Patents

Literature

56results about How to "Bright and uniform color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of golden red temmku kiln fancy glaze Western-style food dinnerware

The invention provides a preparation method of a golden red temmku kiln fancy glaze Western-style food dinnerware. In the preparation method, the used ground enamel comprises the following components: 61.4-7.02 of SiO2, 8.6-14.6 of Al2O3, 7.6-13.1 of CaO, 2.9-8.3 of K2O, 1.4-5.9 of Fe2O3, 0.3-2.4 of Na2O, 0.3-1.5 of MnO2, 0.2-1.2 of B2O3, 0.2-1.0 of MgO, 0.09-0.2 of Li2O and less than or equal to0.7 of other components; and the cover glaze comprises the following components: 53.4-58.1 of SiO2, 12.4-20.9 of ZnO, 5.1-14.9 of Al2O3, 3.5-10.6 of CaO, 2.2-8.7 of B2O3, 1.9-7.4 of K2O, 1.1-4.0 of Na2O, 0.4-1.4 of TiO2, 0.4-1.0 of BaO, 0.1-0.8 of MgO and less than or equal to 0.7 of other inevitable components. The process flow is as follows: preparing the green body of the dinnerware; carrying out ball-milling on the ground enamel and the cover glaze slurry; adding 5-10 parts of red zirconium silicate-coated cadmium sulfide selenide pigment in the cover glaze slurry; and glazing on the green body, and finally, completing calcination.

Owner:JIANGSU GAOCHUN CERAMICS

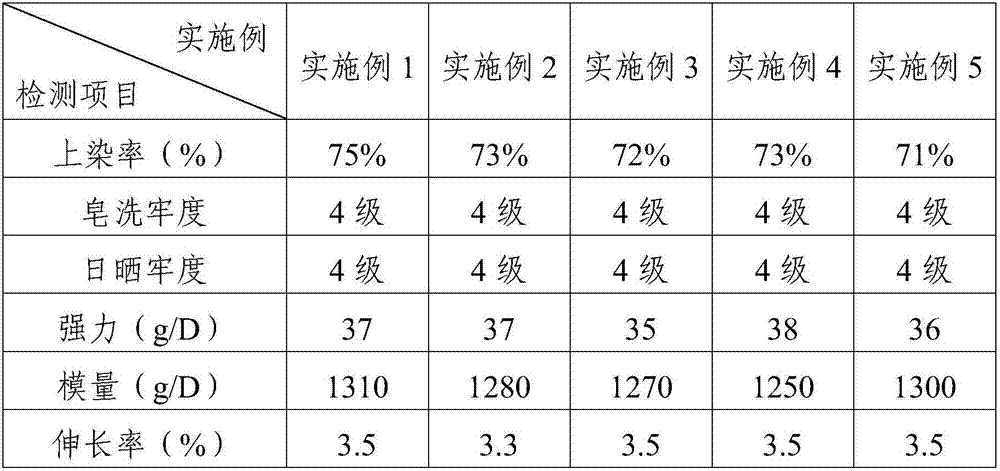

Production process for coloured polyester staple fibre

InactiveCN102517685ARealize resource reuseReduce manufacturing costArtificial filament heat treatmentMelt spinning methodsColour fastnessPolyester

The invention discloses a production process for coloured polyester staple fibre. In the production process, regenerative PET (Polyethylene Terephthalate) material is used as the raw material, and the finished product is acquired by pre-treating, rotary drum drying, melt spinning, cooling forming, winding, drafting, curling, oil applying, thermosetting and cutting-off in sequence, wherein the rotary drum drying comprises the steps of firstly drying the regenerative PET material for 7.5h-8.5h and then adding master batches with the final mass fraction of 2%-10%, and toner; the total drying time is 9.5h-10.5h; both the screw rod and the spinning beam of a screw extruder in the melt spinning step are at the temperature from 265 DEG C to 275 DEG C; spinneret plates are provided with 3500 bores having the diameter of 0.2mm and are arranged in 14 circles; cooling forming is realized through circular air blow, the temperature of the circular air is 22 DEG C to 26 DEG C, and the velocity of the circular air is 4.0m / s to 5.0m / s; the total draft multiple is 3.0-3.2 times; and the thermosetting temperature is 168 DEG C to 172 DEG C, and the thermosetting time is 13 minutes to 17 minutes. Theproduction process can save the cost and is helpful for environmental protection; the produced product has smaller linear density, higher colour fastness and smooth and comfortable hand feeling.

Owner:HANGZHOU BEST CHEM FIBER

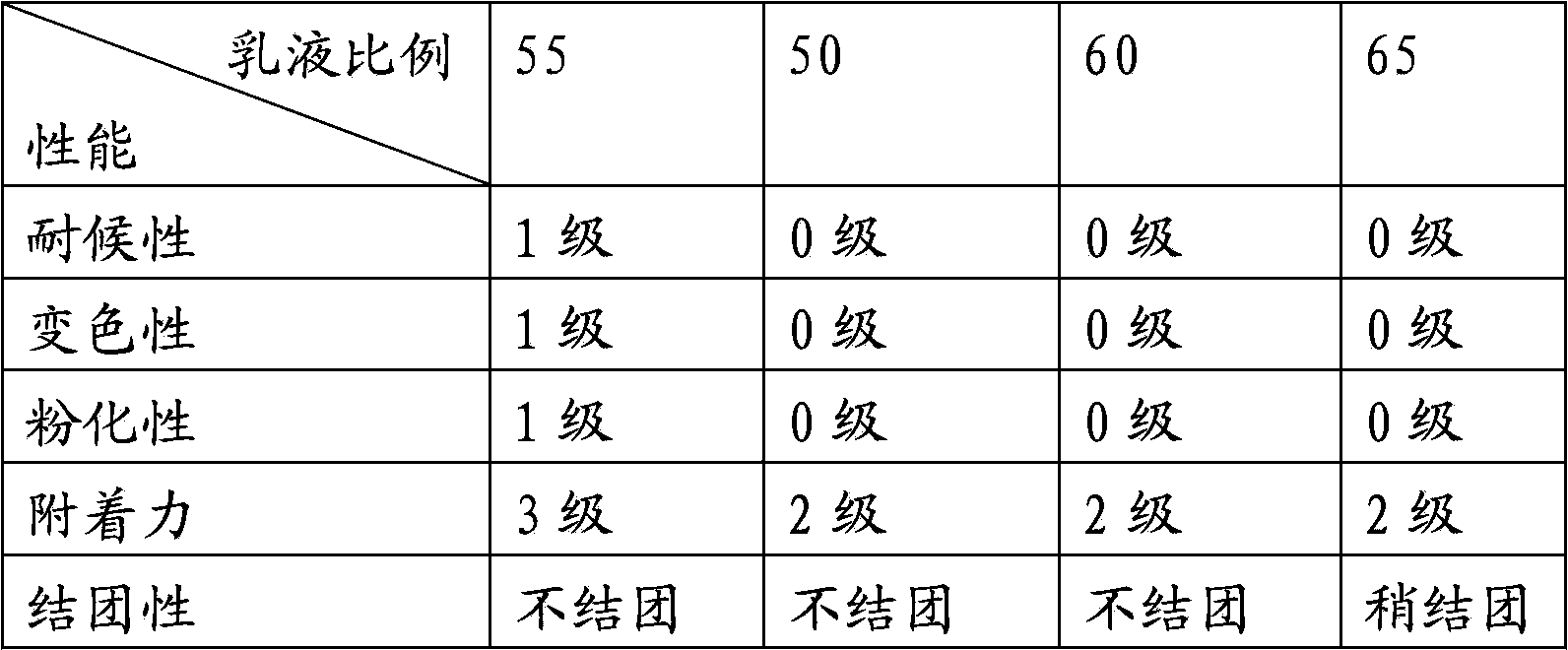

Artificial colored sand

The invention provides an artificial colored sand which is manufactured by composite color paste and gravel, wherein the composite color paste includes acrylic ester emulsion, toner, auxiliaries and water. According to the technical scheme, the produced artificial colored sand is rich in color, has bright and uniform color and luster, and has little limitation from the ore source; and meanwhile, the artificial colored sand has the cost lower than that of the natural colored sand, and the demand of a customer on personalized color can be met; and the economy and environmental protection can be achieved; and moreover, the composite color paste and the gravel have high attaching force during being sintered, so that the flexibility of the colored sand is improved. Compared with currently used natural colored sand, the artificial colored sand provided by the invention has uniform color, excellent film forming property, high attaching force, high resistance to water and alkali, relatively high pollution resistance, and super wear resistance, is economic and environment-friendly, and solves the problems of the natural colored sand that the ore sources are gradually reduced, the demands on production cannot be met, products in different batches have color difference, and the timeliness of the production cannot be met.

