Laser positioning electrochemical aluminum and manufacturing method thereof

A manufacturing method, anodized aluminum technology, applied in printing, printing device, ink transfer from original manuscript, etc., can solve the problem of poor anti-counterfeiting effect, achieve improved visual effect and anti-counterfeiting effect, changeable graphic effect, and obvious layers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

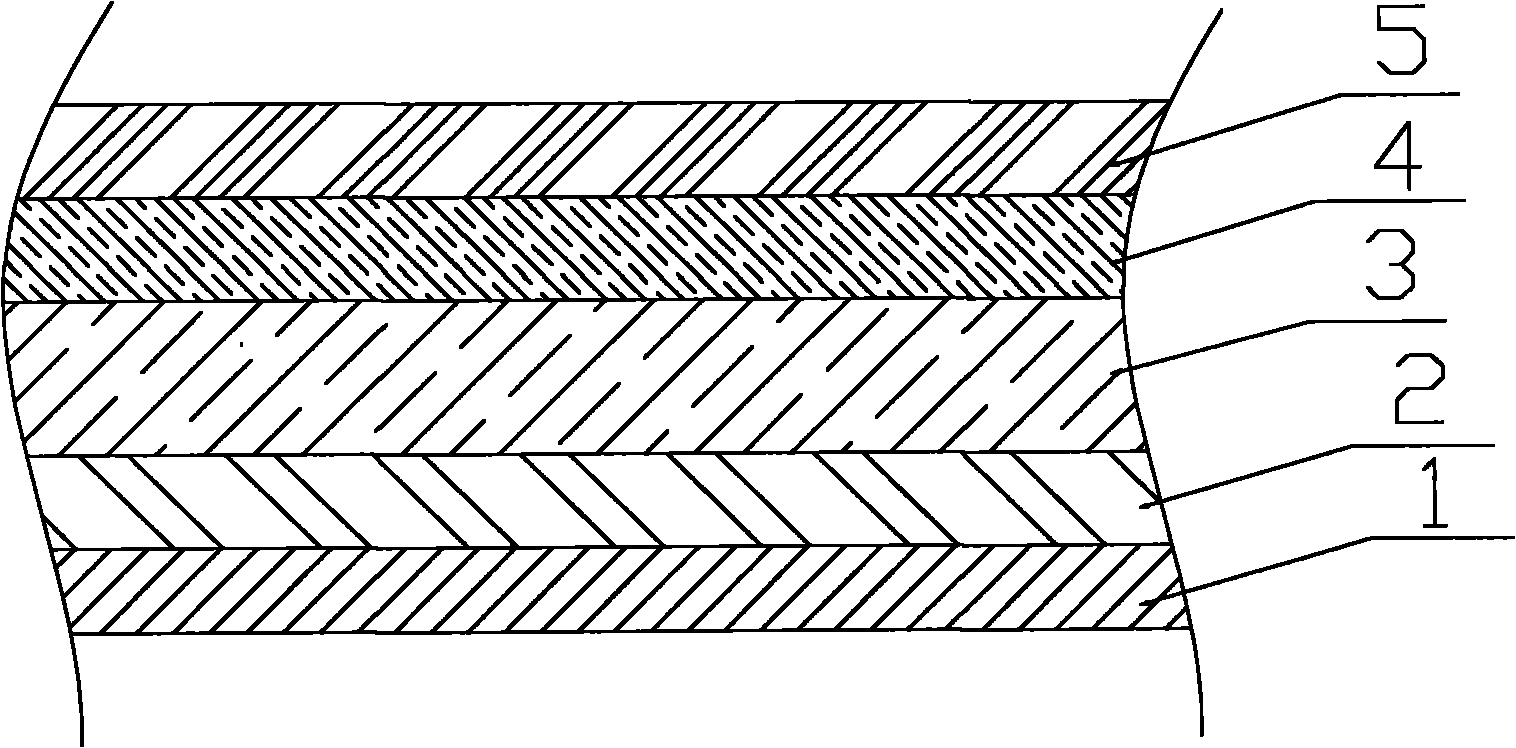

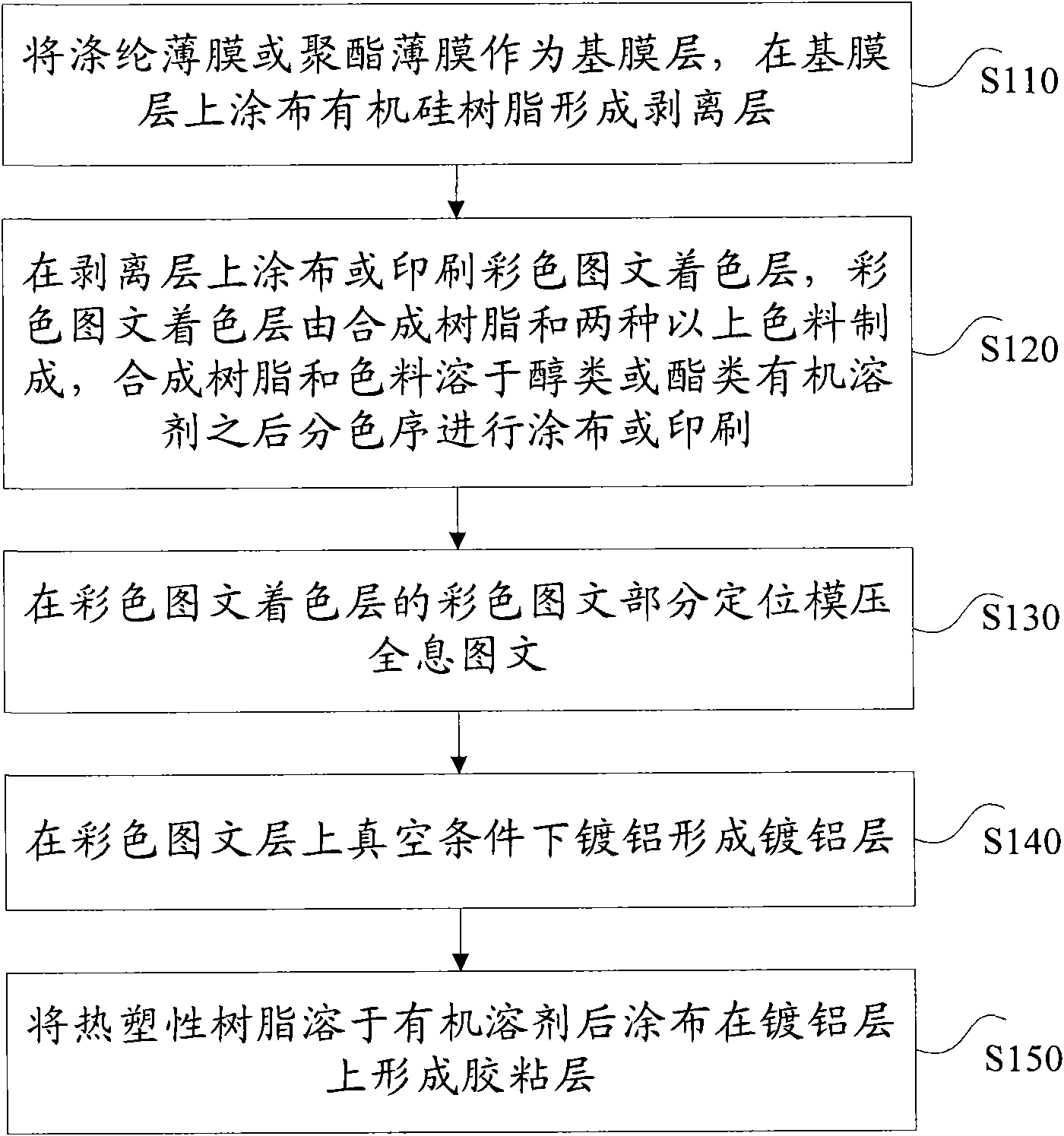

