Patents

Literature

66results about How to "Reduce axial thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

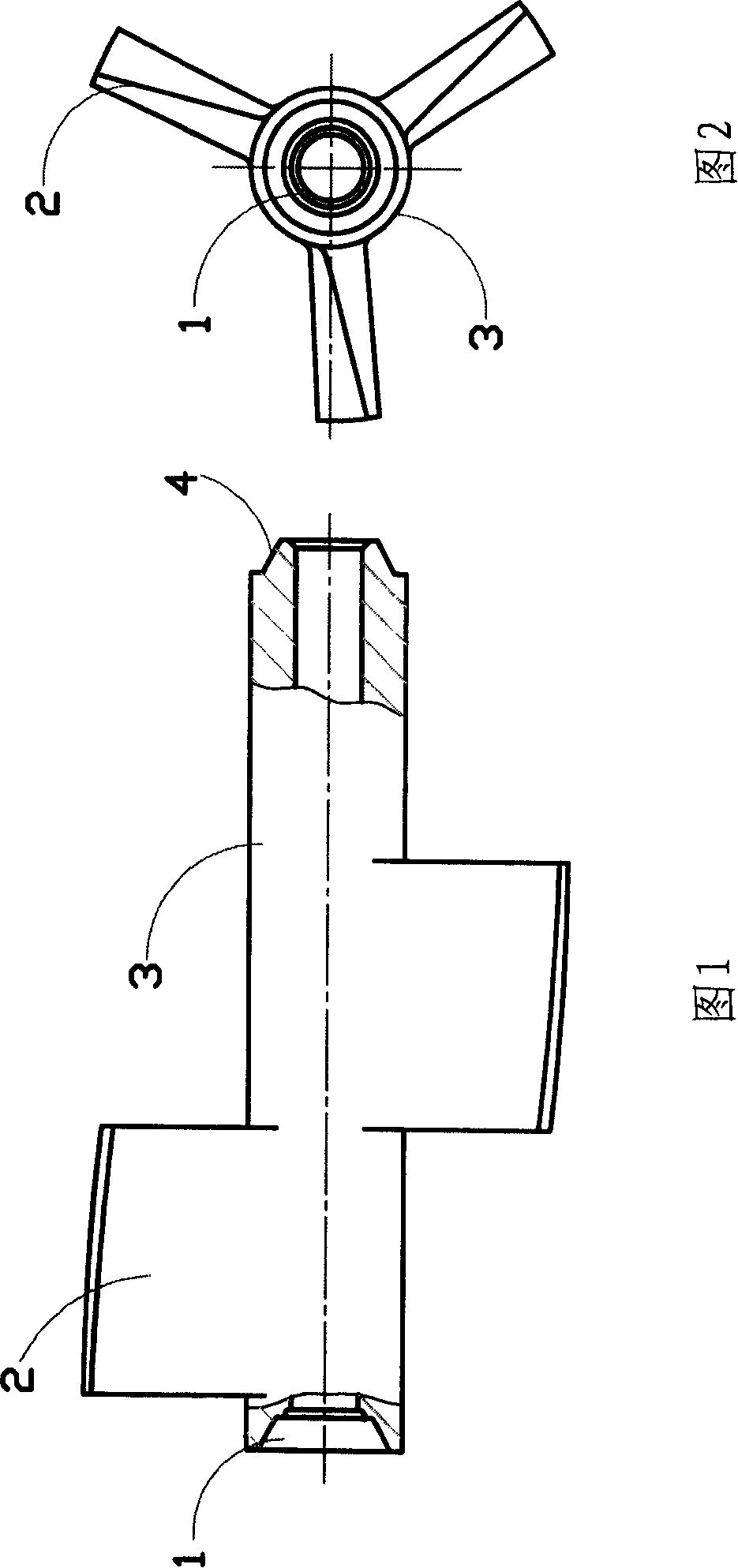

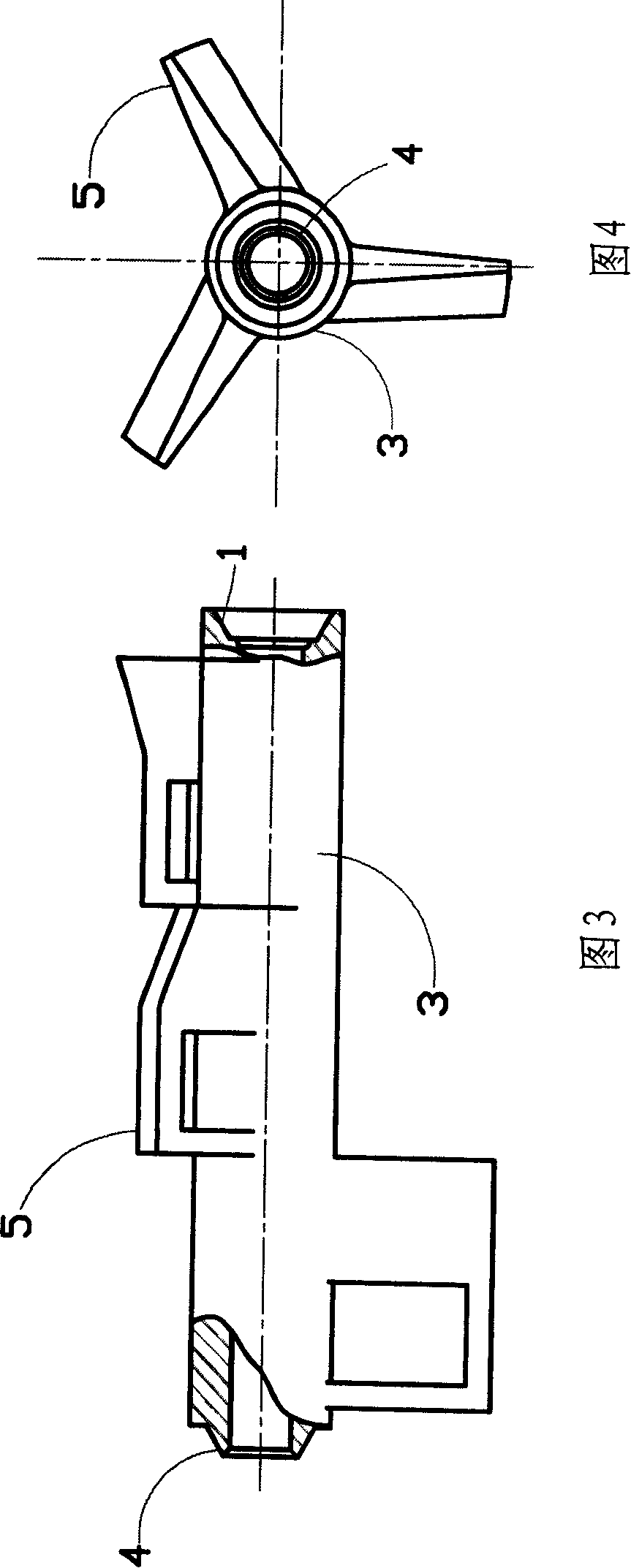

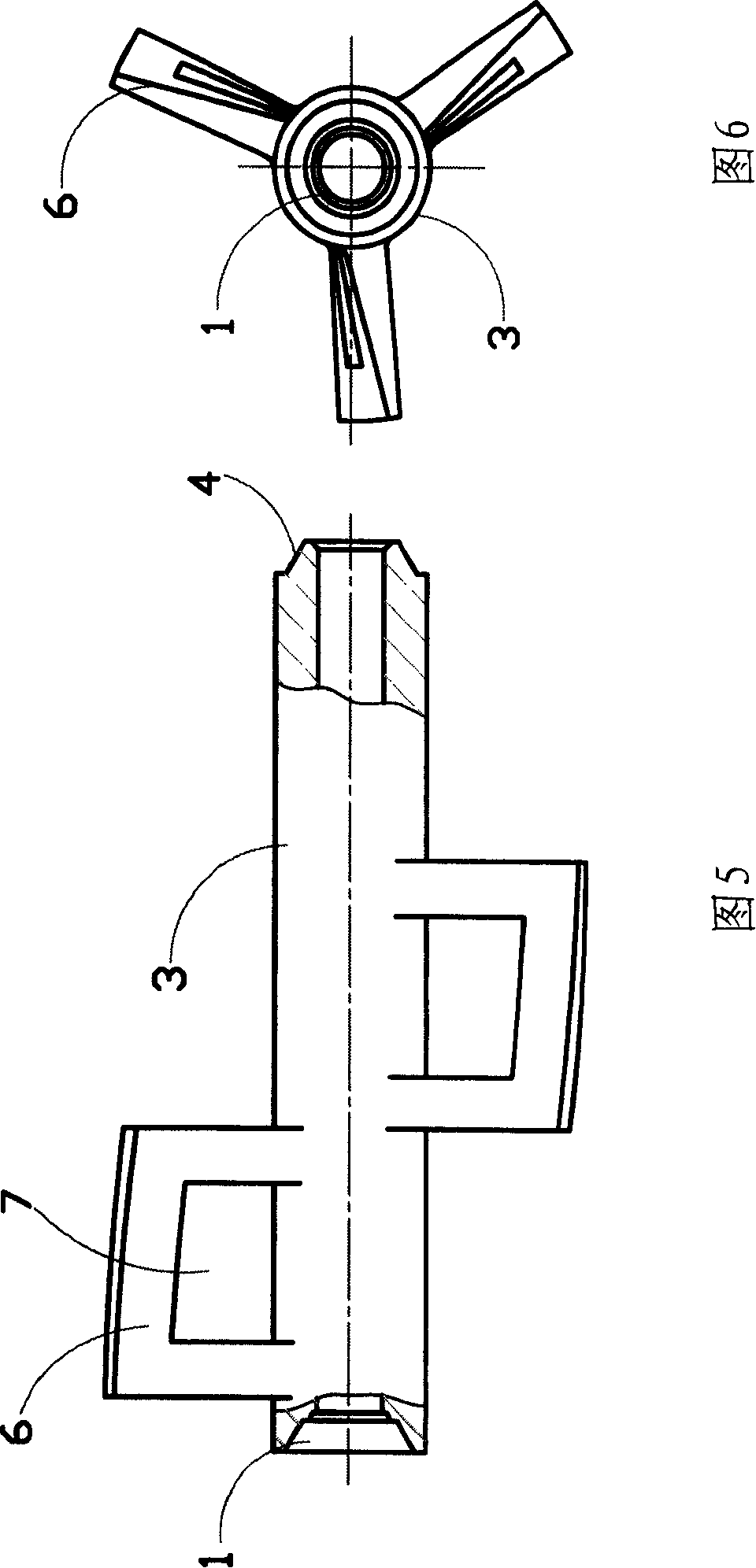

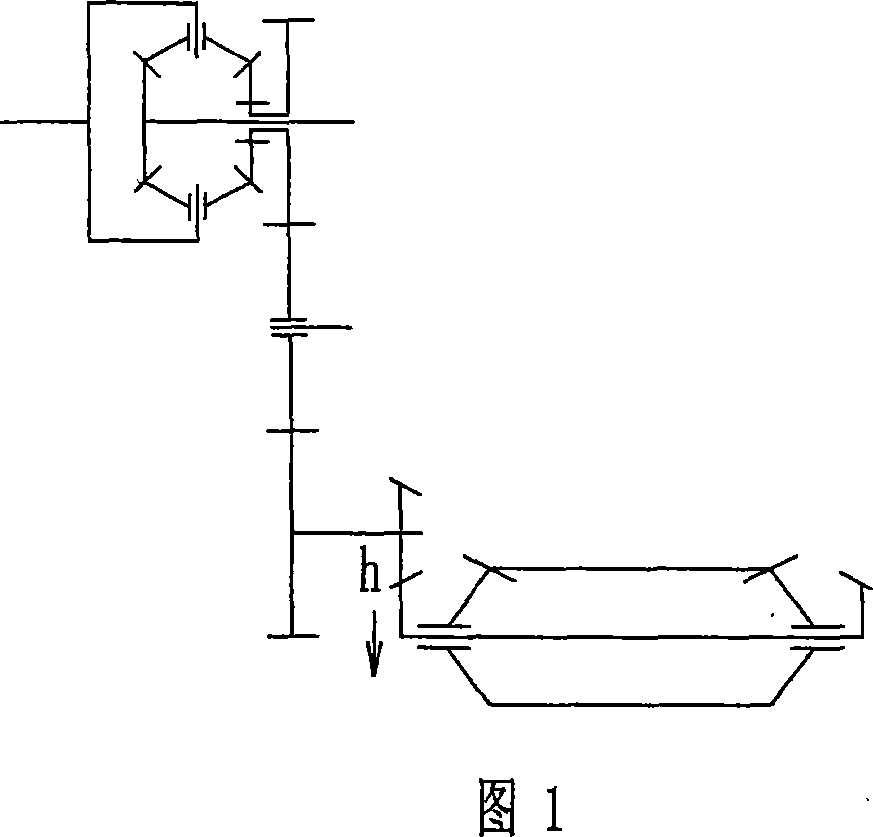

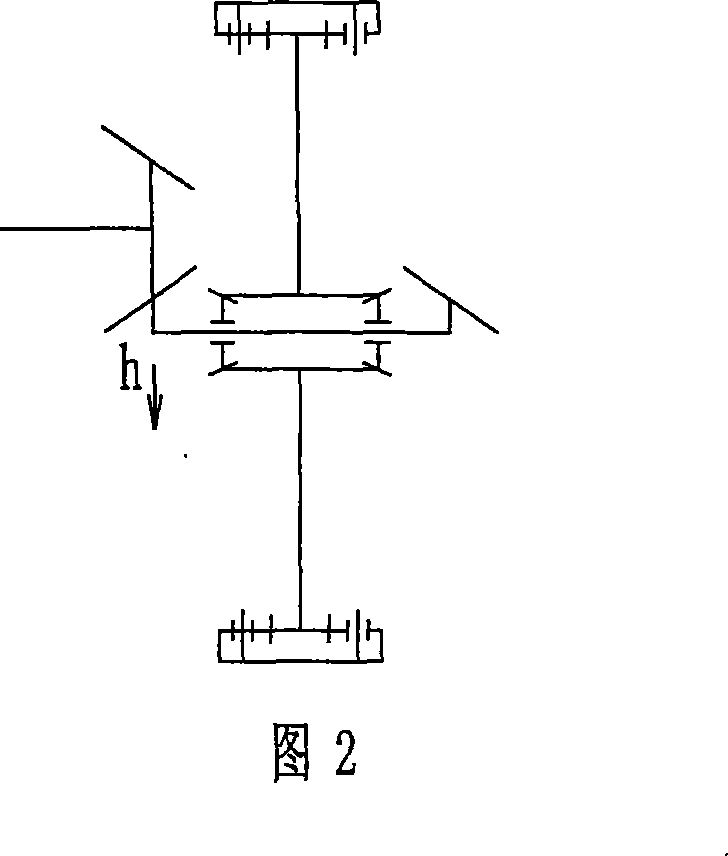

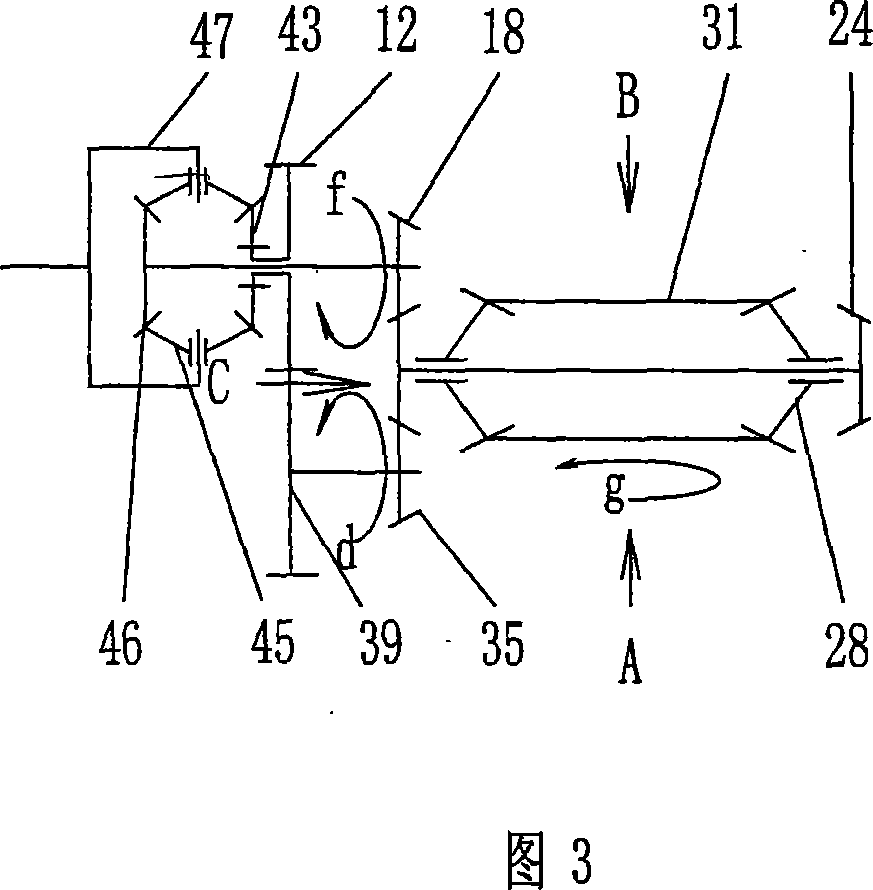

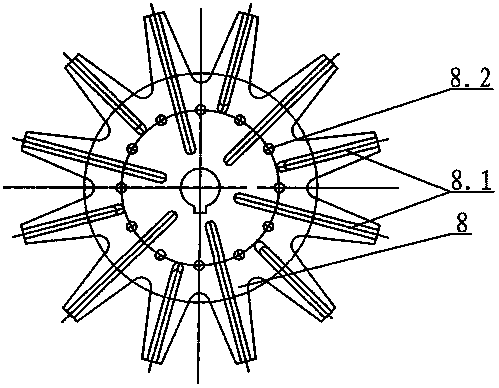

Self-cleaning reinforcement heat transfer low flow resistance rotor in heat-transfer pipe

InactiveCN101210791ATake up a lot of spaceExtended service lifeHeat transfer modificationRotary device cleaningEngineeringConvection heat

