Patents

Literature

2531 results about "Distribution characteristic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three characteristics of distributions. There are 3 characteristics used that completely describe a distribution: shape, central tendency, and variability. We'll be talking about central tendency (roughly, the center of the distribution) and variability (how broad is the distribution) in future chapters.

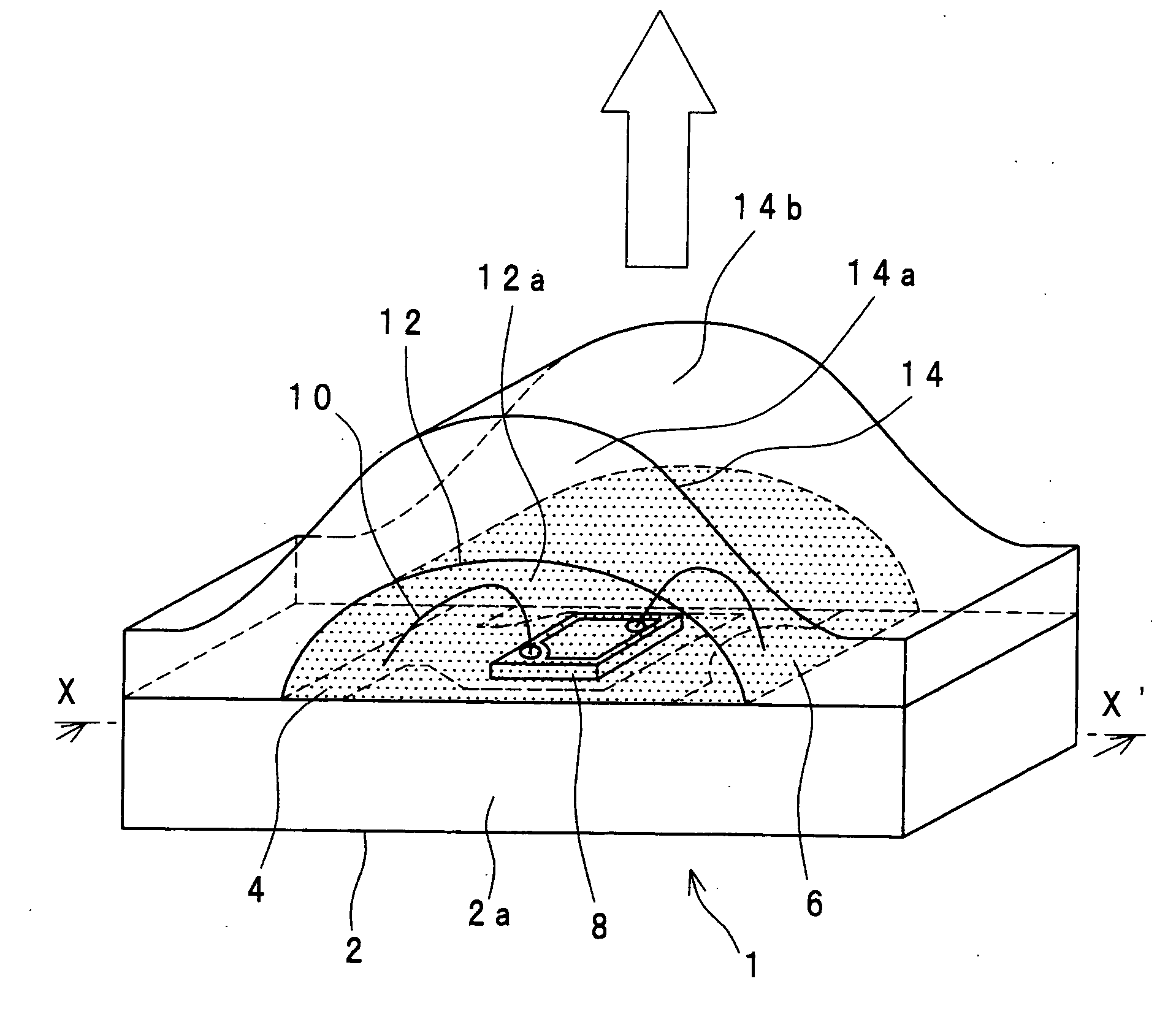

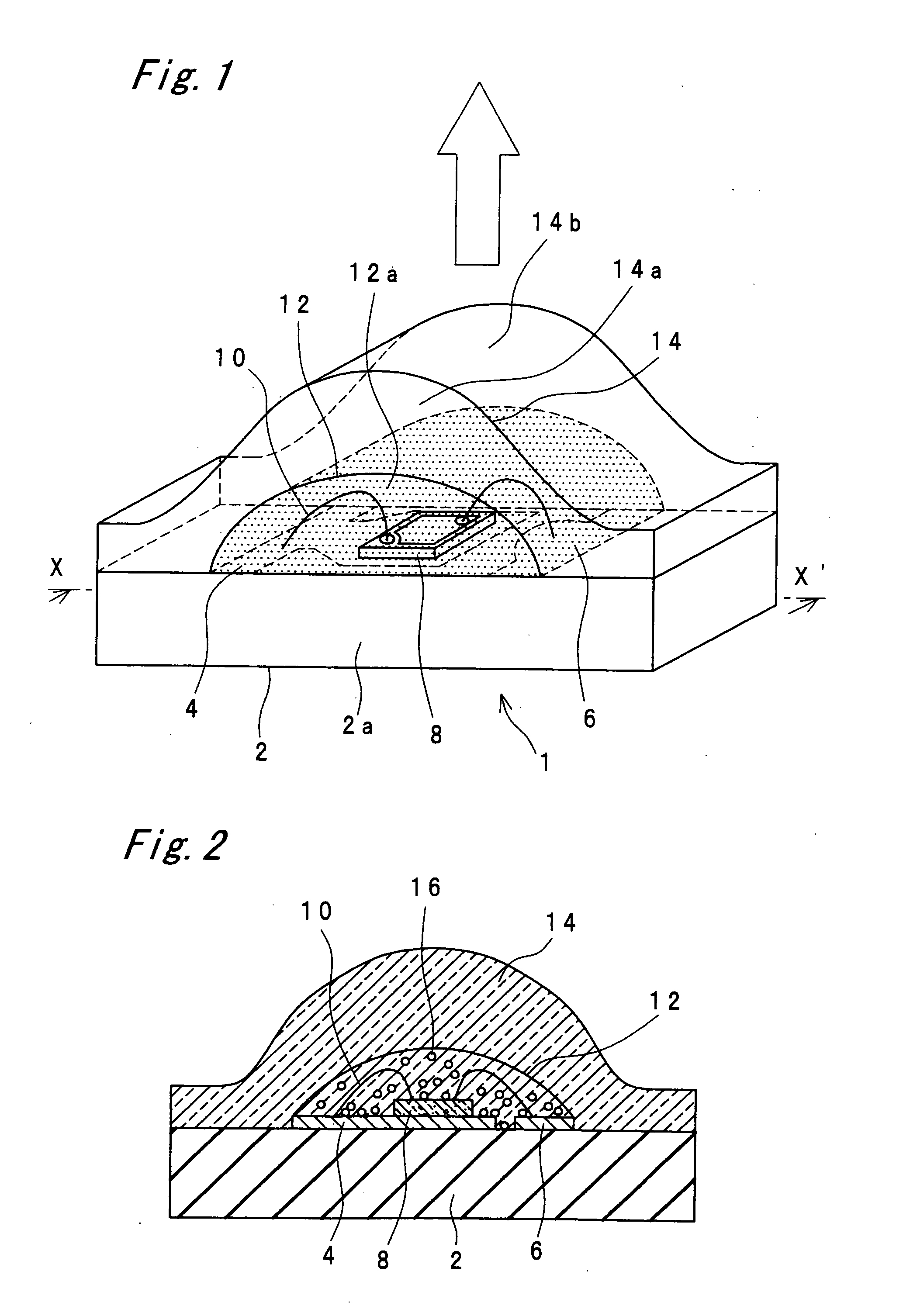

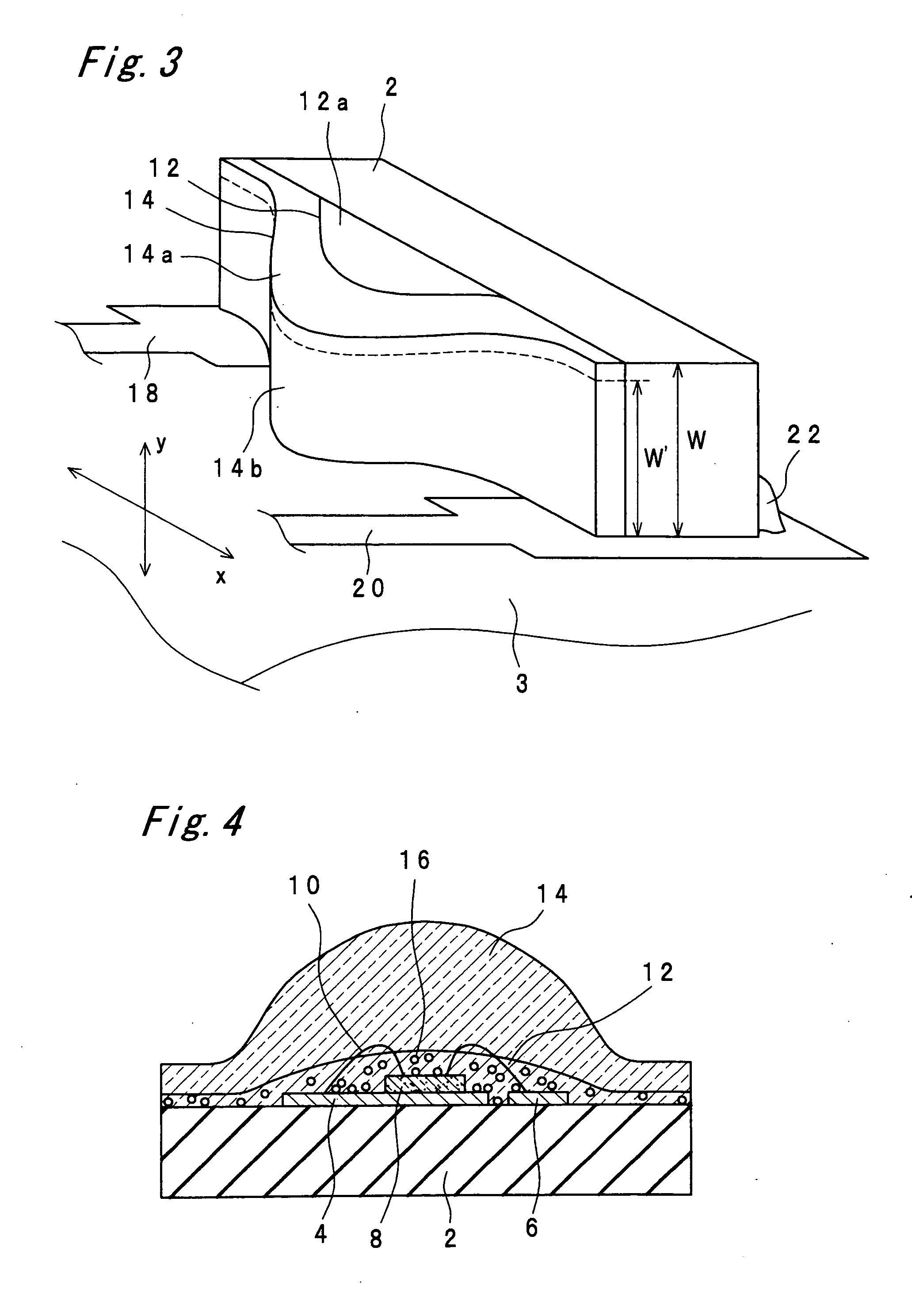

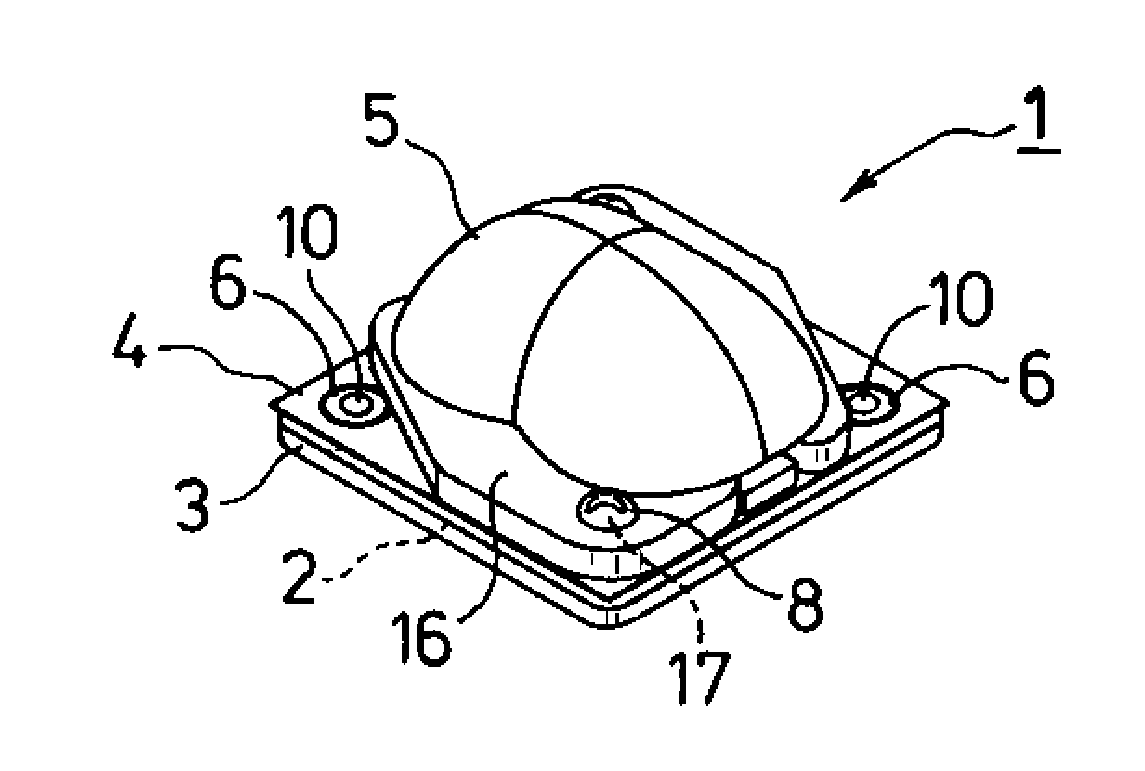

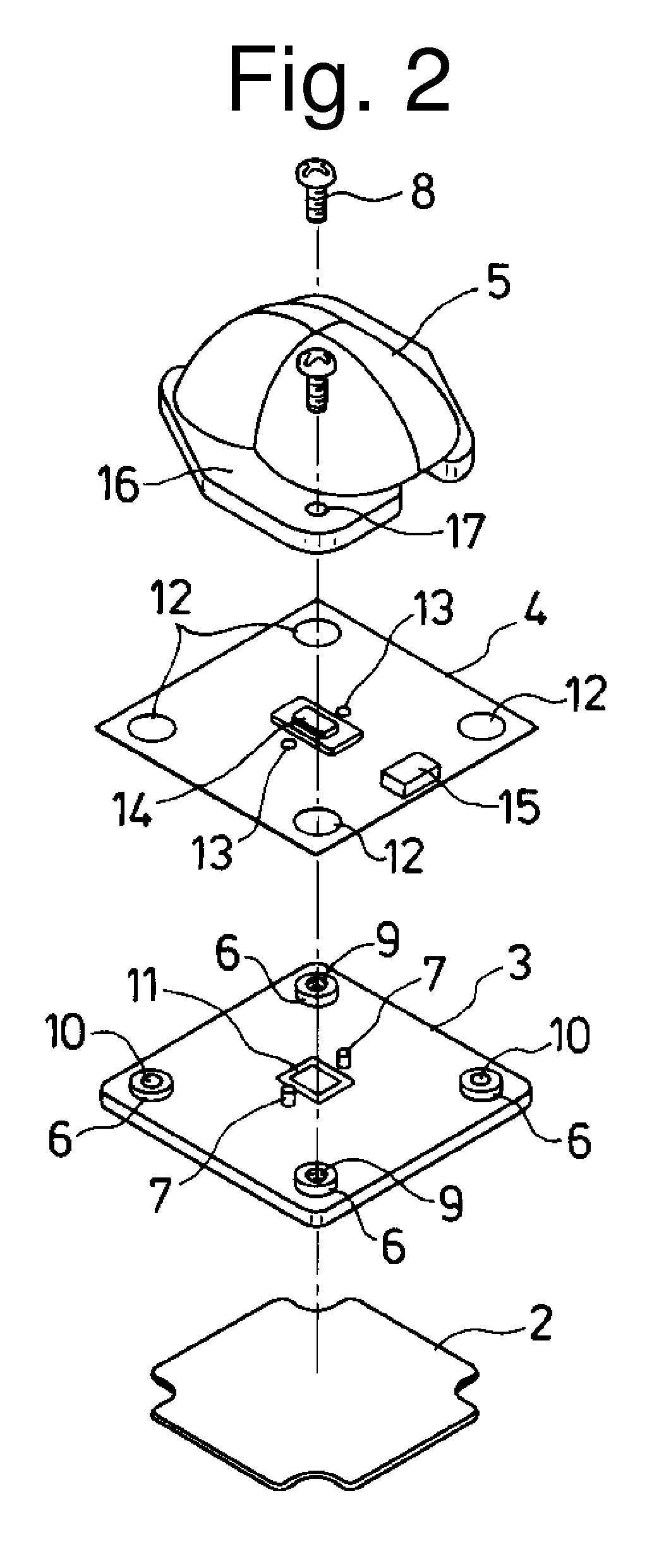

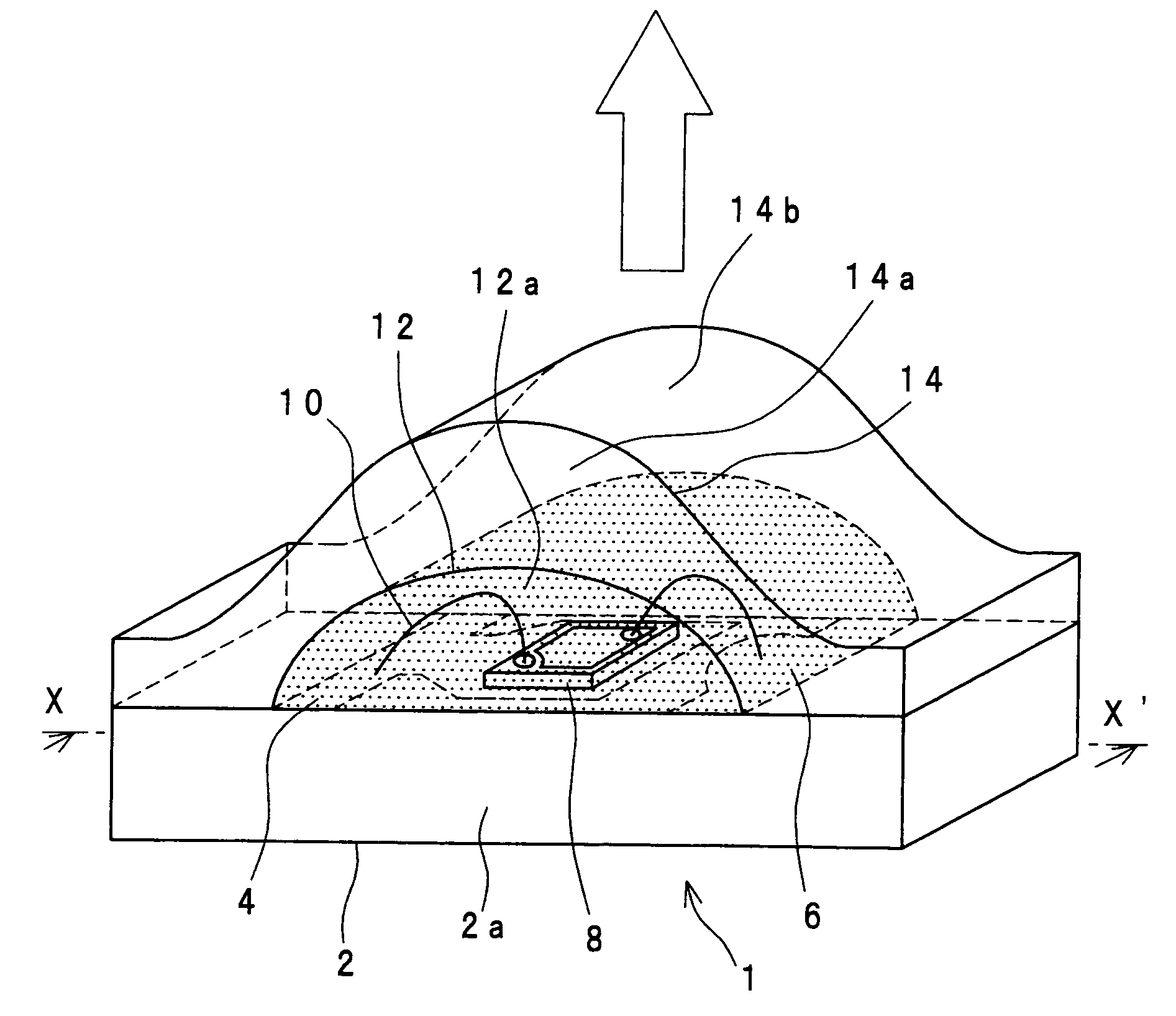

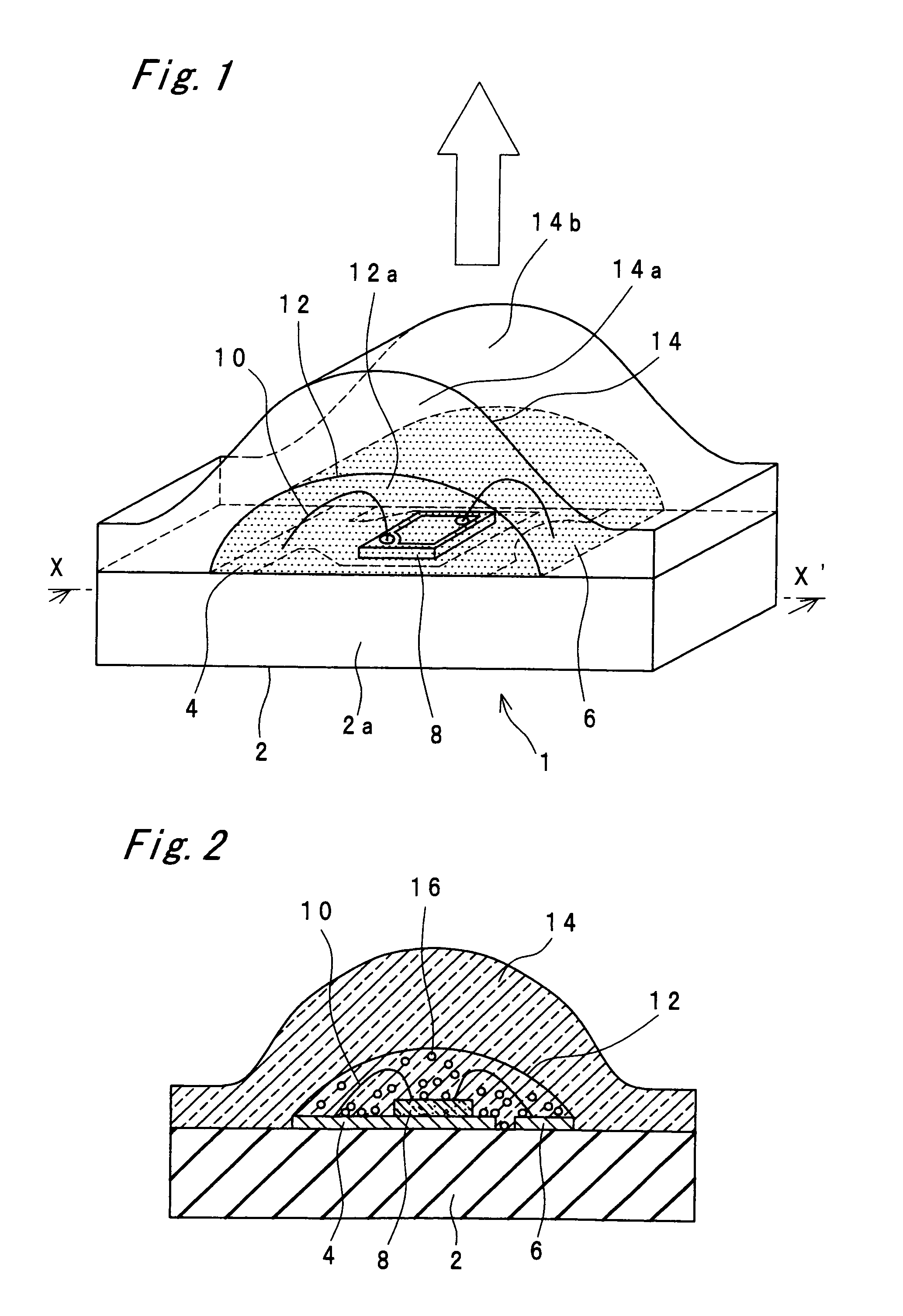

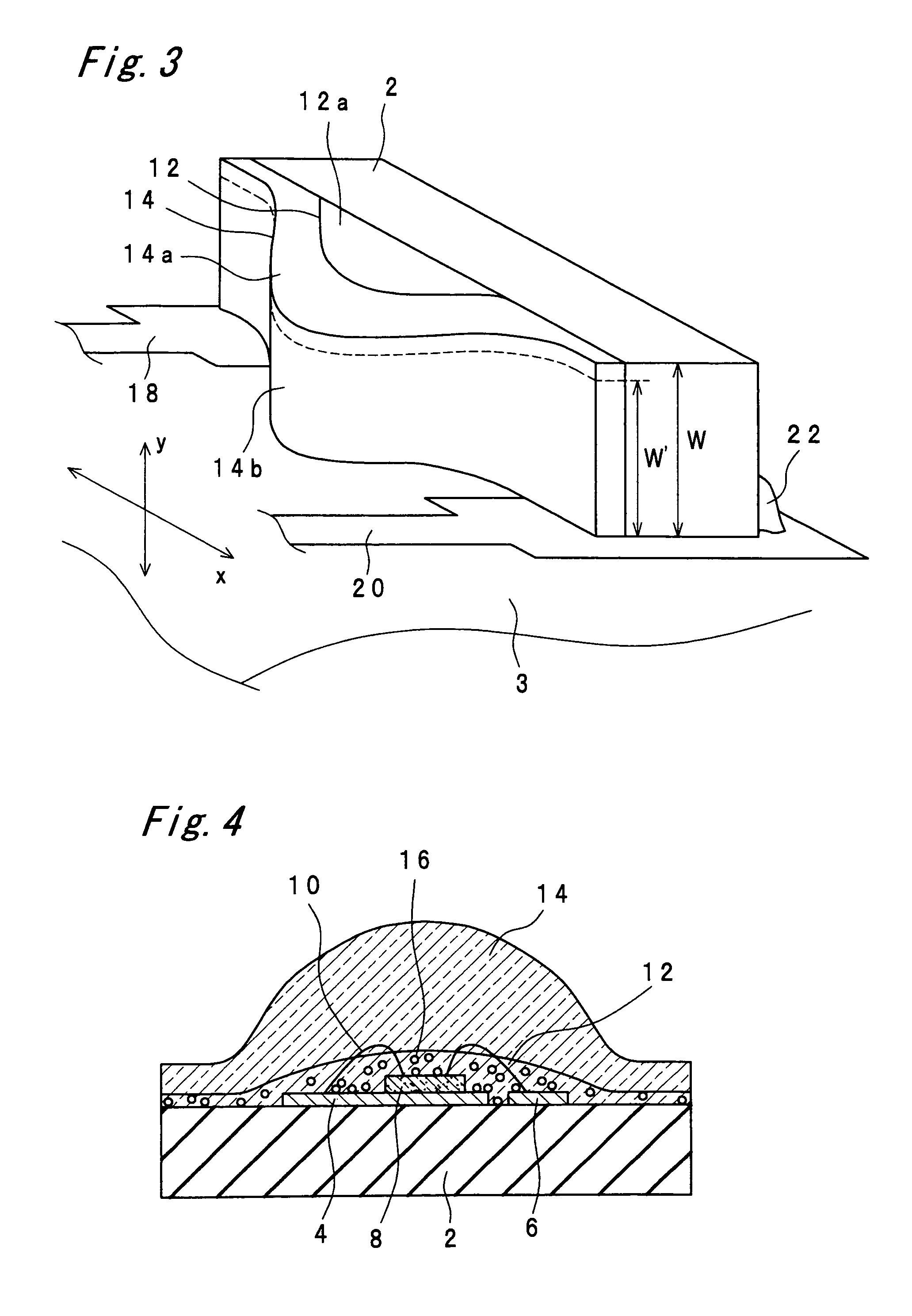

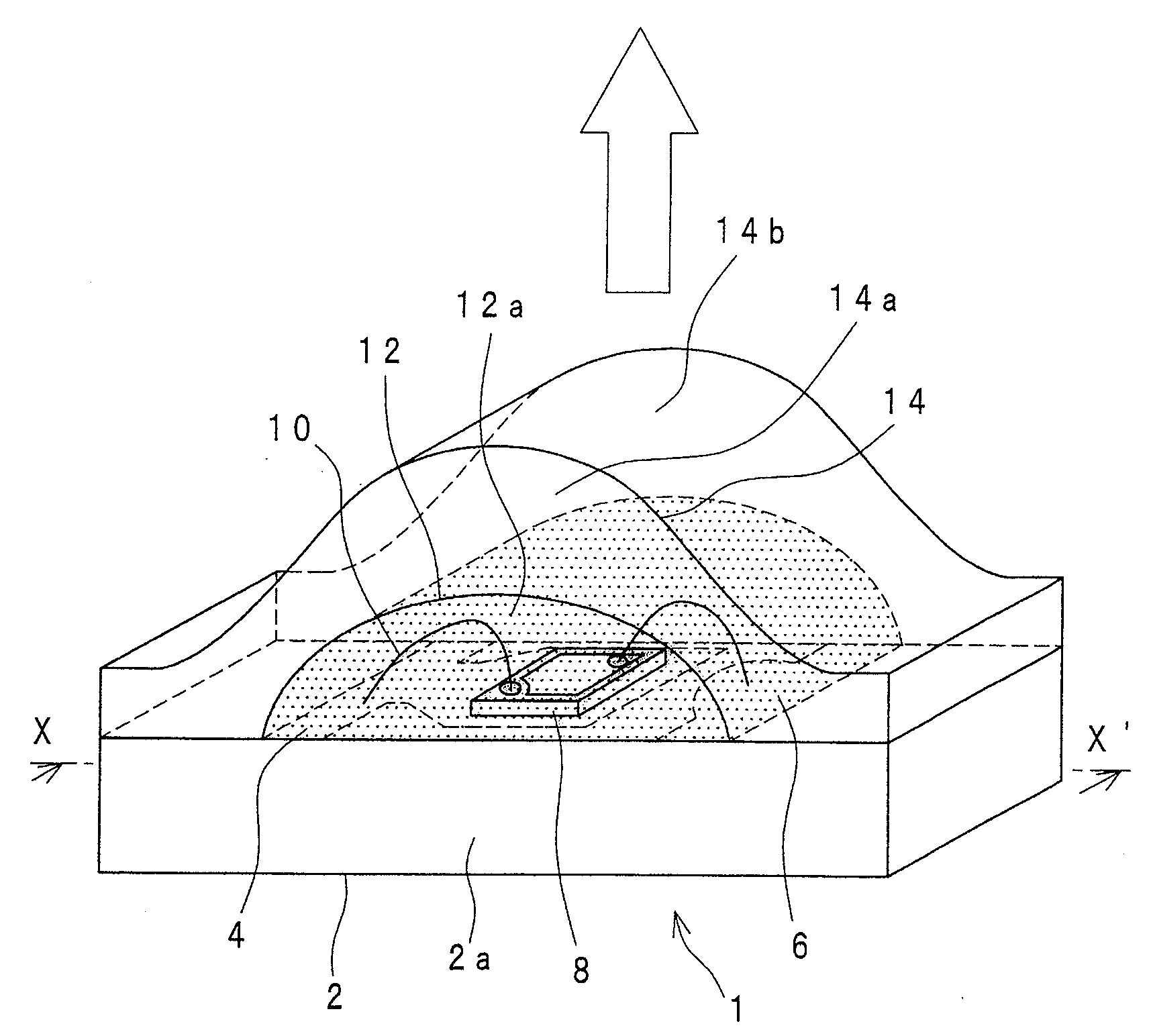

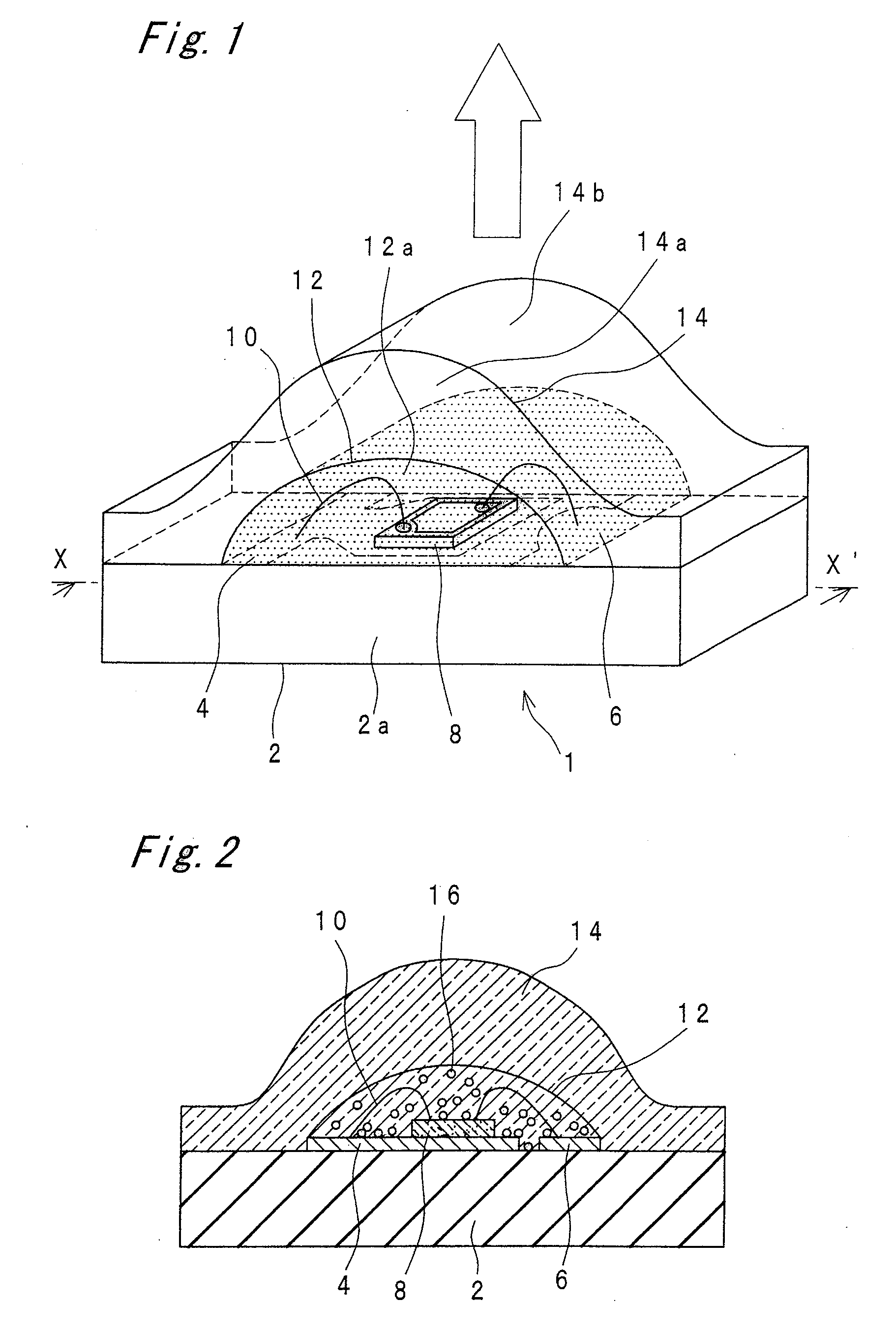

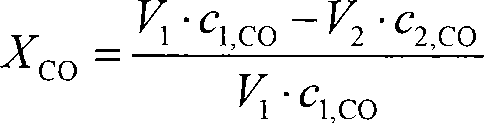

Light emitting device provided with lens for controlling light distribution characteristic

