Patents

Literature

330results about How to "Uniform control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

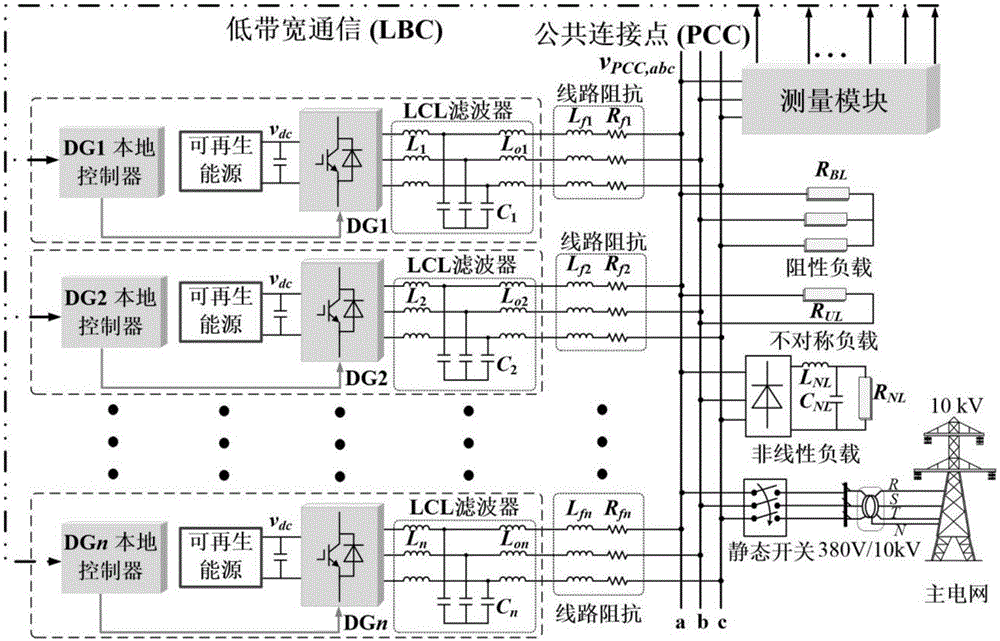

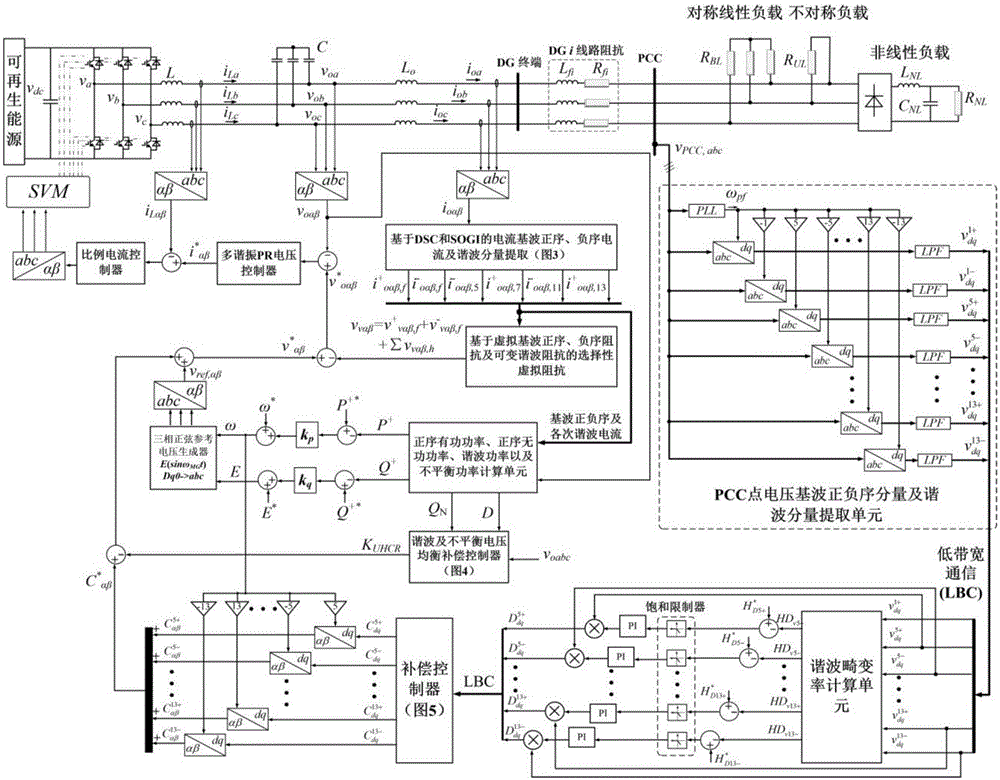

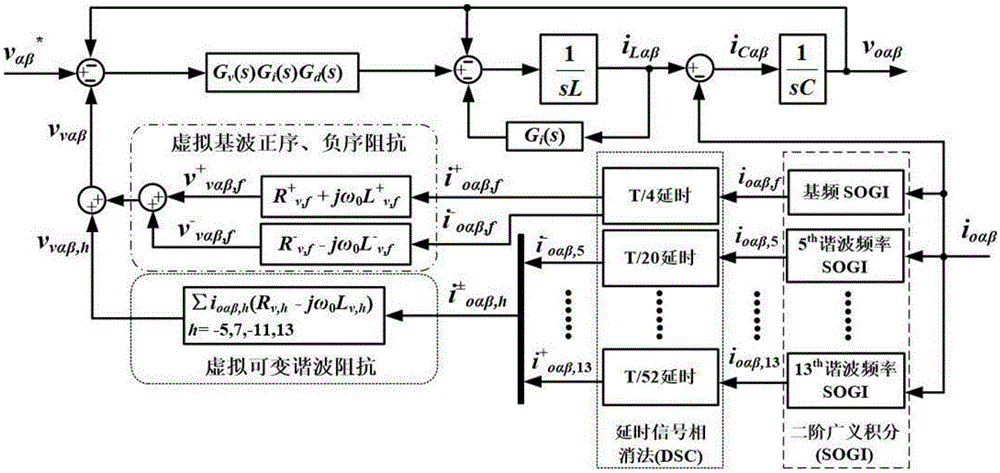

Microgrid system with asymmetric non-linear load and power balancing control method

InactiveCN105071405ASolving Harmonic ProblemsSolve balance problemsPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationMicrogridPower balancing

The invention dsiclsoes a microgrid system with an asymmetric non-linear load and a power balancing control method. The system comprises a plurality of DG units connected in parallel and line impedors connected with all DG units. The line impedors are connected to a microgrid bus by PCC points. A three-phase balancing resistive load, an asymmetric linear load, and a diode rectifier non-linear load of a load unit are connected to the microgrid bus by PCC points. A measurement module for measuring voltage fundamental wave positive sequence and negative sequence components and harmonic wave components of the PCC points is also connected to the microgrid bus. The microgrid bus is connected with a 10-kV main power grid by a static switch and a transformer successively. According to the invention, reactive and harmonic power balancing of the microgrid is realized by using a selective virtual impedance based on the virtual fundamental positive and negative sequence impedance and the virtual variable harmonic impedance; a harmonic and unbalancing voltage compensation controller enables equal division of an unbalanced power and a harmonic power to be realized; and a problem of unbalancing of the harmonic wave and the voltage of the microgrid can be solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

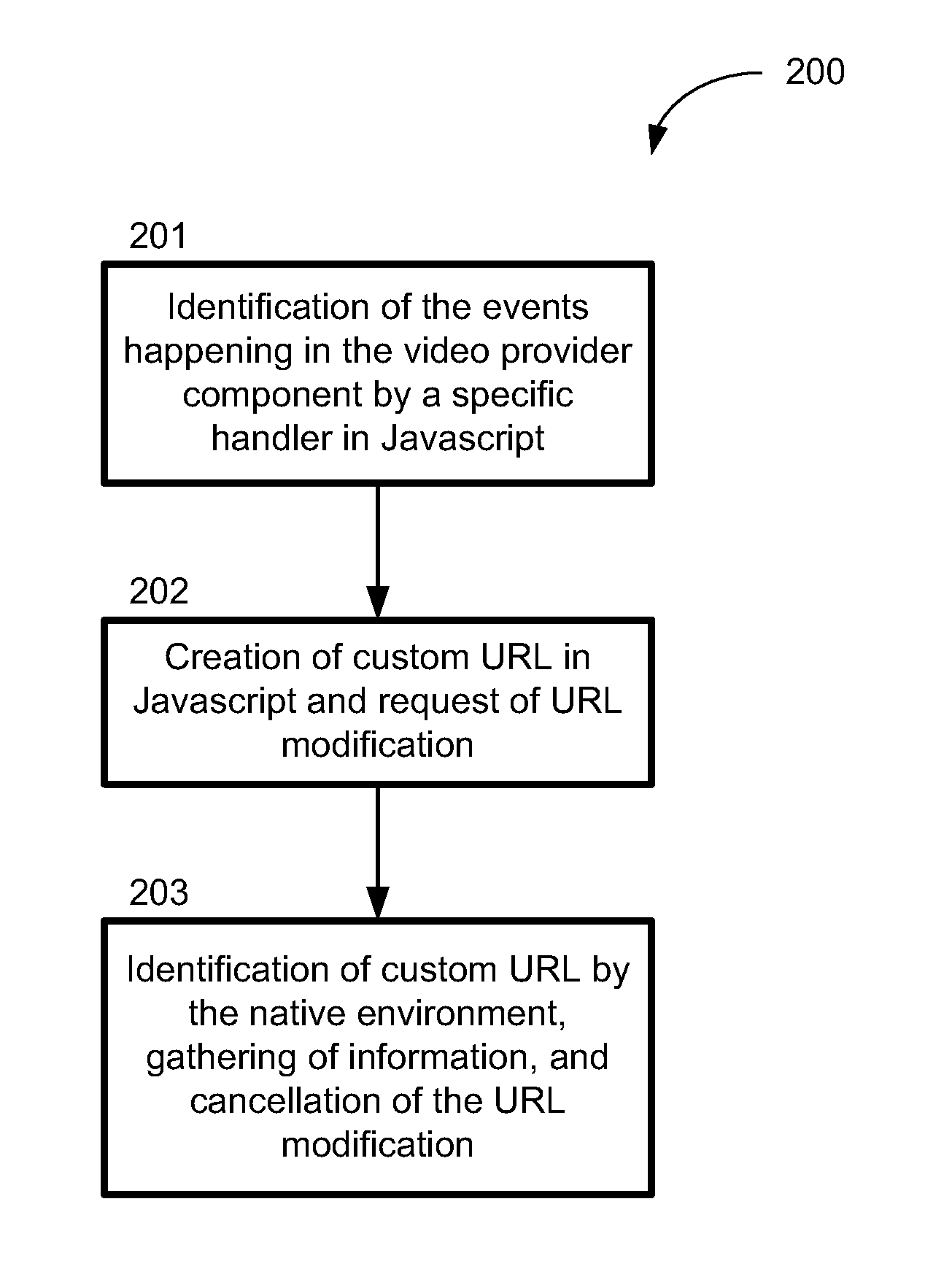

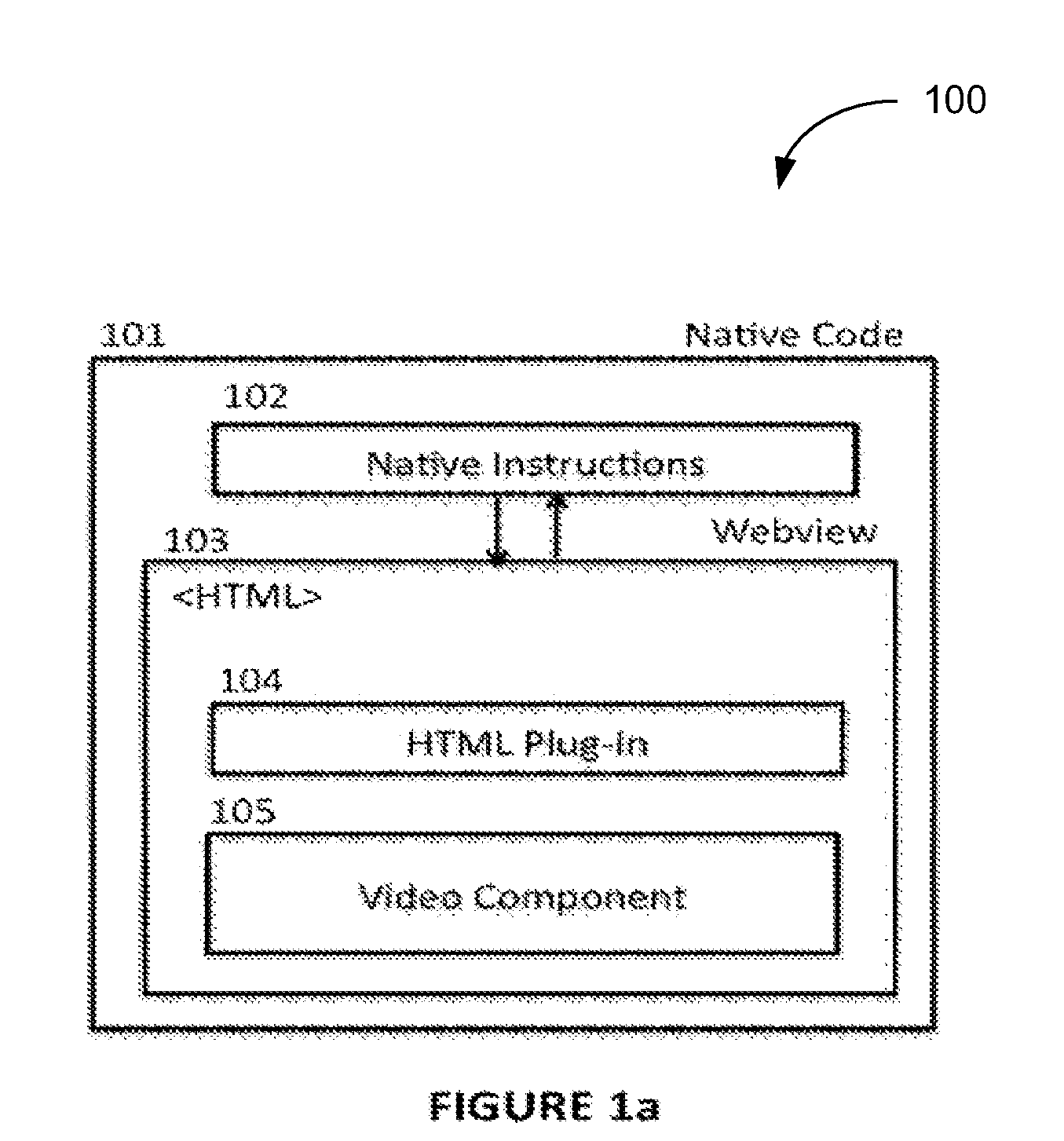

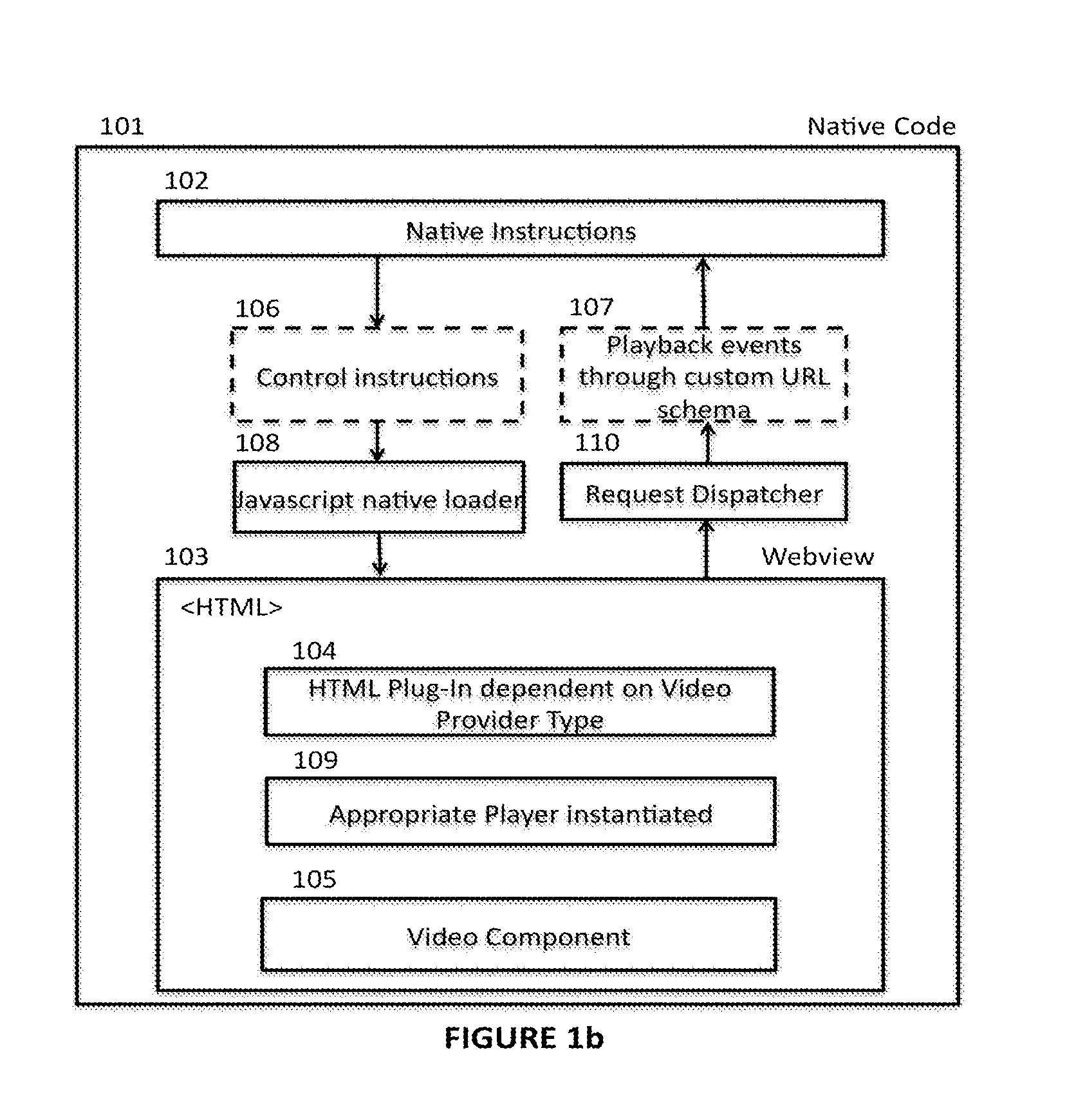

System and method for integrating and controlling web-based HTML players in a native context

InactiveUS20130074131A1Uniform controlUniform displayTwo-way working systemsProgram controlApplication programming interfaceUniform resource locator

Javascript code in an HTML Plug-In identifies a video playback event, from an application programming interface (API) of a video provider, during playback of a video in a web view instantiated within a native environment of a computing device. In response, the Javascript code generates a custom uniform resource locator (URL) for the web view that reflects the identified video playback event and provides the custom URL to native instructions executing in the native environment.

Owner:MILESTONE PROJECT

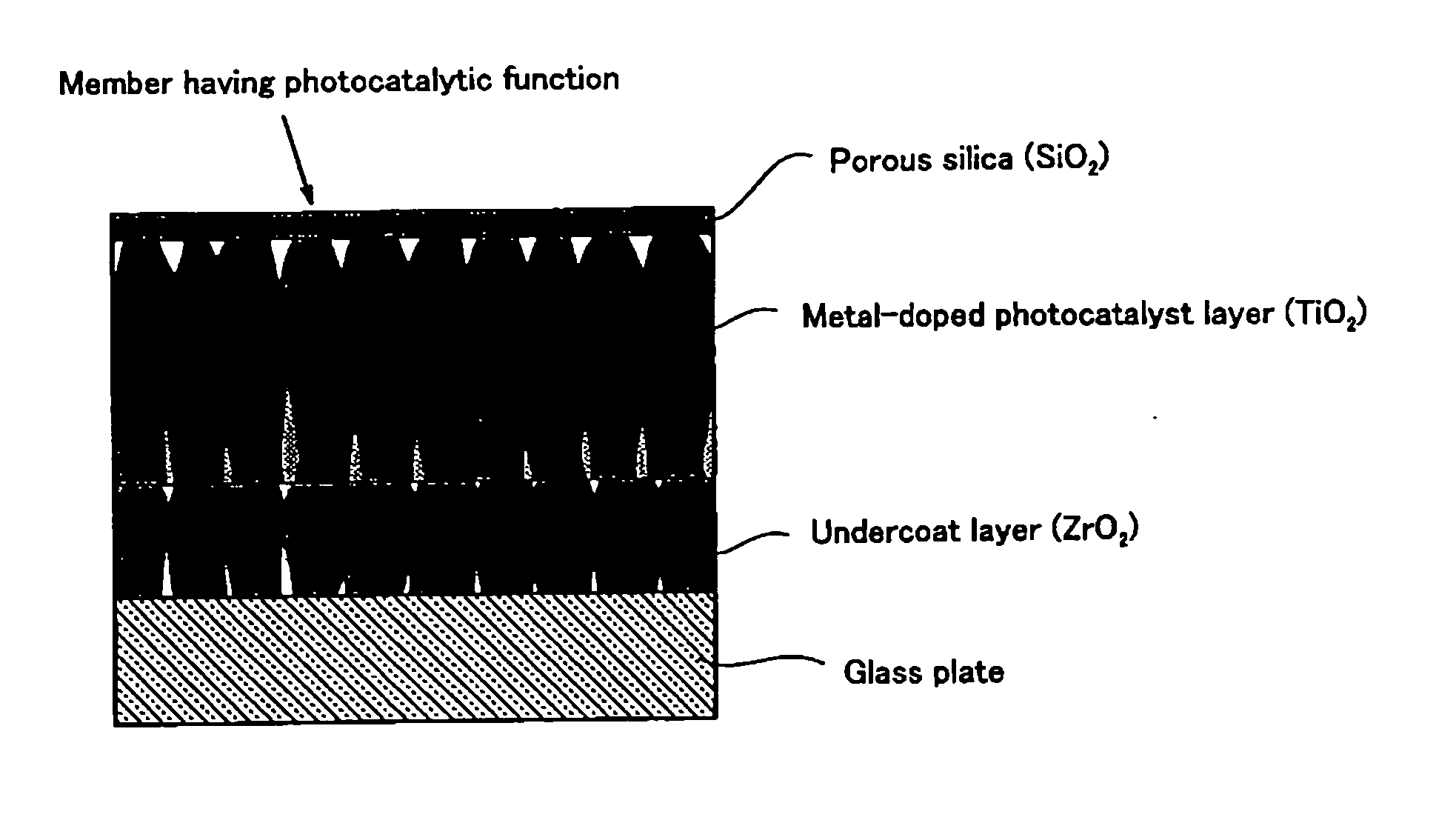

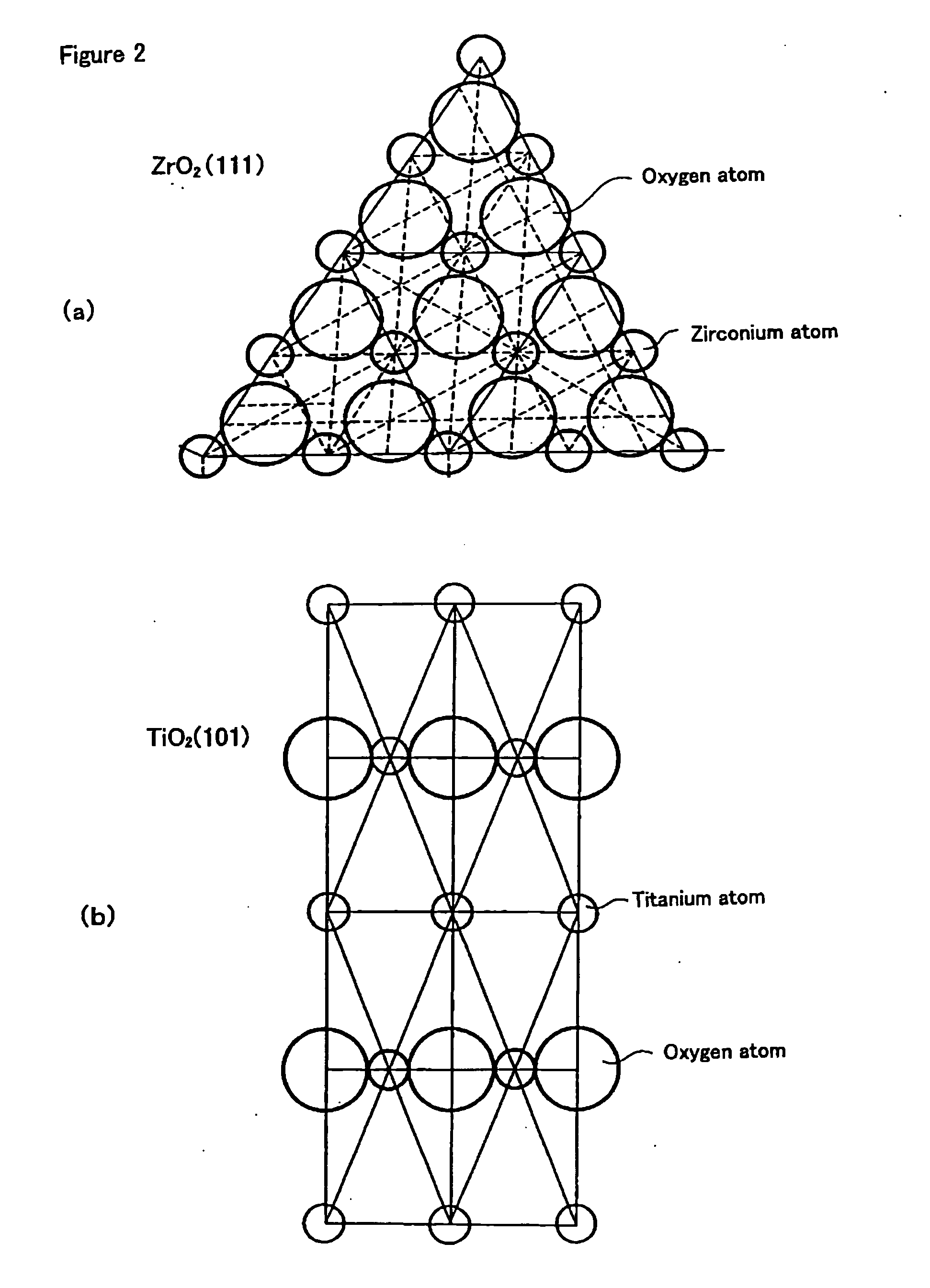

Member having photocatalytic function and method for manufacture thereof

ActiveUS20050233899A1Low heat resistanceUniform controlBiocideVacuum evaporation coatingOptoelectronicsZinc

A photocatalyst layer (TiO2) is formed on the surface of a substrate (glass plate) through the intermediary of a monoclinic undercoat layer (ZrO2), and no dead layer is substantially present between the photocatalyst layer and the undercoat layer. Also, by providing a peel preventing layer between the substrate and the undercoat layer, it is possible to eliminate film peeling between the photocatalyst layer and the substrate, defects and discoloration. In the above-described TiO2 layer, metal such as tin (Sn), zinc (Zn), molybdenum (Mo) or iron (Fe) is doped. The phrase “no dead layer is substantially present” means that the thickness of the dead layer is 20 nm or less. The thickness of the photocatalyst layer is preferably from 1 nm to 1,000 nm, more preferably from 1 nm to 500 nm.