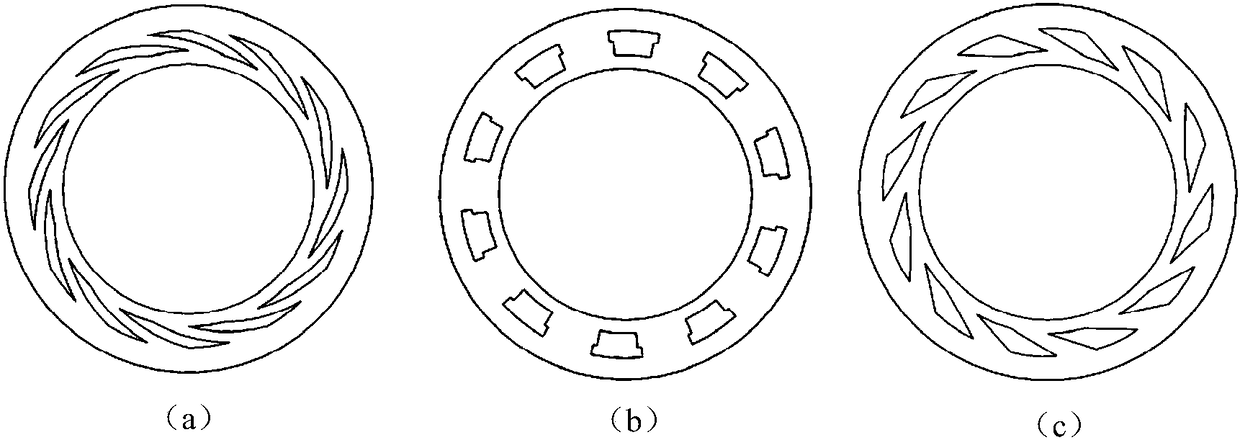

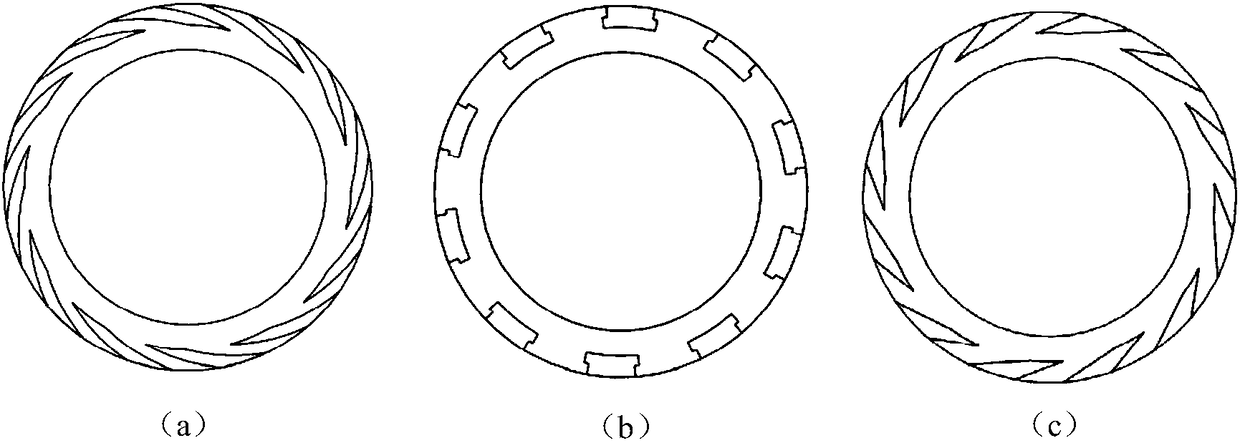

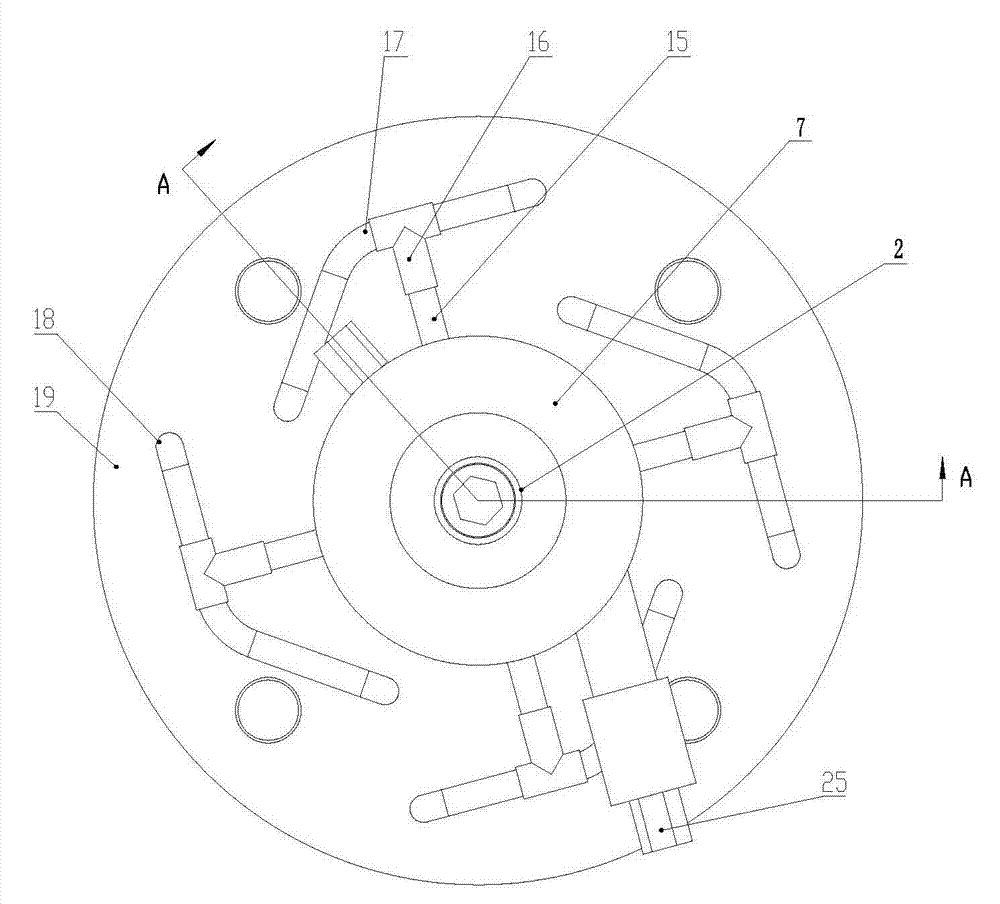

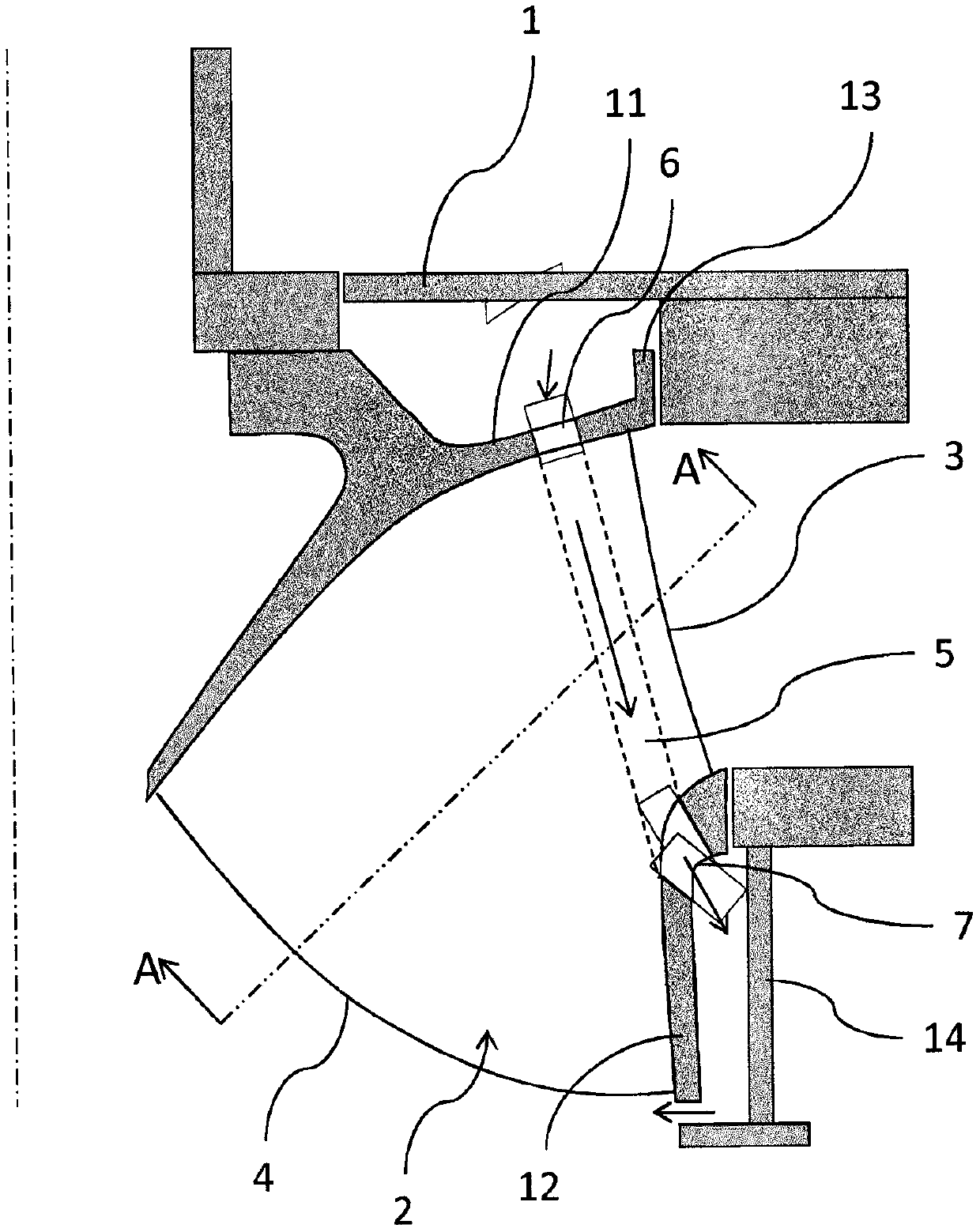

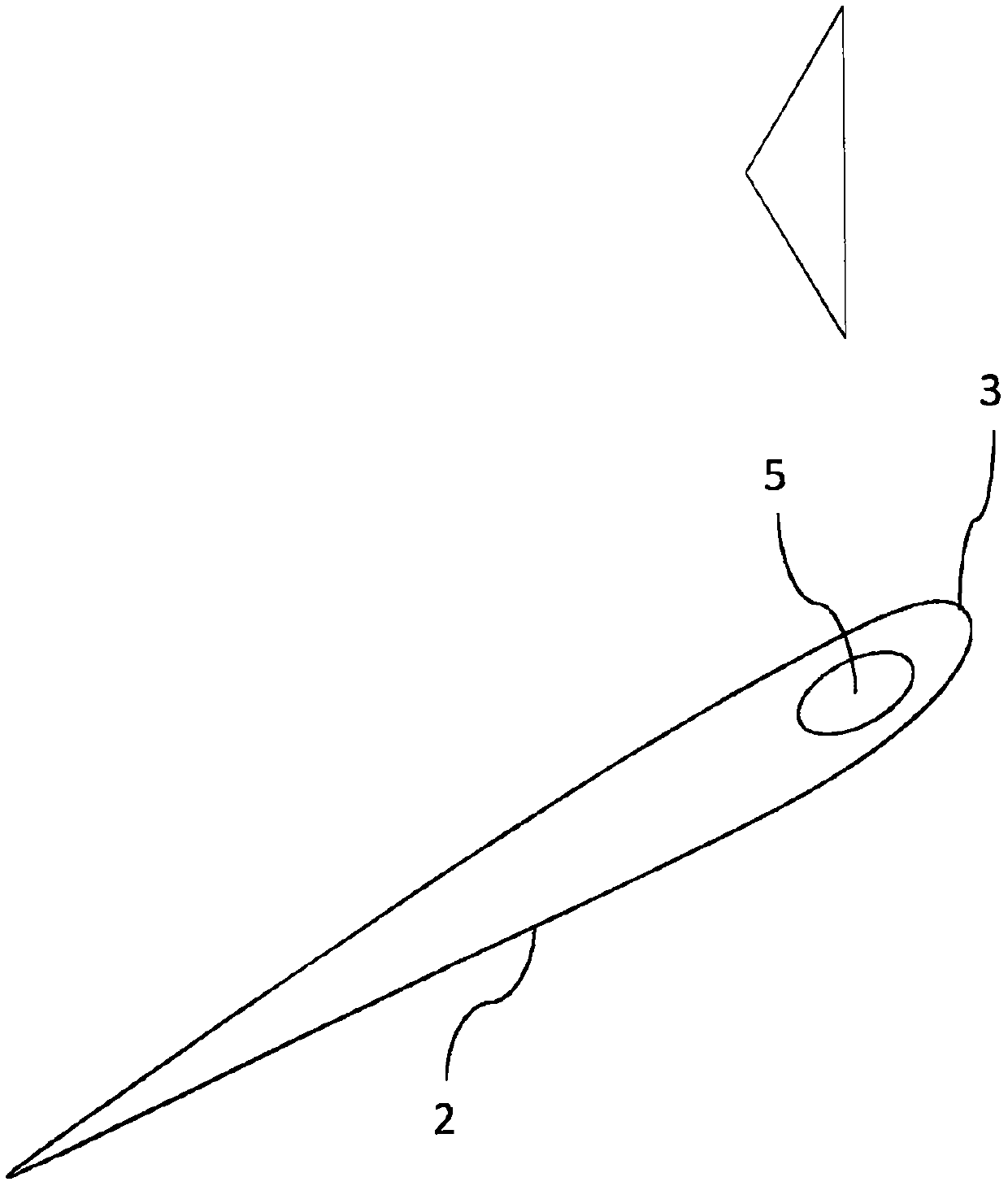

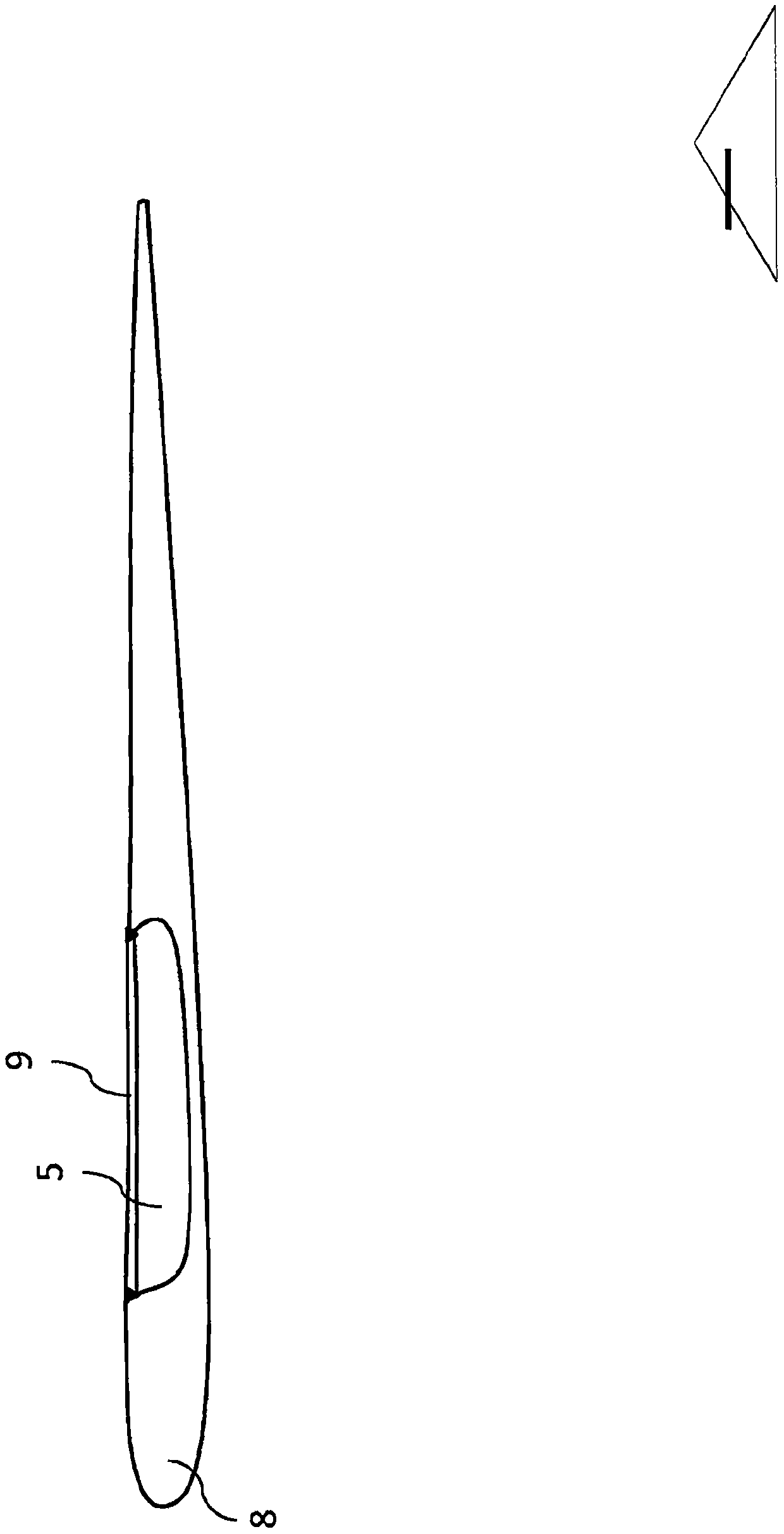

The invention relates to a low-flow resistance rotor with self-cleaning function and heat transfer enhancement used in a heat transfer tube, which comprises a plurality of rotors, supporting frames and a connecting shaft line. The supporting frames are fixed at the two ends of the heat transfer tube. The two ends of the connecting shaft line are fixed on the supporting frames respectively. The plurality of rotors are skewered on the connecting shaft line between the two supporting frames. The rotor consists of a hollow shaft and fins, wherein the hollow shaft is provided thereon with one and more fin(s), each fin is oblique to the central line of the hollow shaft, the working surface of each fin is swirl or flat or a combination thereof, and the fins are fixed uniformly on the outer surface of the hollowing shaft. In the inventive technical proposal, a fluid inside a tube can drive the rotor by the fins to rotate at a proper speed, so as to inhibit and eliminate the deposition of dirt, the fins can disturb the fluid inside the tube to enhance the convection heat transfer, the rotor occupies a small area inside the heat transfer tube to increase the axial flow area and reduce the blockage rate and flow resistance in the heat transfer tube, and the service life of the rotor is significantly prolonged.

Owner:山西英蓝科技有限公司

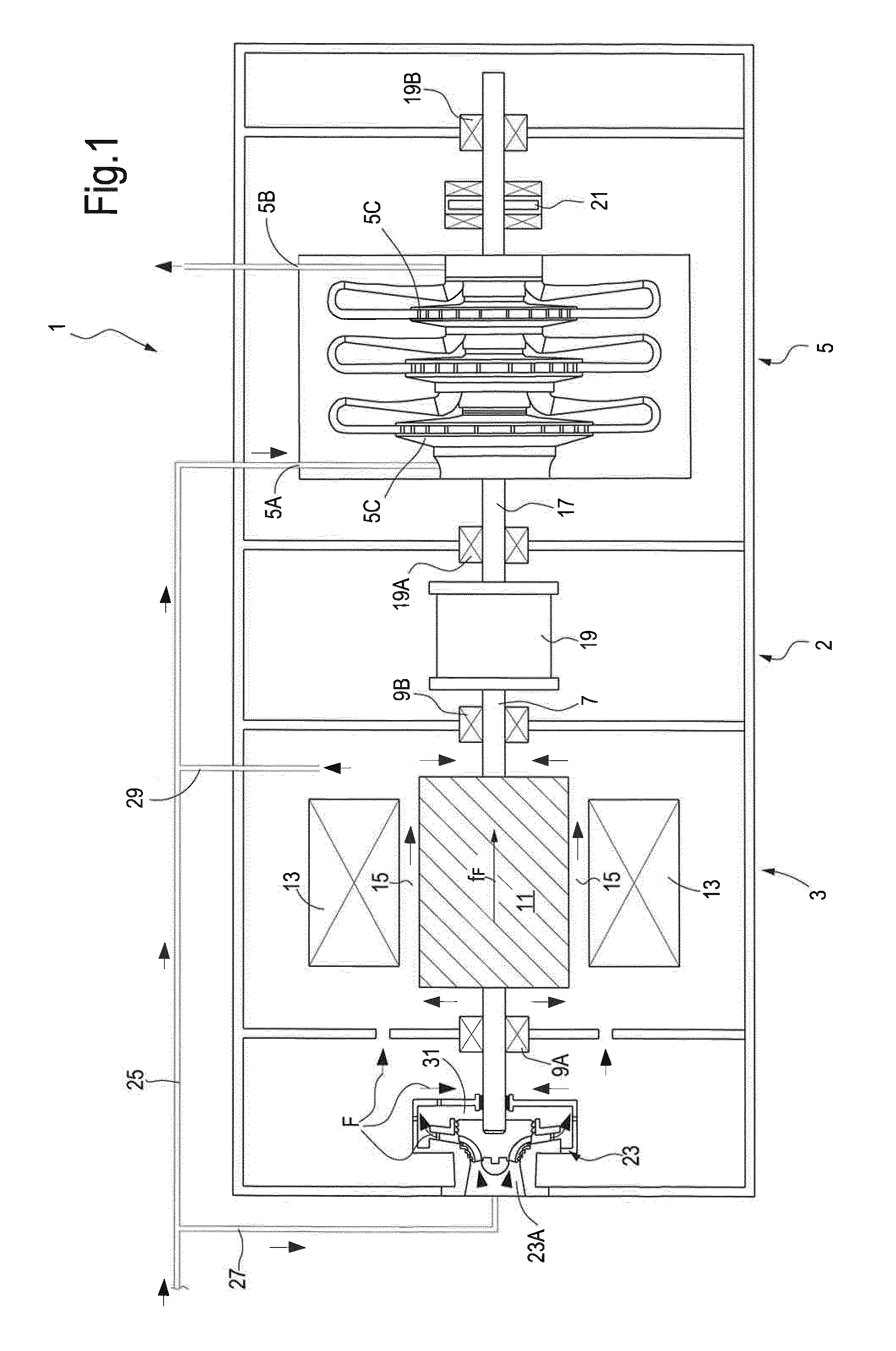

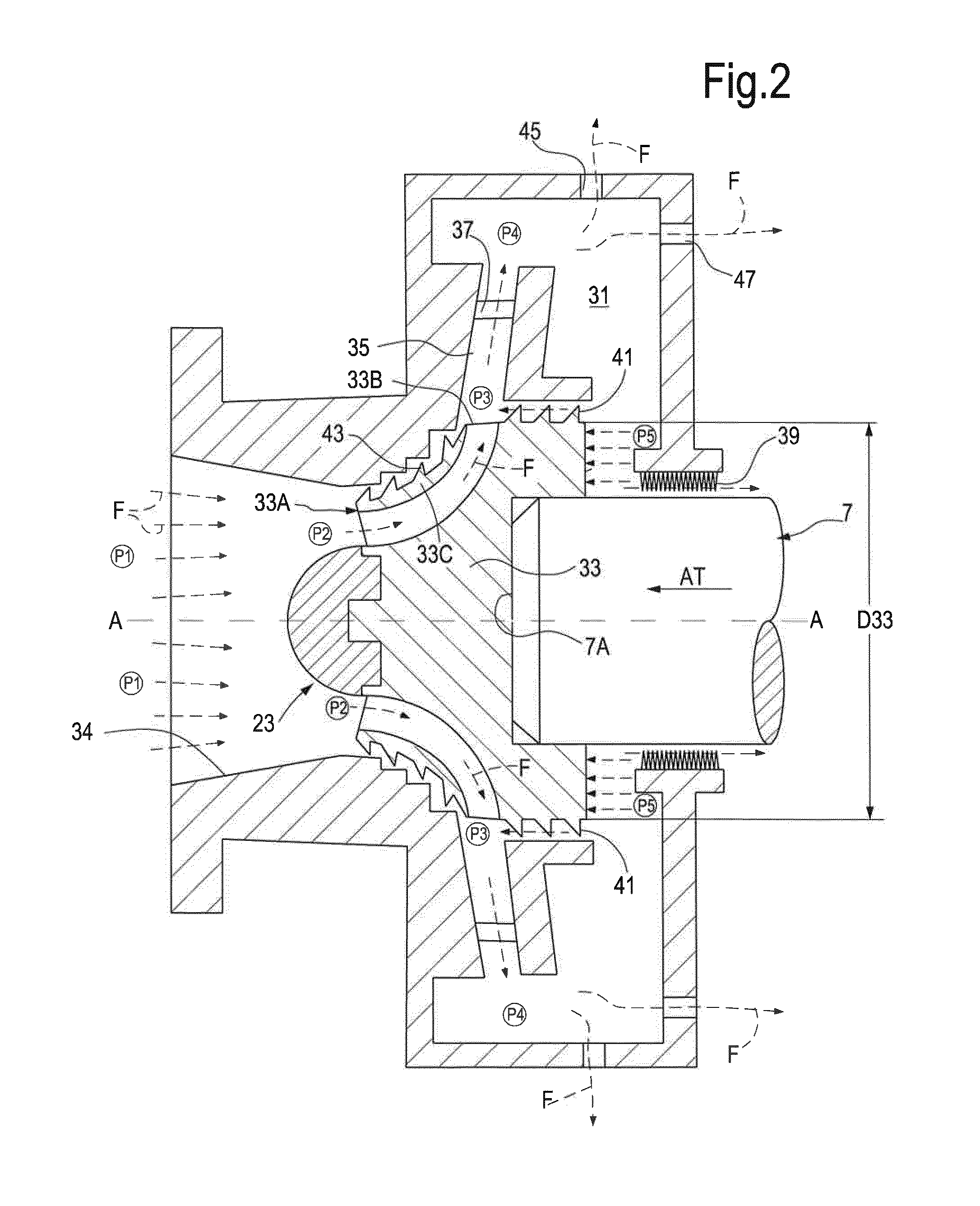

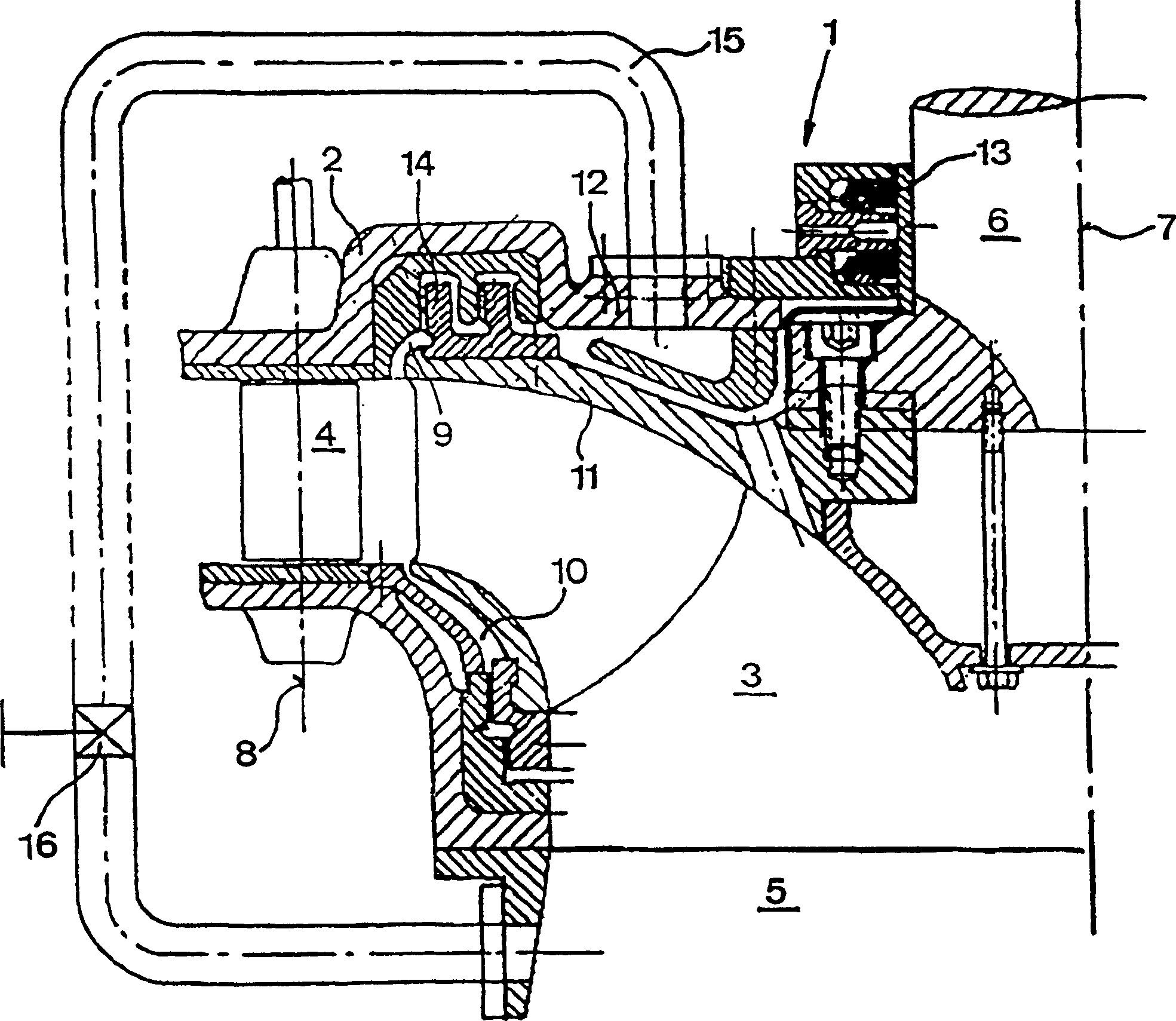

Fancooled electrical machine with axial thrust compensation

A rotating machinery equipment is disclosed, comprising a rotating electrical machine having a stator and a rotating shaft, whereon a rotor is mounted. The machinery equipment further comprises a cooling fan comprised of a rotating impeller mounted on the rotating shaft for co-rotation therewith. Cooling gas passages are provided for delivering compressed cooling gas through the stator and rotor. The cooling gas is delivered by the impeller into a cooling-gas distribution chamber. The pressure of the cooling gas in the cooling-gas distribution chamber generates an axial force balancing the axial thrust generated on the electrical machine by the cooling gas flow.

Owner:NUOVO PIGNONE TECH SRL

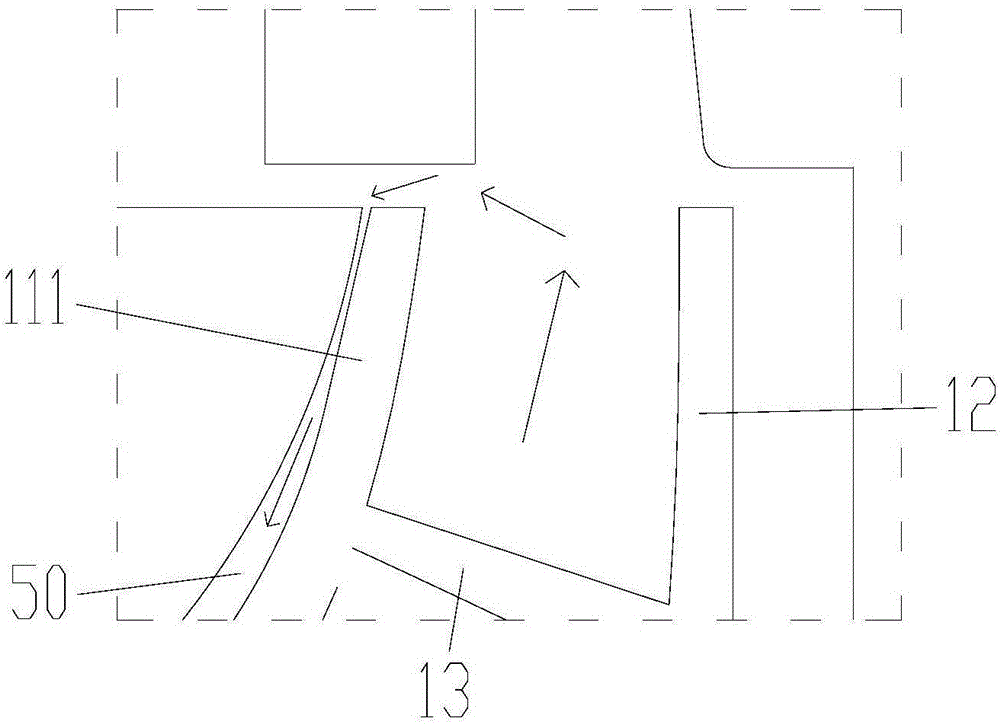

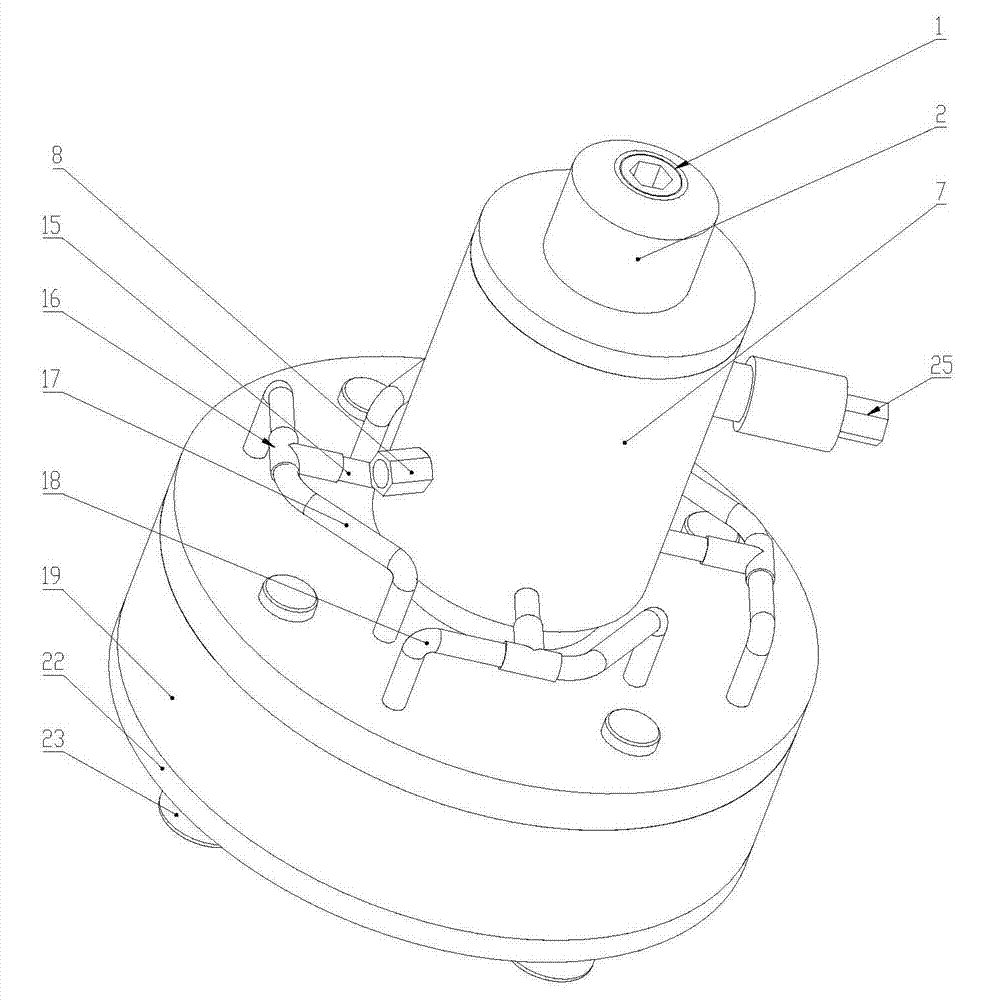

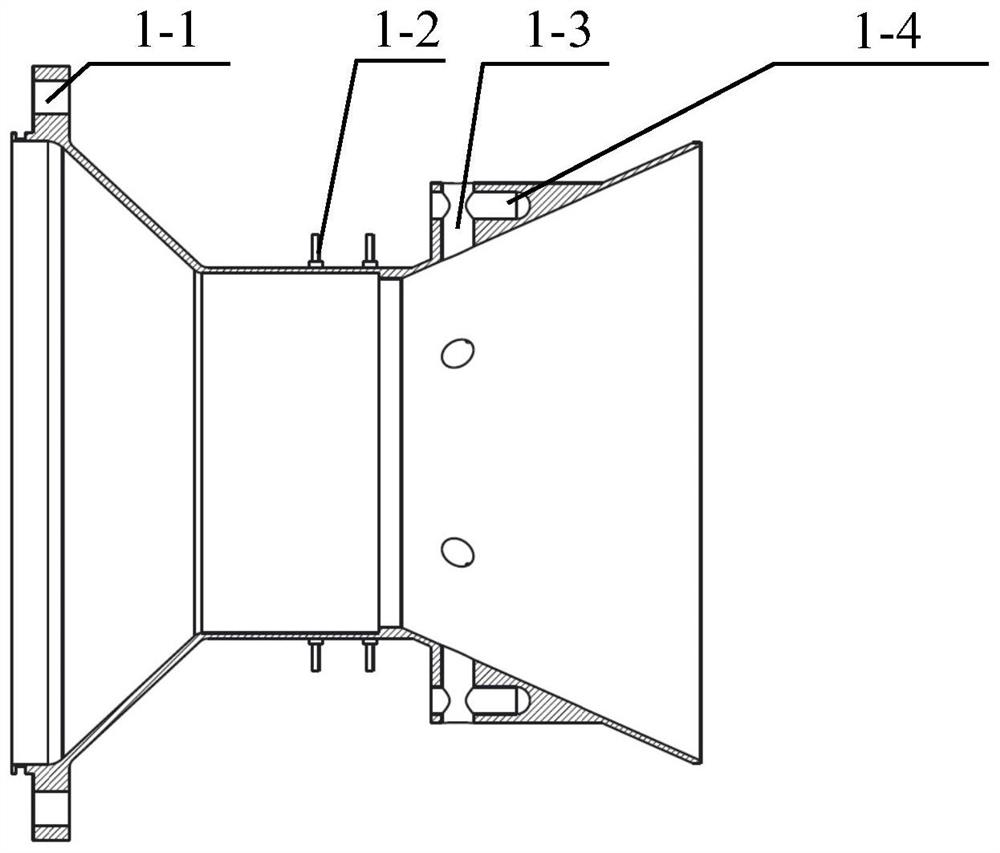

Vectored thrust ducted propeller

The invention relates to a vectored thrust ducted propeller. The vectored thrust ducted propeller comprises a screw propeller and a duct cylinder body, wherein the screw propeller can rotate to generate air currents and the duct cylinder body surrounds the screw propeller; a first rotating piece, a second rotating piece and a blocking piece which are arranged in an air current deflection mechanism are respectively and directly derived from a part of a duct body; a complete duct is jointly formed by the first rotating piece, the second rotating piece, the blocking piece and the duct cylinder body part. Under the driving of a speed reducing motor, a rotation driving shaft is rotated, so that the first rotating piece and the second rotating piece are driven to rotate to expected positions; the blocking piece moves forward and backward along a sliding groove formed in the duct cylinder body to prevent the air currents from flowing out of the right side of the duct, and the blocking piece is matched with the first rotating piece and the second rotating piece so that the air currents can flow out of the remained empty part formed after the first rotating piece is rotated; therefore, the whole system bears lateral force which is reversed to the air currents. According to the vectored thrust ducted propeller disclosed by the invention, the thrust direction of a ducted fan is substantially changed, large enough lateral force is provided for an aircraft to balance the reaction torque of a main rotor, so that the residual thrust in the axial direction of the aircraft is as small as possible, and more suitable for the aircraft of the type to ascend and descend perpendicularly and hang in the air.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sealing in hydraulic turbine unit

InactiveCN1459003AReduced risk of infiltration into sealed areasReduce frictionEngine sealsHydro energy generationImpellerFree rotation

Owner:DIPL ING DR TECHN GITTLER PHILIPP

Main gear down device

InactiveCN101055018ASimple structureImprove support rigidityToothed gearingsDifferential gearingsGear wheelEngineering

The present invention provides a main decelerate device which includes a planet gear load-uniformed mechanism, a driver gear and a initiative bevel gear driven by the device, a driven bevel gear engaged with the initiative bevel gear and a speed differientiator connected to the driven bevel gear. It is characterized in that one of the sun gear in the planet gear load-uniformed mechanism is connected to the initiative bevel gear, another sun gear is connected to one of two engaged intermediate drive gears by an axle sleeve, another intermediate drive gear is connected to a secondary initiative bevel gear, the initiative bevel gear and the secondary initiative bevel gear are both connected to a driven bevel gear with double cog. The device divides the power into two parallel path powers with reverse rotate direction and equal torsion, and then combines the two powers into one power by making the main, secondary initiative bevel gears engage with the driven bevel gear with double cog, and passes the power to the speed differientiator by the driven bevel gear and output the power by an axle shaft gear, thereby complete the power output between interleaving shafts, conquers the axial direction offset of the driven bevel gear and increases the drive ability by times.

