Patents

Literature

1098results about "Ink transfer from master sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

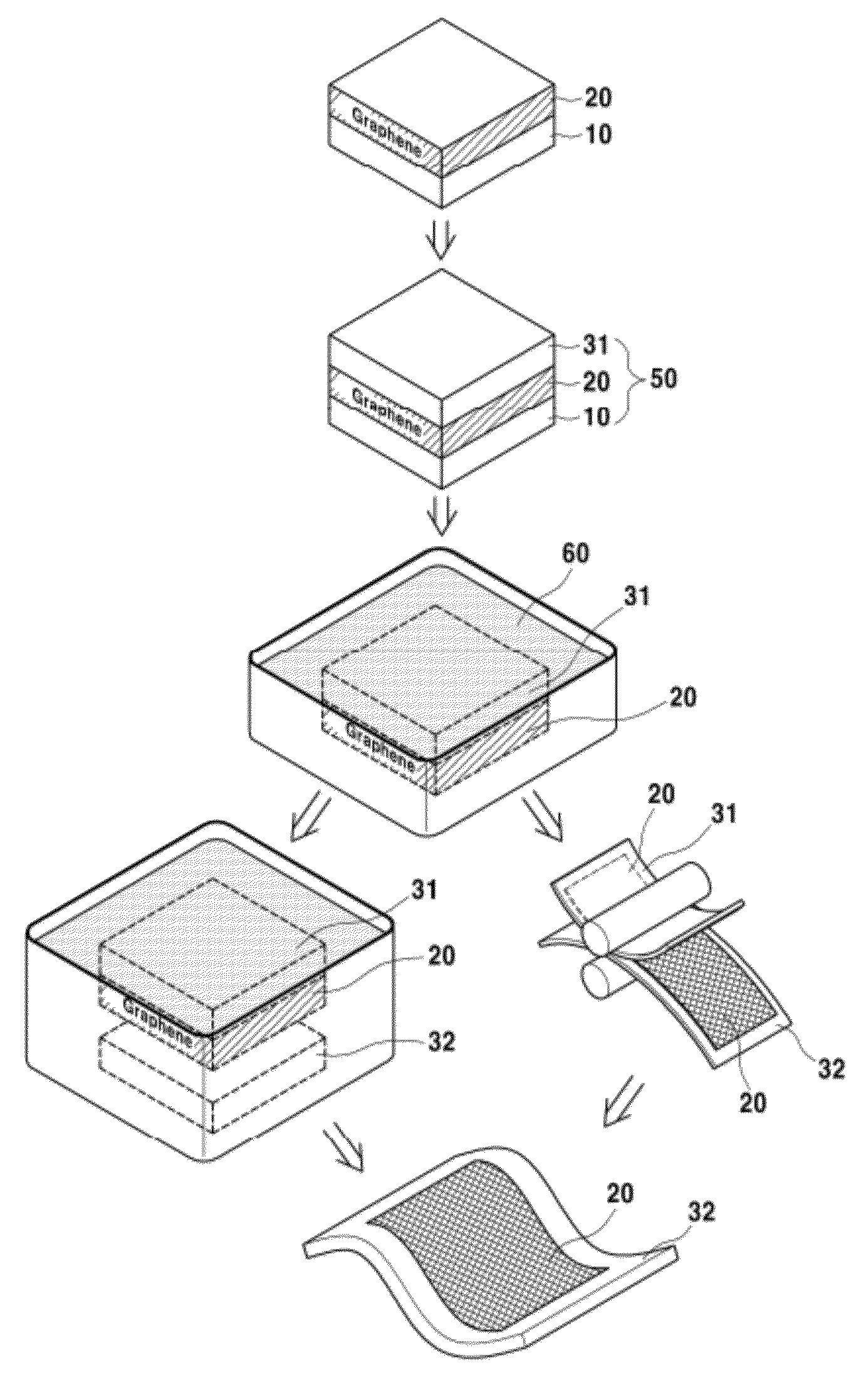

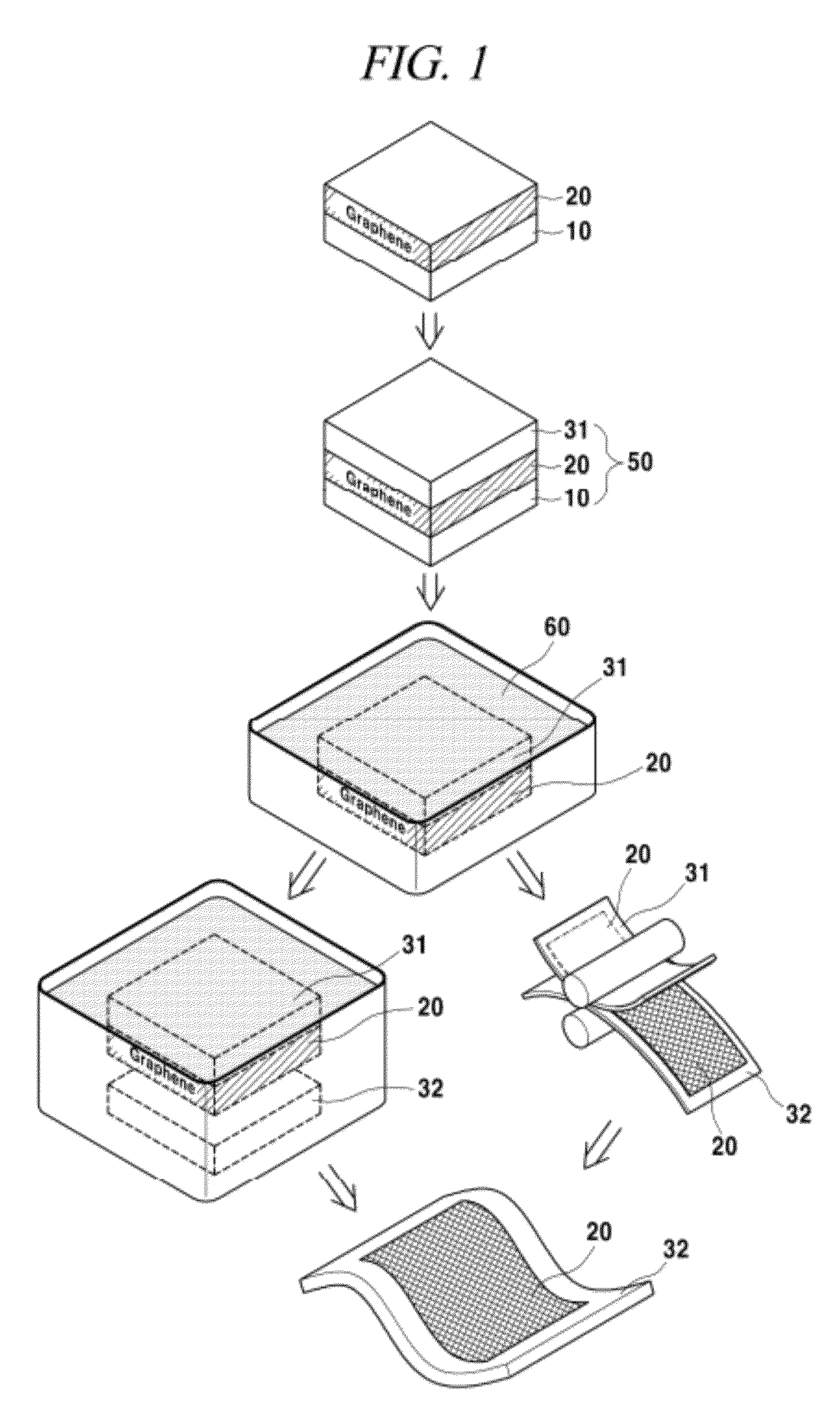

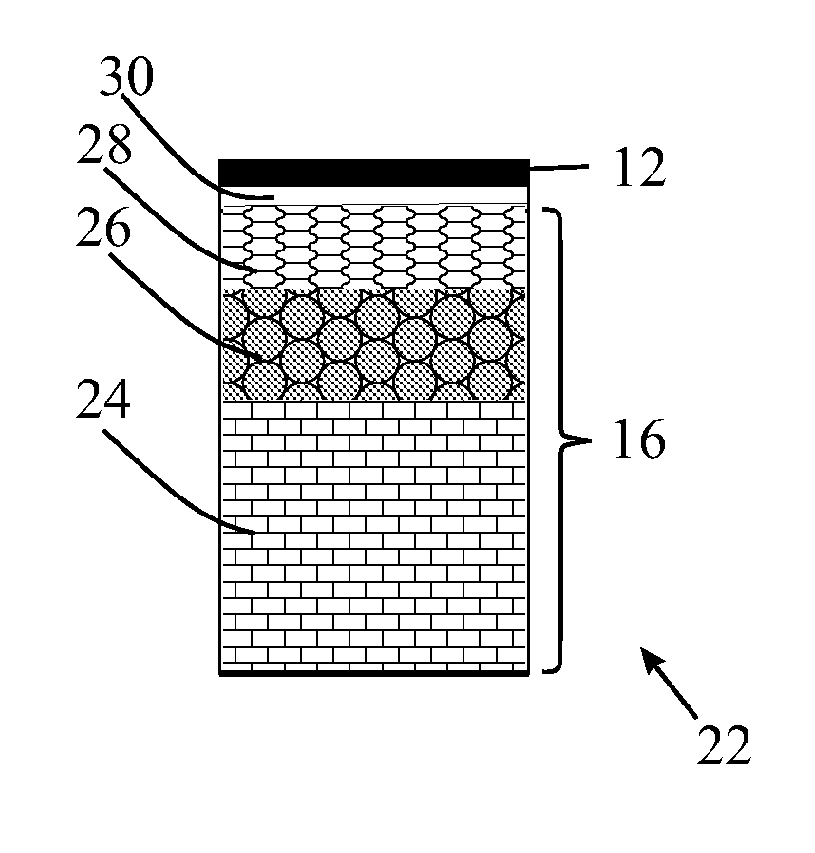

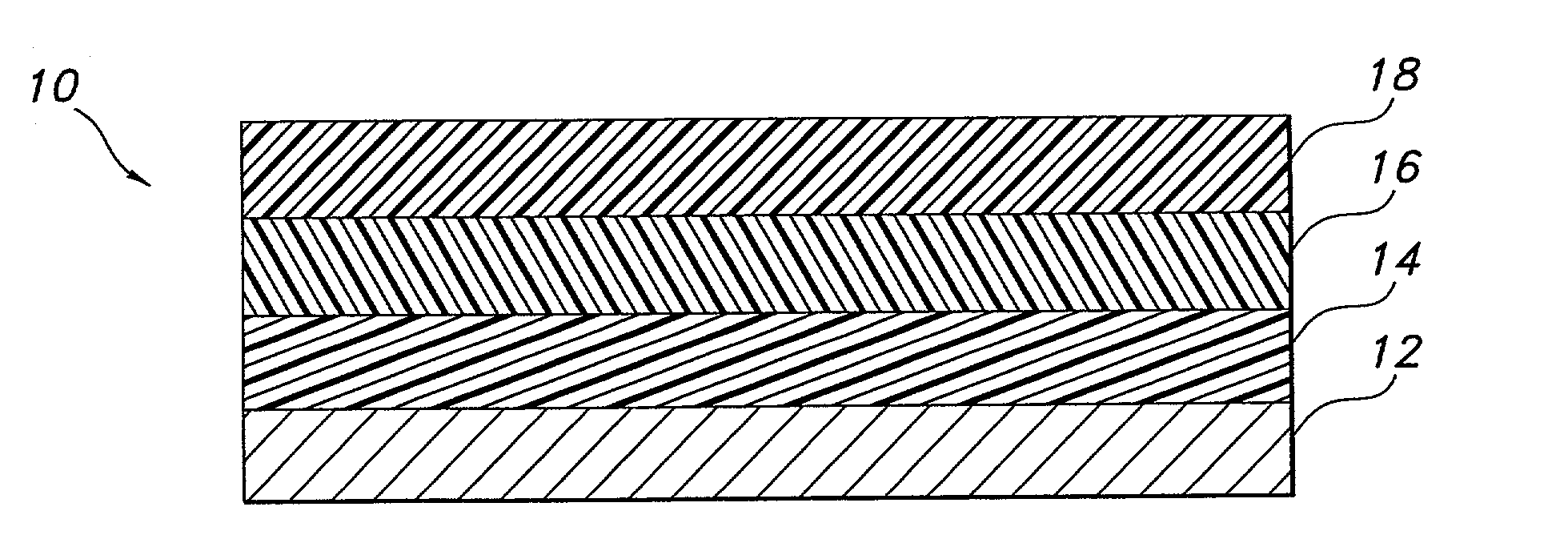

Graphene protective film serving as a gas and moisture barrier, method for forming same, and use thereof

ActiveUS20120282419A1Improve featuresImprove electrical characteristicsMaterial nanotechnologyDecorative surface effectsTectorial membraneGraphene

The present invention relates to a method for forming a graphene protective film having gas and moisture barrier properties, to a graphene protective film formed by the method, and to the use thereof. A single-layer or multi-layer graphene protective film can be used as a material for a barrier coating or bags, and improves the gas and moisture barrier properties of a variety of devices in a wide array of industrial fields to thereby maintain the electrical characteristics of devices over a long period of time.