Owner:NIPPON SHEET GLASS CO LTD

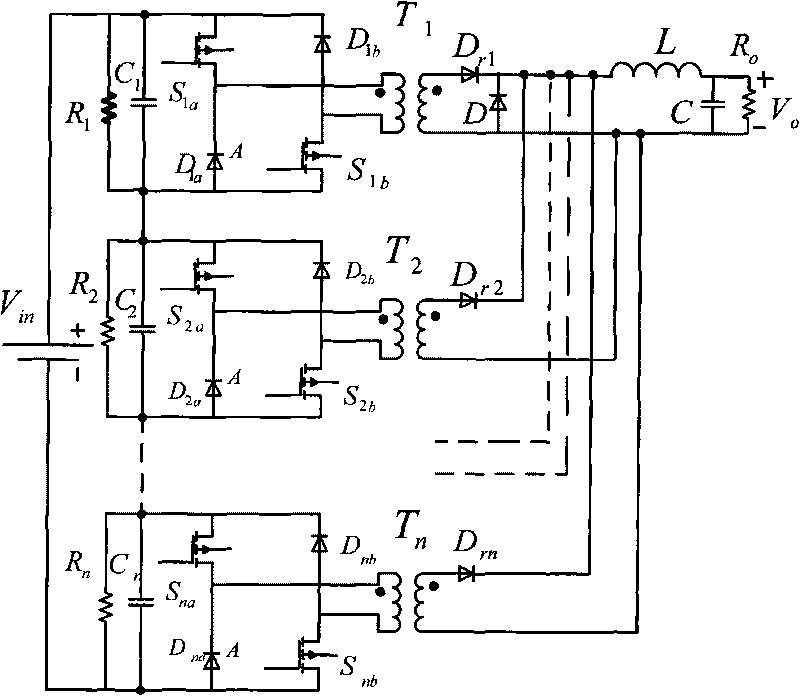

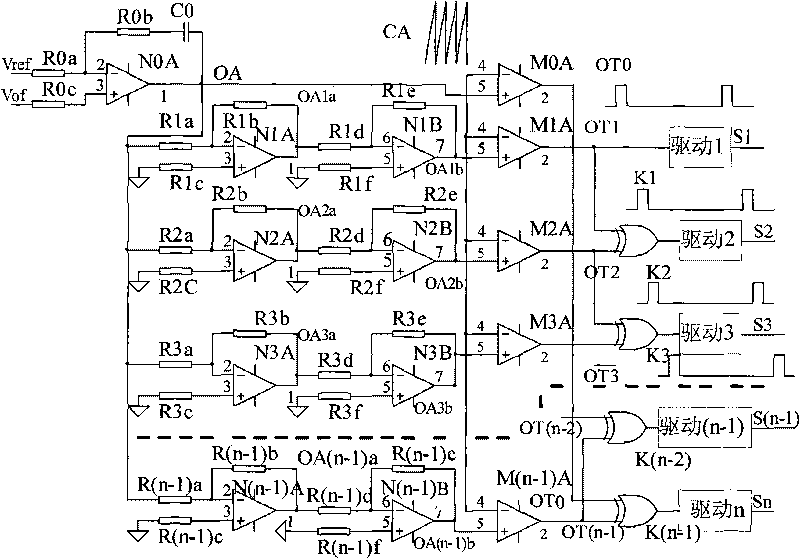

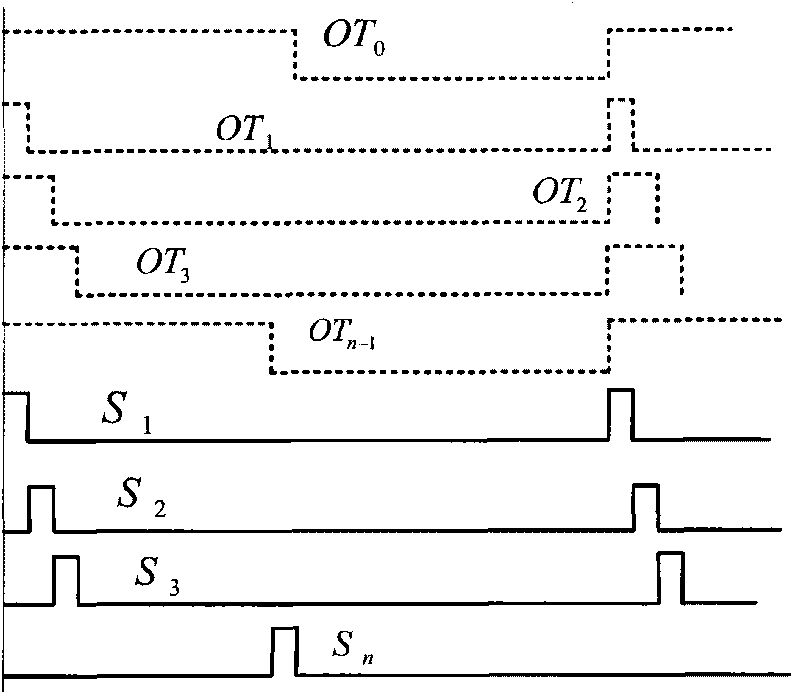

DC-DC converter

InactiveCN101719727AUniform controlSimple topologyDc-dc conversionElectric variable regulationCapacitanceLow voltage

The invention relates to a low and medium power high frequency DC-DC converter suitable for high-voltage input, which is based on the fundamental principle that: series capacitors are connected to a high-voltage direct current input, each capacitor serves as an input of the high-frequency forward DC-DC converter, and the outputs of the high-frequency forward DC-DC converter share a filter inductor, a freewheeling diode and an output filter capacitor; voltage feedback is acquired by sampling the output voltage of the high-frequency forward DC-DC converter, and a given reference voltage is compared with the voltage feedback so as to obtain a voltage loop output, namely a main output, by voltage regulation and calculation; and then, high-frequency forward DC-DC converter driving signals which are equational and alternate in phase are acquired to realized the control over a main circuit. The DC-DC converter has the advantages that: a low-voltage switching element is used under high voltage direct current input; the topology is simple; the cost is low; and the output has excellent dynamic and static performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

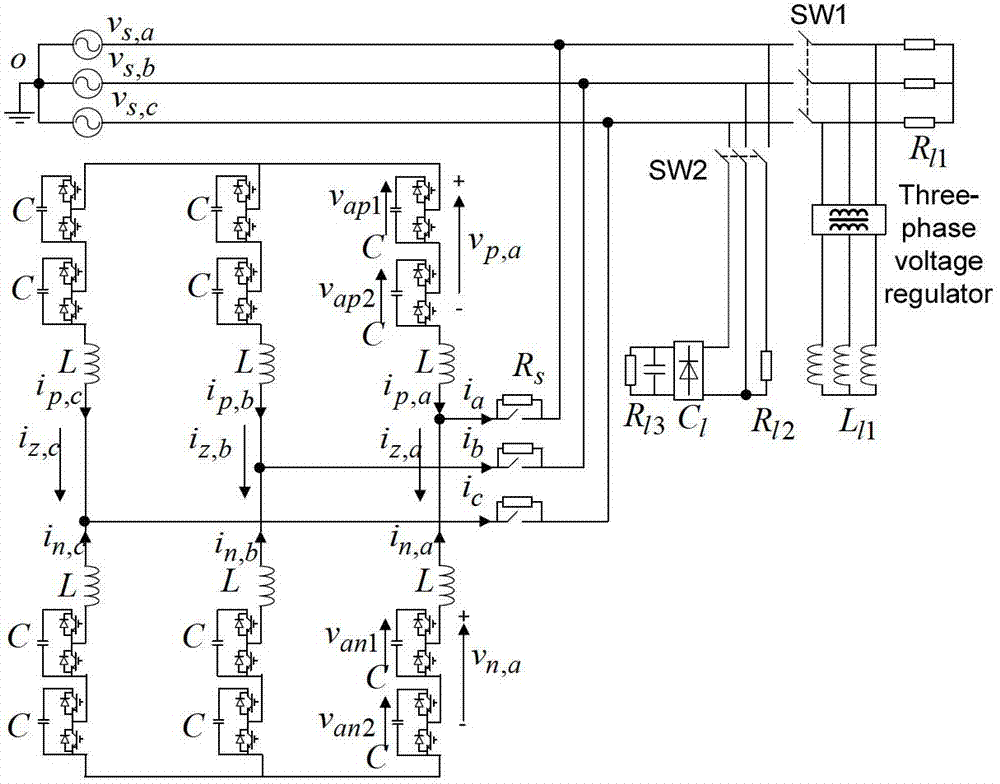

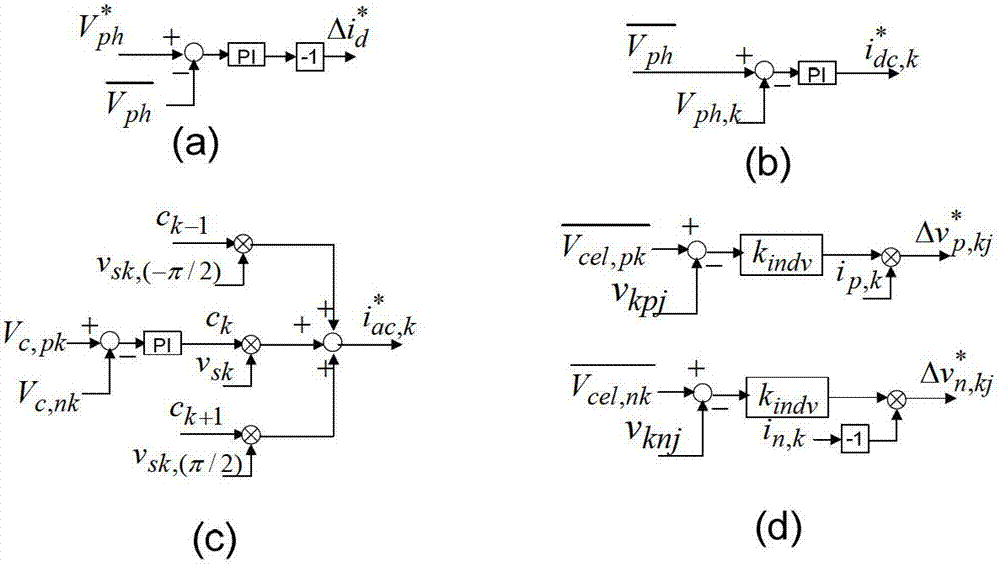

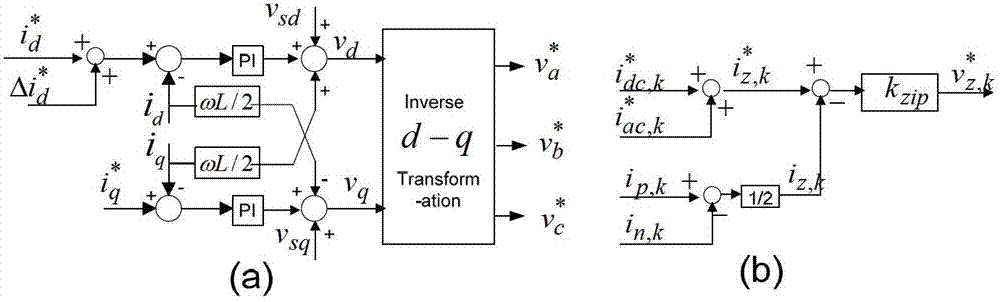

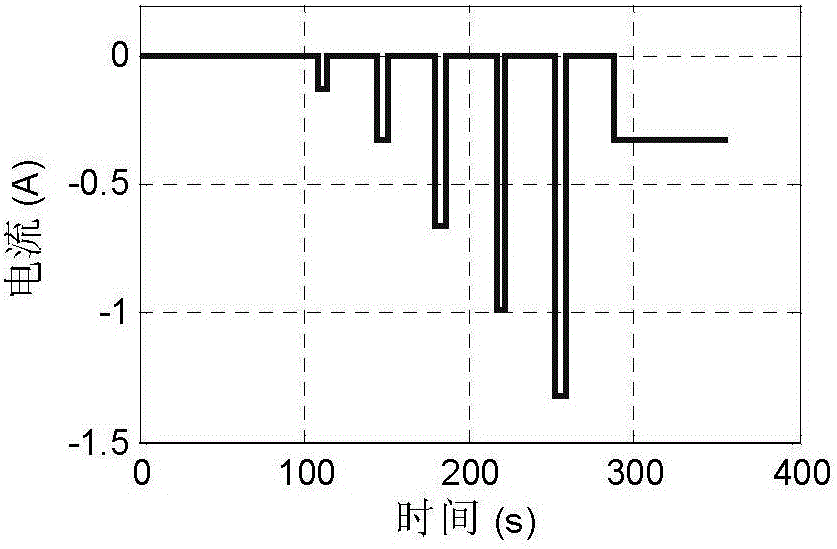

Method for controlling direct current capacitor voltage of modular multi-level converter based on circulating current decoupling

The invention discloses a method for controlling the direct current capacitor voltage of a modular multi-level converter based on circulating current decoupling. The method is characterized by comprising the following steps of: controlling the total direct current generatrix voltage by using active current which is absorbed from a power grid by the modular multi-level converter; balancing three-phase direct current voltage by using direct current components in circulating current; controlling balance of the direct current generatrixes of upper and lower bridge arms of each phase by using decoupling fundamental wave components in the circulating current; and finely adjusting the output voltage of each module along the current direction of the bridge arms, so the direct current capacitor voltage of each module in the bridge arms is balanced. The control method has the advantages that balanced control over the direct current generatrix voltage of the upper and lower bridge arms can be well realized; by using voltage control rings in other three layers, the direct current voltage of each module can be well balanced and stabilized to be in a given value range; and the method is accurate and reliable, and provides a good reference value for engineering application.

Owner:XI AN JIAOTONG UNIV

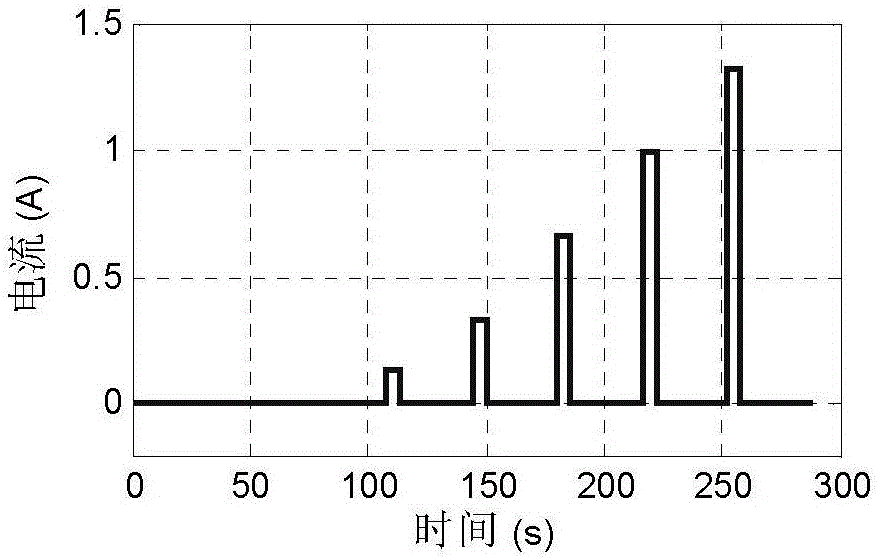

Balance control method for lithium-ion battery pack

ActiveCN105811500AUniform controlSimple and flexible controlCharge equalisation circuitElectric powerNew energyPoor balance

Owner:珠海中力新能源科技有限公司

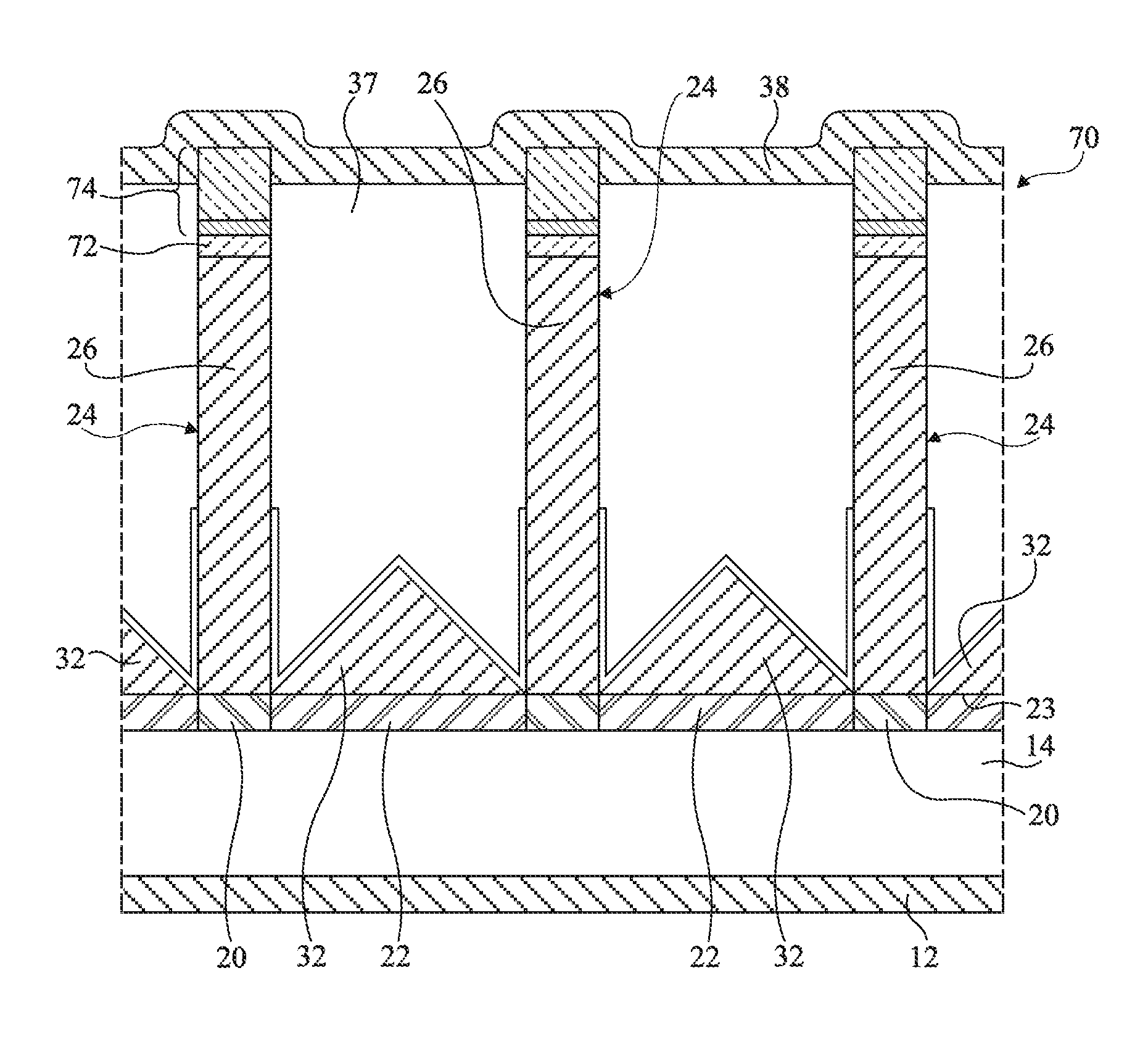

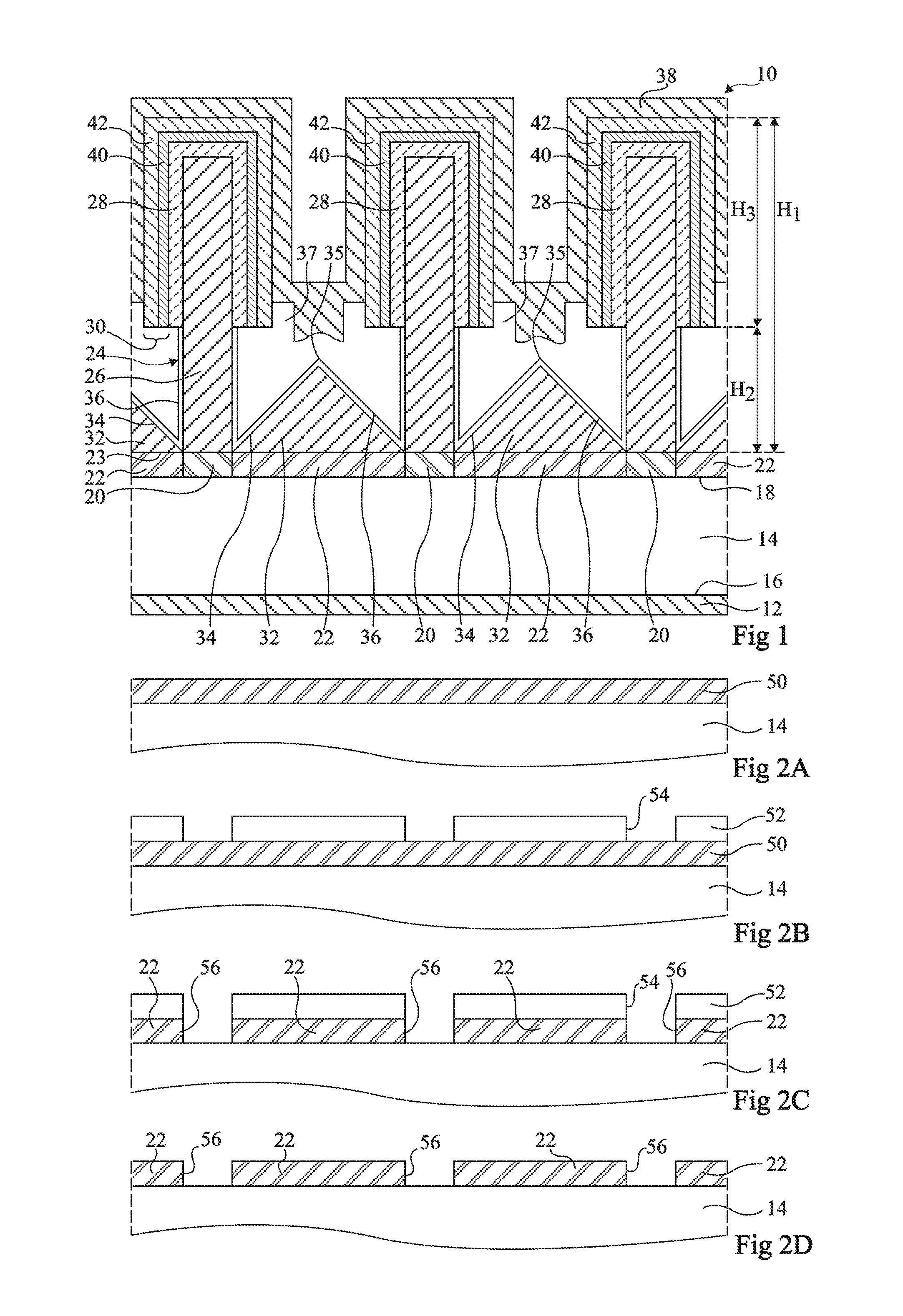

Optoelectric device with semiconductor microwires or nanowires and method for manufacturing the same

ActiveUS20140077151A1Uniform controlLow costFinal product manufactureSemiconductor/solid-state device manufacturingOs elementNanometre

An optoelectric device including microwires or nanowires on a support, each microwire or nanowire including at least one portion mainly containing a III-V compound in contact with the support, wherein the III-V compound is based on a first group-V element and on a second group-III element, wherein a surface of the support includes first areas of a first material promoting the growth of the III-V compound according to the polarity of the first element distributed in a second area of a second material promoting the growth of the compound according to the polarity of the second element, the microwires or nanowires being located on the first areas.

Owner:ALEDIA +1

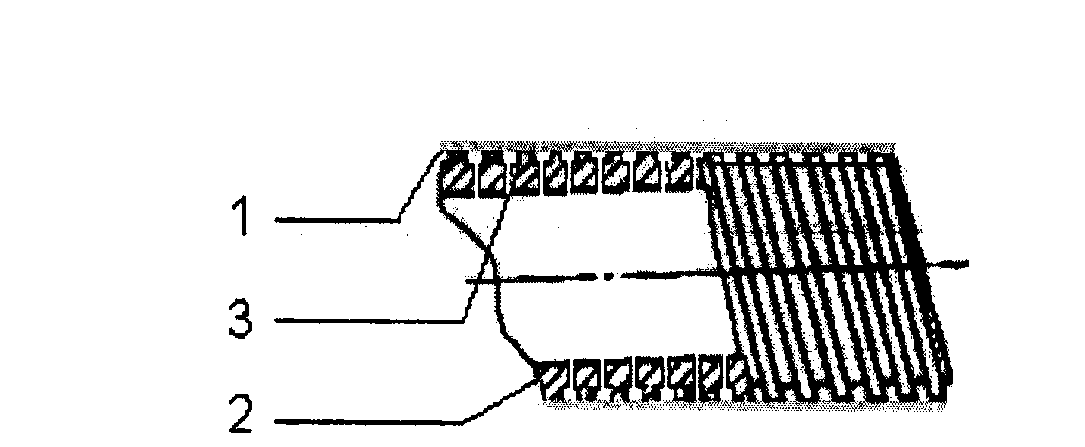

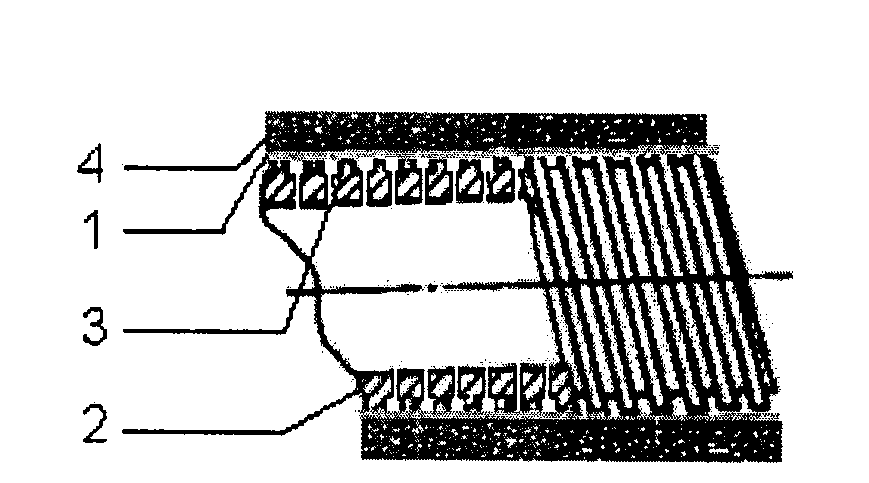

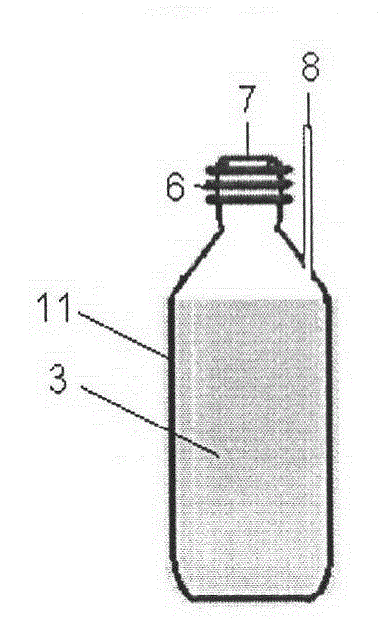

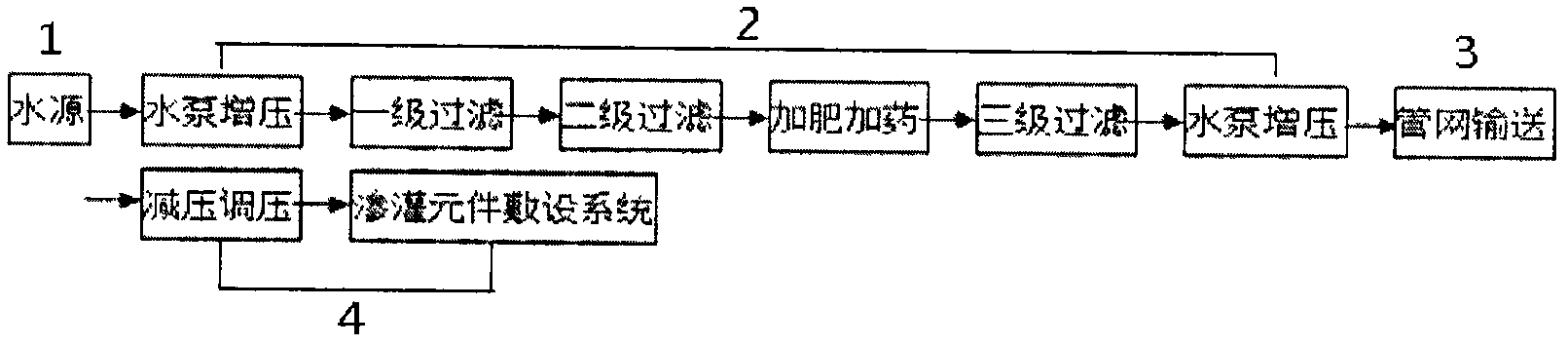

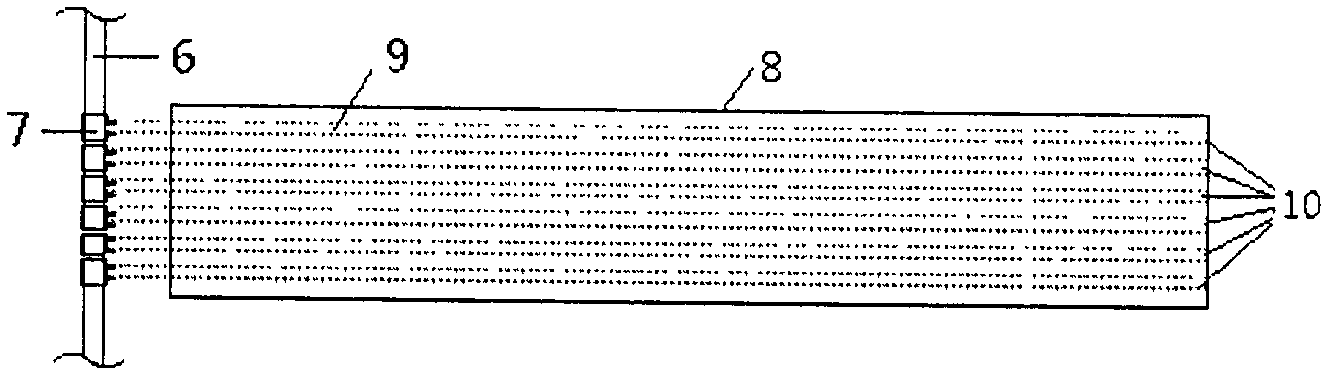

Micro-irrigation permeating tube and manufacturing method thereof

InactiveCN103372505AAntibacterialRodent-proofWatering devicesSynthetic resin layered productsThermoplasticWater saving

The invention relates to a micro-irrigation permeating tube and a manufacturing method thereof. The micro-irrigation permeating tube comprises a capillary permeating tube (1) made of materials having a capillary permeating function is provided with hydrophilic inorganic fillers and a three-dimensional network capillary water seepage structure of thermoplastic plastics, and has unpowered, self-adaptive, continuous and balanced permeation functions, so that water can automatically permeates outward through a tubing or stops permeating outward according to water level of soil contacted with the capillary permeating tube. The capillary permeating tube further comprises a gel protective layer (4), high water retention tree powder is thrown into gaps of non-woven fabric and absorbs water to swell to form the gel protective layer. The tubing having good water permeating capacity can resist blockage, bacteria and prevent rats; by the adoption of the micro-irrigation permeating tube assisted by other irrigation components, an unpowered, self-adaptive, continuous and balanced permeating system which is applicable to the field of water-saving micro-irrigation is formed.