Owner:张春

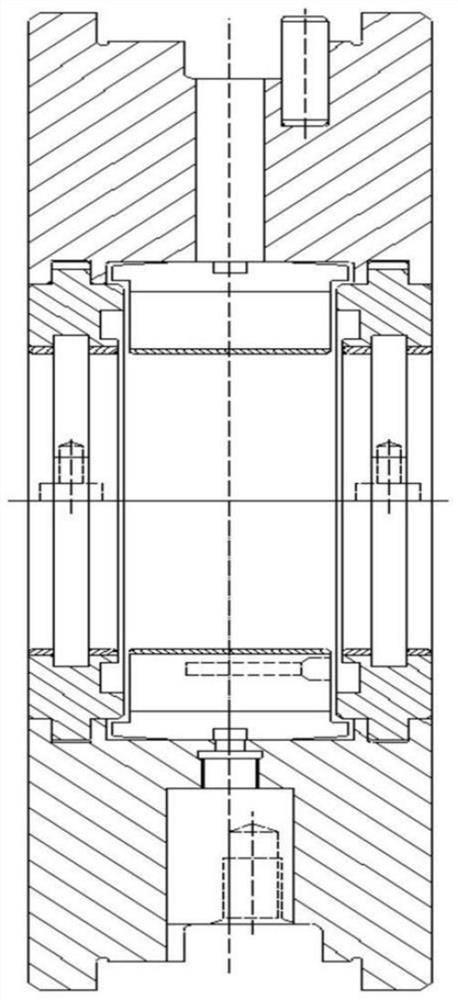

Dry gas sealing device suitable for supercritical working medium

The invention discloses a dry gas sealing device suitable for a supercritical working medium. Two-stage level dry gas seal is composed of a static ring-moving ring-static ring structure. The sealed supercritical working medium flows through, in the radial direction, a first-stage dry gas seal, and then flows through, in the radial direction, the flow channel between the moving ring and a cavity wall, and then flows through a second-stage dry gas seal. Divergent clearance is adopted in the first-stage dry gas seal, cooling channels are separately arranged on the two static rings, and a heat transfer enhancement structure is arranged on the cavity wall to reduce the end face temperature of a sealing ring. The sealed supercritical working medium is subjected to two-stage level dry gas seal, the leakage rate is greatly reduced, and the sealing performance is good. The dry gas sealing device suitable for the supercritical working medium has the remarkable advantages of reducing the temperature of the sealing ring, reducing the leakage rate and ensuring the sealing performance, and has broad market prospect.

Owner:XI AN JIAOTONG UNIV

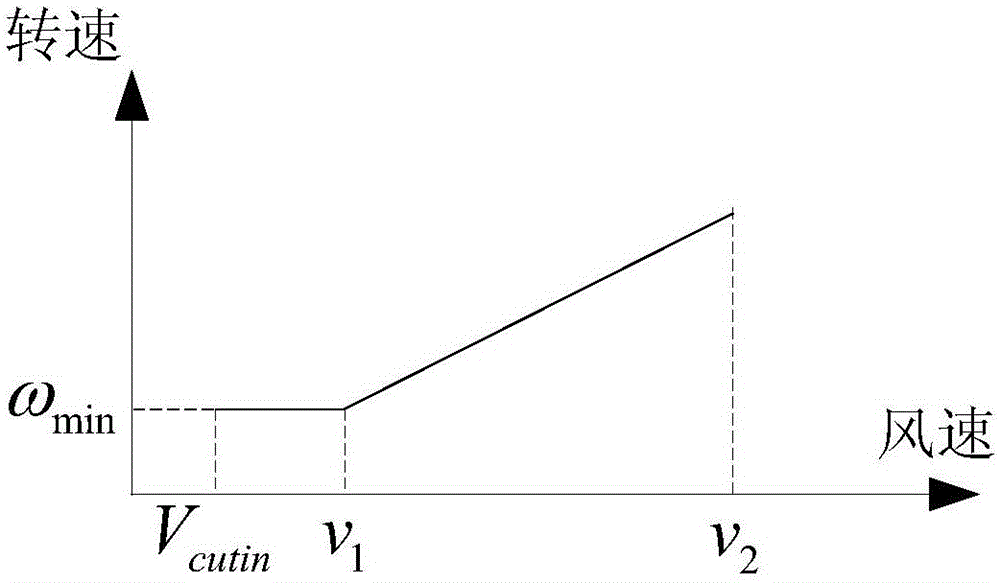

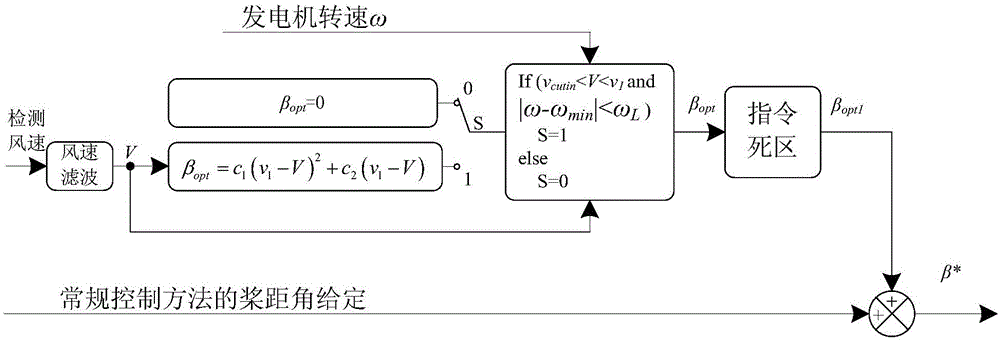

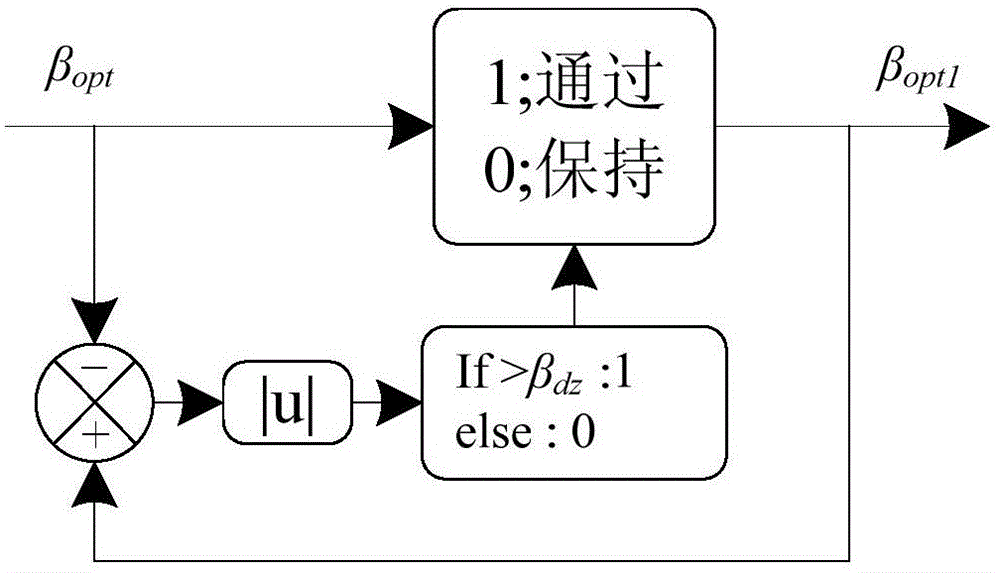

Variable-pitch control method for improving weak wind generating capacity of wind turbine generator

ActiveCN105041565AReduce swinging momentReduce axial thrustWind motor controlFinal product manufactureElectricityEngineering

The invention provides a variable-pitch control method for improving weak wind generating capacity of a wind turbine generator. According to the variable-pitch control method, the generating capacity is improved by advancing the pitch angle action in a constant minimum rotation speed region, the constant minimum rotation speed region where the generating capacity is improved is described through a wind speed interval, wherein the wind speed interval means the weak wind speed interval between the cut-in wind speed and the start wind speed of a maximum power point tracking (MPPT) segment. According to the variable-pitch control method, the generating capacity in the wind speed interval [Vcutin, vl] is improved based on the prior art, only an existing variable-pitch control strategy needs to be modified properly, no extra hardware device is needed, and the waving torque and axial thrust of blade roots can be lowered to a certain degree.

Owner:SHANGHAI JIAODA INTELLECTUAL PORPERTY MANAGEMENT CO LTD +1

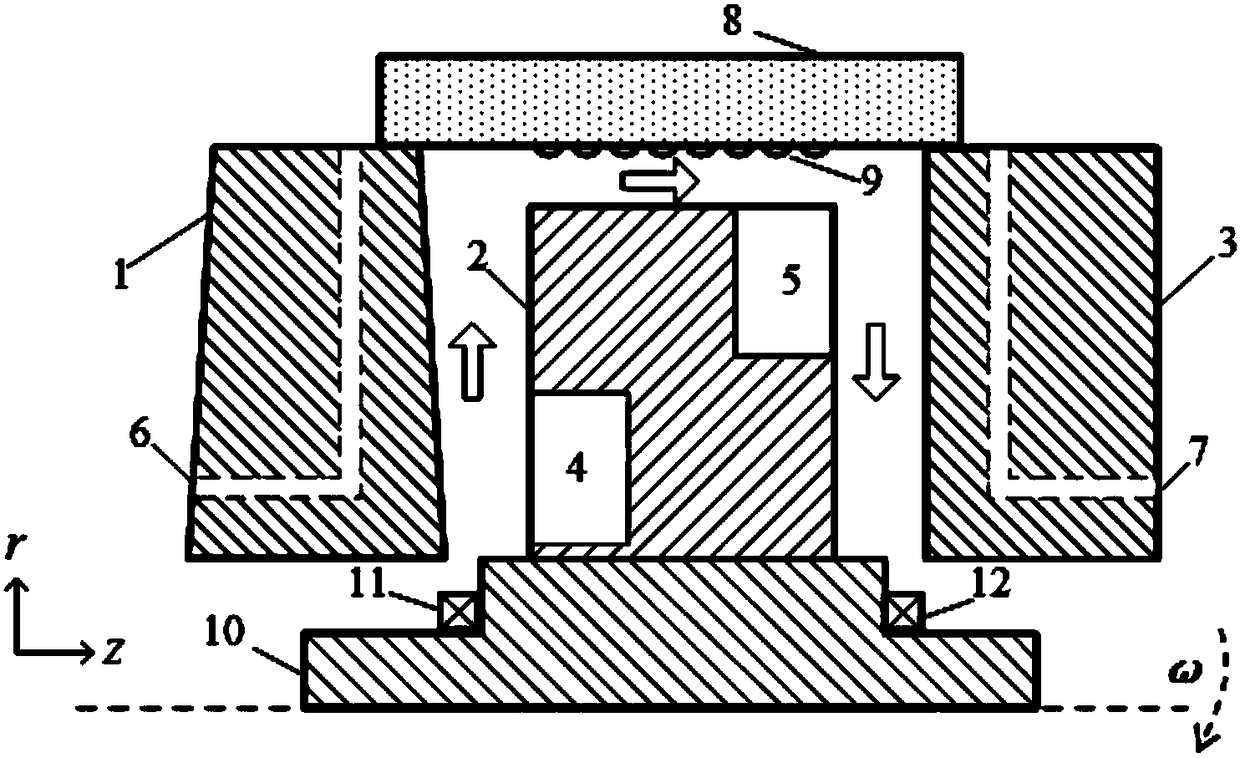

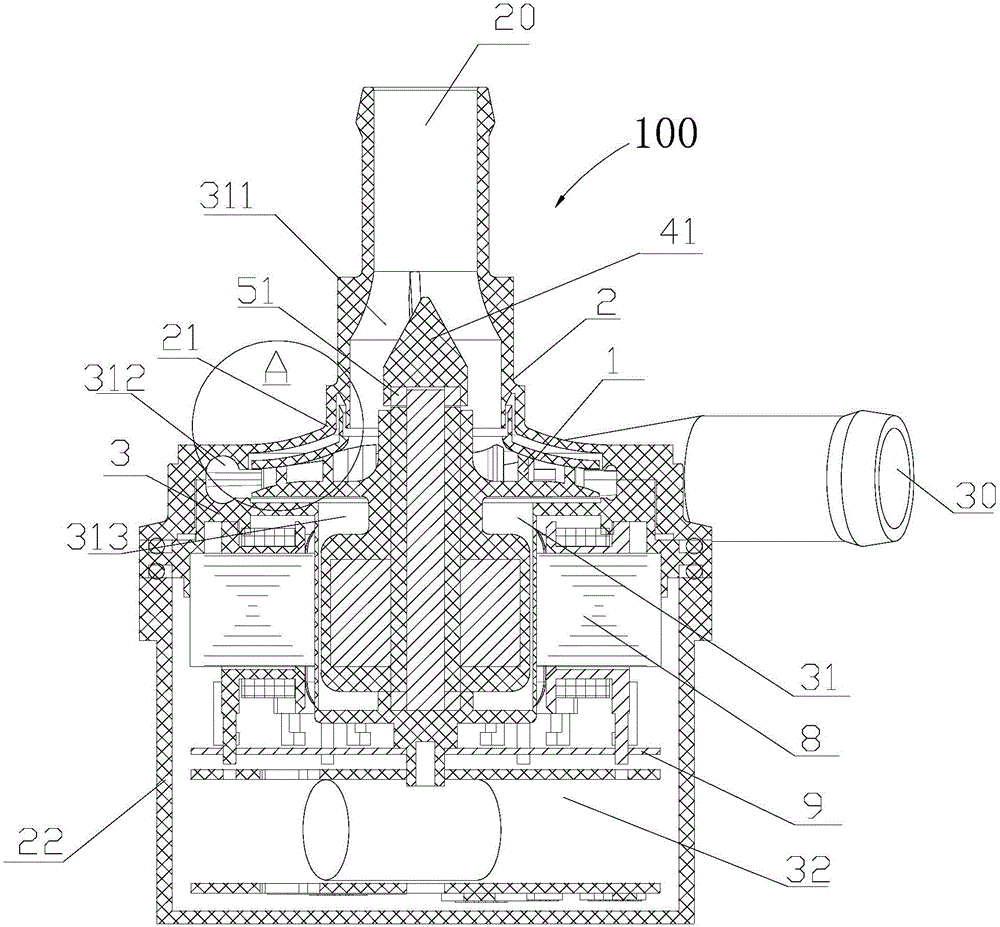

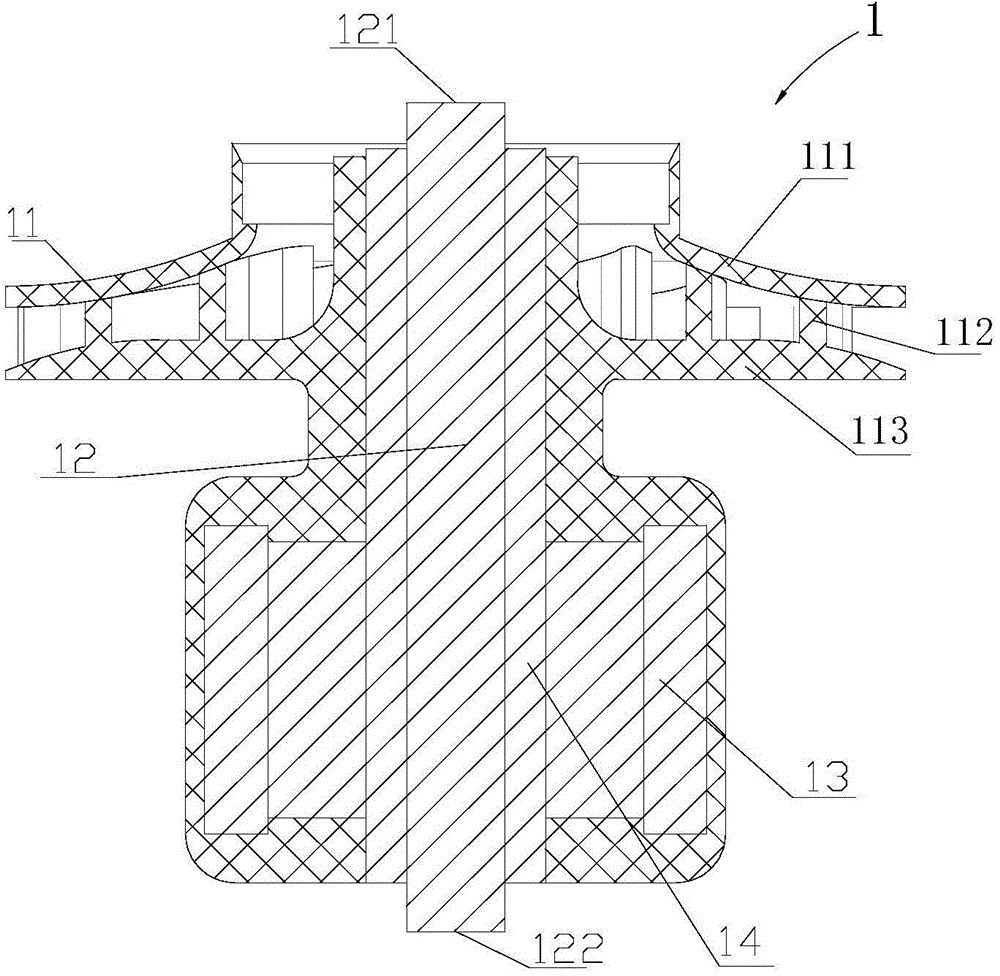

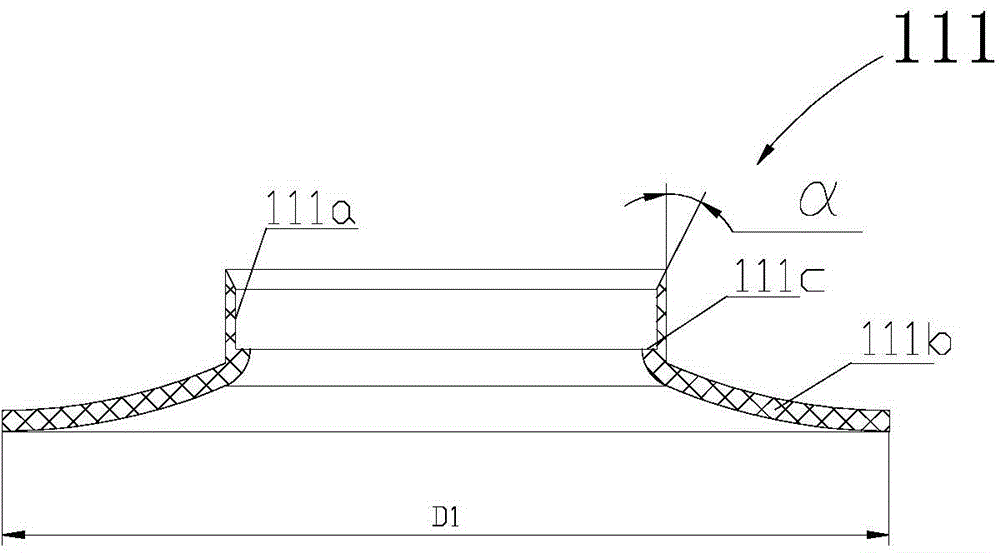

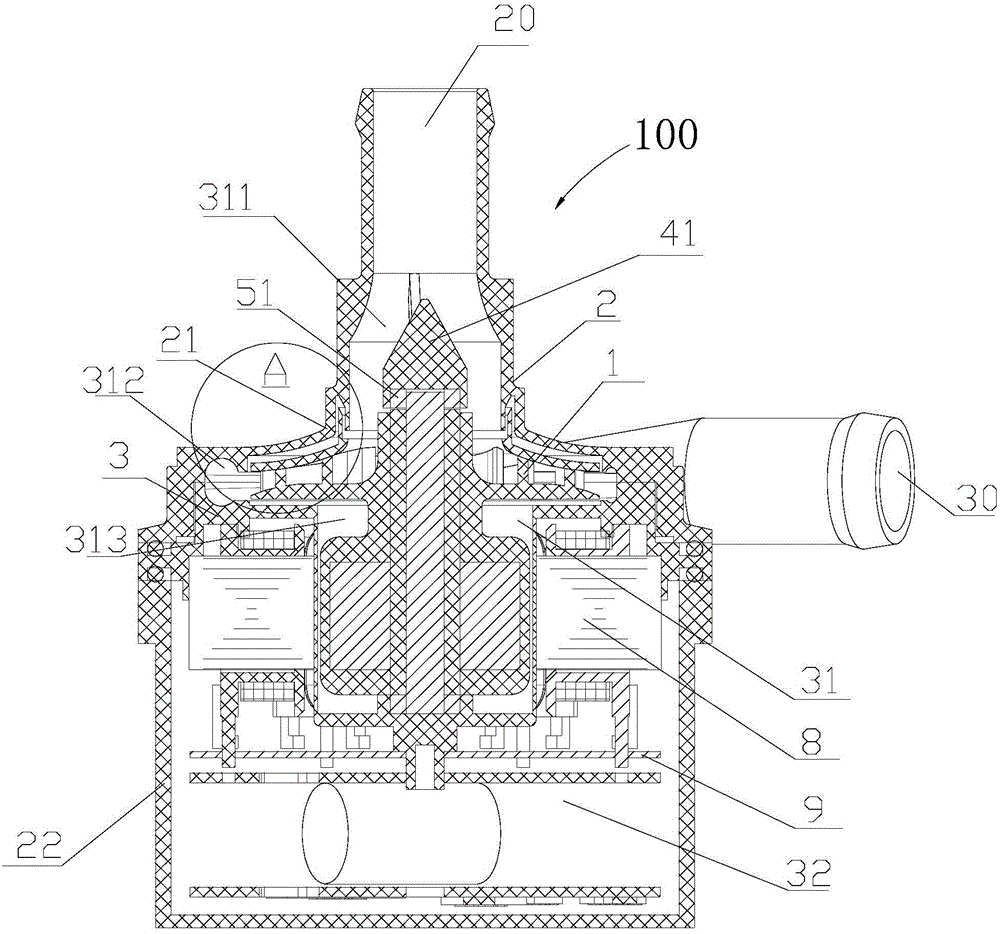

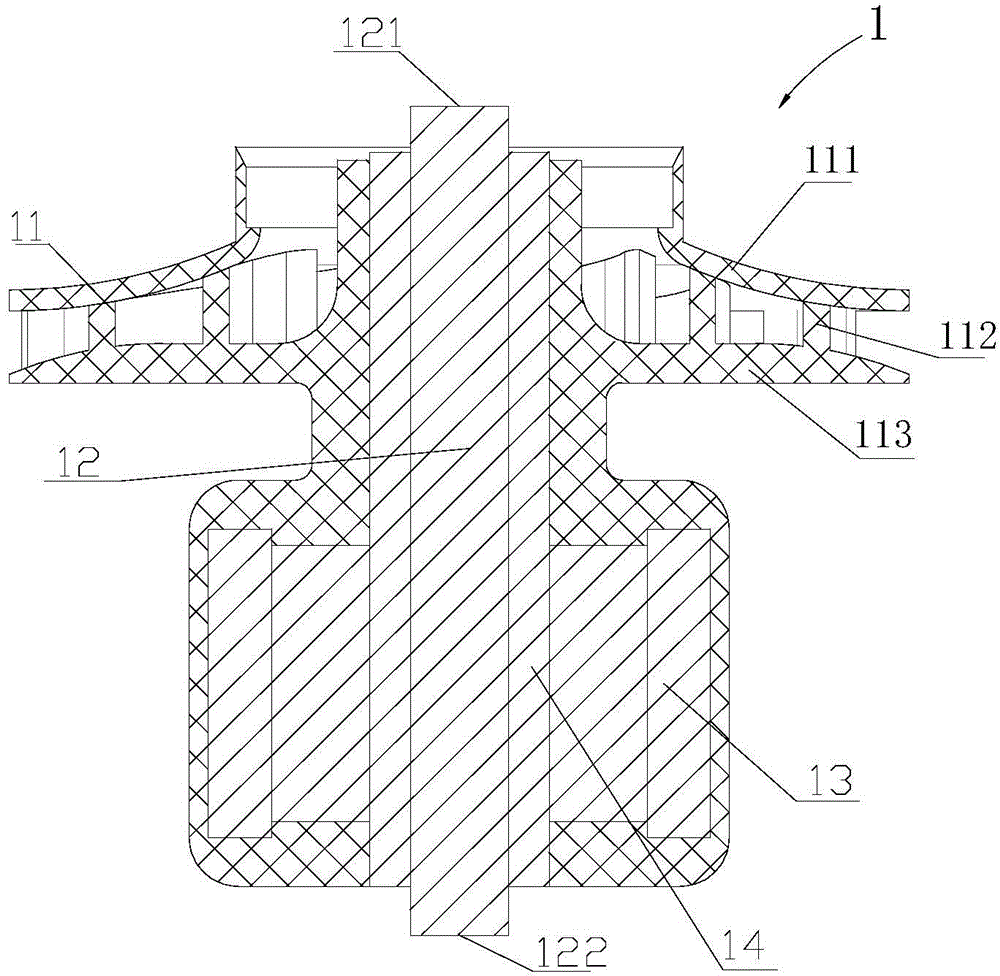

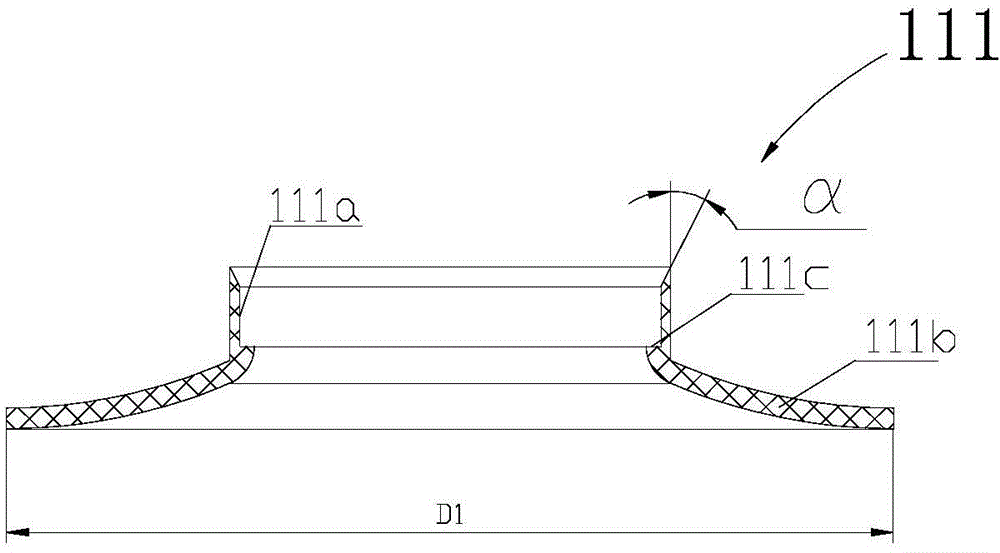

Electronic pump

Disclosed is an electronic pump. The electronic pump comprises a first shell body, a separation sleeve, a second shell body, a rotor component and a stator component. The rotor component comprises an impeller, a pump shaft and a rotor. The first shell body and the second shell body form the inner cavity of the electronic pump. The electronic pump further comprises an axial limiting device which is used for limiting the distance of axial motion of the impeller toward the first tail end of the pump shaft. The impeller comprises a front impeller covering plate, vanes and a rear impeller covering plate. The front impeller covering plate comprises a guiding part which comprises a convex ring formed from a connection part to the inlet direction. The first shell body is provided with an annular groove corresponding to the convex ring which is inserted into the annular groove. A certain distance is reserved and a gap is formed between the outer edge of the convex ring and an inner wall where the annular groove is formed. In this way, axial thrust and part abrasion are reduced, and the service life of the electronic pump can be prolonged.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