Owner:GRAPHENE SQUARE

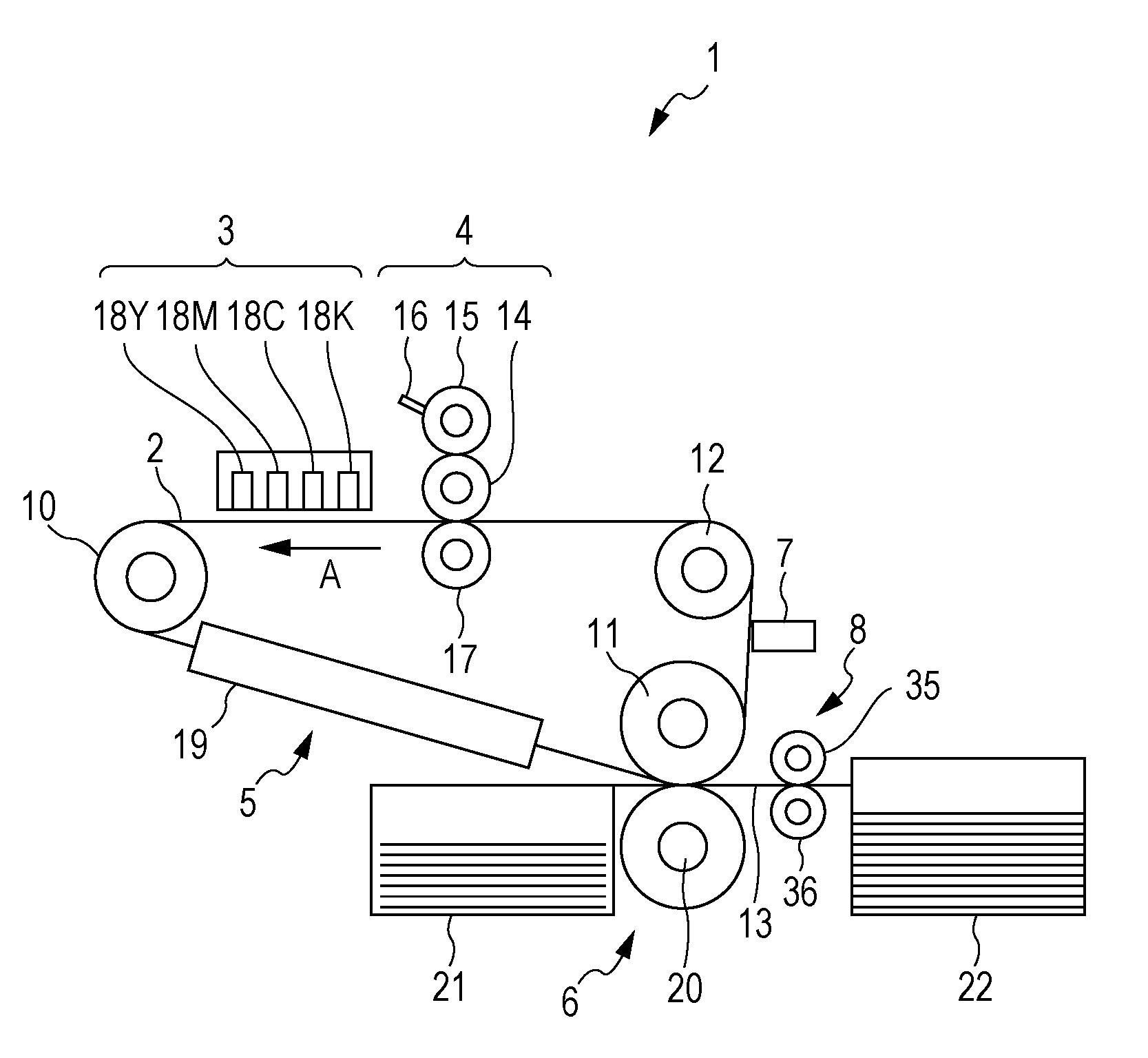

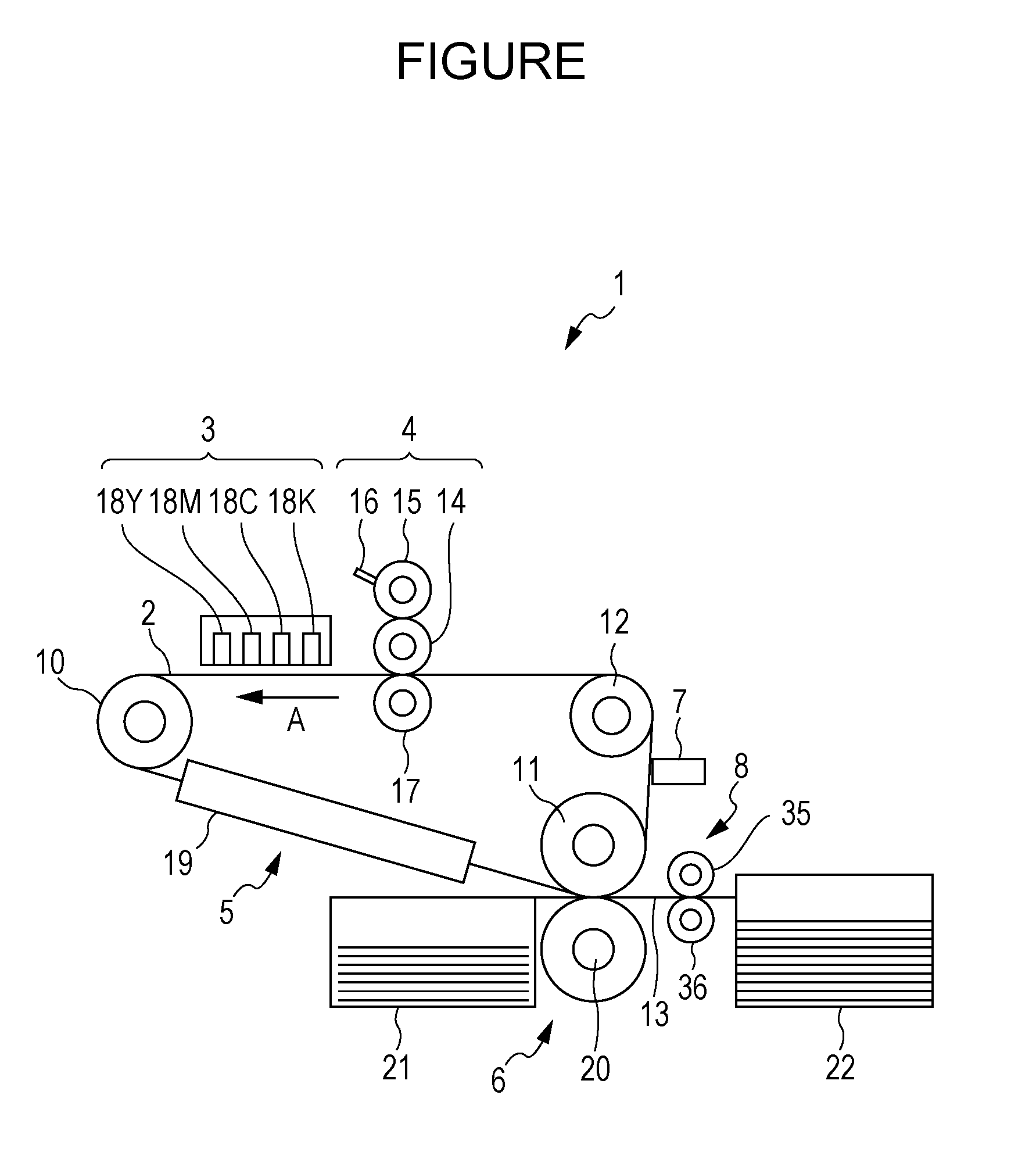

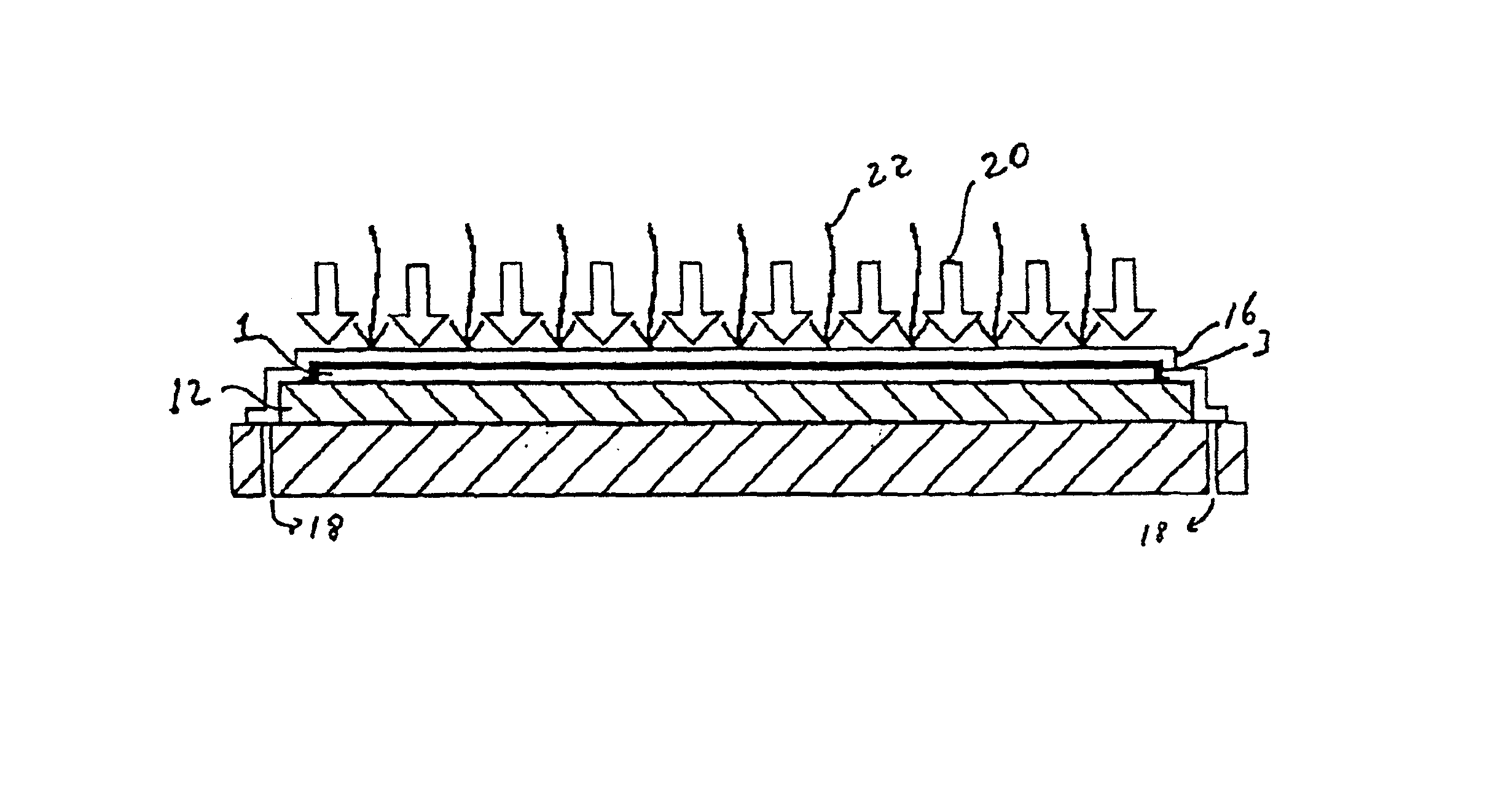

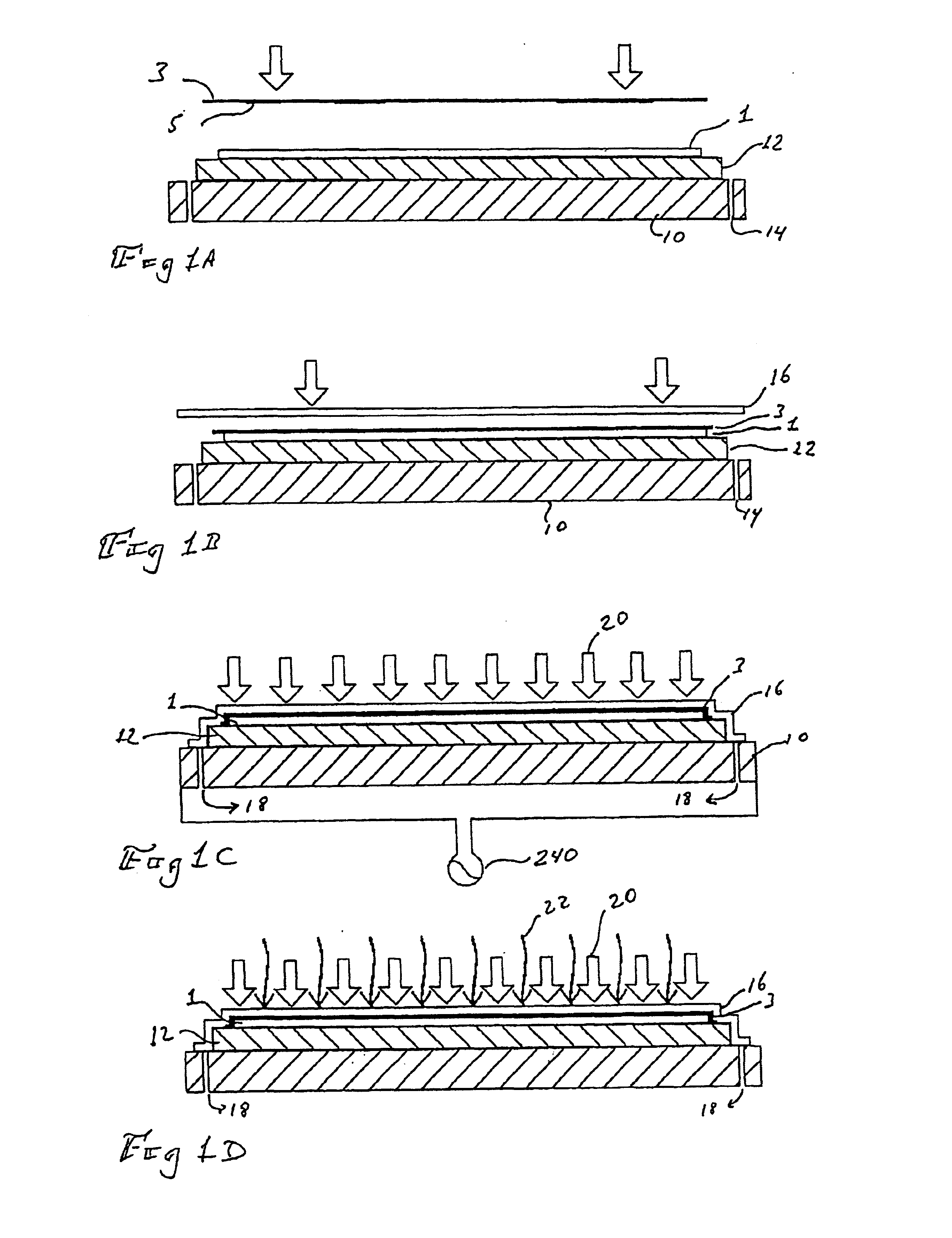

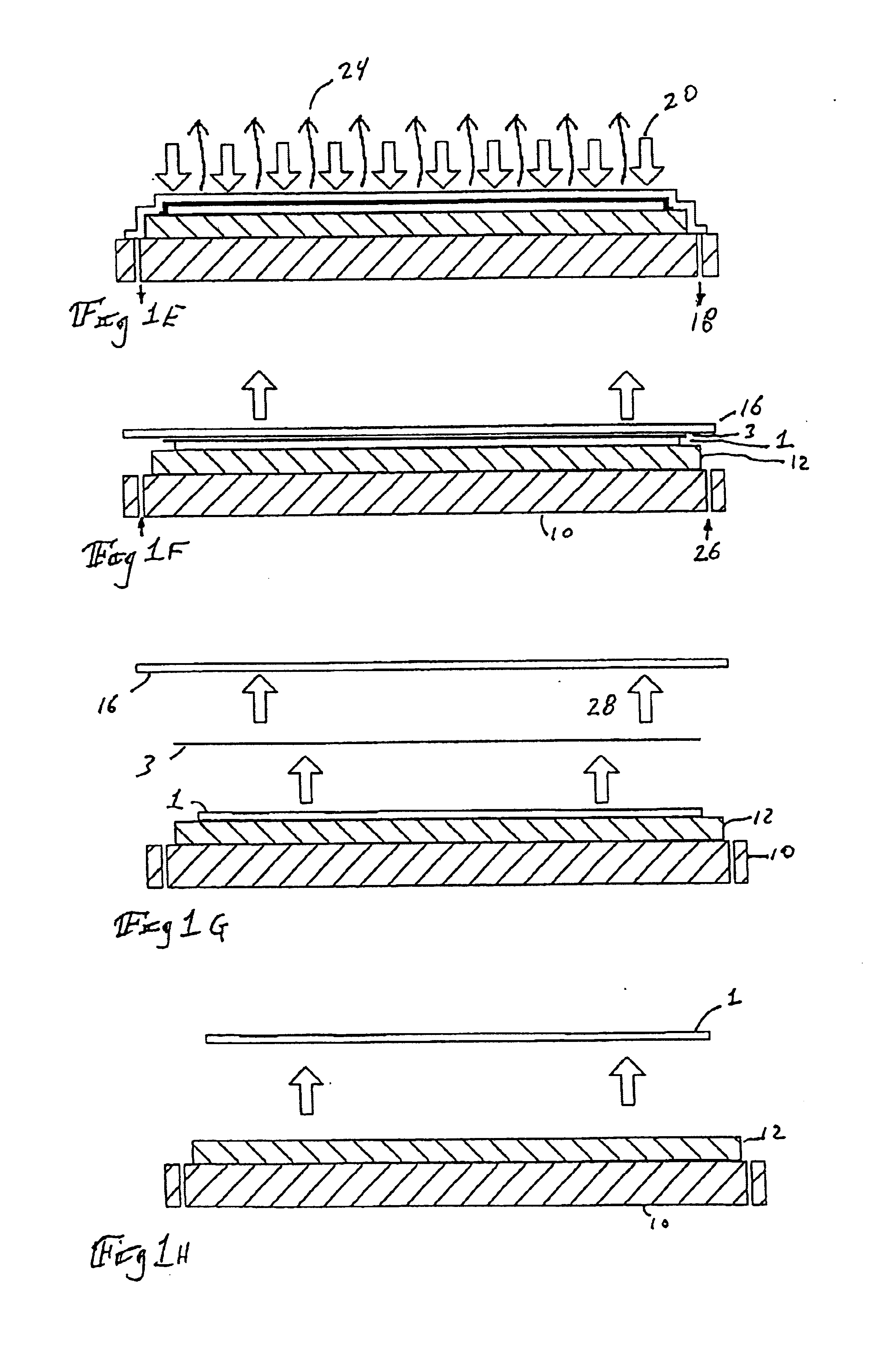

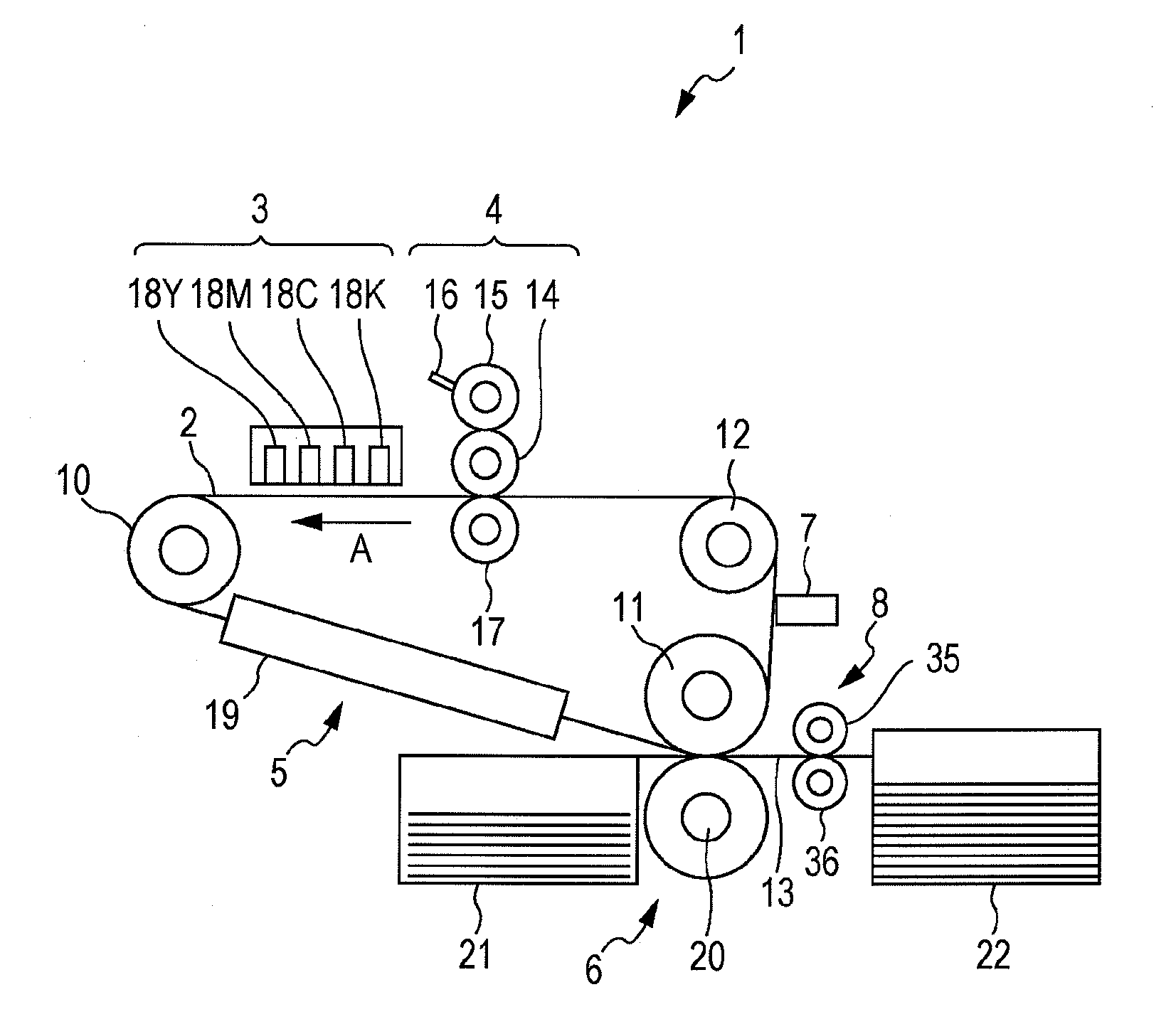

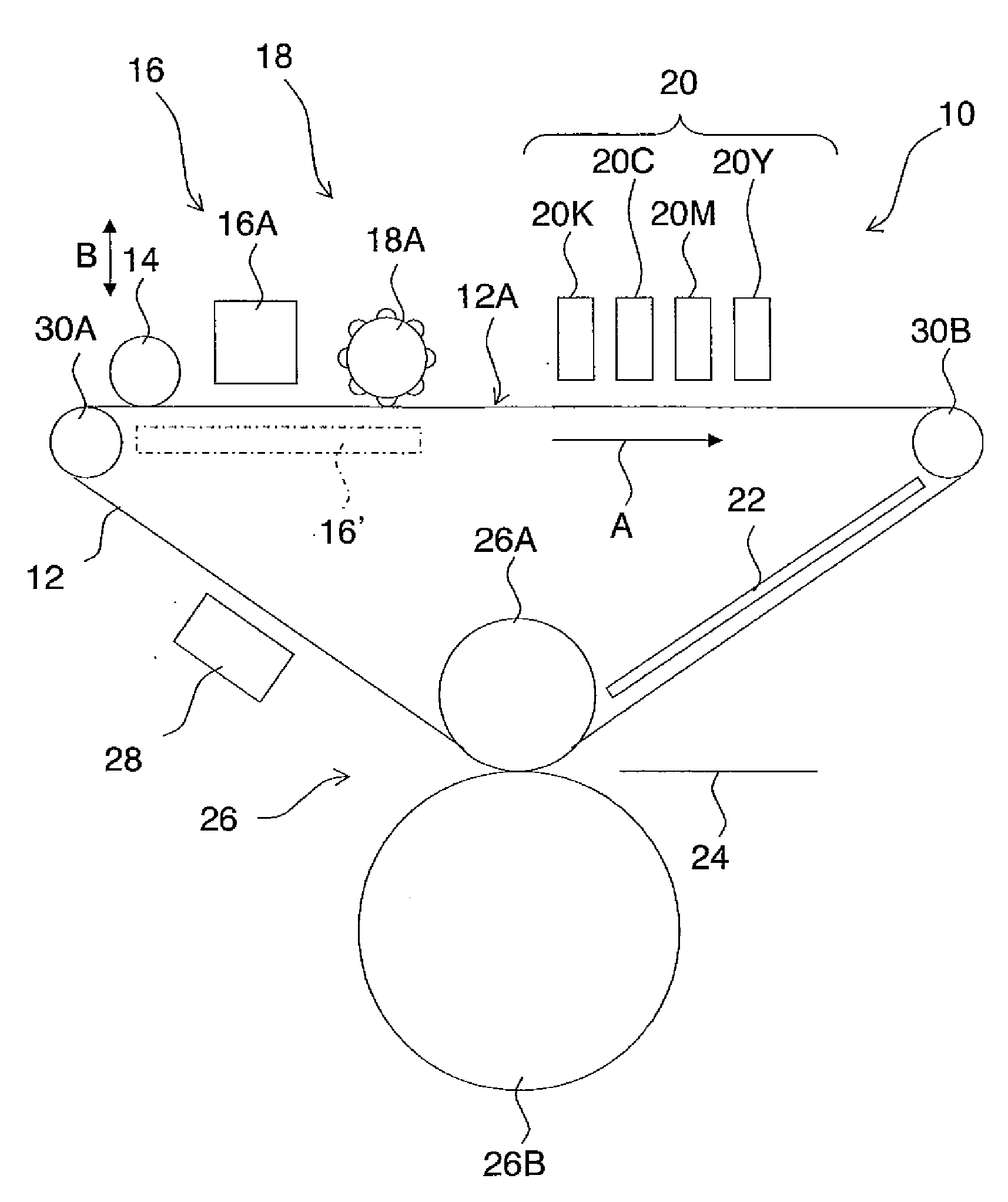

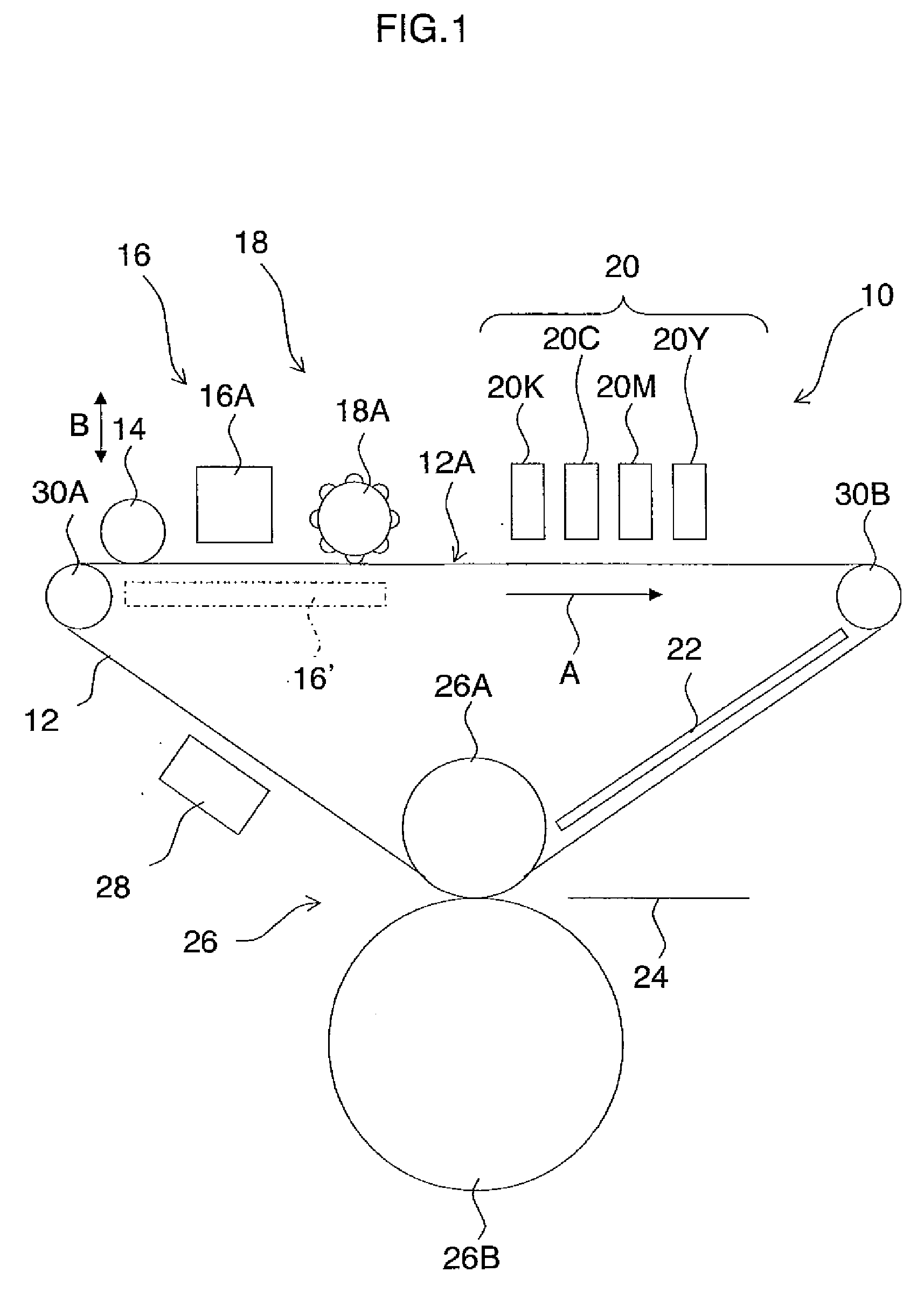

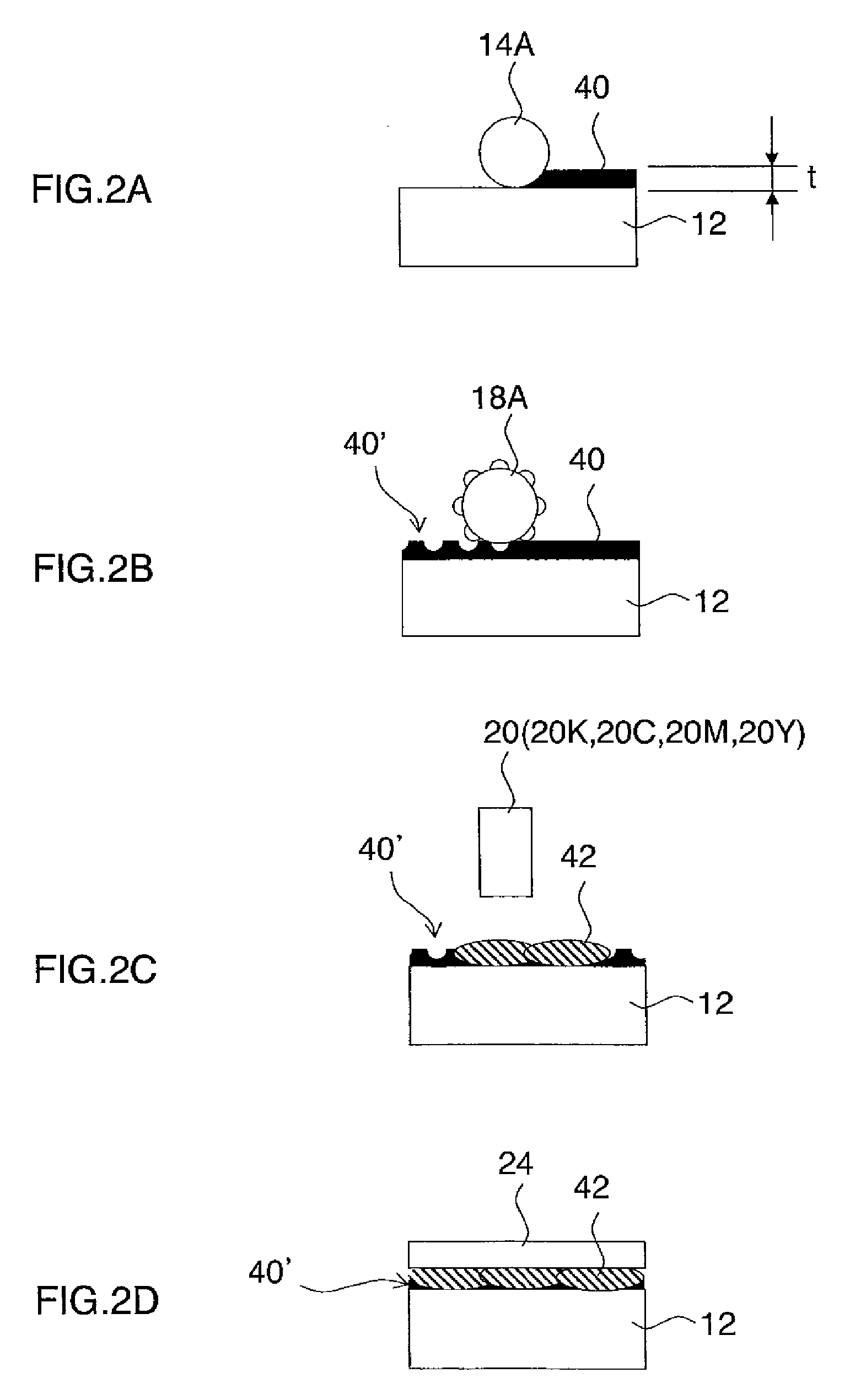

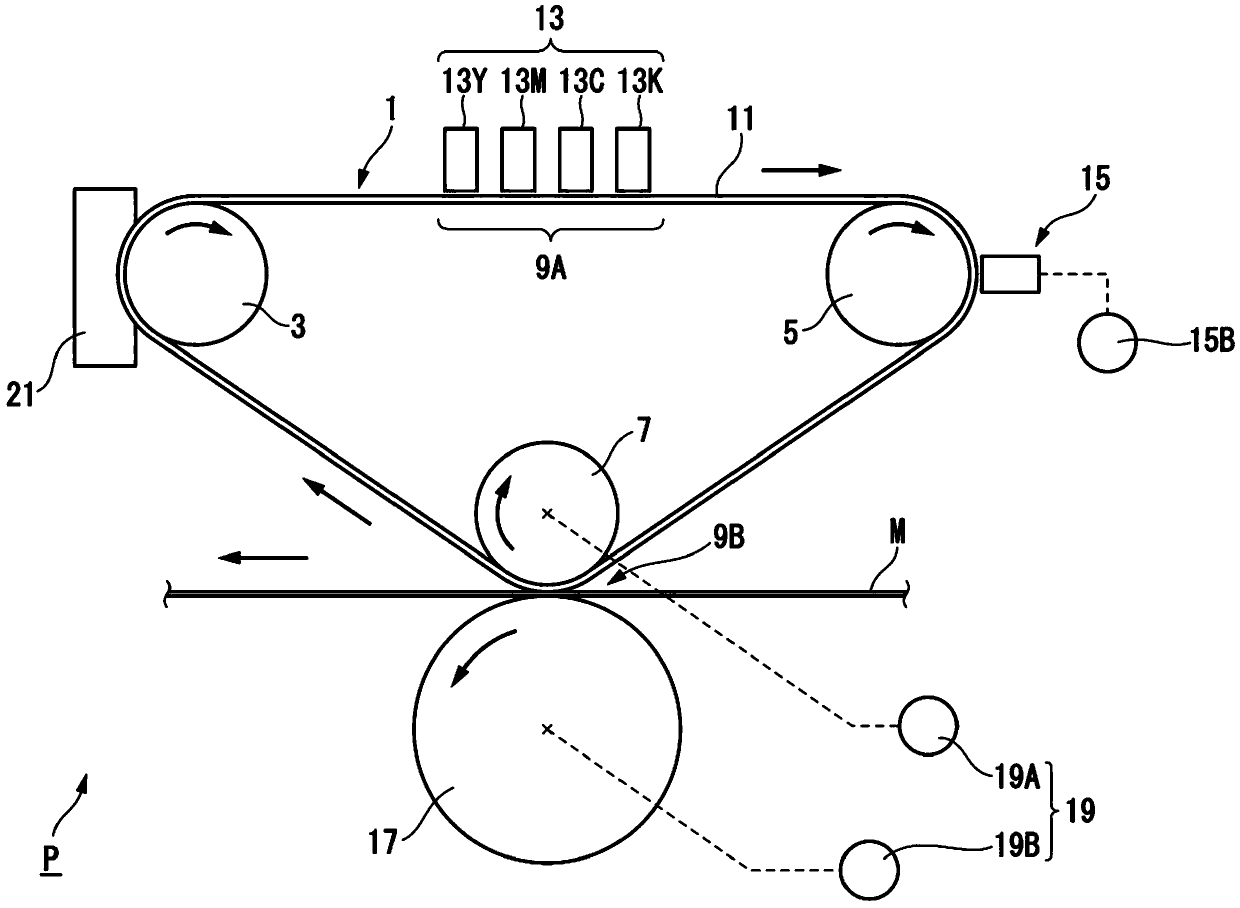

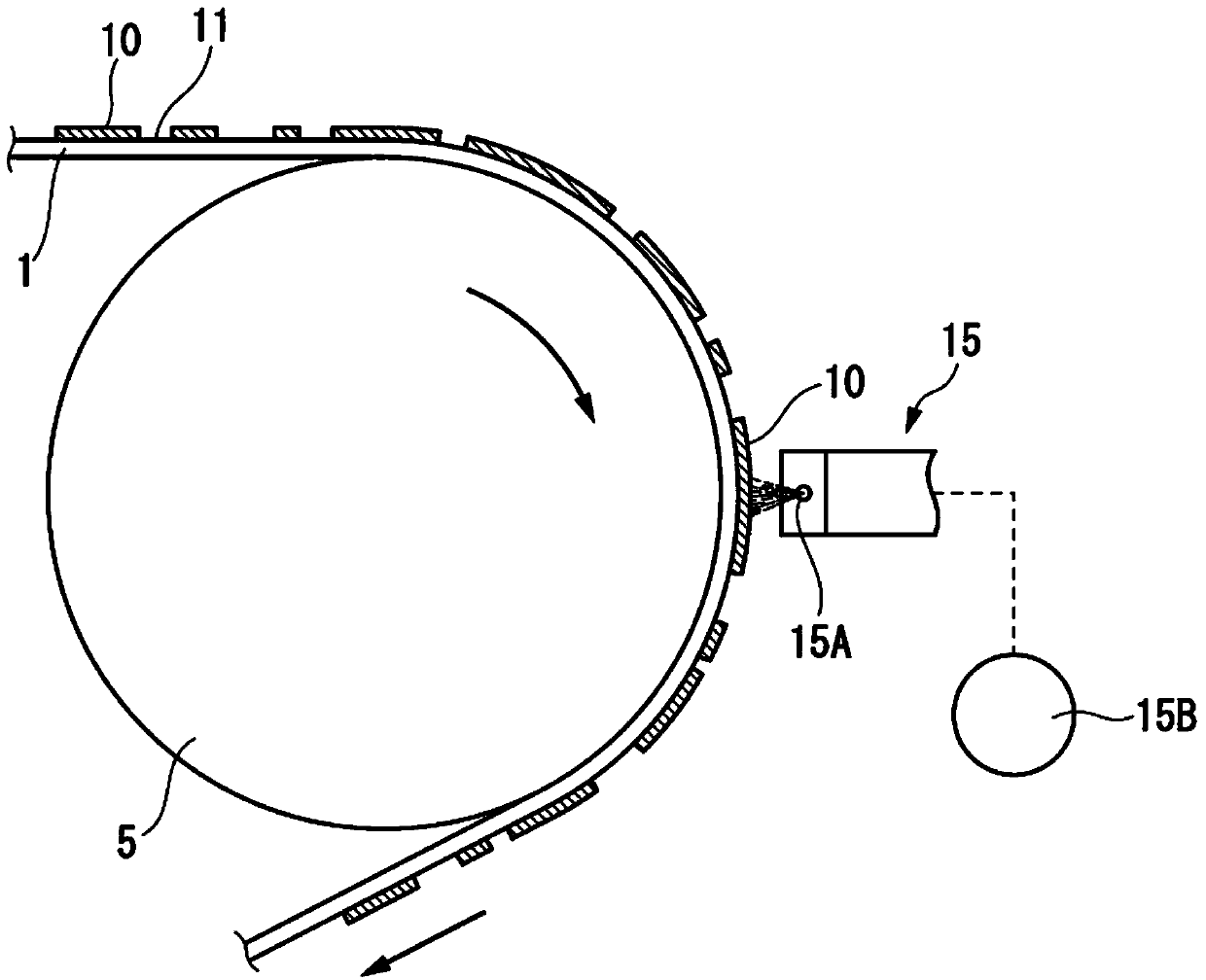

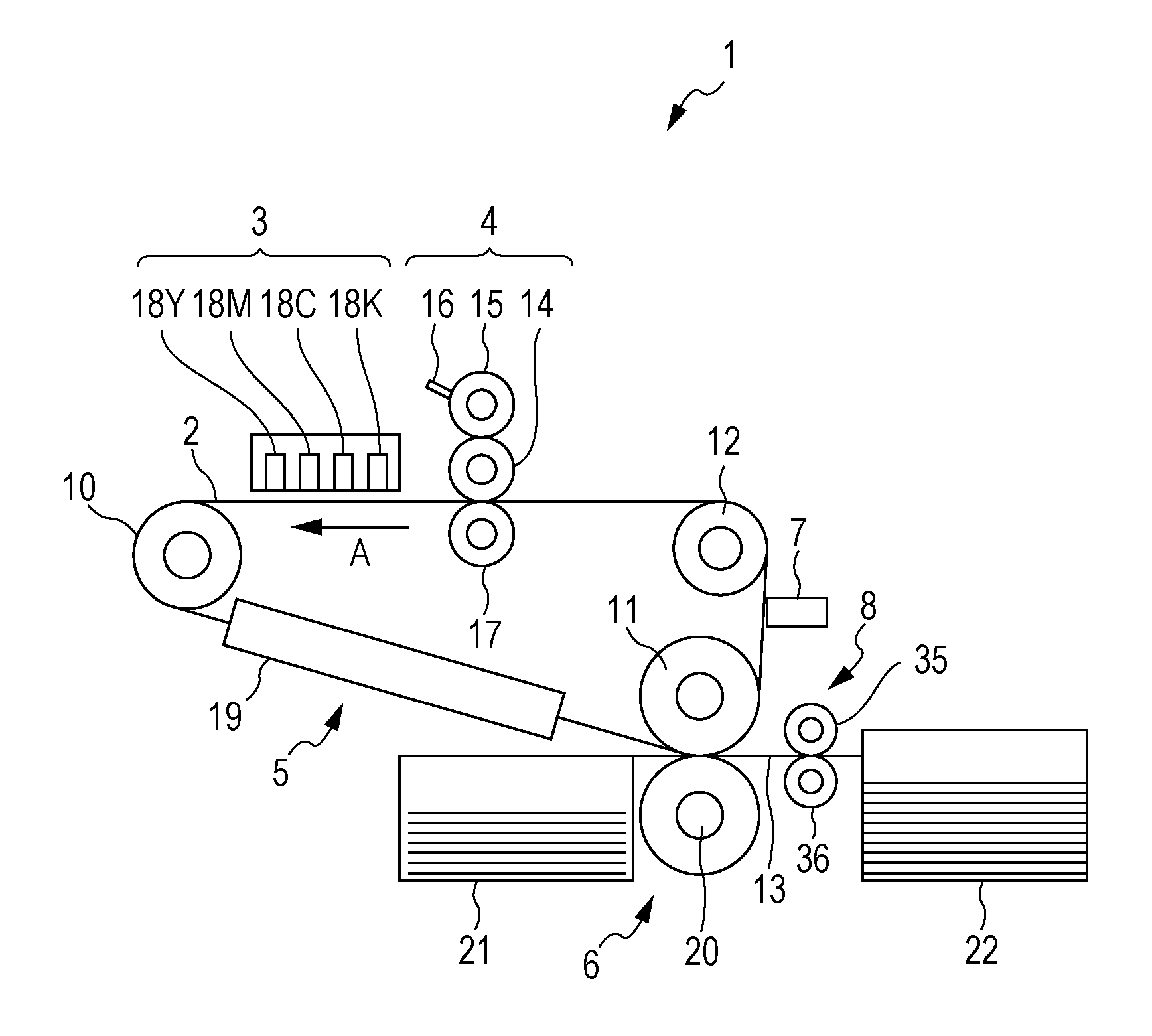

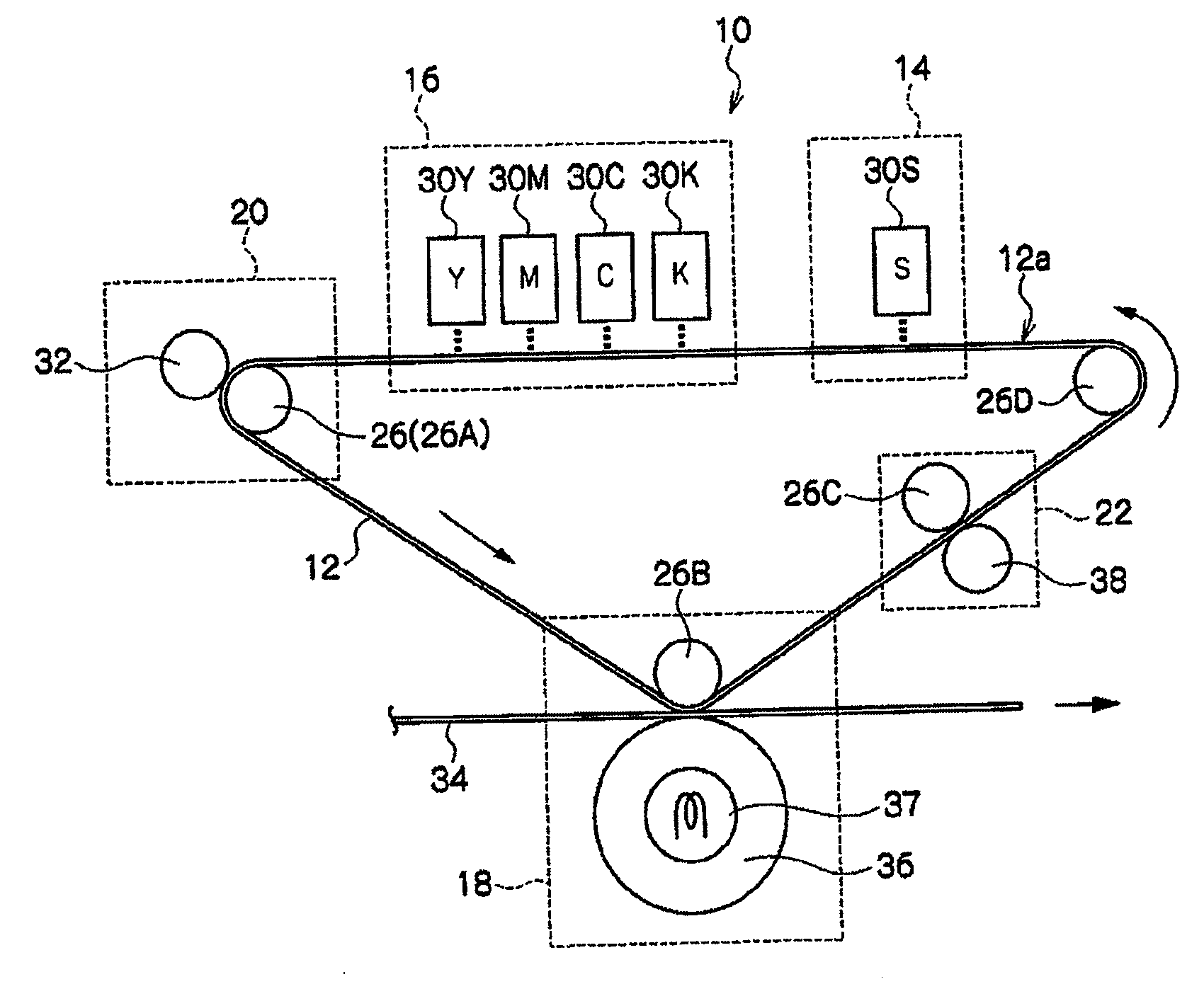

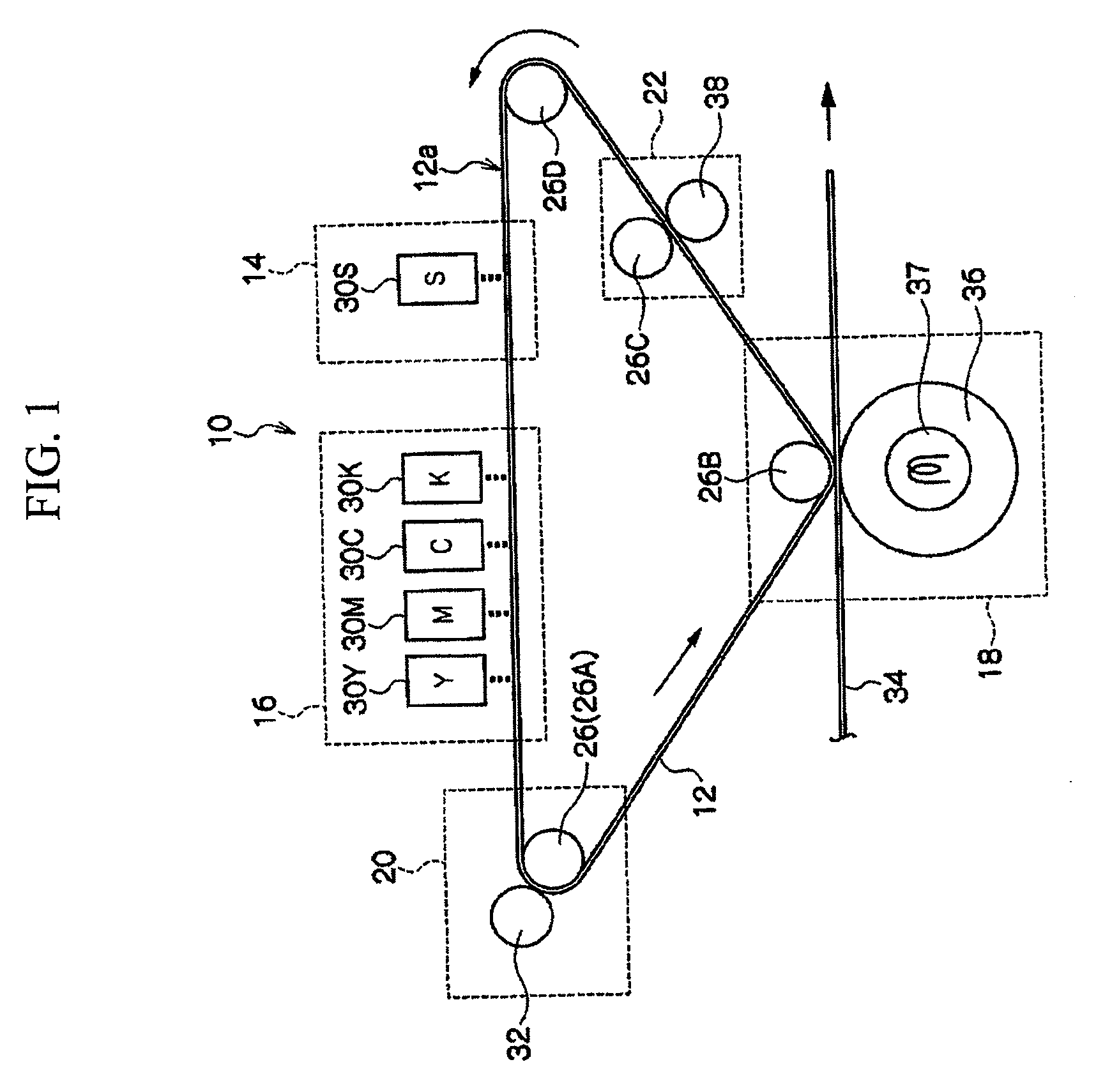

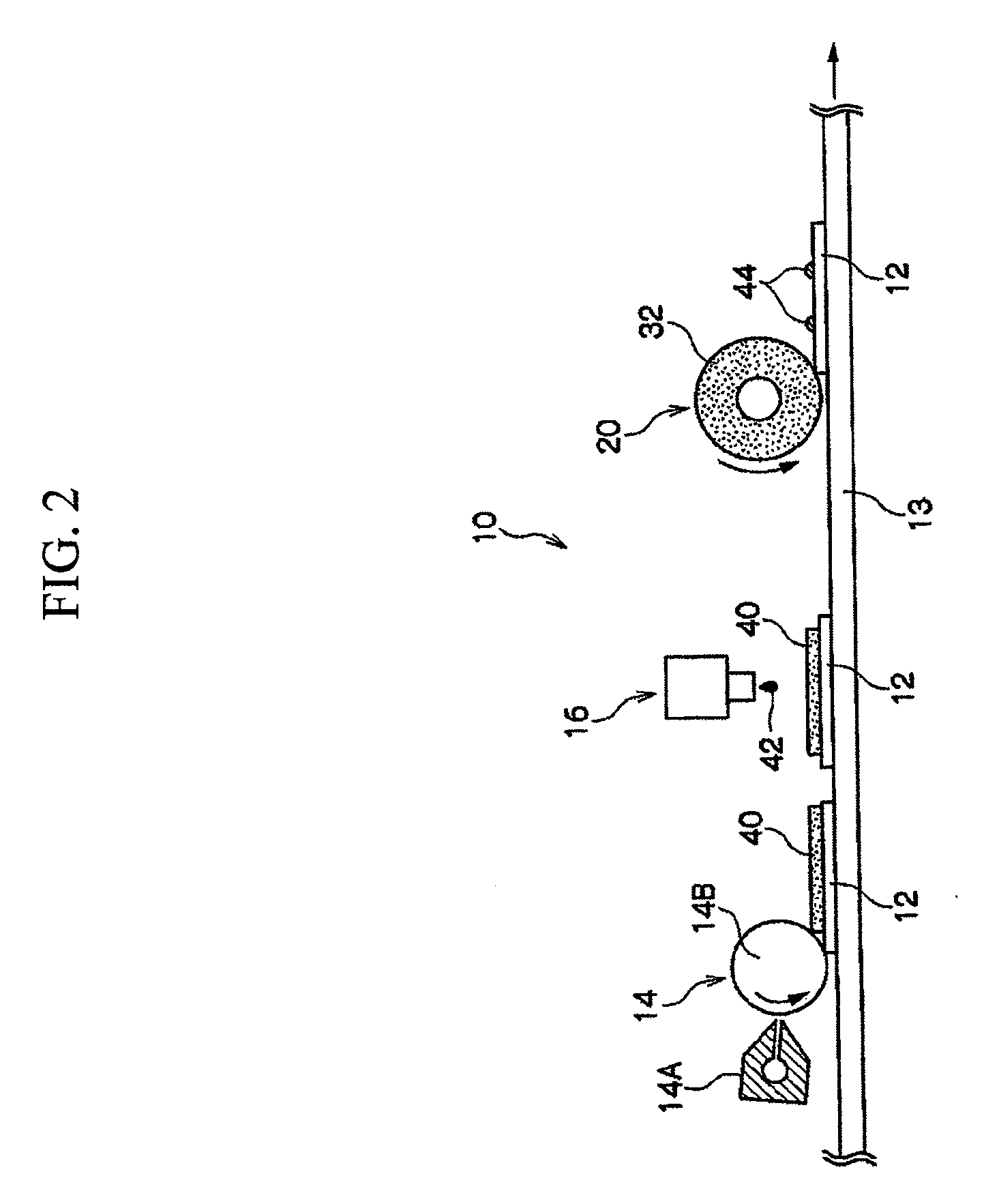

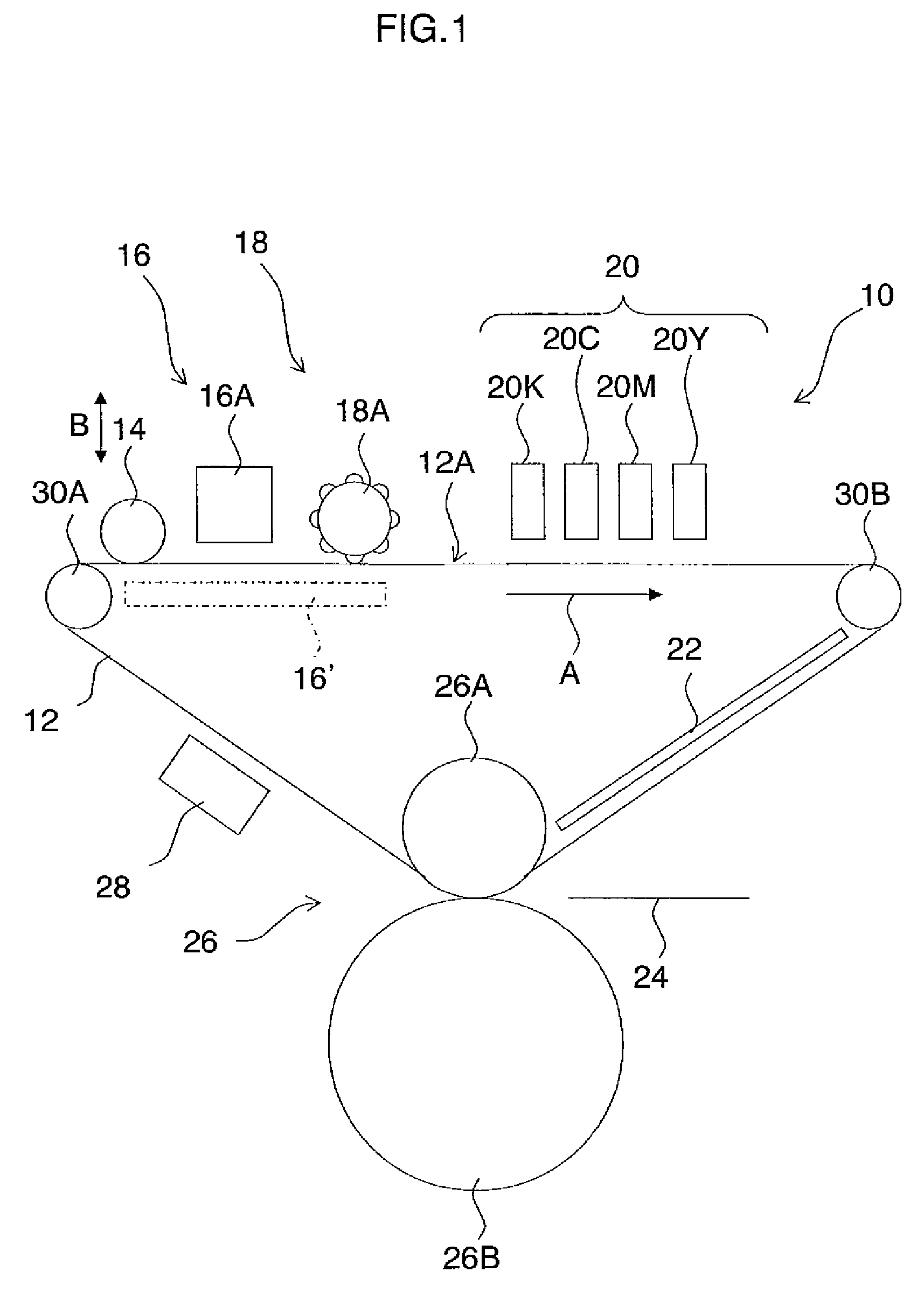

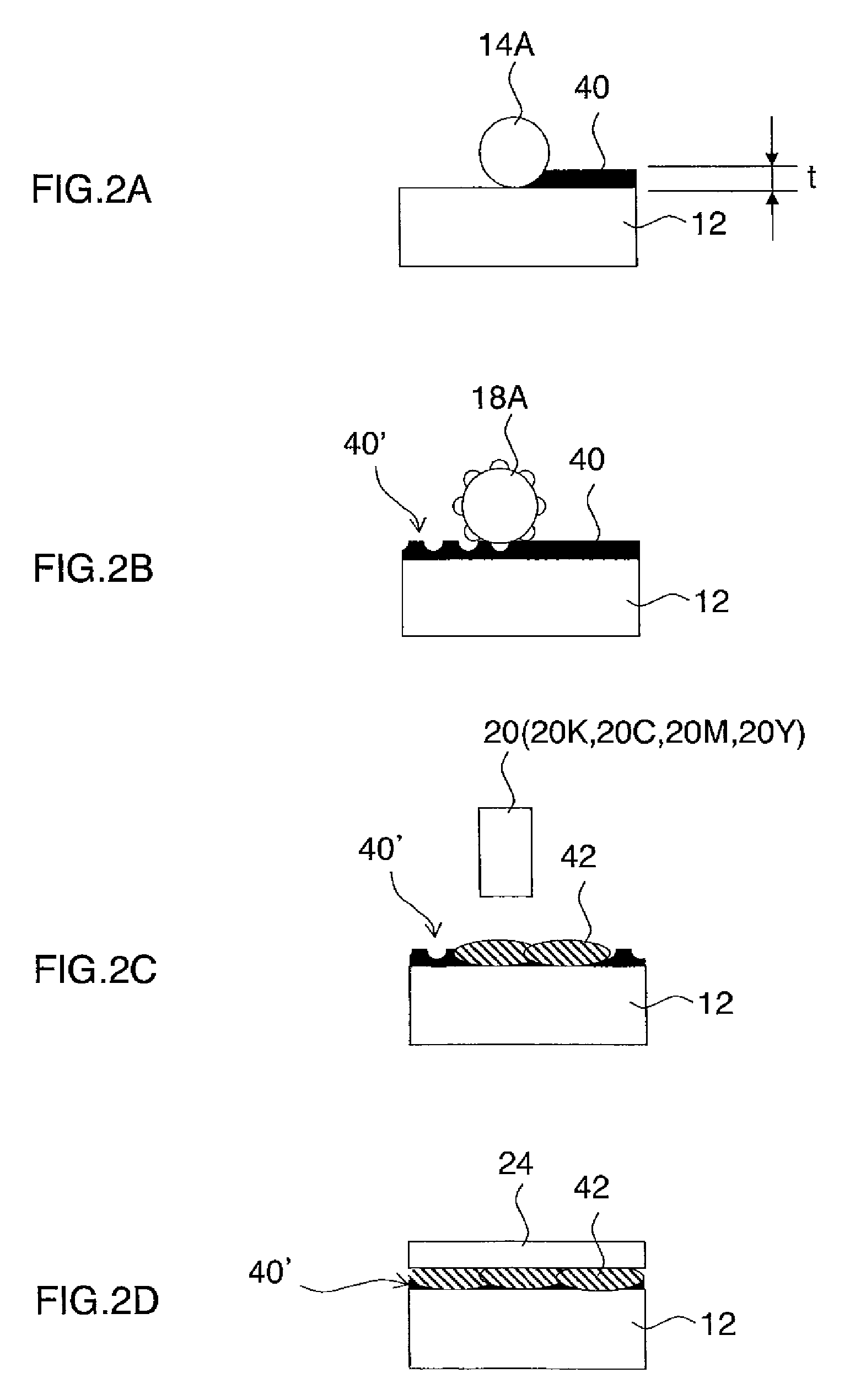

Method of producing recorded product (printed product) and image forming apparatus

