Patents

Literature

346 results about "% diameter reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

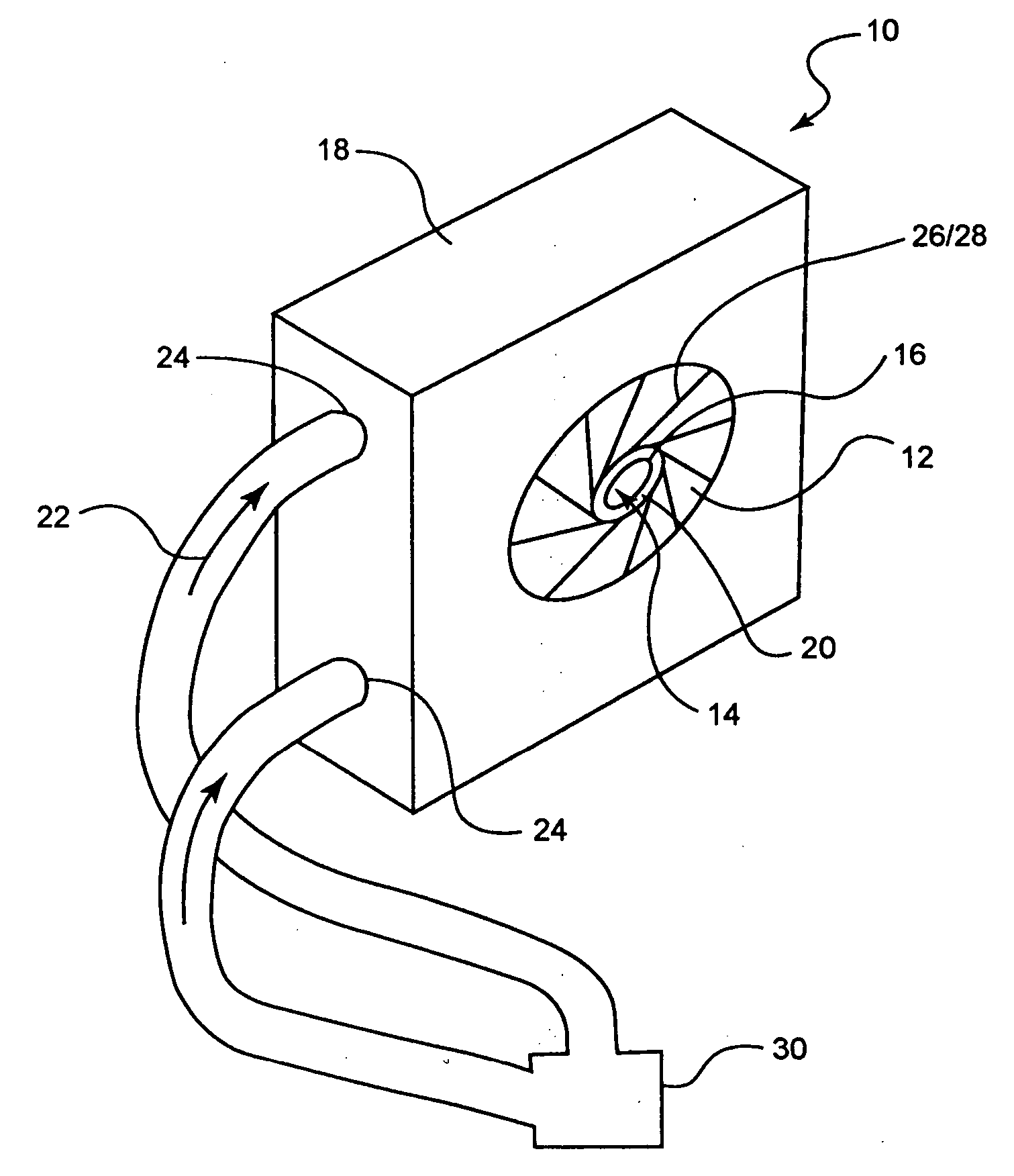

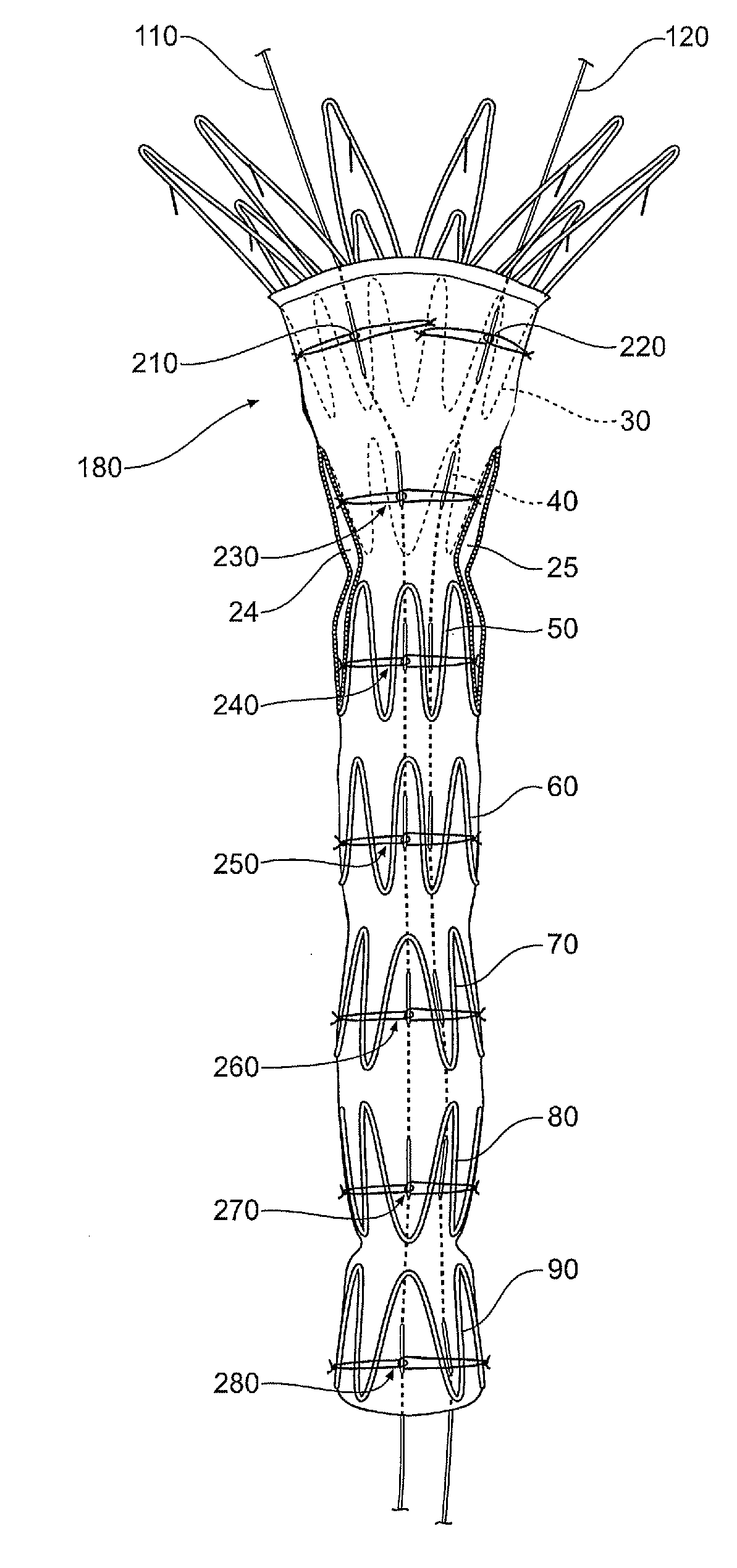

Assembly of stent grafts

ActiveUS20070043425A1Reduce the overall diameterReduce distanceStentsBlood vesselsStent grafting% diameter reduction

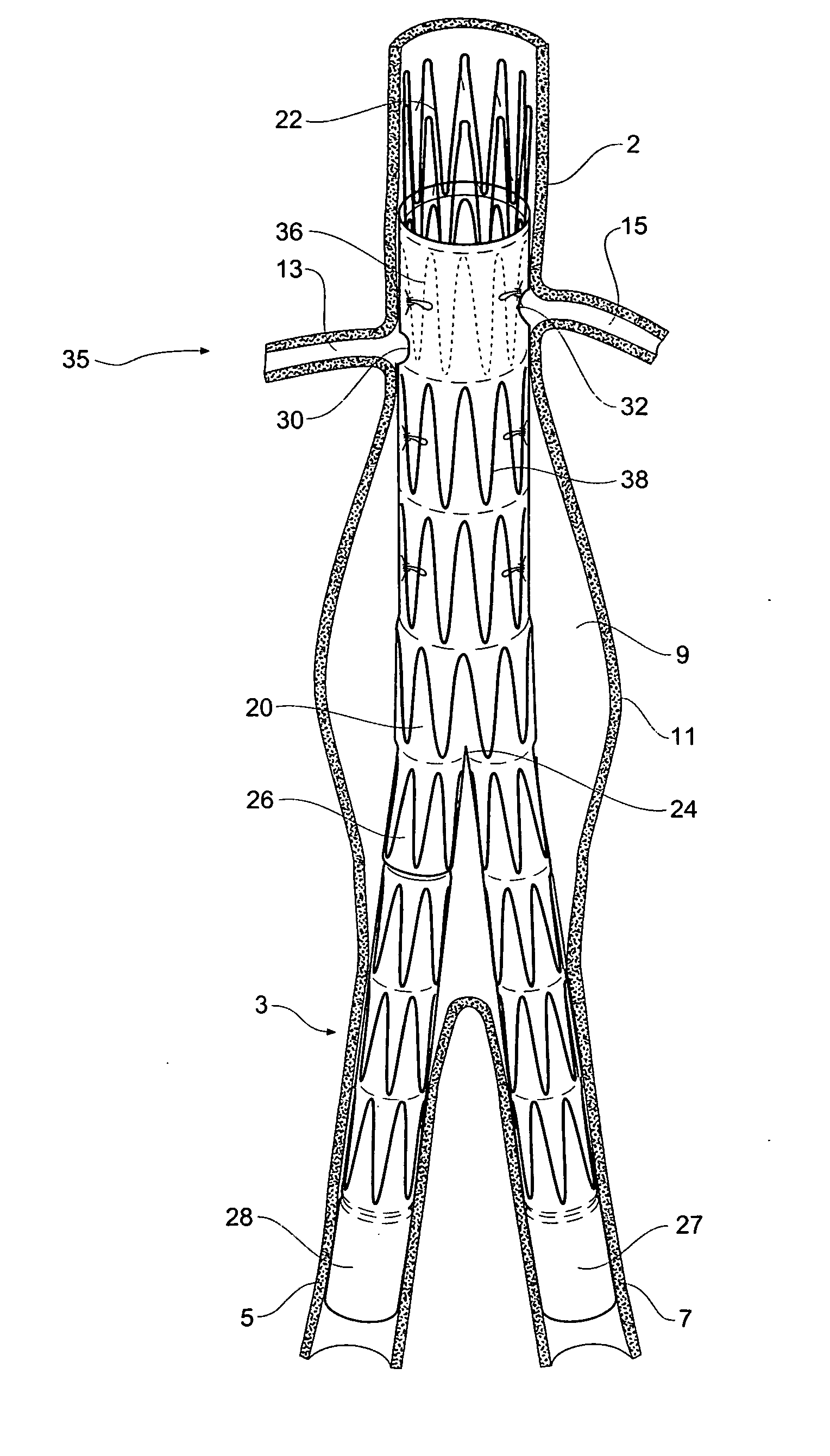

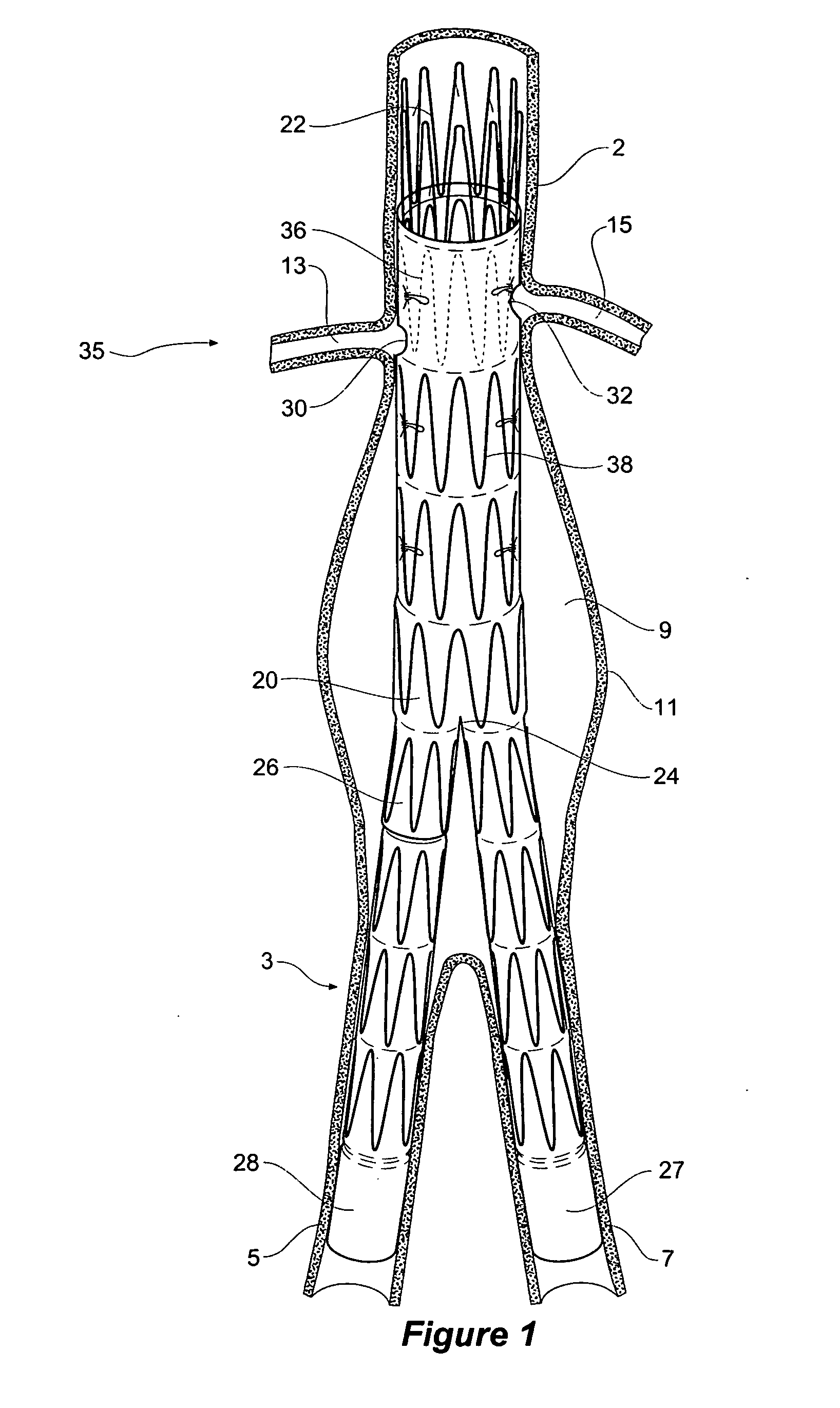

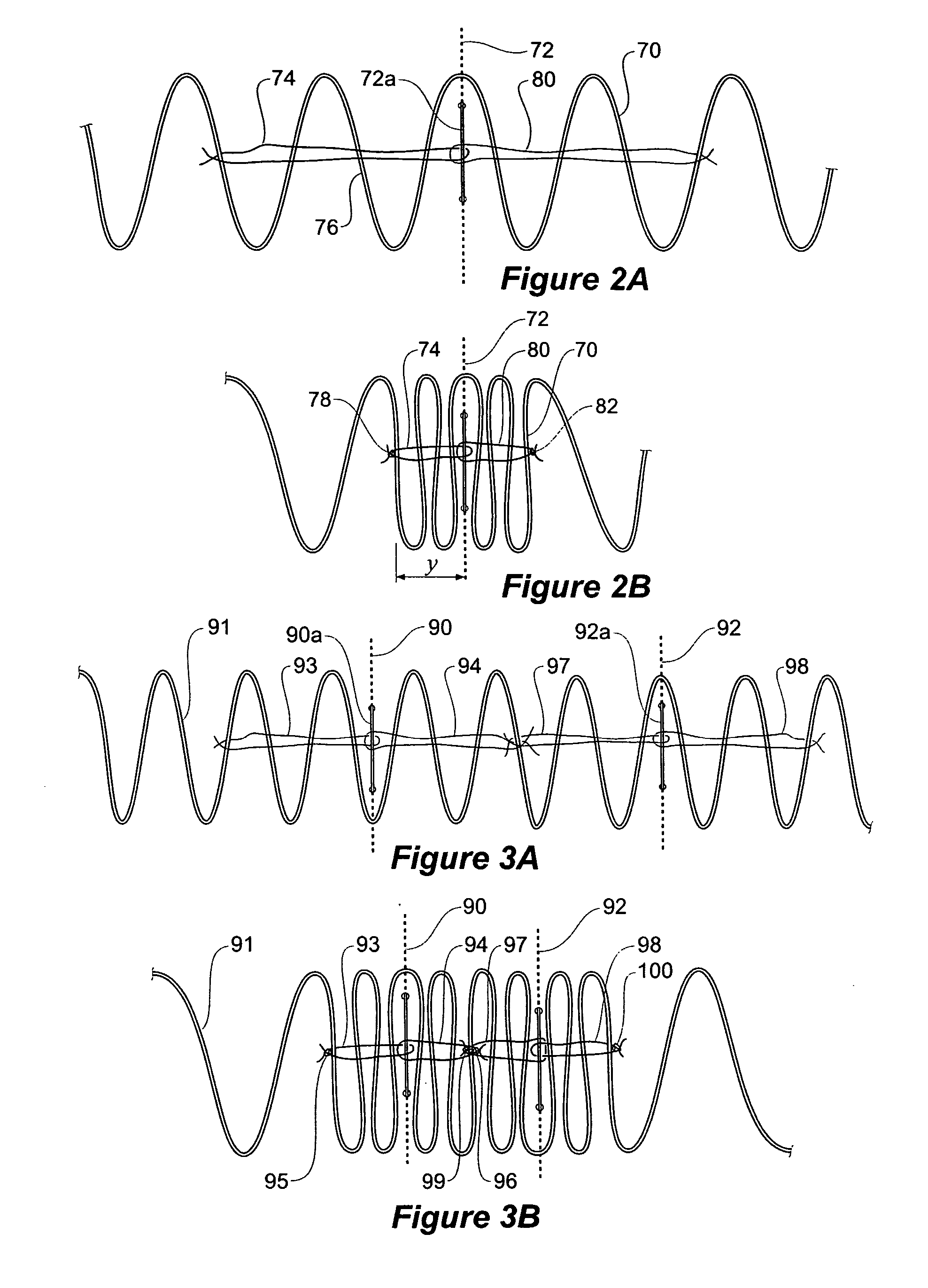

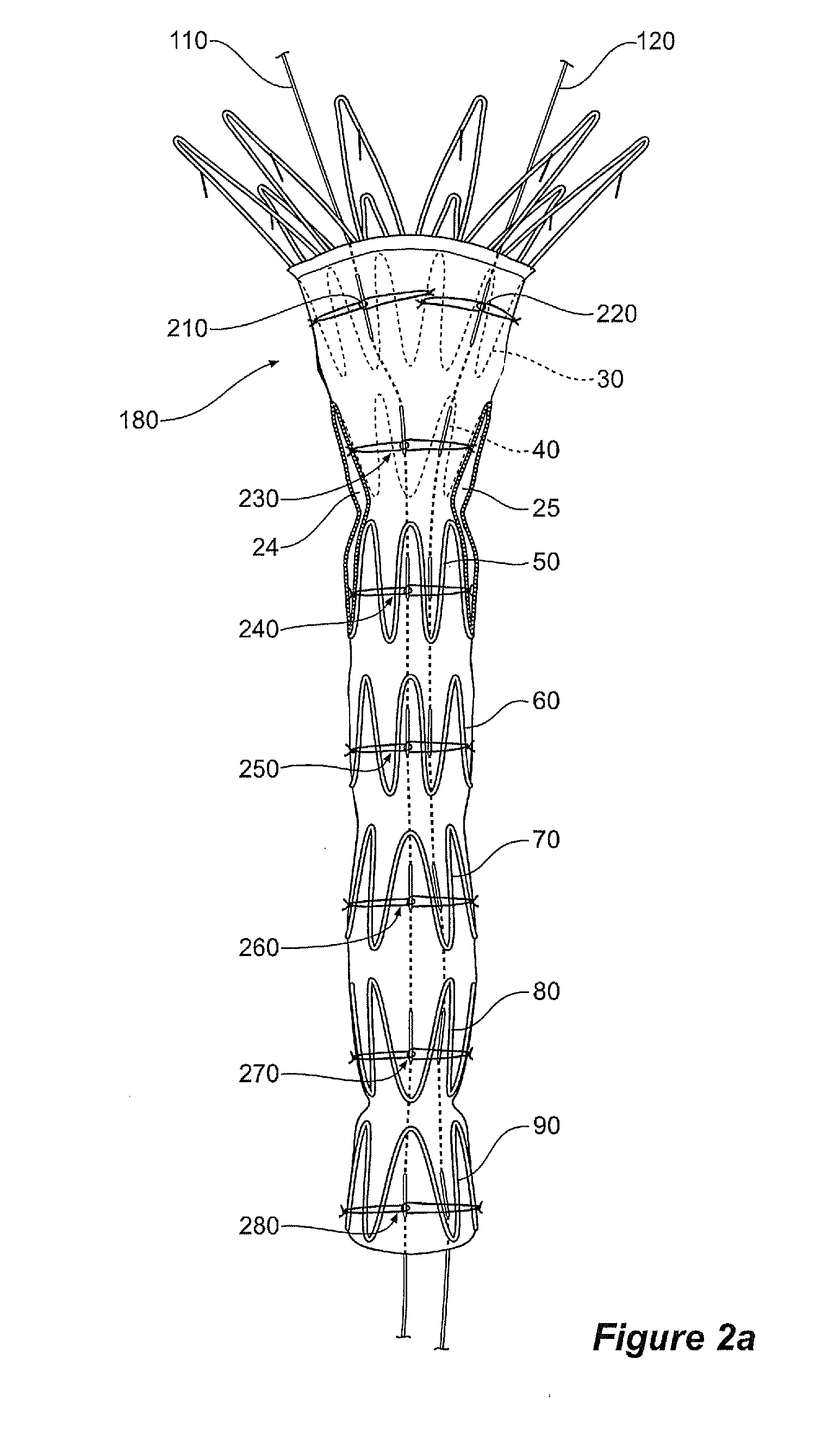

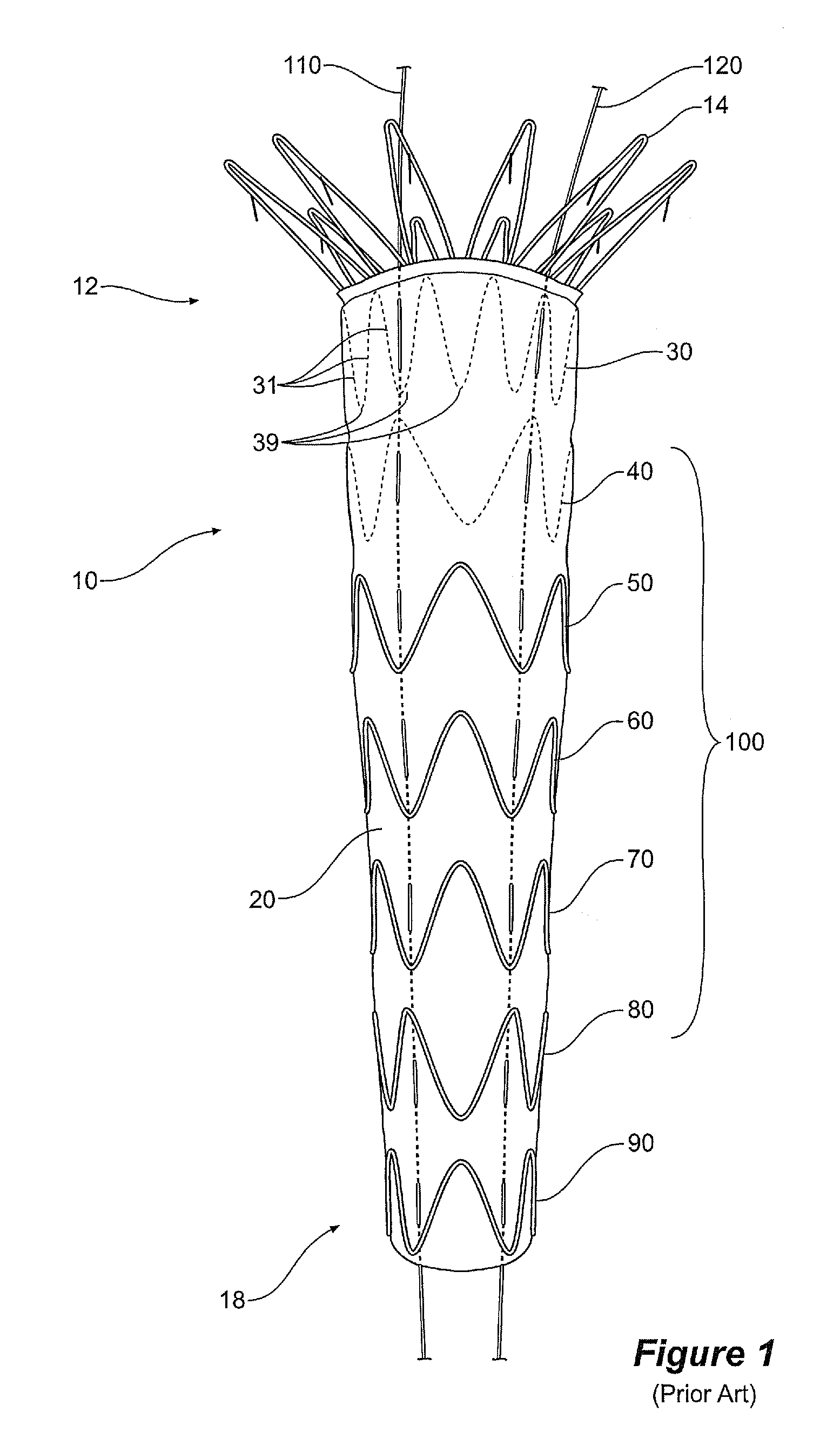

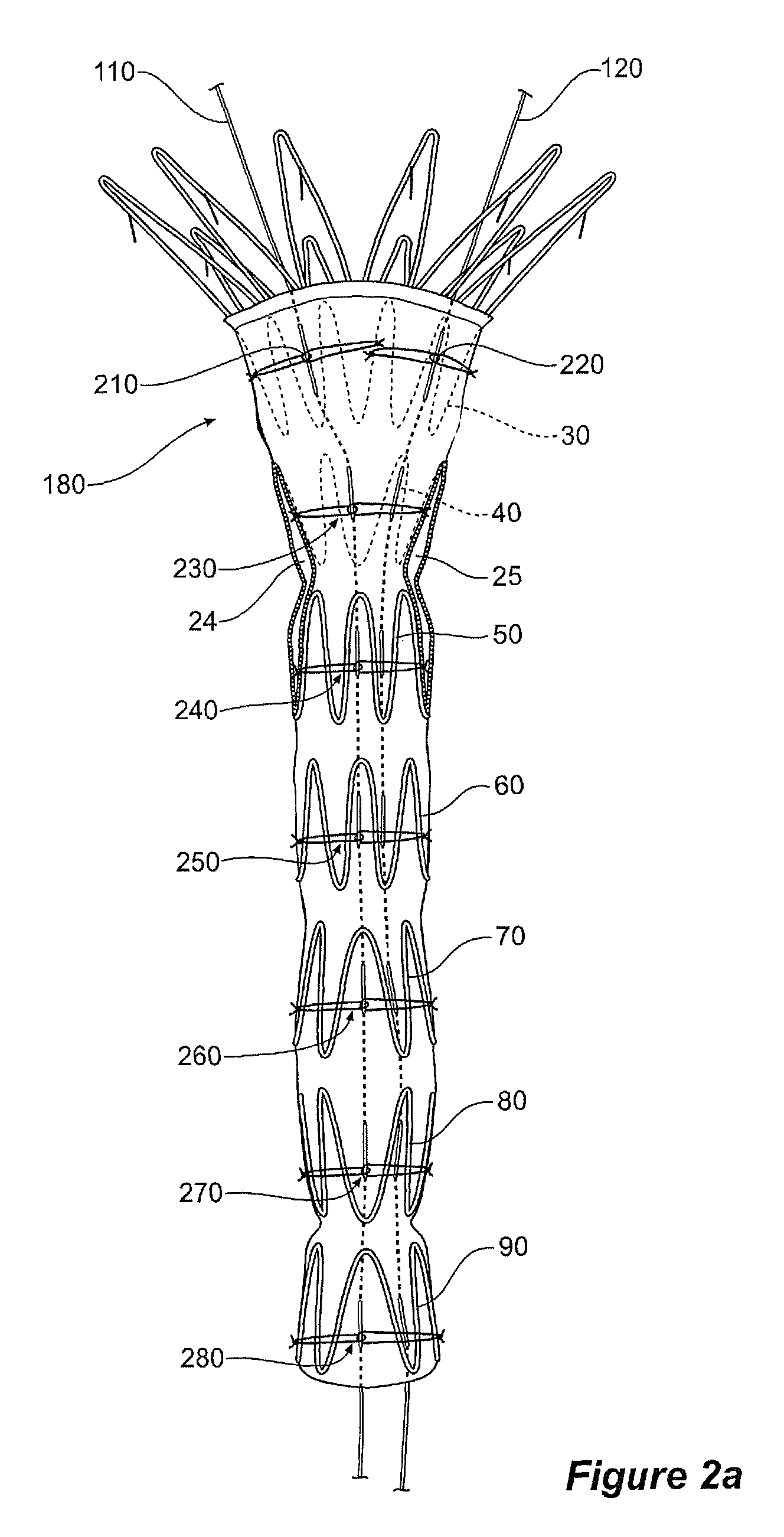

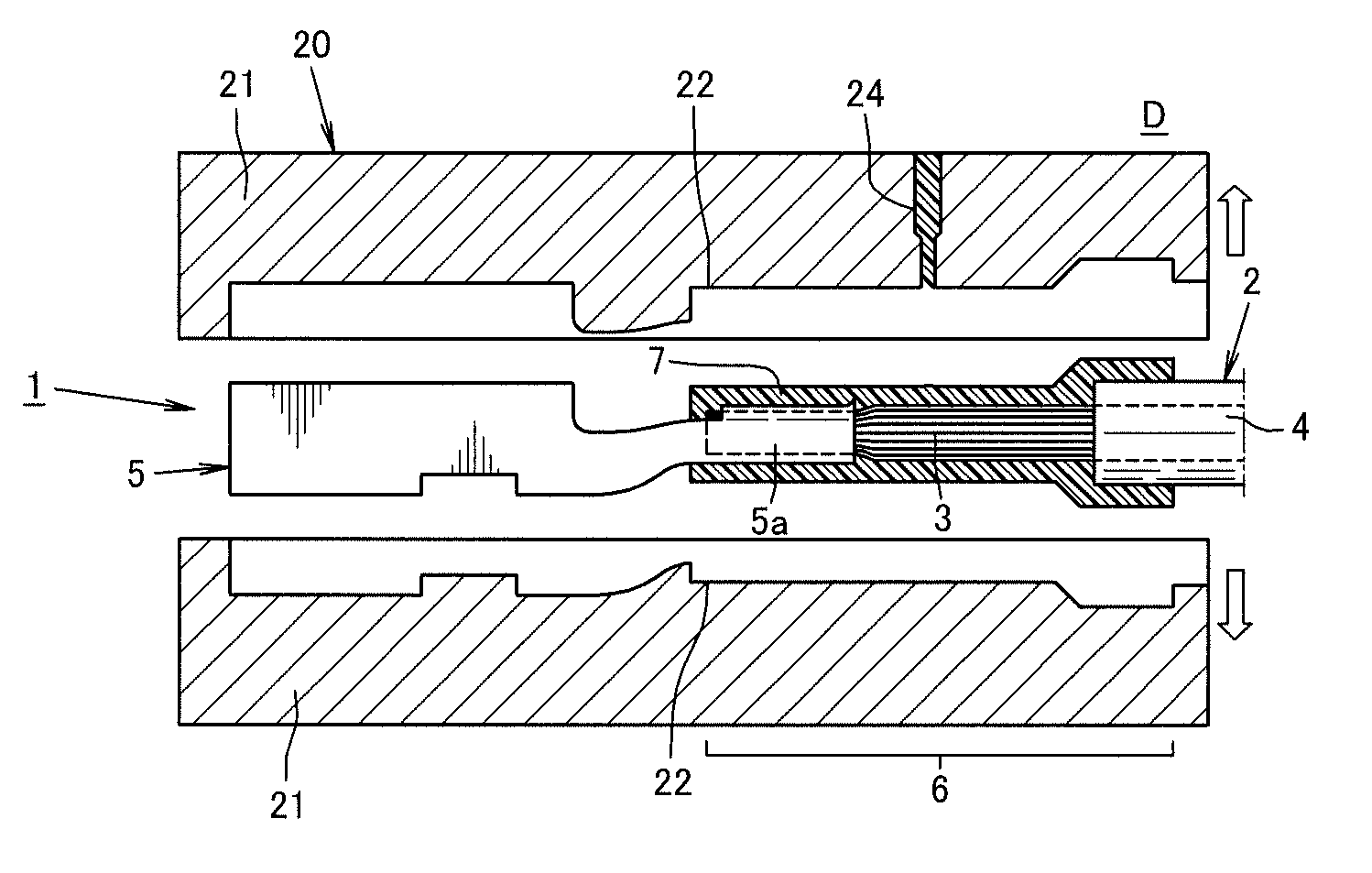

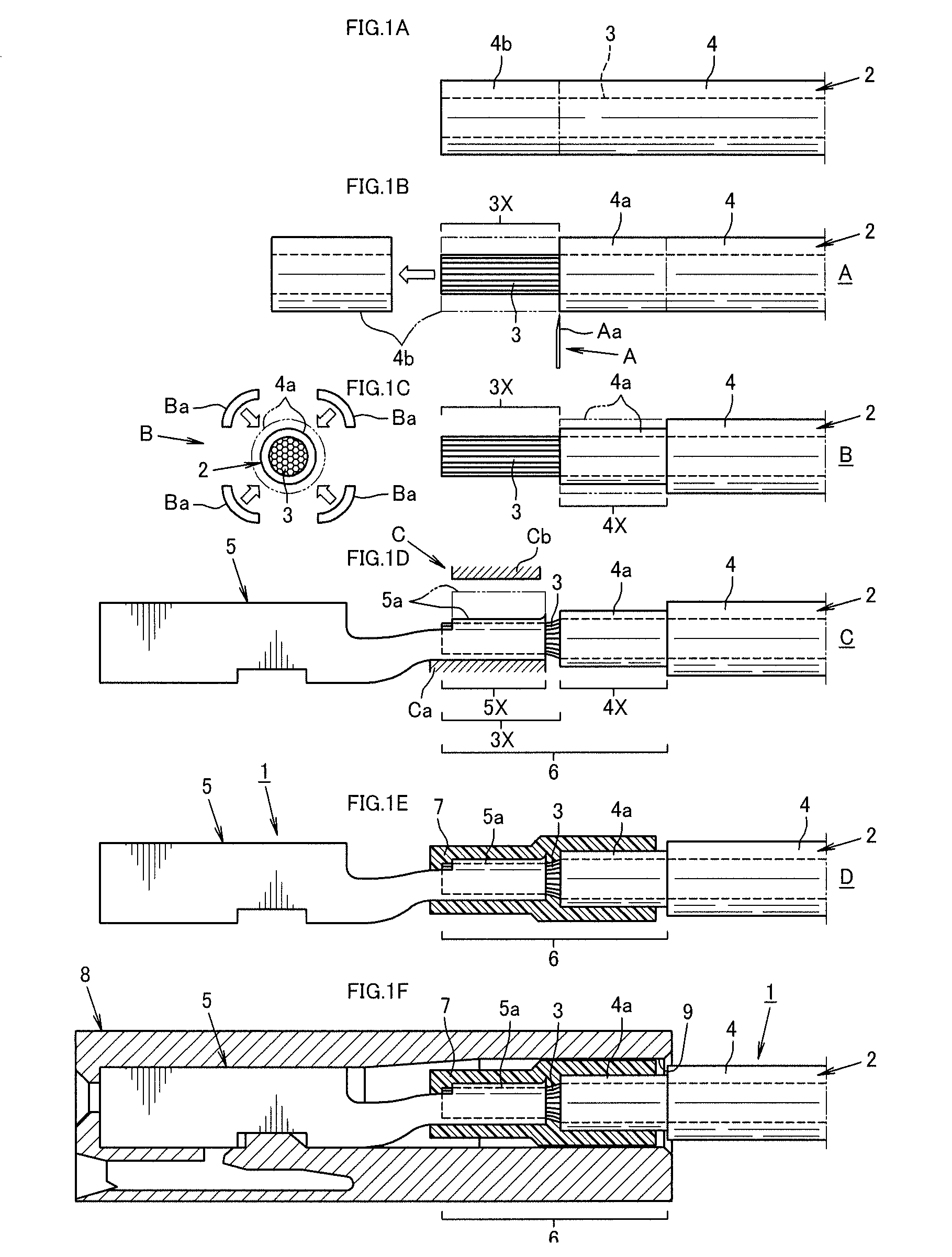

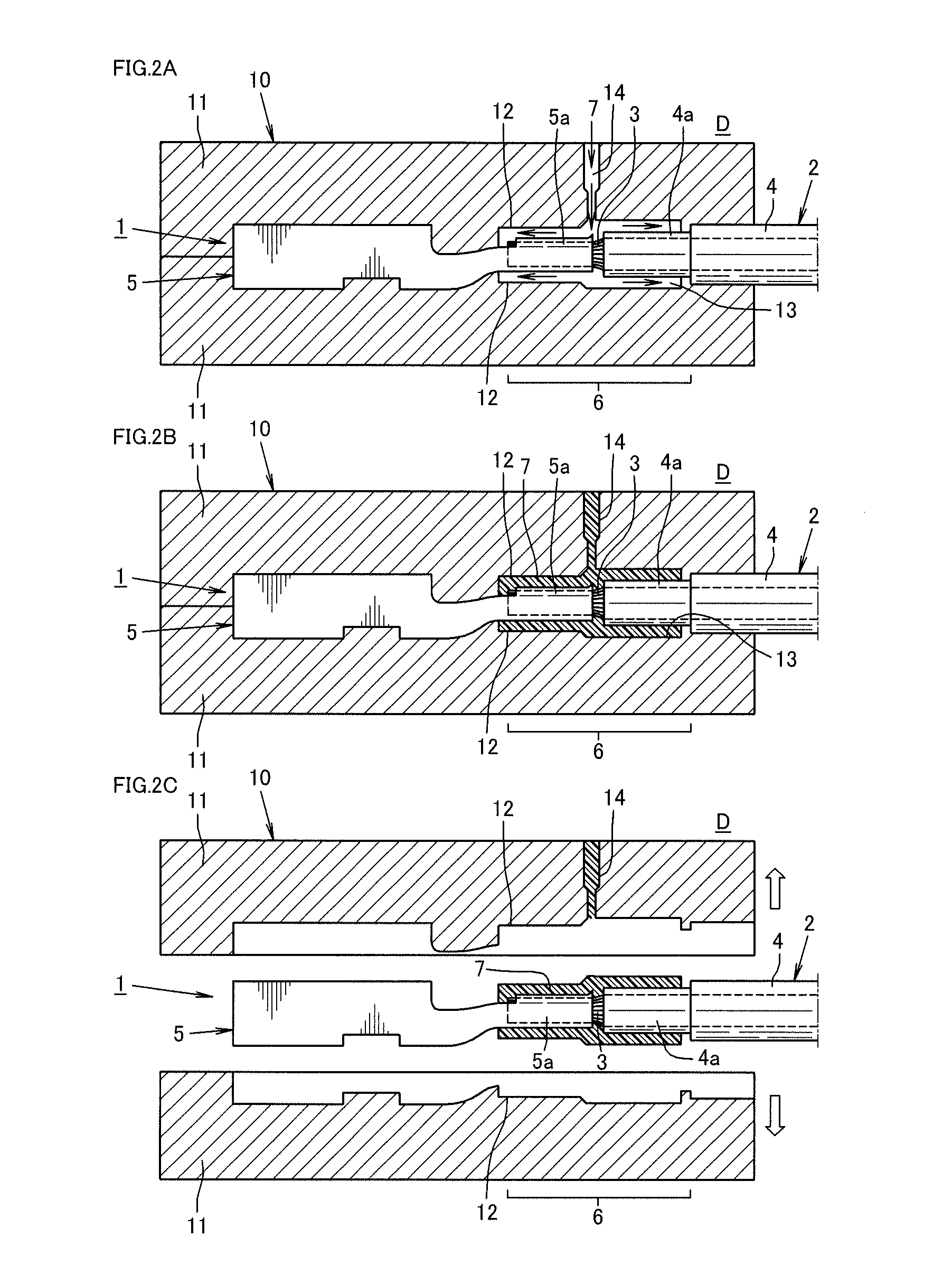

A method of assembling of a stent graft (20) including temporarily diameter reduction arrangements to enable partial release of a stent graft to assist with positioning before complete release. The diameter reduction arrangement includes a release wire (72) and flexible threads (74, 80) extending to struts (76) of a self expanding stent (70) either side of the release wire and being pulled tight. Removal of the release wire enables full expansion of the self expanding stent.

