Patents

Literature

2534 results about "Stamping process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

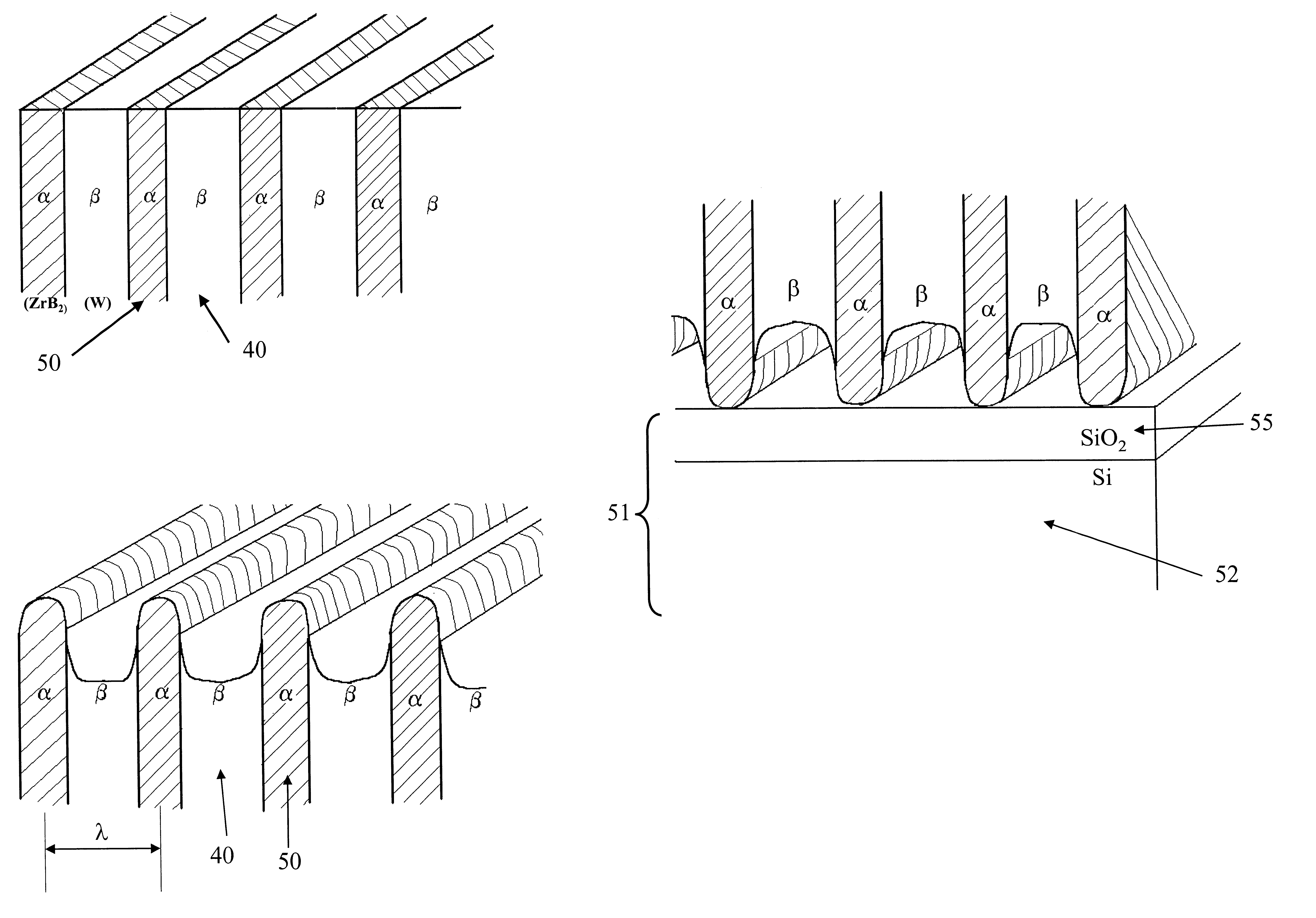

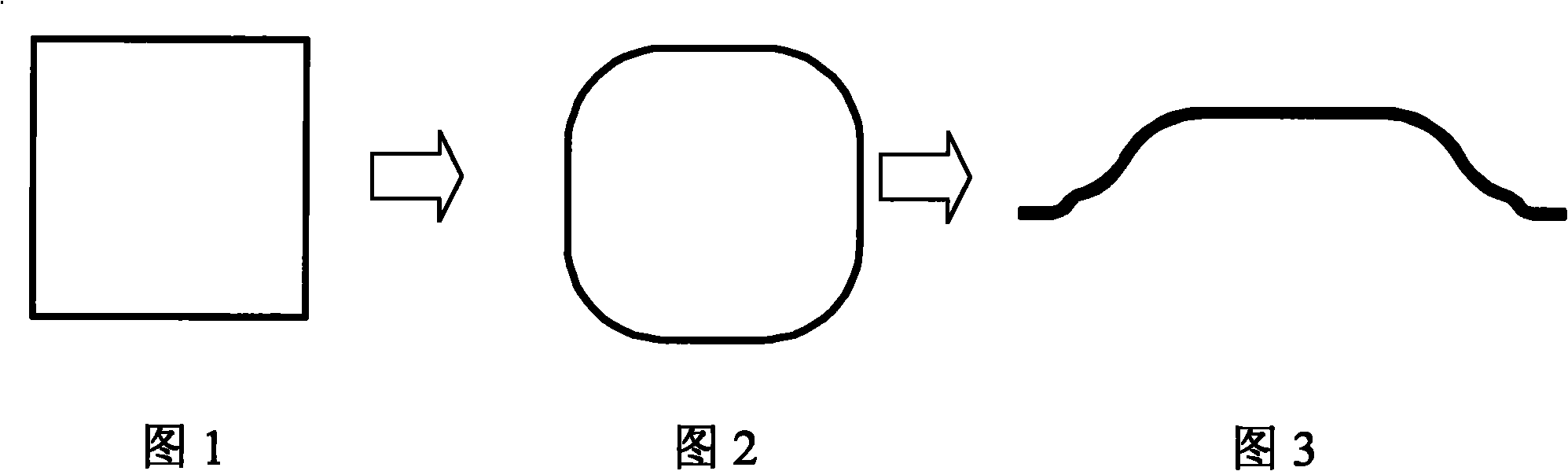

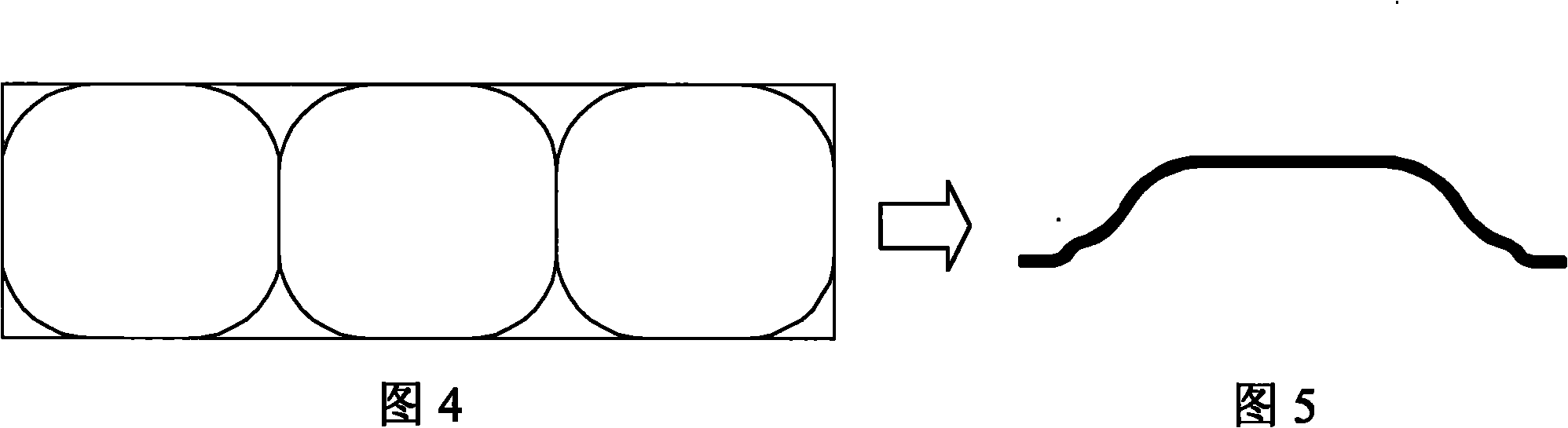

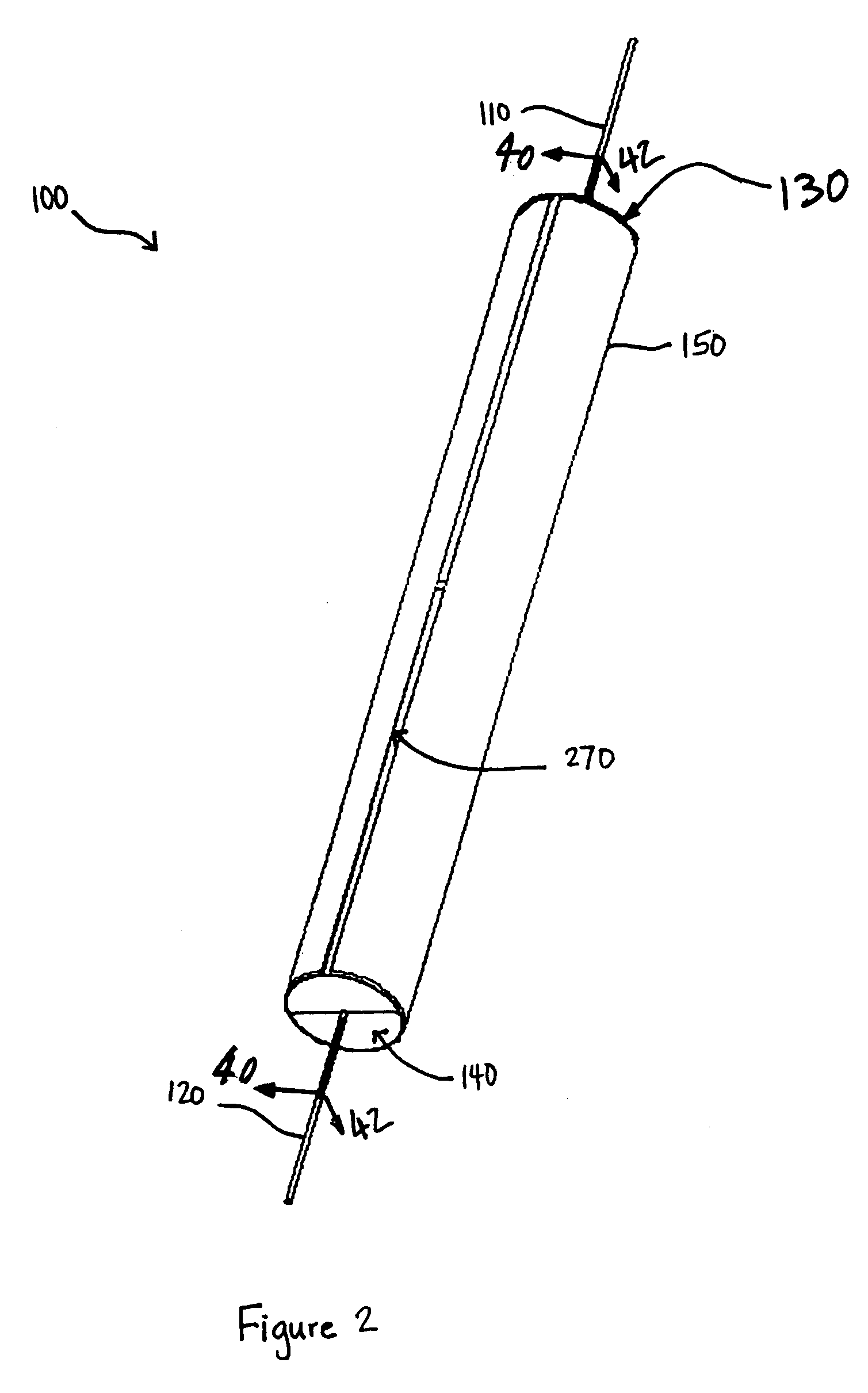

Method for making a nano-stamp and for forming, with the stamp, nano-size elements on a substrate

The stamping process and a method of fabrication of nano-stamps with characteristic dimensions below 1 nm and up to 100 nm intended for usage in making patterns of characteristic dimensions the same as those of the nano-stamp on surface of a substrate is provided. In the process a very hard stamp is fabricated by first depositing alternating layers of two materials, one of which has very high hardness, on some sacrificial substrate via PVD, CVD or any other deposition procedure that produces alternating layers of selected thickness, from sub 1 nm to above 100 nm. The layered film is then polished to an atomically smooth finish perpendicular to the plane of the layers and etched to produce dips in the softer layers. These steps produce a grid of parallel elevations and valleys on the etched surface, which now can be used as a stamp to stamp out patterns on a substrate of lower hardness than the hardness of the elevated layers. If the substrate is stamped twice with a turning of the stamp 90 degrees between first and second stampings, a square pattern of elevations or hills and valleys is formed, which can be used for magnetic memory storage by subsequently sputtering magnetic material on the tops of the elevations or hills.

Owner:VIGIL THOMAS R +1

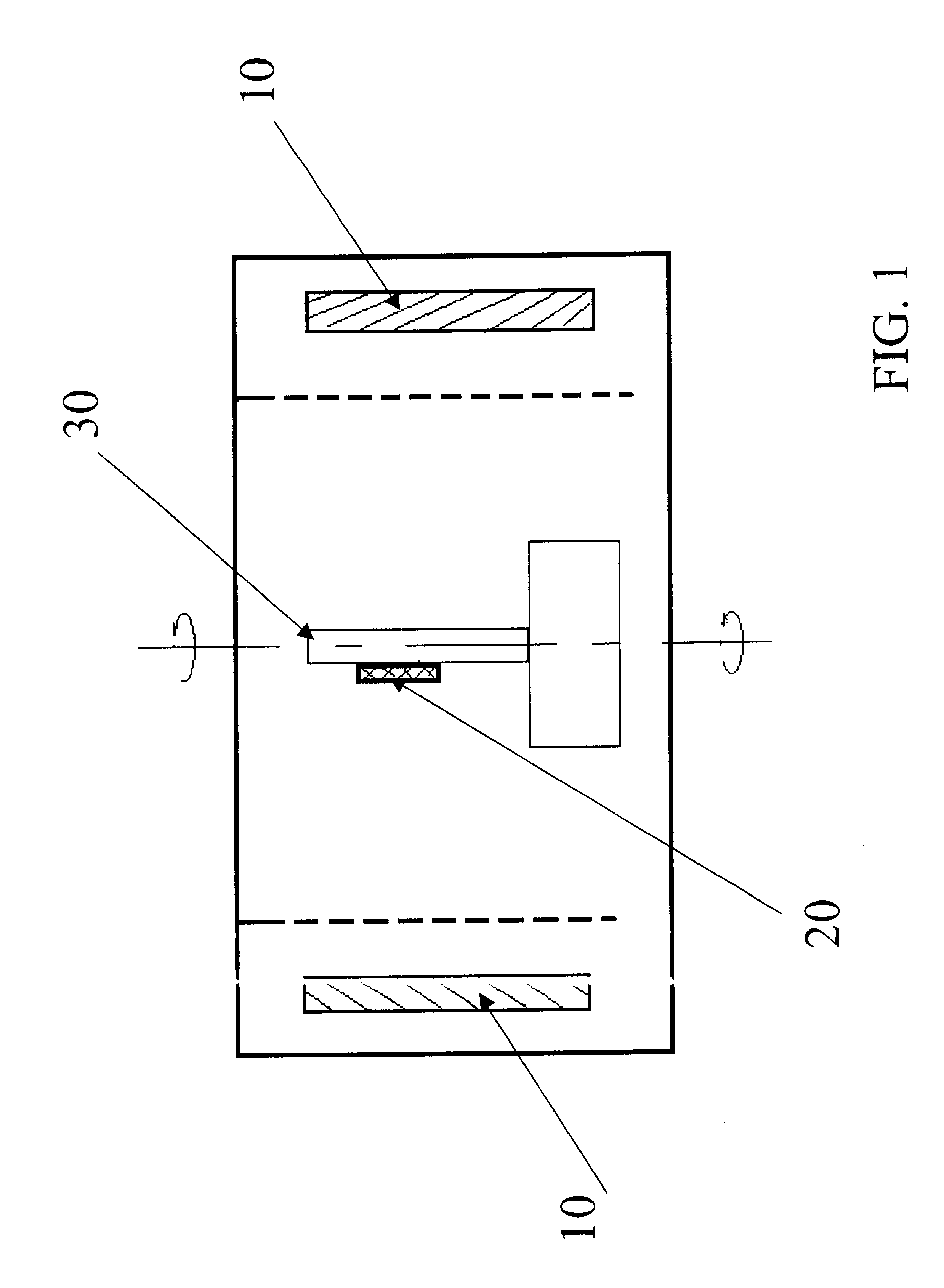

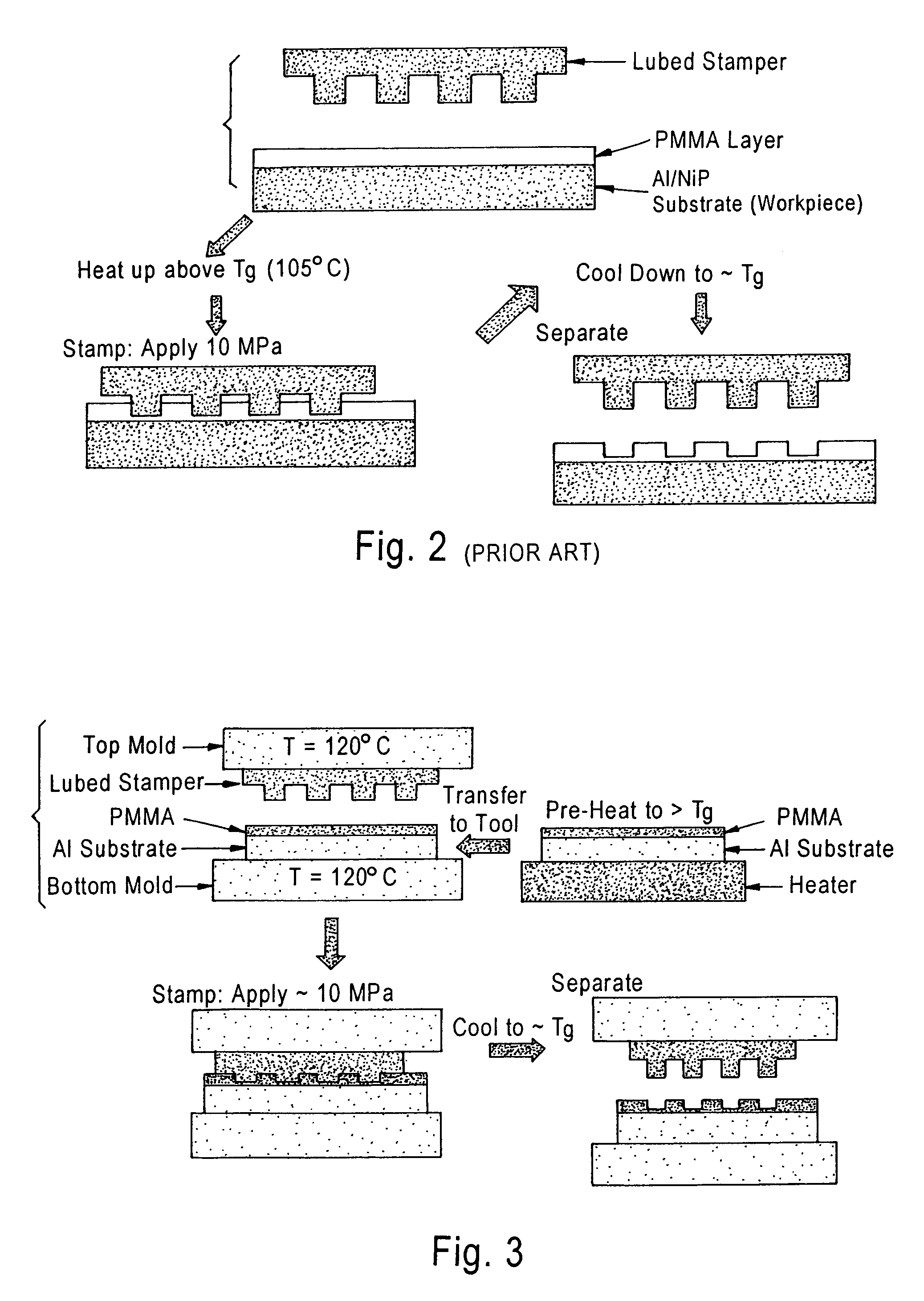

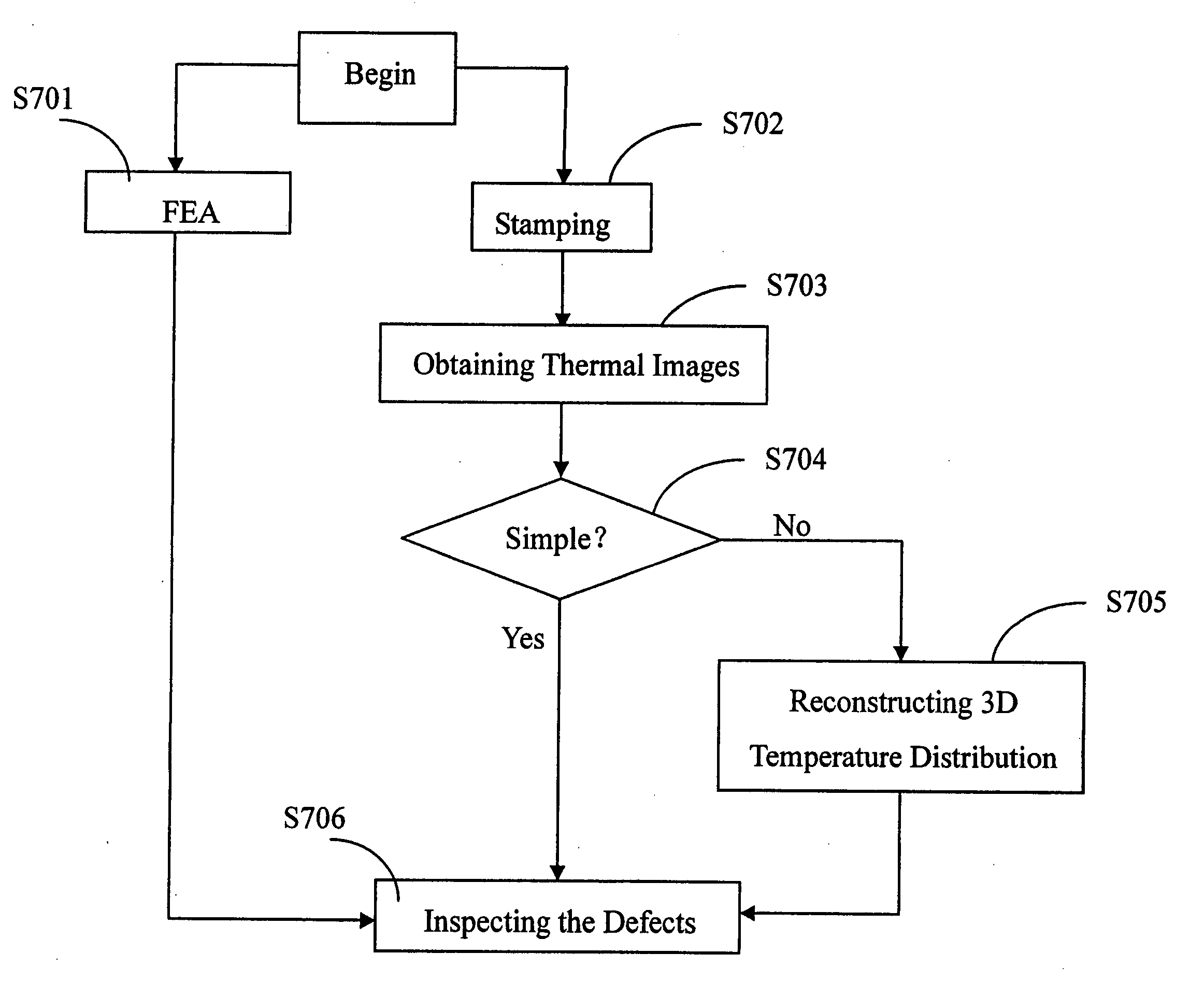

Heat-transfer-stamp process for thermal imprint lithography

InactiveUS6949199B1Eliminate disadvantagesSimple methodNanostructure manufactureDecorative surface effectsStamping processPlanographic printing

A method of performing thermal imprint lithography of a surface of a thermoplastic layer-coated workpiece for forming a pattern therein comprises pre-heating the workpiece to a pre-selected high temperature prior to inserting the workpiece in a stamping / imprinting tool maintained at a predetermined lower temperature, whereby the interval for thermal cycling of the stamping / imprinting tool between higher and lower temperatures is eliminated or at least reduced. Applications of the method include forming servo patterns in disk-shaped substrates for hard disk recording media.

Owner:SEAGATE TECH LLC

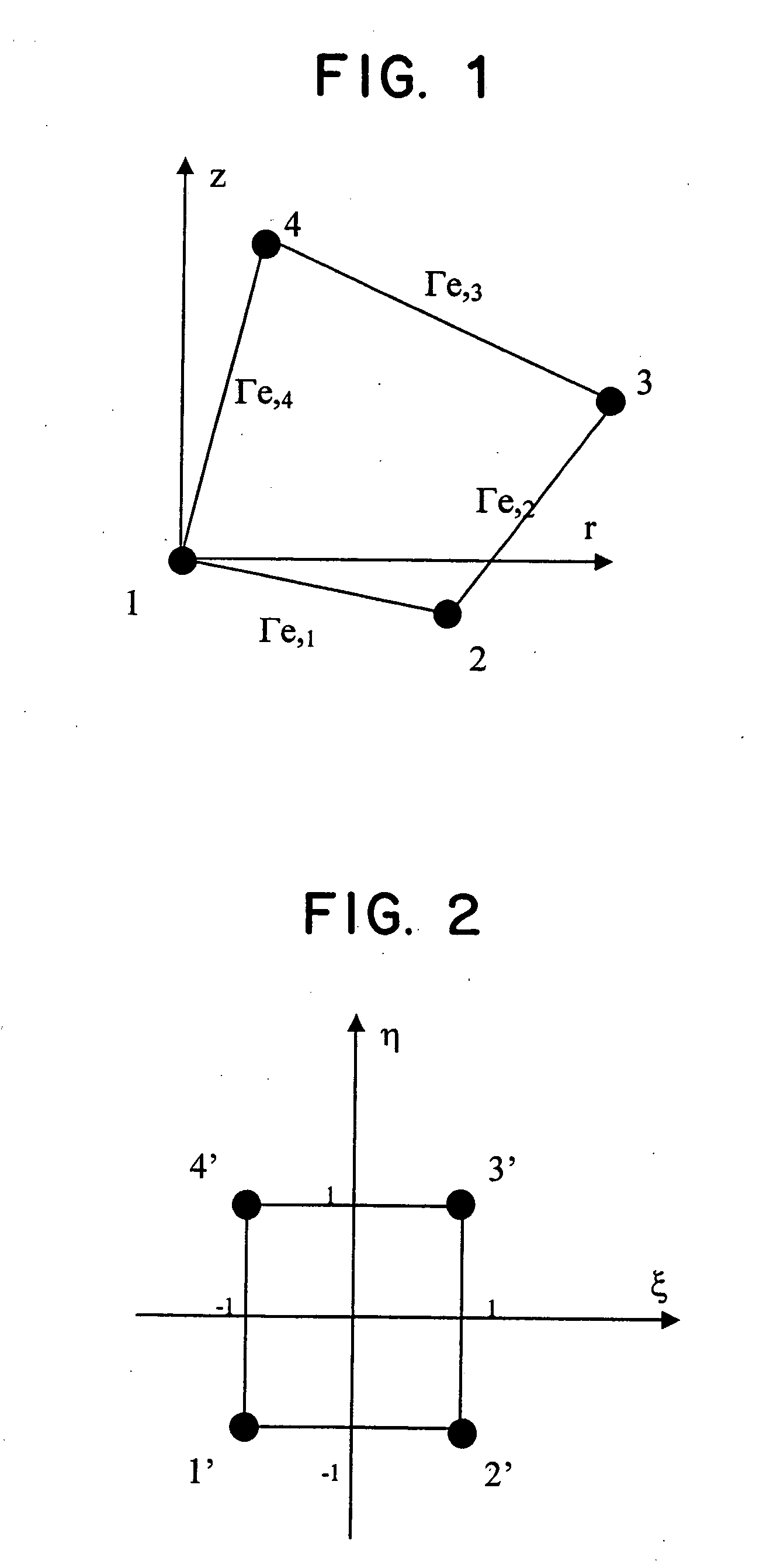

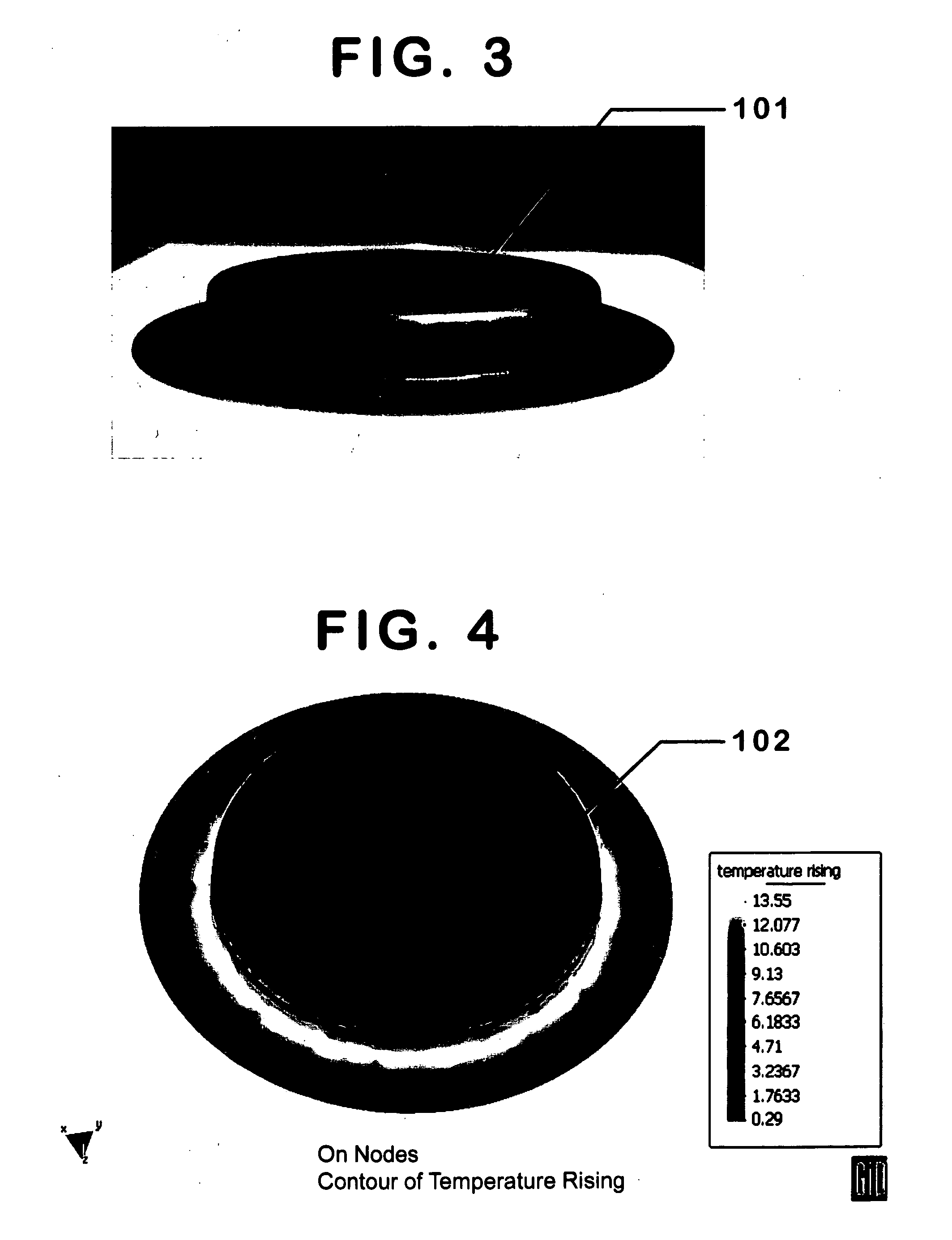

Method and apparatus for inspecting an object after stamping

InactiveUS20060222237A1Character and pattern recognitionMaterial flaws investigationStamping processComputer science

A method and apparatus for inspecting an object after stamping is described. The method and apparatus comprises determining a temperature distribution of an object after stamping; obtaining one or more thermal images of the object after stamping; and comparing the determined temperature distribution with the obtained thermal images so as to identify defects existing in the object after stamping, in which the difference between the temperature distribution and the thermal images indicates the presence of defects in the object. The method and apparatus can therefore inspect and analysis problems of the object occurred during the stamping process.

Owner:THE CHINESE UNIVERSITY OF HONG KONG +1

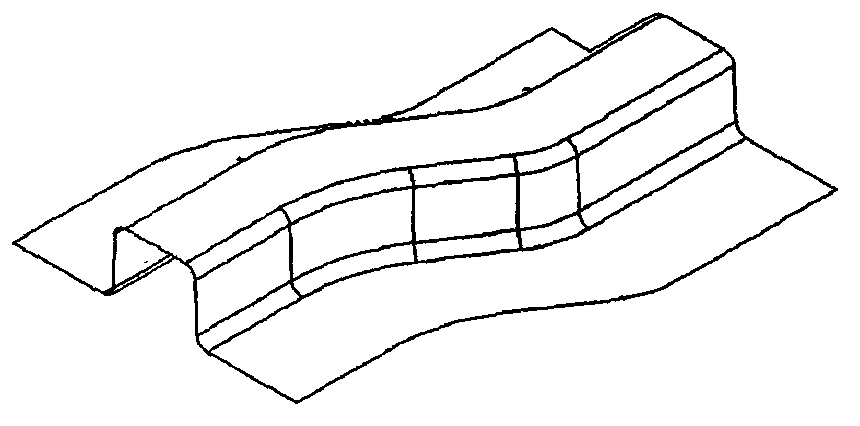

Hot stamping and superplastic gas-bulging combined forming process

InactiveCN101786128ARelaxed Grain Size RequirementsLow costVehicle componentsQuality processHot stamping

The invention provides a new process of quick superplastic forming of automotive body parts of aluminum alloy automobiles, which is mainly characterized in that hot stamping is combined with superplastic gas-bulging forming, so that the advantages of the hot stamping and the superplastic gas-bulging forming are relatively complemented to achieve the aim of quick superplastic forming. The process reduces the requirements of the conventional superplastic forming on grain sizes of sheet materials, and allows for the use of ordinary commercial aluminum alloy sheet materials. Compared with a cold stamping process, the new process has the advantages of overcoming the drawbacks of cracks and large springback, along with fewer working procedures and high yield; and compared with the conventional superplastic forming process, the new process improves the forming speed obviously, and reduces the material cost. The new process eliminates the technical barriers in making light weight automobile bodies of the low and medium-grade automobiles by using aluminum alloy, and is an efficient and high-quality process for the mass production of the automobile bodies of the aluminum alloy automobiles.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method of producing battery plates

InactiveUS20050164091A1Smooth connectionImprove adhesionFinal product manufactureElectrode carriers/collectorsManufacturing technologyStamping process

A method of forming battery grids or plates that includes the step of mechanically reshaping or refinishing battery grid wires to improve adhesion between the battery paste and the grid wires. The method is particularly useful in improving the paste adhesion to battery grids formed by a continuous battery grid making process (such as strip expansion, strip stamping, continuous casting) that produces grid wires and nodes with smooth surfaces and a rectangular cross-section. In a preferred version of the method, the grid wires of battery grids produced by a stamping process are deformed such that the grid wires have a cross-section other than the rectangular cross-section produced by the stamping process. The method increases the cycle life of a battery.

