Patents

Literature

384results about How to "Solve warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

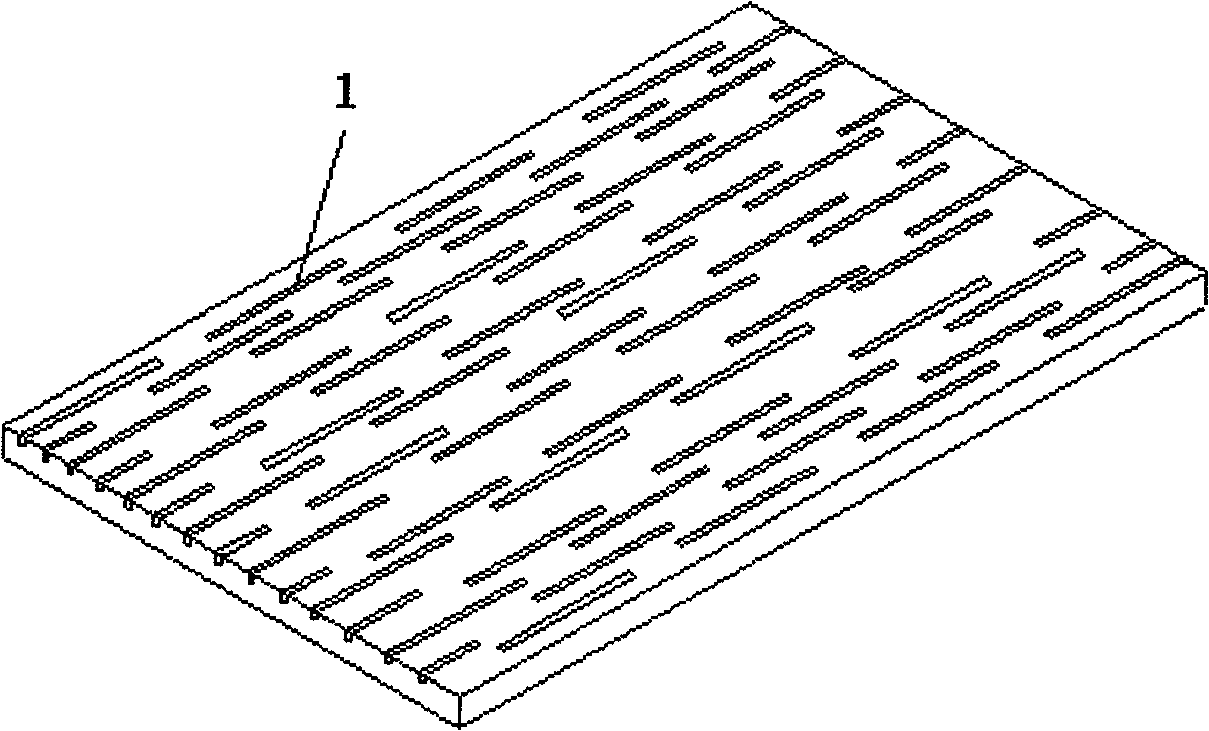

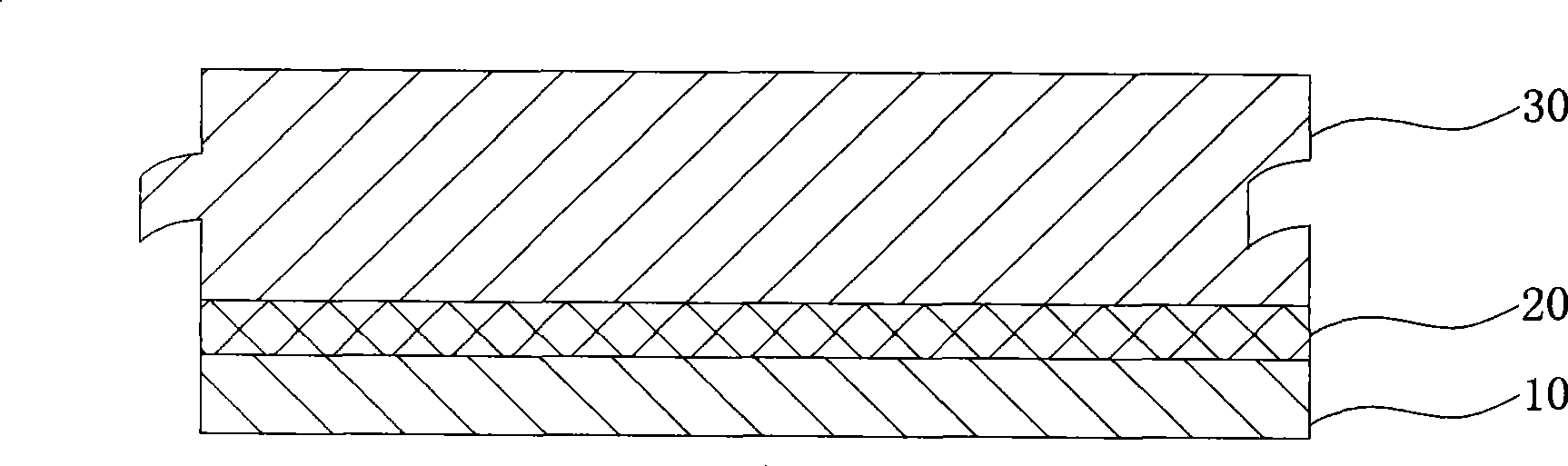

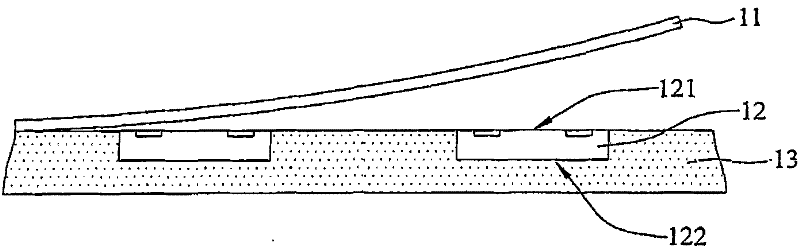

Super-thick bamboo-wood composite board and producing method thereof

ActiveCN101524858ASolve the problem of poor thermal conductivity that is difficult to produce by hot pressingSolve warpingPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesAdhesiveEngineering

The invention provides a super-thick bamboo-wood composite board, which comprises a core board, a surface board and a back board, wherein the core board is a super-thick rotary-cut single board with the thickness of 6-12 mm, the surface board and the back board are made of bamboo, the core board comprises a plurality of super-thick single boards, the contiguous layers of the super-thick single boards are in the combination along the grain, a glue layer is arranged between contiguous single boards, the adhesive of the glue layer is an aqueous macromolecule isocyanate adhesive, the super-thick single boards of the core layer are single boards after the processing of stress degradation, and spot-shape or segment-shape crack grains are formed in the direction along the grain of the loosened surface of every single board. Compared with the prior composite board of the same thickness, the composite board has greatly-reduced glue amount and no deformation or distortion.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

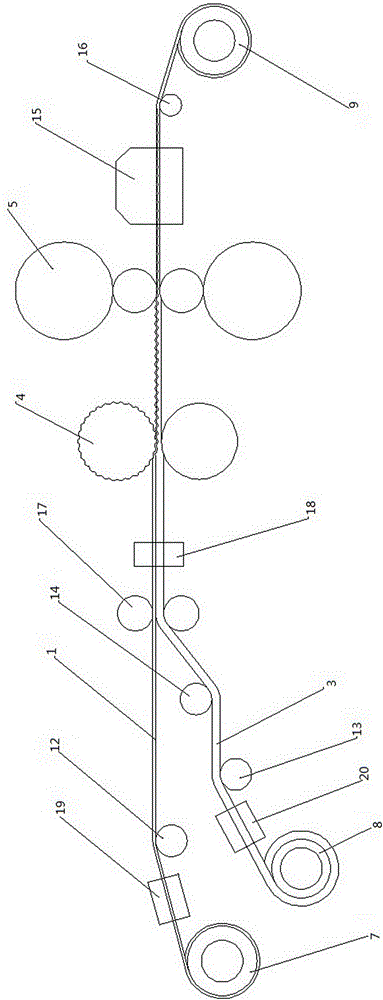

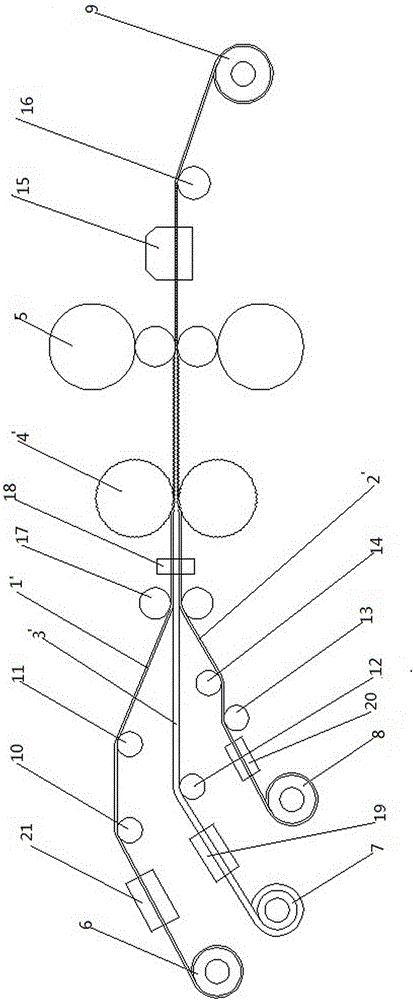

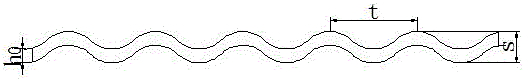

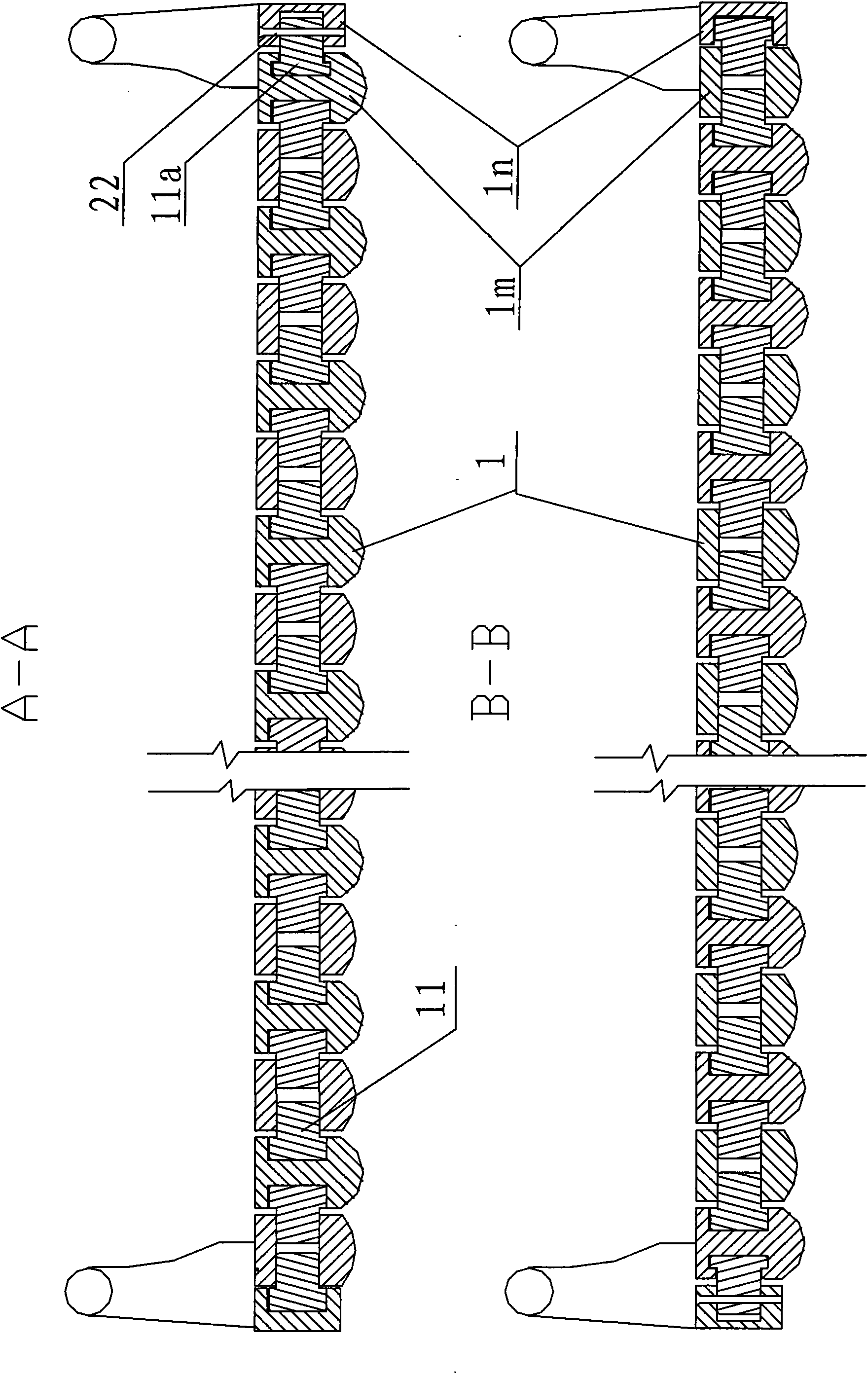

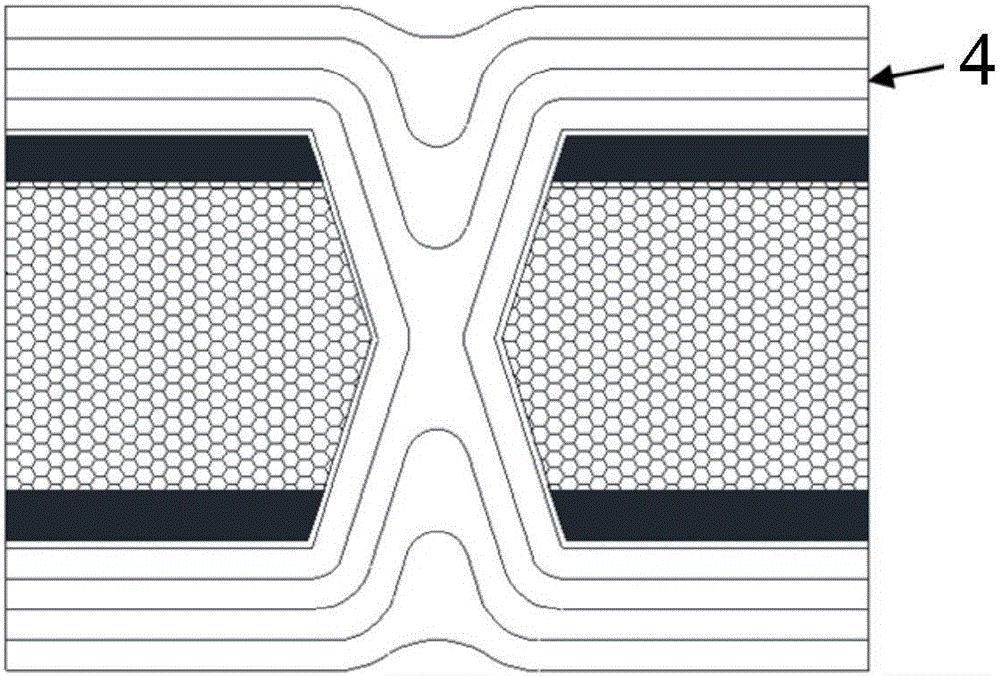

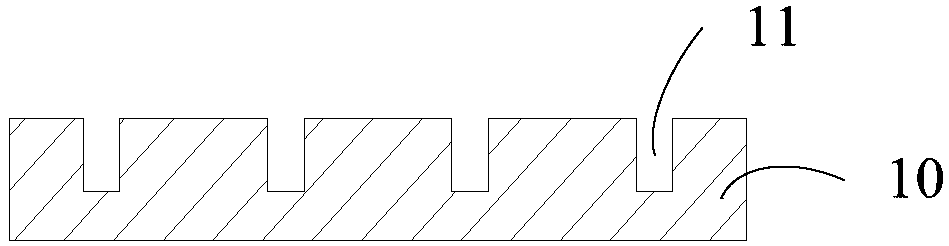

Device and method for producing metal composite sheet strips through corrugated-flat continuous rolling

ActiveCN105057386AHigh bonding strengthUniform deformationMetal rolling arrangementsCrazingContinuous annealing

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

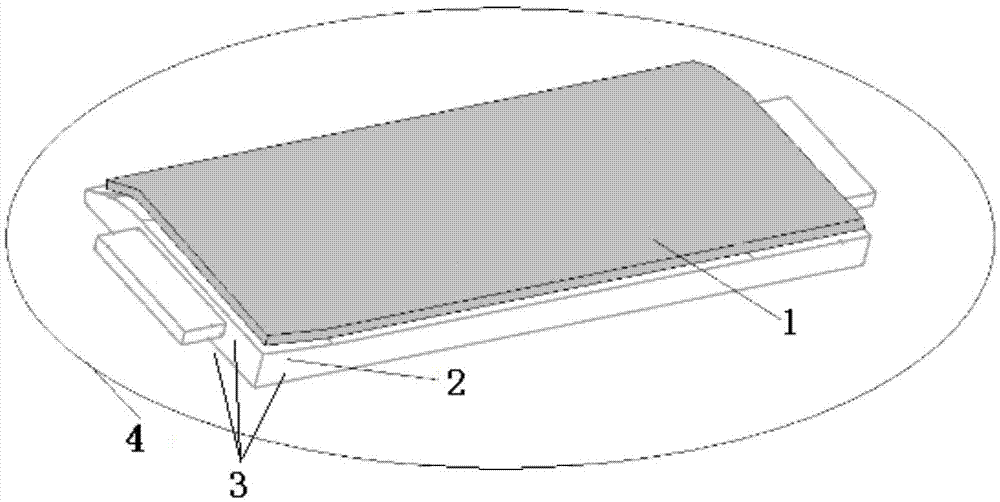

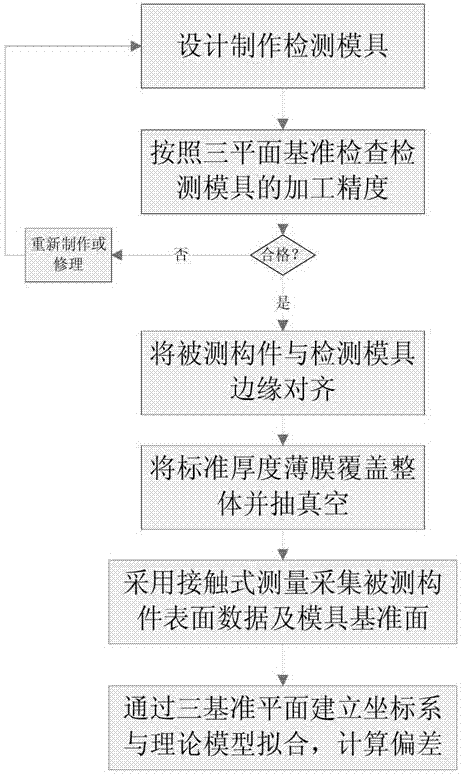

Molded surface detection method for non-rigid irregular composite material component

ActiveCN105444721ASolve warpingEvenly distributed loading forceMeasurement devicesVacuum pumpingFree state

The invention discloses a molded surface detection method for a non-rigid irregular composite material component, and belongs to the detection field for part processing and manufacturing. The molded surface detection method for a non-rigid irregular composite material component can solve the problem that detection of a molded surface under the free state does not conform to the final usage state, and can guarantee that the component can exclude the deformation error of the component during the detection process. The molded surface detection method comprises the steps: 1 designing a set of detection molds with three plane references according to a mold processed by the component; 2 fitting the component with the detection molds through the edge, and covering the surface of the molds with a standard thickness film to closely fit the component with the detection molds through a vacuum pumping mode; 3 utilizing contact measurement means to acquire the data points on the surface of the component; and 4 by means of the three reference planes, establishing the reference, and obtaining the result after being fitting the reference with a theoretical model coordinate system. The molded surface detection method for a non-rigid irregular composite material component guarantees that the surface of the detected component is provided with uniformly distributed loading force, and perfectly solves the problem that uneven loading force causes tilting of an unstrained part.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