Owner:COOK MEDICAL TECH LLC

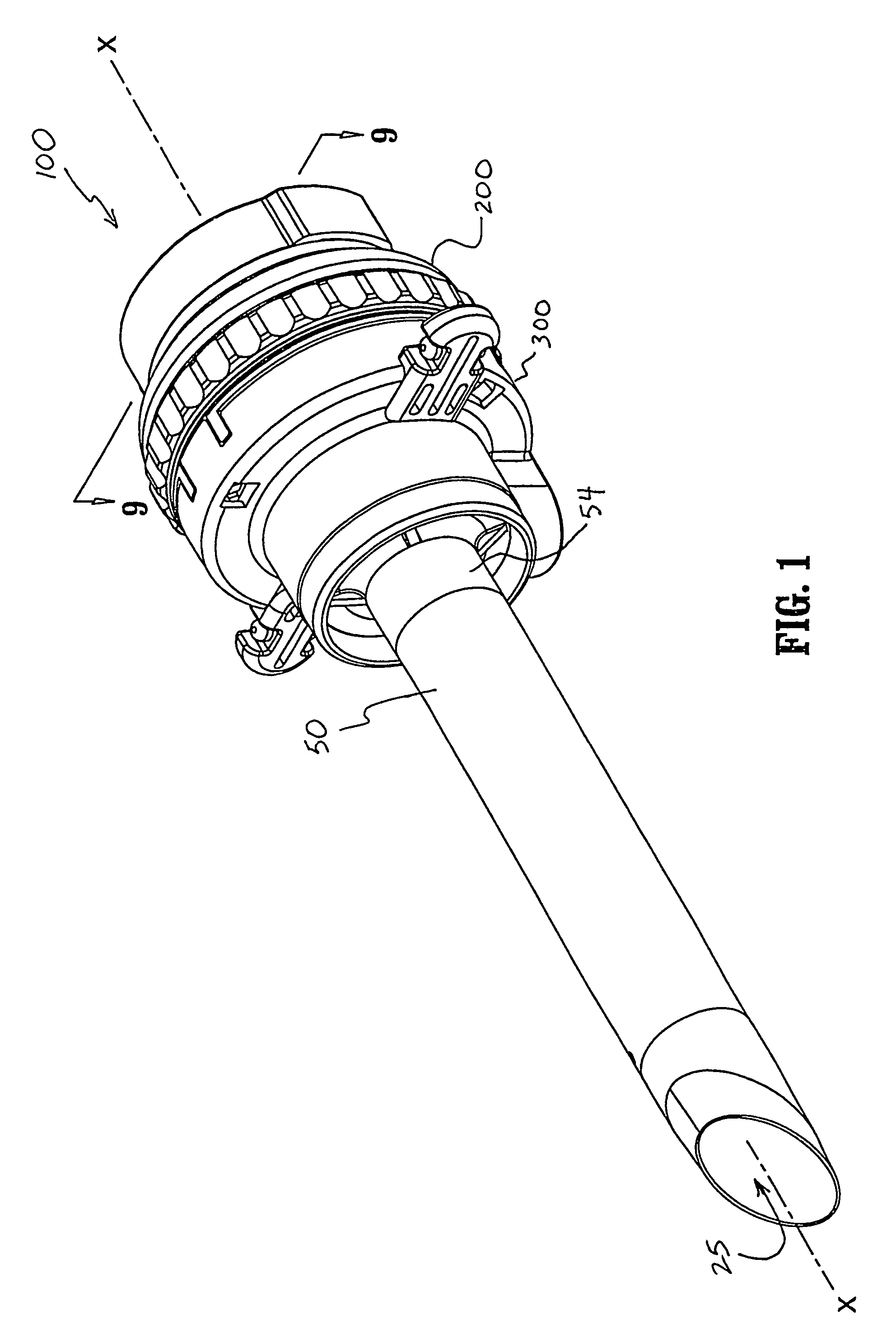

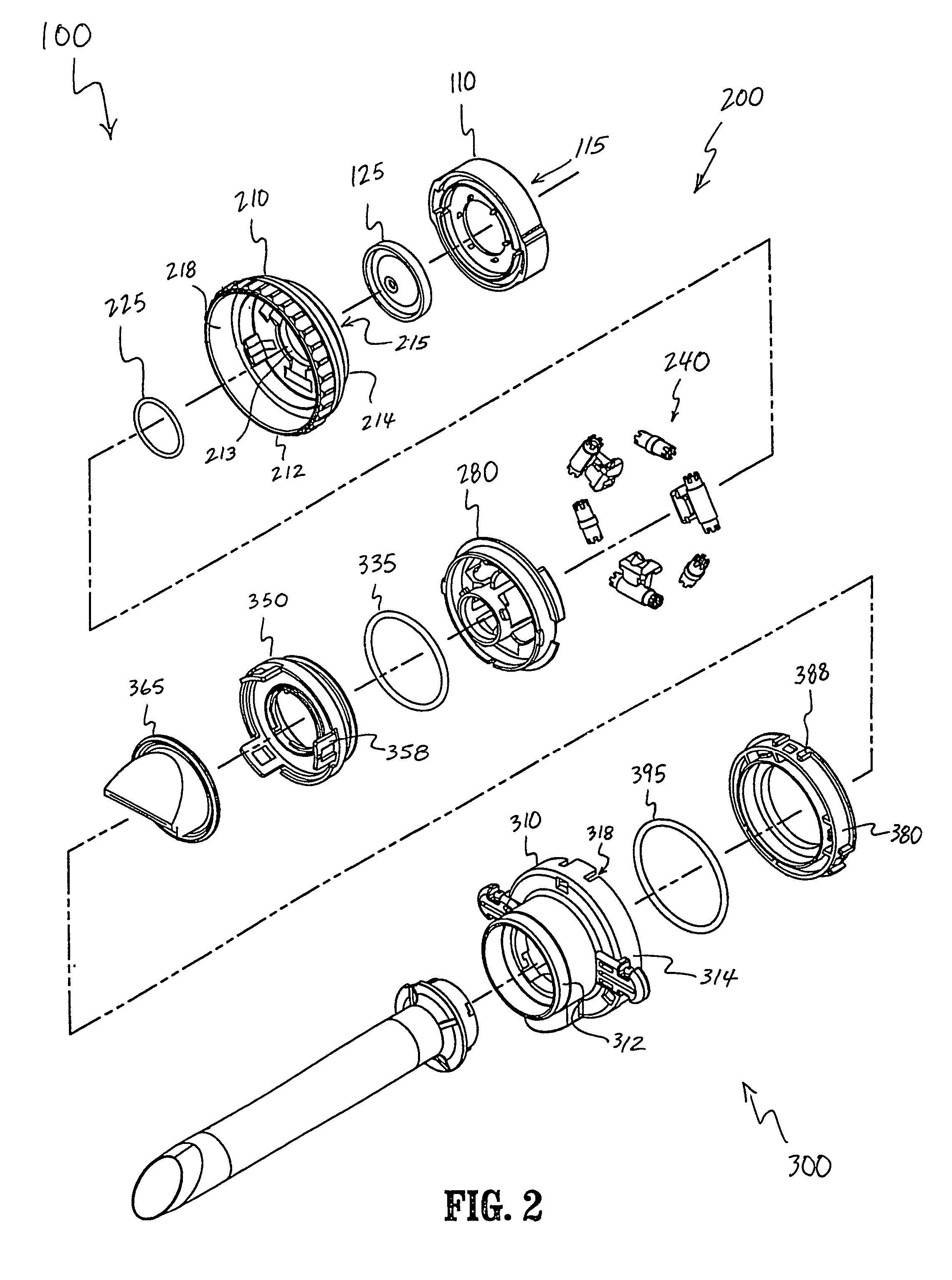

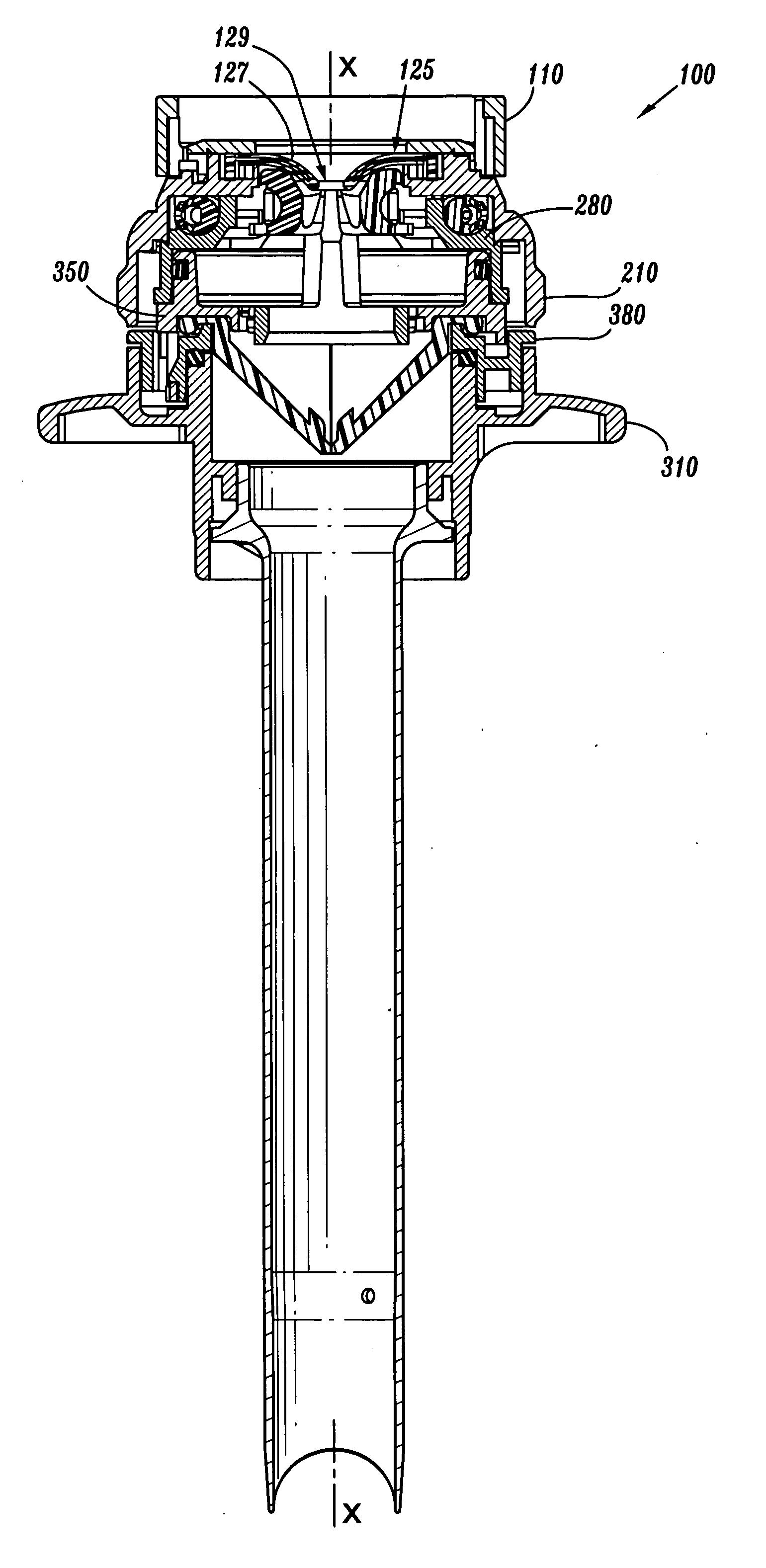

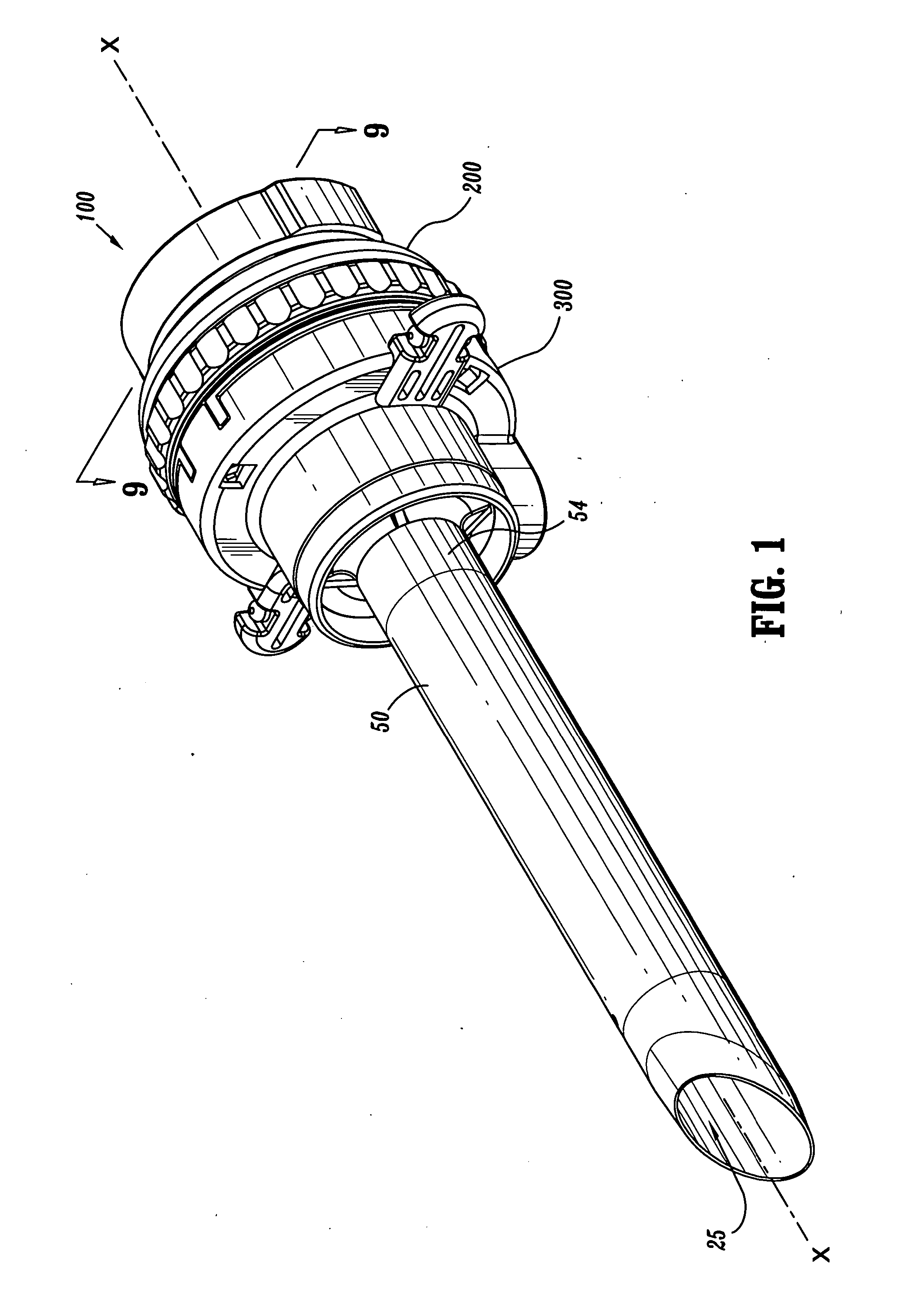

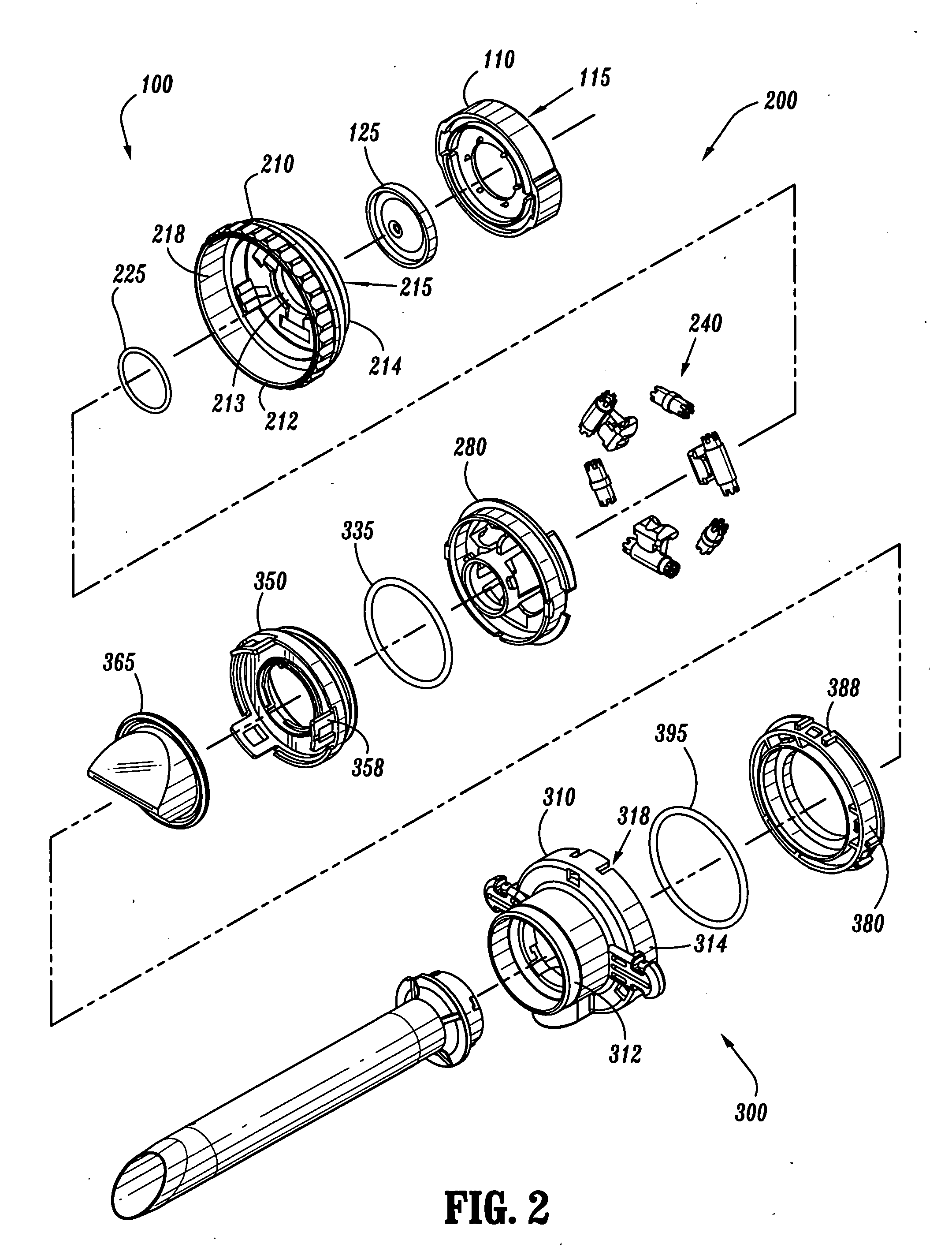

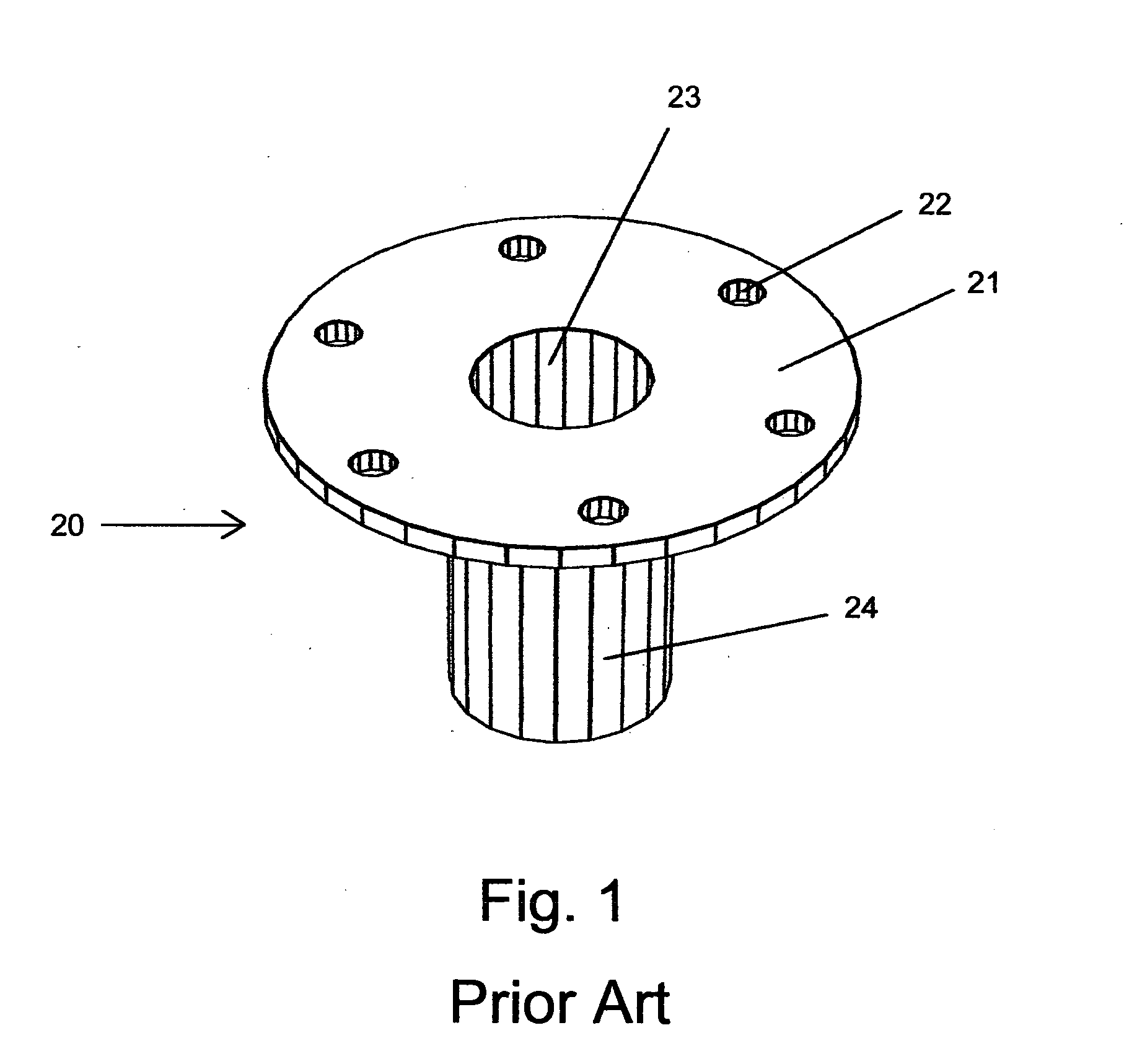

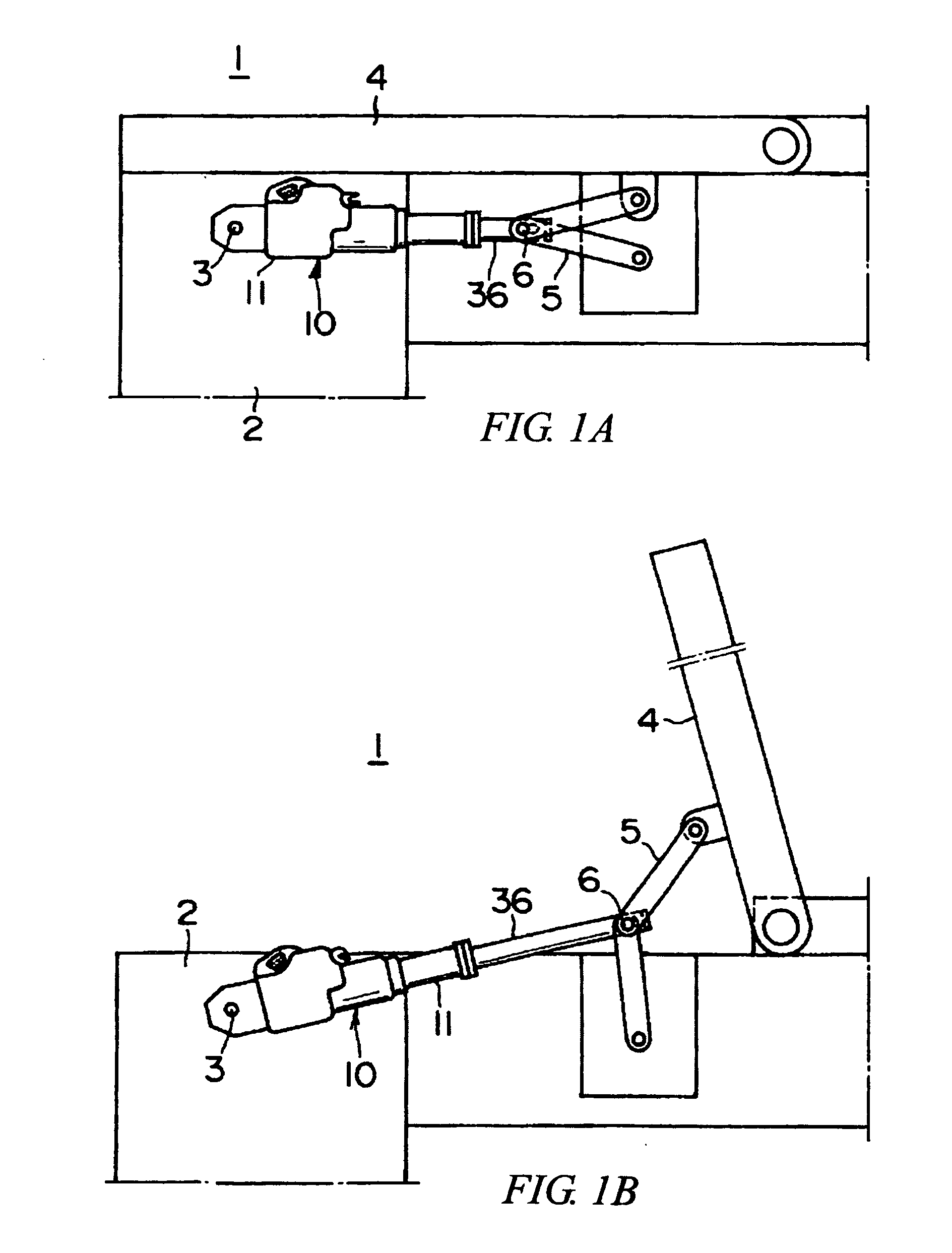

Valve assembly including diameter reduction structure for trocar

InactiveUS7025747B2Convenient introductionSmall sizeCannulasInfusion syringes% diameter reductionVALVE PORT

A valve assembly and diameter reduction structure for trocar employing a movable diameter reduction structure. The diameter reduction structure is positioned in proximity to a first seal and includes a plurality of stand off members movable between a first position, a second position, and a third position. The diameter reduction structure in the first position reduces the likelihood of the first seal losing its integrity by limiting excessive off-axis and angular movements of small diameter surgical instruments. When large diameter surgical instruments are positioned through the trocar, the diameter reduction structure pivots to accommodate the passage of larger diameter surgical instruments without any operational adjustments.

Owner:TYCO HEALTHCARE GRP LP

Valve assembly including diameter reduction structure for trocar

A surgical seal assembly includes a sleeve housing adapted to be operatively connected to a surgical sleeve, a seal housing adapted for releasable mounting to the sleeve housing and having a seal member with inner portions adapted to permit passage of a surgical object in substantial sealed relation therewith, and a manual lock member associated with the sleeve housing. The manual lock member is adapted for movement relative to the seal housing between a first position corresponding to a release position of the seal housing to permit removal of the seal housing from mounting to the sleeve housing and a second position corresponding to a lock position of the seal housing to secure the seal housing to the sleeve housing. The manual lock member is preferably adapted for rotational movement relative to a longitudinal axis of the seal housing to move between the first and second positions thereof.