InactiveUS20080032072A1Quality improvementImprove transfer rateMeasurement apparatus componentsPrinting press partsSurface layerImage formation

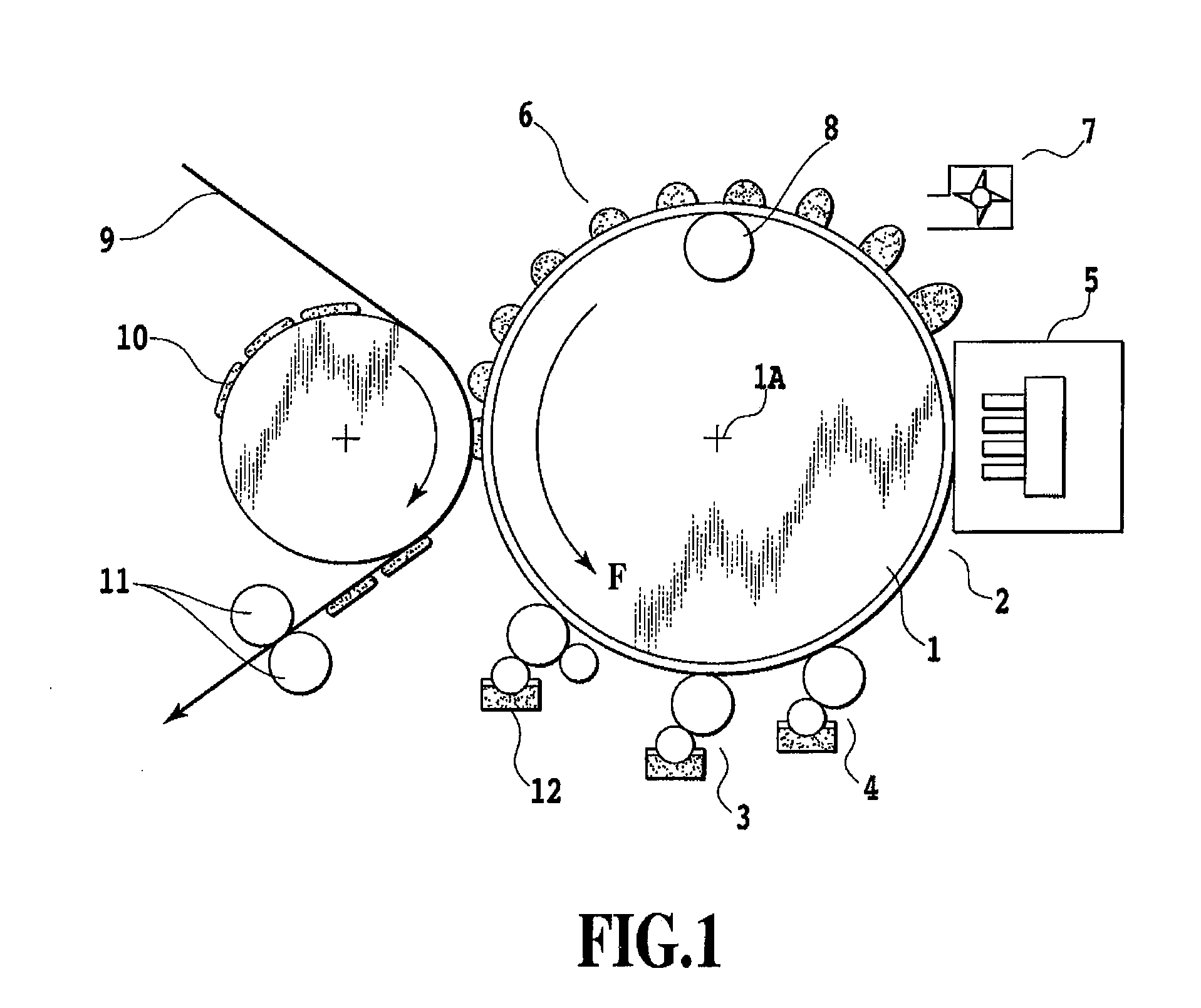

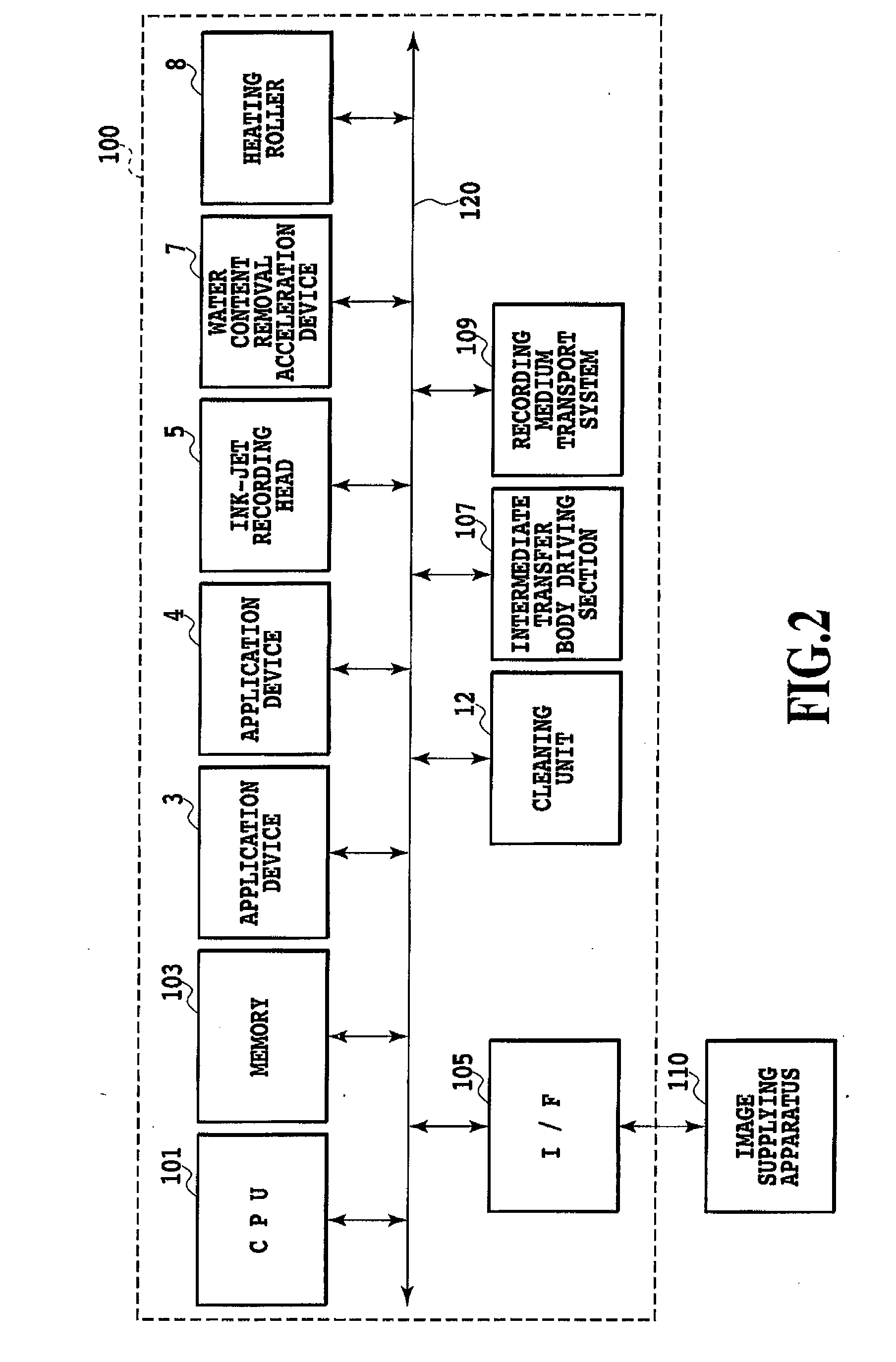

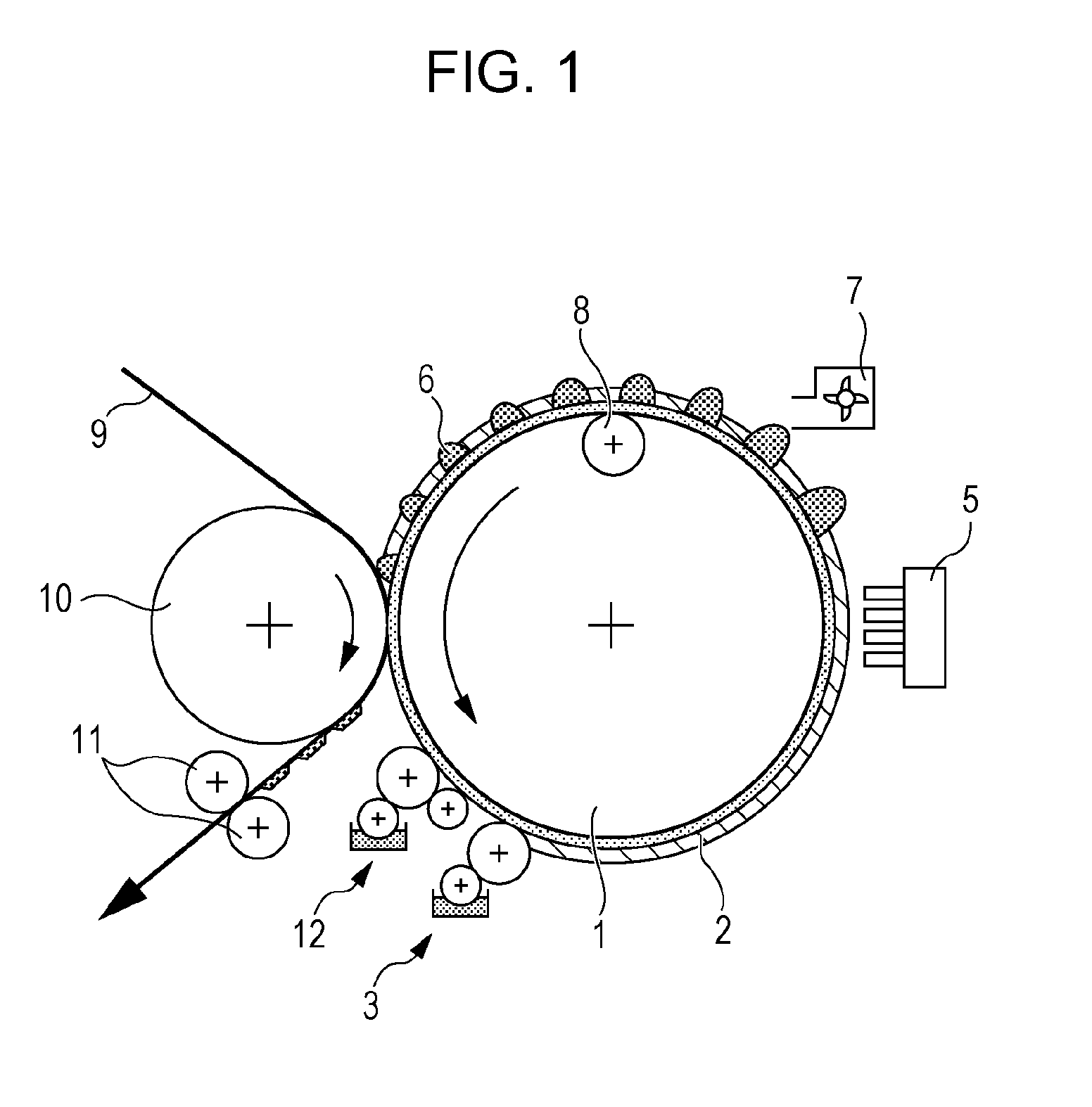

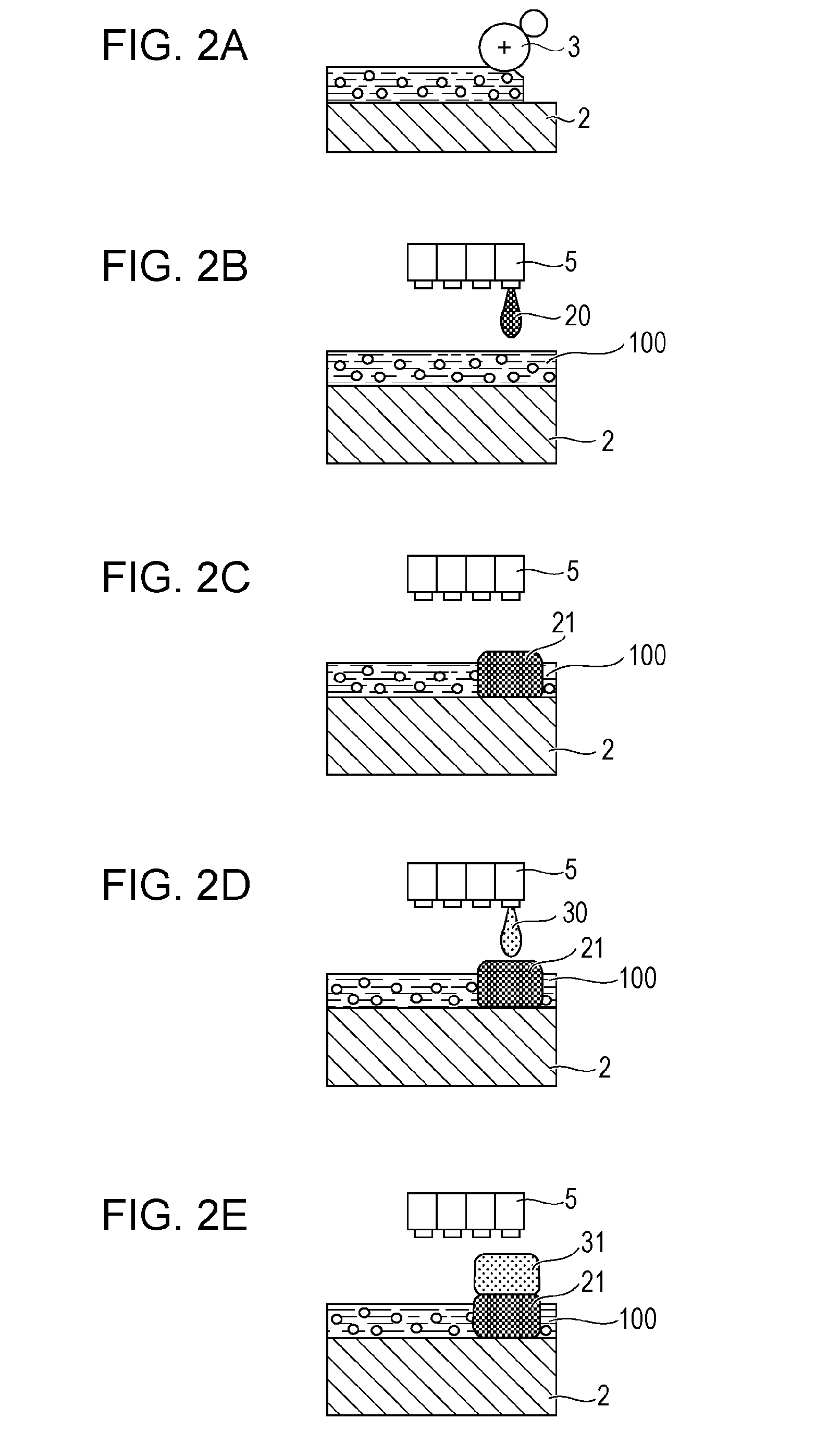

An embodiment of the present invention provides a method of forming an image, which allows a high quality image to be formed on an intermediate transfer body including a surface layer with an ink-repelling property, and then to be transferred at a high transfer rate, and provides an image forming apparatus therefor. In the embodiment of the present invention, an ink image is formed on the intermediate transfer body, on the surface of which an oil and a water-soluble surfactant having surface tension in a range between more than 0 times and not more than 1.1 times of that of the oil are present. Subsequently, the formed ink image is transferred to a recording medium.

Owner:CANON KK

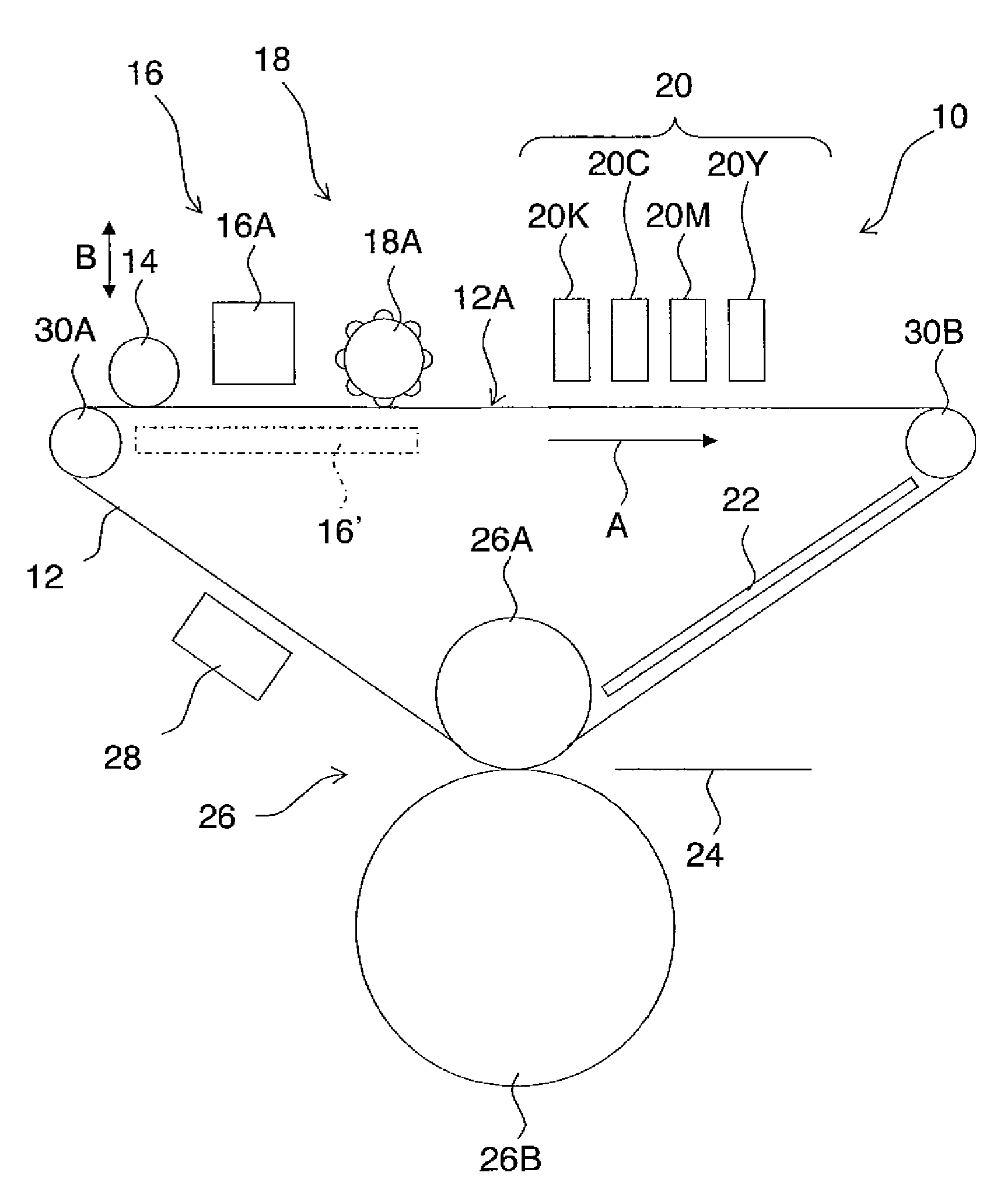

Image forming apparatus and ink set

InactiveUS20080006176A1Improve image qualityIncrease speedInksElectrographic process apparatusLiquid ChangeEmulsion

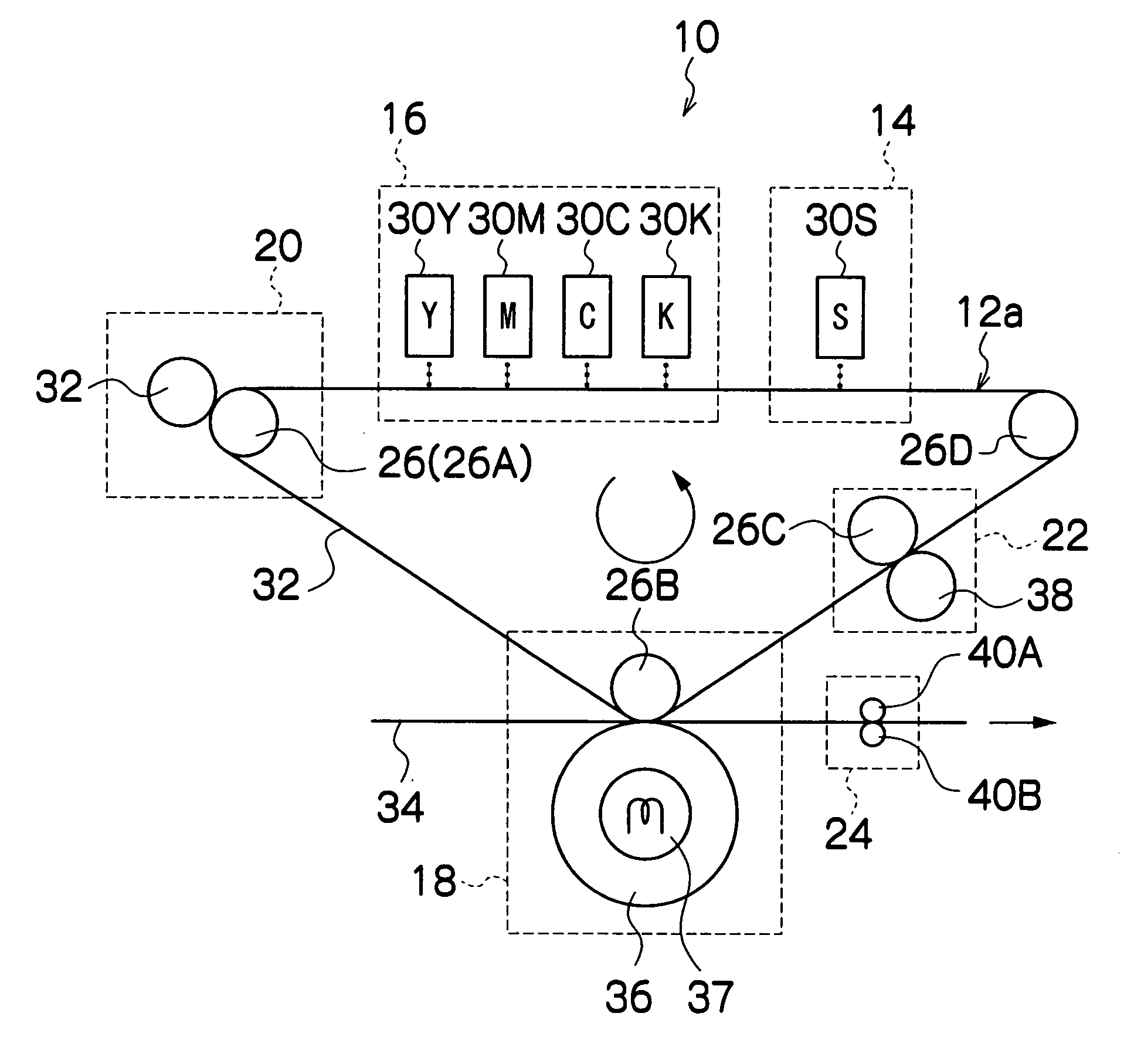

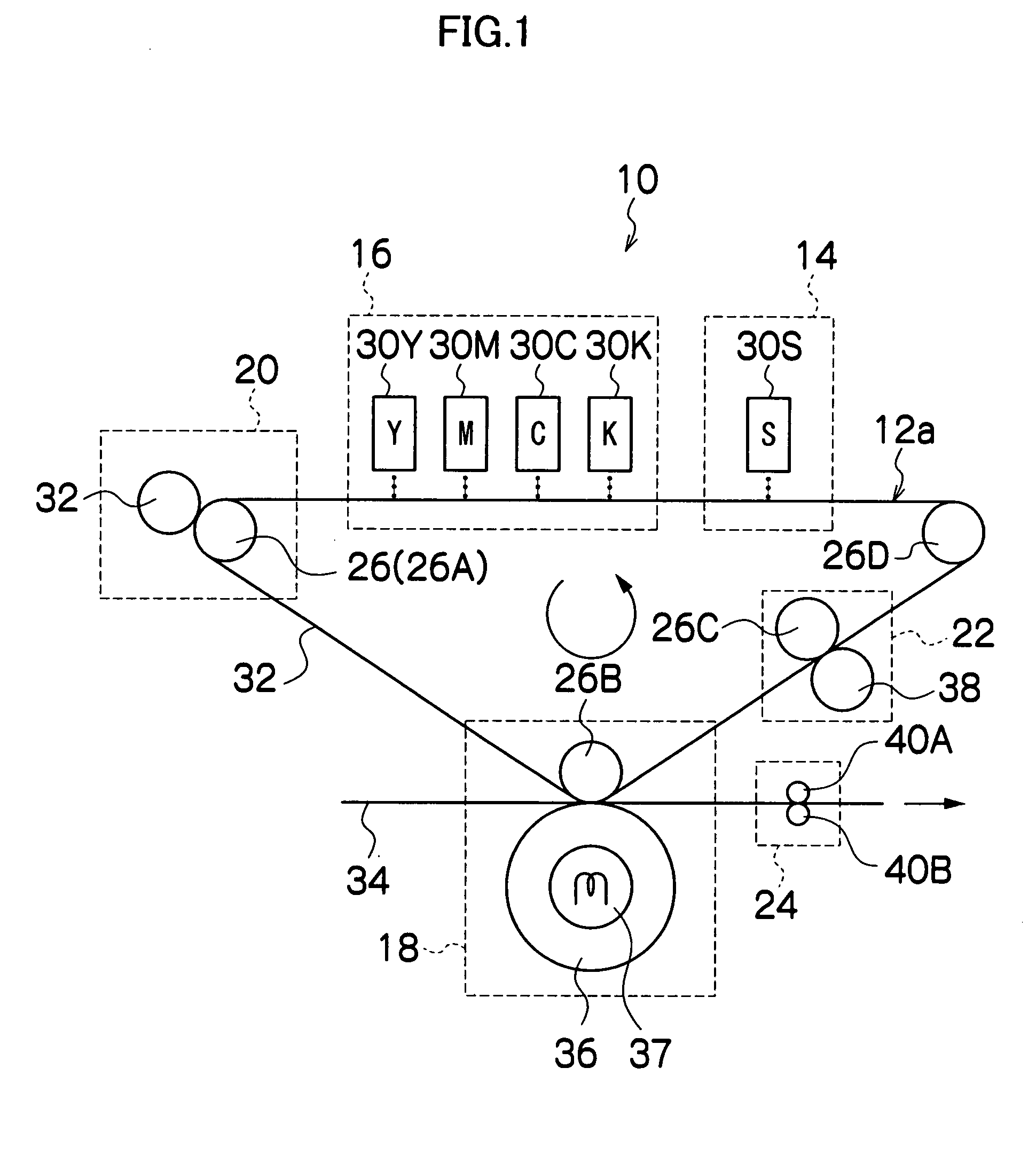

The image forming apparatus includes: an intermediate transfer body on which an ink image is formed; a treatment liquid application unit which applies treatment liquid on the intermediate transfer body; an ink ejection unit which ejects ink to be deposited on the treatment liquid to form the ink image; and a transfer unit which transfers the ink image formed on the intermediate transfer body to a recording medium, wherein: the ink contains coloring material and an emulsion of resin having an ionic group; the treatment liquid changes a pH of the ink when making contact with the ink so that the coloring material and the emulsion of resin having the ionic group aggregate; and a pH differential between the ink and the treatment liquid is not less than 3.

