Patents

Literature

99results about How to "Uniform physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

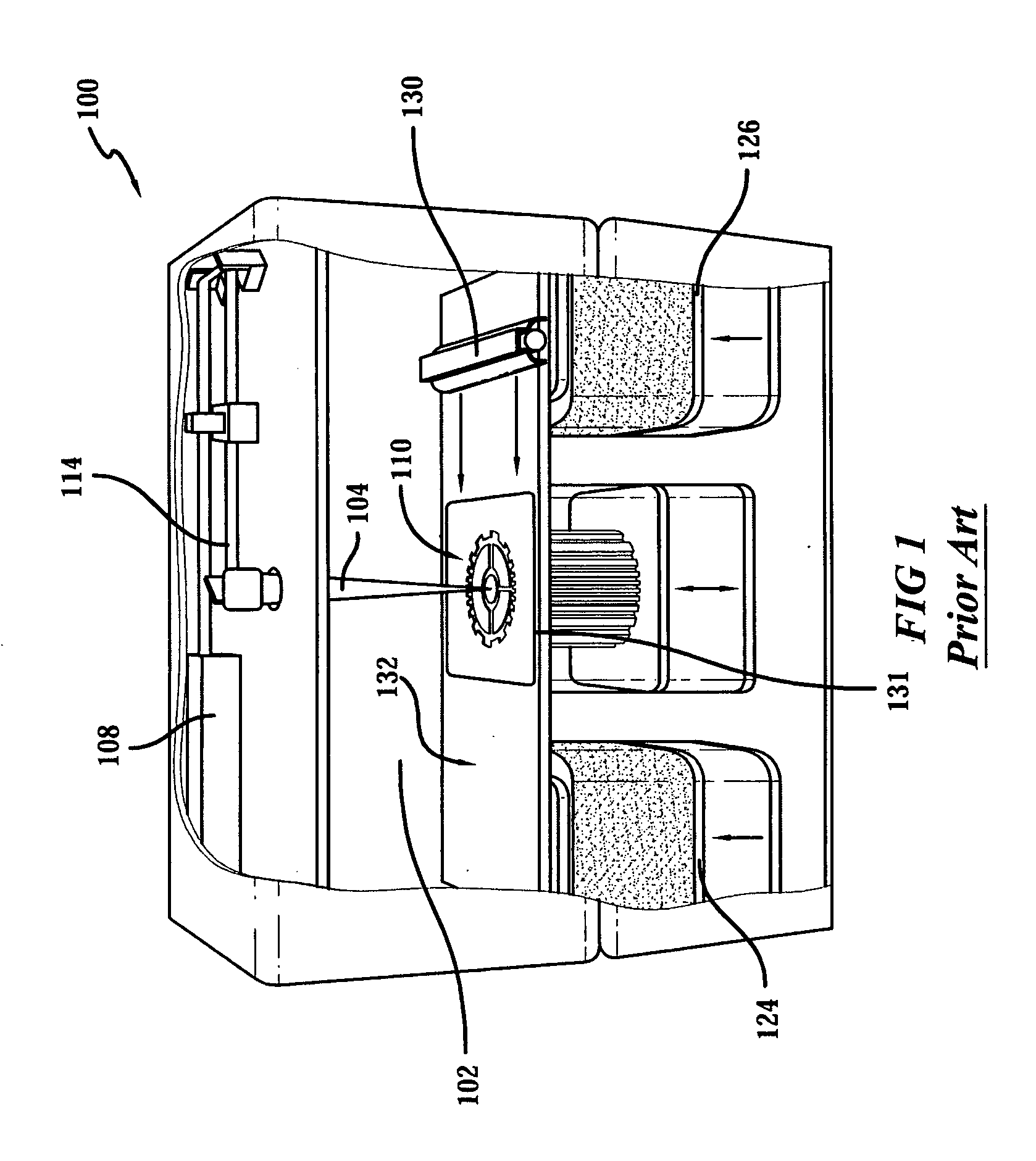

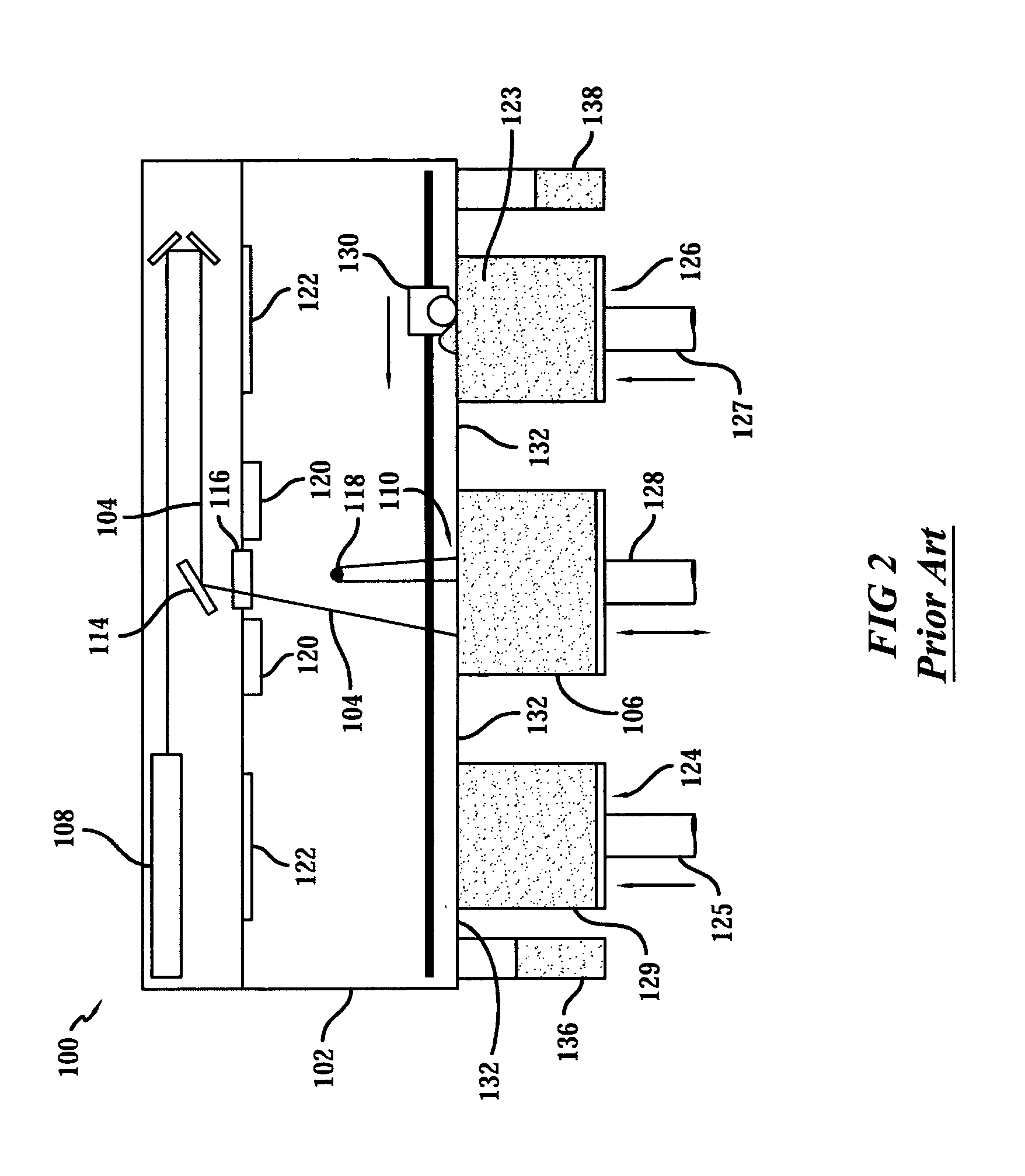

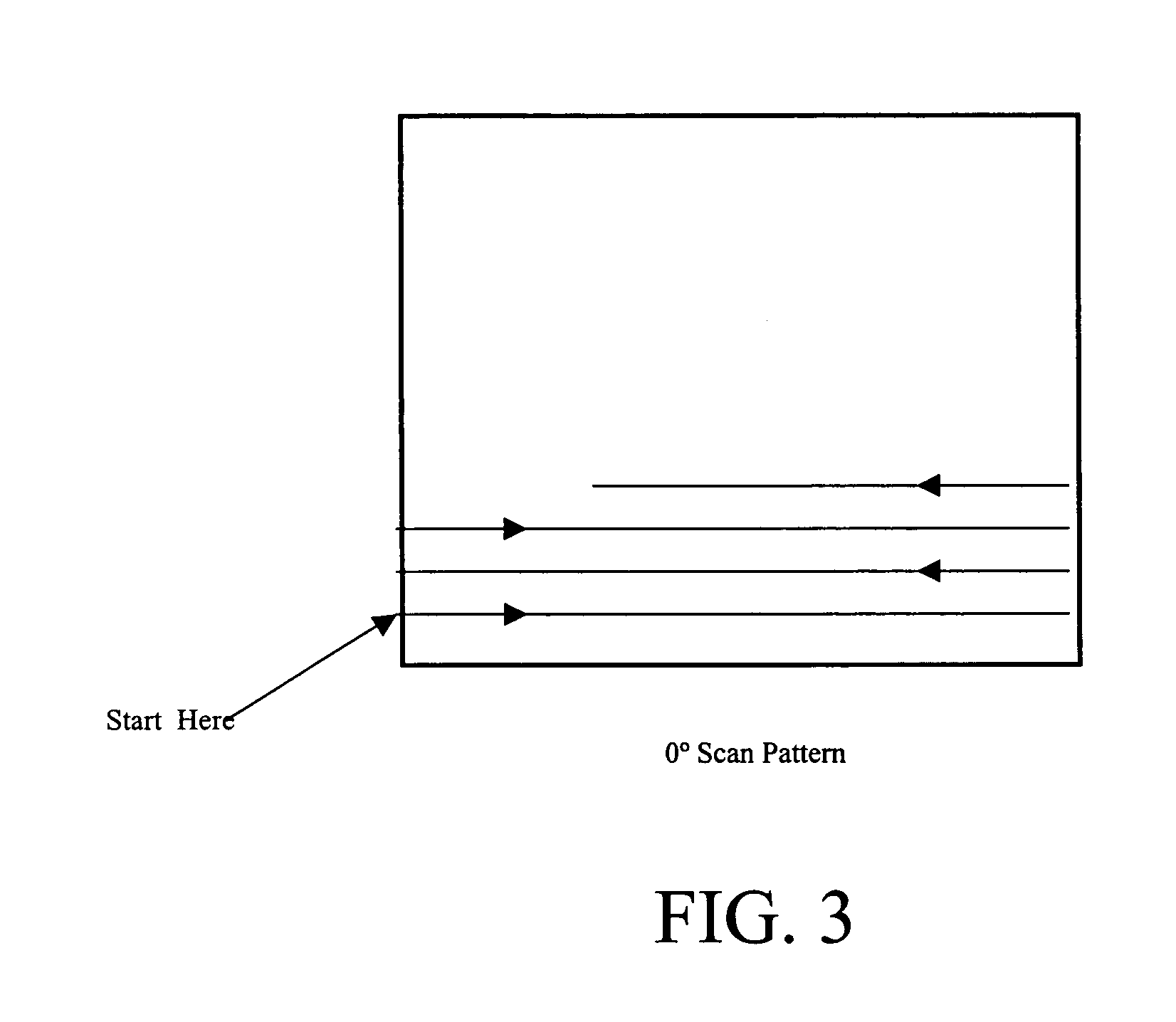

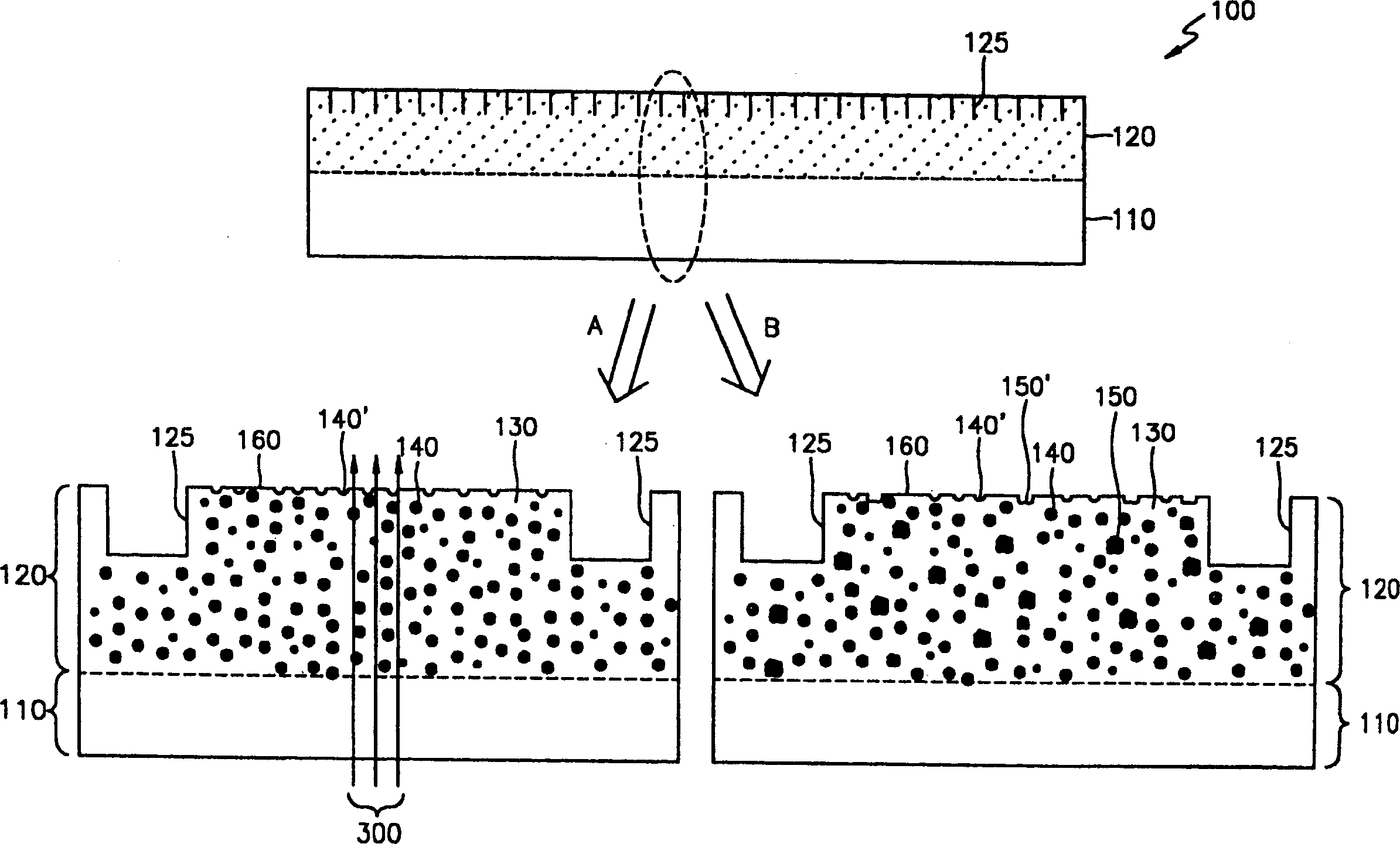

Uniform thermal distribution imaging

InactiveUS20050242473A1Uniform physical propertiesSimple technologyAuxillary shaping apparatusCoatingsImproved methodMaterials science

A method of obtaining uniform thermal distribution imaging in a thermally initiated and thermally based laser sintering process whereby a three-dimensional object is formed layer-by-layer in which the scanning sequences in successive layers is varied to more uniformly control the build up of heat within a three-dimensional object being formed. An improved method of image scanning multiple parts in a single build process is also employed.

Owner:3D SYST INC

Polyamide-imide copolymer film and method of preparing polyamide-imide copolymer

ActiveUS20140243482A1Improve mechanical propertiesExcellent optical propertiesNon-linear opticsPolymer sciencePolyamide-imide

Disclosed herein is a polyamide-imide copolymer film, comprising a copolymer resin in which a unit structure derived from TFDB (2,2′-bistrifluoromethyl-4,4′-biphenyl diamine), a unit structure derived from 6FDA (4,4′-(hexa-fluoroisopropylidene)diphthalic anhydride), a unit structure derived from BPDA (3,3′,4,4′-biphenyltetracarboxylic dianhydride) and a unit structure derived from TPC (terephthaloyl chloride or 1,4-benzenedicarbonyl chloride) are copolymerized, wherein the copolymer resin has a weight average molecular weight of 10,000˜400,000.

Owner:KOLON IND INC

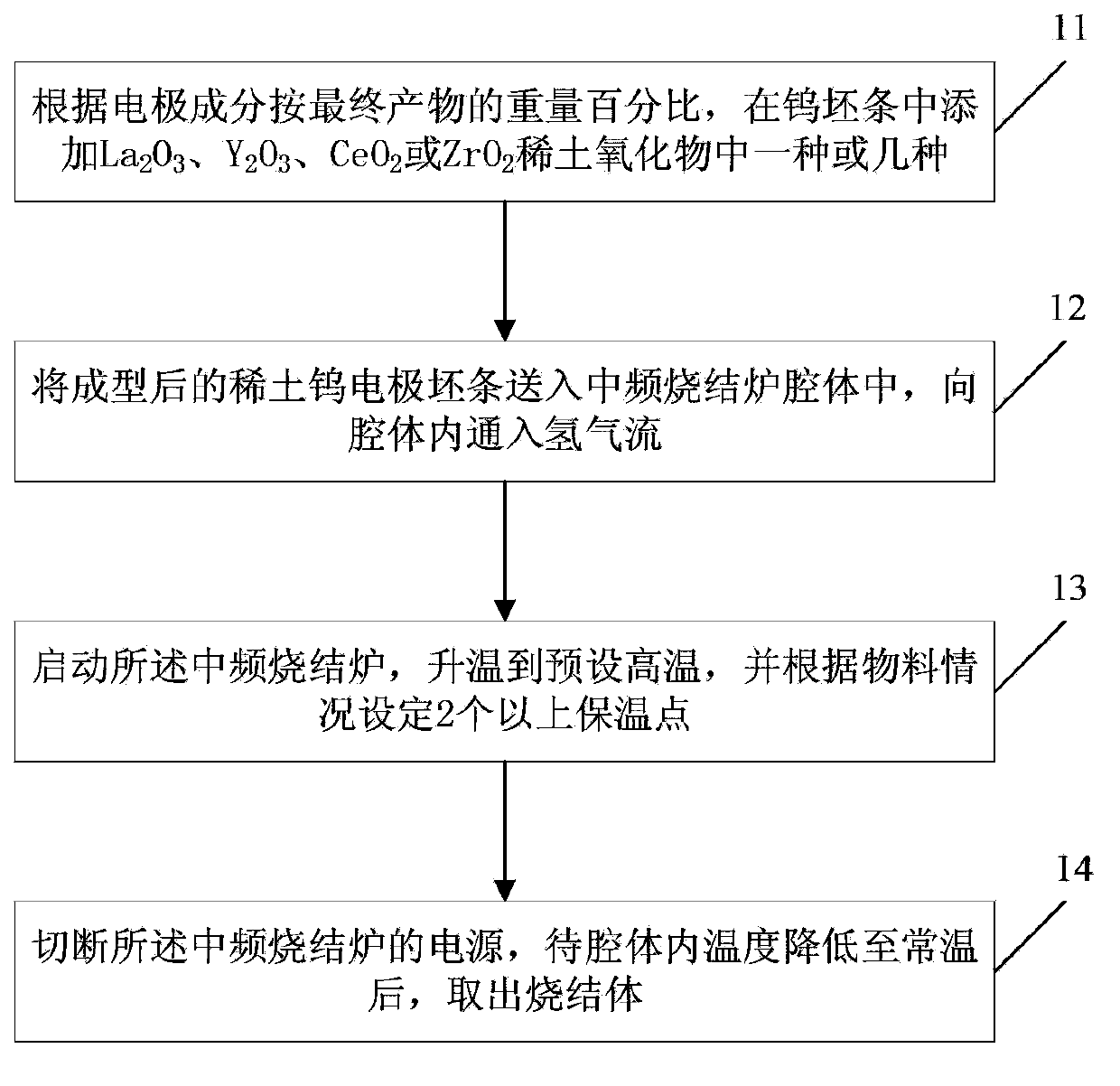

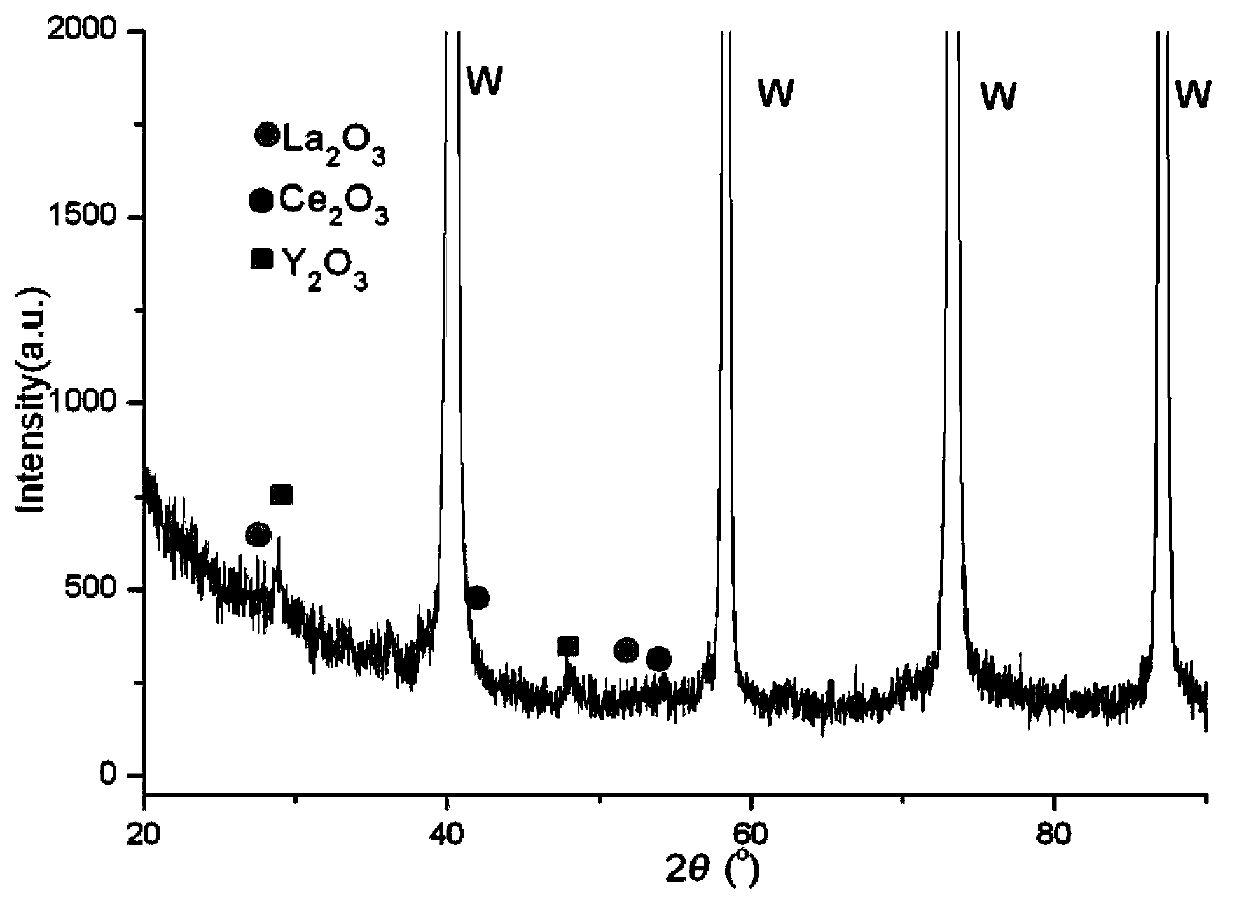

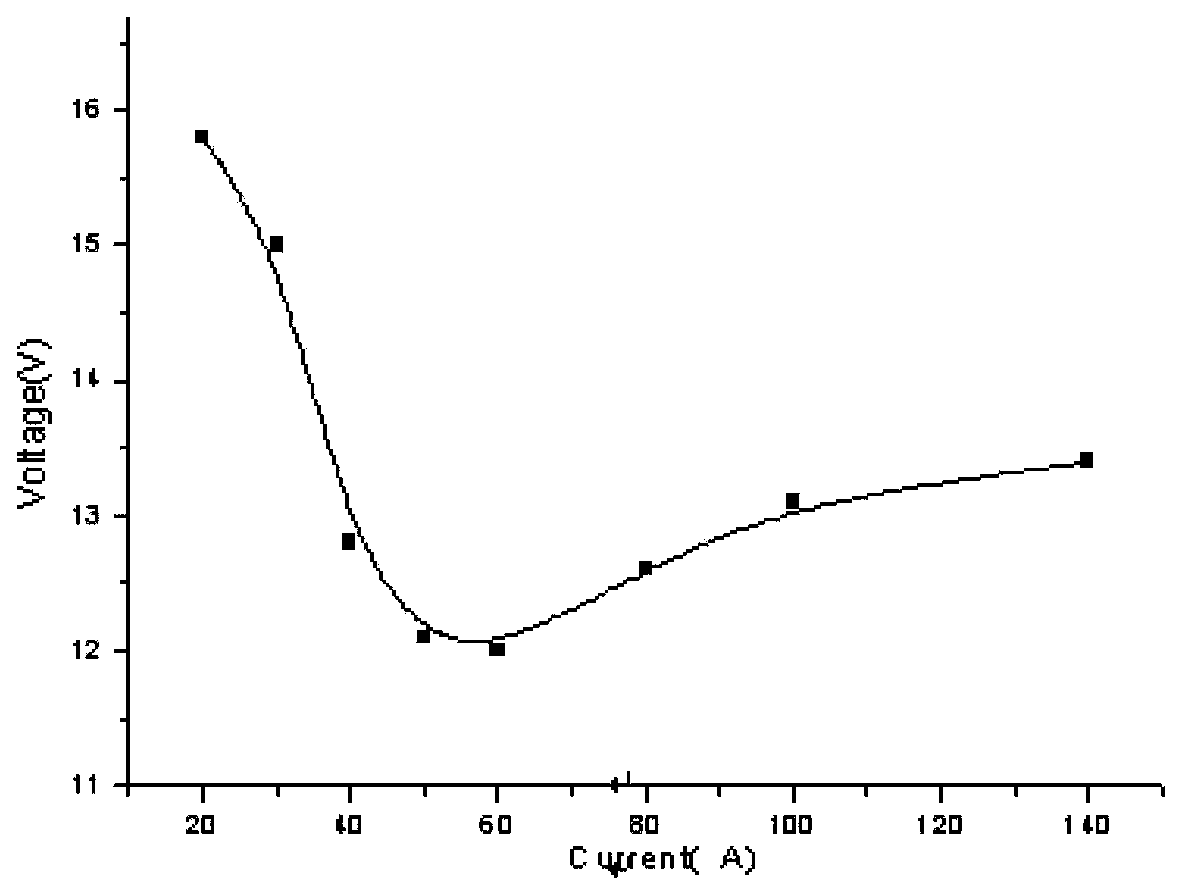

Sintering method for rear earth tungsten electrode billets

The invention discloses an sintering method for rear earth tungsten electrode billets. The sintering method comprises: firstly enabling electrode compositions to accord with the weight ratio of a final product, adding one or multiple of rear earth oxides such as La2O3, Y2O3, CeO2 and ZrO2 into a tungsten billet; sending the molded rear earth tungsten electrode billet into the chamber of a medium-frequency sintering furnace, and introducing hydrogen flow into the chamber; starting the medium-frequency furnace, heating to 2000-2400 DEG C with a temperature-raising speed of 100-300 DEG C / h, and setting two or more thermal-insulation points according to material condition, and setting the thermal-insulation time of each thermal-insulation point to be 2-4 h; and switching off the power supply of the medium-frequency sintering furnace, when the temperature of the chamber is reduced to normal temperature, taking out the sintering body. By employing the sintering method, uniform-physical-property high-yield rear earth tungsten billets can be supplied in large scale with high efficiency.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