Owner:TYCO HEALTHCARE GRP LP

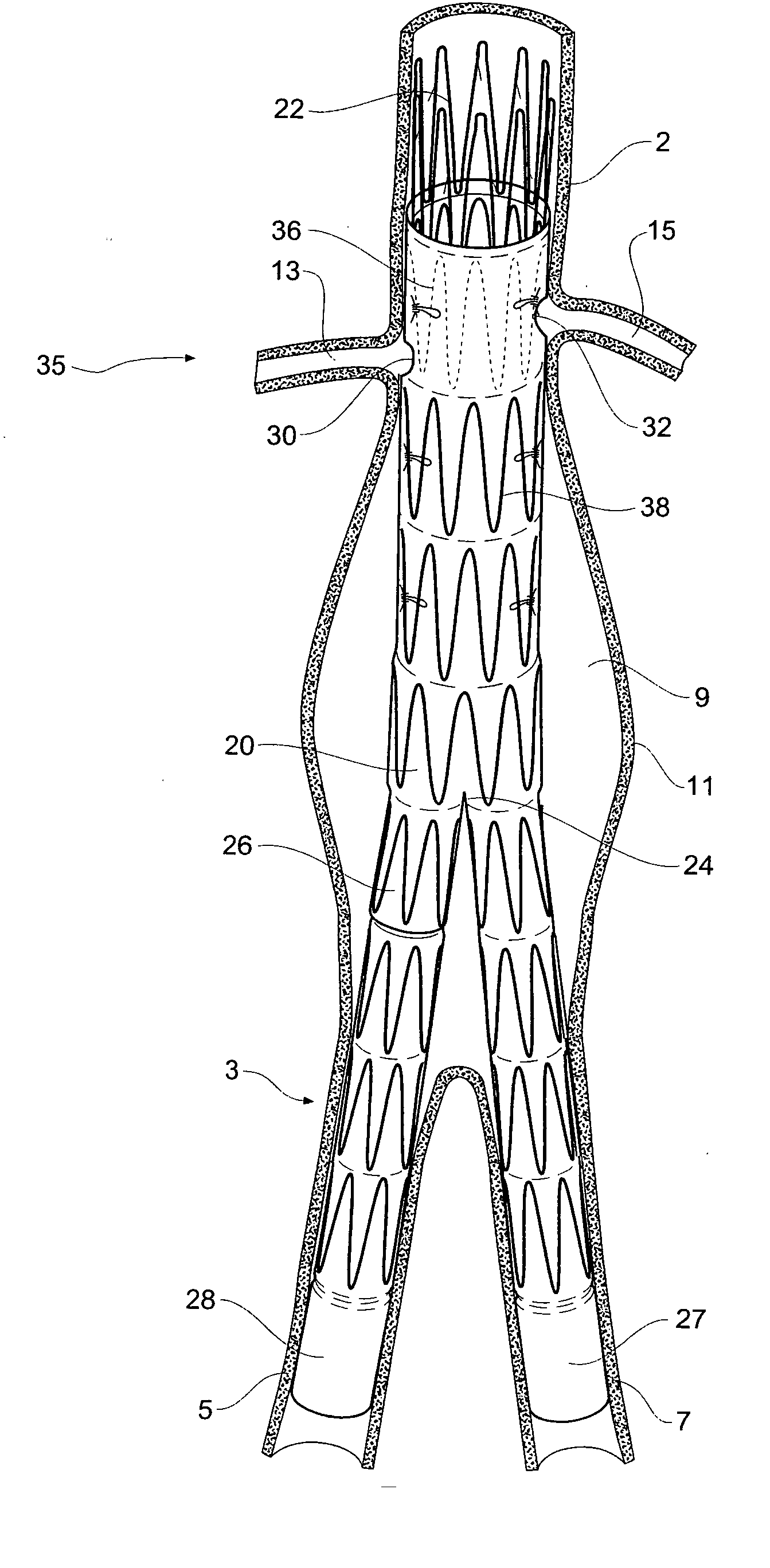

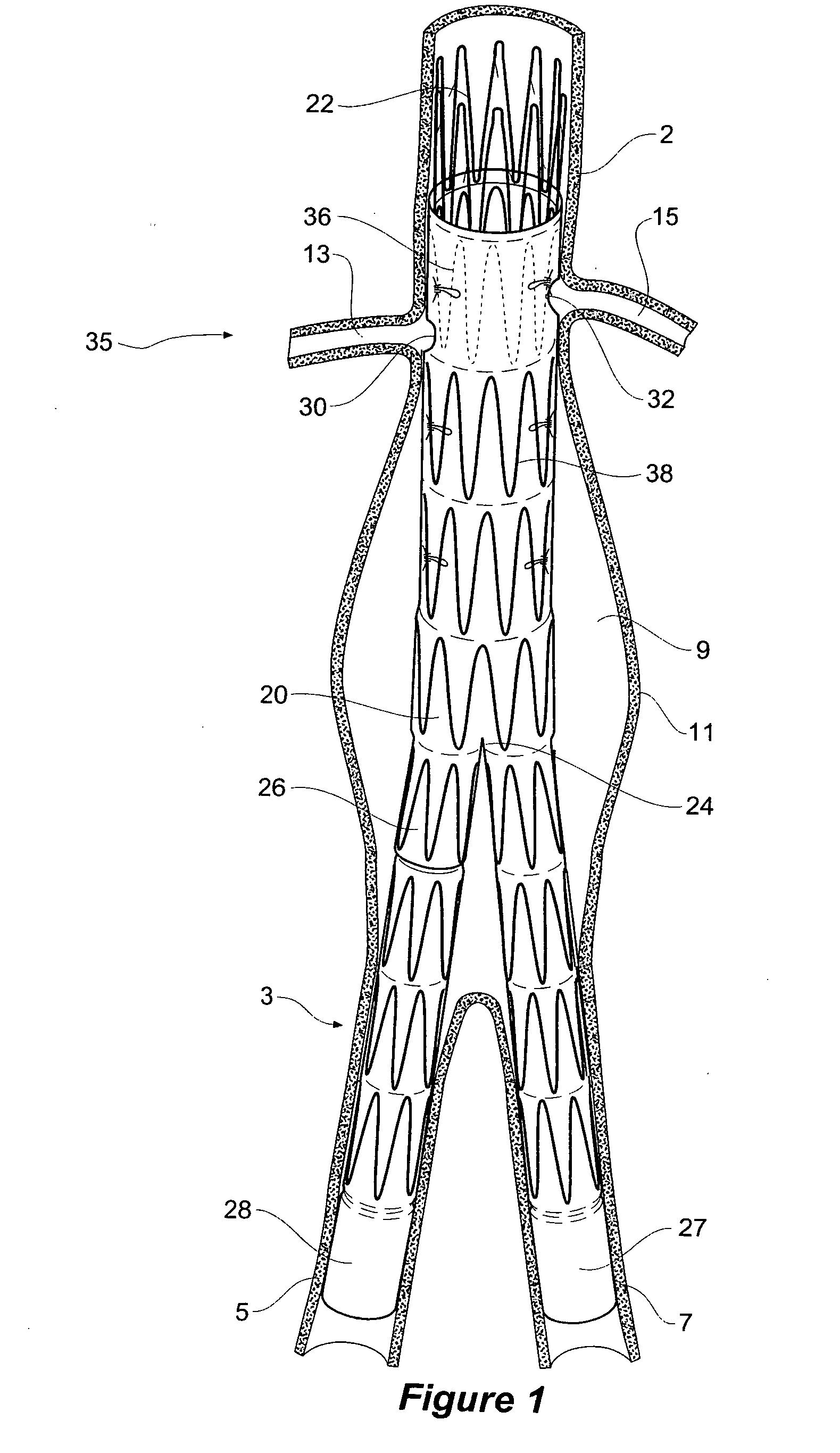

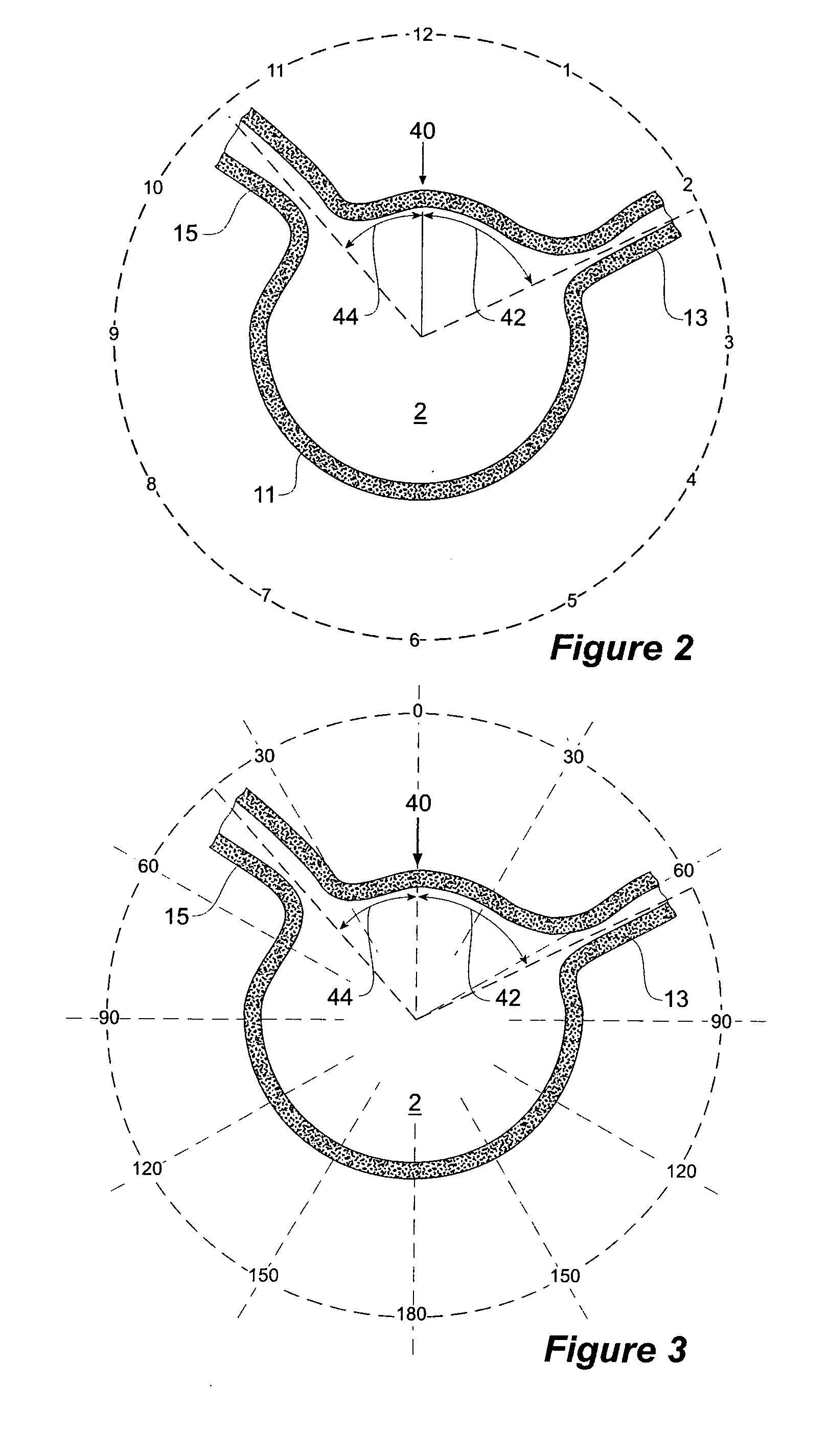

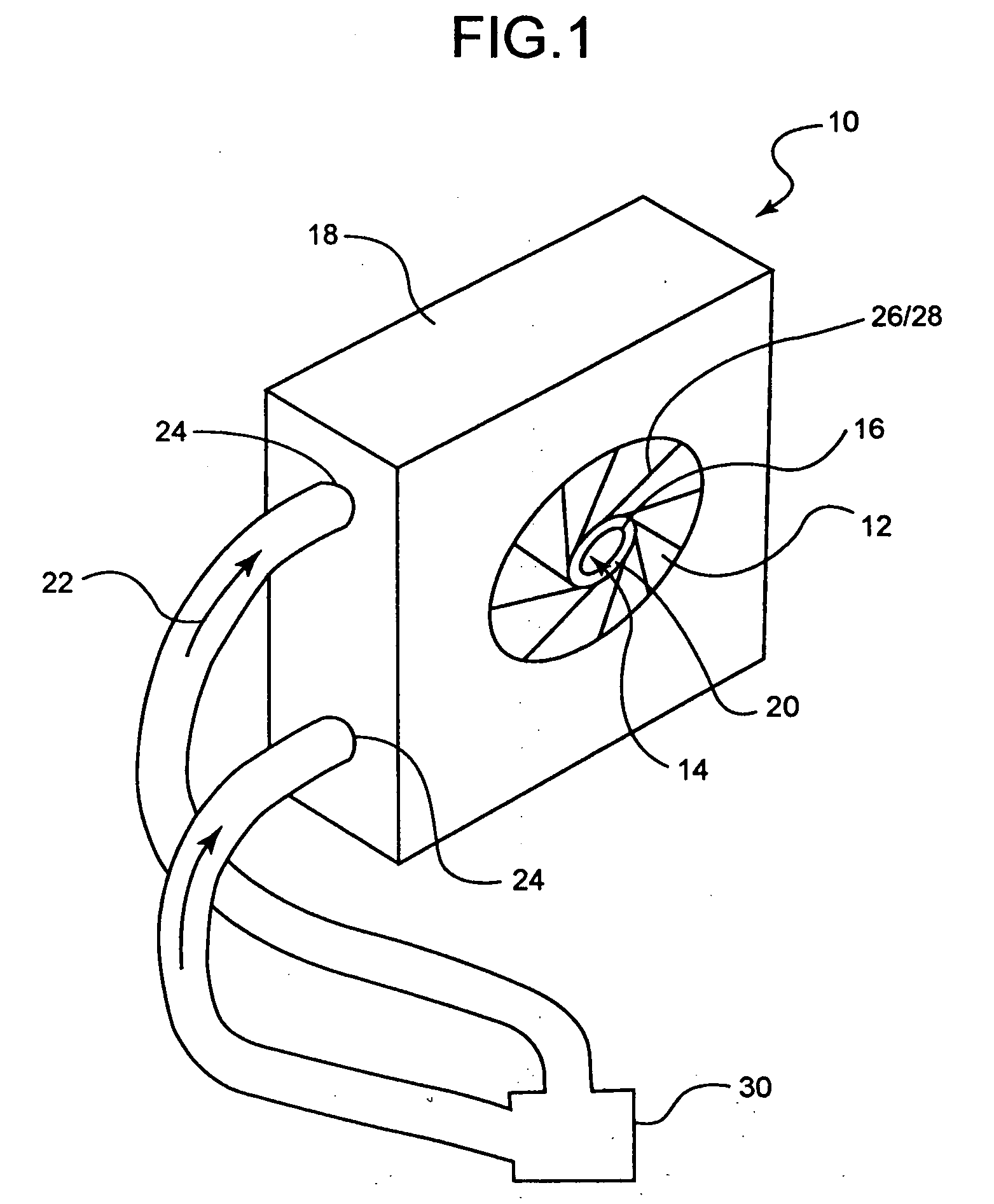

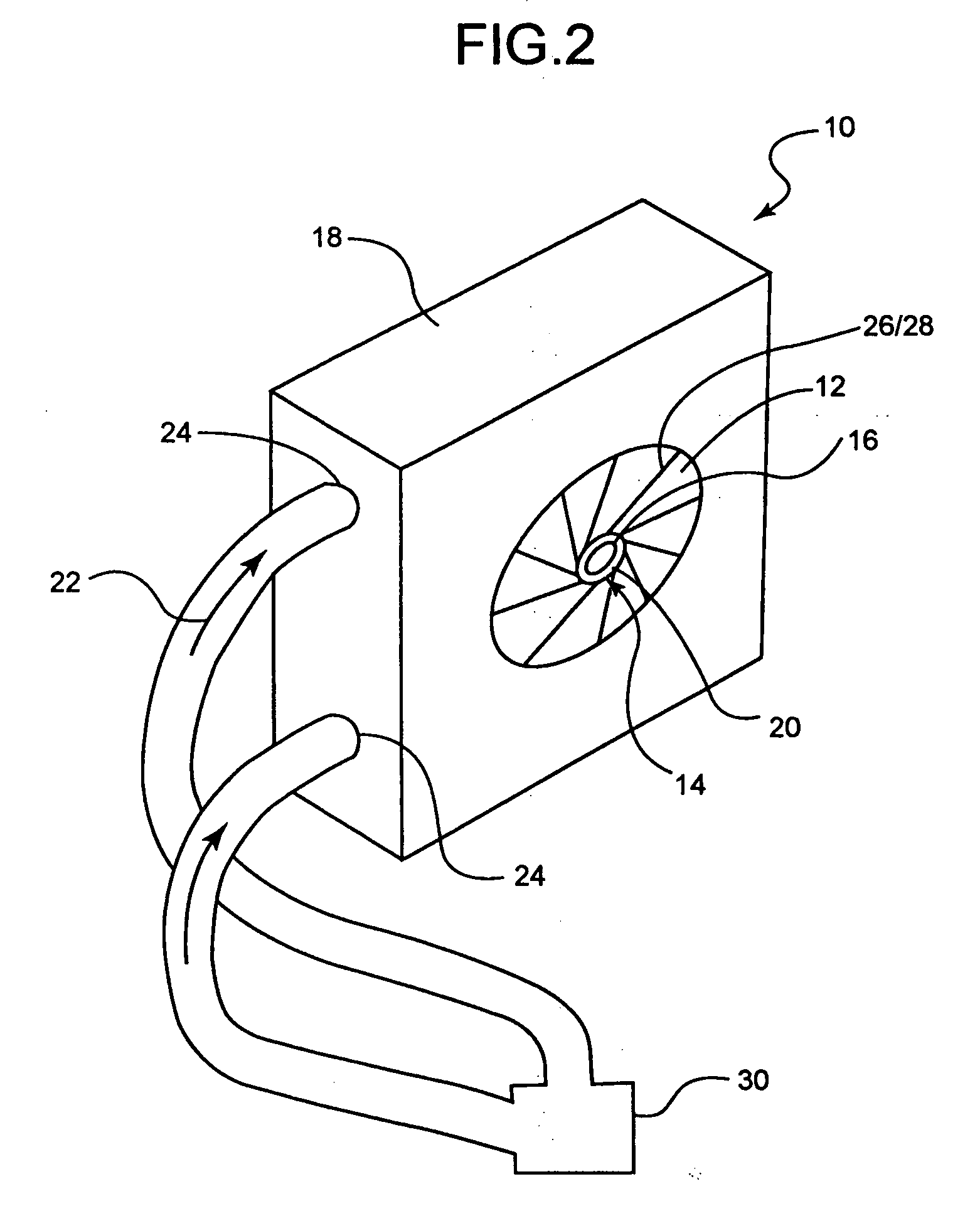

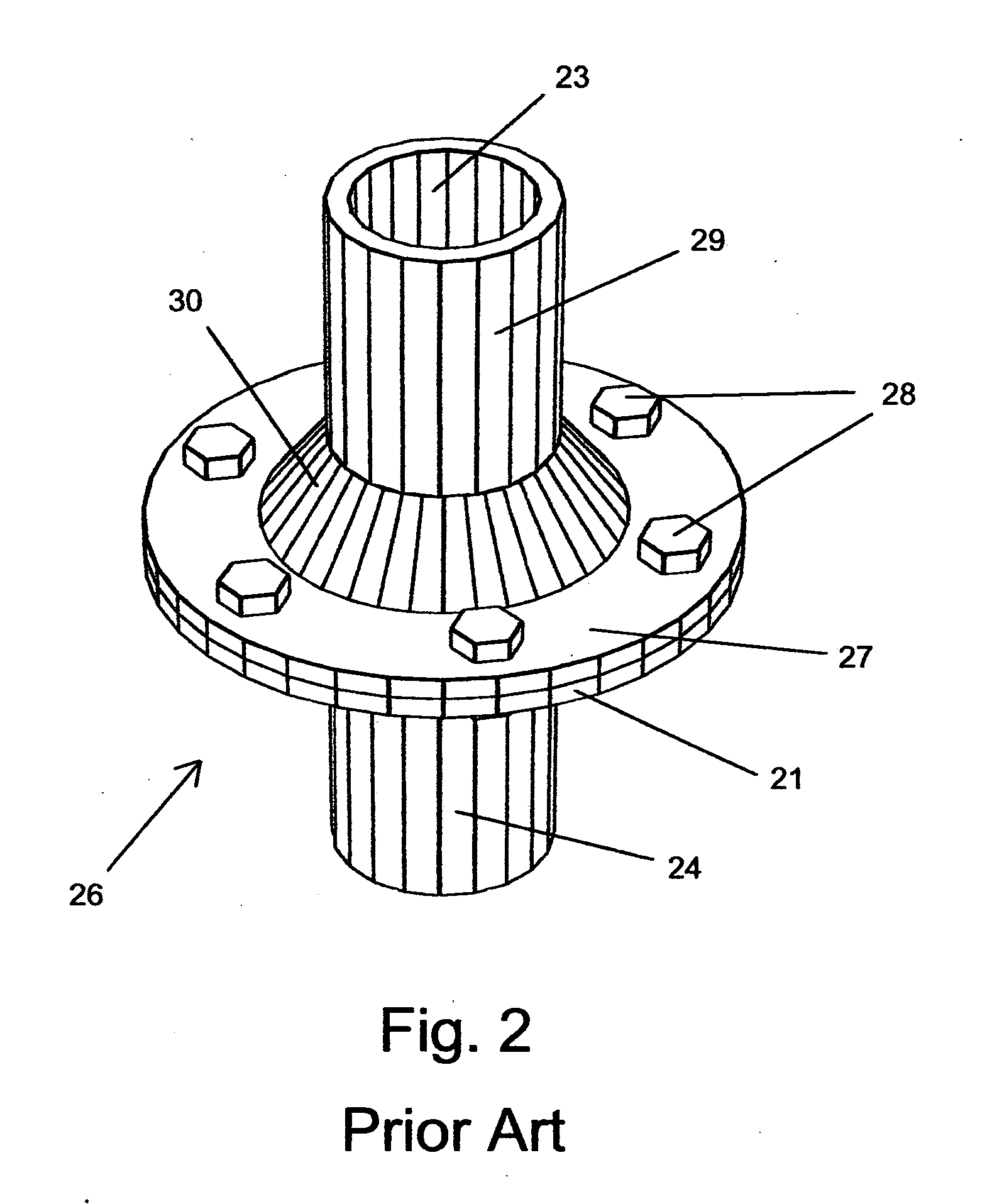

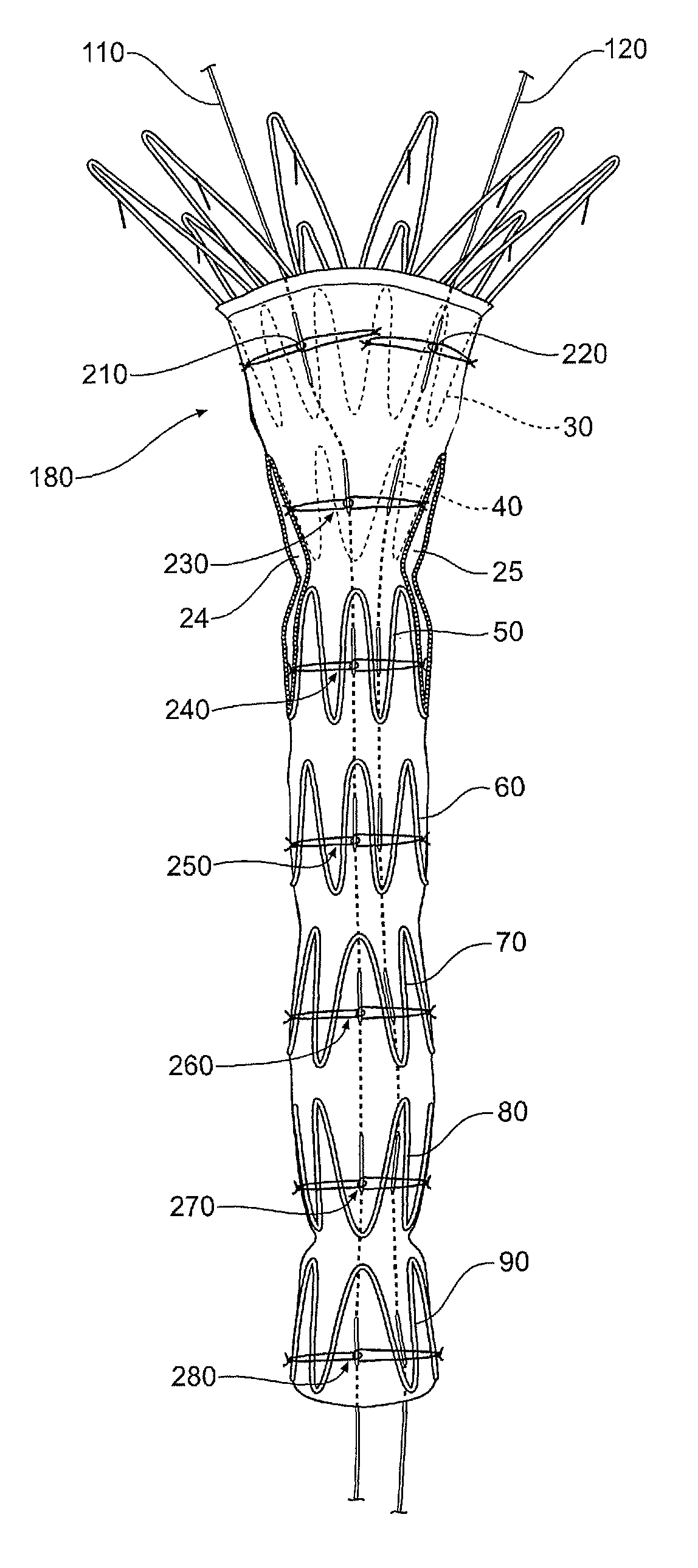

Design and assembly of fenestrated stent grafts

ActiveUS20070142896A1Reduce the overall diameterStentsBlood vesselsStent grafting% diameter reduction

A method of sizing of a stent graft (20) including placement of fenestrations (30, 32) to ensure access to side branch vessels (13, 15) through the fenestrations when the stent graft is introduced into a body vessel and an assembly method for a stent graft including temporary diameter reduction arrangements to enable partial release of a stent graft to assist with positioning of fenestrations with respect to side branch vessels. The method includes spacing the fenestrations to be the same circumferential distance as the side branch vessels irrespective of the diameter of the stent graft.

Owner:COOK MEDICAL TECH LLC

Stent reducing system and device

ActiveUS20050154450A1Reduce frictionMinimize adhesionStentsForging hammersInsertion stent% diameter reduction

A system for reducing the diameter of a stent comprises a stent contracting assembly and a fluid source. The assembly comprises a plurality of contracting members that define a diameter reduction chamber for receiving a stent. When the chamber is in a pre-reduction configuration the stent has a first diameter and when the chamber is in a reduced configuration the stent has a second diameter. The second diameter is less than the first diameter. The fluid source is in fluid communication with the chamber and is constructed and arranged to inject a fluid therein. The fluid forms a fluid bearing between the contracting members and the stent which prevents the contracting members from contacting the stent in the reduced diameter configuration.

Owner:BOSTON SCI SCIMED INC

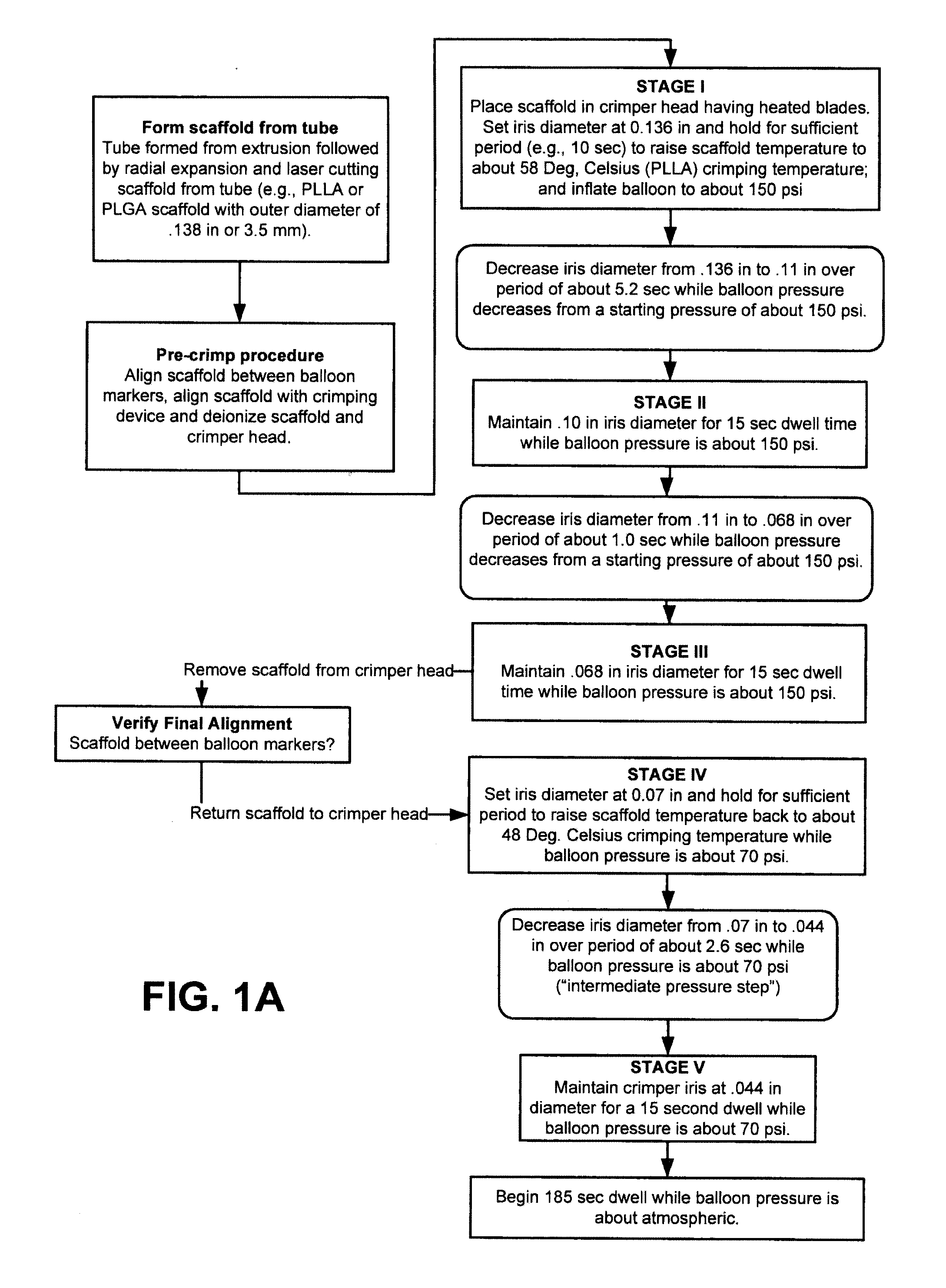

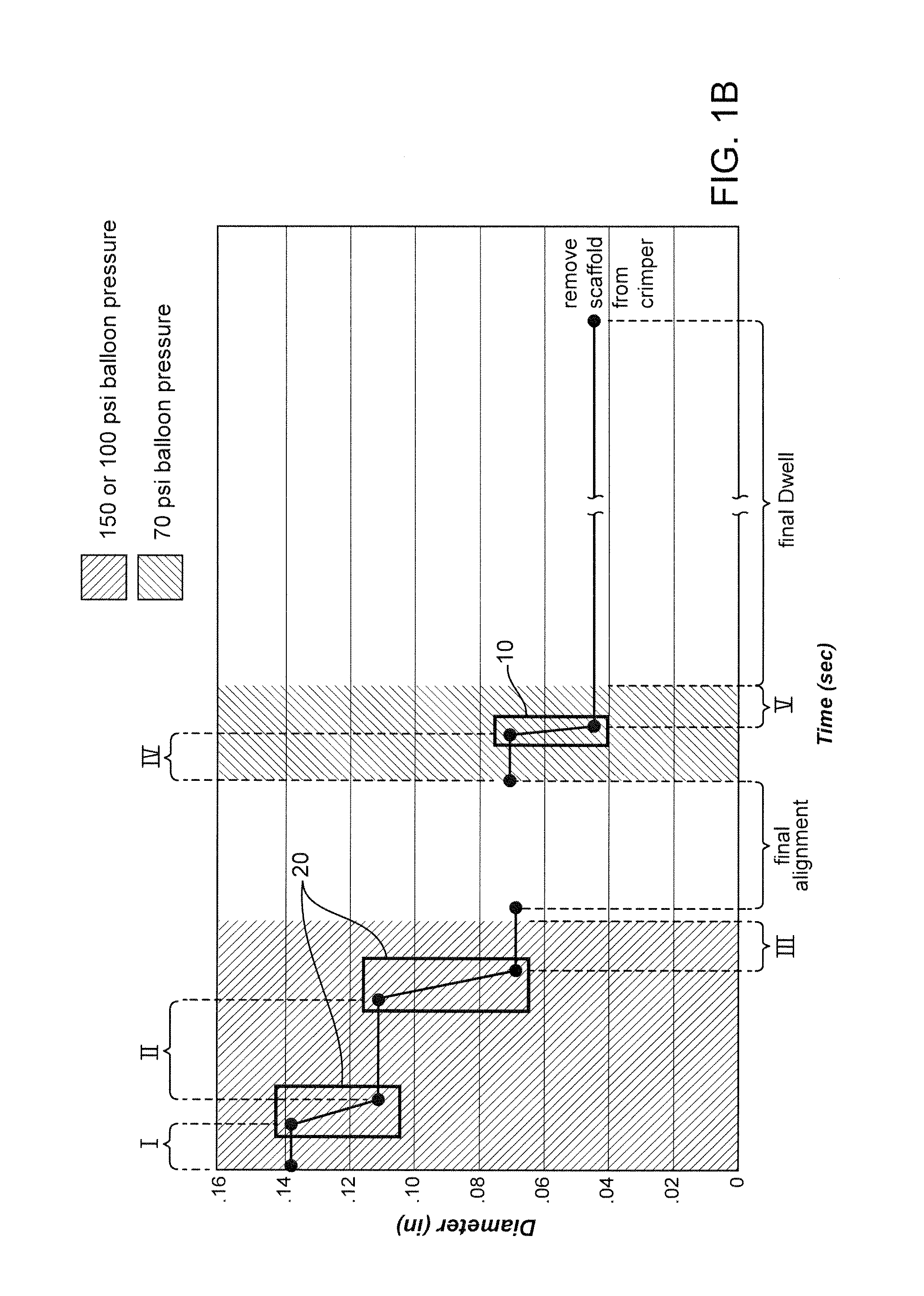

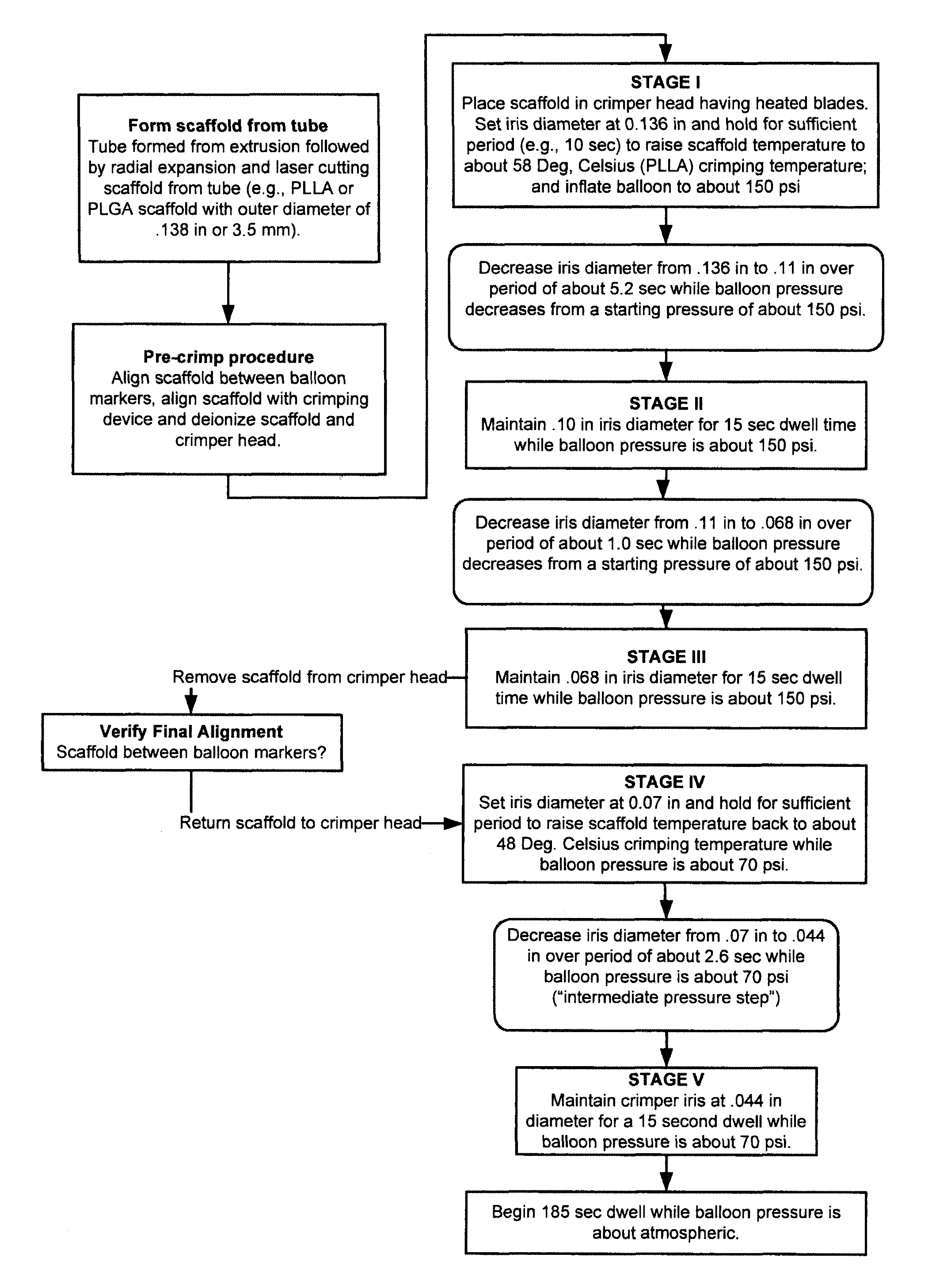

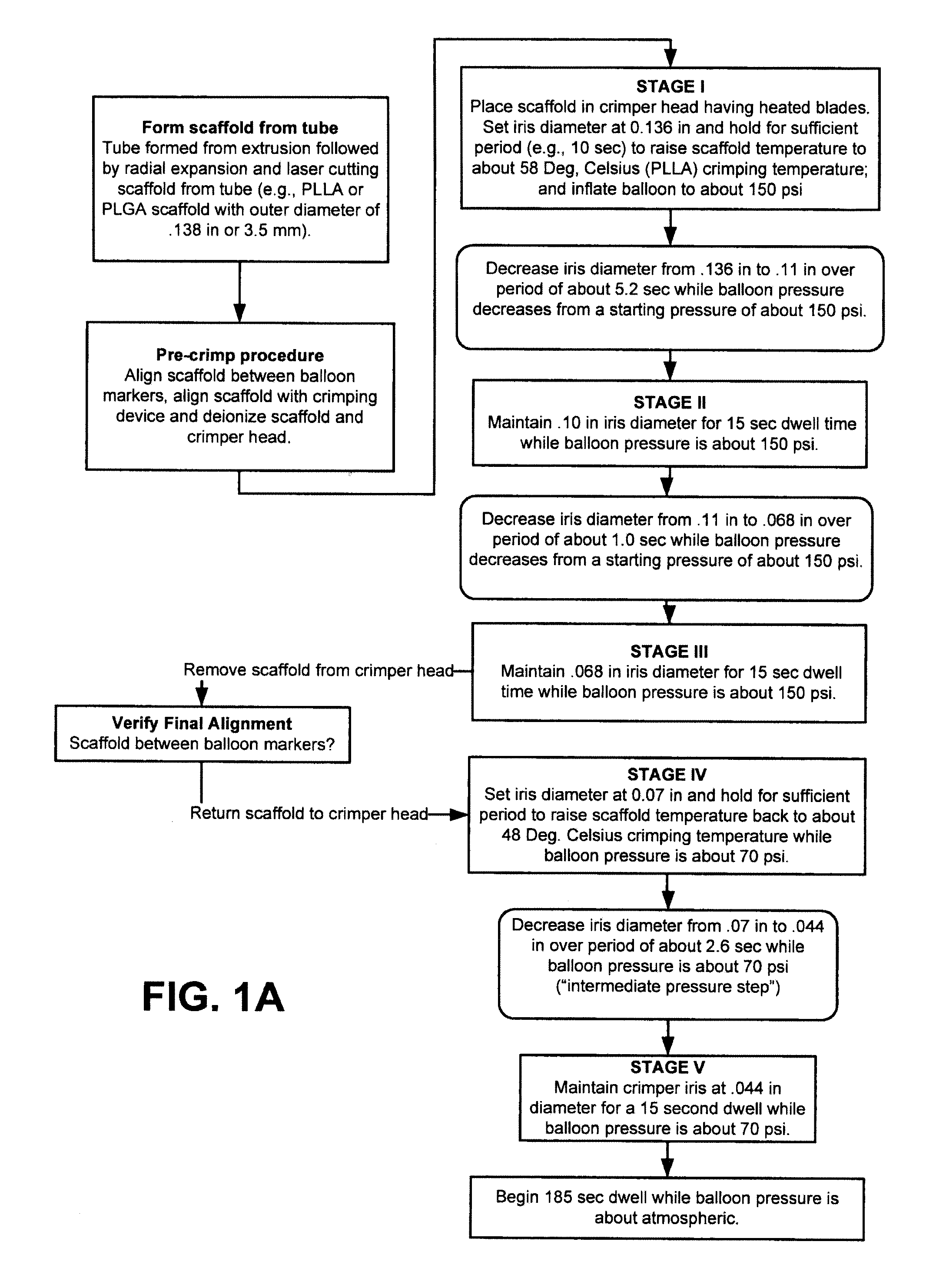

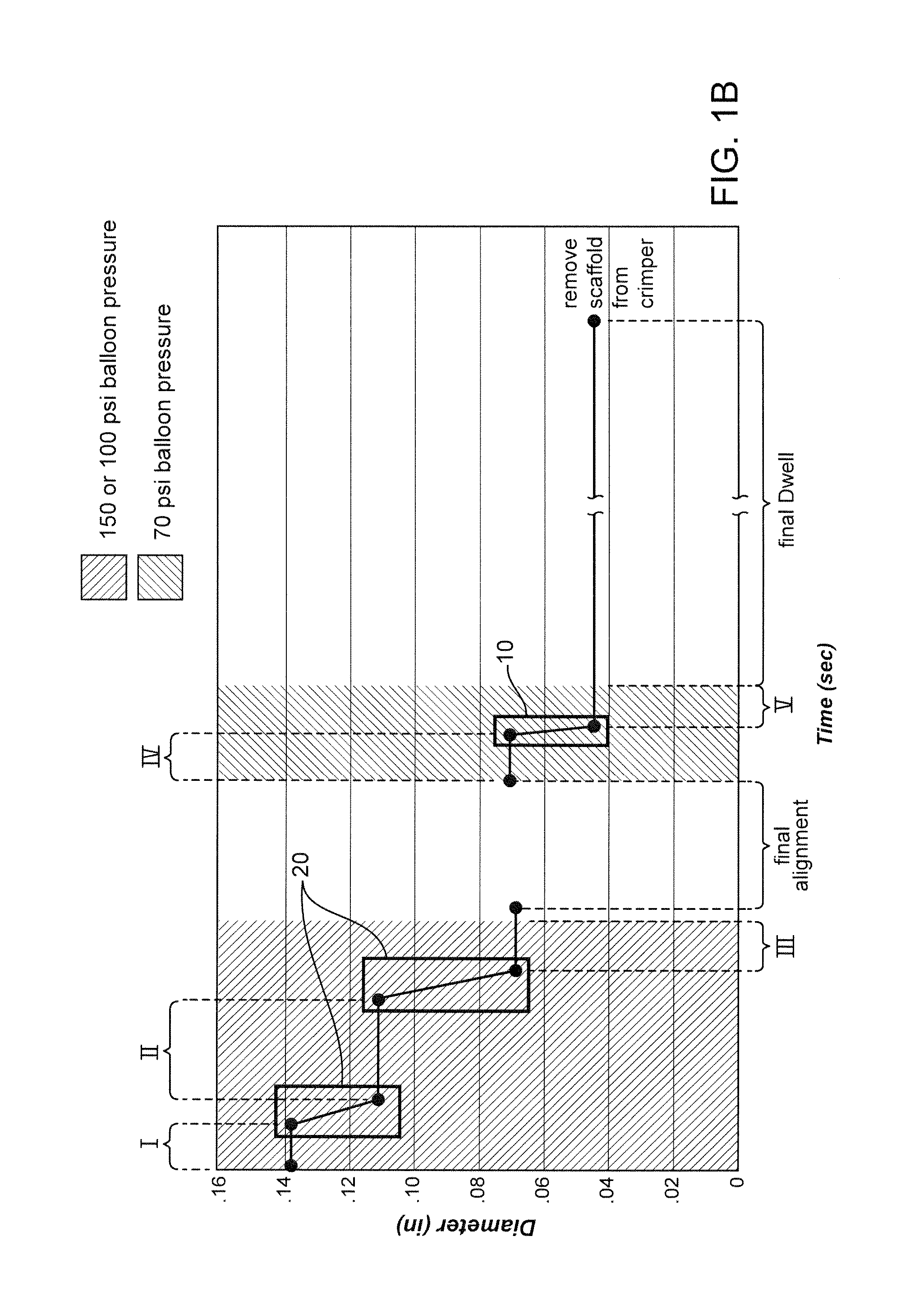

Methods for Crimping a Polymeric Scaffold to a Delivery Balloon and Achieving Stable Mechanical Properties in the Scaffold After Crimping

InactiveUS20120285609A1Reduce the overall diameterShorten the overall cycleStentsLabelling non-rigid containersVitrificationGlass transition

A medical device-includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the balloon by a process that includes inflating the delivery balloon during a diameter reduction to improve scaffold retention. A crimping temperature is maintained at about the onset of glass transition of the polymer material to facilitate more rapid stabilization of mechanical properties in the scaffold following crimping.