Owner:FUJIFILM CORP

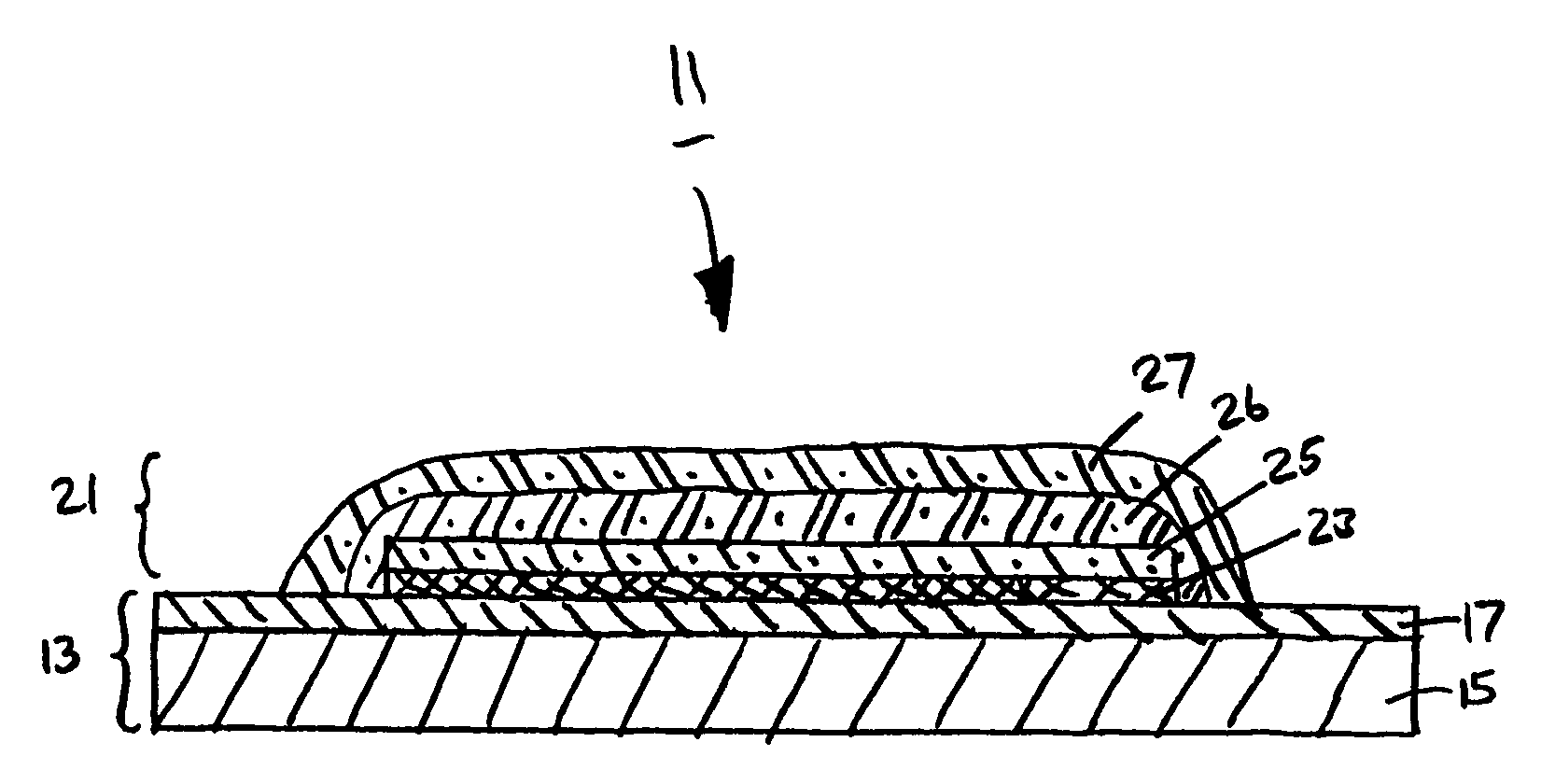

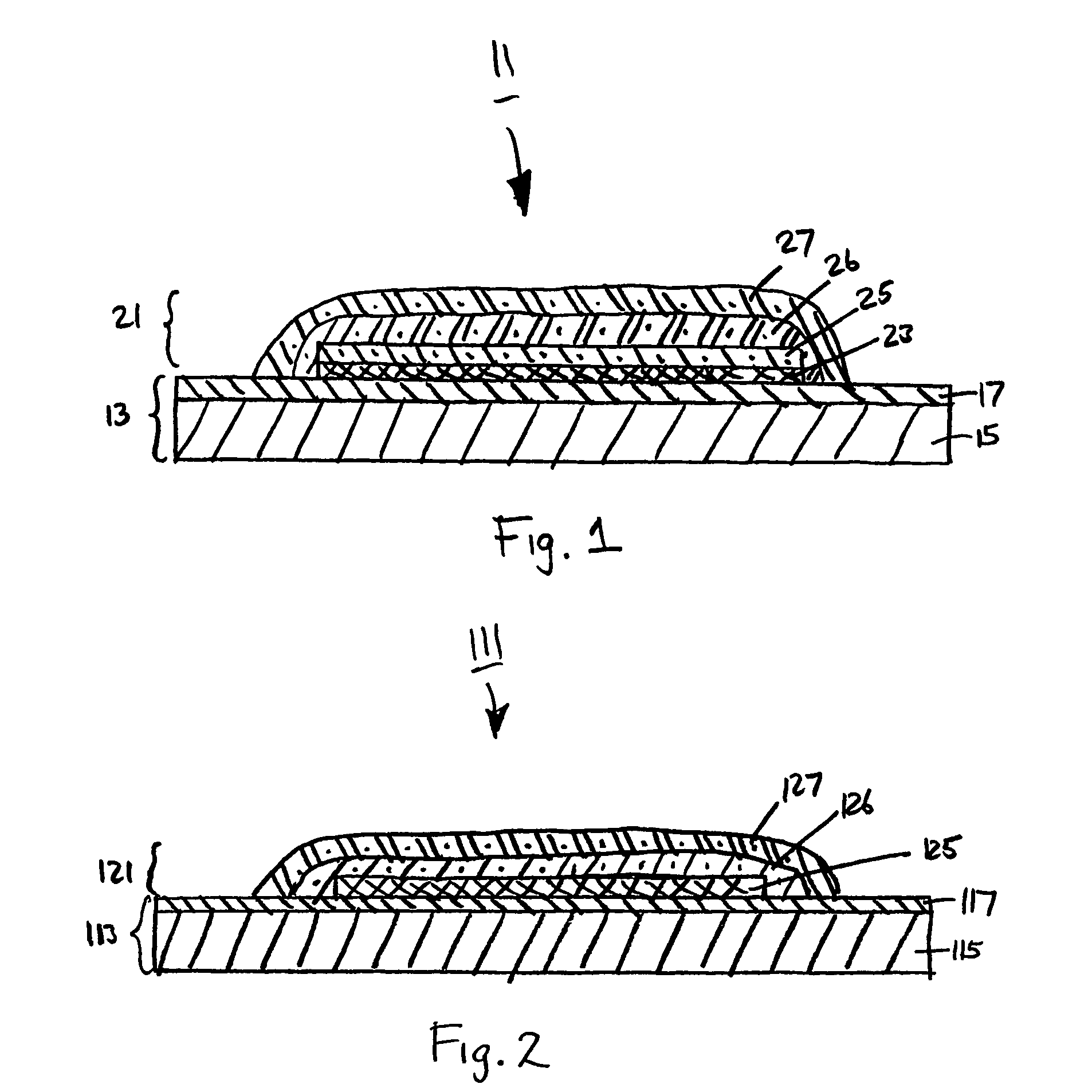

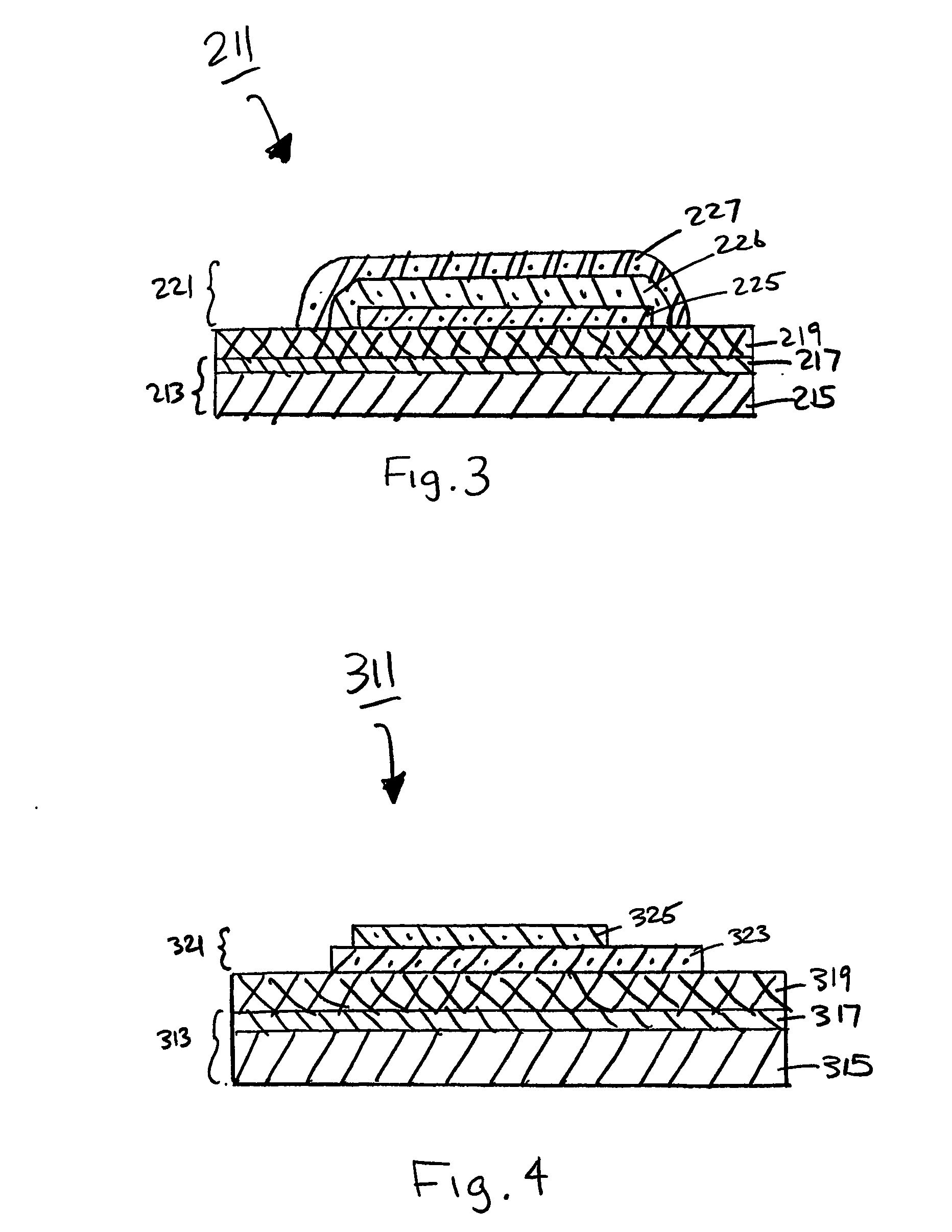

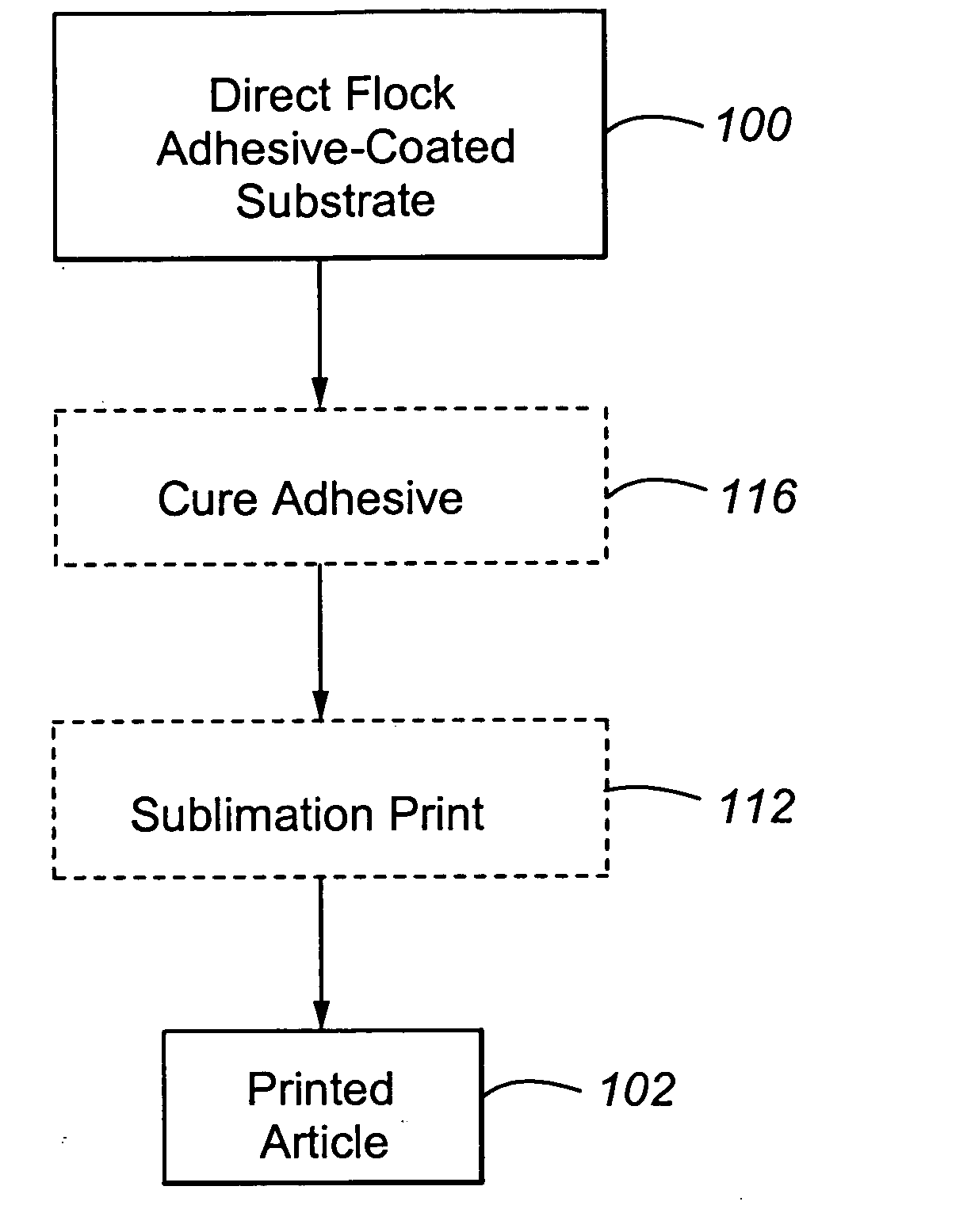

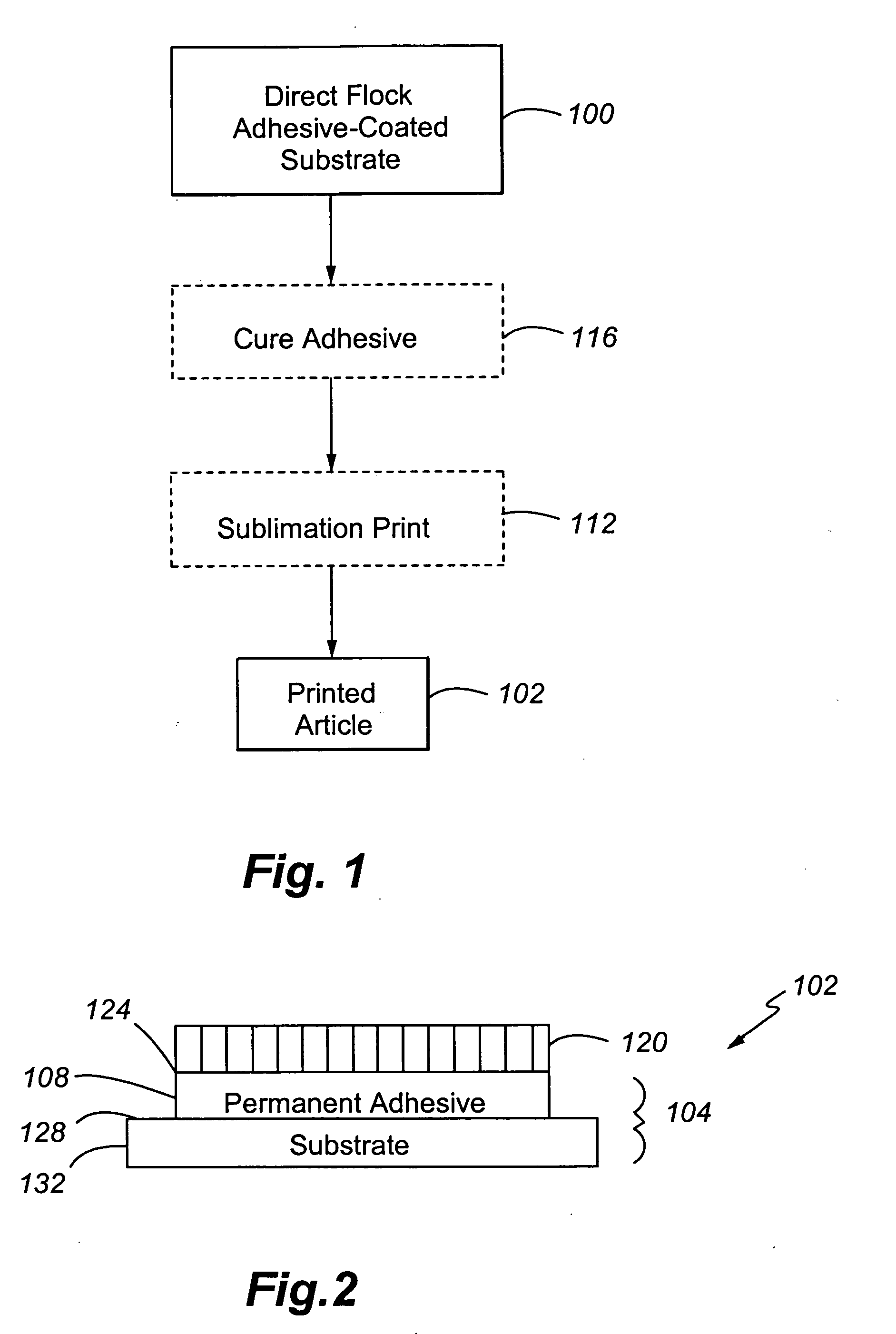

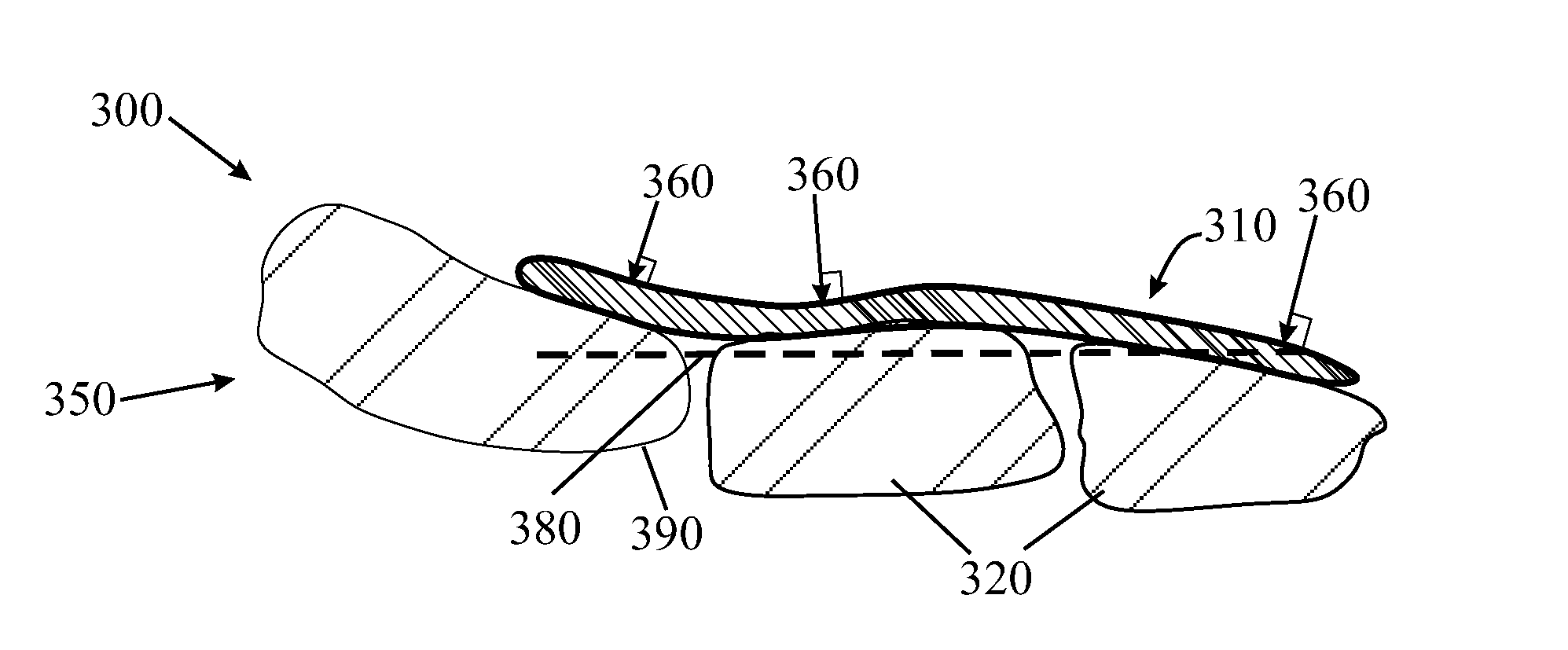

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

A method for labeling fabrics, such as fabric garments, and a heat-transfer label well-suited for use in said method. In one embodiment, the heat-transfer label comprises (i) a support portion, the support portion comprising a carrier and a release layer; (ii) a wax layer, the wax layer overcoating the release layer; and (iii) a transfer portion, the transfer portion comprising an adhesive layer printed onto the wax layer and an ink design layer printed onto the adhesive layer. Preferably, at least a portion of the ink design layer is printed using a variable printing technique, such as thermal transfer printing.

Owner:AVERY DENNISON CORP

Transfer type inkjet recording method

ActiveUS20120140009A1Good transferabilityIncrease resistanceInksInk transfer from master sheetCompound (substance)Polysaccharide

A transfer type inkjet recording method uses an aggregation liquid, in which the aggregation liquid contains a polymer compound having either one of a polysaccharide having an amino group or a polysaccharide salt having an amino group.

Owner:CANON KK

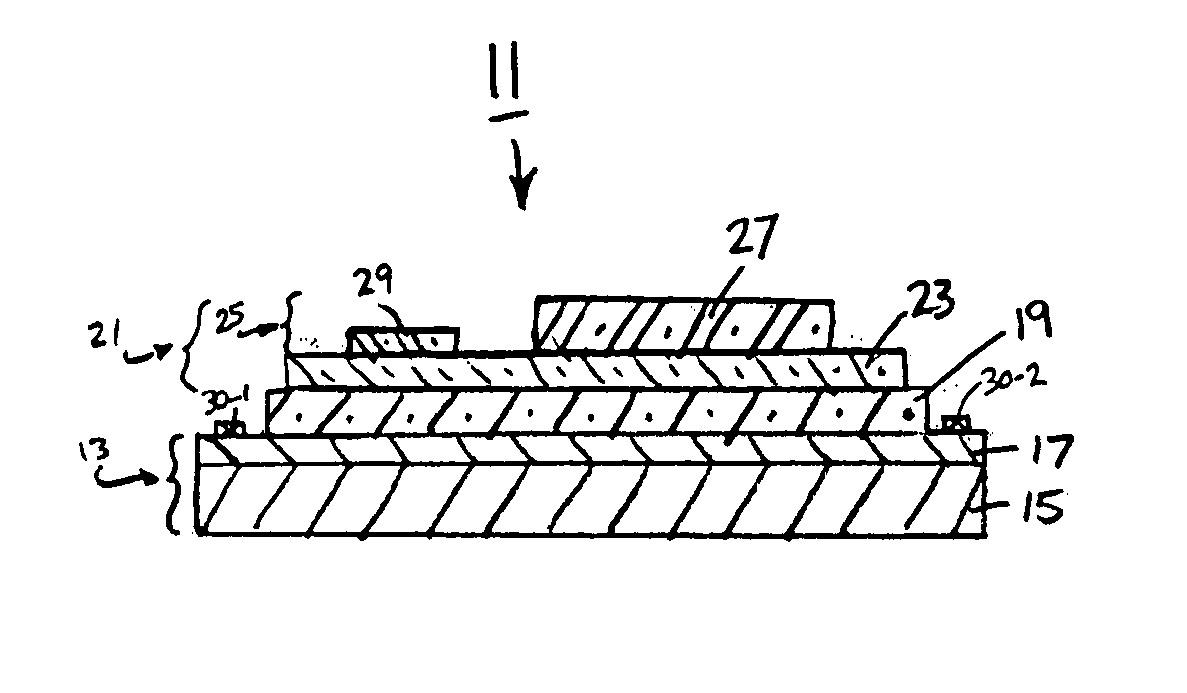

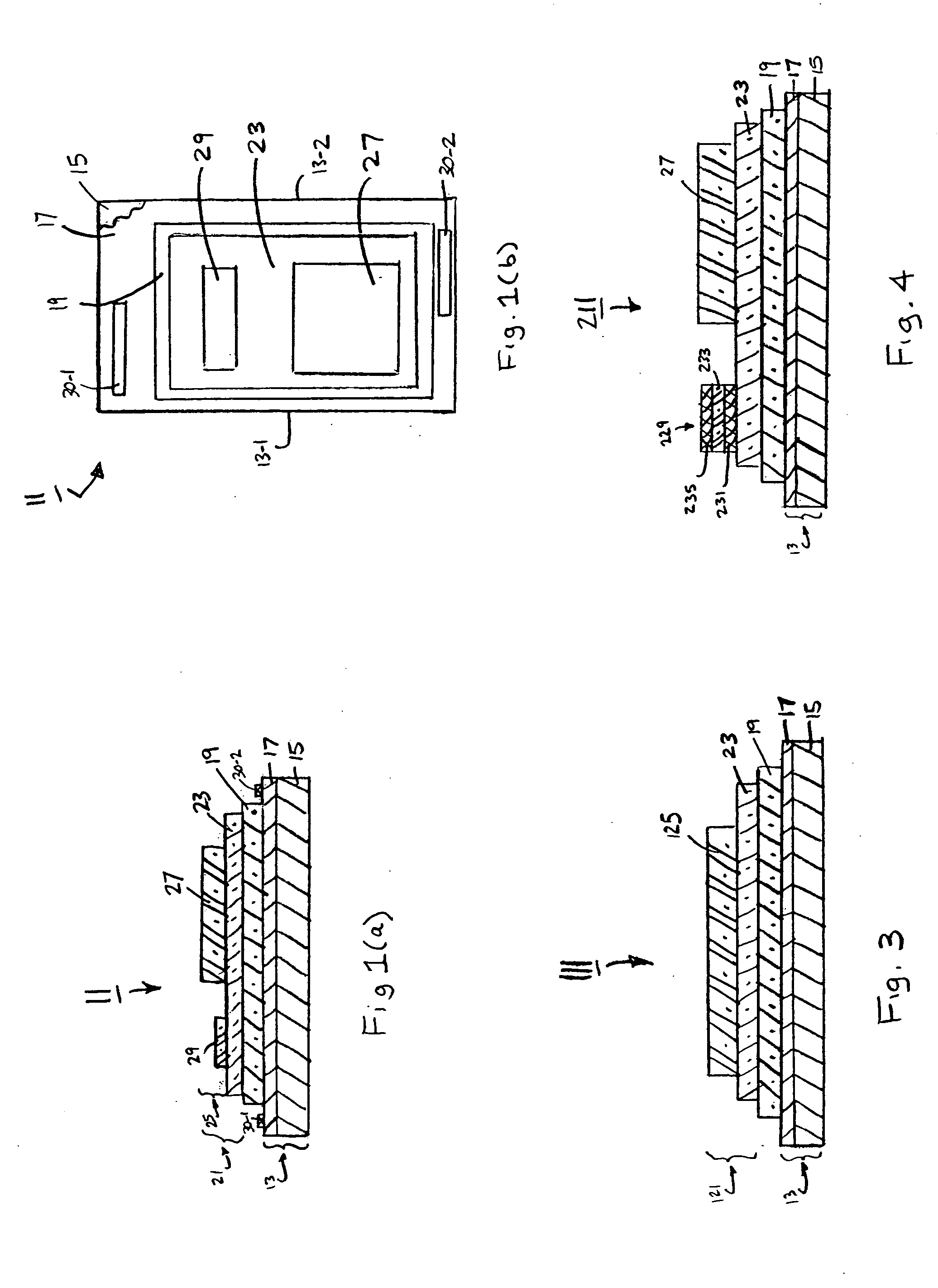

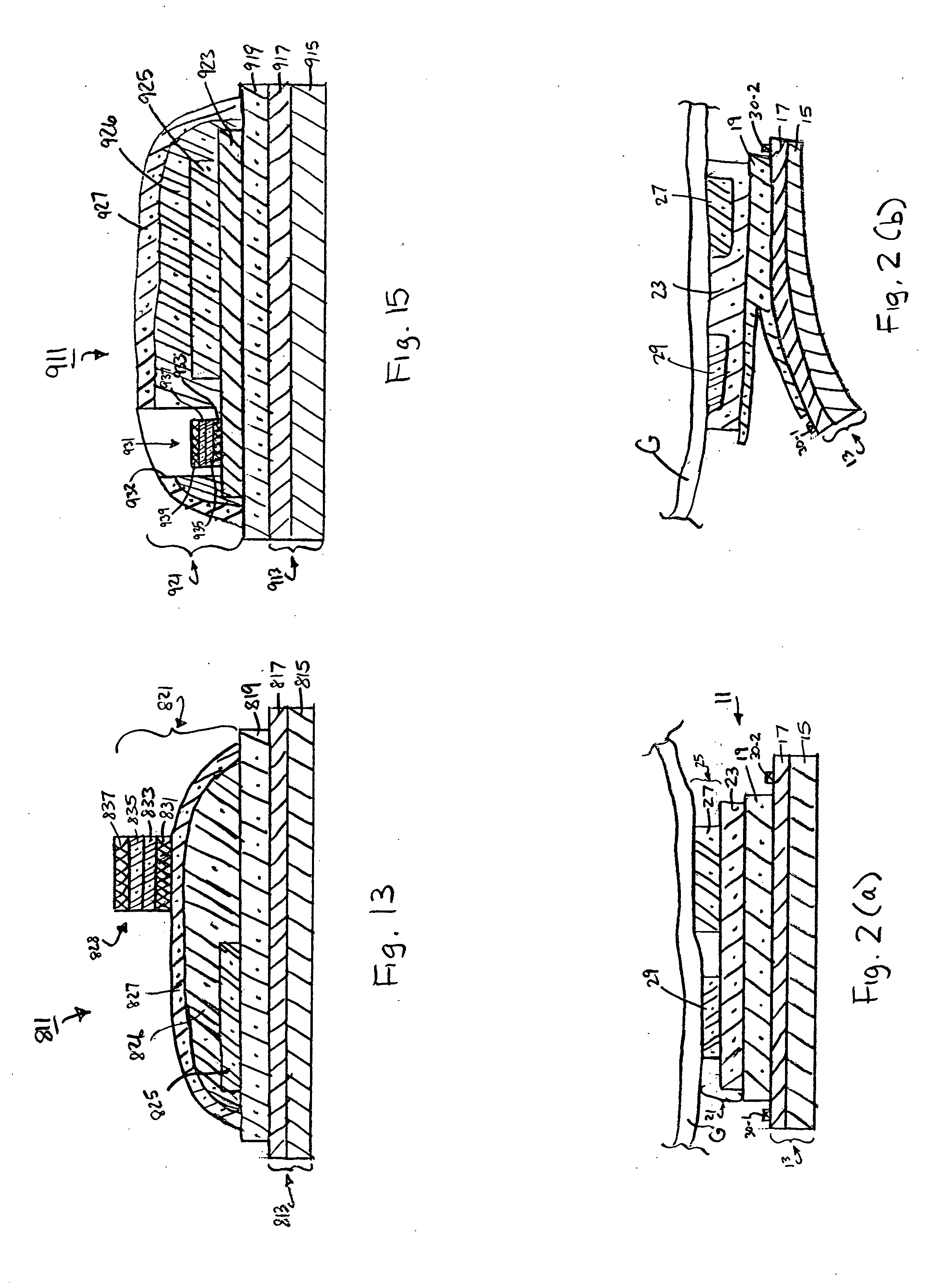

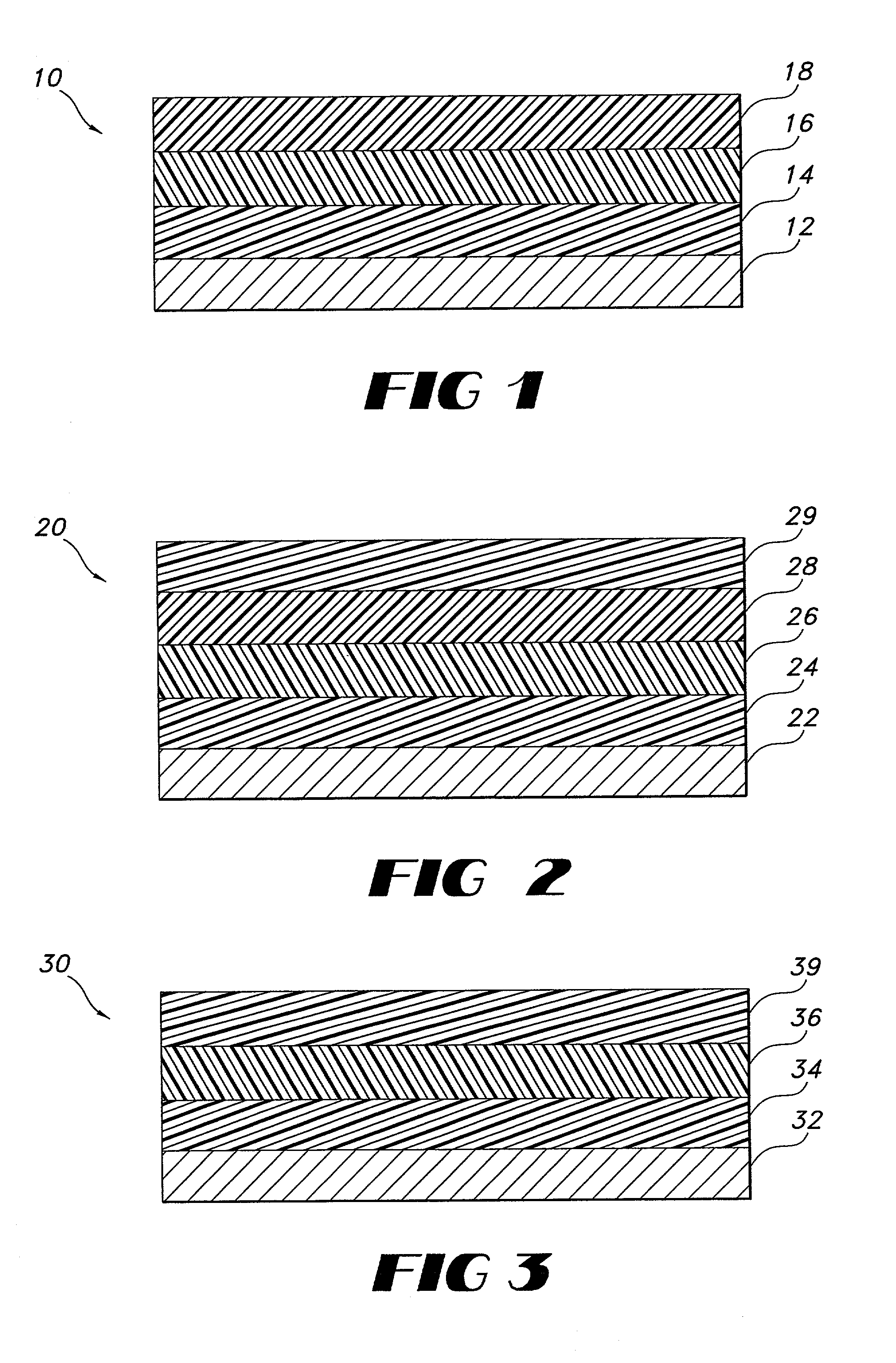

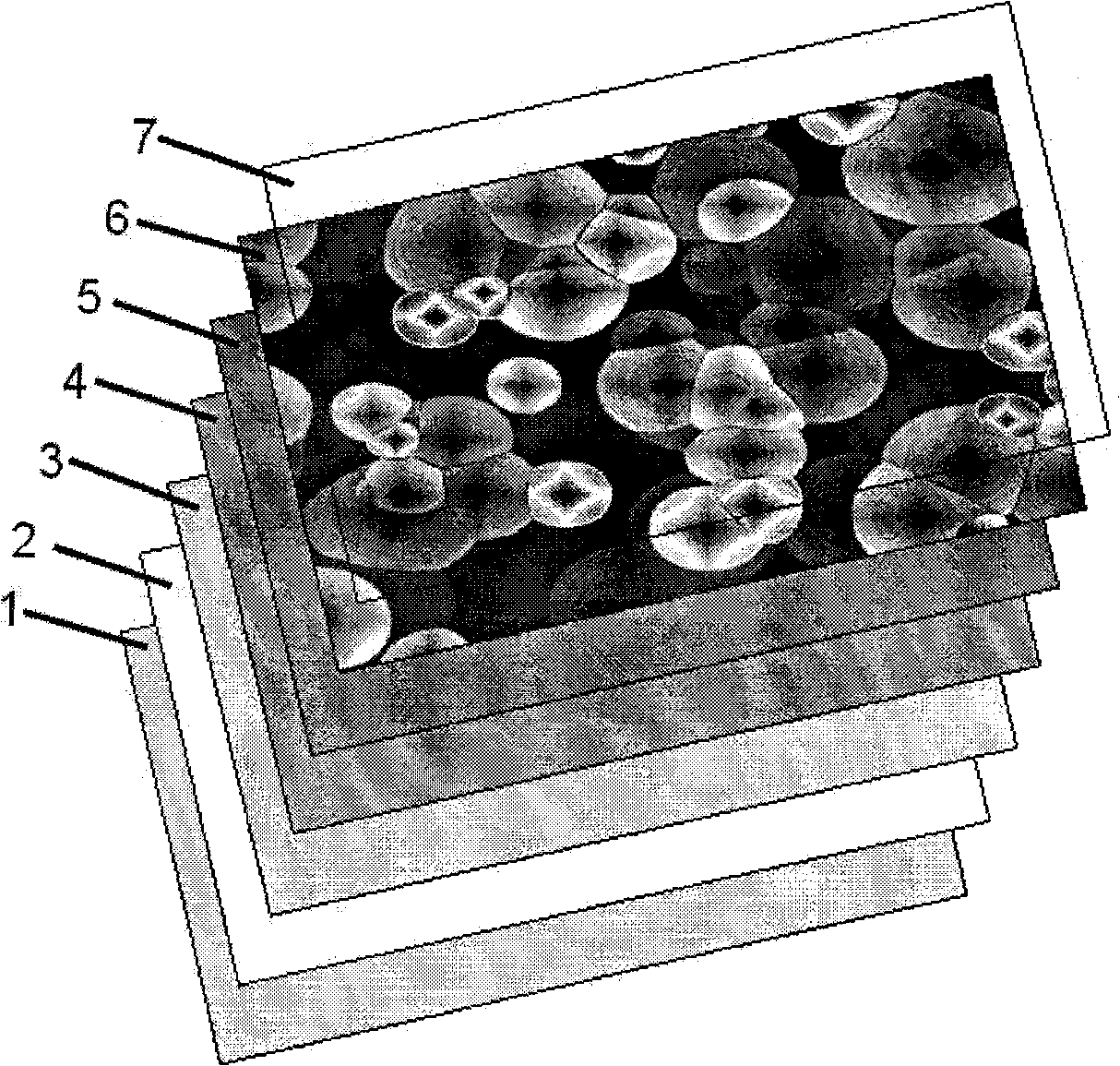

Method for labeling fabrics and heat-transfer label well-suited for use in said method cross-reference to related applications

