Patents

Literature

247 results about "Harmonic drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Harmonic Drive is the brand name of strain wave gear trademarked by the Harmonic Drive company, and invented in 1957 by C.W. Musser. It is very commonly implemented in robotics today and used in aerospace as well, for gear reduction but may also be used to increase rotational speed, or for differential gearing.

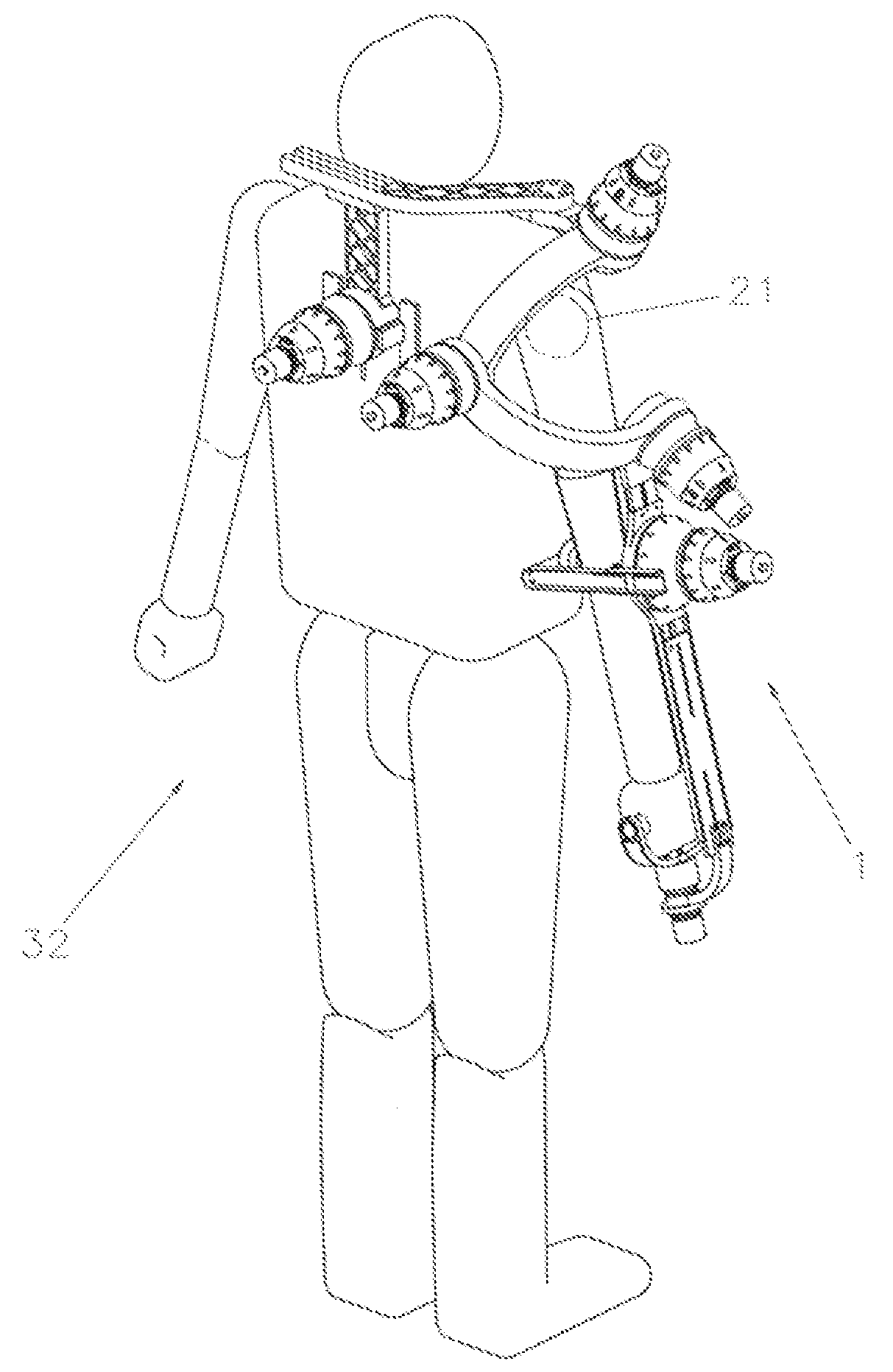

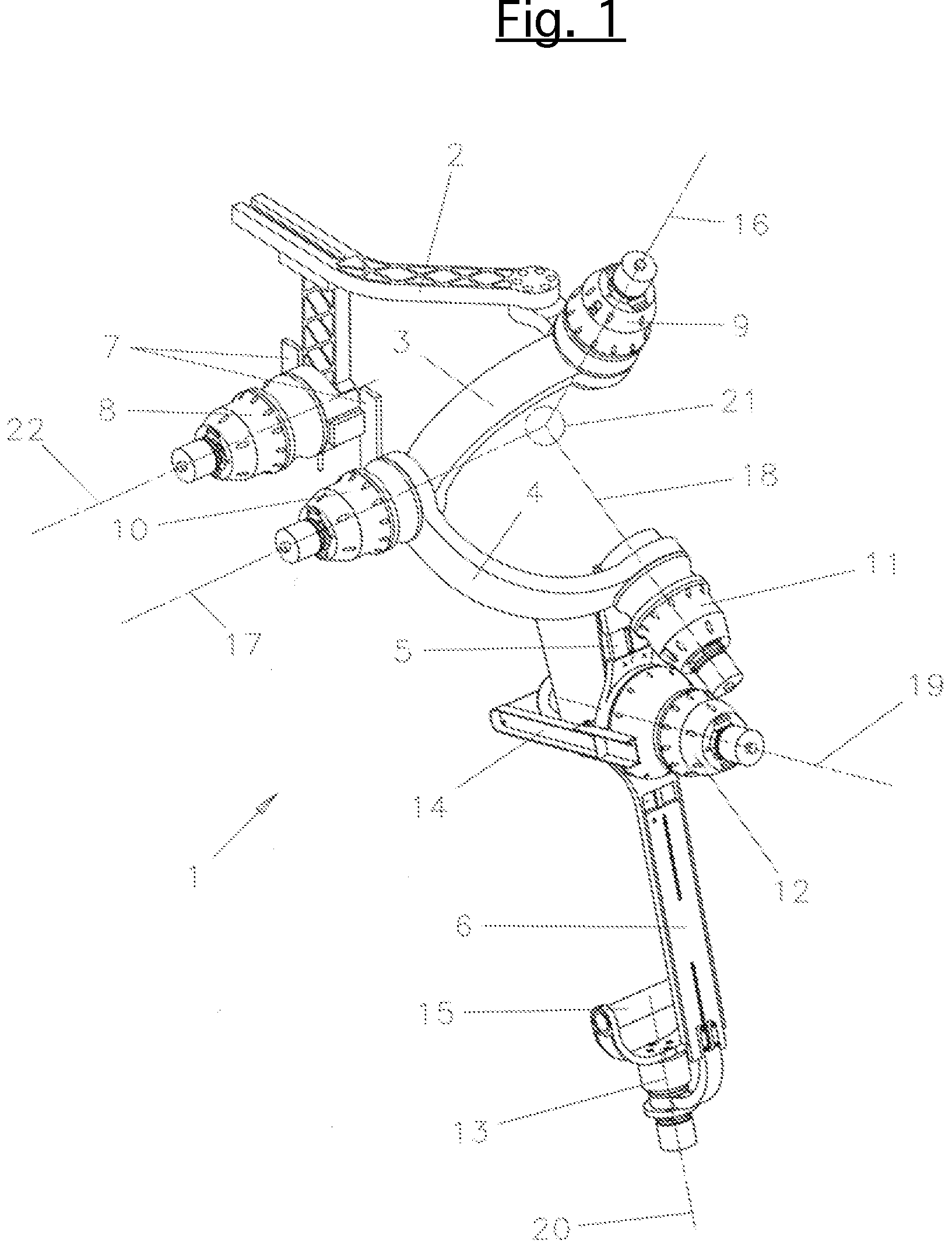

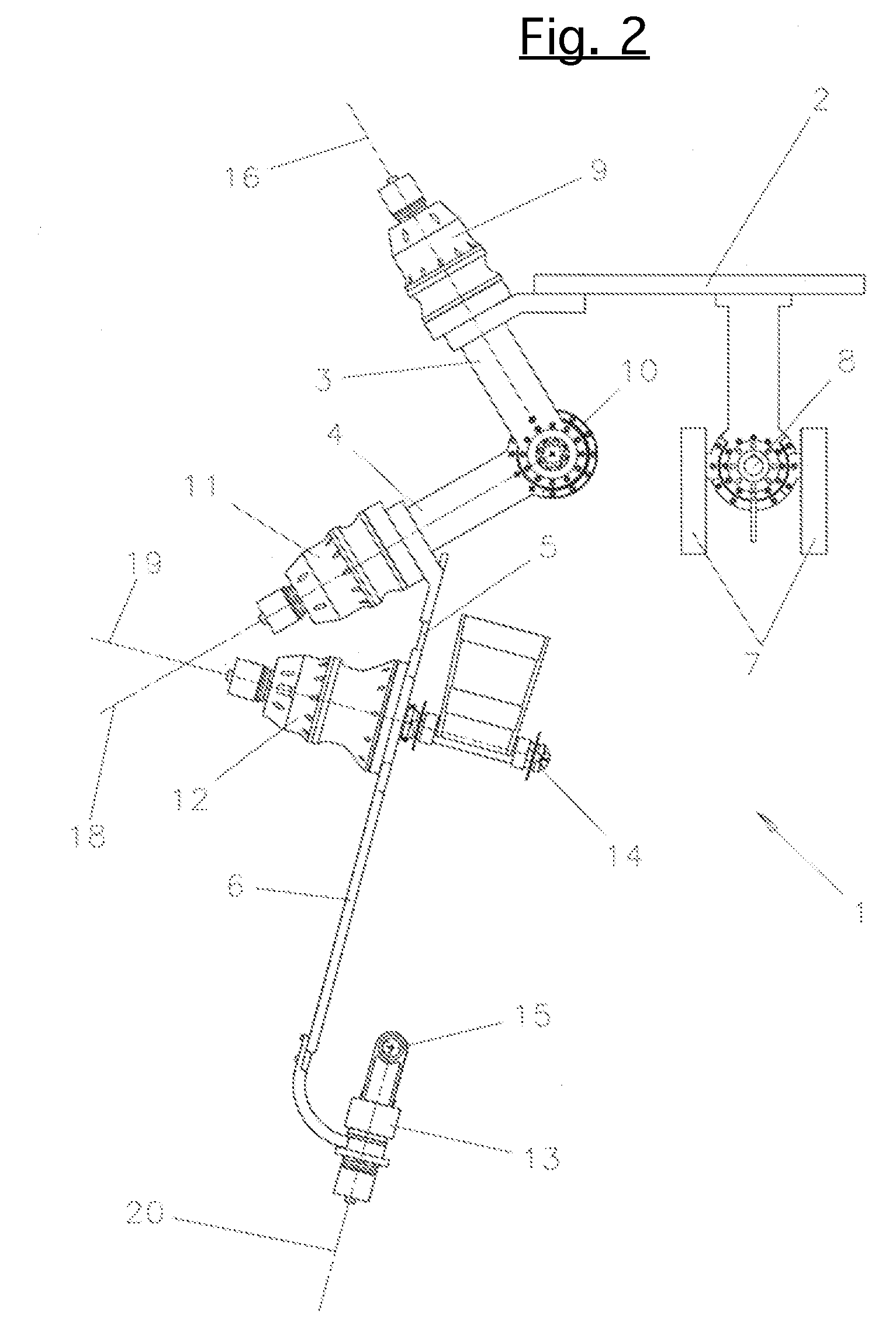

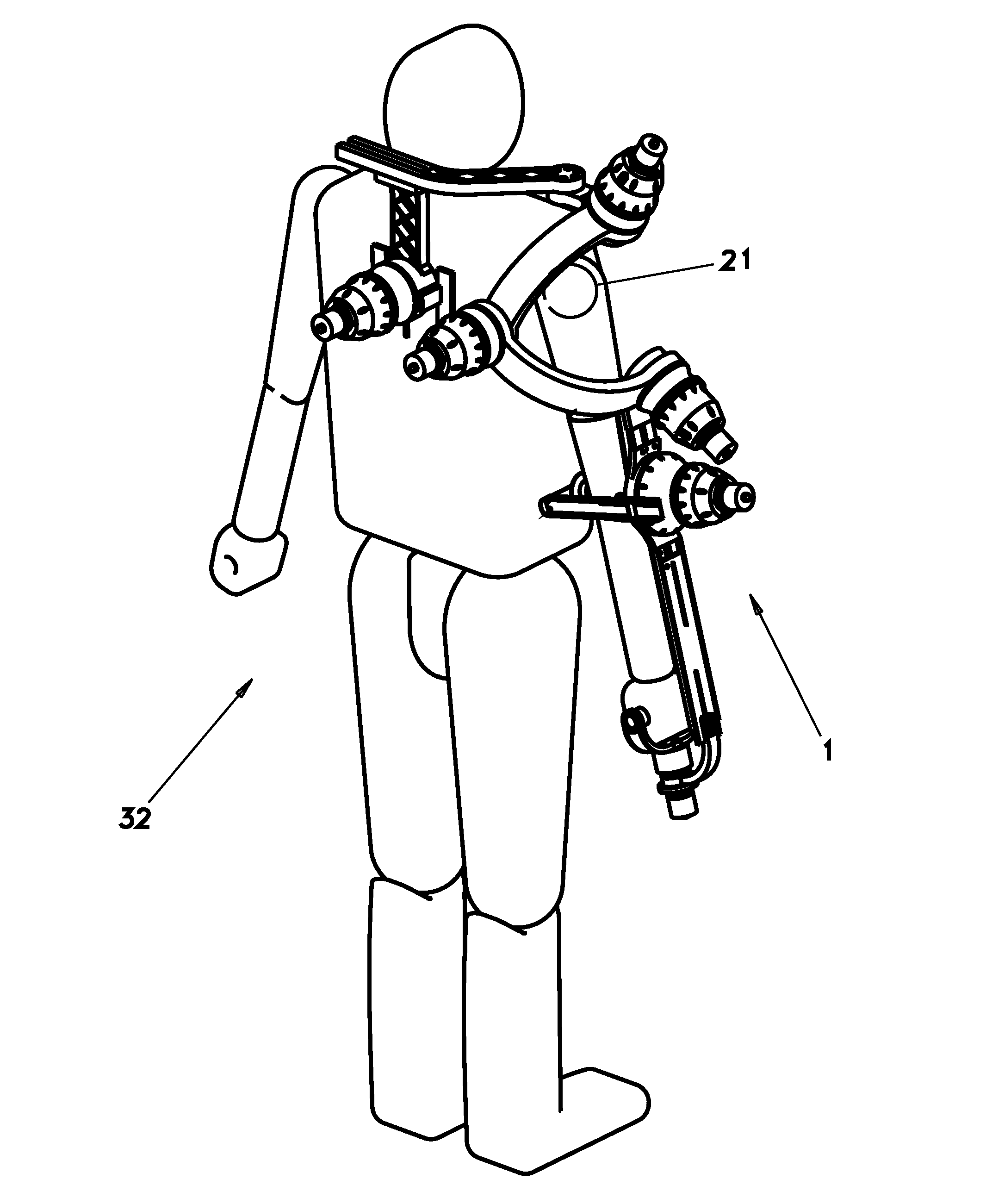

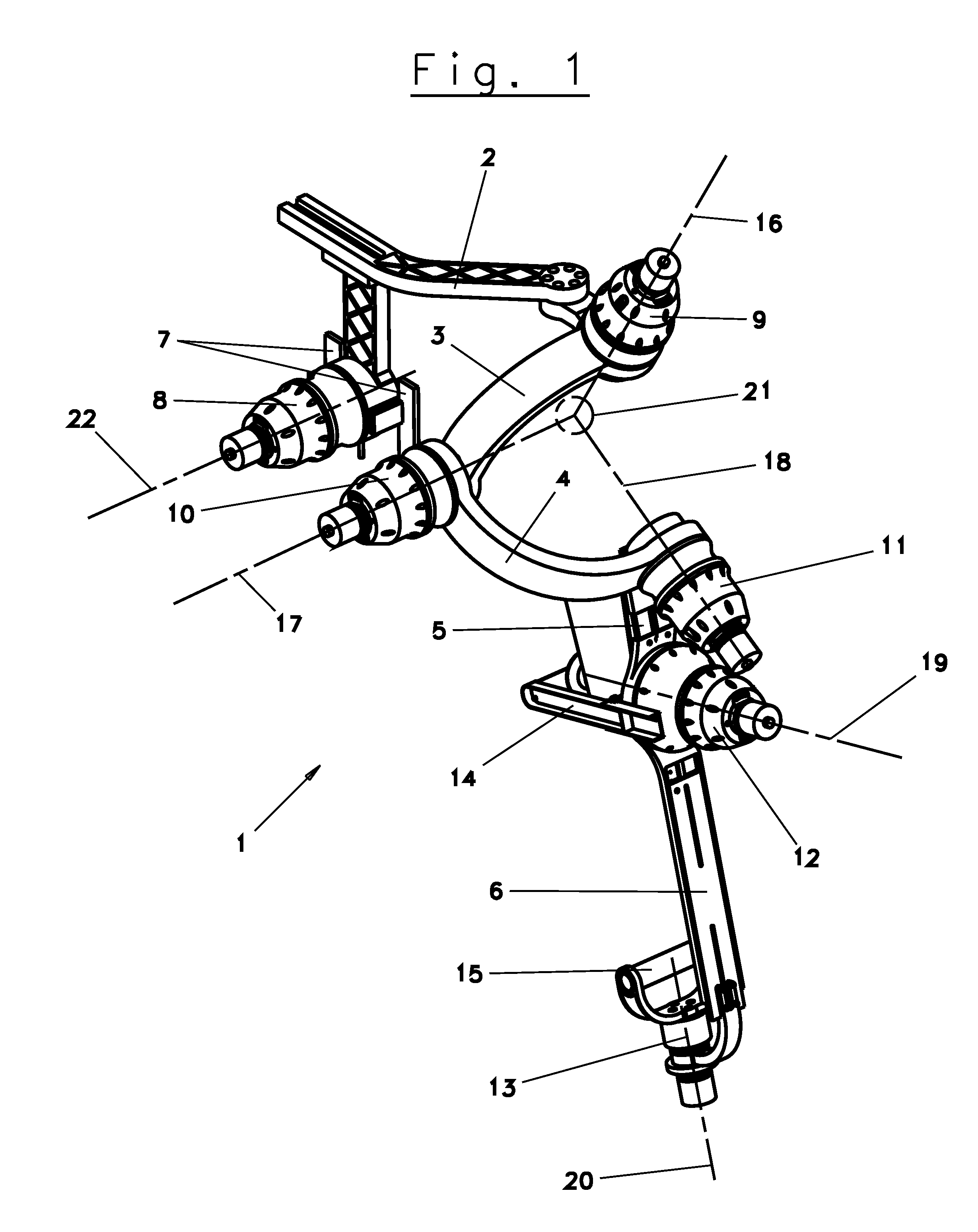

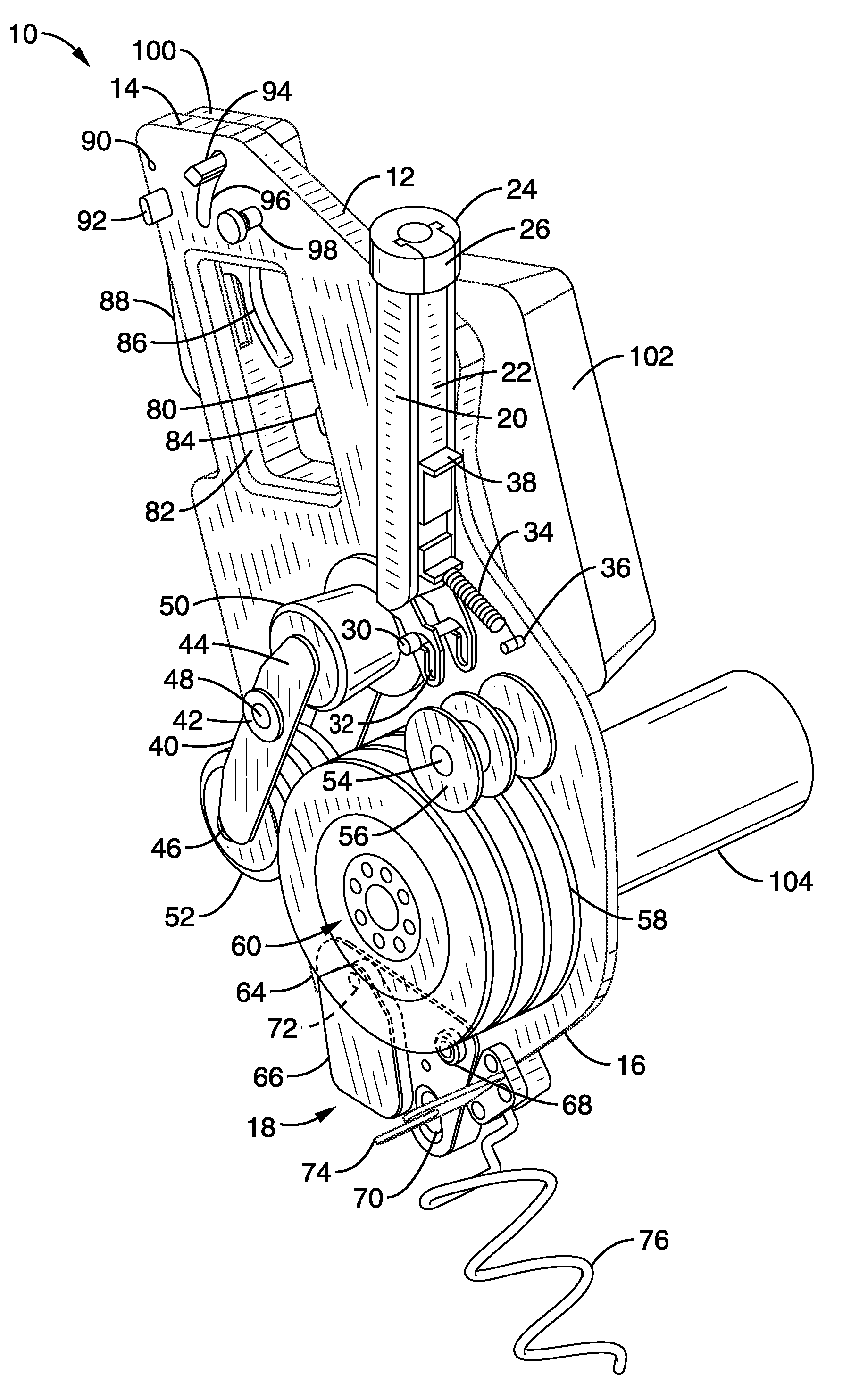

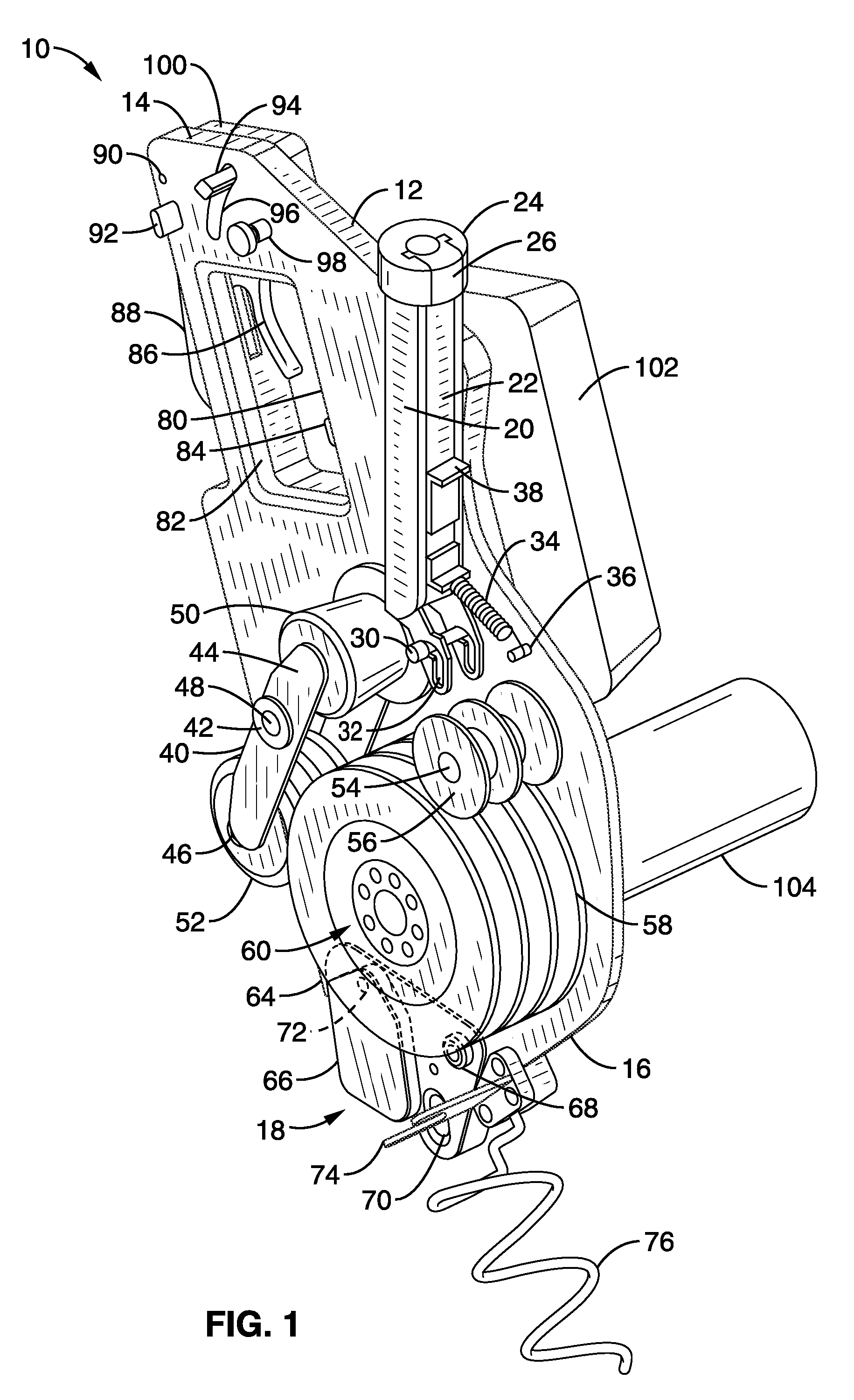

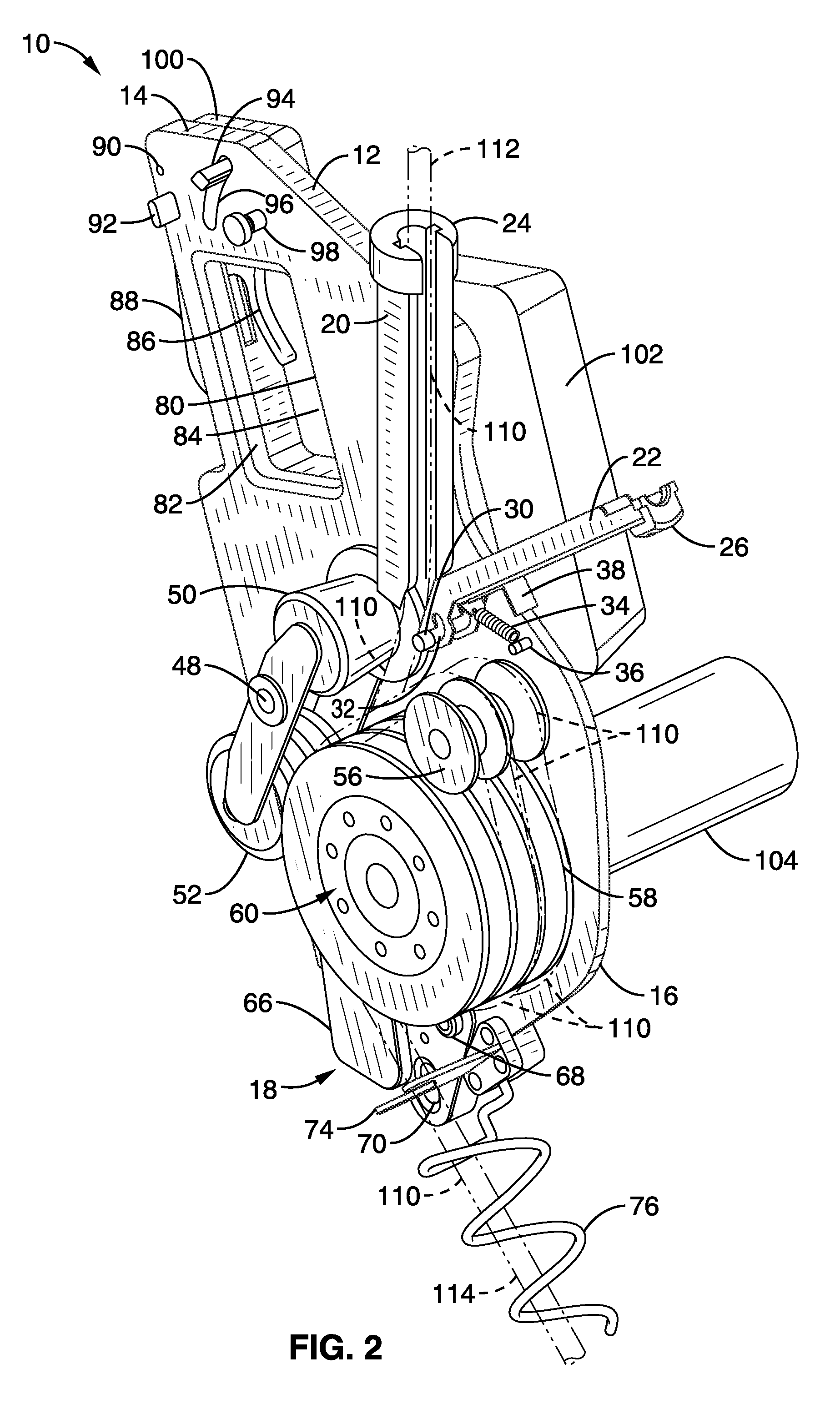

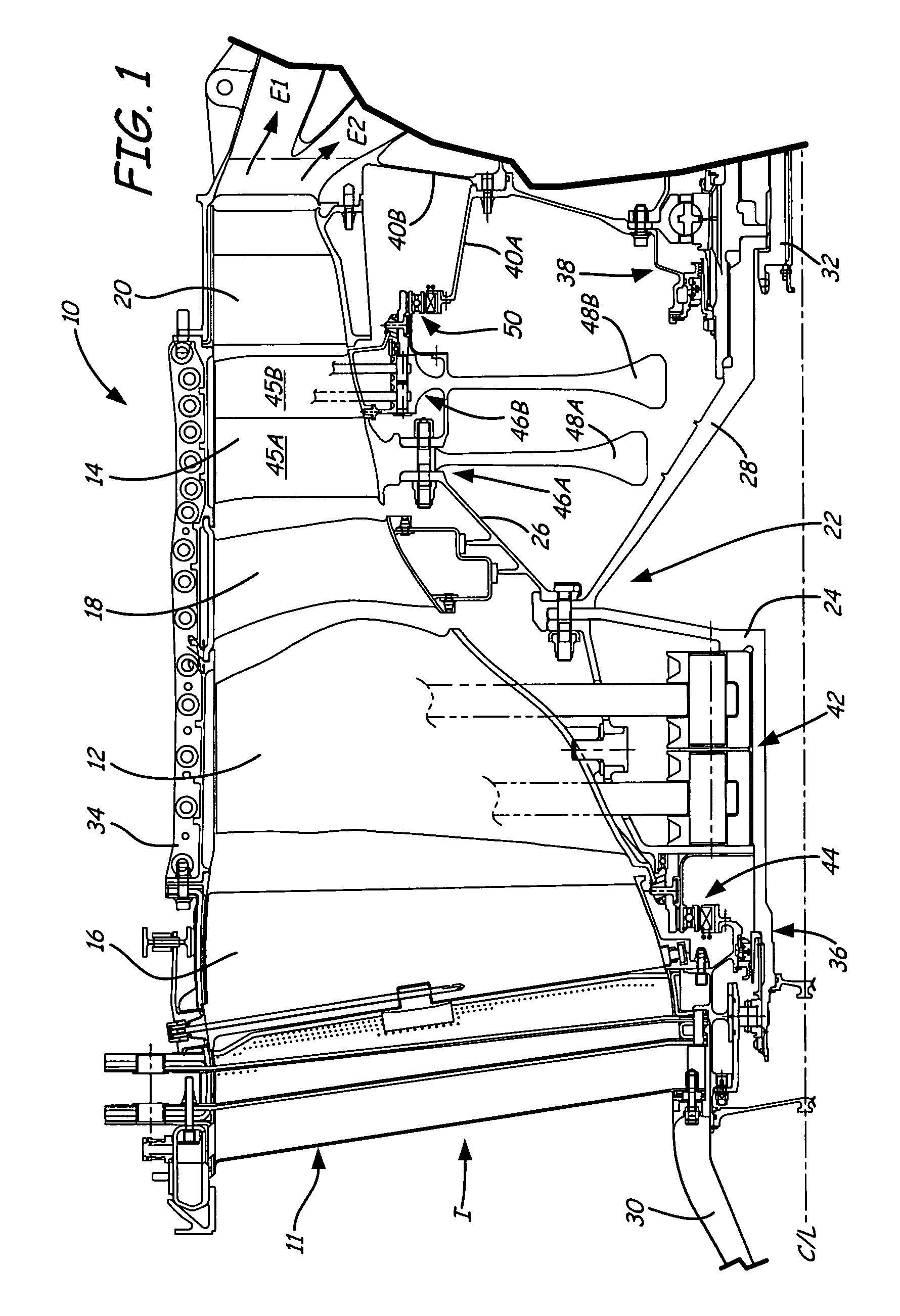

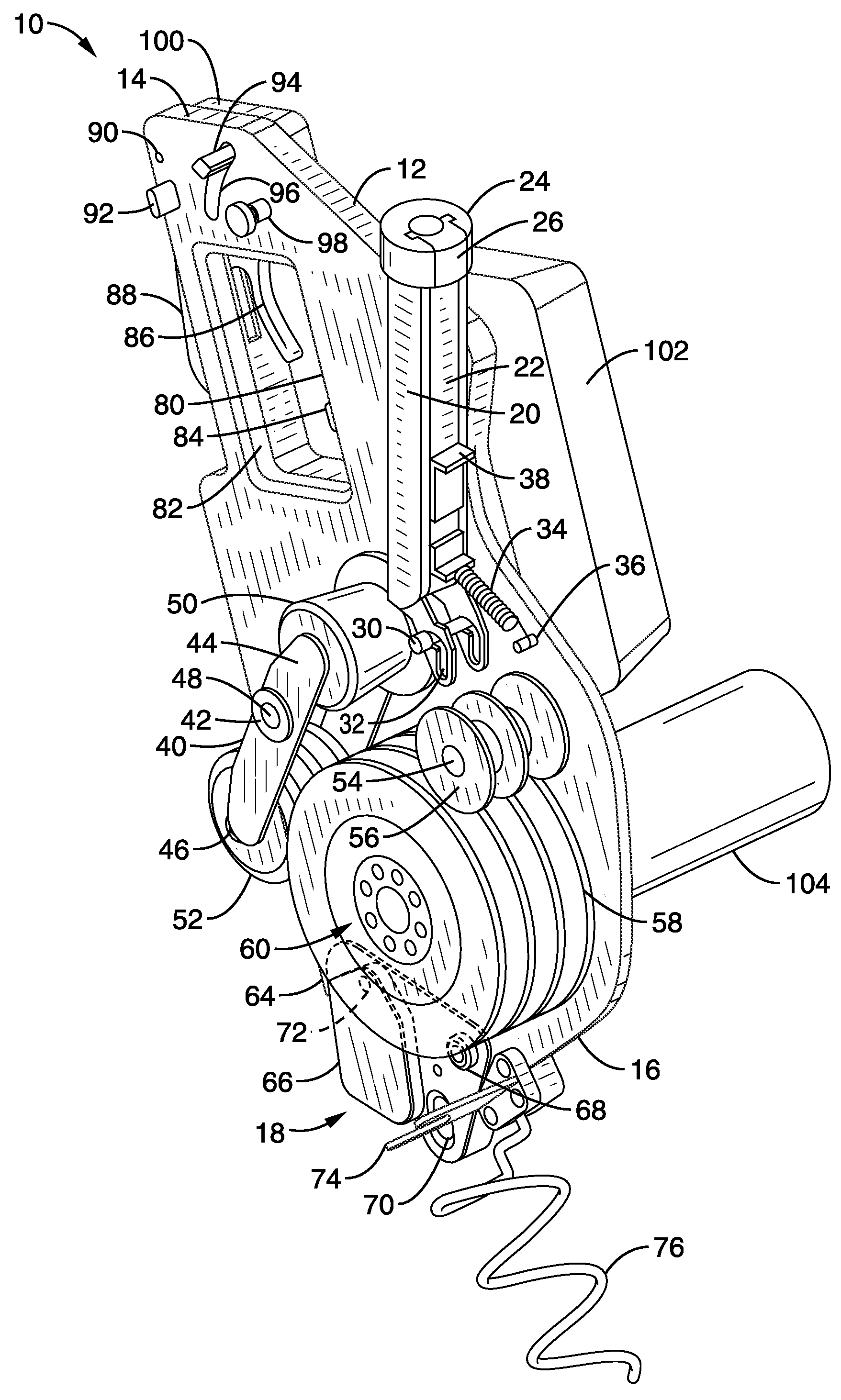

Portable Arm Exoskeleton for Shoulder Rehabilitation

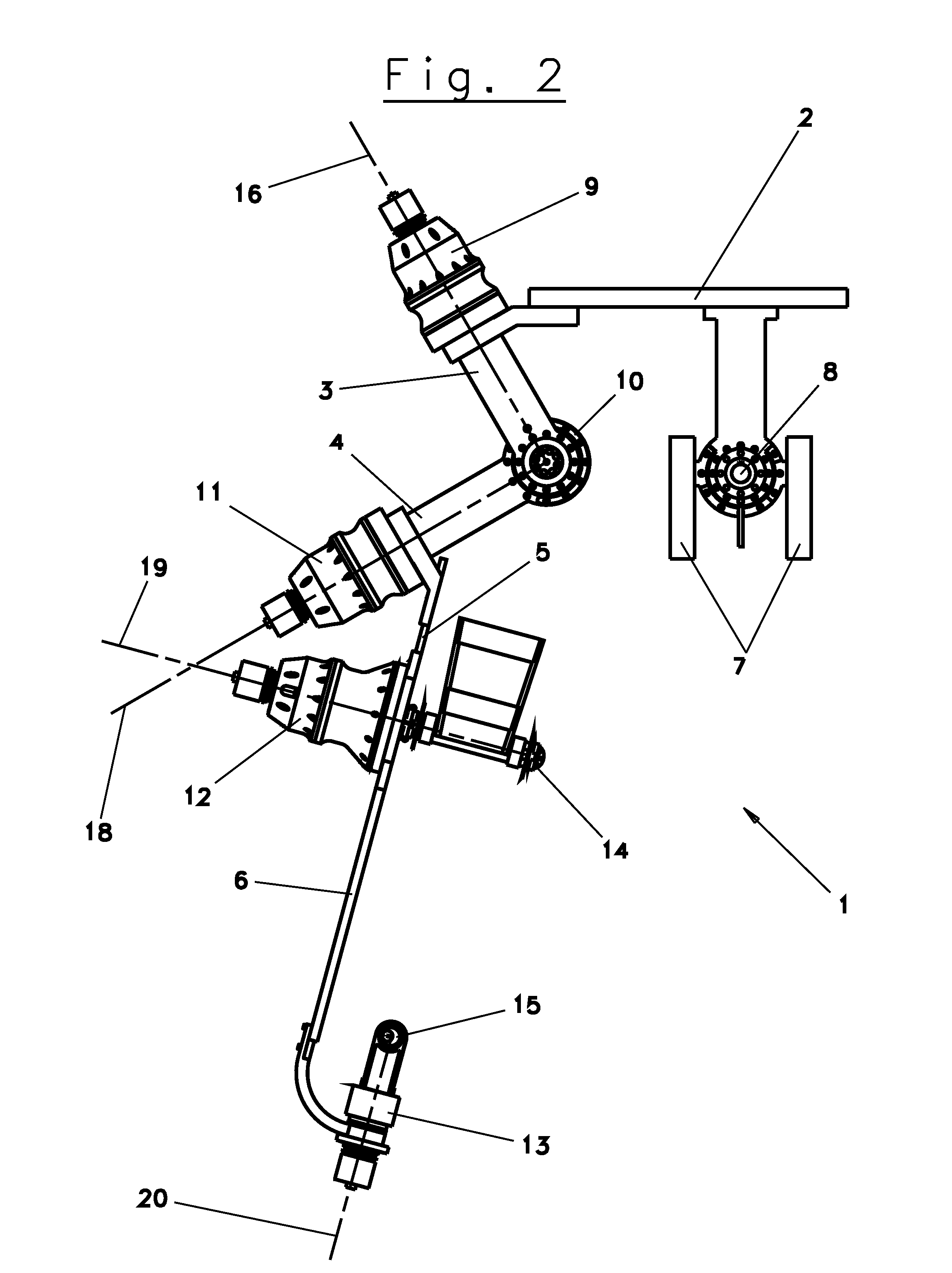

The present invention relates to an exoskeleton interface apparatus that parallels human arm motion and is comprised of a serial assemblage of five powered linkages and joints based at a rigid support structure worn on the torso of the human subject. Such apparatus generates shoulder rotation using three orthogonal revolute joints mounted on serial linkages encompassing and intersecting at the anatomical glenohumeral joint. Elevation of the shoulder joint is articulated using a link member driven by a single revolute joint mounted in the torso structure. Passive adjustable linkages are used to match variation in anatomical forearm length, upper arm length, and scapula-to-glenohumeral radius. A plurality of integrated dc motor / harmonic drive transmission modules is co-located on adjoining linkages to power the joints. Force is exchanged with the human at the handgrip and elbow brace, and reacted to the torso structure via the base attachment. The present invention is applicable in particular to rehabilitation of the shoulder.