Owner:CPS TECH HLDG LLC

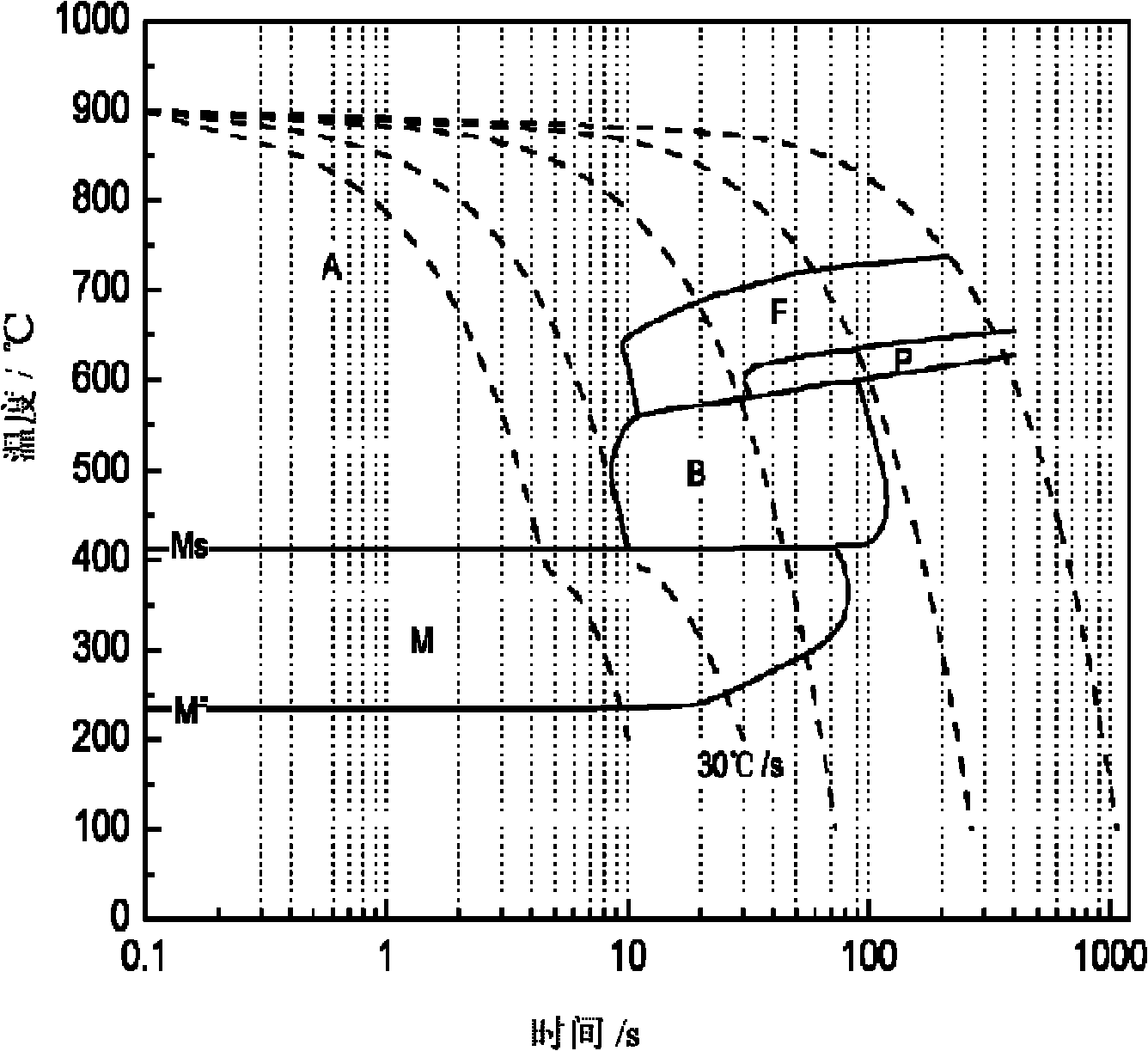

Ultrahigh-strength steel laser tailor welded blank and forming process thereof

InactiveCN102162574AGood formabilityReduce weightSheets/panelsLaser beam welding apparatusHot stampingRoom temperature

The invention relates to an ultrahigh-strength steel laser tailor welded blank and a forming process thereof. The forming process provided by the invention comprises the following steps: carrying out the laser tailor welding on ultrahigh-strength steel and high-strength steel according to the needed shape; then, delivering the obtained welded blank to a furnace filled with a protective gas and heating to 920-940 DEG C to be continued for at least 5 minutes; fully austenitizing; transferring the austenitized welded blank to a press machine to be rapidly molded and formed; cooling to 100-150 DEG C through pressurization quenching; and cooling along room temperature to obtain the needed parts. The hot stamping process of the laser tailor welded blank provided by the invention has the double advantages of the forming and hot stamping forming of the laser tailor welded blank and simultaneously solves the problems that the ultrahigh-strength steel is difficultly applied to the production ofautomobile structural components / framework components in a laser tailor welded blank mode.

Owner:SHANDONG JIANZHU UNIV

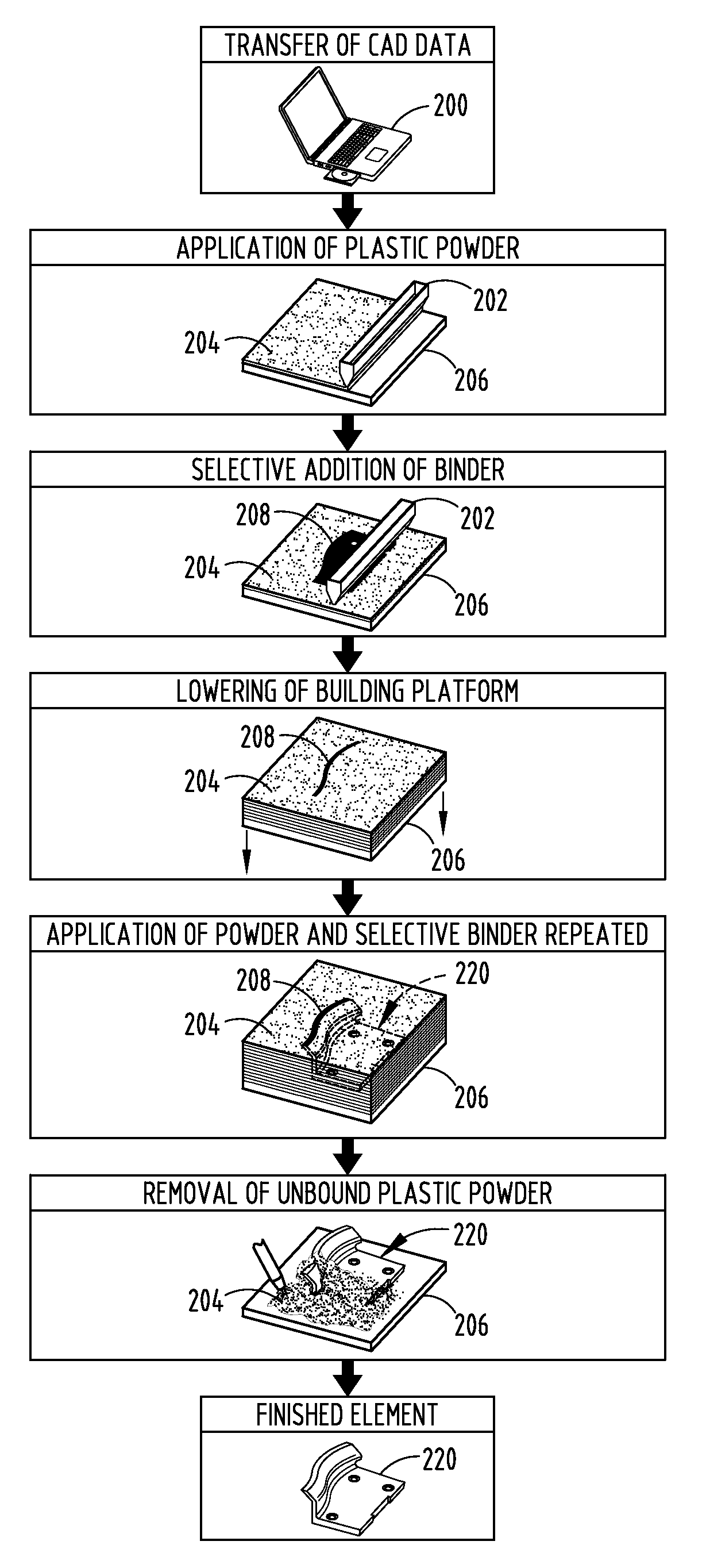

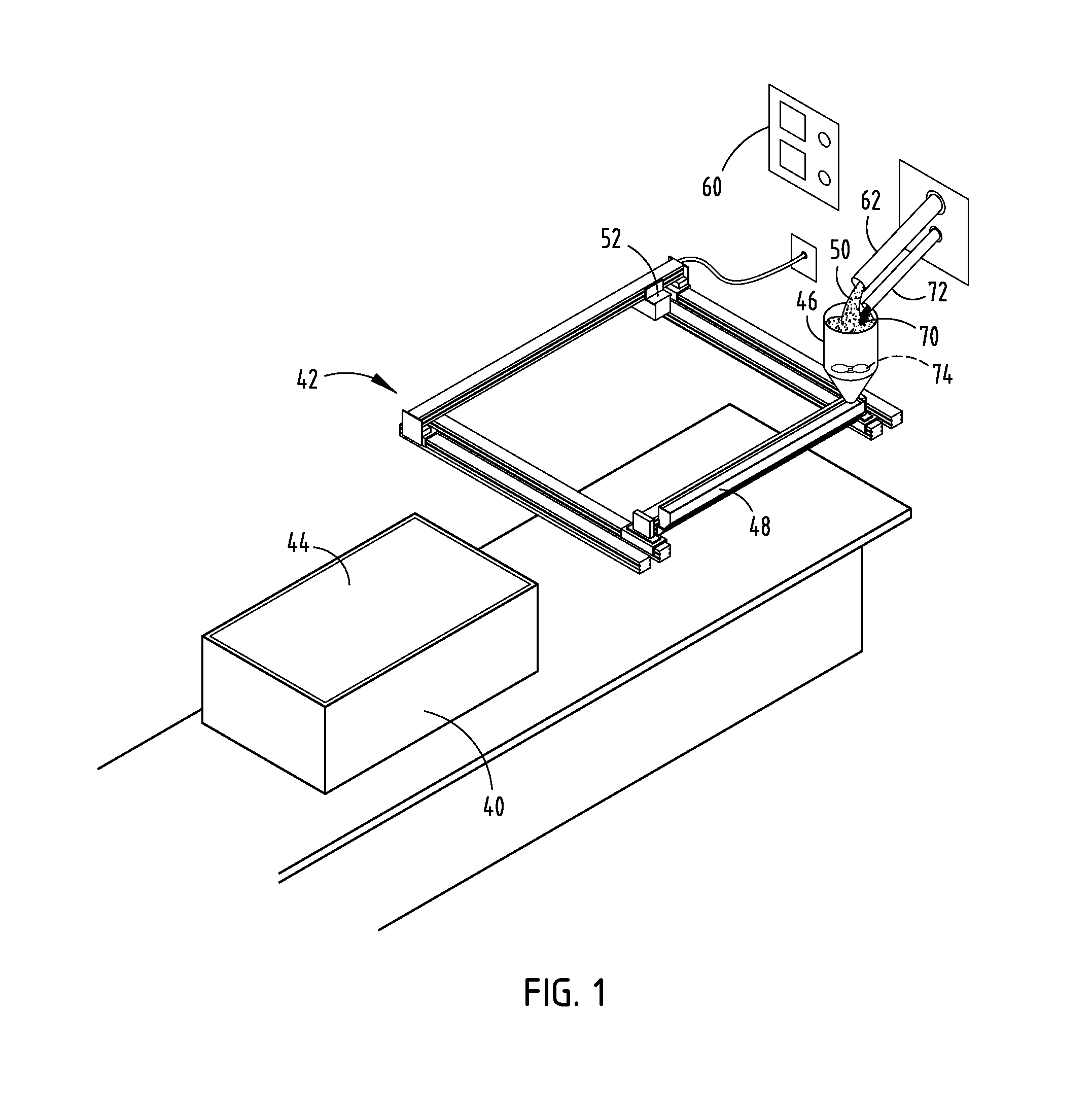

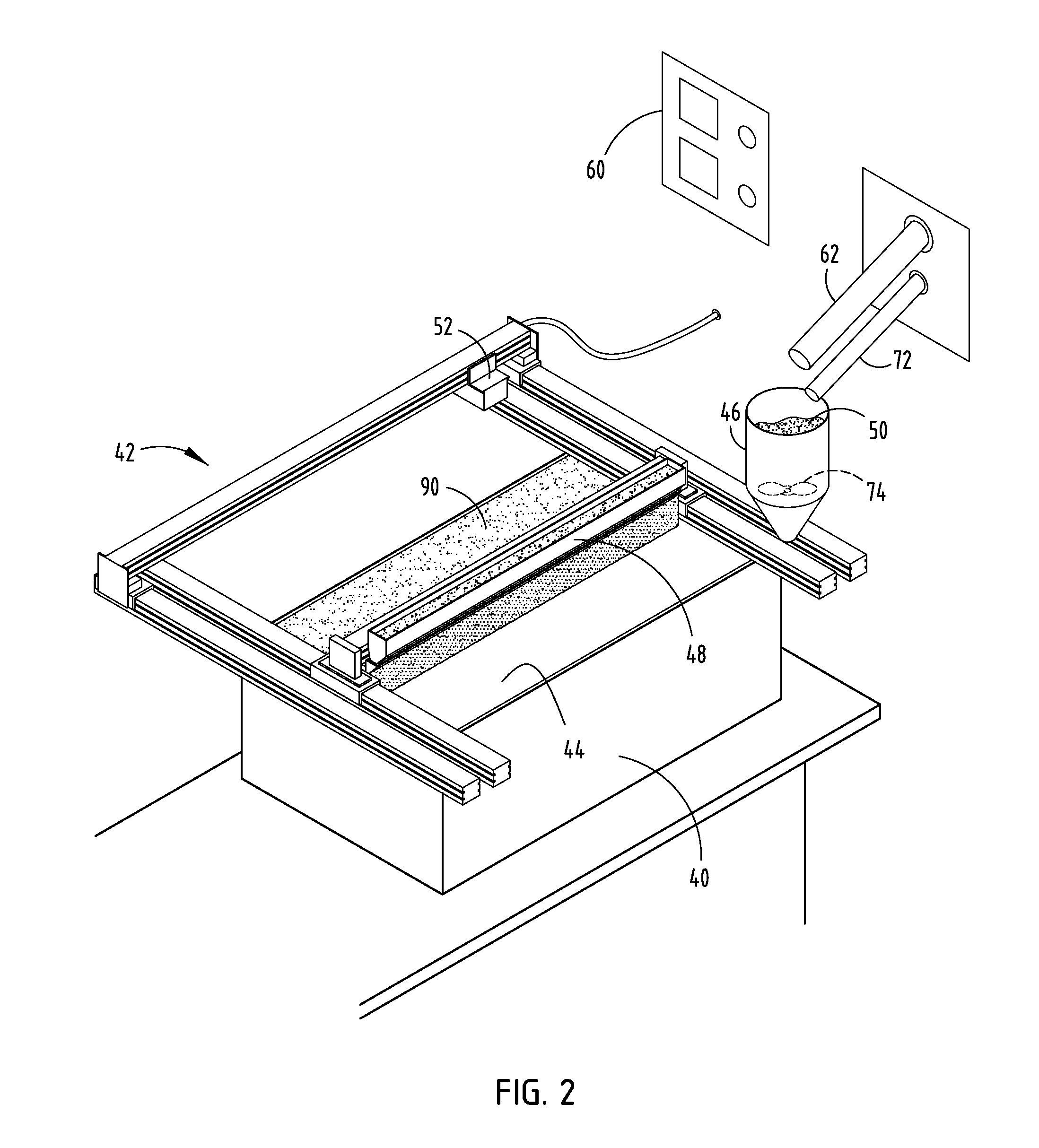

Additive fabrication technologies for creating molds for die components

InactiveUS20130220570A1Additive manufacturing apparatusFoundry mouldsStamping processAdditive layer manufacturing

Owner:FORD MOTOR CO

Filter medium and preparation method thereof

InactiveCN101837213AReduce manufacturing costWide variety of sourcesOther chemical processesFiltration separationWater basedActivated carbon

The invention relates to a filter medium, in particular to a filter medium and a preparation method thereof. The preparation method is as follows: raw materials are taken according to the weight percent of a formula, are added with materials to be mixed and stirred evenly according to the prescribed steps, and then are formed by extrusion and punch in a prefabricated mold, and the forming body is dried and cured at certain temperature to form the filter medium. Absorbing raw materials such as activated carbon, kaolin, diatomaceous earth and the like, and a water based binder such as polyvinyl alcohol, sodium carboxymethyl cellulose, modified starch and the like adopted by the invention are of nontoxic and non-harmful raw materials, and are formed by extrusion and punch under the condition of normal temperature, and in the process of high-temperature curing, water can remove the blockage of the binder for micropores of the absorbing raw materials in the process of extrusion or punch when evaporating, so that the finished product keeps the original absorption characteristics of the absorbing raw materials and simultaneously overcomes the defects that medium raw materials are precipitated when the filter medium is used for filtering.

Owner:张顺

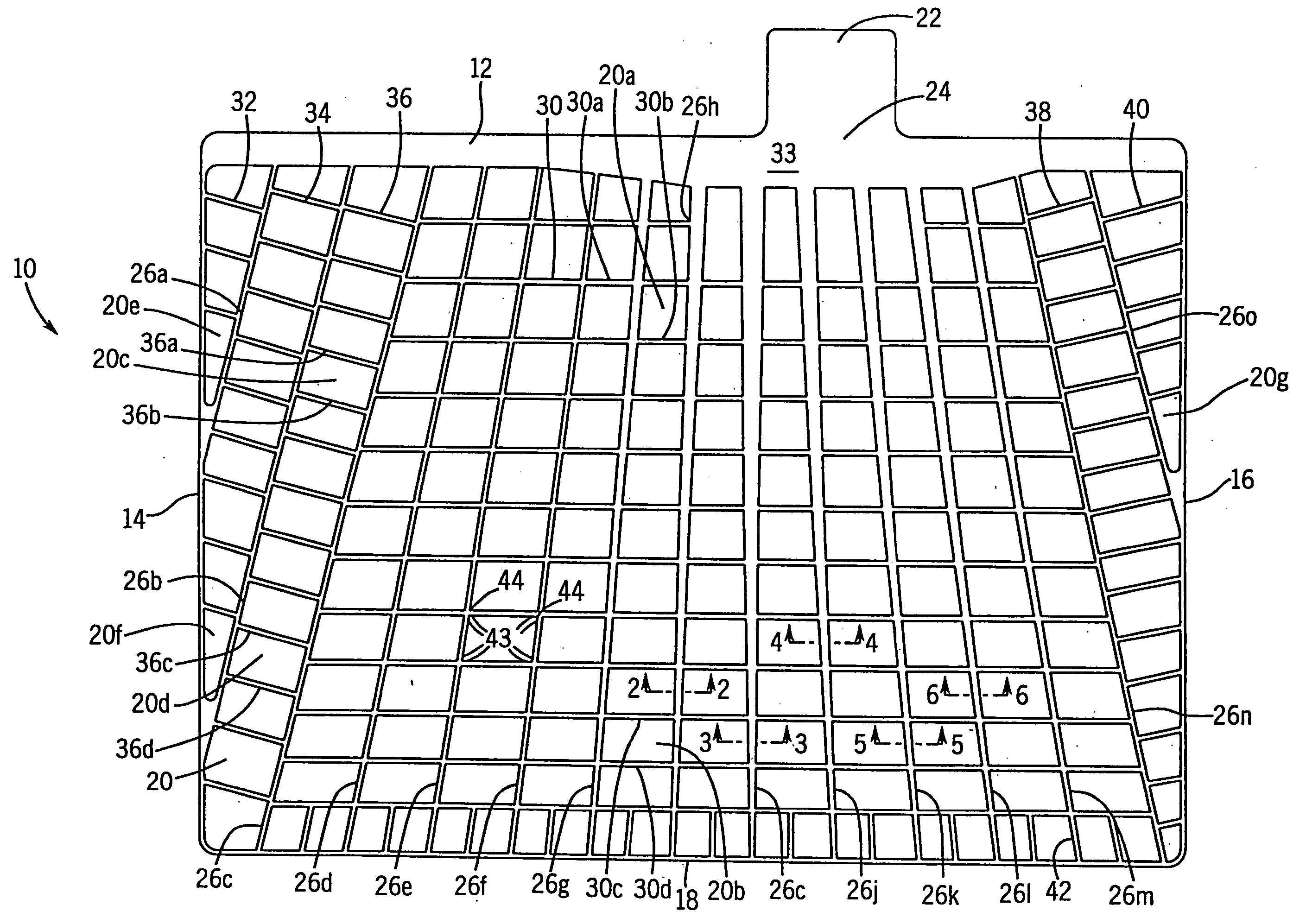

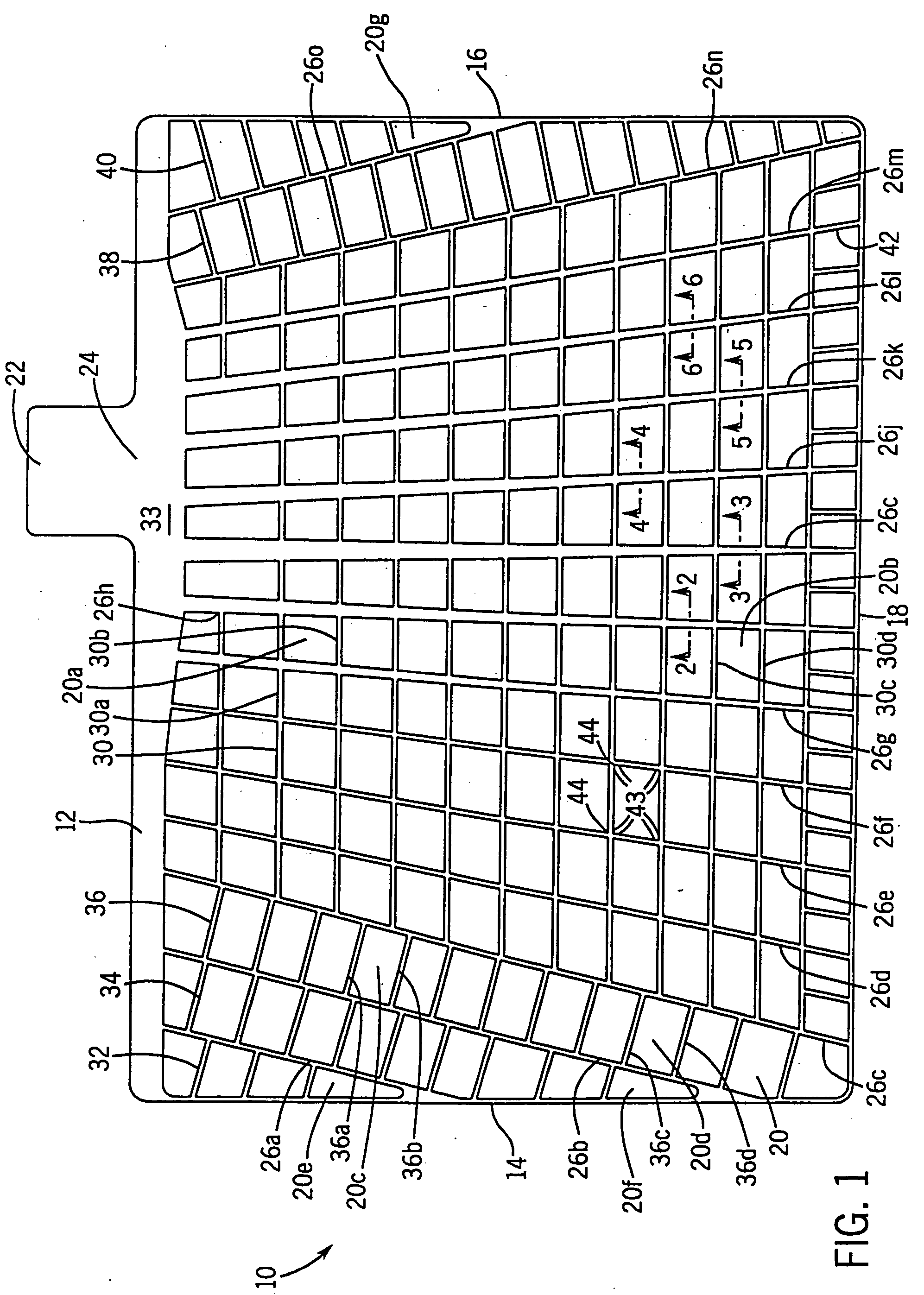

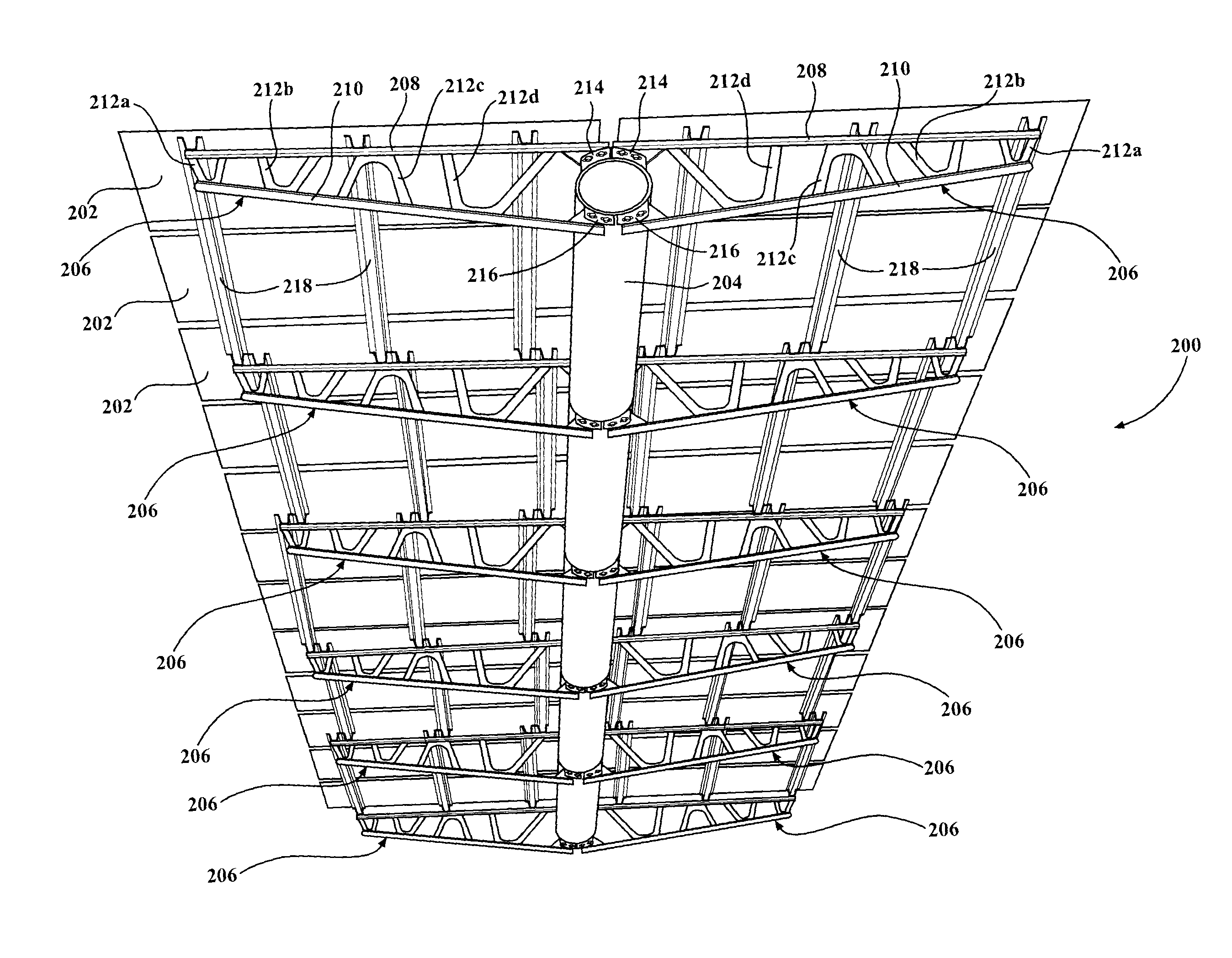

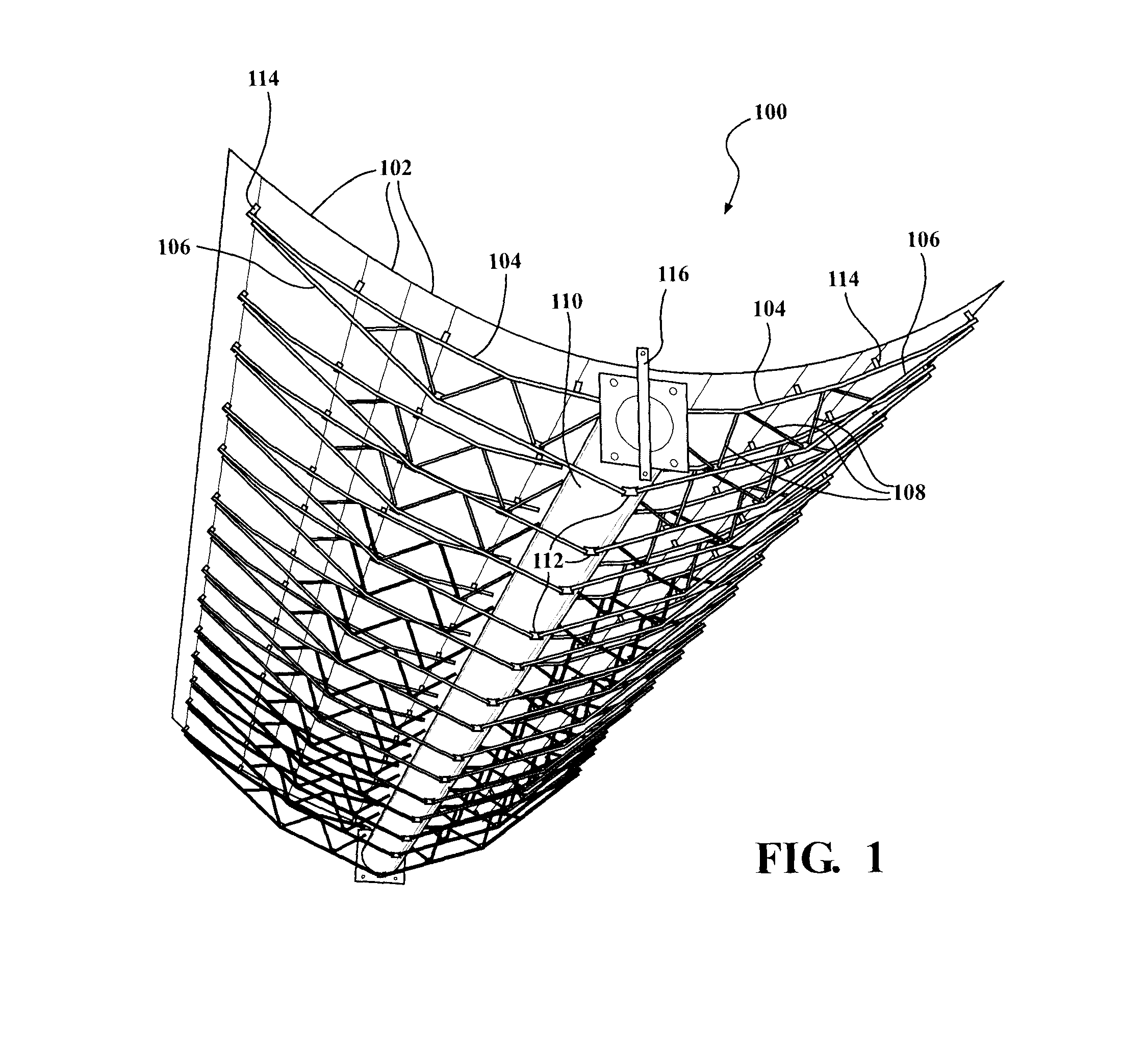

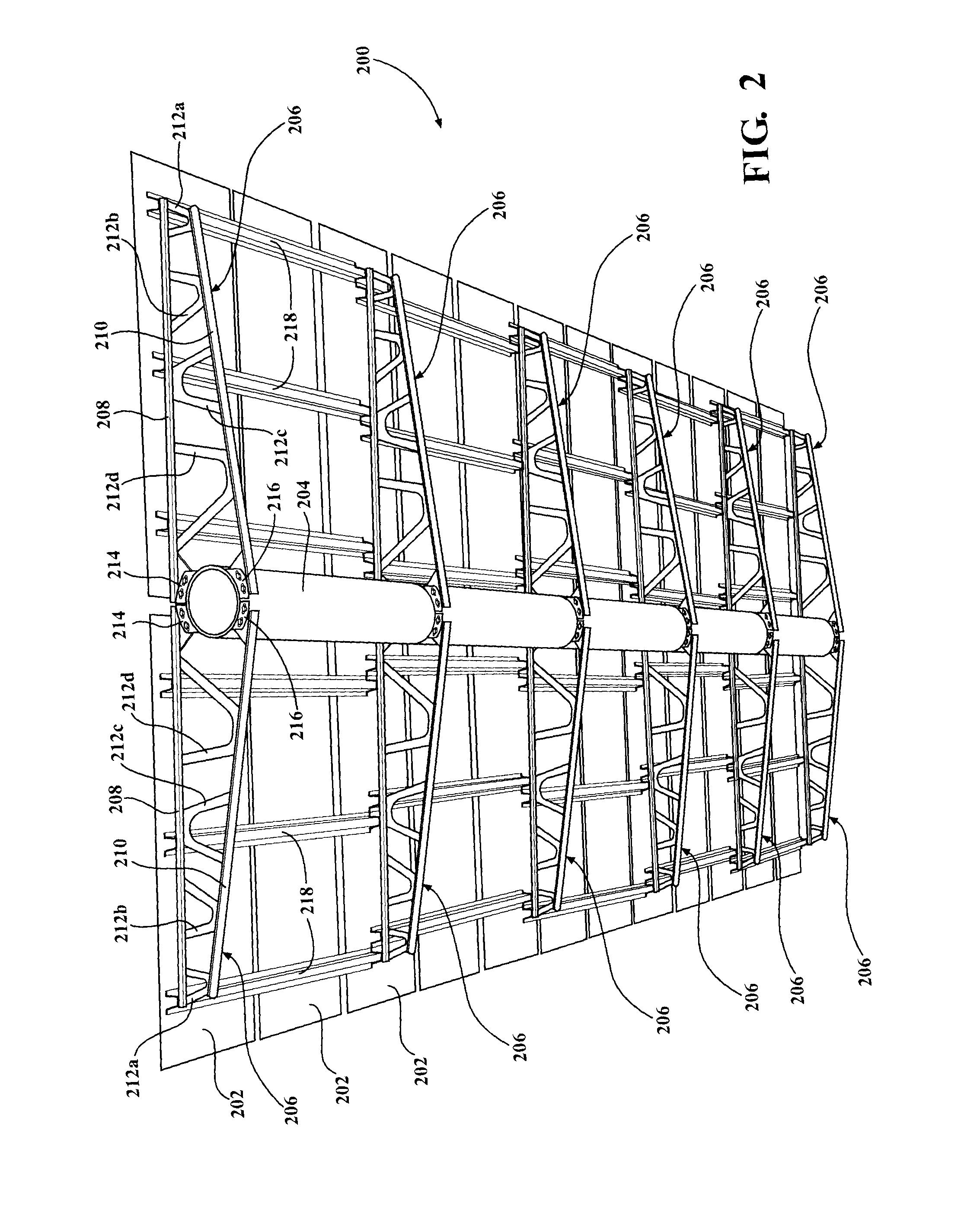

Support Frame Assembly And Method Of Forming A Support Frame Assembly

InactiveUS20140117190A1Easy to adaptLess strict toleranceSolar heating energySolar heat devicesWeb structureEngineering

At least one aspect of the present invention is related to a support frame assembly for supporting a solar device, such as an array of mirror elements and / or photovoltaic panels. The support frame assembly includes a plurality of support arm assemblies, each of which includes a pair of rails and a plurality of web structures interconnecting the rails. Specifically, each of the web structures has a base which is attached to one of the rails and a pair of legs extending towards and attached to the other of the rails. The web structures are preferably formed through a single stamping process with at least one of the web structures being at least partially in a nesting relationship with another of the web structures.