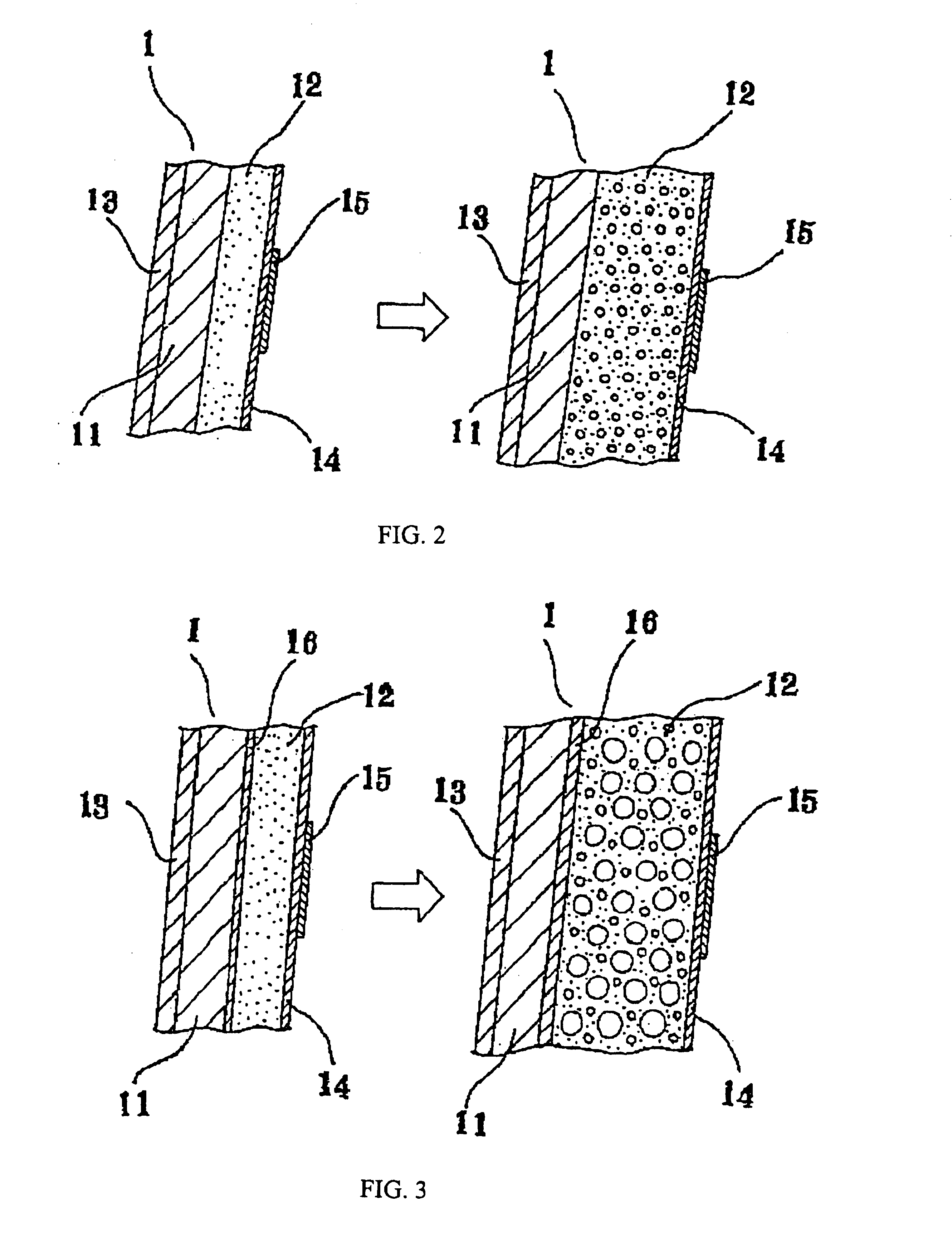

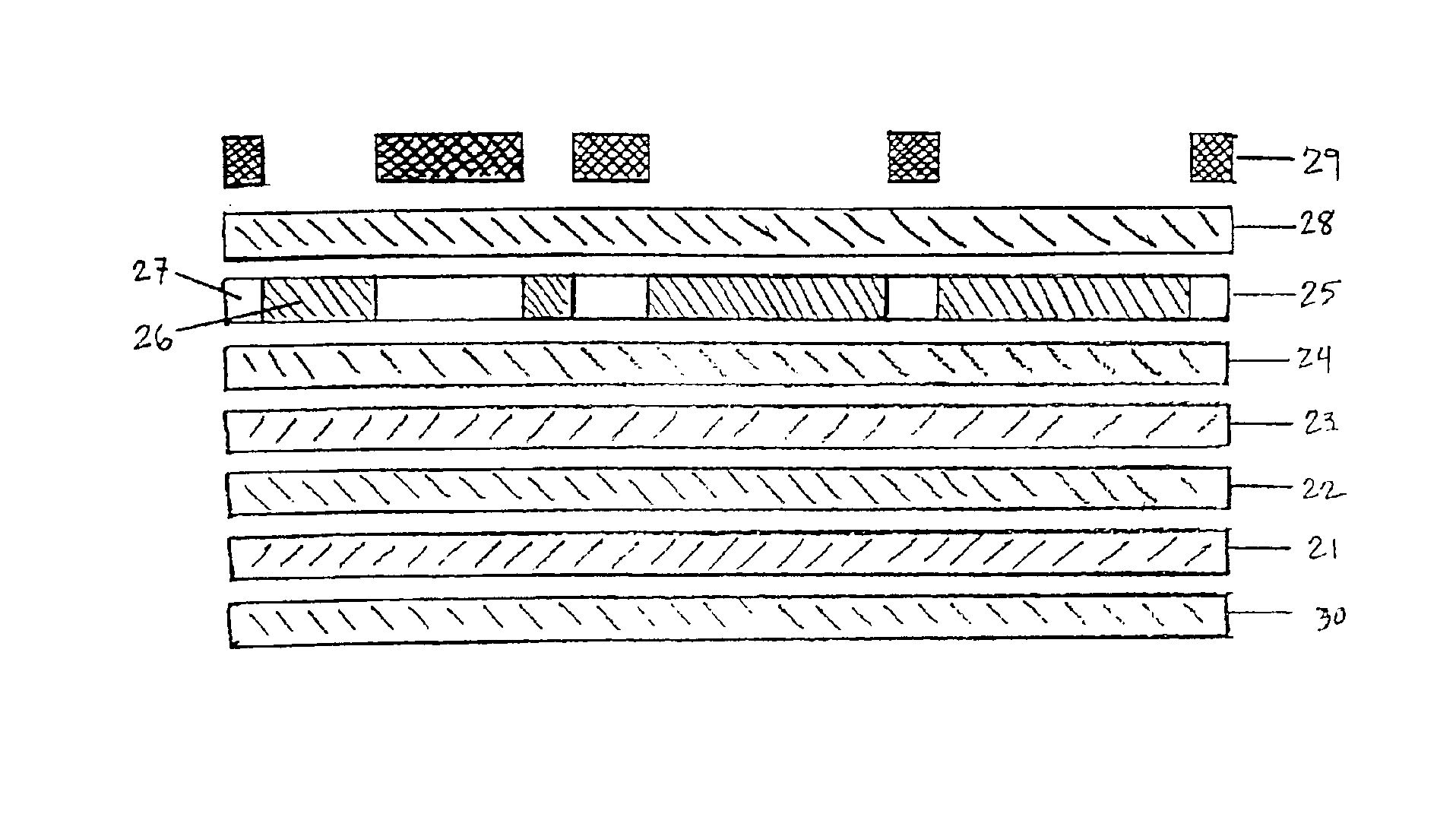

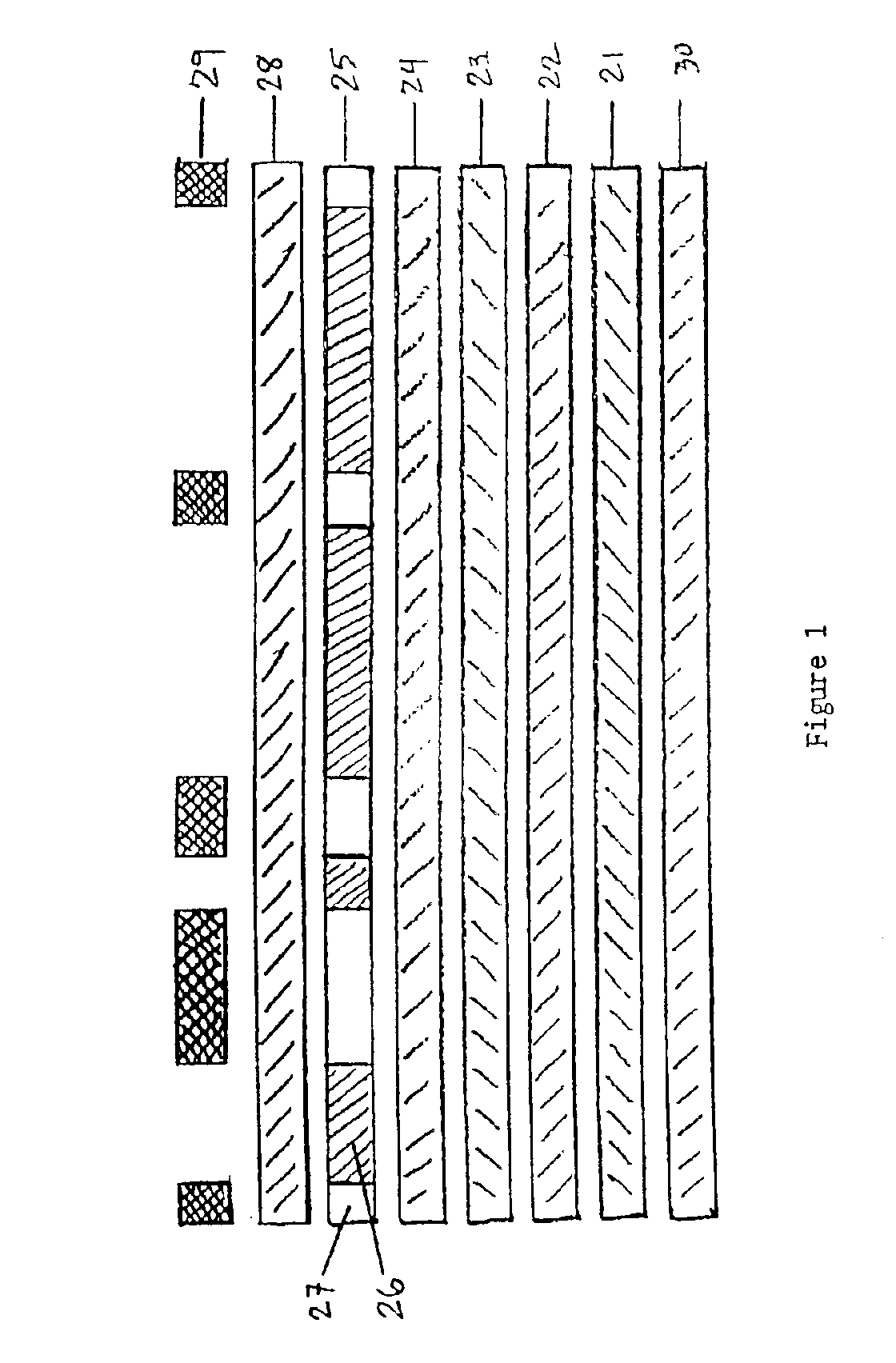

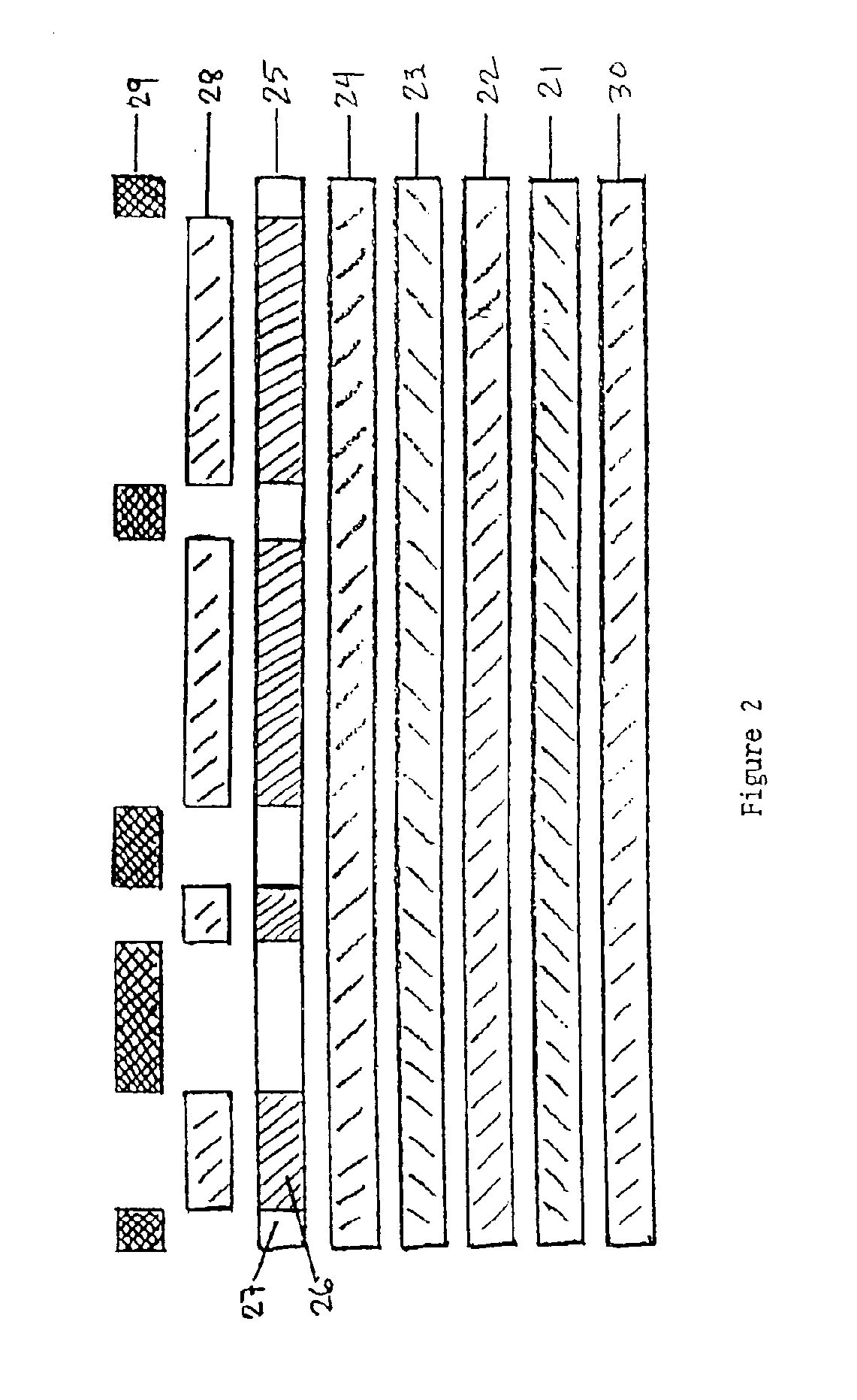

A method for labeling fabrics, such as fabric garments, and a heat-transfer label (311) well-suited for use in said method. In one embodiment, the heat-transfer label (311) comprises (i) a support portion (313), the support portion (313) comprising a carrier (315) and a release layer (317); (ii) a wax layer (319), the wax layer overcoating the release layer (317); and (iii) a transfer portion (321), the transfer portion (321) comprising an adhesive layer (323) printed directly onto the wax layer (319) and an ink design layer (325) printed directly onto the adhesive layer (323). Each of the adhesive layer (323) and the ink design layer includes a non-cross-linked PVC resin. The ink design layer may be screen printed onto the adhesive layer (323) or may be printed onto the adhesive layer (323) using thermal transfer printing, ink jet printing or laser printing.

Owner:AVERY DENNISON CORP

Sublimination dye thermal transfer paper and transfer method

InactiveUS7220705B2Simple technologyAccurate imagingTransfer printing processAblative recordingPolyesterReverse order

An image transfer sheet is provided which comprises a support, a barrier layer, a polyester layer and an optional a sublimation dye receiving layer; wherein the polyester is capable of being physically separated by the user without water, chemicals or heat. The peeled and imaged polyester is placed onto a receptor element and a non-stick sheet is optionally placed thereon. An iron is placed onto the optional non-stick sheet to drive the polyester and image into the receptor. The invention allows for both correct order image-wise printing and reverse order image-wise printing. This invention allows sublimation dye printing onto a cotton receptor.

Owner:SCHWENDIMANN JODI

Method and apparatus for forming dye sublimation images in solid plastic

InactiveUS6998005B2Avoid stickingEnhance the imageLamination ancillary operationsDecorative surface effectsEngineeringPlastic film

Owner:SEKISUI KYDEX LLC

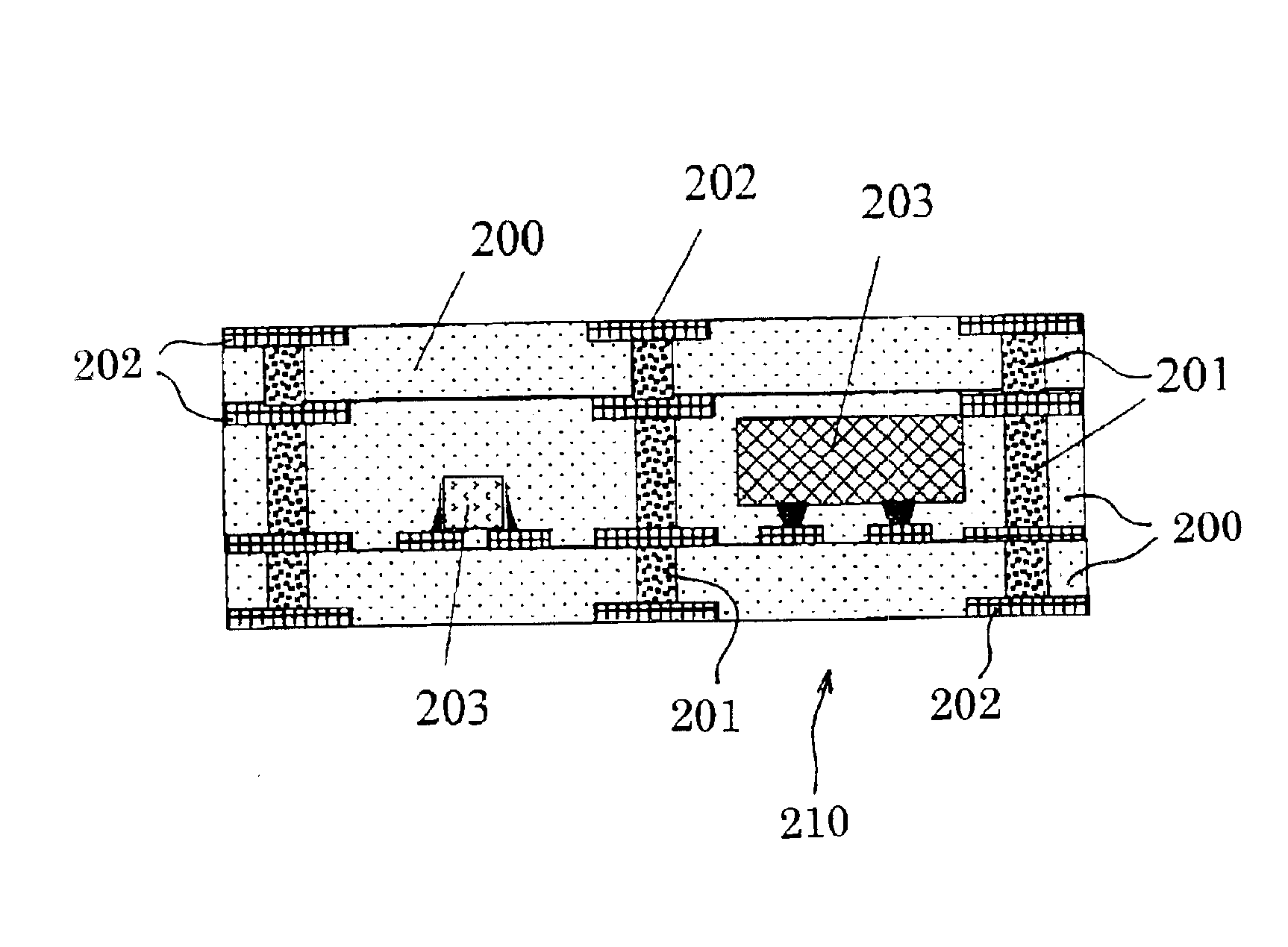

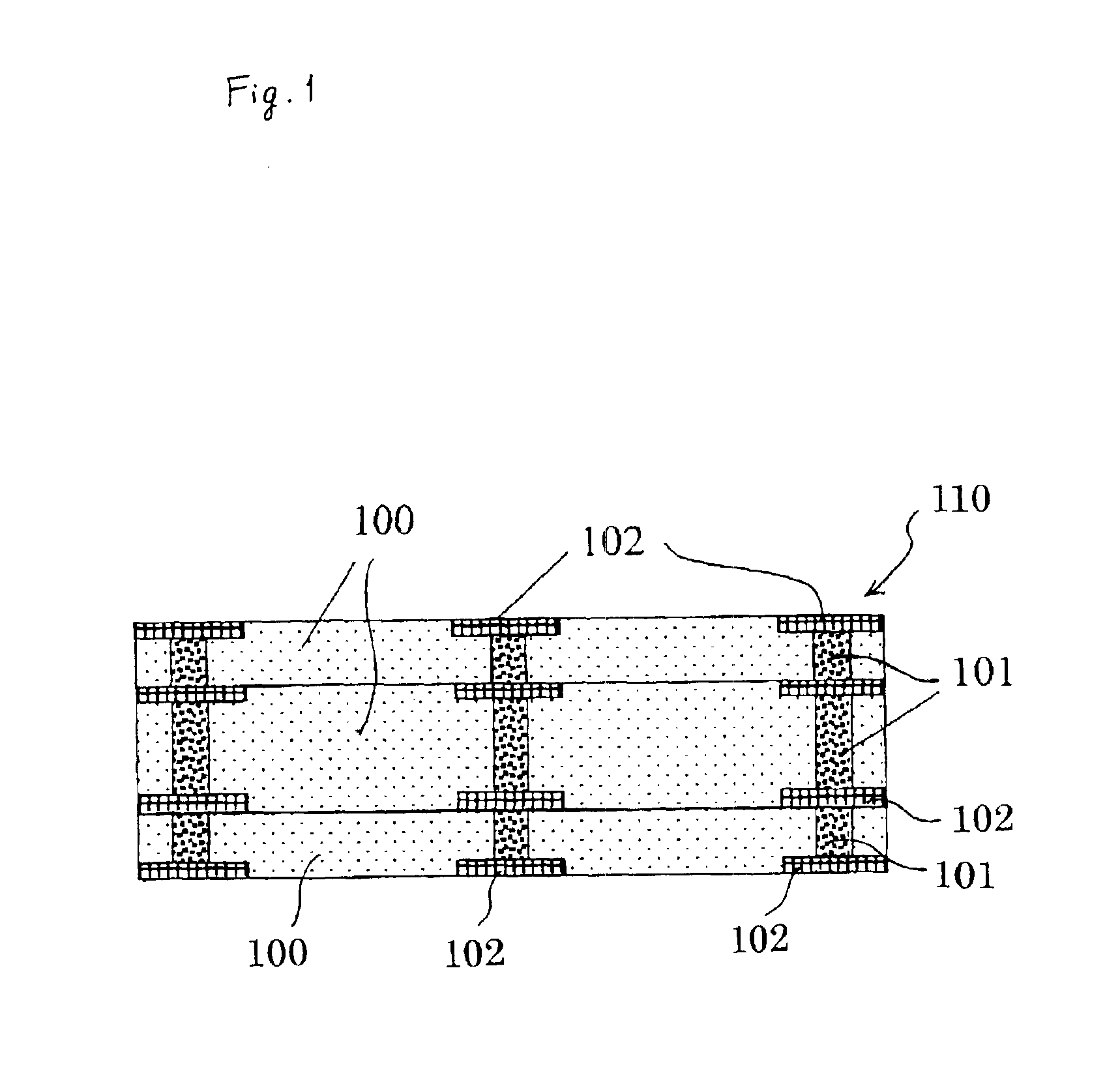

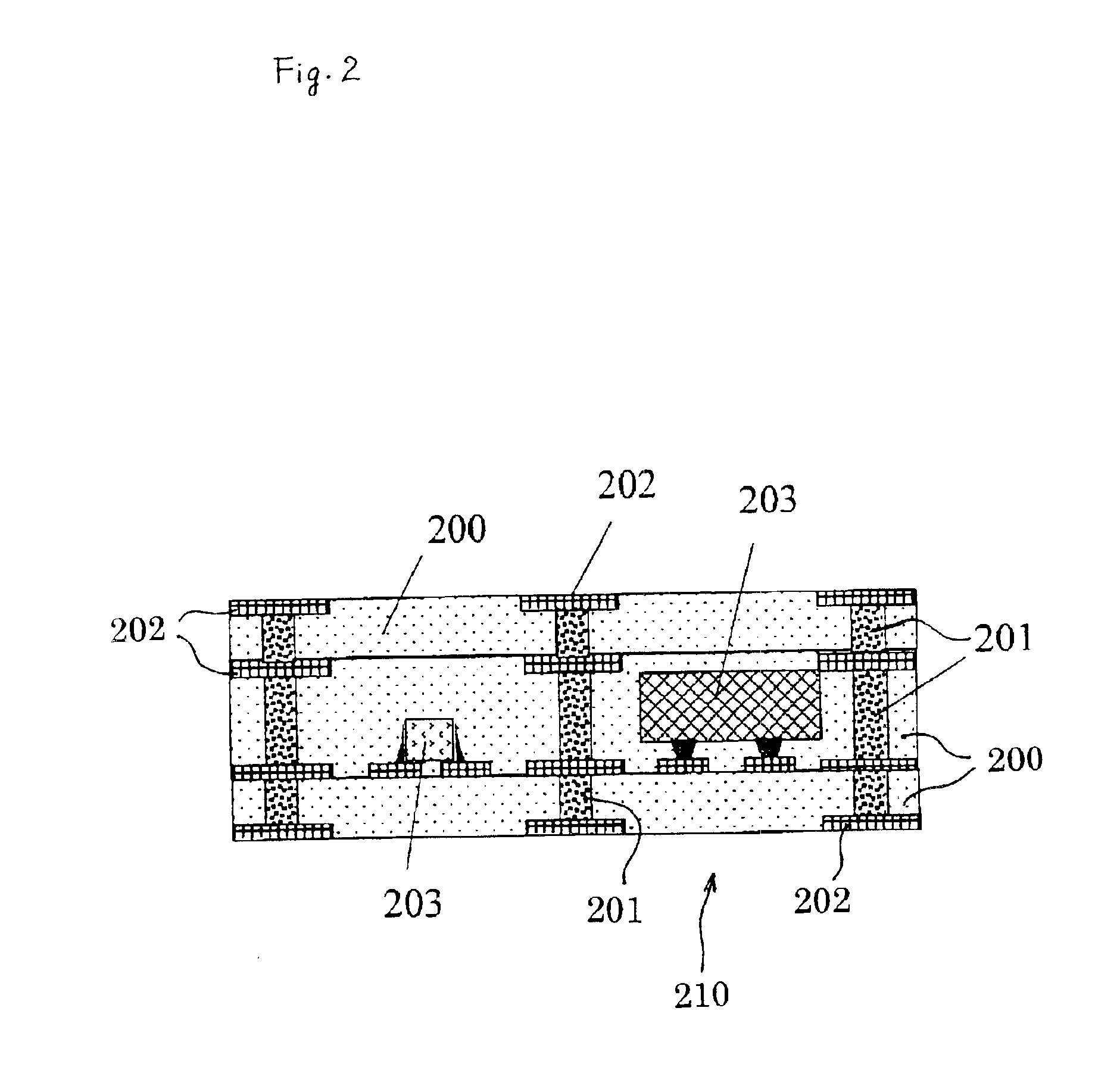

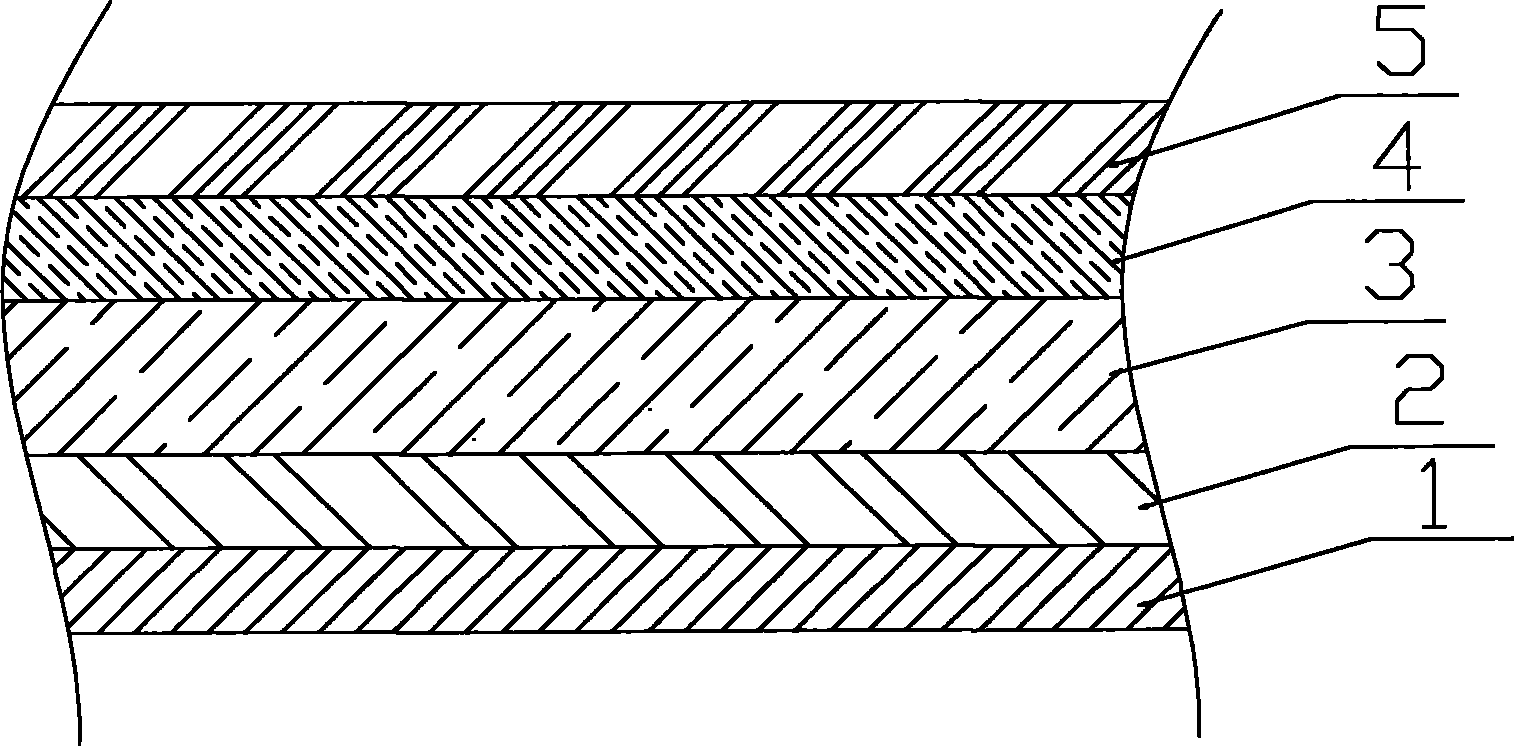

Insulation sheet, multi-layer wiring substrate and production processes thereof

InactiveUS6855892B2Solid-state devicesElectrical connection printed elementsConductive pasteDislocation

An insulation sheet for use in producing a wiring substrate comprises, as via bole conductors, conductive paste filled in via holes formed through the insulation sheet, and a curing-starting temperature of the conductive paste is lower than a melting-starting temperature of the insulation sheet. A wiring substrate is produced by laminating such insulation sheets, that have conductive paste in via holes, and subjecting this laminate to thermo-compression bonding, wherein deformation of via holes and dislocation of the via holes, because of a molten insulation sheet, does not occur.

Owner:PANASONIC CORP

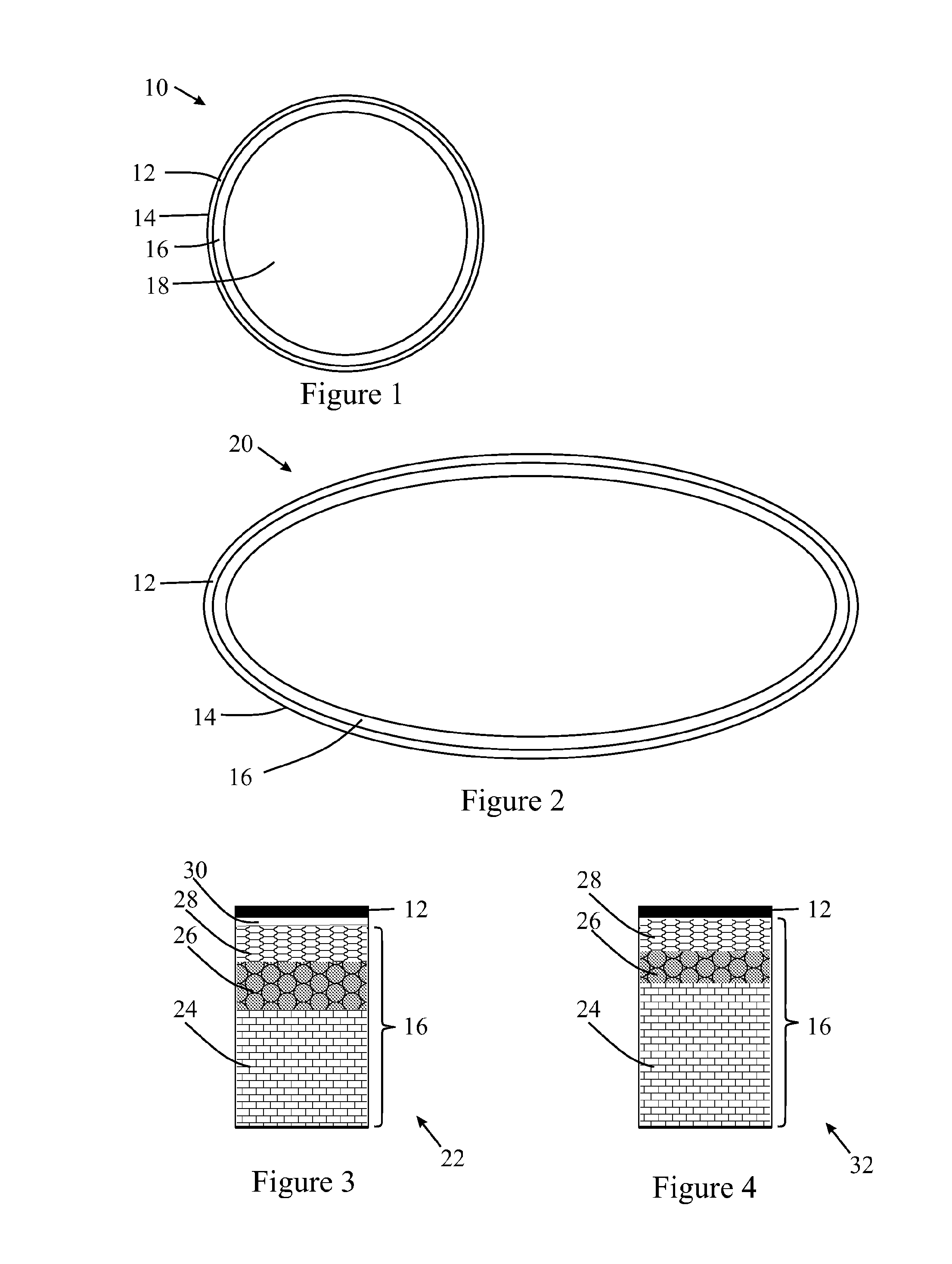

Protonatable intermediate transfer members for use with indirect printing systems

Disclosed are intermediate transfer members useful in the art of printing having a release layer with an image transfer surface having protonatable functional groups apparent thereupon. Also disclosed are methods of making such intermediate transfer members.

Owner:LANDA

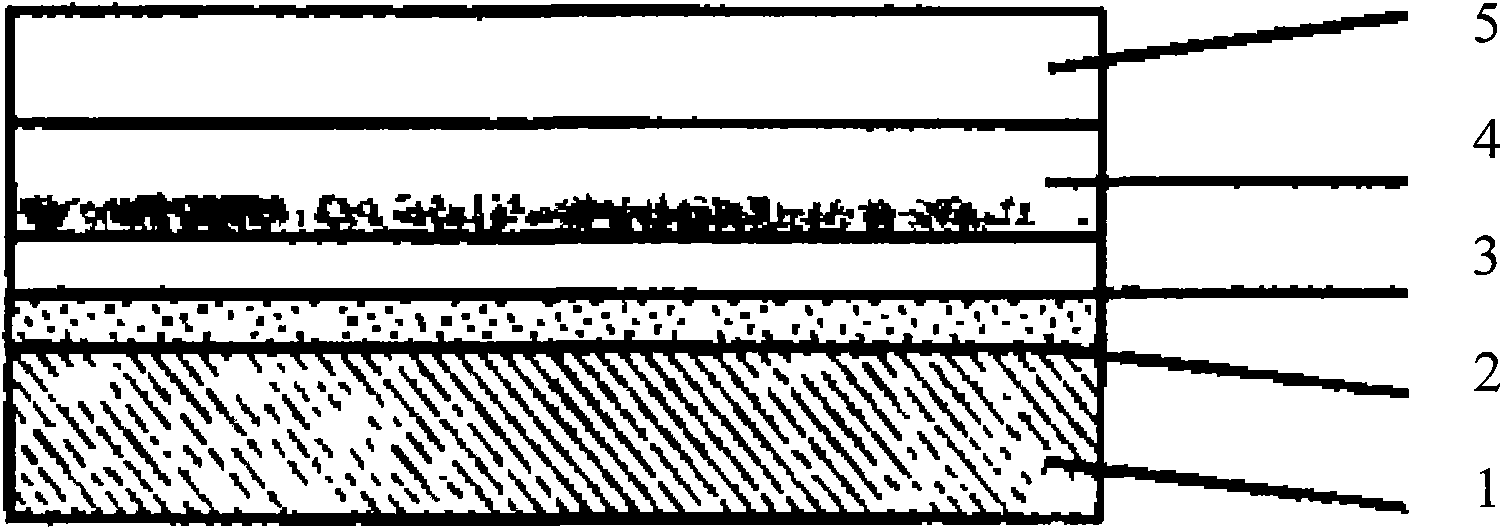

Heat transfer paper with peelable film and crosslinked coatings

InactiveUS7364636B2Contributes significantly to the durability of the transferred imagePrevent penetrationDecorative surface effectsLayered productsEngineeringCoating

The present invention was directed to a unique heat transfer material for use in transferring an image-bearing coating onto a substrate, such as an article of clothing. The heat transfer material of the present invention may be used in cold peel transfer processes, resulting in an image-bearing coating having superior washability, compared to conventional image-bearing coatings. Additionally, the materials may be used on dark colored fabrics without graying of the opaque background or dulling of colored images typically associated with printing on darker fabrics. The heat transfer material of the present invention produces superior results due to the addition of crosslinking agents to the coatings.