Owner:CARIGNAN CRAIG R +1

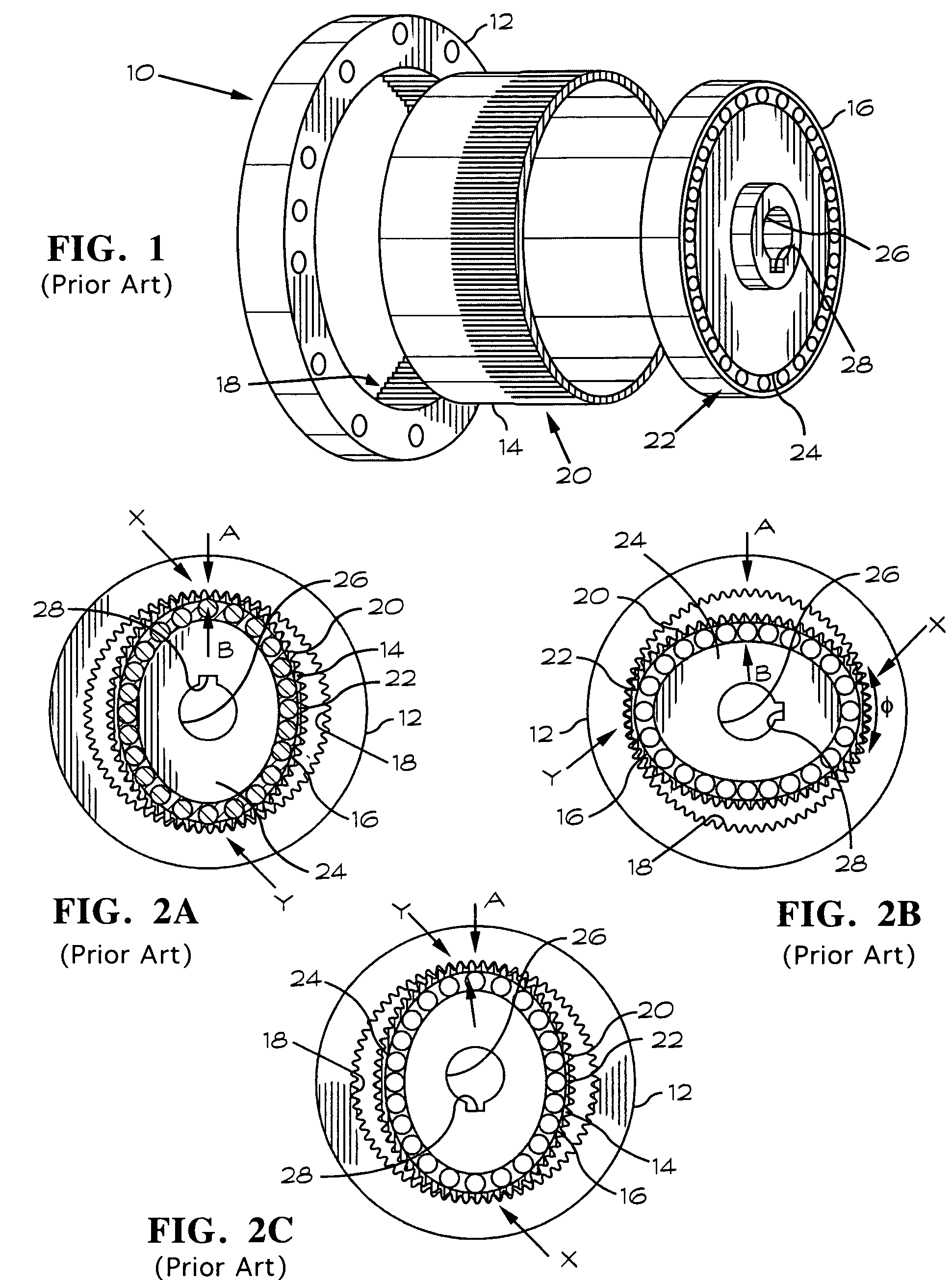

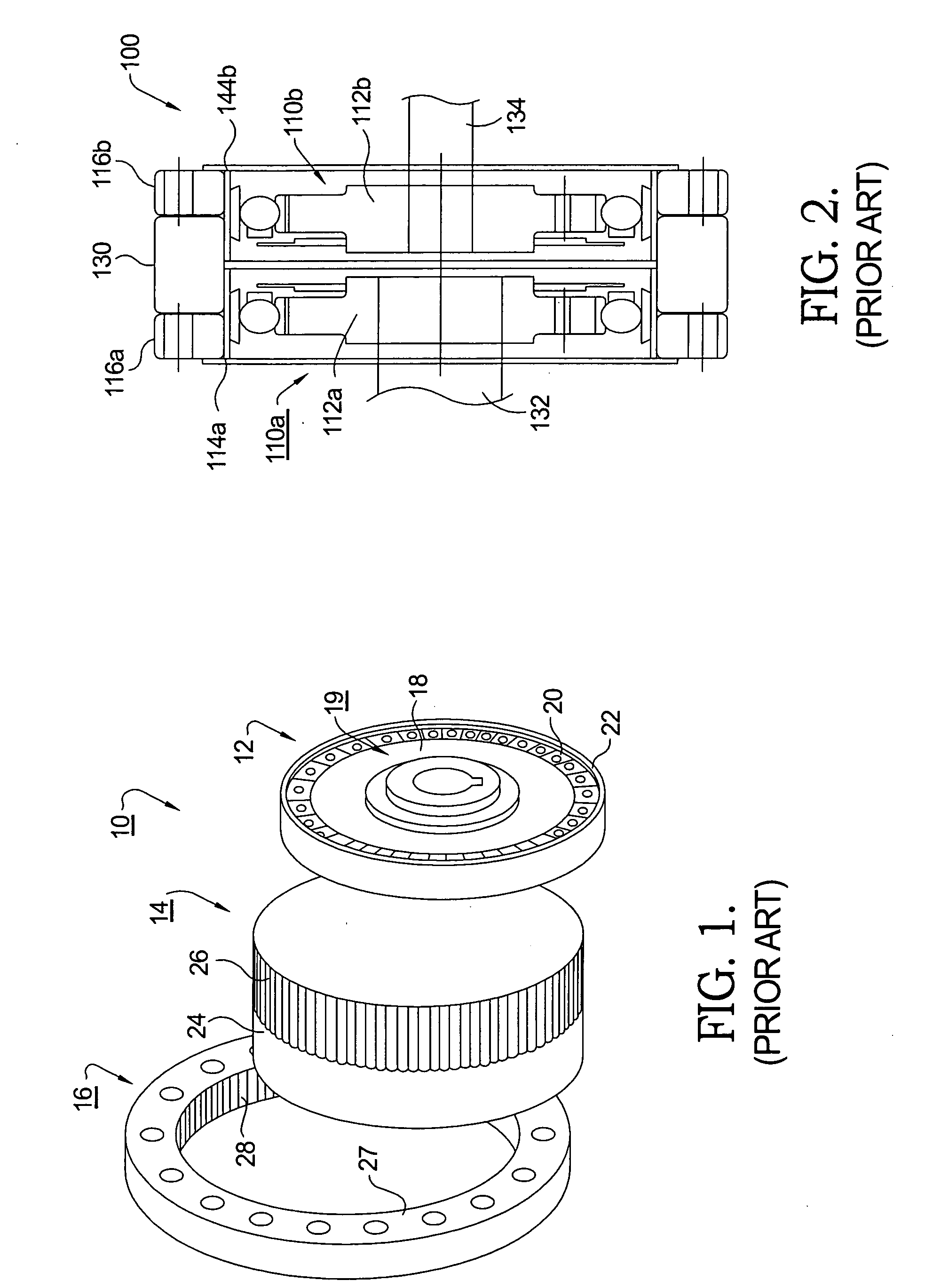

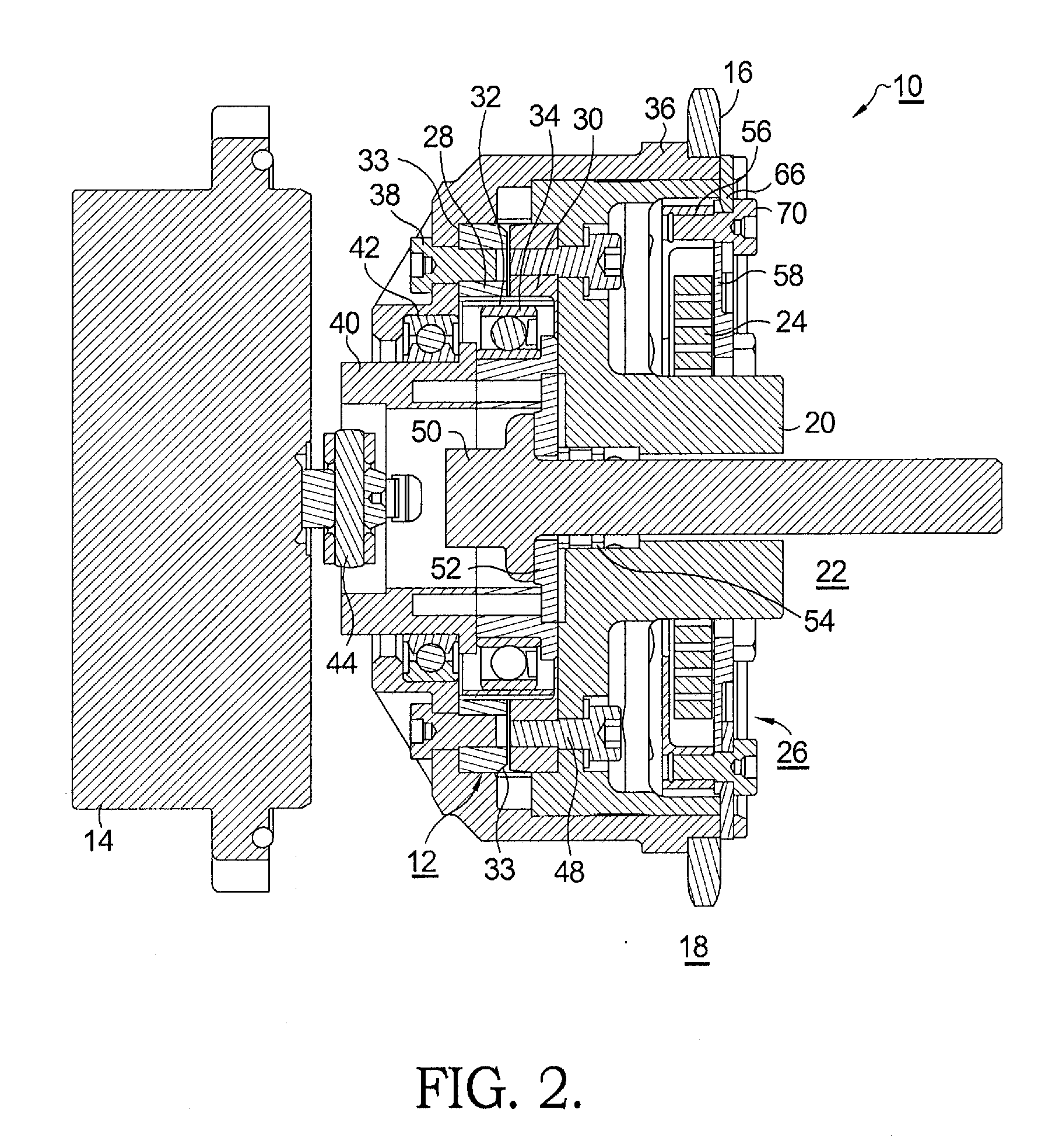

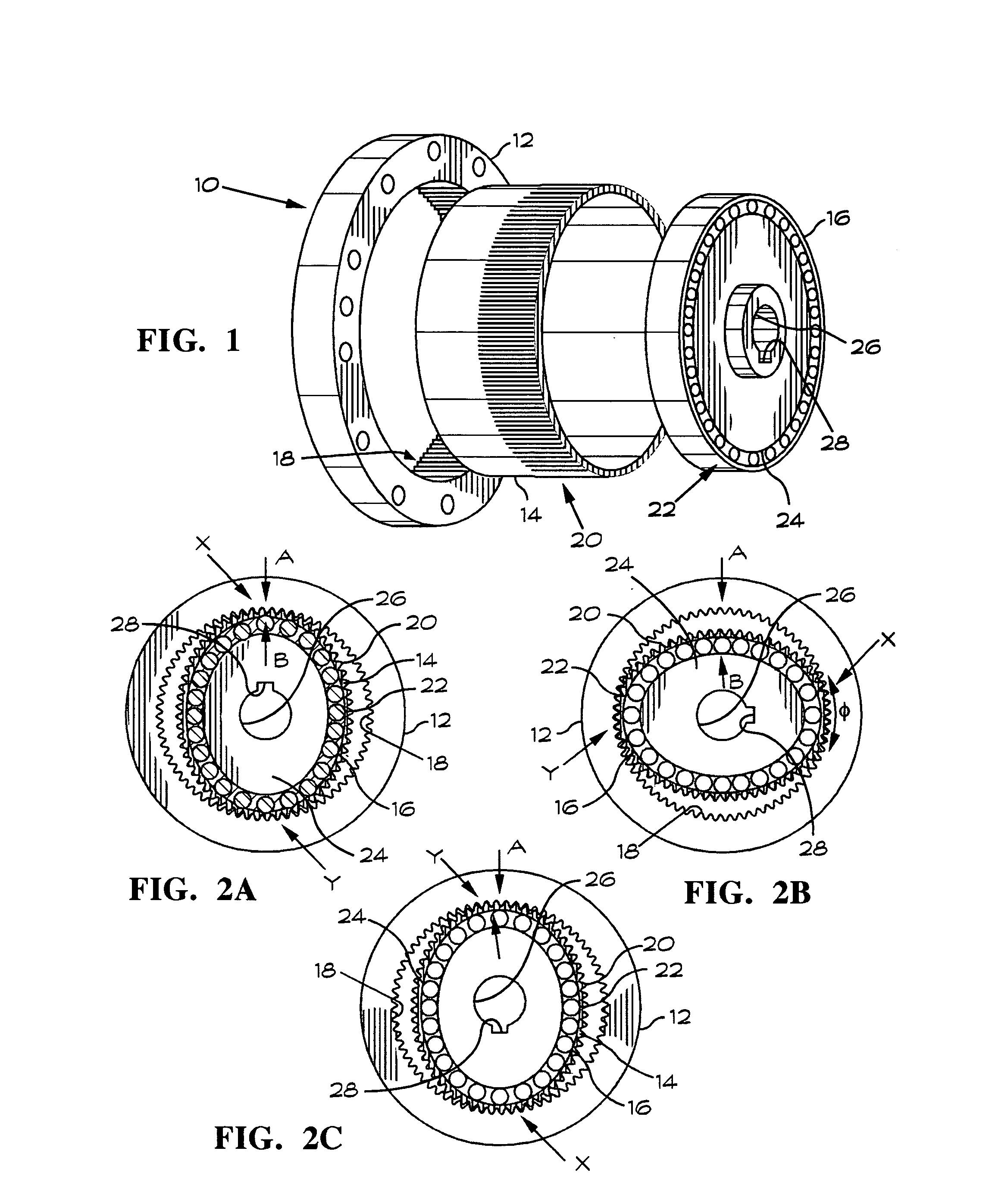

Harmonic drive gear assembly with asymmetrical wave generator and associated flexspline

Owner:NORTHROP GRUMMAN SYST CORP +1

Portable arm exoskeleton for shoulder rehabilitation

The present invention relates to an exoskeleton interface apparatus that parallels human arm motion and is comprised of a serial assemblage of five powered linkages and joints based at a rigid support structure worn on the torso of the human subject. Such apparatus generates shoulder rotation using three orthogonal revolute joints mounted on serial linkages encompassing and intersecting at the anatomical glenohumeral joint. Elevation of the shoulder joint is articulated using a link member driven by a single revolute joint mounted in the torso structure. Passive adjustable linkages are used to match variation in anatomical forearm length, upper arm length, and scapula-to-glenohumeral radius. A plurality of integrated dc motor / harmonic drive transmission modules is co-located on adjoining linkages to power the joints. Force is exchanged with the human at the handgrip and elbow brace, and reacted to the torso structure via the base attachment. The present invention is applicable in particular to rehabilitation of the shoulder.

Owner:CARIGNAN CRAIG R +1

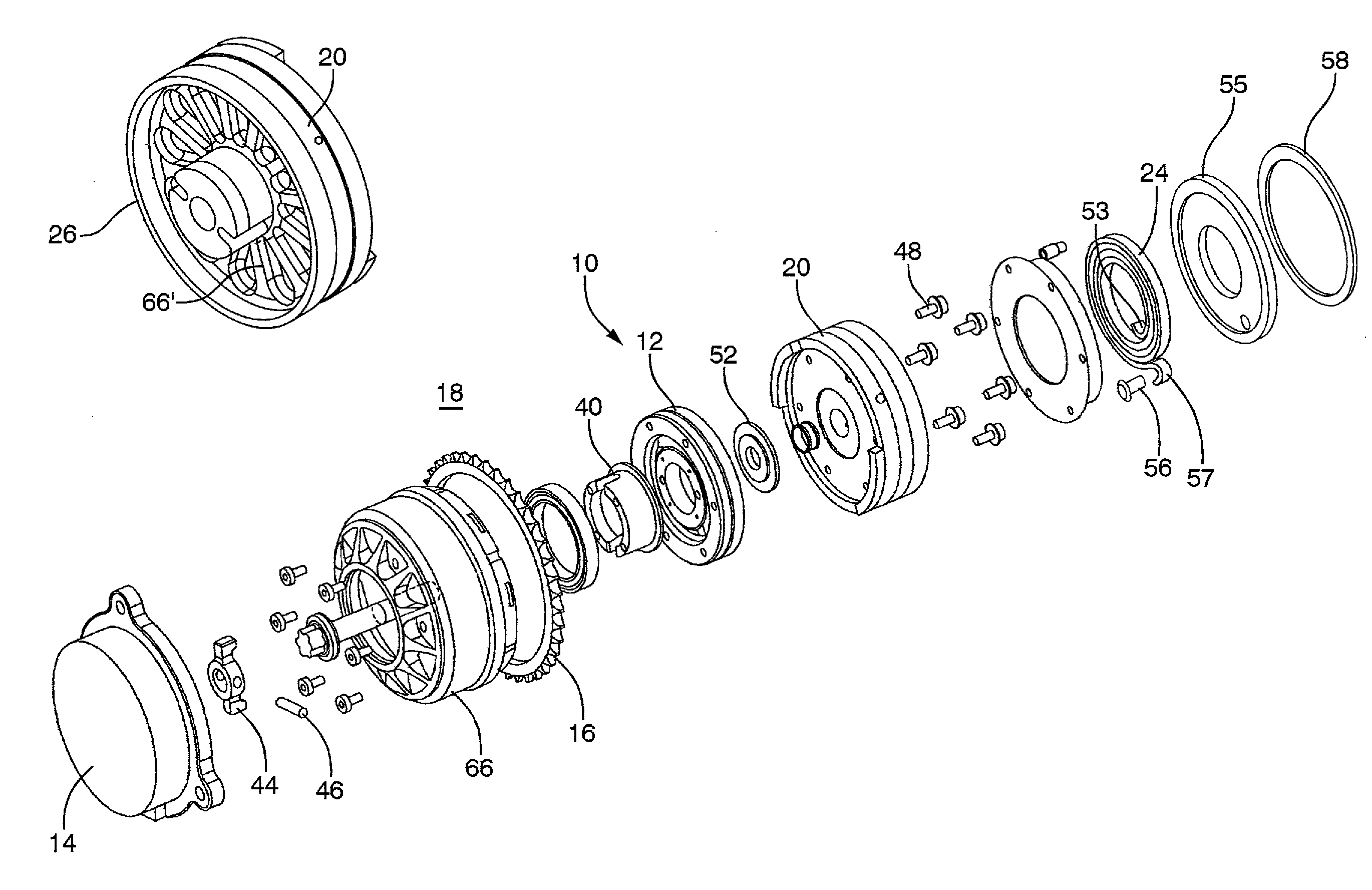

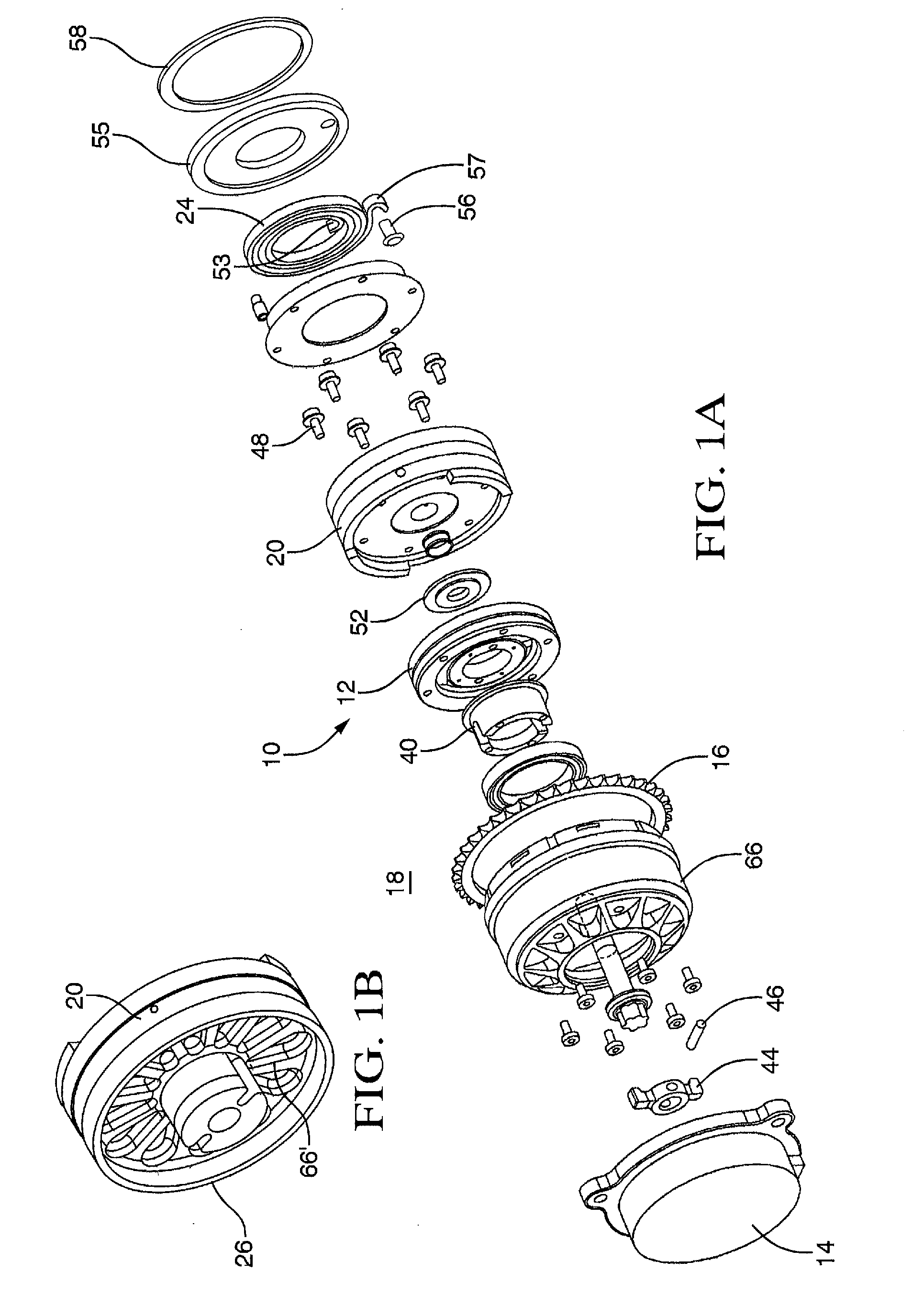

Hub motors

InactiveUS20060273686A1Raise countIncrease surface areaSingle-phase induction motor startersSynchronous motors startersDrive wheelStator coil

The present invention discloses small compact motor systems which may be located inside a vehicle drive wheel, and which allow a drive motor to provide the necessary torque with reasonable system mass. The motor systems of the invention utilize polyphase electric motors, and are preferably connected to appropriate drive systems via mesh connections, to provide variable V / Hz ratios. In one embodiment the stator coils are wound around the inside and outside of the stator. In a further embodiment, the machine contains a high number of phases, greater than three. In a further embodiment, the phases are connected in a mesh connection. In a further embodiment, each half-phase is independently driven to enable second harmonic drive for an impedance effect. Improvements are apparent in efficiency and packing density.

Owner:BOREALIS TECH LTD

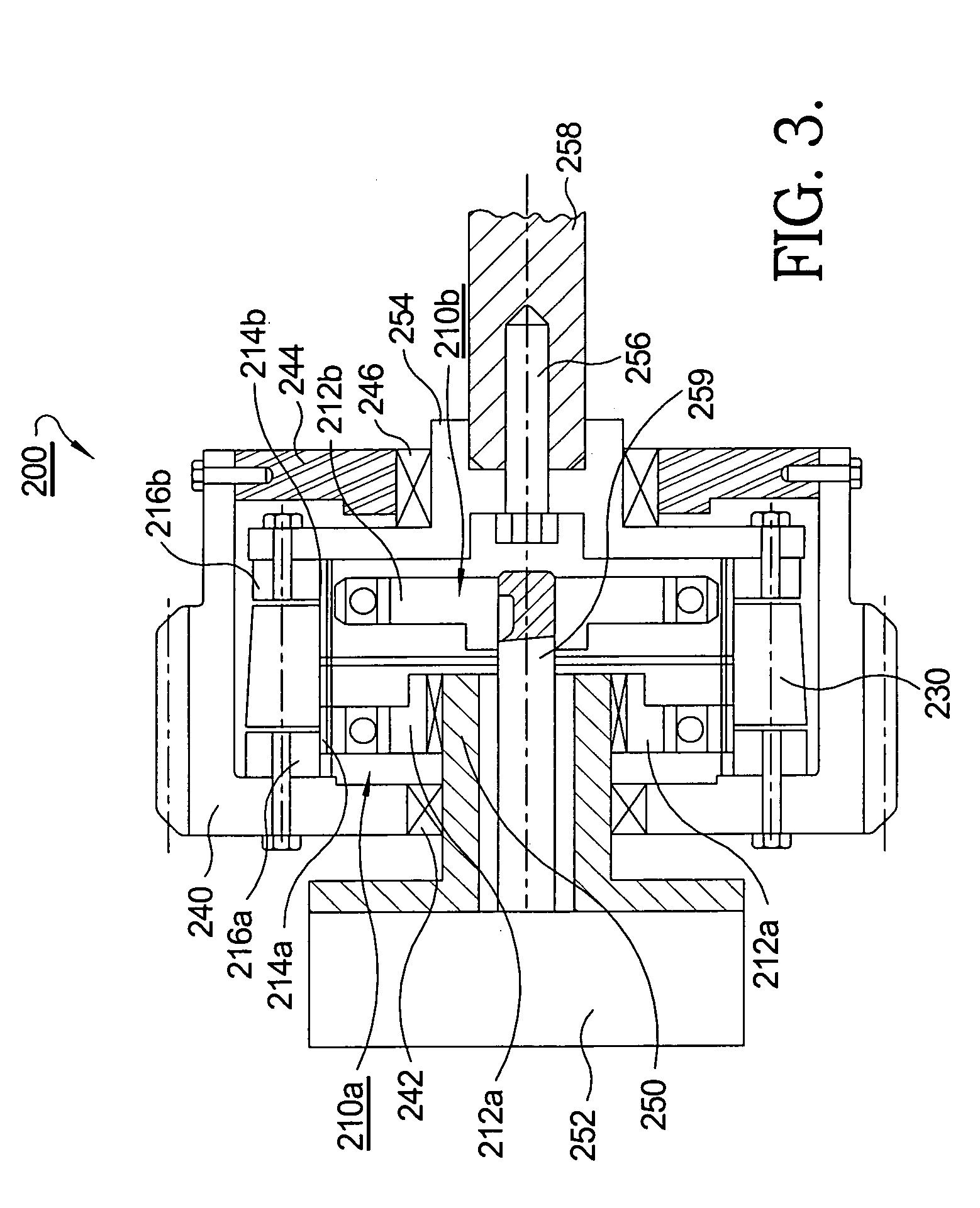

Harmonic drive camshaft phaser

Owner:DELPHI TECH IP LTD

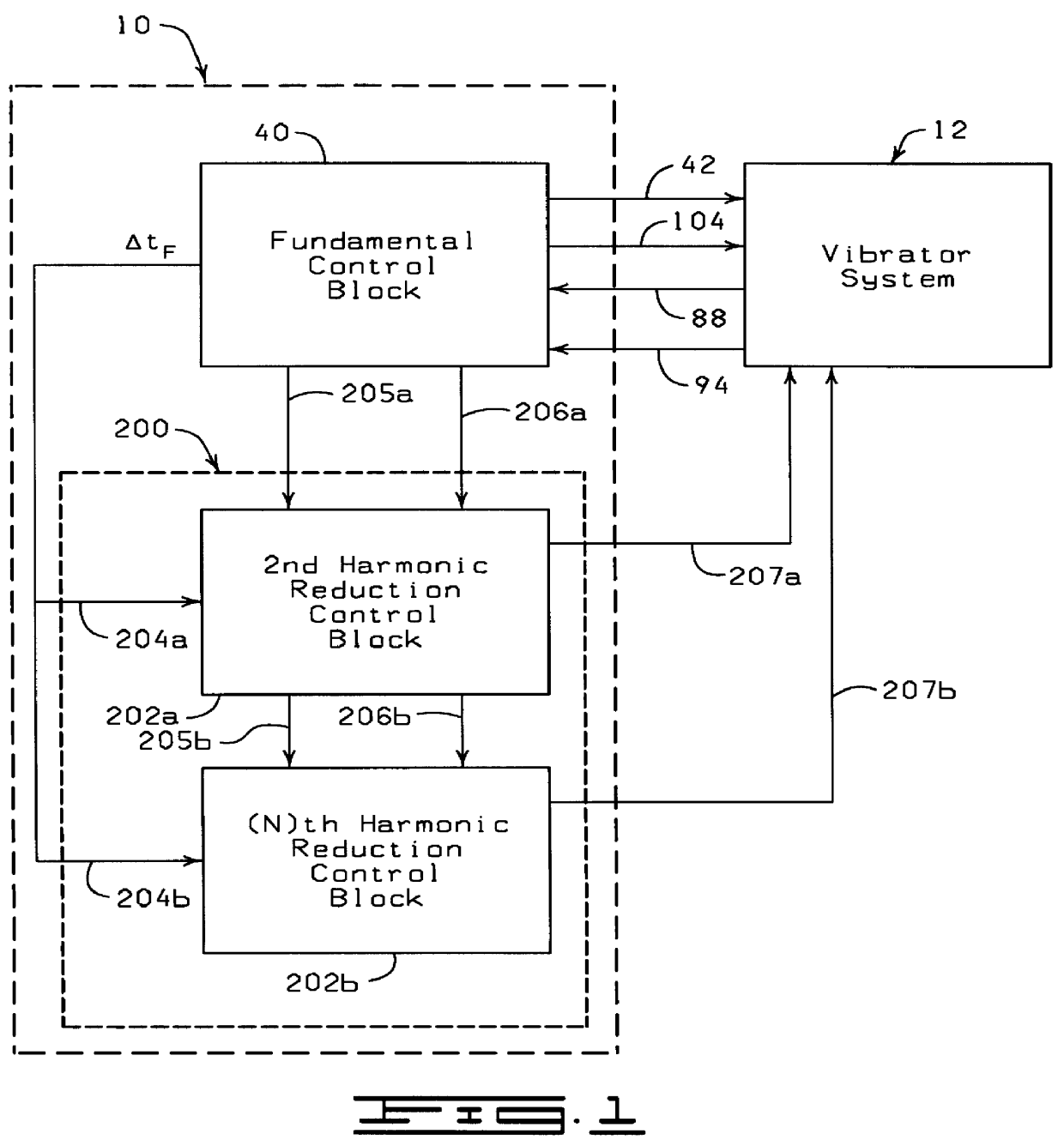

Method and apparatus for reducing harmonic distortion

InactiveUS6035257AImprove signal-to-noise ratioEasy to detectAnti-hunting elementsSeismic signal processingSignal-to-noise ratio (imaging)Total harmonic distortion

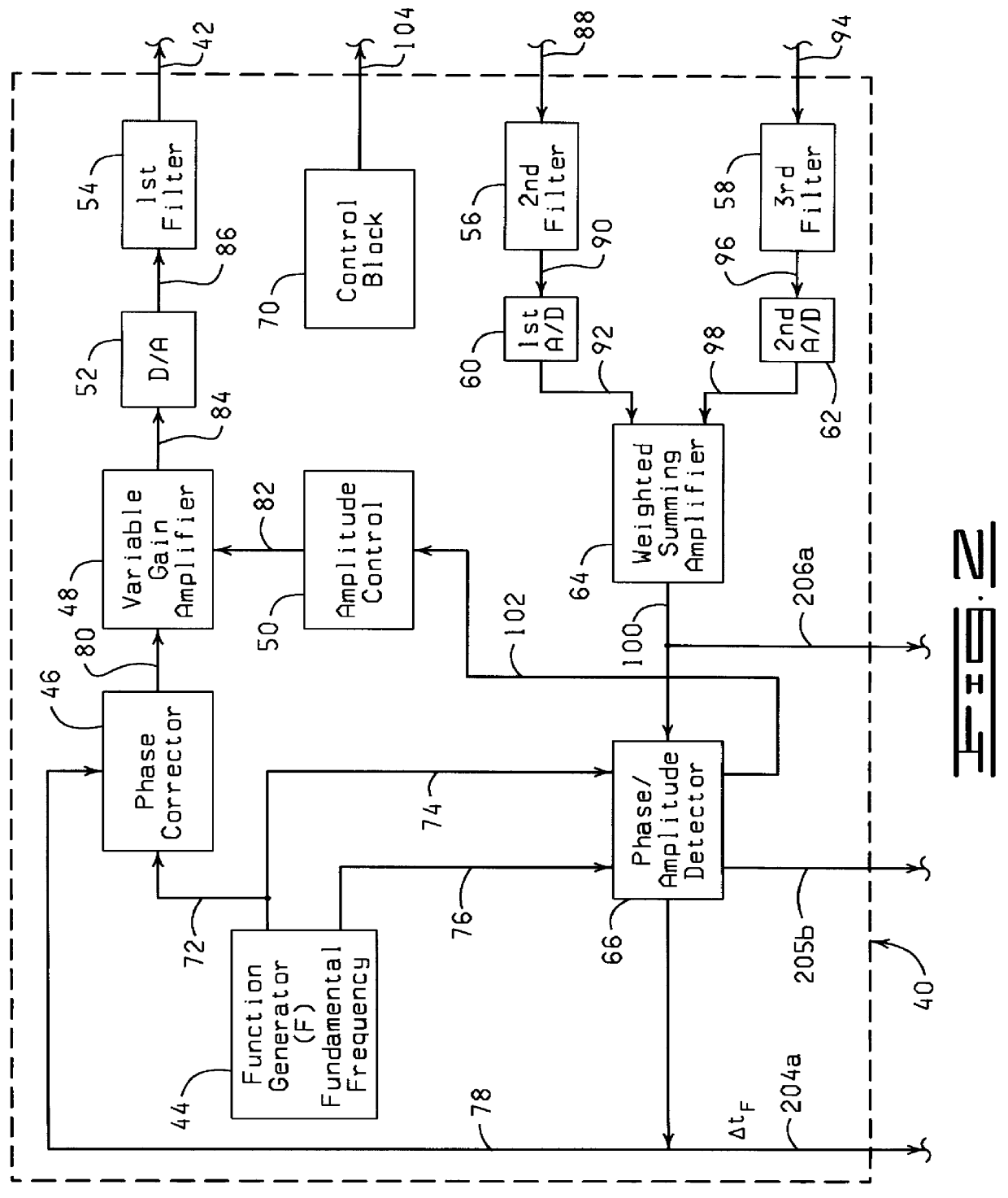

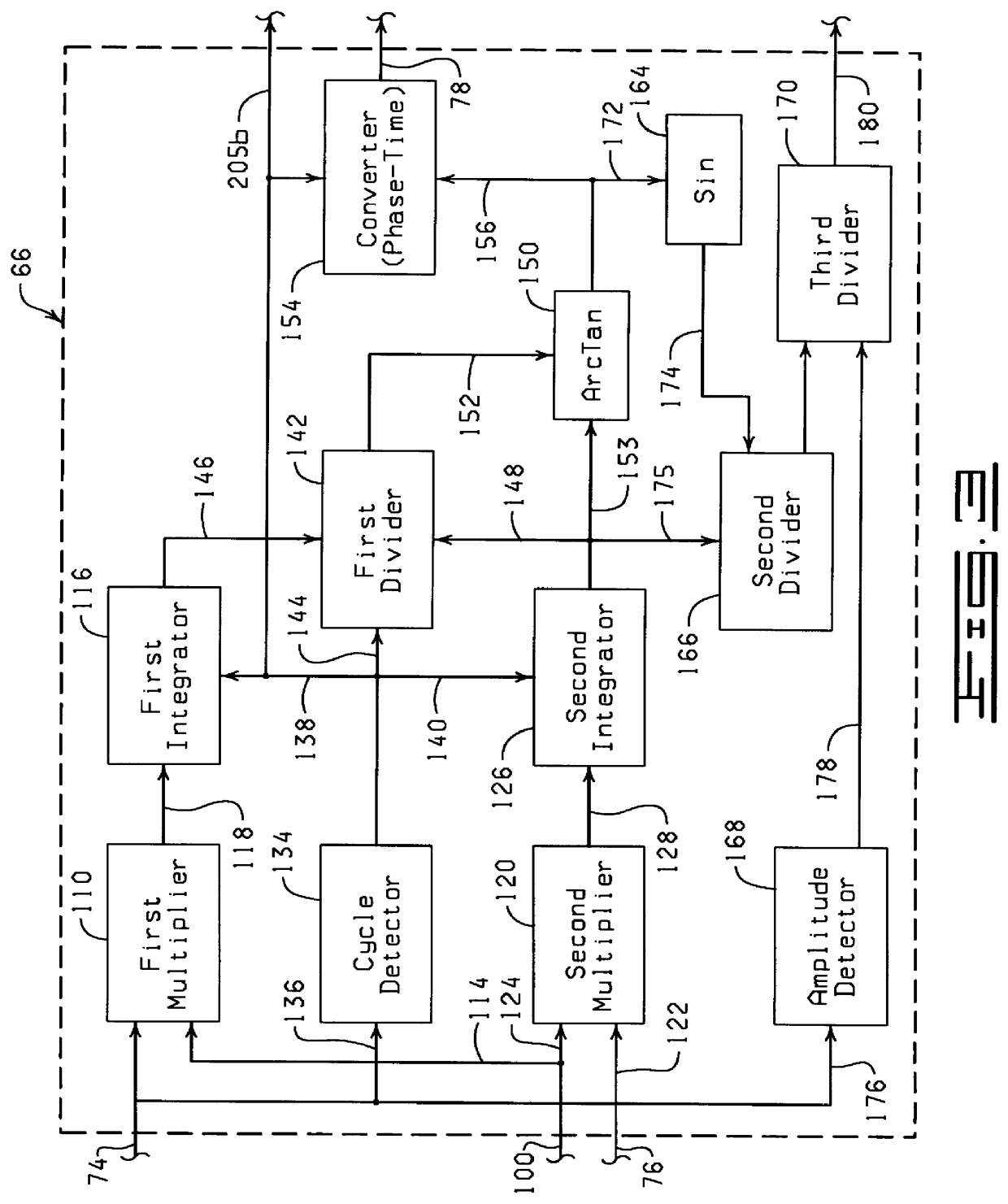

The present invention relates to a control system for a vibrator system capable of generating and applying a reciprocating force to an object, such as the underlying ground or water. The control system is generally provided with a means for outputting a drive signal having a fundamental frequency to the vibrator system to activate the reciprocating of the base plate of the vibrating system and a means for receiving a vibrator output signal indicative of the force applied to the object. The vibrator output signal includes at least one harmonic frequency signal and is delayed with respect to the phase of the initial drive signal. To increase the signal-to-noise ratio of the vibrator system, the control system includes a harmonic distortion reduction means receiving the vibrator output signal for outputting at least one harmonic drive signal to the vibrator system. The harmonic drive signal has a proper phase, amplitude, polarity, and frequency which are adjusted to minimize at least one of the harmonic frequency signals being produced by the vibrator system.

