Patents

Literature

455results about How to "Reduce contact stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

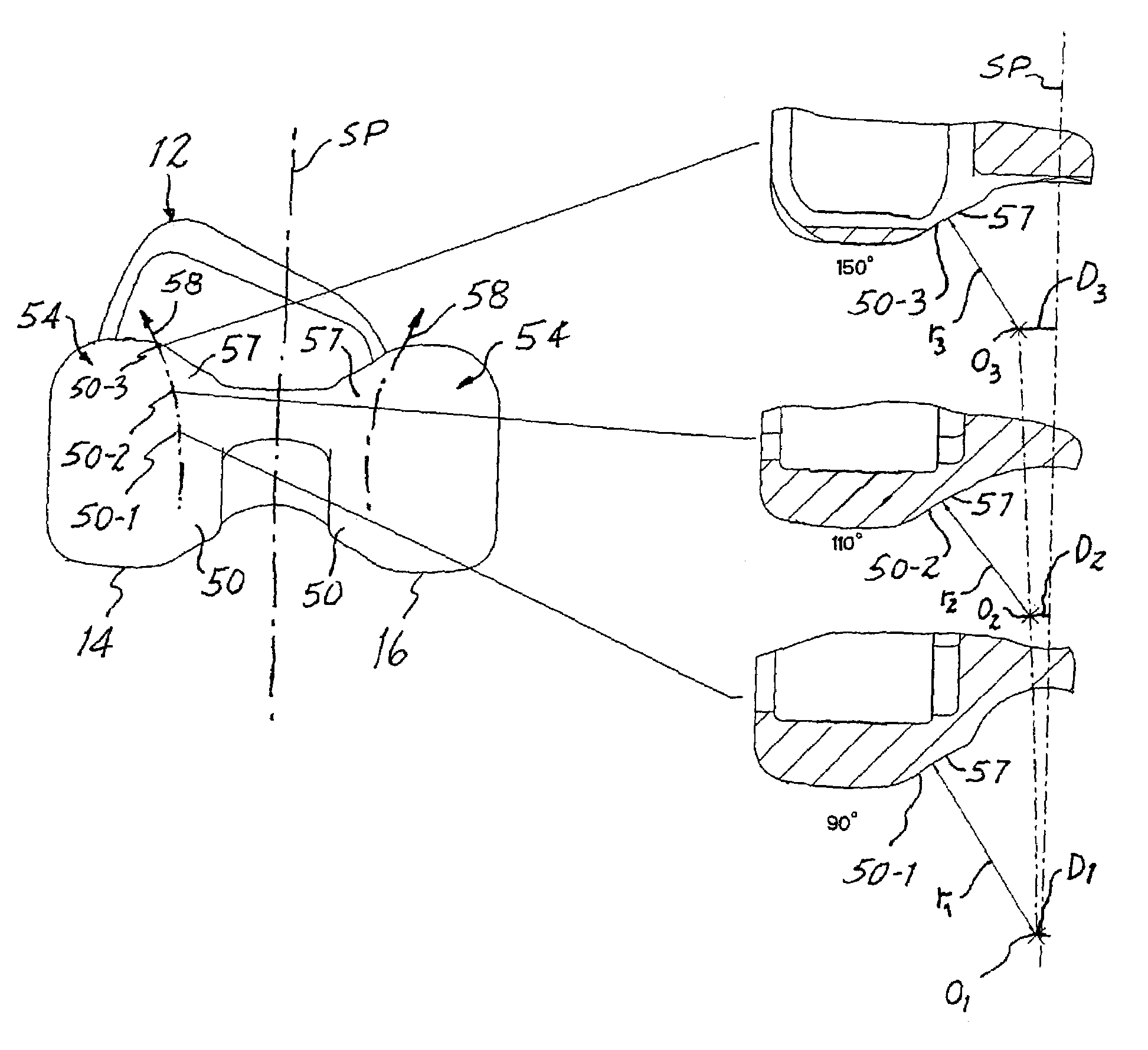

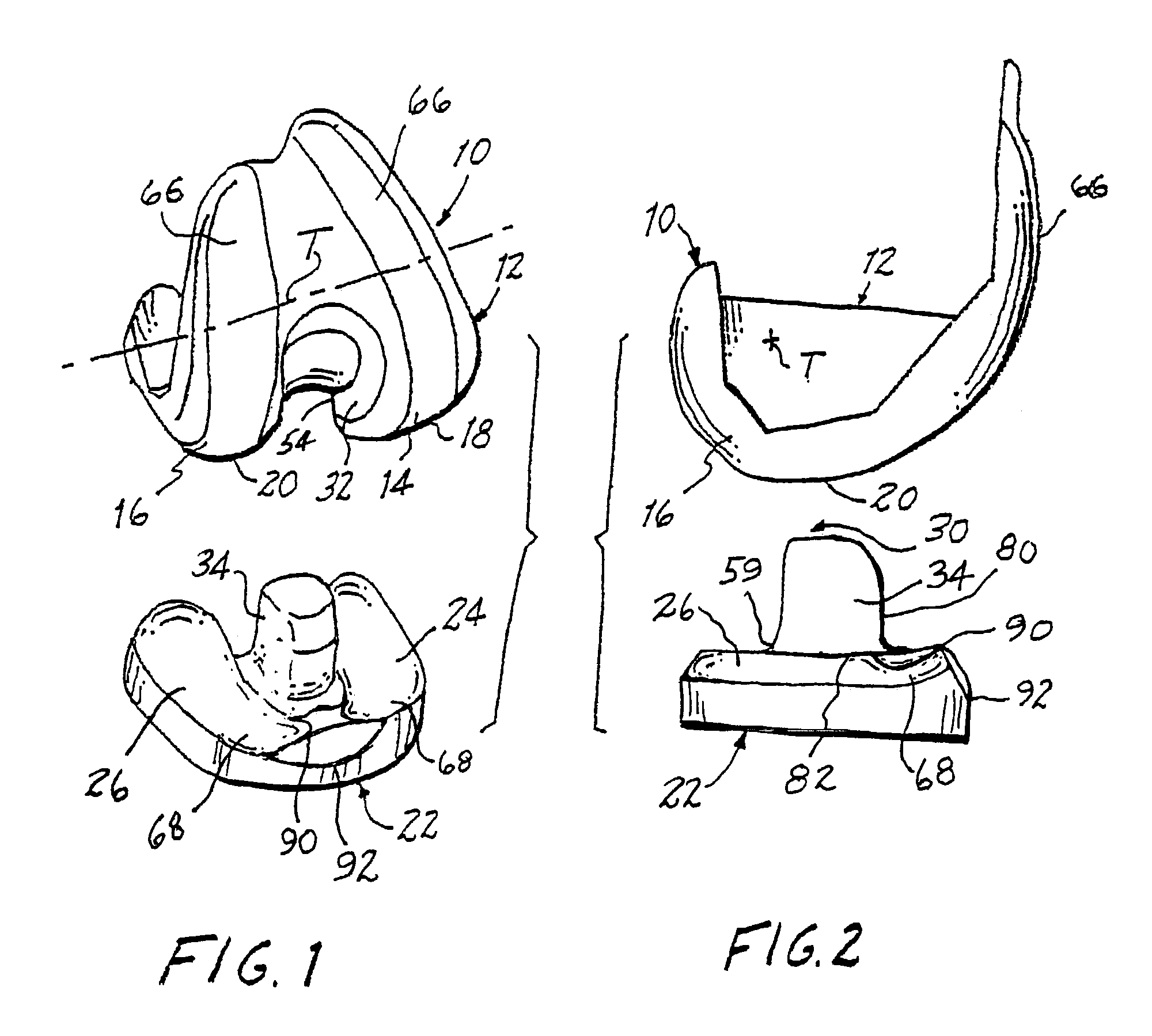

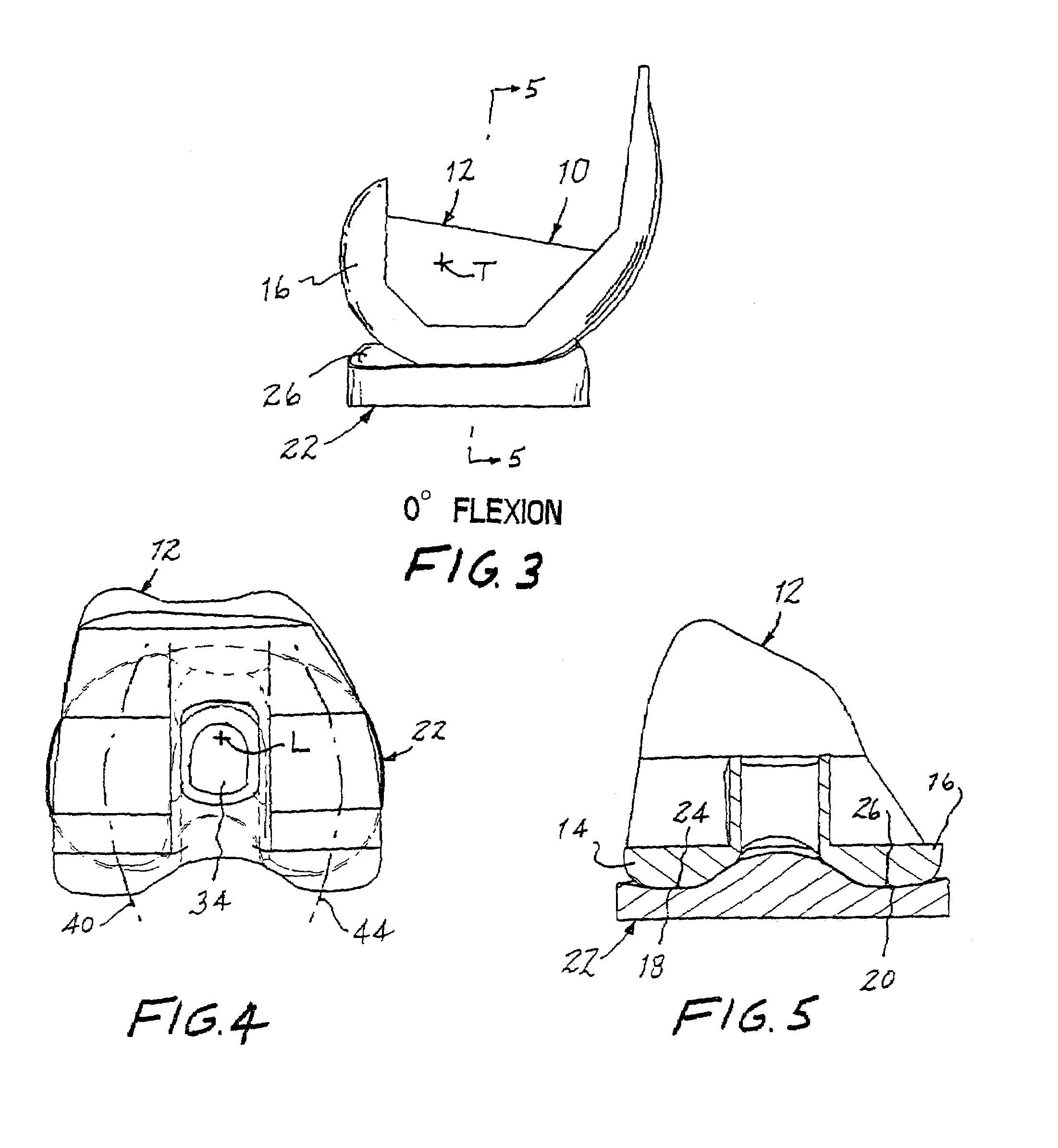

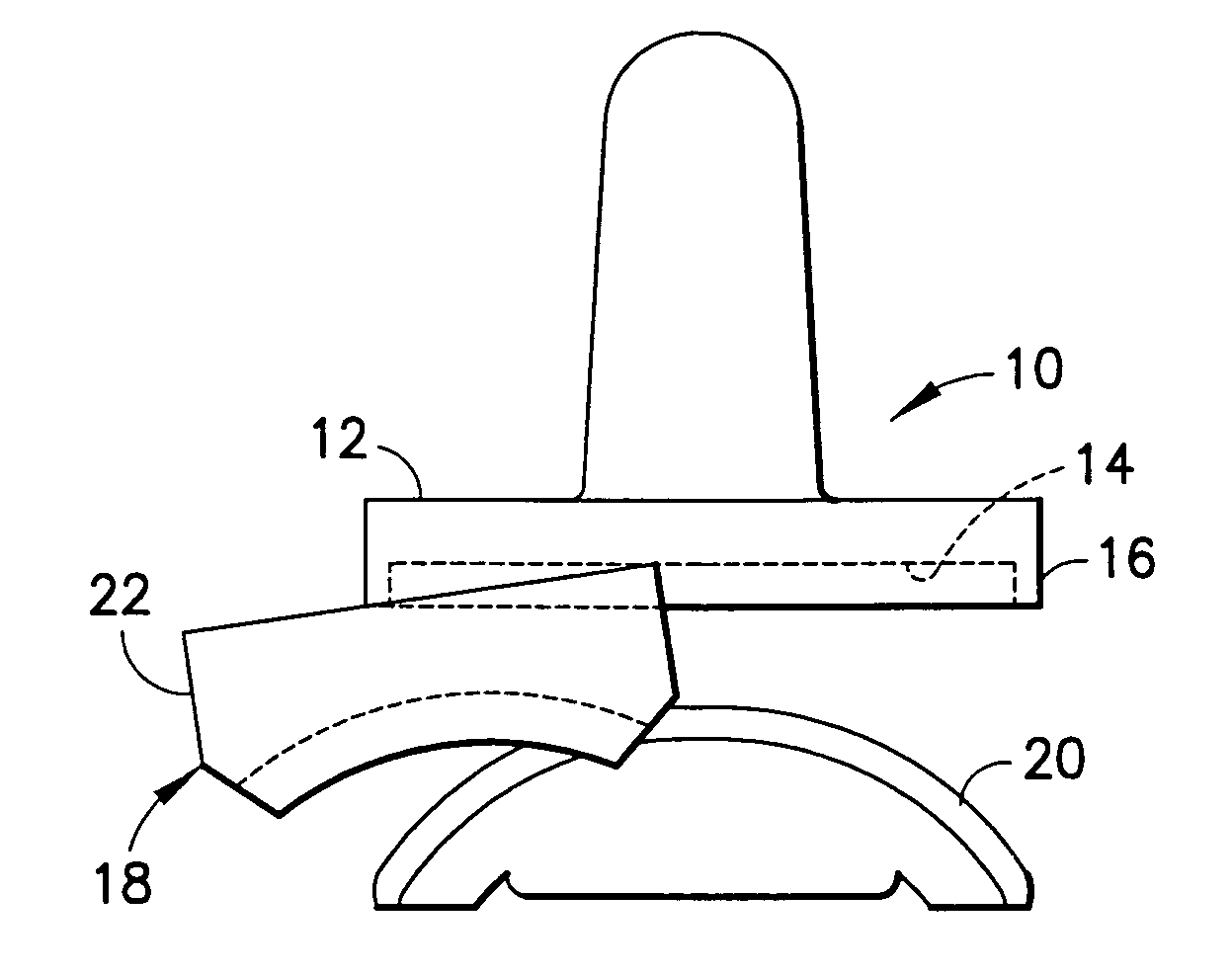

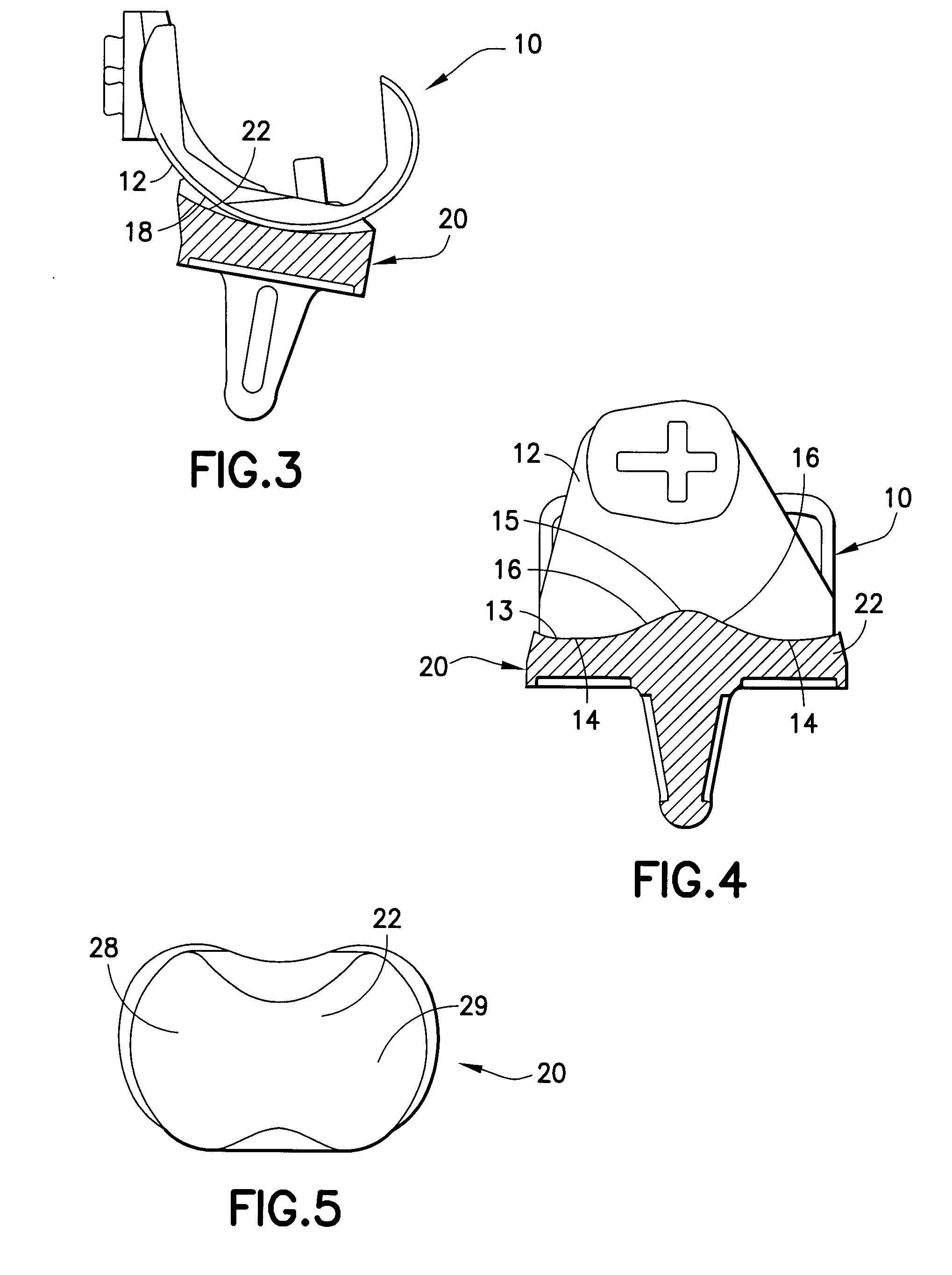

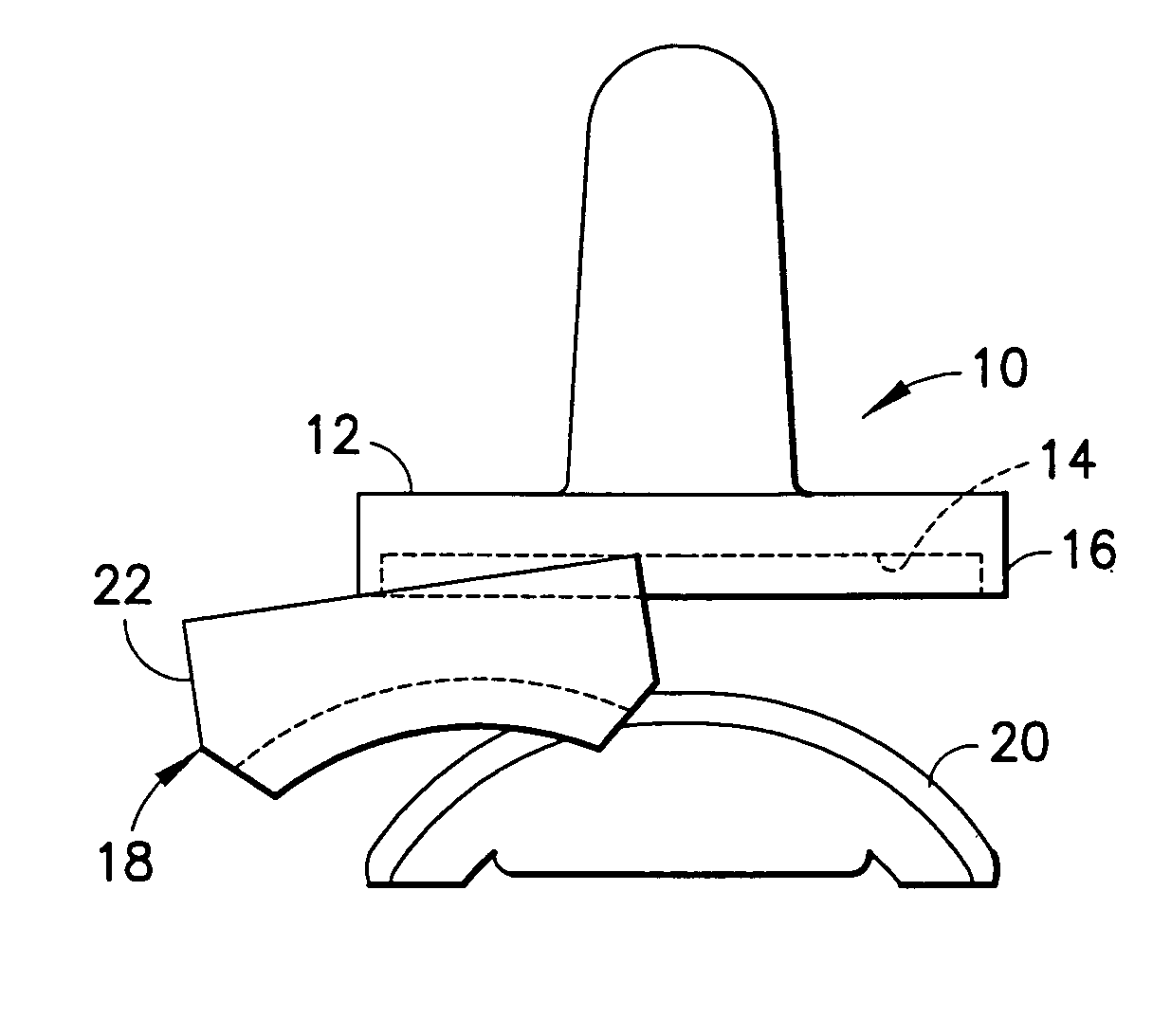

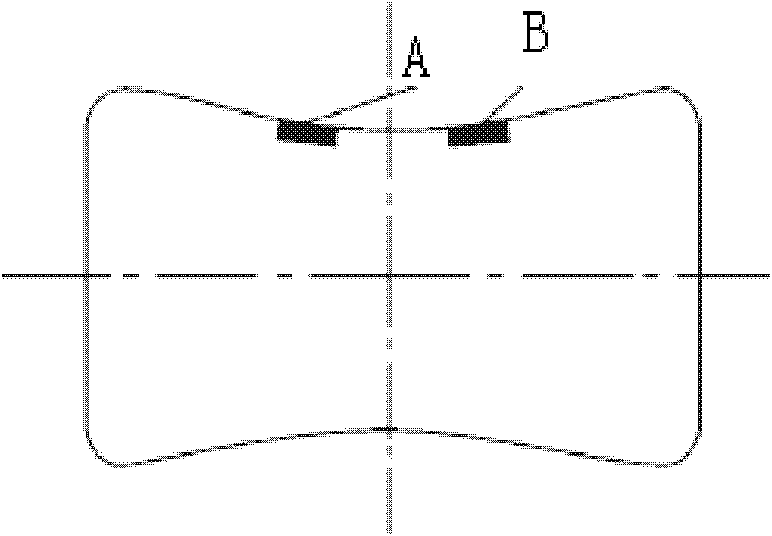

Knee prosthesis with extended range of motion

ActiveUS7081137B1Avoids unwanted distractionLarge range of motionJoint implantsKnee jointsDistractionArticular surfaces

In a knee prosthesis, the condylar surfaces of a femoral component engage corresponding articular surfaces of a tibial component along prescribed tracks of predetermined curvature which enable relative rotation between the femoral component and the tibial component about a longitudinal axis during articulation of the knee prosthesis, and at least the condylar surfaces or the articular surfaces are flared in a direction away from corresponding articular surfaces or condylar surfaces along engaged posterior and anterior portions of the condylar surfaces and articular surfaces to provide an increased area of contact in deep flexion and in extended hyperextension for reducing contact stresses and concomitant wear while militating against unwanted distraction of the knee prosthesis. In addition, the radius of curvature of the condylar surfaces is reduced along posterior portions of the condylar surfaces to further avoid distraction of the knee prosthesis in deep flexion, thereby enabling deep flexion with greater ease and without excessive contact forces between the femoral component and the tibial component in deep flexion.

Owner:HOWMEDICA OSTEONICS CORP

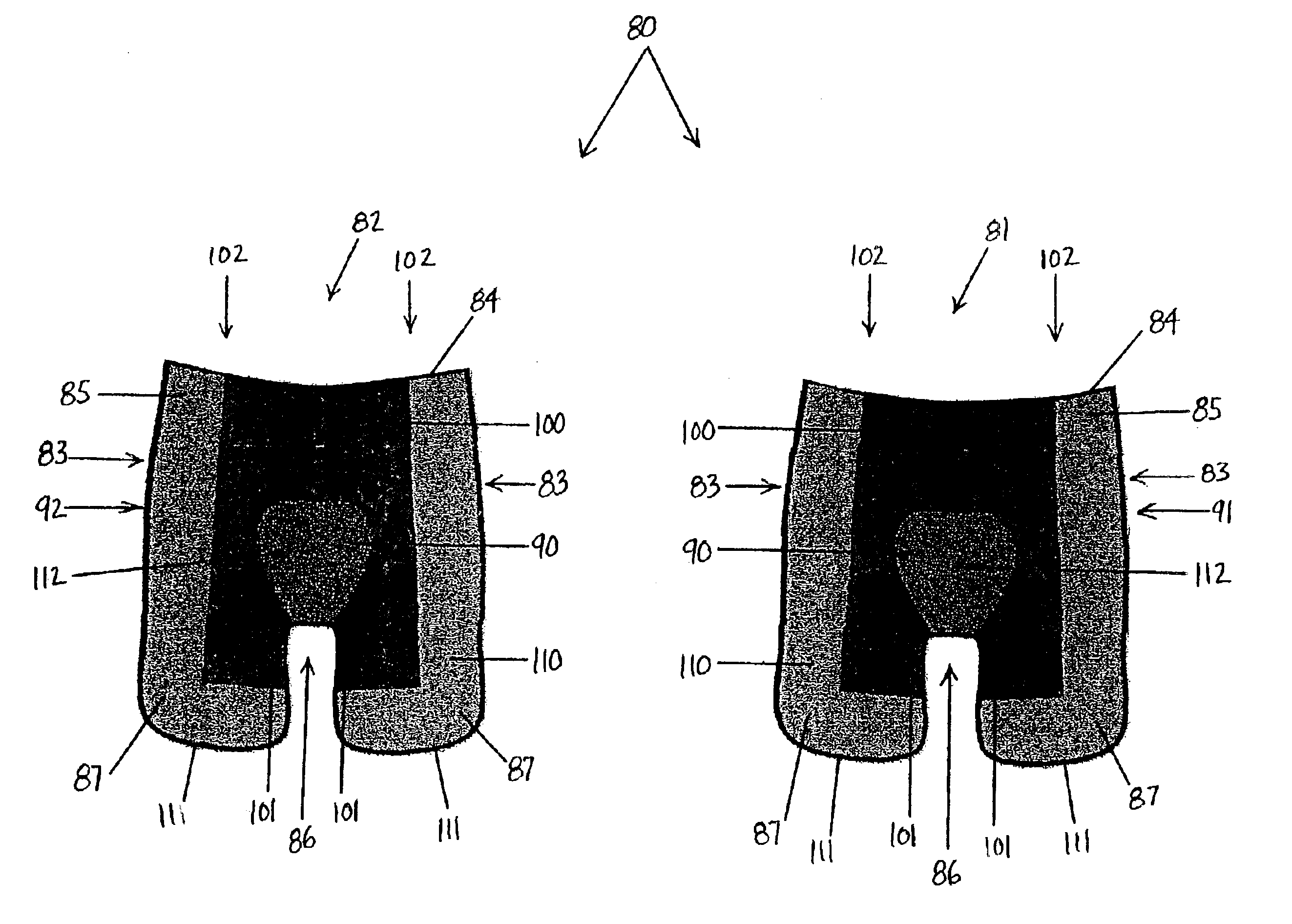

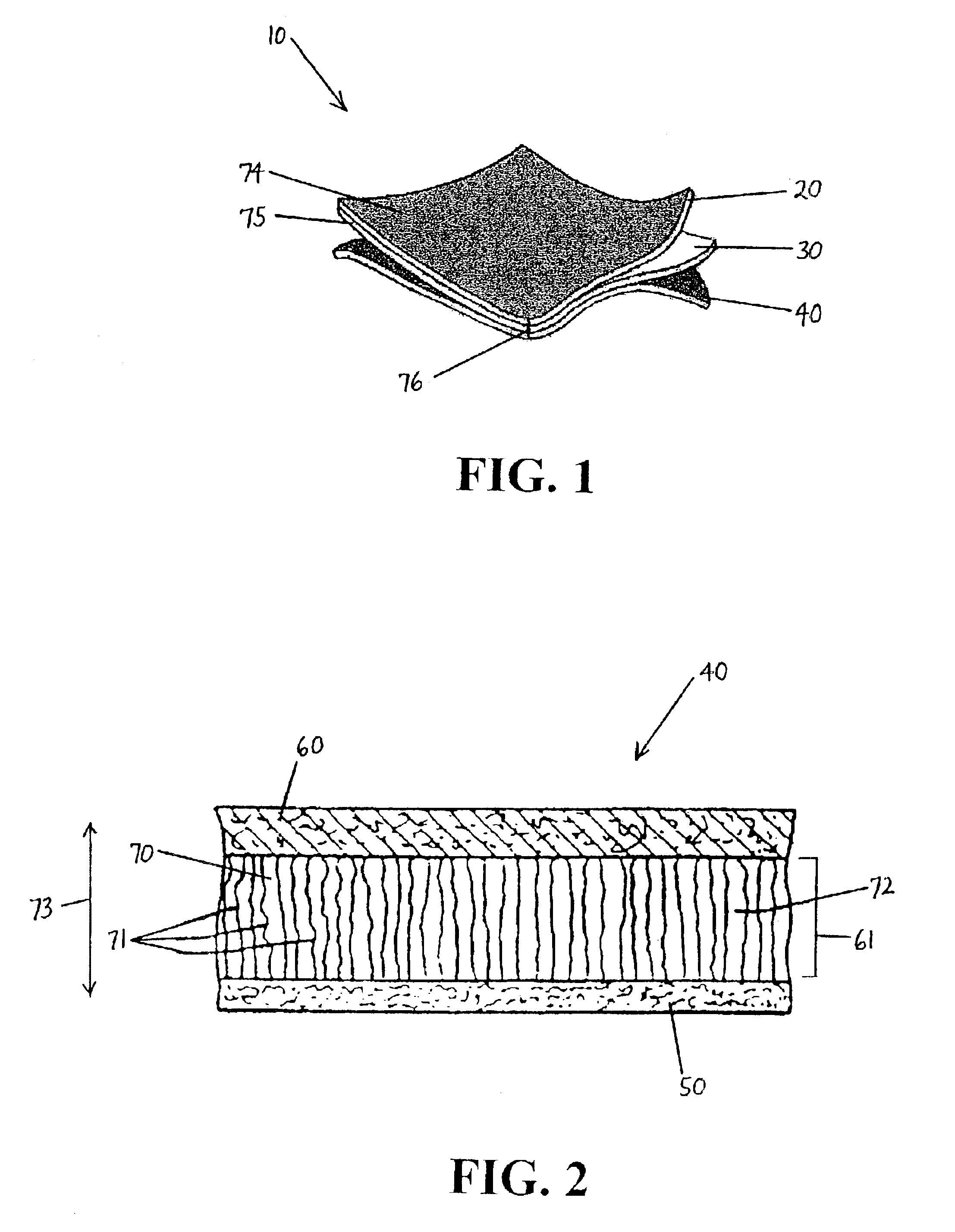

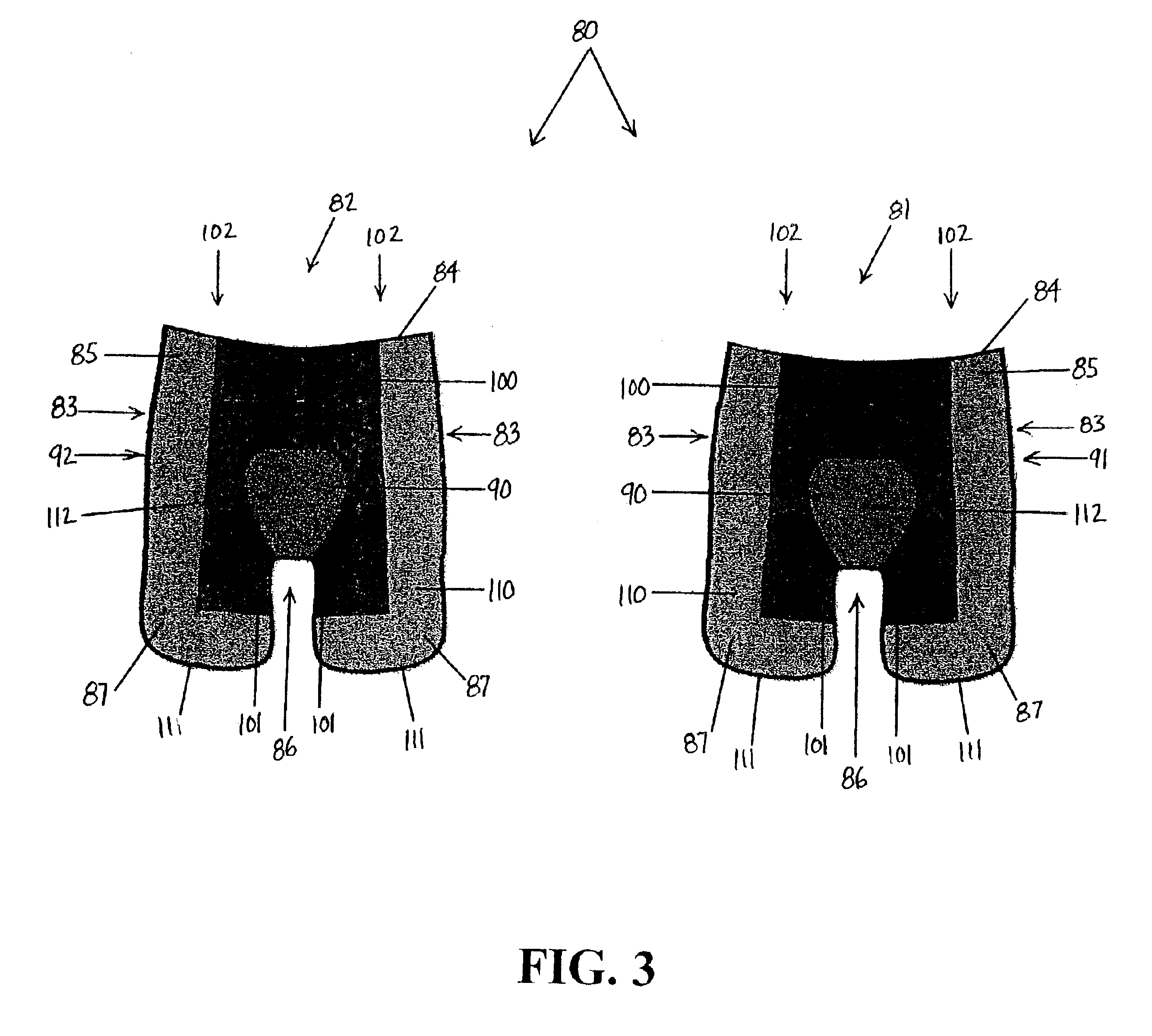

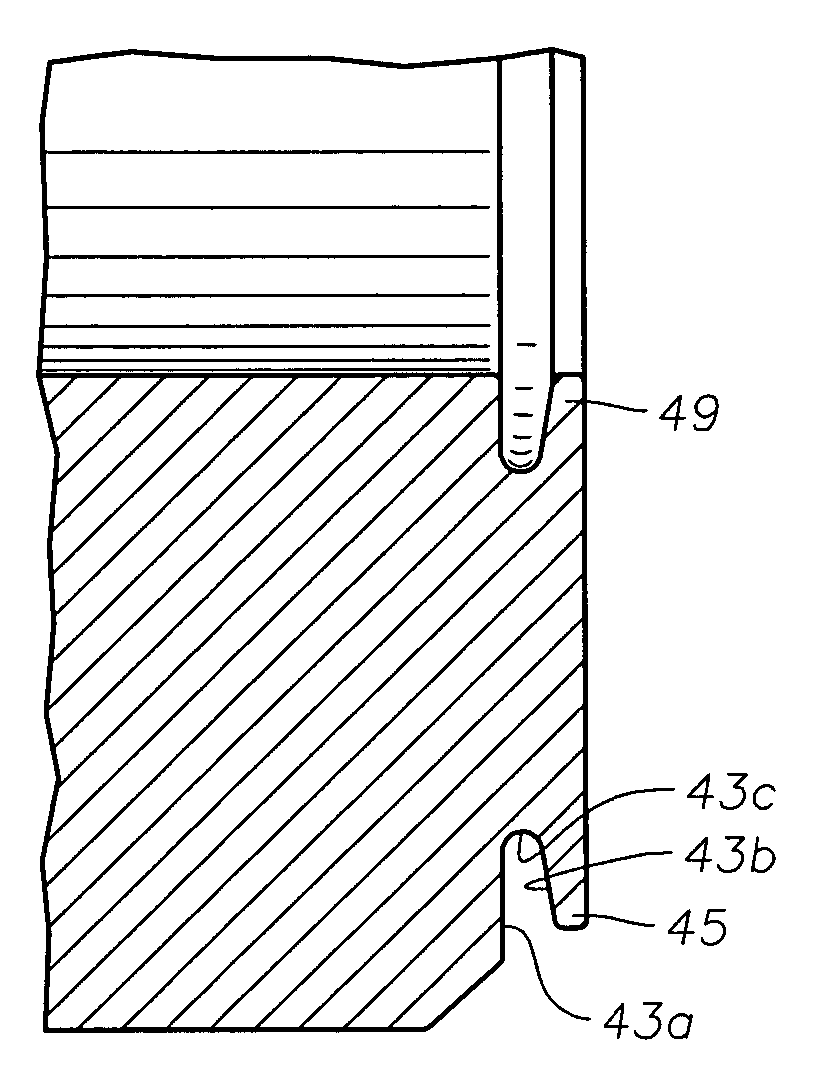

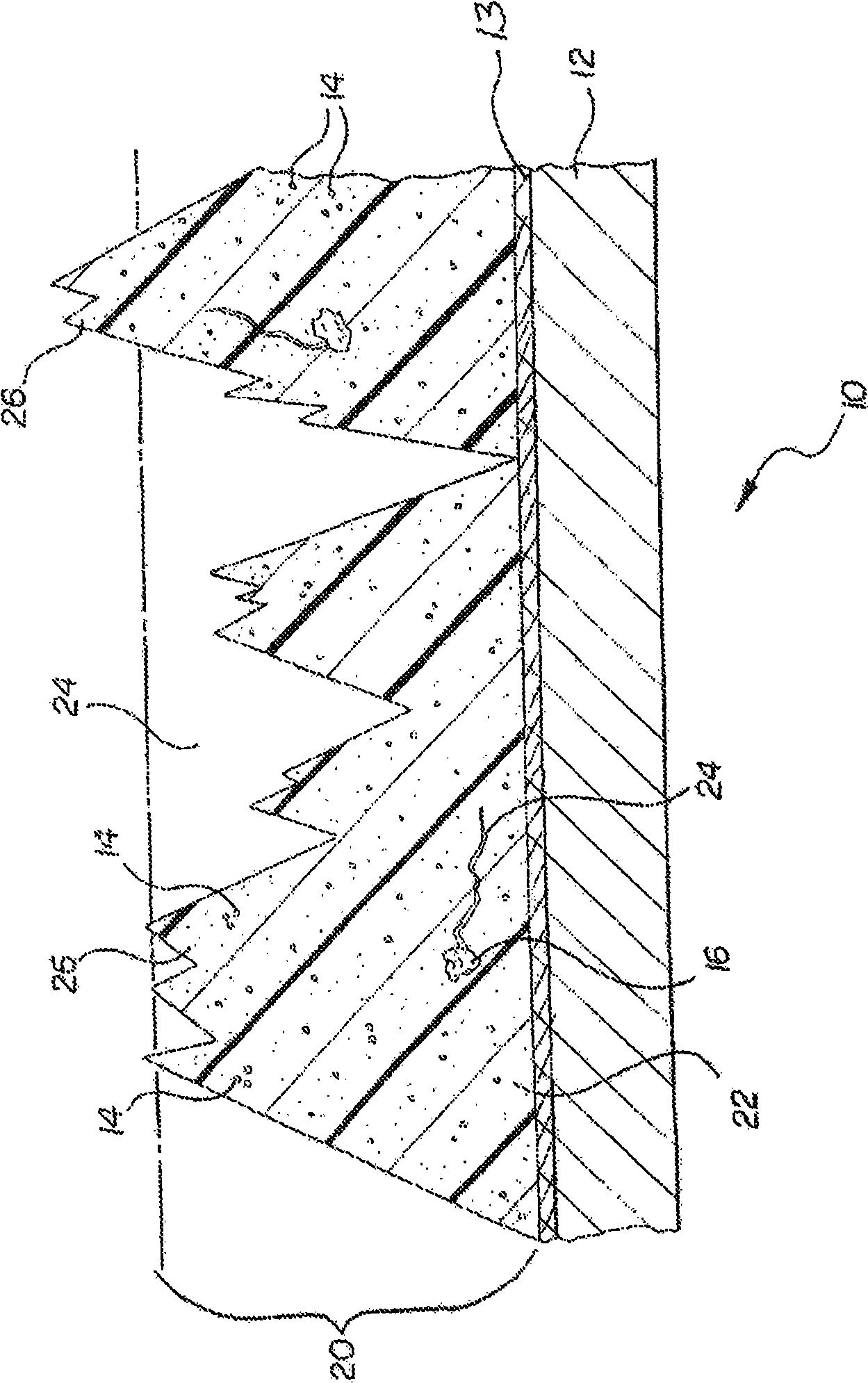

Protective fabric and apparel systems

InactiveUS6918140B1Remove moistureReduce contact stressOrnamental textile articlesTrousersCushioningYarn

A multi-layer protective fabric includes an inner layer, an middle layer, and an outer wicking layer. The outer fabric layer includes an inside layer of hydrophobic material, an outside layer of hydrophilic material, and an intermediate layer of hydrophobic monofilament yarns extending between and knitted together with the outside and inside layers, and promotes wicking of moisture from a wearer's skin to the outer layer. The multi-layer protective fabric middle layer includes a porous, cushioning material. The multi-layer protective fabric inner layer includes a cushioning, abrasion-resistant material, such as doeskin. Articles of apparel, for example cycling shorts, can include such a multi-layer protective fabric either alone or in combination with other moisture-managing, cushioning fabrics. Such protective fabric and apparel systems provide improved removal of moisture from skin, reduction of contact stress, and decrease in abrasion.