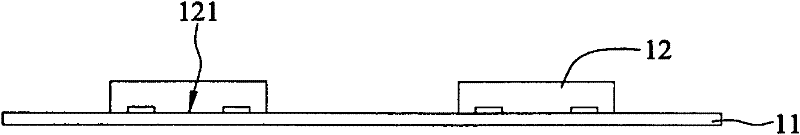

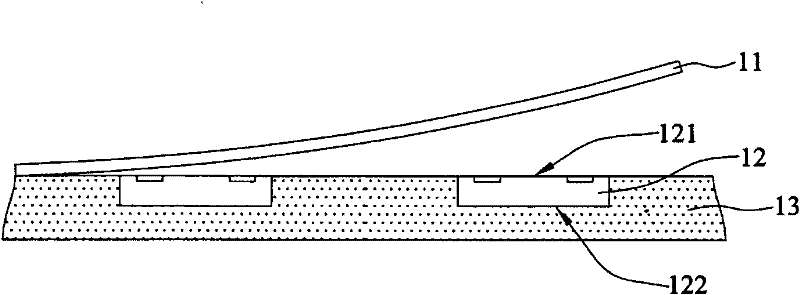

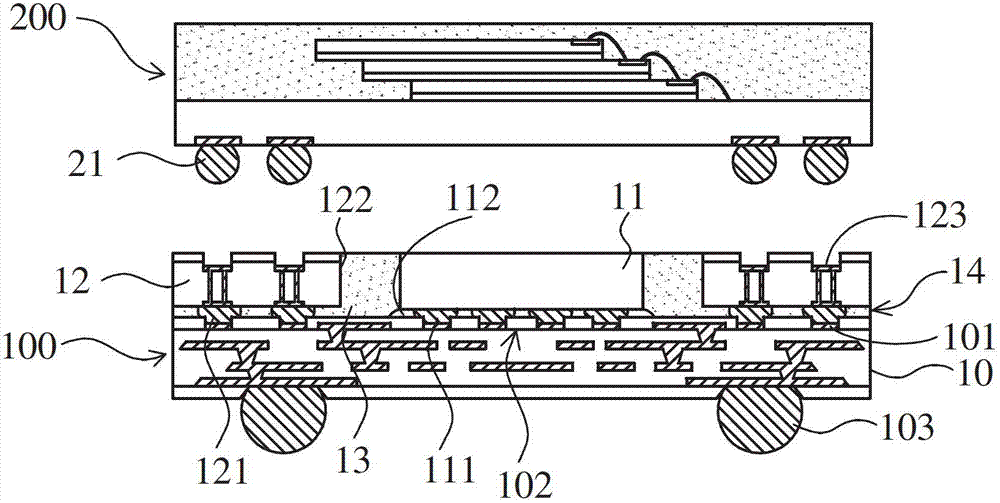

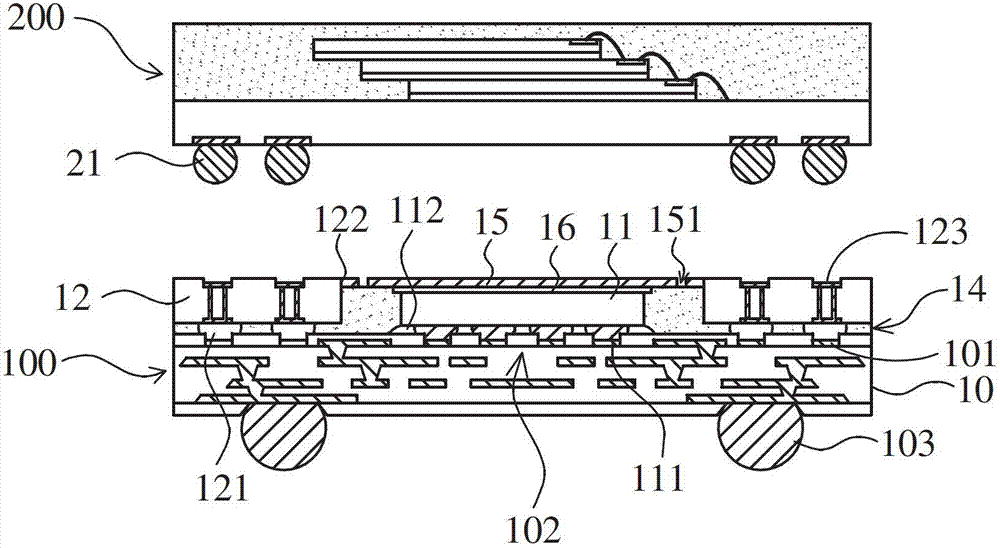

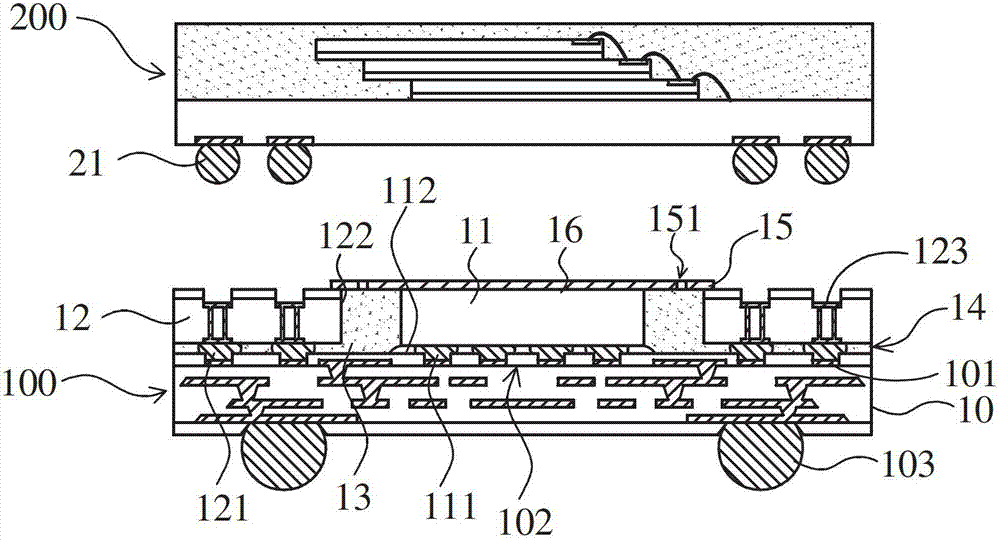

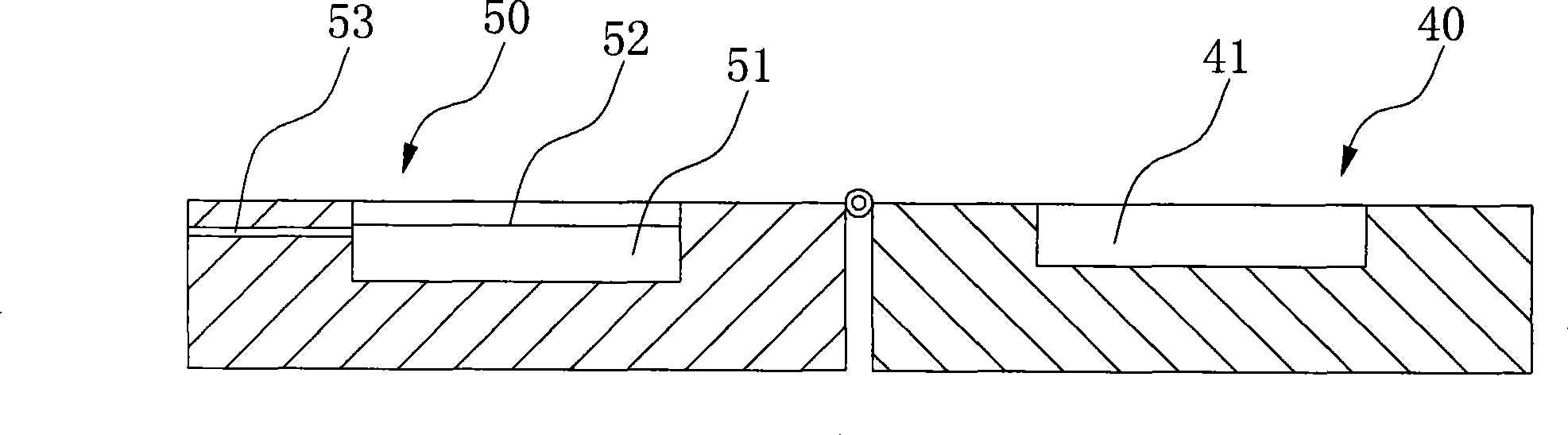

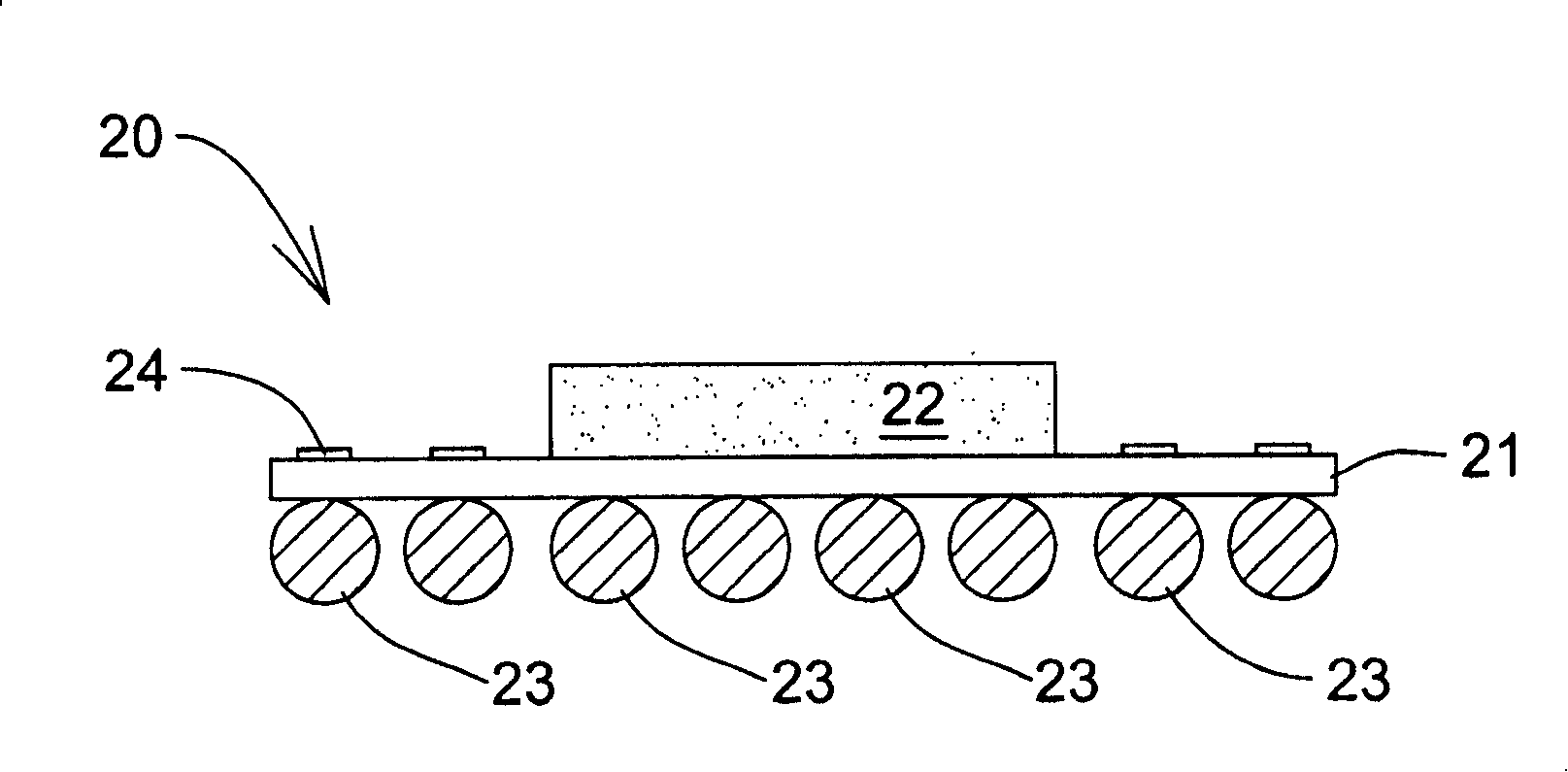

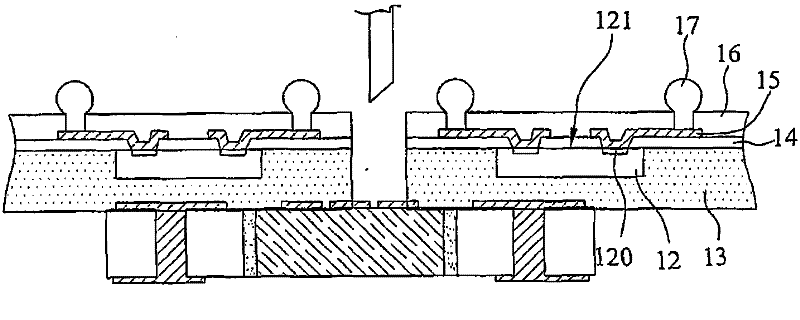

Package of embedded chip and manufacturing method thereof

ActiveCN102456636AAvoid offsetAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringChip-scale package

The invention relates to a package of an embedded chip and a manufacturing method thereof. The package comprises: a dielectric layer, which has a first surface and a second surface that is opposite to the first surface; conductive projections, which are arranged in the dielectric layer and are exposed outside the dielectric layer; a chip, which is embedded in the dielectric layer; a line layer, which is arranged on the first surface of the dielectric layer; conductive blind holes, which are arranged in the dielectric layer and are electrically connected with the line layer, the chip and the conductive projection; and a first welding-resistant layer, which is arranged on the first surface of the dielectric layer and the line layer. Therefore, other electronic apparatuses can be externally connected by the conductive projections, so that a stacked structure is formed; and the technology is effectively simplified. In addition, the invention also provides a manufacturing method of a chip scale package.

Owner:SILICONWARE PRECISION IND CO LTD

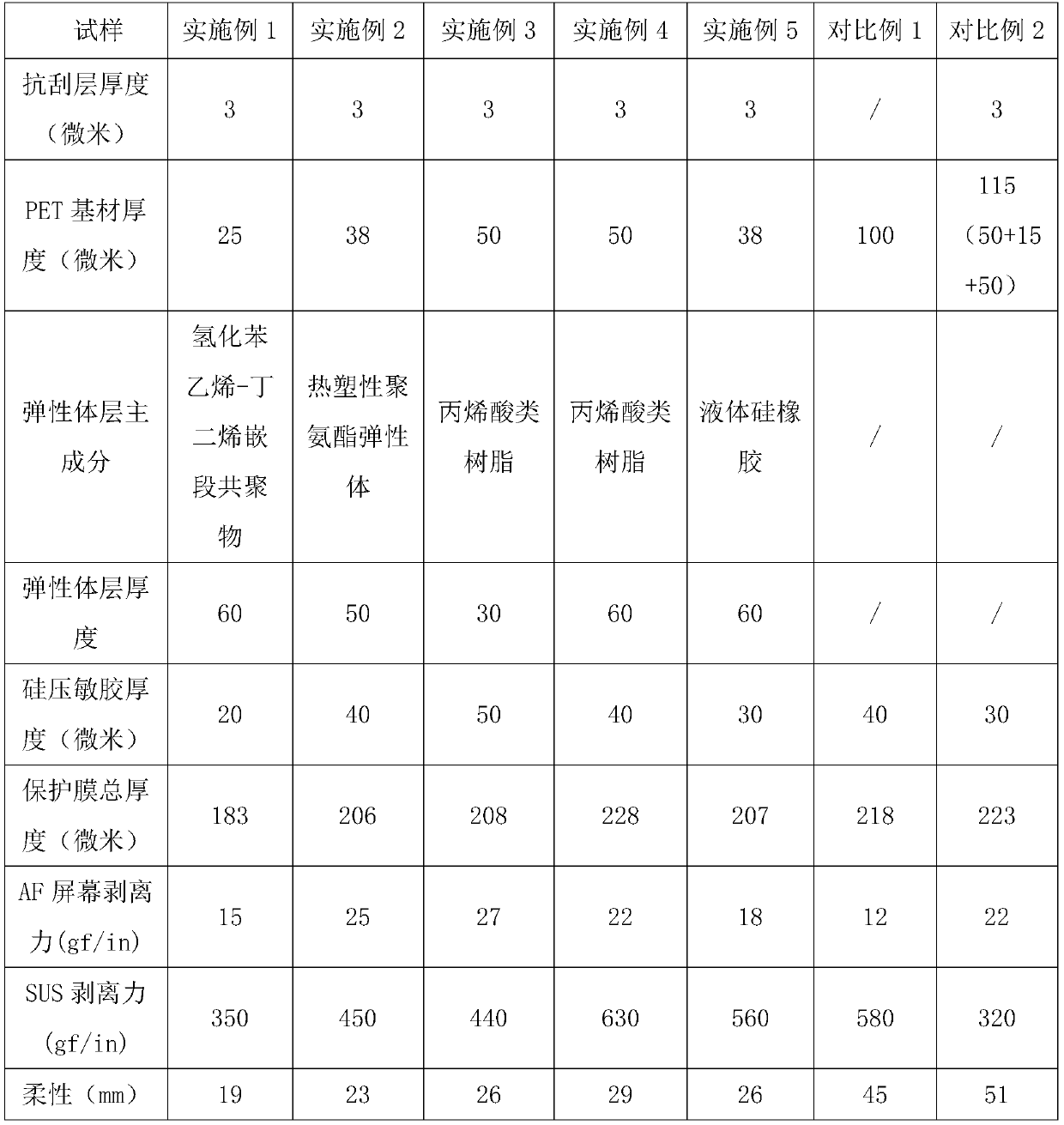

Curved screen protection film and preparation method thereof

ActiveCN110105896AImprove bendabilityImprove impact performanceFilm/foil adhesive primer layersPolyurea/polyurethane coatingsElastomerTectorial membrane

The invention relates to the technical field of curved screen protection films, in particular to a screen protection film for protecting curved liquid crystal screens and a manufacturing method of thescreen protection film. The curved screen protection film structurally comprises an anti-scratching layer, a PET base material, an elastomer layer, a silica gel layer and a fluorine release film which are sequentially arranged. According to the protection film, the arranged elastomer layer is beneficial to improving the bending property and drop resistance of the protection film, and under cooperation with the silica gel layer arranged on a protection film body, improvement of the fixing and fitting property of the protection film is facilitated, so that the problem of edge warping is effectively solved, and the protection film is suitable for the design of large angles and radians of the edge positions of mobile phone screens. Through the reasonable arrangement of the structure and thickness of each layer, the protection film has the basic performance of a PET screen protection film, and meanwhile, the flexibility, drop resistance and edge warping resistance of the protection film are further improved.

