Patents

Literature

66 results about "Solvent dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solvent dye is a dye soluble in organic solvents. It is usually used as a solution in an organic solvent. Solvent dyes are used to color organic solvents, hydrocarbon fuels, waxes, lubricants, plastics, and other hydrocarbon-based nonpolar materials. Fuel dyes are one use of solvent dyes. Their molecules are typically nonpolar or little polar, and they do not undergo ionization. They are insoluble in water. They form a colloidal solution in solvents. They have poor (basic dyes) to good (metal complex based) light fastness.

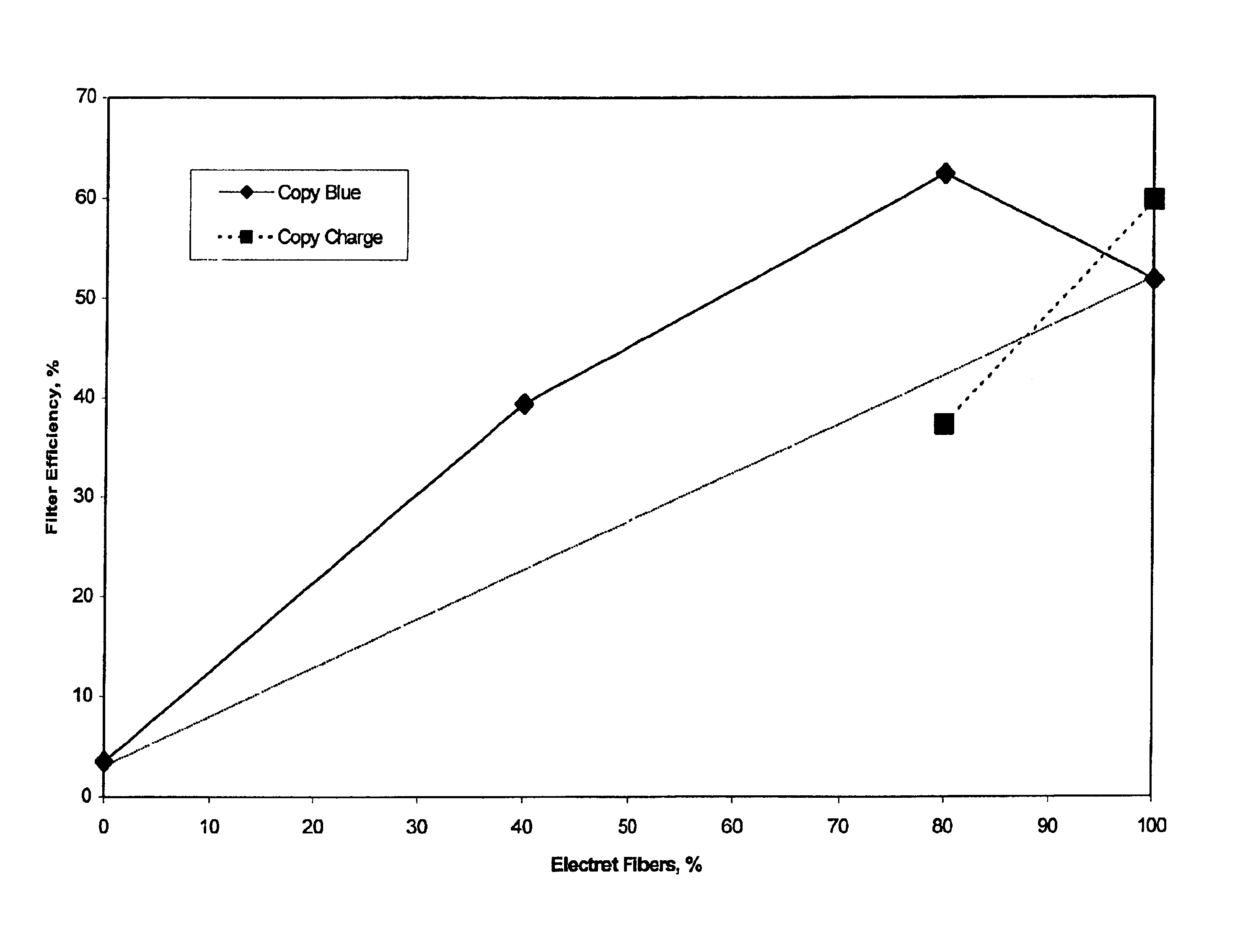

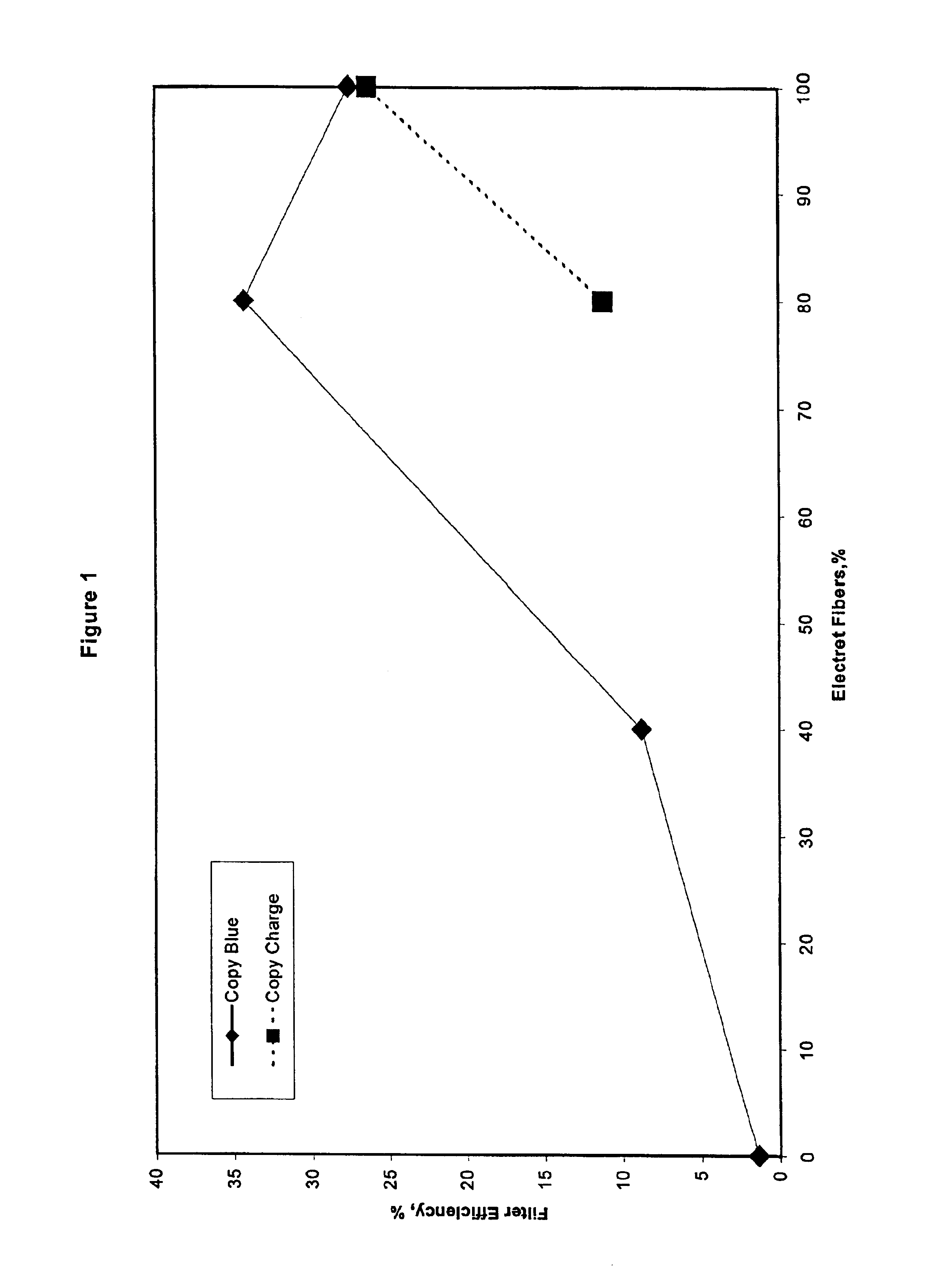

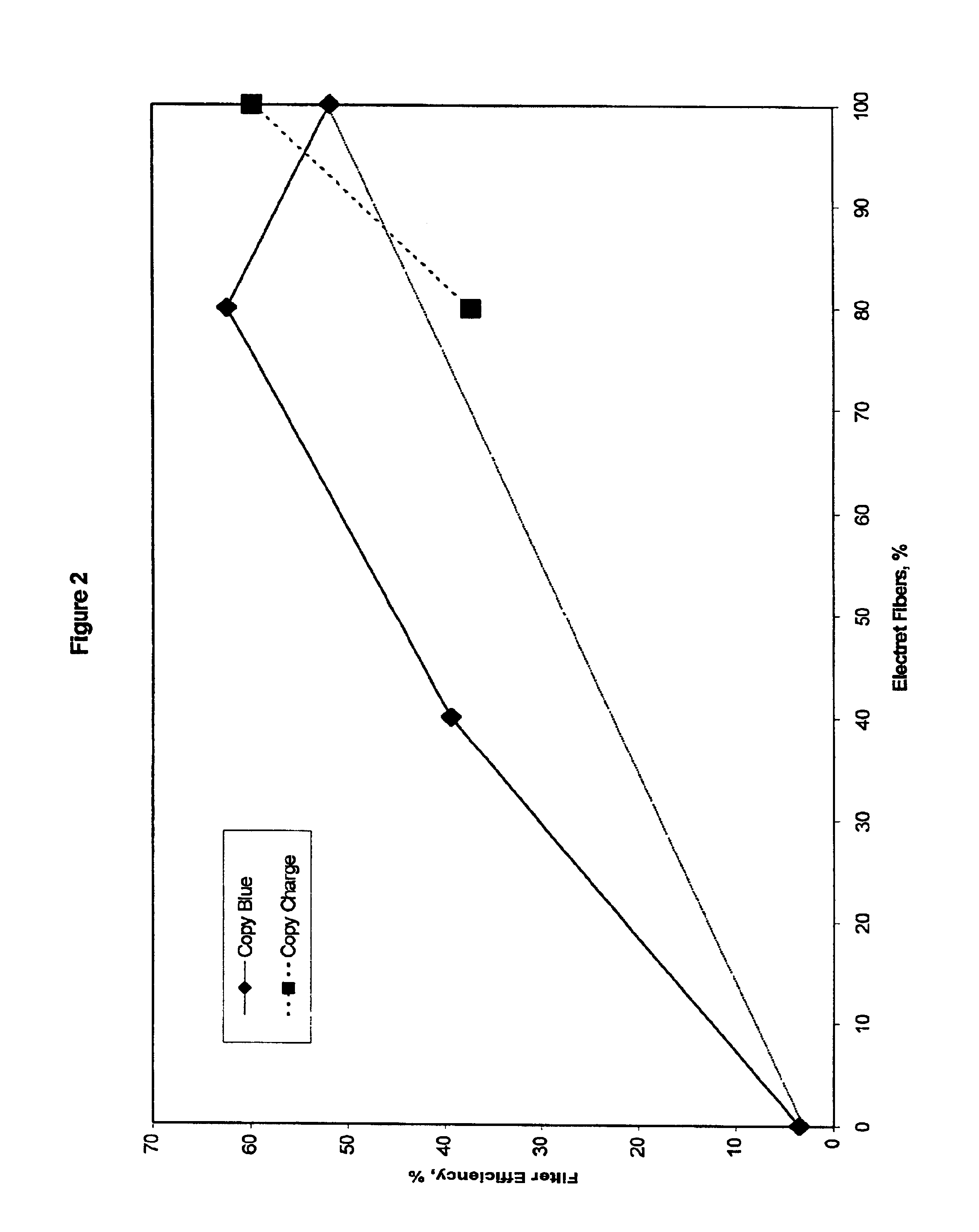

Nonwoven blend with electret fiber

InactiveUS6926961B2Inorganic material magnetismLoose filtering material filtersFiberAmmonium compounds

