Patents

Literature

185results about How to "Reduce one process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

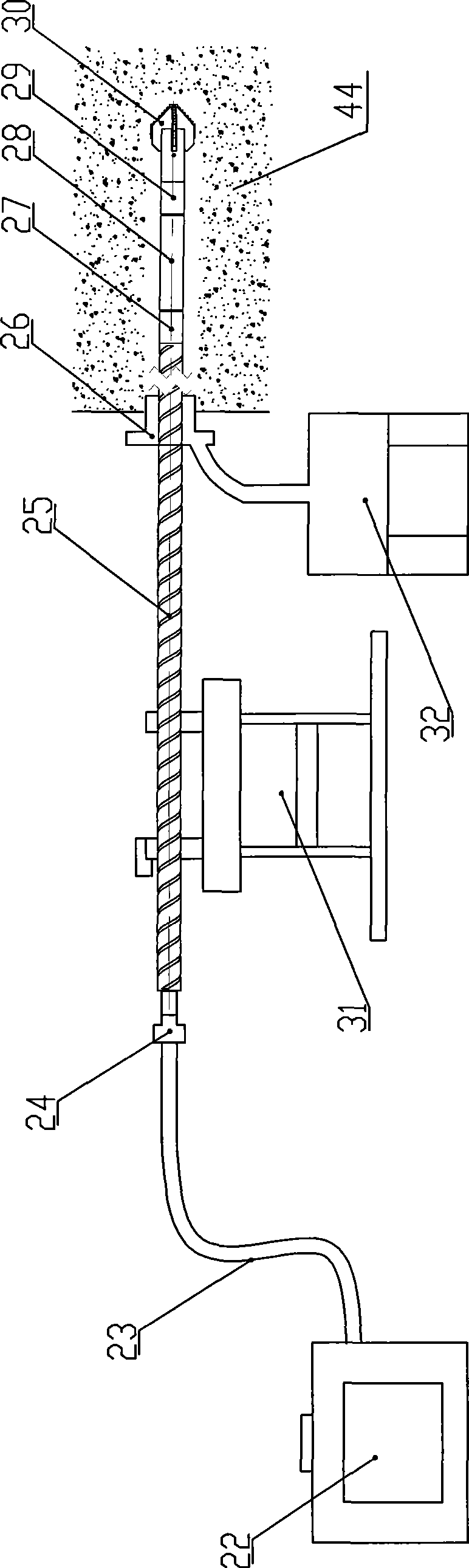

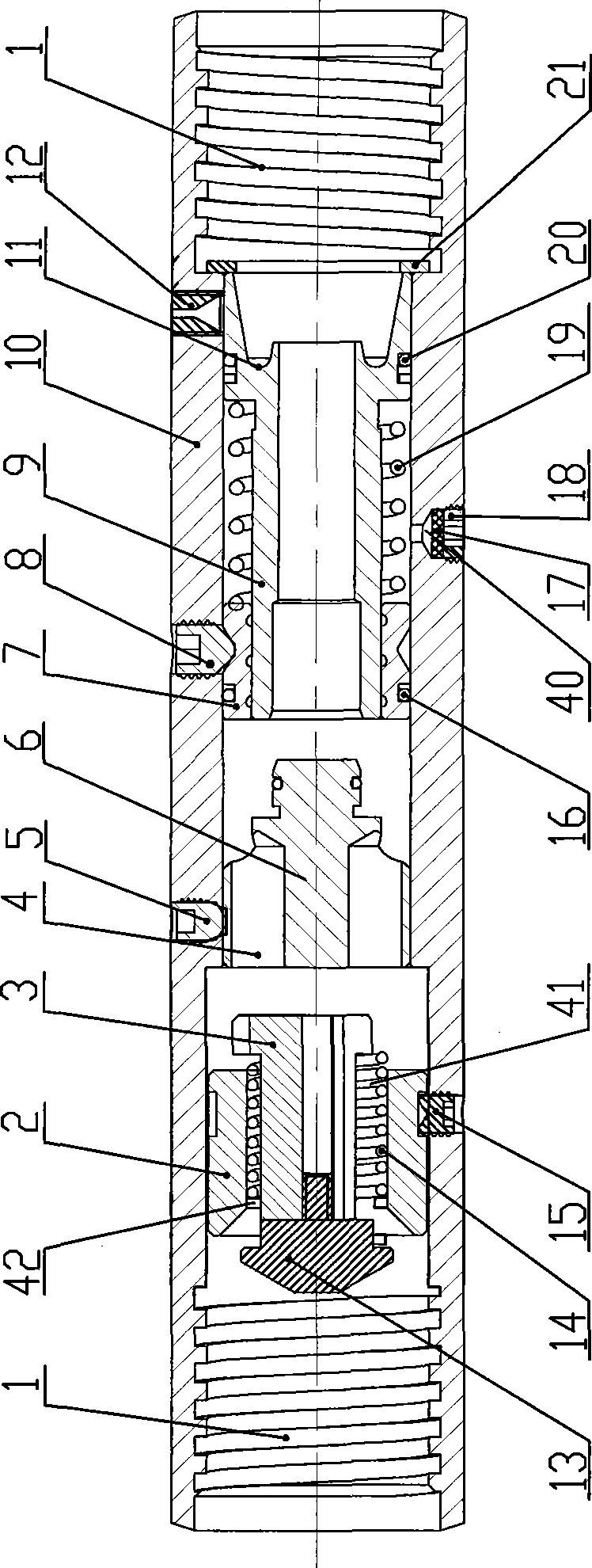

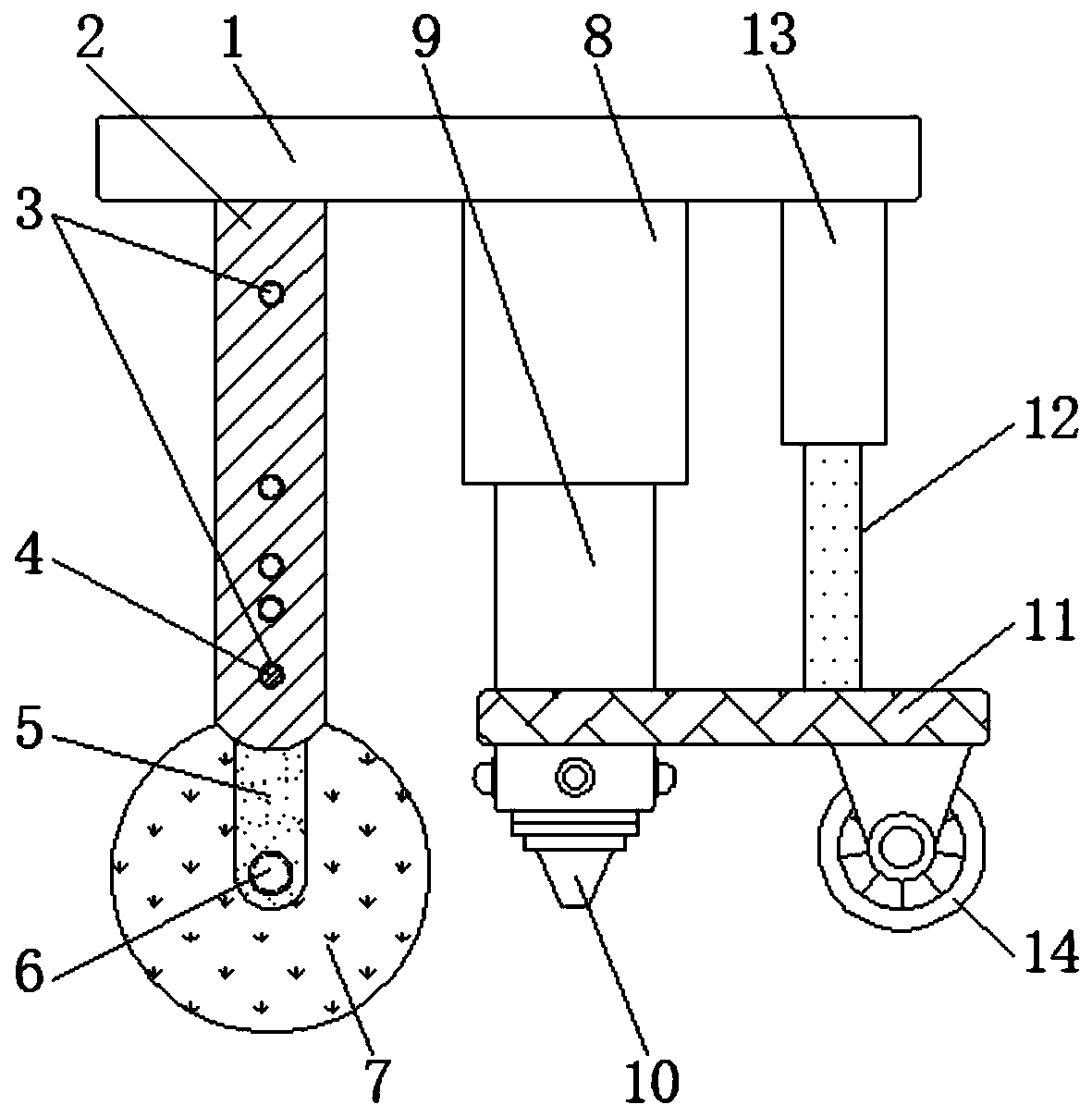

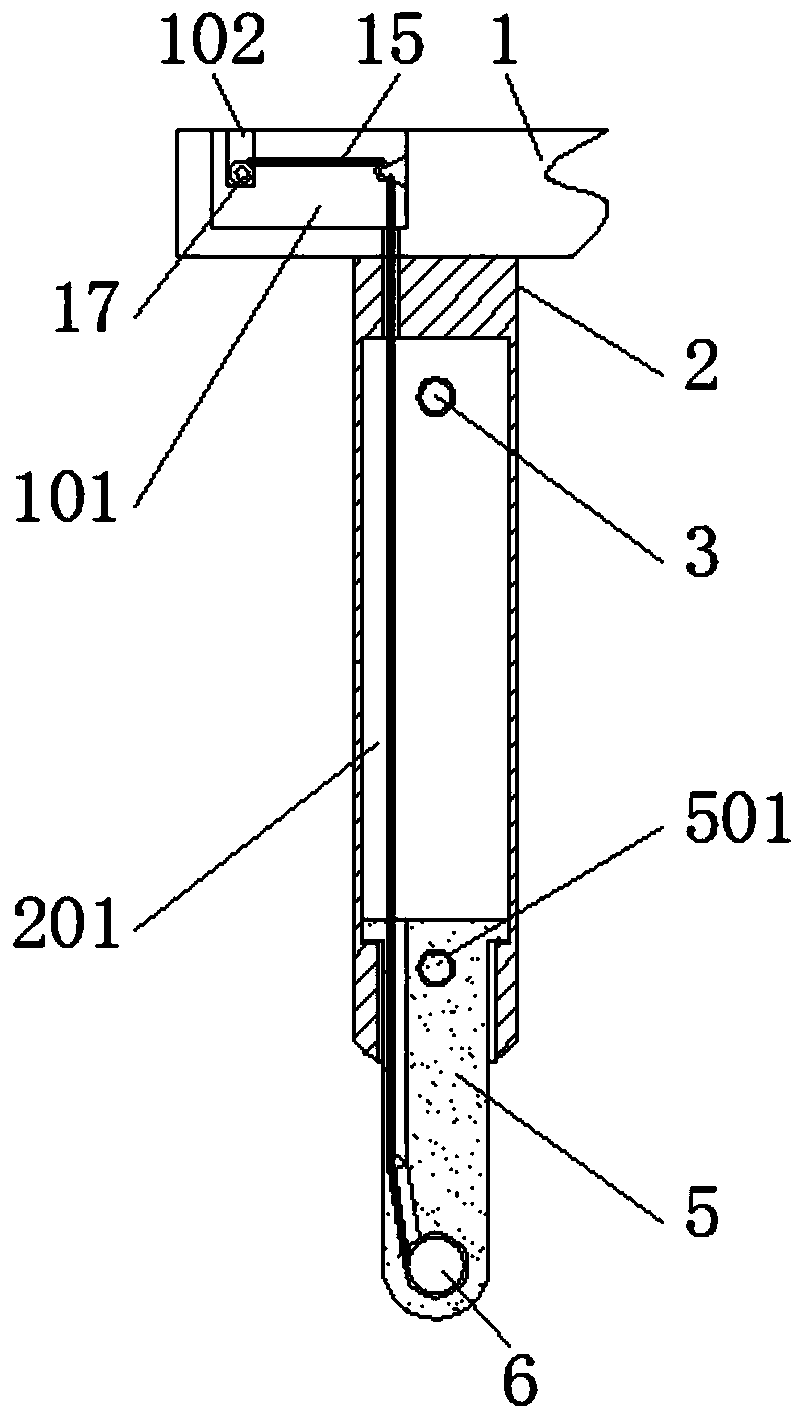

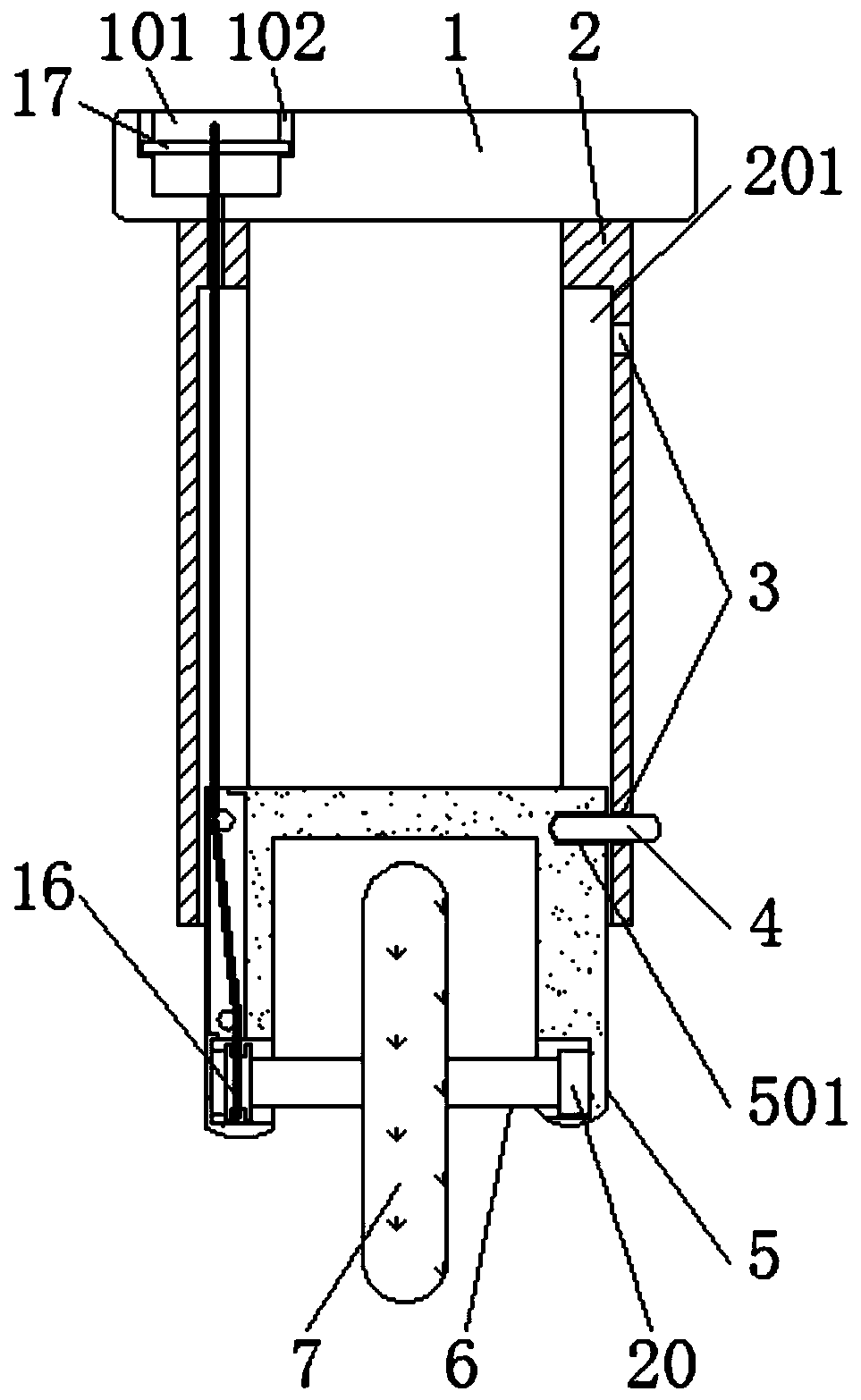

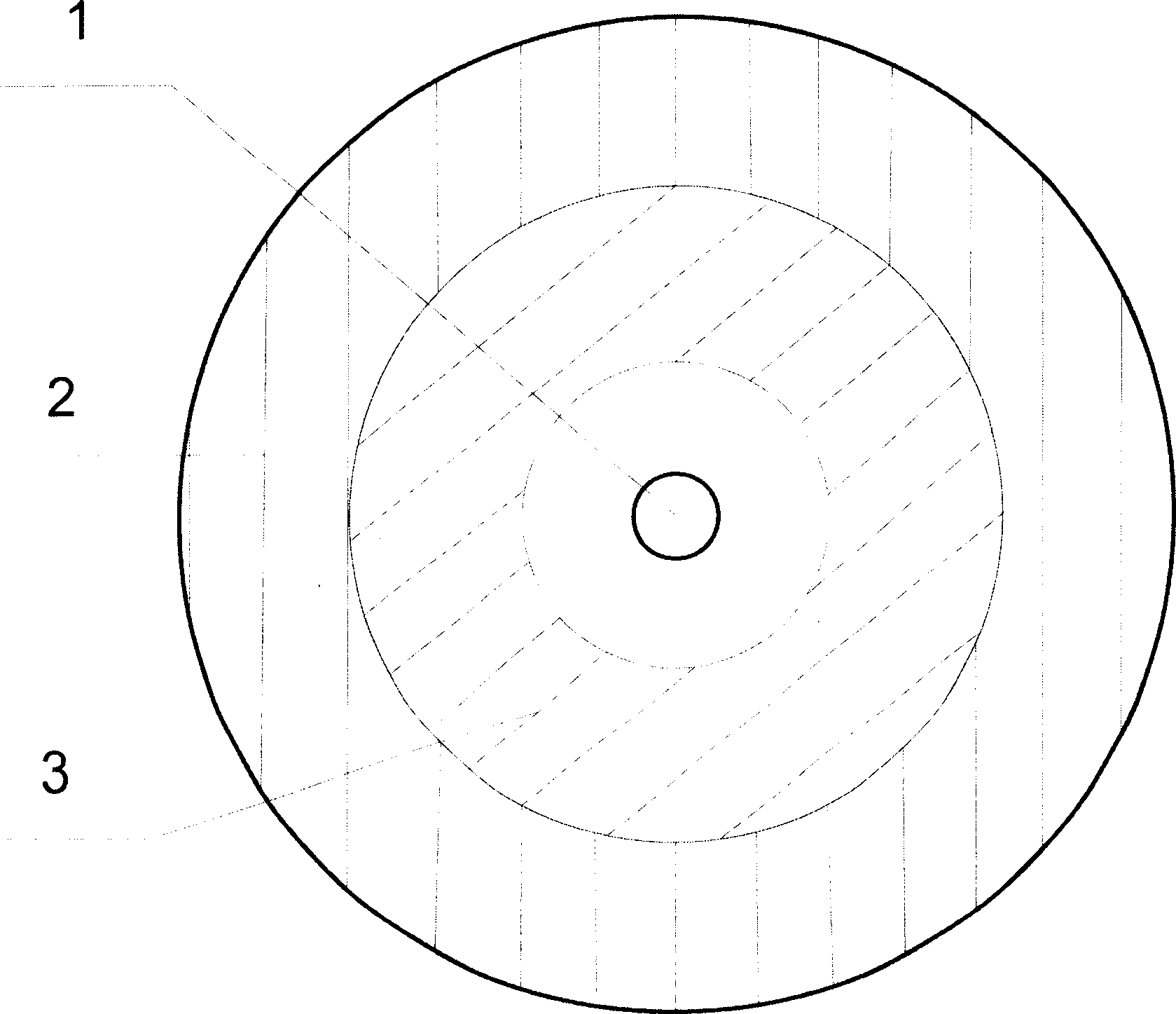

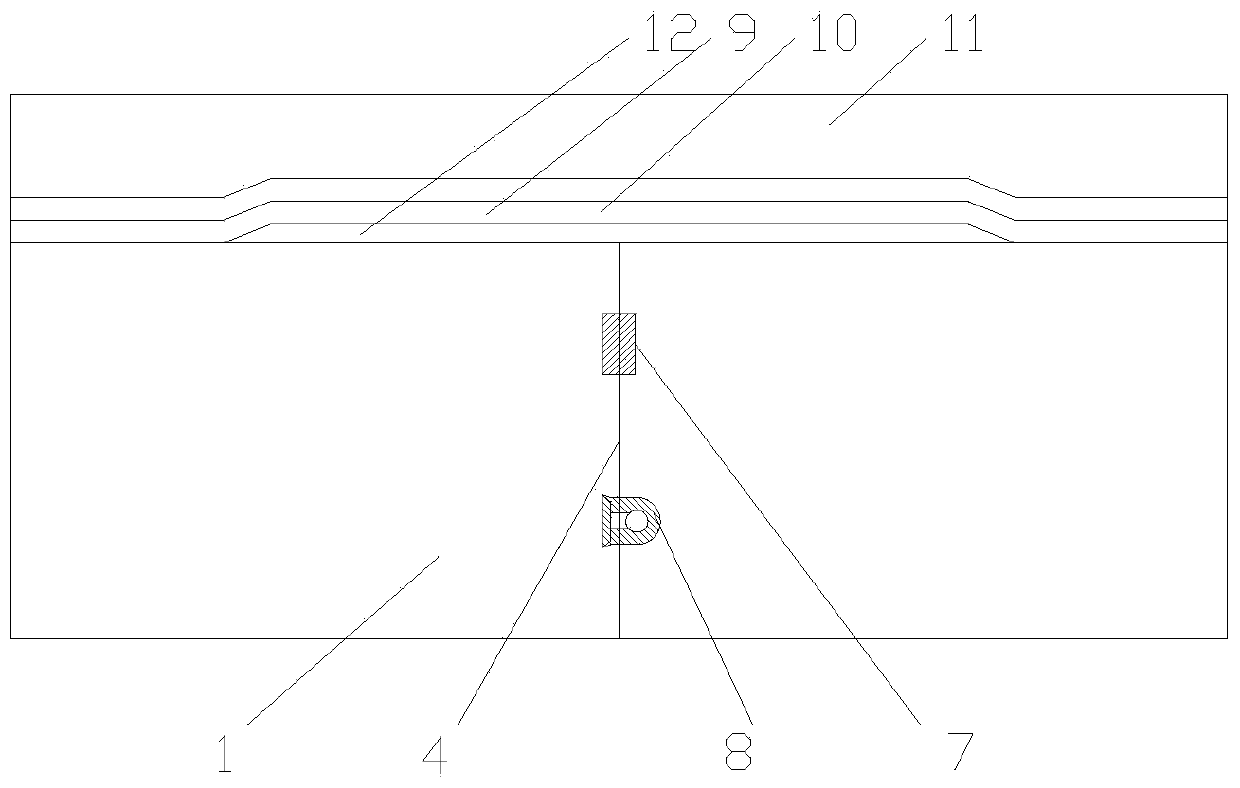

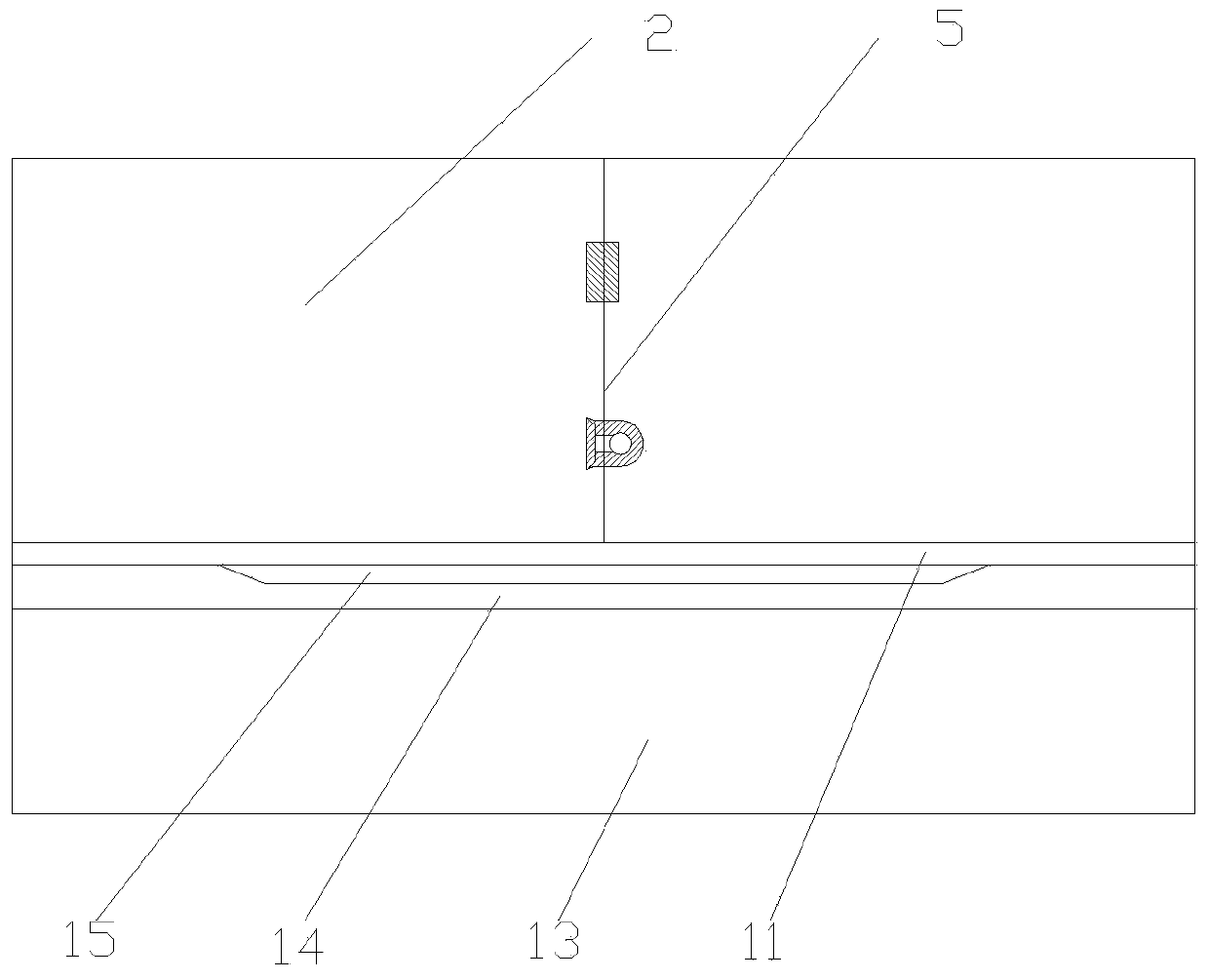

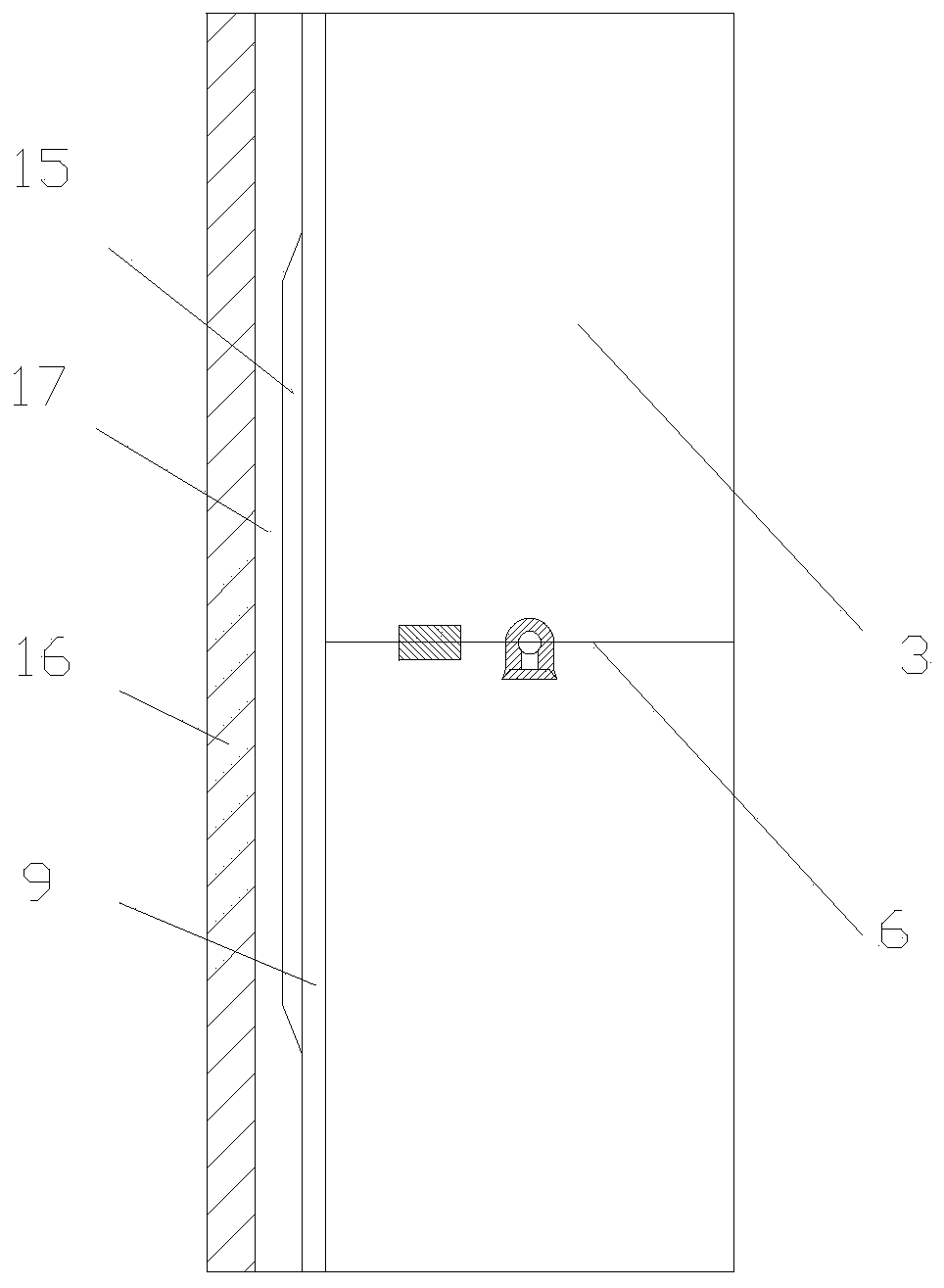

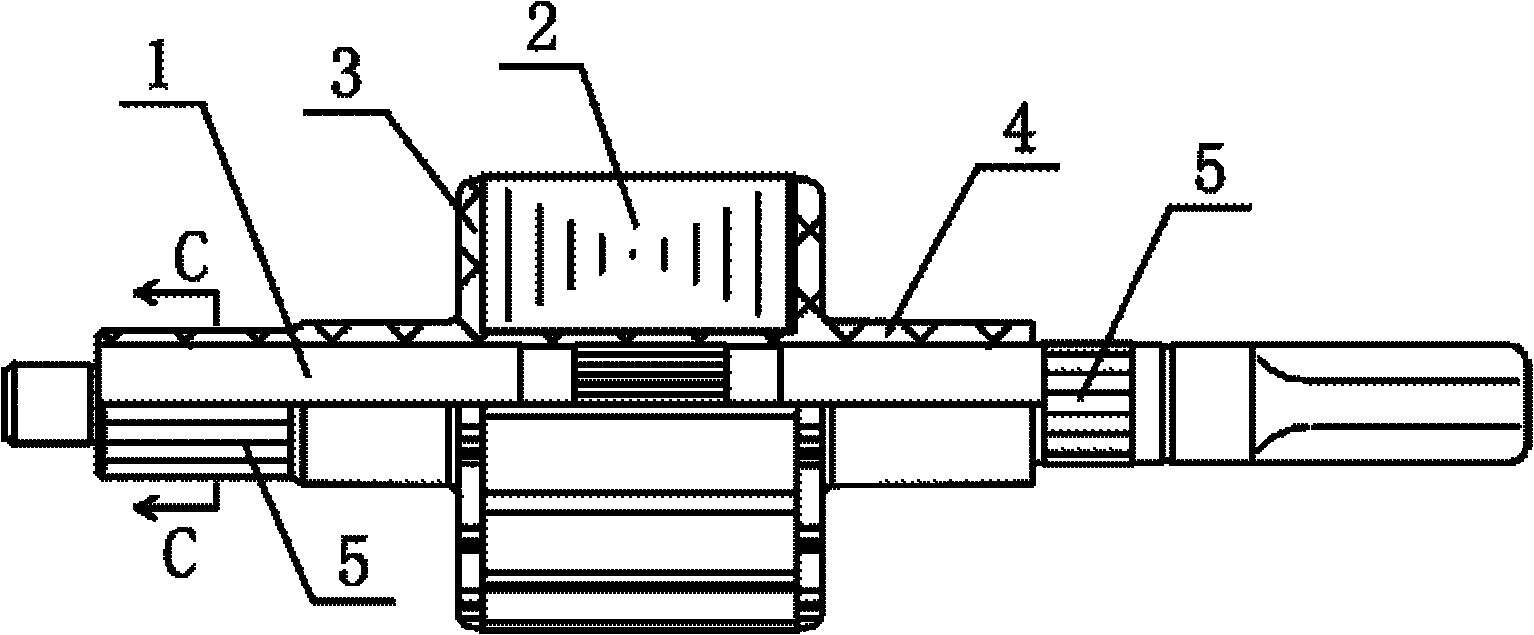

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

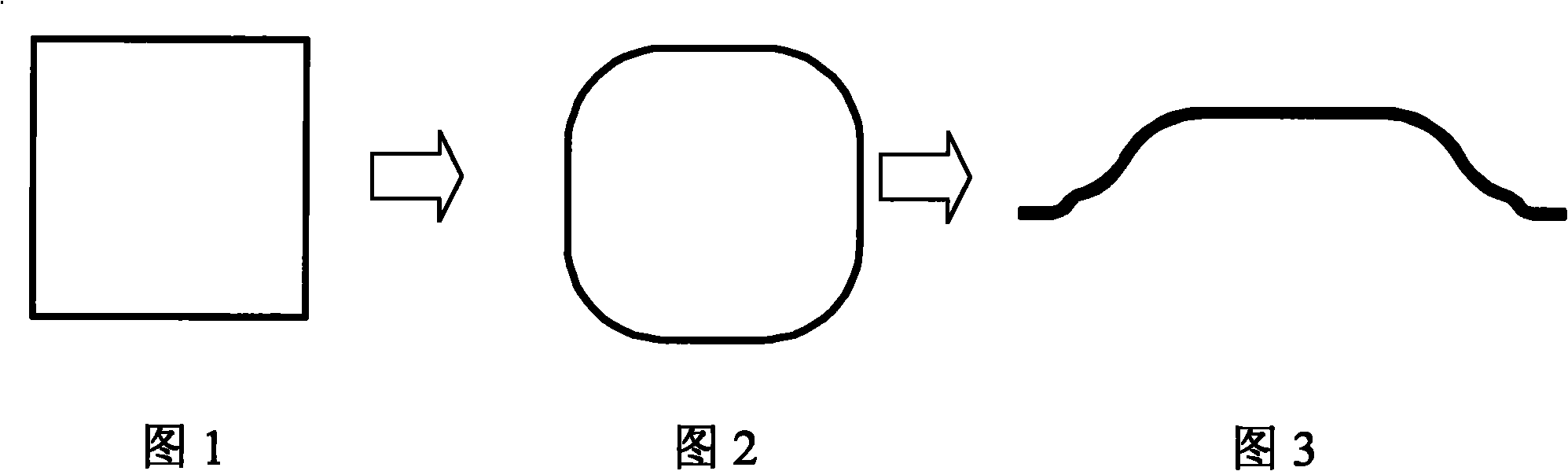

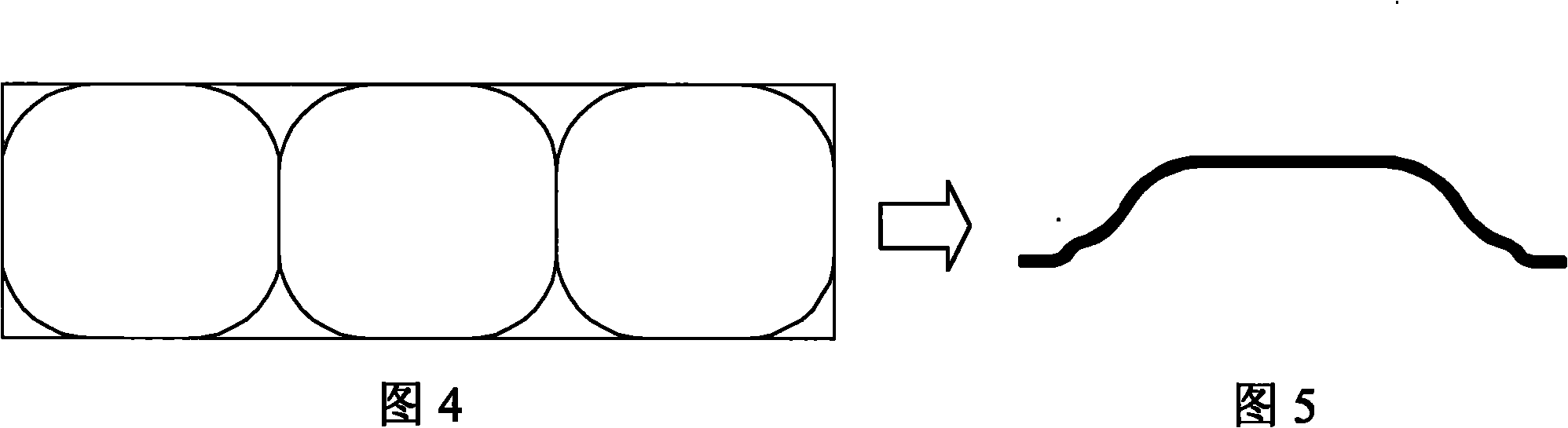

Steel wheel spoke stamping process for passenger car and processing mould

The invention relates to a steel wheel spoke stamping process for a passenger car, comprising the following steps of: (1) cutting a panel veneer: placing the rectangular panel veneer on a material support, the left and right ends as well as the front end of which are positioned by a set rule; when a press descends, cutting the panel veneer at the same time by using a peripheral cutting edge at the lower part of the outer edge of an upper mold core and a trim blade to form a spoke panel veneer; (2) stretching the panel veneer: placing the trimmed spoke panel veneer on a blank pressing ring, and pressing down the spoke panel veneer through the upper mold core and the blank pressing ring, wherein in the descending process of the press, the middle part of the spoke panel veneer firstly contacts the lower mold core to prevent the middle part of the spoke panel veneer from descending, and the peripheral part of the spoke panel veneer without being blocked continuously stretches the spoke panel veneer along with the descending of the upper mold core and the blank pressing ring; (3) punching central holes of the spoke; and (4) resetting and discharging. The invention integrates the blanking and stretching processes, adopts the one-step positioning way to ensure the concentricity of the central hole of the spoke and the outer edge of the spoke to ensure the processing quality of the spoke and reduces one process compared with the prior art, thereby greatly improving the production efficiency.

Owner:SHANGHAI BAOSTEEL WHEEL

Water-insoluble modified polyvinyl alcohol coating liquor and its preparation process

The invention discloses an insoluble modified polyvinyl alcohol coating liquid and preparing method and film through the coating liquid, which comprises the following parts: polyvinyl alcohol, modifier, inorganics, crosslinking agent, catalyst and water. The coating liquid improves levelling, adhering and even property greatly, which increases obstruct property for kinds of gas.

Owner:刘建林

Production method of cold-rolled steel strip for flux cored wire

InactiveCN102755992ASimple production processLow costWork treatment devicesRollsExtensibilityCarbide

