Glass fiber reinforced nylon 66 composite material for panel of dish-washing machine and preparation method thereof

A composite material and dishwasher technology, applied in the field of nylon 66 composite materials, can solve the problems of unstable mechanical properties of materials, easy warpage and deformation of panels, dimensional stability, etc., and achieve the effect of solving compatibility problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

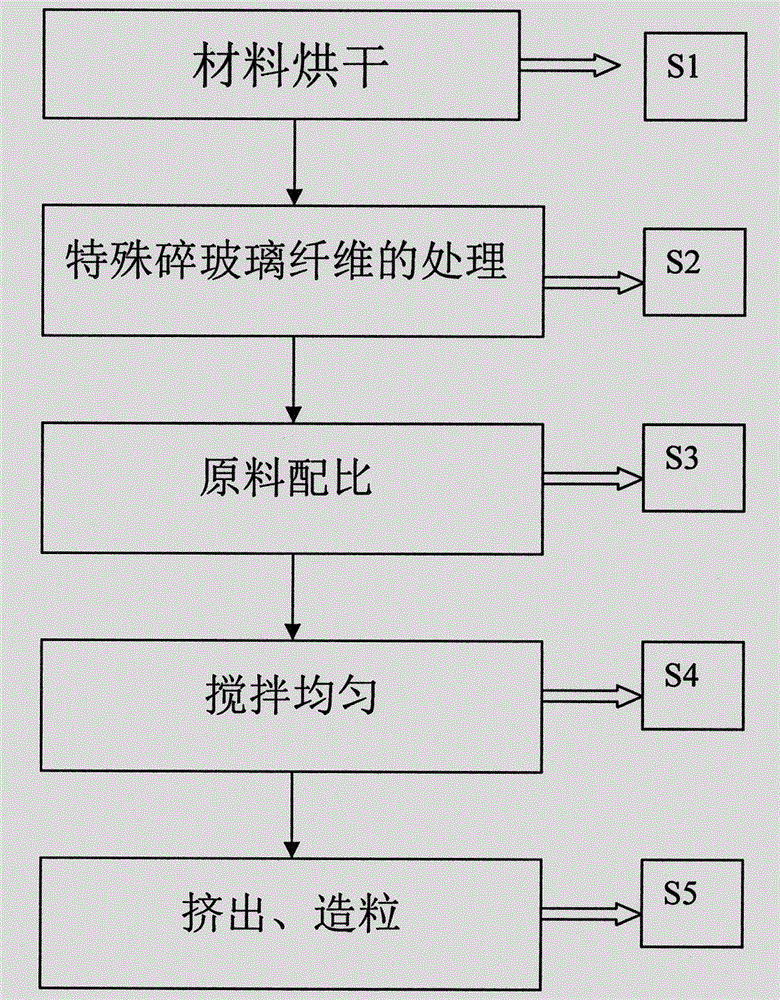

[0035] figure 1 A glass fiber reinforced nylon 66 composite material for a dishwasher panel is shown, and its preparation method includes the following steps:

[0036] Step 1 (S1), take by weight nylon 66 resin, nylon anti-hydrolysis agent, antioxidant, lubricant, nucleating agent;

[0037] Step 2 (S2), placing the nylon 66 resin in an oven at 100° C. to dry for 3-4 hours, so that its moisture content is less than 3‰;

[0038] Step 3 (S3), adding nylon 66 resin, nylon anti-hydrolysis agent, antioxidant, lubricant, and nucleating agent to the high-speed mixer, stirring and mixing to obtain a mixture, and the stirring speed of the high-speed mixer is 1480 rev / min, The stirring time is 5min;

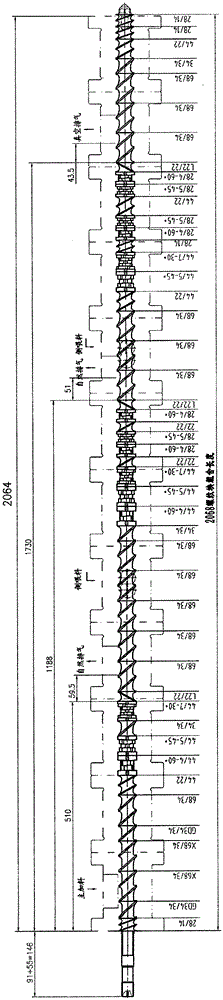

[0039] In step 4 (S4), the alkali-free chopped hydrolysis-resistant glass fibers with a diameter of 10 μm and a length of 3 mm are ground and subjected to surface silane treatment to obtain broken glass fibers. The average length of the broken glass fibers is 100 μm, and the surface treatm...

Embodiment 1

[0043] Add 76.9kg of dried nylon 66 resin, 0.15kg of antioxidant 1098, 0.15kg of antioxidant 1010, 0.5kg of nylon anti-hydrolysis agent, 0.2kg of silicone powder, and 0.1kg of talcum powder to the high-speed mixer. Set to 1480 rev / min, stirring time is 5min, stir evenly, then weigh 10kg flat chopped glass fiber and 10kg broken glass fiber respectively and add, according to the above three materials (stirring mixture, flat chopped glass fiber, broken glass fiber ) in the mass ratio of 80:10:10 for material addition in the weight loss metering system. Feeding is carried out according to the mass ratio of the above mixing, extruded and pelletized through a twin-screw extruder.

Embodiment 2

[0045] Add 66.8kg of dried nylon 66 resin, 0.3kg of antioxidant 1098, 0.3kg of antioxidant 1010, 0.8kg of nylon anti-hydrolysis agent, 1.5kg of silicone masterbatch, and 0.2kg of adipamide dimer to the high-speed mixer , the rotating speed of the high-speed mixer is set to 1480 rpm, and the stirring time is 5 minutes. After stirring evenly, 15kg of flat chopped glass fibers and 15 kg of broken glass fibers were weighed and added. According to the above three materials (stirred mixture, flat chopped glass fiber The mass ratio of , broken glass fiber) is added in the weight loss metering system, and the ratio is 70:15:15. Feeding is carried out according to the mass ratio of the above mixing, extruded and pelletized through a twin-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com