Owner:深圳市金麦田网络技术有限公司

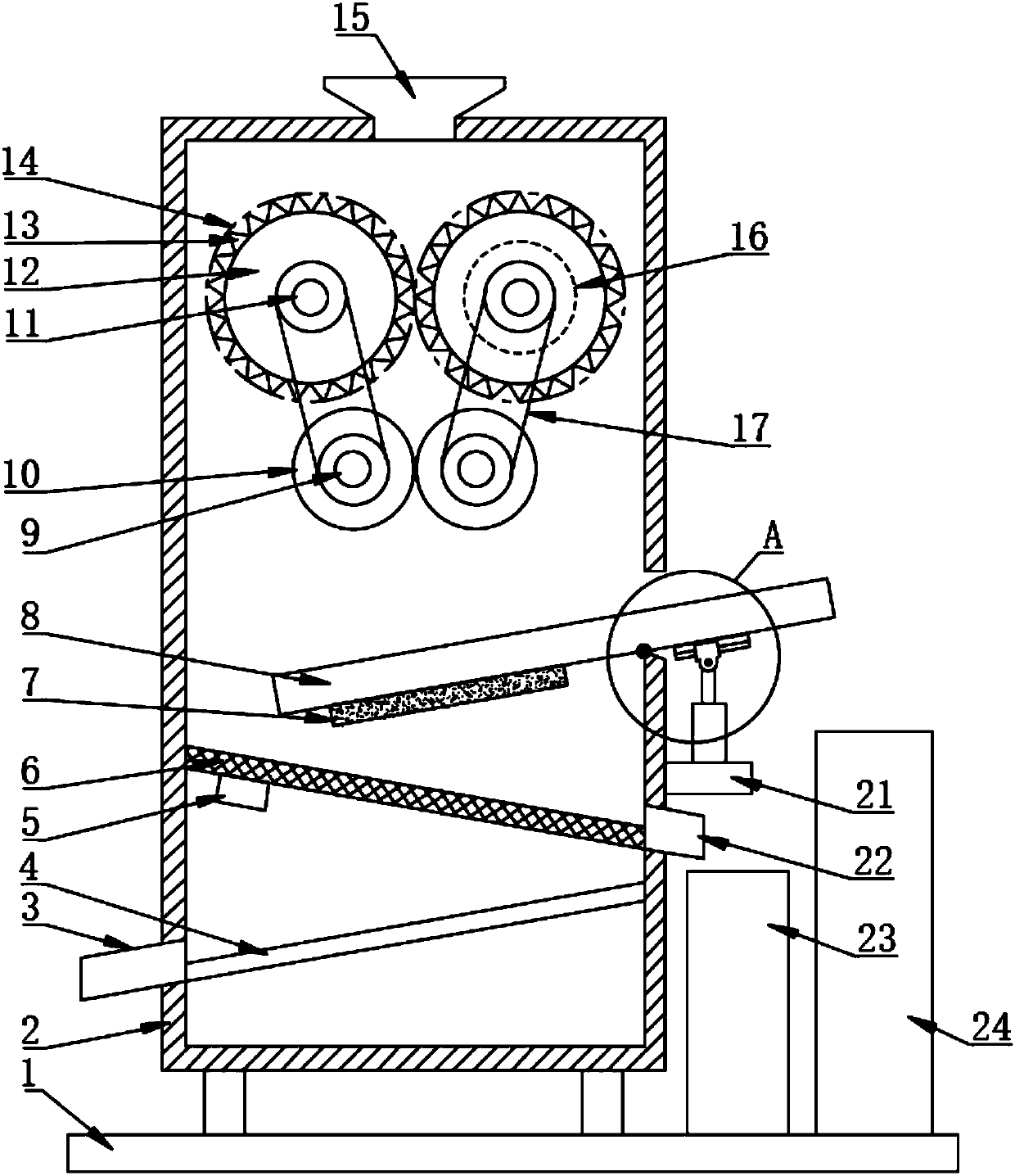

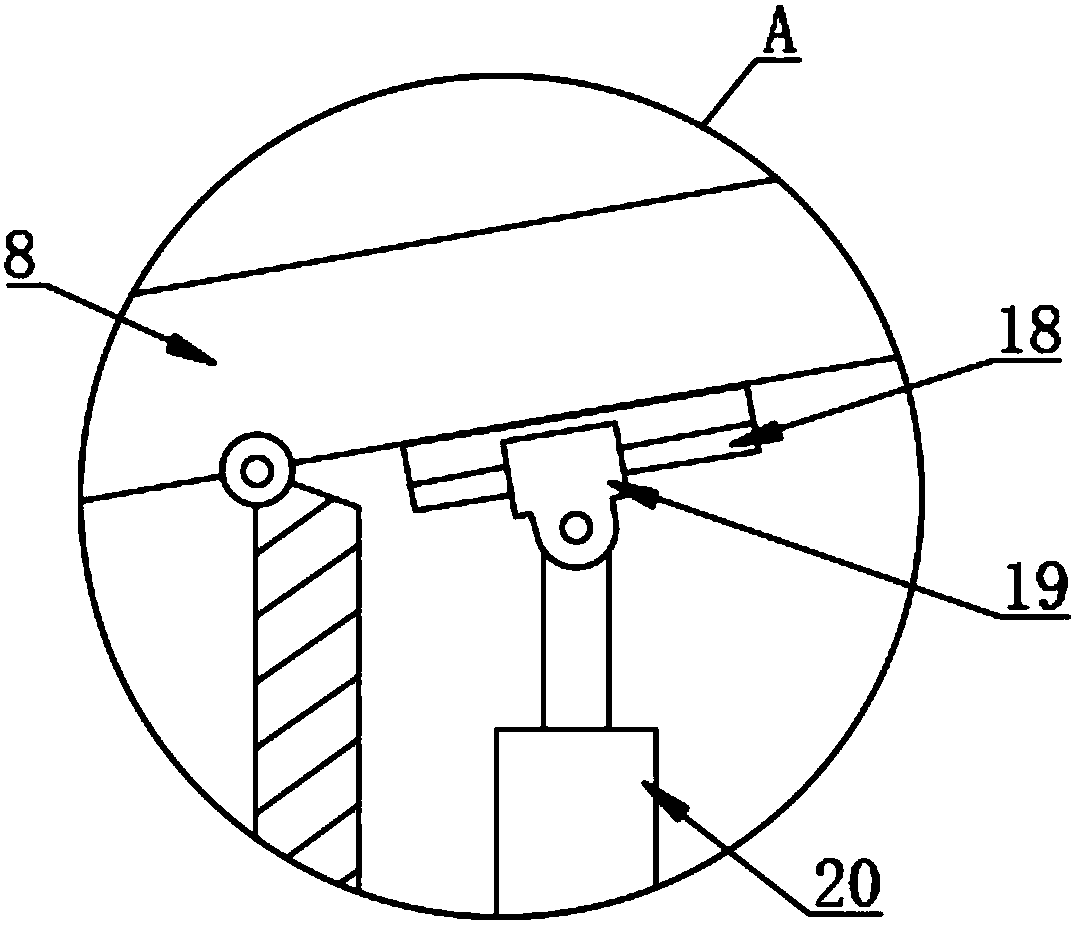

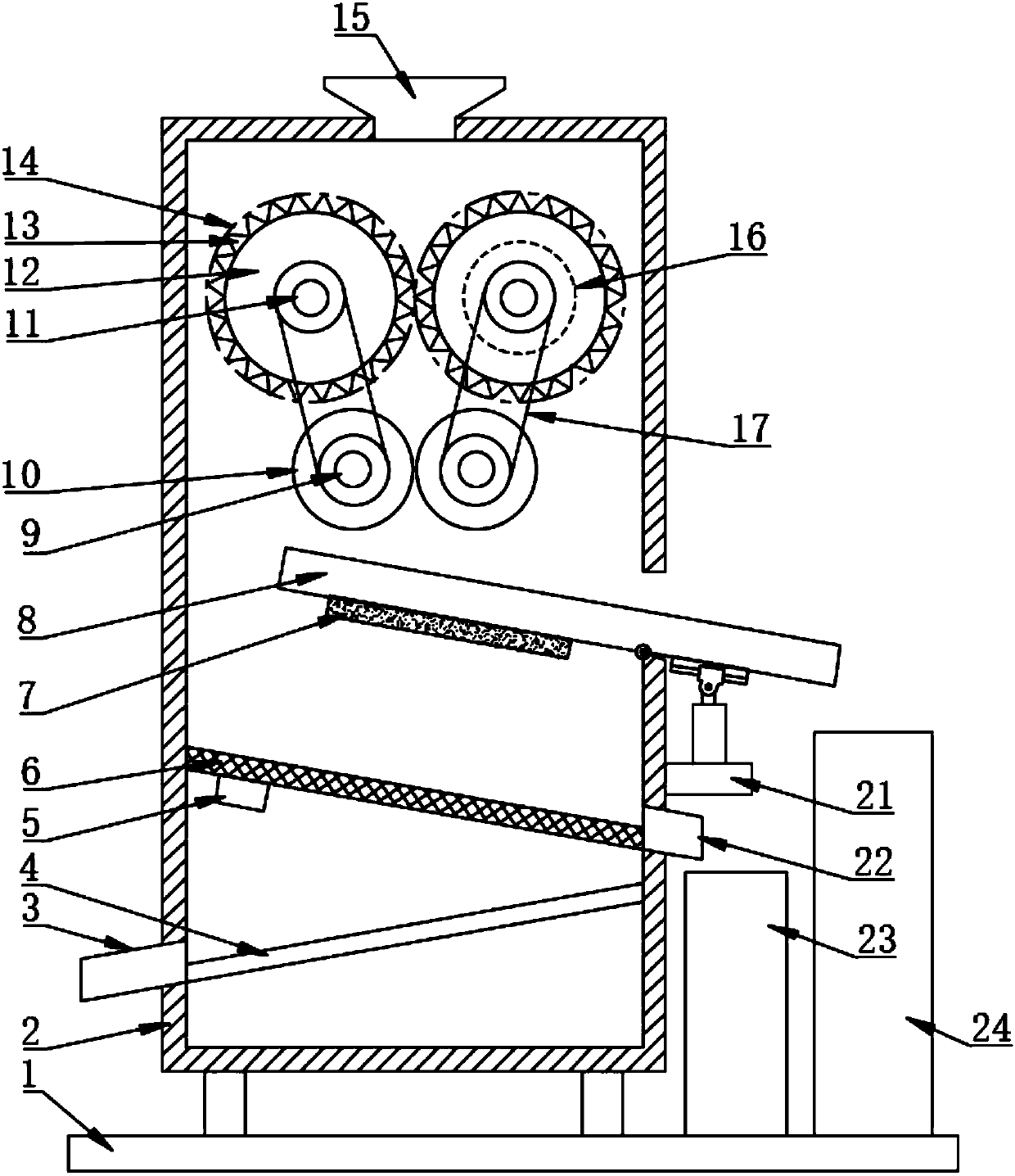

Construction waste crushing and reusing device with iron recovery function

InactiveCN107737631AImprove crushing efficiencyImprove the fineness of crushingMagnetic separationGrain treatmentsMotor shaftScrap

The invention discloses a construction waste crushing and reusing device with an iron recovery function. The construction waste crushing and reusing device comprises a base. A working box is fixedly arranged on the top of the base through a bracket. A left second rotary shaft and a right second rotary shaft are arranged on the top in the working box. Second crushing rollers which are matched witheach other are correspondingly and fixedly mounted in the middle parts of the left second rotary shaft and the right second rotary shaft. Gears which are engaged with each other are correspondingly mounted on the left second rotary shaft and the right second rotary shaft. A gear motor is fixedly arranged on the rear side wall of the working box. A motor shaft at the front end of the gear motor isconnected with the rear end of the second rotary shaft on the right side. An opening is formed in the right side wall of the working box. A receiving tank is hinged to the opening position through a hinge. The receiving tank is located below a first crushing roller. The receiving tank is inclined to the lower left corner. An electromagnet is fixedly arranged at the bottom of the receiving tank andlocated in the working box. According to the construction waste crushing and reusing device with the iron recovery function, iron is attracted by the electromagnet at the bottom of the receiving tankand accordingly recovered; and when the receiving tank is inclined to the lower right corner, the electromagnet is de-energized, and the iron can slide into the iron recovery box.

Owner:徐得强

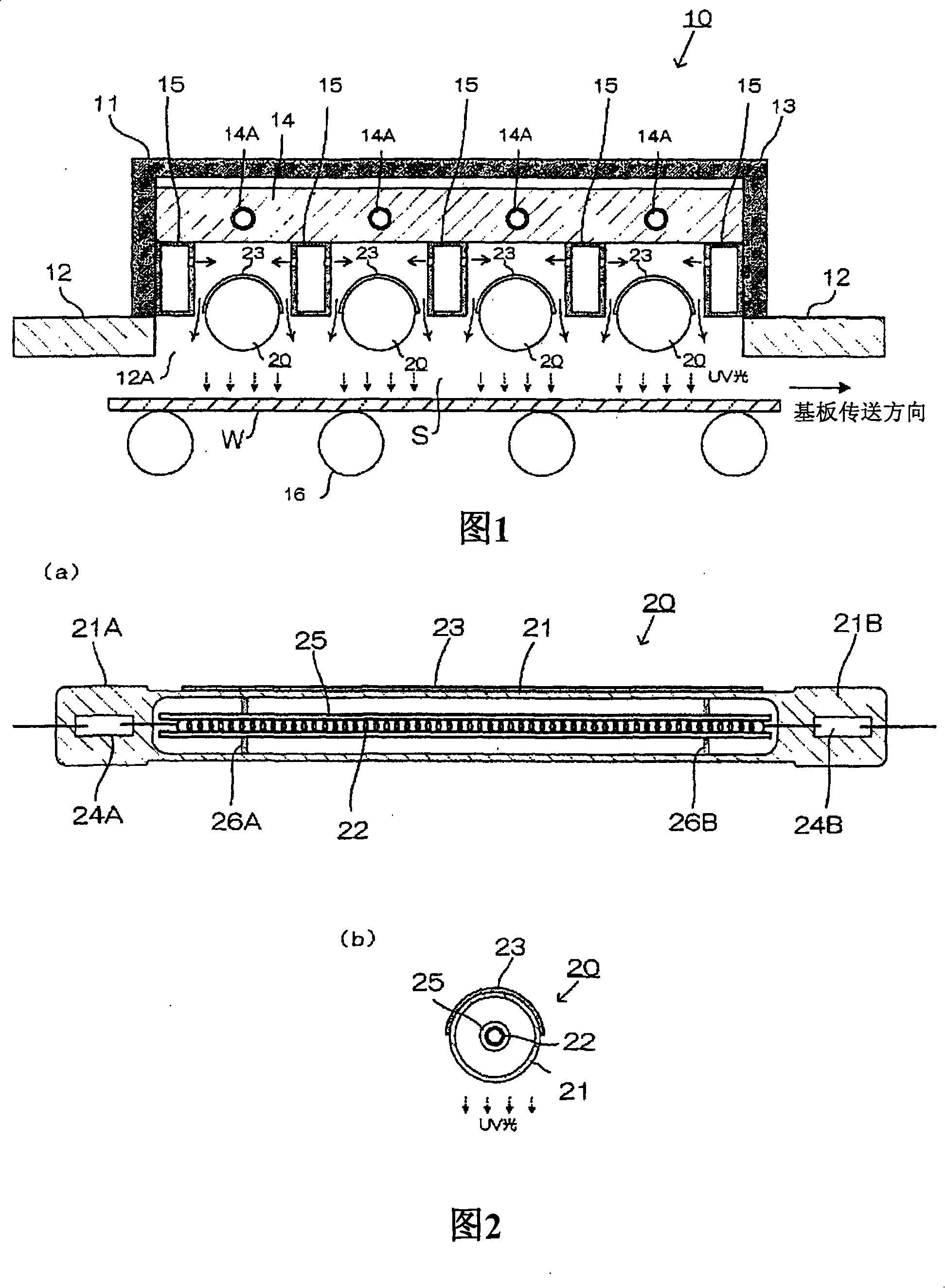

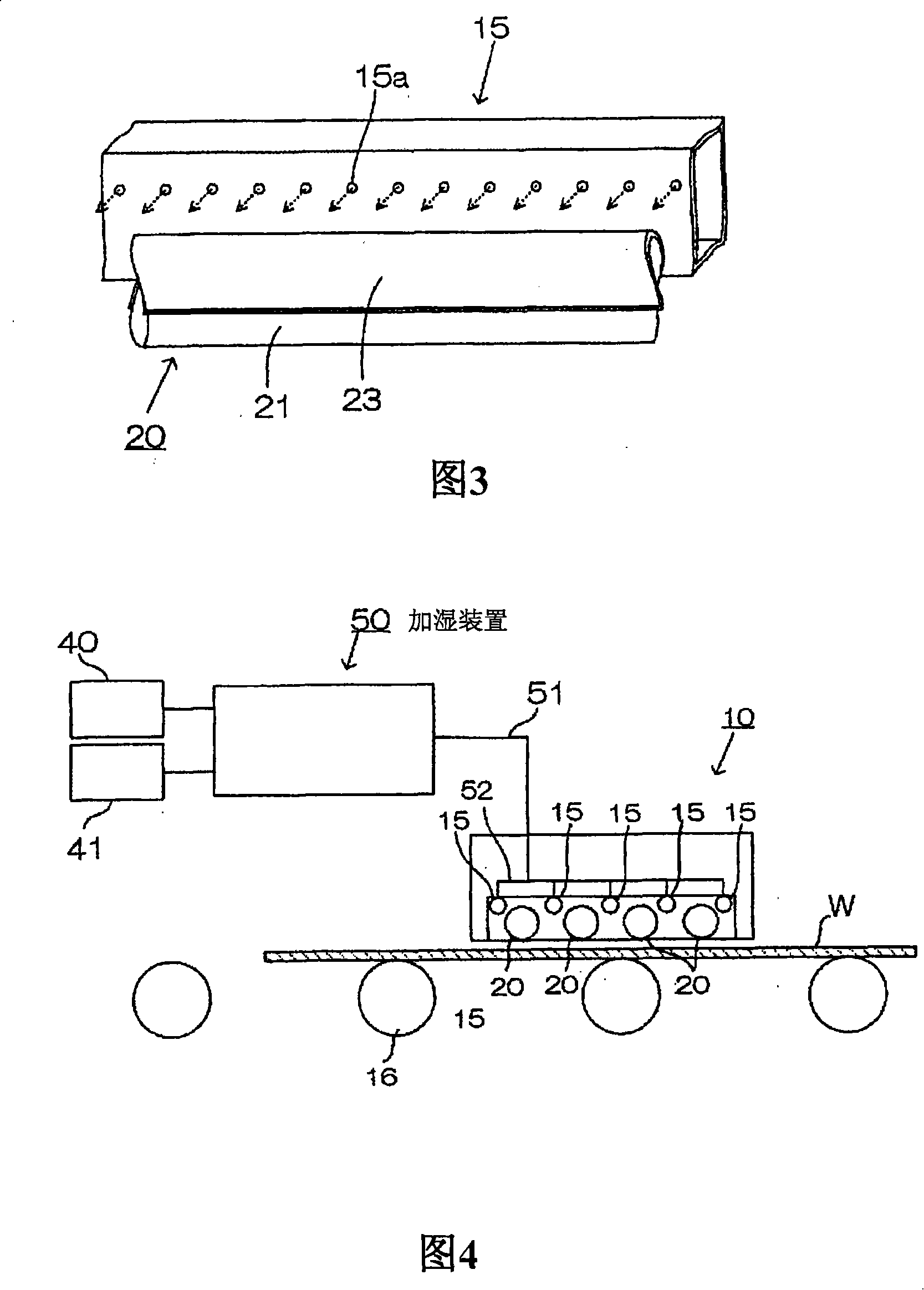

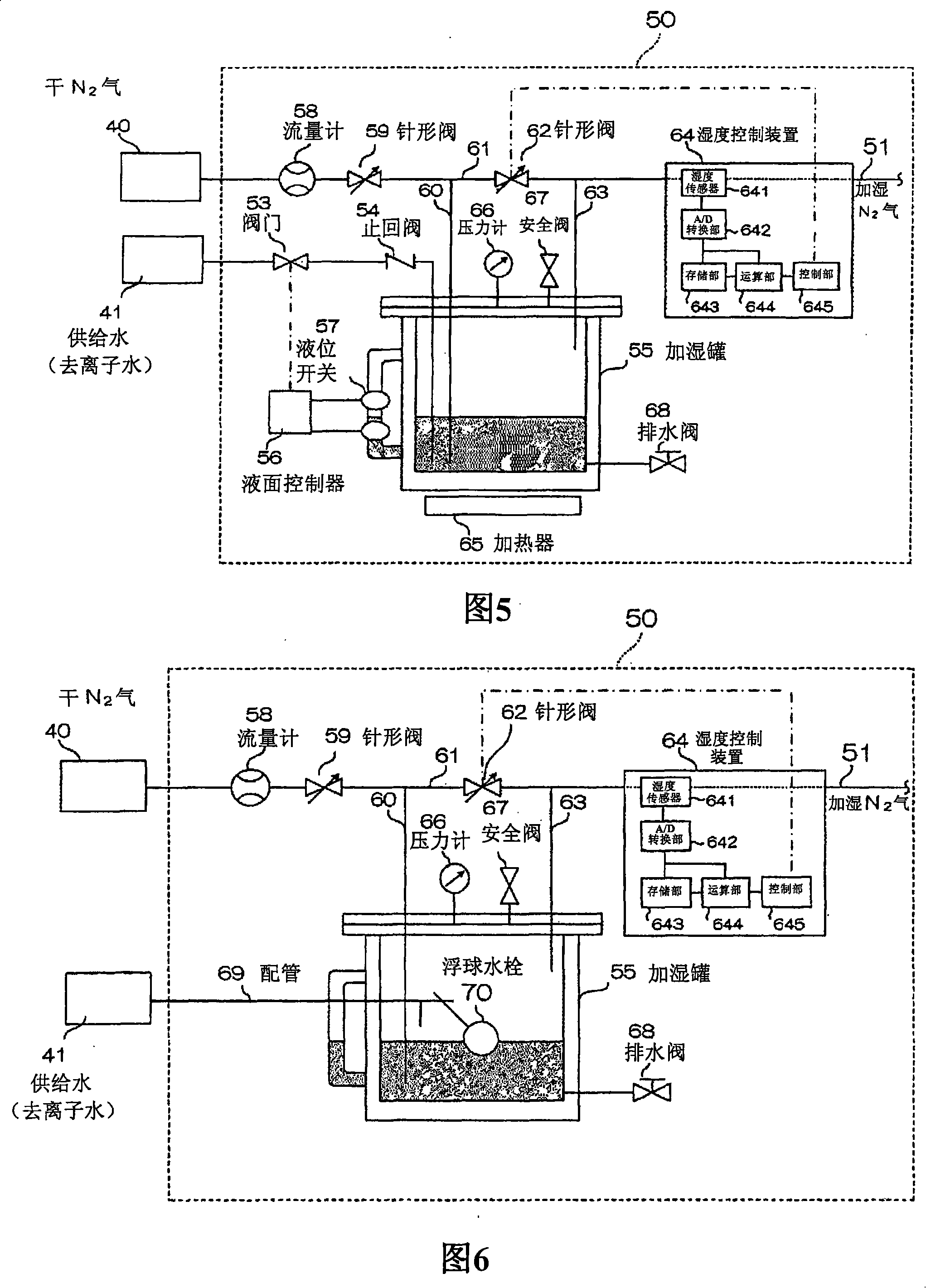

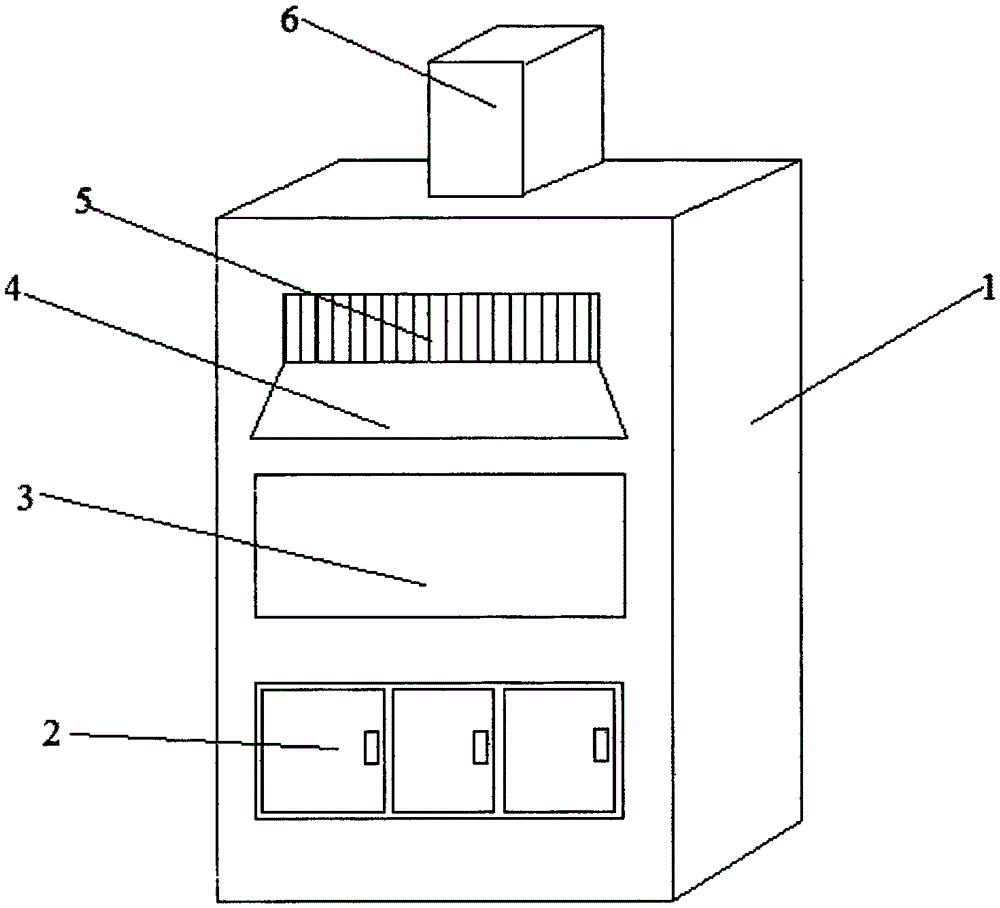

Excimer lamp device

ActiveCN101131228ASuppress excessive attenuationEasy to cleanLighting applicationsSemiconductor/solid-state device manufacturingWater vaporProcess engineering

To provide an excimer lamp device suitably coping with enlargement of a substrate, reducing running cost, and surely treating the surface of the substrate. The excimer lamp device related to the present invention is provided with a lamp house storing excimer lamps; a gas supply pipe having gas jetting ports disposed in the lamp house and located in parallel and alternately with the excimer lamps; and a gas supply means introducing inert gas containing steam to the gas supply pipe. The inert gas with the absolute humidity controlled to a given value is supplied to the gas supply pipe by the gas supply means. The absolute humidity is preferably controlled to 0.5-6.5 g / kg in terms of the weight absolute humidity.

