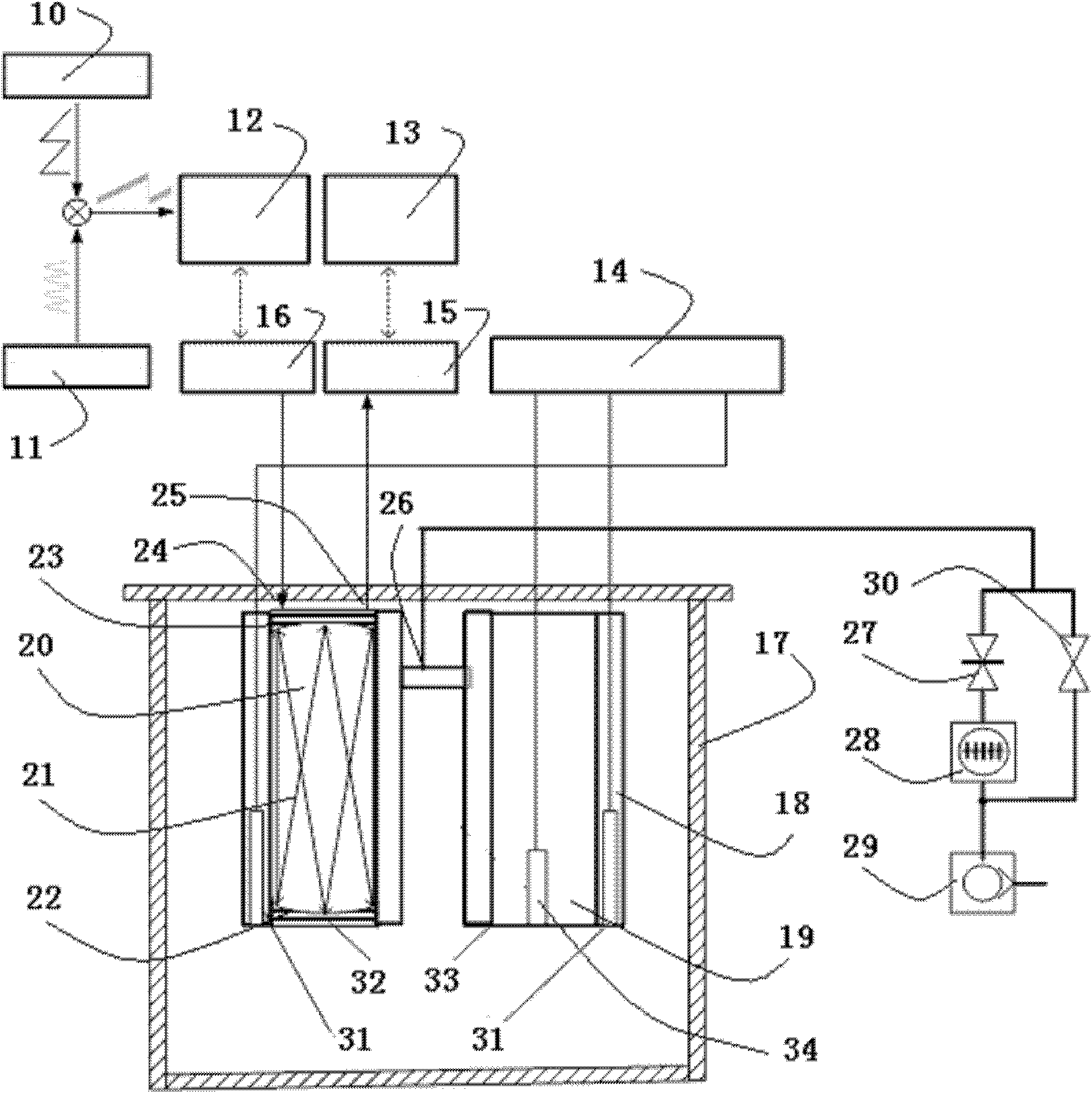

Temperature measurement and calibration platform in space vacuum environment

ActiveCN102539019ASolve the problem of large differences in measurement resultsSolve the traceability problemThermometer testing/calibrationVacuum pumpingSpace environment

The invention relates to a temperature measurement and calibration platform in space vacuum environment. The temperature measurement and calibration platform is favorable for realizing the simultaneous calibration of contact type temperature measurement and non-contact type temperature measurement, so the temperature measurement and calibration platform is served for heat vacuum and heat balance experiments of spacecrafts such as satellites, spaceship and the like. The temperature measurement and calibration platform comprises a constant temperature bath, wherein a double-sub-cavity vacuum cavity, the double-sub-cavity vacuum cavity comprises a first vacuum cavity body and a second vacuum cavity body, the first vacuum cavity body and the second vacuum cavity body are connected with a vacuum pumping device through a three-way valve, standard temperature indicator sensors are respectively arranged on the outer wall of the first vacuum cavity body and on the outer wall of the second vacuum cavity body, the standard temperature indicator sensors are connected with a temperature secondary meter, a laser light path reflecting device is arranged in the vacuum cavity of the first vacuum cavity body for calibrating a non-contact type temperature measuring system based on the tunable diode laser absorption spectrum technology, and the vacuum cavity of the second vacuum cavity body is used for accommodating a temperature sensor for calibrating a contact type temperature measuring system adopting the temperature sensor.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

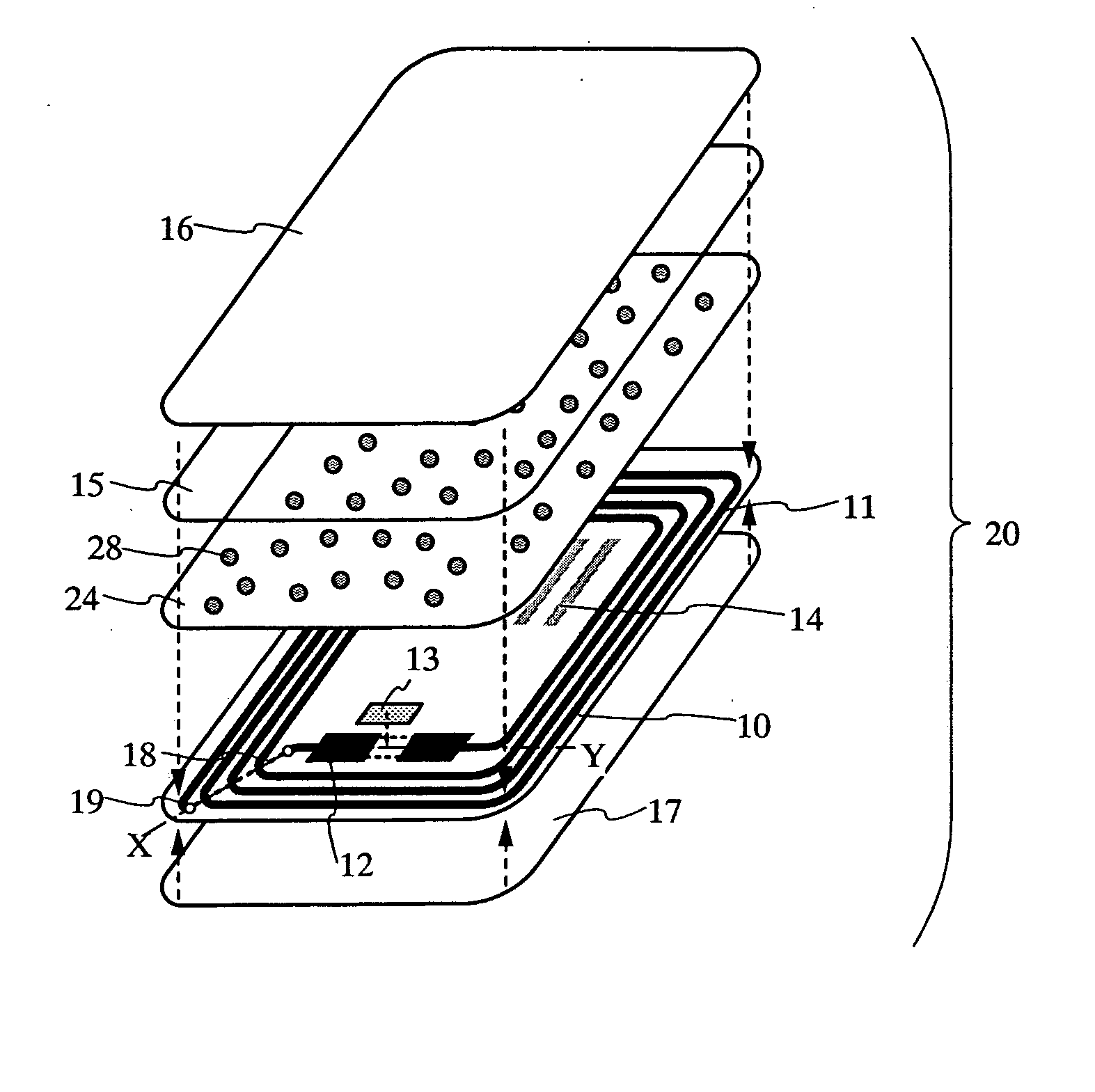

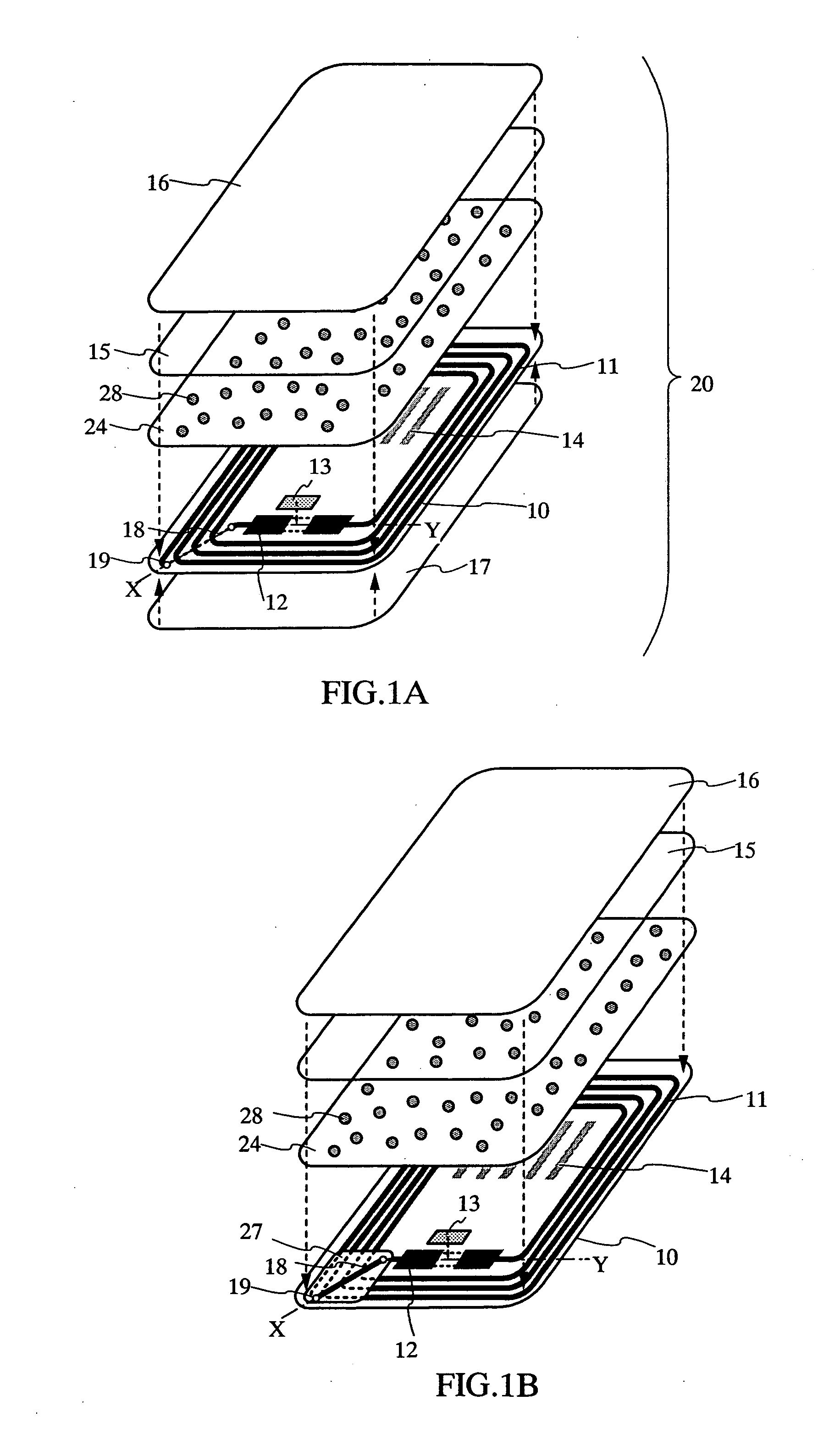

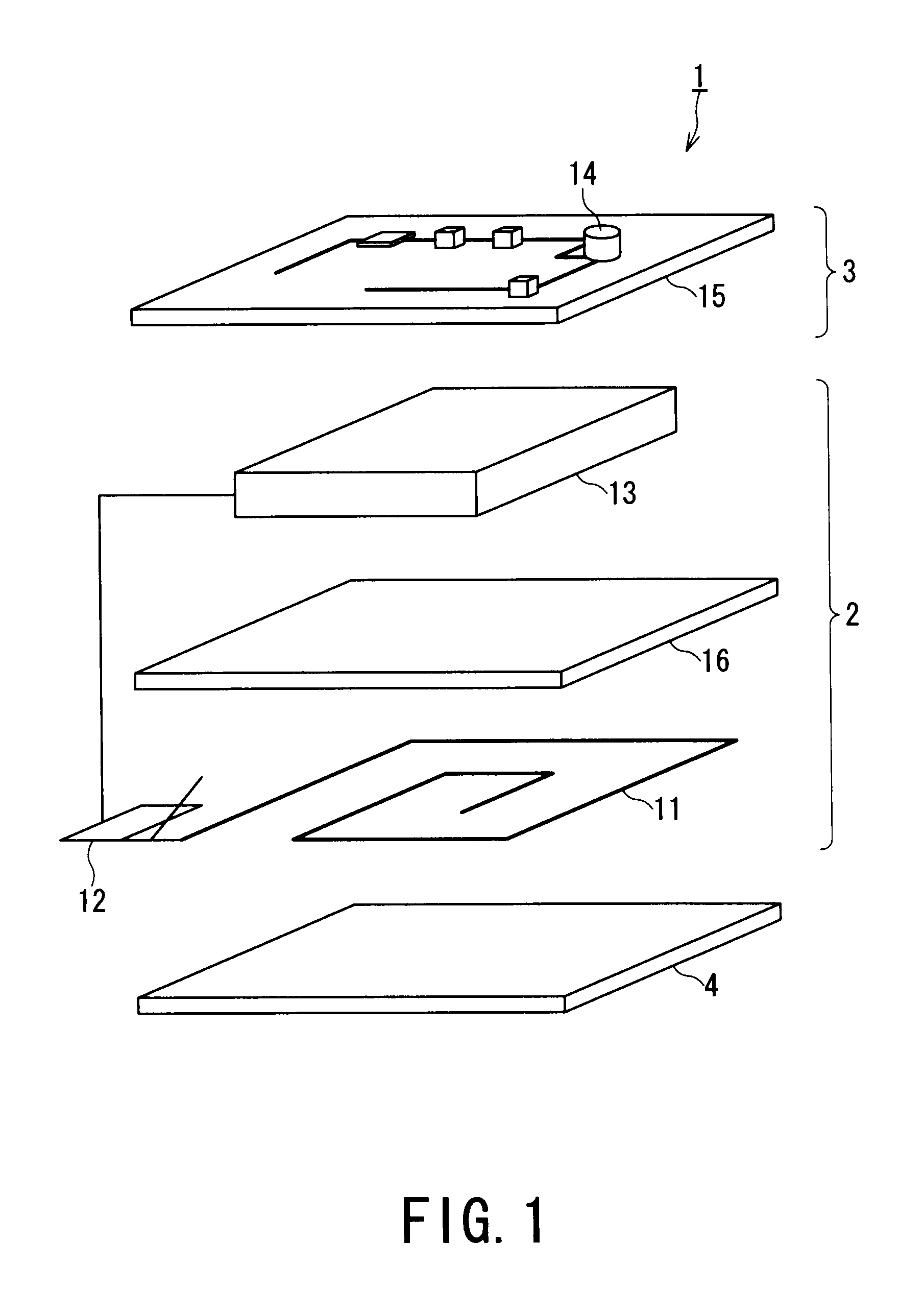

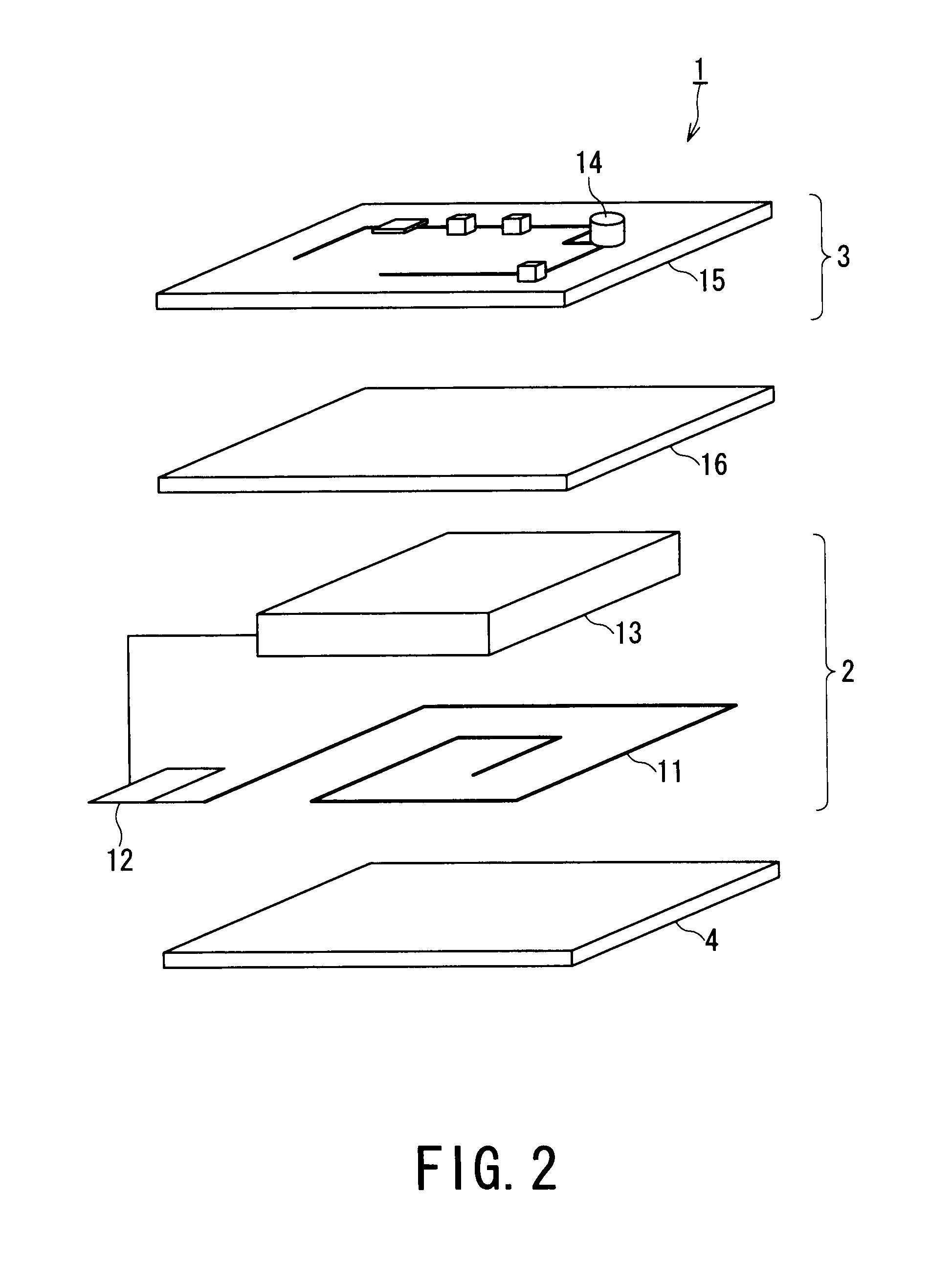

ID label, ID tag, and ID card

InactiveUS20050168339A1Lower Reliability RequirementsReduce yieldRecord carriers used with machinesBurglar alarm by hand-portable articles removalEngineeringThermal expansion

In commercial products to which a non-contact type or contact type ID label or ID tag is attached and ID cards, there is fear that, due to a difference between coefficients of thermal expansion between an antenna for communication and a resin provided around the antenna, stress is applied to the resin with the larger coefficient of thermal expansion to break the resin. This contributes to decrease in manufacturing yield, lifetime, and reliability of an ID label or the like. In an article such as an ID label, an ID tag, and an ID card according to the present invention, a filler is included in a filling layer provided around an antenna forming an ID label, an ID tag, and an ID card so that the difference in coefficient of thermal expansion between the antenna and the filling layer can be reduced. This makes it possible to ease generation of stress due to the difference in coefficient of thermal expansion and prevent peeling and cracks of the filling layer.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of thin film integrated circuit device and manufacturing method of non-contact type thin film integrated circuit device

InactiveUS7271076B2Low costSemiconductor/solid-state device detailsSolid-state devicesEngineeringContact type

A method of manufacturing a thin film integrated circuit device according to the present invention includes steps of forming a peel-off layer over a thermally oxidized silicon substrate, forming a plurality of thin film integrated circuit devices over the peel-off layer with a base film interposed therebetween, forming a groove between the plurality of thin film integrated circuit devices, and separating the plurality of thin film integrated circuit devices by introducing one of a gas and a liquid including halogen fluoride into the groove to remove the peel-off layer.