Owner:INVISTA NORTH AMERICA S A R L

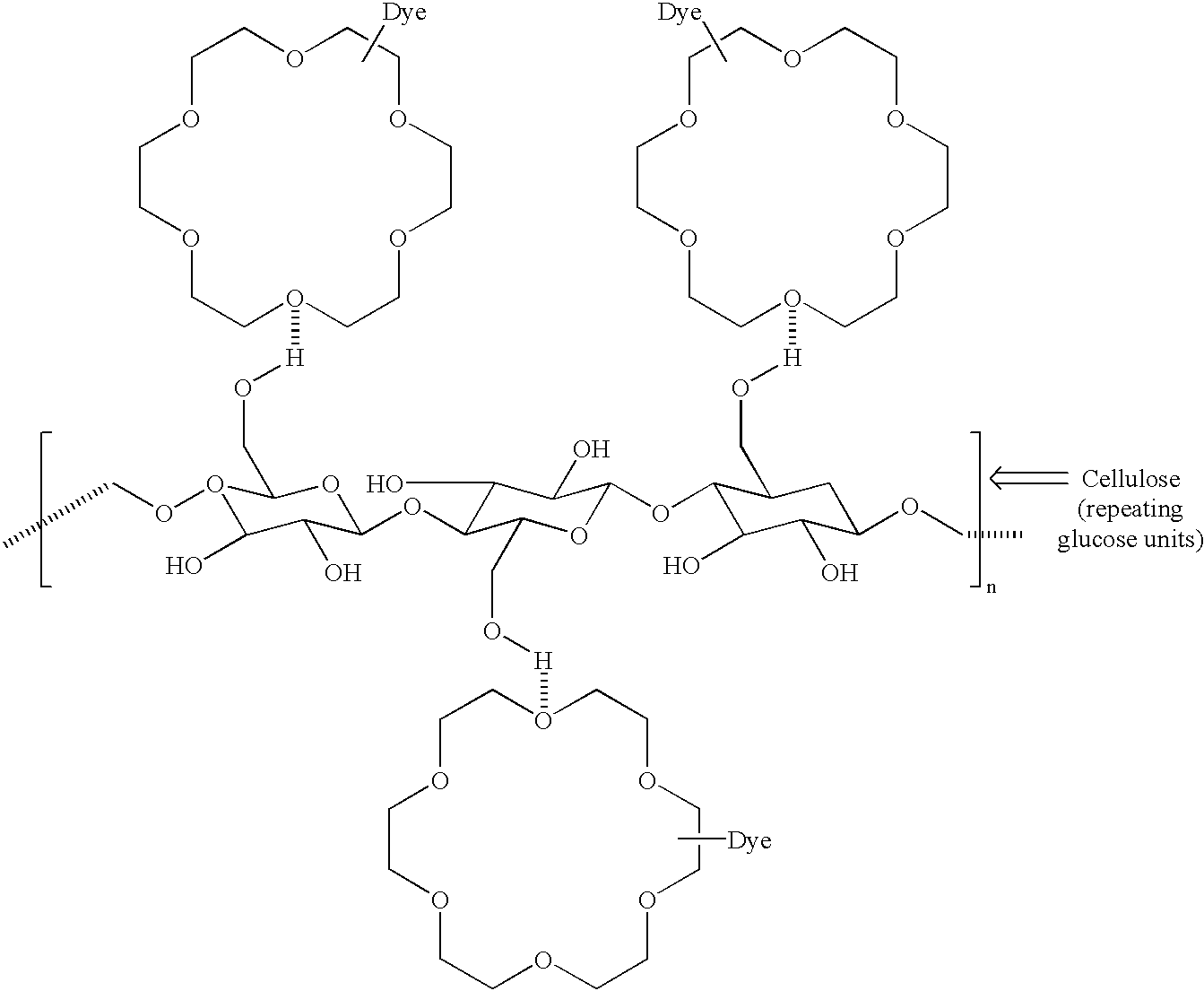

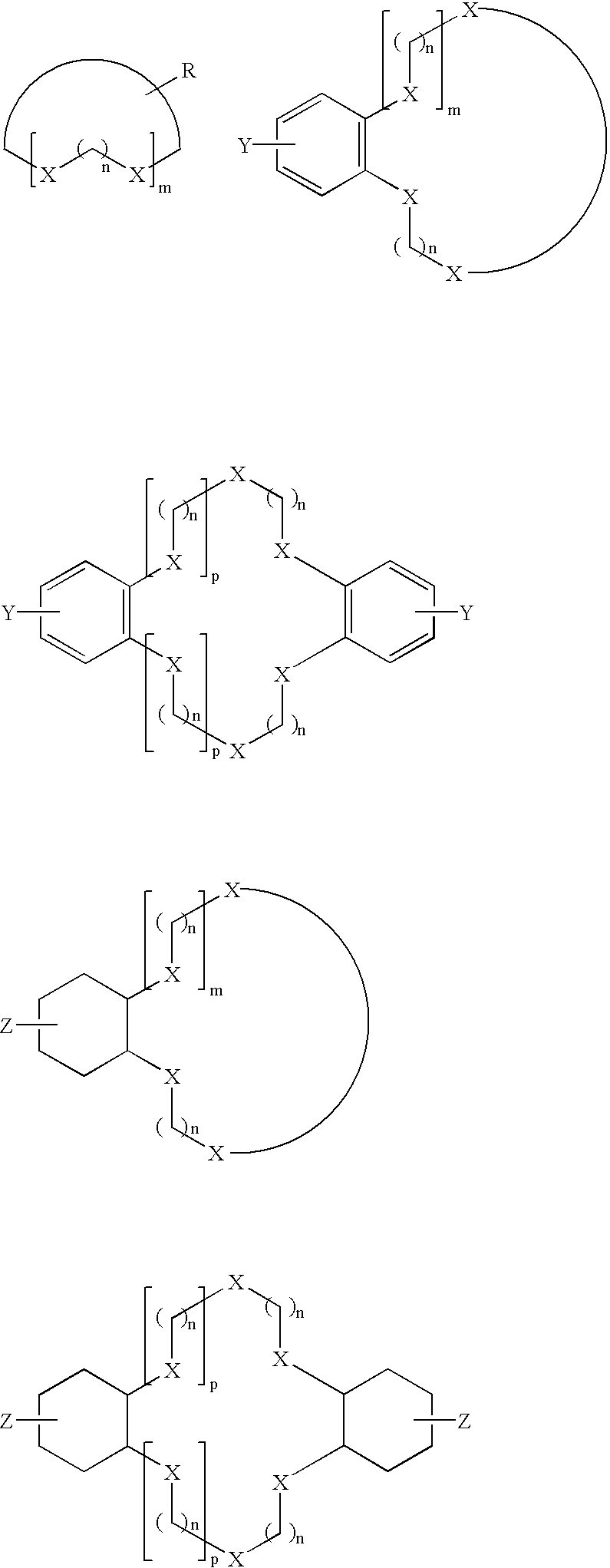

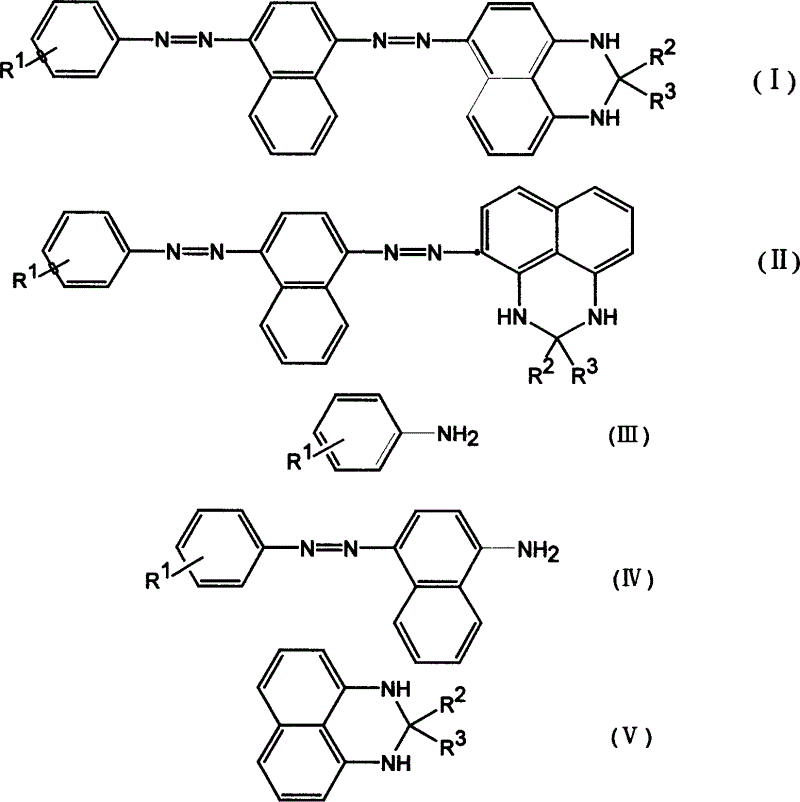

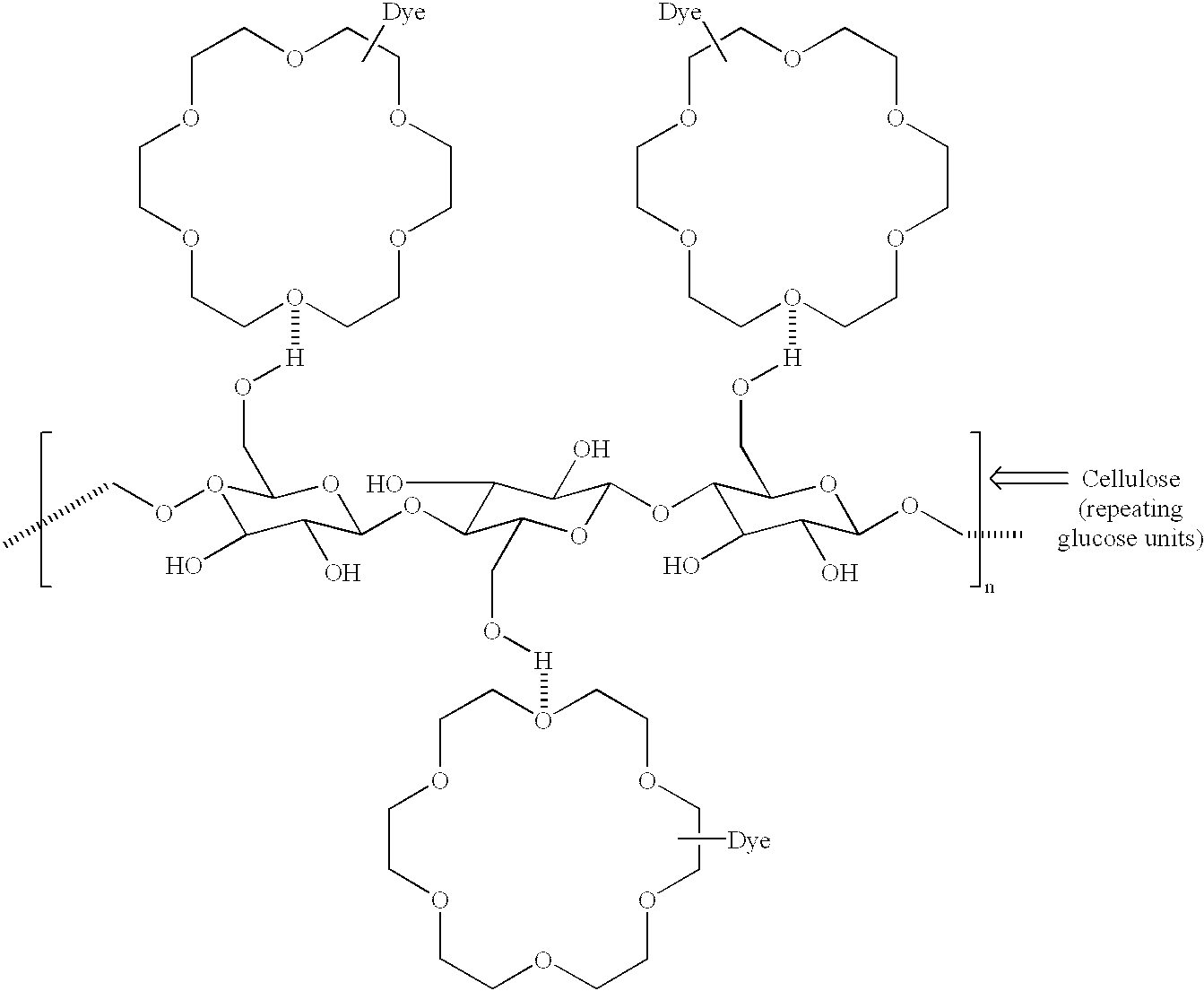

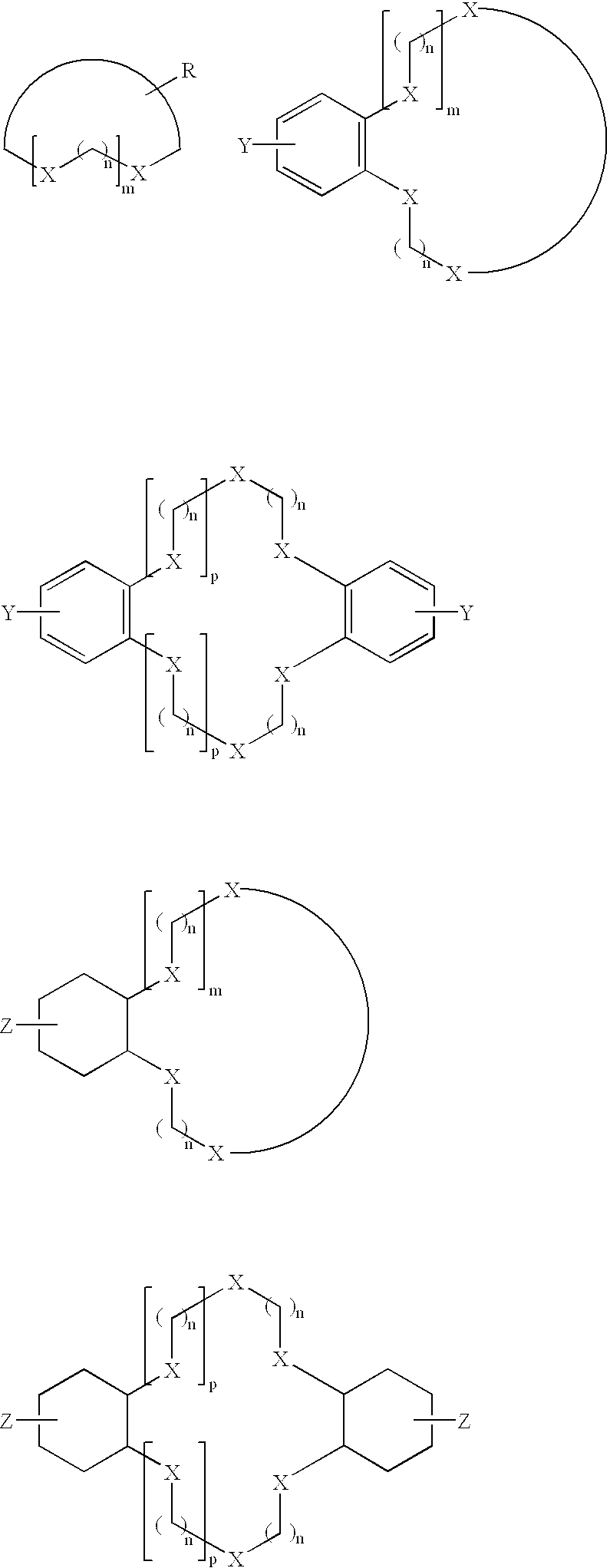

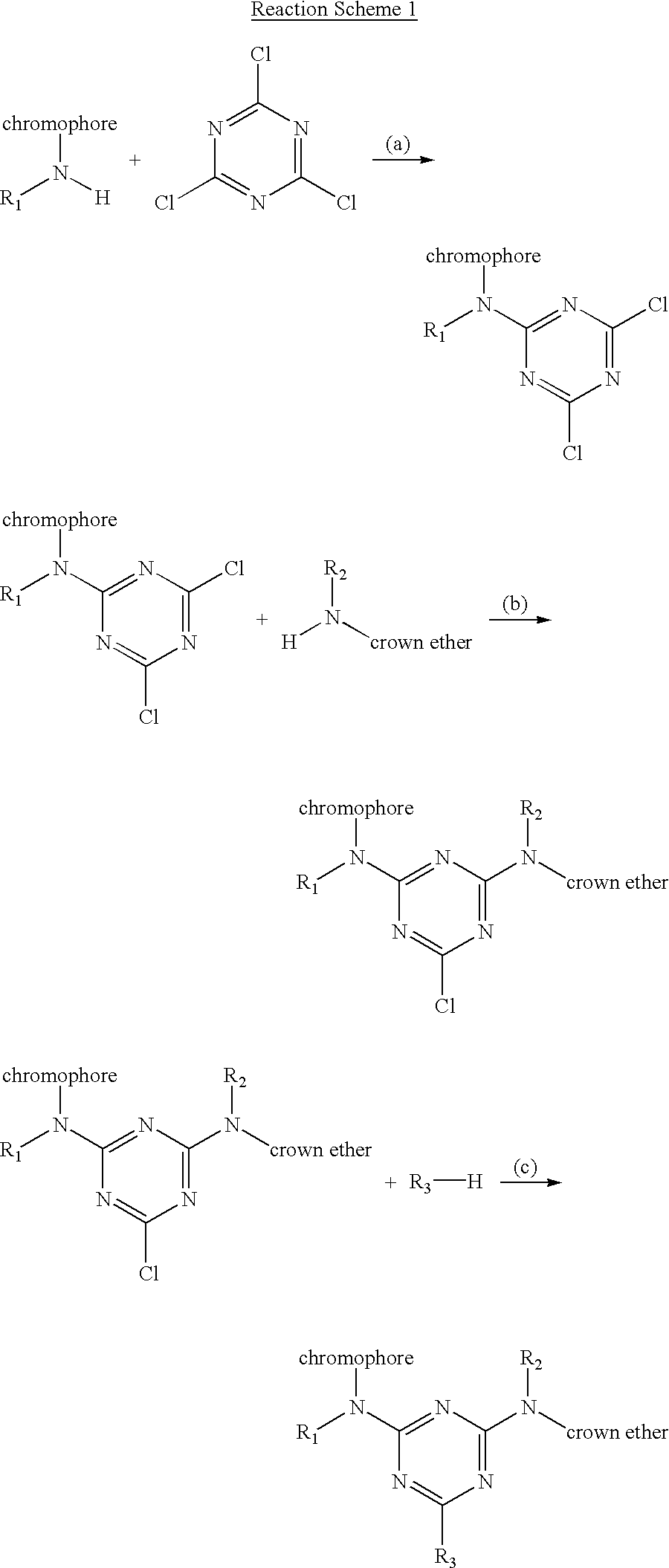

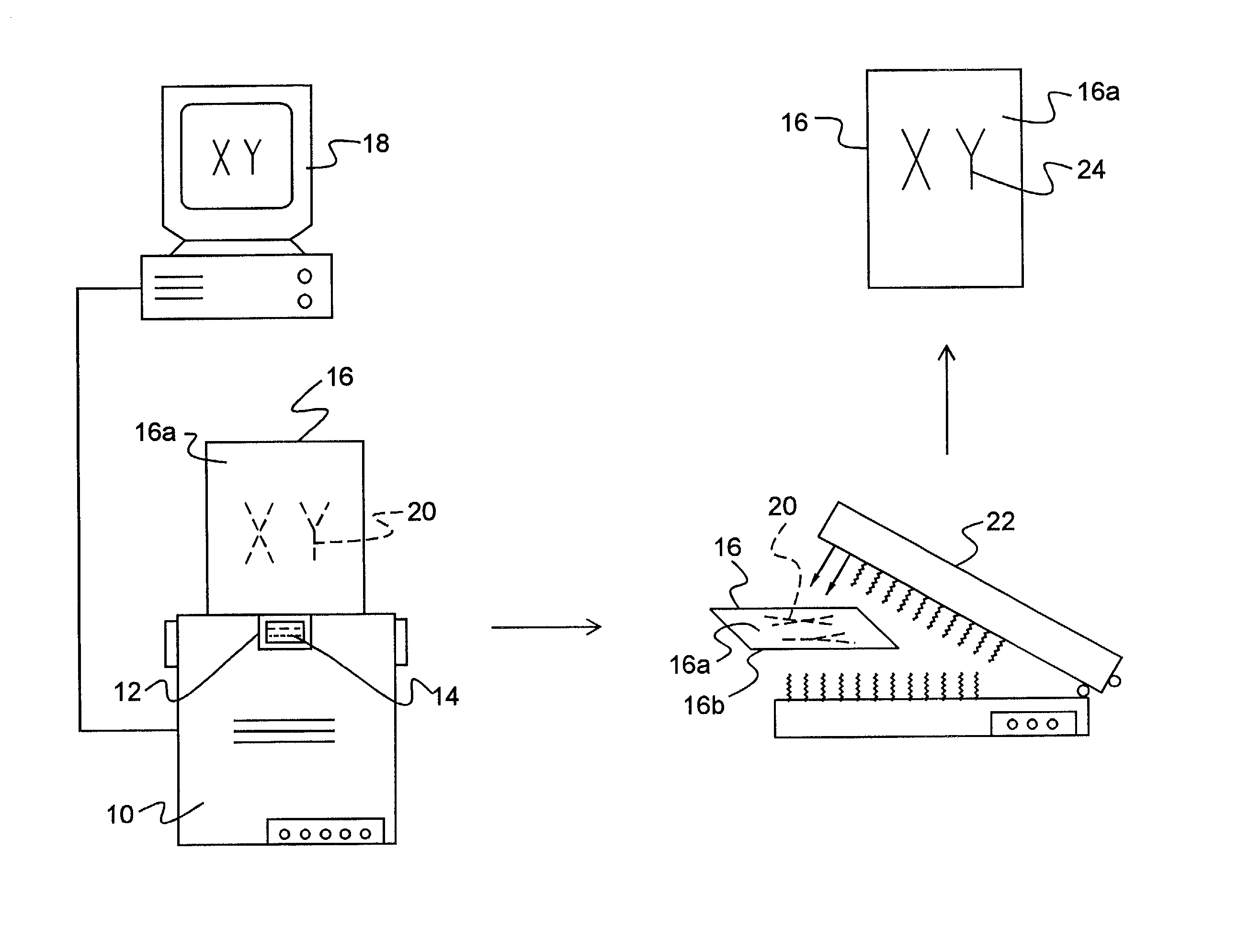

Derivatization of dyes/pigments with crown ethers and inkjet printing fluids containing the same

InactiveUS20020144626A1Improved lightfastnessImproved smearfastnessInksOrganic dyesDisperse dyeOrganic solvent

An inkjet ink is provided that employs one or more water-soluble colorants or water-insoluble colorants, such as solvent dyes, disperse dyes, or pigments. The colorant, whether water-soluble or water-insoluble, is derivatized with one or more crown ethers to render the water-insoluble colorants soluble in water and in water-miscible organic solvents commonly employed in inkjet printing, particularly thermal inkjet printing, and to impart improved properties to the colorants, such as lightfastness, smearfastness, and waterfastness. The inkjet ink comprises a vehicle and at least one crown ether derivatized colorant. The resulting inkjet ink evidences improved print quality properties, compared to inkjet inks containing colorants that are not so derivatized.

Owner:HEWLETT PACKARD DEV CO LP

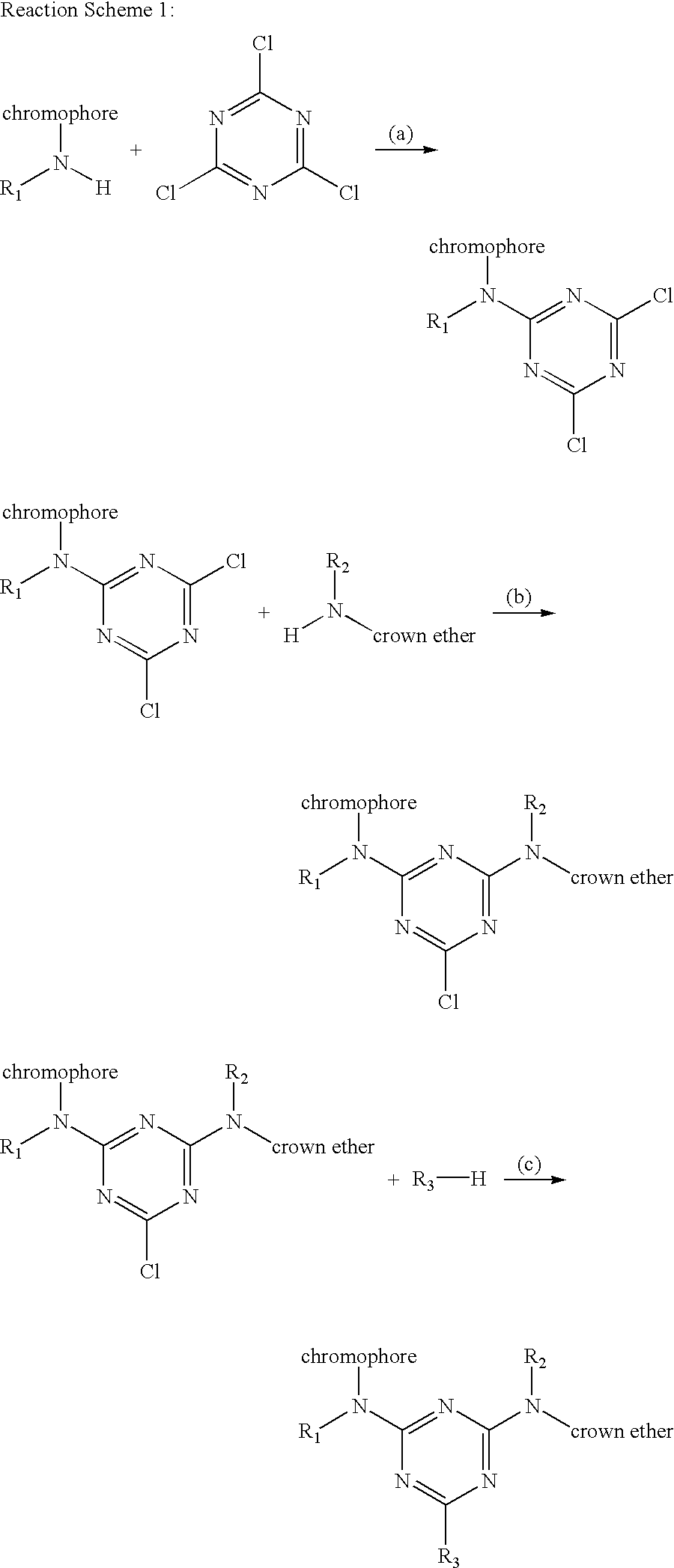

Modified polyurethane resin emulsion dye ink and application thereof

ActiveCN101914324AHigh color reproductionRaw materials are abundant and completeFibre treatmentInksTextile printerUltraviolet