Owner:USHIO DENKI KK

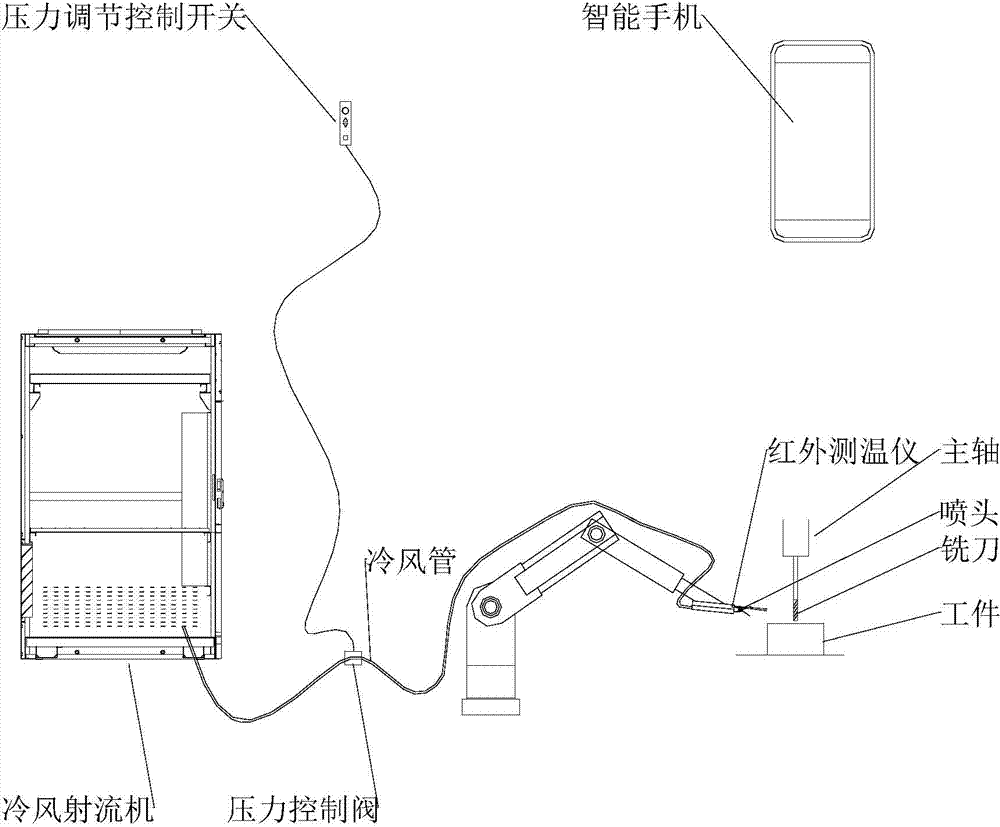

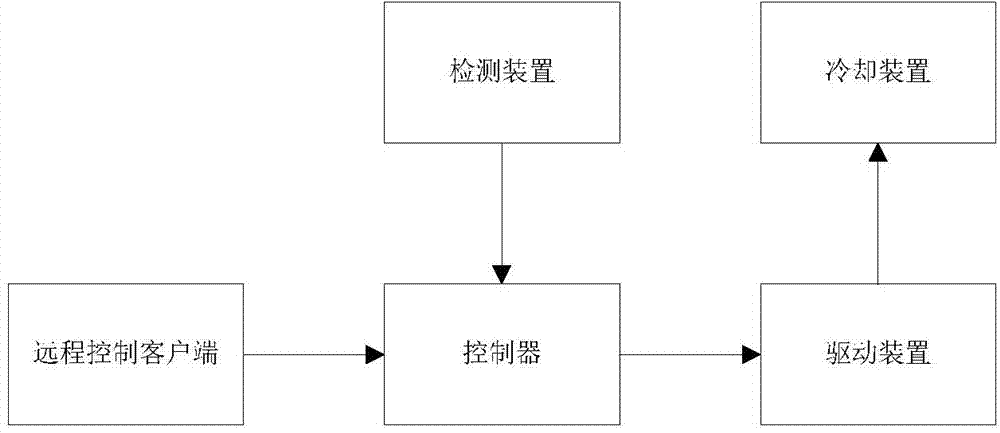

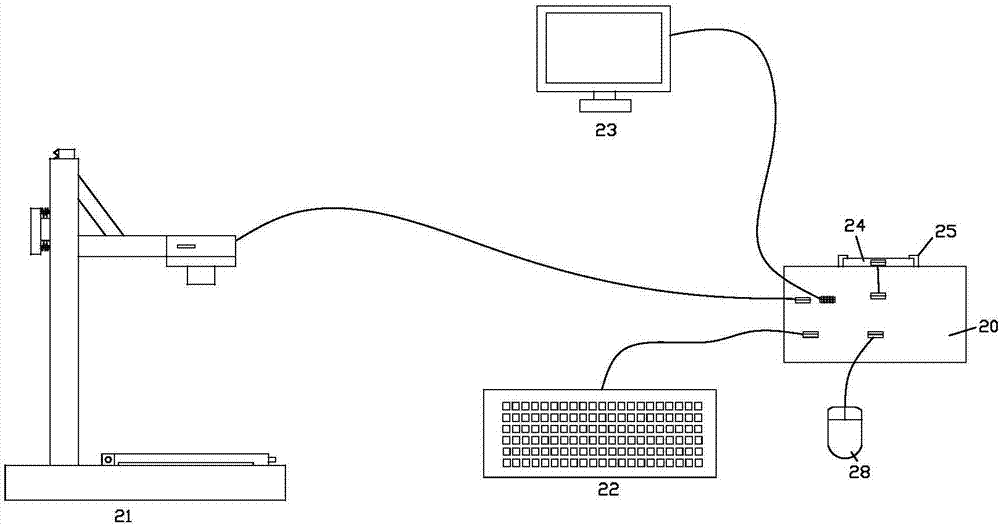

Long-distance temperature control system of machine machining tool

ActiveCN104765391AUniform coolingEasy to useAuxillary controllers with auxillary heating devicesCold airMachine tool

The invention provides a long-distance temperature control system of a machine machining tool. The long-distance temperature control system comprises a cooling device, a drive device, a detection device used for detecting the temperature of the machine machining tool, a controller and a long-distance control client-side. The cooling device is connected with the drive device. The drive device is connected with the controller and used for controlling the drive device to change the position where the machine machining tool is cooled through the cooling device. The detection device is connected with the controller. The long-distance control client-side is connected with the controller in a wireless data transmission mode and used for sending a control command to the controller. By means of the long-distance temperature control system, the cooling of a traditional machine machining tool and the internet of things are combined, a cold air blast jet flow machine is controlled through an intelligent mobile phone, the position of a spray nozzle can be adjusted according to actual requirements, the machine machining tool is uniformly cooled, the long-distance control over the temperature of the machine machining tool is achieved, and the long-distance temperature control system has the advantages of being easy to use, convenient to control, good in cooling effect, low in energy consumption and capable of controlling the tool temperature any time any place.

Owner:珠海精芯科技有限公司

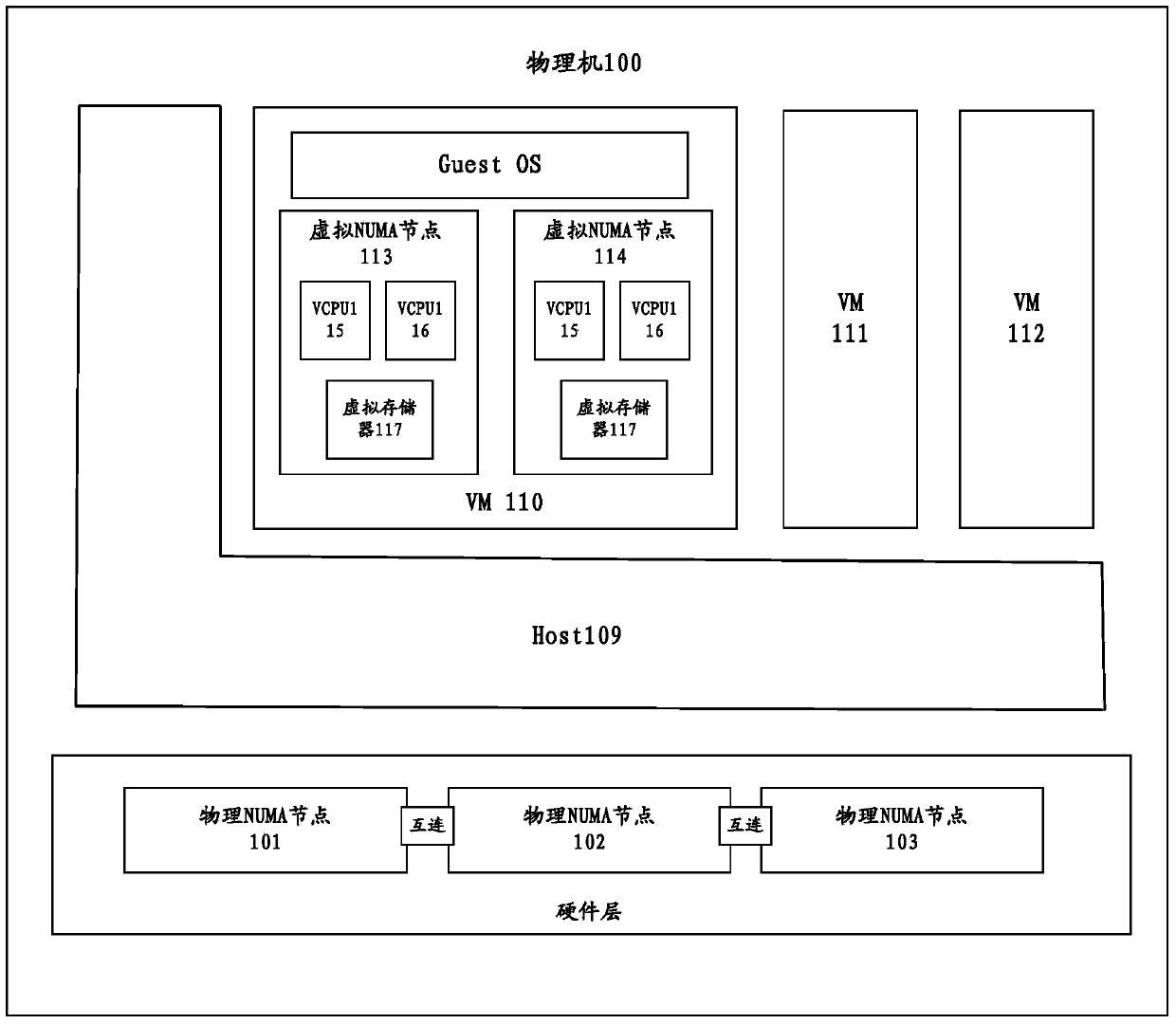

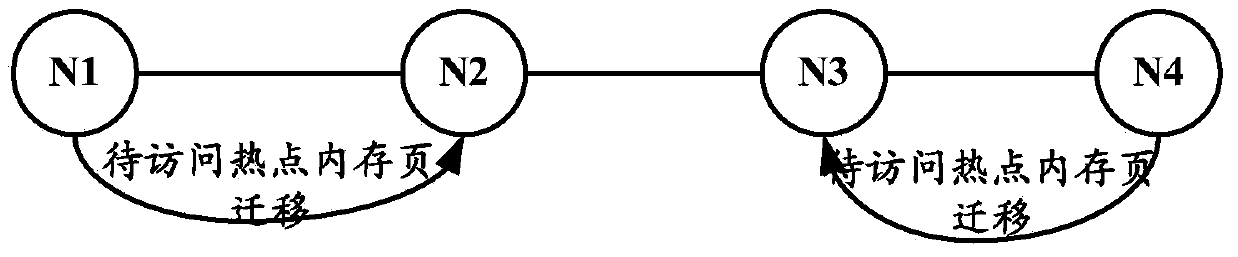

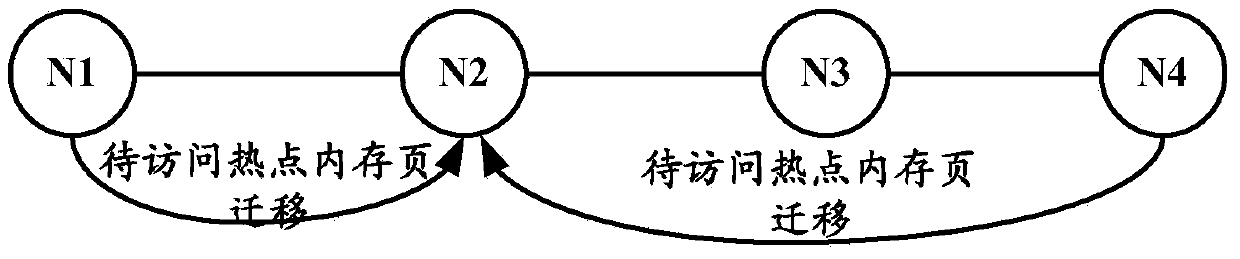

Hotspot balance control method and related device

InactiveCN104216784AUniform controlReduce the chance of overheatingResource allocationSoftware simulation/interpretation/emulationVirtual machine

The embodiment of the invention discloses a hotspot balance control method and a related device. The method comprises the following steps of establishing a current hottest node set; predicting a to-be-accessed hotspot memory page of each physical NUMA node in the current hottest node set; determining a hottest virtual machine; migrating the to-be-accessed memory page corresponding to the hottest virtual machine to an idle physical NUMA hotspot. In the embodiment, the to-be-accessed hotspot memory page on a physical machine is predicted, and the to-be-accessed hotspot memory page of the hottest virtual machine is migrated. The predicted to-be-accessed hotspot memory page is the memory page which is possibly frequently accessed in future, after the predicted to-be-accessed hotspot memory page is migrated, the probability that one NUMA node is overheated in future can be reduced to certain extent, and the hotspot balance control can be realized.

Owner:HANGZHOU HUAWEI DIGITAL TECH

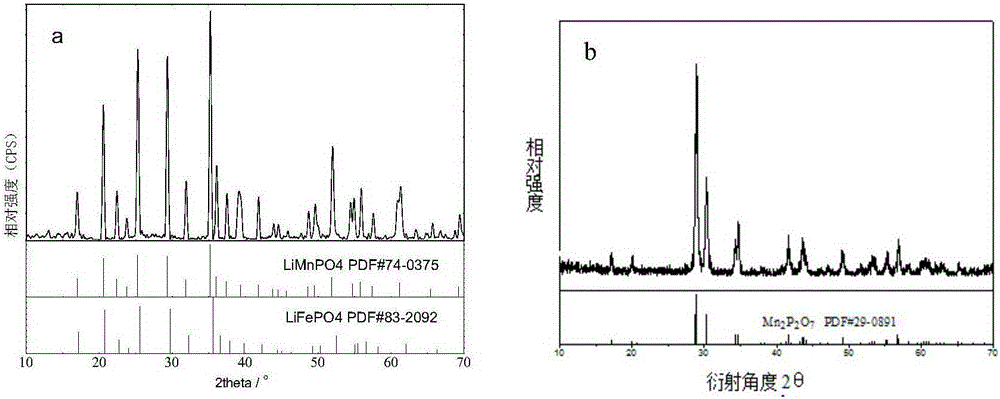

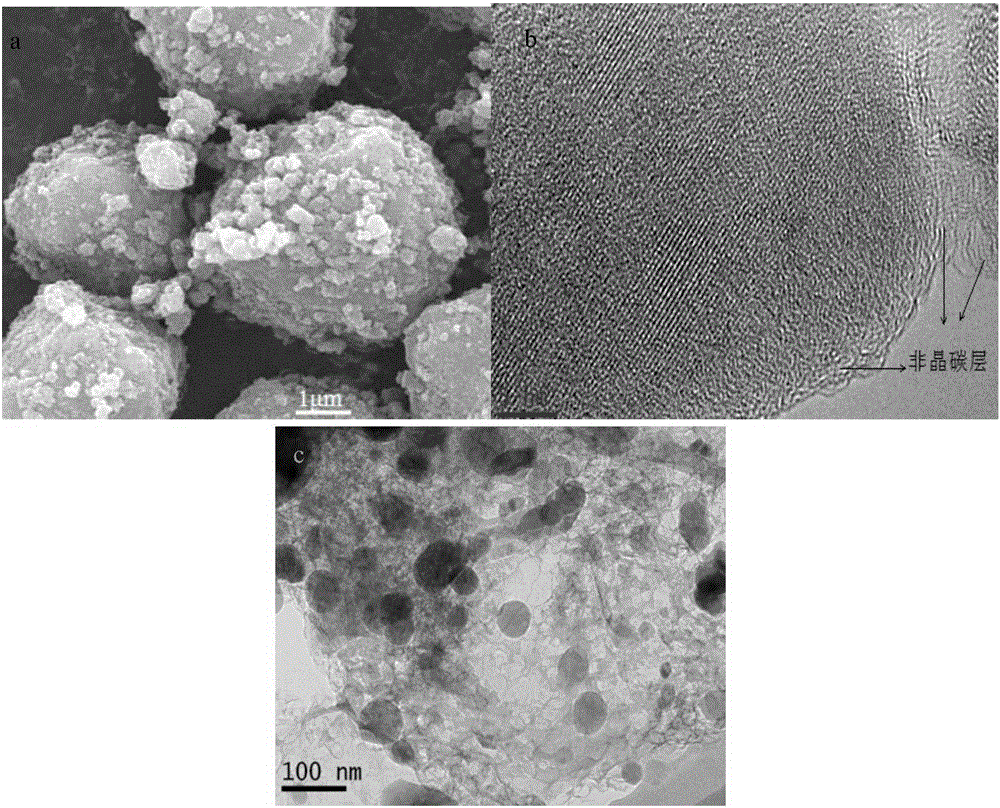

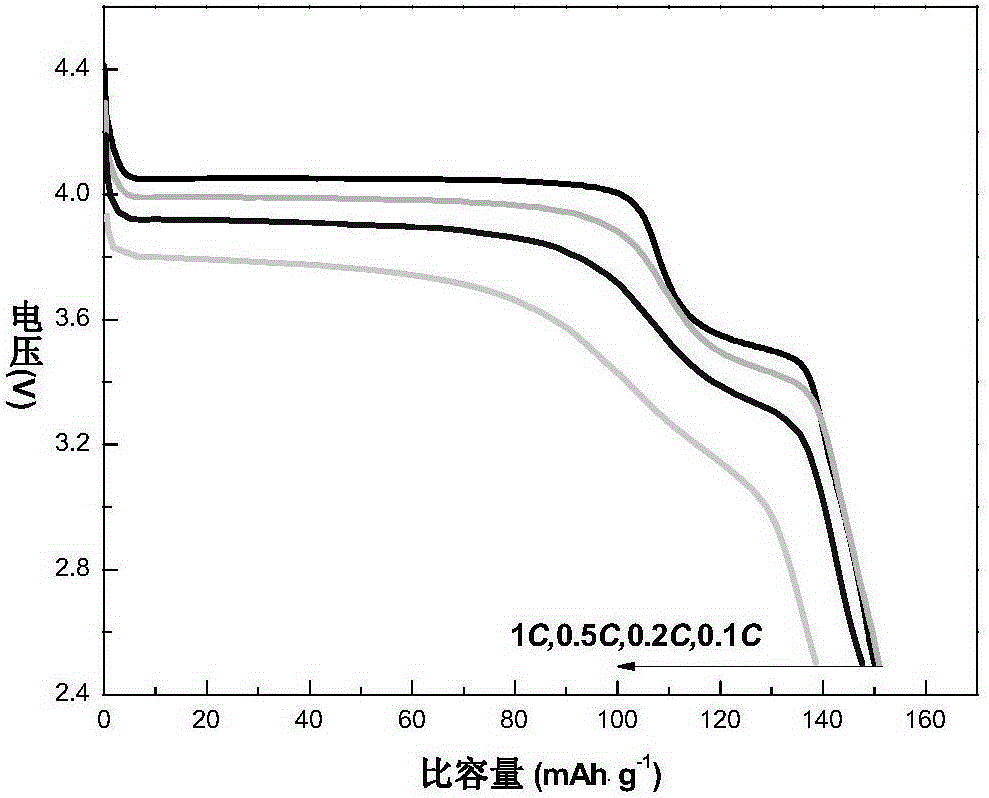

Synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4/C

InactiveCN105355885AUniform controlAdd lessSecondary cellsPositive electrodesHigh rateSynthesis methods

The invention relates to a synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4 / C. A manganese source, an iron source, a phosphorus source and an organic carbon source are evenly mixed and processed by a high-energy ball mill. Mixtures are subjected to heat treatment at 500-700 DEG C under the protection of inert atmosphere so that (Mn1-xFex)2P2O7 / C can be prepared; then, pyrophosphate / carbon, a lithium source and a carbon source are mixed, heat treatment is performed at 600-750 DEG C under protection of inert atmosphere, and ferromanganese lithium phosphate / carbon anode materials with a composite conductive network are obtained. The synthesis method is suitable for large-scale industrialized production, the prepared materials are composed of secondary particles of primary nano-crystals covered with amorphous carbon, distribution is uniform, and the uniform conductive network is formed on the surfaces of phosphate particles in an in-situ mode. The obtained composite cathode material has high rate capacity and high compaction intensity and has good application prospects in the aspect of high-energy-density lithium ion batteries.

Owner:CENT SOUTH UNIV

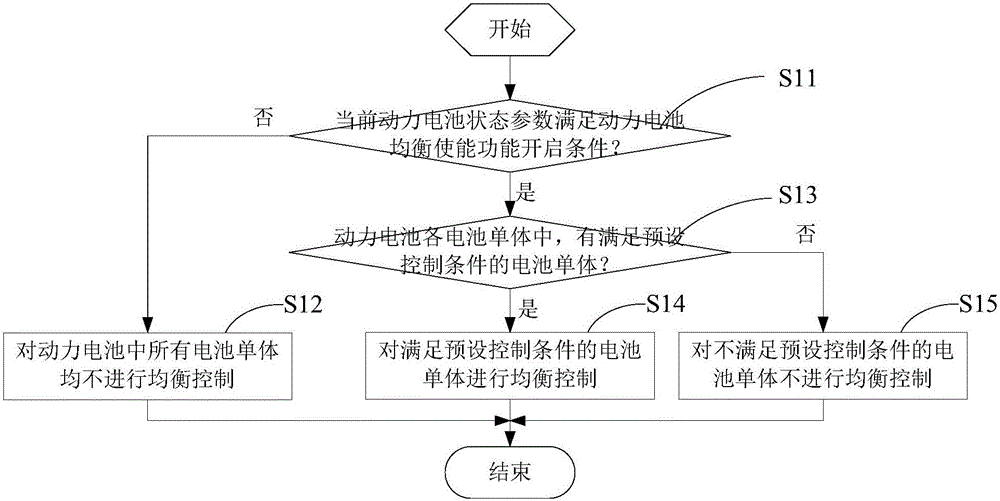

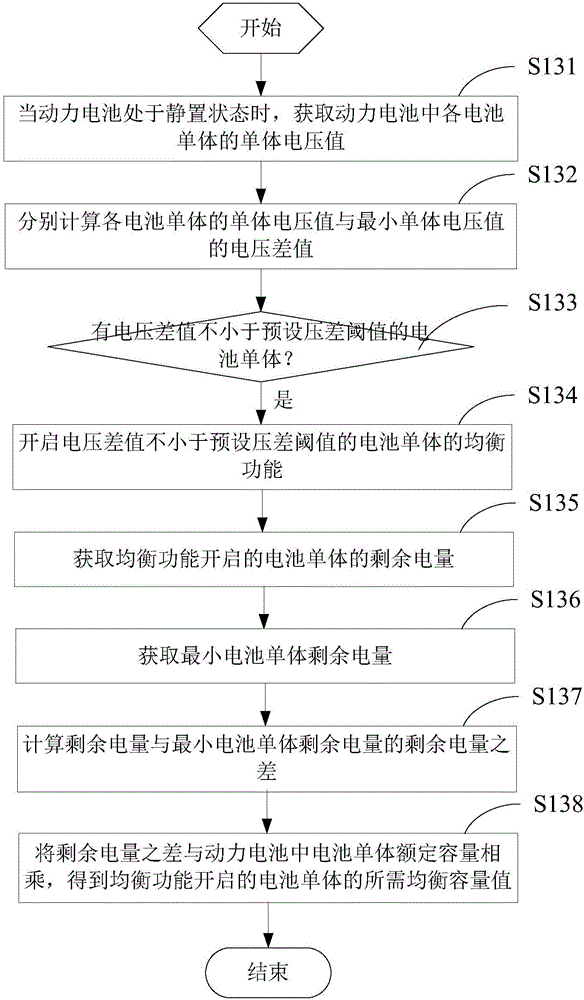

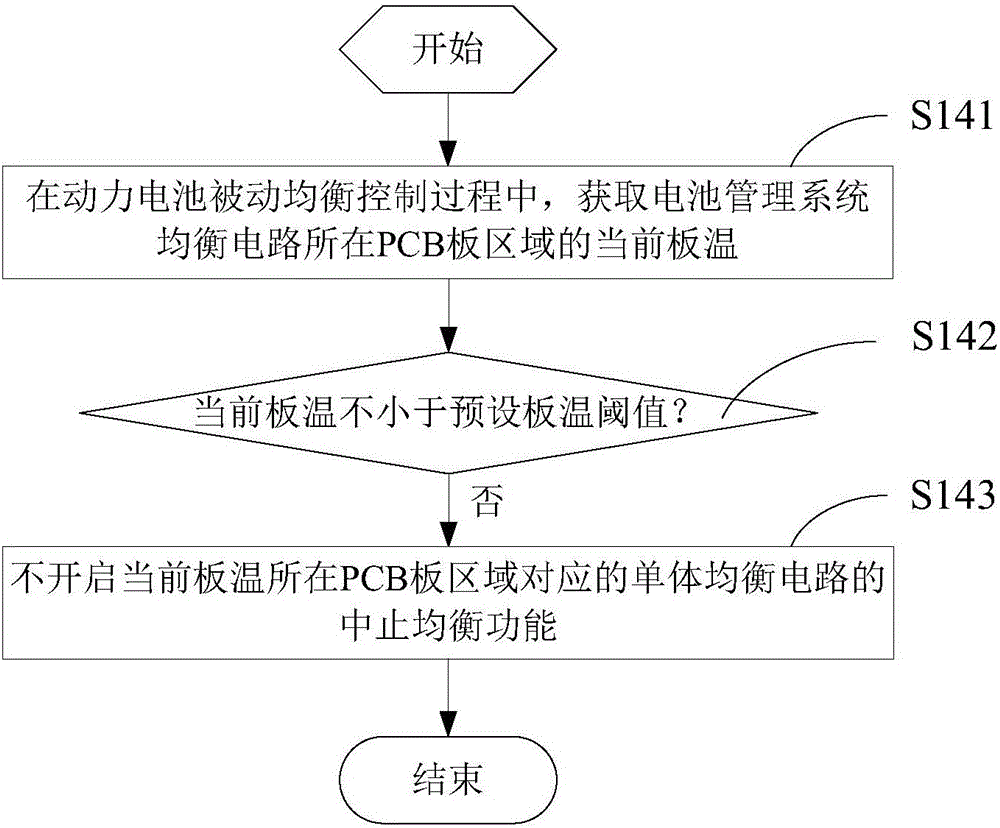

Power battery passive equalization control method and system

ActiveCN106042961AAvoid the risk of overcharging and overdischargingExtended service lifeElectric devicesVehicular energy storagePower batteryState parameter

The invention discloses a power battery passive equalization control method and system. The power battery passive equalization control method comprises the steps that when the current power battery state parameter does not meet the power battery equalization enable function open condition, equalization control is not conducted on all single battery bodies in a power battery; and when the current power battery state parameter meets the power battery equalization enable function open condition, equalization control is conducted on the single battery bodies which meet the preset control condition, and equalization control is not conducted on the single battery bodies which do not meet the preset control condition. Therefore, equalization control over all the single battery bodies in the same power battery is achieved through the power battery passive equalization control method and system, so that over-charging and over-discharging risks during full charging and full discharging of the power battery are effectively avoided, and the service life of the power battery is prolonged.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

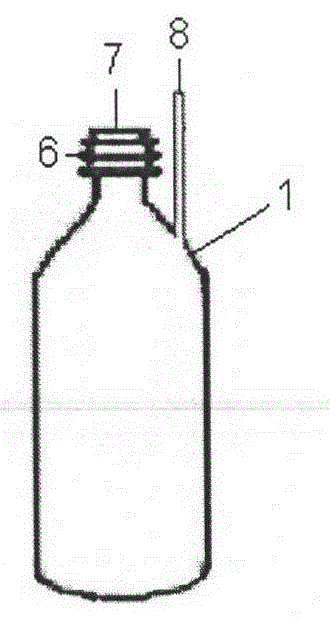

Seeping micro-irrigation container and preparation method thereof

InactiveCN102742489AAntibacterialRodent-proofWatering devicesSynthetic resin layered productsThermoplasticCapillary network

The invention relates to a seeping micro-irrigation container and a preparation method thereof. The container is made of a micro-irrigation material with a capillary water seeping function, has a three-dimensional network capillary water seeping structure of inorganic particles and thermoplastic plastics, and has a power-free self-adaptation, continuous and balanced seeping function. According to water potential of soil contacted with the container, water can seep outwards automatically through the capillary network structure inside the container or stop seeping outwards. The container further comprises a gel protective layer (11). The container has good water seeping capacity, can prevent blocking, bacteria and rats, can be used as a mini reservoir independently, can also be connected with a pipeline system, and forms a power-free self-adaptation, continuous and balanced seeping micro-irrigation system.

