Patents

Literature

30results about How to "No inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

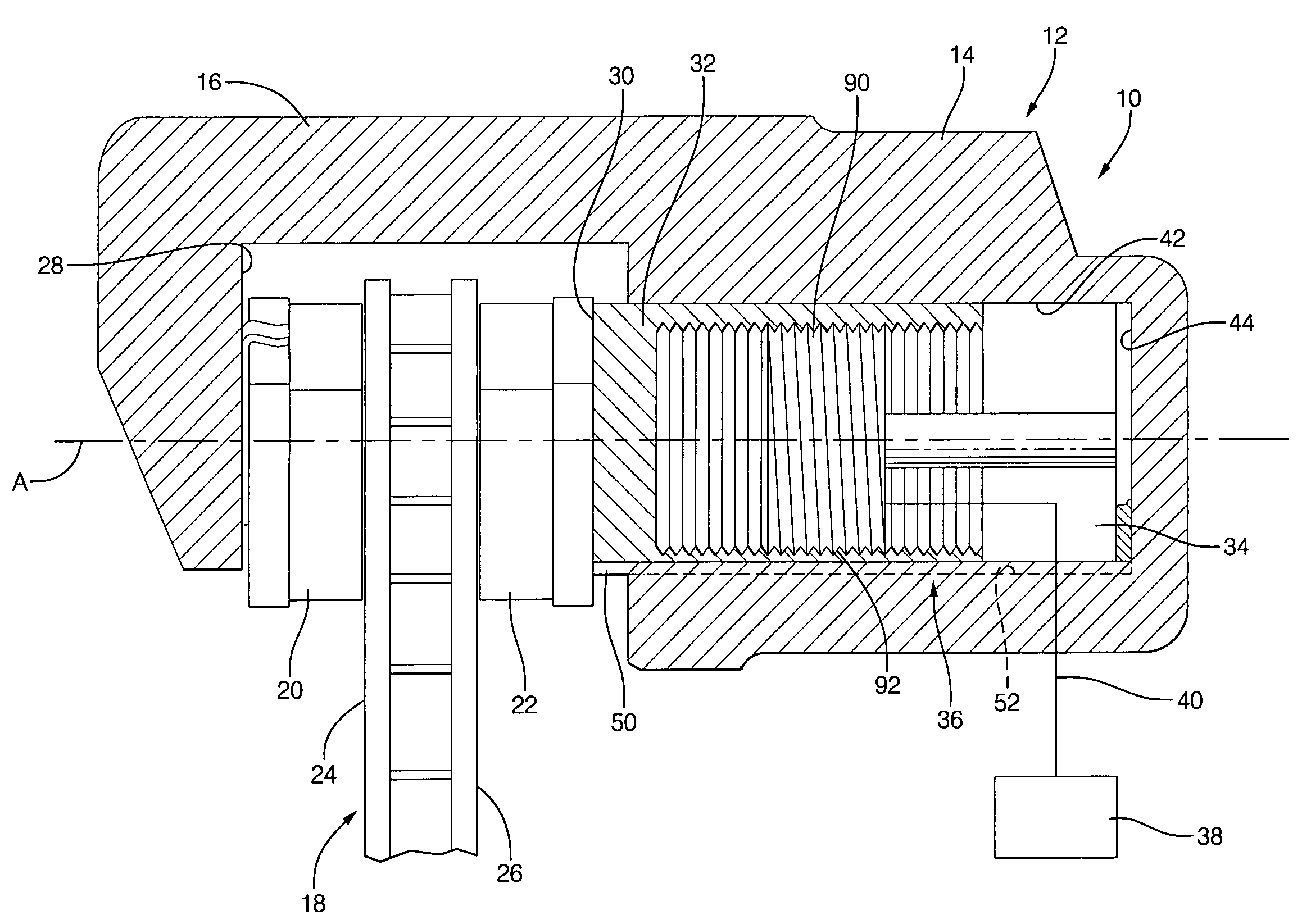

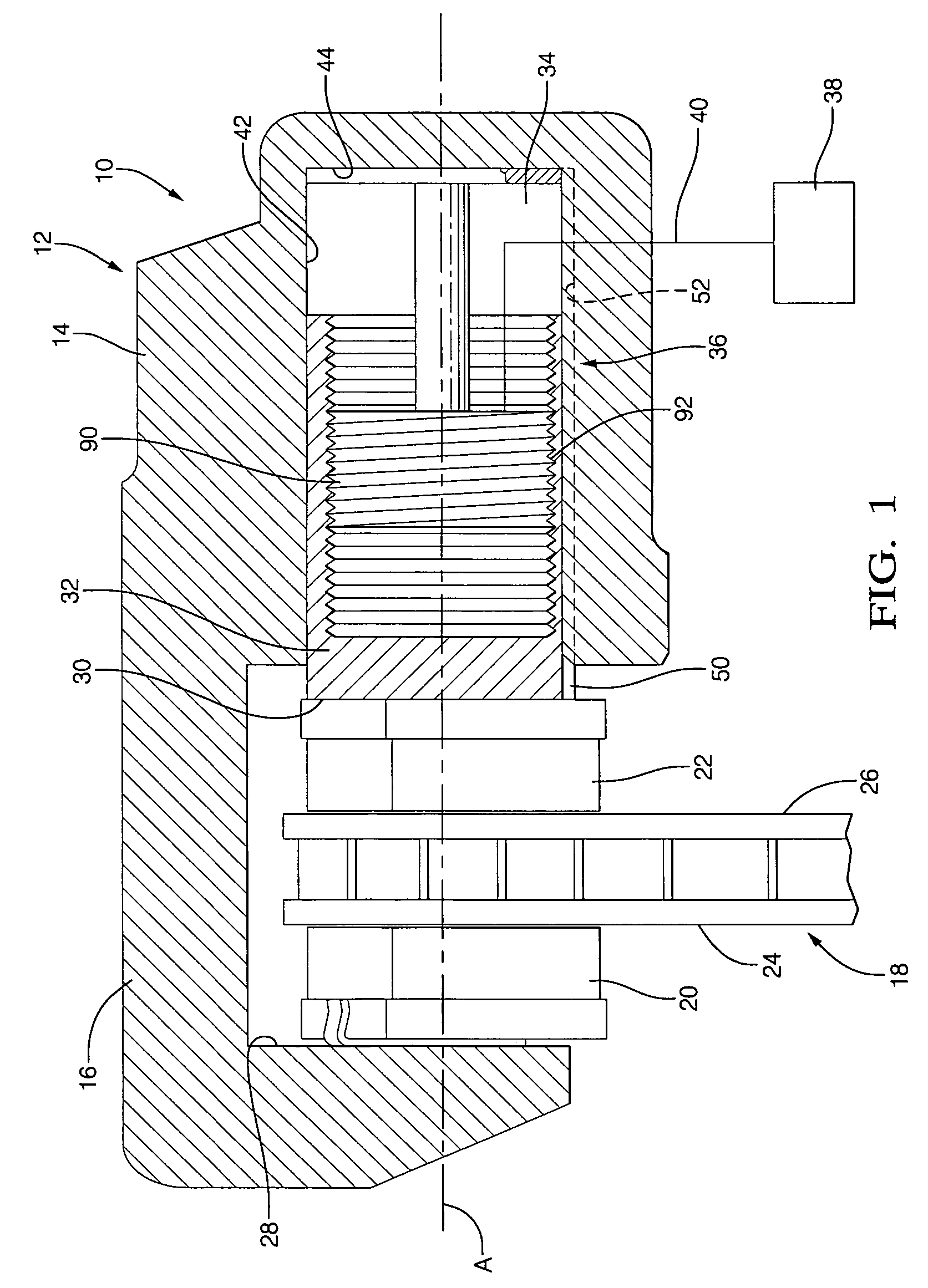

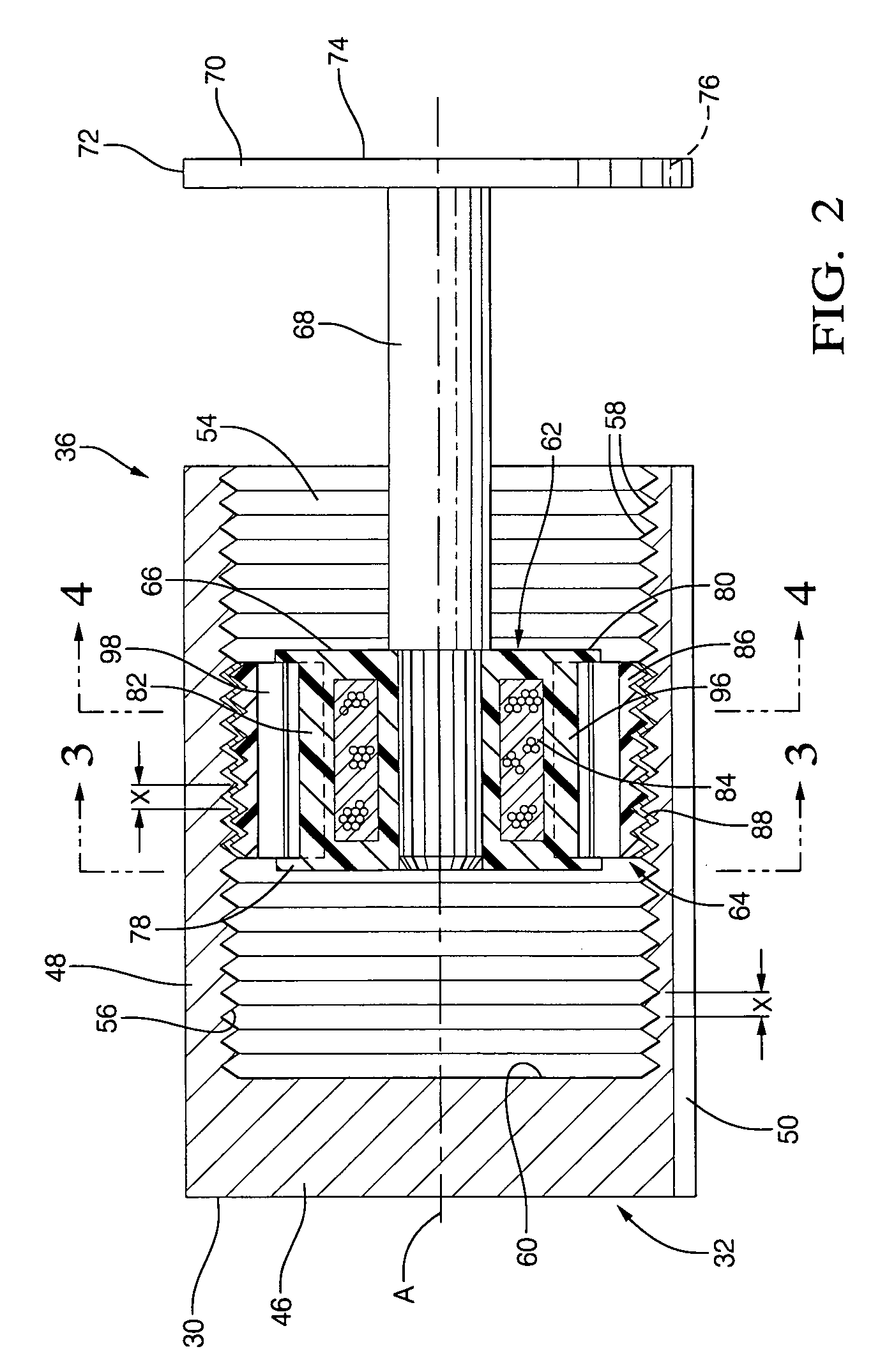

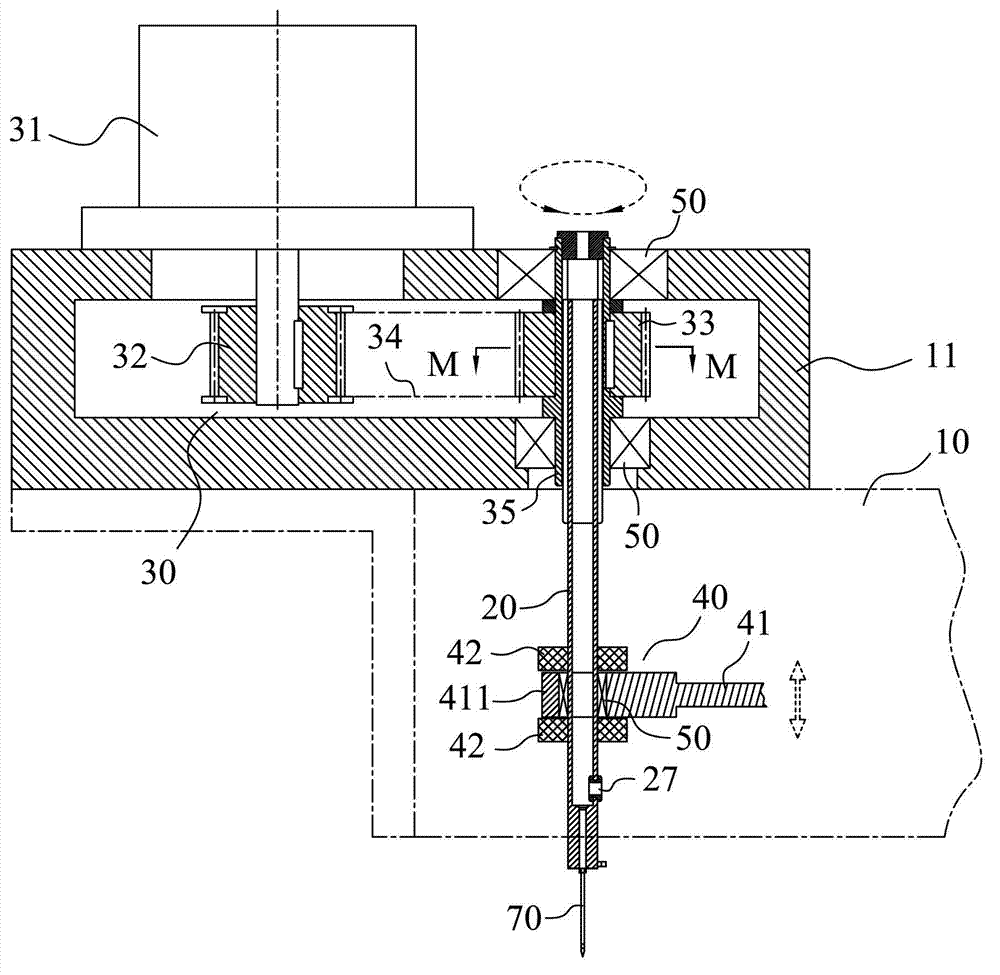

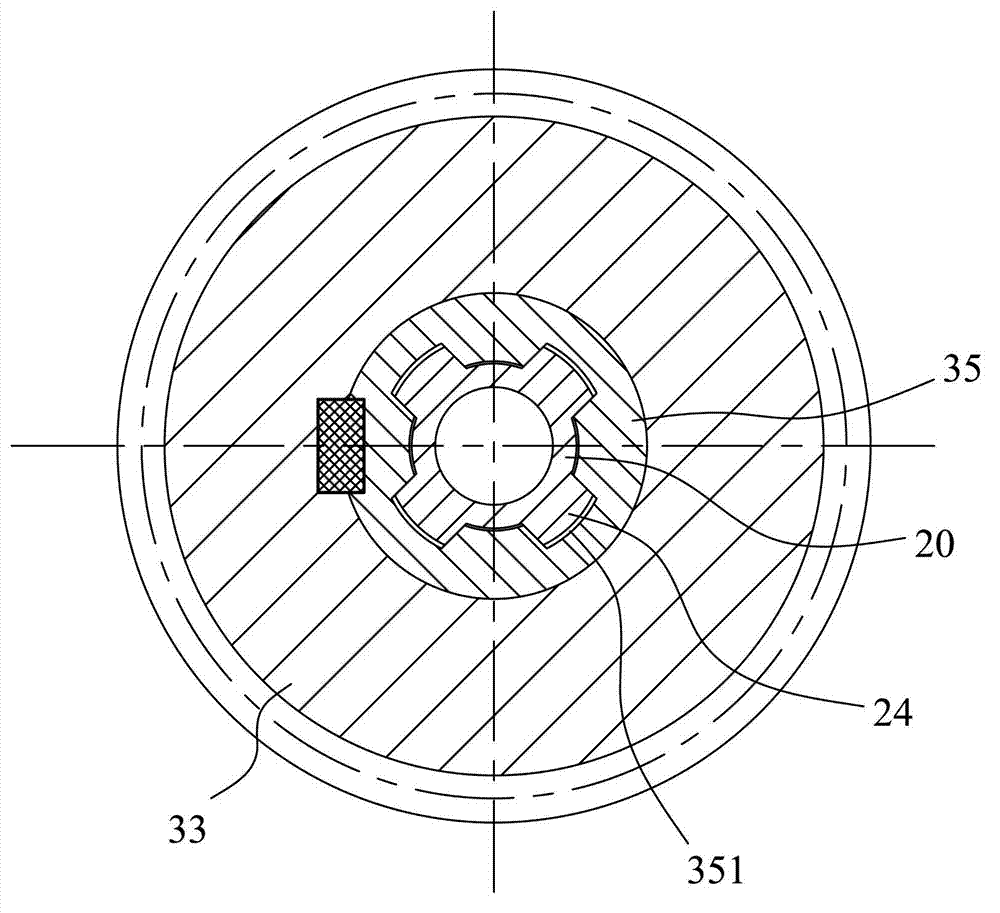

Harmonic drive linear actuator

InactiveUS7527130B2High outputNo inertiaControlling membersControlled membersAxial displacementCalipers

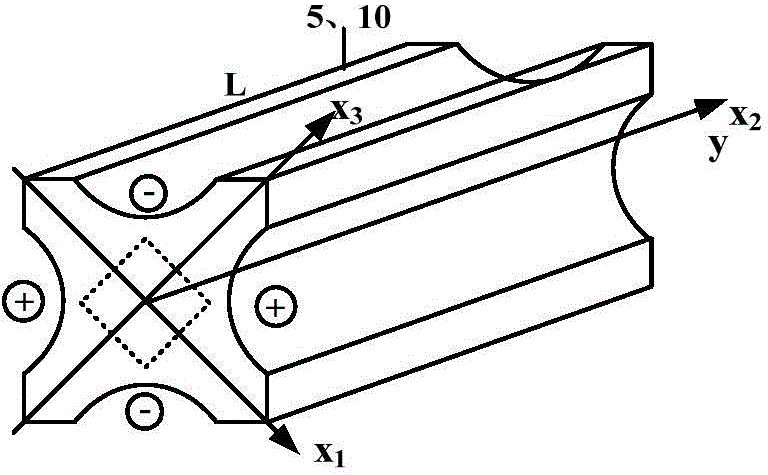

A harmonic drive linear actuator includes a first annular member defining a longitudinal axis and lying on a plane, which is perpendicular to the longitudinal axis. The first member is relatively flexible along a direction parallel to the plane. A second member is substantially coaxially aligned with the first member to define opposed substantially cylindrical surfaces and are fixed for non-relative rotation about the longitudinal axis. An actuator is provided for flexing the first annular member into at least two spaced-apart points of contact between the opposed surfaces and for sequentially flexing the first member to rotate the at least two points of contact circumferentially about the axis. The first and second surfaces define cooperating thread-forms thereon, which selectively engage to effect controlled, bidirectional relative axial displacement between the members in response to sequential flexure of the first member. The linear actuator can be conjoined with an actuator piston of a vehicle brake caliper assembly.