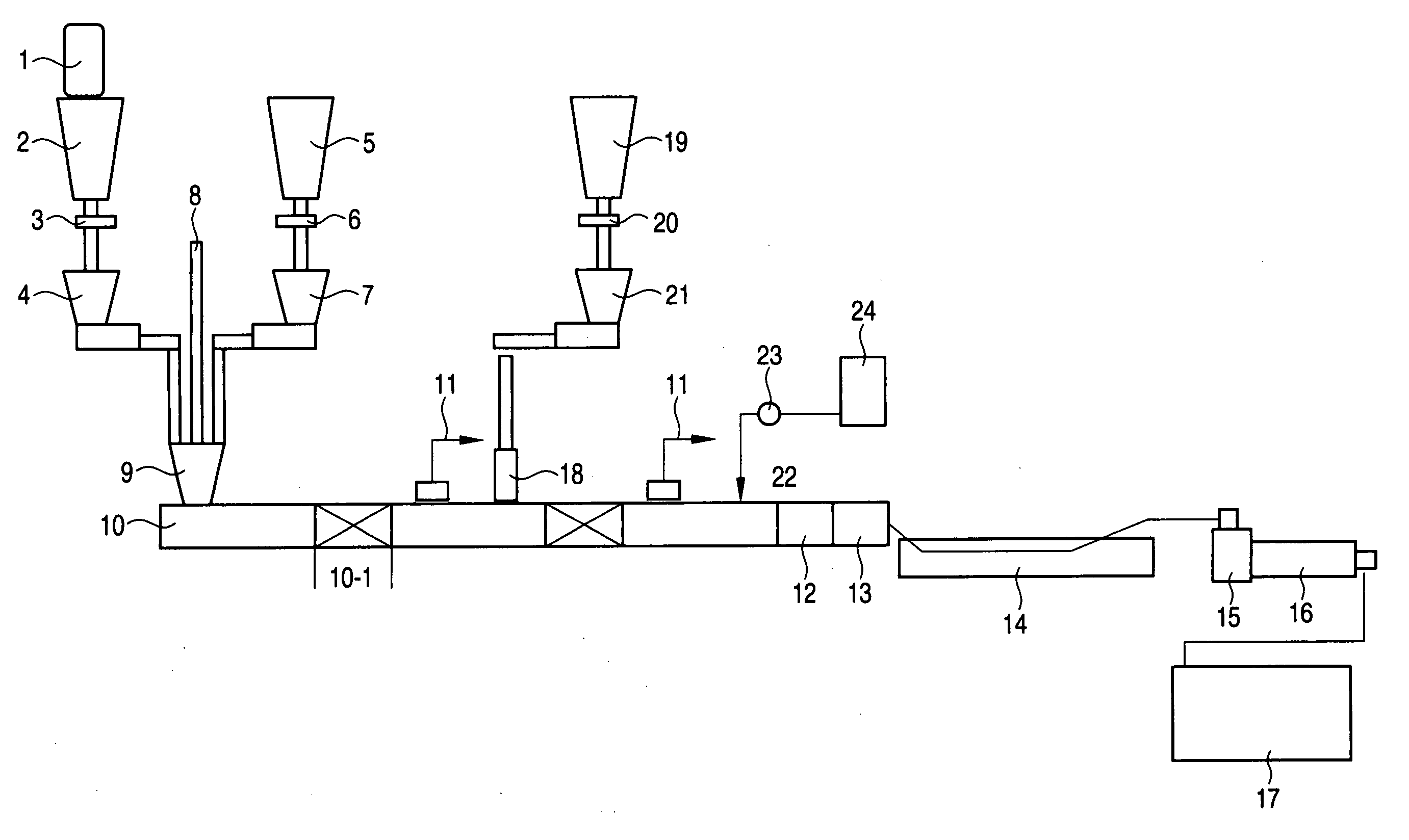

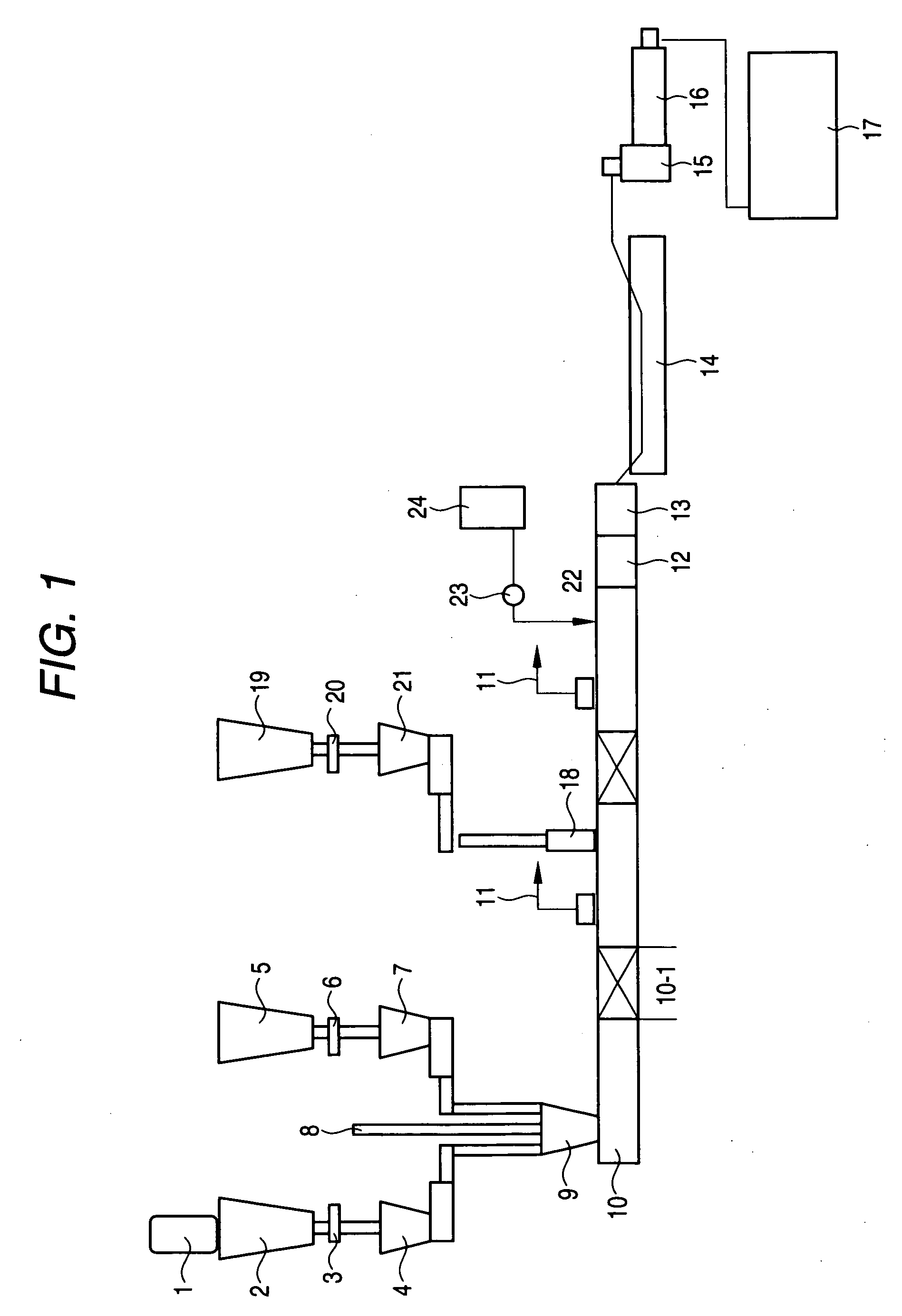

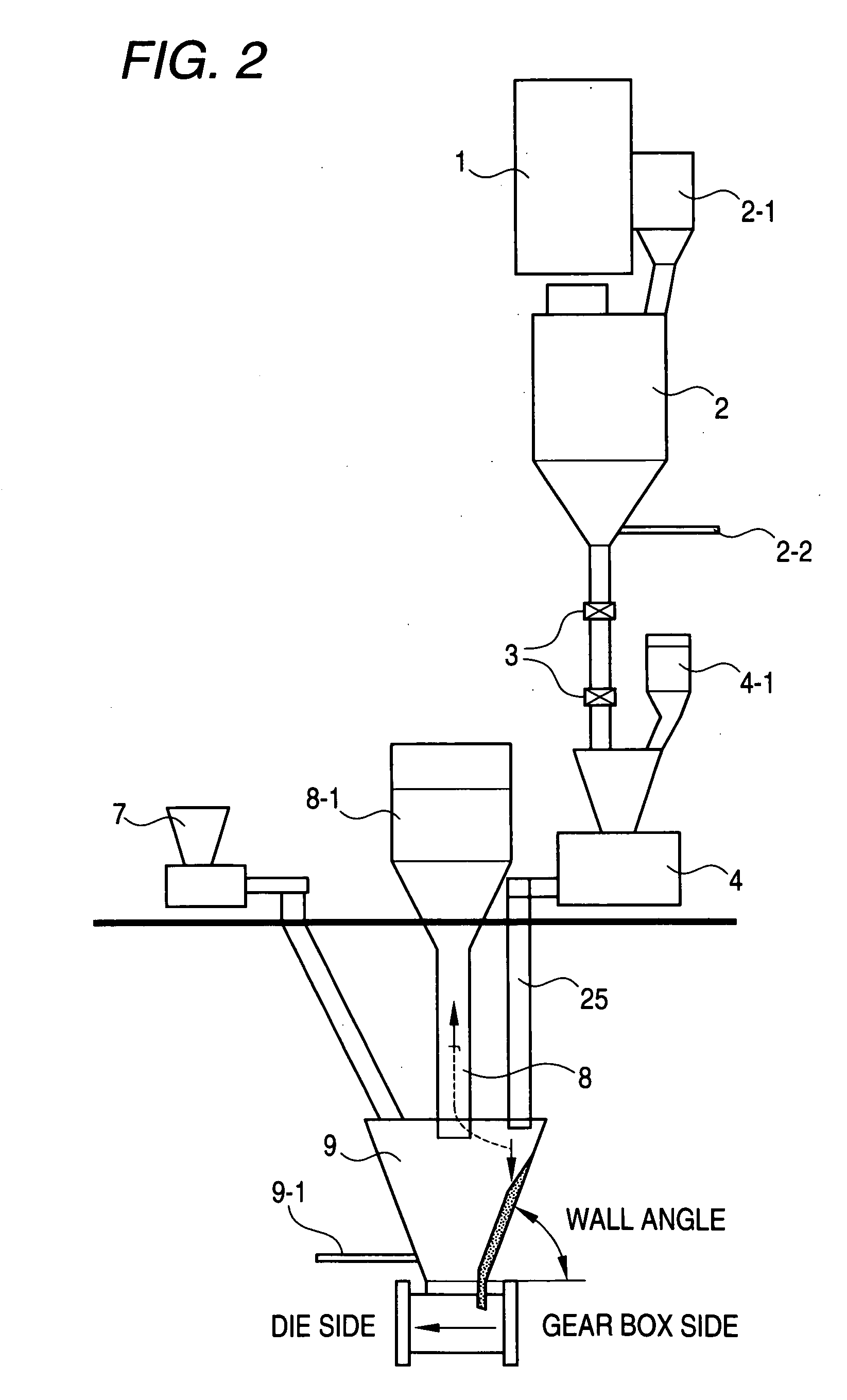

Process for producing PPE resin composition

ActiveUS20060255498A1Increase production capacityStable supplyDough homogenizationFrozen sweetsPolymer scienceEther

The invention provides process for producing a PPE resin composition containing PPE powder using an extruder comprising: a vent pipe; a polyphenylene ether (herein after referred to as “PPE”) powder supplying pipe; an extruder supply hopper having an opening with a wall angle of 60° or more; and an extruder unit, wherein the vent pipe and the PPE powder supplying pipe each have an terminal orifice located in the opening of the extruder supply hopper, and wherein the PPE powder supplying pipe is disposed at a gear box-side portion of the extruder supply hopper, and the vent pipe is disposed at a die-side portion, relative to the PPE powder supplying pipe, of the extruder supply hopper, which process comprises the steps of: supplying the PPE powder to a gear box-side wall of the extruder supply hopper through the PPE powder supplying pipe; removing a gas accompanying the PPE powder in an effective amount through the vent pipe; and melt-kneading a mixture containing the degassed PPE powder with the extruder unit.

Owner:ASAHI KASEI CHEM CORP

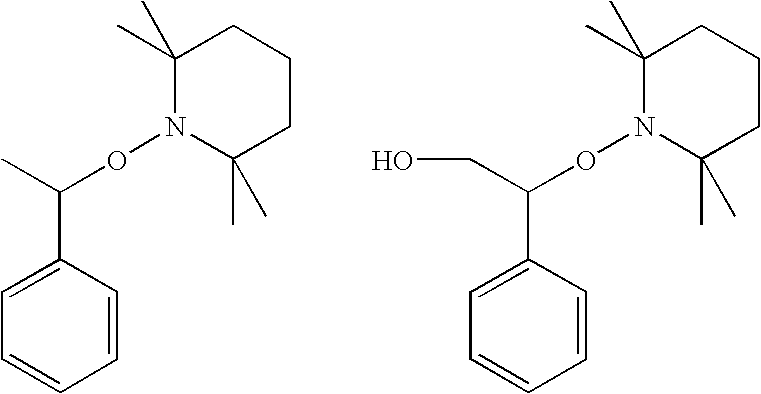

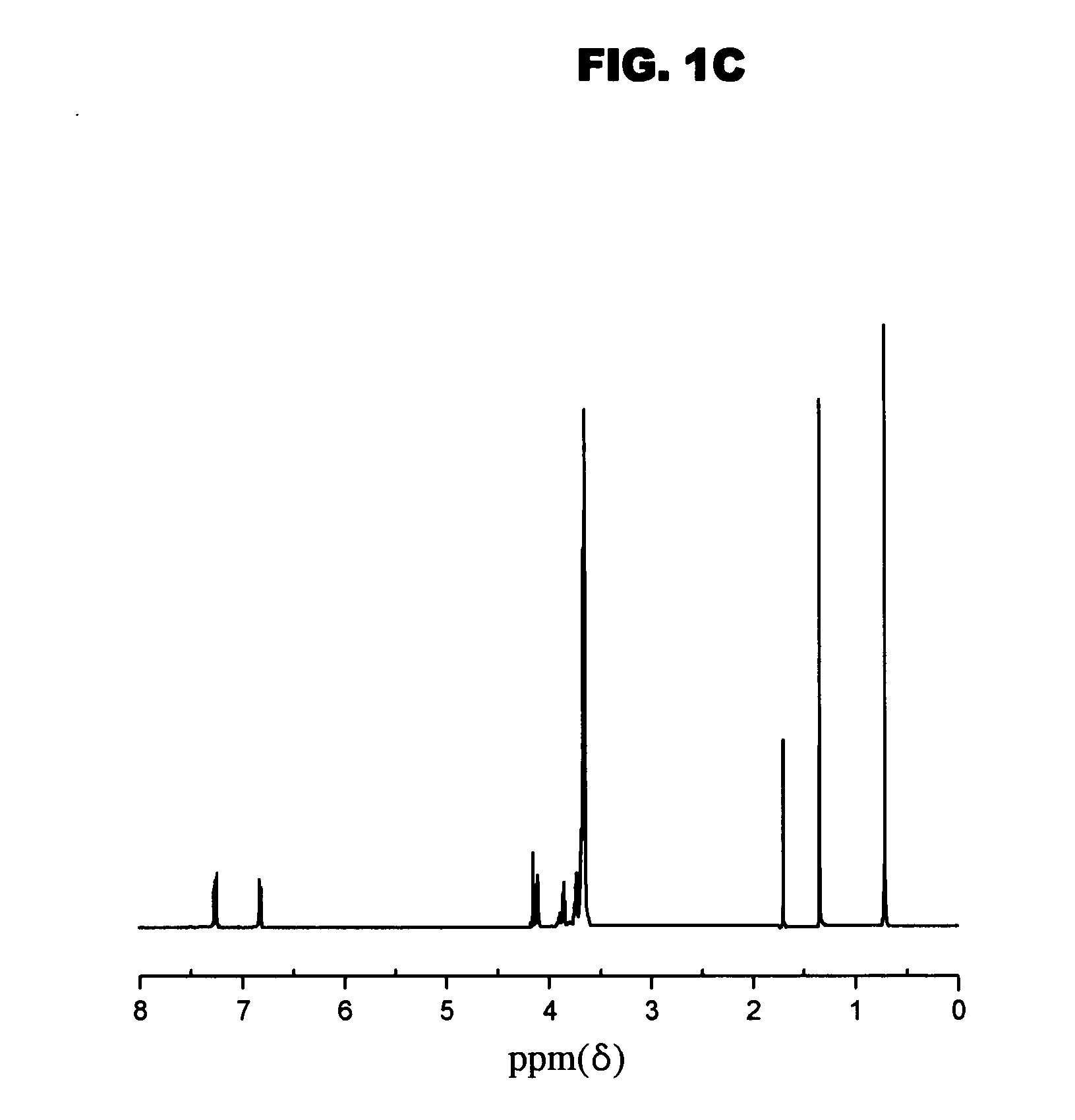

Curable composition for damping material and damping material

Provided is a curable composition for damping materials excellent in heat resistance, oil resistance and damping property, as well as a damping material obtained therefrom. Specially provided is a curable composition for damping materials, containing a vinyl-based polymer (I) having more than one crosslinkable functional groups on average and having at least one of the crosslinkable functional groups at the terminus thereof, and a vinyl-based polymer (II) having one or less crosslinkable functional group on average, wherein the content of the vinyl-based polymer (II) is 50 to 95 parts by weight based on 100 parts by weight of the vinyl-based polymers (I) and (II), as well as a damping material obtained by curing the curable composition.

Owner:KANEKA CORP

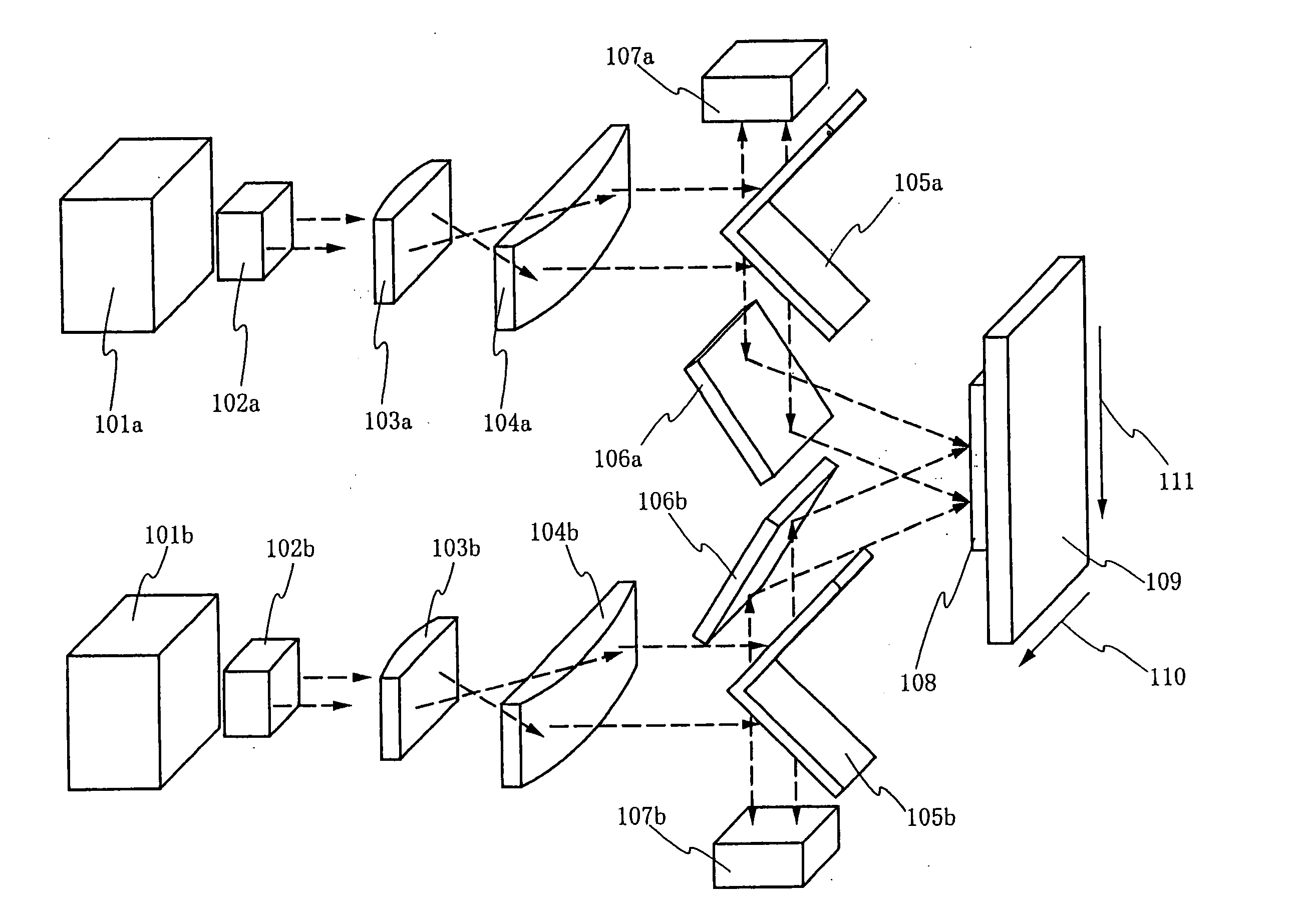

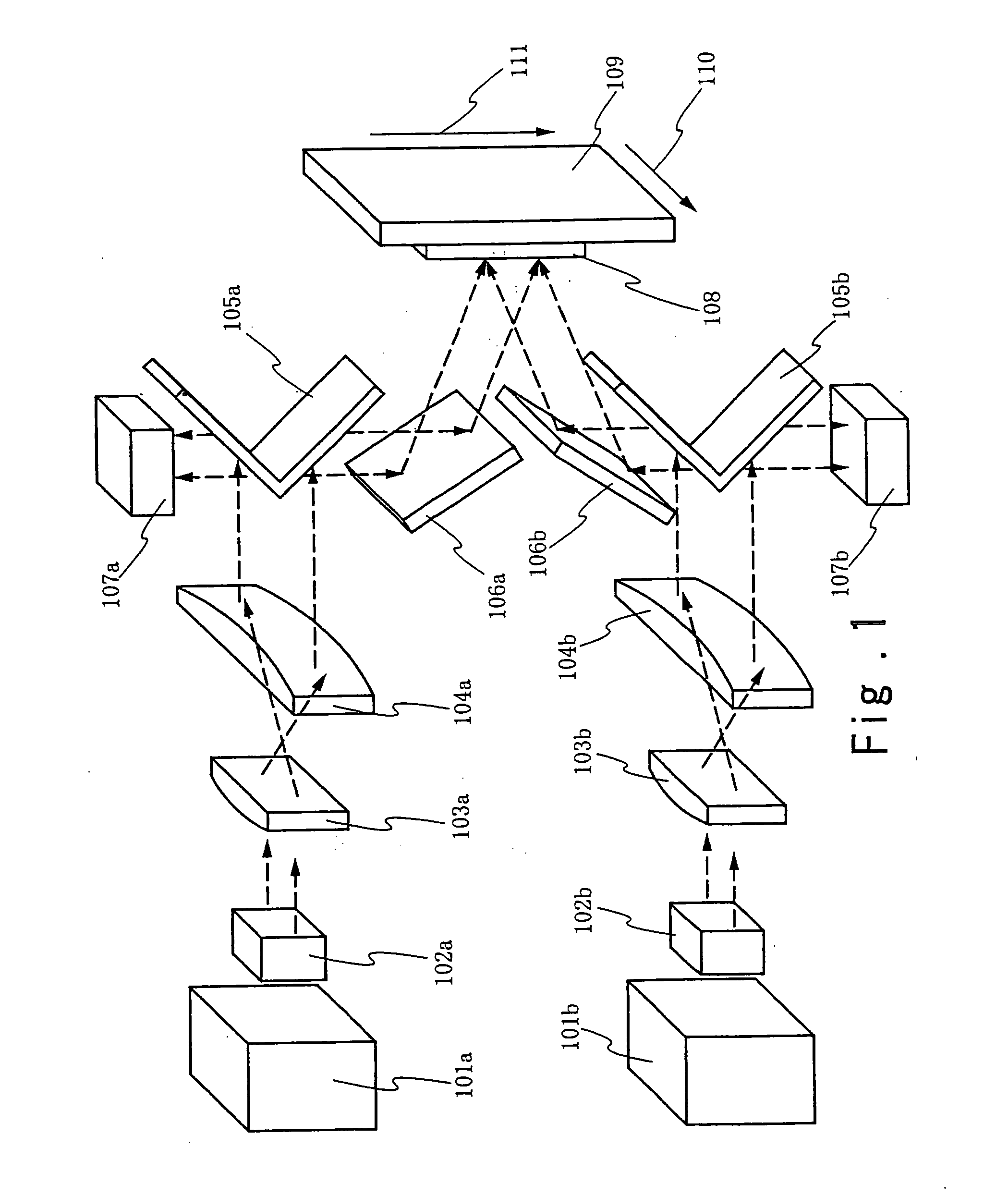

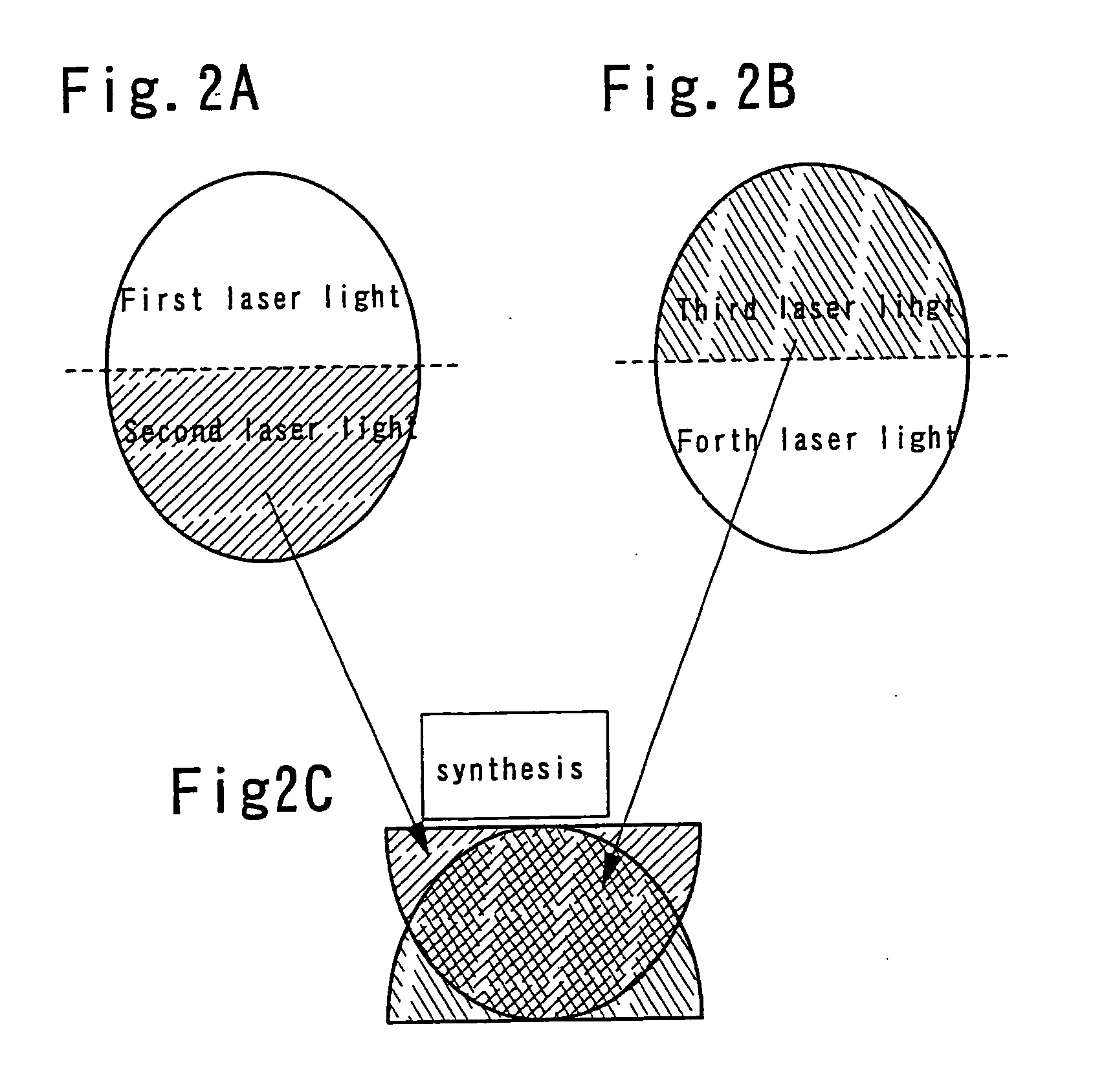

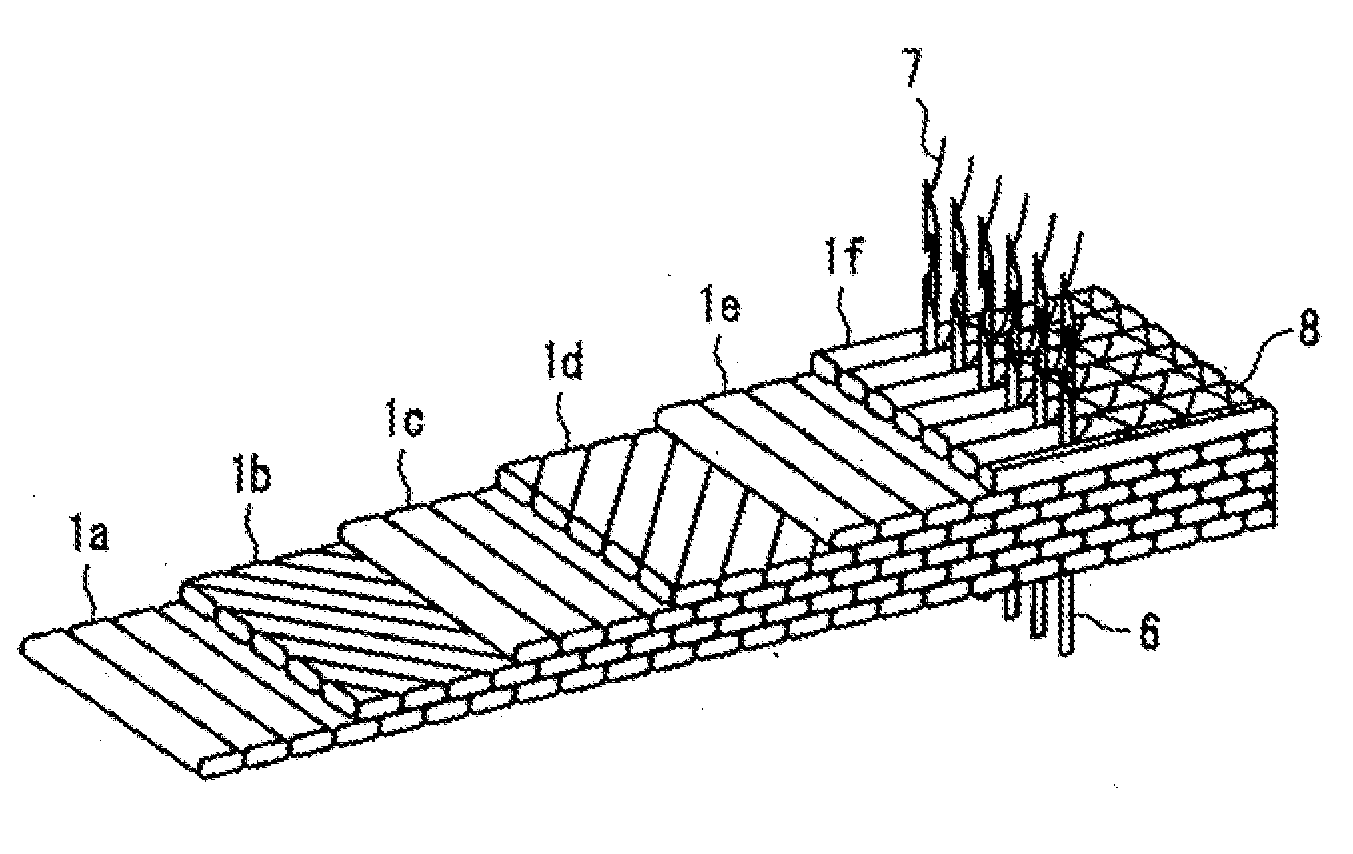

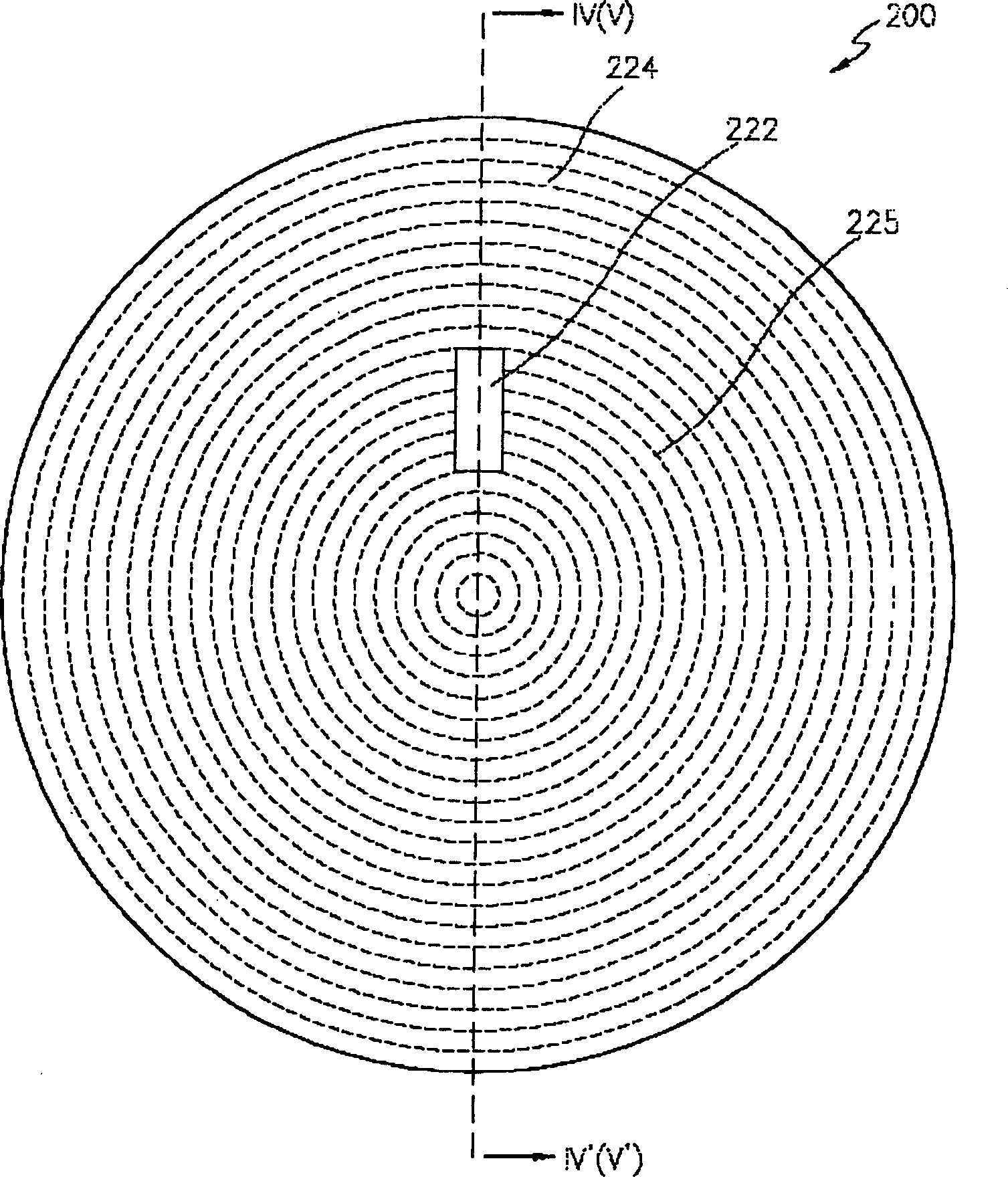

Laser irradiation method, laser irradiation apparatus, and method of manufacturing a semiconductor device

ActiveUS20050035104A1Excellent uniformity in energy distributionReduce weightSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialLaser light

In the present invention, each laser light emitted from a plurality of lasers is divided, and laser light including at least one laser light that is emitted from a different laser and that has different energy distribution is synthesized with another such laser light, or laser light including at least one laser light that has different energy distribution is synthesized with another such laser light through a convex lens that is set at an angle to the direction each laser light travels, to form laser light having excellent uniformity in energy distribution.