Owner:SEMICON ENERGY LAB CO LTD

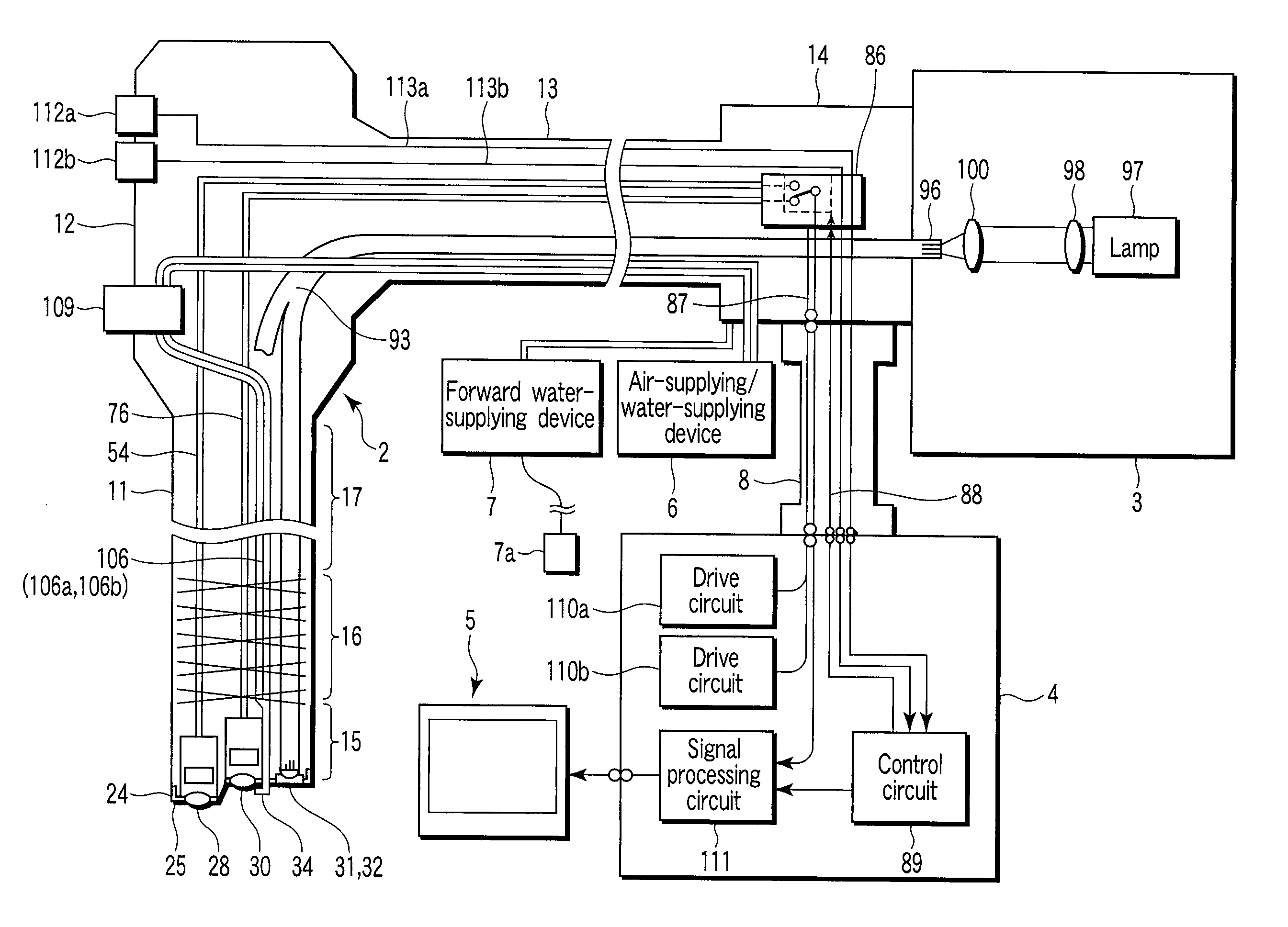

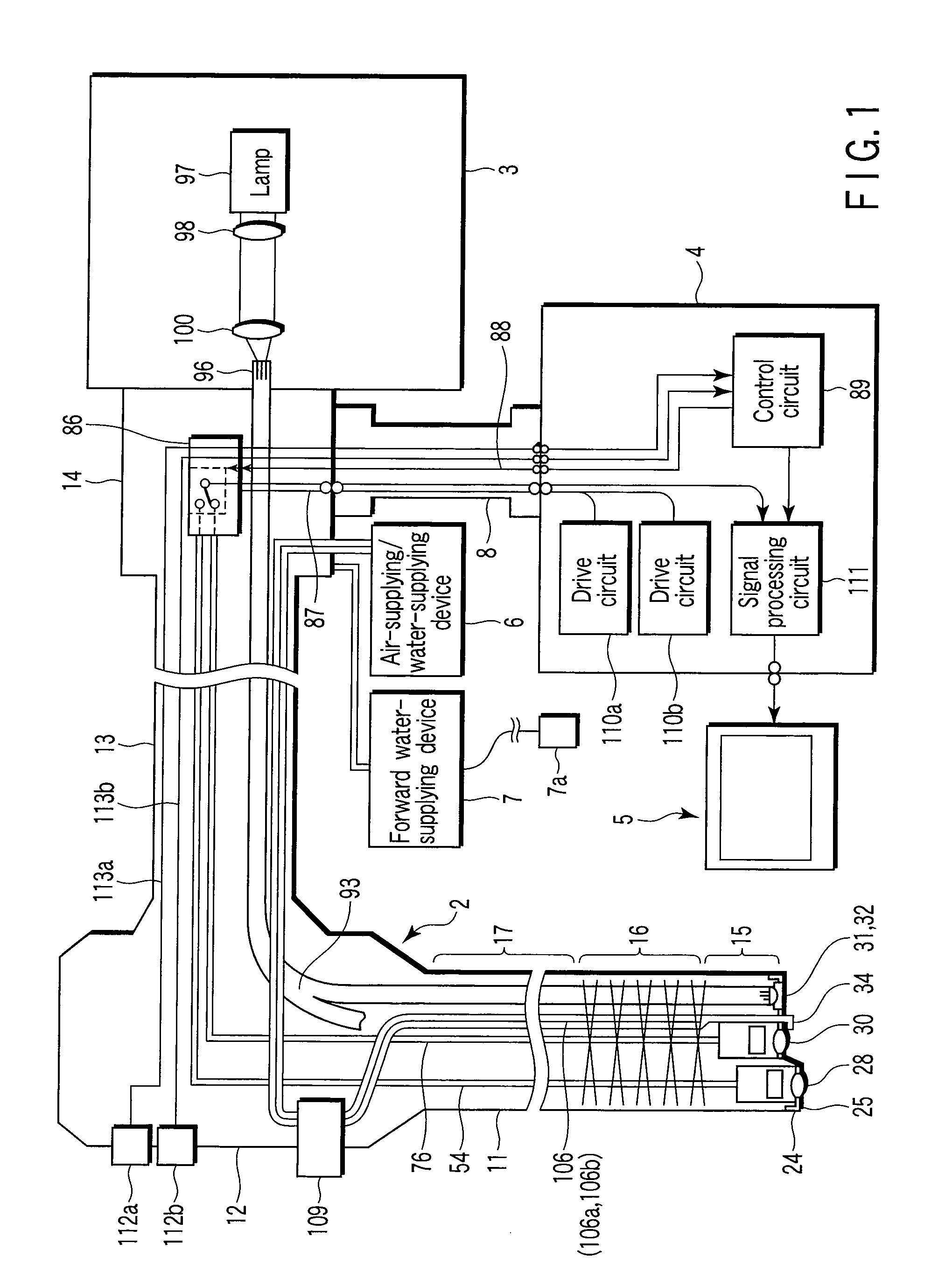

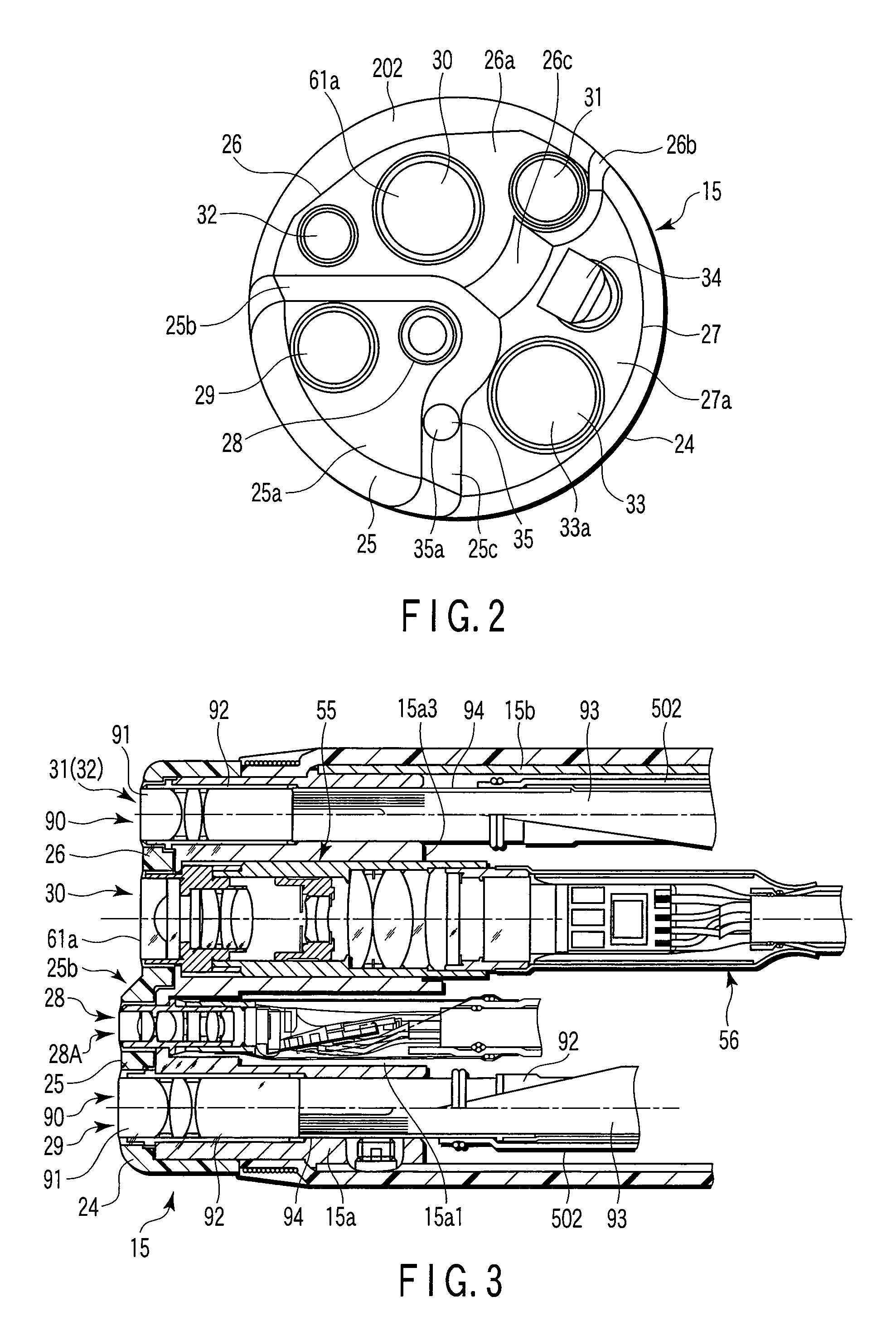

Distal end portion of endoscope

InactiveUS20090253966A1Reduce the possibilityEasy to implementSurgeryEndoscopesDistal portionContact type

An air-supplying / water-supplying nozzle for delivering fluid to a second imaging unit for observing a body to be examined which is provided at a distal end portion of an insertion portion to be inserted into a body to be examined in a projecting manner is provided on a non-projecting face of the insertion portion, the non-projecting portion being disposed at a position lower than a flat face of a middle step portion on which the second imaging unit is disposed. Thereby, such a possibility can be reduced that an opening portion of the air-supplying / water-supplying nozzle is caught by an object to be examined and observation or diagnosis work conducted using an observation optical system of an object-contacting type can be conducted.

Owner:OLYMPUS MEDICAL SYST CORP

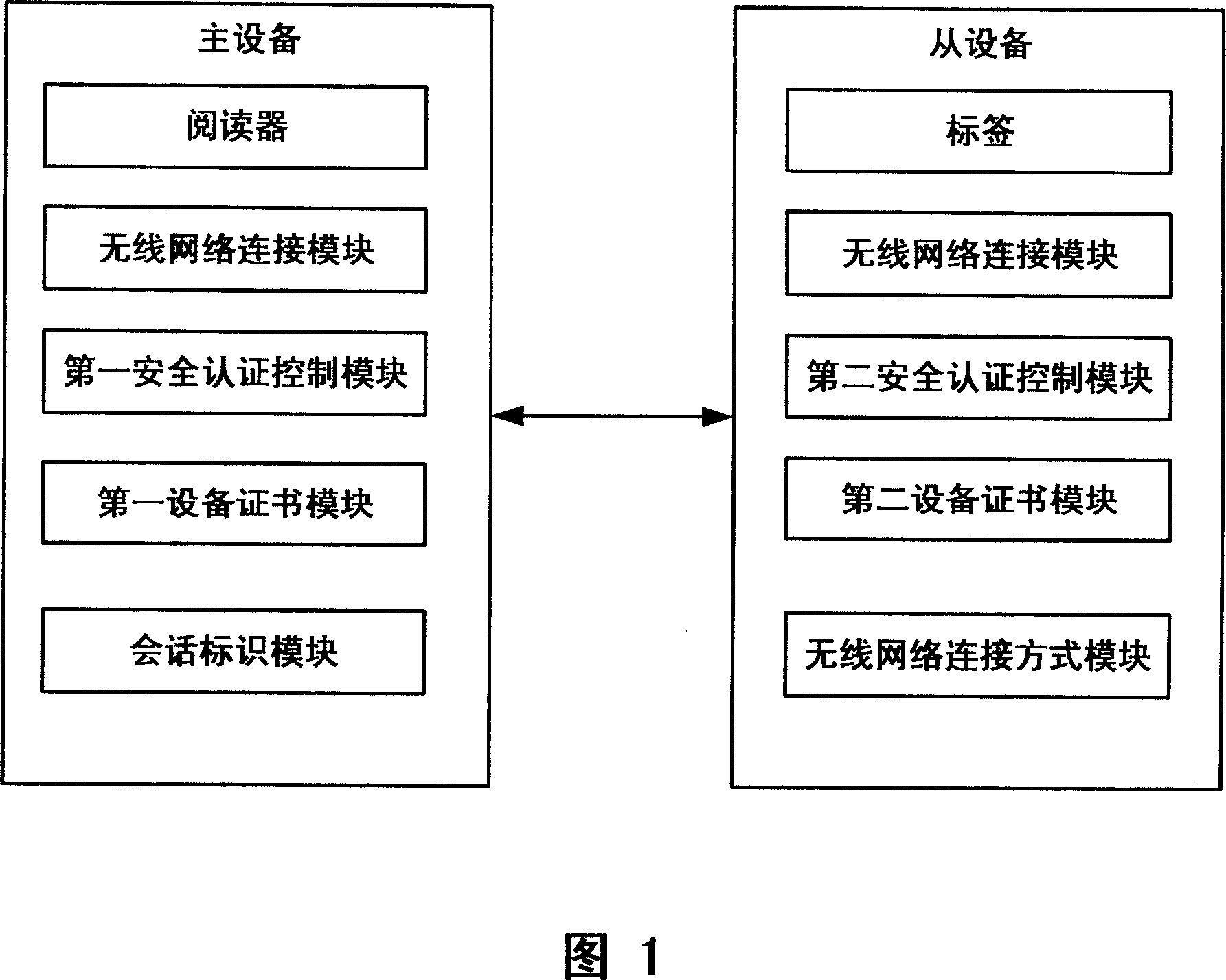

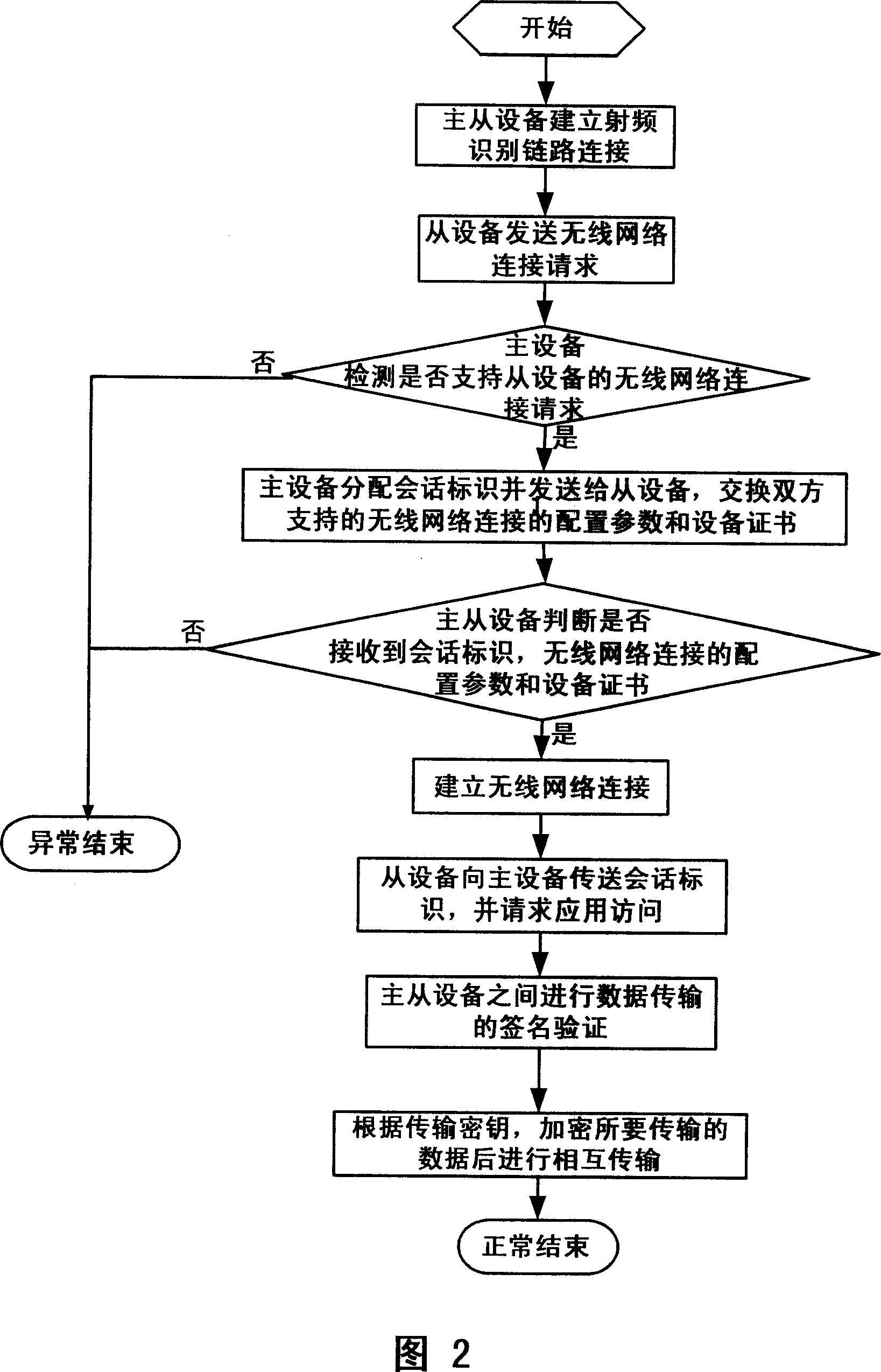

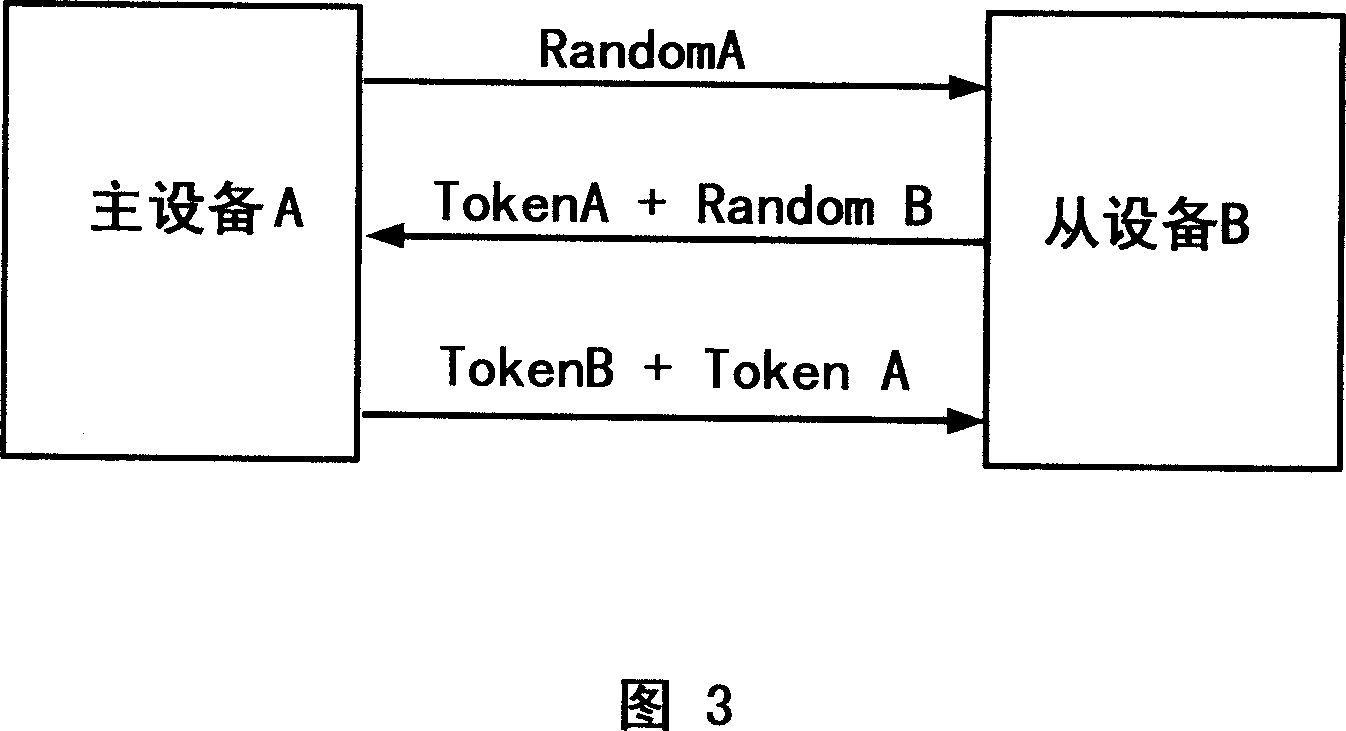

Safety authentication system, apparatus and method for non-contact type wireless data transmission

ActiveCN101114901AReduced usabilityImprove securityNear-field transmissionPublic key for secure communicationContact typeUsability

The invention discloses a system, a device and a method of a non-contact wireless data transmission safety certification. The method comprises the following steps that: when the examination of a main equipment enters a short-range RF-induced (radio frequency) area from the equipment, a radio frequency identification link connection is built between the main equipment and a slave equipment; then the safety certification parameter of the wireless network connection supported by both the main and the slave equipments is exchanged; then the main and the slave equipments judges whether the safety certification parameter is successfully received or not; if so, the wireless network connection is built; if not, users are prompted to restart or end the radio frequency identification communication connection; finally a signature verification of the non-contact equipment wireless data transmission is carried out on the wireless network link connection between the main and the slave equipments. Under the premise of convenience of users, the higher security is ensured.

Owner:LENOVO (BEIJING) CO LTD

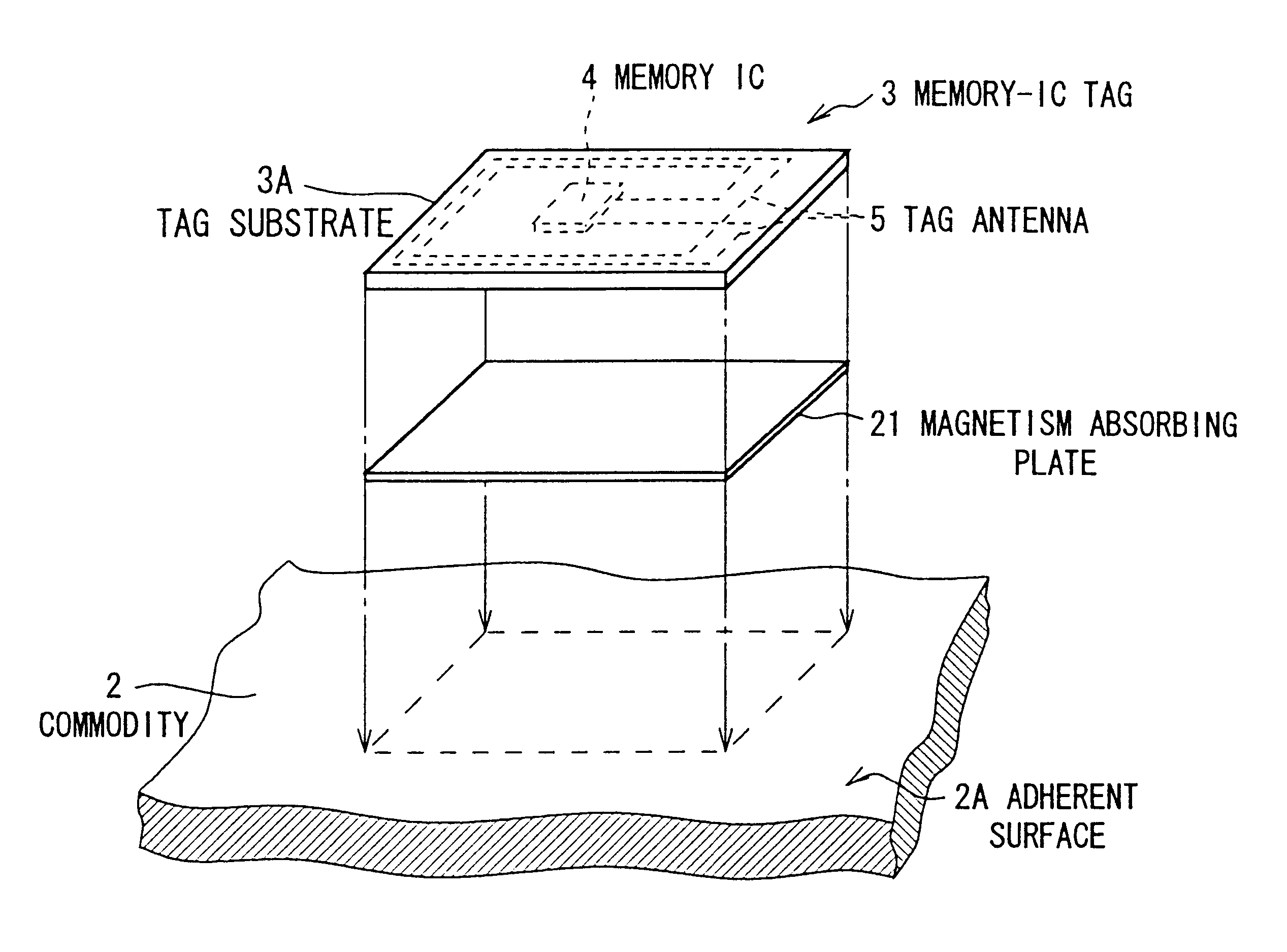

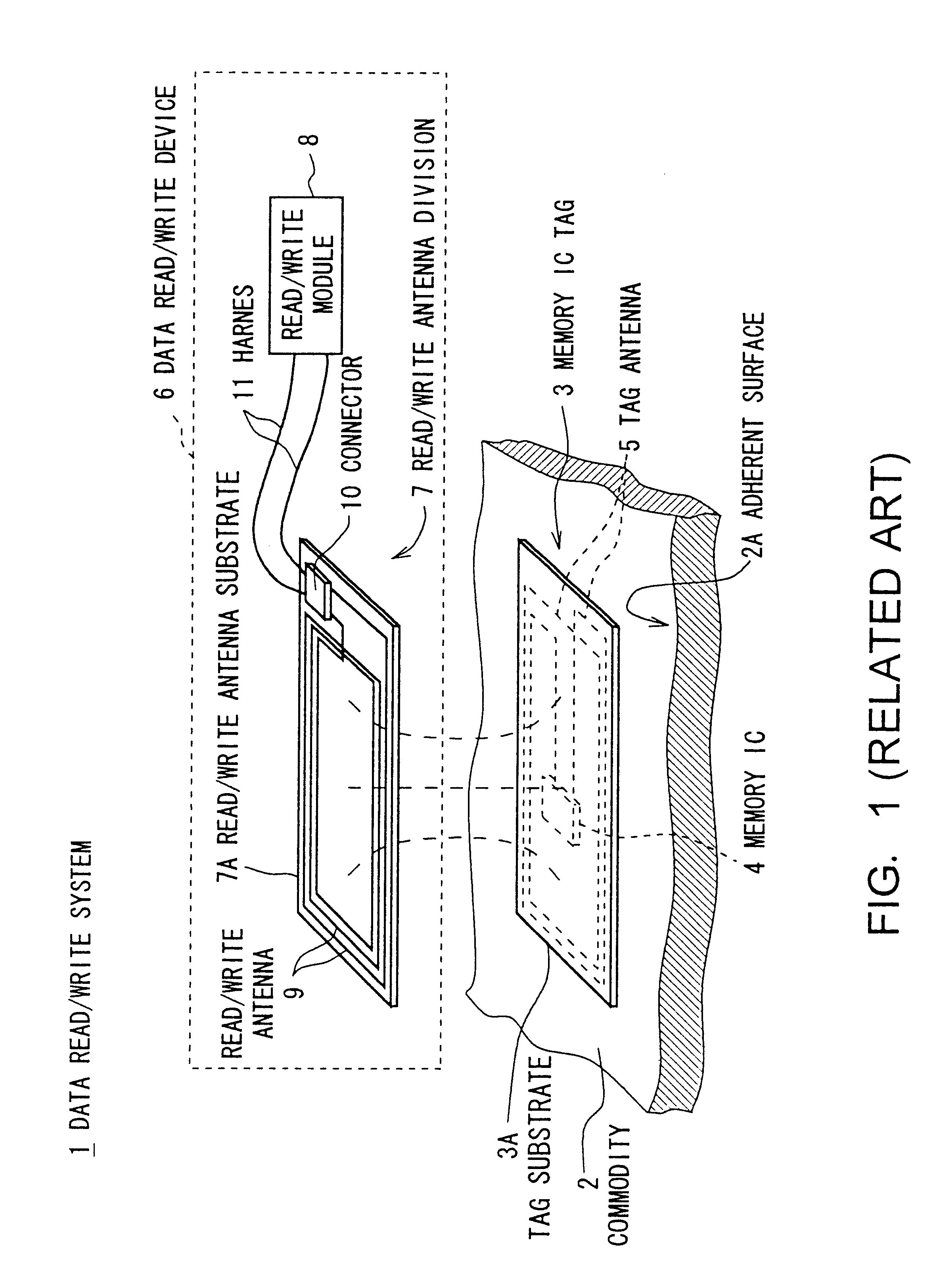

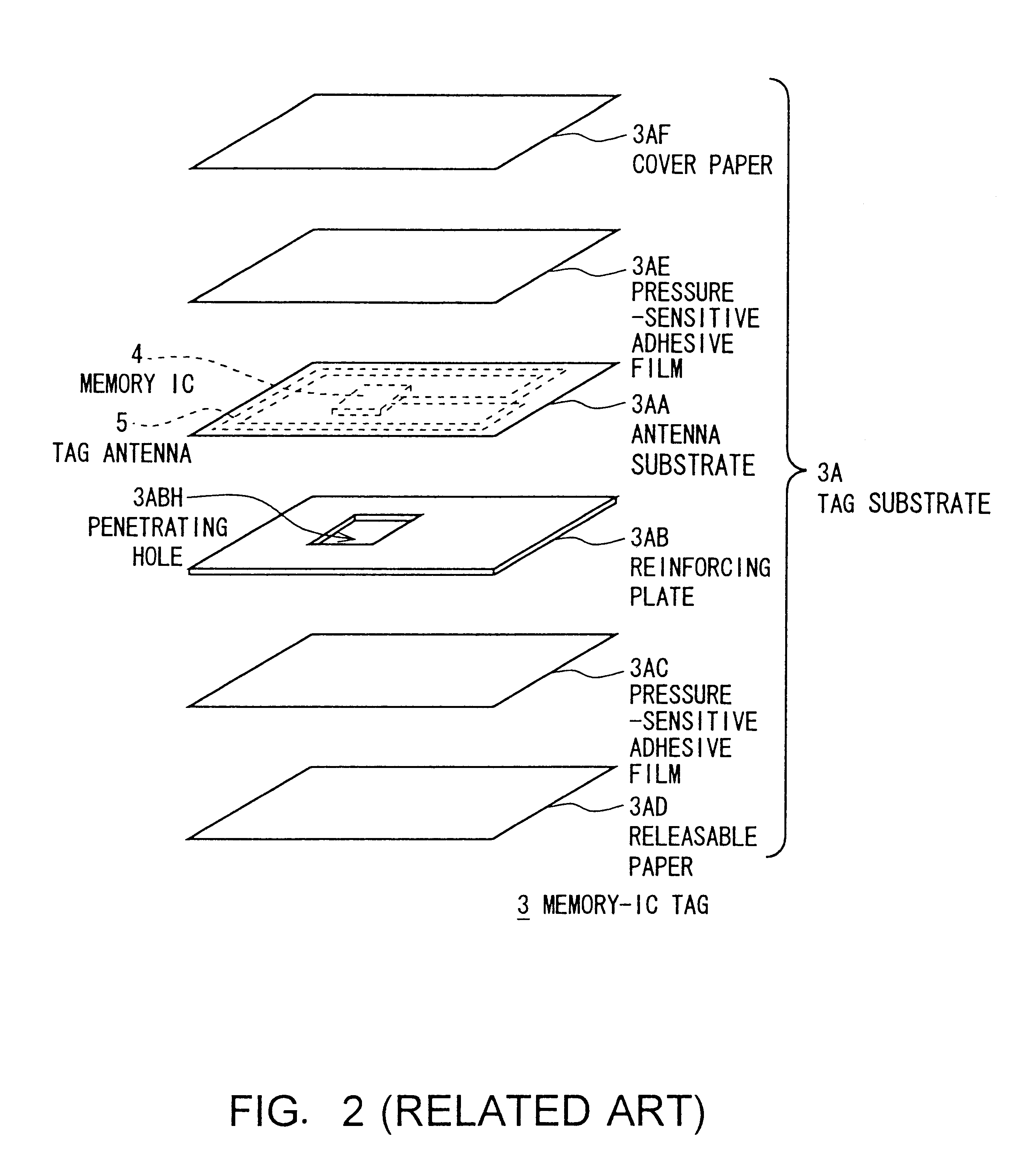

Non-contacting-type information storing device

InactiveUS6371380B1Co-operative working arrangementsSensing record carriersContact typeComputer science

A non-contacting-type information storing device is stuck to the adherent surface of the object, and includes a storing means for storing the stated information and an antenna which has the stated loop form and which is connected to the storing means. The non-contacting-type information storing device further includes a magnetism absorbing plate which is made from high-permeable material and which is placed so that it is interposed between the adherent surface of the object and the antenna at the time when the information storing device is stuck to the adherent surface of the object. As a result, it is possible to provide a non-contacting-type information storing device in which the modulated magnetic-field given from the exterior can be absorbed by the antenna without being leaked to the adherent surface of the object even though the adherent surface of the object is made of metal. Thus the information can be read irrespective of the type of the material of the adherent surface of the object.