Owner:MAGNA INTERNATIONAL INC

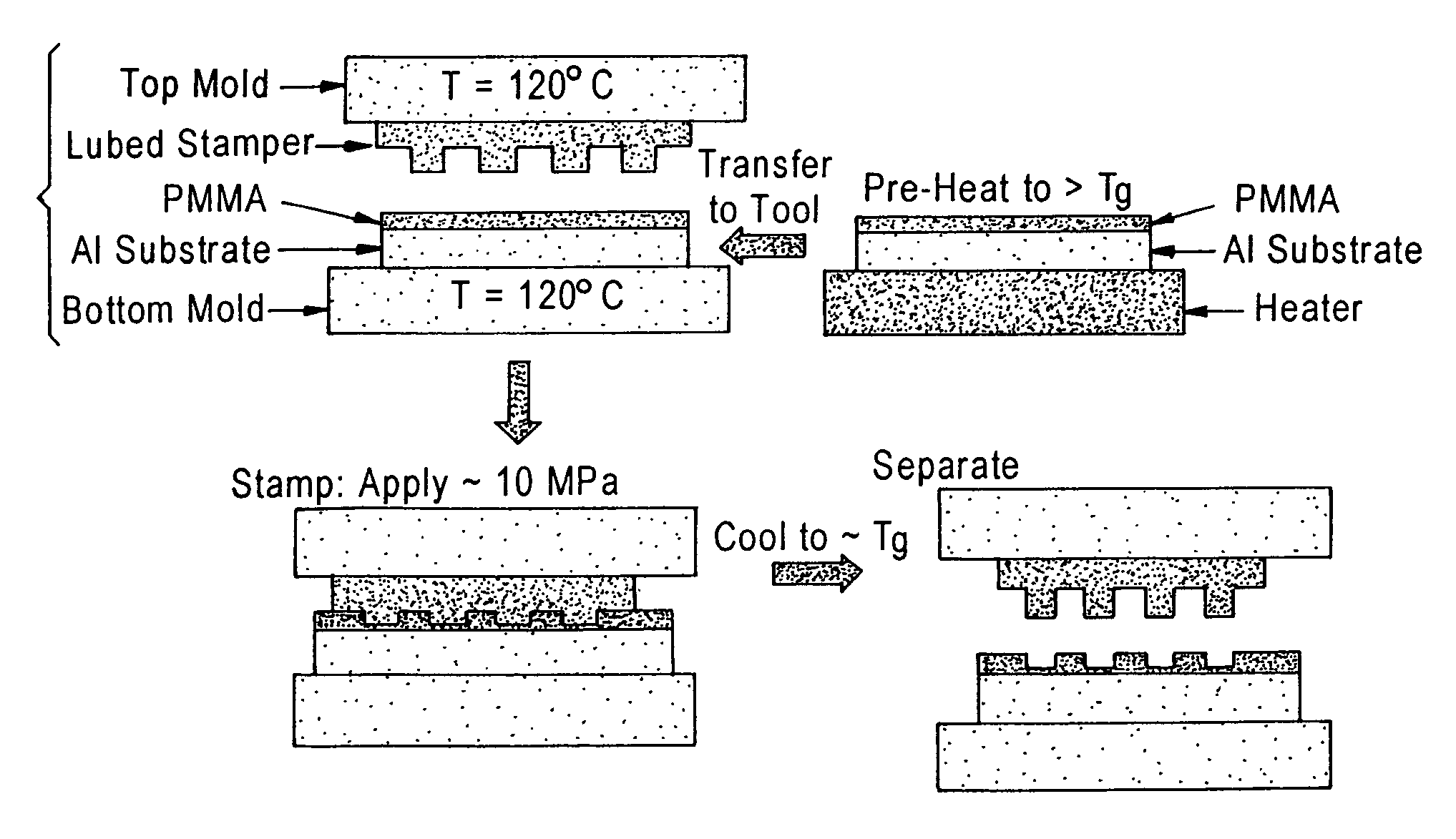

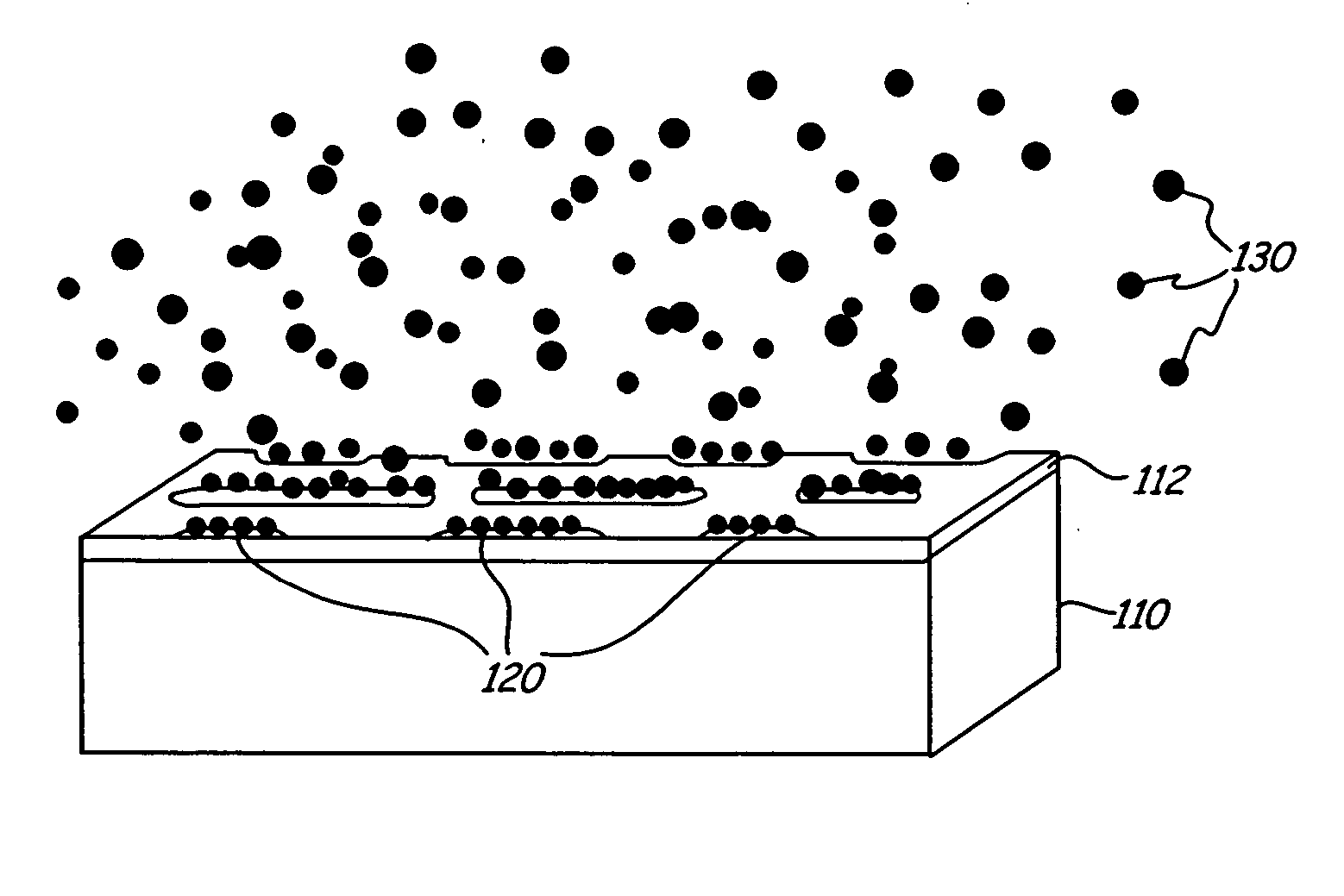

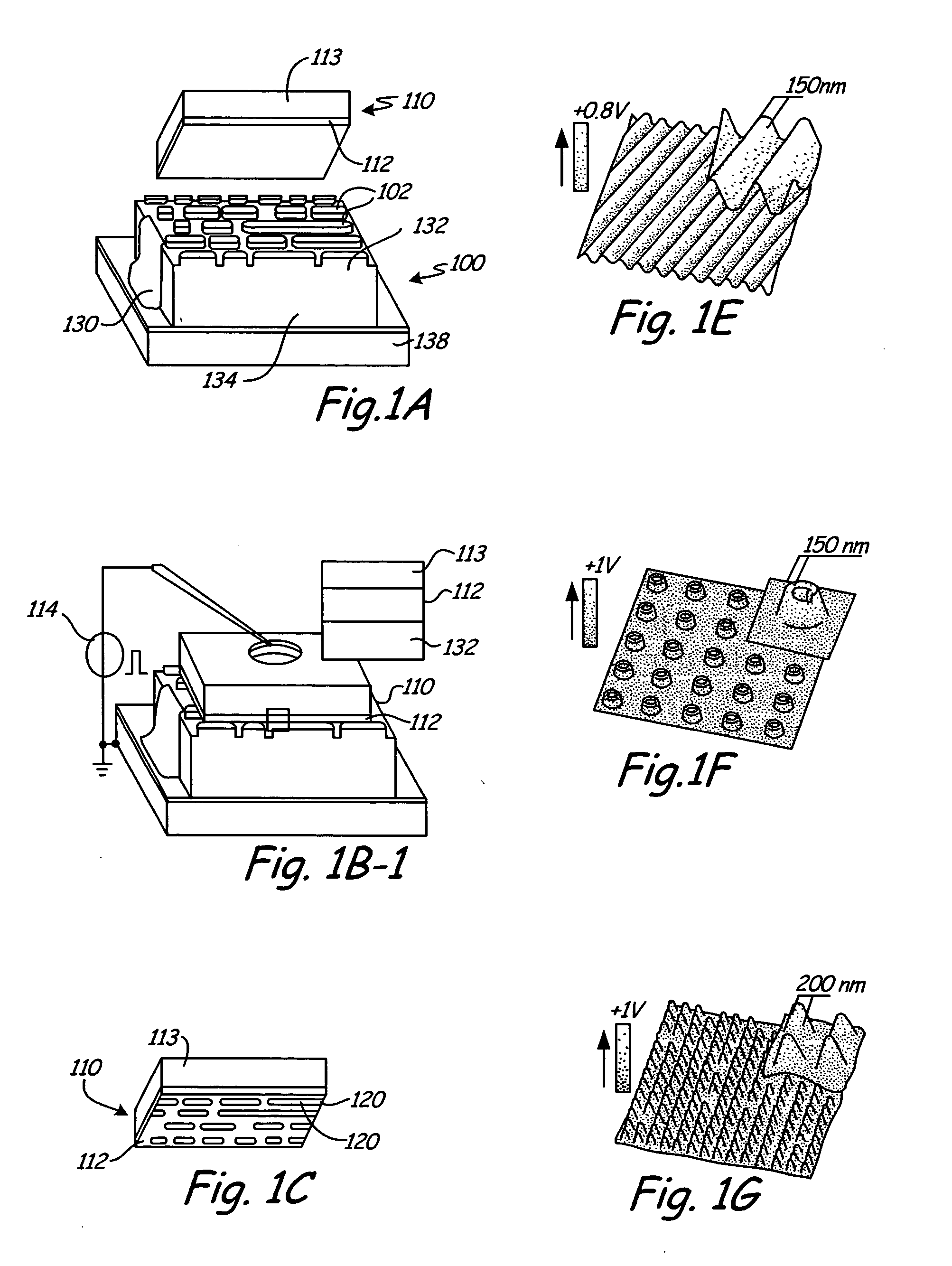

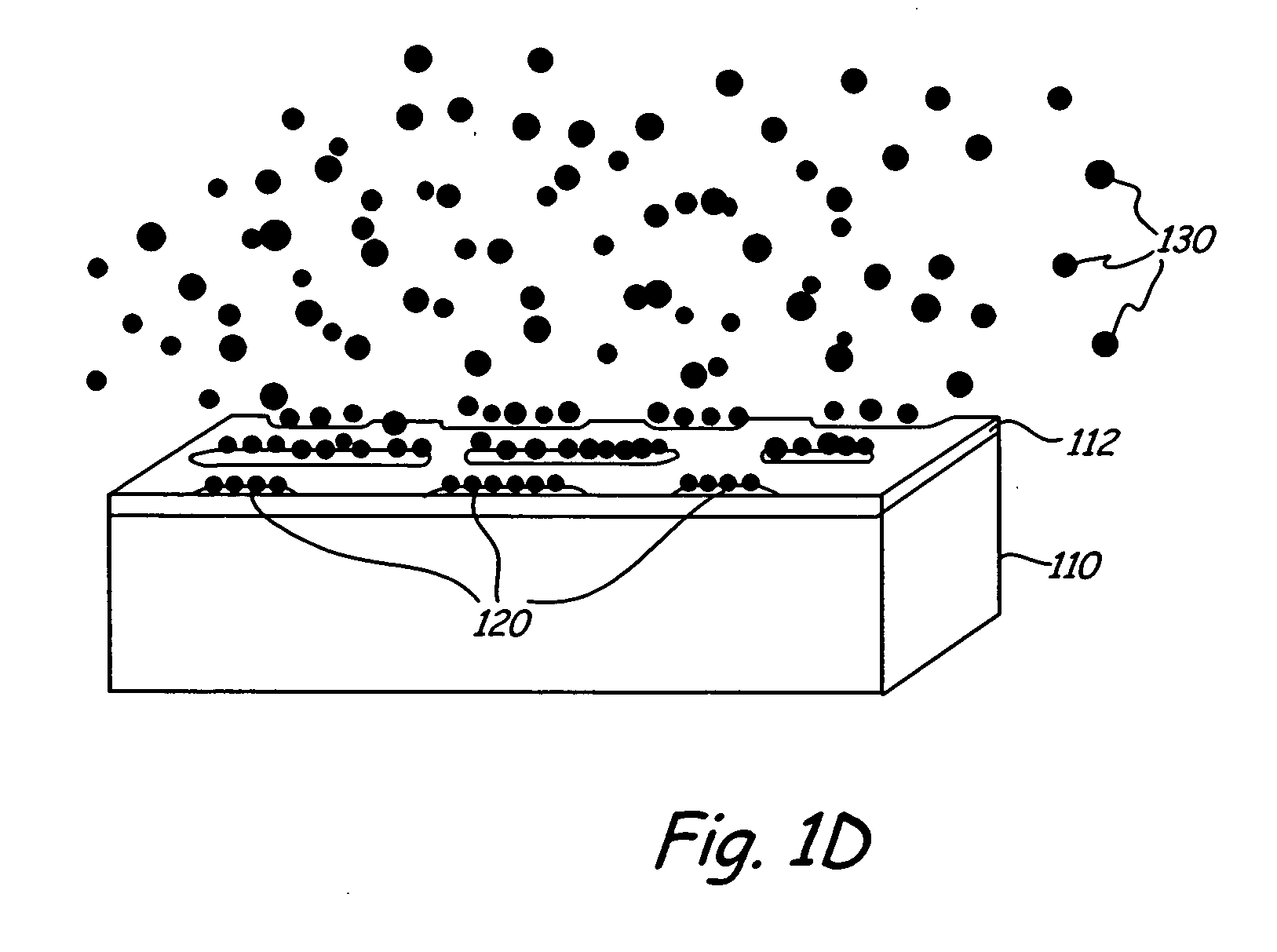

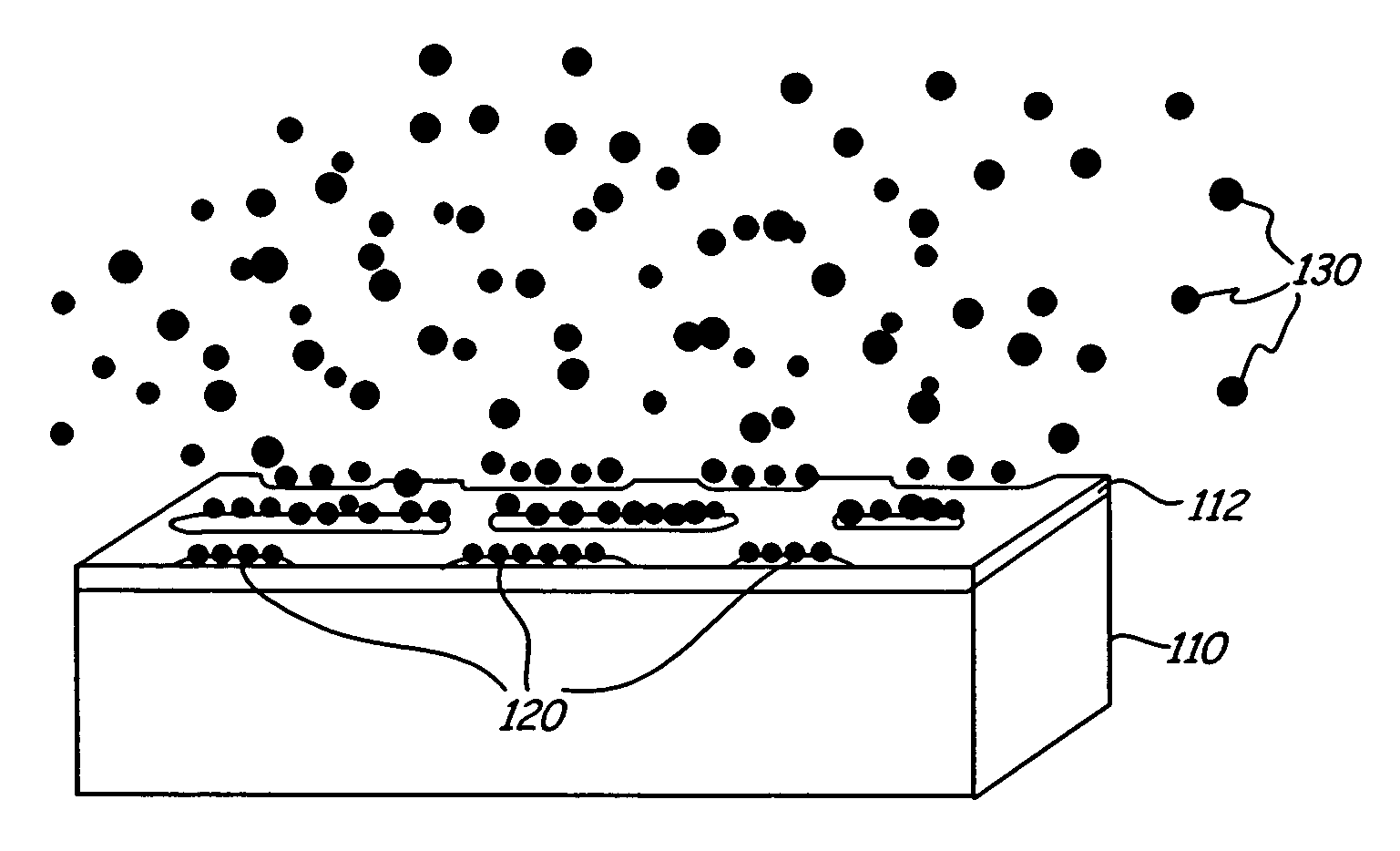

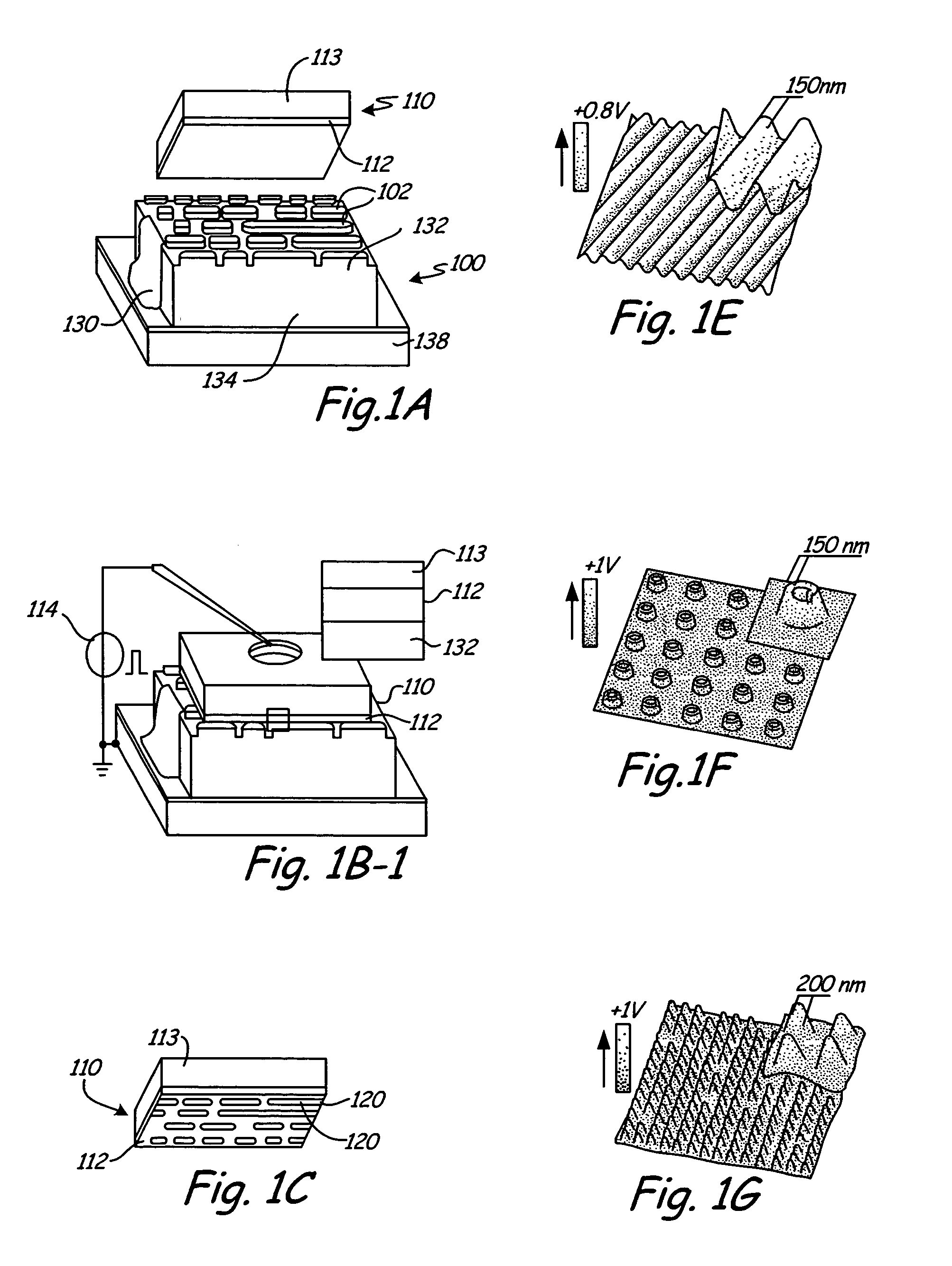

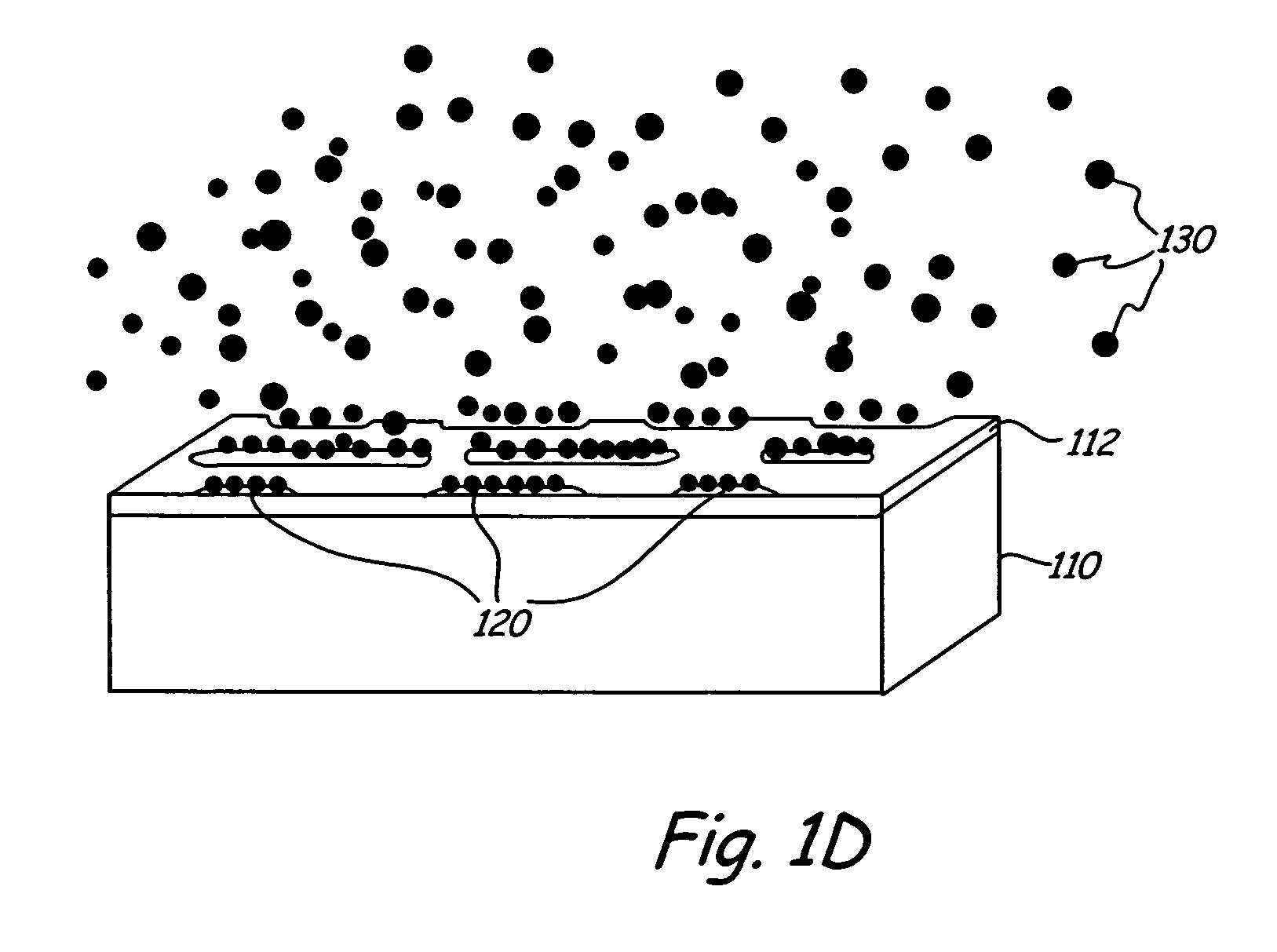

Method and apparatus for depositing charge and/or nanoparticles

ActiveUS20050123687A1NanotechSemiconductor/solid-state device manufacturingNanoparticleWork function

A method and apparatus for use in depositing electrical charge and / or nanoparticles is provided. A stamping process is used in which a stamp having a flexible layer such as a flexible semiconductor layer applies a charge pattern on a substrate. Other techniques include lithographic patterning, the use of pre-patterned dissimilar materials, deposition by ions or radiation, the use of differing work functions, the use of liquid phase materials. Deposition monitoring techniques and apparatuses are also provided.

Owner:RGT UNIV OF MINNESOTA

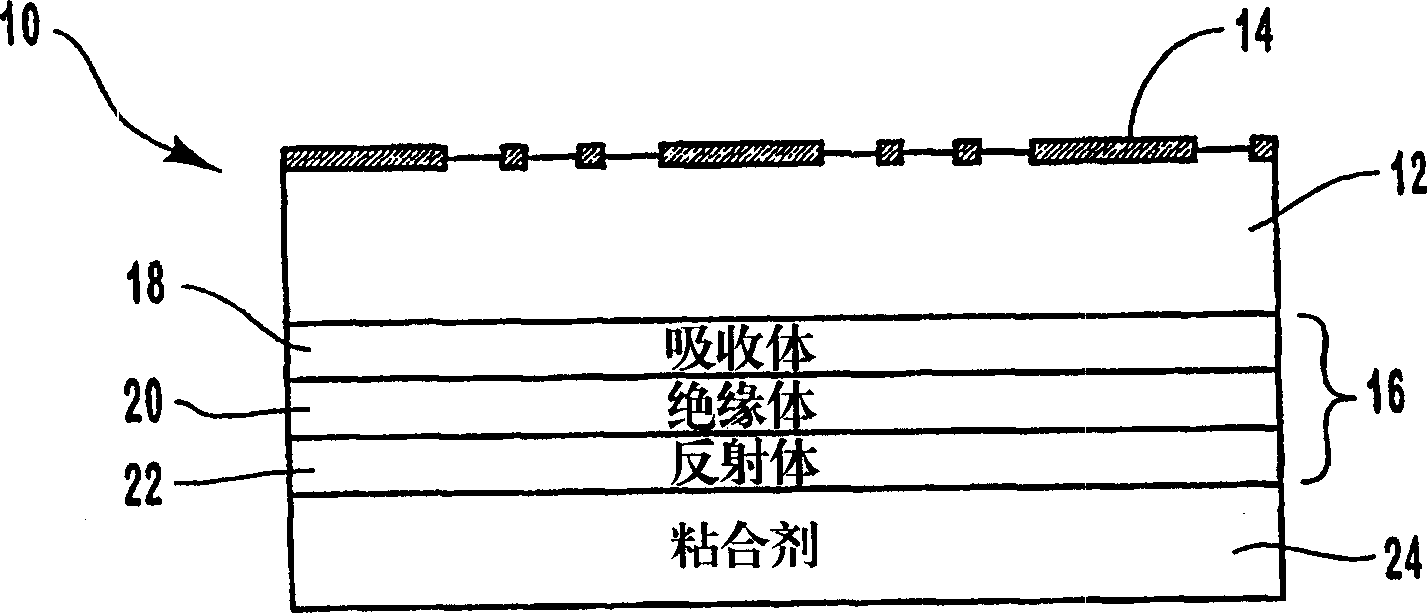

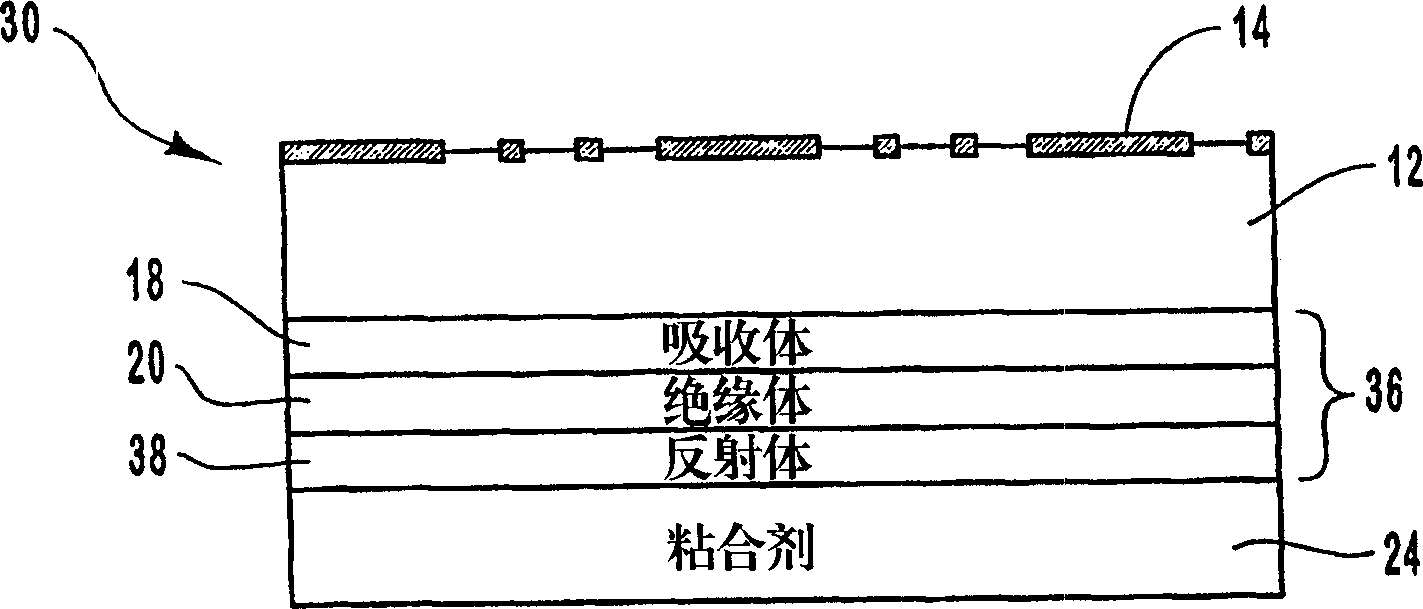

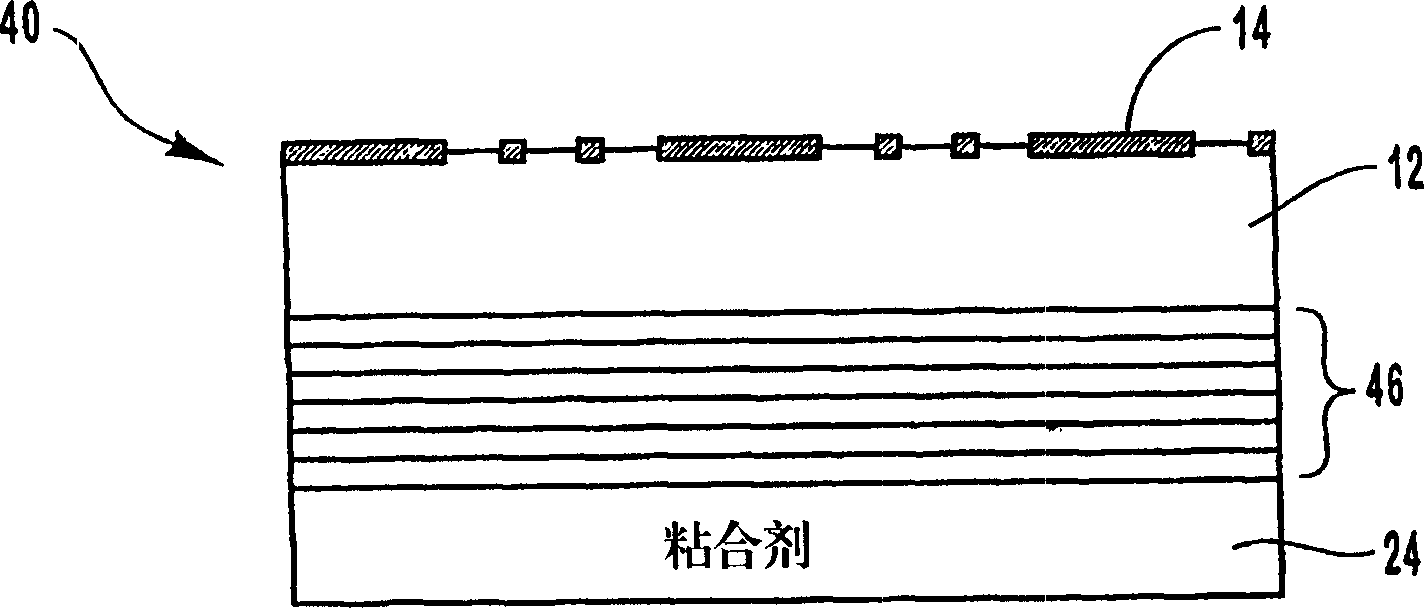

Uptically variable security devices

InactiveCN1423598AGood anti-counterfeiting measuresOther printing matterSynthetic resin layered productsHot stampingEngineering

A security article (10) includes a light transmissive substrate (12) having a first surface and an opposing second surface, with the first surface having an optical interference pattern (14) such as a holographic image pattern or an optical diffraction pattern thereon. A color shifting optical coating (16) is formed on the substrate such as on the interference pattern or on the opposing second surface of the substrate, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. Various processes can be utilized to form the security article (10), such as vacuum coating processes, lamination, laser scribing, and laser imaging. The security article (10) can be affixed to a variety of objects through various attachment mechanisms, such as pressure sensitive adhesives or hot stamping processes, to provide for enhanced security measures such as anticounterfeiting.