Owner:佛山固泰明科技有限公司

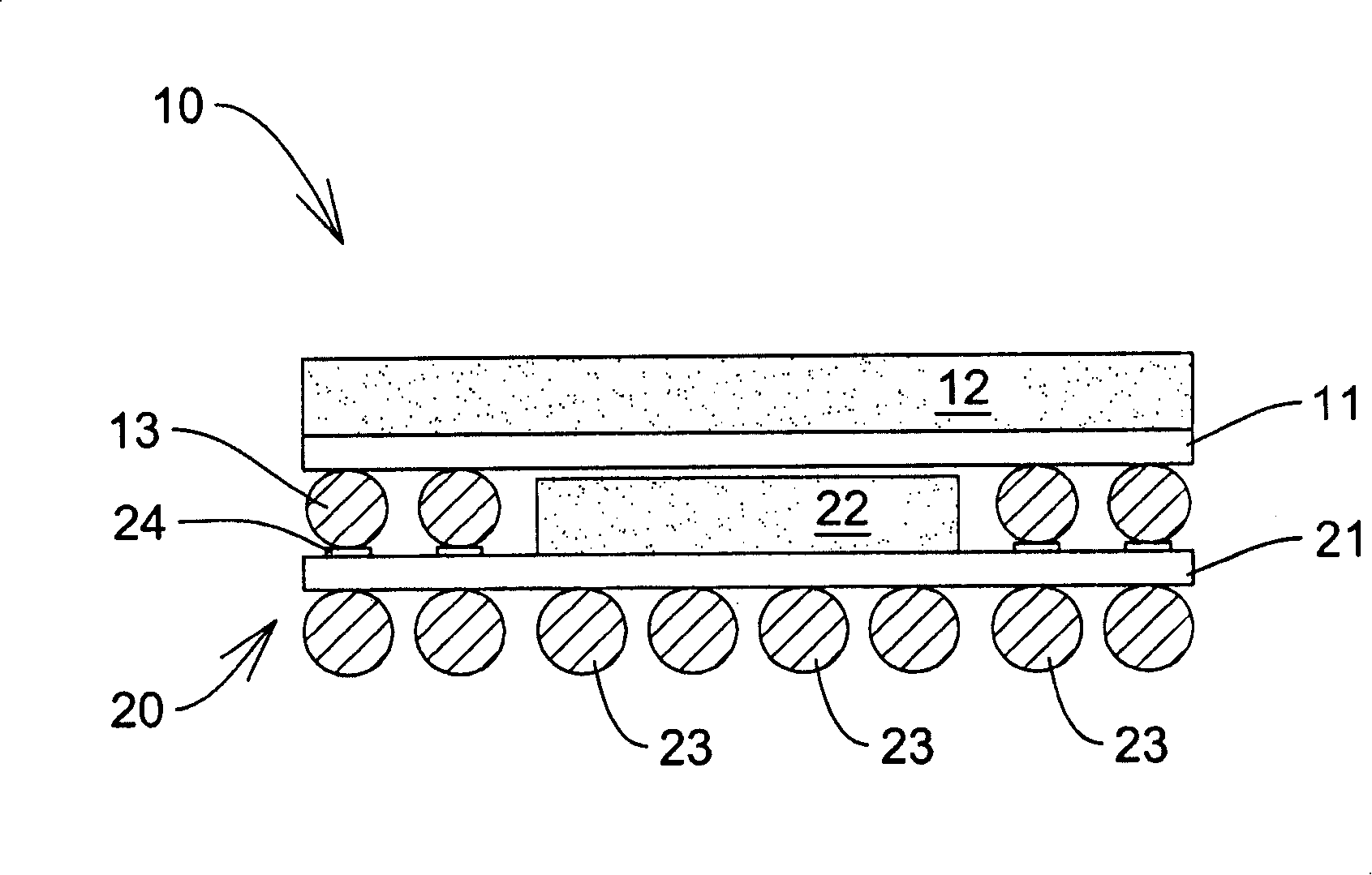

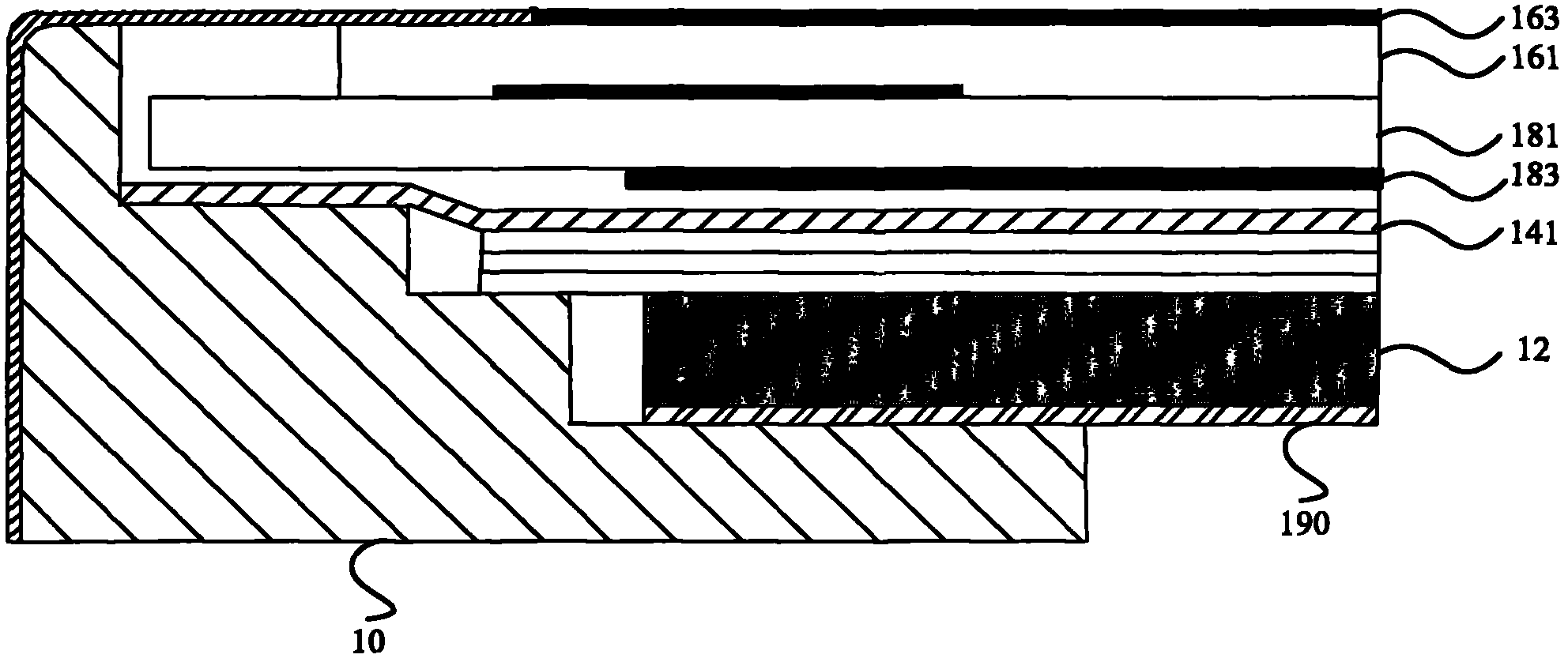

Semiconductor packaging structure for stacking and manufacturing method thereof

ActiveCN102738094ASolve warpingSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention discloses a semiconductor packaging structure for stacking and a manufacturing method thereof. The semiconductor packaging structure comprises a bottom substrate, a chip, an annular switchover substrate and packaging colloid. The bottom substrate is provided with a plurality of welding pads and a chip bearing area; the chip is fixedly arranged on the chip bearing area of the bottom substrate; a plurality of switchover assemblies and an opening are arranged on the annular switchover substrate; the switchover assemblies surround the opening and are electrically connected with the welding pads of the bottom substrate; the packaging colloid is filled in a gap between the bottom substrate and the annular switchover substrate, and is filled in the opening of the annular switchover substrate; and the packaging colloid in the opening is exposed to one top surface of the chip. With the adoption of the annular switchover substrate, the upper side and the lower side of a packaged body are slightly different in coefficient of thermal expansion, so that the warping rate is relatively lowered.

Owner:ADVANCED SEMICON ENG INC

Low-temperature-hot-stamped gold-stamped type tipping paper for cigarettes and preparation method of tipping paper

ActiveCN105200863AImprove efficiencyImproving hot stamping inaccuracySpecial paperInksAdhesive glueProcess engineering

The invention provides low-temperature-hot-stamped gold-stamped type tipping paper for cigarettes and a preparation method of the tipping paper. The low-temperature-hot-stamped gold-stamped type tipping paper for the cigarettes and the preparation method of the tipping paper are used for overcoming the disadvantages in existing high-temperature hot-stamping that the energy consumption is high, and that the rate of finished products is low and the cold hot-stamping effect is poor. The gold-stamped type tipping paper for the cigarettes, provided by the invention, is prepared through firstly printing environment-friendly alcohol-soluble white ink and printing ink on a base paper layer, then, additionally printing a layer of an adhesion-assisting glue material on the environment-friendly alcohol-soluble ink layer, then, carrying out low-temperature hot-stamping at the temperature of 85-100 DEG C, and carrying out laser boring, slitting and rewinding. According to the low-temperature-hot-stamped gold-stamped type tipping paper for the cigarettes, provided by the invention, an adhesion-assisting layer is additionally printed on the ink layer and has the functions of protecting the ink layer, enhancing the hydrophobicity of the ink layer and improving the adherence with a gold-stamped layer and the fastness of adhering of winding-adhesive glue, and special electrochemical aluminum hot-stamping foil for low-temperature hot-stamping is used in a matched manner, so that a low-temperature hot-stamping procedure can be completed at the temperature of 85-100 DEG C, and the energy consumption of a gold-stamping process is greatly lowered, and the service efficiency of a gold-stamping plate is increased, and thus the cost of gold-stamping is reduced.

Owner:玉溪接装纸制造有限公司

Novel composite flooring, mold thereof and processing method

The invention belongs to the technical field of floor, in particular to a novel composite floor, a die and a processing method thereof. The substrate of the composite floor is a plastic-wooden plate, the surface layer of the composite floor is a solid wood plate, and an elastic layer is arranged between the substrate and the surface layer. When the composite floor is processed, raw materials such as PVC resin and so on are mixed and extruded to obtain a PVC plastic-wooden plate; the PVC plastic-wooden plate taken as the substrate and the solid wood plate taken as the surface layer are placed into the die respectively, and polyurethane foam materials are injected to a space enclosed by the solid wood plate, the PVC plastic-wooden plate and the die through a passage on a base of the die, and is foamed; and the composite floor is pressed by a press machine after the polyurethane foam materials are foamed fully. The invention has simple processing and manufacturing, high production efficiency and low production cost; and the obtained composite floor is safe, environment-friendly, moistureproof, waterproof and mothproof, has soft and comfortable foot feeling, good temperature insulating effect and high service performance, and has good effect of vibration reduction and sound insulation because the polyurethane foam materials play a role of vibration reduction in the middle layer.

Owner:郎玉山

Packaging body capable of repeatedly stacking

InactiveCN101221945AReduce usageFast transmissionSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringFlip chip

The invention relates to a package which can be repeatedly piled, comprising a substrate which has a plurality of first welding pads; a chip which is arranged on the substrate and exposes an active surface which is in electric connection with the substrate; a plurality of second welding pads which are arranged on the active surface of the chip; and a package colloid which is arranged on the substrate for covering part of the chip, wherein, the package colloid forms a groove on the active surfaces and exposes second welding pads on the active surface; a plurality of conductive balls are arranged on the second welding pads for electrically connecting first welding pads of another package which can be repeatedly piled. Two packages are piled with the mode of flip chip, the periphery of the substrate is protected by the package colloid, thereby reducing the use of wire leads and improving the warping problem of the two piled packages.

Owner:POWERTECH TECHNOLOGY

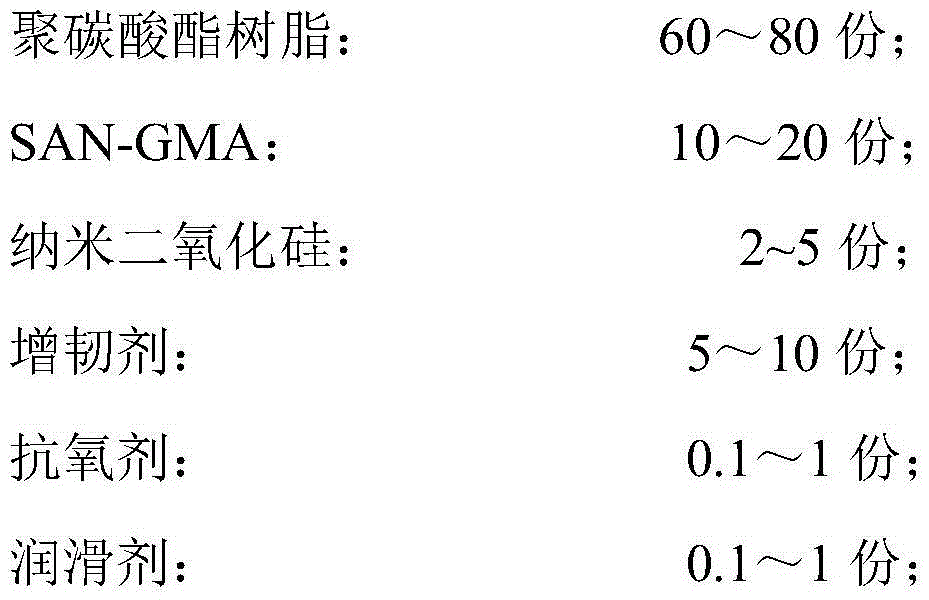

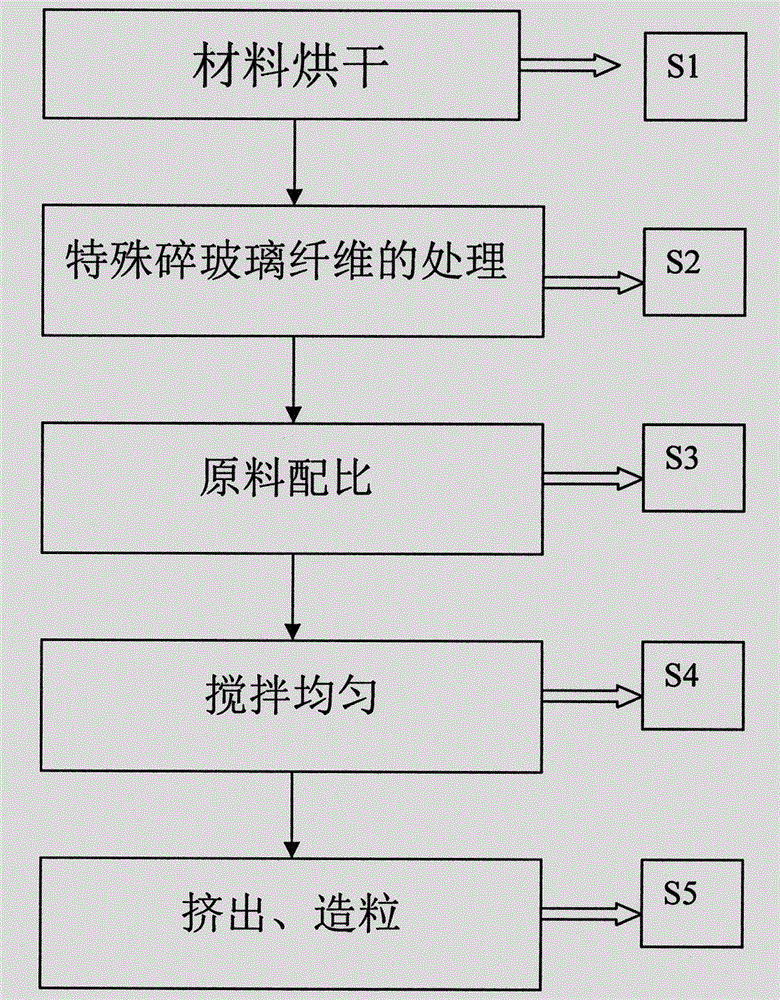

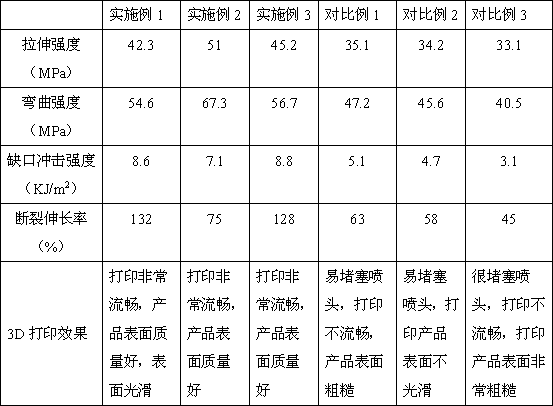

Polycarbonate composition for 3D printing technology and preparation method thereof

InactiveCN104830040AImprove heat transfer performanceShorten PC/ABS melting rangeAntioxidantDiameter ratio

The invention relates to a polycarbonate composition for 3D printing technology and a preparation method thereof. The composition is composed of the following components according to a certain ratio: polycarbonate resin, SAN-GMA, nano silicon dioxide, a flexibilizer, an antioxidant, and a lubricant. The diameter of the screw rod of an extruder used in alloy preparation is 58 mm, and the length / diameter ratio is 60. The preparation method comprises the following steps: adding PC resin, SAN-GMA resin, nano silicon dioxide, a flexibilizer, an antioxidant, and a lubricant into a mixing and stirring machine, mixing, transferring the mixture to a double-screw-rod extruder, blending, melting, extruding, and granulating to obtain the polycarbonate composition for 3D printing. Compared with the prior art, during the preparation process, the PC / ABS melting range is shortened, furthermore, nano silicon dioxide is added to enhance the heat transferring performance of the polycarbonate composition, and the warping problem during the 3D printing process is solved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

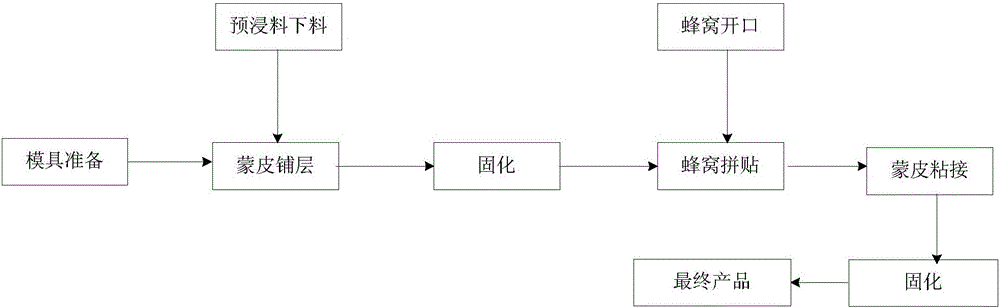

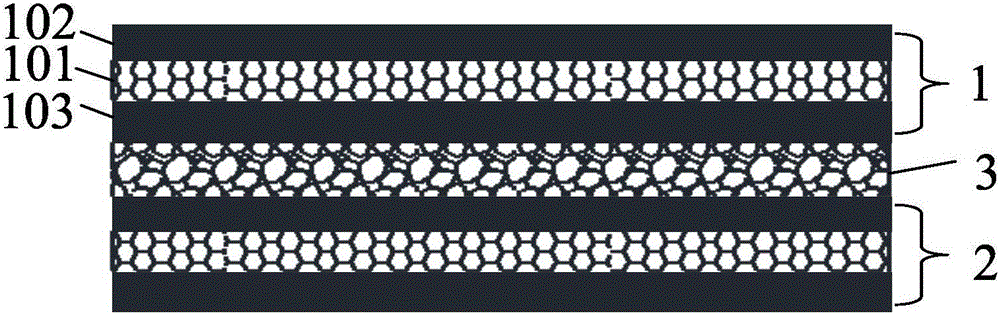

Preparation method of ultra-light sandwich structure composite material

ActiveCN106042503AStrong designabilityEliminate edge bandingLaminationLamination apparatusHoneycombMetal mold

Disclosed is a preparation method of an ultra-light sandwich structure composite material. The method comprises the steps that a hot melting prepreg material is prepared; then, the prepared hot melting prepreg material is laid according to the preset paving direction and paving layers, and a laminate preform body is obtained; then, the surface of a curved metal mold is paved with metal barrier strips, the metal barrier strips and a metal mold are fixedly connected mechanically, and then, the laminate preform body is laid on the side face flanges of the barrier strips; then, a coating for an opening honeycomb with the density being 30-50 kg / m<3> coats the surface of the laminate preform body, and then the honeycomb is paved with the hot melting prepreg material; finally, the preform body is sealed by adopting a silicone rubber sealing strip, curing is performed for 2 h under the temperature of 130 DEG C, and the ultra-light sandwich structure composite material is obtained. According to the method, the weight of the product is lowered, the problem that the honeycomb on the side face is exposed is solved; meanwhile, the skin can be effectively prevented from warping, and the phenomenon that honeycomb cores in a local area are sunken is avoided.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

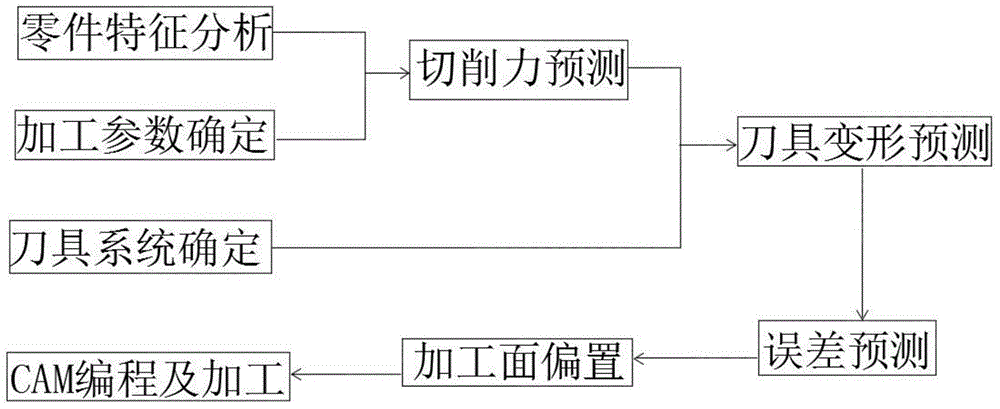

High precision manufacturing method and injection mold for plastic injection mold for complex curved surface

InactiveCN104933220AQuality improvementSolve warpingSpecial data processing applicationsProcessing accuracyMesh grid

The present invention discloses a high precision manufacturing method and injection mold for plastic injection mold for complex a curved surface, wherein a numerical control machining center, a computer and software are configured. The manufacturing method comprises the following steps: (1) modeling and deformation analysis of a plastic part; (2) cutter deformation compensation; and (3) visual inspection and processing error compensation. According to the present invention, by using HyperMesh powerful geometric processing and mesh generation techniques, a model having a better mesh indicator is rapidly created, and the cooling solution is optimized in MoldFlow, basically solving the dashboard warpage and shrinkage problem, and avoiding the loss caused by re-molding in the cost and time. Subsequently, the error is compensated by the prediction of the cutting tool, and the error is compensated offline, thereby improving the initial manufacturing precision. During the manufacturing process, by means of visual inspection of the manufacturing error, the manufacturing error is further compensated. Through twice error compensations, the manufacturing precision of the complex surface of the automobile injection mold is improved.