Owner:SONY CORP

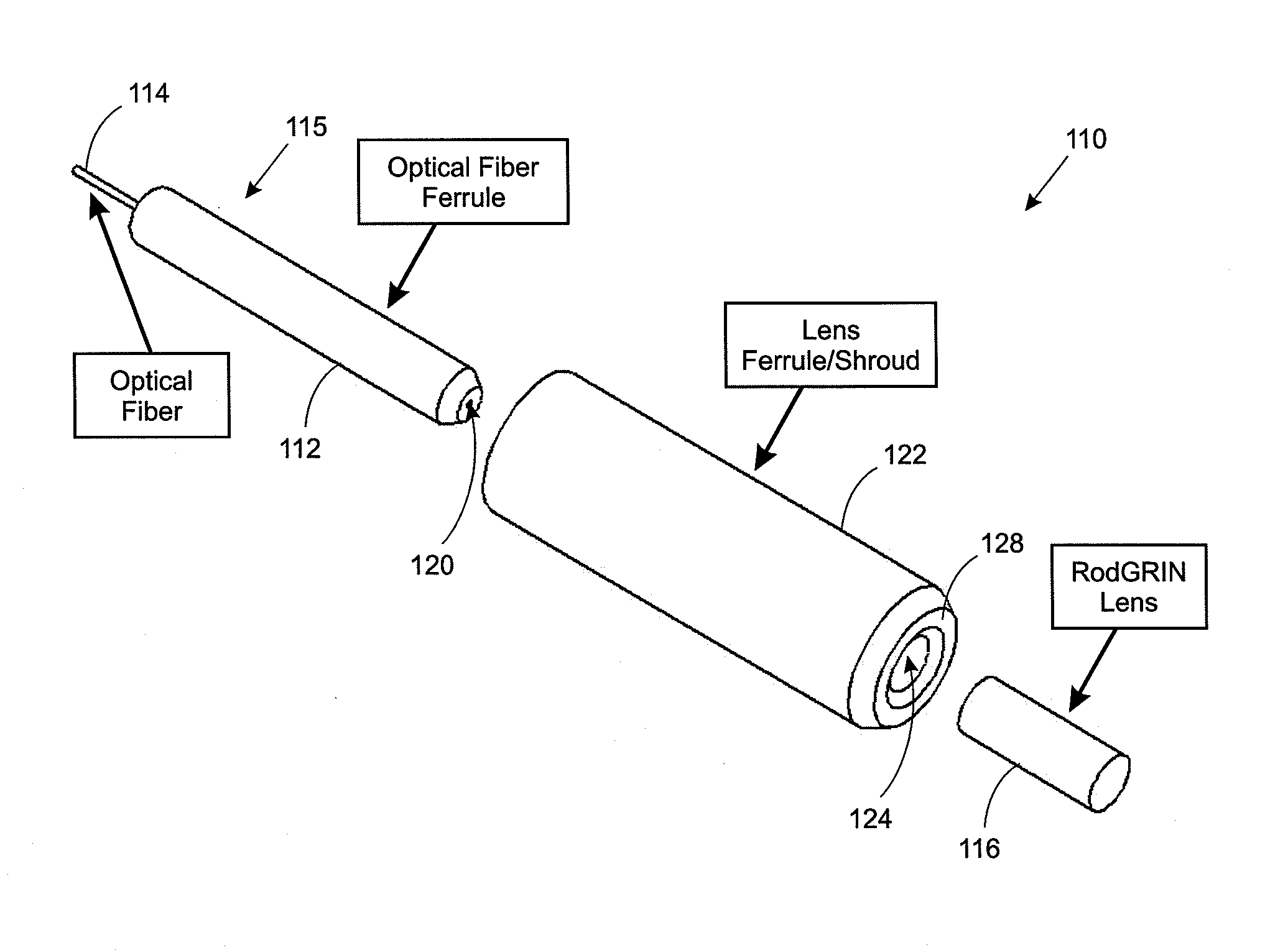

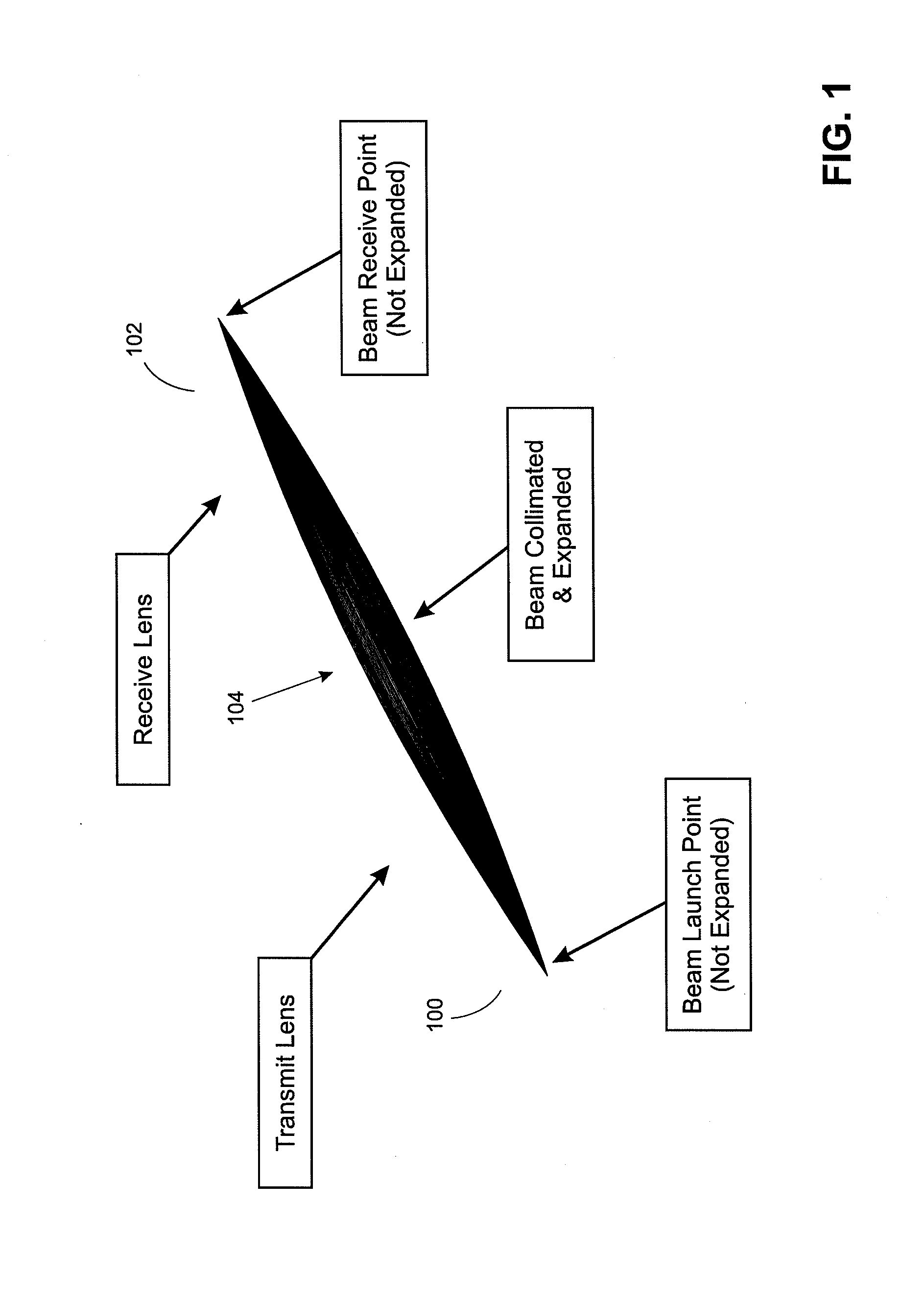

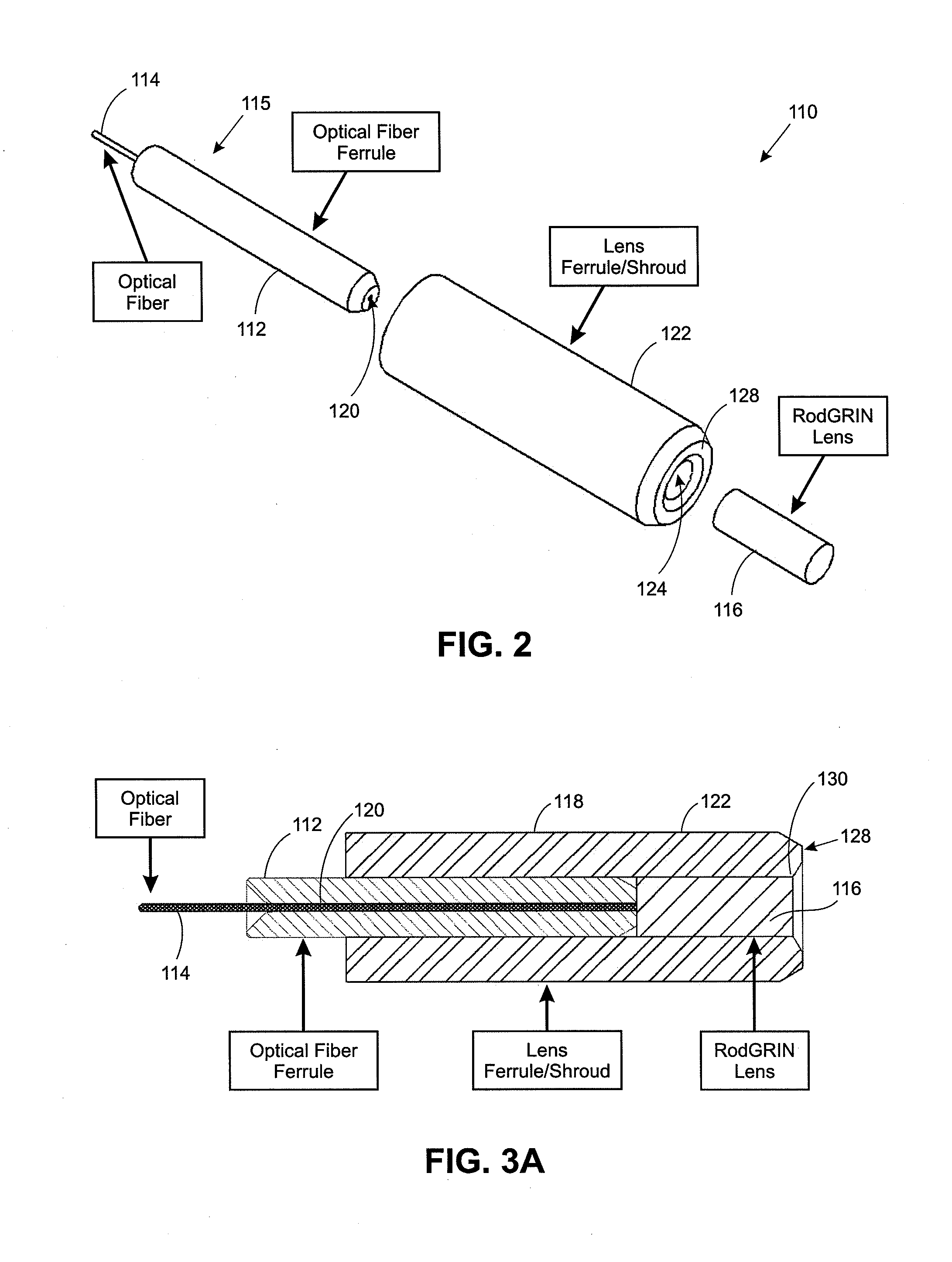

Expanded beam fiber optic connection system

ActiveUS20100027943A1Low costNumber of component requiredHeating or cooling apparatusLaboratory glasswaresFiberEngineering

An expanded beam fiber optic connection system is disclosed which overcomes the problems associated with known expanded beam fiber optic connection systems. In particular, the expanded beam fiber optic connection system in accordance with the present invention includes a pair of mating fiber optic connectors. Each fiber optic connector includes a connector body and fiber optic termini. In accordance with an important aspect of the invention, the fiber optic termini utilize expanded beam technology and are configured with virtually the same form factor as existing physical contact fiber optic termini. The configuration of the expanded beam termini provides several benefits. First, existing physical contact fiber optic connection systems can be updated in the field by simply replacing the existing physical contact fiber optic termini with the new expanded beam fiber optic termini in accordance with the present invention and re-using the existing connector body, thus significantly reducing cost of upgrading existing physical contact type fiber optic connection systems. Secondly, since the same connector bodies are used for both the physical contact termini and the expanded beam termini, the number of components for the two types of fiber optic connection systems is reduced, thus reducing manufacturing costs.

Owner:GLENAIR

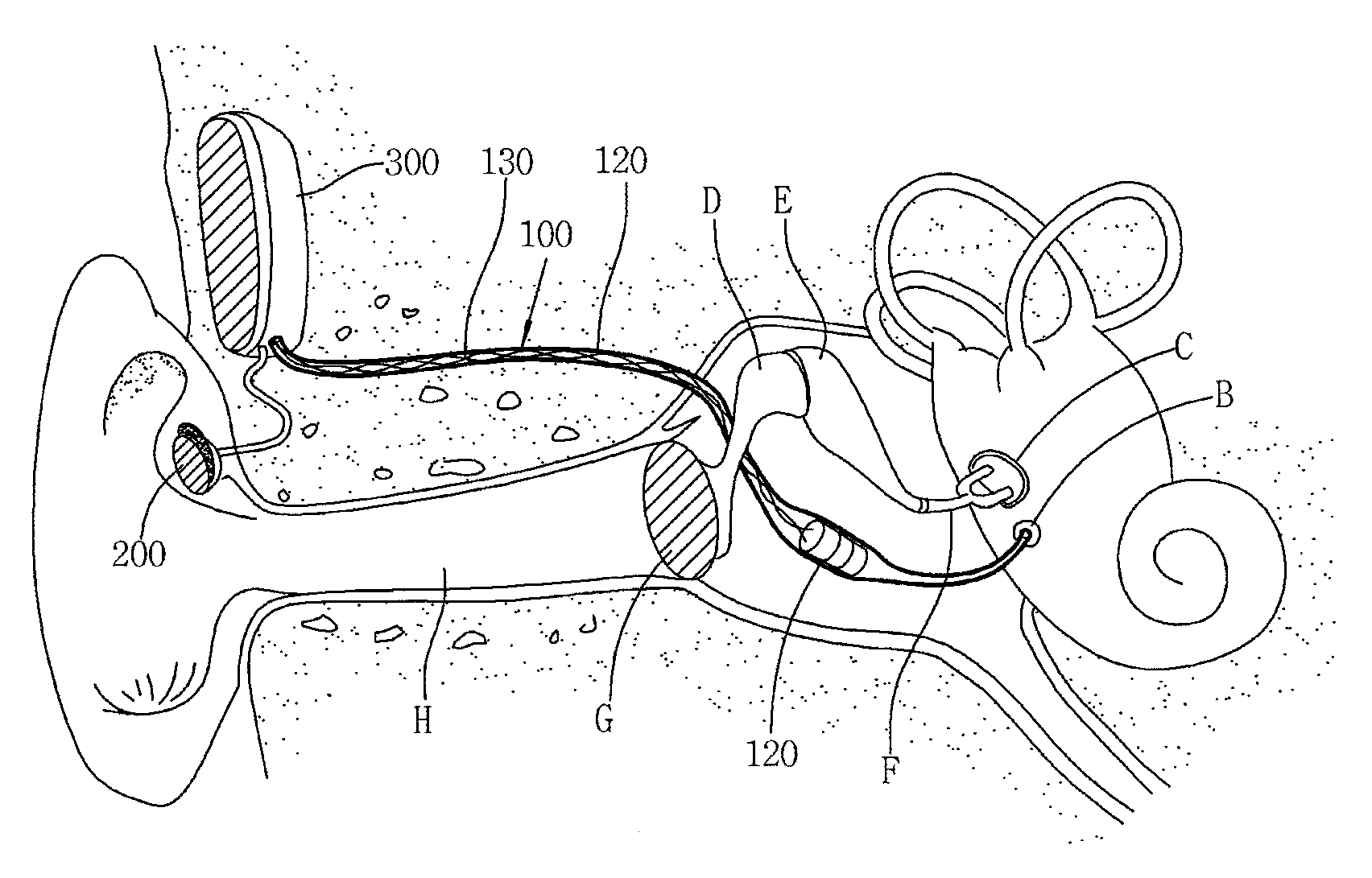

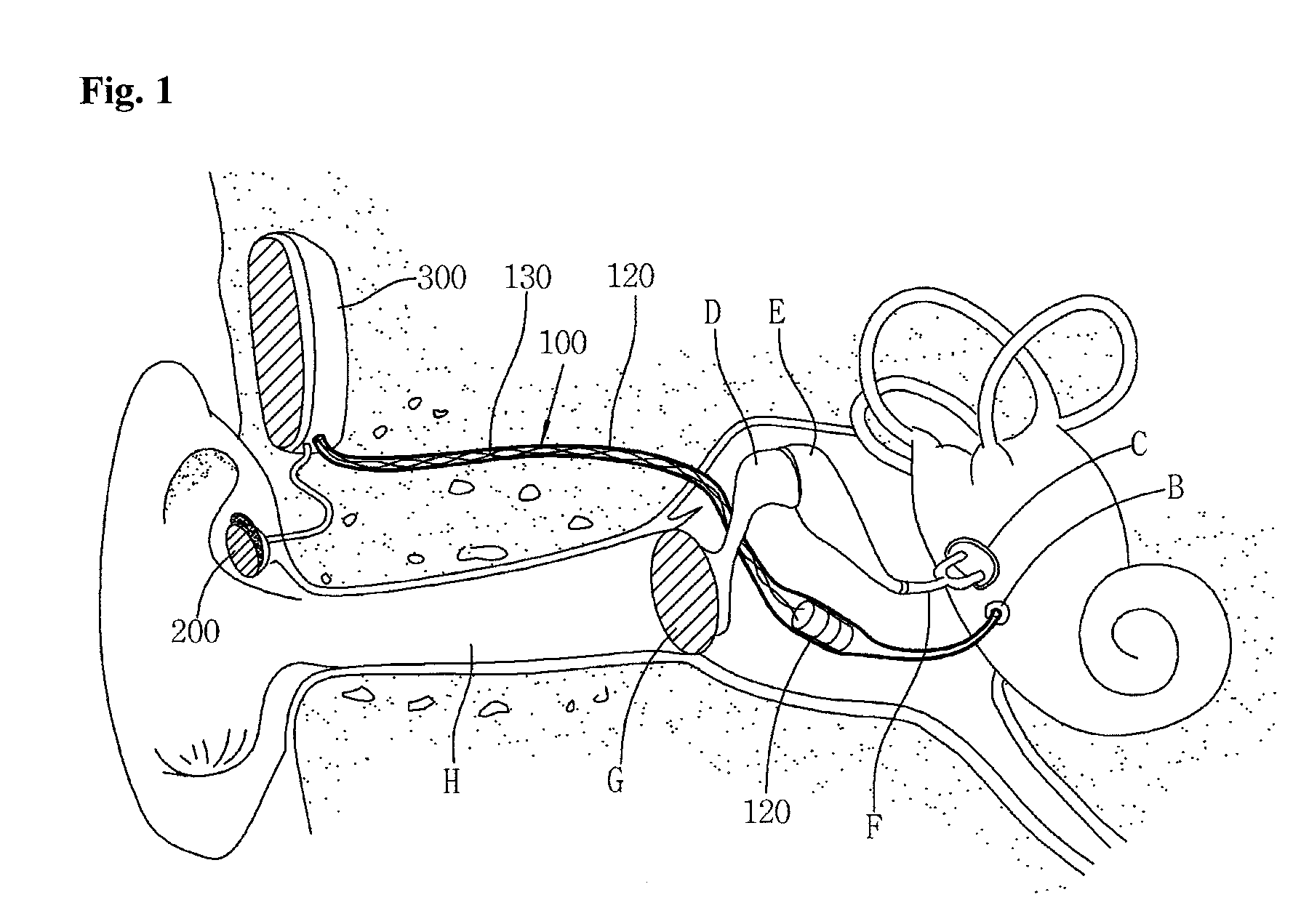

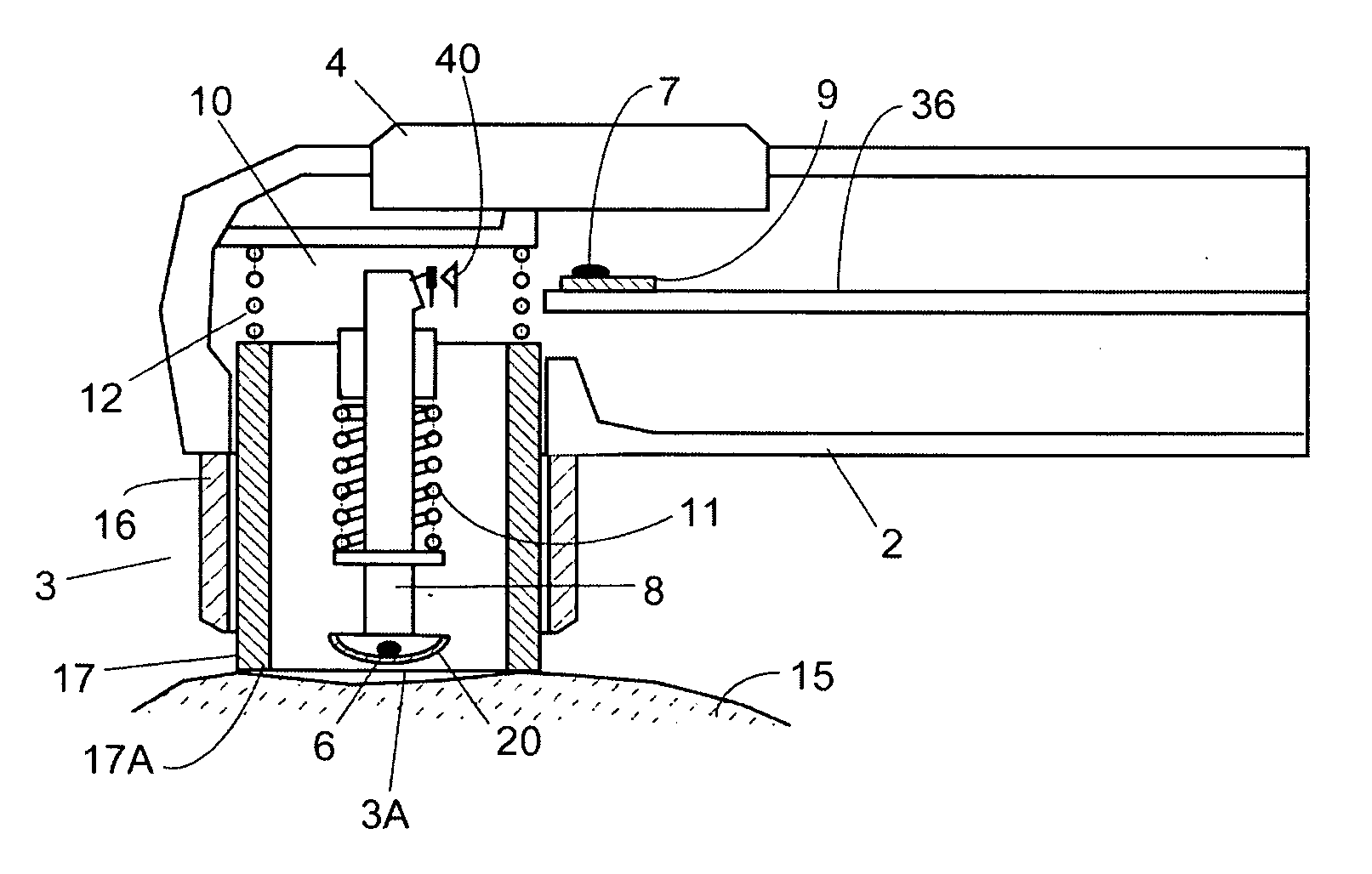

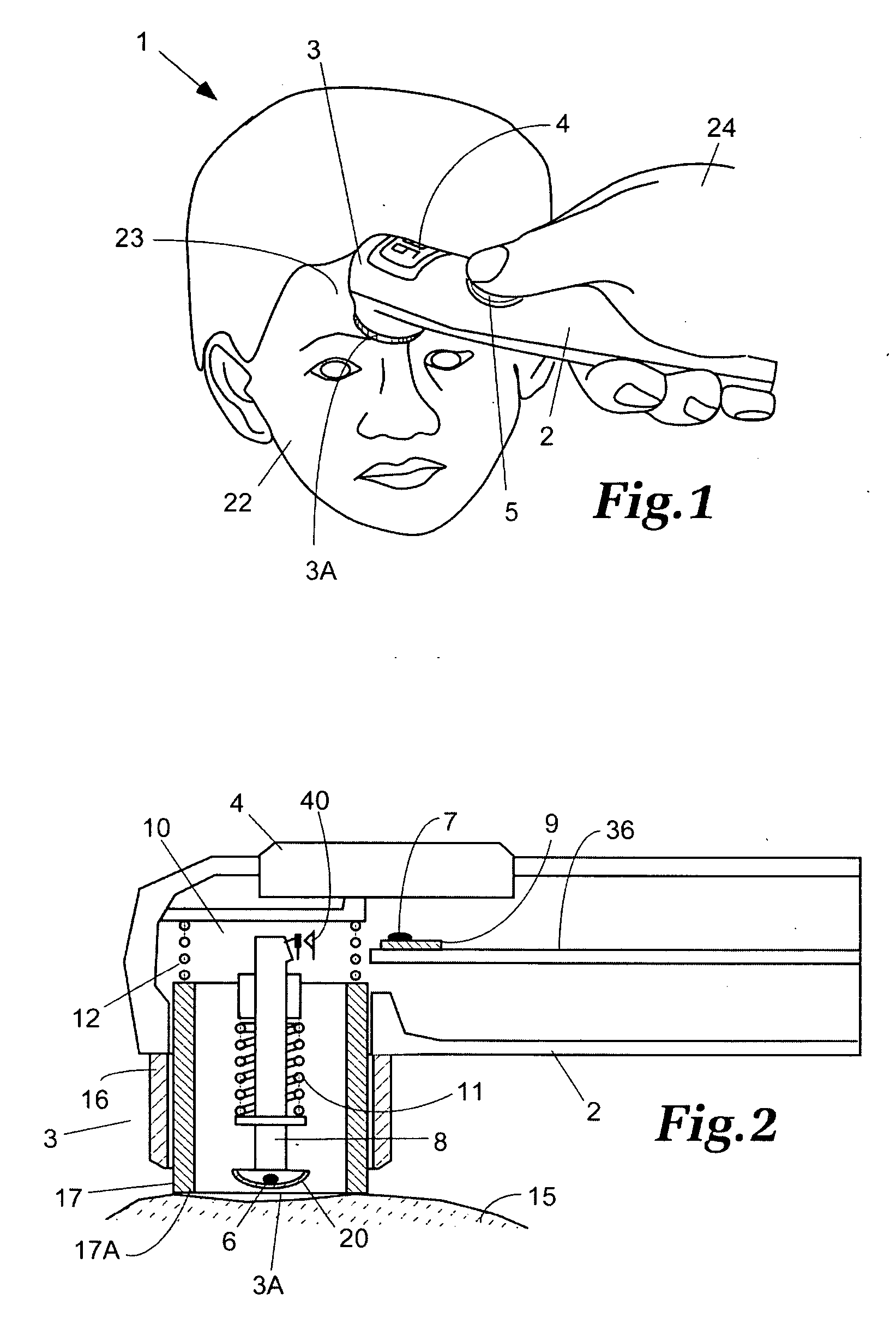

Implantable middle ear hearing device having tubular vibration transducer to drive round window

ActiveUS20090023976A1Reduce deliveryGood compensationEar treatmentDeaf-aid setsMiddle ear functionSensorineural hearing loss

An implantable middle ear hearing device having a tubular vibration transducer to drive a round window is designed to input sound to a round window opposite an oval window in an inner ear. The tubular vibration transducer has a unique structure that does not attenuate the magnitude of a signal, particularly, in a high frequency band. Sound delivery effect is much higher than those of conventional schemes. It is also possible to minimize difficulties associated with and problems resulting from the operation, which the conventional methods would have. Further, the transducer can have a relatively less compact than ossicle contact type transducers, and thus be easily fabricated. The hearing device can be applied to a sensorineural hearing loss patient with the ossicle damaged. Moreover, since sound is directly transmitted without through the ear drum and the ossicle, high efficiency sound delivery is achievable and hearing loss compensation are easy.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

Electrically Conductive Ink, Electrically Conductive Circuit, and Non-Contact-Type Medium

InactiveUS20080169122A1Improve conductivityWell formedConductive layers on insulating-supportsPrinted circuit aspectsHigh humidityContact type

Owner:TOYO INK SC HOLD CO LTD

Paste for back contact-type solar cell

InactiveUS20080230119A1Reduce contact resistanceExcellent electrical propertiesFinal product manufactureConductive materialFritMetal alloy

Disclosed is a paste for a back contact-type solar cell that includes: (a) electrically conductive particles containing silver particle and added particles selected from the group consisting of (i) metal particles selected from the group consisting of Mo, Tc, Ru, Rh, Pd, W, Re, Os, Ir and Pt particles, (ii) a metal alloy containing the metal particles, and (iii) particles loaded with the metal particles, (b) glass frit, and (c) a resin binder.