Owner:DEFEET INT

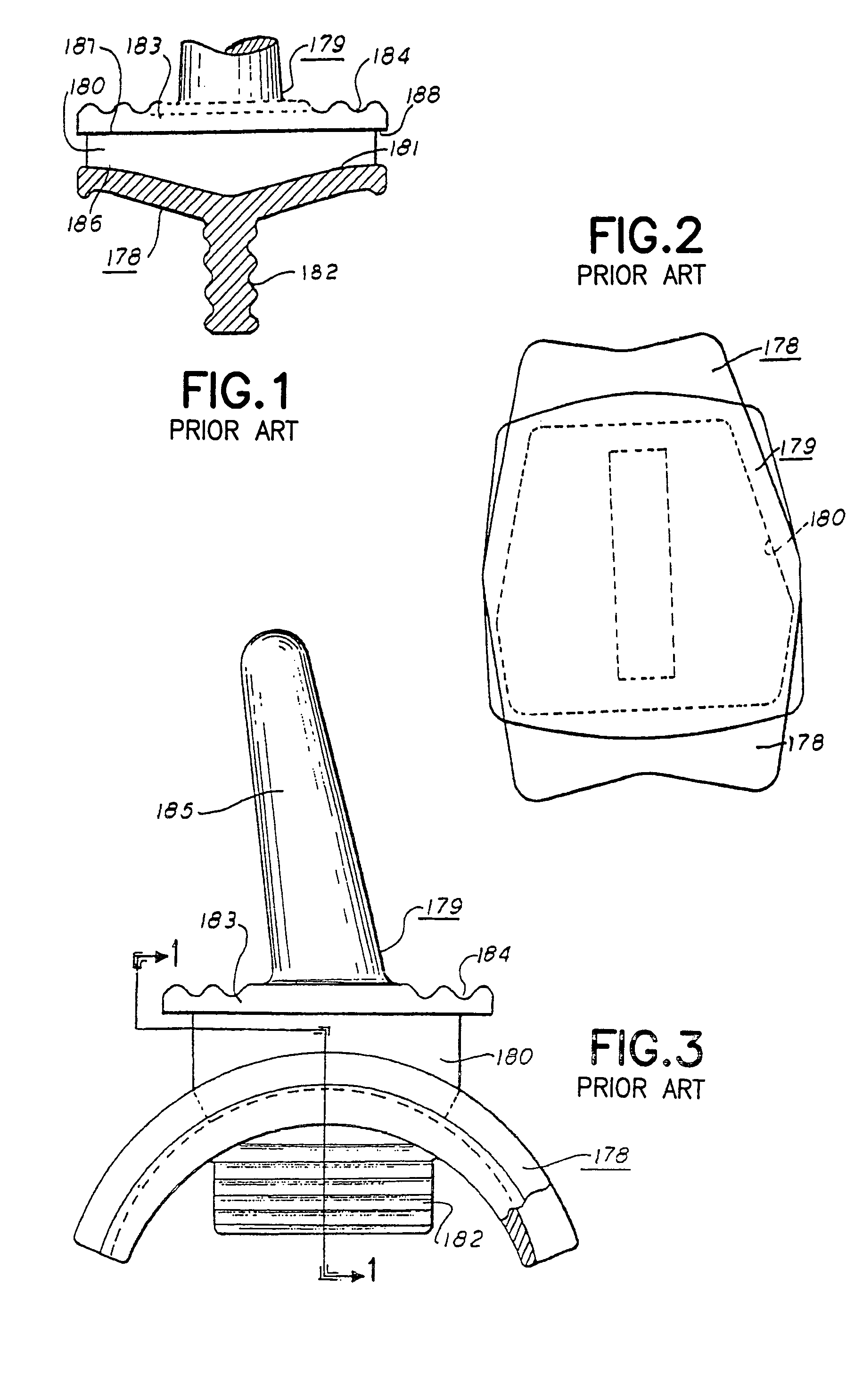

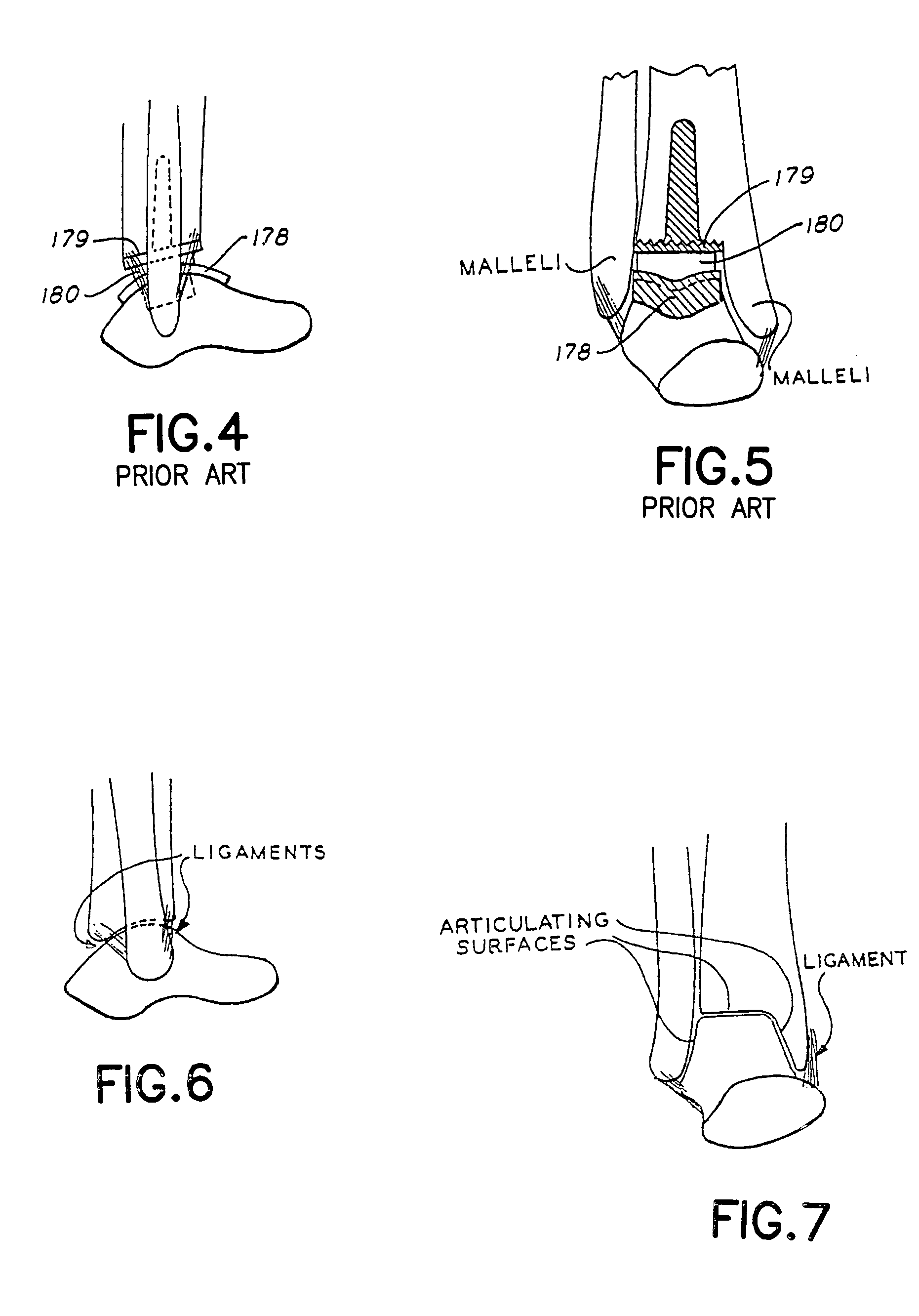

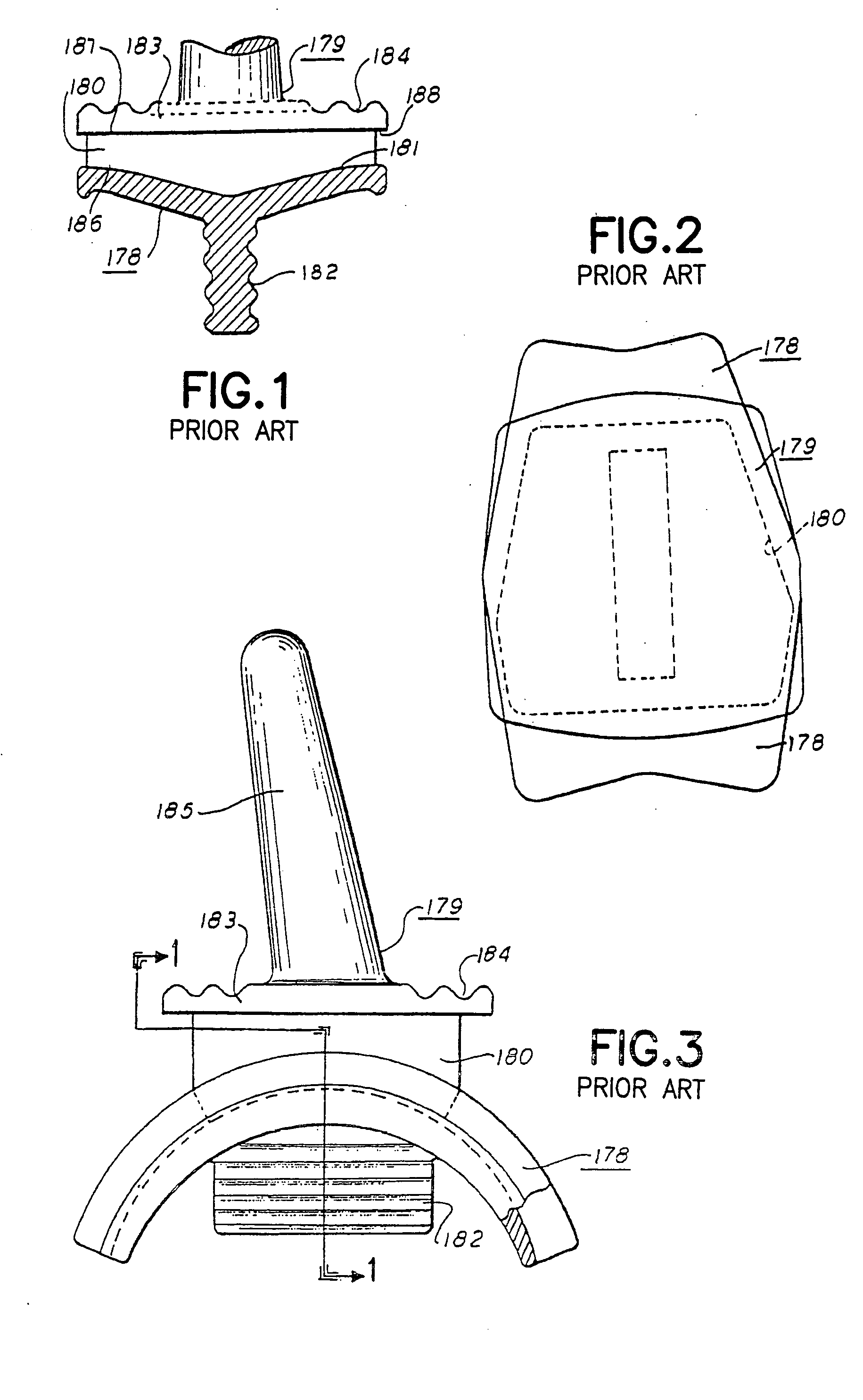

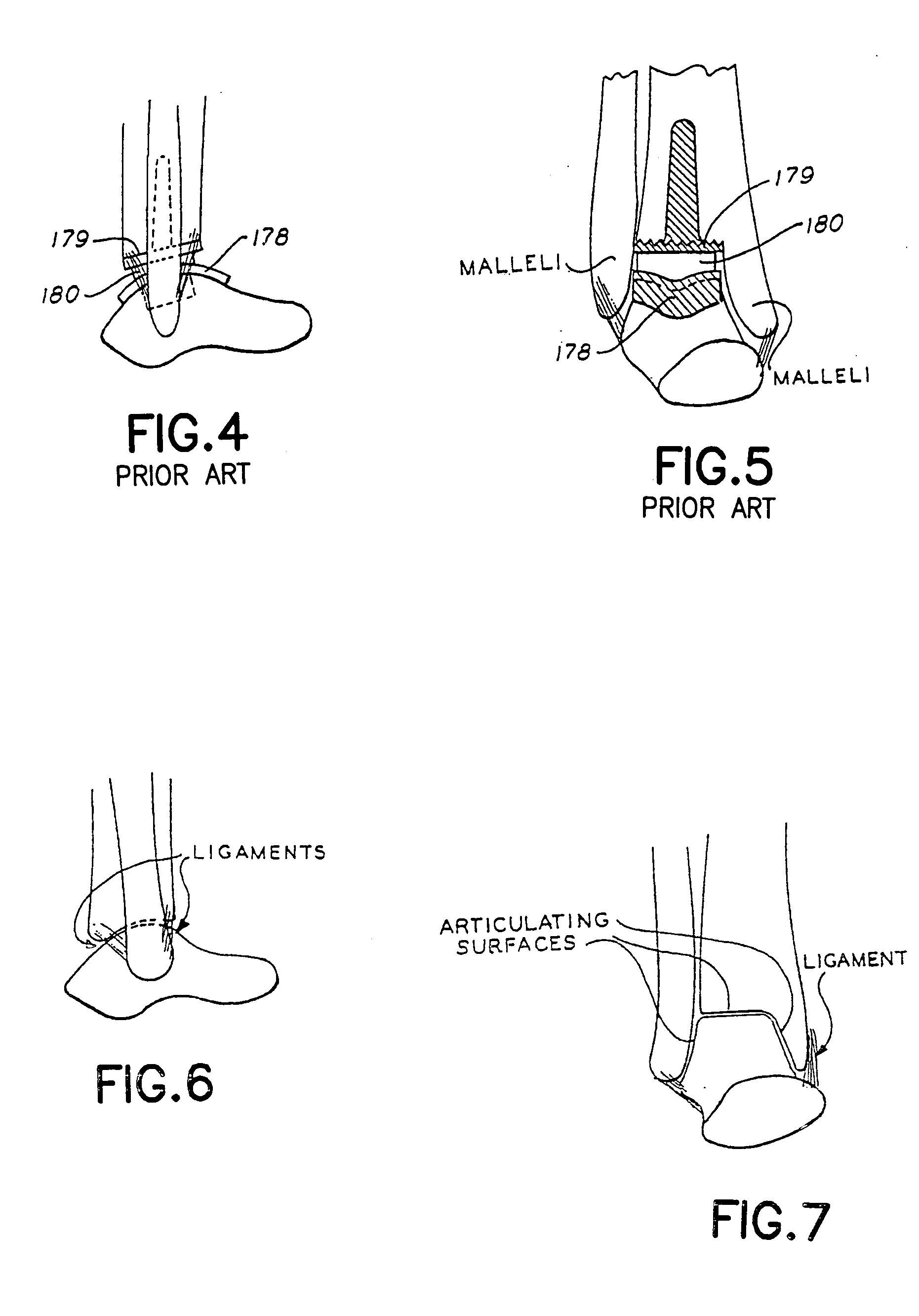

Ankle prosthesis including tibial component having peripheral wall for preventing the formation of bone cysts

InactiveUS7485147B2Reduce possible abrasionEffectively shielding the bearingAnkle jointsJoint implantsTibiaWear particle

The tibial component of a prosthetic ankle joint including a tibial component, a talar component, and an intermediate sliding plastic bearing, with the tibial component including a depending peripheral wall that surrounds and is spaced from the plastic bearing and is intended to reduce rubbing of the plastic bearing against tissue which would produce wear particles that lead to the formation of bone cysts. The depending peripheral wall of the tibial component is intended to reduce such possible abrasions by at least partially shielding the plastic bearing from the surrounding tissue.

Owner:BUECHEL PAPPAS TRUST

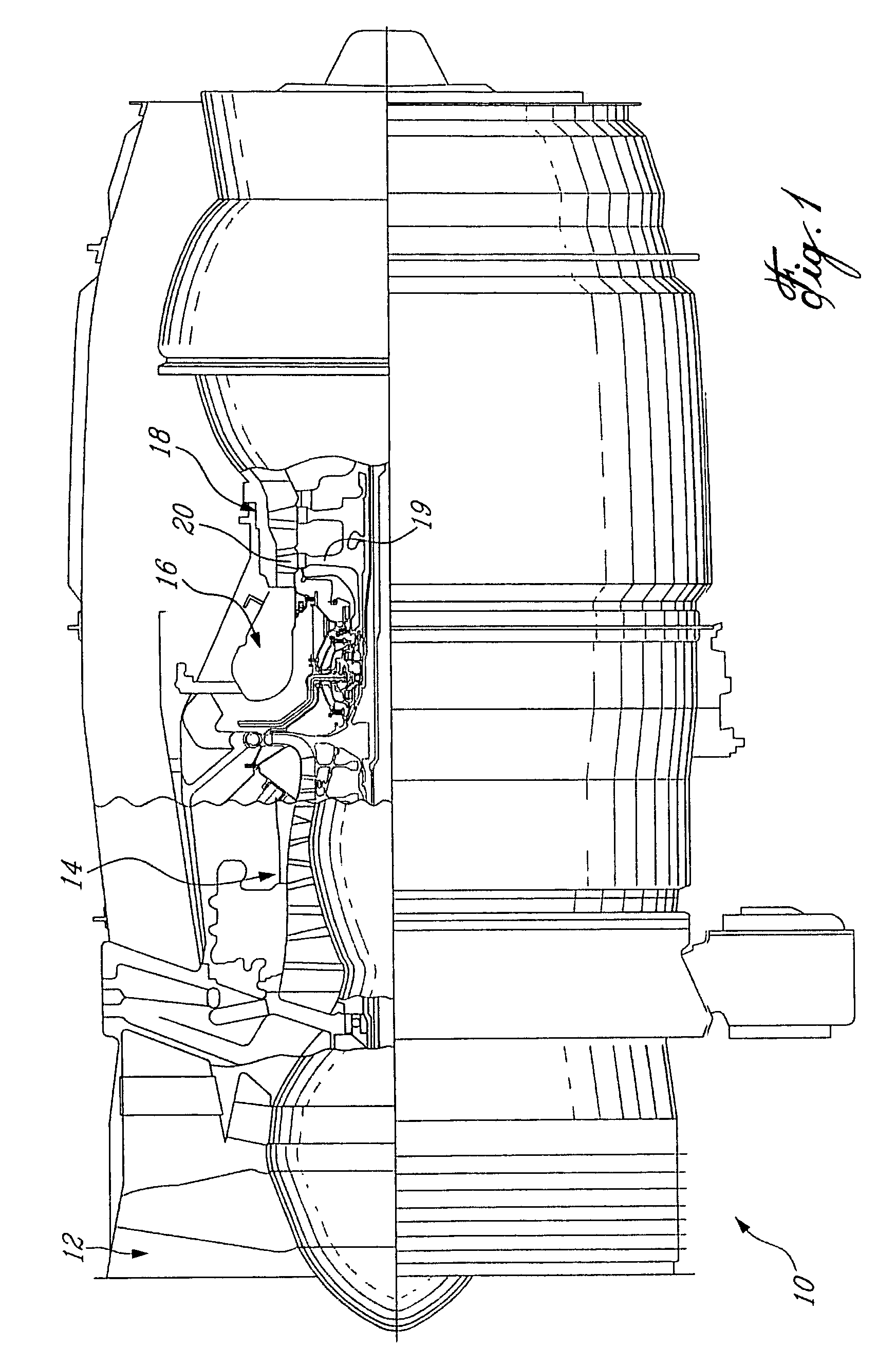

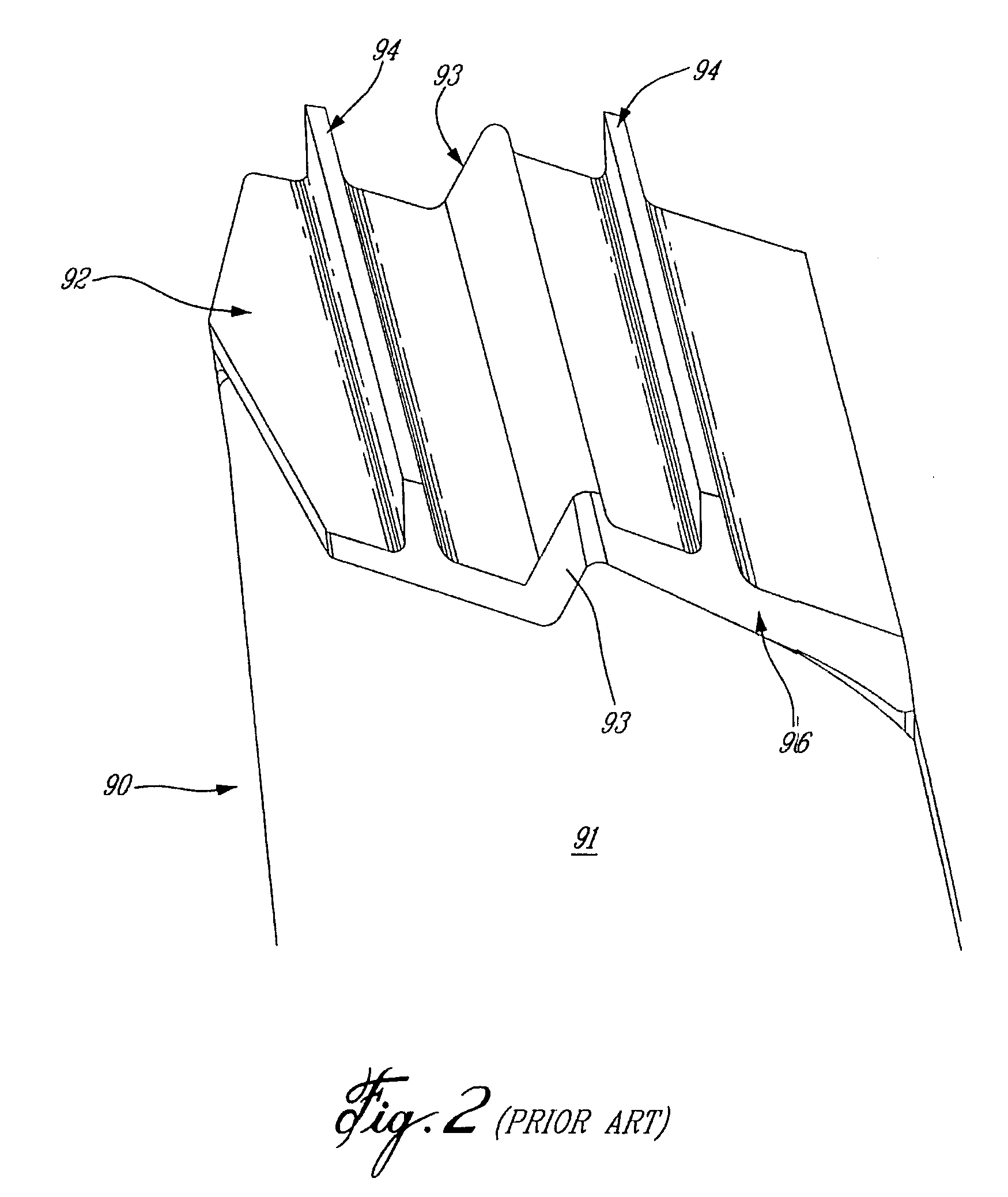

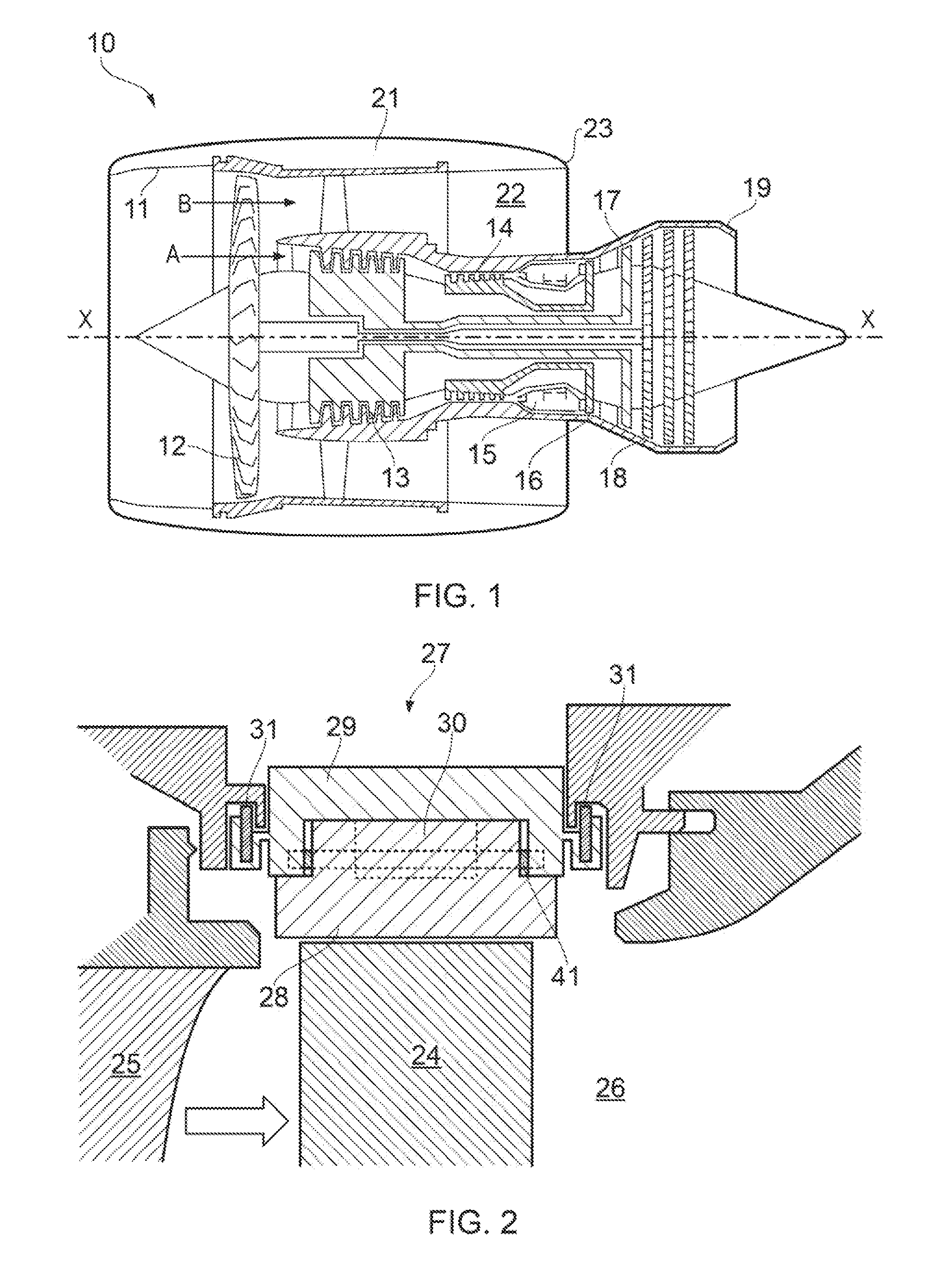

Shrouded turbine blades with locally increased contact faces

InactiveUS7001152B2Improved contact wear performanceLess sensitivePropellersPump componentsTurbine bladeGas turbines

A one-piece blade for a turbine section of a gas turbine engine, the blade comprising a root, an airfoil and a shroud. The shroud extends generally perpendicularly from a tip of the airfoil and is defined by a pair of opposed bearing faces and a pair of opposed non-bearing faces. The bearing faces each have a contact portion adapted to contact a shroud of an adjacent blade. The shroud has a substantially constant nominal thickness and the bearing faces have a substantially constant face thickness across the contact portion, the face thickness being greater than the nominal thickness. The transition between the face thickness and the nominal thickness is substantially discontinuous.