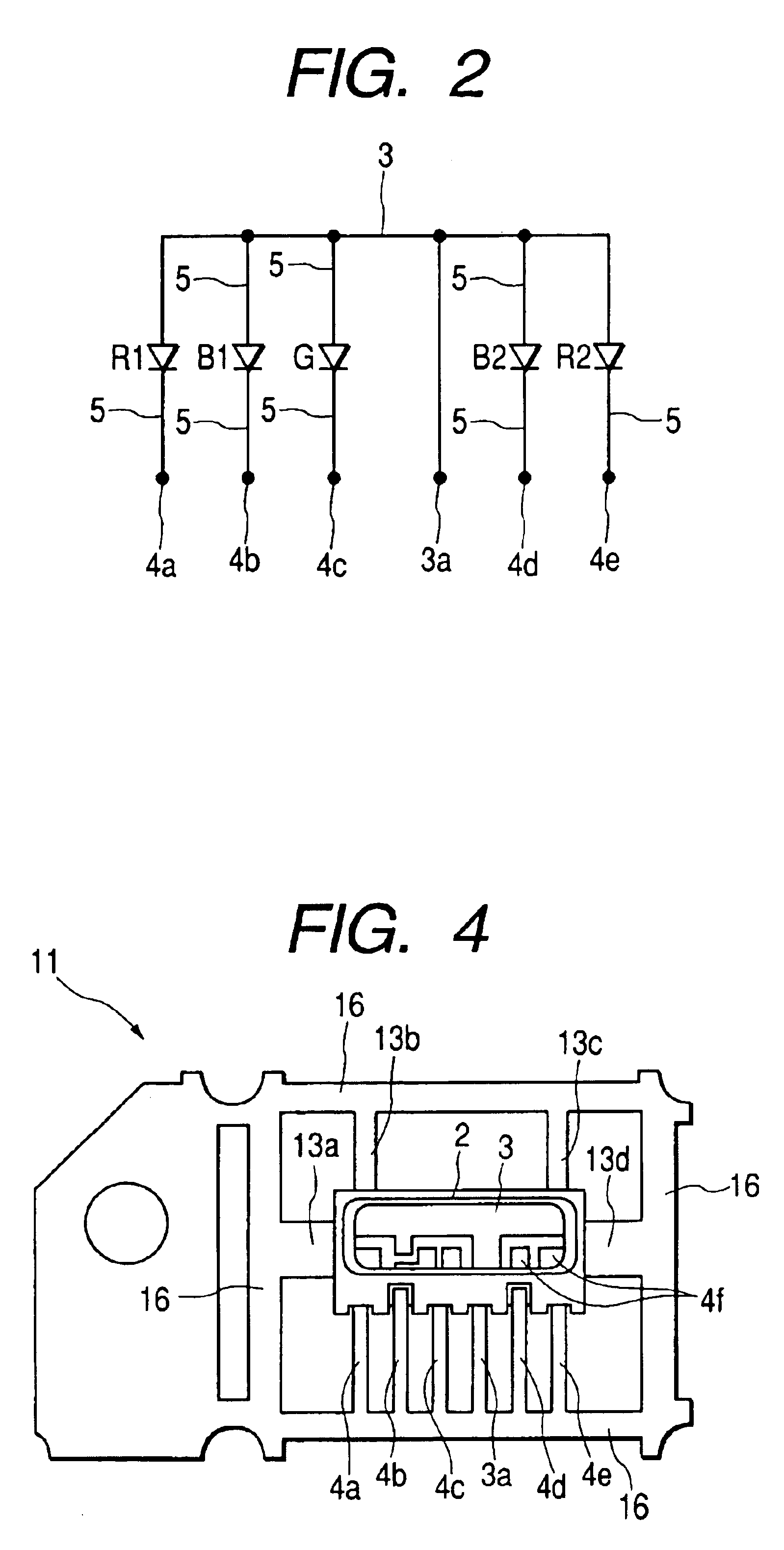

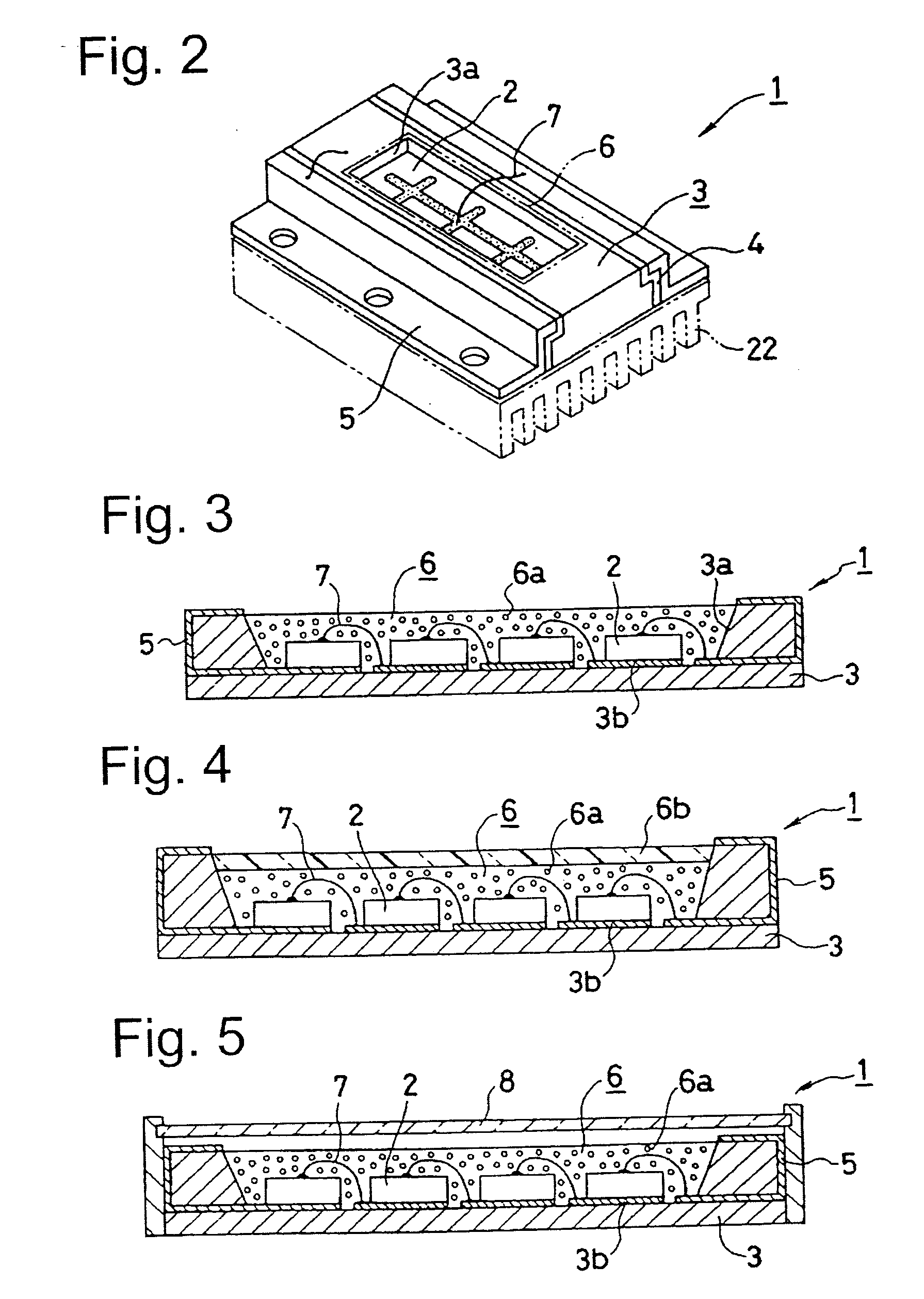

ActiveUS20060186431A1Low profileExcellent light distribution characteristicsDischarge tube luminescnet screensLamp detailsHigh concentrationDistribution characteristic

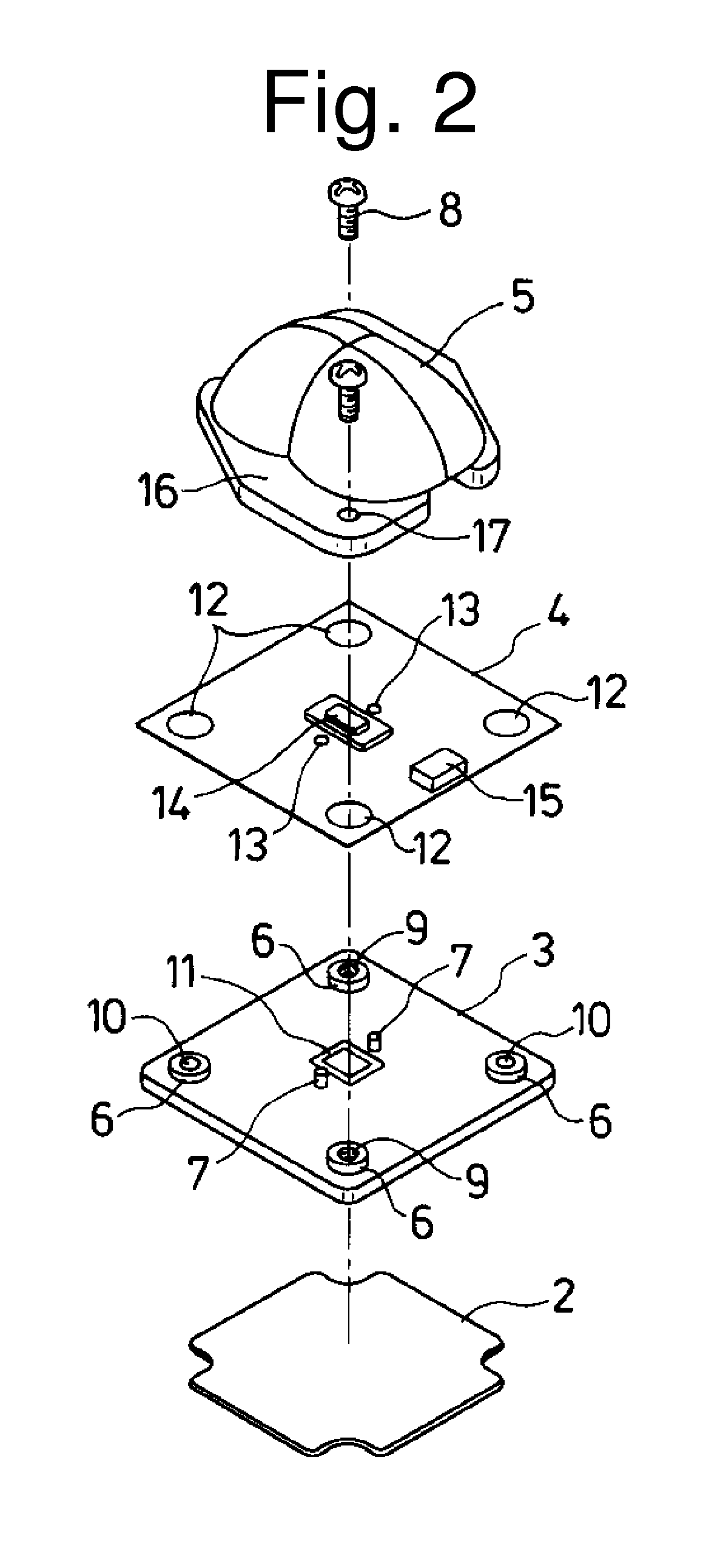

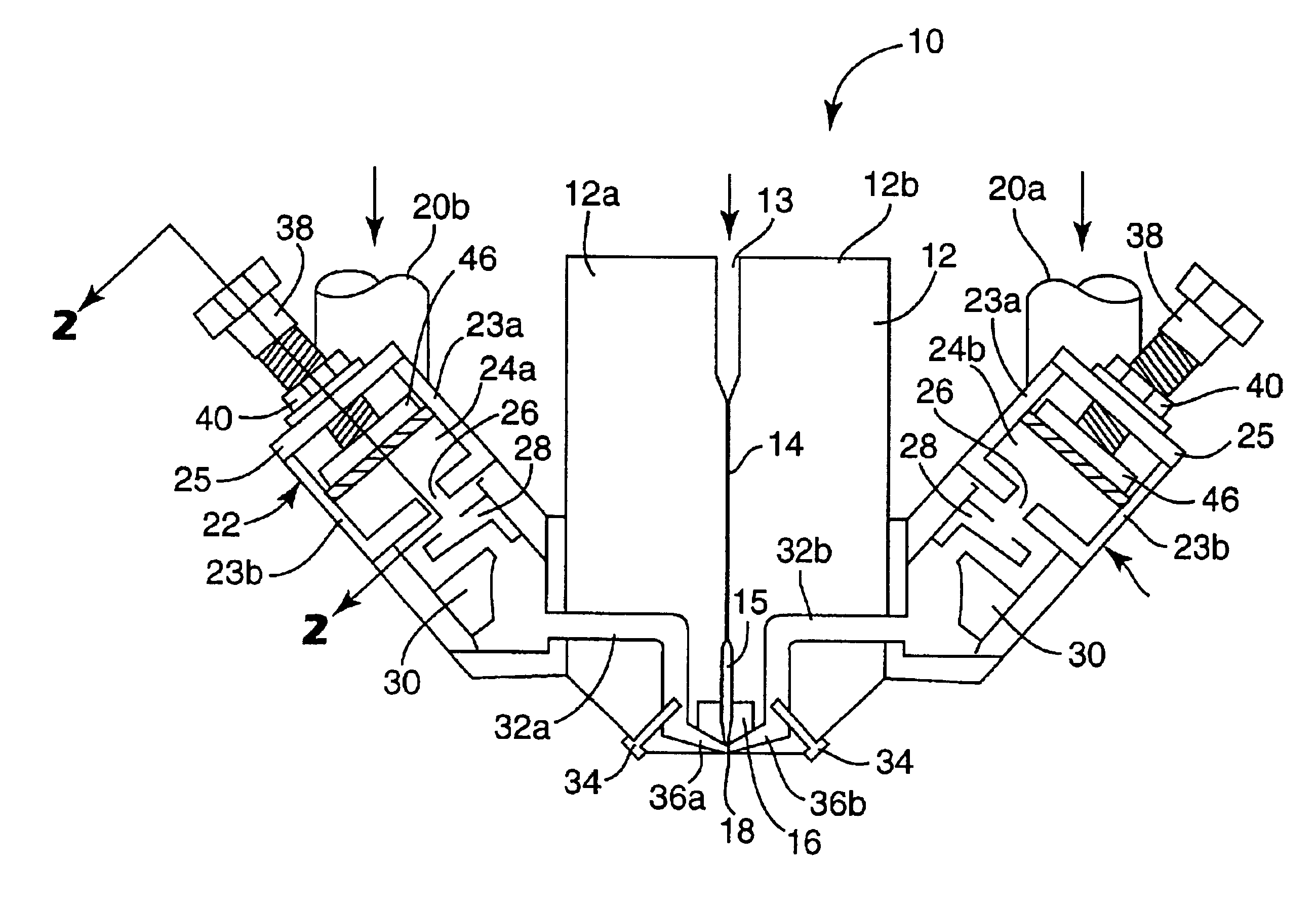

The light emitting device comprises a substrate (2), a positive electrode (6) and a negative electrode (4) formed on the substrate (2), a light emitting diode (8) connected to the positive electrode (6) and the negative electrode (4), the transparent resin (12 and 14) that covers the light emitting diode (8), a fluorescent material (16) that absorbs at least part of light emitted by the light emitting diode (8) and converts it to light of longer wavelength, and the lens that changes the direction of light emission from the light emitting diode (8) and / or the fluorescent material (16). The resin (12 and 14) includes the fluorescent material (16) and is formed so as to constitute the lens of substantially semi-cylindrical shape, and the fluorescent material (16) included in the resin (12 and 14) is distributed with a higher concentration in a region near the surface of the light emitting diode (8) than in a region near the surface of the portion that constitutes the lens.

Owner:NICHIA CORP

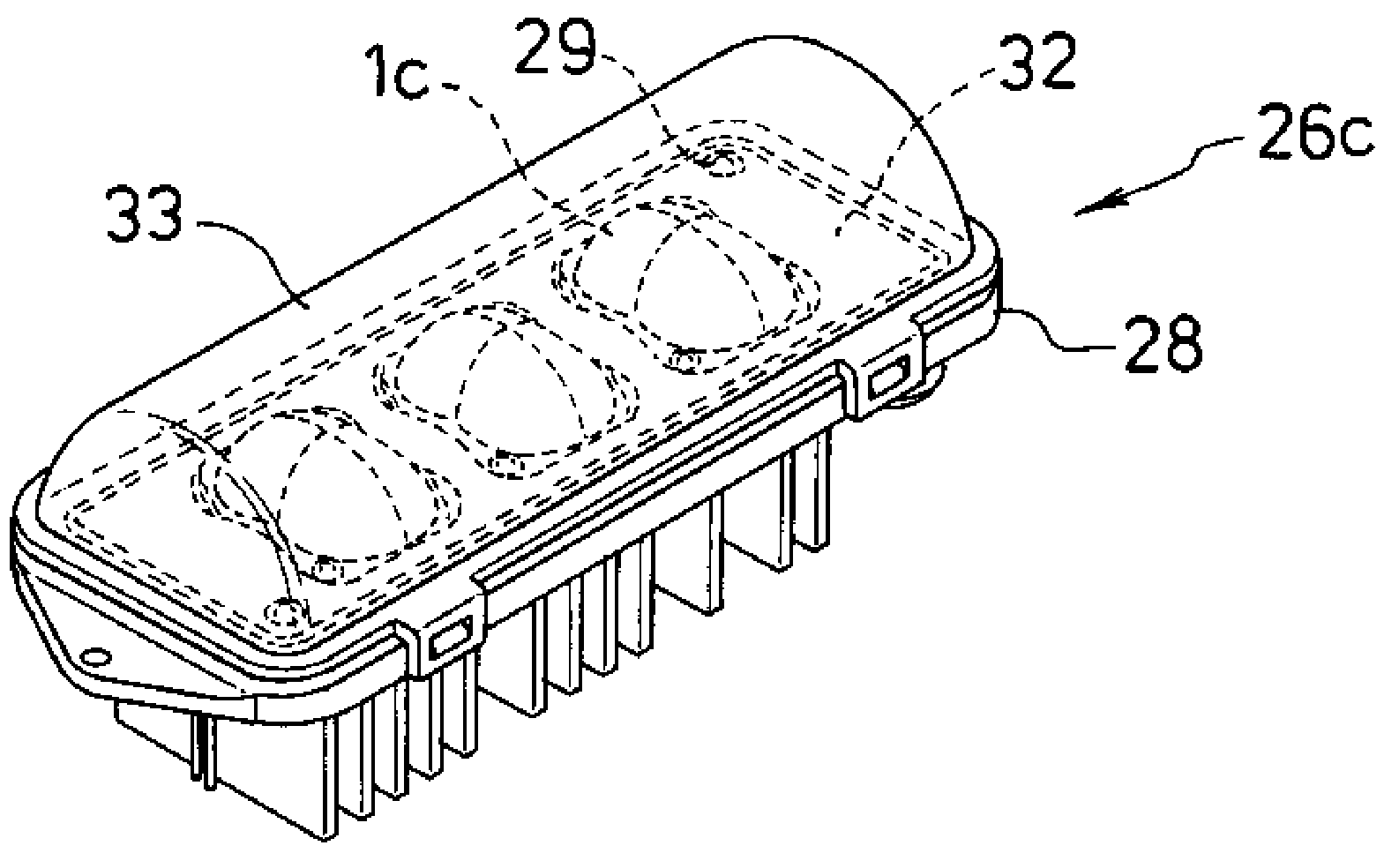

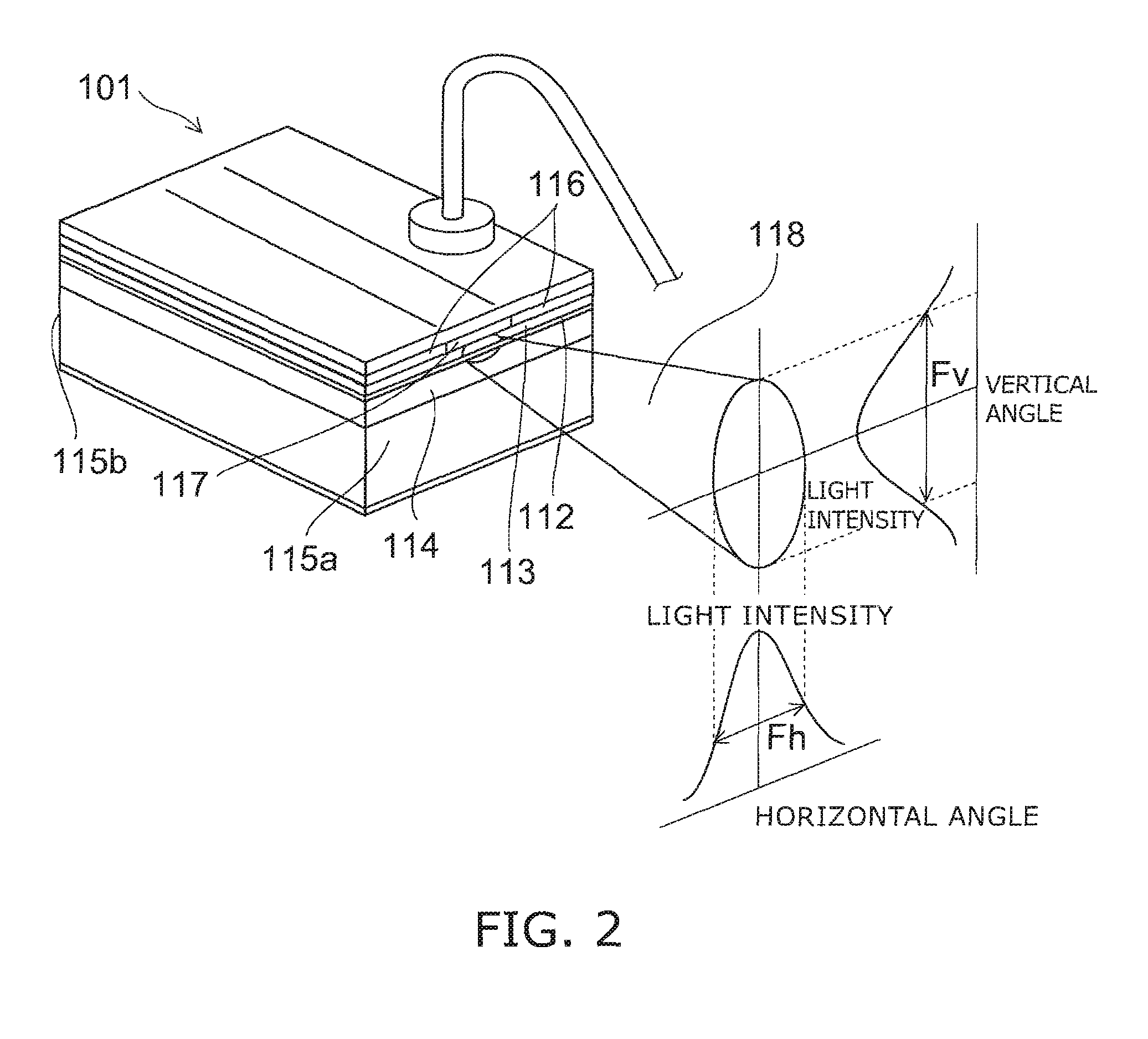

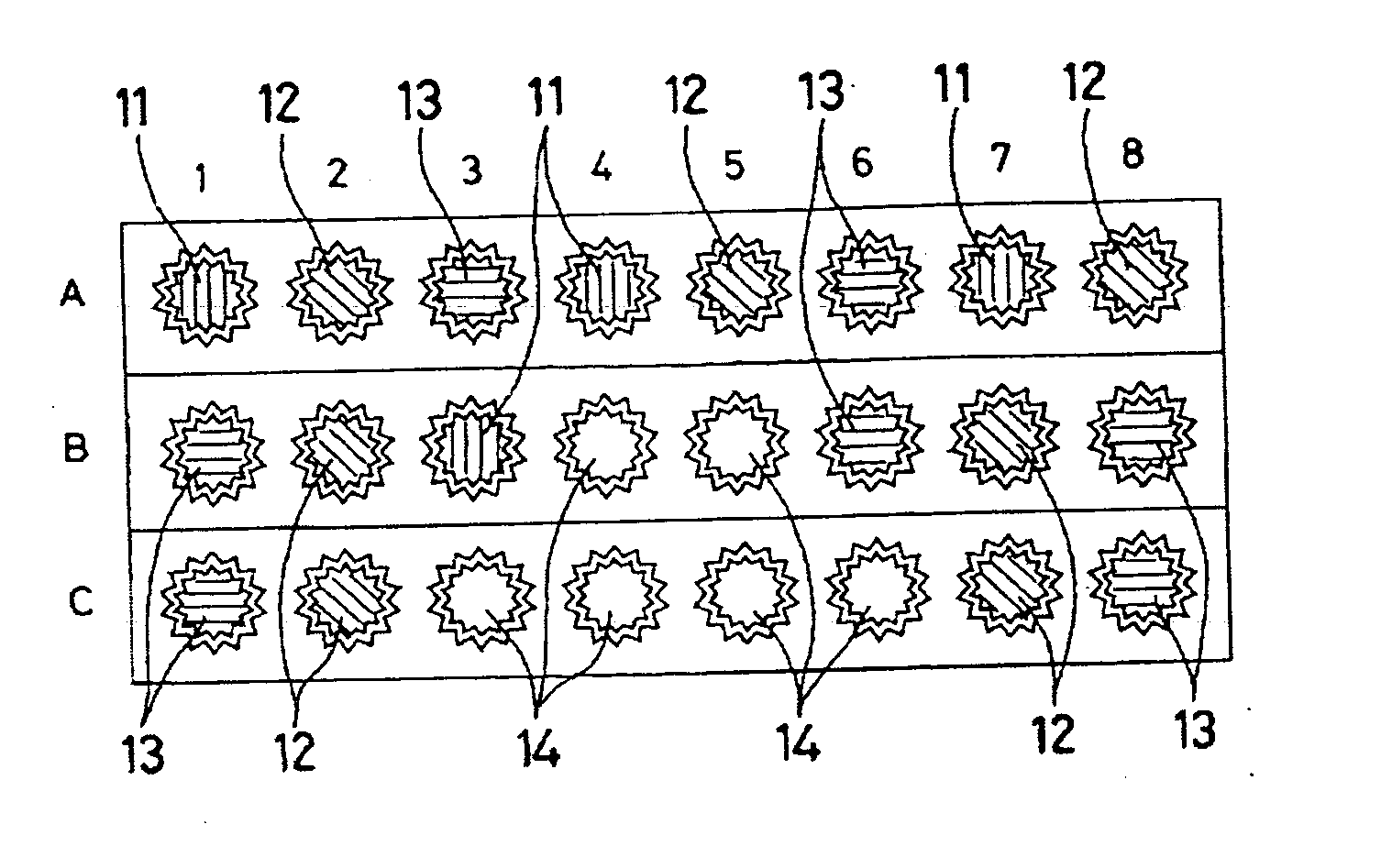

LED Lighting Fixture

InactiveUS20080101063A1Light utilization efficiencyUniform lightMechanical apparatusLight source combinationsOptical ModuleDistribution control

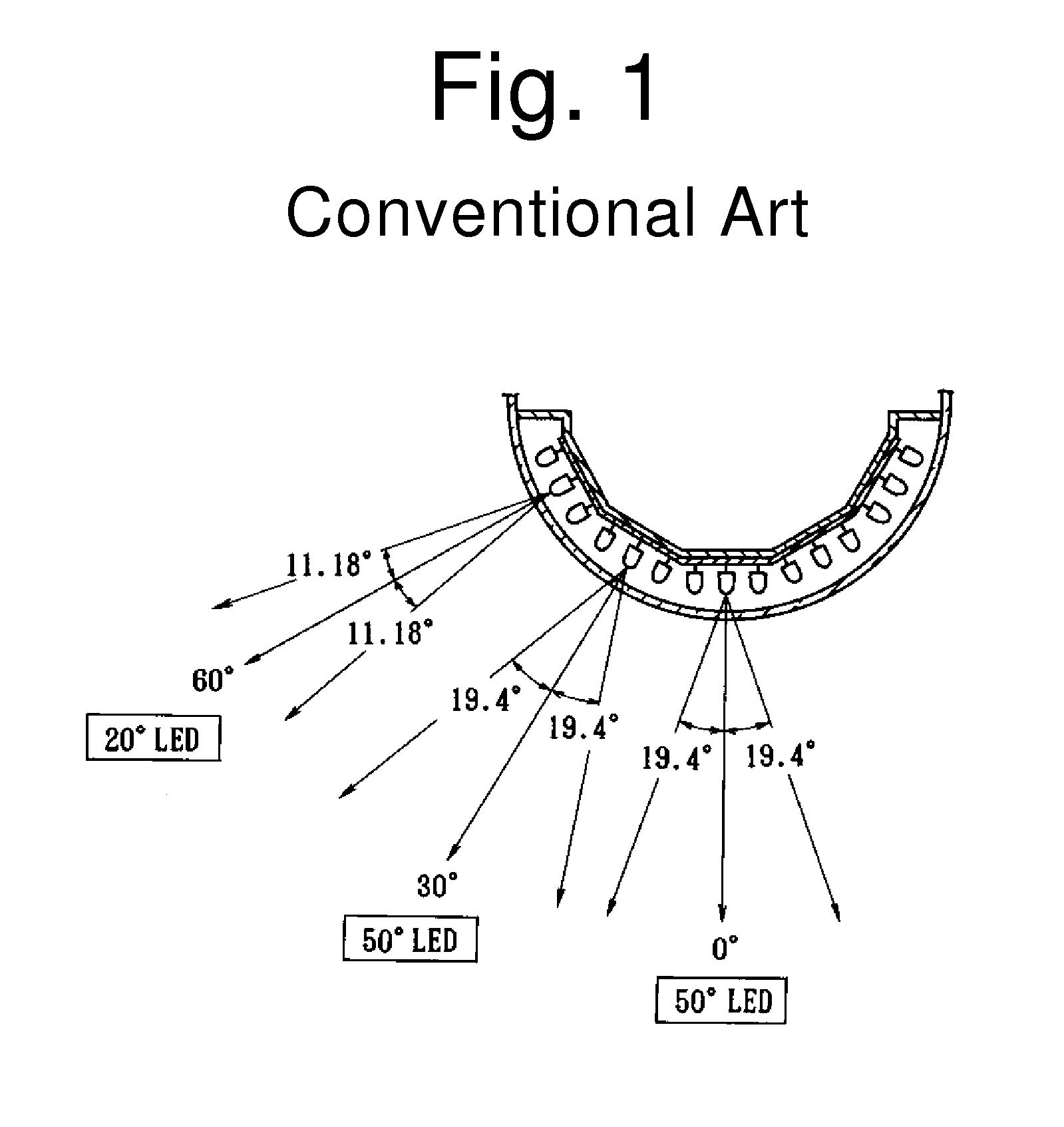

An LED lighting fixture is provided which achieves effective use of light, uniformly illuminates a large area and, has a high degree of freedom in designing light distribution characteristics. Three types of LED optical modules are used each having different light distribution characteristics. Each LED optical module includes an LED light source and a light distribution controlling lens of a different shape which constitute an optical system. Three types of LED optical units having different light distribution characteristics can be used. Each LED optical unit includes a set of LED optical modules having the same light distribution characteristics. The LED lighting fixture is configured to have a combination of the LED optical units having different light distribution characteristics.

Owner:STANLEY ELECTRIC CO LTD

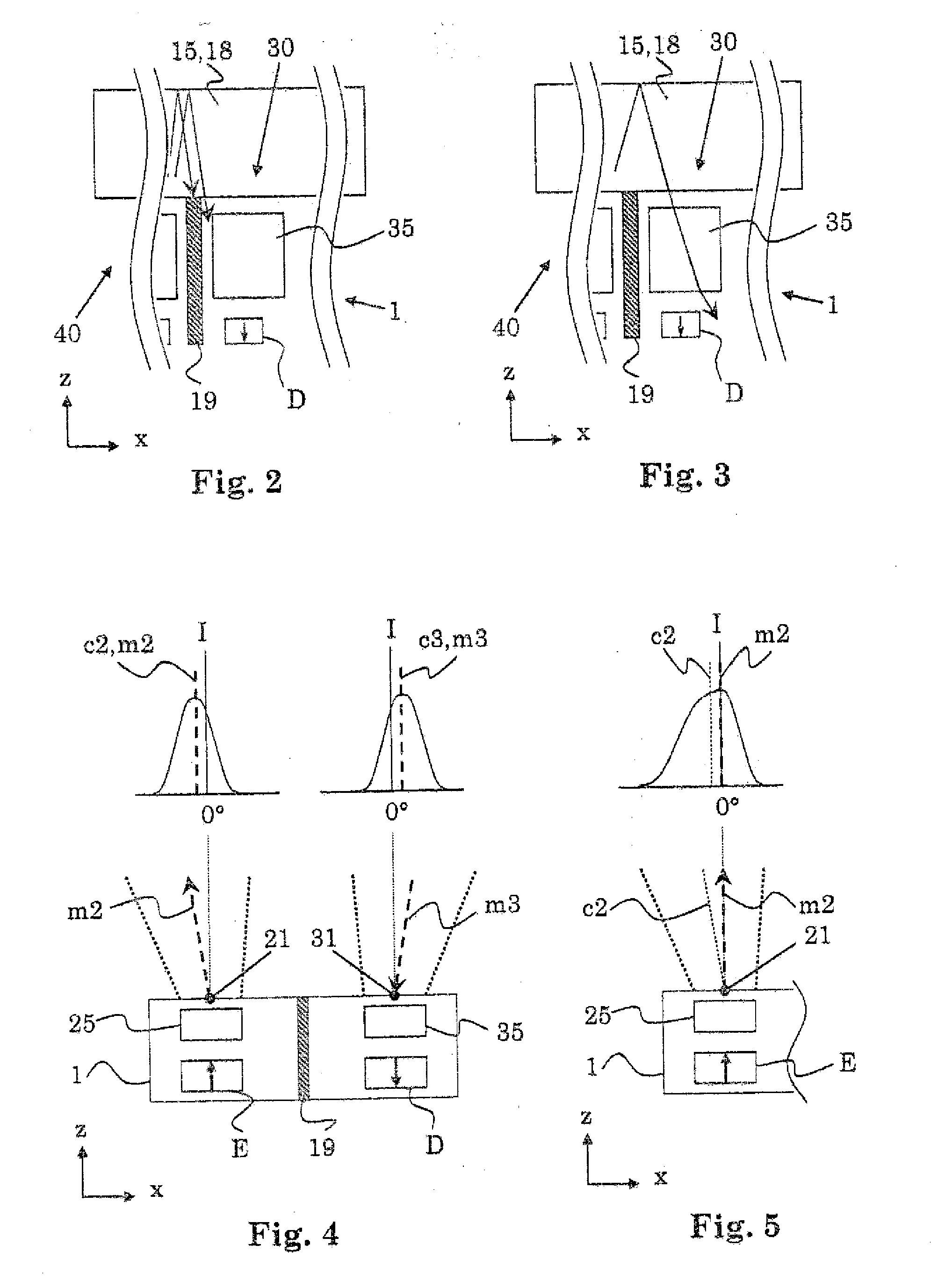

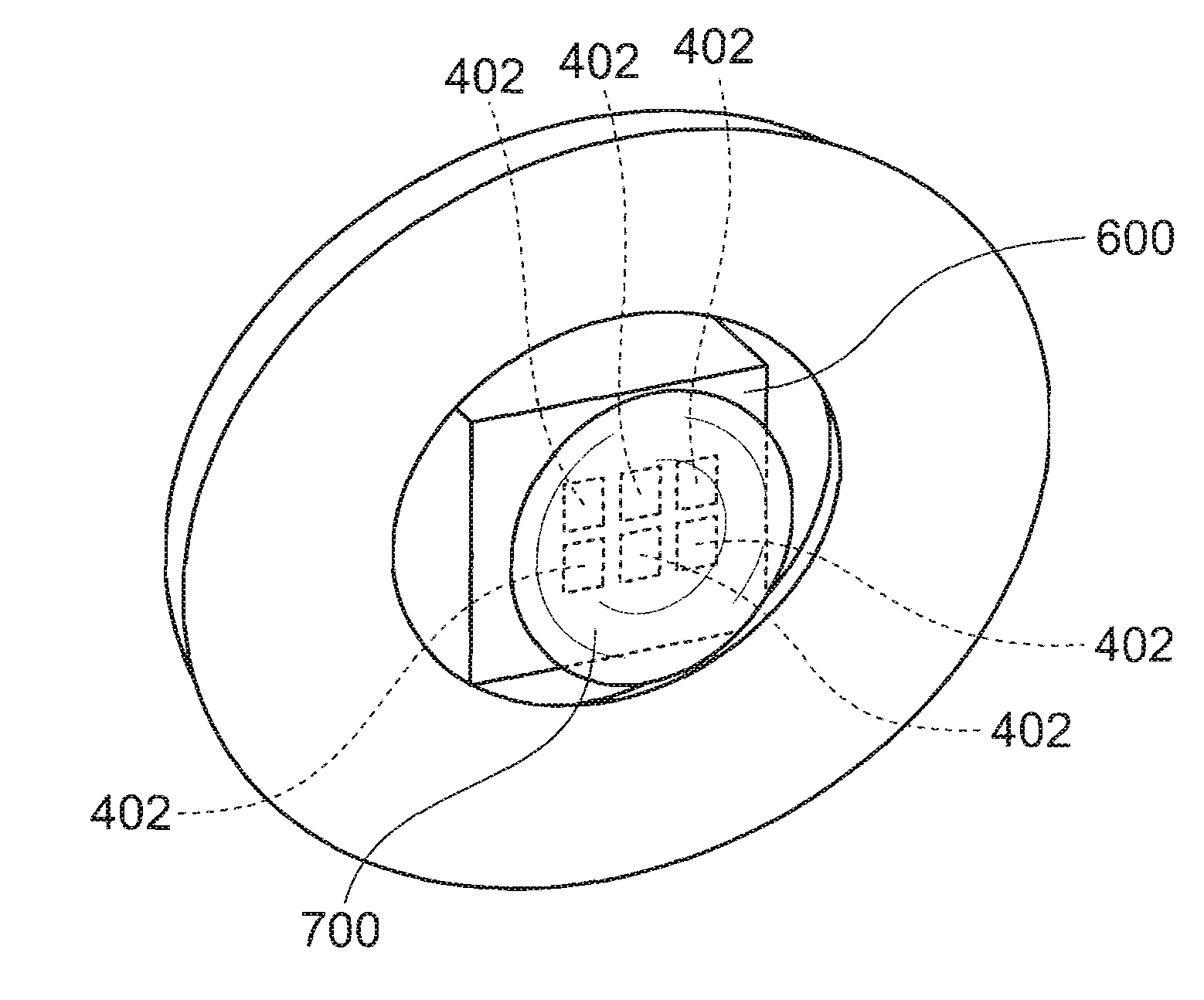

Opto-electronic module and devices comprising the same

ActiveUS20130153772A1Safely proximityPredictable and safe operationRadiation pyrometryPhotometryEmission channelingDistribution characteristic

An opto-electronic module includes a detecting channel comprising a detecting member for detecting light and an emission channel comprising an emission member for emitting light generally detectable by said detecting member. Therein, a radiation distribution characteristic for an emission of light from said emission channel is non rotationally symmetric; and / or a sensitivity distribution characteristic for a detection in said detecting channel of light incident on said detection channel is non rotationally symmetric; and / or a central or main emission direction for an emission of light from said emission channel and a central or main detection direction for a detection of light incident on said detection channel are aligned not parallel to each other; and / or at least a first one of the channels comprises one or more passive optical components.