Owner:BWI CO LTD SA

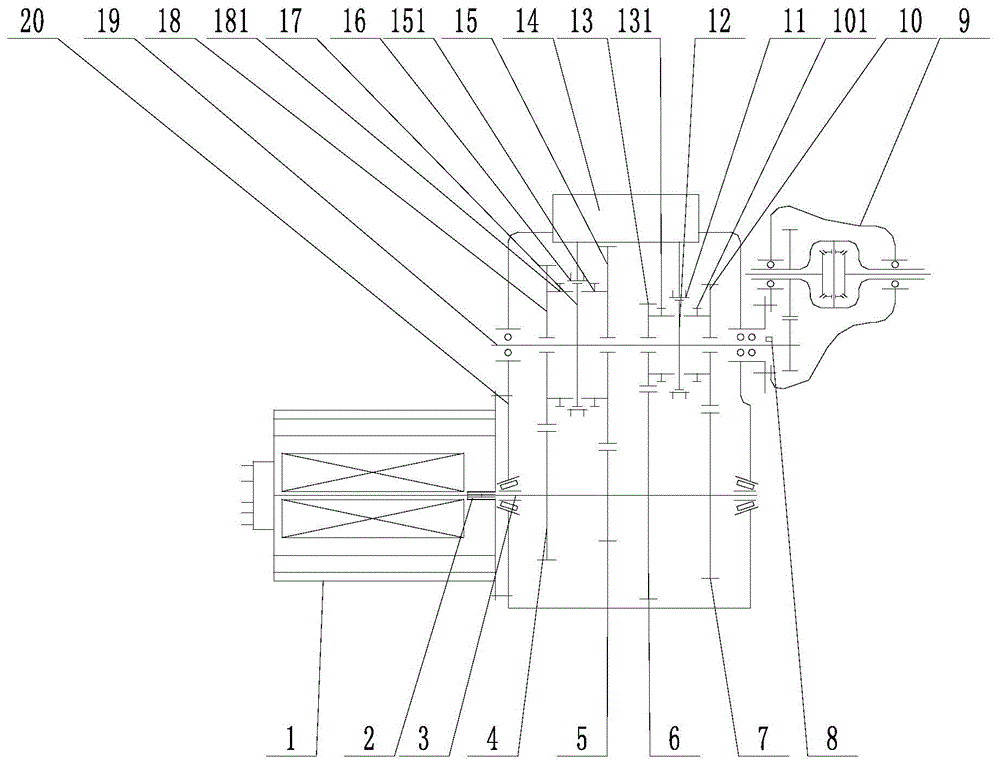

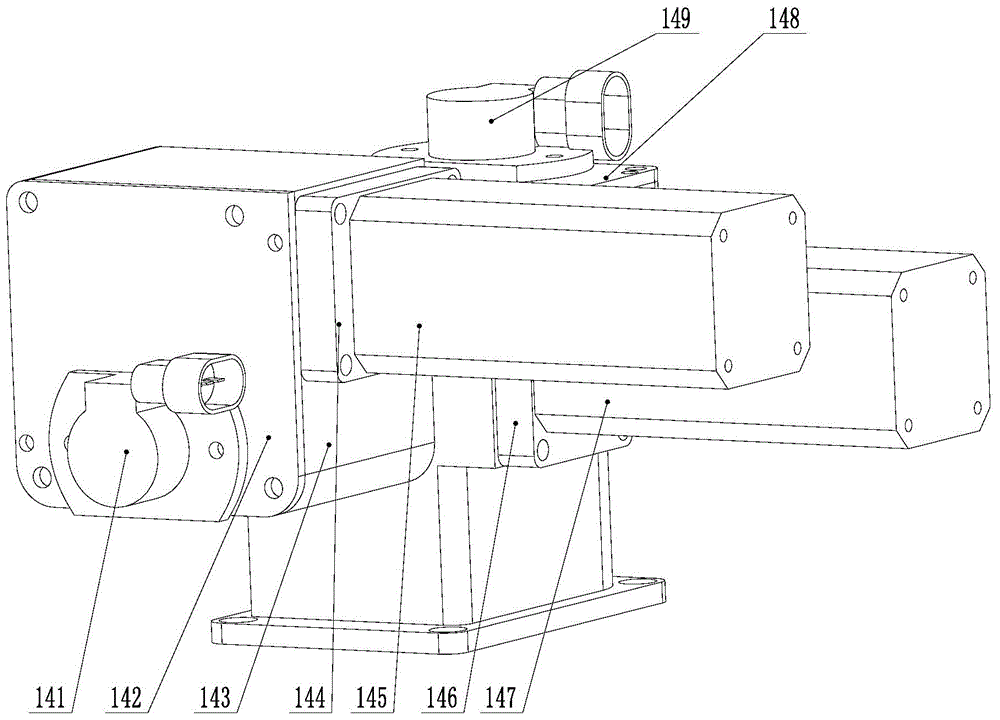

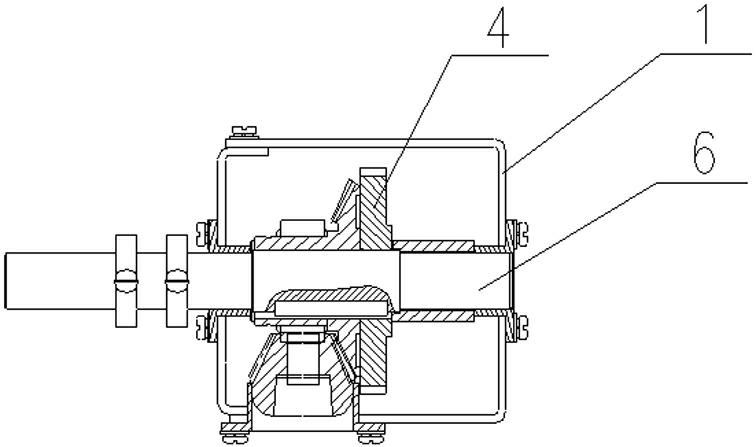

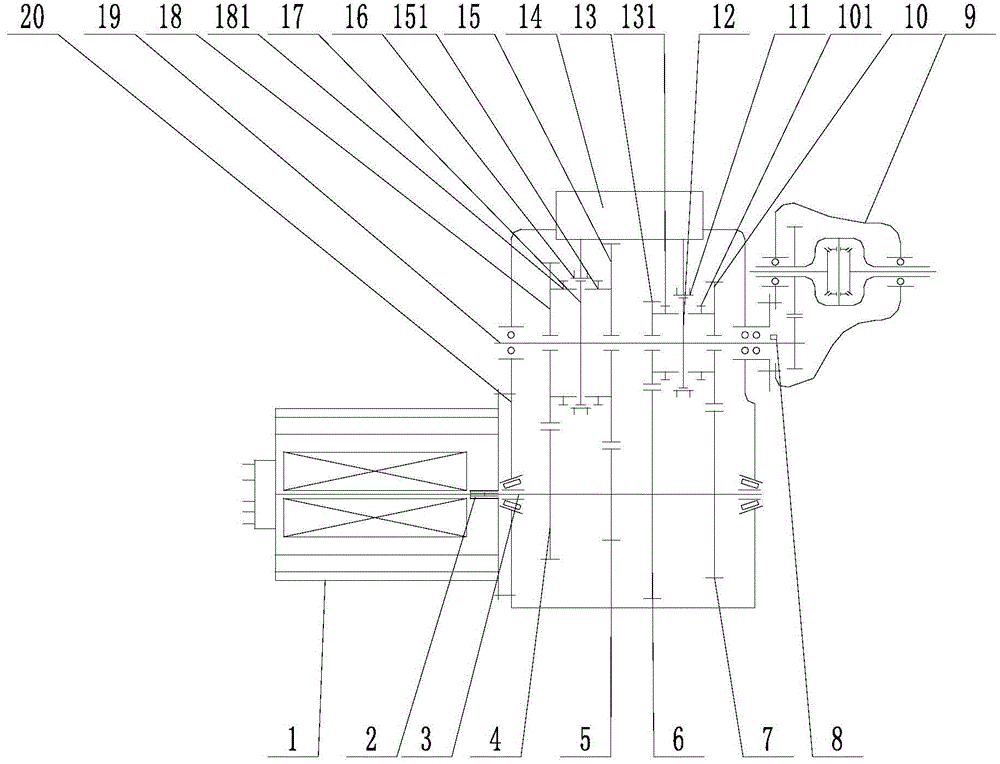

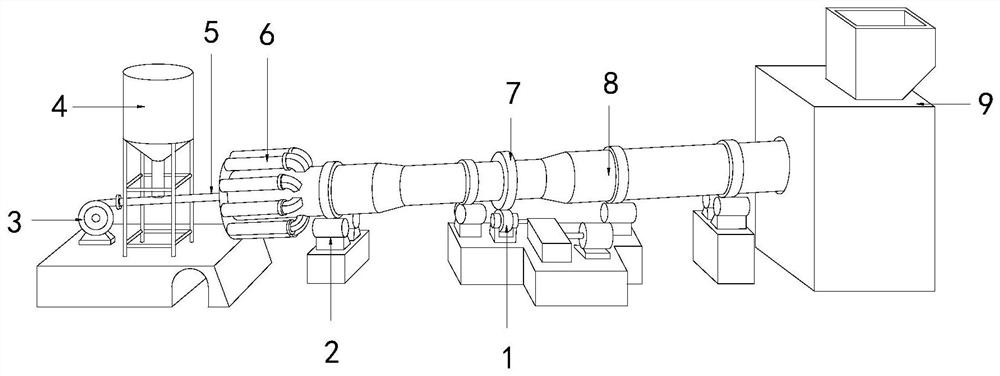

Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

InactiveCN103552448ASmall sizeFlexible and convenient layoutSpeed controllerElectric propulsion mountingBrushless motorsElectric machine

The invention discloses a motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and a motor and AMT integration-based electric vehicle driving method. The driving system comprises a driving motor, a motor controller, a transmission drive assembly, a gear selection and shifting execution mechanism and a controller for the gear selection and shifting execution mechanism, wherein the transmission drive assembly comprises driving and driven gears of four gears, two splined hubs, two jointing sleeves and an output sensor; the driving motor is a direct current brushless motor; an output shaft of the driving motor is provided with an internal spline; a shell of the driving motor is integrally and directly connected with a transmission case through fine thread screws after being positioned through fixing pins; the output shaft, with the internal spline, of the motor is positioned in the motor; an input shaft of a transmission is directly inserted into the motor to be connected with the output shaft, with the internal spline, of the motor. According to the system, a clutch is eliminated, so that power interruption time during gear shifting is reduced, and the cost is also lowered; the jointing sleeves and the gears of a target gear can be synchronized during gear shifting by actively regulating the speed of the driving motor, and a synchronizer with high requirements on materials is eliminated from the transmission, so that the cost is further lowered.