Owner:光学涂层实验公司

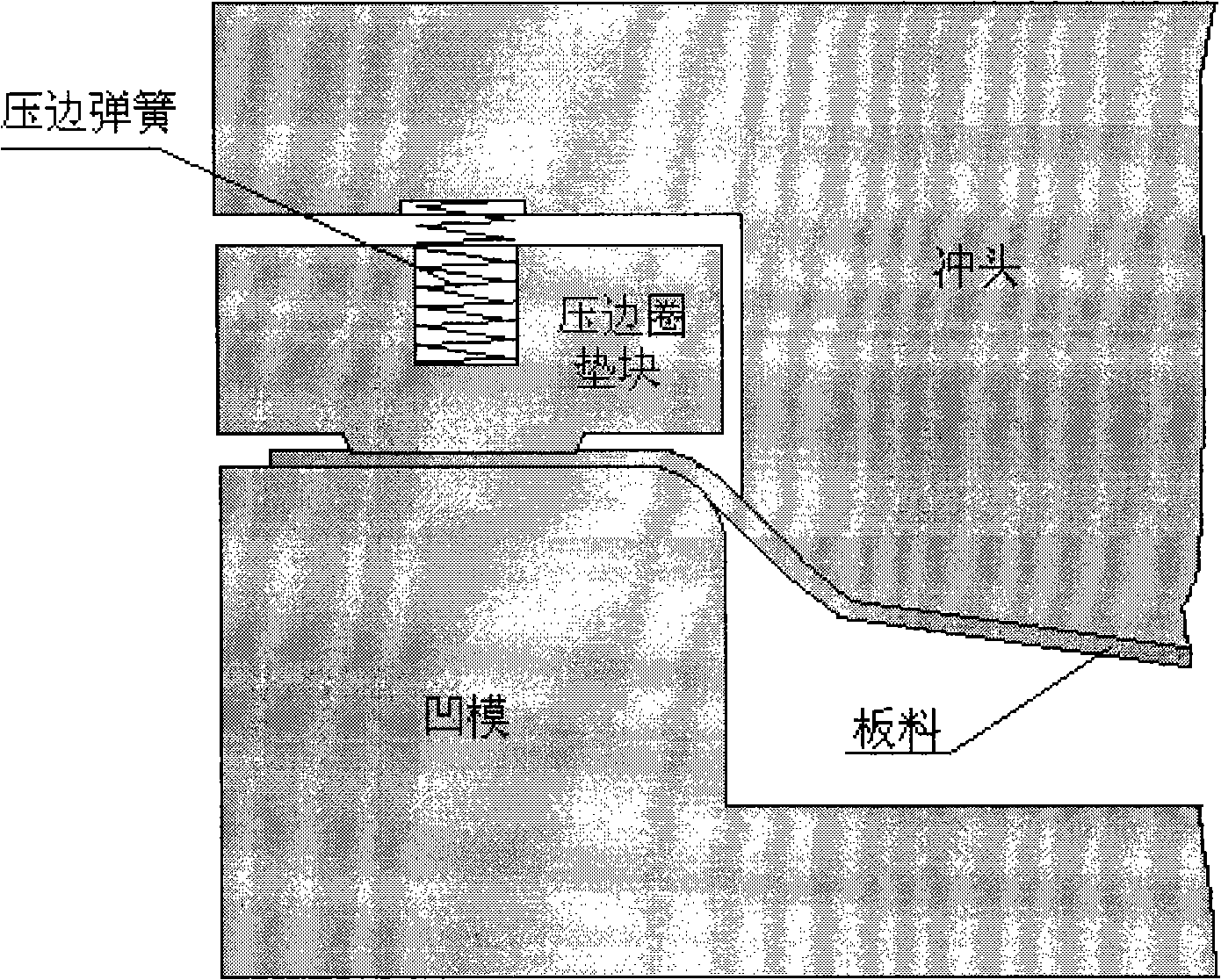

Steel wheel spoke stamping process for passenger car and processing mould

The invention relates to a steel wheel spoke stamping process for a passenger car, comprising the following steps of: (1) cutting a panel veneer: placing the rectangular panel veneer on a material support, the left and right ends as well as the front end of which are positioned by a set rule; when a press descends, cutting the panel veneer at the same time by using a peripheral cutting edge at the lower part of the outer edge of an upper mold core and a trim blade to form a spoke panel veneer; (2) stretching the panel veneer: placing the trimmed spoke panel veneer on a blank pressing ring, and pressing down the spoke panel veneer through the upper mold core and the blank pressing ring, wherein in the descending process of the press, the middle part of the spoke panel veneer firstly contacts the lower mold core to prevent the middle part of the spoke panel veneer from descending, and the peripheral part of the spoke panel veneer without being blocked continuously stretches the spoke panel veneer along with the descending of the upper mold core and the blank pressing ring; (3) punching central holes of the spoke; and (4) resetting and discharging. The invention integrates the blanking and stretching processes, adopts the one-step positioning way to ensure the concentricity of the central hole of the spoke and the outer edge of the spoke to ensure the processing quality of the spoke and reduces one process compared with the prior art, thereby greatly improving the production efficiency.

Owner:SHANGHAI BAOSTEEL WHEEL

Sedan tubular V-shaped torsion beam stamping process

The invention discloses a sedan tubular V-shaped torsion beam stamping process, which includes blanking, inner V shape forming, primary formed outer V shape port expansion, secondary port expansion and cutting, consequently, the original process of primarily stamping an inner V-shaped surface and an outer V-shaped surface and secondarily expanding the shape of the port is changed into primary inner V-shaped surface stamping, the port is then primarily expanded as the outer V-shaped surface is stamped, and the process of secondarily expanding the port is carried out. Not only is the production of a bump at the intersection between the port expansion and the middle V shape effectively prevented, but also the port is prevented from being cracked due to expansion, so that the rigidity and strength of a product are ensured; moreover, the process is simple, the number of the steps of the process are little, and the production cost is effectively controlled.

Owner:天人汽车底盘(芜湖)股份有限公司

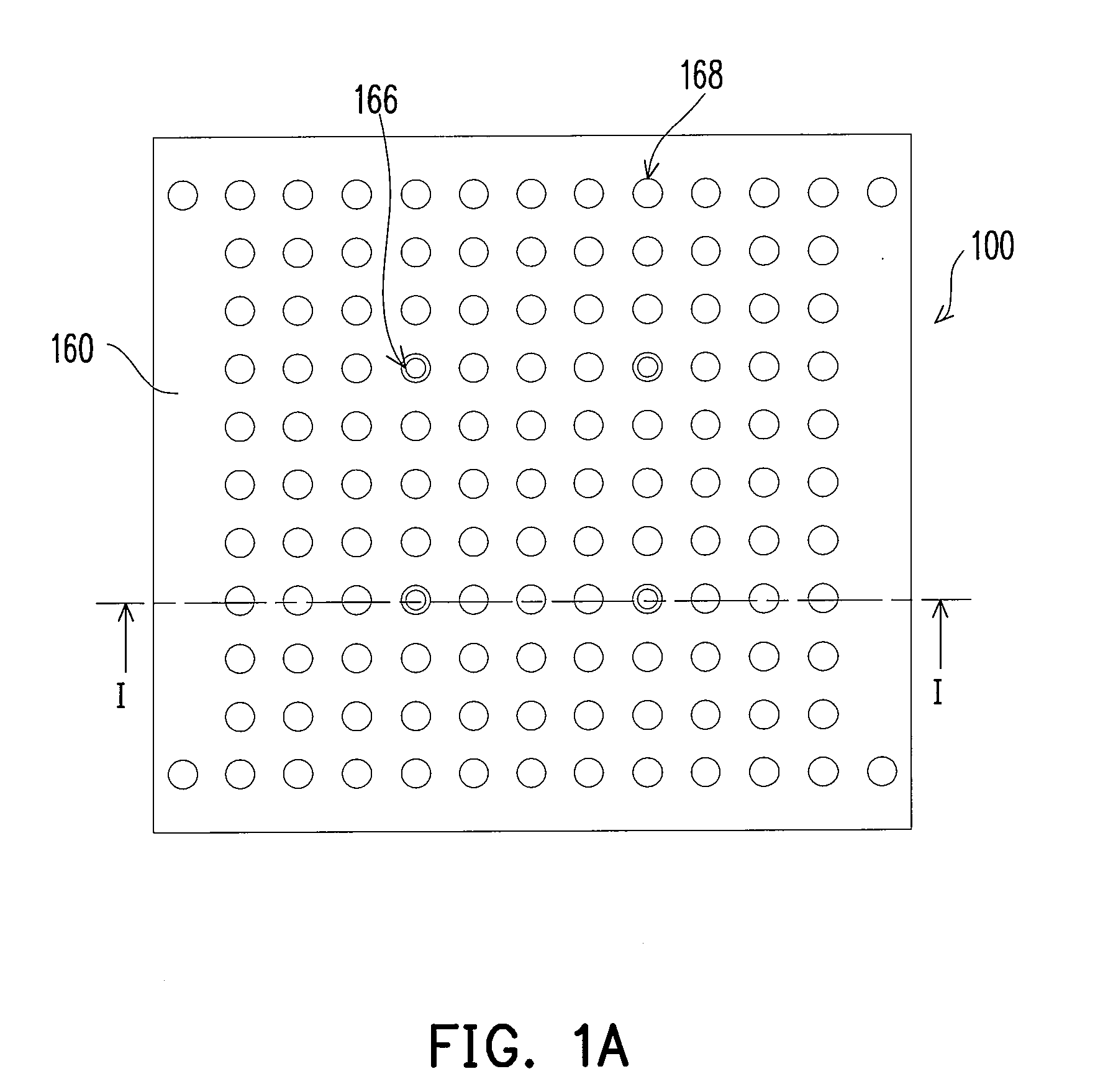

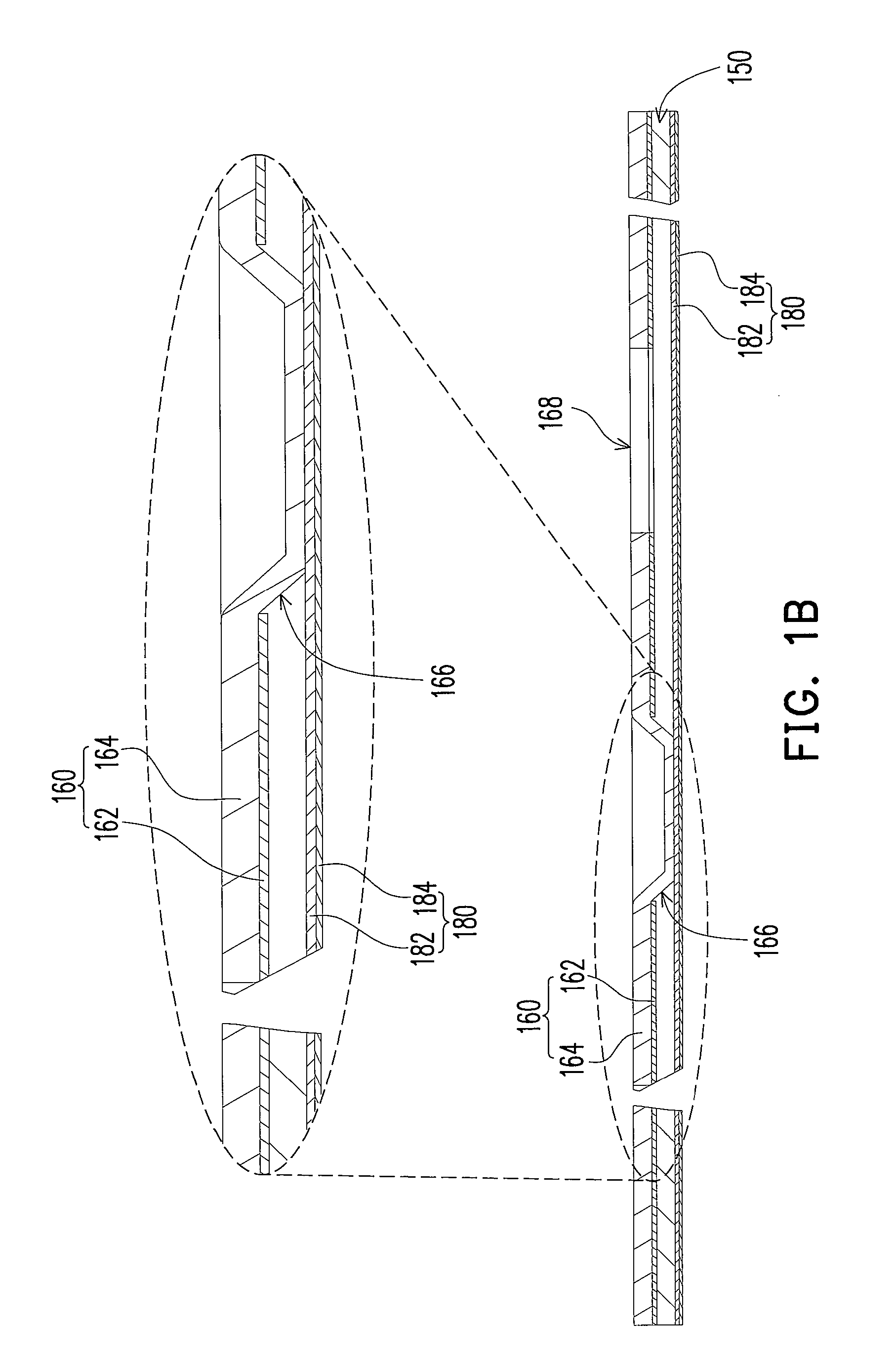

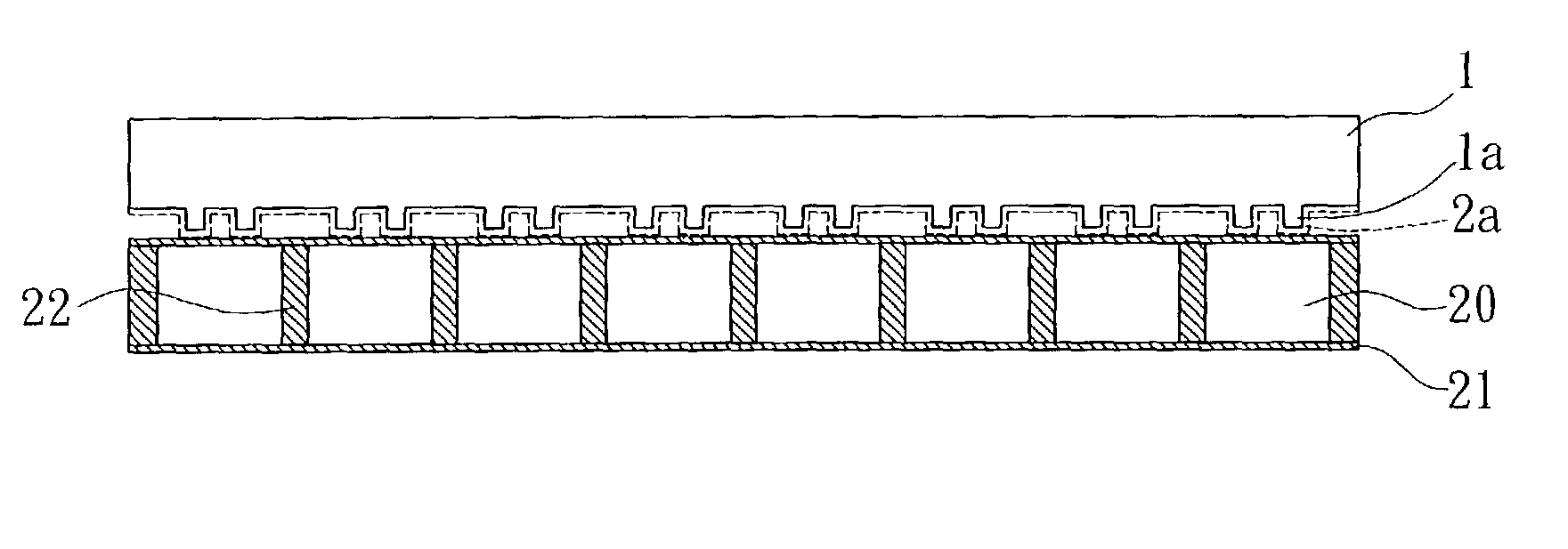

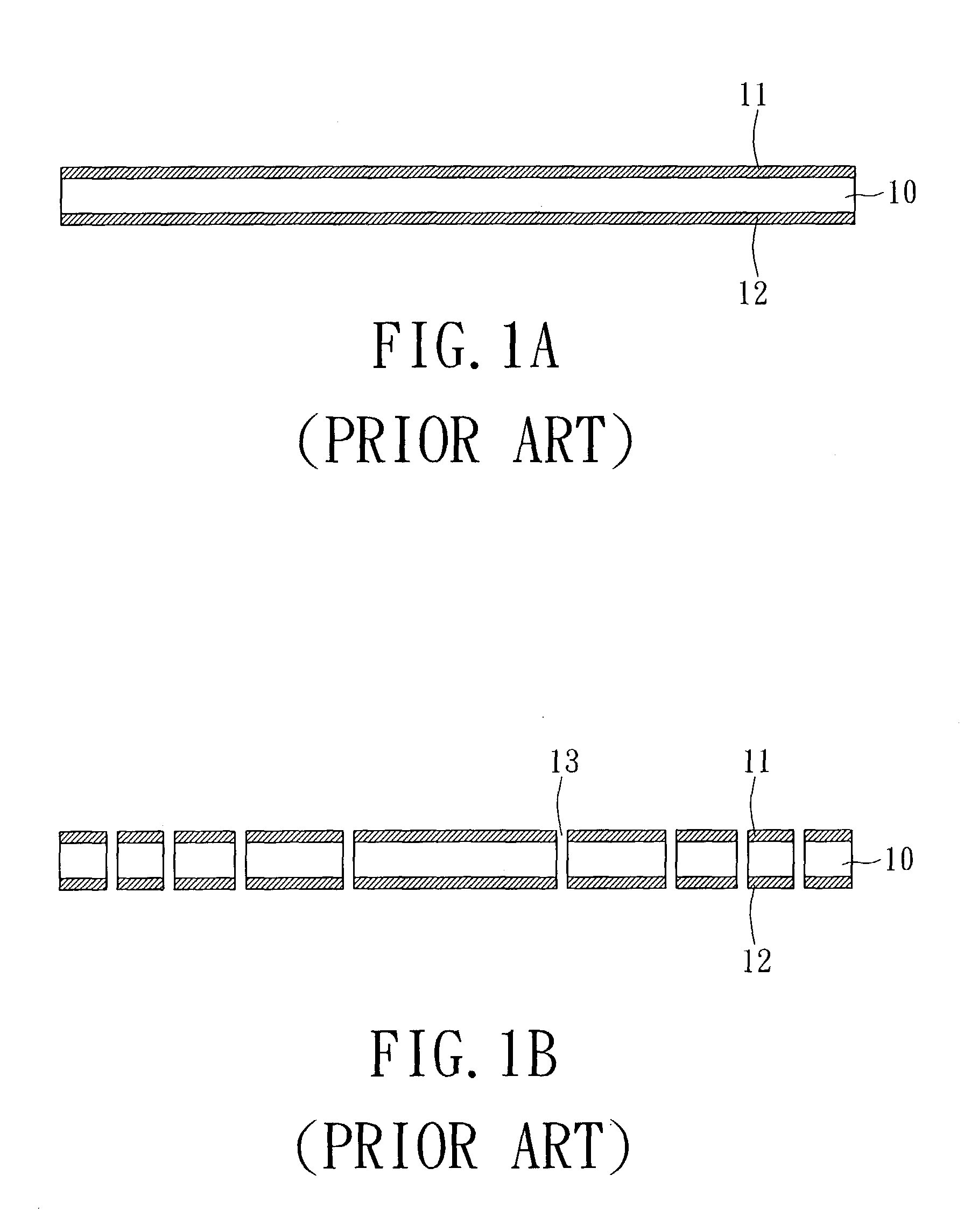

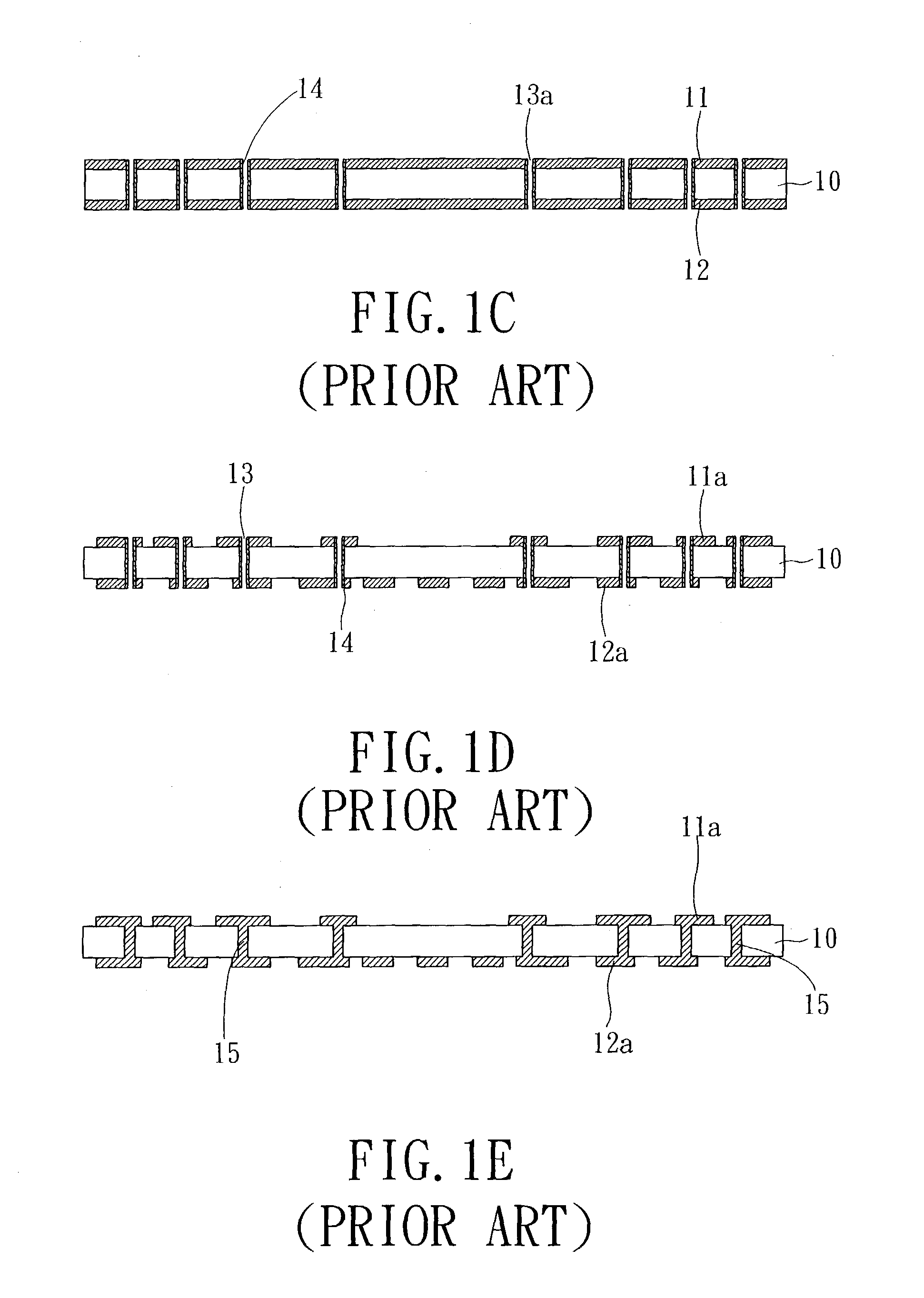

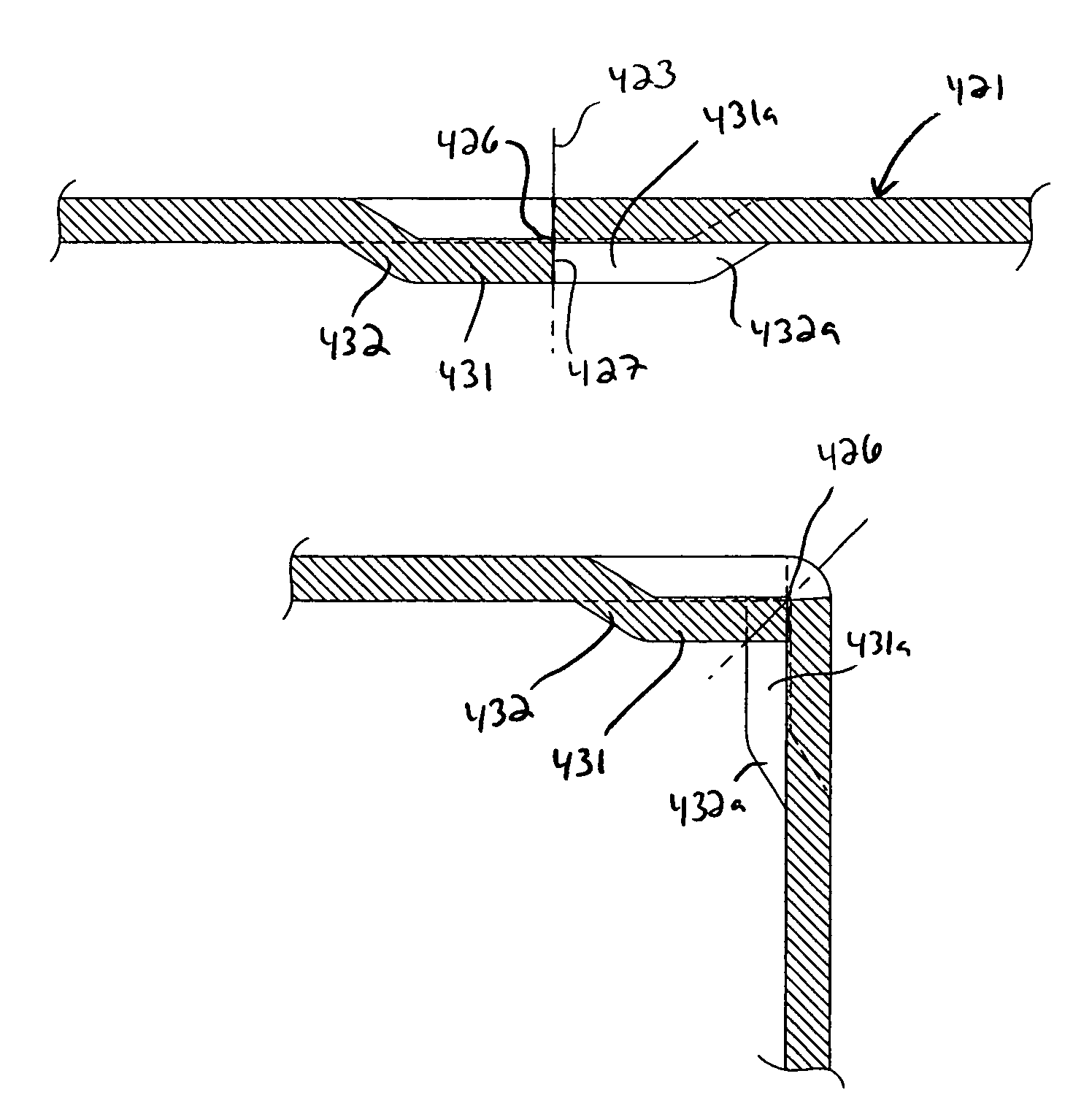

Flexible electret transducer assembly, speaker, and method for fabricating flexible electret transducer assembly

ActiveUS20090304212A1Precise processImprove audio qualityElectrets selectrostatic transducerSemiconductor/solid-state device manufacturingTransducerEngineering

A flexible electret transducer assembly including an electrical backplate and a membrane made of an electret material is disclosed. A plurality of spacers is formed on a surface of the electrical backplate in a longitudinal or latitudinal direction, and the spacers are used for supporting a vibrating room of the membrane. A working area of the membrane is formed between adjacent spacers, and in each of the working area, the space between the electrical backplate and the membrane is smaller than that in a conventional electrostatic speaker. The spacers between the electrical backplate and the membrane are mass produced through a stamping process. Thereby, an accurate space between the electrical backplate and the membrane can be maintained and accordingly the audio quality can be improved. In addition, a speaker including the flexible electret transducer assembly and a method for fabricating the flexible electret transducer assembly are also disclosed.