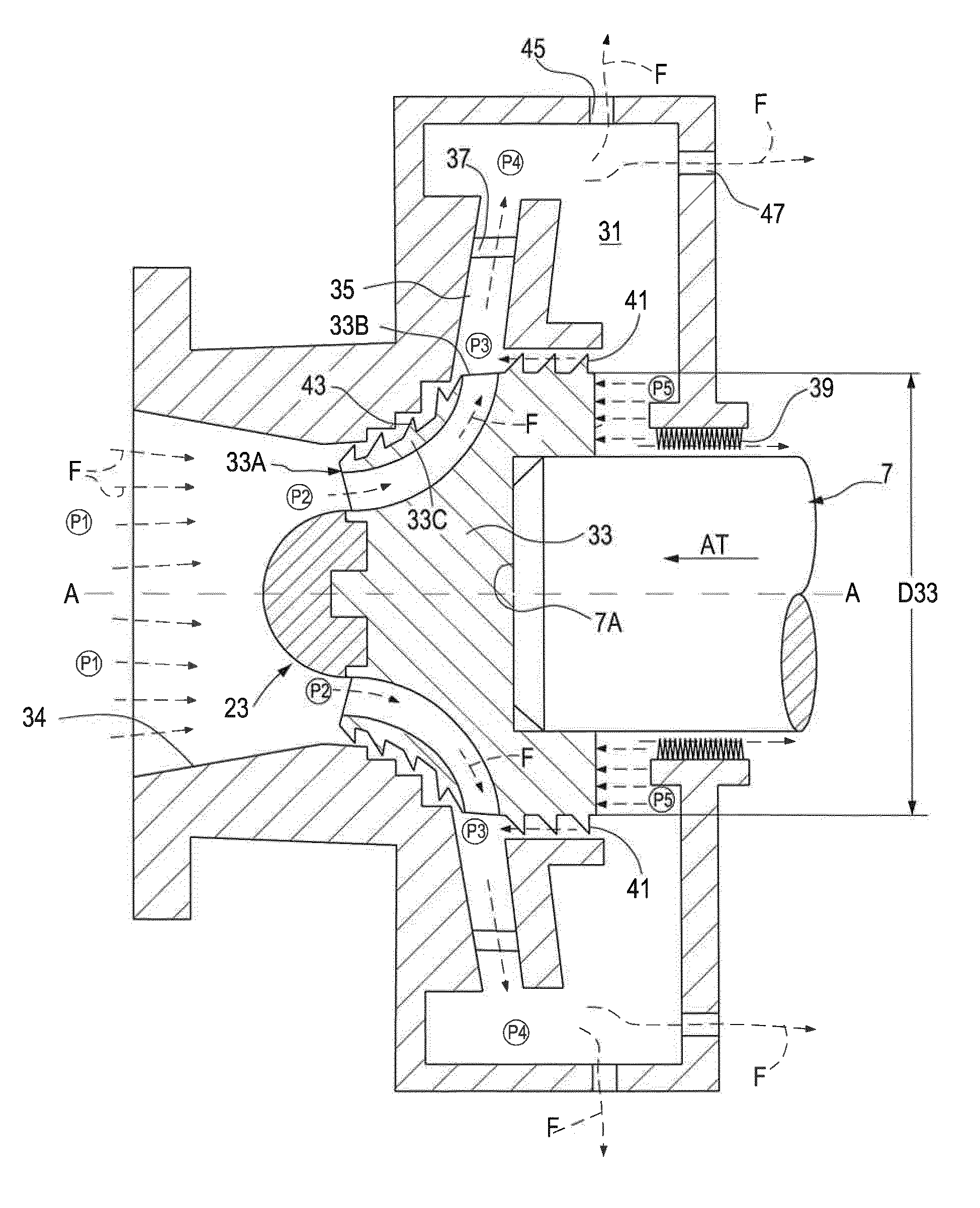

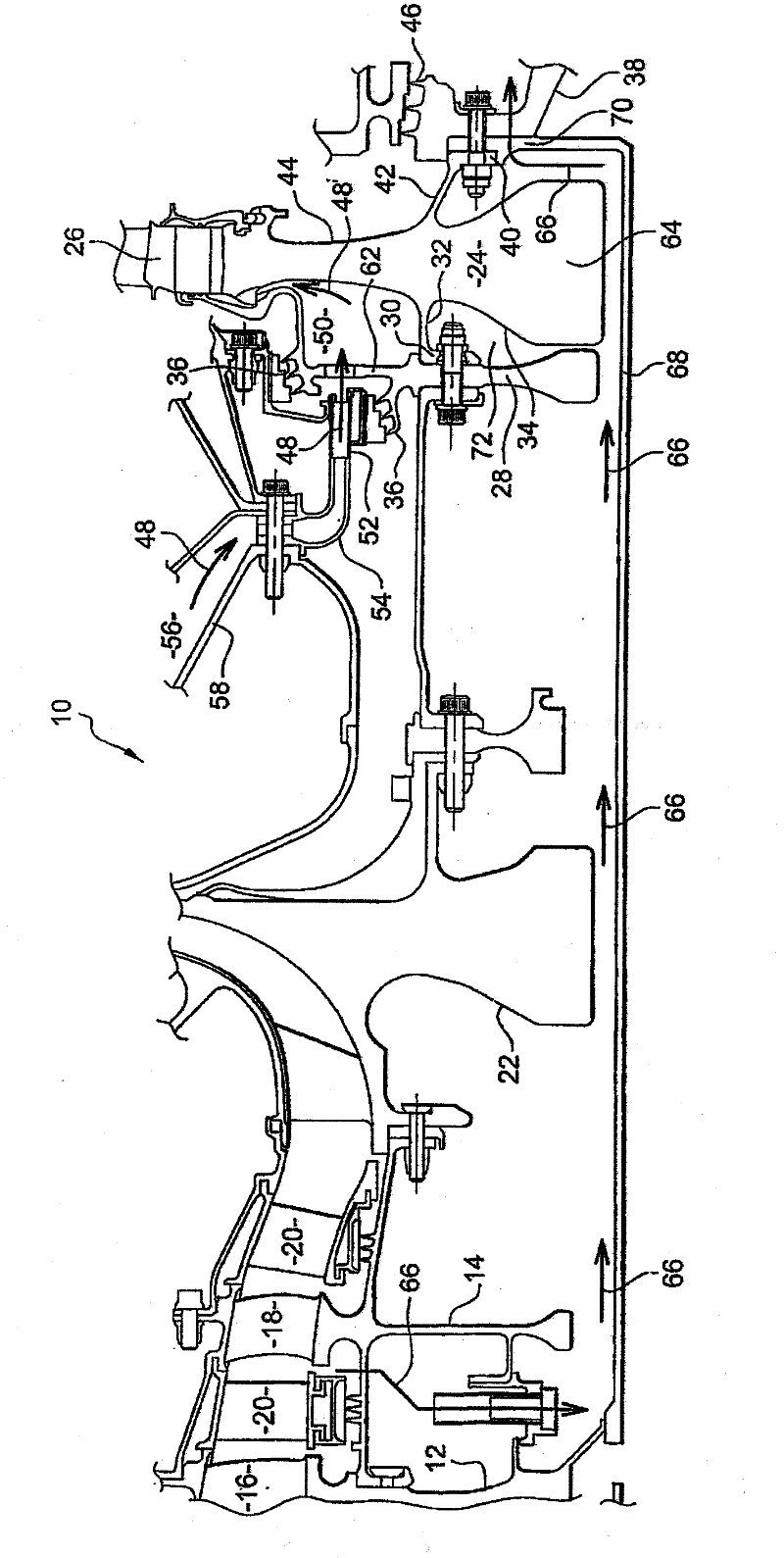

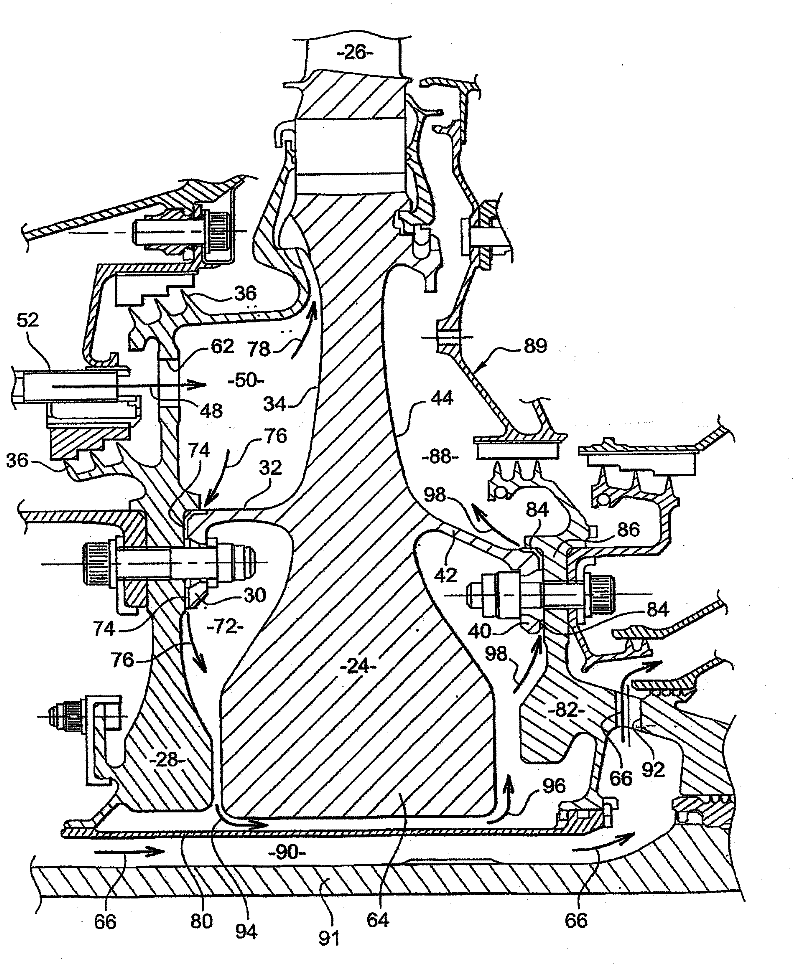

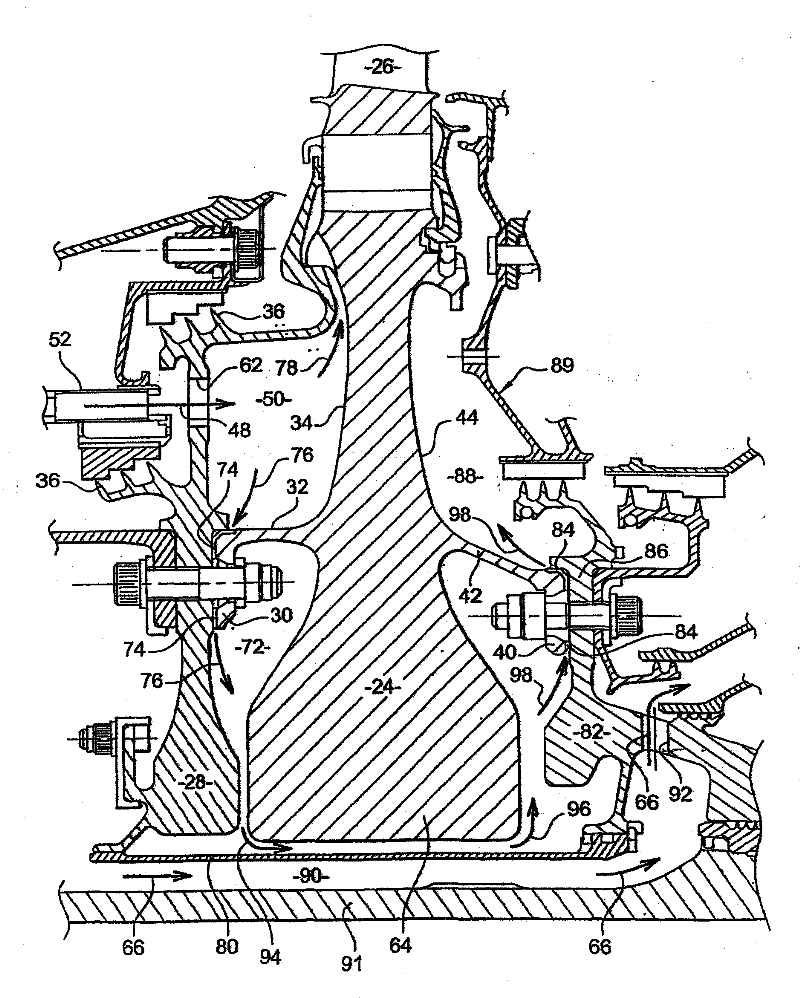

Ventilation of a high-pressure turbine in a turbomachine

InactiveCN102187062AShort flow pathNo delayEngine fuctionsTurbine/propulsion engine coolingHigh pressureTurbine