Owner:DONGGUAN LINGYING MOLD PLASTIC CO LTD

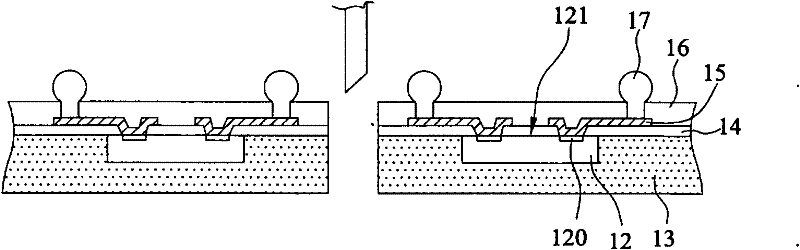

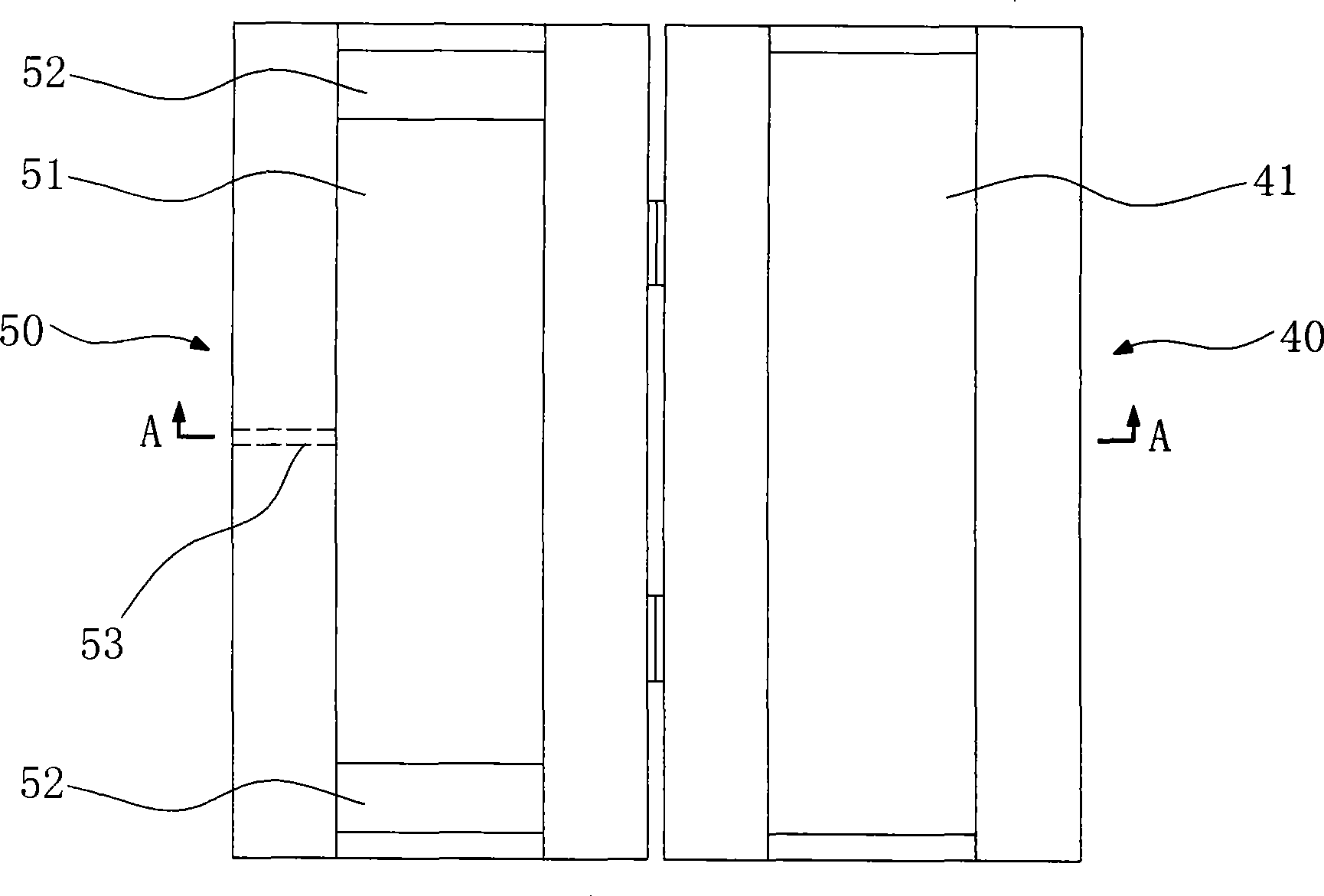

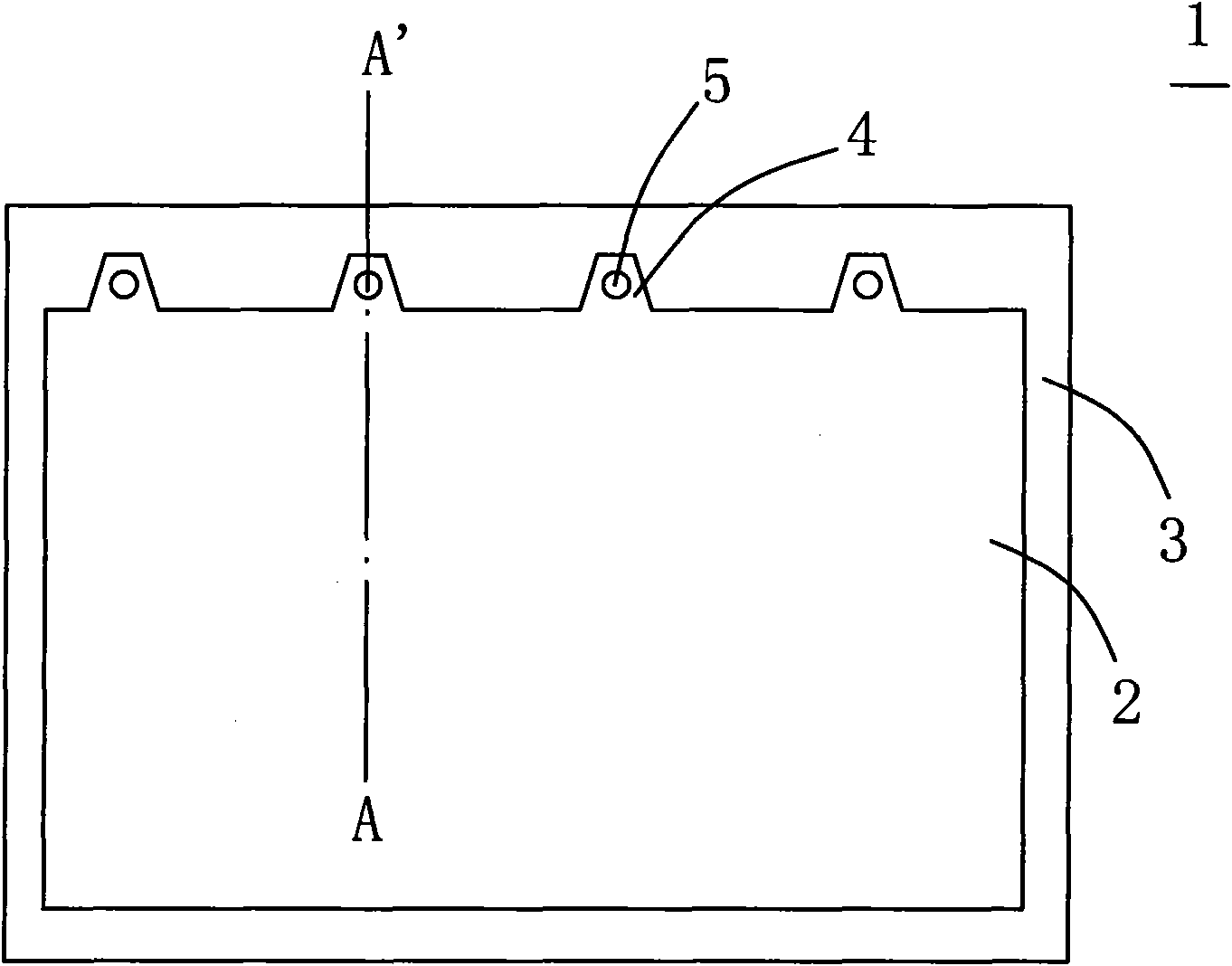

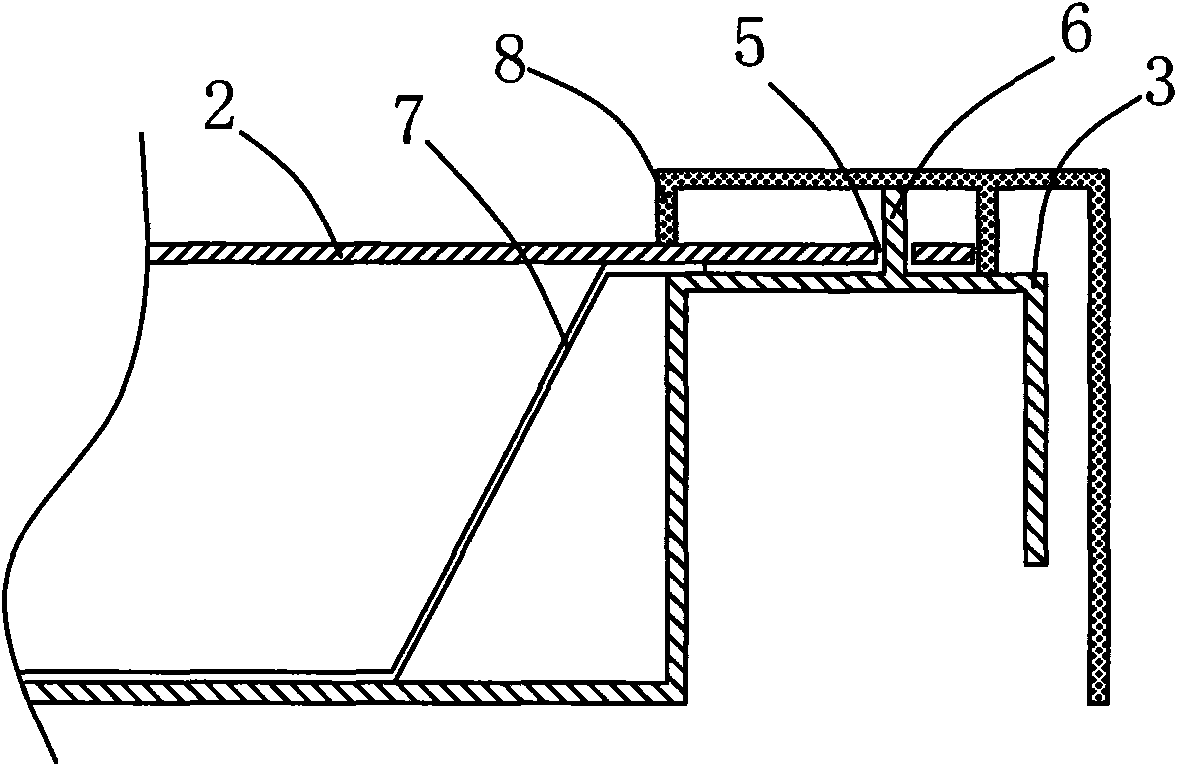

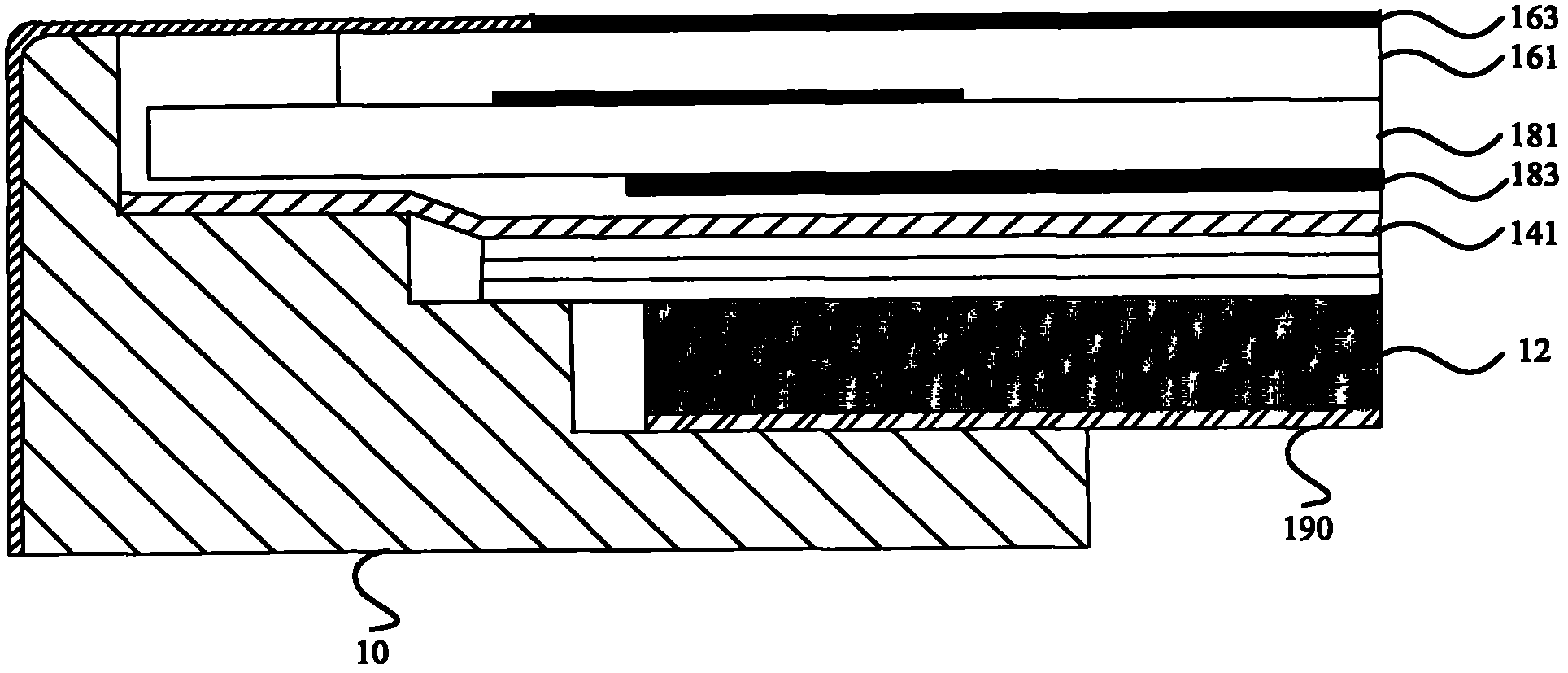

Positioning mechanism and back light module

InactiveCN101907262ASolve warpingEliminate warpingLight fasteningsNon-linear opticsEngineeringMembrane configuration

The invention provides a positioning mechanism and a back light module. The positioning mechanism is used for positioning a membrane, and the edge of the membrane is provided with at least one position limiting part. The positioning mechanism comprises a frame and an elastic structure, wherein the elastic structure is provided with a first part and a second part, the first part is combined and fixed with the frame, and the second part is matched with the position limiting part to provide pretension force on the membrane. The pretension force for the membrane is provided by using the elastic structure of the positioning mechanism and is used for regulating the expansion and shrinking amount of the membrane due to temperature and humidity variation so as to eliminate the problem of membrane wrapping.

Owner:AU OPTRONICS CORP

Chip-scale package and fabrication method thereof

ActiveCN102412208AAvoid poor contact and lead to waste problemsAvoid heat softeningSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention discloses a chip-scale package and a fabrication method thereof. The chip-scale package comprises a packaging colloid, conductive bumps, a chip, a dielectric layer, a circuit layer, conductive blind holes and a soldering-resistant layer, the packaging colloid is provided with a first surface and a second surface which are opposite from each other, the conductive bumps are arranged in the packaging colloid and exposed out of the first and the second surfaces of the packaging colloid, the chip is embedded in the packaging colloid and exposed out of the first surface of the packaging colloid, the dielectric layer is arranged on the first surface of the packaging colloid, the conductive bumps and the chip, the circuit layer is arranged on the dielectric layer, the conductive blind holes are arranged in the dielectric layer and electrically connected with the circuit layer, electrode pads and the conductive bumps, and the soldering-resistant layer is arranged on the dielectric layer and the circuit layer. Consequently, the conductive bumps can be directly connected with other external electronic devices, so that a stack structure can be formed, and the fabrication process is effectively simplified.

Owner:SILICONWARE PRECISION IND CO LTD

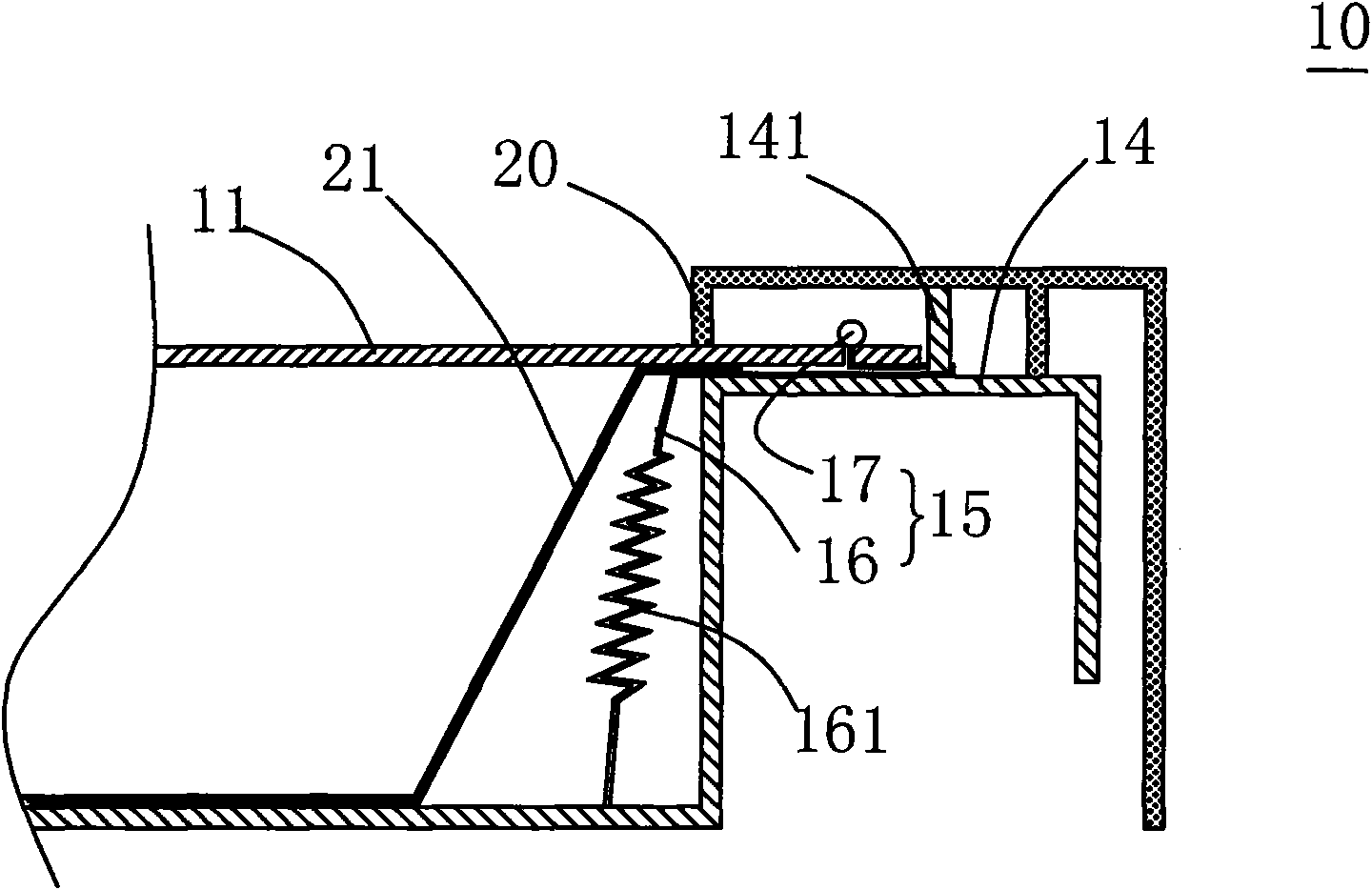

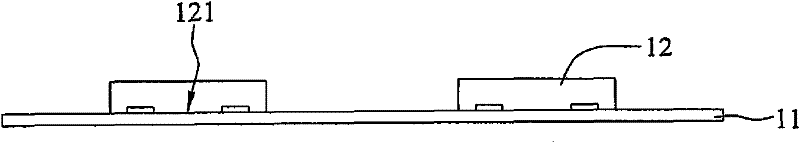

Backlight module

InactiveCN102606943AAvoid light leakageHigh mechanical strengthNon-linear opticsLight fasteningsLight guideEngineering

The invention provides a backlight module. The backlight module comprises an outer frame including a first step part and a second step part; a light guide plate arranged on the flat surface of the first step part; and a plurality of optical films stacked between the first step part and the second step part, wherein the top optical film of the plurality of optical films has an extension part at the periphery; the extension part is configured to a fold line structure to enhance the mechanical strength of the top optical film. According to the invention, the warpage problem of the film can be solved effectively by stacking the plurality of optical films between the first step part and the second step part of the outer frame of the backlight module and by forming the fold-line-like extension part at the periphery of at least the top optical film to enhance the mechanical strength of the top optical film.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