Owner:ASIA PAINT SHANGHAI

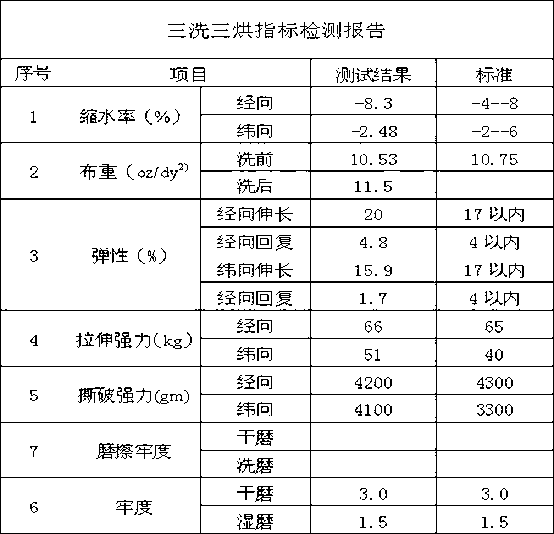

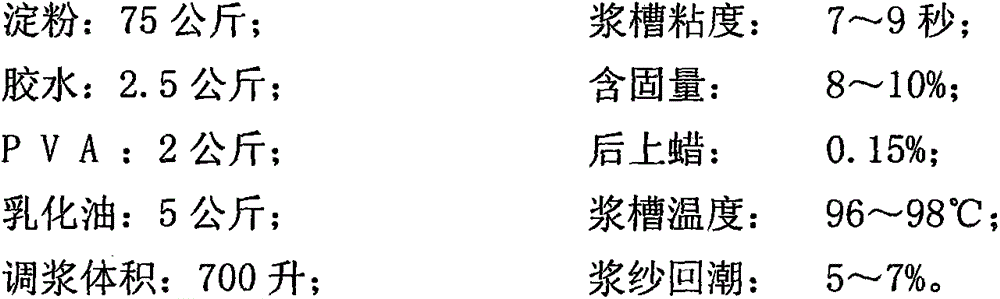

Method for producing warp and weft dual-elastic denim fabric by bundled lines

ActiveCN102936811ABright and uniform colorHigh color fastnessFibre treatmentHeating/cooling textile fabricsEngineeringPre treatment

The invention discloses a method for producing a warp and weft dual-elastic denim fabric by bundled lines. The warp and weft dual-elastic denim fabric is produced by a long technological process through dyeing of a plurality of dyeing cylinders for the bundled lines. The method comprises the following steps of: (1) making warp yarns by cotton-wrapped spandex bamboo joints, and making weft yarns by triple wrapped yarns formed by wrapping cotton on terylene and then wrapping the cotton-wrapped terylene on spandex; (2) always keeping stable temperature and humidity in a ball warp working procedure; (3) performing pressurization by a heavy hammer, before dyeing is executed, performing pretreatment until tension of each part is stable, then implementing an elastic ball shaft connection method, wherein the dyeing process is a multi-dyeing-cylinder low-content dyeing process, so that the penetration and the dyeing rate of a dye can be improved; (4) performing a weft division process by low tension; (5) slashing by a sizing process with low viscosity and low concentration; (6) weaving by a feeding process with a high rear beam, high tension and a small opening; (7) arranging by a desizing pre-contraction arrangement process; and (8) treating by adopting a sizing method. The warp and weft dual-elastic denim fabric produced by the method is bright and uniform in color, relatively high in color fastness and similarly stable in elasticity.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

Artificial colour sand and preparation method thereof

The invention discloses artificial colour sand and belongs to the field of building coating. The artificial colour sand comprises stone sand and base slurry, wherein stone sand comprises at least one of silica sand, basalt and calcite, the grain size of the stone sand is 30-120 meshes, the base slurry is prepared from the following raw materials in parts by weight: 40-50 parts of fluorocarbon resin, 25-35 parts of base solvent, 0.5-0.9 part of dispersing agent, 0.1-0.3 part of wetting agent, 10-20 parts of colour powder, 18.8-20 parts of cosolvent, 0.1-0.5 part of accelerant, 5-10 parts of coupling agent and 0.5-0.8 part of thickening agent, and the weight ratio of stone sand to base slurry in the artificial colour sand is 19:1. The invention also provides a preparation method of the artificial colour sand. The artificial colour sand is uniform in colour, good in weather resistance, economical and environment-friendly, the problem that natural colour sand is scare is solved, and requirements of building decoration are met.

Owner:浙江曼得丽涂料有限公司

Preparation of coloured antibiotic viscose fiber

InactiveCN101302661AWill not polluteImprove the bactericidal effectMonocomponent cellulose artificial filamentArtifical filament manufactureSilver colloidAqueous solution

The invention relates to a preparation method for colored antibacterial viscose fiber, which consists of the following steps: (1) formulating the vat dyes of one or a plurality of colors into a paste respectively by alkaline solution according to the coloring requirements of fibers, and then adding hydrosulfite and stirring for reacting and generating vat dye leuco salt solution, mixing the vat dye leuco salt solution of a plurality of colors according to the color matching proportion; or formulating the vat dyes of a plurality of colors into a paste by alkaline solution after mixing according to the color matching proportion, then adding the hydrosulfite for generating vat dye leuco salt mixed solution, (2) fully mixing the nanometer silver powder having the particle size no more than 100 nm with the colloid mixture to formulate a nanometer silver colloid water solution containing 2-5 percent of nanometer silver and 4-10 percent of colloid protective agent, (3) mixing the two solutions prepared by step (1) and step (2) and adding the mixed solution into the raw material solution of viscose rayon in any phase of the aging process of the viscose to spin, refine and dry, thus preparing the colored antibacterial viscose fiber.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Method for producing colored short fibers by using regenerated polylactic acid slices

InactiveCN106868626ALow costPromote environmental protectionMelt spinning methodsFilament-forming treatmentLinear densityHeat setting

The invention relates to a method for producing colored short fibers by using regenerated polylactic acid slices. A regenerated PLA material is used as a raw material. The method comprises the following specific production steps of: (1) pretreatment; (2) rotary drum drying; (3) melt spinning; (4) cooling molding; (5) winding; (6) drafting; (7) curling; (8) curling; (9) heat setting; and (10) cutting off. The method of the invention has the advantages that the regenerated PLA material is used as the raw material, the cost is reduced, the environmental protection is favorable, the finished product has low linear density, feels smooth, and has bright and uniform color, and high color fastness. The characteristics of polylactic acid short fiber are kept, the damage of post-dyeing to the polylactic acid short fiber property is also avoided, the pollution of dyeing to the environment is reduced, and the method is extremely beneficial to a spinning material and environmental protection.

Owner:HENAN LONGDU BIOLOGY TECH

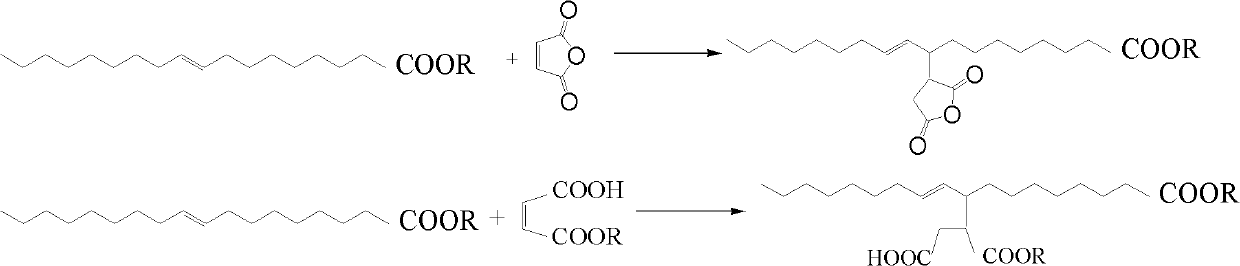

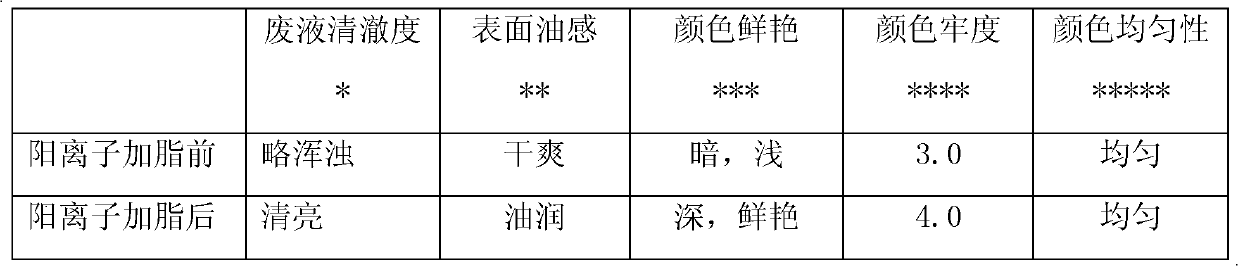

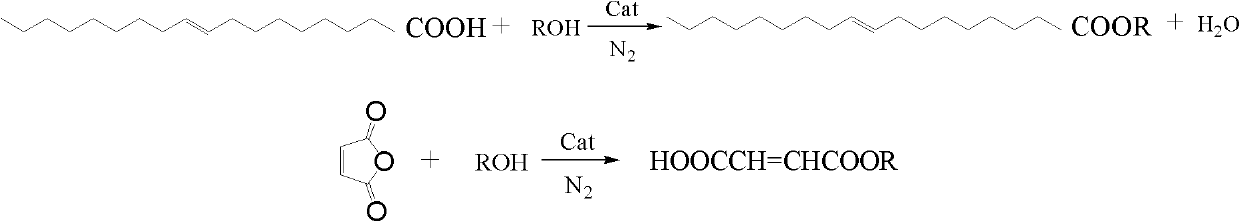

Method for preparing cation synthetic sperm oil fat liquor

ActiveCN101948714ARealize cationic modificationFatliquor composition is goodFatty acid chemical modificationLeather impregnationSperm oilEmulsion

The invention provides cationic synthetic sperm oil fat liquor and a preparation method thereof. In the fat liquor, synthetic sperm oil, maleic anhydride, epichlorohydrin and quaternization reagent are used as raw materials, maleic anhydride modified synthetic sperm oil is obtained by addition reaction of the synthetic sperm oil and the maleic anhydride; the maleic anhydride modified synthetic sperm oil is added with the epichlorohydrin, and reacts with the quaternization reagent to prepare the cationic synthetic sperm oil fat liquor. By adopting an internal emulsification method, a cationic active group is introduced to the molecular structure of the synthetic sperm oil, so the stability of the emulsion, uniformity and permeability of the fat can be greatly improved, and the cationic synthetic sperm oil fat liquor has better effects of dyeing, burnishing and color fixing than that of the cationic fat liquor by the traditional external emulsification method.