The invention provides a production method of a cold-rolled steel strip for a flux cored wire. The production method comprises the following steps of: (1) selecting a raw material, to be specific, selecting an SPCE hot-rolled acid-washed raw material with thickness of 2.2-3.0 mm and width of 300-850 mm, wherein the raw material comprises the following components in percentage by weight: 0.01-0.025 percent of C, 0.002-0.010 percent of Si, 0.150-0.350 percent of Mn, not greater than 0.01 percent of S, not greater than 0.015 percent of P, not greater than 0.003 percent of N, not greater than 0.05 percent of Alt and the balance of iron element and inevitable impurities; (2) cold-rolling, to be specific, performing cold-rolling on the acid-washed raw material to be 0.5-1.2 mm and controlling total screw-down rate to be 700-85 percent; (3) performing recrystallization annealing, to be specific, holding a rolled steel strip in a forced circulation hood type annealing furnace, heating, preserving heat and cooling, wherein the holding temperature is 610-660 DEG C and the holding time is controlled to be 9-12 hours; (4) leveling; and (5) cutting to obtain the cold-rolled steel strip for the flux cored wire. The produced flux cored wire steel strip has a simple production process and is low in cost. The produced flux cored wire steel strip has stable performance; solid solution carbide is fully separated through staged slow cooling in the process of the hood type annealing furnace; the influence of time limitation on subsequent drawing is avoided; the hardness of the product is HV 90-110; and the extensibility A reaches 42-50 percent.

Owner:武钢集团有限公司

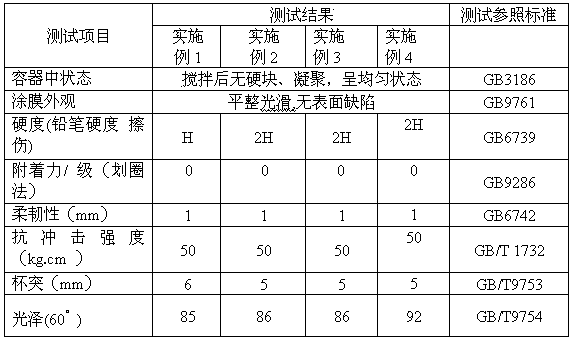

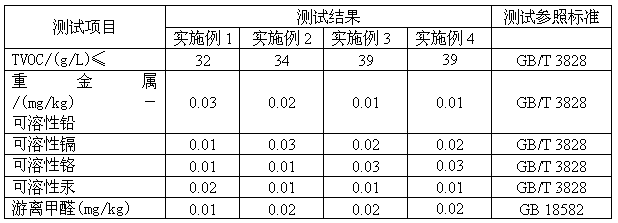

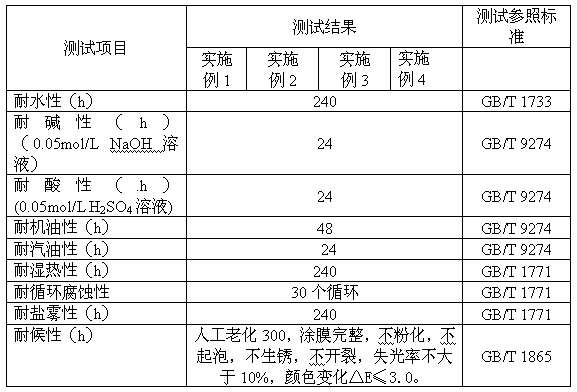

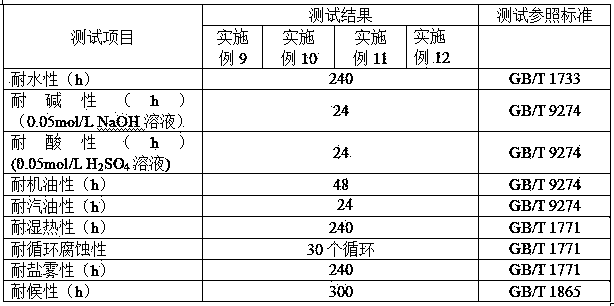

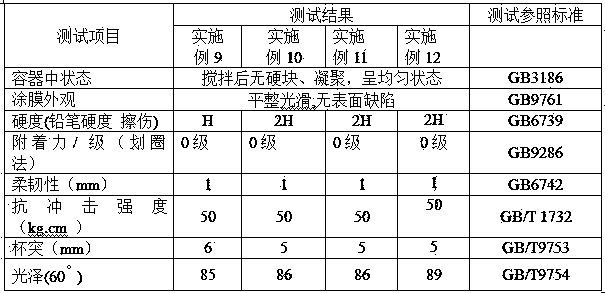

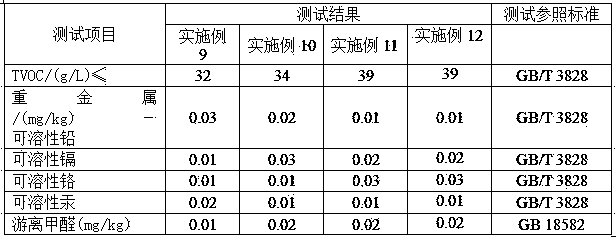

Water-based automotive paint, and preparation method and application method thereof

The invention discloses a water-based automotive paint, and a preparation method and an application method thereof. The water-based automotive paint is prepared from water-based castor oil-modified alkyd resin, water-based acrylic resin, water-based color paste, amino resin A, amino resin B, a coalescing agent, deionized water, a dispersing agent, a wetting agent, a pH regulator, a defoamer, anti-settling pulp, a corrosion remover, a thickener, an adhesion promoter and a flatting agent. The preparation method refers to orderly adding the raw materials to evenly agitate. The application method comprises the following steps: evenly mixing and stirring the water-based automotive paint and water according to the ratio of 1:(0.1-0.3), and then spraying, placing, baking and solidifying, so as to obtain a stoving varnish coating. A solvent stoving varnish is replaced by using the water-based automotive paint disclosed by the invention; a complete coating, of which the adhesive force is 0 level, and the flexibility is 1mm, which is excellent in weather fastness, high in fullness, and vivid in color and luster, and has excellent protectiveness and decorative property can be formed on the metal surface; the water-based automotive paint is safe in production procedure, environment-friendly, simple, and environment-friendly and convenient in construction.