Owner:AMS SENSORS SINGAPORE PTE LTD

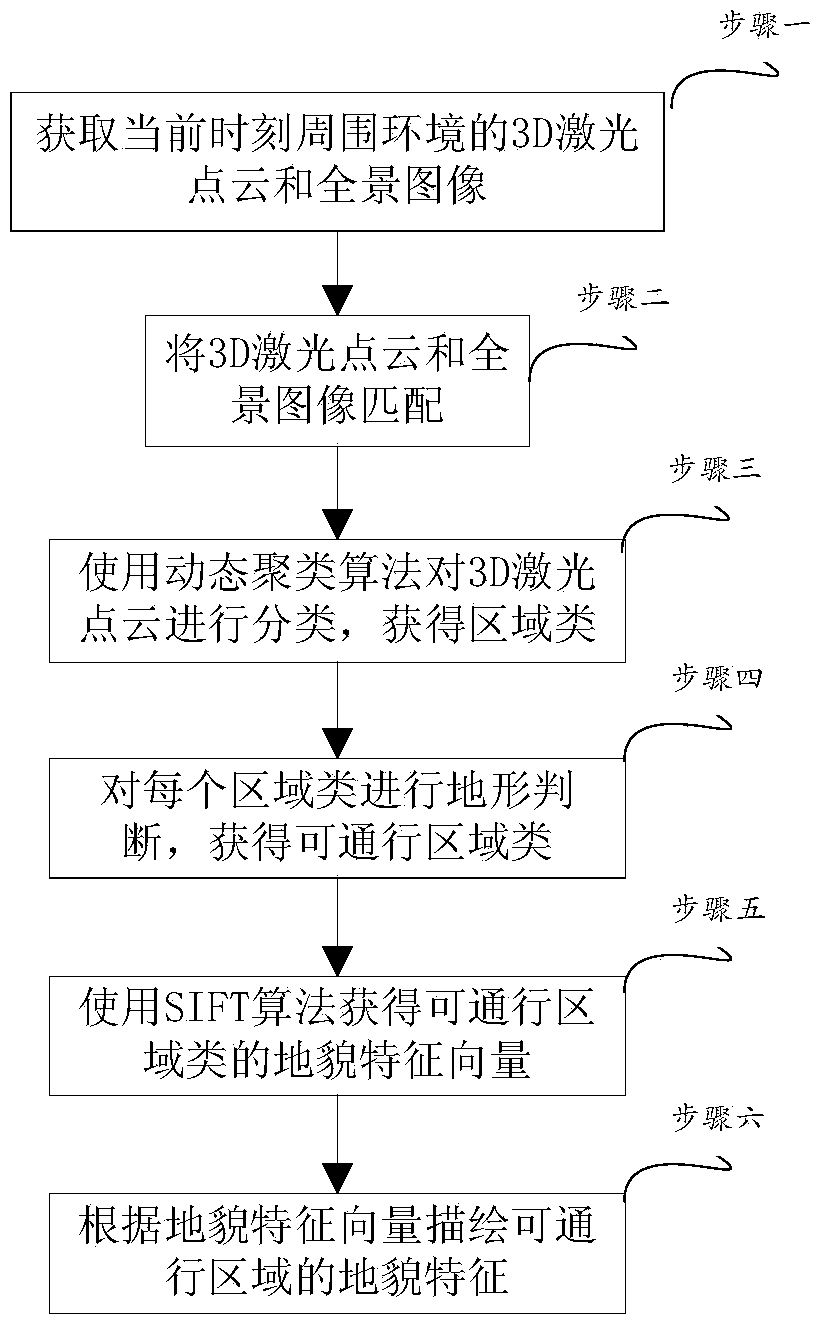

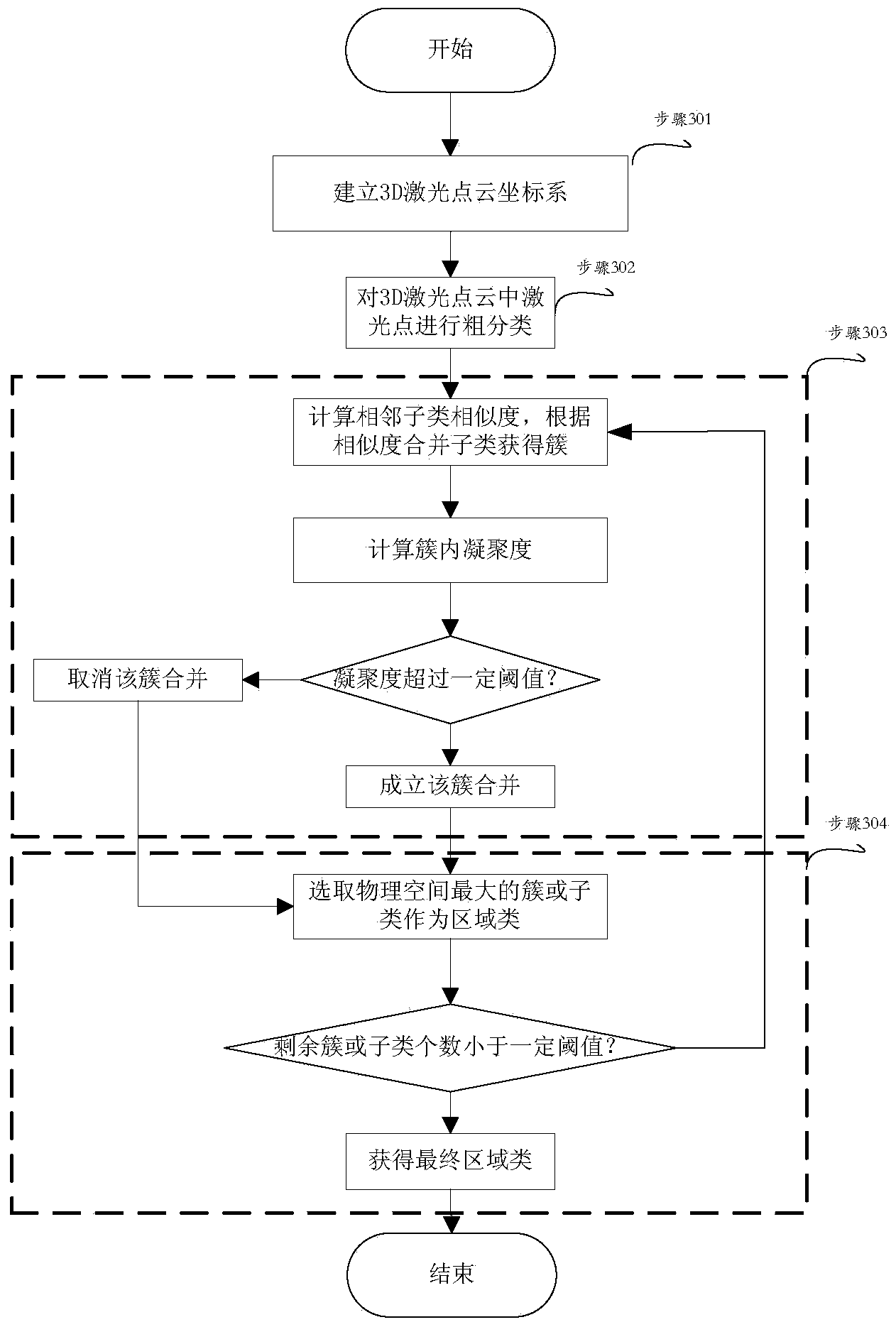

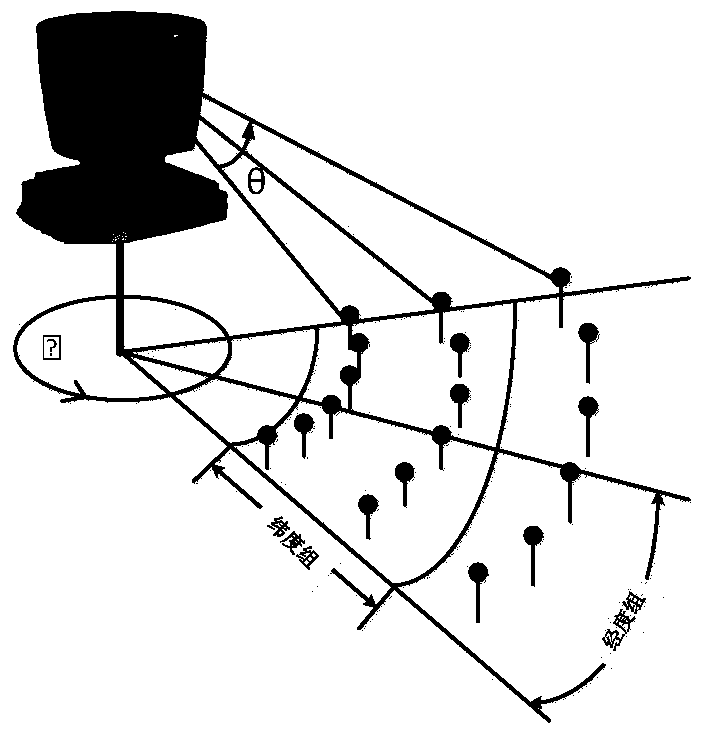

Geographic and geomorphic characteristic construction method based on laser radar and image data fusion

ActiveCN103645480AGuaranteed accuracyReduce complexityElectromagnetic wave reradiationAutomatic controlPoint cloud

The invention discloses a geographic and geomorphic characteristic construction method based on laser radar and image data fusion and belongs to the automatic control field. The method specifically comprises 1) obtaining 3D laser point clouds and panoramic pictures of the surrounding environment of a ground unmanned mobile platform at present; 2) matching the 3D laser point clouds and the panoramic pictures and obtaining matched images; 3) dividing the 3D laser point clouds based on different distribution characteristics corresponding to each laser point and carrying out clustering based on a dynamic clustering algorithm of each distribution characteristic to obtain a plurality of region classes; 4) finding passable region classes in the plurality of region classes based on travel ability of the ground unmanned mobile platform; 5)obtaining landform identification vectors of the passable region classes by utilizing a denseness SIFT algorithm; and 6) carrying out landform classification on the passable region classes based on the landform identification vectors and by utilizing a classifier. The method is suitable for passable geographic and geomorphic characteristic construction of the ground unmanned mobile platform.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for enhancing recovery ratio through three-dimensional streamline regulation of water drive reservoir

InactiveCN102146788AReach controlEnhanced overall recoveryFluid removalSealing/packingDistribution characteristicResidual oil

The invention discloses a method for enhancing recovery ratio through three-dimensional streamline regulation of a water drive reservoir. The method is characterized by comprising the following steps: identifying the planer development segment and vertical development segment of a preferential seepage channel to quantificationally calculate sampling parameters; establishing a three-dimensional geologic model comprising the characteristics of the preferential seepage channel, establishing a reservoir numerical simulation model, and finely determining a residual oil distribution characteristic under current heterogenous condition through reservoir numerical simulation; carrying out pattern modification and optimized water shutoff and profile control design; and determining whether layered injection and recovery is required according to water adsorption characteristics of a vertical water well and liquid generation characteristics of an oil well by utilizing the reservoir numerical simulation result. In the invention, on the basis that the preferential seepage channel is blocked through deep profile control and water shutoff, the planer flow line direction is changed through the combination water shutoff and profile control with pattern modification optimization, water shutoff and profile control are optimally combined with subdivided development layers and layered injection and recovery optimization to control and regulate the density of vertical flow lines, and the purpose of maximally control underground flow lines is achieved through the synergistic effect of different means.

Owner:CHINA PETROLEUM & CHEM CORP +1

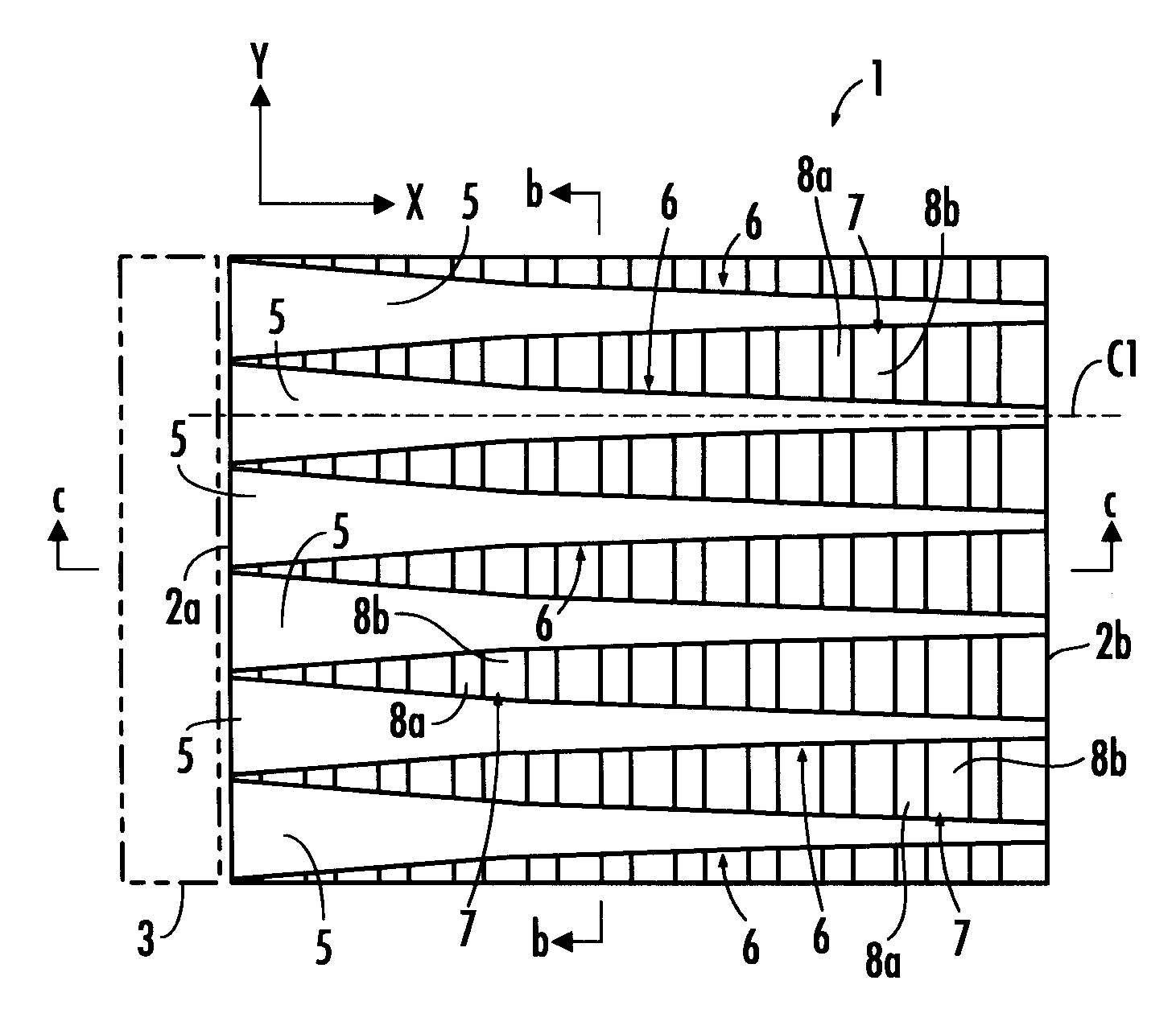

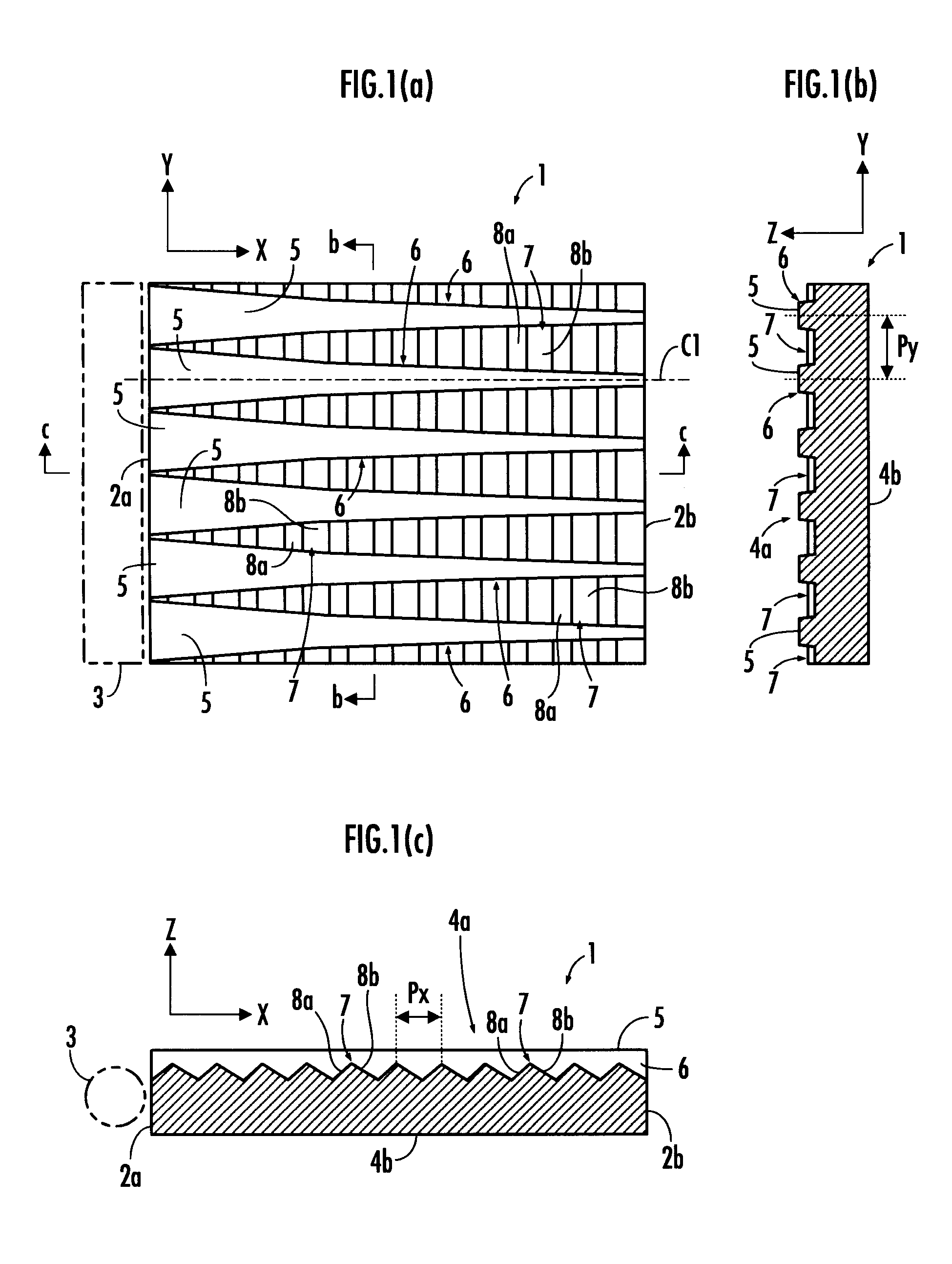

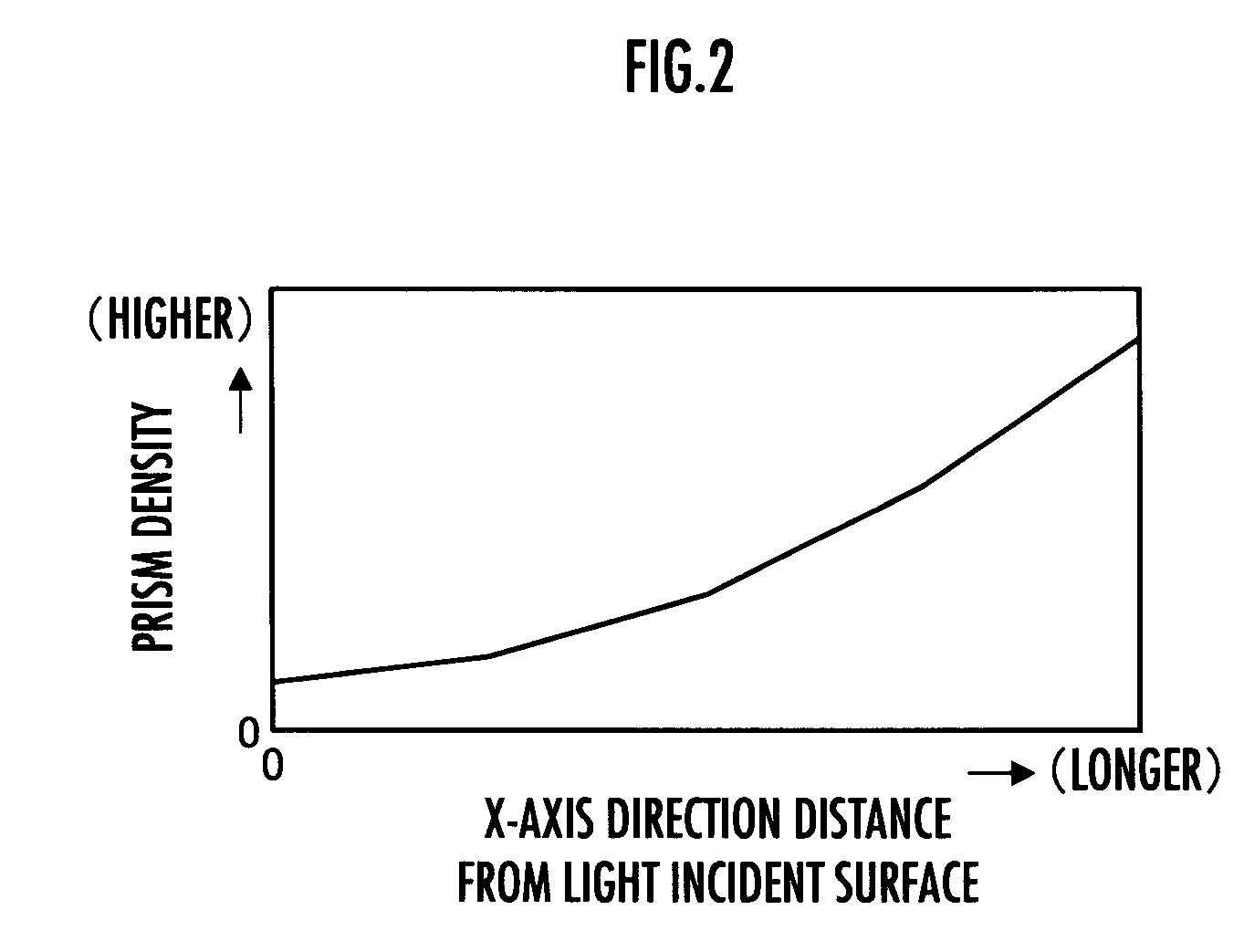

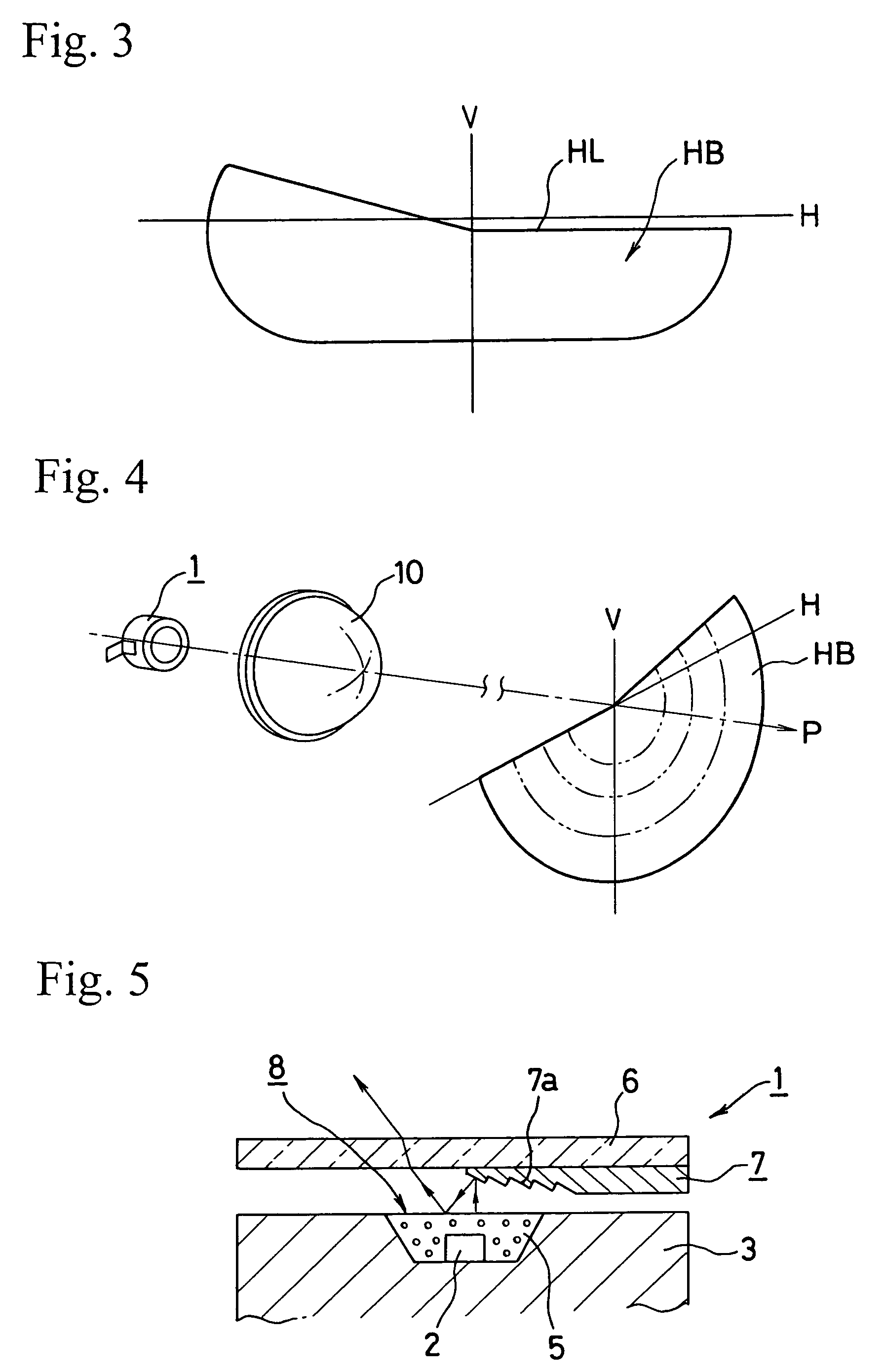

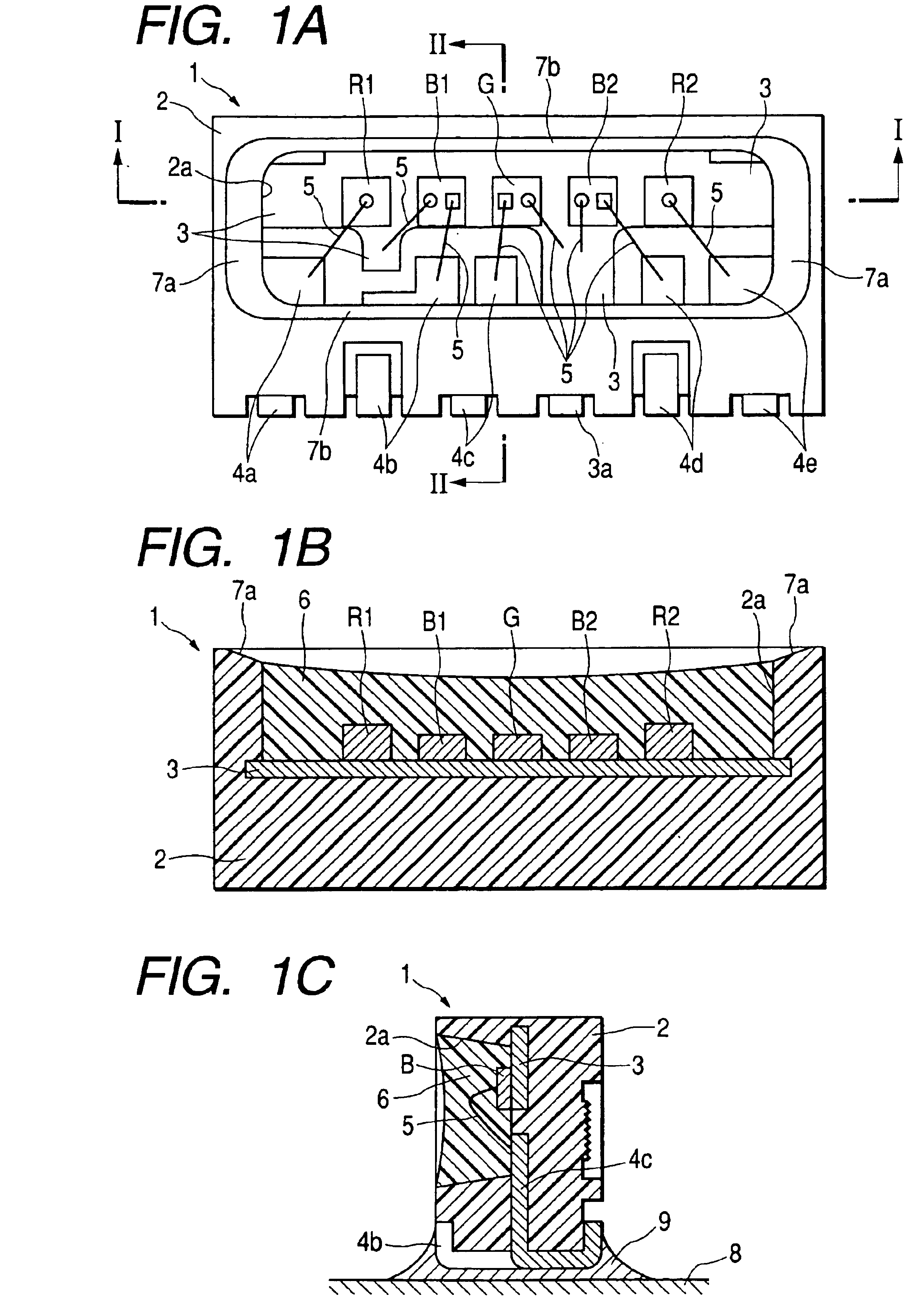

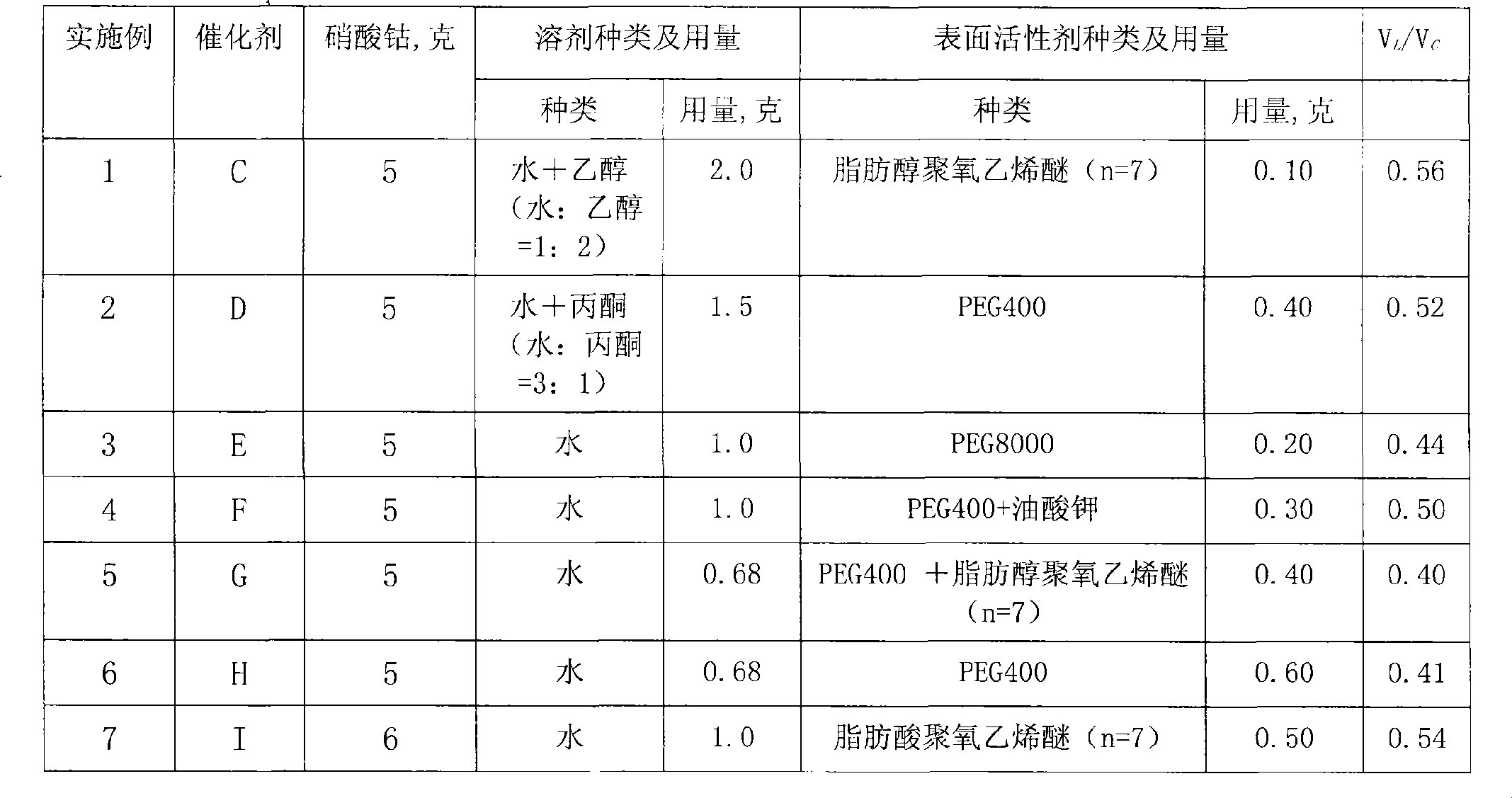

Light guide plate for surface light source

ActiveUS20090086509A1Preventing situationEfficient emissionsShow cabinetsImpedence networksDistribution controlLight guide

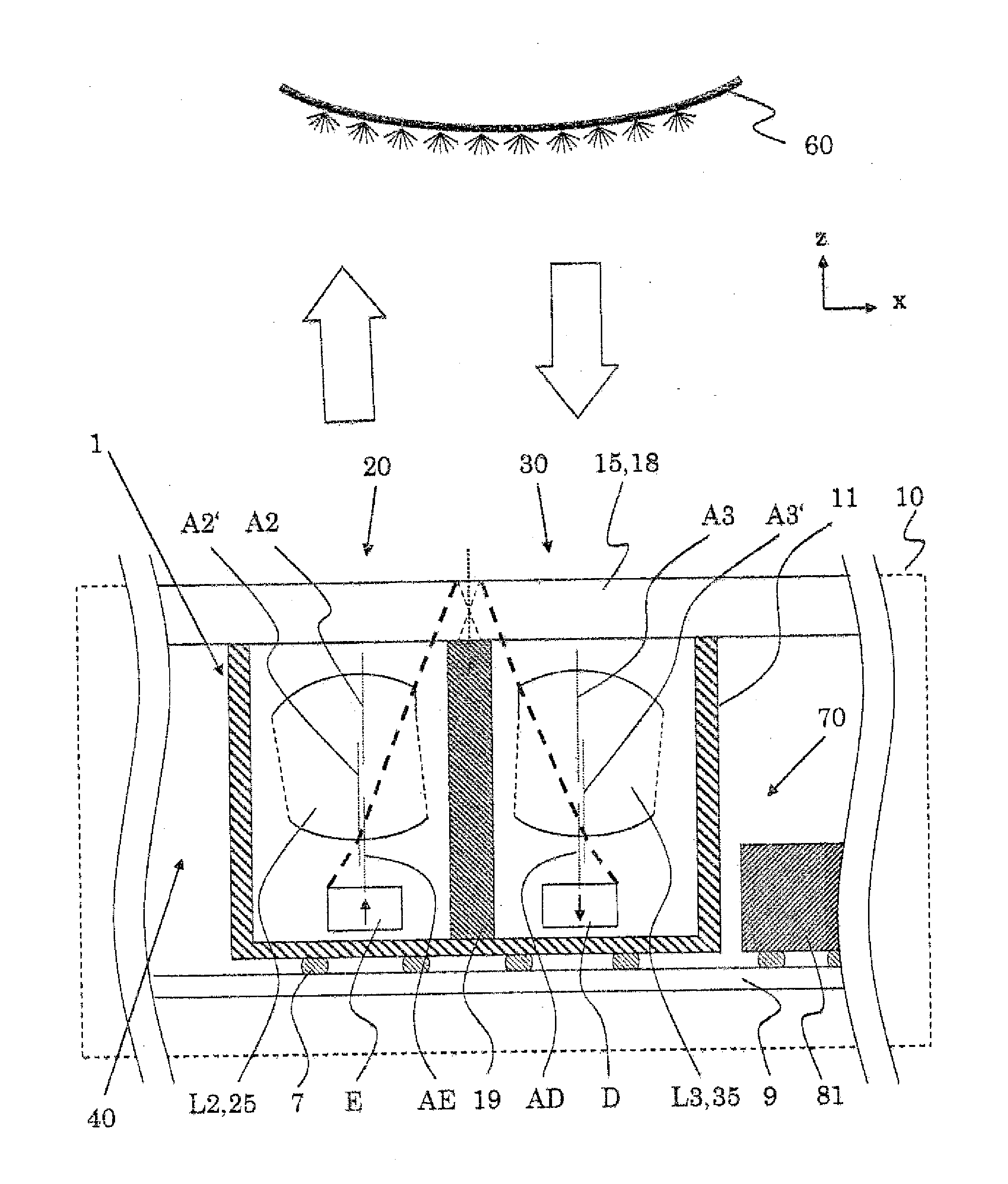

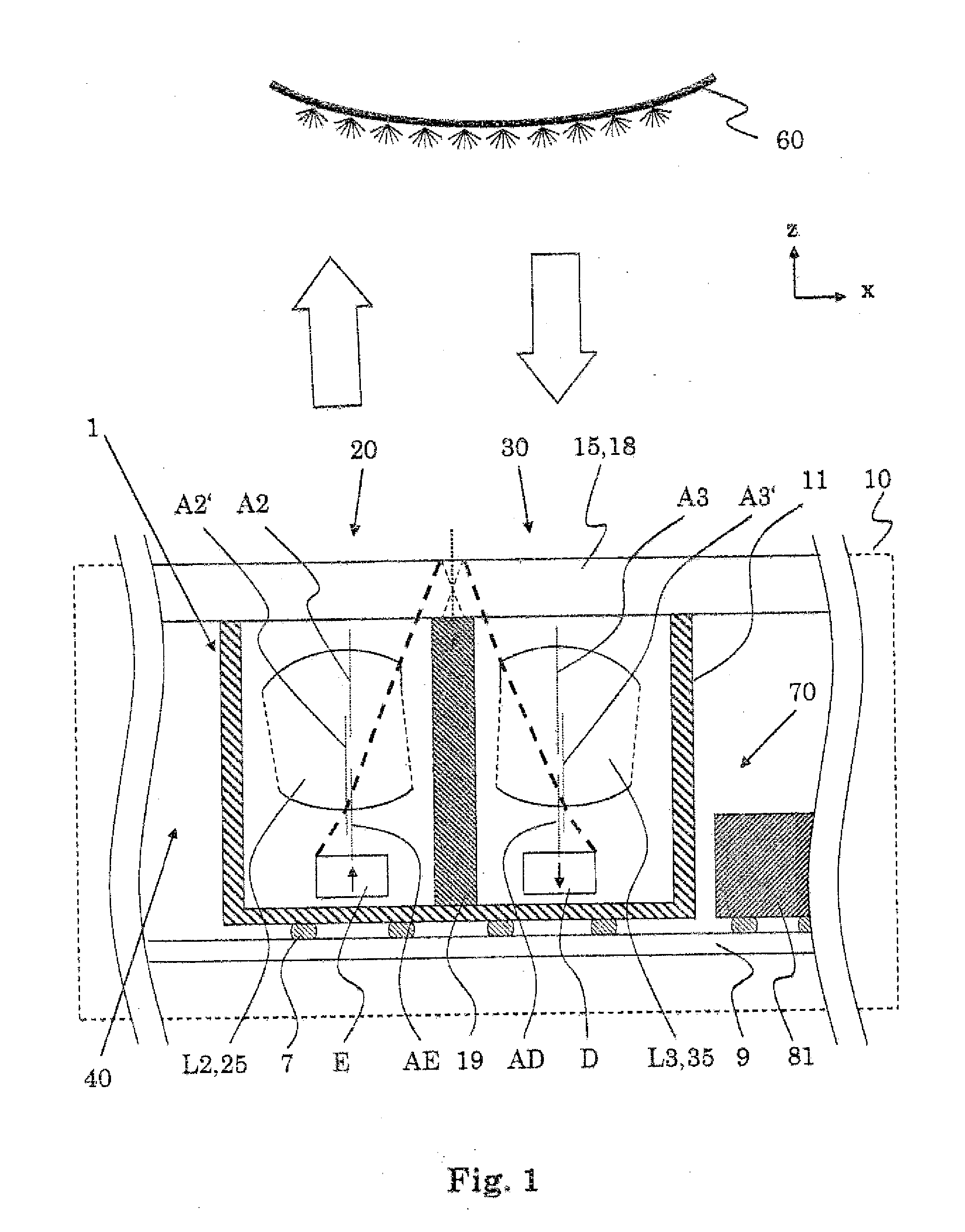

A plurality of mirror surfaces (5), which extend in a direction (X-axis direction) perpendicular to a light incident surface (2a), are formed side by side in a longitudinal direction (Y-axis direction) of the light incident surface (2a) on a light distribution control surface (4a) of both surfaces (4a, 4b) of a light guide plate (1) in a thickness direction (Z-axis direction) thereof, and a plurality of prisms (7) extending in the Y-axis direction are formed side by side in the X-axis direction in areas other than the mirror surfaces (5). The mirror surfaces 5 are formed in such a way that Y-axis direction widths thereof vary in the X-axis direction. This enables the setting of the light distribution characteristics and luminance distribution of emitted light, which are viewed in two directions, namely a longitudinal direction of the light incident surface of the light guide plate and the direction perpendicular to the light incident surface, to target light distribution characteristics and luminance distribution.