The invention discloses a modified polyurethane resin emulsion dye ink and an application thereof. The modified polyurethane resin emulsion dye ink comprises the following components based on weight ratio: 0.1-12% of solvent dye and / or water-soluble dye, 13.5-49.8% of polyurethane resin solid content, 0.01-1% of ultraviolet absorber and the balance of solvent, wherein various additives can be added in the dye ink. The dye ink disclosed in the invention can be used in the fields such as jet ink, cipher paint ink, textile printing ink, aqueous printing ink, fountain pen word ink, rolling maker ink, coating, leather finishing agent, surface finishing and the like, and has the advantages of good storage stability, excellent water resistance, chemical resistance and light resistance, favorable mechanical performance, high brightness, high and low temperature resistance, ageing resistance, good color reproducivity and transparency, easily-obtained raw materials, simple manufacture, easy detection, low cost and wide market application prospect.

Owner:GUANGDONG BANGGU CHEM TECH

Inkjet ink

ActiveUS20170037269A1Improving printing fixabilityGood storage stabilityInksPrintingPolyolefinAlcohol

[Problem] An inkjet ink is provided that has quick-drying properties, that is capable of satisfactorily improving printing fixability with respect to a non-absorptive printing object made of polyolefin or the like, that is excellent in storage stability so that precipitation etc., do not easily occur for a long time, and that is excellent in intermittent printability so that a nozzle of an inkjet printer is not easily clogged for a decapping time. [Solution] A terpene phenol resin and / or a rosin ester that serve as a tackifier and whose hydroxyl value is 10 mgKOH / g or more and is 45 mgKOH / g or less were compounded with a polyamide resin, an alcohol having 1 to 3 carbon atoms, and an solvent dye.