Owner:IND TECH RES INST

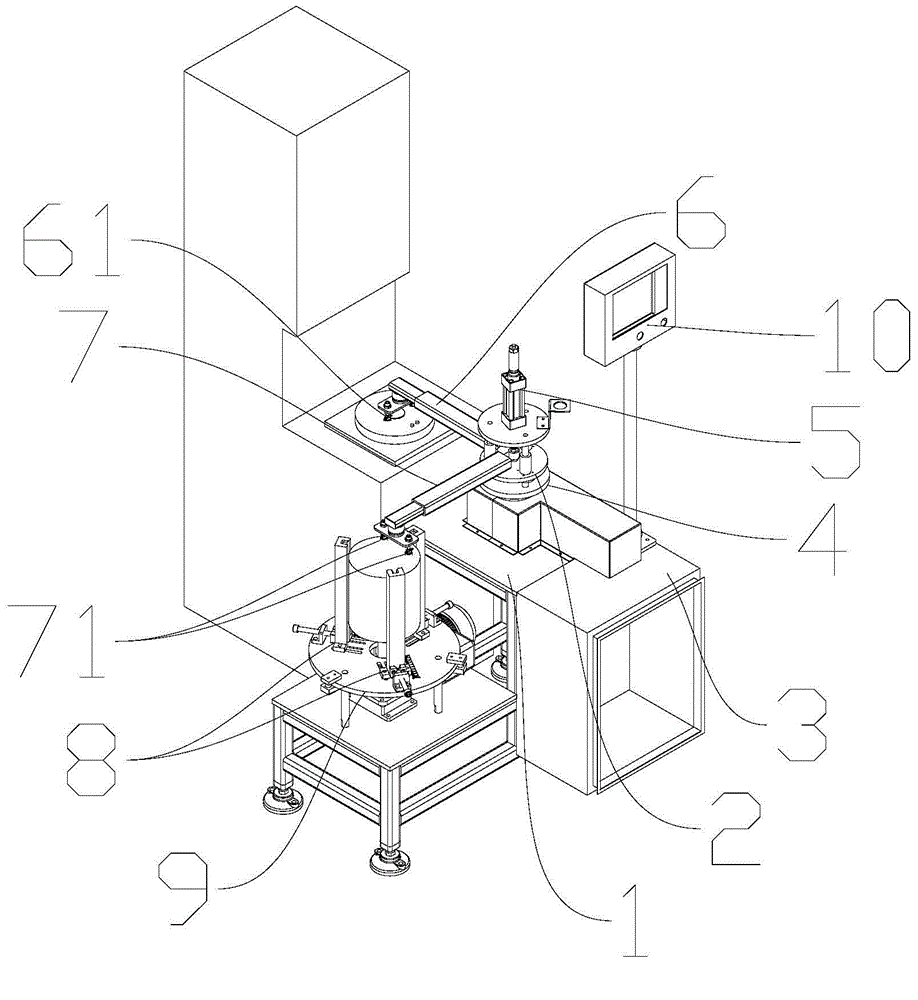

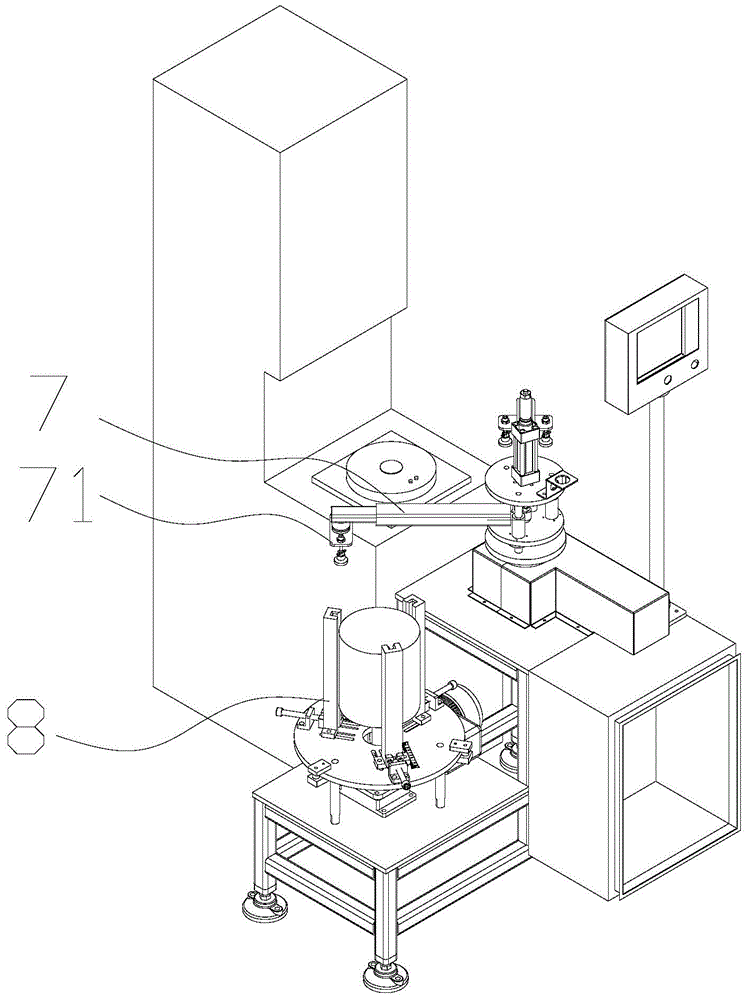

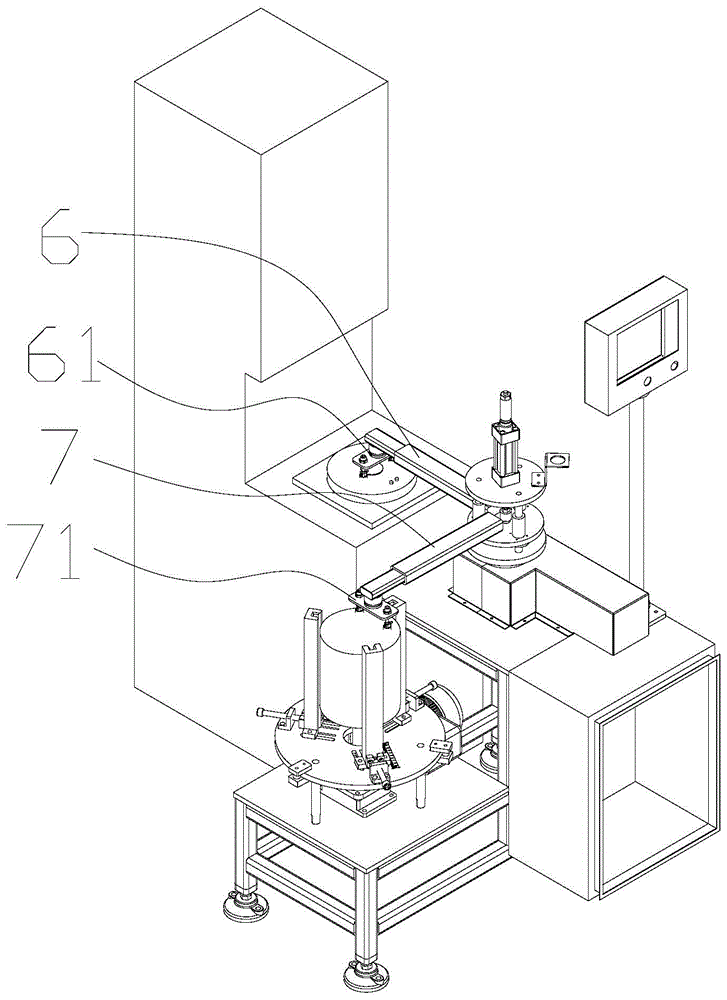

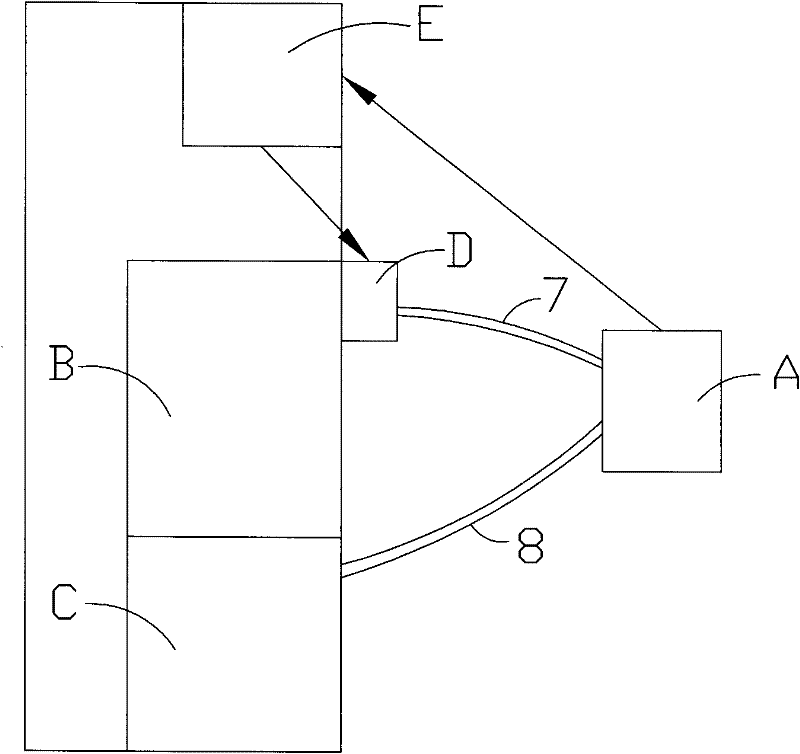

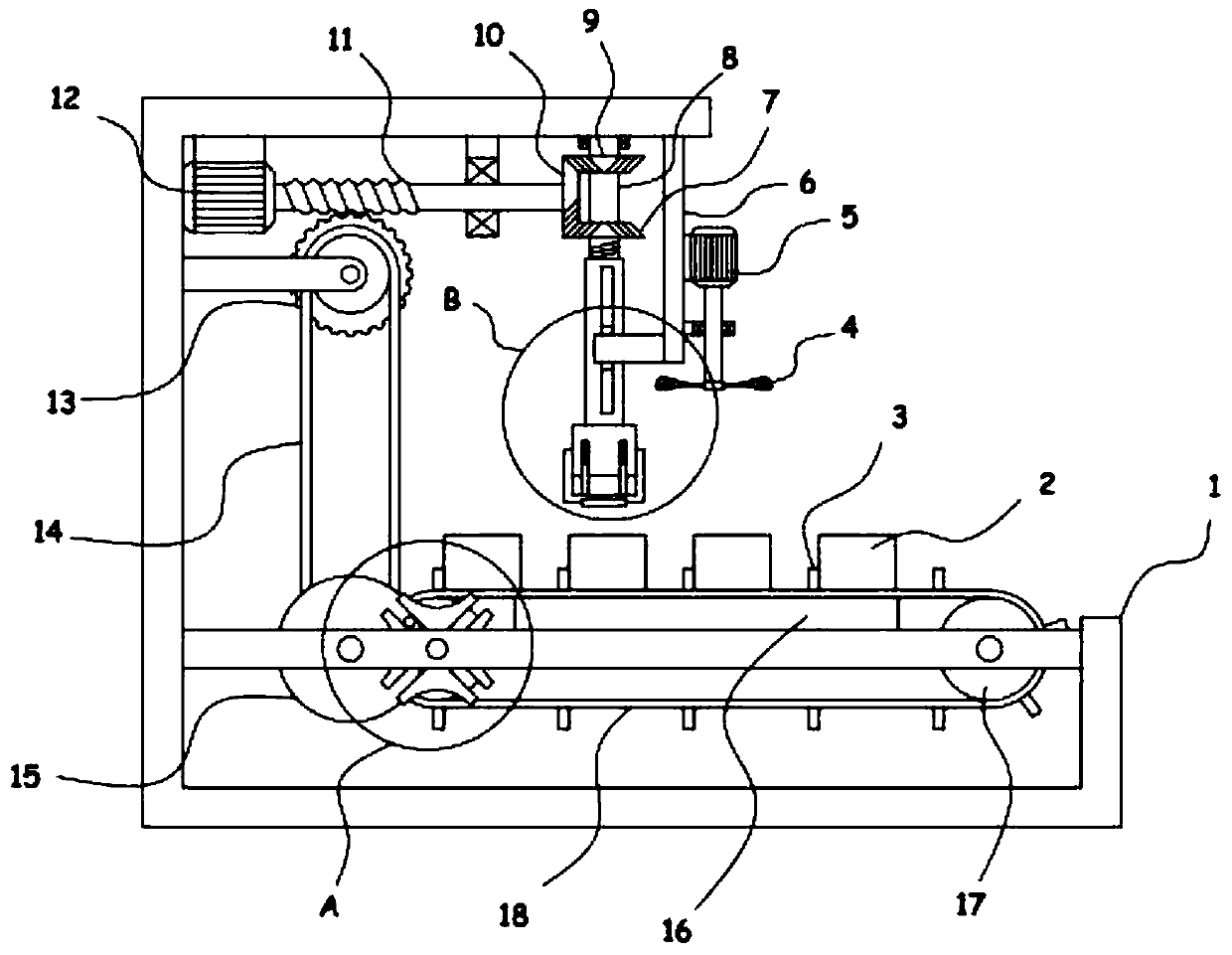

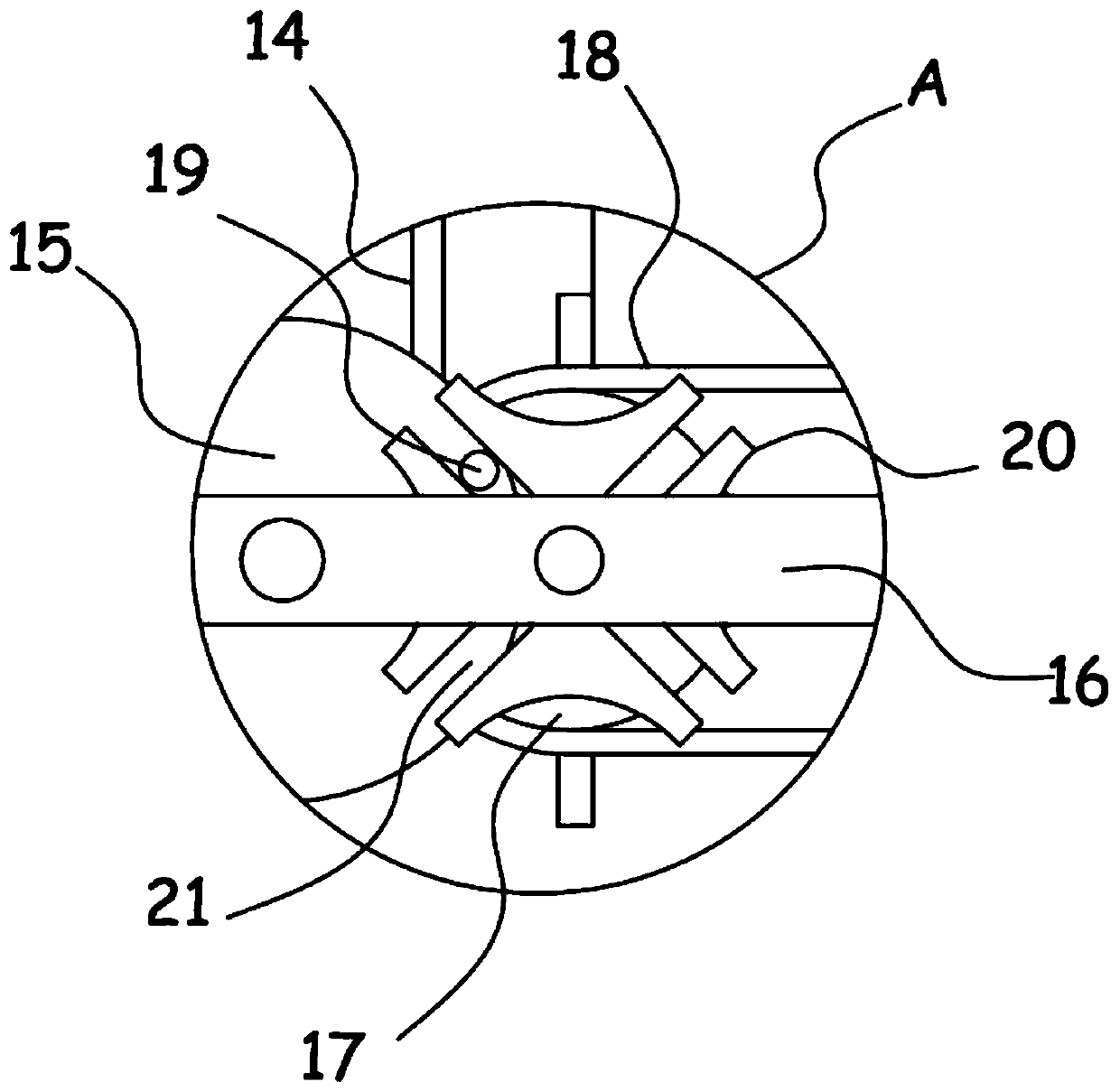

Feeding and discharging mechanical arm and device for stamping process

InactiveCN104785655AAutomatic and flexible reclaimingAutomatic and flexible feedingProgramme-controlled manipulatorMetal-working feeding devicesElectricitySingle process

The invention discloses a feeding and discharging mechanical arm and device for the stamping process. The feeding and discharging mechanical arm structurally comprises an electric control cabinet, a rack, a main rotating shaft, a fixing base, a vertical shaft, a first mechanical arm body, a second mechanical arm body, a first mechanical claw and a second mechanical claw. The included angle between the first mechanical arm body and the second mechanical arm body ranges from 90 degrees to 120 degrees, and the first mechanical arm body and the second mechanical arm body can move vertically along with the vertical shaft. The vertical shaft and the fixing base can rotate horizontally along with the main rotating shaft. The main rotating shaft, the vertical shaft, the first mechanical arm body and the second mechanical arm body are driven by different motors, and all the motors are electrically connected with the electric control cabinet. The feeding and discharging mechanical arm has the functions of taking and placing materials automatically and flexibly, is suitable for single-process stamping as well as whole-line multi-station stamping, solves the technical problems that existing equipment is low in applicability, low in working efficiency and likely to cause industrial accidents, and improves working efficiency, flexibility and safety.

Owner:FOSHAN IROBOT AUTOMATIC

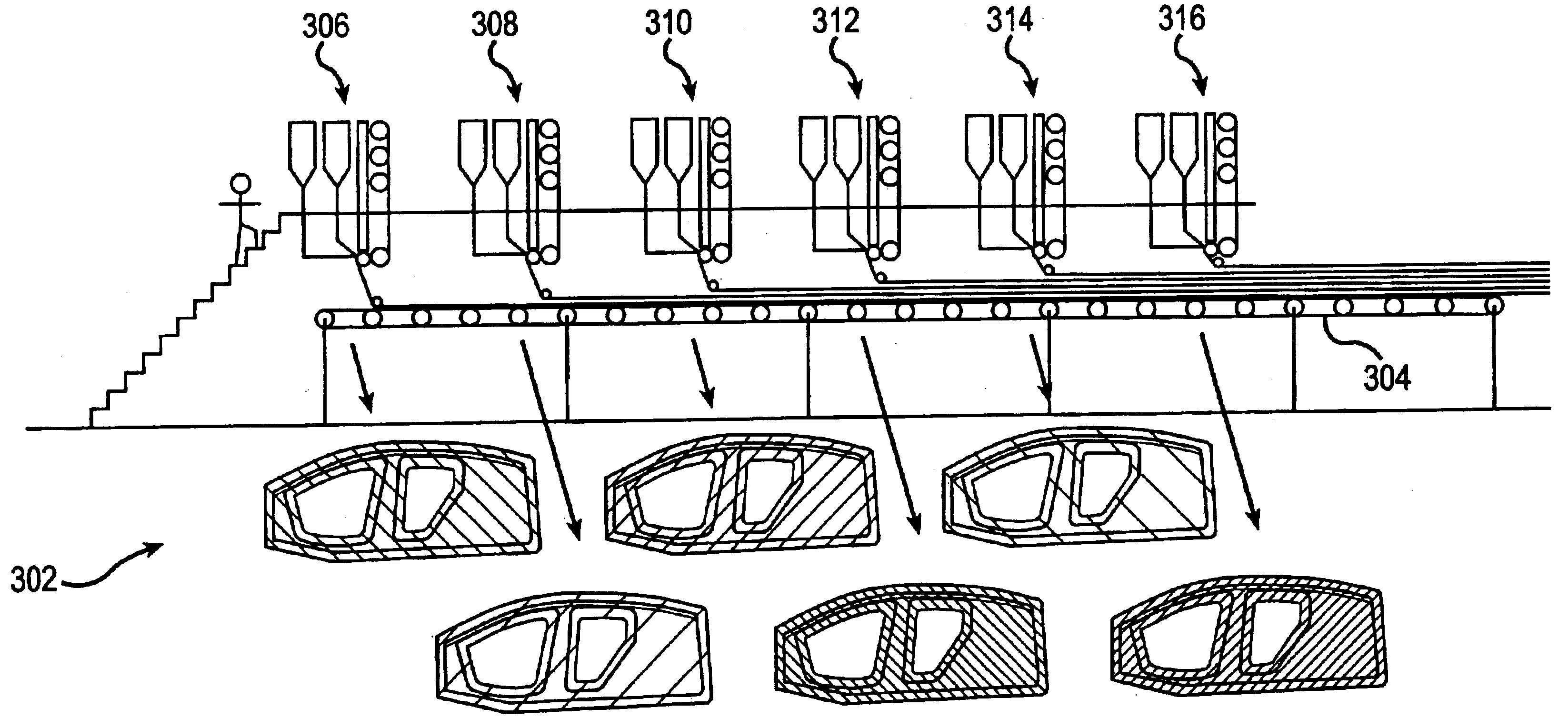

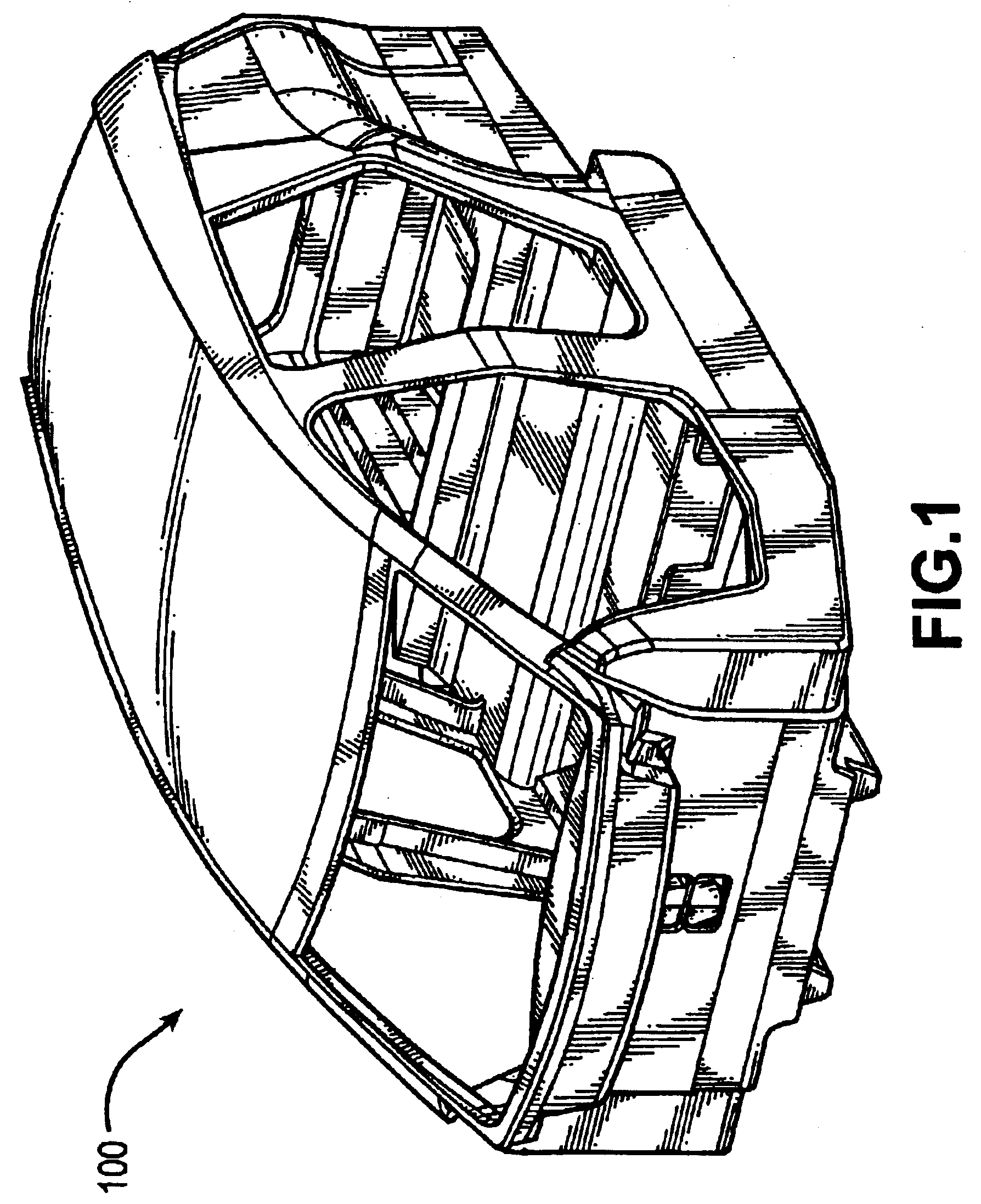

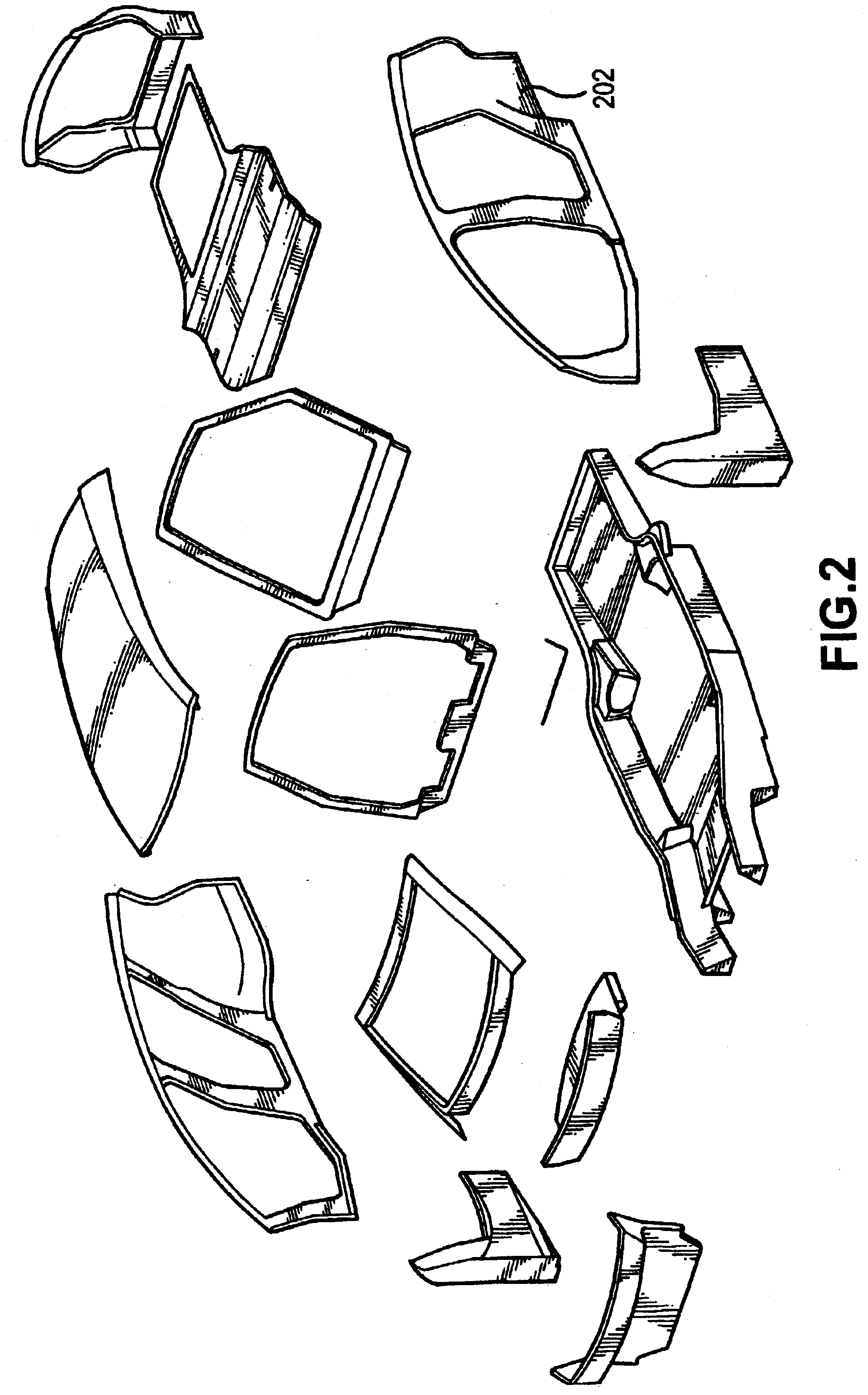

Process and equipment for manufacture of advanced composite structures

InactiveUS6939423B2Flexible useMinimal touch laborLaminationLamination apparatusEngineeringInjection moulding

A process for continuous, tailored lamination of aligned composite materials in such a way that either pre-formed or pre-consolidated sheets are made available for subsequent infusion molding or stamping processes, the process comprising the steps of: material placement, consolidation / stabilization, cut and kit, fabrication, and final trim. A tailored blank machine is also described. The blank machine includes a series of material placement heads arranged in a linear or serial fashion along a single moving placement table, wherein each head lays down a single angle of the prescribed stacking sequence as the conveyer passes under the head at a constant speed wherein the angle is proportional to head traverse rate divided by conveyer speed.