Owner:SEMICON ENERGY LAB CO LTD

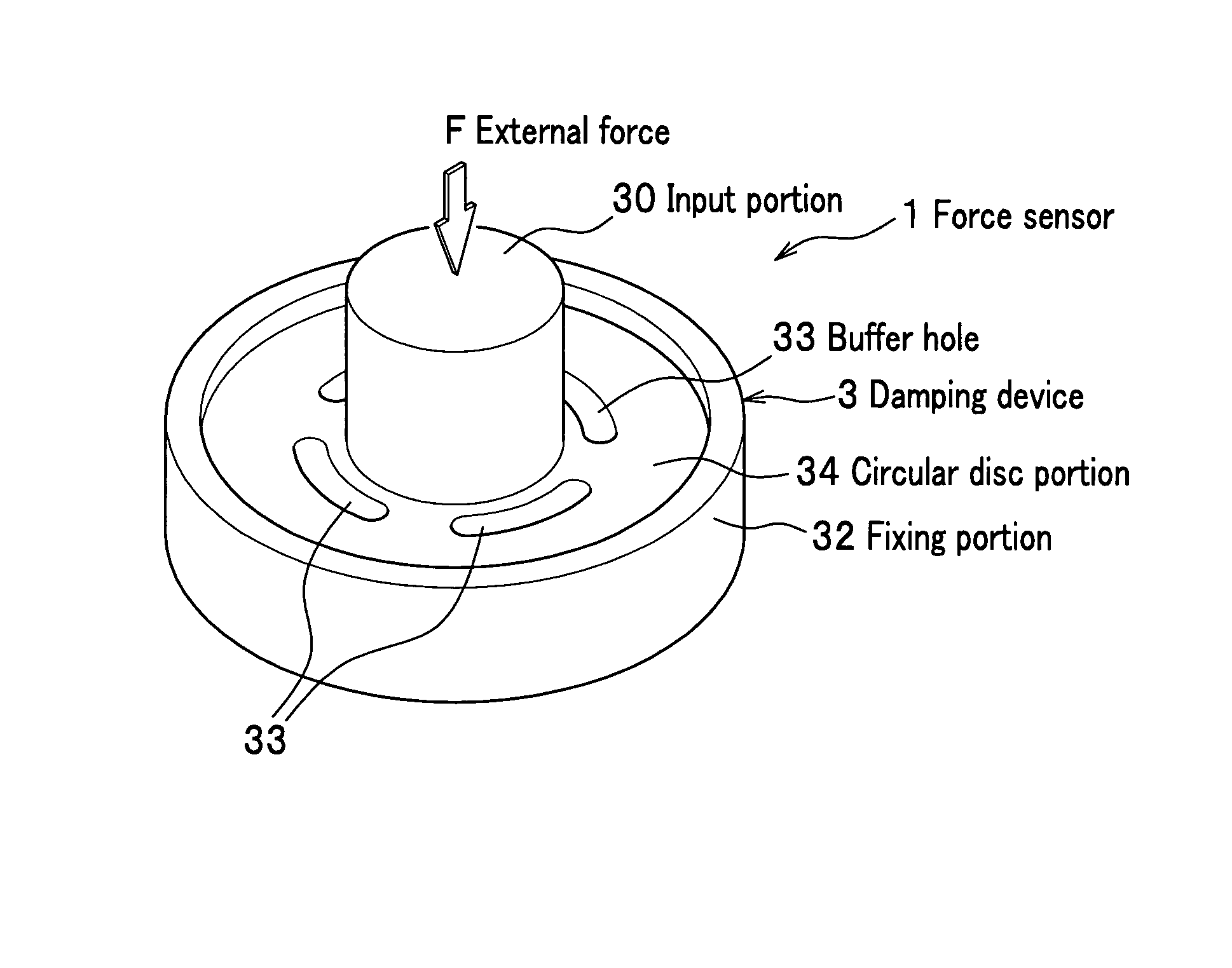

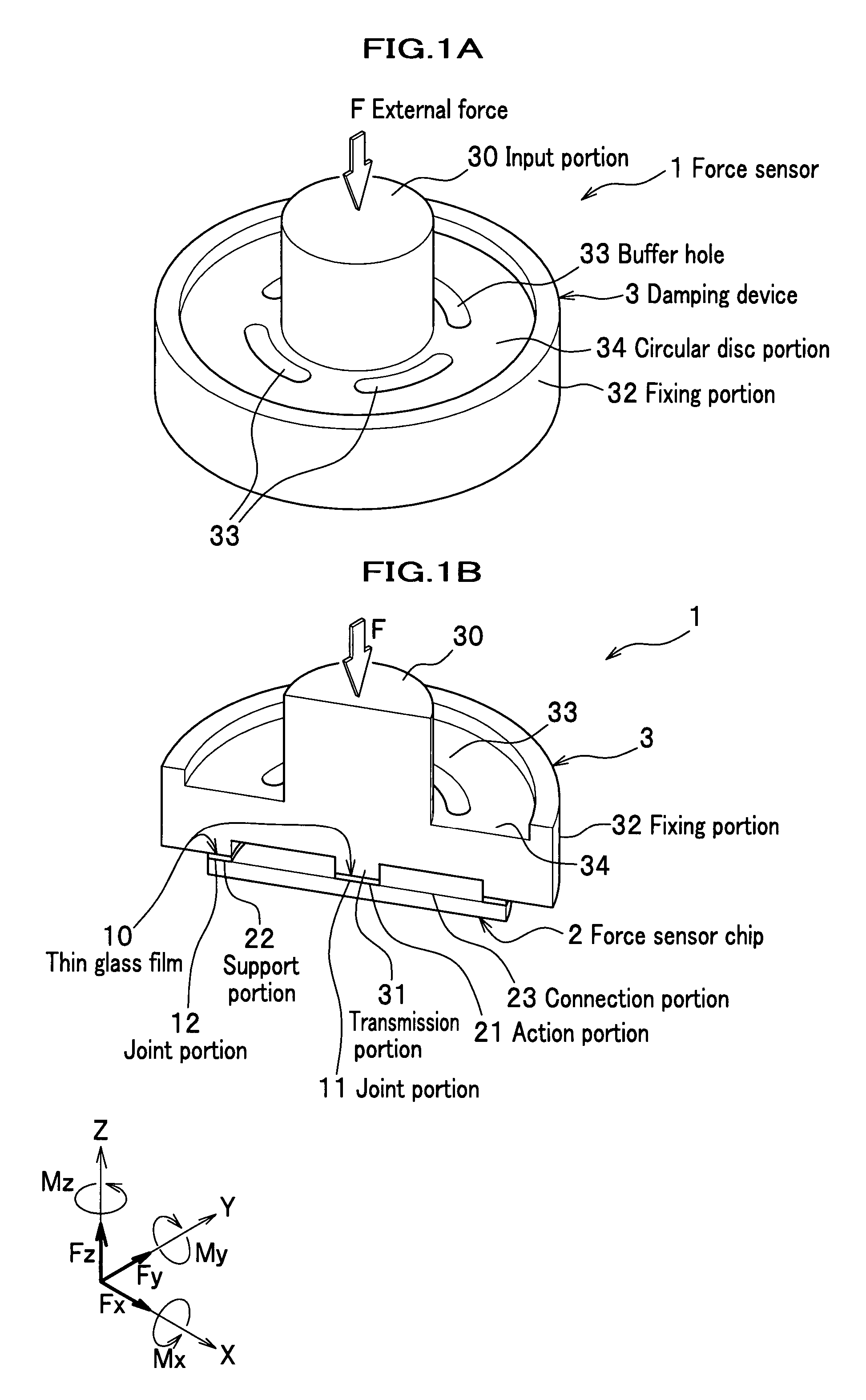

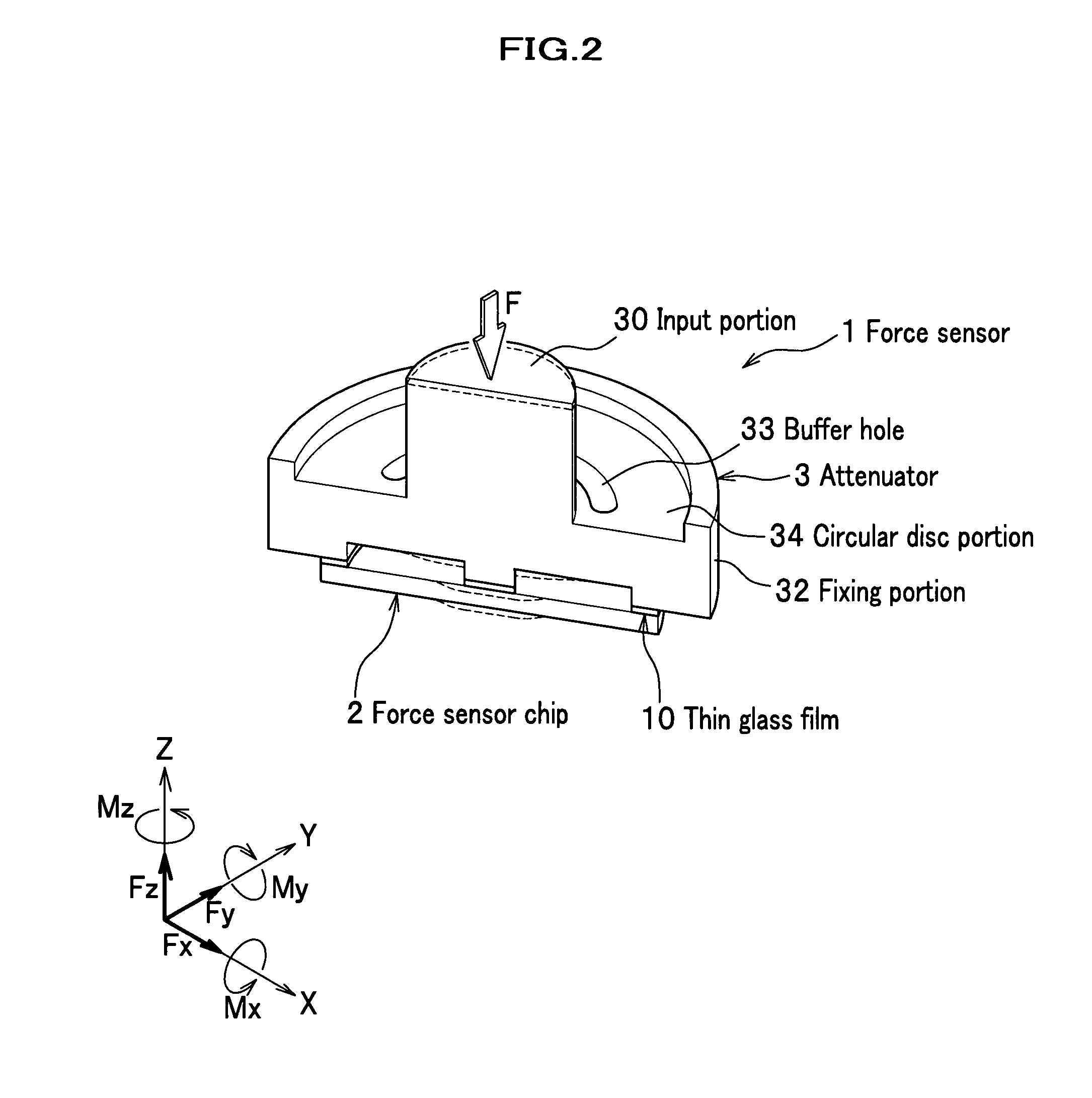

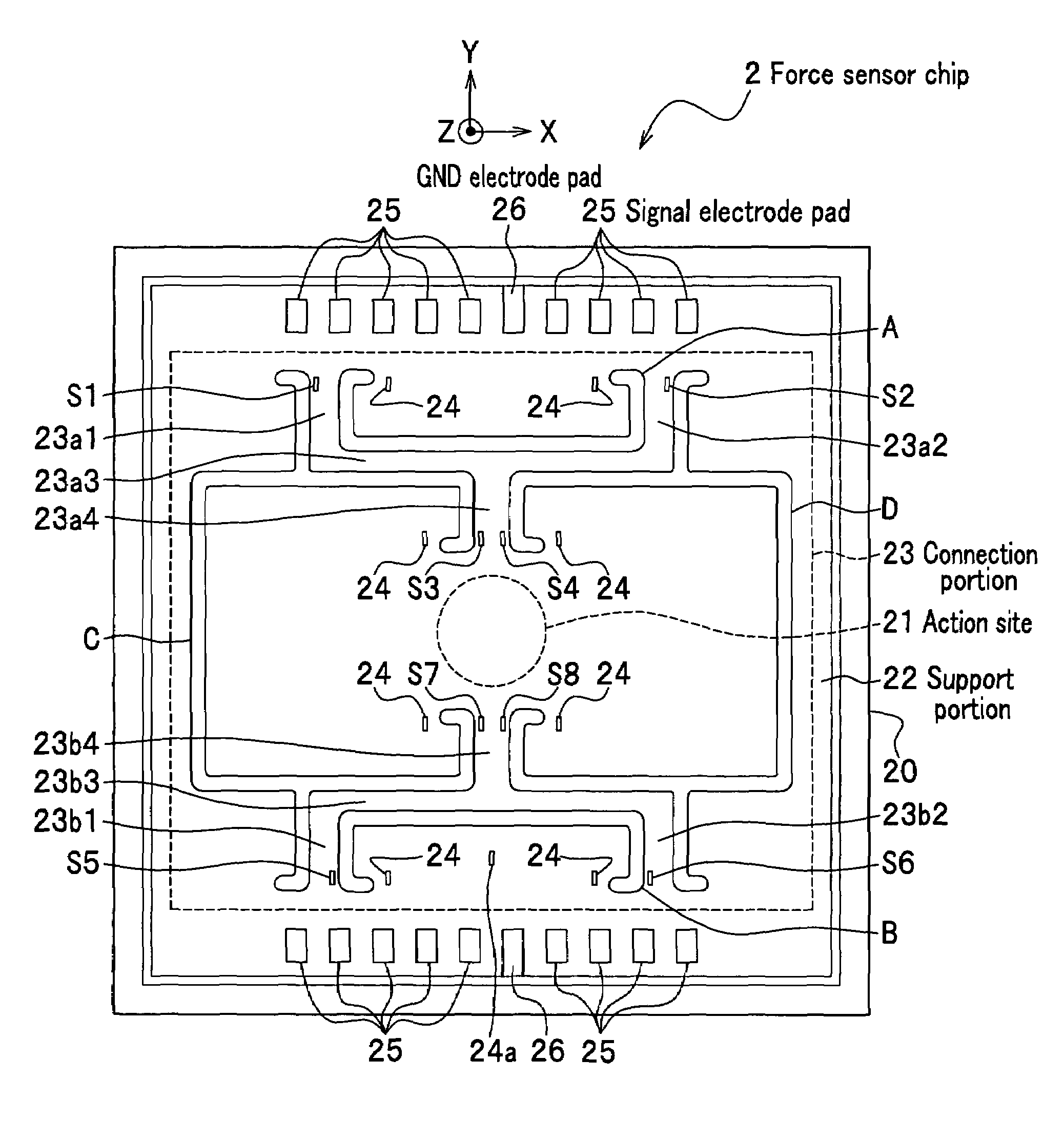

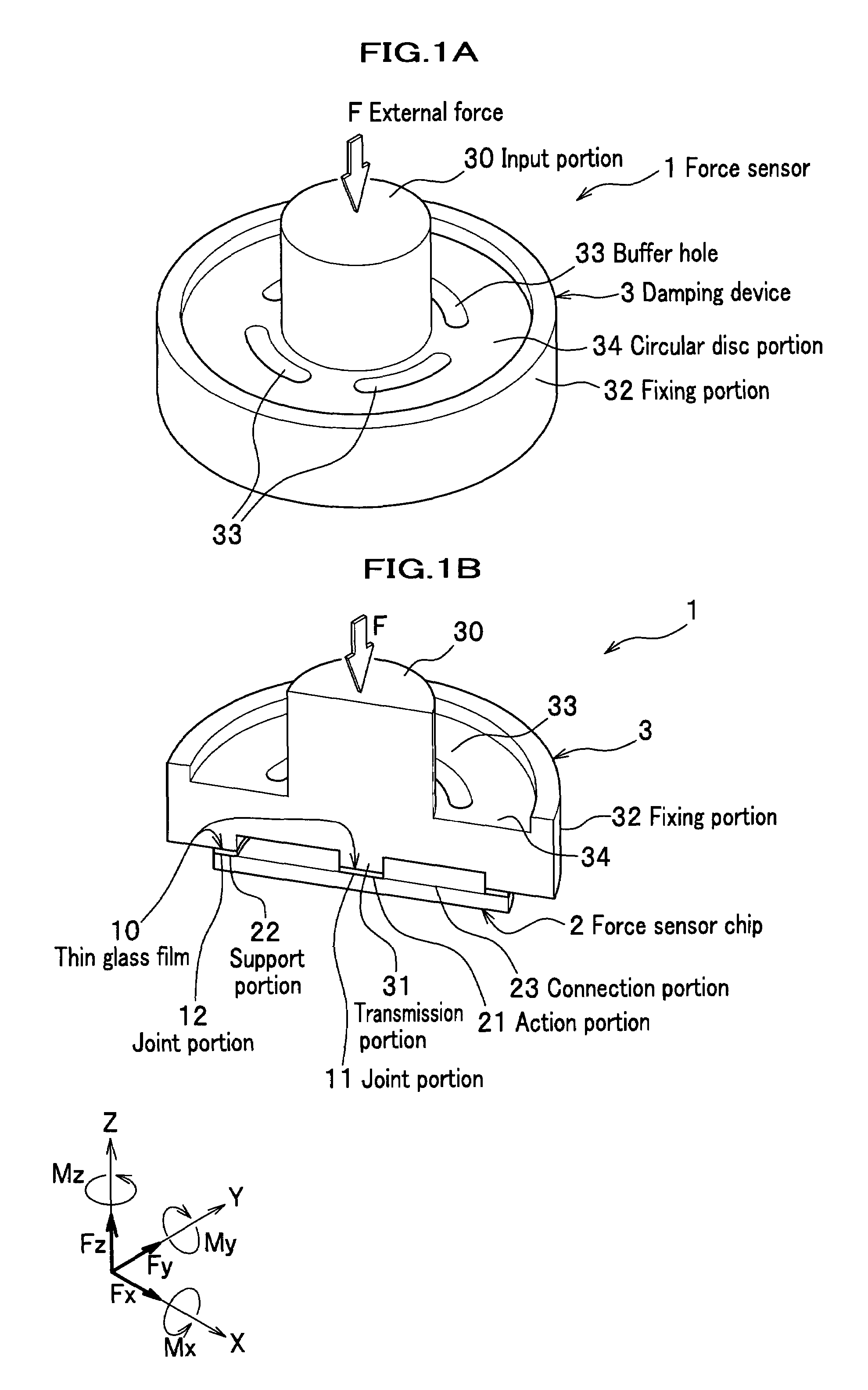

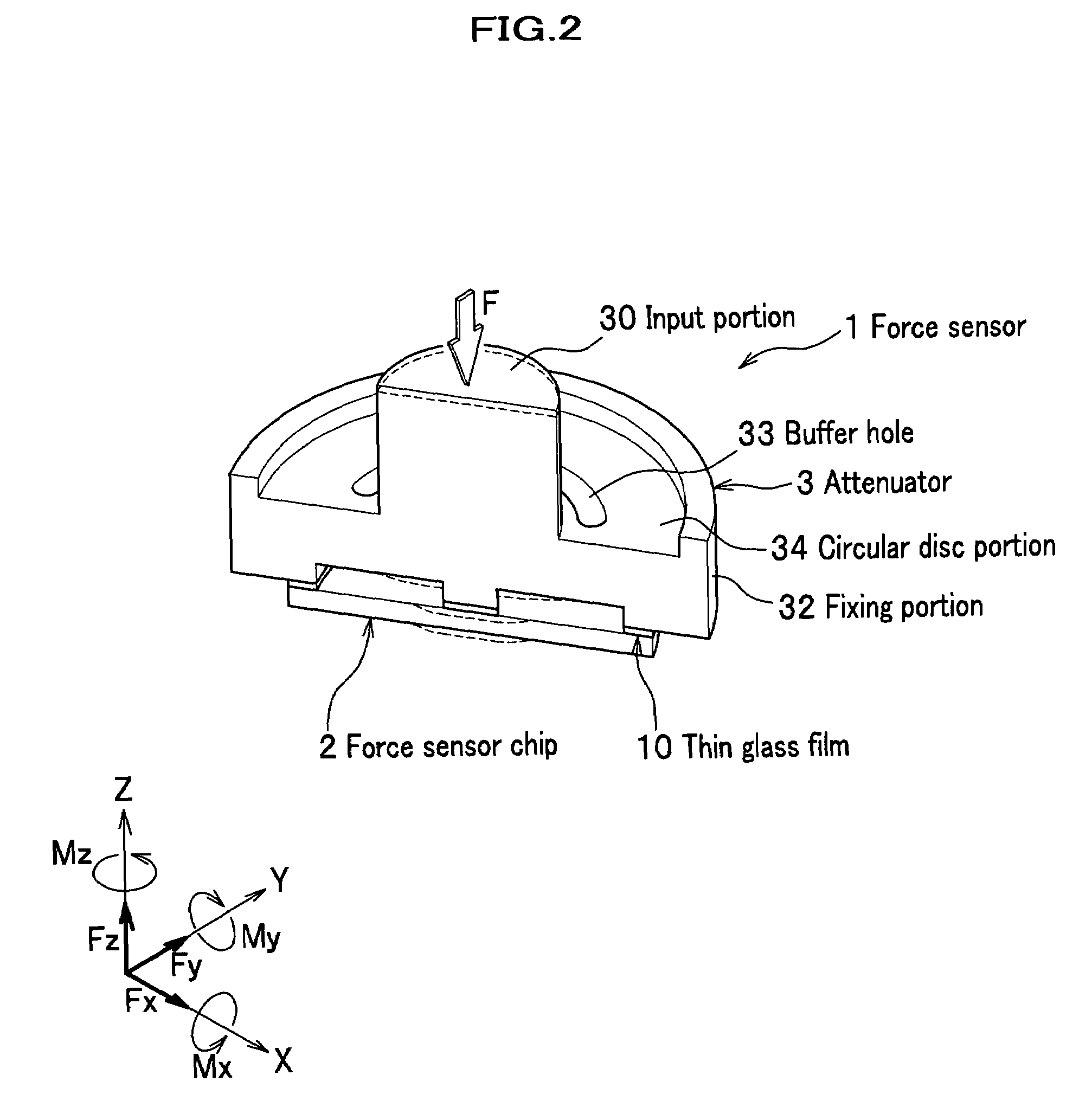

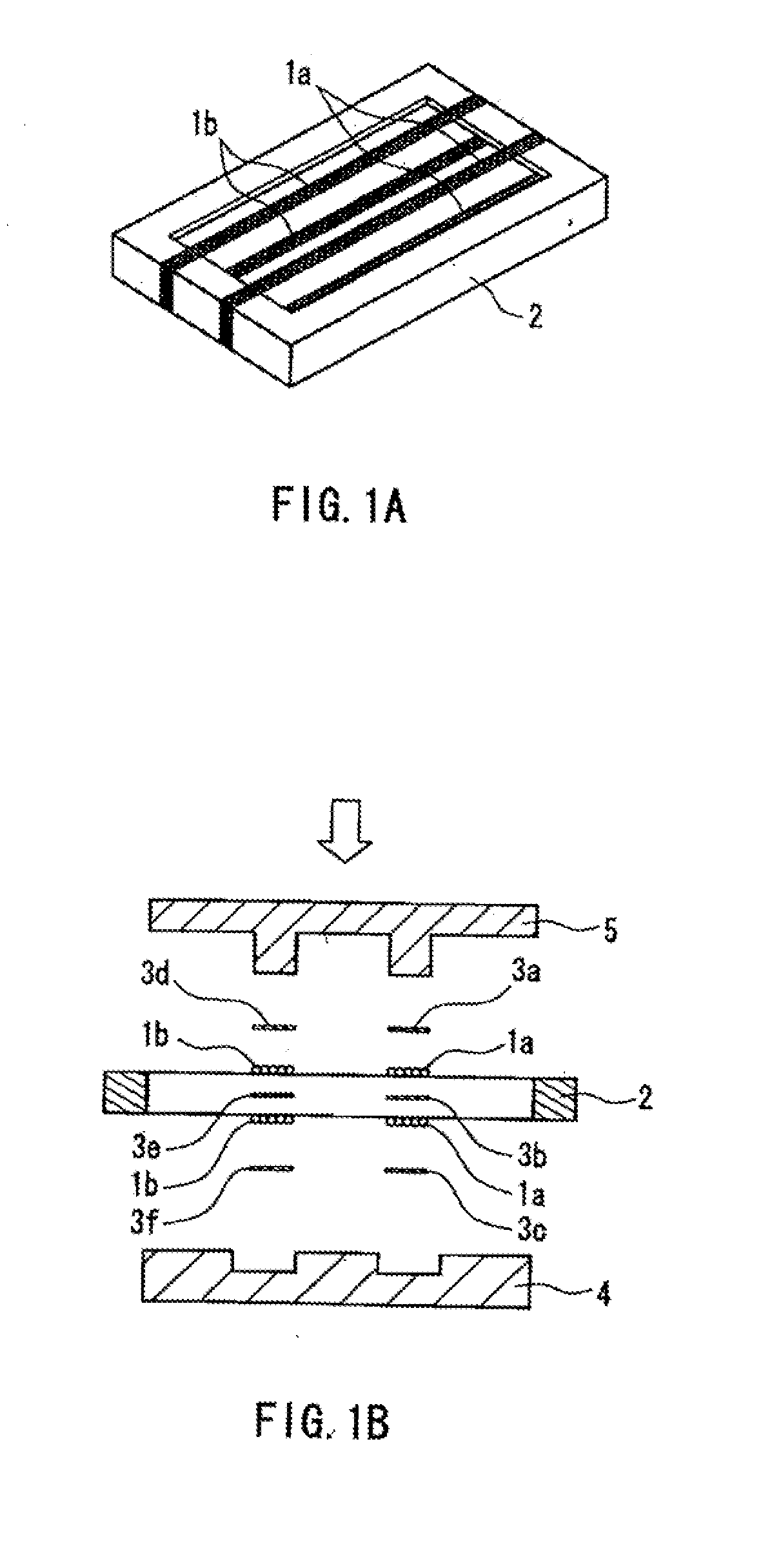

Chip for force sensor and force sensor

ActiveUS20080066562A1Avoid damageImprove featuresPiezoelectric/electrostriction/magnetostriction machinesForce measurementEngineeringForce sensor

A force sensor chip which comprises: a base member, which includes an action portion to which an external force is applied through an attenuator, a support portion supporting the action portion, and a connection portion which connects the action portion and the support portion and deflects according to the applied external force; and a plurality of strain resistance elements which are arranged in the connection portion and detect the applied external force based on a deflection of the connection portion, wherein longitudinal directions of the plurality of the strain resistance elements are oriented in an identical direction.