Owner:肇庆千江高新材料科技股份公司

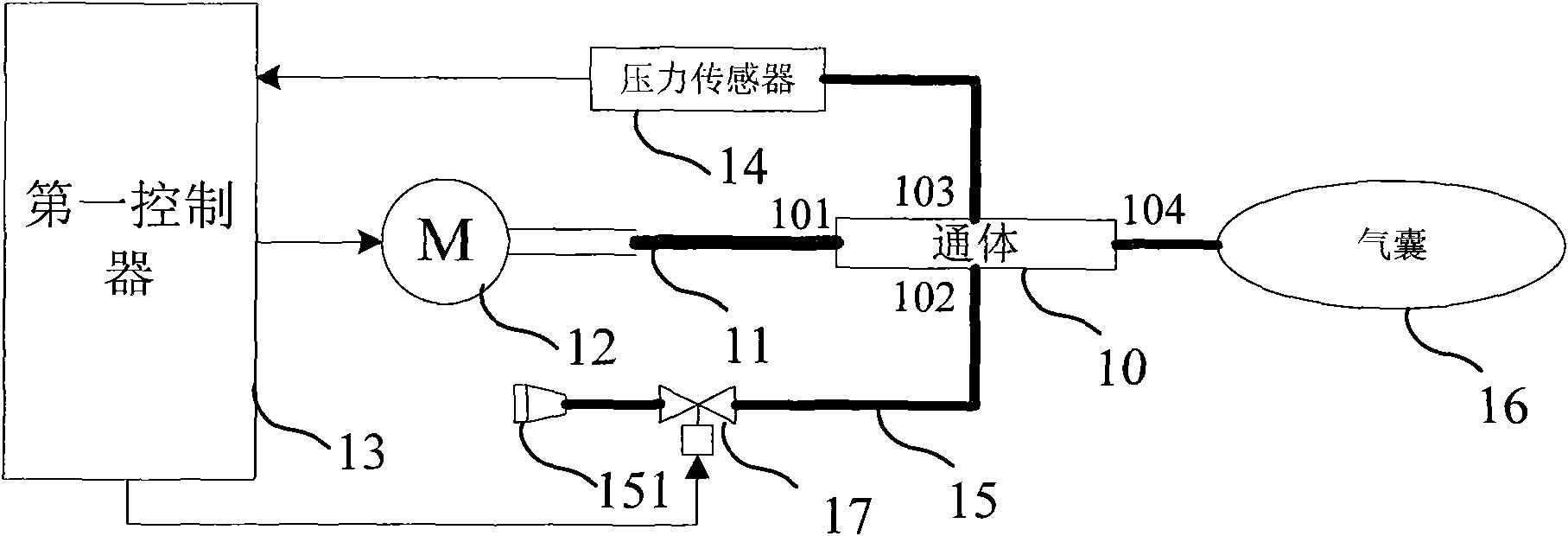

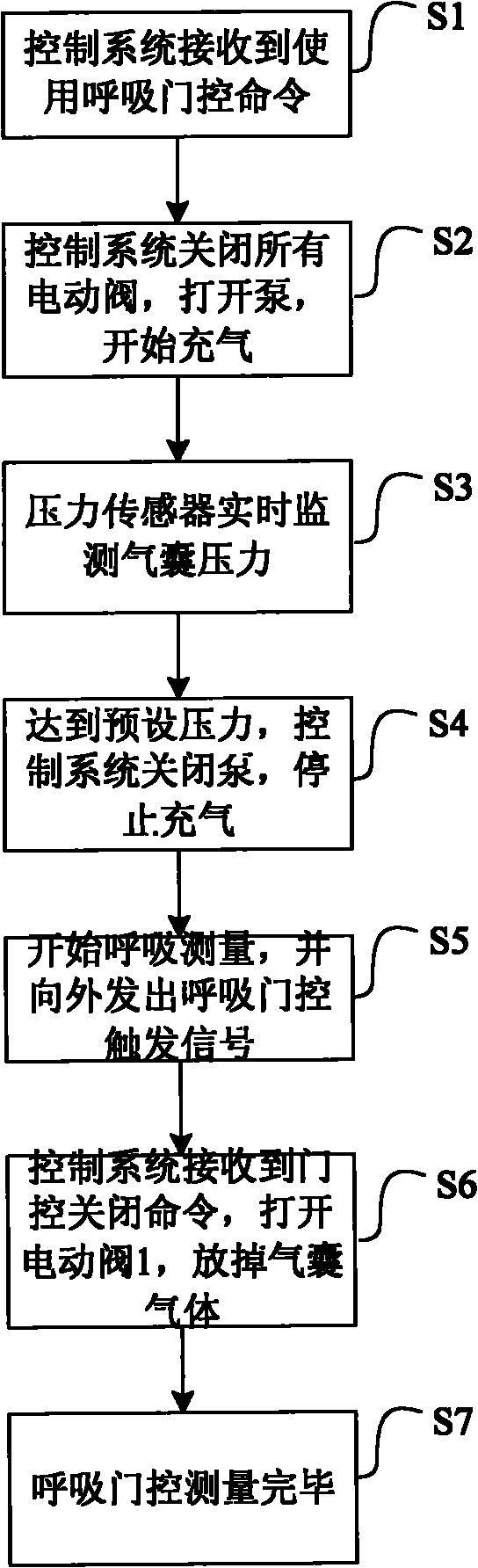

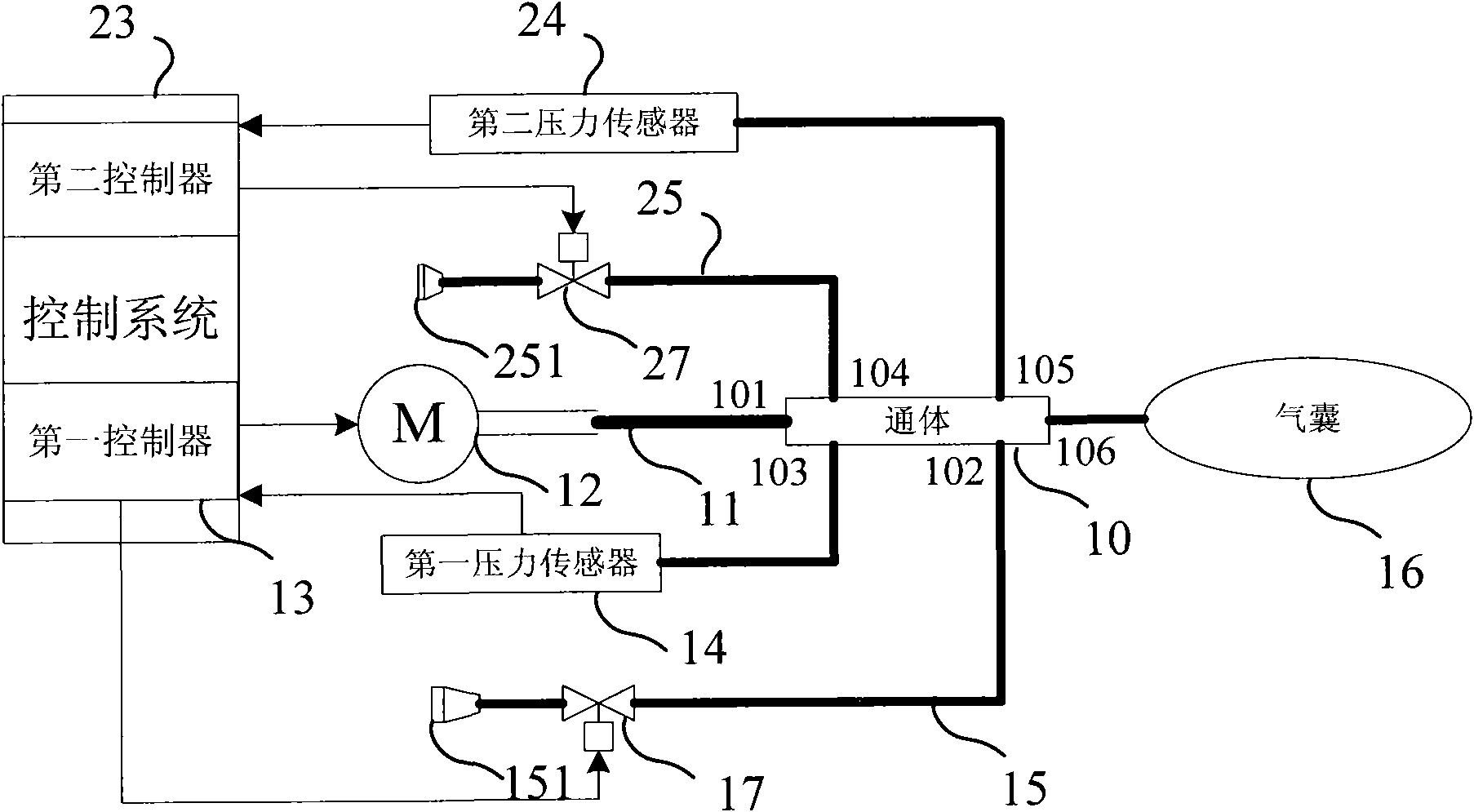

Respiration gate-controlled inflation system, inflation method and medical imaging equipment

InactiveCN101884536AImprove work efficiencyOutput signal optimizationSurgeryComputerised tomographsMedical imagingAir cell

The invention discloses a respiration gate-controlled inflation system, respiration gate-controlled inflation method and medical imaging equipment. The system comprises an air pump, a first controller, a first pressure sensor and an inflation passage, wherein the first controller is connected with the air pump, the air outlet of the air pump is communicated with one end of the inflation passage, and the other end of the inflation passage is used to be communicated with an air cell; and the first pressure sensor is arranged on the inflation passage, the output end of the first pressure sensor is coupled to the first controller which controls the air pump to stop inflating according to the pressure detected by the first pressure sensor, namely controlling the air pump to stop inflating when the pressure detected by the first pressure sensor reaches a first pressure value. The inflation system and the inflation method have the advantages that: medical care personnel do not have to inflate the air cell manually, and the working efficiency is improved; and as the reference pressure in the air cell is monitored and controlled, the output signal is optimized and the amplitude and accuracy of the signal are not seriously affected.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

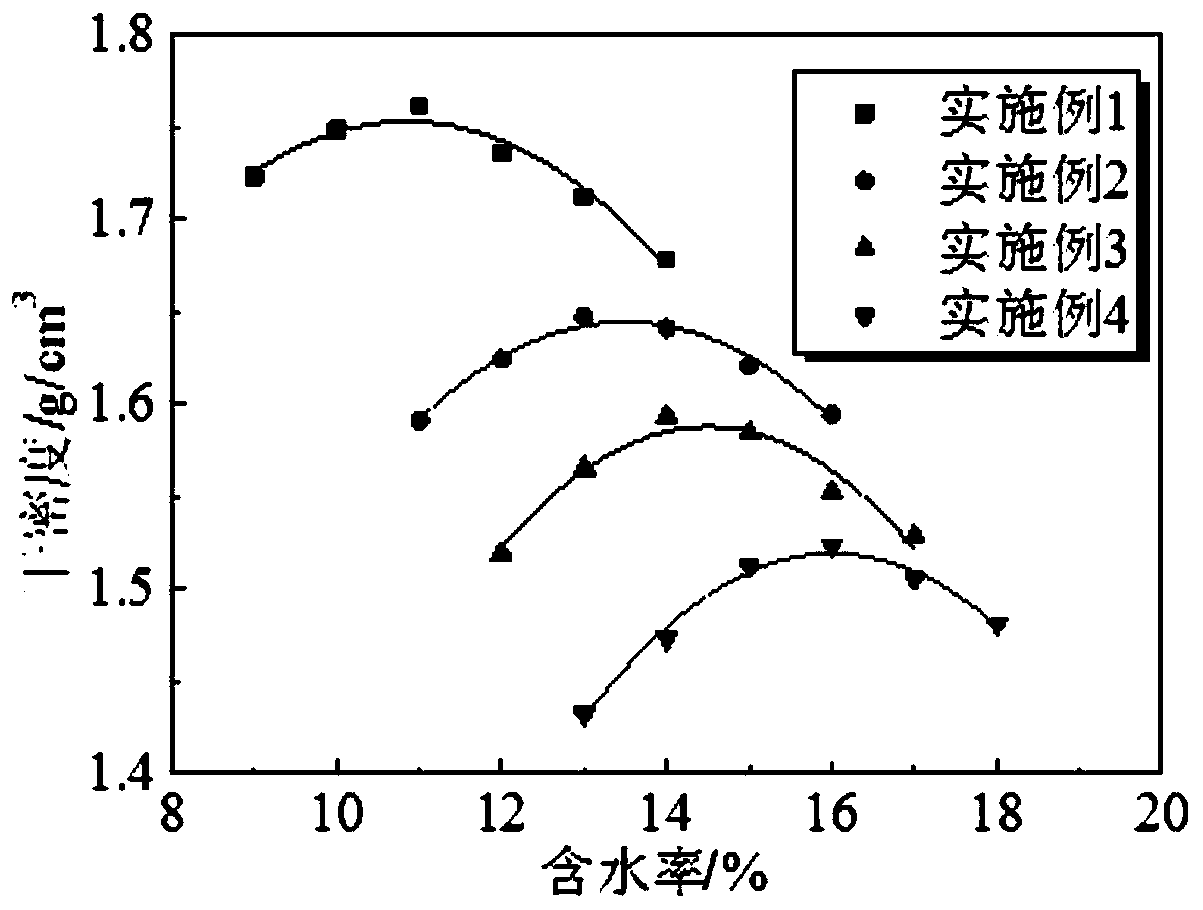

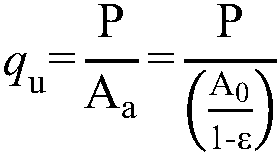

Alkali excited material cured iron tailings, preparation method therefor and use method

The invention relates to alkali excited material cured iron tailings, a preparation method therefor and a use method. The alkali excited material cured iron tailings comprise iron tailings and a curing agent which are in a corresponding proportioning ratio, wherein the curing agent comprises carbide slag, blast furnace granulated slag, flyash and red mud. The alkali excited material cured iron tailings are prepared through weighing various ingredients according to a proportioning ratio, carrying out uniform mixing to obtain a mixture, adding water into the mixture in a manner of adjusting themoisture content of the mixture to 11.4% to 17.7%, carrying out uniform stirring, and then, carrying out stewing for 4 to 8 hours. Corresponding use procedures are controlled, and the alkali excited material cured iron tailings are used as a road subbase material. According to the alkali excited material cured iron tailings, the preparation method therefor and the use method, the production process is simple, and recycling of wastes is achieved by applying raw materials such as the carbide slag and the red mud; and by applying the fine iron tailings to roadbed fillers, the utilization ratio ofthe fine iron tailings is increased, the cost of reconstruction and protection of tailing warehouses is reduced, and the engineering cost is reduced.

Owner:LIAONING TECHNICAL UNIVERSITY

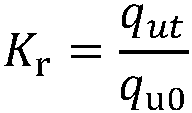

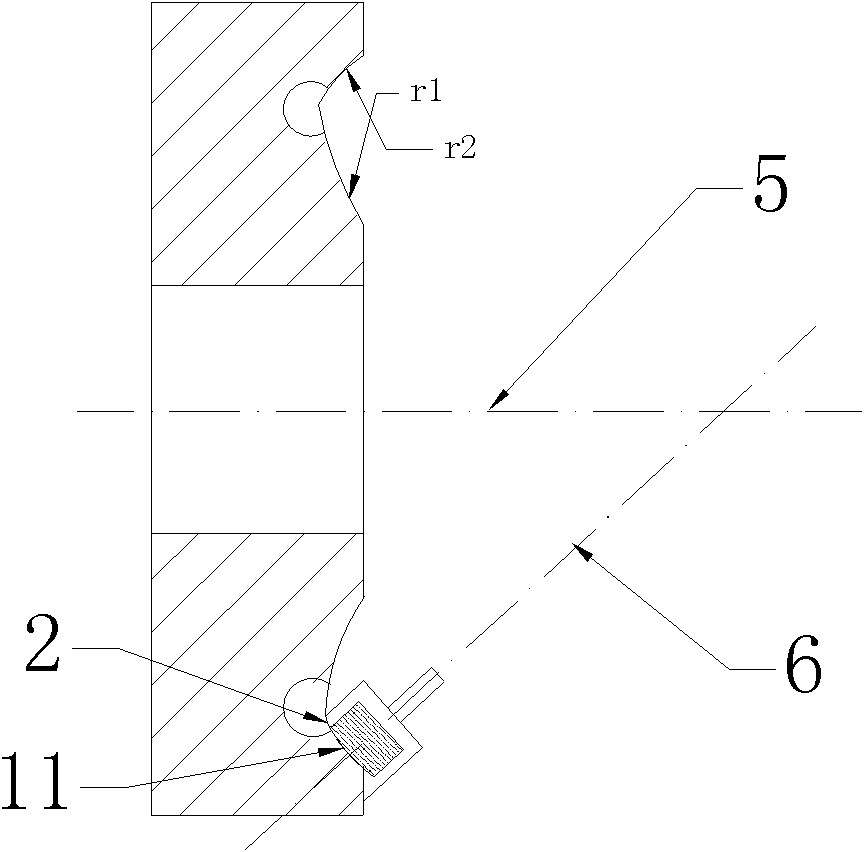

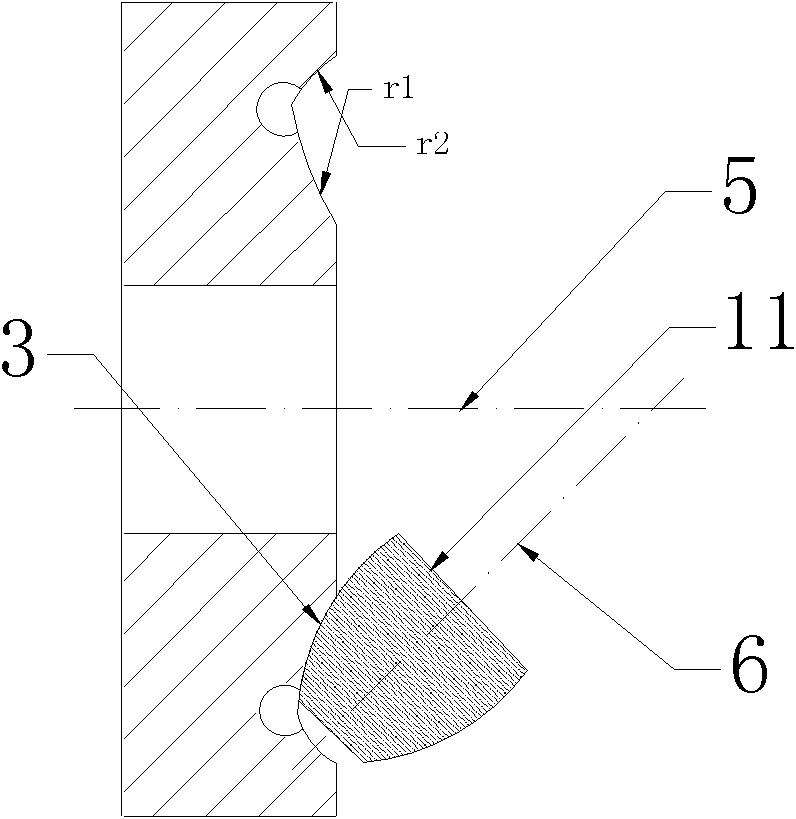

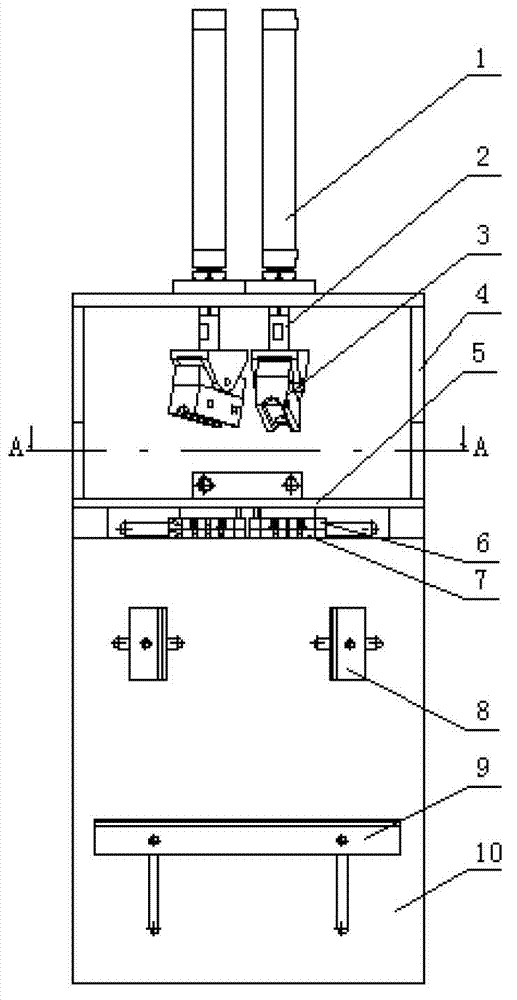

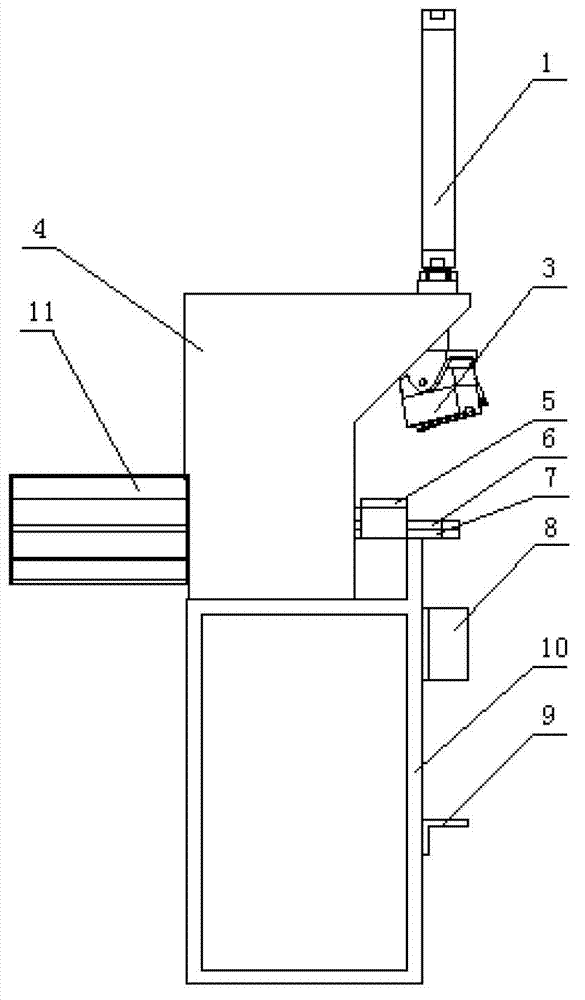

Dedicated machine tool for compound grinding of shaft washer raceway and flange of thrust aligning roller bearing

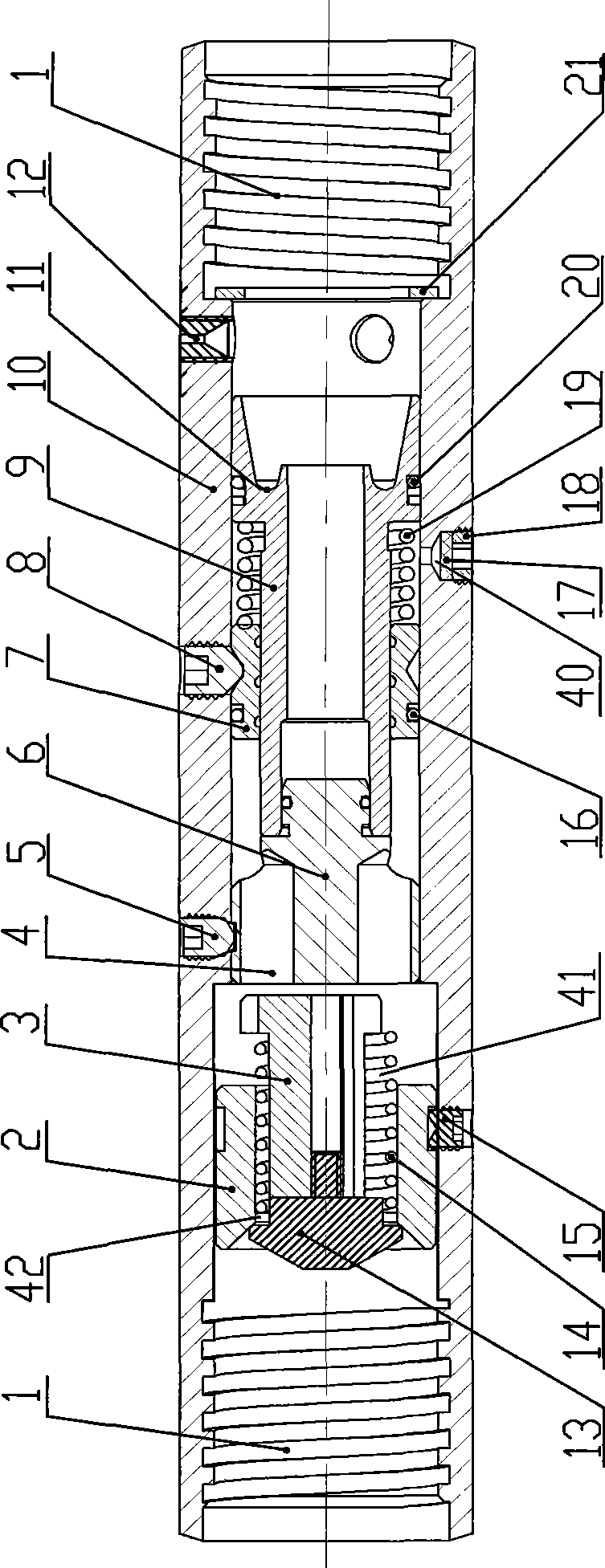

InactiveCN102091989AHigh feed accuracyImprove efficiencyGrinding machinesSpherical roller bearingEngineering

The invention discloses a dedicated machine tool for compound grinding of a shaft washer raceway and a flange of a thrust aligning roller bearing, which is used for realizing integrated processing for a flange and a raceway and ensuring the processing precision. The technical scheme is characterized in that a headstock slideway is arranged on the surface of the machine tool, a headstock is arranged on the headstock slideway and can slide front and back; an electromagnetic centreless fixture is fixed on a headstock output shaft, workpieces are clamped on the electromagnetic centreless fixture, a grinding wheel axle box is fixed on a backing plate, the backing plate is arranged on a backing plate slideway and can slide left and right; a grinding wheel is fixed on the headstock output shaft, and the contour line of the working face of the grinding wheel consists of straight lines and curves; and the axial line of each workpiece is perpendicular to the axial line of the grinding wheel. The machine tool has the following advantages of vertical grinding, unidirectional feeding and high precision, not only is suitable for the single-face grinding, but also is suitable for compound grinding of two spherical faces of the shaft washer raceway and the flange, and meets the requirements on shape precision and position precision simultaneously. By compound grinding, the machine tool reduces one procedure, has multiple purposes, and increases the efficiency.