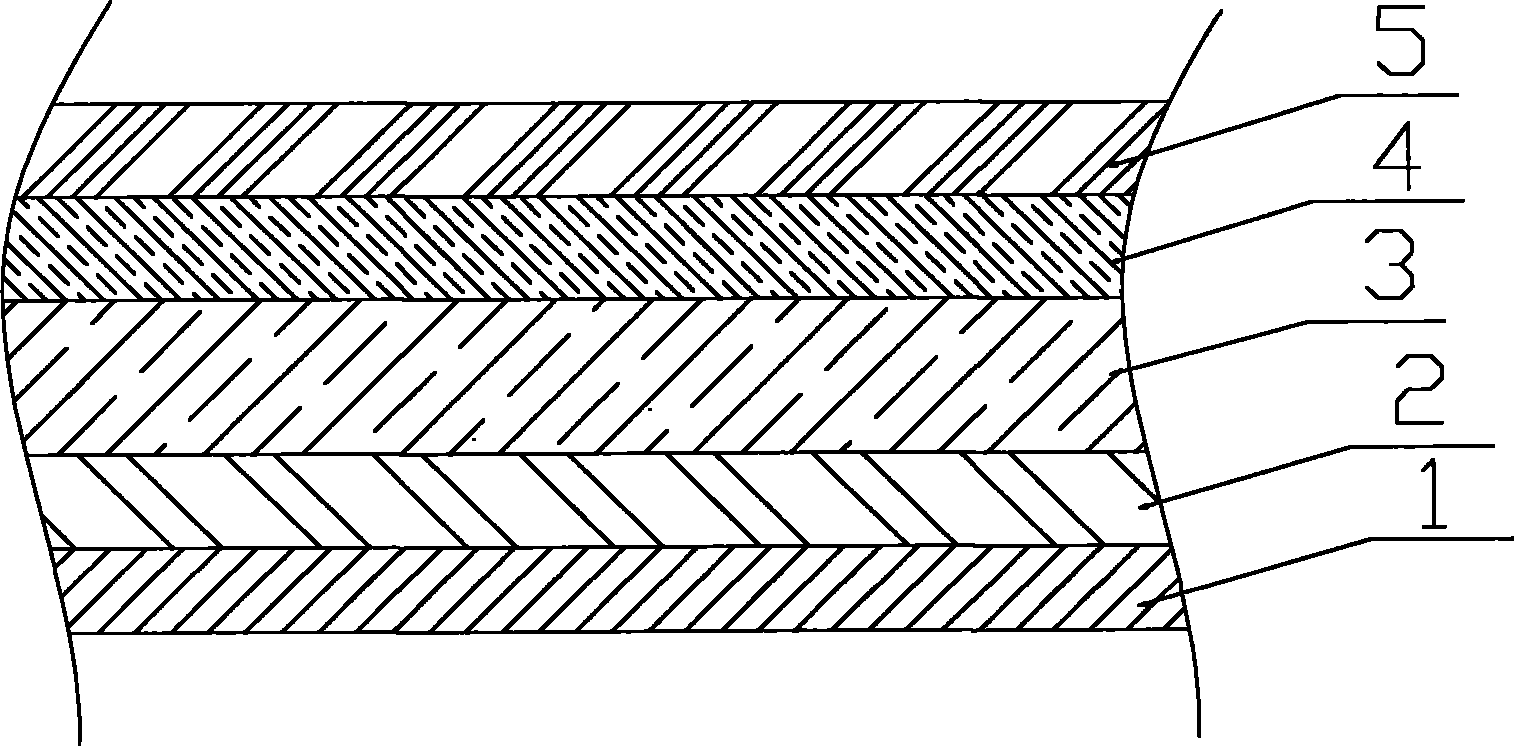

[0019] like figure 1 As shown, the laser positioning anodized aluminum in this embodiment includes a base film layer 1 , a peeling layer 2 , a color graphic layer 3 , an aluminum plating layer 4 and an adhesive layer 5 . Among them, the base film layer 1 is a biaxially oriented polypropylene (BOPP) film with a thickness of 16 μm, and its main function is to support the layers attached to it and facilitate the continuous action during hot stamping processing. The base film layer 1 has the properties of high strength, tensile strength and high temperature resistance, so as to ensure that it will not be deformed due to temperature rise during the hot stamping process. The peeling layer 2 is located on the base film layer 1 and is coated with silicone resin. , can quickly detach from the base film layer 1 and be transferred and bonded to the surface of the hot stamping object. The color graphic coloring layer 3 is located on the peeling layer 2 and is made of synthetic resin and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com