Owner:PELTON CO

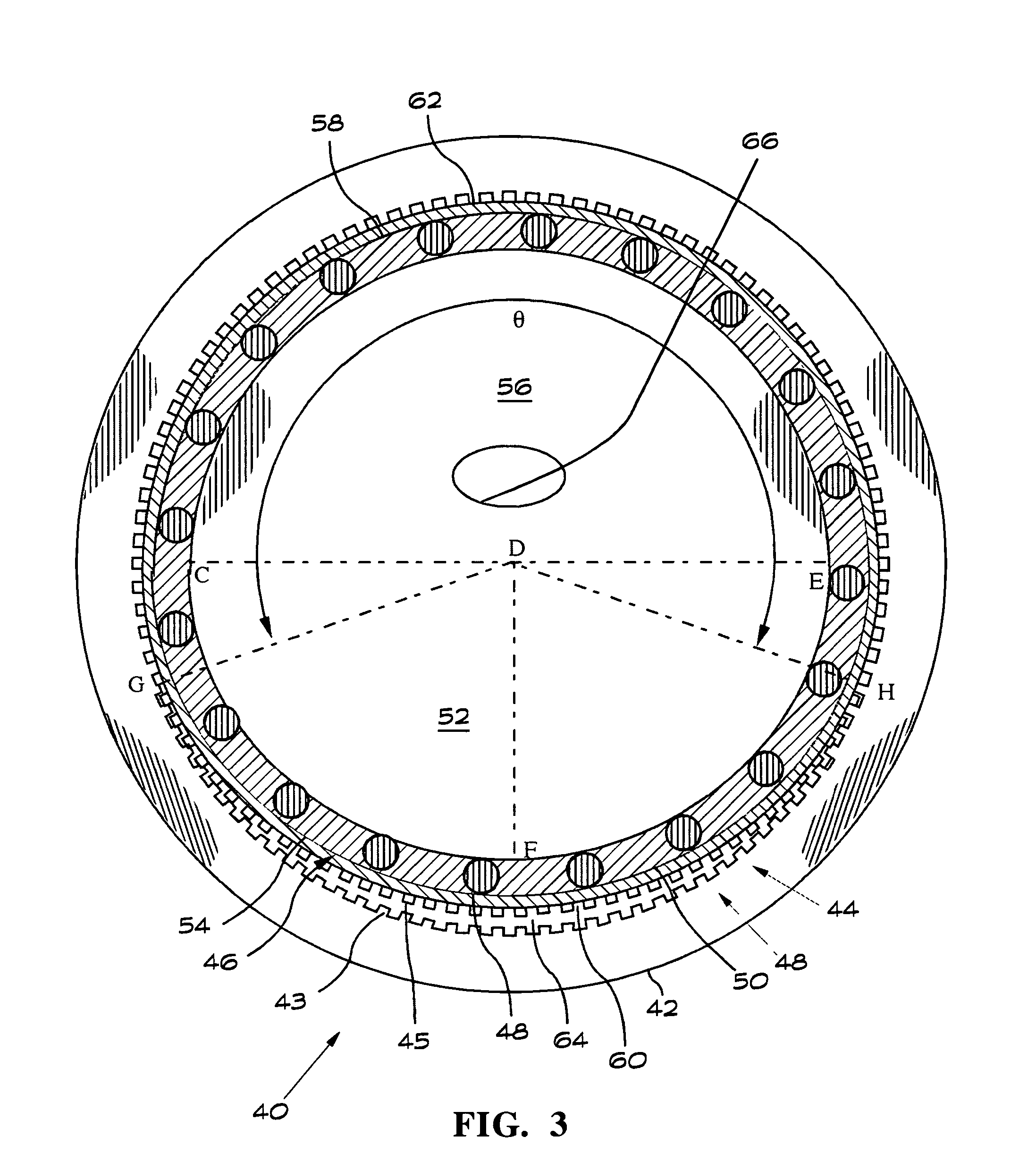

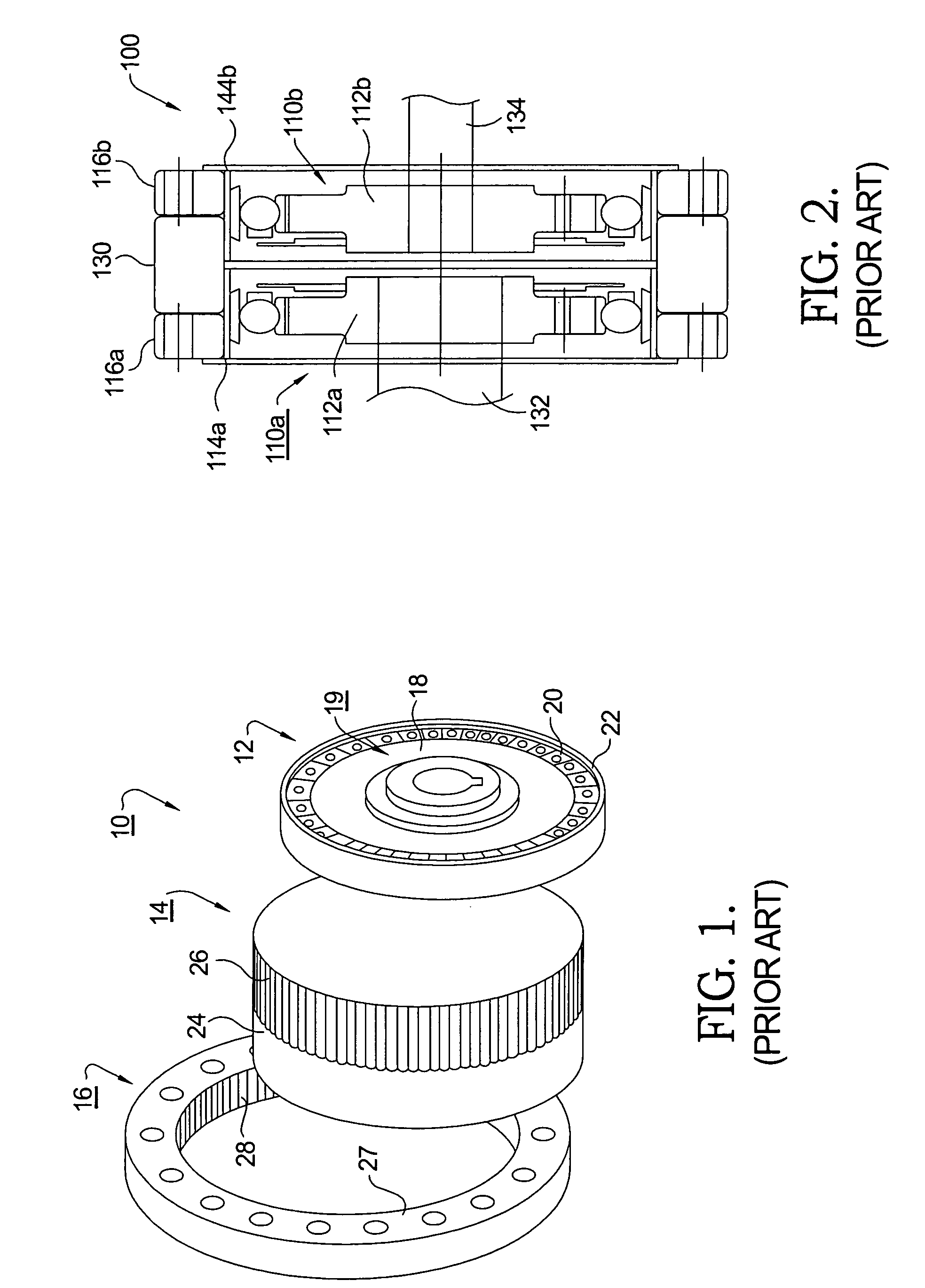

Harmonic drive using profile shifted gear

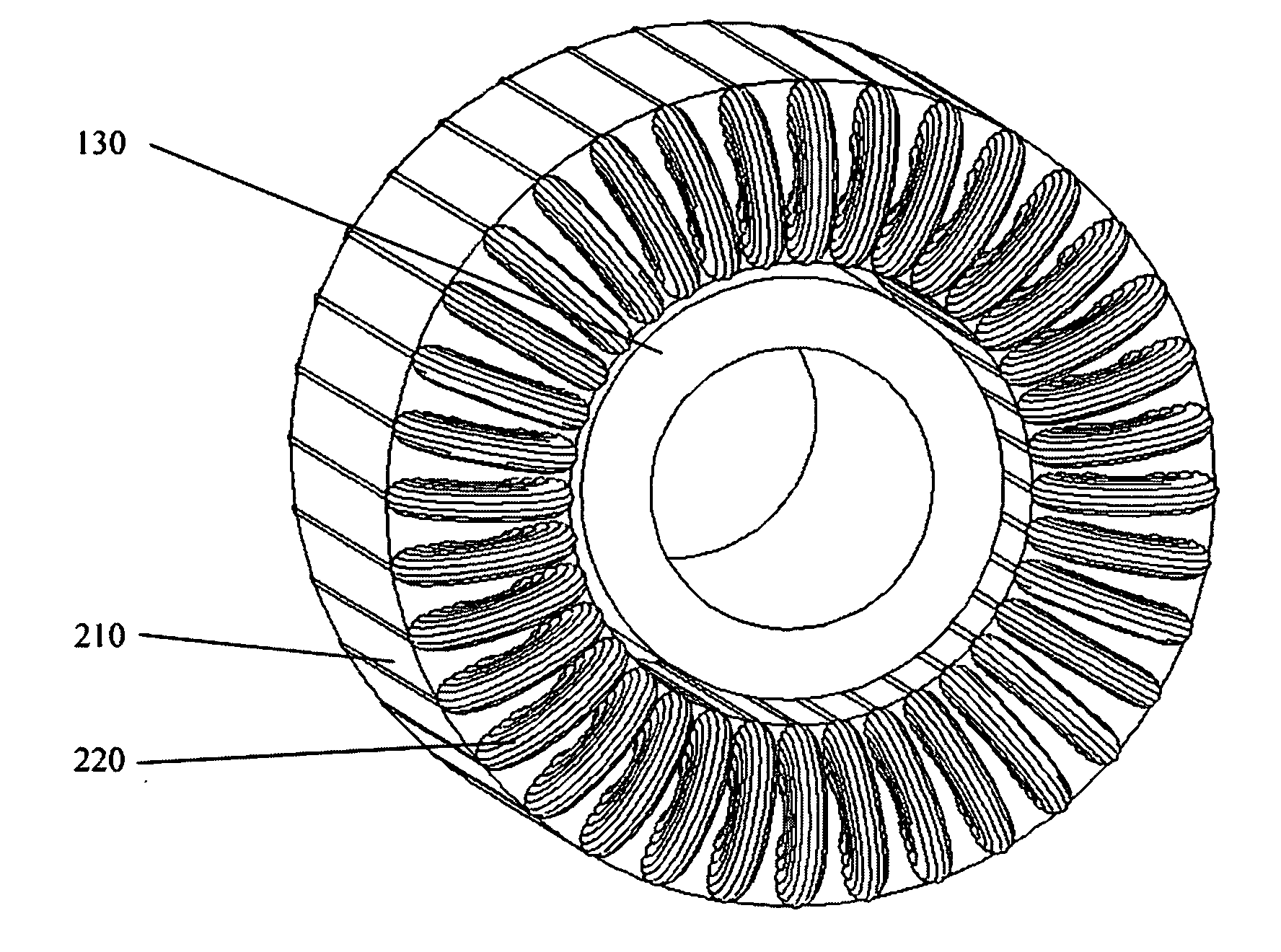

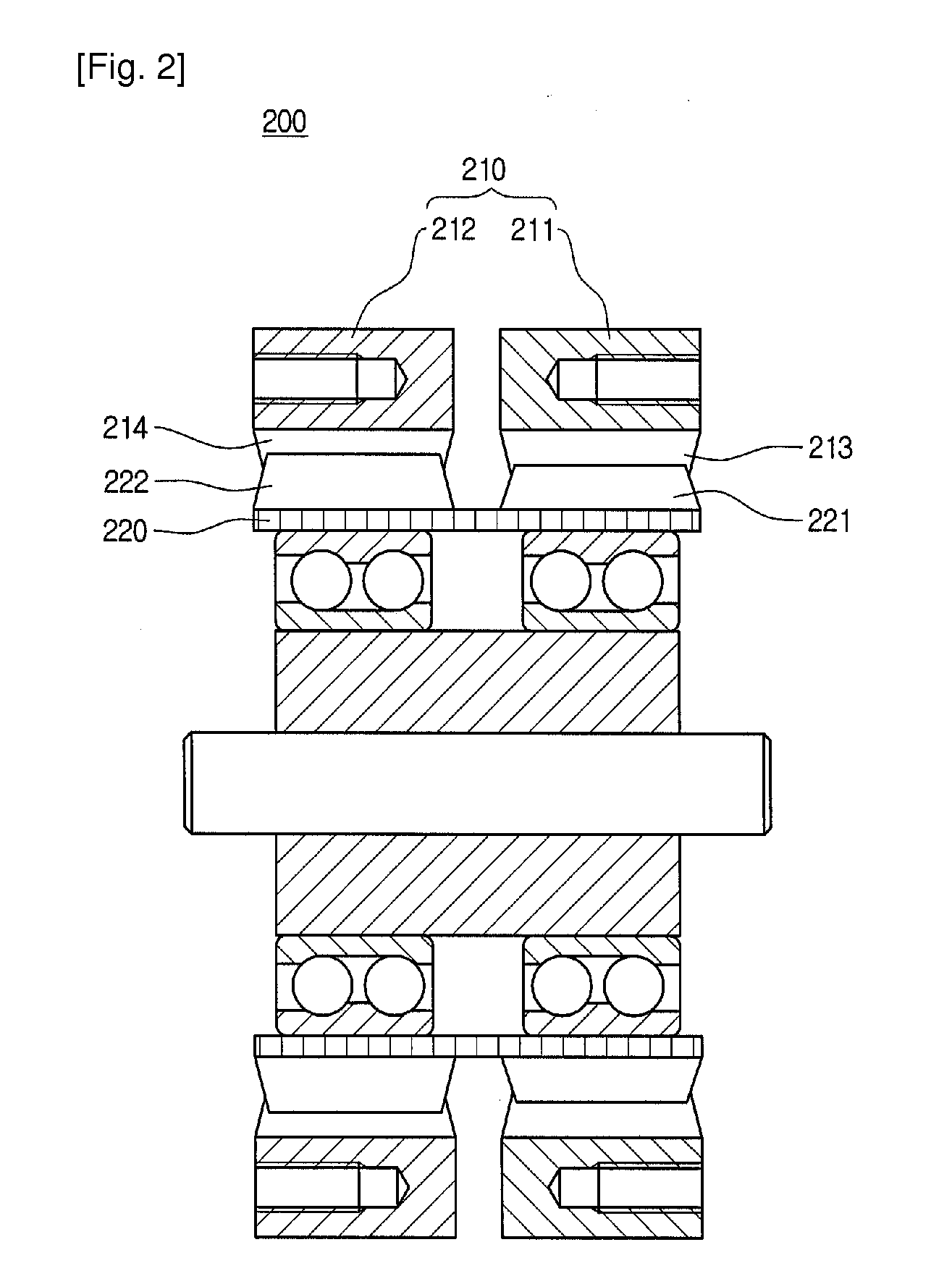

InactiveUS20110088496A1Thickness minimizationEnergy loss generated when the flexible gear is deformed is minimizedToothed gearingsPortable liftingBand shapeEngineering

A harmonic drive according to the present invention comprises a plurality of internal gears; a band type of flexible gear provided with teeth engaged with each of the internal gears on its outer circumferential surface, the flexible gear having a pitch circumference length shorter than that of said internal gears; and a wave generating part disposed on an inner side of said flexible gear, the wave generating part generating a plurality of harmonic motions by deforming said flexible gear as the wave generating part rotates. Further, said flexible gear is formed integrally to engage with said plurality of internal gears so that the plurality of harmonic motions are overlapped, and one or more of said plurality of internal gears and said flexible gear are formed of profile shifted gears.

Owner:KOREA INST OF SCI & TECH

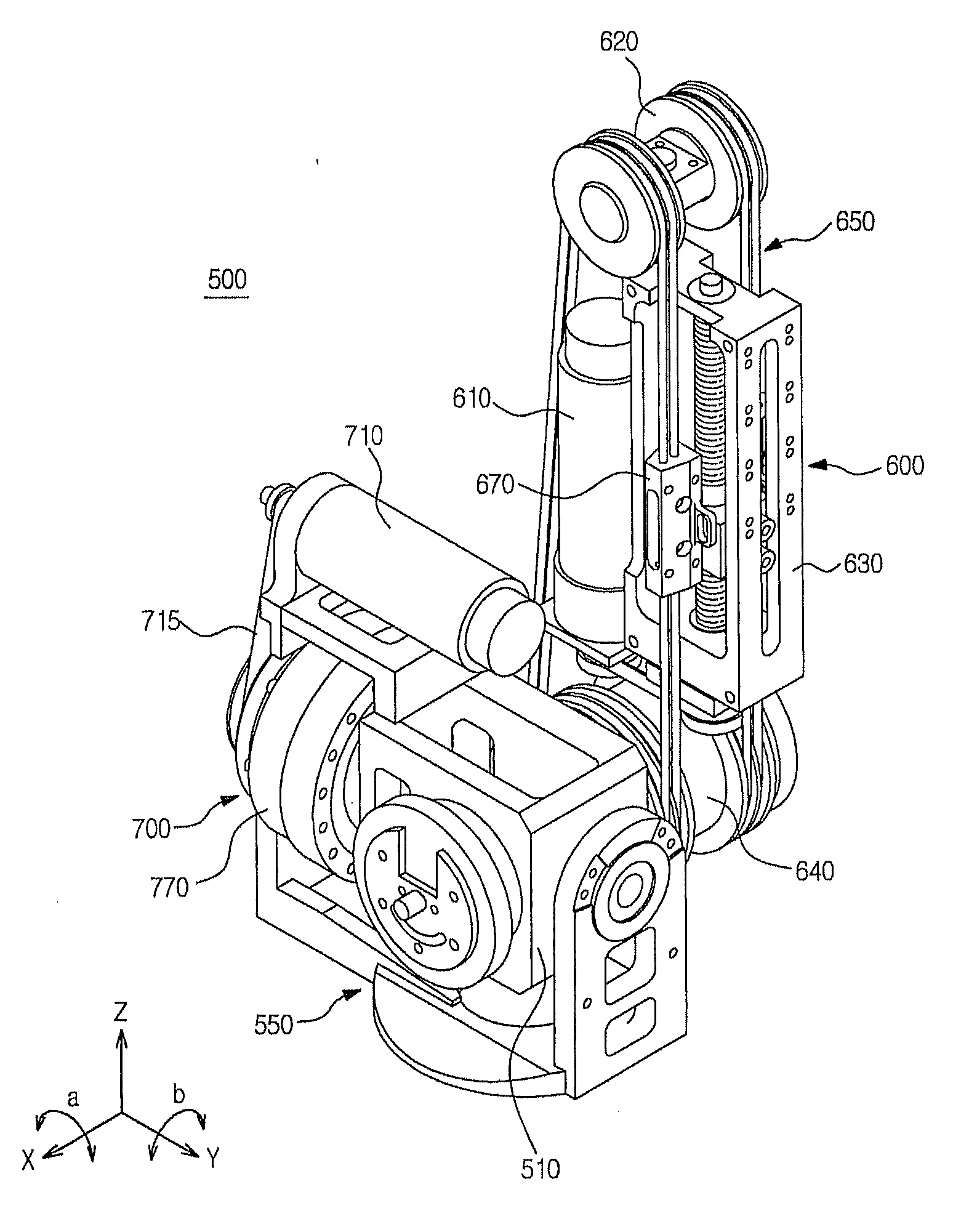

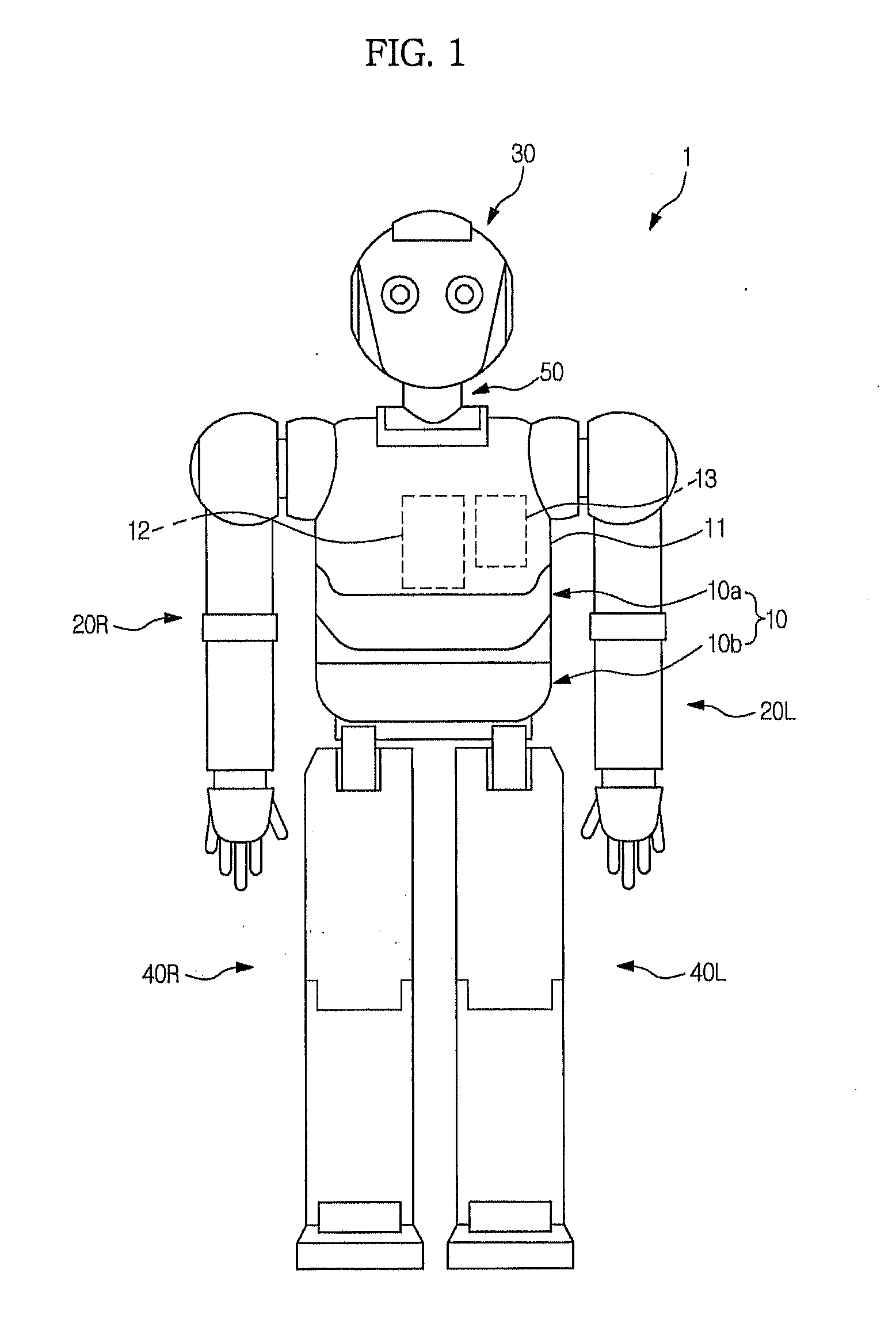

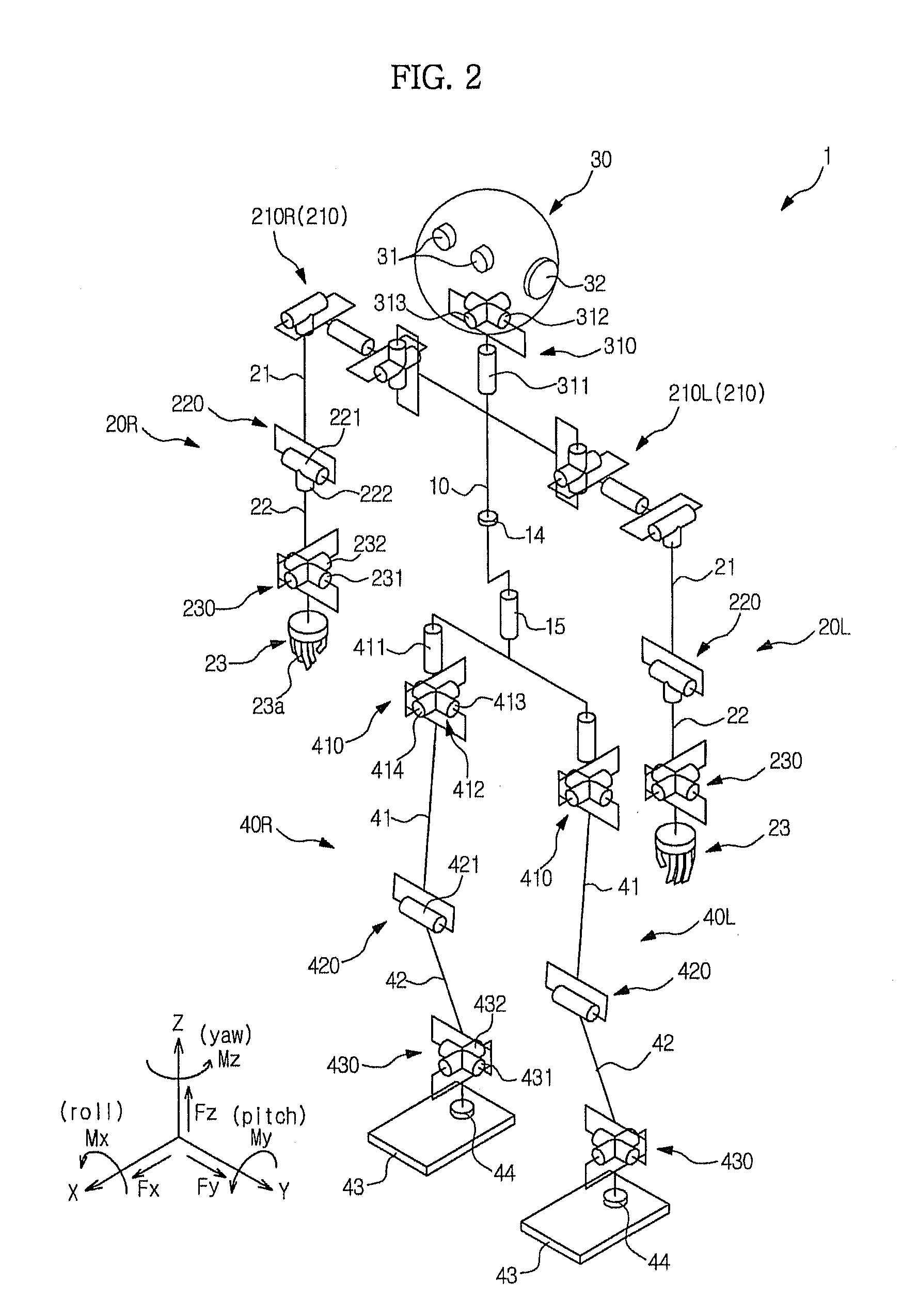

Robot joint driving method, computer-readable medium, device assembly and robot having the same

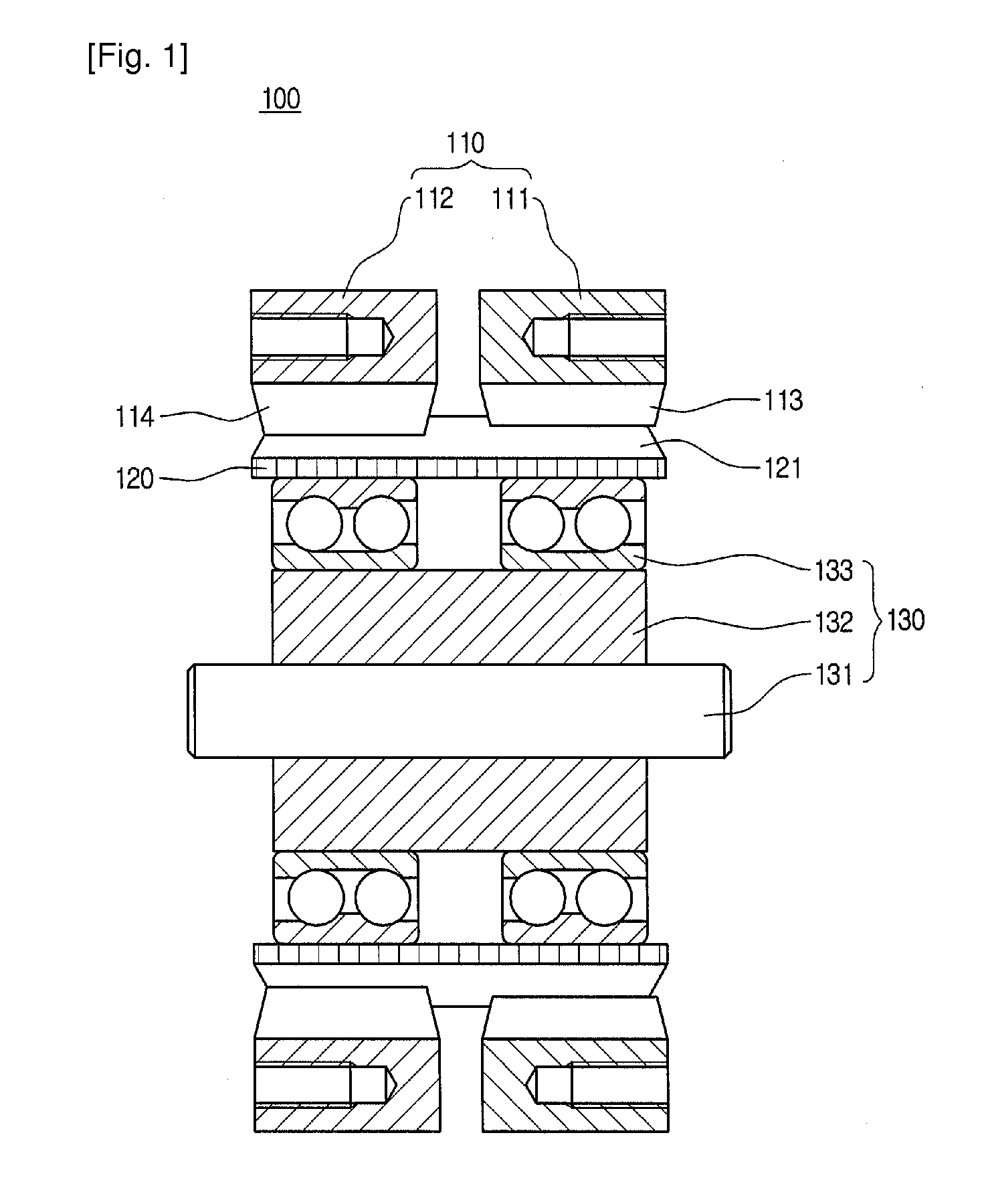

ActiveUS20110056321A1Improve rigidityImprove accuracyProgramme-controlled manipulatorJointsGear wheelSimulation

Disclosed herein are a robot joint driving method, computer-readable medium, and device assembly which conducts motions similar to those of humans, and a robot having the same. These motions are achieved by arranging joint driving devices suited to characteristics of respective joints. The robot joint driving device assembly includes a tendon-type joint driving device using a wire, and a harmonic drive-type joint driving device using a gear reduction method. The tendon-type joint driving device is used to drive a rotary joint requiring high back-drivability, and the harmonic drive-type joint driving device is used to drive a rotary joint requiring high rigidity and high precision.