Owner:山东莱福特皮革制品有限公司

Preparation method of special color master batch for ultrahigh-molecular-weight polyethylene spinning

ActiveCN102875881ABright and uniform colorSimple production processMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberUltrahigh molecular weight polyethylene

The invention relates to a preparation method of special color master batch for ultrahigh-molecular-weight polyethylene spinning. The preparation method is implemented through the following four steps of: 1) selecting high-molecular-weight polyethylene resin as main materials, then adding organic pigment powder, antioxidant, light stabilizer and mineral oil, and mixing by using a mixing machine to prepare colored resin mixture; 2) extruding in a fused state by using an exhaust-type double-screw extruder to obtain a plurality of lines; cooling and solidifying the extruded colored lines through a water trough, and cutting the lines into colored master batch grains by using a grain cutting machine; 3) fully drying the colored master batch grains by using a dryer; and 4) grinding the colored master batch grains into even powder to obtain the special color master batch with uniform grain size for ultrahigh-molecular-weight polyethylene spinning. The preparation method of special color master batch for ultrahigh-molecular-weight polyethylene spinning has the advantages that the demands for various colors needed for ultrahigh-molecular-weight polyethylene spinning are met, the production technology is simple, the cost is low and the preparation method is the best technique for preparing various colored fibers at present.

Owner:宁波大盛新材料有限公司

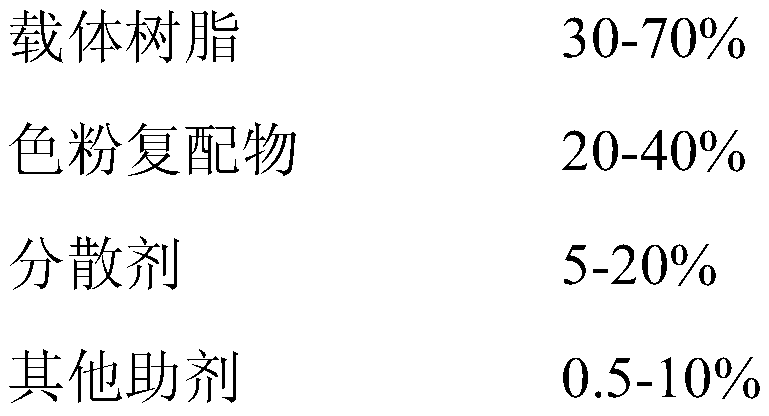

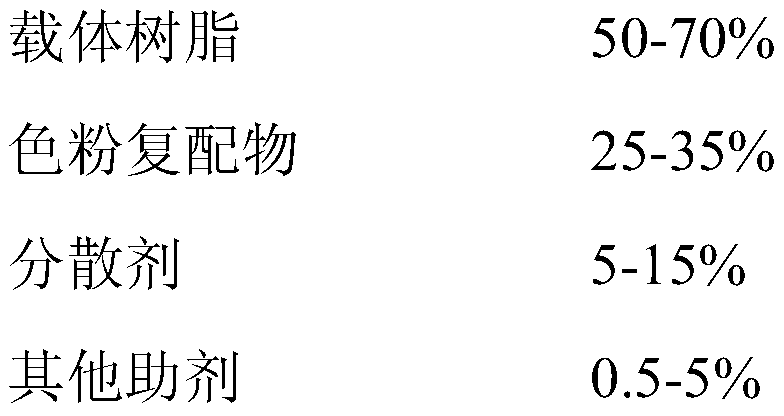

Boiling-resistant color master batch, preparation method and applications thereof

The invention relates to the technical field of nylon color masterbatch, and discloses uses of a toner complex in improvement of color stability in a nylon boiling process, wherein the toner complex comprises an organic pigment and a solvent dye according to a weight ratio of 1:0.2-2. The invention further discloses a boiling-resistant color master batch, which comprises the following raw materials by weight: 30-70% of a carrier resin, 20-40% of a toner complex, 5-20% of a dispersing agent and 5-10% of other auxiliary agents. The preparation method of the boiling-resistant color master batch comprises: uniformly mixing a toner complex and a dispersing agent, and carrying out melt blending on the mixture, a carrier resin and other auxiliary agents in blending equipment to obtain the boiling-resistant color master batch. According to the invention, the color master batch prepared from the toner complex compounded by the organic pigment and the solvent dye is applied to nylon products, sothat the color retention degree of the products can be improved, and the color difference value [delta]E of the nylon products before and after boiling is less than or equal to 1.0 while the productperformance and the appearance are met.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Photovoltaic silicon wafer cleaning agent and cleaning method thereof

InactiveCN103897862ALow costImprove efficiencyInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSodium metasilicateCleaning methods

A photovoltaic silicon wafer cleaning agent and a cleaning method thereof relate to a photovoltaic silicon wafer cleaning agent and chemical and ultrasonic cleaning methods of the photovoltaic silicon wafer. The invention can be applied to the fields of photovoltaic silicon wafer rinsing and cleaning. The cleaning agent is characterized by comprising the components of pure water, sodium carbonate, sodium metasilicate, fatty alcohol polyoxyethylene polyoxypropylene terminated polyether: C12 fatty alcohol polyoxyethylene ether, alkyl benzene sulfonate and alkyl dihydroxy acid salt in a weight ratio of 100:2:2:3:3.5:2:1. The above raw materials are mixed and stirred. A technical scheme of the cleaning method is as below: 1, preparing a cleaning agent by mixing the raw materials are in proportion, and stirring; 2, flushing with pure water: placing the silicon wafer into a container, adding pure water, conducting ultrasonic cleaning at the temperature of 50 DEG C for 5 min; 3, washing with the cleaning agent: placing the silicon wafer in a container, adding the cleaning agent, conducting ultrasonic cleaning at the temperature of 65 DEG C for 5 min; 4, pure water flushing: placing the silicon wafer in a container, adding pure water, conducting ultrasonic cleaning at the temperature of 50 DEG C for 5 min; and 5, drying.