Owner:STANLEY ELECTRIC CO LTD

Street lighting device

InactiveUS20120120666A1Simple fashionMechanical apparatusPoint-like light sourceLuminous intensityLight equipment

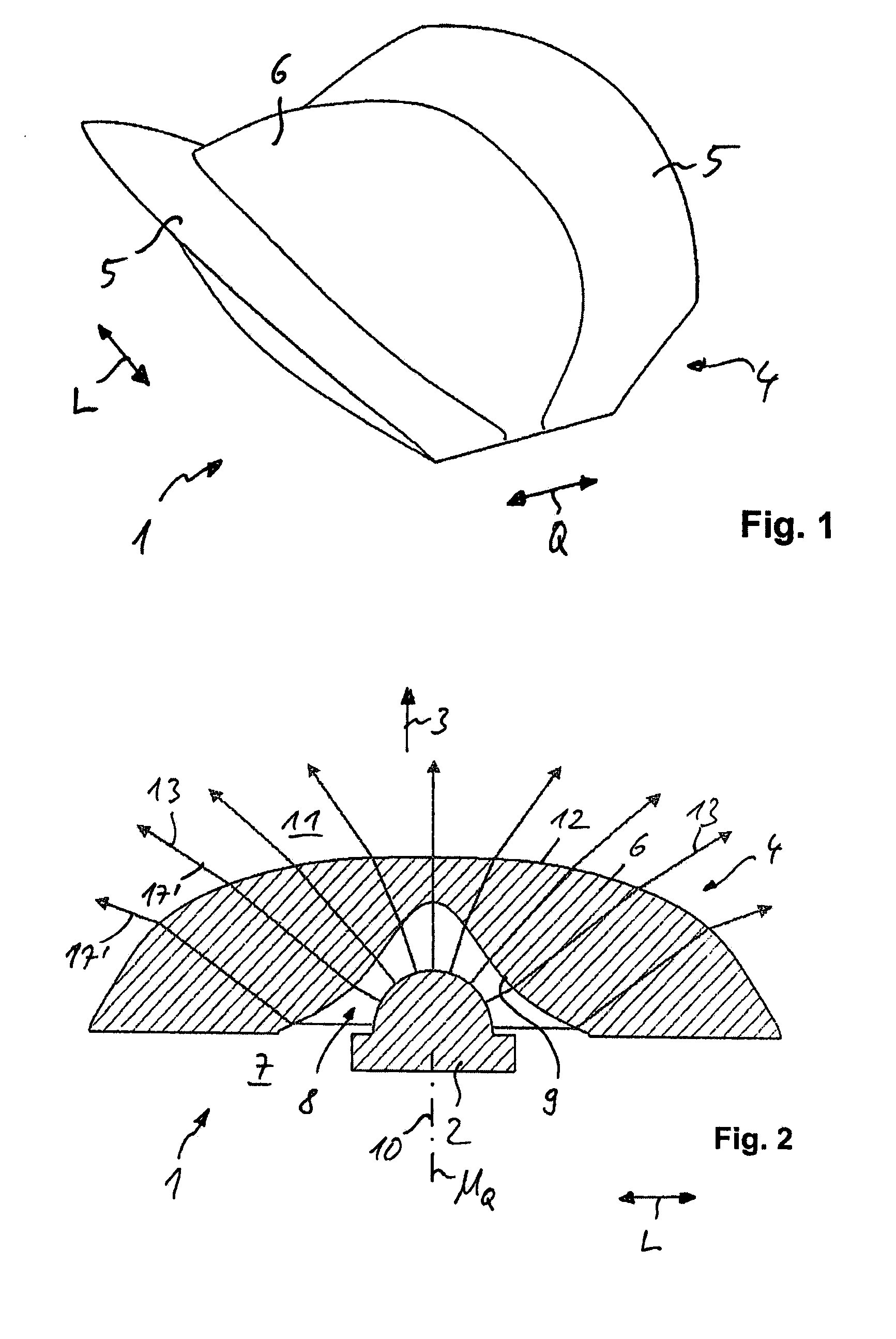

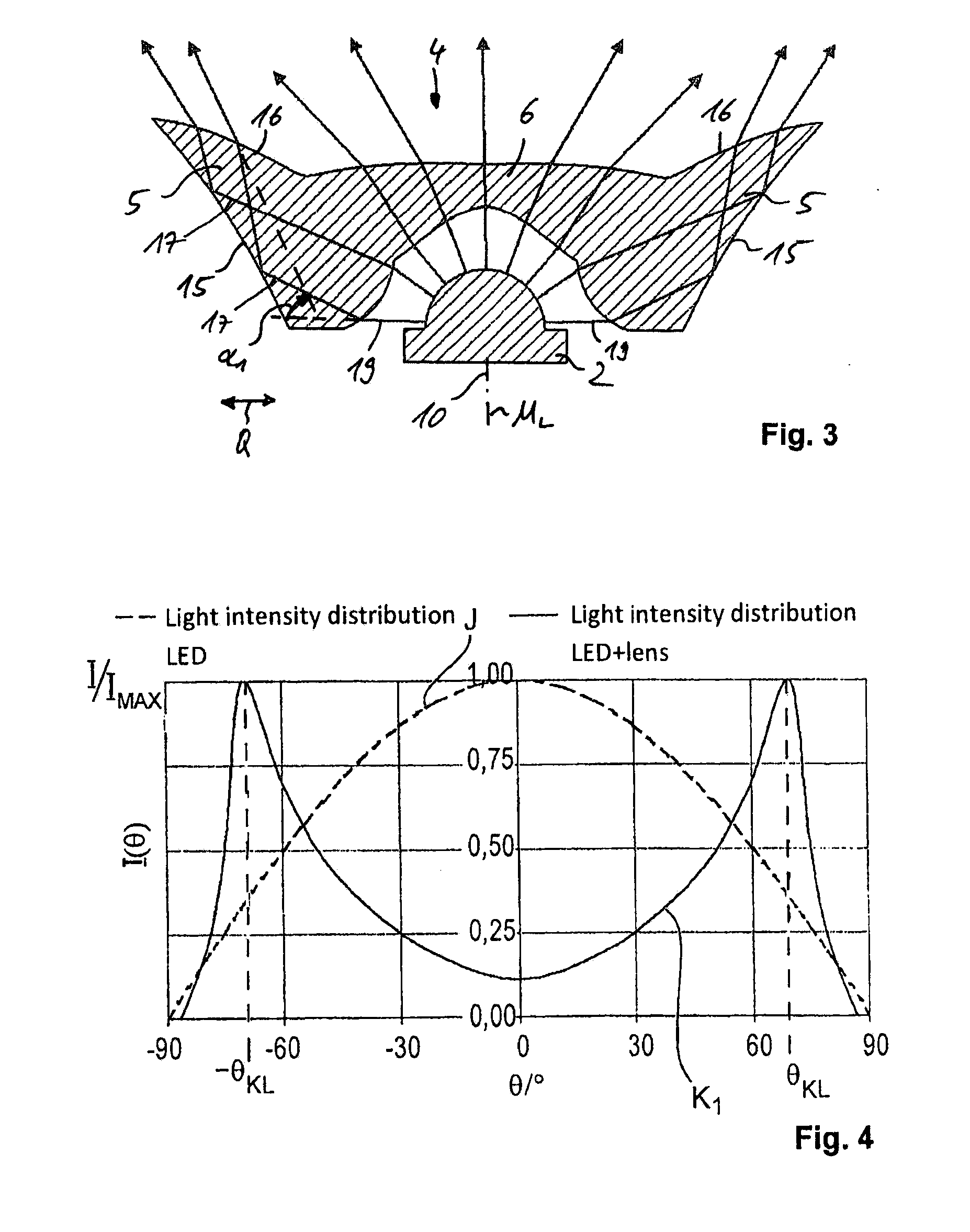

A lighting device for streets, paths, and the like, includes a lighting unit containing a lighting element and a lens arranged in front of the lighting element in the main emission direction to produce a specified light distribution characteristic. The lens includes a light entrance surface on a light entrance side facing the lighting element and a light exit surface on a light exit side facing away from the lighting element, at which surfaces the light is refracted. The light entrance surface and / or the light exit surface of the lens is shaped in a direction transverse to the optical axis of the lighting element in such a way that the luminous intensity of the coupled out light, starting from a center plane that intersects with the optical axis, rises with an increasing emission angle from the optical axis at least partially according to a tangent function.

Owner:HELLA KG HUECK & CO

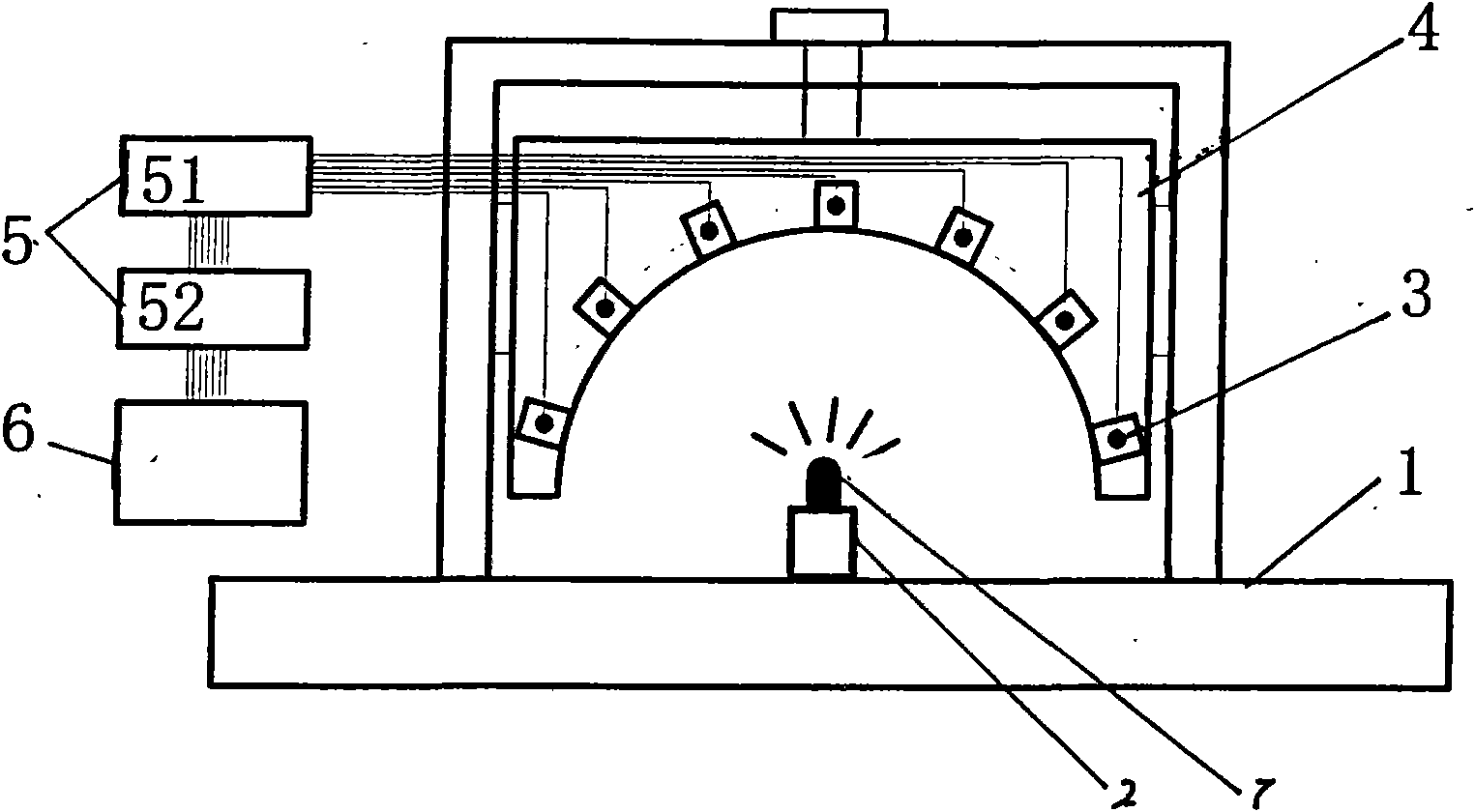

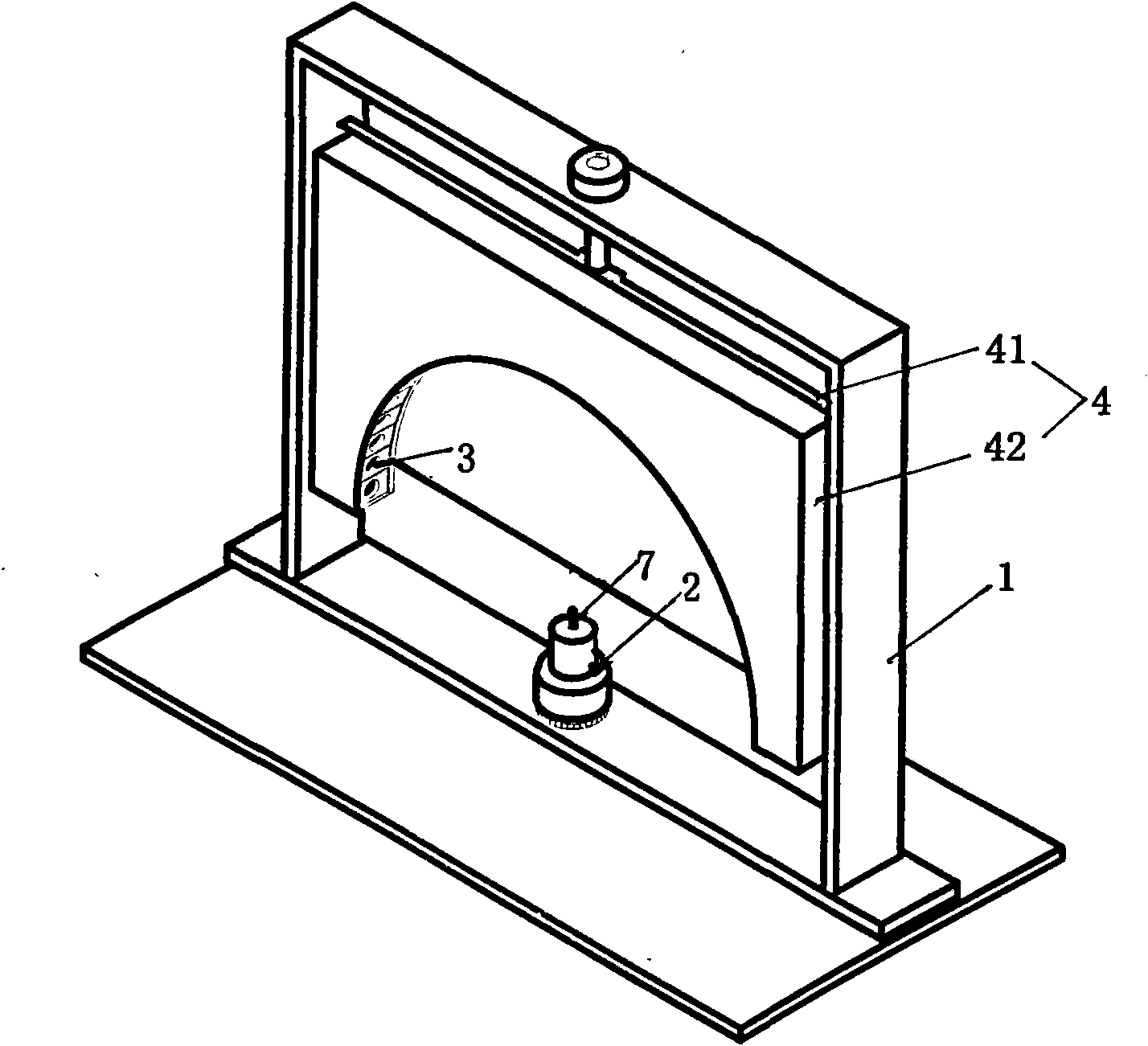

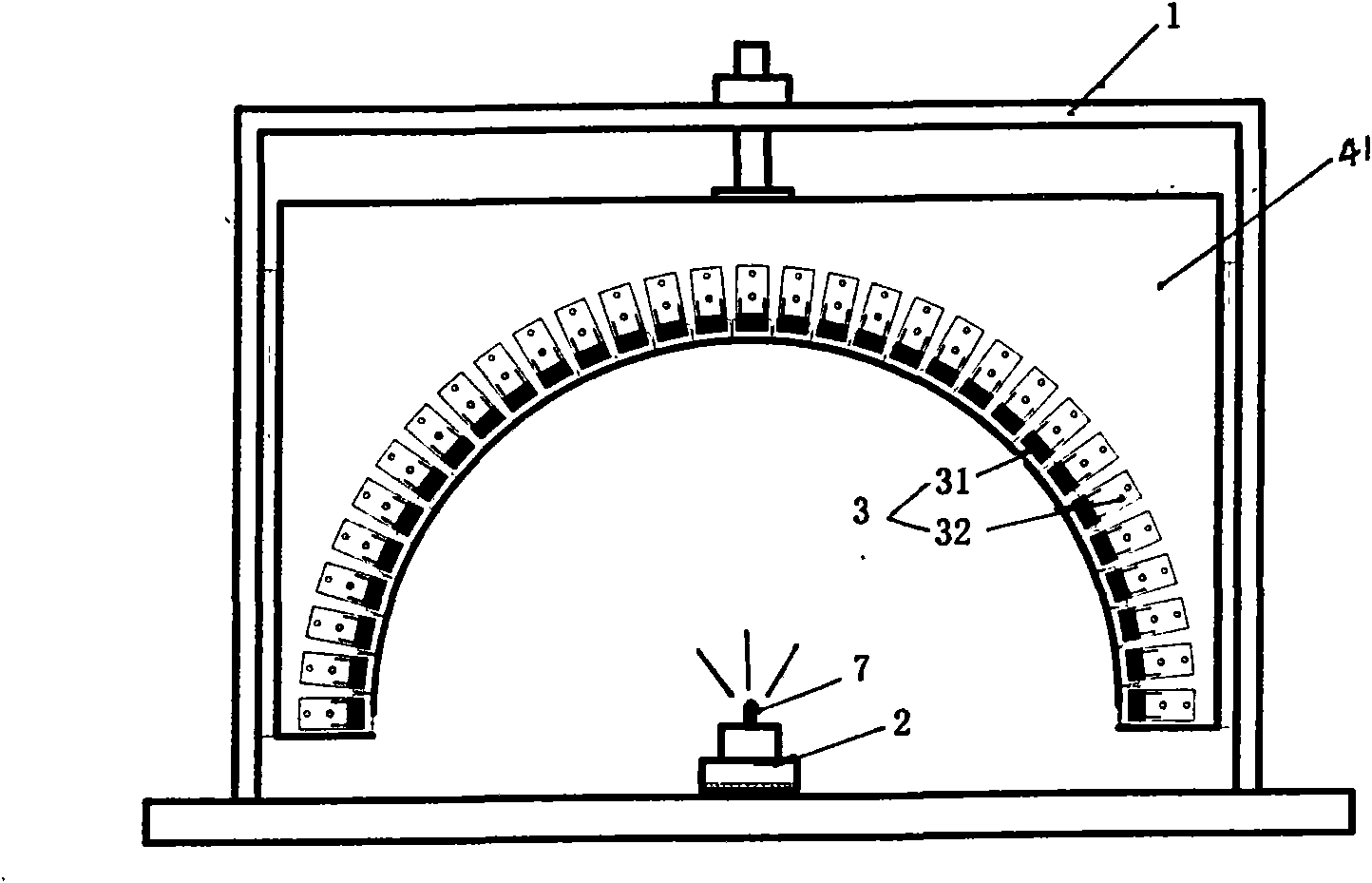

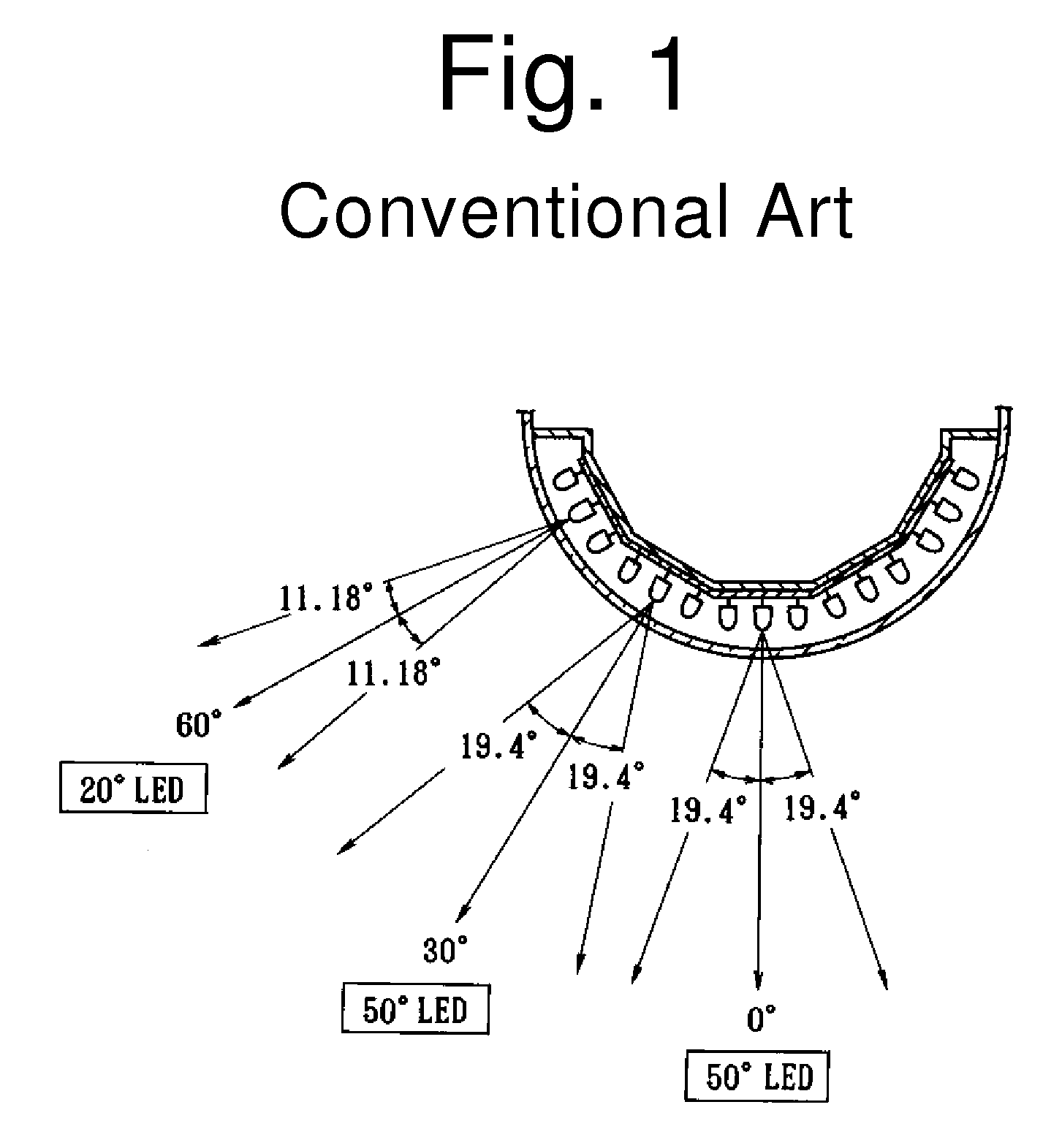

Device and method for testing LED light source intensity space distribution characteristic

InactiveCN101566500AFast testReal-timePhotometry using electric radiation detectorsTesting optical propertiesLuminosityDistribution characteristic

The invention relates to a device and a method for testing the LED light source intensity space distribution characteristic. The device comprises a base, a testing sample seat, a light intensity detecting unit, a detector bracket, a testing circuit, a computer and testing software. A multi-path synchronous testing method of a plurality of light intensity detecting units is adopted to replace one light intensity detector to sequentially test a plurality of points so as to realize the quick testing of the LED light source intensity space distribution characteristic. Compared with a conventional light distribution curve measuring method adopting one light intensity detector, if N light intensity detectors are used, the testing speed can be improved by more than N times. The device has the advantages of high testing speed and precision, abundant information content and real time and visualization.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL TECH RES INST

LED lighting fixture

InactiveUS7857497B2Effective lightingUniform lightMechanical apparatusLight source combinationsOptical ModuleDistribution control

Owner:STANLEY ELECTRIC CO LTD

Optical system for endoscopes

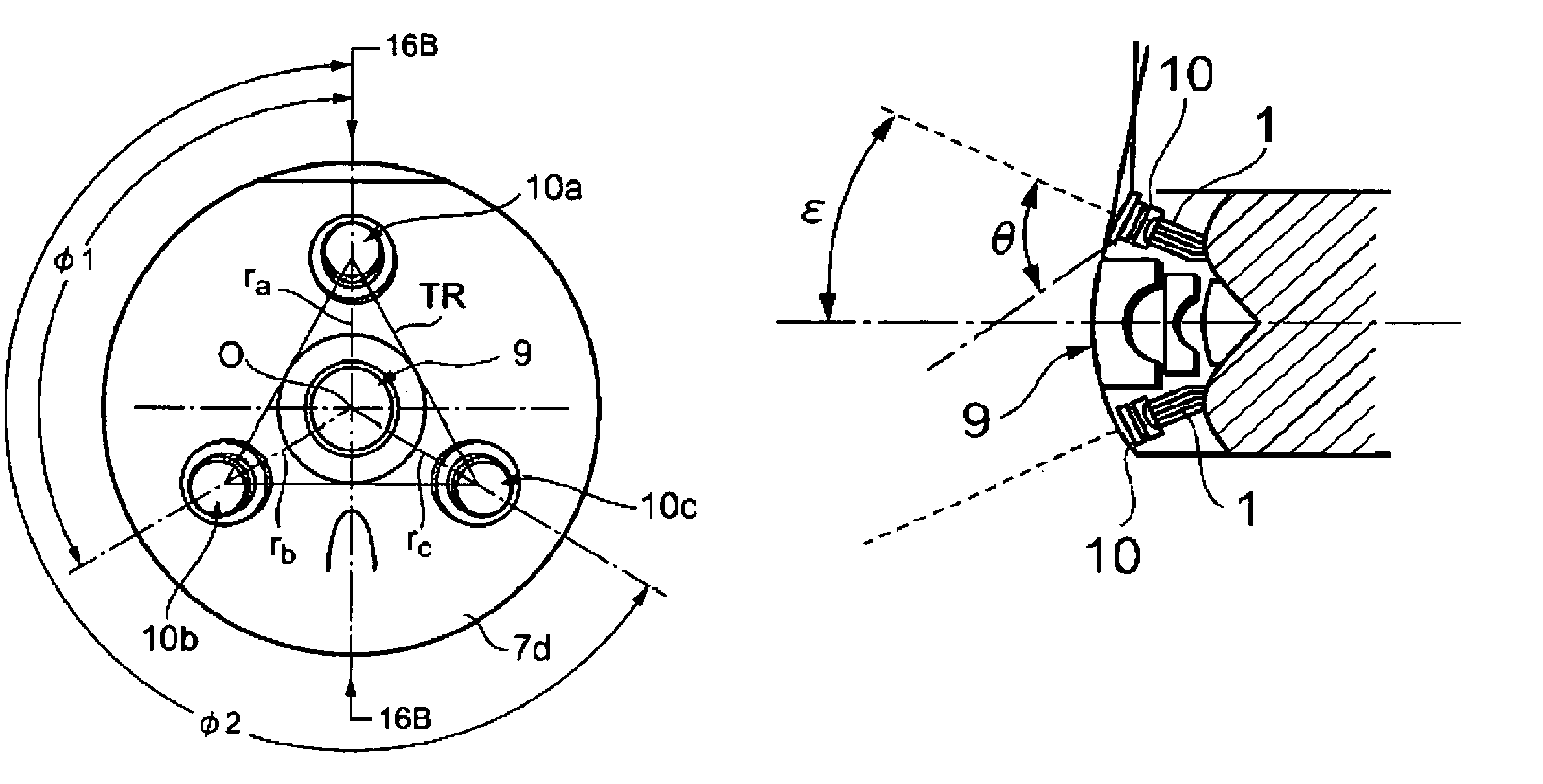

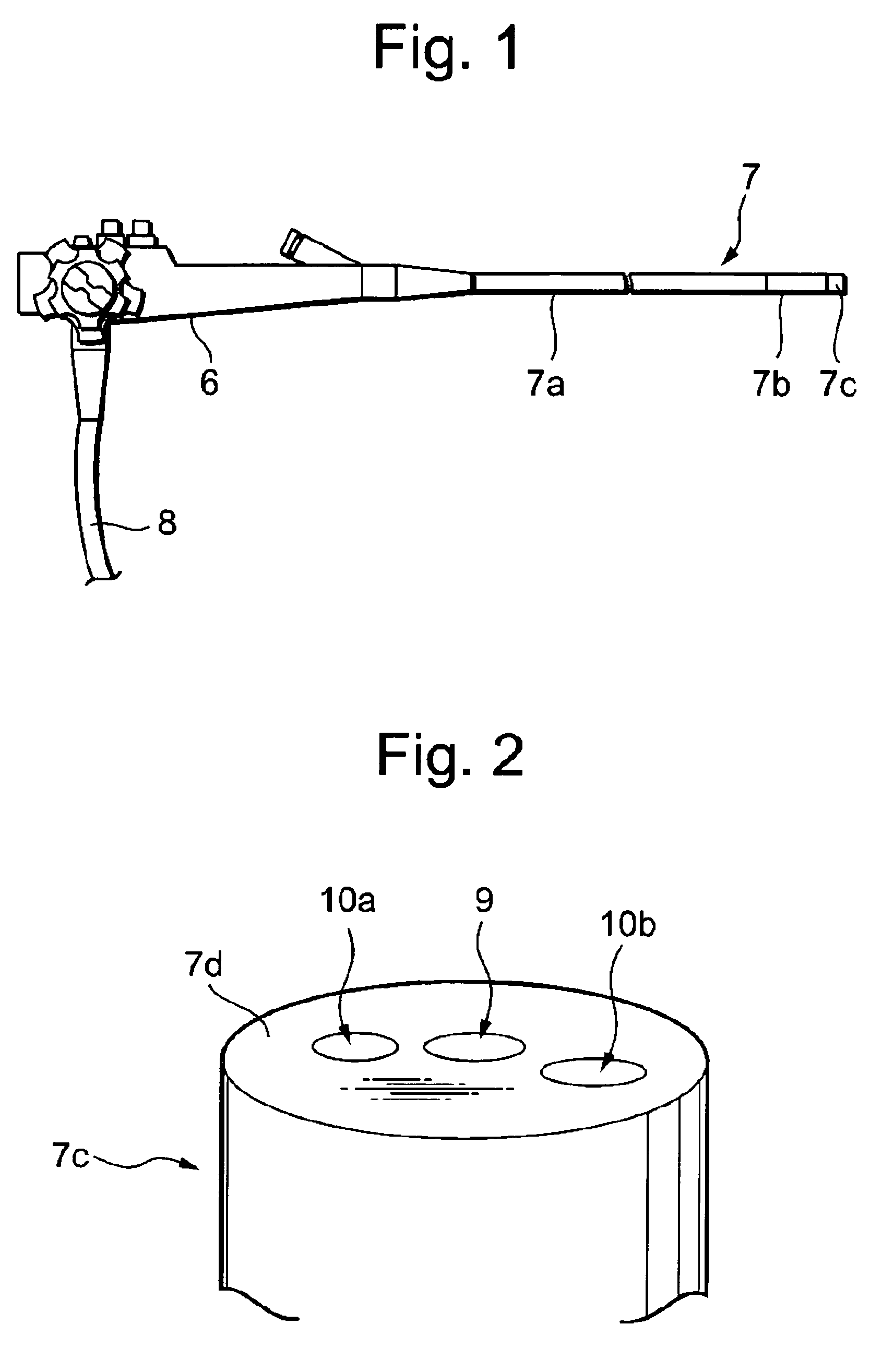

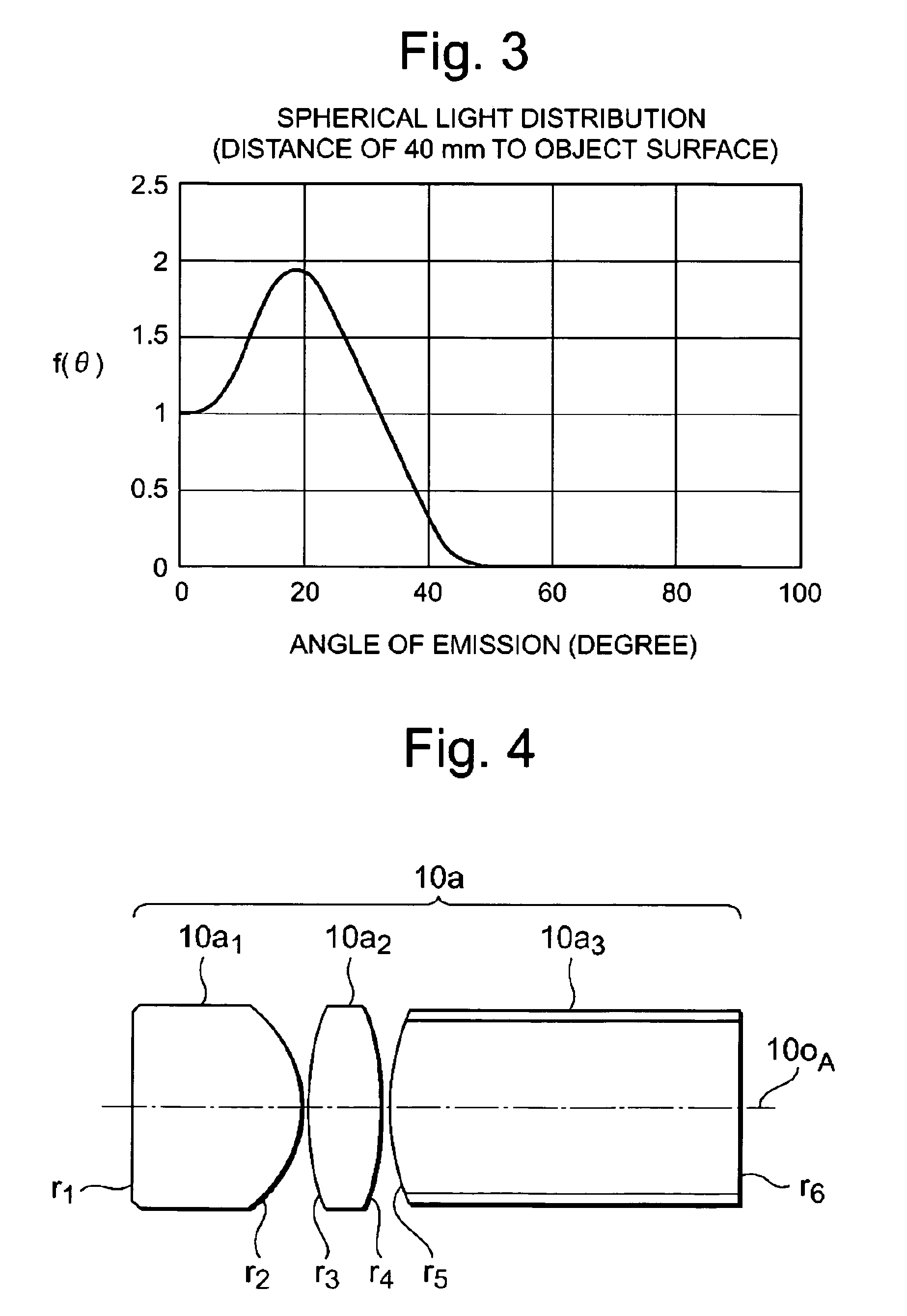

An optical system for an endoscope can be used by being disposed in the distal end portion of the endoscope, the optical system having a plurality of illumination optical systems, which allow light emitted from a light source to diverge, and an observation optical system, in which at least one of the plurality of illumination optical systems satisfies the following formula (1):0≦−df(θ) / dθ≦0.025, 10°≦θ≦85° (1),wherein θ denotes an angle of emission from a center of the illumination optical system, and f(θ) denotes a value obtained by standardizing, at an illuminance at a time when the angle θ of emission is 0°, an illuminance distribution (spherical light distribution characteristics) at a time when a spherical object is illuminated by the illumination optical system.