Owner:PRATT & WHITNEY CANADA CORP

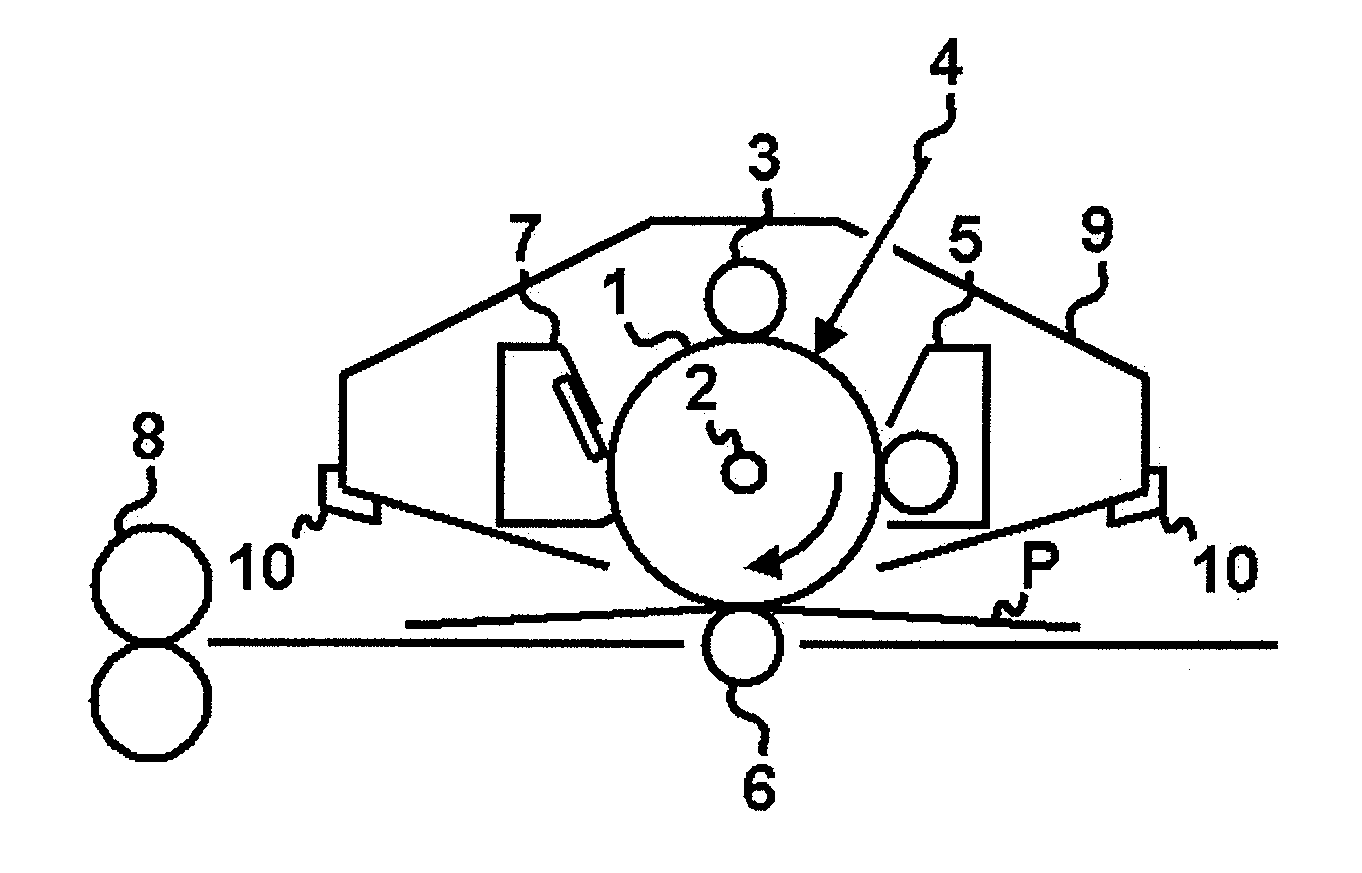

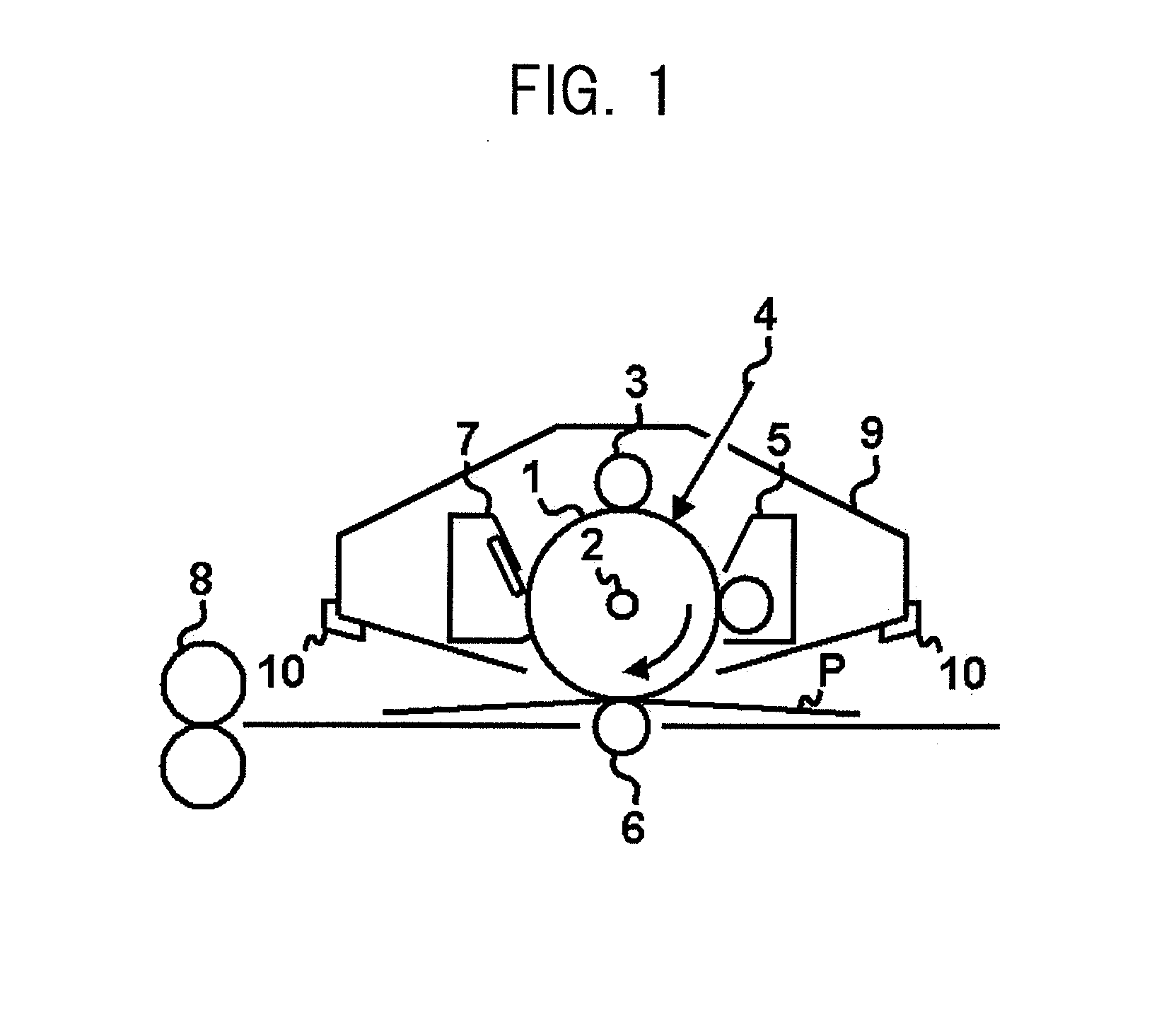

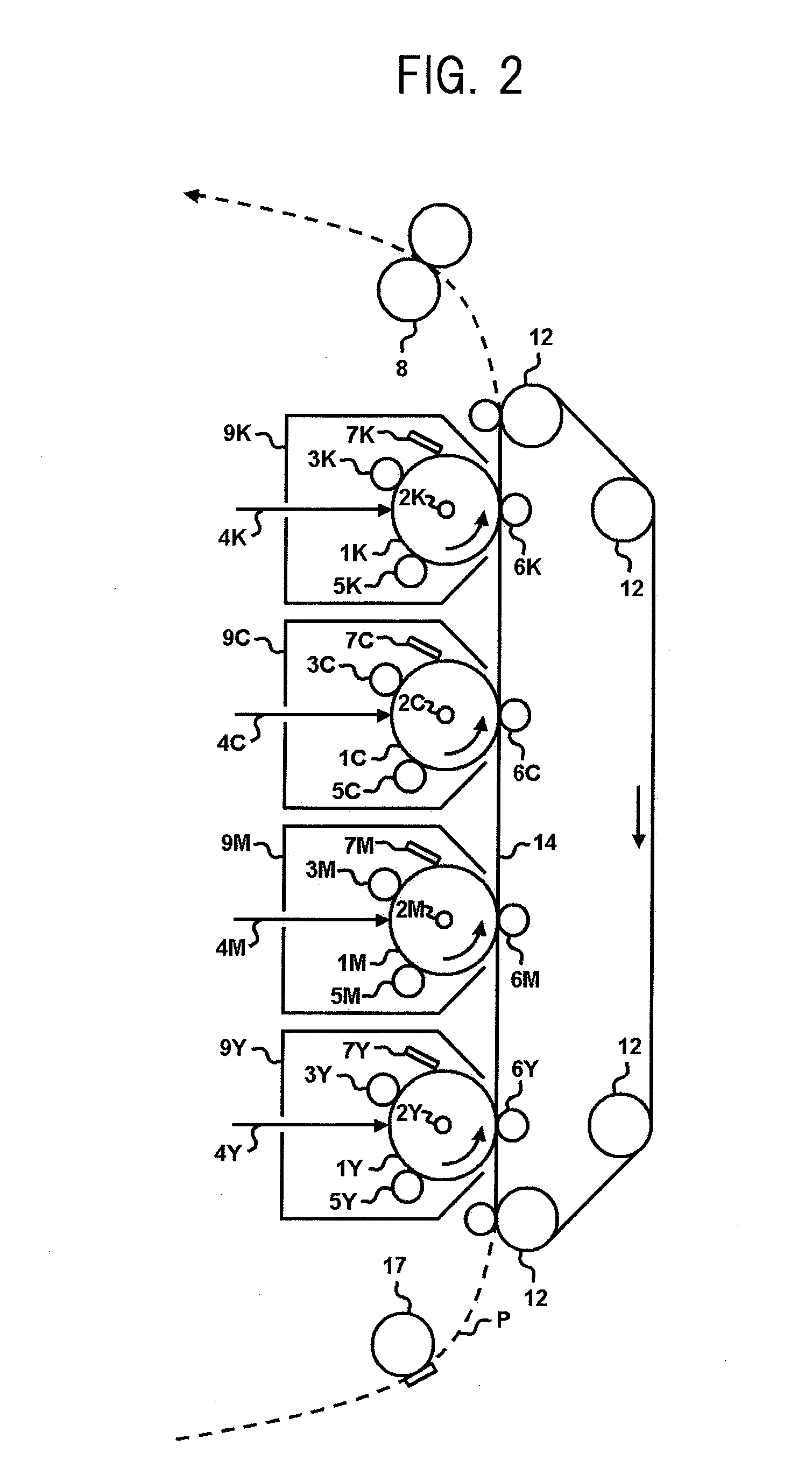

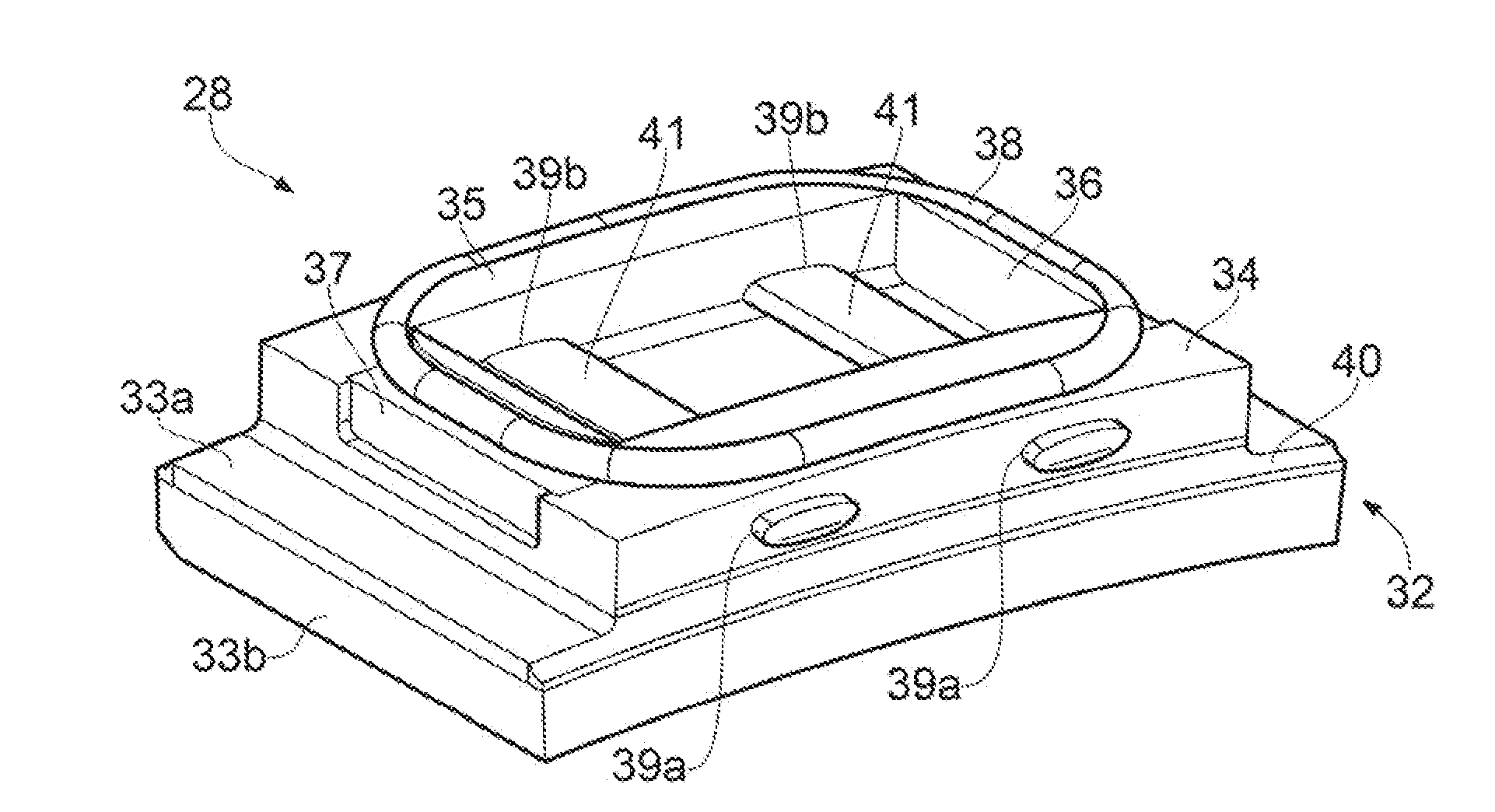

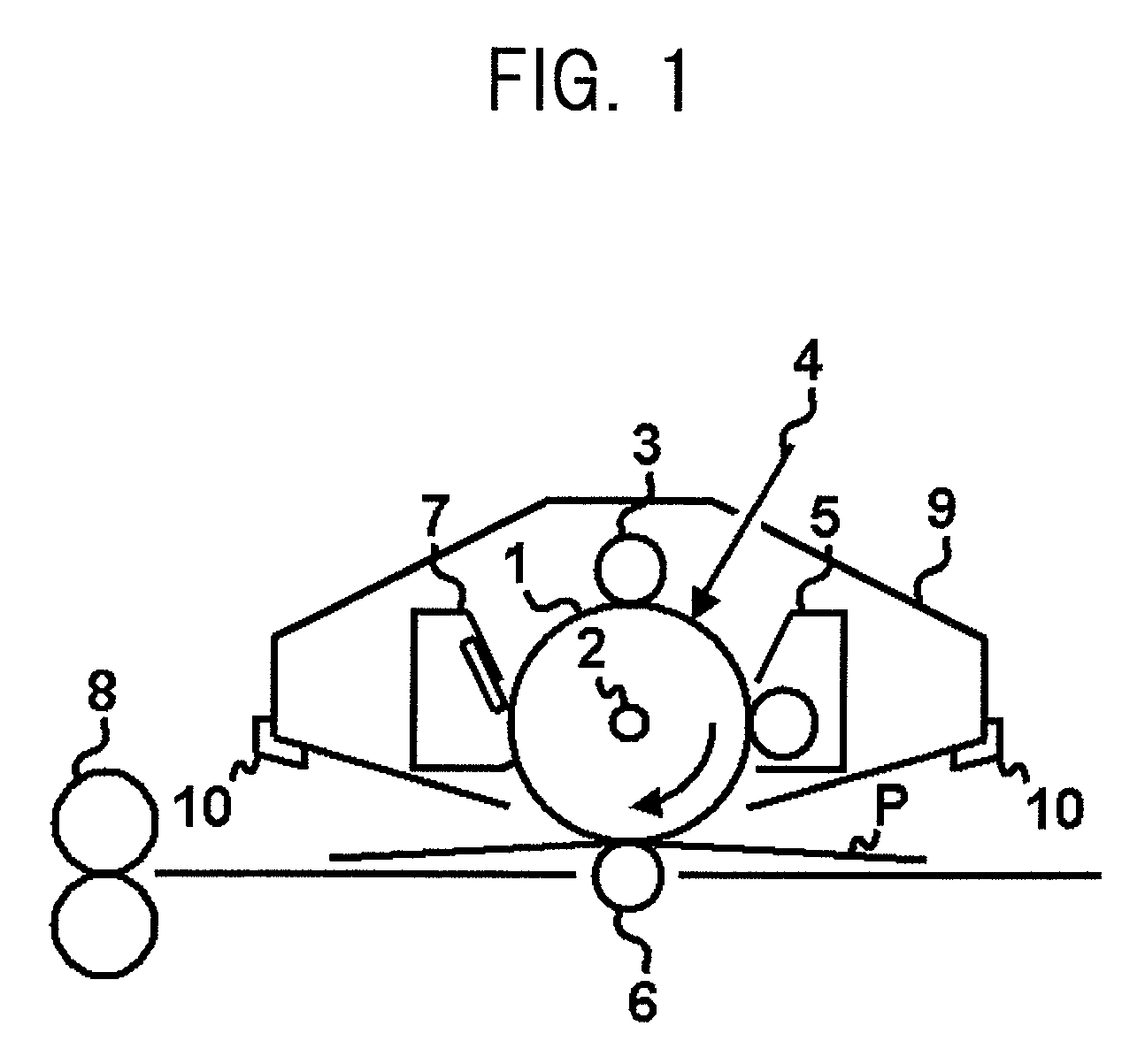

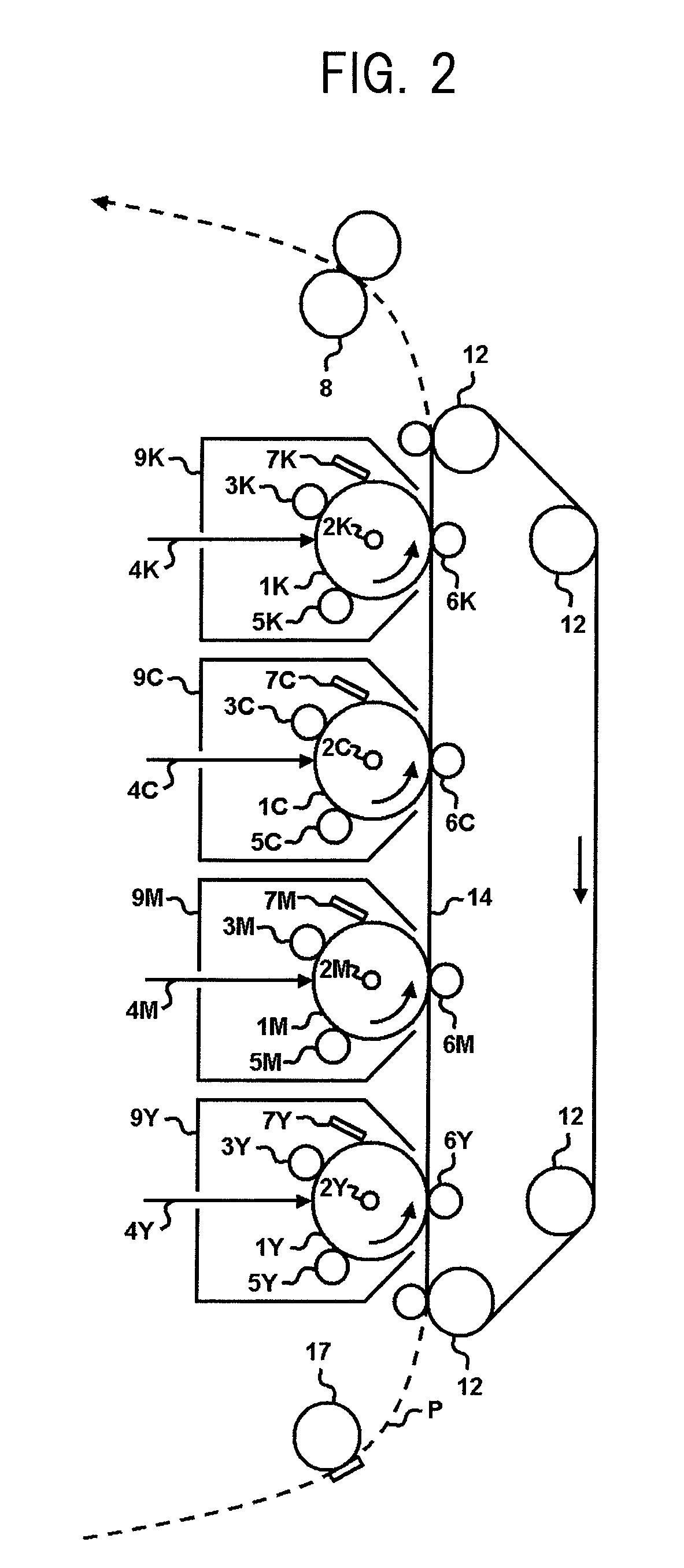

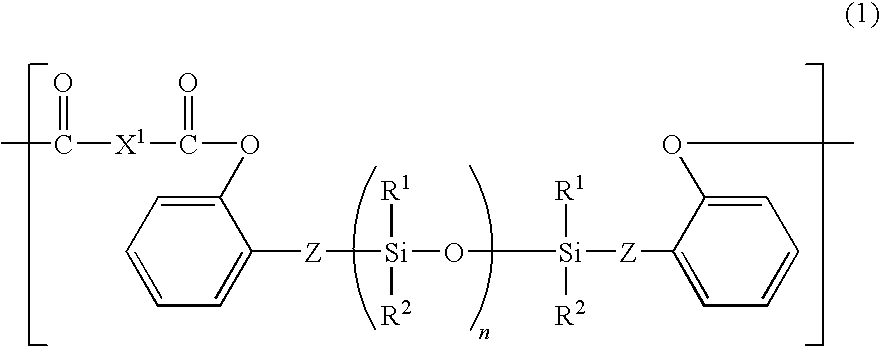

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

ActiveUS20100092208A1Excellent potential stabilityMitigate contact stressElectrographic process apparatusCorona dischargePolycarbonateChemistry

A charge transport layer serving as a surface layer of an electrophotographic photosensitive member contains a charge transporting material, polyester resin A containing a siloxane moiety and at least one of polyester resin C and polycarbonate resin D. The content of a siloxane moiety in polyester resin A is not less than 10% by mass and not more than 40% by mass relative to the total mass of polyester resin A. The charge transport layer has a matrix-domain structure having a matrix formed of the charge transporting material and at least one of polyester resin C and polycarbonate resin D and a domain formed of polyester resin A in the matrix.

Owner:CANON KK

Wall section for the working gas annulus of a gas turbine engine

InactiveUS20140294572A1Easy to attachIncrease contact areaEngine manufacturePump componentsEngineeringGas turbines

A seal segment is provided for a shroud ring of a rotor of a gas turbine engine. The seal segment is positioned, in use, radially adjacent the rotor. The seal segment has two or more spaced passageways. In use, a respective support bar can be contained within each passageway. The support bars allow attachment of the seal segment to the engine casing. Each passageway has an elliptical or substantially elliptical cross-section with a minor diameter and a major diameter, the minor diameter being substantially aligned with the radial direction. The respective support bar has a correspondingly elliptical or substantially elliptical cross-section for a close fit in the passageway.