Owner:HONDA MOTOR CO LTD

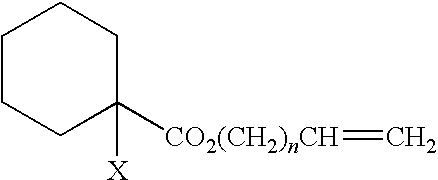

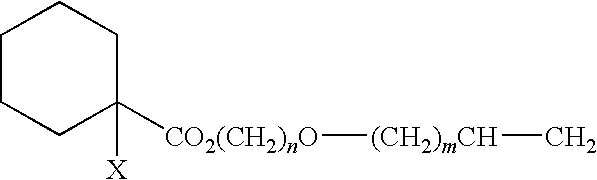

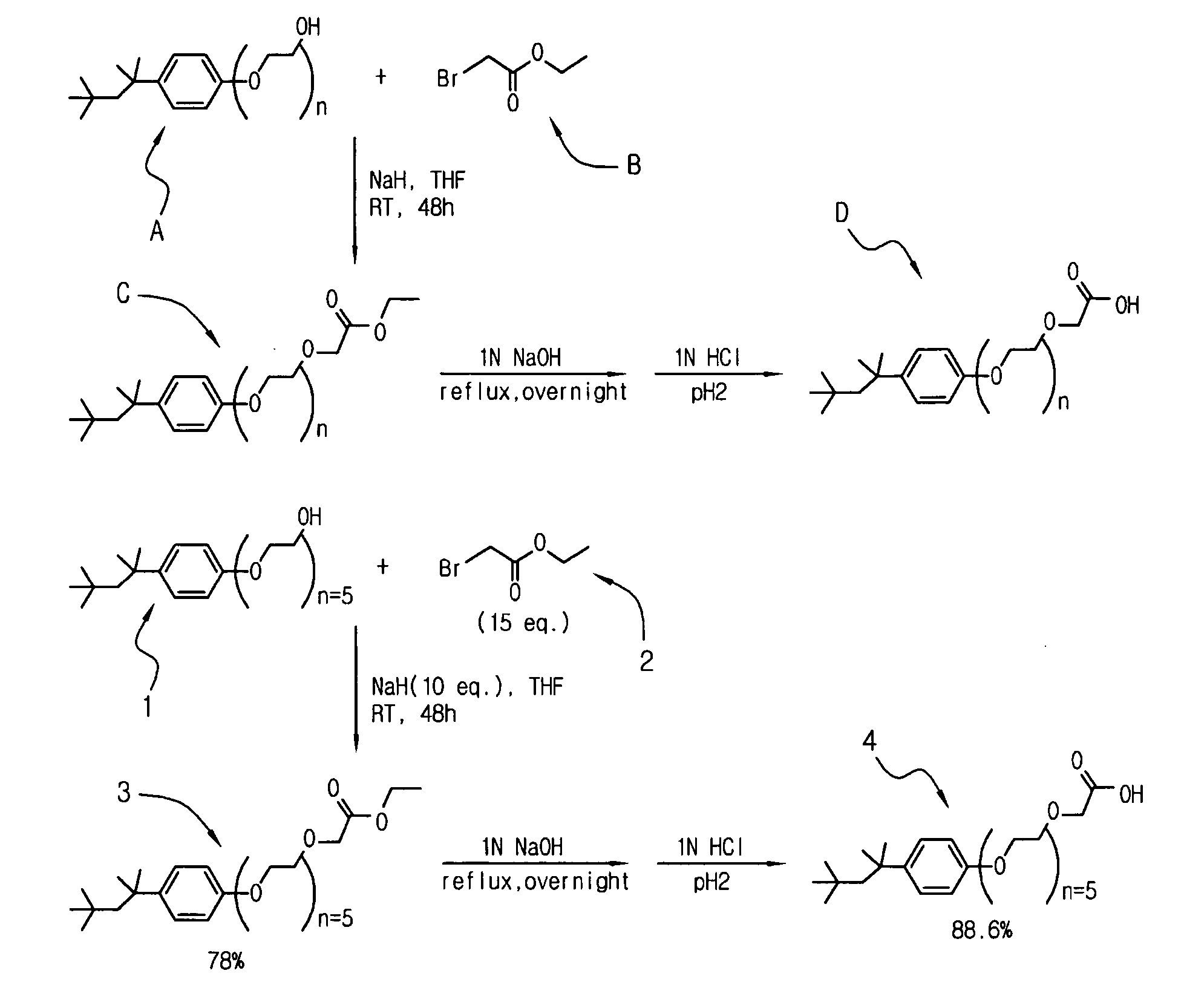

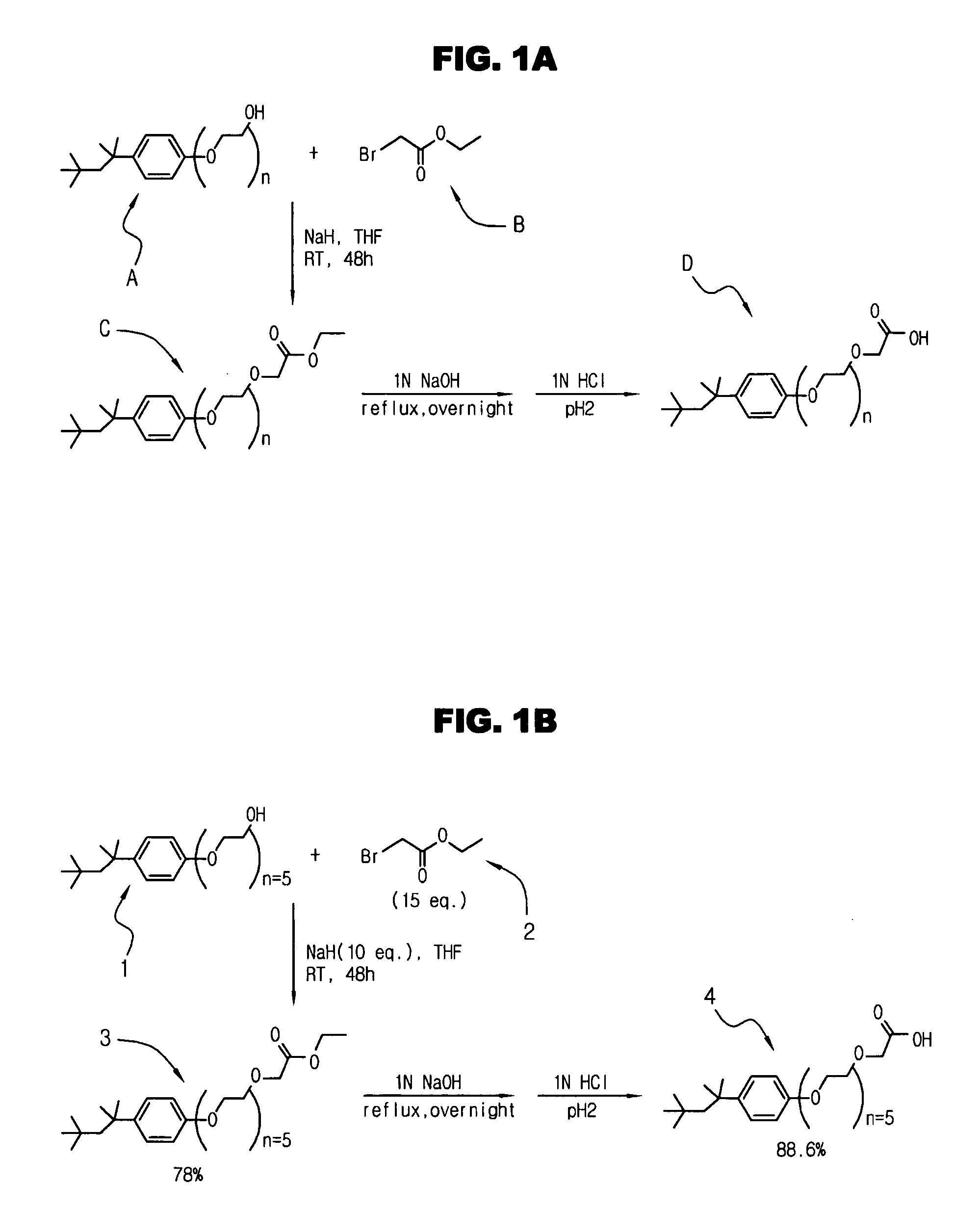

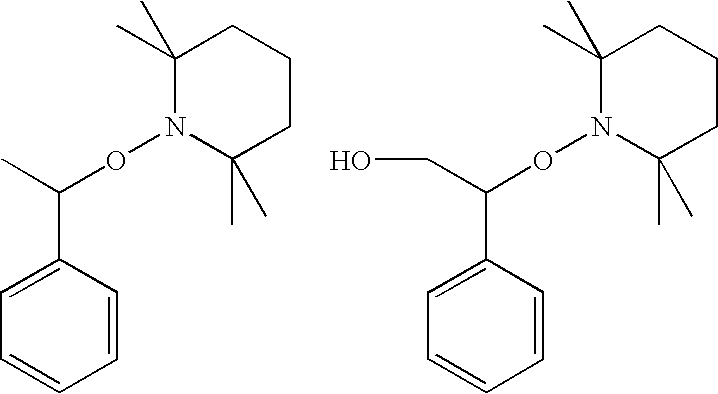

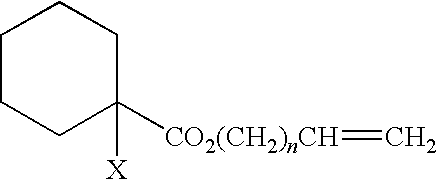

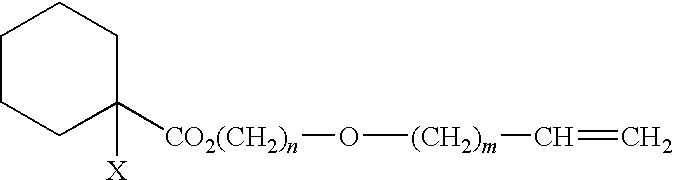

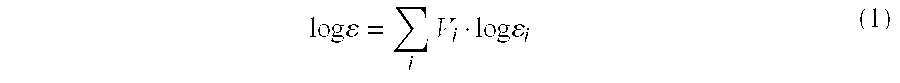

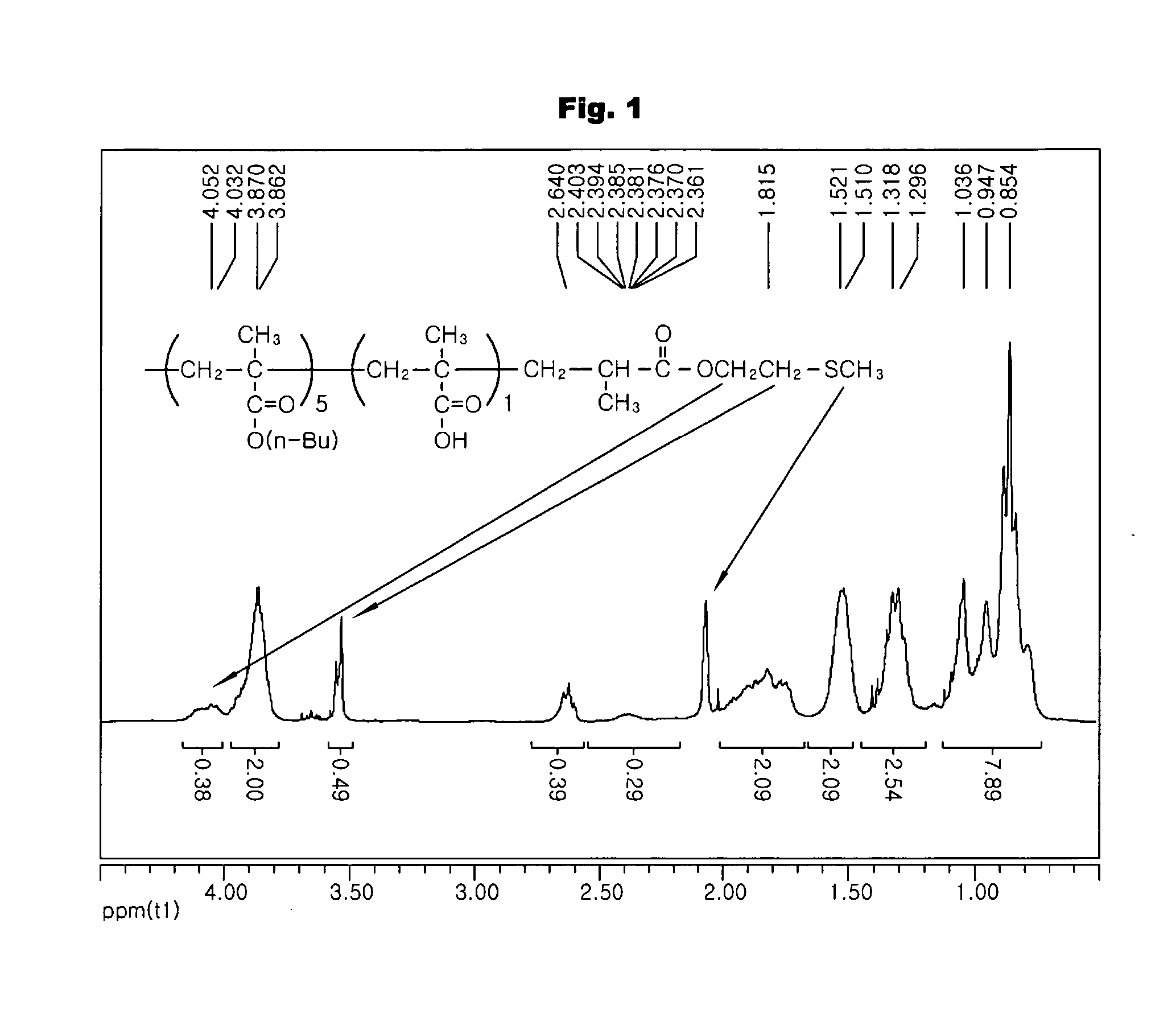

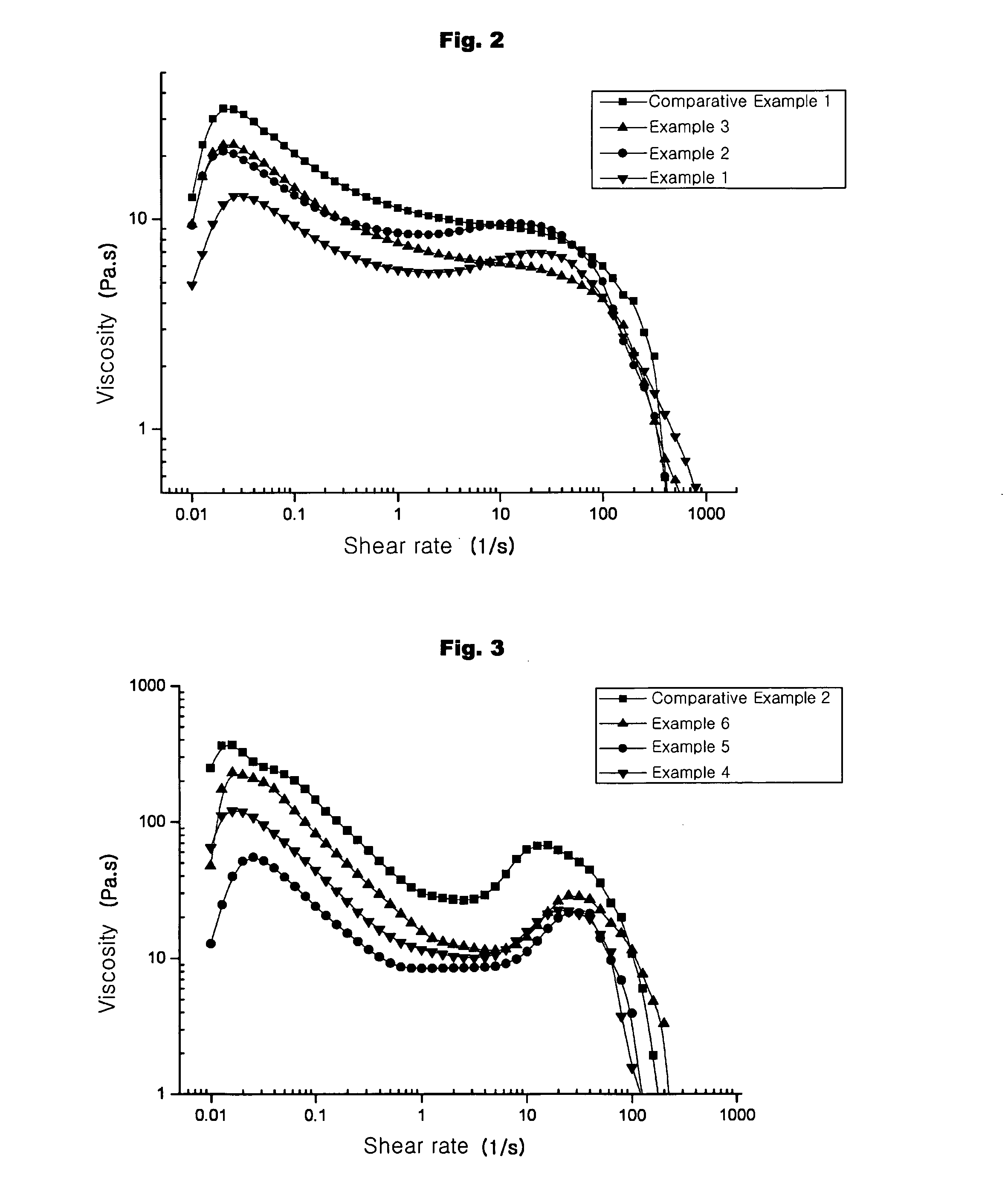

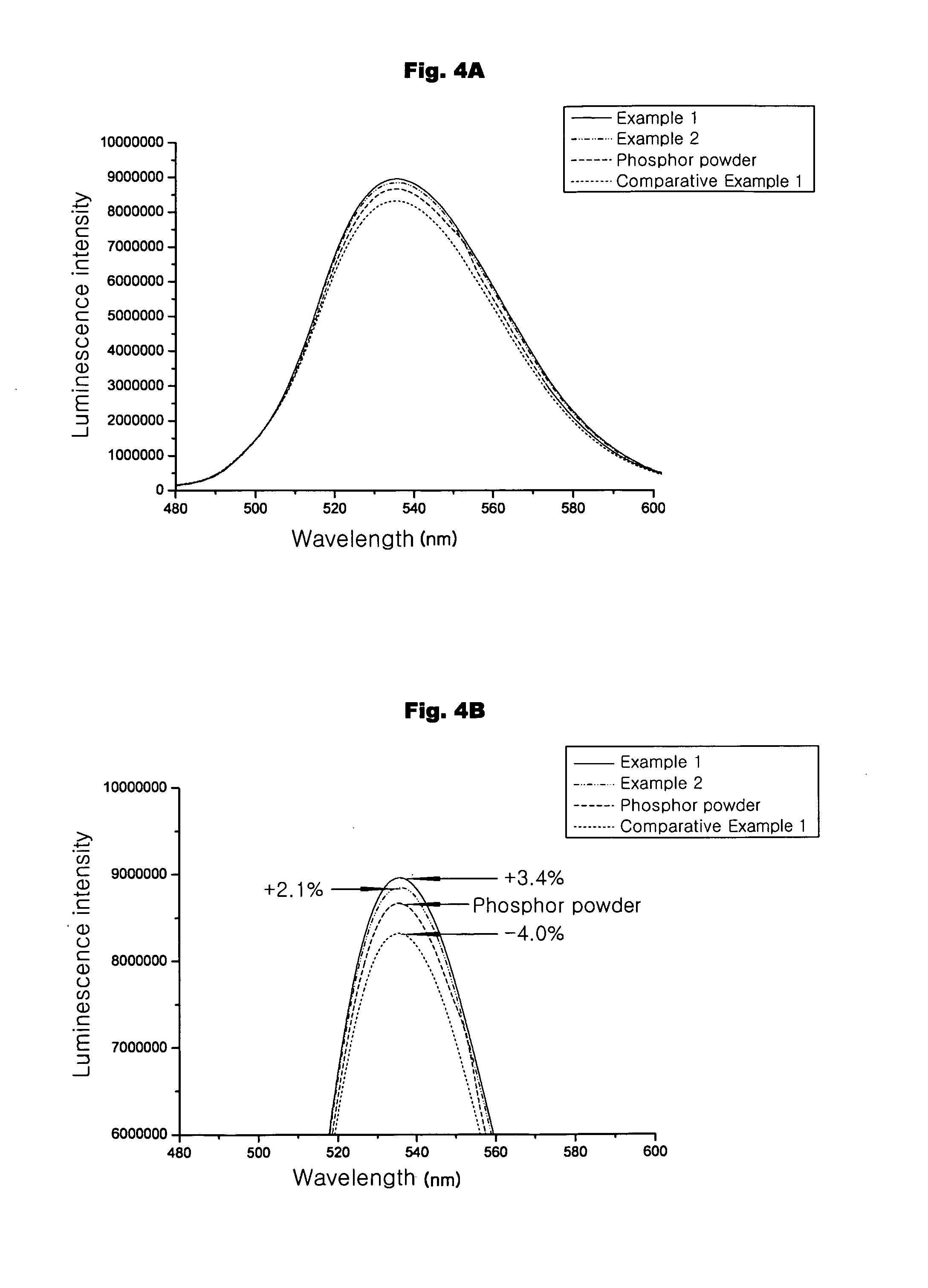

Carboxylic ester dispersant and sulfide phosphor paste composition having same

InactiveUS20070072969A1Good dispersionPrevent oxidationOrganic chemistryGas discharge electrodesPolymer scienceFluorescence

Disclosed herein is a carboxylic ester dispersant shown in the following Formula 1 and a sulfide phosphor paste composition containing the dispersant. The dispersant improves the dispersibility of the sulfide phosphor paste composition and prevents oxidation by a solvent, thus improving processability and the luminescent properties of a phosphor film made from the paste and of a display produced using the film. In Formula 1, n is 1-20.

Owner:SAMSUNG ELECTRONICS CO LTD

Paste composition and dielectric composition using the same

InactiveUS20060159927A1Easy to getImprove reliabilityPlastic/resin/waxes insulatorsFixed capacitor dielectricCapacitanceConstant composition

A paste composition contains an inorganic filler, a resin and a solvent, wherein the paste composition is characterized in that it contains one or more solvents of which the boiling point is 160° C. or higher and an inorganic filler of which the mean particle diameter is 5 μm or smaller, and the total content of the solvent is 25 wt % or less based on the total amount of the paste composition, and a dielectric composition contains an inorganic filler and resin, wherein the inorganic filler includes inorganic fillers of at least two kinds of mean particle diameter, and the greatest mean particle diameter of said mean particle diameters is 0.1-5 μm and is 3 times or more to the minimum mean particle diameter. It is possible to obtain a high dielectric constant composition of which linear expansion coefficient is low, and which has a large capacitance.

Owner:TORAY IND INC

Chip for force sensor and force sensor

ActiveUS7703340B2Uniform physical propertiesImprove uniformityPiezoelectric/electrostriction/magnetostriction machinesForce measurementEngineeringForce sensor

A force sensor chip which comprises: a base member, which includes an action portion to which an external force is applied through an attenuator, a support portion supporting the action portion, and a connection portion which connects the action portion and the support portion and deflects according to the applied external force; and a plurality of strain resistance elements which are arranged in the connection portion and detect the applied external force based on a deflection of the connection portion, wherein longitudinal directions of the plurality of the strain resistance elements are oriented in an identical direction.

Owner:HONDA MOTOR CO LTD

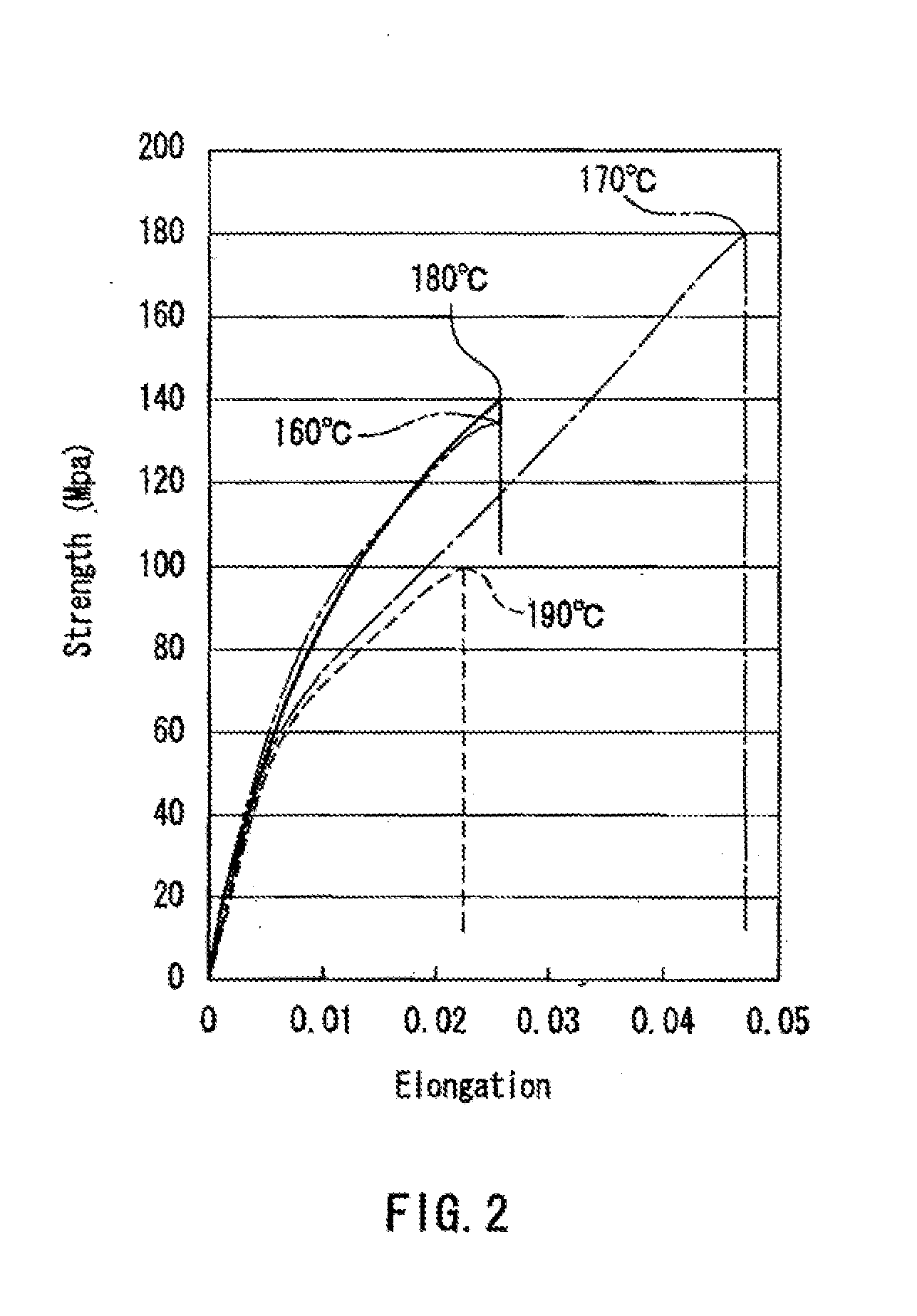

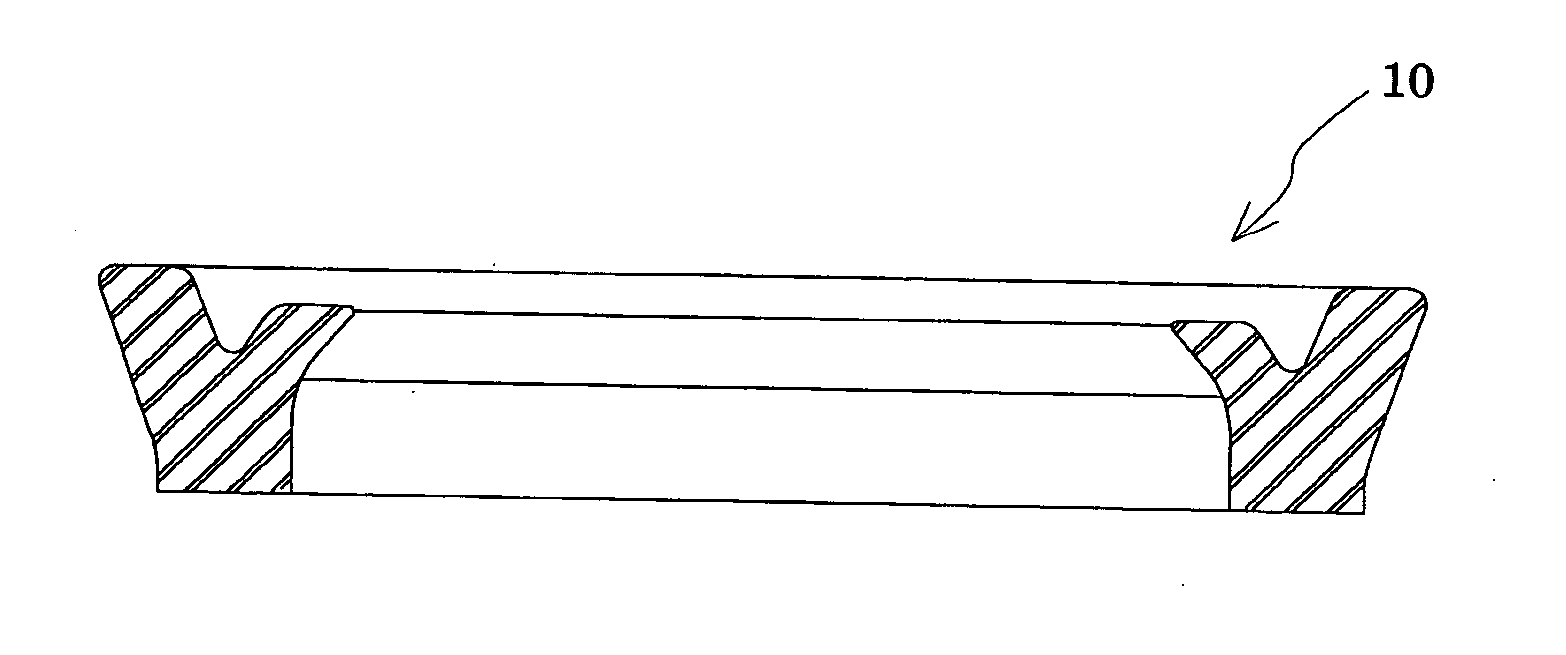

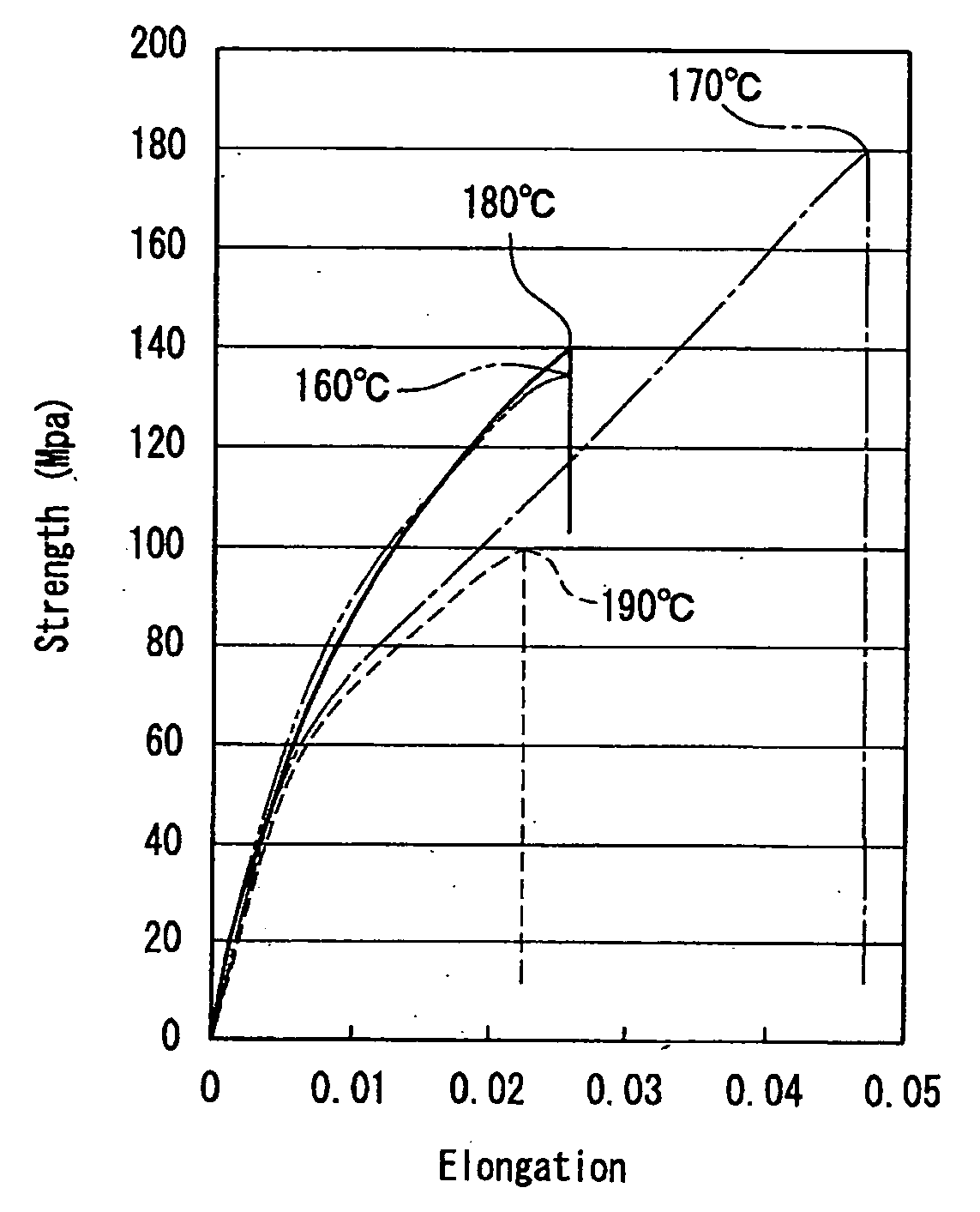

Epdm composition for torsional damper

ActiveUS20160177076A1Less stressUniform physical propertiesSpecial tyresRubber-like material springsPolyolefinOligomer

An EPDM composition for a torsional damper. The EPDM composition is made of (a) an EPDM polymer, (b) liquid polyolefin oligomer, and (c) carbon black, the EPDM composition containing 100 parts by weight of EPDM polymer that is the EPDM polymer of (a) having a propylene content of 35 to 50 wt % in the total amount of ethylene and propylene, 5 to 30 parts by weight of liquid polyolefin oligomer that is the liquid polyolefin oligomer of (b) having a number average molecular weight Mn within a range of 3,000 to 4,000, and 10 to 120 parts by weight of carbon black that is the carbon black of (c) having a nitrogen adsorption specific surface area within a range of 100 to 150 m2 / g, an iodine adsorption within a range of 110 to 160 mg / g, and a DBP oil absorption within a range of 70 to 135 cm3 / 100 g.

Owner:NOK CORP

Curable composition

InactiveUS8389630B2Excellent curabilityImprove the heating effectSpecial tyresEmulsion paintsEpoxyMechanical property

Provided is a curable composition excellent in curability and mechanical properties as well as a cured product thereof. Specially provided is a curable composition containing a vinyl-based polymer (I) having one or more crosslinkable functional groups at a terminus on average and a nucleophilic agent (II) and a cured product obtained by curing the curable composition. Preferably, the curable composition of the invention further contains an epoxy resin (III).