Owner:EI DU PONT DE NEMOURS & CO

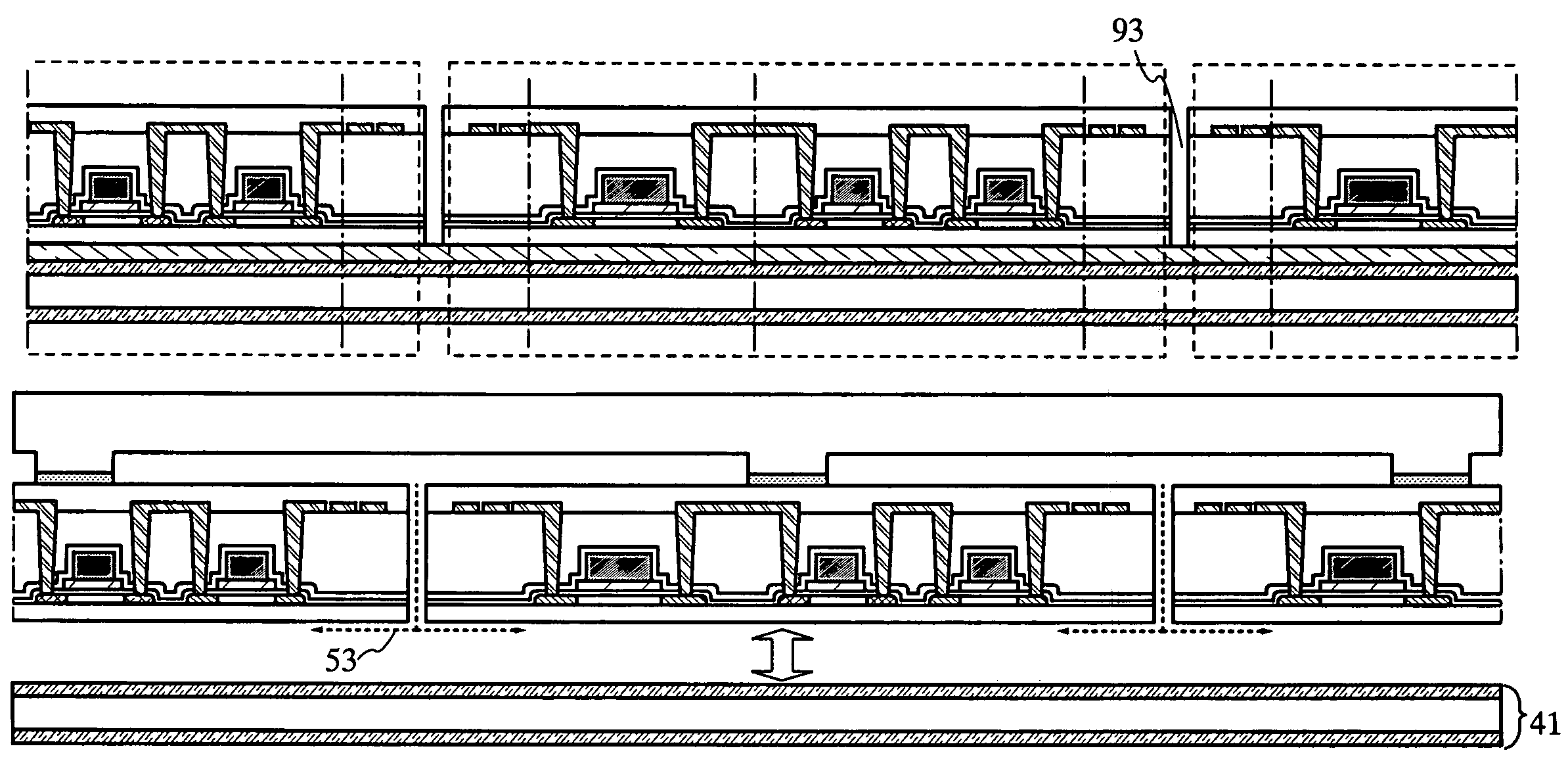

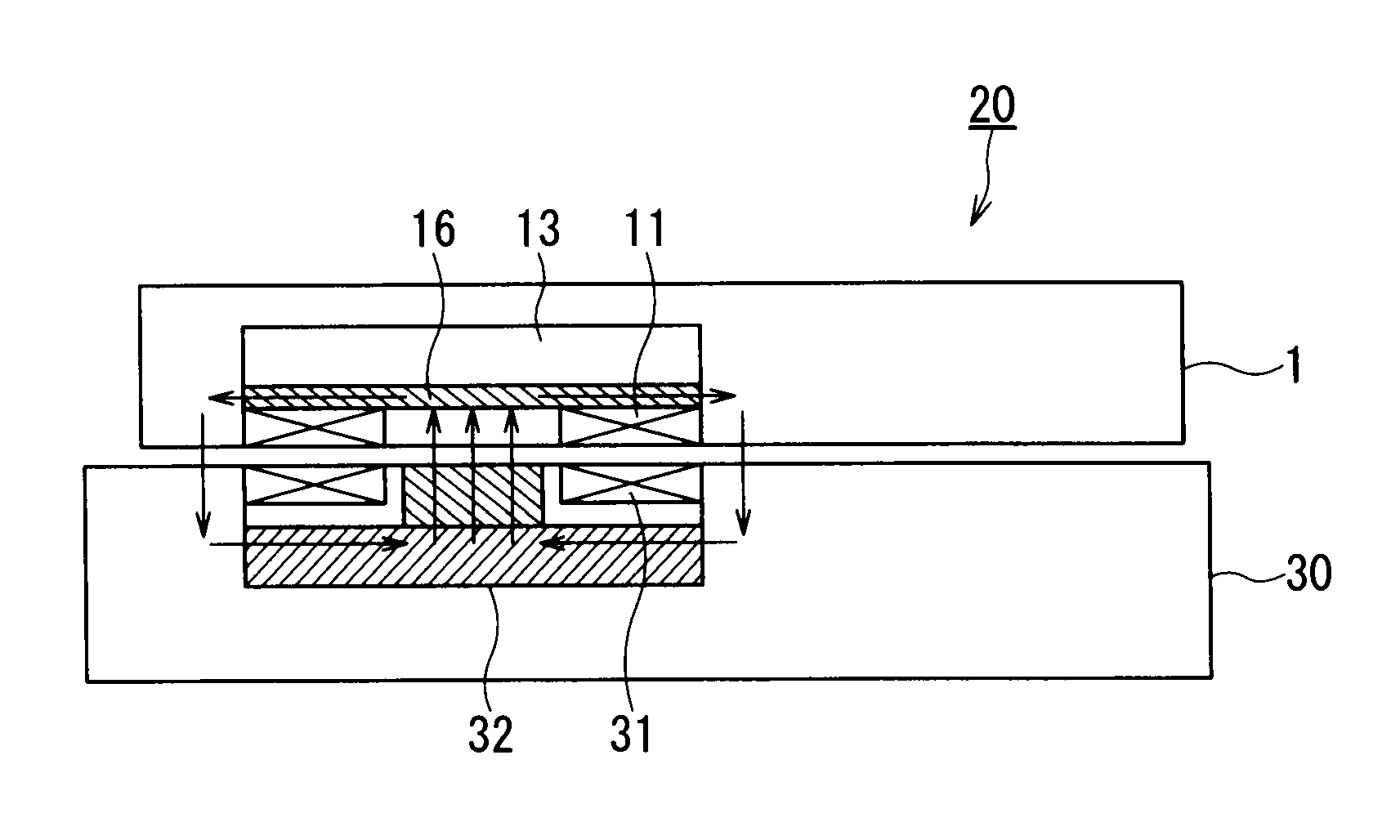

Non-contact type power receiving apparatus, electronic equipment and charging system using the power receiving apparatus

ActiveUS20110210696A1Oscillation can be effectively controlledImprove propertiesTransformersElectric powerContact typeTotal thickness

A non-contact type power receiving apparatus including: a power receiving coil having a spiral coil; a rectifier; a secondary battery; an electronic device operated by being supplied with direct voltage from the secondary battery, wherein a composite magnetic body is provided to at least one portion between the secondary battery and the spiral coil, and a portion between the electronic device and the spiral coil. The composite magnetic body includes at least first and other layers of magnetic sheets through an insulating layer in which when a relative magnetic permeability of the first magnetic sheet provided to a side of the spiral coil is μd, a thickness of the first magnetic sheet is tu, an average relative magnetic permeability of the other magnetic sheets other than the first magnetic sheet is μu, and a total thickness of the other magnetic sheets is tu, the composite magnetic body satisfies the following relations: μd·td≦60 [mm]; and μu·tu≧100 [mm].

Owner:KK TOSHIBA +1

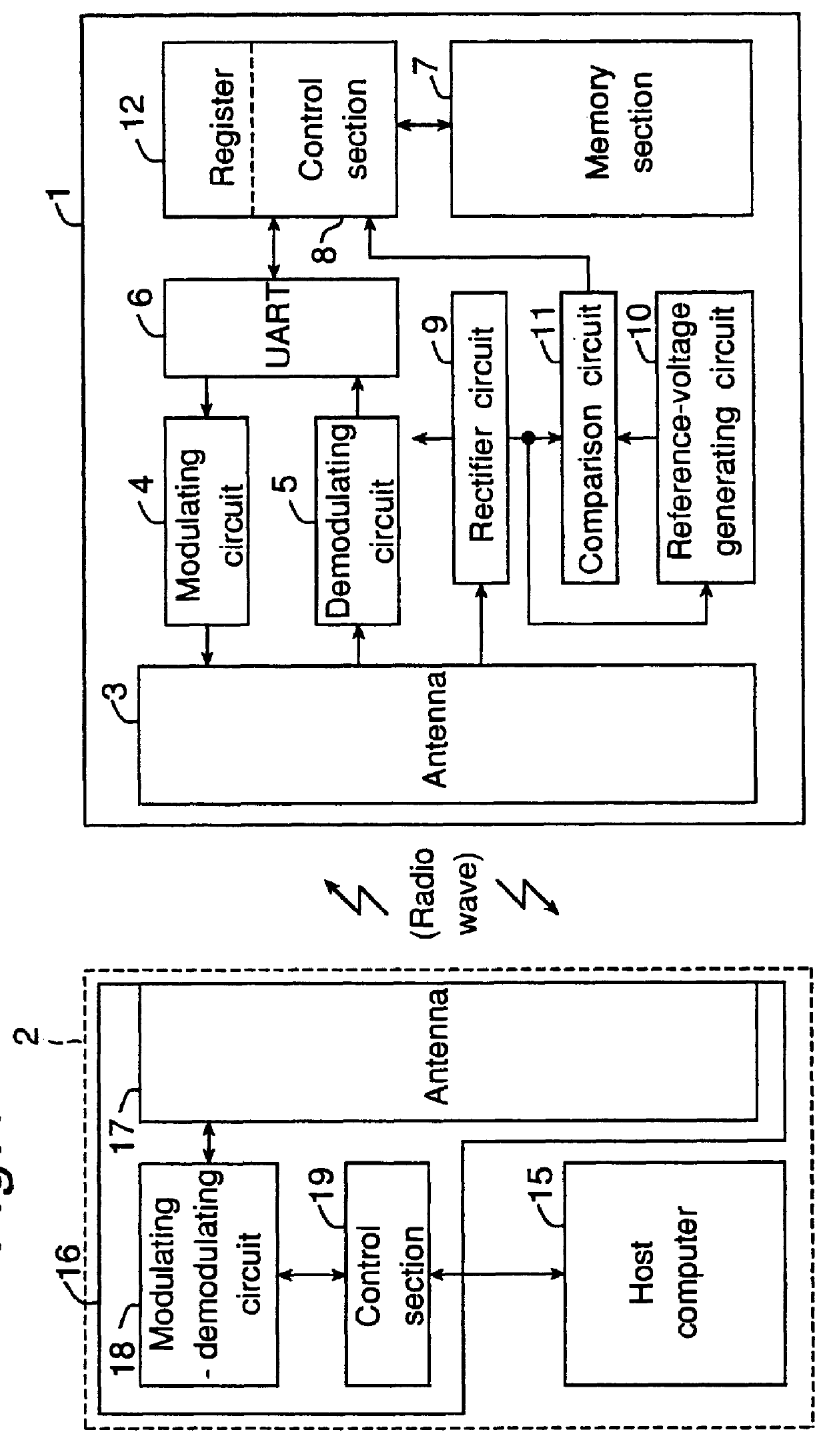

Non-contact IC card with monitor for source power

InactiveUS6070804AReliable dataImprove reliabilityCo-operative working arrangementsStatic storageVoltage referenceContact type

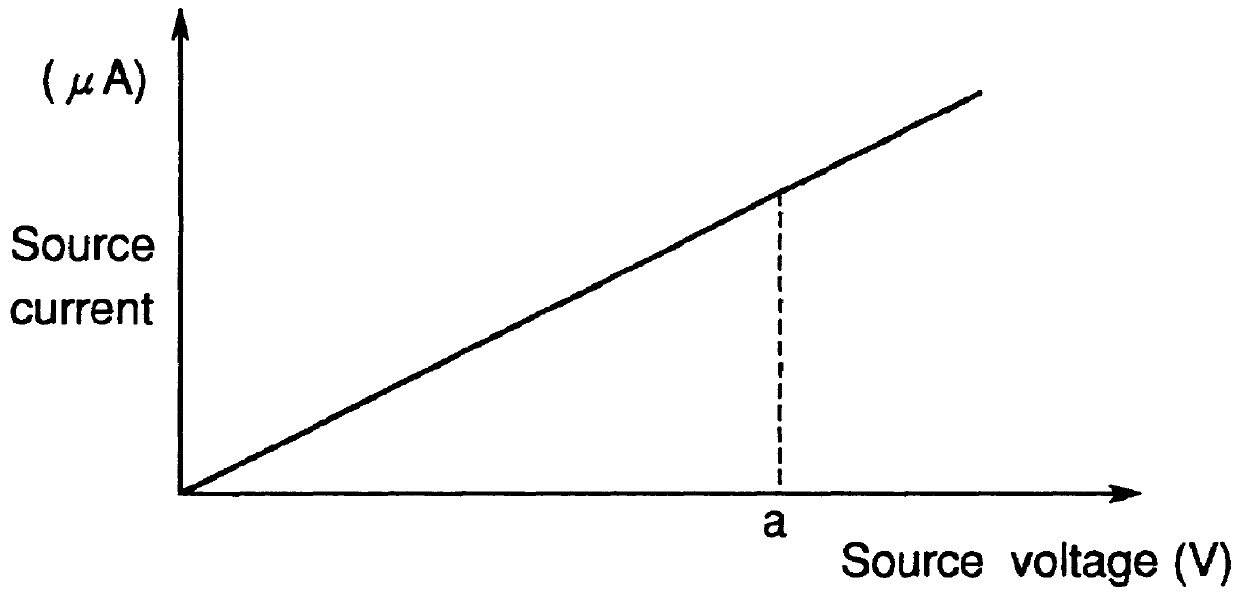

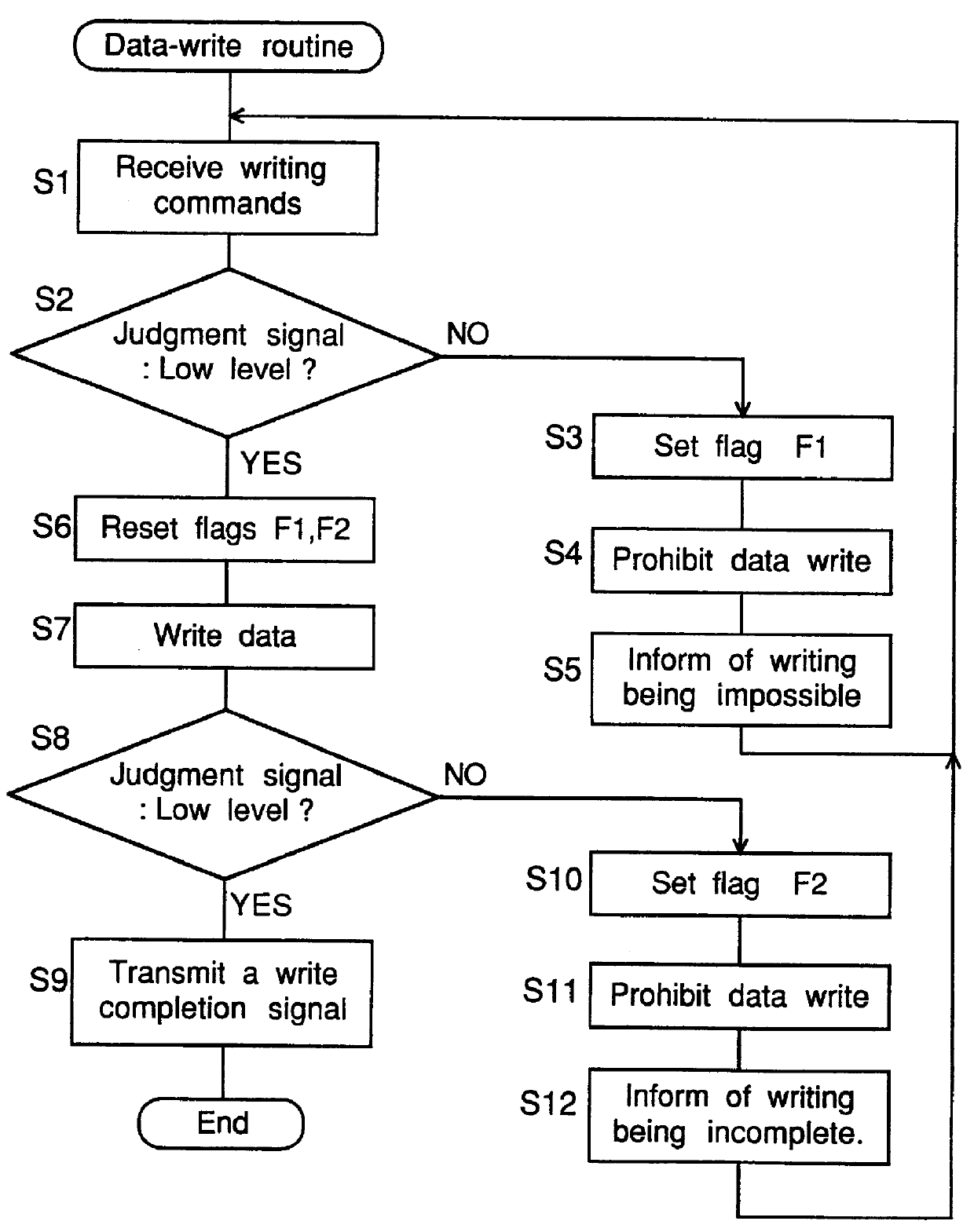

A non-contact type IC card includes a rectifier circuit for supplying a source voltage to respective circuits of an IC card based on the strength of radio waves received from a host computer. A reference voltage generating circuit generates a reference voltage. A comparison circuit compares the source voltage with the reference voltage. A control circuit prohibits the writing of data if the source voltage becomes less than the reference voltage.

Owner:MITSUBISHI ELECTRIC CORP +1

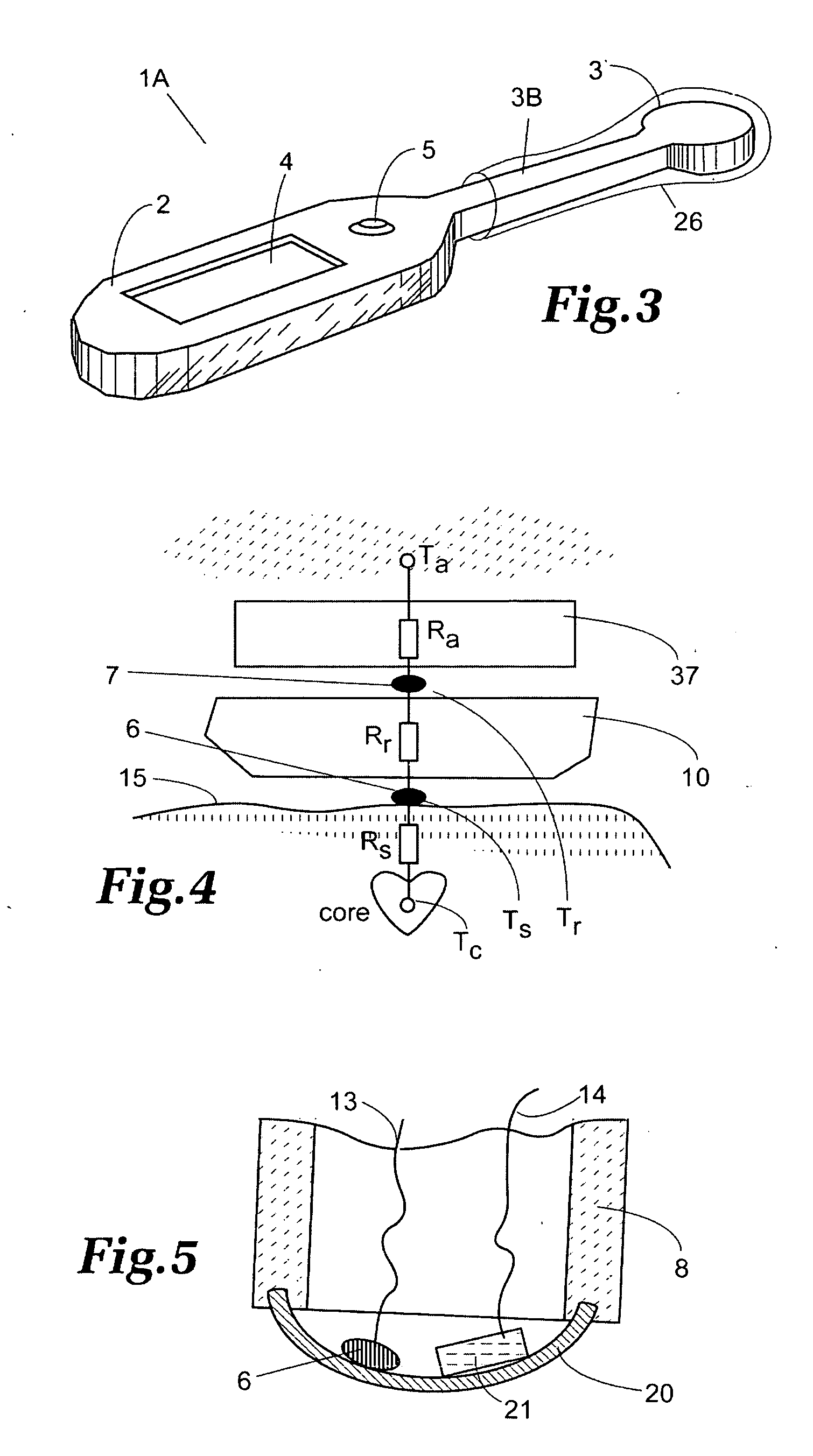

Medical thermometer for determining body core temperature

InactiveUS20070055171A1Thermometer detailsThermometers using electric/magnetic elementsMedical thermometerContact type

A temperature sensing device including at least a first contact type temperature sensing element determines body core temperature of a warm blooded animal or human based on an estimated skin temperature of the patient which is computed based on temperature measurements obtained by the first sensing element.

Owner:HELEN OF TROY LIMITED

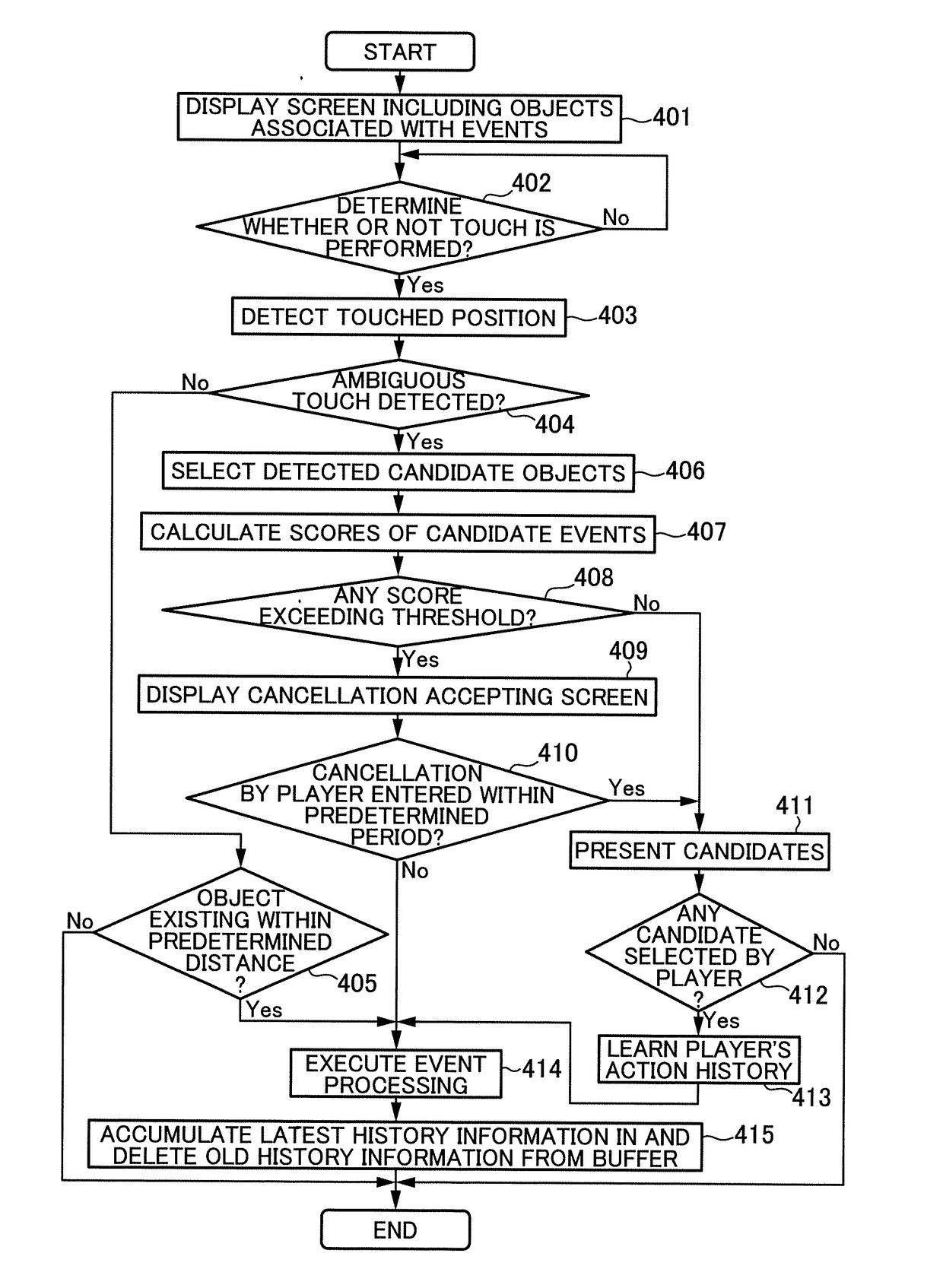

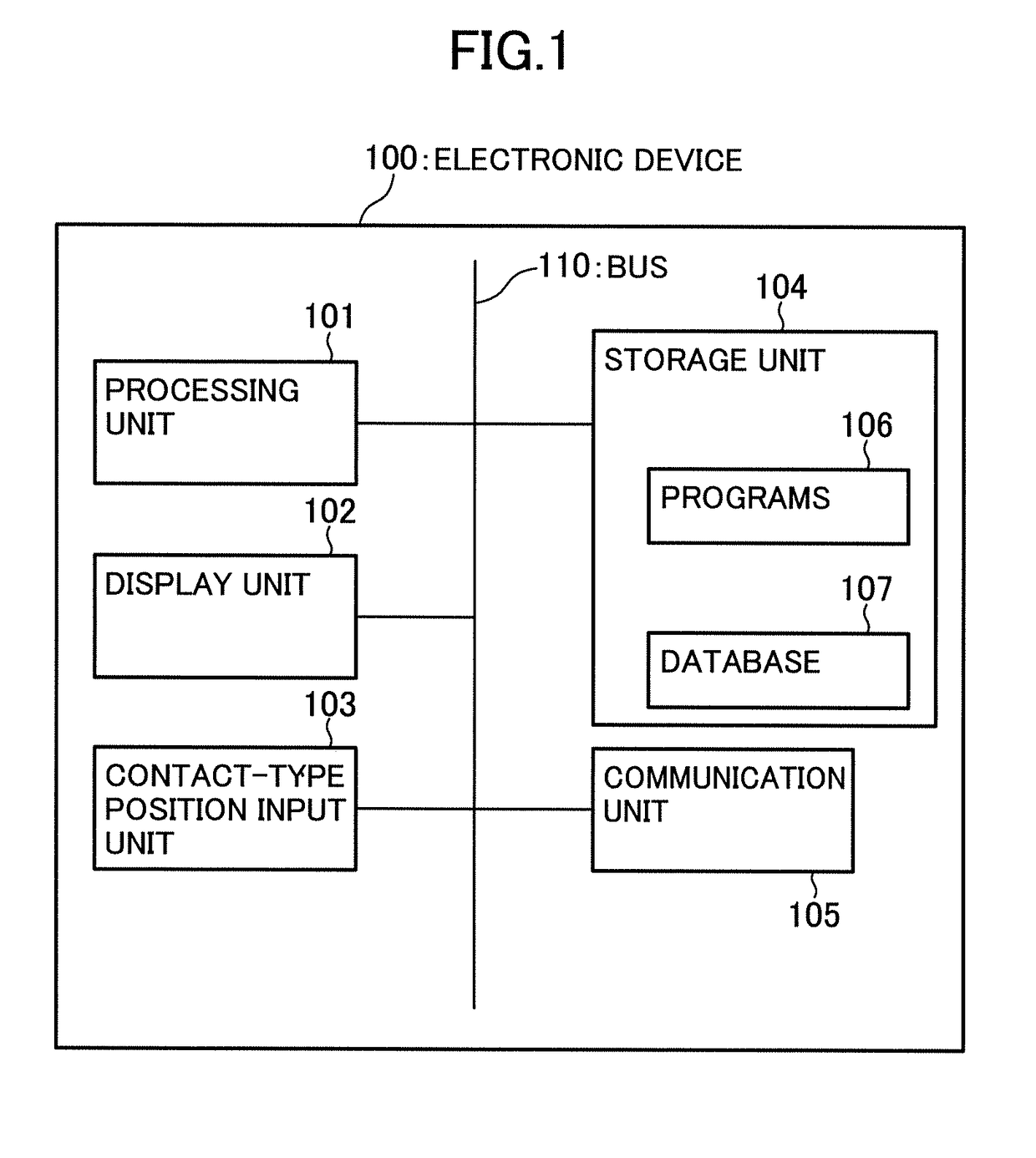

Program, electronic device, system, and control method with which touch target is predicted on basis of operation history