Owner:ABBOTT CARDIOVASCULAR

Stent reducing system and device

ActiveUS7284401B2Reduce frictionMinimize adhesionShaping toolsStentsFluid bearing% diameter reduction

Owner:BOSTON SCI SCIMED INC

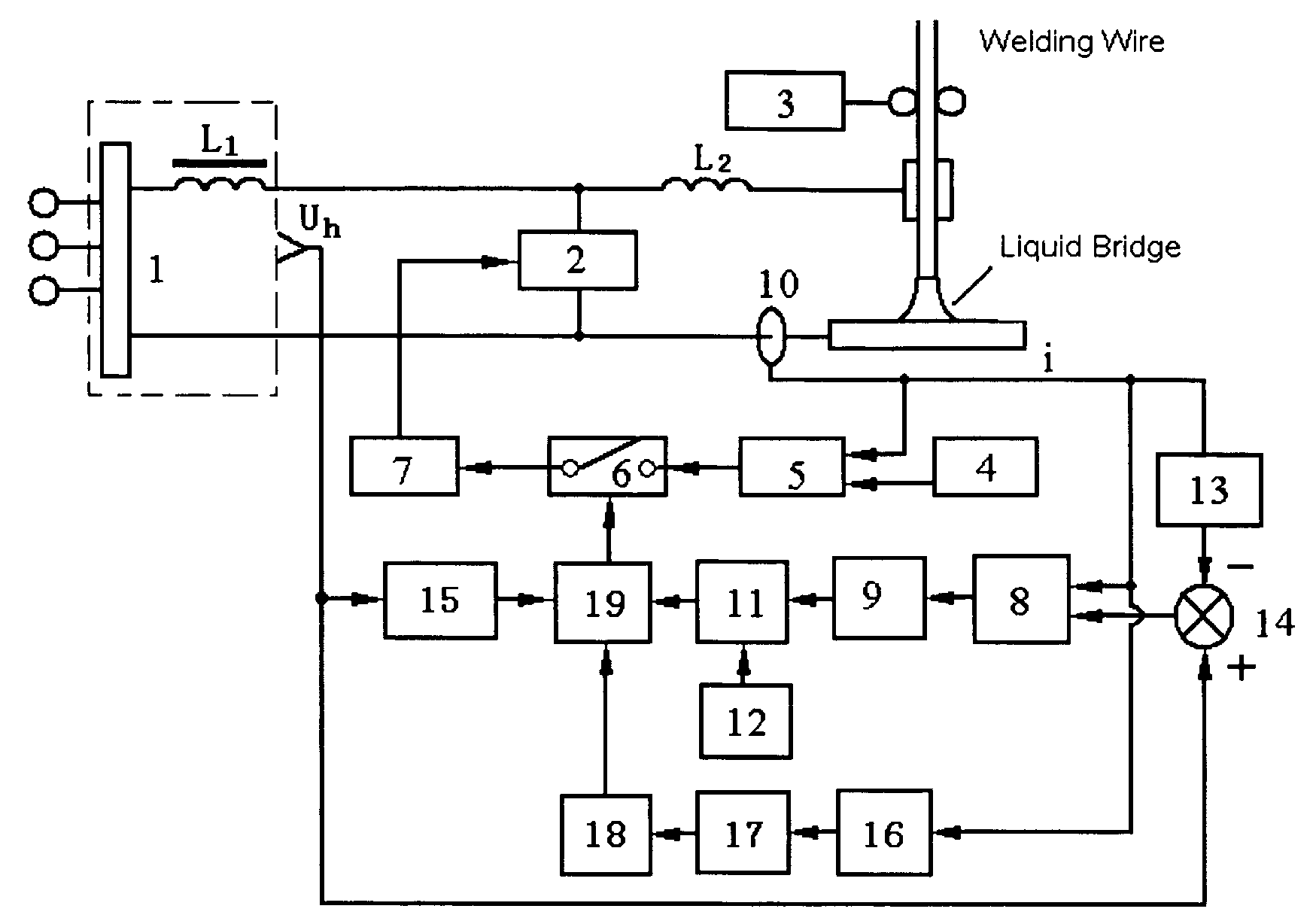

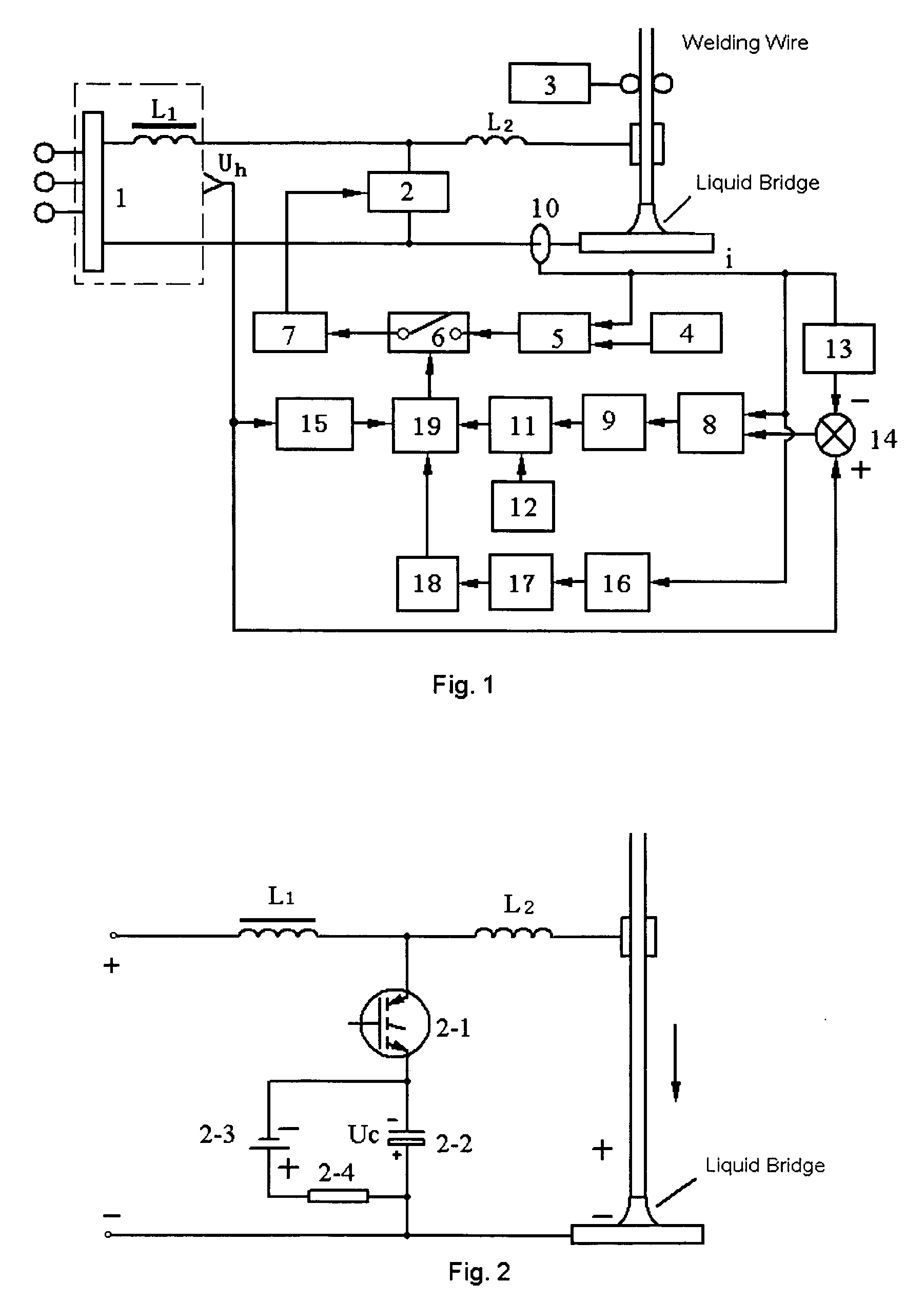

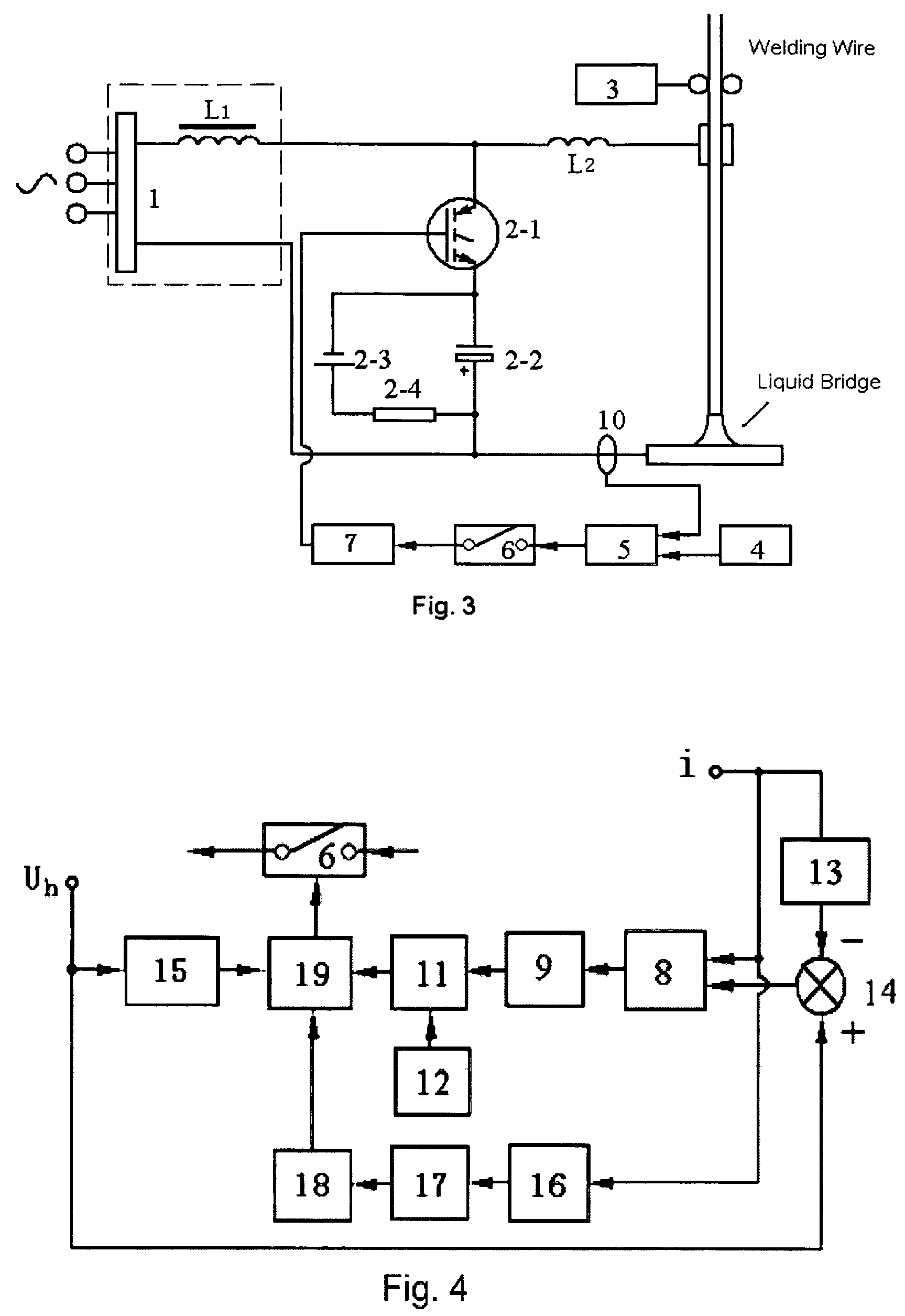

Method and system for reducing spatter in short-circuit transfer gas shielded arc welding

InactiveUS7265320B2Reduce decreaseArc welding apparatusElectrical resistance and conductancePower flow

A method for reducing spatter in the short-circuit transfer gas shielded arc welding is disclosed. In this method, the resistance changing rate or the impedance changing rate of the welding circuit loop is detected for estimating the diameter of the short-circuit liquid bridge. When the diameter of the short-circuit liquid bridge shrinks to the preset value, the short-circuit bridge current is bypassed or shunted by the current closed loop feedback bypass control, and the current is decreased to a very low level rapidly and maintained this level until the bridge is broken, which results in a gentle and smooth drop transfer in a low current level condition, so as to avoid the mass spatter. Furthermore, a system for performing the method has also been disclosed.

Owner:TSINGHUA UNIV

Adaptor cap trocar assembly

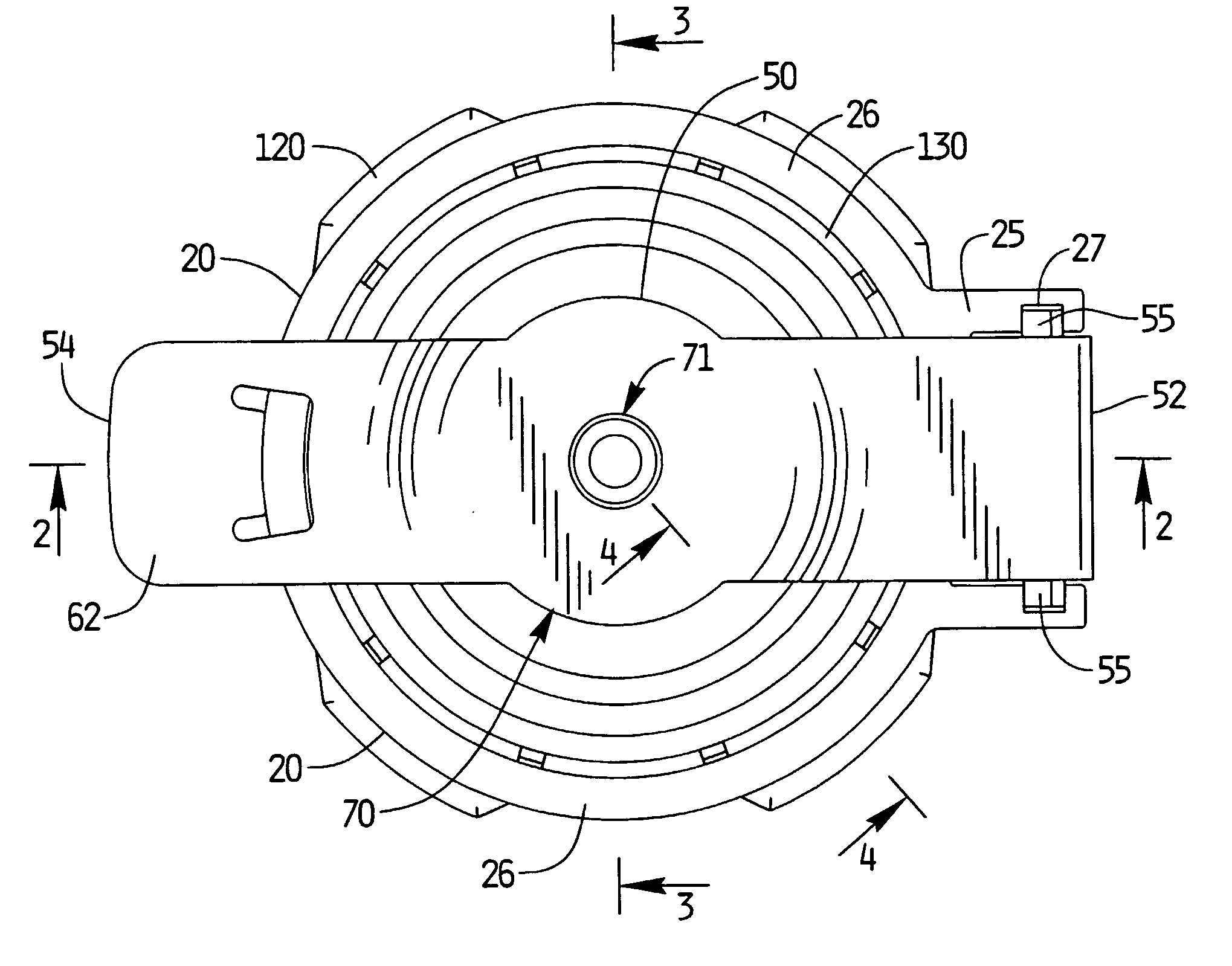

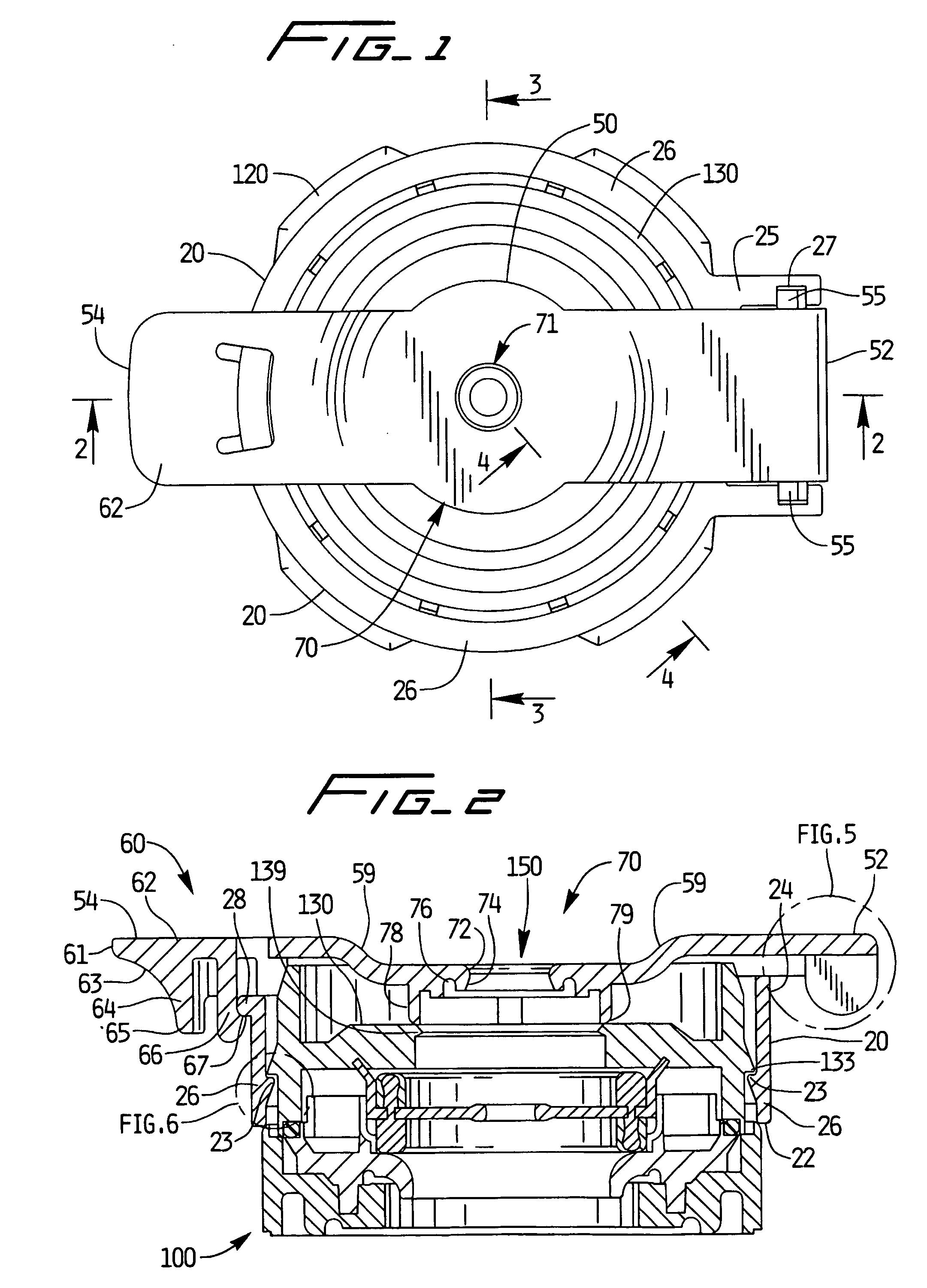

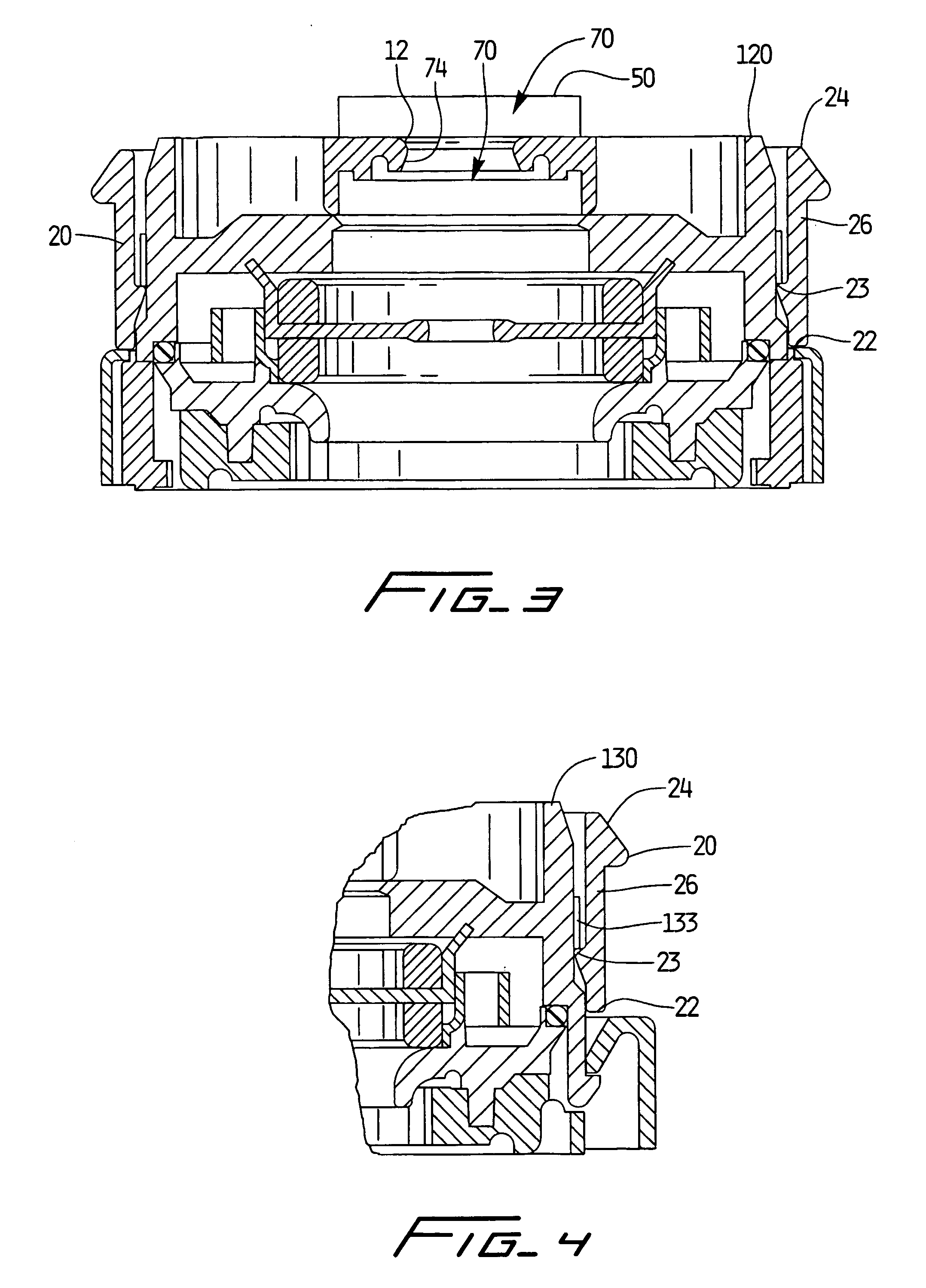

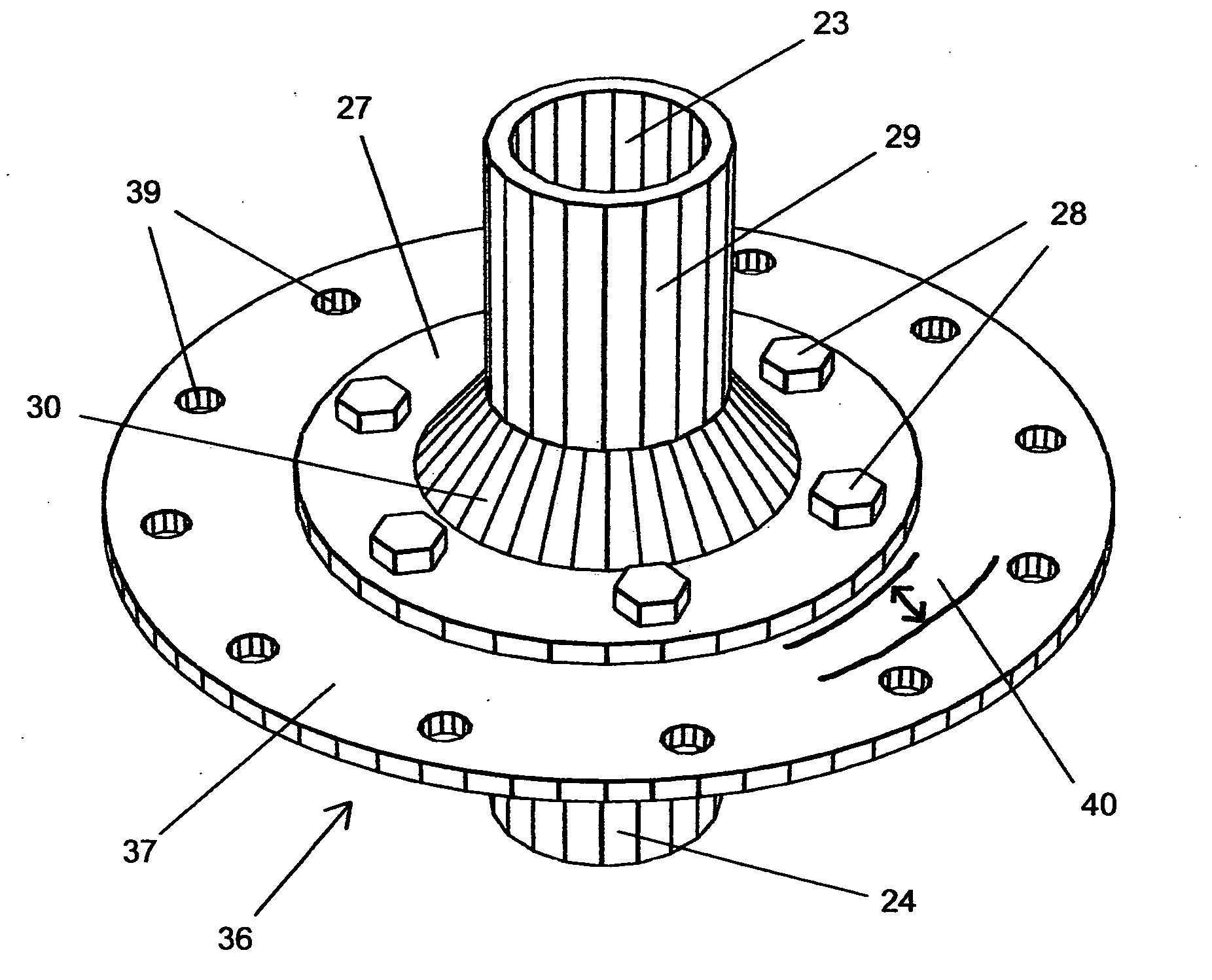

A diameter reduction mechanism for a fixed seal trocar employing a movable reduction member pivotally connected with a housing (20). The housing (20) is adapted to be mounted on a proximal end of a valve assembly (120) of the trocar (100). The reduction member (50) defines a hole (71) aligned with a passageway (150) defined by the trocar (100). The hole (71) defines an operable area less than an operable area defined by the passageway (150). The diameter reduction mechanism is configured for the ease of selectively employing the reduction member (50) between a first position reducing the operable area of the passageway (150) and a second position wherein the reduction member (50) is clear of the passageway (150). The first position is configured to limit excessive off-axis and angular movements of small diameter surgical instruments and the second position is configured to accommodate an unrestricted use of large diameter surgical instruments in the passageway.

Owner:TYCO HEALTHCARE GRP LP

Extended flange plumbing for deep-sea oil containment

InactiveUS20110304138A1Fast cappingReduce riskSleeve/socket jointsFlanged jointsReinforced concreteBarrel Shaped

An emergency redundant mounting flange is provided for incorporation into an oil-well blow-out-preventer (BOP), enabling rapid, tight-fitting attachment of an oil containment cap over a BOP outflow port in an emergency. This flange extends radially outward from the protected port, and includes an annular region with a connection feature, such as a ring of bolt-holes, permitting cap attachment. The cap, also provided, is a barrel-shaped diameter-reduction pipe which can be connected onto the emergency mounting flange at its bottom end, and onto a standard riser pipe at its top end, thus containing or stopping the flow of oil. After installation, the cap fully encloses the protected port, while creating a tight seal with the emergency mounting flange. Extension of these methods to bell-and-spigot plumbing fixtures, including reinforced concrete pipe, is also provided.