Owner:张利鹏 +1

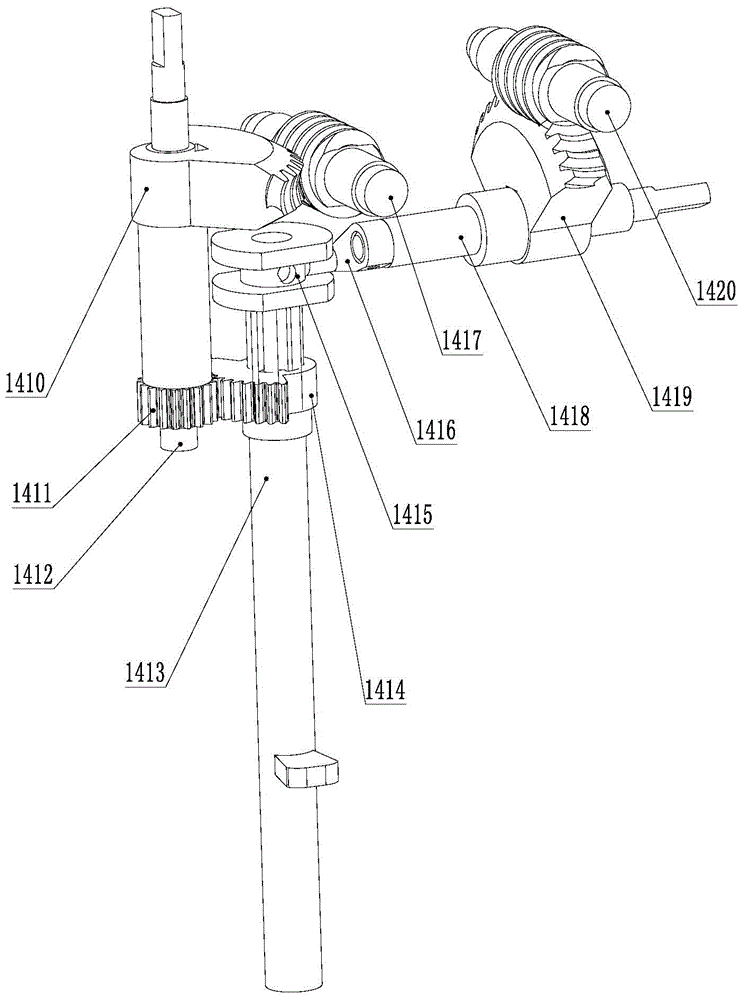

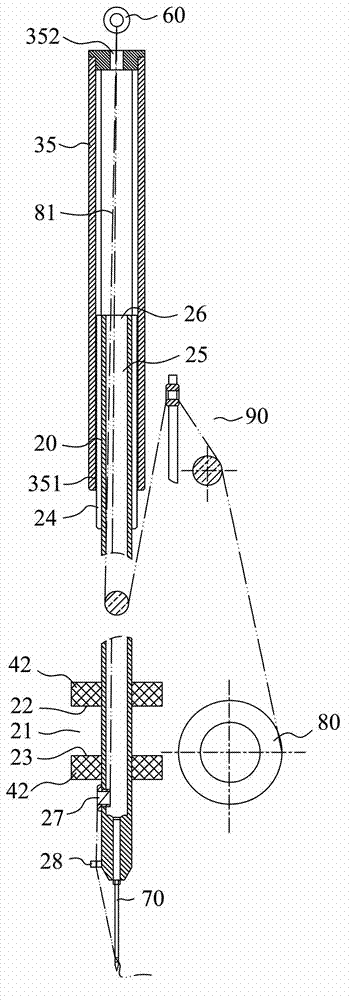

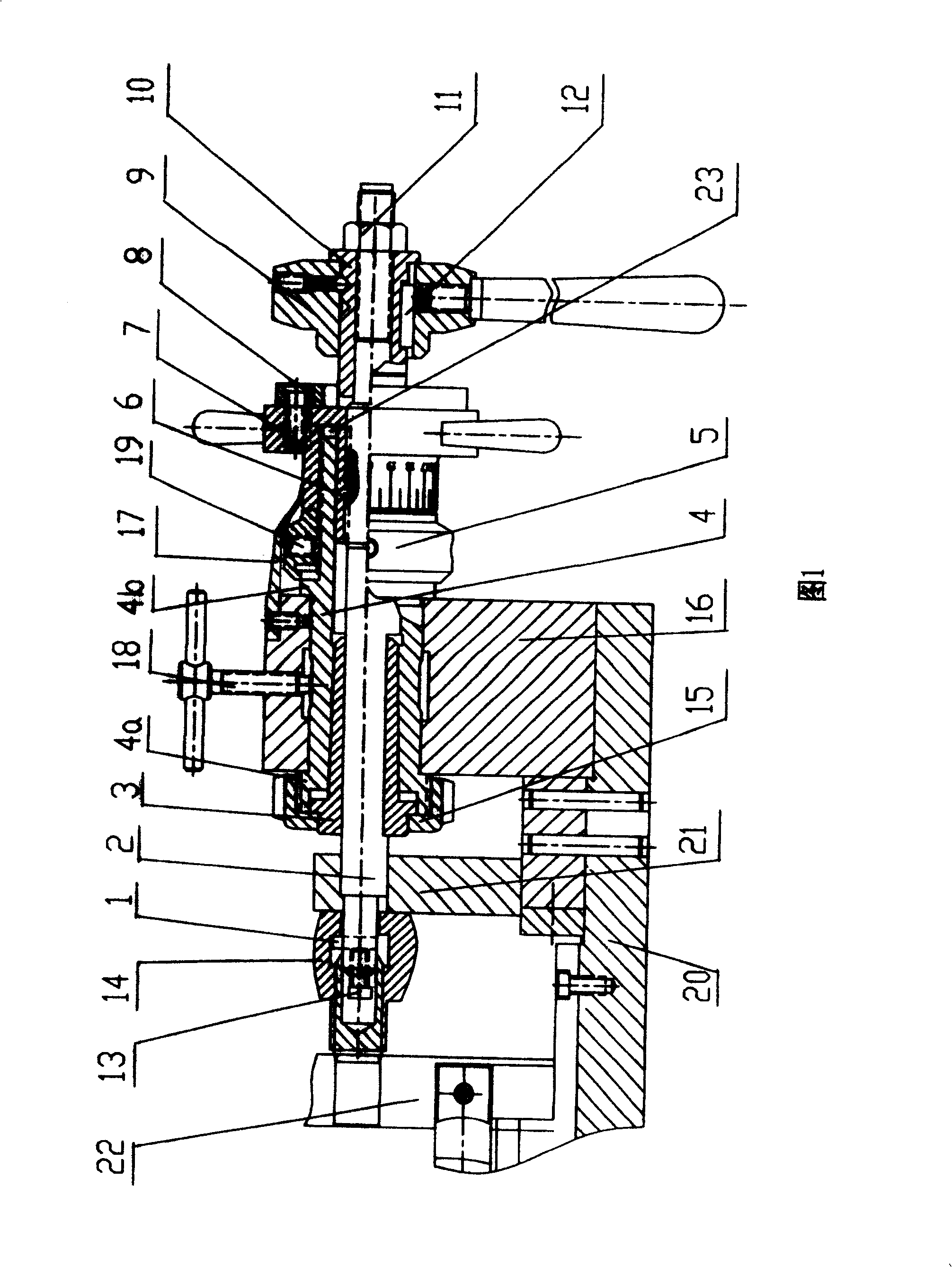

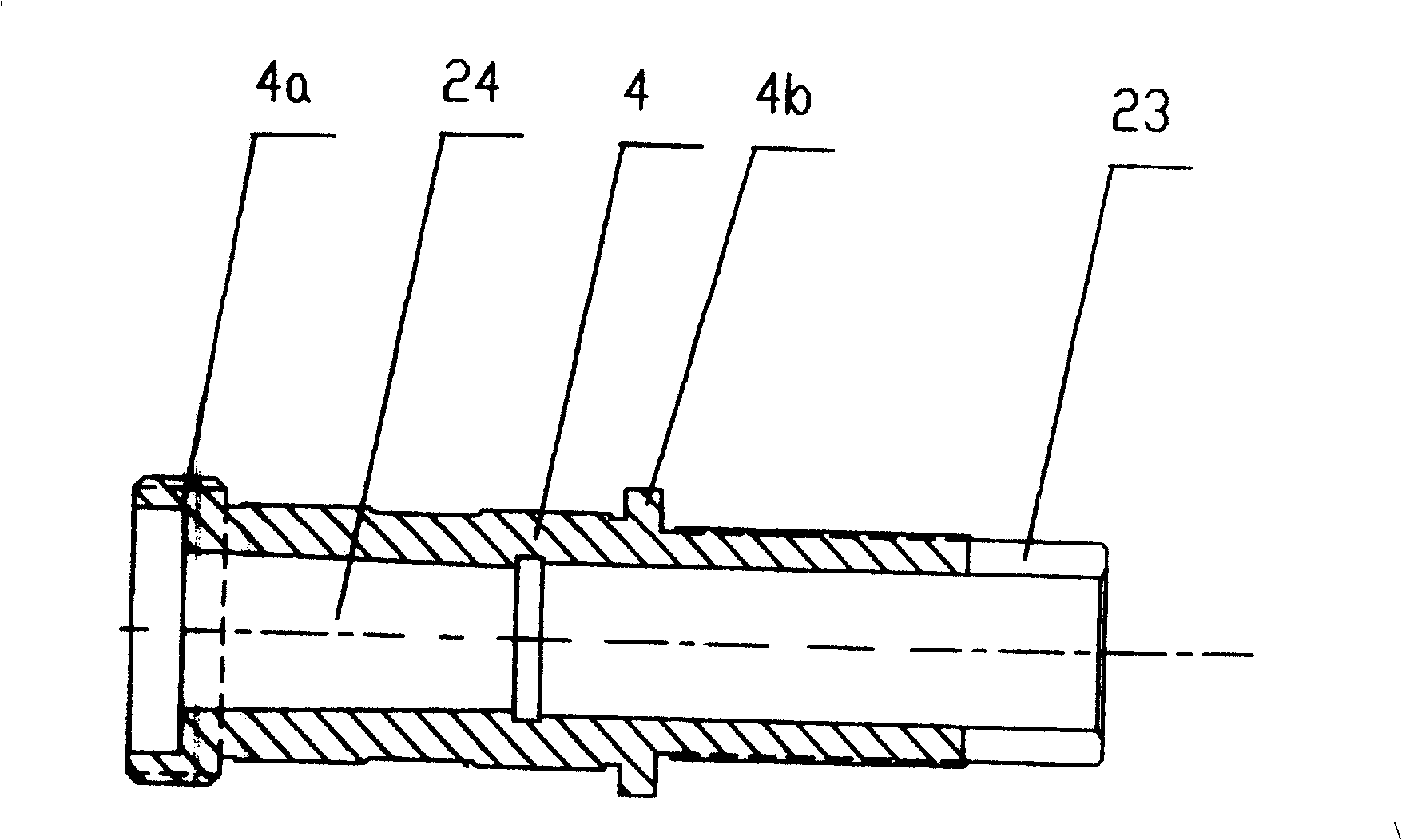

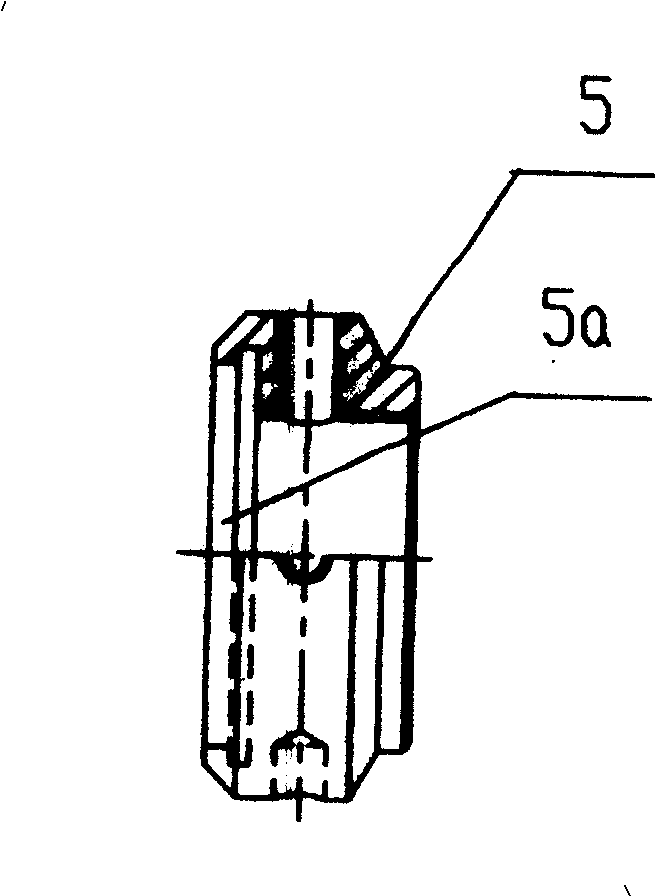

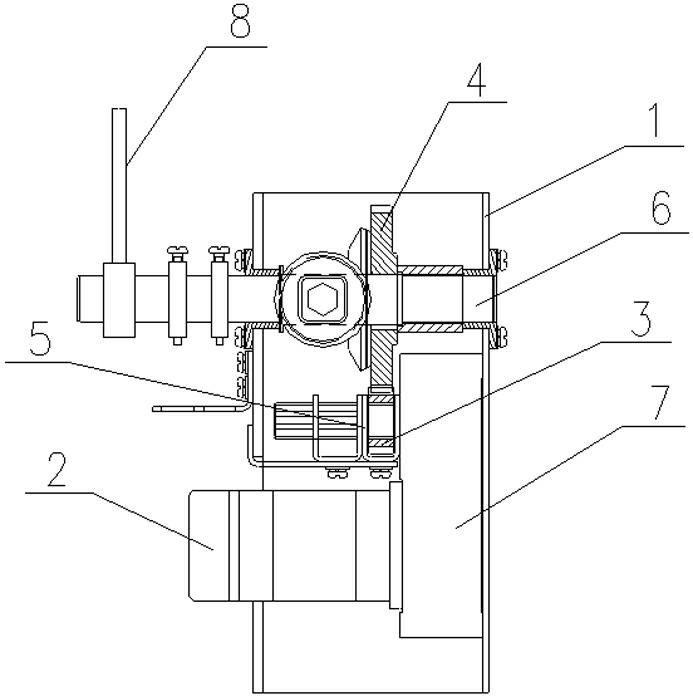

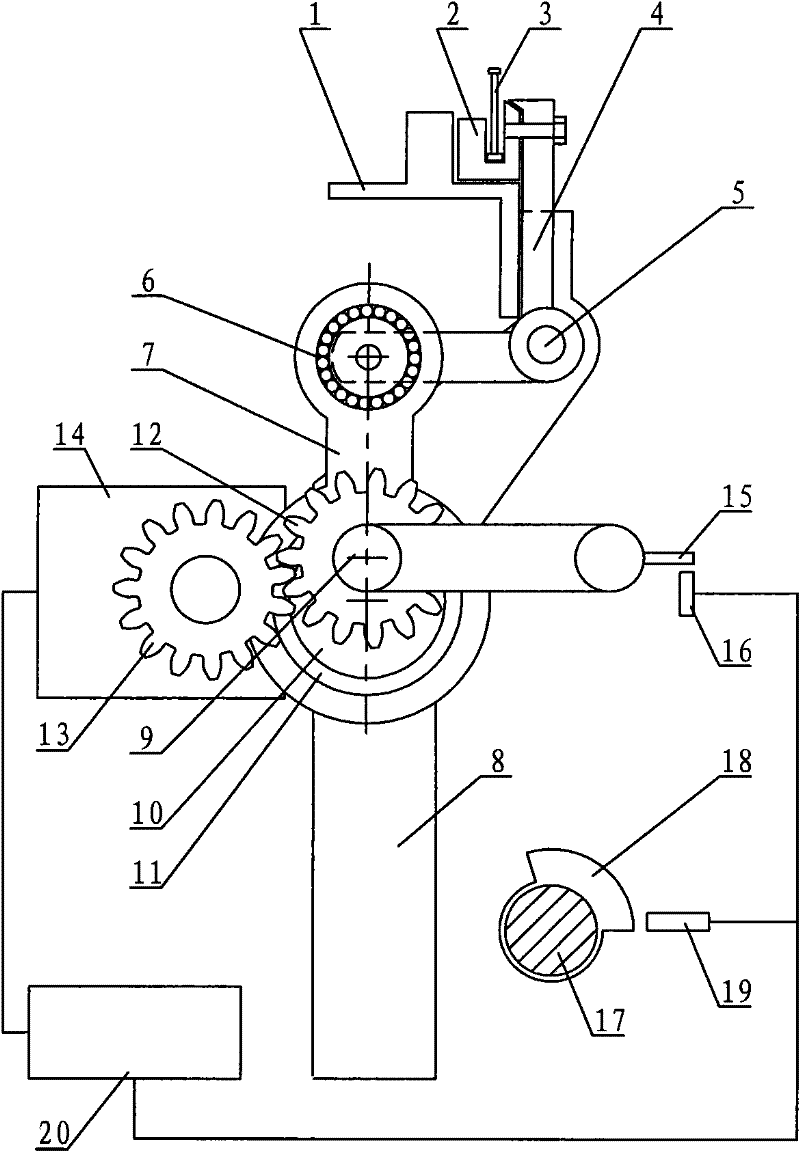

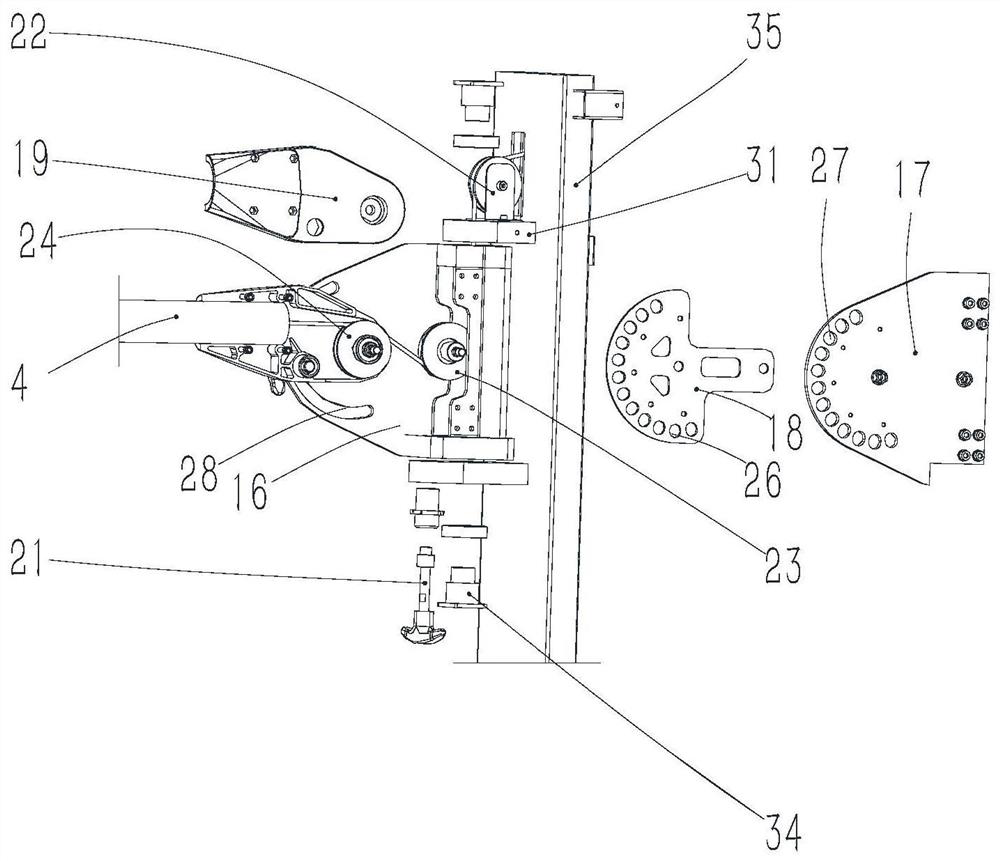

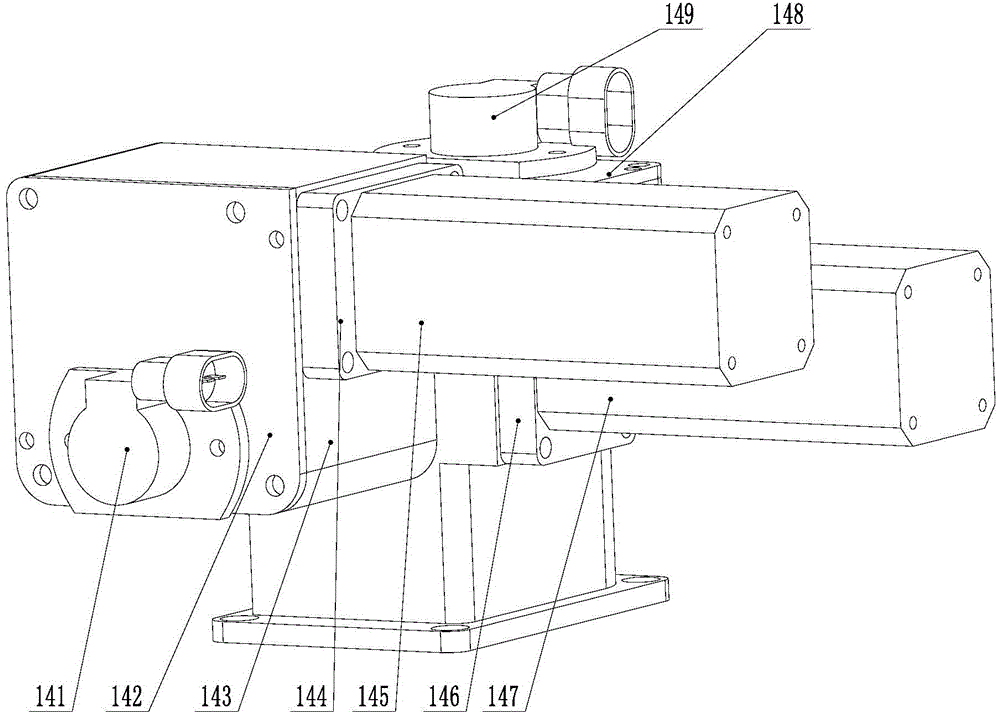

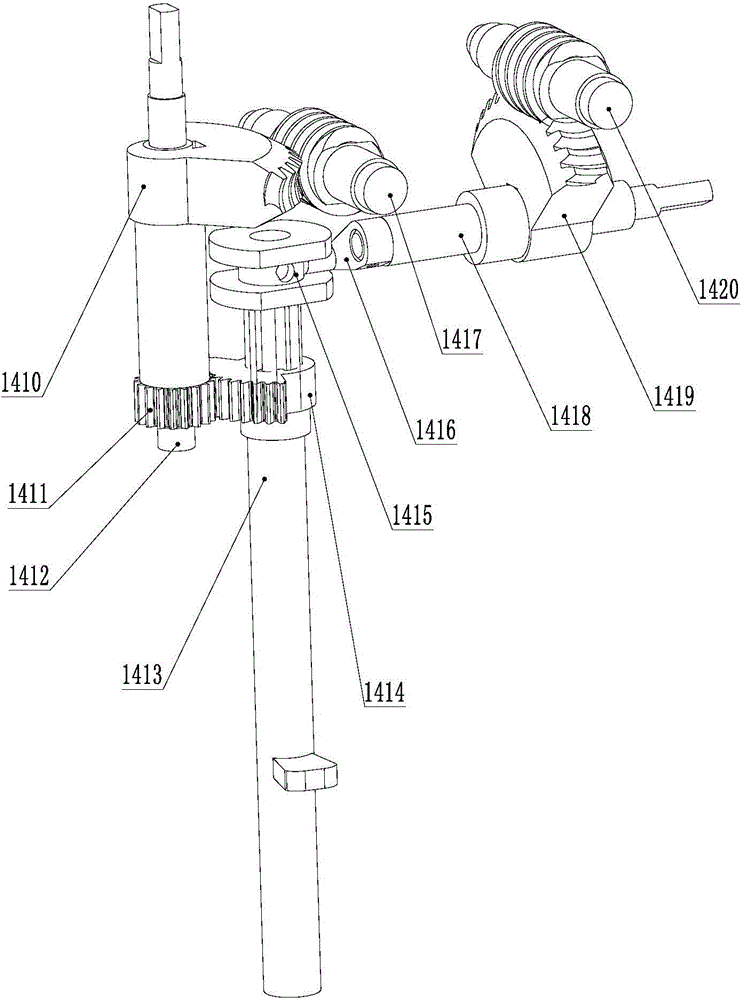

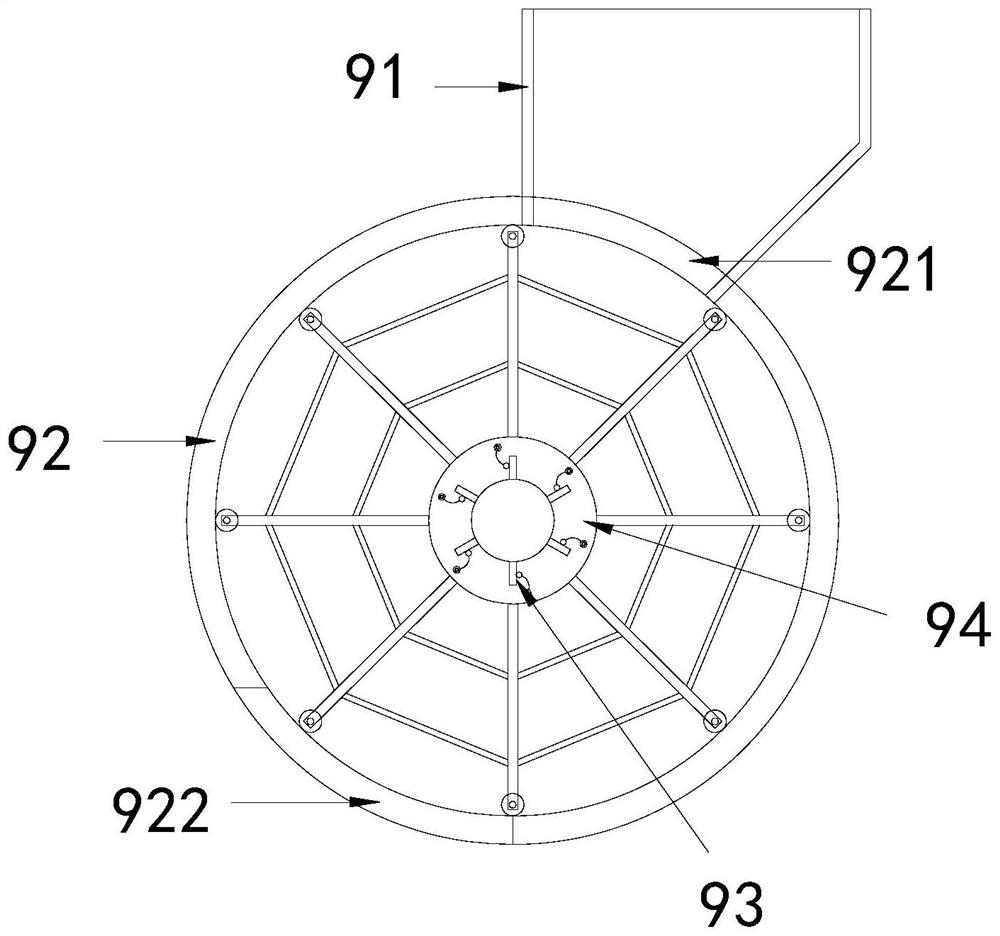

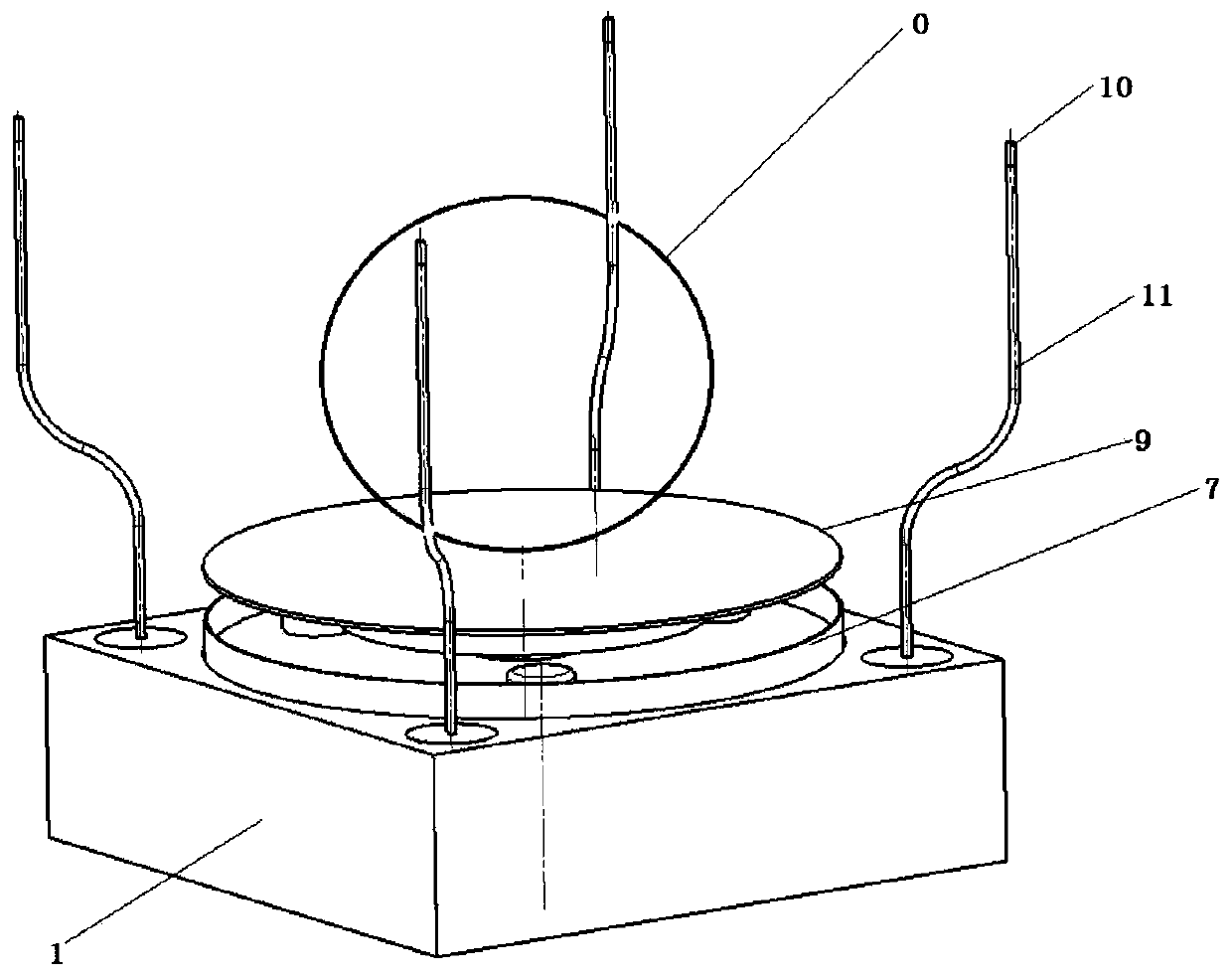

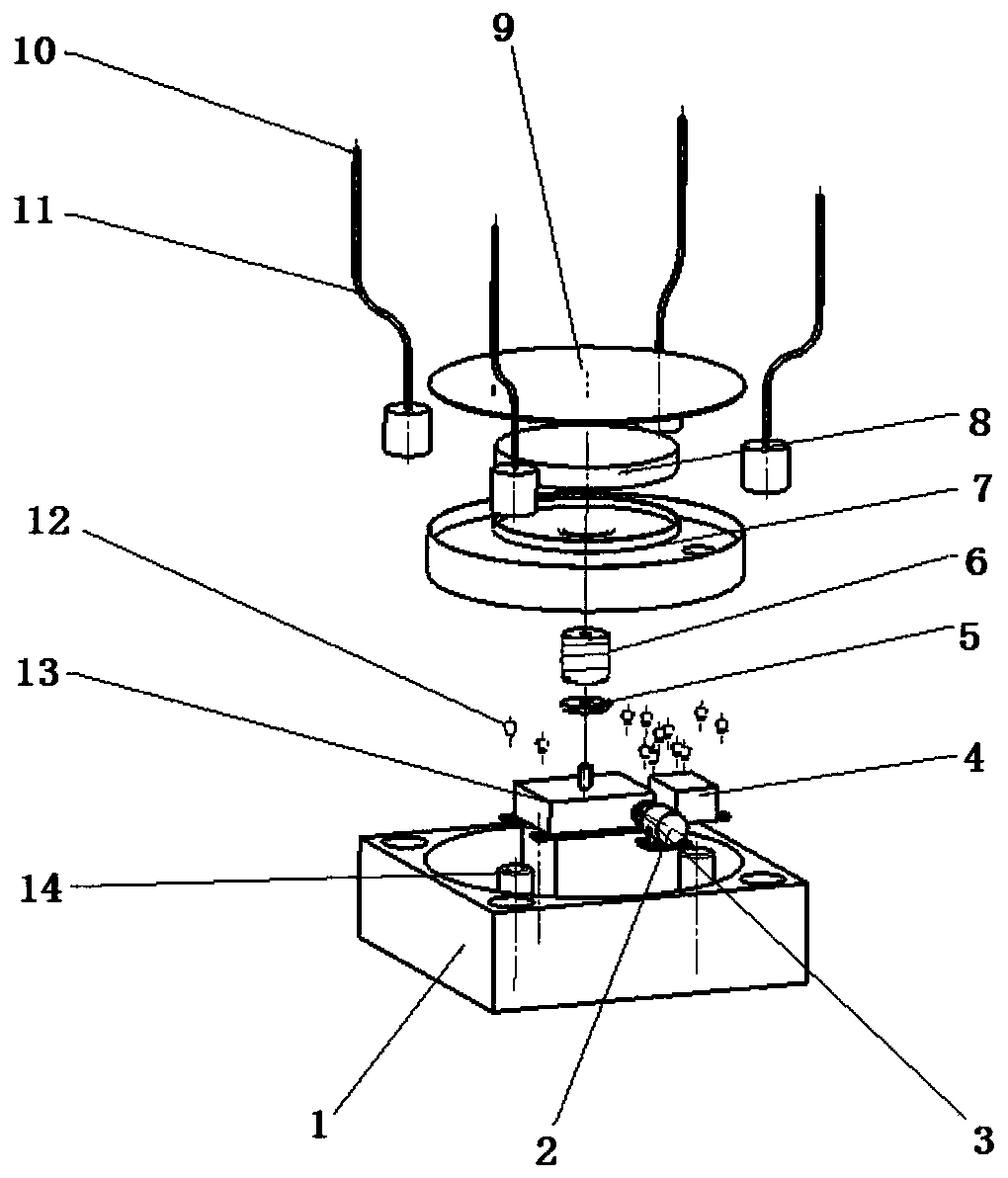

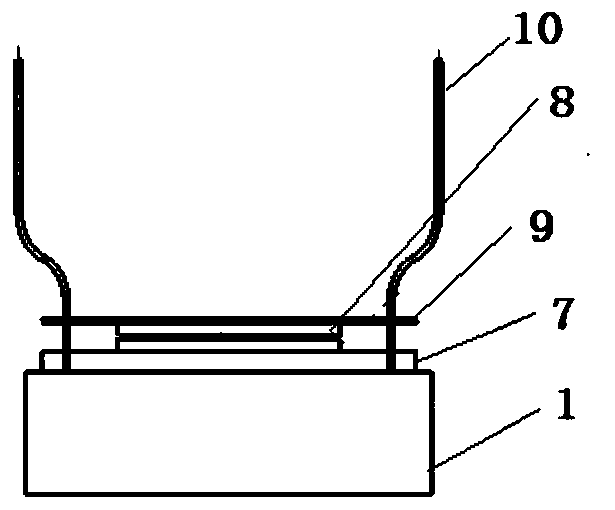

Needle-bar-rotating pattern sewing machine

InactiveCN102776722AGuaranteed aestheticsThere will be no twisting phenomenonHem-stitch machinesNeedle barsYarnElectric machinery

The invention disclosed a needle-bar-rotating pattern sewing machine, which comprises a needle bar, a needle bar rotating mechanism and a needle bar up-and-down movement mechanism, wherein the needle bar rotating mechanism comprises a needle bar sheath; the needle bar moves up and down relative to the needle bar sheath; an axial thread inlet is arranged at the top of an axial thread hole formed in the hollow part of the needle bar; and a thread outlet is arranged at the lower end of the axial thread hole. As the needle bar up and down motion mechanism drives the needle bar into up-and-down movement to conduct stitching action, the needle bar rotating mechanism drives the needle bar to rotate; through regulating sewing stitches and directions, the changes of patterns and design directions are adaptive, and stitch esthetic appearance is ensured; and as the yarn passes through the axial thread hole of the needle bar, the phenomenon of twisted threads does not occur during the process of rotation of the needle bar. Therefore, the needle-bar-rotating pattern sewing machine provided by the invention has the beneficial effect that by replacing the way of large-volume machine head rotation with thin and small-volume needle bar rotation, stitches can be formed along the tangential direction of designs and patterns in sewing, the rotation inertia is reduced, the vibration is reduced, the rotation speed is improved, and the motor power is greatly reduced.

