Titanium alloy hot-rolled seamless pipe production system and production process thereof

A technology of production process and production system, which is applied in the production system of titanium alloy hot-rolled seamless pipe and its production process, can solve the problems of difficult production and low yield, and achieve narrow rolling deformation temperature range and low energy consumption of the unit Low, flexible and reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with embodiment: present embodiment is implemented on the premise of technical solution of the present invention, has provided detailed embodiment and concrete operation process, but protection scope of the present invention is not limited to following embodiment.

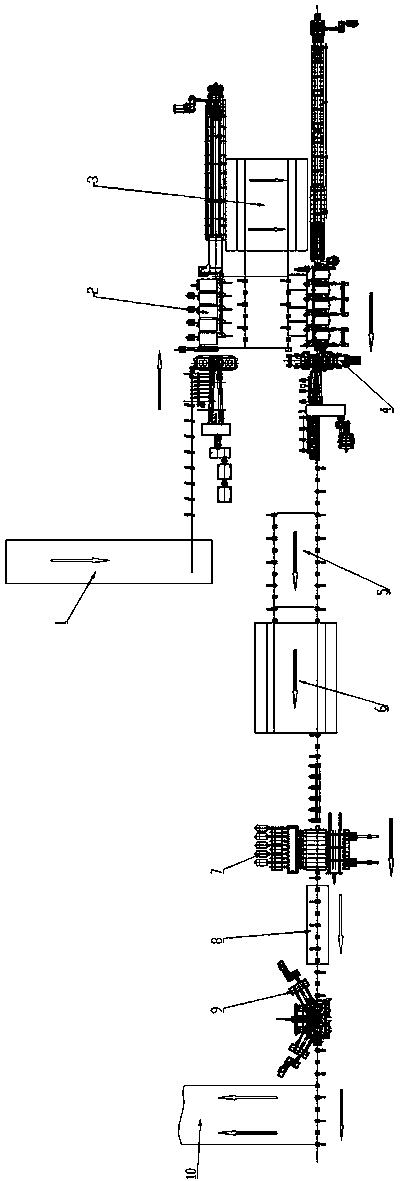

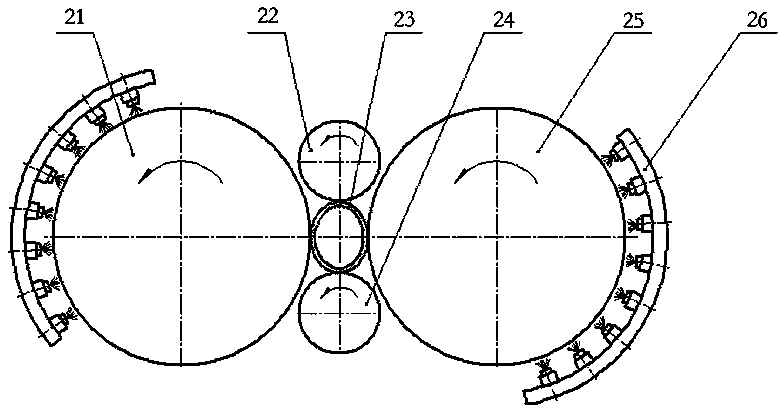

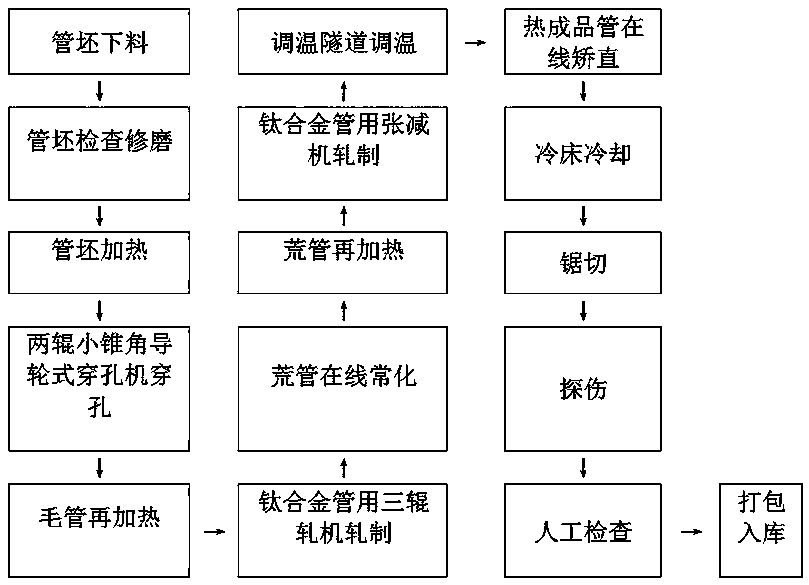

[0042] like figure 1 and figure 2 As shown, a titanium alloy hot-rolled seamless pipe production system in this embodiment includes a piercer 2, a three-roll pipe mill 4, a tensioning and reducing unit 7, a temperature-adjusting tunnel 8, The straightening machine 9 and the cooling bed 10 also include an electric heating furnace, and the electric heating furnace includes a billet heating furnace 1, a transitional reheating furnace 3 and a blank pipe reheating furnace 6, wherein: the billet heating furnace 1 is arranged in the production At the head end of the system, the tube billet is heated by the tube billet heating furnace 1 and then tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com