Owner:ROLLS ROYCE PLC

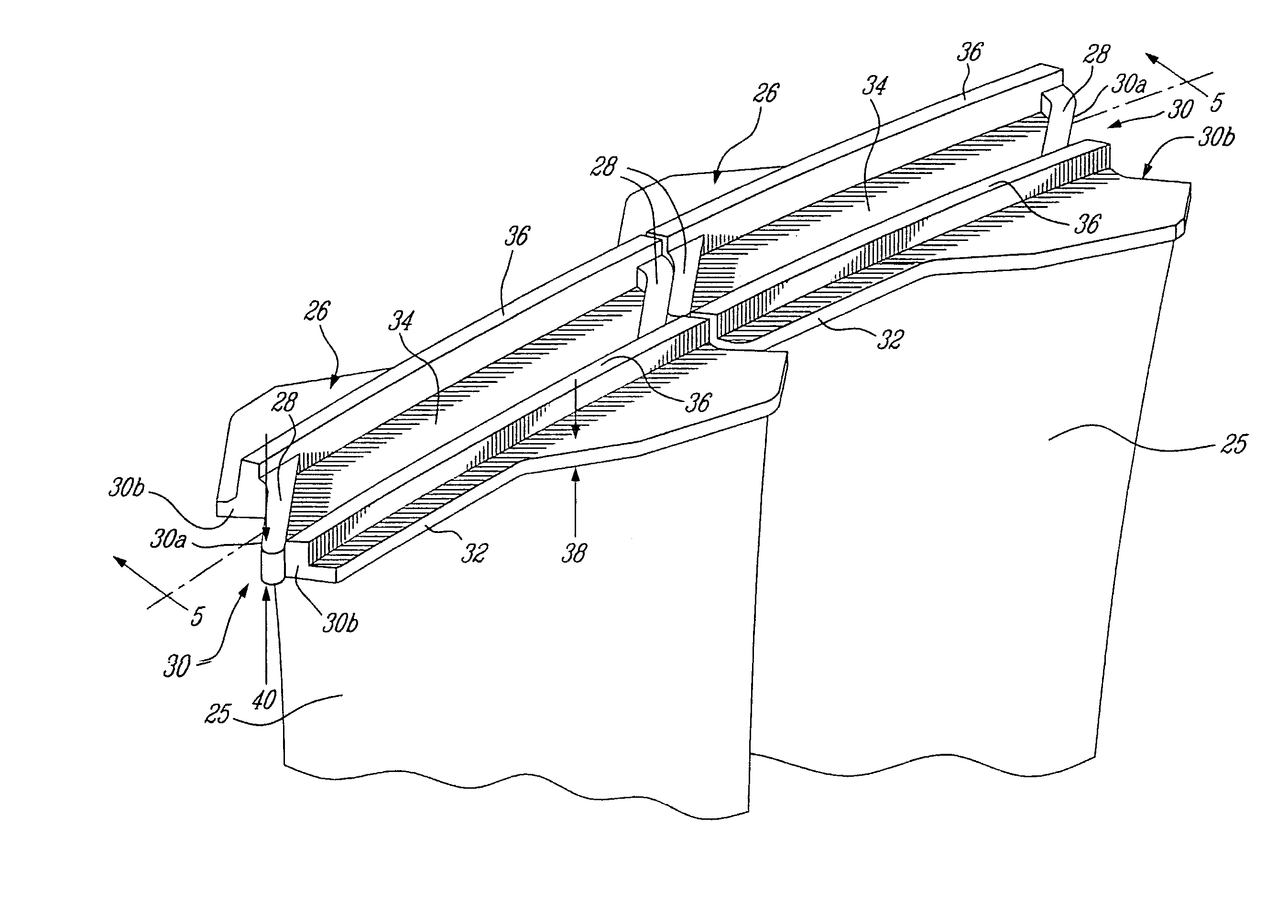

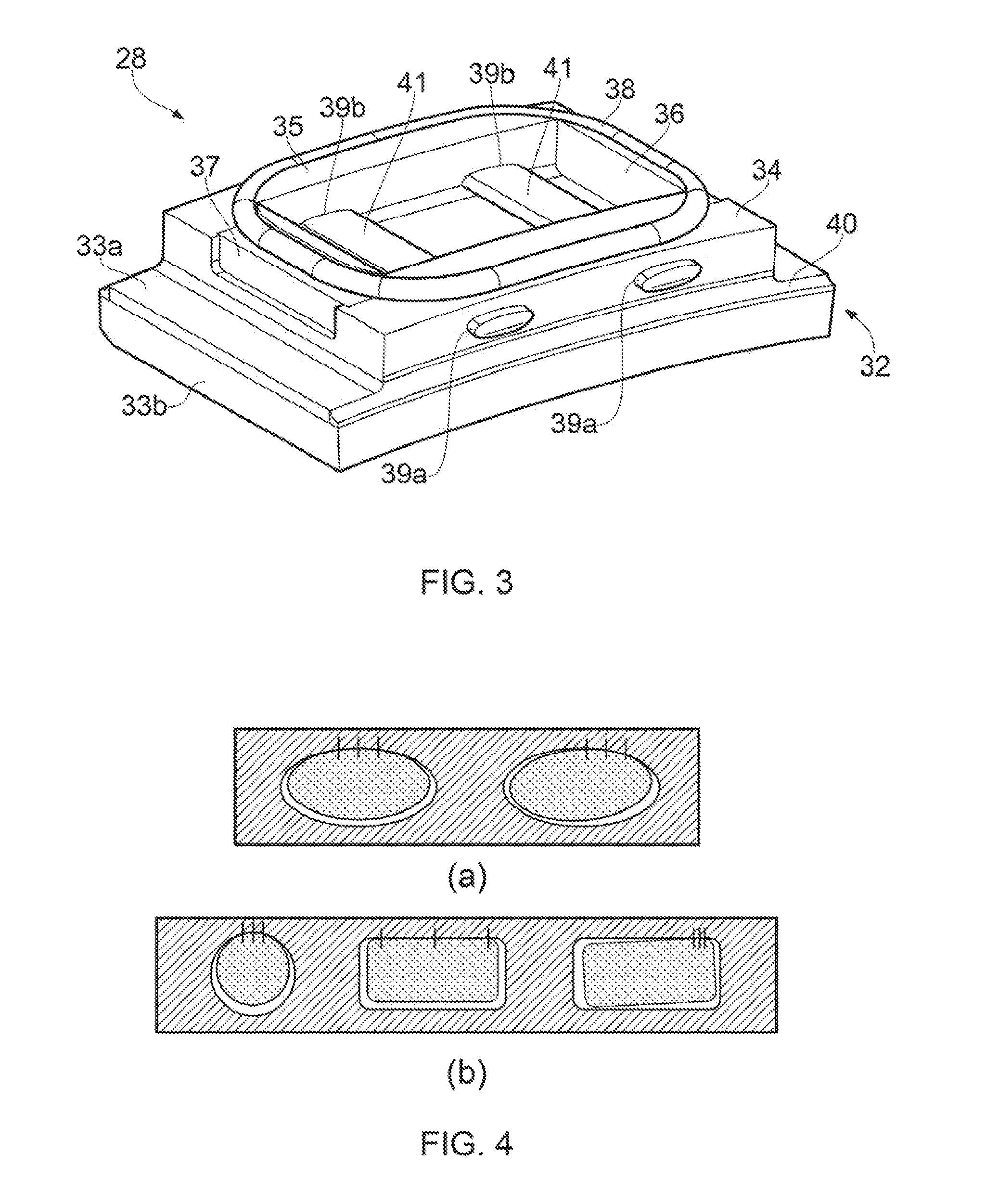

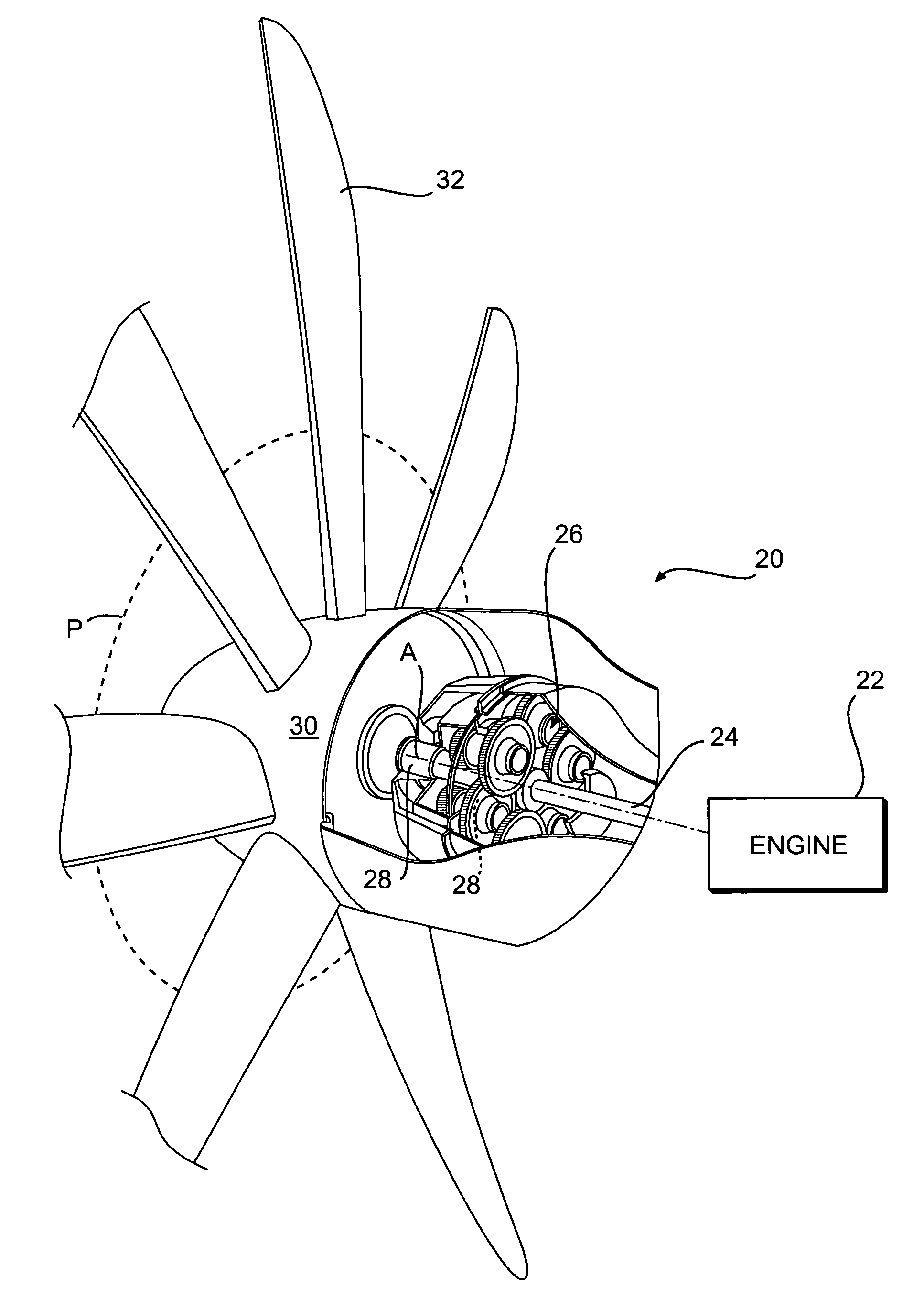

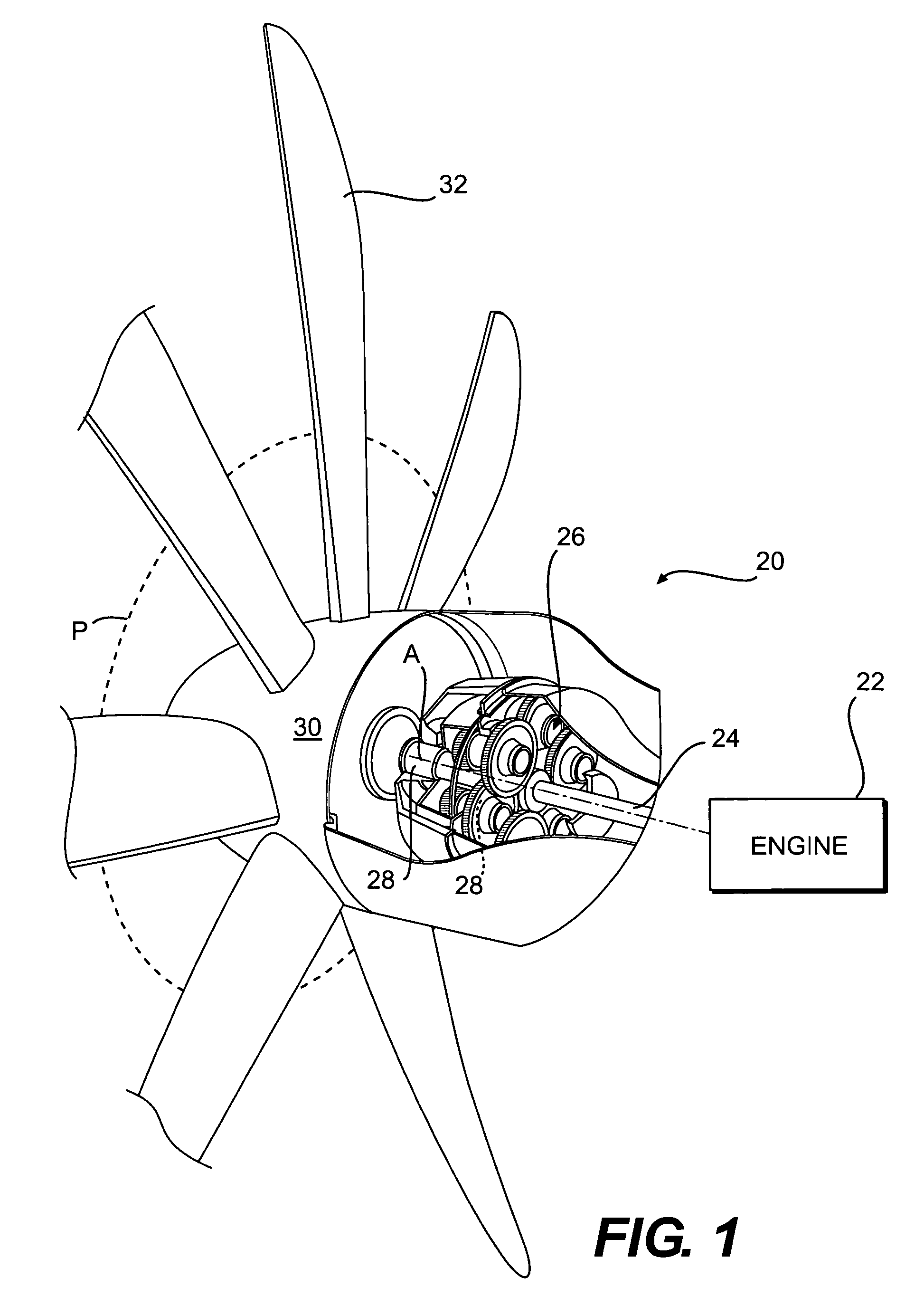

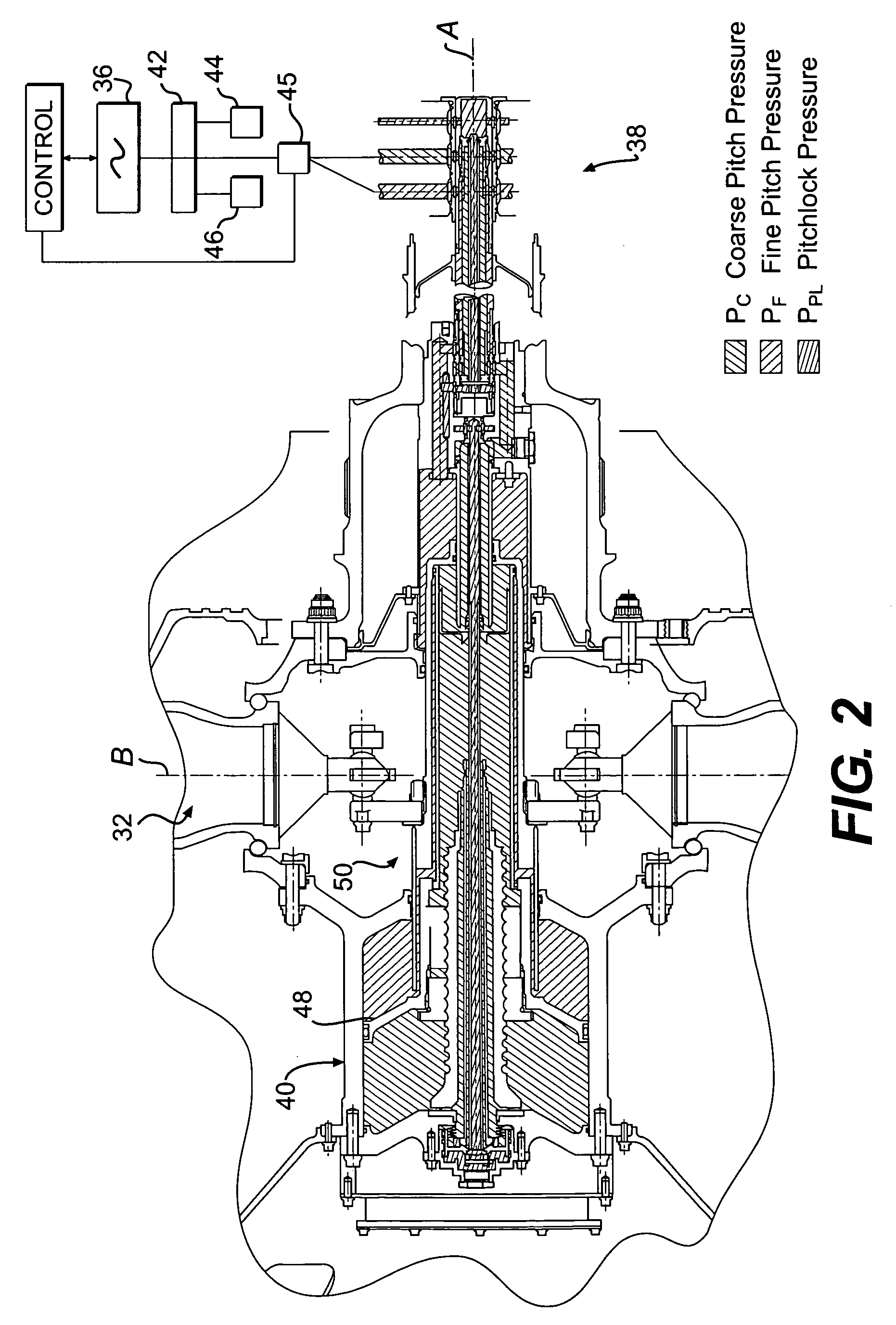

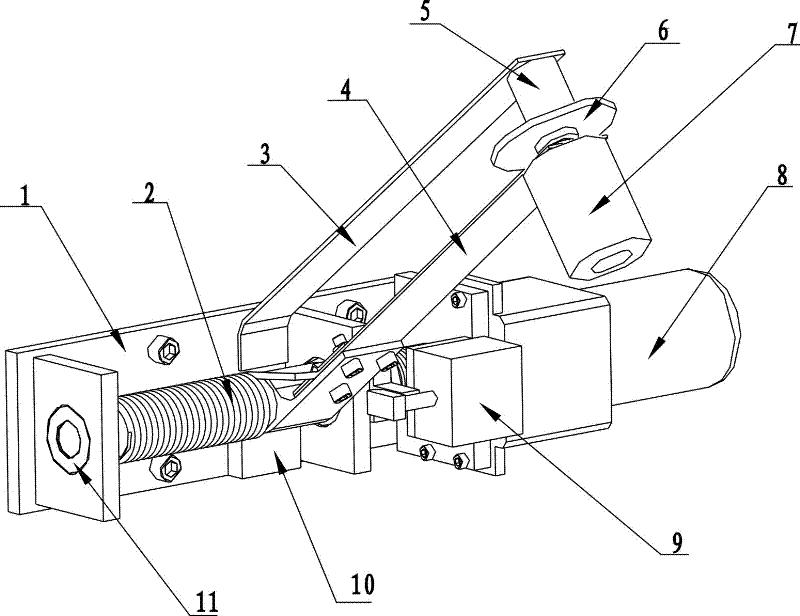

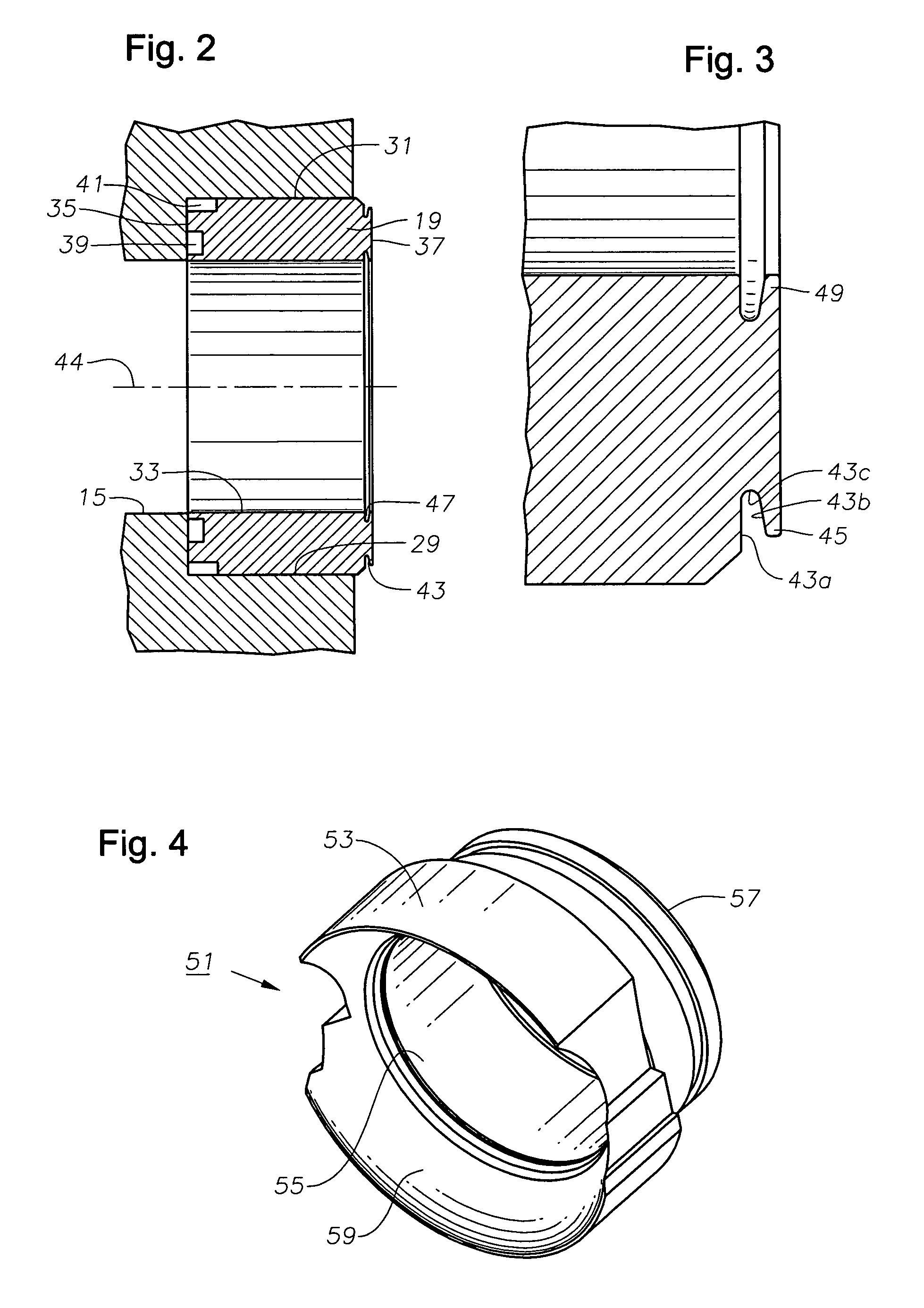

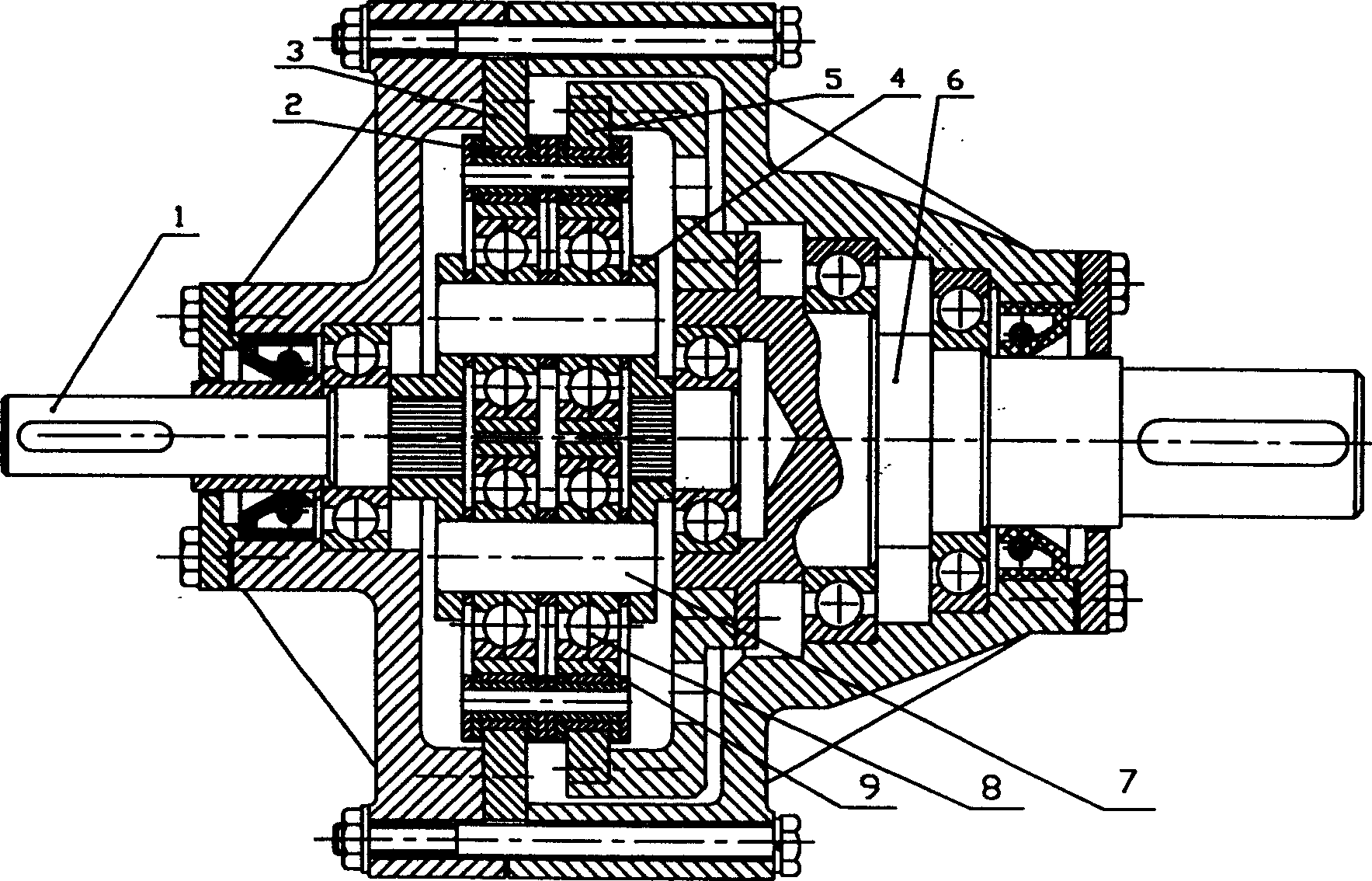

Propeller pitch change system

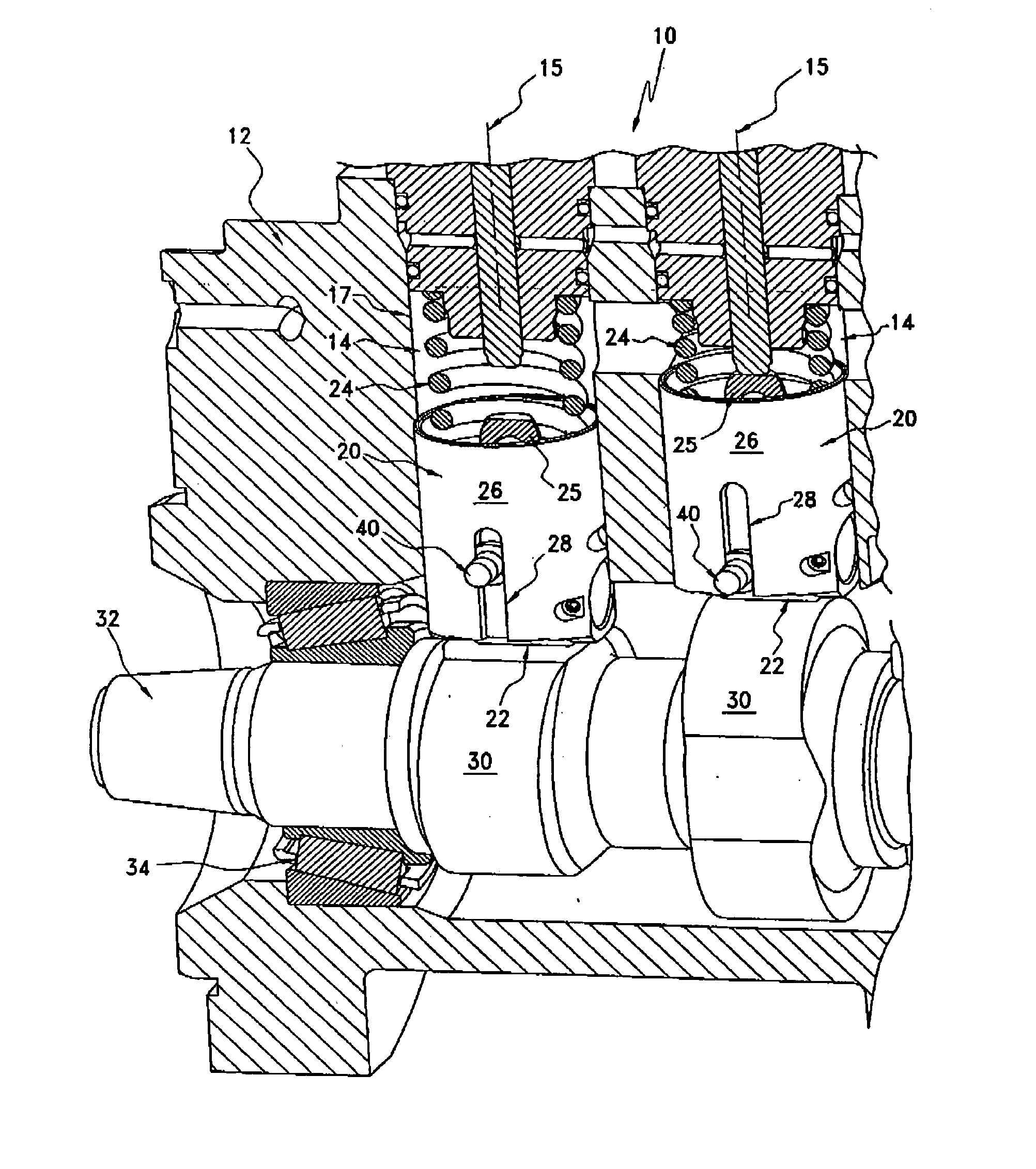

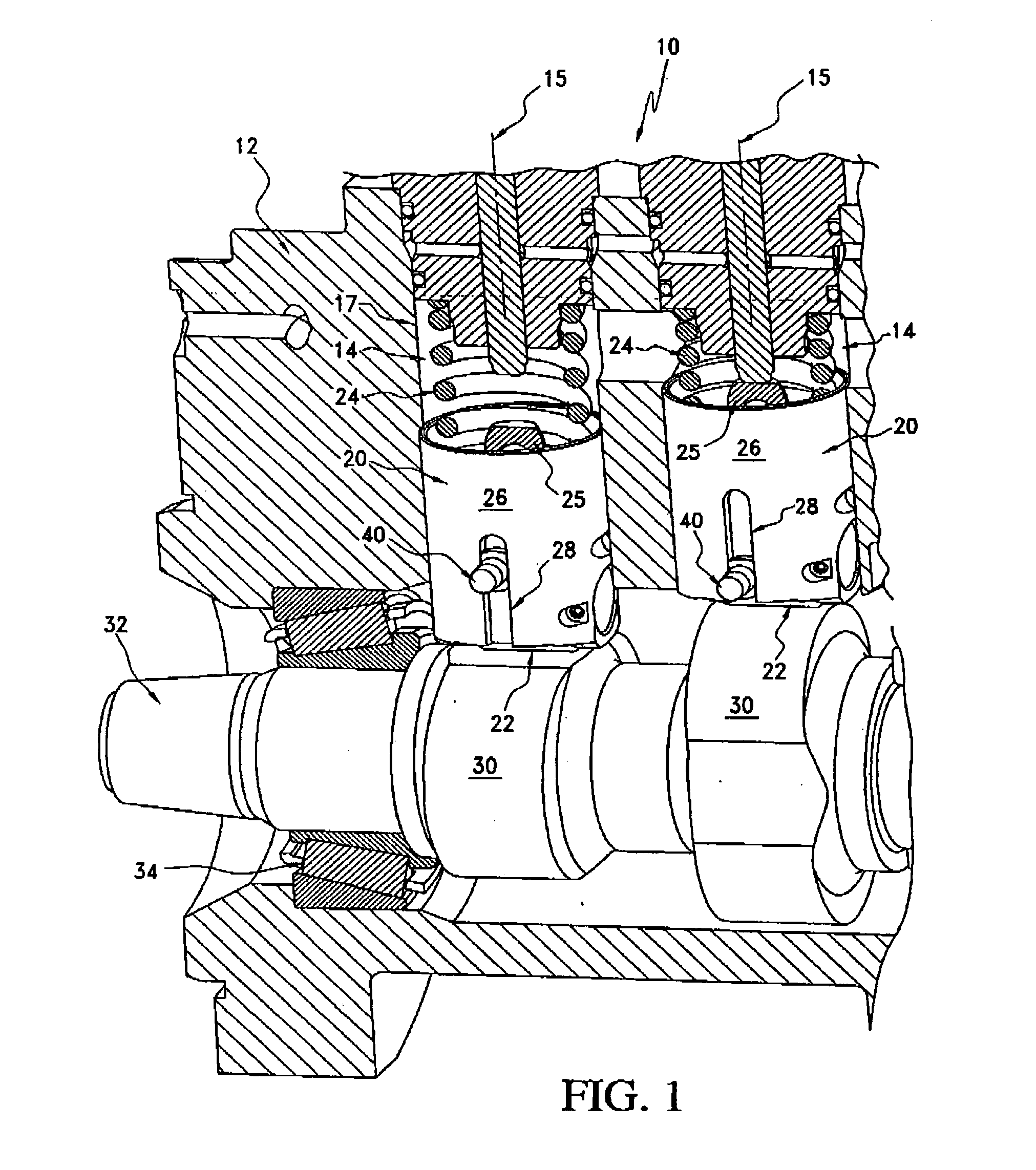

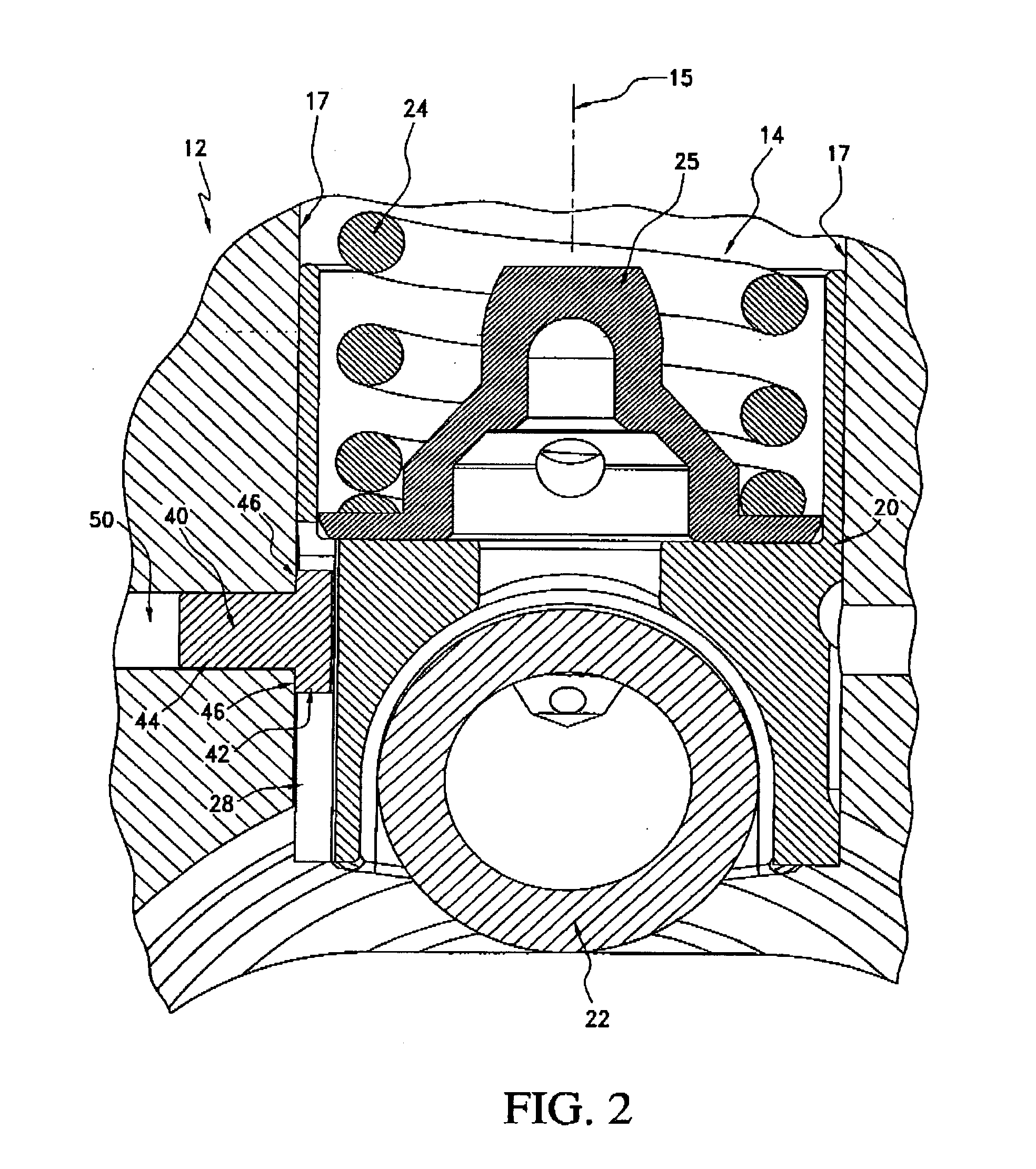

ActiveUS7296969B2Reduce contact stressAccommodates significant horsepowerPropellersPump componentsPropellerHigh load

A pitch change system includes a yoke assembly which receives a pitch trunnion that extends from each propeller blade assembly. Each pitch trunnion is received within a respective bearing assembly mounted in the yoke assembly. The bearing assemblies are mounted between a forward yoke plate and an aft yoke plate. A spacer is mounted between each adjacent bearing assembly to position and restrain each bearing assembly. Each spacer includes an extension which retains the adjacent bearing assembly on a pitch trunnion pin in a direction generally parallel to axis. Each of the bearing assemblies includes a generally rectilinear outer race and a spherical inner race inside diameter to receive the pitch trunnion pin. The rectilinear outer race reduces contact stresses to acceptable levels for high load applications yet permits blade installation without actuator disassembly.

Owner:HAMILTON SUNDSTRAND CORP

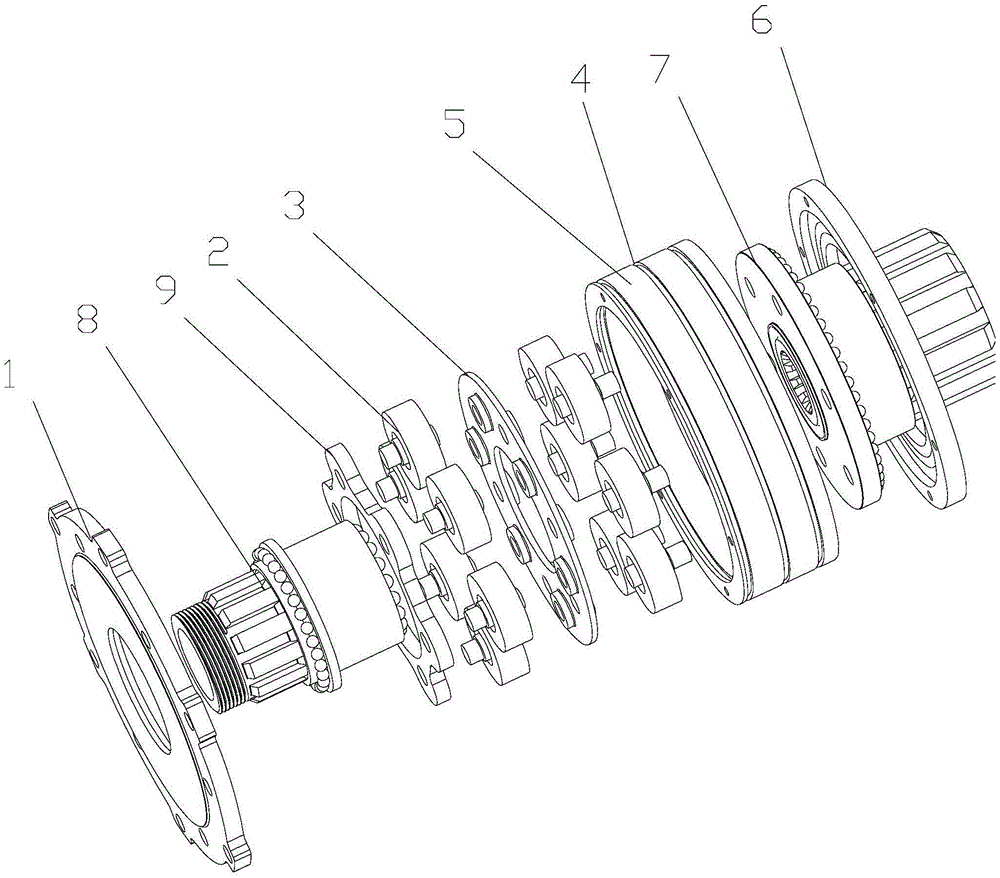

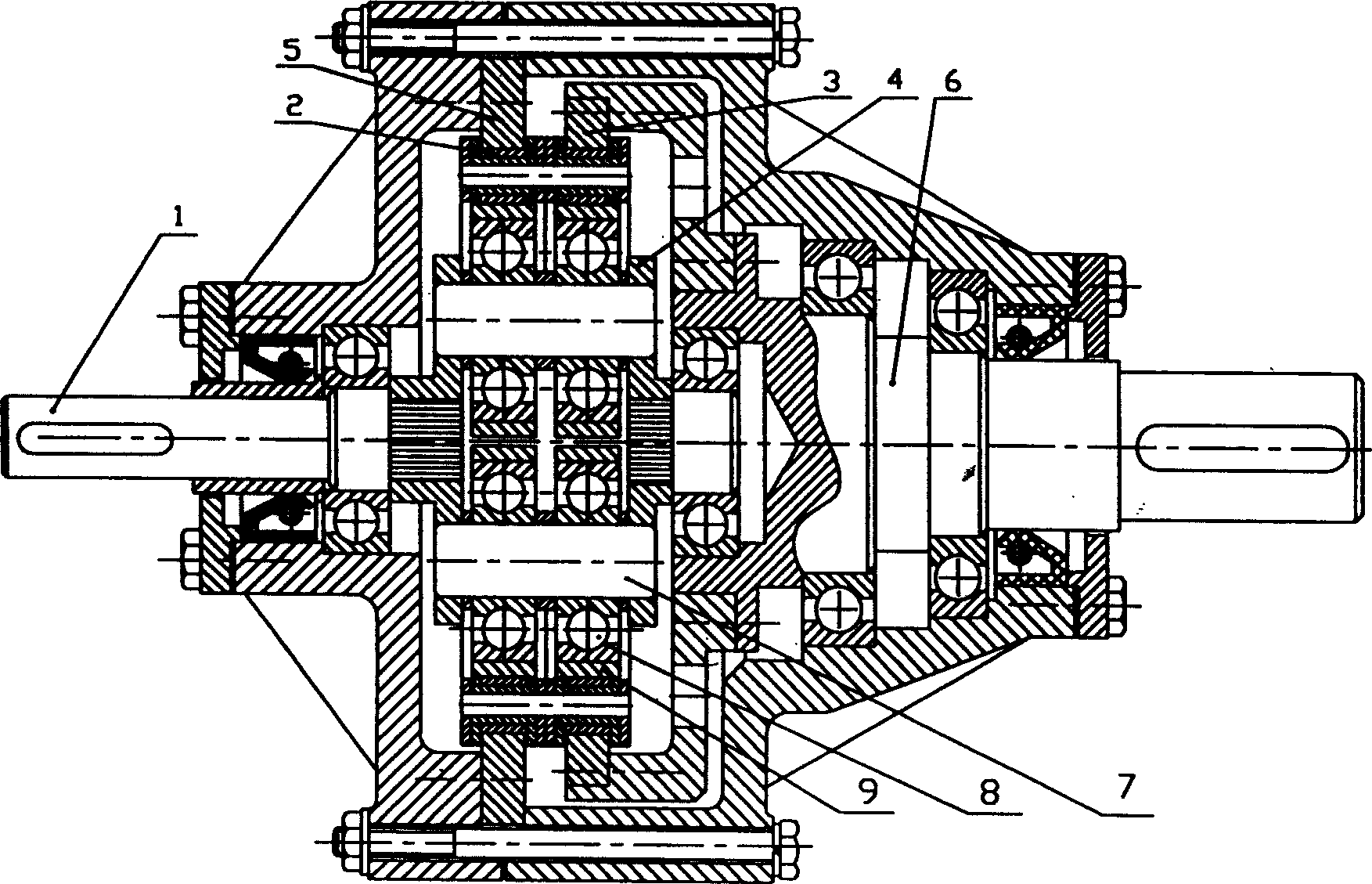

Epicyclic gear train

InactiveUS7022042B2Reduced dimensionSmall and efficientToothed gearingsGearing detailsEngineeringGear train

Owner:EDELWEISS DENTISTRY PROD

Fuel pump with a guided tappet assembly and methods for guiding and assembly

ActiveUS7311087B2Reduce contact stressImprove reliability and durabilityFuel injecting pumpsSpecial fuel injection apparatusInternal combustion engineTappet

A fuel pump for an internal combustion engine including a fuel pump housing, a cylindrical bore having a central axis and being defined by a bore wall surface, a receiving hole formed in the housing, and a tappet assembly received in the cylinder bore. The tappet assembly includes an outer peripheral surface with an elongated key slot longitudinally extending parallel to the central axis. A guide key partially received in the receiving hole is provided, the guide key including a head that extends into the cylindrical bore to engage the elongated key slot of the tappet assembly. The head has an outer dimension that is larger than a dimension of the receiving hole along the central axis. Methods for guiding a reciprocating tappet assembly in a fuel pump and assembling a fuel pump are also provided.

Owner:CUMMINS INC

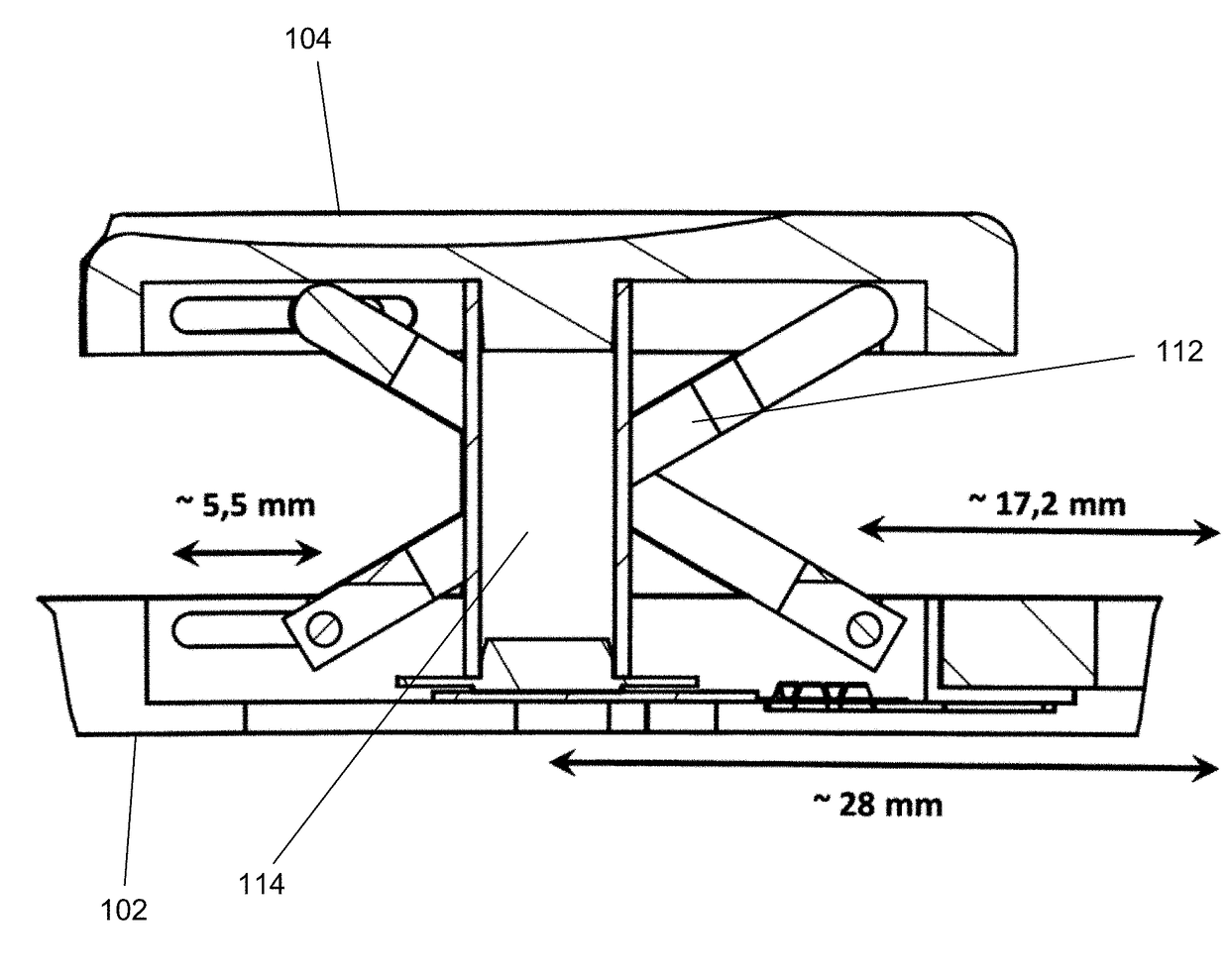

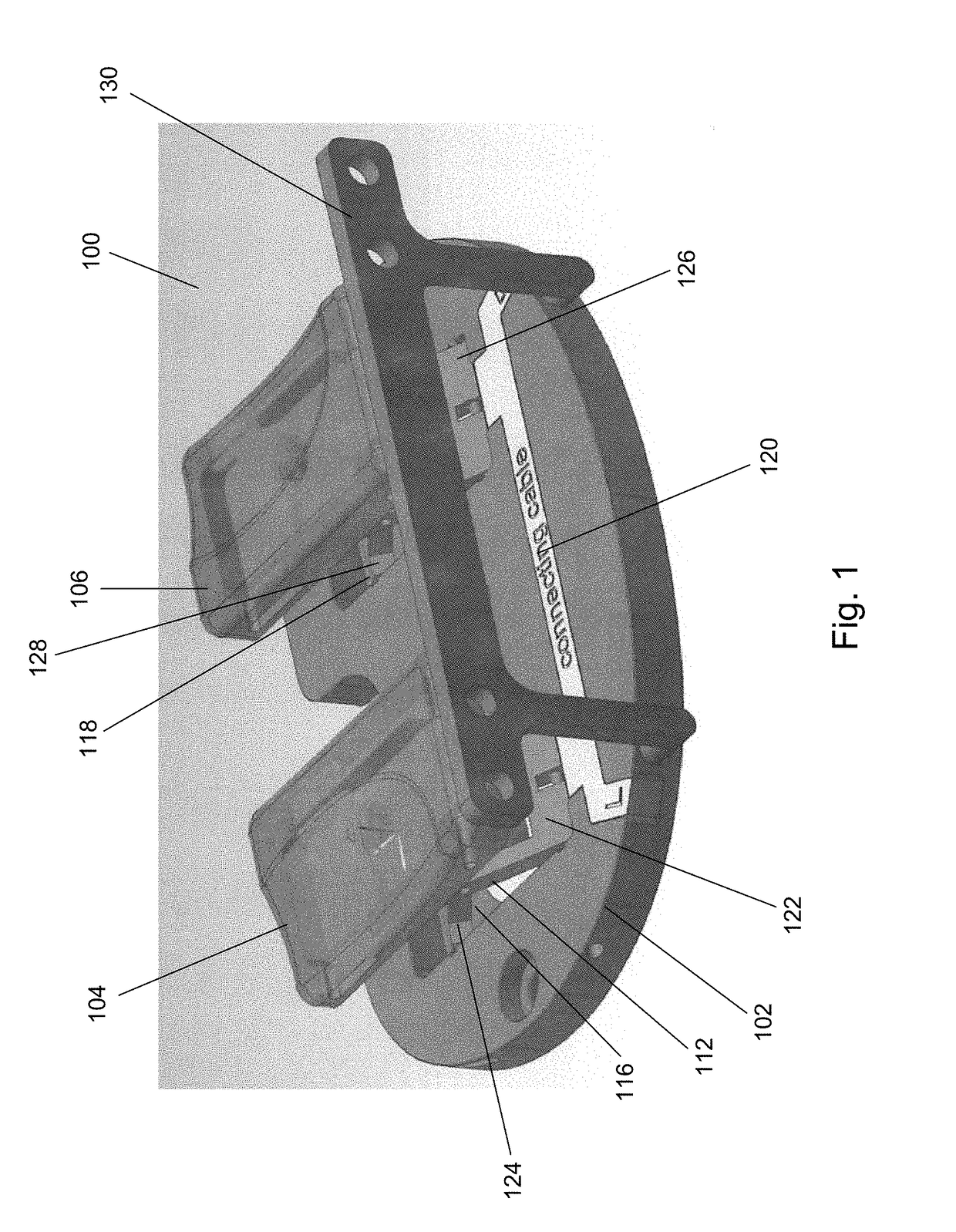

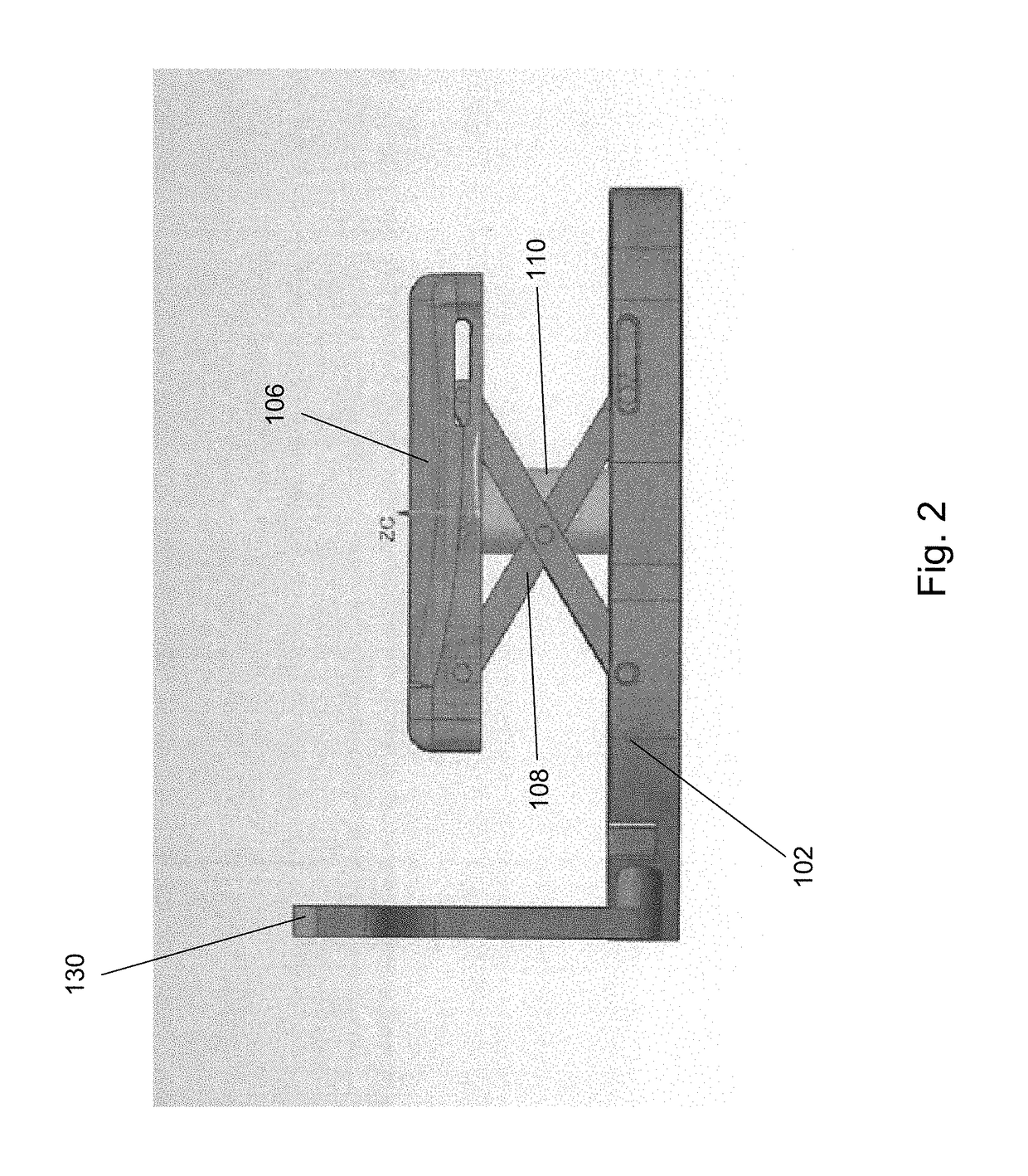

Dynamic Ligament Balancing System

ActiveUS20170312099A1Improve overall lifespanSignificant abrasion reductionJoint implantsComputer-aided planning/modellingCoil springEngineering

A method and system for measuring tension, pressure, and distance of knee tissue, the system comprising a prosthetic inlay device comprising at least two platform structures, wherein each of the platforms are supported on a scissor arm structure and a coil spring, a force sensing sensor configured beneath each coil spring, and a connector cable coupled to the force sensing sensors.

Owner:MEDFIT BERATUNGS UND BETGES M B H

Fixed bearing joint endoprosthesis with combined congruent - incongruent prosthetic articulations

InactiveUS20100241237A1Limited degreeHeavy loadFinger jointsAnkle jointsFixed bearingJoint component

An orthopedic joint replacement has first and second joint components that can be placed in load-bearing articulation with one another. The first joint component has first and second convex spherical condylar segments defining first and second radii. The second joint component has a spherical first concave condylar segment with a radius equal to the radius of the first convex spherical condylar segment. The second joint component also has a non-spherical second concave condylar segment. The first convex spherical condylar segment of the first joint component is in congruent contact with the first spherical concave condylar segment of the second joint component. The second spherical convex condylar segment of the first joint component is in line contact with the non-spherical concave condylar segment of the second joint component.

Owner:BUECHEL PAPPAS TRUST

Electrophotographic photosensitive member having siloxane-polyester, process cartridge and electrophotographic apparatus

ActiveUS7875410B2Improve potential stabilityReduce contact stressElectrographic process apparatusCorona dischargePolymer sciencePolyester resin

A charge transport layer serving as a surface layer of an electrophotographic photosensitive member contains a charge transporting material, polyester resin A containing a siloxane moiety and at least one of polyester resin C and polycarbonate resin D. The content of a siloxane moiety in polyester resin A is not less than 10% by mass and not more than 40% by mass relative to the total mass of polyester resin A. The charge transport layer has a matrix-domain structure having a matrix formed of the charge transporting material and at least one of polyester resin C and polycarbonate resin D and a domain formed of polyester resin A in the matrix.