Owner:瓦房店大中型轴承厂

Auxiliary grinding and modifying agent and preparation method thereof

InactiveCN102002262ALow manufacturing costReduce use costPigment physical treatmentPigment treatment with non-polymer organic compoundsEngineeringDiesel fuel

The invention discloses an auxiliary grinding and modifying agent and a preparation method thereof, i.e. the traditional auxiliary grinding agent and the traditional modifying agent are mixed according to a certain proportion to form a novel mixture which has the functions of the auxiliary grinding and modifying and comprises the components of saponification agent, water, diesel and linseed oil. The auxiliary grinding and modifying agent has the characteristics of simple preparation, low costs of the raw materials, and good use effect.

Owner:王东民

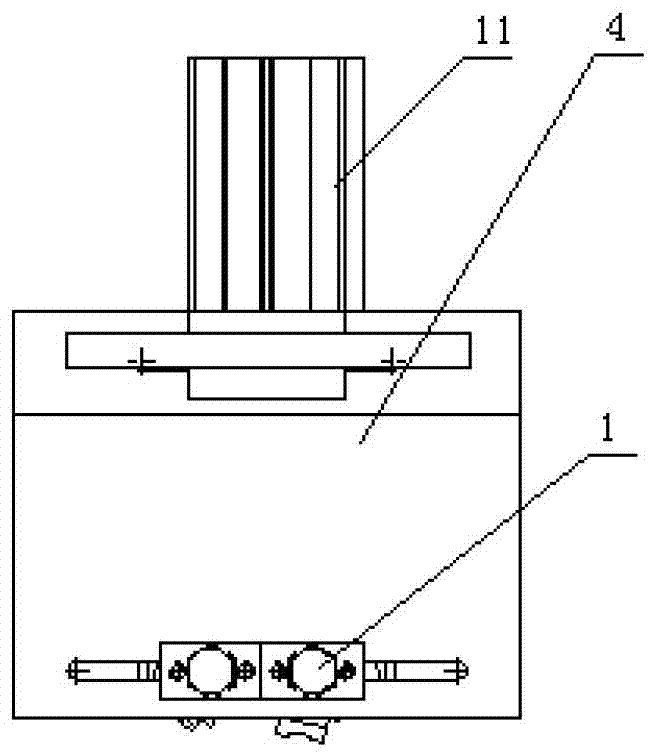

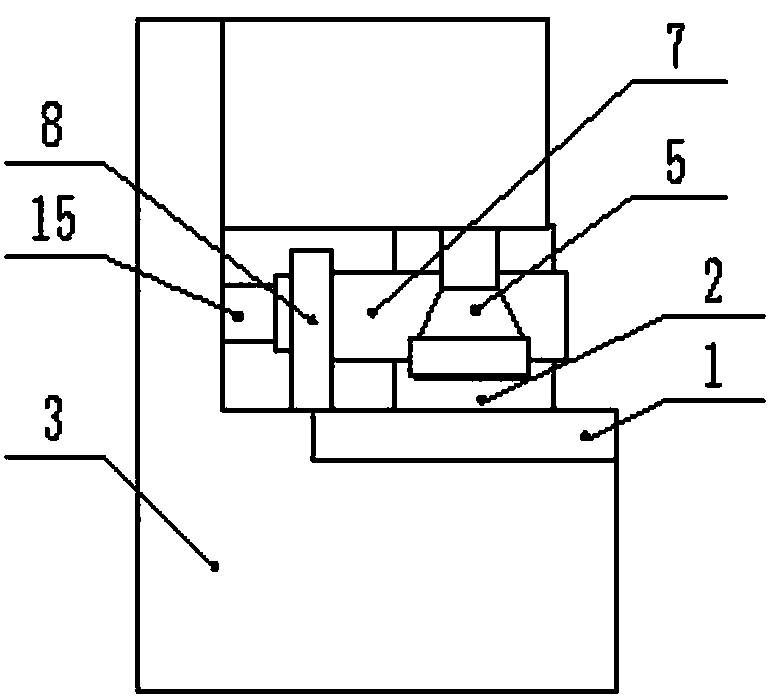

Machine for riveting heating series movable connection pipe seat and inlet and outlet pipes

The utility model relates to a machine for riveting a heating series movable connection pipe seat and inlet and outlet pipes; an upper support and a lower support are fixedly arranged up and down; two side installation seats and a lower bracket are respectively arranged on the front side of the lower support fixedly; a riveting device is fixedly arranged on the upper plane of the lower support in the upper support; a side push cylinder is fixedly arranged at the rear part of the upper support which corresponds to the riveter; two upper compression cylinders which are arranged in parallel are fixedly arranged at the middle part of the upper plane of the upper support; a pipe clamping seat is respectively hinged on plunger heads of the two upper compression cylinders which are arranged in the upper support; the pipe clamping seats are respectively used for pressing and fixing an air inlet pipe and an air outlet pipe of a heater; and the pipe clamping seats are arranged corresponding to the riveter. According to the riveting machine, the operation process of an operator can be greatly simplified, the difficult riveting problem between any pipeline and pipe seat with small spacing as well as the pipe seat and the pipe of any pipe seat heating product with or without incision is solved, one machine can solve the difficult riveting problem between the movable connection pipe seat and the pipe of any heater, the status quo that production cannot be carried out because the trend of the pipeline and the position of the pipe seat are different is avoided, the production efficiency and the quality are improved, and conditions are conveniently provided for customizing standardized production in future.

Owner:TIANJIN YAXING RADIATOR

Resin composition for water-based high-performance color gloss coating and preparation method of resin composition

The invention discloses a resin composition for a water-based high-performance color gloss coating and a preparation method of the resin composition. The resin composition is prepared from 30%-60% of water-based castor oil-modified alkyd resin and 40%-70% of water-based acrylic resin, wherein the water-based castor oil-modified alkyd resin is mainly prepared from castor oil, trimethylolpropane, phthalic anhydride, trimellitic anhydride, butoxyethanol, n-butyl alcohol and xylene; and the water-based acrylic resin is prepared from a solvent, methyl methacrylate, butyl acrylate, styrene, hydroxyethyl methylacrylate, crylic acid, benzoyl peroxide, tert-butyl peroxybenzoate, ammonium hydroxide and water. The pigment disclosed by the invention is easily dispersed to below 10 microns, and is stable in storage; the prepared coating performance is excellent; and the glossiness of a film is not reduced during adding water and diluting.

Owner:肇庆千江高新材料科技股份公司

Method for block-by-block casting of concrete continuous beam bridge by using military truss shift mould

InactiveCN102206934ALight weightEasy to assemble and disassembleBridge erection/assemblyBridge materialsContinuous beamPre stress

The invention relates to a method for block-by-block casting of a concrete continuous beam bridge by using a military truss shift mould. The method is characterized by comprising the following steps of: firstly, dividing a full-span concrete continuous beam with span of L into two segmented box girders, casting the segmented box girder A located on a bridge pier and tensioning the prestress on the upper edge of the segmented box girder A; secondly, transferring withdrawn templates to the segmented box girder B located at the middle span and pouring after the segmented box girder A is cast completely, tensioning the linkage prestress of the segmented box girder A and the segmented box girder B and the prestress on the lower edge of the segmented box girder B after the strength is achieved, finally, transferring the withdrawn templates to the segmented box girder A of the next span to cast. The cross section of the concrete continuous beam can be of a single-box single-chamber type, a single-box two-chamber type, a single-box three-chamber type, a single-box four-chamber type, a single-box fifth-chamber type or a single-box six-chamber type; the bridge pier adopts a non-cover beam column structure comprising a single-column bridge pier, a dual-column bridge pier or a three-column bridge pier. Due to the adoption of the method for block-by-block casting of the concrete continuous beam bridge by using the military truss shift mould, only one set of military truss beam construction equipment with light weight, convenience in mounting / dismounting and good universality is used in construction, high construction speed and a short construction period are realized, and the majority of the members can be used repeatedly, so that good quality, cost reduction and investment saving are realized.

Owner:COMM DESIGN INST CO LTD OF JIANGXI PROV

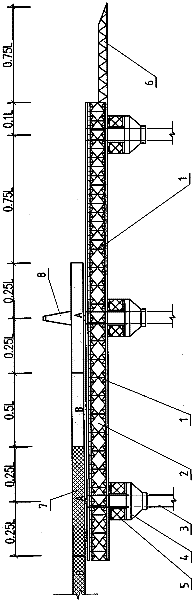

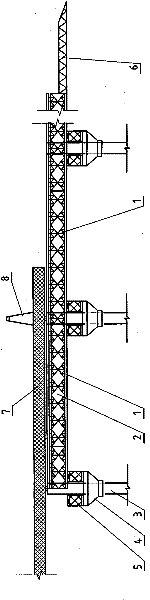

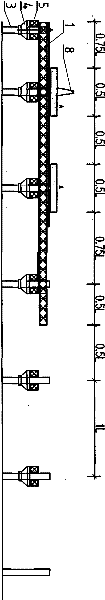

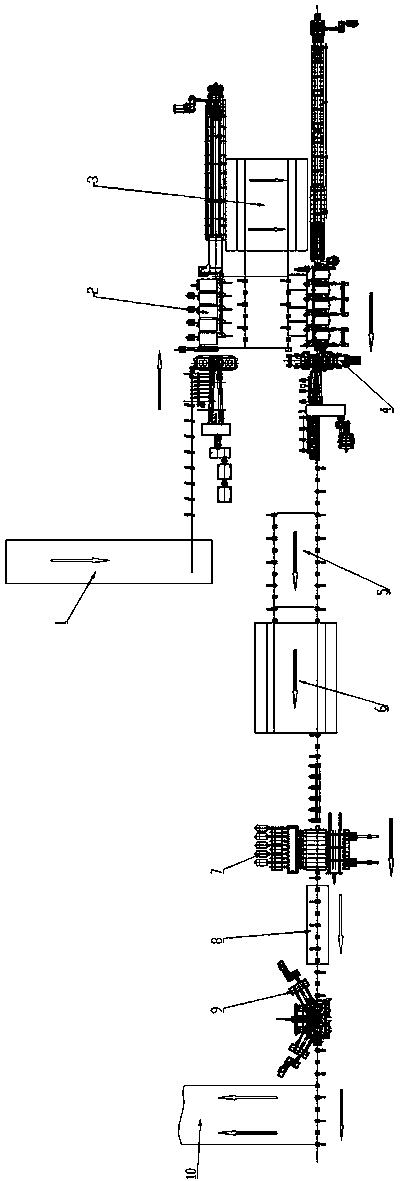

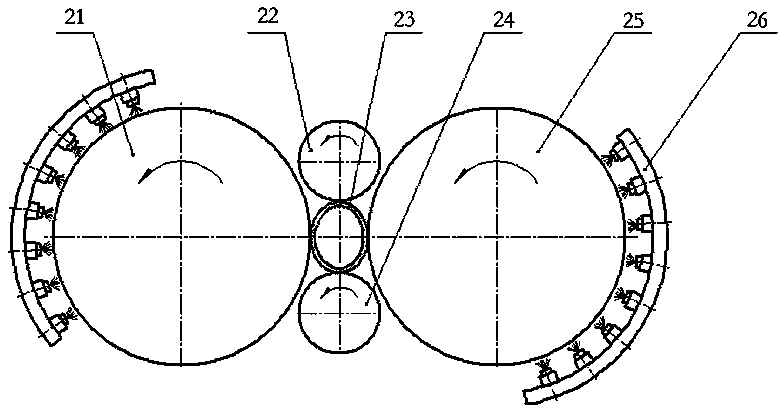

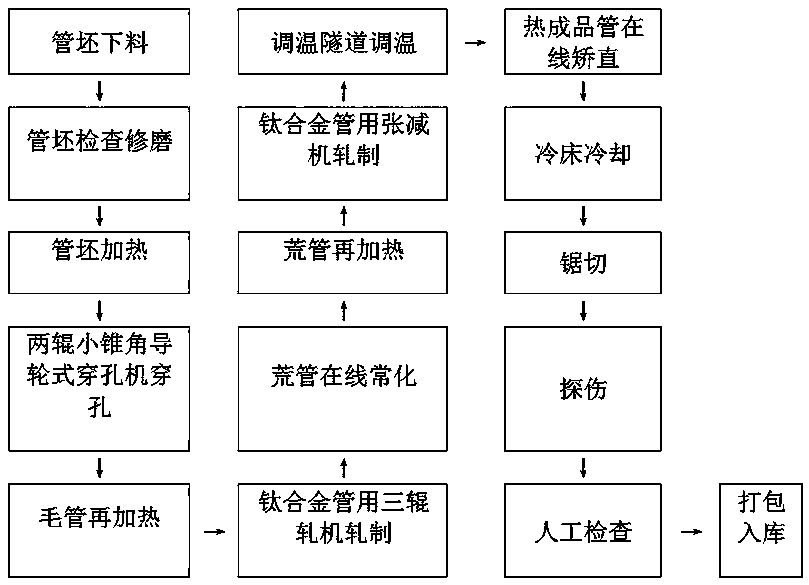

Titanium alloy hot-rolled seamless pipe production system and production process thereof

PendingCN108160709AReduce power consumptionHigh yieldTemperature control deviceGuiding/positioning/aligning arrangementsHeating furnace% diameter reduction

The invention relates to a titanium alloy hot-rolled seamless pipe production system and a production process thereof, belongs to the technical field of titanium alloy seamless pipe machining, and solves the technical problems of coating of coating layers, high production difficulty and low yield in the titanium alloy seamless pipe rolling process. The system comprises a piope blank heating furnace, a perforating machine, a transition reheating furnace, a three-roller pipe rolling machine, a online normalization area, a pierced billet reheating furnace, a tension reducing unit, a temperature adjusting tunnel, a straightener and a cold machine arranged according to a production process path in sequence; a pipe blank is unloaded for perforation rolling, pipe rolling, tension and diameter reduction, online hot straightening and cooling by the cold bed to prepare a finished titanium alloy hot-rolled seamless pipe; as electric heating furnaces are arranged in different phases in the rollingprocess, the quality of the pipe blank is guaranteed, and reasonable rolling temperature of the pipe blank is provided to the next procedure; brushing of protective materials is not needed in the rolling process, so that one procedure is reduced; and the rolling temperature is strictly controlled, so that the deformation resistance is reduced, the unit power consumption is reduced, the cost is saved, and the yield of titanium alloy pipes is improved.

Owner:张国庆

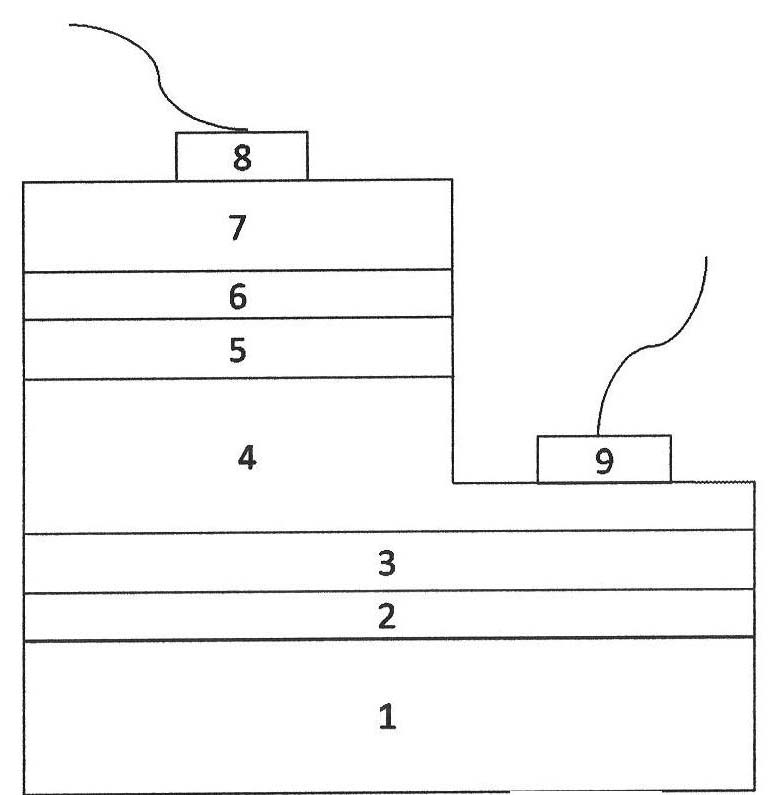

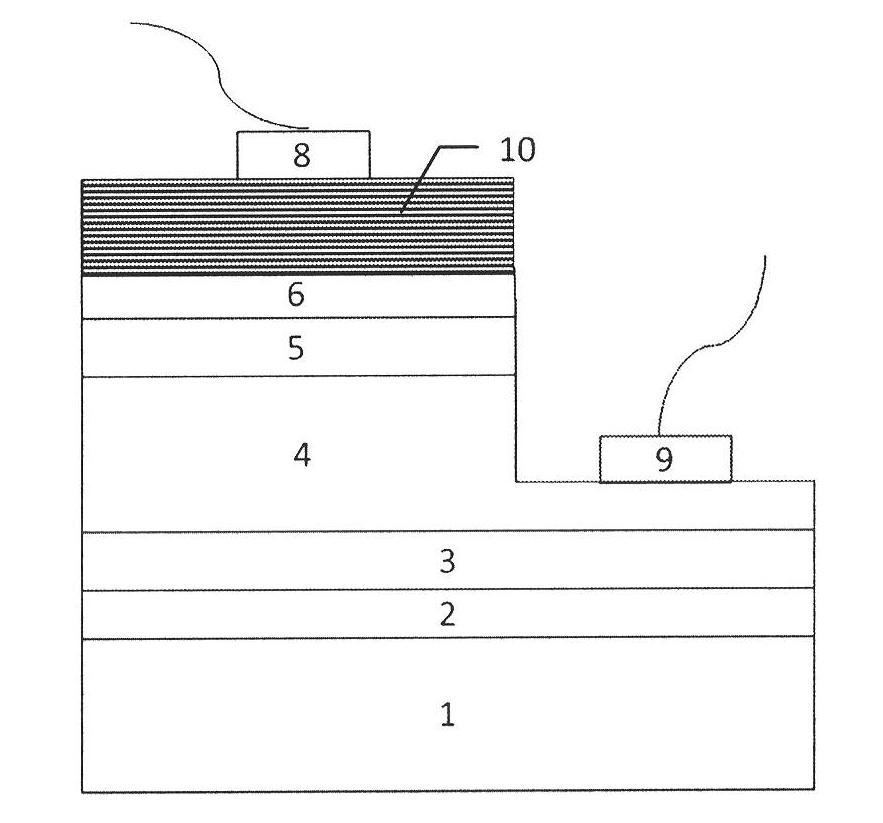

GaN-based light-emitting diode (LED) epitaxial wafer capable of improving luminous efficiency, and preparation method and application thereof

ActiveCN102487113AImprove luminous efficiencyGood effectSemiconductor devicesNitrogenGallium nitride

The invention relates to a GaN-based light-emitting diode (LED) epitaxial wafer capable of improving the luminous efficiency, and a preparation method and the application thereof. A multicycle repetition structure of Mg-doped InGaN and Mg-doped GaN is used to replace a traditional P-type Mg-doped GaN layer, so on the one hand, higher carrier concentration is produced by utilizing polarization effects of InGaN and GaN, and a nitrogen annealing process does not need to be conducted again, and on the other hand, surface coarsening is realized by utilizing surface cavities produced by the multicycle repetition structure of the InGaN and the GaN, and the luminous efficiency of a GaN LED is improved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

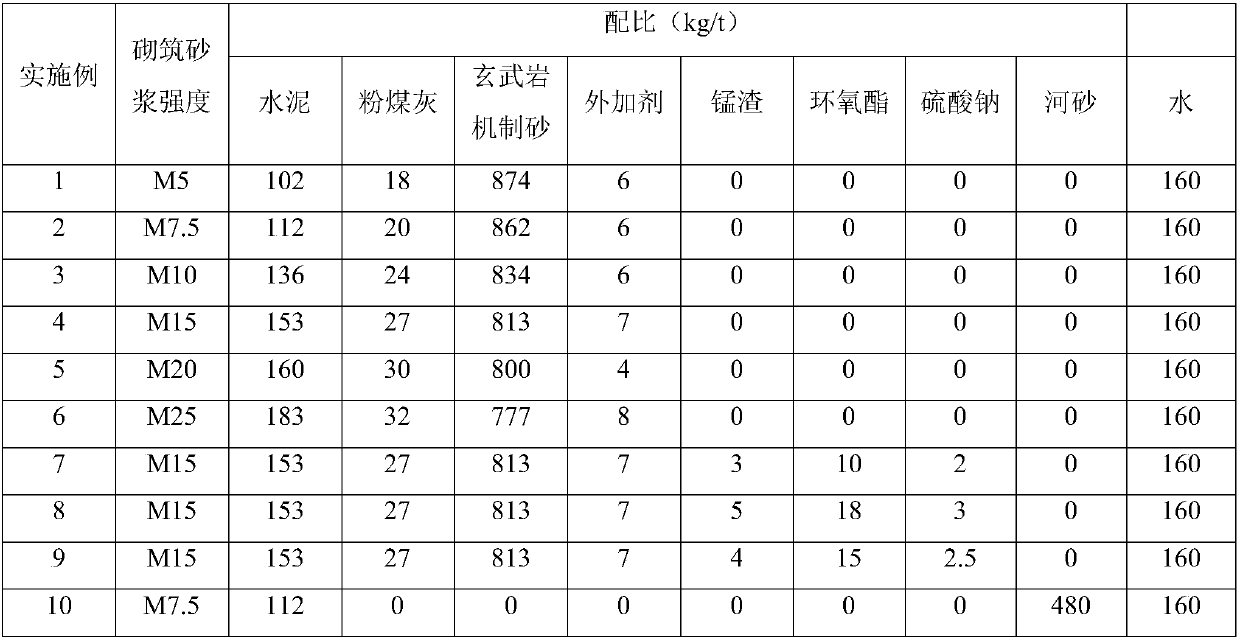

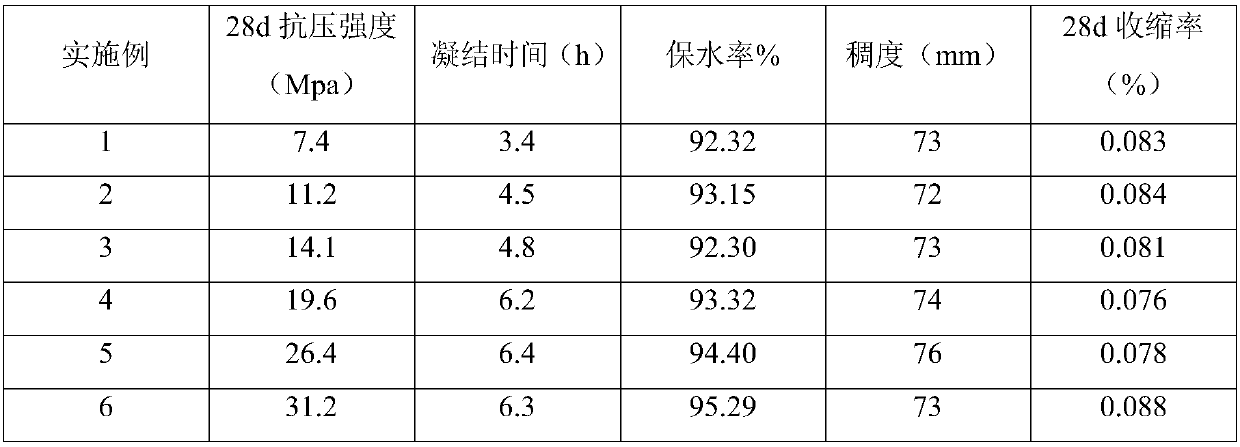

Basalt machine-made sand dry-mixed mortar and preparation method thereof

The invention discloses basalt machine-made sand dry-mixed mortar and a preparation method thereof. The preparation method comprises the following steps: drying machine-made sand in a raw material, and controlling the moisture content in the machine-made to be less than 0.4 percent, the silt content to be less than 1.0 percent and the grain diameter to be less than 5mm; then uniformly mixing and stirring all components in the raw material, metering and bagging, thus obtaining the basalt machine-made sand dry-mixed mortar, wherein the raw material is prepared from 10.2 to 18.3 parts of cement,1.8 to 3.2 parts of pulverized fuel ash, 77.7 to 87.4 parts of basalt machine-made sand and 0.4 to 0.8 part of an additive. The basalt machine-made sand dry-mixed mortar disclosed by the invention isprepared by using the basalt machine-made sand locally produced in Lanzhou to replace original river sand and mixing with the cement, the pulverized fuel ash and the additive special for mortar and belongs to application of new materials, performance indexes of the basalt machine-made sand dry-mixed mortar meet the requirements, the technology is simple, and the cost is low.