Owner:QINGHAI TIANYUHUI NEW ENERGY DEV

Irradiation indicating card and methods for preparing and using the same

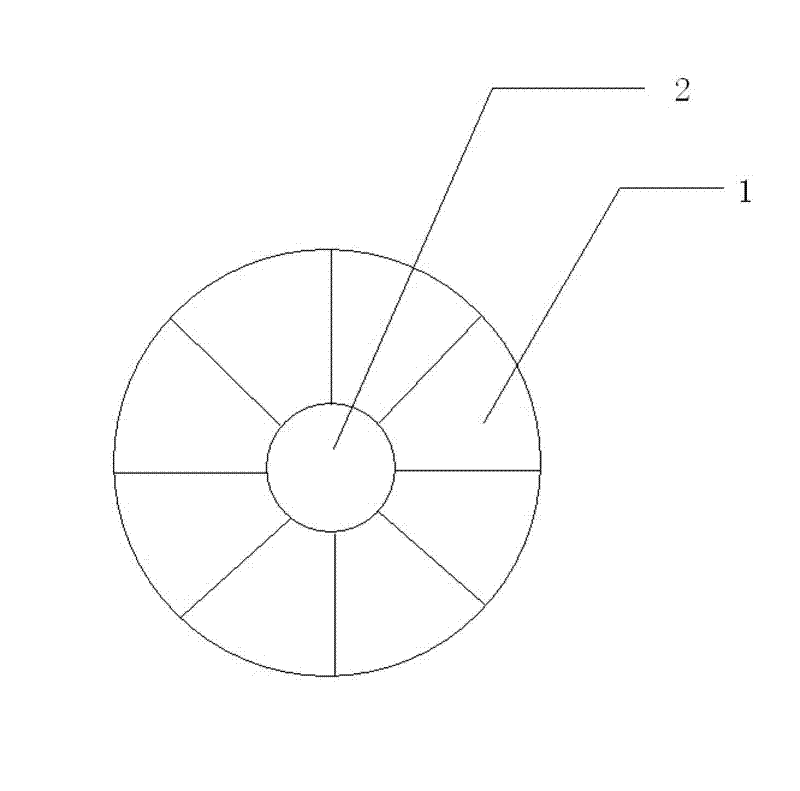

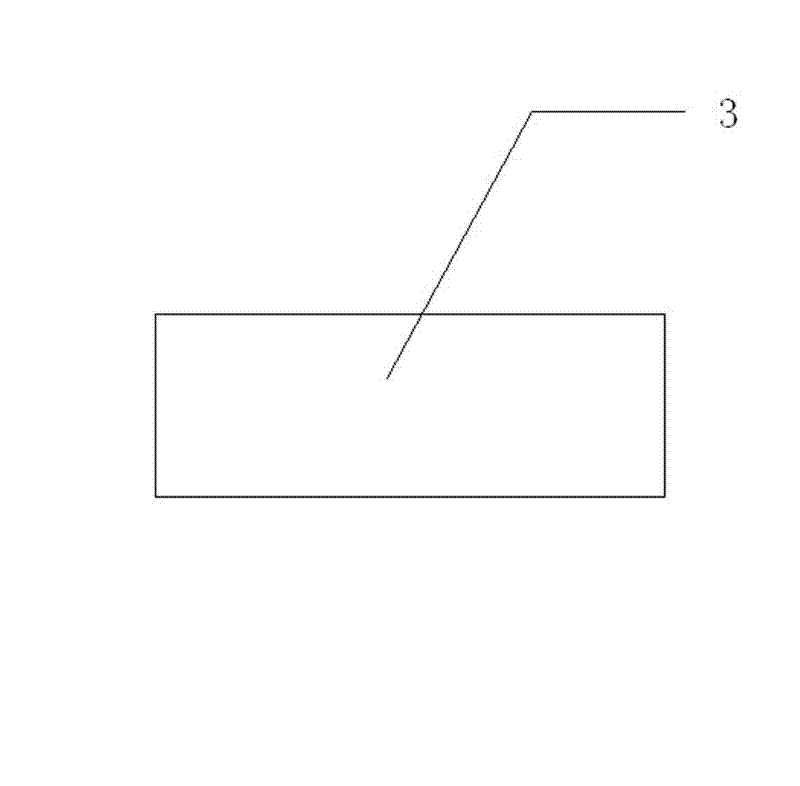

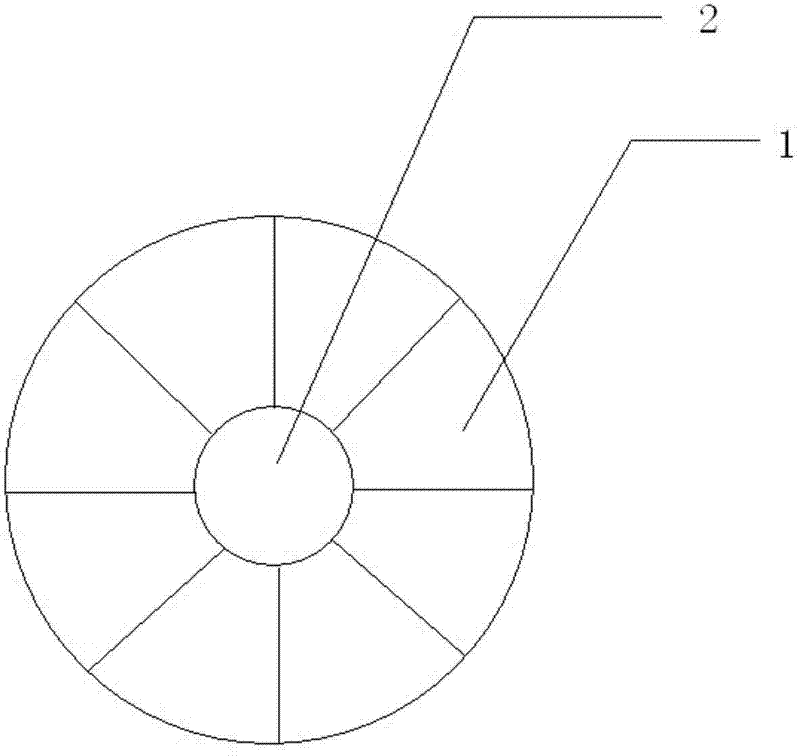

The invention discloses an irradiation indicating card and methods for preparing and using the same. The irradiation indicating card comprises a standard color code and an indicating card; the standard color code is an annular card and is divided into six equal parts that are six areas with different colors; each area represents a corresponded irradiation dose; and the six kinds of colors of the six areas respectively represent the following irradiation doses: 50 G y, 30 G y, 25 G y, 15 G y, 5 G y and 1 G y from deep to shallow; a center of the annulus is an empty hole and is used for placing a colorimetric area of the indicating card; and a diameter of the empty hole is 7 to 11 mms; besides, right and back sides of the standard color code are processed by film pressing processing. Moreover, the indicating card is a rectangular card with a length of 40 to 60 mms, a height of 12 to 22 mms and a thickness of 0.5 to 1.0 mms. According to the invention, the above-mentioned structure is employed; the irradiation indicating card has lightweight and is easy to be taken by hands to carry out color comparison; furthermore, the preparation and the usage methods are simple; it is easy to determine irradiation doses; and the detection result is accurate; besides, the irradiation indicating card can be cleaned and disinfected as well as be used repeatedly for many times.

Owner:周明非

Light-absorption heating denim and production method thereof

InactiveCN104831452ABright and uniform colorHigh color fastnessSucessive textile treatmentsWoven fabricsPolyesterEngineering

The invention relates to light-absorption heating denim woven by a production method of interweaving warp yarns and weft yarns. The light-absorption heating denim is characterized in that the warp yarns are formed by the mixture of three flat yarns including cotton yarns, light-absorption acrylic yarns and hollow polyester yarns by the adoption of siro tight spinning; the weft yarns are made of yarns of the cotton and the hollow polyester wrapped by spandex. The production method of the light-absorption heating denim comprises the production steps of a, yarn spinning; b, ball warping; c, warp separating; d, dyeing; e, slashing; f, weaving; g, desizing. The light-absorption heating denim and the production method thereof have the advantages that the production method solves the problem that the coloring is not uniform in the dyeing process; the produced light-absorption heating denim is bright and uniform in color, the color fastness is high, the blurred degree of the cloth surface after being washing with water is greatly reduced, and space is created for washing deep processing of downstream clothing.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