Owner:深圳市金麦田网络技术有限公司

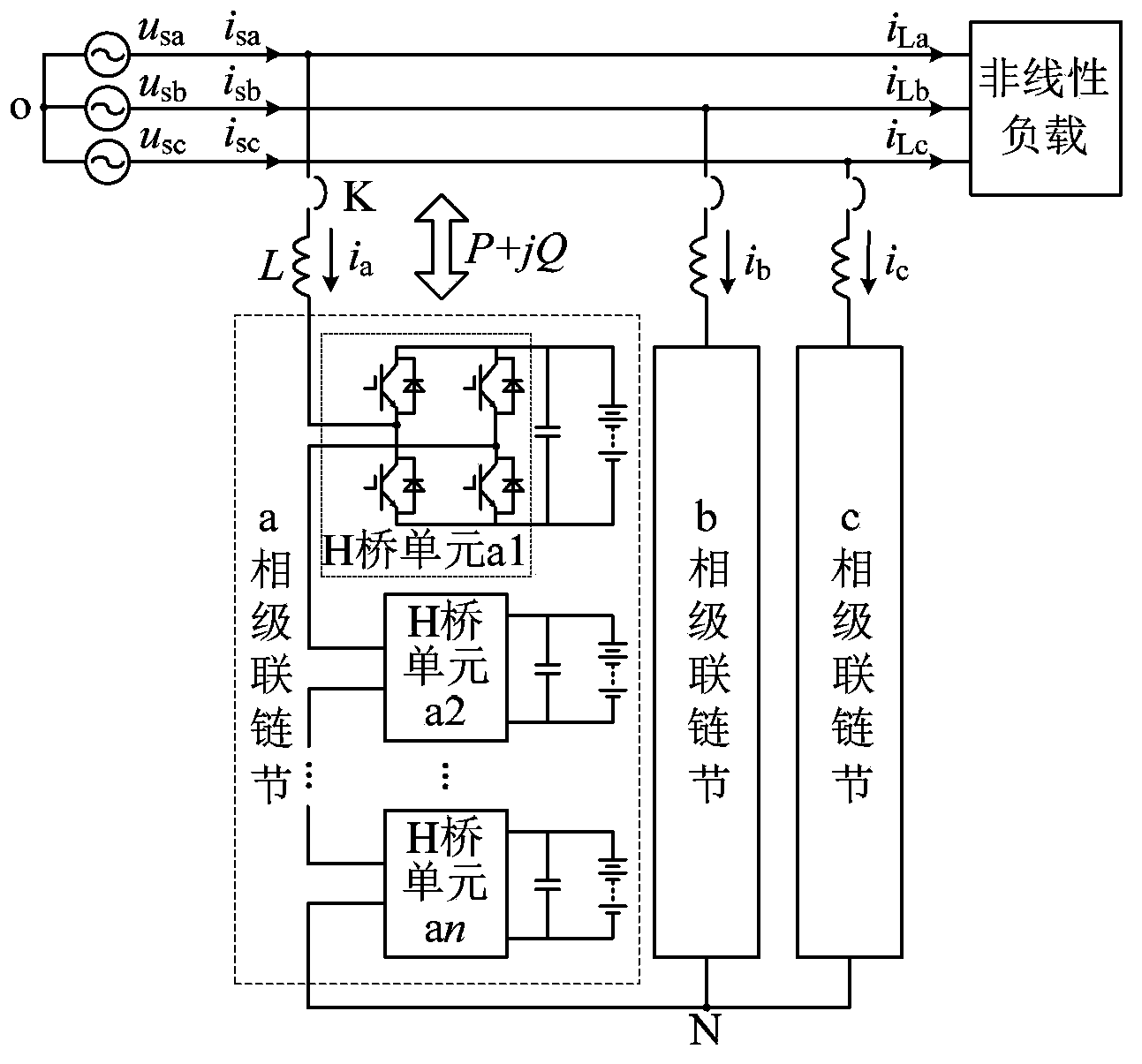

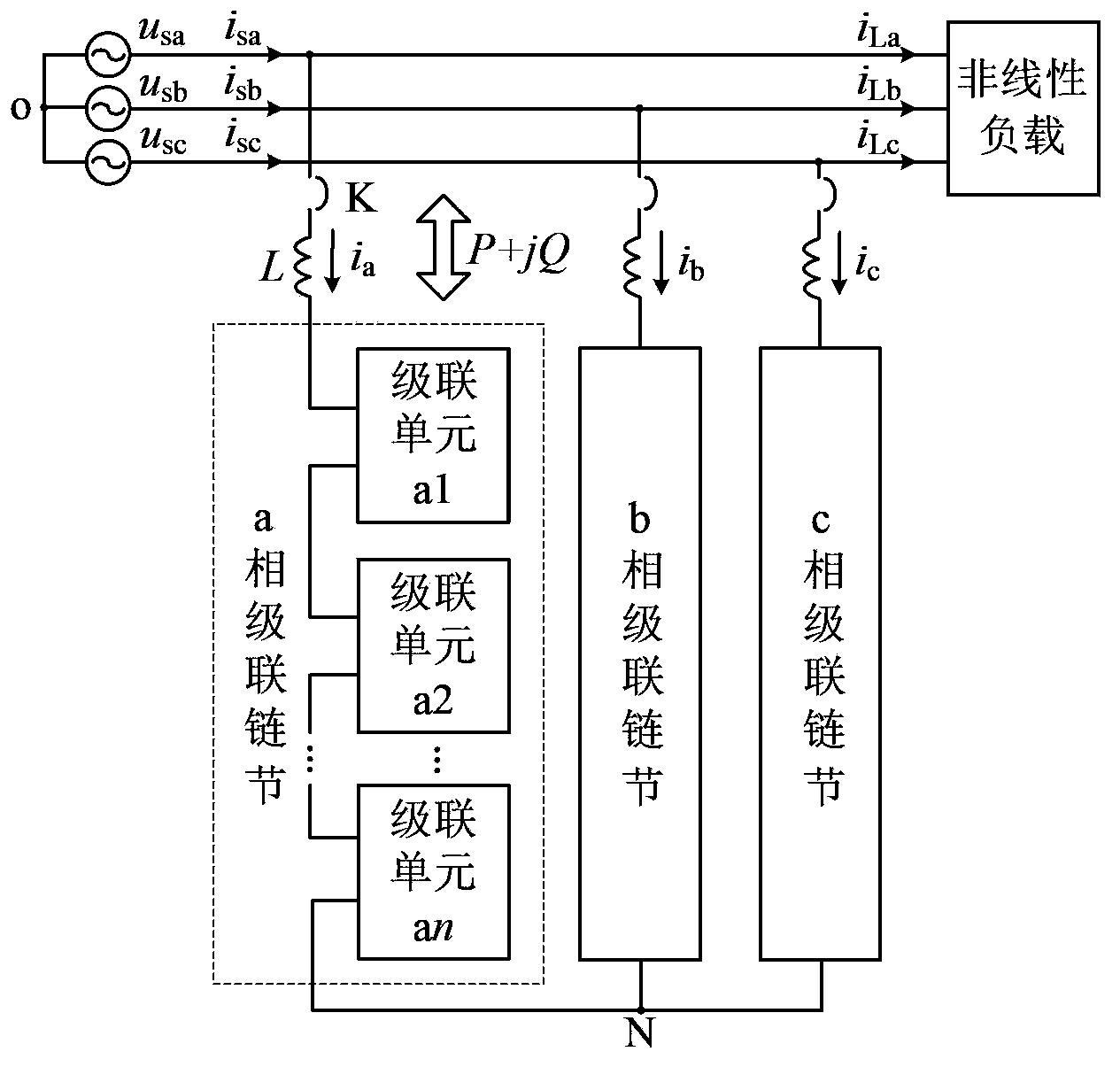

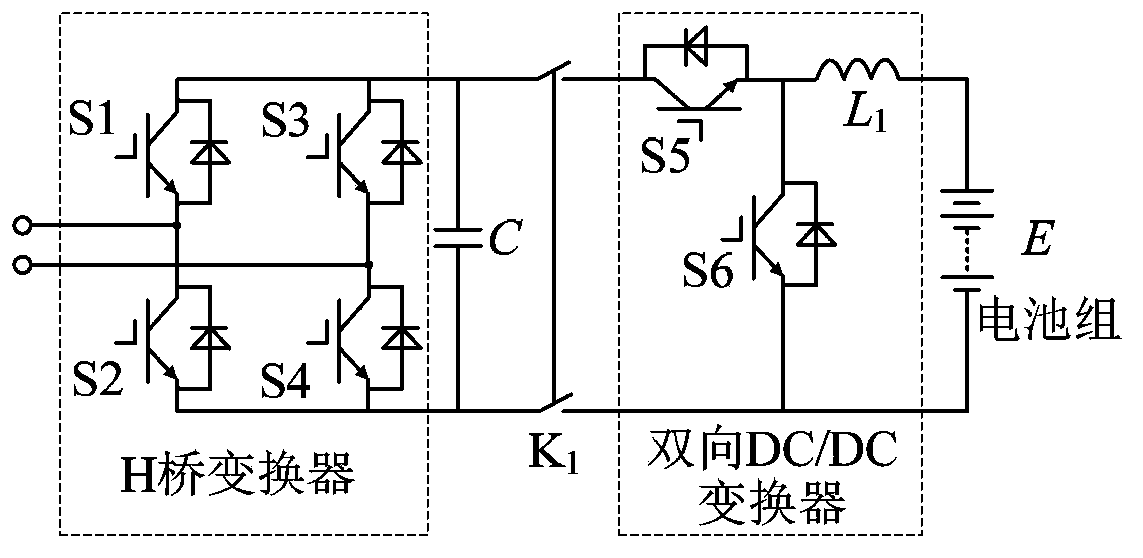

Chained static synchronous compensator with active power adjusting capacity and cascading unit thereof

InactiveCN103457271AAchieve powerFlexible and diverse power adjustment functionsFlexible AC transmissionAc network load balancingGrid connectionThree-phase

The invention provides a chained static synchronous compensator with an active power adjusting capacity. The chained static synchronous compensator with the active power adjusting capacity comprises three phases of cascading chain links, connection reactors and breakers. Each phase of the cascading chain link comprises n cascading units which are connected in series at the alternating current side. One ends of the three phases of the cascading units are connected to form a neutral point of the static synchronous compensator, and the other ends of the three phases of the cascading units are connected into a three-phase grid through the corresponding connection reactors and the corresponding breakers. The invention further provides a corresponding cascading unit. An STATCOM and a BESS are combined, the capacity of controlling active power and reactive power at the same time is achieved, grid connection of medium voltage and high voltage is achieved in a manner of cascading multiple cascading units, a power switch device which is low in voltage resistance is used for achieving energy conversion of high voltage levels, modularization and redundancy design are easy to achieve, the function of balancing a battery is achieved, meanwhile, a bidirectional DC / DC converter is introduced at the direct current side, and ensuring the cycle life of the battery is facilitated.

Owner:SHANGHAI JIAO TONG UNIV

Environmental-friendly permeable ceramic brick and preparation method thereof

InactiveCN106892675ASolve the problem of accumulating and polluting the environmentRealize recyclingCeramic materials productionCeramicwareEnvironmental resistanceFrost

The invention belongs to the technical field of ceramic flooring tiles and in particular relates to an environmental-friendly permeable ceramic brick and a preparation method thereof. The permeable ceramic brick comprises the following components in percentage by mass: 60-80% of waste ceramic chip granules of the ceramic brick, 5-10% of a high-temperature inorganic adhesive, 5-10% of a fluxing agent, 10-20% of a pore forming agent and a low-temperature organic adhesive accounting for 1-1.5% of the mass sum of the previous four basic materials. The preparation method comprises the following steps: mixing all the materials, molding, drying and roasting, thereby obtaining the permeable ceramic brick. The permeable ceramic brick has excellent water permeability, strength and anti-frost property.

Owner:辽宁法库陶瓷工程技术研究中心

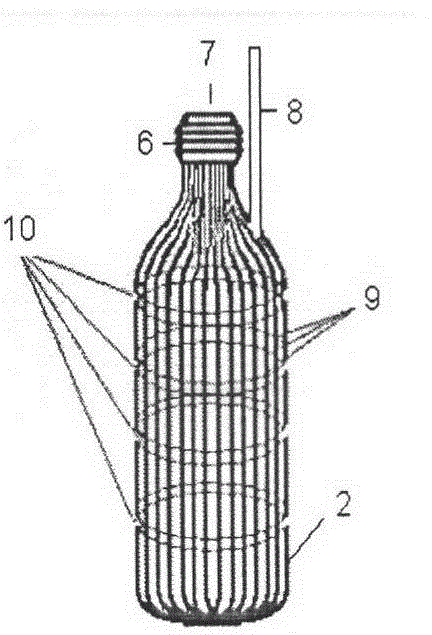

Infiltrating micro-irrigation system

InactiveCN102907294AAntibacterialRodent-proofWatering devicesSynthetic resin layered productsIrrigation managementWater saving

The invention relates to a micro-irrigation system, a manufacturing method and an application of the micro-irrigation system. An irrigation element of an irrigation section of the micro-irrigation system is an unpowered self-adapting, lasting and balanced infiltrating micro-irrigation pipe or container; the irrigation element comprises a capillary infiltration layer (11) with a three-dimensional mesh structure; and the capillary infiltration layer is made from a capillary infiltrating micro-irrigation material with the three-dimensional mesh structure, and the micro-irrigation element is further coated with a gel protective layer (13). The micro-irrigation system has a composite infiltration structure, and the water can automatically permeate outwards or stop permeating outwards through the infiltrating micro-irrigation element according to the water potential height of the soil contacting the water. The system has the functions of resisting blockage and bacterium and can prevent a mouse, can be widely applied to the field of water-saving micro-irrigation and applied to a desert to play the roles of stabilizing sand and improving the desert, and can be applied to saline and alkaline lands to play the roles of holding down salt and alkali and transforming the saline and alkaline lands.

Owner:深圳市金麦田网络技术有限公司

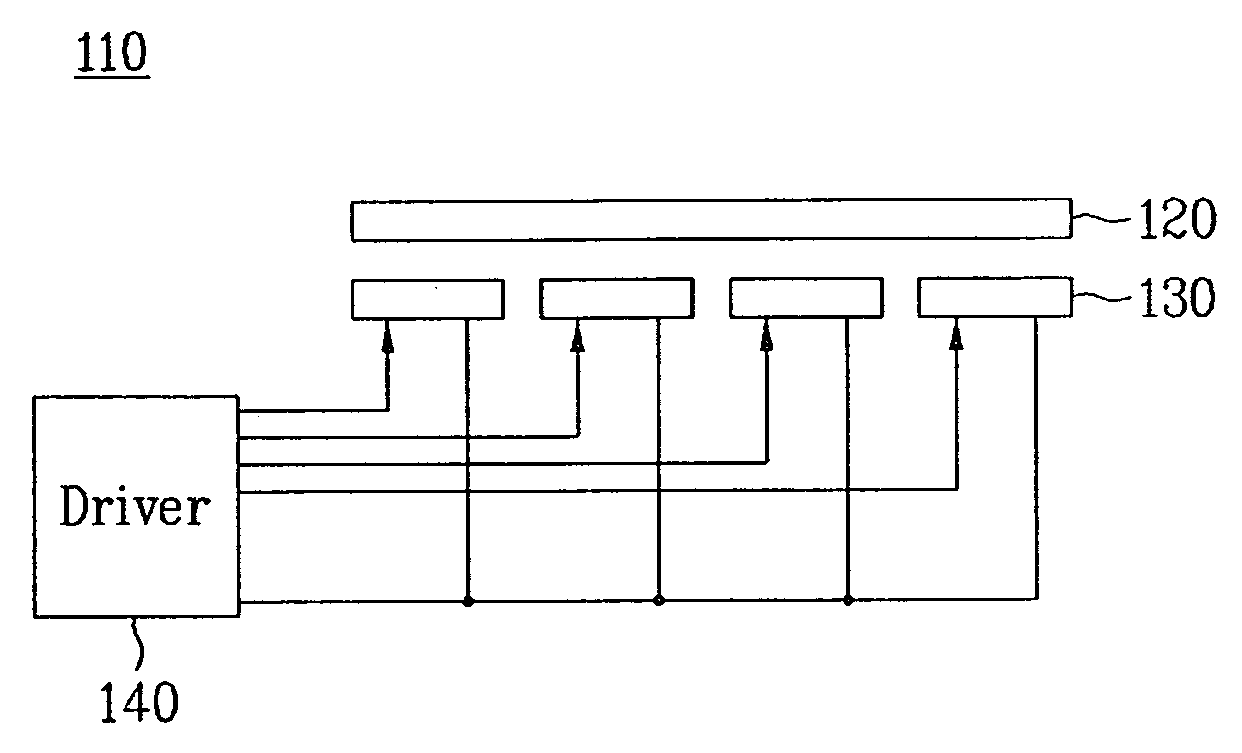

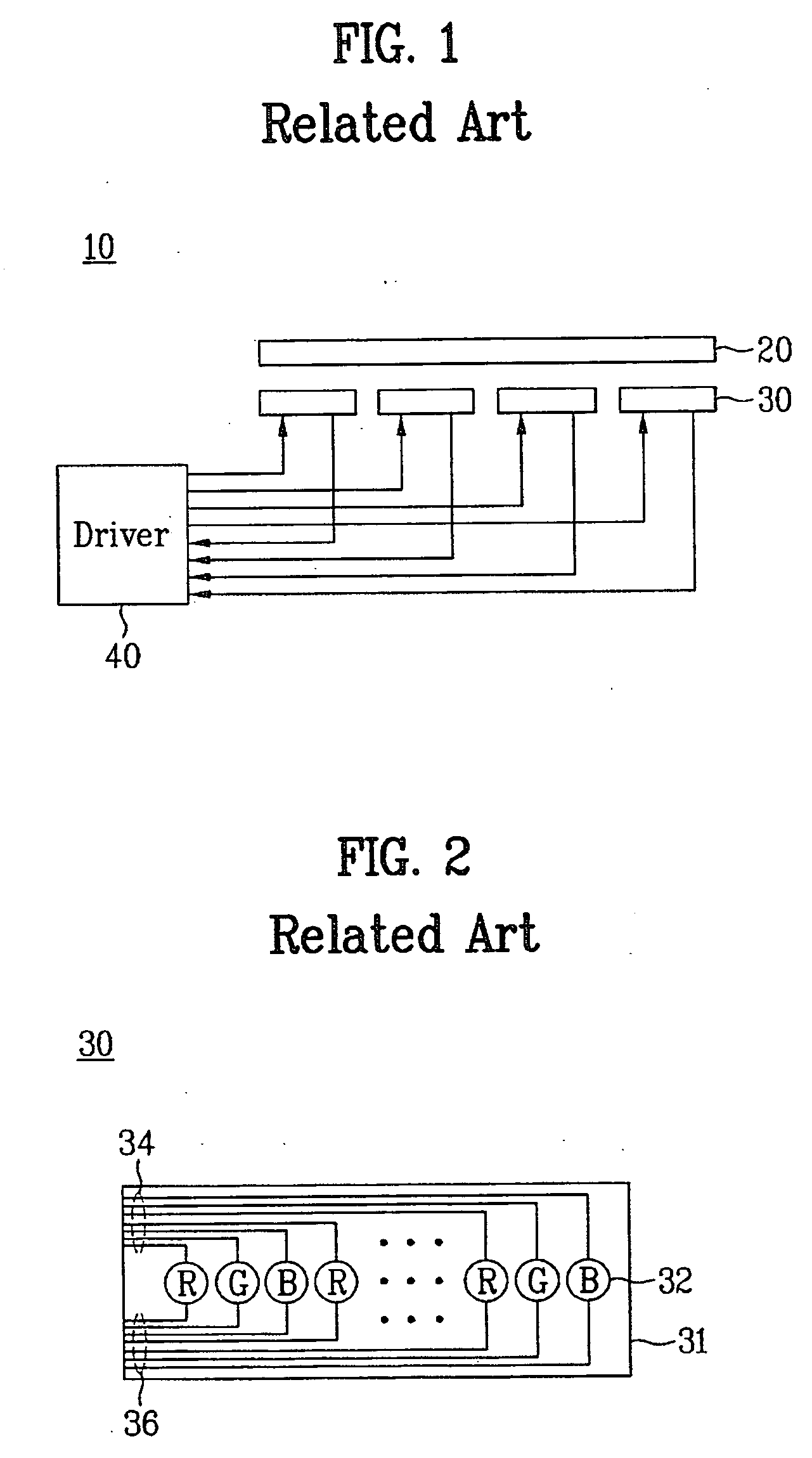

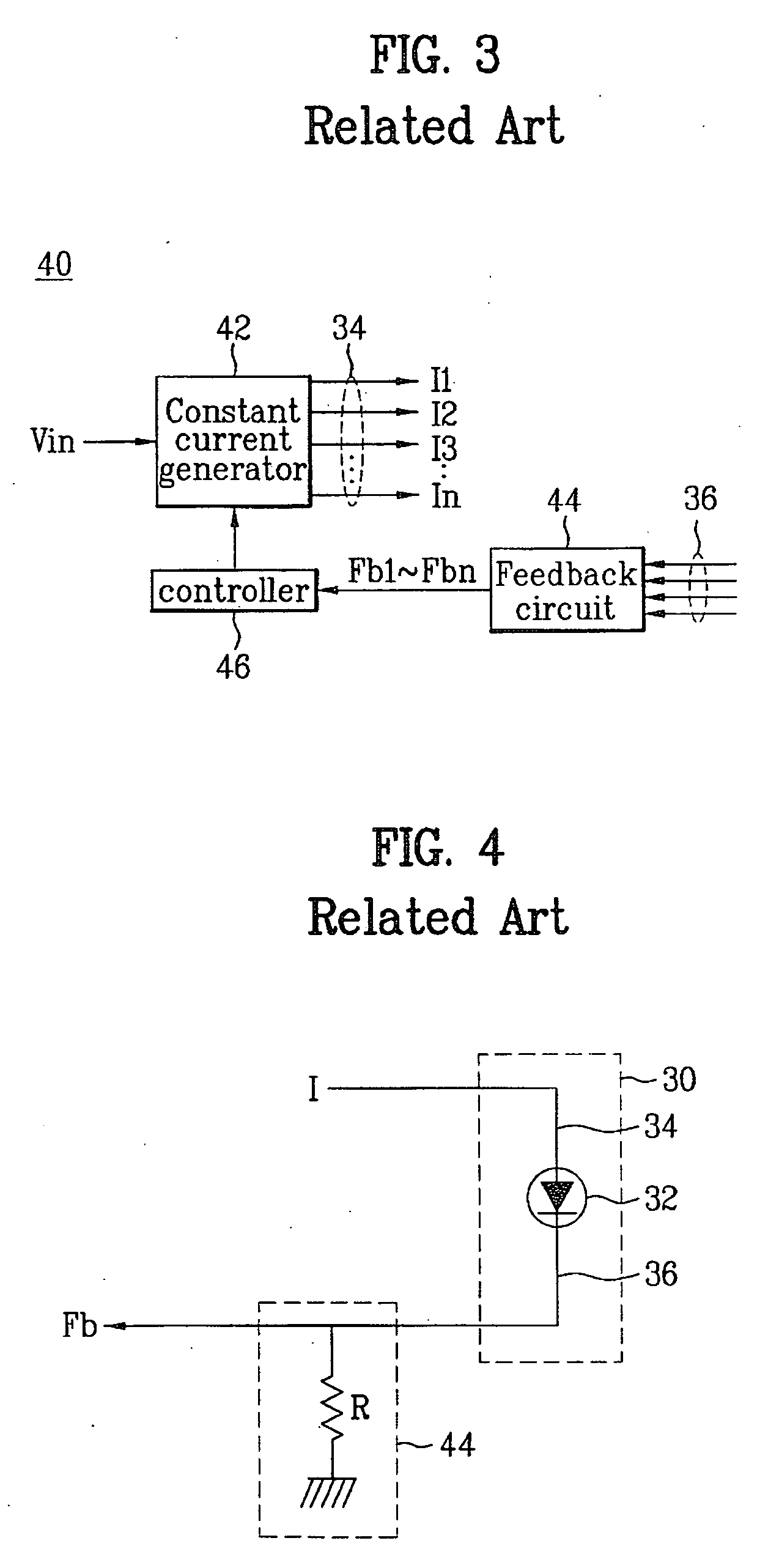

Back light unit and liquid crystal display device using the same

InactiveUS20060187180A1Reduce sizeUniform controlStatic indicating devicesElectric light circuit arrangementLiquid-crystal displayEngineering