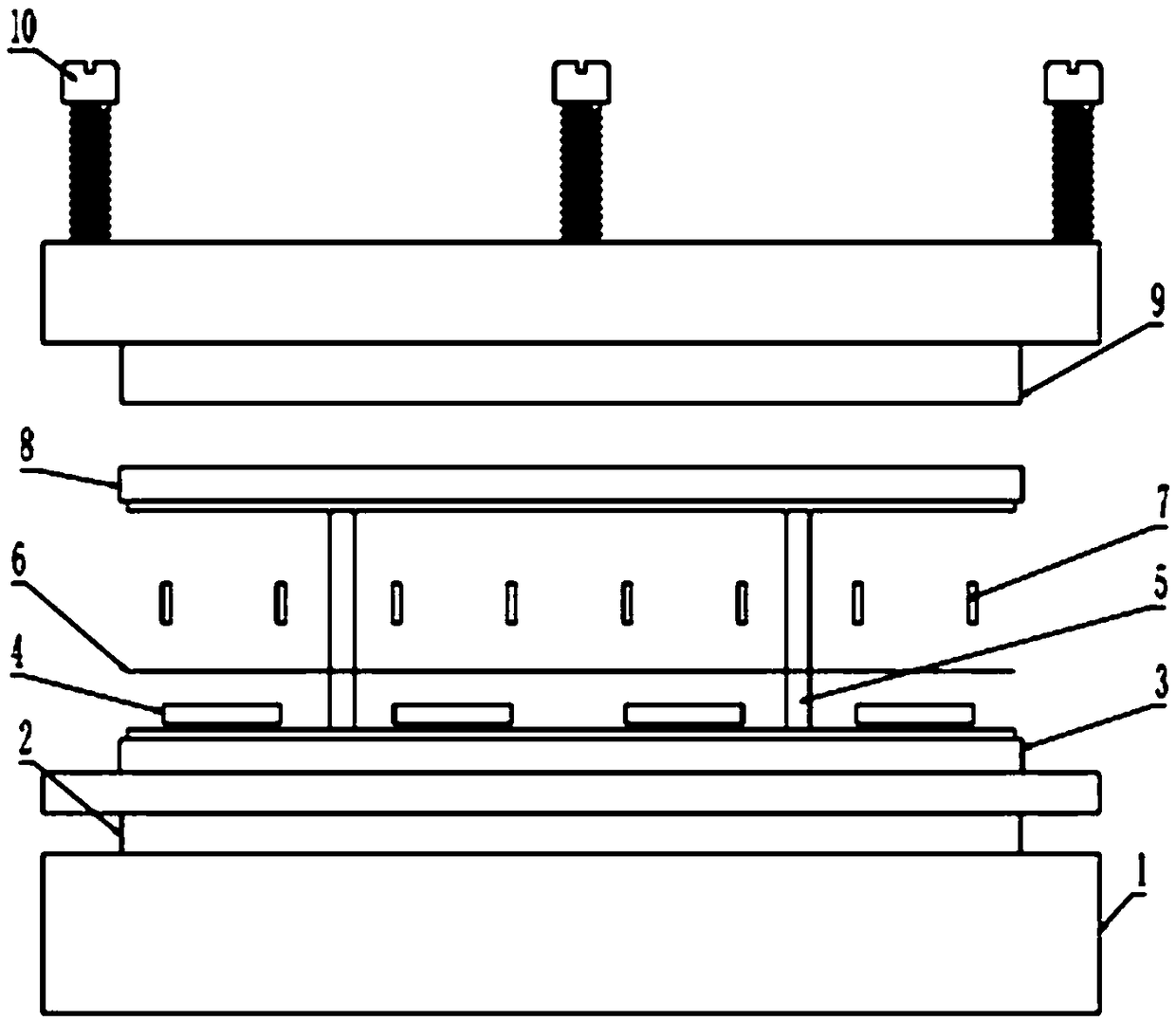

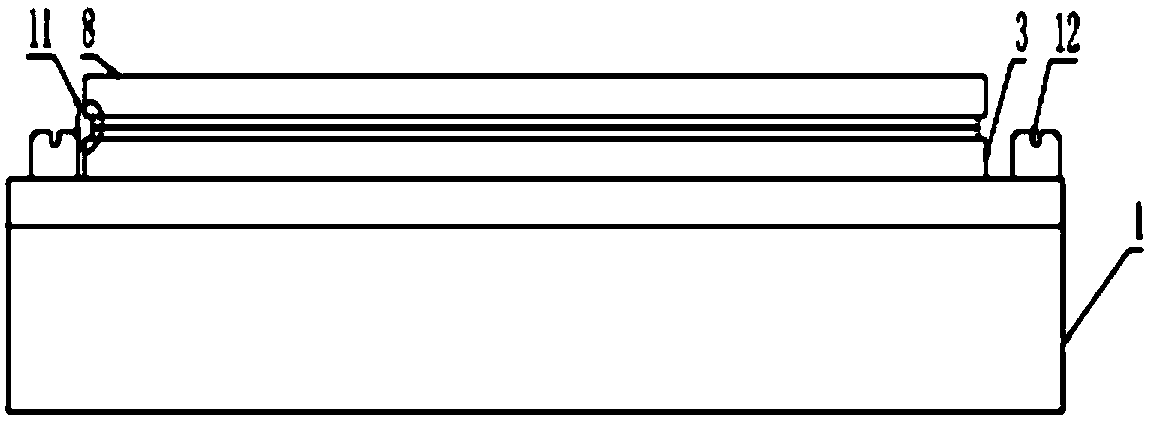

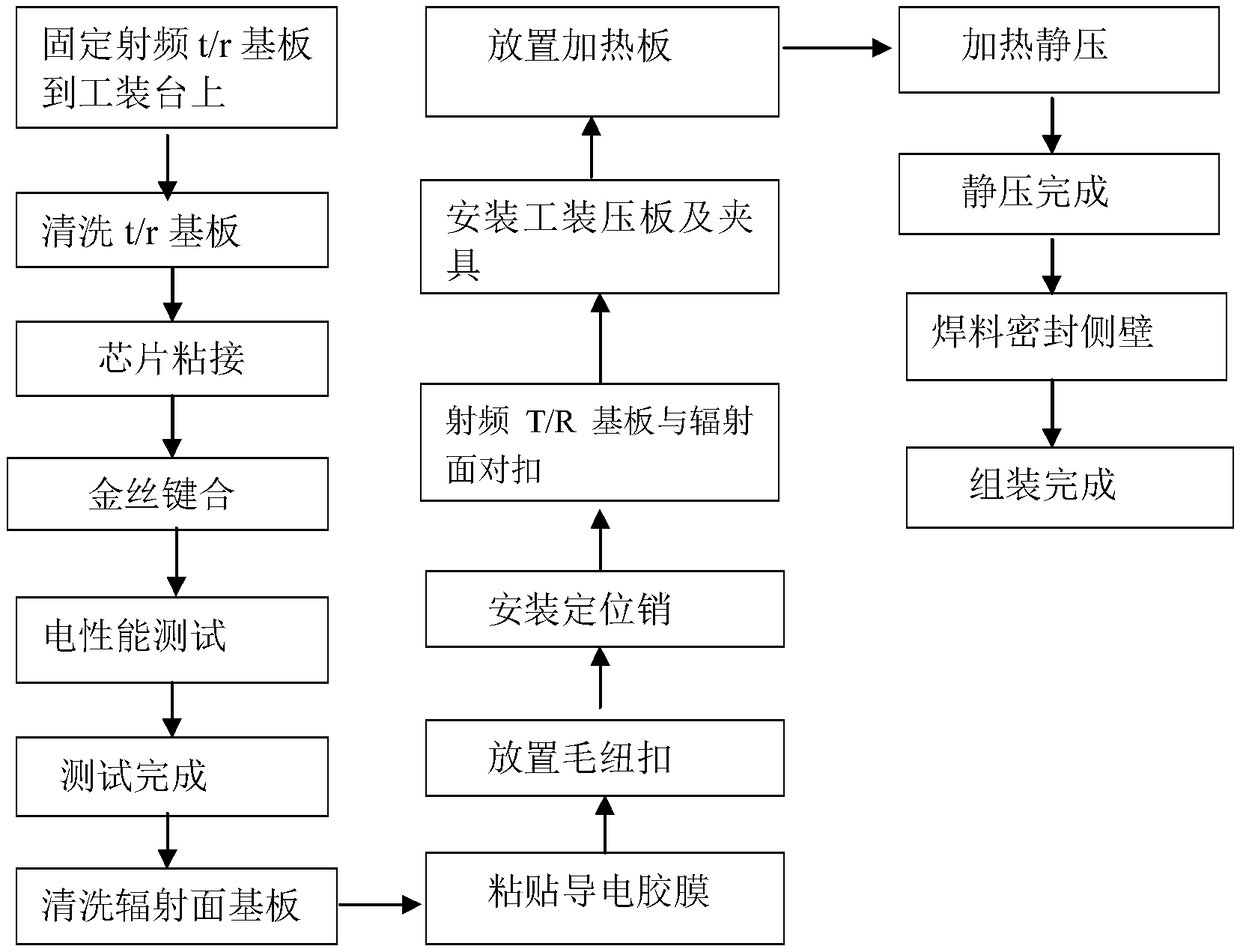

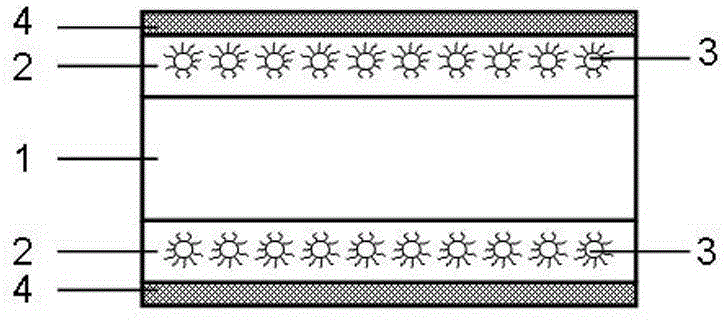

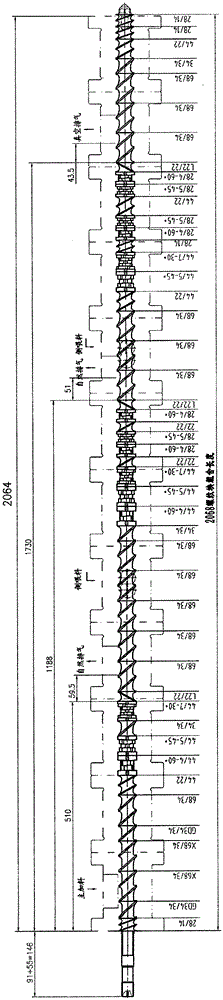

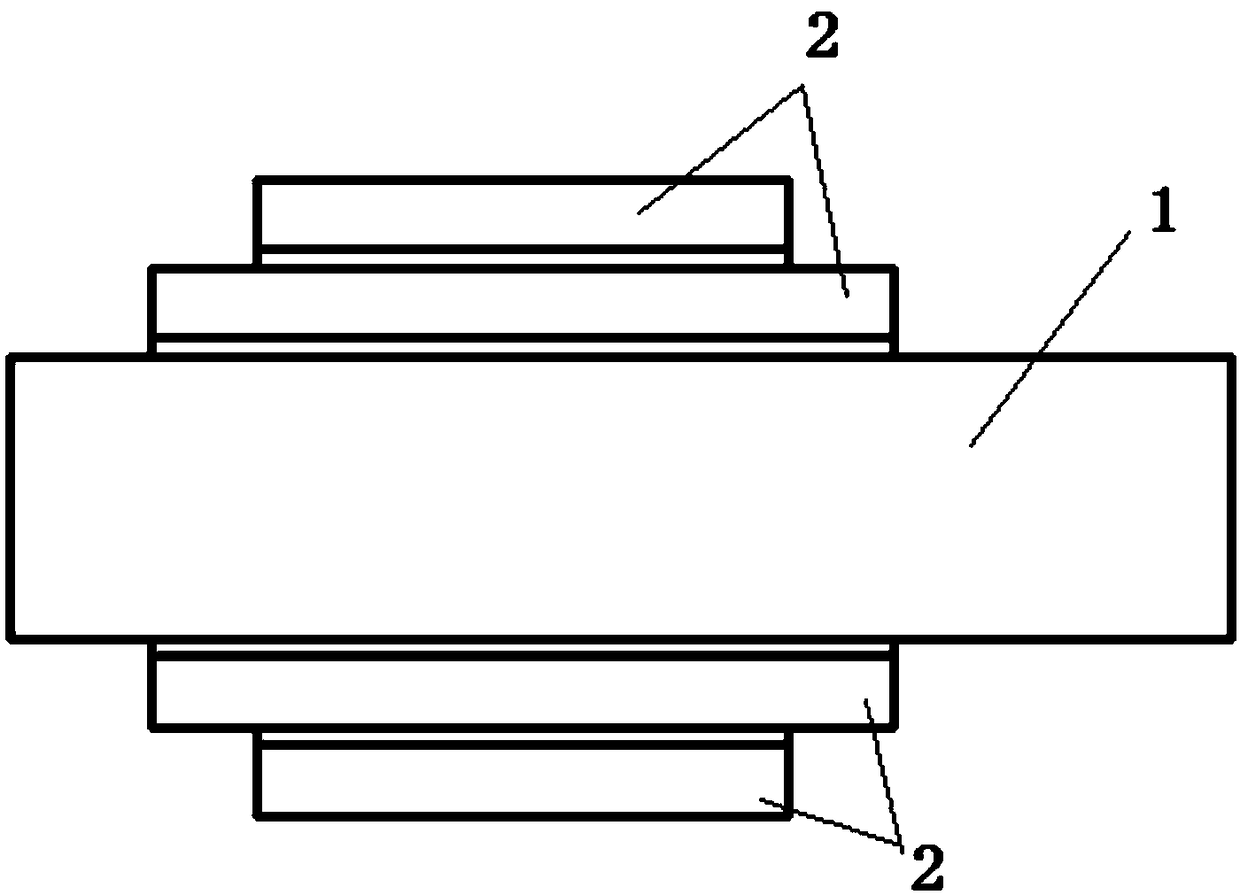

Three-dimensional integration method for tile TR component subarray element

InactiveCN108767427AEasy to GrindThin and lightPrinted circuit assemblingAntenna supports/mountingsElectrical conductorInterconnection

The invention provides a three-dimensional integration method for a tile TR component subarray element and aims at providing a three-dimensional integration method for a subarray element which is thinin body and light in weight and is capable of effectively improving the assembly efficiency and quality. The three-dimensional integration method is implemented through the following technical schemeof producing a tool base consistent with a radio-frequency T / R printed board in shape and a tool pressing plate, producing opposite and symmetric electroplated metallization steps on the upper and lower surfaces of the radio-frequency T / R printed board and a radiation surface printed board, making the radio-frequency T / R printed board vertically aligned at the radiation surface printed board andshielding and sealing the peripheries of work cavities of T-type MMIC chips; and burying fuzz buttons into circular holes in the radiation surface printed board and then fastening the radio-frequencyT / R printed board and the radiation surface printed board between the steps of the tool pressing plate and a TR low-frequency and wave-controlled circuit board and vertically interconnecting and fastening the radiation surface printed board and the radio-frequency T / R printed board together to achieve interconnection of radio-frequency inner and outer conductors and inner and outer conductors of an antenna board. Radio-frequency assembly of the subarray element of a chip phased-array antenna is achieved through integral integration.

Owner:10TH RES INST OF CETC

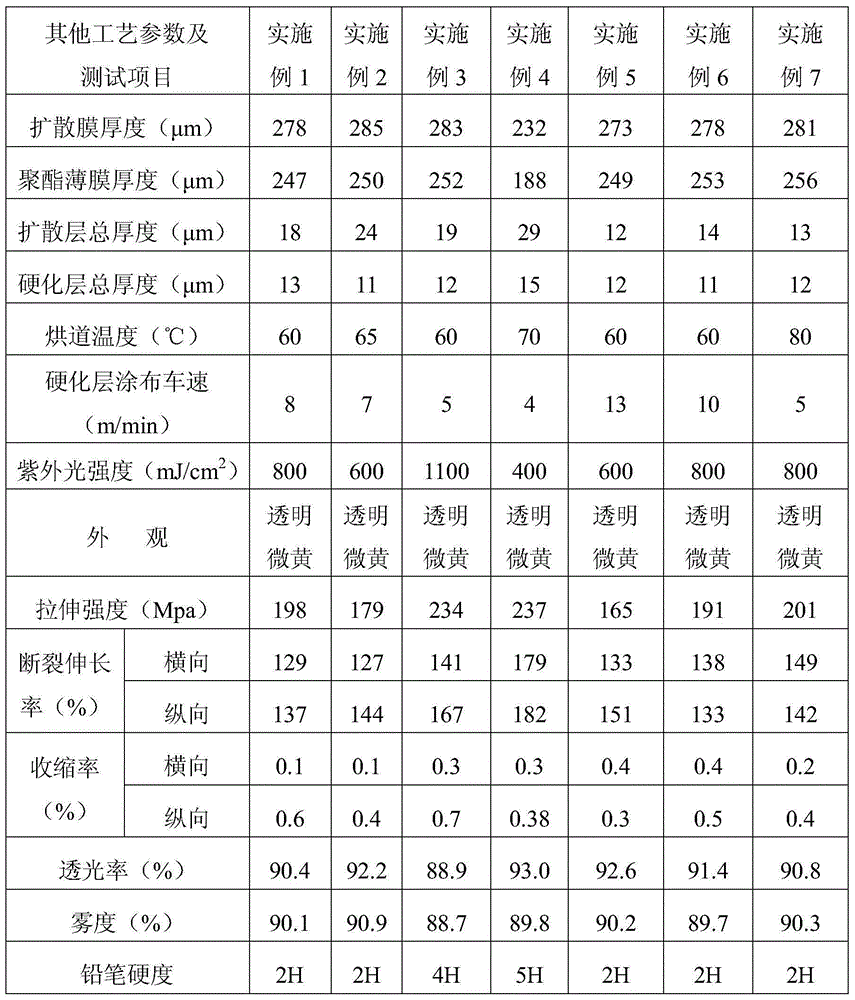

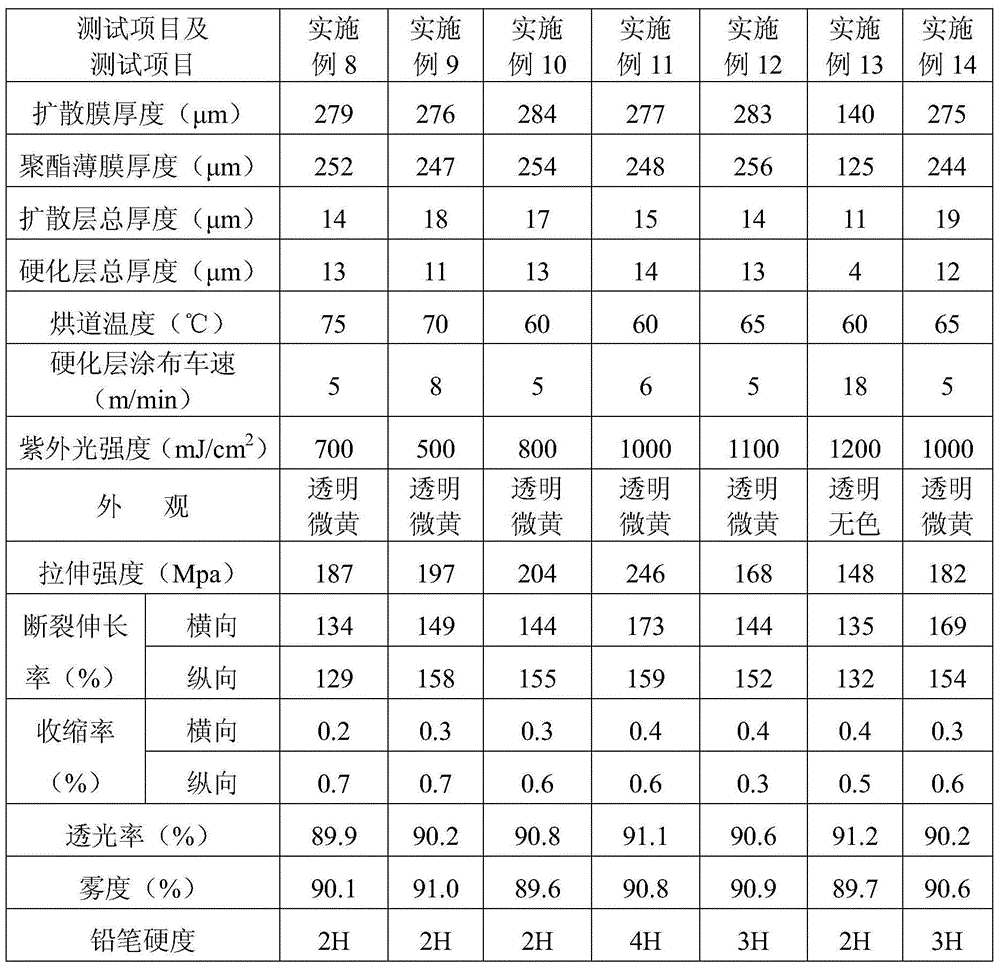

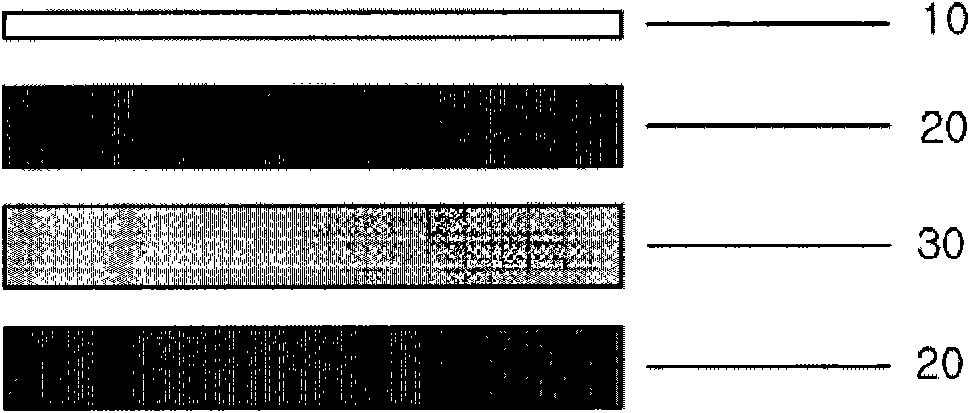

Optical diffusion film and preparation method thereof

ActiveCN104459844AWill not gather with each otherTo achieve the purpose of surface modificationDiffusing elementsPolyesterAcrylic resin

The invention discloses an optical diffusion film. The optical diffusion film is characterized by being composed of a polyester film layer, diffusion layers and hardened layers, wherein the polyester film layer is located in the middle, the two sides of the polyester film layer are coated with the diffusion layers, and the diffusion layers on the two sides of the polyester film layer are coated with the hardened layers; the thickness of the optical diffusion film ranges from 63 microns to 345 microns; each diffusion layer is a coating formed in the mode that a diffusion layer coating composition composed of a silicon source, a silane coupling agent, A-101 thermoplastic acrylic resin, ethanol, water and diluted hydrochloric acid is dried and cured at the temperature of 60-80 DEG C; each hardened layer is a coating formed in the mode that a hardened layer coating composition composed of ultraviolet cured resin, reactive diluent, photoinitiator and a leveling agent is cured under ultraviolet irradiation. The optical diffusion film has balanced light transmittance, haze and light diffusion performance, maintains high rigidity and dimensional stability and can be widely applied to manufacturing of liquid crystal display devices, advertising lamp boxes, illumination lamps and other devices requiring light sources.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