Owner:OLYMPUS CORP

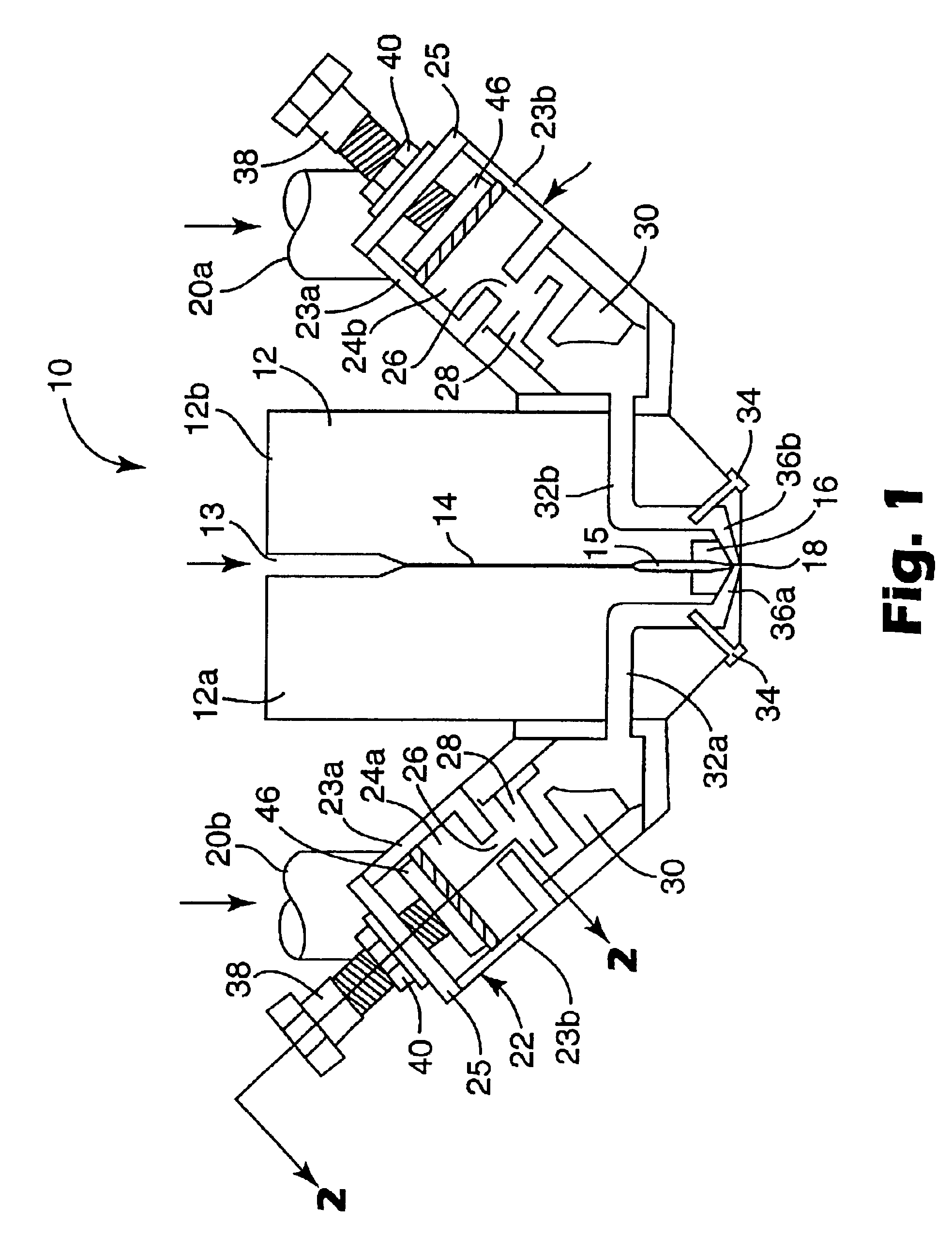

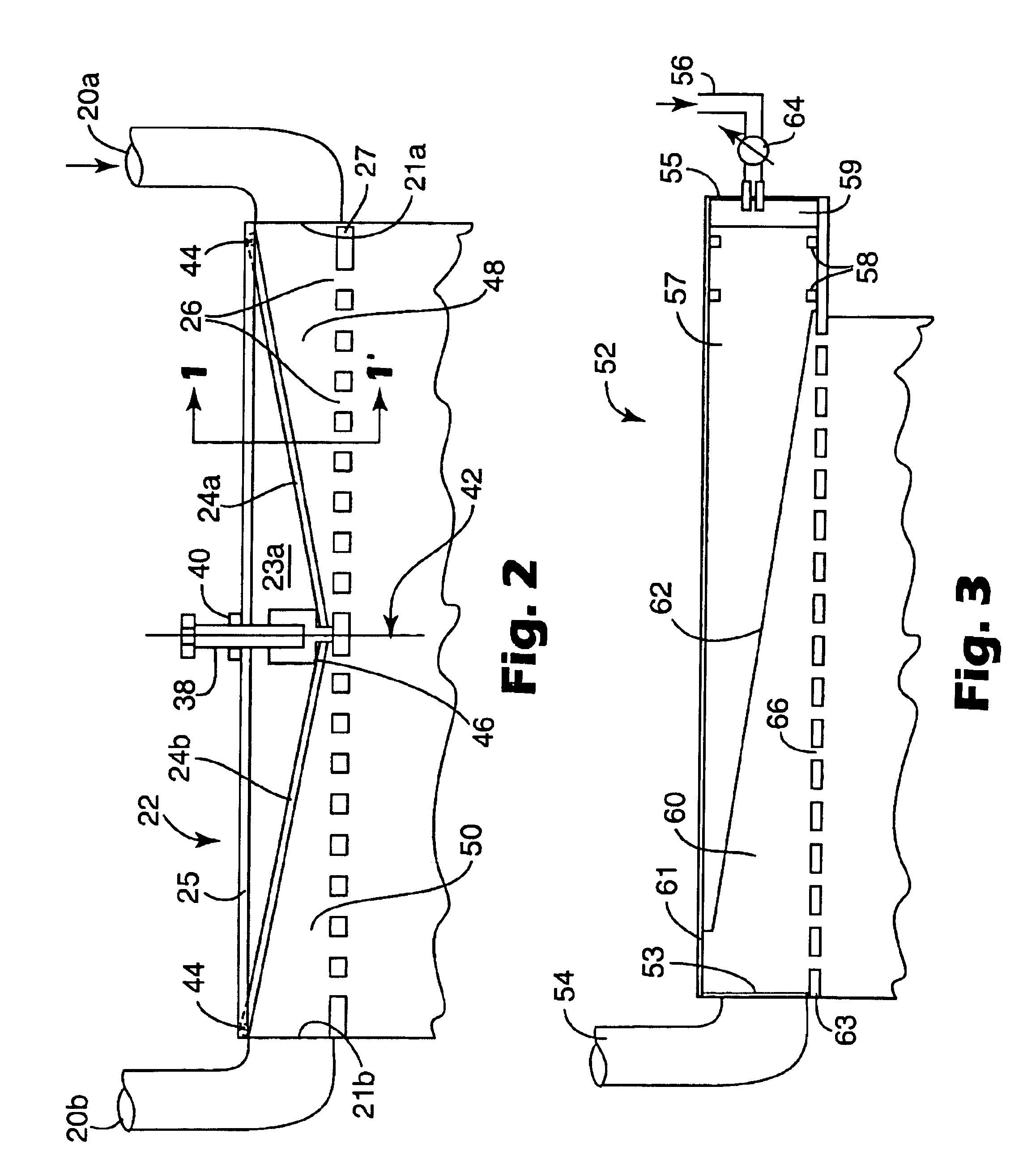

Attenuating fluid manifold for meltblowing die

InactiveUS6861025B2Quality improvementUniform physical propertiesSpinning head liquid feederConfectioneryDistribution characteristicEngineering

Melt blown nonwoven webs are formed by supplying attenuating fluid to a meltblowing die through an attenuating fluid distribution passage whose distribution characteristics can be changed while the die and manifold are assembled. By adjusting the distribution characteristics of the passage, the mass flow rate of attenuating fluid to channels in the meltblowing die and the temperature of the attenuating fluid at the die outlets can be made more uniform.

Owner:3M INNOVATIVE PROPERTIES CO

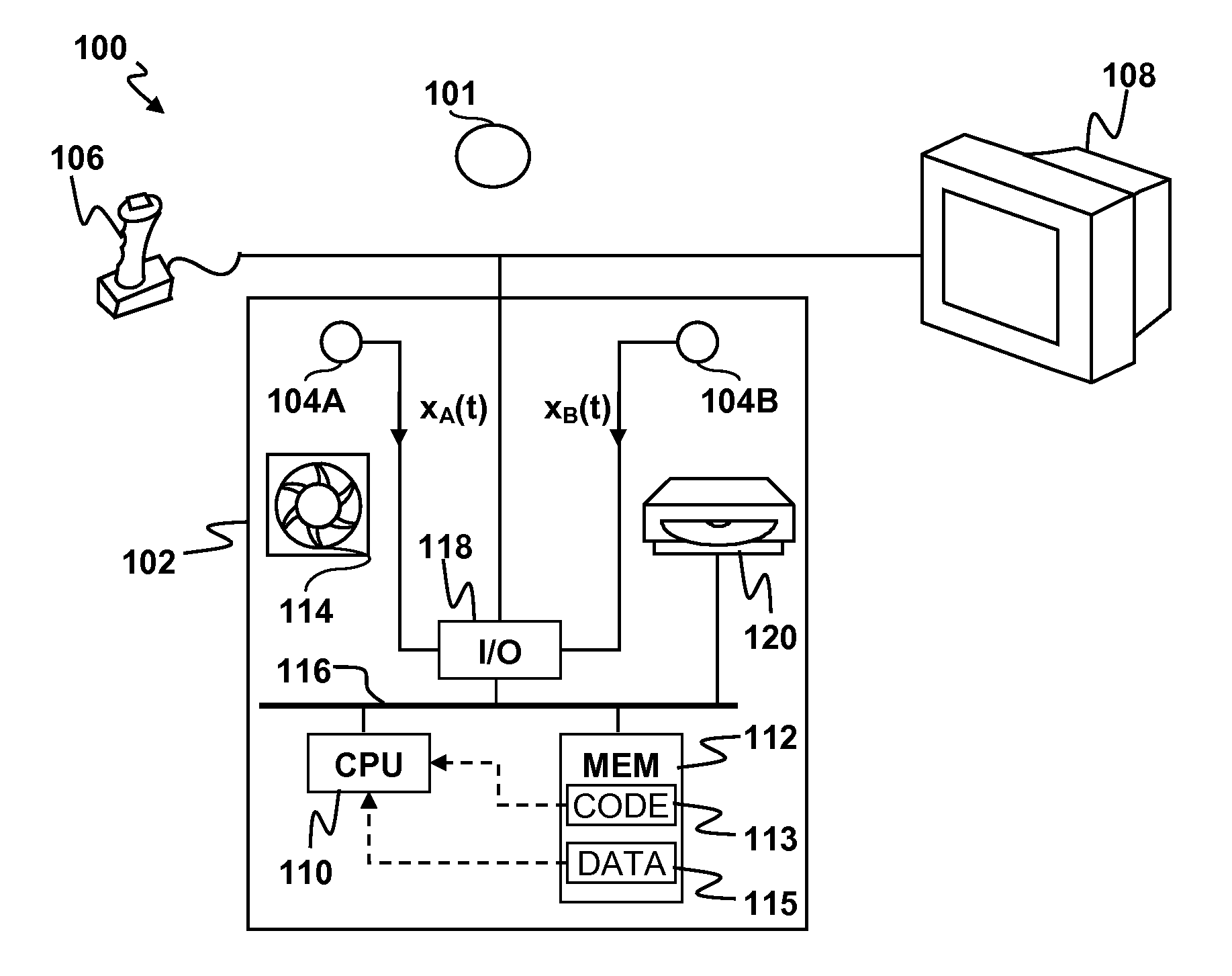

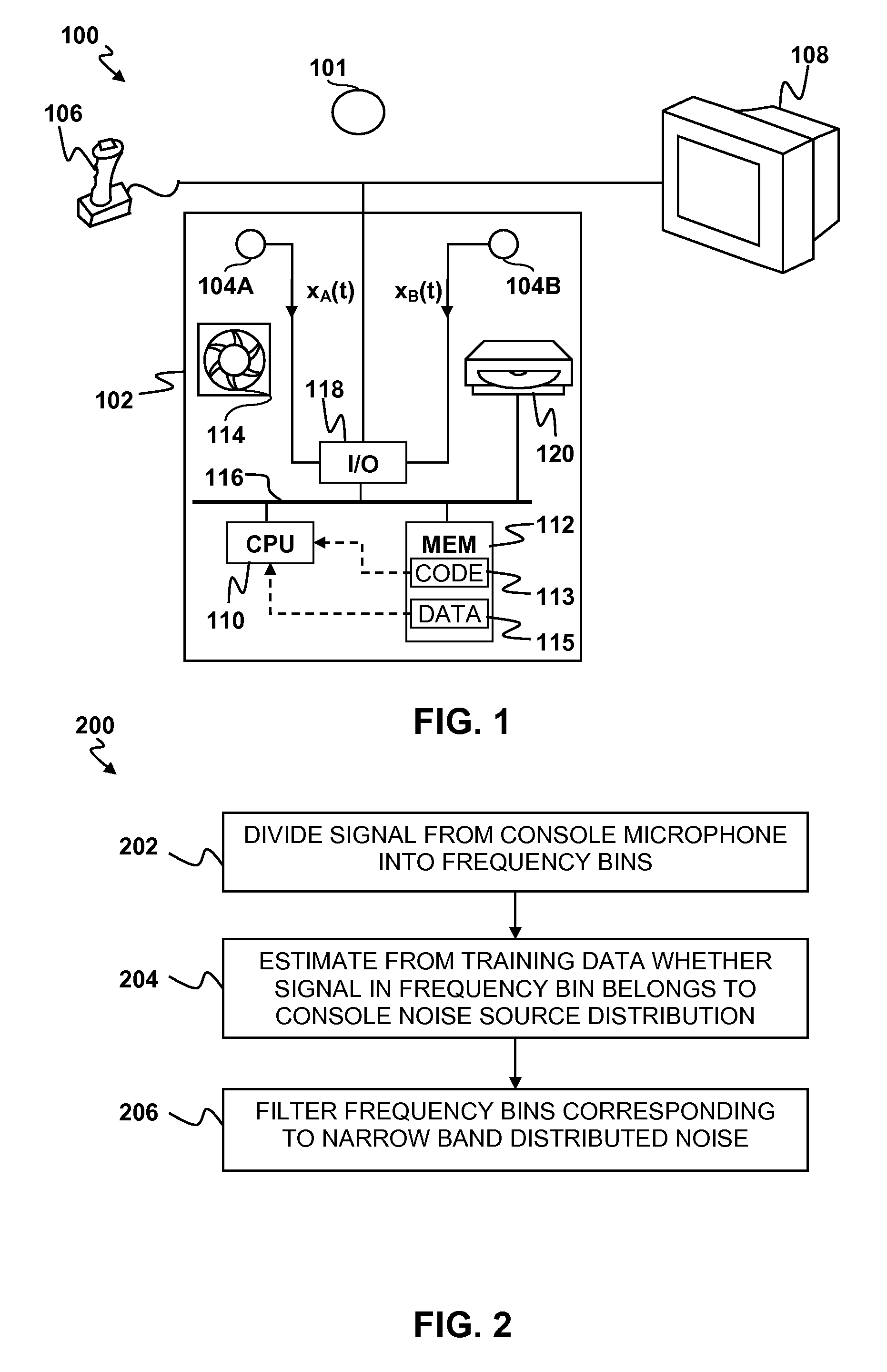

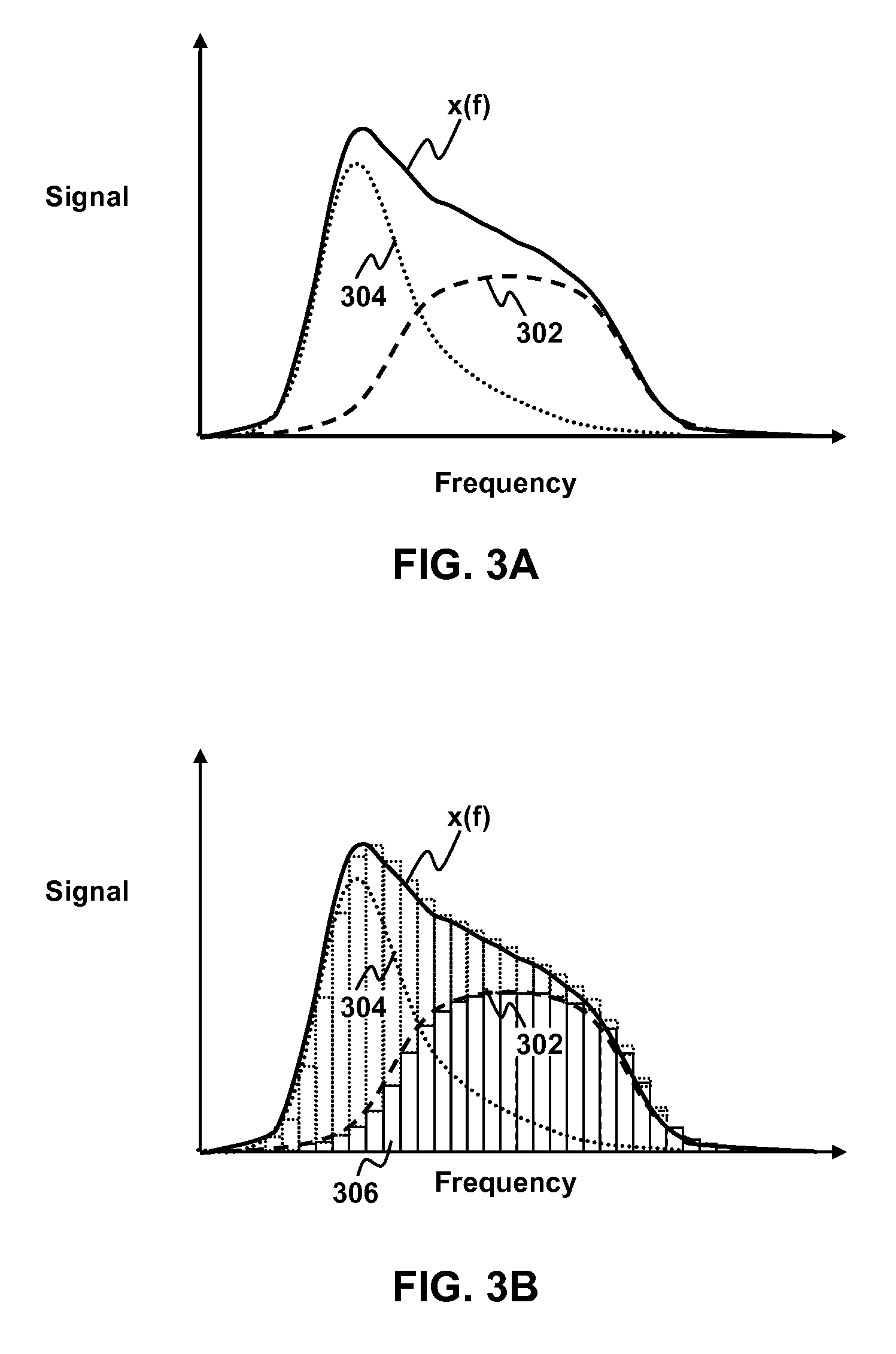

Noise removal for electronic device with far field microphone on console

Reduction of noise in a device having a console with one or more microphones and a source of narrow band distributed noise located on the console is disclosed. A microphone signal containing a broad band distributed desired sound and narrow band distributed noise is divided amongst a plurality of frequency bins. For each frequency bin, it is determined whether a portion of the signal within the frequency bin belongs to a narrow band distribution characteristic of the source of narrow band noise located on the console. Any frequency bins containing portions of the signal belonging to the narrow band distribution are filtered to reduce the narrow band noise.

Owner:SONY COMPUTER ENTERTAINMENT INC

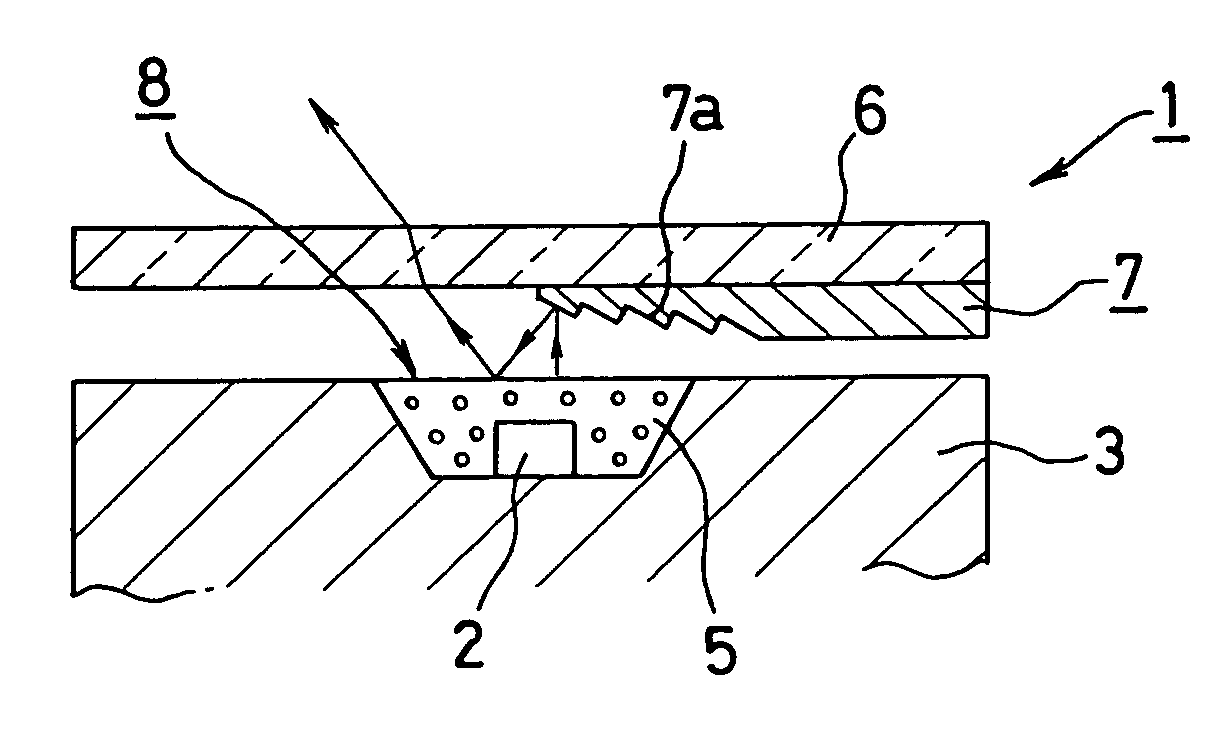

LED lamp for light source of a headlamp

InactiveUS7019334B2Accurately and easily achievedVehicle headlampsDischarge tube luminescnet screensDistribution characteristicOptoelectronics

Whereas incandescent light bulbs and other similar light sources known in the prior art emit light in all directions, LED lamps emit light in a single direction only, and this is manifested in the problem of being unable to achieve light distribution characteristics satisfied by conventional headlamp designs. The present invention realizes an LED lamp for a light source of a headlamp disposing an LED chip 2 in the vicinity of the focus of a projection means and providing a shielding member 7 covering a portion of the LED chip 2 in a formation allowing a light distribution characteristic suitable for a vehicle front-illumination light to be obtained when light from the LED chip 2 is magnified and projected in an illumination direction by a projection lens 10 or the like constituting the projection means; accordingly, accurate light distribution characteristics can be obtained in a simple manner by projecting in the illumination direction using the projection lens 10.

Owner:STANLEY ELECTRIC CO LTD

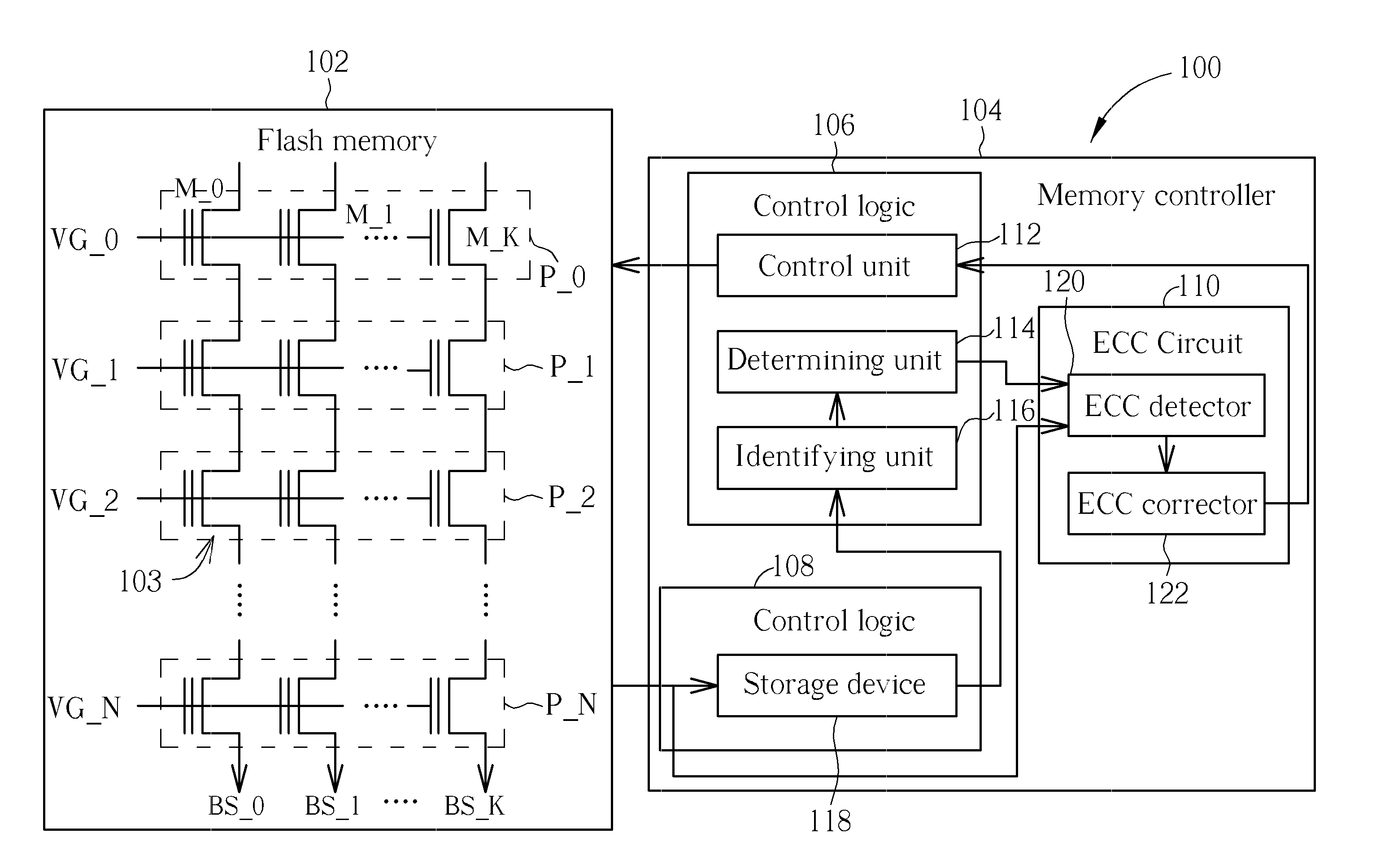

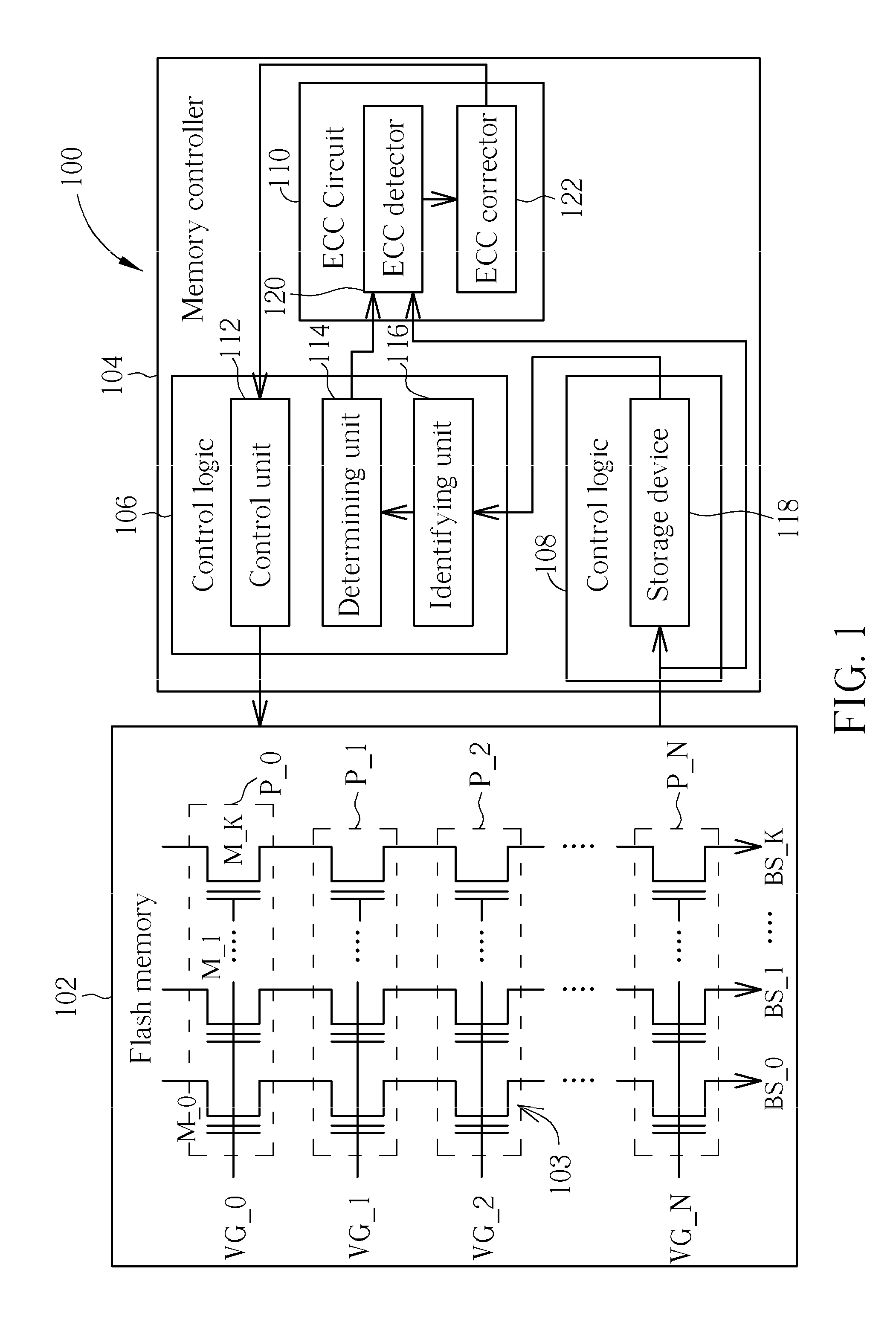

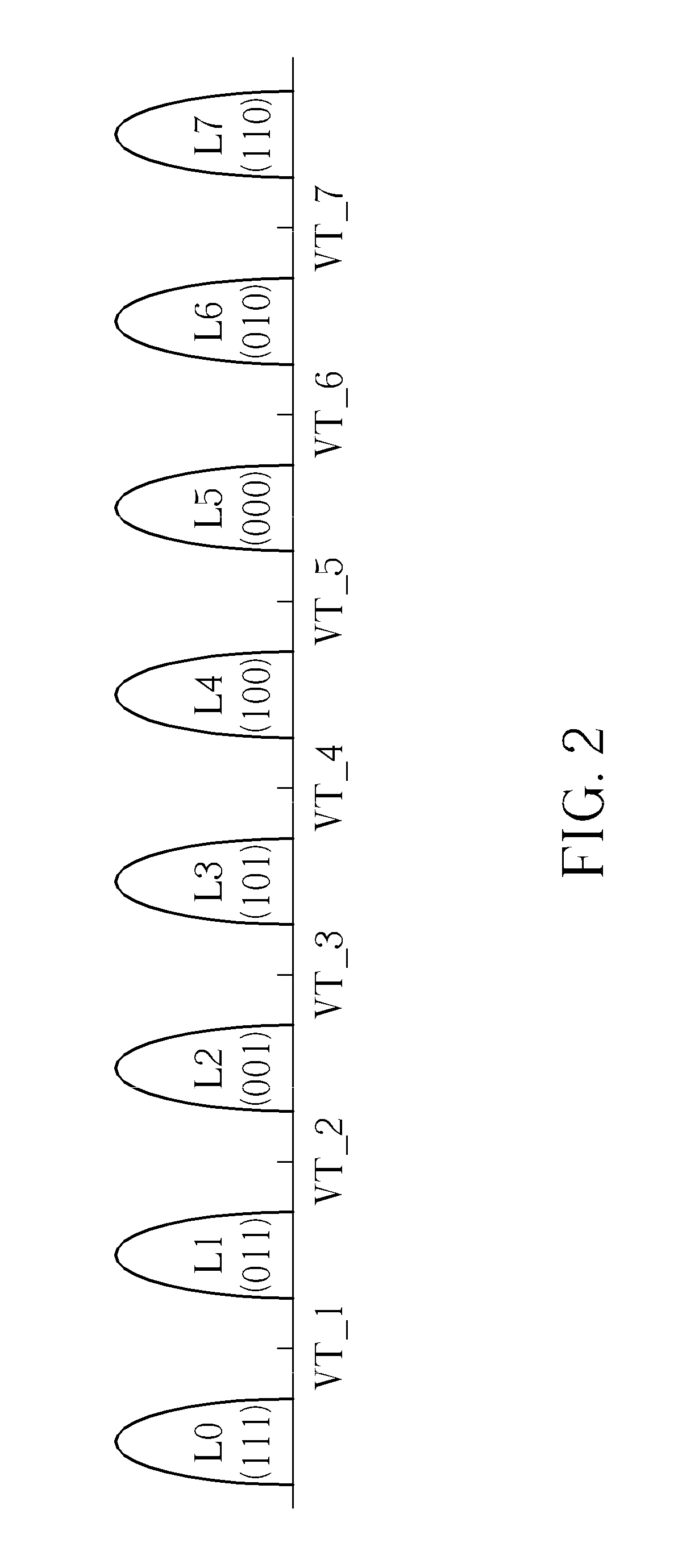

Method and memory controller for reading data stored in flash memory by referring to binary digit distribution characteristics of bit sequences read from flash memory

ActiveUS20120140560A1Error detection/correctionRead-only memoriesDistribution characteristicMemory controller

An exemplary method for reading data stored in a flash memory includes: controlling the flash memory to perform a plurality of read operations upon each of a plurality of memory cells included in the flash memory; obtaining a plurality of bit sequences read from the memory cells, respectively, wherein the read operations read bits of a predetermined bit order from each of the memory cells as one of the bit sequences by utilizing different control gate voltage settings; and determining readout information of the memory cells according to binary digit distribution characteristics of the bit sequences.