Owner:颜新宁

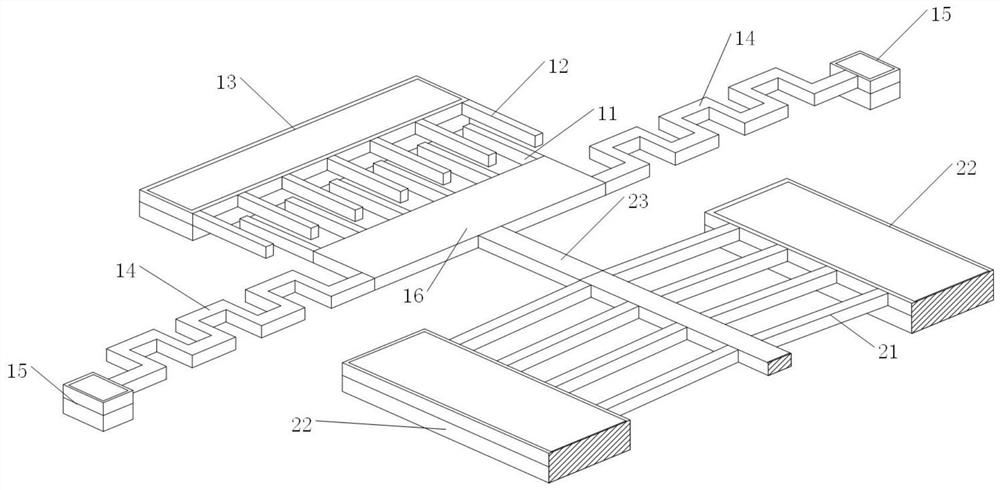

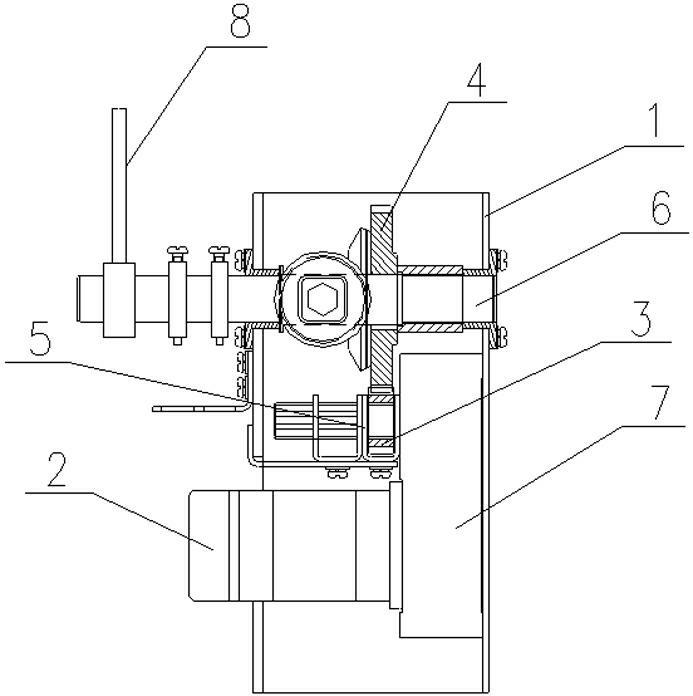

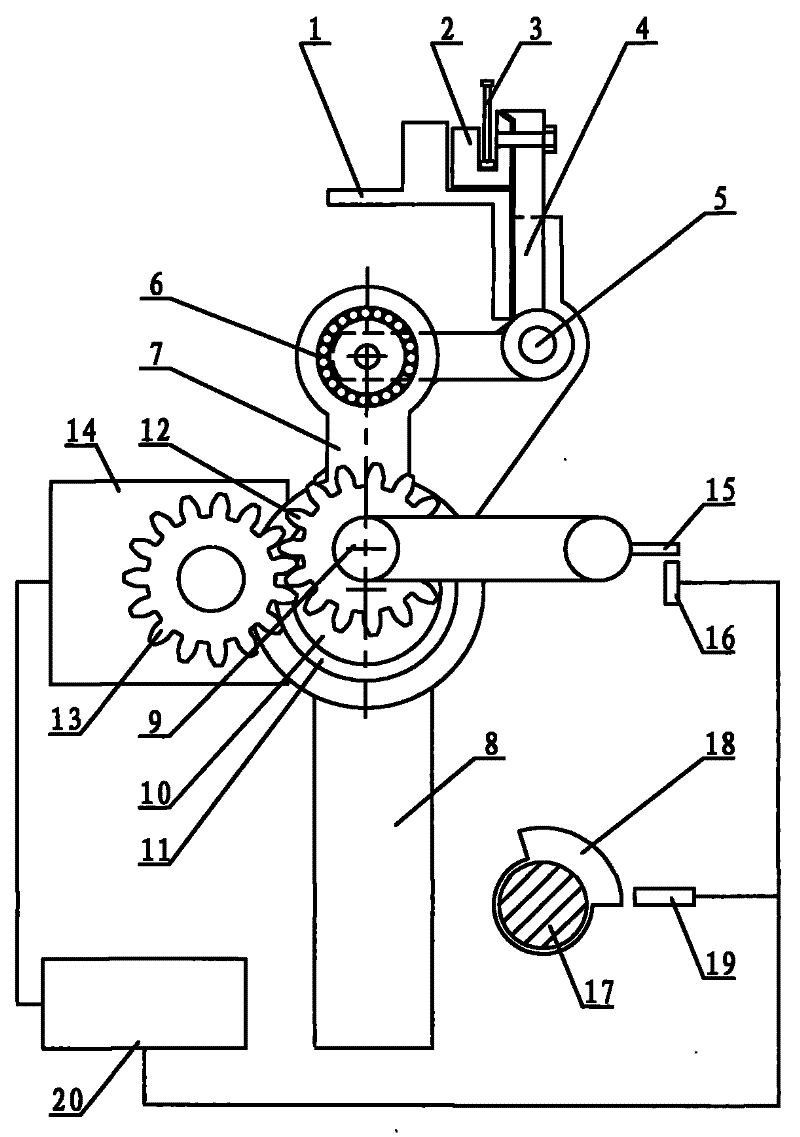

Numerical control fly reed mechanism of towel machine

The invention relates to a numerical control fly reed mechanism of a towel machine, comprising an electric control box, a numerical control motor, an origin signal acquisition mechanism, a main signal acquisition mechanism and a fly reed, wherein the origin signal acquisition mechanism is arranged on a shaft or a gear which is synchronous with a rotating shaft of the fly reed; the main signal acquisition mechanism is arranged on a shaft or a gear which is synchronous with a main shaft of the towel machine; the main signal acquisition mechanism generates an electric signal and sends the electric signal to the electric control box to control the numerical control motor to rotate forwardly or reversely so as to drive the fly reed to be opened or closed; and the origin signal acquisition mechanism generates an electric signal and controls the numerical control motor to stop working by the electric control box. The numerical control fly reed mechanism adopts the main signal acquisition mechanism to control the opening and closing of the fly reed and adopts the origin signal acquisition mechanism to control the closing and stationary of the fly reed; and the numerical control motor adjusts a rotating angle of a reed seat, thus being capable of realizing fast or slow weaving of various fur-type or special-type furs, and the wool yarn has good weaving quality. The numerical control fly reed mechanism has simple structure, convenient operation, stable running, low energy consumption, low noise and long service life.