Owner:甘肃建投矿业有限公司

Non-ionic N-vinyl butyrate lactam iodine, high-stability non-ionic N-vinyl butyrate lactam iodine and relevant overspeed preparation method

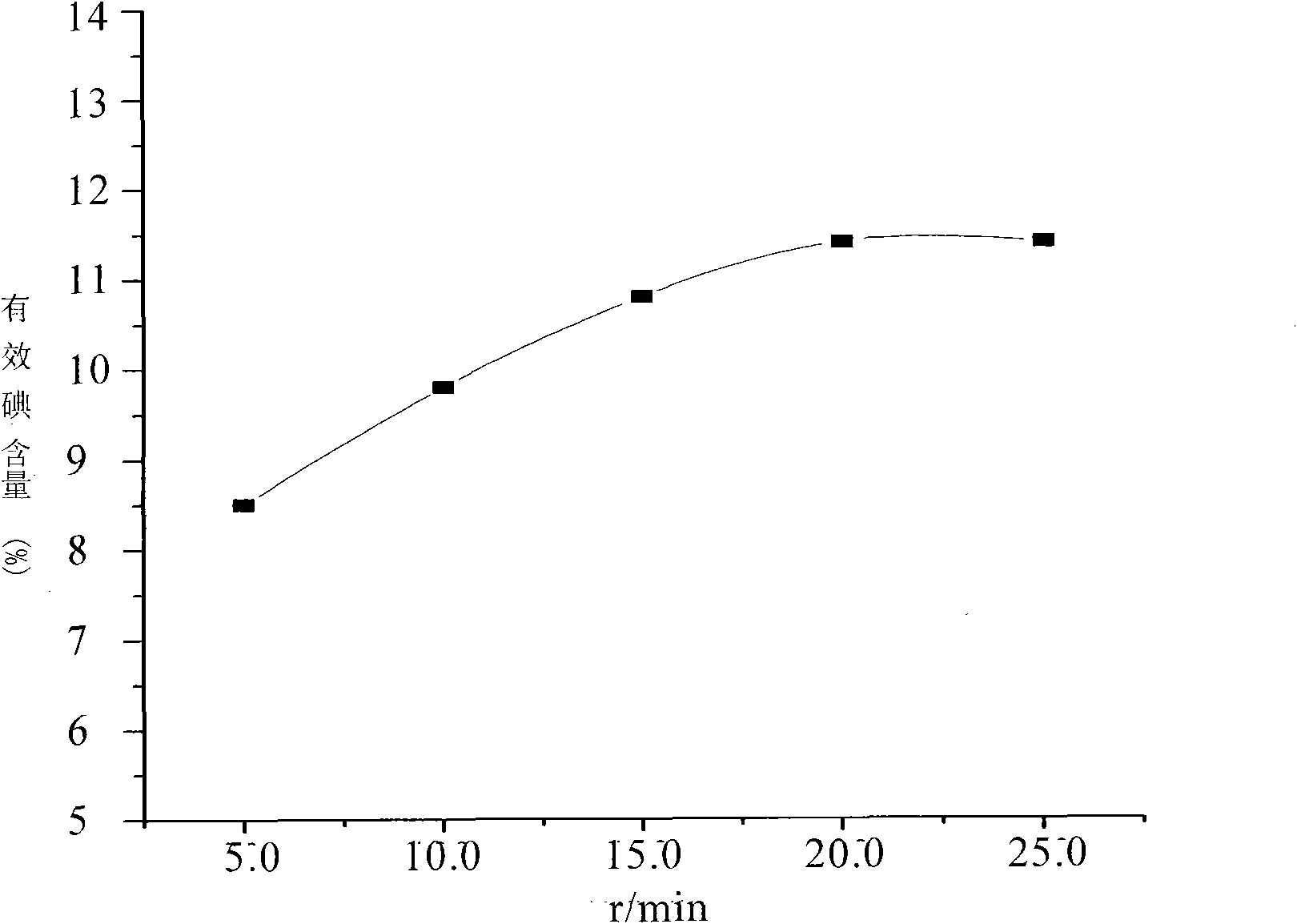

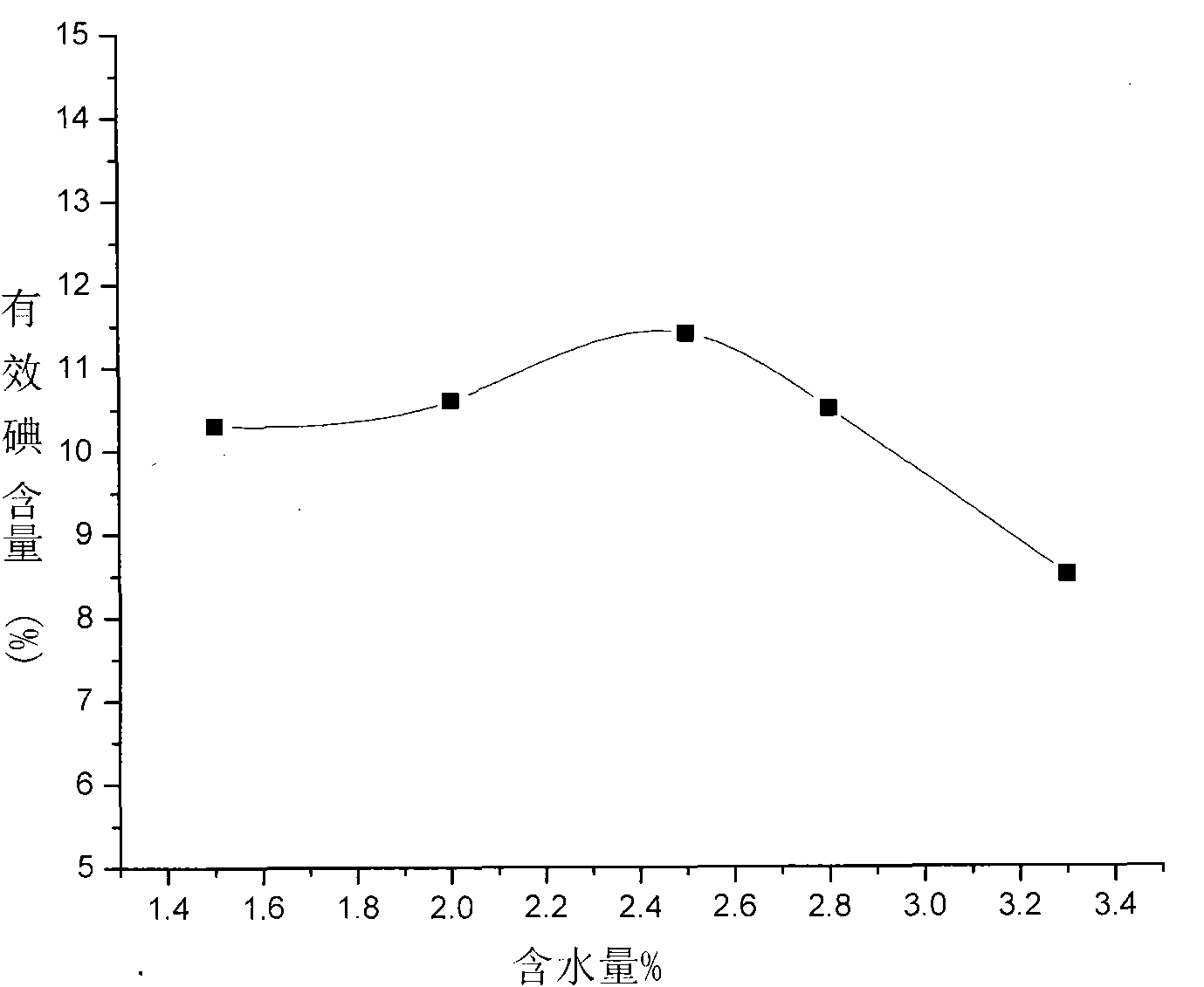

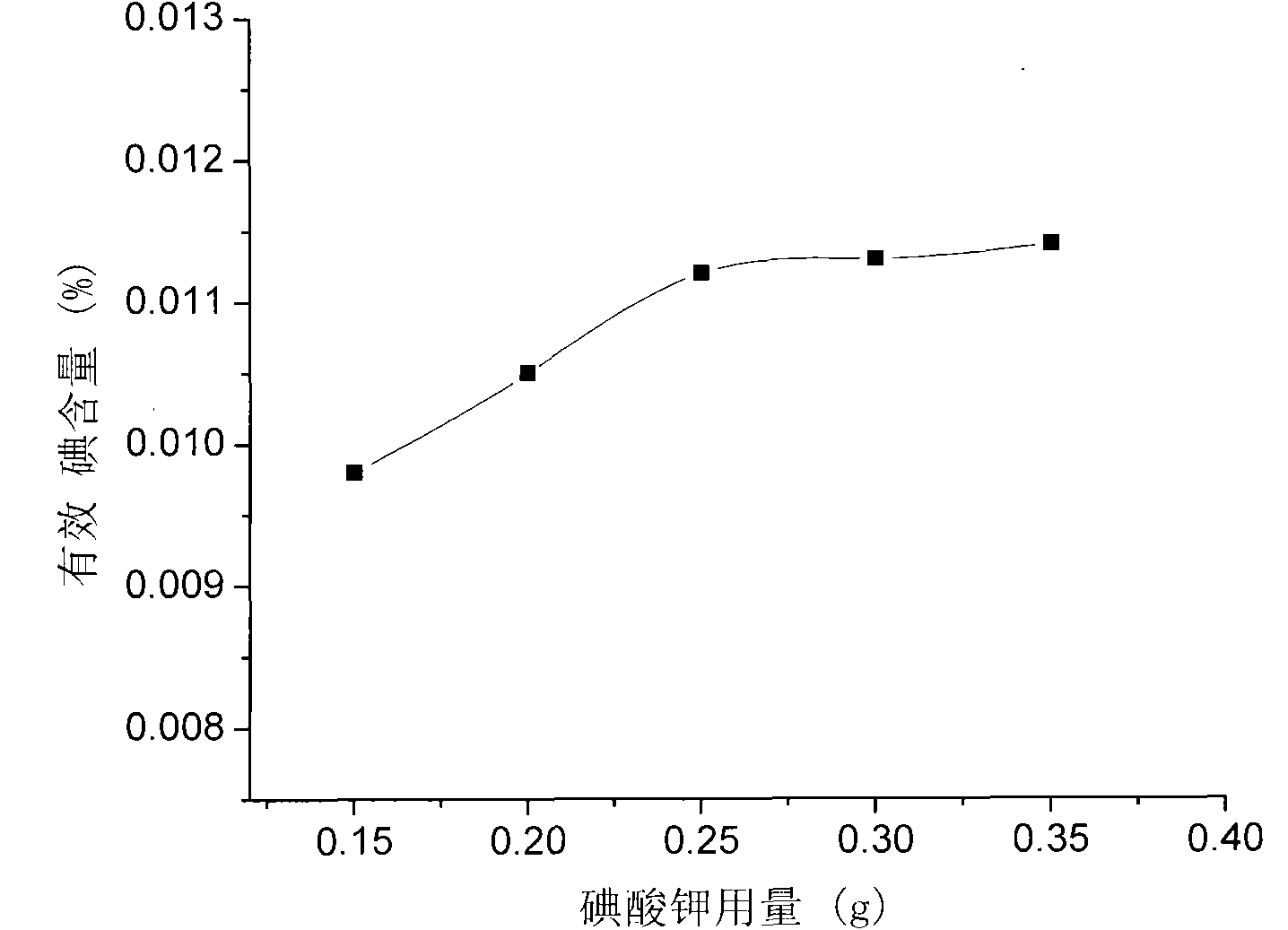

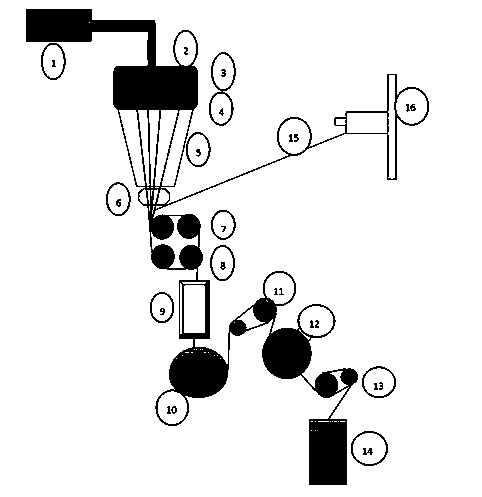

The invention provides a preparation method of non-ionic N-vinyl butyrate lactam iodine. The non-ionic N-vinyl butyrate lactam iodine is prepared by stirring homopolymerized N-vinyl butyrate lactam and iodine for 20 to 25 minutes at the temperature of 60 to 70 DEG C and the speed of 200 to 250r / min, wherein the viscosity-average molecular weight of the homopolymerized N-vinyl butyrate lactam is 40000 to 45000, and the PD value is smaller than 5.5; and the water content is 2.0 to 3.0 percent. The invention also provides non-ionic N-vinyl butyrate lactam iodine prepared in such a way, a method for preparing high-stability non-ionic N-vinyl butyrate lactam iodine in such a way and the relevant high-stability non-ionic N-vinyl butyrate lactam iodine. The non-ionic N-vinyl butyrate lactam iodine has high iodine content, simple, convenient and quick preparation and low cost, and the high-stability non-ionic N-vinyl butyrate lactam iodine has high stability and convenient use, meets the highest requirements of the relevant dispensatories of USP, ISP, BP, EP, CP and the like completely and is suitable for large-scale popularization and application.

Owner:宇昂科技有限公司

Process for producing antistatic polyamide 6 (PA6) bulk yarns through one-step process

ActiveCN104278385ASoftness is consistent withAvoid separation or protruding of conductive fibersMelt spinning methodsYarnElectrically conductiveChemistry

The invention discloses a process for producing antistatic polyamide 6 (PA6) bulk yarns through a one-step process. According to the technology, the polyamide 6 (PA6) bulk yarn fibers produced by the one-step production process have excellent electrical conductivity, and the manufactured carpet is rubbed to generate static electricity so as to be timely conducted out under severe pedaling, so the carpet has excellent antistatic properties. According to the technology, the polyamide 6 conductive fibers refer to 10-20-denier polyamide 6 carbon black composite fibers, and the composite fiber refers to a core-sheath composite fiber which takes the polyethylene dispersed with carbon black as the core and takes polyamide 6 as the core, is a conductive fiber with physical and chemical performances of polyamide 6 fibers, and can finish the drafting and bulking deformation process with polyamide 6 (PA6) fibers in high-speed production process.

Owner:TAICANG UNIVERSAL FIBERS COMPANY

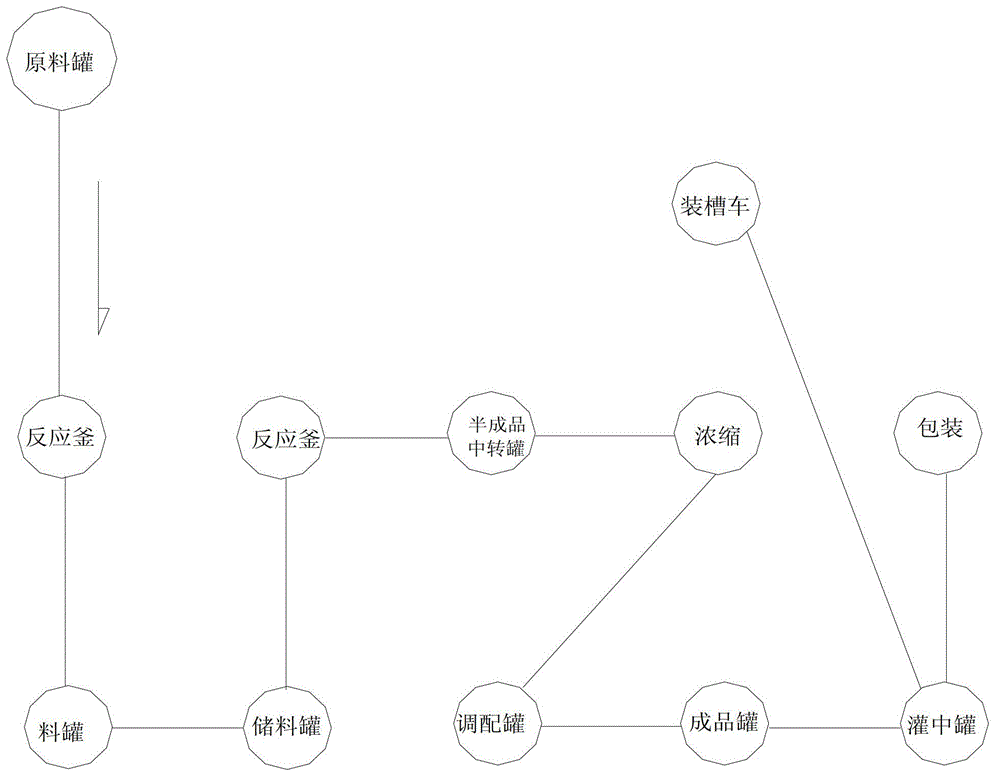

Production method of caramel

InactiveCN102719112AShorten the production cycleReduce energy consumptionNatural dyesChemistryWork in process

The invention discloses a production method of caramel, which comprises the following steps: after filtering the hydrolyzed molasses serving as the raw material with a plate-and-frame filter press, extracting the filtered molasses into a reaction vessel for hydrolyzing and coking; and extracting the hydrolyzed and coked molasses serving as the raw material into a semi-finished product transit tank. The hydrolyzing and coking process comprises the following steps: the reaction vessel is washed, water and dietary alkali are added in the reaction vessel, and the reaction vessel is heated to 90 DEG C and preserving the temperature for at least two hours; the molasses serving as the raw material filtered by the plate-and-frame filter press is added in the reaction vessel, the reaction vessel is heated to 115-120 DEG C, and the reaction is regarded as the normal reaction when the reaction vessel is heated to 115 DEG C; time is started from the time when the reaction vessel is heated to 115 DEG C, and after one hour, samples are taken for test; and when the tested samples meet the specified eligibility criteria, the reaction vessel is cooled. The production cycle of the caramel prepared by the method provided by the invention is greatly shortened, the energy consumption is greatly reduced, one step of the whole production process is omitted, and the equipment investment is reduced.

Owner:GUANGXI BADI FOOD

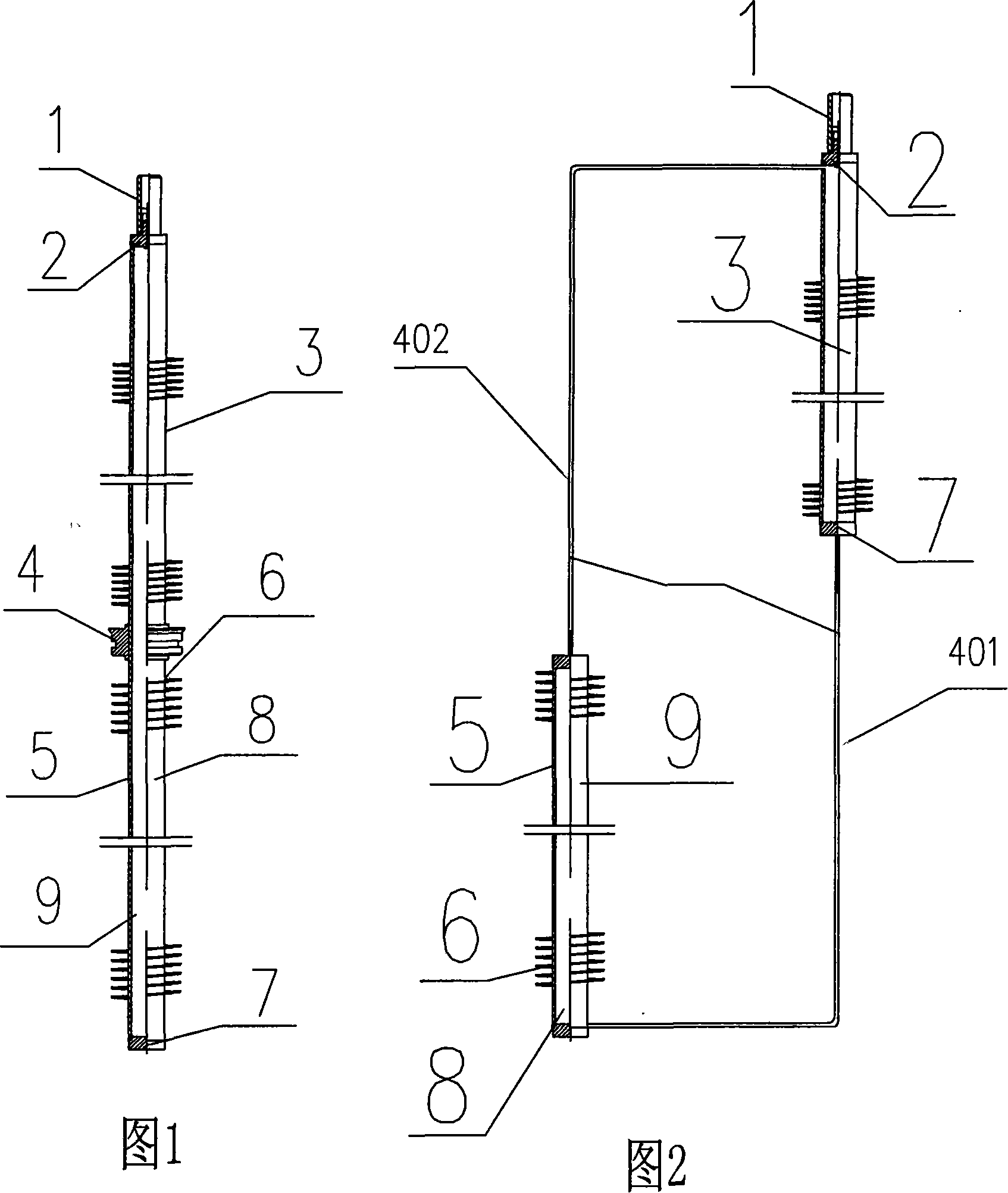

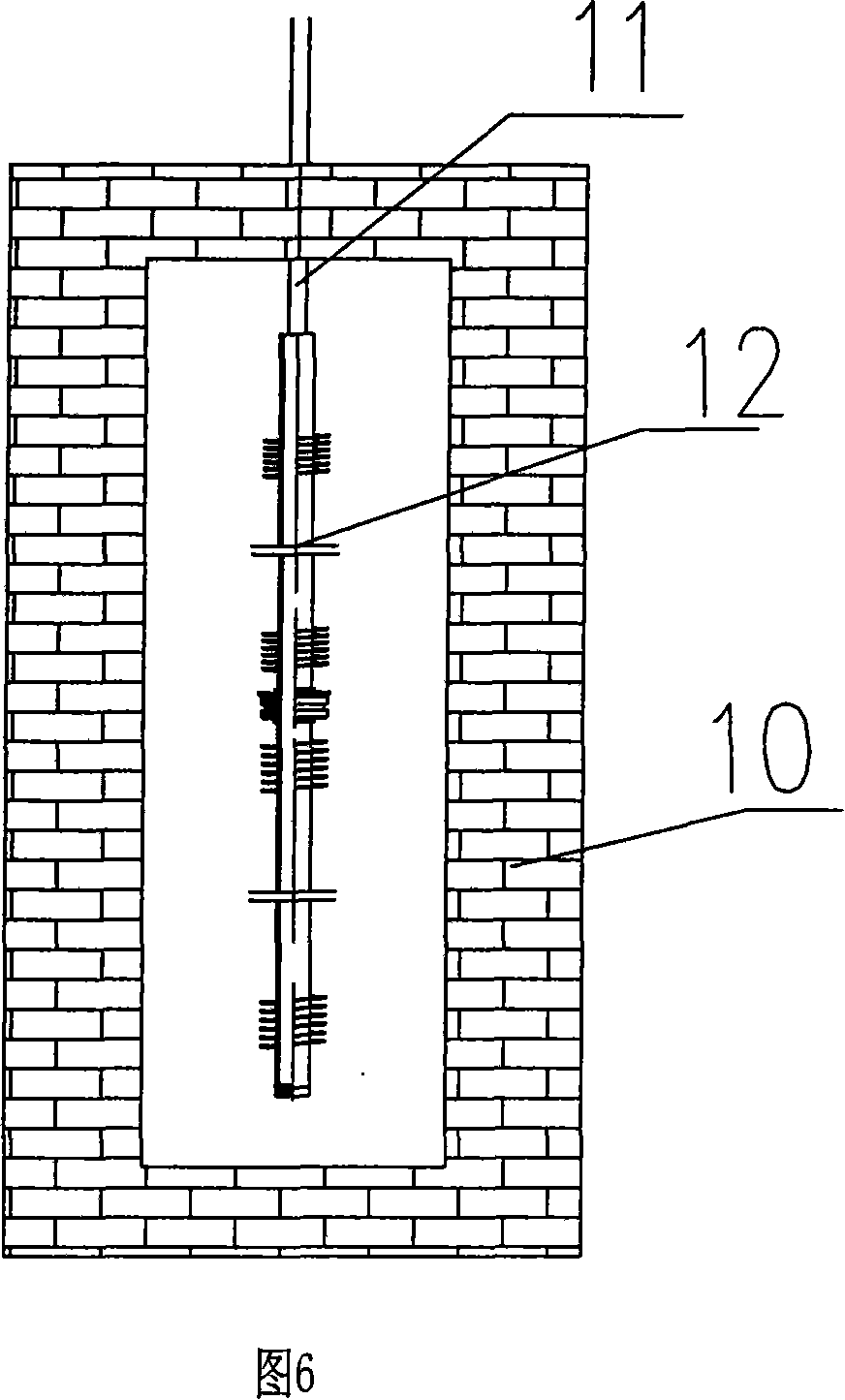

Corrosion resistant enamel hot pipe

InactiveCN101113879AImprove straightnessGood outer surface integrityIndirect heat exchangersCoatingsHeating furnaceCarbon steel

A corrosion resistant enamel heat pipe pertains to heat pipe technical field, and is characterized in that the invention is made by the method: firstly, a basic pipe is produced with carbon steel and the edges of fins on the surface of the basic pipe are made in arch structures; secondly, an enamel layer with a thickness of 0.05-0.3 mm is coated on the inner and outer surfaces of the basic pipe and the surfaces of the fins; thirdly, the basic pipe coated with enamel is vertically put in a heating furnace for enameling burning, with the enameling burning temperature being controlled at 700-950 DEG C and the enameling burning time at 5-15 minutes, so as to fully vitrify the enamel layer, then the corrosion resistant heat pipe of the invention is obtained after cooling. The invention solves the problem of low production cost of the corrosion resistant heat pipe and has the advantages of simple production, good corrosion resistant performance and a cost that is far lower than the cost of a stainless steel heat pipe.