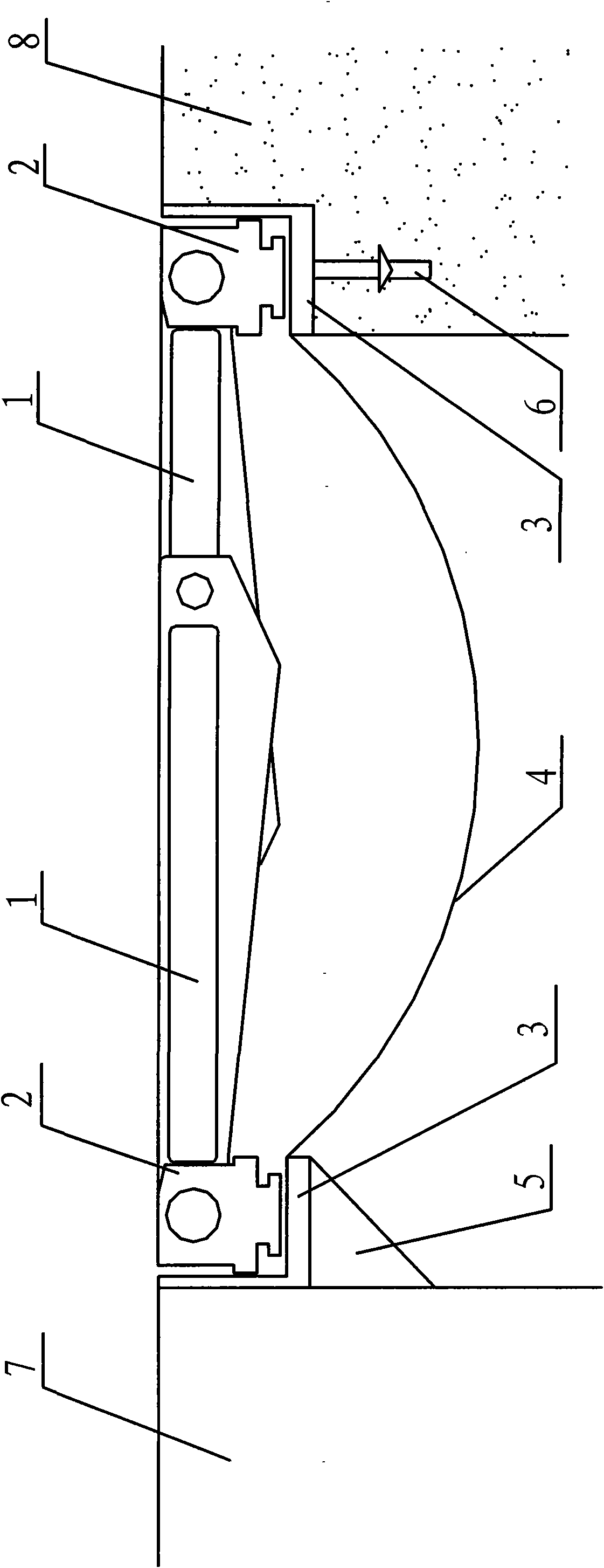

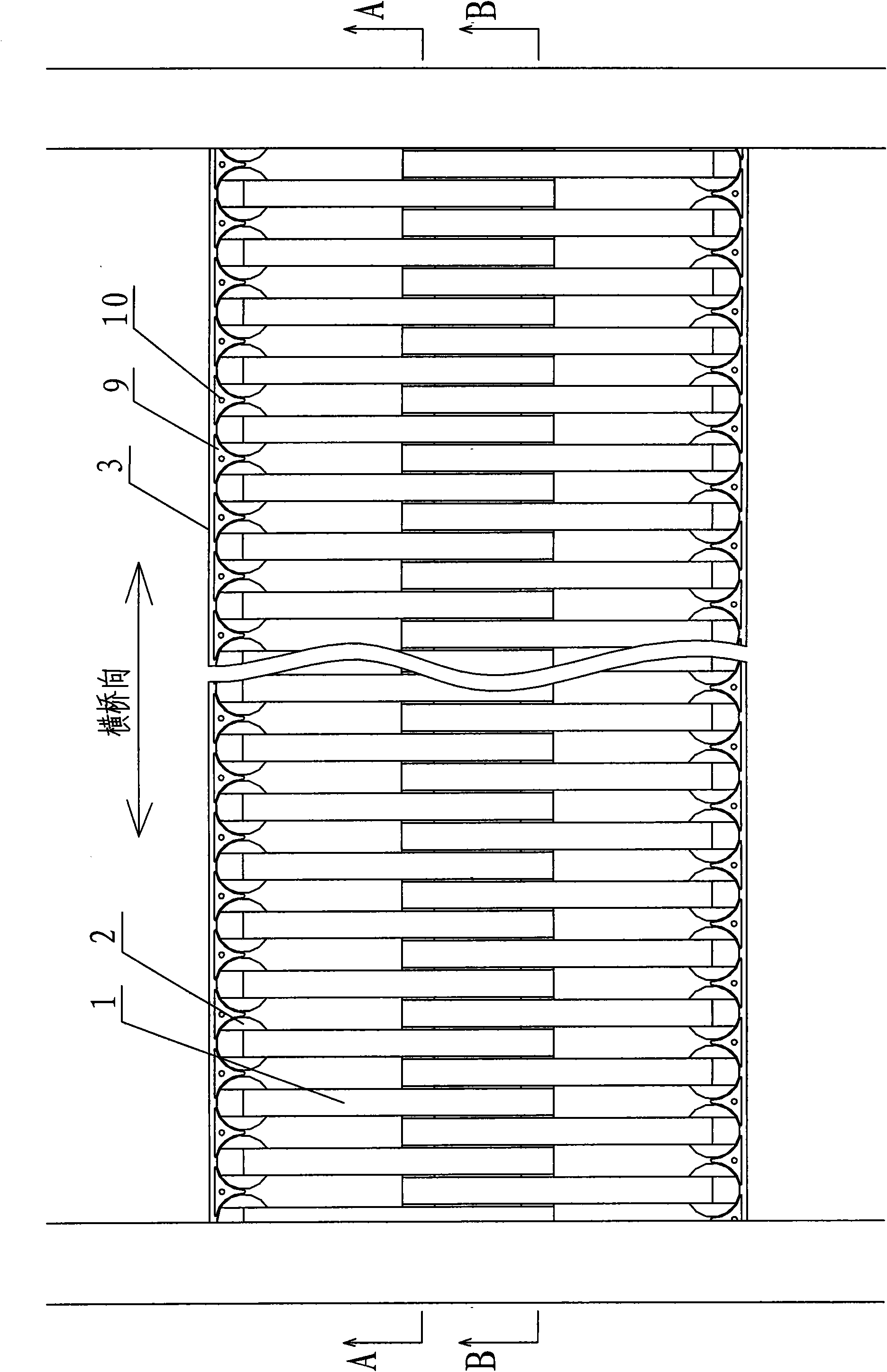

Mutual support type bridge expansion device

ActiveCN101956366ASolve the problem of tooth end warpingReasonable structureBridge structural detailsMutual supportSupport system

The invention relates to a mutual support type bridge expansion device which not only can meet the needs of the expansion of the general bridge, but also can be adapted for large displacement and comprehensive composite deformation of skew bridges, curved bridges and ramp bridges. Half beams (when the displacement is large, center beams are additionally arranged) are distributed along the bridge direction, the beam far ends of the half beams of one side obtain support through the half beams of the other side and supply support for the beam far ends of the half beams of the other side at the same time, and expansion is realized. The center beams are mutually supported during the additional arrangement and expansion is realized to form an expansion support system. The beam near ends of the half beams are respectively linked with a beam body of a bridge through a linking system (rotating bracket) to meet the needs of longitudinal and lateral dislocation and sector change among the beam ends of the bridge. The expansion support system is combined with the linking system, the problem of vibration of a broken beam of a modular expansion device and the problem of tilt of gear ends of gear plate seams are eliminated, the rotation is flexible, and the adaptability is strong. The invention has the characteristics of long service life, stable traffic, convenient production, transportation, installation and maintenance, and the like.

Owner:吴树超

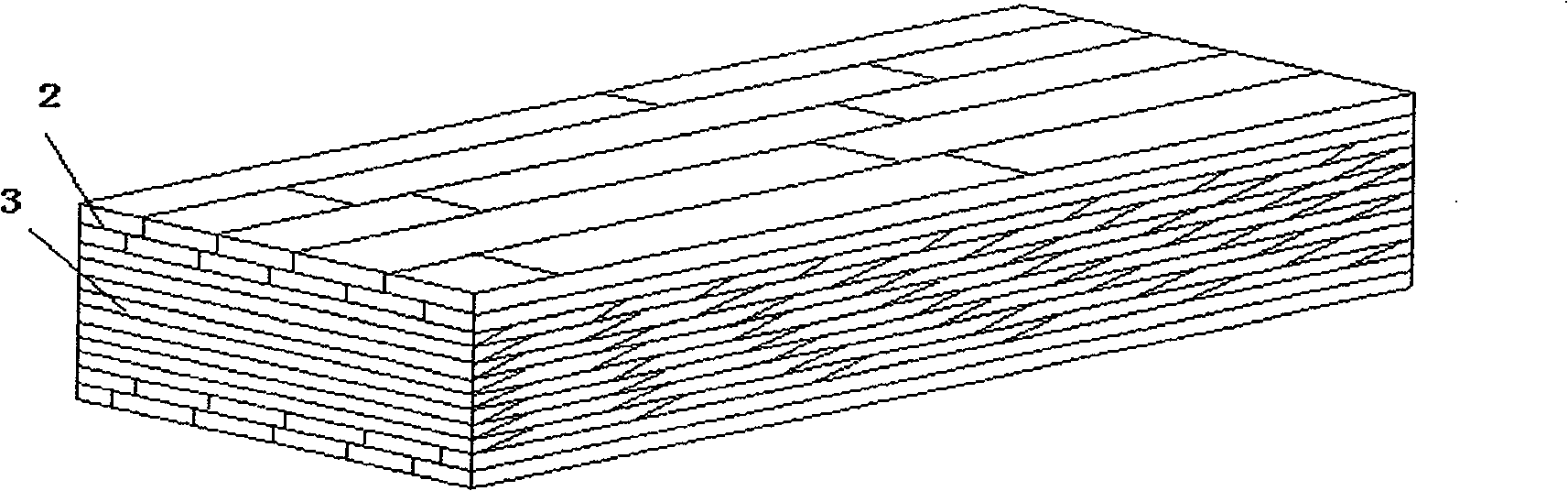

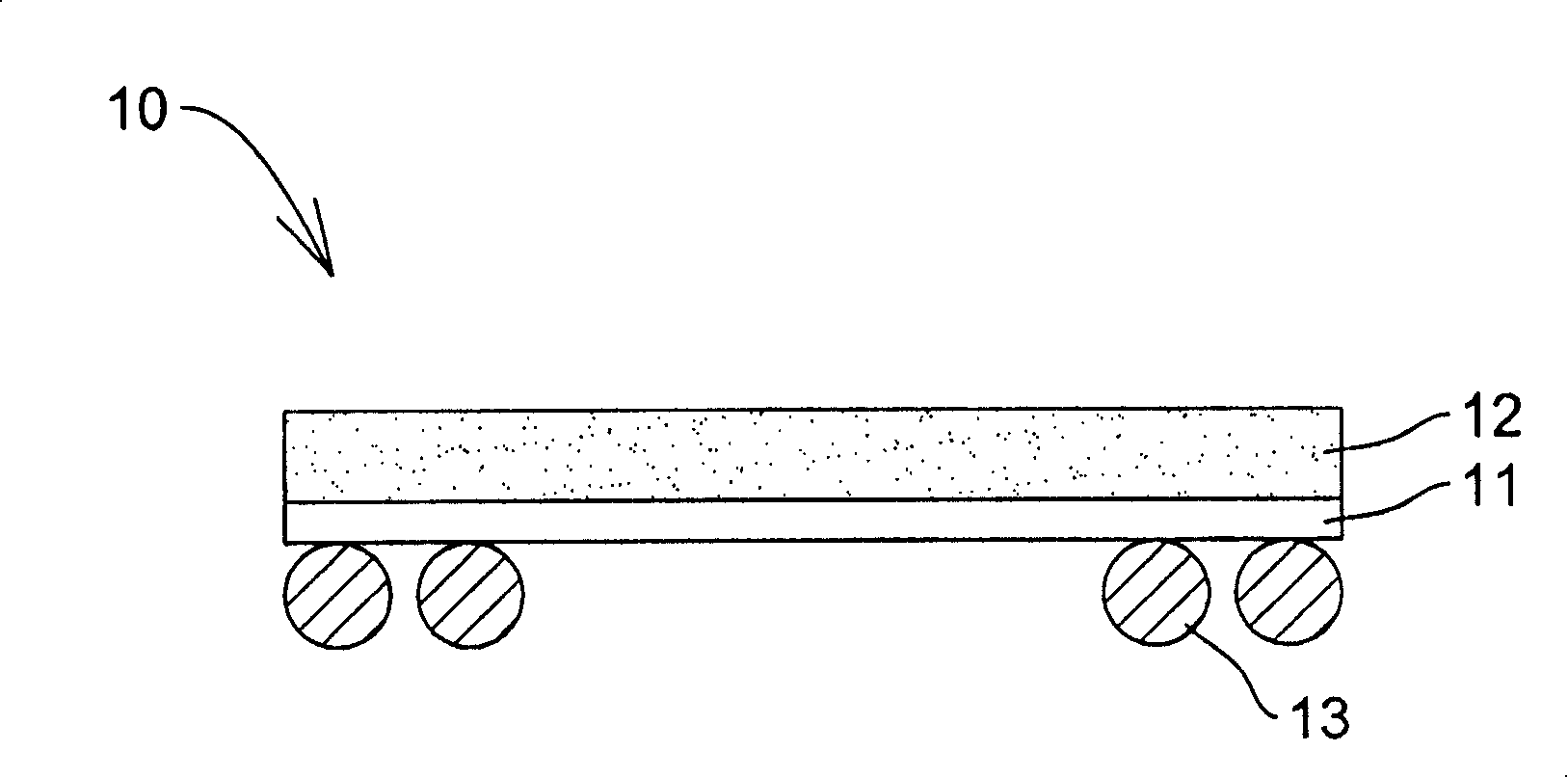

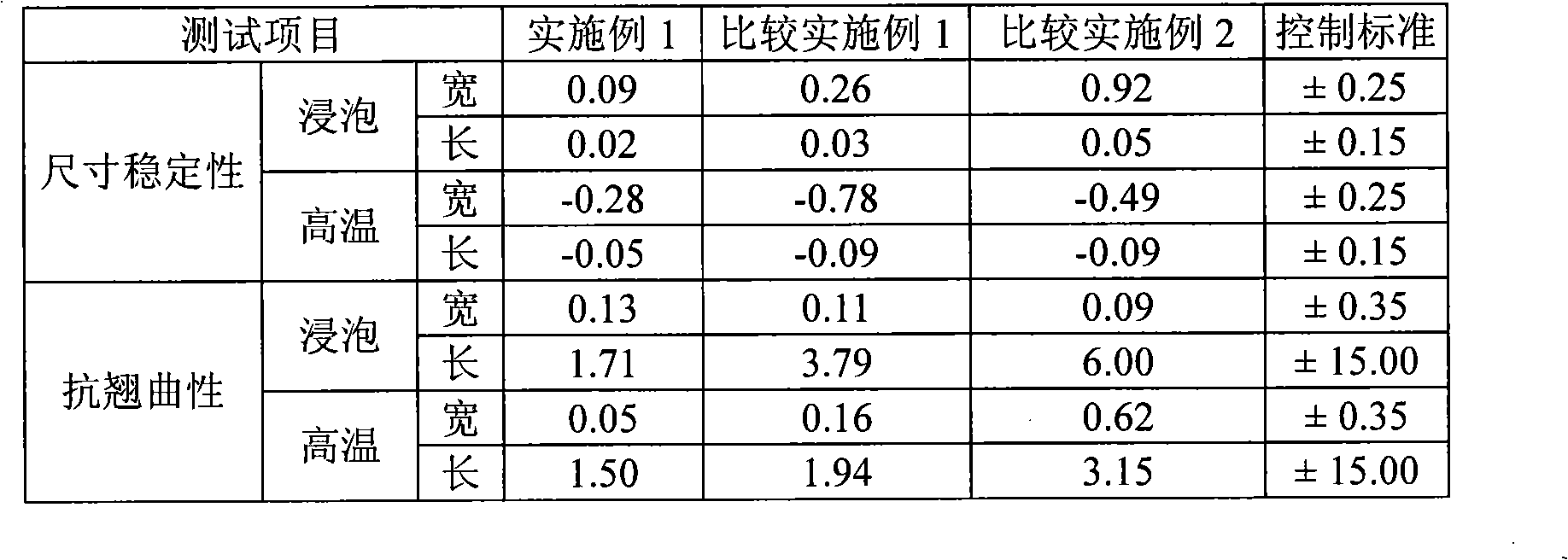

Wood flooring with carbonized solid wood using symmetric structure and process for preparing the same

InactiveCN101517177AGood dimensional stabilitySolve warpingWood layered productsFlooringSolid woodLower grade

Provided is wood flooring having a symmetric structure comprising application of carbonized solid wood to top and bottom layers and a process for preparing the same. The wood flooring of the present invention has a symmetric structure by symmetric lamination of high-temperature heat-treated veneers having a thickness of more than 2 mm on top and bottom layers and integration of the layers under given temperature and pressure conditions. Therefore, the wood flooring is capable of maintaining the balance, is capable of completely solving a problem of deformation due to environmental fluctuations, is capable of achieving dimensional stability and high-quality color of product, and is capable of removing surface contamination, thus making it possible to use contaminated lower-grade coniferous lumber as a wood flooring material.

Owner:LG CHEM LTD

Glass fiber reinforced nylon 66 composite material for panel of dish-washing machine and preparation method thereof

The invention relates to a nylon 66 composite material, especially to a glass fiber reinforced nylon 66 composite material for a panel of a dish-washing machine and a preparation method thereof. The material is composed of, by weight, 66.8 to 76.9% of nylon 66 resin, 10 to 15% of flat short cut glass fiber, 10 to 15% of cullet fiber, 0.5 to 0.8% of a nylon anti-hydrolysis agent, 0.3 to 0.6% of an anti-oxidant, 0.2 to 1.5% of a lubricant and 0.1 to 0.2% of a nucleating agent. According to the invention, through combined action of a variety of functional auxiliary agents, the special cullet fiber and the flat short cut glass fiber and adoption of special twin-screw extrusion technology, the problems of surface warping and surface floating fibers of the glass fiber reinforced nylon 66 composite material and problems in adhesion between a product and glass cement are overcome, and dimensional stability and mechanical property stability of the glass fiber reinforced nylon 66 composite material in a high-temperature humid environment are guaranteed.

Owner:NINGBO EAGLE NEW MATERIAL

High-performance PBAT plant fiber composite wire material applied to 3D printing and preparation method thereof

InactiveCN108677270ANatural closenessGood physical and mechanical propertiesAdditive manufacturing apparatusConjugated synthetic polymer artificial filamentsFiberPliability

The invention discloses a high-performance PBAT plant fiber composite wire material applied to 3D printing. The wire material is prepared from the following raw materials in parts by weight: 70 to 90parts of a PBAT raw material, 5 to 25 parts of plant fiber, 1 to 10 parts of nano filler, 1 to 15 parts of polylactic acid and 0.2 to 1 part of a chain extender. According to the wire material disclosed by the invention, a renewable resource of plant fiber is added into a totally degradable biological material of poly adipic acid / butylenes terephthalate (PBAT) to prepare the composite wire material. Compared with a traditional polylactic acid wire material, the wire material has a lower printing temperature, can prevent the warping problem after printing and has better tensile strength and flexibility; furthermore, the printing appearance of a product is smooth, the printing process of the product is smooth, a printing machine spray head is prevented from being plugged, and the composite wire material is suitable for varieties of 3D forming technologies; in addition, a printed product has natural texture of wood, and the composite wire material has a wide application prospect in the field of 3D printing.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