ActiveUS20180157372A1Improve responsivenessQuickly narrow down the operation historyVideo gamesInput/output processes for data processingComputer graphics (images)Contact type

Owner:CYGAMES

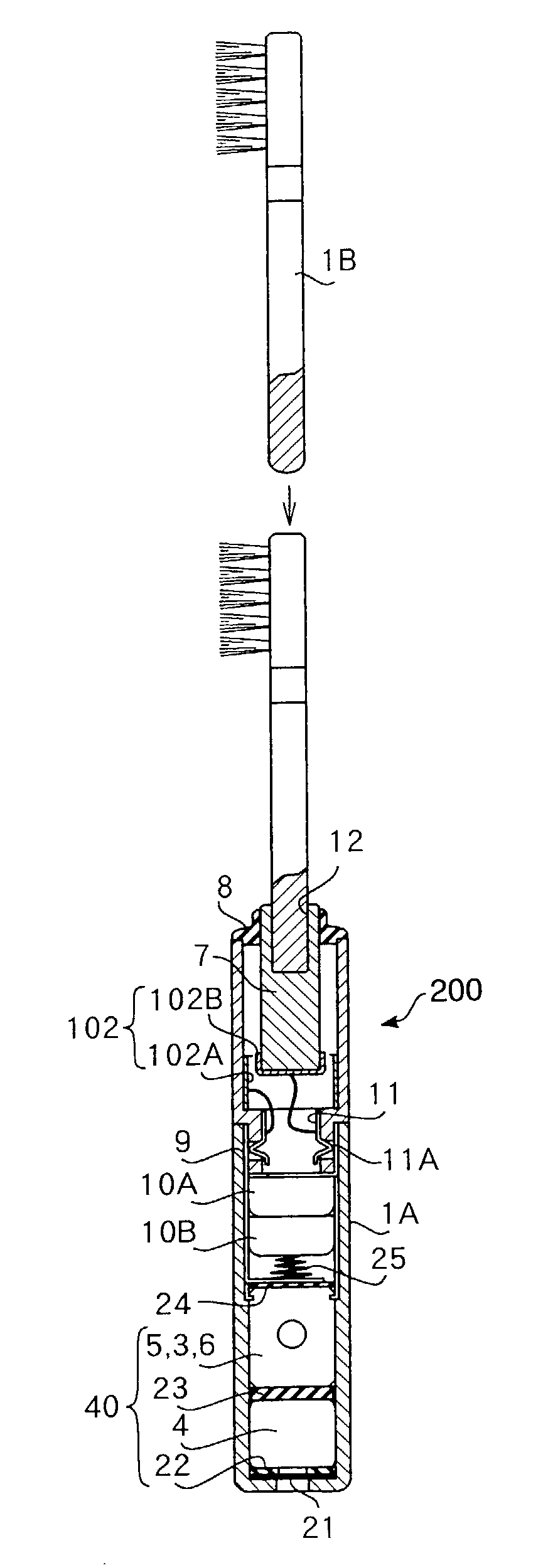

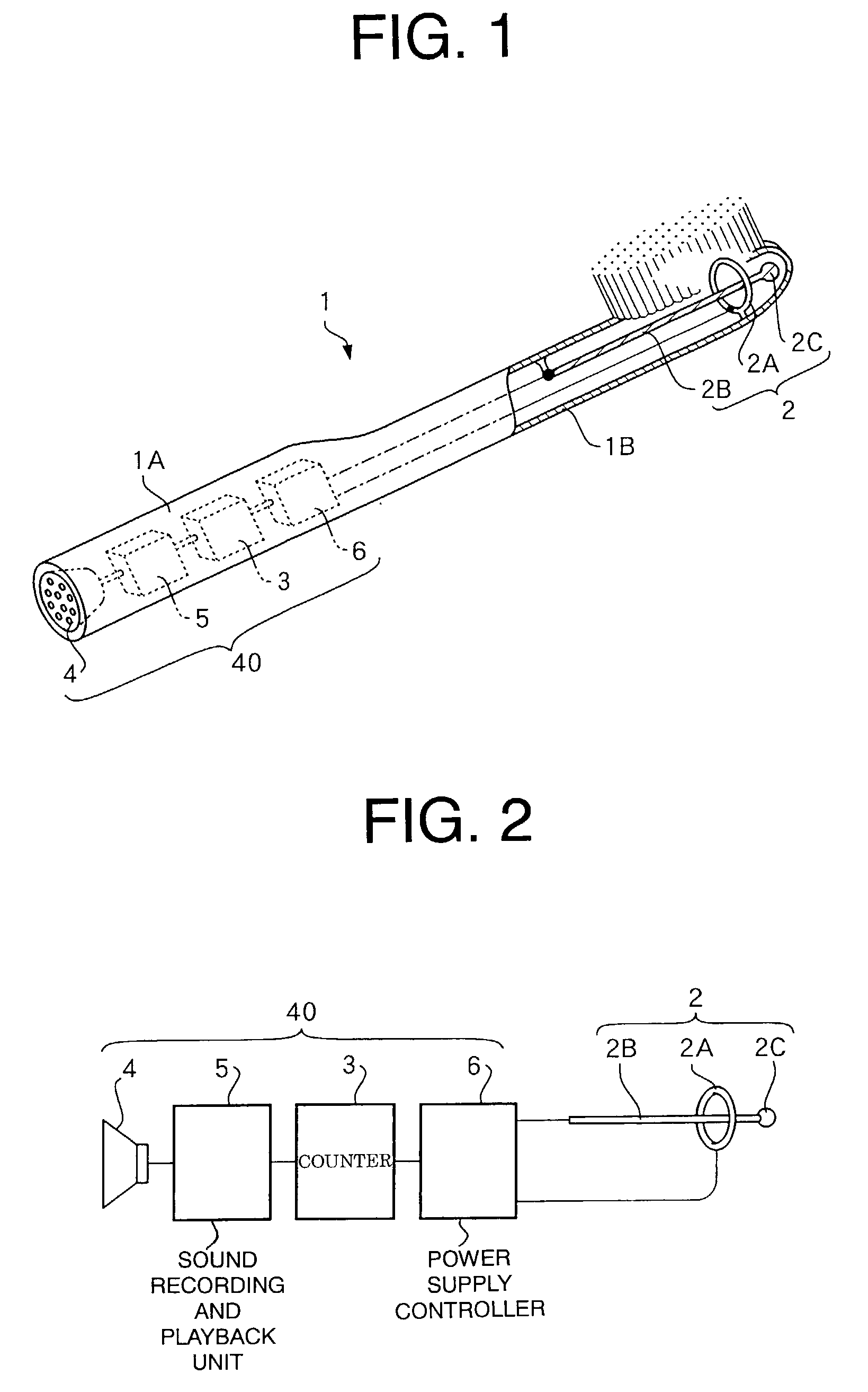

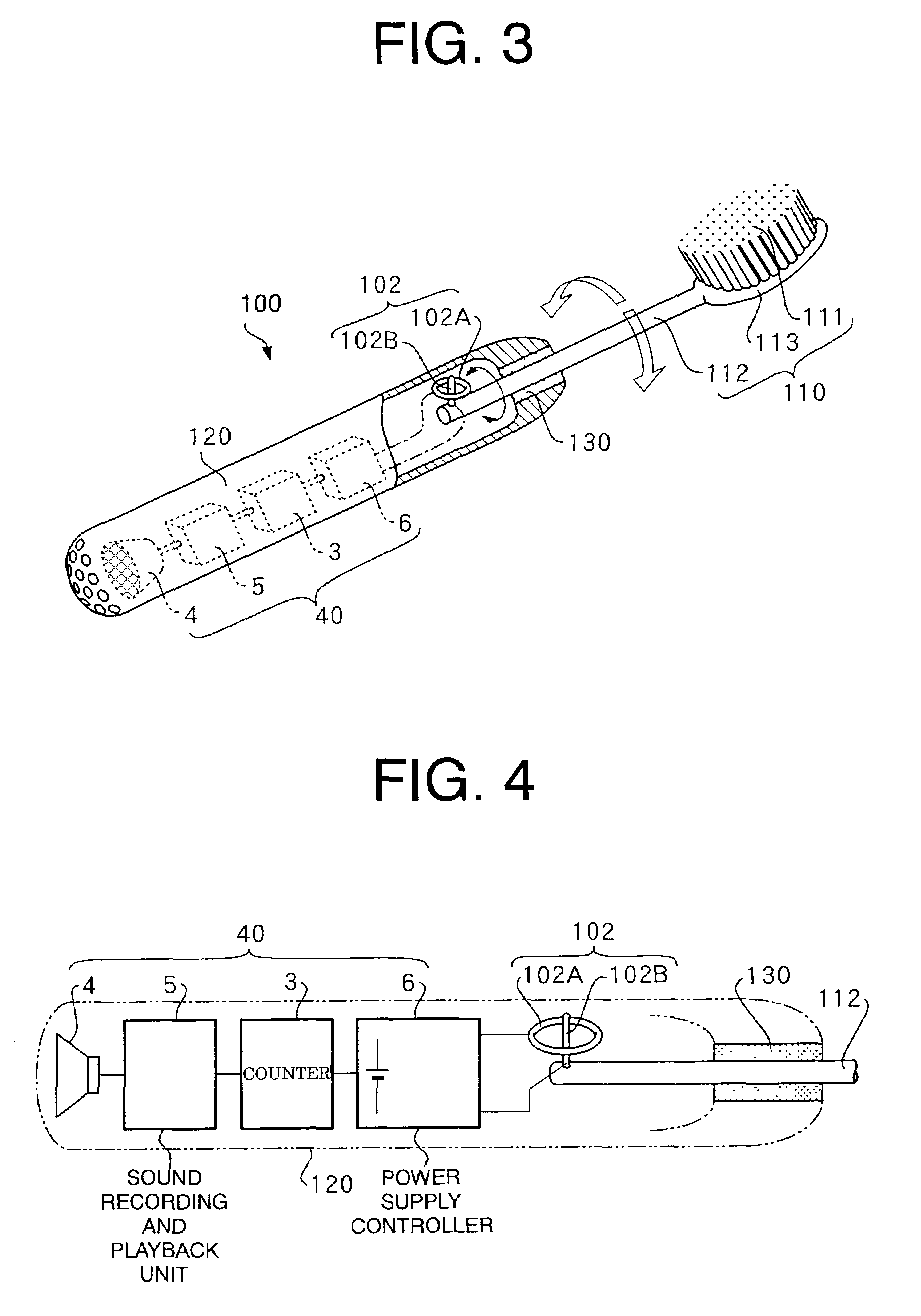

Toothbrush assembly with sound generating function

A toothbrush assembly with a sound generating function for providing excitement and entertainment to a user and for encouraging a young child to brush his or her teeth is provided. The toothbrush assembly has a contact-type switch and a sound generator. The contact-type switch has a swingable contact and generates a pulse when a power switch of the assembly is instantaneously closed for every swing of the swingable contact according to the tooth-brushing movement of a user. The sound generator has a counter for counting pulses from the contact-type switch and a sound recording and play back unit for generating a voice message or musical tone when the sum of the pulses counted by the counter reaches a predetermined value. The sound recording and play back unit of the sound generator outputs different voice messages or musical tones according to different predetermined values reached by the sum of the pulses counted by the counter.

Owner:METRO CORP

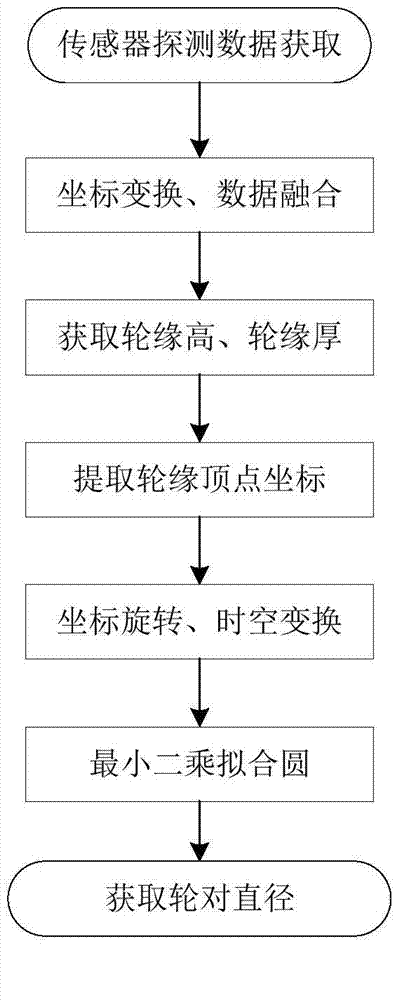

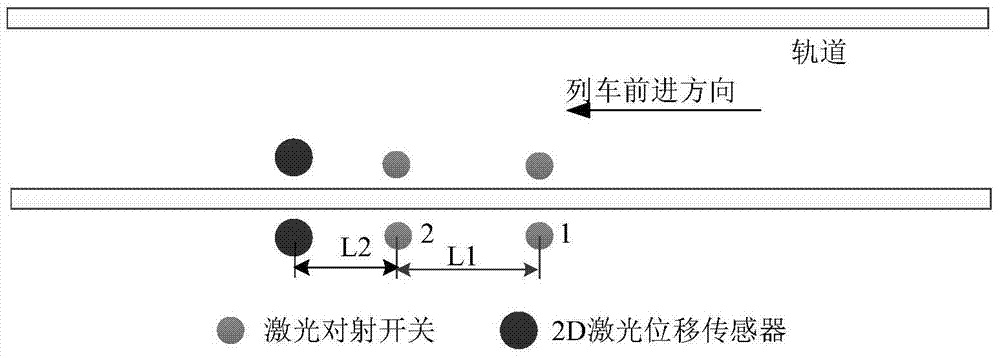

Method and device for online detection of size of city rail train wheel set

ActiveCN104228875ALow costEasy to operateWheel-rims surveying/measuringGeometric relationsContact type

The invention discloses a method and device for online detection of the size of a city rail train wheel set. A system is mainly comprises two 2D laser displacement sensors arranged along a train rail in a mirror symmetric mode, and two laser bijection switches arranged on the two sides of the same rail in a certain geometrical relation. The 2D laser displacement sensors detect and obtain tread contour lines, and the two laser bijection switches detect the wheel passing speed. The rim height and the rim thickness are worked out by extracting the tread contour lines of wheels passing through a detection system according to the geometrical relation. The coordinates of the lowest rim points of the detected tread contour lines of the wheels at different moments are extracted, the coordinates at the different moments are restored to coordinate values at the same moment on the condition that the speed is given, so that the circle where the top points of the rims of the wheels are located is fitted out, the two times of the height of the rims is subtracted from the diameter of the circle of the top points of the rims, and thus the diameters of the wheels are obtained. The method and device for online detection of the size of the city rail train wheel set are low in cost, simple in operation and high in non-contact type measurement precision.

Owner:NANJING UNIV OF SCI & TECH +1

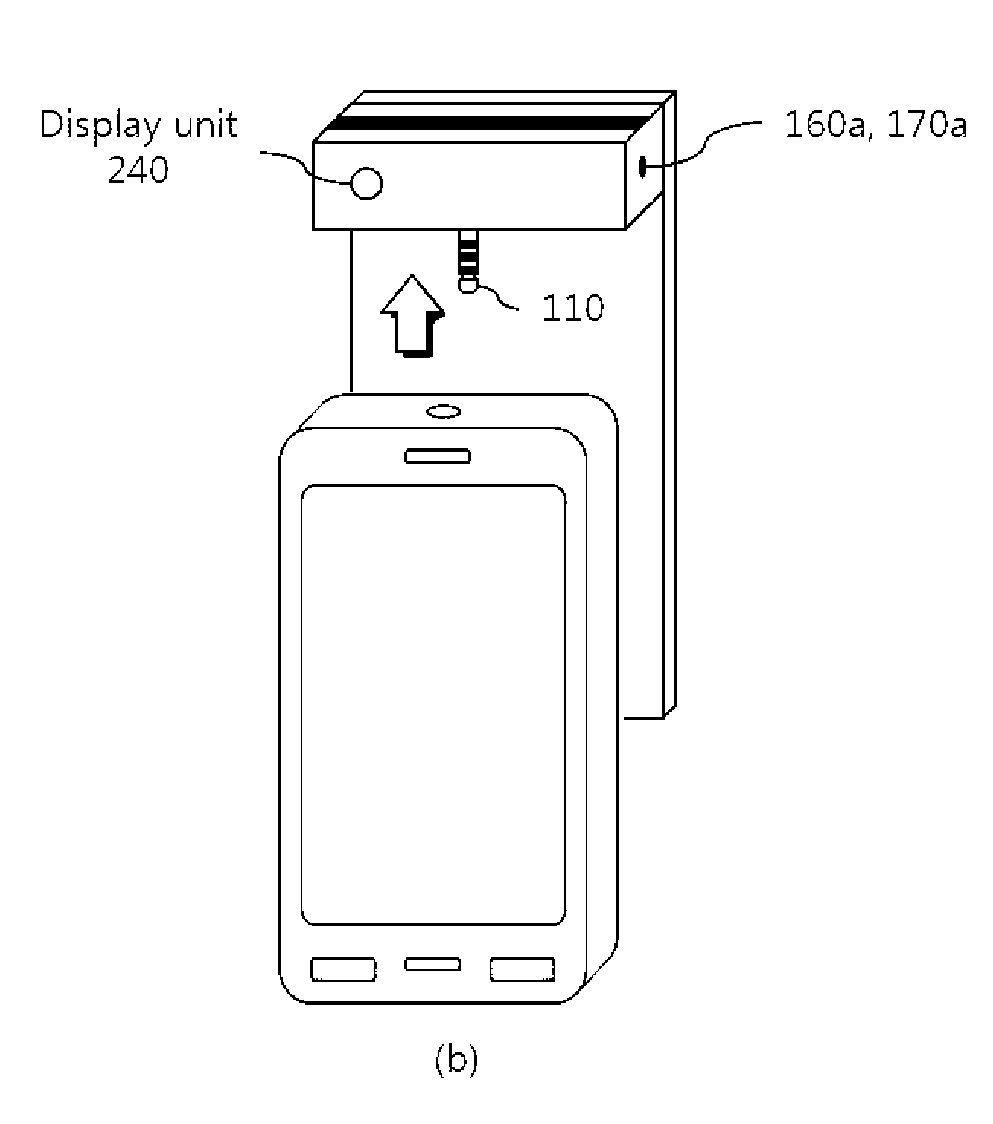

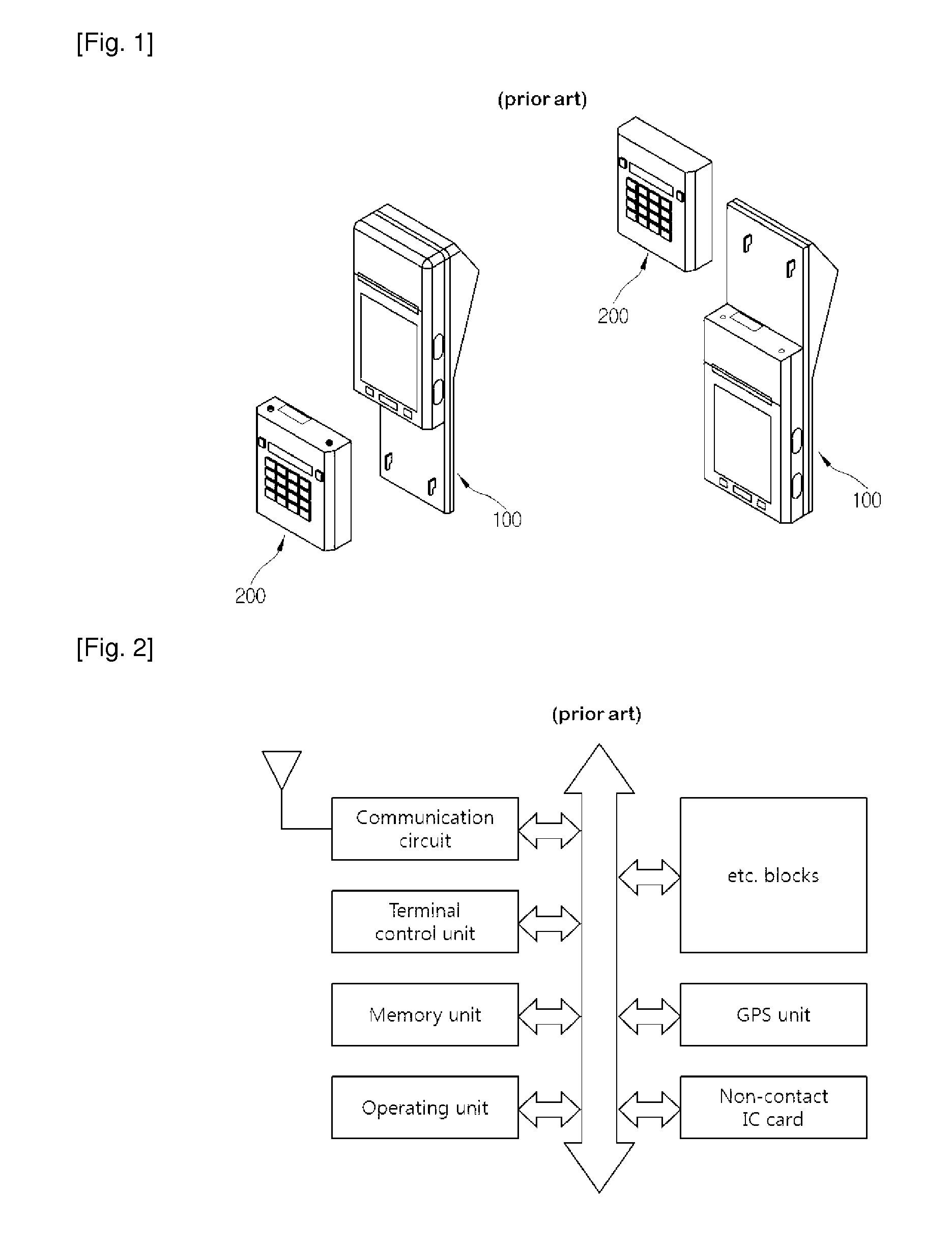

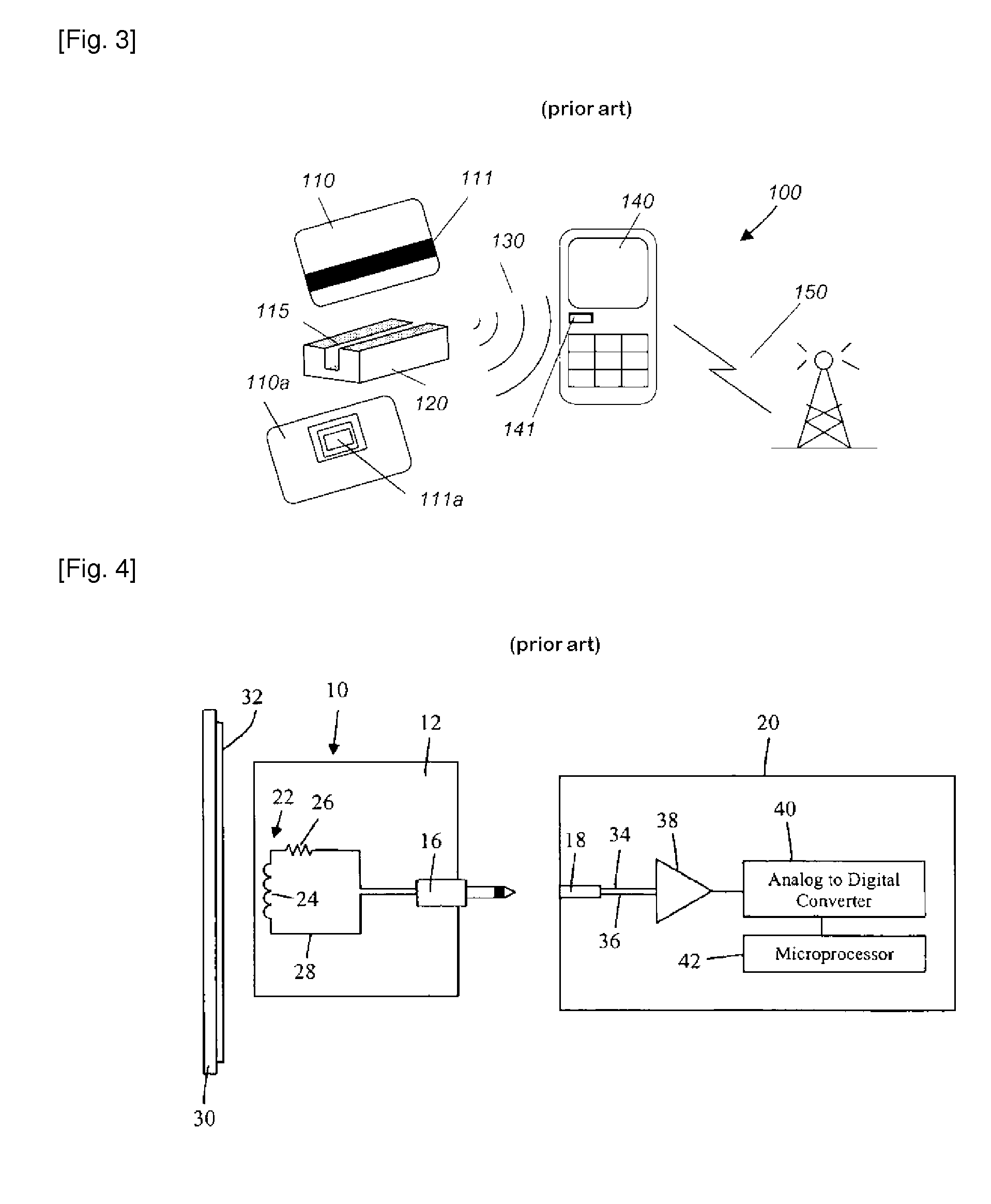

Card reader device using a mobile, and the method thereof

InactiveUS20140203082A1Less difficultySensing detailsCo-operative working arrangementsContact typeMobile device

A card reader device using a mobile and the method thereof is introduced. The mobile is adopted to supply electric power through audio output jack, and to transmit card data applied from the card reader device via microphone input jack. The card reader unit is connected to the audio jack of the mobile, and offers card data read by the card reader units via microphone input of the mobile. The card reader device comprises a contact type card reader unit to read cards with magnetic strips, and a contactless type card reader unit for contactless smart cards. The card reader device of the present invention enables and simplifies card transaction through mobile devices, and the reader is combinable with any mobiles with audio jack only.