Owner:HAWK J RICHARD AGENT FOR CERTAIN LENDERS

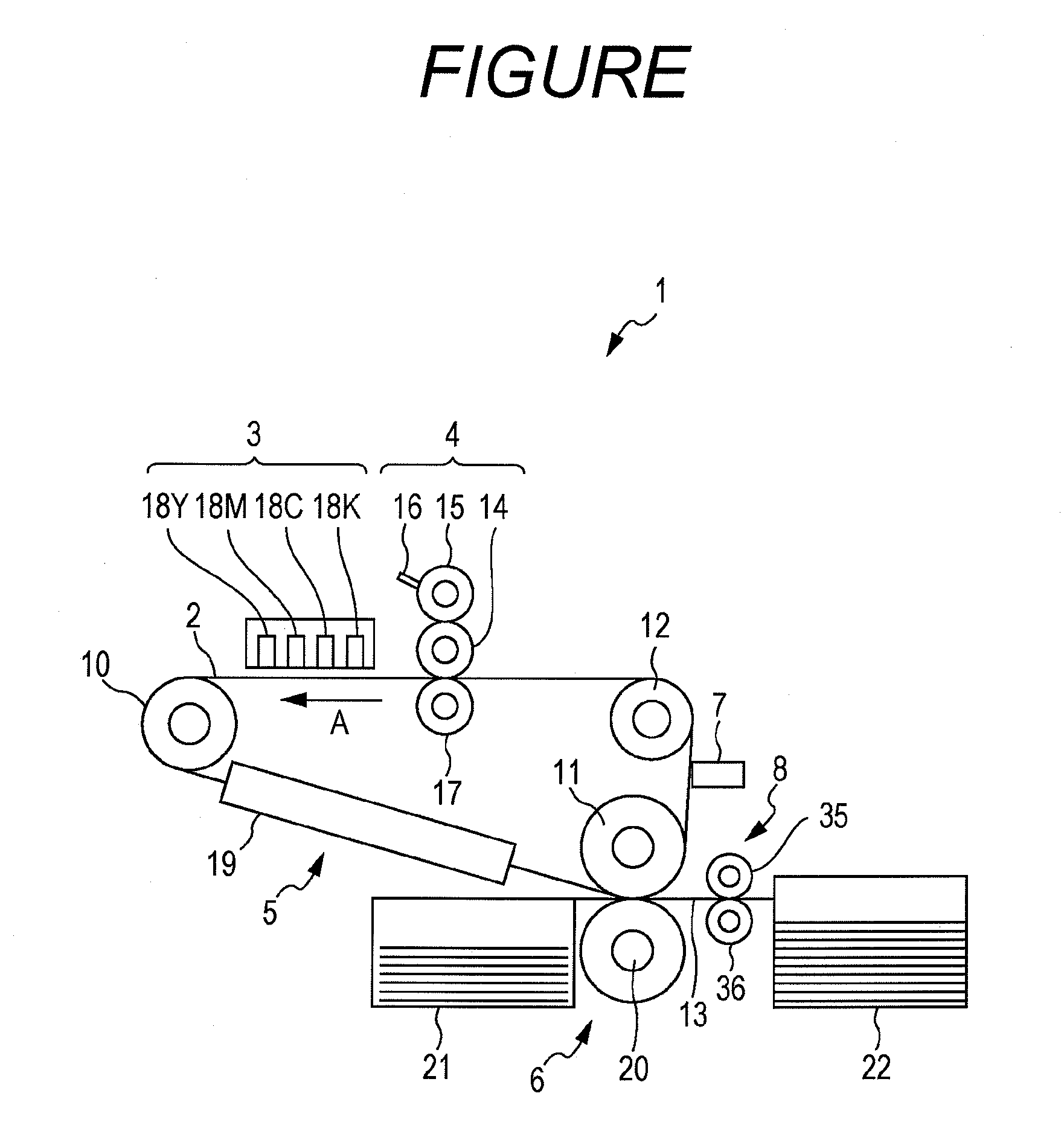

Transfer ink jet recording method

InactiveUS20120127250A1Satisfactory transferabilitySatisfactory wet scratch resistance of a final imageInksInk transfer from master sheetPolymerizationPolyamino acid

Provided is a transfer ink jet recording method, which provides satisfactory transferability and satisfactory wet scratch resistance of a final image even at high printing duty. The transfer ink jet recording method includes using an aggregation liquid, in which the aggregation liquid includes a polymer compound including one of a polyamino acid and a polyamino acid salt each having an amino group, each of which is obtained by polymerization of an amino acid compound represented by the general formula (1).

Owner:CANON KK

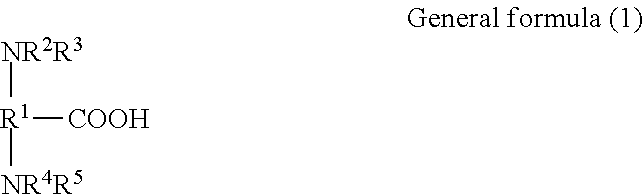

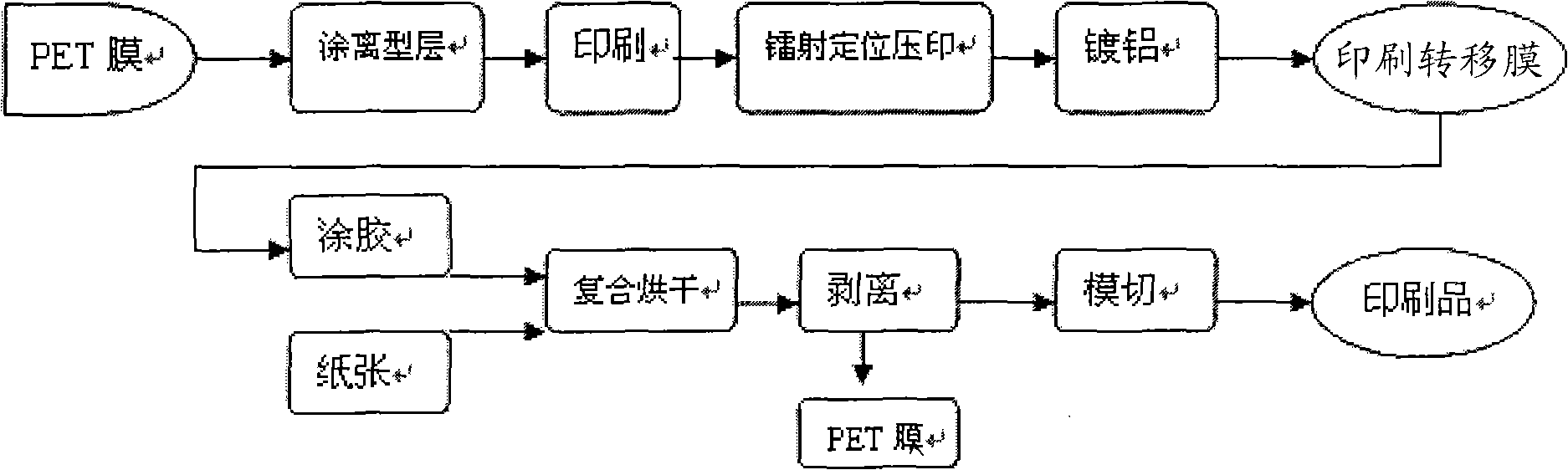

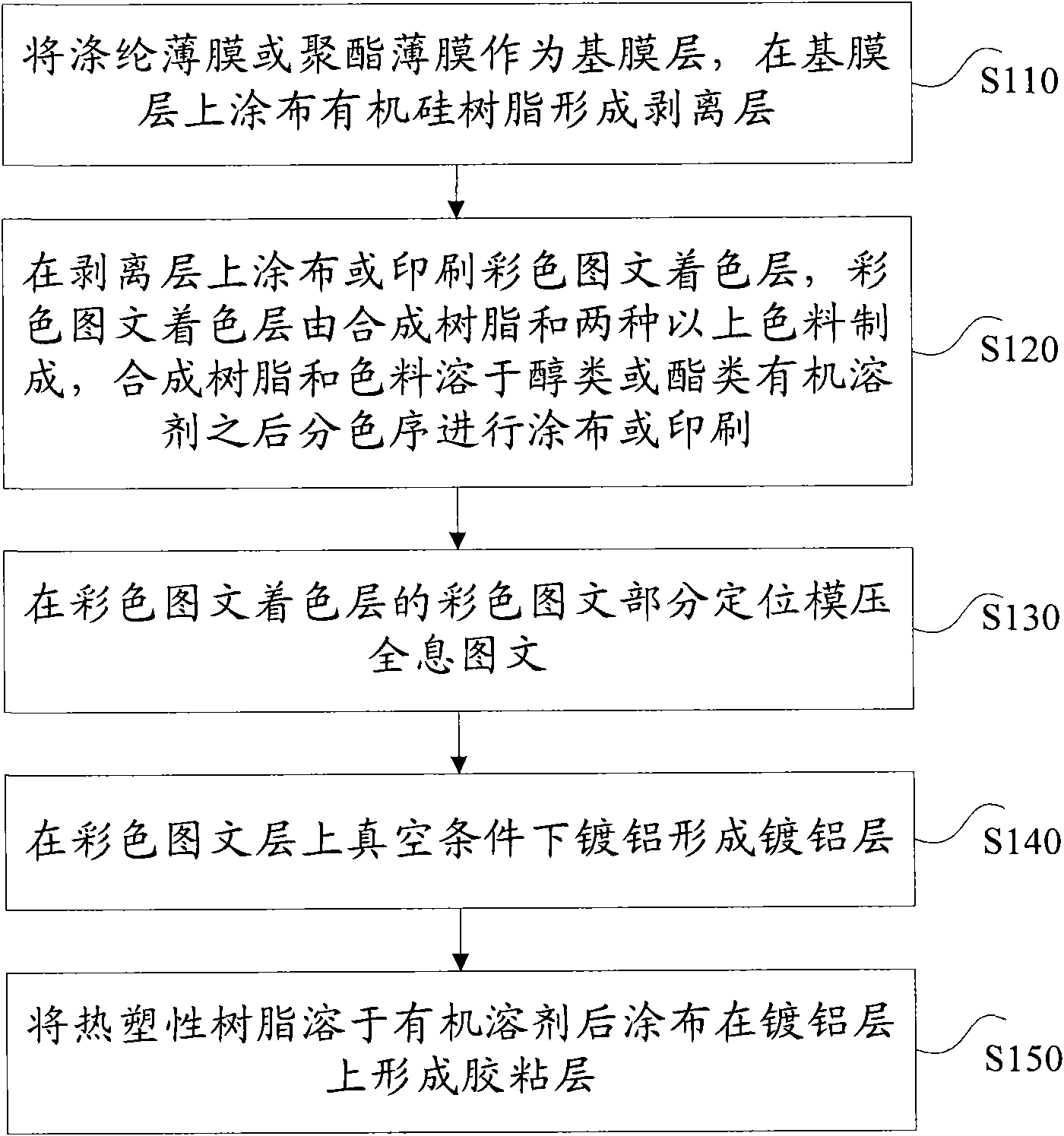

More environment-friendly print transferring method and product thereof

InactiveCN101524930AImprove printing qualityImprove printing efficiencyVacuum evaporation coatingSputtering coatingPulp and paper industryLaser

The invention discloses a more environment-friendly print transferring method and a product thereof. The method comprises steps of coating, picture and text printing, laser stamping, aluminium plating, glue coating, compositing and peeling. Instead of printing on rough paper or manufacturing a laser transfer paper first before carrying out picture and text printing in the traditional technique, printing is carried out on surface of more smooth PET light membrane. Therefore, the product has higher printing quality and printing efficiency, more beautiful appearance, more precise overprint and lower cost.

Owner:FUJIAN TAIXING SPECIAL PAPER CO LTD

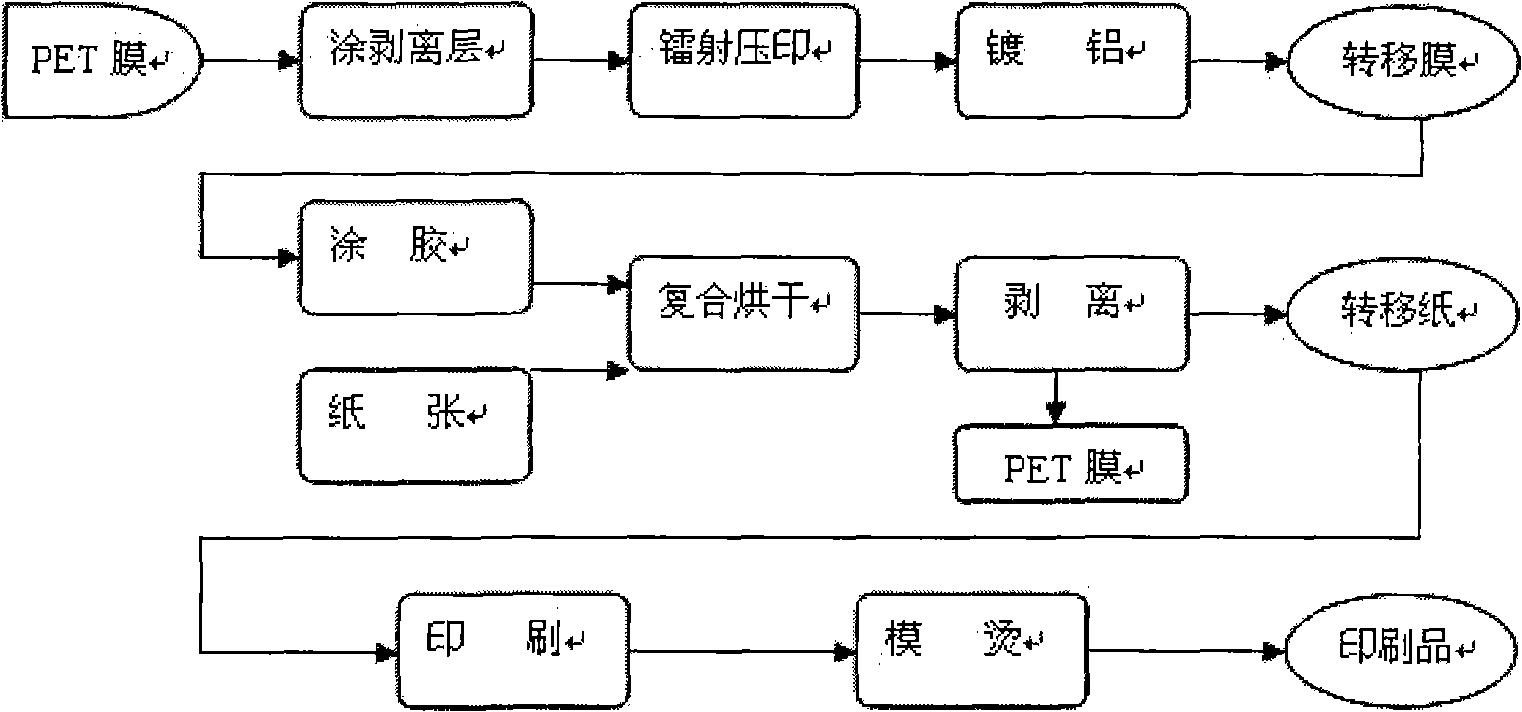

Image forming apparatus and image forming method

InactiveUS20090080949A1Quality improvementPrevent ink from flowingInking apparatusElectrographic process apparatusImage formationEngineering

Owner:FUJIFILM CORP

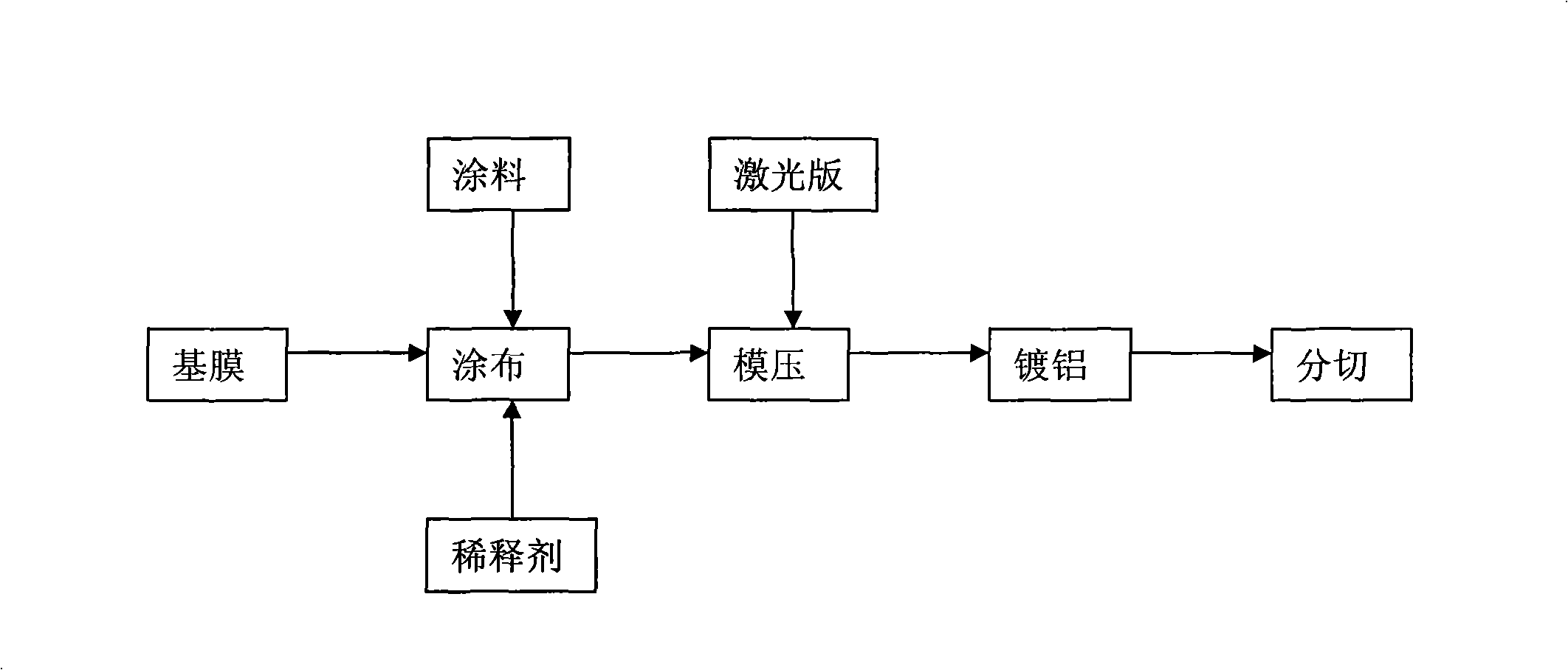

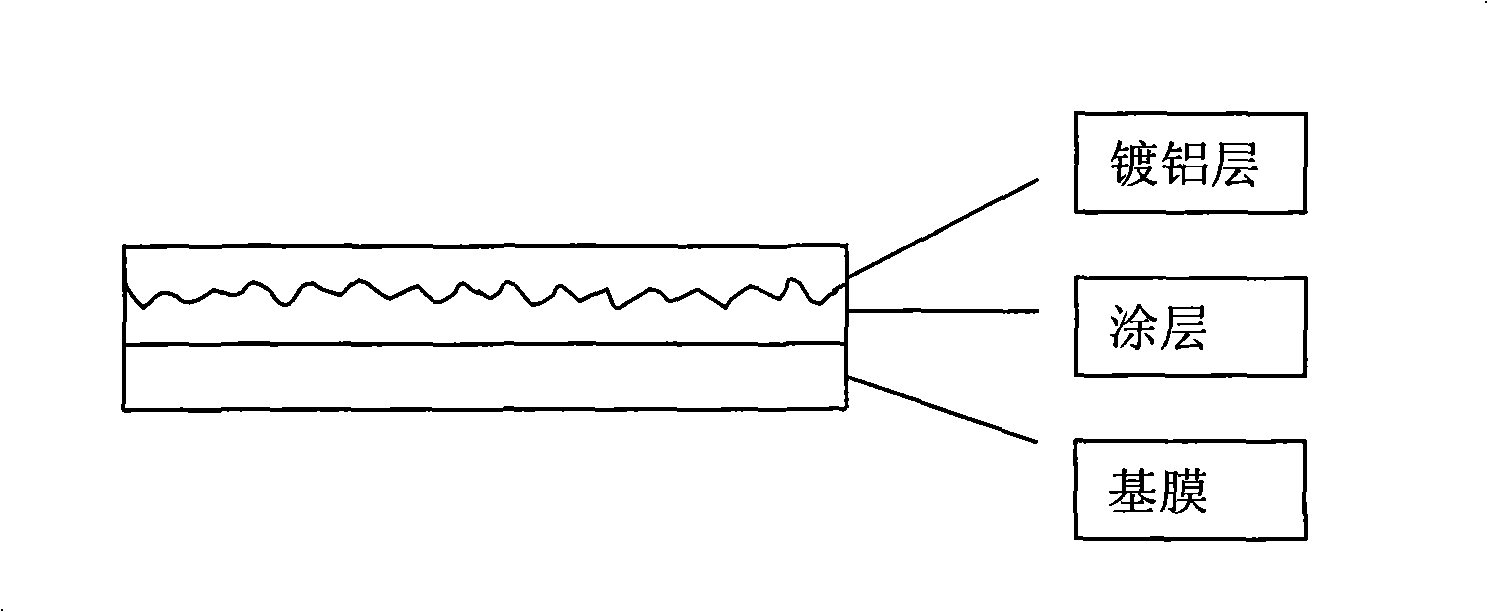

Process for producing PET laser transfer membrane

InactiveCN101537745ASimple processNovel processDecorative surface effectsPretreated surfacesBasementCoated membrane

The invention relates to a process for producing a PET laser transfer membrane. A PET membrane is used as a basement transfer membrane, and laser transfer pigment is coated and spread on the PET membrane. The method includes the following steps: a laser transfer pigment is coated and spread on the PET basement transfer membrane by an anilox roll at one step to form a coating layer, and a precoating membrane can be formed after the operation of drying is carried out; the precoating membrane is processed by the operation of laser mould pressing, and interference figures on a laser slab are printed on the coating layer of the precoating membrane by heat pressing so as to form a mould pressing membrane; and aluminum is coated on the mould pressing membrane, an aluminum layer is formed on an information layer, and the PET laser transfer membrane can be prepared, wherein the pigment includes thermoplastic acroid resin and cellulose acetate. The process has the advantages that the special singly coated laser transfer pigment and the unique manufacture process control are selected, and the entire process is simple, novel, stable and reliable. As the laser mould pressing transfer coating layer has the properties of easy mould pressing, favorable stripping, and the like, the operation of coating just needs to be carried out for one time, and therefore the production efficiency can be greatly improved. After being transferred and stripped, the aluminum coated membrane can be recycled to be repeatedly used for many times, and therefore cost can be greatly reduced; and the PET laser transfer membrane is the environmentally friendly anti-counterfeit laser material for packaging and printing.