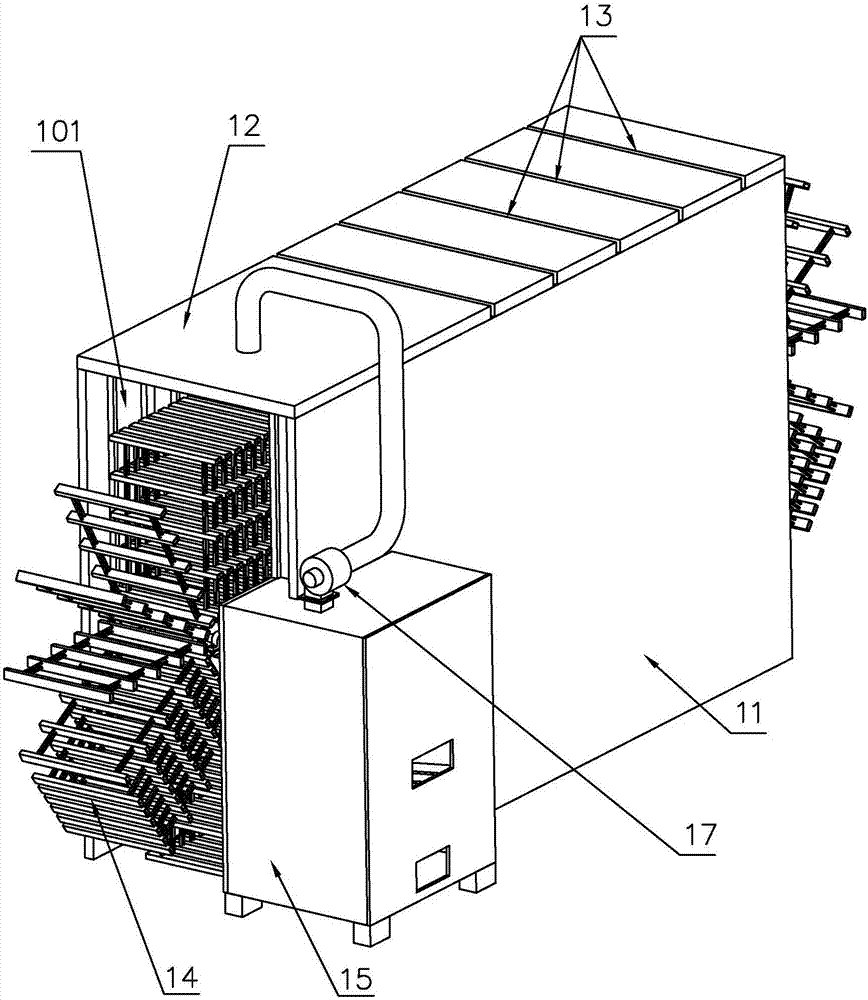

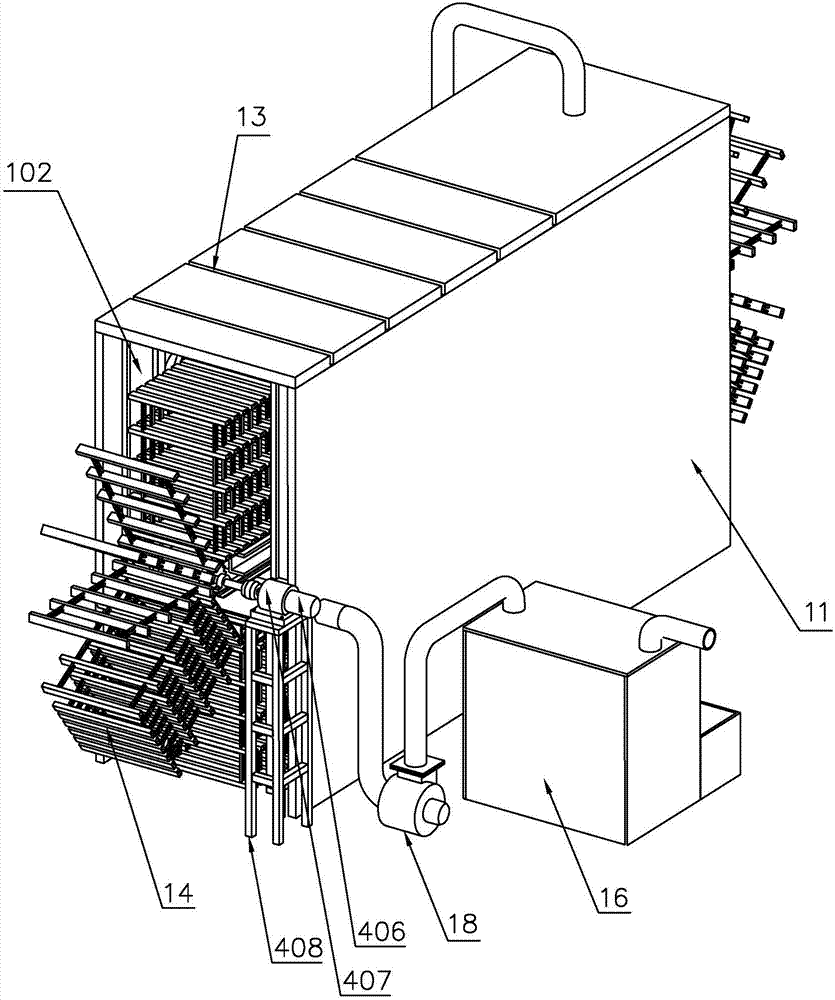

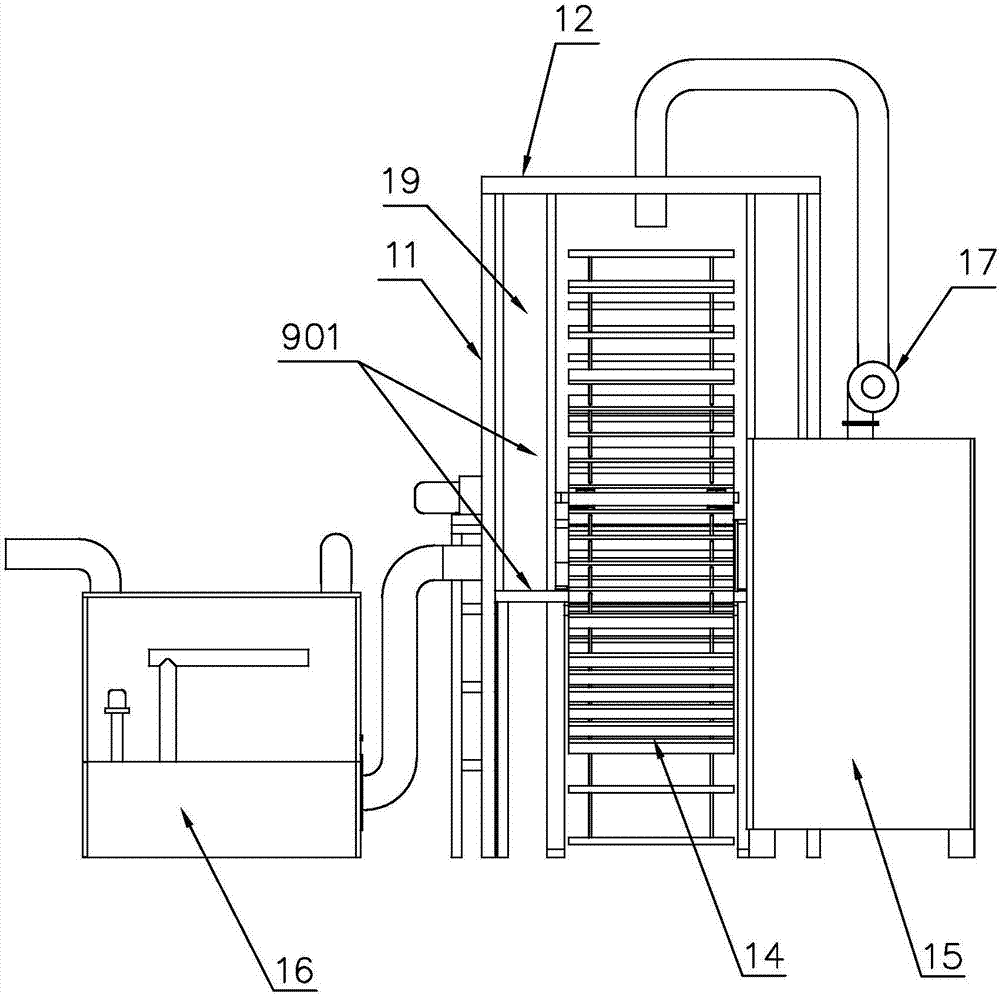

Environment-friendly efficient veneer drying device

ActiveCN107084607AUniform moisture contentImprove flatnessDrying gas arrangementsDrying chambers/containersDrive shaftFixed frame

The invention provides an environment-friendly efficient veneer drying device comprising a veneer inlet, a veneer outlet, a machine frame, a heat preservation box, a top cover, a plurality of moisture outlets, a conveying mechanism, air blowing devices, a flame path, smoke pipelines and a flue. The heat preservation box is arranged on the outer side of the machine frame. The upper portion of the heat preservation box is provided with a top cover. The top cover is provided with the multiple moisture outlets which are close to the veneer outlet. The conveying mechanism comprises a transmission shaft, clamping arms, supporting cushion blocks, a chain, chain wheels, carrier rollers, a motor, a speed reducer and a motor fixing frame. The supporting cushion blocks are arranged on the upper portion of the chain. The clamping arms are arranged on the upper portion of the supporting cushion blocks. The flame path, the smoke pipelines and the flue are fixedly connected to the machine frame. The air blowing devices are arranged on the two sides of an upper circulation position of the conveying mechanism and the two sides of the flame path. Each air blowing device comprises partition plates, air blowing fans and fan supports. The environment-friendly efficient veneer drying device is low in energy consumption, reduces the production cost of a traditional large-sized drying device, is good in veneer drying effect and solves the problem that after being dried, veneer naturally warps.

Owner:李学淑

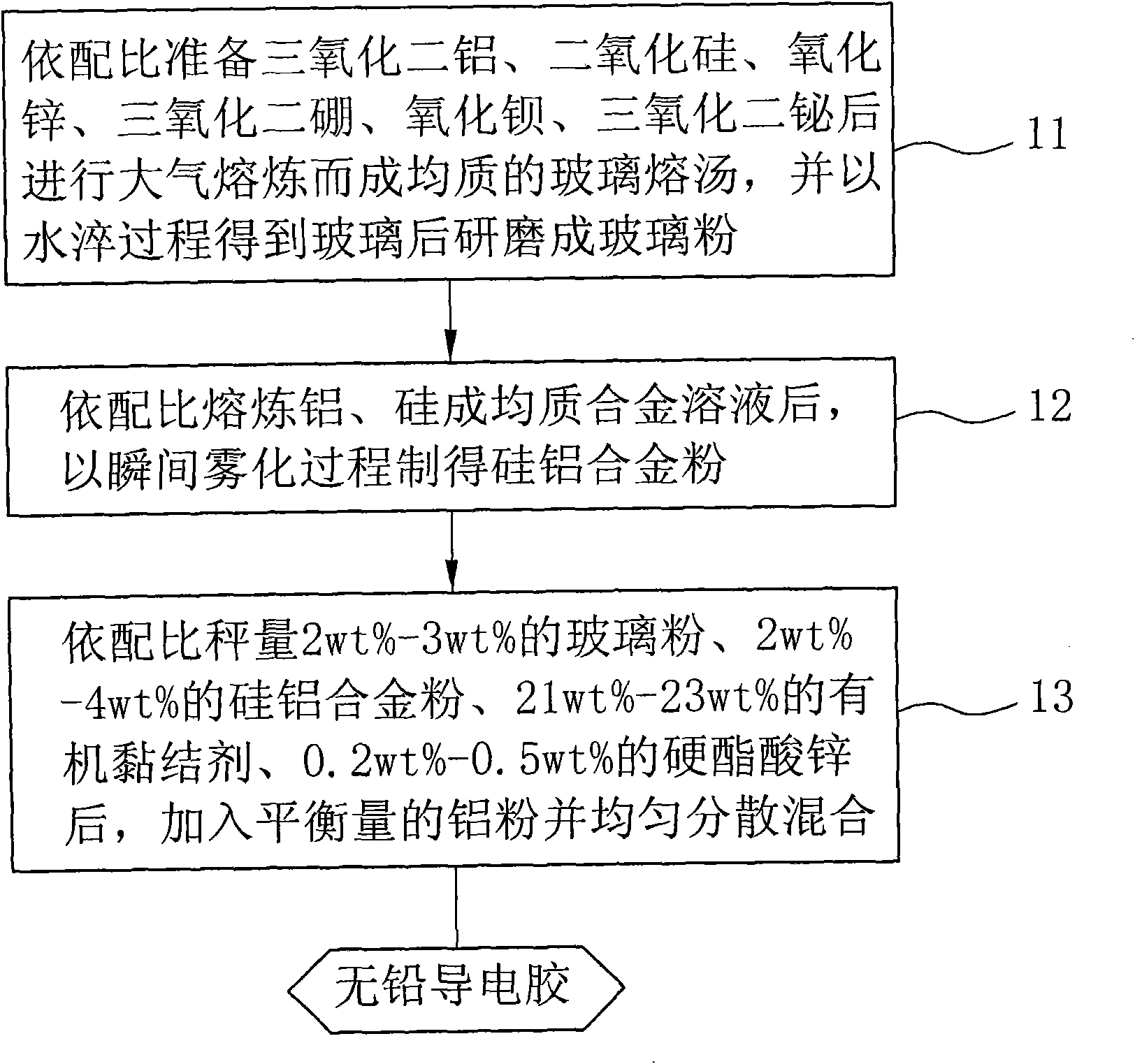

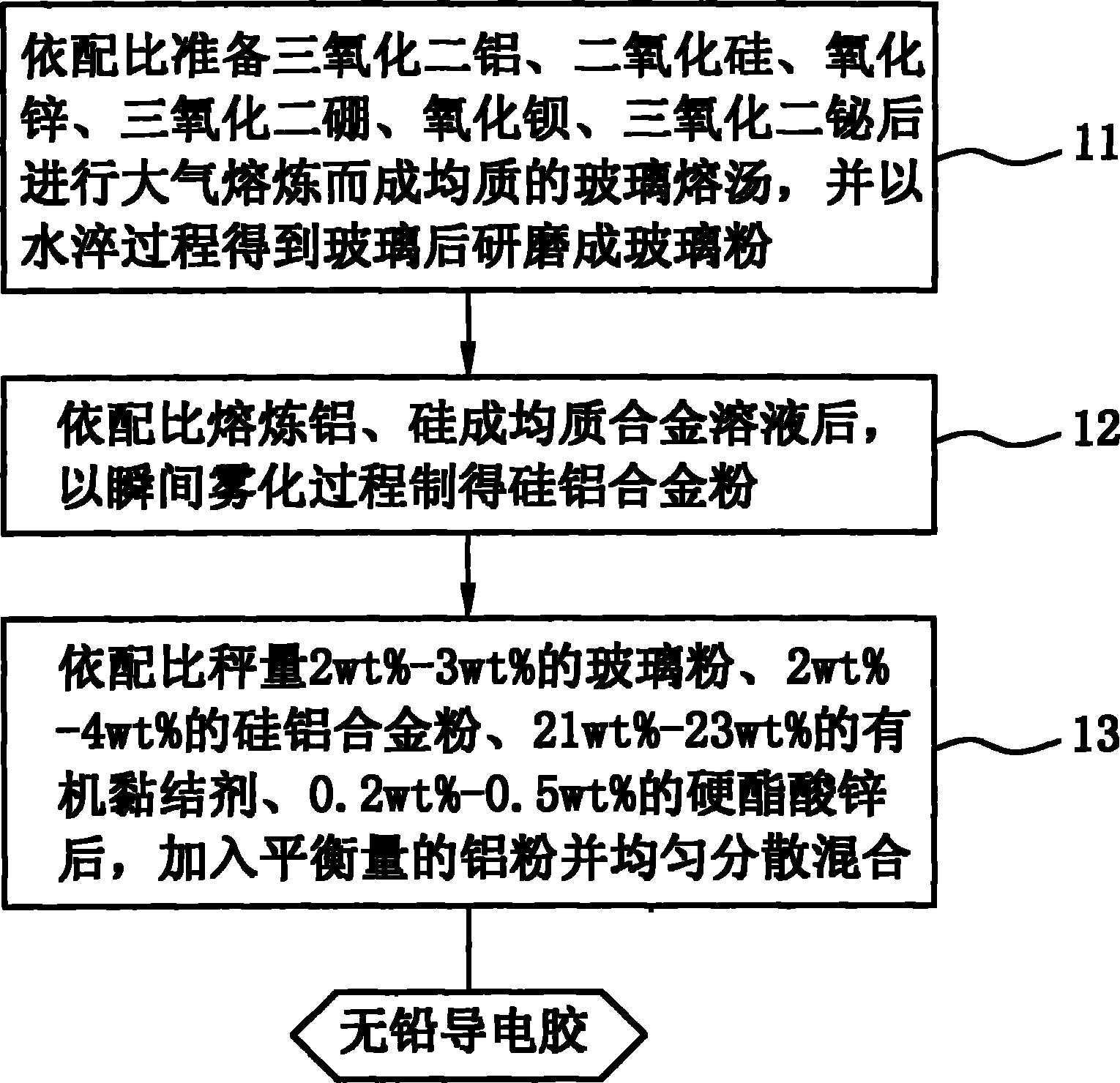

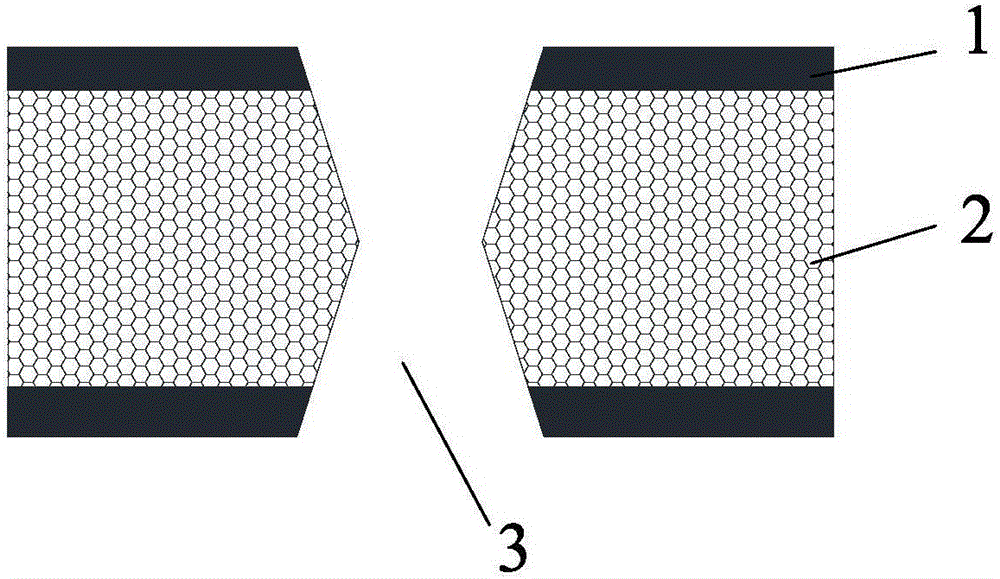

Lead-free conducting resin and manufacture method thereof

InactiveCN102646458ASolve warpingNon-conductive material with dispersed conductive materialCable/conductor manufactureAluminiumAdhesive

The invention discloses lead-free conducting resin which comprises 2-3wt percent of glass powder, 2-4wt percent of silicon-aluminum alloy powder, 21-23wt percent of organic adhesive, 0.2-0.5wt percent of zinc stearate and the balance of aluminum powder, wherein the glass powder comprises aluminium oxide, silica, zinc oxide, diboron trioxide, barium monoxide and bismuth trioxide. The lead-free conducting resin for a solar cell, provided by the invention, can be stably attached and bound with a silicon chip when being burnt into a back electrode by adding the silicon-aluminum alloy powder, thus warping of the silicon chip is avoided. The invention also provides a manufacture method of the lead-free conducting resin.

Owner:CHINA STEEL

Sandwich structure for ultrathin laminated board processing and laminated board manufacturing method

ActiveCN105934110ASimple processReduce processing difficultyMultilayer circuit manufacturePrinted circuit simultaneous processingCopper foilBoard structure

The invention provides a method for manufacturing laminated board. The method comprises the following steps: firstly laminating two double-sided copper-clad boards on an upper surface and a lower surface of one bearing plate board at low temperature at a second prepreg and a third prepreg so as to form a sandwich structure for the ultrathin laminated board processing; forming blind holes on the two double-sided copper-clad boards on the upper surface and the lower surface of the sandwich structure for the ultrathin laminated board processing through laser drilling; forming the other surface circuit of each of two double-sided copper-clad boards on the structure of step S5 through metallization; laminating two outer layer copper foils on the upper surface and the lower surface of the sandwich structure for the ultrathin laminated board processing through a fourth prepreg and a fifth prepreg so as to form cured sandwich structure; forming two four-layer circuit board structures on the outside of a release film of the bearing board; and finally peeling off two four-layer circuit board structures on the outside of the release film of the bearing board. Through the adoption of the structure provided by the invention, the process difficulty can be reduced, two circuit boards are prepared at once, the efficiency is improved, and the warping problem produced in the base plate manufacturing is solved.