Owner:COMMONER FREDERIC G

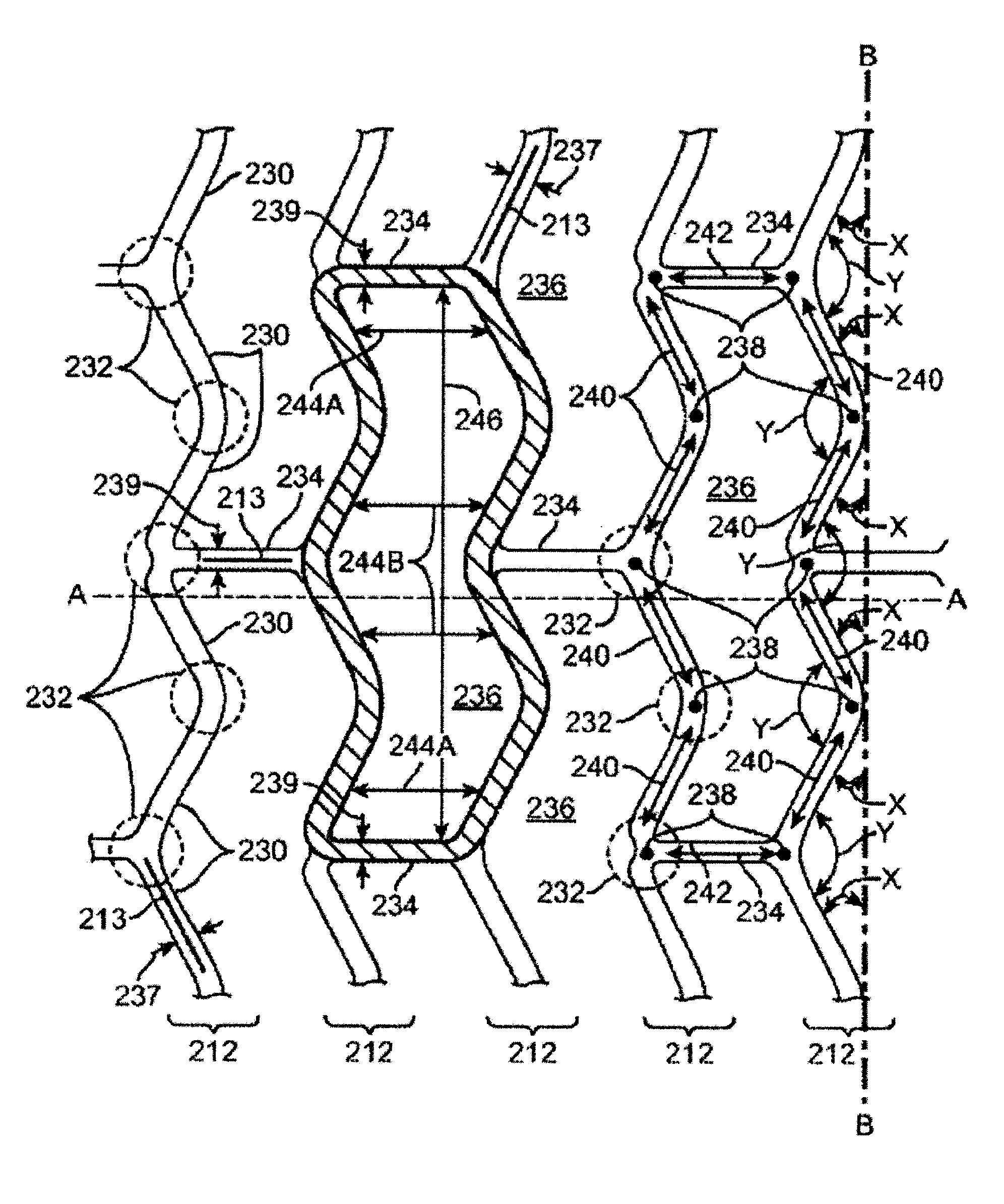

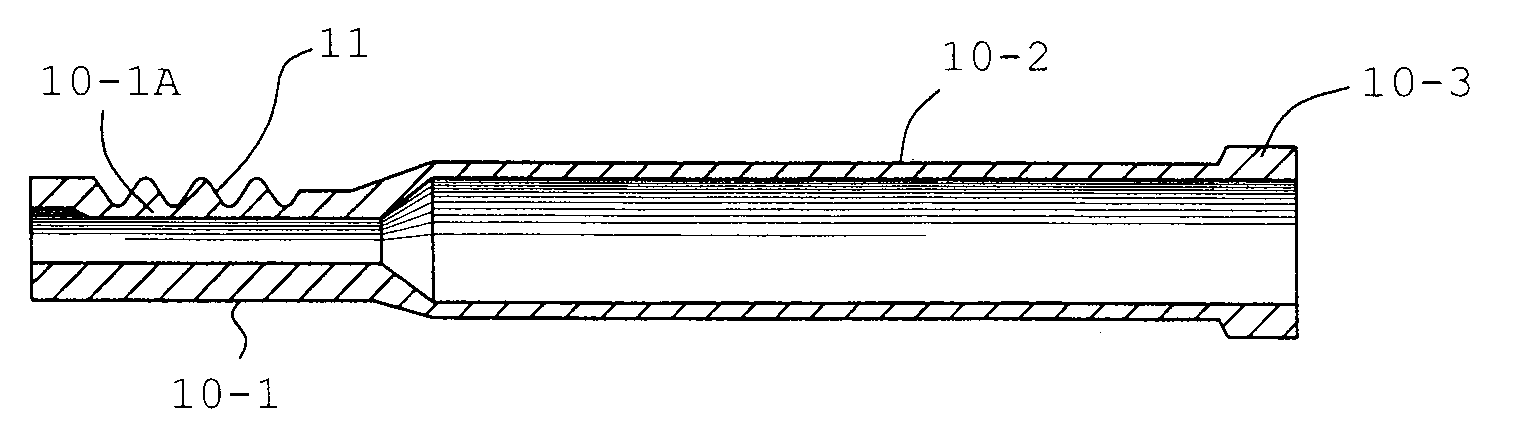

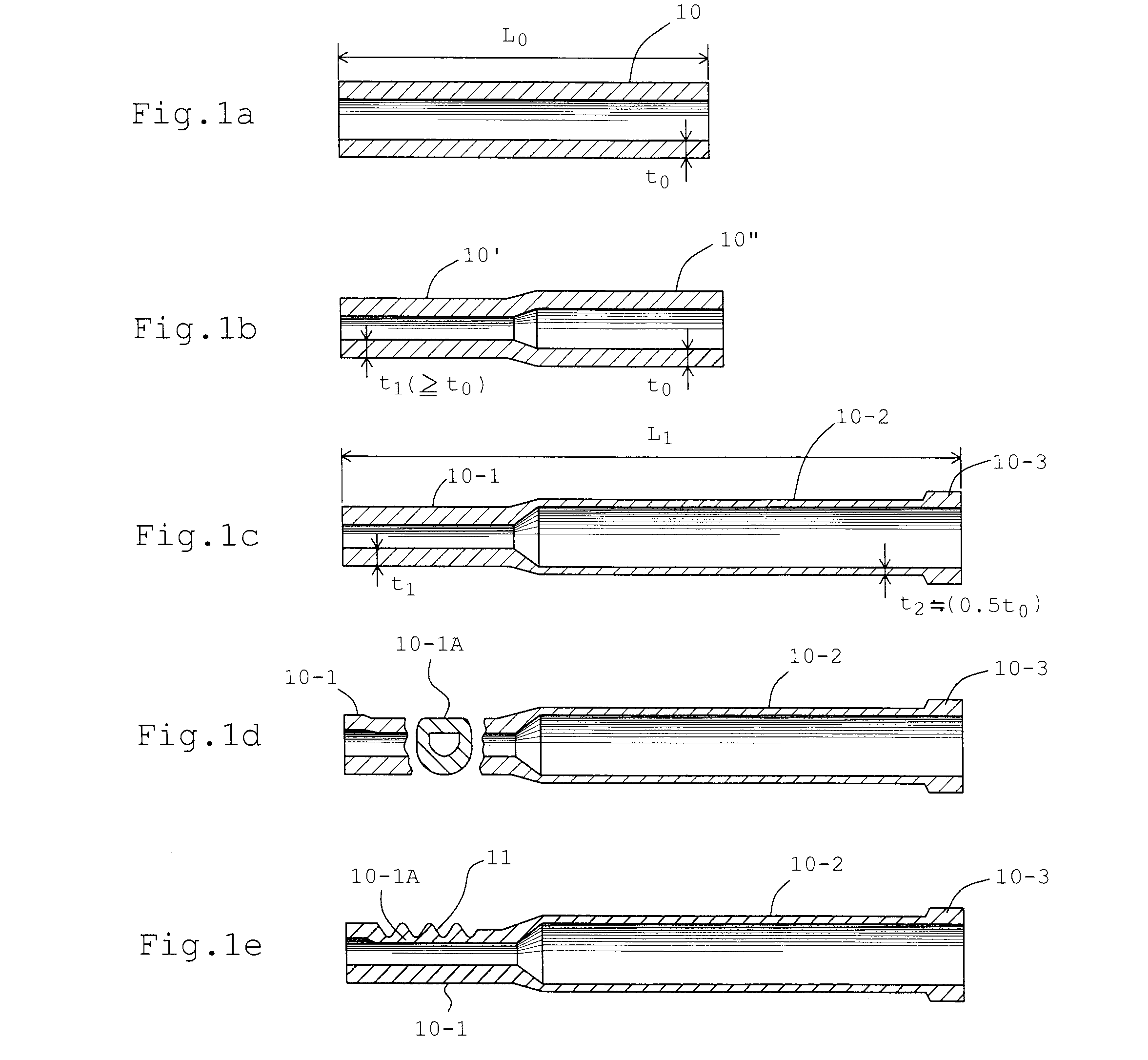

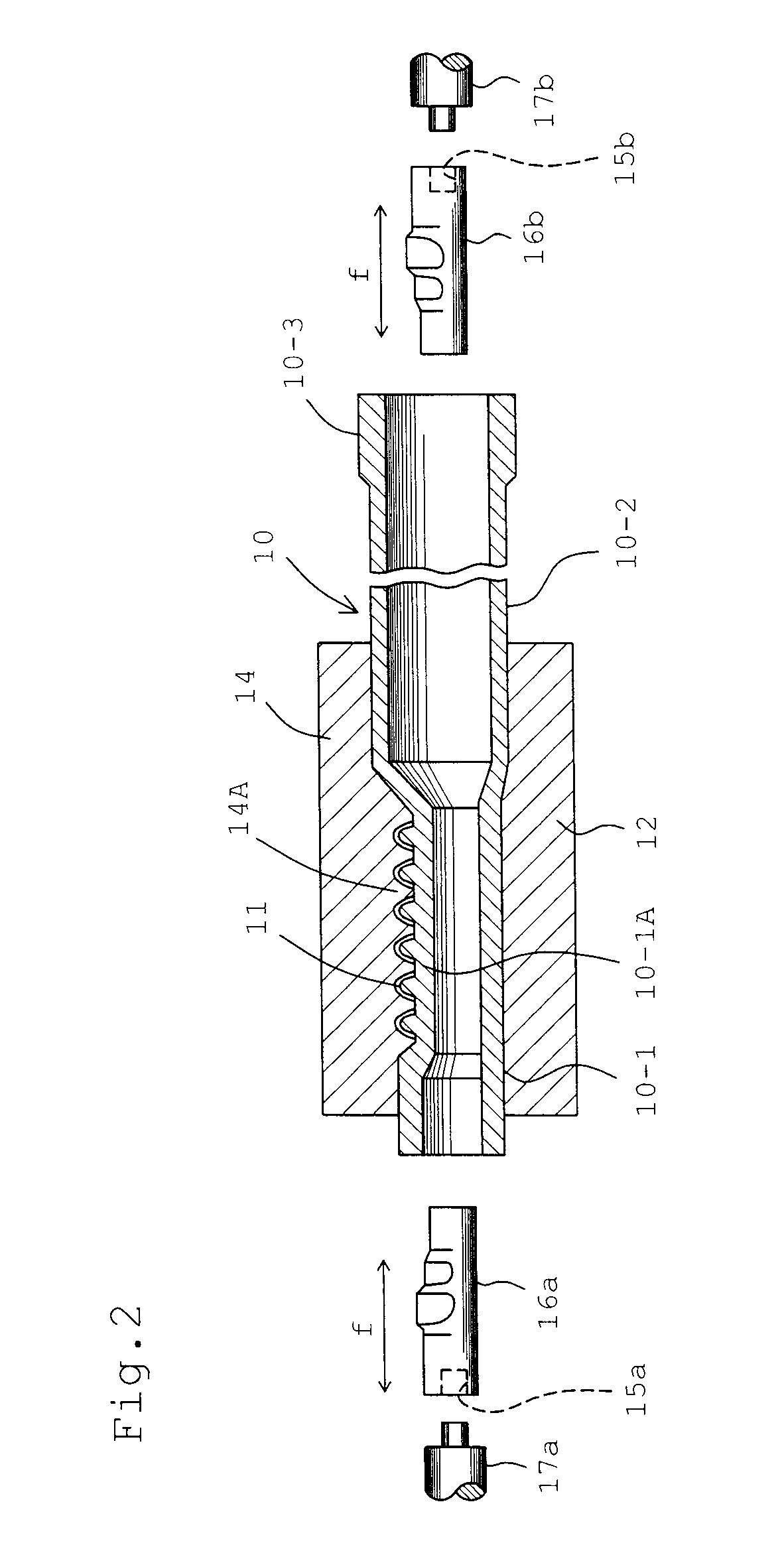

Assembly of stent grafts with diameter reducing ties

A temporary diameter reduction constraint arrangement for a stent graft is disclosed. The arrangement comprises: primary and secondary release wires extending along the graft; a plurality of loops of thread, each loop engaged with either the primary or secondary wire and engaged around a portion of the graft circumferentially spaced away from its release wire, and drawn tight to reduce the diameter of the graft; an end constraint arrangement comprising four of the plurality of loops of thread arranged into a first and second pairs engaged with respective primary and secondary wires; and an intermediate constraint arrangement comprising a fifth and sixth of the plurality of loops of thread arranged into a third pair, the third pair engaged with the primary release wire, the primary release wire deviating towards the secondary release wire so as to locate the intermediate constraint arrangement substantially in-line with the end constraint arrangement.

Owner:COOK MEDICAL TECH LLC

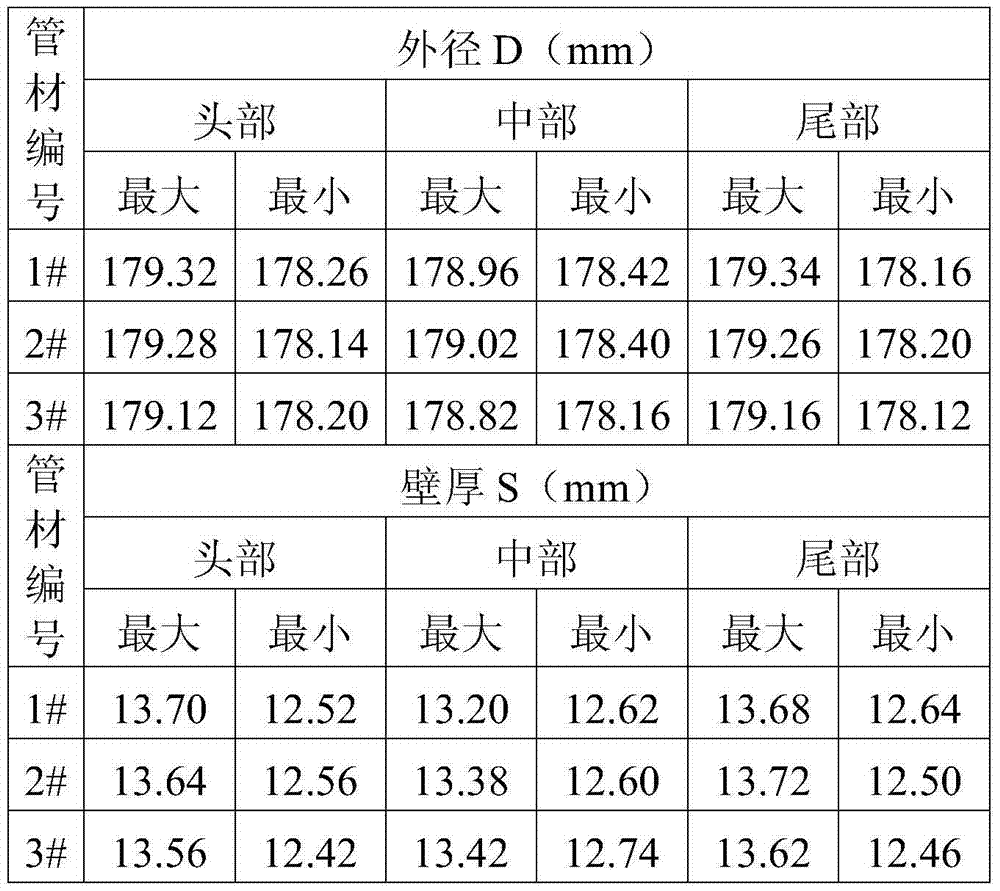

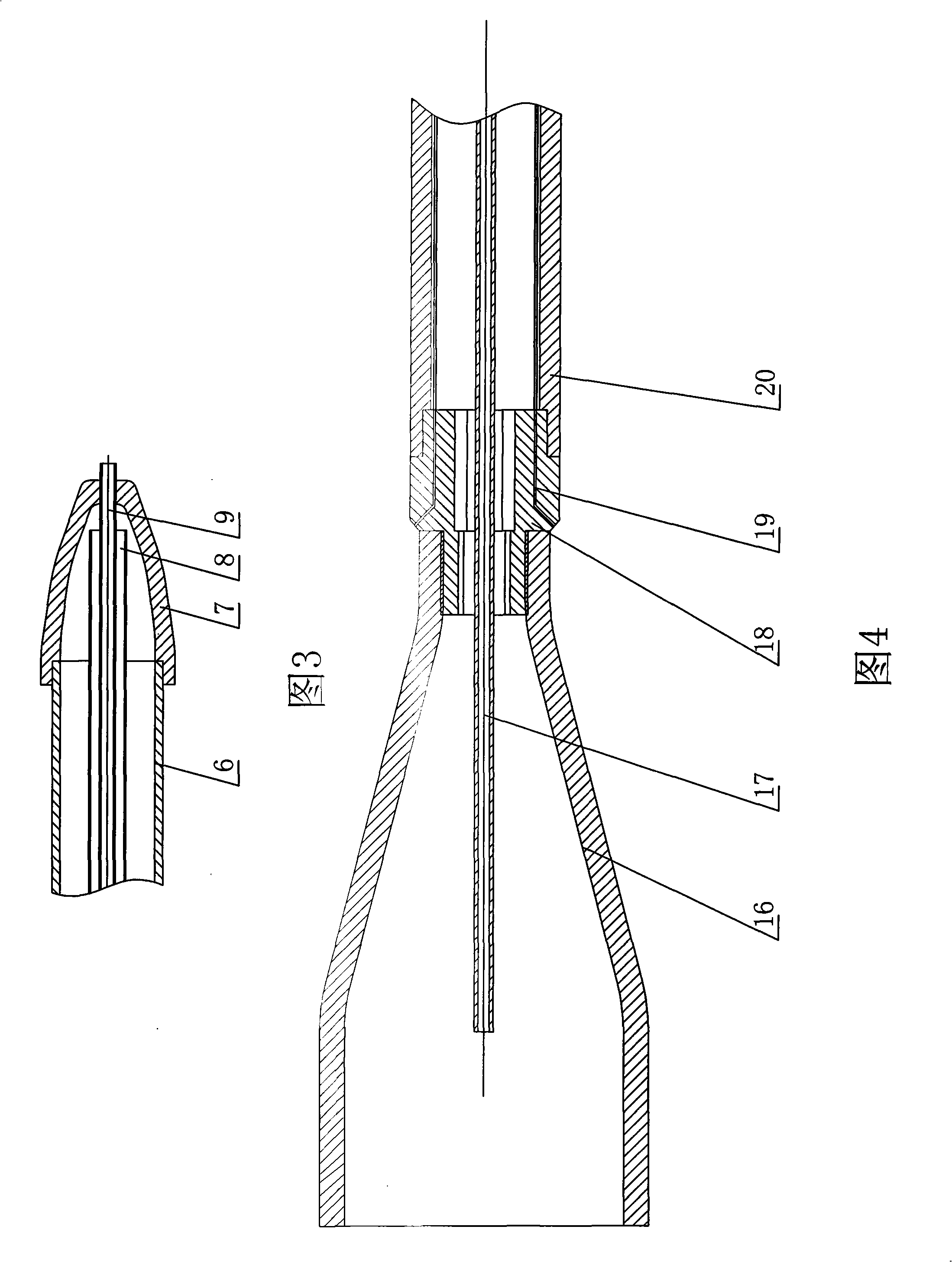

TC4 titanium alloy seamless tube and production method thereof

ActiveCN103934269AGood mechanical propertiesReasonable processTemperature control deviceMetal rolling arrangementsReduction ratePunching

The invention provides a TC4 titanium alloy seamless tube and a production method thereof. The method comprises the steps of heating a round billet of a TC4 titanium alloy to 920-980 DEG C; conducting on-line hot centering on the round billet; conducting cross piercing, wherein controlling the total diameter reduction rate to be 9-16%, controlling the before-head reduction rate to be 2.5-11%, controlling the ovality coefficient to be 1.13-1.20, and controlling the punching rate to be 0.2-0.5m / s; conducting precise skew rolling to form a pierced billet, enabling the total diameter reduction rate to be 12-18%, enabling the ovality coefficient to be 1.08-1.15, enabling the tube rolling rate to be 0.3-0.4m / s; controlling the temperature of the pierced billet to be 860-940 DEG C, sizing and conducting air cooling to obtain the TC4 titanium alloy seamless tube. By means of the production method, the TC4 titanium alloy seamless tube with the excellent mechanical property can be obtained, production efficiency is high, mass production can be achieved, and the yield can reach 90% and more.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Abrasive wear resistant weld deposit flux-cored wire

InactiveCN101402161AUniform compositionOvercome the disadvantages of easy to cause uneven compositionWelding/cutting media/materialsSoldering mediaWear resistantSmelting process

The invention discloses an overlaying welding agent core welding wire with abrasive wear resistance. A steel strip is wrapped with alloy powder and is subjected to drawing path by path and diameter reduction through a wire-drawing die to form the overlaying welding agent core welding wire, wherein the diameter of the overlaying welding agent core welding wire is between 2.4 and 3.2 mm; the length of the overlaying welding agent core welding wire is freely set; the steel strip is one of an SPCC steel strip, a 08A steel strip and a 08Al steel strip with width of between 18 and 22 mm and thickness of 0.45 and 0.6 mm; and the aluminum alloy powder is manufactured from waste steel and an alloying agent. The overlaying welding agent core welding wire is designed according to the composition requirement of overlaying welding metal; and compositions are fully homogenized in the smelting process of pulverization, thereby overcoming the disadvantages that the prior medicine powder for producing the overlaying welding agent core welding wire adopts a mechanical mixing process to easily cause unevenness of the compositions. The overlaying welding agent core welding wire uses the waste steel as one of raw materials of the overlaying welding agent core welding wire with abrasive wear resistance, fully utilizes contained alloy elements, improves the utilization rate of the alloy elements, reduces the cost for the overlaying welding agent core welding wire and achieves the aims of energy conversation and emission reduction.

Owner:SHANDONG UNIV

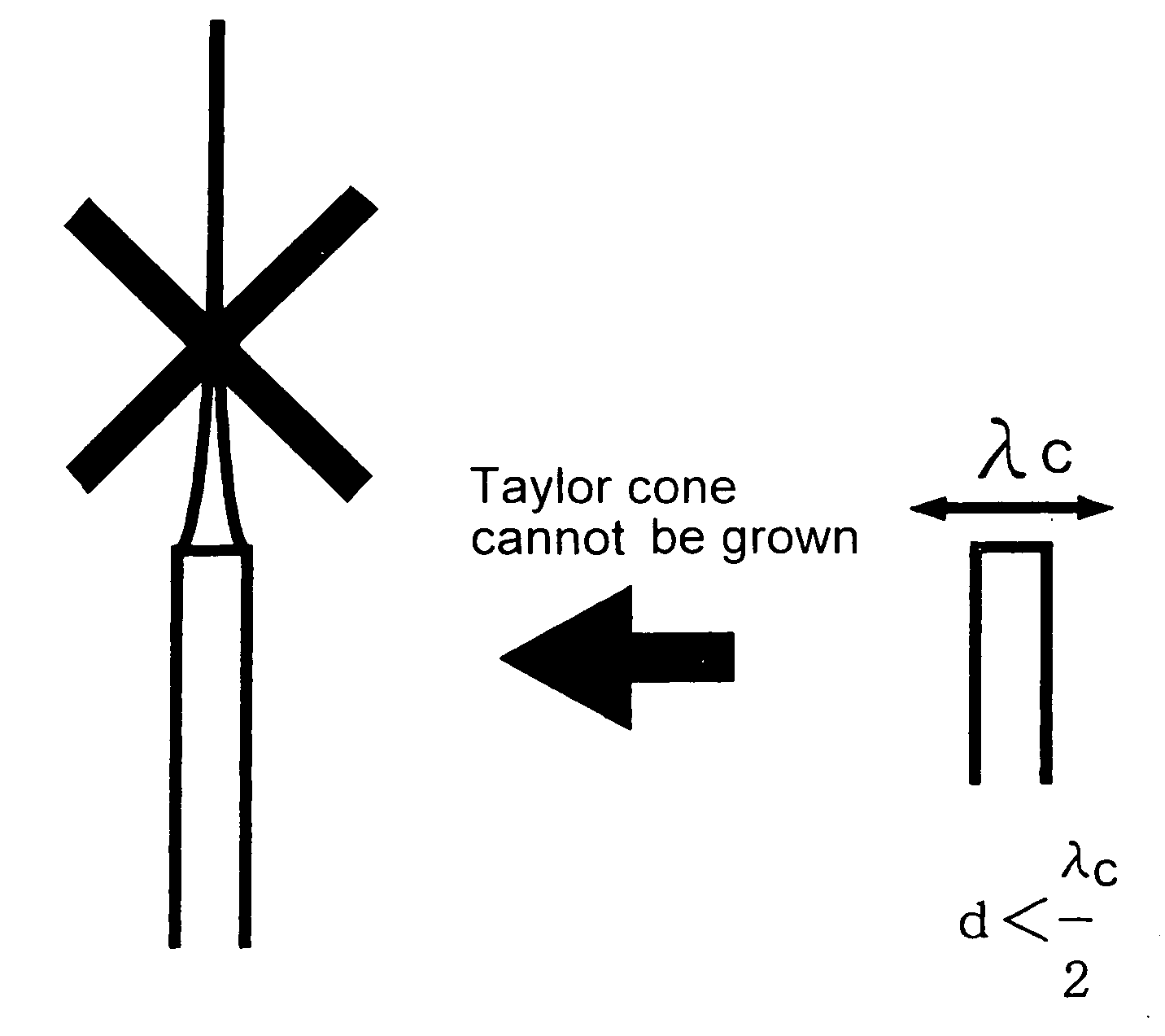

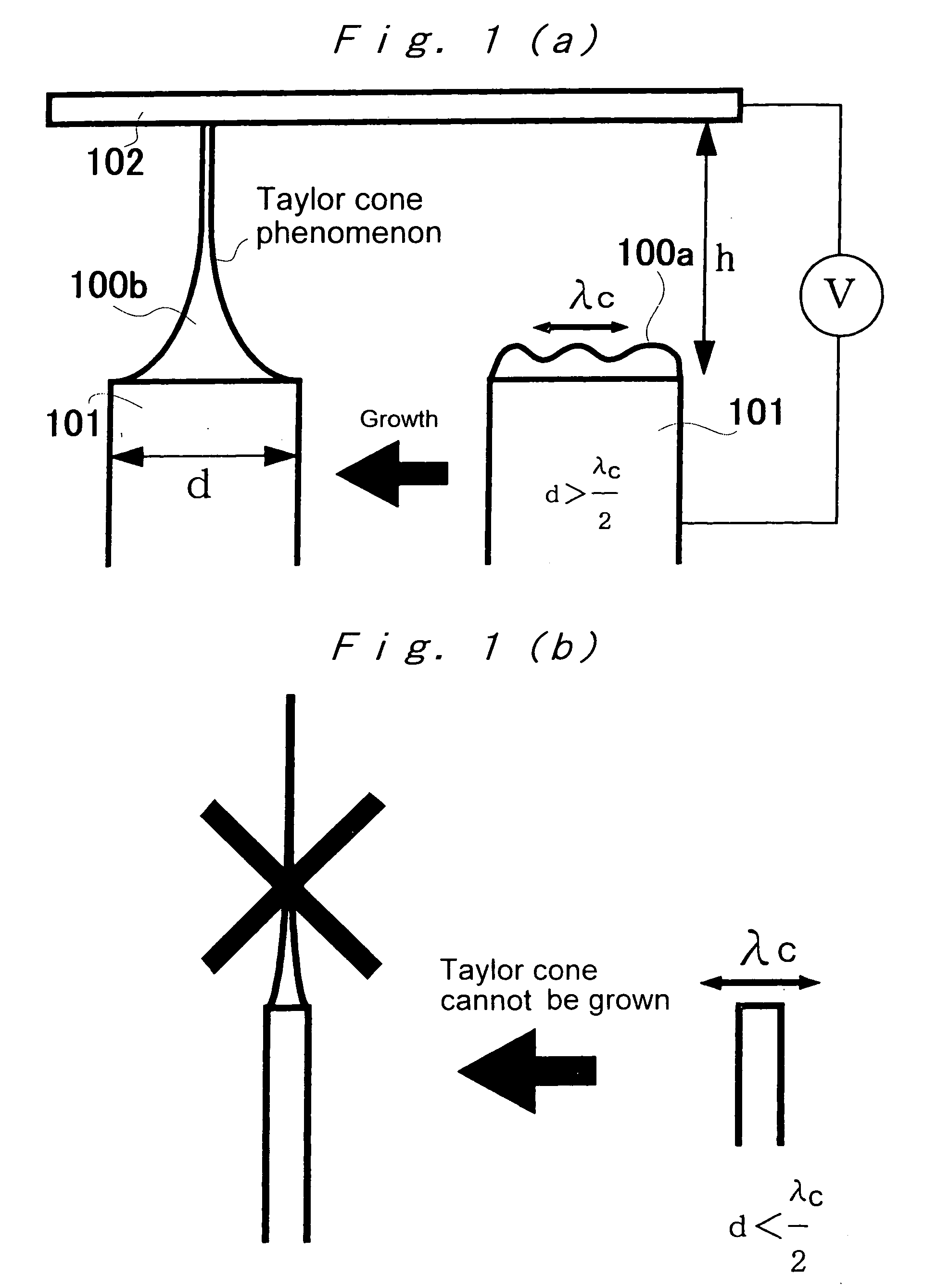

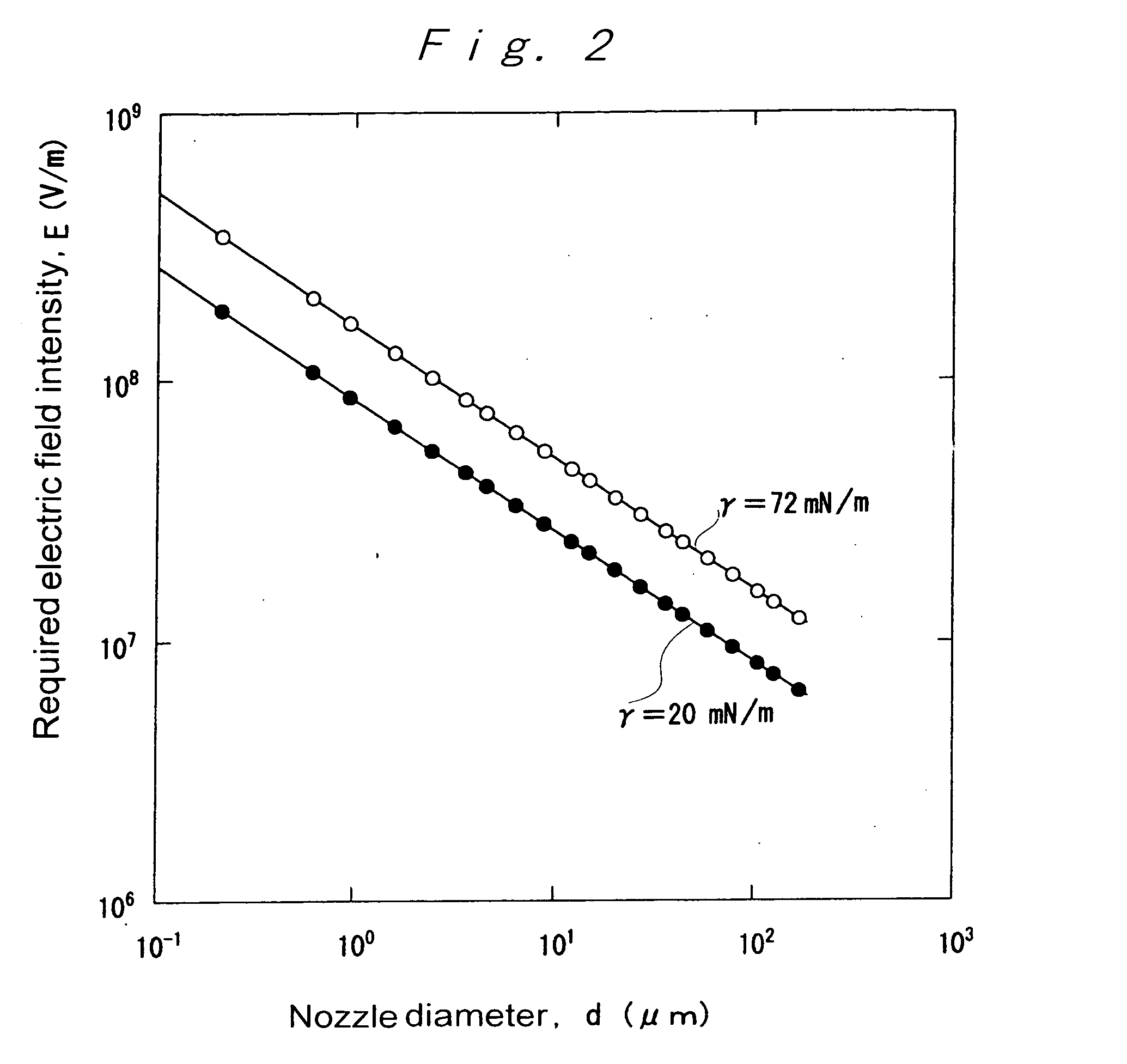

Ultrafine fluid jet apparatus

ActiveUS20050116069A1Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEvaporation

An ultrafine fluid jet apparatus comprising a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