Owner:CANON KK

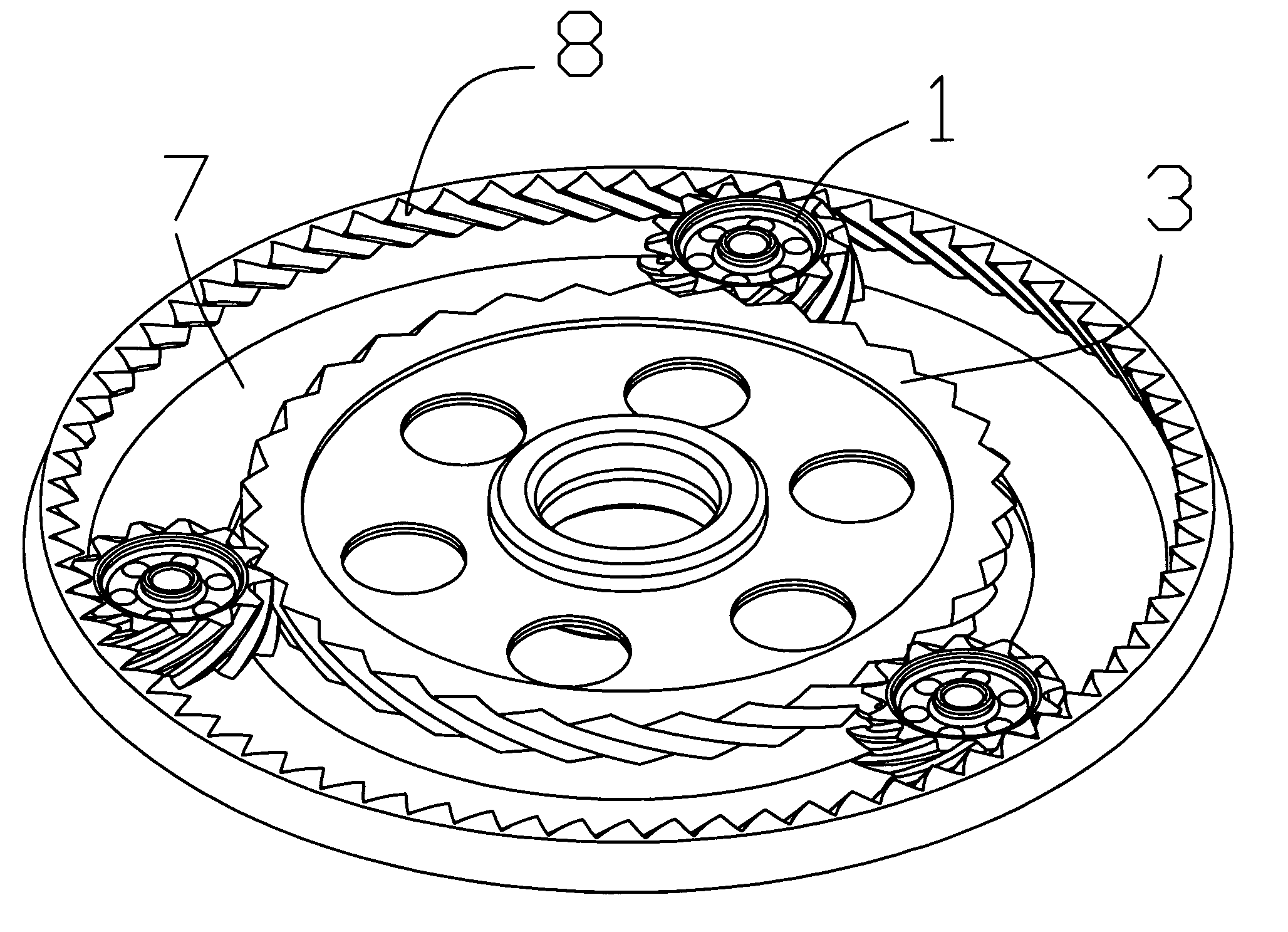

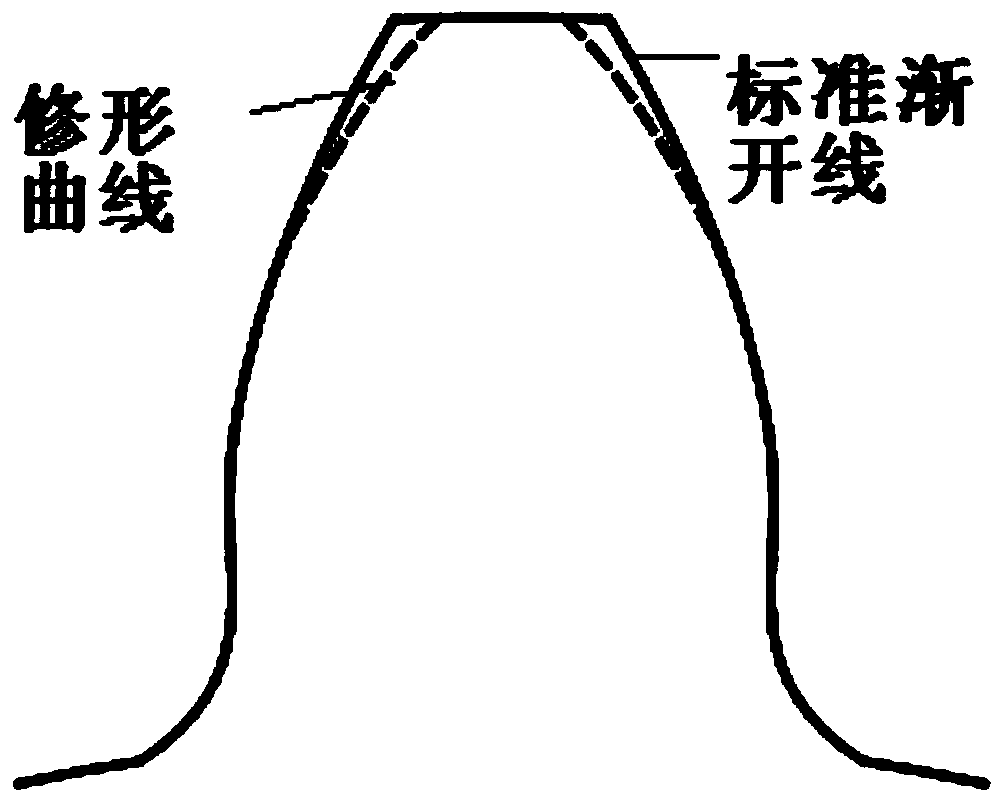

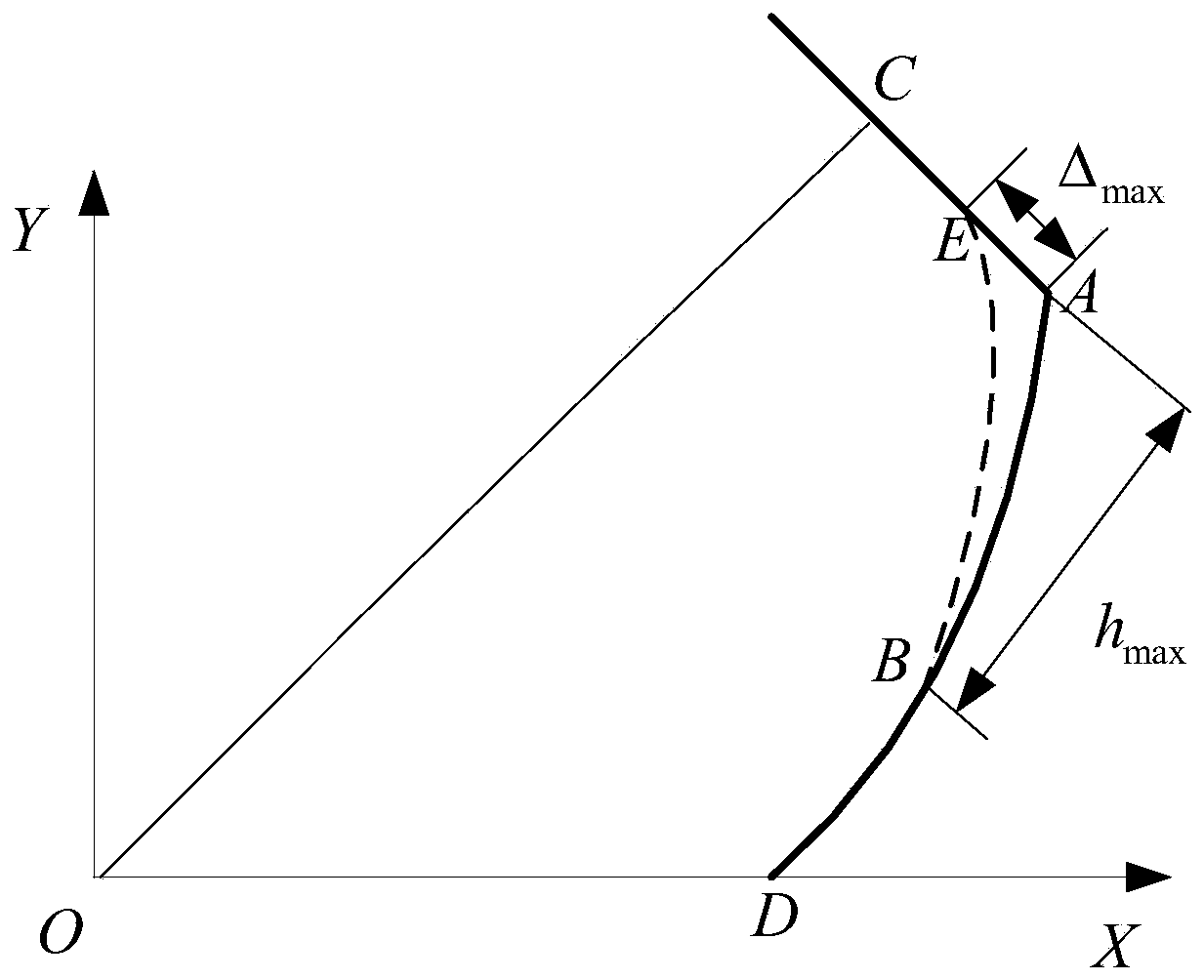

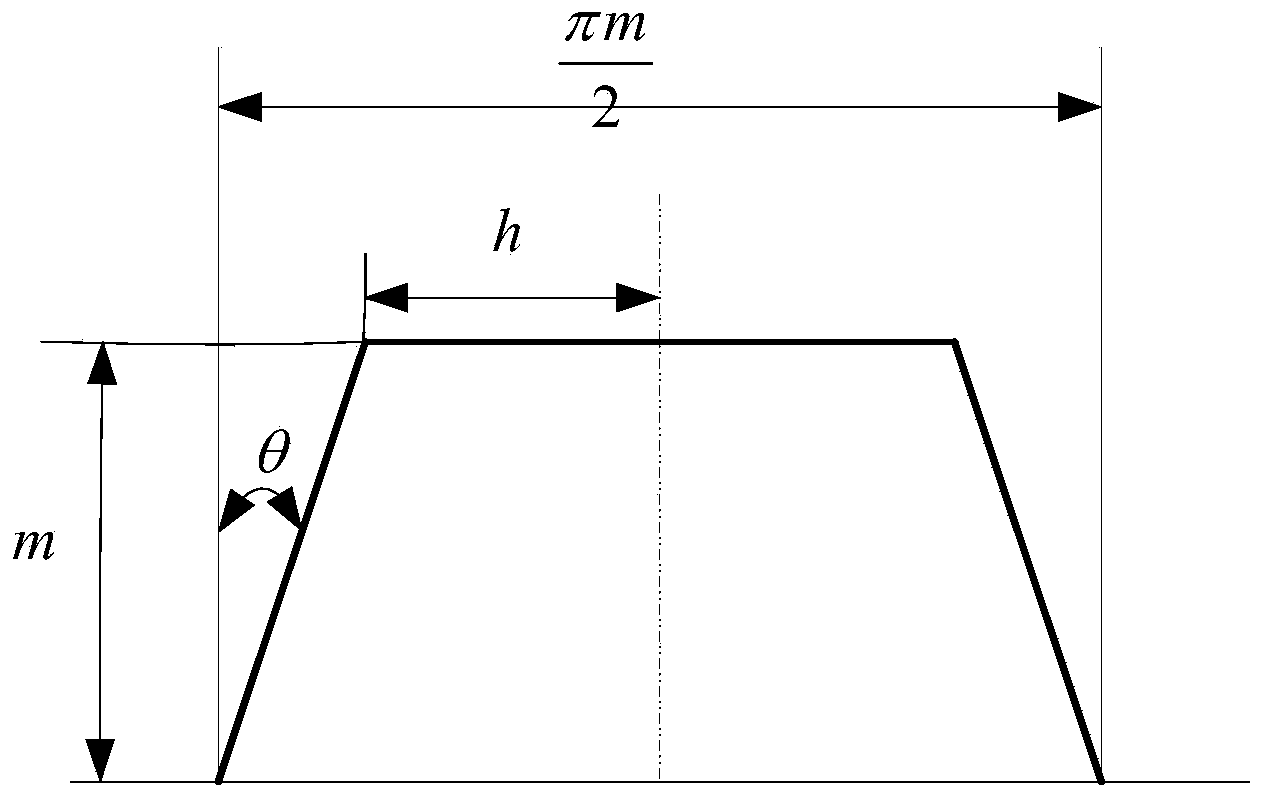

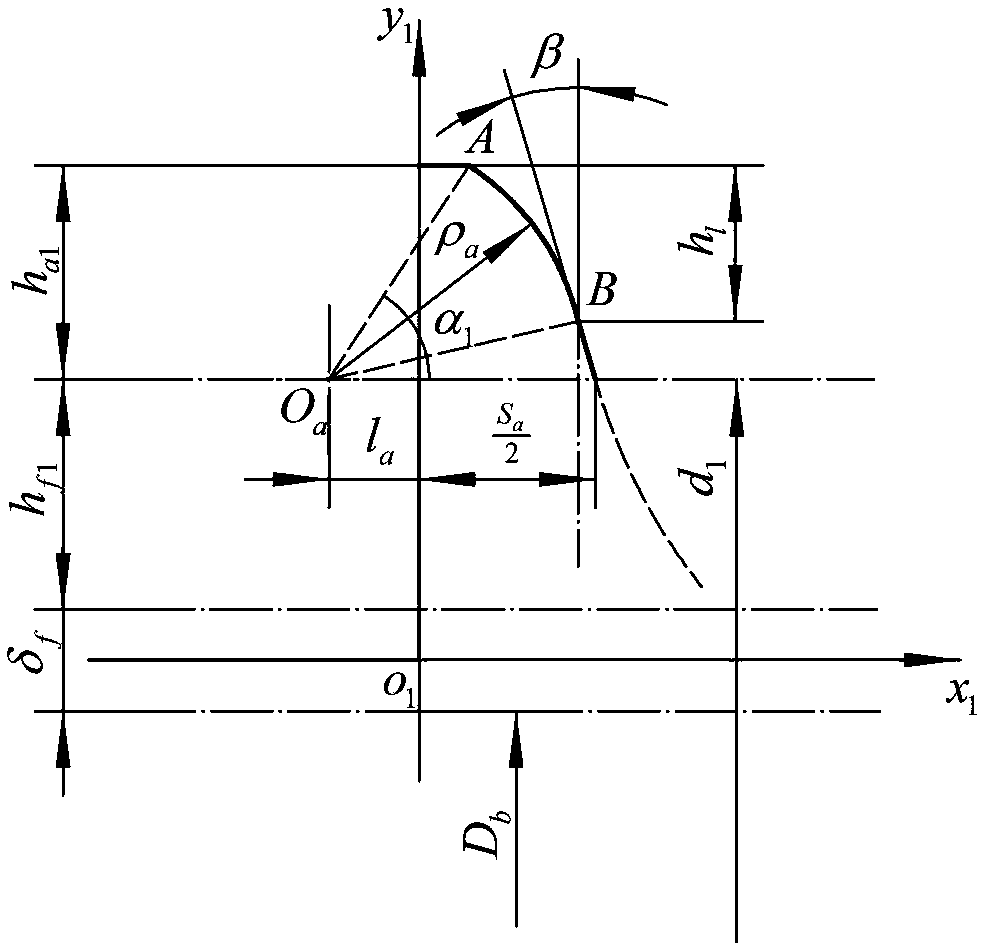

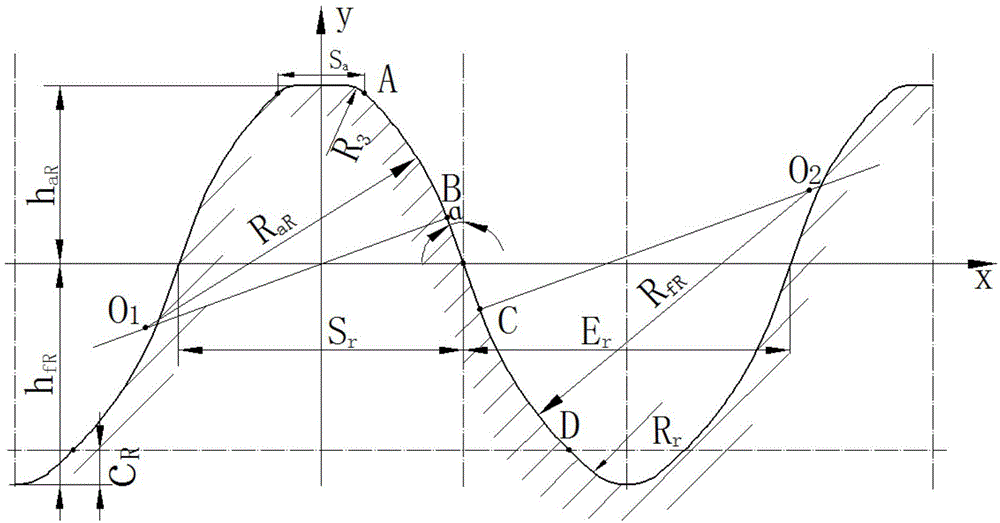

Involute gear tooth profile modification method, modified tooth profile and application of method

ActiveCN103821905ASmooth transitionReduces bite-in and bite-out shocksPortable liftingGearing elementsInvolute gearGear system

The invention discloses an involute gear tooth profile modification method. The method is characterized in that addendum modification is performed on a driving wheel and a driven wheel which are mutually meshed, so that the tooth surface and the addendum of a gear are in transition by a formed modification curve; the modification curve is tangent to a non-modified involute of the tooth surface and the addendum, and the smooth transition of the tooth surface and the smooth transition of the modification curve and the addendum are ensured, so contact deformation and contact stress during the meshing-in and meshing-out of gear teeth are improved. The invention further discloses a tooth profile and the gear which are obtained by the method, and the application of the method. By adopting the method, the smooth transition of the tooth surface and the smooth transition of the modification curve and the addendum are ensured, so that the meshing-in and meshing-out impact of the gear is reduced, the transmission stability is ensured, the vibration and noise reduction of a gear system is benefited, and the service life of the gear is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

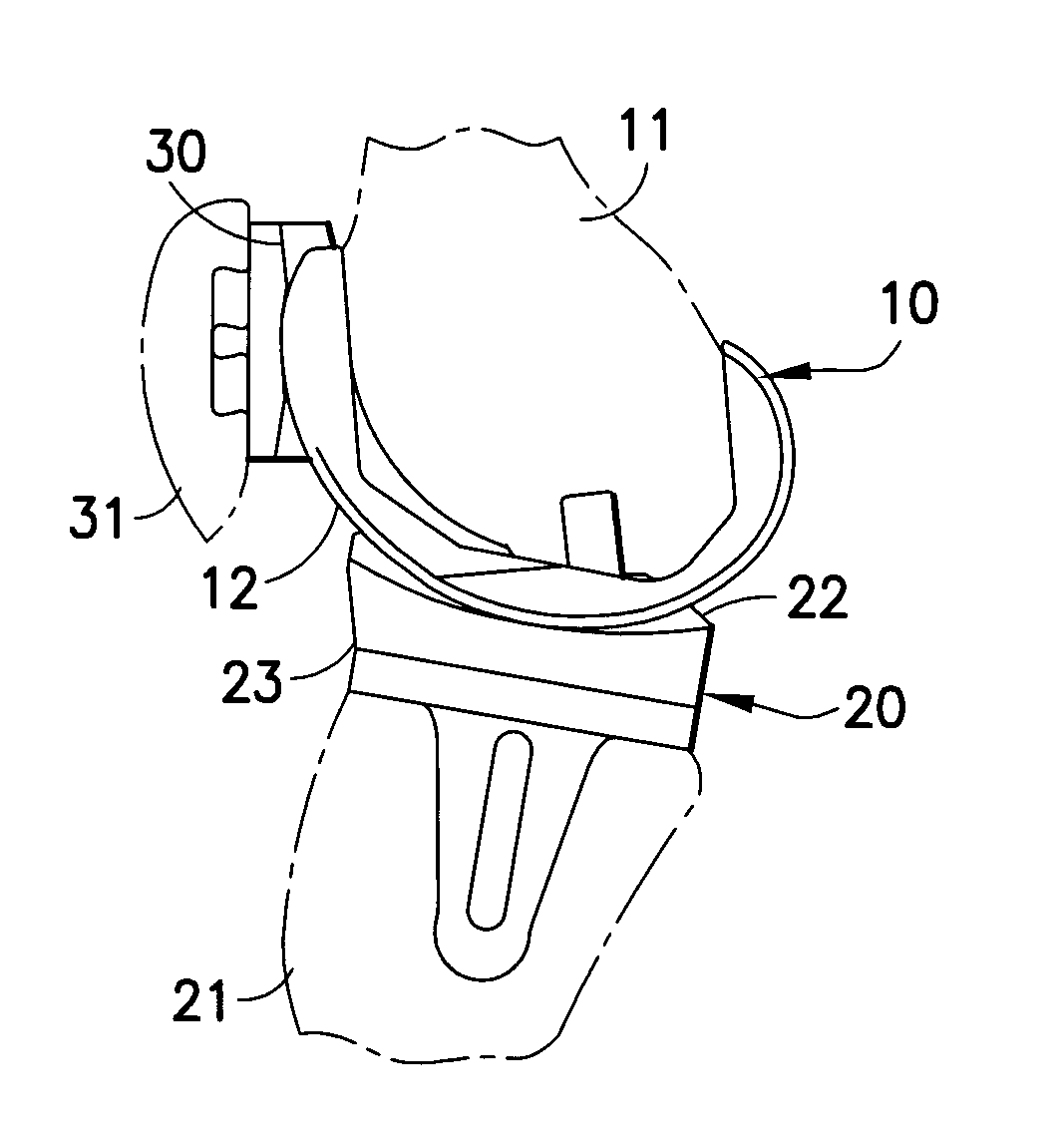

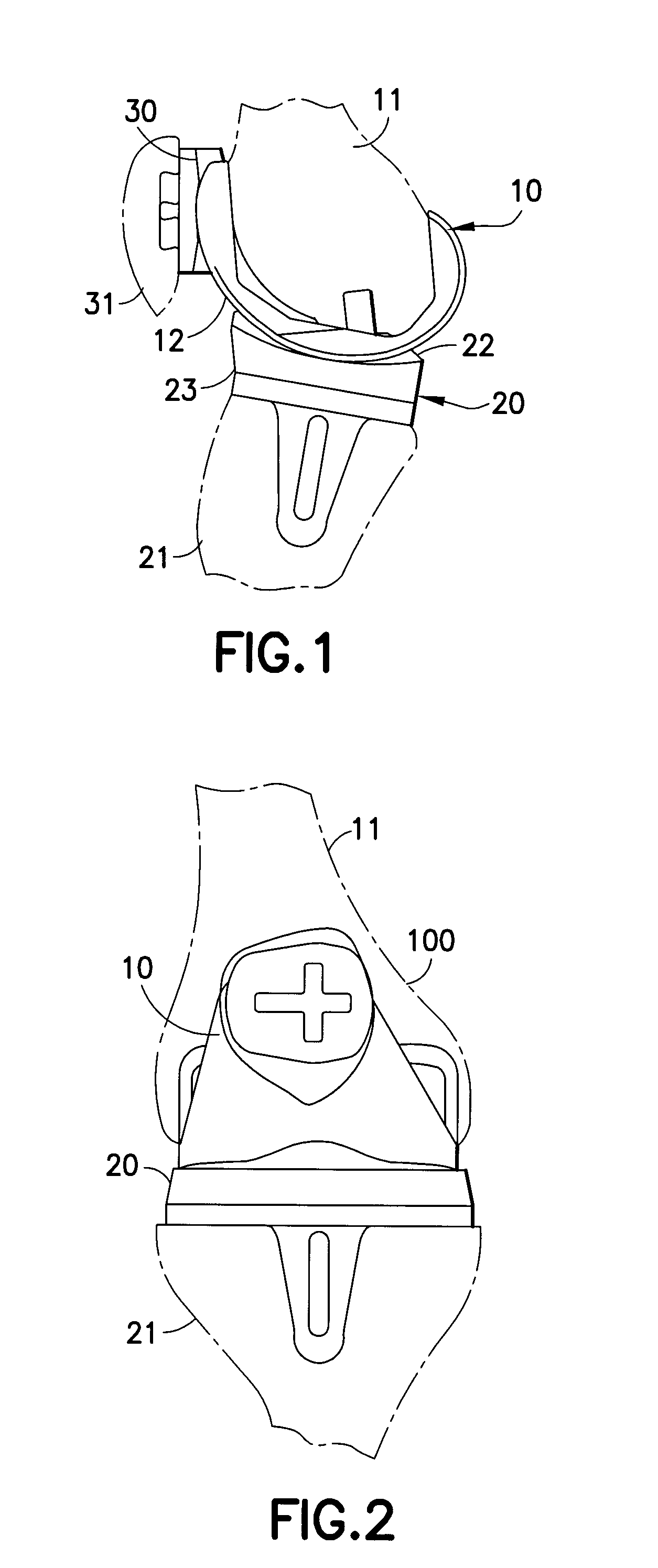

Ankle prosthesis including tibial component having peripheral wall for preventing the formation of bone cysts

InactiveUS20050182492A1Reduce possible abrasionReduce contact stressAnkle jointsJoint implantsAnkle prosthesisBiomedical engineering

The tibial component of a prosthetic ankle joint including a tibial component, a talar component, and an intermediate sliding plastic bearing, with the tibial component including a depending peripheral wall that surrounds and is spaced from the plastic bearing and is intended to reduce rubbing of the plastic bearing against tissue which would produce wear particles that lead to the formation of bone cysts. The depending peripheral wall of the tibial component is intended to reduce such possible abrasions by at least partially shielding the plastic bearing from the surrounding tissue.

Owner:BUECHEL PAPPAS TRUST

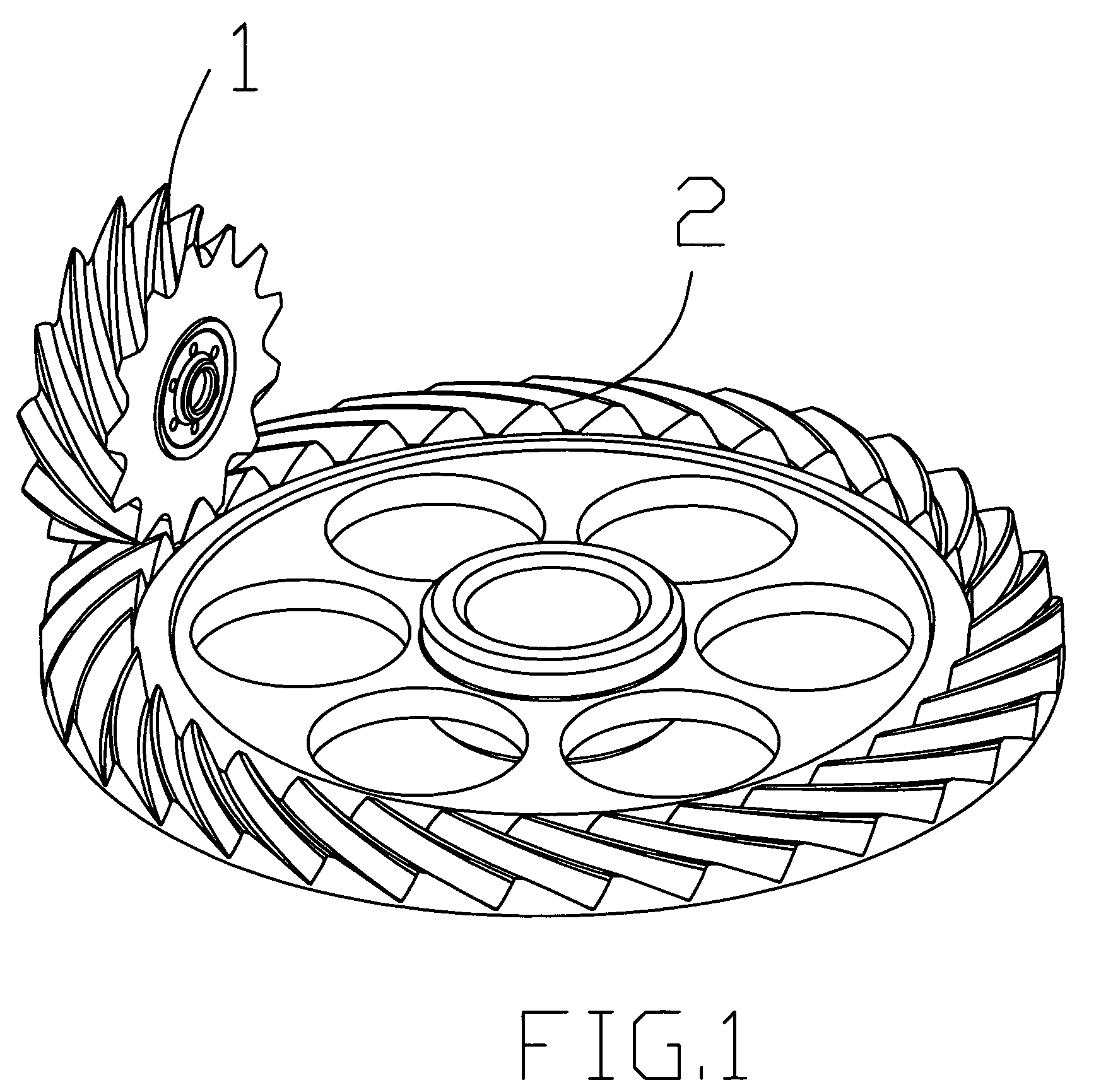

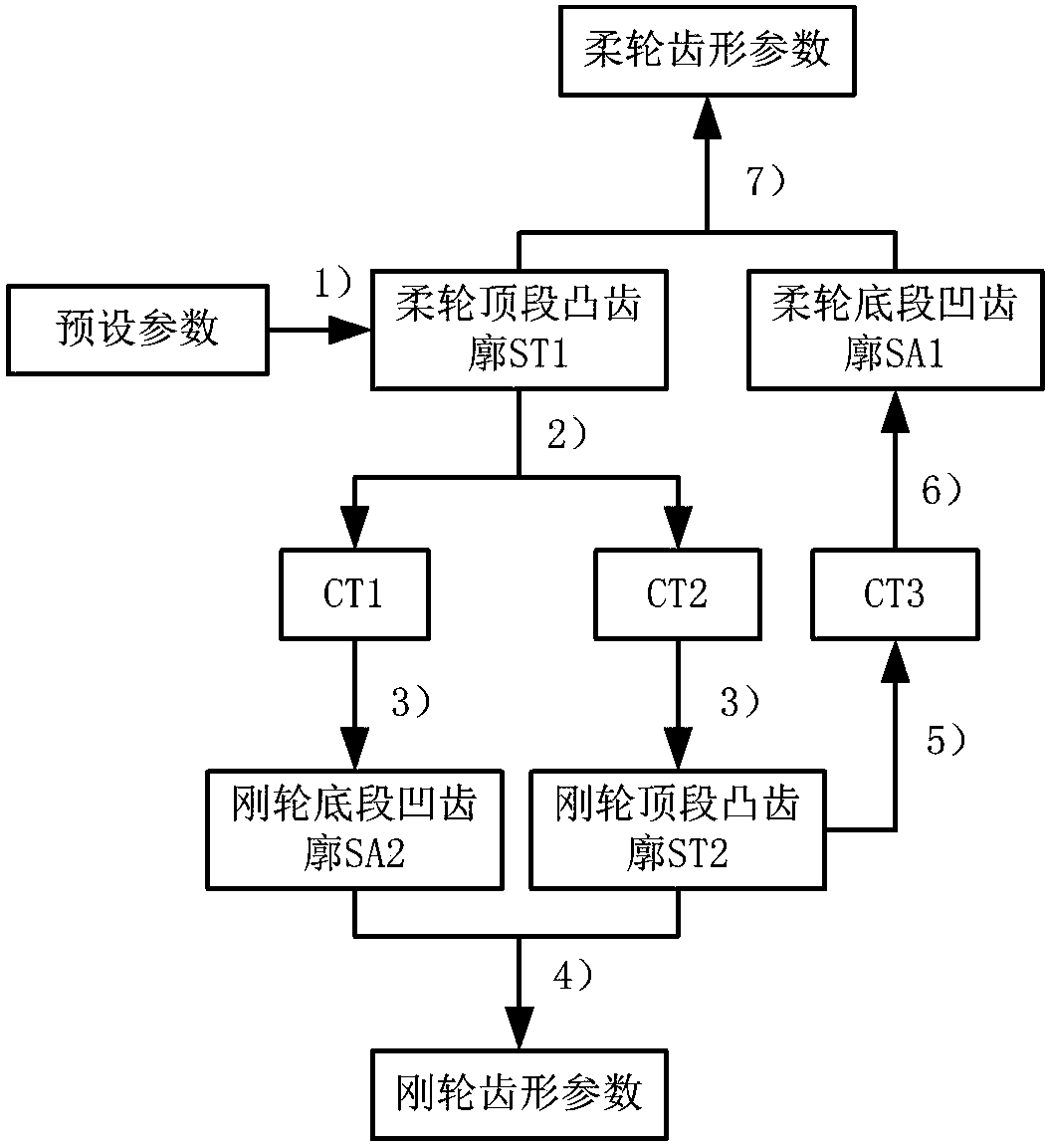

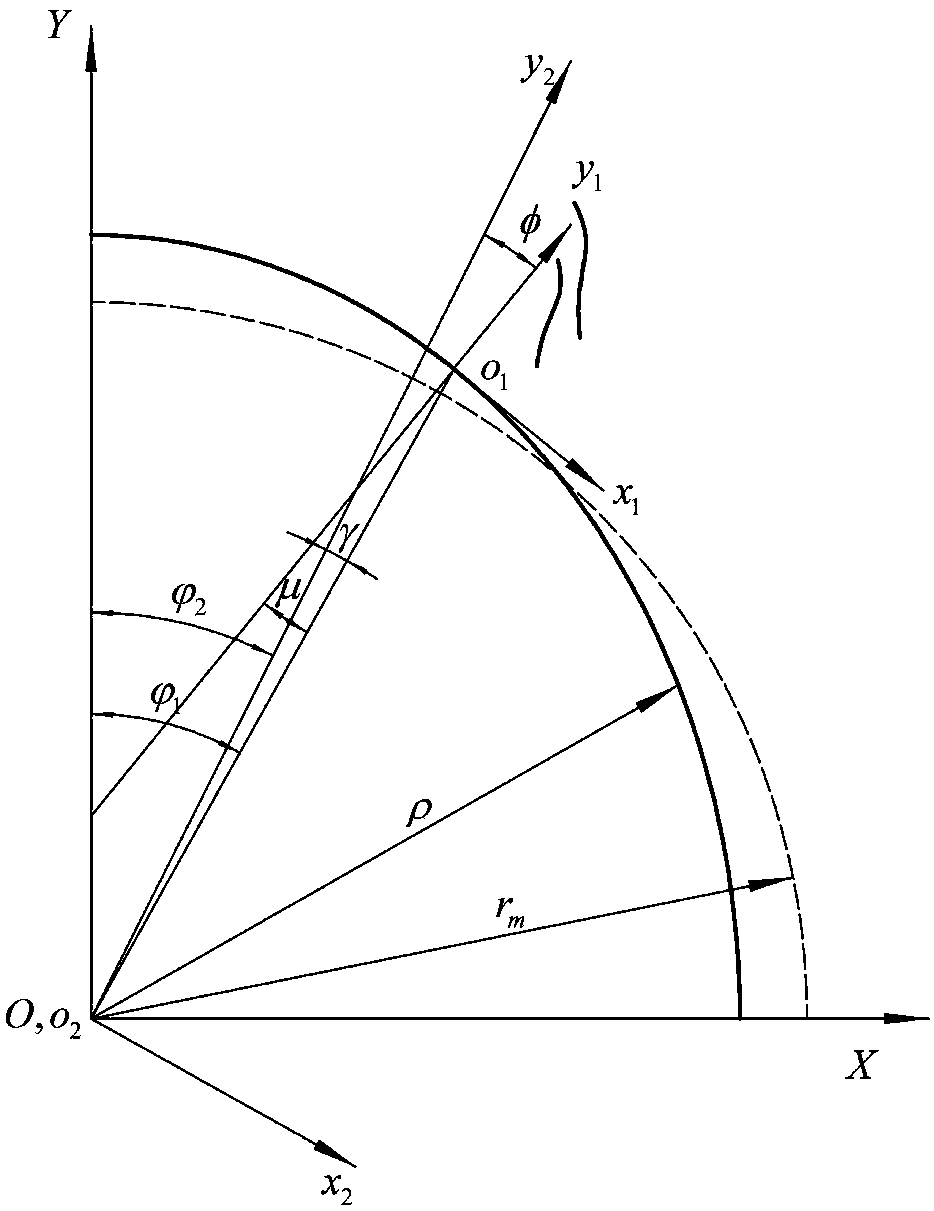

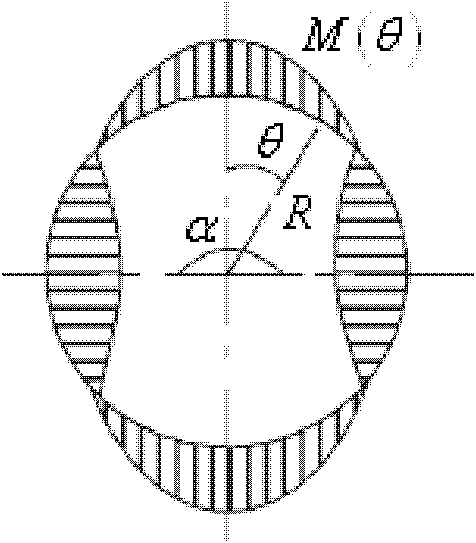

Bidirectional conjugate tooth profile design method for harmonic gear drive

ActiveCN108533715AIncrease logarithmReduce contact stressPortable liftingGearing elementsGear driveReduction drive

The invention relates to a bidirectional conjugate tooth profile design method for harmonic gear drive. The bidirectional conjugate tooth profile design method for harmonic gear drive comprises the steps of firstly, expressing a flexible wheel top-section convex tooth profile coordinate through a parameter equation, converting to a rigid wheel coordinate system, solving to obtain discrete point coordinates of a theorical conjugate concave tooth profile and a concave tooth profile of a flexible wheel top-section convex tooth profile, determining the working tooth depth of a rigid wheel tooth profile through least square fit, determining a fitted curve section to be a rigid wheel bottom-section concave tooth profile and a rigid wheel top-section concave tooth profile, and calculating to accomplish a tooth profile design of a rigid wheel; and then expressing a rigid wheel top-section convex tooth profile coordinate through a parameter equation, converting to a flexible wheel coordinate system, solving to obtain discrete point coordinates of a theorical concave conjugate tooth profile in a flexible wheel bottom-section range, determining the tooth depth of a flexible wheel through least square fit, determining a fitted curve to be a flexible wheel bottom-section concave tooth profile, and calculating to obtain a flexible wheel working tooth profile. According to the bidirectional conjugate tooth profile design method for harmonic gear drive provided by the invention, the flexible wheel tooth profile and the rigid wheel tooth profile with bi-conjugate and secondary-conjugate phenomena are directly obtained, so that a conjugate contact area and a meshing zone are increased, the tooth surface contact stress is reduced, and the drive accuracy of a harmonic reducer is improved.