Owner:KANEKA CORP

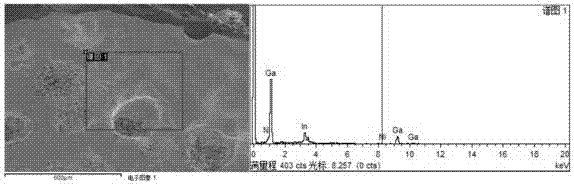

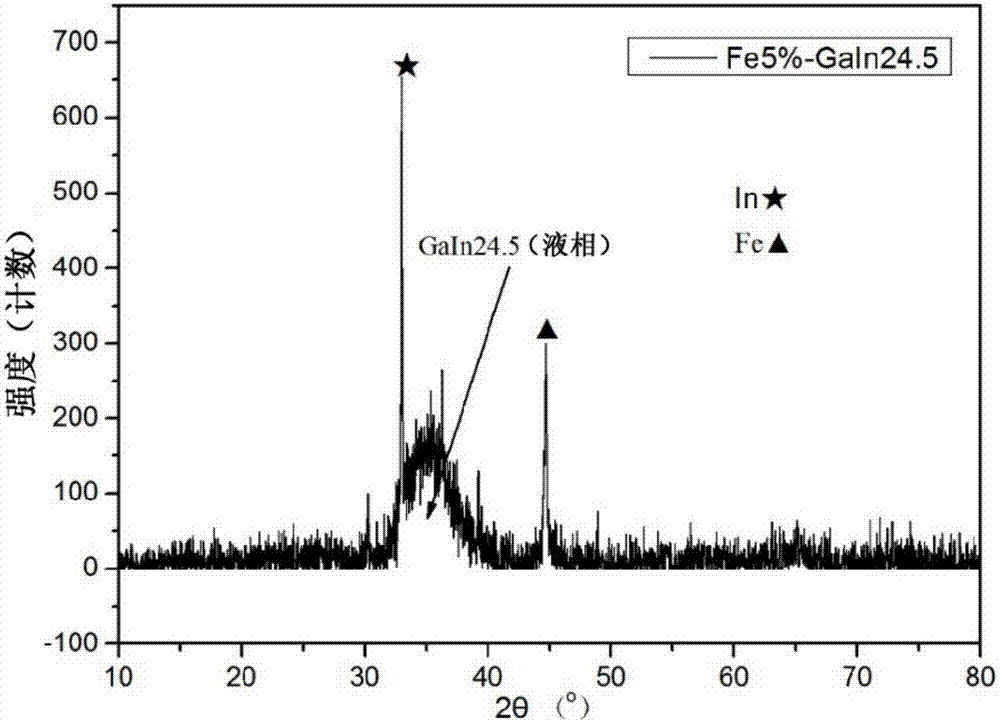

Liquid-state metal magnetic fluid and preparation method thereof

InactiveCN107545973AUniform physical propertiesImprove conductivityMagnetic liquidsInductances/transformers/magnets manufactureHigh volume manufacturingLiquid state

The invention relates to a liquid-state metal magnetic fluid and a preparation method thereof. In the liquid-state metal magnetic fluid, liquid-state metal alloy is used as a fluid medium, magnetic metal particles are doped, the weight ratio of the liquid-state metal alloy and magnetic metal is 100:(1-10), and the magnetic fluid is prepared by mixing of a ball-milling tank. The method is simple tooperate, is efficient and rapid and is suitable for industrial production, mass production can be achieved, and the prepared liquid-state metal magnetic fluid has the advantages of uniform physical property, high electrical conductivity, high heat conductivity and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

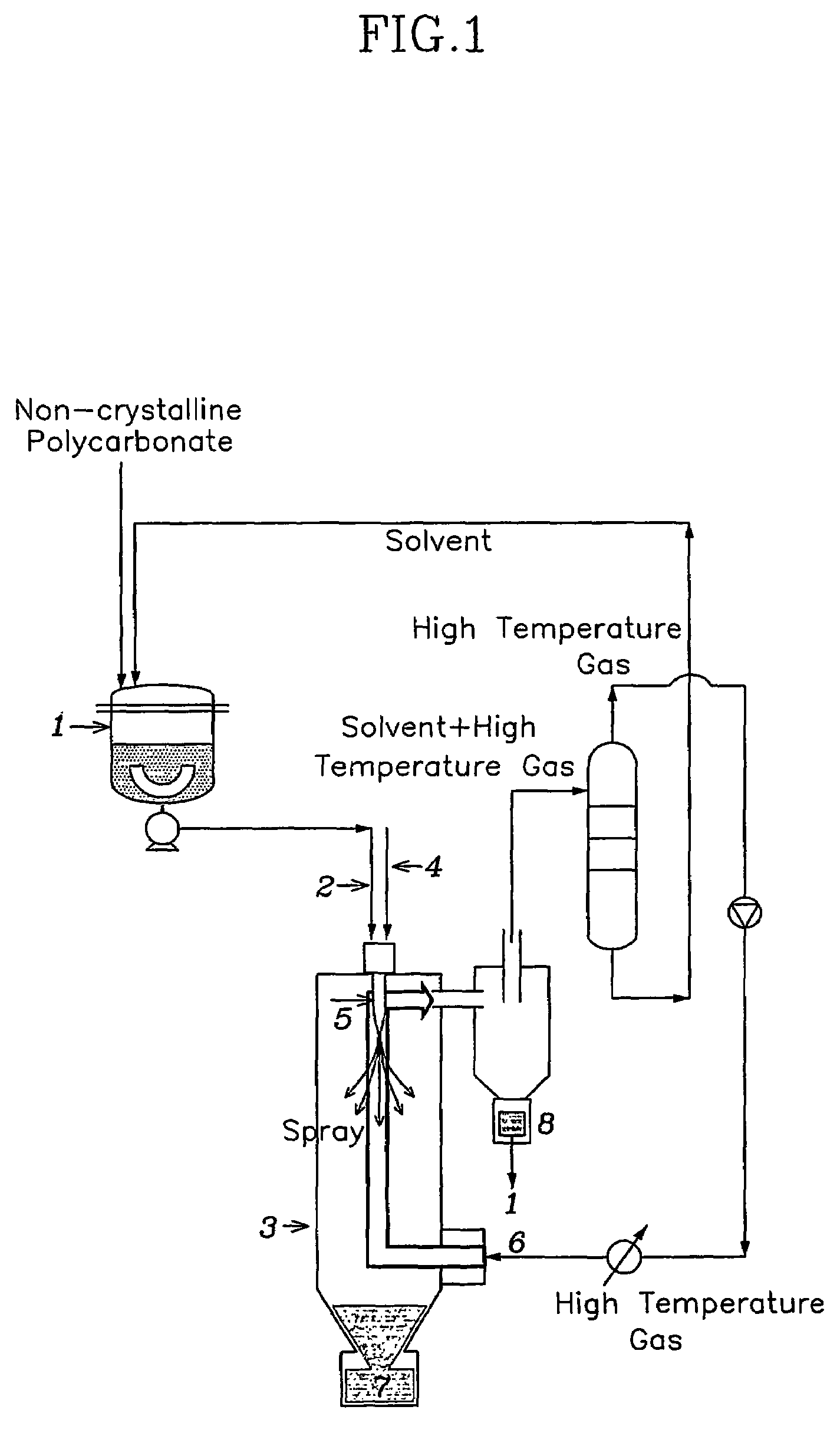

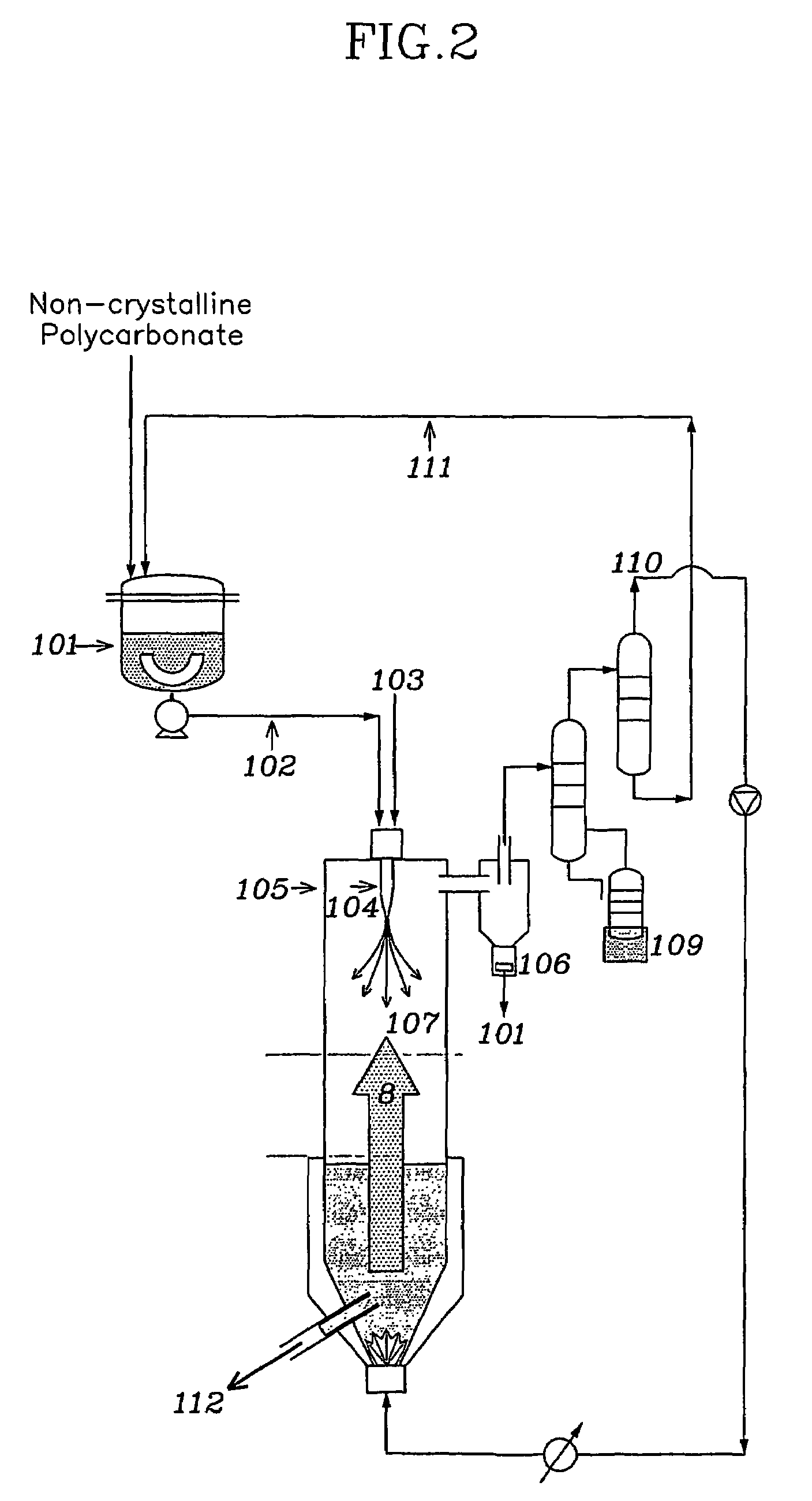

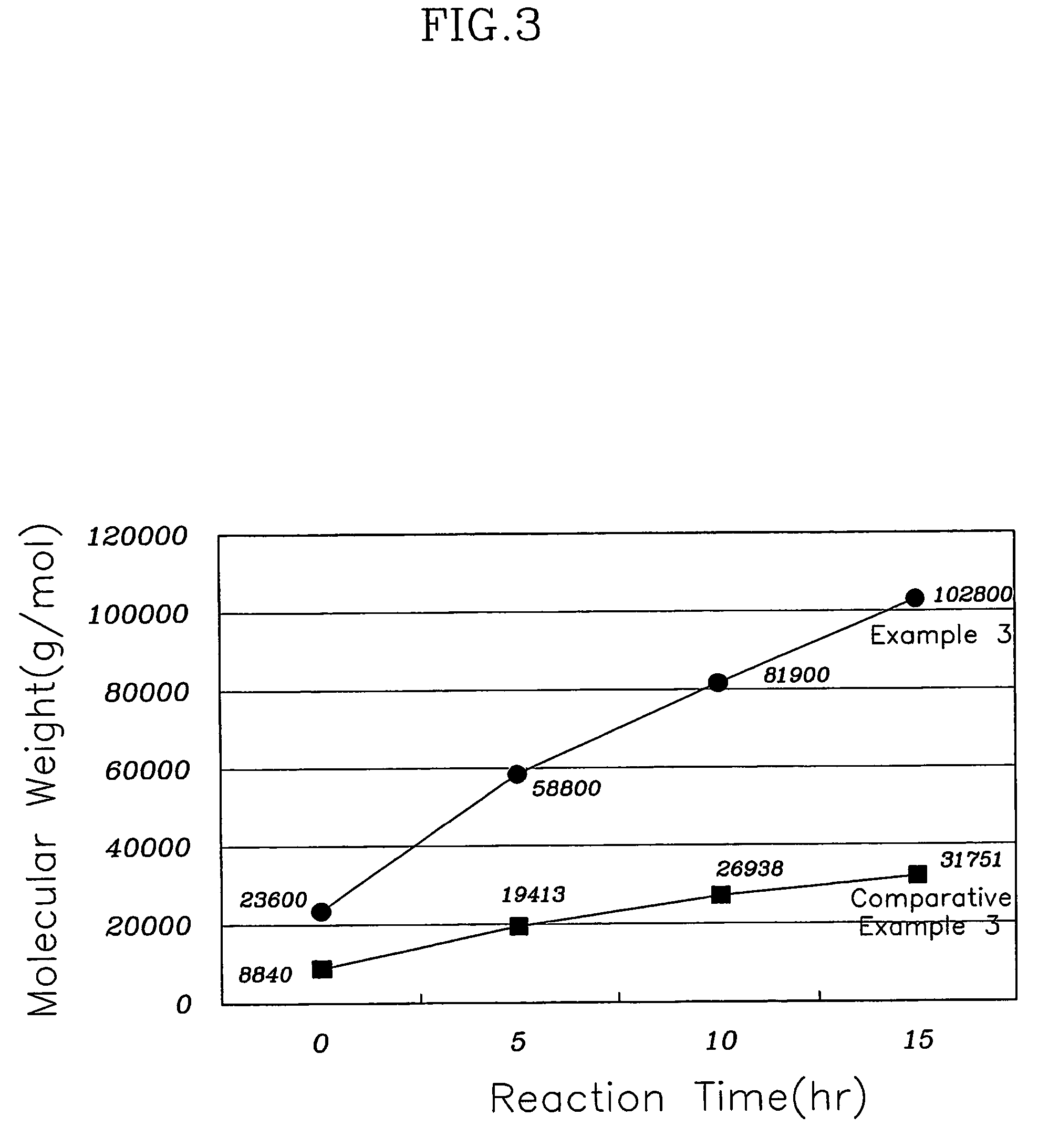

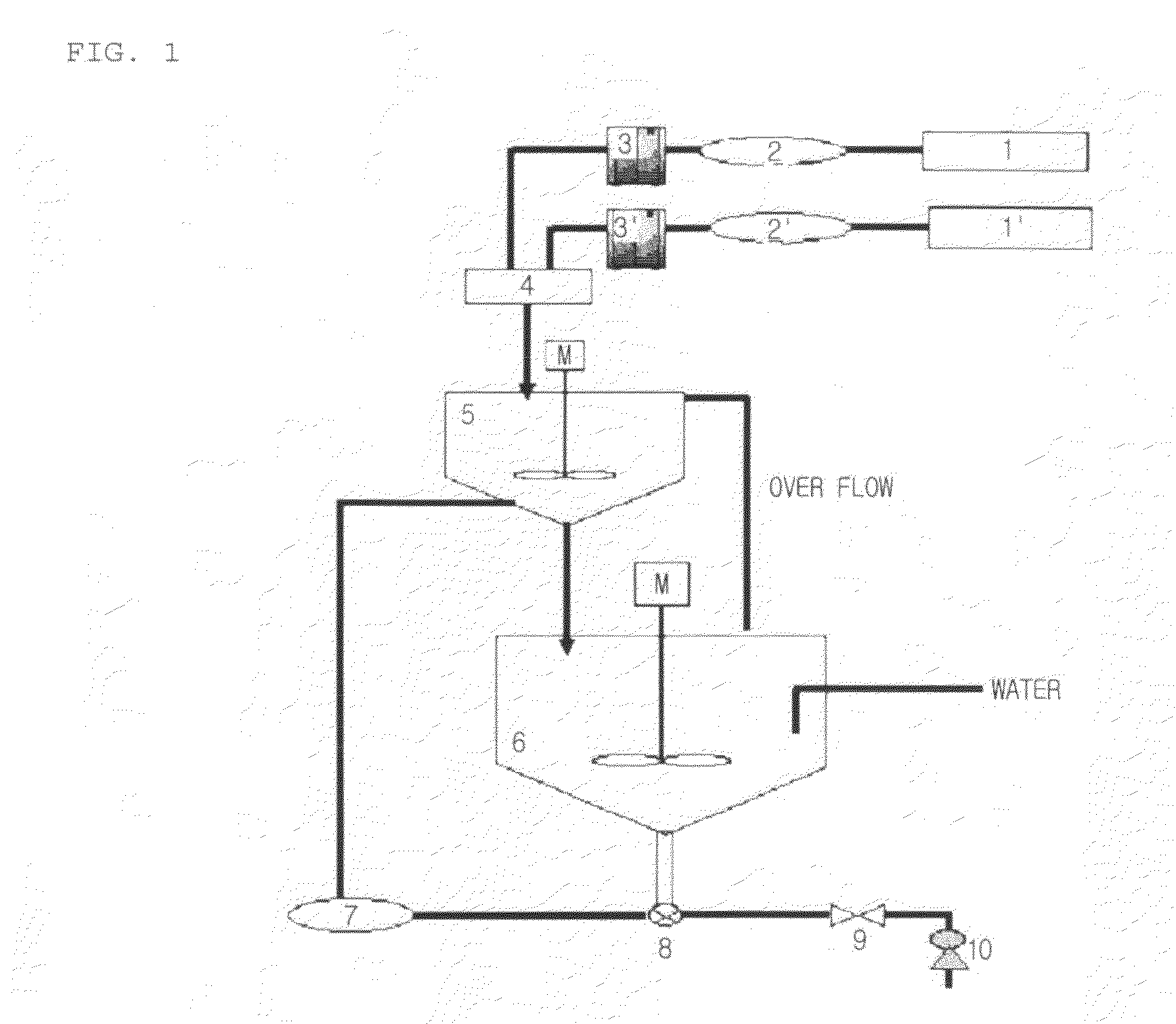

Preparation method of high molecular weight polycarbonate resin

InactiveUS7148312B2High molecular weightUniform physical propertiesChemical/physical/physico-chemical processesPolymer sciencePolycarbonate

The present invention relates to a method for the preparation of a high molecular weight polycarbonate resin, and more particularly to a method for preparing a high molecular weight polycarbonate resin using a solid state polymerization method after the preparation of a crystalline polycarbonate or-conducting the preparation of the crystalline polycarbonate and the solid state polymerization thereof simultaneously. According to the method for the preparation of a high molecular weight polycarbonate resin of the invention, it is possible to produce a high molecular weight polycarbonate resin having a narrow molecular weight distribution and uniform properties and that is applicable to injection and extrusion in large quantities with a low cost within a short time.

Owner:LG CHEM LTD

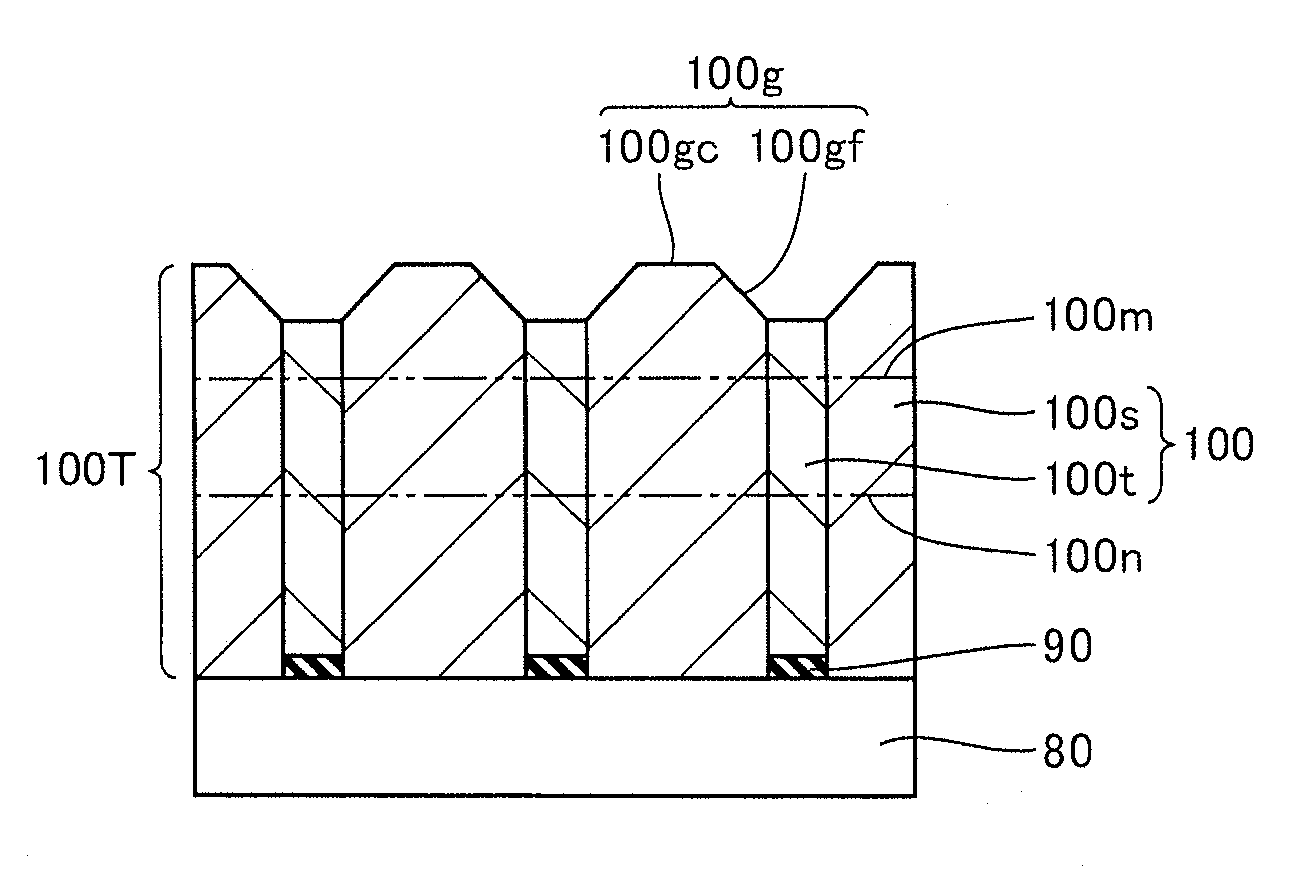

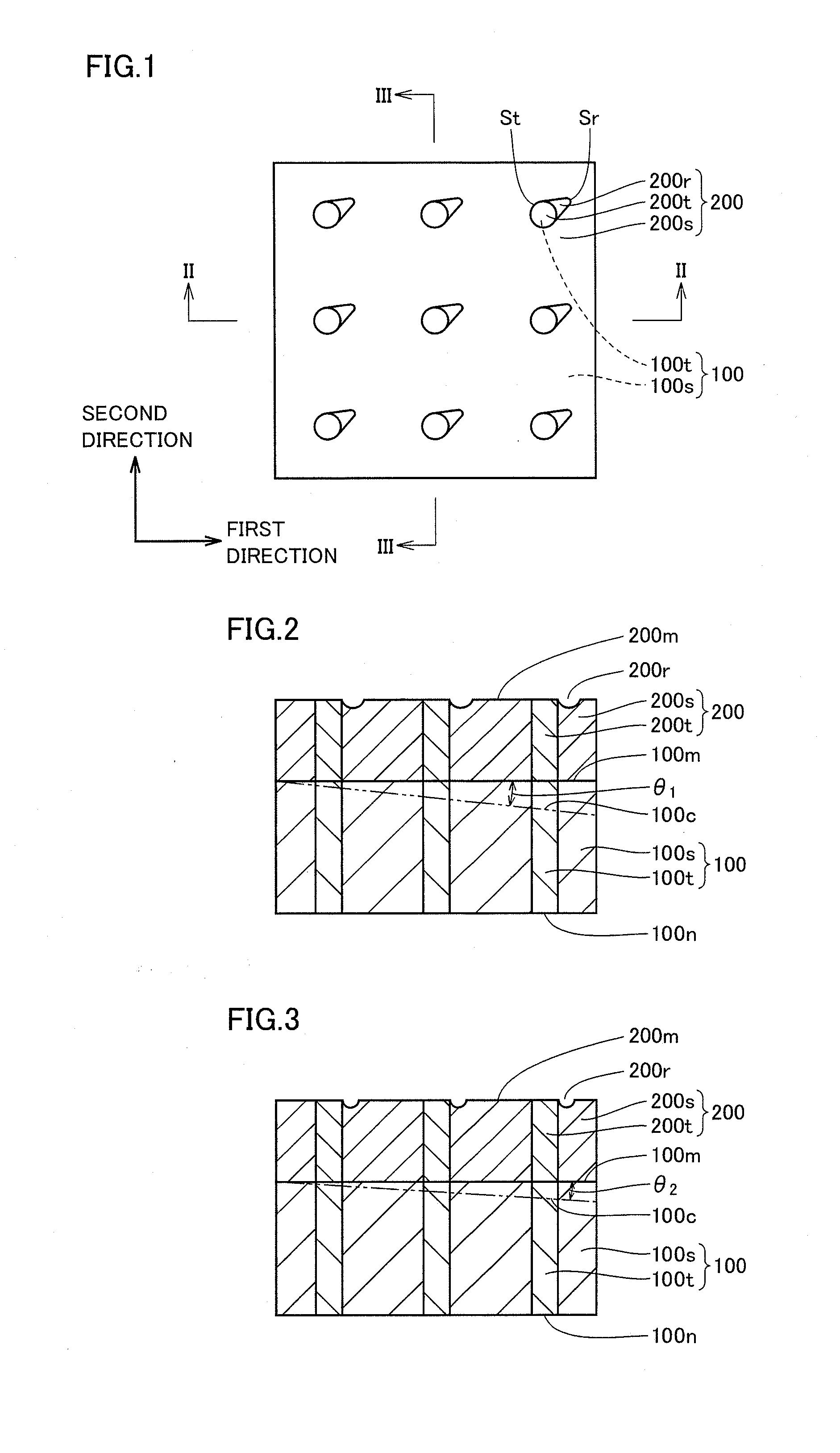

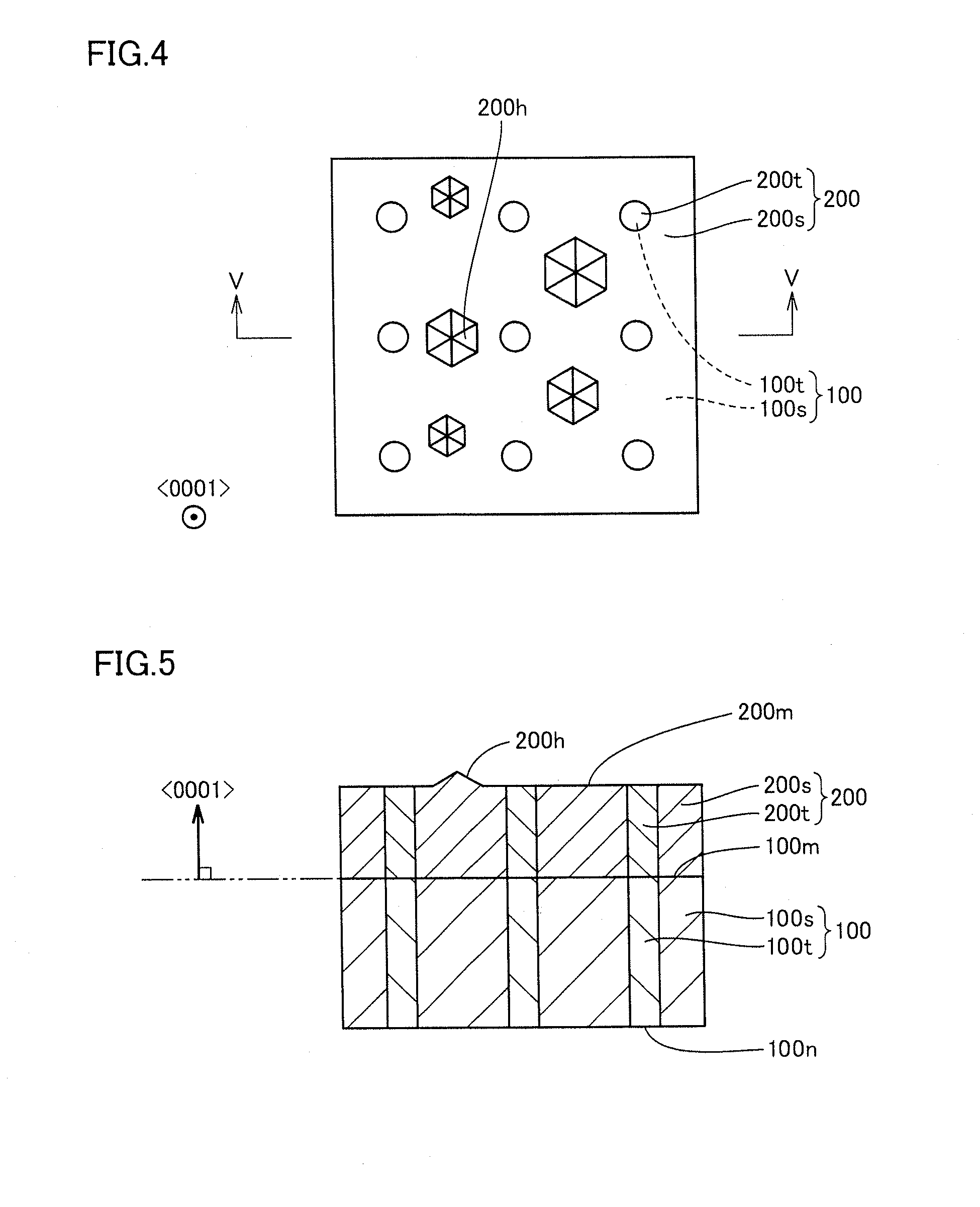

Group iii nitride semiconductor light-emitting device

InactiveUS20120305933A1Improve featuresEasy to shapeOptical wave guidanceNanoopticsLight emitting devicePhysical property

A group III nitride semiconductor light-emitting device includes a GaN crystal substrate and at least one group III nitride semiconductor layer disposed on a main surface of the GaN crystal substrate. The substrate includes a matrix crystal region and a c-axis-inverted crystal region. An off angle θ is formed between the main surface and a {0001} plane, and an off-angle component of a first direction has an absolute value |θ1| of 0.03° or more and 1.1° or less and an off-angle component of a second direction has an absolute value |θ2 of 0.75×|θ1| or less, where the first direction is one of <10-10> and <1-210> directions and the second direction is the other thereof. Accordingly, the group III nitride semiconductor light-emitting device with excellent characteristics including the group III nitride semiconductor layer having good morphology and uniform physical properties and formed on the GaN crystal substrate is obtained.