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

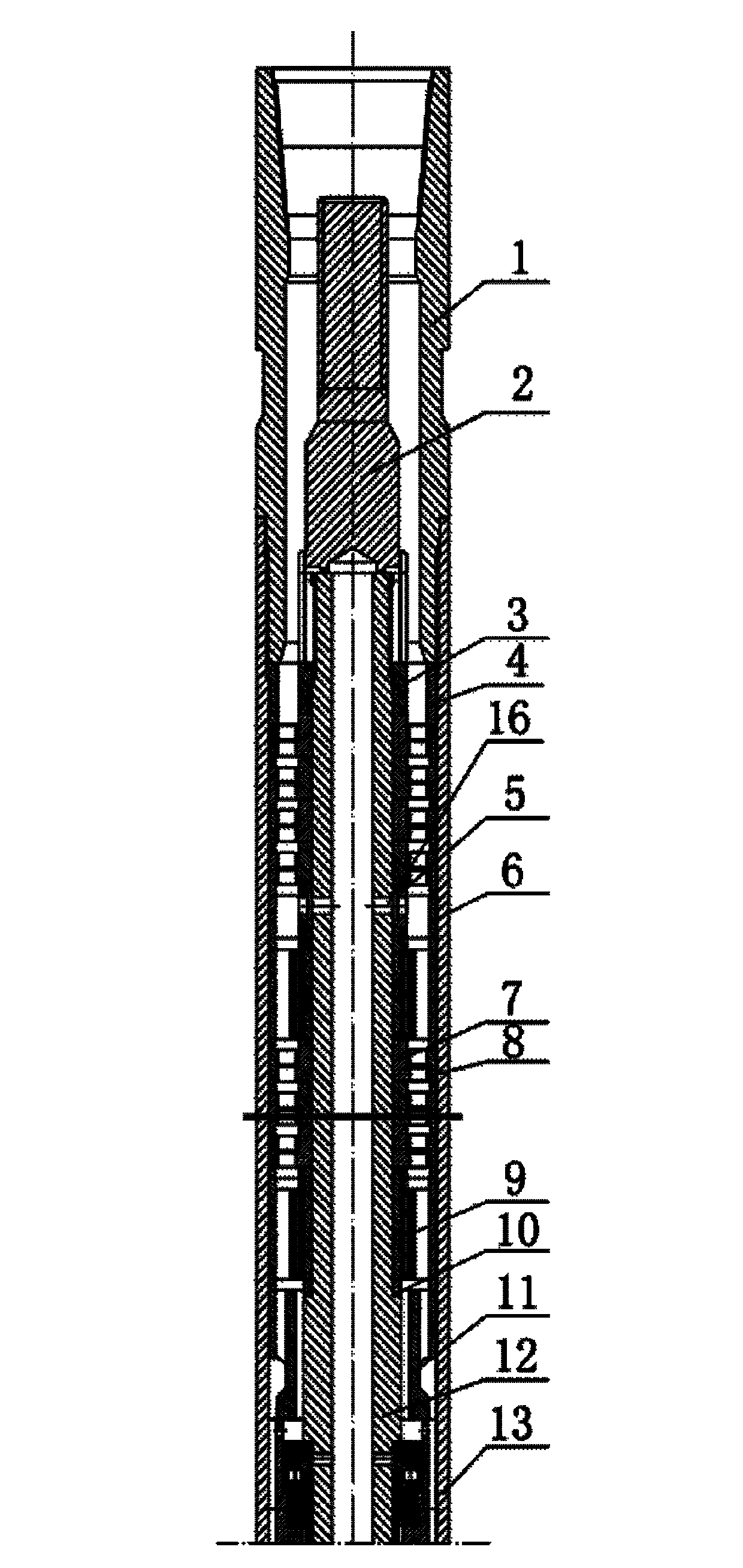

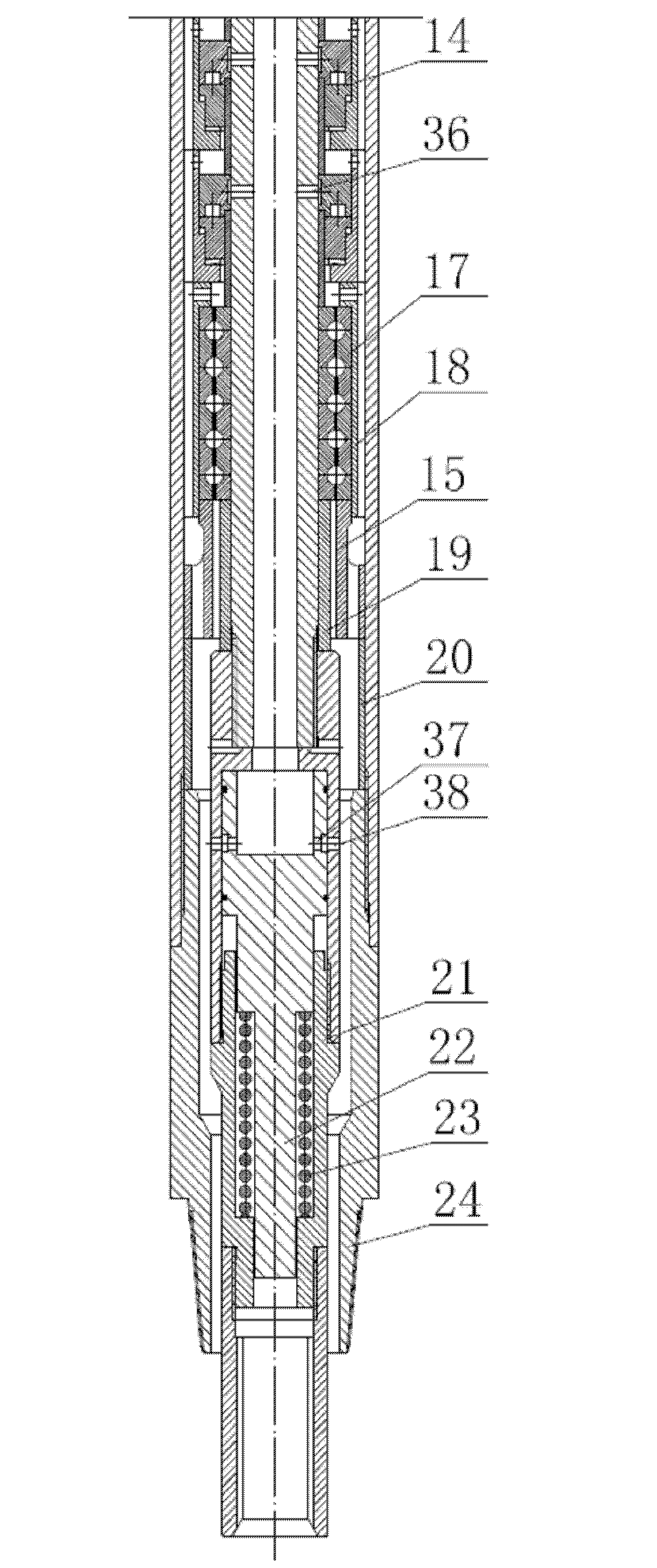

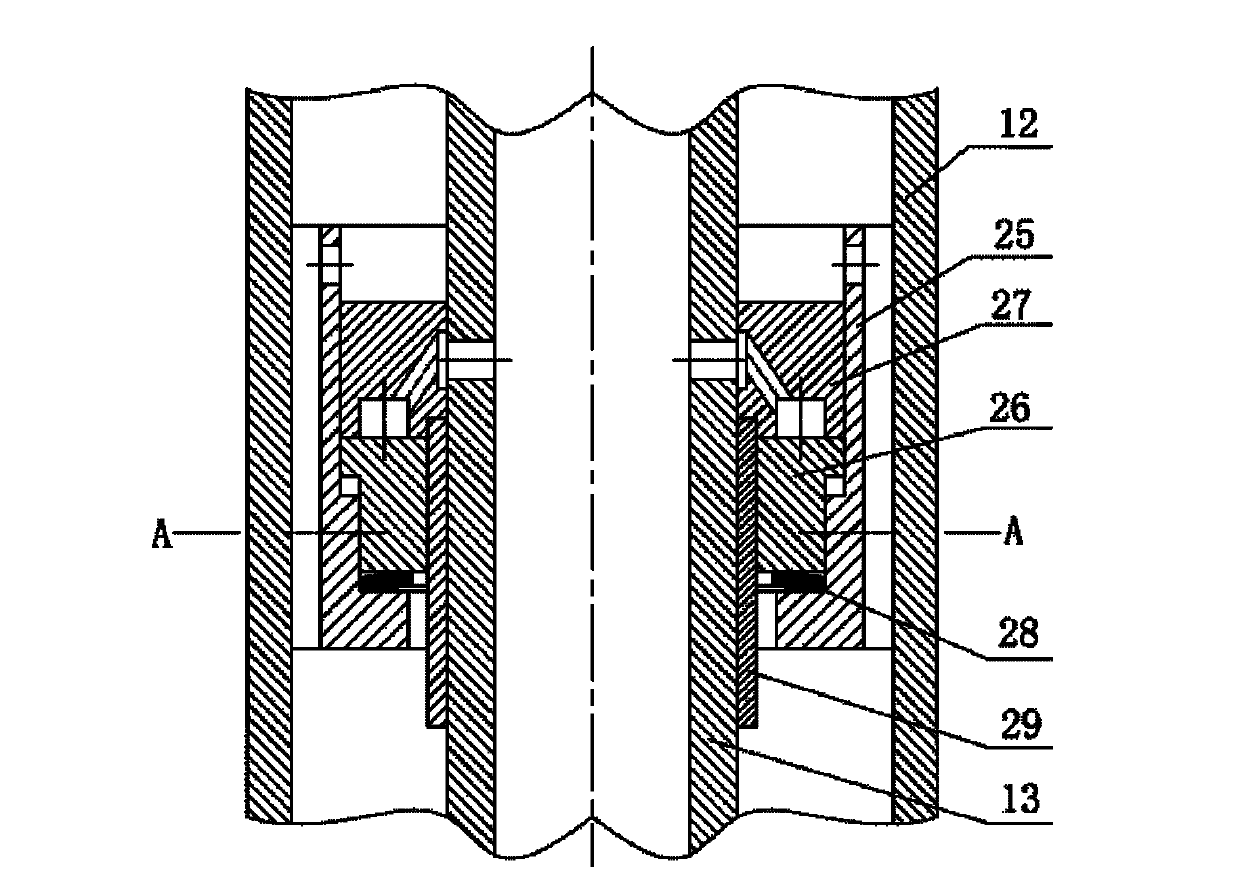

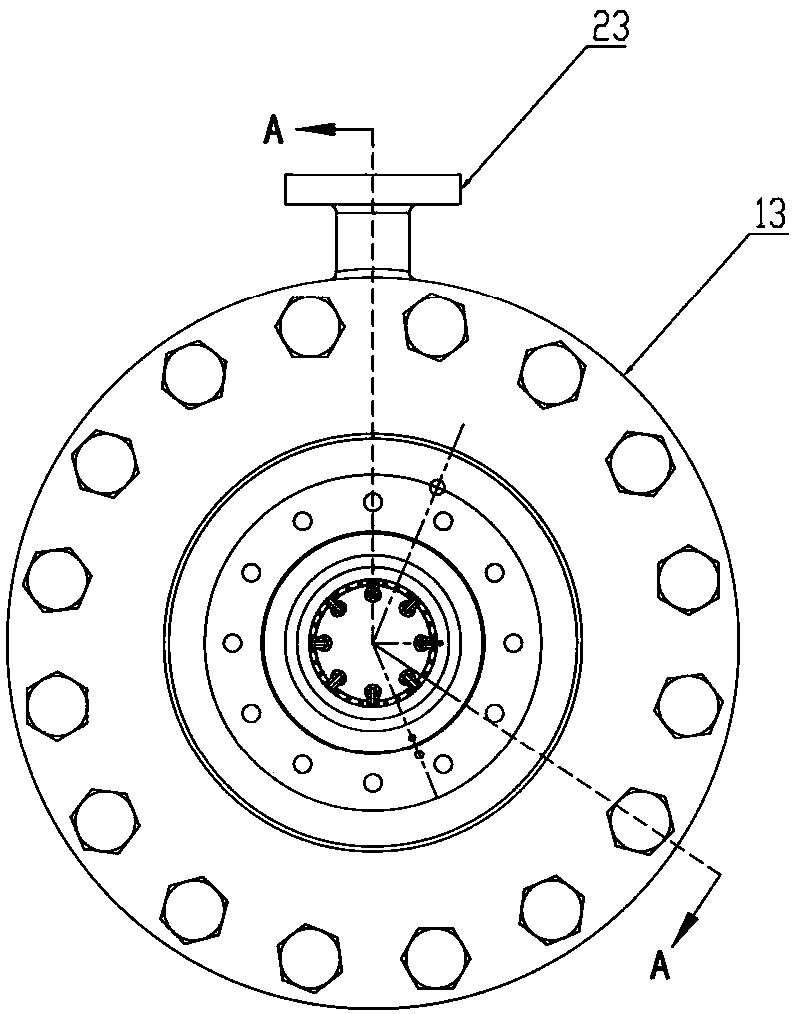

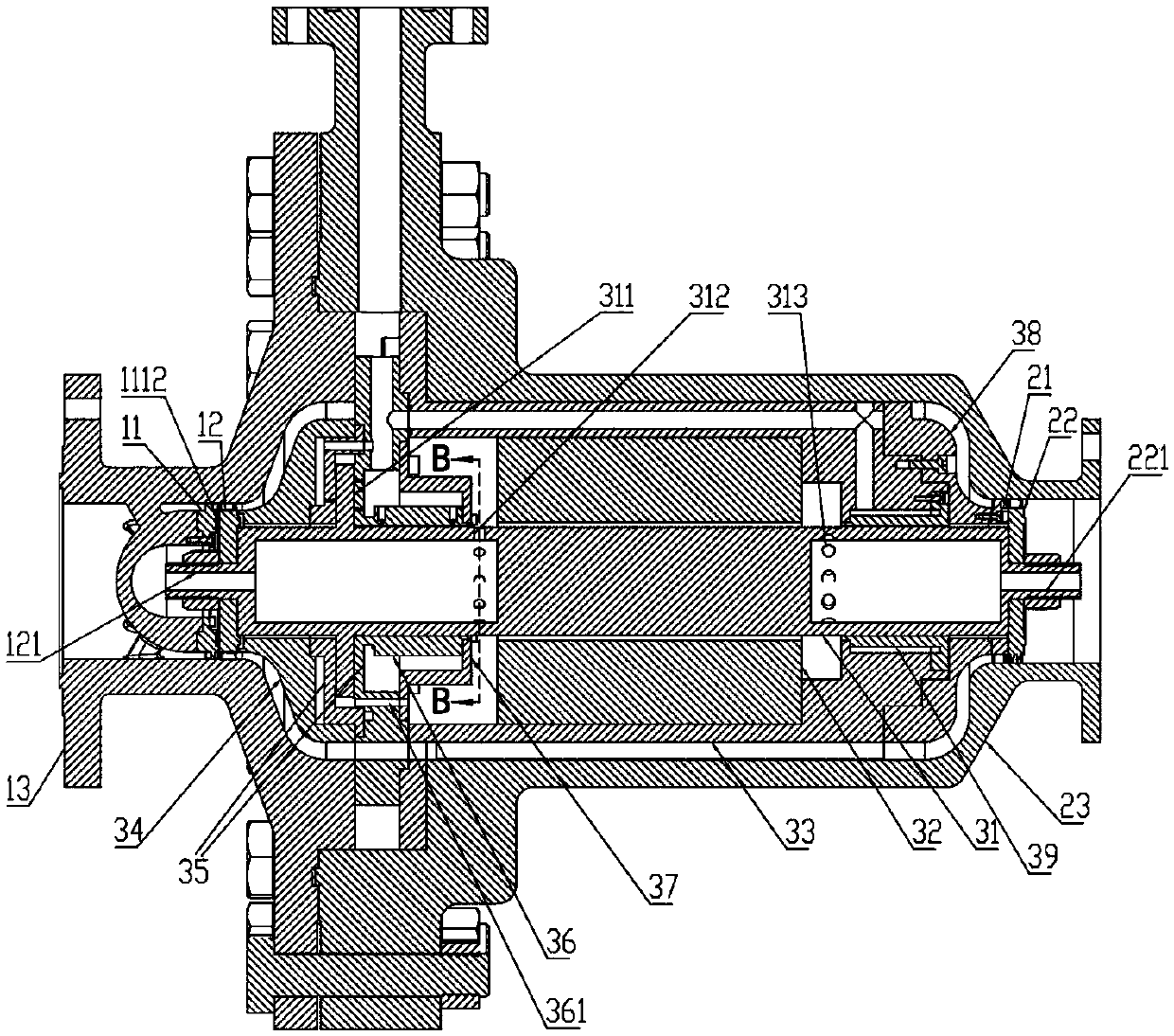

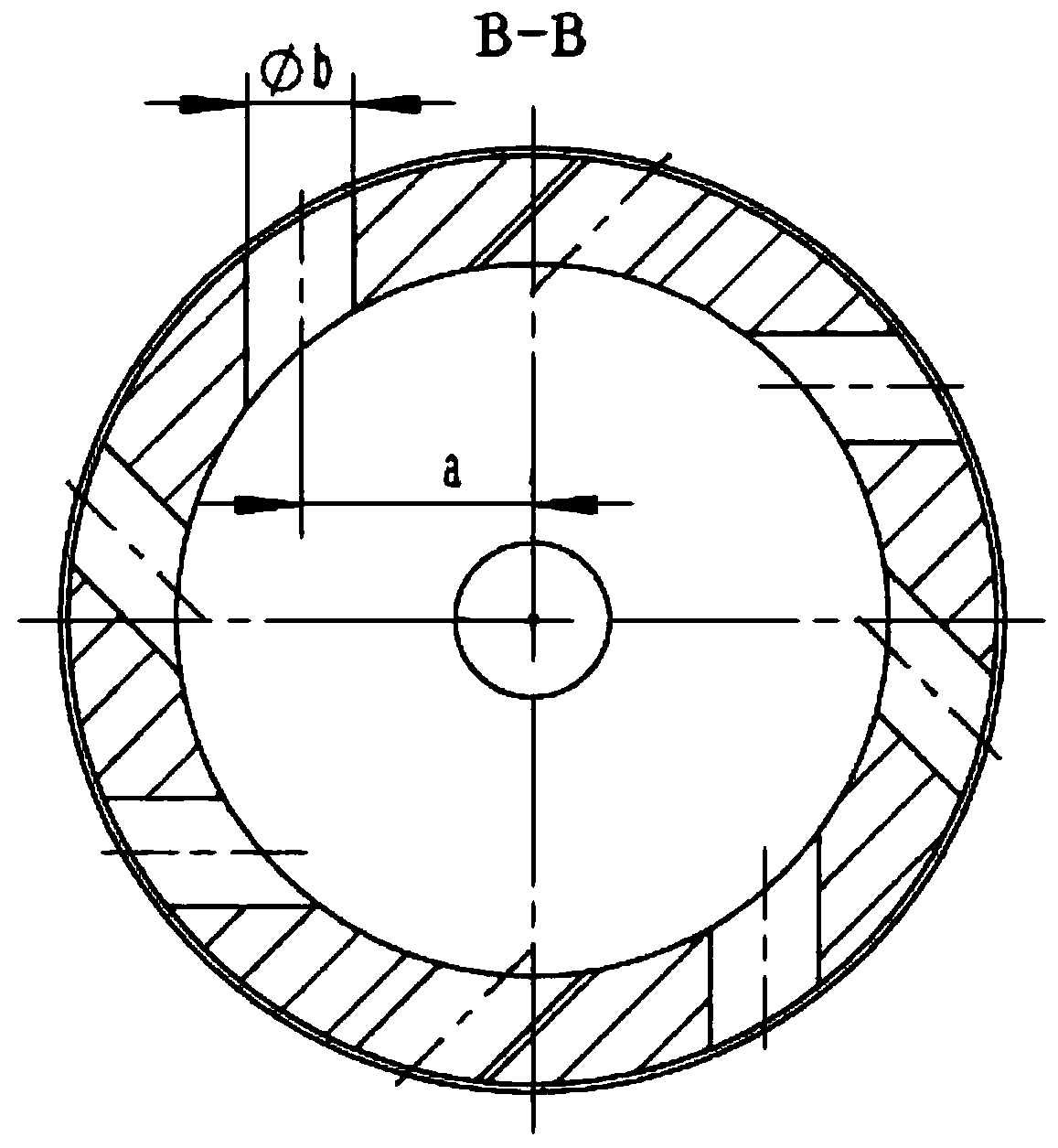

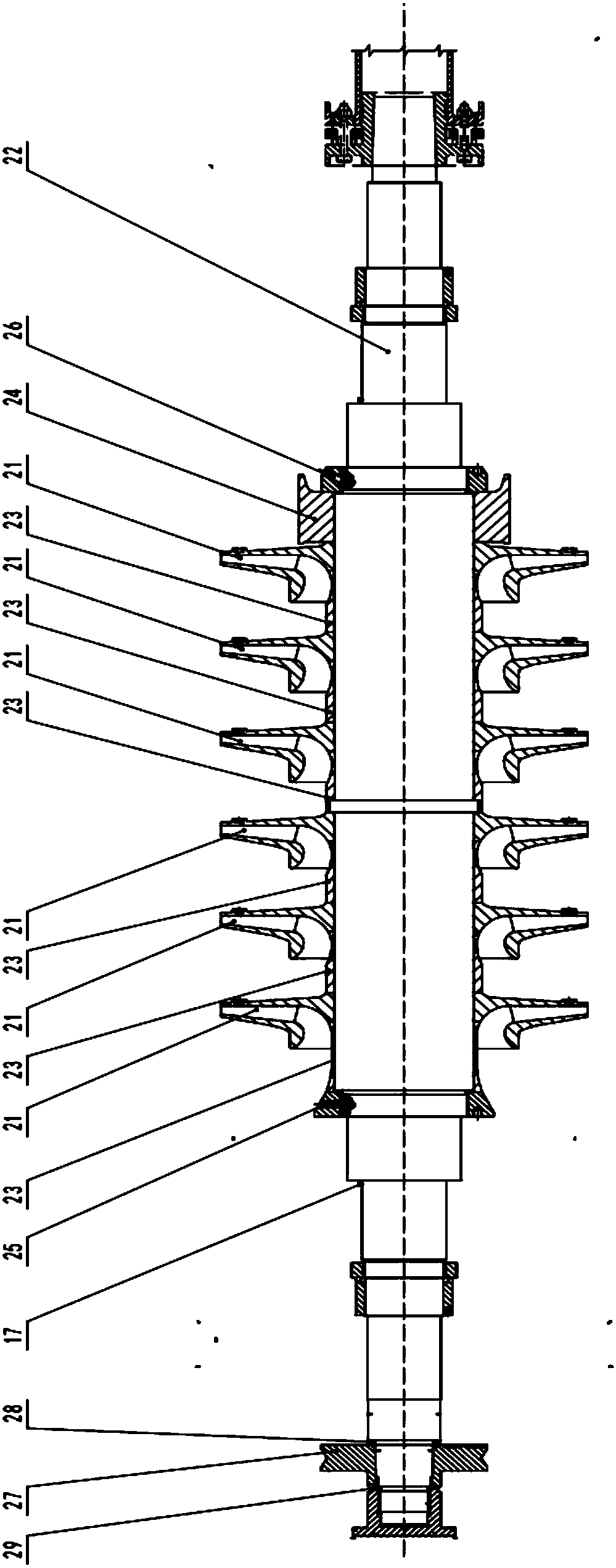

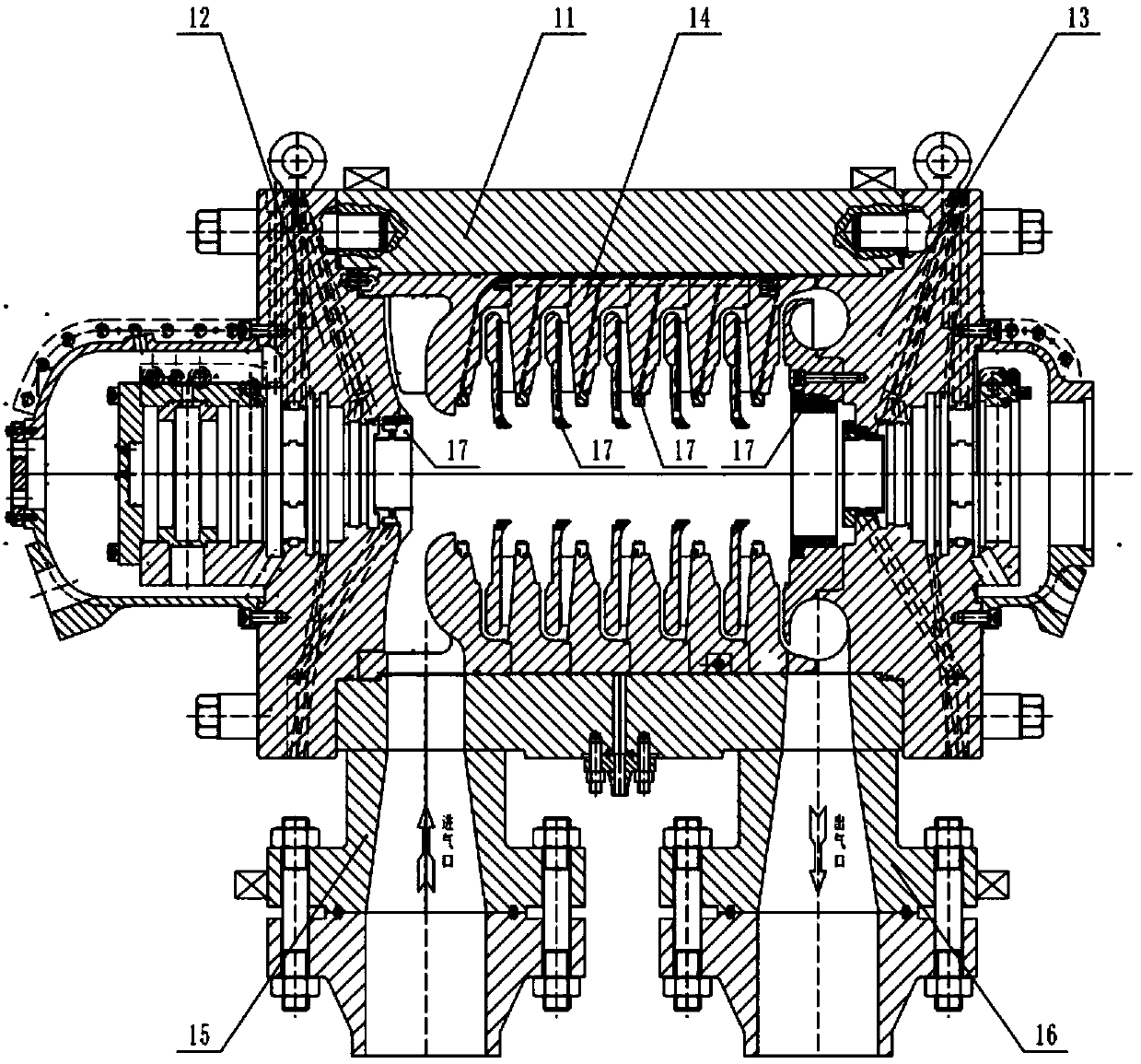

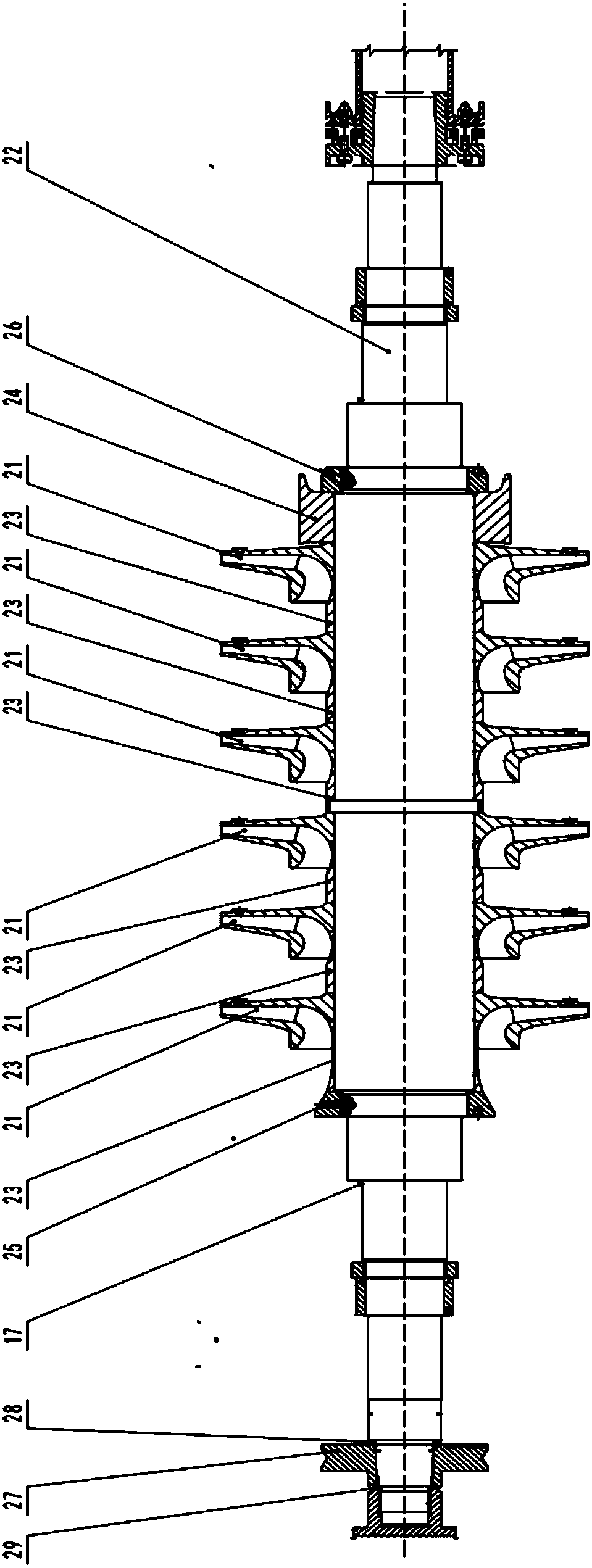

High-speed turbine section for turbine drilling tool

ActiveCN102434110AImprove thrust force conditionThe flow area changes smoothlyEarth drilling toolsBorehole drivesBall bearingDirectional well

The invention relates to a high-speed turbine section for a turbine drilling tool in the field of oil exploration, which is particularly suitable for a deep well and a directional well. The high-speed turbine section comprises a shell, wherein a turbine shell is mounted inside the shell in a penetrating manner; a spline shaft and a spline sleeve are respectively connected with the turbine shaft up and down; a turbine subassembly and a centering bearing are axially arranged in an annular runner between the turbine shaft and a shell inner cavity; and a bearing group is arranged below the turbine shaft. The high-speed turbine section is characterized in that a hydraulic balancing subassembly is mounted at the upper part of the bearing group below the turbine shaft; a center through hole which is through up and down is arranged on the turbine shaft; an upper radial through hole communicating with the center through hole is arranged above the turbine shaft so that the center through hole is communicated with the part above the shell inner cavity; and a lower radial through hole communicated with the center through hole is arranged corresponding to the hydraulic balancing subassembly, below the turbine shaft. In the invention, the runner of the turbine section is improved, the pressure consumption of the turbine drilling tool is reduced, and the whole machine efficiency of the turbine drilling tool is improved; meanwhile, the thrust load carrying conditions of the turbine shaft and the ball bearing group are improved, and the service life of the turbine drilling tool is prolonged.

Owner:KINGDREAM PLC CO +1

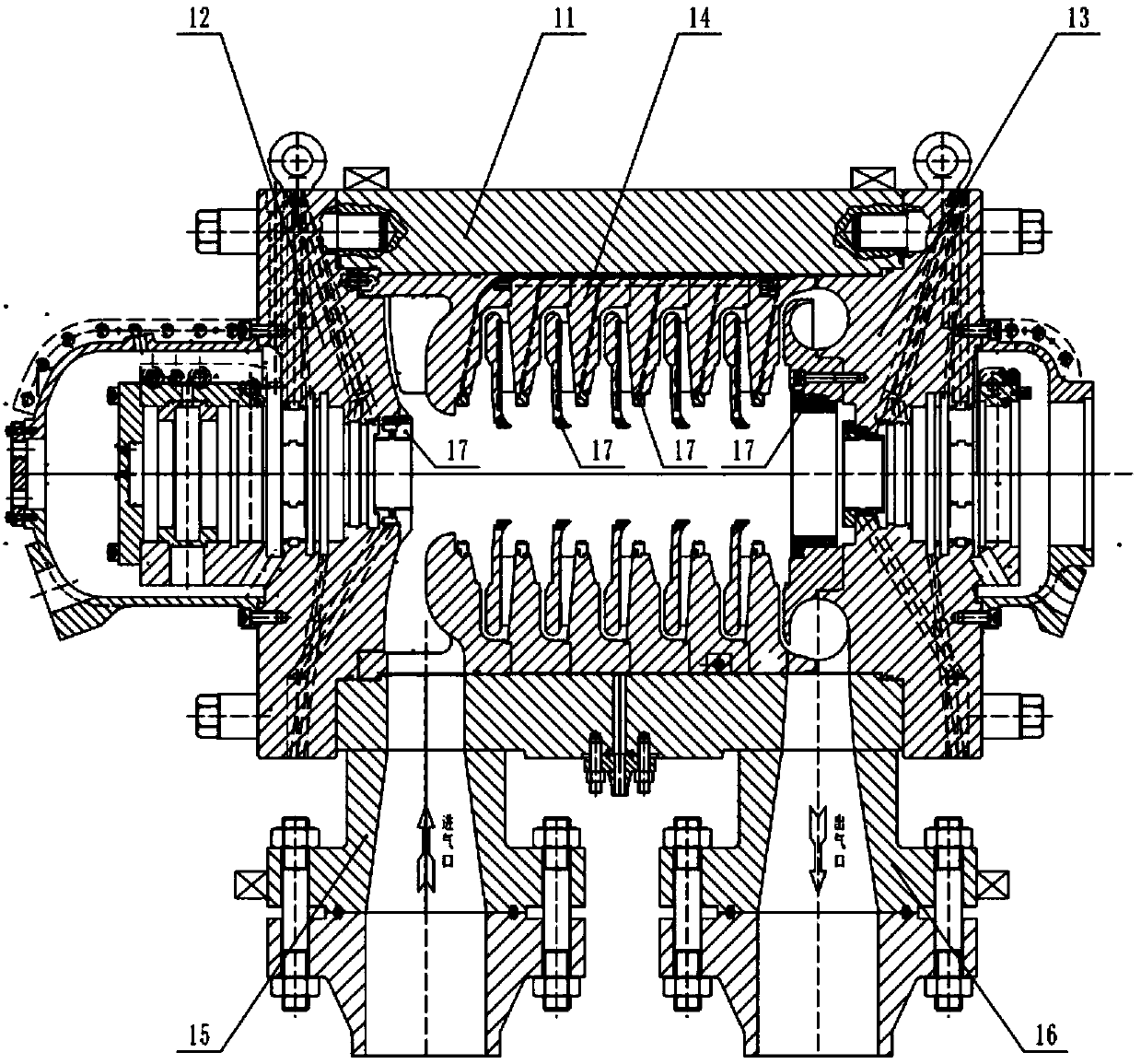

Centrifugal compressor and air conditioner provided with same

The invention provides a centrifugal compressor and an air conditioner provided with the same. The centrifugal compressor comprises centrifugal impellers, sealing rings and annular structures. Each centrifugal impeller comprises a first end plate, a second end plate and blades arranged between the first end plate and the second end plate. A refrigerant inlet is formed in each first end plate. A refrigerant outlet is formed between the circumferential edge of each first end plate and the circumferential edge of the corresponding second end plate. Each sealing ring is arranged on the circumferential outer side of the corresponding first end plate and sealed in the position of the corresponding refrigerant inlet. Each annular structure is arranged on the side, facing the corresponding second end plate, of the corresponding sealing ring. A buffer cavity is formed between each annular structure and the corresponding first end plate. By the adoption of the technical scheme, the problem that in the prior art, the axial force borne by a rotor of a centrifugal compressor is large is solved.

Owner:GREE ELECTRIC APPLIANCES INC

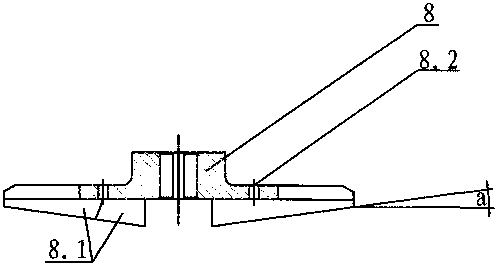

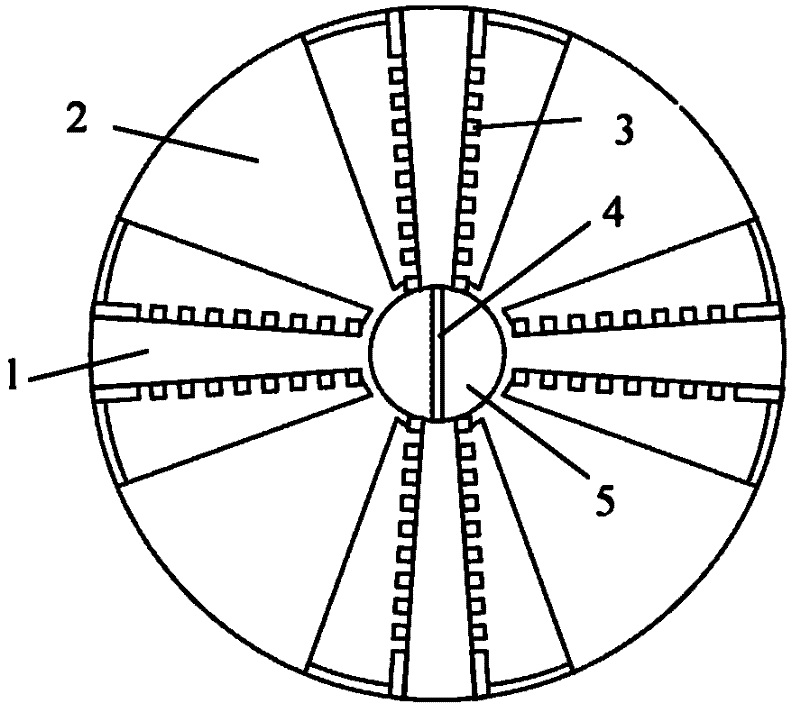

Ultrafine grinder

InactiveCN102896026AHigh speedImprove crushing efficiencyGrain treatmentsAgricultural engineeringEngineering

The invention discloses an ultrafine grinder in the field of grinding devices. The ultrafine grinder comprises a stand. The stand is provided with a bearing block; the center of the bearing block is provided with a vertical shaft; the stand is also provided with a grinding chamber; a cylindrical gear ring is arranged in the grinding chamber; the inner periphery of the gear ring is provided with a plurality of protruding pointed teeth; the vertical shaft extends into the gear ring from the center of the bottom part of the gear ring; the upper end of the vertical shaft is provided with a hammering cutter disk; the periphery of the hammering cutter disk is provided with a plurality of hammering cutters corresponding to the protruding pointed teeth; a grading mechanism is also arranged above the hammering cutters and the gear ring in the grinding chamber; the stand is fixedly provided with a first motor; the output shaft end of the first motor is in transmission connection with the vertical shaft; the vertical shaft is coaxially arranged in a hollow outer shaft through a bearing; the outer shaft is fixedly arranged on the bearing block through the bearing; the outer shaft is in the transmission connection with the output shaft end of a second motor arranged on the stand; and the upper end of the outer shaft is fixedly connected with the gear ring. When the ultrafine grinder works, the vertical shaft and the outer shaft rotate in opposite directions, and therefore, the efficiency of the grinder can be increased, and moving parts are low in rotate speed, and therefore, mechanical vibration and noise can be reduced, and the service life is prolonged.

Owner:李振欣

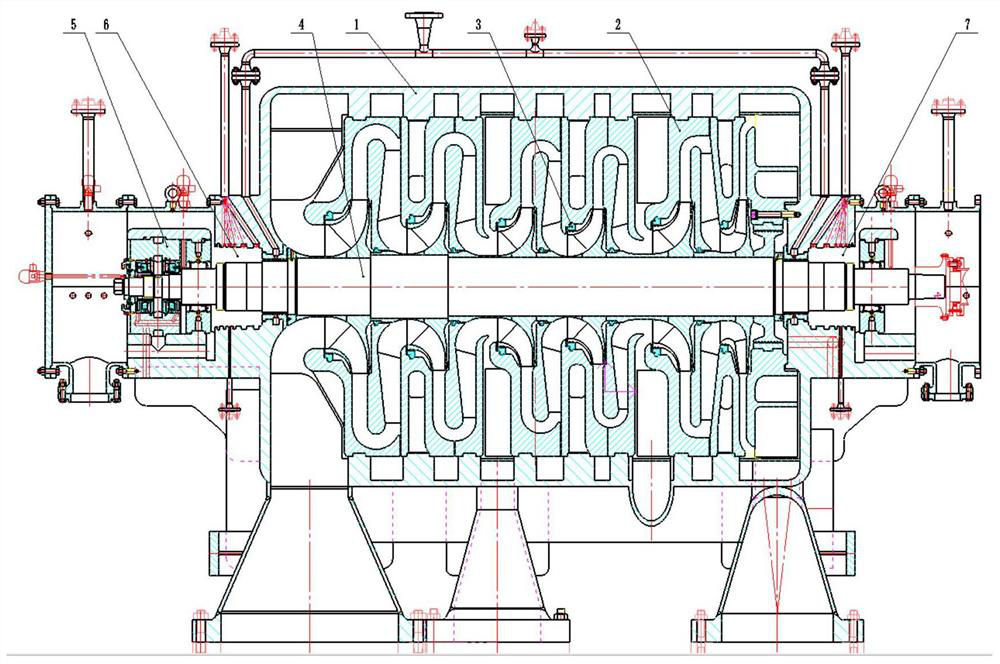

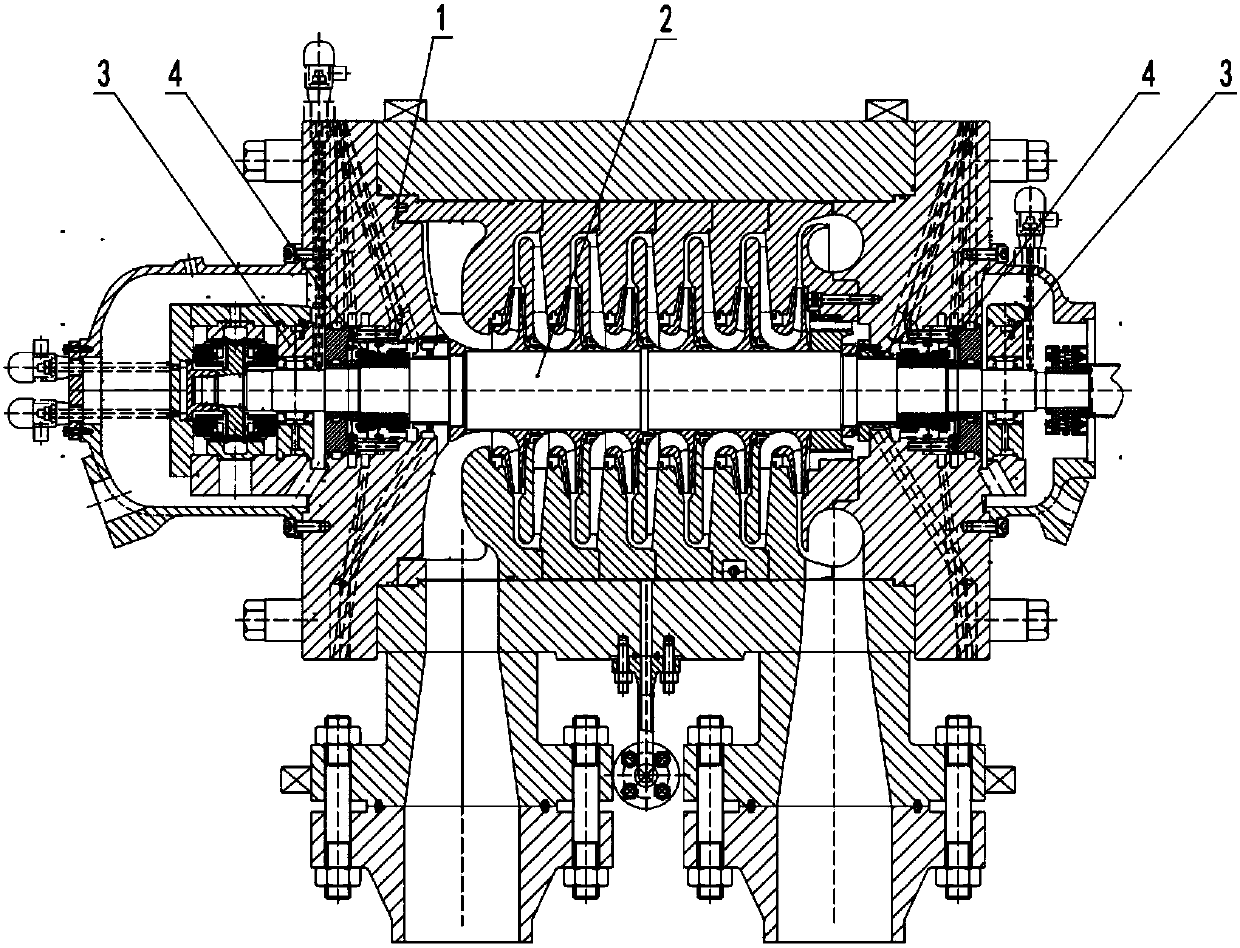

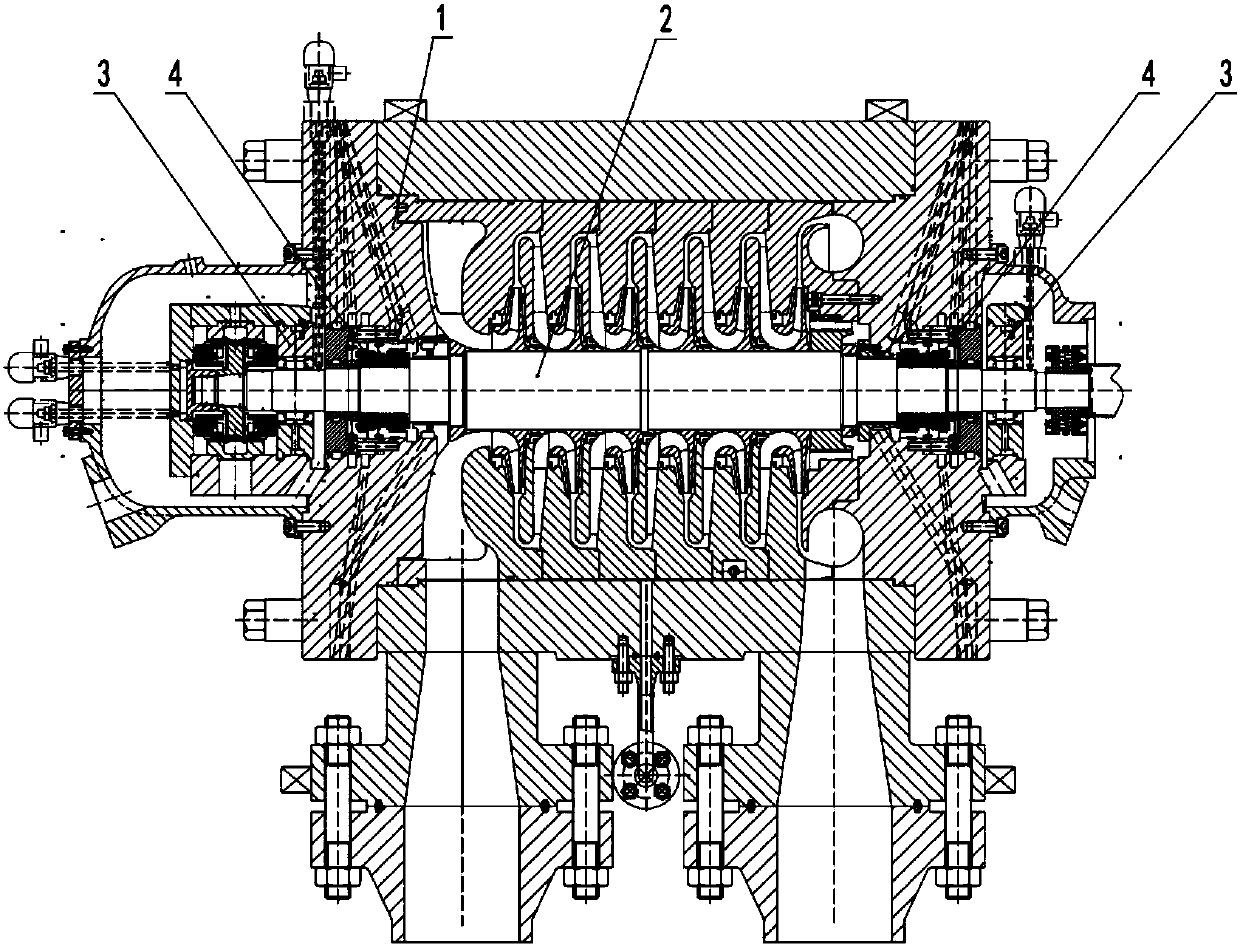

Propylene compressor

PendingCN112555173AReduce axial thrustGuaranteed uptimePump componentsRadial flow pumpsPrime moverImpeller

The invention discloses a propylene compressor. The propylene compressor is mainly composed of a stator set, a rotor set, a bearing set, a dry gas seal and the like, and is characterized in that (1) the compressor adopts a single-shaft multi-stage centrifugal type, and a single-cylinder three-stage mode is adopted, and the number of the stages are six total; (2) impellers are forged, milled and welded through ternary and binary closed type; (3) medium gas sealing is carried out on two shaft ends by adopting shaft end sealing and series dry gas sealing; (4) a unit adopts a split base, a compressor body and a prime mover have independent bases, and the compressor body is connected with the prime mover through a diaphragm coupling; (5) a shell of the compressor body is divided into an upper body and a lower body from the horizontal plane of a rotating shaft, and the rotating shaft is arranged on the lower shell; (6) the compressor body is provided with three air inlet air ducts and one air outlet air duct; (7) the number of the compressor impellers is six, the diameter of each impeller is 800 mm, the impellers are arranged on a main shaft in sequence, and a balance disc is arranged onthe high-pressure side; and (8) a tilting-pad bearing is adopted as a supporting bearing, the structures same on the two sides are adopted on the two sides of the main shaft, and a thrust bearing isa Kingsbury or Michell bearing.