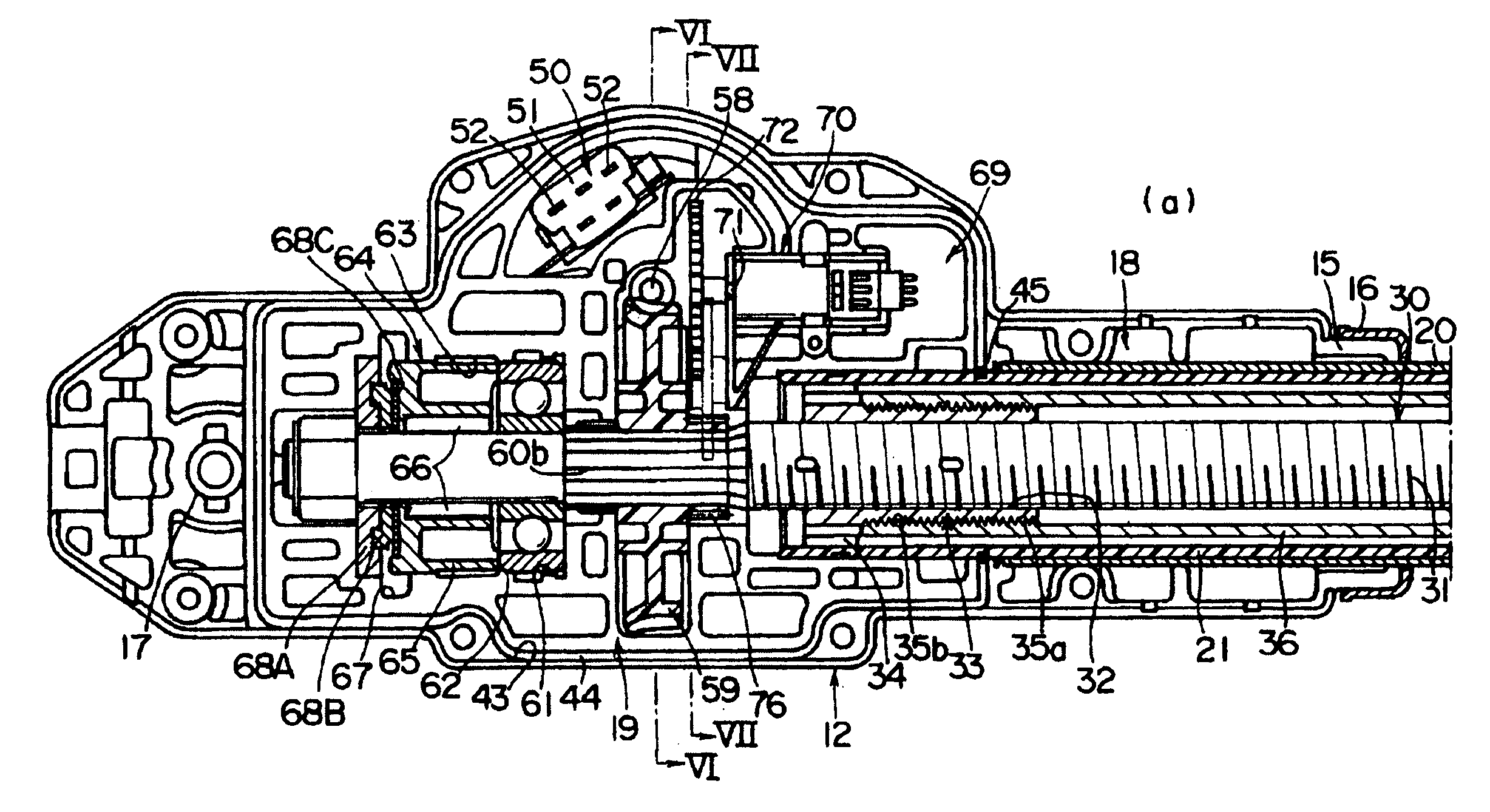

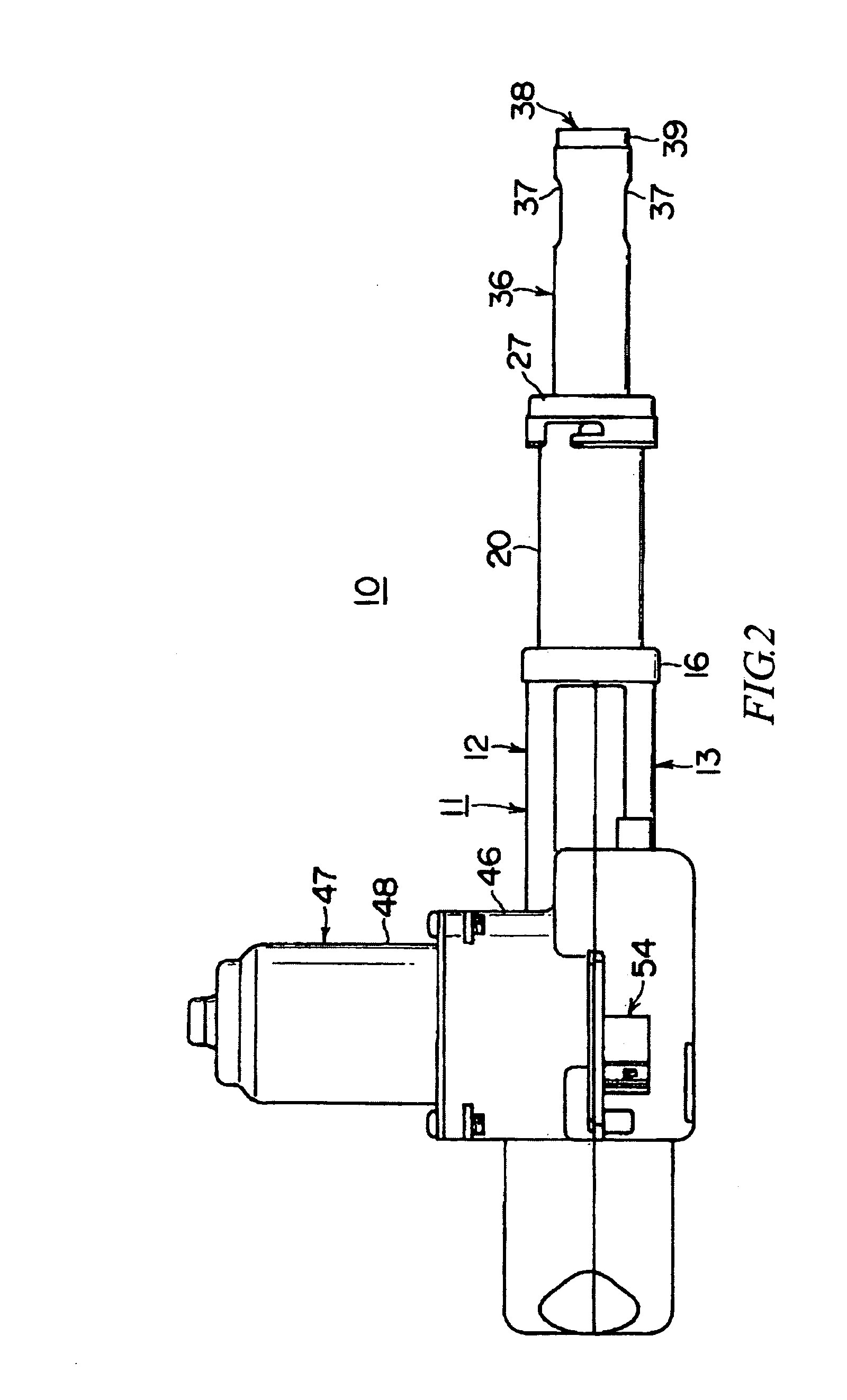

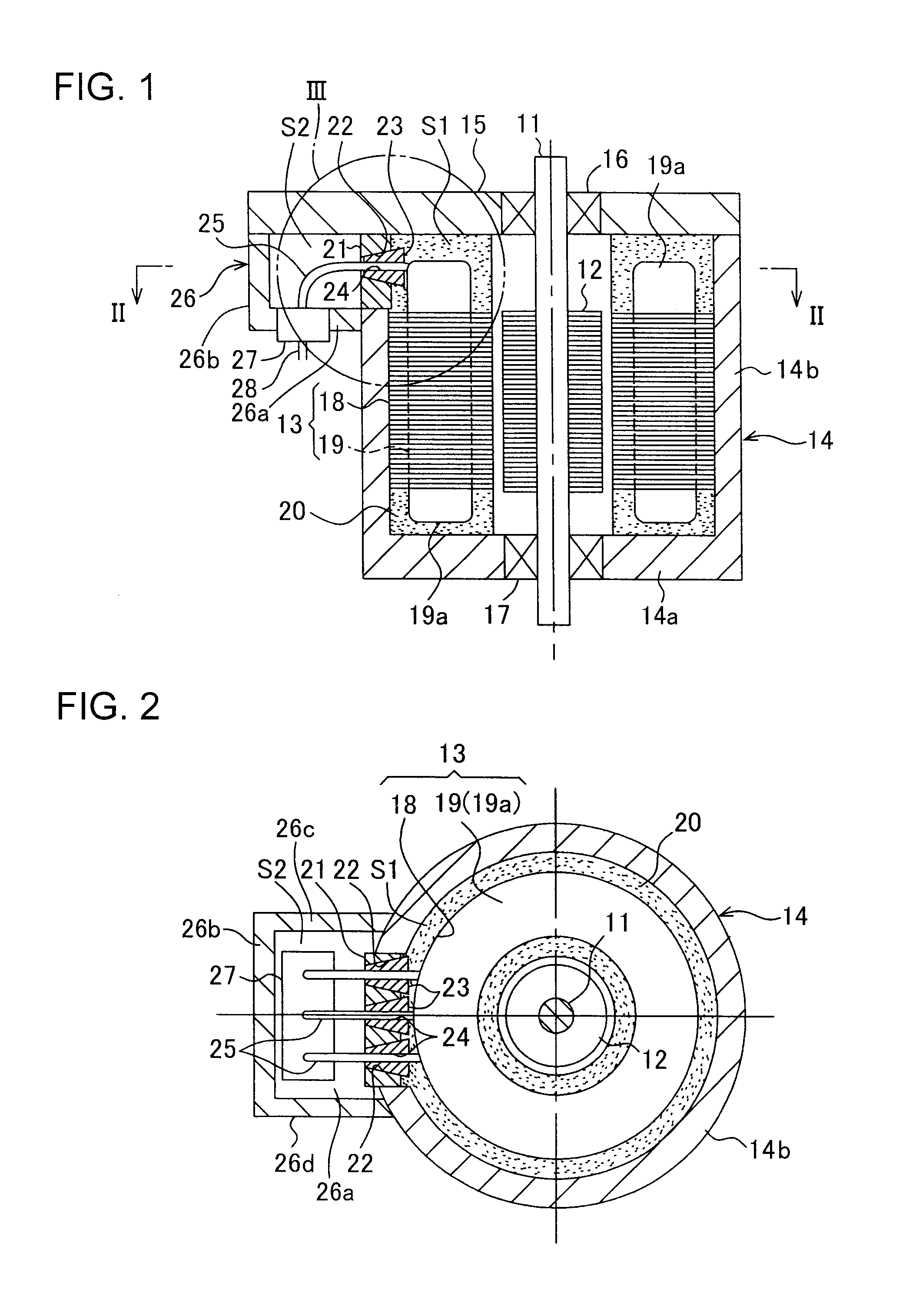

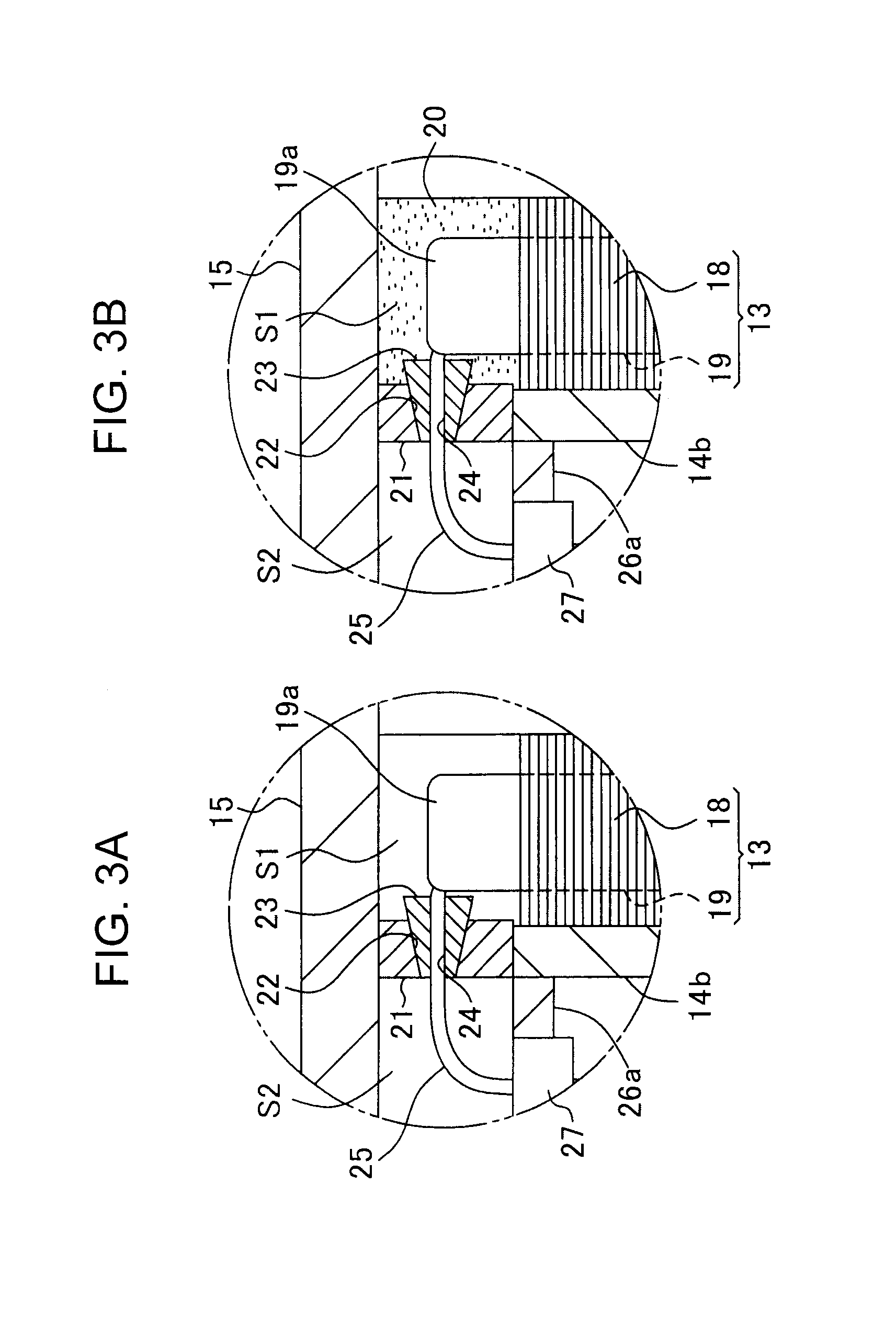

Linear actuator

InactiveUS20070144281A1Easy to operateAssembly precisionToothed gearingsStructural associationBall bearingEngineering

A shaft 30 in which all of a moving cylinder 36 and a deep groove ball bearing ball bearing 62 are assembled and a reduction gear shaft 73 are assembled to a first shell 12 and then, a potentiosensor 70 is assembled to the first shell 12. A feed coupler is connected to a terminal 50, the driven gear 72 is rotated and adjusted to a predetermined sensor voltage value. The potentiosensor 70 is allowed to slide toward a worm wheel 59, and a large-diameter reduction gear 74 is meshed with a pinion 76.

Owner:MITSUBA CORP

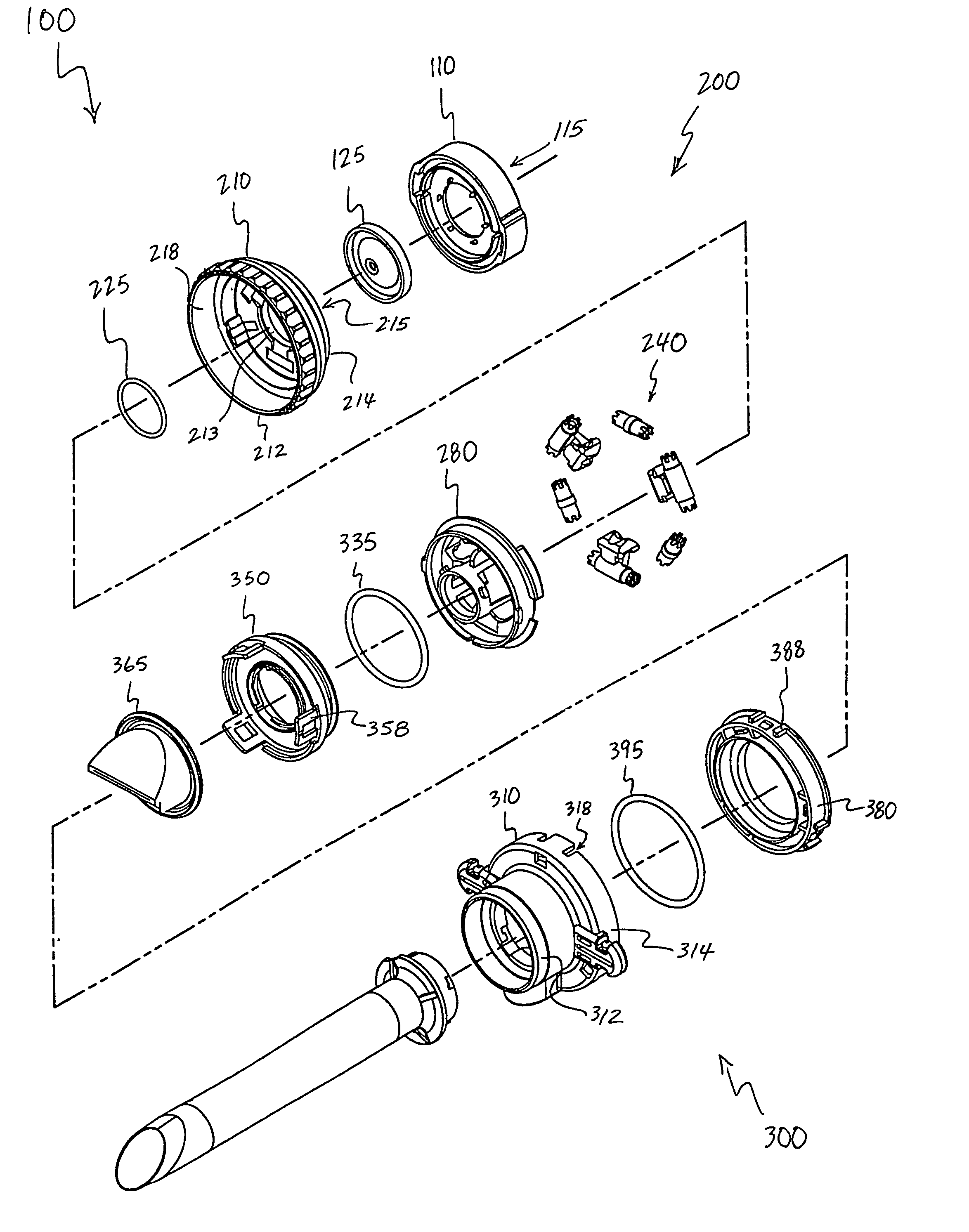

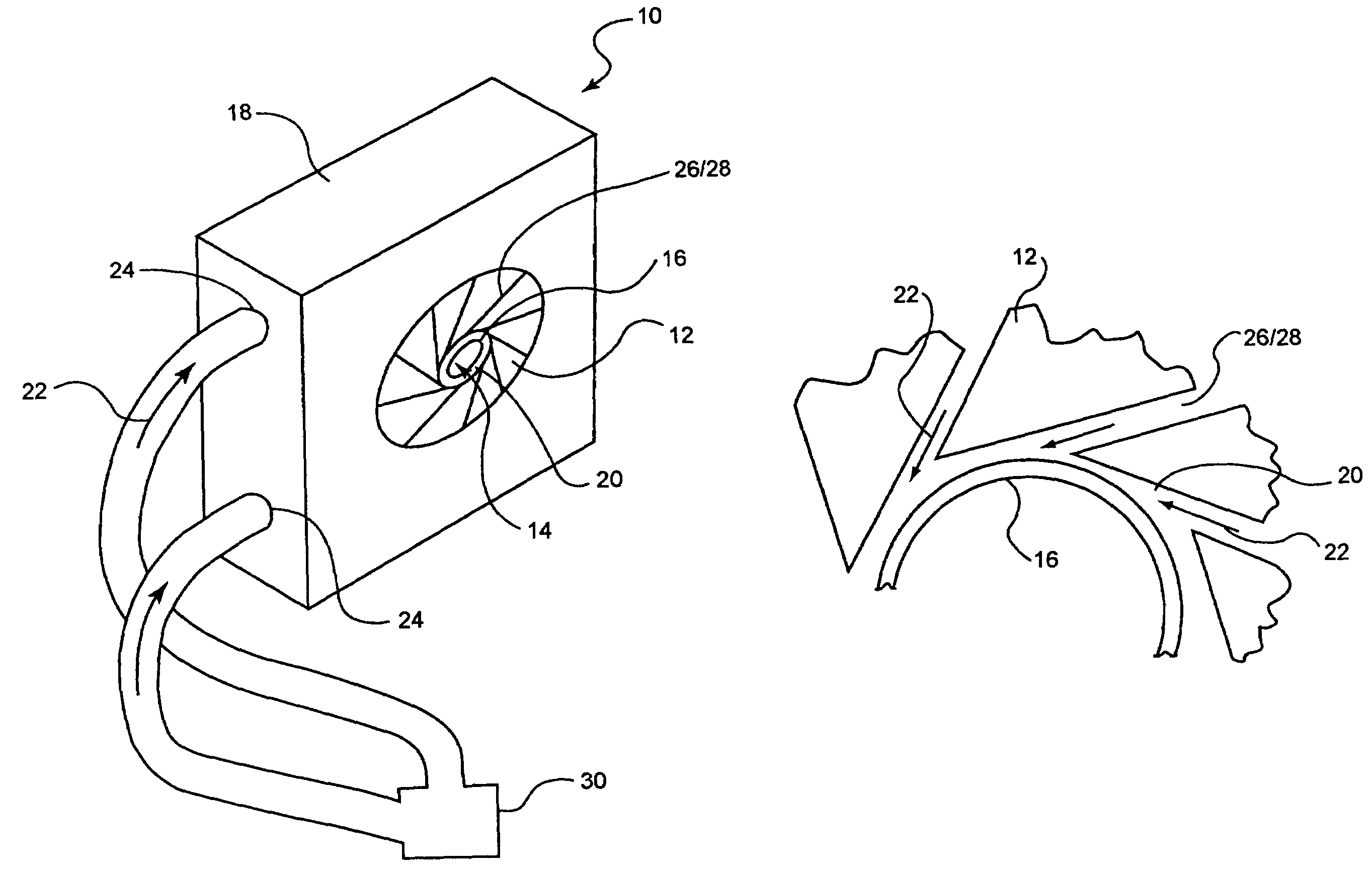

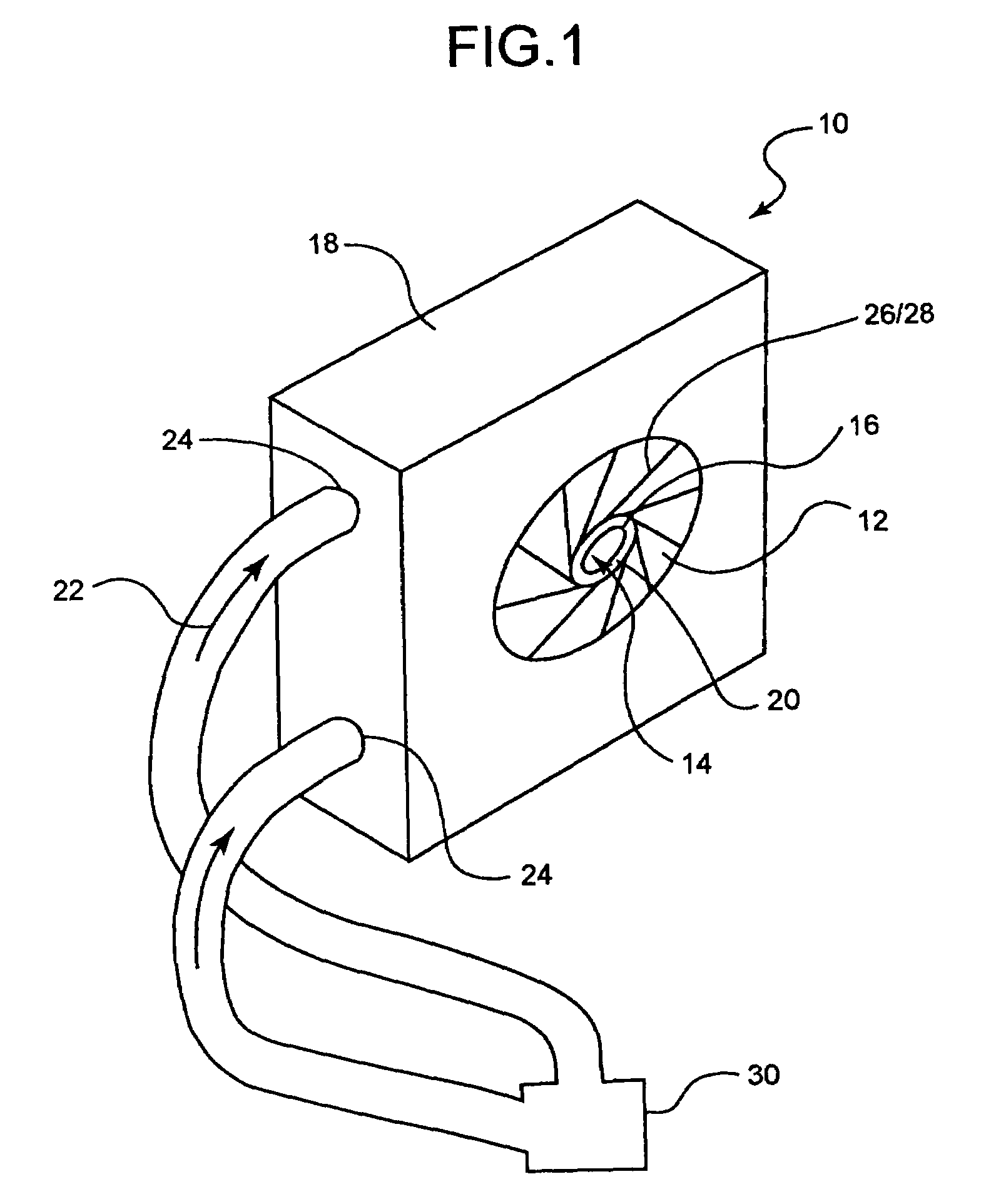

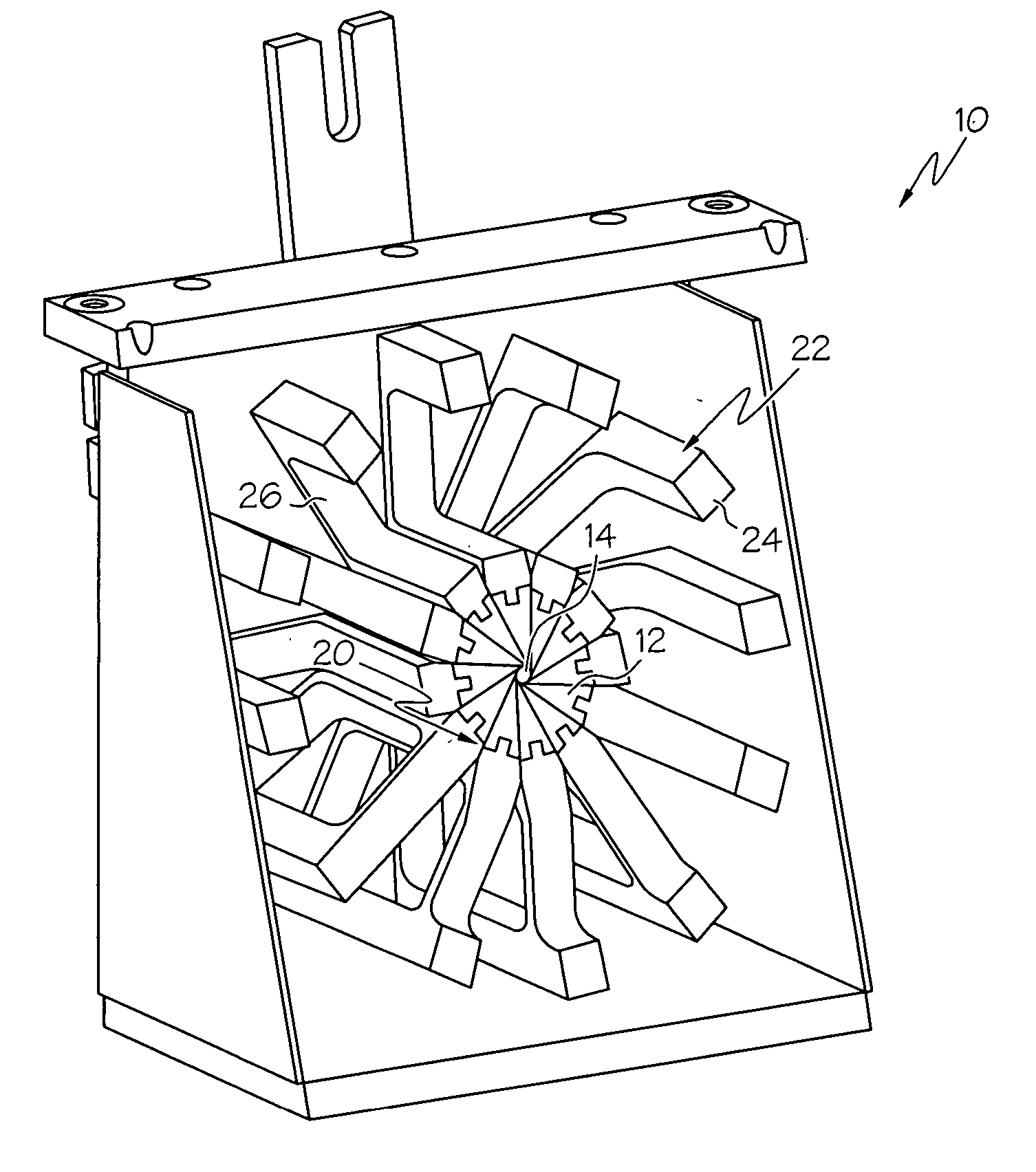

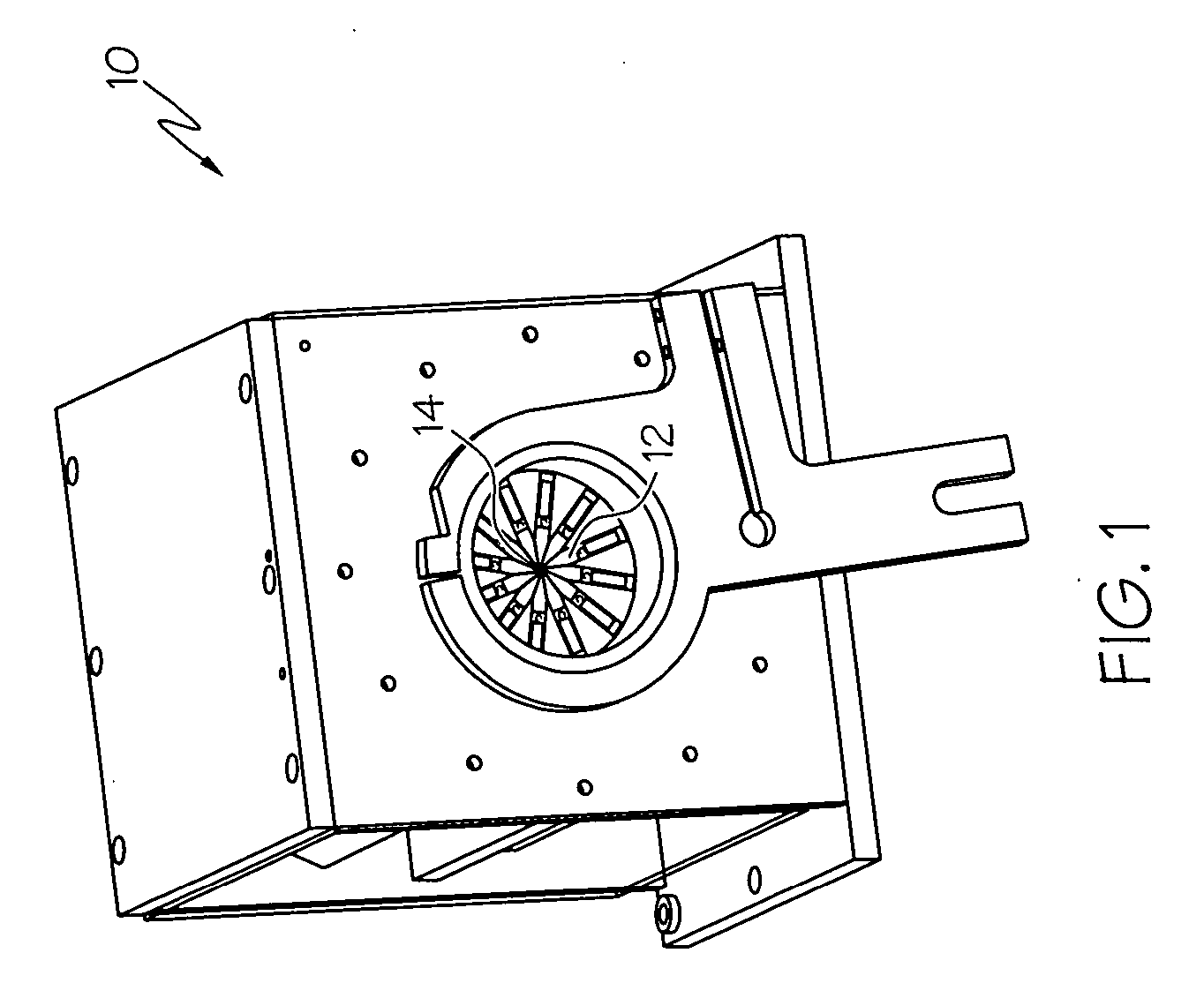

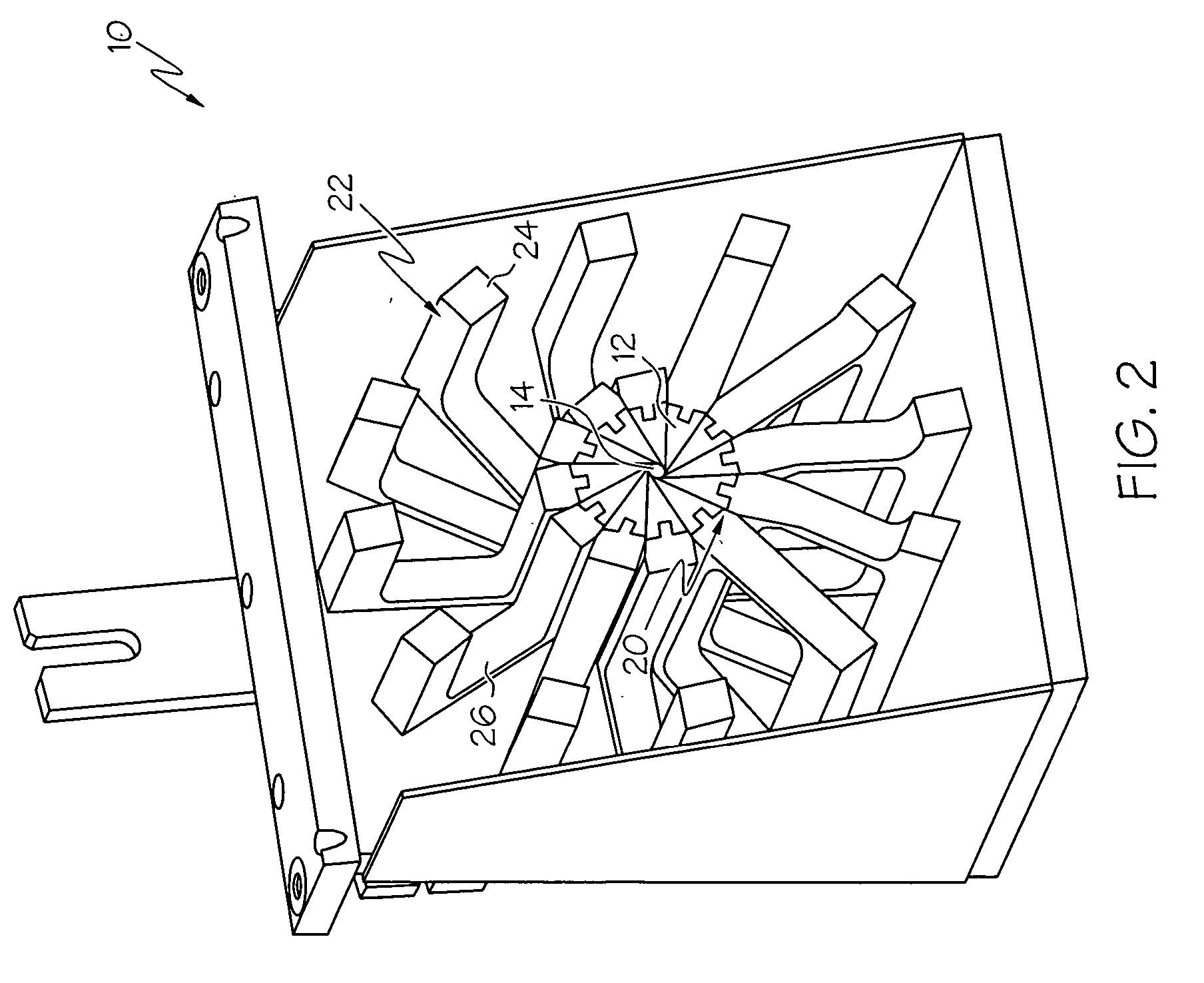

Stent crimping mechanisms

ActiveUS20060213049A1Minimize the possibilityReduce in quantityShaping toolsStentsEngineeringStent crimper

A system for reducing the diameter of a stent comprises a stent contracting assembly. The assembly comprises a plurality of blades, which define a diameter reduction chamber. The chamber has an open diameter configuration and a closed diameter configuration. The plurality of blades comprises active blades and floating blades, wherein each active blade is engaged to an actuation mechanism. The actuation mechanism is constructed and arranged to move each active blade from the open diameter configuration to the closed diameter configuration. Each floating blade is moved from the open diameter configuration to the closed diameter configuration only as a result of the movement of the active blades.

Owner:BOSTON SCI SCIMED INC

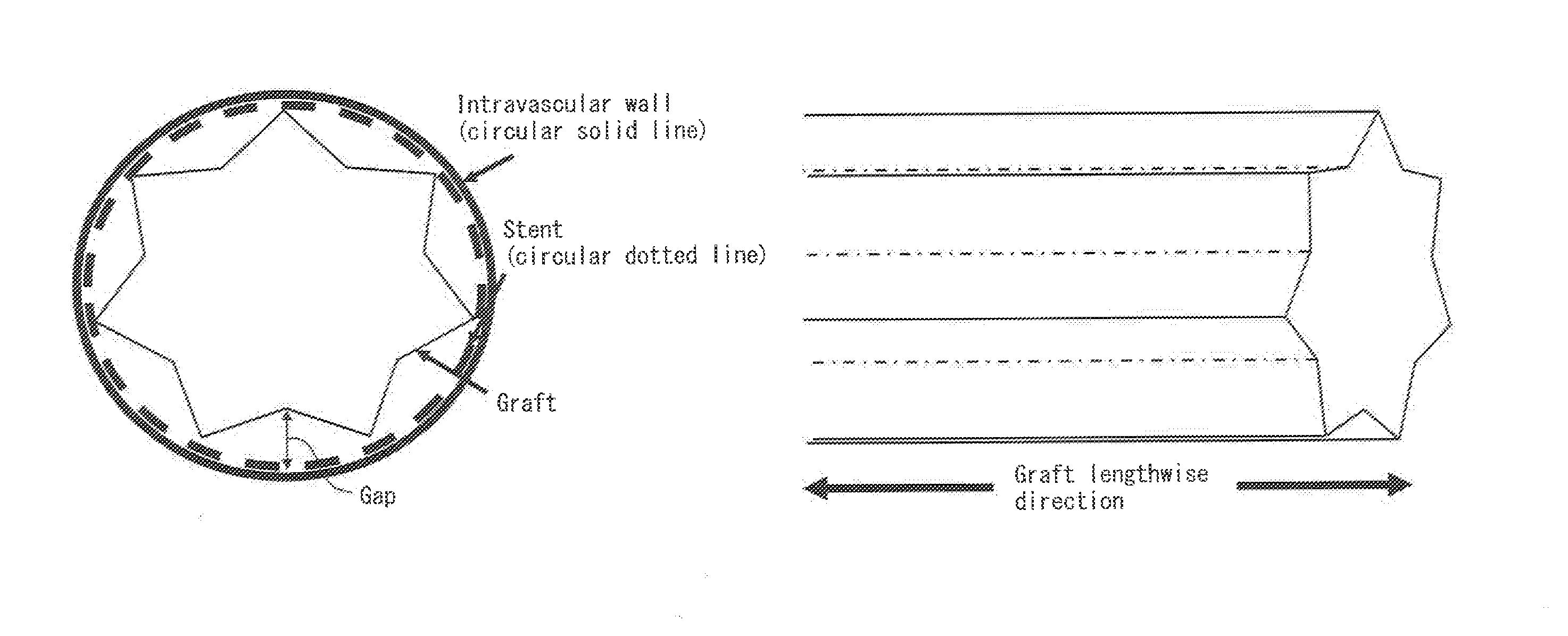

Ultrafine polyester fiber

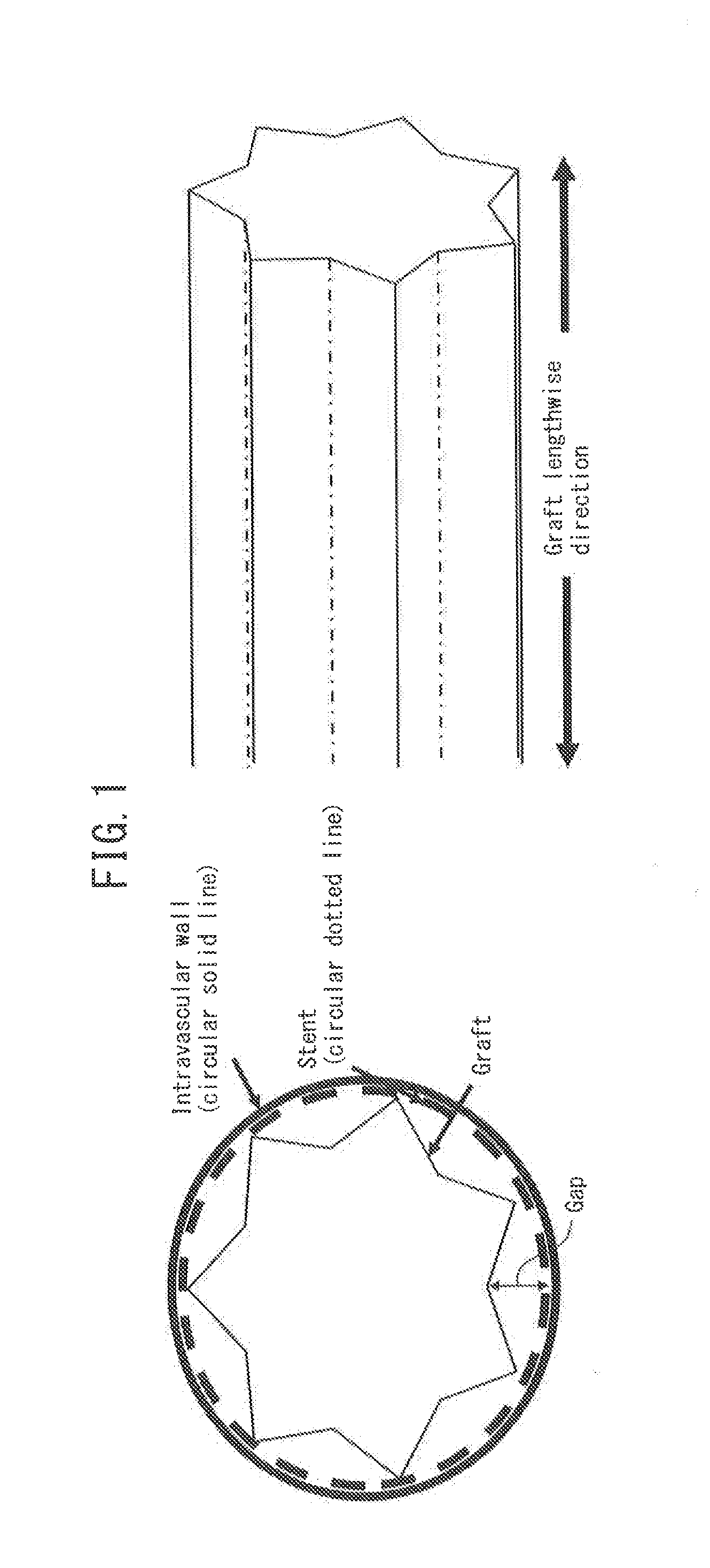

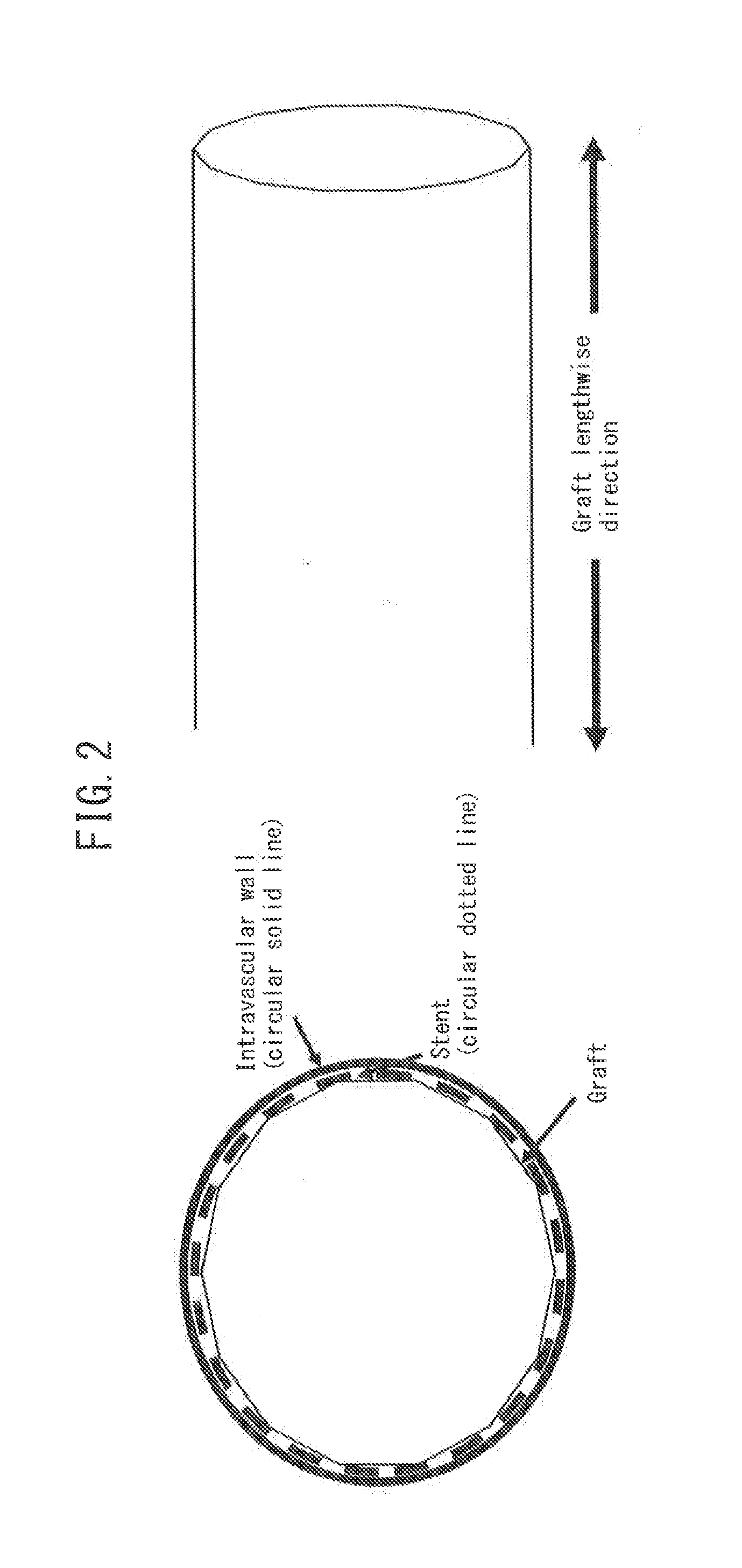

InactiveUS20160184488A1Highly integratedEnsure long-term stabilityStentsSurgeryPolyesterPolyethylene terephthalate glycol

Provided is an ultrafine polyester fiber which is useful as a constituent material for a cloth for a stent graft or other medical device that is to be implanted in the body and which can simultaneously solve both a clinical need (diameter reduction) and a clinical challenge (integration of a stent with a stent graft). An ultrafine polyester fiber which has a polyethylene terephthalate content of 98 wt % or more, characterized by: having (1) a reduced viscosity (ηsp / c) of 0.80 dl / g or higher and (2) a total fineness of 7 to 120 dtex and a single-fiber fineness of 0.5 dtex or less; and exhibiting (3) a maximum thermal shrinkage stress of 0.05 cN / dtex or more in a temperature range of 80 to 200° C. or (4) a degree of crystallinity of 35% or more in a region spreading from the surface of the fiber to a depth of 0.1 μm.