Owner:NANJING SHENGNUO HEAT PIPE

Laser cutting head for conducting smoothing processing on burrs of cutting surface during cutting

ActiveCN110549011AAvoid contactReduce manufacturing costOther manufacturing equipments/toolsLaser beam welding apparatusSpray nozzleLaser cutting

The invention discloses a laser cutting head for conducting smoothing processing on burrs of a cutting surface during cutting. The laser cutting head comprises a main mounting plate body, a main lasercutting head body and a spraying nozzle; a supporting plate is fixed to the left side of the bottom of the main mounting plate body, mounting holes are formed in the front side face of the supportingplate, a supporting frame is installed on the inner side wall of the supporting plate, and mounting pillars are in threaded connection with the interiors of the mounting holes. The laser cutting headfor conducting smoothing processing on the burrs of the cutting surface during cutting is provided with a levelness measuring wheel, the levelness measuring wheel at the right side can be driven to move when the whole laser cutting head moves rightwards on a guide rail, and then walks on the surface of a workpiece, when meeting a bulging face during walking, the levelness measuring wheel can moveupwards, thus a fixed plate drives the main laser cutting head body to move upwards, the situation that the spraying nozzle at the bottom of the main laser cutting head body is in contact with the bulging face of the workpiece is avoided, and then the spraying nozzle is protected.

Owner:重庆茂和兴科技有限公司

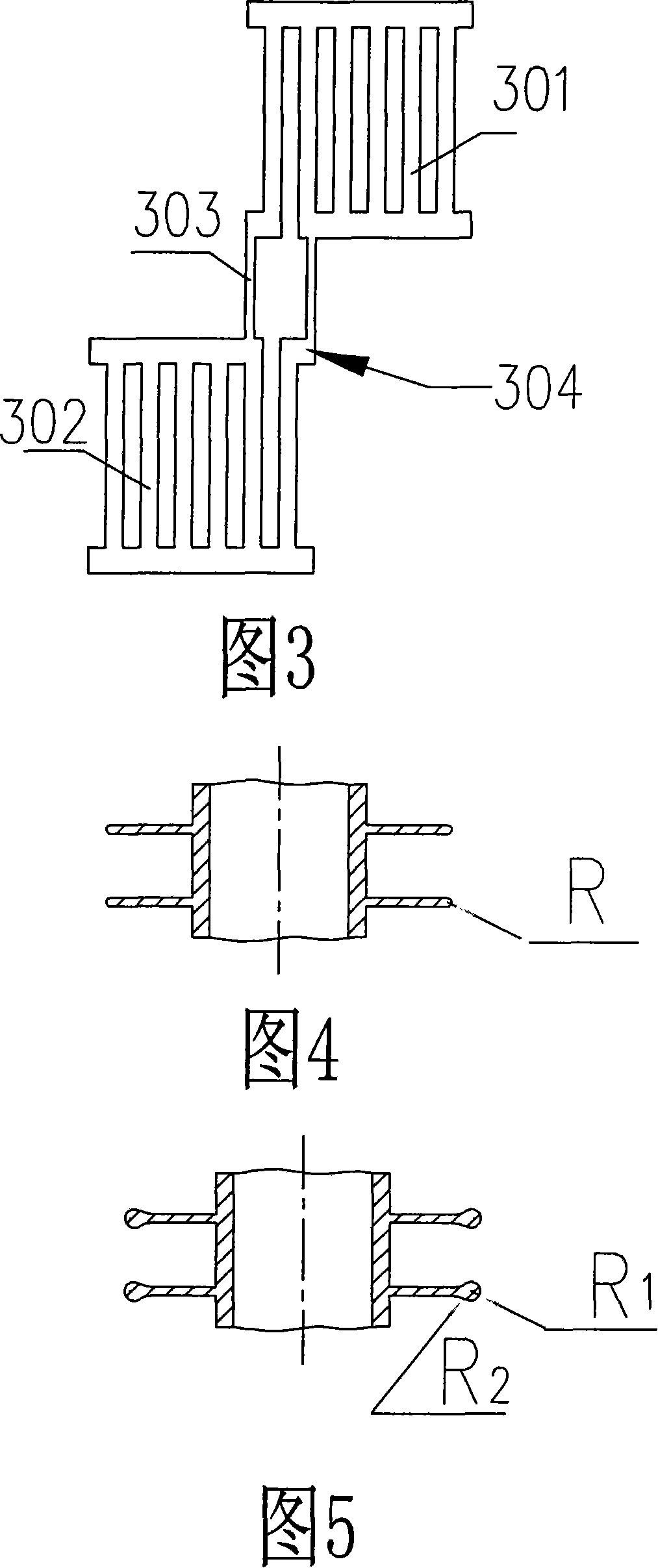

Electroplating diamond grinding block and its production

InactiveCN1895849AReduce one processSave time at workBonded abrasive wheelsGranularityElectroplating

An electroplated abrasive diamond disc is composed of a steel disc as basic body and with central axle hole, an electroplated abrasive diamond particle layer on the external ring on steel disc and an electroplated abrasive diamond particle layer on the internal ring on steel disc. The diamond particles for external and internal rings have different granularities. Its preparing process includes such steps as plating Ni layer on steel disc, shielding internal ring, plating coarse diamond particles onto external ring, removing the shielding layer, plating fine diamond particles onto internal ring, and cleaning.

Owner:邓华庆

Road passage underground project construction method

ActiveCN103590424AGuaranteed two-way trafficEfficient constructionArtificial islandsUnderwater structuresSurface layerC sections

The invention discloses a road passage underground project construction method which includes the following steps: (1) dividing a construction ground into three sections, namely an A section on one side, a B section on the other side and a C section in the middle, (2) closing the C section, constructing the C section, excavating earth in the surface layer, and making a roof plate of the C section, (3) backfilling the earth of the C section, constructing the A section, excavating earth in the surface layer to a bottom plate base layer, and making a base plate of the A section, (4) making wall plates of the A section, (5) making a roof plate of the A section, (6) backfilling the A section with the earth, constructing the B section, excavating earth in the surface layer to a bottom plate base layer, making a base plate of the B section and a base plate of the C section, making wall plates of the B section, and making a roof plate of the B section, and (7) backfilling the B section with the earth.

Owner:李涛 +2

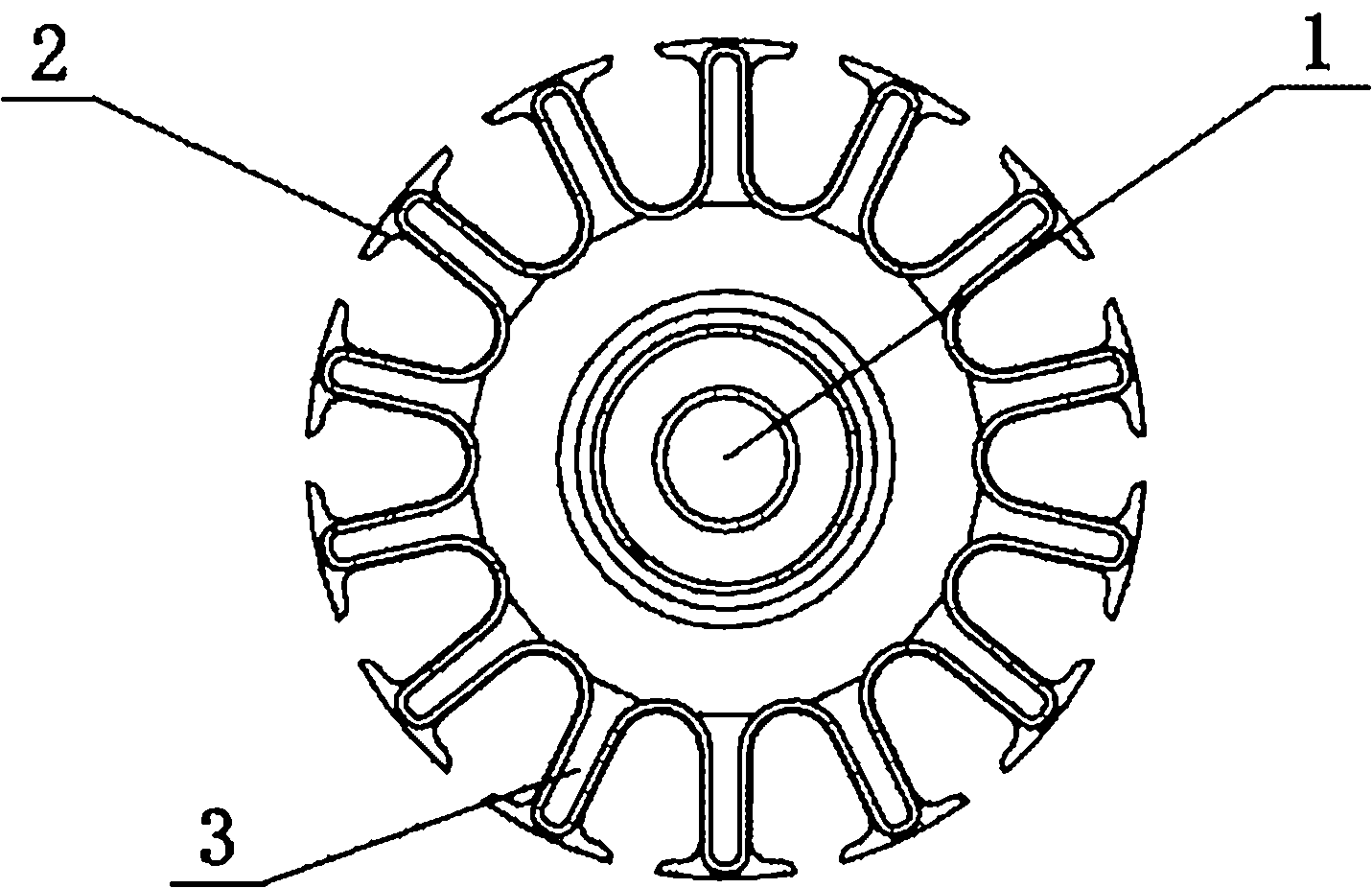

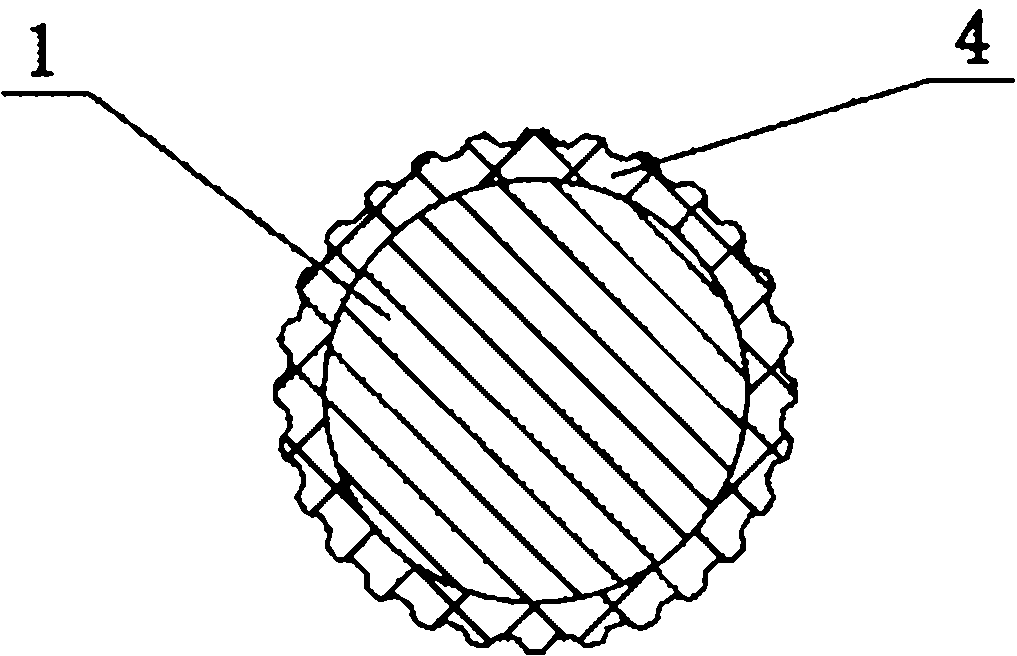

Electromechanical rotor

InactiveCN102157995AIncrease torqueQuality assuranceWindings insulation shape/form/constructionMagnetic circuit rotating partsEngineeringMechanical engineering

The invention discloses an electromechanical rotor which comprises a rotating shaft, a rotor iron core, end plates and an insulating shaft sleeve, wherein the insulating shaft sleeve is clung on the rotating shaft, the rotor iron core is sleeved on the rotating shaft and is connected with the rotating shaft through the insulating shaft sleeve clung on the rotating shaft, the end plates are clung on two sides of the rotor iron core, and the insulating shaft sleeve and the end plates are integrated into a one body. In the electromechanical rotor, since the insulating shaft sleeve and the end plates are integrated into a one body, one processing step is omitted during the manufacturing of the electromechanical rotor, thereby saving time and reducing cost.

Owner:KANGPING TECH SUZHOU CO LTD

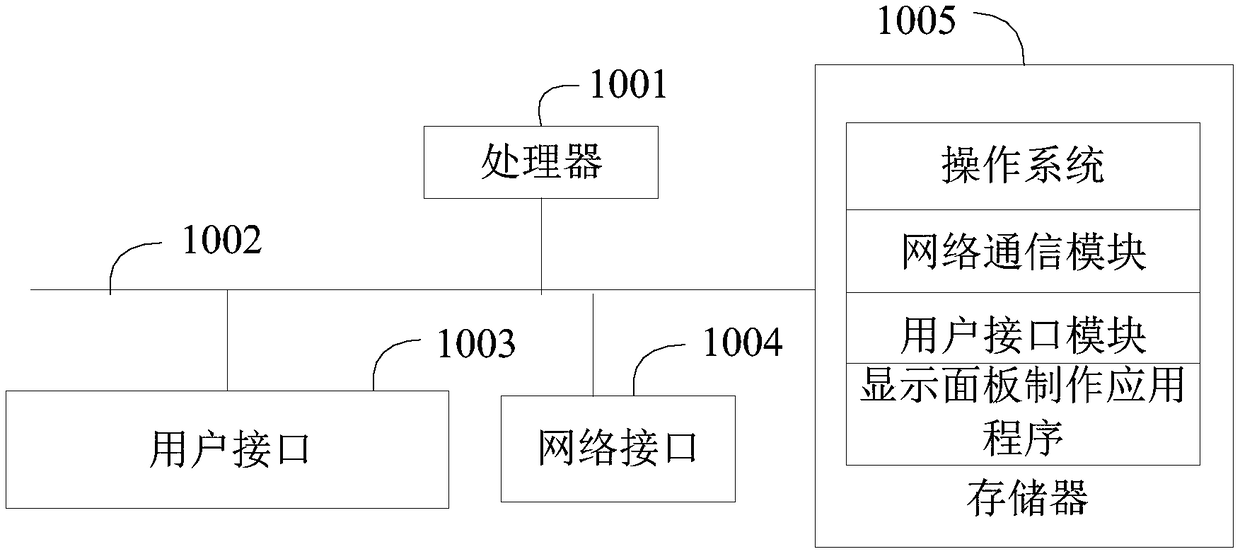

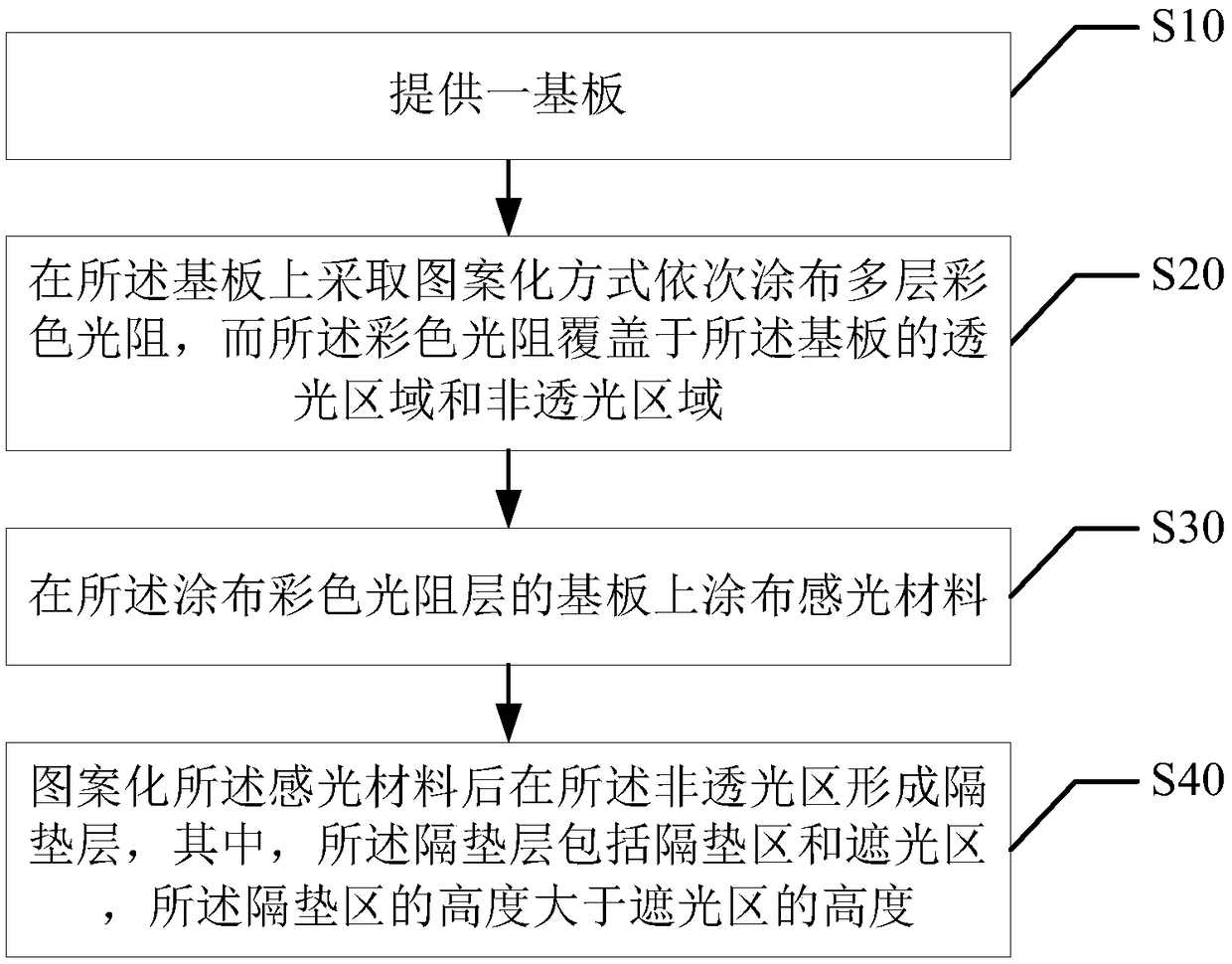

Manufacturing method and device for display panel and display panel

The invention discloses a manufacturing method and device for a display panel and the display panel. The manufacturing method for the display panel comprises the following steps that a substrate is provided; by adopting a patterning mode, the substrate is coated with multiple layers of colored photoresists in sequence, and the colored photoresists cover a light-transmission area and a non-light-transmission area of the substrate; the substrate coated with the colored photoresist layers is coated with a photosensitive material; after the photosensitive material is patterned, an insulation pad layer is formed on the non-light-transmission area, wherein the insulation pad layer comprises an insulation pad area and a light shielding area, and the height of the insulation pad area is larger than that of the light shielding area. According to the manufacturing method, one process is omitted, the number of the types of required light covers can be reduced by one, the process of manufacturingthe display panel is improved, the time is shortened, the efficiency is improved, and the cost is reduced.