Owner:LG DISPLAY CO LTD

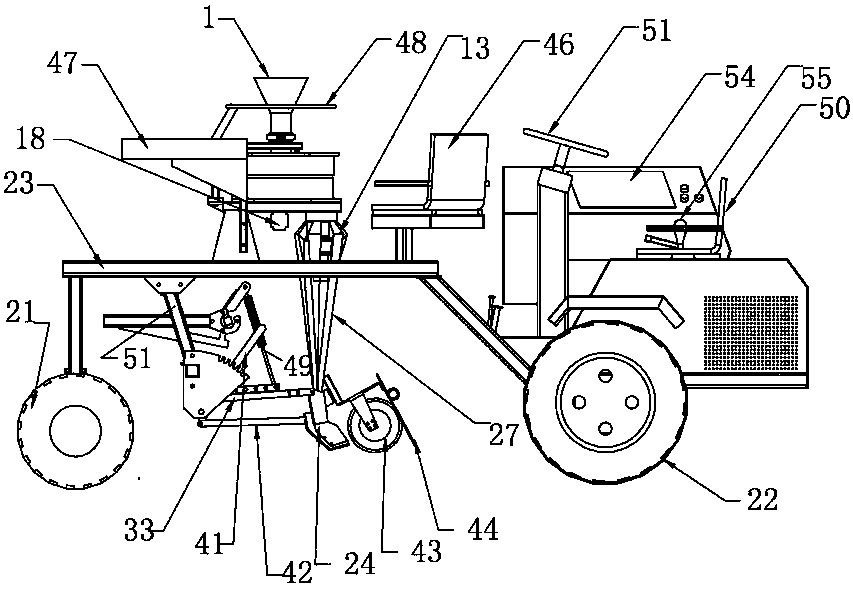

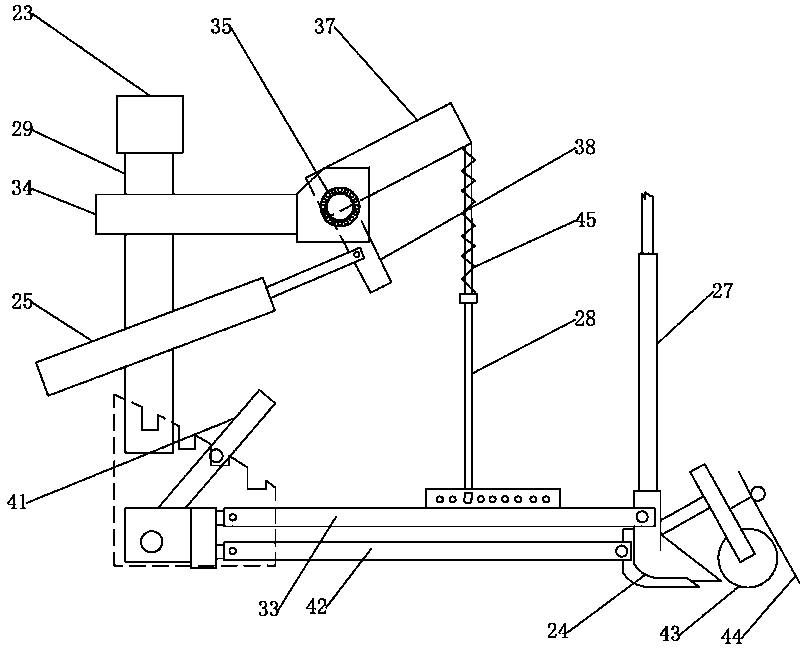

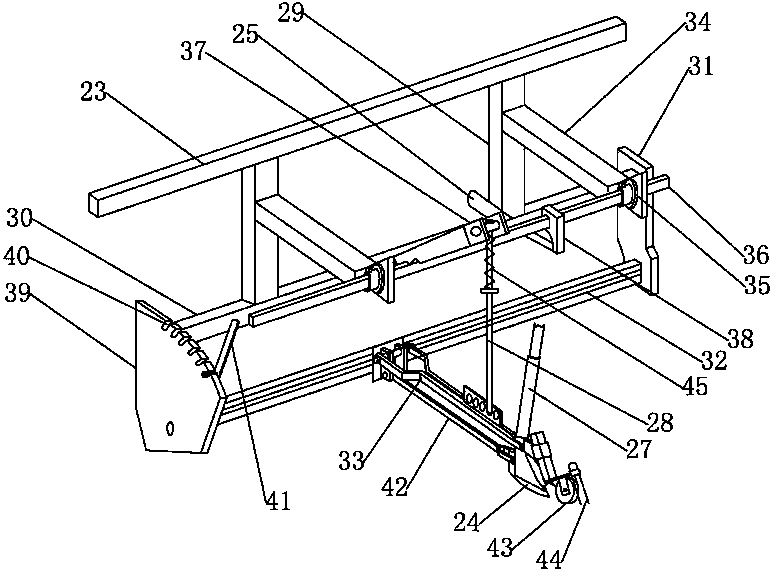

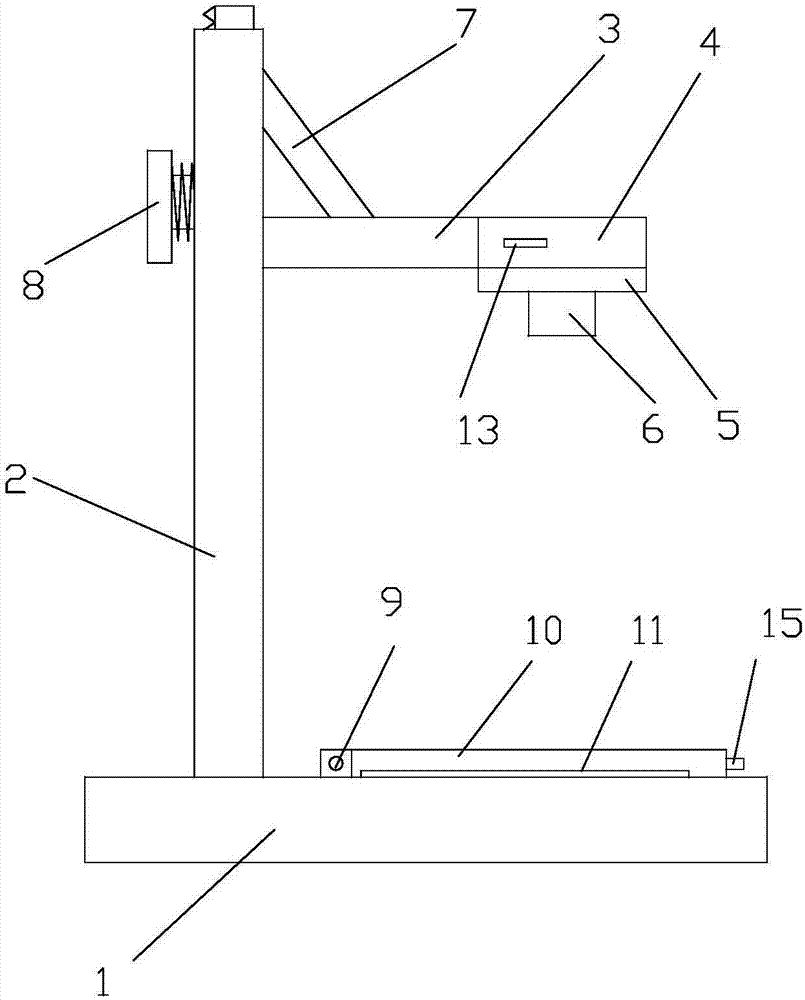

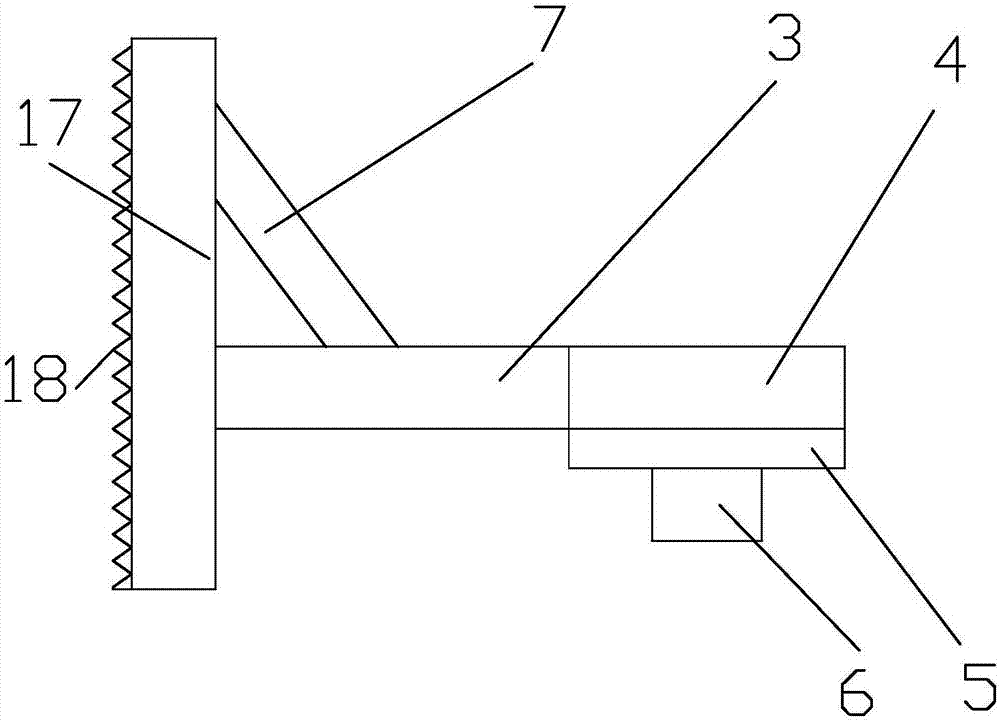

Electric self-propelled numerical-control plot drill seeder

ActiveCN104012222APrecise Control of UniformityEasy to operateSeed depositing seeder partsBroadcast seedersNumerical controlSeeder

The invention relates to an electric self-propelled numerical-control plot drill seeder aiming to solve the technical problems that plot seeders in the prior art are nonuniform in seeding and not precise enough in row length control. The electric self-propelled numerical-control plot drill seeder comprises a walking mechanism, an automatic control device, a seed separation mechanism, a furrowing and seeding mechanism and a lifting mechanism, and the seed separation mechanism, the furrowing and seeding mechanism and the lifting mechanism are correspondingly arranged on the walking mechanism; the seed separation mechanism comprises a seed separation unit and a seed storage unit, the seed separation unit is arranged above the furrowing and seeding mechanism, and the seed storage unit is arranged above the seed separation unit; the walking mechanism is an electric walking mechanism; the seed separation unit comprises a seed separation disc, a seed separation servo motor or a seed separation stepping motor, and the seed separation servo motor or the seed separation stepping motor is arranged below the seed separation disc, and drives the seed separation disc to rotate; the electric self-propelled numerical-control plot drill seeder has the advantages of uniform between-row and in-row seeding, high degree of automation, stepless row length setting (arbitrary row length setting), high row length control accuracy, simple operation, high sowing efficiency and the like.

Owner:李延民

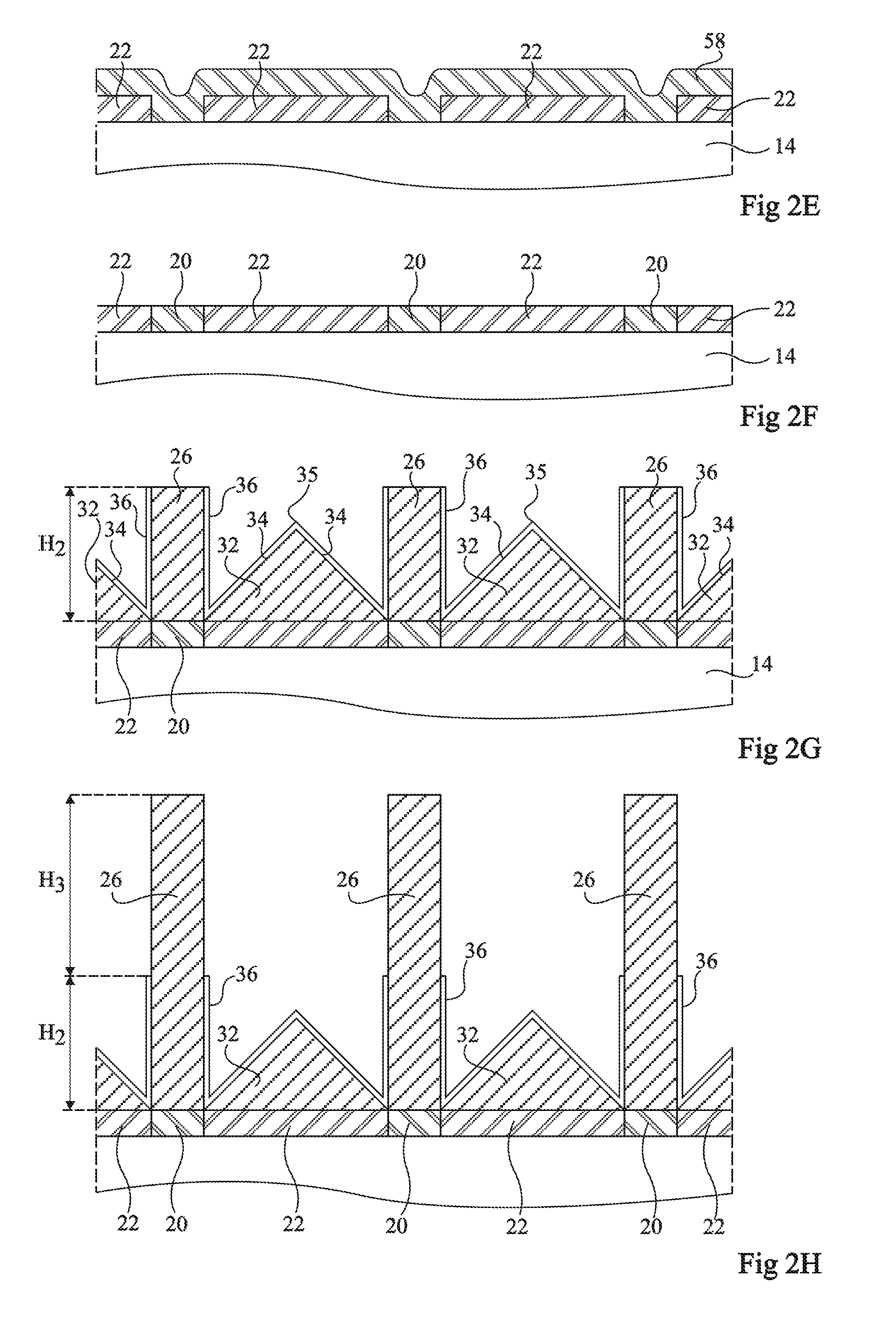

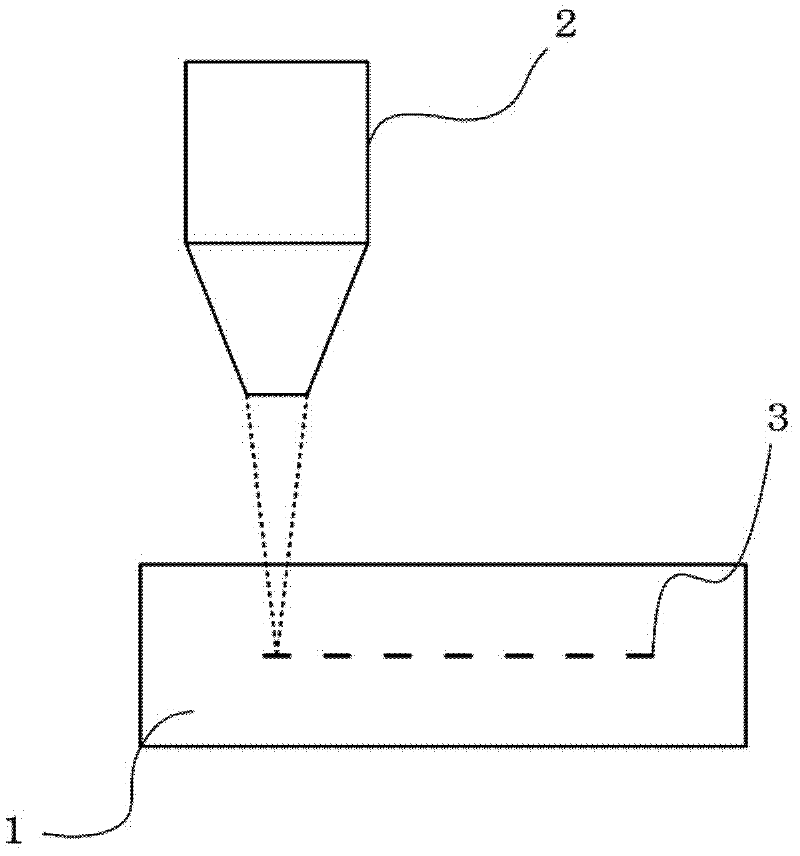

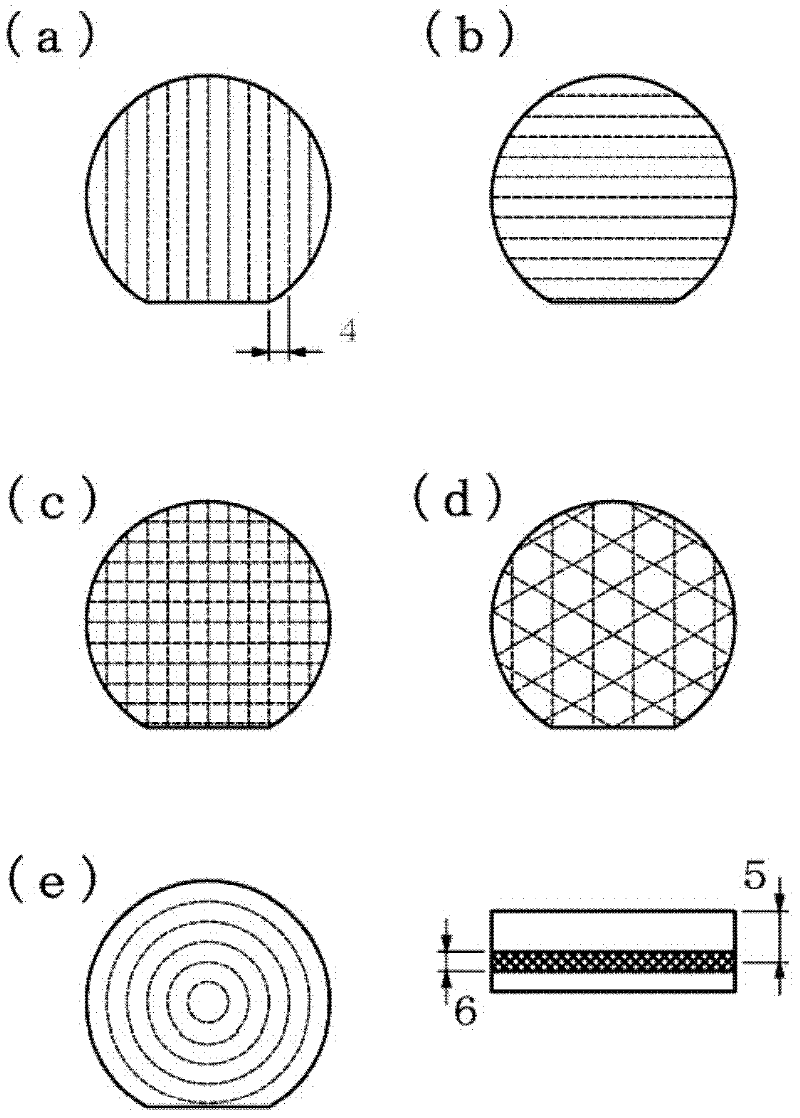

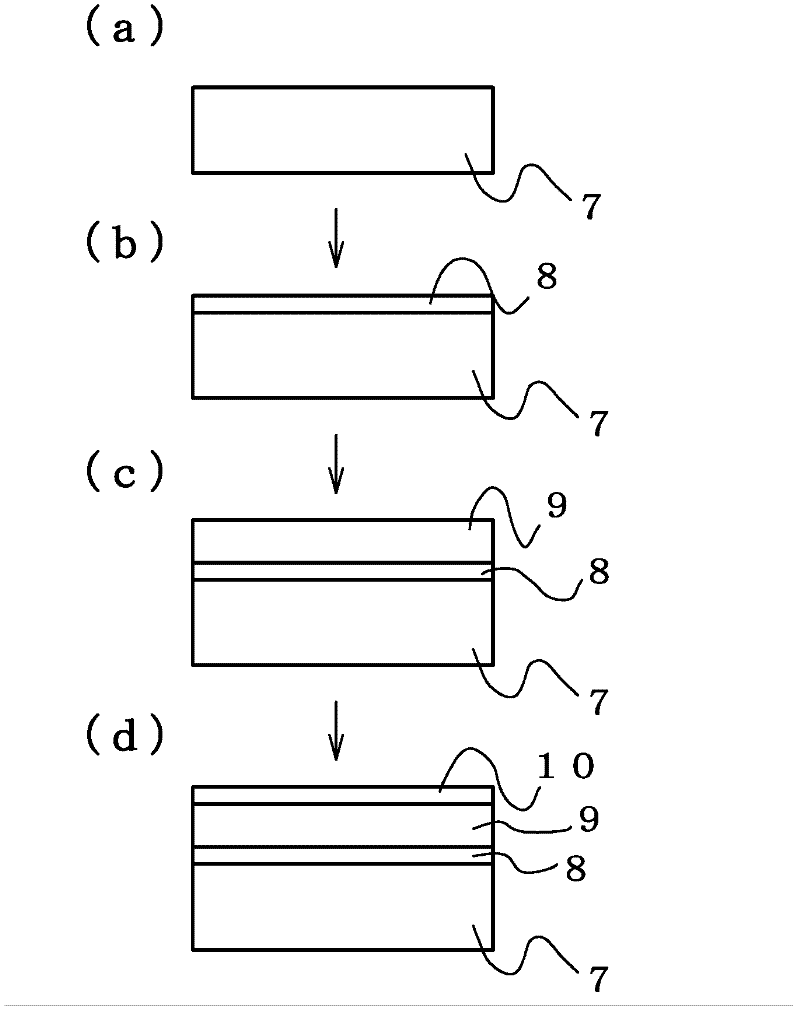

Internally modified substrate for epitaxial growth, crystal film-forming body, device, bulk substrate manufactured using same, and method for manufacturing them

ActiveCN102272891ASolve warpingQuality improvementPolycrystalline material growthAfter-treatment detailsYield ratioNitride semiconductors

Provided is a sapphire substrate mainly for epitaxial growth of a nitride semiconductor layer, wherein the shape and / or the amount of deflection of the substrate can be efficiently and accurately controlled; and the deflection of the substrate occurring when a film is formed is suppressed so that the deflection behavior of the substrate can be reduced. Further, a film forming element for a nitride semiconductor layer, a nitride semiconductor device, and a nitride semiconductor bulk substrate, which are produced using the sapphire substrate, and a method for producing the same are provided. Pulse lasers are concentrated in the inside of the sapphire substrate through the polished surface of the sapphire substrate, to scan the inside of the sapphire substrate, and reforming region patterns are formed using multiphoton absorption performed by the pulse lasers, so that the shape and / or the amount of deflection of the substrate can be controlled. When a nitride semiconductor layer is formed using the sapphire substrate, the deflection of the substrate occurring when a film is formed can be suppressed, and the deflection behavior of the substrate can be reduced. Thus, the quality and the uniformity of the film can be improved, and the quality and the yield ratio of the nitride semiconductor device can be improved.

Owner:NAMIKI PRECISION JEWEL CO LTD +1

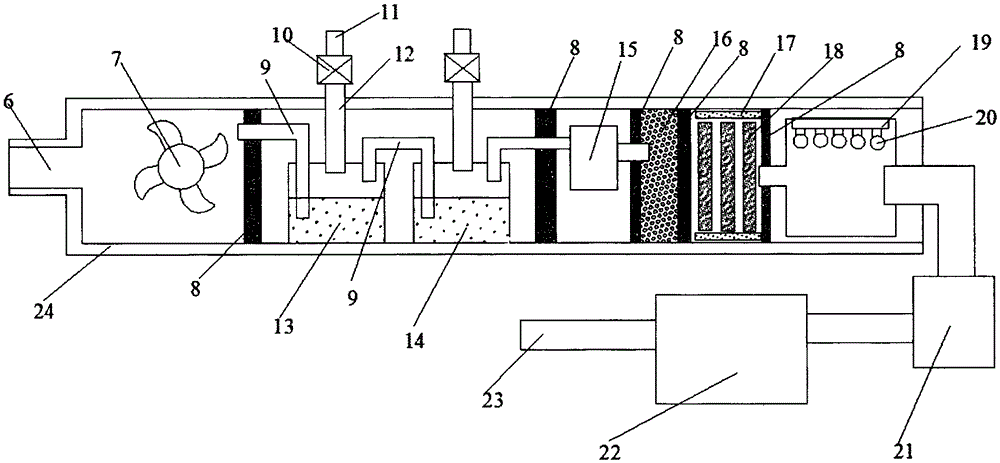

Experimental ventilation cabinet filtering device

ActiveCN105311911AReasonable structureUniform controlCombination devicesDirt cleaningActivated carbonUltraviolet

The invention provides an experimental ventilation cabinet filtering device. A gas inlet is formed in one end of a filter tank, and an exhaust port is formed in the other end of the filter tank; an acid absorption device, an alkali absorption device, an activated carbon adsorption device, an ultraviolet sterilization device, a spray-washing device, a gas drying device and a gas detection device are arranged between the gas inlet and the exhaust port sequentially. According to the invention, waste gas is well controlled to be within a safe range through arranging a plurality of gas filtering devices, and gases can be uniformly and thoroughly filtered separately through arranging a plurality of seal plates; besides, the detection device is arranged, and the concentrations of solutions for acid and alkali absorption can be automatically fed back and adjusted according to data from the detection device, so that the gas meets requirements of safety and environmental protection; further, the spray-washing device is arranged to further effectively treat gas; the ventilation cabinet filtering device provided by the invention can optimally realize the effective treatment to waste gas, thereby meeting the emission requirements of environmental protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