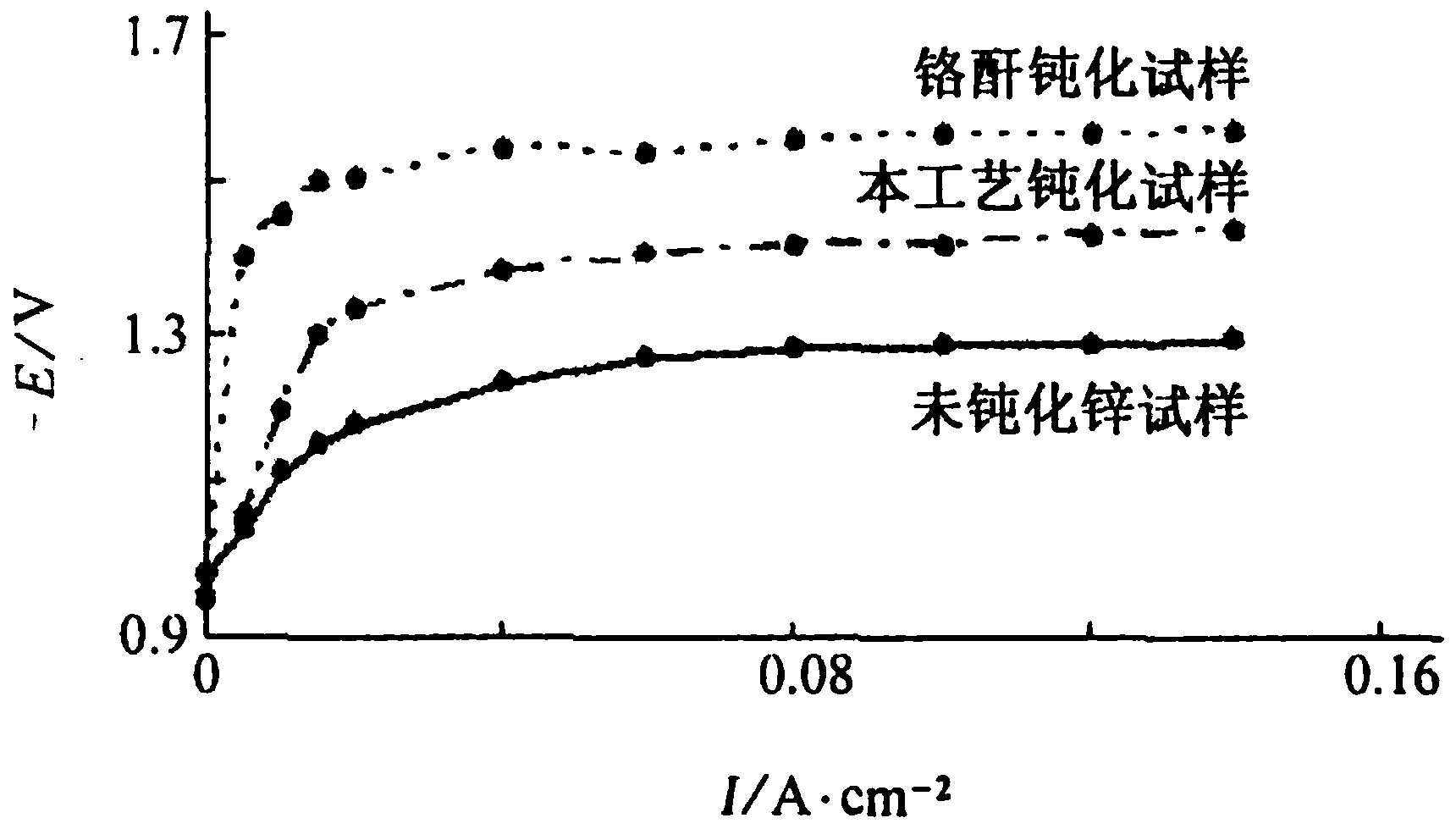

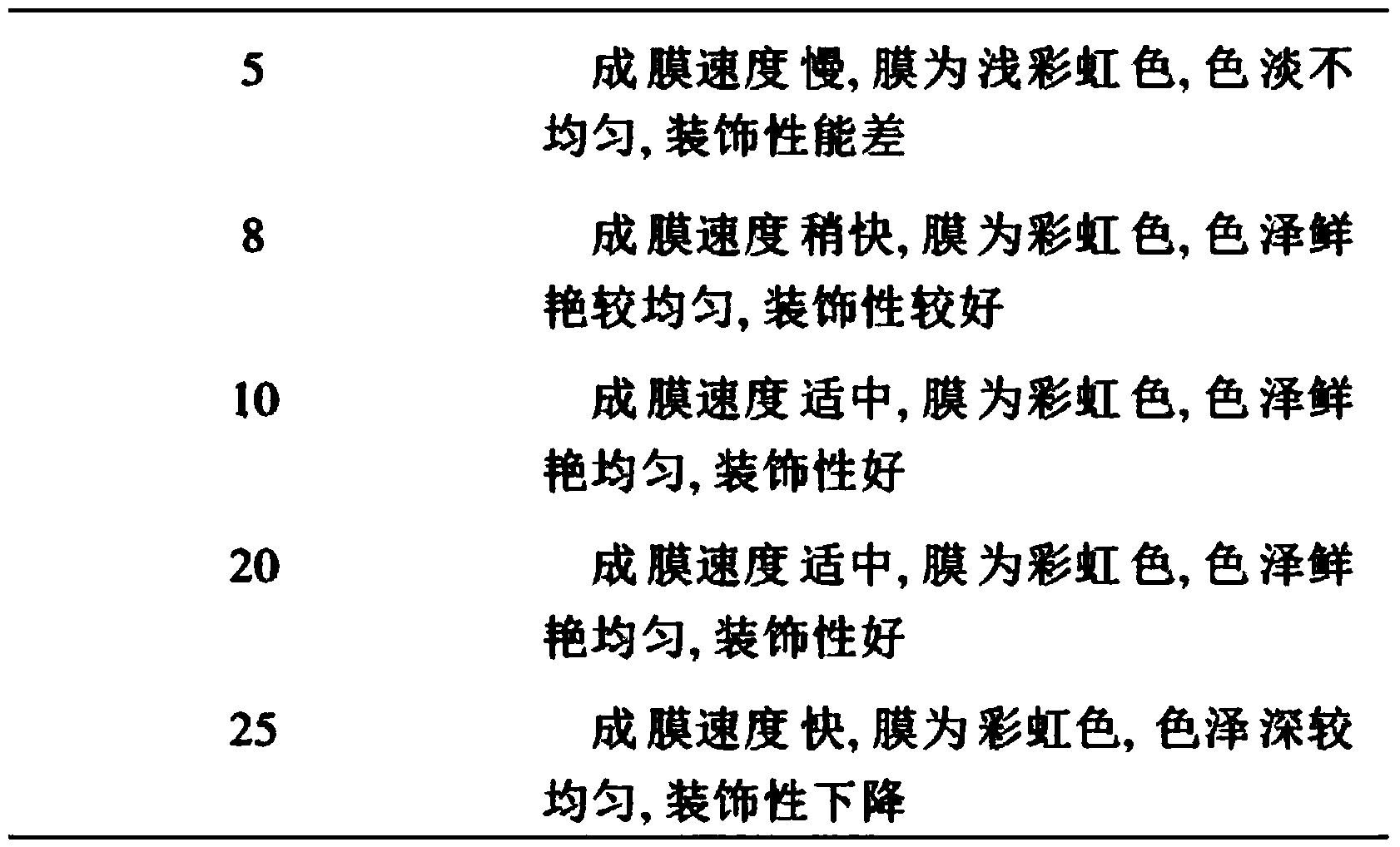

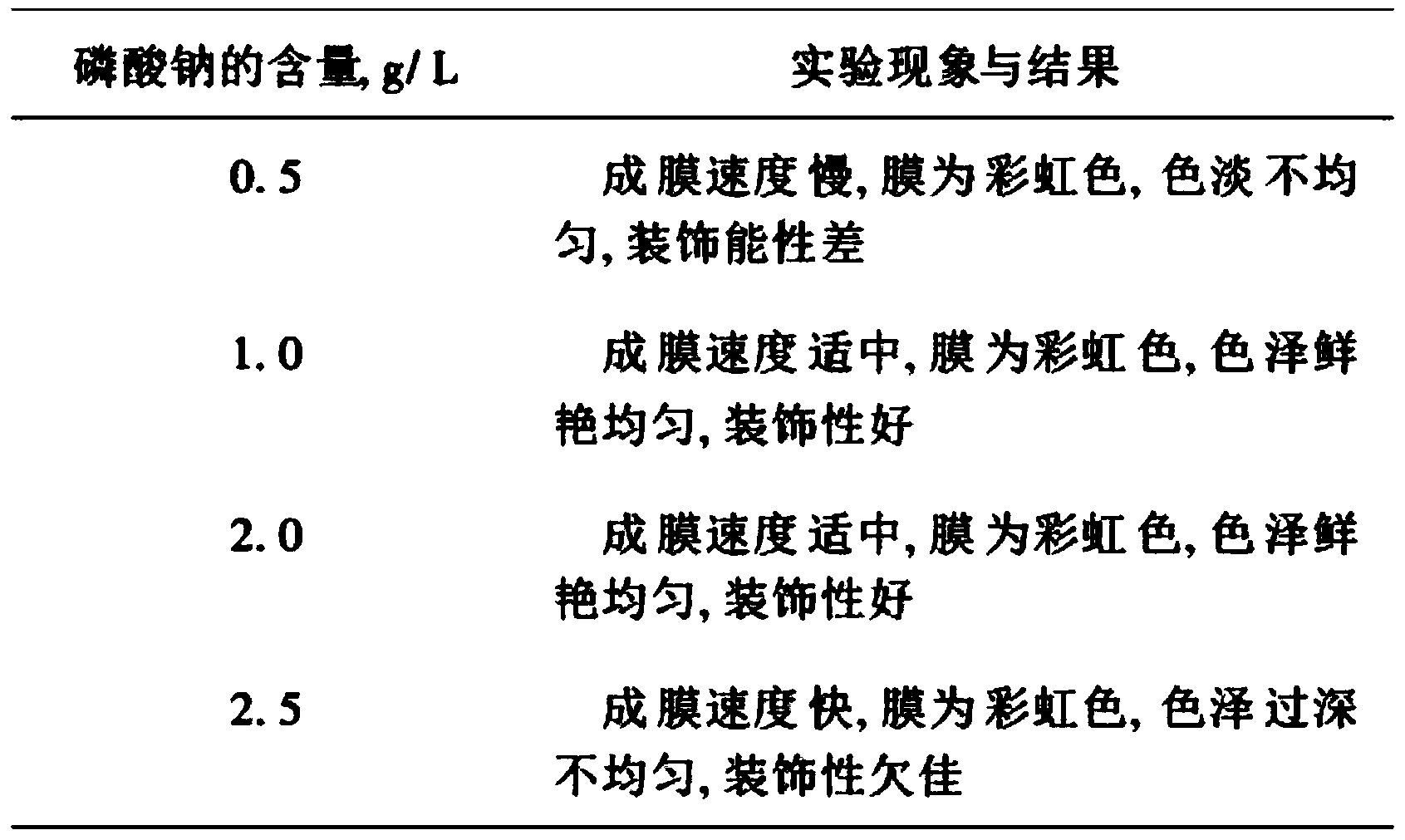

Non-chromium passivation technology for zinc coating

InactiveCN104233251AReduce pollutionBright and uniform colorMetallic material coating processesSodium phosphatesPollution

The invention discloses a non-chromium passivation solution for a zinc coating and a non-chromium passivation technology using the non-chromium passivation solution. The passivation solution comprises ammonium molybdate, sodium phosphate and additives XZ-03B and OP-10. The composite passivation technology comprises the step that the passivation solution is subjected to passivation treatment for 1-2 min at the temperature of 20-60 DEG C, preferably 30-55 DEG C, more preferably 40-50 DEG C, and the preferable treatment time is 60-90 s. A non-chromium passive film prepared by adopting the non-chromium passivation solution for the zinc coating and the passivation technology is iridescent, the color is bright and uniform, the decorative effect is good, and the color is close to that of a chromate passivated film; and the performance of the passive film is close to that of the chromate passivated film, the corrosion resistance is excellent, the passivation solution does not contain hexavalent chromium, so that environment pollution is little, and the technology is environmental-friendly.