Owner:上海宝绿包装材料科技有限公司

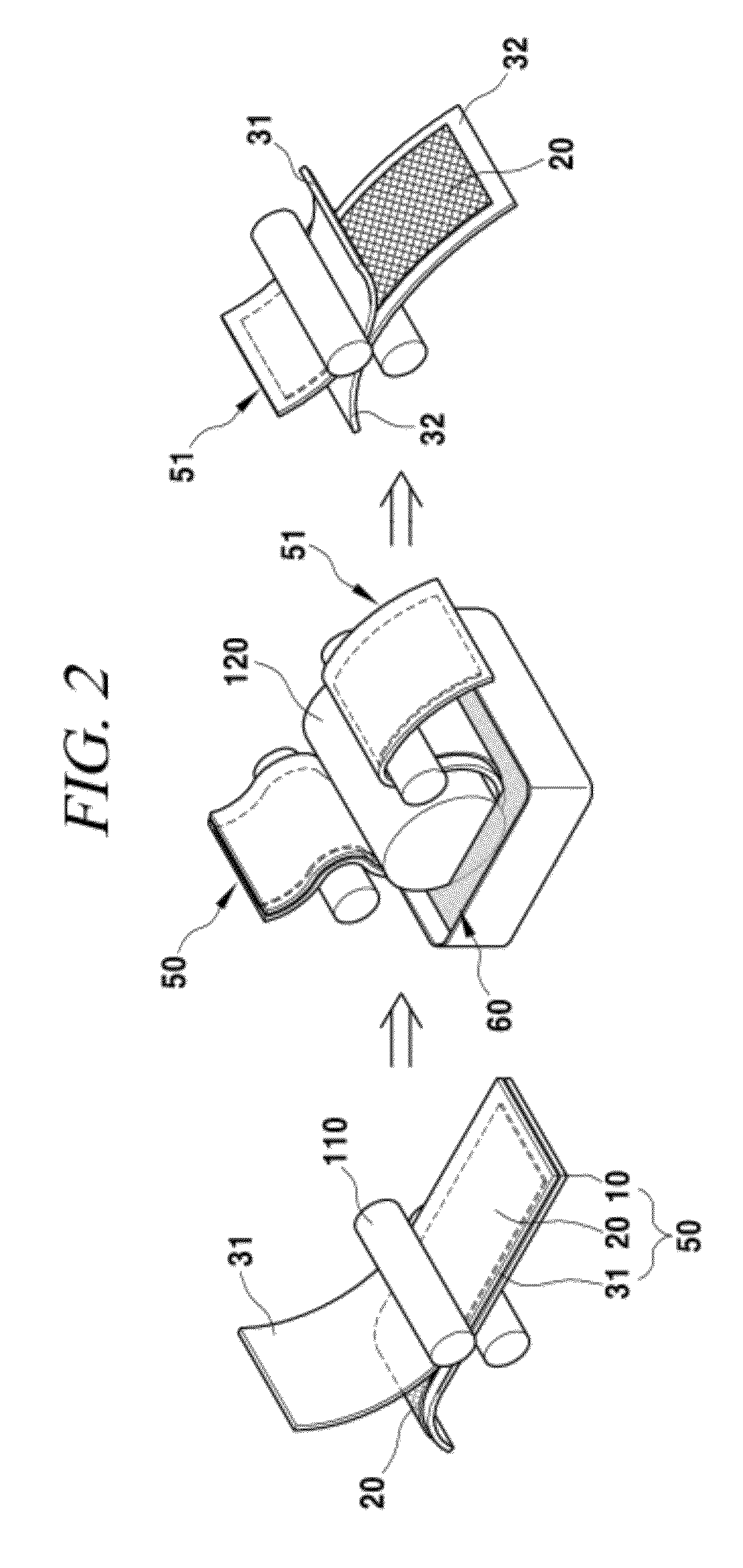

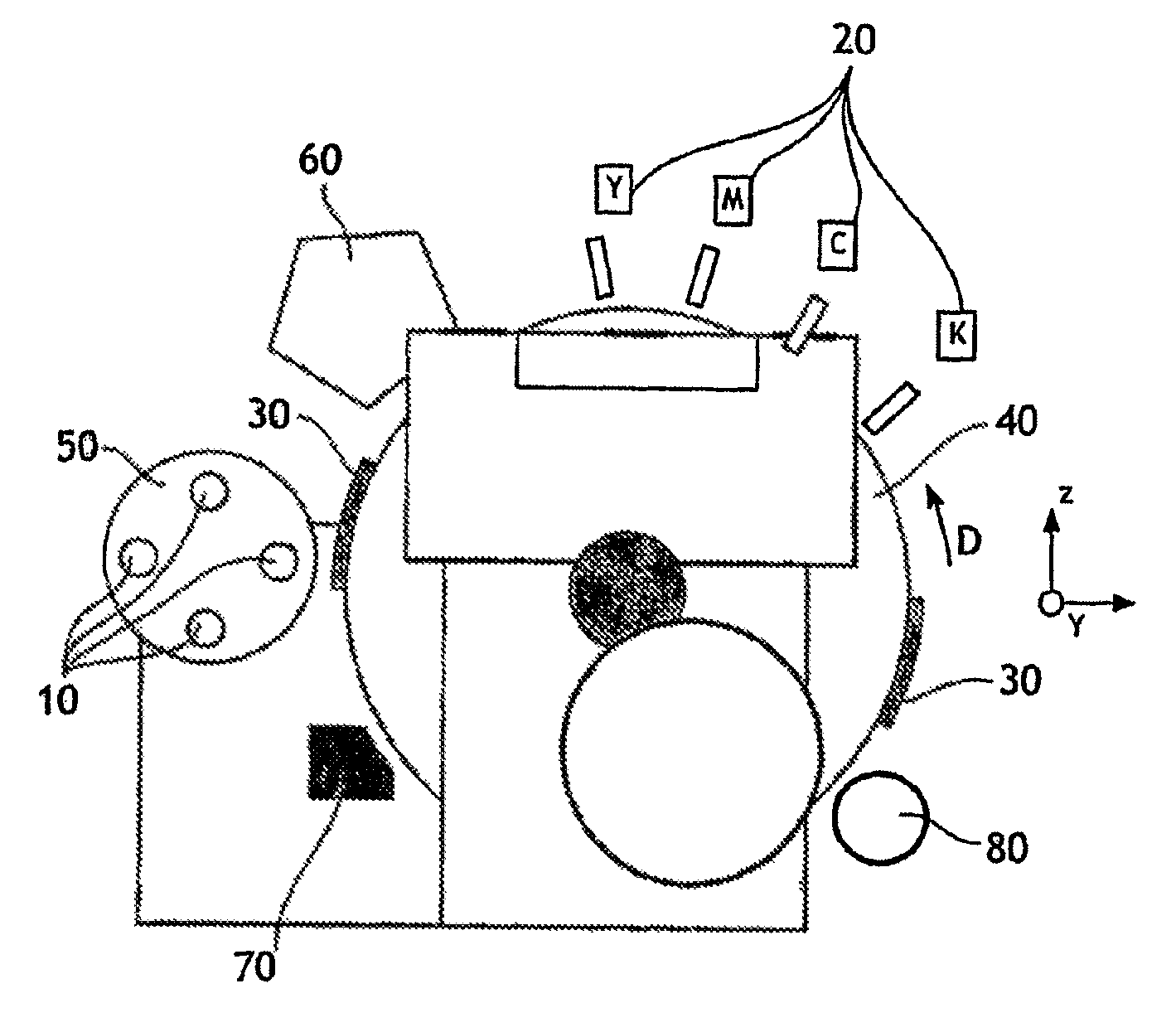

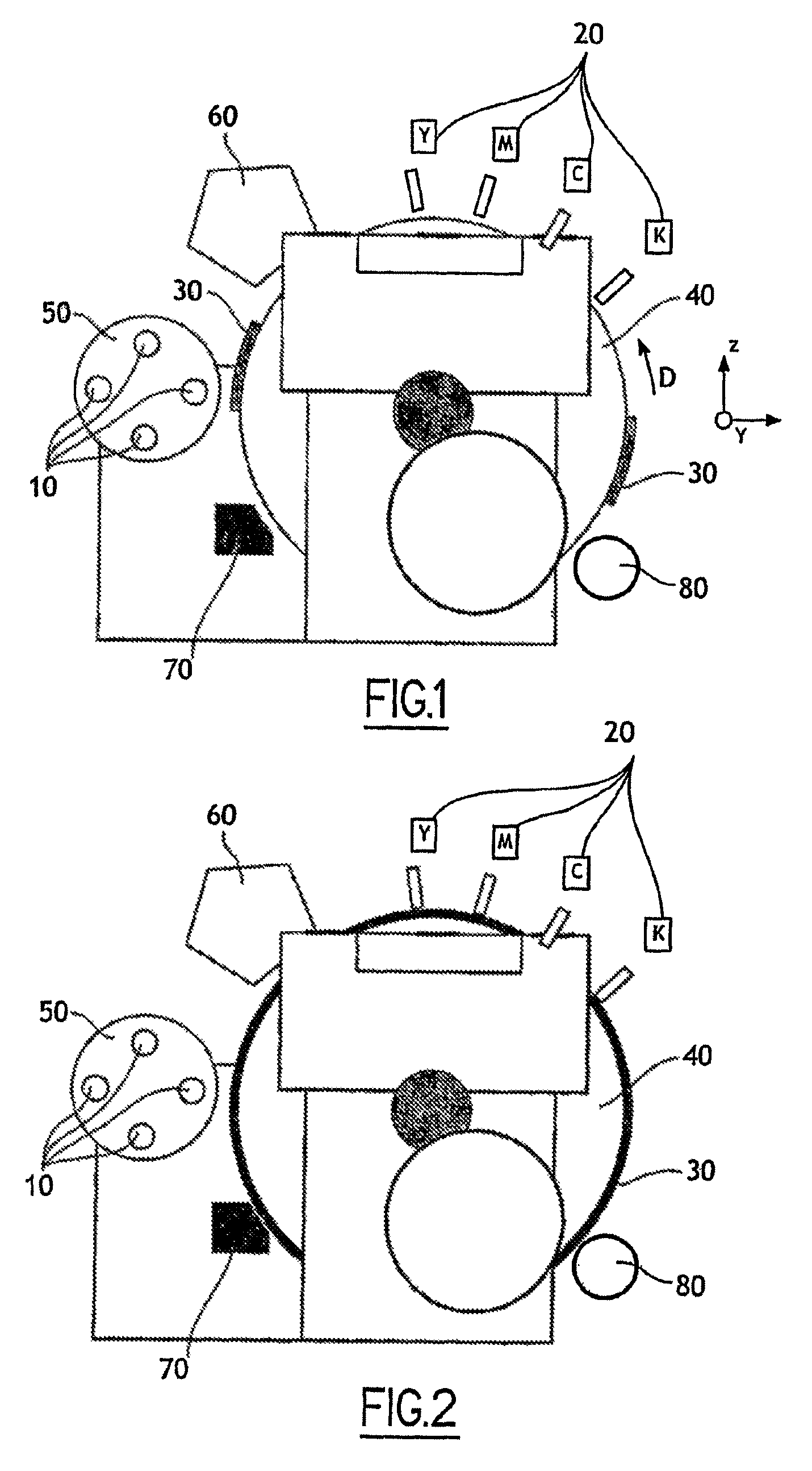

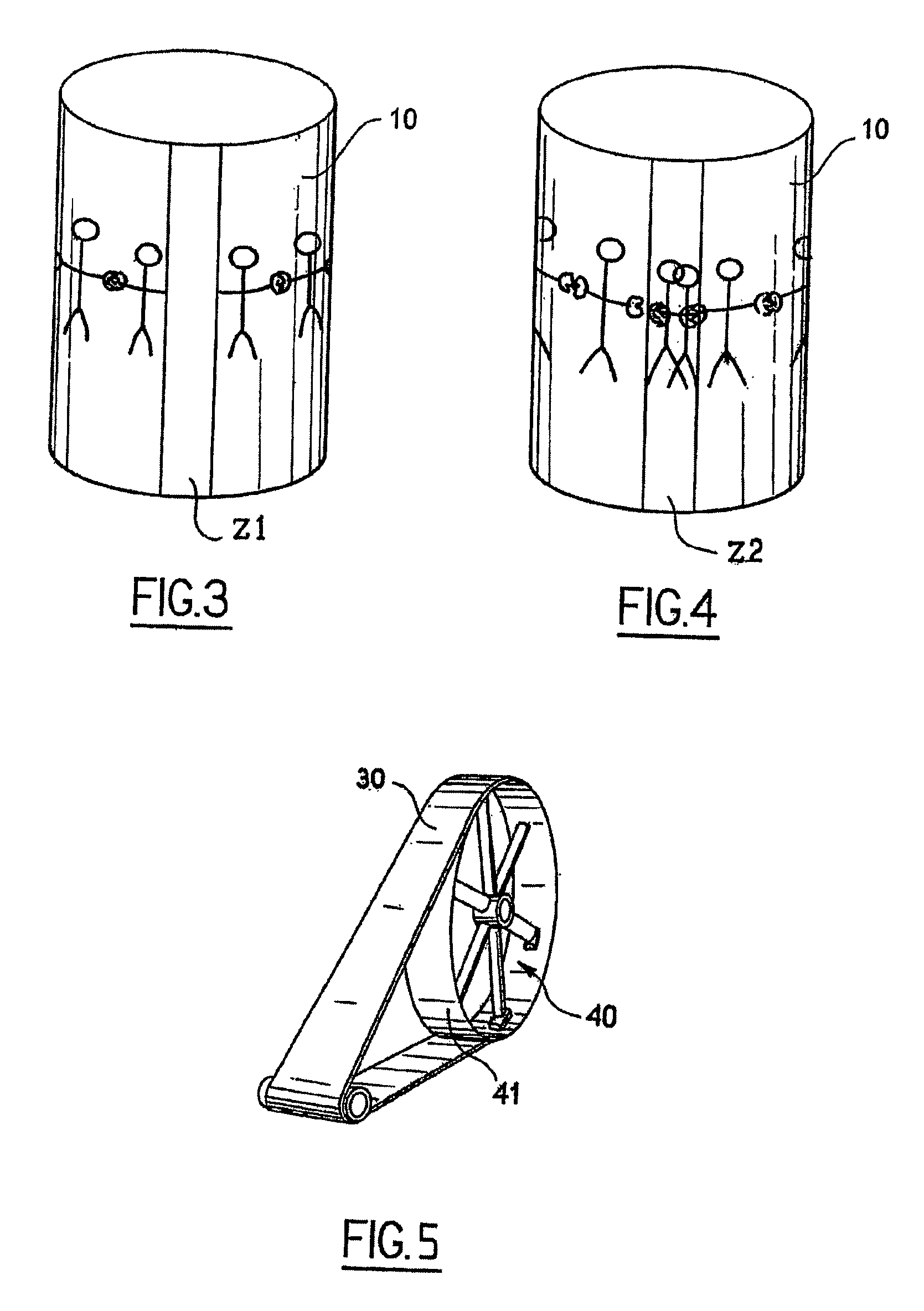

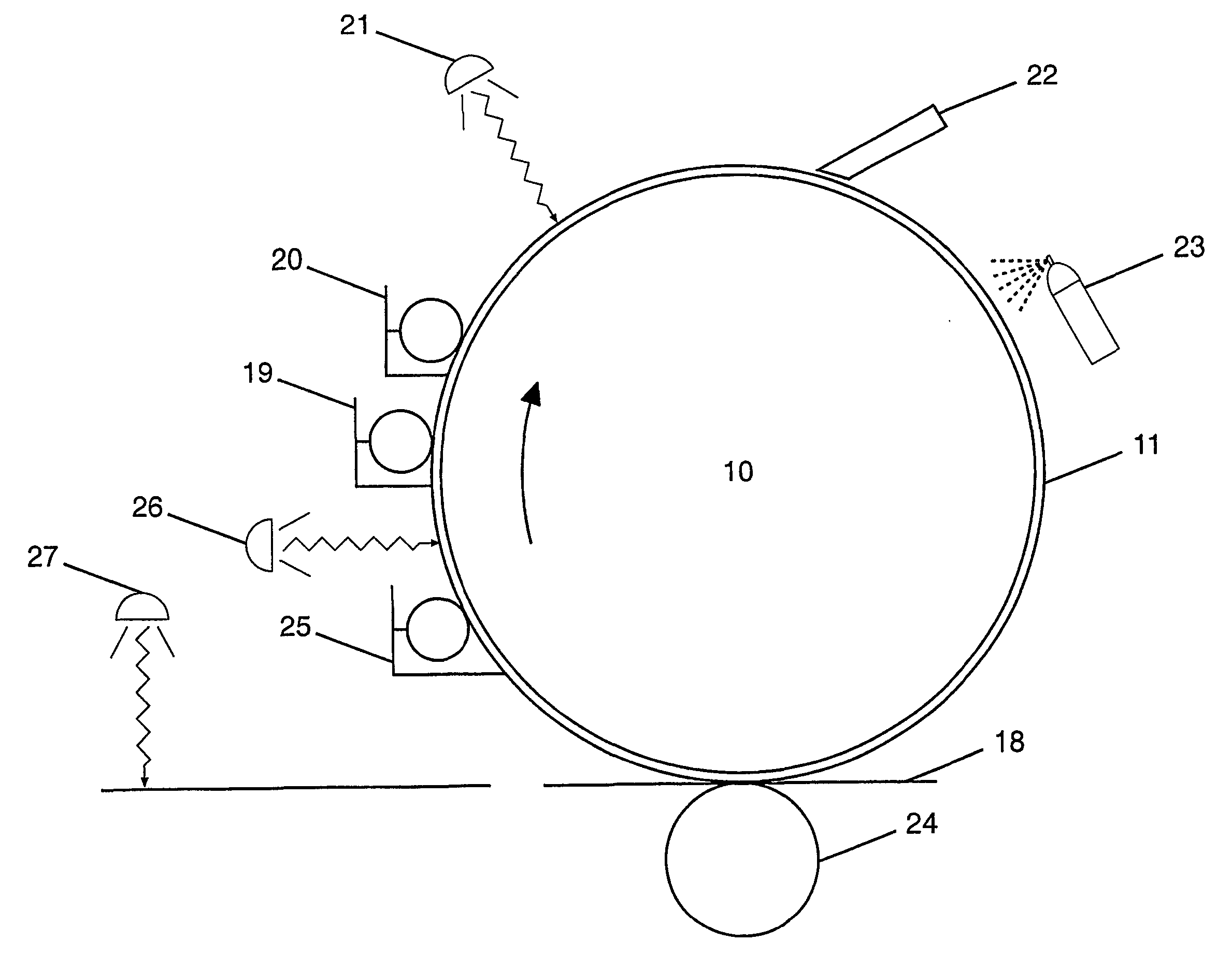

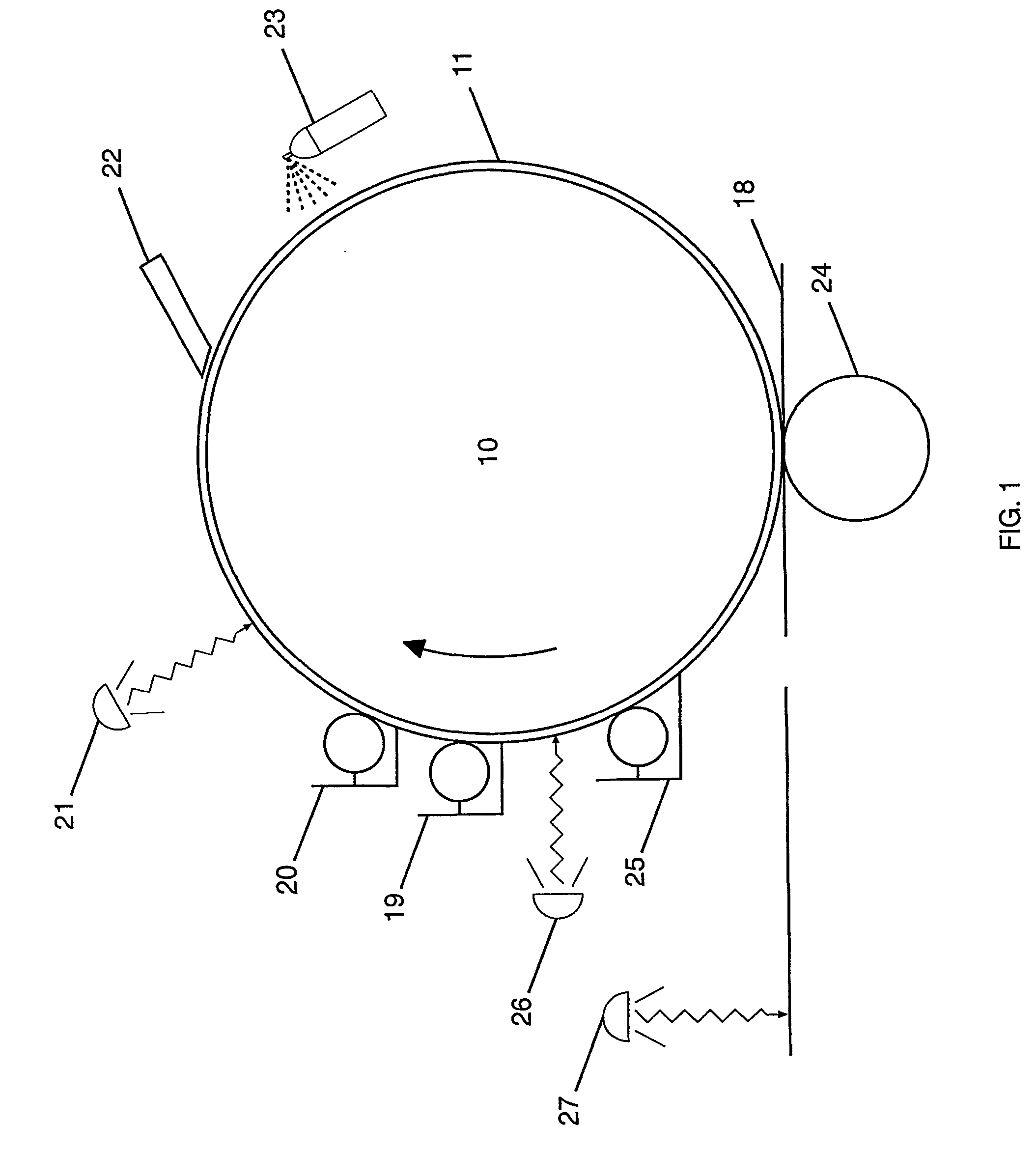

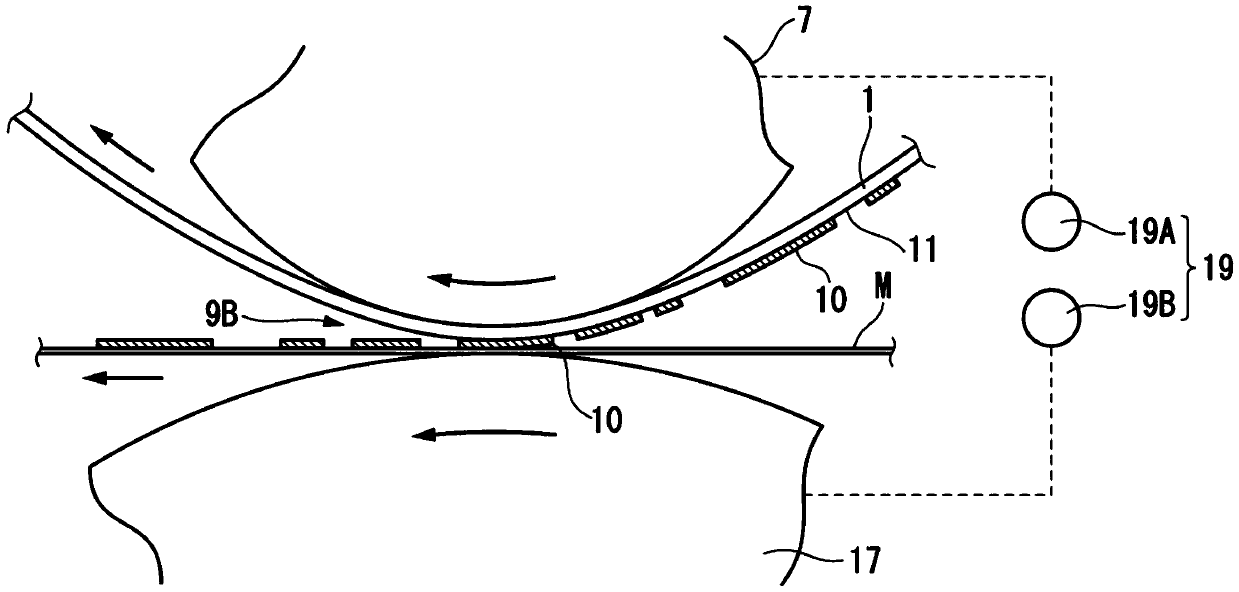

Device and method for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

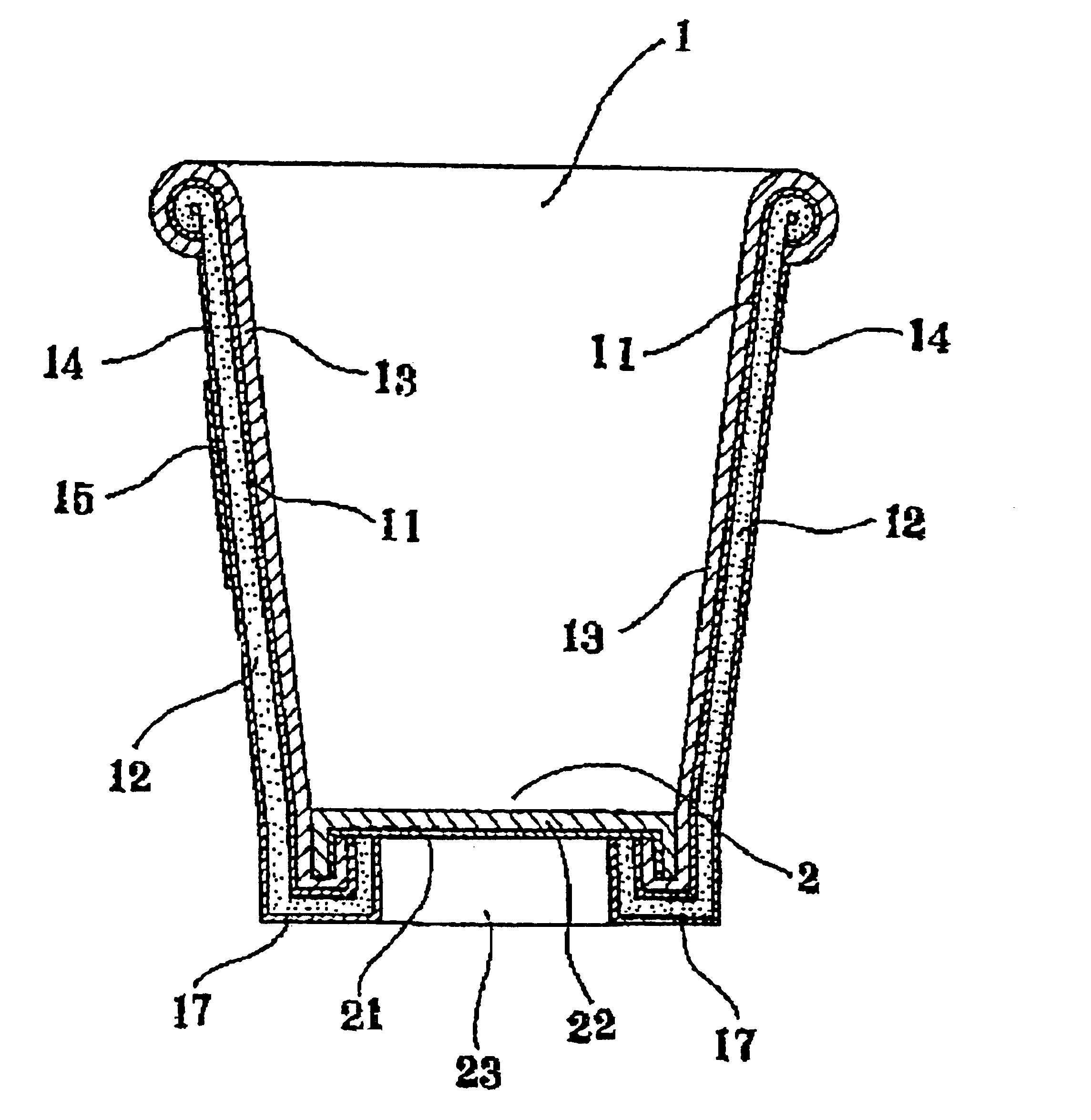

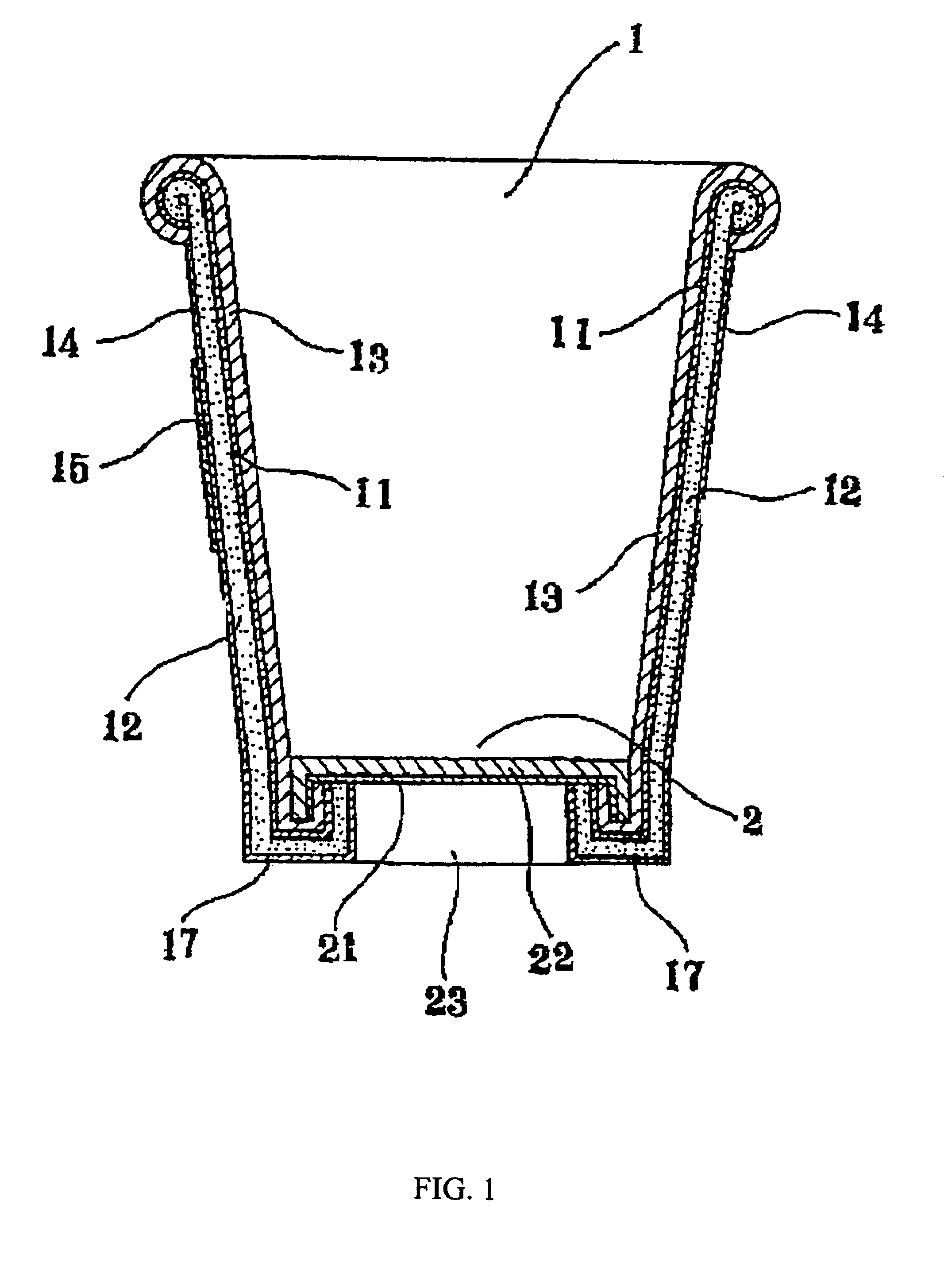

Stock material for container body of insulating paper container, insulating paper container and process for making them

InactiveUS6908651B2Good printabilityPaper/cardboardContainer/bottle contructionEngineeringSynthetic resin

An insulating paper container's body has a low m.p. thermoplastic synthetic resin film laminated on its outer wall surface and a compatibly expansile ink applied to the outer surface either as a primer or as indicia to provide stock material improved in its printability for bar codes or the like as well as in its insulating property. In addition there is provided a process for making such stock material.

Owner:SOLO CUP OPERATING CORP

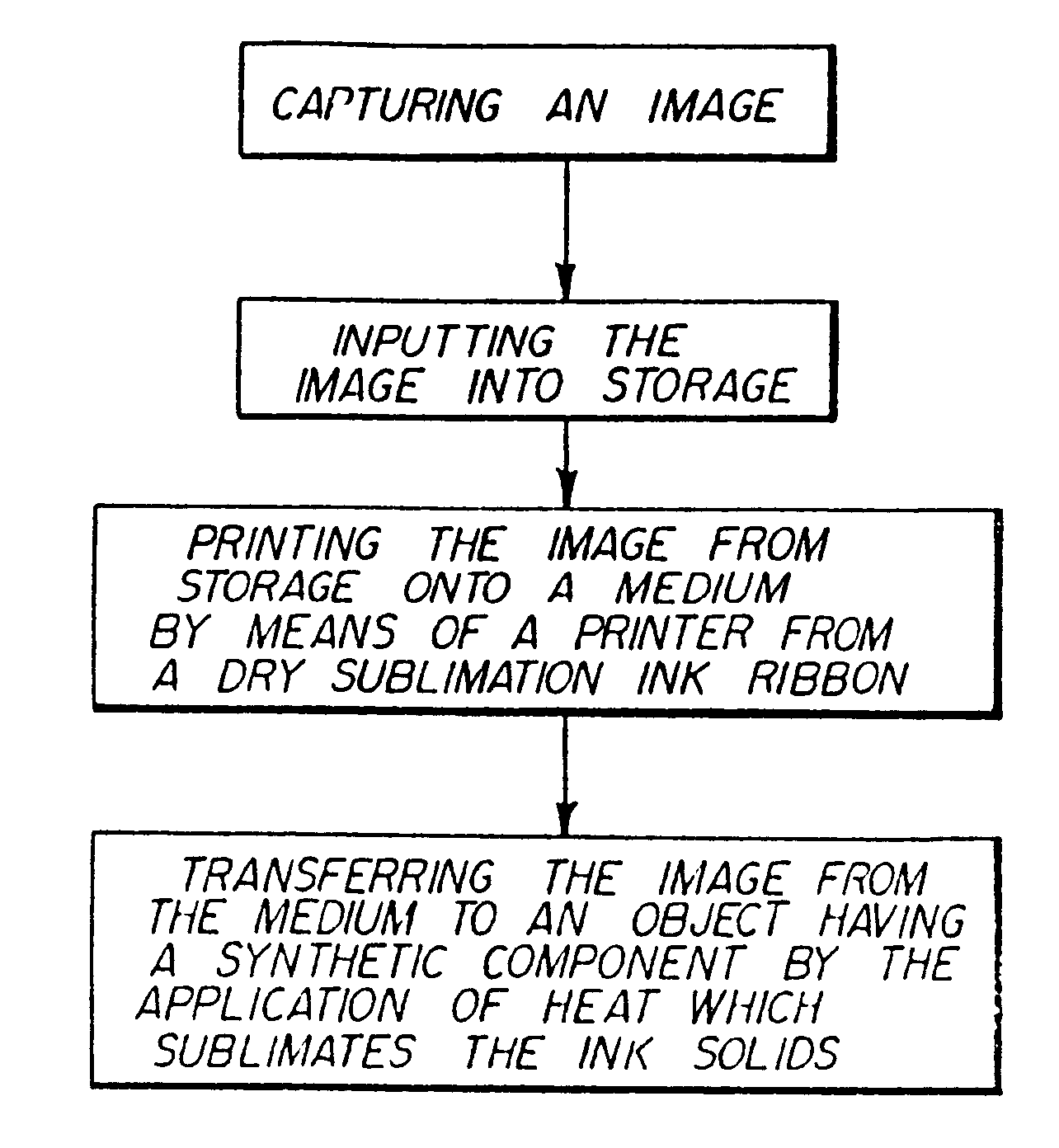

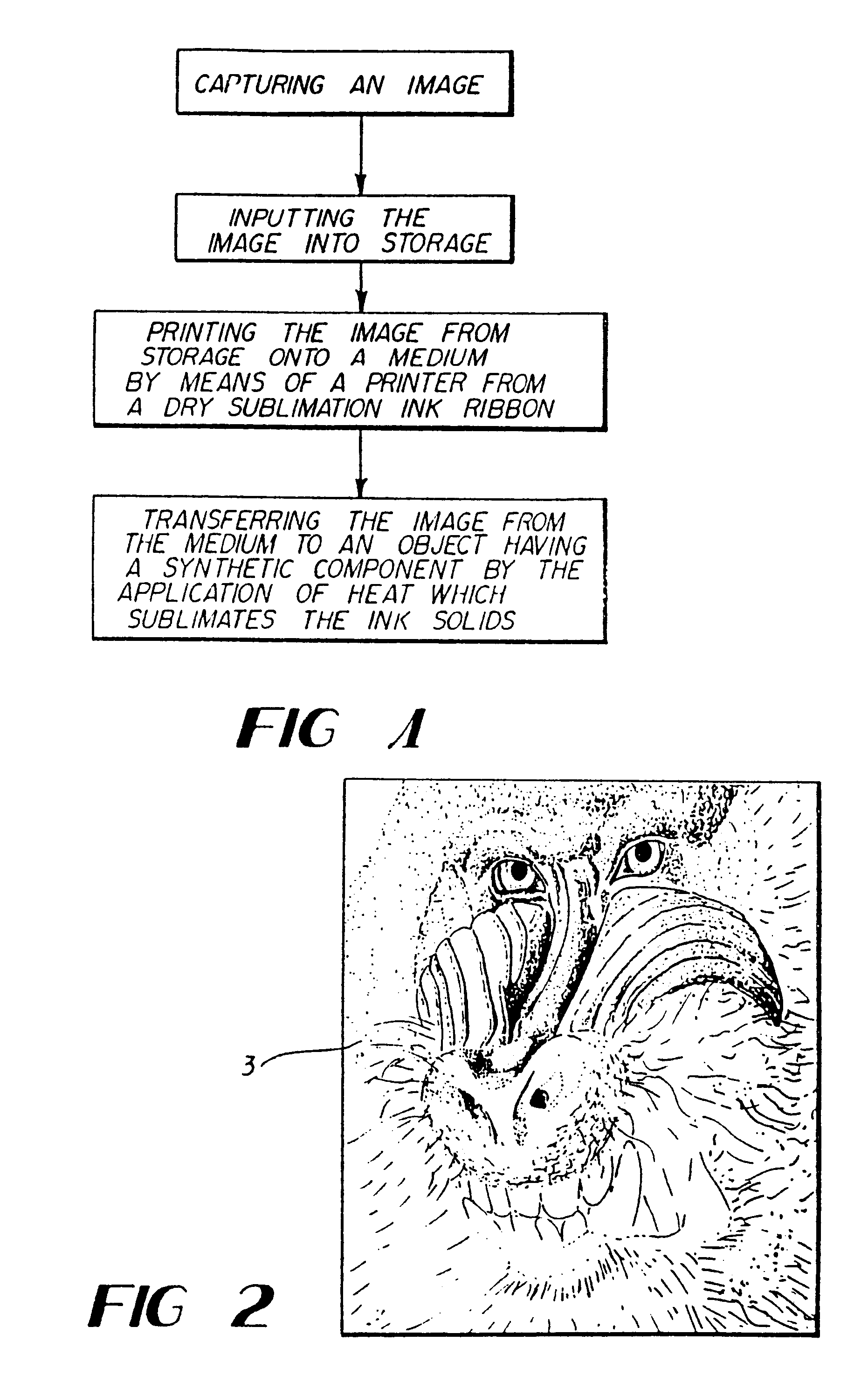

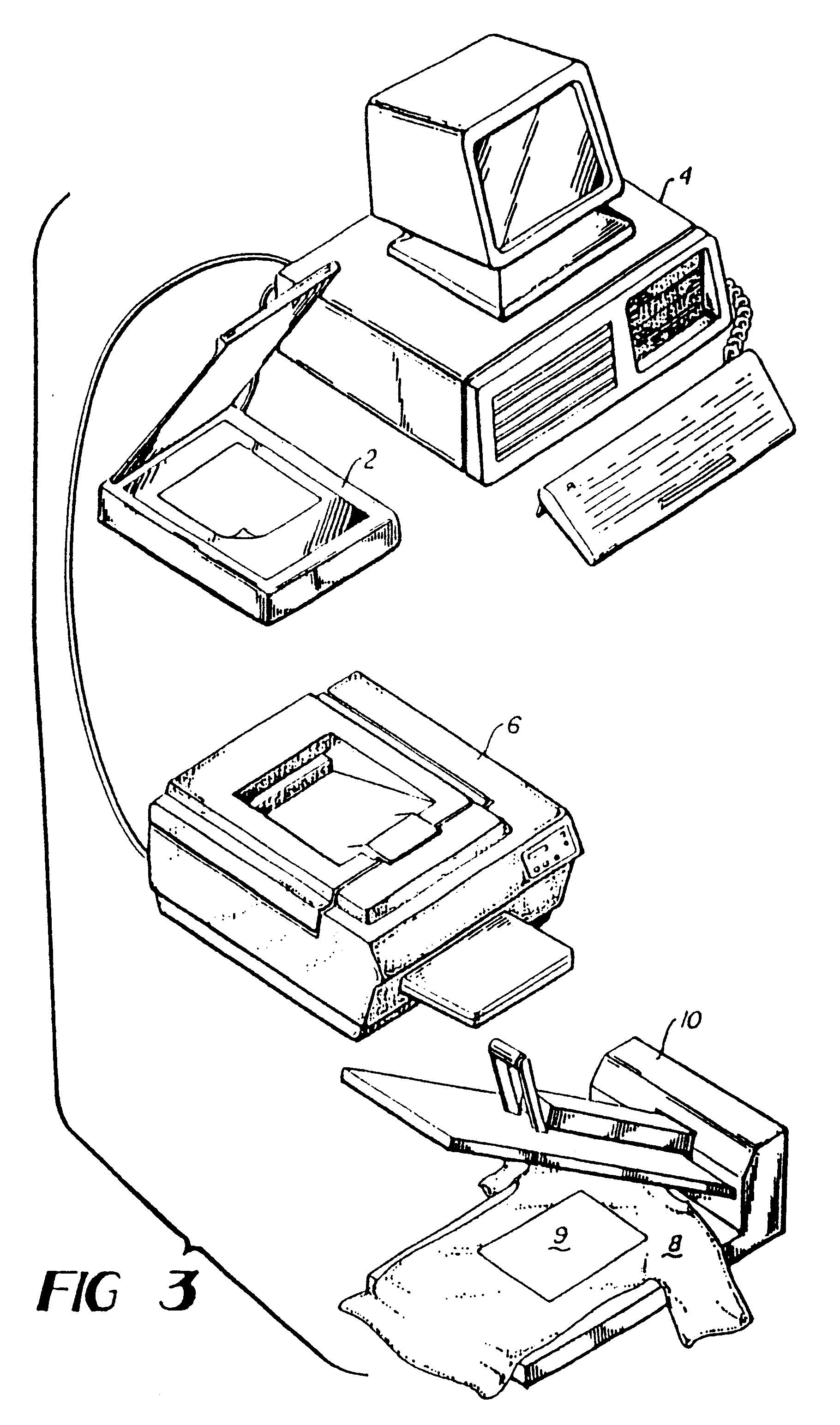

Permanent heat activated ink jet printing process

InactiveUS6450098B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsEngineeringComputer drive

Owner:SAWGRASS SYST INC

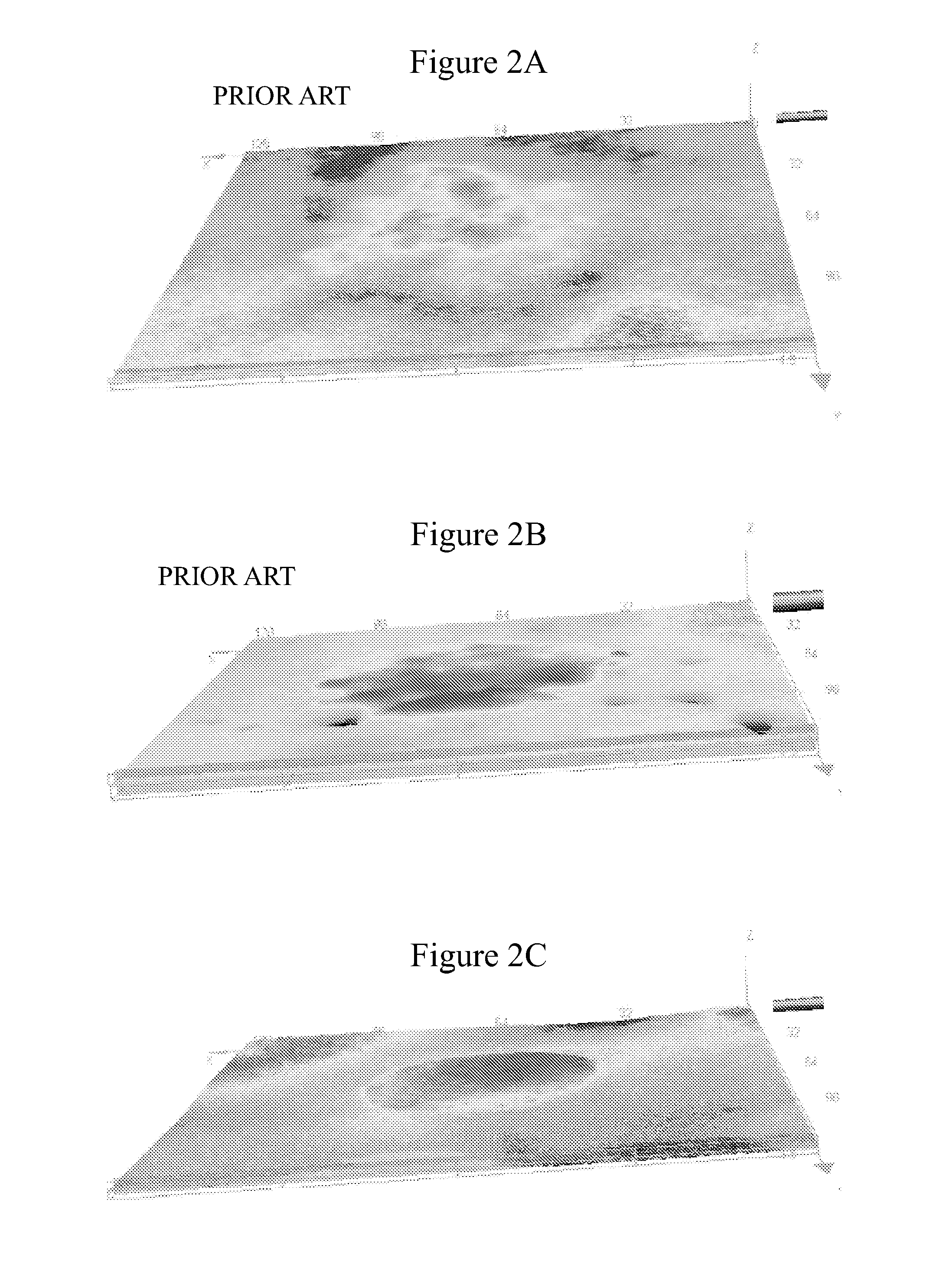

Method of printing variable information

The gel method of printing variable information of the present invention involves applying inks onto a substrate that is part of or attached to a cylinder of the printing machine. Imaging is by means of an energy source in the UV, visible or infrared regions, modulated to represent a digital image pattern that has been composed on a computer. The consequence of imaging is to gel the ink and increase its adhesion to the substrate of the printing cylinder. The non-gelled background ink with lower adhesion is then removed by a squeegee action and returned to an ink reservoir. The remaining image is transferred to an offset blanket or directly to print stock by pressure. The process does not use a master, but produces an image that is erased after printing with each cylinder rotation so that the next rotation producing the next print can have fresh information written upon it.