Owner:SILICON MOTION INC (TW)

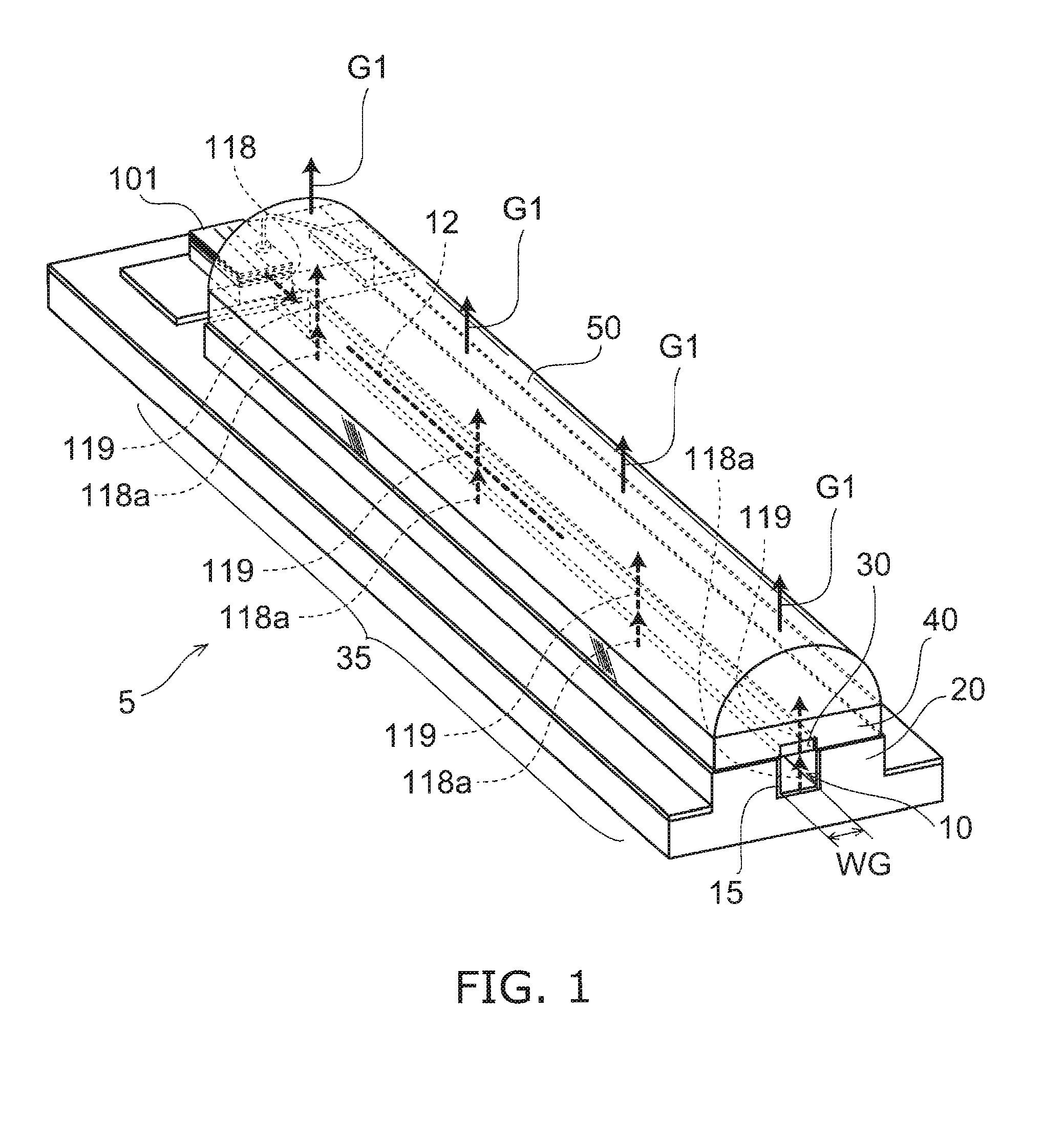

Light emitting device and method for manufacturing same, lighting fixture, and lighting system

InactiveUS20110032724A1Point-like light sourceLighting support devicesLight guideDistribution characteristic

A light emitting device includes: a light emitting element; a substrate including a groove-like light guide extending along a first direction, emission light emitted from the light emitting element and introduced into the light guide being reflected by an inner wall surface of the light guide, spreading along the first direction, and being turned into upward light directed upward above the substrate; and a lens provided above the light guide and configured to collect the upward light and control light distribution characteristic in a plane generally perpendicular to the first direction.

Owner:HARISON TOSHIBA LIGHTING CORP +1

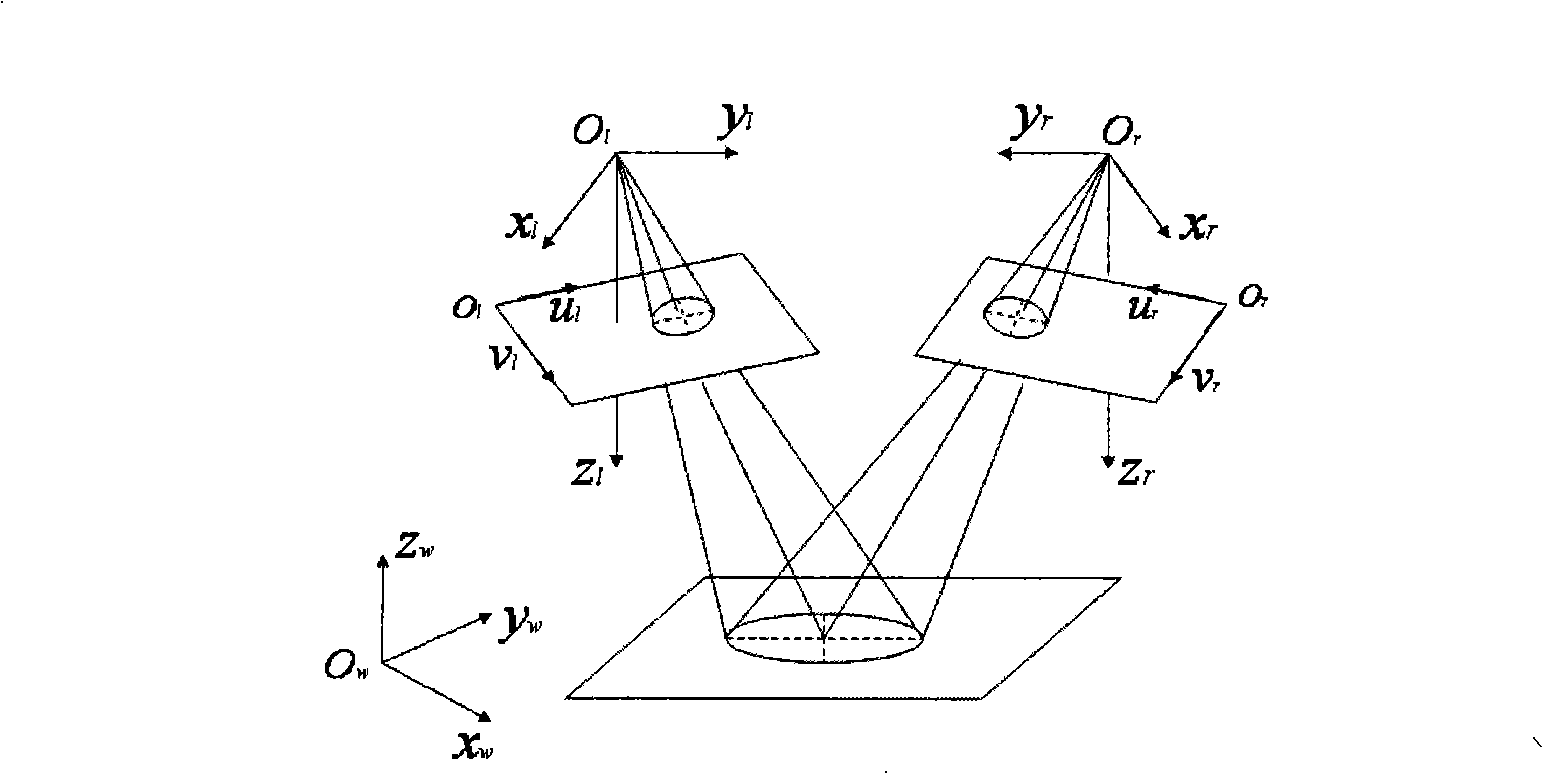

Spatial circular geometric parameter binocular stereo vision measurement method

InactiveCN101261115APrecise sub-pixel precisionSmall amount of calculationBiological neural network modelsUsing optical meansBinocular stereoVisual perception

The invention discloses a spatial circle geometrical parameter dual-eye solid visual measurement method suitable for non-contact type online measurement of the spatial circle geometrical parameter of an industrial product, aiming at overcoming the existing problems of low measurement precision, slow measurement speed and low automation degree. The method is divided into a calibrating stage, an image processing stage and a spatial circle fitting stage. A neural network technique is firstly adopted to carry out the calibration of a camera; a dual-camera is utilized to carry out the extraction of sub-pixel image edges of the spatial circle, a simple algorithm is developed based on the image gray gradient distribution characteristic so as to realize the match of edge points, the practical 3D spatial coordinates of the circle edges are then obtained, and the geometrical parameters of the spatial circle comprise radius, position of center of circle and orientation of the plane where the spatial circle is arranged are gained by the fitting of the spatial circle with corresponding mathematical geometrical knowledge. The spatial circle geometrical parameter dual-eye solid visual measurement method has fast image processing speed and high automation degree, and has relative measurement error of the spatial circle of superior to plus or minus 0.6% when the plane where the spatial circle is arranged has an angle of about 50 DEG with the image plane.

Owner:JILIN UNIV

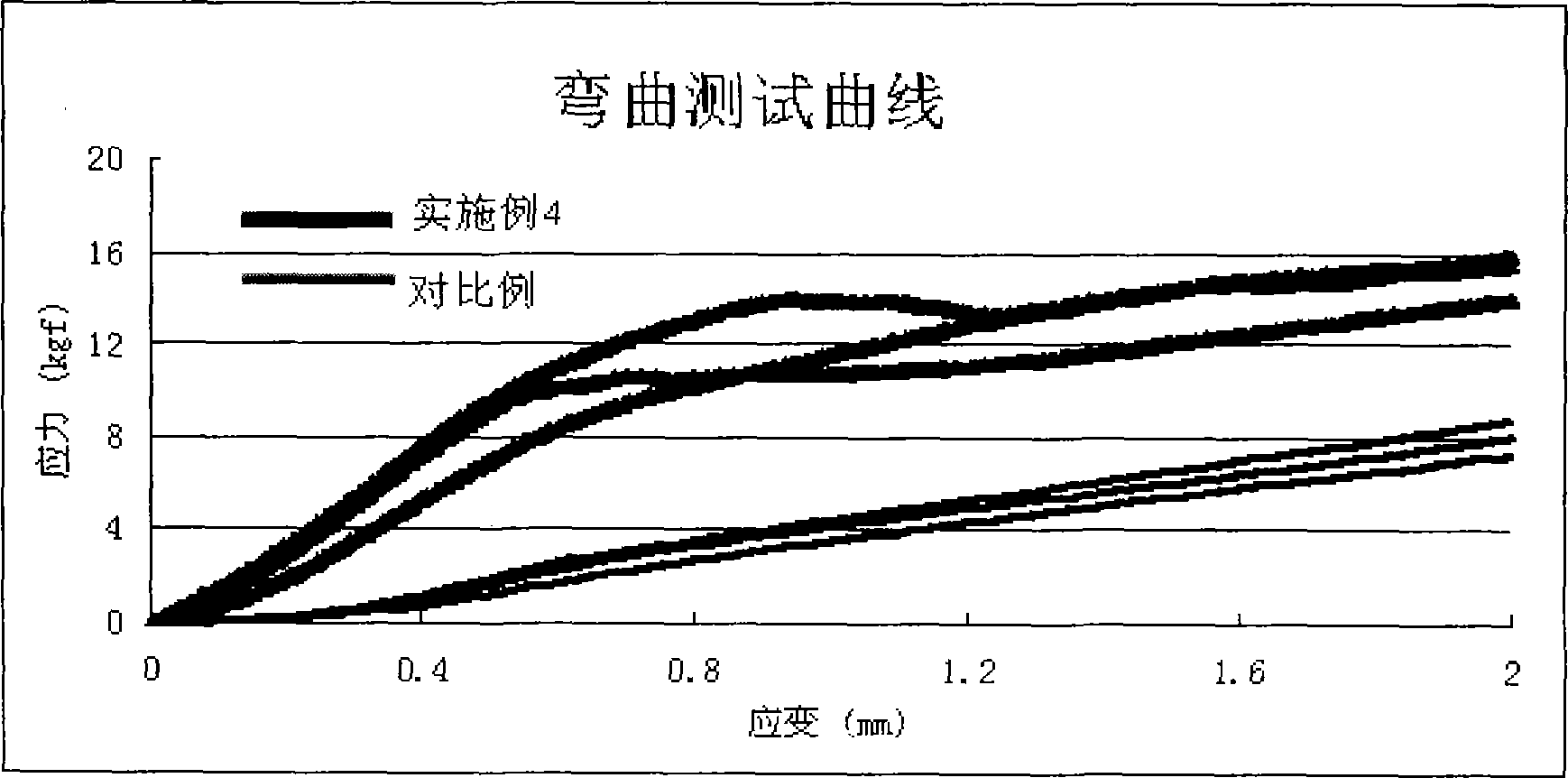

Polymer lithium ion battery and diaphragm thereof

ActiveCN102610773AImprove thermal stabilityImprove mechanical propertiesSecondary cellsCell component detailsCyclic processSwelling capacity

The invention belongs to the technical field of polymer lithium ion batteries, in particular to a diaphragm for the polymer lithium ion battery. The diaphragm comprises a multihole base material, wherein an inorganic substance coating layer and an organic substance coating layer are coated on at least one surface of the multihole base material; and the organic substance coating layer is in island-type and / or linear distribution and coated on the surface of the multihole base material and / or the inorganic substance coating layer. Compared with the prior art, due to the inorganic substance coating layer, the diaphragm can keep relatively high heat stability and mechanical performance, so that the lithium ion battery has high safety performance; the organic substance coating layer has high imbibition swelling capacity, and an interface has high stability, so that the manufactured lithium ion battery has perfect mechanical performance; due to the distribution characteristic of the organic substance coating layer, spaces are provided for charging and discharging processes of a pole piece and a circulation process; and the problem of deformation of the polymer lithium ion battery is well solved. Furthermore, the invention also discloses a polymer lithium ion batter with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

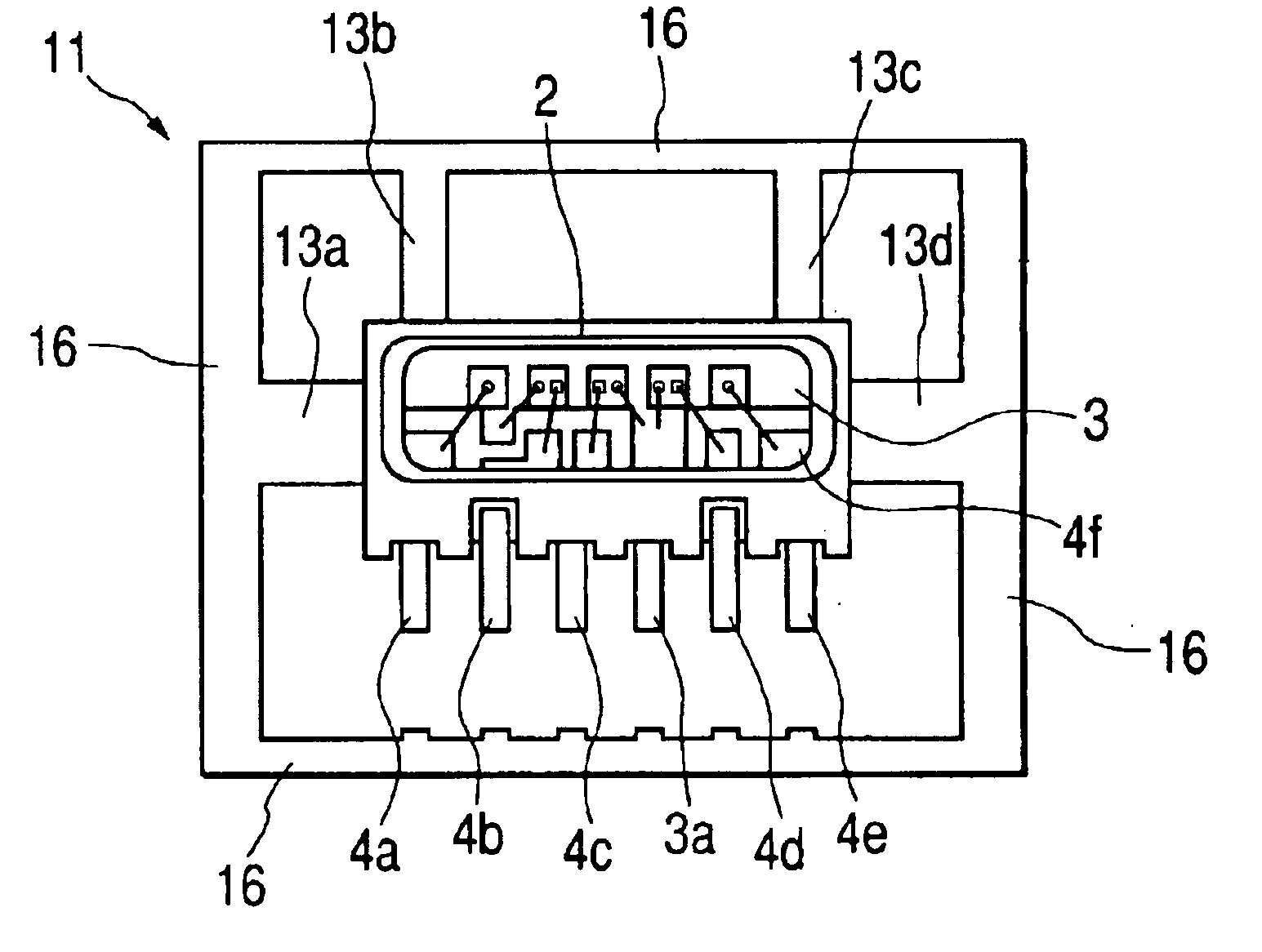

LED device and manufacturing method thereof

InactiveUS6872585B2Improve featuresUniform luminous intensitySolid-state devicesSemiconductor/solid-state device manufacturingEpoxyLuminous intensity

In an LED device, an opening portion of a package in which a plurality of five light-emitting elements are mounted is filled with a transparent epoxy resin and sealed with the resin. The transparent epoxy resin is shrunk when cured. Hence, the surface of the transparent epoxy resin is dented in the center portion so that the outer edge portion becomes higher than the center portion. The light-emitting elements located at opposite ends are the highest in element height among the five light-emitting elements. Hence, when the light-emitting elements are mounted at opposite ends of a single row, distances from light-emitting surfaces of the five light-emitting elements to the surface of the transparent epoxy resin are made uniform and luminous intensity distribution characteristics thereof are made uniform. Tips of leads are further bent up along side surfaces of the package. Hence, when the LED device is soldered onto a mount board, solder is deposited even on the up-bent tips of the leads, so that surface tension of solder is balanced on the front and rear of the package. As a result, the LED device can be mounted in a predetermined position while prevented from sliding. In an LED lead frame, hanger leads are provided so as to be extended in three directions of a package. Hence, the electrically conductive leads can be bent stably and accurately without tottering of the package in the process of bending the electrically conductive leads.

Owner:TOYODA GOSEI CO LTD +1

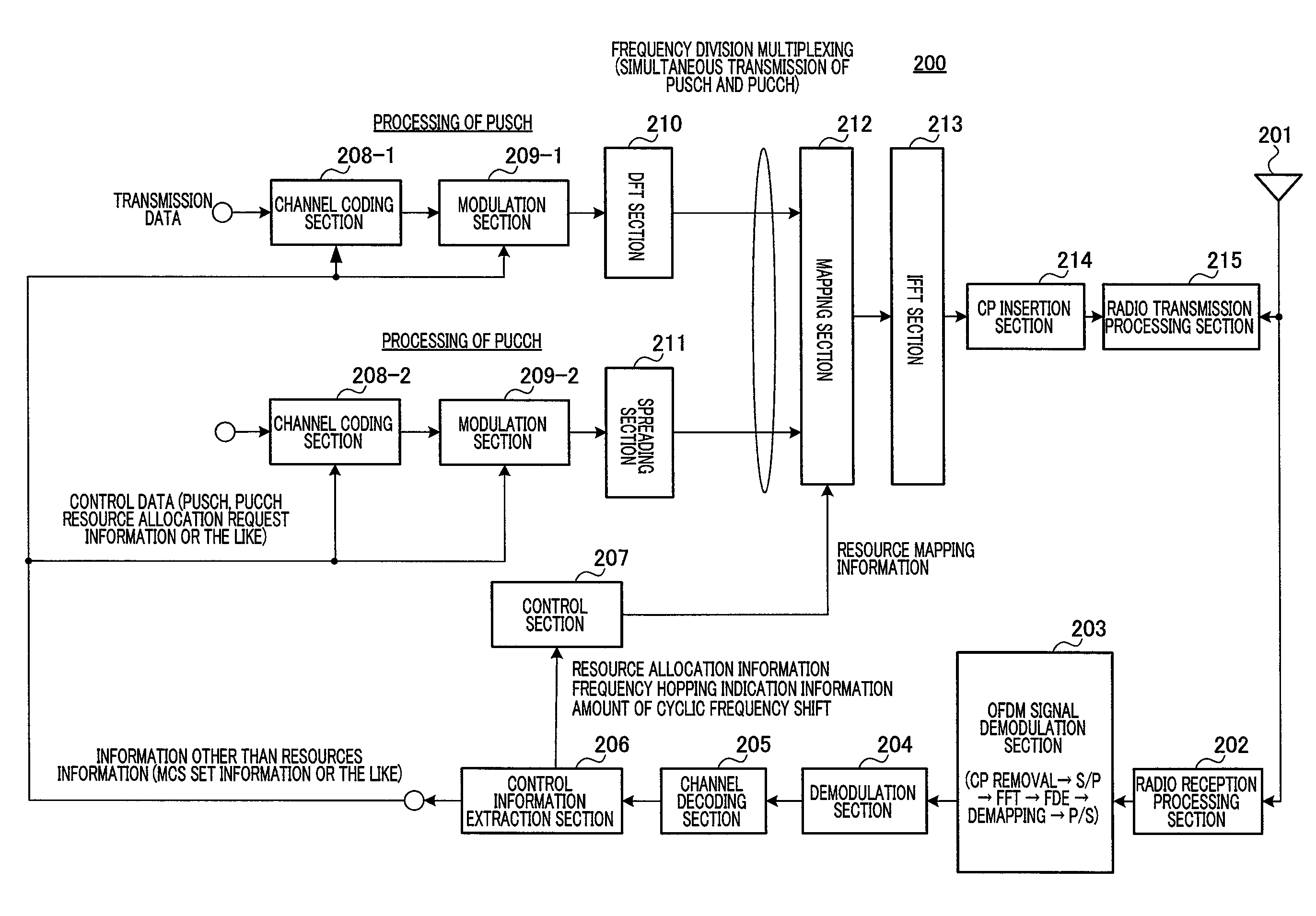

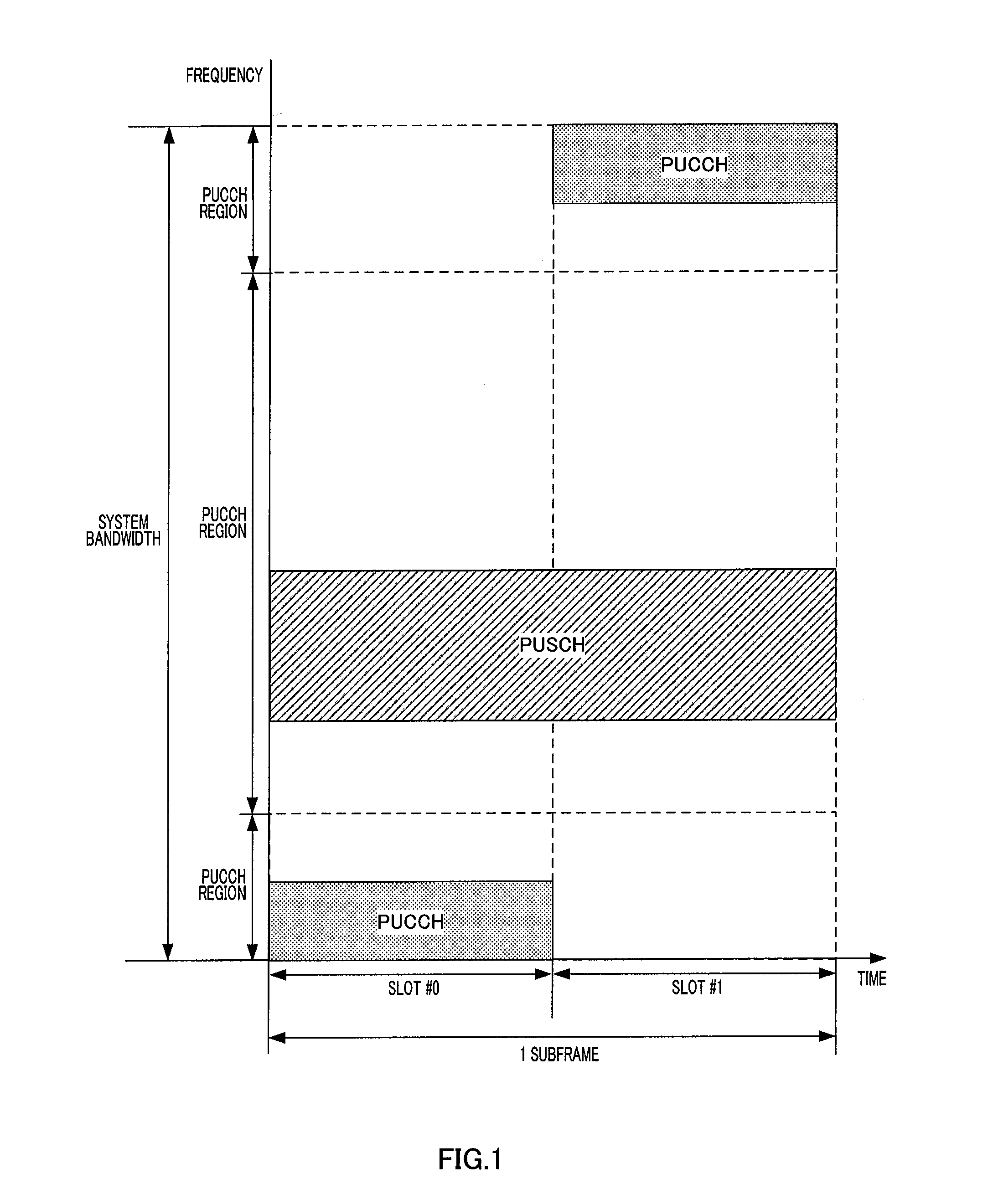

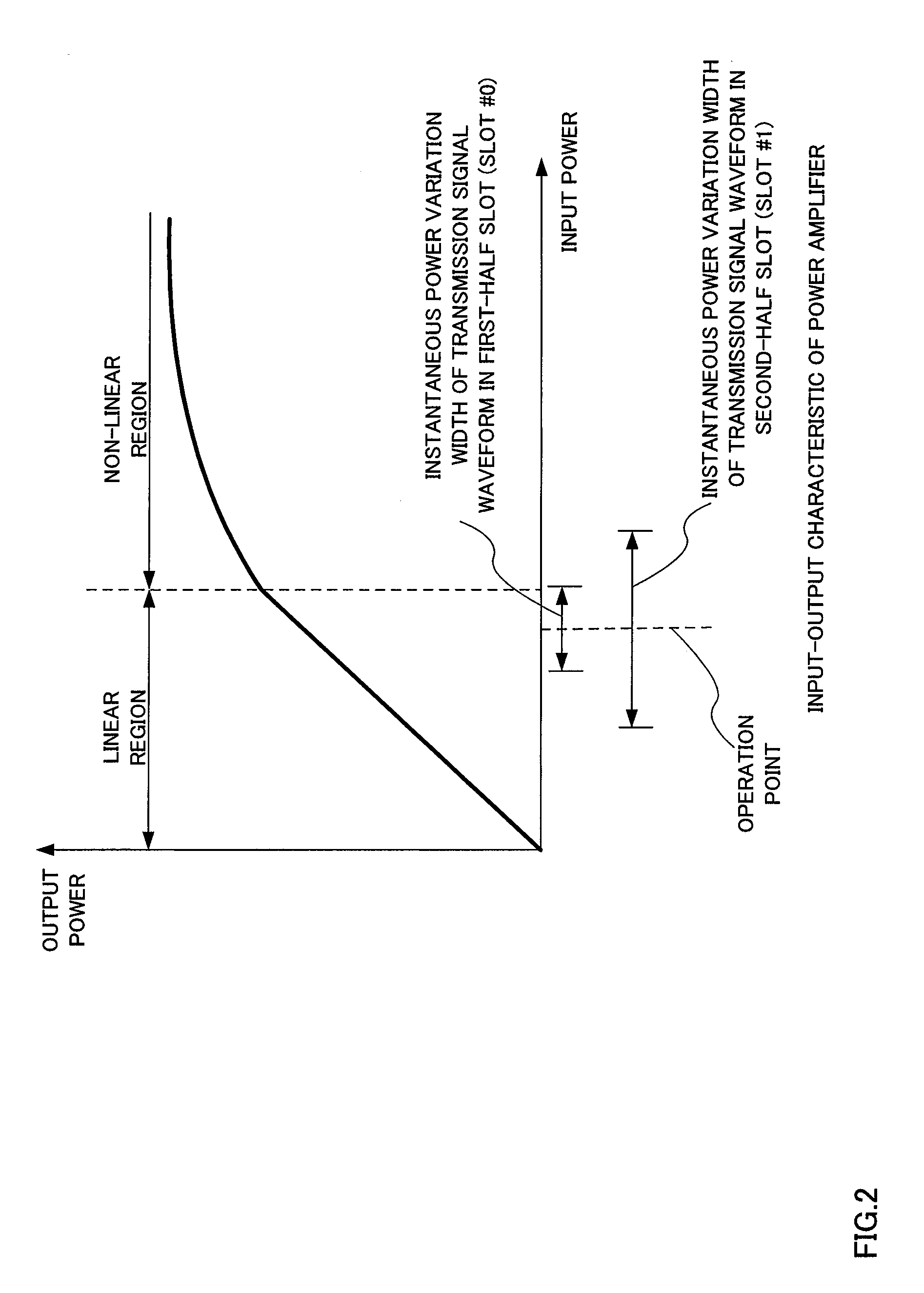

Wireless communication apparatus and frequency hopping method

ActiveUS20120057449A1Inhibit deteriorationFrequency-division multiplex detailsModulated-carrier systemsMultiplexingDistribution characteristic

Disclosed are a wireless communication apparatus and frequency hopping method which minimize the change in the instantaneous power distribution characteristics of the time waveform of transmission signals when a plurality of channels are multiplexed by frequency division. At a terminal (200), a mapping unit (212) maps the PUCCH to frequency resources of a first slot, maps the PUSCH to frequency resources, among the frequency resources of the first slot, separated exactly by predetermined frequency spacing (B) from the frequency resources to which the PUCCH is mapped, and cyclically shifts the frequencies so as to map the PUCCH and PUSCH to frequency resources, within an IDFT or IFFT bandwidth, of a second slot while maintaining the predetermined frequency spacing (B), thereby allowing frequency hopping of the PUCCH and PUSCH between the first slot and the second slot.

Owner:SUN PATENT TRUST

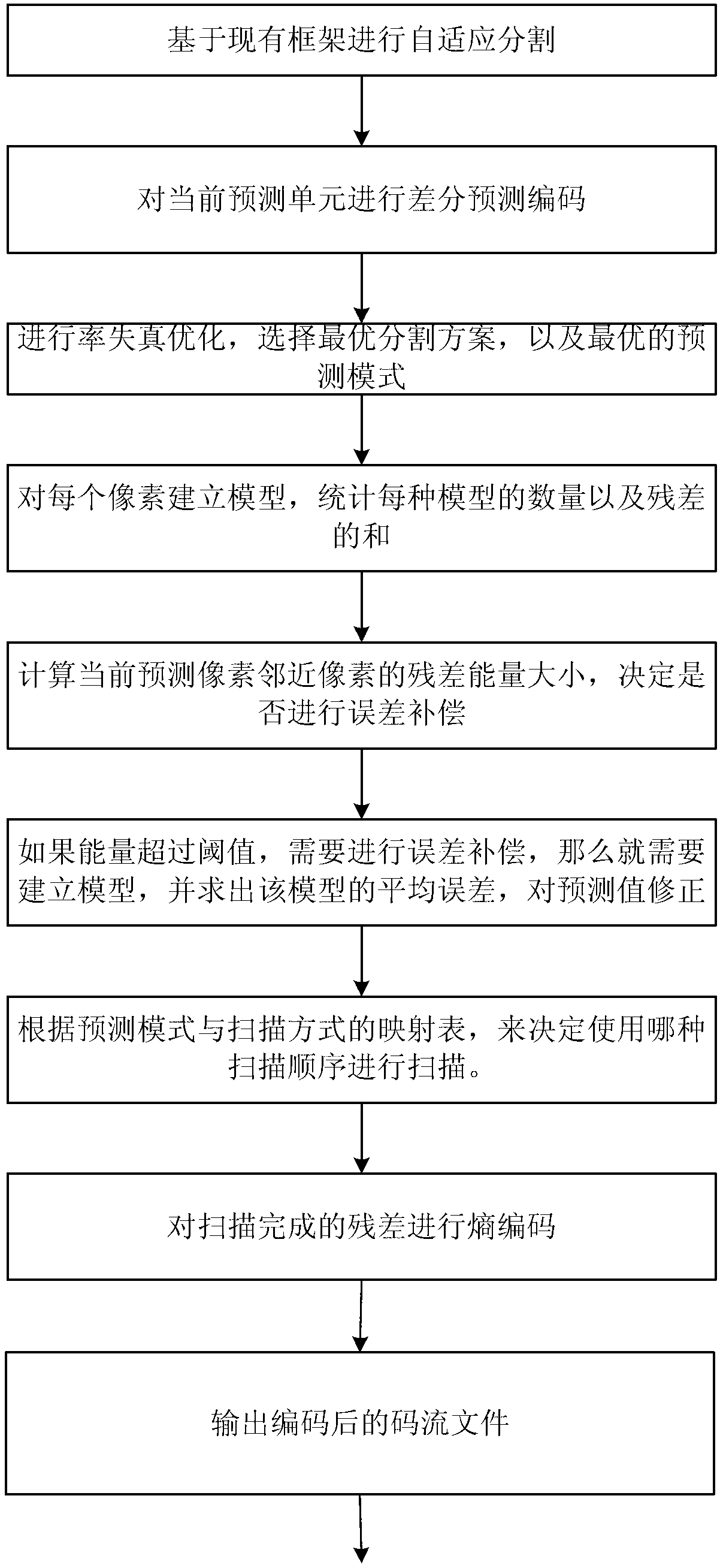

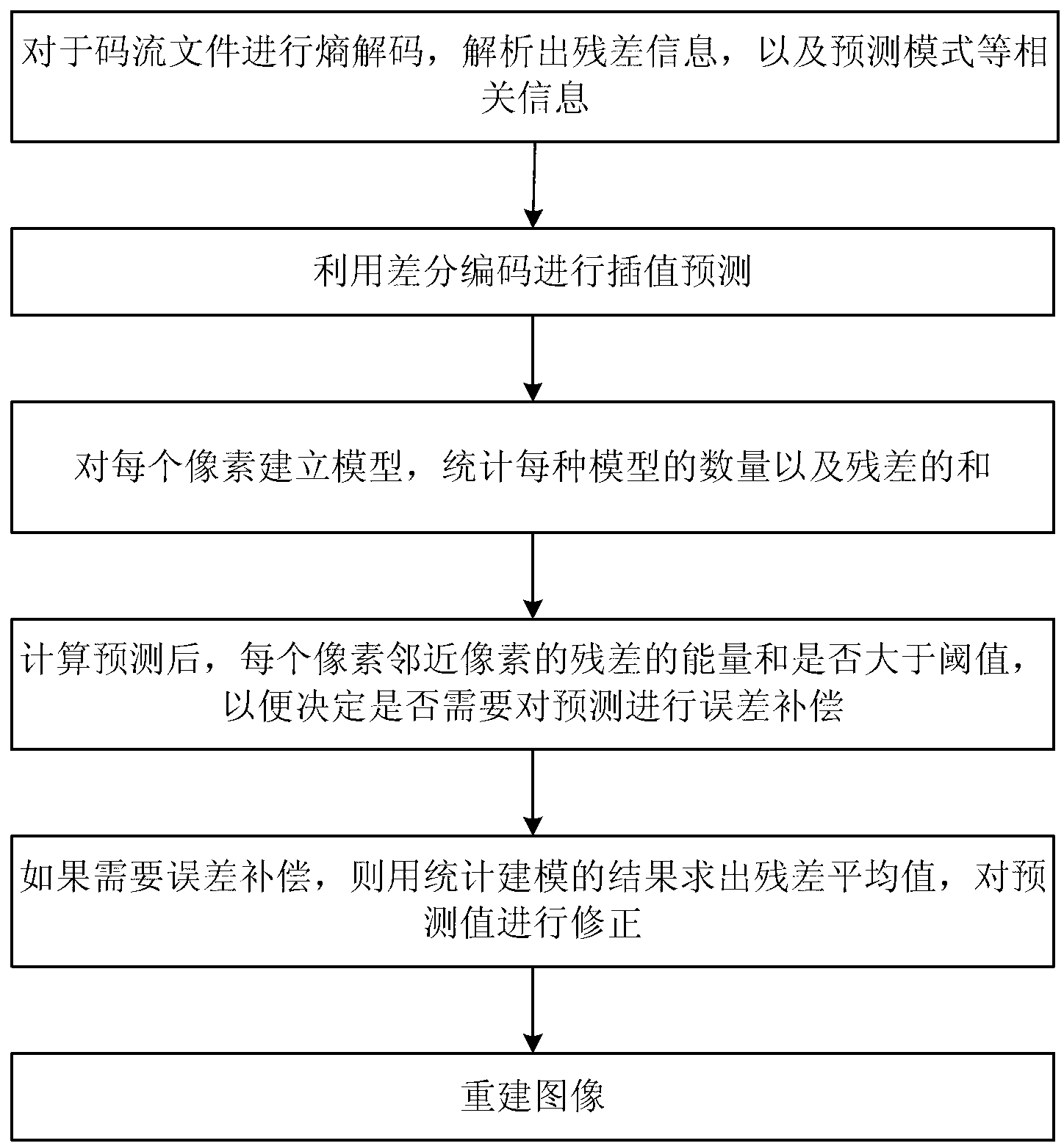

Intra-frame lossless compression coding method based on HEVC (high efficiency video coding) frame

ActiveCN103024383AReduce bit rateImprove forecast accuracyTelevision systemsDigital video signal modificationDistribution characteristicPulse-code modulation

The invention discloses an intra-frame lossless compression coding method based on an HEVC (high efficiency video coding) frame, wherein the method is low in time complexity and high in prediction accuracy and increases compression ratio. By the aid of the HEVC frame, a coding unit can be adaptively divided according to image flatness, the best division scheme is determined, and the optimal prediction mode is selected. DPCM (differential pulse code modulation) differential codes are used for preliminary prediction, prediction errors are possibly large when only the differential codes are used for an area with complex texture, and accordingly, prediction values are corrected for the area by means of error compensation. By combining the two methods, reduction of time complexity and improvement of prediction accuracy can be effectively compromised. Distribution characteristics of residual errors depend on the prediction mode, so that the scanning sequence of the residual errors is determined according to the prediction mode, and entropy coding can be more effective.