Owner:朱忠良

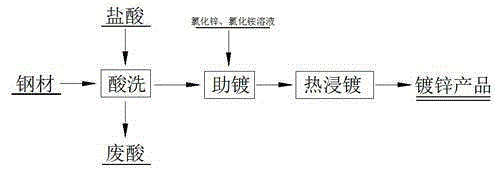

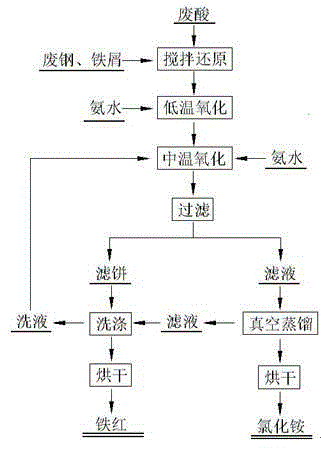

Preparation method of iron oxide red and ammonium chloride

InactiveCN105217694AImprove dynamic conditionsLess investmentFerric oxidesAmmonium halidesOxygenFerric

The invention relates to a preparation method of iron oxide red and ammonium chloride, and belongs to the technical field of waste resourceful treatment. The method is as below: mixing and evenly stirring waste acid and steel scrap or steel scrap leftover to obtain a solution with all iron in the form of Fe<2+> (reducing all Fe<3+> in the waste acid to Fe<2+>); adjusting the pH value of the obtained solution with ammonia, and at the same time introducing air or oxygen for oxidation at low temperature; heating the solution subjected to low temperature oxidation to 70-95 DEG C, adjusting the pH value of the solution by hydrochloric acid, introducing air or oxygen for middle temperature oxidation; filtering the turbid liquid to obtain a filter cake and a filtrate, washing the filter cake, drying at a temperature of 80-130 DEG C for 30-180 min to obtain iron oxide red with uniform color bright and purity greater than 99.5wt%; conducting vacuum distillation on the obtained filtrate and washing water to obtain a crystal, and drying the crystal at the temperature of 80-130 DEG C for 30-180 min to obtain NH4Cl with purity greater than 99.5 wt%. The method can produce high purity ammonium chloride and high tinting strength iron oxide red.

Owner:KUNMING UNIV OF SCI & TECH

Culture and breeding methods for apple tree of new species

ActiveCN105941071AHigh flowering rateStrong disease resistanceGraftingCultivating equipmentsFruit treeApple peel

The invention relates to a culture method for an apple tree of new species. The culture method comprises the following steps: A1, enabling the Qinguan apple tree to be subjected to branch grafting or bud grafting on the Qiaohuaxinhongxing apple tree; A2, enabling the cultured Qiaohuaxinhongxing apple tree obtained in the step A1 to be subjected to branch grafting or bud grafting on the Qiaohuachangfu No.2 tree; A3, enabling the cultured Qiaohuachangfu No.2 tree obtained in the step A2 to be subjected to branch grafting or bud grafting on the M26 dwarfing interstock; and A4, enabling the first cultured M26 dwarfing interstock obtained in the step A3 to be subjected to branch grafting or bud grafting on the red fuji spur apple tree, so as to obtain the apple tree of the new species. The invention also relates to a breeding method of the apple tree of the new species. The breeding method comprises the following steps: grafting the M26 dwarfing interstock on selected tree seedlings, and grafting the branches or buds of the apple tree of the new species on the M26 dwarfing interstock. The fruit tree obtained by the culture and breeding methods for the apple tree of the new species has the advantages that the quality is good, the fruiting period and the mature period are advanced, and the fruits are larger, uniform in color, palatable in sweetness and crispness, large in yield and high in economic value.

Owner:姚亦登

Wet-state dyeing finishing and fixation method for leathers based on zirconium-aluminum-titanium complex

ActiveCN105155307ABright and uniform colorImprove coloringDyeing processLeather impregnationFiberWastewater

The invention relates to the technical field of leather making techniques and provides a wet-state dyeing finishing and fixation method for leathers based on a zirconium-aluminum-titanium complex. The zirconium-aluminum-titanium complex is added in a later period of dyeing and fat-liquoring; the zirconium-aluminum-titanium complex is a multi-metal cation tanning agent which may combine with leather fibers so as to increase positive charge on leather surface, to improve tinting strength of the leather surface and color brightness and to basically solve the shading problem, color fullness of cationic crust leathers is improved, consumption of dyes and formic acid in traditional fixation methods is lowered, dyeing rate and fastness of dyes are increased, the content of dyes in spent dye liquor is further decreased, wastewater treatment is easier, and a leather making process is greener.

Owner:XINGYE LEATHER TECH CO LTD

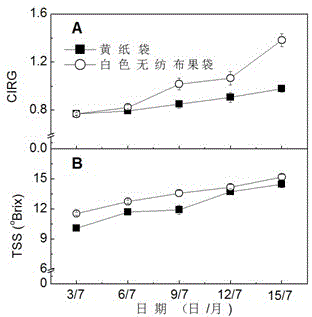

Bagging method for improving coloring of peach fruits

InactiveCN103598049AGood colorImprove appearance qualityPlant protective coveringsFruit treeFruit maturation

The invention provides a bagging method for improving coloring of peach fruits. The bagging method includes that a non-woven material fruit bag proper in size and color is selected, bagging is performed about 60 days after a fruit tree blossoms to enable the fruits to be suspended in the bag, fruit stems are arranged on an opening base of the fruit bag without being wound by a sealing ribbon, and the fruit bag is picked together with the fruits during harvesting; after the bag is conveyed to a packaging field through a transfer container, the ribbon is turned on to have the fruits taken out. By the bagging method, coloring of the fruits can be remarkably improved and enhanced, good flavor quality can be effectively sustained, and a fruit bag removing step before fruit maturation harvesting is omitted. The bagging process is simple, additional technical training is not needed, production cost is lowered, TSS of the fruits is effectively increased, the flavor quality is enhanced, and commercial value of the fruits is further improved.

Owner:ZHEJIANG UNIV

Method for processing ready-to-eat sea cucumber with different flavors

InactiveCN107041520AGuaranteed qualityImprove qualityFood freezingFood thermal treatmentReady to eatNutrition

The invention relates to a method for processing ready-to-eat sea cucumber with different flavors. The method comprises the following steps: 1) performing pre-treatment; 2) boiling: placing the pre-treated fresh sea cucumber in boiling water at the temperature of 80-100 DEG C, boiling the material for 3-10 min and cooling the material; placing the material in the boiling water at the temperature of 80-100 DEG C for 10-40 min, and cooling the material to room temperature; 3) performing low-temperature low-pressure seasoning or performing nutrition reinforcement; 4) product package: cooling a system to room temperature, performing ozone sterilization and vacuum package to obtain the finished product, which is the ready-to-eat sea cucumber with different flavors; and 5) packaging the ready-to-eat sea cucumber with different flavors according to the requirement to obtain the dried cucumber with different types. The method has the advantages of simple process, high nutrition value, and convenient eating.

Owner:YANCHENG TEACHERS UNIV

Bamboo pulp fiber fabric based on grape pigment dyeing and preparation method thereof

The invention provides bamboo pulp fiber fabric based on grape pigment dyeing and a preparation method thereof. The preparation method comprises the following steps of: washing fresh grape skin and grape seeds to dry in air, freezing and grinding the fresh grape skin and grape seeds by use of liquid nitrogen, filtering and screening to obtain powder raw materials, putting the powder raw materials into a supercritical carbon dioxide device to extract, thereby obtaining grape pigments; adding the grape pigments into deionized water, adding a silk fibroin aqueous solution, uniformly stirring, and adding sodium dodecyl benzene sulfonate to obtain grape pigment dye; boiling off and bleaching bamboo pulp fiber fabric, soaking the bamboo pulp fiber fabric in an oxidant solution to carry out activation treatment, taking out, spin-drying, putting the bamboo pulp fiber fabric into the grape pigment dye to directly dye, adding rare-earth elements to fix color, continuously dyeing, taking out the bamboo pulp fiber fabric to carry out soaping, washing, drying and sizing, thereby obtaining the bamboo pulp fiber fabric based on grape pigment dyeing.

Owner:东莞市伊卓服装有限公司

Artificial colored sand

The invention provides an artificial colored sand which is manufactured by composite color paste and gravel, wherein the composite color paste includes acrylic ester emulsion, toner, auxiliaries and water. According to the technical scheme, the produced artificial colored sand is rich in color, has bright and uniform color and luster, and has little limitation from the ore source; and meanwhile, the artificial colored sand has the cost lower than that of the natural colored sand, and the demand of a customer on personalized color can be met; and the economy and environmental protection can be achieved; and moreover, the composite color paste and the gravel have high attaching force during being sintered, so that the flexibility of the colored sand is improved. Compared with currently used natural colored sand, the artificial colored sand provided by the invention has uniform color, excellent film forming property, high attaching force, high resistance to water and alkali, relatively high pollution resistance, and super wear resistance, is economic and environment-friendly, and solves the problems of the natural colored sand that the ore sources are gradually reduced, the demands on production cannot be met, products in different batches have color difference, and the timeliness of the production cannot be met.