Owner:SHENYANG SITE MACHINERY MFG

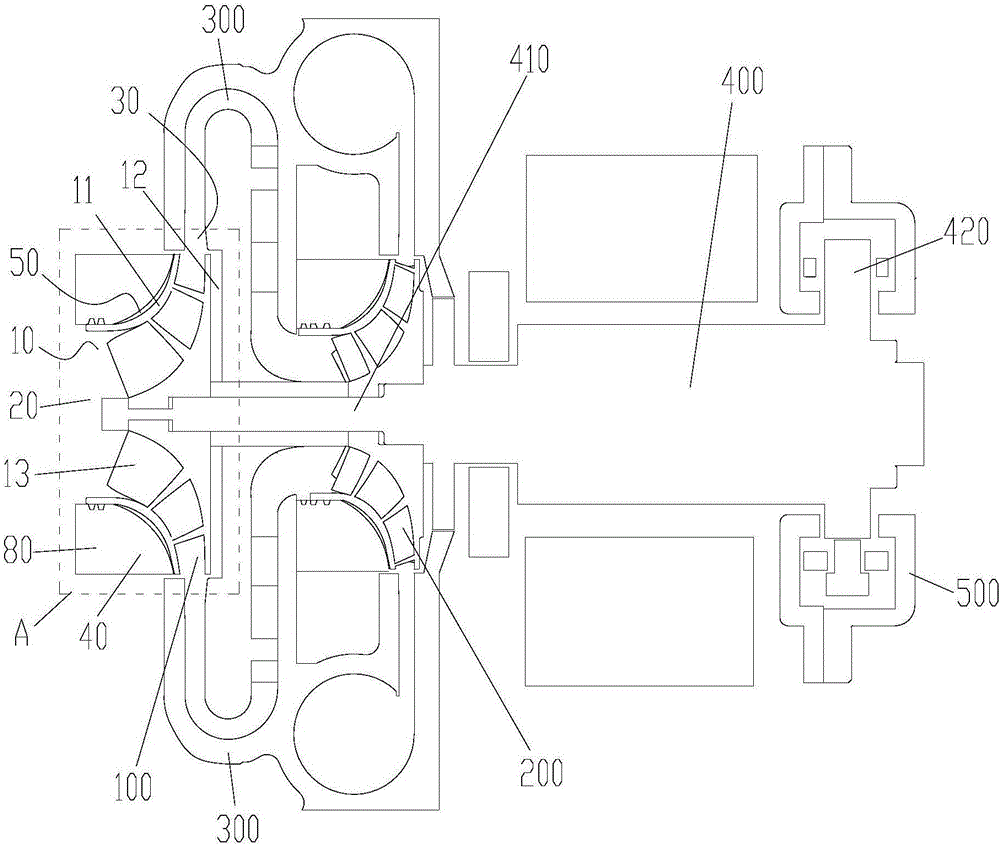

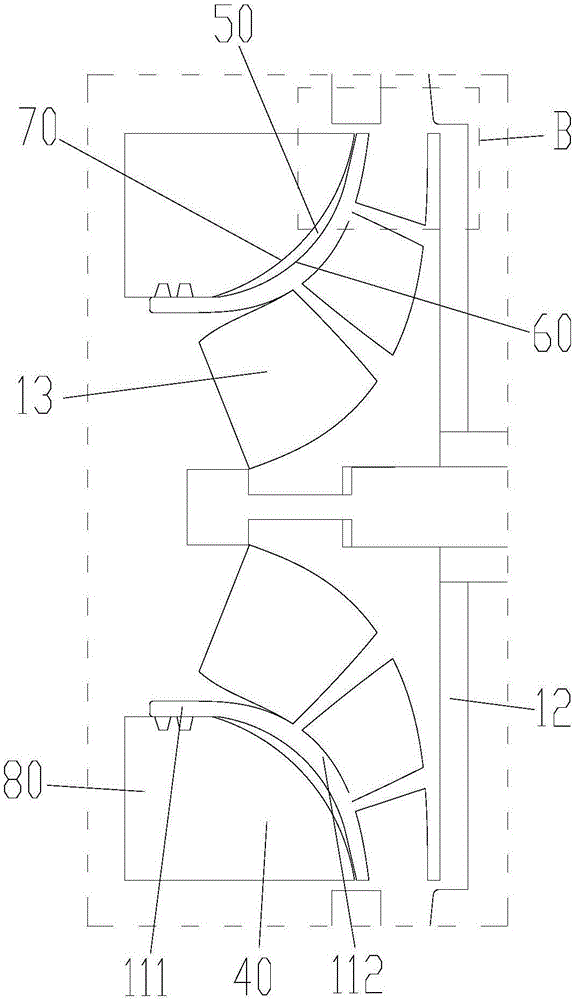

Two-stage cantilever type axial-flow expander

PendingCN107725113AReduce friction lossImprove mechanical efficiencyBlade accessoriesCombination enginesHigh energyCantilever

The invention discloses a two-stage cantilever type axial-flow expander. The two-stage cantilever type axial-flow expander comprises a primary expander, a secondary expander and a motor, wherein the primary expander comprises a gas inlet housing, a primary spray nozzle ring and a primary rotor impeller; the secondary expander comprises a unit housing, a secondary spray nozzle ring and a secondaryrotor impeller; the motor comprises a motor rotor and a stator winding; the gas inlet housing and the unit housing are oppositely arranged to form a cavity; the motor rotor is arranged in the cavity along the axis of the cavity; an auxiliary pushing bearing shell, a motor housing and a secondary guide housing are sequentially arranged on the outer edge of the motor rotor in a direction from the gas inlet housing to the unit housing; the end surface, close to the gas inlet housing, of the motor rotor is coaxially equipped with a primary input end; and the end surface, close to the unit housing,of the motor rotor is coaxially equipped with a secondary input end. The two-stage cantilever type axial-flow expander disclosed by the invention can effectively reduce rotation speed of the expanders through two-stage axial flow, improves reliability and efficiency of the motor and a frequency converter, and obtains a relatively high energy conversion rate.

Owner:陈贤

Centrifugal compressor for gasoline and diesel oil hydrogenating and upgrading device

PendingCN109519396AReduce axial thrustGuaranteed uptimePump componentsRadial flow pumpsControl systemGasoline

The invention relates to a centrifugal compressor for a gasoline and diesel oil hydrogenating and upgrading device. The centrifugal compressor for the gasoline and diesel oil hydrogenating and upgrading device comprises four parts of a stator group part, a rotor group part, a bearing group part and dry gas seals. The centrifugal compressor for the gasoline and diesel oil hydrogenating and upgrading device is characterized in that (1) a vertical partition structure is adopted in the compressor; (2) partition plates are assembled together to form a partition bundle, and vaneless diffusers are adopted in diffusers between the partition plates and the partition plates; (3) the arrangement form of impellers on a main shaft is in a straight row, the number of the impellers is six to eight, and the diameter is 400mm; (4) between the two adjacent impellers, blades of the latter impeller are arranged to deflect at a certain angle relative to the blades of the previous impeller; (5) a tilting pad bearing is adopted in a supporting bearing adopts; (6) a kingsbury type structure is adopted by a thrust bearing, and a same structure is adopted by the two sides of the thrust bearing; and (7) thedry gas seals are installed at both ends of the compressor, and independent control systems are arranged on the dry gas seals. The centrifugal compressor is particularly suitable for the application of a gasoline and diesel oil hydrogenating and upgrading process.

Owner:SHENYANG SITE MACHINERY MFG

Swing arm rotation type compressor

InactiveCN103114997AReduce friction lossReduce leakageOscillating piston pumpsOscillating piston liquid enginesRotary valveMoving parts

The invention discloses a swing arm rotation type compressor which comprises a housing, a main shaft and an air guide pipe for communicating a two-stage compression chamber with an air inlet cavity or an air outlet cavity of a rotary valve, wherein the upper end surface of the housing is covered with an upper bearing sealing seat with a gland; an eccentric shaft section is formed in the middle of the main shaft; the inner circle of a rotary sleeve arranged in an inner cavity of the housing is connected with the eccentric shaft section of the main shaft through a sleeve bearing; the main shaft on the upper side and the lower side of the rotary sleeve is connected with the upper bearing seat and the housing through a pair of upper and lower rolling bearings; the rotary valve with the air inlet cavity and the air outlet cavity is arranged on the main shaft on the outer side of the upper bearing; the rotary valve is axially fixed by a locking nut through a valve plate and a gasket; an air inlet connector communicated with the air inlet cavity of the rotary valve and an air outlet connector communicated with the air outlet cavity of the rotary valve are arranged on the outer wall of the upper bearing seat; multiple sets of swing arm mechanisms contacted with the outer circle of the rotary sleeve are arranged along the inner circumferential direction of the housing; and the swing arm mechanisms, the housing, the rotary sleeve and the upper bearing seat form the two-stage compression chamber. According to the swing arm rotation type compressor, the functions of air suction, compression, air discharge and residual air expansion can be effectively achieved, multiple times of sequential compression operation can be finished by rotating the main shaft for a circle, the two-stage compression operation can be performed in each compression process, and the compressor is very small in frictional loss between moving parts, energy-saving, efficient and wide in application range.

Owner:SHENZHEN SAILANGKEN SCI & TECH

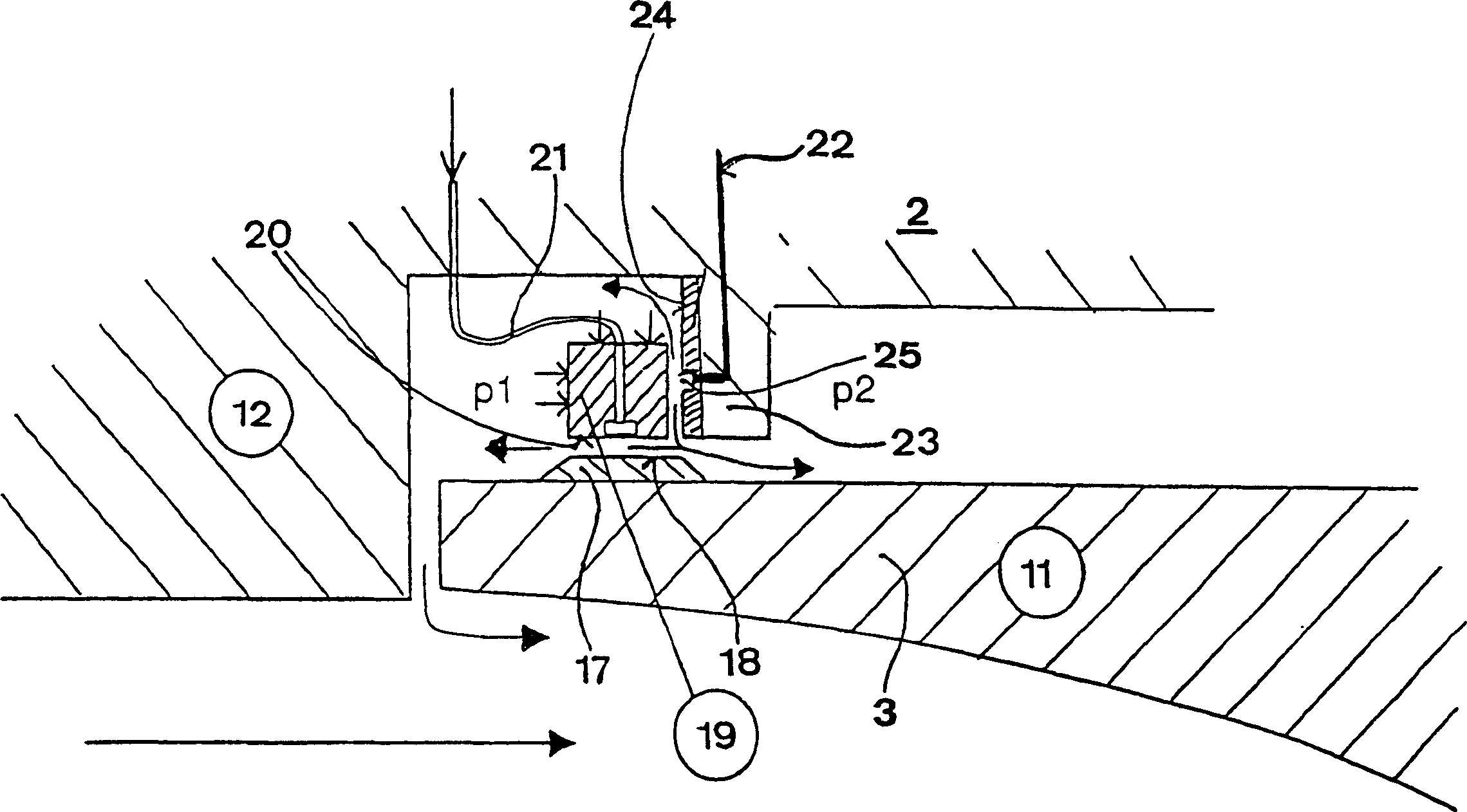

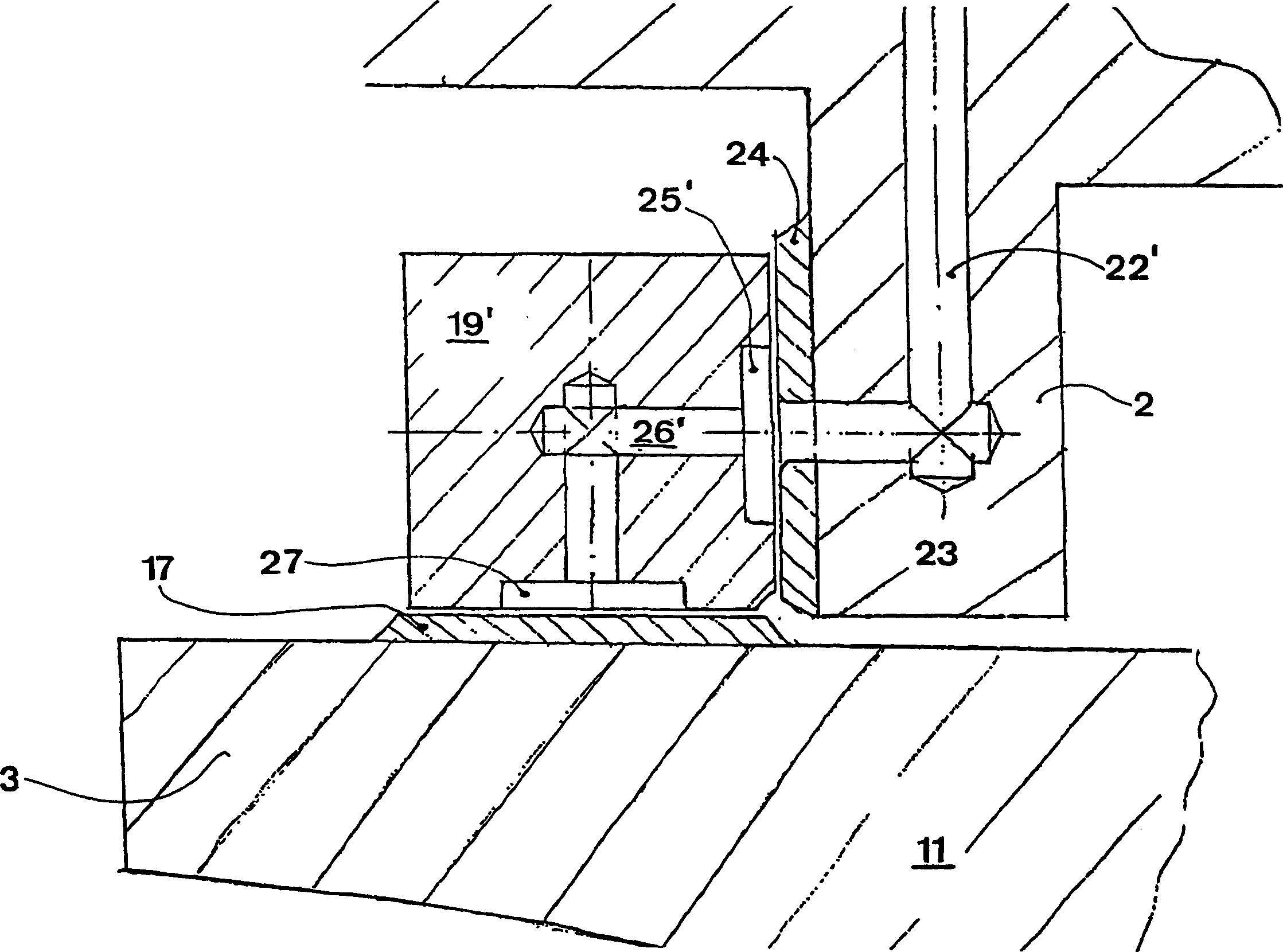

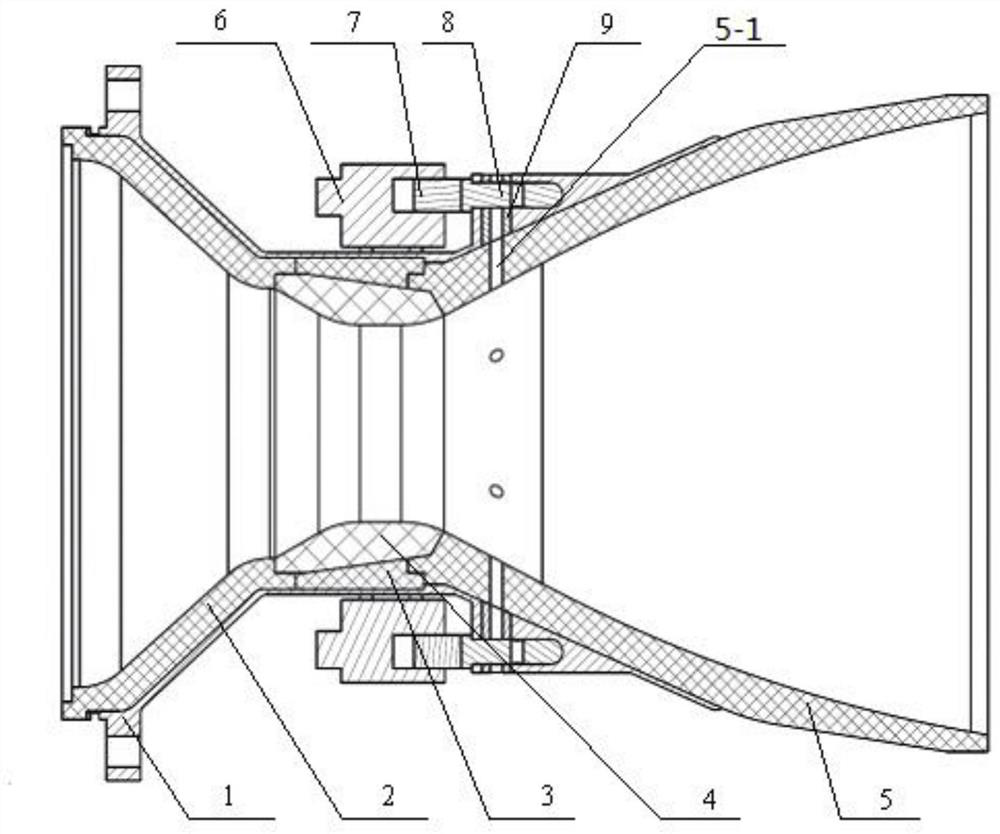

Hydraulic machine comprising a radial flow runner

A hydraulic machine comprising a runner of Francis type, a head cover and a lower cover is provided, whereas the runner comprises a low and a high pressure side, a crown, a band, a plurality of blades, whereas the crown comprises sealing means to seal the space between the crown and head cover against water from the high pressure side, whereas the runner comprises at least one passage being capable to drain high pressure leakage water passing the sealing means to the low pressure side, and the passage comprises an inlet aperture located in a portion of the crown which during operation is exposed to high pressure leakage water. The machine is characterized in that the passage is located within one of the blades and leads from the inlet aperture to the band, wherein the passage forms an opening leading to the space between the band and the lower cover.

Owner:VOITH PATENT GMBH

Electronic pump

ActiveCN105443397AExtended service lifeRelieve pressurePump componentsPump installationsImpellerHigh-pressure area

Disclosed is an electronic pump. The electronic pump comprises a first shell body, a separation sleeve, a second shell body, a rotor component and a stator component. The rotor component comprises an impeller, a pump shaft and a rotor. The first shell body and the second shell body are arranged oppositely in a sealed mode to form the inner cavity of the electronic pump. The electronic pump further comprises an axial limiting device which is used for limiting axial motion of the impeller toward the first tail end of the pump shaft. The impeller comprises vanes and a rear impeller covering plate. The electronic pump further comprises an axial force balance structure which comprises a pressure discharging hole penetrating through the rear impeller covering plate. The pressure discharging hole is communicated with a low-pressure area where an inlet is located and a high-pressure area where the rotor is located. The axial force balance structure further comprises a convex ring and an annular groove. The convex ring is formed in the position, close to an outlet, of the rear impeller covering plate and in the reverse direction toward the inlet. The annular groove is formed in the second shell body in correspondence with the convex ring. The convex ring is inserted in the inner cavity of the annular groove. In this way, the axial force balance structure is arranged, so that axial thrust and part abrasion are reduced, and the service life of is prolonged.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

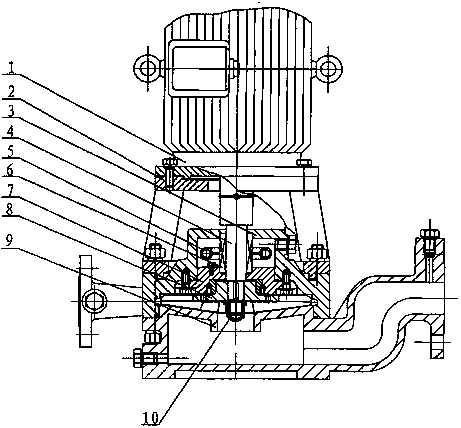

Tangent pump for ship

The invention discloses a tangent pump for a ship. The tangent pump comprises a motor, a bracket, a pump body, a pump shaft, a sealing expansion part, a mechanical seal, a gland, an impeller, a pump cover and a nut. The bracket is in direct linkage with the motor and the pump body, the mechanical seal and the sealing expansion part are installed on the pump shaft, and the gland is matched with thepump body so that mechanical seal can be axially positioned and a sealing cavity for storing lubricating oil can further be formed. The impeller is installed at the end of the pump shaft and locked to be of a structure rotating along with the motor by the nut. The pump cover is matched with the pump body to form a pump chamber for installing the impeller. According to the tangent pump for the ship, the impeller is of an open type structure and in a gear shape in the axial direction, 8-16 long and short radial blades which are arranged alternately are evenly distributed on the side plate faceof the impeller in an exposed mode, and axial balance holes are formed among the long and short blades; each radial blade is wide in inner portion and narrow in outer portion; frictional loss of a circular disc of the impeller is small, the axial force is small, the structural strength is high, and the impact resistance is high; and in addition, the cooling condition of the mechanical seal is good, a too large temperature difference cannot be generated between the mechanical seal and a medium, and therefore the mechanical seal is not liable to be damaged.