Owner:ASAHI KASEI FIBERS CORPORATION

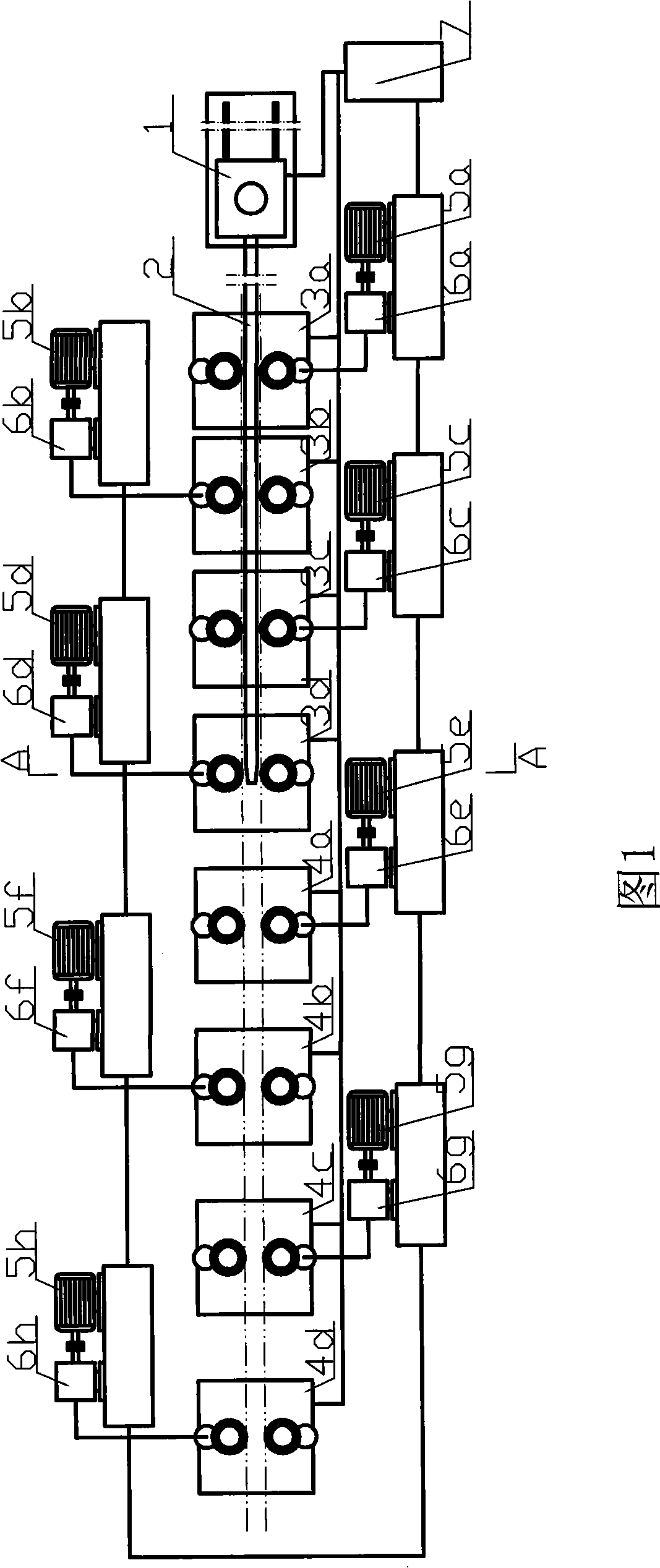

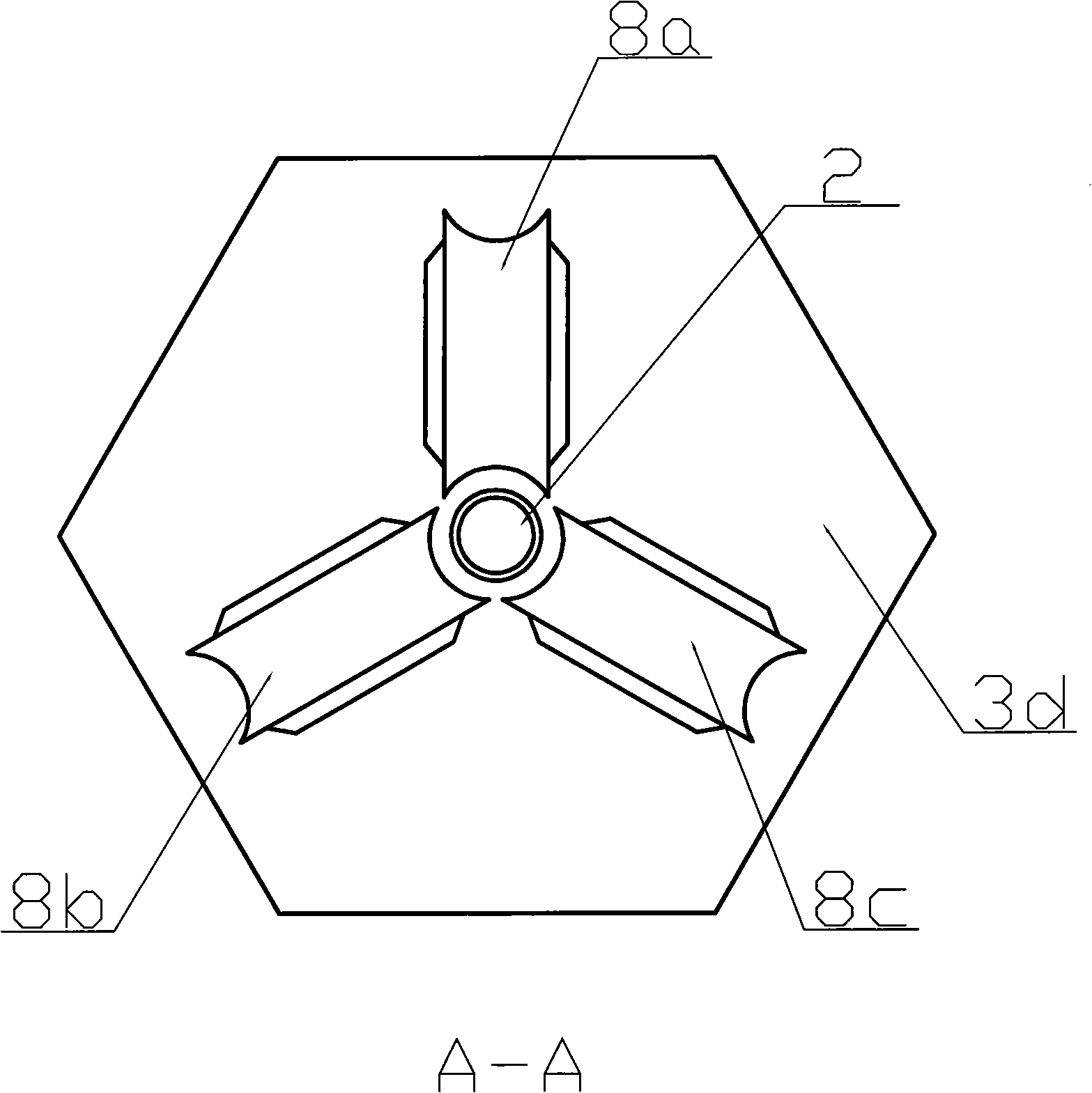

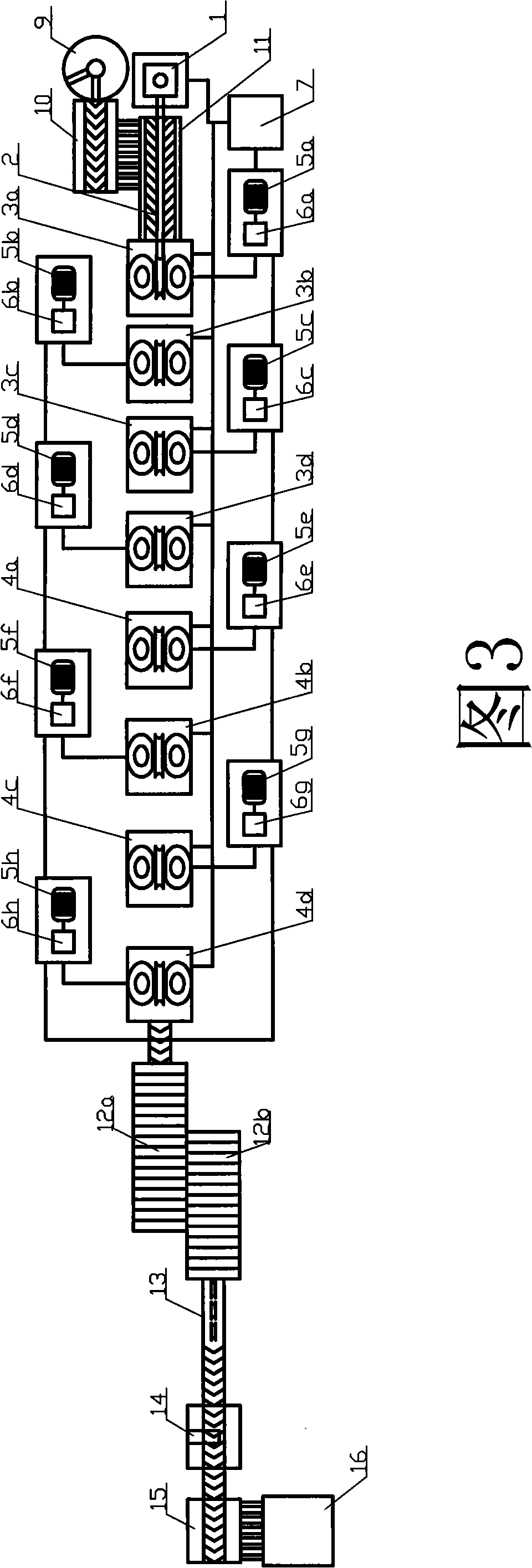

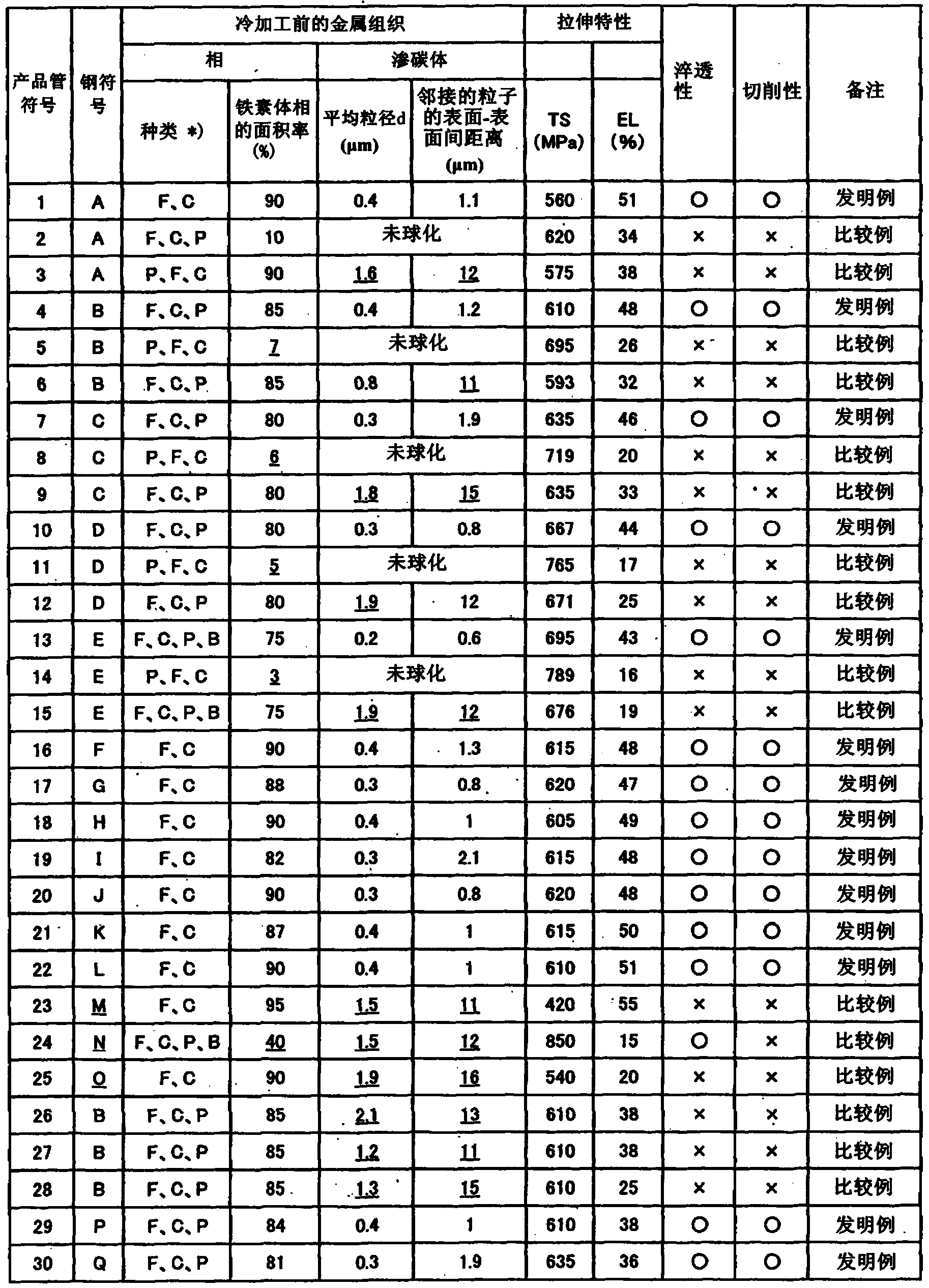

Fewer stands longitudinal hot rolling minor diameter thin wall seamless steel tube rolling technique and equipment thereof

InactiveCN101259588AEnsure implementationIncrease speedTemperature control deviceMandrelsHeating furnace% diameter reduction

The invention discloses the rolling technology of a fewer stander longitudinal hot rolling small diameter thin wall seamless steel tube which uses a heating furnace to heat a pierced billet to 950 DEG C to 1150 DEG C, a mandrel trolley pushes a mandrel into the heating pierced billet and is pushed to move forward, and the pierced billet is pushed into a wall reduction rolling unit that is formed by a plurality of wall reduction rolling mills to lead the pierced billet to be carried out longitudinal wall reduction rolling; the pierced billet that breaks away from the mandrel continues to be pushed into a stretch reducing rolling unit that is formed by a plurality of stretch reducing rolling mills to lead the pierced billet to be carried out longitudinal stretch reducing rolling until the rolling is finished; the pierced billet is put into a cold bed to cool; a straightening machine is used for straightening; a finished product is used for delivering and cutting; a flat head machine is used and a detecting machine is used for inspecting; a hydrostatic testing machine is used for detecting; the finished product is bundled and is put in storage. The invention uses the combination of the three-roll longitudinal rolling technology and a retained mandrel to adjust the straight roller longitudinal rolling with umbrella-shaped gears hydraulically and preciously to carries out diameter reduction and wall reduction rolling, and a rolled tube pipeline main control cabinet is used for operating stepless speed regulation of various stands so as to guarantee implementation of the technology, thus rolling the small diameter thin wall seamless steel tube with the diameter of Phi 12mm to Phi 76mm and wall thickness of 1mm to 6mm.

Owner:LUOYANG BANGQIANG MACHINERY

Novel technique for producing large-sized seamless steel pipe

InactiveCN101352728AExtended service lifeQuality improvementGuiding/positioning/aligning arrangementsWork treatment devicesHeating furnaceOrbit

The invention discloses a new production process of a large seamless steel pipe. The process comprises the following steps: pipe billets are preheated to the temperature of 1050-1290 DEG C by a heating furnace, and delivered to a three-roll skew rolling piercing mill for piercing by a skew roll table conveying mechanism to finish diameter expansion and wall reduction rolling, the maximal ratio of diameter to wall D / S is over 32, and hollow billets are produced; the hollow billets are delivered to a three-roll skew rolling elongating finishing mill by a shift oblique orbit conveying mechanism to finish diameter expansion and wall reduction rolling or diameter reduction and wall reduction rolling, and the pierced billets are rolled, straightened, cropped end, cut to length, defect are detected, and the finished products are obtained after passing inspections. The new production process also perfects and improves the conventional three-roll skew rolling seamless steel pipe process, solves the problems of not rolling thin walls and great extension in the three-roll skew rolling process, the diameter expansion and wall reduction rolling can be carried out, and the diameter reduction and wall reduction rolling can be carried out. The new production process is especially suitable for rolling large and oversized seamless steel pipes (Phi is 500-2000mm), the ratio of single reduced diameter and expanded diameter is more than 30%, the reduced wall diameter is more than 70%, and the reduced wall thickness is 5-7 times of that of a longitudinal pipe rolling mill.

Owner:沈阳东方钢铁有限公司

Methods for crimping a polymeric scaffold to a delivery balloon and achieving stable mechanical properties in the scaffold after crimping

InactiveUS8752265B2Reduce the overall diameterShorten the overall cycleStentsLabelling non-rigid containersMedicineCatheter

A medical device-includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the balloon by a process that includes inflating the delivery balloon during a diameter reduction to improve scaffold retention. A crimping temperature is maintained at about the onset of glass transition of the polymer material to facilitate more rapid stabilization of mechanical properties in the scaffold following crimping.

Owner:ABBOTT CARDIOVASCULAR

Assembly of stent grafts with diameter reducing ties

A temporary diameter reduction constraint arrangement for a stent graft is disclosed. The arrangement comprises: primary and secondary release wires extending along the graft; a plurality of loops of thread, each loop engaged with either the primary or secondary wire and engaged around a portion of the graft circumferentially spaced away from its release wire, and drawn tight to reduce the diameter of the graft; an end constraint arrangement comprising four of the plurality of loops of thread arranged into a first and second pairs engaged with respective primary and secondary wires; and an intermediate constraint arrangement comprising a fifth and sixth of the plurality of loops of thread arranged into a third pair, the third pair engaged with the primary release wire, the primary release wire deviating towards the secondary release wire so as to locate the intermediate constraint arrangement substantially in-line with the end constraint arrangement.

Owner:COOK MEDICAL TECH LLC

Connecting structure, connecting device and connecting method for electric wire and terminal, and wire harness

ActiveUS9065261B2Contact member assembly/disassemblyConnections effected by permanent deformationElectrical conductorEngineering

A connecting structure is applied for connecting an electric wire and a terminal. For coating a connecting portion of a conductor of the electric wire and the terminal, which form a wire harness, with a coating resin, a portion of an insulator, which is to be inserted into a terminal insertion hole of a connector housing, is subjected to a diameter reduction process such that an outer diameter of the coating resin coated on the insulator is smaller than the terminal insertion hole.

Owner:FURUKAWA ELECTRIC CO LTD +1

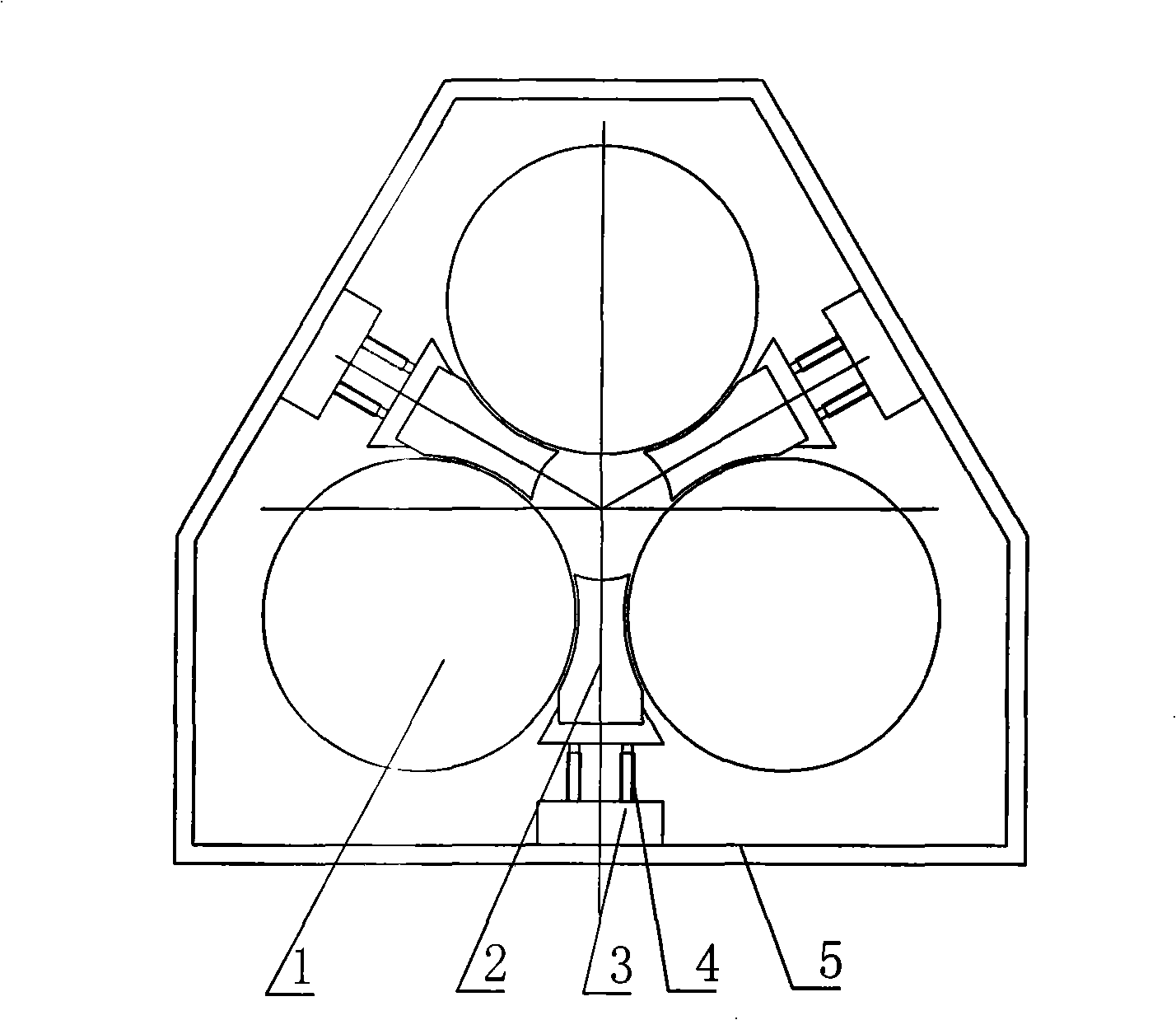

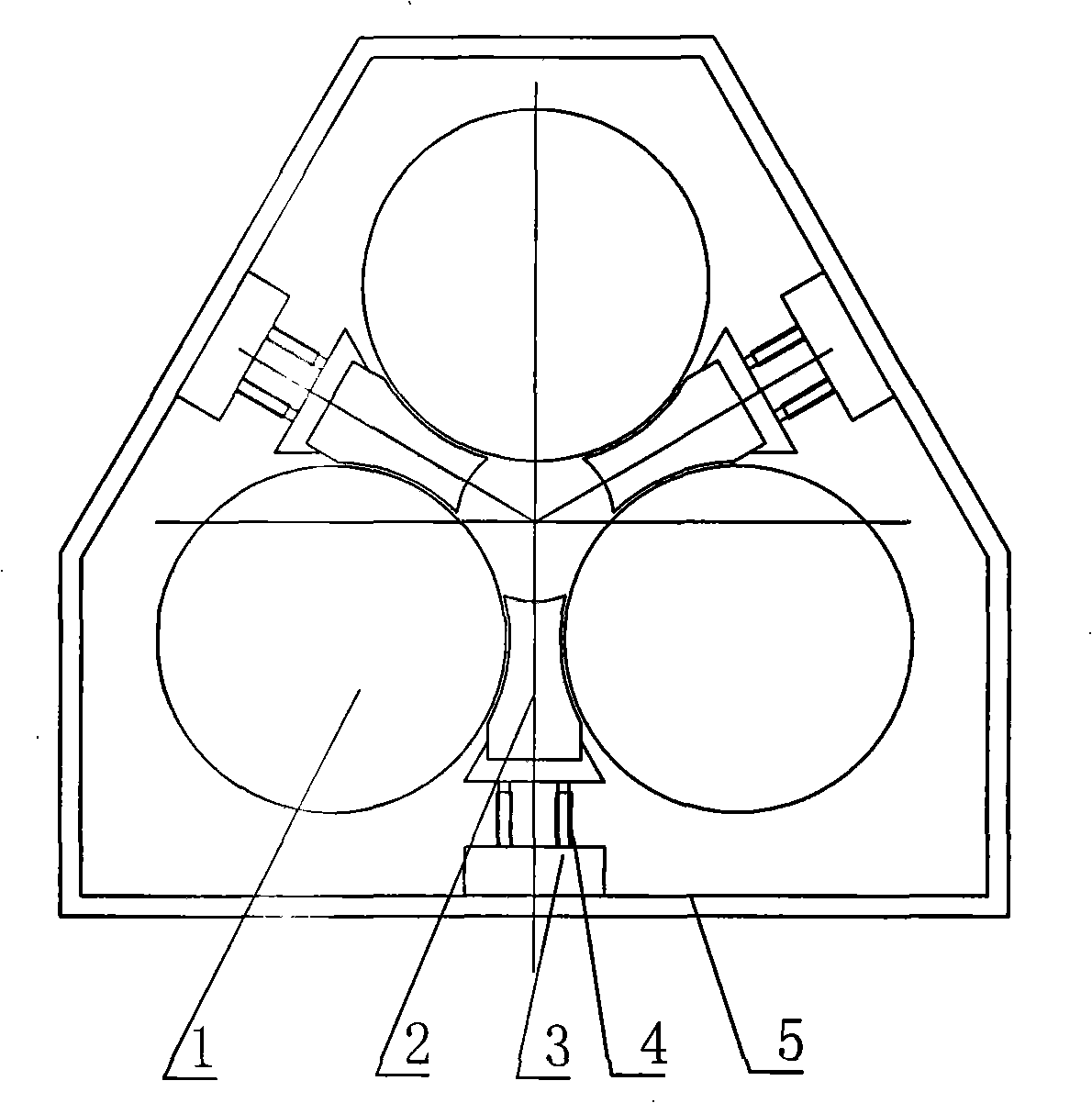

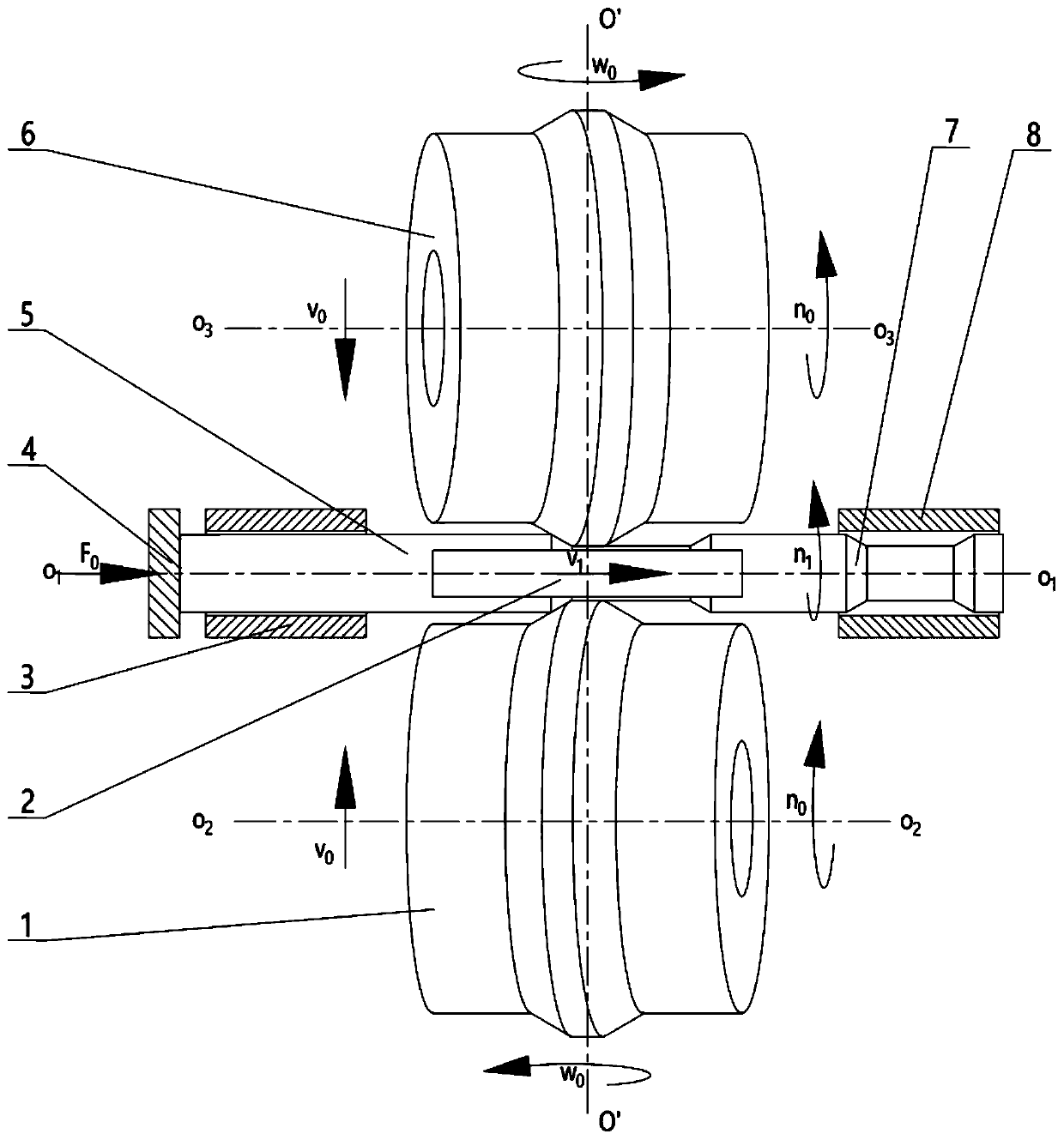

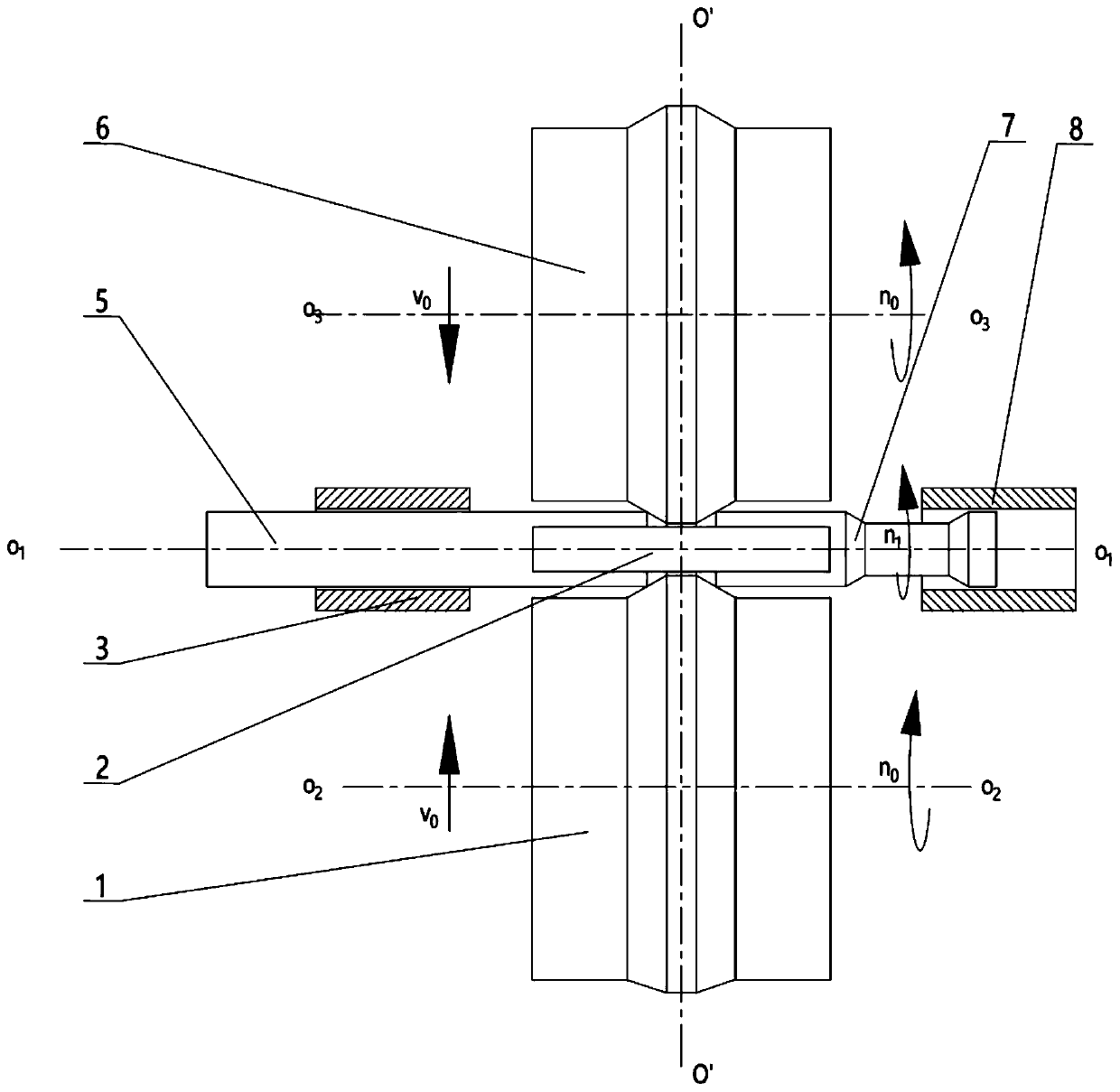

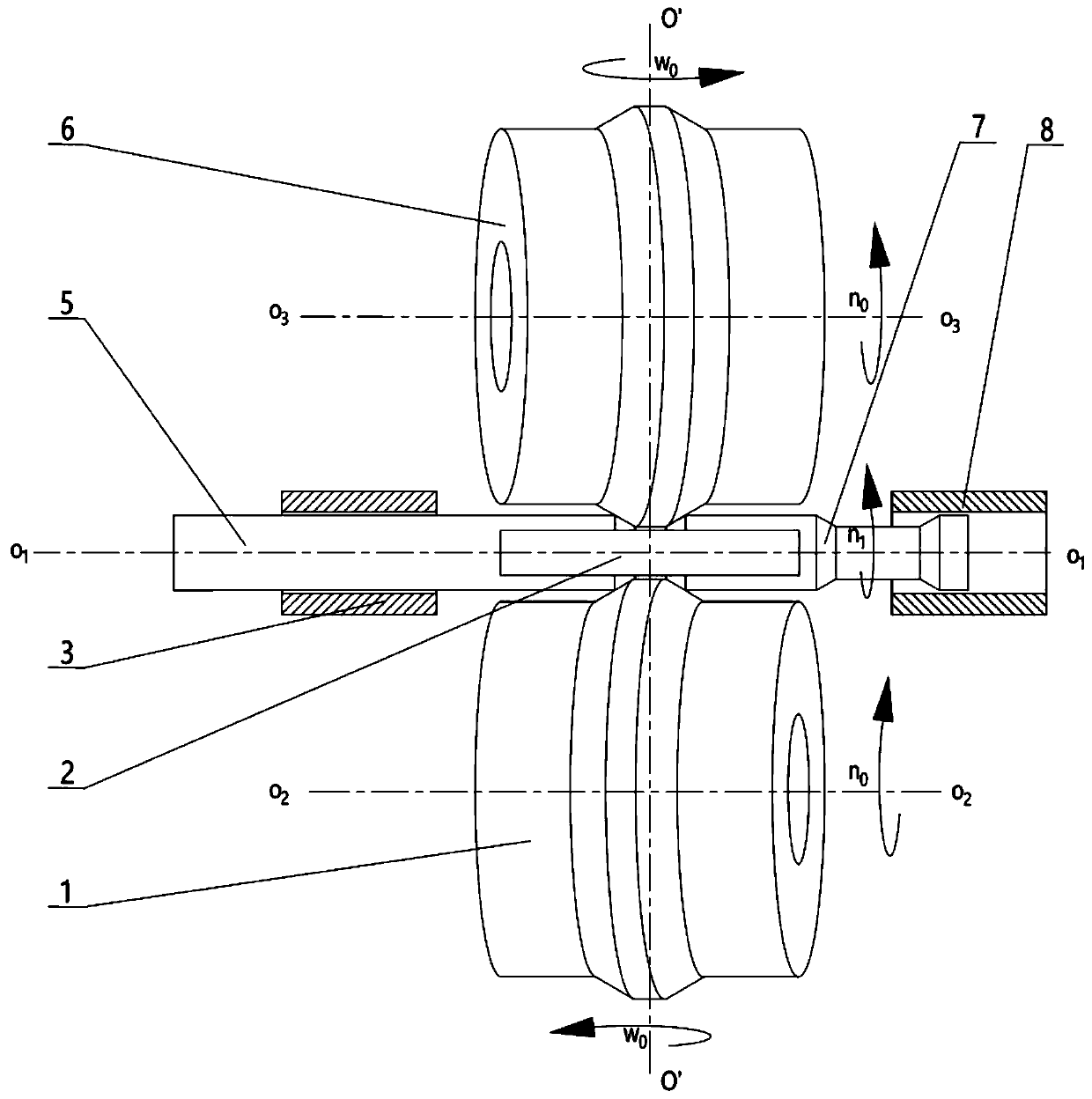

Shaft part two-roller flexible oblique rolling forming device and method

ActiveCN110102575AForming equipment is simpleReduce axial thrustSkewed roll standMetal rolling stand detailsRadial compressionAxial thrust

The invention relates to the technical field of metal plastic forming processes and equipment, and provides a shaft part two-roller flexible oblique rolling forming device and method. The device comprises two oblique rollers, a guide plate, two guiding cylinders and an axial pushing device; the oblique rollers can do motions including same direction rotation, radial feeding and oblique angle adjustment; the guide plate is arranged between the two oblique rollers and is used for limiting radial movement of a blank; the two guiding cylinders are arranged on the two sides of the two oblique rollers to limit swing of the blank; and the axial pushing device is arranged at one end of the blank and applies axial thrust to the blank, the blank is rolled into a shaft part in a space formed by the oblique rollers and the guide plate. The method includes radial compression, roller tilting, oblique rolling diameter reduction and roller leveling forming processes. The shaft part two-roller flexibleoblique rolling forming device and method have the advantages that forming equipment is simple, the tonnage is small, flexible production can be achieved, and core loose defects can be reduced even avoided.