Owner:KODAK IL

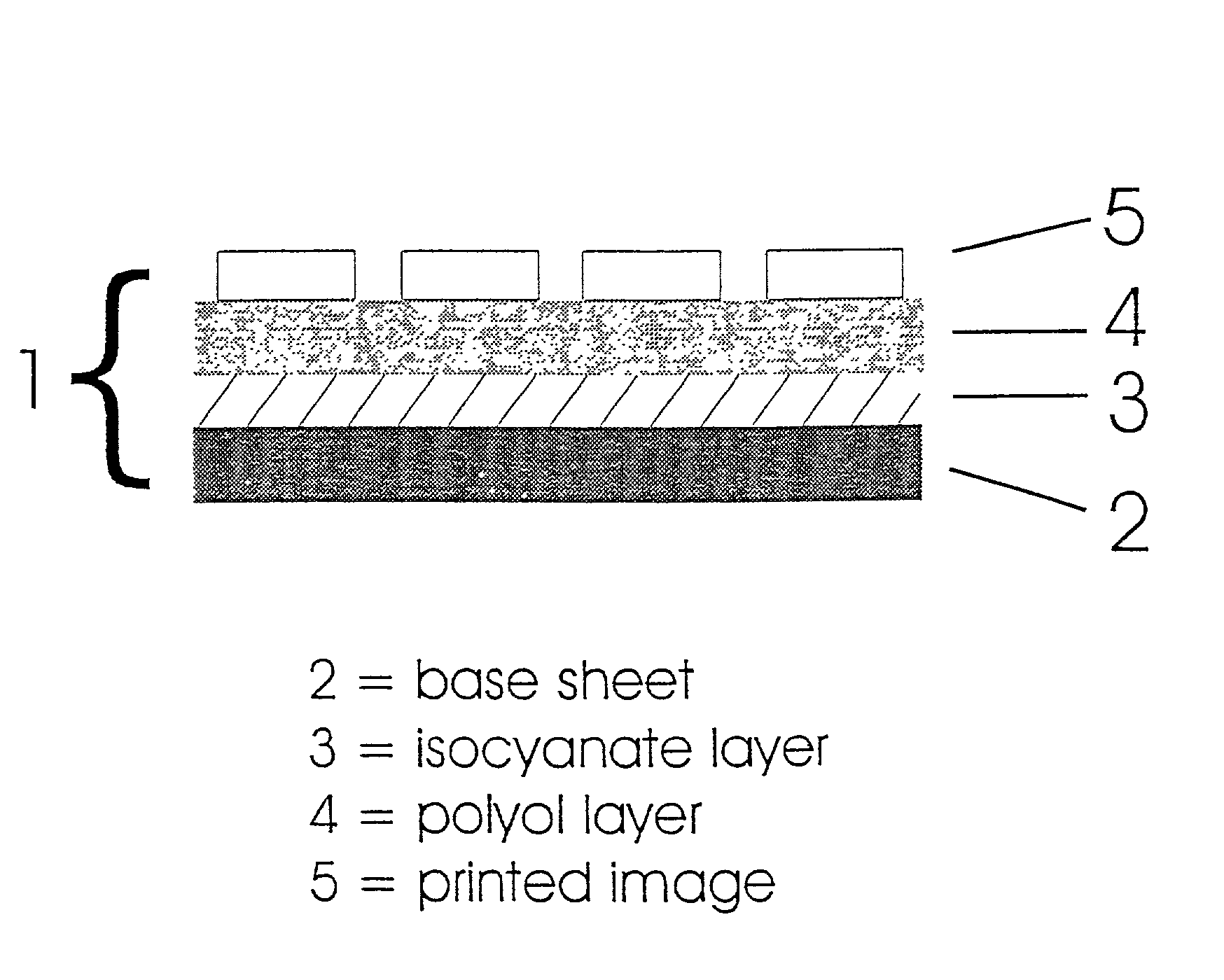

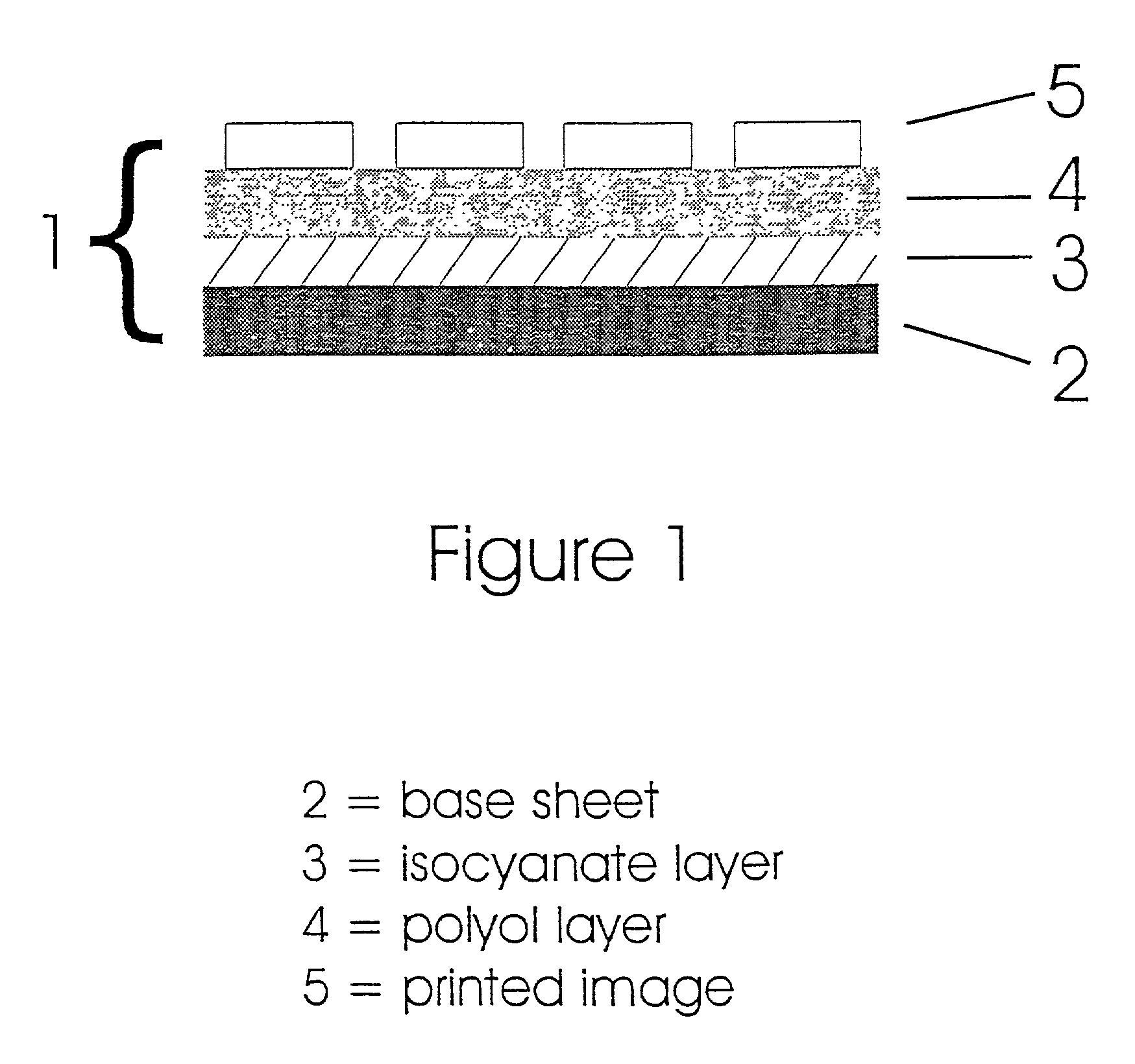

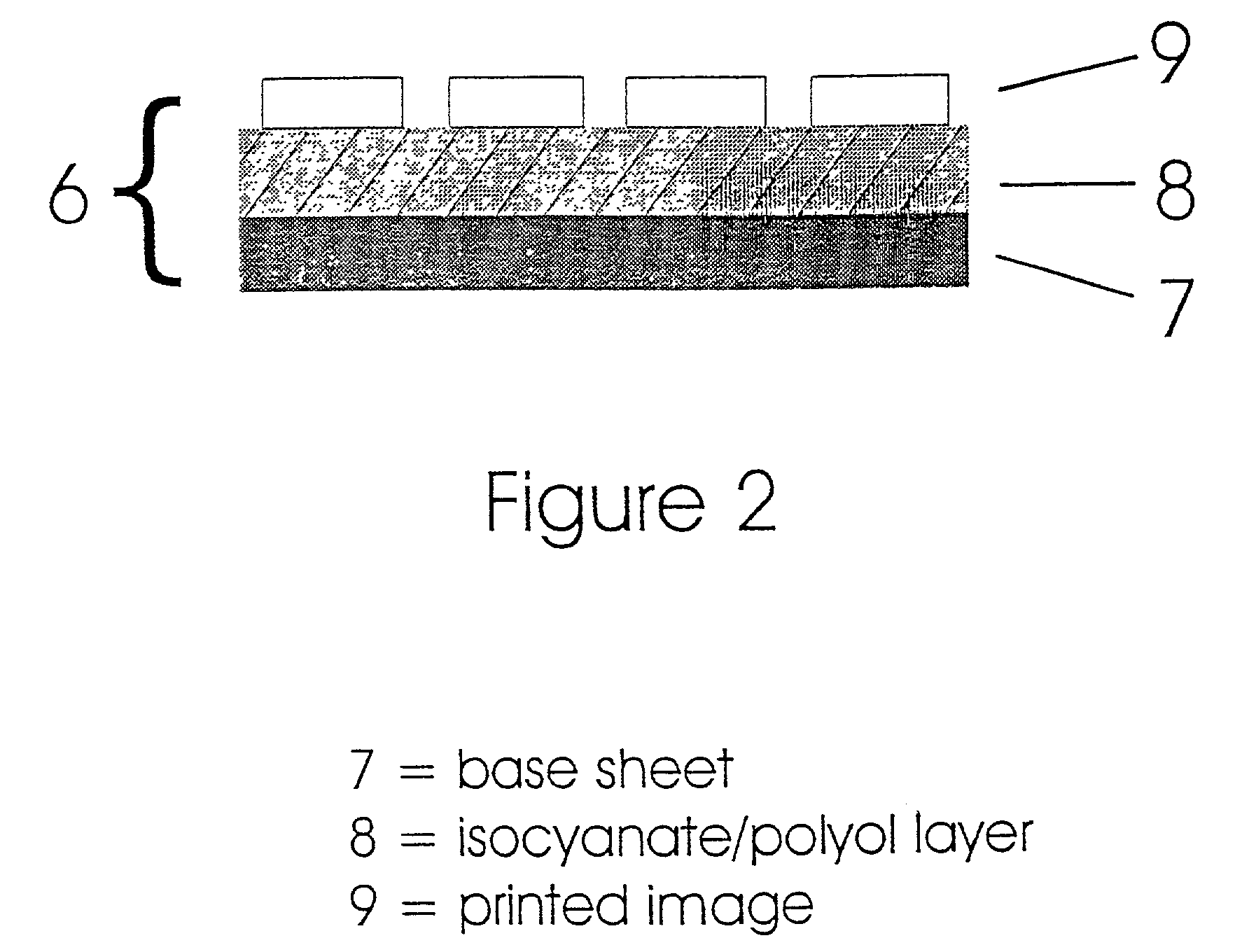

Intermediate transfer recording medium

InactiveUS7001649B2Avoid premature reactionExcellent abrasion resistanceDecorative surface effectsTransfer printing processColor imageHydrogen

A color image is digitally printed onto an intermediate transfer medium. The image is subsequently transferred from the intermediate transfer medium to a final substrate, which may be a cellulosic textile, such as cotton. Bonding of the color images is provided by the reaction between compounds selected from each of two chemical groups contained in the intermediate transfer medium. The first groups comprises compounds with functional groups capable of reacting with active hydrogen, such as isocyanate or epoxy groups. The second group comprises compounds with functional groups containing active hydrogen, or compounds with functional groups containing active hydrogen after a conversion process. The functional groups of one or both reactive chemical groups may be protected either by blocking with internal or external blocking agents or by a physical barrier such as encapsulating agents. The blocking agents are removed by the application of energy, such as heat, during the transfer of the image from the intermediate transfer medium to the final substrate. The intermediate transfer medium may be comprised of additional components which may be combined with either or both of the above two chemical groups, or applied as separate layers. Examples of such components are a thermally expandable material, an exothermic chemical, a release agent, and / or absorbent material. Transferred images so produced have a soft hand, particularly when applied to a textile, and excellent fade and abrasion resistance.

Owner:SAWGRASS TECH INC

Production method of environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film

InactiveCN101570090APromote environmental protectionThermographyInk transfer from master sheetPolyvinyl butyralAcrylic resin

The invention relates to a production method of an environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film. The production method comprises the following steps: a PET film of 6 to 15 micron is adopted as a carrier film; the carrier film is sequentially provided with four coatings such as a releasing layer, a color layer, an aluminum layer and an adhesive layer; wherein the releasing layer, the color layer and the adhesive layer coat the coating materials on a PET basal membrane substrate by a smooth roll or an anilox roll in a forward coating mode or backward coating mode; the aluminum layer is spray-plated in a vacuum spray-plating mode; the invention adopts the environment-friendly material and the production technique to produce the aluminothermic transfer printing film product, and the key points are as follows: solvent based acrylic resin, ethylene-vinyl acetate resin, ketone resin and cellulosic resin hot melt adhesive are changed into cellulose acetate and products made by cellulose acetate; and vinyl cellulose, polyvinyl butyral and powdery silicon dioxide are synthesized by water and a mixed solvent in a mode of wetting and dispersing. The production method has the characteristics of having no solvent residue harmful to human body and being beneficial to environmental protection and the like.

Owner:莫国平

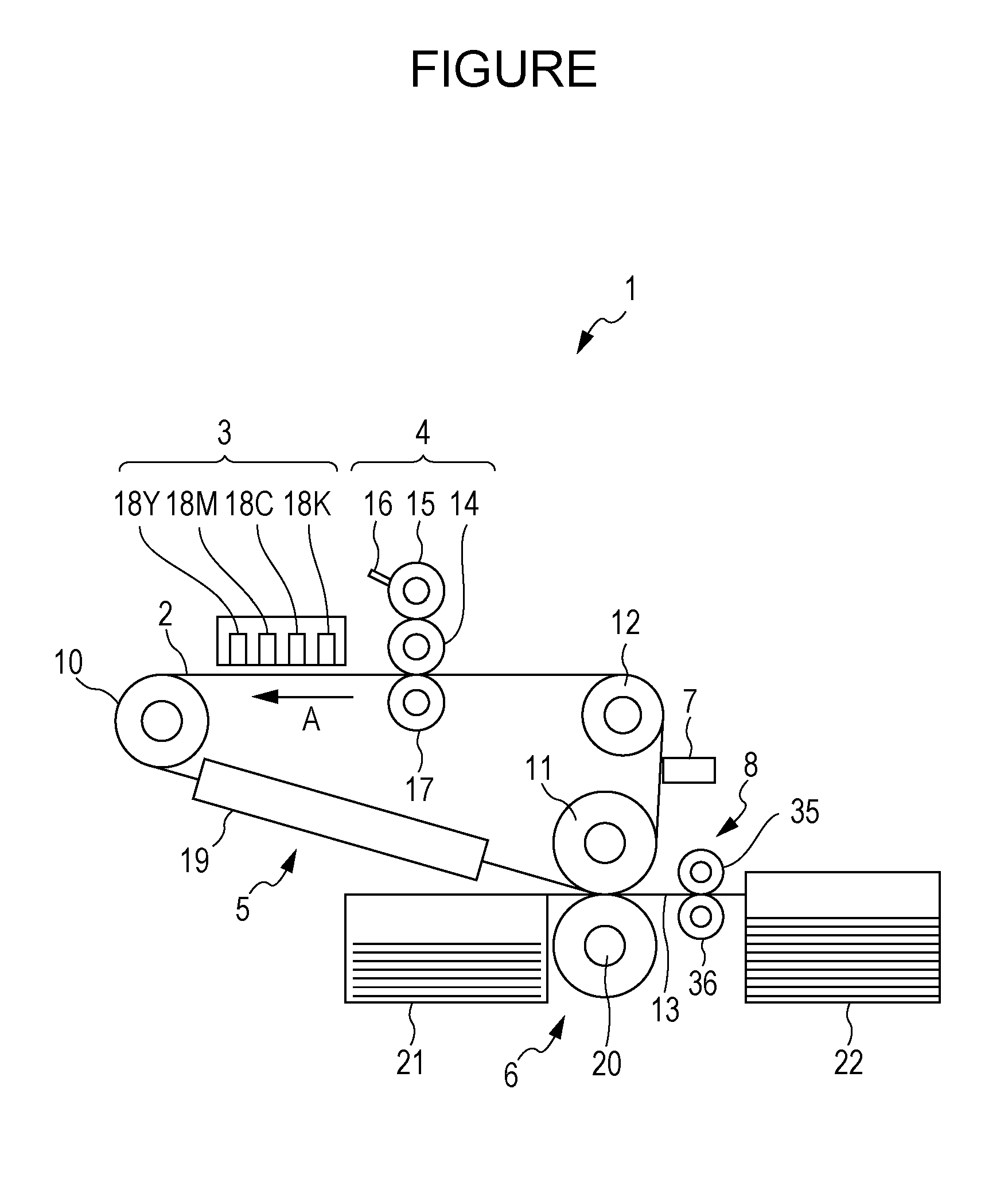

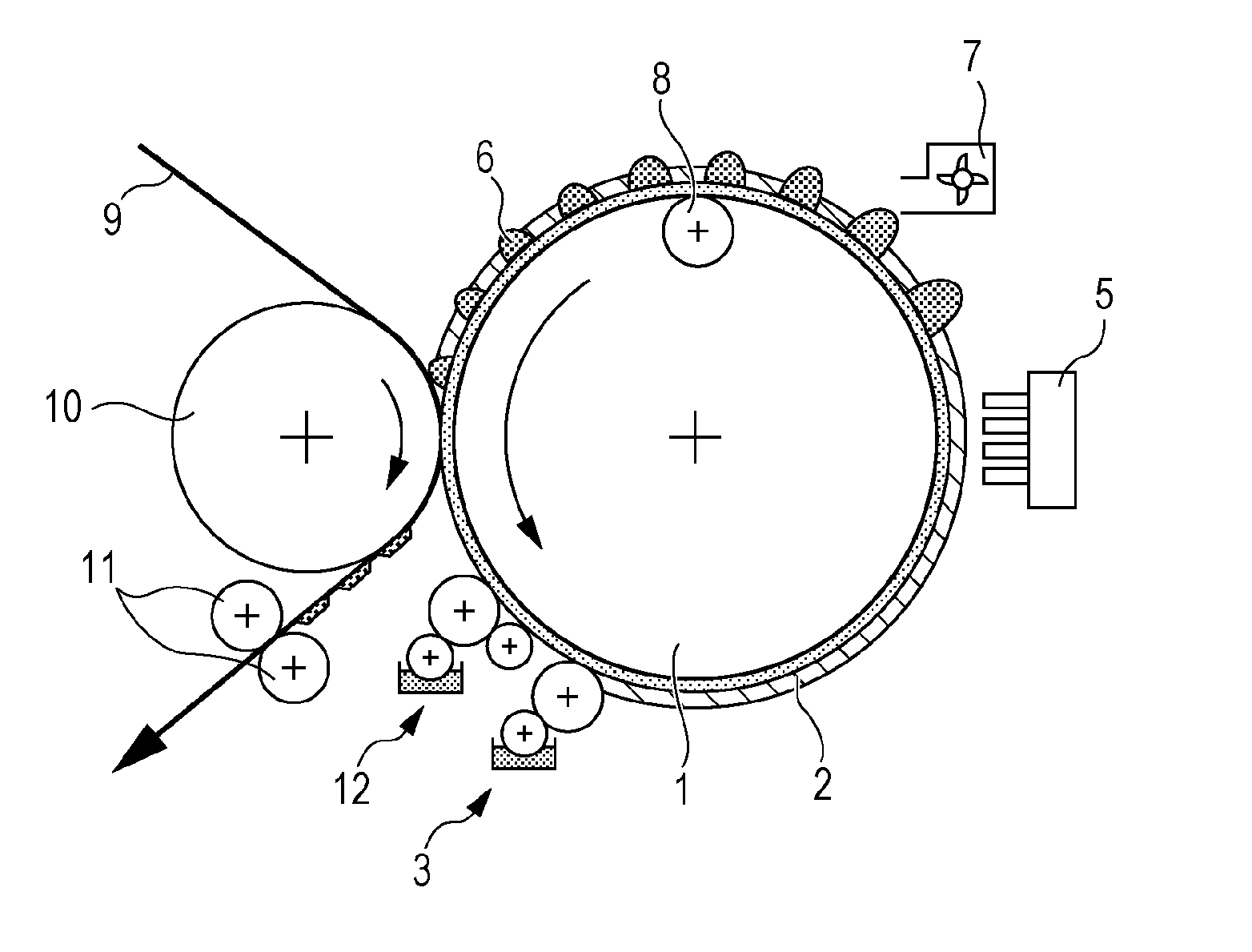

Transfer inkjet printer device

InactiveCN103991293ALess unevenIncreased durabilityInking apparatusInk transfer from master sheetIntermediate imageElectric field

The invention relates to a transfer inkjet printer device including an intermediate transfer body including an intermediate transfer surface capable of moving along a rotation route; an inkjet head used to discharge ink including toner particles onto the intermediate transfer surface at a first area in the rotation route in a state where the toner particles are charged, so as to form an intermediate image composed of an ink layer on the intermediate transfer surface; a pressure device used to press the ink layer of the intermediate image on the intermediate transfer surface, onto a surface of a recording medium at a second area in the rotation route; and an electric field application device used to electrophorese the charged toner particles in the ink layer of the intermediate image toward the recording medium at the second area.

Owner:MIYAKOSHI PRINTING MACHINERY

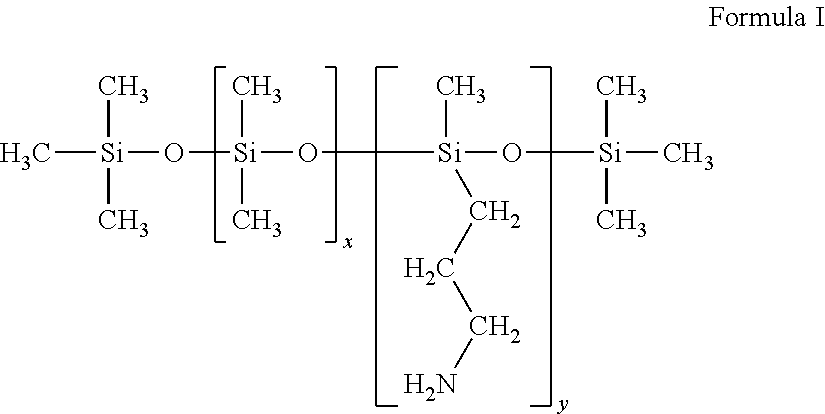

Transfer type inkjet recording method

ActiveUS20120127251A1Good transferabilityIncrease resistanceInksInk transfer from master sheetPolyurethane

A transfer type inkjet recording method uses an aggregation liquid, in which the aggregation liquid contains a polyurethane resin having an amino group and the polyurethane resin has a number average molecular weight of 10,000 or more and 1,000,000 or lower and an amine value of 0.5 mmol / g or more and 3.0 mmol / g or lower.

Owner:CANON KK

Image-forming method

ActiveUS20130088543A1Quality improvementInksInk transfer from master sheetIntermediate imagePhotochemistry

An image-forming method includes a reaction solution-applying step of applying a reaction solution containing a thickening agent and a colorant-aggregating component aggregating a colorant in ink to an intermediate transfer medium, a first ink-applying step of applying a first ink to the intermediate transfer medium provided with the reaction solution, a second ink-applying step of applying a second ink to the intermediate transfer medium provided with the first ink, and a transfer step of transferring an intermediate image formed on the intermediate transfer medium provided with the second ink to a recording medium. An ink layer formed on the intermediate transfer medium by applying the first ink thereto has a yield value of 0.5 Pa or more.

Owner:CANON KK

Image transfer material with image receiving layer and heat transfer process using the same

InactiveUS6869910B2Cost efficientDecorative surface effectsAblative recordingWater dispersiblePrecipitated calcium carbonate

An image transfer sheet, having a support sheet, an optional barrier layer on the support sheet, at least one heat release layer on the optional barrier layer or on the support sheet, an image receiving layer on the heat release layer, an optional image layer on the image receiving layer, an optional non-water-dispersible polymer layer on the image layer, and an optional transfer blocking overcoat layer on the optional polymer layer or the image layer, is used in a dry heat transfer process to transfer an image to a receptor element. The image receiving layer of the present invention is a precipitated calcium carbonate (PCC)-containing image receiving layer, a polyvinylpyrrolidone (PVP)-containing image receiving layer, or an image receiving layer containing both PCC and PVP (PCC / PVP).

Owner:SCHWENDIMANN JODI

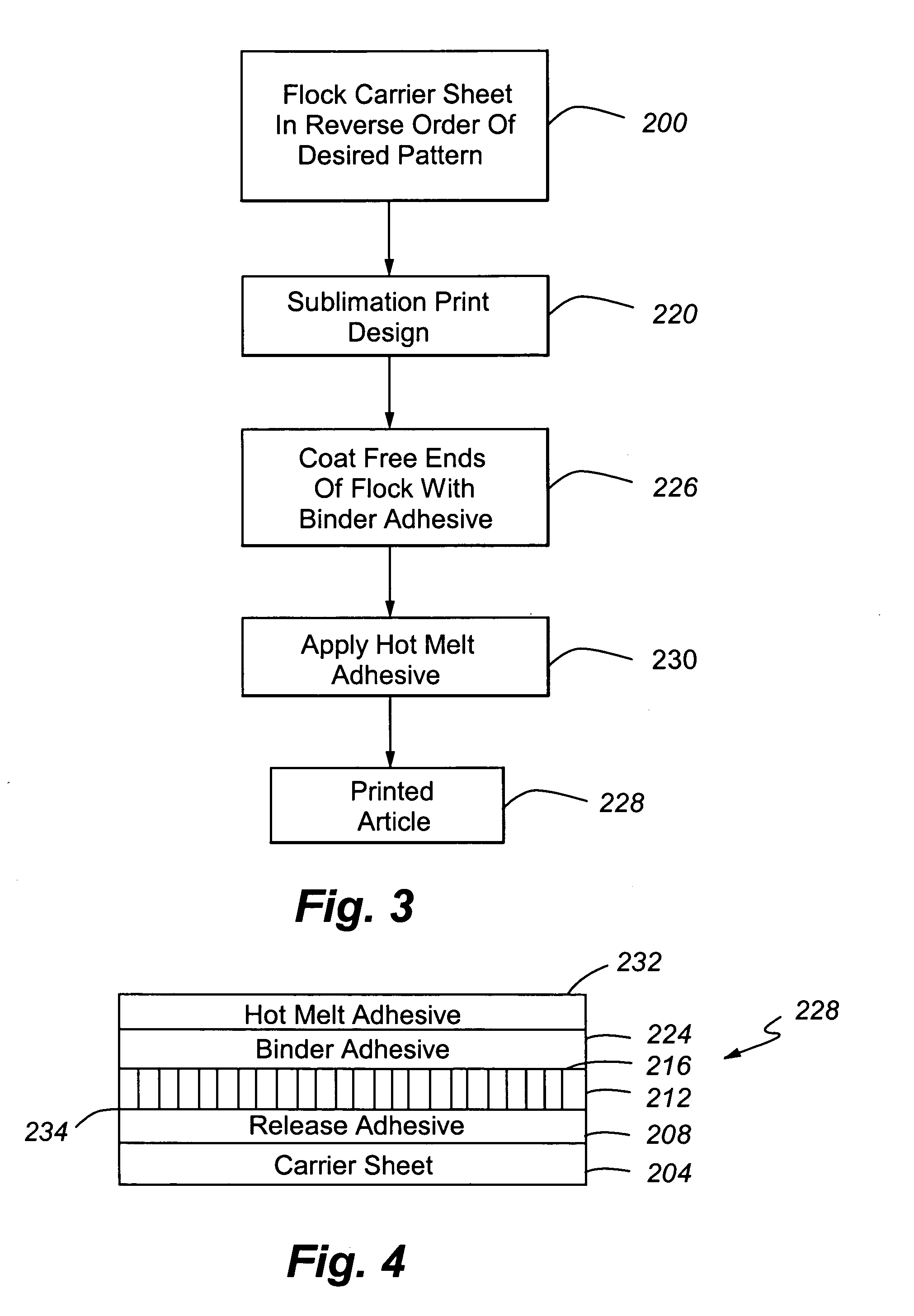

Process for printing and molding a flocked article

InactiveUS20050266204A1Feel goodSoft touchLiquid surface applicatorsTransfer printing processFiberTextile printer

Owner:HIGH VOLTAGE GRAPHICS

Water-based ink composition, ink set and image recording method

Owner:FUJIFILM CORP

Image forming apparatus and image forming method

InactiveUS8025389B2Quality improvementDecline in qualityInking apparatusElectrographic process apparatusImage formationEngineering

Owner:FUJIFILM CORP

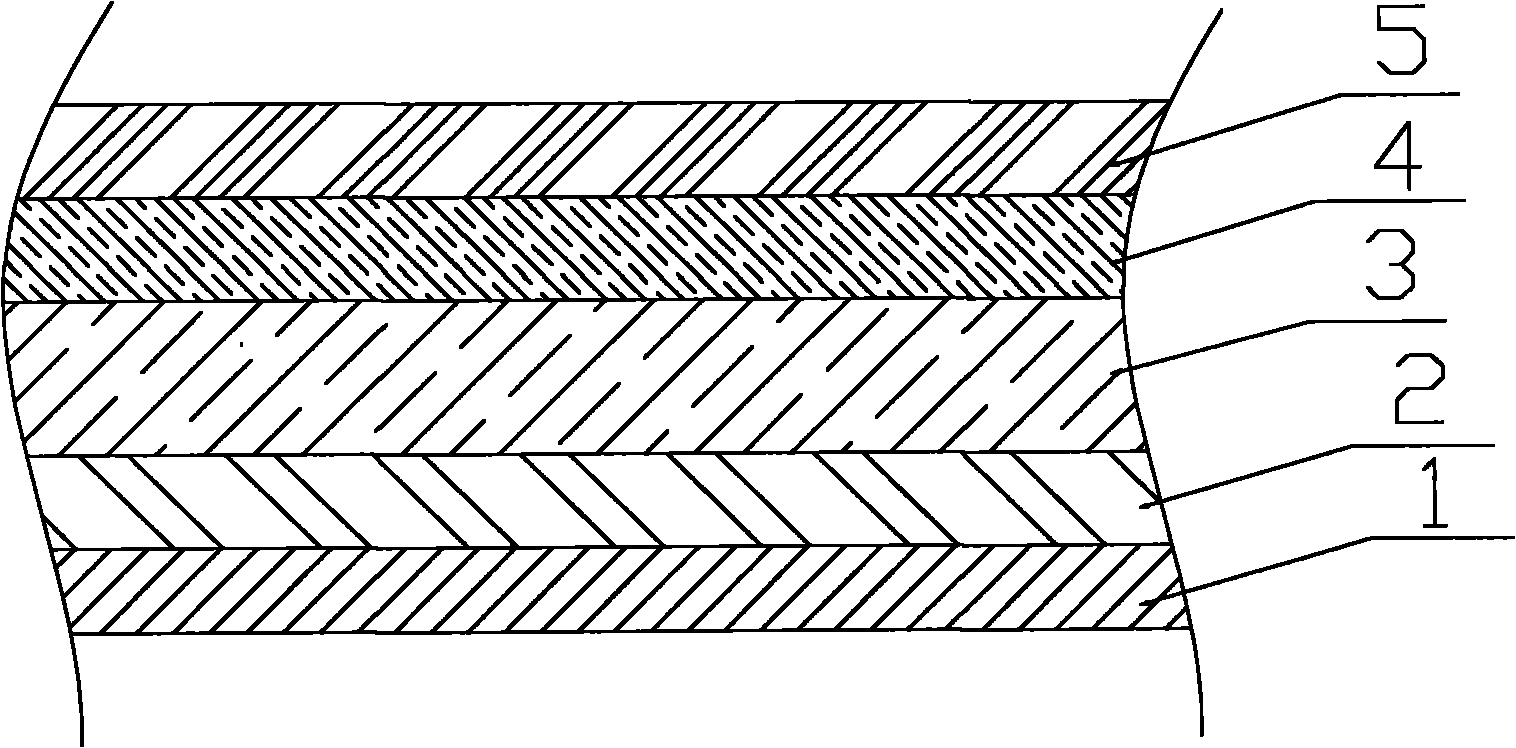

Laser positioning electrochemical aluminum and manufacturing method thereof

InactiveCN101780733AReduce lossGraphic and text effects are changeableOther printing apparatusPrinting after-treatmentPolyesterOptoelectronics

The invention provides a laser positioning electrochemical aluminum and a manufacturing method thereof. The laser positioning electrochemical aluminum comprises a base film layer, a peeling layer, an aluminum plating layer and an adhesive layer, wherein the base film layer is made of a terylene film or a polyester film; the peeling layer is positioned on the base film layer and made of organic silicon resin; the aluminum plating layer is plated by gaseous aluminum under the vacuum condition; the adhesive layer is positioned on the aluminum plating layer and made of thermoplastic resin; a color pattern coloring layer is arranged between the peeling layer and the aluminum plating layer and formed by printing synthetic resin and over two pigments on the peeling layer; and holographic patterns are positioned and die-pressed on the color pattern part of the color pattern coloring layer. The laser positioning electrochemical aluminum of the invention can stamp and transfer color patterns and holographic laser positioning pictures at one time so as to improve the visual effect and the anti-counterfeiting effect.

Owner:SHENZHEN JINJIA GRP

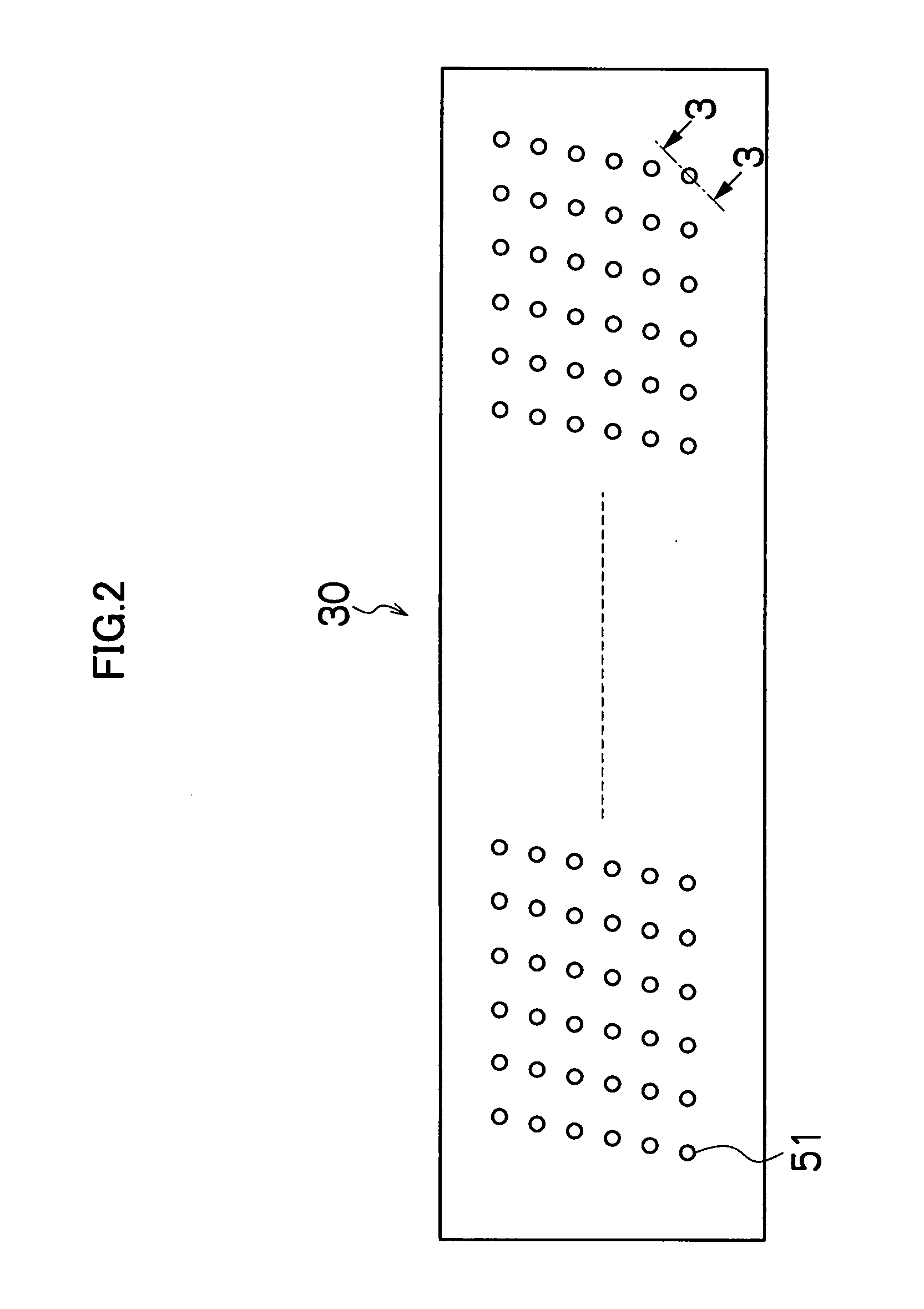

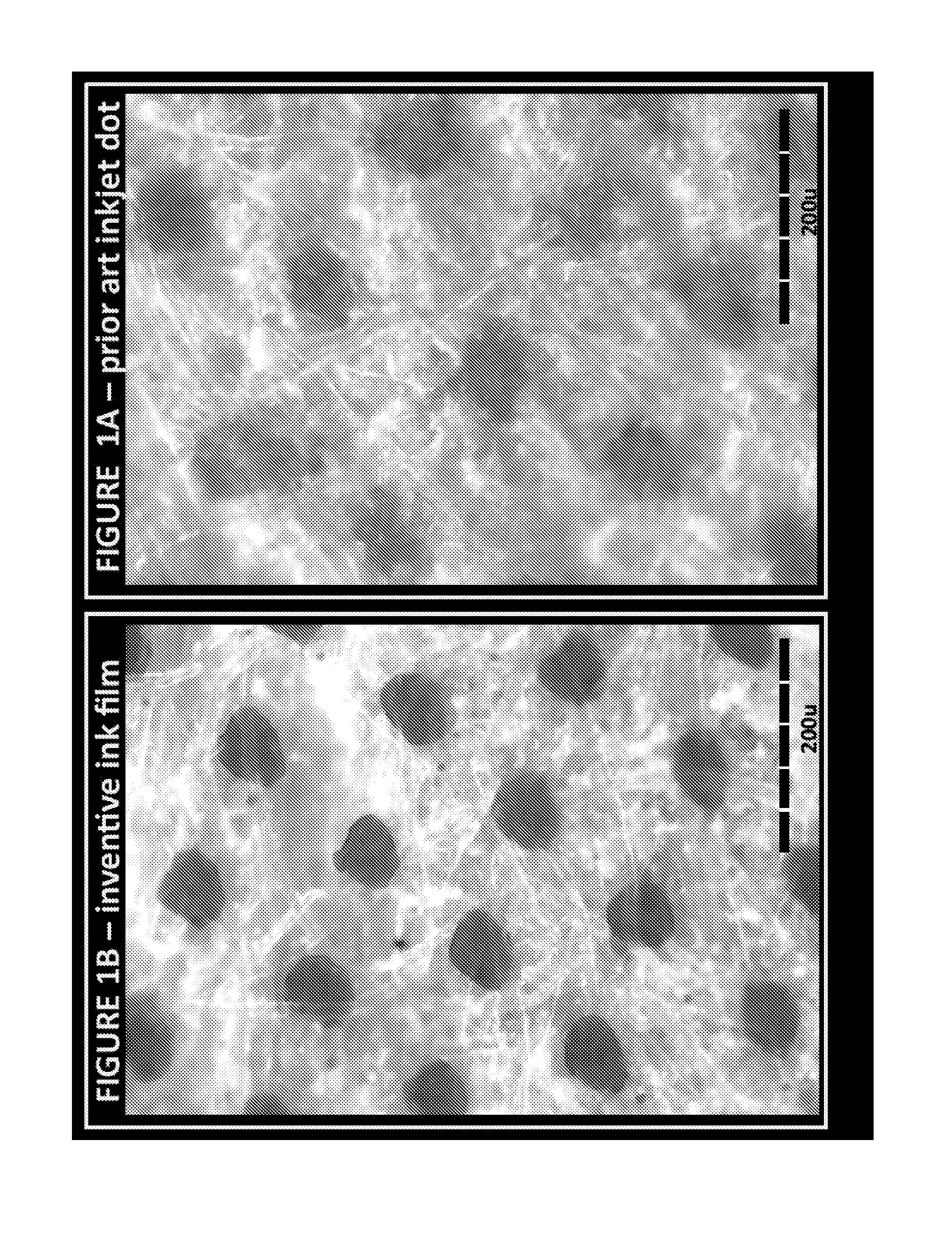

Ink film constructions

An ink film construction including: (a) a first printing substrate selected from the group consisting of an uncoated fibrous printing substrate, a commodity coated fibrous printing substrate, and a plastic printing substrate; and (b) an ink dot set contained within a square geometric projection projecting on the first printing substrate, the ink dot set containing at least 10 distinct ink dots, fixedly adhered to a surface of the first printing substrate, all the ink dots within the square geometric projection being counted as individual members of the set, each of the ink dots containing at least one colorant dispersed in an organic polymeric resin, each of the dots having an average thickness of less than 2,000 nm, and a diameter of 5 to 300 micrometers; each ink dot of the ink dots having a generally convex shape in which a deviation from convexity, (DCdot), is defined by: DCdot=1−AA / CSA, AA being a calculated projected area of the dot, the area disposed generally parallel to the first fibrous printing substrate; and CSA being a surface area of a convex shape that minimally bounds a contour of the projected area; wherein a mean deviation from convexity (DCdotmean) of the ink dot set is at most 0.05.

Owner:LANDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com