Owner:DIEFFENBACHER GMBH & CO KG

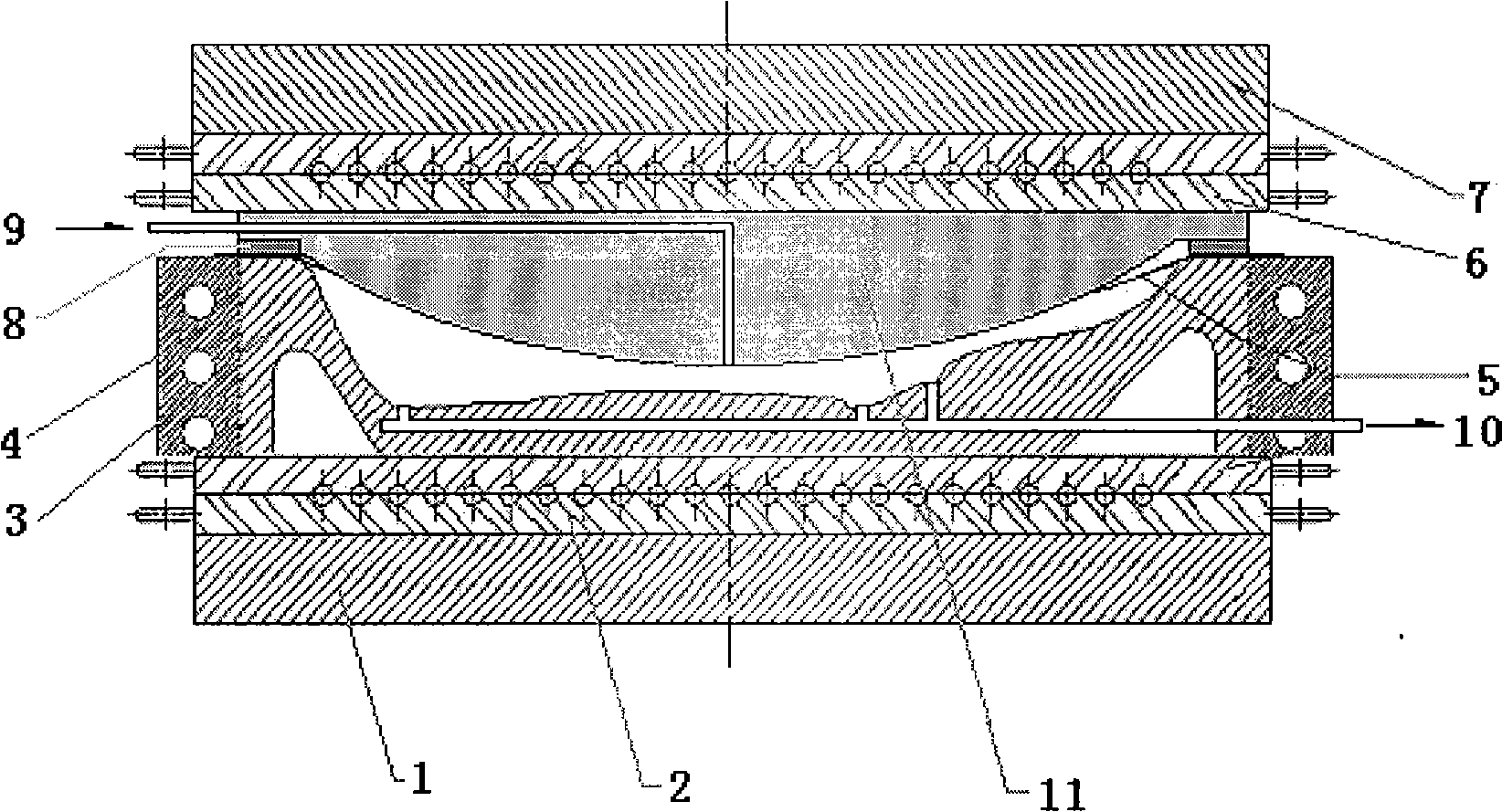

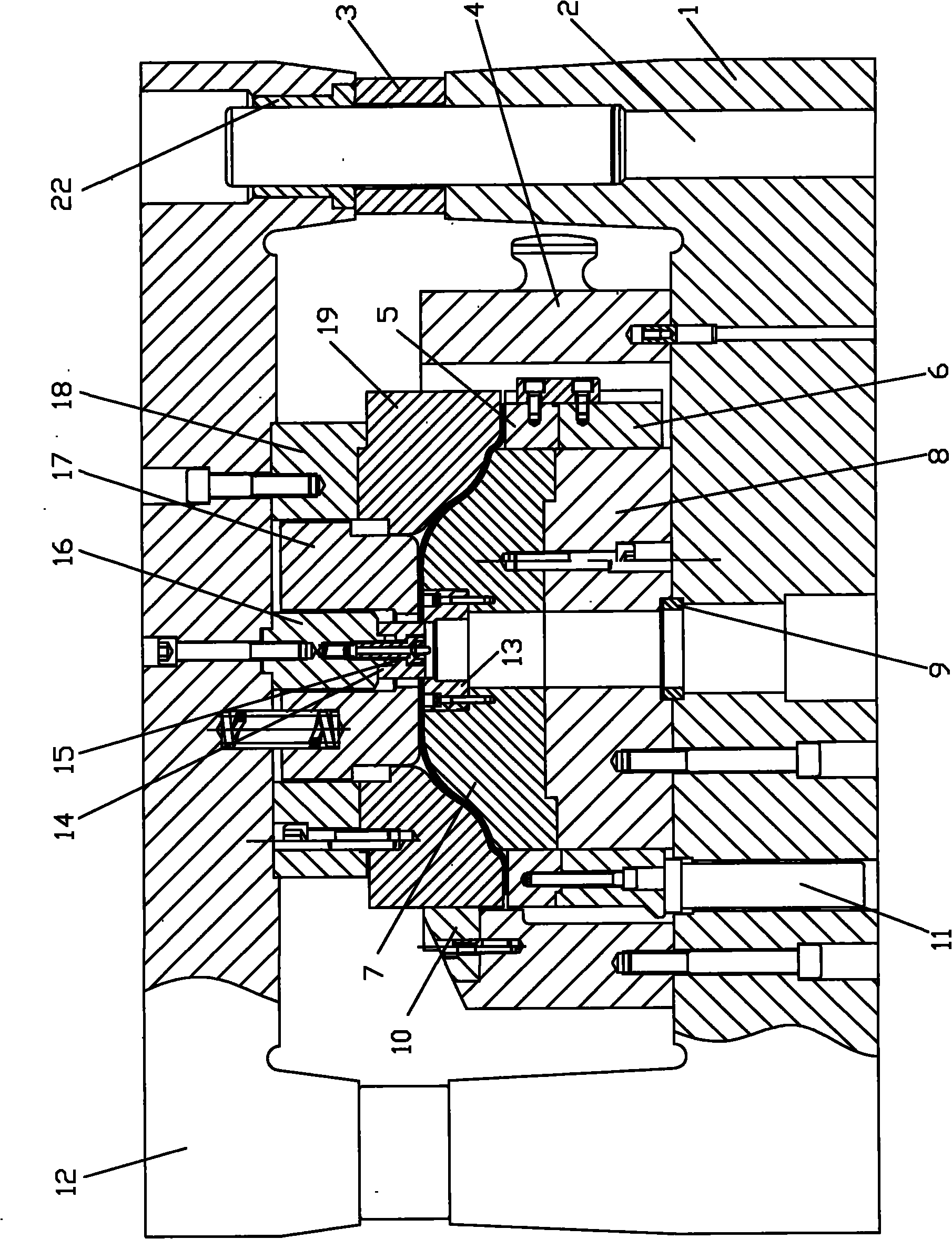

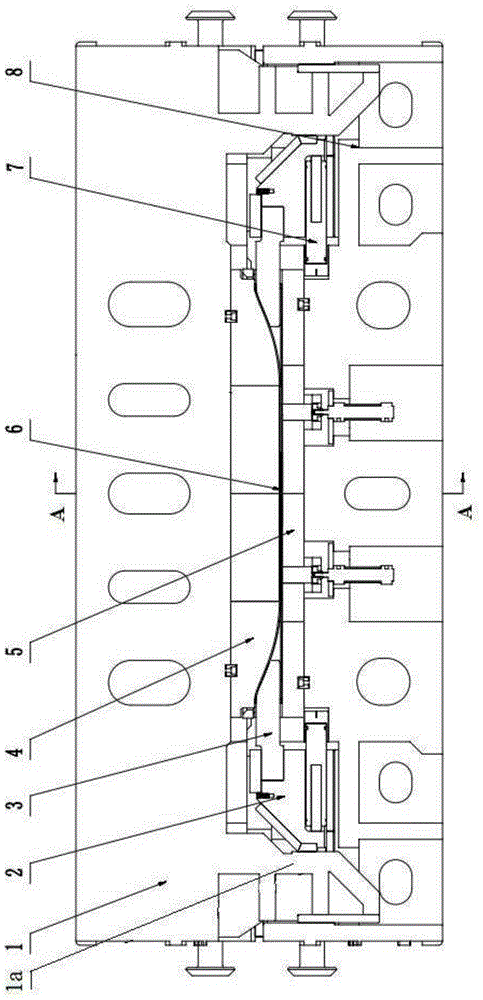

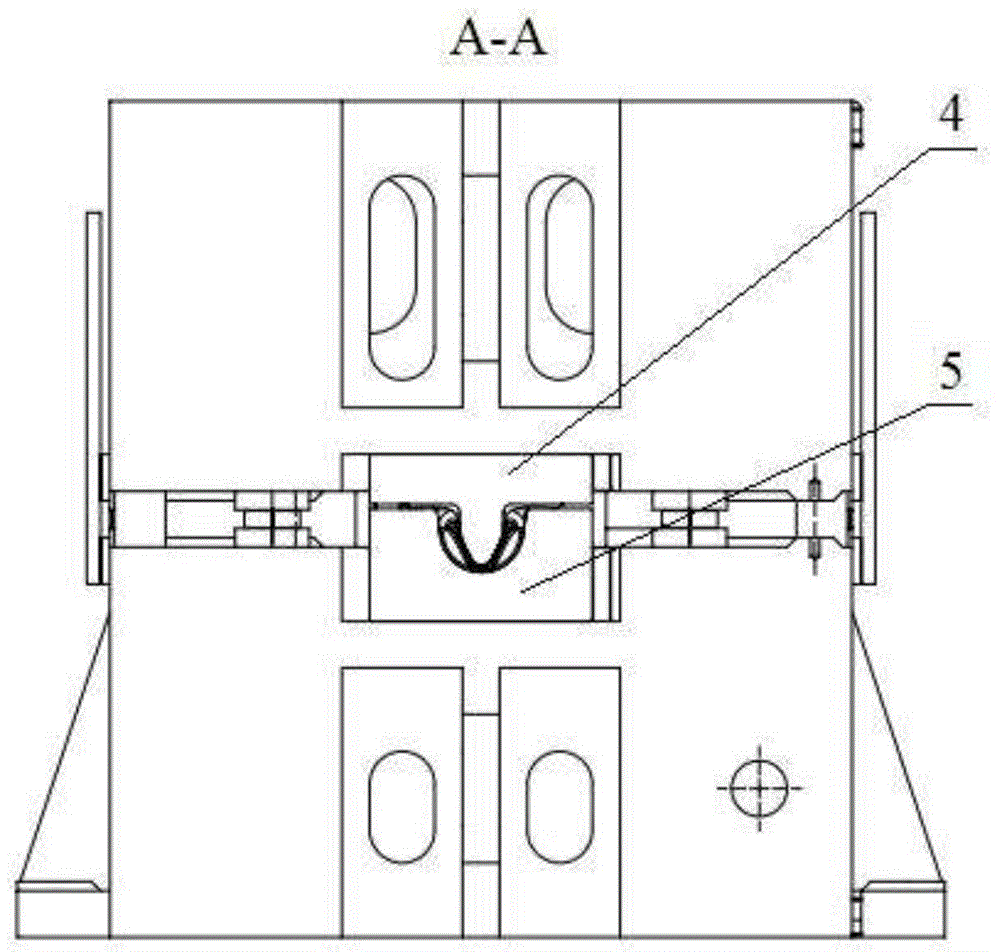

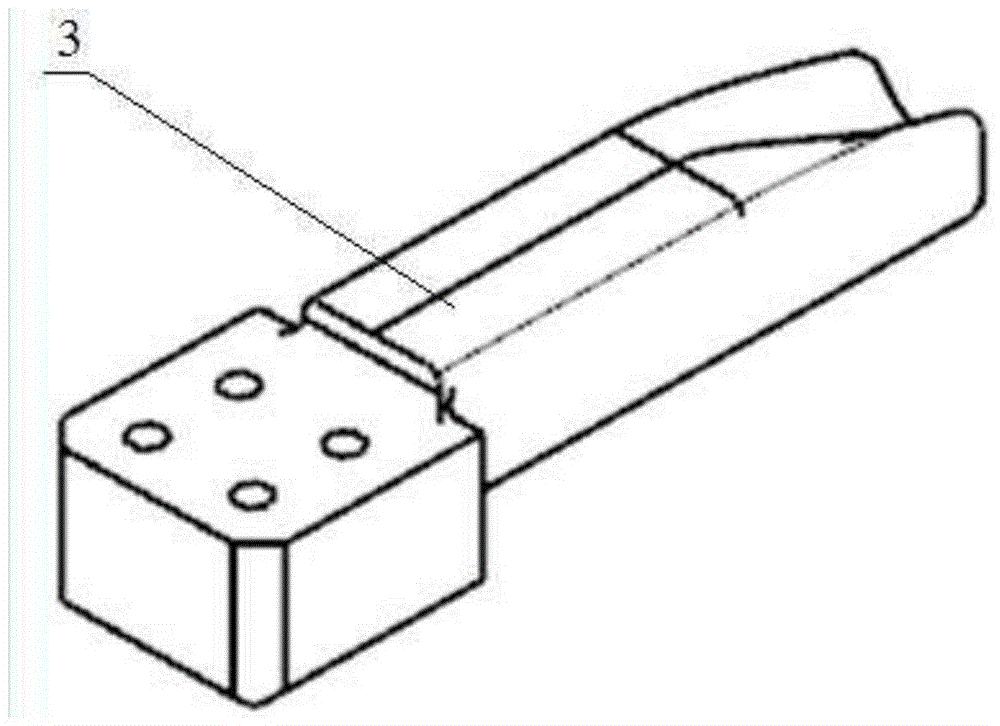

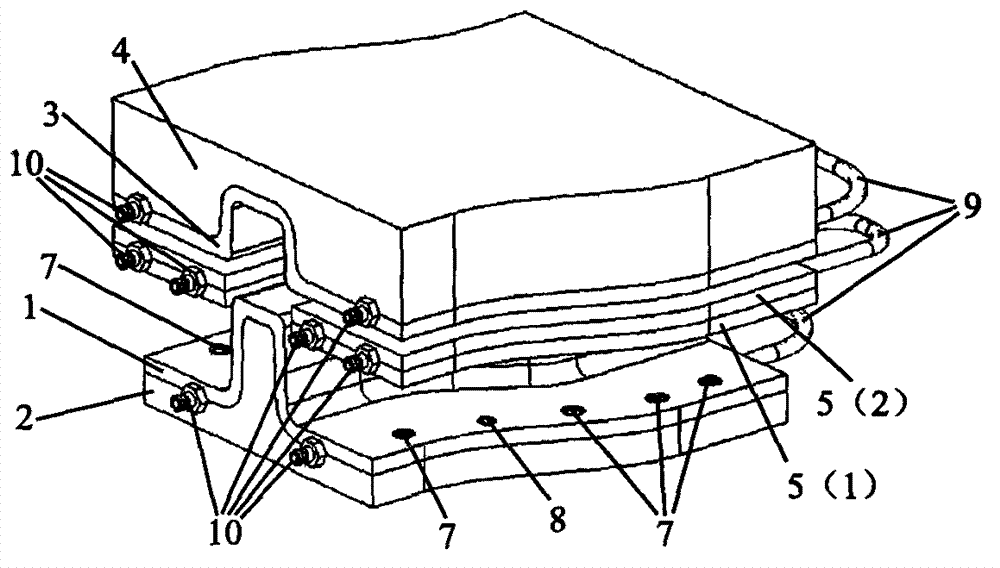

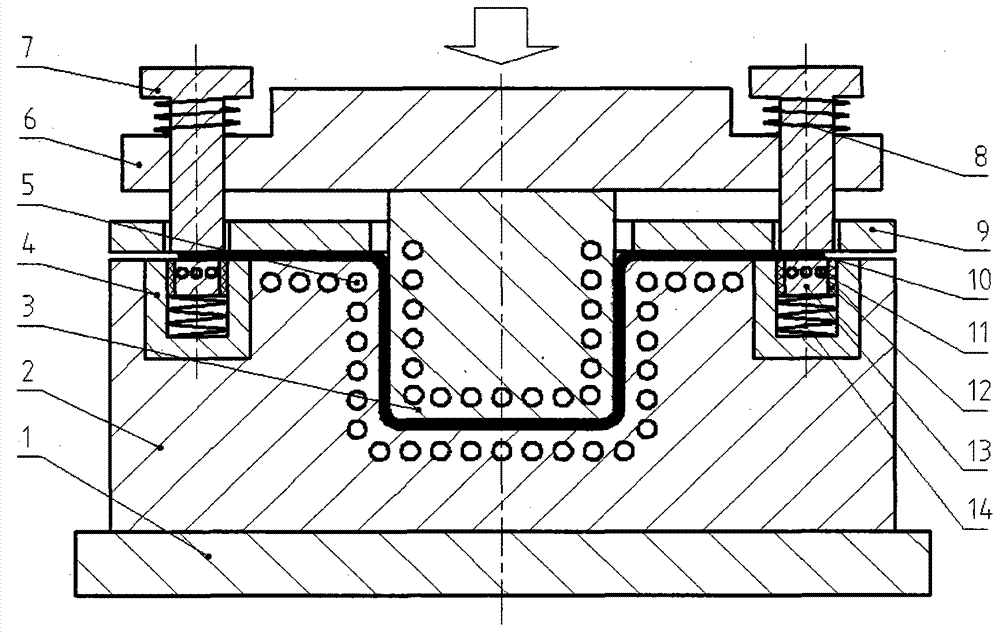

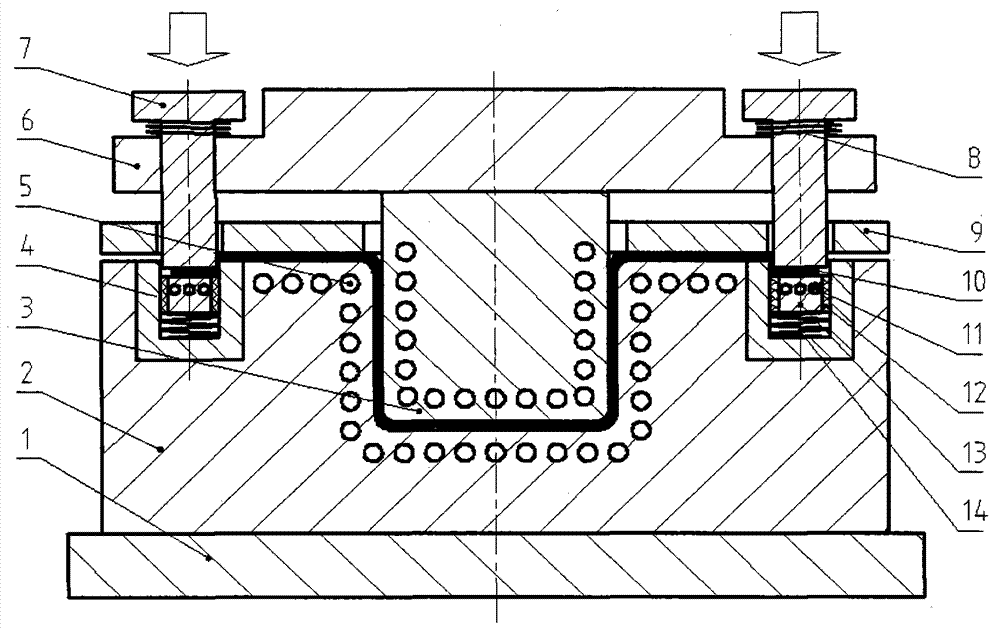

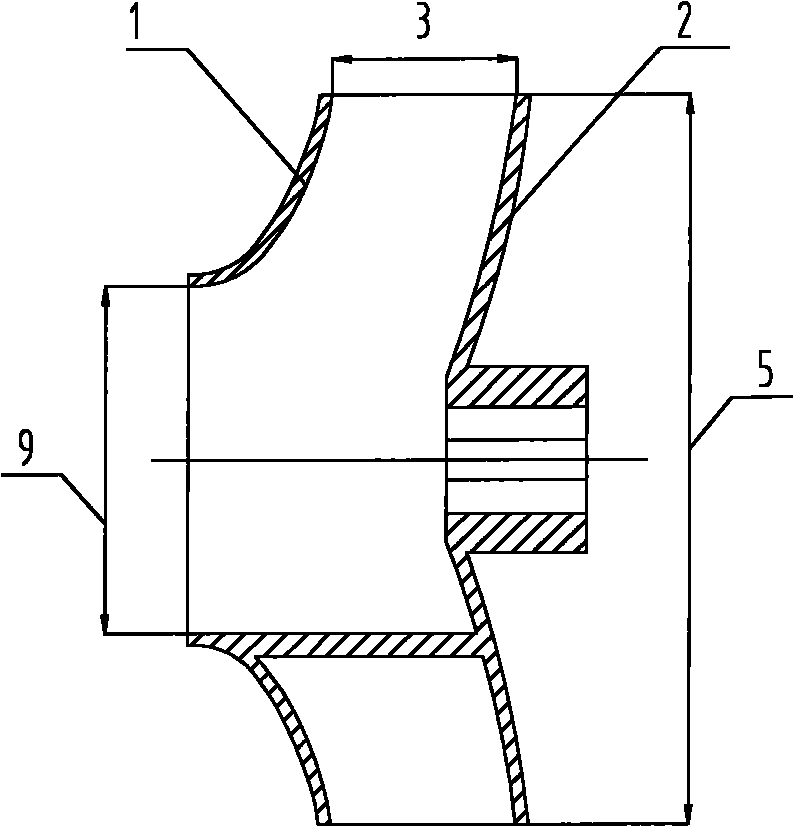

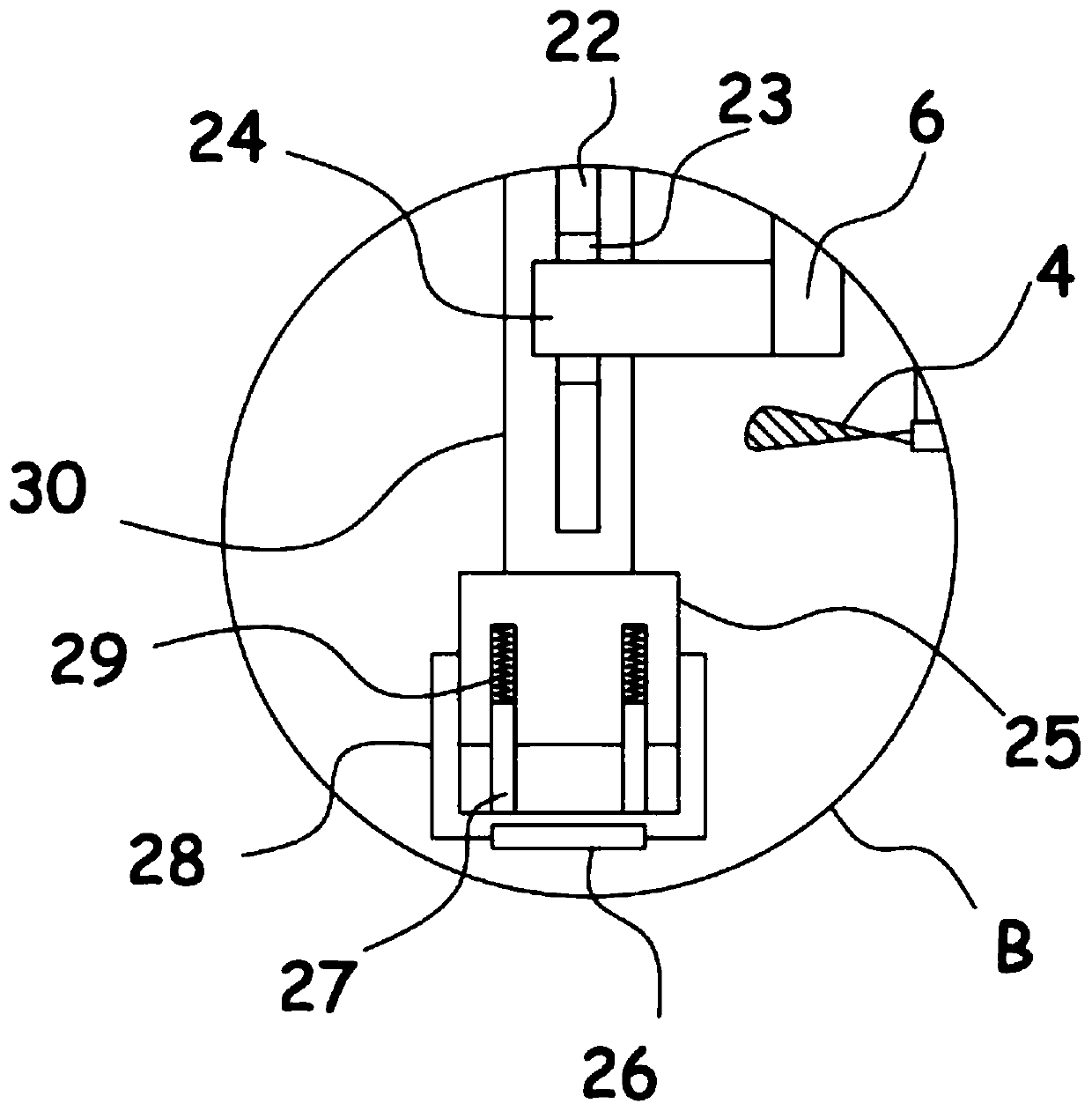

High strength steel plate hot stamping die for automobile parts

The invention discloses a high strength steel plate hot stamping die for automobile parts. The high strength steel plate hot stamping die for the automobile parts mainly consists of a male die body (a male die and a male die connecting fixing plate), a female die body (a female die and a female die connecting fixing plate), blank holders, cooling pipelines, connecting devices, positioning devices, U-shaped connecting hoses and pipe joints. The male die, the male die connecting fixing plate, the female die, the female die connecting fixing plate and the blank holders are respectively manufactured, and grooves used for fixing the cooling pipes are respectively processed. The cooling pipelines are manufactured into shape-following cooling pipelines which are consistent with the shape trends of the parts by adopting copper pipes, are respectively arranged in the grooves respectively arranged in the male die body, the female die body and the blank holders, and are externally connected with a master cooling pipeline through the U-shaped connecting hoses and the pipe joints to form a cooling closed loop. The hot stamping die disclosed by the invention is simple and compact in structure and convenient in maintenance, is reliable and practical, can be used for evenly and rapidly cooling the parts during a stamping process and is in favor of enhancing the working stability per se and prolonging the service life per se.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

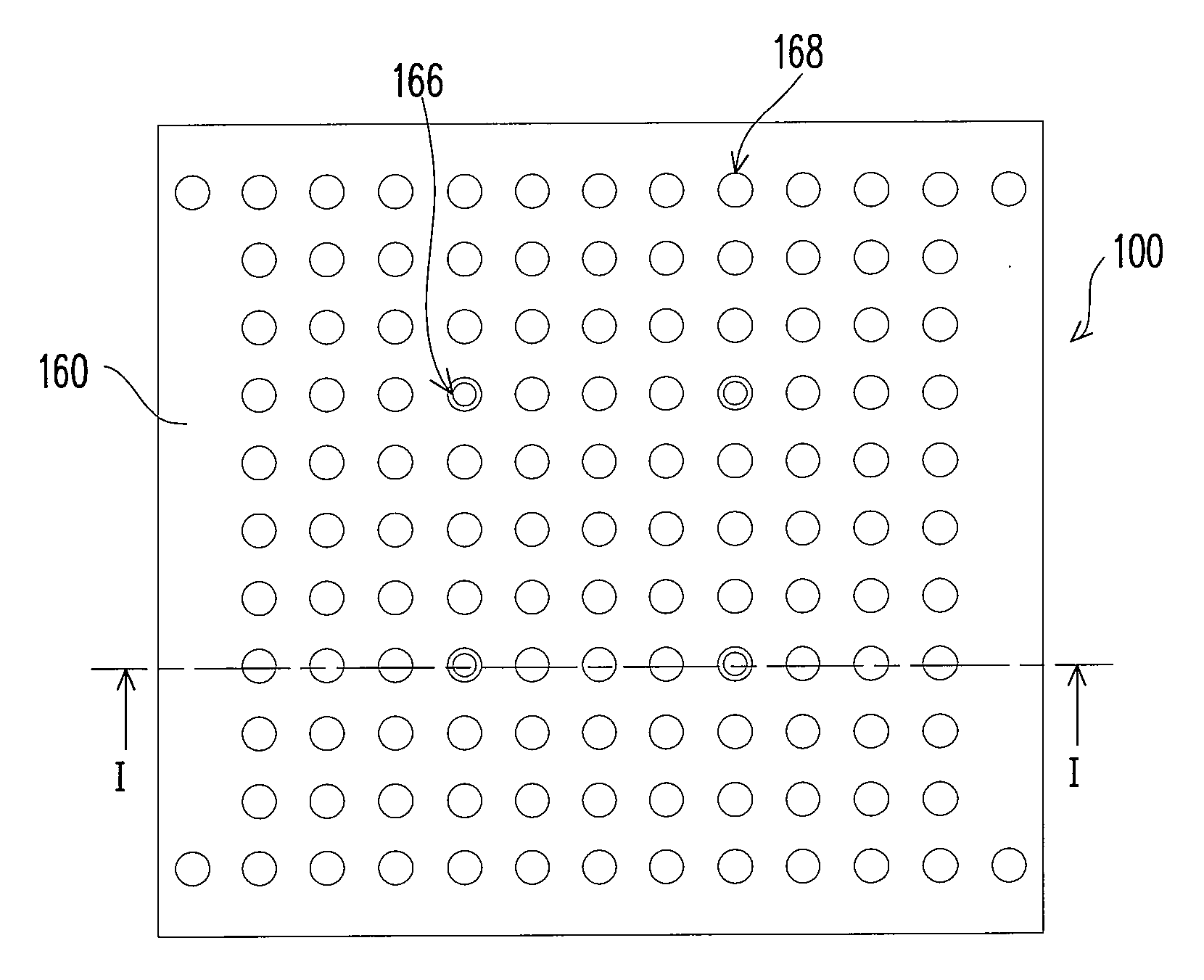

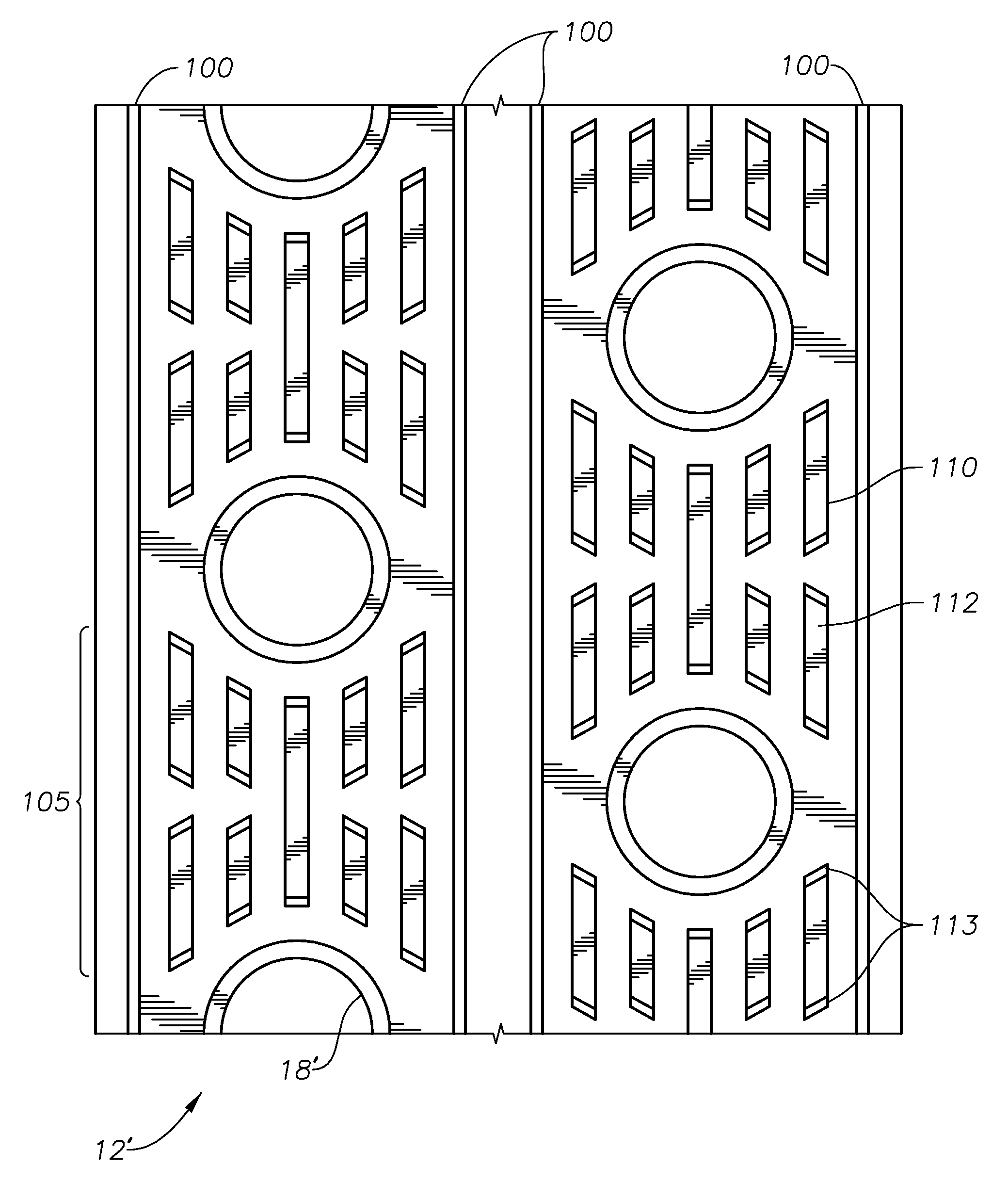

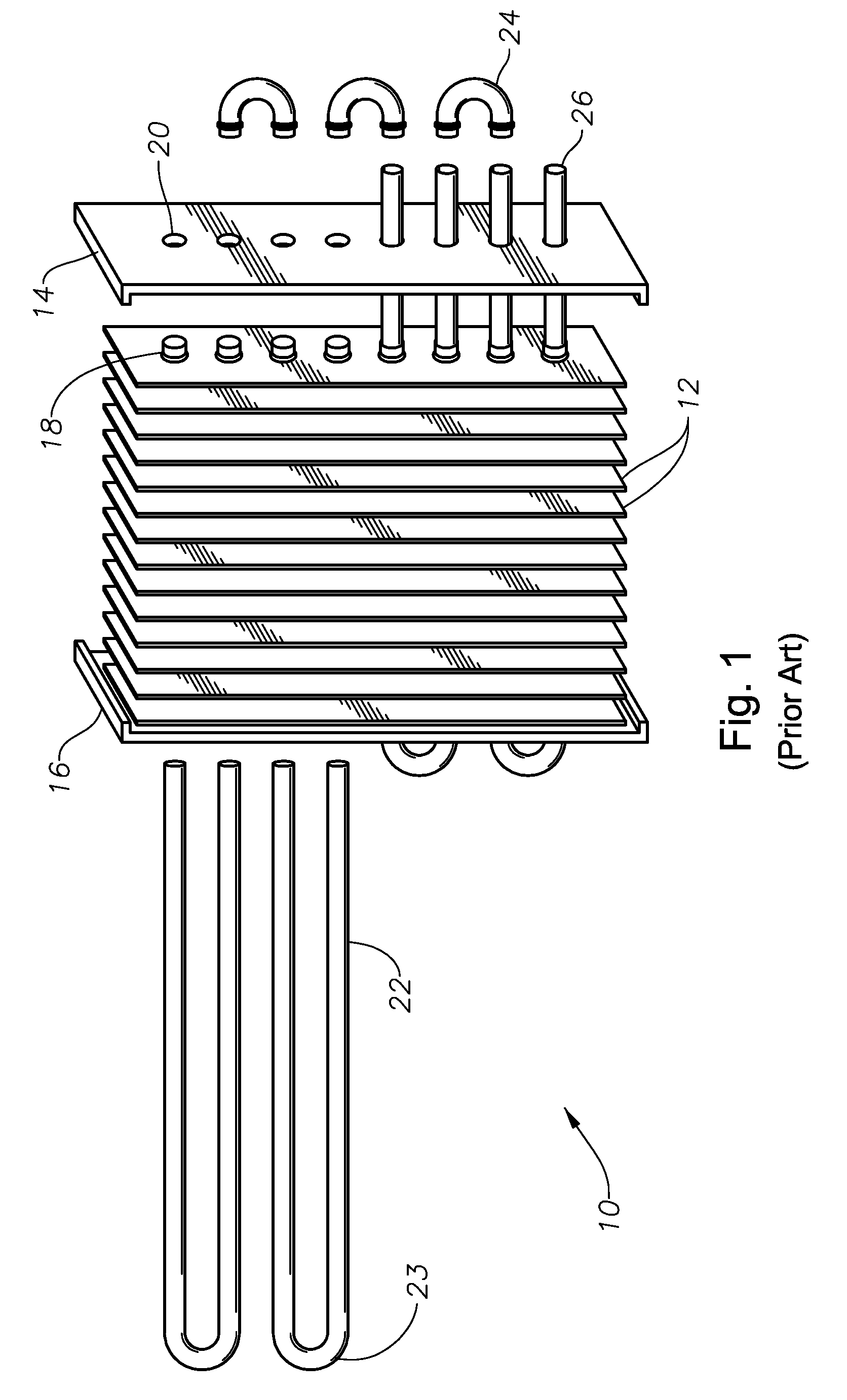

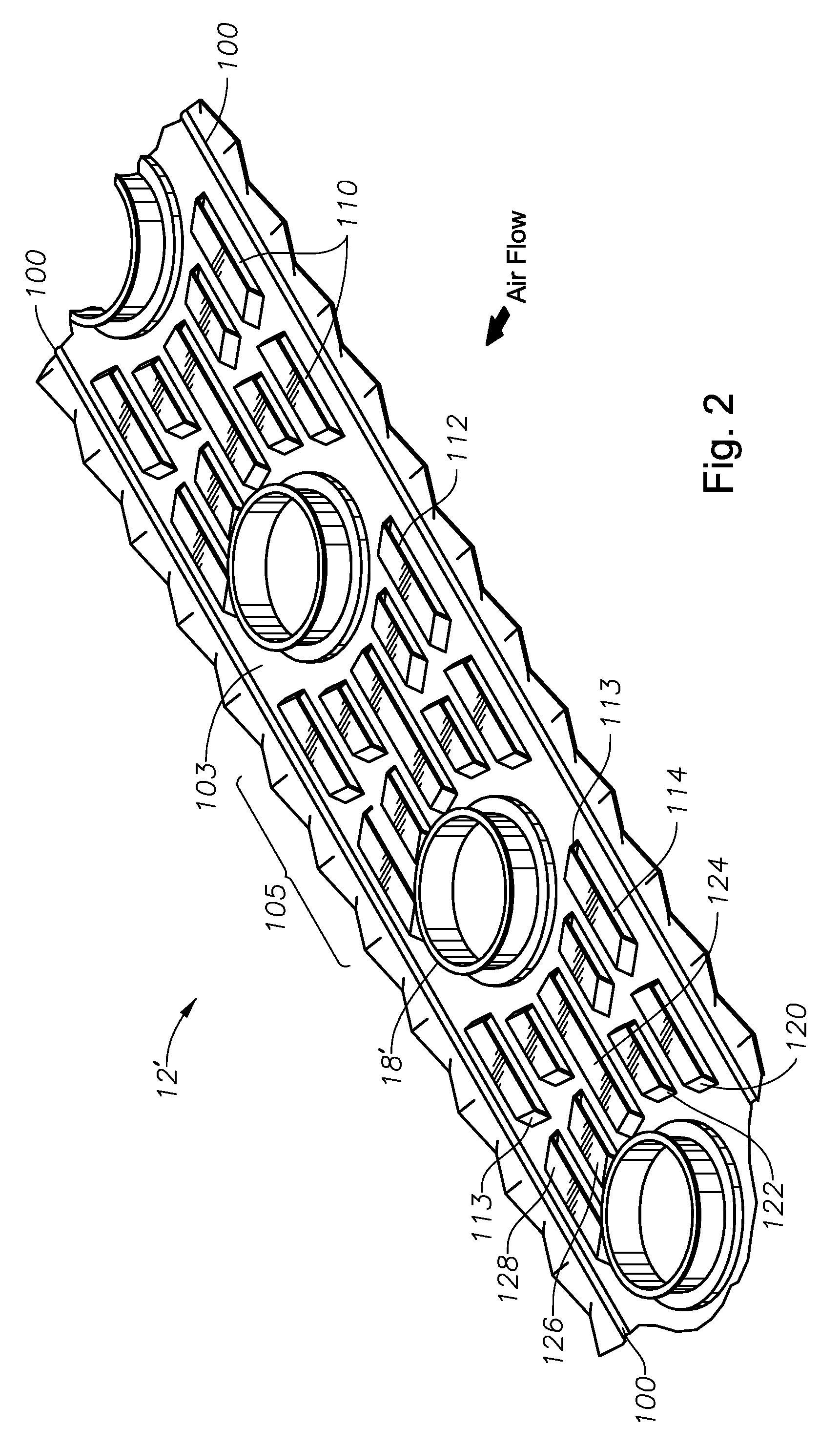

Method for Manufacturing Tube and Fin Heat Exchanger with Reduced Tube Diameter and Optimized Fin Produced Thereby

InactiveUS20090308585A1Increase stiffnessImprove rigidityHeat exhanger finsStationary conduit assembliesEngineeringImproved method

An improved method for manufacturing tube and fin heat exchangers that, according to a preferred embodiment, includes a process for increasing the stiffness and rigidity of heat exchanger fins. Stiffer fins have a greater tendency to maintain proper alignment within a stack of fins, which aids in lacing long stacks of fins with small (e.g., 5 mm) diameter tubing. Preferably, fin stiffness is increased by forming a plurality of longitudinal ribs within the fin during the fin stamping process. More preferably still, two ribs for each longitudinal row of collared holes are provided. The preferred embodiment also includes a slotted heat exchanger fin that is dimensioned and arranged for optimized thermodynamic performance when used with small diameter tubing, thus reducing the space required for a given heat exchanger system.

Owner:GOODMAN GLOBAL INC

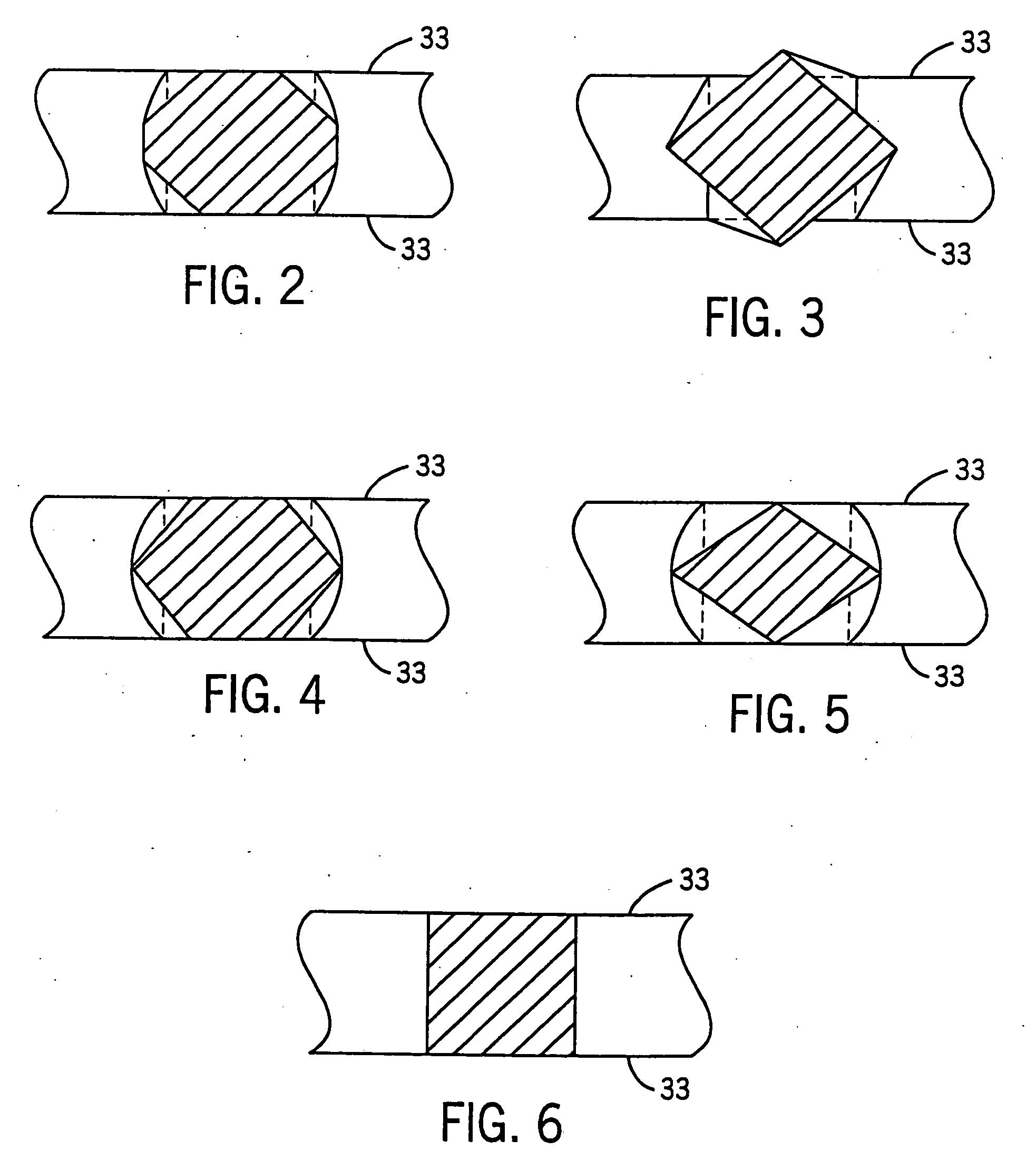

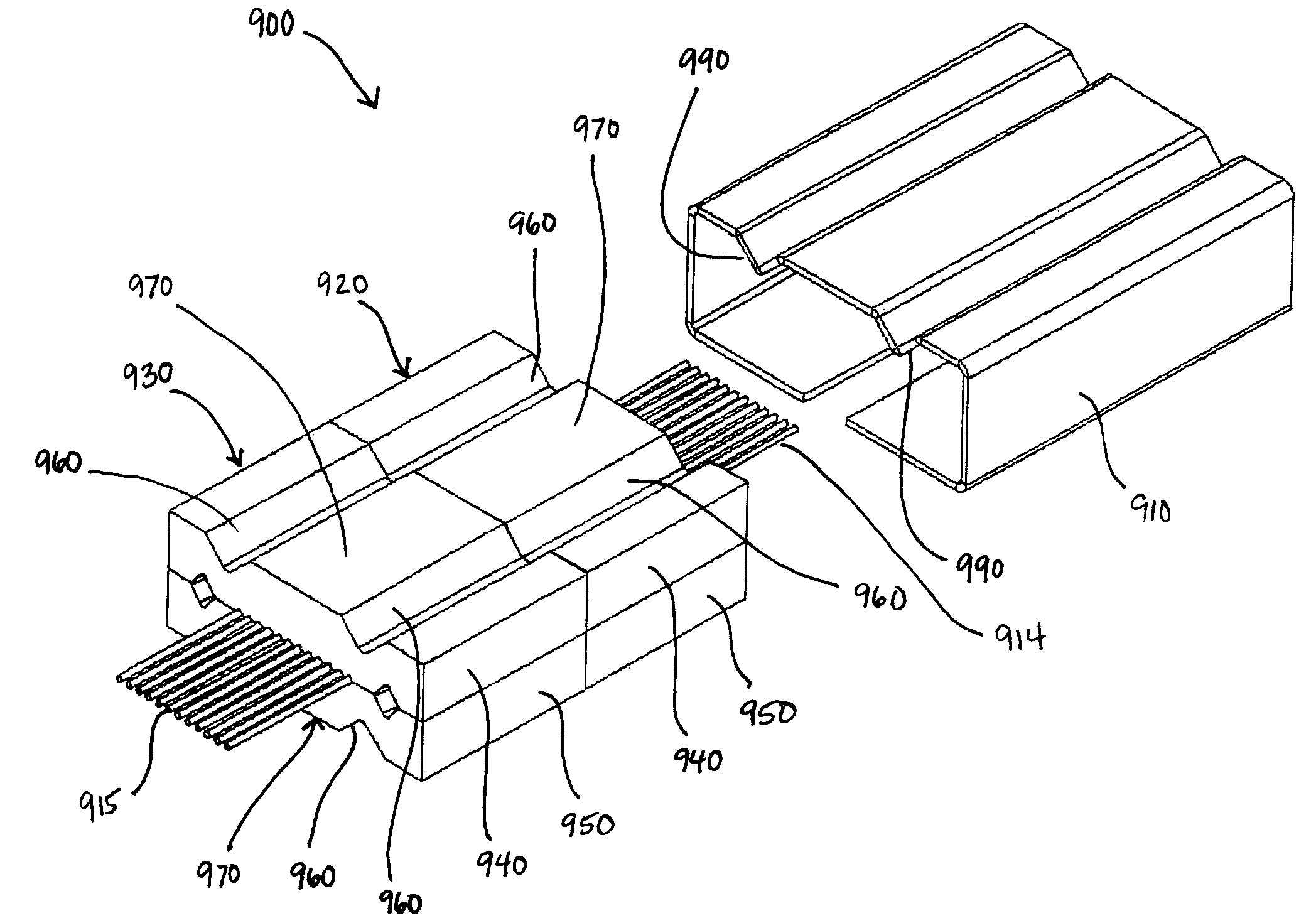

High precision optoelectronic components

An optoelectronic assembly having components designed to be fabricated on a stamping process capable of producing parts having tolerances below 1000 nanometers. The optoelectronic assembly includes ferrules and sleeves. The ferrules can include two identical half ferrules that are forged and assembled together to form the ferrule body. The ferrules can also be designed to be alternatively produced by forming processes or produced by a combination of forging and forming processes. The pair of ferrules supporting one or more optical fibers are guided together by a high precision split sleeve for coupling the fibers together.