Owner:GENERAL CO LTD

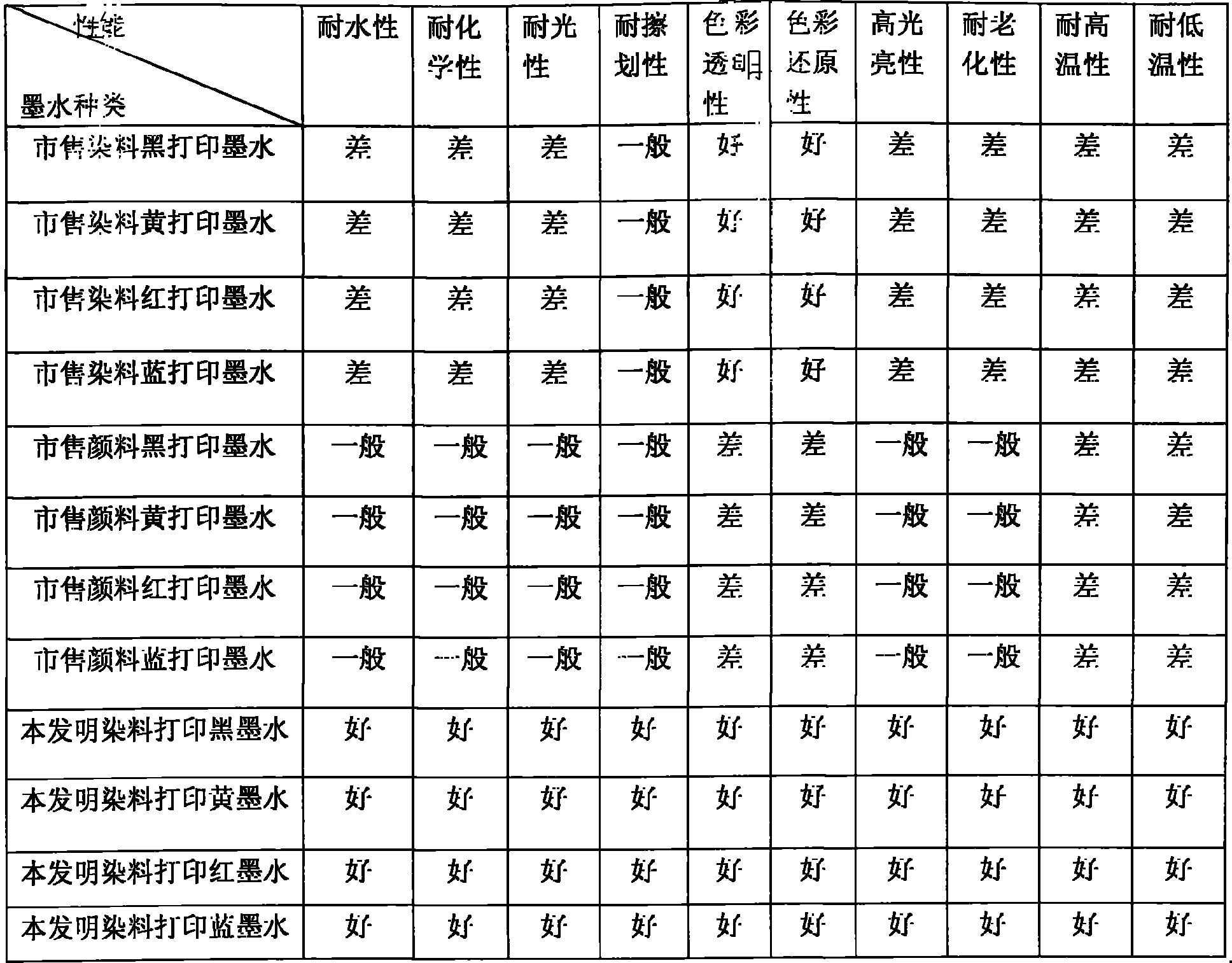

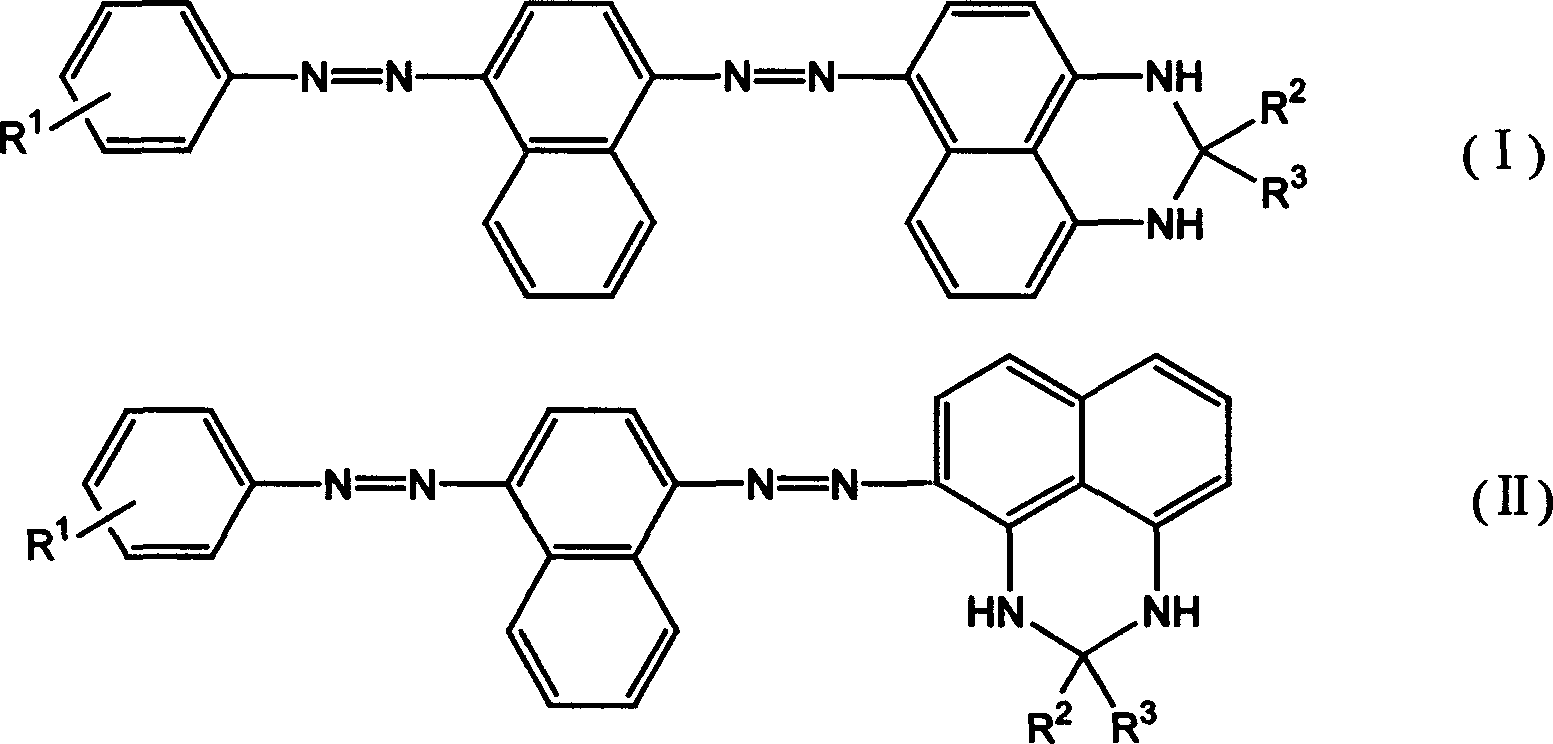

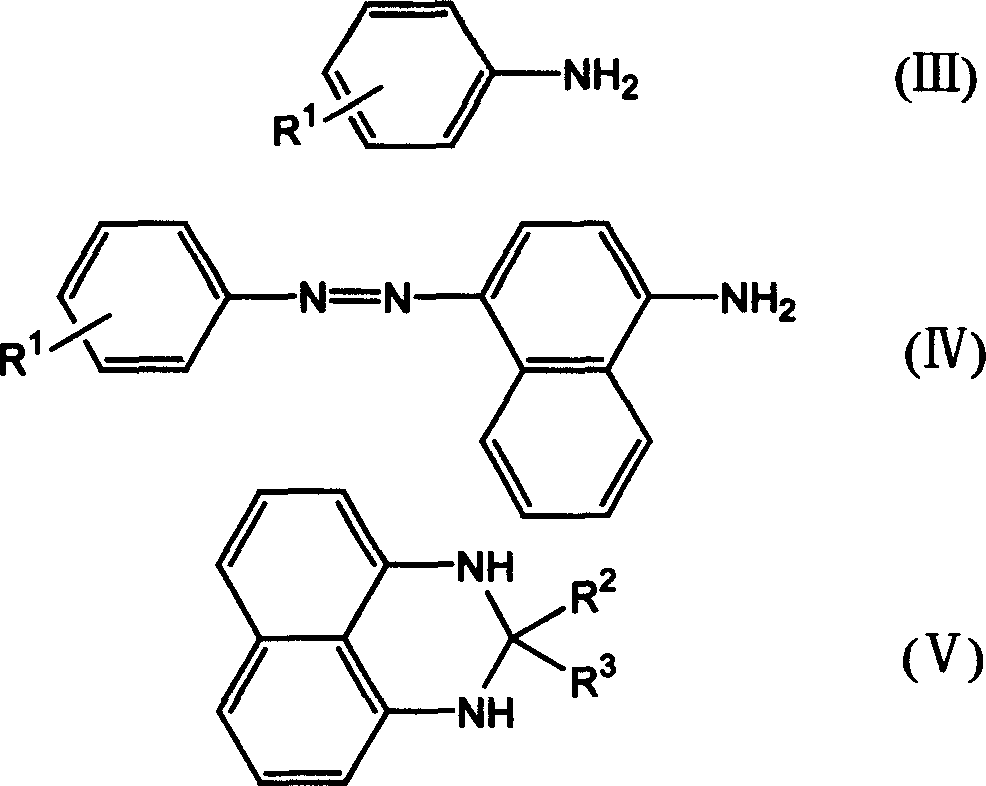

Bisazo solvent dye preparation method and uses

The invention relates to a process for preparing bisdiazo solvent dye which comprises, dissolving 1-naphthylamine into 0.5-5wt% of water solution of hydrochloric acid or sulfuric acid, charging sodium acetate till pH=3-4, charging diazonium salt of arylamine for coupling reaction at 0-15 deg. C, neutralizing the reaction mixture with alkali till pH=8-13, filtering, water scrubbing to obtain the monoazo dye, subjecting monoazo dye to diazo reaction with sodium nitrite, coupling the reacted mixture and 1, 8 di-naphthylamine with the condensation product of alkyl ketone R2-CO-R3, neutralizing the coupling product with alkali till pH=8-13, processing 90-100 minutes at 90-100 deg. C, filtering, rinshing to absence of chloride ion.

Owner:HUBEI DINGLONG CO LTD

Digital painting printing ink containing pigment and dye, preparation thereof

A numerical-code spraying ink containing pigment and dyestuff is prepared by adding in the pigment and dyestuff, because the price of solvent dyestuff is cheaper than the organic dyestuff. So it will decrease the cost. Colors of the ink include bluish, fuchsin, yellow and black. The process is so simple enough to industrial production.

Owner:DONGHUA UNIV

Colored polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for a synthetic leather, and specifically relates to a colored polyurethane resin for the synthetic leather and a preparation method thereof. Provided is the colored polyurethane resin for the synthetic leather; the colored polyurethane resin is obtained by mainly preparing the raw materials as follows: a macromolecular polyhydric alcohol, a dye, a micromolecular polyhydric alcohol chain extender, diisocyanate, an accessory ingredient and a solvent. The dye is a dye containing di-hydroxyl or double primary amino groups. The colored polyurethane resin for the synthetic leather can be used for a polyurethane synthetic leather layer or a post-processing. Due to the fact that the dye molecules react on a polyurethane main chain, a phenomenon of color-transfer cannot happen, thereby solving the problem that the dye is easy to transfer after dyeing by a common polyurethane resin, and further solving the problem that the color is not bright and thorough enough caused by coloring the synthetic leather with pigments.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Derivatization of dyes/pigments with crown ethers and inkjet printing fluids containing the same

InactiveUS6558459B2Improve solubilityResponsiveness to specificInksOrganic dyesDisperse dyeOrganic solvent

An inkjet ink is provided that employs one or more water-soluble colorants or water-insoluble colorants, such as solvent dyes, disperse dyes, or pigments. The colorant, whether water-soluble or water-insoluble, is derivatized with one or more crown ethers to render the water-insoluble colorants soluble in water and in water-miscible organic solvents commonly employed in inkjet printing, particularly thermal inkjet printing, and to impart improved properties to the colorants, such as lightfastness, smearfastness, and waterfastness. The inkjet ink comprises a vehicle and at least one crown ether derivatized colorant. The resulting inkjet ink evidences improved print quality properties, compared to inkjet inks containing colorants that are not so derivatized.

Owner:HEWLETT PACKARD DEV CO LP

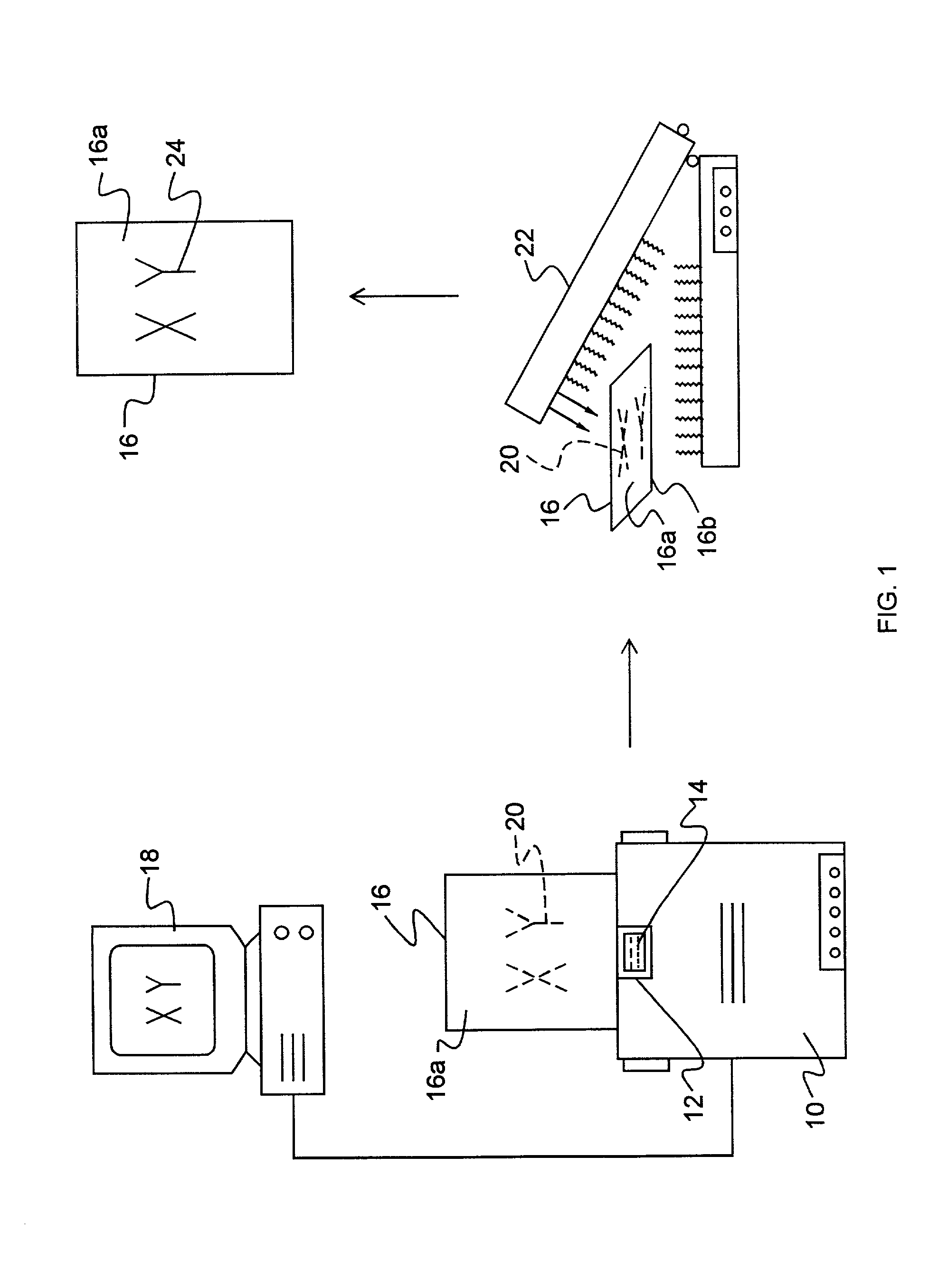

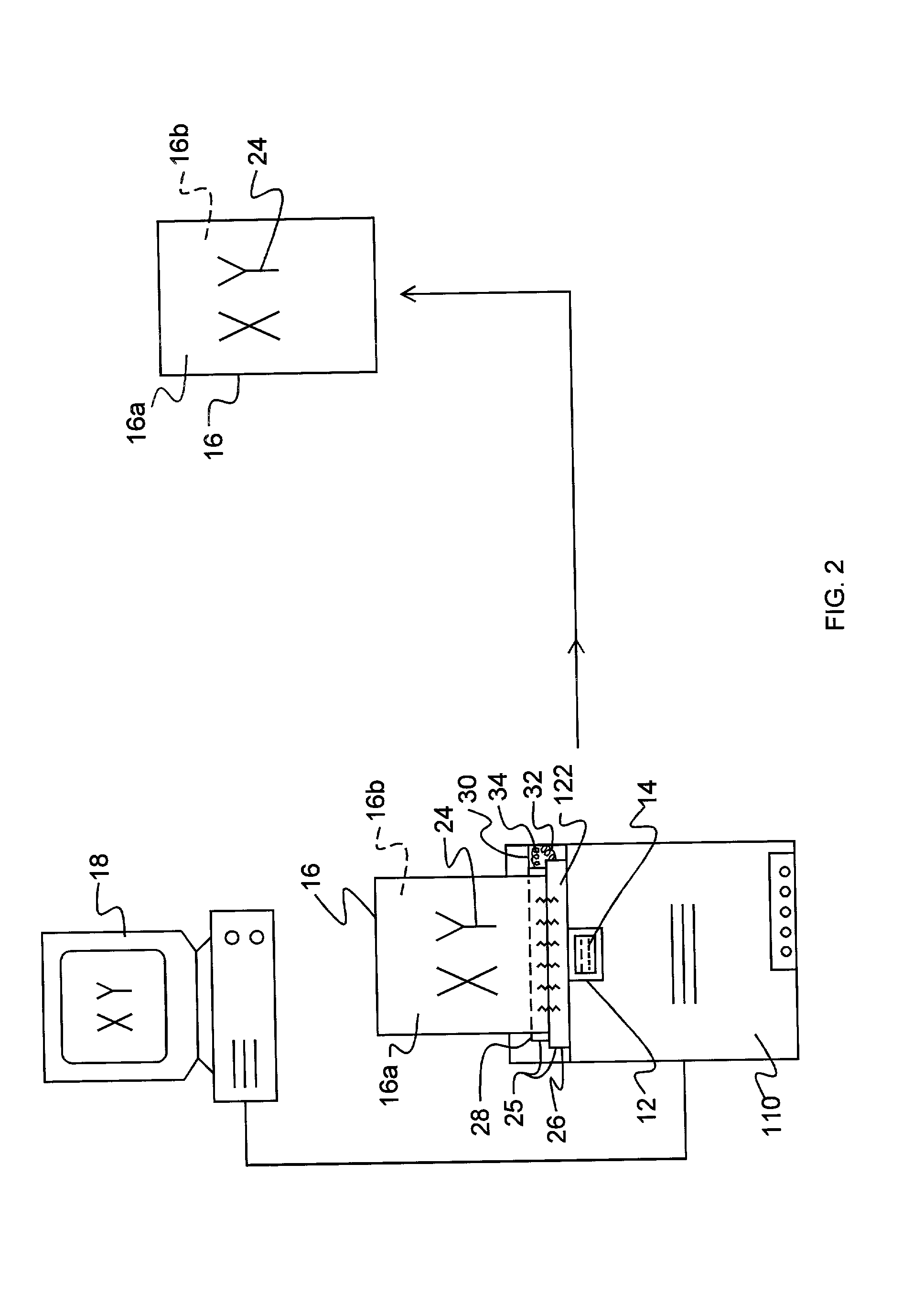

Waterfast and smearfast inks using ink jet delivered dye sublimation dyes

InactiveUS20020130938A1Increased smearfastnessDuplicating/marking methodsInksParticulatesDisperse dye

A method of printing an ink jet ink on a print medium is provided, wherein a printed image is formed that is both waterfast and smearfast. The method employs a water-insoluble colorant and comprises: (a) providing an aqueous-based ink containing at least one disperse, sublimation dye and at least one dispersant for dispersing the dye; (b) jetting the ink onto the print medium to form an intermediate printed image; and (c) subjecting the print medium to a combination of heat and pressure for a period of time to convert the intermediate printed image to the waterfast and smearfast printed image. The temperature is high enough to cause the disperse, sublimation dye to disintegrate and diffuse into the print medium, thereby diffusing the coloring agents out of the dispersant "shell" around the dye particulate and recondensing in the same place as solvent dyes, free of the dispersant. Solvent dyes are insoluble in water. Thus, the recondensed solvent dyes on the substrate are essentially impervious to water, and the printed ink attains a waterfastness and smearfastness not previously achieved in aqueous thermal ink jet printing.