Owner:BEIJING UNIV OF TECH

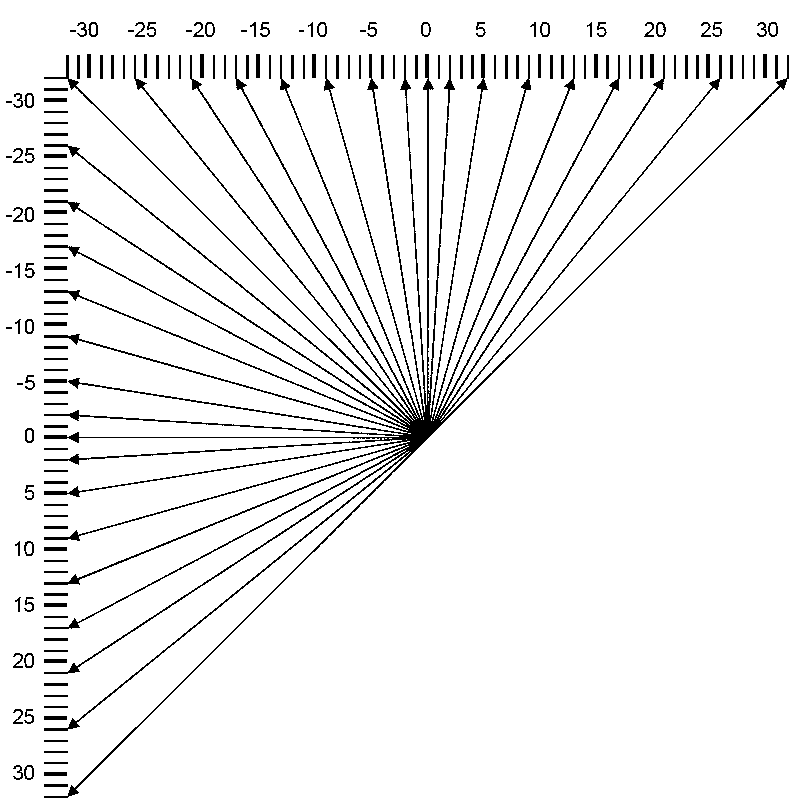

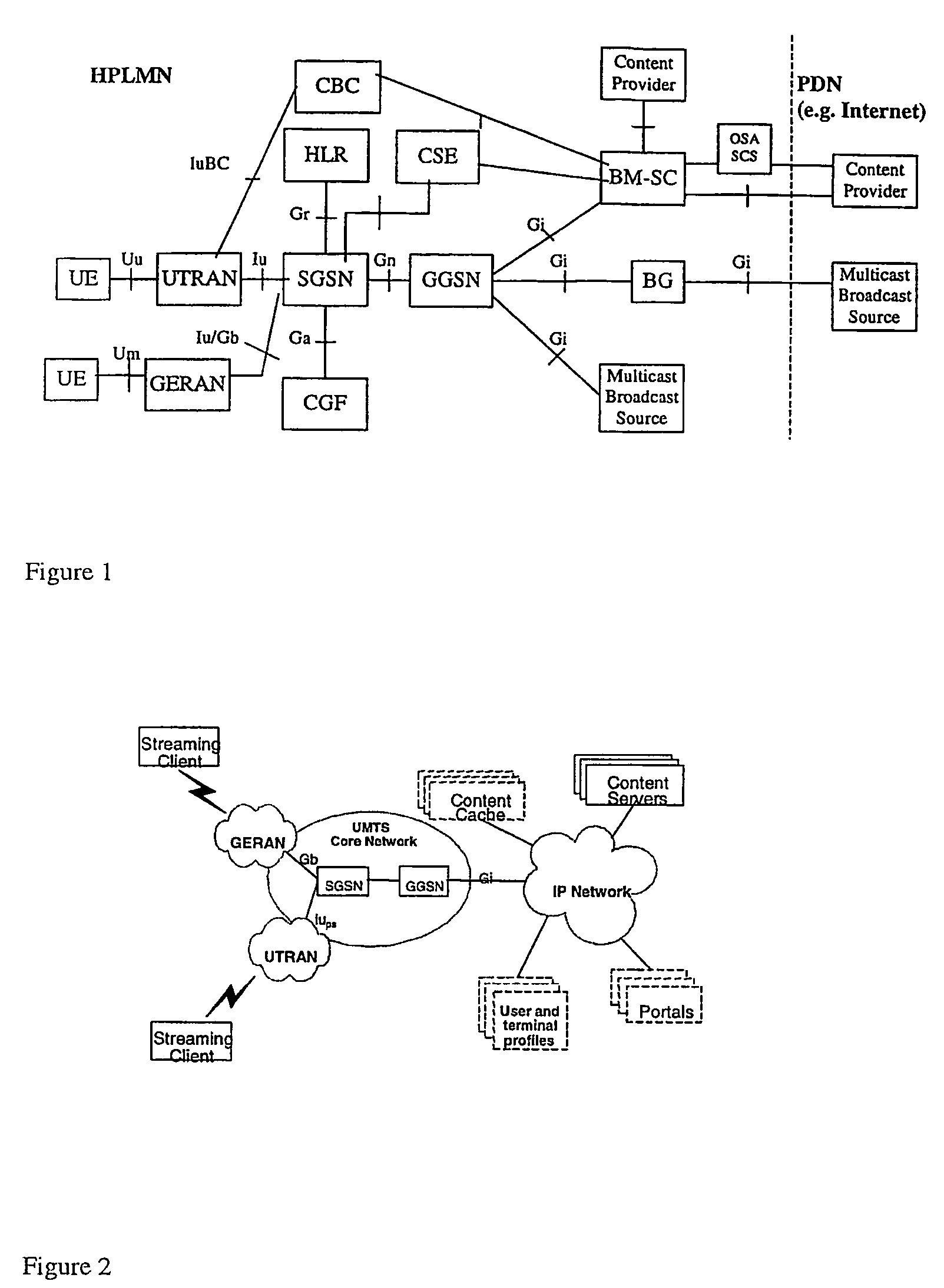

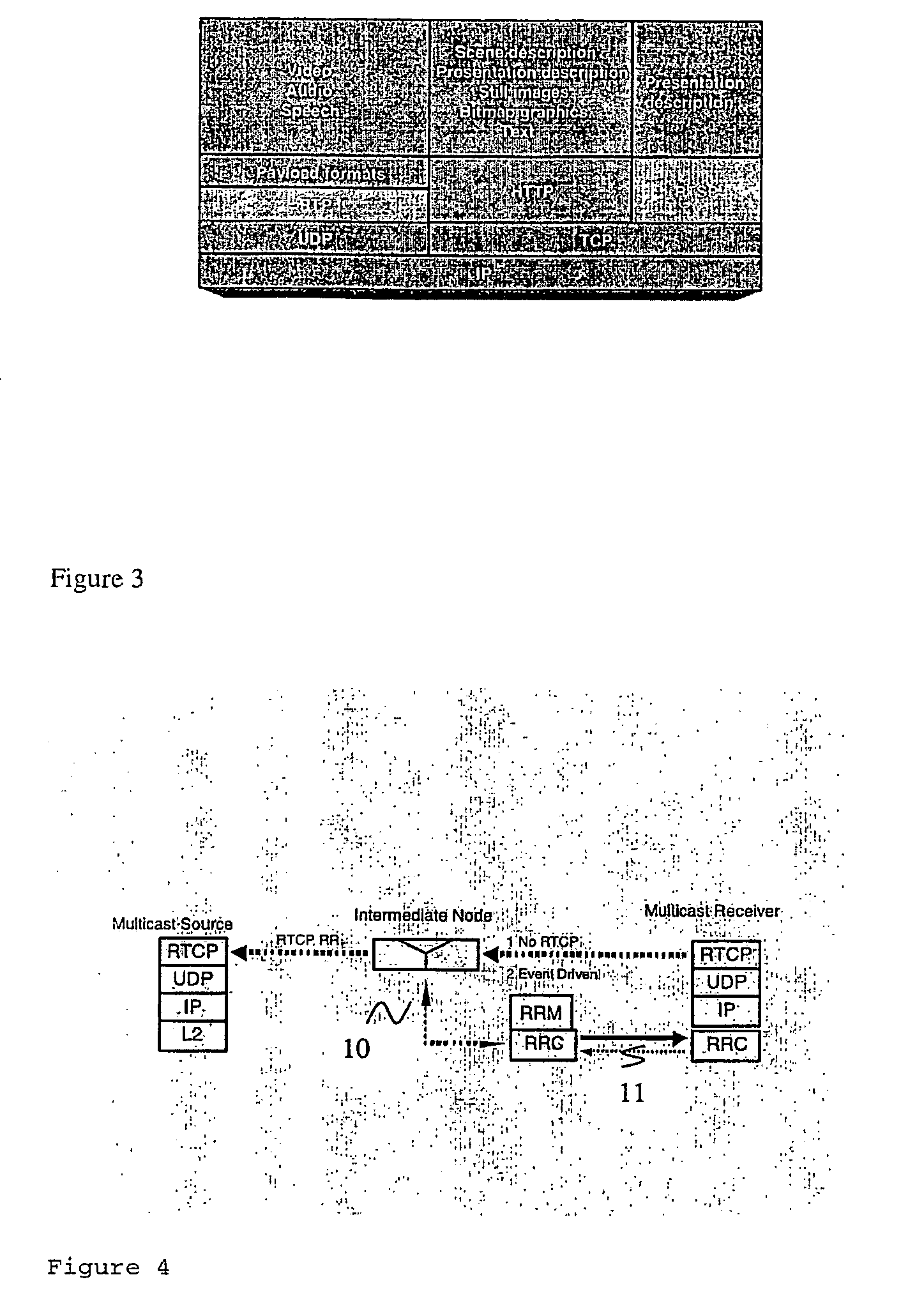

Reporting for multi-user services in wireless networks

ActiveUS20060069799A1Efficient use ofReduce loadError preventionFrequency-division multiplex detailsCommunications systemDistribution characteristic

The basic idea of the present invention is to adapt multi-user multimedia data in a communication system with a server providing the multi-user multimedia data to clients and with an intermediate network part. Said intermediate network part is arranged to provide information on communication between the server and the clients. The server sends multimedia data to the clients. Distribution characteristics are determined for the clients, which are considered by the generation of an aggregated feedback report on the clients' reception conditions of the multimedia data in the intermediate network part. Said feedback report includes additional information about aggregation fashion. Said aggregated feedback report is sent to the server in order the server adapts the transmission of the multimedia data from the server to the clients according to the aggregated feedback report.

Owner:TELEFON AB LM ERICSSON (PUBL)

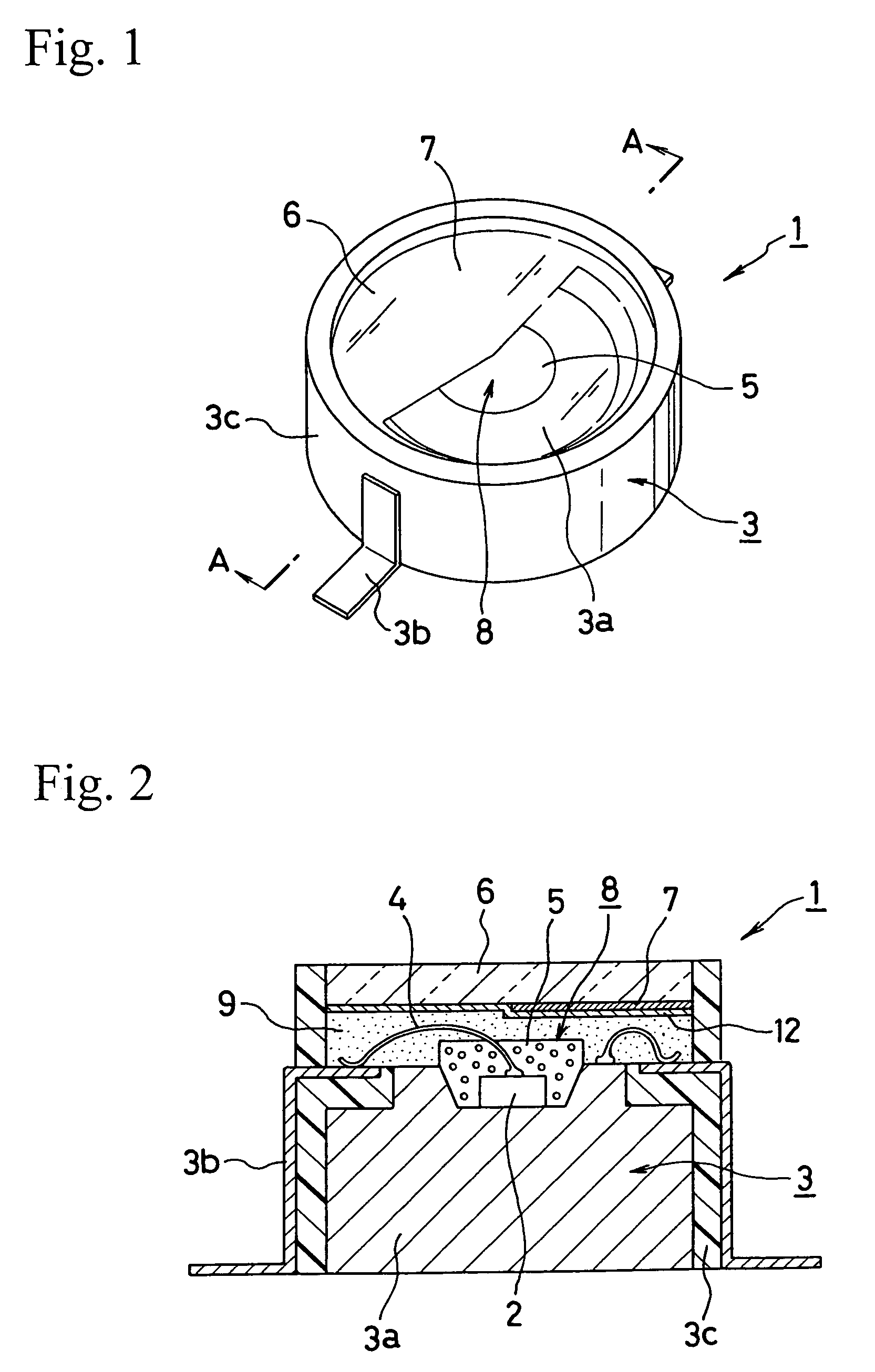

LED lamp for light source of lighting device

InactiveUS20060022211A1Reduce areaIncrease brightnessVehicle headlampsLighting support devicesDistribution patternDistribution characteristic

An LED lamp can be used as a light source of a lighting device. The LED lamp can be combined with a reflecting mirror formed as a paraboloid of revolution, to obtain desired light distribution characteristics, as with a conventional light source. The emission surface of the LED lamp for the light source of the lighting device can be rectangular, and the ratio between a short side and a long side thereof is set in a range of 1:2 to 1:6. Therefore, it is possible to form a light distribution pattern similar to that of a filament, which is conventionally used as an emission source. It is also possible to use almost all light emitted from the LED lamp as illumination light.

Owner:STANLEY ELECTRIC CO LTD

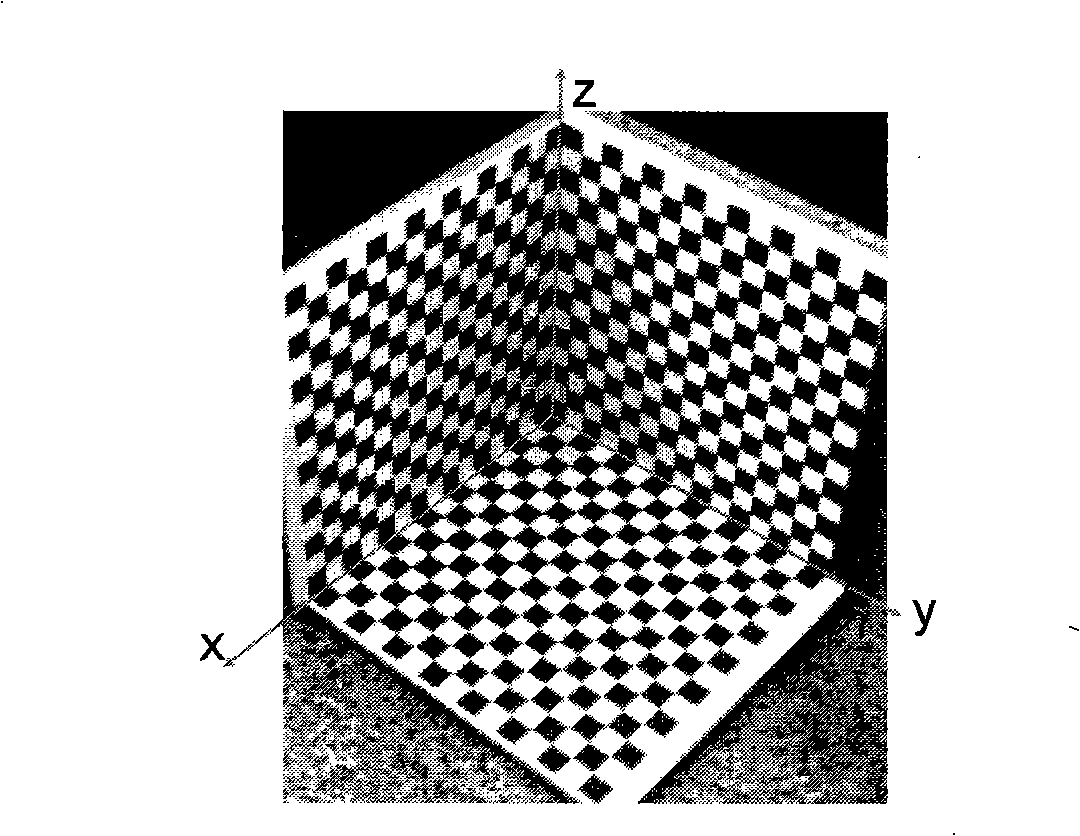

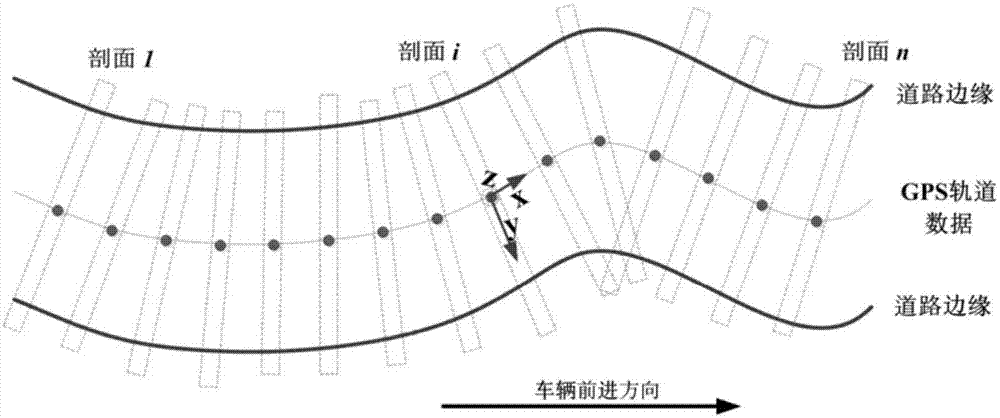

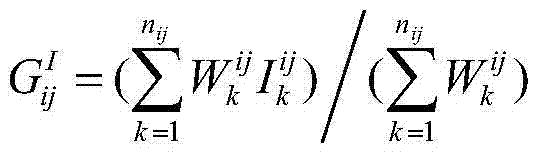

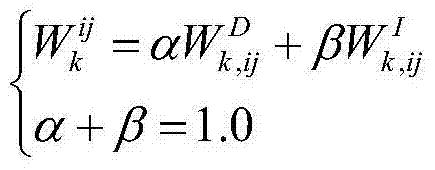

Road zebra crossing automatic extraction method based on vehicle-mounted laser scanning point cloud

ActiveCN103500338AImplement extractionImplement classificationImage analysisCharacter and pattern recognitionPoint cloudLaser scanning

The invention provides a road zebra crossing automatic extraction method based on vehicle-mounted laser scanning point cloud, and relates to public traffic road zebra crossings. According to the method, global positioning system data for recording vehicle positions and tracks in real time is used for extracting a plurality of cross sections from the vehicle-mounted laser scanning point cloud data, and the road and non-road classification is realized through detecting the elevation mutation of road shoulders of the roads in the scanning line data; then, the three-dimension road data is converted into an intensity characteristic image with space distribution characteristics, the laser scanning point normal distribution characteristics are utilized for dynamically cutting the road zebra crossings, the GPS (global positioning system) track data is used again for calculating the linear morphology closed operation direction and size, and the extraction of the road zebra crossings is realized. Through the cross section subdivision on the vehicle-mounted moving scanning data, and the three-dimension road surface data detection is converted into the detection of the elevation mutation of the road shoulders of the roads in the two-dimension profile for realizing the road and non-road classification. Compared with a method of directly processing mass three-dimension data, the method has the advantages that the calculation quantity is small, and the efficiency is high.

Owner:XIAMEN UNIV

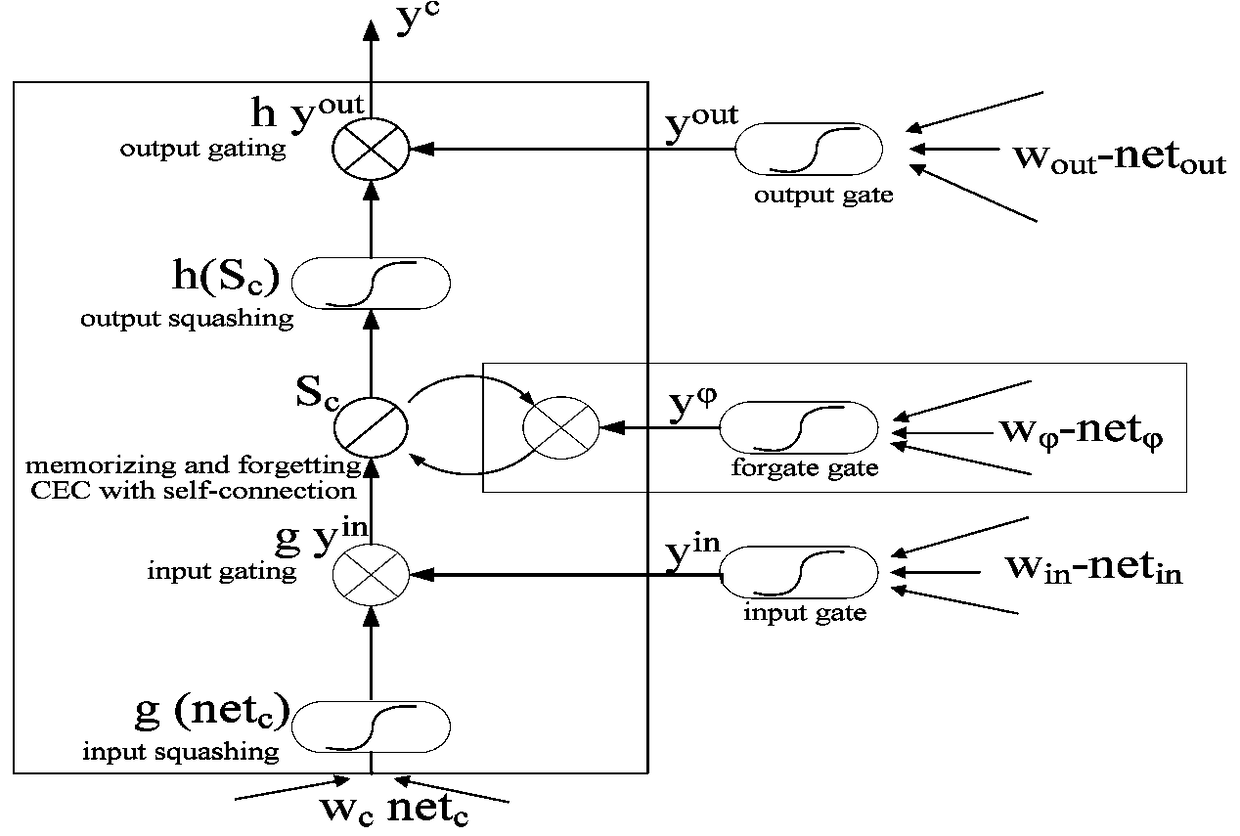

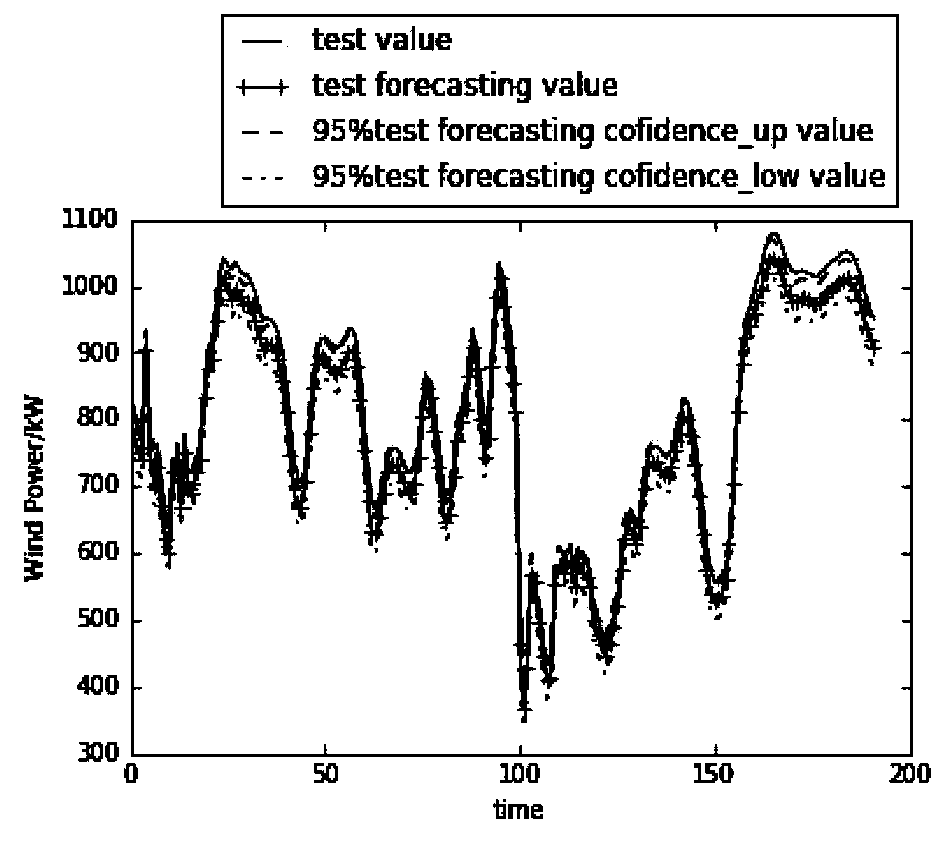

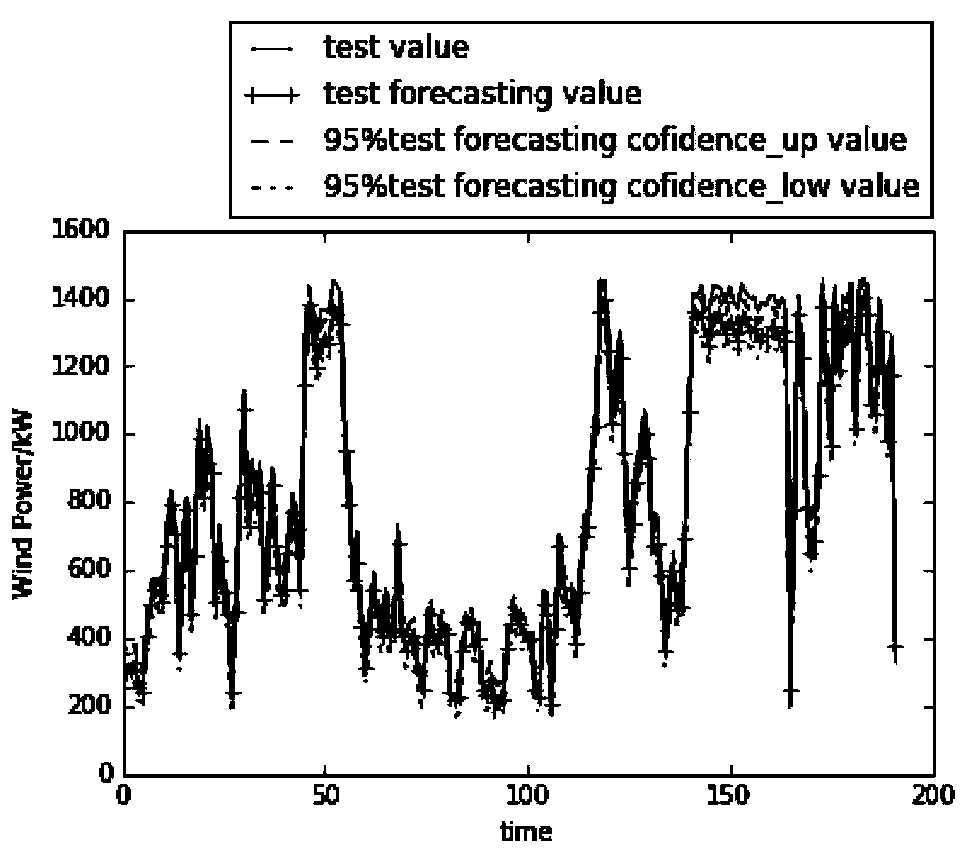

Short-term wind power forecasting method based on long-term and short-term memory network

The invention discloses a wind power short-term prediction method based on a long-term and short-term memory network, comprising a long-term and short-term memory neural network training algorithm, ashort-term wind power prediction error distribution algorithm and a wind turbine generator power short-term prediction model design. A long-term and short-term memory network algorithm (LSTM)-based wind pow prediction model is established based on the depth learning network, and the Gaussian mixture model (GMM) is used to analyze the error distribution characteristics of the short-term wind powerprediction. The invention can obtain different confidence intervals of two units through the GMM model. It is proved that LSTM method has higher precision and faster convergence rate, and GMM method has practical application value for wind power dispatching.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

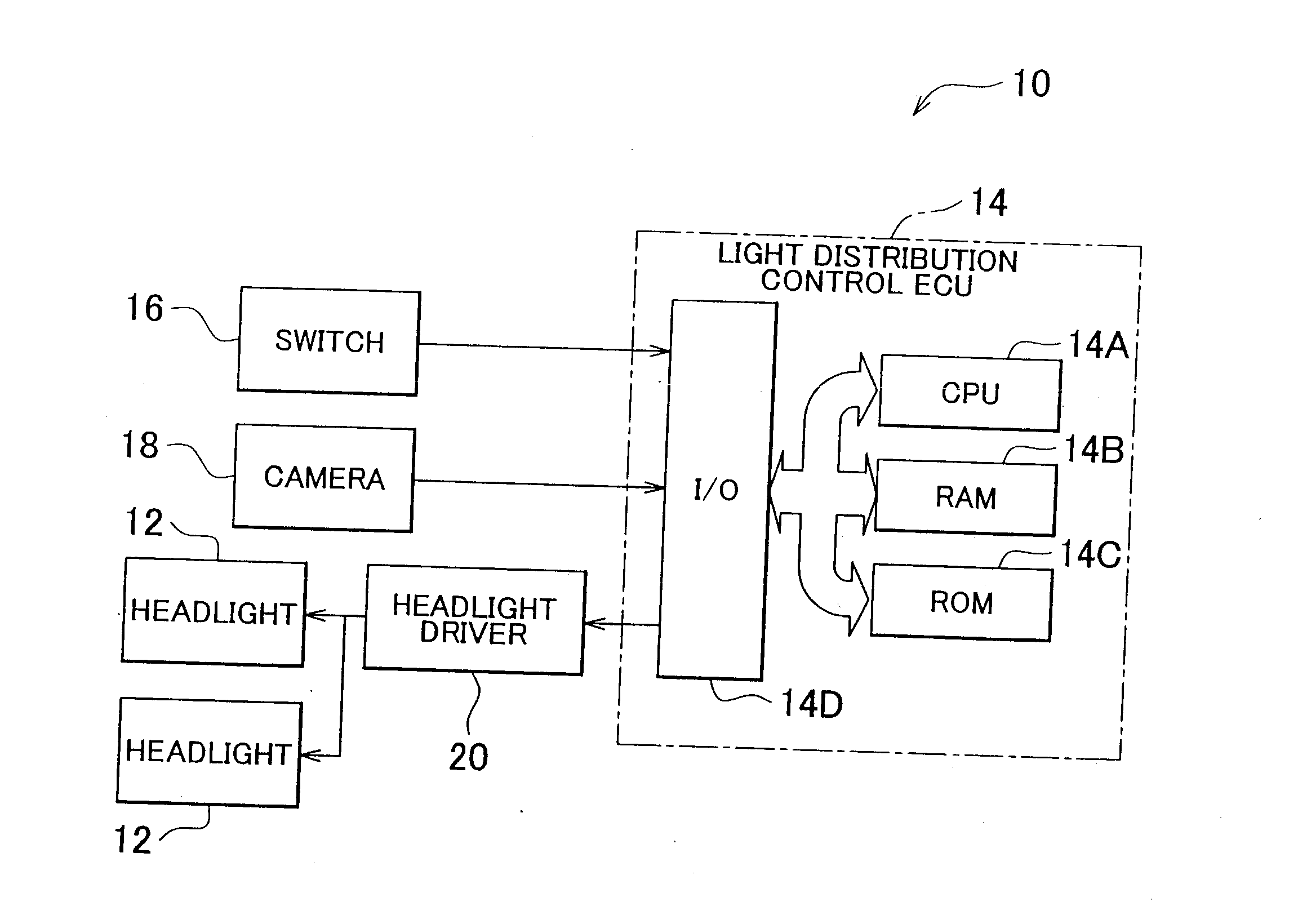

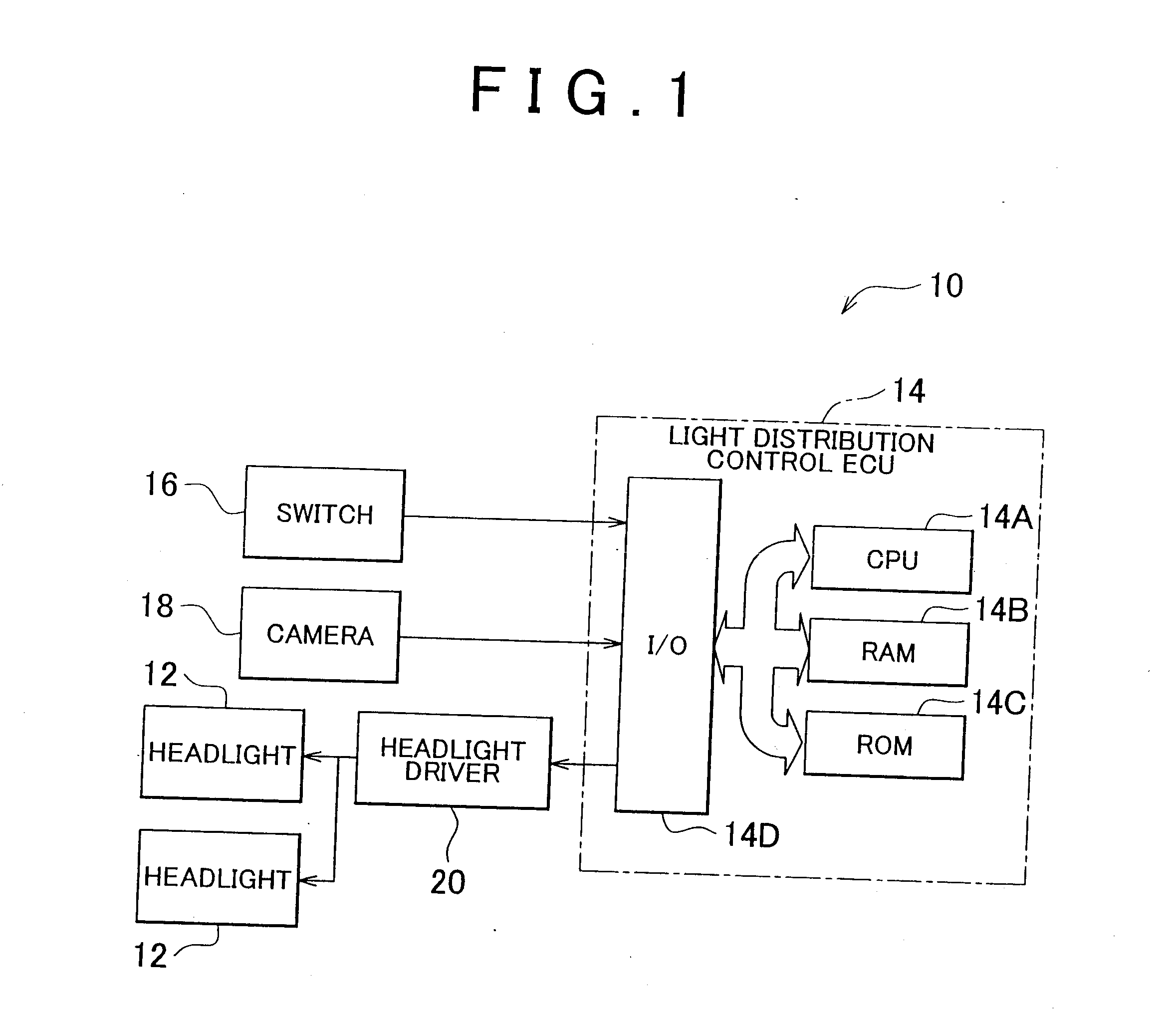

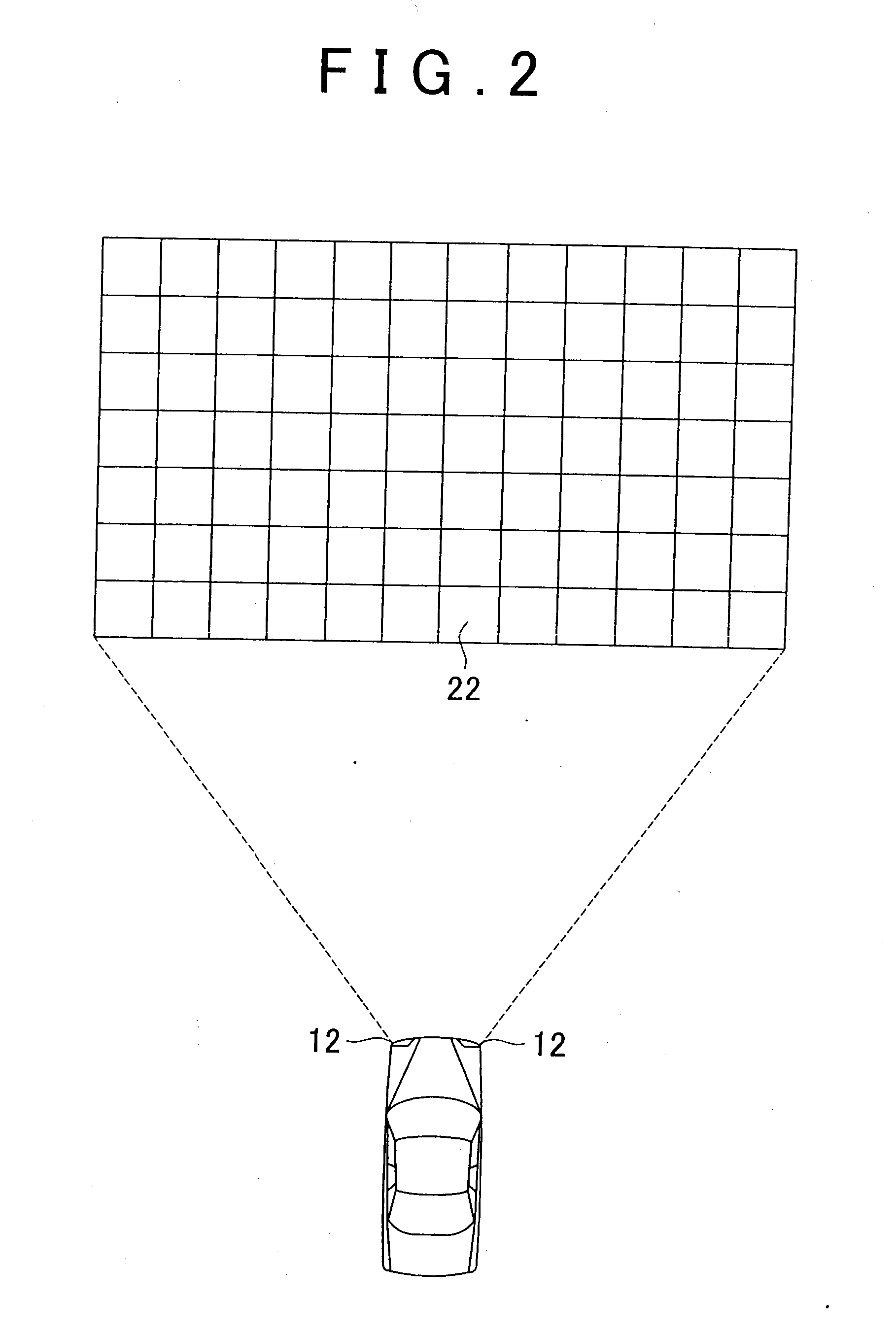

Vehicle lighting device and lighting method

ActiveUS20110012511A1Secure visibilityMisconception can be preventedVehicle headlampsLighting support devicesDistribution controlEffect light