Owner:SUMITOMO ELECTRIC IND LTD

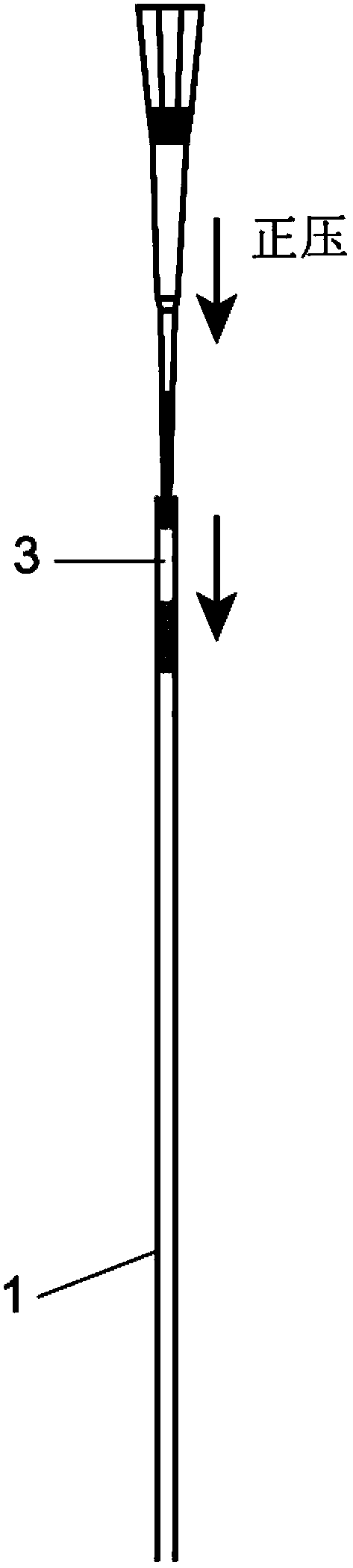

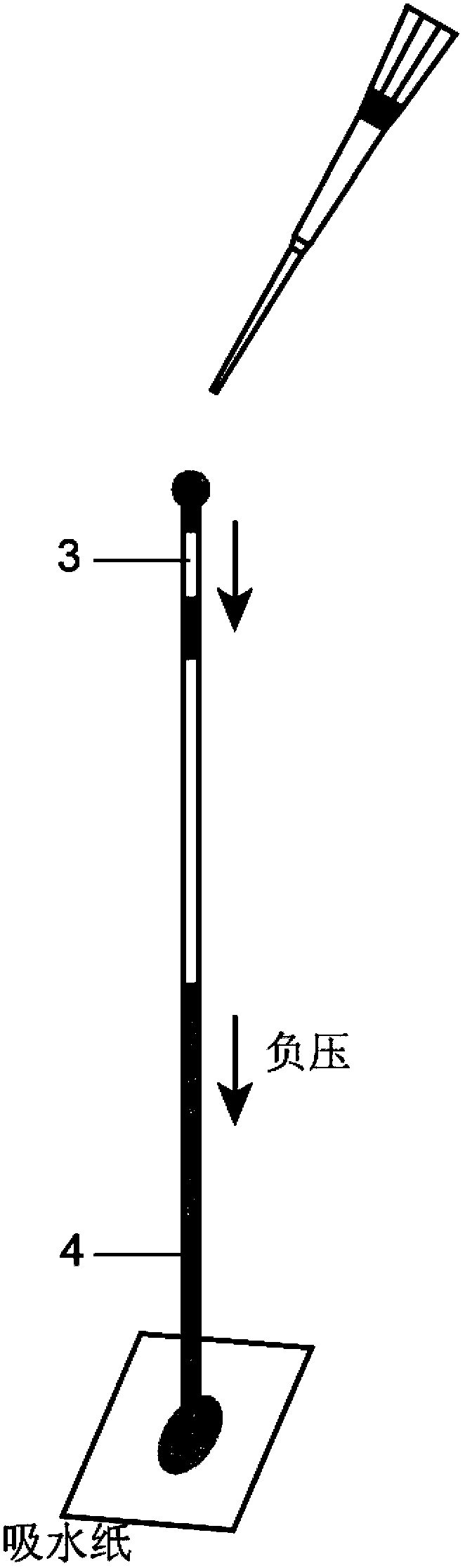

Nucleic acid isothermal amplification reaction system, and making method and applications thereof

InactiveCN103421676ALow costUniform physical propertiesBioreactor/fermenter combinationsBiological substance pretreatmentsProduct gasLiquid layer

The invention provides a nucleic acid isothermal amplification reaction system, and a making method and applications thereof. The nucleic acid isothermal amplification reaction system comprises a capillary main body, at least one sample amplification reaction liquid layer is filled in the capillary main body, and two ends of the sample amplification reaction liquid layer are respectively sequentially filled with a gas layer and at least one liquid layer; and the applications comprise an application of the nucleic acid isothermal amplification reaction system in nucleic acid amplification and an application of the nucleic acid isothermal amplification reaction system in the preparation of disease detection medicines. The system eliminates a problem of the leakage pollution of an aerosol in a nucleic acid isothermal amplification reaction, and substantially improves the credibility of an isothermal amplification technology; and the system has the advantages of extremely simple operation, low cost, easy integration, diversified heating mode and diversified signal exciting mode, makes the whole flow completely divorced from an external power supply, and allows a final signal to be directly observed by naked eyes.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

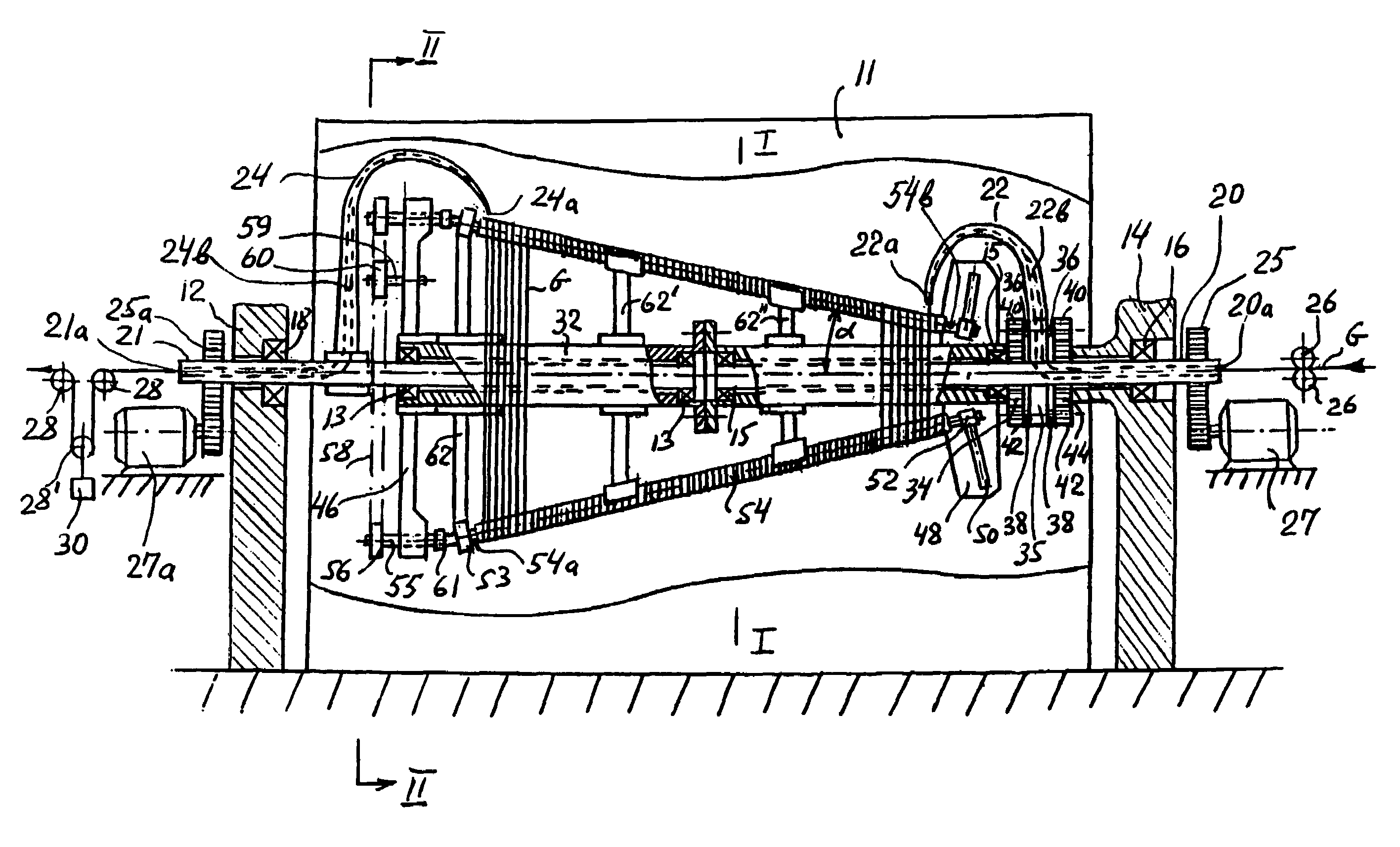

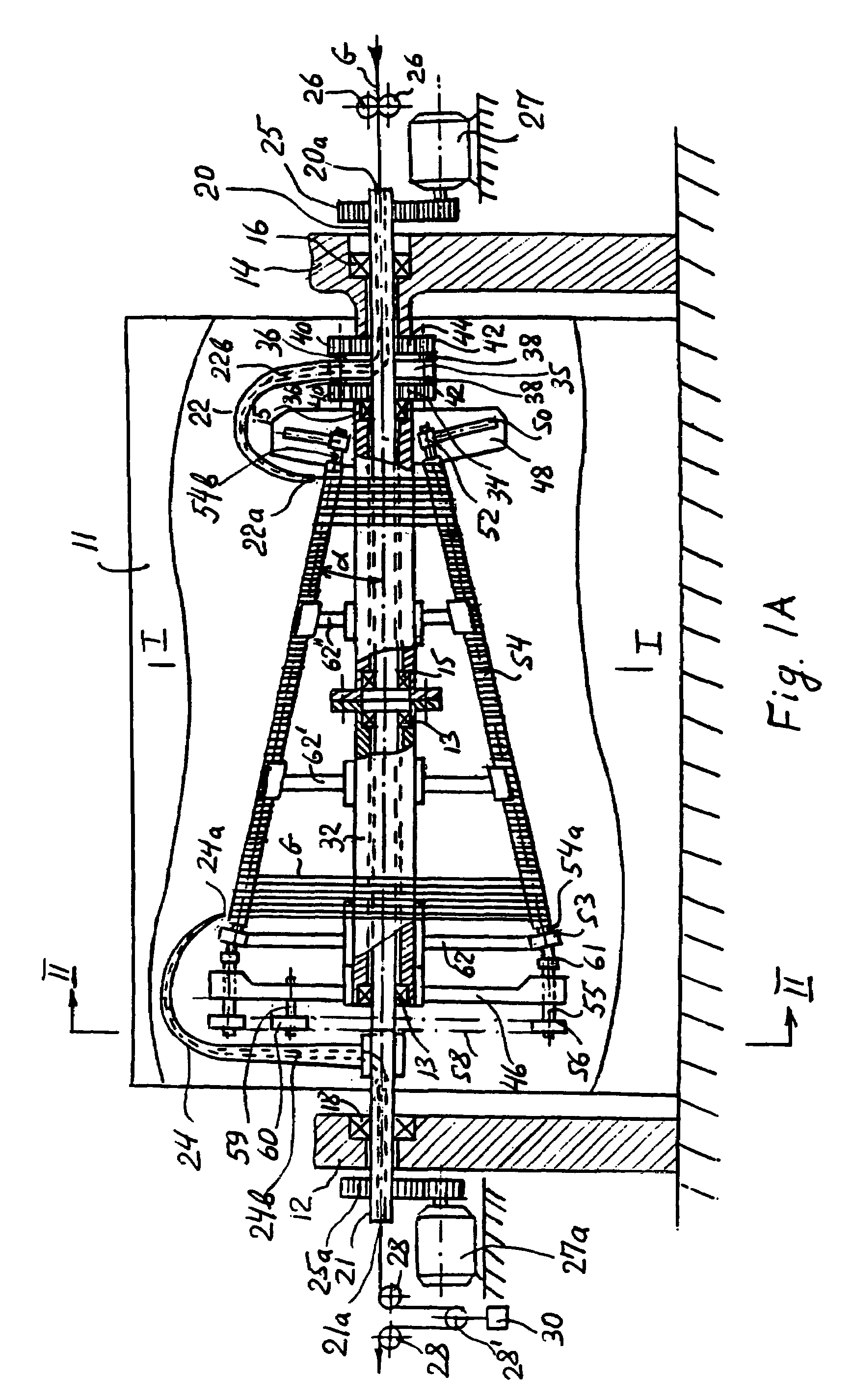

Method and apparatus for low-speed, high-throughput fiber drawing using coiled fiber loops

InactiveUS7273578B1Reduced strain rateGood physical propertiesTextiles and paperLow speedHigh intensity

A method and apparatus for continuous drawing of fibers in the form of coiled fiber loops (e.g., polygonal or serpentine loops). The successive fiber loops are continuously laid on receiving ends of a plurality of conveyer-drawing members (CDM) [e.g., rotating threaded spindles (54) or circulating endless chains (80) and (108)] disposed about a central axis and diverged from this axis. Coiled fiber loops are conveyed along the central axis and simultaneously drawn by enlarging a circumference of the fiber loops by the CDM. The leading fiber loops are continuously taken off at delivery ends of the CDM and conveyed from the drawing apparatus at an outlet speed. Heat chambers (11) and (148) envelop at least the most part of CDM. The process can operate at low drawing speed and long drawing time typical for lab-scale experiments and equal or higher outlet speed and throughput typical for commercial drawing processes. The method can produce low-cost / high-strength / high-modulus / low-shrinkage commercial polymer fibers.

Owner:POLYMER FIBER ENTERPRISE PARTNERSHIP

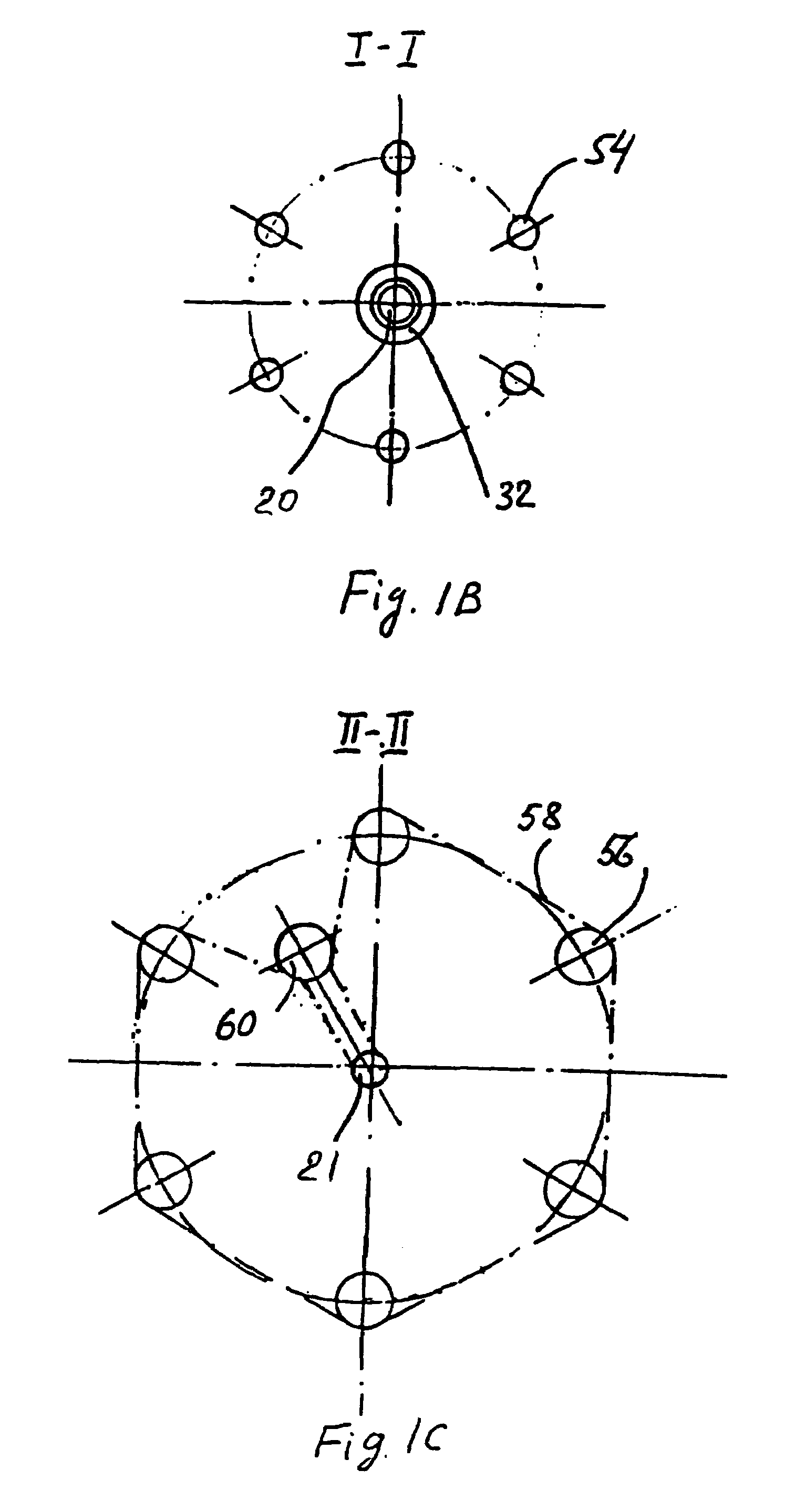

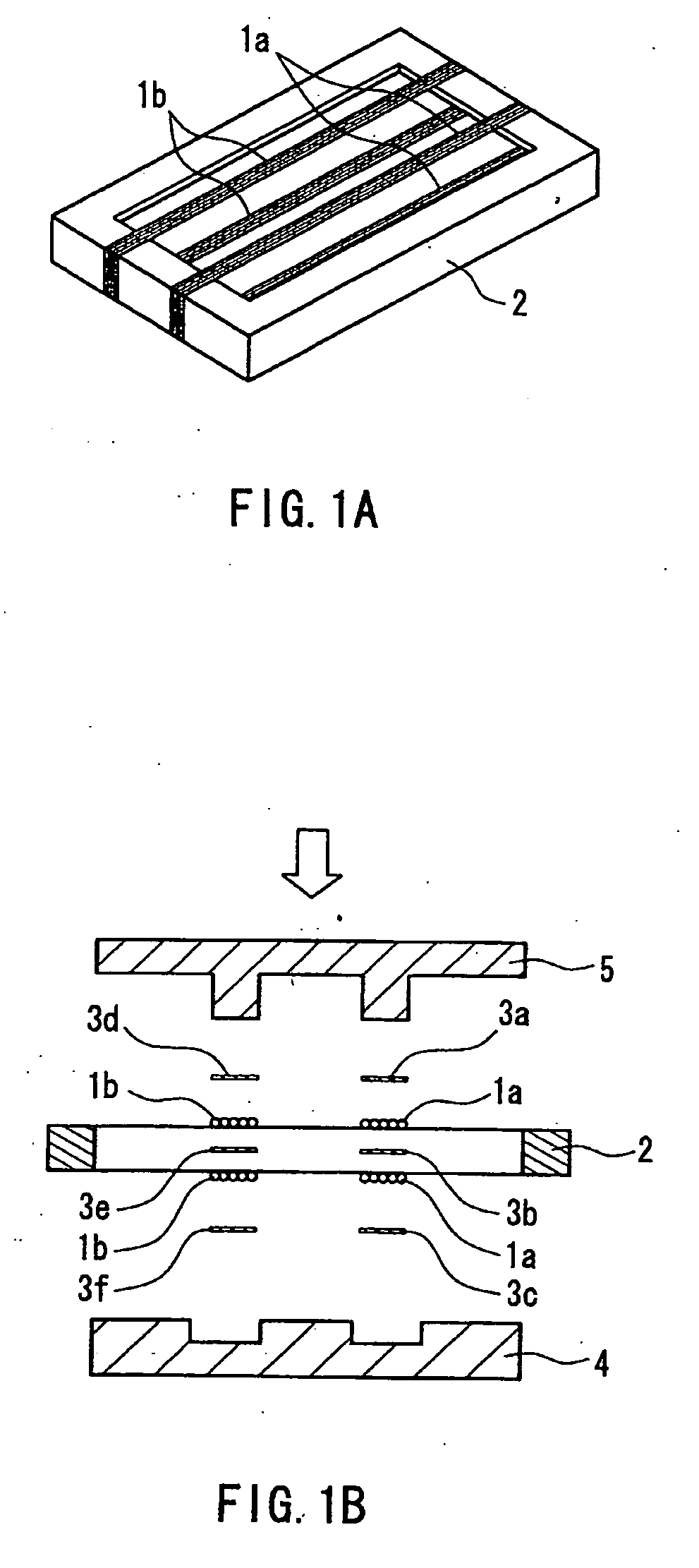

Fiber reinforced thermoplastic resin molding

InactiveUS20110198016A1High strengthUniform physical propertiesLayered productsLaminationYarnPlant fibre

The present invention provides thermoplastic resin molding fiber that is reinforced with natural fiber. The natural fiber is linen fiber to be twisted into spun yarns, and the spun yarns are pulled parallel in at least one direction and are molded integrally with a thermoplastic resin. The linen fiber is flax yarn (linen) fiber molded into the fiber thermoplastic resin molding by a film-stacking method in which a thermoplastic resin film is melted and compressed while having an equilibrium moisture regain. Consequently, the thermoplastic resin molding reinforced with a plant fiber of the present application poses no environmental problem, has a high strength, and has a uniform physical property.

Owner:KURASHIKI BOSEKI KK +1

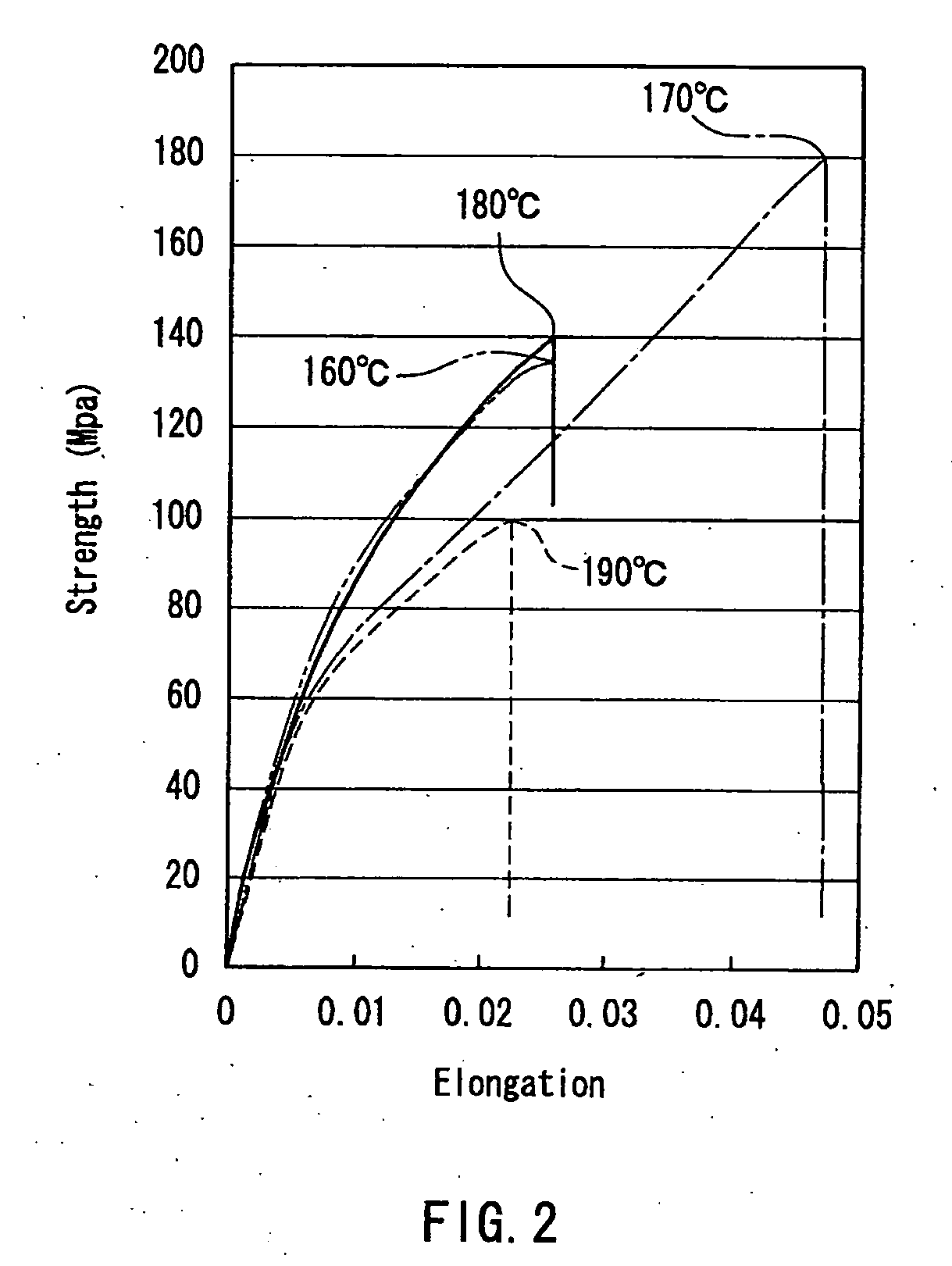

Method for producing oil-resistant elastomer and oil-resistant seal member

The invention provides a method for producing an oil-resistant elastomer being cross-linked millable polyurethane obtained by polyaddition of at least one polyester diol and at least one diisocyanate, comprising the steps of:selecting the kinds and blend proportion of the at least one polyester diol and the at least one diisocyanate, respectively, so that the resulting polyurethane has an ester group concentration of at least 25 wt. % (5.7 mmol / g) and less than 35 wt. % (8 mmol / g) and a urethane group concentration of at least 7 wt. % (1.2 mmol / g) and less than 12 wt. % (2.0 mmol / g), reacting the at least one polyester diol and at least one diisocyanate to produce a millable polyurethane, and crosslinking the millable polyurethane with a curing agent to form an oil-resistant elastomer which has a rubber hardness of JIS A 95° or less and an elongation at break of at least 100%, wherein the elastomer exhibits a percent change in weight, when exposed to IRM 903 lubricating oil, of 20% or less.

Owner:SYNZTEC

Fiber reinforced thermoplastic resin molding

InactiveUS20070116923A1High strengthUniform physical propertiesLayered productsLaminationYarnHigh intensity

A fiber reinforced thermoplastic resin molding according to the present invention is reinforced with natural fiber. The natural fiber is linen fiber to be twisted into spun yarns, and the spun yarns are pulled parallel in at least one direction and are molded integrally with a thermoplastic resin. The linen fiber is flax yarn (linen) fiber, for example, and preferably is molded into a fiber reinforced thermoplastic resin molding while having an equilibrium moisture regain. The fiber reinforced thermoplastic resin molding preferably is formed by a film-stacking method in which a thermoplastic resin film is melted and compressed. Consequently, there is provided a plant fiber reinforced thermoplastic resin molding that poses no environmental problem, has a high strength, and has a uniform physical property.

Owner:KURASHIKI BOSEKI KK +1

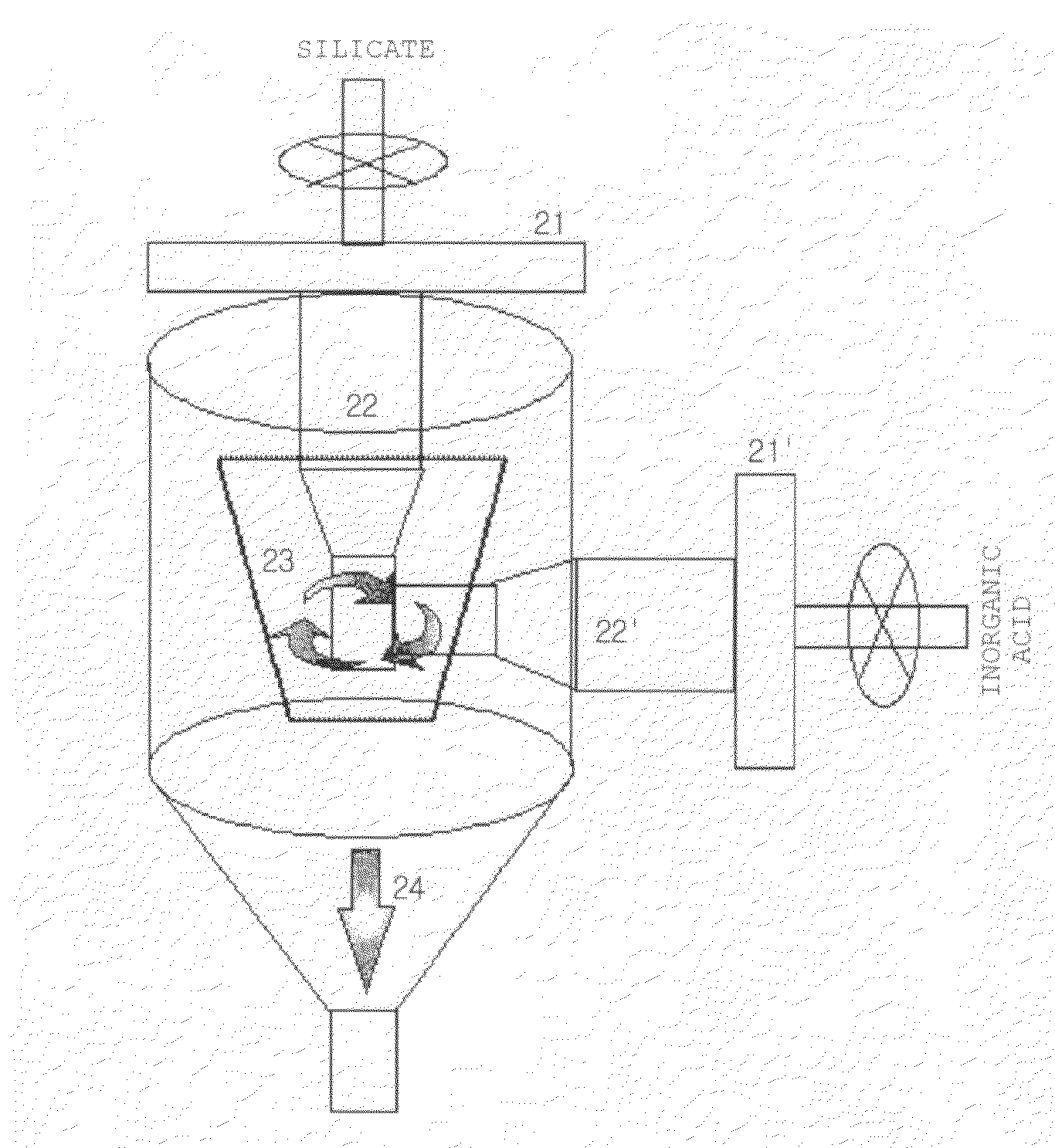

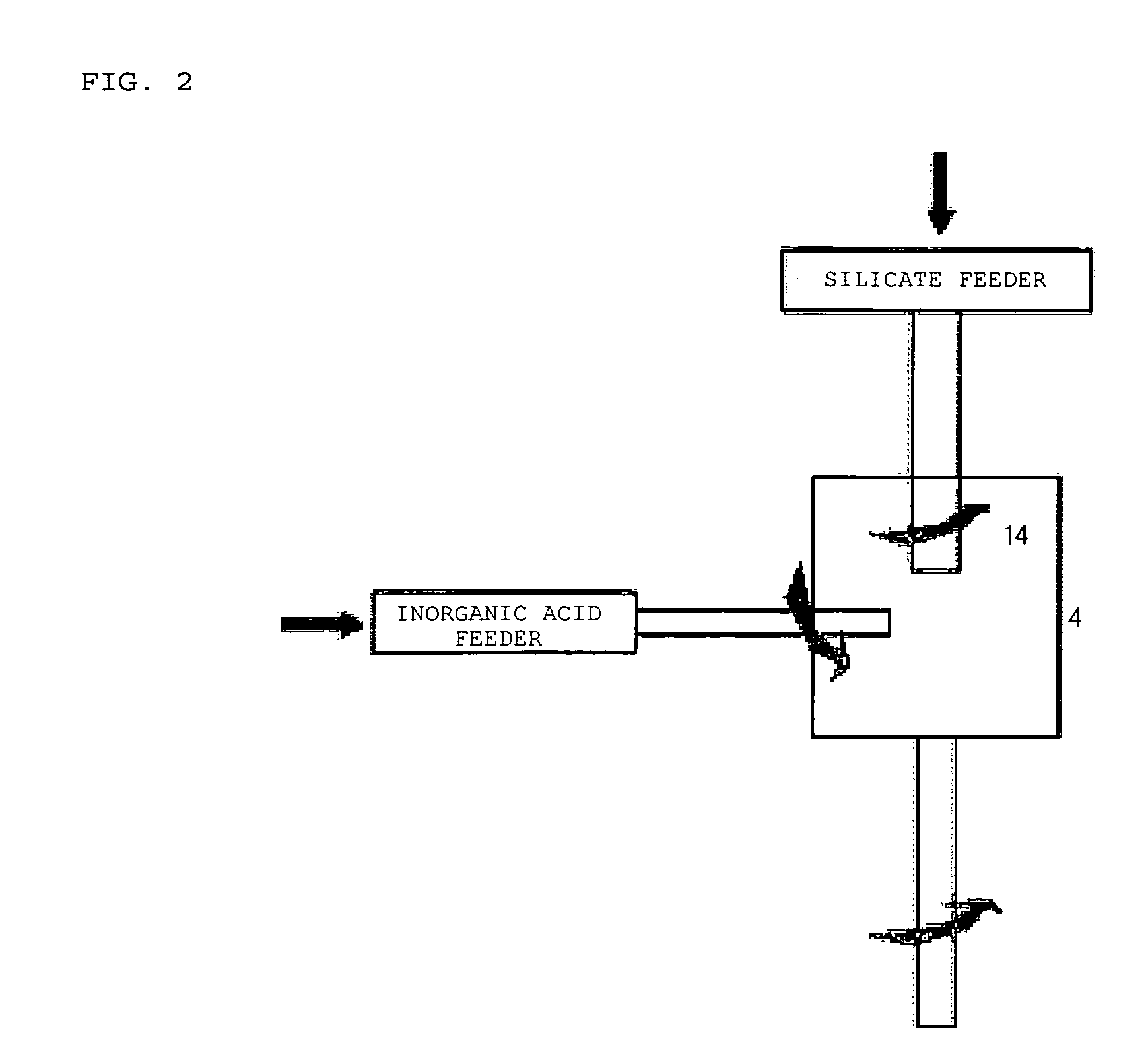

Apparatus for Manufacturing Nanoporous Silica Method Thereof

The present invention relates to an apparatus and a method for manufacturing amorphous nanoporous silica enabling mixing of source materials with accurate equivalence ratio by generating an eddy current using high-speed reaction nozzles and capable of controlling physical properties using a continuous circulation polymerizer which performs high-speed stirring and low-speed stirring and amorphous nanoporous silica prepared by the method, which has a BET surface area of 100-850 m2 / g, a pore size of 2-100 nm and a pore volume of 0.2-2.5 mL / g.