Owner:HEWLETT PACKARD DEV CO LP

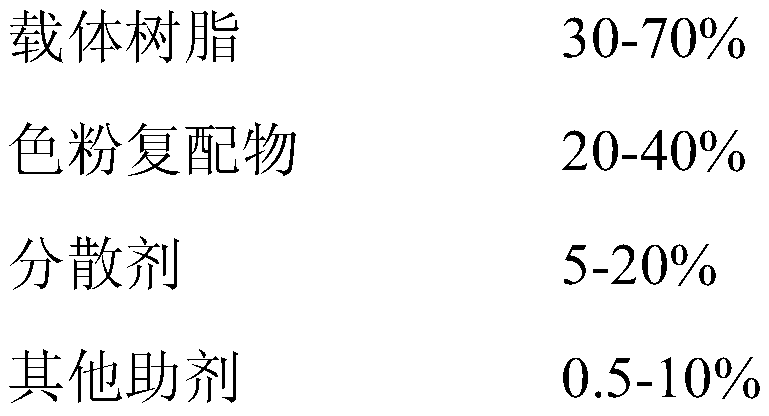

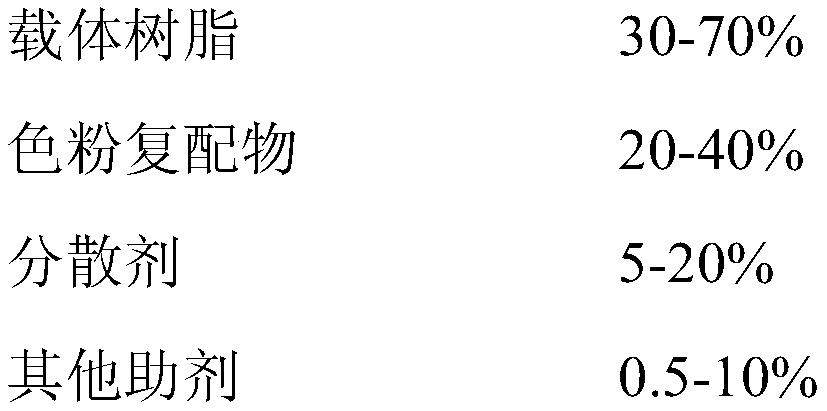

Boiling-resistant color master batch, preparation method and applications thereof

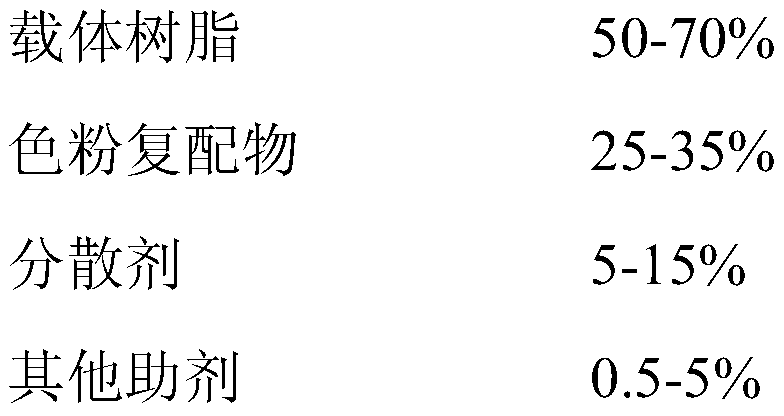

The invention relates to the technical field of nylon color masterbatch, and discloses uses of a toner complex in improvement of color stability in a nylon boiling process, wherein the toner complex comprises an organic pigment and a solvent dye according to a weight ratio of 1:0.2-2. The invention further discloses a boiling-resistant color master batch, which comprises the following raw materials by weight: 30-70% of a carrier resin, 20-40% of a toner complex, 5-20% of a dispersing agent and 5-10% of other auxiliary agents. The preparation method of the boiling-resistant color master batch comprises: uniformly mixing a toner complex and a dispersing agent, and carrying out melt blending on the mixture, a carrier resin and other auxiliary agents in blending equipment to obtain the boiling-resistant color master batch. According to the invention, the color master batch prepared from the toner complex compounded by the organic pigment and the solvent dye is applied to nylon products, sothat the color retention degree of the products can be improved, and the color difference value [delta]E of the nylon products before and after boiling is less than or equal to 1.0 while the productperformance and the appearance are met.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Waterfast and smearfast inks using ink jet delivered dye sublimation dyes

A method of printing an ink jet ink on a print medium is provided, wherein a printed image is formed that is both waterfast and smearfast. The method employs a water-insoluble colorant and comprises: (a) providing an aqueous-based ink containing at least one disperse, sublimation dye and at least one dispersant for dispersing the dye; (b) jetting the ink onto the print medium to form an intermediate printed image; and (c) subjecting the print medium to a combination of heat and pressure for a period of time to convert the intermediate printed image to the waterfast and smearfast printed image. The temperature is high enough to cause the disperse, sublimation dye to disintegrate and diffuse into the print medium, thereby diffusing the coloring agents out of the dispersant "shell" around the dye particulate and recondensing in the same place as solvent dyes, free of the dispersant. Solvent dyes are insoluble in water. Thus, the recondensed solvent dyes on the substrate are essentially impervious to water, and the printed ink attains a waterfastness and smearfastness not previously achieved in aqueous thermal ink jet printing.

Owner:HEWLETT PACKARD DEV CO LP

Flat polyester fiber master batch applicable to spun dyeing process and preparation method of master batch

InactiveCN106700439AMeet post-processing color fastness requirementsMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides flat polyester fiber master batch applicable to a spun dyeing process. The flat polyester fiber master batch comprises the following components in parts by weight: 0-30 parts of PBT (polybutylece terephthalate), 40-80 parts of bottle-grade PET (polyethylene terephthalate), 0-30 parts of a coloring agent, 0-5 parts of an aid and 0.1-0.6 part of calcium carbonate, wherein the coloring agent is selected from one or more of a condensed azo pigment, a phthalocyanine pigment, an aminoketone red solvent dye, a quinophthalone yellow solvent dye, a perylene series green solvent dye, an anthraquinone blue solvent dye, an anthraquinone purple solvent dye and an inorganic pigment carbon black; the aid comprises an organic silane high molecular weight dispersing agent. The invention further provides a preparation method of the flat polyester fiber master batch. The flat polyester fiber master batch provided by the invention is applicable to a spun dyeing process, the problems that fiber has very large deformation when being produced and a cross section of the fiber cannot be well maintained can be solved, meanwhile situations of fiber deviation, breakage and fiber burring can be solved, and moreover aftertreatment color fastness requirements can be met.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Microbead latex ink and preparation method thereof

InactiveCN101519554AUniform particle size distributionImprove dispersion stabilityInksOrganic solventSurface-active agents

The invention relates to a microbead latex ink and a preparation method thereof. The microbead latex ink is characterized by comprising the following components with the weight percent: (1) 0.5 percent to 5 percent of solvent dye, (2) 1 percent to 10 percent of surface active agent, (3) 5 percent to 35 percent of organic solvent, (4) 10 percent to 40 percent of auxiliary agent, and (5) 25 percent to 60 percent of deionized water. The prepared ink is not only suitable for special ink-jet printing media, but also is suitable for uncoated media, such as coated paper, and the like, has even grain size distribution and good disperse stability, can be stored for a long period, has quick printing and drying speed and has high edge sharpness.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Laser transfer coating for pre-coloring and preparation method thereof

InactiveCN101967346AImprove wear resistanceHigh tensile strengthPolyamide coatingsPolyester coatingsPolymer scienceLaser coating

The invention relates to a laser transfer coating for pre-coloring, which is prepared from the following components: 0-12% of polyamide resin, 0-10% of polyester resin, 0-5% of vinyl chloride-vinyl acetate resin, 2-30% of polyacrylate resin, 0-4% of amino resin, 0-9% of nitro-cotton resin, 0.2-0.6% of cross-linking agent, 0.4-1% of dispersing agent, 1.2-1.5% of wetting agent, 68-84% of solvent and 0.8-1% of dye. The preparation method of a water transfer printing laser coating comprises the following steps: preparing raw materials; adding the solvent into a reaction kettle, stirring, and heating; sequentially adding the resin, and stirring at high speed until the resin is completely dissolved; sequentially adding the cross-linking agent, the dispersing agent and the wetting agent slowly, and stirring at medium speed until the cross-linking agent, the dispersing agent and the wetting agent are dispersed uniformly; adding the dye slowly, and stirring at high speed until the dye is dispersed uniformly to obtain a solution of the laser transfer coating for pre-coloring; sampling, and measuring solid content and viscosity; and stirring at medium speed, cooling, and filtering to obtain the laser transfer coating for pre-coloring. The laser transfer coating for pre-coloring and the preparation method thereof can be applied to the pre-coloring process of laser transfer products.

Owner:DONGGUAN K LASER TECH

New micro fiber leather or leather or cork wet transfer printing method and wet transfer printing film thereof

InactiveCN101837692ASolve the problem that cannot be printedIncrease color varietiesTransfer printing processInk transfer from master sheetFiberOrganic solvent

The invention discloses a new micro fiber leather or leather or cork wet transfer printing method comprising the following steps of: preparing a wet transfer printing film by carrying out gravure of a film by using solvent dye ink; moistening an organic solvent for the micro fiber leather or the leather or the cork by spraying or rolling marks; bonding the moistened micro fiber leather or the leather or the cork and the transfer printing film; transferring solvent dye on the transfer printing film on the micro fiber leather or the leather or the cork by pressurizing and heating; and drying or airing the transfer-printed micro fiber leather or leather. The invention also discloses a wet transfer printing film used in the method. The invention creatively proposes to use the solvent dye as the wet transfer printing colorant and use a solvent which can smoothly dissolve the solvent dye as a wetting agent of printing stocks, breaks through the limitation that water is necessary for the traditional wet transfer printing, and enlarges the application range of the wet transfer printing.

Owner:张家港市普坤羊绒制品有限公司

Colored anhydrous gel element

A colored anhydrous gel element for perfuming or deodorizing air or enclosed spaces is provided. The element is formed by cross-linking a functionalized liquid polymer selected from maleinized polybutadiene, maleinized polyisoprene or a copolymer of ethylene and maleic anhydride with a cross-linking agent which contains at least one complementary functional group in the presence of a non-aqueous perfume or deodorizing base and a least one metal-free solvent dye which is soluble in the non-aqueous perfume or deodorizing base, or which is provided as a solution in a non-aqueous solvent which is compatible with the non-aqueous perfume or deodorizing base. The gel elements may be incorporated into devices which are used as air fresheners or deodorizers.

Owner:RECKITT BENCKISER (UK) LTD

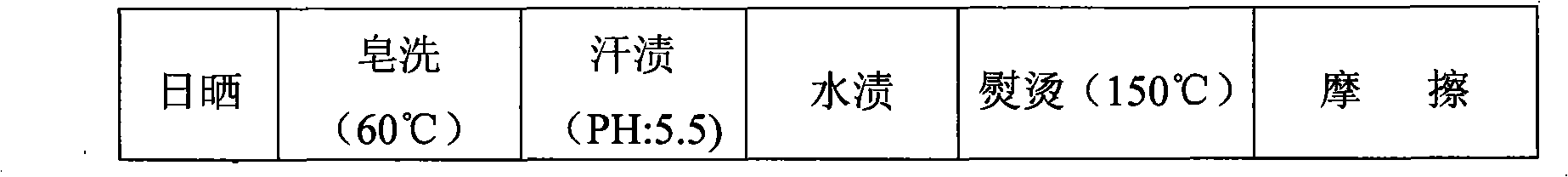

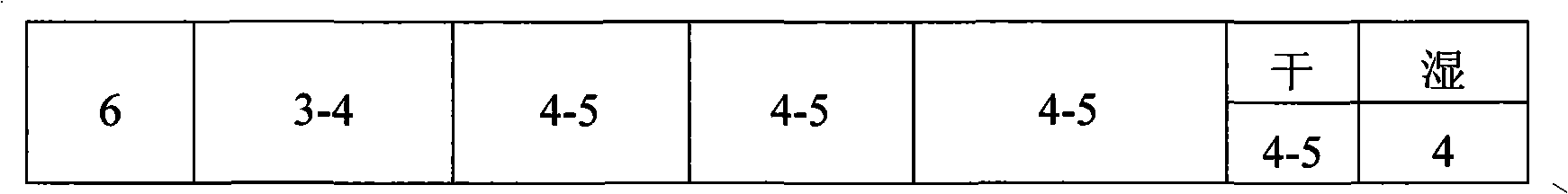

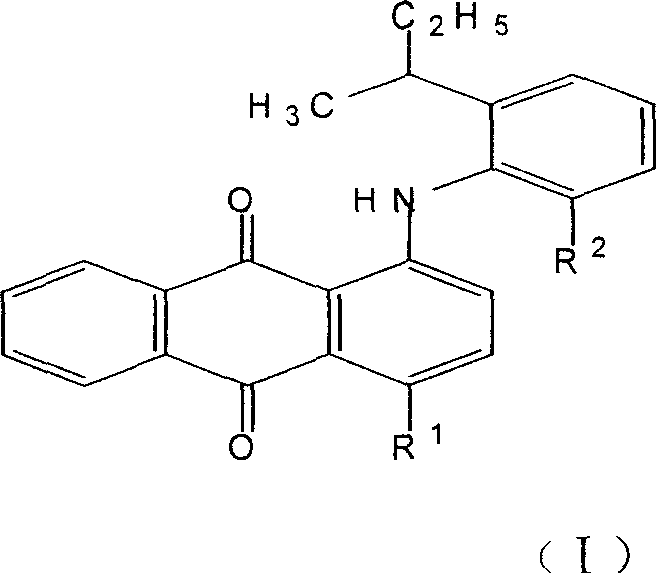

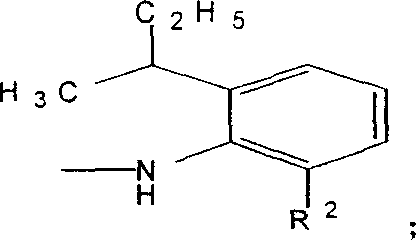

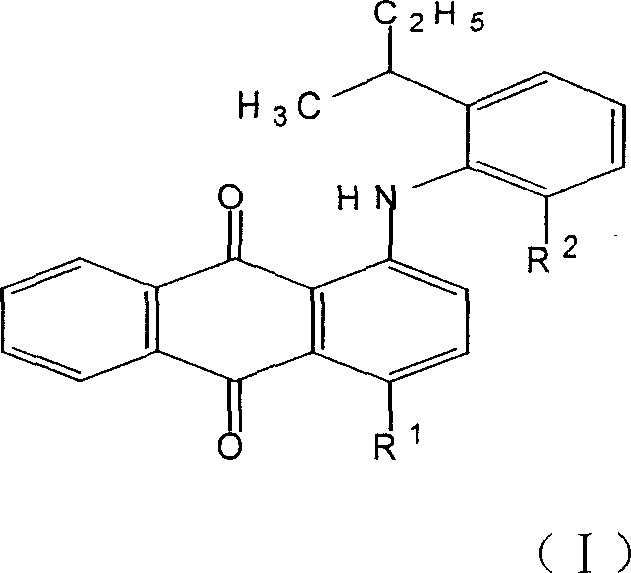

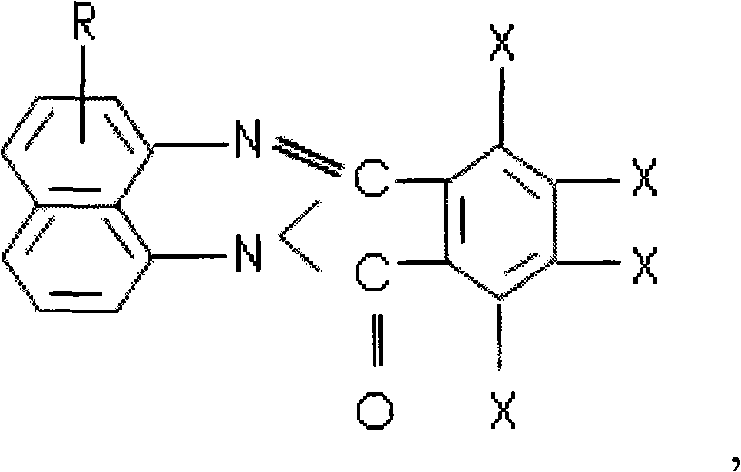

Anthraquinone type solvent dye and preparation and application thereof

The invention discloses an anthraquinone dissolvent dye and preparation and application in dye technical domain, which is characterized by the following: setting the composite as general formula (I); choosing R1 from hydroxyl group or II; choosing R2 from metyl group or ethyl group; adopting vacuum rectifying craft; extracting 2-ethyl group-6-secondary butyl aniline or 2-metyl group-6-secondary butyl aniline; proceeding condensation reaction with 1, 4-alizarin; preparing the general formula (I) component; decreasing the cost of dye. This dye can be used to color oil, hard plastic rubber and resin, which can get brilliance red light blue and bright violet.