Owner:王友宏

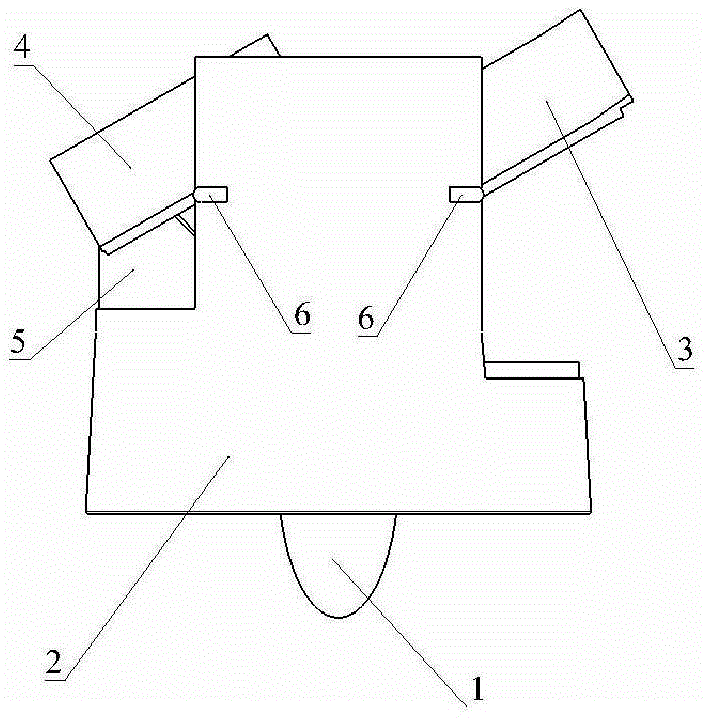

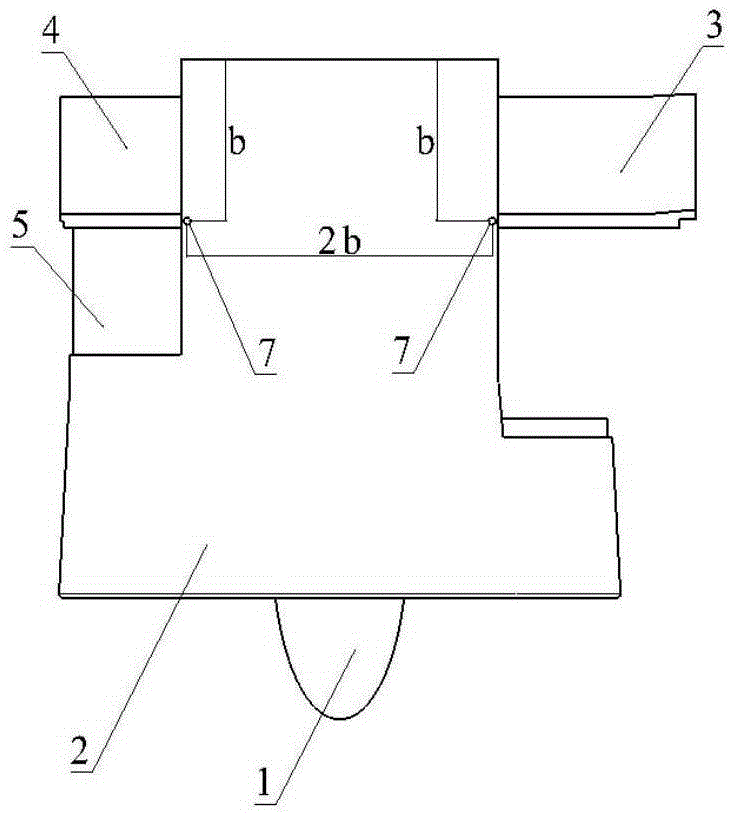

Center knife rear type shield machine cutter head

The invention discloses a cutter head of a shield machine with a rear center knife. Its technical proposal is that the center knife in front of the traditional cutter head is removed, and a round hole is opened in the center of the cutter head through the cutter head, and the center knife is fixed by the tool holder. behind the round hole. The minimum distance between the center knife edge and the rear end face of the circular hole is not less than half of the radius of the circular hole. When the cutter head is working, the soil outside the central circular hole of the cutter head is first excavated by an ordinary excavating knife, and the soil in the central circular hole of the cutter head forms a soil cylinder and gradually passes through the circular hole. When the soil column hits the rear center cutter, because the confining soil without the surrounding soil is in a unidirectional compression state, it can be broken with only a small axial thrust. Therefore, the cutter head of the shield machine with the center knife behind can greatly reduce the axial thrust of the center knife, thereby reducing the total axial thrust, avoiding the phenomenon of soil cake during excavation, and improving the excavation efficiency.

Owner:TIANJIN UNIV

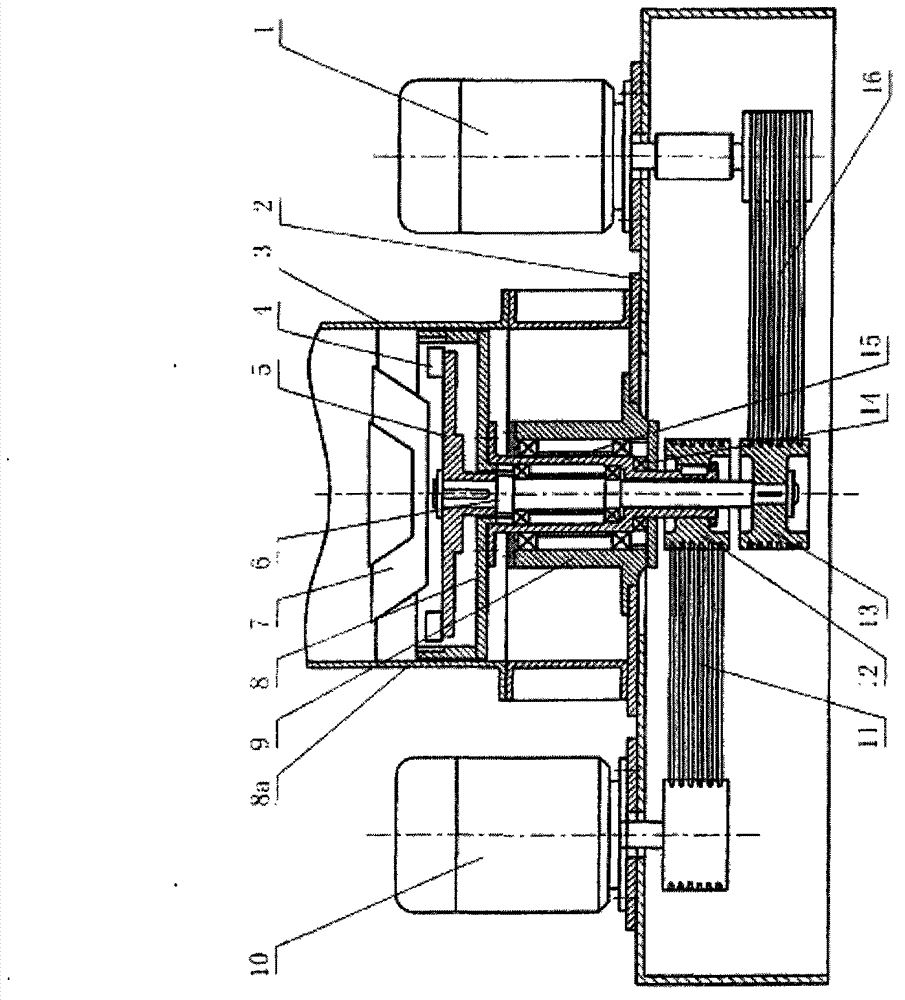

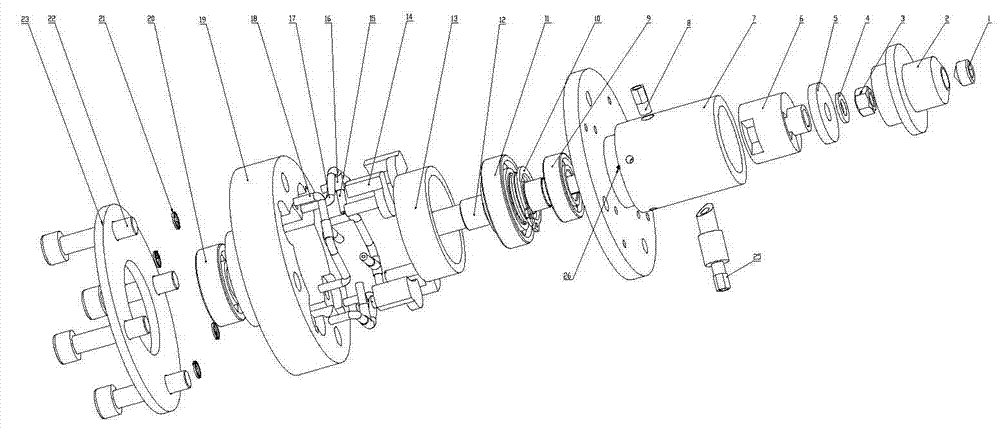

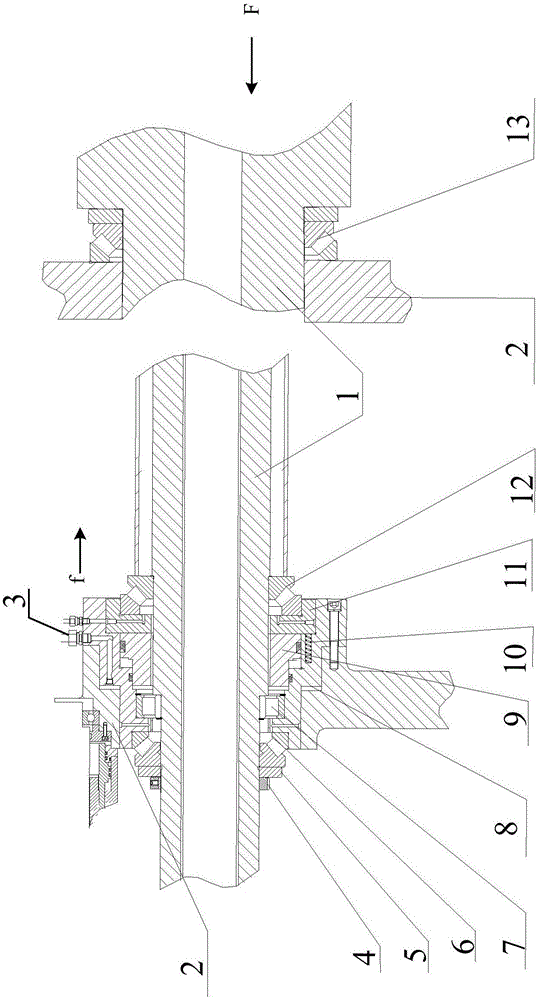

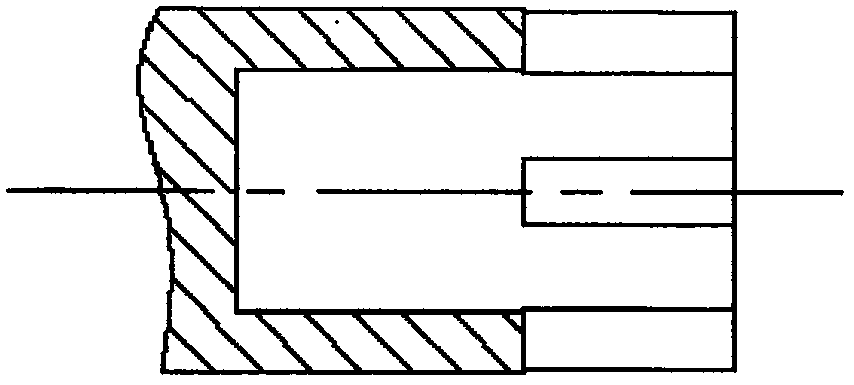

Friction welding machine and spindle force balancing assembly thereof

InactiveCN106334871ALarge axial forceLarge axial thrustNon-electric welding apparatusFriction weldingAxial thrust

The invention relates to a spindle force balancing assembly of a friction welding machine. The assembly comprises a spindle and a spindle box and further comprises a balancing device which is assembled on the spindle box and used for exerting axial force on the spindle; and the direction of the force exerted on the spindle by the balancing device is opposite to that of the axial force on the spindle during working. After the balancing device is added, the axial force exerted on the spindle by the balancing device can partially or completely offset the axial force on the spindle during working, so that the axial force on a bearing of the spindle is reduced, and correspondingly, the axial thrust capable of being borne by the friction welding machine is remarkably increased; and meanwhile, the axial force on the spindle is remarkably reduced, and the service life of the bearing of the spindle is correspondingly prolonged. The invention further discloses the friction welding machine provided with the spindle force balancing assembly.

Owner:CHONGQING TURBO FLOW MACHINERY MFG

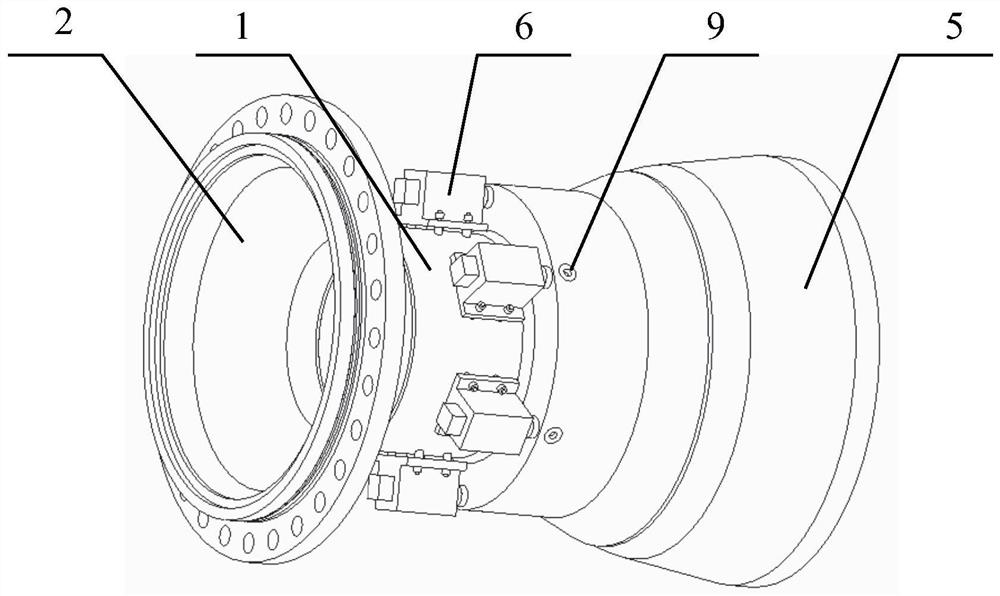

Expansion section lateral drainage thrust vector control spray pipe

ActiveCN112761823AImprove sealingImprove thermal protection performanceRocket engine plantsControl vectorControl system

The invention relates to an expansion section lateral drainage thrust vector control spray pipe. A thrust vector control system is mainly composed of a control system, a driving motor, a driving rod, a flow guide rod and a drainage pipe. A fuel gas drainage hole is formed in the expansion section of a spray pipe body, a drainage pipe is connected into the fuel gas drainage hole in an embedded mode, and a second flow guide rod through hole perpendicular to a second drainage channel is formed in the drainage pipe. A flow guide rod channel is arranged on the expansion section of the spray pipe body. The flow guide channel is blocked or opened by controlling the position of the flow guide rod, and when fuel gas in the spray pipe is sprayed out of the flow guide channels, reverse control torque is generated. A plurality of thrust vector control devices can be symmetrically arranged on the spray pipe, and each thrust vector control device can be opened and closed for multiple times; and when one drainage channel is independently opened or multiple drainage channels are asymmetrically opened, thrust vector control can be achieved. When the multiple drainage channels are symmetrically opened, lateral force in all directions counteracts one another, lateral torque is not generated, but the axial thrust of the engine can be reduced.

Owner:湖北航天飞行器研究所

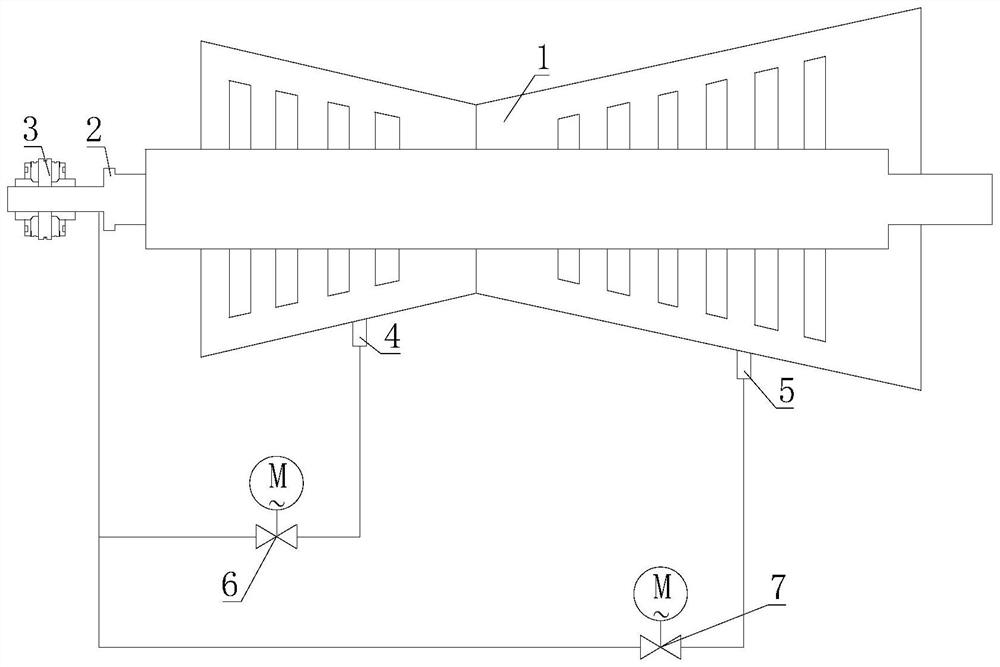

Adjusting system for axial thrust of steam turbine under variable working conditions and using method of adjusting system

ActiveCN112412548AReduce axial thrustAvoid damageMachines/enginesEngine componentsThrust bearingCogeneration

The invention belongs to the technical field of combined heat and power generation steam turbine power generation, and particularly relates to an adjusting system for axial thrust of a steam turbine under variable working conditions and a using method of adjusting system. According to the technical scheme, the adjusting system for the axial thrust of the steam turbine under variable working conditions comprises a steam turbine, a balance disc is installed on a rotor of the steam turbine, and a thrust bearing is connected to a stator of the steam turbine. The steam turbine is provided with a first steam extraction opening and a second steam extraction opening, the first steam extraction opening and the second steam extraction opening are connected with the balance disc through pipelines correspondingly, and the distance between the first steam extraction opening and a steam inlet of the steam turbine is smaller than the distance between the second steam extraction opening and the steaminlet of the steam turbine. A first adjusting valve is connected to the pipeline between the first steam extraction opening and the balance disc, and a second adjusting valve is connected to the pipeline between the second steam extraction opening and the balance disc. According to the adjusting system and the using method thereof, the stress condition of the thrust bearing can be changed under the variable working condition of a steam turbine mechanism so as to guarantee the control allowable range of the resultant force borne by the thrust bearing.

Owner:DONGFANG TURBINE CO LTD

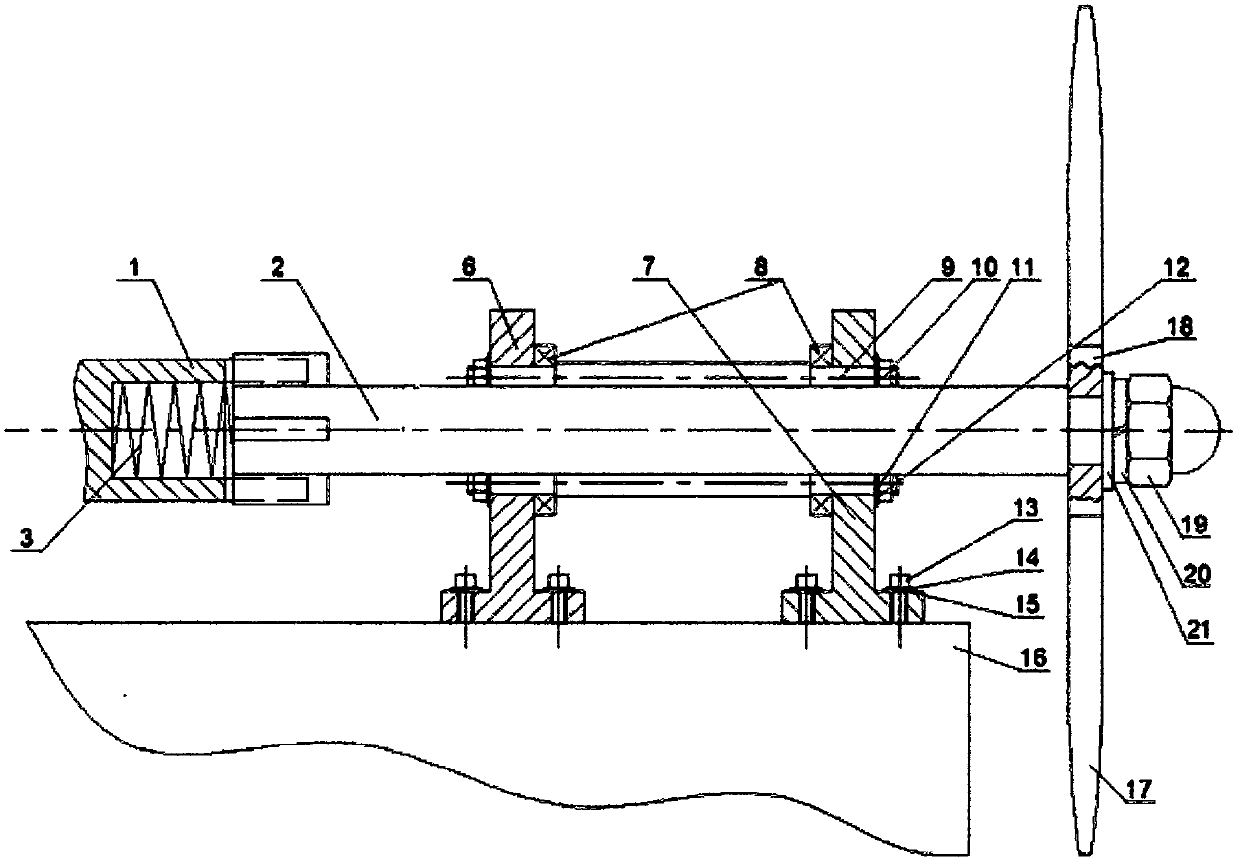

Axial supporting structure of small horizontal axis wind turbine

PendingCN107740751AReduce axial thrustGuaranteed power transmissionWind motor supports/mountsMachines/enginesImpellerElastomer

The invention discloses an axial supporting structure of a small horizontal axis wind turbine. The axial supporting structure comprises a base and the small horizontal axis wind turbine arranged at the top of the base; the small horizontal axis wind turbine comprises a horizontal input shaft, a horizontal output shaft and an impeller arranged at the front end of the horizontal input shaft; at least two supporting seats are arranged at the top of the base in the axial direction, at least three horizontal bearing shafts are uniformly distributed between the at least two supporting seats in the circumferential direction, and bearings are arranged at the front end and the rear end of each bearing shaft; the horizontal input shaft is clamped between outer rings of the bearings, and the horizontal input shaft can move backwards in the axial direction when being subjected to axial thrust; and an elastomer is arranged in a hollow cylinder body of the front end of the horizontal output shaft, and the elastomer is compressed only when the horizontal input shaft is subjected to the axial thrust. A connecting mechanism can buffer the axial thrust generated by a wind wheel to a great extent while guaranteeing power transmission between the input shaft and the output shaft, impact on other subsequent power units is avoided, and stability of a system is improved.

Owner:YICHUN UNIVERSITY

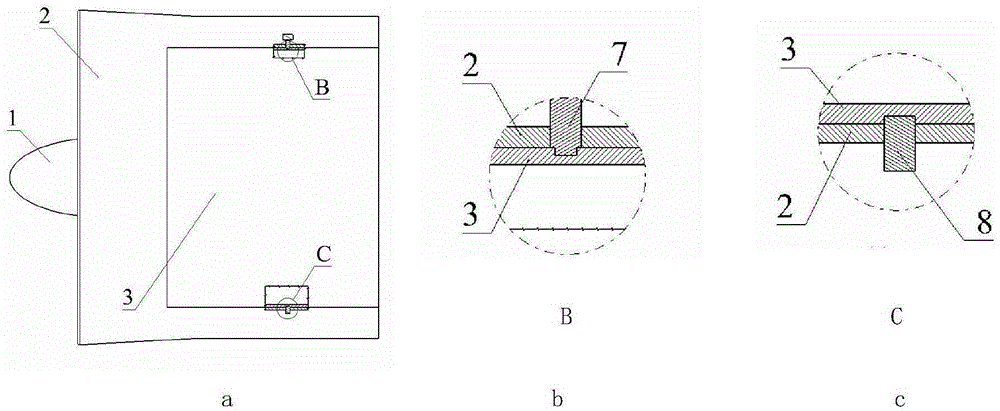

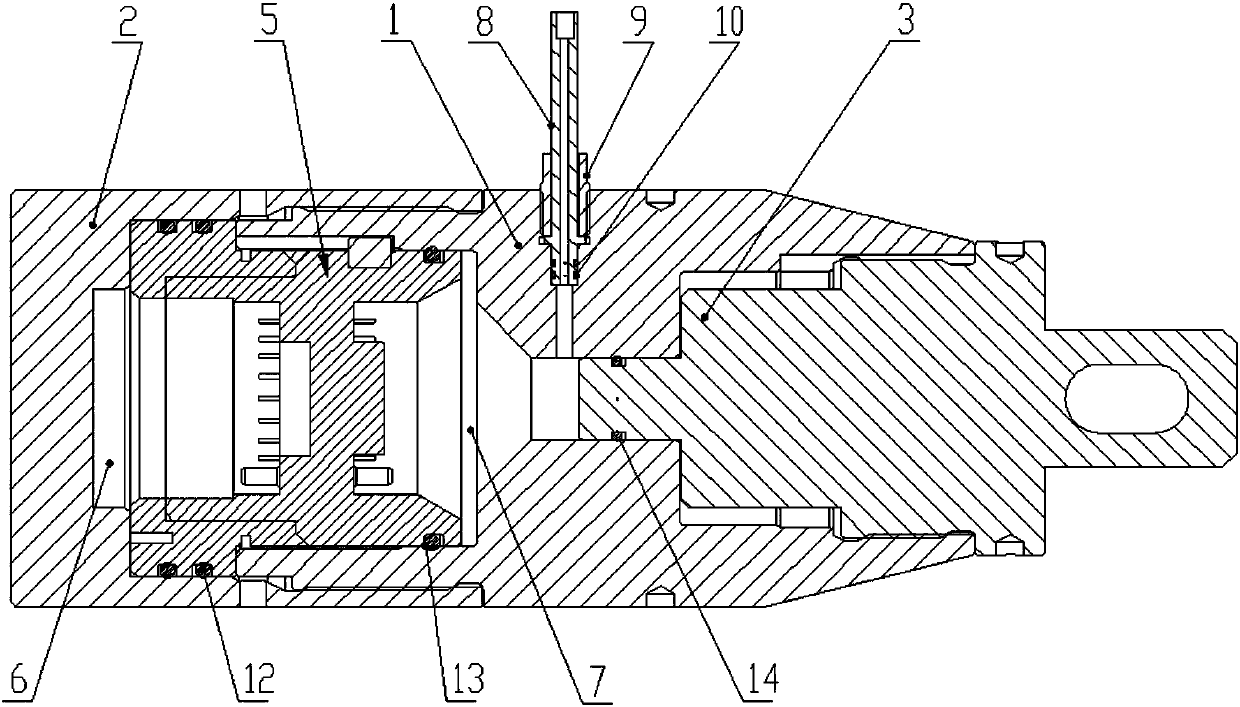

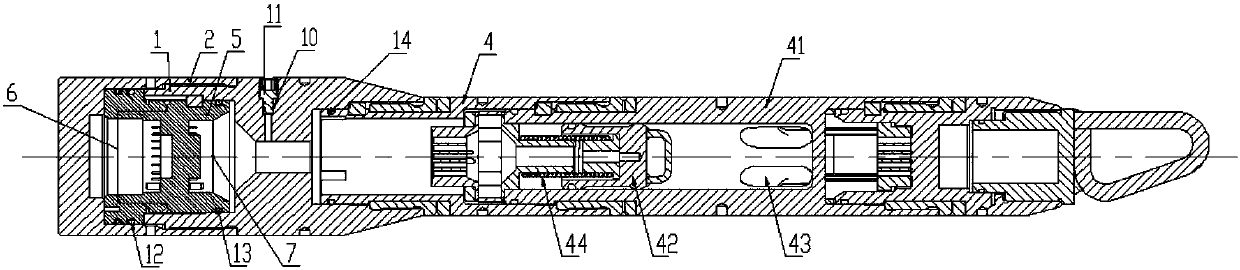

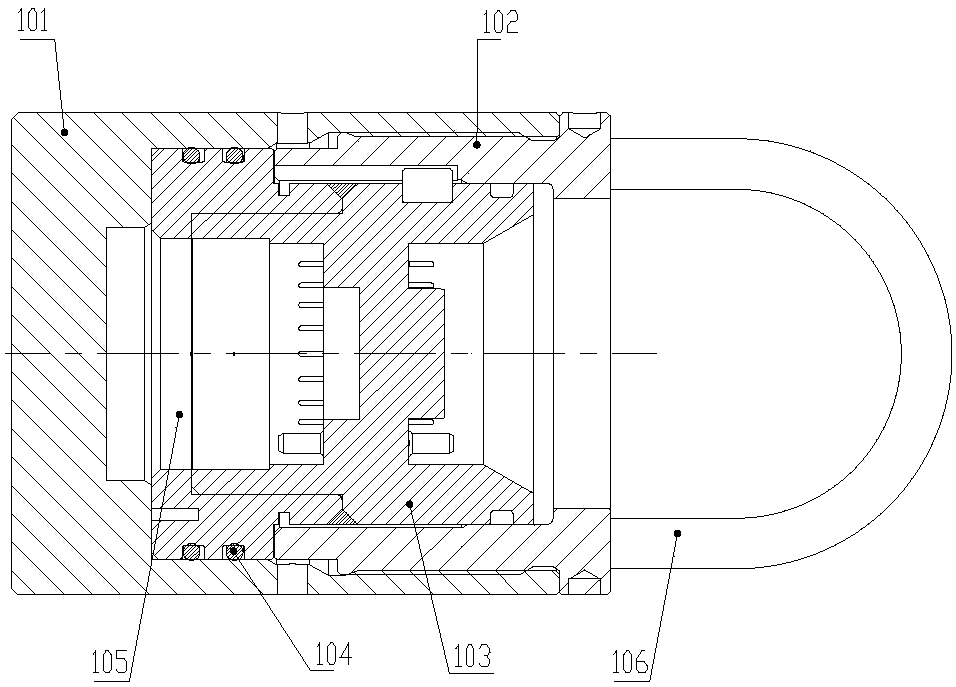

Device for testing voltage resistance of plug

PendingCN107796562AAvoid deformationInsulation effectFluid-tightness measurement using fluid/vacuumEngineeringHigh pressure

The invention discloses a device for testing voltage resistance of a plug. The device comprises a body (1), a sealing sleeve (2), a sealing plug (3), a balance piston assembly (4) and a voltage applying device. One end of the body (1) is connected with the sealing sleeve (2), and the other end is connected with the sealing plug (3) or the balance piston assembly (4). A chamber for placing a testing plug (5) is formed between the body (1) and the sealing sleeve (2). The testing plug (5) divides the chamber to a low-pressure chamber (6) and a high-pressure chamber (7). The voltage applying device is fixedly mounted outside the body (1). The sealing plug (3) and the balance piston assembly (4) have the same screw specification and the same sealing surface dimension, and can be freely switched. The device can effectively prevent influence of a detecting process to insulating property of the testing plug (5) so that normal use of the testing plug (5) is not affected after testing and furthermore can realize free switching between normal-temperature preliminary testing and high-temperature high-voltage testing of the plug.