Owner:SAMSUNG ELECTRONICS CO LTD

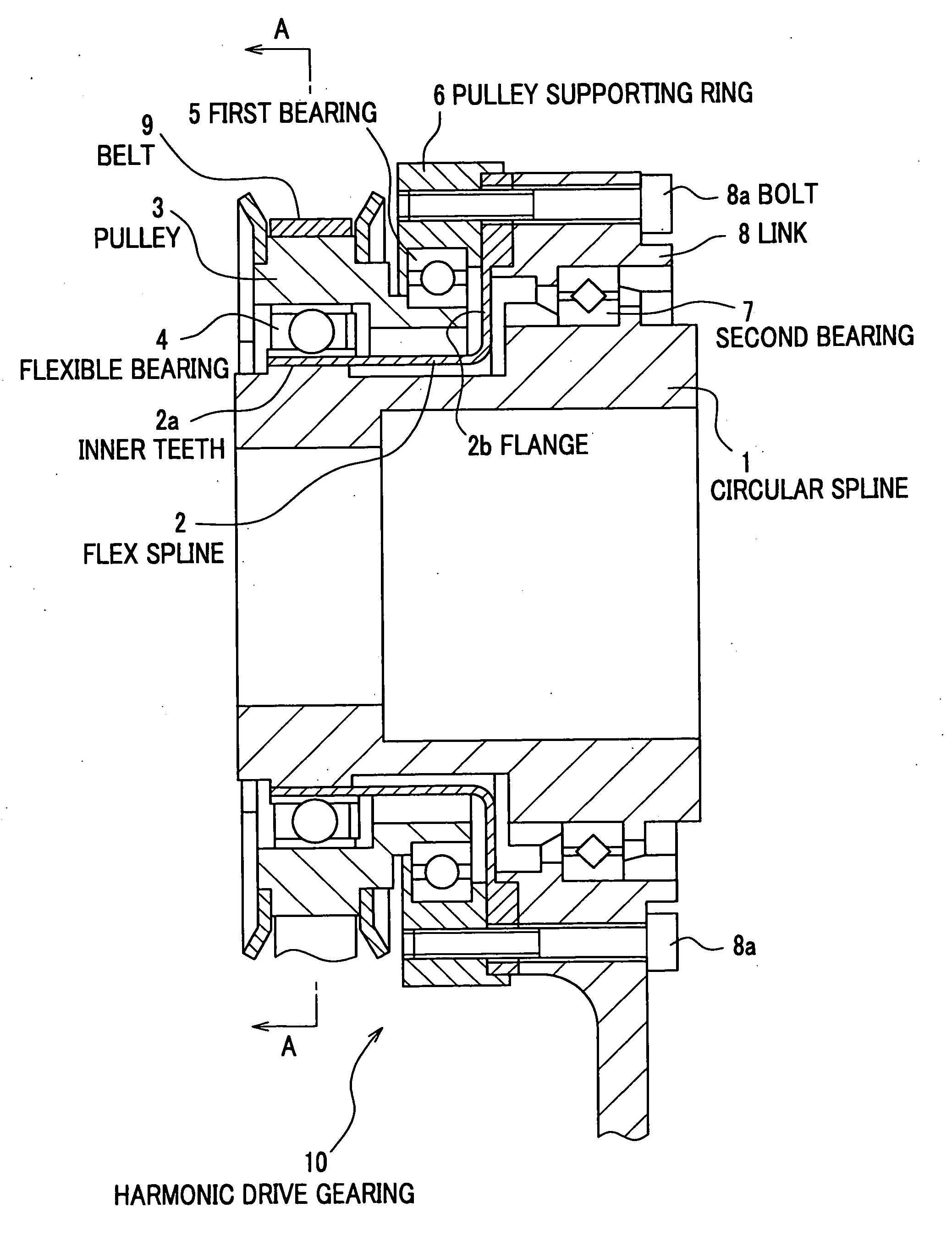

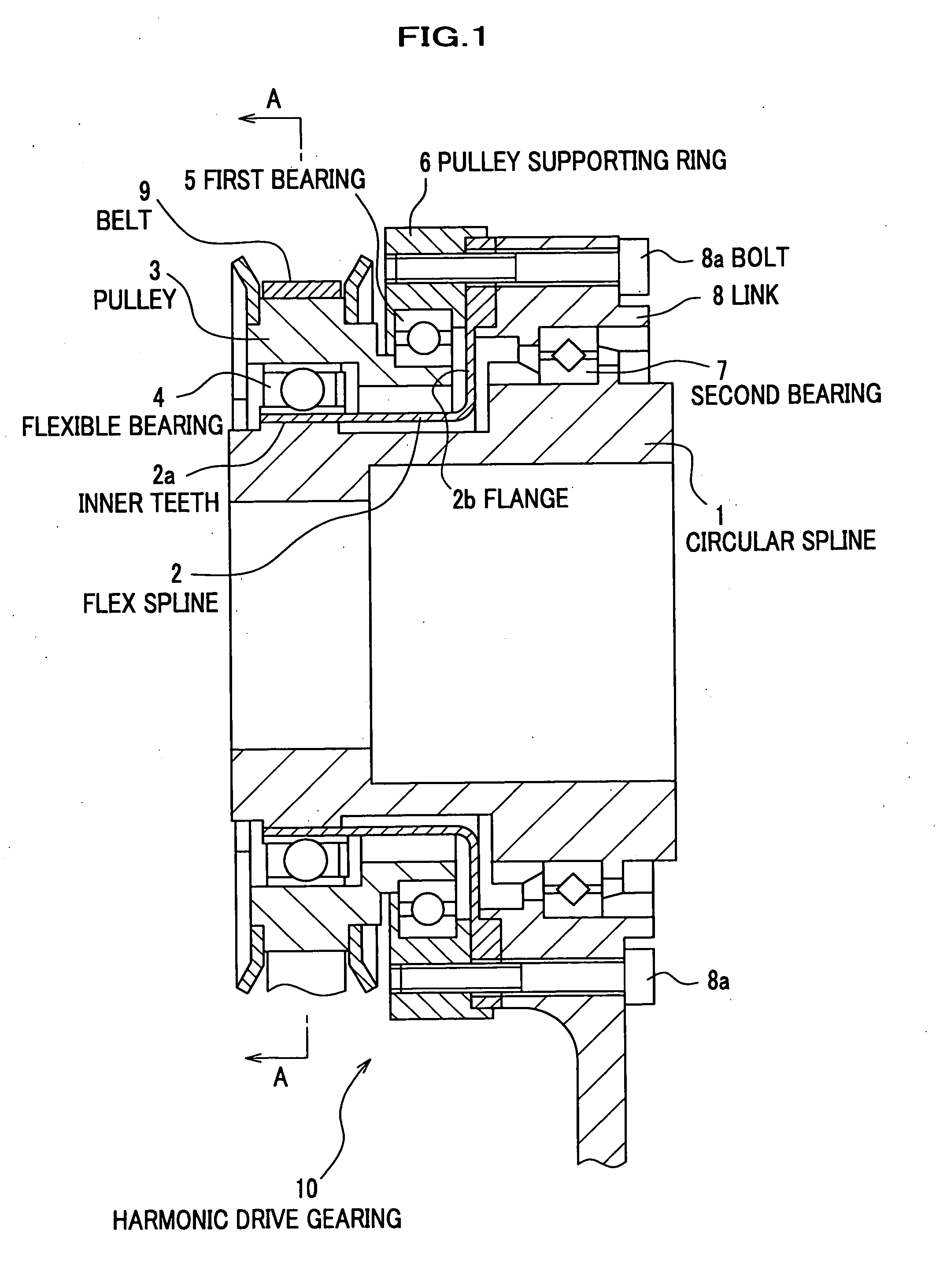

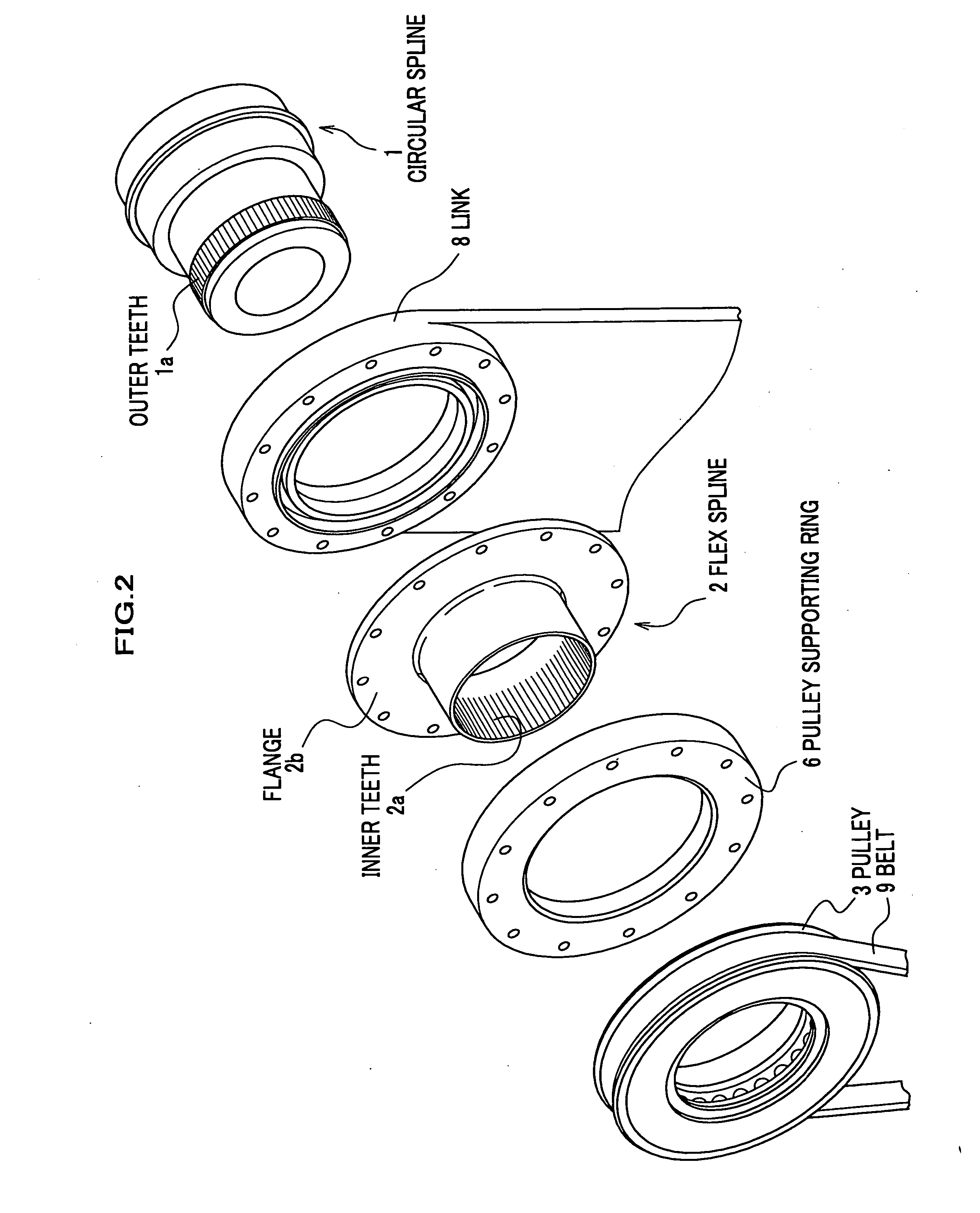

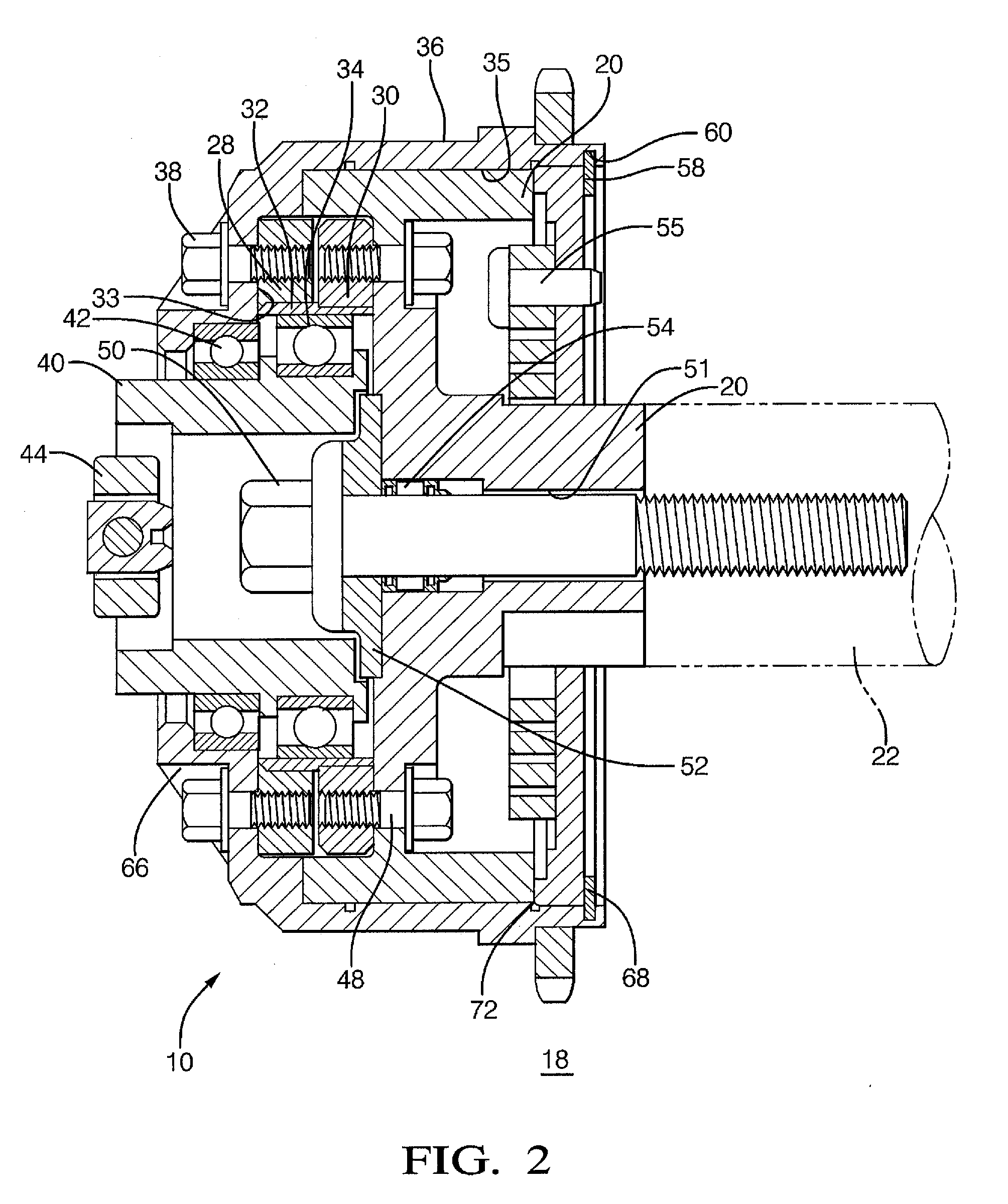

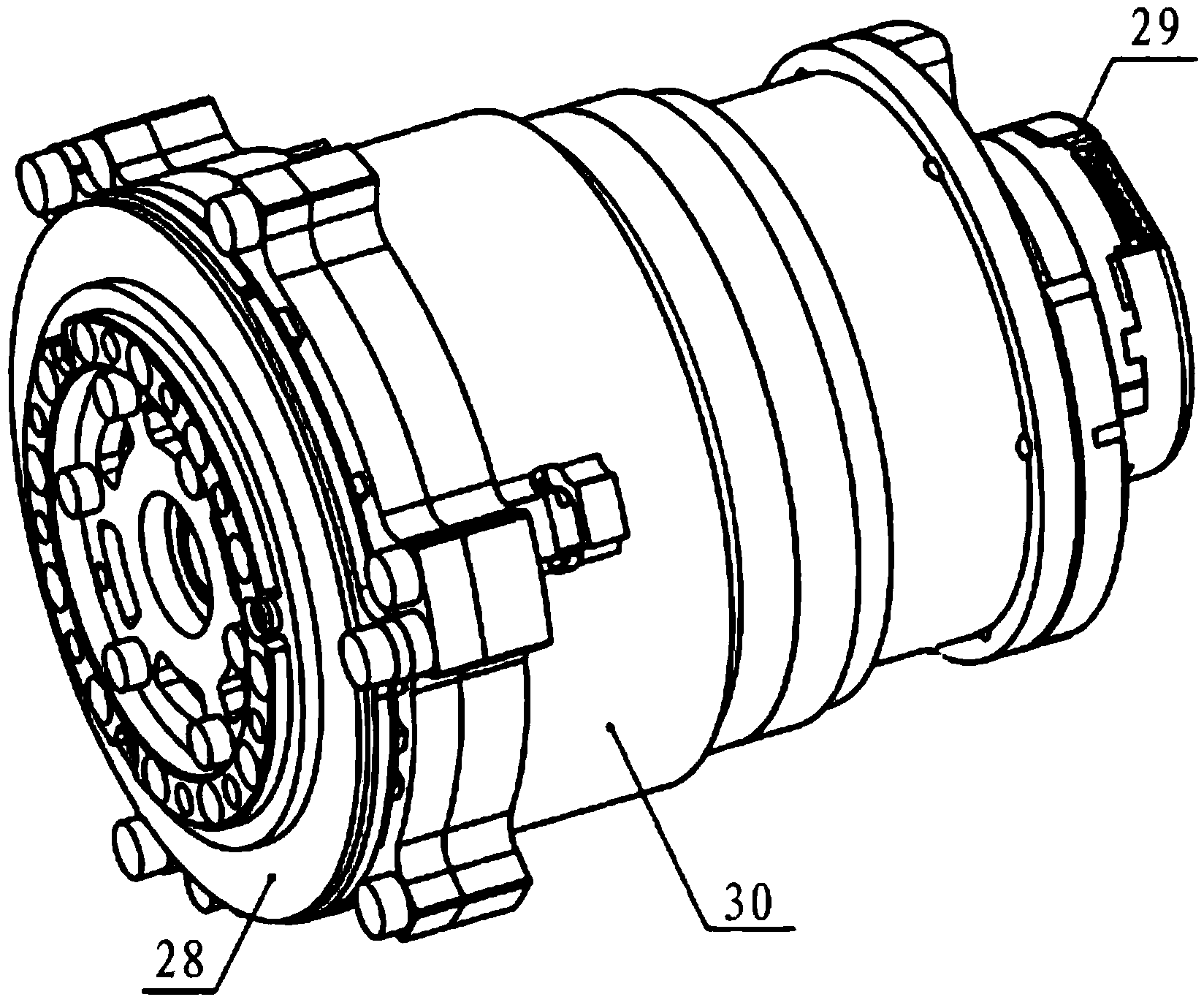

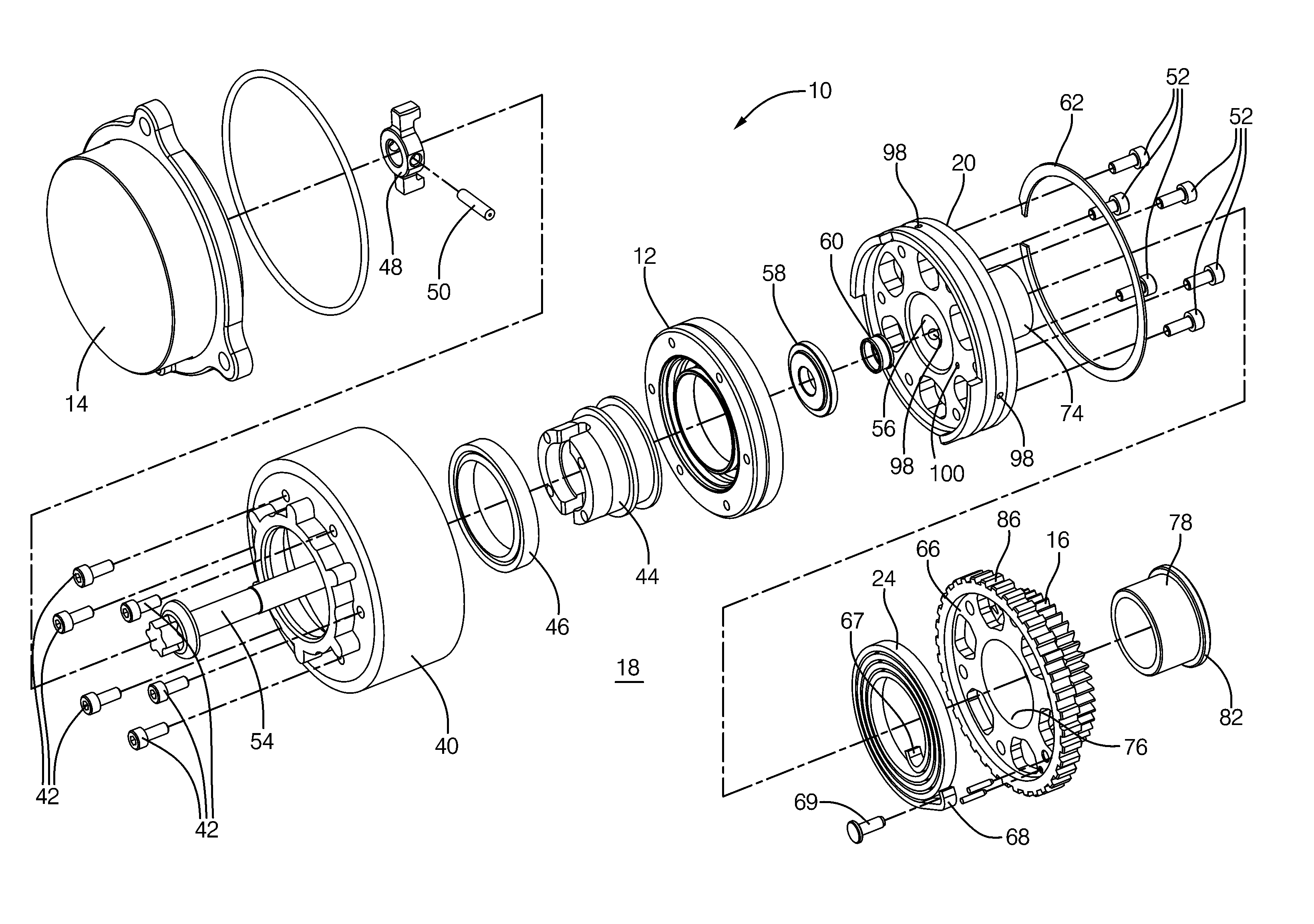

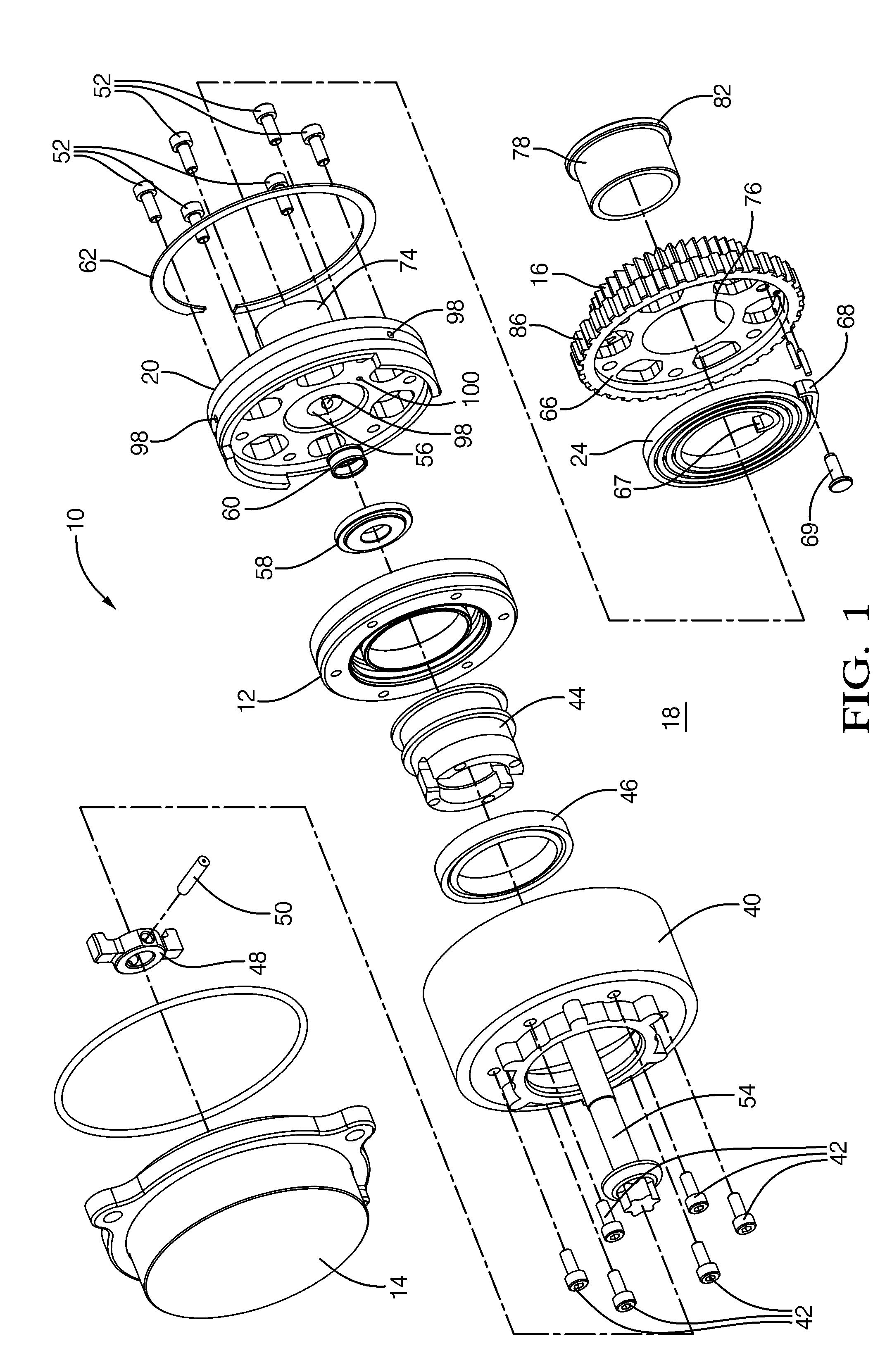

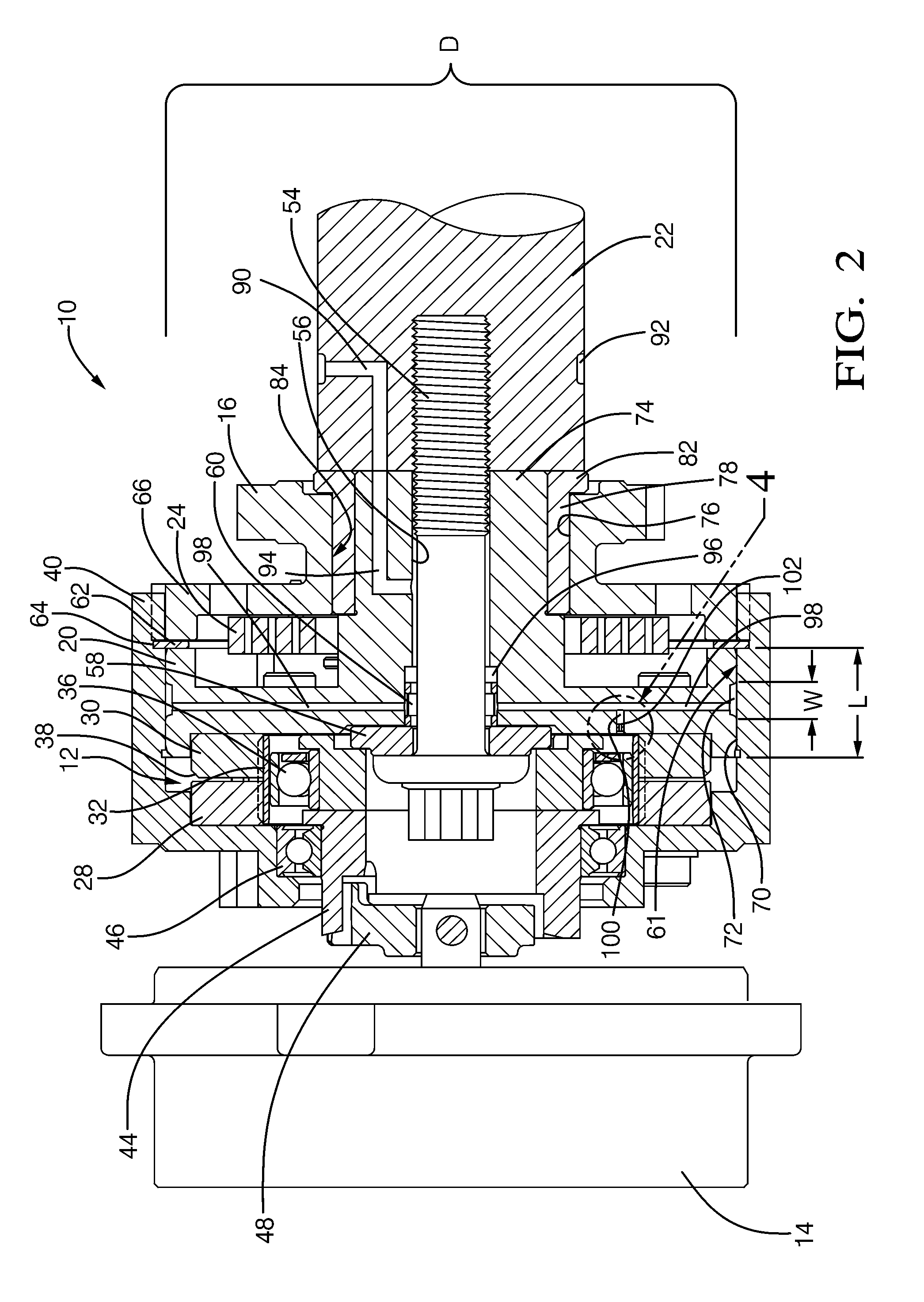

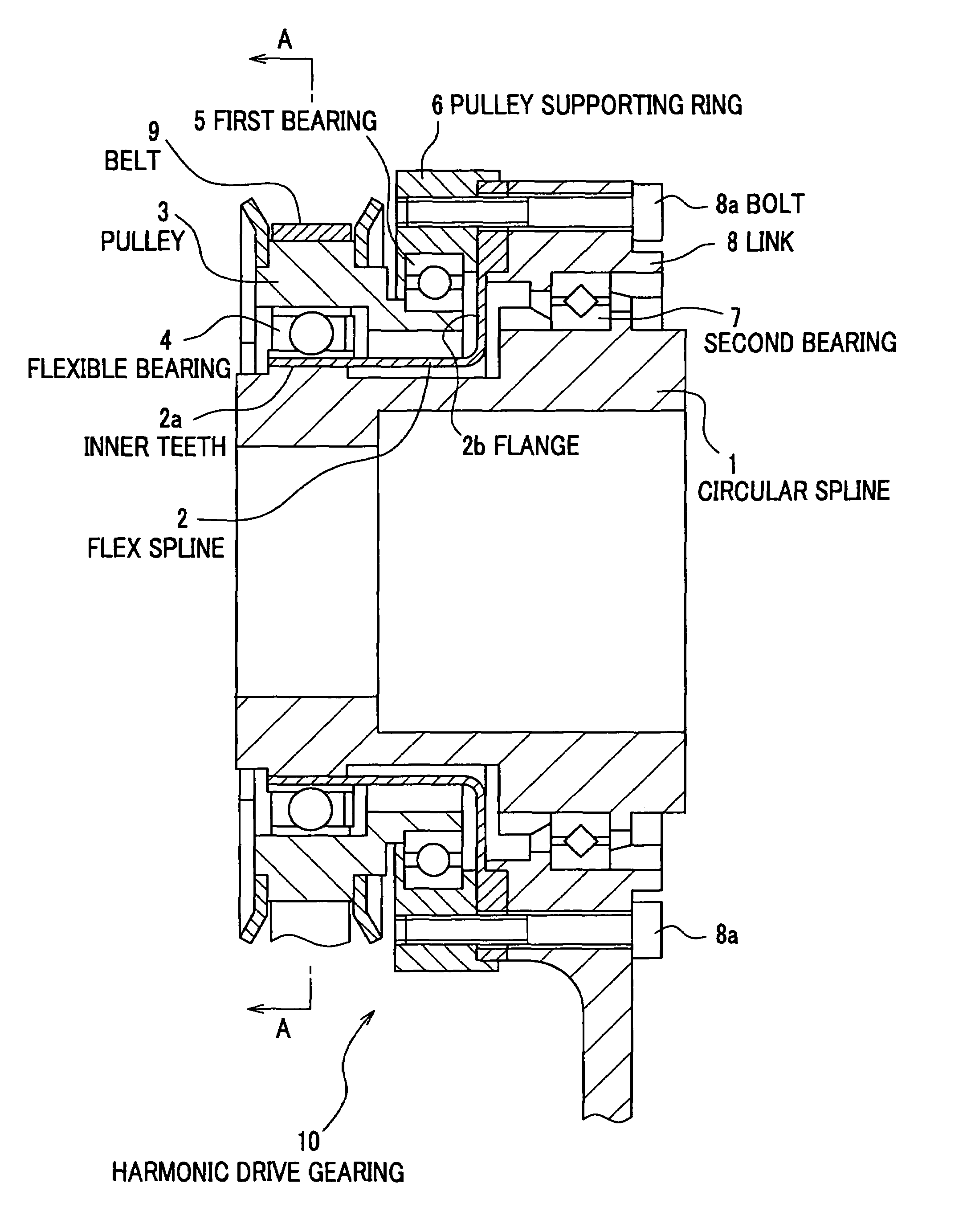

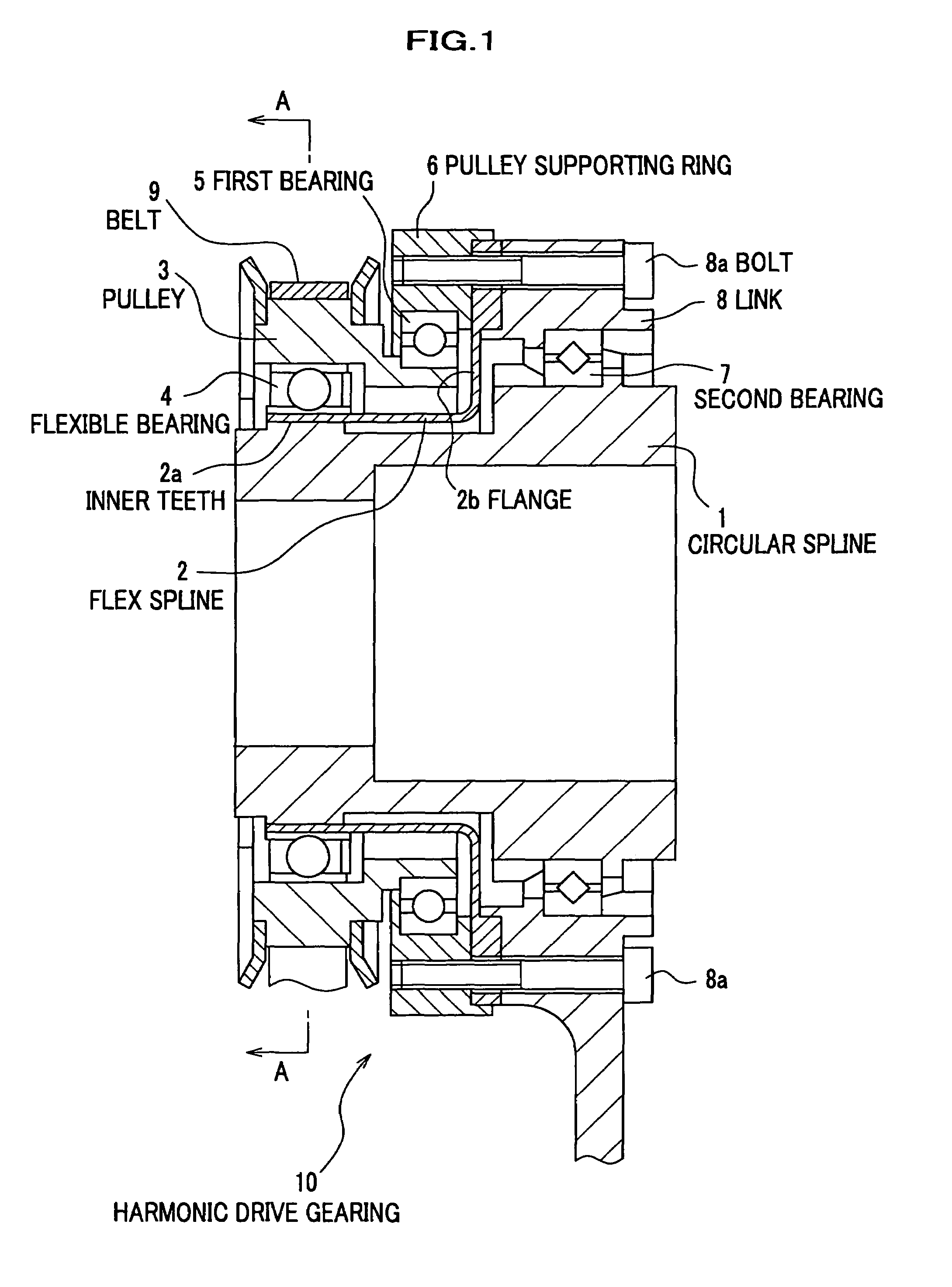

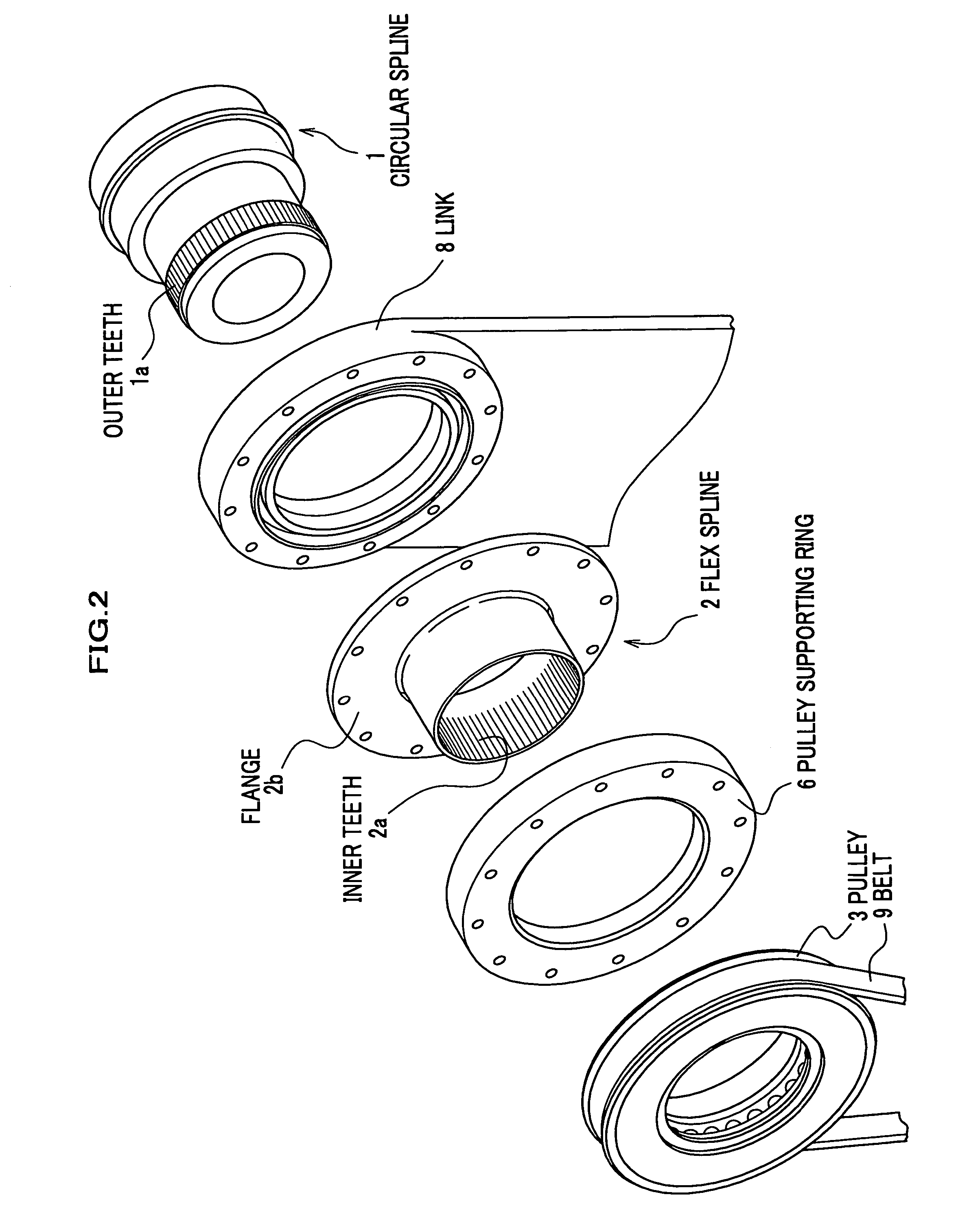

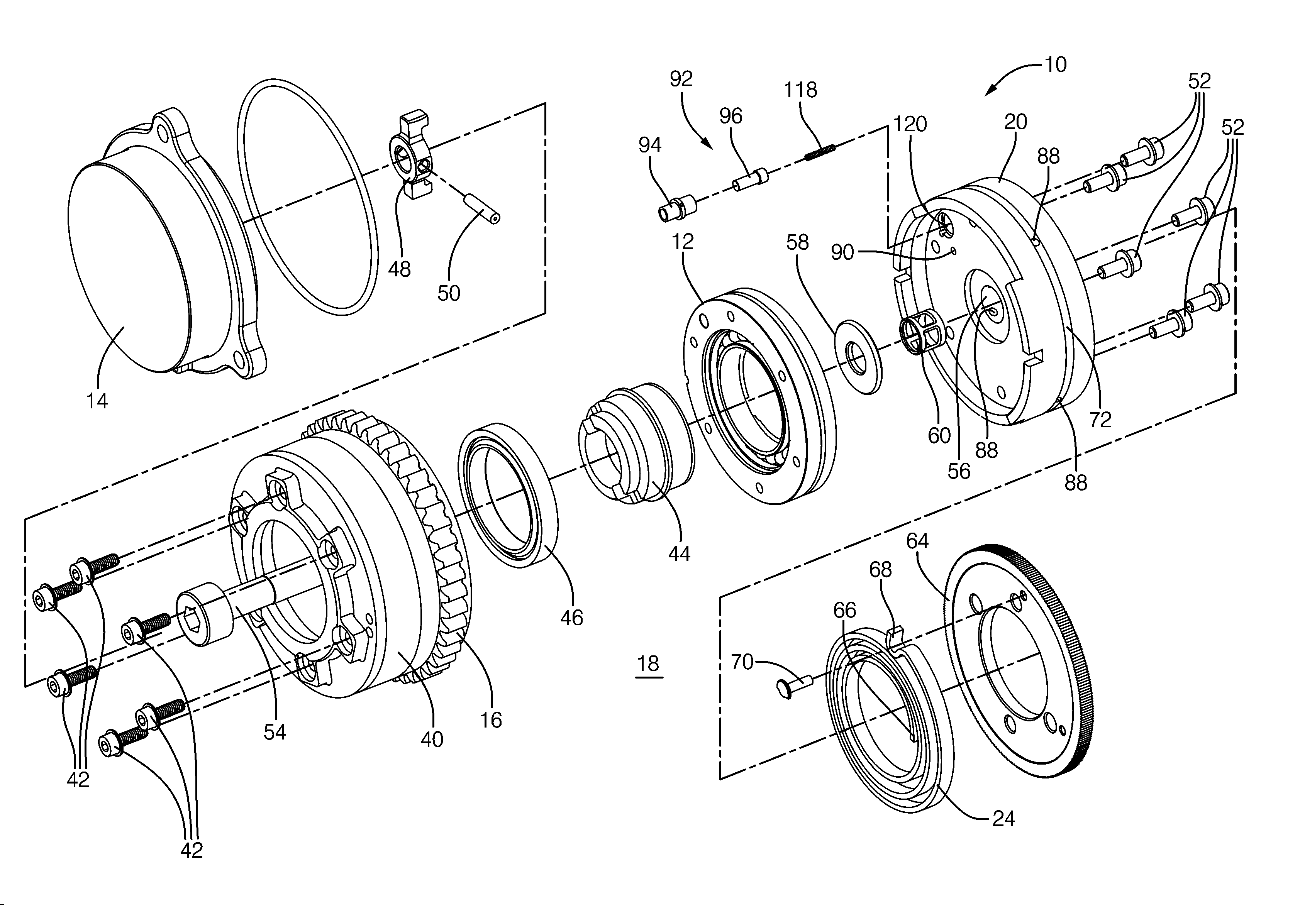

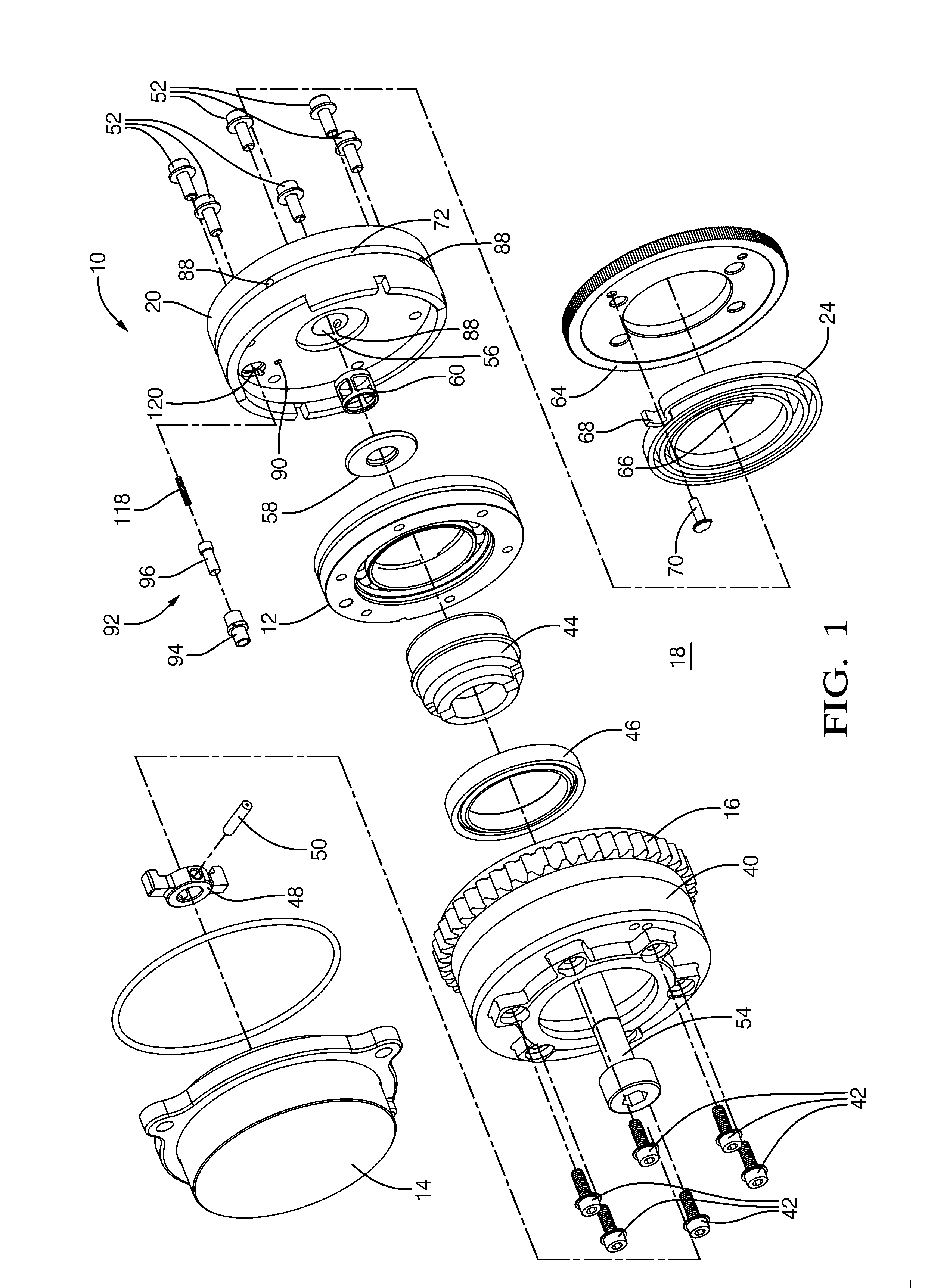

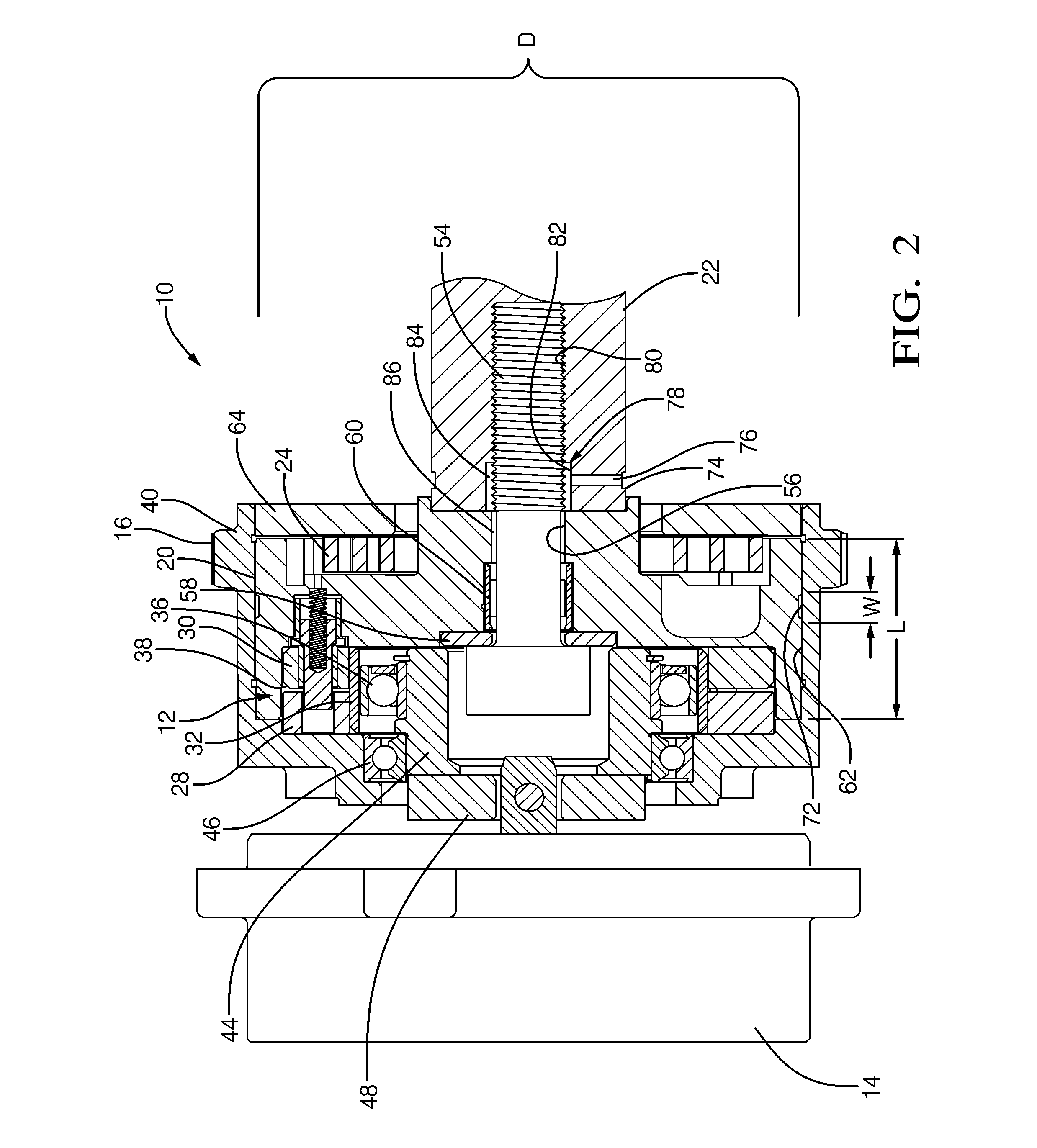

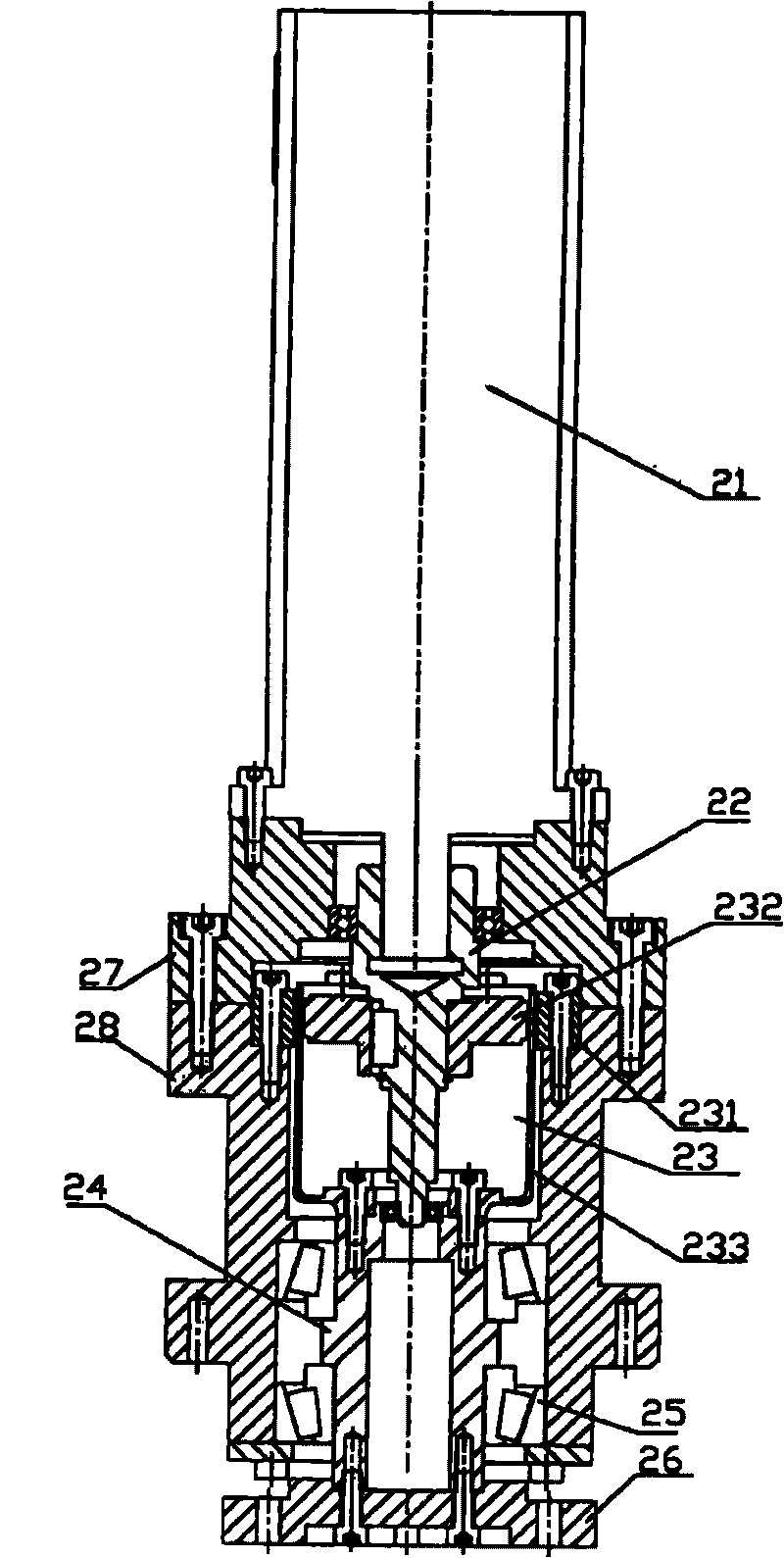

Drive unit with reducer

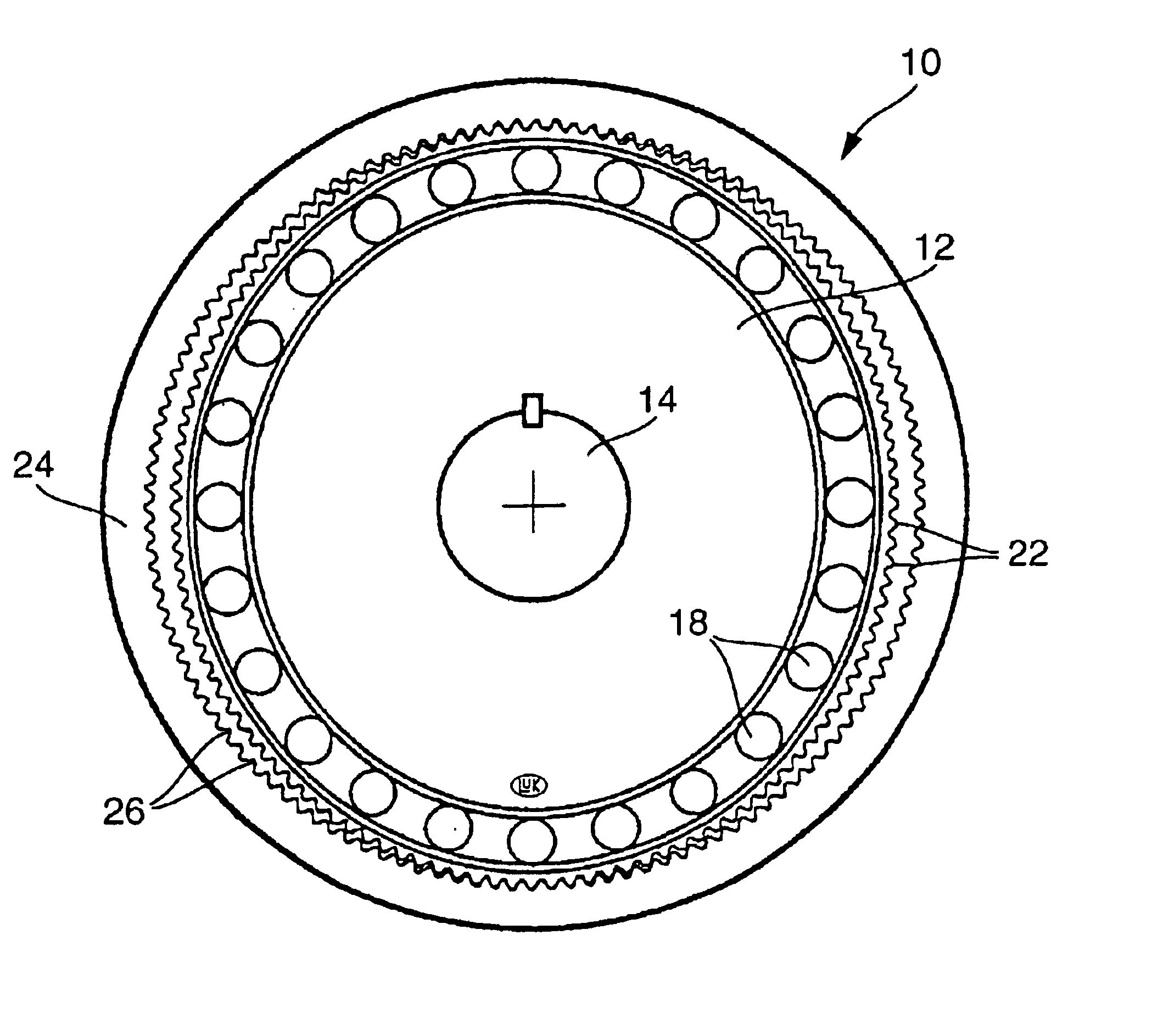

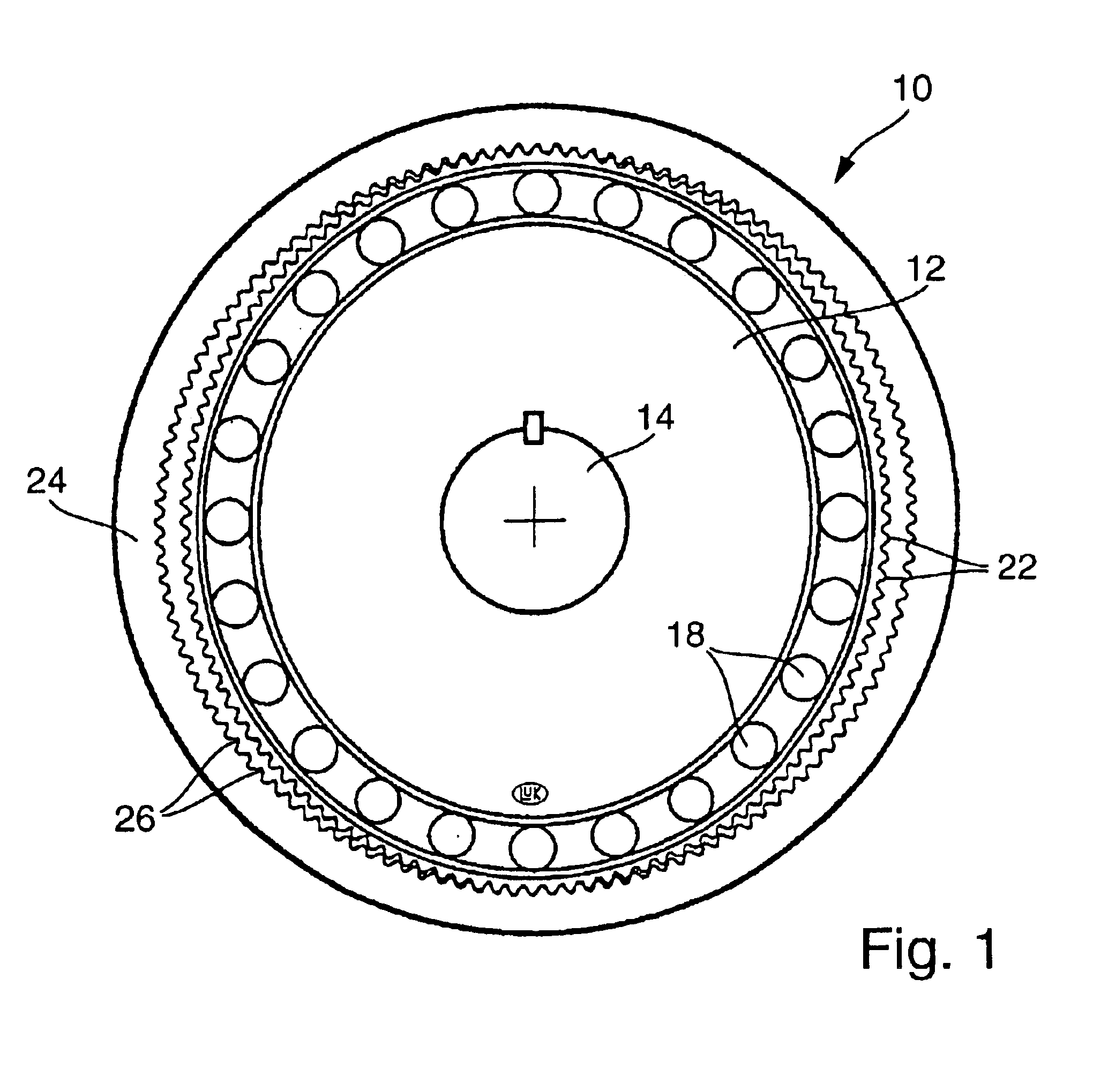

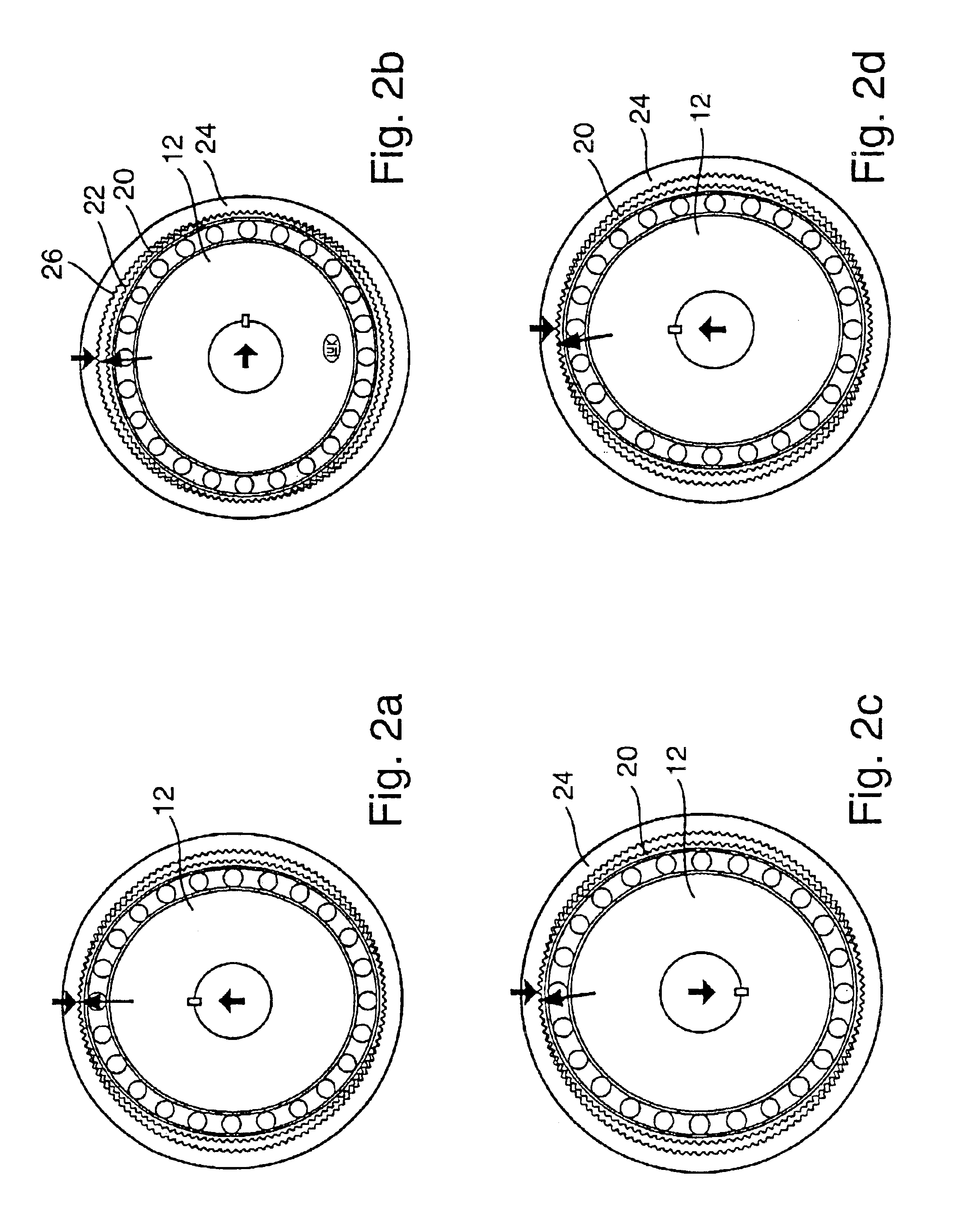

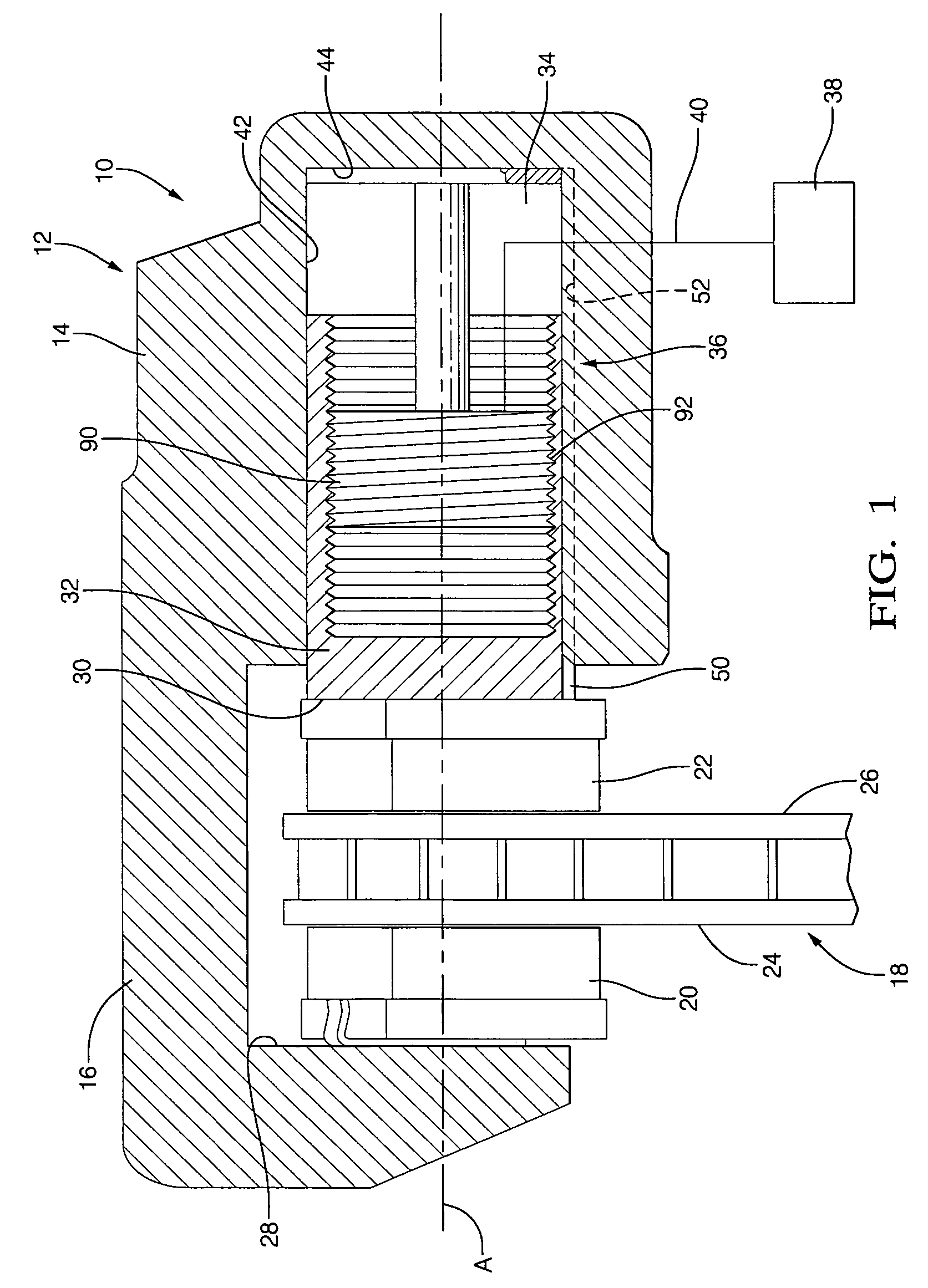

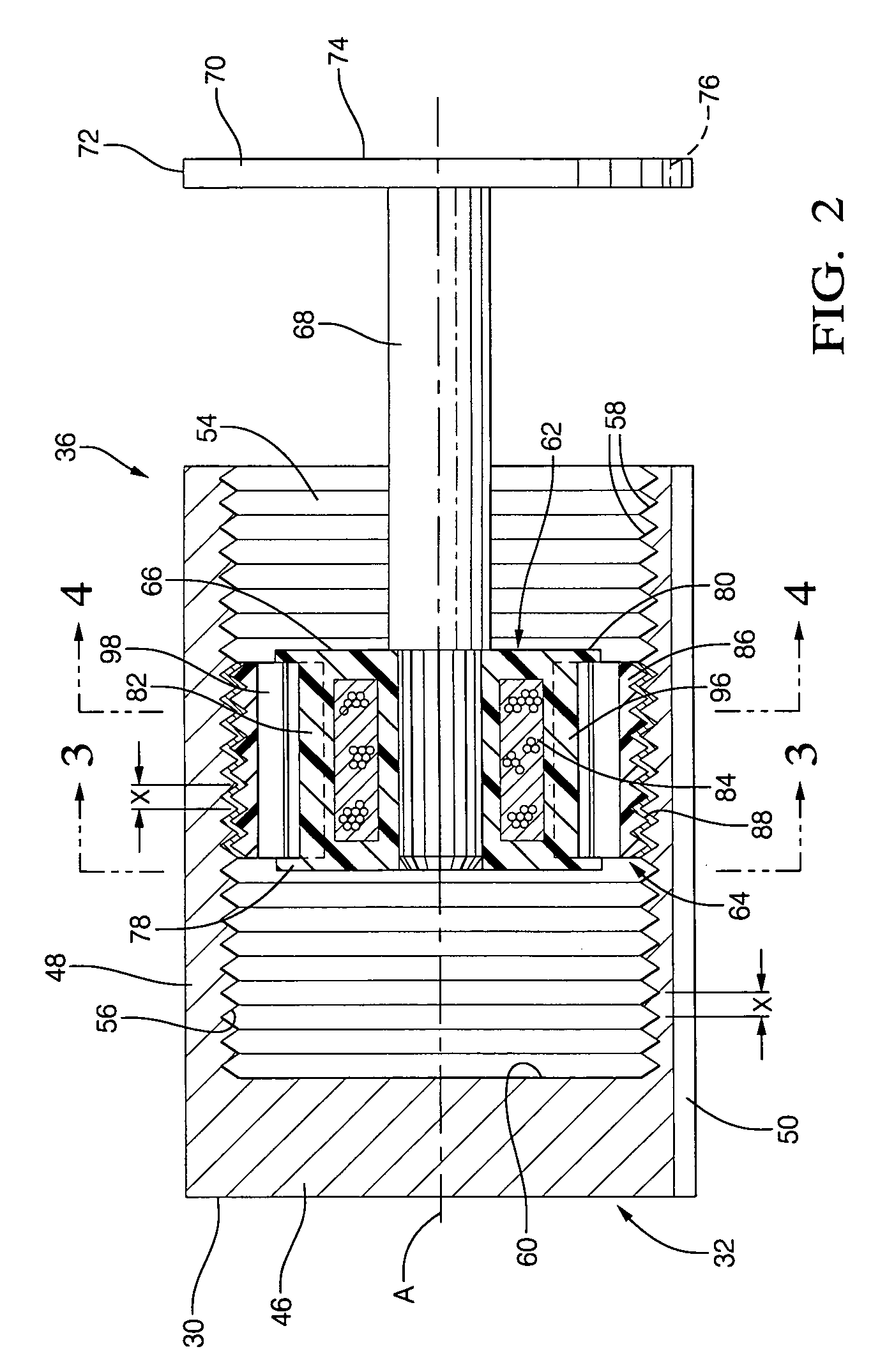

ActiveUS20070039414A1High torque transmissionMinimized in sizeGearingPropulsion systemsHarmonic driveMinor axis

To provide a harmonic drive gearing with high degree of freedom in terms of layout. A harmonic drive gearing 10 includes a circular spline 1′, having outer teeth formed on an outer peripheral surface; an flexible spline 2, positioned at the outside of the circular spline 1′, and having inner teeth, which are engageable with the outer teeth of the circular spline 1′, formed on an inner peripheral surface; and a rotor 16 which is disposed at outside of the flexible spline 2 and serves as a wave generator, wherein the rotor 16 deflects the flexible spline 2 by minor axis portions of the inner peripheral surface of the flexible spline 2 and engages the inner teeth of the flex spline with the outer teeth of the circular spline 1′ and thereby the engagement position between the inner teeth and the outer teeth is adapted to move in a circumferential direction.

Owner:HONDA MOTOR CO LTD

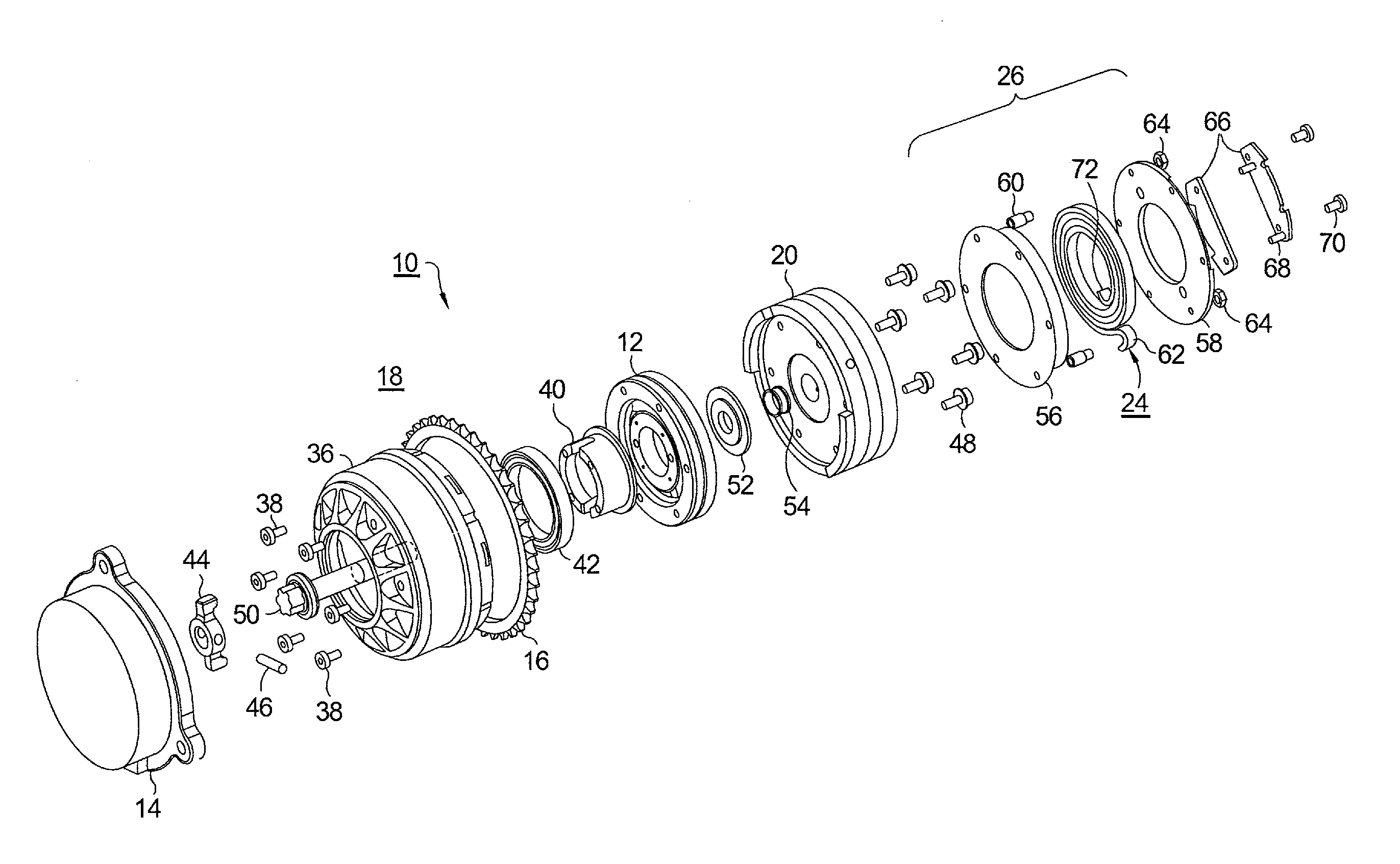

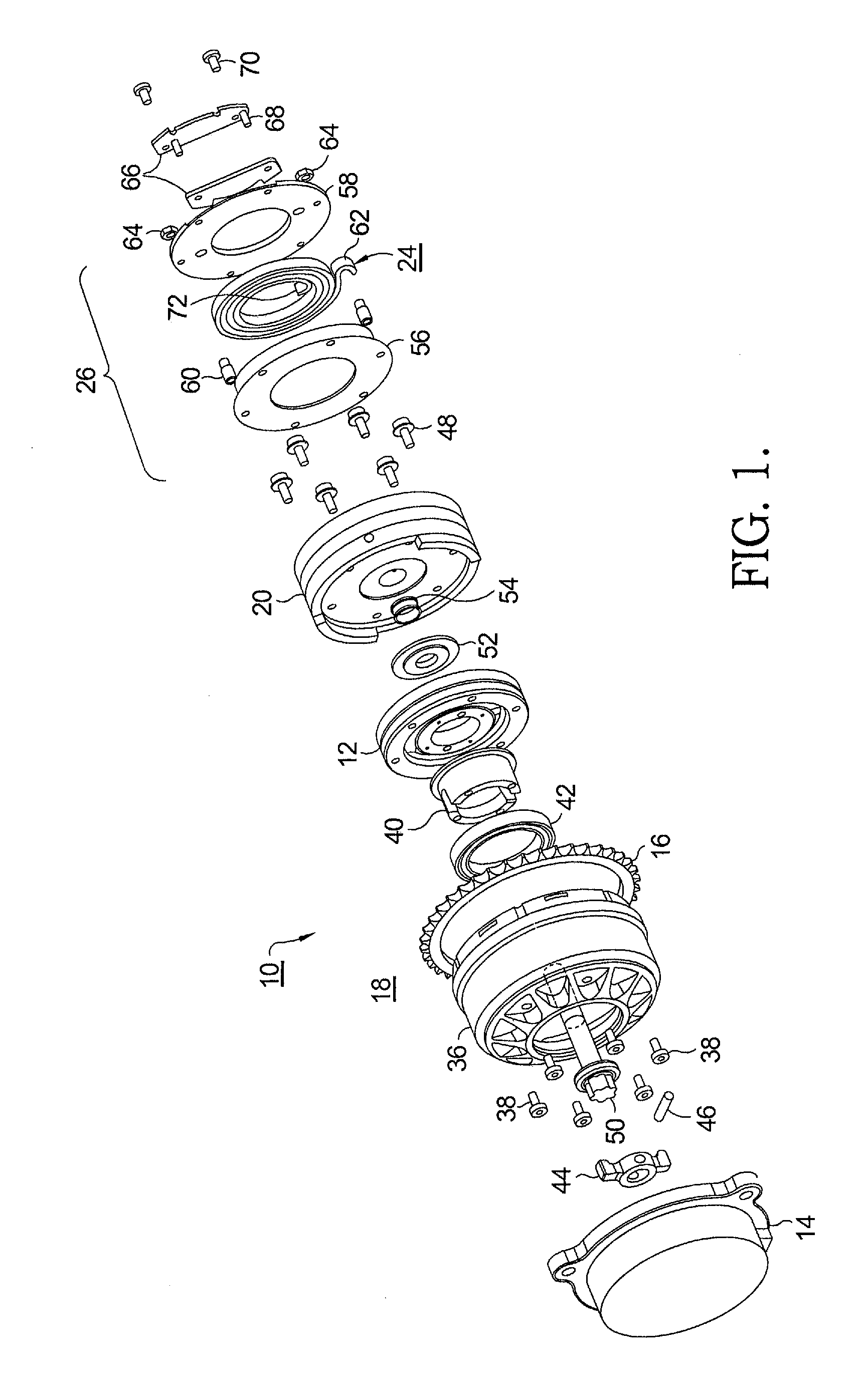

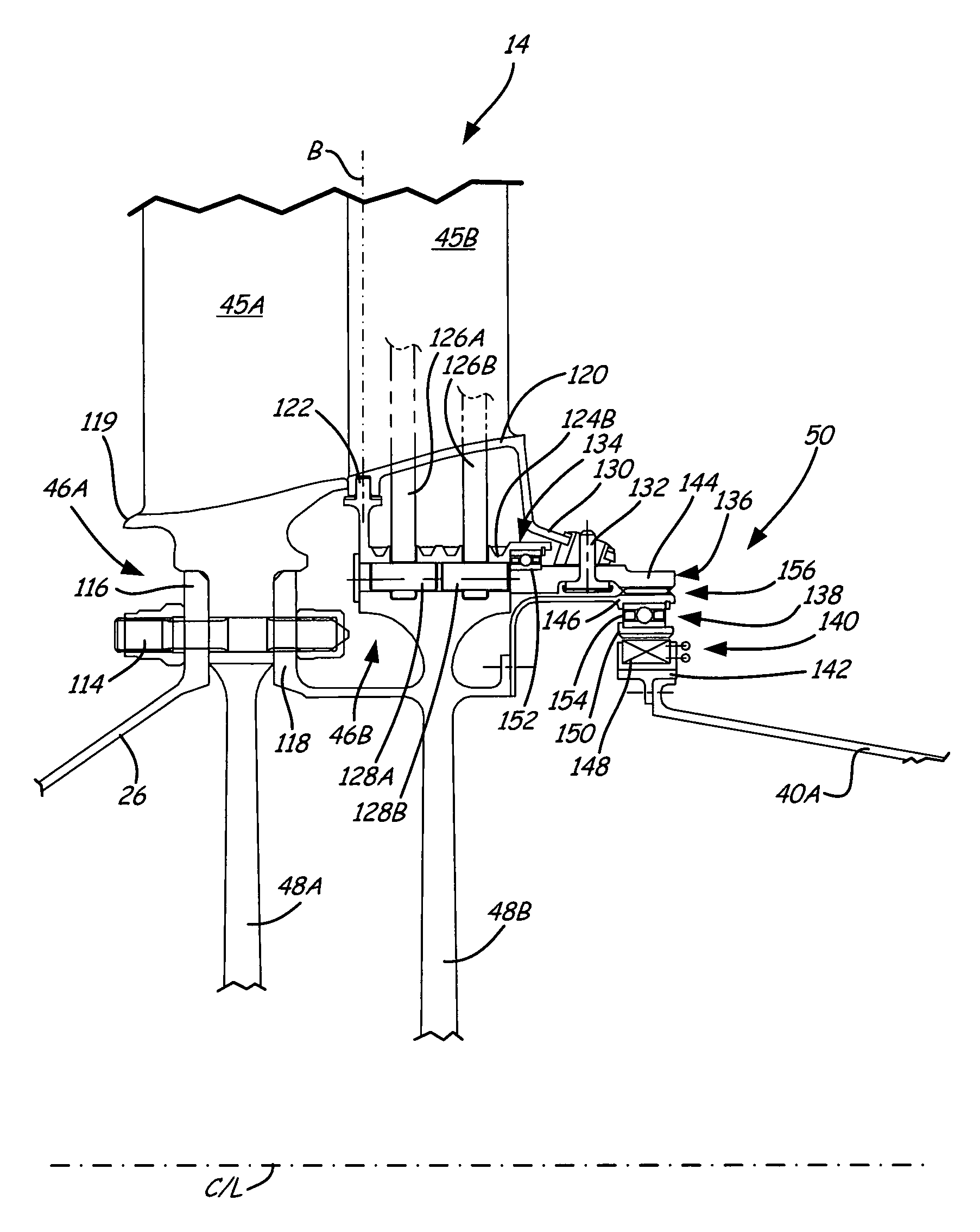