Owner:E&B NANOTECH CO LTD

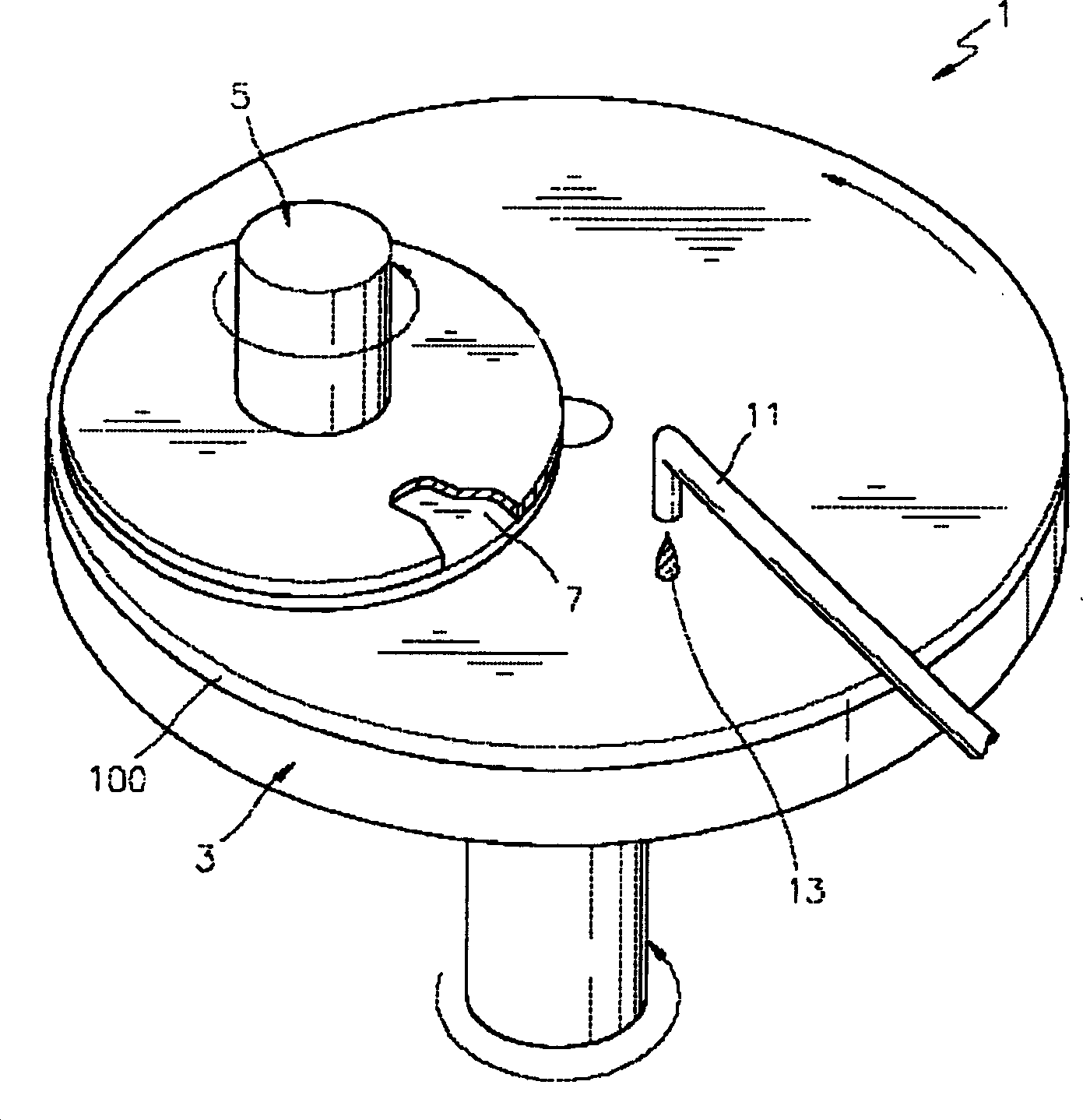

Integrated grinding pad and its mfg. method

InactiveCN1494986AImprove planarization efficiencyUniform physical propertiesLapping machinesAbrasion apparatusAdhesiveHardness

An integral polishing pad includes an elastic support layer and a polishing layer, which is formed on the elastic support layer and has a higher hardness than the elastic support layer. The elastic support layer and the polishing layer are made from materials chemically compatible with each other so that a structural border between the elastic support layer and the polishing layer does not exist. In addition, the integral polishing pad also includes a transparent region, which is transparent to a light source used to detect the surface state of an object being polished and integrated with the other elements of the integral polishing pad. The integral polishing pad has high planarization efficiency and uniform properties, and thus can be reliably used for polishing. In addition, the integral polishing pad prevents a congestion of a polishing slurry and facilitates delivery of the polishing slurry. The integral polishing pad does not need an adhesive for connecting elements or a process for bonding the elements, thereby simplifying manufacturing processes.

Owner:KPX CHEM

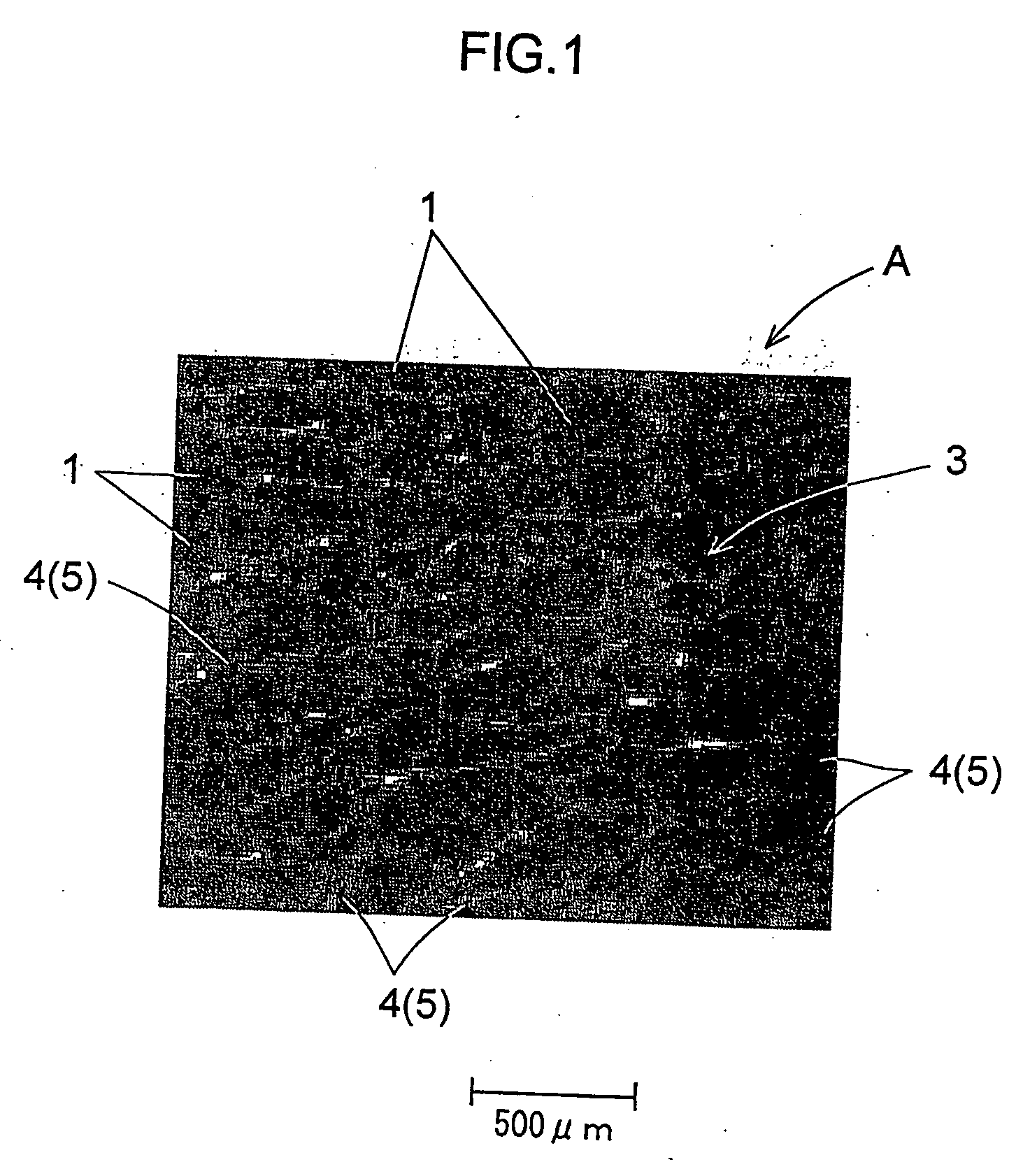

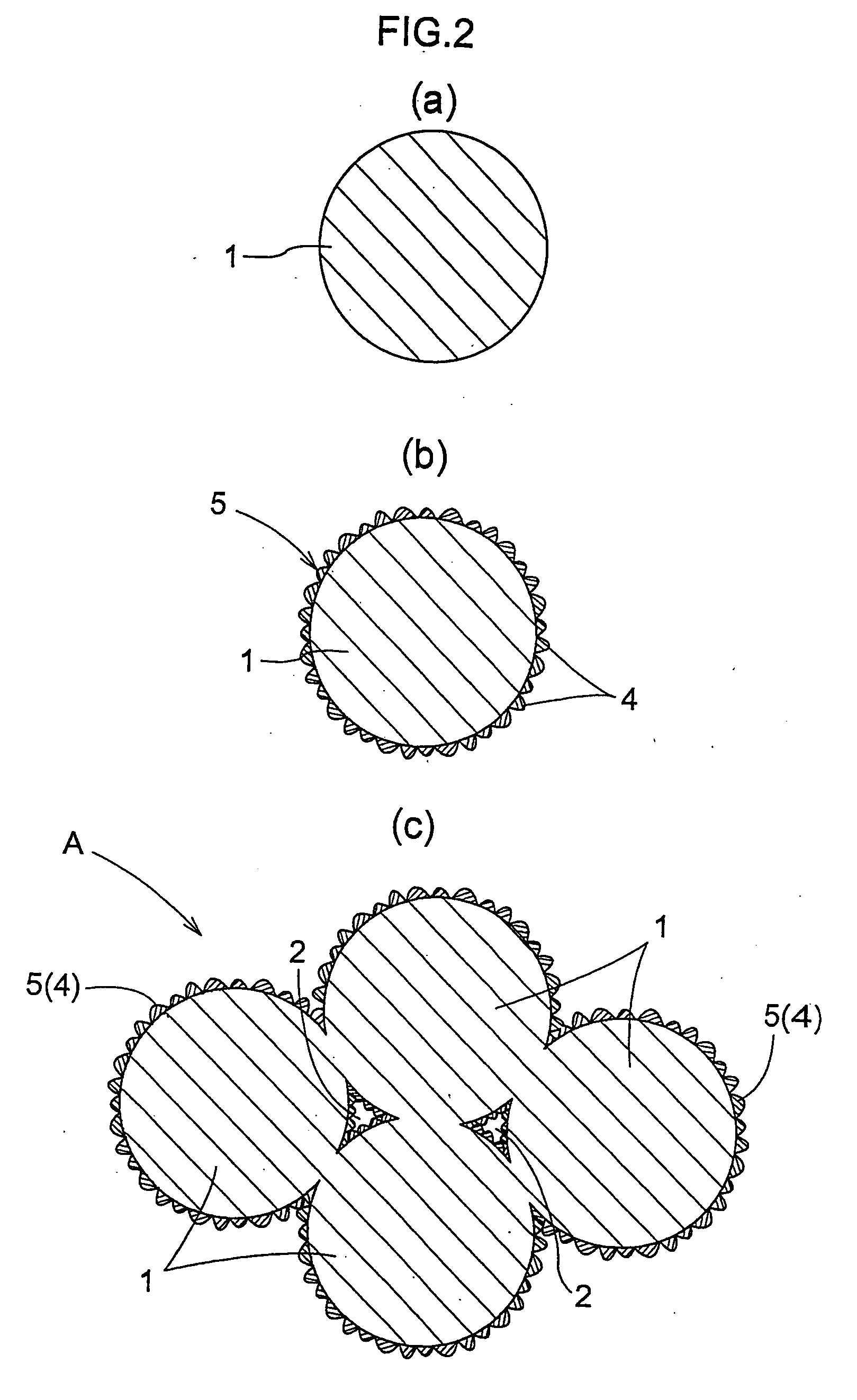

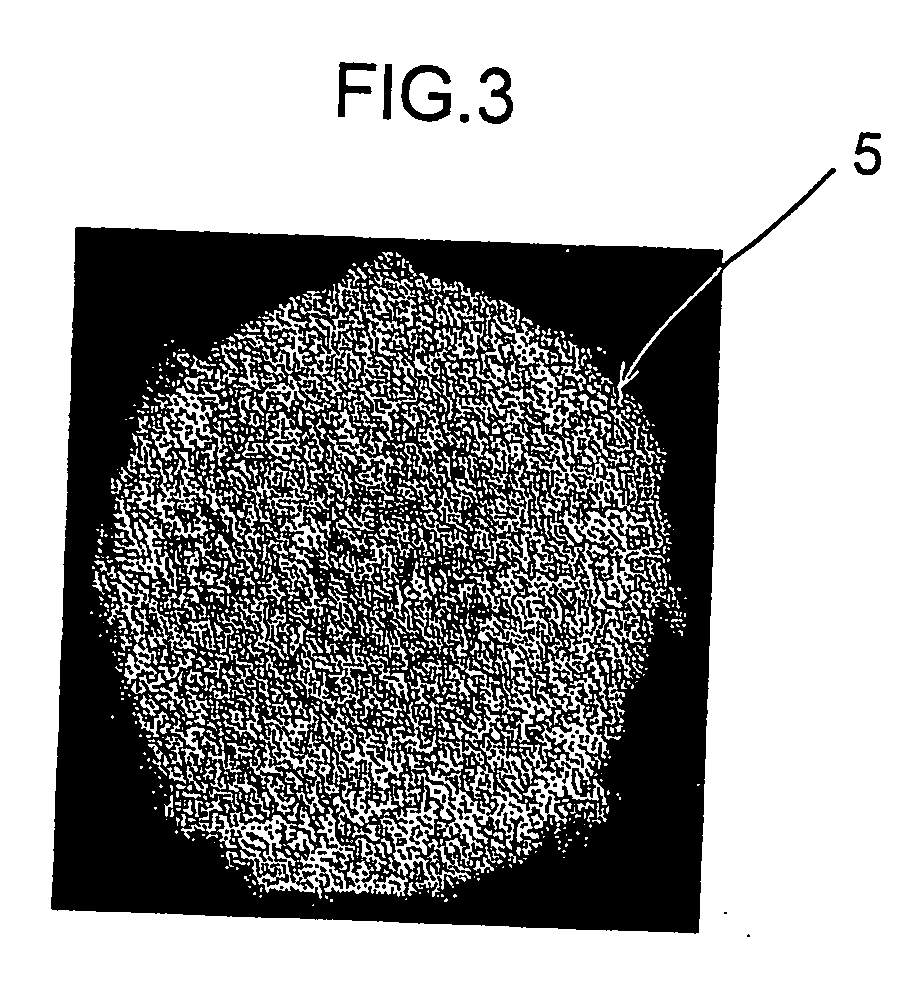

Metal resin composite and process for producing the same

InactiveUS20060111470A1Low costLow cost manufacturingElectrolytic coatingsCell electrodesThree dimensional matrixMetal

Numerous particles of thermoplastic resin supporting a metal on surfaces thereof are joined together by pressure welding. The metal is supported in a three-dimensional matrix on the group of joined particles.

Owner:NICCA CHEM COMPANY +4

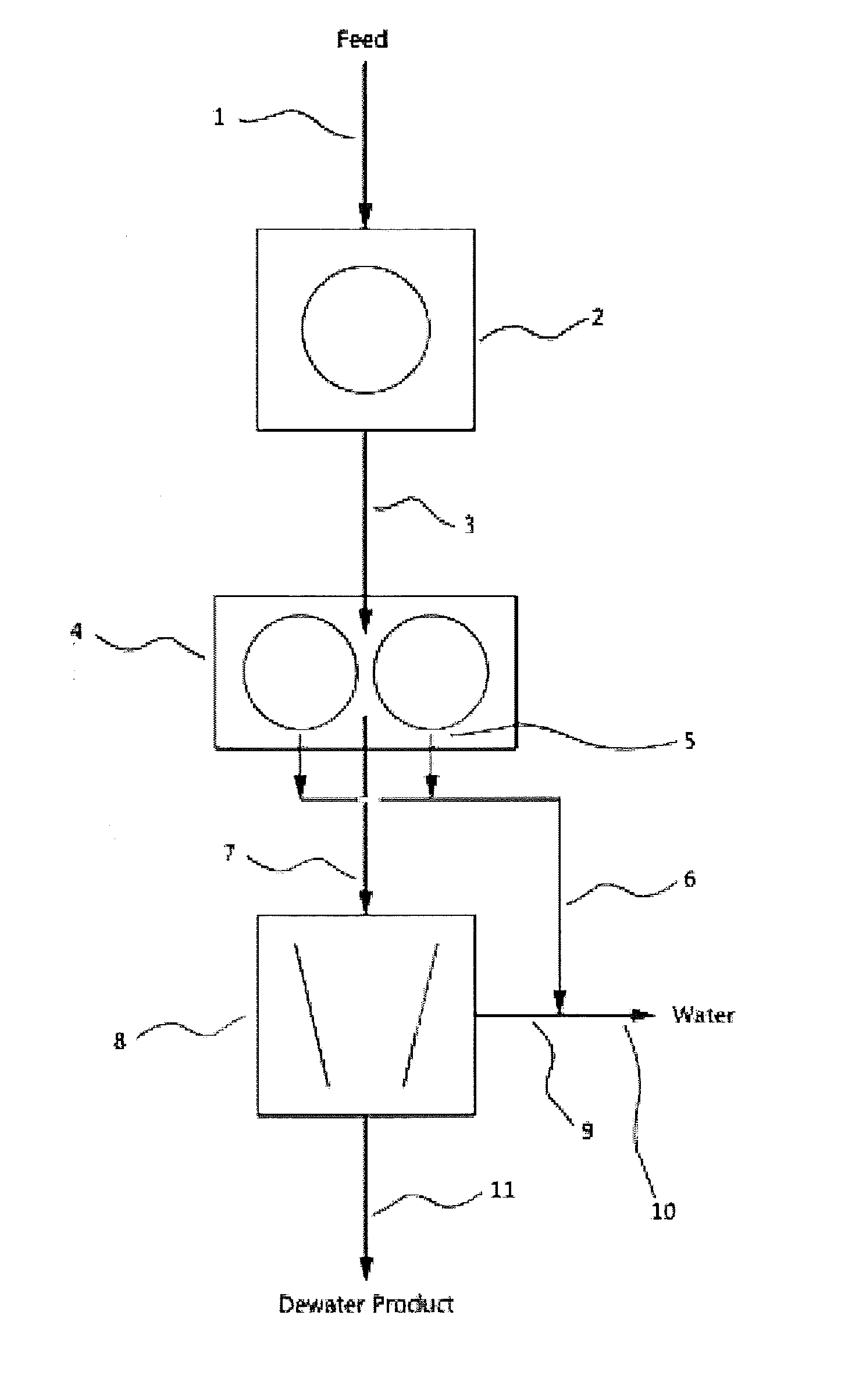

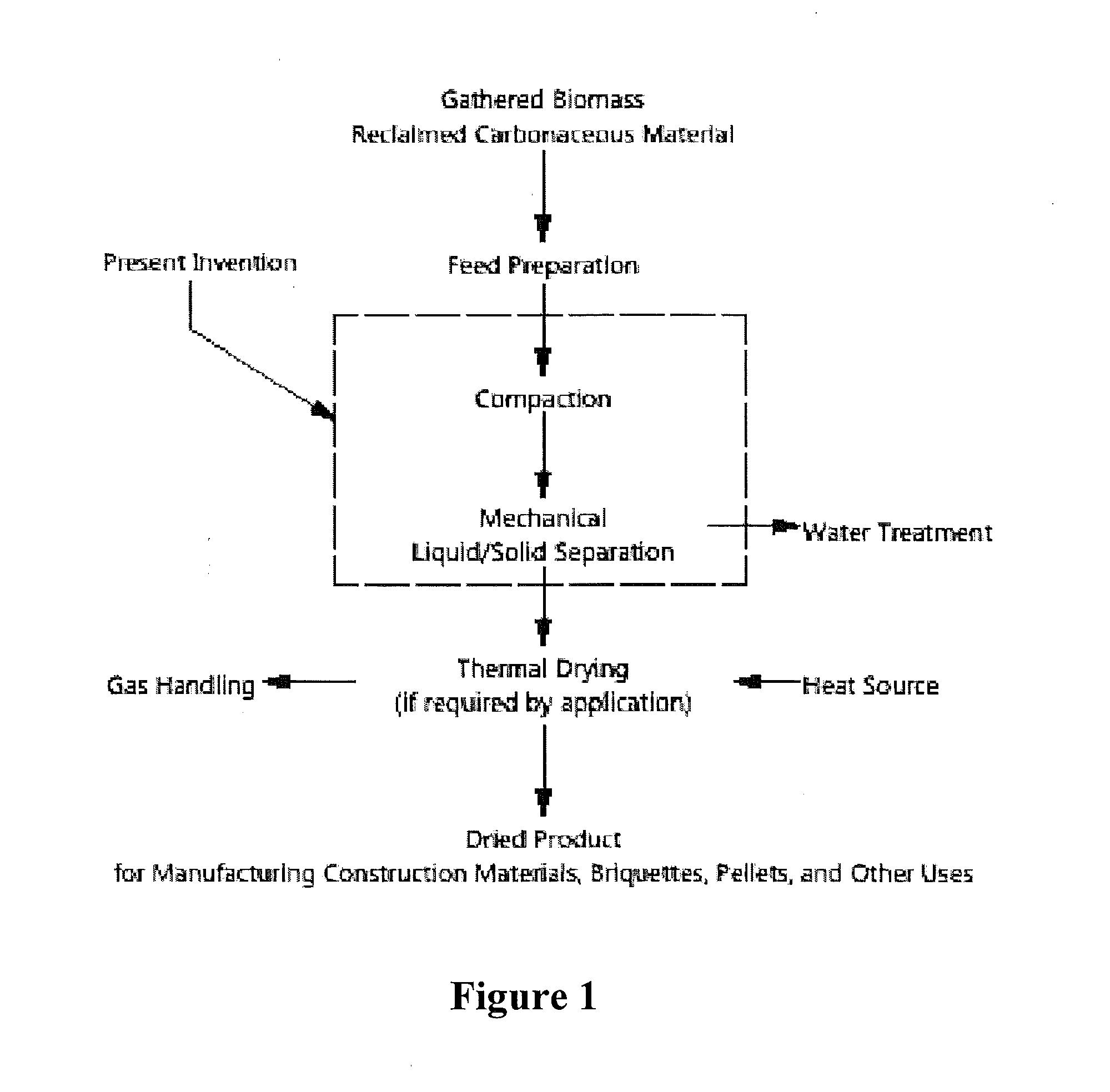

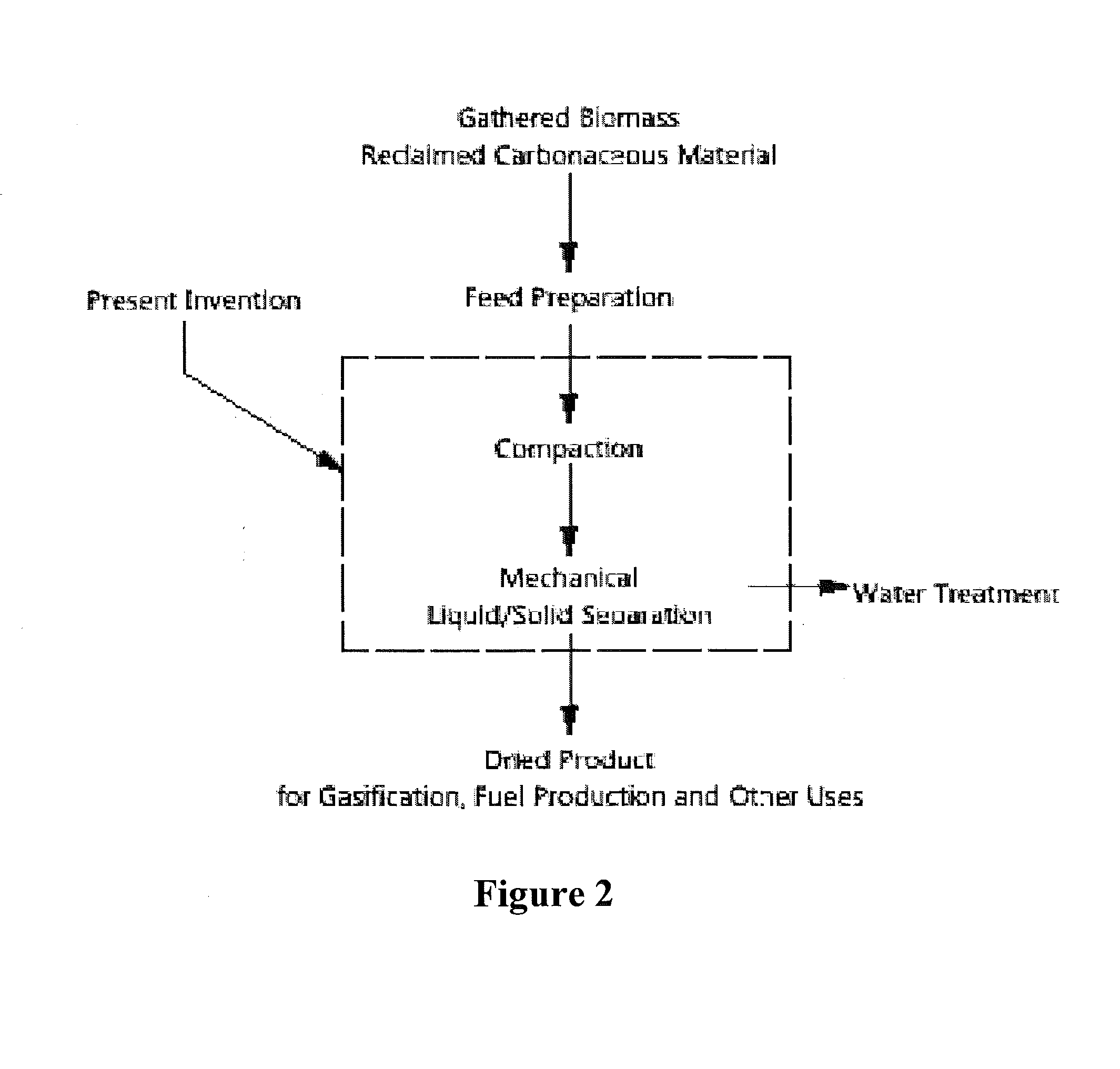

Methods of drying biomass and carbonaceous materials

InactiveUS20130326938A1Low costWeaken energyDrying solid materials without heatBiofuelsEngineeringMoisture

The invention provides methods of reducing the energy required to remove moisture from biomass, carbonaceous materials and mixtures of the same. The method significantly reduces the energy requirements by removing moisture as a liquid and by transferring the moisture to the surface of the material where it is more easily and efficiently evaporated.

Owner:GTL ENERGY LTD

Biaxial stretching polyamide film and preparation method thereof

ActiveCN101058358AGood dimensional stabilityUniform physical propertiesFlexible coversWrappersPolyamideMoisture absorption

The invention relates to the excellent feature of biaxial pull and stretch polyamide film with stable dimension, small heat extraction rate, consistence in magnitude direction. Along the random position of the horizontal direction of the film, the moisture absorption rate is 0. 5% or less. Treating the film under 100-degree hot water for five minutes, we find that the max. hot water extraction rate of the film is 3. 7% or even less, with their difference being 2. 5% or even less.