Owner:DAURI SOLUTION CO LTD

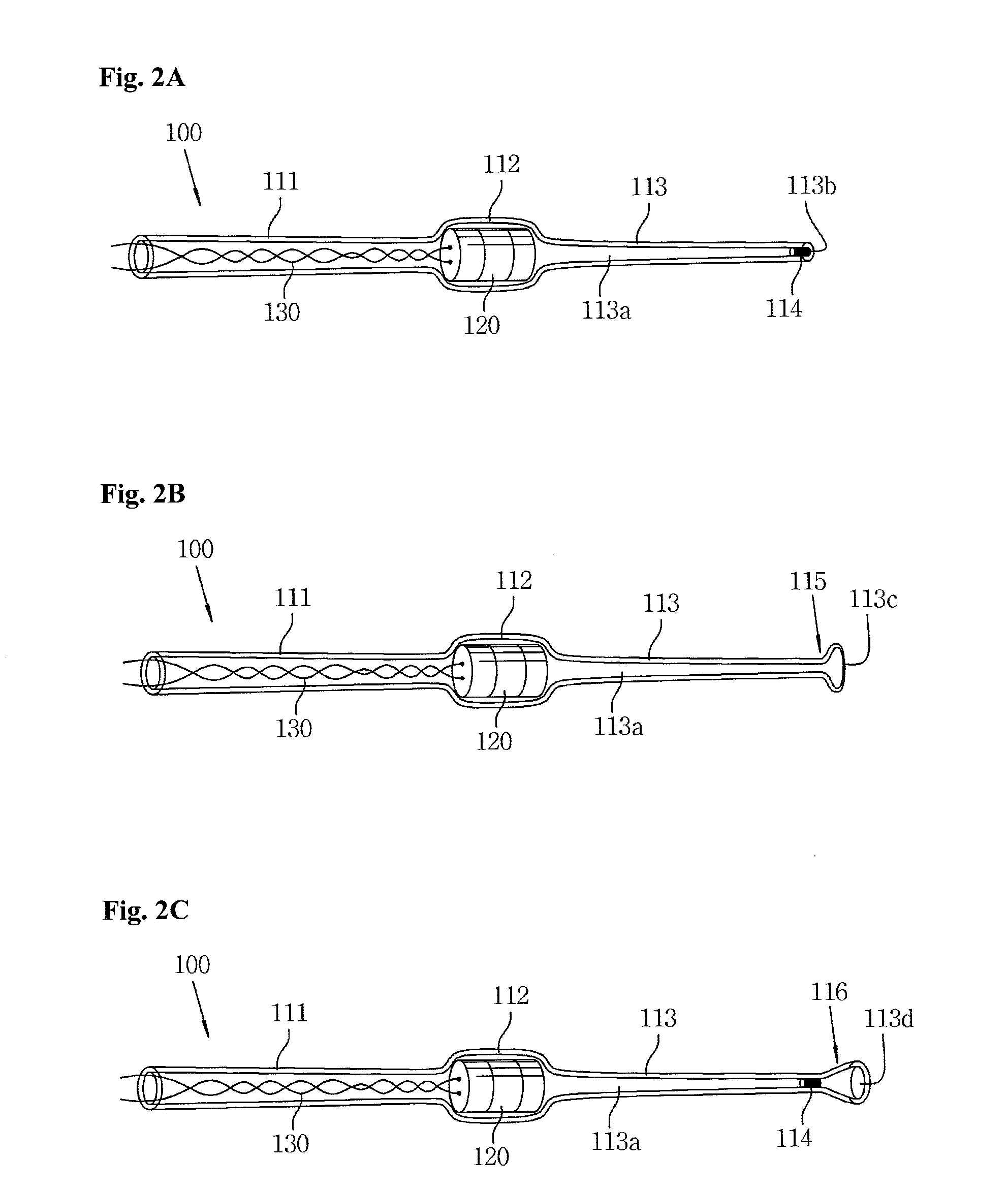

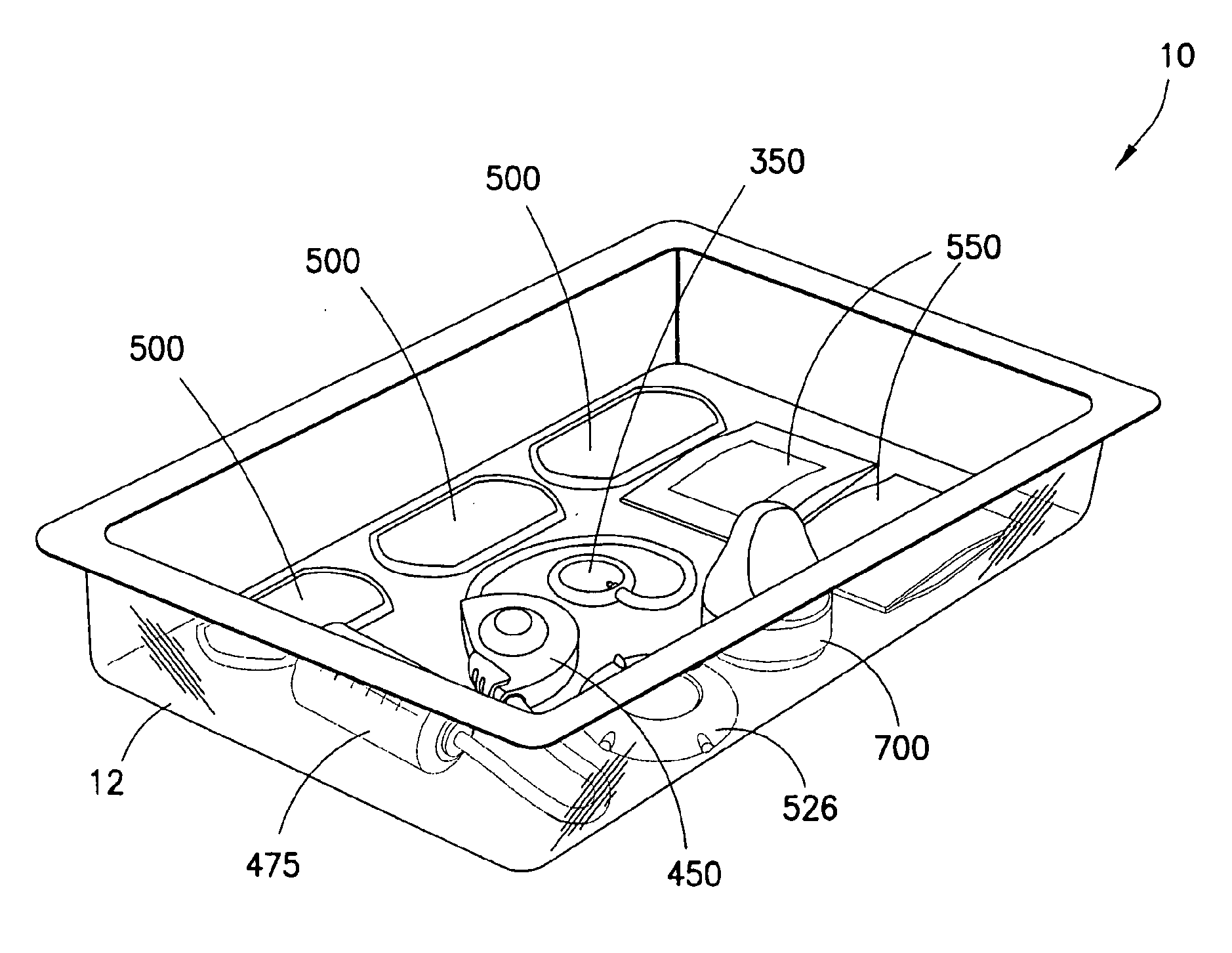

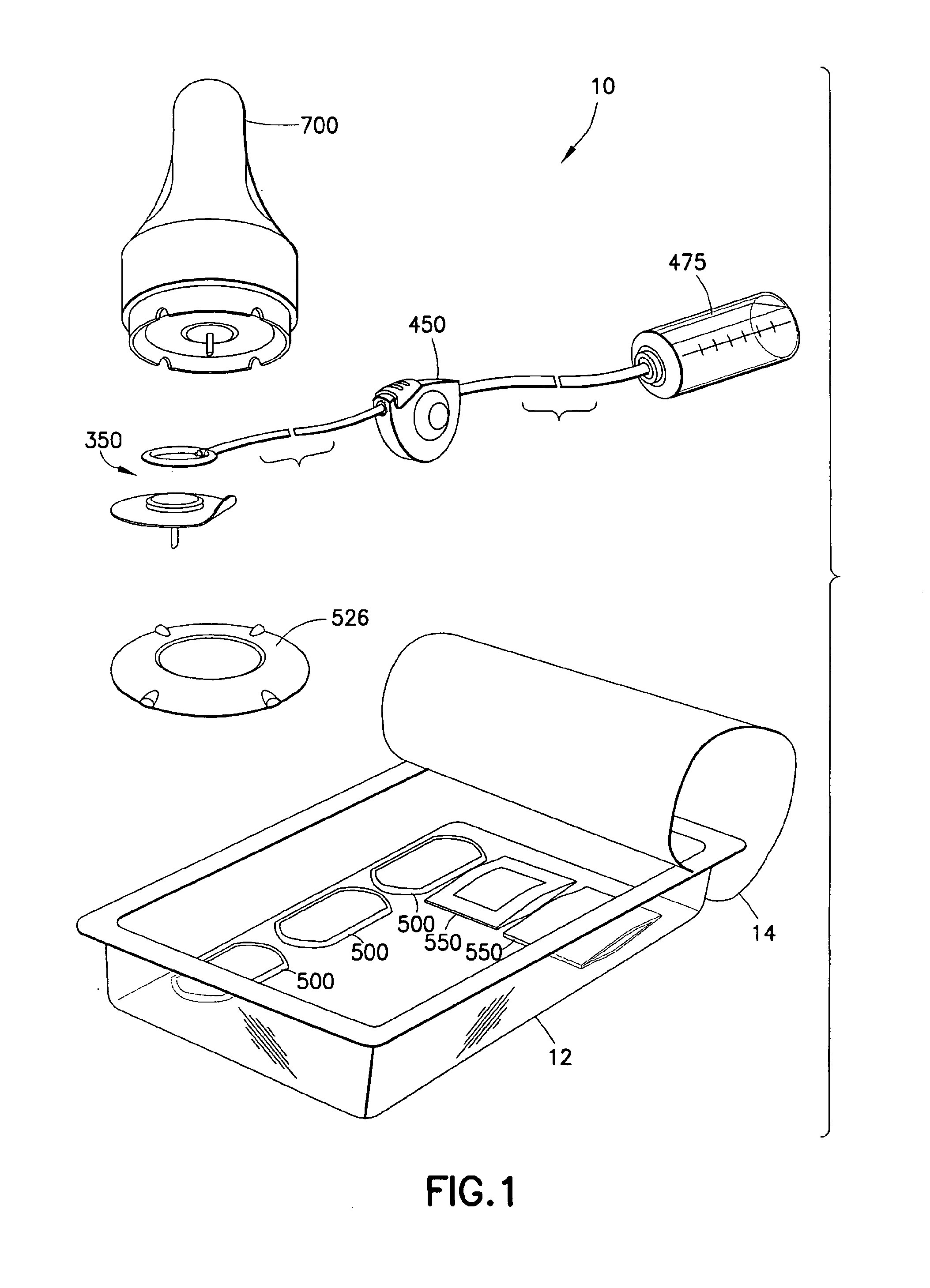

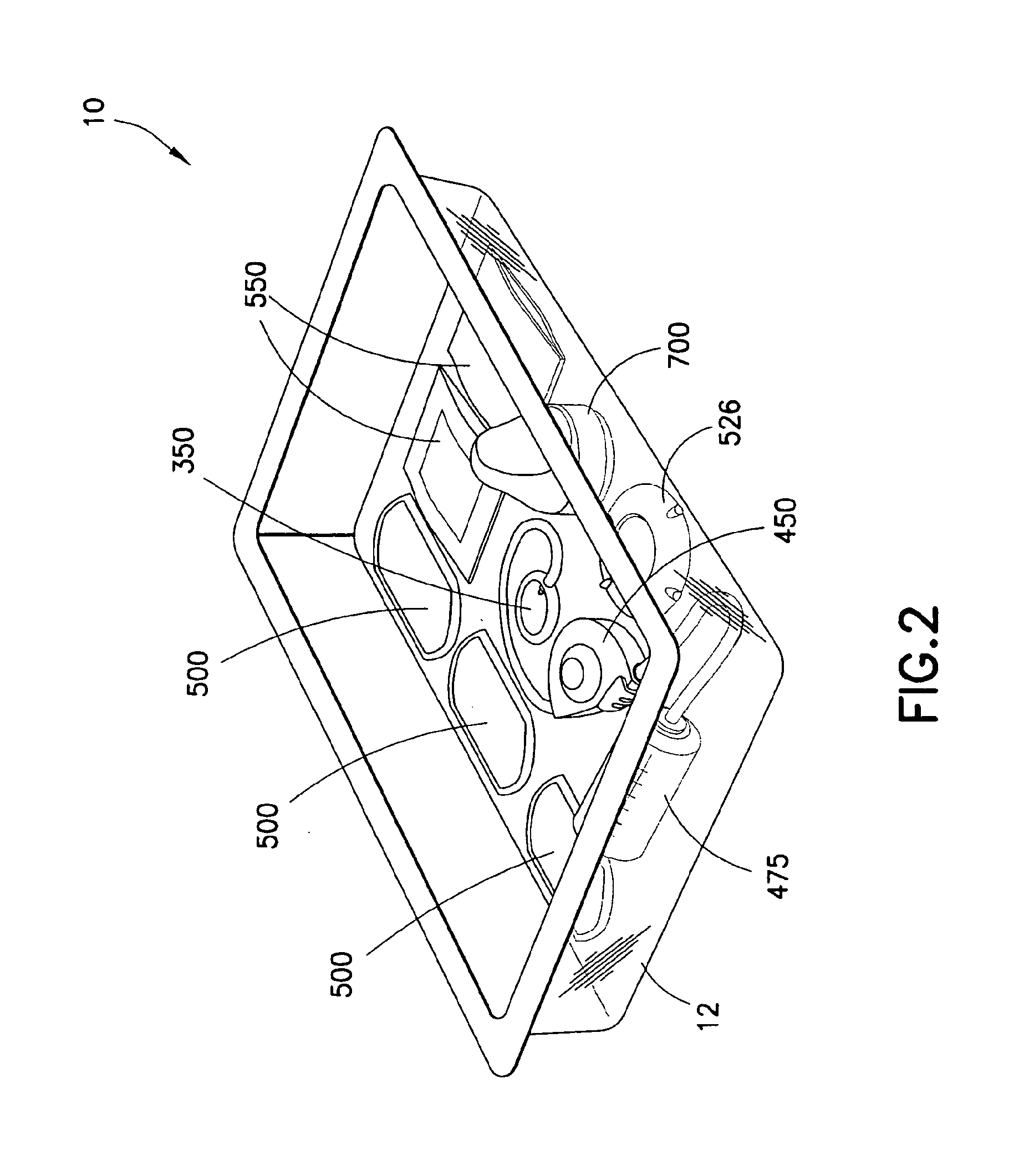

Infusion set

ActiveUS20120150123A1Easy to assembleSimplify useDispensing apparatusDiagnosticsMedicineInfusion set

A single package infusion set is provided, including one or more of the following inserters: pushbutton-type, squeeze-type, contact-type, skin pinching-type, folding retraction-type, or multistage-type inserter having at least one reusable stage. The infusion set further includes adhesion means with user-selectable degrees of adhesion strength, self-sealing tube connection means, a lens feature to view, a site beneath the set, exemplary tube management and connection elements, insulin supply, adhesion concealment means, finger loops on the inserter and site preparation wipes or sprays, optionally provided as part of the inserter. The system further includes a package which may hold a number of easily released sets, retrievable by an inserter, an exemplary insertion needle handle and shroud, an exemplary squeeze-type latch between an upper portion and a lower portion of the set, and / or a tool removable upper portion of the set.

Owner:BECTON DICKINSON & CO

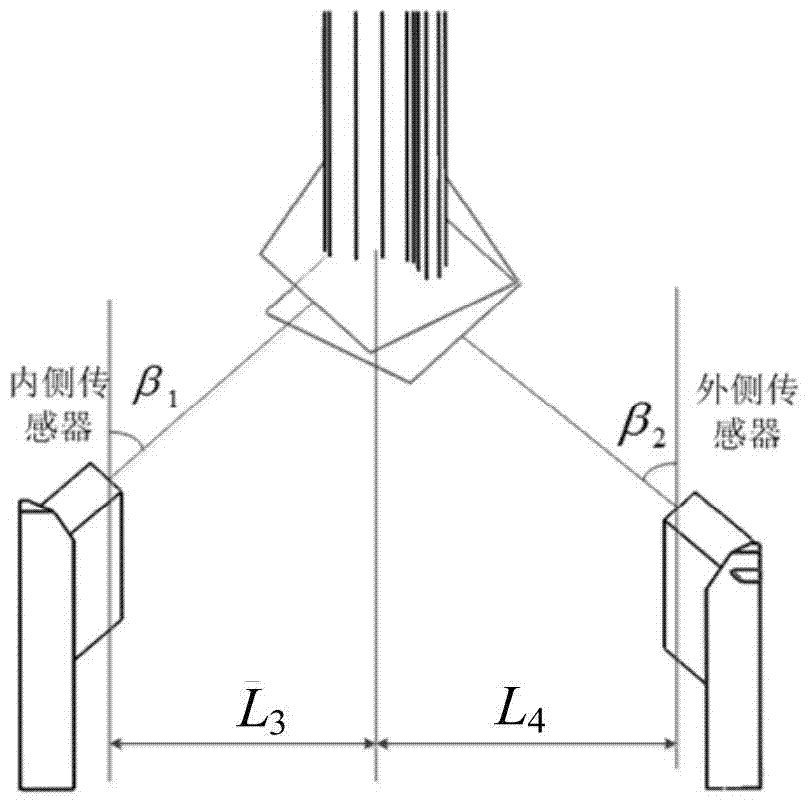

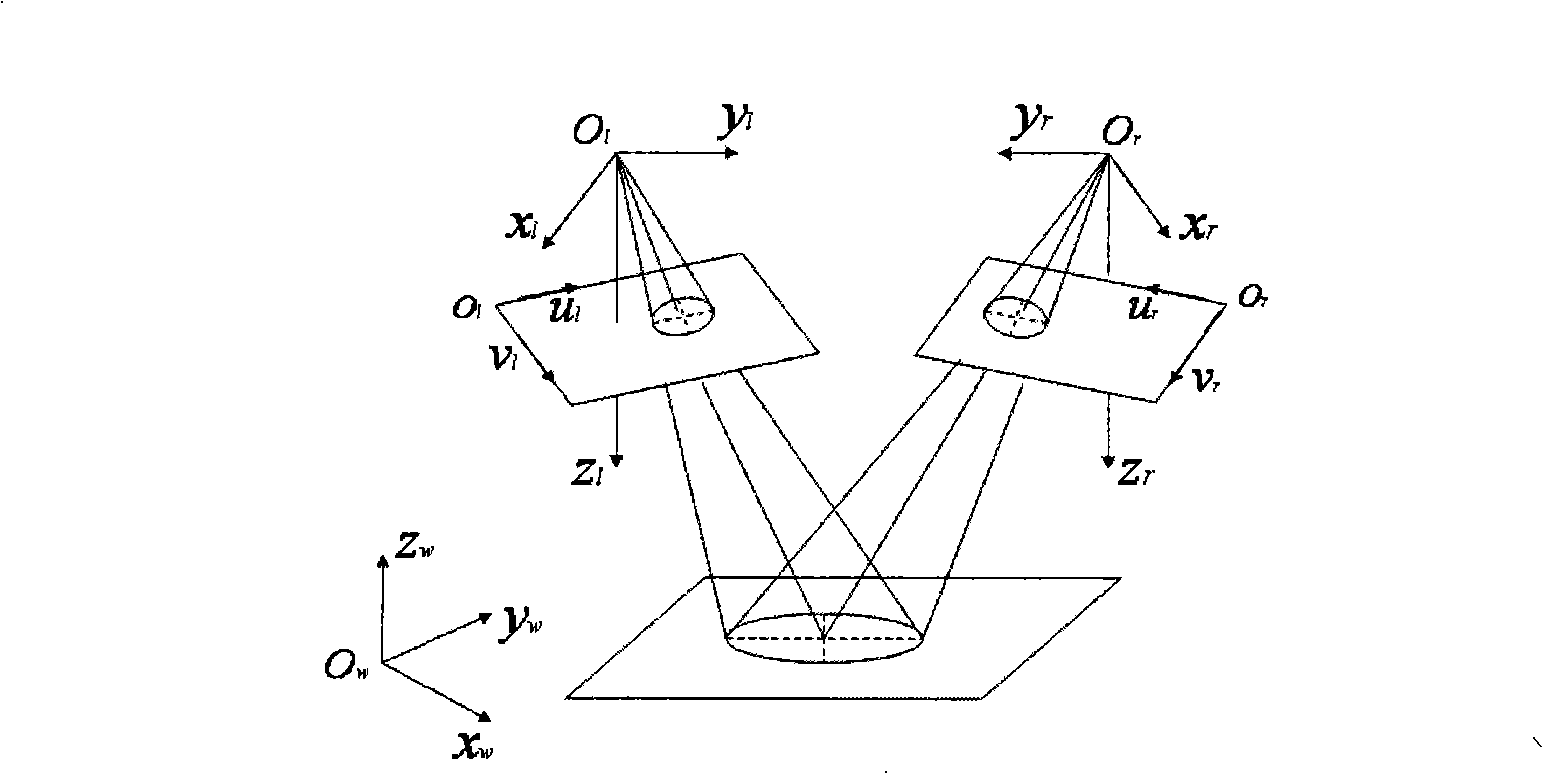

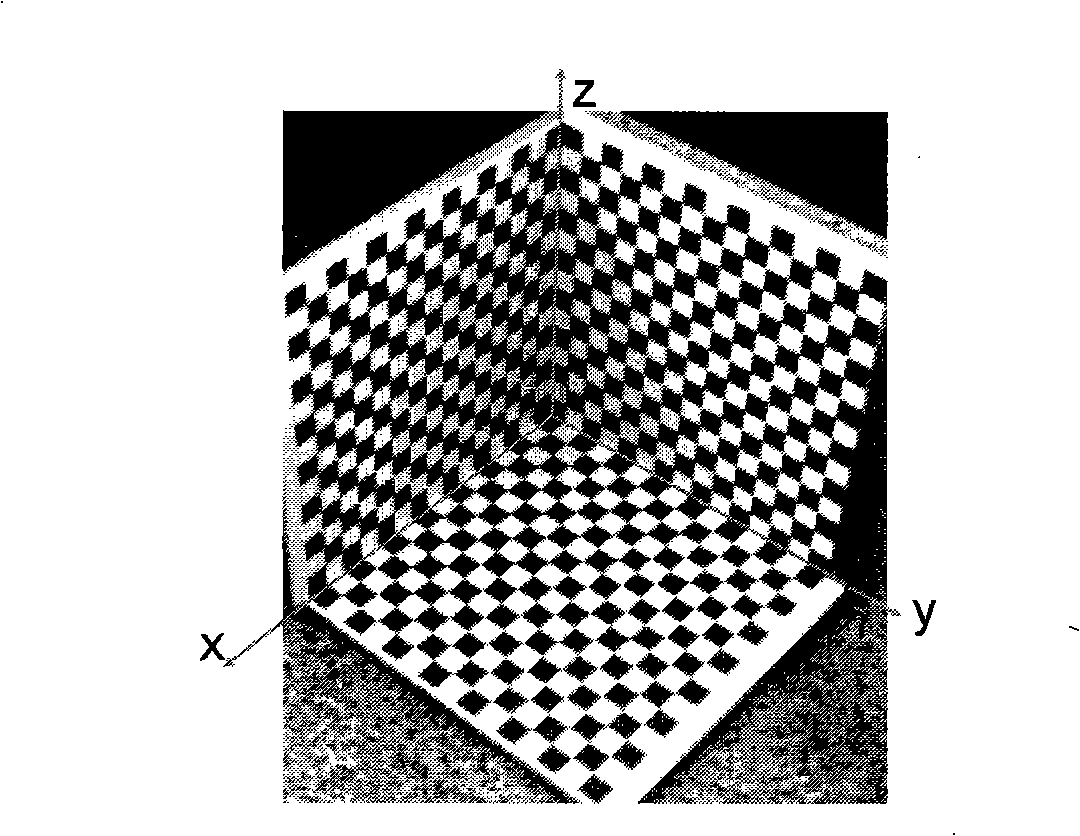

Spatial circular geometric parameter binocular stereo vision measurement method

InactiveCN101261115APrecise sub-pixel precisionSmall amount of calculationBiological neural network modelsUsing optical meansBinocular stereoVisual perception

The invention discloses a spatial circle geometrical parameter dual-eye solid visual measurement method suitable for non-contact type online measurement of the spatial circle geometrical parameter of an industrial product, aiming at overcoming the existing problems of low measurement precision, slow measurement speed and low automation degree. The method is divided into a calibrating stage, an image processing stage and a spatial circle fitting stage. A neural network technique is firstly adopted to carry out the calibration of a camera; a dual-camera is utilized to carry out the extraction of sub-pixel image edges of the spatial circle, a simple algorithm is developed based on the image gray gradient distribution characteristic so as to realize the match of edge points, the practical 3D spatial coordinates of the circle edges are then obtained, and the geometrical parameters of the spatial circle comprise radius, position of center of circle and orientation of the plane where the spatial circle is arranged are gained by the fitting of the spatial circle with corresponding mathematical geometrical knowledge. The spatial circle geometrical parameter dual-eye solid visual measurement method has fast image processing speed and high automation degree, and has relative measurement error of the spatial circle of superior to plus or minus 0.6% when the plane where the spatial circle is arranged has an angle of about 50 DEG with the image plane.