Owner:HKC CORP LTD

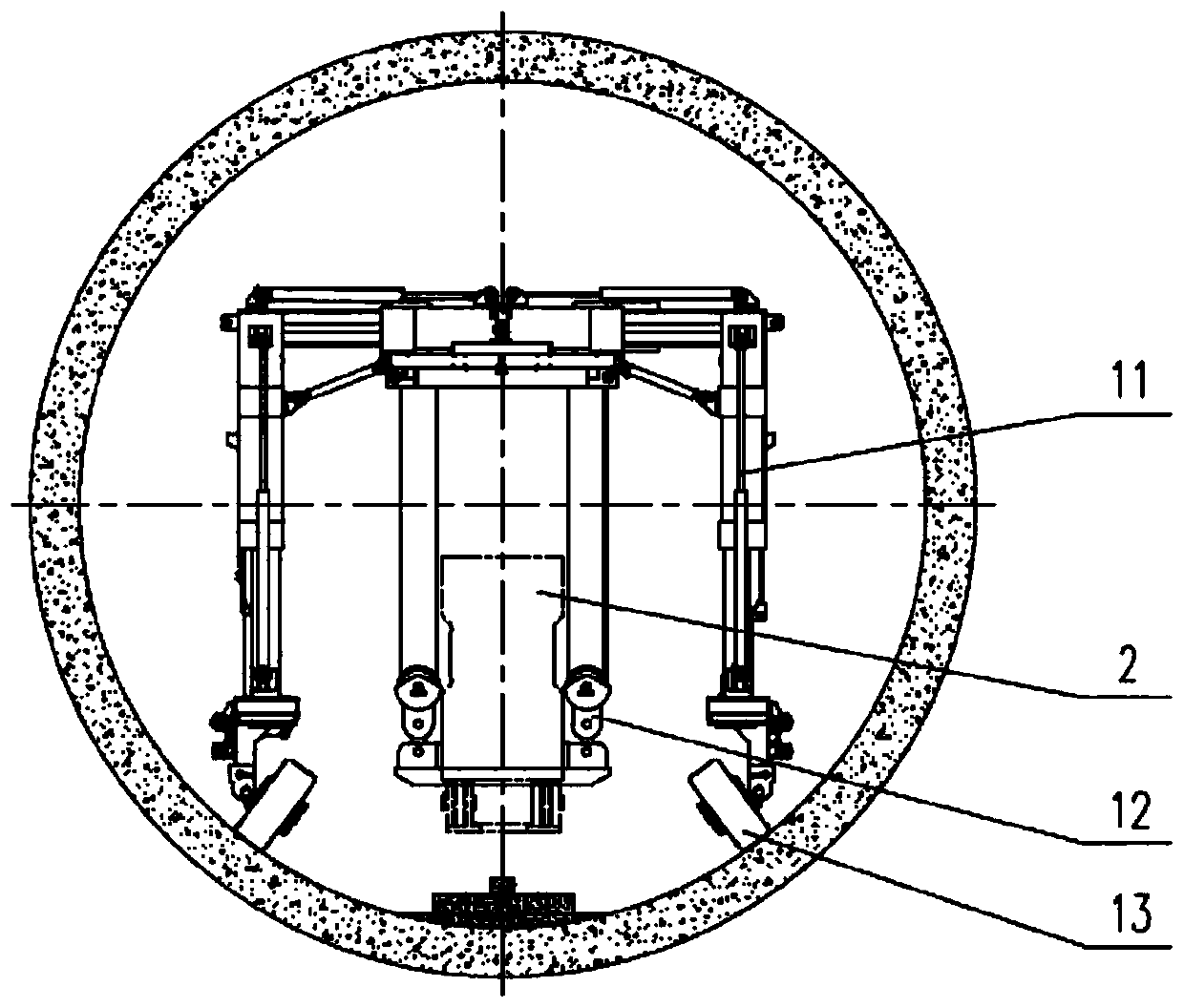

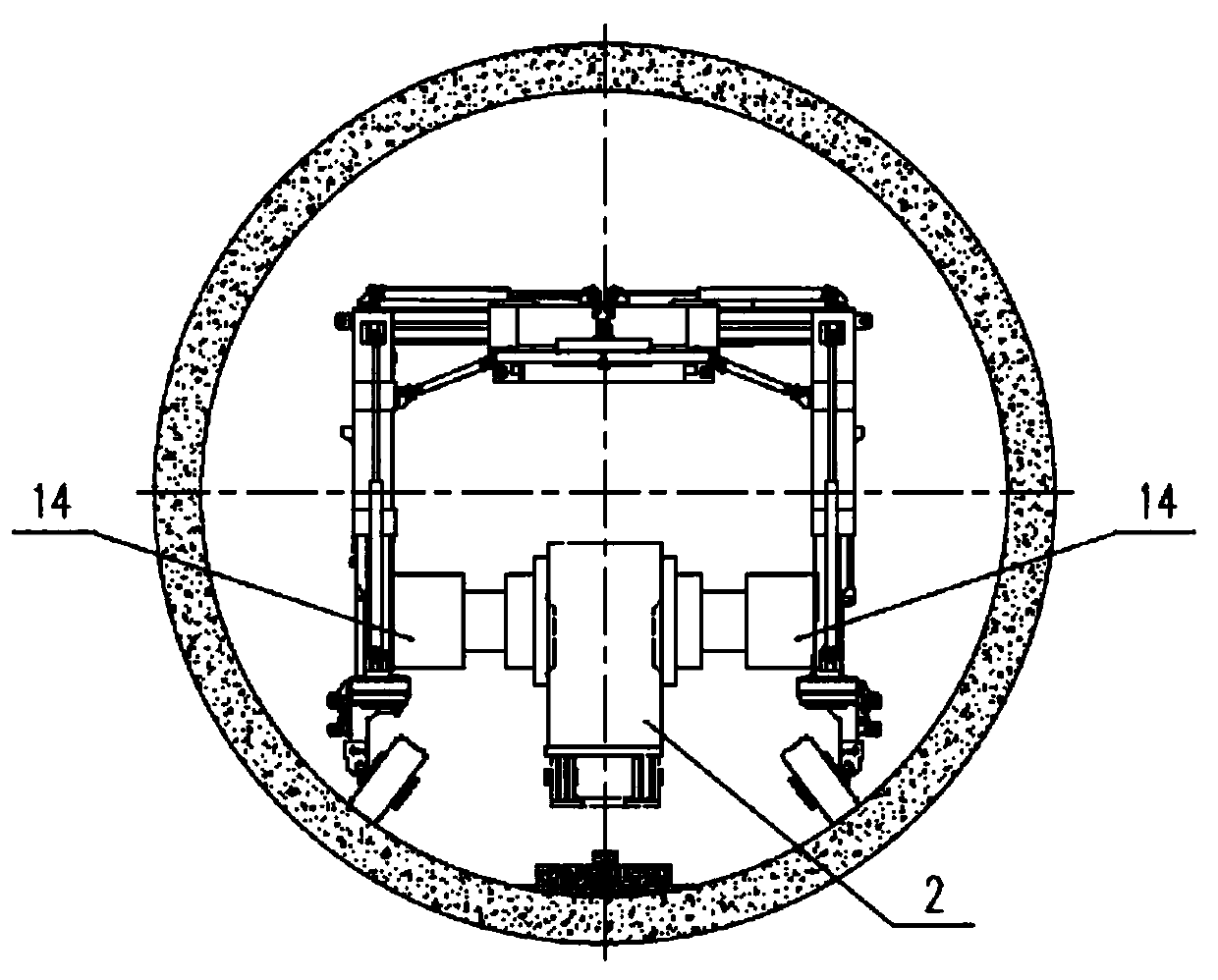

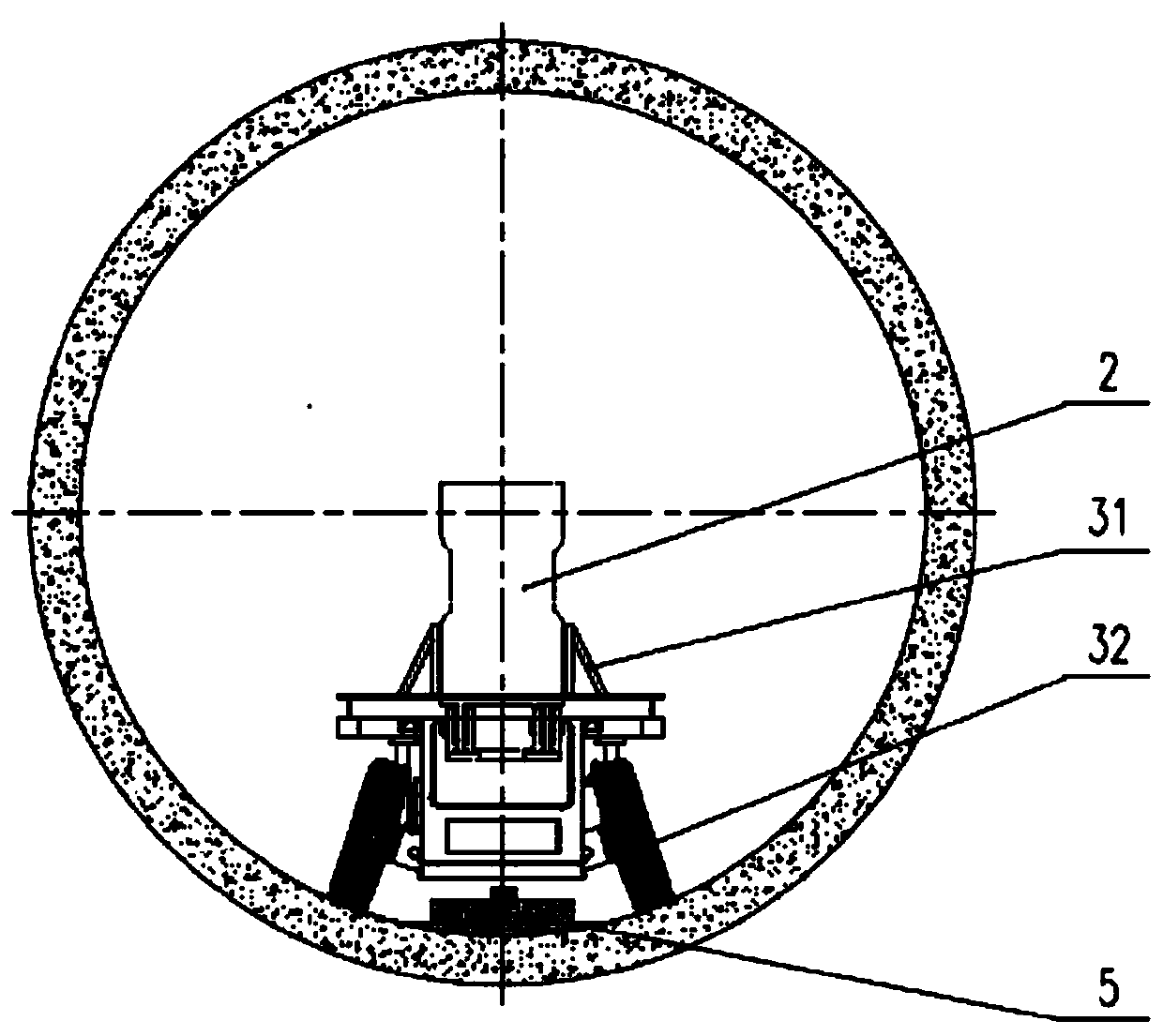

Straddle type monorail PC track girder construction method inside circular cross section tunnel

InactiveCN109930435AReduce construction costsFlexible operation and transitionRailway tracksShop drawingStraddle

The invention discloses a straddle type monorail PC track girder construction method inside a circular cross section tunnel. The method comprises the following steps of providing a girder erection machine and a girder transporting vehicle capable of walking on the hook face; a PC track girder is fixedly installed on the girder transporting vehicle, and the girder erection machine is put in place;the girder transporting vehicle transports the PC track girder into the girder erection machine; a transverse clamping device of the girder erection machine is started, the PC track girder is lifted,and the girder transporting vehicle exits from the circular cross section tunnel; the girder erection machine erects the PC track girder according to a design construction drawing, the girder transporting vehicle is returned to transport a next PC track girder; after erection of the girder erection machine is completed, the next PC track girder is erected when the girder erection machine is put inplace forwards. The method has the advantages that walking devices of an existing girder erection machine and a girder transporting vehicle are modified, the modified girder transporting vehicle andthe girder erection machine achieve erection of the straddle type monorail PC track girder inside the circular cross section tunnel, the construction cost is low, operation and transition are flexible, cross operation can be performed, construction organizations are flexible, and the construction efficiency is high.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

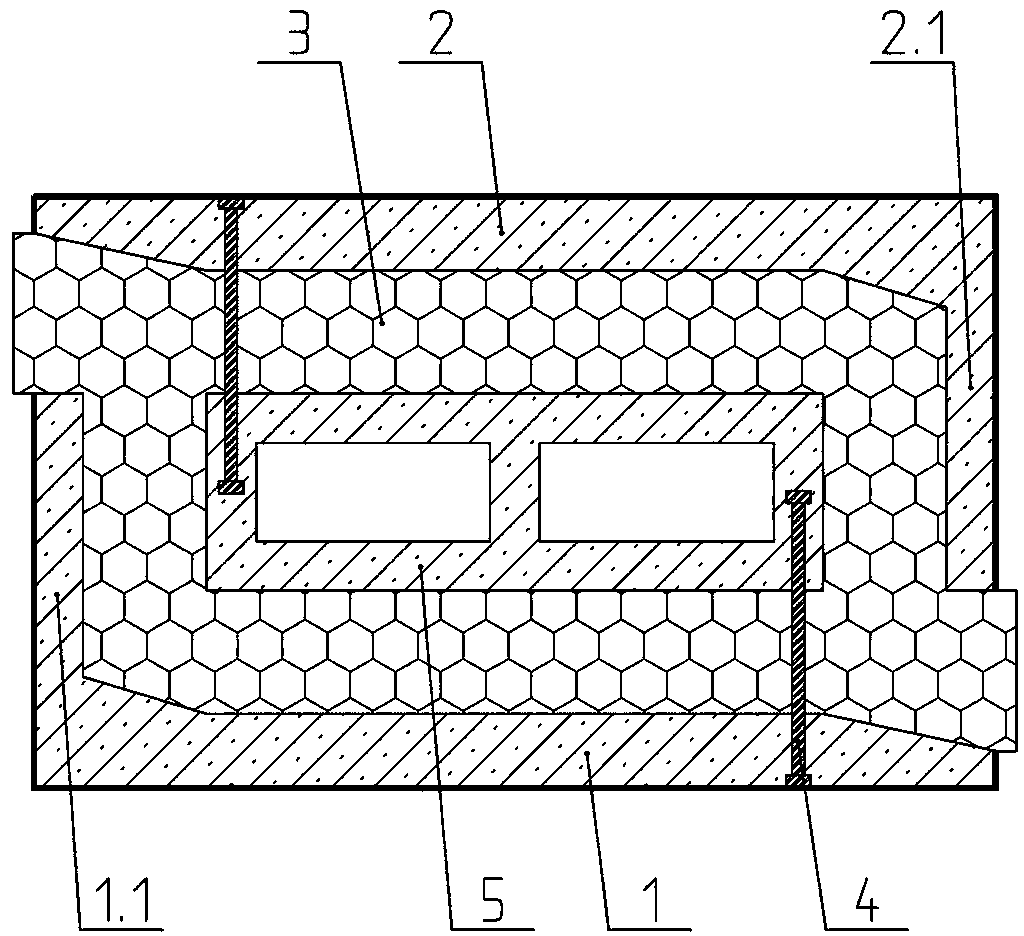

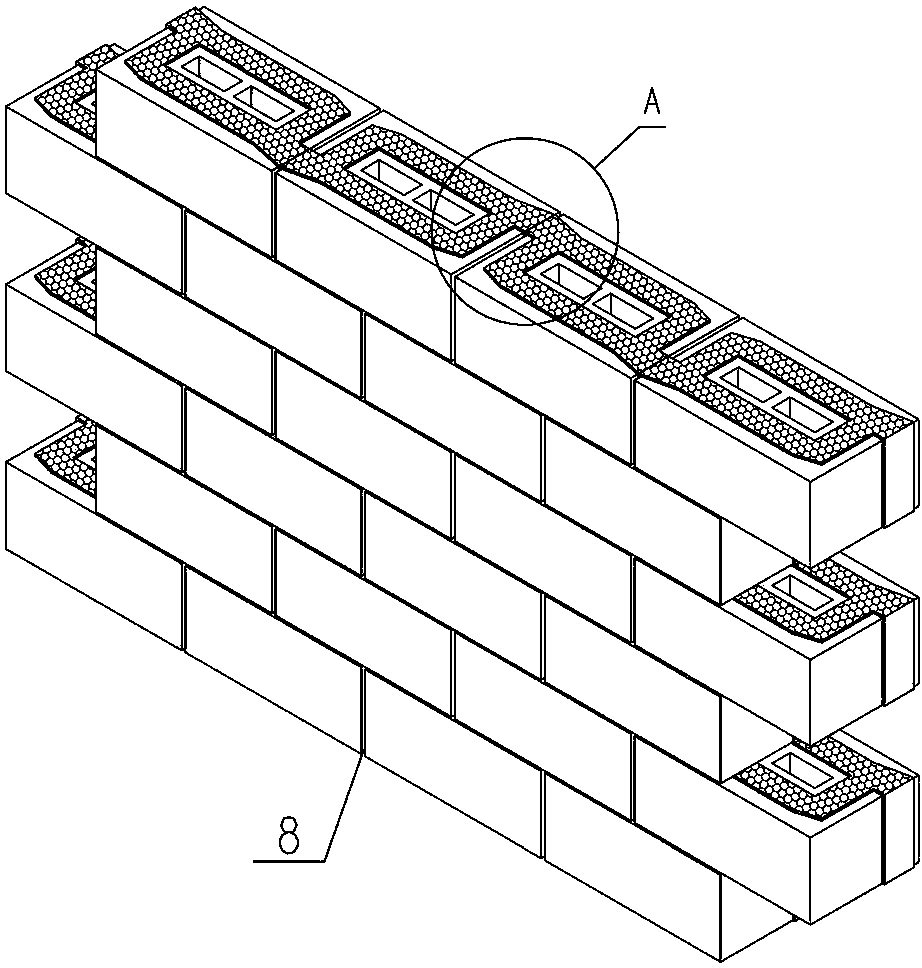

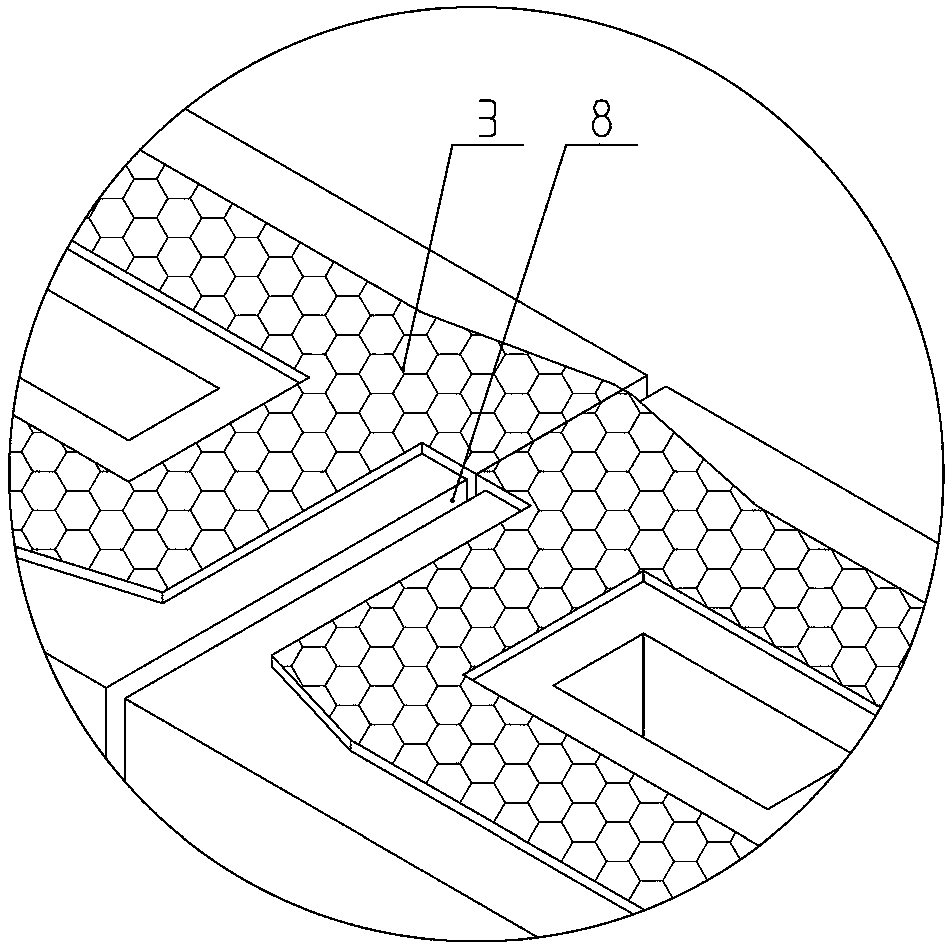

All-obstruction bridge concrete composite self-heat-preservation integrated building block

ActiveCN104278790ASynchronous lifespanLife SynchronizationConstruction materialStructural engineeringConcrete composites

Owner:刘立才

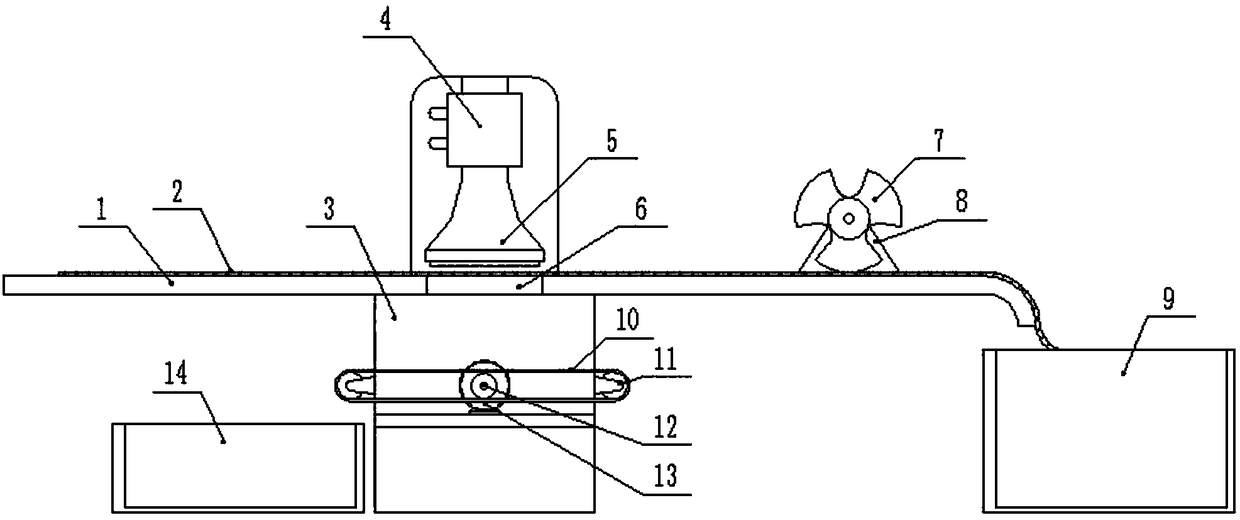

Energy-saving die cutting equipment capable of producing automatically

InactiveCN108437064AHigh degree of automationImprove work efficiencyMetal working apparatusHydraulic cylinderEngineering

The invention discloses energy-saving die cutting equipment capable of producing automatically. The energy-saving die cutting equipment capable of producing automatically comprises a transfer table, adie cutter, a pushing hydraulic cylinder and a pushing three-blade wheel, wherein a product is placed on the transfer table; the die cutter is placed on one side of the transfer table, the pushing hydraulic cylinder is mounted on the die cutter, a die cutting knife is mounted at the lower end of the pushing hydraulic cylinder, the die cutting knife is located right above the product, a falling hole is formed in the transfer table right below the die cutting knife, and a conveyor belt is placed below the falling hole; the pushing three-blade wheel is also mounted on the transfer table, and theend parts of the blades of the pushing three-blade wheel are in contact with the upper surface of the product. The product can be produced automatically by matching the pushing hydraulic cylinder with the pushing three-blade wheel, so that the degree of automation of die cutting processing is improved; the processed finished product material and waste are separately processed, so that a step is reduced, the work efficiency is improved, and the energy-saving die cutting equipment is energy-saving and environment-friendly; driving pieces of parts are controlled to control the processing precision precisely according to different processed product materials.