Owner:UNITIKA LTD

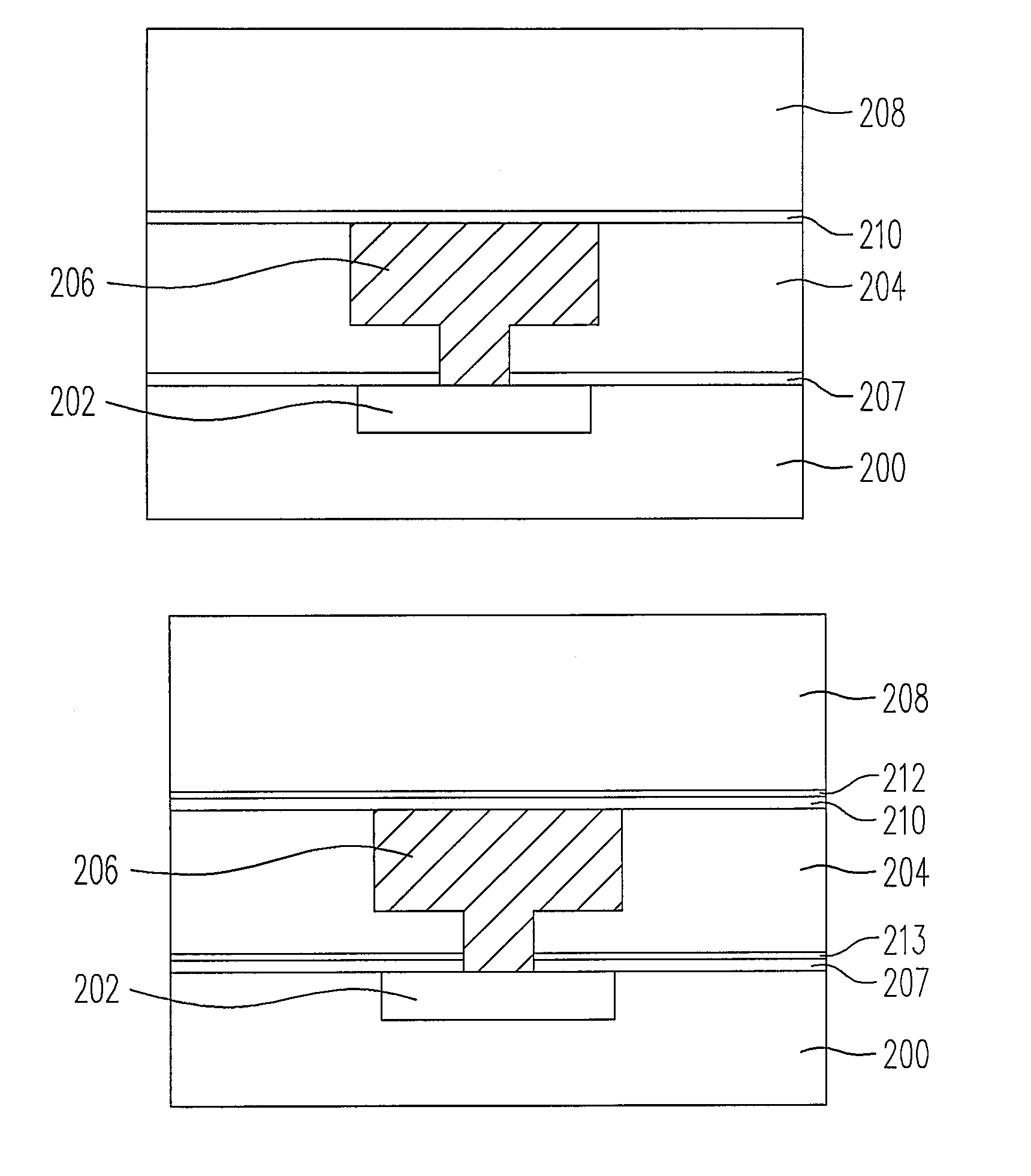

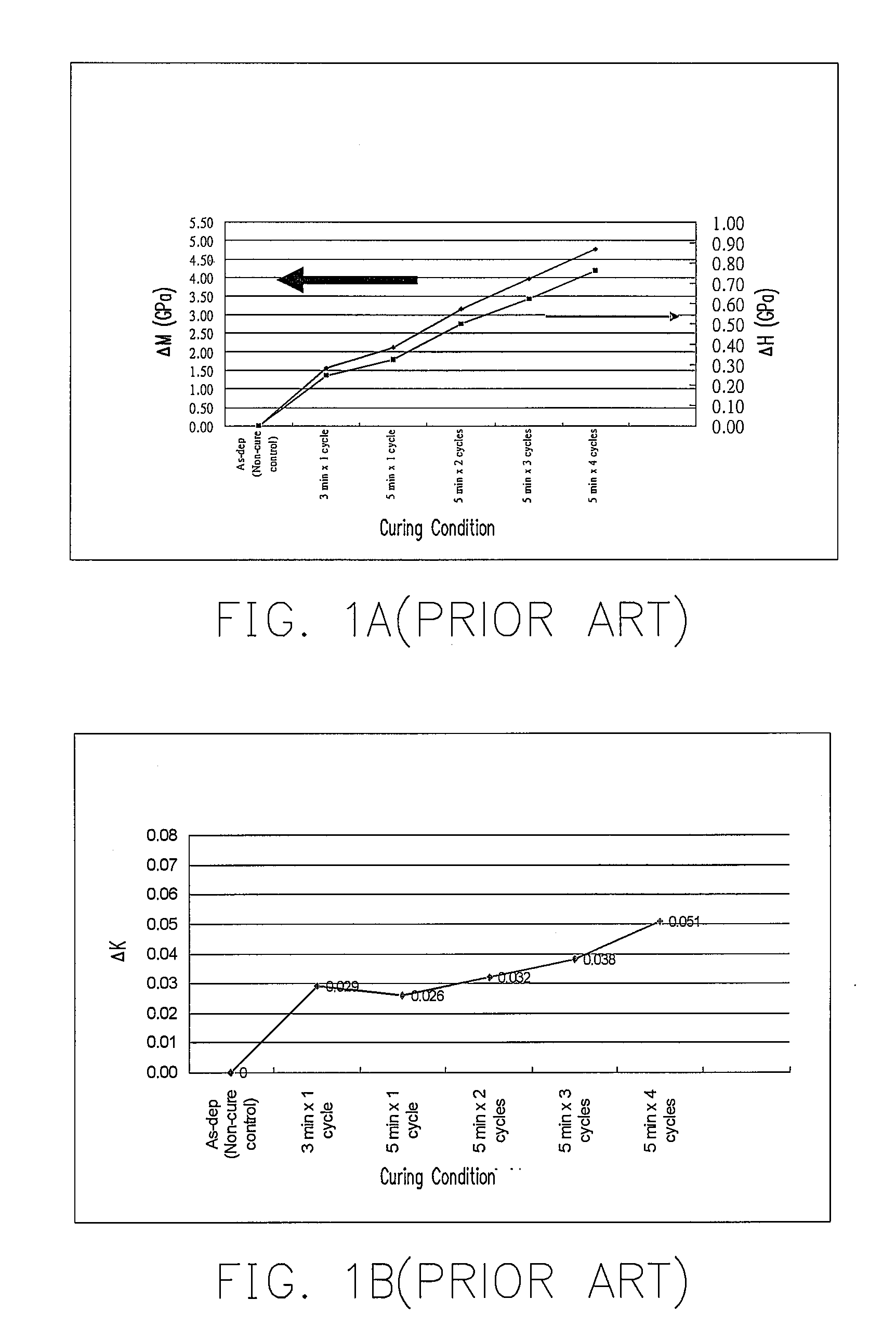

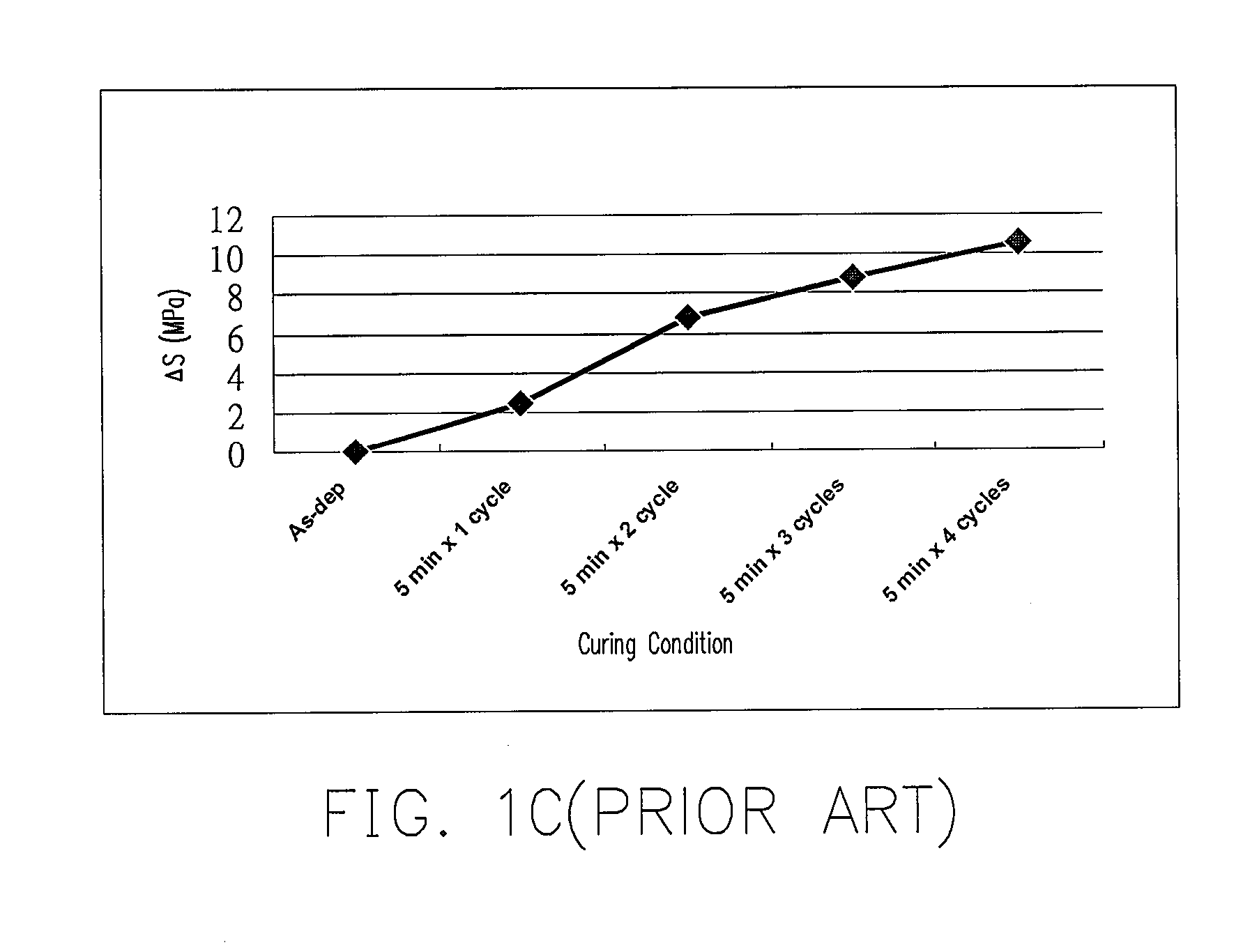

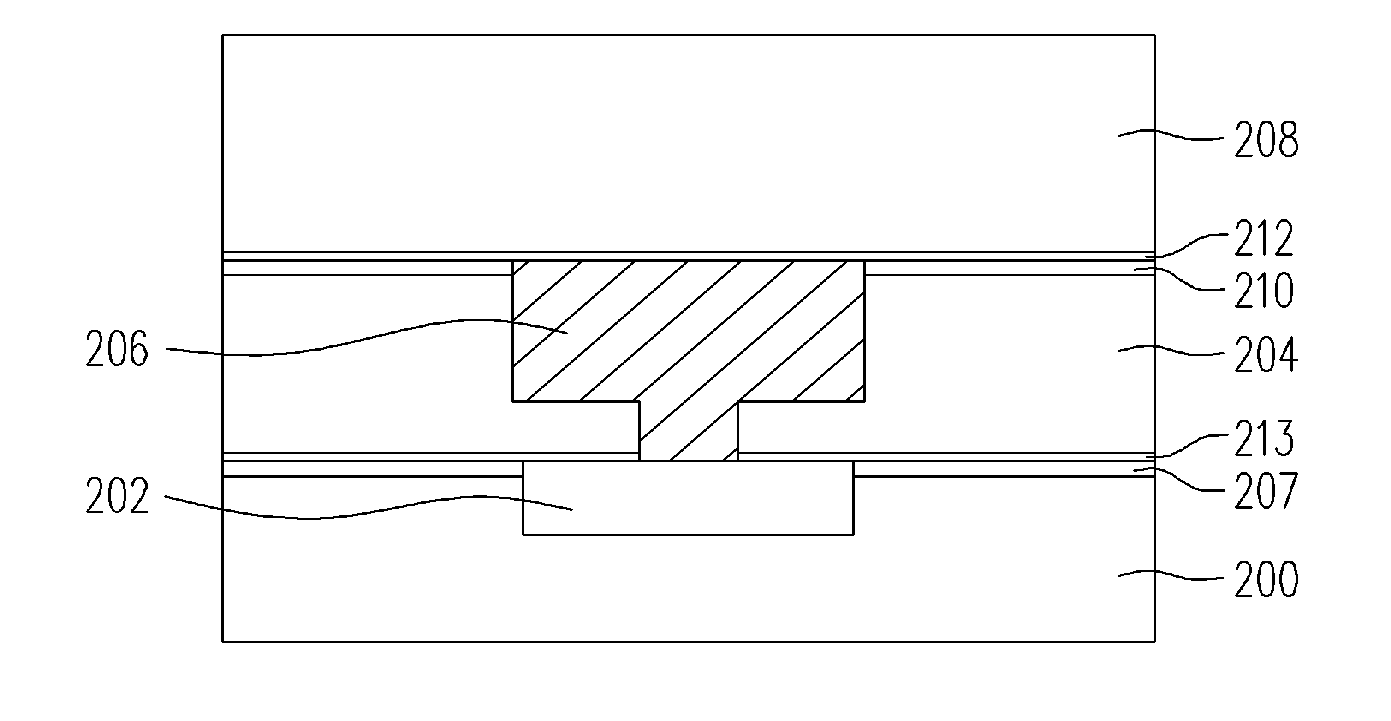

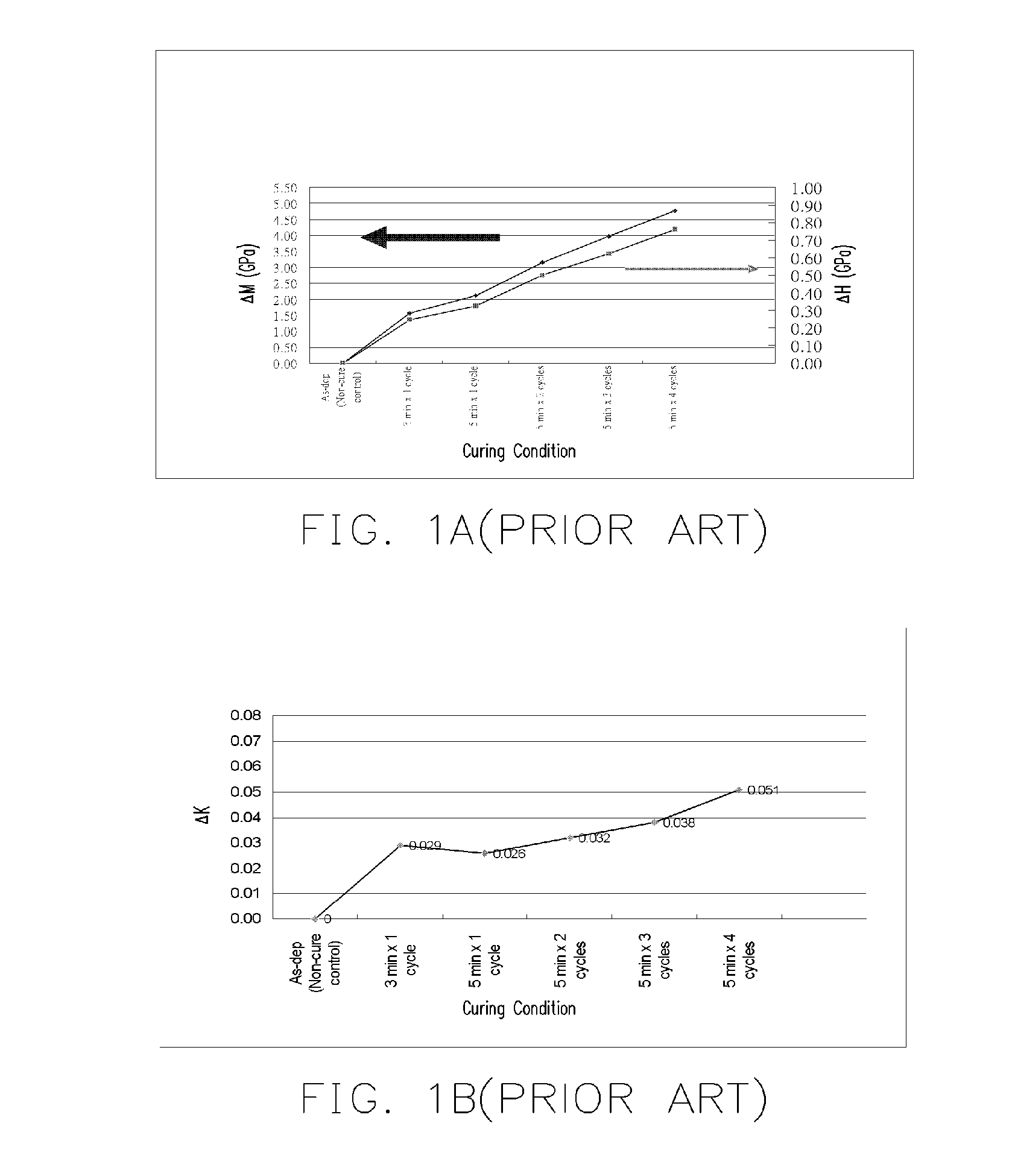

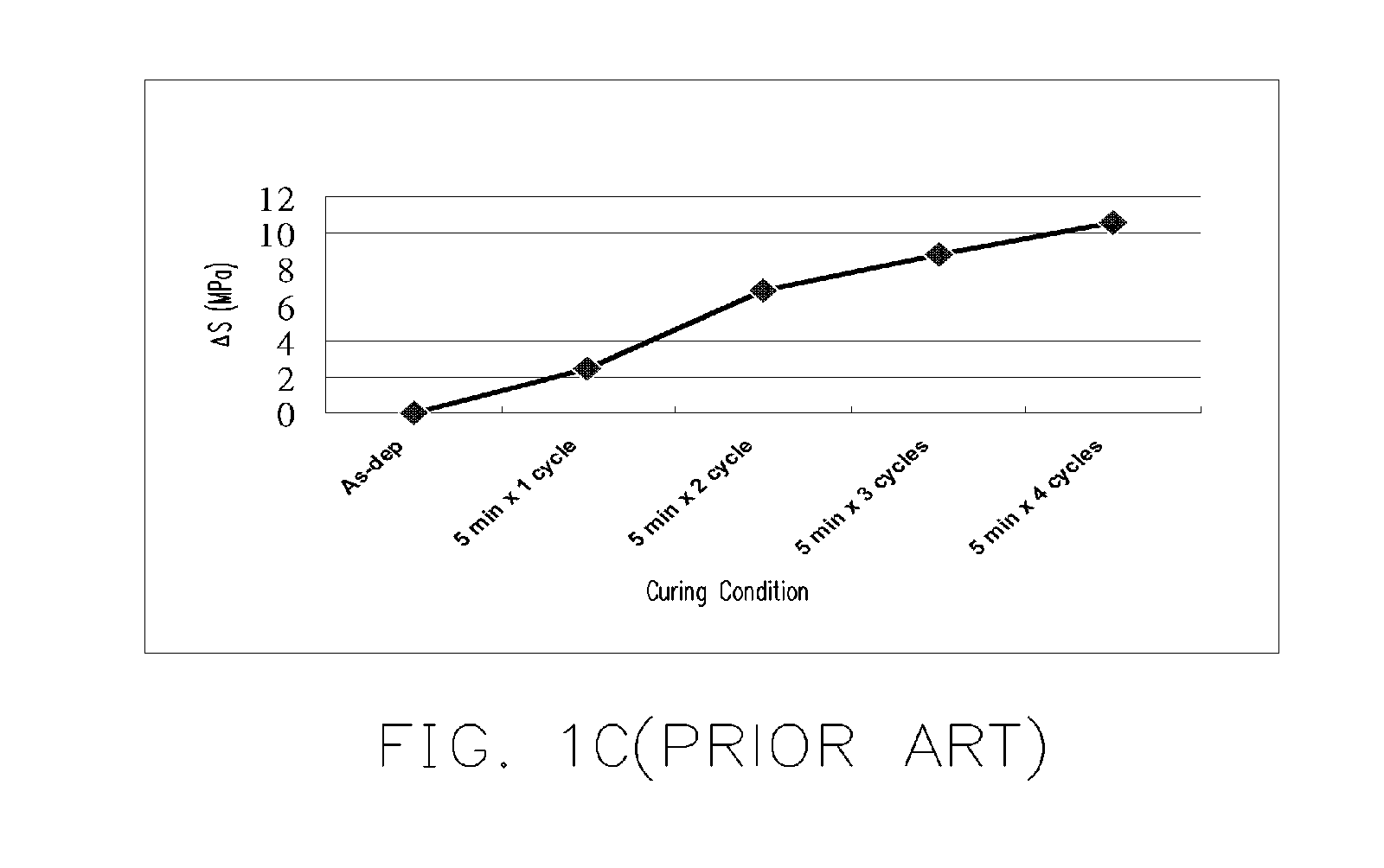

Method of fabricating interconnect structure

ActiveUS20070093053A1Uniform physical propertiesGood physical propertiesSemiconductor/solid-state device detailsSolid-state devicesUV curingOptoelectronics

Owner:UNITED MICROELECTRONICS CORP

Interconnect structure and fabricating method thereof

ActiveUS20070085210A1Preventive effectUniform physical propertiesSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceReflective layer

An interconnect structure is described, disposed on a substrate with a conductive part thereon and including a first porous low-k layer on the substrate, a damascene structure in the first porous low-k layer electrically connecting with the conductive part, a second porous low-k layer over the first porous low-k layer and the damascene structure, and a UV cutting layer at least between the first and the second porous low-k layers, wherein the UV cutting layer is a UV reflection layer or a UV reflection-absorption layer.

Owner:UNITED MICROELECTRONICS CORP

Paste composition and dielectric composition using the same

InactiveUS9058912B2Easy to getImprove reliabilityPlastic/resin/waxes insulatorsFixed capacitor dielectricBoiling pointSolvent

A paste composition containing an inorganic filler, a resin and a solvent, wherein the paste composition is characterized in that it contains one or more solvents of which the boiling point is 160° C. or higher and an inorganic filler of which the mean particle diameter is 5 μm or smaller, and the total content of the solvent is 25 wt % or less based on the total amount of the paste composition, and a dielectric composition containing an inorganic filler and resin, wherein the inorganic filler includes inorganic fillers of at least two kinds of mean particle diameter, and the greatest mean particle diameter of said mean particle diameters is 0.1-5 μm and is 3 times or more the minimum mean particle diameter.

Owner:TORAY IND INC

Sulfur-containing dispersant and sulfide phosphor paste composition comprising the same

ActiveUS20070092838A1Improve dispersibilitySuperior dispersibilityDischarge tube luminescnet screensGas discharge electrodesFluorescenceChemistry

A sulfide phosphor paste composition comprising a sulfur-containing dispersant, and a fluorescent film prepared therefrom, are provided. The sulfur-containing dispersant has a dual head structure containing both a carboxyl group and a thiol group or a structure containing a thiol or thiophene group as a head group. An oligomeric sulfur-containing dispersant is also provided. Adsorption of the dispersant on the surface of the sulfide phosphor prevents aggregation of the phosphor particles, and thereby improves the dispersibility of the sulfide phosphor paste composition, the homogeneity of the phosphor in the paste composition, and the density of a film produced from the paste composition. Fluorescent films and display devices produced from the phosphor paste composition exhibit improved luminescent properties and excellent processability.

Owner:SAMSUNG ELECTRONICS CO LTD

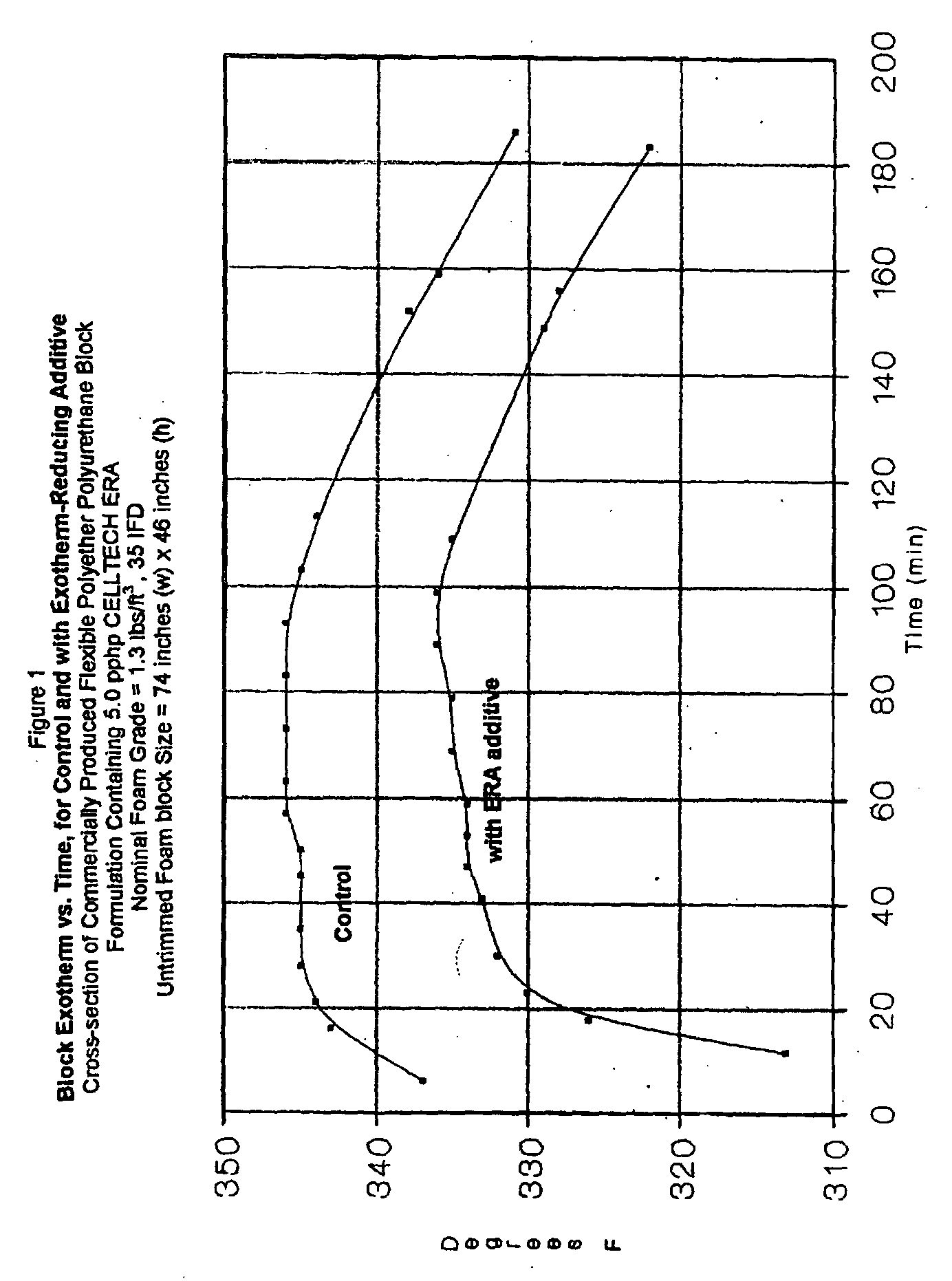

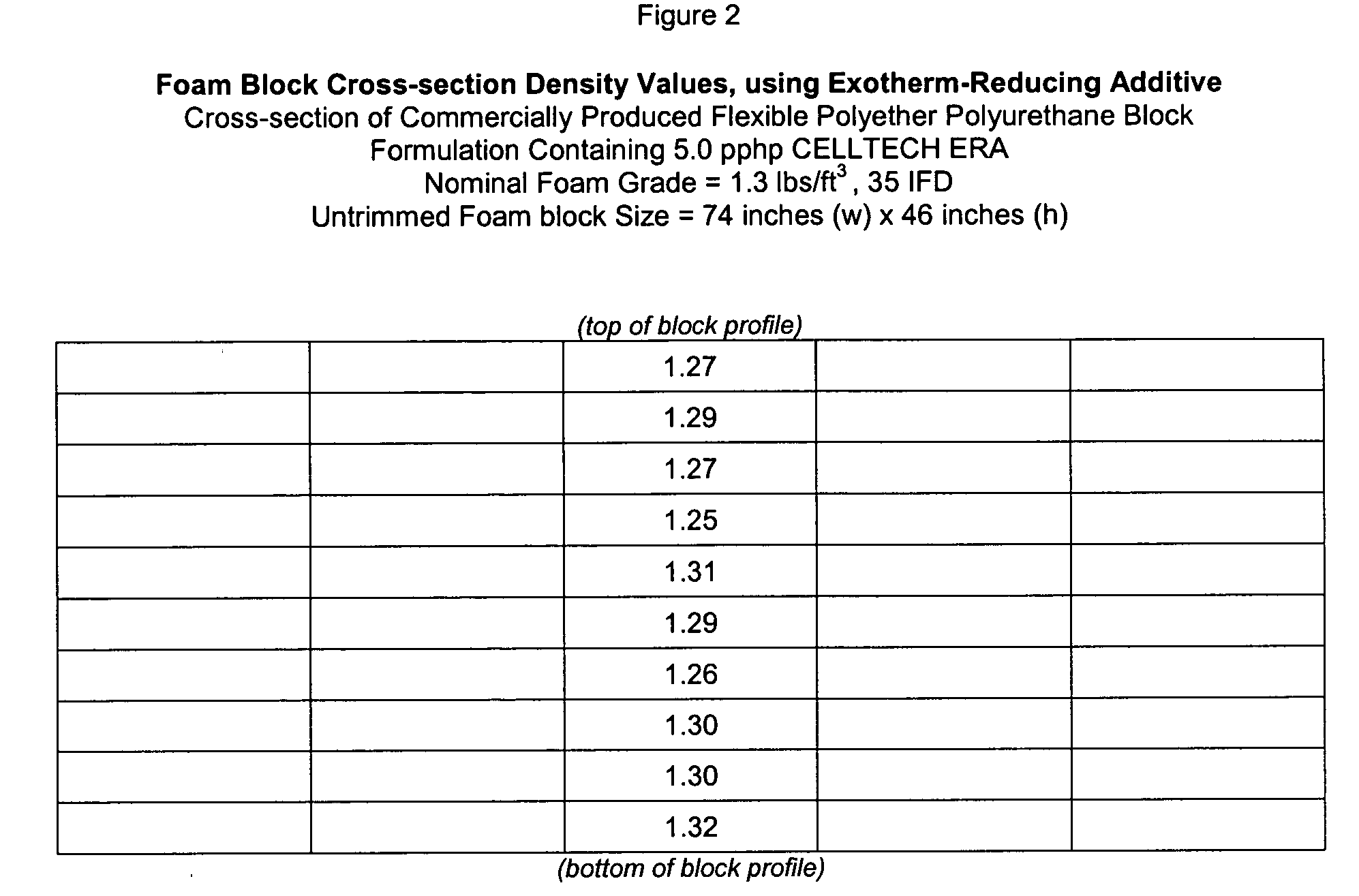

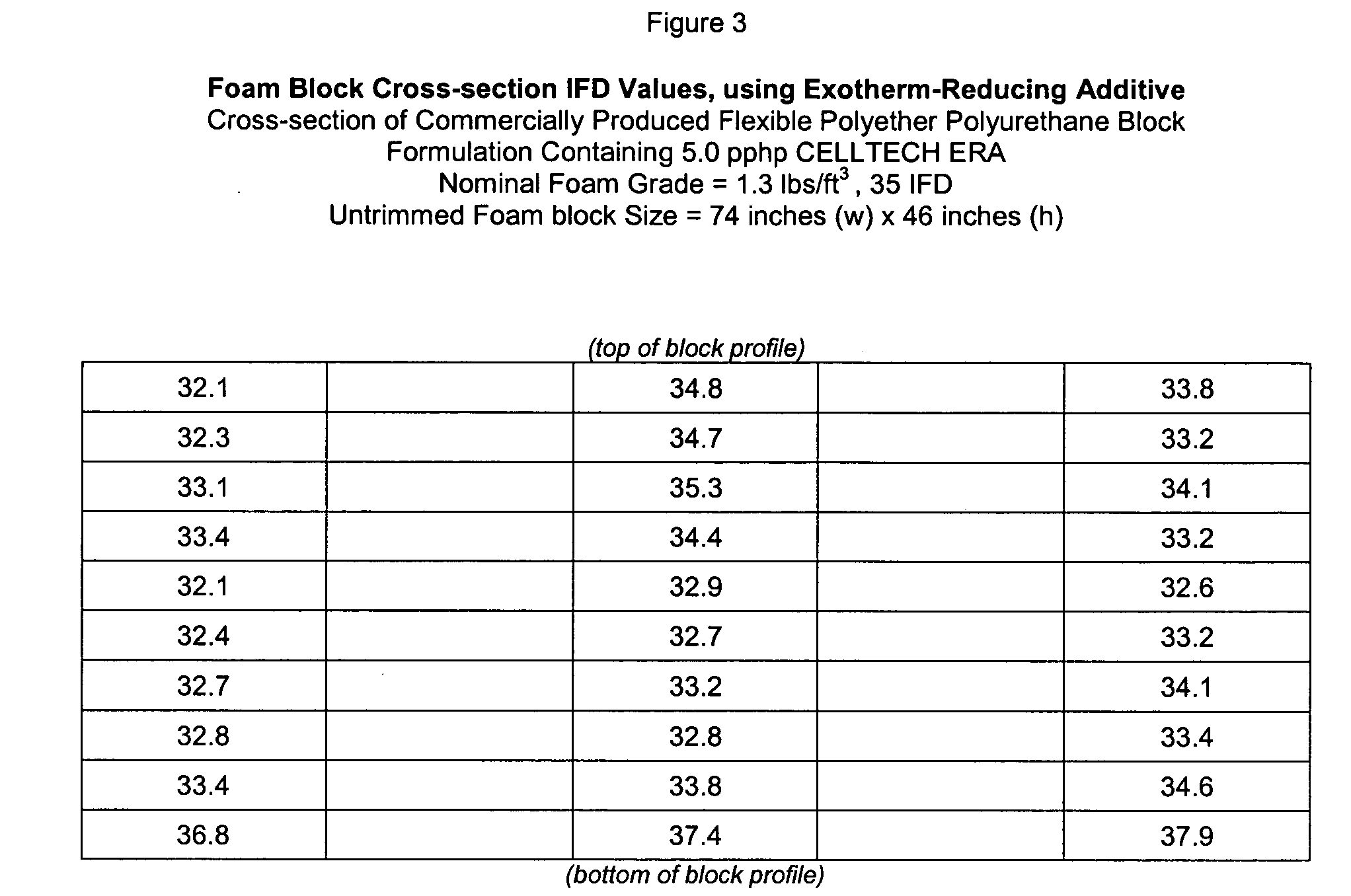

Physical properties improvement additive for flexible polyurethane foam

An exotherm reducing additive including a tetrahalogenated ionic compound and an exotherm reducing additive composition for organic polymer compositions including an exotherm reducing-effective amount of the tetrahalogenated ionic compound, a solvent for the tetrahalogenated ionic compound, and a diluent compatible with the tetrahalogenated ionic compound, the solvent and the organic polymer composition, The tetrahalogenated ionic compound preferably is a tetrahalogenated borate, and more specifically lithium or sodium tetrafluoroborate. Organic polymer compositions containing the additive also are provided, as are methods incorporating the additive into the polymer compositions.

Owner:CELLULAR TECH INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com