Owner:JILIN UNIV

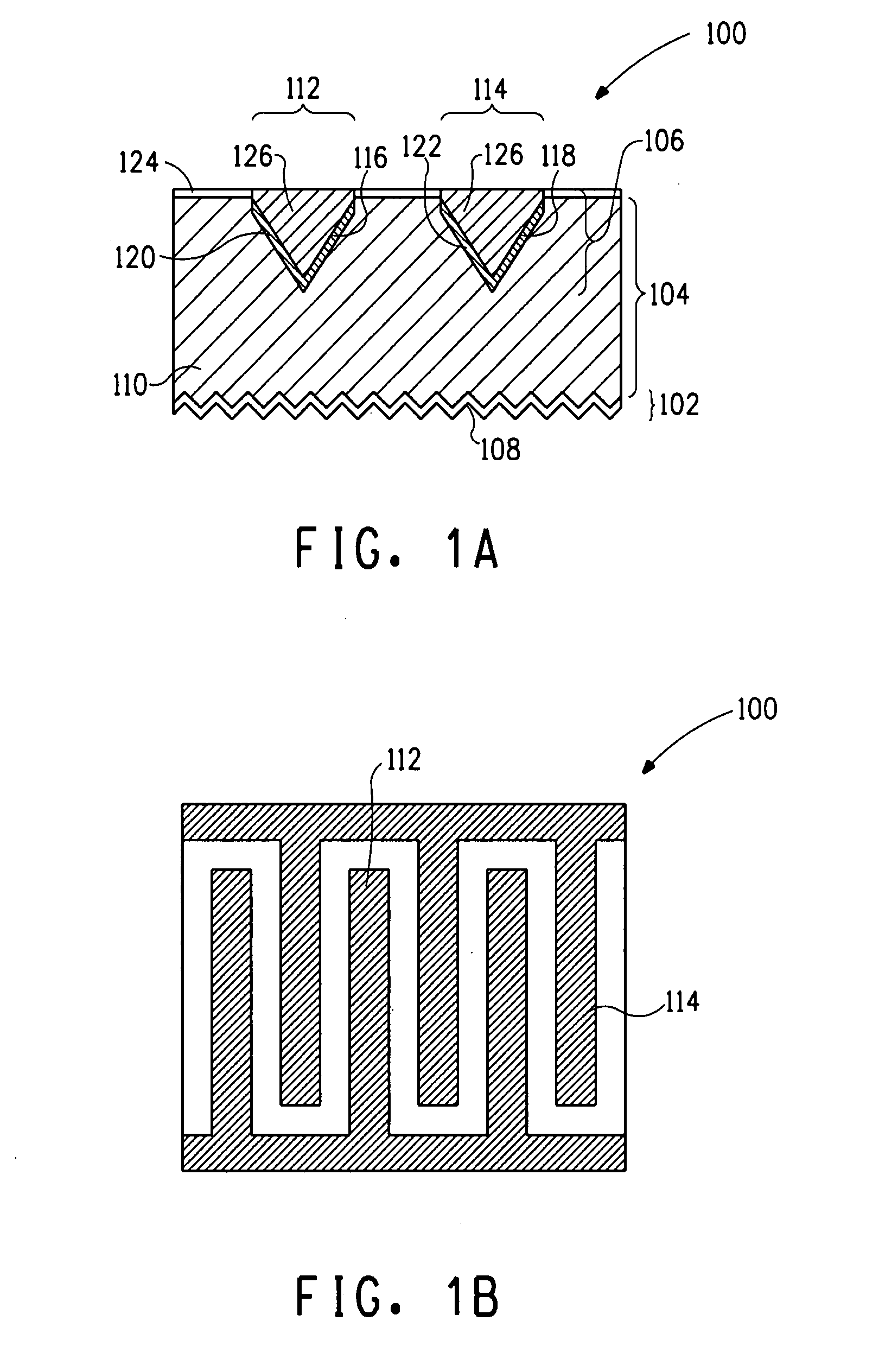

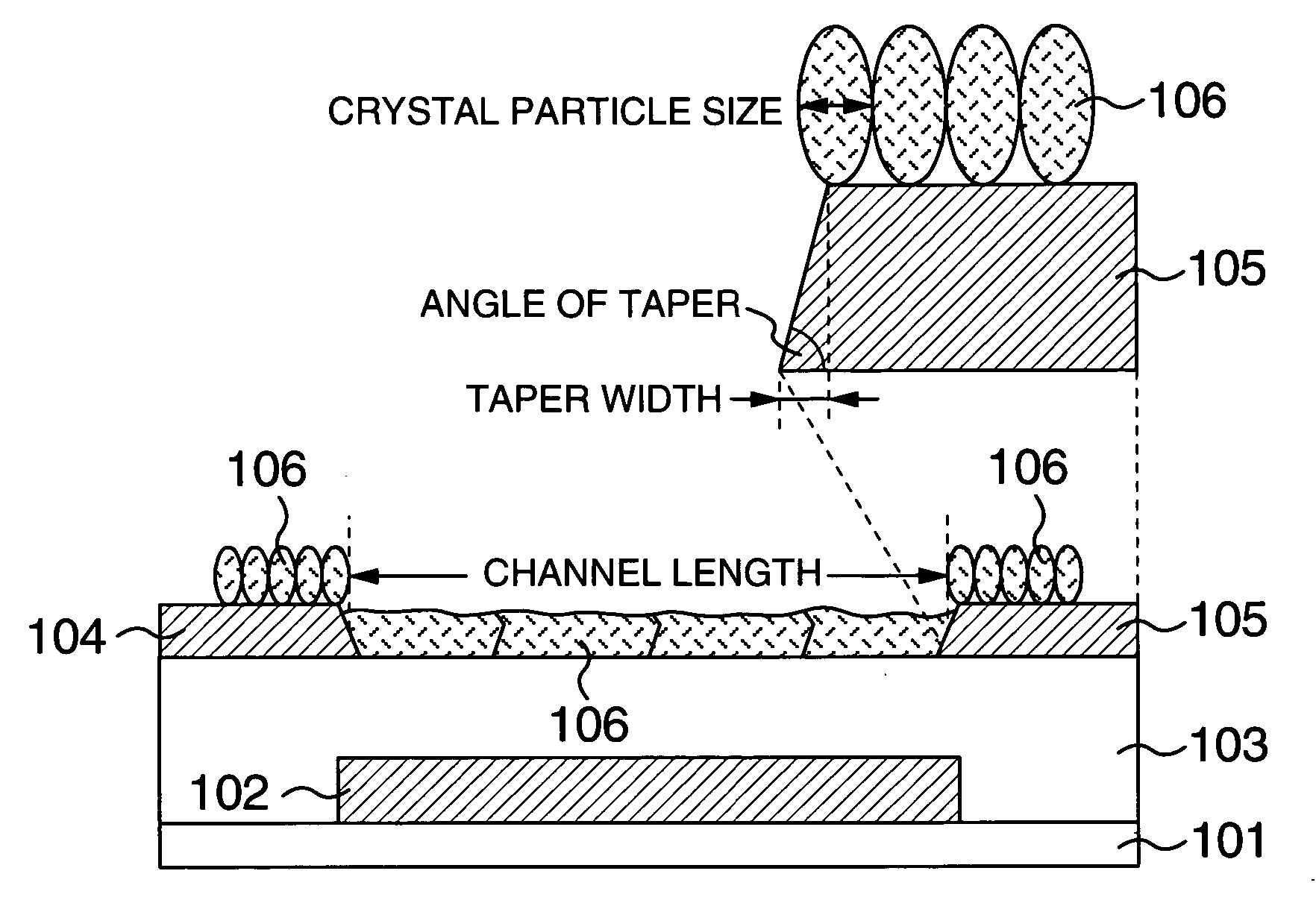

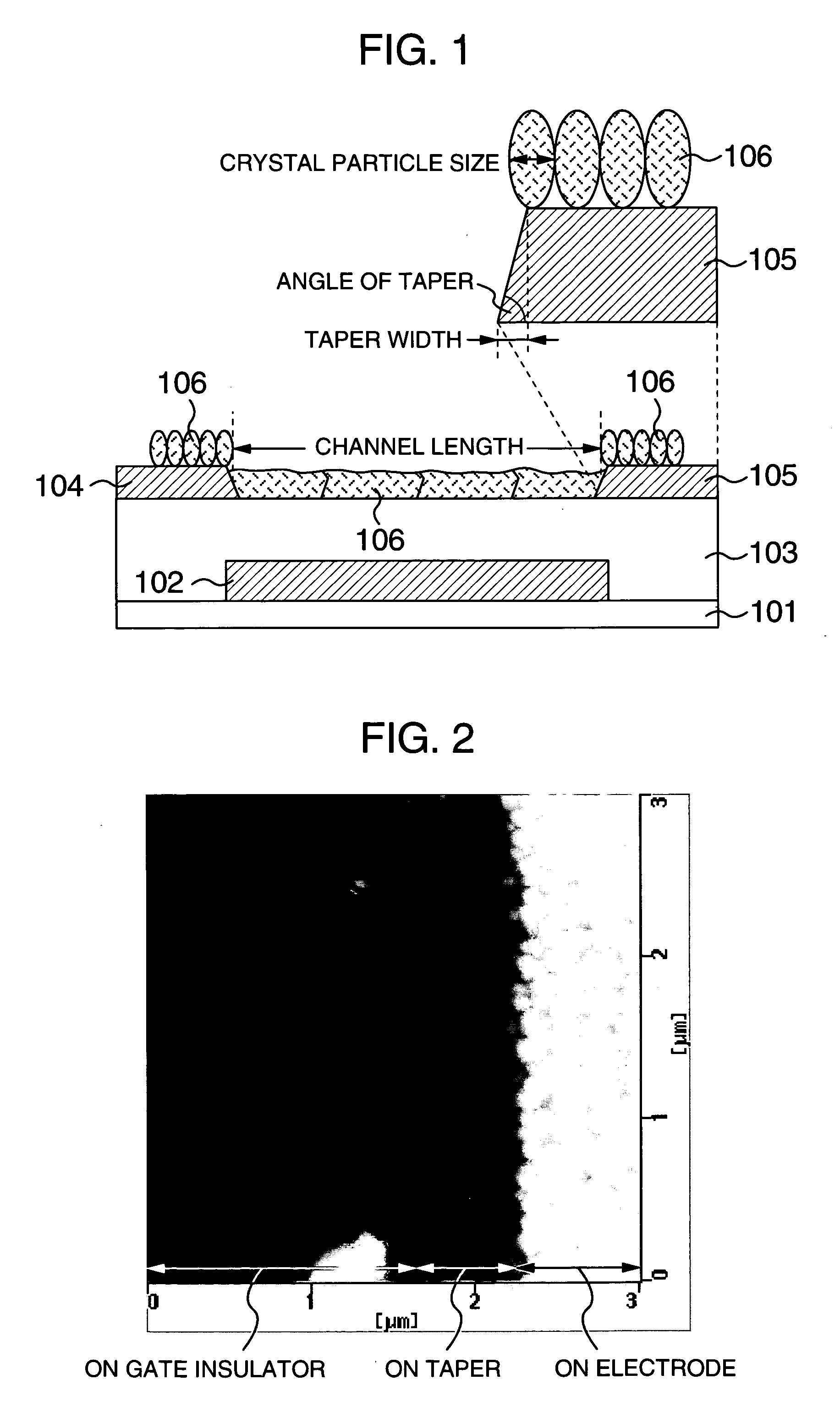

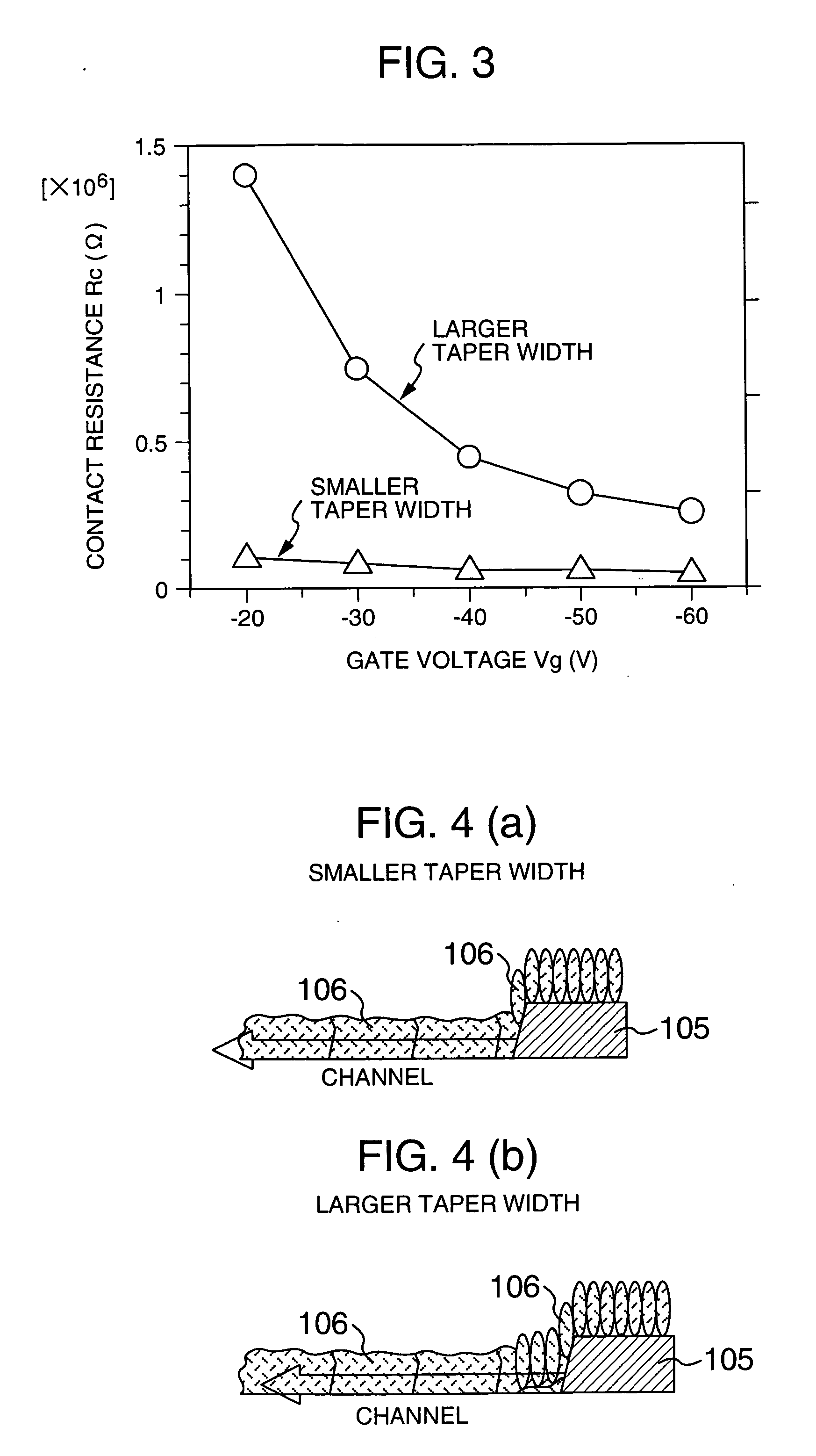

Semiconductor device and manufacturing method thereof

InactiveUS20050056897A1Reduce contact resistanceIncrease volumeTransistorSemiconductor/solid-state device detailsSimple Organic CompoundsDevice material

An object of the present invention is to provide a semiconductor device such as a display device, ID tag, sensor or the like at low cost by using a bottom contact type organic TFT as a switching element. In the present invention, the semiconductor layer of the bottom contact type organic TFT is formed of a polycrystalline material, and the taper width of each of the source and drain electrodes of the TFT in the direction of the channel length is smaller than the average particle size of semiconductor crystals grown on the source and drain electrodes. Alternatively, the side on the channel side of each of the source and drain electrodes of the bottom contact type organic TFT is formed so as to be convex upward with respect to the substrate surface. Alternatively, an organic compound layer different from the semiconductor layer of the bottom contact type organic TFT is made present between each of the source and drain electrodes of the bottom contact type organic TFT and said semiconductor layer, in a thickness of not more than 10 Å and not less than 1 Å.

Owner:HITACHI LTD

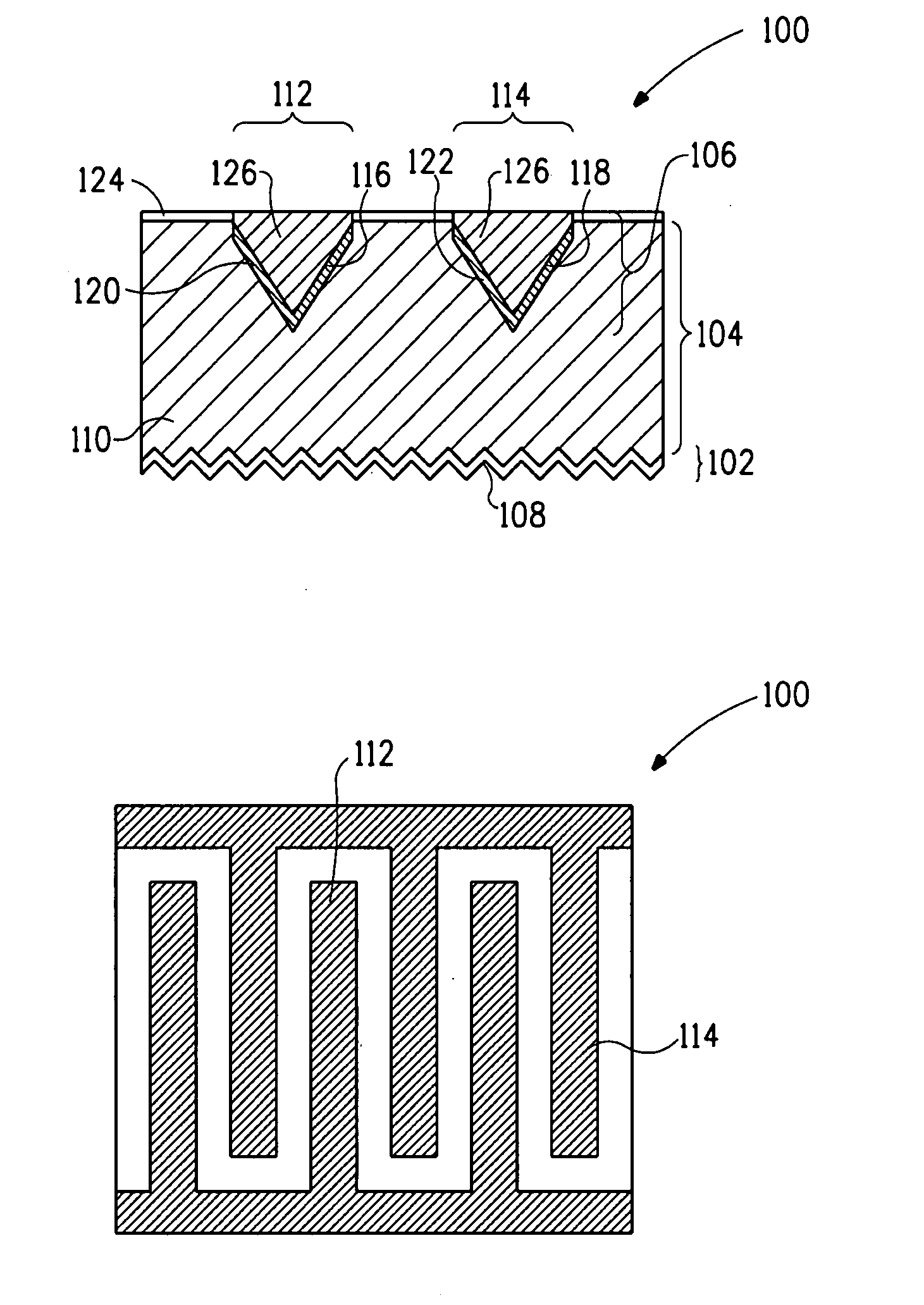

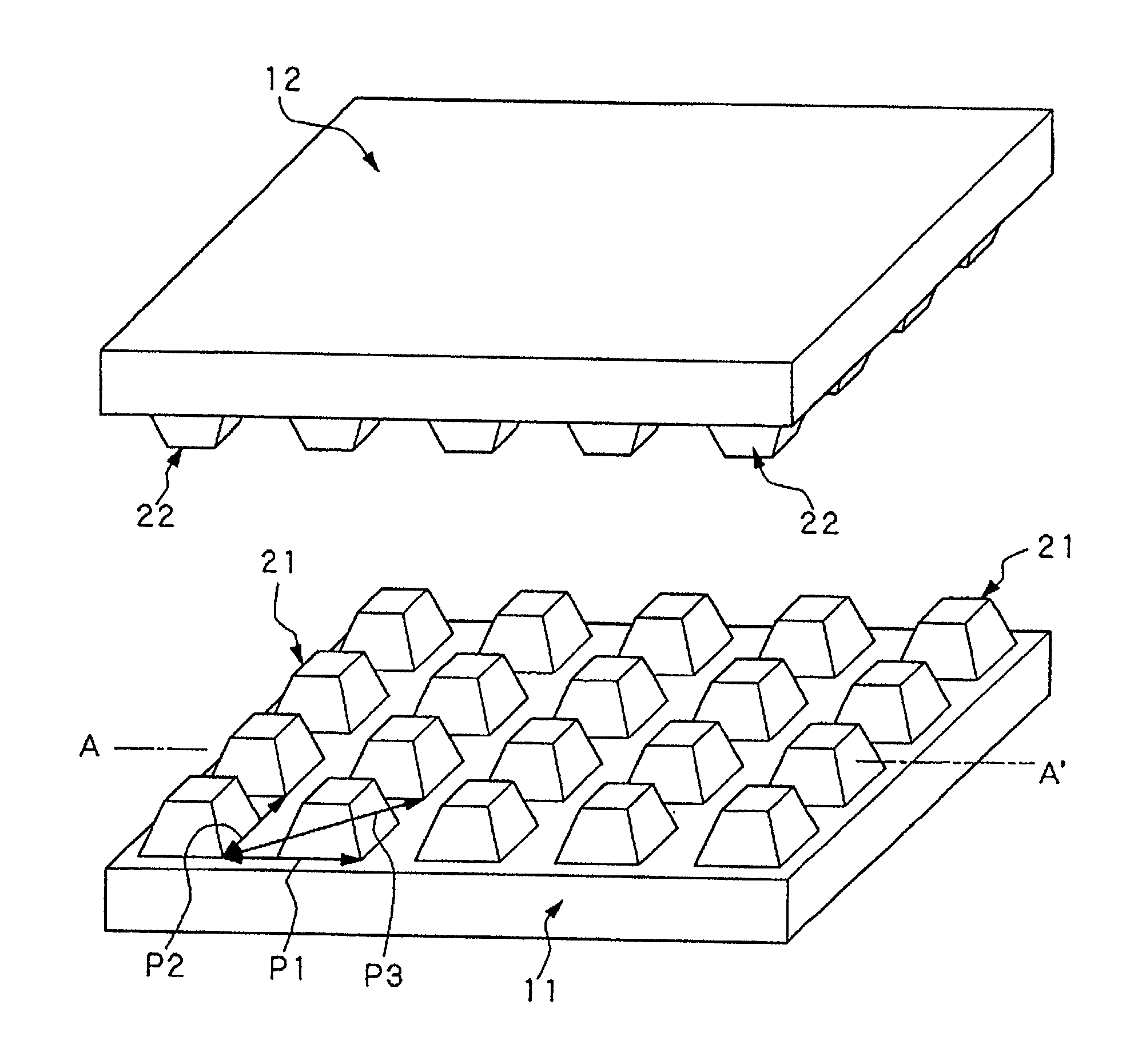

Touch panel and electronic device

InactiveUS7034808B2Reduce light reflectionHigh light transmittanceInput/output for user-computer interactionCathode-ray tube indicatorsCapacitanceEngineering

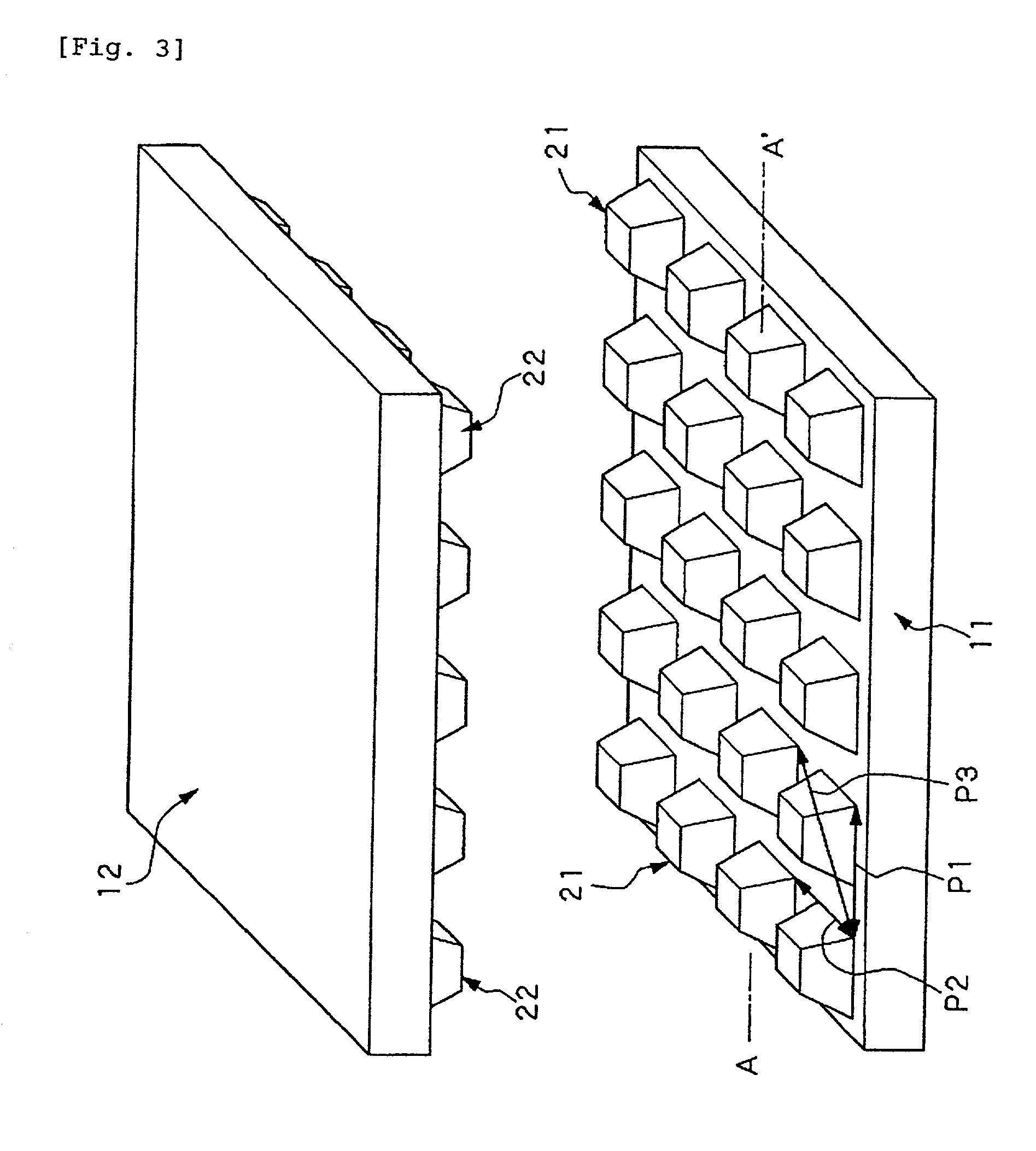

The present invention provides a touch panel having pluralities of projections, each of the projections having a predetermined shape, formed on inner surfaces of a lower substrate and an upper substrate, respectively. The projections being formed in at least two directions with a substantially periodical pitch that is shorter than any wavelength of visible light. The touch panel can also include a lower transparent electrode and an upper transparent electrode formed over the inner surfaces of the lower substrate and the upper substrate having the pluralities of projections, respectively. The cross-sectional area of each of the projections parallel to the outer surface of the lower substrate is configured to decrease continuously from bottom to top of the projection. The same applies to the combination of each of the projections, the bottom and a top thereof, and the upper substrate. Accordingly, this structure reduces the light reflection and diffraction at the boundary between an air space and the transparent electrode, thereby providing a resistive contact-type touch panel or a electrostatic capacitive coupling-type touch panel having high light transmittance.