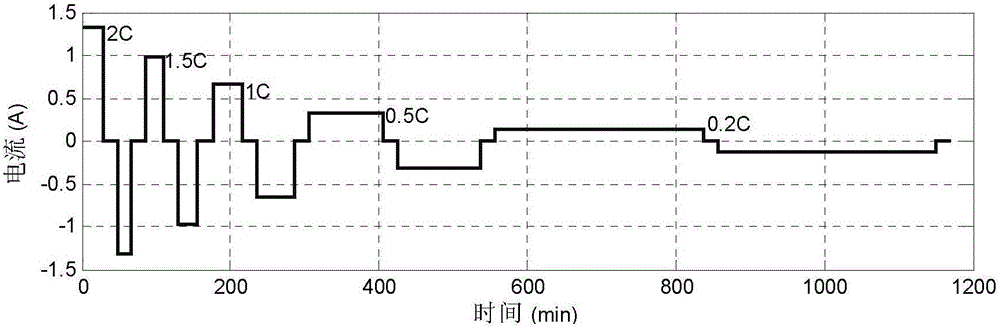

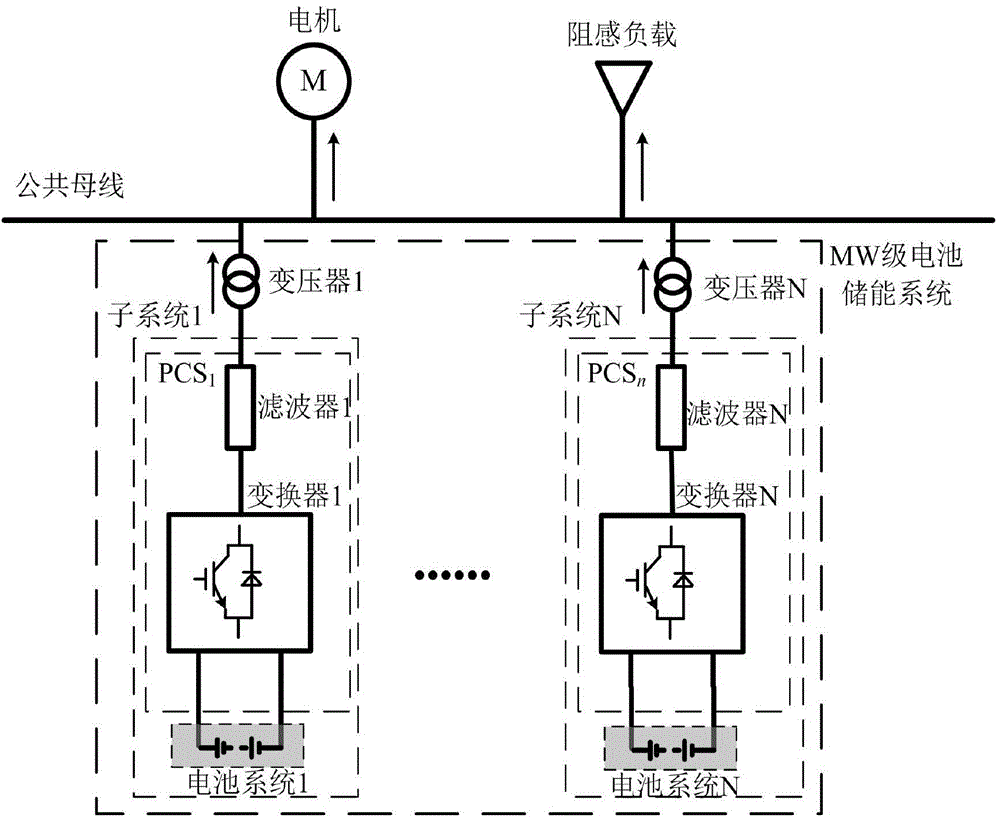

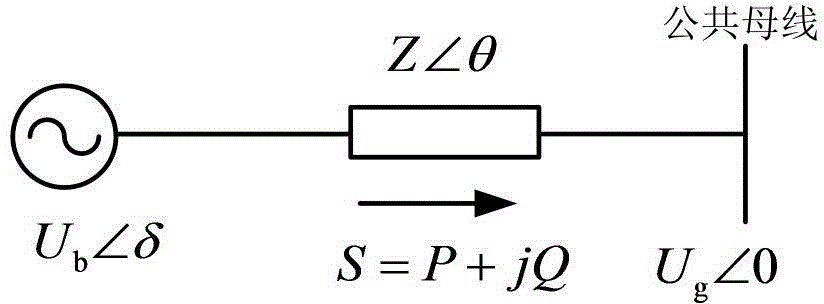

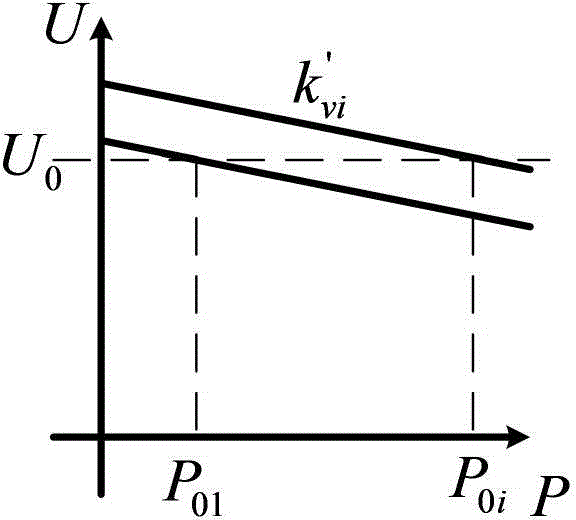

Active power control method for MW-level battery energy storage system based on battery charge state

InactiveCN104810843ABeneficial control effectStable voltage amplitudeFlexible AC transmissionBatteries circuit arrangementsVoltage amplitudeFrequency stabilization

The invention discloses an active power control method for a MW-level battery energy storage system based on the battery charge state. The method comprises that voltages and currents of a common bus are collected, and the active power, reactive power and voltage amplitude are calculated; a given voltage amplitude is obtained by sagging control of the active power based on the battery charge state; and a voltage difference between the given voltage amplitude and the practically measured voltage amplitude is processed by a proportion-integration regulator to obtain the modulation ratio of a PWM generator, and the PWM generator generates a switch drive signal to control the switching state of a power conversion system, and further to realize effective control for the active power output of the MW-level battery energy storage system. Thus, the MW-level battery energy storage system can effectively distribute the load active power and control output of the active power, the voltage amplitude and frequency of the common bus are stabilized around the rated values, and the charge states of modularized battery energy-storage subsystems of the MW-level battery energy storage system are controlled in an equalized manner.

Owner:YANCHENG INST OF TECH

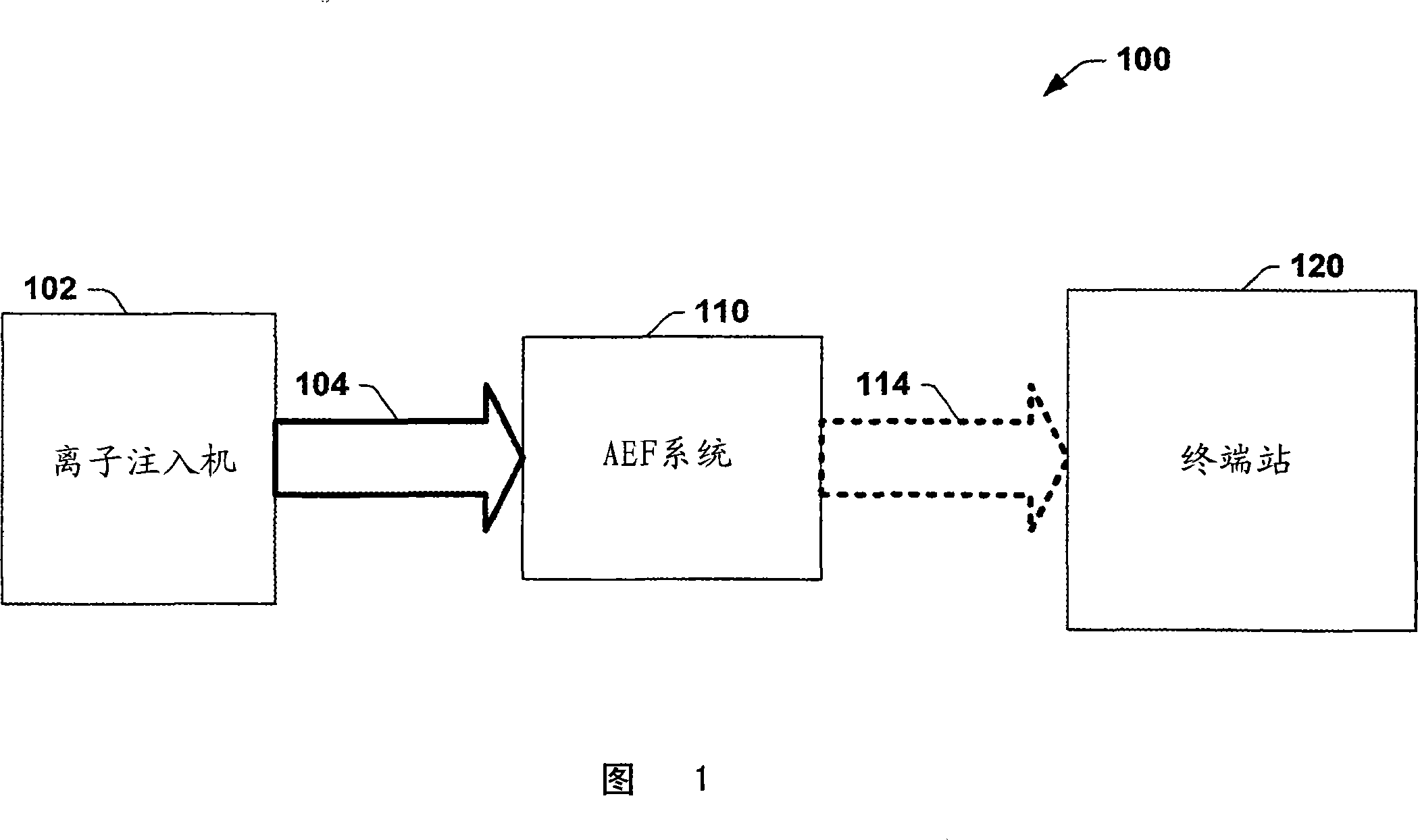

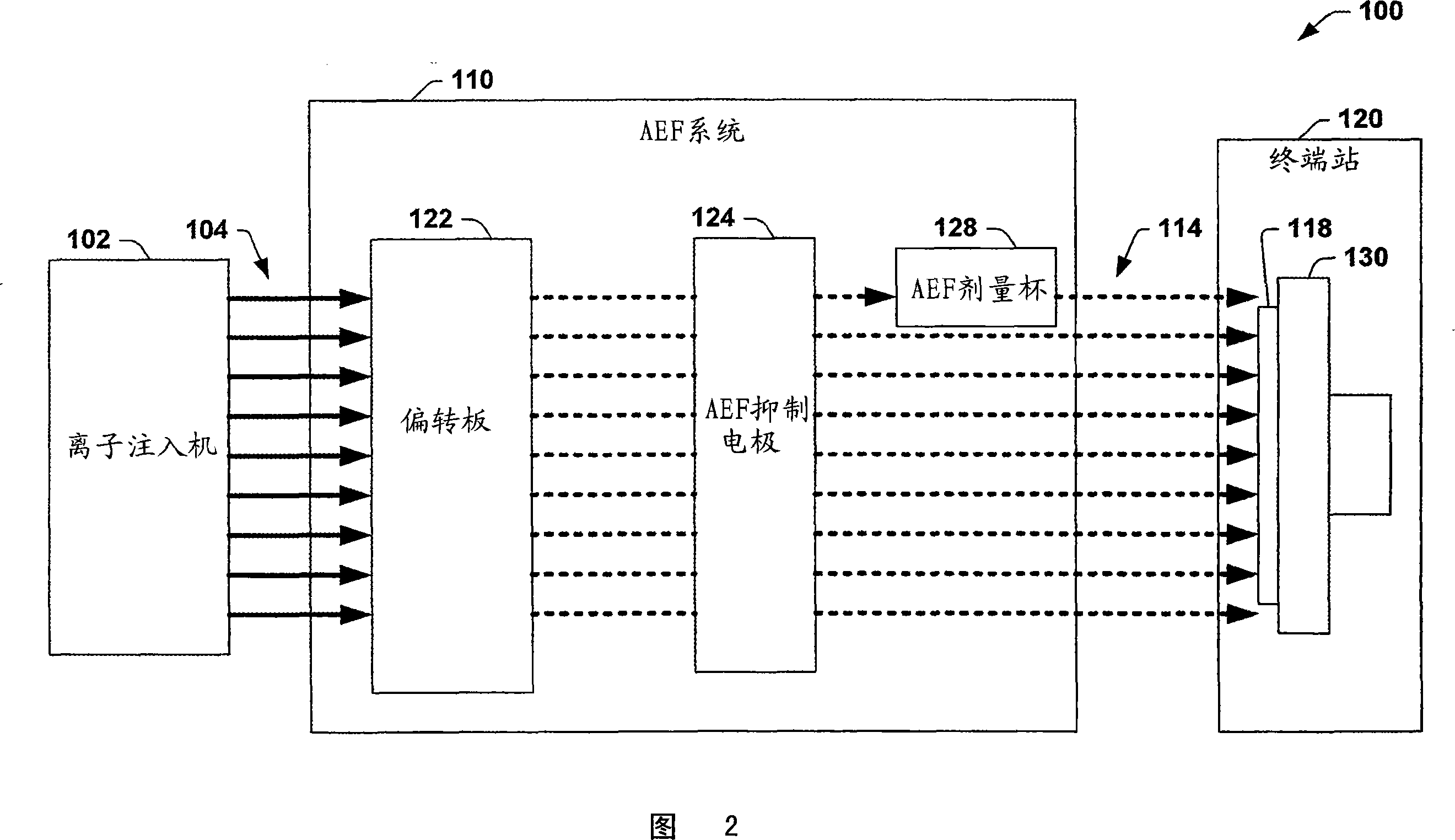

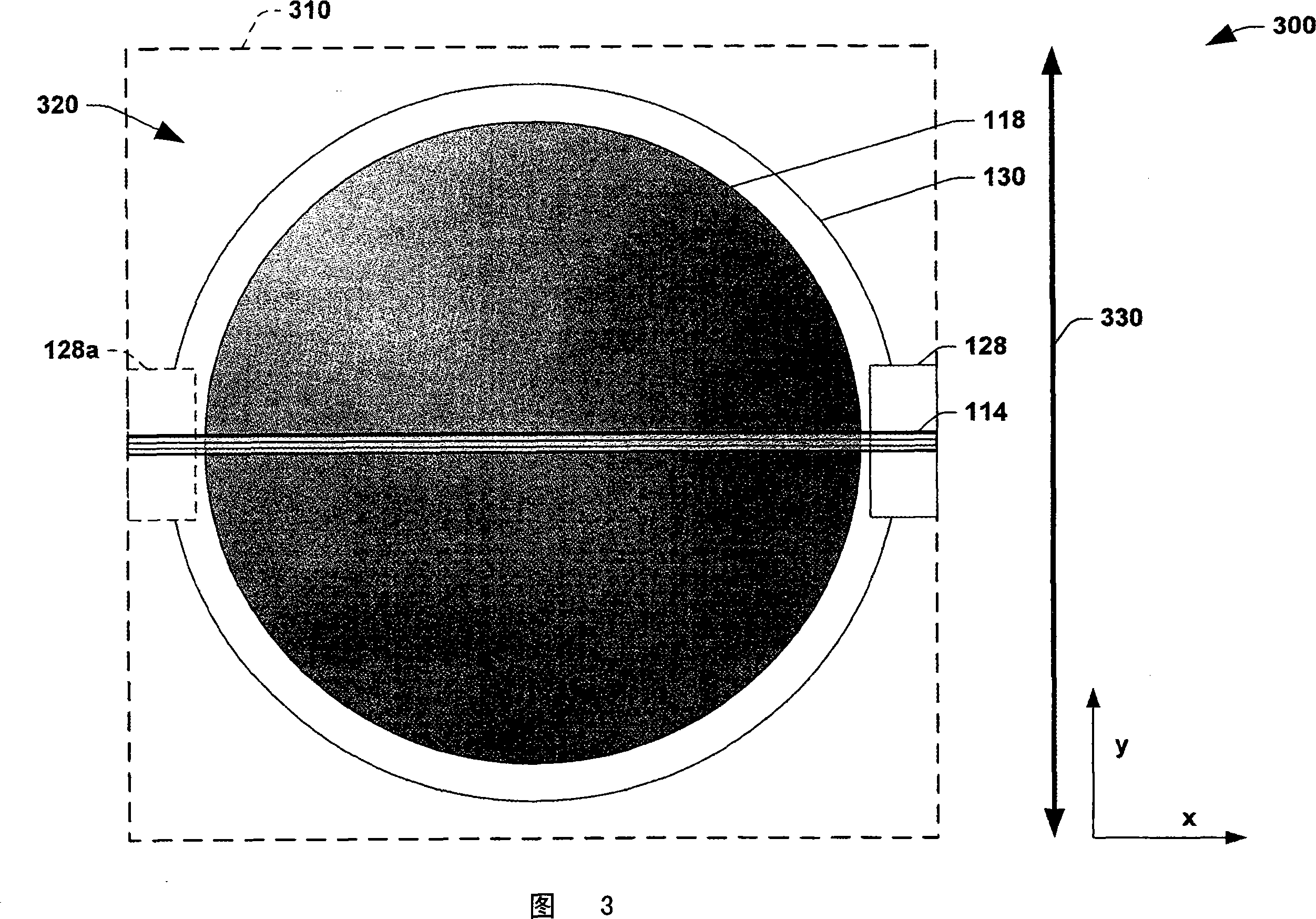

Dose cup located near bend in final energy filter of serial implanter for closed loop dose control

InactiveCN101238539AAccurate measurementUniform controlElectric discharge tubesIon currentBand shape

An ion implantation system (600) having a dose cup (634) located near a final energy bend of a scanned or ribbon-like ion beam of a serial ion implanter for providing an accurate ion current measurement associated with the dose of a workpiece or wafer. The system comprises an ion implanter having an ion beam source for producing a ribbon-like ion beam (602). The system further comprises an AEF system configured to filter an energy of the ribbon-like ion beam by bending the beam at a final energy bend. The AEF system further comprises an AEF dose cup associated with the AEF system and configured to measure ion beam current, the cup located substantially immediately following the final energy bend. An end station (610) downstream of the AEF system is defined by a chamber wherein a workpiece is secured in place for movement relative to the ribbon-like ion beam for implantation of ions therein. The AEF dose cup is beneficially located up stream of the end station near the final energy bend mitigating pressure variations due to outgassing from implantation operations at the workpiece. Thus, the system provides accurate ion current measurement before such gases can produce substantial quantities of neutral particles in the ion beam, generally without the need for pressure compensation. Such dosimetry measurements may also be used to affect scan velocity to ensure uniform closed loop dose control in the presence of beam current changes from the ion source and outgassing from the workpiece.

Owner:AXCELIS TECHNOLOGIES

Multifunctional ecological floating island

InactiveCN107380365AGood flexibilityGuarantee efficient reproductionWaterborne vesselsClimate change adaptationFloating islandEngineering

The invention discloses a multifunctional ecological floating island which comprises a floating island platform and a net cage (44) for culture of aquatic organisms. The net cage is installed under the floating island platform. The floating island platform is provided with a plurality of planting pits (416). Bottom plates of the planting pits are provided with bottom through-holes (413); the bottom through holes are used for plants in the planting pits to absorb water from the lower side of the planting pits. The multifunctional ecological floating island is compact in structure, rich in function and flexible and convenient to use.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

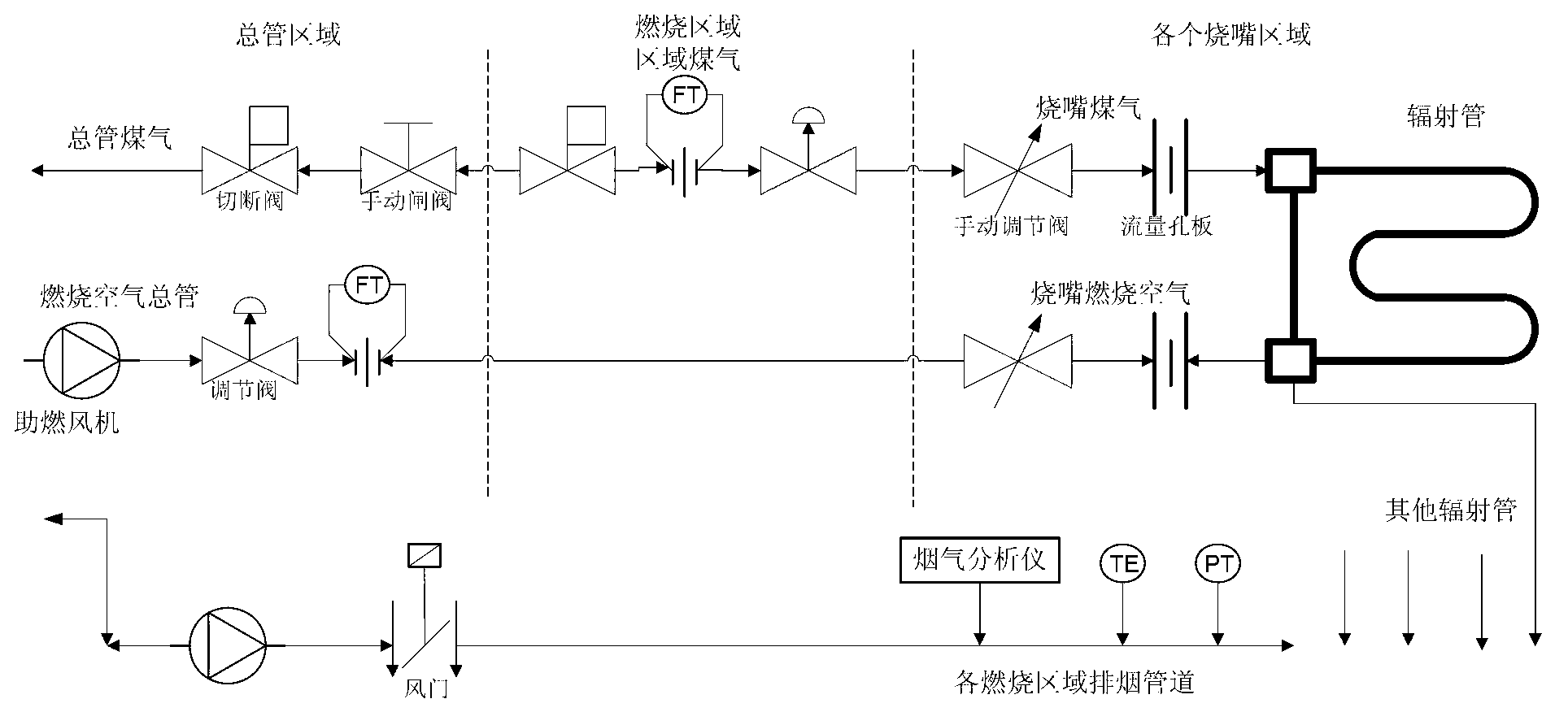

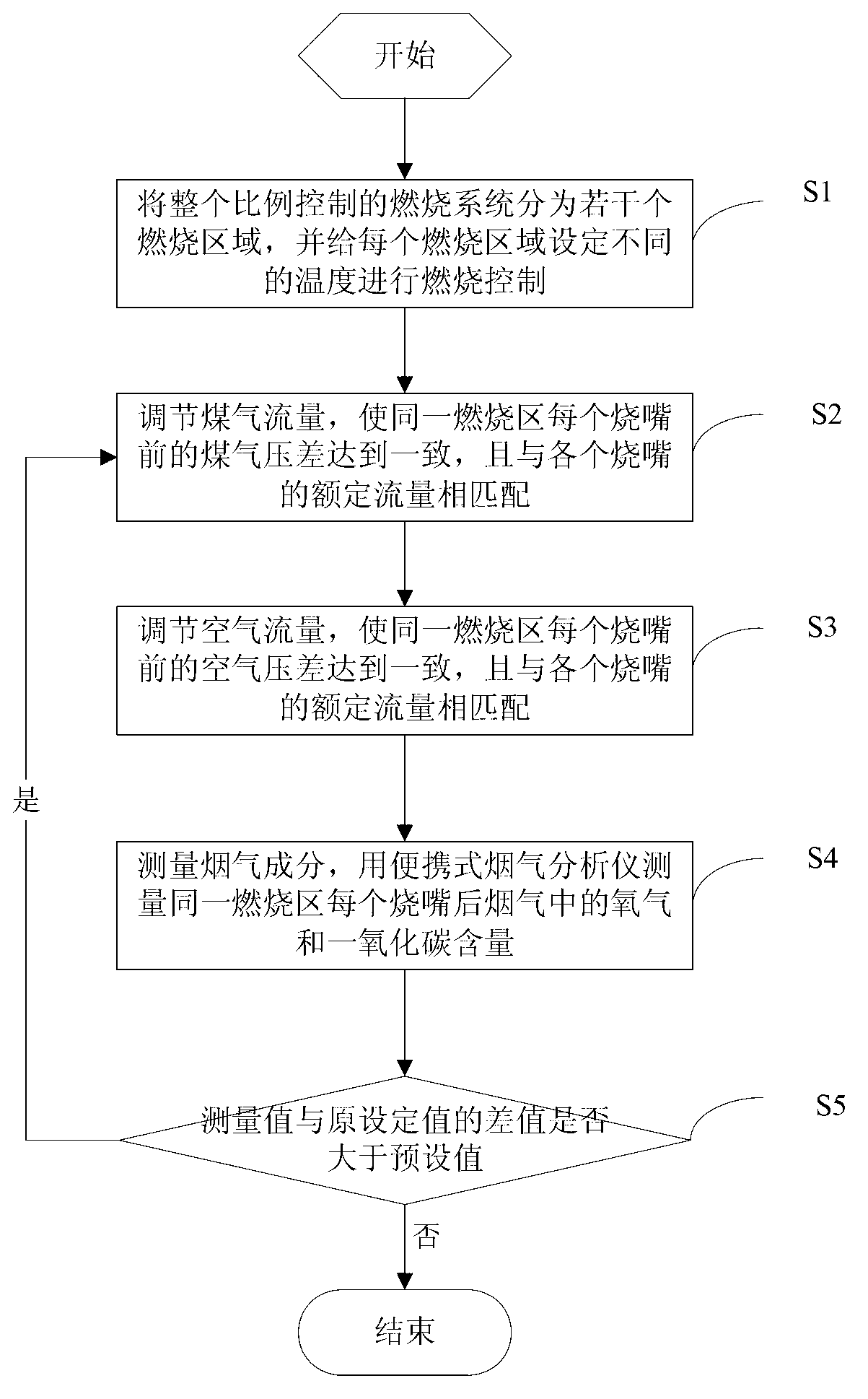

Adjusting and optimizing method of ratio-controlled combustion system

InactiveCN102937382AGuaranteed uptimeUniform temperature controlControl devices for furnacesGaseous fuel burnerCombustion systemTemperature control

The invention discloses an adjusting and optimizing method of a ratio-controlled combustion system. The adjusting and optimizing method includes the following steps: S1 the whole ratio-controlled combustion system is divided into a plurality of combustion areas, and different temperatures are set for the combustion areas for combustion control; S2 coal gas flow is adjusted; S3 air flow is adjusted; and S4 flue gas content is measured: a portable flue gas analyzer is adopted to measure contents of oxygen and carbonic oxide which are contained in flue gases of each burner arranged in the same combustion area, the coal gas flow and the air flow are readjusted if the difference value of the measurement valve and the originally set value is larger than the preset value, and adjusting and optimizing are completed if the measurement valve is identical to the originally set value. The adjusting and optimizing method especially aims at the ratio-controlled combustion system, and is simple and convenient to operate and convenient to popularize; and integrally adjusts and optimizes all the combustion areas, can ensure that the burners of all the combustion areas are identical in power and combustion state, enables temperature in a furnace to be uniformly controlled, and improves control accuracy in low load.