Harmonic drive camshaft phaser

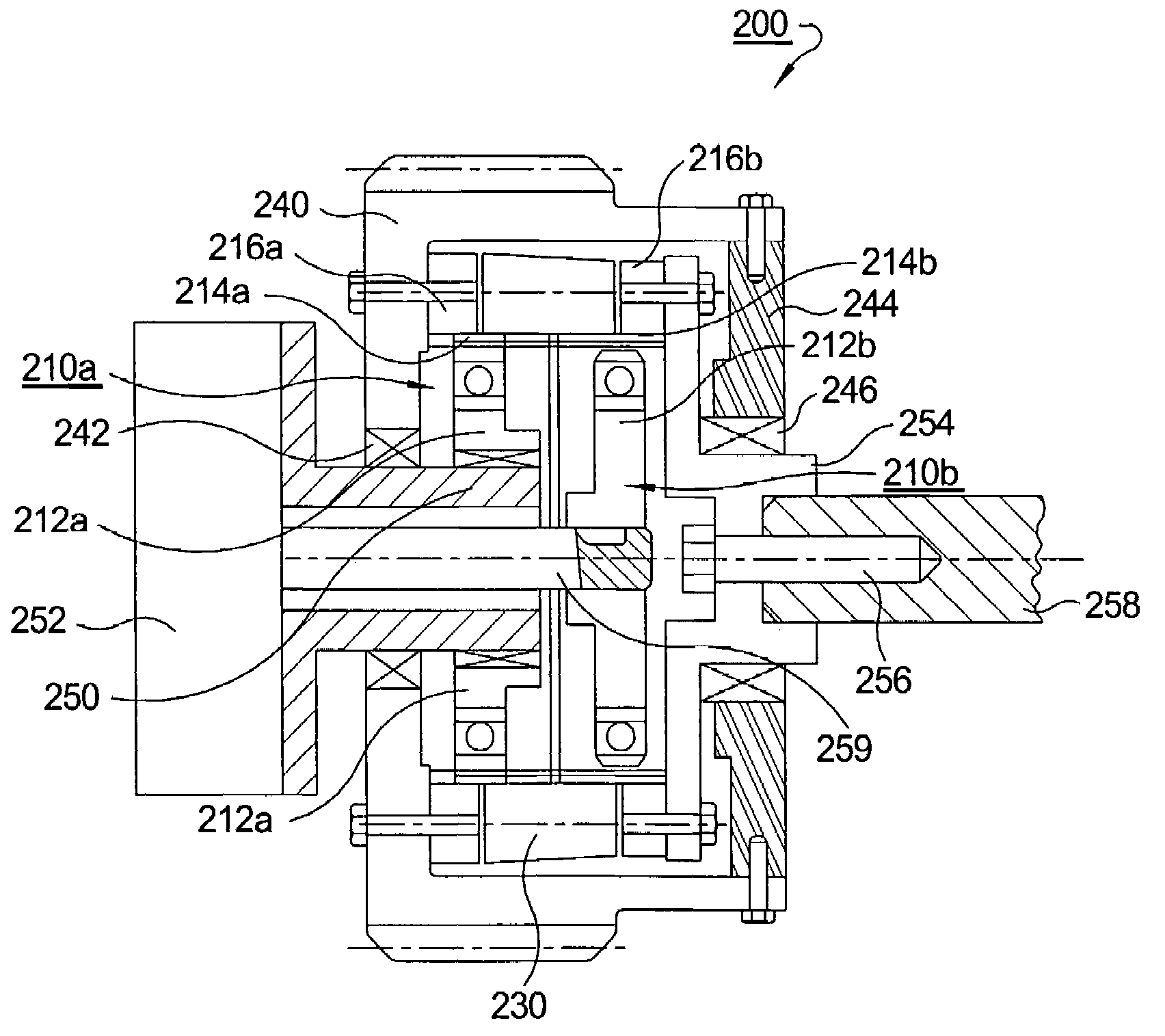

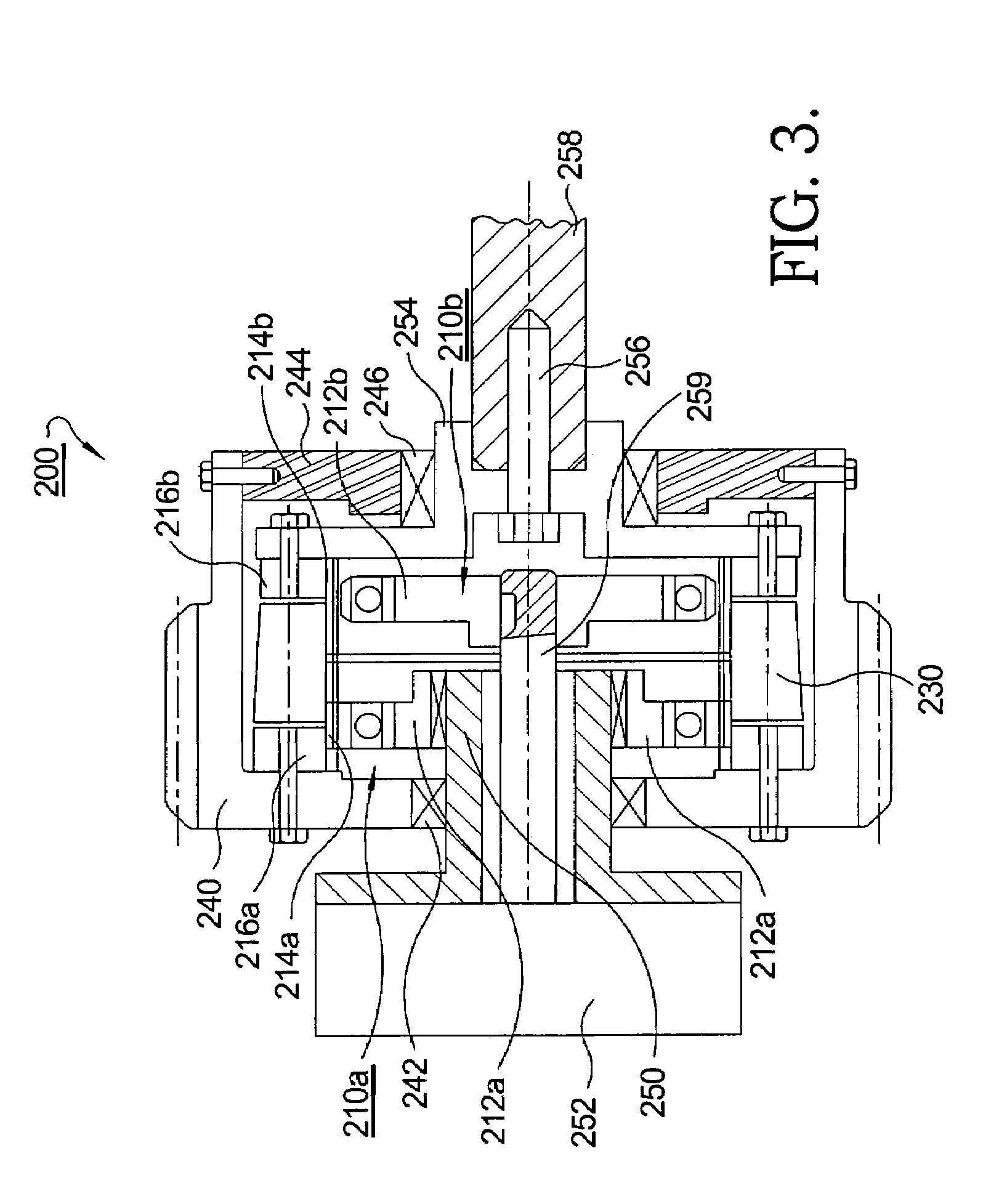

A camshaft phaser comprising first and second harmonic gear drive (HD) units disposed in back-to-back relationship. Each HD includes an elliptical wave generator (WG), a flexspline (FS) deformable by the WG, and a circular spline (CS) for engaging the FS. A dynamic spline (DS) connects the first and second FSs. The first HD is an input HD driven by an engine crankshaft via a sprocket wheel connected to the input CS. The second HD is an output HD driving an engine camshaft. The DS is meshed with both the input FS and the output FS. The phase relationship between the crankshaft and the camshaft may be changed by changing the angular relationship between the first and second WGs. Such change is effected by holding the first WG stationary and varying the angular position of the second WG via an electric motor.

Owner:DELPHI TECH IP LTD

Harmonic Drive Camshaft Phaser with Improved Radial Stability

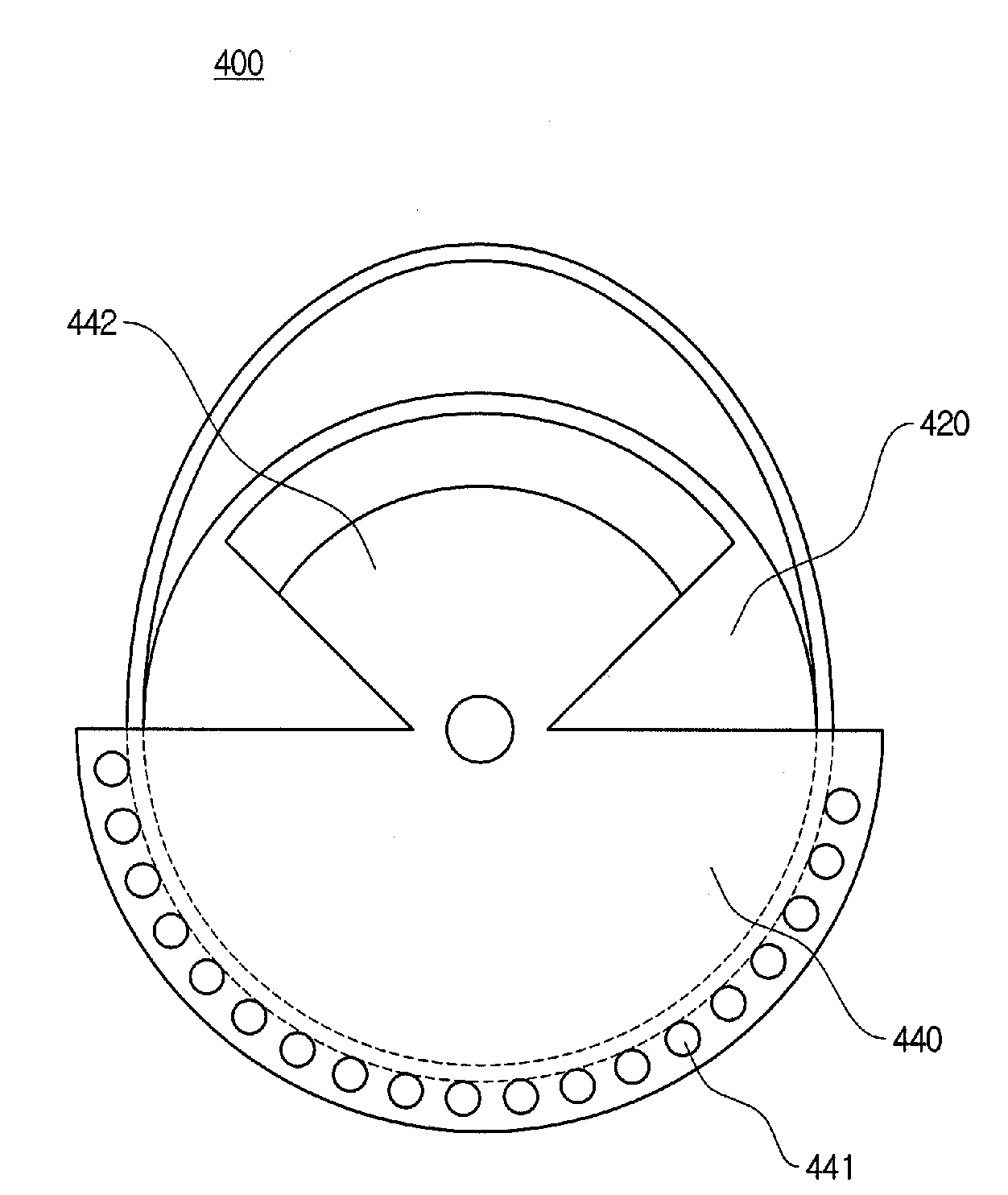

ActiveUS20110030632A1Obtained inexpensivelyMinimize distortionValve arrangementsMachines/enginesEngineeringHarmonic drive

Improved stiffening and minimized distortion of a housing for an eVCP achieved by forming a plurality of radial housing stiffeners into the housing around the motor mount end and into the eVCP's hub. A back plate is press fit into the rear of the housing, and a straight axial knurl is applied to the surface of the back plate or housing, which knurl permits a larger tolerance-higher press fit class to be used without resulting in significant deformation of the housing. The knurled back plate is harder than the housing, causing the high points of the knurl to plastically deform or plow the housing material during assembly, resulting in less radial deformation of the bore and the journal bearing. An interface between the housing and the hub provides a journal bearing interface to improve axial stability between the hub and housing.