Owner:XI AN JIAOTONG UNIV

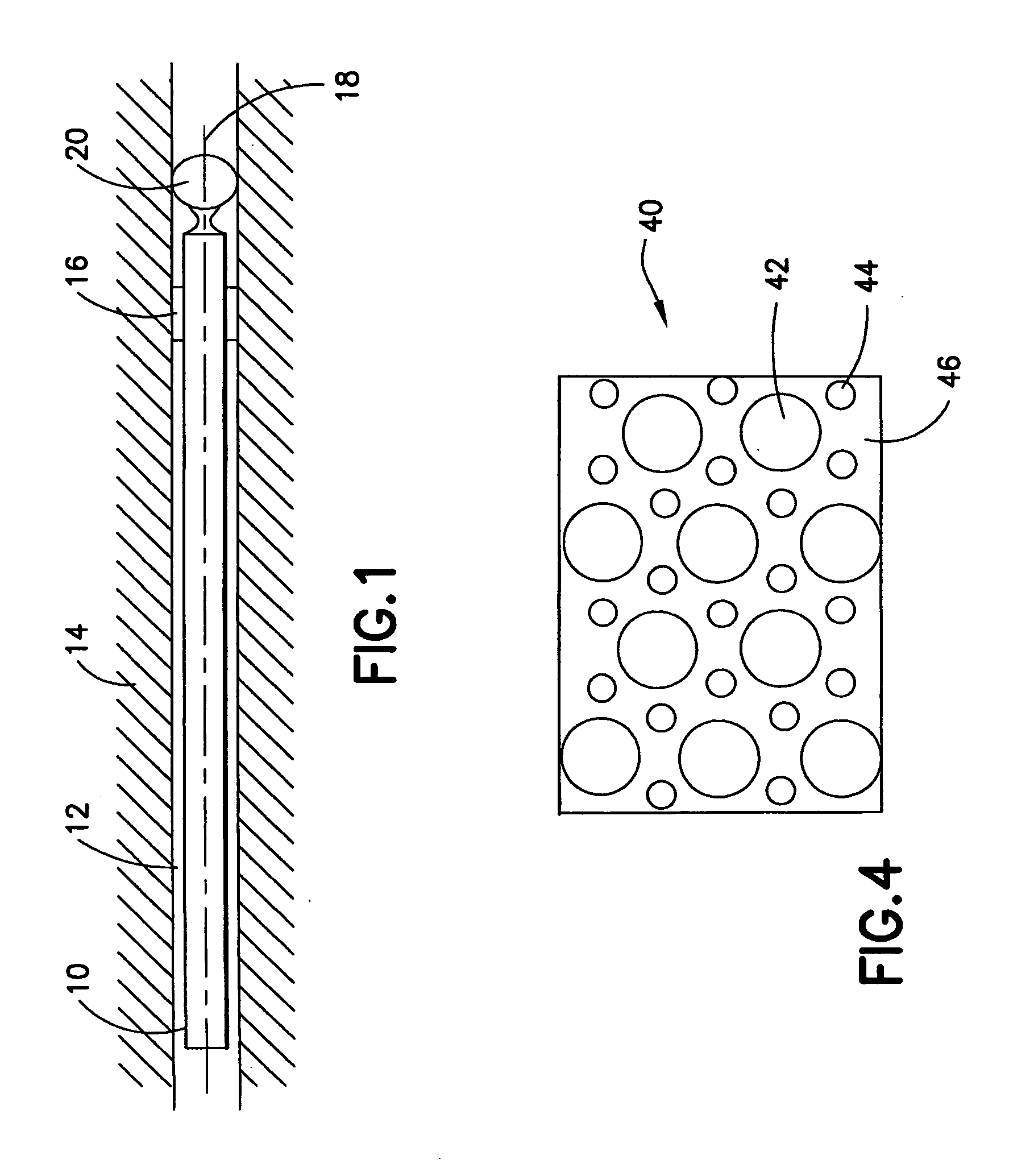

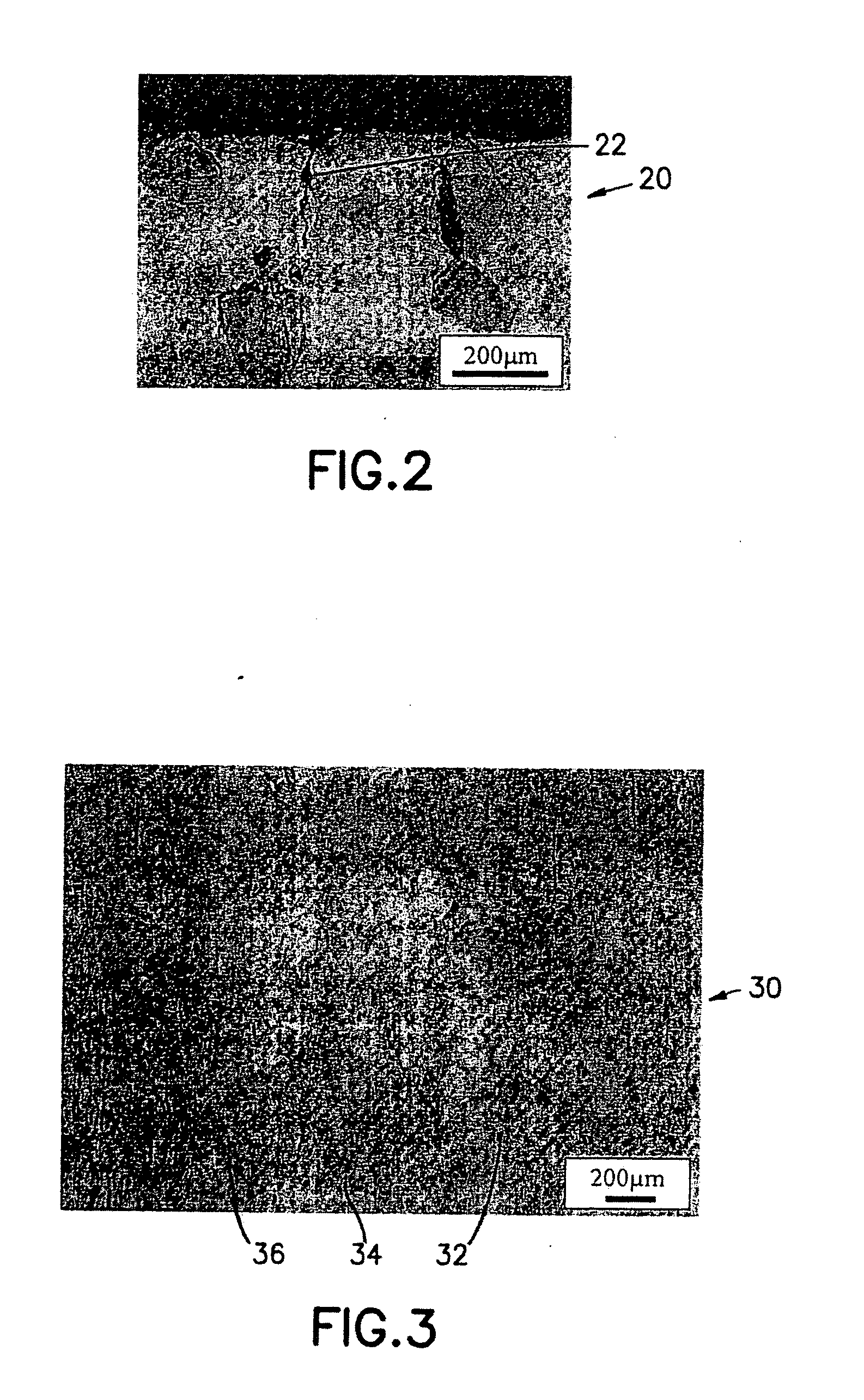

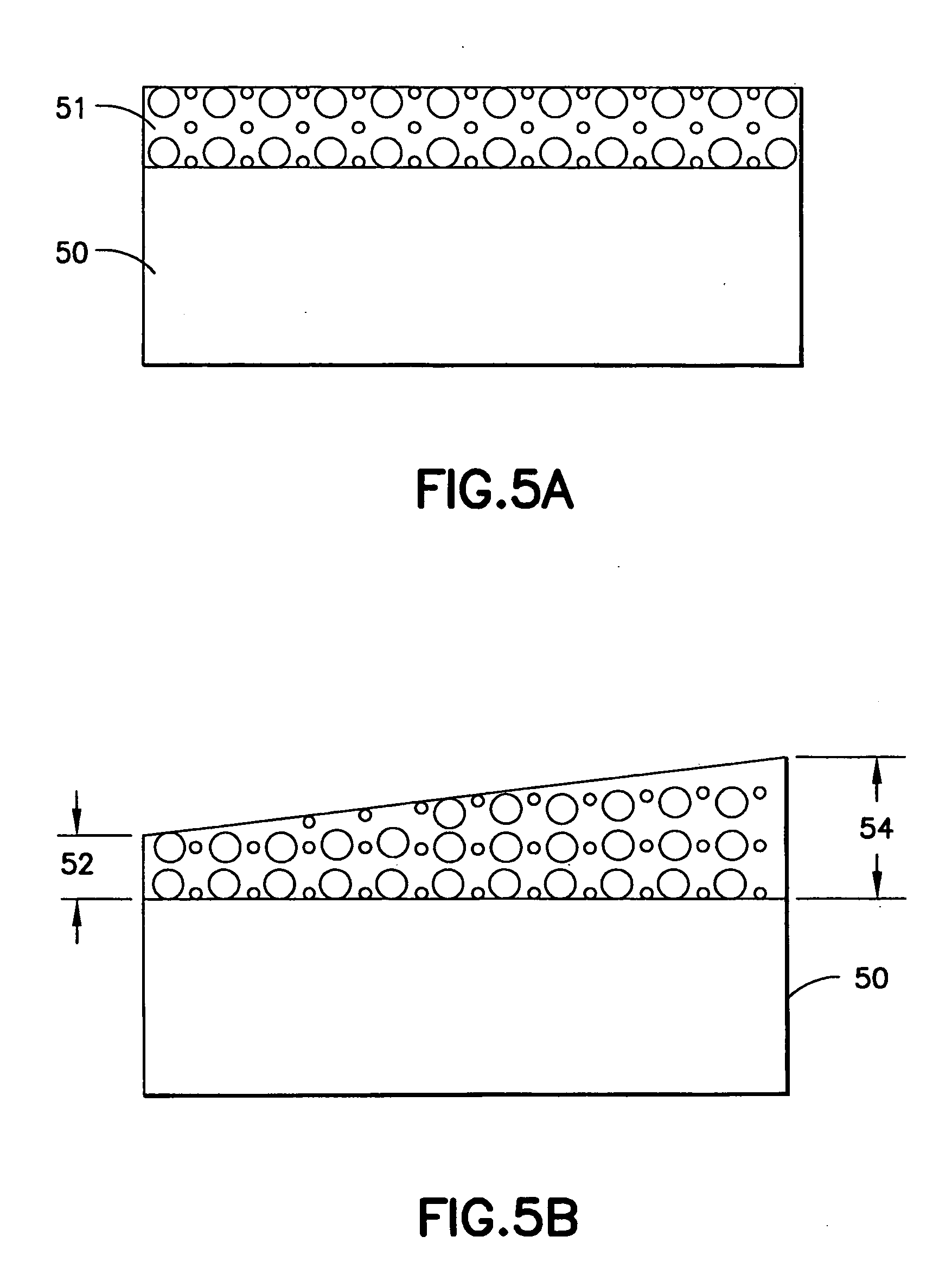

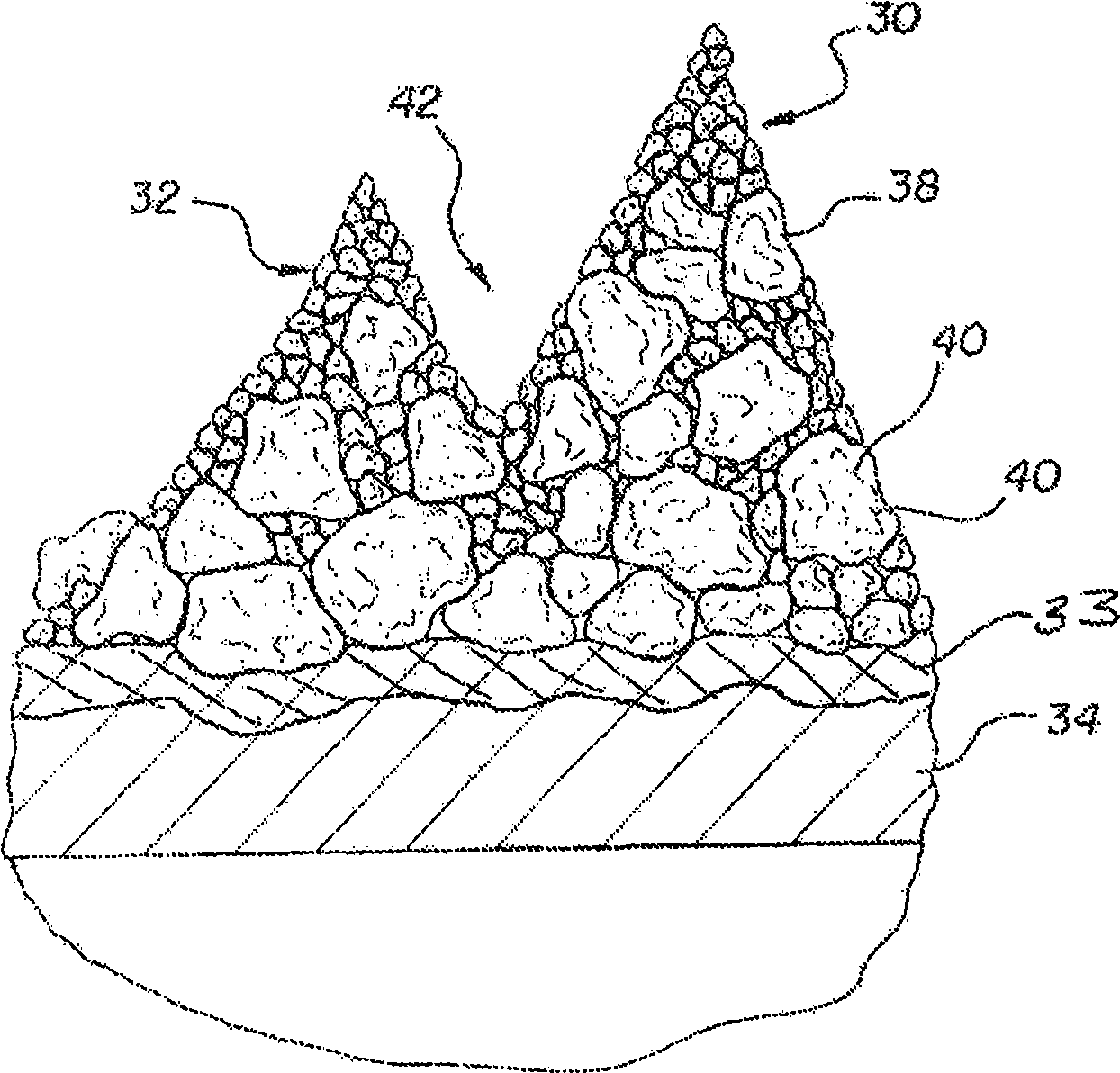

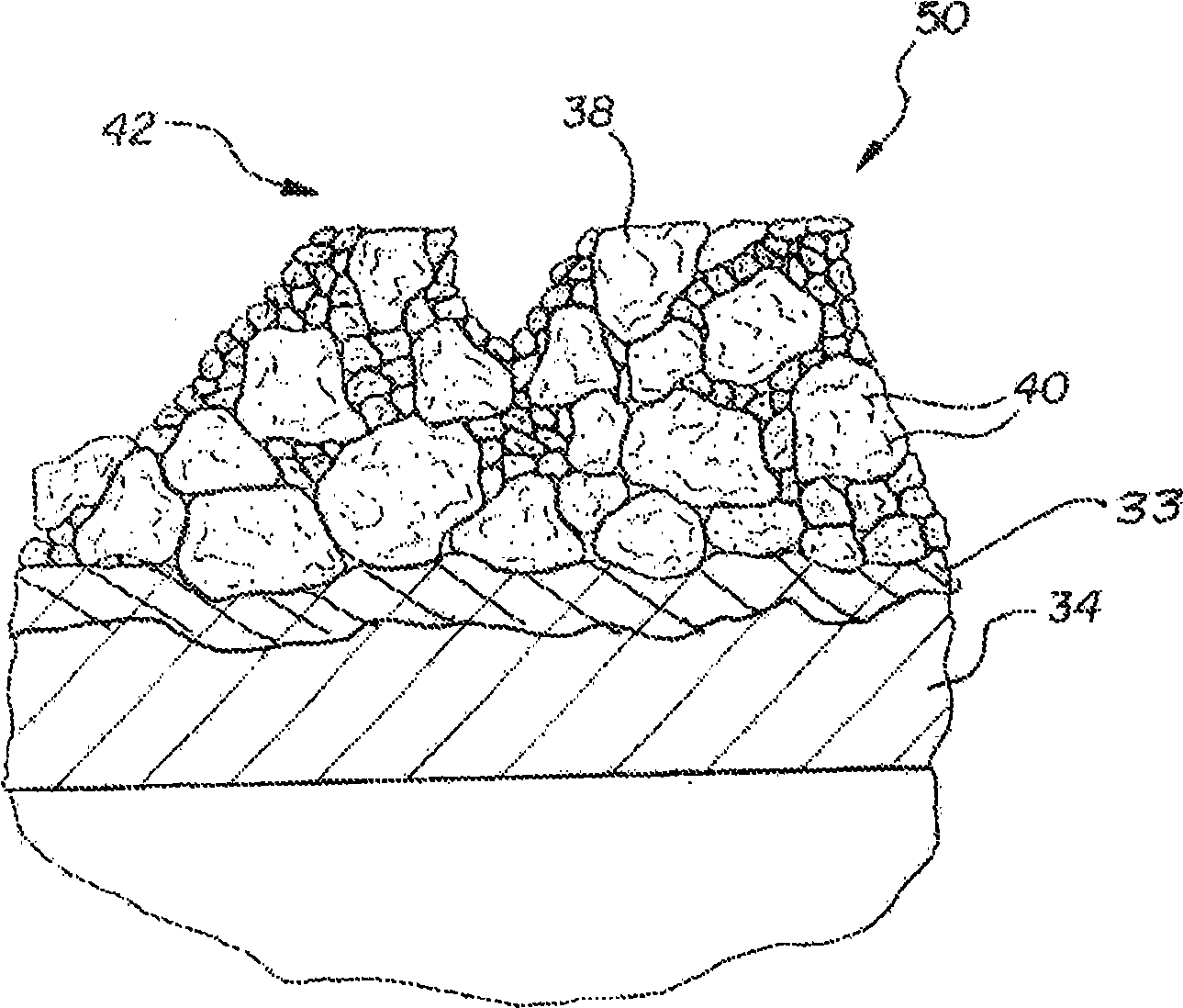

Reducing abrasive wear in wear resistant coatings

ActiveUS20070202350A1Reduce wear rateReduce wearPigmenting treatmentMolten spray coatingWear resistantBrittleness

An abrasion resistant coating and method are provided wherein the abrasion resistant coating contains both ductile and brittle components having a bimodal size distribution. The abrasion resistant coating is initially applied to a substrate in contact with an abrasive environment. The abrasive resistant coating having a bimodal size distribution results in the minimized exposure of the ductile components of the wear surface to the abrasive environment such that the life of the abrasive resistant coating is extended.

Owner:SCHLUMBERGER TECH CORP

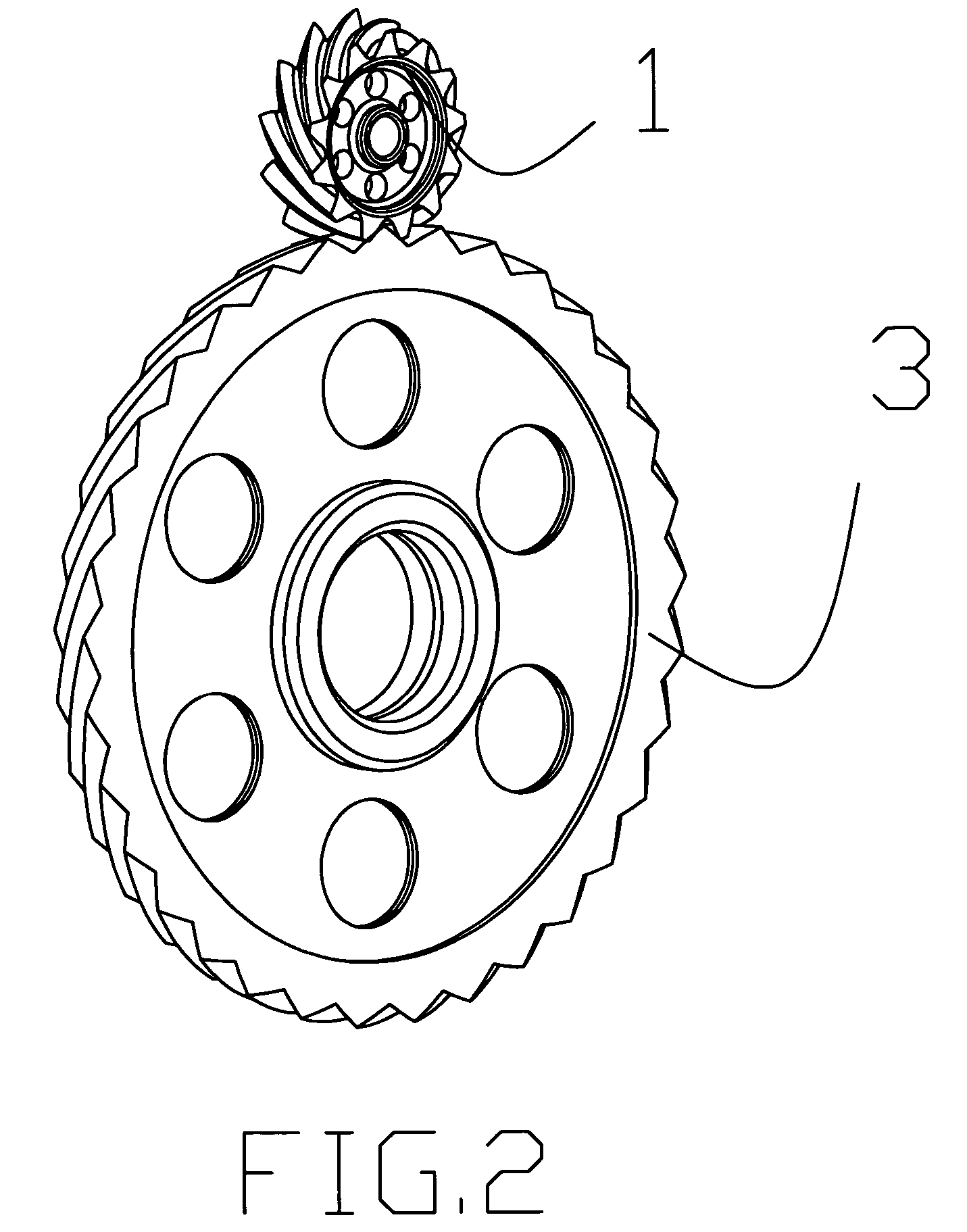

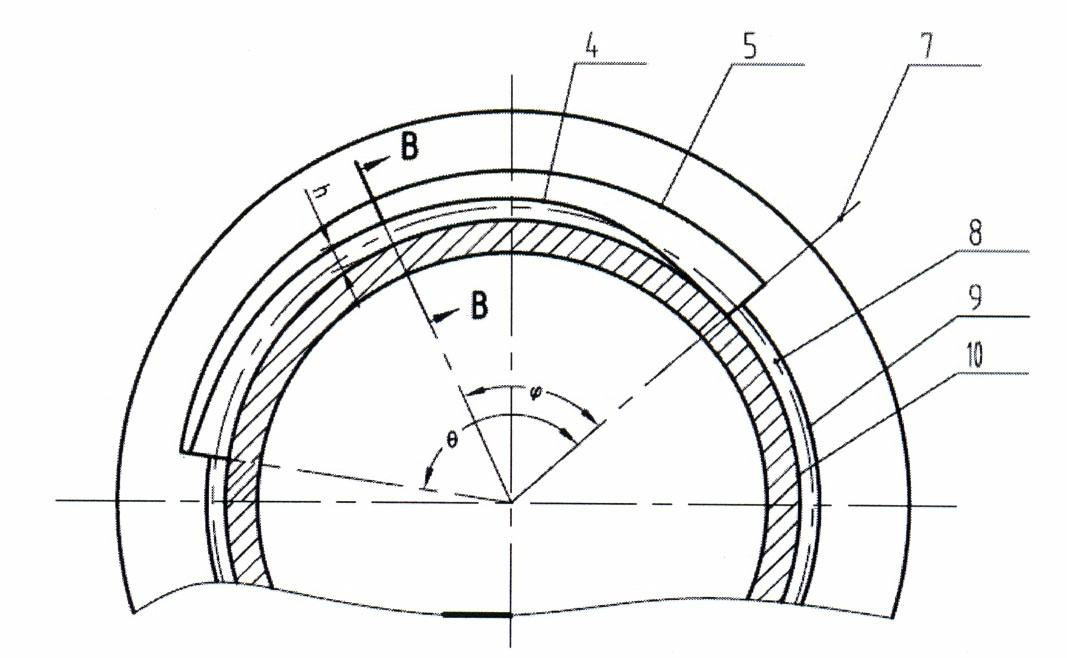

Harmonic gear reducer

ActiveCN105299151AIncrease mesh stiffnessImprove transmission efficiencyToothed gearingsReduction driveGear wheel

The invention discloses a harmonic gear reducer which comprises a flexible gear, a rigid gear and an elliptical cam wave generator. The cup bottom of the flexible gear is connected with an output shaft. The elliptical cam wave generator is connected with an input shaft. The outer wall, along the cup rim, of the flexible gear is provided with an arc-involute-arc-tooth profile. The elliptical cam wave generator is arranged on the inner wall of the cup rim of the flexible gear. The rigid gear is fixedly connected with a shell and the inner wall is provided with an arc-involute-arc-tooth profile matched with the flexible gear tooth profile. The rigid gear is connected with the flexible gear through the tooth profiles in an engaged manner. In the engagement process, the flexible gear is in continuous conjugated engagement with the rigid gear, a convex tooth profile and a concave tooth profile of the flexible gear and a concave tooth profile and a convex tooth profile of the rigid gear are located in the double-conjugation engagement interval of the conjugation motion at the same time. The harmonic gear reducer has the beneficial effects that both arc tooth-shaped harmonic driving and involute-tooth-shaped harmonic driving are achieved; and deflection driving can be achieved, the gear tooth engagement region can be enlarged, and the engagement rigidity, driving efficiency and bearing capacity of the harmonic gear reducer are improved.

Owner:瑞邦智能科技(南京)有限公司

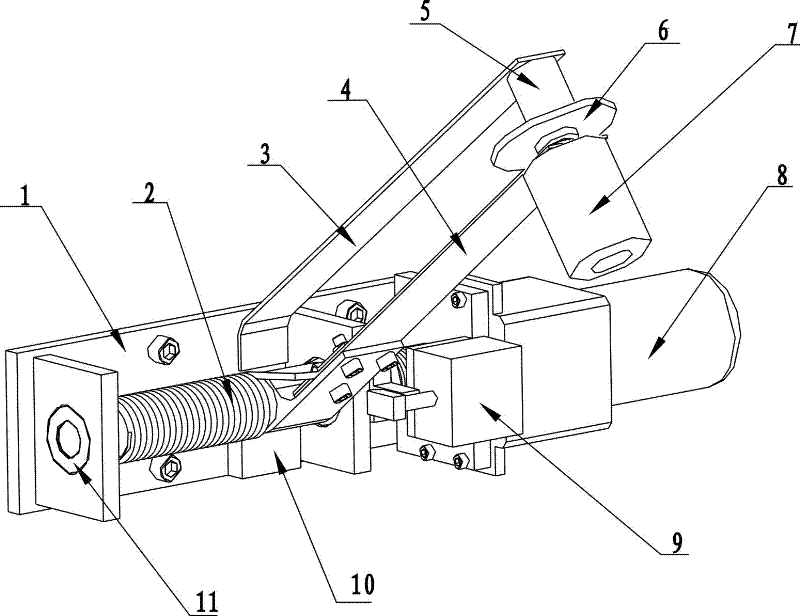

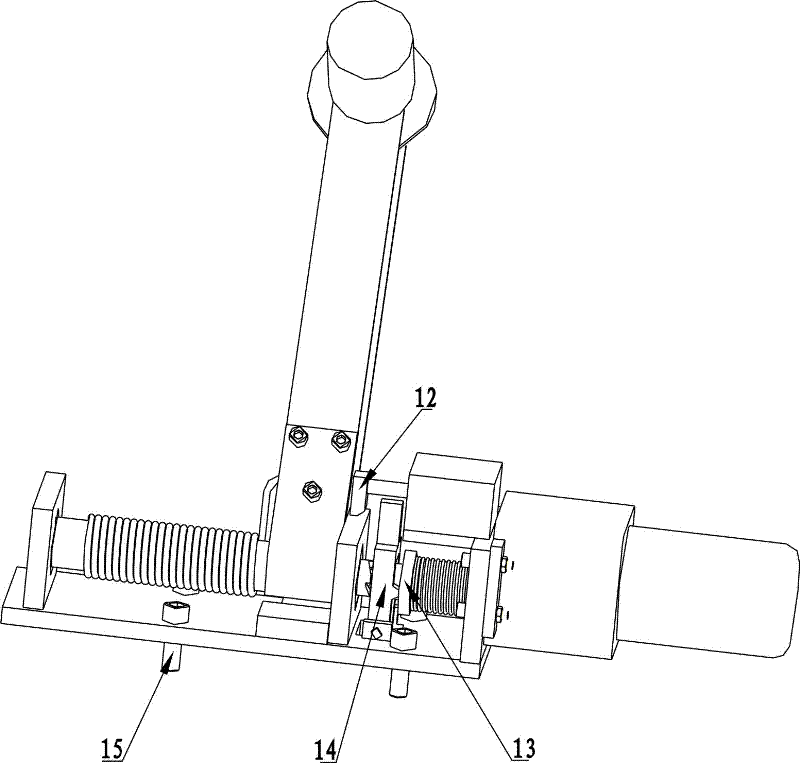

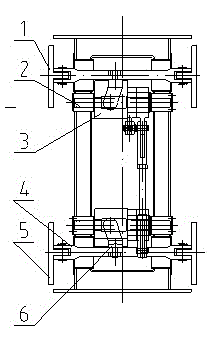

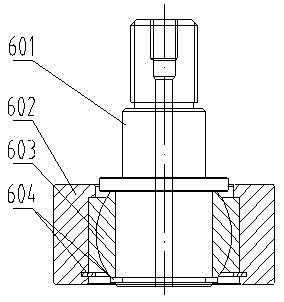

Mechanical double energy storage impact mechanism and impact method

InactiveCN102357634AReduce contact stressProtect working facePower hammersHammer drivesElectric driveEngineering

The invention discloses a mechanical double energy storage impact mechanism and a mechanical double energy storage impact method. The mechanism comprises a frame, a rotating shaft is arranged on the frame, the rotating shaft is fixedly connected with a swinging arm, the swinging arm is connected with a hammer head, a torsion spring is arranged coaxial with the rotating shaft, the swinging arm is fixedly connect to one end of the torsion spring, and the other end of the torsion spring is fixed on the frame. An electric driving mechanism and a first electromagnet are arranged on the frame, the first electromagnet is connected with a drag hook, a gear clutch is arranged on the electric driving mechanism, and a lever is movably connected to the frame and movably matched with the drag hook; and a second electromagnet is arranged on the frame through a mounting arm. The mechanism has two energy storage links, namely deformation energy storage of the torsion spring and elastic bending energystorage of the swinging arm, so that the contact stress during impacting can be effectively reduced and the working surface of a workpiece is well protected. By using the mechanism and the method, conventional heavy manual hammering can be replaced, and the labor intensity is lightened; and the mechanism can also be used for replacing the conventional starting pneumatic striker in the powder conveying process to prevent blockage.

Owner:CHINA THREE GORGES UNIV

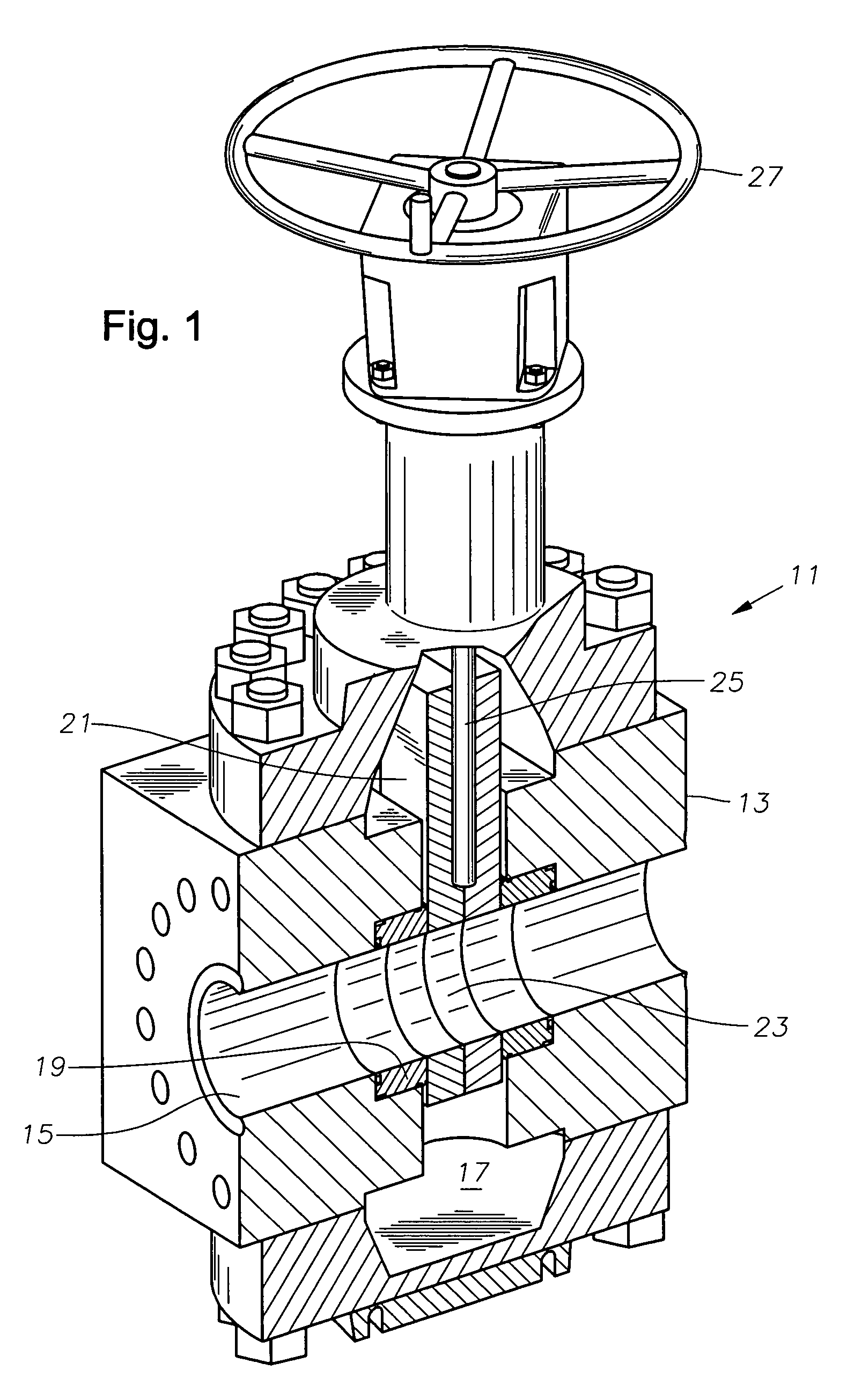

Valve seat edge relief profile

ActiveUS7325783B2Improve stress distributionReduce axial stiffnessPlug valvesCheck valvesStress reliefEngineering

A valve seat has an outer surface, a rearward end, a face and a forward end. A passage extends from the rearward end to the face. A valve element slidingly contacts the face. Stress relief flanges are located on the face in areas of high bearing stress. Each flange has a thickness that allows it to deflect slightly to reduce bearing stresses.