Owner:SHENYANG RES INST OF CHEM IND +1

Solvent dye ink-jet printing ink and preparation method thereof

The invention relates to a solvent dye ink-jet printing ink and a preparation method thereof, relating to an ink. The solvent dye ink-jet printing ink comprises the following components: 5%-8% of acrylic resin, 1%-8% of colorant, 0.1%-1% of acidity regulator, 0.01%-0.02% of defoaming agent, 0.01%-12% aminating agent, 0.01%-1% of surfactant, 0.01%-0.02% of drier, and the balance solvent. When in preparation, all raw materials are poured into a sealed reaction kettle according to the above formula, and then a shearing mulser is utilized for shearing and stirring to obtain the solvent dye ink-jet printing ink. Printed pictures have good definition, and the copper plate paper of the printing ink has a color gamut range which can be up to national ink-jet printing standard; images can be clearly formed on printing stock medium without a coating layer; the ink has good fluency and unblocks the ink jet head of the ink jet printer within one week, has good the water-proof performance and light stability, can not corrode the printer, is safe, protects environment, and can be applicable to brand ink jet printers such as EPSON and the like.

Owner:厦门好印像数码科技有限公司

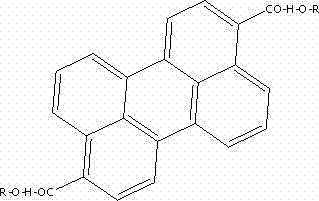

Solvent green 5 isomer based solvent dye

ActiveCN103773080ASimple componentsImprove high temperature resistanceAzo dyesSolvent freeSolvent dye

The invention discloses a solvent dye composition for solving the problems of poor high-temperature resistance and limited application range of solvent green 5 in the prior art. The solvent dye composition is composed of the following components in percentage by mass: 85-88% of 3, 9-perylenedicarboxylic acid bis(2-methylpropyl) ester and 12-15% of 3, 10-perylenedicarboxylic acid bis(2-methylpropyl) ester. The solvent dye composition disclosed by the invention is simple and reasonable in component ratio, good in high-temperature resistance and capable of completely replacing a solvent green 5; the melting point of the solvent dye composition can be up to 328-330 DEG C. The invention also discloses a preparation method of the solvent dye composition. The preparation method comprises the following steps: (1) preparing 3, 9-perylenedicarboxylic acid and 3, 10-perylenedicarboxylic acid; (2) preparing 3, 9-perylenedicarboxylic acid bis(2-methylpropyl) ester and 3, 10-perylenedicarboxylic acid bis(2-methylpropyl) ester; (3) compounding. The preparation method disclosed by the invention is simple in process step, strong in operability, low in cost and suitable for industrial production.

Owner:杭州荣彩实业有限公司

Solvent-based dye sublimation ink composition

InactiveUS8263682B1Minimizes and prevents paper cocklingImprove stabilityLayered productsInksSolvent basedSolvent dye

A solvent-based dye sublimation ink composition includes specific chemical formulations of production agents for its manufacture in several colors. The sublimation ink composition includes a vinyl chloride-vinyl acetate copolymer, a polymeric amide, 2-methoxy-1-methylethyl acetate, N-butyl acetate, butan-2-OL, petroleum distillate, disperse and / or solvent dyes, propylene glycol and one or more acetates. Once produced, the solvent-based dye sublimation ink of the present invention may be used with ink jet printers and prevents or minimizes paper cockling while exhibiting outstanding stability and high print density capabilities.

Owner:HILORD CHEM CORP

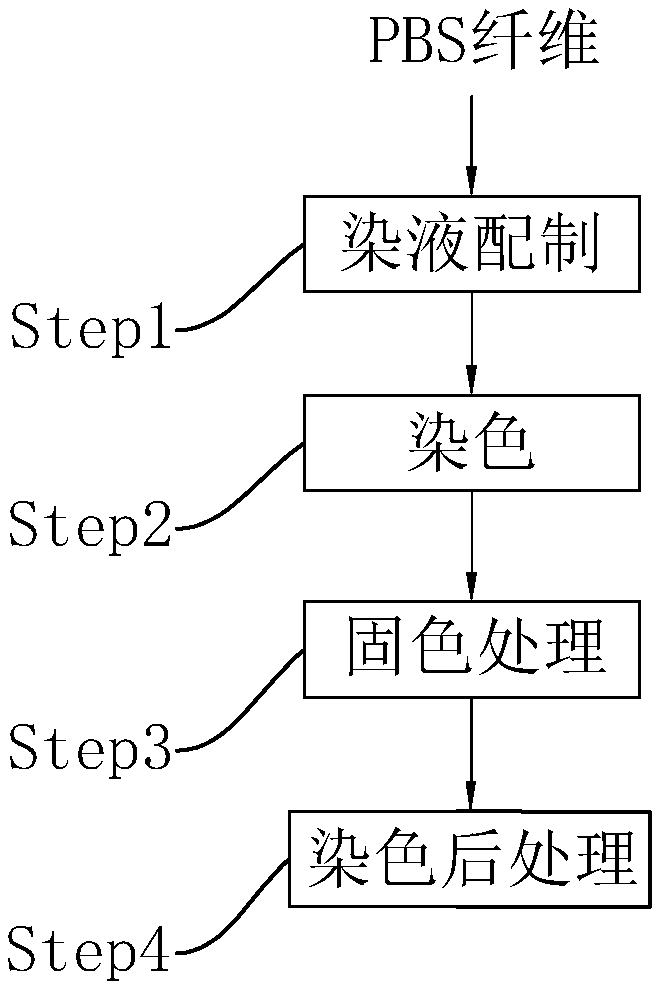

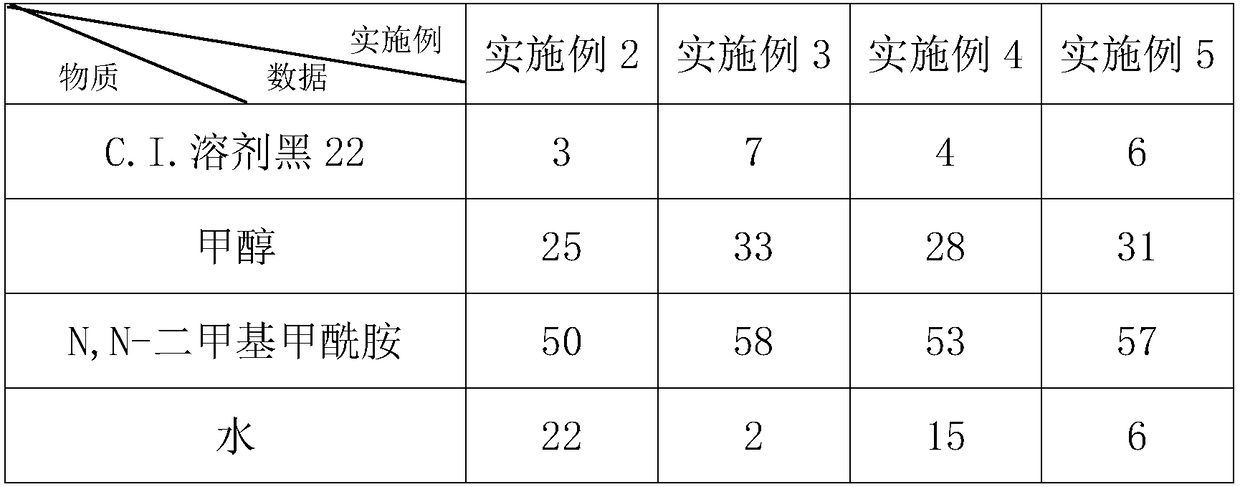

Dyeing technology of poly(butylene succinate) fibers

The invention relates to the technical field of dyeing and finishing of polymers and discloses a dyeing technology of poly(butylene succinate) fibers. PBS fibers are treated in the following steps: step one, preparation of a dye solution; the dye solution is prepared from the following substances in percentage by mass: 3 to 7 percent of solvent dye, 25 to 33 percent of methanol, 50 to 58 percent of N,N-dimethylformamide and 2 to 22 percent of water; step two, dyeing; step three, color fixation treatment; step four, dyeing post-treatment, wherein the PBS fibers subjected to the dyeing post-treatment in the fourth step are dyed PBS fibers. Because solubility parameters of the solvent dye are similar to those of PBS, and the methanol and the N,N-dimethylformamide are simultaneously used as solvents, the solvent dye can be dyed on the PBS, and further PBS can be dyed with different colors and the use value of the PBS is improved.

Owner:SHAOXING GLOBAL CHEM FIBER +1

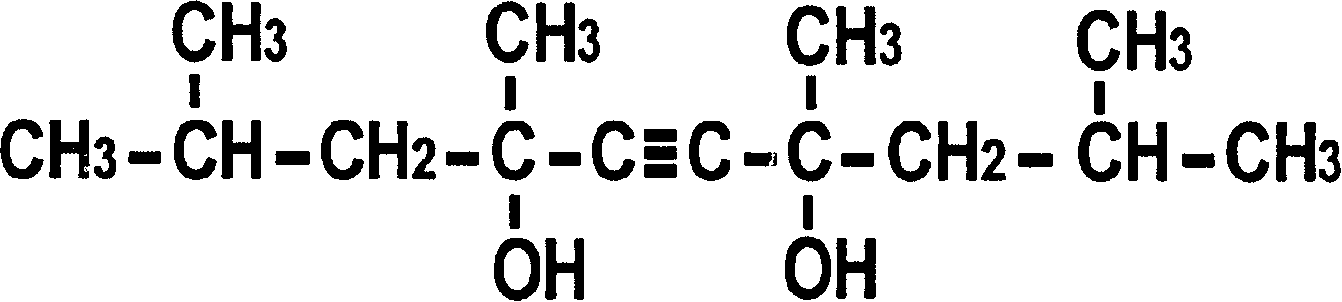

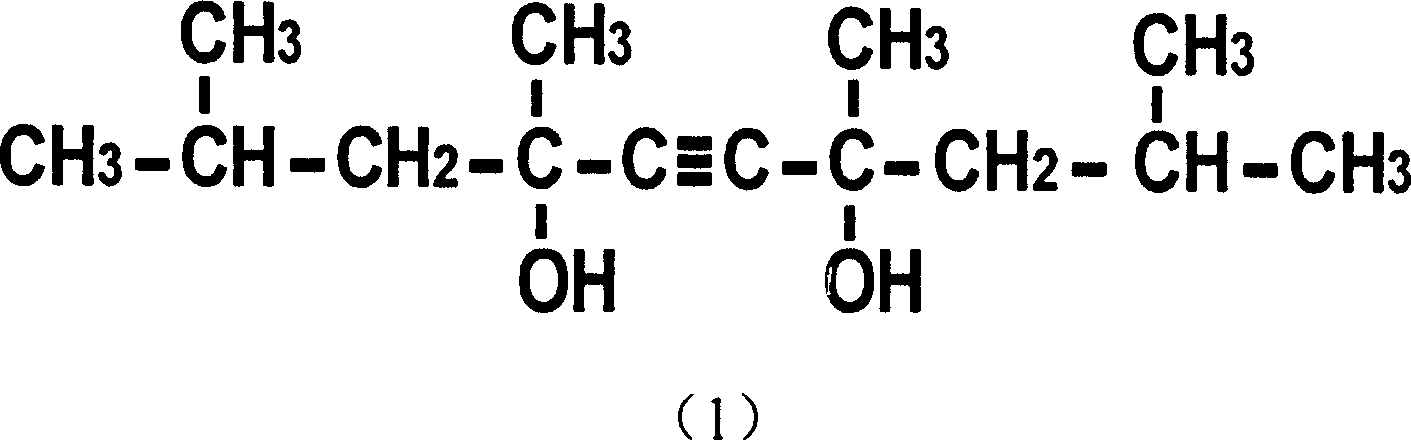

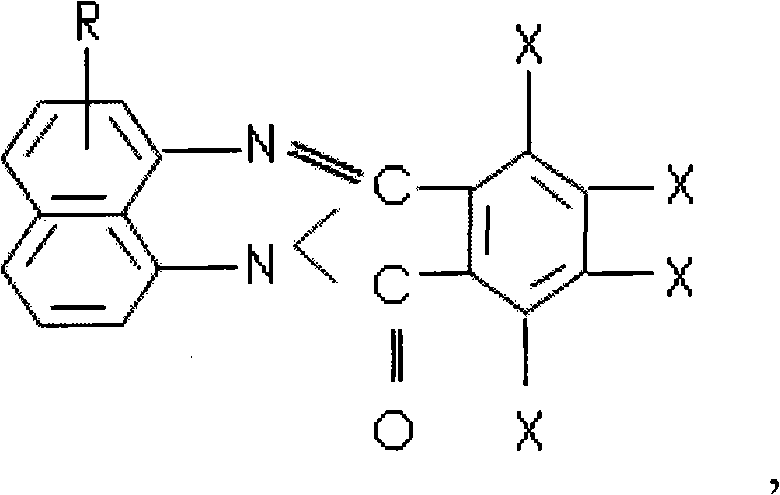

Red naphtocyclinon solvent dye and preparation method thereof

The invention relates to a red naphtocyclinon solvent dye and a preparation method thereof. The red high-purified solvent dye has a general formula shown in the figure, wherein R is H or CH3 and X is Br or Cl. The solvent dye is prepared by the following steps: condensation reaction of substituted 1,8-diaminonaphthalene and tetrahalogenated benzene at a high temperate in the presence of organic solvents and catalysts, cooling, filtration, refining of the filter cake and drying. The red solvent dye has single component and high purity, is dedicated to dyeing engineering plastics and dyeing polyester fibers before spinning, and has the advantages of good heat resistance, light fastness and acid and alkali resistance, bright color and high transparency. The solvents used in the preparation process are recoverable. The red solvent dye is environment-friendly.

Owner:海宁市现代化工有限公司

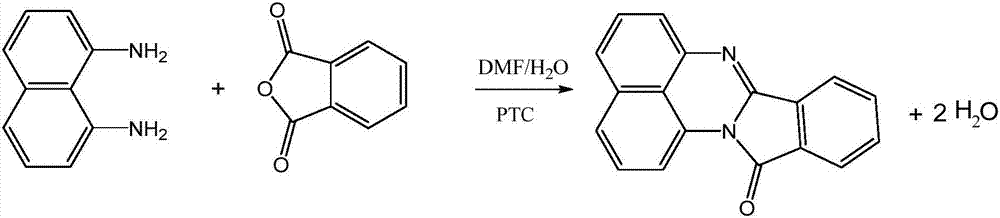

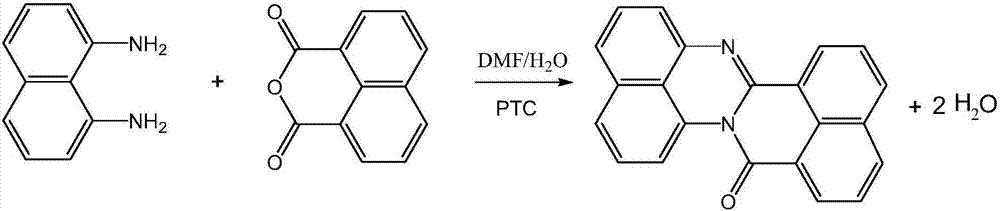

Preparation method of pyrene ketone solvent dye

ActiveCN107474053AQuality improvementGood value for moneyPerinonesOrganic chemistryKetone solventsSolvent free

The invention discloses a preparation method of a pyrene ketone solvent dye. The preparation method comprises the following steps: (1) under double protection of a nitrogen atmosphere and a reducing agent, reacting 1,8-diaminonaphthalene with phthalic anhydride (or 1,8-naphthalic anhydride) under the action of phase transfer catalyst polyethylene glycol in DMF aqueous solution under reflux temperature; (II) after condensation end point, cooling the reaction solution to room temperature, filtering and washing a filter cake by the DMF aqueous solution with low concentration. The dyes involved are solvent orange 60 (C.I.564100) and solvent red 179 (C.I.564150). Under the double protection of the reducing agent and the nitrogen atmosphere, the target product is formed with high conversion rate in DMF-water mixed solvent by means of the phase transfer catalyst, high quality dye is obtained by simple separation, and more than 90% solvent (in DMF) is recovered, and the preparation method of the pyrene ketone solvent dye is a green preparation method.