Owner:DELPHI TECH IP LTD

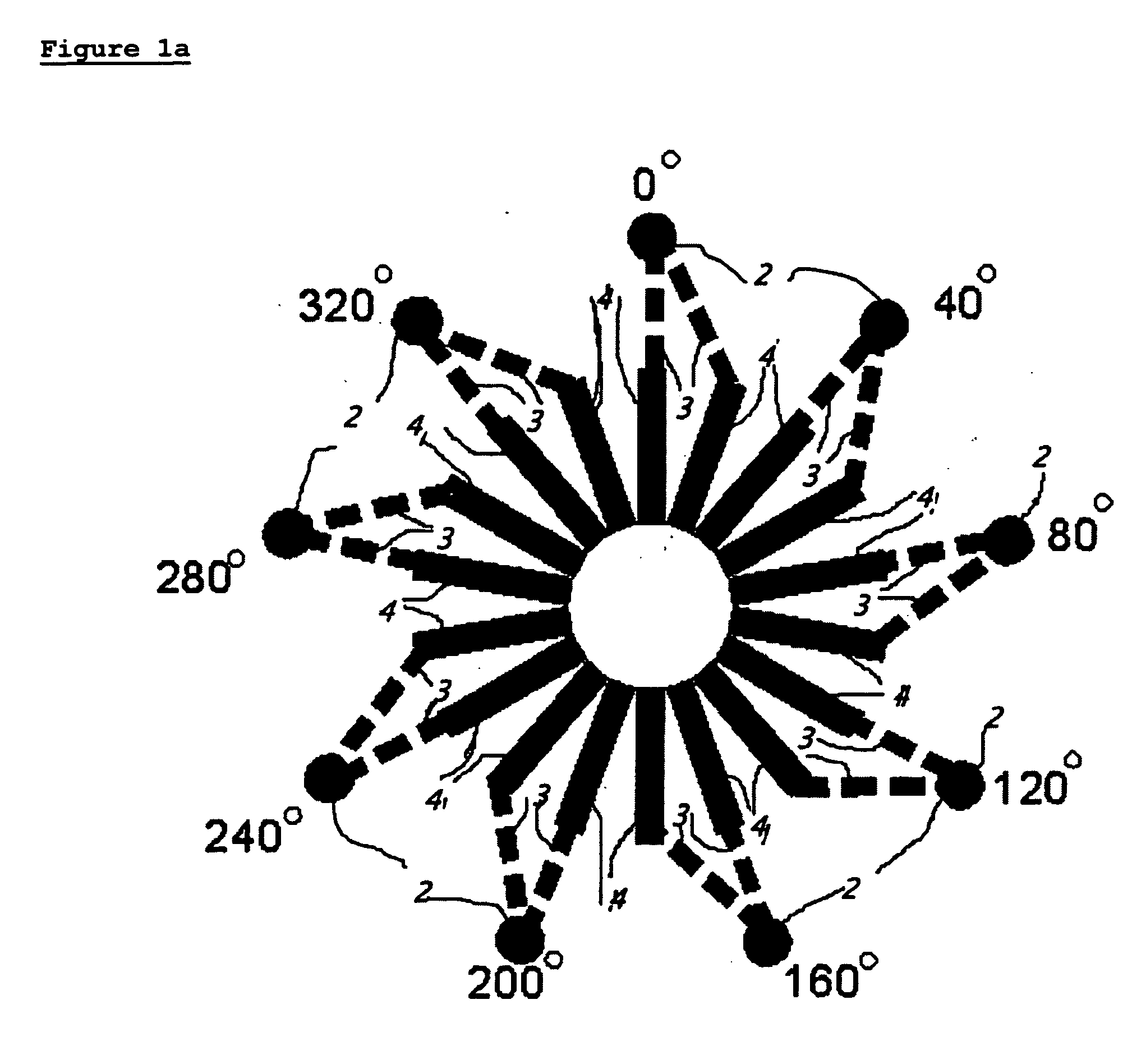

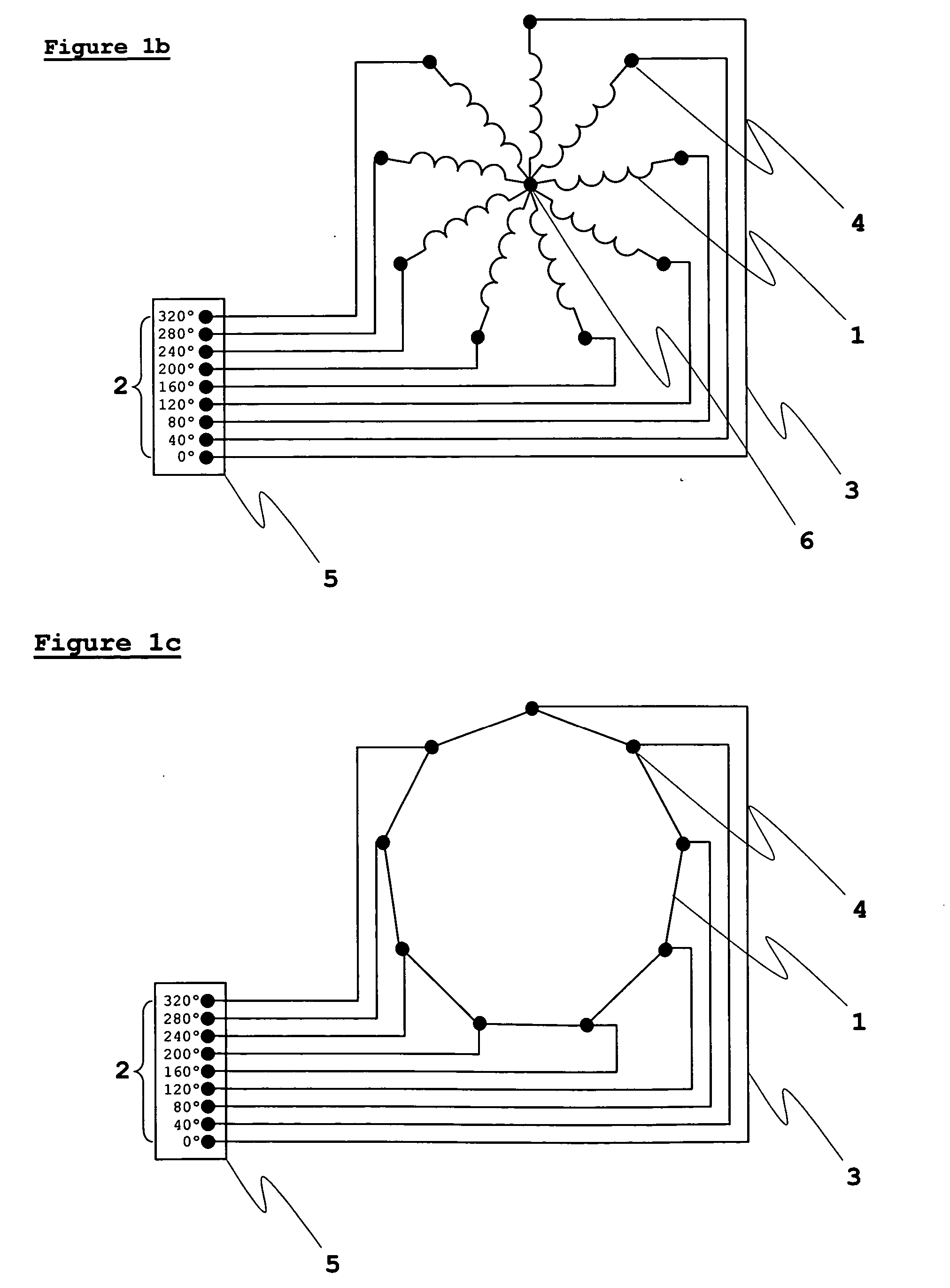

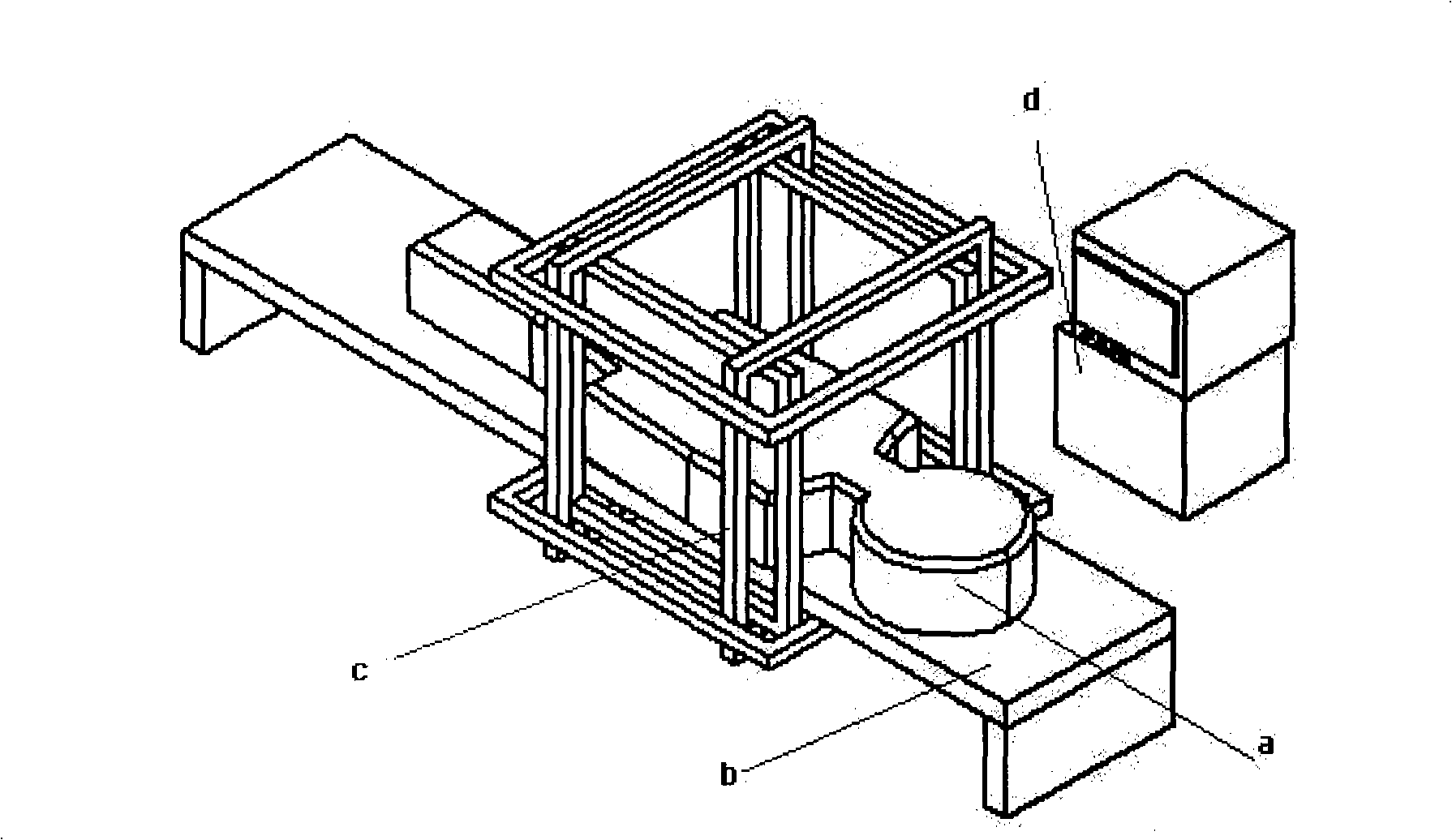

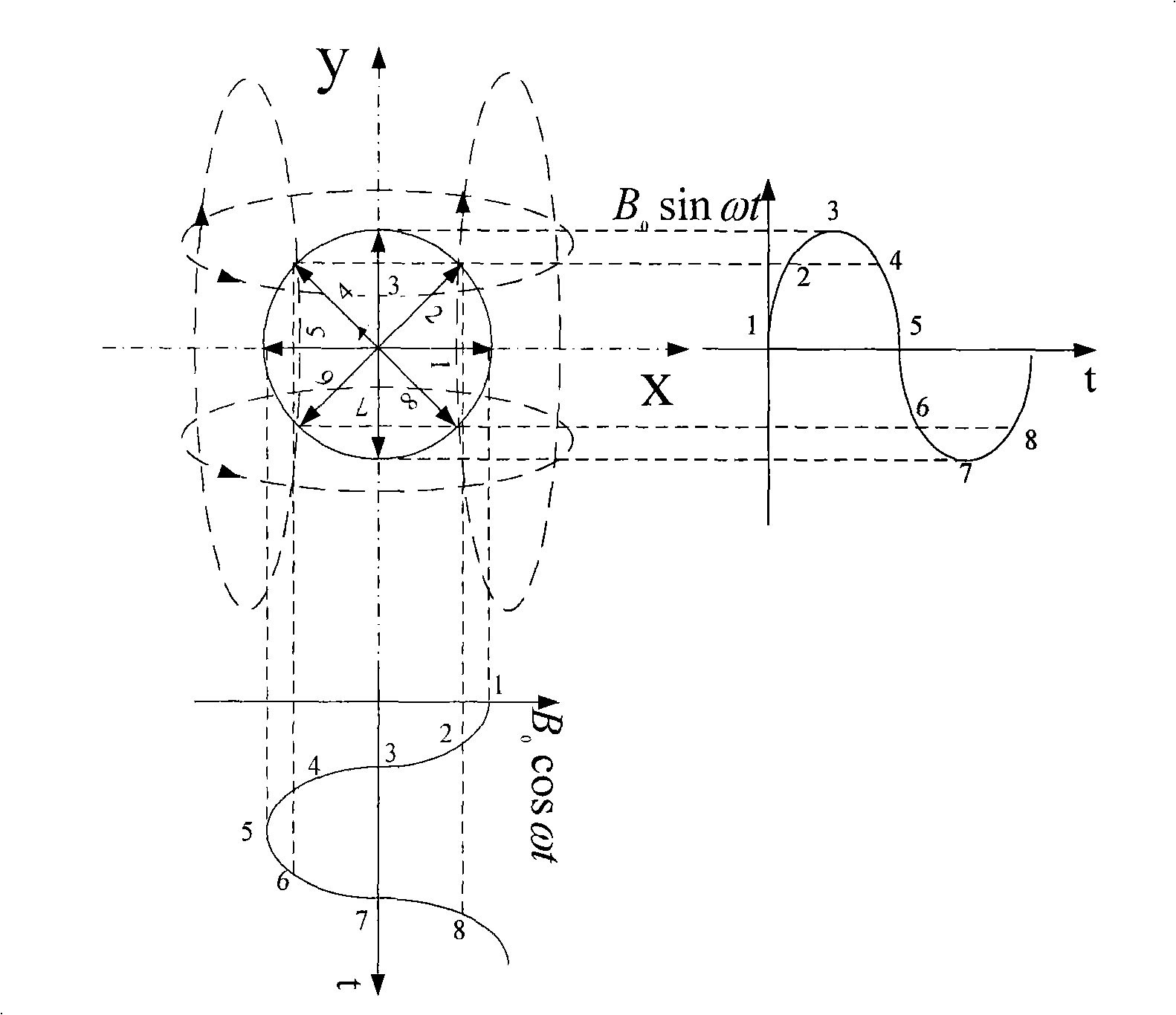

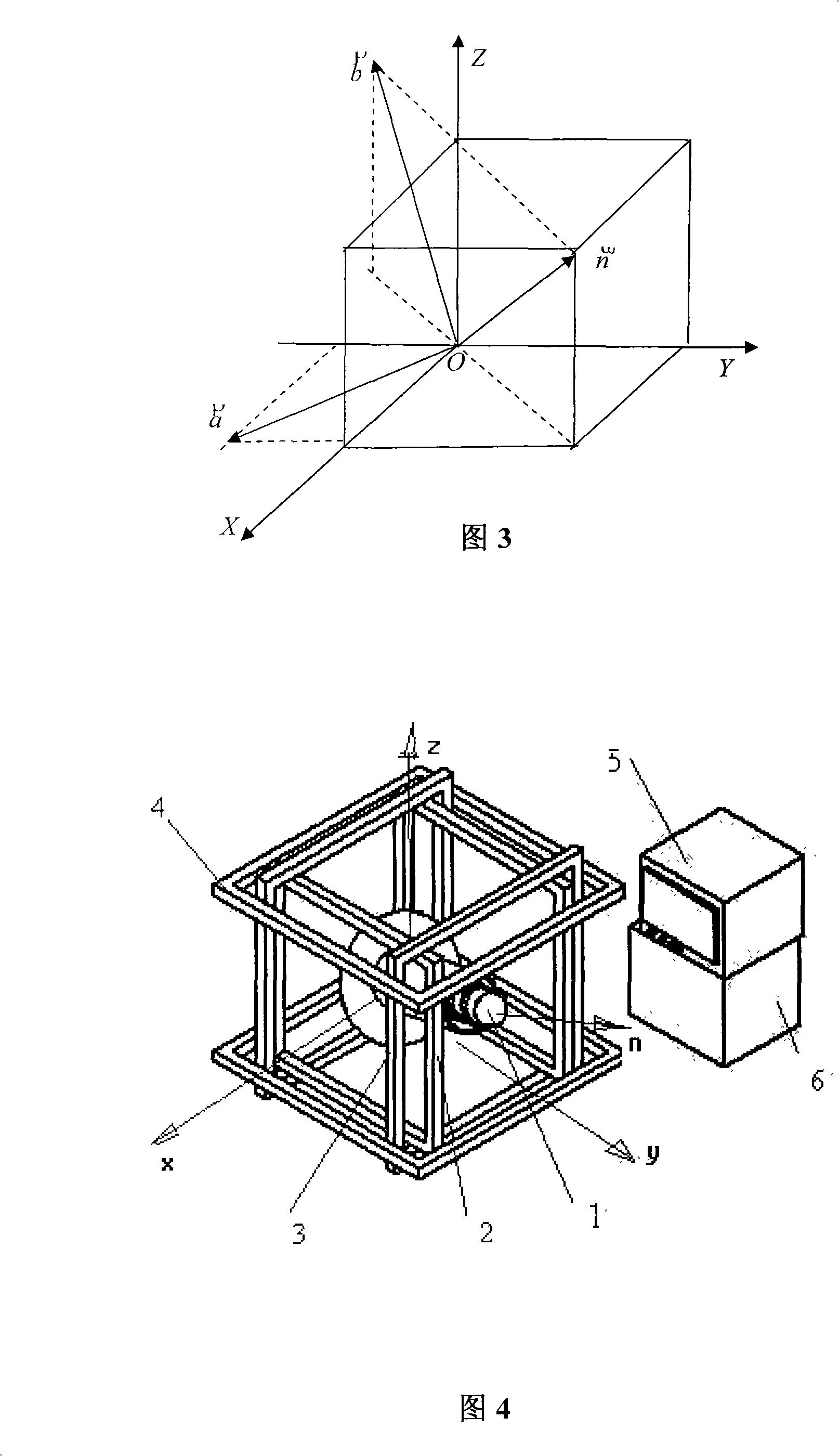

Method for driving and controlling universal rotary magnetic field of the medical treatment miniature robot in the body

InactiveCN101262198ARealize drive controlEasy drive controlElectronic commutation motor controlAC motor controlDriving currentHelmholtz coil

The invention pertains to the technical field of medical engineering and discloses a method for driving and controlling a universally rotating magnetic field of a medical micro-robot in a human body. The method is characterized in that three groups of Helmholtz coils on z, y and x axes are arranged by orthogonal nesting so as to ensure that respective combined inductance is equal and the amplitude of intensity of magnetization of a harmonic magnetic field generated respectively is equal when the three groups of coils are driven by the same harmonic current. The relevant amplitude of an axis azimuth angle of the robot and a same frequency sine harmonic driving current of a phase are overlapped to form a spatial universally and evenly revolving magnetic field corresponding to the revolving axis of the azimuth angle in a certain space surrounded by the orthogonal Helmholtz coils on the three axes. The self-rotating direction of the universally rotating magnetic field can be changed by changing the current frequency to adjust the revolution of the magnetic field and changing the orthogonal Helmholtz coils on the three axes to drive the current direction. The method of the invention has the beneficial effects that the method is applicable to a bending inner environment of the human body and can realize a plurality of functions of rotation, going forward and backward and speed adjusting, etc., of the robot in the human body, and the positioning operation in the human body.

Owner:DALIAN UNIV OF TECH

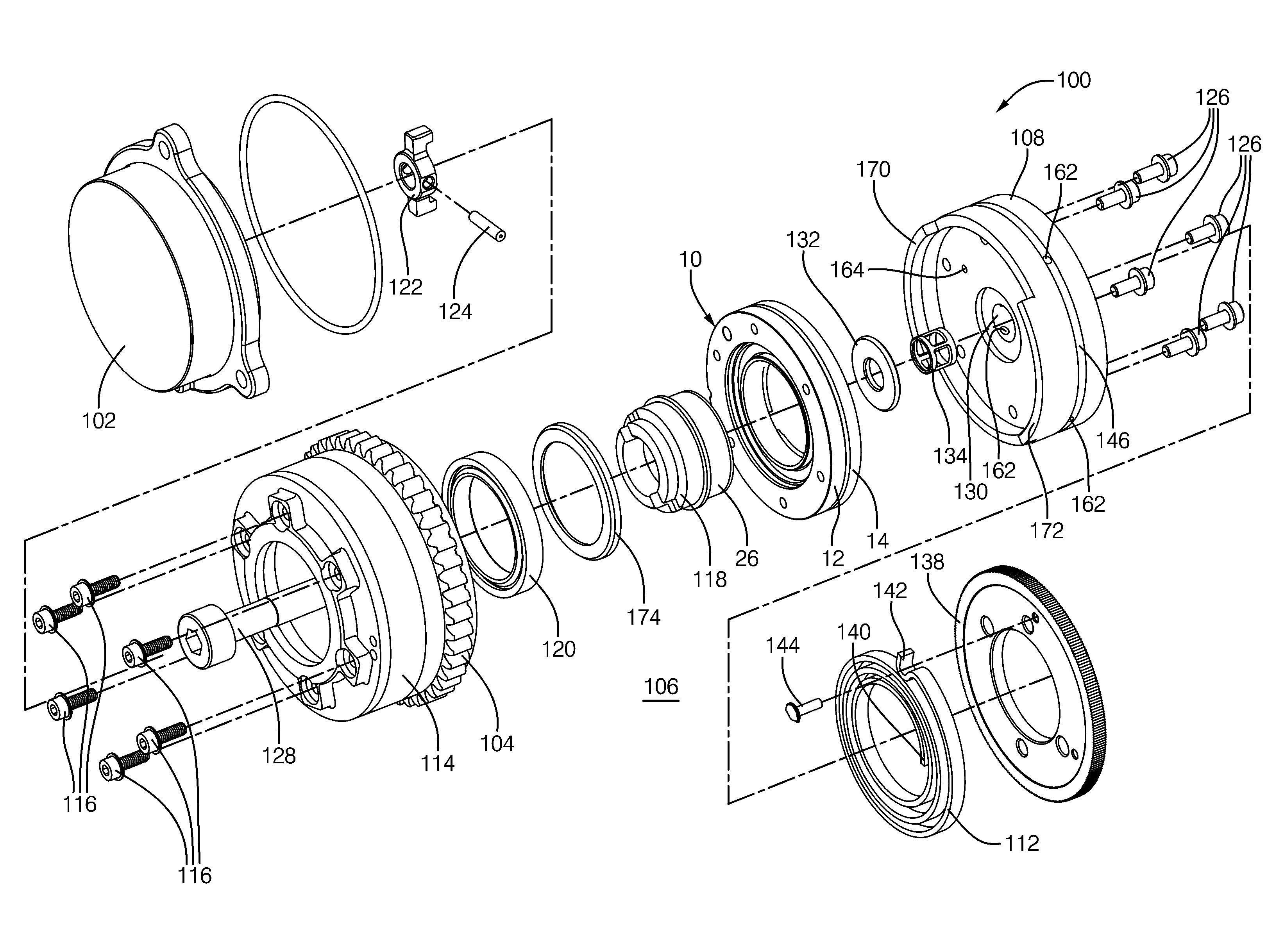

Transmission actuator driven by an electric motor

InactiveUS6893371B2Compact spaceSimple and cost-effective to manufactureGearboxesToothed gearingsReduction ratioEngineering

An actuator for a motor vehicle transmission has a shift cylinder performing rotary actuating movements. An electric motor is arranged inside the shift cylinder and drives the latter either through a harmonic drive mechanism or a planetary drive mechanism. The arrangement provides a high reduction ratio and an efficient use of limited space.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

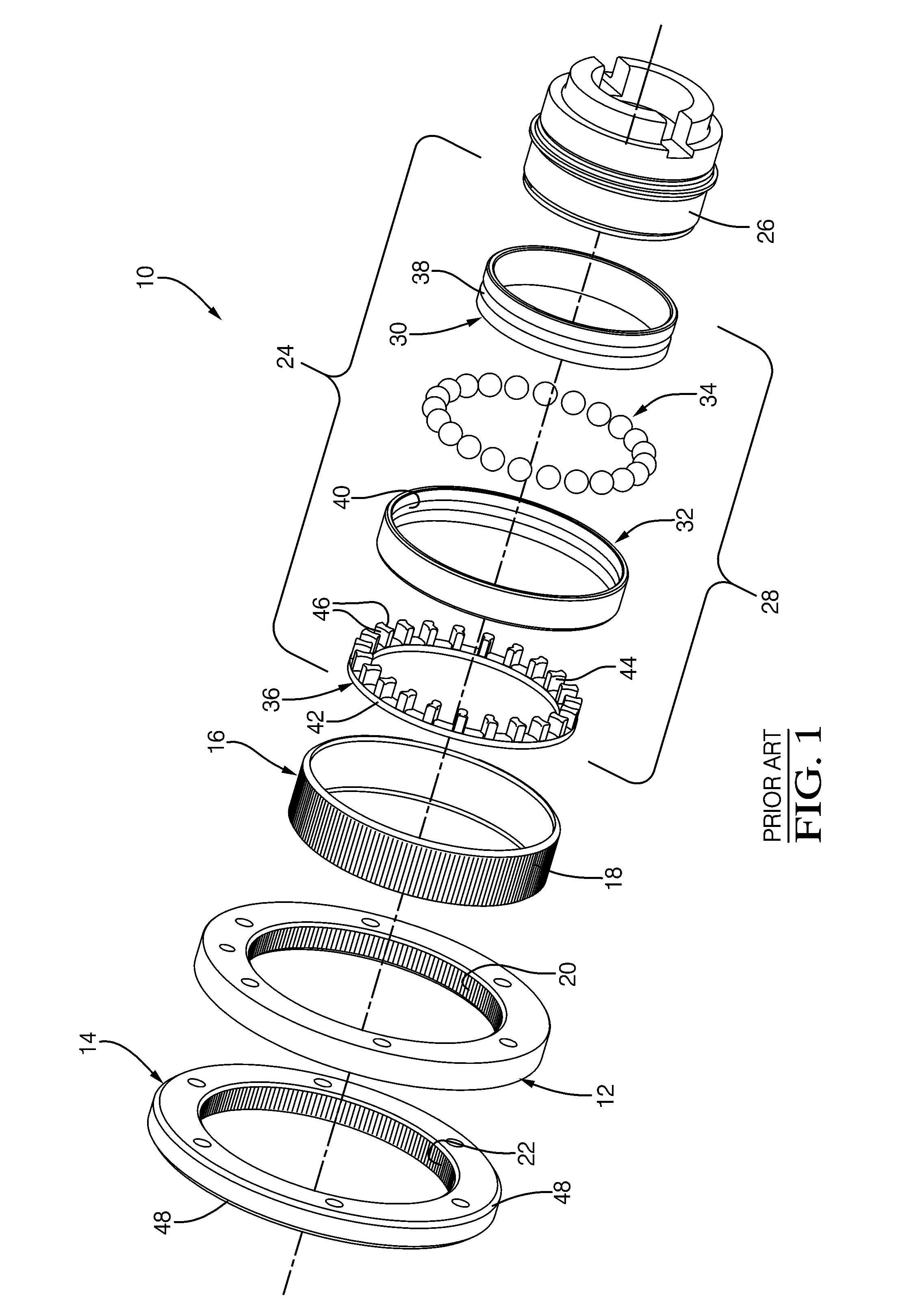

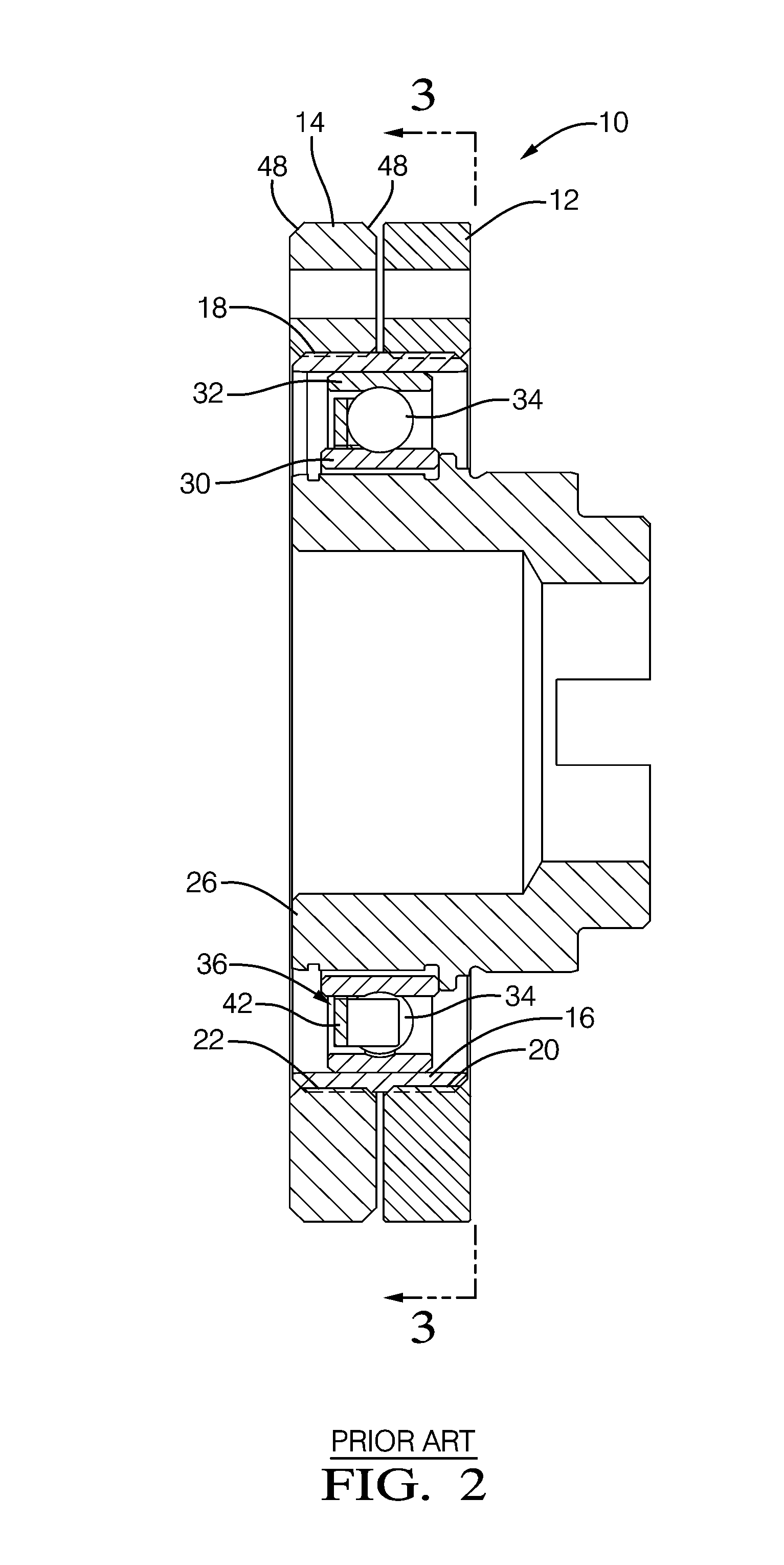

Harmonic Drive Camshaft Phaser with a Harmonic Drive Ring to Prevent Ball Cage Deflection

A camshaft phaser includes a housing. A harmonic gear drive unit is disposed within the housing and includes a circular spline and a dynamic spline, a flexspline disposed within the circular spline and the dynamic spline, a wave generator disposed within the flexspline, and a rotational actuator connectable to the wave generator. A wave generator bearing includes an inner race with an inner race axial end, an outer race, a plurality of balls between the inner and outer races, and a ball cage. The ball cage includes an annular section disposed axial from the balls proximal to the inner race axial end and a plurality of ball separators such that consecutive balls are separated by one of the ball separators. A rigid support ring extends axially beyond the inner race axial end toward the annular section to limit axial distortion of the annular section.

Owner:DELPHI TECH IP LTD

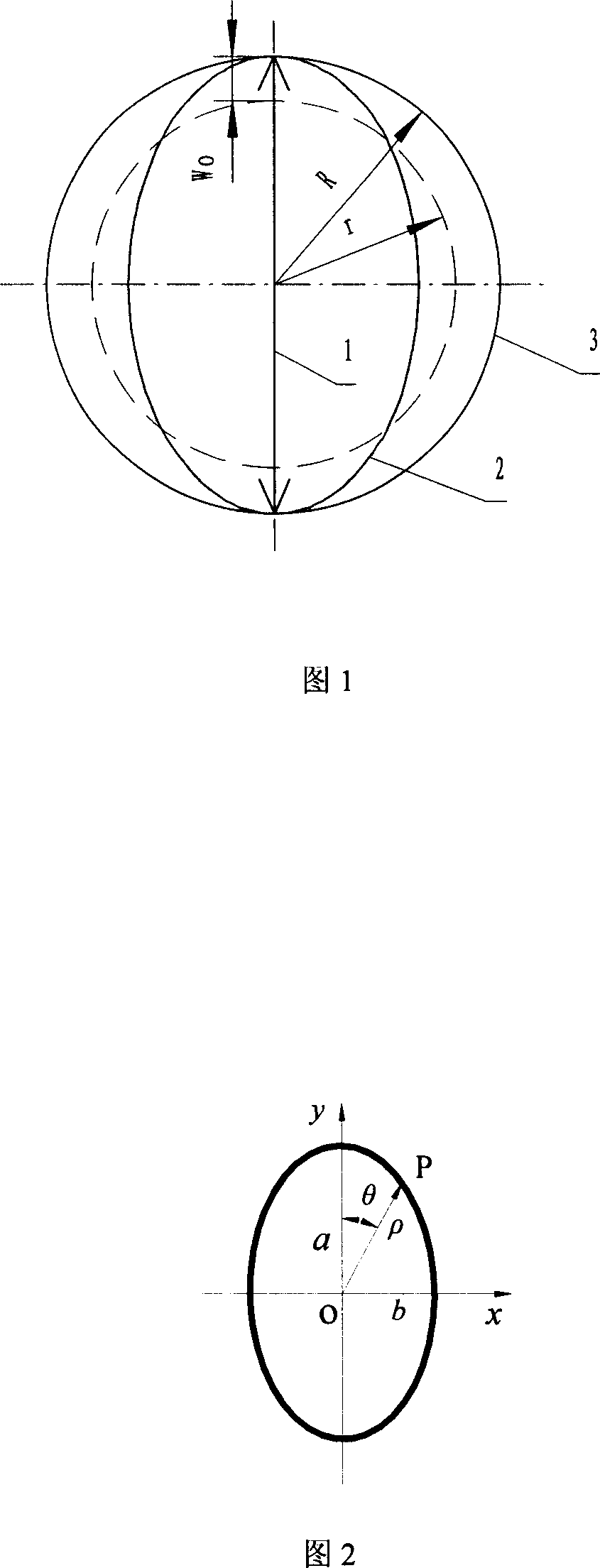

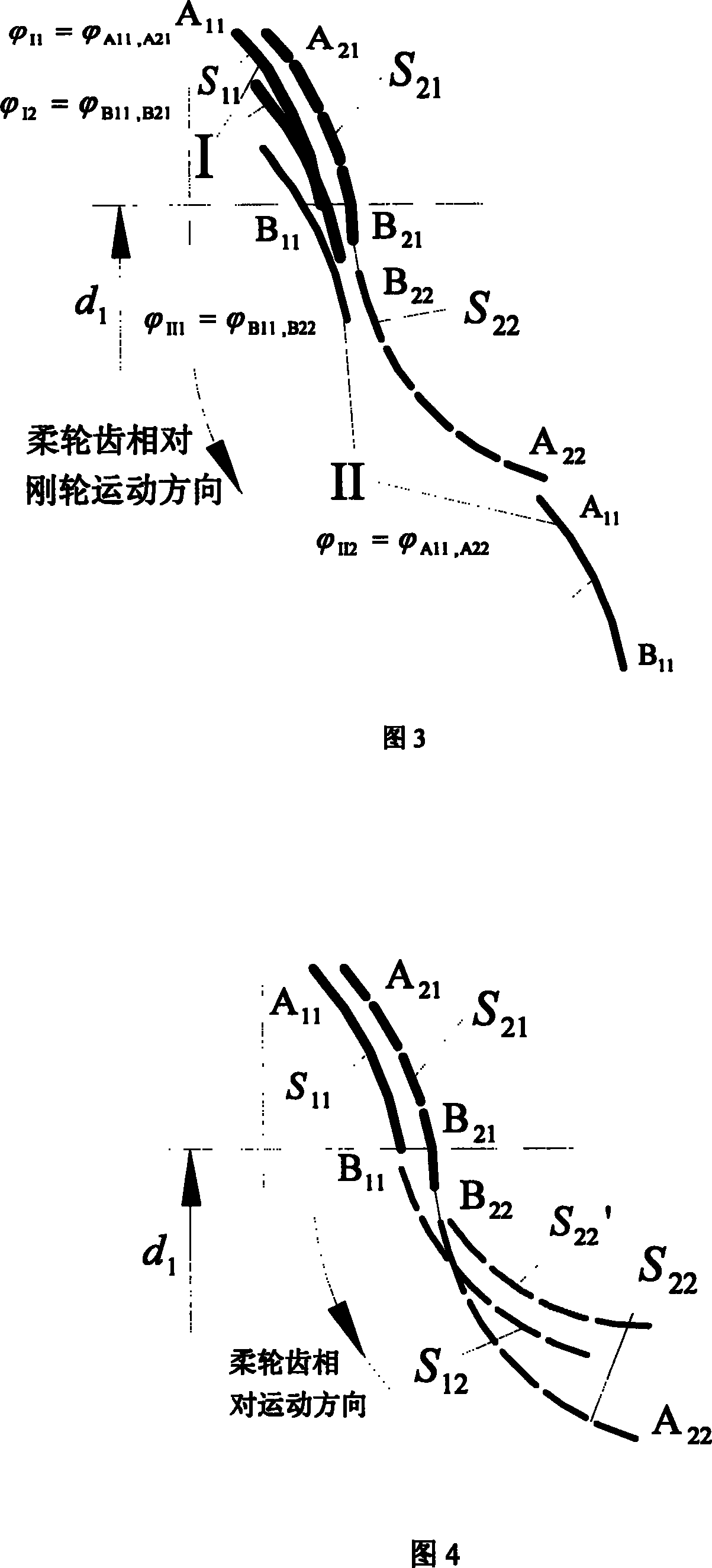

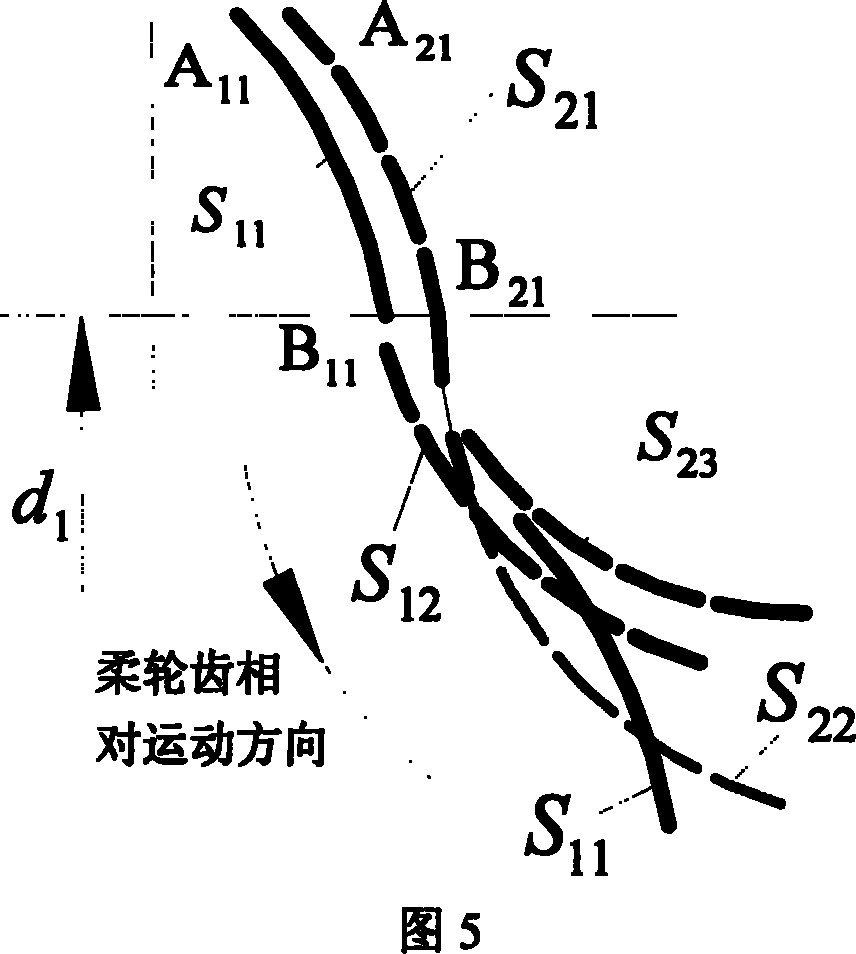

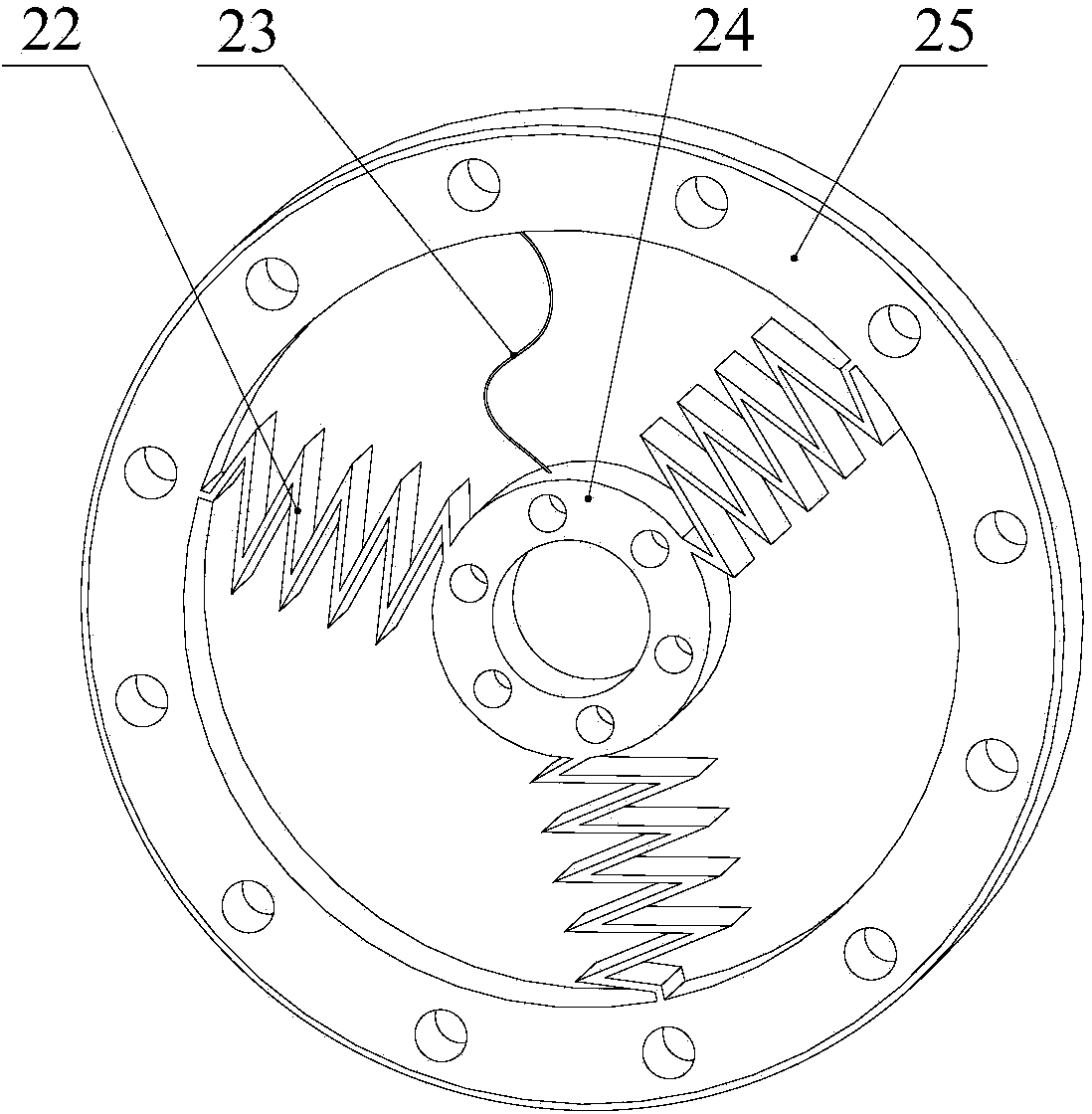

Harmonic gear power transmission with double circular arc tooth outline

InactiveCN101135357AImprove carrying capacityIncreased torsional stiffnessToothed gearingsStress conditionsHarmonic

The harmonic wave gear driver with two-arc teeth profile comprises wave generator, flexible wheel and rigid wheel. The wave generator is in form of elliptic cam, the flexible wheel and the rigid wheel has a two-arc teeth profile respectively which can realize conjugation motion. The driver can effectively improve the stress condition of the flexible wheel tooth-root and drive quality and increase load-bearing ability and torque rigidity of harmonic wave driver, and further lower minimum drive ratio of harmonic wave driver. Advantages: good processing property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