Owner:ASIA PAINT SHANGHAI

Dyeing technology of chemical fibers

The invention provides a dyeing technology of chemical fibers and relates to the field of dyeing of chemical fibers. A dyed chemical fiber product can be obtained through steps of pretreatment, purification treatment, presetting, dyeing, reduction and soaping, fixation and smooth setting. Oil solutions, stained oil dirt, dust, pigments and the like added in chemical fiber spinning and weaving processes are removed during pretreatment, the purification treatment is added to the technology, staged heating is adopted in the dyeing process, a leveling agent and a penetrating agent are added, a fixation foam liquid is sprayed for fixation, so that the dye utilization rate in the production process is high, the produced chemical fibers have full color, high color fastness and good uniformity, meanwhile, energy consumption is low, and little wastewater is produced.

Owner:马鞍山市永运家纺有限公司

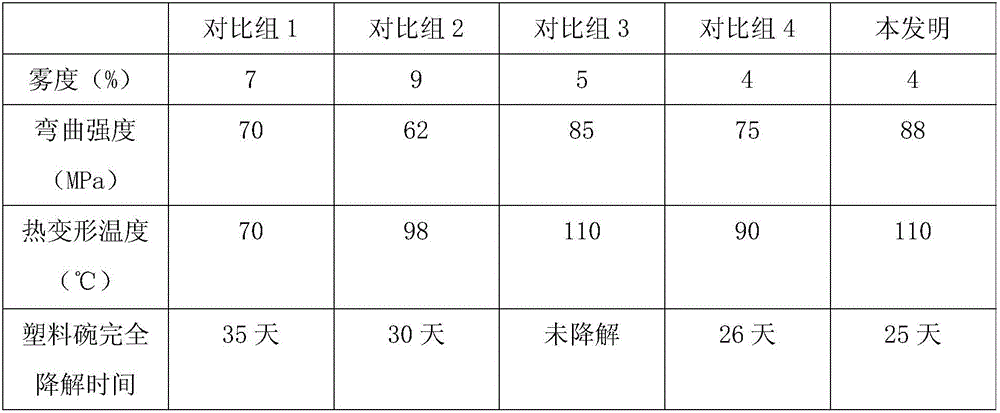

Production process of plastic bowl

ActiveCN106519595AThe production process is easy to controlLow costDomestic articlesElastomerPolyester

The invention relates to a production process of a plastic bowl, and belongs to the technical field of plastic production manufacturing. The plastic bowl is manufactured by taking high-density polypropylene granules as the matrix, and taking the PBAT, corn starch, functional auxiliaries, nano talcum powder and modified materials as the auxiliary material, wherein the polypropylene granules as the matrix are prepared by taking polypropylene, glass fiber, polyformaldehyde, thermoplasticity polyester elastomer, deionized water, isopropanol, antioxidant, plasticizer and methyl vinyl silicone oil as the raw materials; and a manufacturing process of the plastic bowl comprises the following steps: weighing raw materials, drying the raw materials, stirring, freezing, mixing, injection-molding, and after-treating; multiple formulas are added for the plastic bowl so that the plastic bowl is endowed with the characteristics of attractive appearance, high heat distortion temperature, good tenacity, excellent performance at all aspects, and biodegradablity after being used. The plastic bowl disclosed by the invention is scientific and rigorous in formula, and also simple and controllable in the production process procedure; the plastic bowl is low in cost and small in pollution, meets the concept of sustainable development, and is worthy of popularizing.

Owner:广东本原塑料制品有限公司

Preparation method of special color master batch for ultrahigh-molecular-weight polyethylene spinning

ActiveCN102875881BBright and uniform colorSimple production processMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberUltrahigh molecular weight polyethylene

The invention relates to a preparation method of special color master batch for ultrahigh-molecular-weight polyethylene spinning. The preparation method is implemented through the following four steps of: 1) selecting high-molecular-weight polyethylene resin as main materials, then adding organic pigment powder, antioxidant, light stabilizer and mineral oil, and mixing by using a mixing machine to prepare colored resin mixture; 2) extruding in a fused state by using an exhaust-type double-screw extruder to obtain a plurality of lines; cooling and solidifying the extruded colored lines through a water trough, and cutting the lines into colored master batch grains by using a grain cutting machine; 3) fully drying the colored master batch grains by using a dryer; and 4) grinding the colored master batch grains into even powder to obtain the special color master batch with uniform grain size for ultrahigh-molecular-weight polyethylene spinning. The preparation method of special color master batch for ultrahigh-molecular-weight polyethylene spinning has the advantages that the demands for various colors needed for ultrahigh-molecular-weight polyethylene spinning are met, the production technology is simple, the cost is low and the preparation method is the best technique for preparing various colored fibers at present.

Owner:宁波大盛新材料有限公司

Simple cow split leather color changing technology

ActiveCN105133398AHigh degree of depigmentationReasonable control of process parametersDyeing processSocial benefitsEconomic benefits

The invention discloses a simple cow split leather color changing technology which comprises the steps of cow split leather weighing, water returning, decolorization, retanning, dyeing, liquid expansion, color fixation and emergence and stacking. The raw materials are semi-finished leather blanks, scientific processing is carried out, technological parameters are reasonably controlled, the decoloration degree of the leather blanks is high, the cow split leather is bright and uniform in color, soft and comfortable after dyeing is carried out again, a leather board is solid, and no adverse influence is produced on the fiber strength. By carrying out decolorization and retanning on the semi-finished cow split leather blanks, the leather blanks can be recolored again, and the product is non-toxic and environmentally friendly. The simple two-layer cow leather color changing technology can be applied to secondary production of leather, a new path is developed for secondary utilization of the leather blanks, the flexibility and safety of business operation can be greatly improved, and the economic benefits and social benefits are remarkable.

Owner:CHINA LIGHT IND WUHAN DESIGN ENG

Water-based transparent polyurethane, water-based UV curing gloss oil, water-based UV curing ink and preparation method thereof

InactiveCN111607057AHigh glossImprove stabilityInksPolyurea/polyurethane coatingsIsophoronePrepolymer

The invention provides water-based transparent polyurethane, water-based UV curing gloss oil, water-based UV curing ink and a preparation method thereof. The water-based transparent polyurethane is prepared from the following raw materials in parts by weight: 30-50 parts of isophorone or diisopropylketone, 5-20 parts of diisocyanate, 80-120 parts of polyester polyol, 1-3 parts of 2, 2-dimethylolpropionic acid, 10-30 parts of neopentyl glycol and 5-30 parts of C7-C22 alkanediol. Isophorone and diisopropylketone not only can be used as reaction monomers, but also can be used as solvents, have high dissolvability to diisocyanate, and are miscible with water, so that the generated prepolymer can form a uniform dispersion in water. 2, 2-dimethylolpropionic acid not only can be used as a chain extender, but also can enable polyurethane to obtain a self-emulsifying property, so that the self-emulsifying water-based polyurethane with excellent stability can be prepared in an internal emulsification manner. Under the action of isophorone, diisopropylketone, neopentyl glycol and alkanediol, a polyurethane aqueous dispersion which is uniformly dispersed can be generated, and the polyurethaneaqueous dispersion has high refractive index and aqueous solution stability.