Owner:北京环鼎科技有限责任公司

Centrifugal compressor for heavy oil hydrogenation device

InactiveCN107829957AReduce axial thrustGuaranteed uptimePump componentsRadial flow pumpsControl systemThrust bearing

A centrifugal compressor for a heavy oil hydrogenation device is composed of the four parts of a stator assembly, a rotor assembly, a bearing group and dry gas seals. The stator assembly comprises a cylinder block, end covers, partition plates and a seal. The rotor assembly comprises 6-8 impellers, a main shaft, spacer sleeves, a balance disk, a thrust disk, nuts, an adjusting pad and a stopper ring. The bearing group comprises two supporting bearings and a thrust bearing. The dry gas seals are provided with independent control units and independent systems and each comprises a body and a control portion. The centrifugal compressor for the heavy oil hydrogenation device is characterized in that (1) the compressor is of a vertical subdivision type structure; (2) the partition plates are assembled together to form a partition plate bundle, and a bladeless diffuser is arranged between every two adjacent partition plates; (3) the 6-8 impellers are sequentially arranged on the main shaft, and the diameter of each impeller is 400 mm; (4) the blade forms of the impellers are identical, and the blades of one impeller deviate by a certain angle relative to the blades of the impeller locatedin the front; (5) the supporting bearings are titling-pad bearings, the thrust bearing is of the Kingsbury type, and the two sides of the thrust bearing are of the same structure; (6) the dry gas seals are installed at the two ends of the compressor, and the dry gas seals are provided with the independent control systems.

Owner:SHENYANG SITE MACHINERY MFG

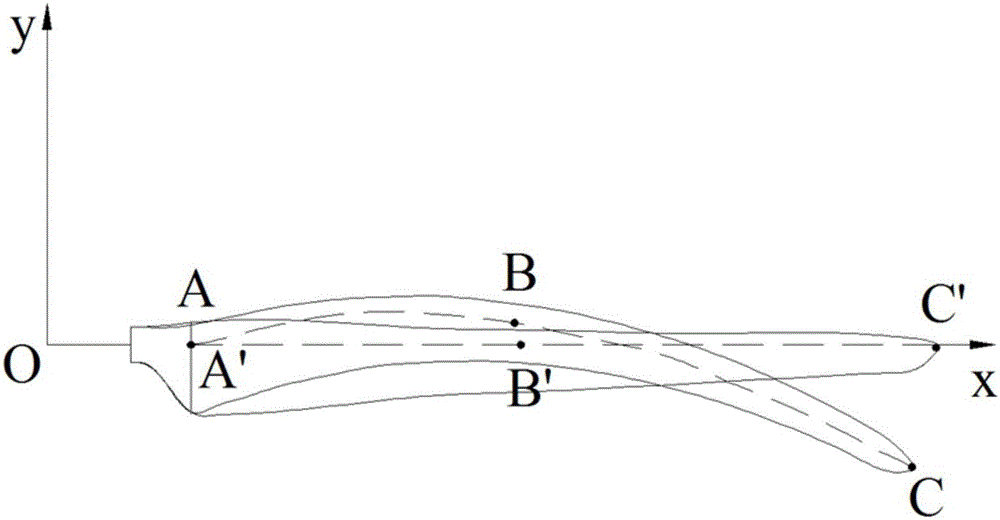

Low-wind-speed wind turbine blade

InactiveCN105888963AIncrease output powerReduce resistanceMachines/enginesWind energy generationTurbine bladeWind speed

The invention discloses a low-wind-speed wind turbine blade which is a skewed blade. A stacking line of the blade meets a specific curvilinear equation. The low-wind-speed wind turbine blade is large in output power and high in wind energy utilization rate.

Owner:YANGZHOU UNIV

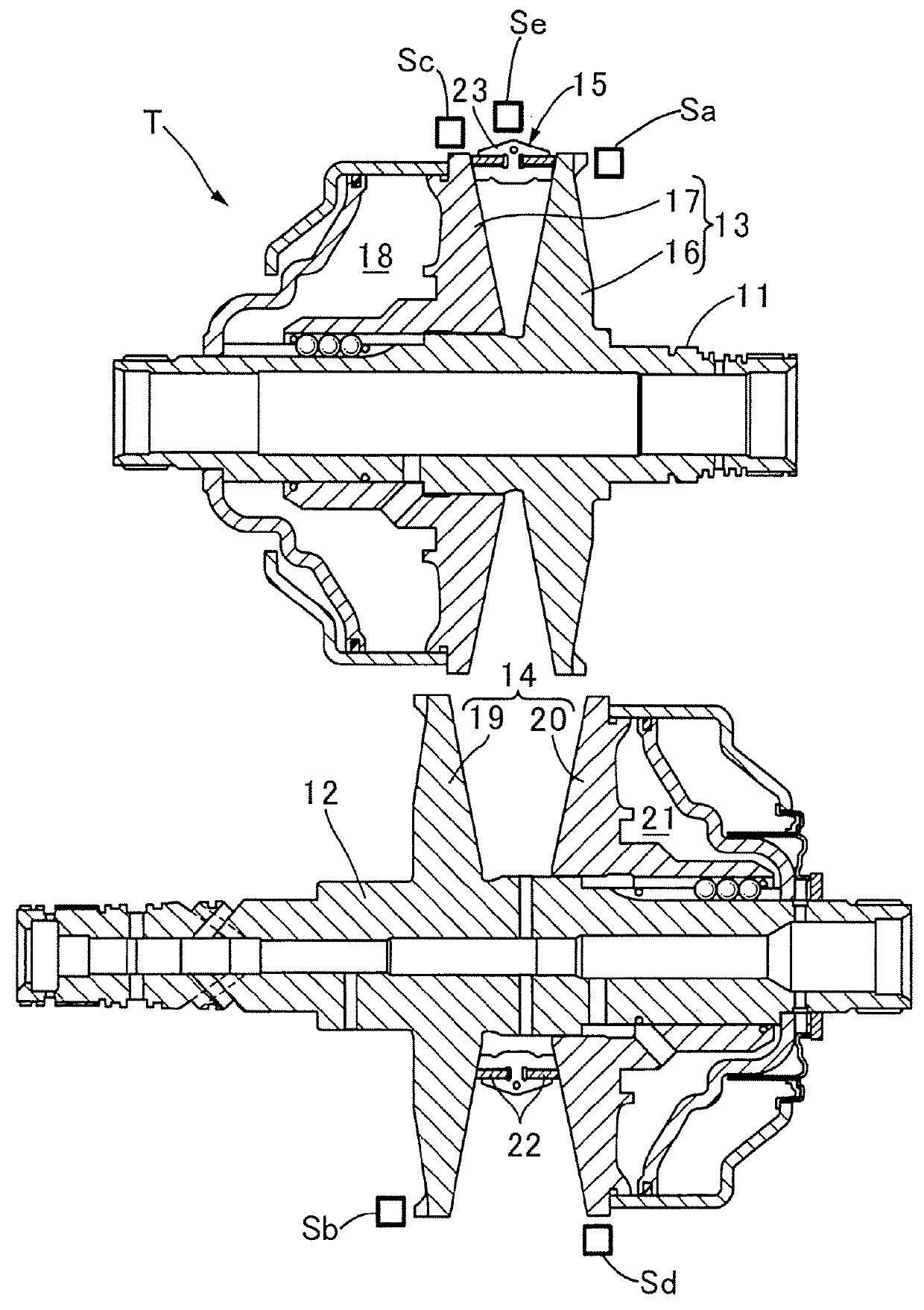

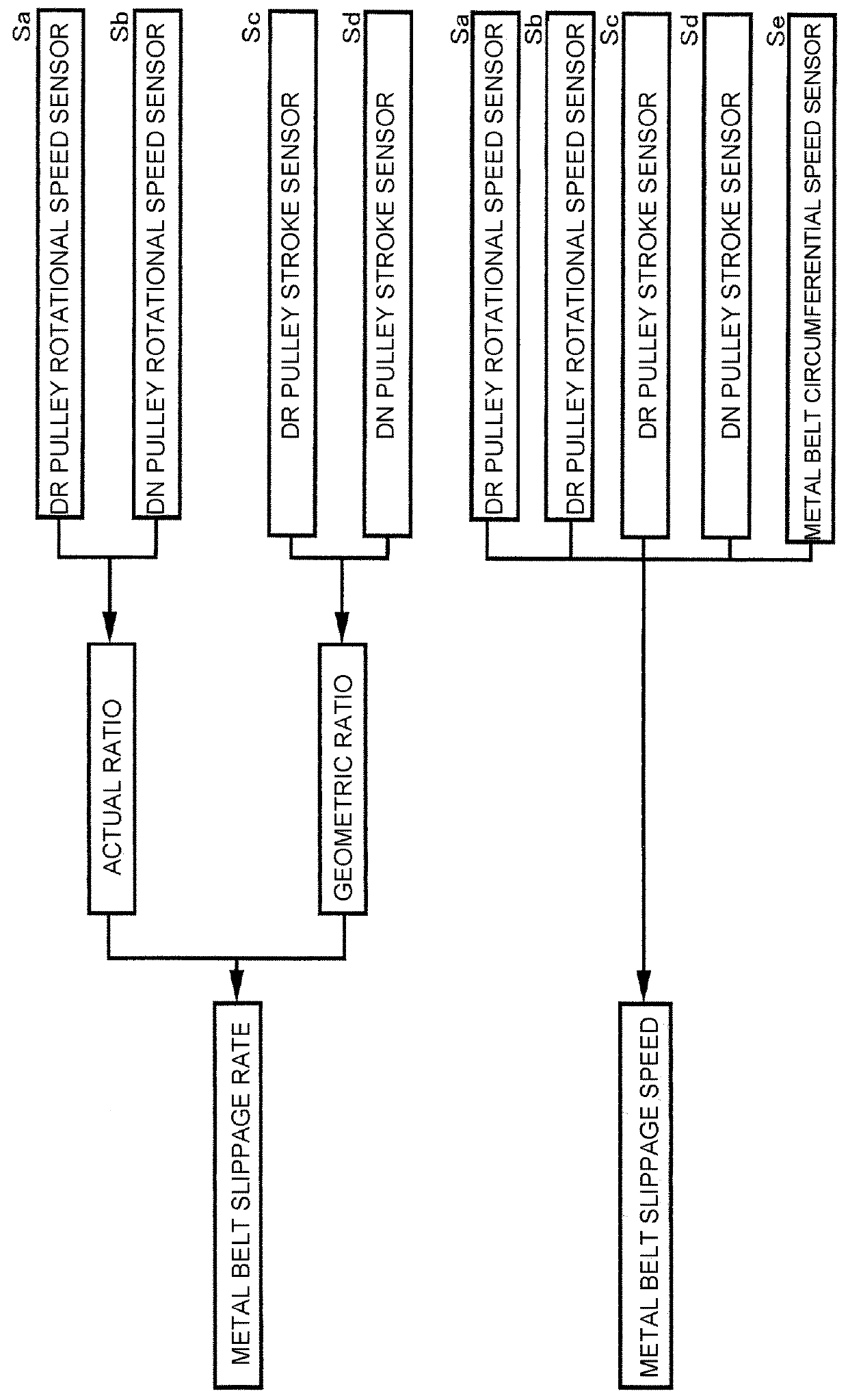

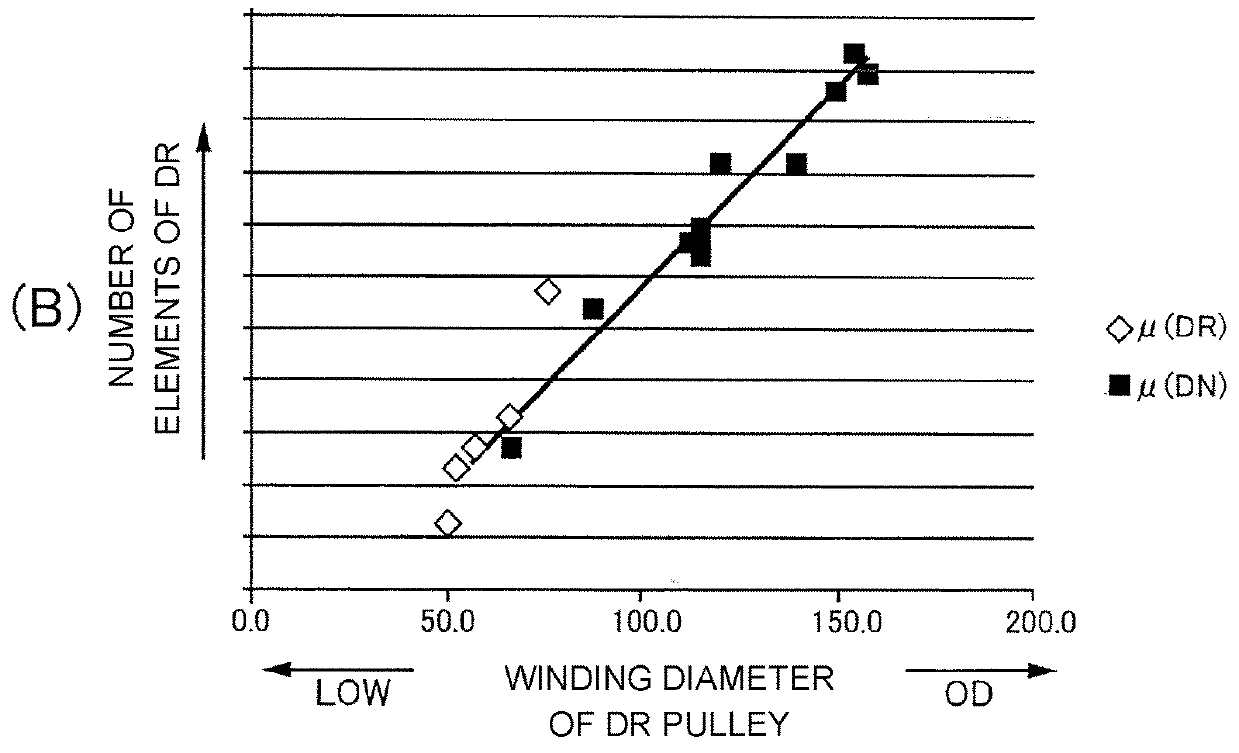

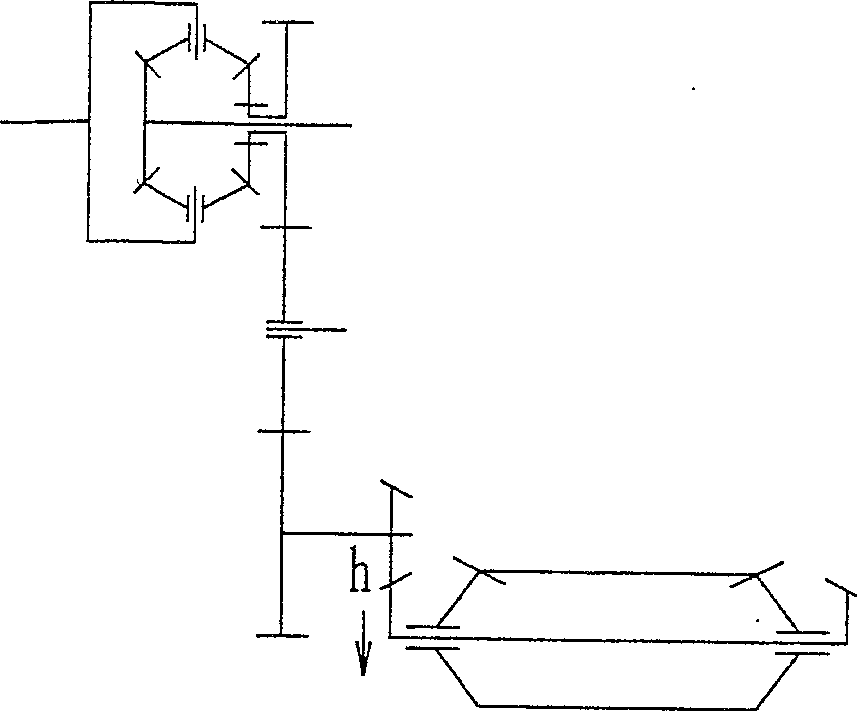

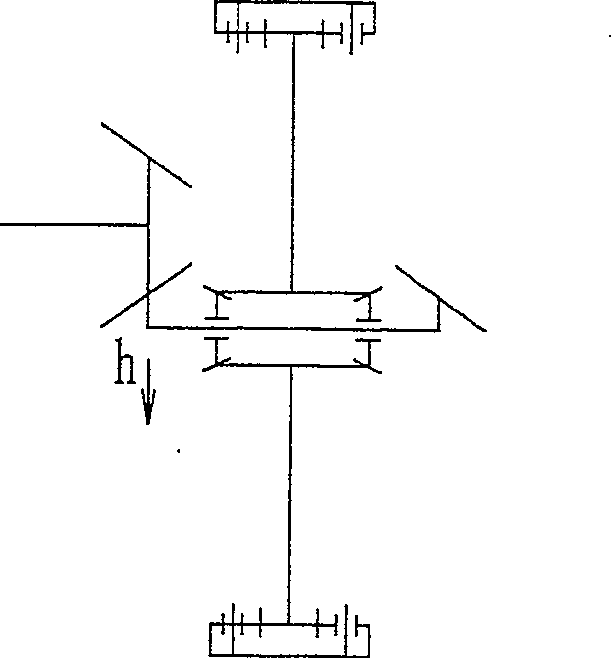

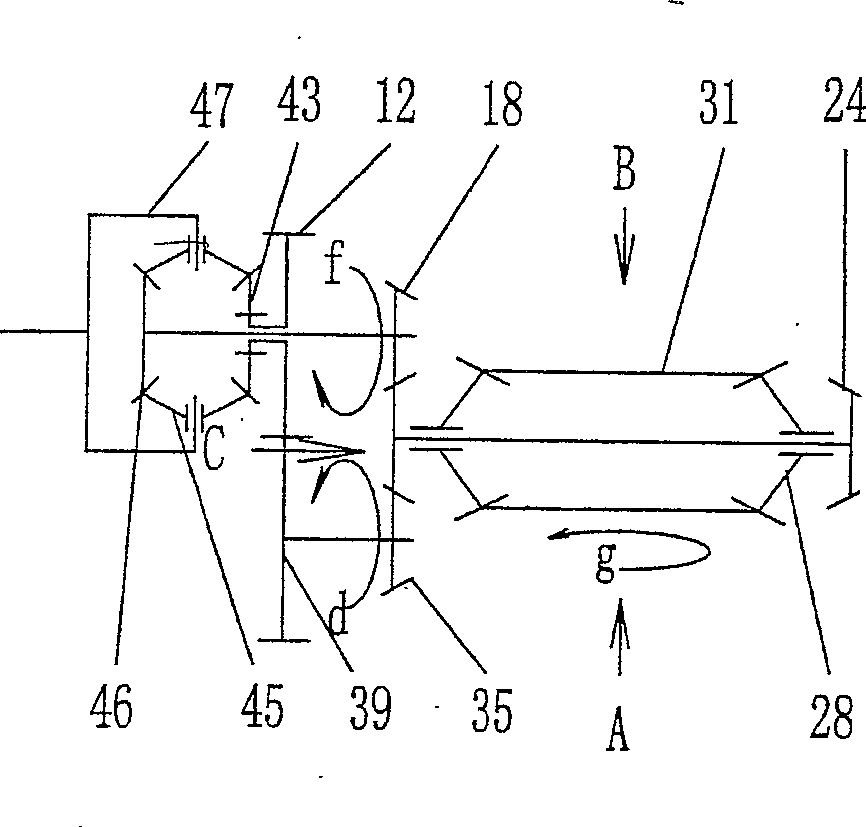

Transmission control method of belt type continuously variable transmission

ActiveUS20180163864A1Coefficient of frictionReduce coefficient of frictionGearingGearing controlHydraulic pumpAxial thrust

In a first process, a tangential friction coefficient of a non-slippage side pulley of a drive pulley and a driven pulley is estimated from a tangential friction coefficient and a winding diameter of a slippage side pulley. In a second process, torque transmitted by a metal belt is calculated from the tangential friction coefficient and the winding diameter. In a third process, a required axial thrust of the non-slippage side pulley is calculated from the torque and the winding diameter. In a fourth process, the gear ratio is changed by reducing a ratio holding axial thrust of the non-slippage side pulley toward the required axial thrust. Therefore, the gear shifting can be performed merely by reducing the axial thrust of the non-slippage side pulley, and thus it is possible to improve the durability of the pulleys or the metal belt and to reduce a load of a hydraulic pump.

Owner:HONDA MOTOR CO LTD

A main deceleration device

InactiveCN100465476CSimple structureImprove support rigidityToothed gearingsDifferential gearingsEngineeringBevel gear

The present invention provides a main decelerate device which includes a planet gear load-uniformed mechanism, a driver gear and a initiative bevel gear driven by the device, a driven bevel gear engaged with the initiative bevel gear and a speed differientiator connected to the driven bevel gear. It is characterized in that one of the sun gear in the planet gear load-uniformed mechanism is connected to the initiative bevel gear, another sun gear is connected to one of two engaged intermediate drive gears by an axle sleeve, another intermediate drive gear is connected to a secondary initiative bevel gear, the initiative bevel gear and the secondary initiative bevel gear are both connected to a driven bevel gear with double cog. The device divides the power into two parallel path powers with reverse rotate direction and equal torsion, and then combines the two powers into one power by making the main, secondary initiative bevel gears engage with the driven bevel gear with double cog, and passes the power to the speed differientiator by the driven bevel gear and output the power by an axle shaft gear, thereby complete the power output between interleaving shafts, conquers the axial direction offset of the driven bevel gear and increases the drive ability by times.

Owner:张春

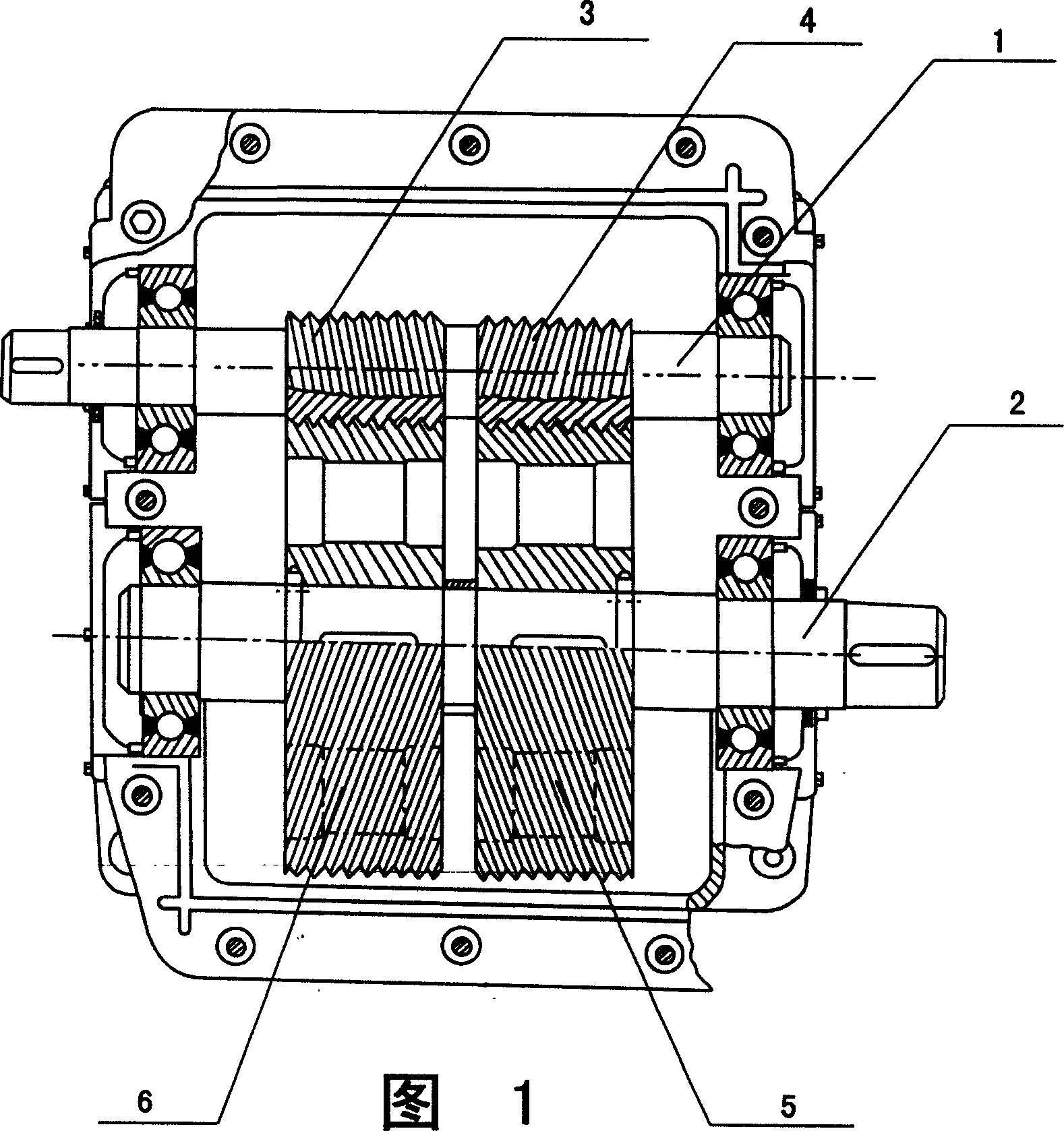

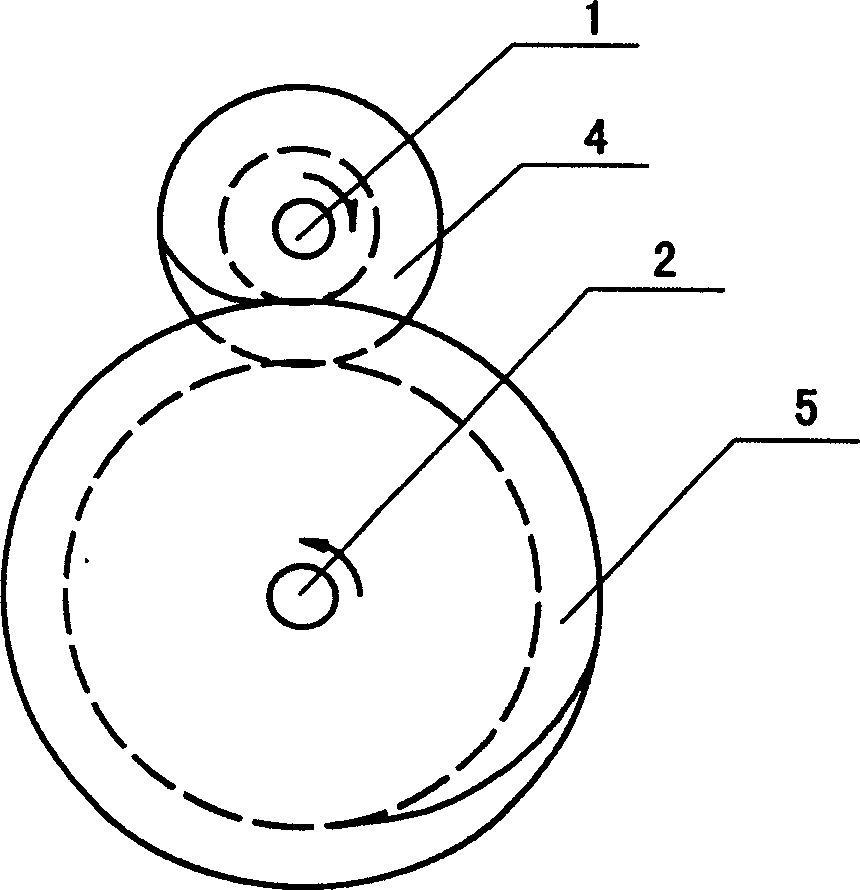

Mechanical double lead-screw drive pair

The invention discloses a mechanical double-screw driving auxiliary, mainly composed of box body, input shaft, output shaft, master driving screw, slave driving screw and bearing, where the screw driving auxiliary is set in the box body, the input shaft is set with two driving screws; the output shaft is set with two slave driving screws; the mutually-engaged master and slave driving screws rotate oppositely. It both has higher transmission efficiency and can be designed with self-locking function or not according to requirements. Compared with ordinary involute gear driving auxiliary of the same power, it has not only the character of driving efficiency but the advantages of small bulk, light, low noise and stable driving, and also mechanical power amplifying effect. Therefore, it can replace ordinary driving gears and applies to driving systems.

Owner:杨新功

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com