Owner:宁波龙欣精细化工有限公司

Method for preparing easily-stored, dust-free and easily-dispersed hollow micro-particle solvent dye

The invention discloses a method for preparing an easily-stored, dust-free and easily-dispersed hollow micro-particle solvent dye, which comprises the following specific steps of: (1) putting a dye filter cake and a compound surfactant into a sanding pot to perform coarse grinding and adding an antifoaming agent in the coarse grinding process; (2) transferring the coarsely ground material to a homogenizer and performing fine grinding to make the particle size of dye particles reach 1 to 80 microns; and (3) conveying the finely ground material to a spray drying tower by using a high-pressure pump and performing spray drying granulation to obtain the hollow micro-particle dye with the particle size of 5 to 1,000 microns. The dye has the advantages of easy storage, no dust, environmental protection, easy dispersion, and easier product coloring.

Owner:TONGLING QINGHUA TECH

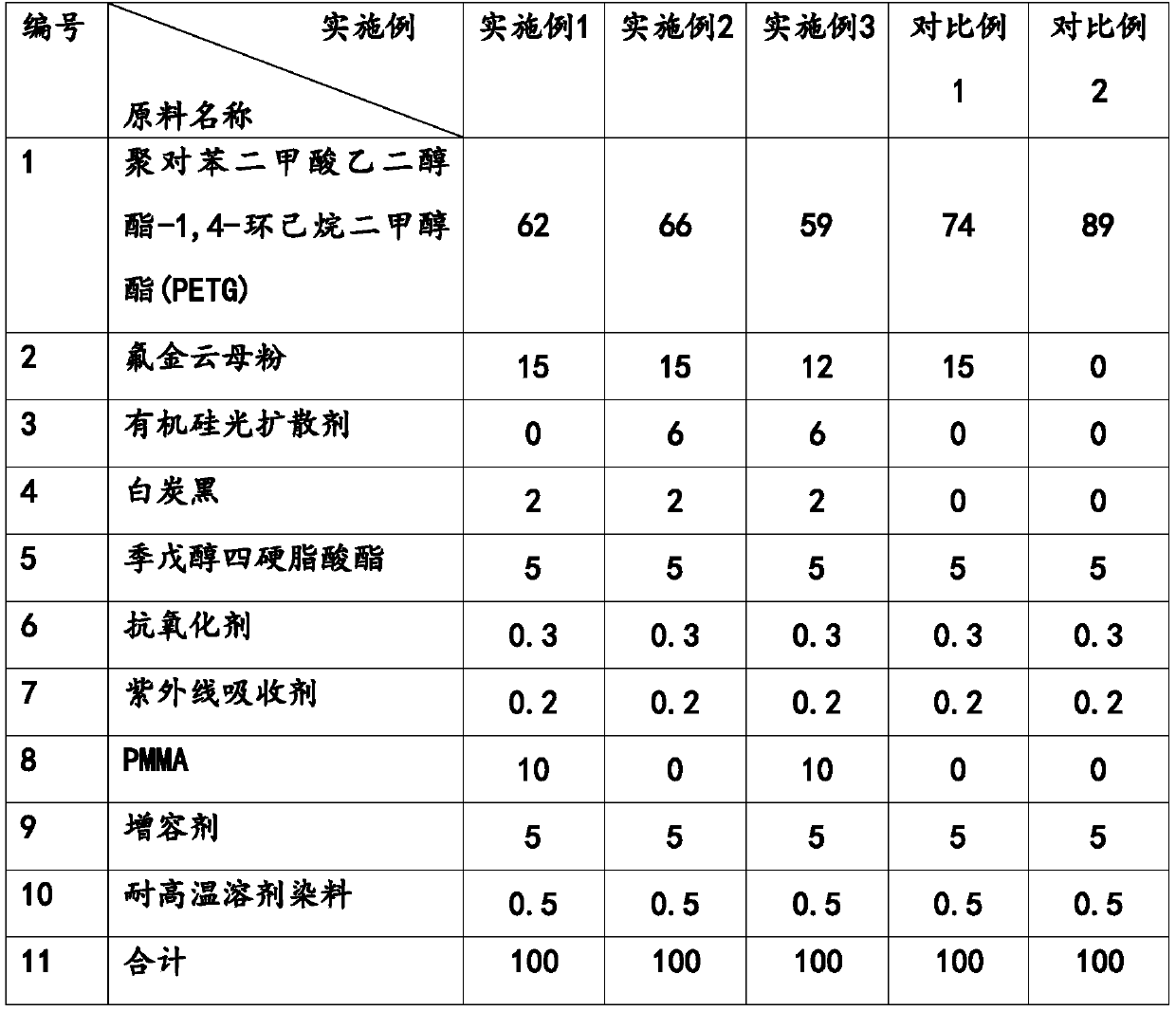

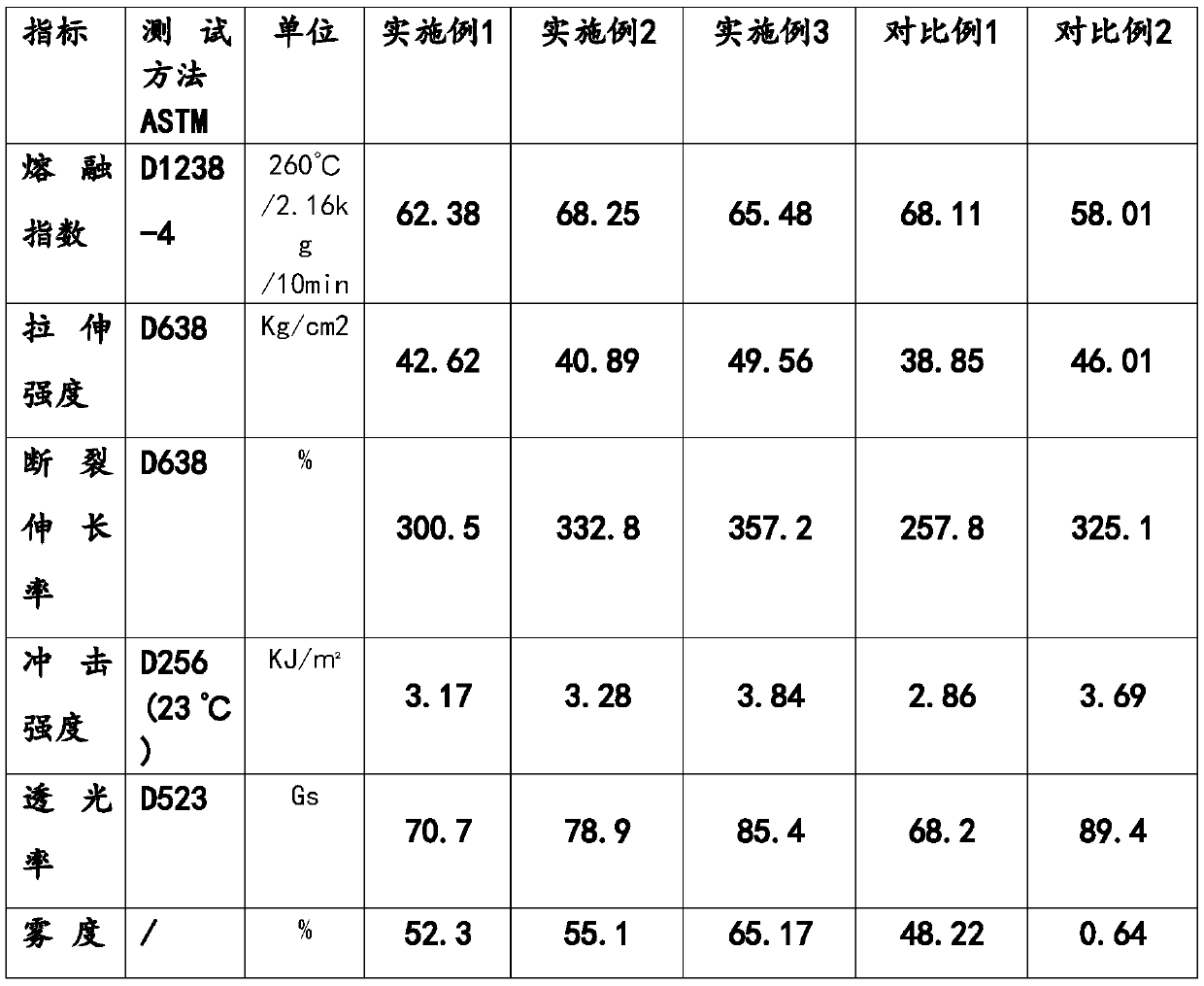

PETG blow molded bottle matte glass effect color masterbatch and preparation method thereof

The invention discloses a PETG blow molded bottle matte glass effect color masterbatch and a preparation method thereof. The raw materials include: PETG, fluorophlogopite powder, an organosilicon light diffusing agent, white carbon black, pentaerythritol tetrastearate, an antioxidant, an ultraviolet absorbent, PMMA, a compatibilizer and a high temperature resistant solvent dye. The invention creatively introduces PMMA and the light diffusing agent into frosting masterbatch, utilizes the differences of PMMA and PETG base material density and refractive index to reach an excellent frosting effect with mica powder having a particle size of less than 10microm during processing, and can guarantee no loss of PETG base material's mechanical properties. At the same time, application of the light diffusing agent can reduce the dosage of mica, and can reach the effect of enhancing the haze while improving the light transmittance of the product. Adding of the color masterbatch provided by the invention can avoid spraying, and brings a similar matte glass effect without changing the mold procedure, thus avoiding the environmental protection problem caused by spraying.

Owner:中山市正合色彩资源有限公司

Coloured anhydrous gel element

A colored anhydrous gel element for perfuming or deodorizing air or enclosed spaces is provided. The element is formed by cross-linking a functionalized liquid polymer selected from maleinized polybutadiene, maleinized polyisoprene or a copolymer of ethylene and maleic anhydride with a cross-linking agent which contains at least one complementary functional group in the presence of a non-aqueous perfume or deodorizing base and a least one metal-free solvent dye which is soluble in the non-aqueous perfume or deodorizing base, or which is provided as a solution in a non-aqueous solvent which is compatible with the non-aqueous perfume or deodorizing base. The gel elements may be incorporated into devices which are used as air fresheners or deodorizers.

Owner:RECKITT BENCKISER (UK) LTD

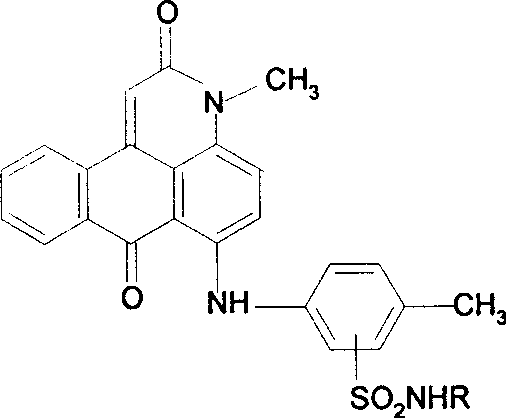

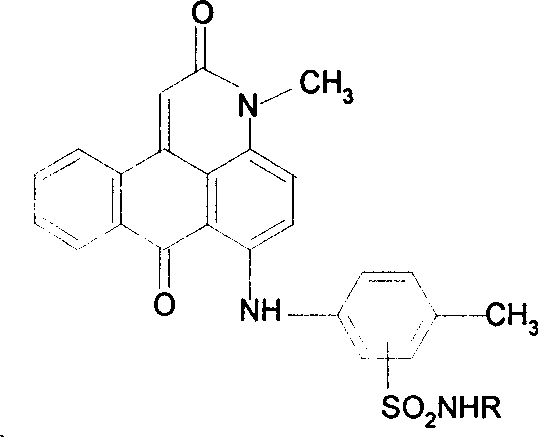

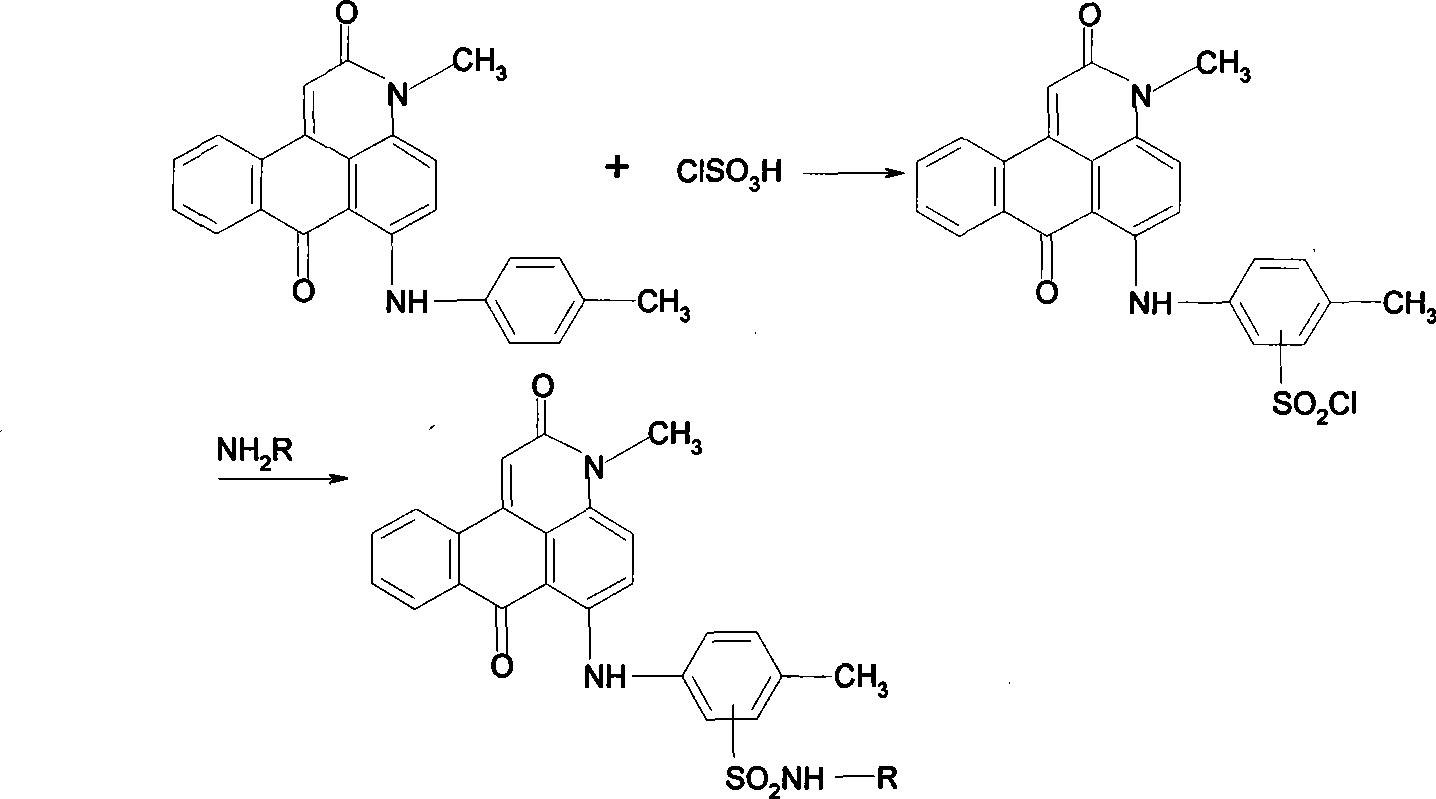

Anthrapyridone solvent dye and synthetic method thereof

ActiveCN101376746AImprove heat resistanceImprove migration resistanceBenz-azabenzanthrone dyesPolyesterIce water

The invention relates to an anthr-pyridone solvent dye and a synthesizing method thereof. The synthesizing steps are as follows: a solvent red 52 is used as the material and is added into a chlorosulfonic acid for stirring reaction under the temperature of 0 to 50 DEG C for 0.5 to 2 hours, then is diluted in ice water, filtered and washed to obtain a filter mass; b, the filter mass is pulped and the pH is adjusted between 6.5 and 7; then an acid-binding agent is added simultaneously or after the organic amine is added; the pH is controlled between 9.5 and 11.5 for reacting for 5 to 8 hours under the temperature of 0 and 50 DEG C; c, the temperature of a reaction product is raised to the temperature between 50 and 70 DEG C and then the temperature is preserved for 30 minutes; then the reaction product is filtered, washed and dried, thus obtaining the dye. The heat resistance and the transference resistance of the dye are improved by different extents. The dye can be applied to thermoplastic resins like ABS, PA6 and PET; besides, the dye can also be applied to polyester and spinning.