Owner:NAT CENT FOR ADVANCED PACKAGING

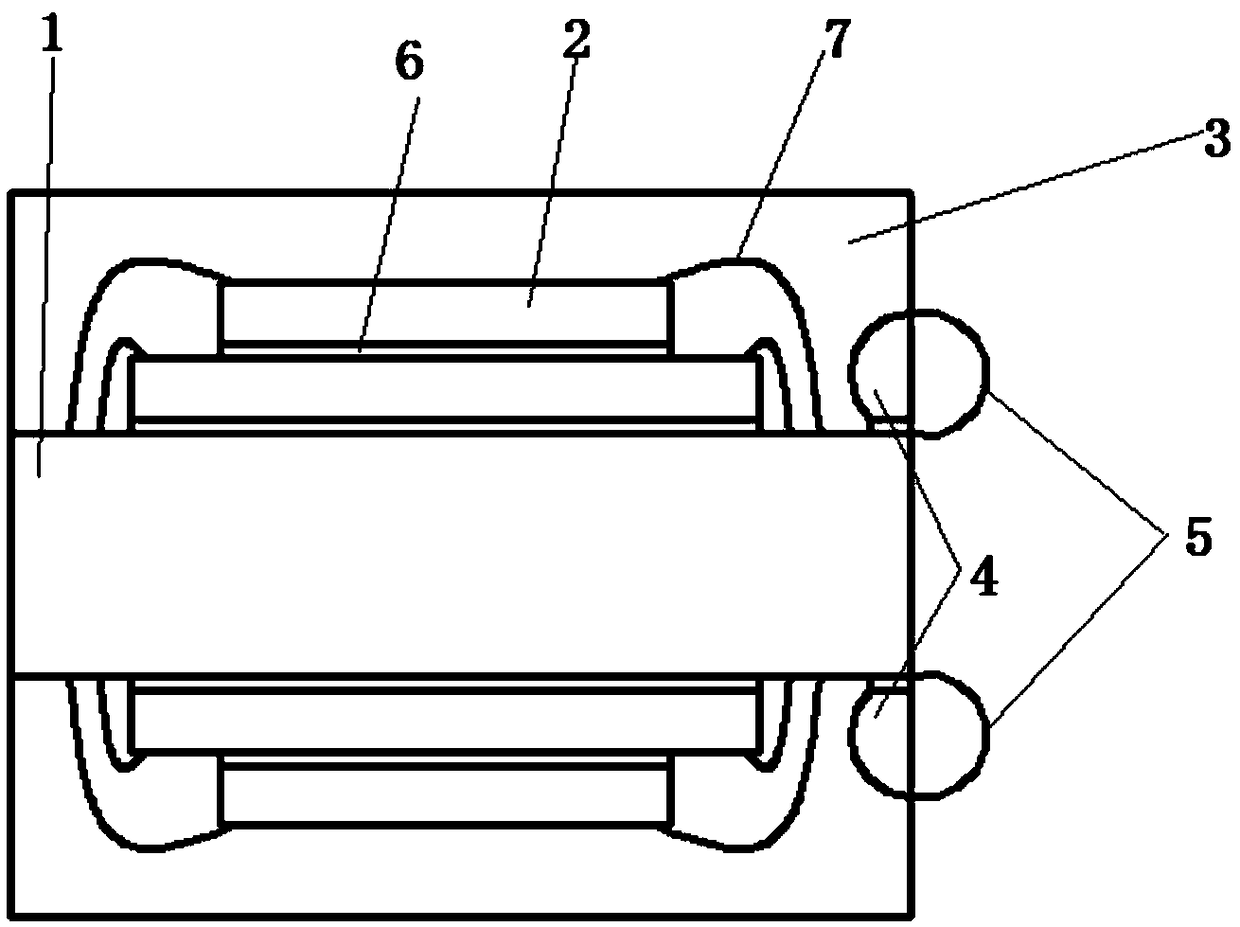

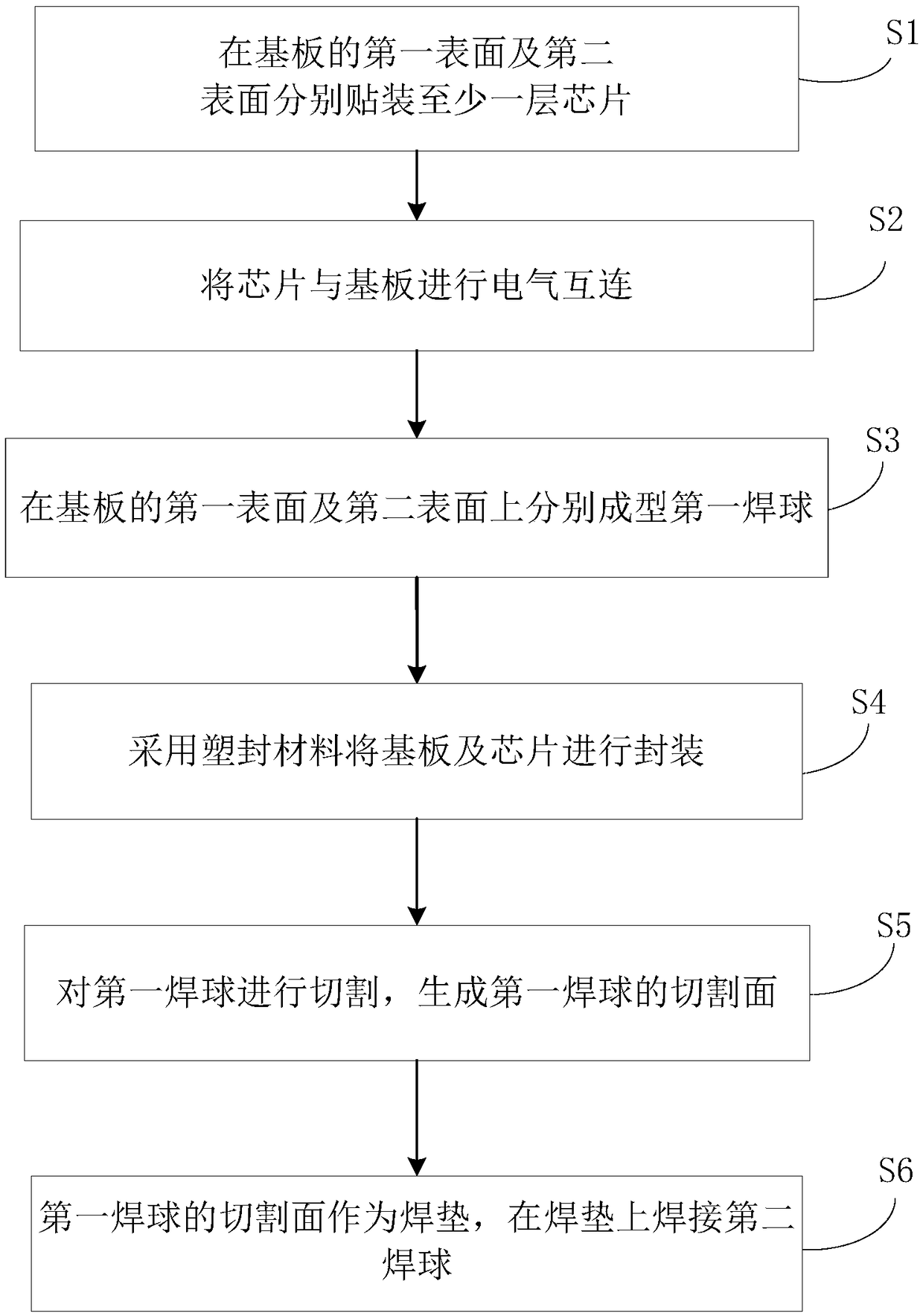

A double-sided three-dimensional stacked packaging structure and packaging method

InactiveCN109003948ASolve warpingSmall footprintSemiconductor/solid-state device detailsSolid-state devicesSystem integrationPlastic packaging

The invention discloses a double-sided three-dimensional stacked packaging structure and a packaging method, The method comprises: At least one chip is respectively mounted on the first surface and the second surface of the substrate, the chip is electrically interconnected with the substrate, the substrate and the chip are encapsulated with a plastic encapsulating material, solder balls are respectively formed on the first surface and the second surface of the substrate, the solder balls are cut to form a cutting surface, and the cutting surface is used as a solder pad for secondary implantation. The invention adopts double-sided plastic sealing process, chips and solder balls mounted on both sides of the substrate are protected by plastic packaging, The invention solves the component warping problem caused by the mismatch of one-sided thermal expansion, realizes the system integration of larger capacity or function through double-sided chip stacking, and reduces the occupied area ofthe board-level assembled circuit board through the side interconnection technology, and improves the utilization ratio of the final board-level assembled circuit board.

Owner:NAT CENT FOR ADVANCED PACKAGING

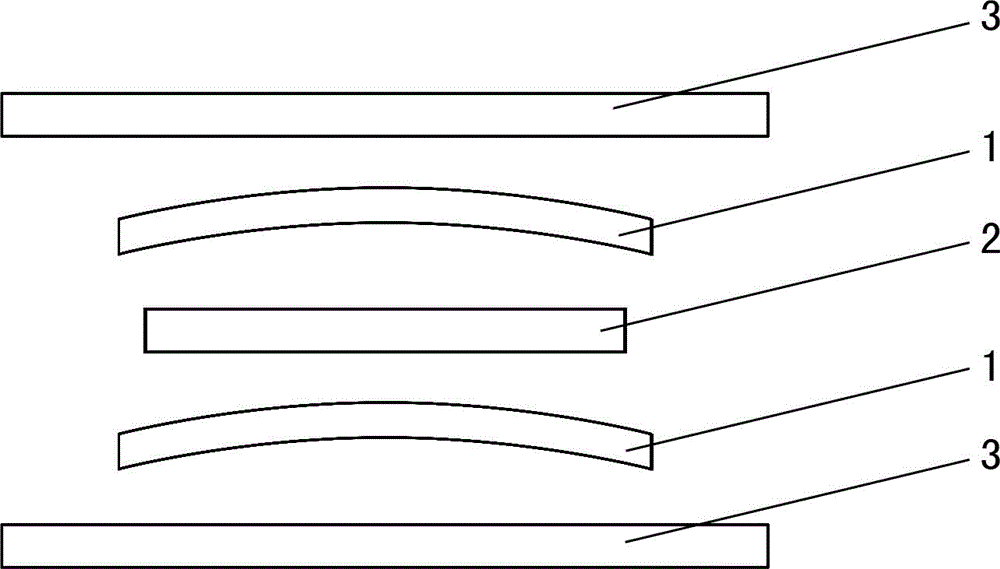

Multilayer printed board lamination method

ActiveCN103153005AImprove straightnessSolve warpingMultilayer circuit manufactureInternal stressElectrical and Electronics engineering

The invention relates to a multilayer printed board lamination method. When the multilayer printed board carries out a high-temperature lamination, a warping guiding board leads the multilayer printed board to carry out compulsory warping in a direction opposite to an original warping direction through the arrangement of two warping guiding boards. After cooling and annealing, the multilayer printed board still carries out warping in the original warping direction because of the asymmetric structural features and internal stress of the multilayer printed board, however, the compulsory warping generated by the warping guiding board plays an balanced role, and the warping degree of the multilayer printed board is far smaller than that of the general warping ( under the circumstances of adopting straight board lamination, warping generated by the multilayer printed board). Therefore, the multilayer printed board lamination method can substantially improve glancing flatness of the multilayer printed board after being laminated, improve the qualification rate of products, and the problem that in the prior art, the warping of the multilayer printed board is influenced by the aging of a hot tray is solved.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY

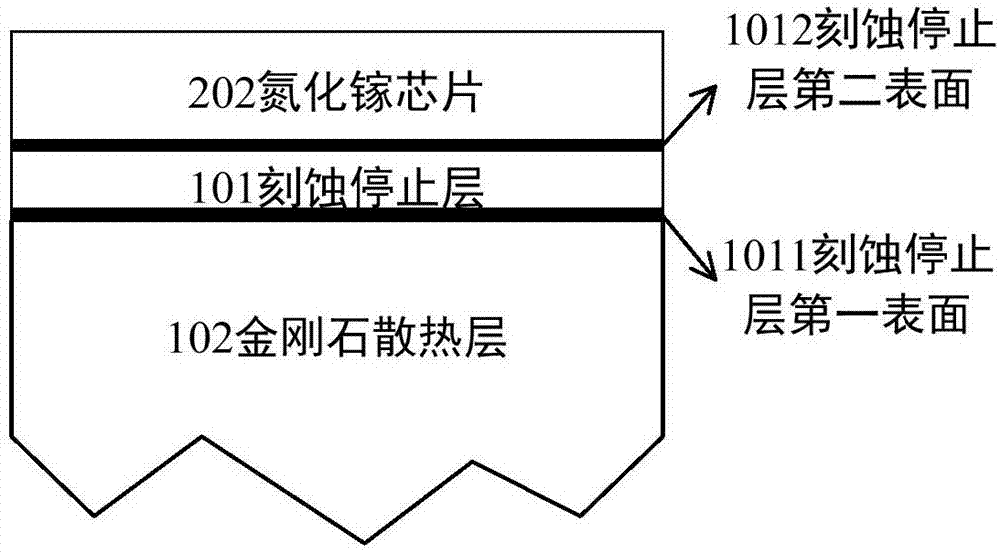

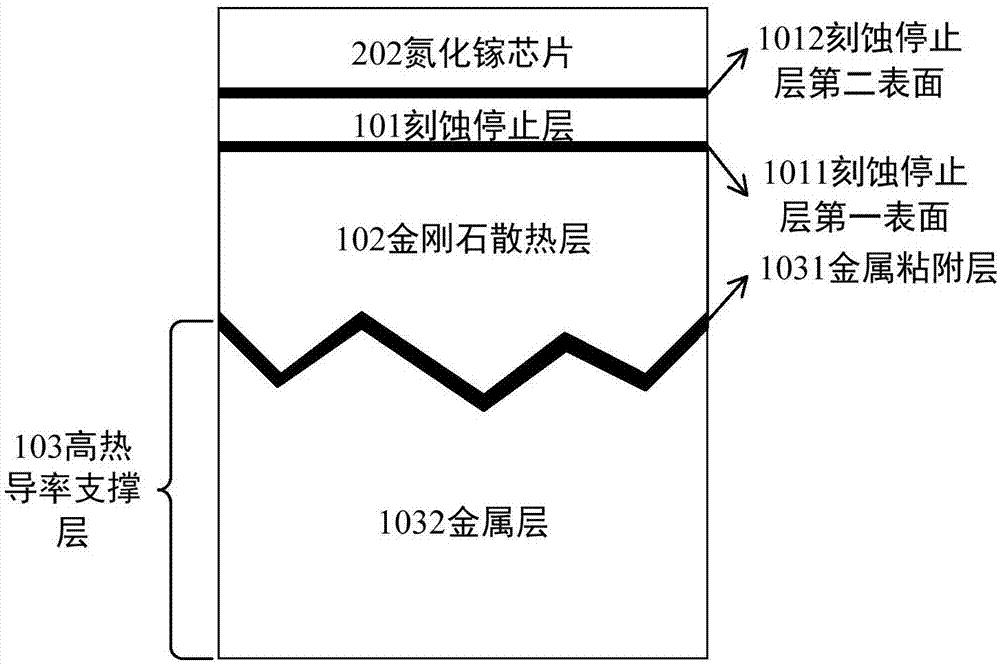

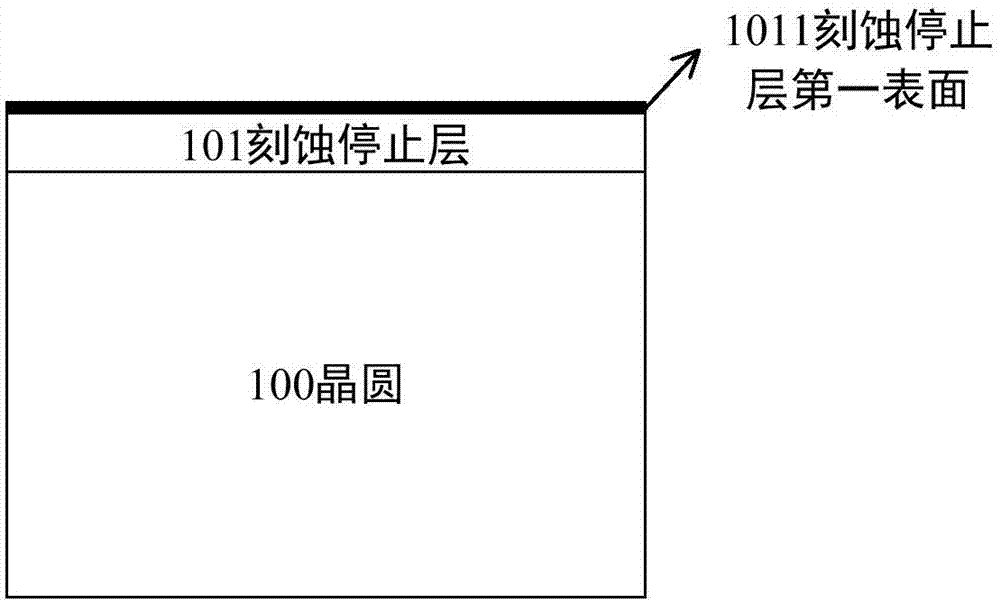

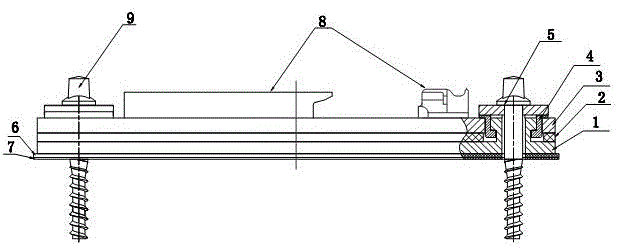

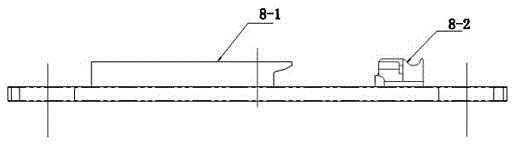

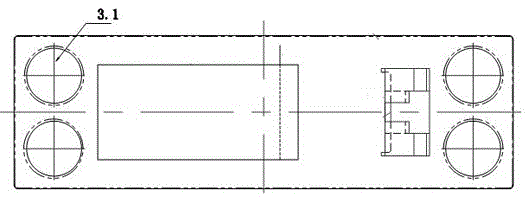

Gallium nitride device structure and preparation method thereof

PendingCN107039373AAchieve integrationSolve the costSemiconductor/solid-state device detailsSolid-state devicesBond interfaceGallium nitride

The invention discloses a gallium nitride device structure having high heat dissipation performance and a preparation method thereof. The gallium nitride device structure comprises a gallium nitride chip, an etching stopping layer, and a diamond heat dissipation layer. The etching stopping layer is provided with a first surface, which is used as a growth interface, and the diamond heat dissipation layer is grown on the first surface of the etching stopping layer. The etching stopping layer is provided with a second surface, which is opposite to the first surface, and is used as a bonding interface, and the gallium nitride chip is disposed on the second surface of the etching stopping layer in a bonding way. The etching stopping layer is formed by adopting a high thermal conductivity material. The production method of the gallium nitride chip and diamond bonding structure adopts a low temperature technology, and a warping problem caused by thermal expansion mismatch under high temperature is prevented, and no damages on existing devices are caused, and therefore integration between the gallium nitride wafer or chip provided with the device and a thin diamond layer is realized, a self-supporting diamond thick film substrate is not required, enhancement of heat dissipation performance is guaranteed, and at the same time, costs are obviously reduced, and then problems of a gallium nitride heat dissipation scheme such as high costs and poor heat dissipation effect are solved.

Owner:母凤文 +1

Manufacturing method for separation type double-layer turnout shock-absorbing fastener system

The invention belongs to the technical field of rail transit and provides a manufacturing method for a separation type double-layer turnout shock-absorbing fastener system. The manufacturing method for the separation type double-layer turnout shock-absorbing fastener system comprises the steps that an upper iron base plate (3) with the required size, a lower iron base plate (1) with the required size, and a middle rubber base plate (2) with the required size are obtained in a direct cutting way; protruding stand columns (9) are welded to corresponding positions of the lower iron base plate (1); a plurality of bosses (10) are welded to the middle of the lower iron base plate; connecting pieces connected with a steel rail are welded to corresponding positions of the upper iron base plate; the protruding stand columns of the lower iron base plate are sleeved with nylon self-locking sleeves (4), and distance adjustment buckle plates (5) are arranged at the upper ends of the protruding stand columns; and anchor bolts sequentially penetrate through through holes of the distance adjustment buckle plates and through holes in the protruding stand columns of the lower iron base plate, so that the separation type double-layer turnout shock-absorbing fastener system is fixed to a ballast bed foundation. By the adoption of the manufacturing method for the separation type double-layer turnout shock-absorbing fastener system, the problem that in the prior art, tilting of fasteners is caused due to the flatness of cast base plates is solved, and the overall stability of a turnout is improved.

Owner:洛阳双瑞橡塑科技有限公司

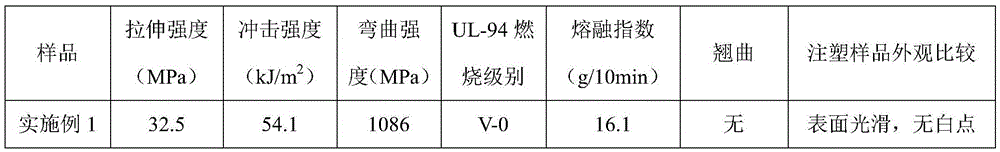

Low-cost warping-free high-flame-retardant polypropylene furniture material and preparation method thereof

The invention discloses a low-cost warping-free high-flame-retardant polypropylene furniture material, prepared from the following components according to a weight ratio: 20-50 percent of polypropylene, 15-35 percent of short glass fiber organic masterbatch, 5-10 percent of flexibilizer, 25-35 percent of nano calcium carbonate and 0.1-1 percent of lubricant; the short glass fiber organic masterbatch is formed by short glass fiber, intumescent flame retardants, a coupling agent of organic titanate and polyethylene wax. Organized modification is performed on the short glass fiber, the surface of the short glass fiber is coated with the coupling agent, the flame retardants and an organic polymeric membrane, so that the compatibility between the short glass fiber and the interface of polypropylene resin can be effectively improved, the uniform dispersion of the glass fiber and the flame retardants is promoted, the warping problem caused by stress is prevented, the mechanical property and flame retardance are improved, the filling content of the short glass fiber is increased, and the product cost is lowered.

Owner:ZHEJIANG SENCHUAN FURNITURE

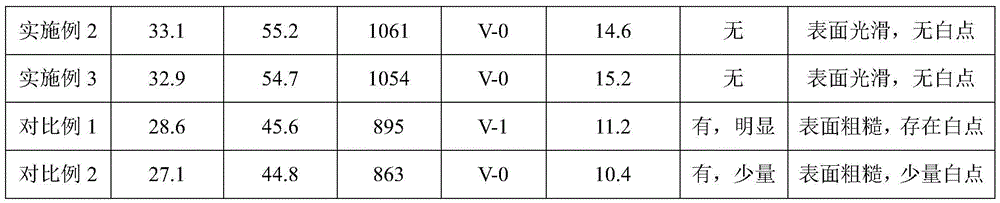

Circuit board manufacturing method, circuit board, and mobile terminal

ActiveCN108347838ARegular and uniform shapeSolve warpingCircuit thermal detailsPrinted circuits stress/warp reductionComputer terminalPrinted circuit board

The invention provides a circuit board manufacturing method, a circuit board, and a mobile terminal. The method comprises the steps: providing a metal plate; forming a first groove, corresponding to apreset pattern, on the first surface of the metal plate; Setting first insulating layers on the first surface of the metal plate and the first groove, and setting a first conductive layer at one side, far from the metal plate, of each first insulating layer; forming a second groove, corresponding to the preset pattern, on the second surface of the metal plate, wherein the second groove is communicated with the first groove; forming a plurality of metal heat dissipation blocks; setting second insulating layers on the second surface of the metal plate and the second groove, setting a second conductive layer at one side, far from the metal plate, of each second insulating layer, and forming an initial circuit board; forming a first circuit connected with the metal heat dissipation blocks onthe first conductive layer of the initial circuit board, forming a second circuit connected with the metal heat dissipation blocks on the second conductive layer, and obtaining a circuit board. Therefore, the method can solve a problem that a conventional circuit board is warped because of the non-uniform stress.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com