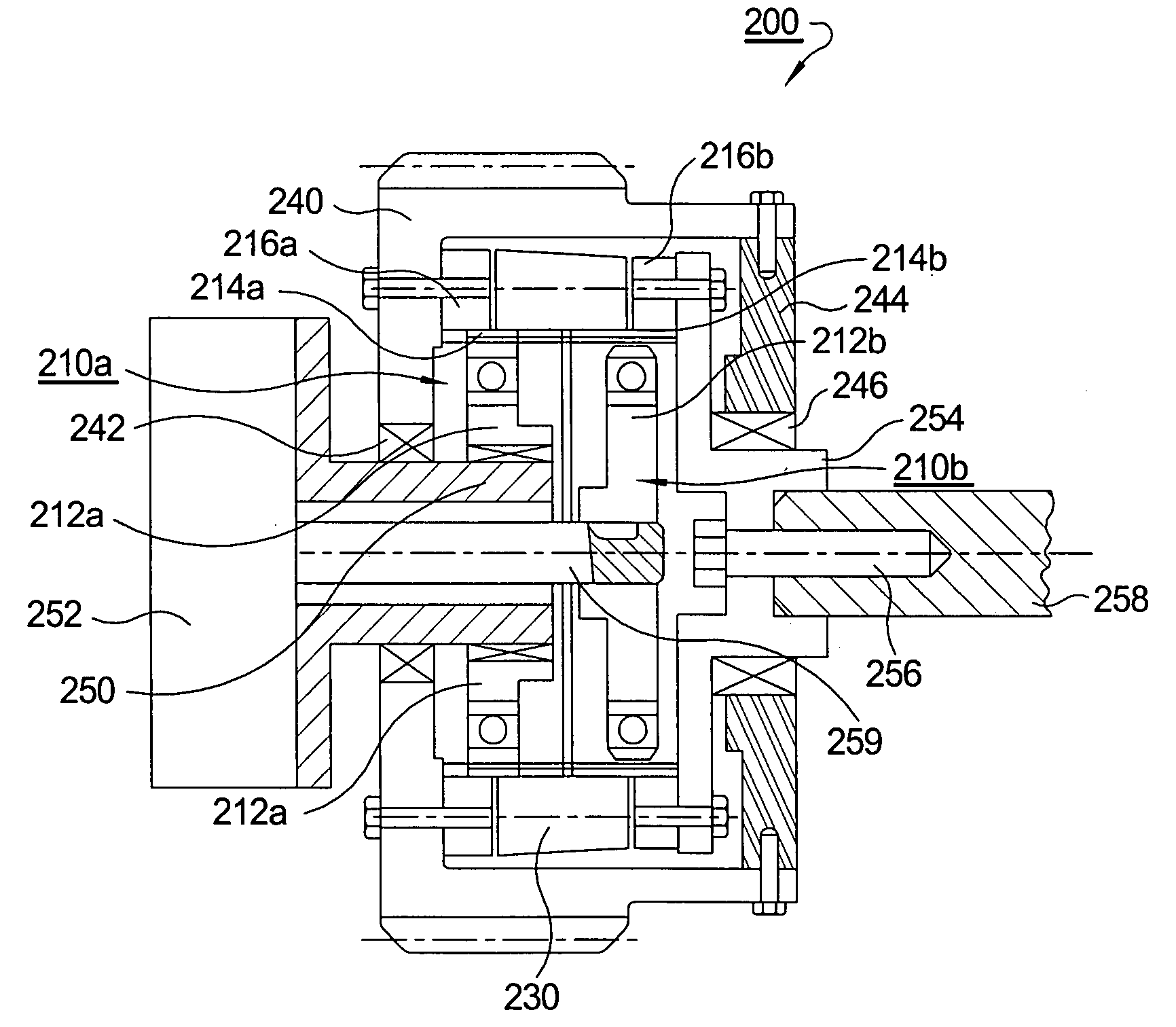

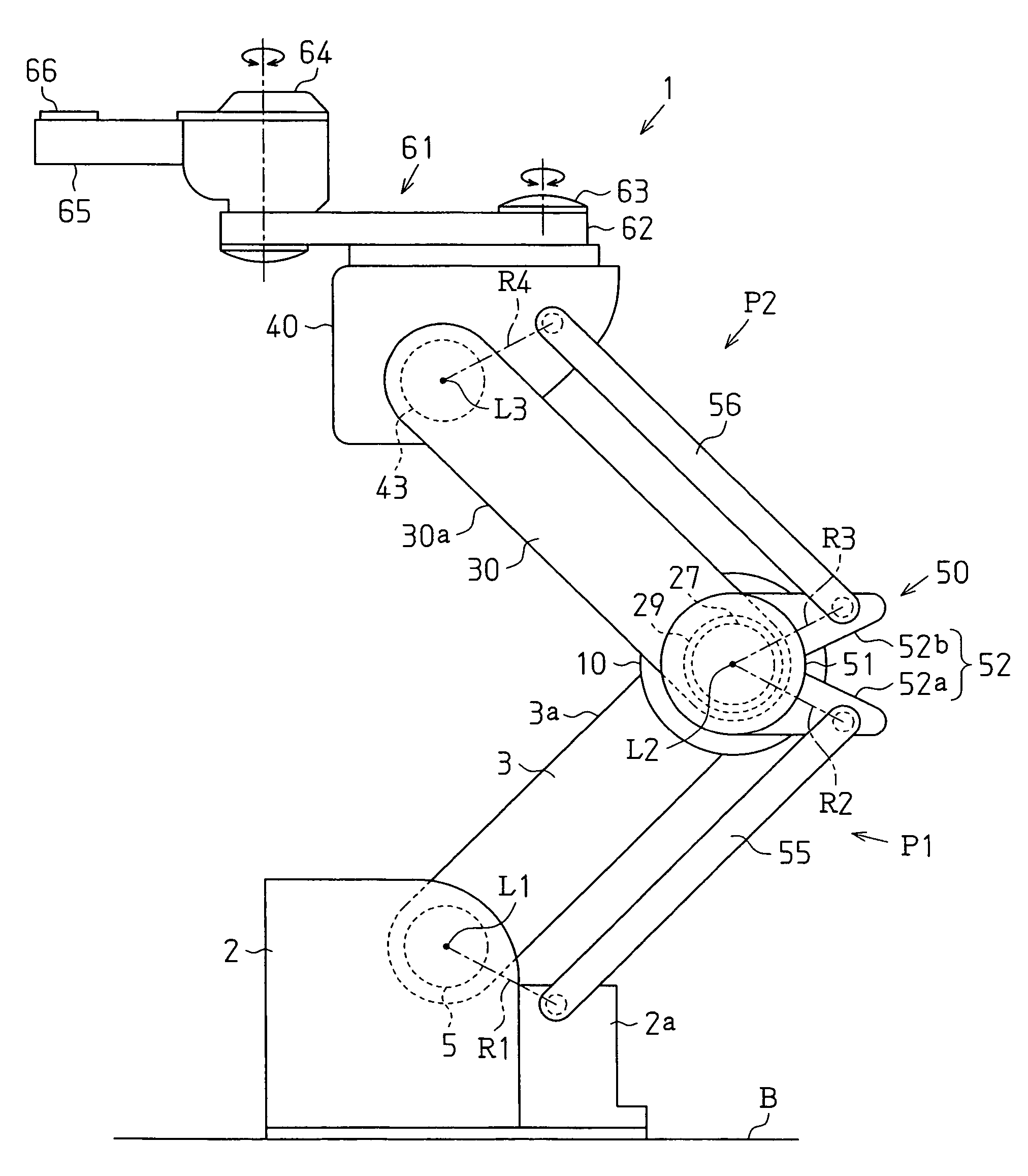

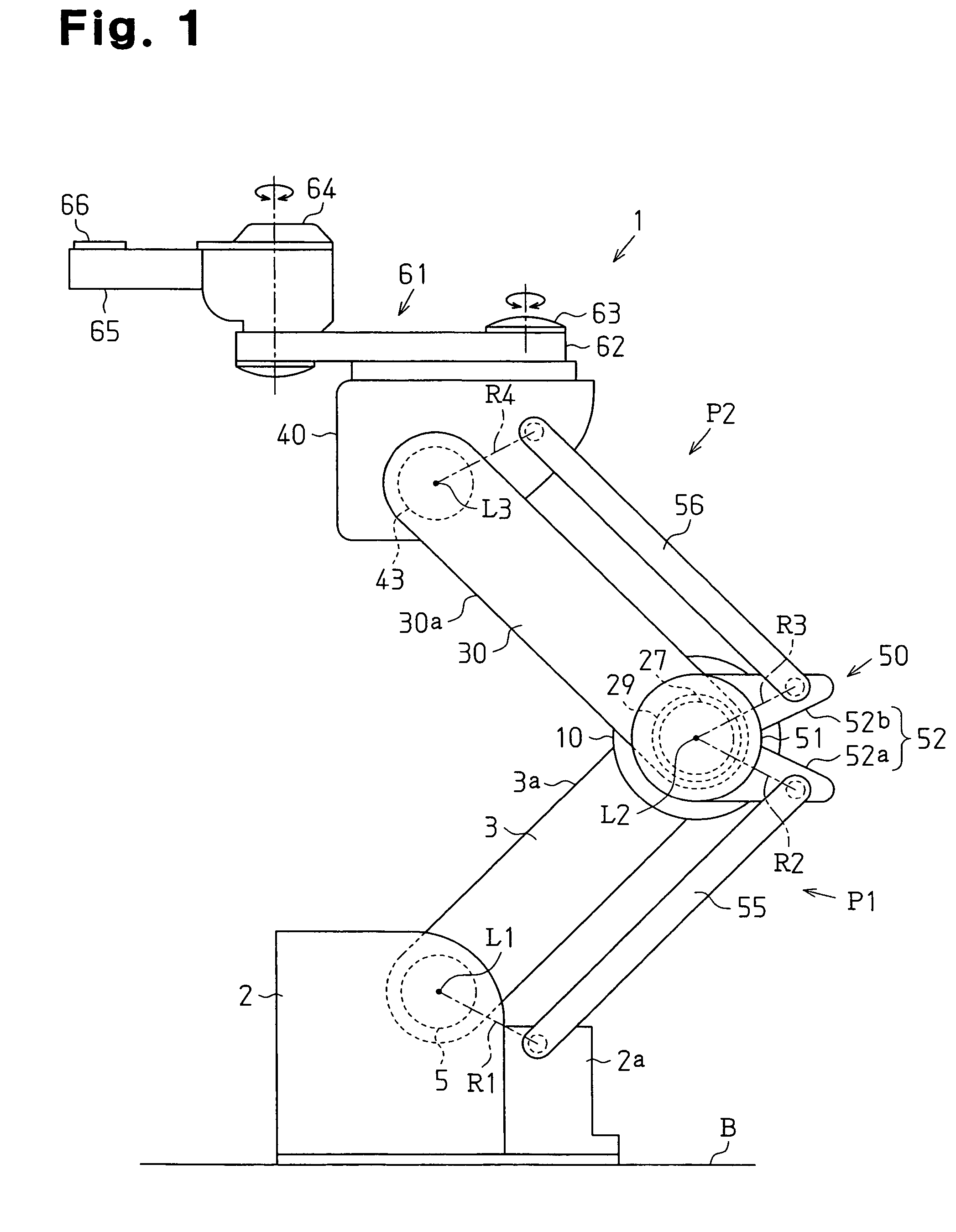

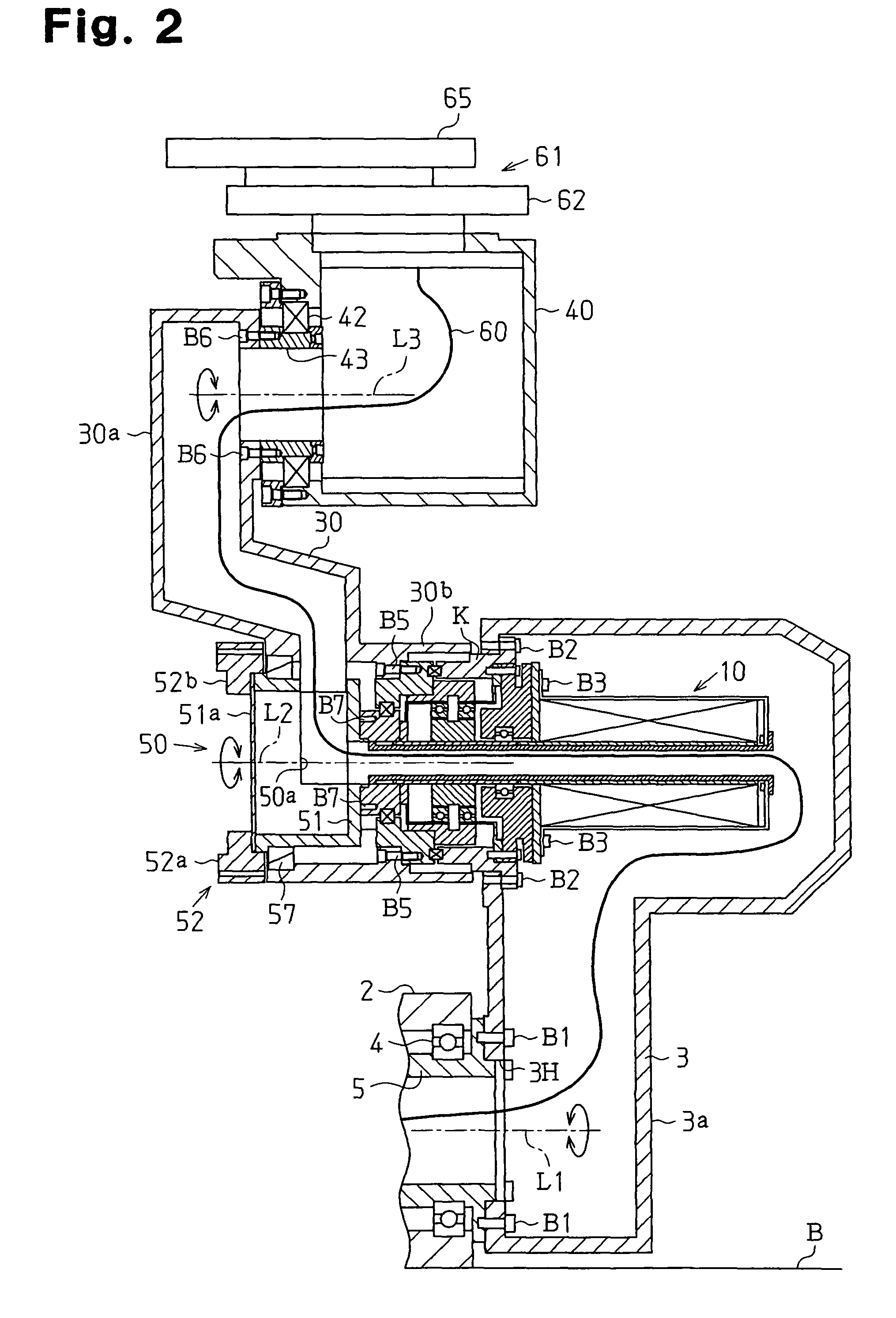

Parallel link mechanism and industrial robot

A parallel link mechanism arranged between a fixed base and a movable base includes a harmonic drive gear reducer, a first arm, a second arm, a connection base, a first auxiliary link, and a second auxiliary link. The harmonic drive gear reducer has a body, an input shaft, a first output shaft, and a second output shaft. The first arm has a proximal end pivotally connected to the fixed base and a distal end connected to the body of the reducer. The second arm has a proximal end connected to the second output shaft and a distal end pivotally connected to the movable base. The connection base is arranged outside the second arm with respect to the reducer and connected to the first output shaft. The first auxiliary link is arranged parallel with the first arm and has an end pivotally connected to the fixed base and an end pivotally connected to the connection base. The second auxiliary link is arranged parallel with the second arm and has an end pivotally connected to the connection base and an end pivotally connected to the movable base.

Owner:SEIKO EPSON CORP

Vehicle steering device

Owner:DELPHI TECH INC

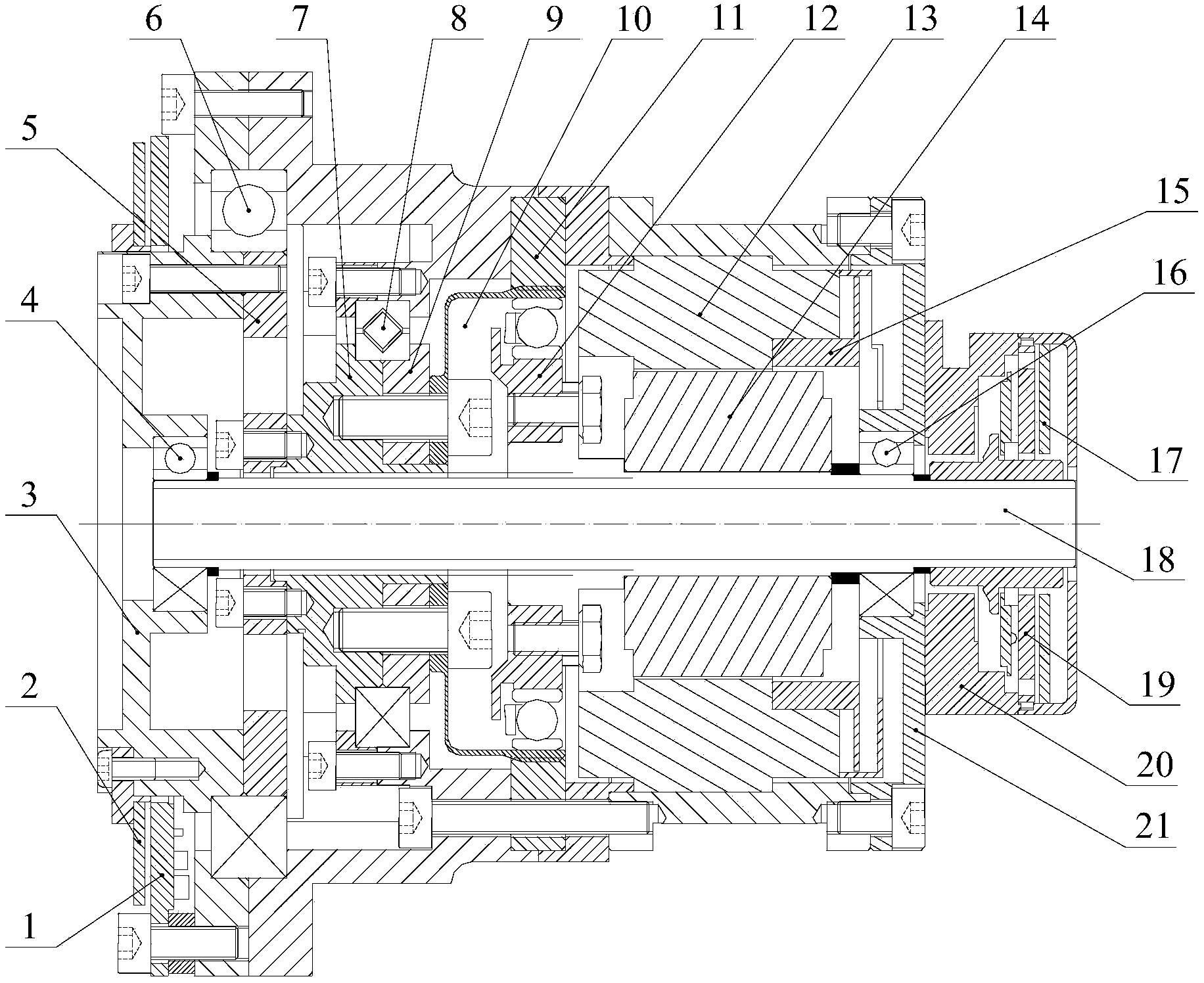

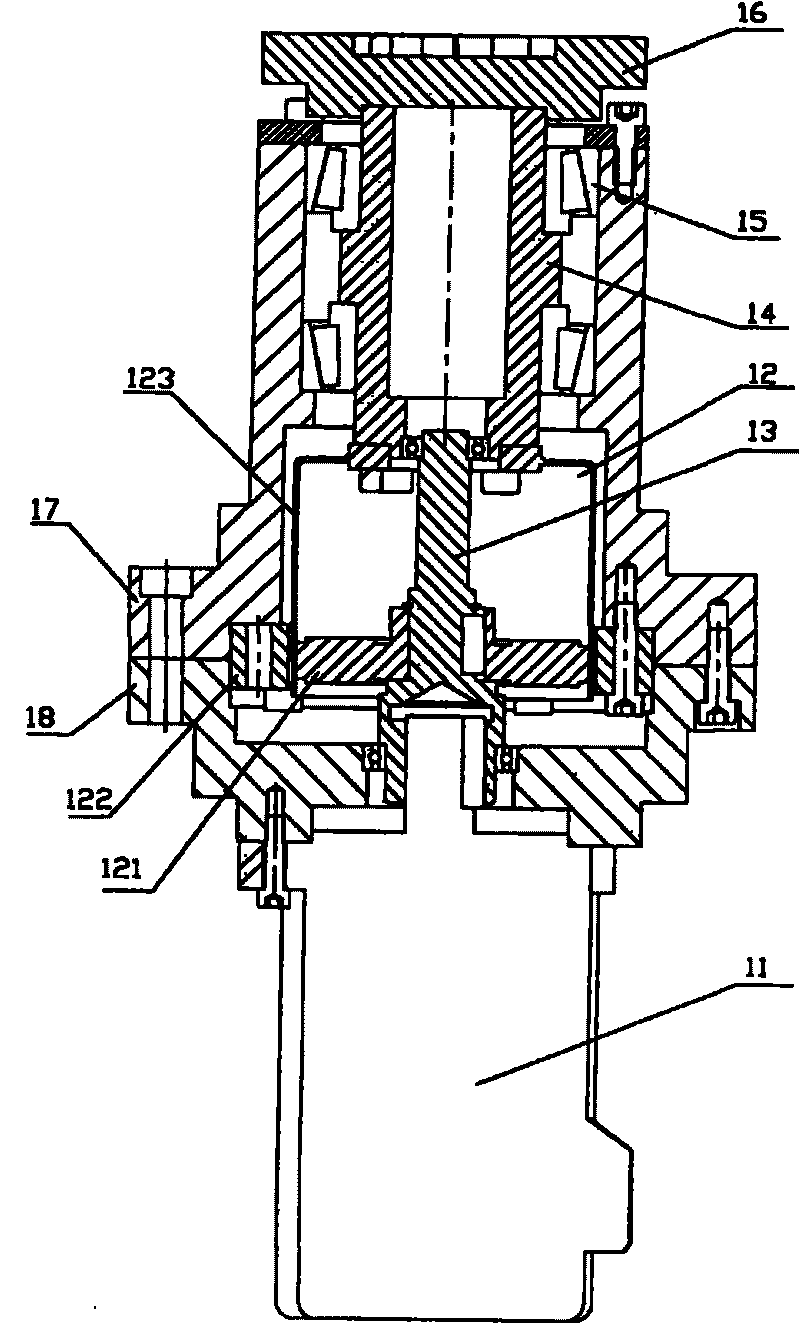

Flexible joint controlled in mixing mode

ActiveCN103817694ASimple structureLow costProgramme-controlled manipulatorReduction driveAngular degrees

The invention discloses a flexible joint controlled in a mixing mode. The flexible joint comprises a motor with a harmonic drive speed reducer, a tornsional spring, a rotating mechanism and a measurement mechanism, wherein the is connected with an output shaft of the harmonic drive speed reducer, the rotating mechanism is driven by the tornsional spring, and the measurement mechanism is used for measuring torque of the rotating mechanism and is formed by a motor coder and an absolute type angle sensor, wherein the motor coder is used for measuring a rotating angle of a rotating shaft of the motor, and the absolute type angle sensor is used for measuring a rotating angle of the rotating mechanism. The rotating angle of the tensional spring is obtained through the motor coder and the absolute type angle sensor, the moment of force is obtained by multiplying the torsion angle by an elastic coefficient of the tornsional spring, and the measurement mechanism is simple in structure and low in cost. A relative rotating angle of an inner ring and an outer ring is limited through a limit cable or a limit block, so that the torsional spring is protected, and reliability of the joint is improved.

Owner:ZHEJIANG UNIV

Harmonic Drive Camshaft Phaser with Bias Spring

An eVCP camshaft phaser comprising a harmonic gear drive unit having a circular spline and a dynamic spline linked by a common flexspline, and a single wave generator disposed within the flexspline. The circular spline is connectable to either of a crankshaft-connectable sprocket or an engine camshaft, the dynamic spline being connectable to the other thereof. The wave generator is driven selectively by an eMotor to cause the dynamic spline to rotate past the circular spline, thereby changing the phase relationship between the crankshaft and the camshaft. A coaxial coil spring is connected to the sprocket and to the phaser hub and is positioned and tensioned to bias the phaser and camshaft to a stop position wherein the engine can run or be restarted after the eMotor is de-energized. Preferably, the spring comprises a spring cassette for easy assembly into the eVCP.

Owner:DELPHI TECH IP LTD

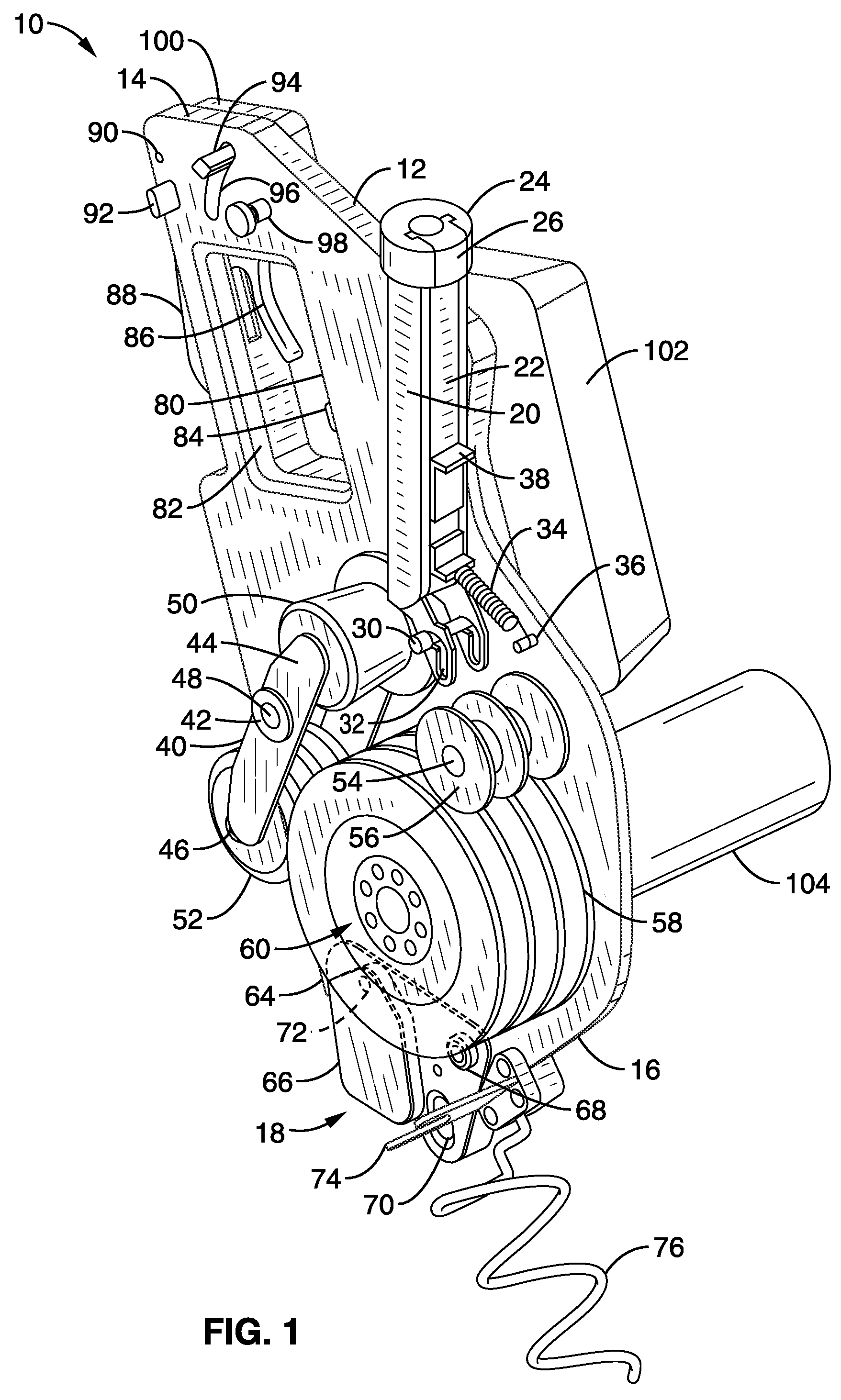

Powered personnel ascender

InactiveUS20080157042A1Reduces starting torqueGrip force decreasePortable liftingWinding mechanismsMotor driveGear wheel

A powered rope ascender that supports a person or a load while ascending a vertical rope. The rope ascender has a motor driven capstan drum that engages the rope. A pinch roller grips the rope against the capstan drum. A load limiting assembly releases the grip by the pinch roller when the load supported by the ascender exceeds a predetermined amount. A centrifugal clutch reduces starting torque required by the motor and the outer drum of the centrifugal clutch interacts with a brake to hold position on the rope. For heavy loads a motion activated brake is used. Hand controls provide a freewheeling, a braking and an ascending mode of operation. A harmonic drive or planetary reduction gears provide speed reduction from the motor to the capstan drum. The powered rope ascender can be threaded on the rope without access to a rope end.

Owner:QUOIN INT

Harmonic drive camshaft phaser using oil for lubrication

A camshaft phaser includes a housing with an array of internal splines formed within a bore. A harmonic gear drive unit is disposed within the housing and includes a circular spline and a dynamic spline, a flexspline disposed within the circular spline and the dynamic spline, a wave generator disposed within the flexspline, and a rotational actuator connectable to the wave generator. One of the circular spline and the dynamic spline is fixed to the housing. A hub is rotatably disposed within the housing and attachable to the camshaft and fixed to the other of the circular spline and the dynamic spline. An oil passage is provided for receiving oil from an internal combustion engine for lubricating the harmonic gear drive unit.

Owner:DELPHI TECH IP LTD

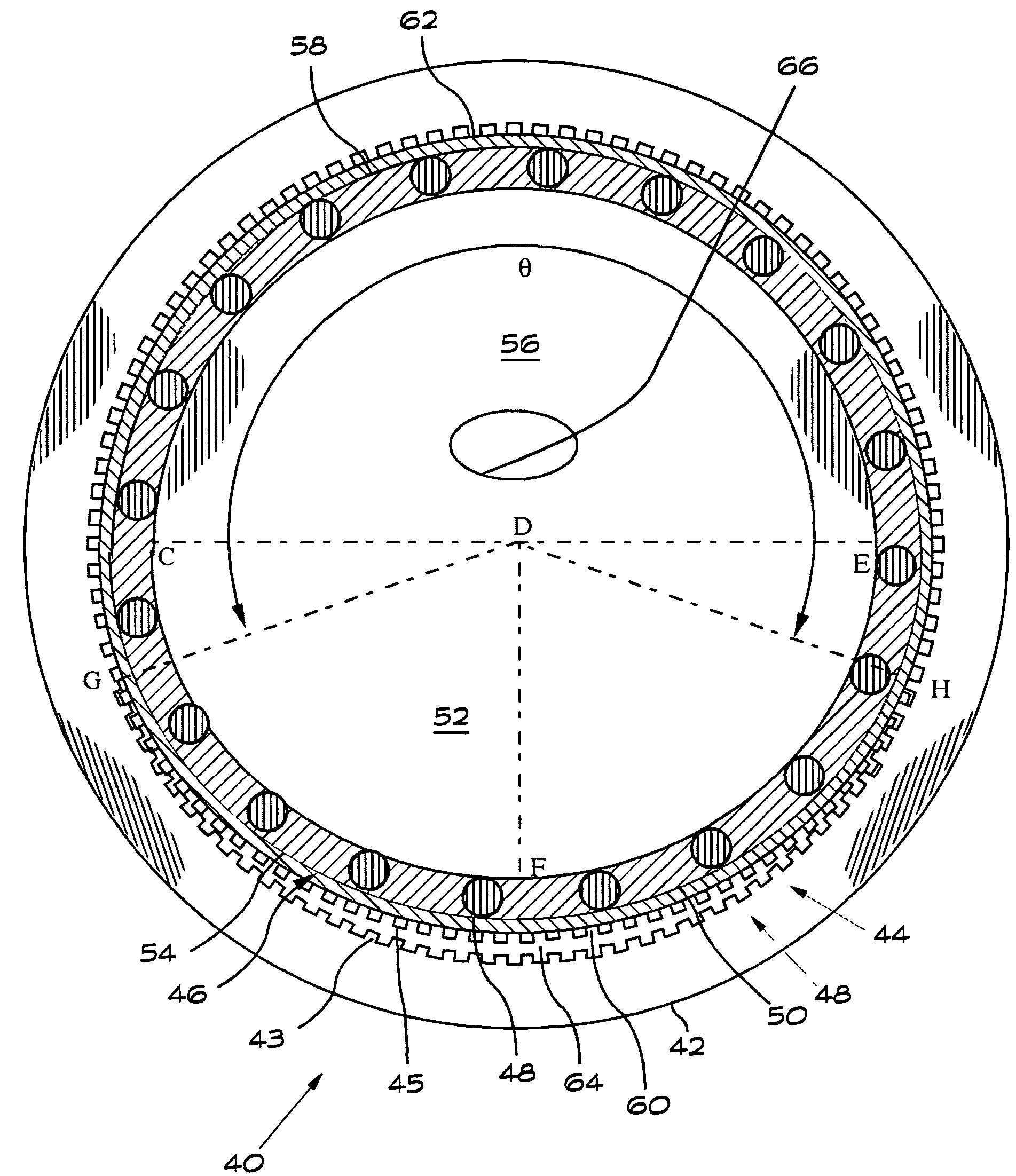

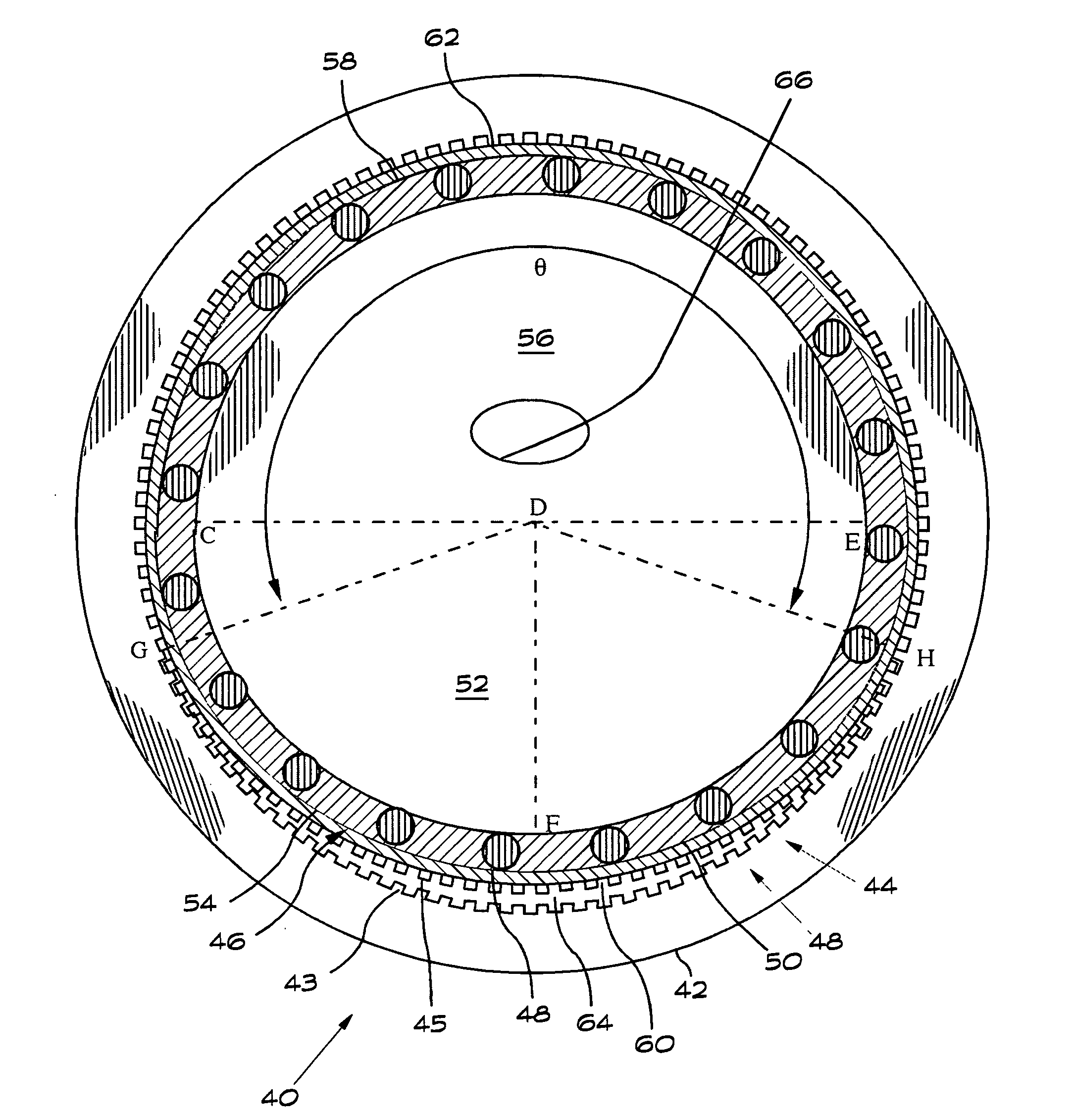

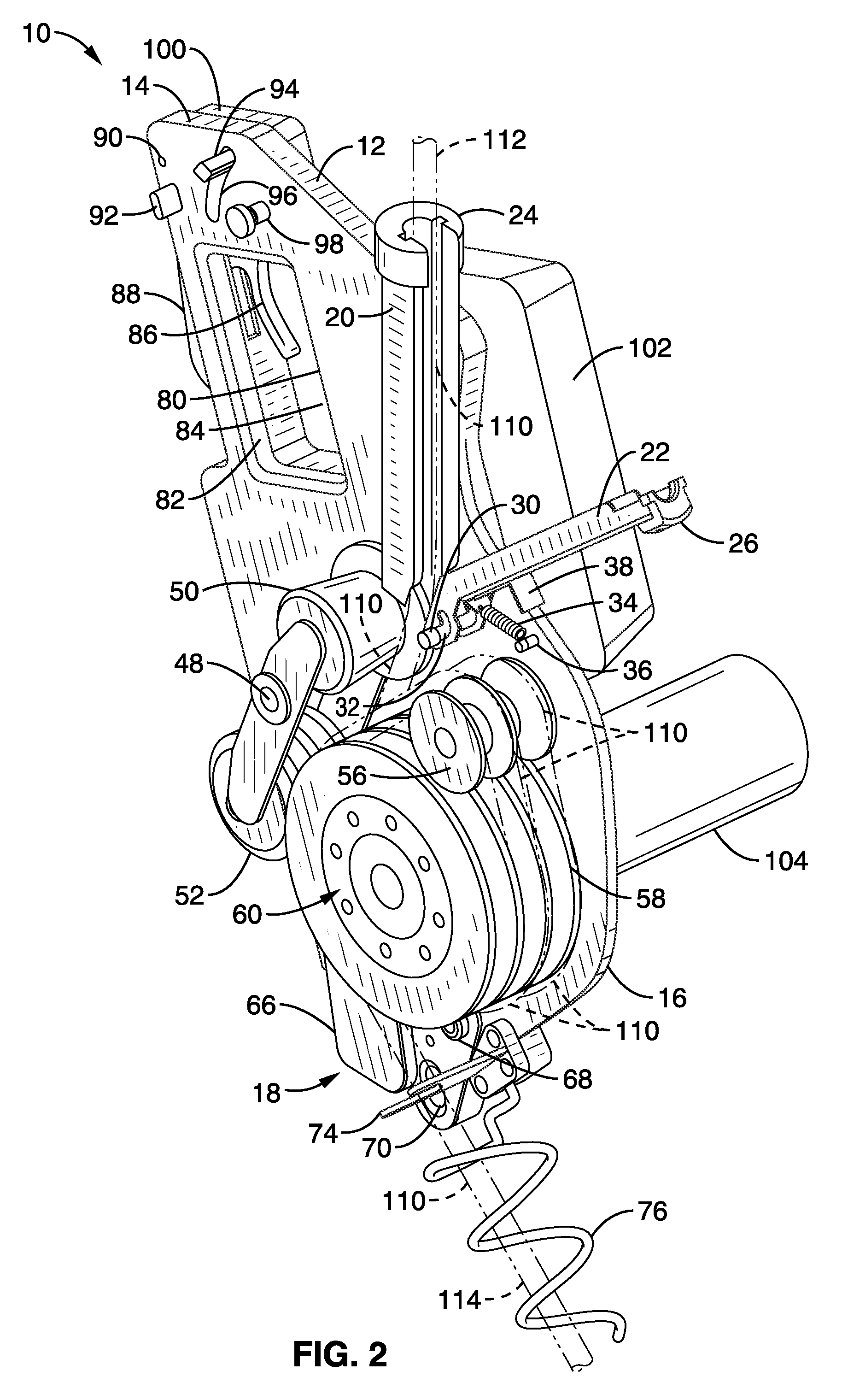

Harmonic drive gear assembly with asymmetrical wave generator and associated flexspline

A wave generator has a circular spline, a flexspline inside the circular spline and a plug inside the flex spline. The plug is asymmetrical and is preferably formed to comprise a semi-elliptical first portion and a semi-cylindrical second portion. The diameter of the semi-cylindrical portion coincides with the major axis of the semi-elliptical portion. Gear teeth on the circular spline and on the flex spline are meshed in only a first zone and unmeshed in a second zone. The flexspline in the harmonic drive gear assembly according to the present invention preferably has only one tooth fewer than the circular spline so that the circular spline rotates through and arc defined by one gear tooth for each complete revolution of the flexspline.

Owner:NORTHROP GRUMMAN SYST CORP +1

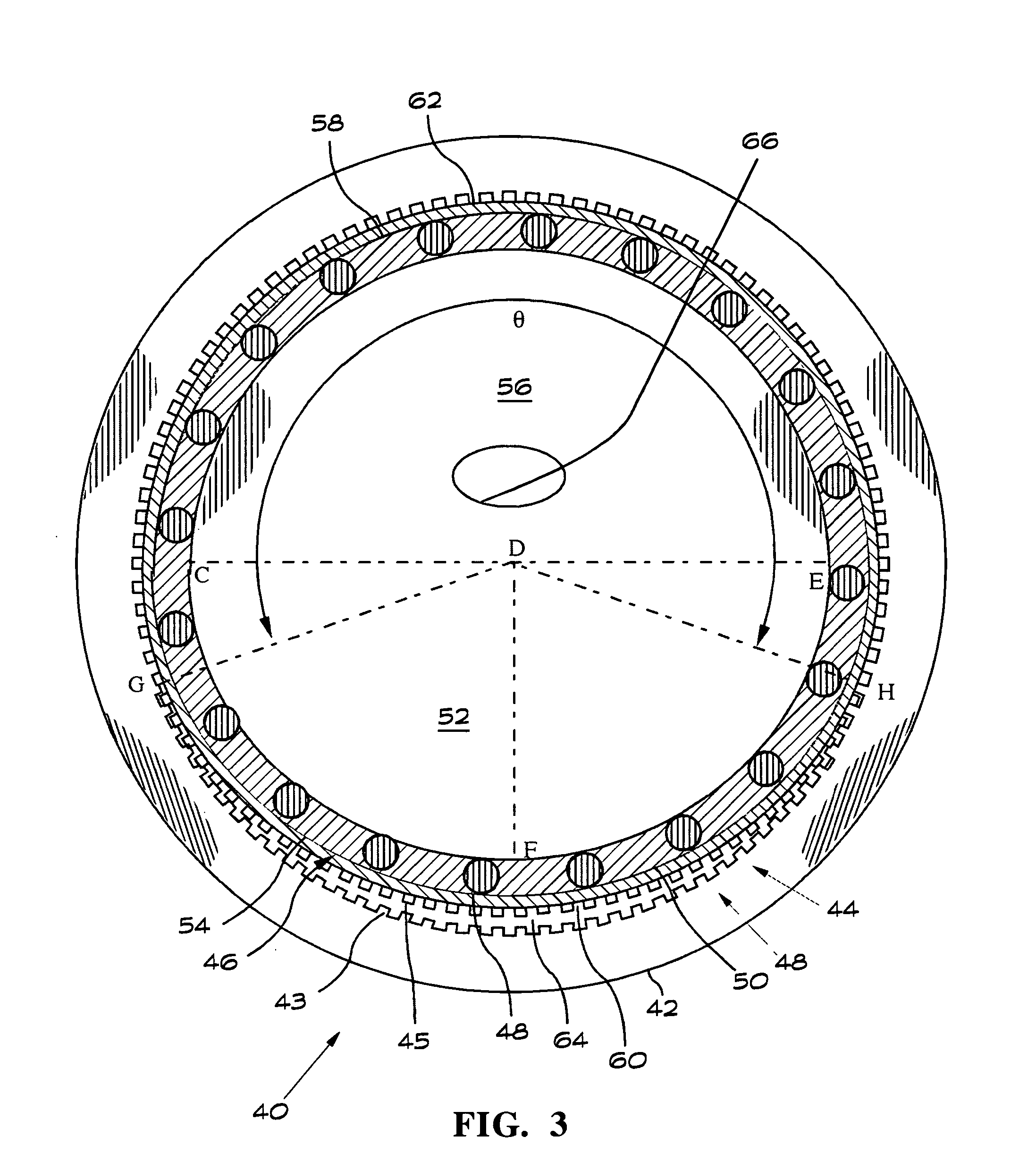

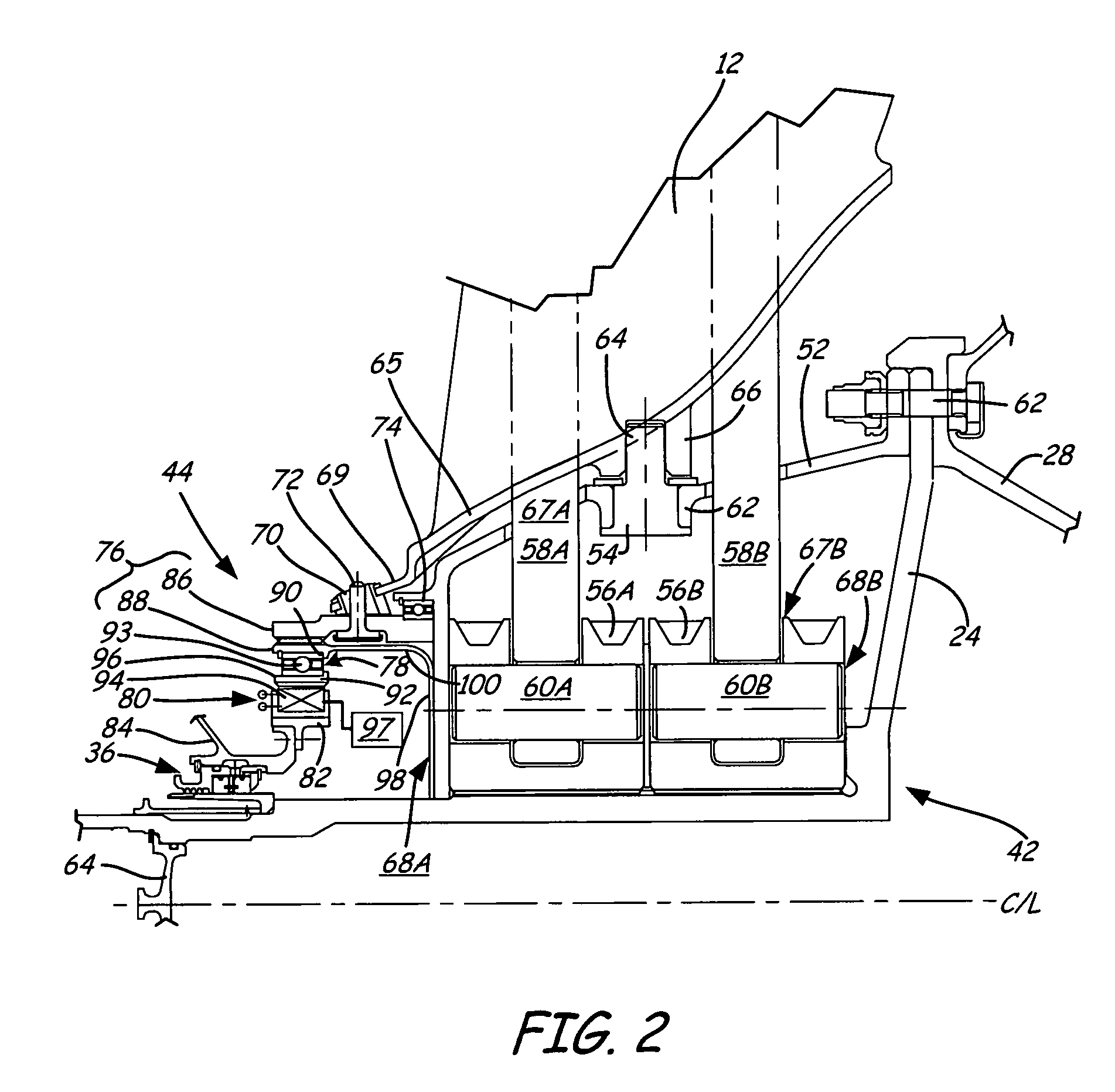

Variable rotor blade for gas turbine engine

A variable rotor blade mechanism for use in a gas turbine engine comprises a blade rotor, a blade, a harmonic drive system, a stepper motor and a bracket. The blade rotor rotates absolutely about an axial engine centerline during operation of the gas turbine engine. The blade extends radially from the blade rotor and is configured to be adjustable by rotation about a radial axis. The harmonic drive system is mounted to the blade rotor and connected to the blade to rotate the blade about the radial axis. The stepper motor drives the harmonic drive with relative rotational input with respect to the absolute rotation of the blade rotor. The bracket is disposed about the engine centerline and supports the stepper motor stationary with respect to the rotation of blade rotor such that the relative rotational input to the stepper motor is generated.

Owner:RAYTHEON TECH CORP

Drive unit with reducer

To provide a harmonic drive gearing with high degree of freedom in terms of layout. A harmonic drive gearing 10 includes a circular spline 1′, having outer teeth formed on an outer peripheral surface; an flexible spline 2, positioned at the outside of the circular spline 1′, and having inner teeth, which are engageable with the outer teeth of the circular spline 1′, formed on an inner peripheral surface; and a rotor 16 which is disposed at outside of the flexible spline 2 and serves as a wave generator, wherein the rotor 16 deflects the flexible spline 2 by minor axis portions of the inner peripheral surface of the flexible spline 2 and engages the inner teeth of the flex spline with the outer teeth of the circular spline 1′ and thereby the engagement position between the inner teeth and the outer teeth is adapted to move in a circumferential direction.