Owner:宁波龙欣精细化工有限公司

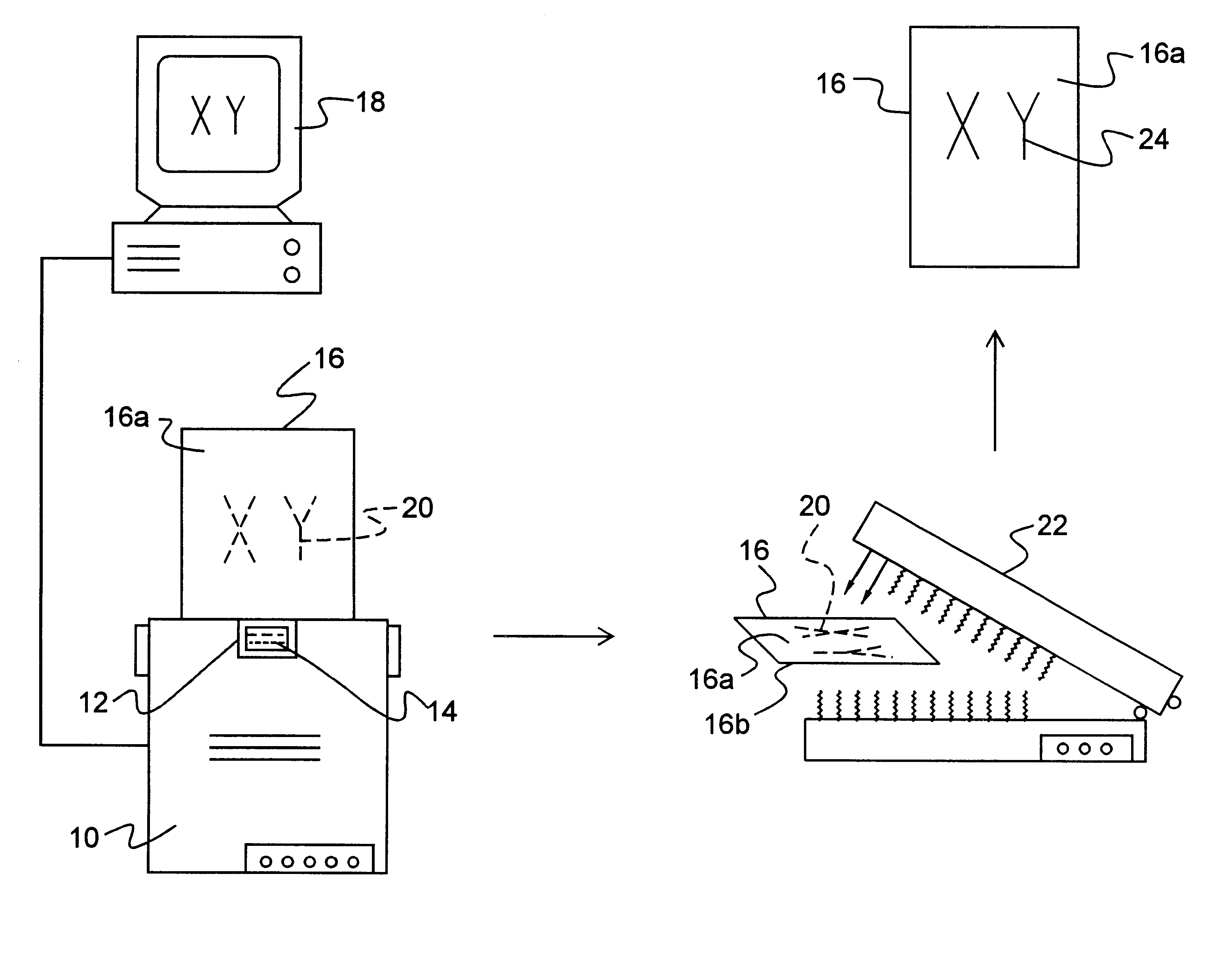

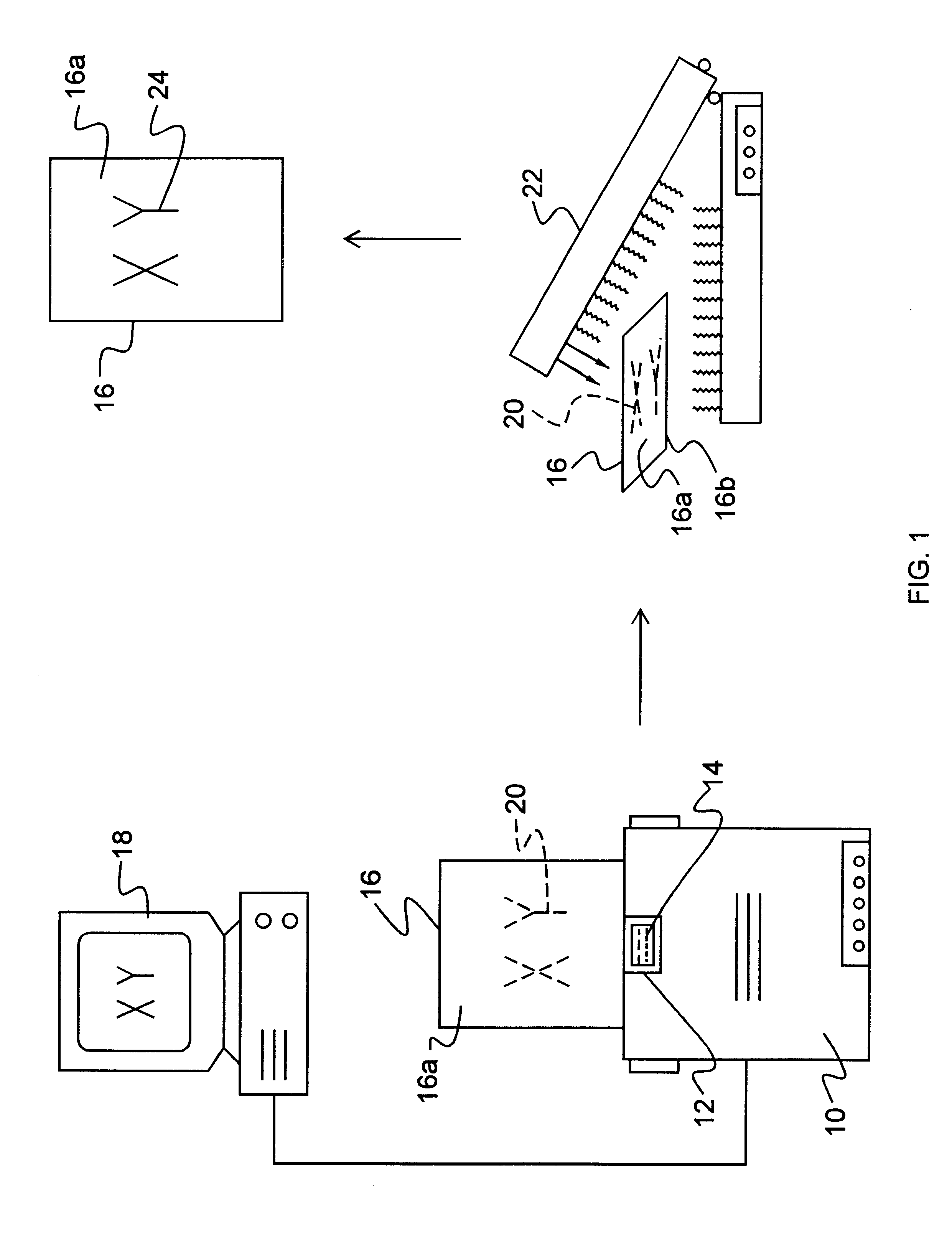

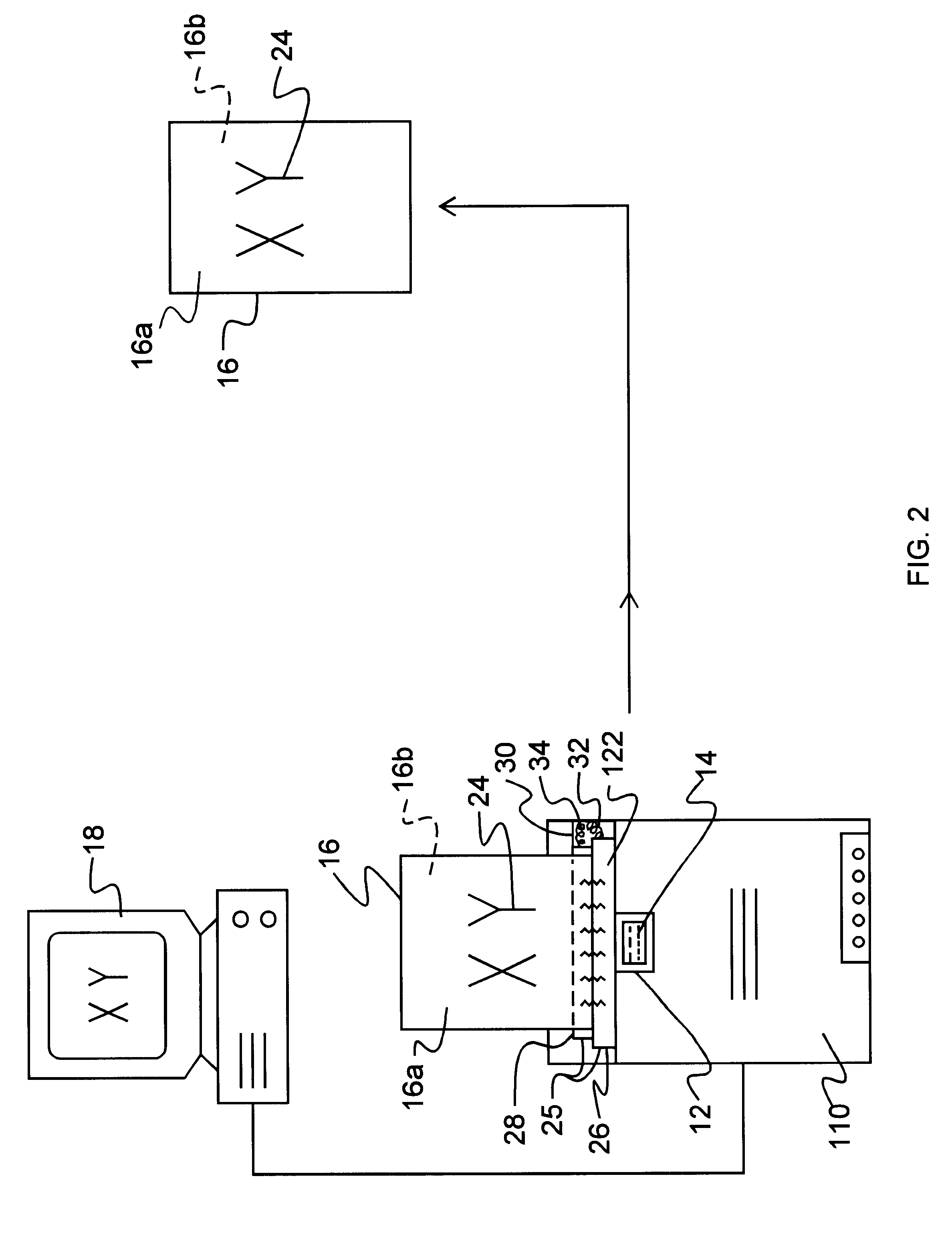

Method for Printing Designs On Sandpaper

ActiveUS20140127407A1Not diminish nail filing efficacyQuality improvementDuplicating/marking methodsInksSucrosePolyvinyl alcohol

A method of printing on the sandpaper face of a nail grinding pad comprises printing, with an inkjet plotter printer onto a sandpaper surface, an ink composition including: 60% to 80% by weight of a polymer selected from the group consisting of: polypropylene glycol and its derivatives whose minimum molecular weight is around 200; polysaccharide and its derivatives; polyvinyl alcohol and its derivatives whose average molecular weight is around 10,000 to 200,000; polysucrose and its derivatives whose average molecular weight is around 40,000 to 400,000; and epoxy glycerol propoxylated glycerol and their derivatives whose average molecular weight is 500 to 10,000; and 2% to 10% by weight of a solvent dye or a pigment; 1% to 5% by weight percent of ethanol; and 0.1% to 1.0% by weight percent of surfactants.

Owner:BODI CORP +1

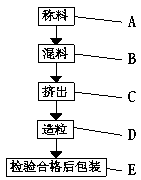

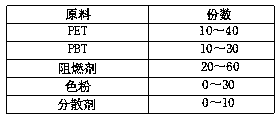

Flame-retardant color master batch applicable to polyester filaments

InactiveCN108048928AImprove product qualityIn line with interestsFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterWax

The invention discloses a flame-retardant color master batch applicable to polyester filaments. A preparation process for the flame-retardant color master batch comprises the following steps: A, material weighing; B, material mixing; C, extrusion; D, granulation; and E, packaging after inspection is passed. In the step A, weighed raw materials for the flame-retardant color master batch are composed of, by mass, 10-40 parts of PET, 10 to 30 parts of PBT, 20 to 60 parts of a flame retardant, 0 to 30 parts of toner and 0 to 10 parts of a dispersant, wherein the PET is bottle-grade chips or superbright chips; the PBT is an engineering plastic; the flame retardant is a pure small-molecular phosphate compound; the toner is an inorganic pigment or solvent dye of various colors; and the dispersant is polar wax. According to the invention, the flame-retardant color master batch is composed of desired parts by mass of the PET, the PBT, the flame retardant, the toner and the dispersant and are prepared through material weighing, material mixing, extrusion, granulation and the like, so the production quality of the flame-retardant color master batch can be improved, and the interests of companies are guaranteed.

Owner:常州富桐纤维新材料有限公司

Preparation method of modified time-resolved fluorescent microspheres

PendingCN111218270ATime resolution does not affectResolution does not affectBiological testingLuminescent compositionsPotassium persulfatePolystyrene

The invention discloses a preparation method of modified time-resolved fluorescent microspheres. The preparation method comprises the following steps: (1) adding ultrapure water into a reaction kettle, introducing nitrogen, stirring while heating, adding rectified polystyrene, mixing and heating, then adding potassium persulfate, and fully reacting to obtain white latex spheres; and (2) weighing asolvent dye, 2-thiophene formyl trifluoroacetone, phenanthroline hydrochloride, europium chloride and an electron mediator, dissolving the solvent dye, the 2-thiophene formyl trifluoroacetone, the phenanthroline hydrochloride, the europium chloride and the electron mediator in petroleum ether to generate a mixture, slowly adding the mixture into a white latex microsphere solution prepared in step(1), uniformly stirring to obtain dyeing time-resolved fluorescent microspheres, heating to completely volatilize petroleum ether, and repeatedly centrifugally washing the synthesized microspheres tocompletely wash away redundant dyes in the solution in order to obtain the microspheres with bright colors and without influencing the time-resolved fluorescence of the microspheres. A user does notneed to read numerical values through an instrument when using the microspheres, and the reason of abnormality can be visually found out for an abnormal test strip.

Owner:长沙美牛生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com