Owner:SENKO ADVANCED COMPONENTS

Preparation method of holographic transfer film for replacing holographic gold stamping

ActiveCN102463757AQuality improvementKeep intactLamination ancillary operationsDuplicating/marking methodsPolyethylene terephthalateHigh volume manufacturing

The invention relates to a preparation method of a holographic transfer film for replacing holographic gold stamping, which comprises the following steps that: a gravure coating machine is adopted, transfer paint with integrated parting and imaging functions is coated on a polyethylene terephthalate (PET) film, and baking and curing are carried out; the mold pressing is carried out on a mold pressing machine, and holographic patterns are copied onto imaging coatings; the vacuum aluminum plating is carried out; a printing aluminum washing protection ink version roller is designed according to gold stamping pattern requirements, and protection ink is printed; the aluminum washing is carried out in an aluminum washing machine, and aluminum layers in positions without printing the protection ink are washed away and baked; extinction oil is coated on the coating machine, and the holographic patterns in hollow positions, i.e. the positions in which the aluminum layers are washed away are removed; the transfer film and paper are compounded on a compounding machine; the PET film is peeled off on a peeling machine and is recovered and utilized, so the transfer paper with the holographic patterns is made; and printing products with holographic gold stamping patterns are made through subsequent offset printing or intaglio printing and the like. The method can completely replace the holographic gold stamping process, the production efficiency is high, and the method is suitable for the large-scale production operation.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

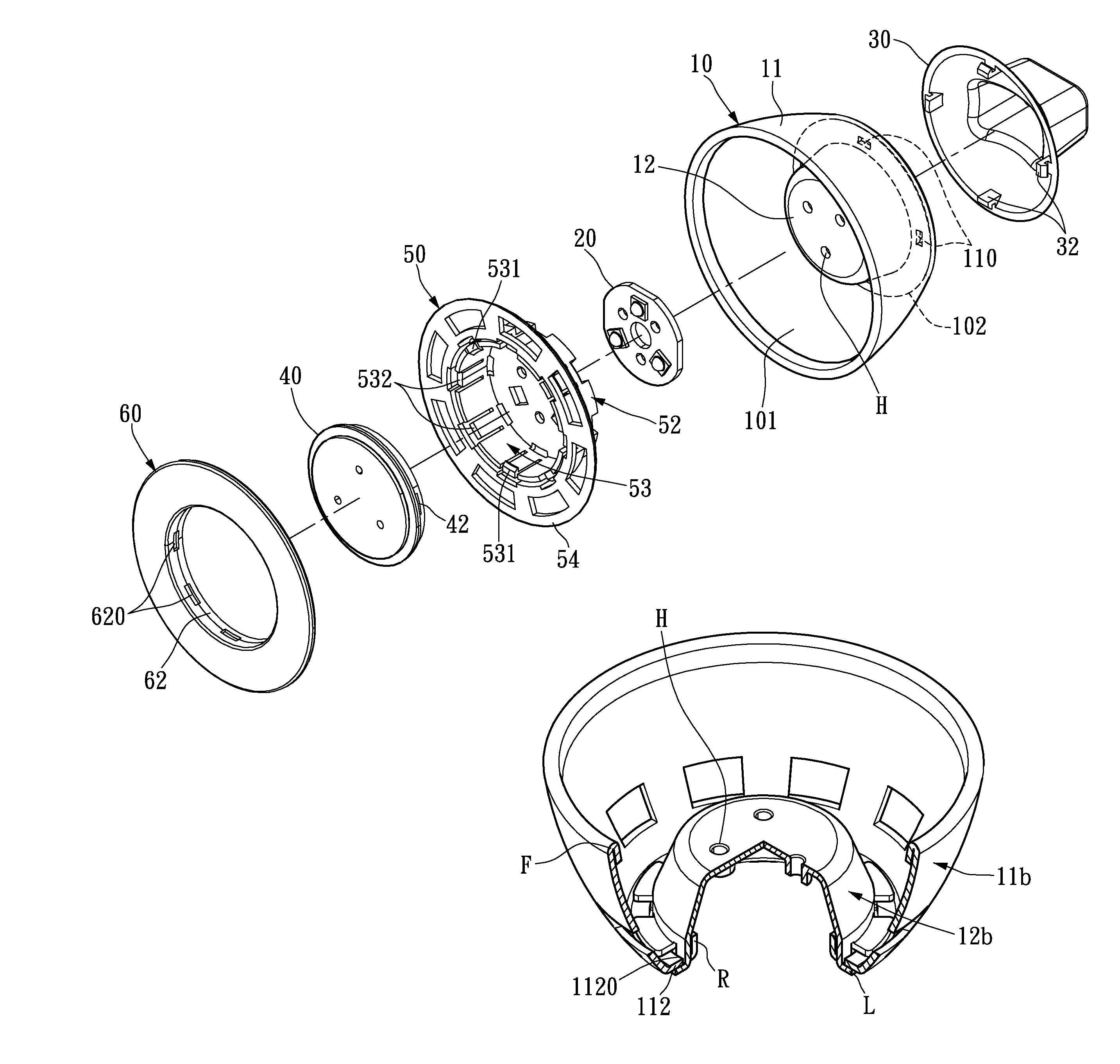

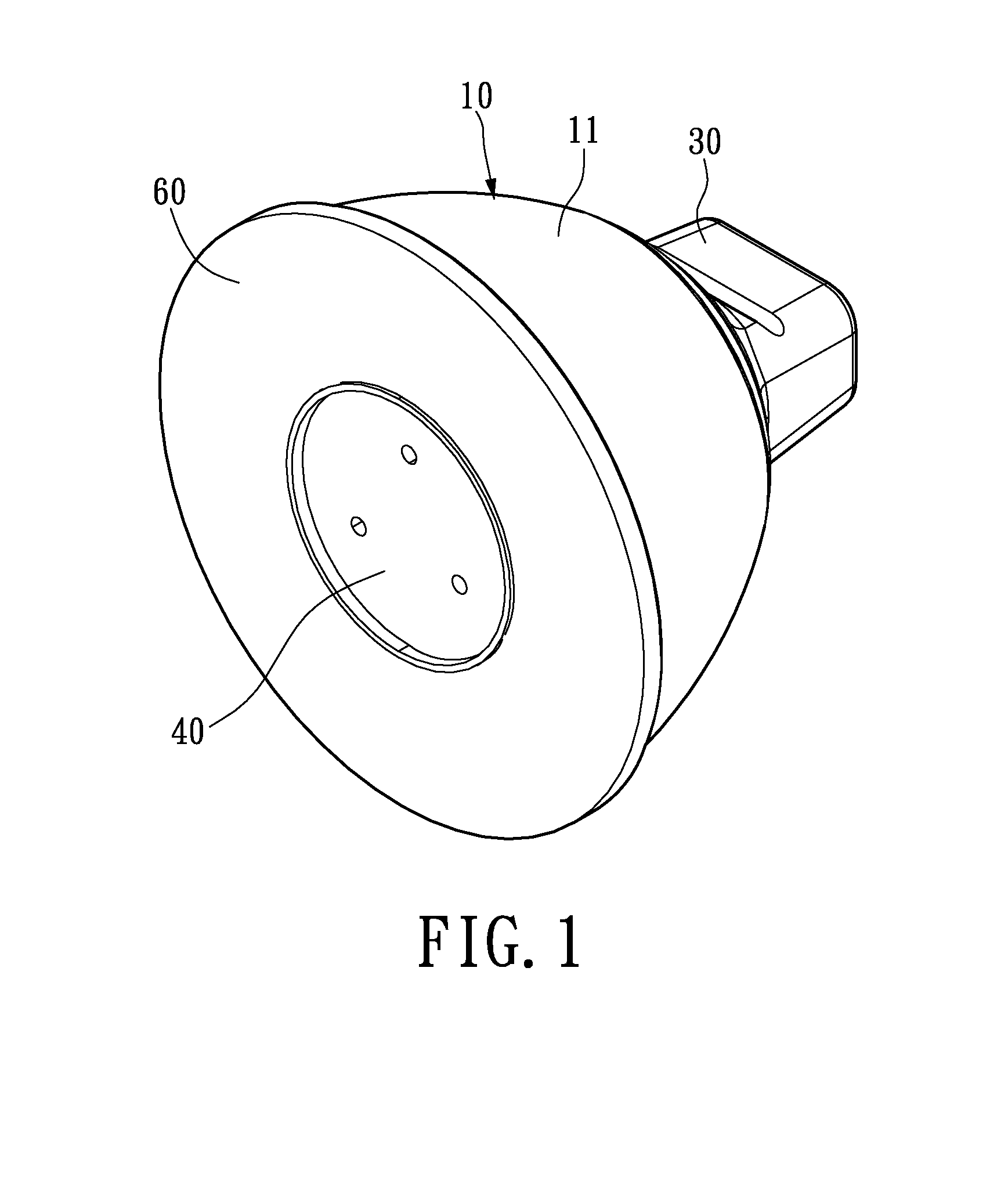

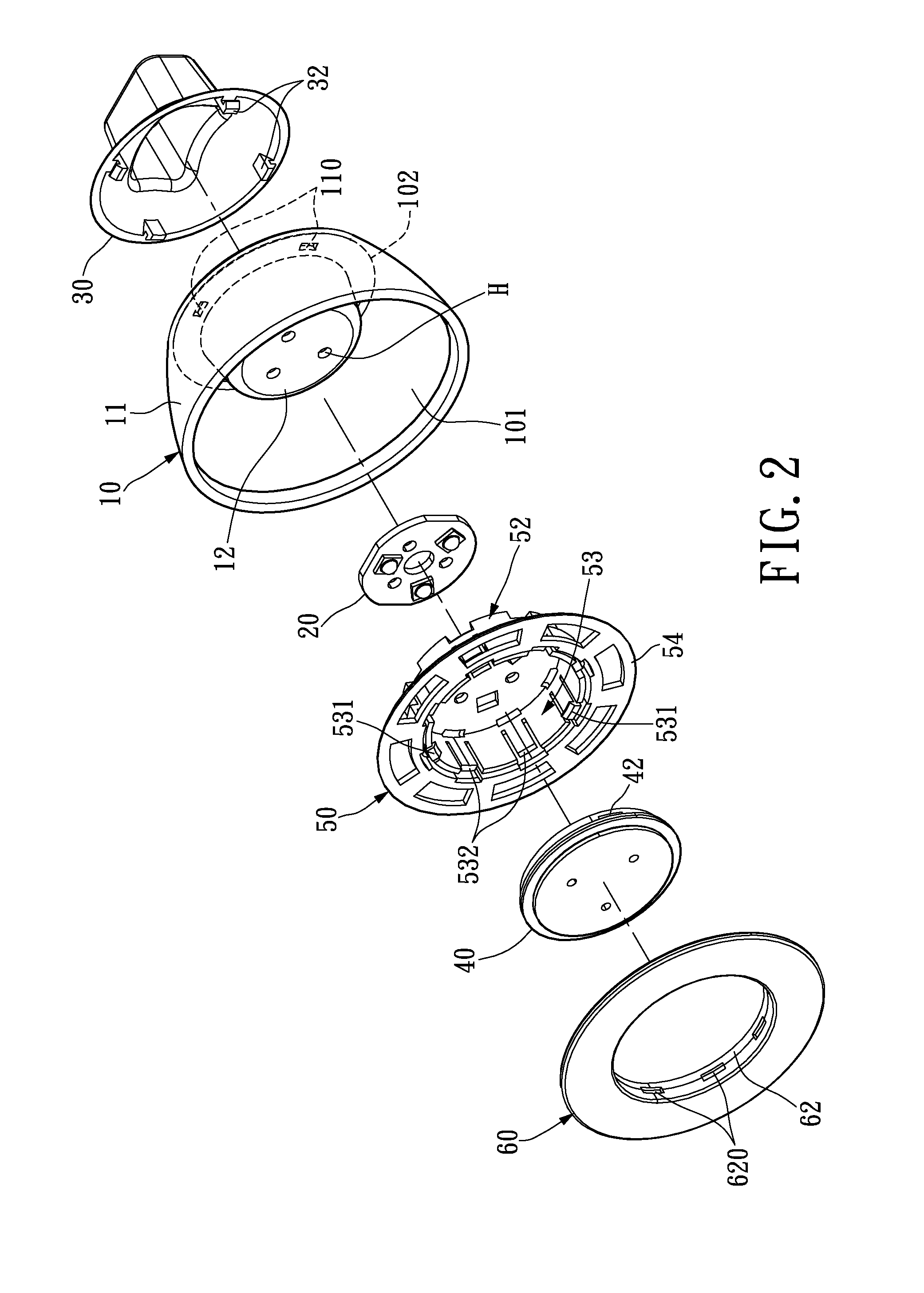

LED lamp

InactiveUS8388197B1Improve efficiencyLight weightPoint-like light sourceLighting heating/cooling arrangementsEngineeringLamp shell

The instant disclosure relates to a lamp having a heat dissipating lamp shell particularly suitable for housing solid state light sources. The lamp comprises a lamp shell of stamping construction and a light source unit. The lamp shell comprises an outer pot portion and an inner tray portion substantially concentrically coupled to the outer pot portion. Externally, the lamp shell forms a substantial portion of the lamp. The light source unit comprises a light module disposed on the inner tray portion of the lamp shell, a controller placed at the rear portion of the lamp shell, and an electrical connecter arranged exposedly from the rear of the lamp. The lamp shell of stamping construction is beneficially characterized by the light weight and strong structural integrity, which attribute to the work hardening property of the stamping process.

Owner:COOLER MASTER DEVELOPMENT CORP

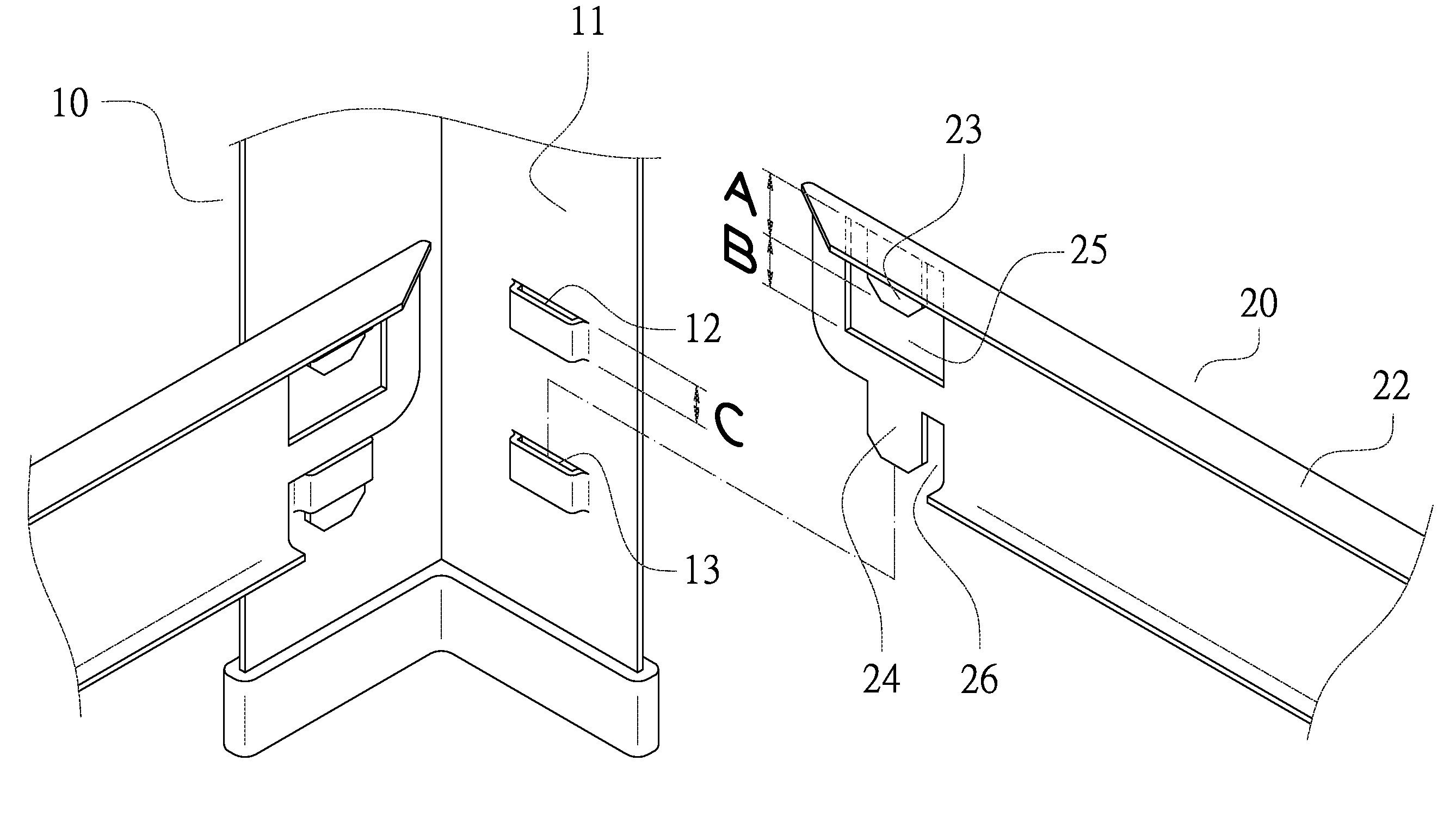

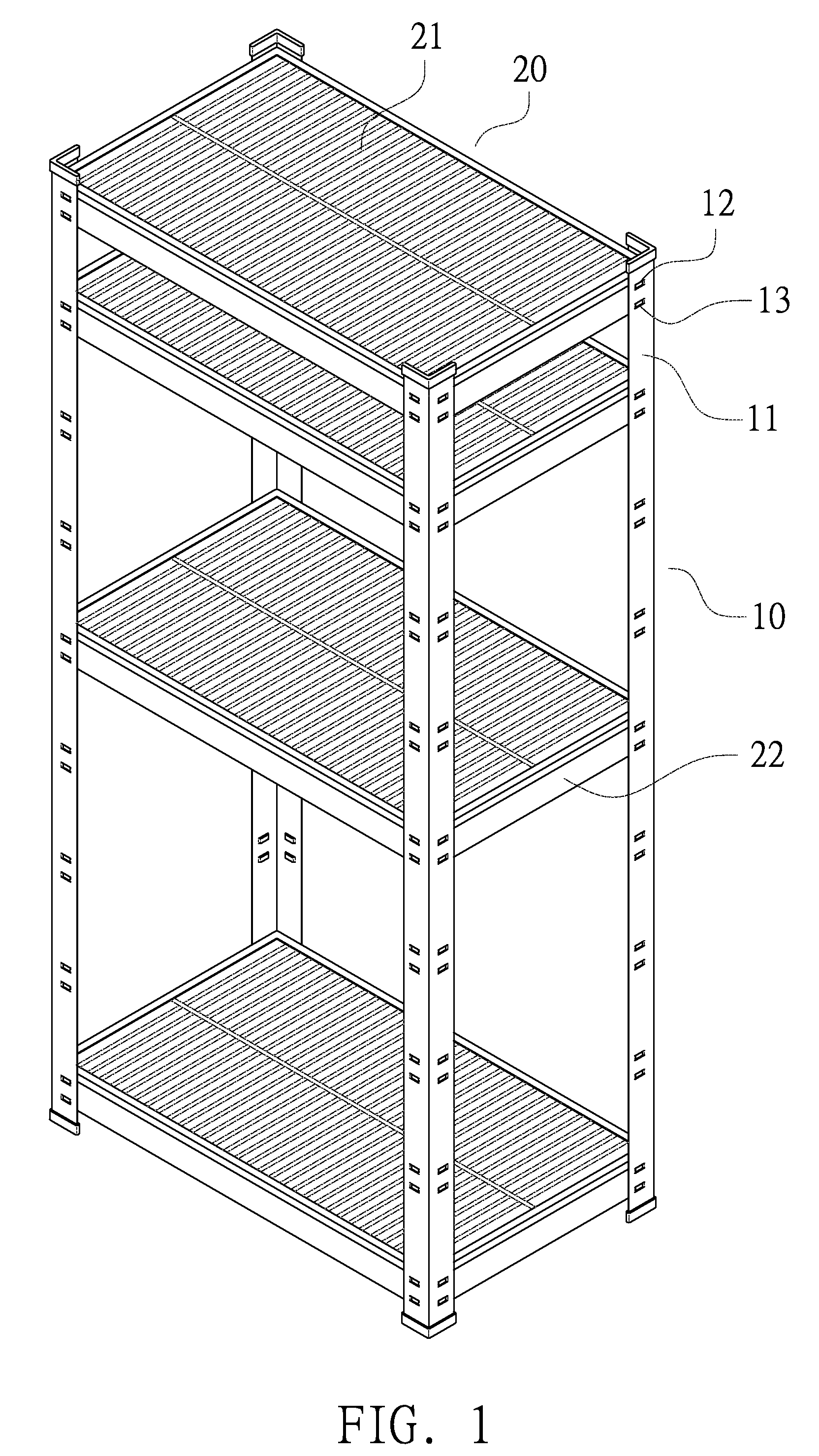

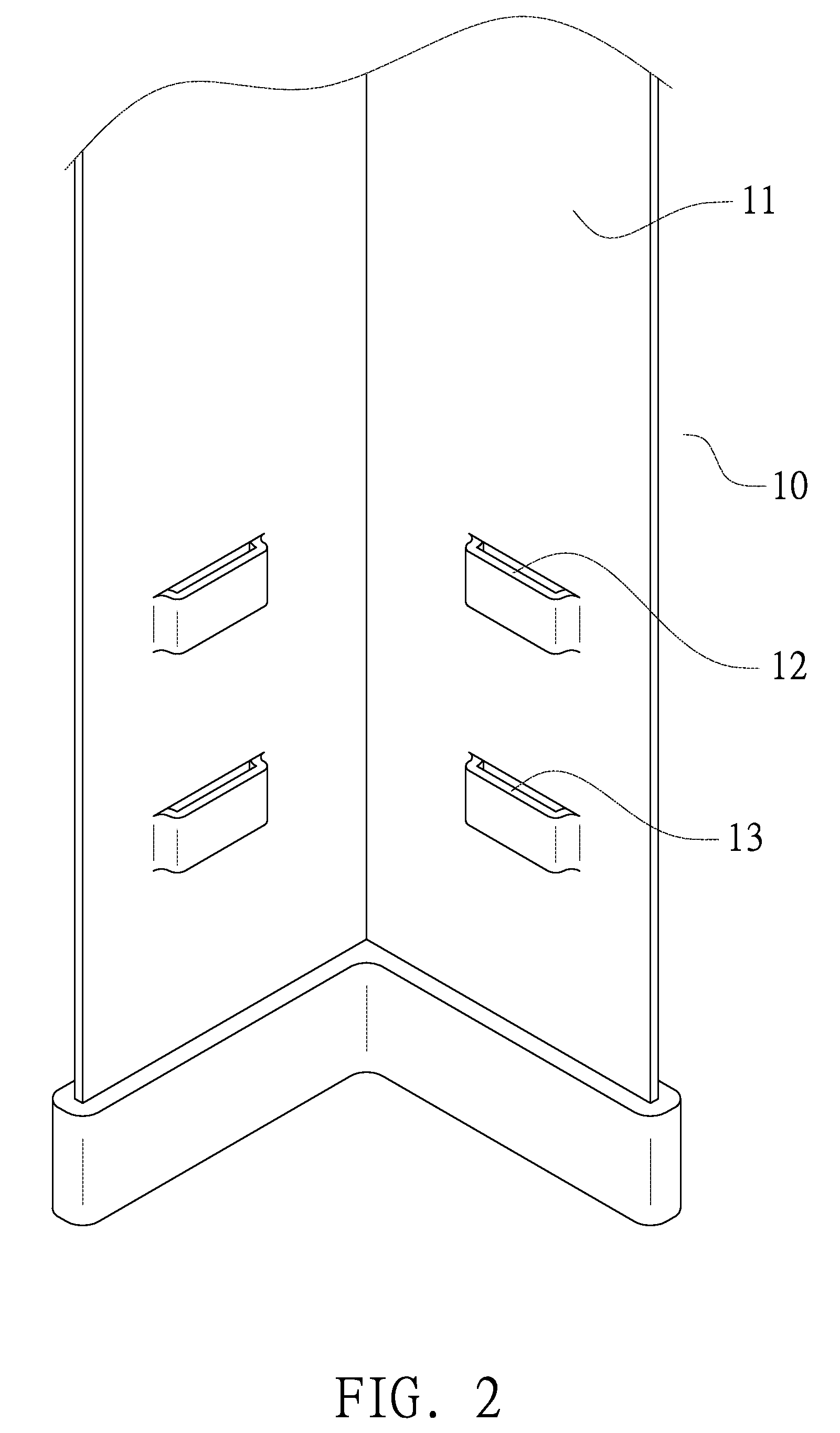

Combination shelf structure

InactiveUS20110042336A1Improve applicabilityHigh strengthFurniture partsFolding cabinetsEngineeringStamping process

A combination shelf structure has a design of combining storage partition layers and support rods of a combination shelf. The support rods are installed at a right angle with the storage partition layers, and two support rods are installed into two upper and lower insert slots with an interval apart from one another. Upper and lower embedding plates are formed on both sides of each corner position of a frame of the storage partition layer respectively by a hollow stamping process, such that the embedding plate and the frame are situated on the same plane, and the storage partition layer can be combined securely and easily by using the embedding plate of the frame and the insert slot of the support rod. In addition, the storage partitions and the insert slots of the support rod can be rearranged with appropriate installation elements to achieve a different shape of the shelf.

Owner:CHENG YANG CHIANG +1

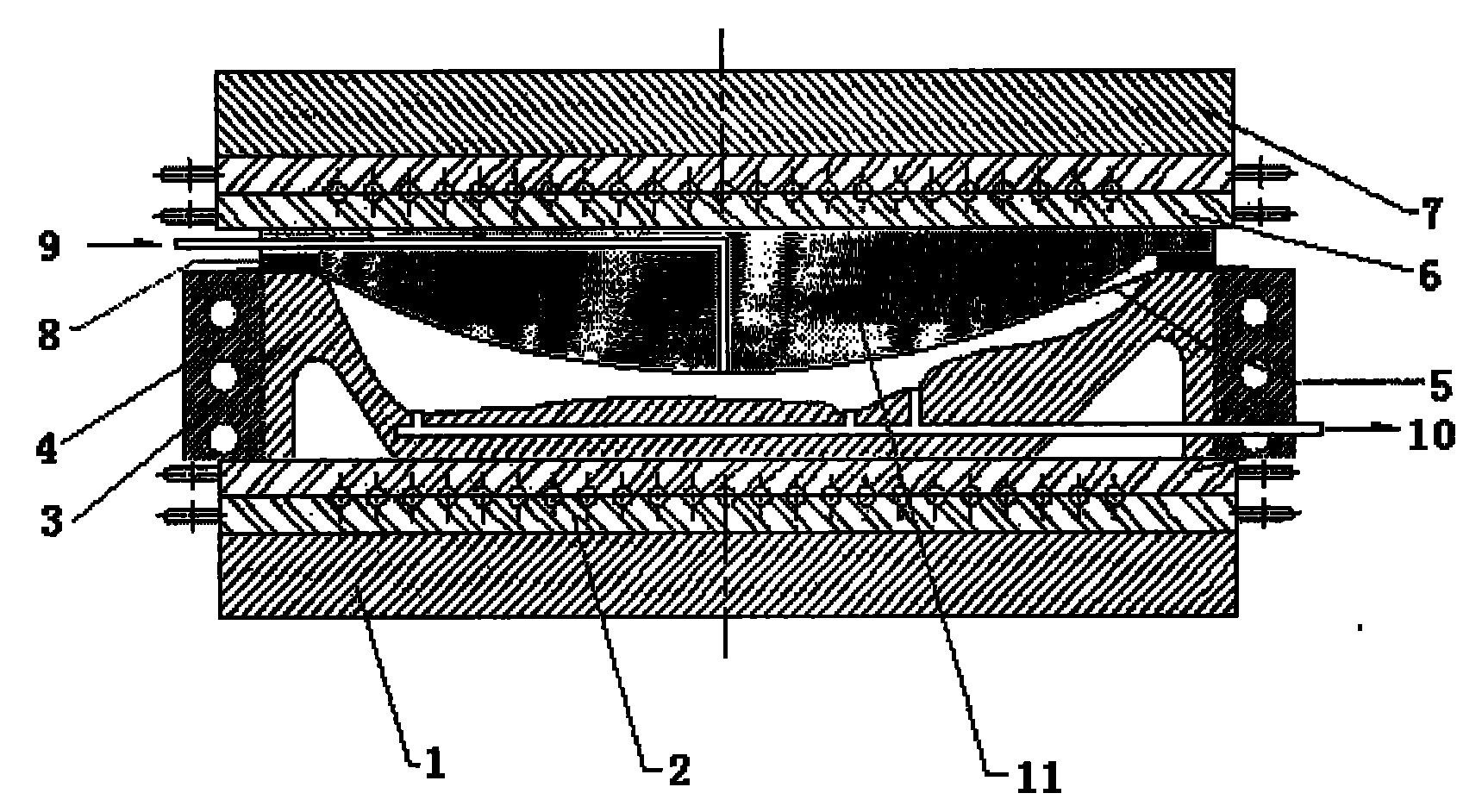

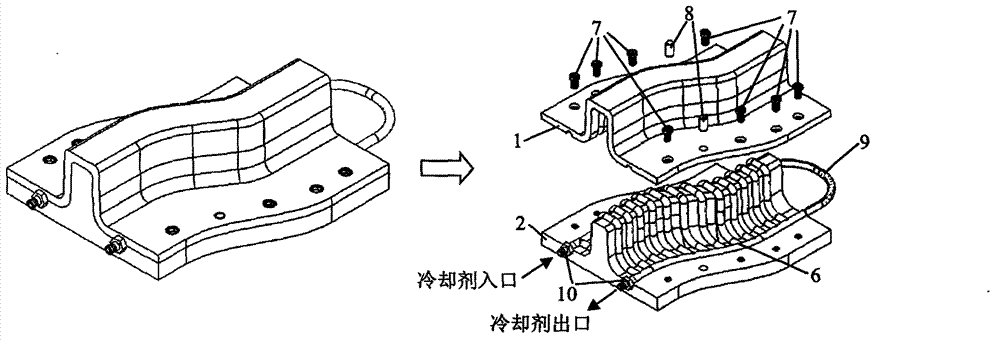

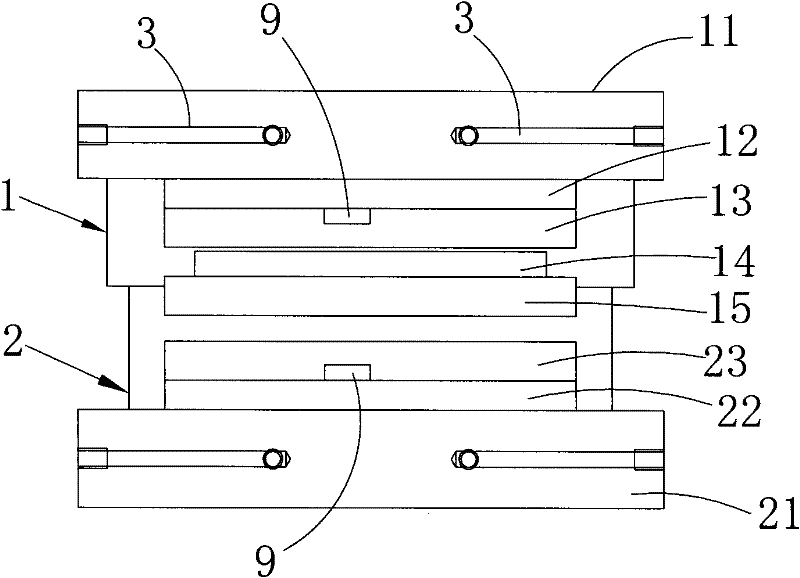

Hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel

The invention provides a hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel. By means of the composite mould, blanking is composited in a hot stamping process, and trimming and punching are performed on sheet metal at a temperature higher than a martensite formation temperature. The hot stamping and warm blanking composite forming technology comprises the following processes of putting the sheet metal of the ultrahigh-strength steel heated to achieve complete austenitizing into the composite mould, performing stamping forming and then performing cooling and quenching; heating sheet metal needing blanking locally, keeping a warm state, performing warm blanking after completion of forming, and performing cooling further in a pressure maintaining mode. The hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel effectively solves the problems of poor quality, low precision, high cost and long period of holes trimmed and punched in the later period of the ultrahigh-strength steel and has great practical significance in production practice.