Owner:VETCO GRAY LLC

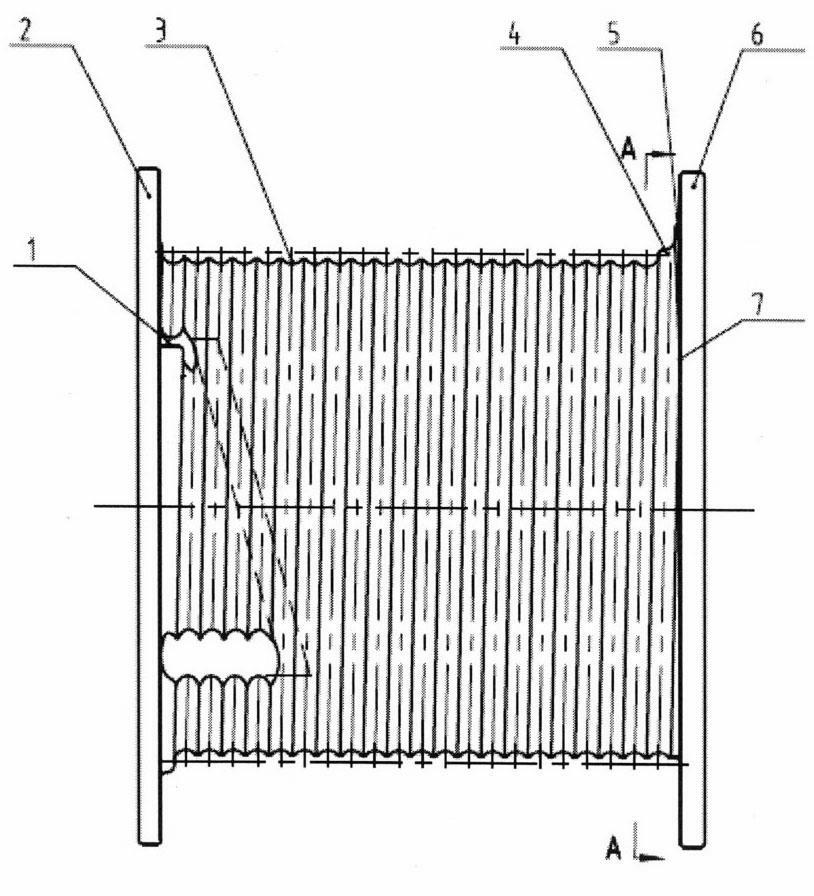

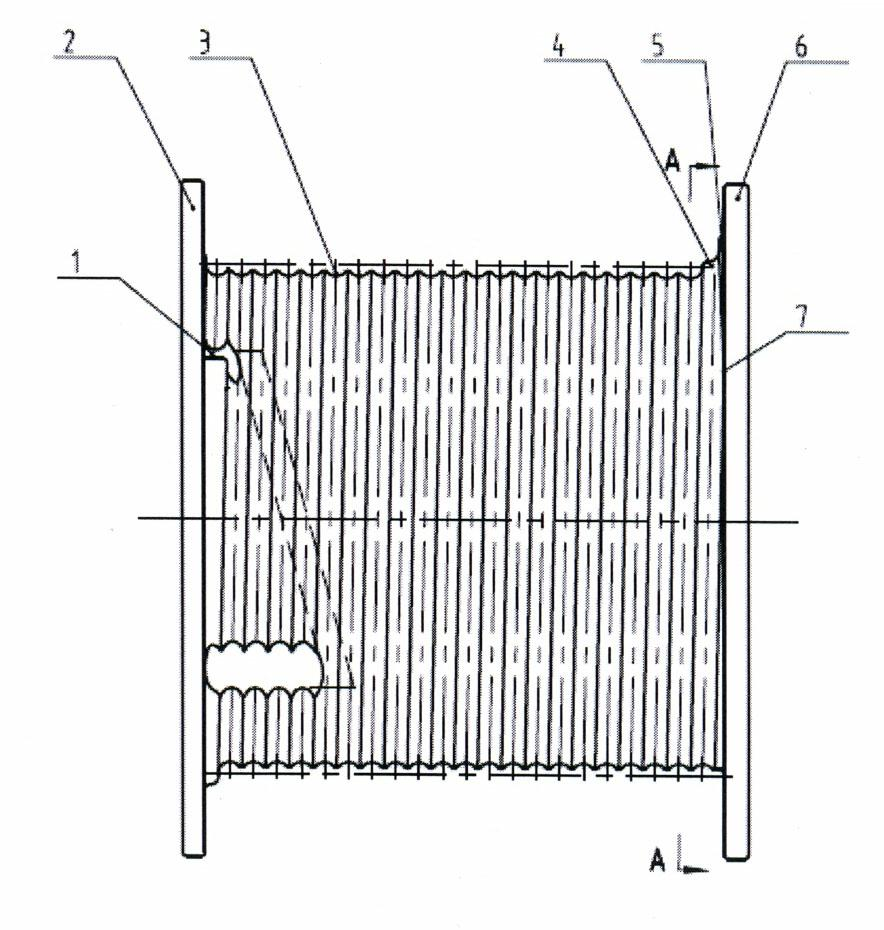

Double-layer winding steel wire rope reel

InactiveCN102107824AReduce contact stressReduce wearWinding mechanismsArchitectural engineeringSpiral line

The invention relates to a double-layer winding steel wire rope groove reel. The double-layer winding steel wire rope groove reel is provided with a reel body with a left flange and a right flange, wherein a rope groove is formed on the circumferential surface of the reel body; a steel wire rope fixing groove is formed at the starting end of the rope groove on the circumferential surface of the reel body; the rope groove is a spiral line rope groove; a climbing boss is arranged on the reel circle, at the tail end of the rope groove, of the reel body; the height of the climbing boss is gradually increased on the circumferential surface of the reel body along the circumferential extension angle; a guide baffle ring is arranged on the inner side, corresponding to the climbing boss, of the right flange; and the thickness of the guide baffle ring is gradually increased in the circumferential direction along with the extension angle. In the process of the steel wire rope climbing among layers, the guide baffle ring can guide the steel wire rope to change the winding direction, so that rope skipping and rope disordering are avoided and the rope can be tidily and tightly arranged on the second layer of the reel; the climbing boss has the effects of supporting and positioning, so that the contact stress between the steel wire ropes in the climbing process is effectively reduced and abrasion is reduced; the reel has a simple structure; the rope groove is easy to process; and precision is high and cost is low.

Owner:SHANDONG SHANTUI MASCH CO LTD

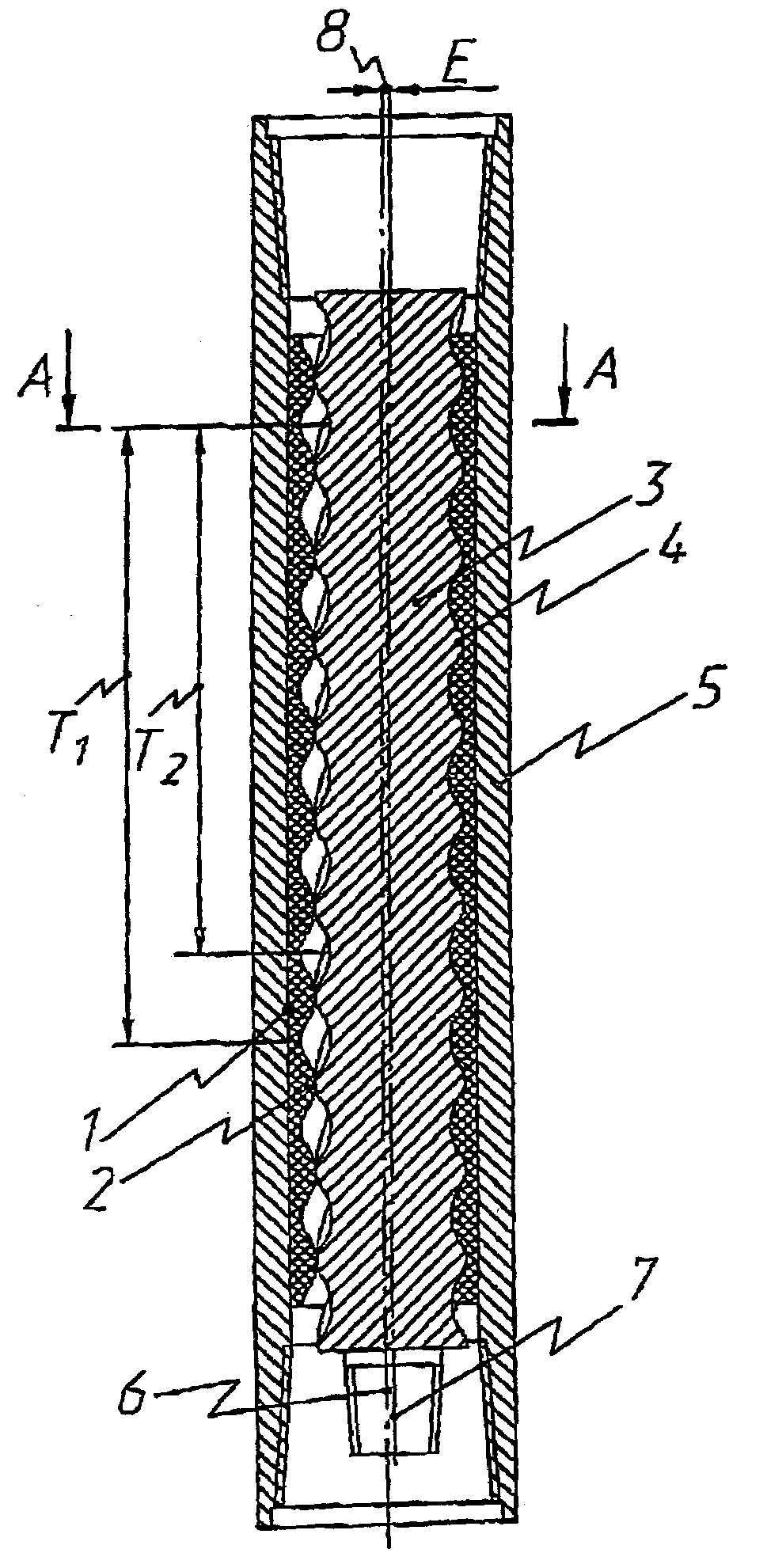

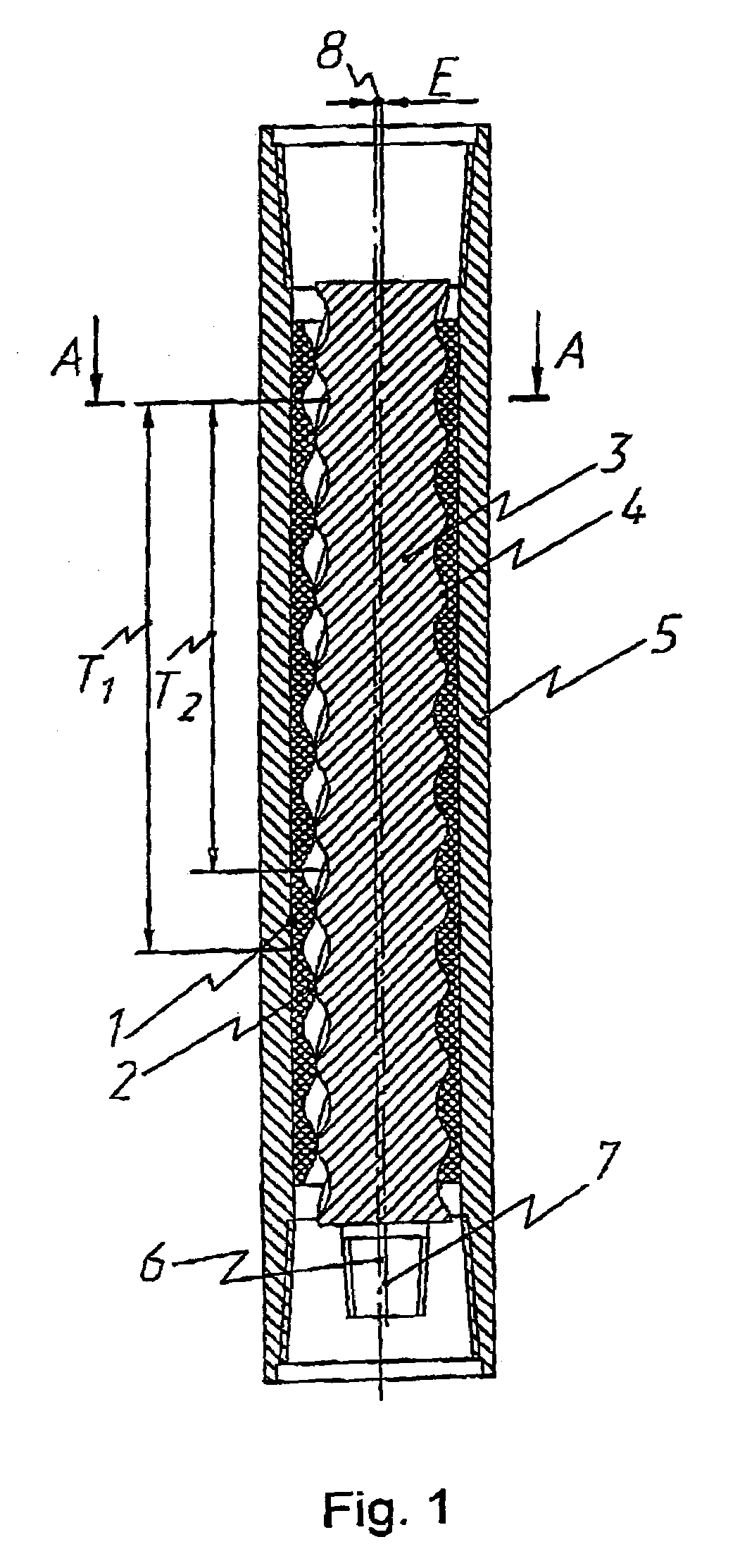

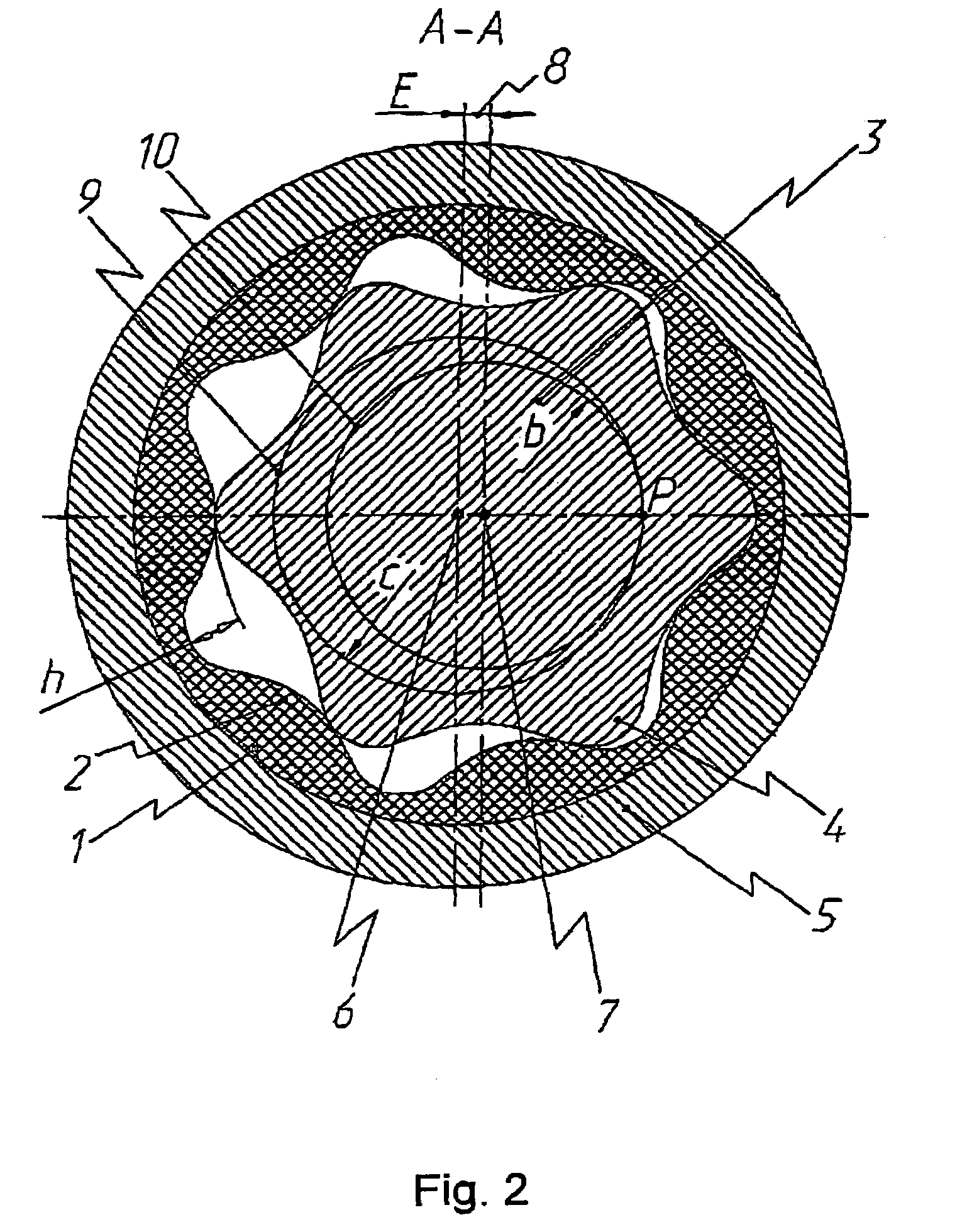

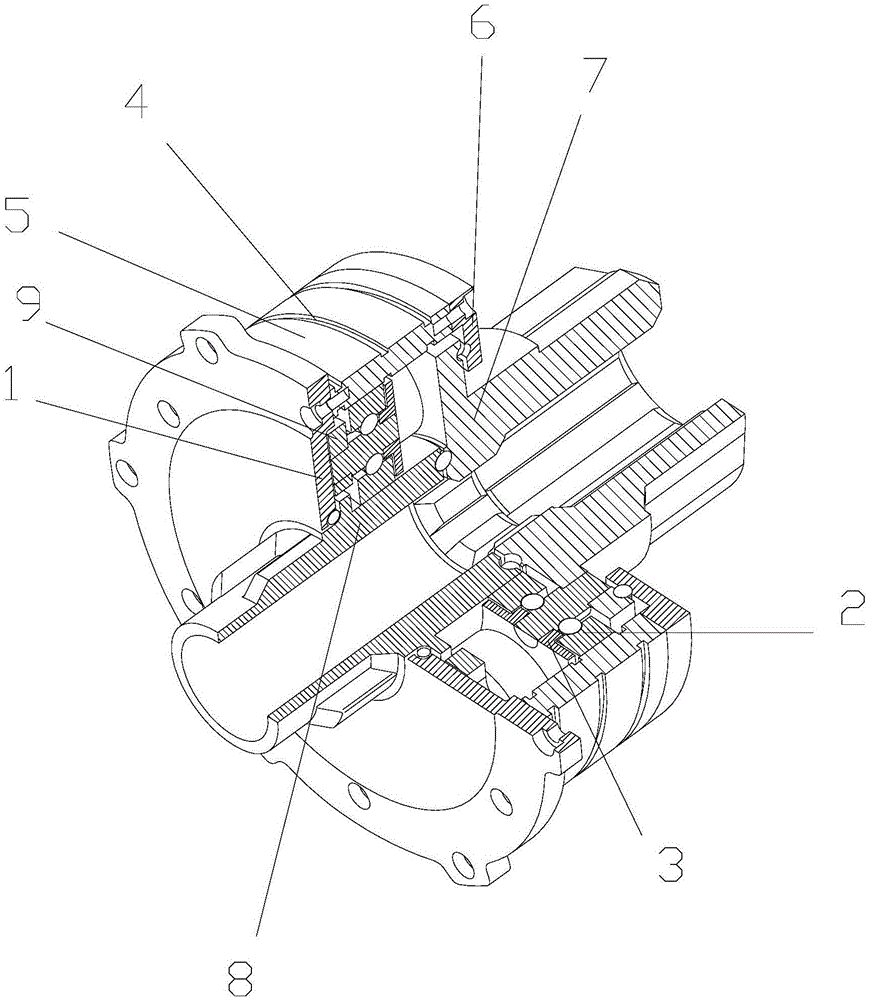

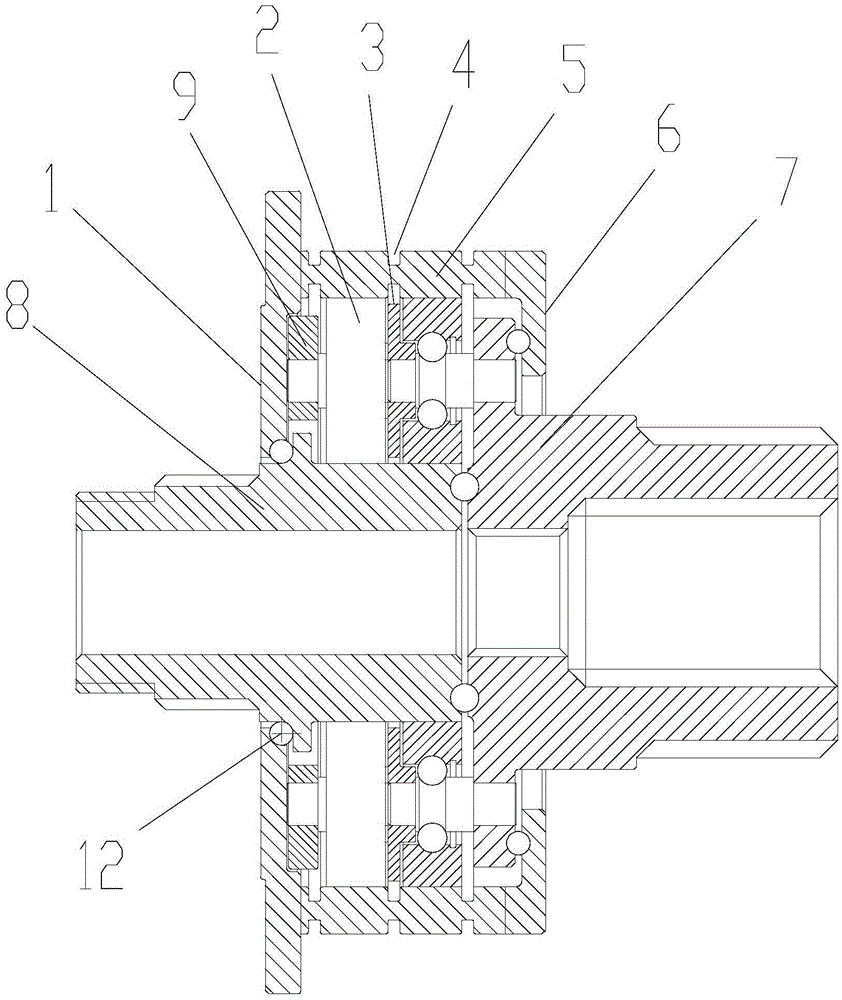

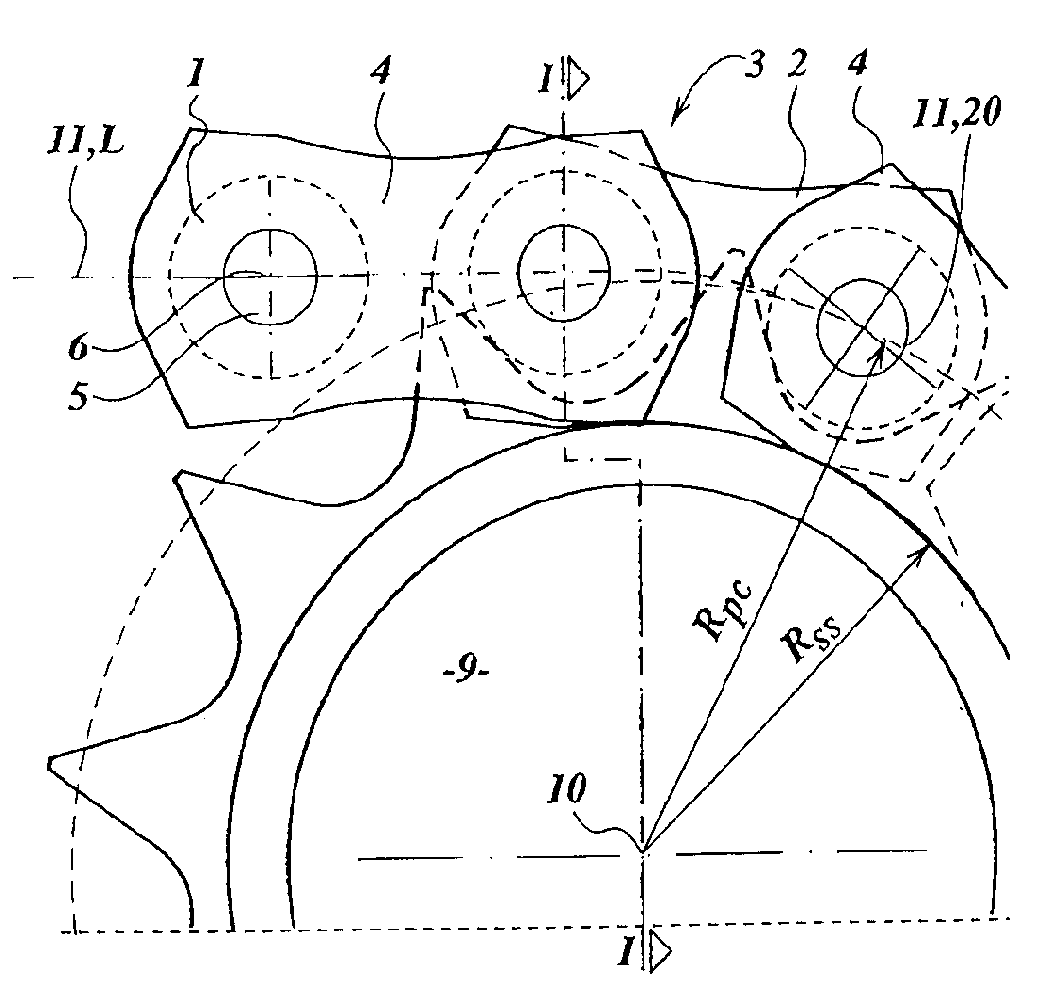

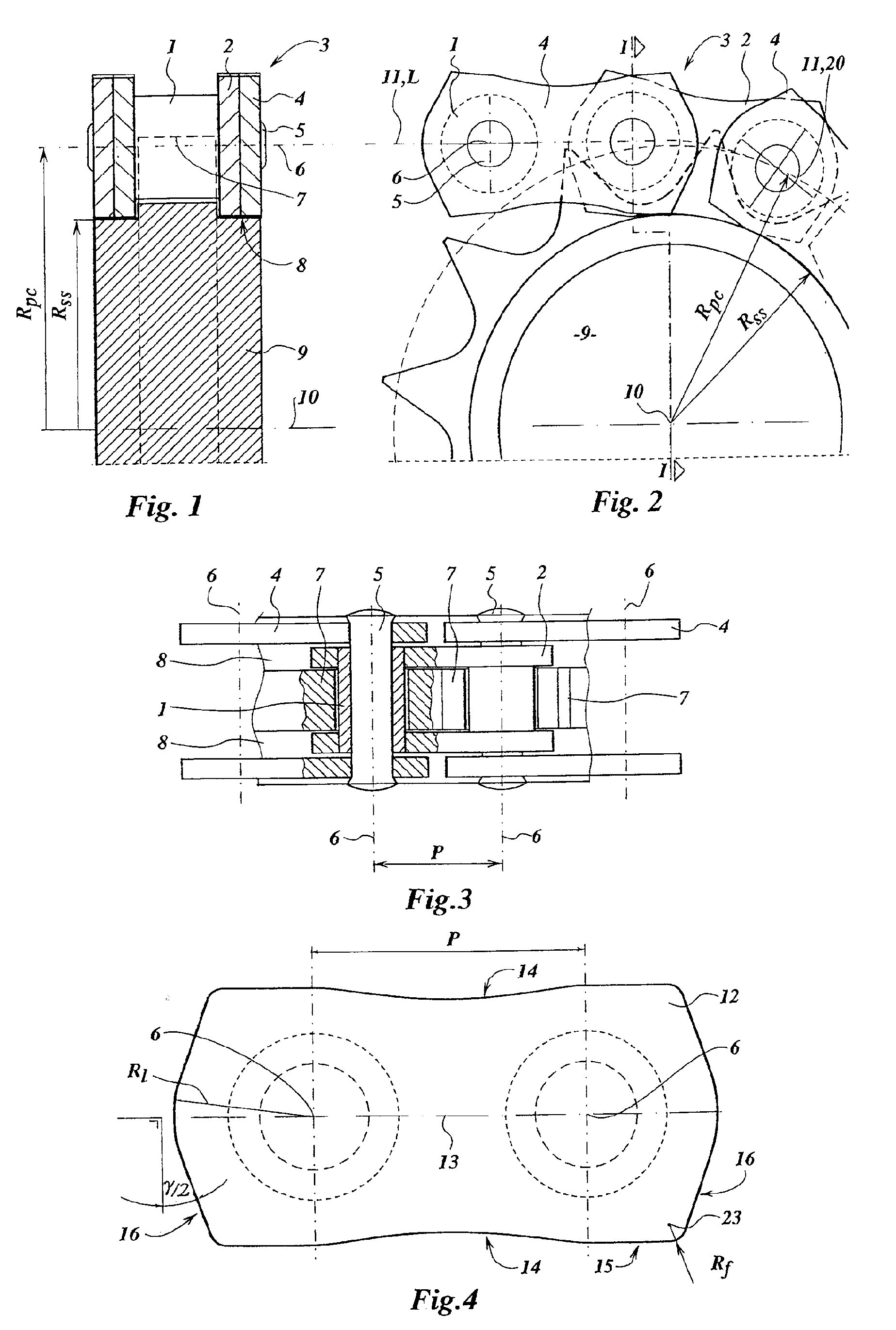

Gerotor mechanism for a screw hydraulic machine

InactiveUS7226279B2Improve energy characteristicsReduced hydro-mechanical lossesOscillating piston enginesEngine of intermeshing engagement typeGeneral purposeEngineering

The invention relates to gerotor mechanisms for screw downhole motors used for drilling oil and gas wells, to screw pumps for producing oil and pumping fluids and to general purpose screw motors. The profiles of a rotor (3) and stator (1) are outlined in the end cross section thereof in the form of the envelop of the initial contour of a rack-type tool, which is formed by conjugation of circle arcs when said initial contour of the rack-type tool is run without sliding along corresponding tool circles. The arc radii of the circle arcs of the initial contour are calculated according to determined relations. Said invention makes it possible to improve energy characteristics, increase a life service and producibility, to reduce hydromechanical losses and costs.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETABTVENNOSTJU FA RADIUS SERVIS

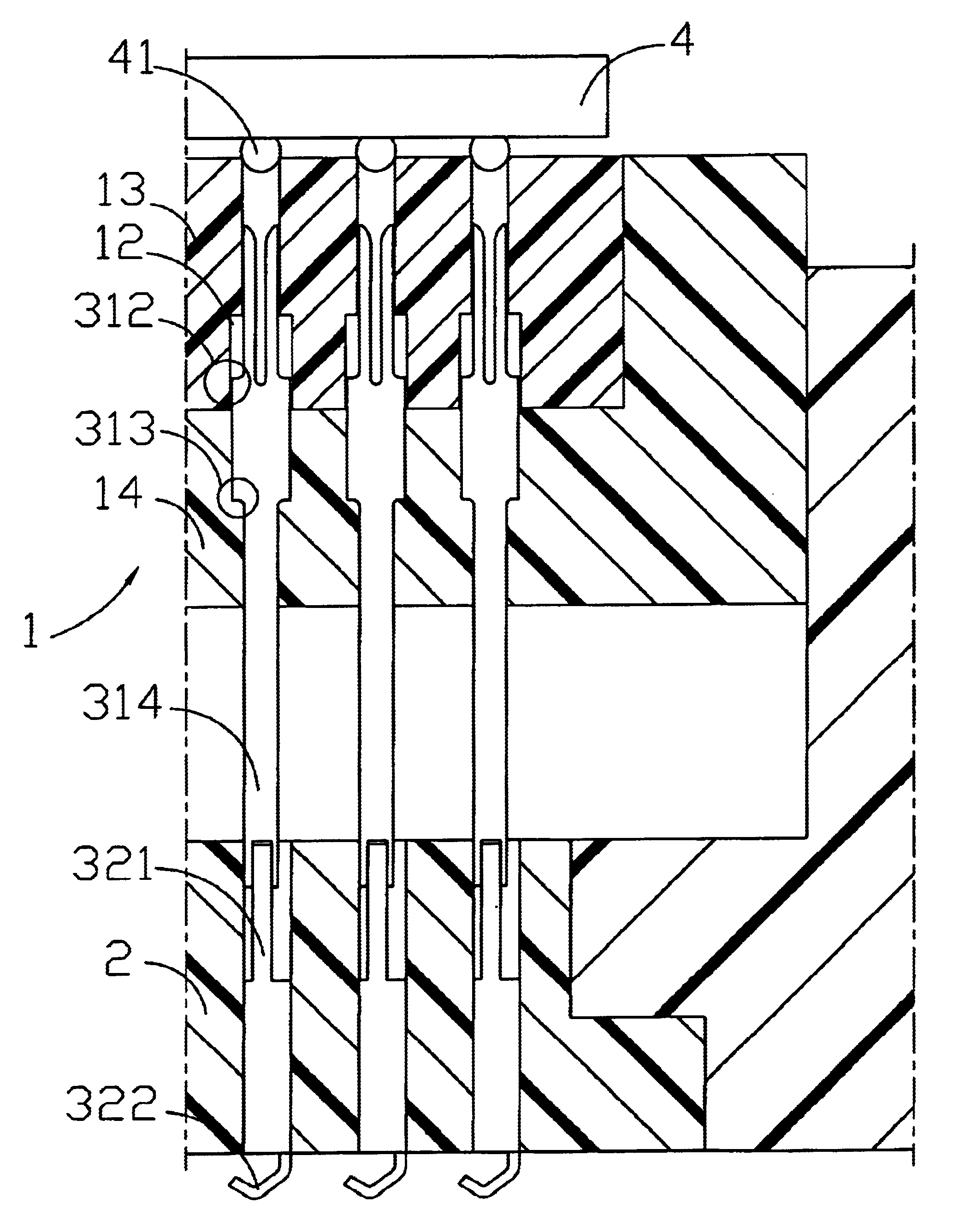

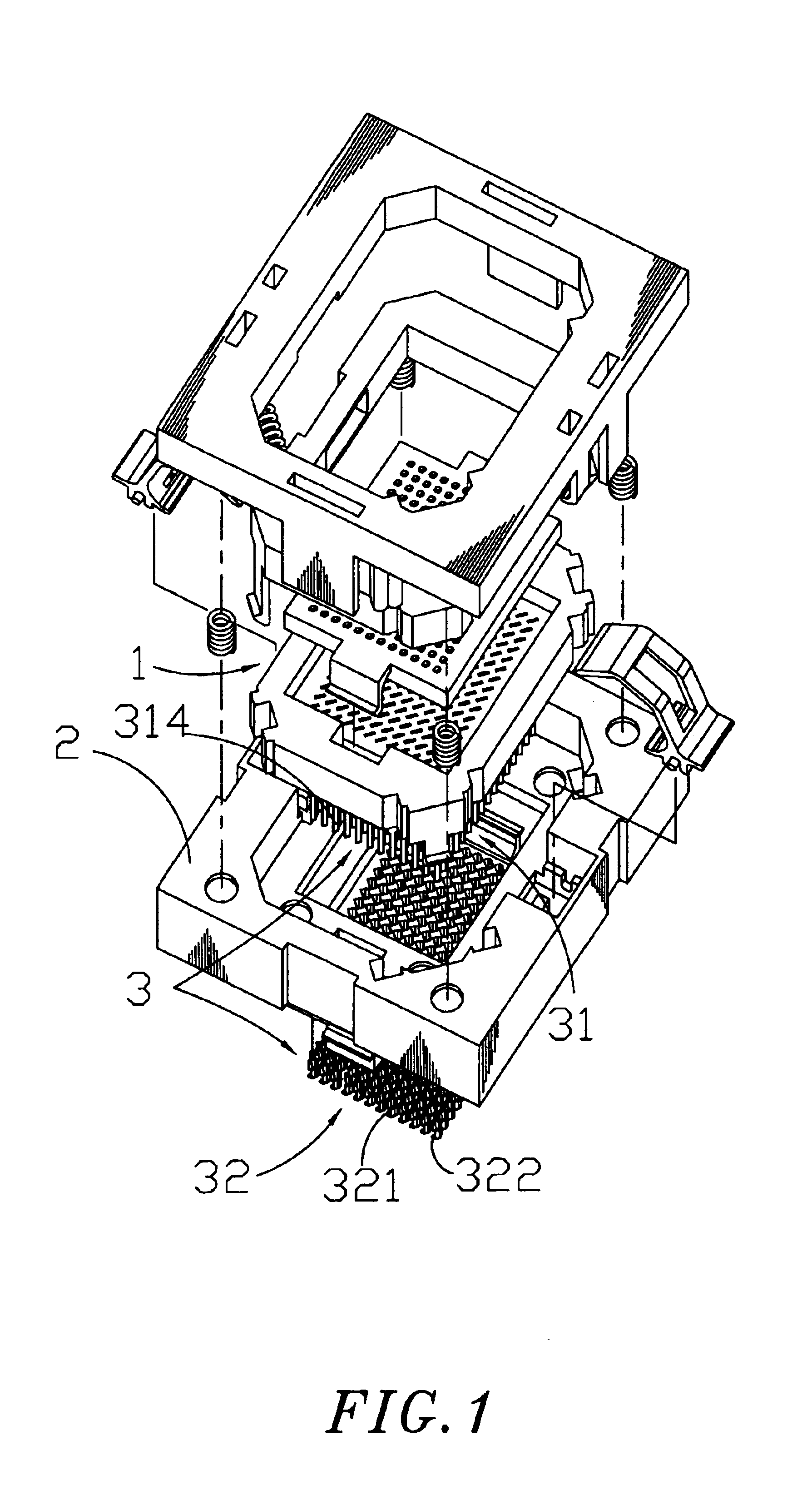

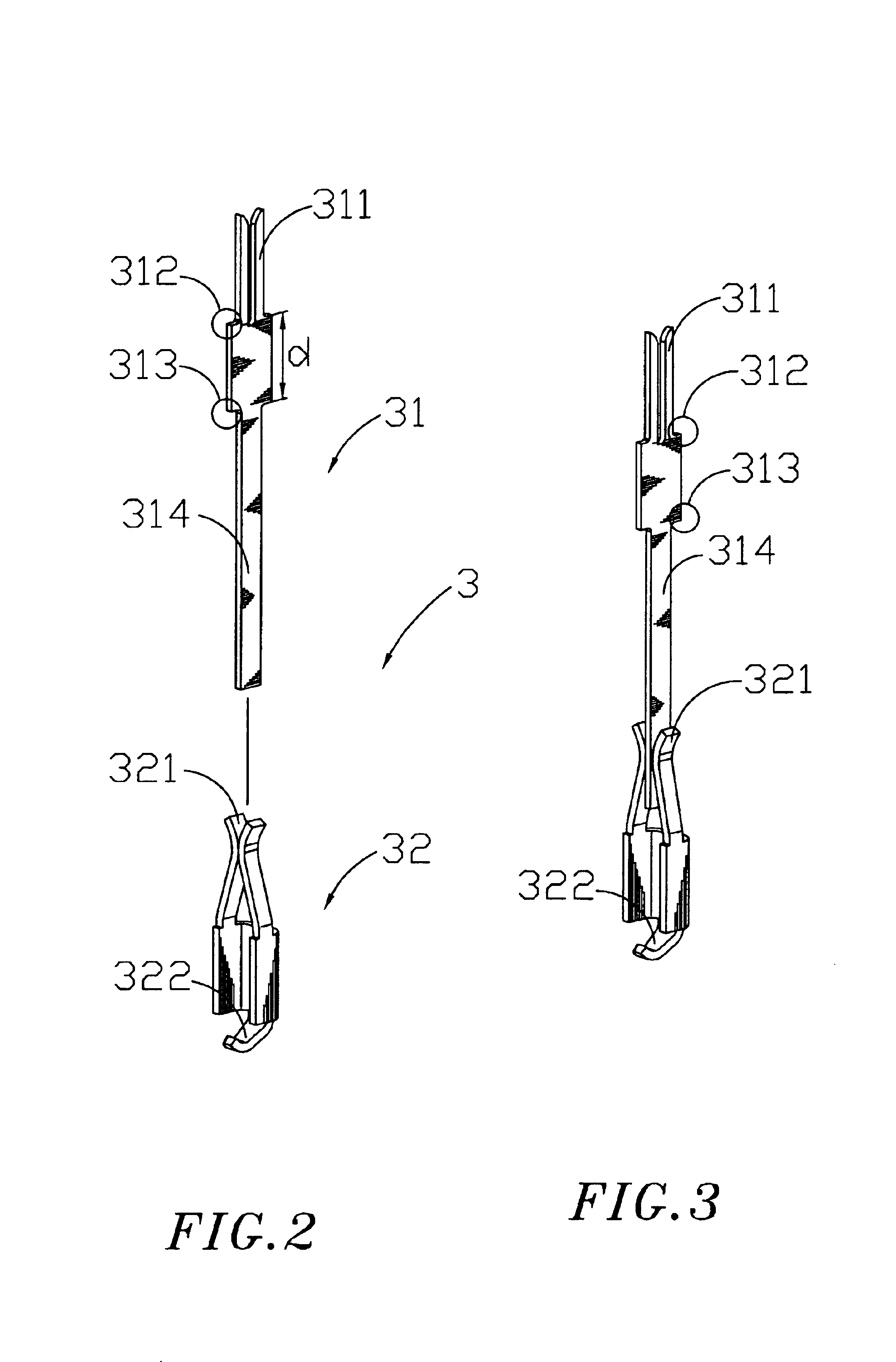

Matrix connector

InactiveUS6948945B2Reduce contact stressAvoid deformationCoupling contact membersLive contact access preventionEngineeringElectrical and Electronics engineering