Owner:SEIKO EPSON CORP

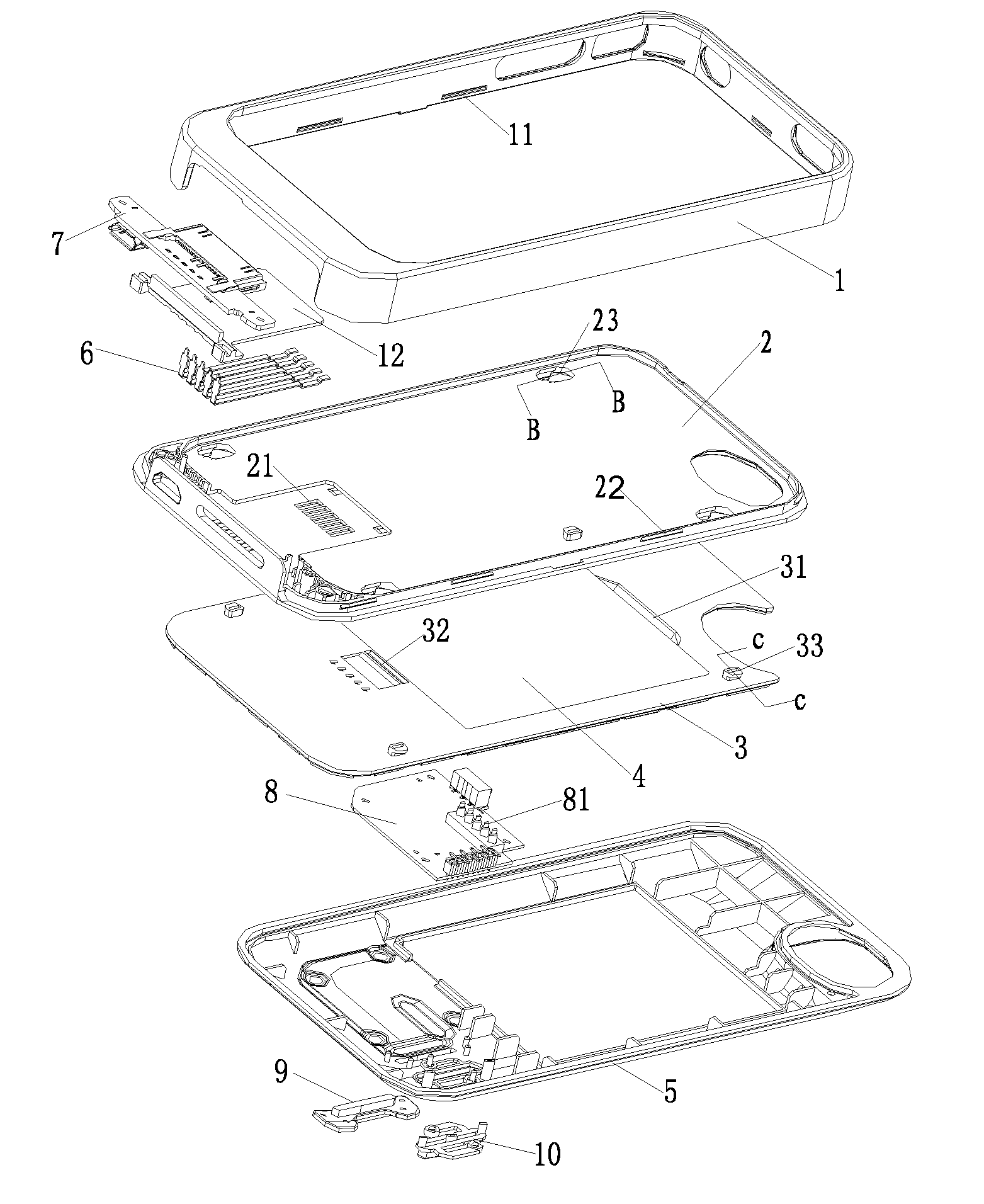

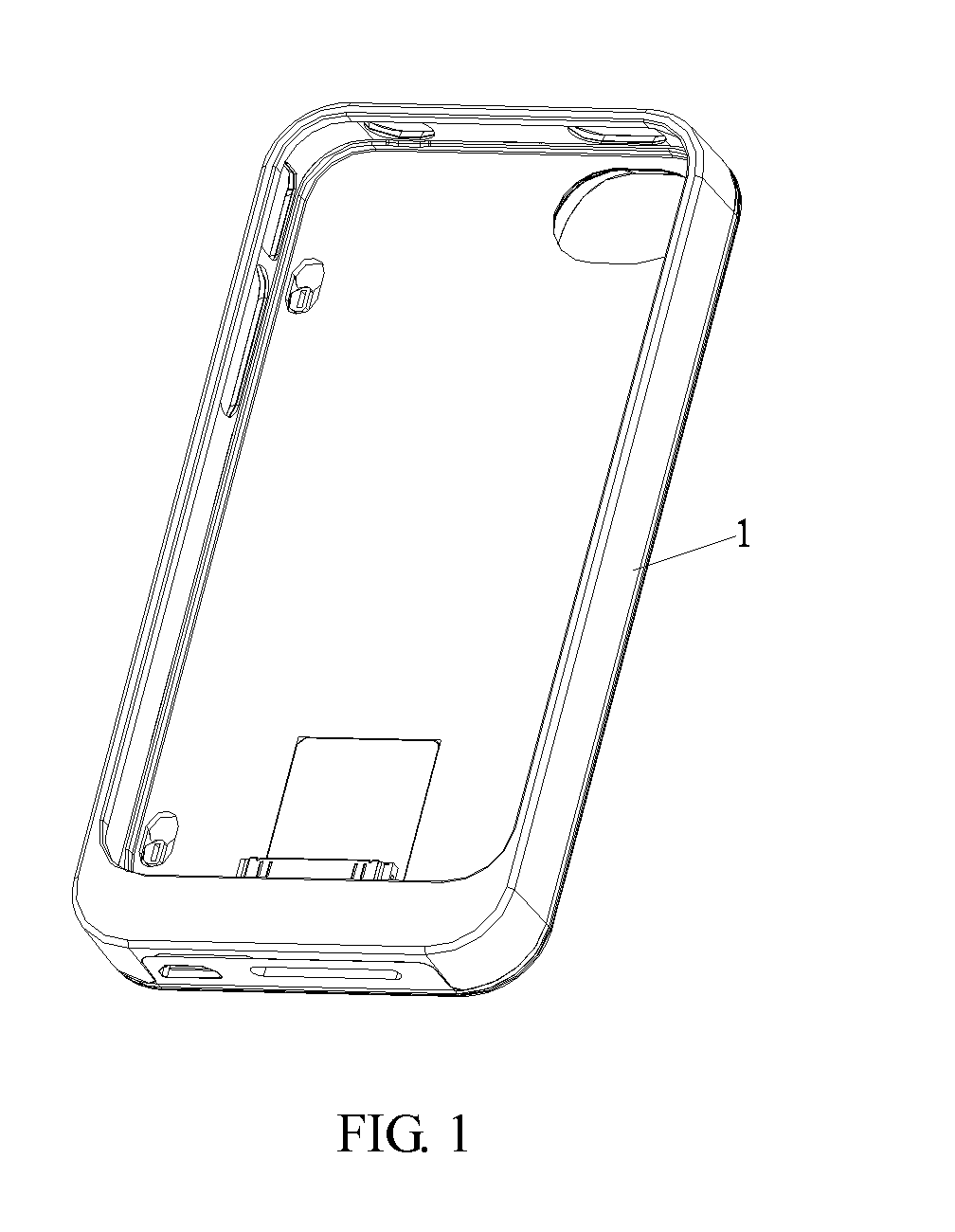

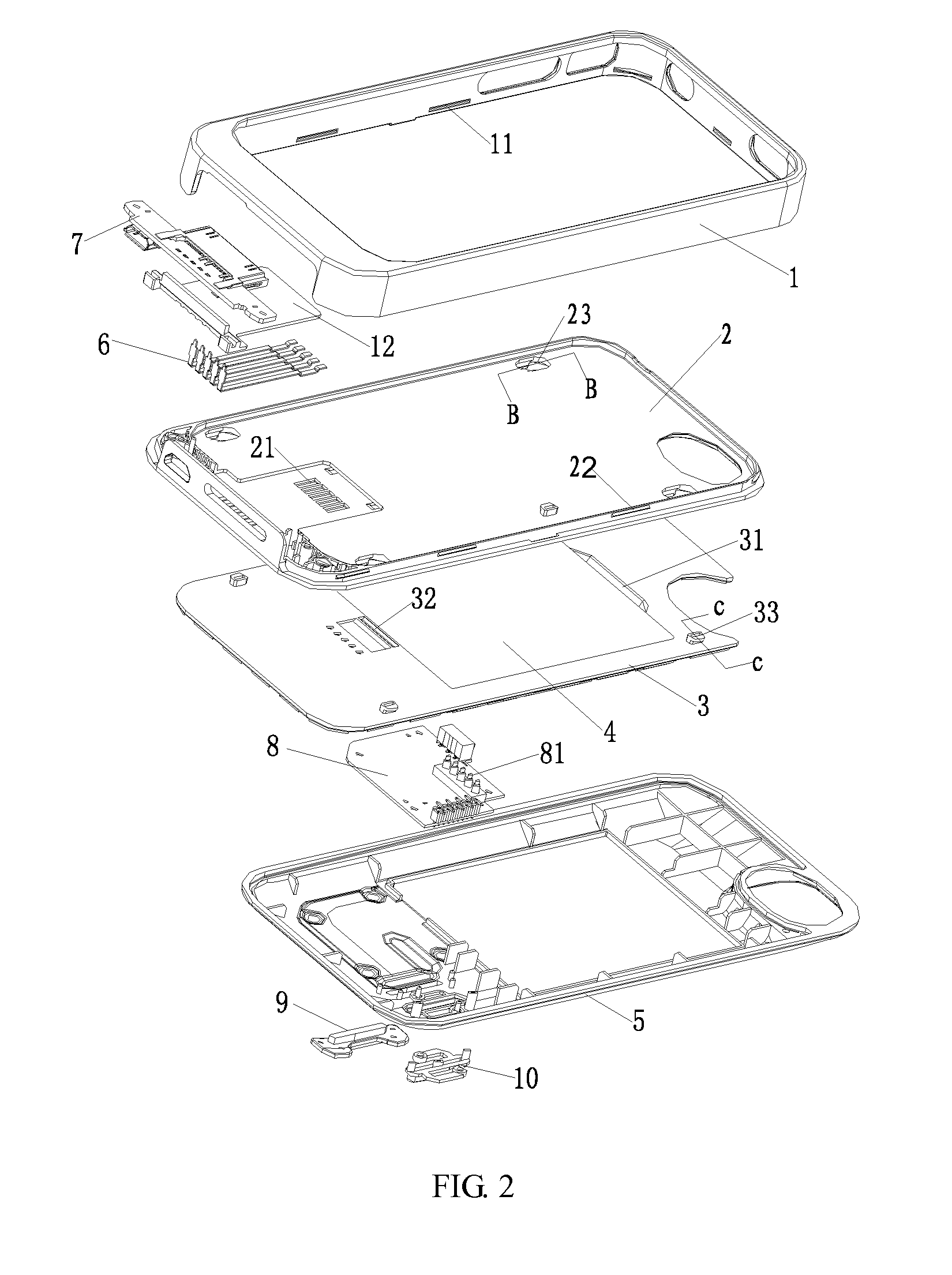

Contact type portable power

InactiveUS20130314880A1Easy to changeEasy to useCasings/cabinets/drawers detailsCells structural combinationPortable powerContact type

The present disclosure includes a protective sleeve assembly and a battery module, wherein the protective sleeve assembly includes a frame and a terminal fixing plate, a terminal circuit board and a connector port are arranged on the terminal fixing plate, an end of a conduction sheet is connected to the terminal circuit board, the other end of the conduction sheet is in a limiting hole of the terminal fixing plate; the battery module includes a upper cover, a lower cover and a charge-discharge control circuit board, a conduction electrode is arranged on the charge-discharge control circuit board and connected with a battery. When the mobile phone is fixed with the protective sleeve assembly, a special port of the mobile phone is transformed into a general port by the conversion circuit of the terminal circuit board, so it's easy to charge the mobile phone by the general port.

Owner:SHENZHEN WIN TOP ELECTRONICS TECH

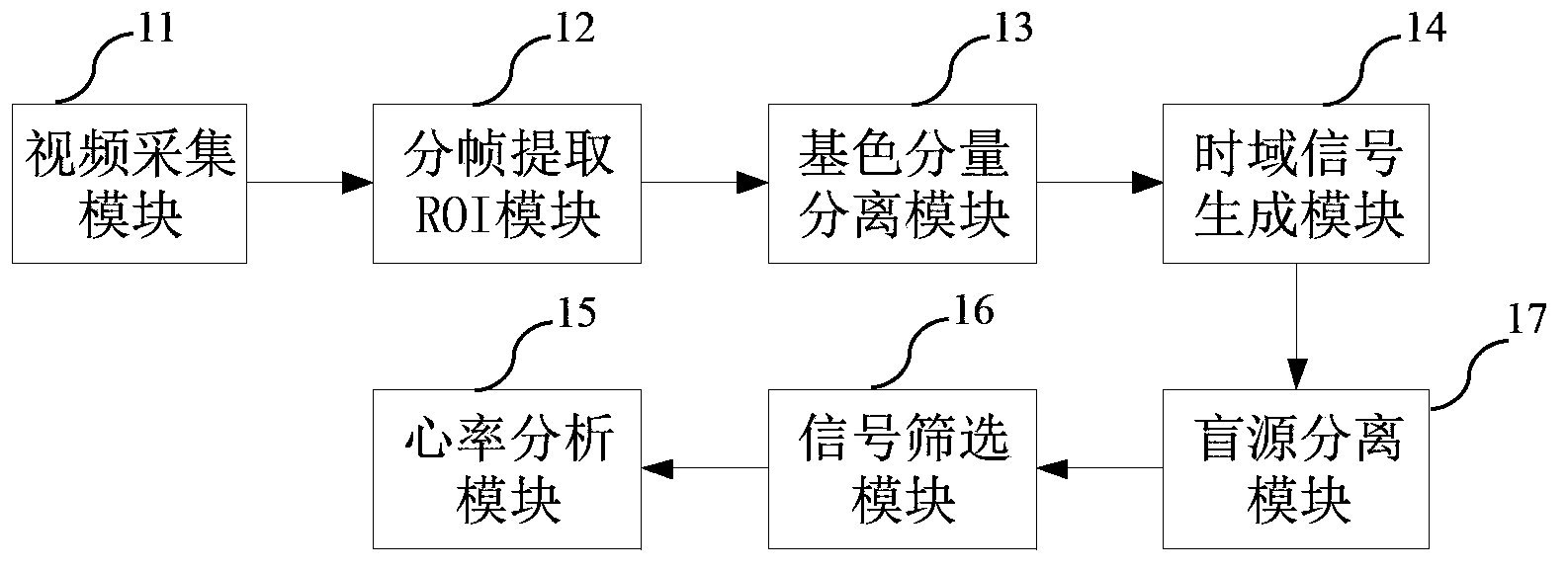

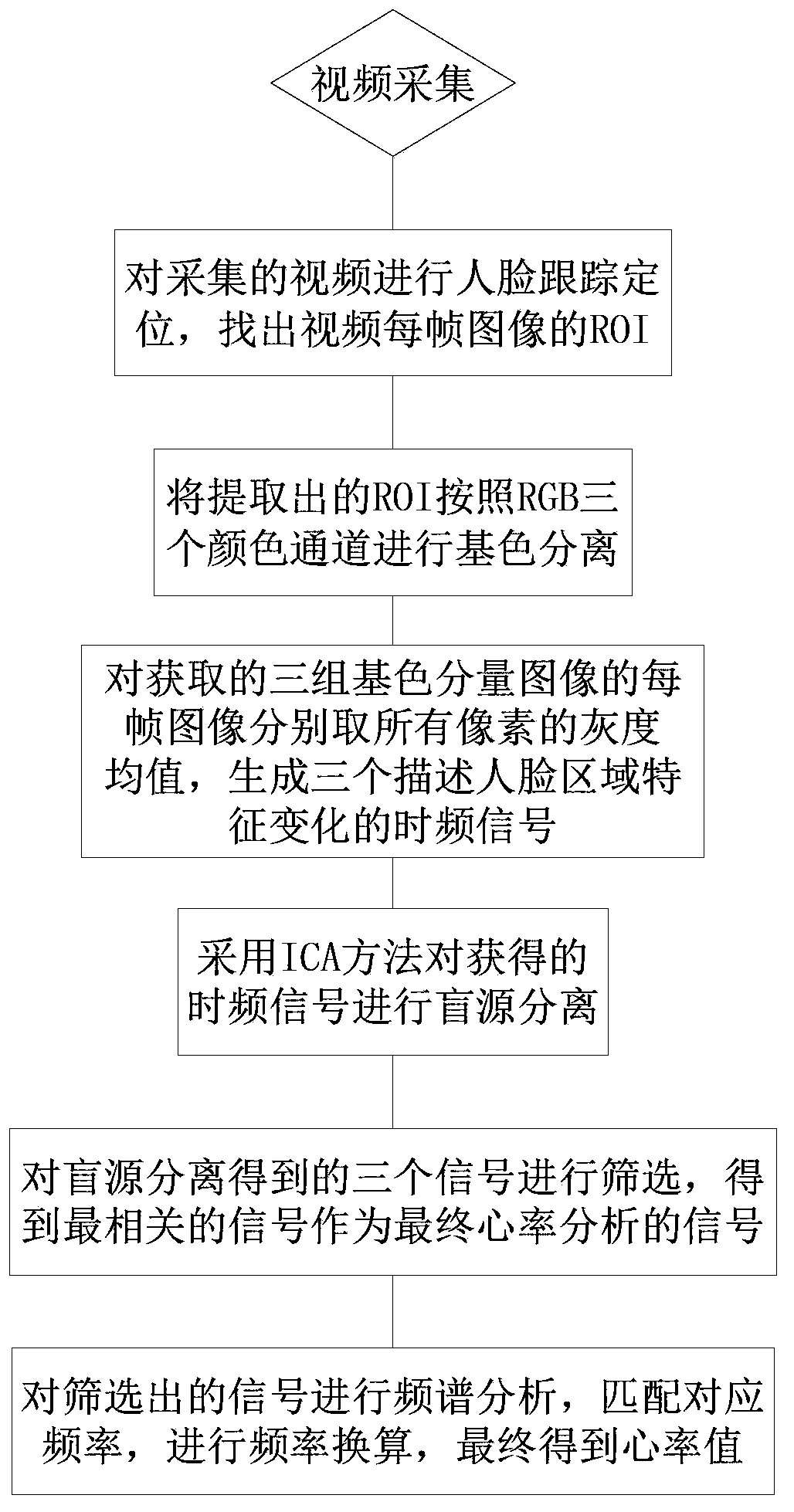

Non-contact type automatic heart rate measurement system and measurement method

InactiveCN104138254AToleranceOvercoming the Effects of Motion ArtifactsDiagnostic recording/measuringSensorsHeart rate measurementVideo record

The invention relates to the field of electronic health detection, and discloses a non-contact type automatic heart rate measurement system and a measurement method. The non-contact type automatic heart rate measurement system adopts a non-contact mode to remotely collect video data of a measured person and performs data conversion to realize automatic heart rate measurement, and is characterized by comprising a video collection module, a framing extraction ROI (region of interest) module, a primary color component separation module, a time-domain signal generation module, a blind source separation module, a signal screening module and a heart rate analysis module. Compared with the prior art, the non-contact type automatic heart rate measurement system and the measurement method are based on an automatic face track and blind source separation technology, adopt a noninvasive and non-contact type remote physiological signal detection method, overcome influence of motion artifact in video record, has motion tolerance, is high in measurement accuracy, and can perform heart rate measurement automatically and simultaneously.

Owner:TIANJIN DIANKANG TECH

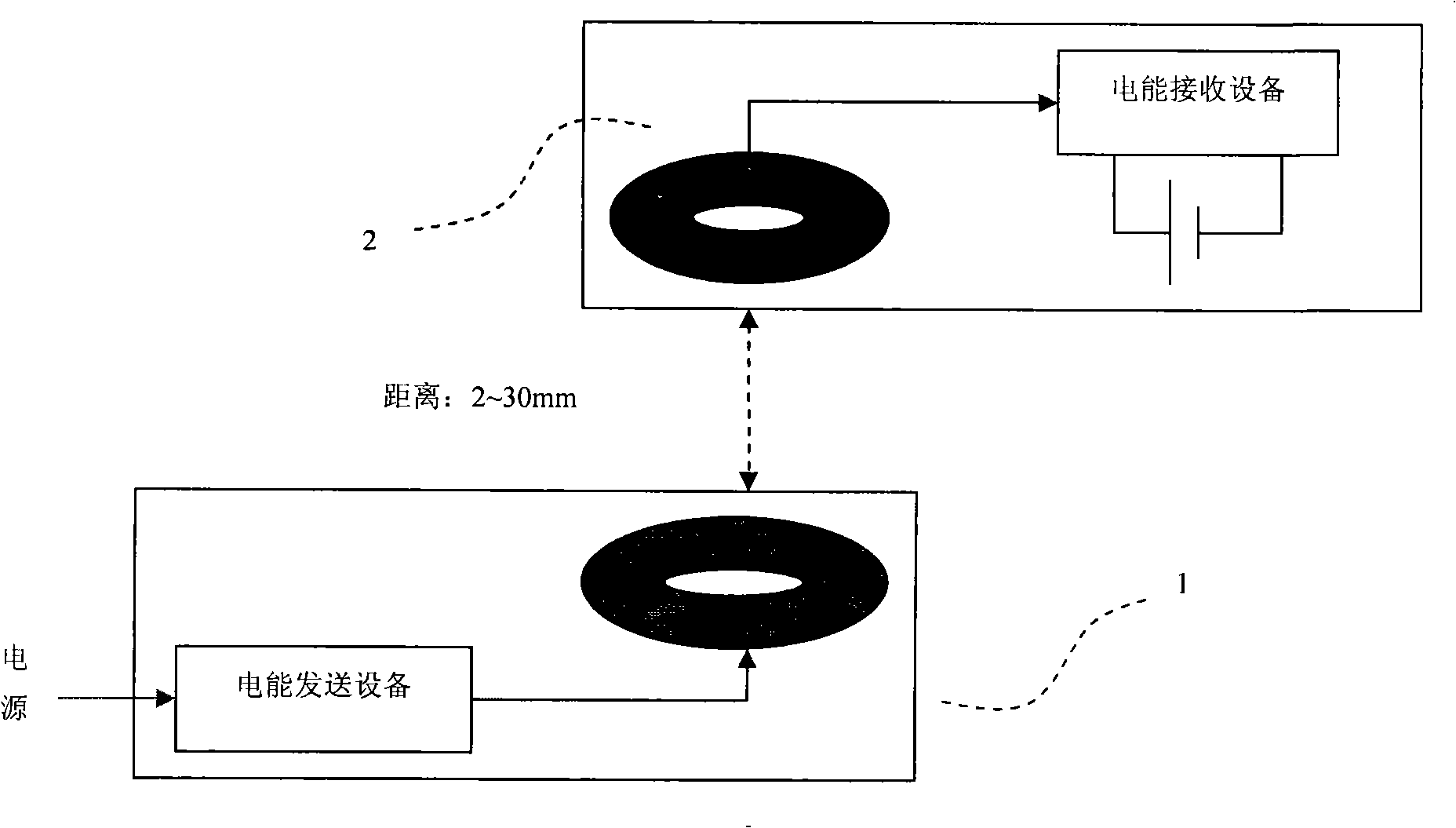

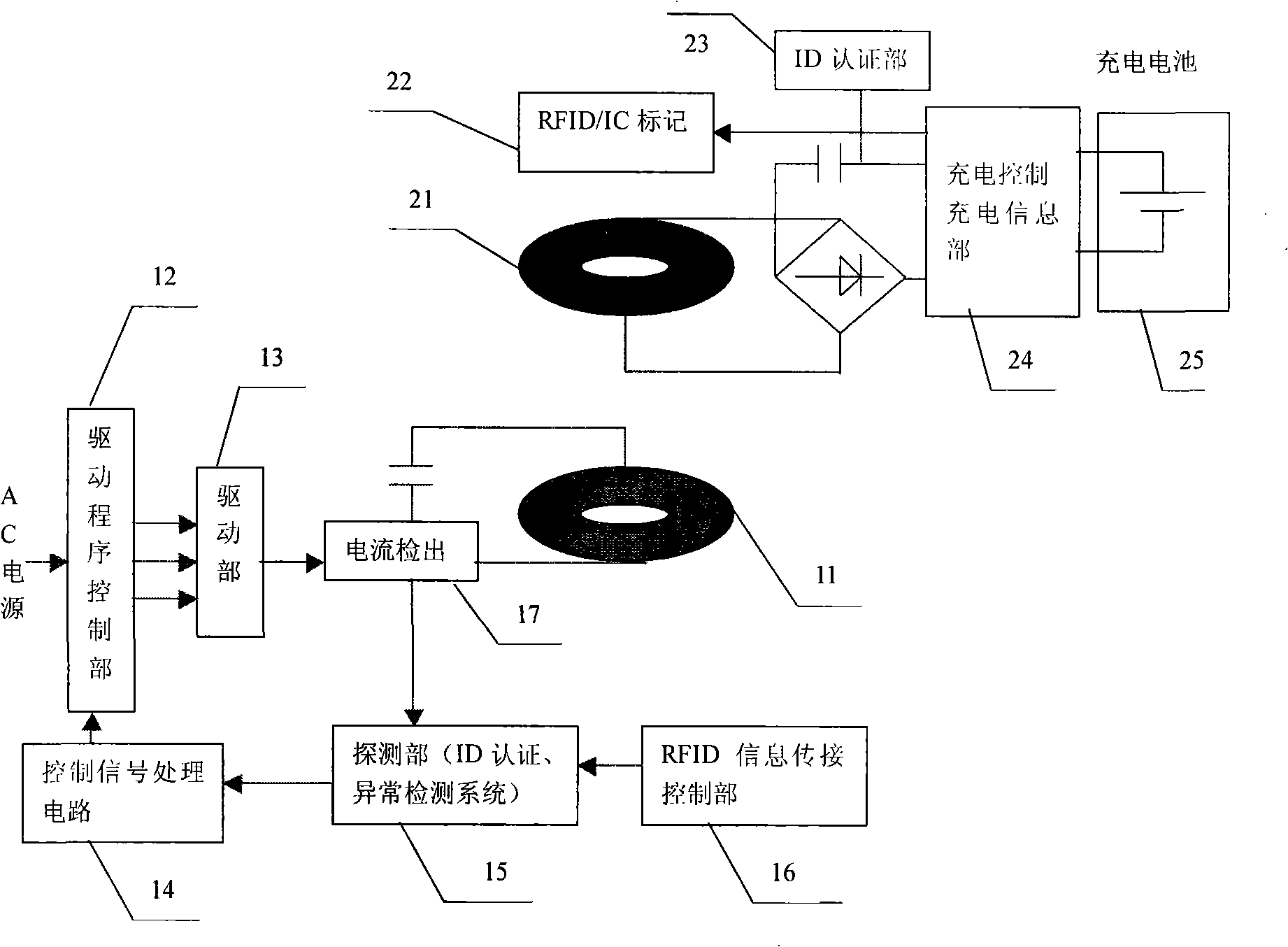

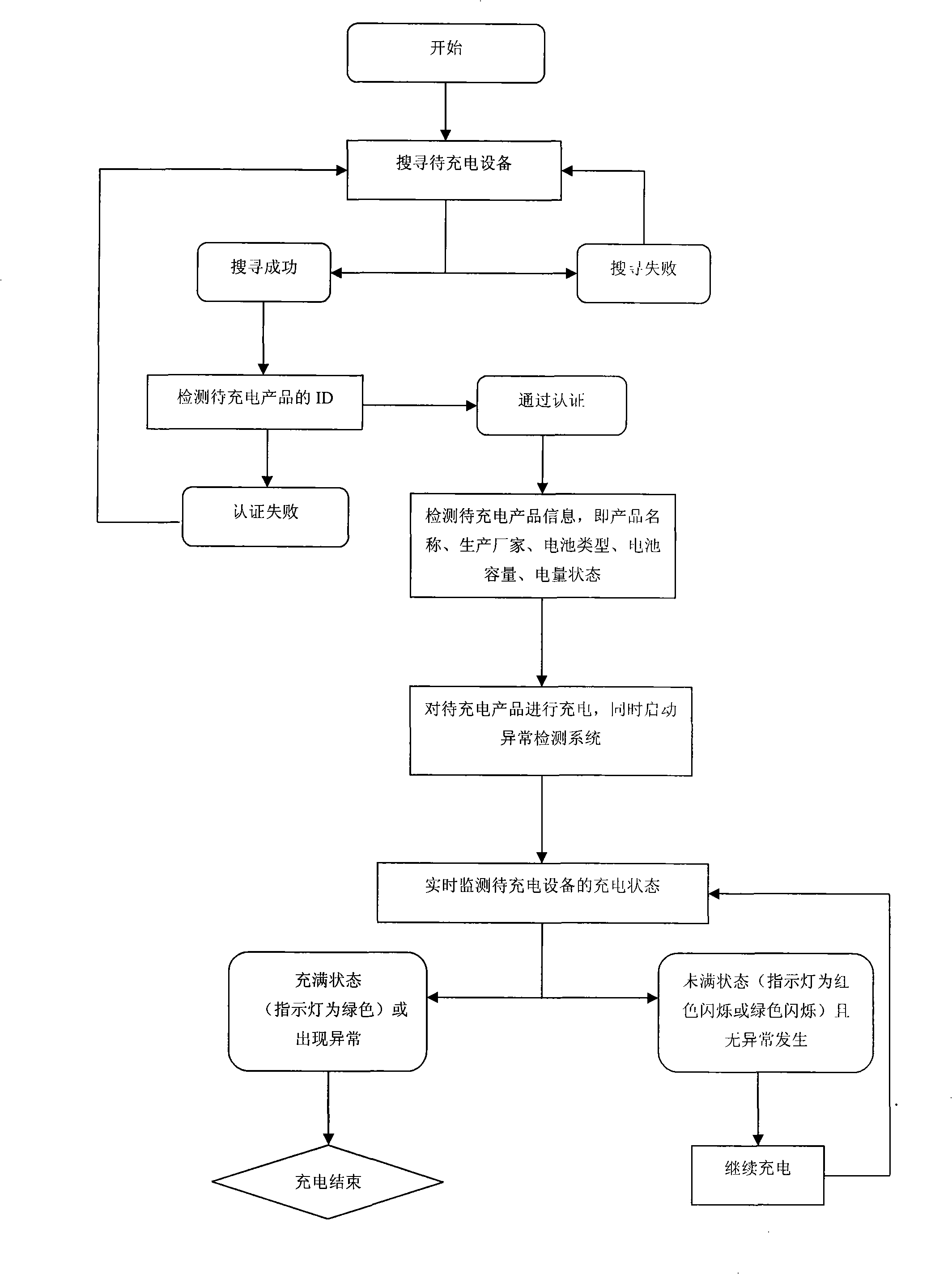

Non-contact type apparatus for transmitting electric energy

InactiveCN101330229AImprove versatilityHigh power transmission efficiencyNear-field transmissionBatteries circuit arrangementsElectricityEngineering

The invention relates to a non-contact electrical energy transmission device, particularly a non-contact charging device between an electrical energy emission device and an electrical energy receiving device, so as to realize the information exchange between the electrical energy emission device and the electrical energy reception device. The technical proposal is as follows: the electrical energy emission device and the electrical energy receiving device carry out the electrical energy transmission through coupling two air core coils. Additionally, the device utilizes the RFID technique to realize the information exchange between the electrical energy emission device and the electrical energy receiving device. On one hand, the electrical energy emission device performs the identification of the electrical energy receiving device, that is, the ID identification; on the other hand, the information exchange of the charging state between the electrical energy emission device and the electrical energy reception device is realized, thereby realizing the real-time monitoring of the charging process. Therefore, the non-contact electrical energy transmission device ensures the safe and controllable electrical energy transmission.

Owner:BEIJING BEIYOU INFORMATION TECH DEVCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com