Owner:JILIN UNIV

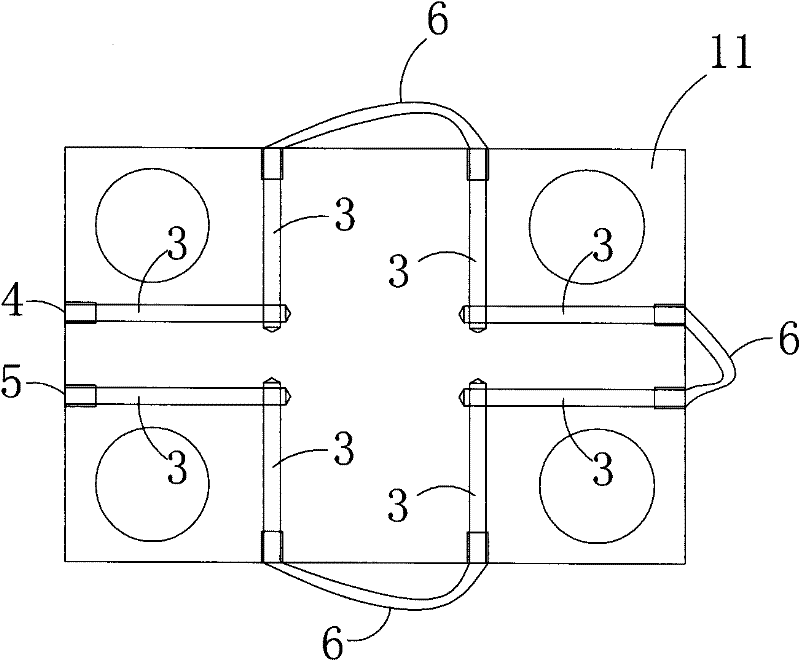

High speed stamping die with cooling structure

InactiveCN102233385AReduce the temperatureGuaranteed stamping accuracyShaping toolsEngineeringStamping process

The invention discloses a high speed stamping die with a cooling structure. The high speed stamping die is internally equipped with a cooling pipeline; a cooling liquid circulates in the cooling pipeline, the initial end of the cooling pipeline is a cooling liquid inlet, and the terminal end of the cooling pipeline is a cooling liquid outlet; and the high speed stamping die is also internally equipped with a temperature sensor for monitoring the temperature in the high speed stamping die. In the invention, the cooling liquid in the cooling pipeline can immediately conduct heat generated during the stamping process out of the high speed stamping die by utilizing a heat exchange mode so as to lower the temperature in the high speed stamping die; and a control device controls an infusion pump to adjust flow of the cooling liquid according to temperature information monitored by the temperature sensor so as to keep the temperature in the high speed stamping die within a certain range. Therefore, the high speed stamping die has the beneficial effects that the deformation and damage of the high speed stamping die are reduced and the service life of the high speed stamping die is prolonged while the stamping precision and production efficiency are ensured.

Owner:KUNSHAN JIAHUA ELECTRONICS

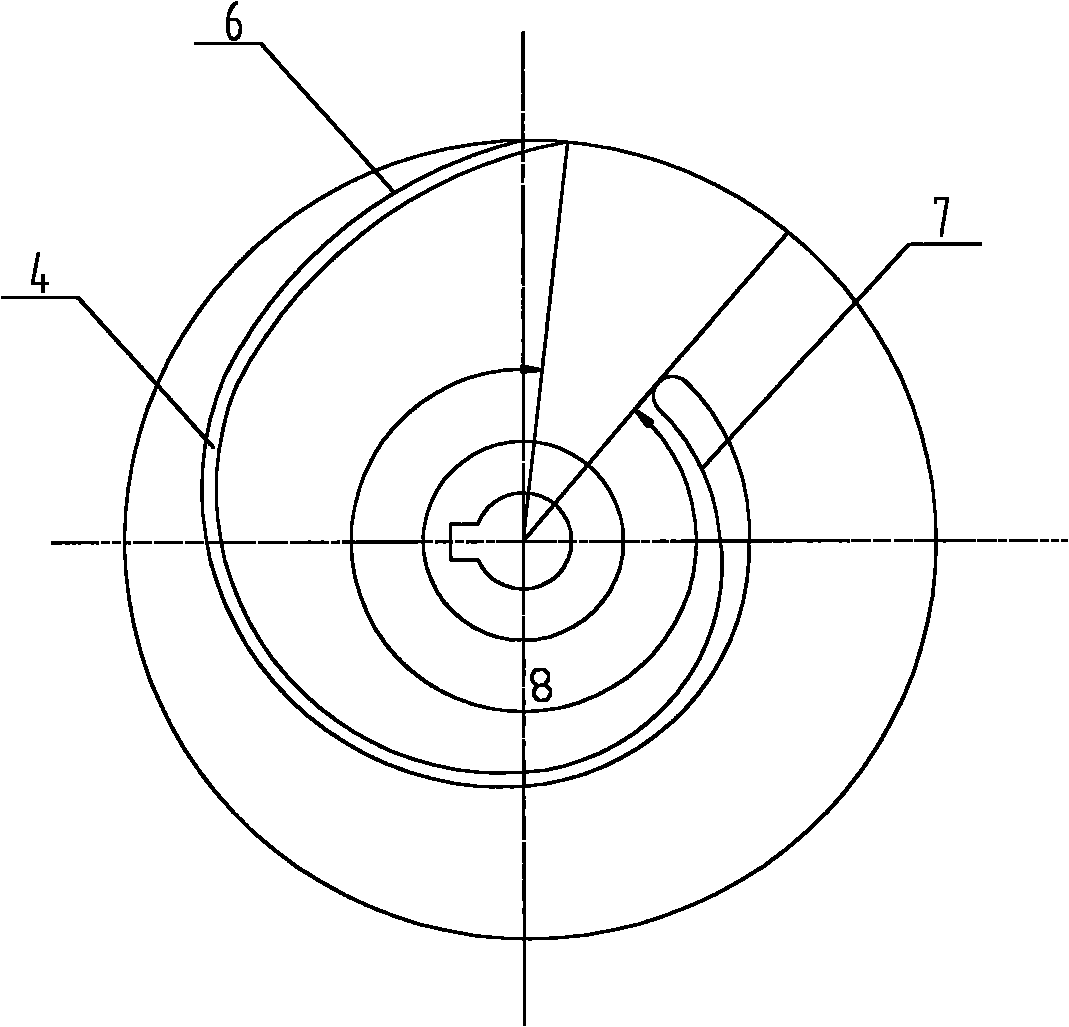

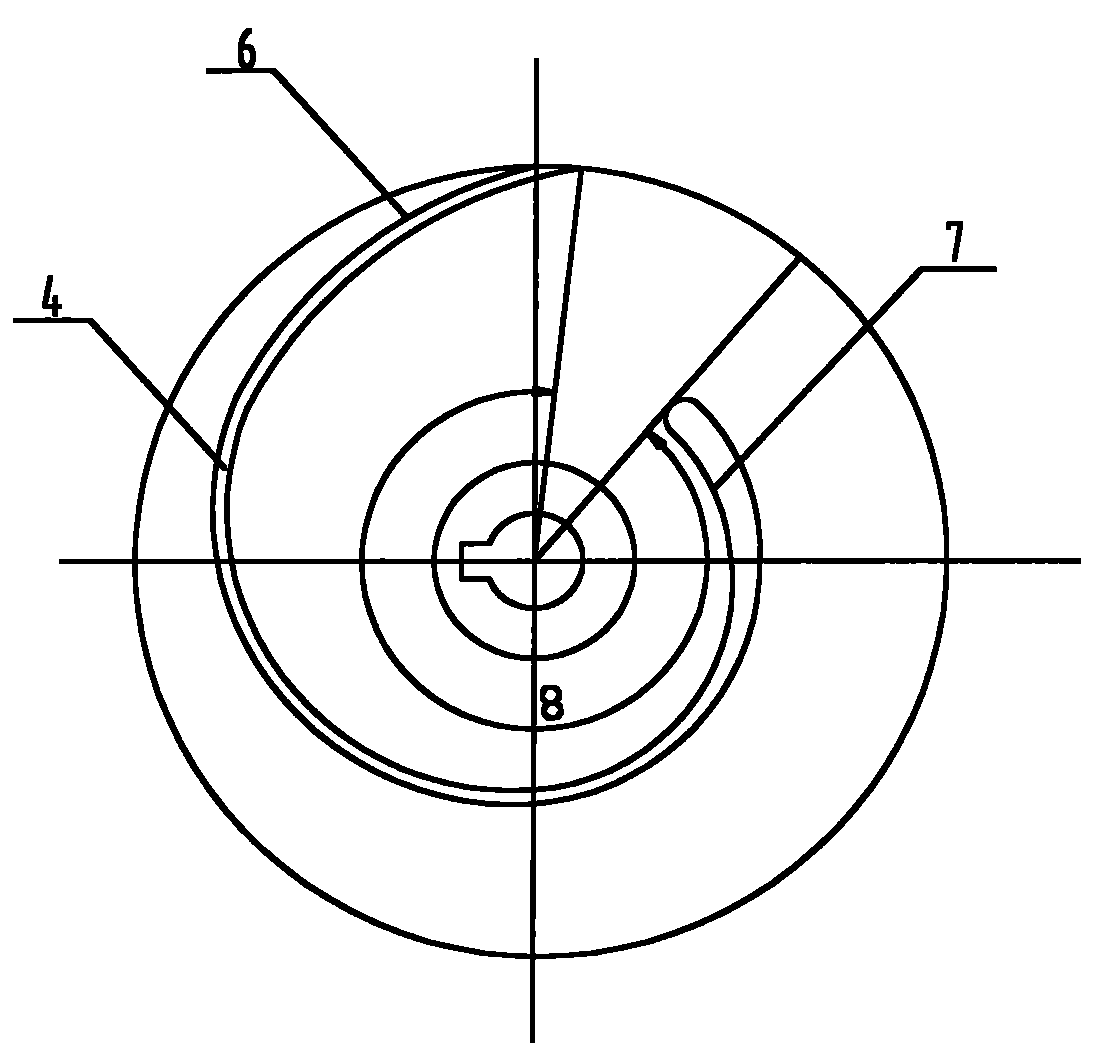

Design method of single-vane stamping type non-clogging impeller

InactiveCN101793261AGood non-clogging performanceImprove the blocking effectPump componentsPumpsImpellerEngineering

The invention relates to a design method of a single-vane stamping type non-clogging impeller. Compared with the single-vane non-clogging impellers designed by the traditional methods, the single-vane non-clogging impeller designed by the invention has high non-clogging performance and efficiency and can meet the requirement of stamping process for the geometric parameters of the impeller.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

Electronic commerce logistics parcel stamping device

PendingCN111070925ARealize automatic stamping operationAdhesive time is sufficientStampingLogistics managementElectric machinery

The invention discloses an electronic commerce logistics parcel stamping device, and relates to the technical field of electronic commerce. The electronic commerce logistics parcel stamping device comprises a supporting frame. A pair of rotating wheels are installed on the supporting frame in a rotating mode. The rotating wheels are sleeved with a conveying belt used for conveying parcels. A motorII which is installed in a rotating mode is fixed to the supporting frame. A threaded sleeve which is vertically arranged is connected to the supporting frame in a driving mode through a lifting mechanism. The lower end of the threaded sleeve is fixedly connected with a stamping mechanism located above the conveying belt. According to the electronic commerce logistics parcel stamping device, theconveying belt can be driven to make stepped movement through an arranged stepping mechanism, the parcels on the conveying belt can be conveyed rightwards at equal intervals under the pushing effect of a push plate, and the arranged lifting mechanism can drive the threaded sleeve to be lifted up and down vertically; a stamping head can stamp the parcels once every time the threaded sleeve is lifted up and down, the parcels can be stamped automatically, and work stamping efficiency is greatly improved; and an arranged moving sleeve can slide vertically relative to a fixing block, attaching timeof the stamping head and the parcels is made sufficient in the stamping process, and the stamping effect is better.

Owner:浙江更土电子商务有限公司

Method and apparatus for depositing charge and/or nanoparticles

A method and apparatus for use in depositing electrical charge and / or nanoparticles is provided. A stamping process is used in which a stamp having a flexible layer such as a flexible semiconductor layer applies a charge pattern on a substrate. Other techniques include lithographic patterning, the use of pre-patterned dissimilar materials, deposition by ions or radiation, the use of differing work functions, the use of liquid phase materials. Deposition monitoring techniques and apparatuses are also provided.

Owner:RGT UNIV OF MINNESOTA

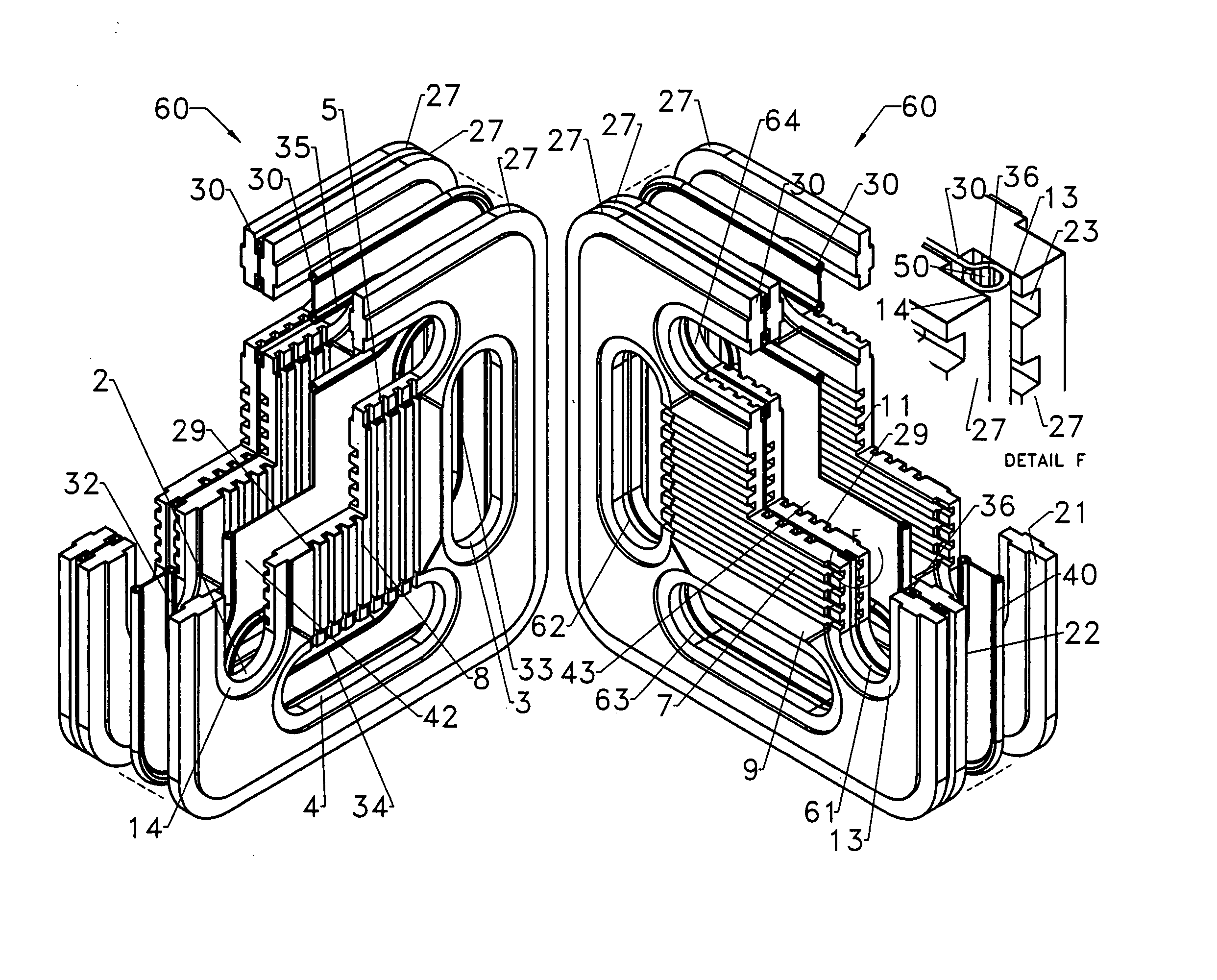

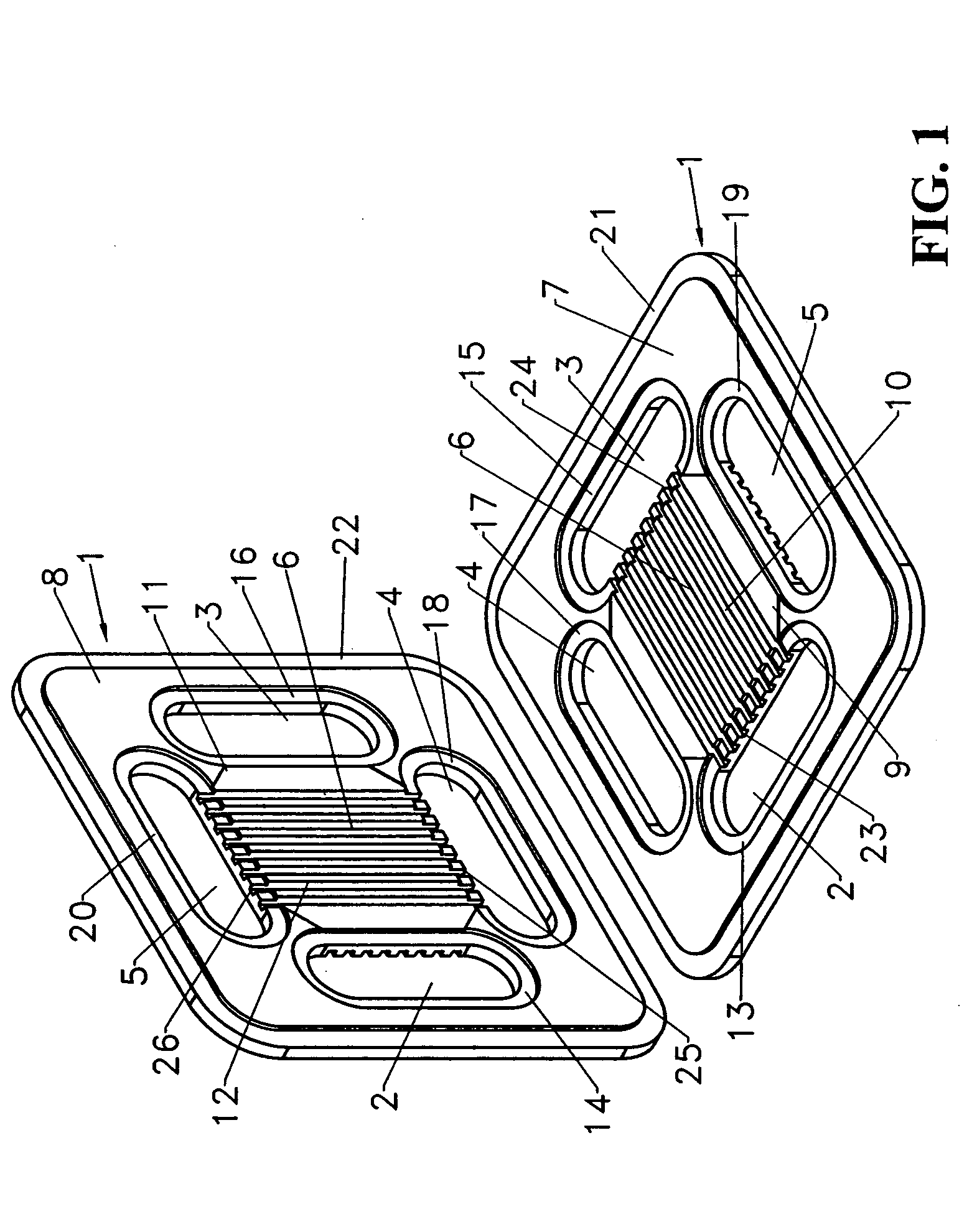

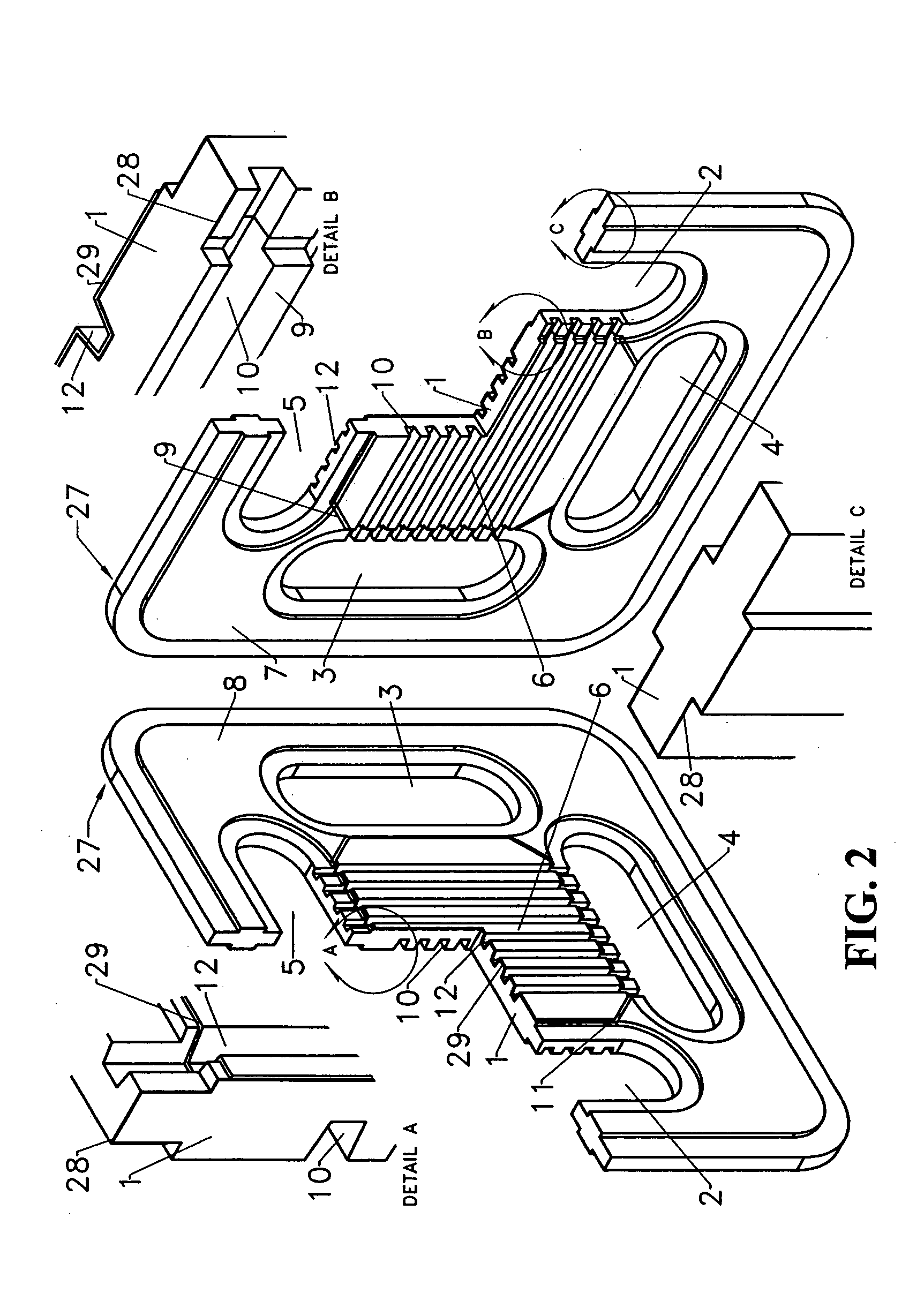

Fuel cell assemblies using metallic bipolar separators

InactiveUS20050249996A1Increased durabilityImprove performanceFuel cells groupingFuel cell auxillariesFuel cellsEngineering

High temperature solid oxide fuel cells (SOFC) and fuel cell stacks incorporating metallic bipolar separators with integral edge seals are provided. The electrochemical cells include reactant manifolds and flow passages, and may have either cathode or anode supported structures. The bipolar separators are thin metallic sheets that minimize thermal expansion stress in the electrochemical cells. The tubular bead edge seals are formed as an integral part of the bipolar separator by a low-cost sheet metal stamping process.

Owner:MEACHAM G B KIRBY

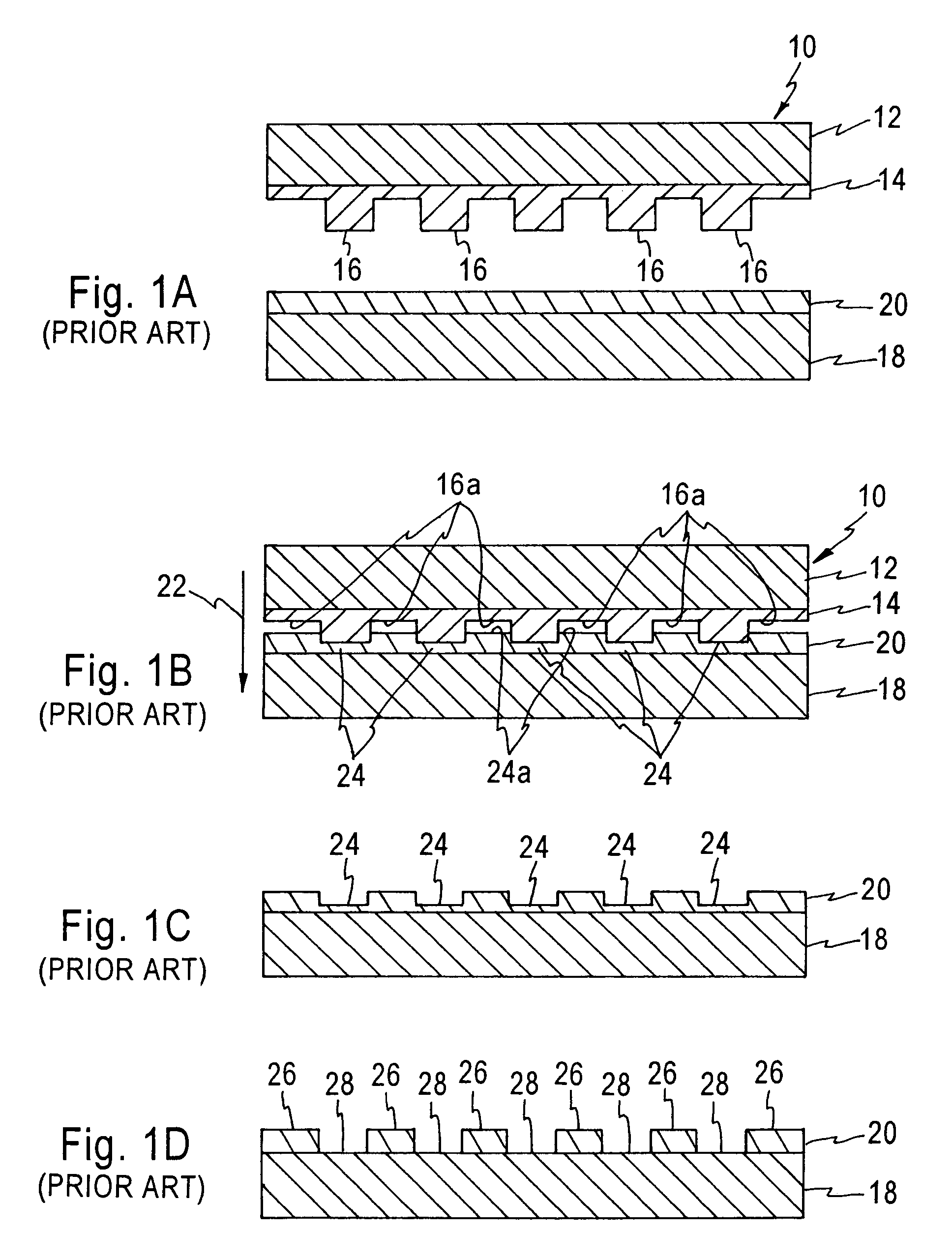

Ultra fine patterning process for multi-layer substrate

InactiveUS20030196987A1Easy to processNanoinformaticsPhotomechanical apparatusResistSelective deposition

The present invention discloses an ultra fine patterning process for multi-layer substrate by using selective deposition resist which inhibits metal nucleation during metal deposition process. The present invention can be executed by a fine pattern stamp adsorbing the self-assembled monolayers (SAM), then proceeds the stamping process on a surface of a substrate to achieve the selective deposited SAM with ultra fine pattern. Then, the metal deposition process will be proceeded to make metal deposited selectively on the portion not covered by the SAM to form the patterned metal layer directly.

Owner:VIA TECH INC

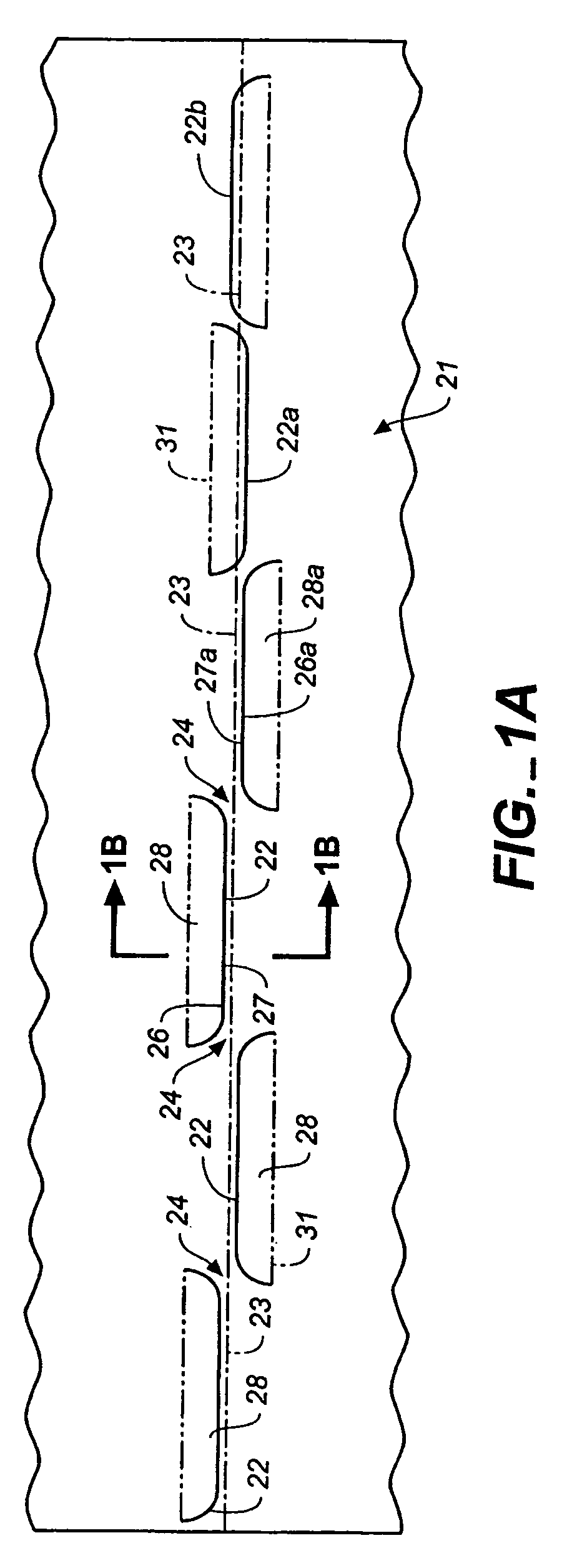

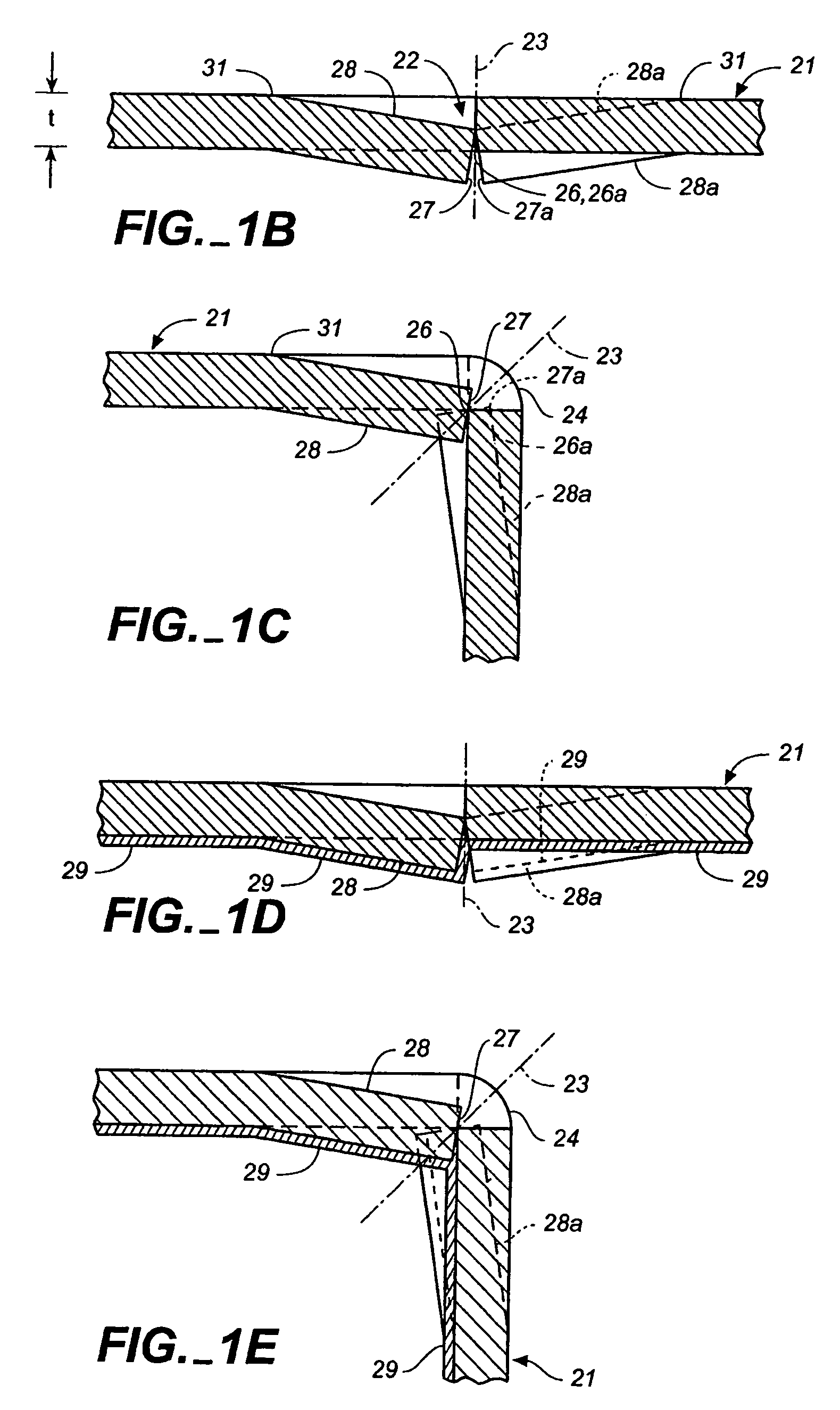

Sheet material with bend controlling displacements and method for forming the same

A method of preparing a sheet of material for bending along a bend line includes the step of forming at least one displacement in the thickness direction of the sheet of material, the displacement including a flat zone substantially parallel to the sheet of material with a portion of the periphery of the flat zone extending along and adjacent to the bend line, and including an angled transition zone interconnecting the flat zone with a remainder of the sheet of material. The forming step is preferably accomplished using one of a stamping process, a punching process, a roll-forming process and an embossing process. A sheet of material suitable for bending using the process also is disclosed, as are the use of coatings, shin guards and displacing the area of the sheet between bending inducing slits.

Owner:IND ORIGAMI INC CA US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com