Owner:苏州澳普林特精密电子有限公司

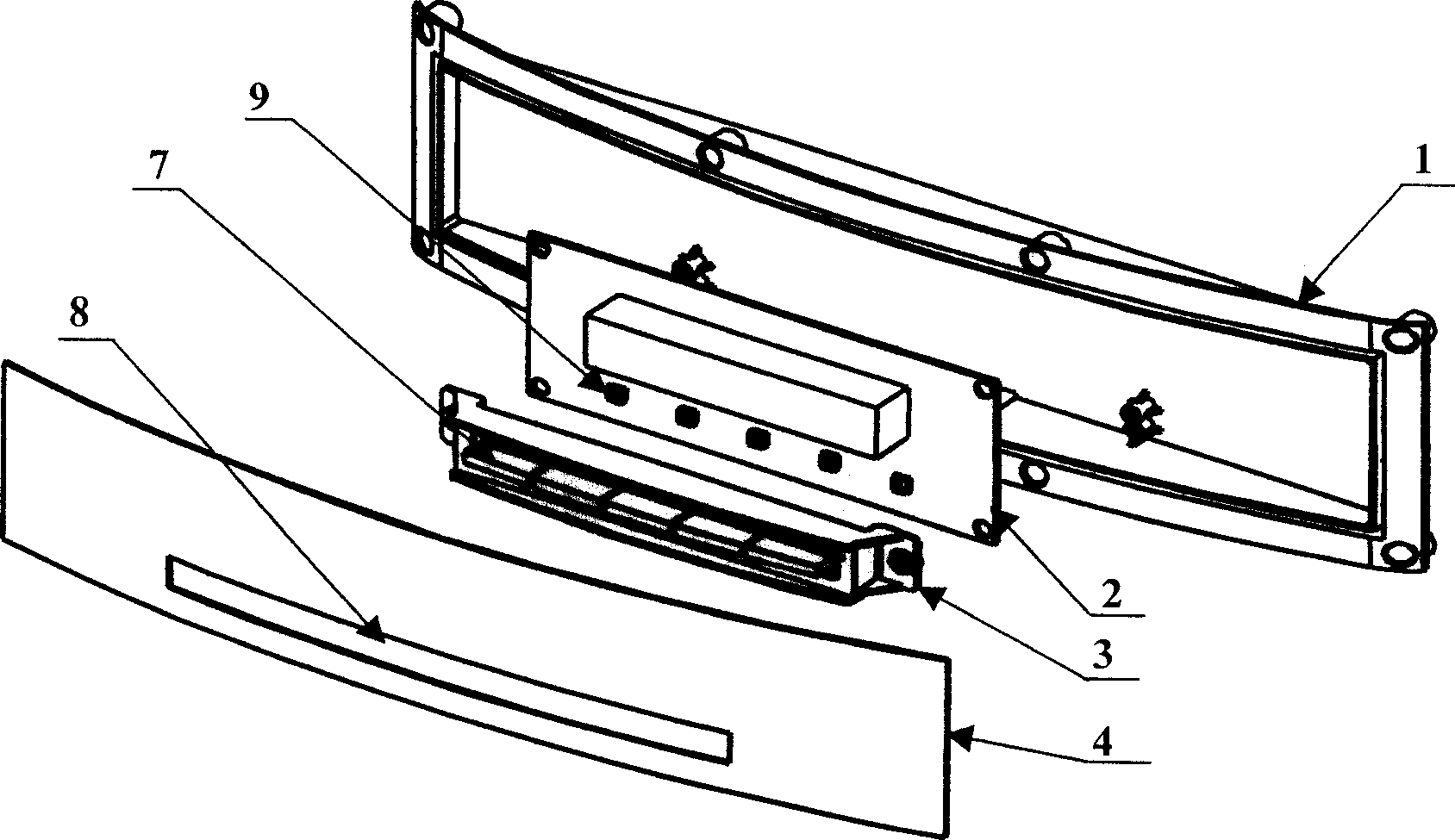

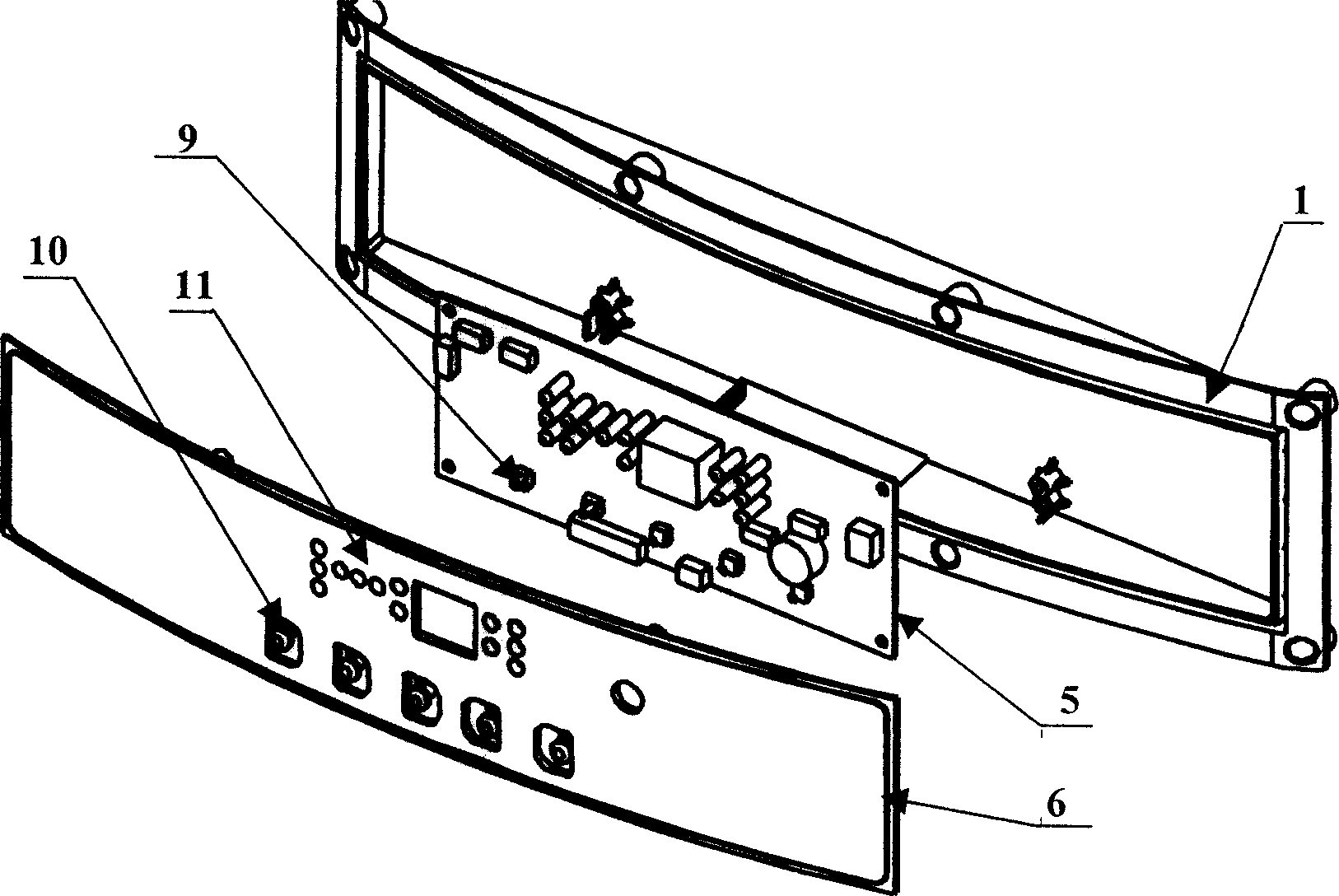

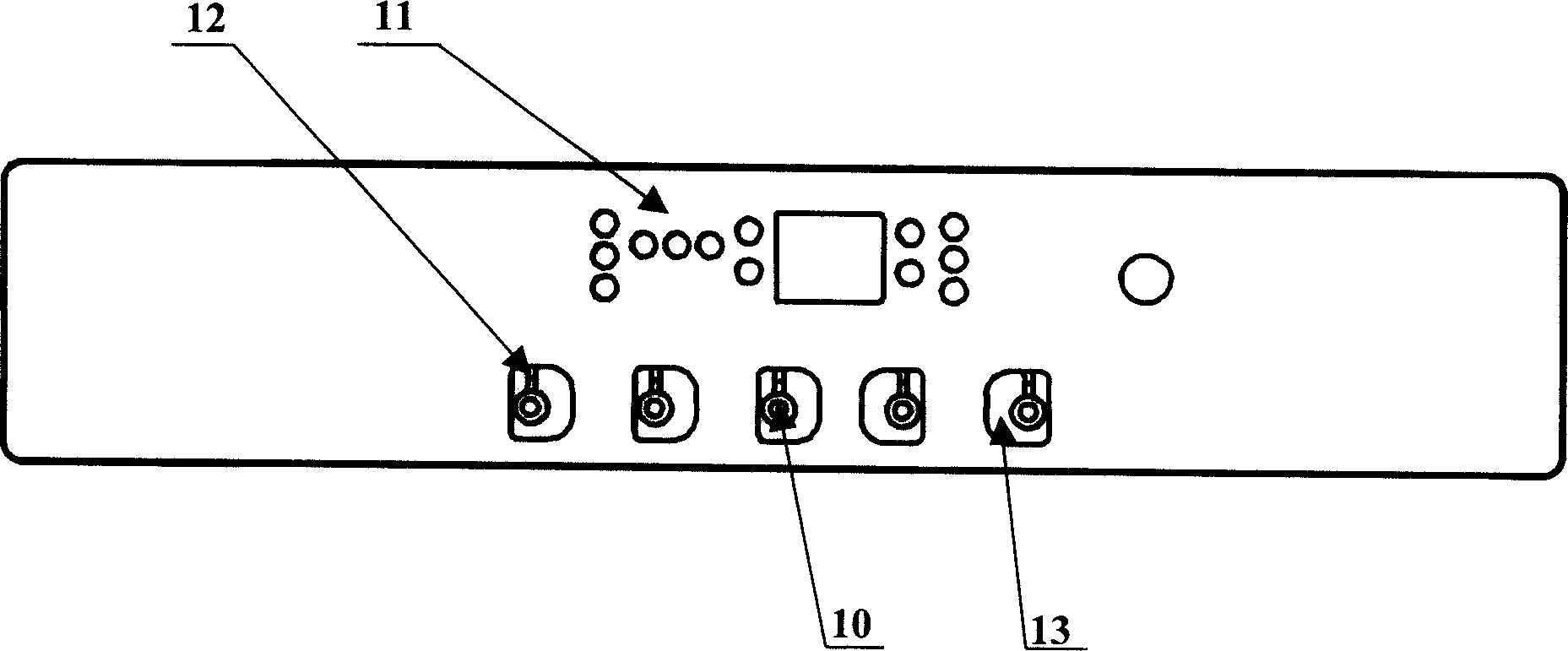

Integral structure of air conditioning in-door machine display panel

InactiveCN1755201AIncrease contactReduce dosageSpace heating and ventilation safety systemsLighting and heating apparatusAir conditioningManufacturing line

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

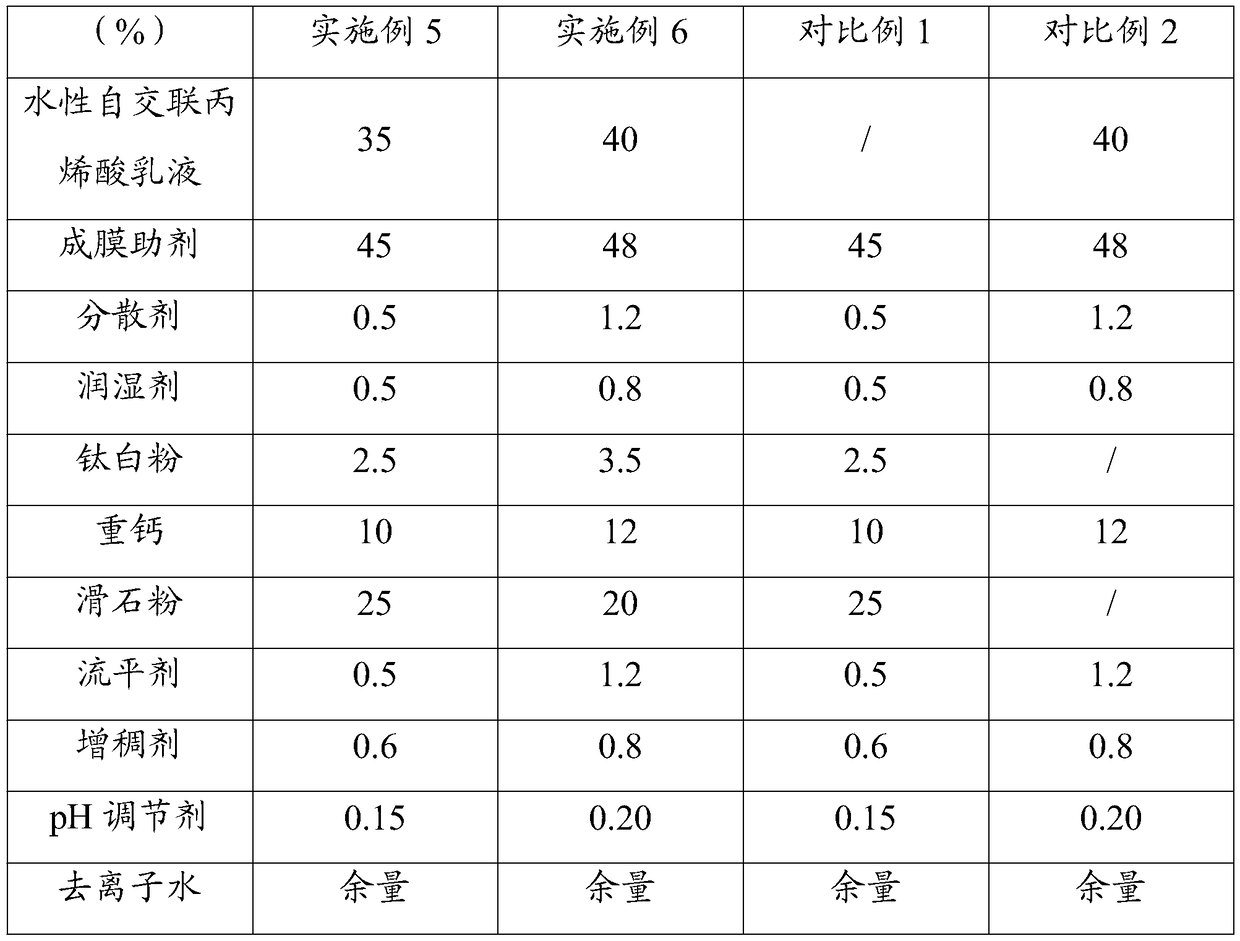

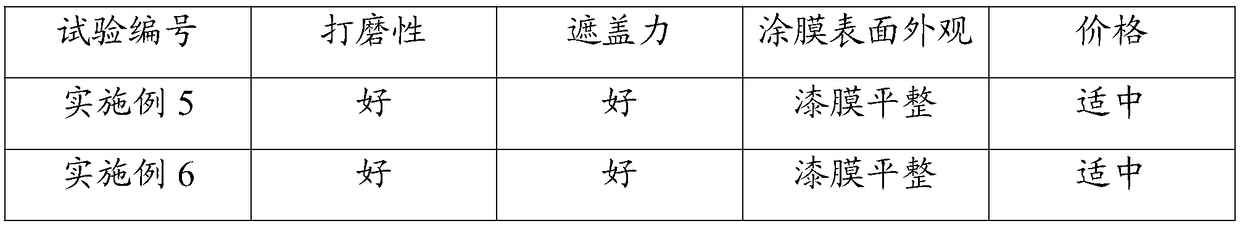

Woodenware water paint and preparation method thereof

The invention discloses a woodenware water paint and a preparation method thereof. The woodenware water paint is prepared from the following raw materials by proportion: 30 to 40 percent of waterborneself-crosslinking acrylic emulsion, 40 to 50 percent of a coalescing agent, 45 to 55 percent of pigment, 0.3 to 1.5 percent of a dispersing agent, 0.1 to 1.0 percent of a wetting agent, 0.3 to 1.5 percent of a leveling agent, 0.1 to 1.0 percent of a thickening agent, 0.1 to 0.3 percent of a pH modifier, 1.5 to 5 percent of titanium dioxide, 3 to 15 percent of heavy calcium carbonate with 800 meshes and the balance of deionized water. The woodenware water paint prepared by the preparation method disclosed by the invention has the advantages of low cost, high hardness and the like; in addition,the woodenware water paint can seal tannic acid in wood and solve the problems of solid wood bloating and fiberboard bloating; construction procedure are effectively simplified and the coating cost is reduced; the woodenware water paint has great market application and popularization value.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

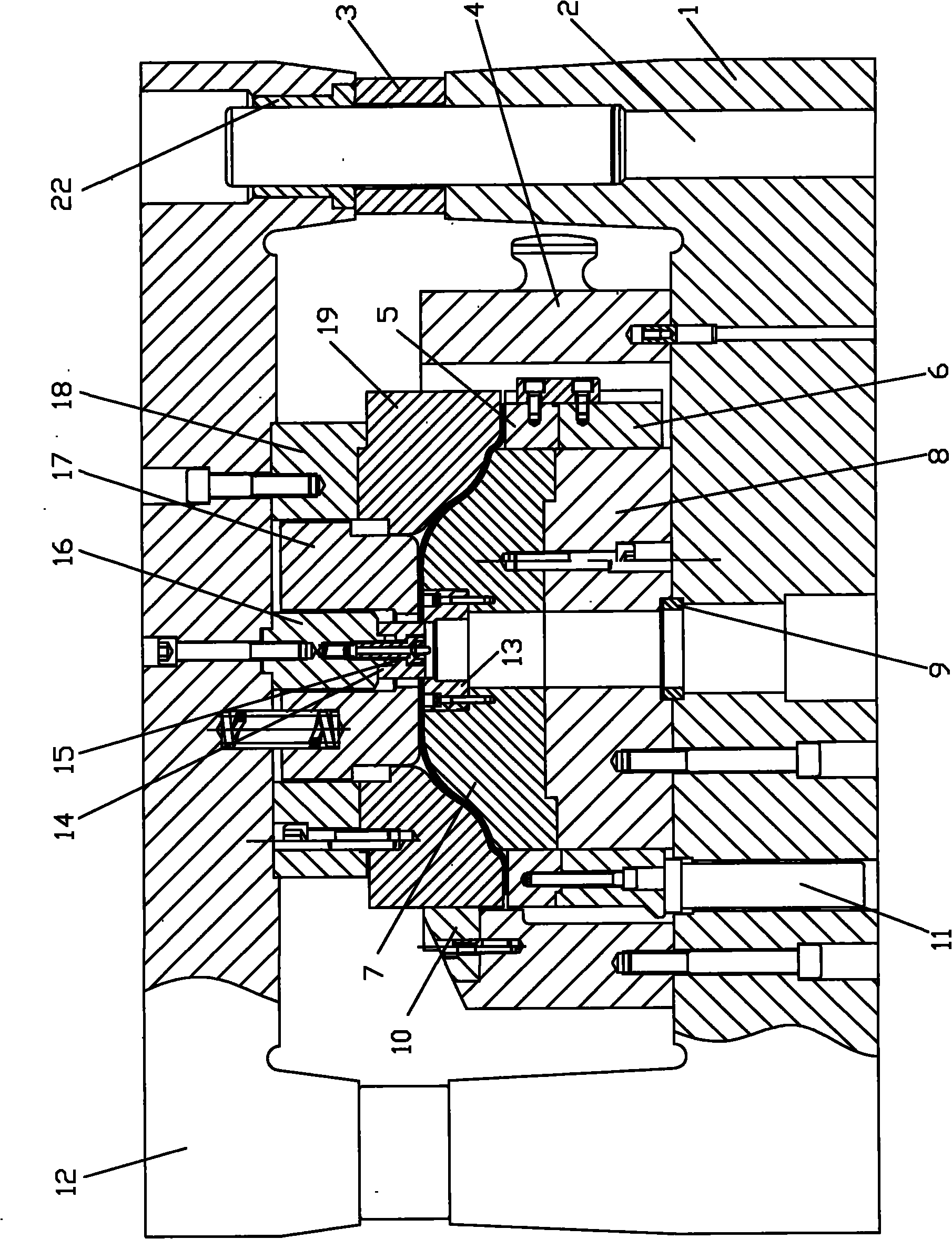

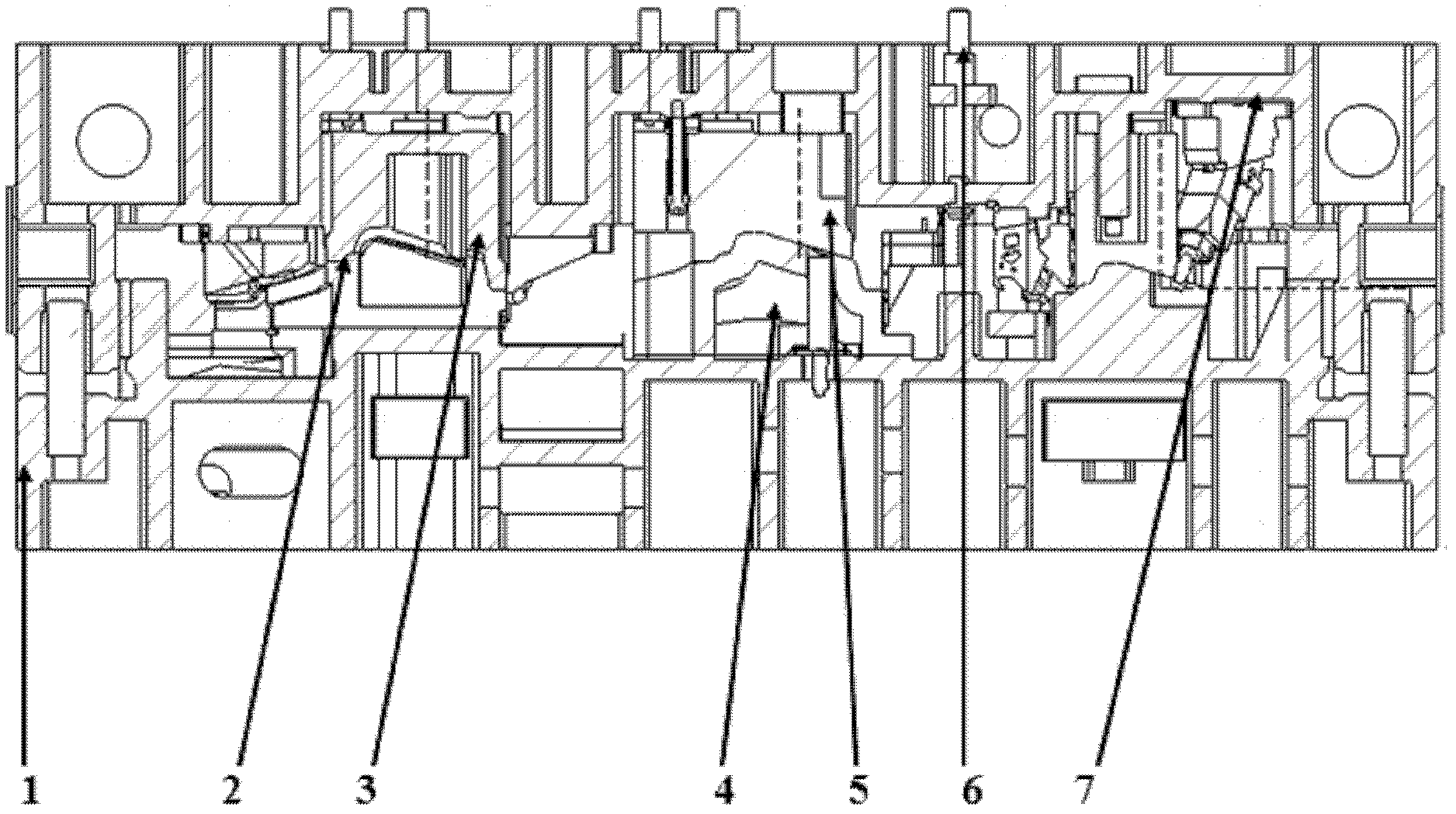

Automobile side frame inner panel part die

InactiveCN103182447AReduce manufacturing costReduce one processShaping toolsEngineeringMechanical engineering

The invention relates to an automobile side frame inner panel part die which comprises an upper die component and a lower die component. The upper die component comprises an upper die holder, as well as an upper die core, an upper die insert block and an upper die eccentric swage, which are arranged on the upper die holder; the upper die core is positioned below the upper die holder; the lower die component comprises a lower die holder, as well as a lower die core and an ejector, which are arranged on the lower die holder; the lower die core is positioned above the lower die holder; the upper die component further comprises a plurality of upper push rods; the upper push rods penetrate through the upper die holder and are propped against the top of the upper die core; a shaving hole punching female die and a flanging sizing female die are arranged on the upper die core; and a shaving hole punching male die and a flanging sizing male die matched with the shaving hole punching female die and the flanging sizing female die are arranged on the lower die core. Compared with the prior art, the automobile side frame inner panel part die has the advantages that three dies are integrated into one die, production processes are reduced, the upper ejector structure is adopted, the die is convenient to maintain, and a swaging power source is not required to be inspected or changed before production every time.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com