Main gear down device

A main deceleration and differential technology, applied in the differential transmission, transmission, gear transmission and other directions, can solve the problems of short service life, low transmission efficiency, etc., to achieve extended service life and reliability, stable transmission, The effect of increased carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

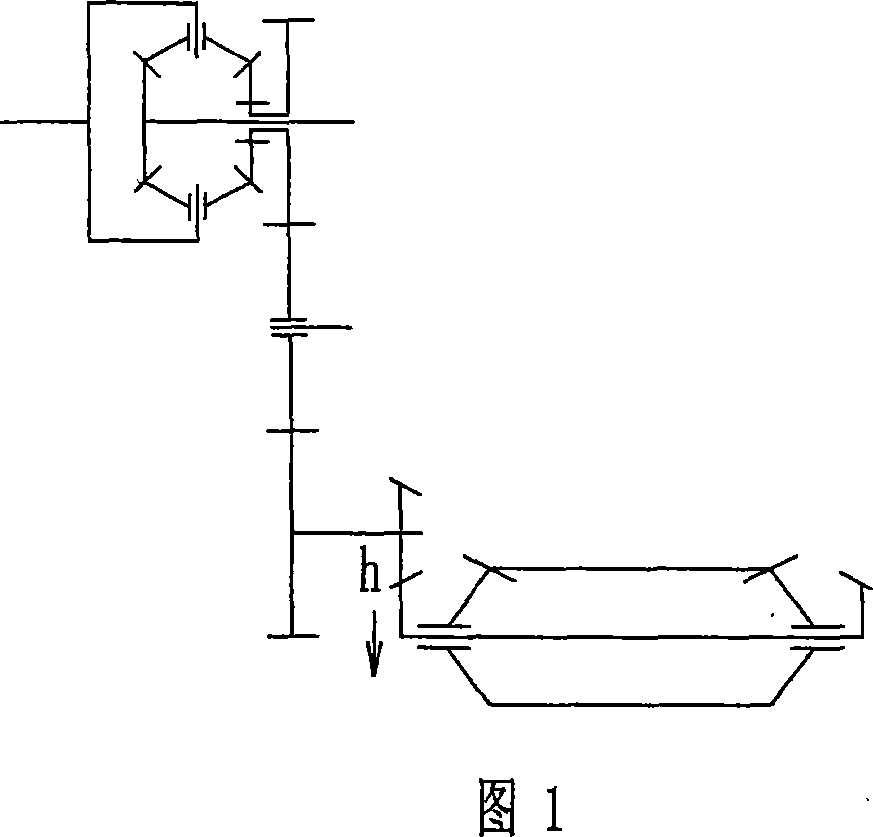

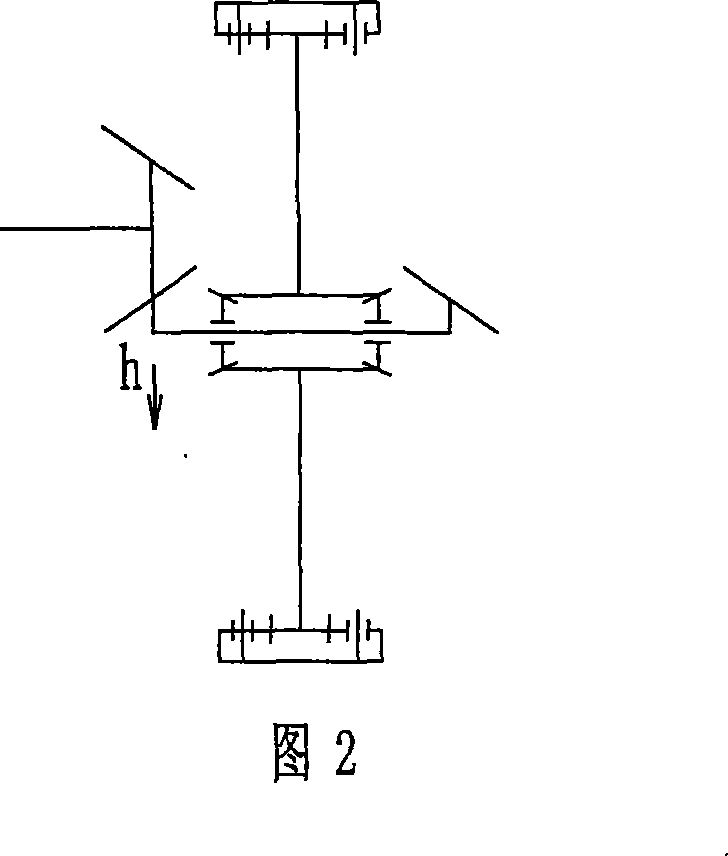

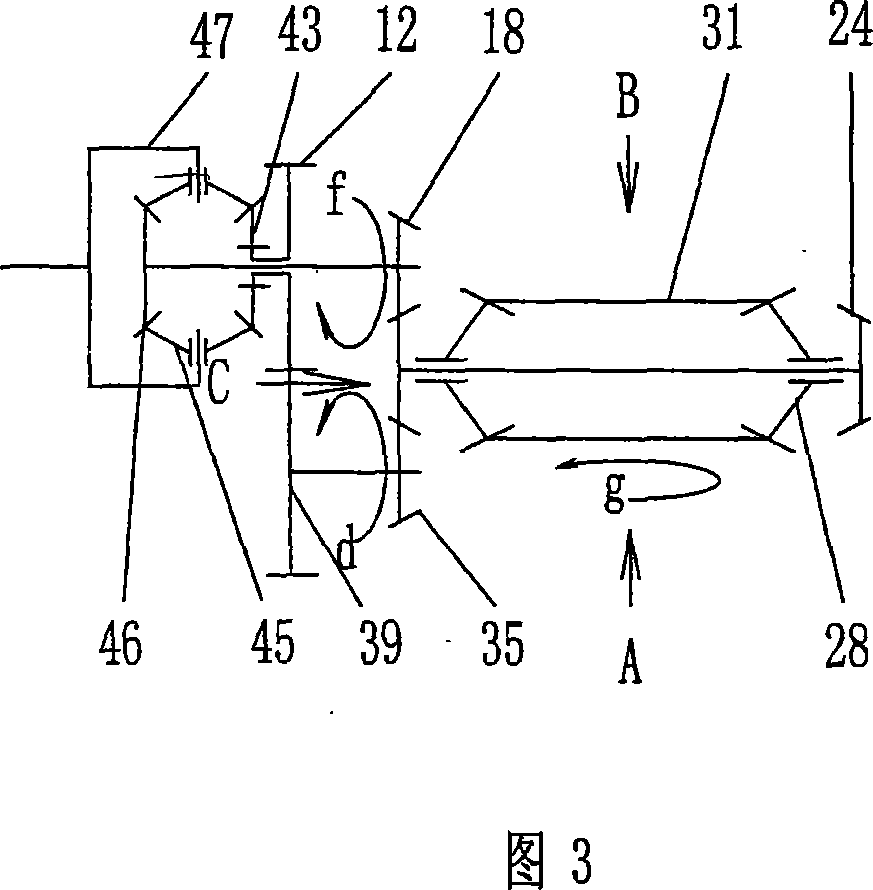

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

[0032]The outside of the load-equalizing planetary gear housing 47 is installed in the housing 6 of the load-equalizing mechanism through the nut 1, the connecting flange 2, the oil seal 3, the oil seal seat 4, and the bearing 5, and the housing is connected with the intermediate transmission gear housing 41 through screws 8 and bearings 9 , the inside of the planetary gear housing 47 is equipped with sun gears 46, 43, planetary gears 45 and cross shafts 44, wherein the sun gear 46 is connected to the tail end of the driving bevel gear 18 through the spline 7, and the driving bevel gear 18 is locked by locking The nut 10 and the needle roller bearing 14 are inserted into the intermediate gear 12, so that the driving bevel gear 18 is driven by the sun gear 46 to rotate, thereby forming the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com