Harmonic gear reducer

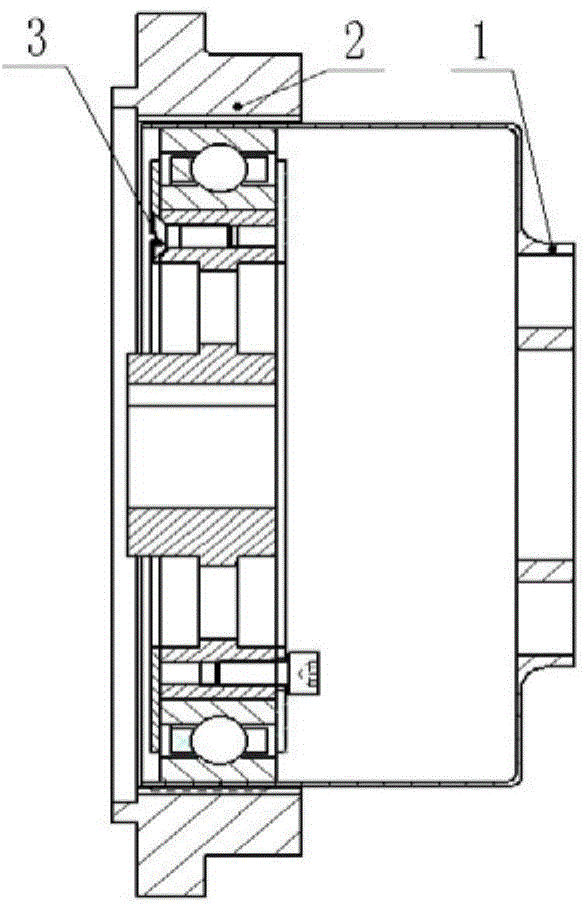

A gear reducer and harmonic technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of small meshing interval, serious stress concentration at the tooth root, and easy distortion of sharp-point meshing flexible splines , to achieve the effect of expanding the meshing area of the gear teeth, reducing the stress concentration of the tooth root, and facilitating the formation of the oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

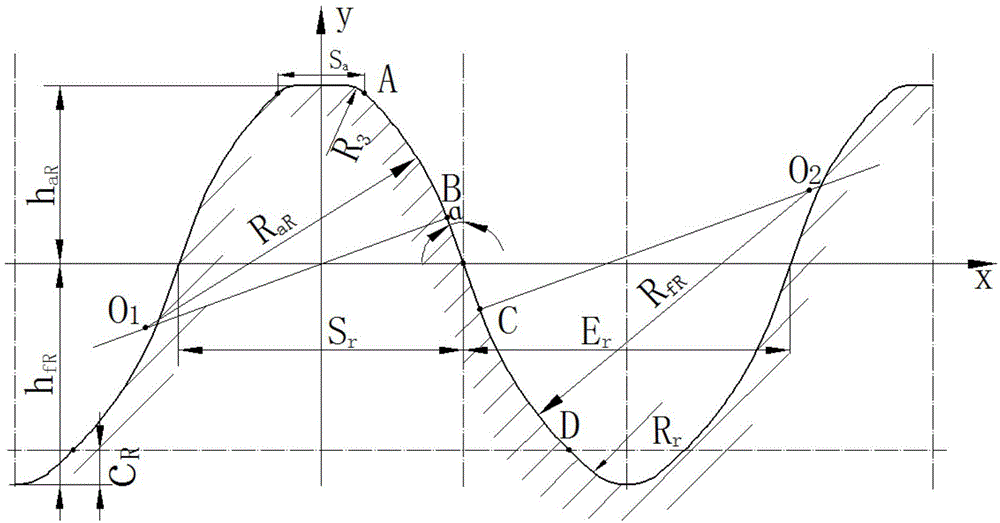

[0028] combine image 3 , image 3 is the tooth profile curve of the flexspline 1 of the harmonic gear reducer of the present invention. The flexible gear 1 of the harmonic gear reducer of the present invention is processed by displacement cutting of a hobbing cutter. The basic tooth profile curve of the flexspline 1 is composed of arc-involute-arc. In this embodiment, the basic tooth profile parameters of the flexspline 1 are:

[0029] Addendum height factor root height factor Headspace Coefficient Pressure angle α=20°, coefficient of variation x R =3.52, the arc radius coefficient of the tooth top working section Radius coefficient of the arc radius of the working section of the dedendum Tooth thickness ratio K=1.05, root transition arc radius coefficient Addendum thickness factor In order to prevent the tooth tip interference phenomenon of the tooth profile of the flexspline during the meshing process, the tooth tip part is rounded, and the fillet radius coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com