Owner:HONDA MOTOR CO LTD

Harmonic Drive Camshaft Phaser with Lock Pin for Selectivley Preventing a Change in Phase Relationship

A camshaft phaser includes a housing. A harmonic gear drive unit is disposed within the housing and includes a circular spline and a dynamic spline, a flexspline disposed within the circular spline and the dynamic spline, a wave generator disposed within the flexspline, and a rotational actuator connectable to the wave generator. One of the circular spline and the dynamic spline is fixed to the housing. A hub is rotatably disposed within the housing and attachable to the camshaft and fixed to the other of the circular spline and the dynamic spline. A lock pin is provided for selective engagement with a lock pin seat such that engagement of the lock pin with the lock pin seat prevents relative rotation between the circular spline and the dynamic spline.

Owner:DELPHI TECH IP LTD

Powered personnel ascender

InactiveUS7448597B2Reduces starting torqueReduce speedPortable liftingWinding mechanismsMotor driveGear wheel

A powered rope ascender that supports a person or a load while ascending a vertical rope. The rope ascender has a motor driven capstan drum that engages the rope. A pinch roller grips the rope against the capstan drum. A load limiting assembly releases the grip by the pinch roller when the load supported by the ascender exceeds a predetermined amount. A centrifugal clutch reduces starting torque required by the motor and the outer drum of the centrifugal clutch interacts with a brake to hold position on the rope. For heavy loads a motion activated brake is used. Hand controls provide a freewheeling, a braking and an ascending mode of operation. A harmonic drive or planetary reduction gears provide speed reduction from the motor to the capstan drum. The powered rope ascender can be threaded on the rope without access to a rope end.

Owner:QUOIN INT

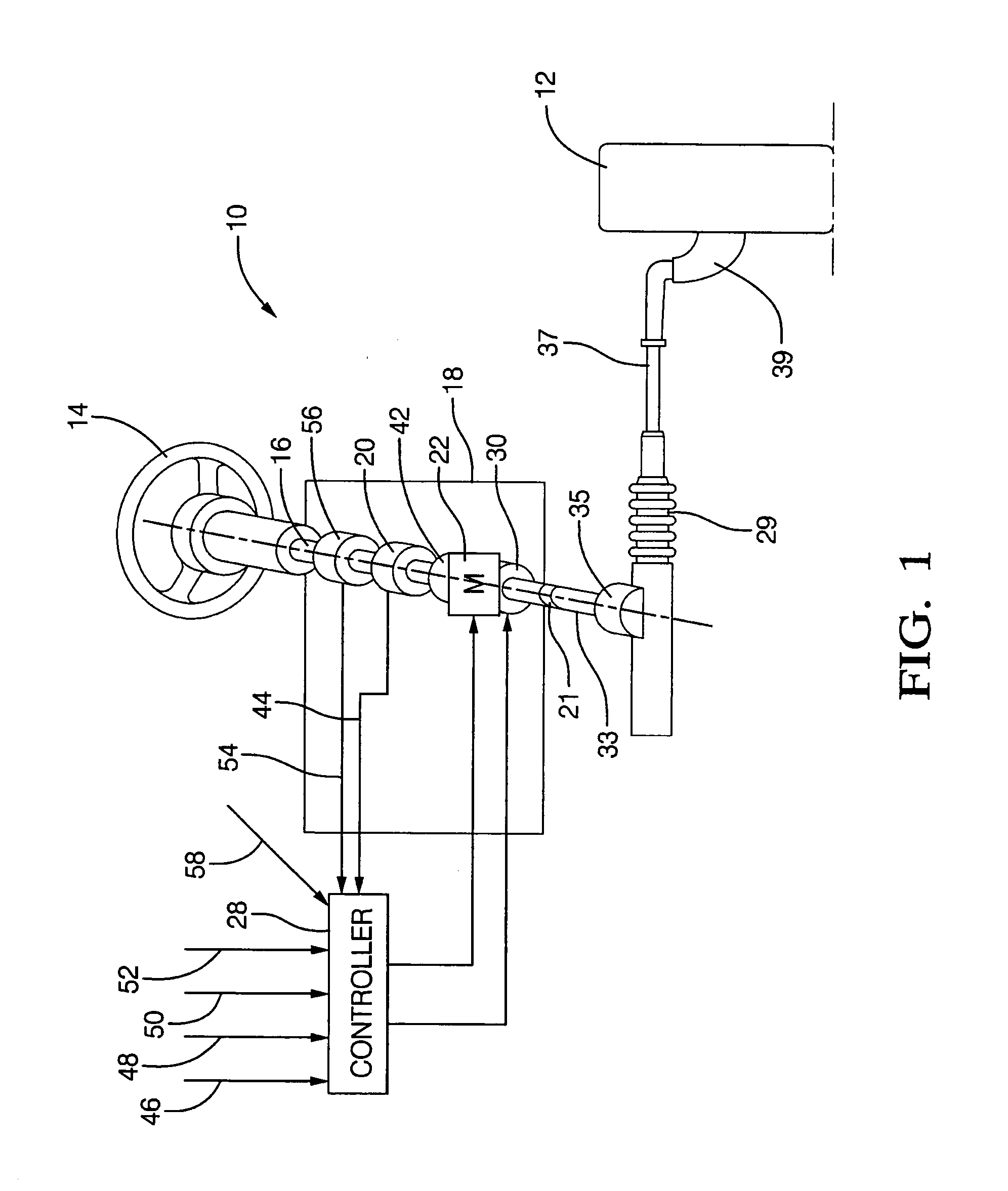

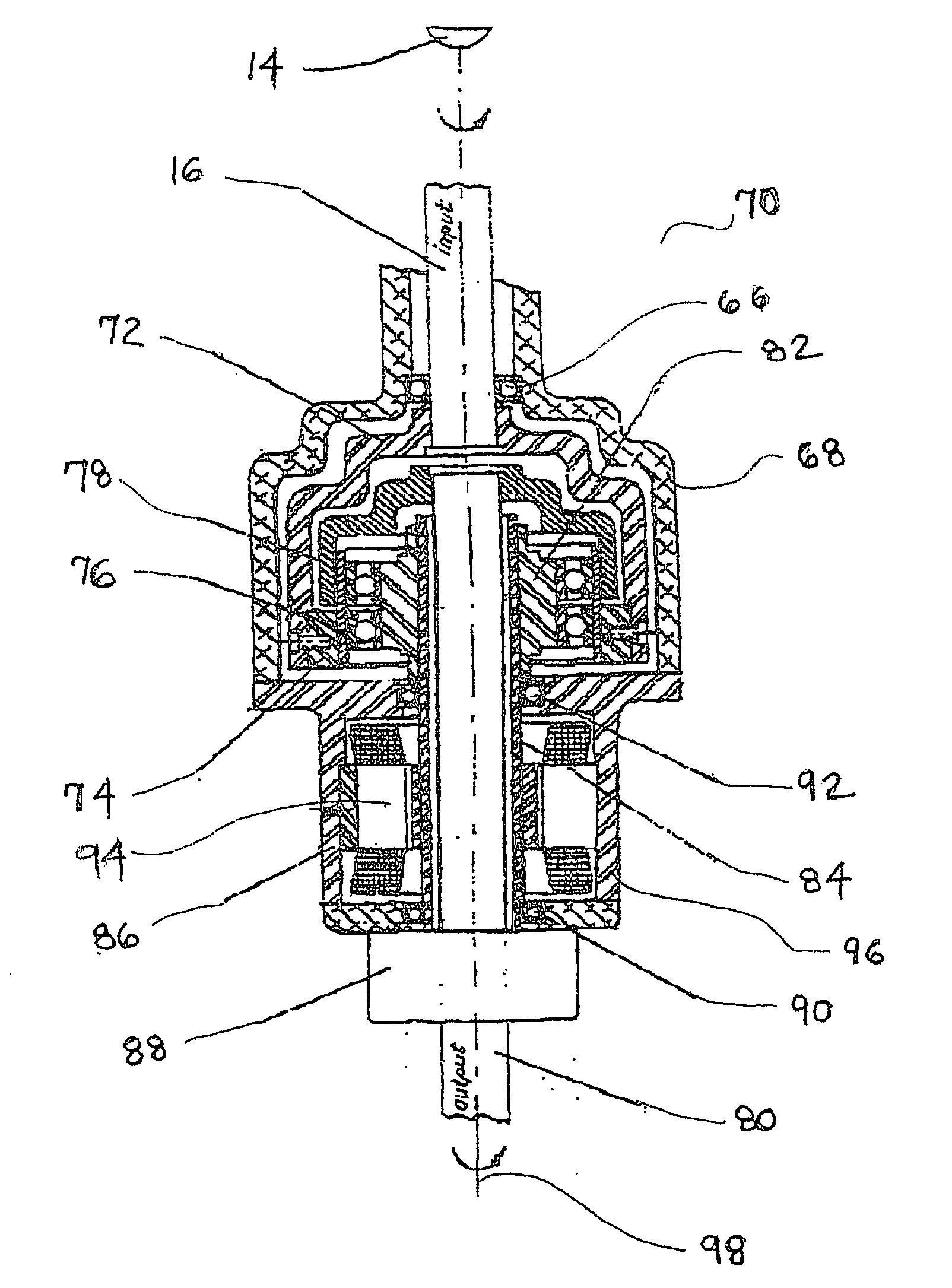

Vehicle steering device and method

A vehicle steering device may include a rotatable input shaft, a motor in communication with an input augmentation shaft, the input augmentation shaft and the input shaft sharing a longitudinal axis, and the motor further having a stator stationary with respect to rotation of the input shaft. The vehicle steering device may further include a differential mechanism for providing variable ratio steering to the steering device. The differential mechanism may be a harmonic drive differential or a planetary gearing system. In one embodiment, an external wave generator may be used within the harmonic drive differential gearing mechanism. The vehicle steering device may include a sensorless synchronous machine.

Owner:STEERING SOLUTIONS IP HLDG +1

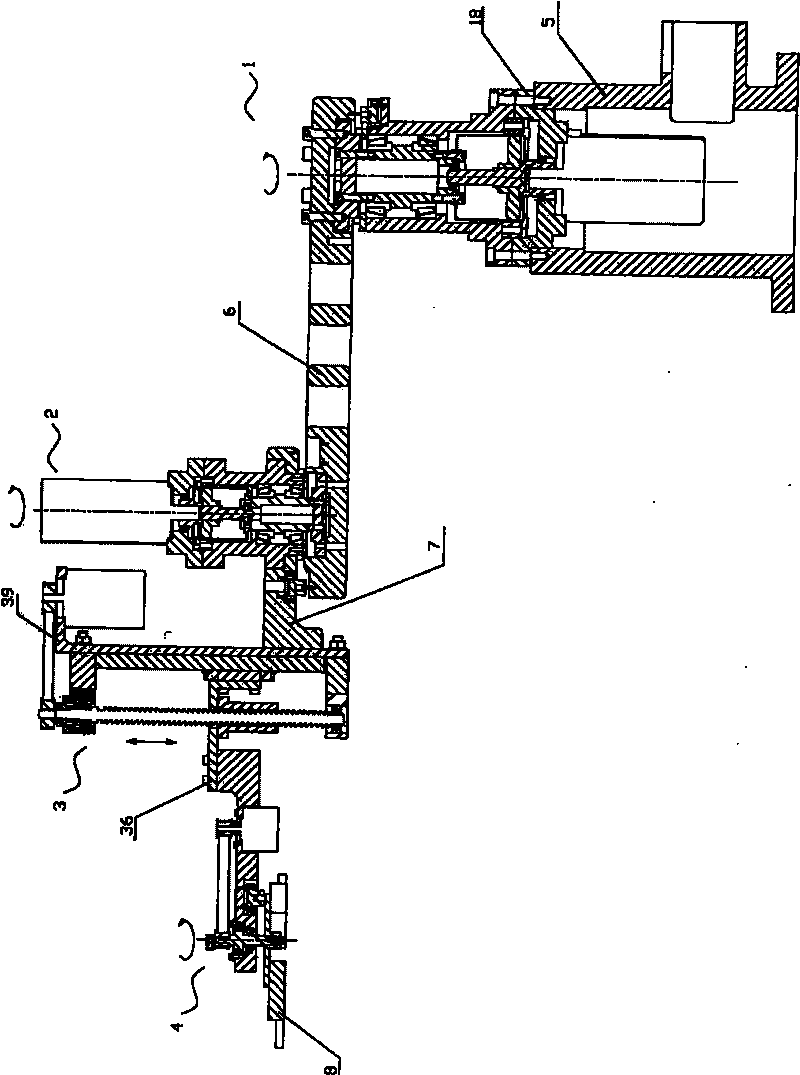

Charging and blanking robot of punch press

InactiveCN101758497AEasy to adjustImprove work efficiencyProgramme-controlled manipulatorMetal-working feeding devicesPunch pressReduction drive

The invention discloses a charging and blanking robot of a punch press, comprising four joints, a base, two arms and an end effector, wherein the first joint, the second joint and the fourth joint have the degree of freedom of rotation, and the third joint has the degree of freedom of up and down translation; one end of the first joint is connected with the base by an input end shell; the other end of the first joint is connected with one end of the first arm by a first joint output flange; the other end of the first arm is connected with a second joint output flange of the second joint; a third joint connecting plate is connected with the joint rack of the fourth joint; and a fourth joint output rotary table is provided with the end effector. A harmonic transmission mode is adopted by a first joint transmission device and a second joint transmission device of the robot. Aiming at the characteristic that a harmonic speed reducer only can bear torque but can not bear bending moment, a pair of tapered roller bearings is arranged on an output shaft and is used for bearing overturning bending moment. The transmission mode has compact structure, high transmission efficiency, small return difference and high transmission accuracy.

Owner:ZHEJIANG UNIV

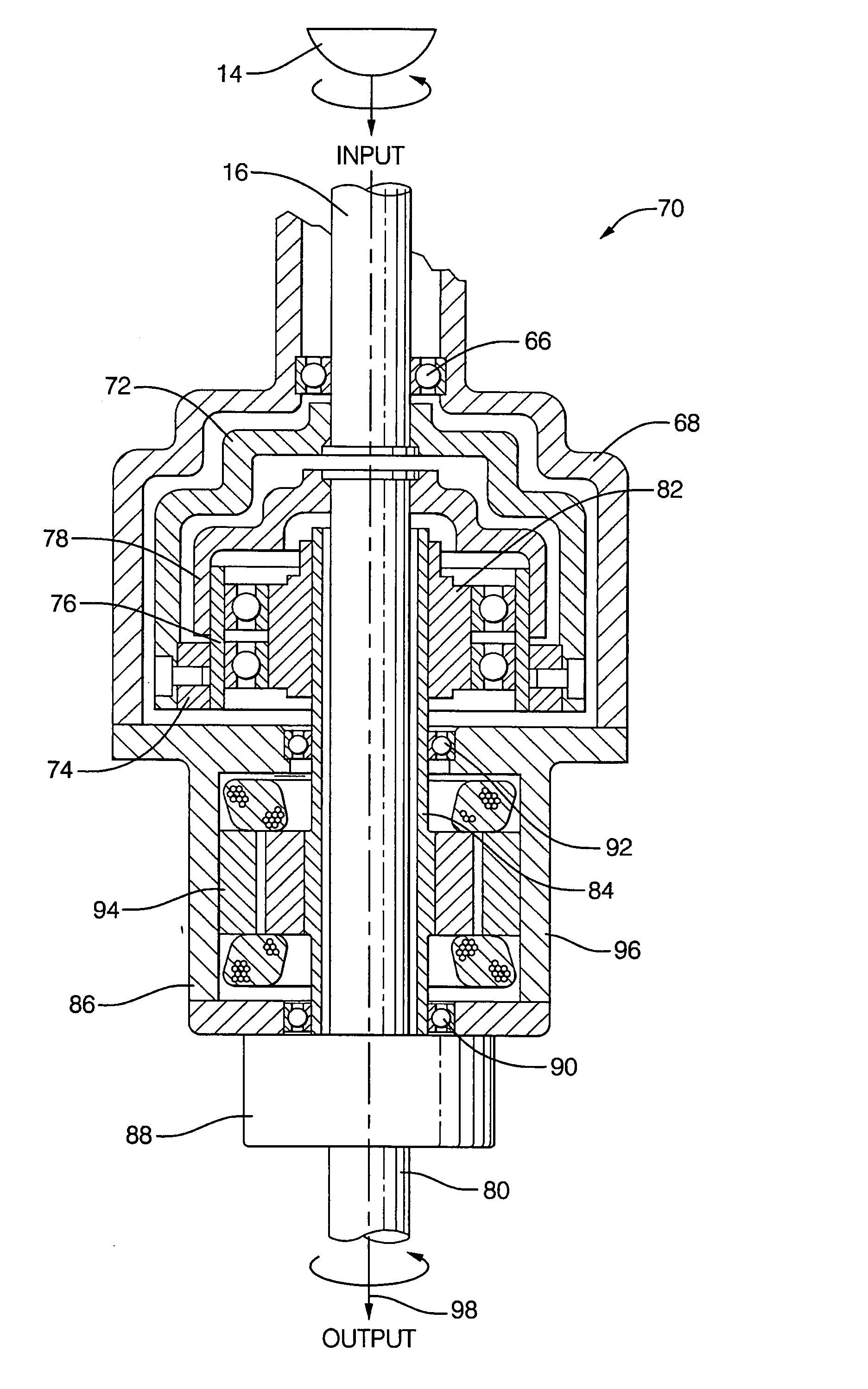

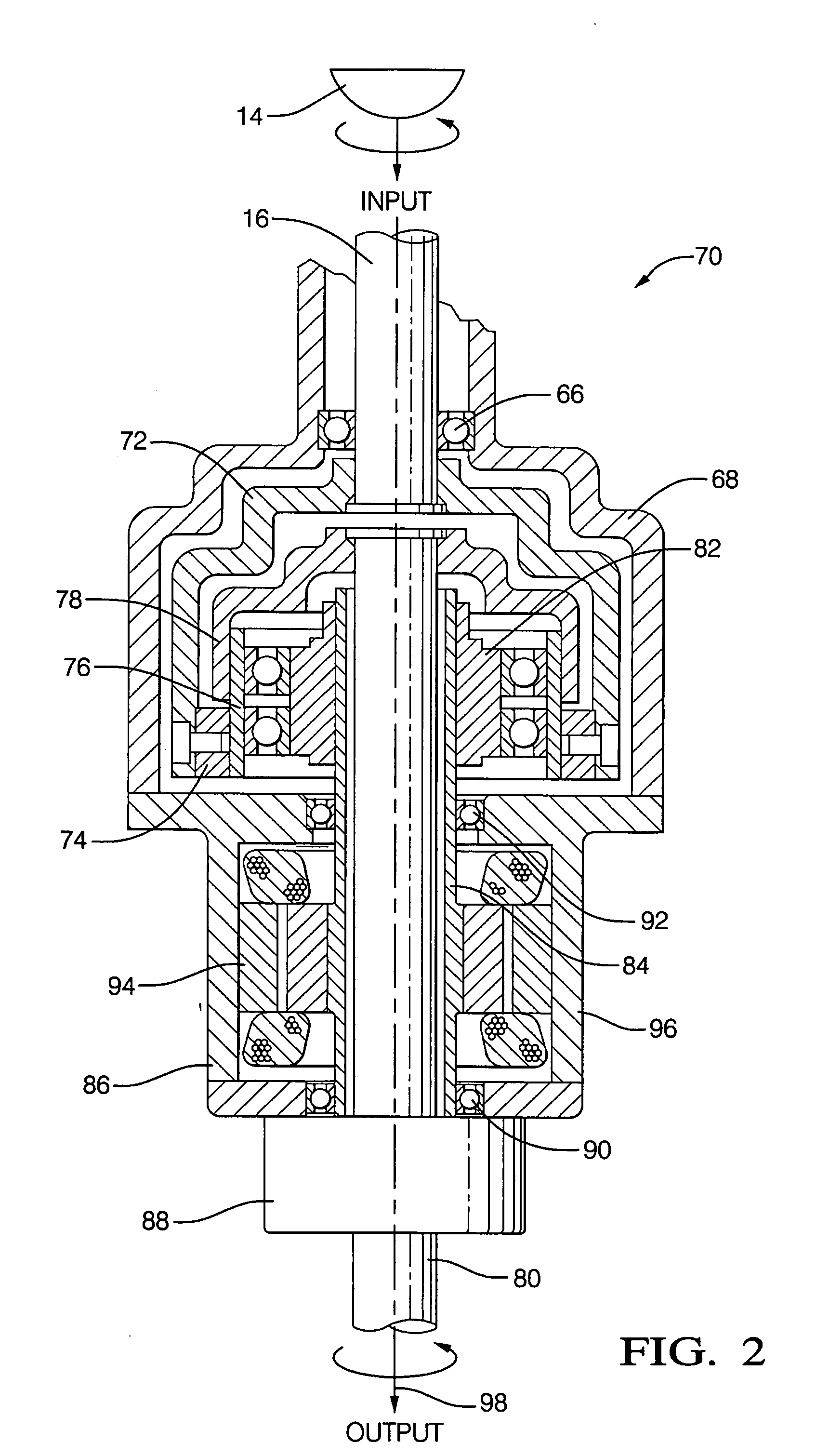

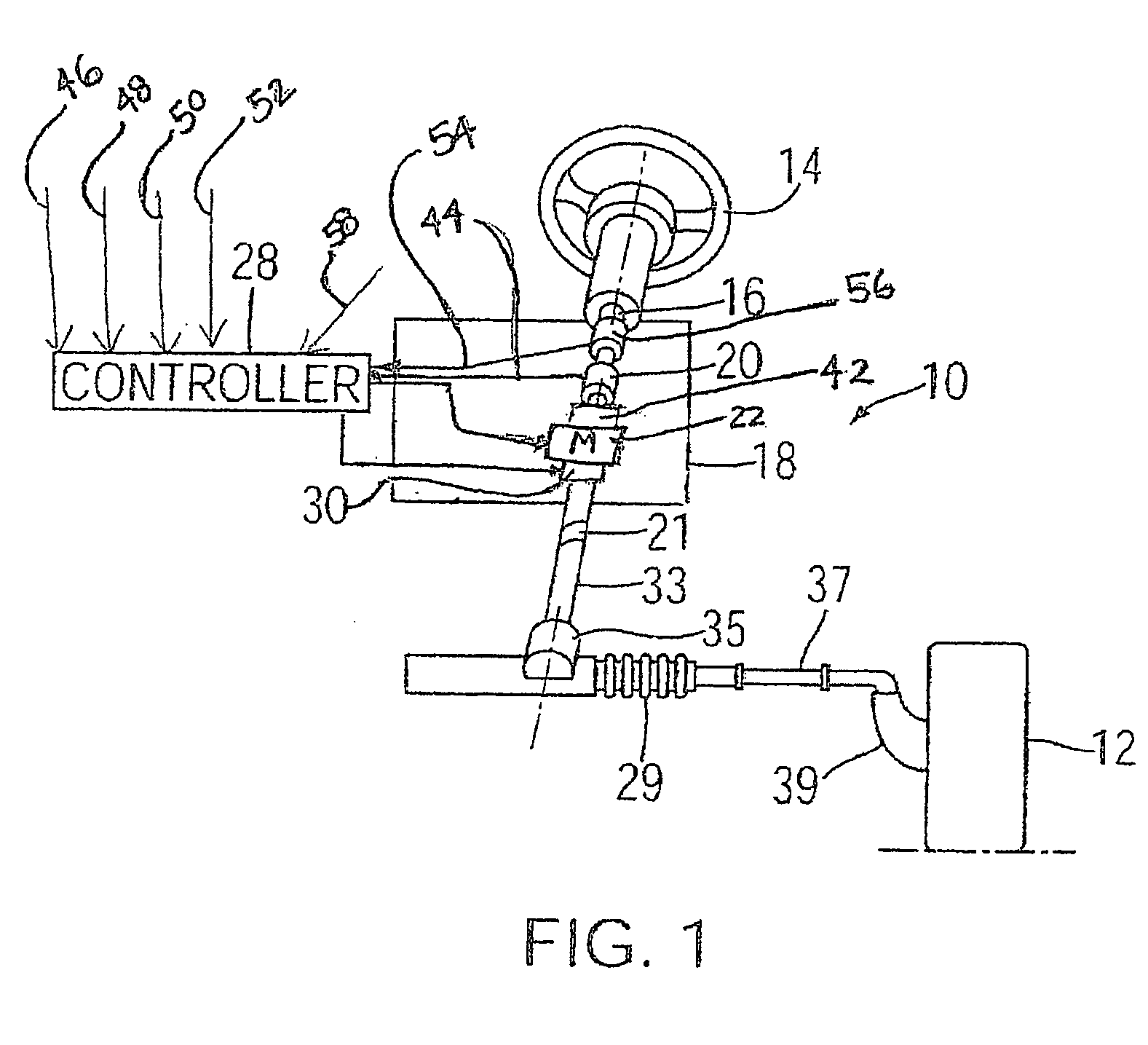

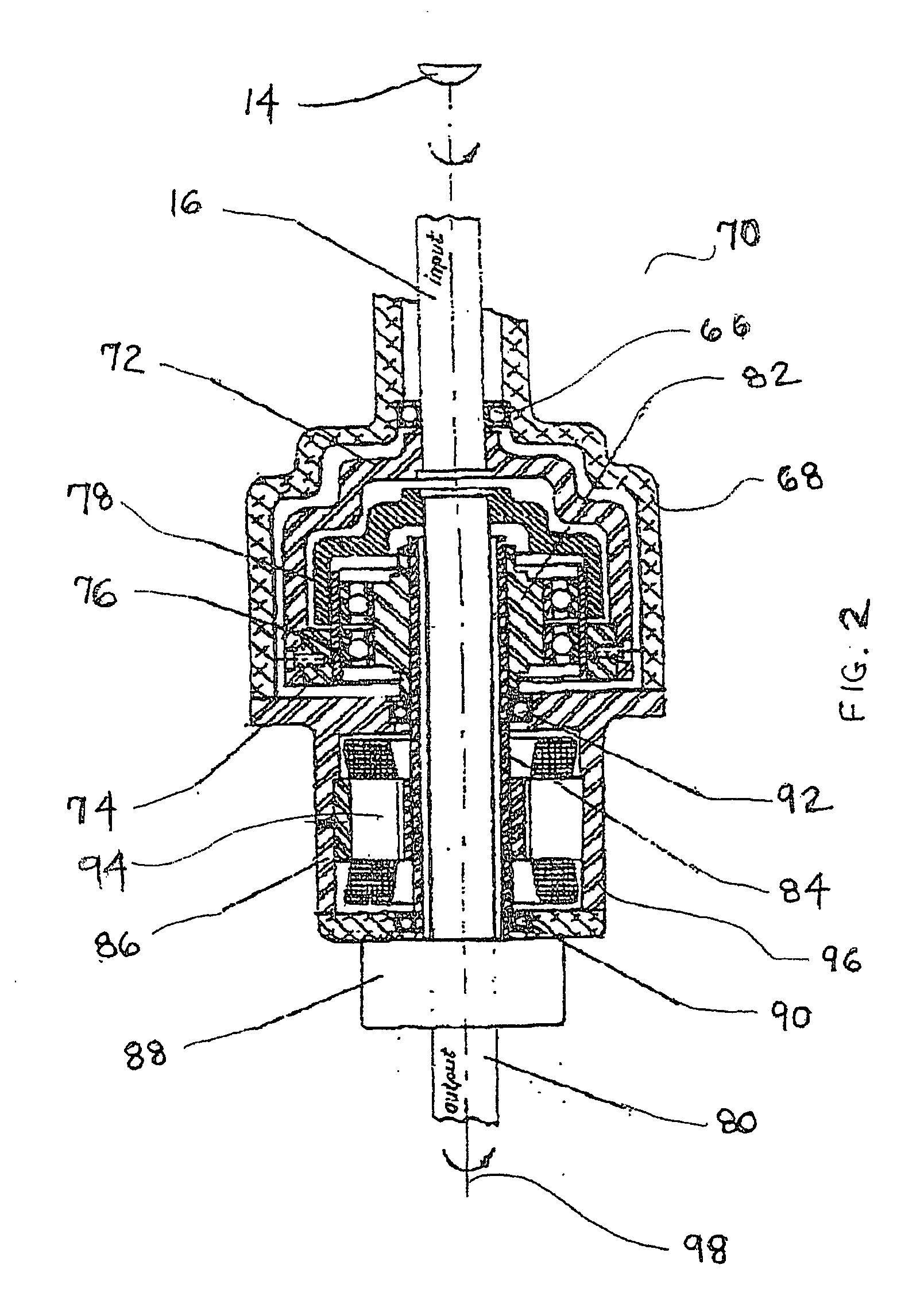

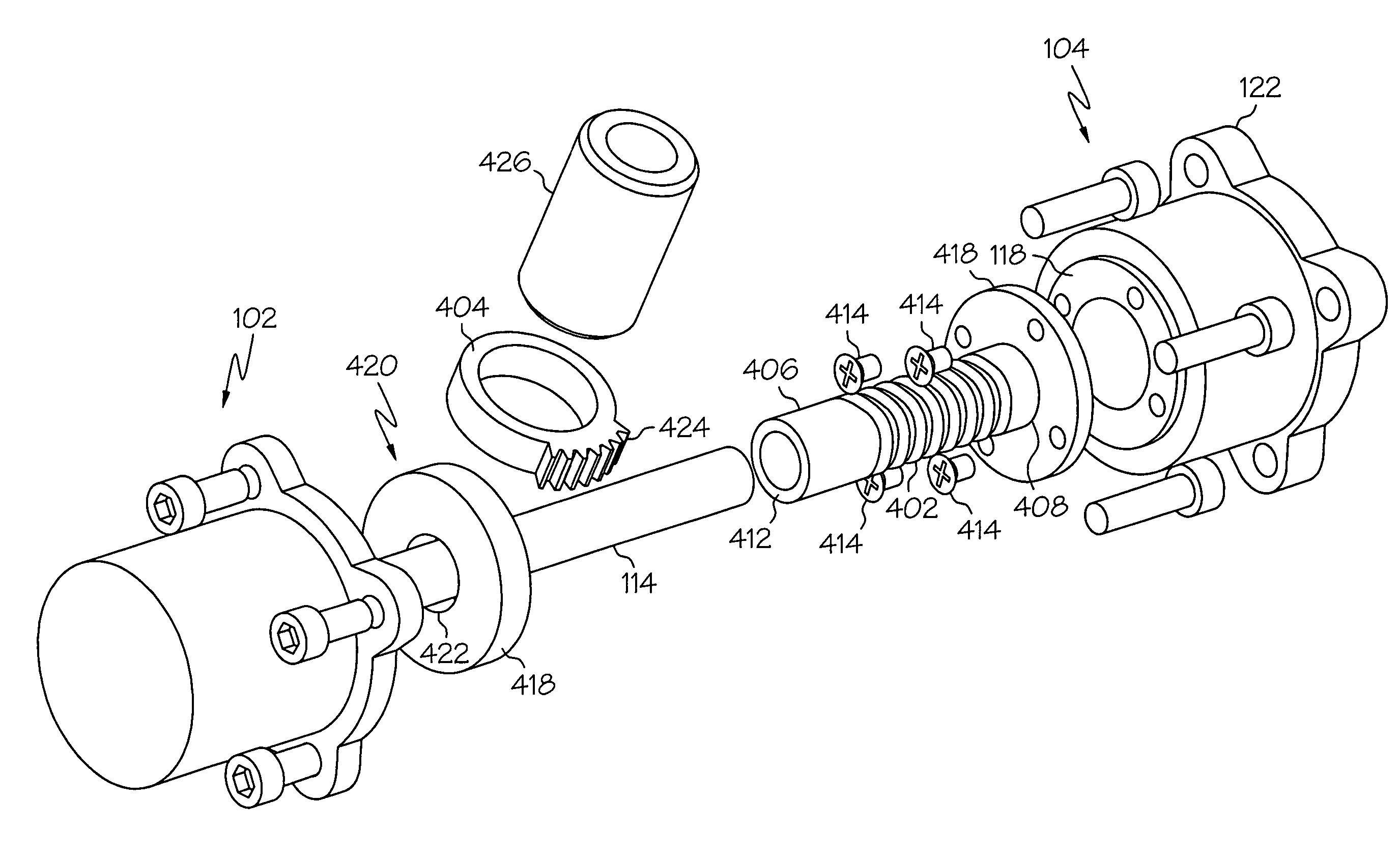

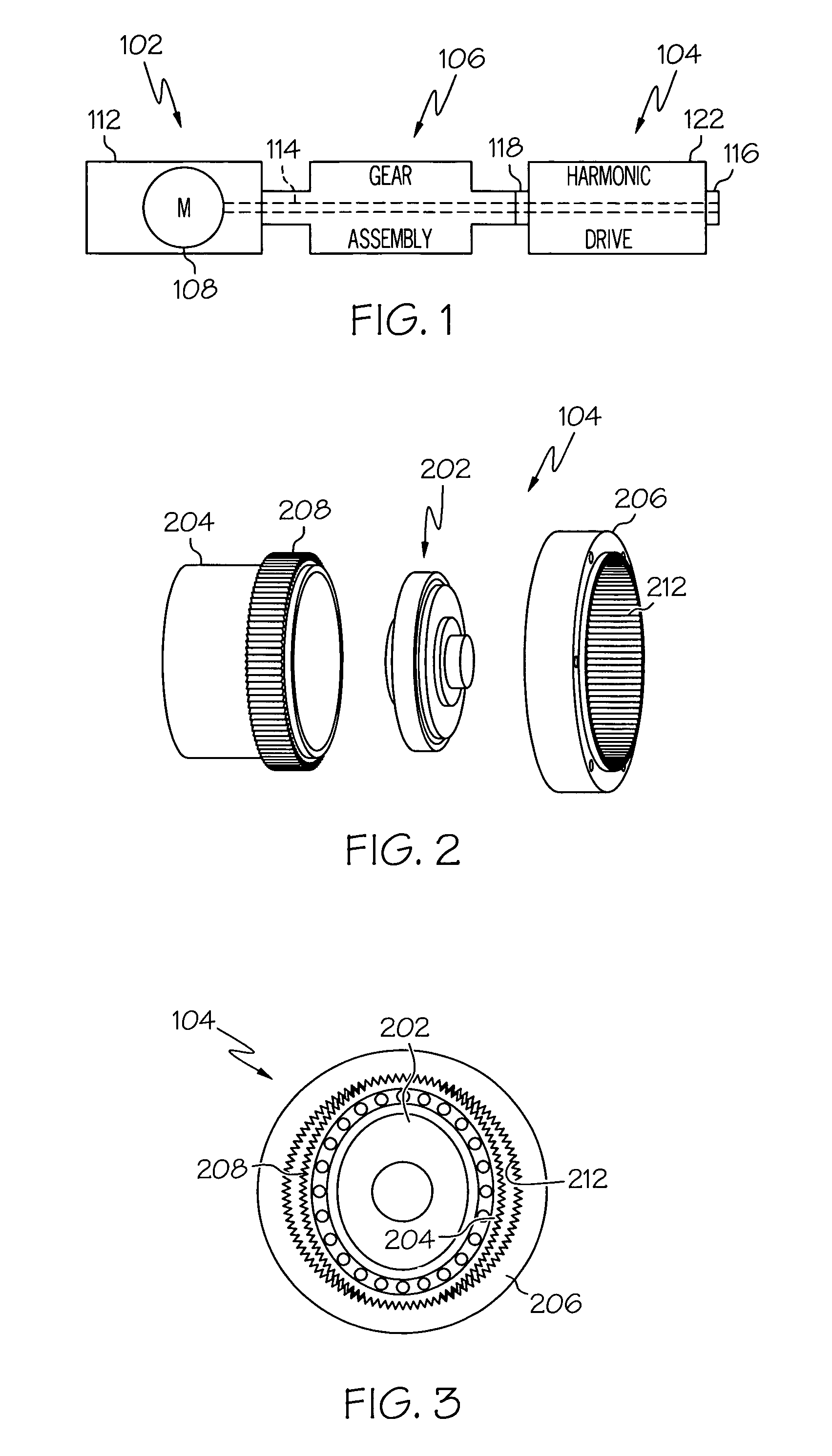

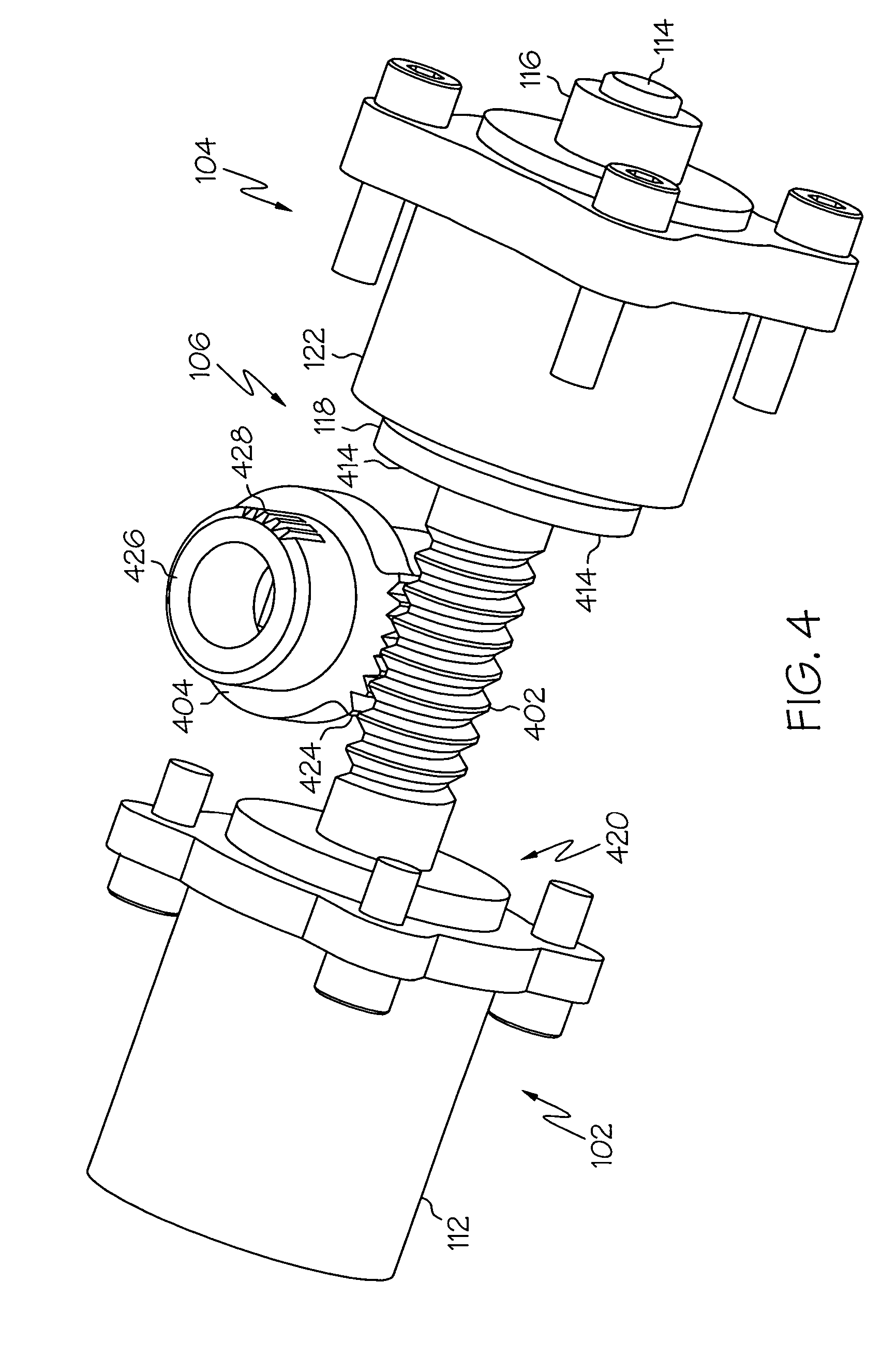

Motor driven harmonic drive actuator having an interposed output mechanism

A relatively small, lightweight electromechanical actuator includes a motor assembly, a harmonic drive, and an interposed gear assembly that functions as an output mechanism. The motor assembly, harmonic drive, and gear assembly are coupled together in an in-line configuration, which reduces the overall size envelope relative to know actuators, and the relative weight and complexity of the gear assembly.

Owner:HONEYWELL INT INC

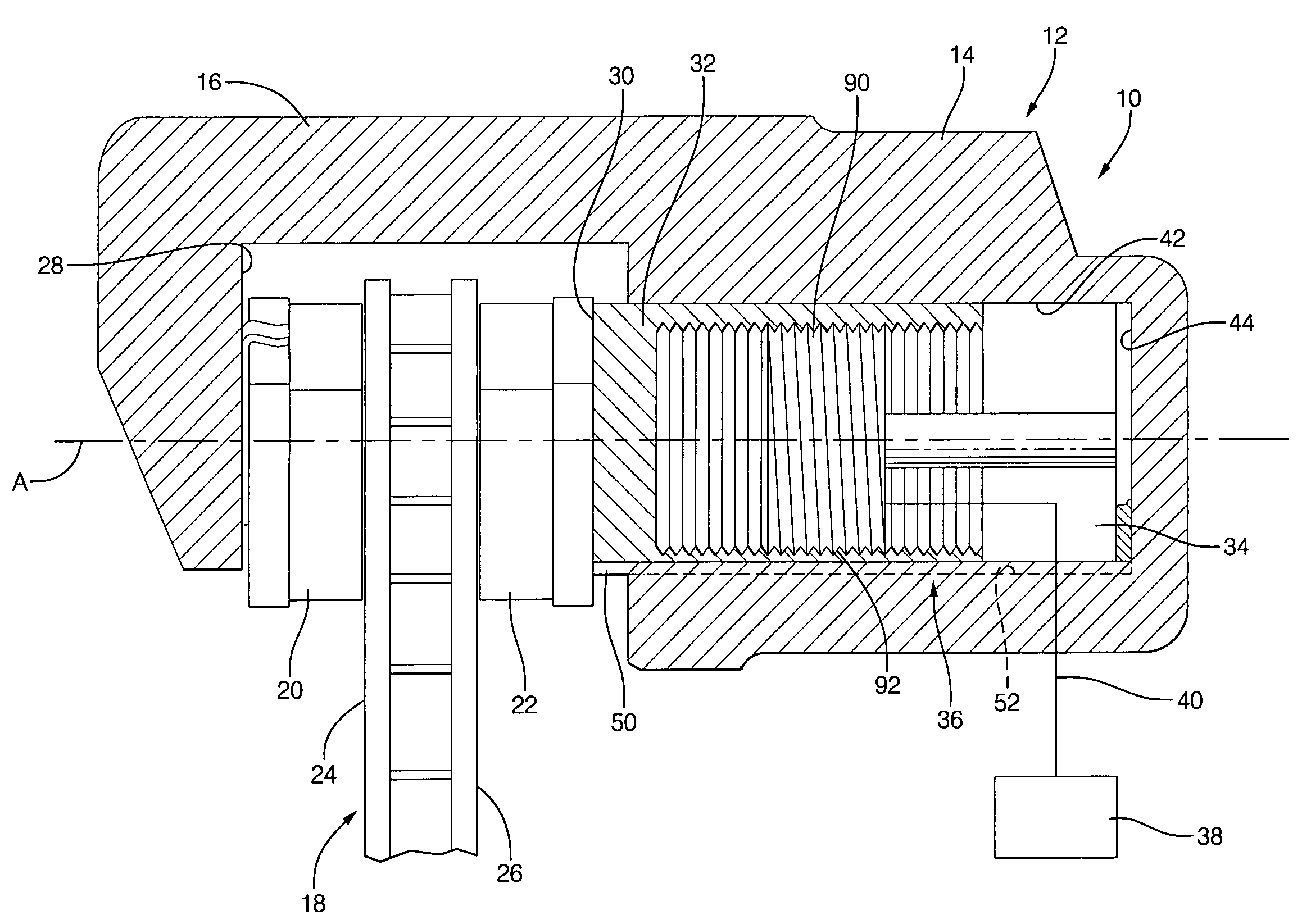

Harmonic drive linear actuator

InactiveUS7527130B2High outputNo inertiaControlling membersControlled membersAxial displacementCalipers

A harmonic drive linear actuator includes a first annular member defining a longitudinal axis and lying on a plane, which is perpendicular to the longitudinal axis. The first member is relatively flexible along a direction parallel to the plane. A second member is substantially coaxially aligned with the first member to define opposed substantially cylindrical surfaces and are fixed for non-relative rotation about the longitudinal axis. An actuator is provided for flexing the first annular member into at least two spaced-apart points of contact between the opposed surfaces and for sequentially flexing the first member to rotate the at least two points of contact circumferentially about the axis. The first and second surfaces define cooperating thread-forms thereon, which selectively engage to effect controlled, bidirectional relative axial displacement between the members in response to sequential flexure of the first member. The linear actuator can be conjoined with an actuator piston of a vehicle brake caliper assembly.

Owner:BWI CO LTD SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com