Owner:UNIV OF SCI & TECH BEIJING

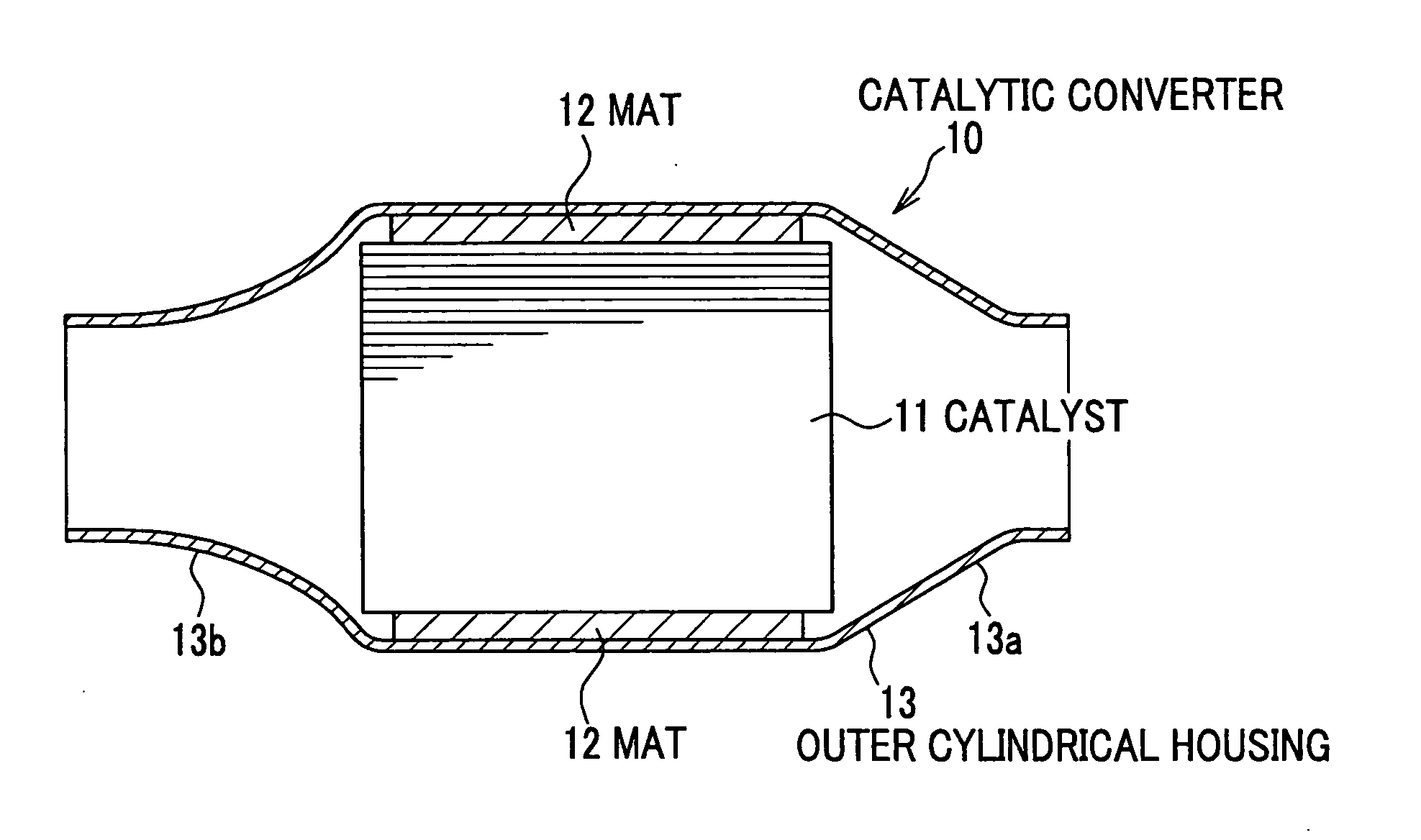

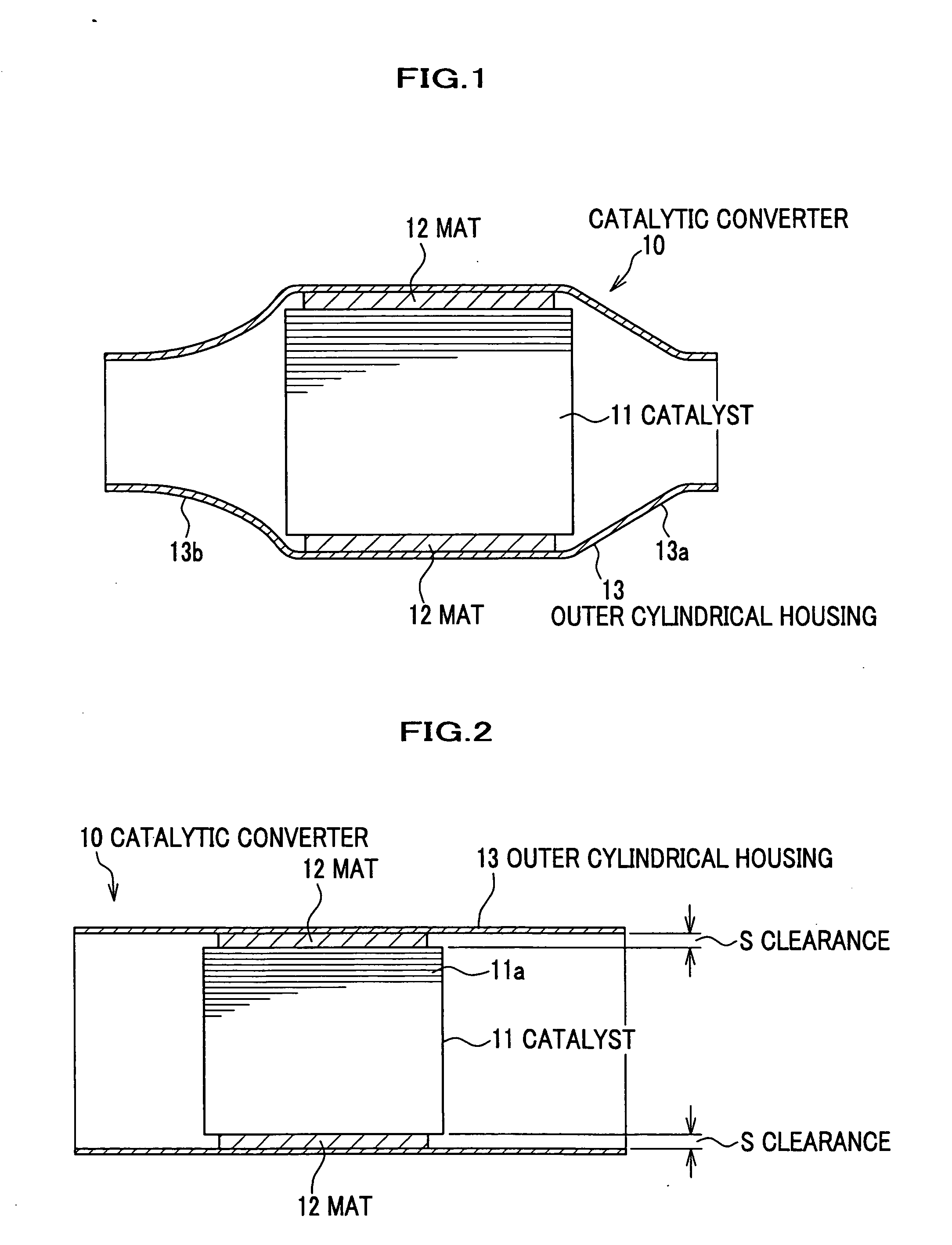

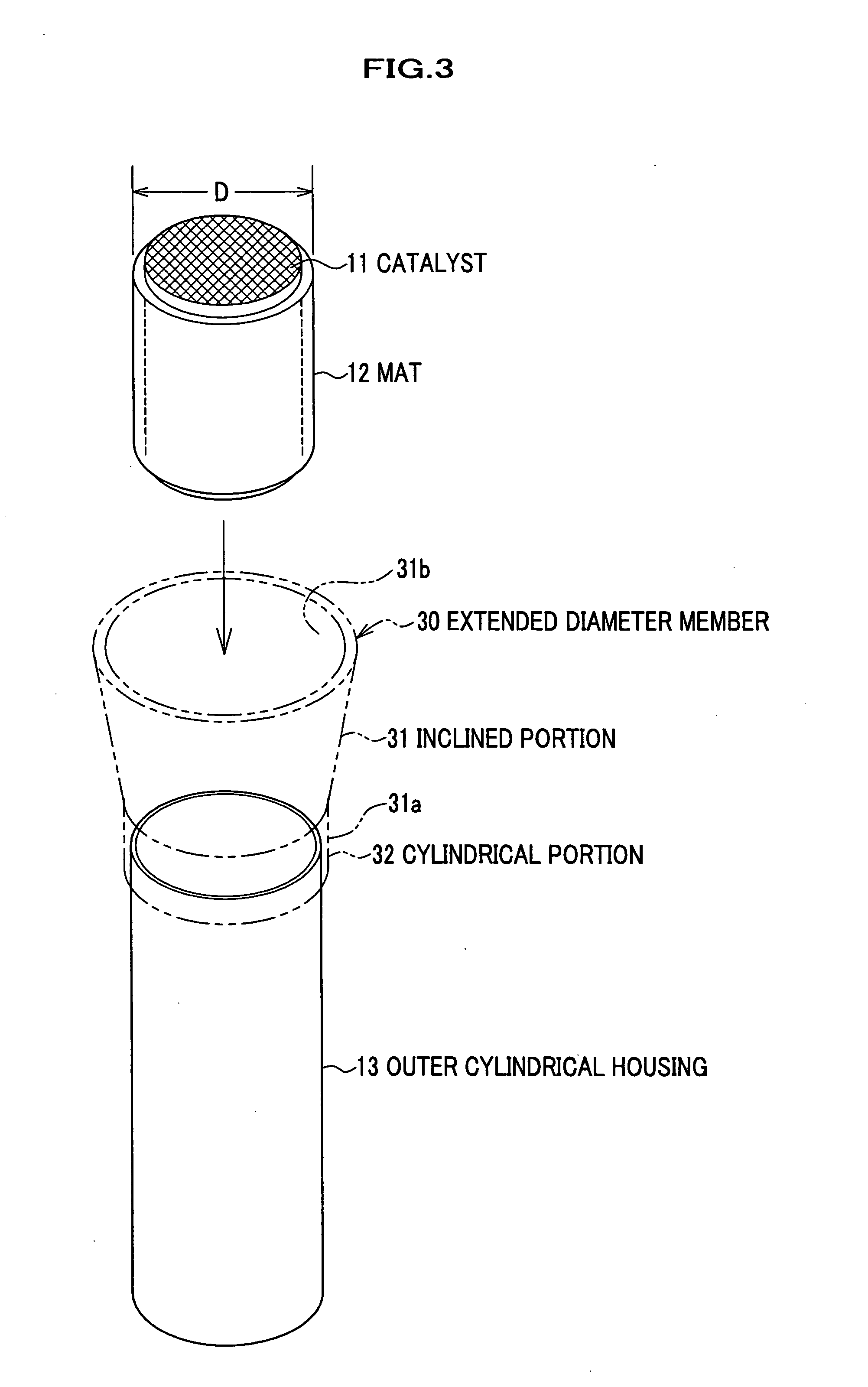

Method Of Manufacturing Catalytic Converters, Catalytic Converters, And Method Of Controlling Catalytic Converters

InactiveUS20070212269A1Improve detection efficiencyLow costCombination devicesCatalyst protection% diameter reductionPetroleum engineering

A method of manufacturing a catalytic converter includes the steps of: a detecting step for detecting a pressing force at a time when a catalyst (11) is press-fitted into an outer cylindrical housing (13); a calculating step for calculating a diameter reduction, by which a clearance value between the outer cylindrical housing (13) and the catalyst (11) is set to a desired target value, based on the pressing force detected by the detecting step; and a swaging step for reducing a diameter of the outer cylindrical housing (13) based on the diameter reduction calculated by the calculating step.

Owner:HIROTEC CORP

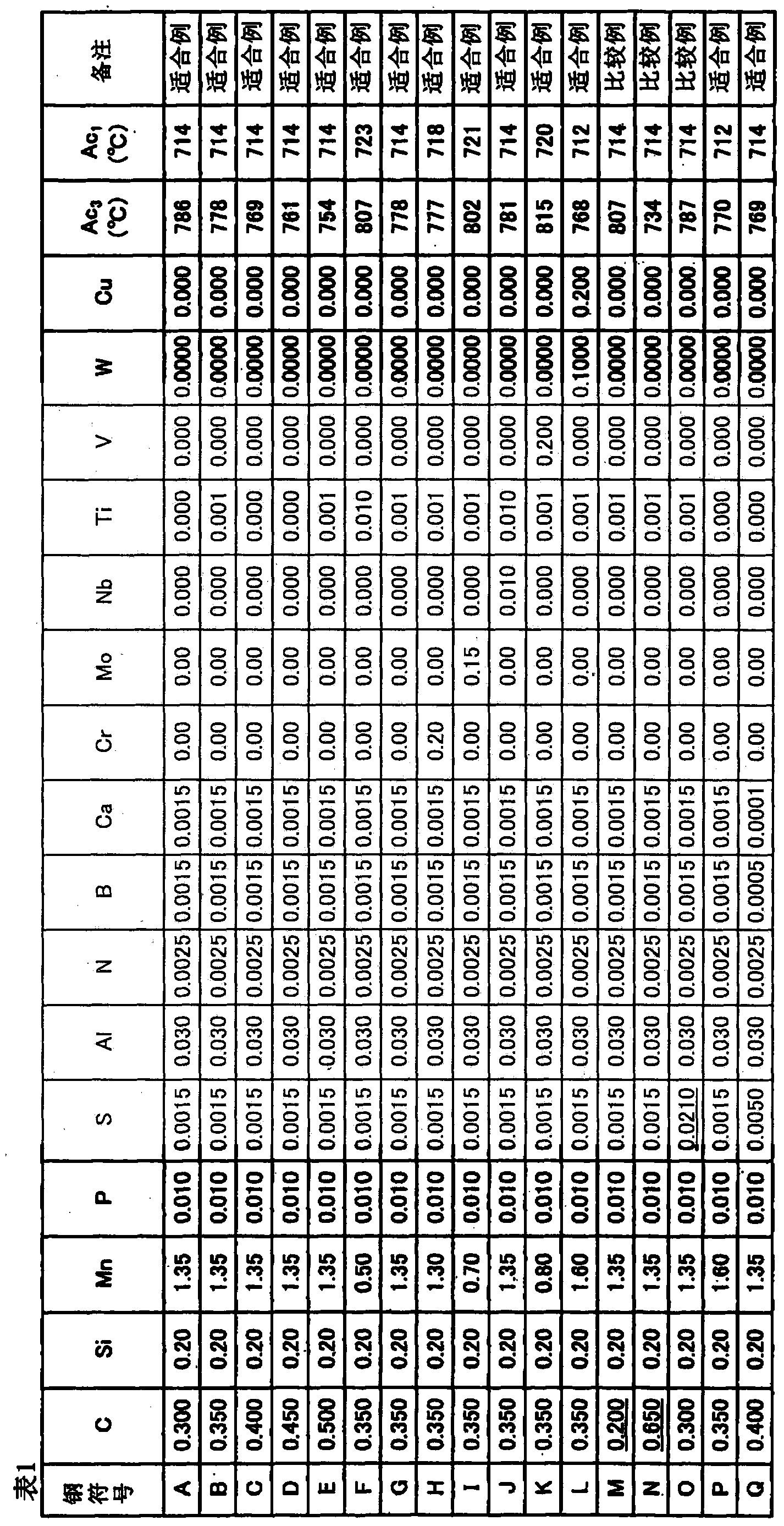

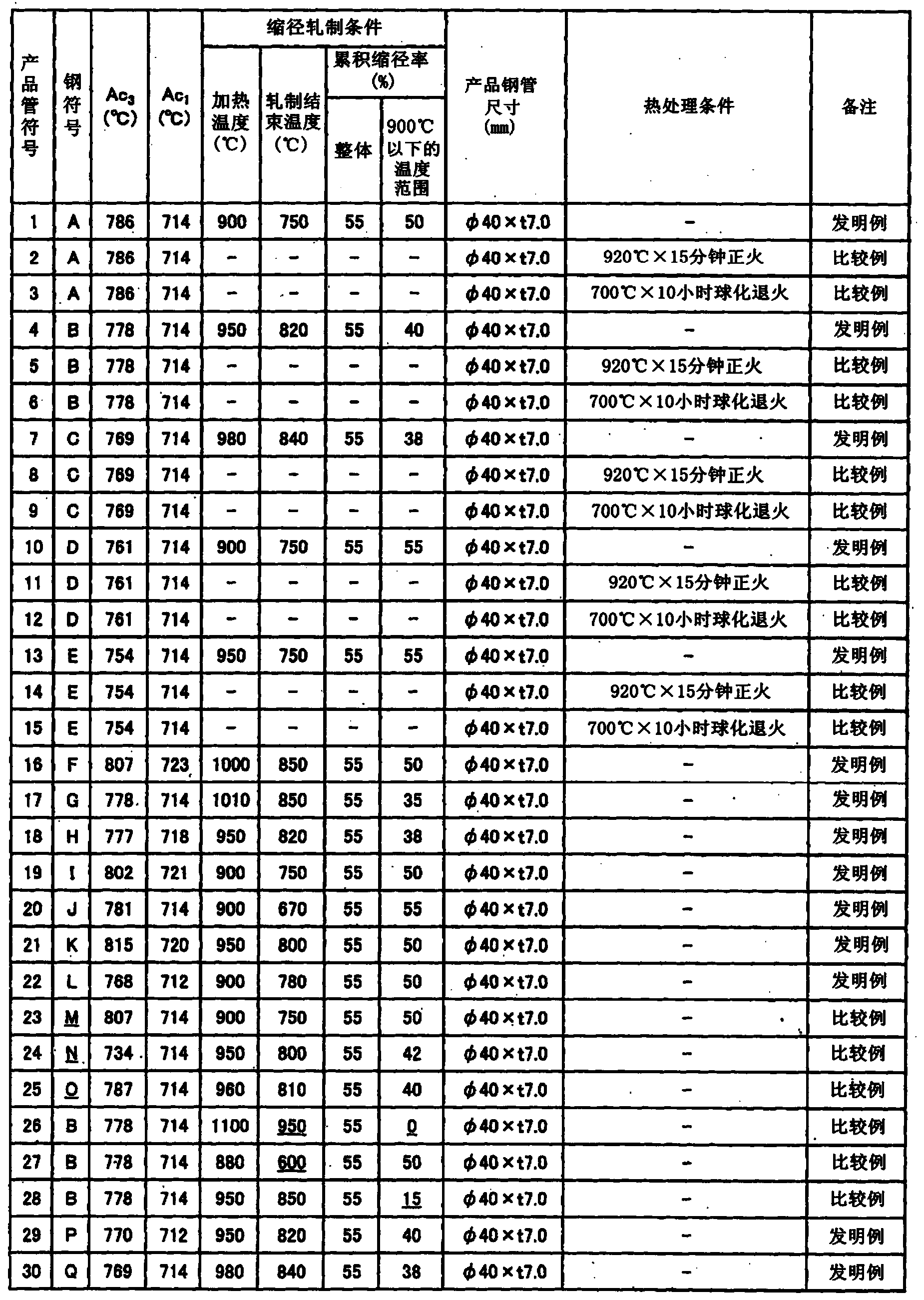

High carbon steel pipe having excellent cold workability, machinability, and quenching properties, and method for manufacturing same

ActiveCN104411846AHelps to reduce weightSimple and cheap to manufactureFurnace typesHigh frequency current welding apparatusMetallurgy% diameter reduction

Provided are a high carbon resistance-welded steel pipe having excellent cold workability, machinability, and quenching properties; and a method for manufacturing the same. Specifically, a high carbon steel pipe having a composition containing, by mass, 0.25 to 0.60% of C, 0.01 to 2.0% of Si, 0.2 to 3.0% of Mn, 0.001 to 0.1% of Al, 0.001 to 0.05% of P, 0.02% or less of S, 0.0010 to 0.0100% of N, 0.0003 to 0.0050% of B, and 0.0001 to 0.0050% of Ca, with the remainder made up by residual Fe and unavoidable impurities, is used as a material steel pipe. Heating and soaking is performed to Ac3 transformation point or above, and diameter-reducing rolling is subsequently performed at a rolling finishing temperature of 900°C or above (Ac1 transformation point) and a cumulative diameter reduction ratio of 30 to 70% in a temperature range no greater than 900°C. This makes it possible to obtain, without performing spheroidizing annealing, a structure in which cementite particles having an average particle diameter (d) from 0.1 mum to less than 0.5 mum and in which the average distance (L) between the surfaces of adjacent cementite particles is 0.5 to 10 mum are dispersed in a ferrite phase. In particular, machinability is significantly improved.

Owner:JFE STEEL CORP

Rolling mill technique of three-roller full-floating core rod tandem rolling tube

InactiveCN101337236AHigh yieldSave energyTemperature control deviceMetal rolling arrangementsSmall caliber% diameter reduction

The invention relates to a process of rolling a three-roll continuous rolling pipe, and belongs to the technical field of the production process of a hot rolled seamless steel pipe. The invention adopts a pipe rolling process by using a three-roll full-floating mandrel continuous rolling pipe; a diameter continuous casting round billet is used as a raw material; the heated raw material is pierced by a cone-shaped roll piercer, enters a continuous pipe rolling mill, and is rolled into an outside pierced billet; through the operation procedures of reheating, diameter reduction, etc., the high-quality small-caliber hot rolled seamless steel pipe is produced. By adopting the process of the three-roll full-floating mandrel continuous rolling pipe, the three-roll continuous rolling pipe achieves high production capacity (is twice as much as the production capacity by the traditional process), high metal yield (can be improved by 1.5 percent) and low consumption (energy resources can be saved by over 15 percent).

Owner:BERIS ENG & RES CORP

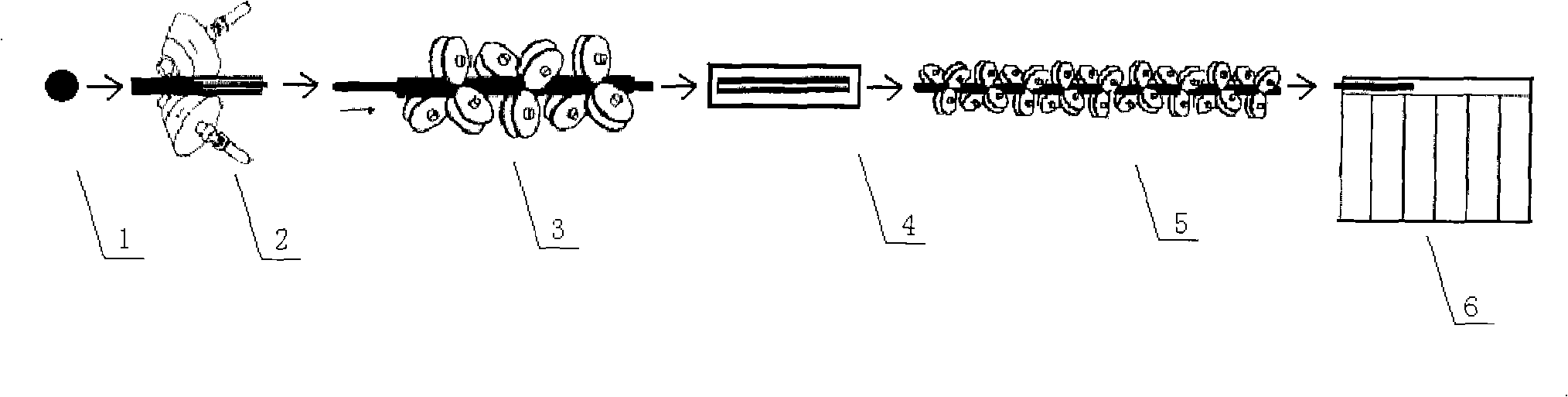

Electric motor assembly and manufacturing method thereof

ActiveUS20150108859A1Inhibit injectionWindings insulation shape/form/constructionManufacturing dynamo-electric machinesInjection pressure% diameter reduction

Provided are, an electric motor assembly capable of preventing a sealant from leakage through a lead-wire drawing portion, and an electric motor manufacturing method with use of the electric motor assembly. The electric motor assembly includes a rotor (12), a stator (13), a casing (14), a partition wall (21) with through-holes (22), plugs (23) made of a highly elastic material and including a tapered outer peripheral surface to be fitted into the through-holes (22), and lead wires (25) connected to the stator (13). The plugs (23) surround lead-wire insertion holes (24). A sealant (20) is injected into the casing (14) in a state that the lead wires (25) are drawn through the lead-wire insertion holes (24). The injection pressure presses the plugs (23) outwardly to bring the outer peripheral surfaces of the plugs (23) into close contact with the inner peripheral surface surrounding the through-holes (22) and elastically deforms the plugs (23) in a diameter-reduction direction to cause the plugs (23) to close the lead-wire insertion holes (24).

Owner:KOBELCO CONSTR MASCH CO LTD

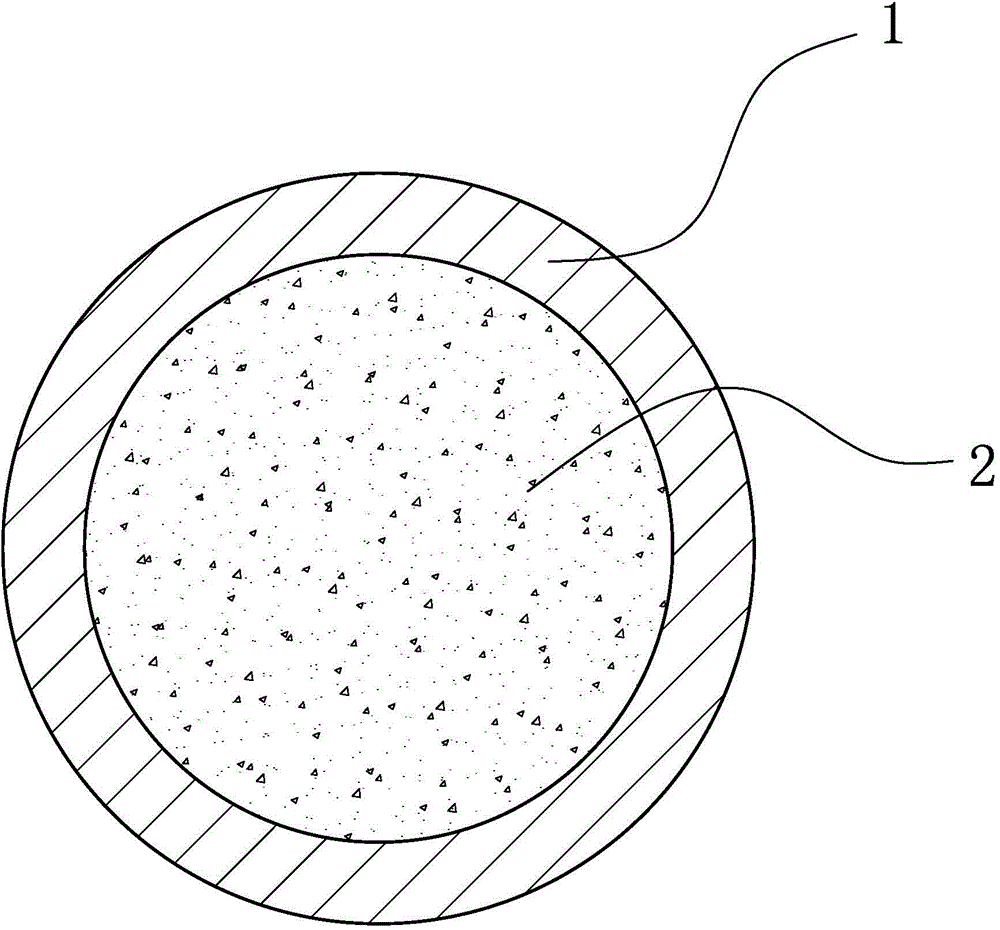

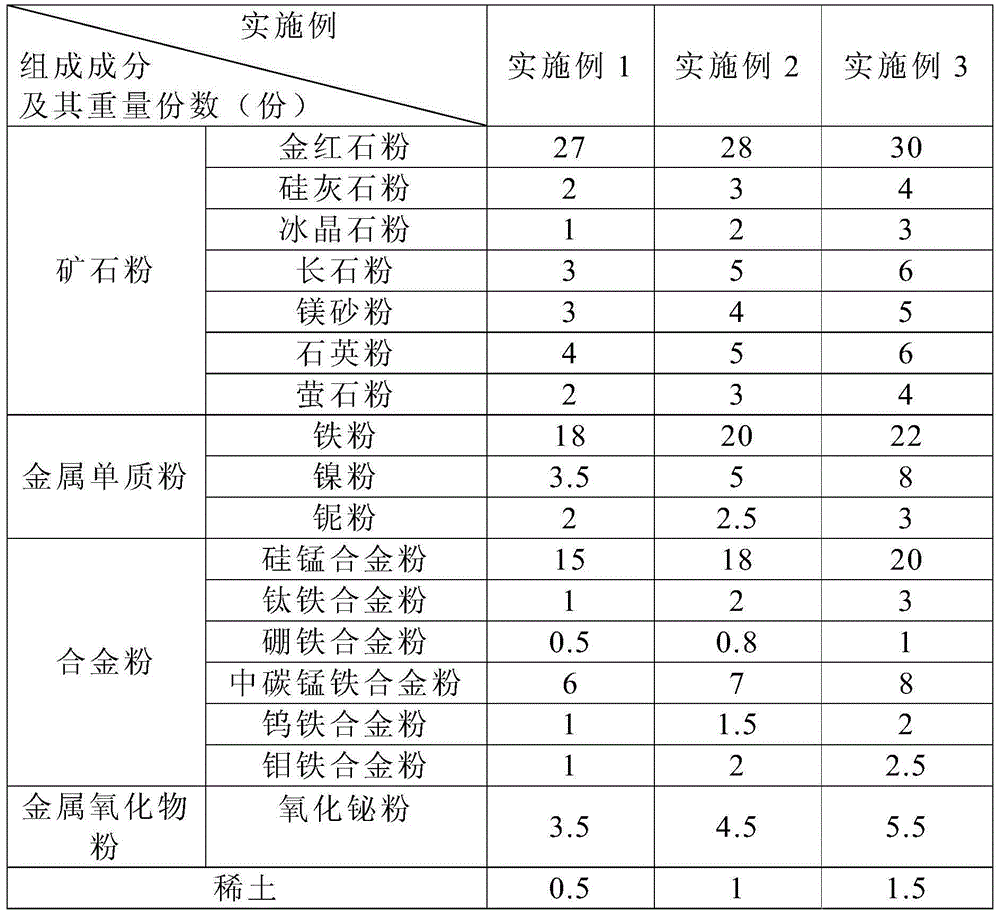

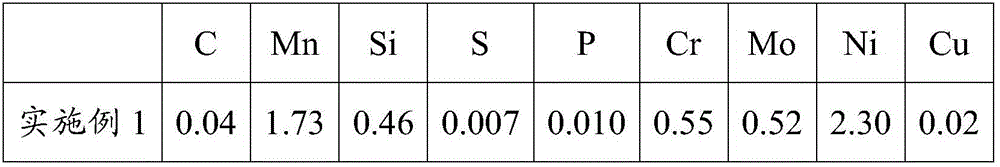

Flux-cored wire for welding low-temperature steel and preparation method thereof

ActiveCN104439760AOxygen limitationLimited diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaRare-earth element% diameter reduction

The invention relates to a flux-cored wire for welding low-temperature steel. The flux-cored wire comprises a cylindrical skin, wherein a through hole penetrating through the skin along the axis line is formed in the skin, and the through hole is filled with flux core powder composed of mineral powder, metal simple-substance powder (except rare earth elements), alloyed powder, metal oxide powder and rare earth. According to a preparation method of the flux-cored wire, the flux core powder is prepared first and then added into a U-shaped groove which is formed by drawing a steel belt; next, after an opening of the U-shaped groove is closed, the through hole penetrating through the steel belt is formed in the axial direction of the steel belt, and the flux core powder is arranged in the through hole; lastly, the flux-cored wire is obtained by means of step-by-step drawing and diameter reduction. The flux-cored wire can be welded in all directions, the welding efficiency is high, and weld joints are stable in metal performance and more attractive in appearance; besides, the average impact work of deposited metal at the low temperature of minus 60 DEG C can reach 65 J, so that the properties such as low-temperature impact toughness and low-temperature anti-cracking performance are improved to a higher grade.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Method and apparatus for plastic working of hollow rack bar and hollow rack bar

InactiveUS20070204668A1Easy to useDegree of improvementEngine componentsEngineering% diameter reduction

A preparatory working device by which a work piece to be fed to a rack bar forging device is obtained. The device is provided with a die sets for obtaining a diameter reduction at a location of a blank pipe, which becomes a toothed part of a rack bar, while the wall thickness being substantially unchanged or slightly increased. The device is further provided with a die set for reducing a wall thickness at a location of the blank pipe, which becomes a connection part of the rack bar. The wall thickness reduction is one half of the initial thickness, which causes the length of the work piece to be elongated. Then a rack bar forging by a die set is done.

Owner:MATSUOKA MINAKO +2

Metal powder flux-cored wire for 1000 MPa high-strength steel and production process thereof

ActiveCN106216882AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaManganeseAlloy

The invention discloses a metal powder flux-cored wire for 1000 MPa high-strength steel and a production process thereof. The flux-cored wire comprises a steel cover and a flux core; the flux core comprises the following components in percentage by mass: 3-6 wt% of silicon manganese alloy, 3-8 wt% of silicon iron powder, 0.5-2.2 wt% of titanium iron powder, 0.01-0.28 wt% of fluoride, 10-19 wt% of manganese powder, 10-18 wt% of nickel powder, 6-10 wt% of molybdenum iron, 3-8 wt% of chromium powder, and the balance of iron powder and inevitable impurities; and the flux core is 12-18 wt% of total mass of the flux-cored wire. The production process comprises the following steps: all the components of the flux core are positioned on the steel core after uniform mixing in proportion, and are wrapped or wound as wires for drawing and diameter reduction to obtain welding wires with predetermined specifications, so that the metal powder flux-cored wire for 1000 MPa high-strength steel is prepared.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com