Owner:WISDRI WUHAN WIS IND FURNACE

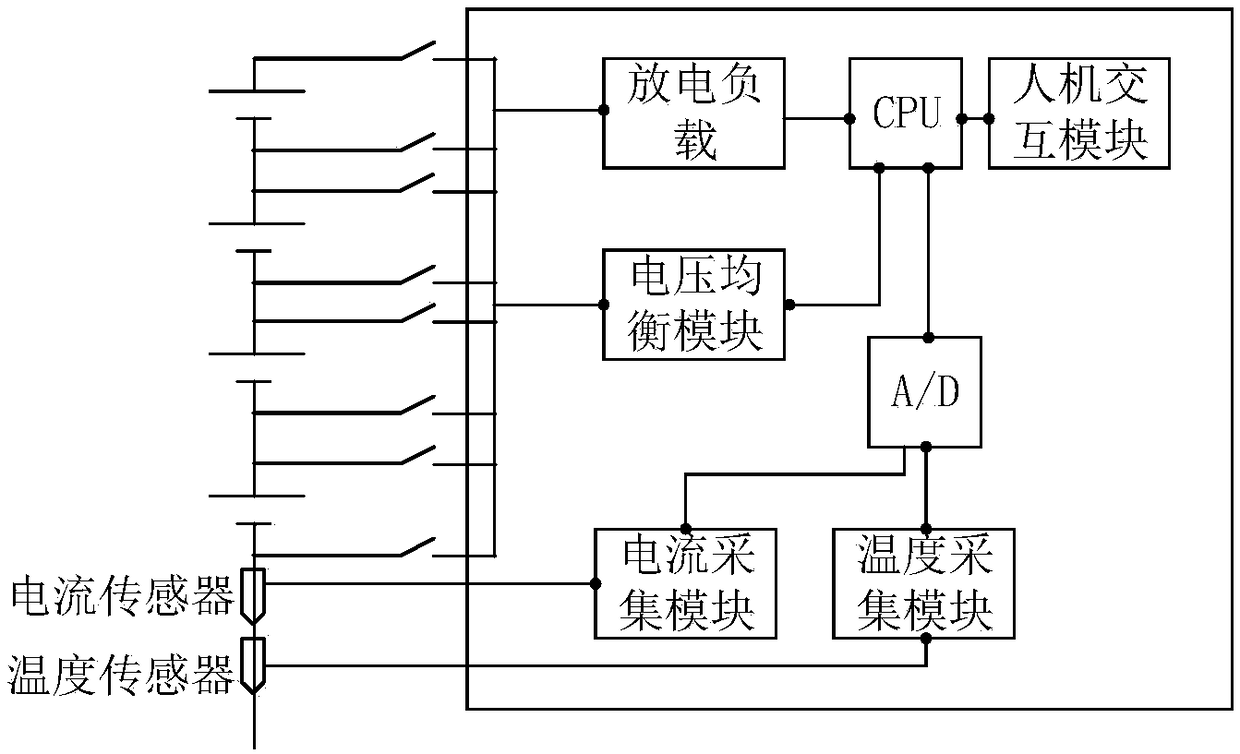

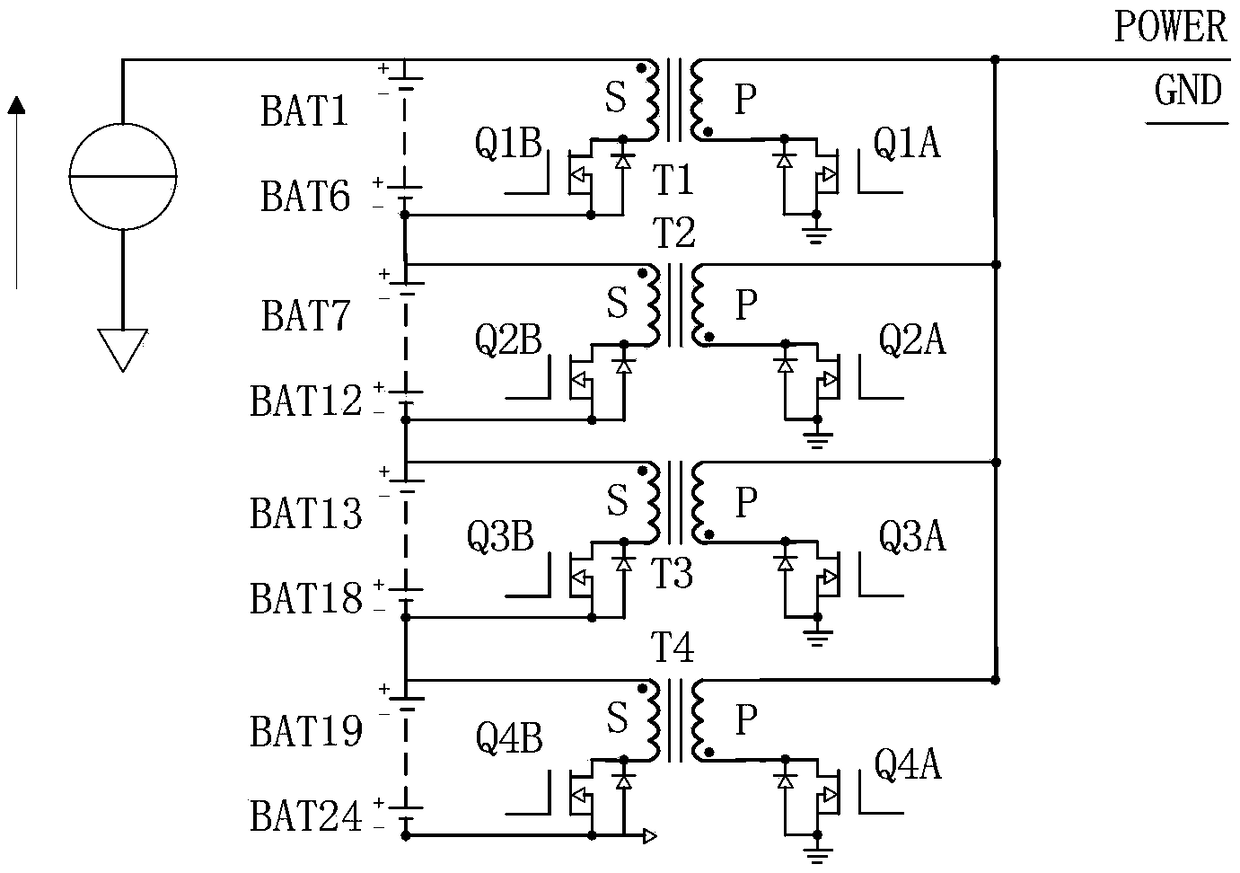

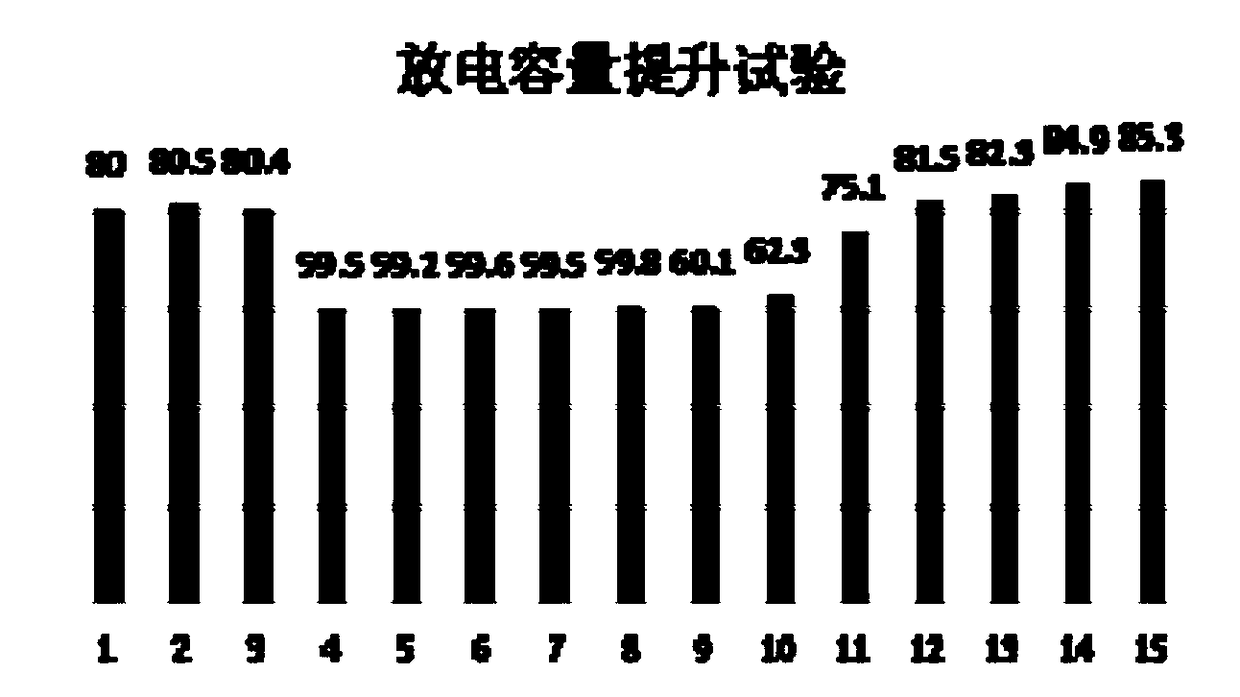

A substation battery multifunction control system and a control method thereof

InactiveCN109004696AAccurate Status DataImprove estimation accuracyCharge equalisation circuitElectric powerElectricityControl system

The invention relates to a multifunctional control system and a control method of a battery used in a substation, which is characterized in that the multifunctional control system comprises a currentacquisition module, an input end of the current acquisition module is connected with a current sensor, and an output end is connected with an input end of an A / D converter. The input end of the temperature acquisition module is connected with the temperature sensor, and the output end is connected with the input end of the A / D converter. The output of A / D converter is connected with CPU through I / O interface. The CPU is also connected with human-computer interaction module, discharge load and voltage balancing module through I / O interface, and the discharge load and voltage balancing module are electrically connected with each single battery respectively. The control method comprises the following steps of: balancing control of a battery pack; SOC estimation of battery pack; measurement ofinternal resistance of battery pack.

Owner:STATE GRID CORP OF CHINA +2

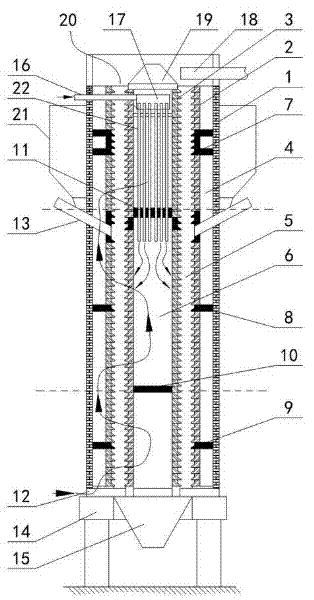

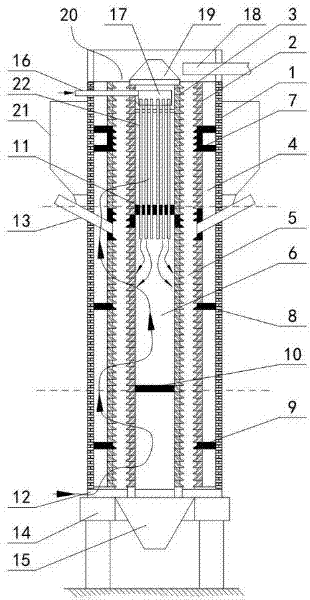

Sleeve type continuous calcining vertical kiln

ActiveCN102230726APrevent burning phenomenonReduce consumptionVertical furnacesEngineeringCalcination

The invention discloses a sleeve type continuous calcining vertical kiln. An annular kiln cavity is formed by the encircling of an inner barrel and an outer barrel which are sleeved together in a kiln body; the annular kiln cavity is provided with a preheating area, a calcining area and a cooling area in sequence from top to bottom; the barrel wall of the inner barrel is provided with a pluralityof ventilation holes for communicating the annular kiln cavity with the inner cavity of the inner barrel; the periphery of the outer barrel is covered with a barrel-shaped kiln shell; a peripheral air channel is arranged between the inner wall face of the barrel-shaped kiln shell and the outer wall face of the outer barrel in an encircling manner; ventilation holes for communicating the annular kiln cavity with the peripheral air channel are distributed on the barrel wall of the outer barrel; radial isolation structures are distributed at intervals in the inner cavity of the inner barrel and the periphery air channel in a staggered way along the axial direction of the kiln body; and a fuel feeding device communicated with the calcining area in the annular kiln cavity is arranged on the upper part of the kiln shell. The vertical kiln has a simple structure and a good energy-saving effect; and calcination of powdery or particulate small-diameter stone raw materials is realized, waste ofraw materials is avoided, meanwhile, the operation of the kiln is simplified, and the fuel consumption is lowered.

Owner:ZHEJIANG DEYAO ENERGY SAVING TECH CO LTD

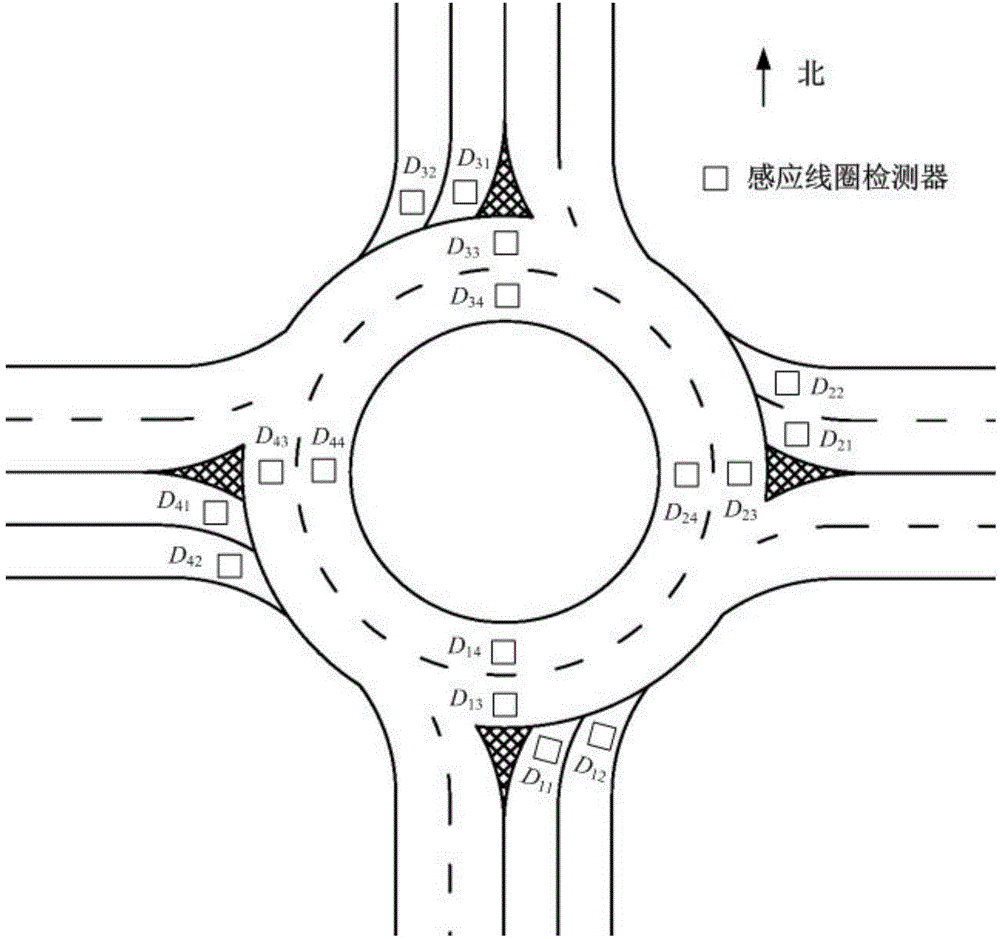

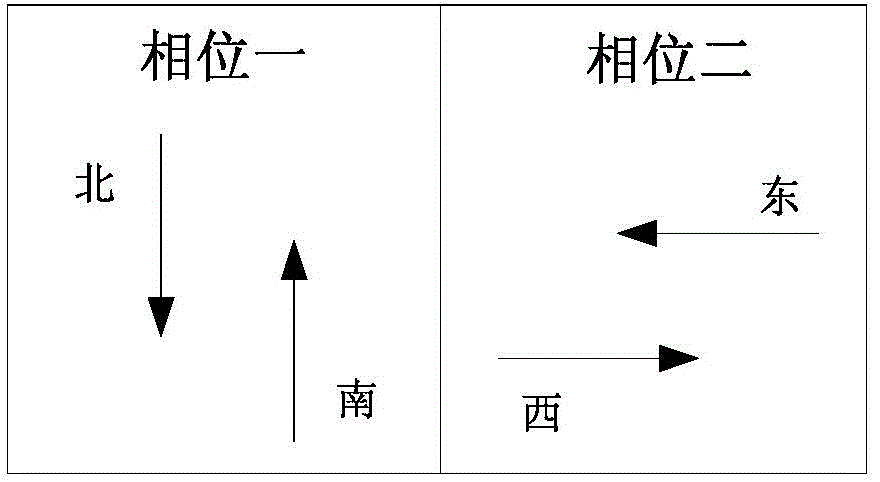

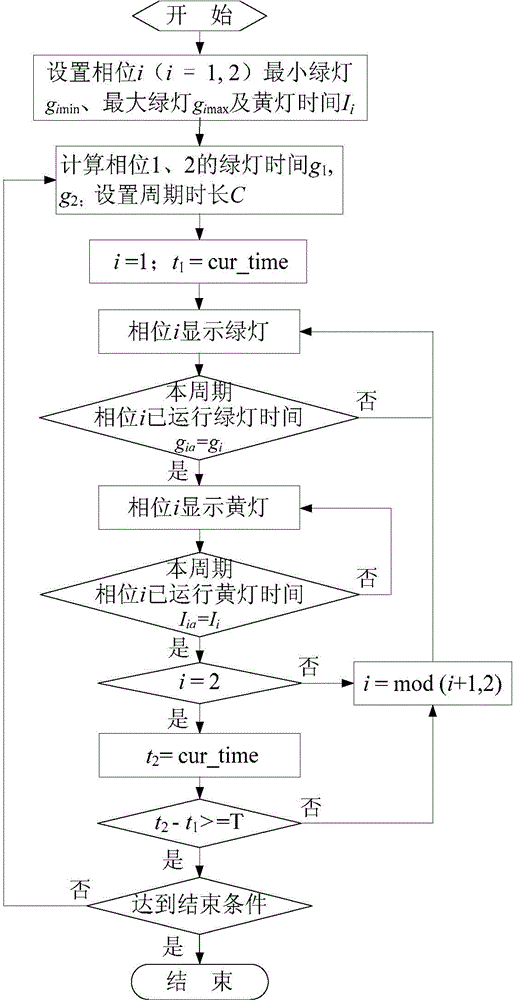

Self-adaptation traffic signal control method for four-way roundabout

ActiveCN104021687AUniform controlAvoid worsening traffic conditionsRoad vehicles traffic controlControl flowTraffic signal

The invention relates to a self-adaptation traffic signal control method for a four-way roundabout and belongs to the technical field of urban traffic signal control. The purpose is to solve the problems that an existing signal control method for the roundabout, the flow of left turning motor vehicles can not be automatically detected, influences on motor vehicles at an entrance by the left turning motor vehicles inside the roundabout fail to be sufficiently considered, and therefore the optimal signal control scheme is difficult to generate. The method includes the steps that step1, annular coil detectors are arranged at the four-way roundabout; step2, the phase sequence of the four-way roundabout is set; step3, the self-adaptation traffic signal control processes of the four-way roundabout are set. The self-adaptation traffic signal control method is applied to the field of traffic control.

Owner:严格集团股份有限公司

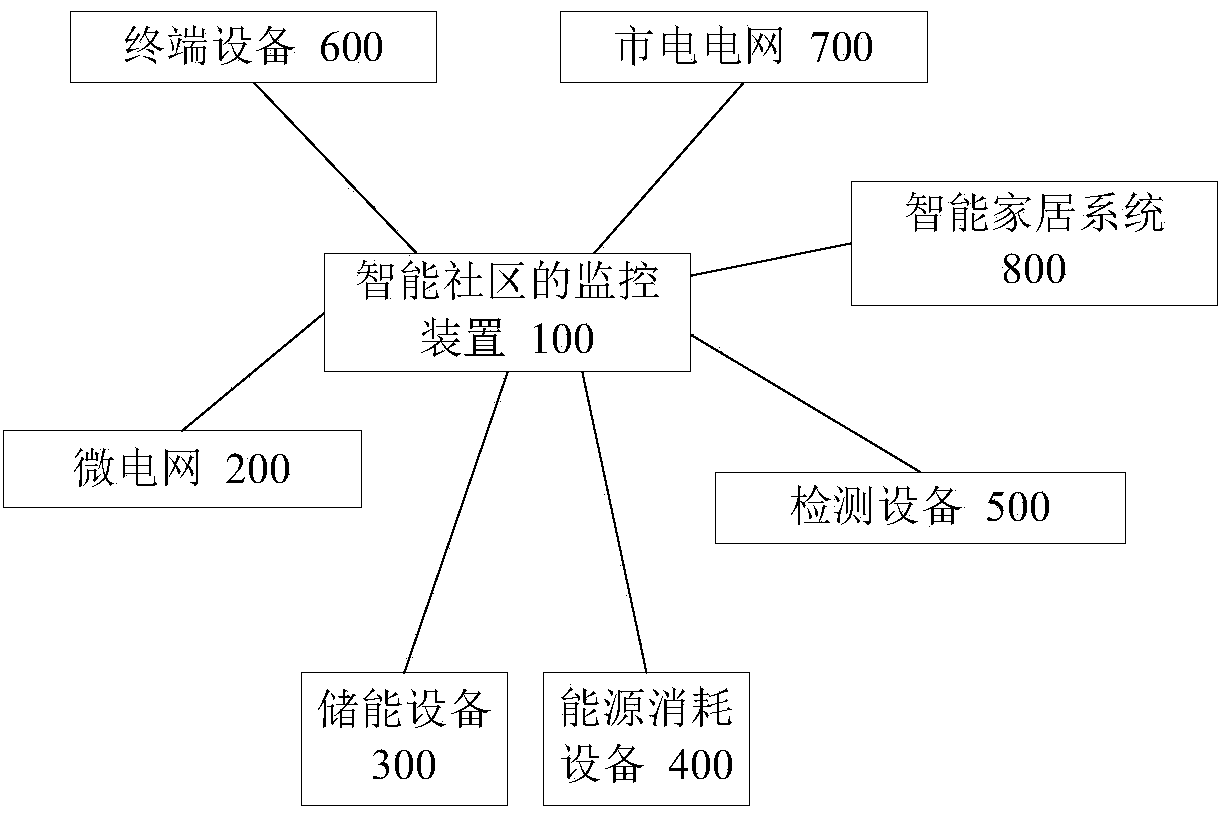

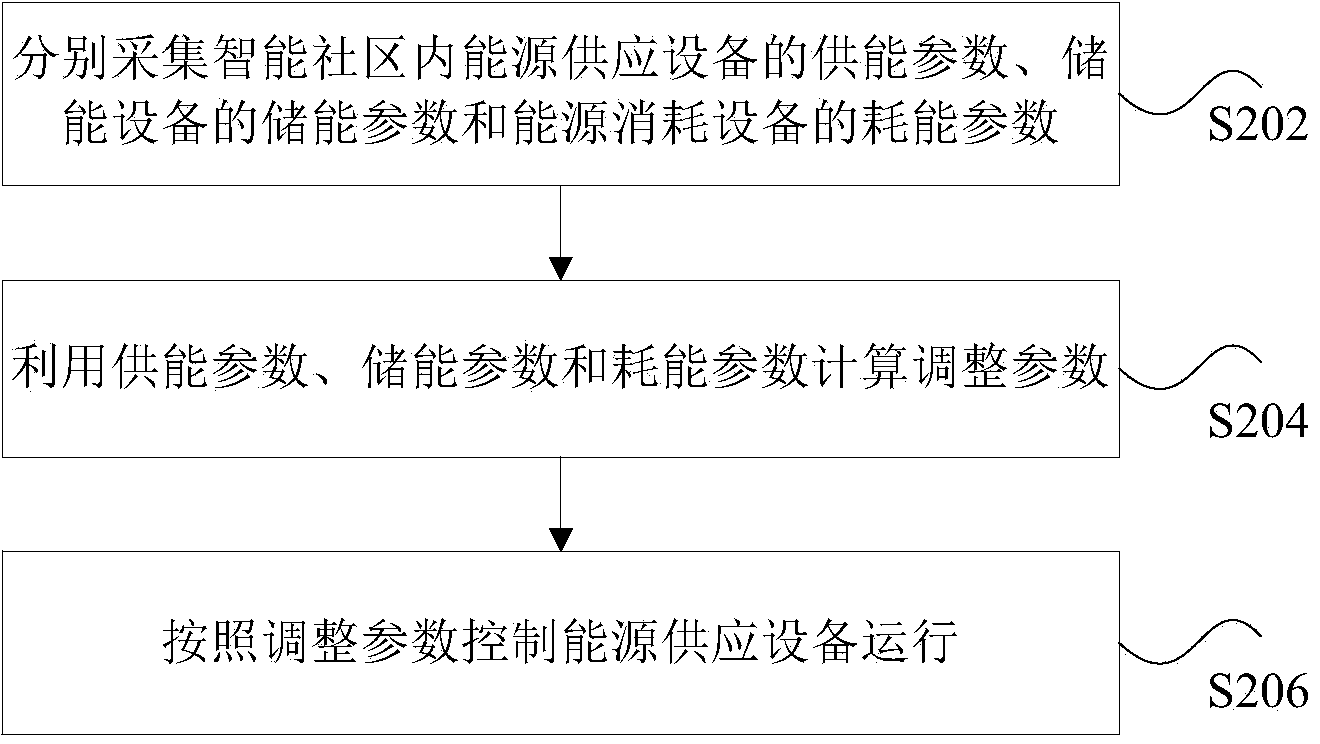

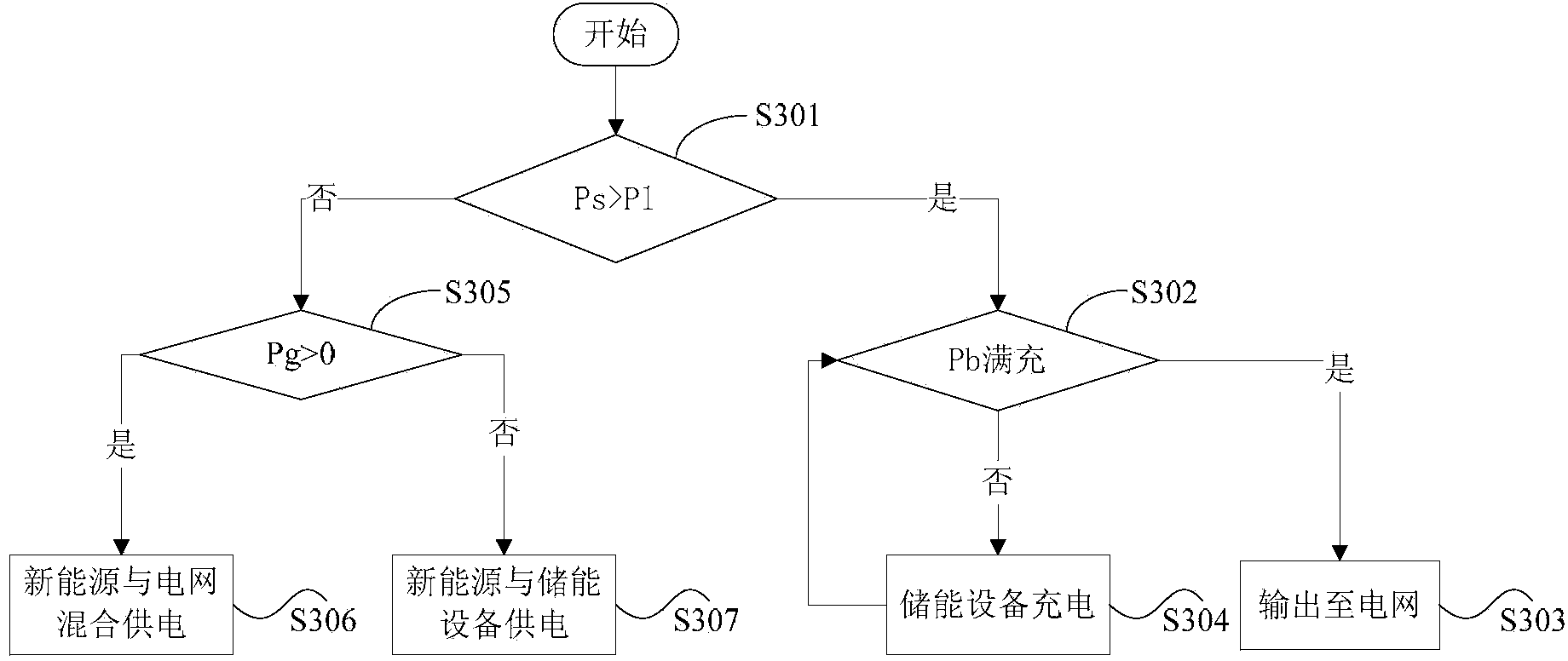

Monitoring method and device for intelligent community

ActiveCN104319774AAchieve optimizationReduce wasteAc networks with different sources same frequencyEnergy supplyEngineering

The invention discloses a monitoring method and device for an intelligent community. The monitoring method for the intelligent community comprises the steps that energy supply parameters of energy supply equipment in the intelligent community, energy storage parameters of energy storage equipment and energy consumption parameters of energy consumption equipment are collected respectively; adjusting parameters are adjusted according to the energy supply parameters, the energy storage parameters and the energy consumption parameters, wherein the adjusting parameters are the parameters used for adjusting the output power of the energy supply equipment; the energy supply equipment is controlled to run according to the adjusting parameters. By means of the monitoring method and device for the intelligent community, the problem that the effective utilization rate of energy in the community in the prior art is low is solved, and the effects of optimizing energy and reducing energy waste are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com