Combination shelf structure

a combination shelf and structure technology, applied in the field of combination shelf structure, can solve the problems of insufficient structural strength or failure to support a heavy weight, limited application of the shelf, difficult to maintain a secured connection, etc., to enhance the strength of carrying a weight, and enhance the overall applicability of the combination shelf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The structure, assembly technical characteristics and effects of the present invention will become apparent with the detailed description of preferred embodiment together with related drawings as follows:

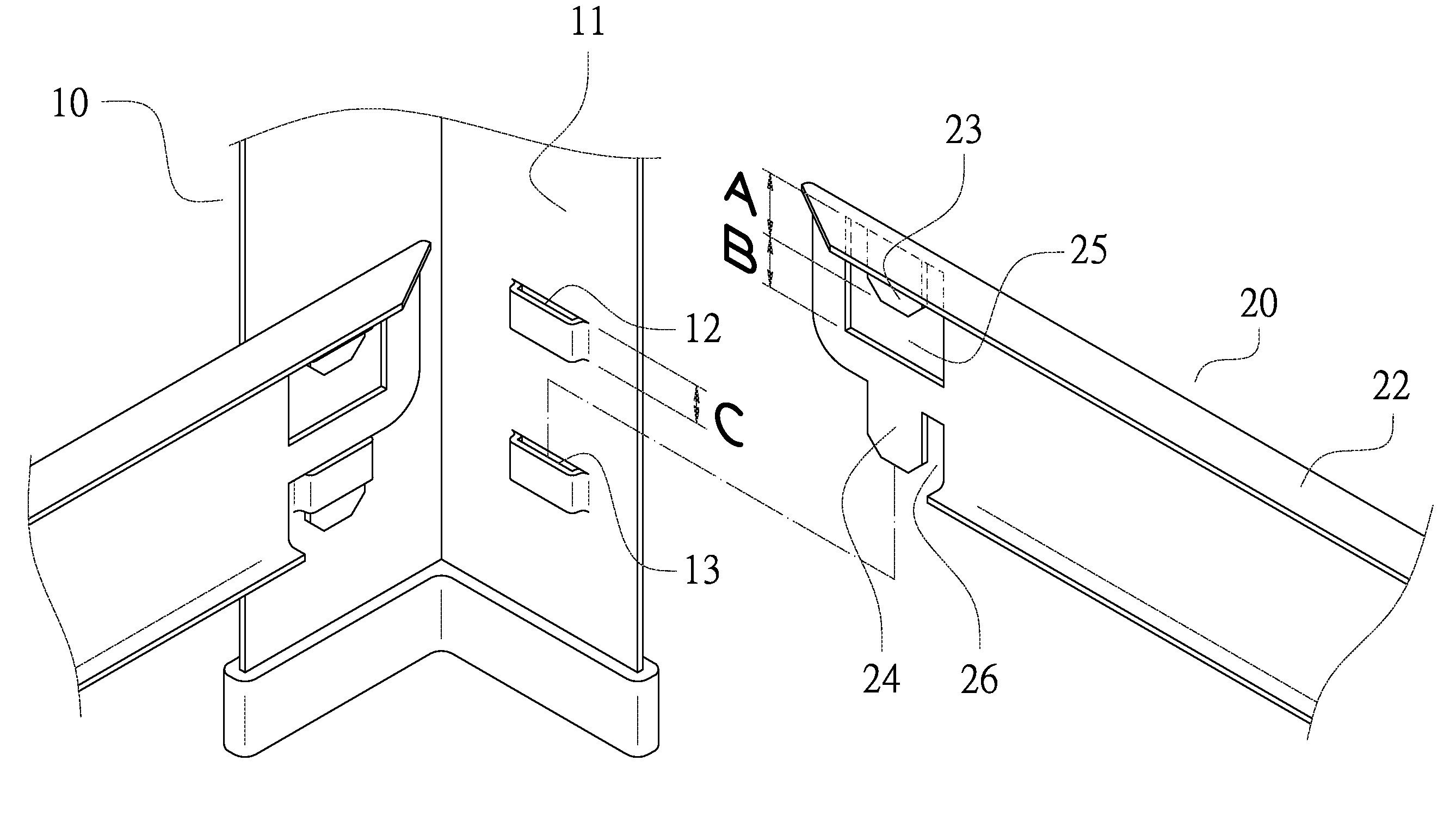

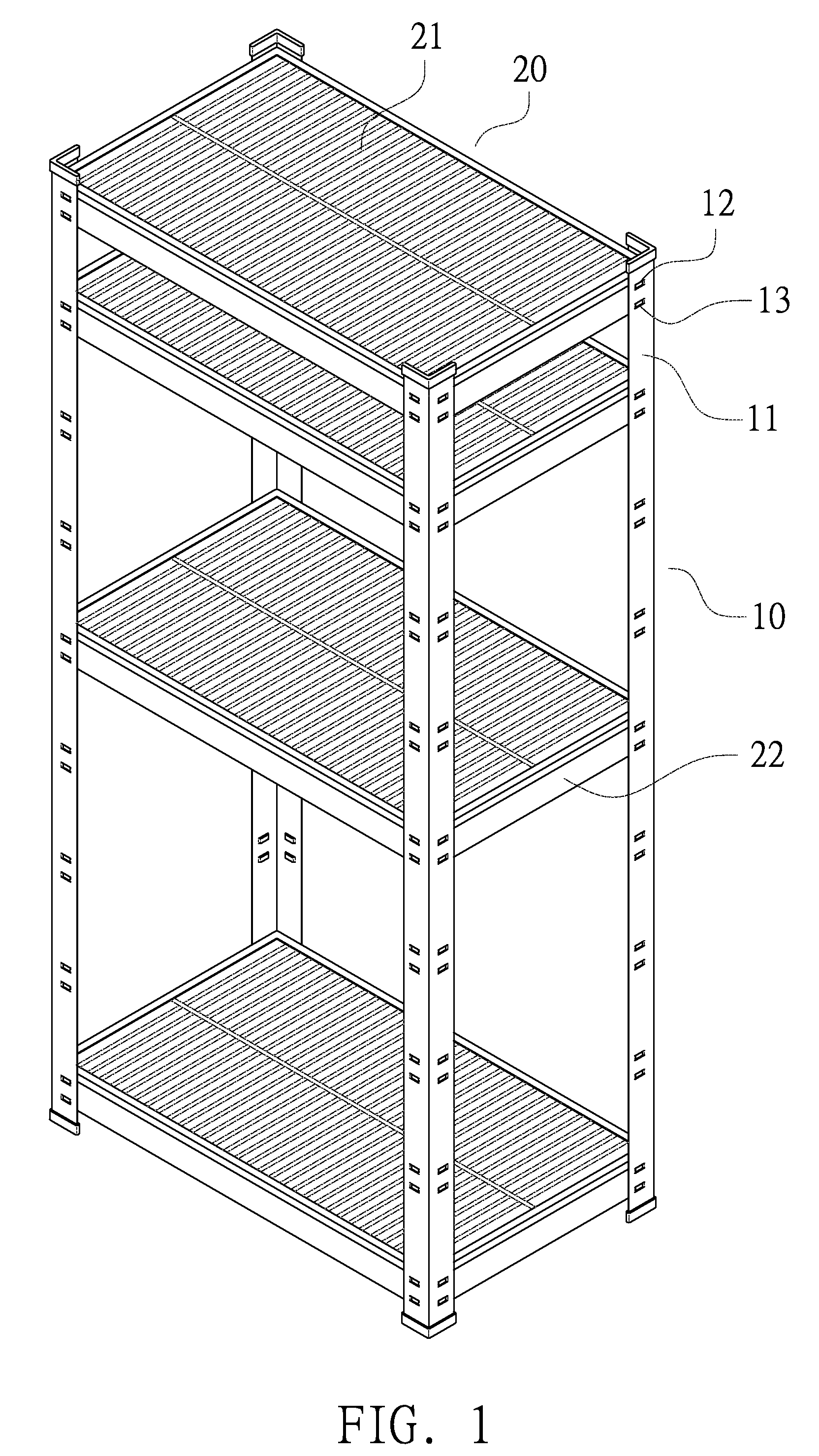

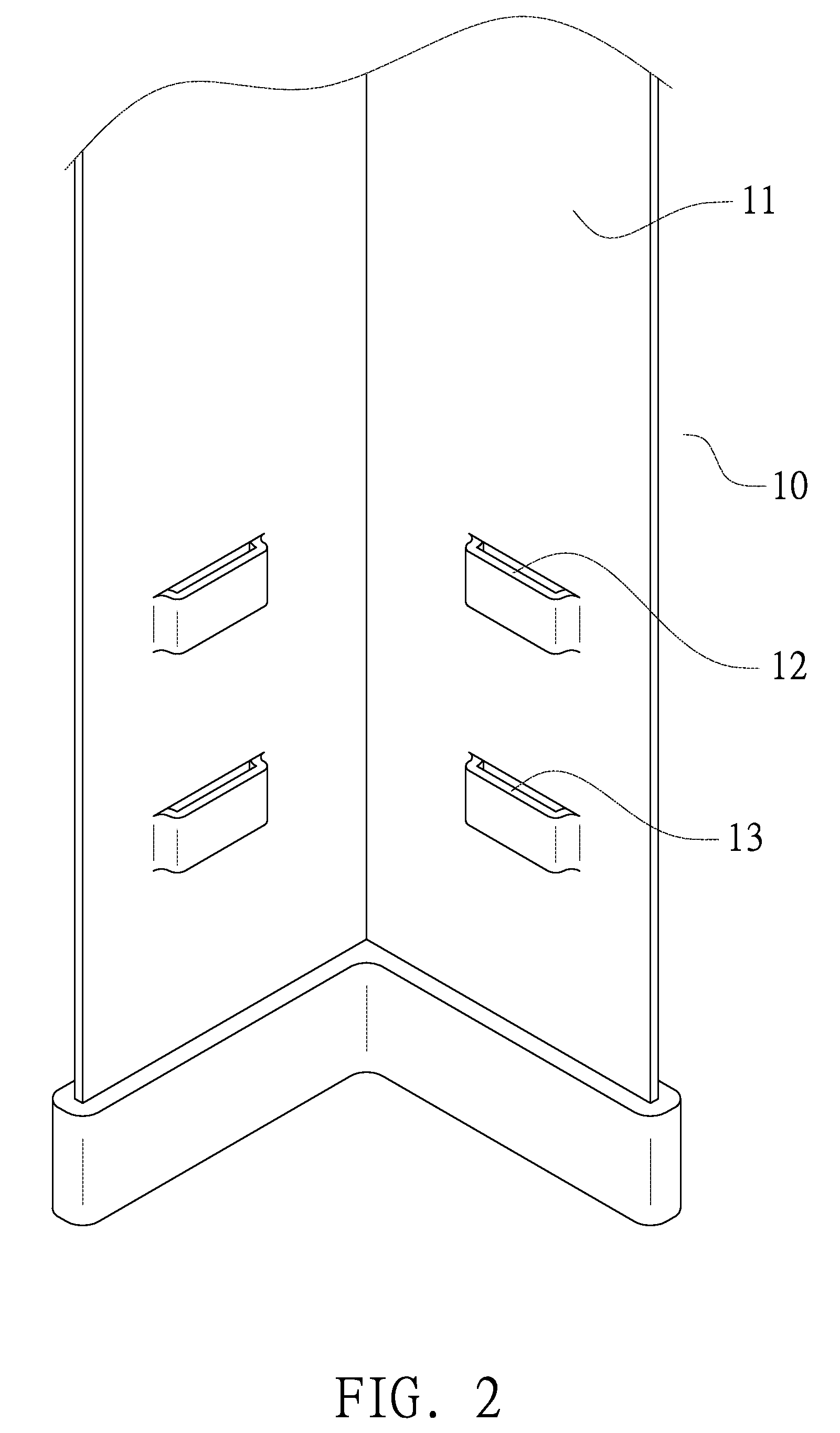

[0022]With reference to FIGS. 1 to 6 for a first preferred embodiment of the present invention, FIG. 1 shows a perspective view of a combination shelf structure. FIGS. 2 and 3 show schematic views of a portion of a combination shelf structure, FIG. 4 shows an exploded view of a portion of a combination shelf structure, FIG. 5 shows a schematic view of the connection of a combination shelf, and FIG. 6 shows a schematic view of an application of a combination shelf. The structural design of the combination shelf in accordance with the first preferred embodiment of the invention comprises four support rods 10 and a predetermined number of storage partition layers 20 embedded with each other.

[0023]The plurality of support rods10 are L-shaped plate-rods formed by stamping a metal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com