Manufacturing method and device for display panel and display panel

A technology of a display panel and a manufacturing method, which is applied in the field of display panel and display panel manufacturing device, can solve the problems of high cost, complicated display panel manufacturing process, long time consumption, etc., so as to improve efficiency, improve the process of manufacturing display panel, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

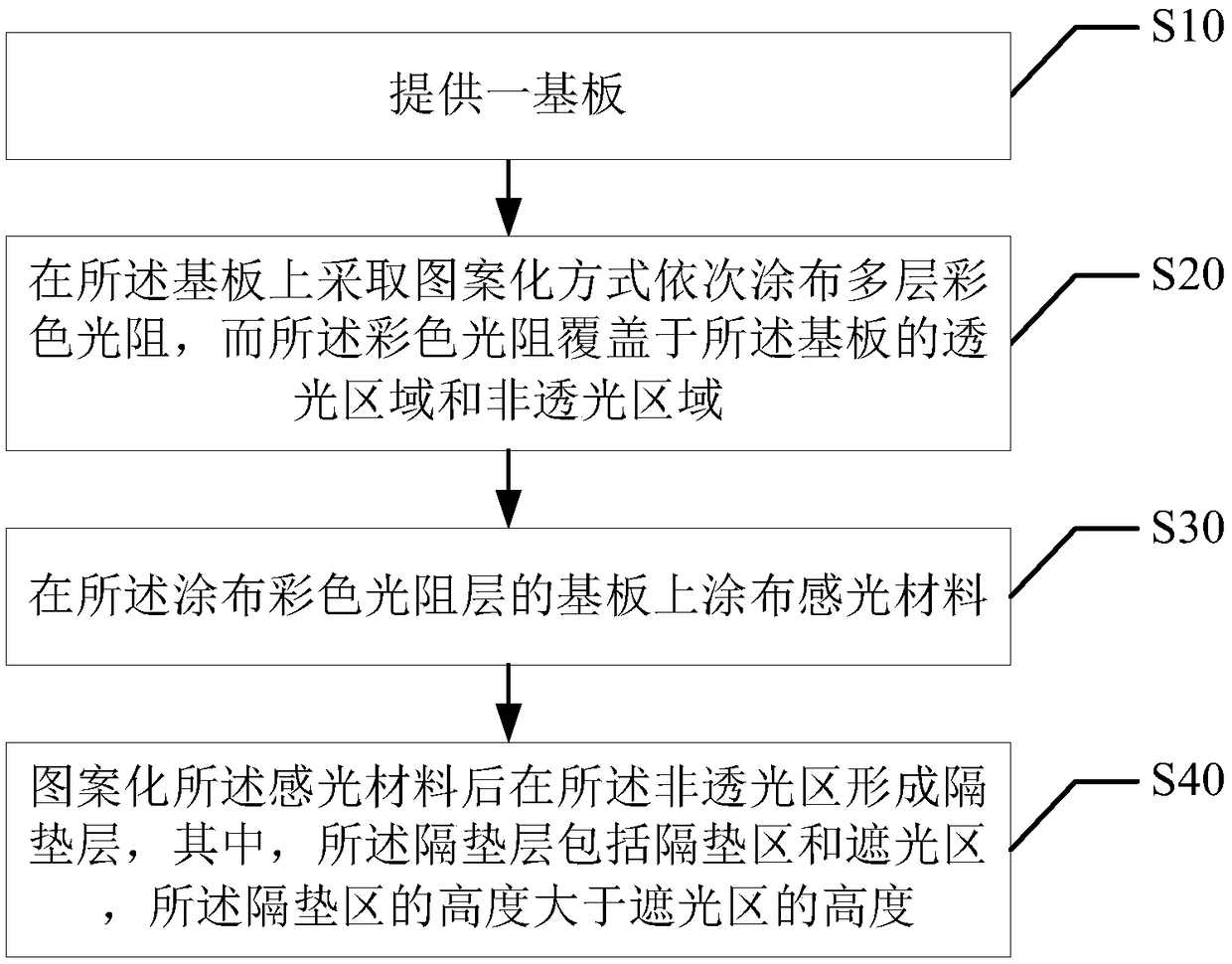

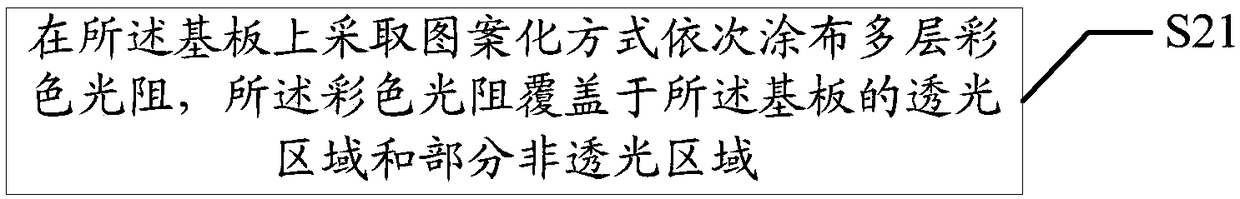

[0034] The main solution of the embodiment of the present invention is to provide a substrate; to sequentially coat multi-layer color photoresist in a patterned manner on the substrate, and the color photoresist covers the light-transmitting area and the non-transmitting area of the substrate. Light area: Coating a photosensitive material on the substrate coated with a color photoresist layer; forming a spacer layer in the non-light-transmitting area after patterning the photosensitive material, wherein the spacer layer includes a spacer area and the light-shielding area, the height of the spacer area is greater than the height of the light-shielding area.

[0035] Since the five processes of the current display panel production all need steps such as photoresist coating, baking, exposure, development, cleaning and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com