Owner:东莞市神乐高分子科技有限公司

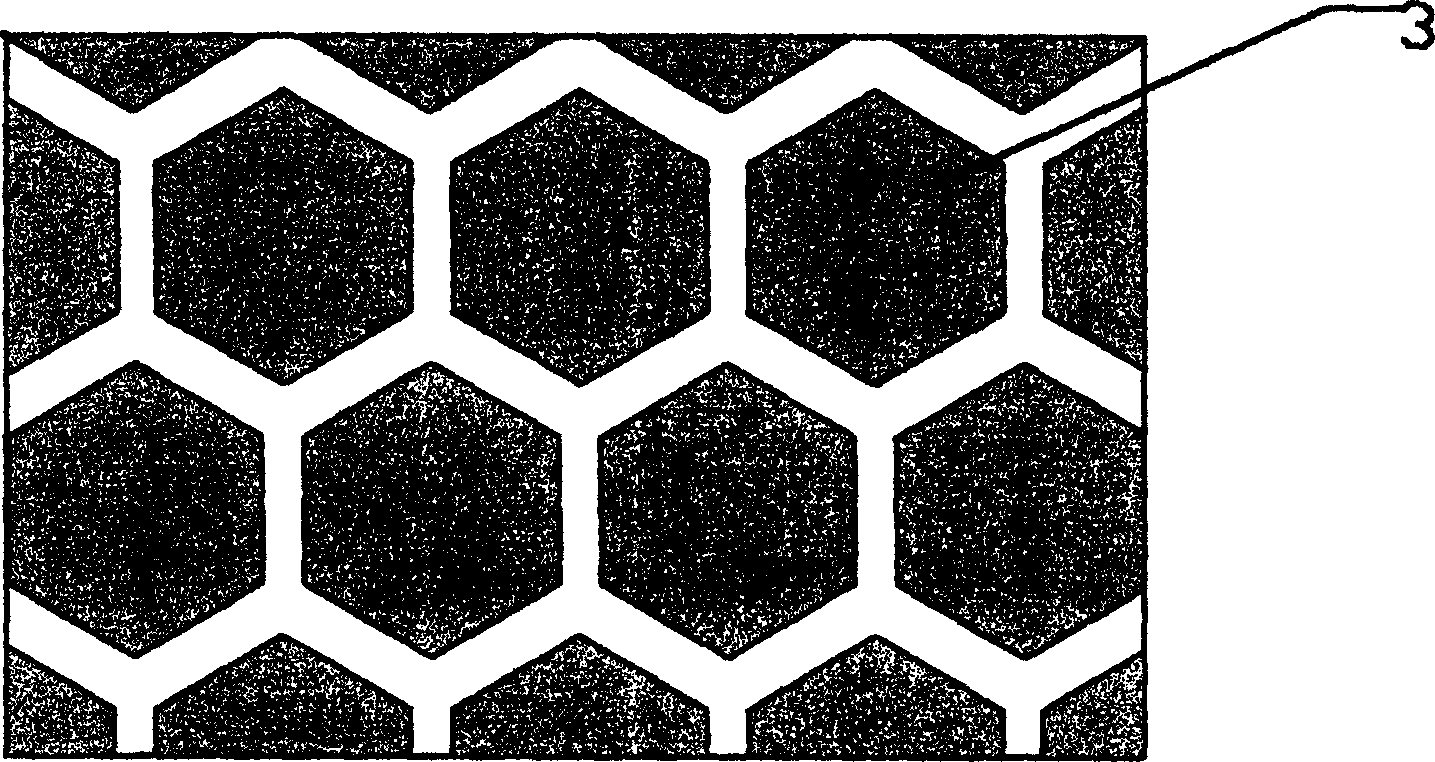

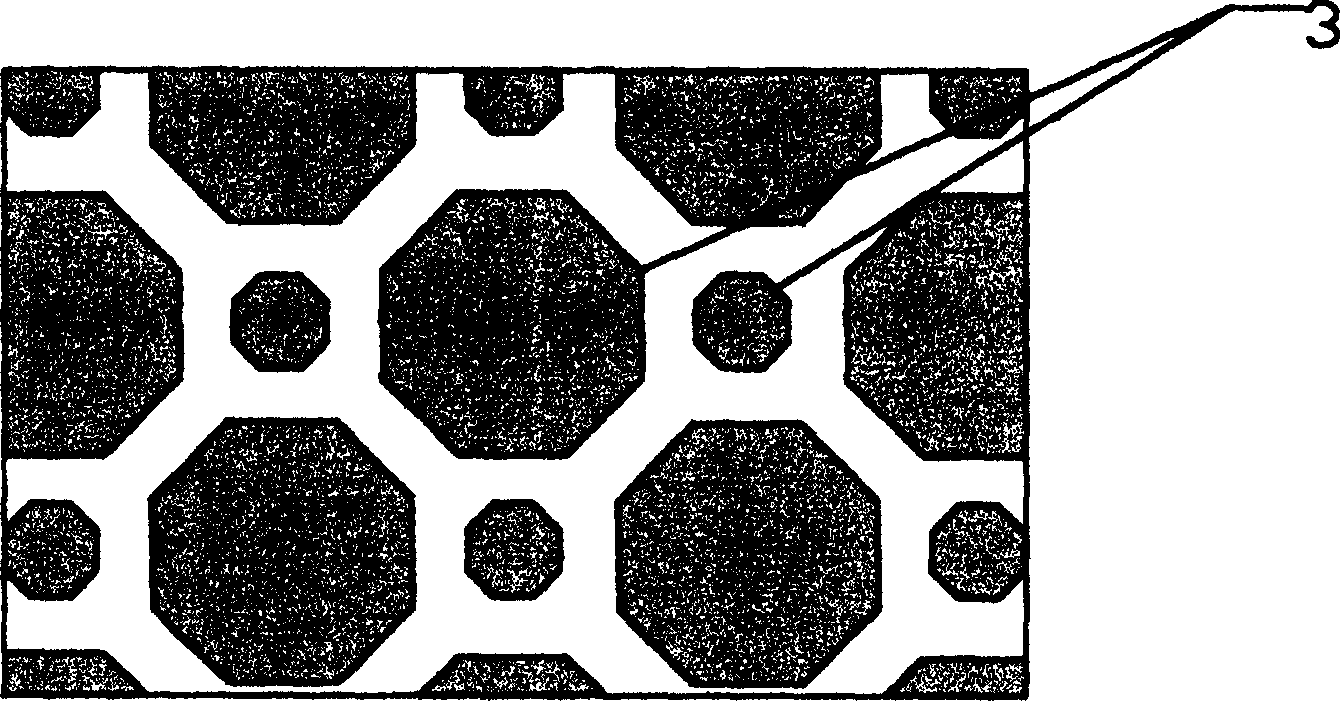

Double-mesh reticulate ceramic roller and its laser carving process

InactiveCN1203958CExtended service lifePrecise quantitative supplyRotary pressesLaser beam welding apparatusAutomatic controlTypes of mesh

The present invention relates to a double-mesh ceramic textured roller and its manufacturing method. On the ceramic layer of roller body of said textured roller two types of meshes which are regularly arranged are set, and the form, size and depth of meshes of said two types are different. The production method of said textured roller incldues the following steps: making two laser beams simulataneously and respectively pass through pass die to change its form and size, then pass through same focusing lens and focus on two points of ceramic layer of the roller obdy to make engraving, utilizingautomatic control of transmitting frequency and energy of the laser beam and movement of ceramic roller or laser device so as to continuously engrave meshes with a certain arrangement regularity and proper depth, and the form of meshes can have various ones, so that it can raise printing quality.

Owner:GUANGDONG BRIGHTAS LASER SCI & TECH

Processing technology for improving transparency of plastic cup

InactiveCN109467801AThe processing process is simple and controllableLow costBiochemical fibre treatmentVegetal fibresElastomerPolyester

The invention relates to a processing technology for improving the transparency of a plastic cup, and belongs to the technical field of production and manufacturing of plastics. According to the plastic cup, high-density polypropylene particles are used as a base material, an anti-aging agent, a transparent agent, a curing agent, ramie fibers and nano calcium carbonate are used as auxiliary materials, wherein the high-density polypropylene particles used as the base material are prepared from raw materials including polypropylene, isopropanol, titanium carbide, nano silica gel, thermoplastic polyester elastomers, modified phenolic resin, calcium stearate, deionized water and an antioxidant; and the preparation process of the plastic cup comprises the following steps: weighing of raw materials, drying of the raw materials, antibacterial treatment of fibers, mixing of the raw materials, injection molding and aftertreatment. The processing technology of the plastic cup is simple and controllable in process, low in cost and low in pollution, conforms to the idea of sustainable development and is worthy of being popularized; and the produced plastic cup has high mechanical strength, andis fine and smooth in texture, high in transparency and long in service life.

Owner:嘉兴松尚电器有限公司

Single tin salt electrolytic coloring method for vertical hanging type electrolytic cell

ActiveCN111218704AExtend working hoursFacilitated DiffusionAnodisationAluminum IonElectrolytic agent

The invention discloses a single tin salt electrolytic coloring method for a vertical hanging type electrolytic cell. The method comprises the following process steps of step S1, surface purificationtreatment of an aluminum product; step S2, preparation of an oxidation film: placing the aluminum product subjected to surface purification treatment in an oxidation tank, wherein the concentration ofsulfuric acid in the oxidation tank is 170-180 g / L, the concentration of aluminum ions is 12-16 g / L, the oxidation temperature is 16-17 DEG C, the voltage is 12.0-18.0V, and anodic oxidation is carried out for 30-60min; step S3, electrolytic coloring: placing the oxidized aluminum product in the electrolytic cell, wherein the pH of a single tin salt electrolyte is 0.5-0.8, the electrolysis temperature is 18-20 DEG C, the voltage of an alternating current power supply is 16-18V, and electrolytic coloring of the aluminum product in the circulating single tin salt electrolyte is carried out for200-250S; and step S4, water washing post-treatment. According to the single tin salt electrolytic coloring method for the vertical hanging type electrolytic cell, the champagne-color aluminum productwith bright and uniform color and strong metal texture can be obtained, the emission of nickel-containing wastewater and waste residues is greatly reduced, and the pollution discharge cost of enterprises is reduced.

Owner:佛山市三水凤铝铝业有限公司 +1

Process for producing plastic cups

InactiveCN106633371AThe production process is easy to controlLow costBiochemical fibre treatmentVegetal fibresPolyesterElastomer

The invention relates to a process for producing plastic cups, and belongs to the field of technologies for manufacturing plastics. High-density polypropylene granules are used as base materials for the plastic cups, anti-aging agents, transparent agents, curing agents, ramie fibers and nanometer calcium carbonate are used as auxiliary materials for the plastic cups, and the high-density polypropylene granules which are used as the base materials are prepared from polypropylene, isopropyl alcohol, titanium carbide, nanometer silica gel, thermoplastic polyester elastomers, modified phenolic resin, calcium stearate, deionized water and antioxidants. The process for manufacturing the plastic cups includes steps of weighing raw materials; drying the raw materials; carrying out antibacterial treatment on fibers; mixing the raw materials with one another; carrying out injection molding; carrying out post-treatment. The process for producing the plastic cups has the advantages that procedures are simple and controllable, the process is low in cost and pollution, conforms to concepts of sustainable development and is worthy of being popularized, and the plastic cups produced by the aid of the process are high in mechanical strength and transparency, exquisite in texture and long in service life.

Owner:NANNING RIJIAN PLASTIC PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com