The light distribution region of headlights (12) is divided into a plurality of regions, and each of the divided regions can be irradiated or non-irradiated by light, and the light distribution characteristic can be changed separately for each divided region. The radiation or non-radiation of light to each divided region is controlled by a light distribution control ECU (14). Besides, light reflection / emission regions (hatched portions in FIG. 4) are detected by detecting light regions of reflection, such as white lines, reflectors, etc., and light regions of light emission, such as street lights or the like, are detected. Then, divided regions corresponding to light distribution region irradiated by the headlights (12) which correspond to the detected light reflection / emission regions are specifically determined, and the headlights (12) are controlled so that the light radiated to the specifically determined divided regions 22 becomes dark in light distribution relative to other regions.

Owner:TOYOTA JIDOSHA KK

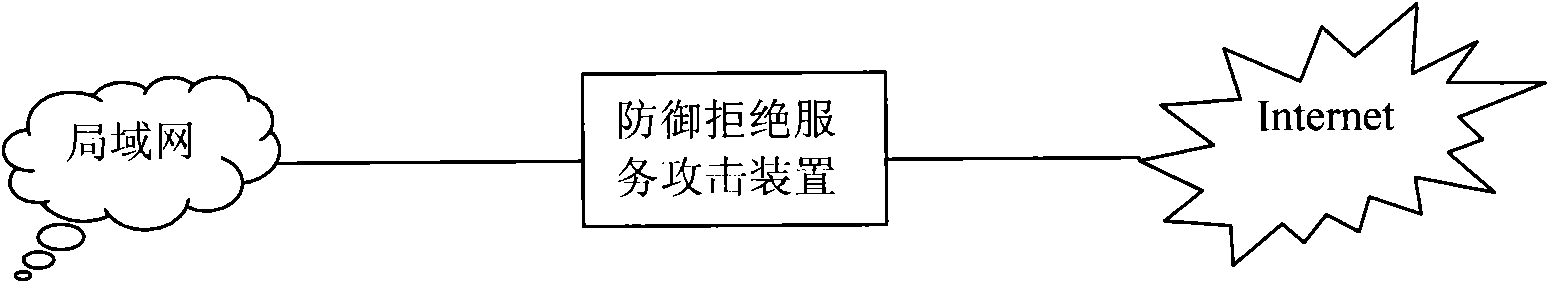

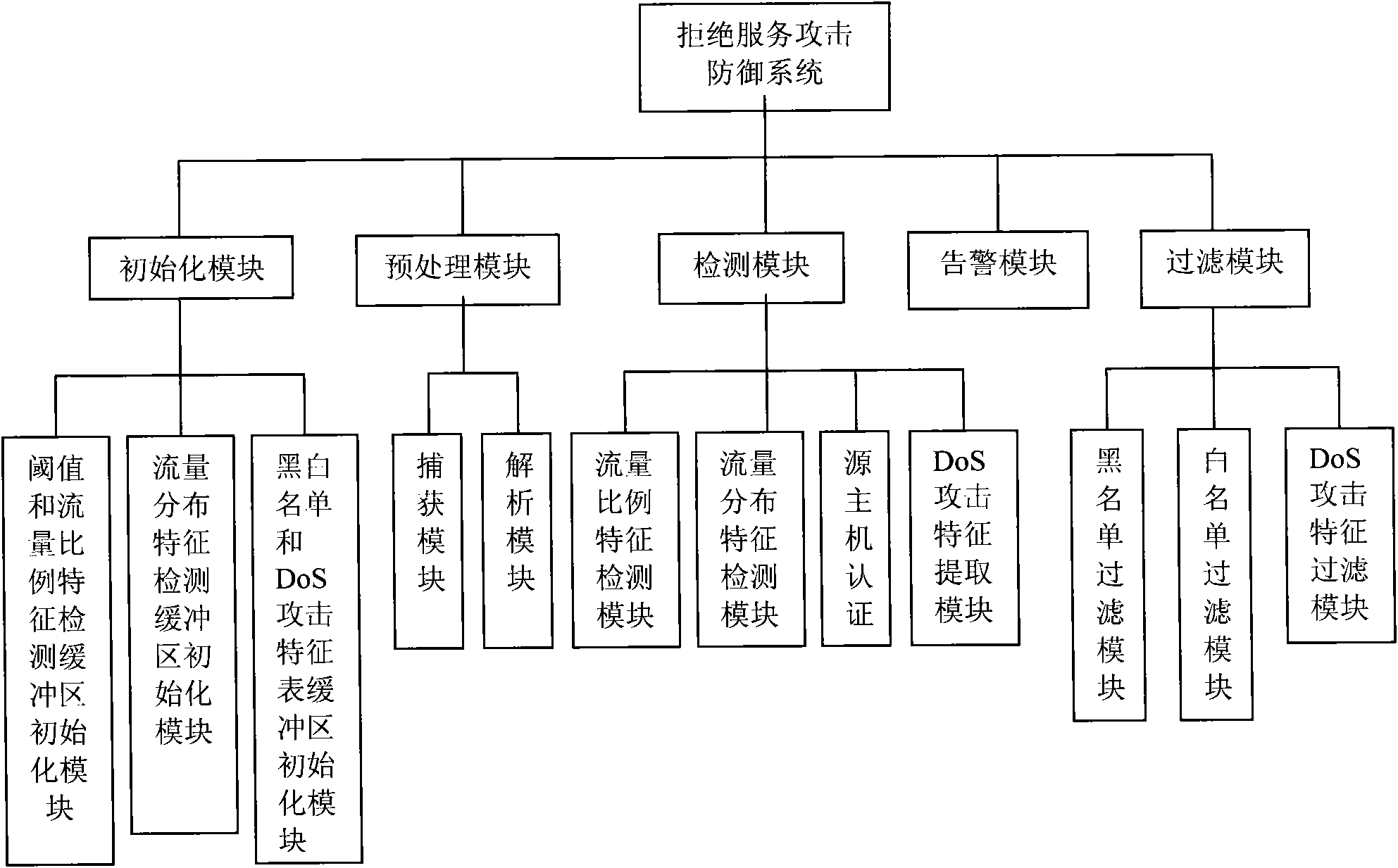

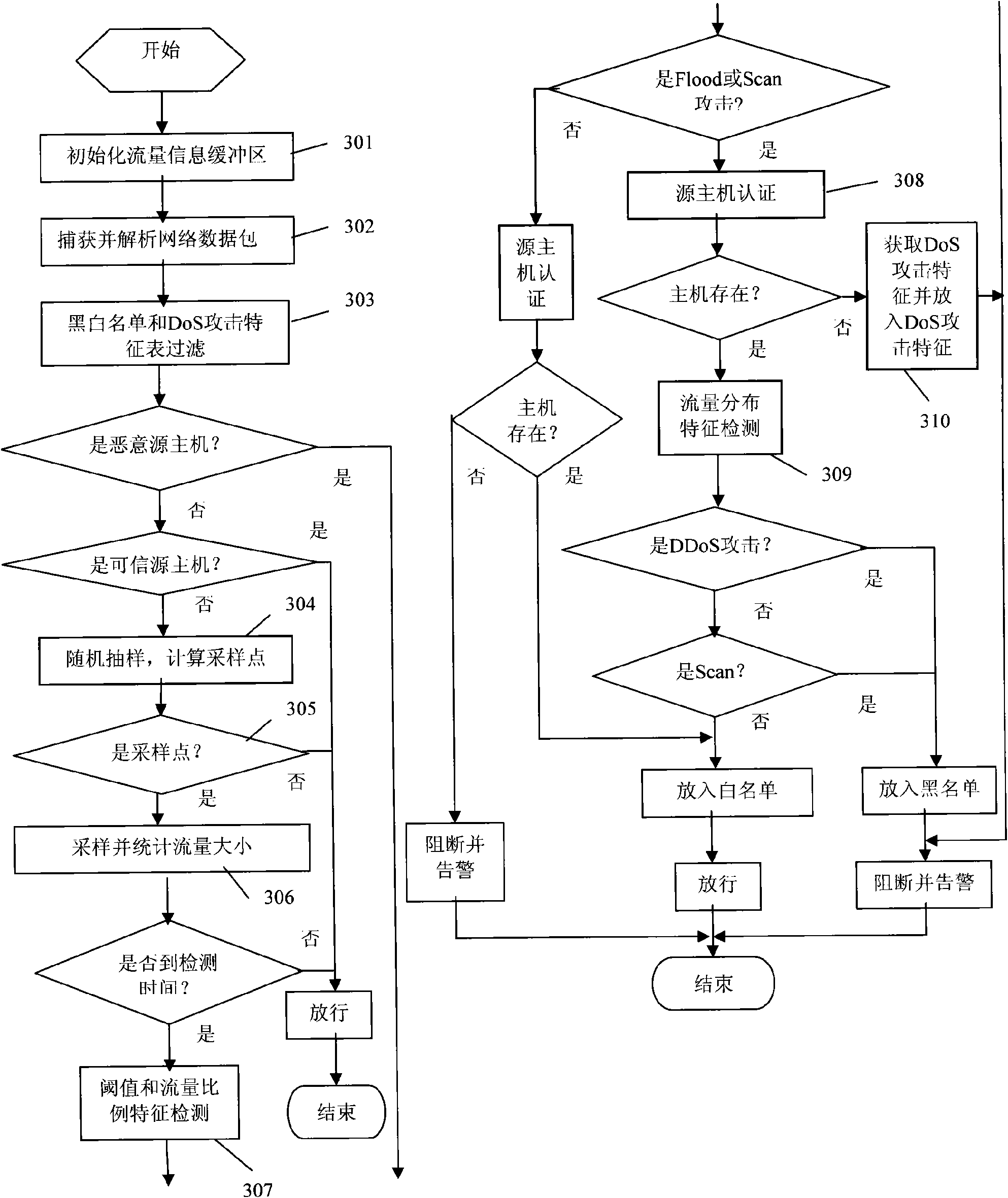

Method and device for defending against denial-of-service attacks

InactiveCN101631026AEnsure safetyDenial of service attack worksComputer security arrangementsSecuring communicationTraffic capacityDistribution characteristic

Owner:BEIJING VENUS INFORMATION TECH +1

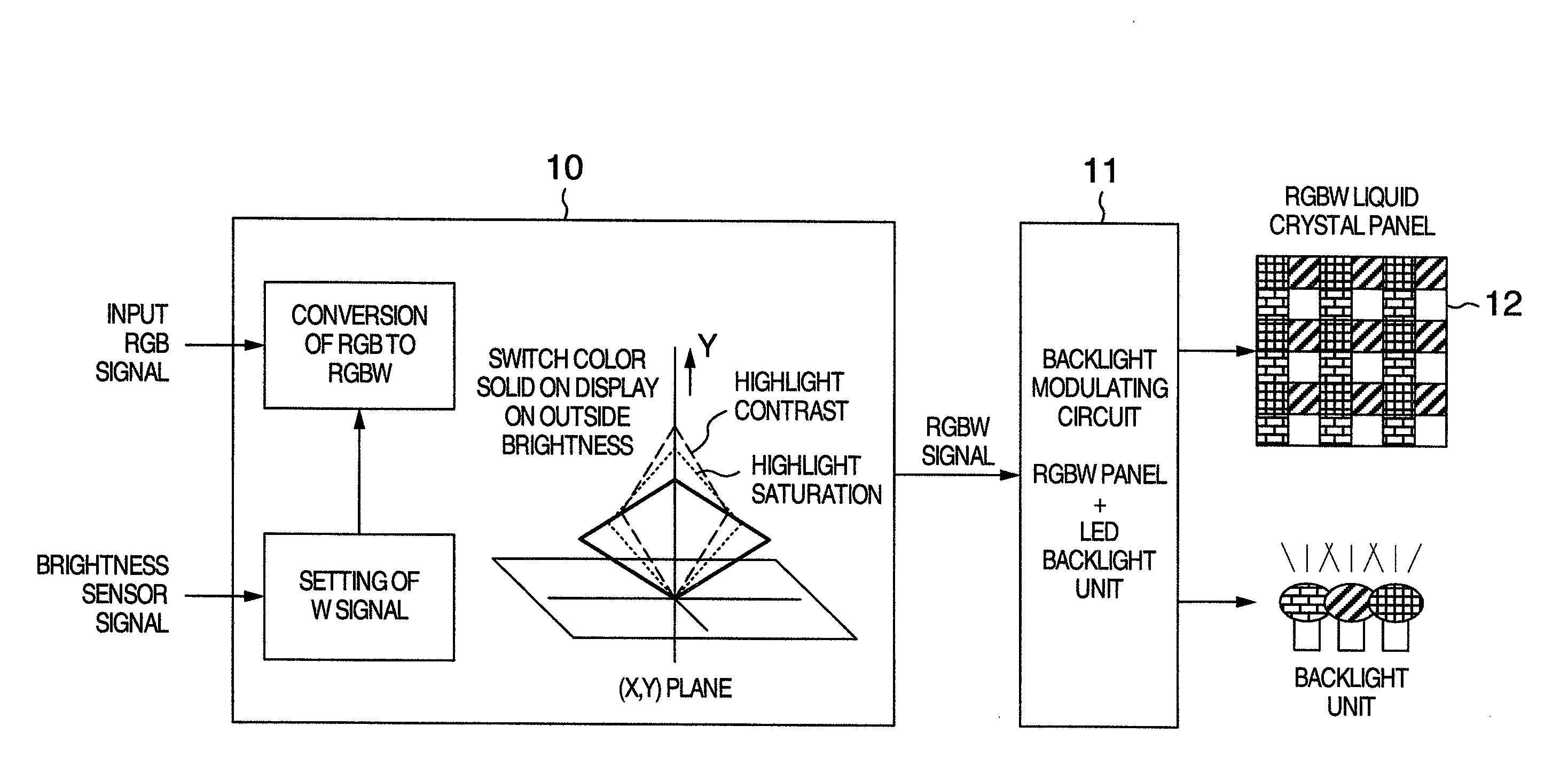

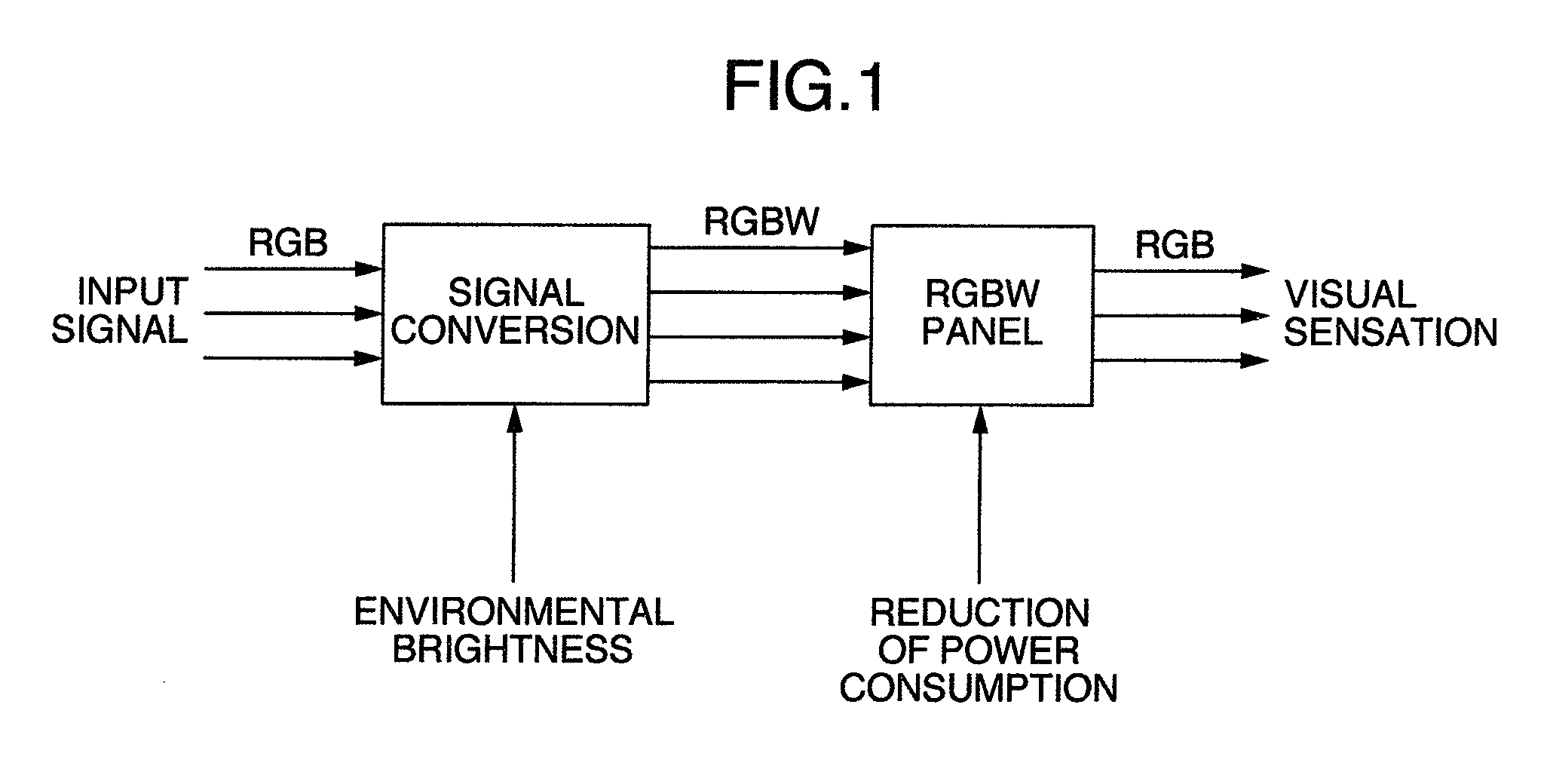

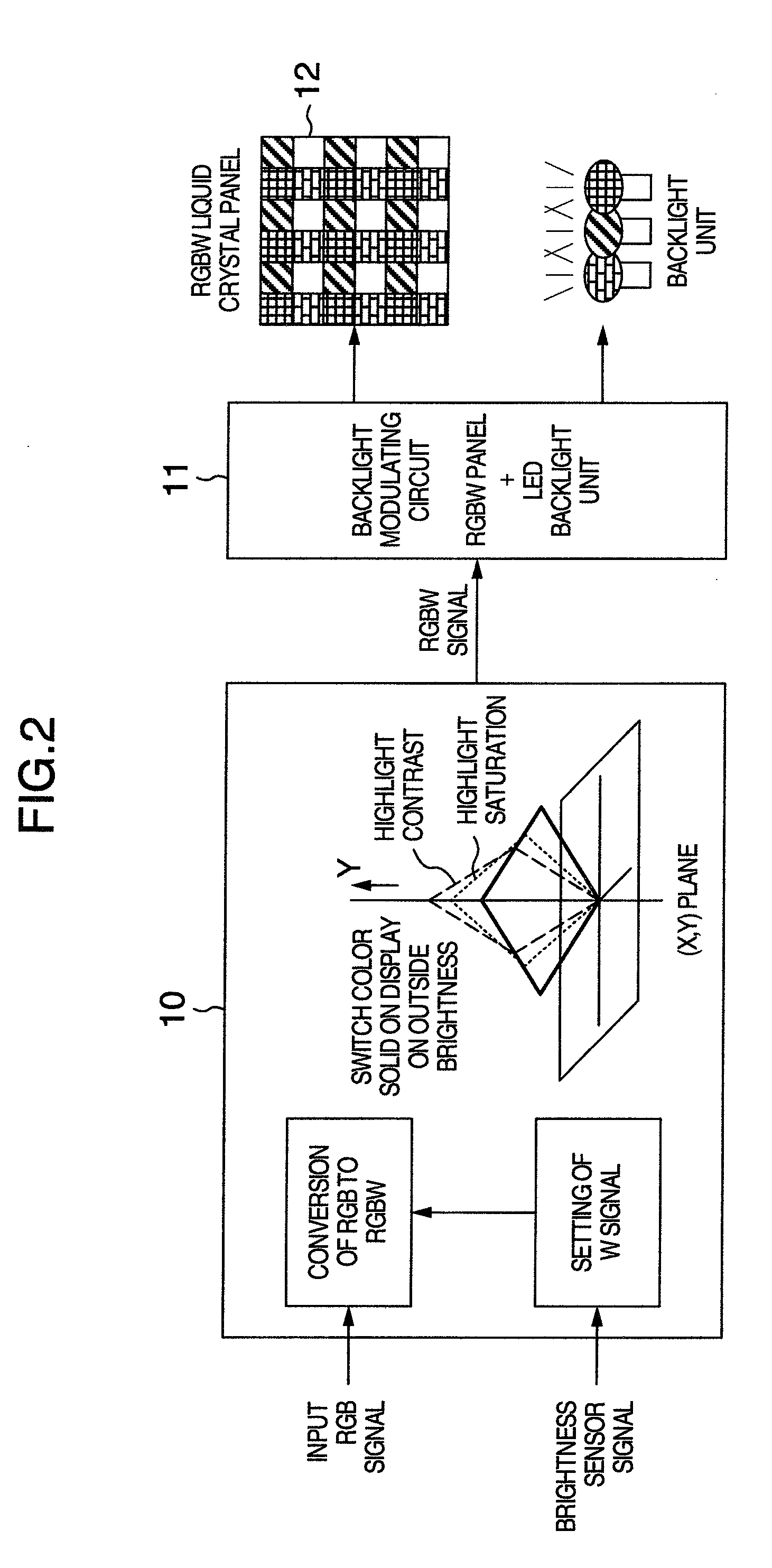

Display apparatus

ActiveUS20080084524A1Increase brightnessVaried chromaticityColor signal processing circuitsCathode-ray tube indicatorsDistribution characteristicDisplay device

A display apparatus is arranged to have pixels, each of which has a RGBW (Red, Green, Blue and White) wavelength distribution characteristic, located two-dimensionally. The display apparatus includes an input unit for inputting a signal for controlling a using ratio of a W signal, a color signal converting unit for calculating a RGBW driving signal from a RGB input signal and the W using ratio. The RGBW signal is calculated so as to control the contribution of the W signal to the image quality. The display apparatus switches the display from the contrast-highlighted display in a relatively bright lighting condition to the color-reproducibility-highlighted display in a relatively gloomy lighting condition.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

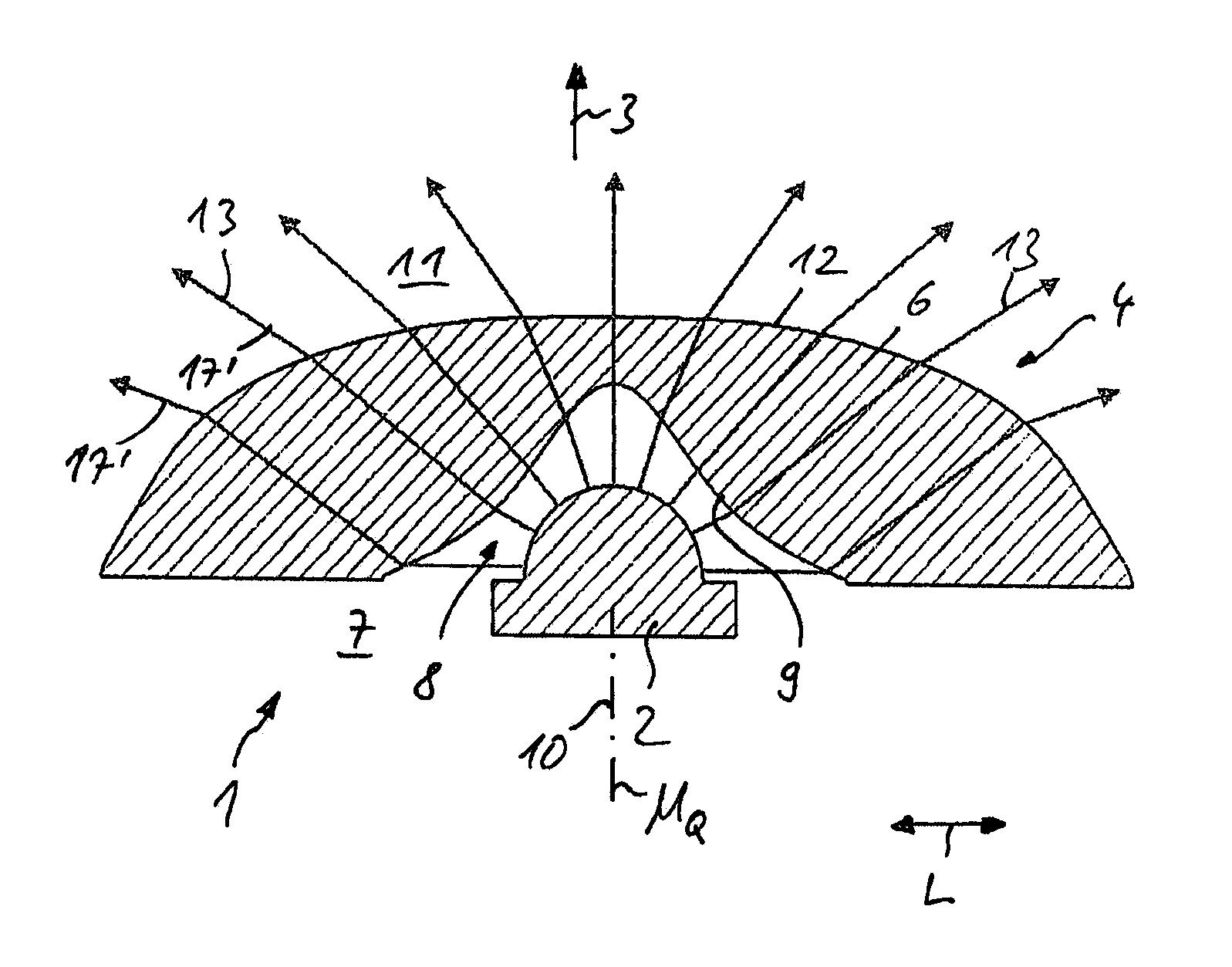

Light emitting device provided with lens for controlling light distribution characteristic

ActiveUS7710016B2Low profileExcellent light distribution characteristicsDischarge tube luminescnet screensLamp detailsHigh concentrationDistribution characteristic

The light emitting device comprises a substrate (2), a positive electrode (6) and a negative electrode (4) formed on the substrate (2), a light emitting diode (8) connected to the positive electrode (6) and the negative electrode (4), the transparent resin (12 and 14) that covers the light emitting diode (8), a fluorescent material (16) that absorbs at least part of light emitted by the light emitting diode (8) and converts it to light of longer wavelength, and the lens that changes the direction of light emission from the light emitting diode (8) and / or the fluorescent material (16). The resin (12 and 14) includes the fluorescent material (16) and is formed so as to constitute the lens of substantially semi-cylindrical shape, and the fluorescent material (16) included in the resin (12 and 14) is distributed with a higher concentration in a region near the surface of the light emitting diode (8) than in a region near the surface of the portion that constitutes the lens.

Owner:NICHIA CORP

Light emitting device provided with lens for controlling light distribution characteristic

ActiveUS20090231833A1Low profileExcellent light distribution characteristicsDischarge tube luminescnet screensLamp detailsHigh concentrationDistribution characteristic

The light emitting device comprises a substrate (2), a positive electrode (6) and a negative electrode (4) formed on the substrate (2), a light emitting diode (8) connected to the positive electrode (6) and the negative electrode (4), the transparent resin (12 and 14) that covers the light emitting diode (8), a fluorescent material (16) that absorbs at least part of light emitted by the light emitting diode (8) and converts it to light of longer wavelength, and the lens that changes the direction of light emission from the light emitting diode (8) and / or the fluorescent material (16). The resin (12 and 14) includes the fluorescent material (16) and is formed so as to constitute the lens of substantially semi-cylindrical shape, and the fluorescent material (16) included in the resin (12 and 14) is distributed with a higher concentration in a region near the surface of the light emitting diode (8) than in a region near the surface of the portion that constitutes the lens.

Owner:NICHIA CORP

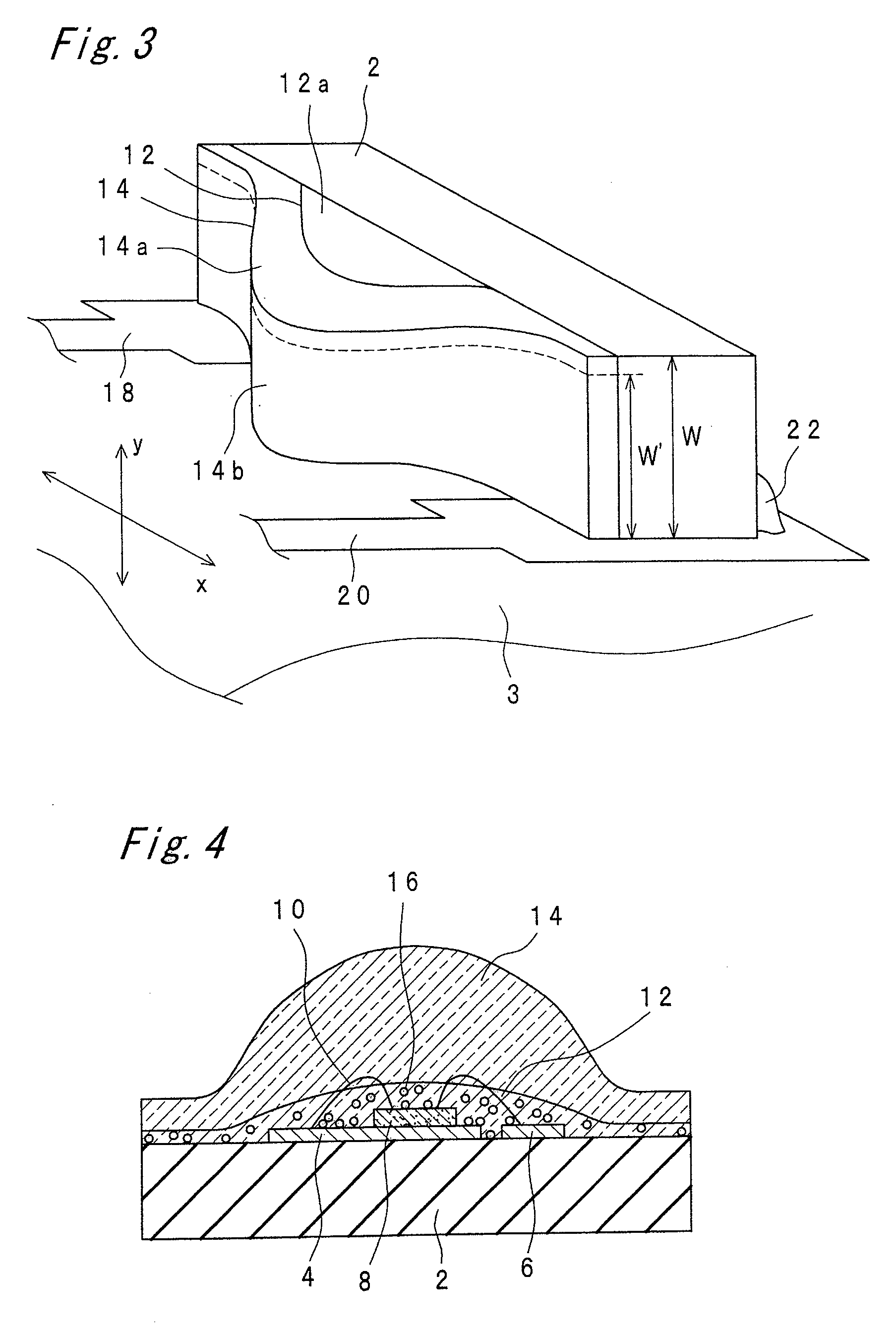

Method for preparing catalyst with lamella distribution

ActiveCN101462079AImprove performanceEvenly distributedCatalyst activation/preparationAlcoholDistribution characteristic

The invention relates to a method for preparing a shell distribution catalyst, which comprises the step of using a solution containing effective quantity of active metal components to soak a carrier. The method is characterized in that a solvent in the solution is a mixture formed by one or more compositions of water, alcohol, ether, aldehyde and ketone and at least one surfactant; the content of the surfactant is between 0.01 and 10.00 weight percent in reference to the total weight of the solution; and the soaking step meets the condition that the VL / VC is equal to 0.01-0.99, wherein VL refers to the volume of the soaking solution, and VC refers to the pore volume of the carrier. The catalyst guarantees that distribution of the active metal components in the carrier reveals obvious shell distribution characteristic, and simultaneously guarantees that the active metal components are more uniformly distributed in a shell.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com