Owner:SPEED TECH

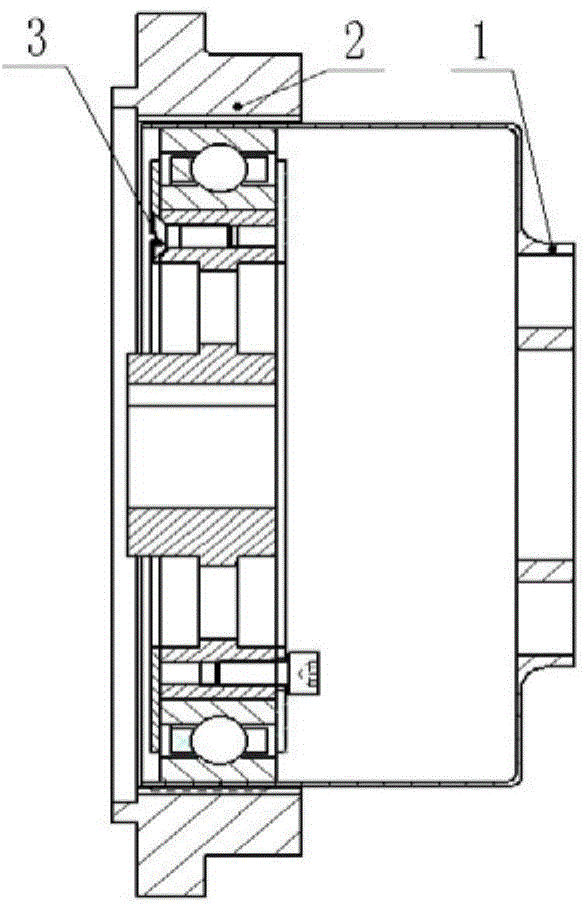

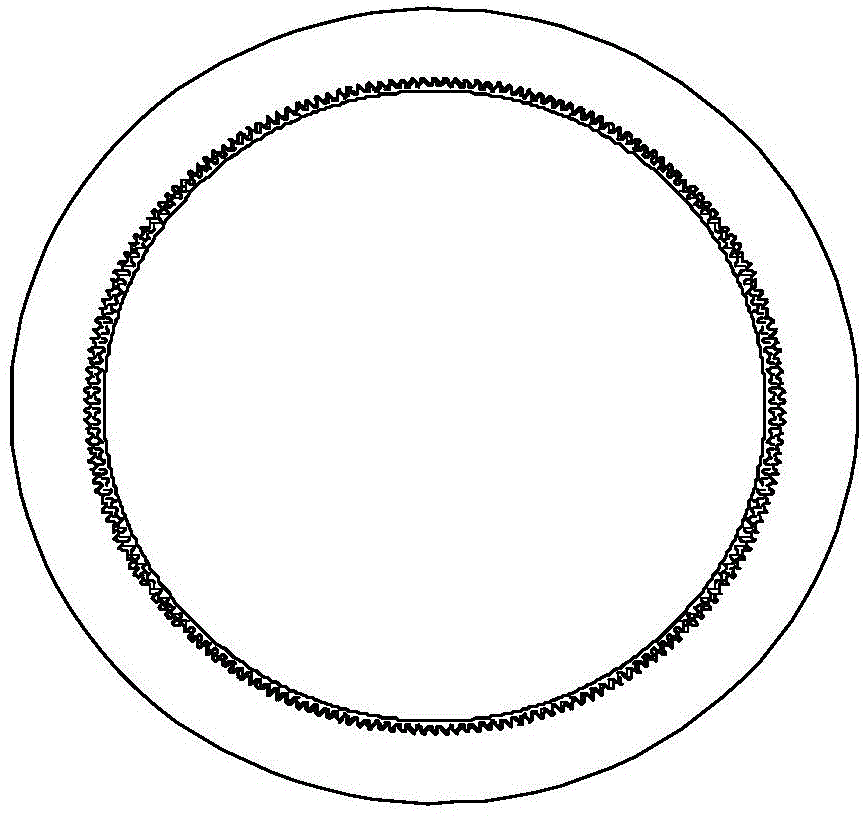

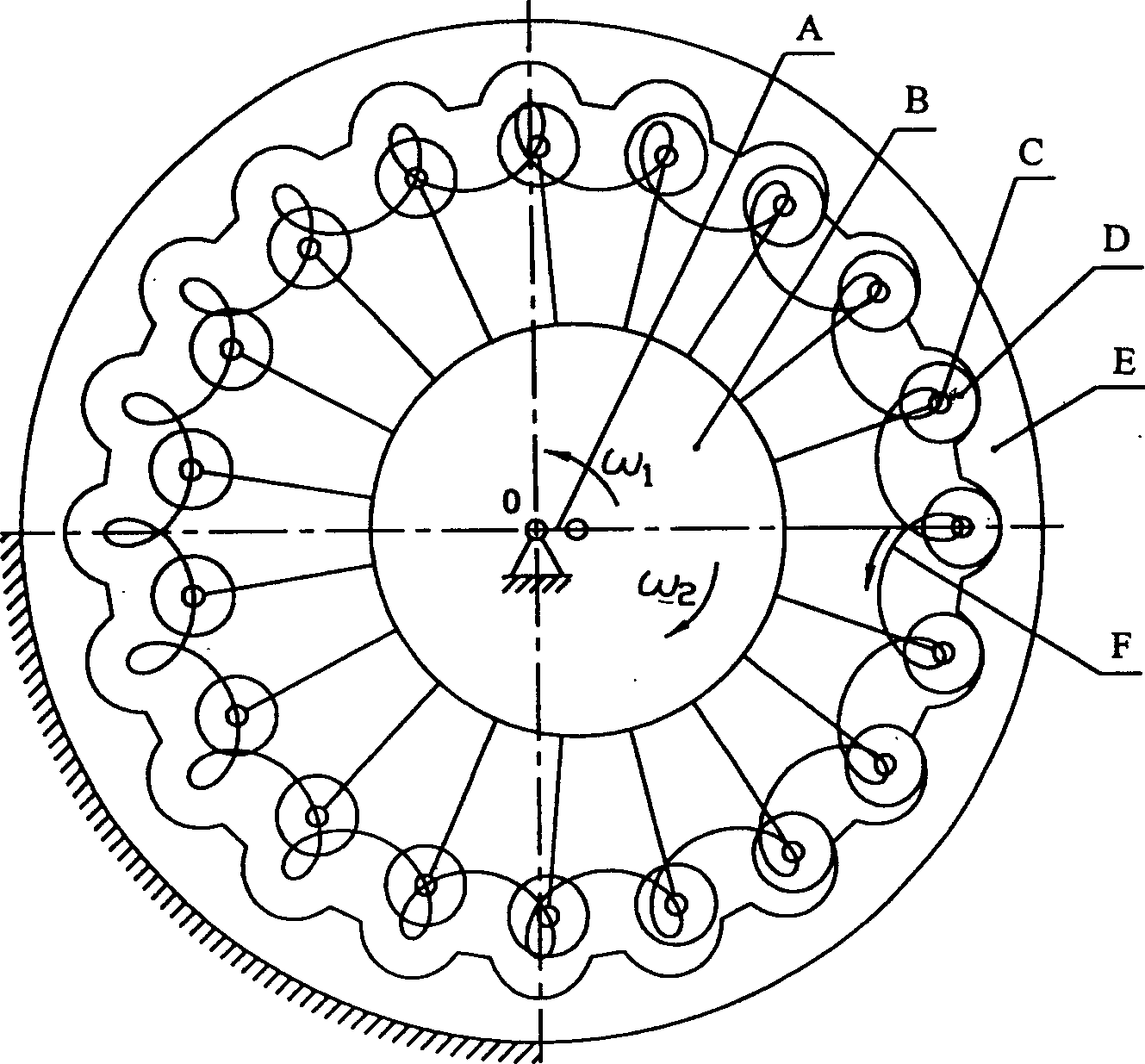

Multi-line planetary traction and transmission type speed reducing bearing

ActiveCN105570410AReduce in quantityThe support runs smoothlyRolling contact bearingsGearing detailsPositive pressureReduction drive

The invention discloses a multi-line planetary traction and transmission type speed reducing bearing. An inner ring, an outer ring and rolling bodies of the speed reducing bearing form a planetary traction and transmission gear train jointly and serve as a sun gear, an outer ring and a planetary gear of the planetary traction and transmission gear train correspondingly. According to the planetary traction and transmission type speed reducing bearing, radial supporting of a shaft is achieved by means of the positive pressure between the contact surfaces of the inner ring, the rolling bodies and the outer ring, and movement and power are transmitted by means of the friction force between the contact surfaces of the inner ring, the rolling bodies and the outer ring. The speed reducing bearing integrates the speed reducing function and the bearing function, and at least two lines of rolling bodies are arranged in the axial direction. An intermediate planetary carrier is arranged between every two adjacent lines of rolling bodies, wherein wheel shafts of the two adjacent lines of rolling bodies are connected through the intermediate planetary carrier. The rolling bodies in every two adjacent lines are evenly arranged in a staggered mode in the circumferential direction. According to the speed reducing bearing, the multiple lines of rolling bodies rotate, so that the contact between the rolling bodies, the inner ring and the outer ring is uniform in the circumferential direction and the axial direction, an inner ring shaft can be well supported, and the contact stress of the rolling bodies in the working process can be reduced; meanwhile, the torsional rigidity of a shaft system of the rolling bodies is high so that the torsional deviation of the shaft system of the rolling bodies can be effectively reduced in the transmission process, the situation that a speed reducer is disturbed or gets stuck during the transmission work can be effectively avoided, and the transmission quality and efficiency are improved.

Owner:CHONGQING UNIV

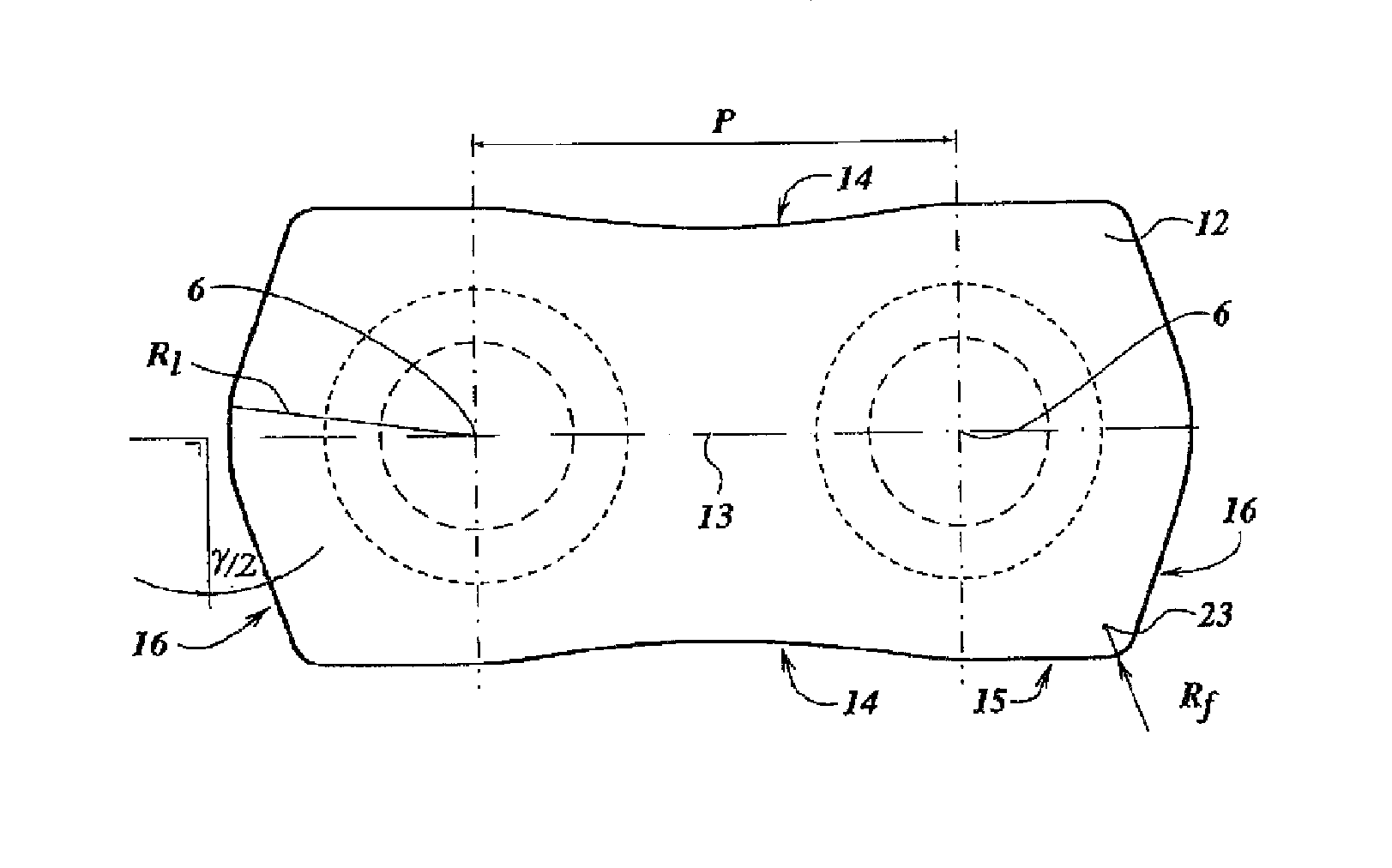

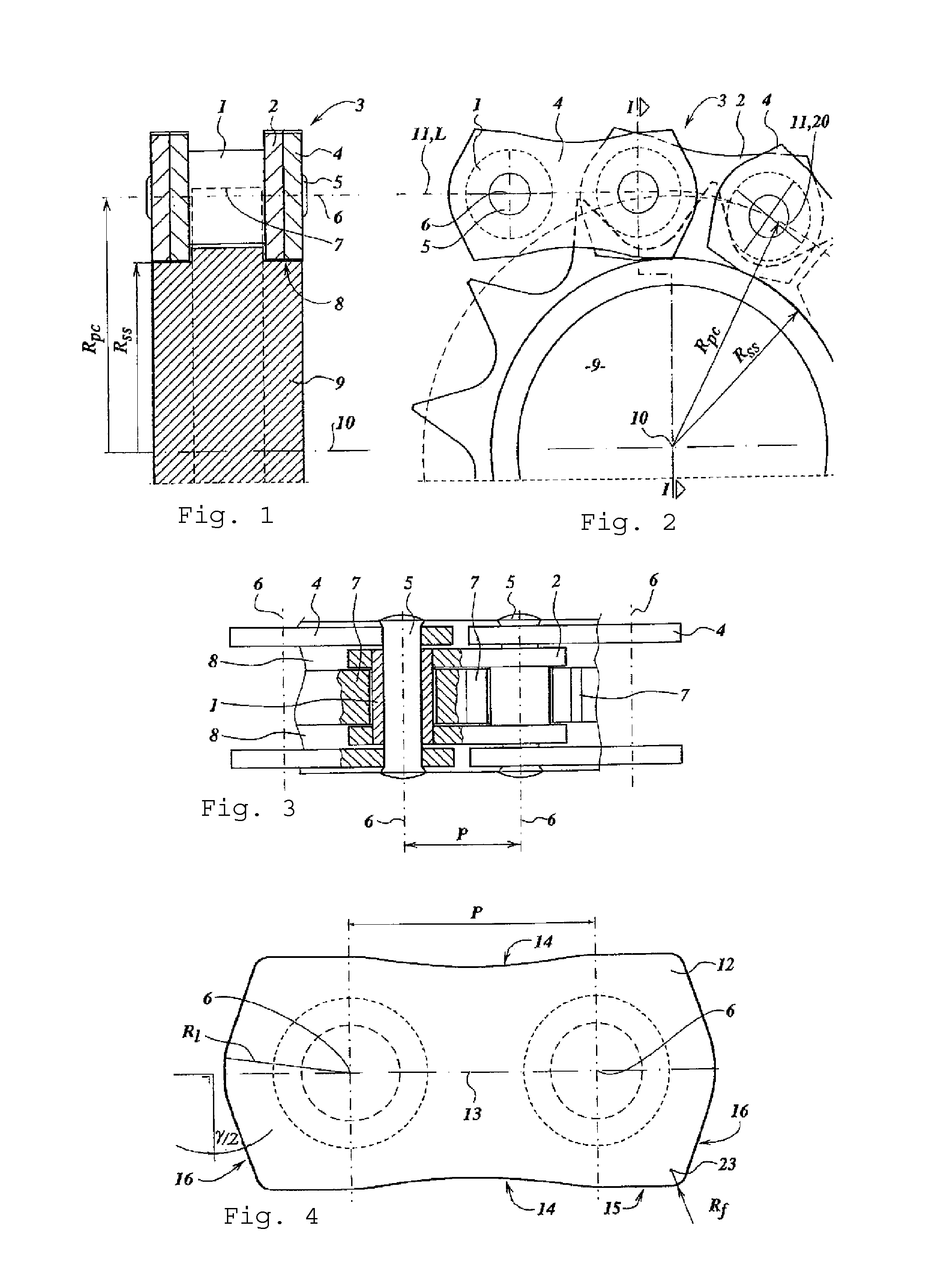

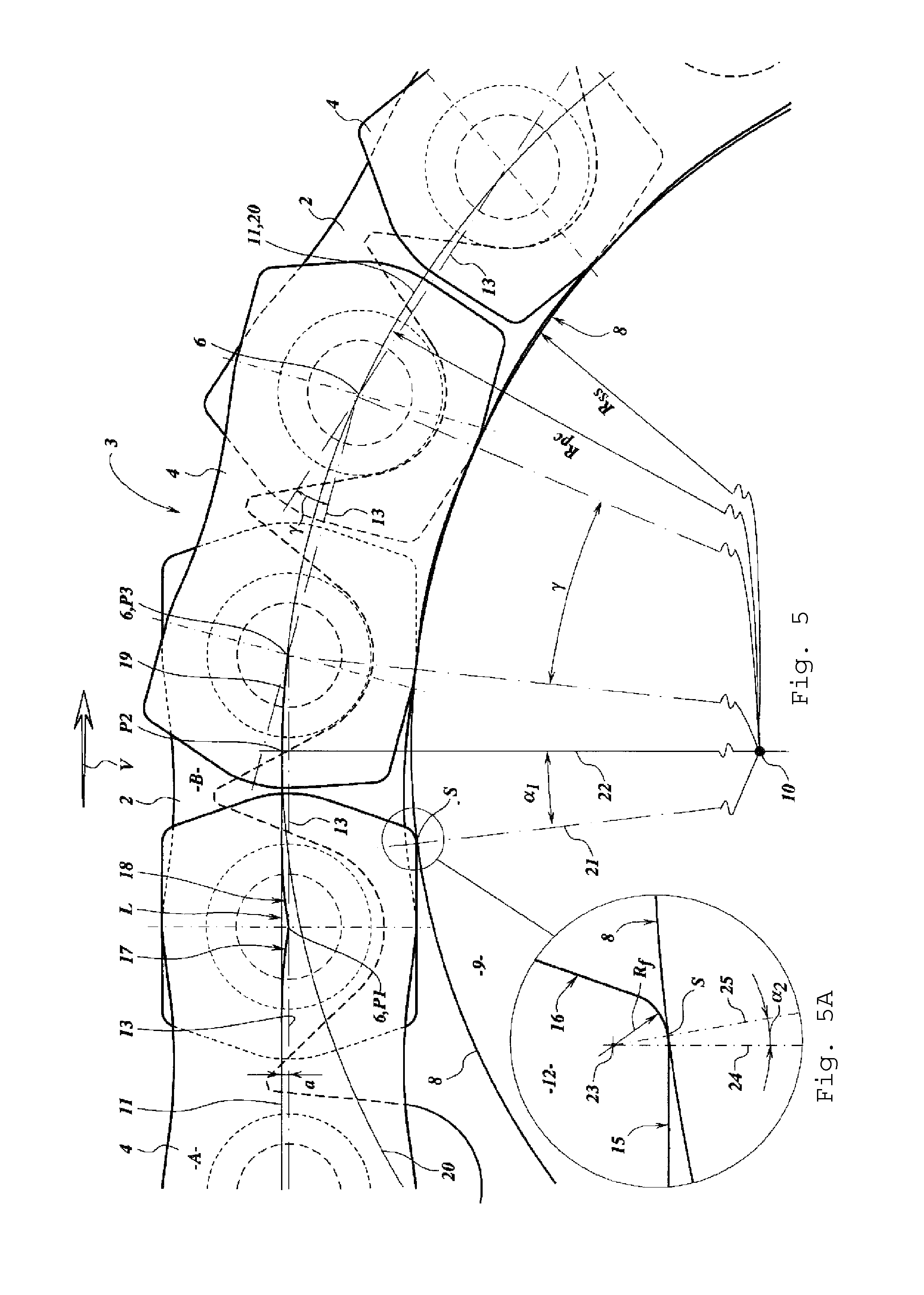

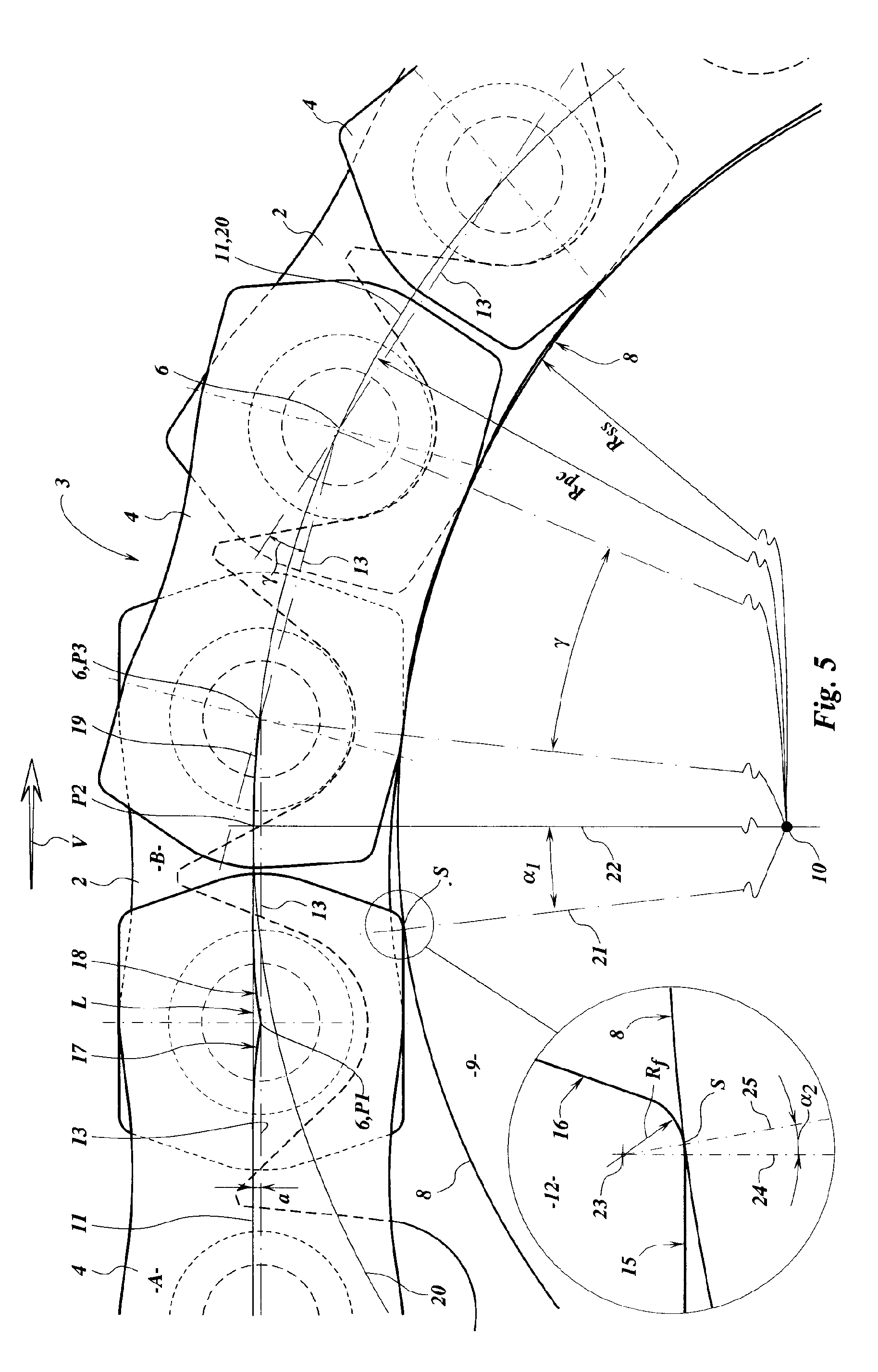

Chain for a chain transmission

InactiveUS8157683B2Increase of the radiusReduce contact stressGearingDriving chainsSlope angleSprocket

The invention concerns a chain for a chain transmission with chain links coupled by a parallel chain pins, each chain link having at least one link plate, the chain pins forming pivot axes for the link plates at a pitch distance whereby a chain link axis perpendicularly intersects the two pivot axes, said link plates having towards at least one end side of the link plate a cam surface for supporting the link plate on a cylindrical support surfaces of a sprocket wheel with a pitch angle. In accordance with the invention the cam surface ends in a convex curved plane with near the end side an increasing slope angle with the link axis whereby the slope angle increases to at least half of the pitch angle or to at least seven degrees.

Owner:KORSE THEODORUS HENRICUS JOHANNES CAROLINA

Chain for a chain transmission

The invention concerns a chain for a chain transmission with chain links coupled by a parellel chain pins, each chain link having at least one link plate, the chain pins forming pivot axes for the link plates at a pitch distance whereby a chain link axis perpendicularly intersects the two pivot axes, said link plates having towards at least one end side of the link plate a cam surface for supporting the link plate on a cylindrical support surfaces of a sprocket wheel with a pitch angle. In accordance with the invention the cam surface ends in a convex curved plane with near the end side an increasing slope angle with the link axis whereby the slppe angle increases to at least half of the pitch angle or to at least seven degrees.

Owner:KORSE THEODORUS HENRICUS JOHANNES CAROLINA

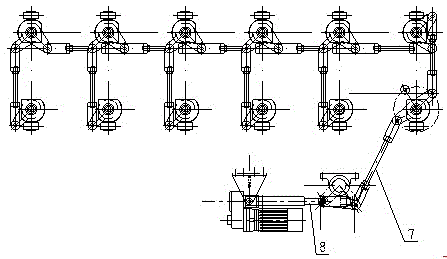

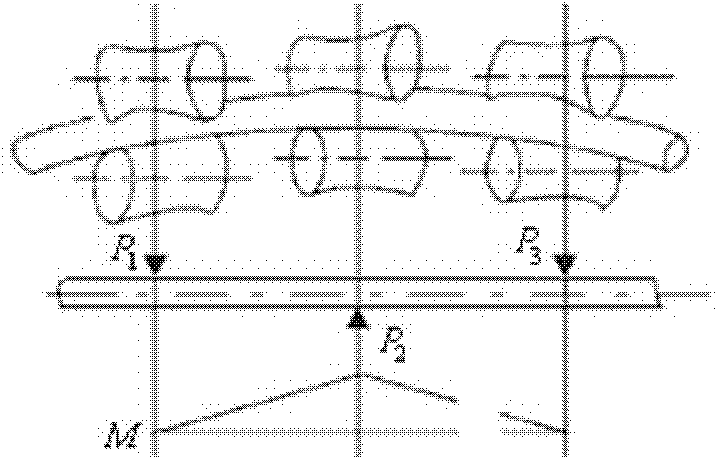

Bending device of joint flexible turnout

The invention relates to a bending device of a special rail transfer joint flexible turnout for straddle type monorail traffic line. The bending device comprises guide panels, stabilization panels, mount supports, cam support shafts, axial cams, double-plug connecting rods, roller assemblies, a connecting rod pair and an electric push rod, and adopts a cam and pull rod series connection driving form to realize synchronous bending of a guide surface and a stabilization surface; the guide panels and the stabilization panels are connected with the two ends of the double-fork-head pull rods by reamed holes; the double-fork-head pull rods are connected with driven components; the driven components are contacted and connected with cylindrical cam mechanisms; the above two adjacent cylindrical cam mechanisms and the two vertically corresponding cylindrical cam mechanisms are connected by connecting rods; when the electric push rod starts to push and pull, the pull rod drives the guide panels to move transversely and synchronously, and therefore, the transverse bending of the guide panels is accomplished.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Harmonic speed reducer of cycloid roller chain

The harmonic speed reducer with cycloid roller chain includes one harmonic generator connected to the input shaft and on double rack, one double-row roller chain ring, the first inner gear fixed to the chassis and with teeth in the number two or three less than the number of the chain sections in the roller chain ring, and the second inner gear fixed to the output shaft and with teeth in the number the same as the number of the chain sections in the roller chain ring. Under the driving of the harmonic generator, one row of the rollers in the double-row roller chain ring meshes with the first inner gear while the other row of the rollers in the double-row roller chain ring meshes with the second inner gear. The mesh pairs are embossed contacted for high bearing capacity and dynamically designed. The present invention realizes the harmonic cycloid mesh transmission by means of the radial flexibility and axial rigidity of the double-row roller chain ring, and has compact structure and low cost.

Owner:宁波凯荣新能源有限公司

Abradable dry film lubricant and the method for applying same and article made therefrom

InactiveCN101535420AEasy meshReduce contact stressShaftsBearing componentsSubstrate surfaceLubricant

An article with an abradable dry powder coating thereon comprises an abradably coated article with a substrate surface and having at least one coating of a liquid primer on the substrate surface and then coating with at least one abradable dry powder coating on the surface of the liquid primer. The sequence of layers may also be reversed, or additional layers may be useful. The abradable dry powder coating is formed of a dry powder coating composition including a thermoset resin having a cure temperature combined with at least one filler material, wherein the filler is formed of a material which does not melt substantially at or below the cure temperature of the resin, whereby an abradable coating results employing a filler to make the coating. A method of making a composition for coating an article with a coating curable into an abradable coating is also disclosed, comprising melt- mixing an evaporative carrier-free mixture of a dry powder thermoset resin having a cure temperature, to form a mass composite, wherein the filler is formed of a material which does not substantially melt at or below the cure temperature of the resin, cooling the mass composite, and breaking the cooled mass composite into powder particles, thereby forming the composite powder composition.

Owner:安德鲁·W·苏曼

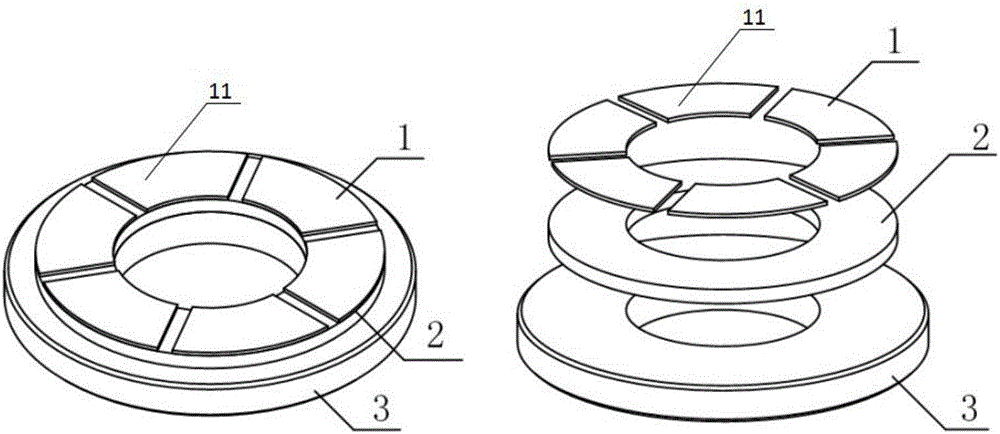

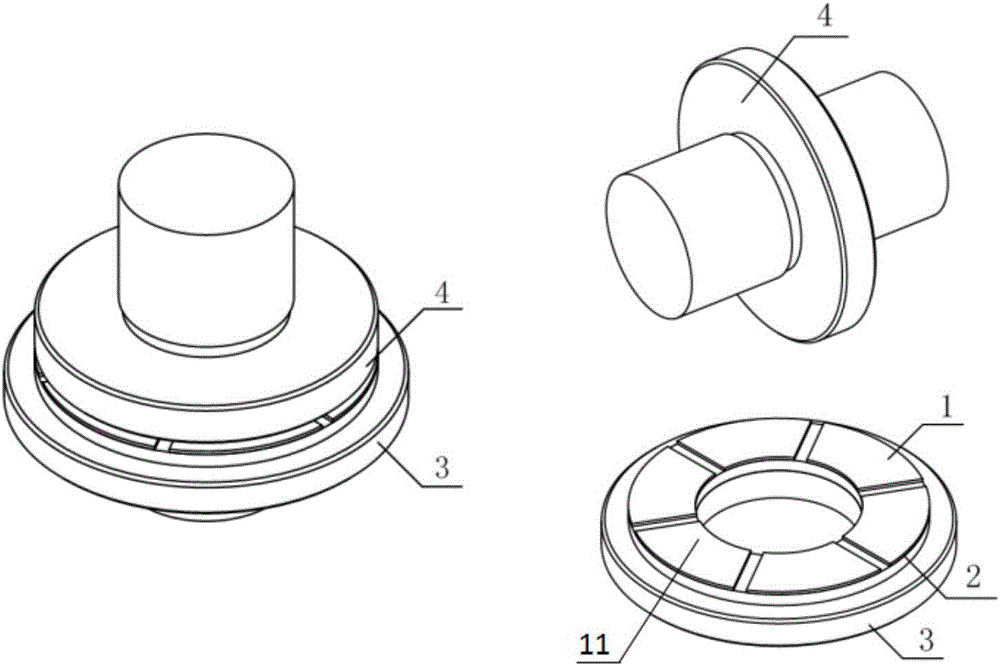

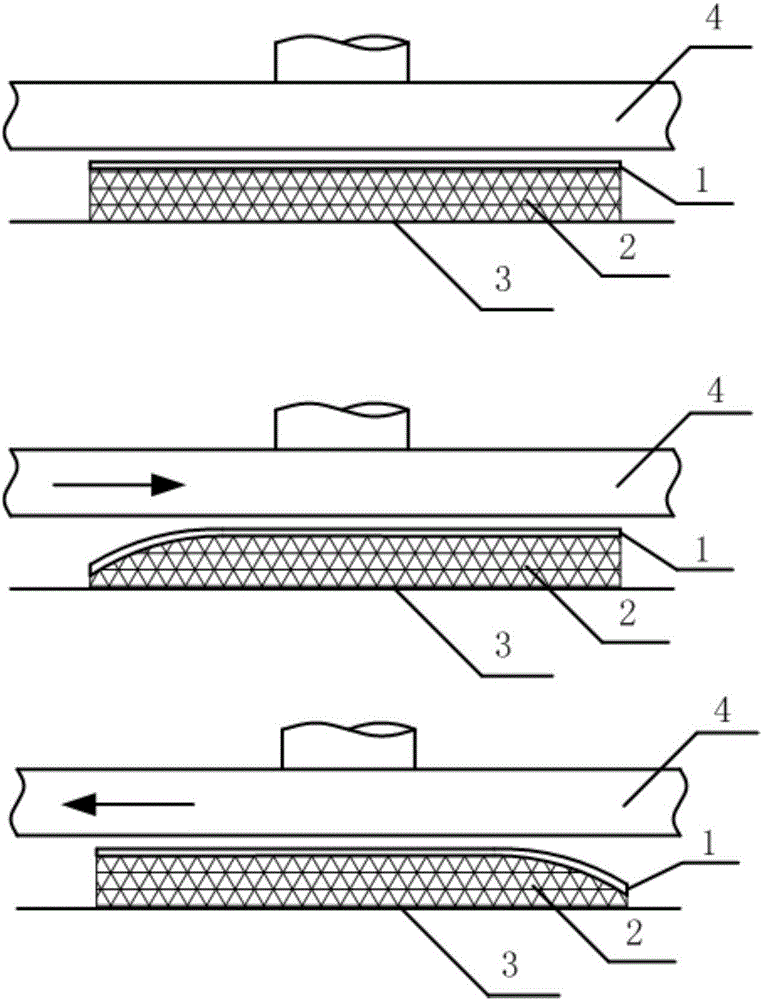

Flexible dynamic-pressure gas thrust bearing and assembling method thereof

ActiveCN106438676AAvoid local severe wear and tearExtended service lifeSliding contact bearingsThrust bearingEngineering

The invention discloses a flexible dynamic-pressure gas thrust bearing and an assembling method thereof. The flexible dynamic-pressure gas thrust bearing comprises a bearing block, an elastic support connected to the bearing block and top-layer flat foil connected to the elastic support. The top-layer flat foil comprises a plurality of flat foil pieces fixedly connected to the elastic support to form a bearing working plane. The flexible dynamic-pressure gas thrust bearing has the advantages that the thrust bearing does not have an inlet slope structure machined in advance, the inlet slope structure of the thrust bearing is formed through self-acting during bearing work, the bearing does not limit the rotation direction of a rotor thrust collar, that is to say, the rotor thrust collar can rotate along different directions, the bearing can work normally, and a traditional flexible dynamic-pressure gas bearing only allows the rotor thrust collar to rotate along one direction; the flexible feature of the dynamic-pressure gas thrust bearing can be regulated simply, and the rigidity feature of the bearing can be regulated conveniently by changing the elasticity of the elastic support so as to adapt to the rigidity requirements on the bearing under different application conditions.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Method for realizing precision straightening of thin-wall seamless steel tubes by adopting six-roller straightener

InactiveCN101927278AReduce the number of squashesIncrease the number of squashesMechanical engineeringSteel tube

The invention discloses a method for realizing the precision straightening of thin-wall seamless steel tubes by adopting a six-roller straightener, aiming at providing a method for obtaining optimum technological parameters and producing thin-wall seamless steel tubes with high surface quality by calculating straightening press-down quantity and correcting press-down quantity, comparing the resultant force of straightening applied force and correcting applied force with and hertz contact force, and checking straightness accuracy and the diameter difference of long shafts and short shafts of an ellipse. The method comprises the following steps: confirming the press-down bending and straightening frequency and press-flat bending and correcting frequency; confirming the straightening press-down quantity, the straightening applied force, the correcting press-down quantity and the correcting applied force; working out the hertz contact force resulting in the sag deformation of the seamless steel tubes according to a hertz contact theory; comparing the hertz contact force with the resultant force of the straightening applied force and the correcting applied force; calculating straightness error according to the actual straightening press-down quantity from 1 to the last straightening; and calculating the corrected diameter difference of the long shafts of the ellipse and the diameter difference of the short shafts of the ellipse from 1 to the last correcting and comparing with a standard value.

Owner:TIANJIN UNIV OF COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com