Owner:王勇

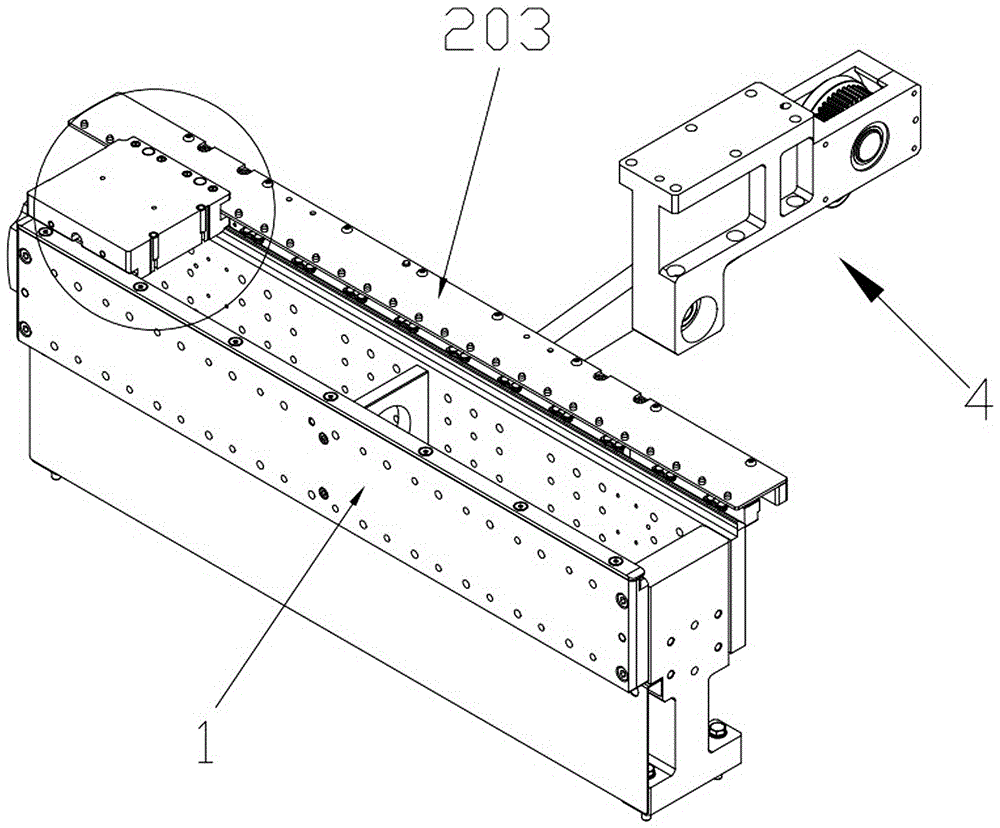

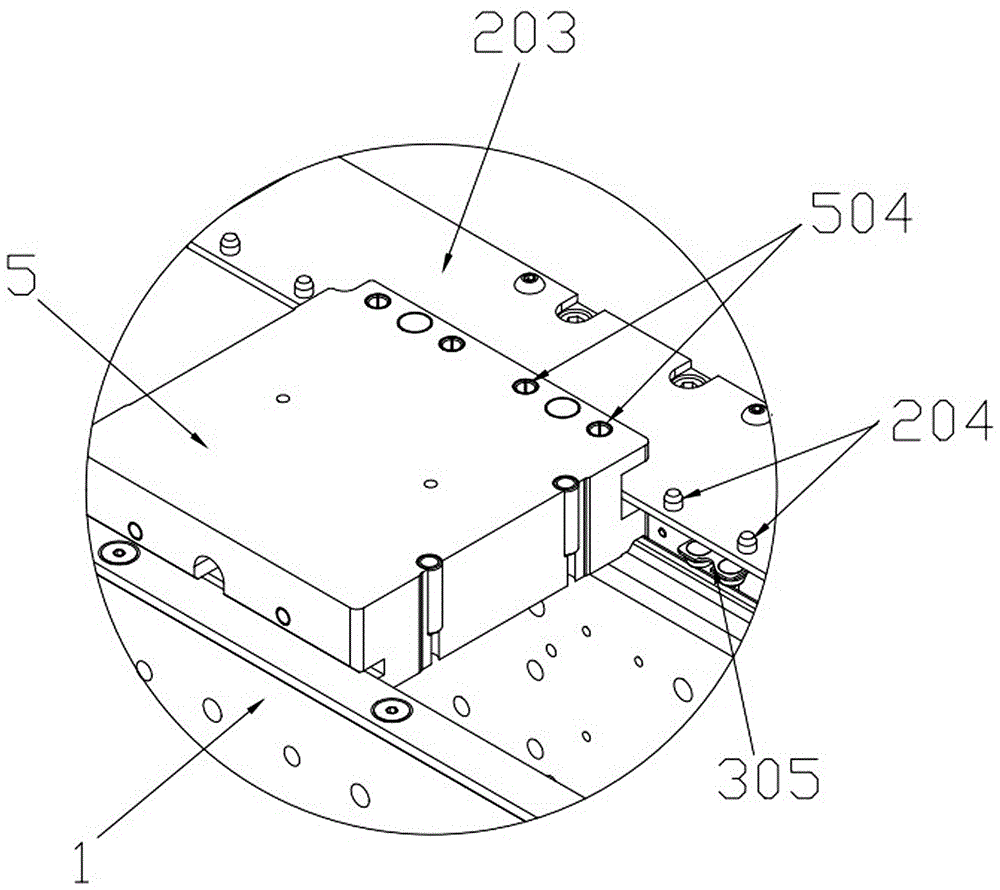

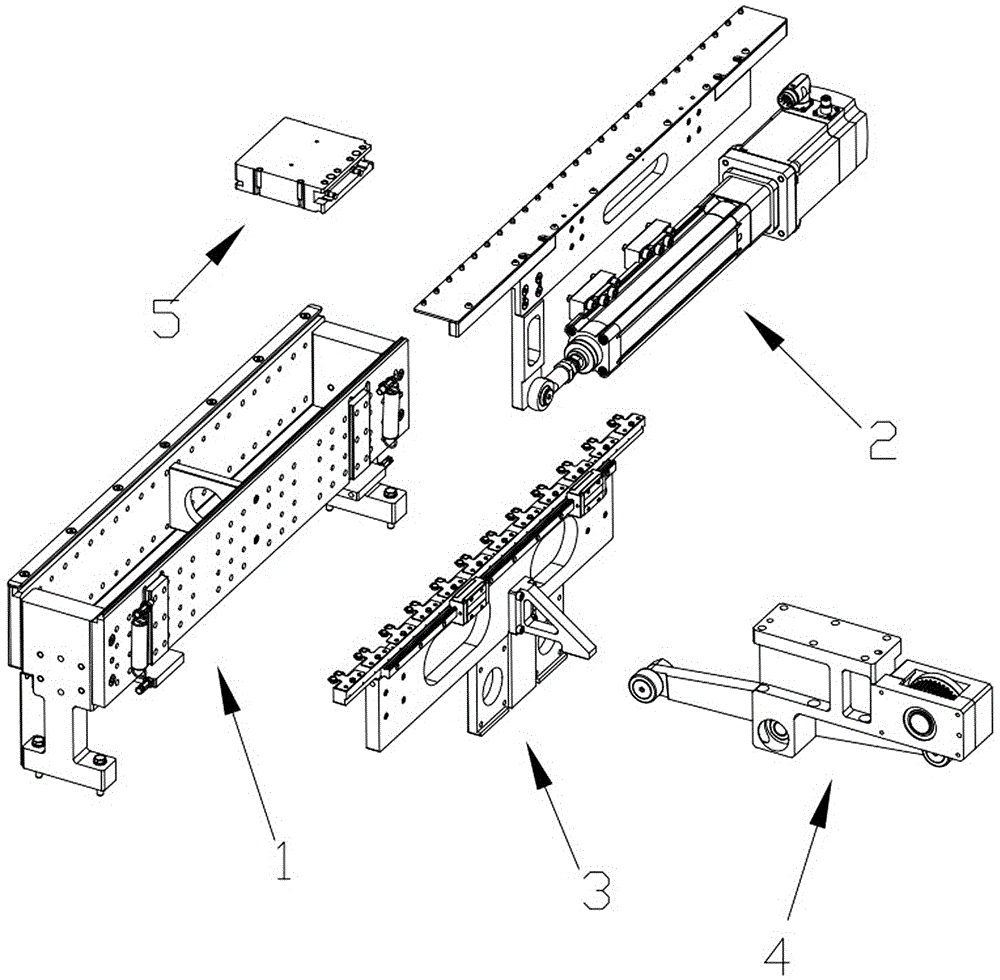

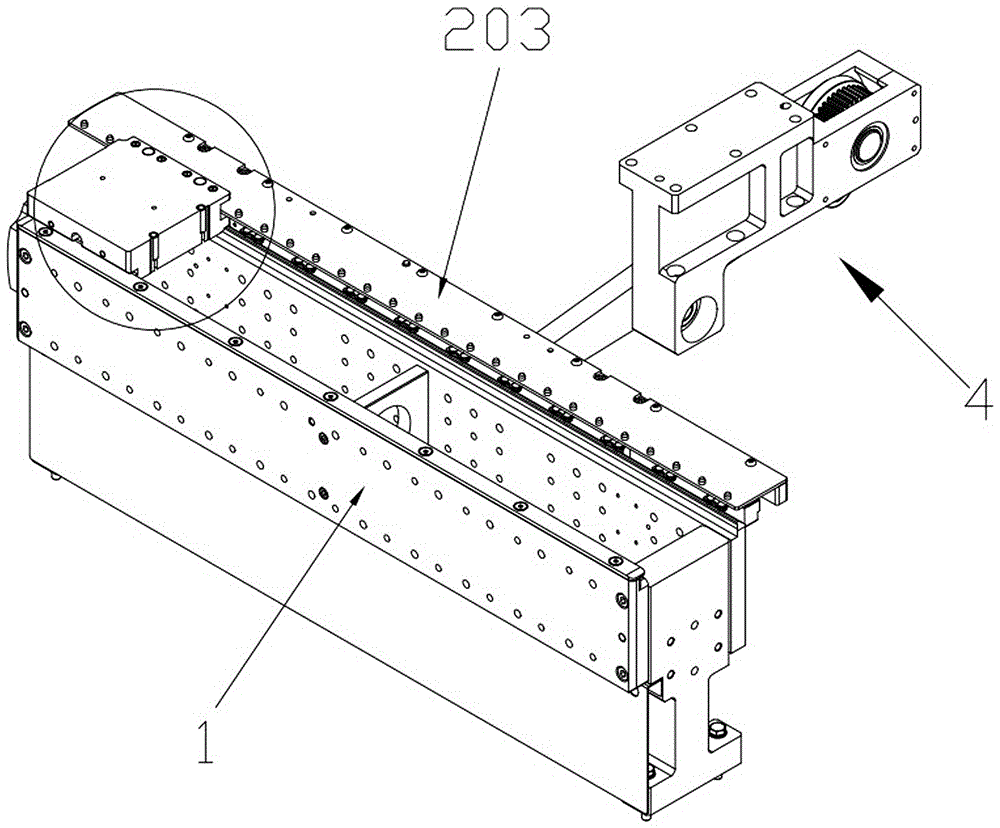

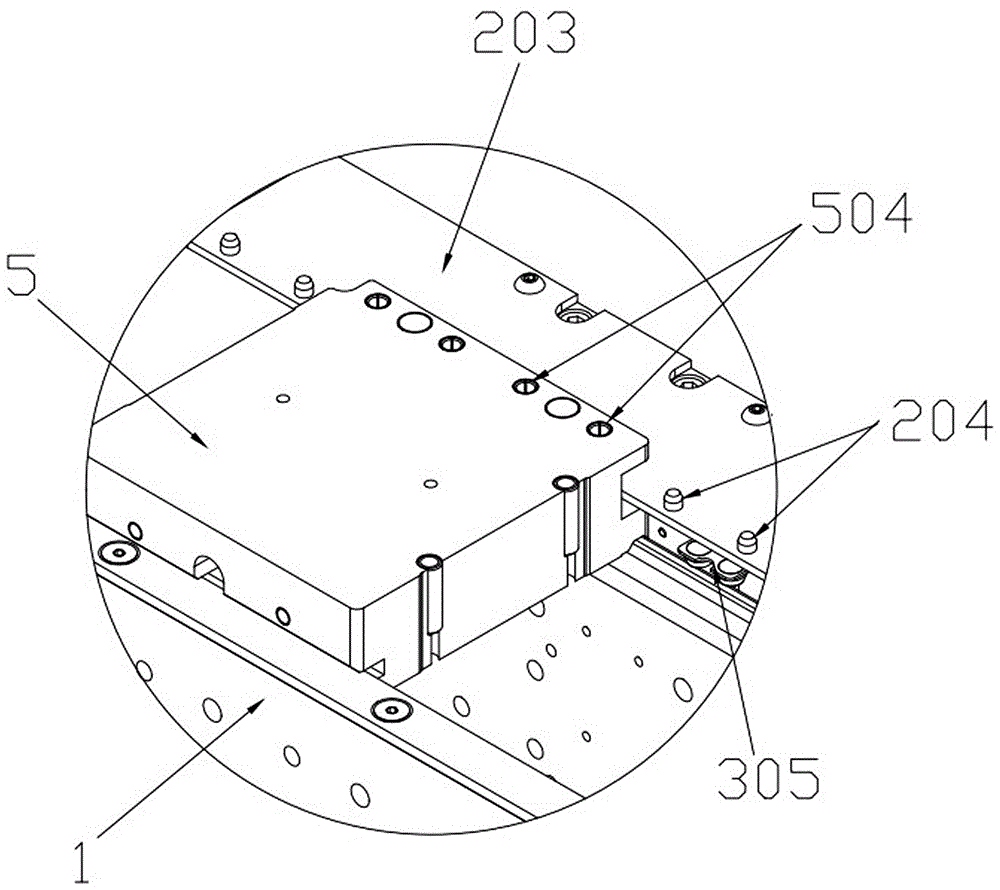

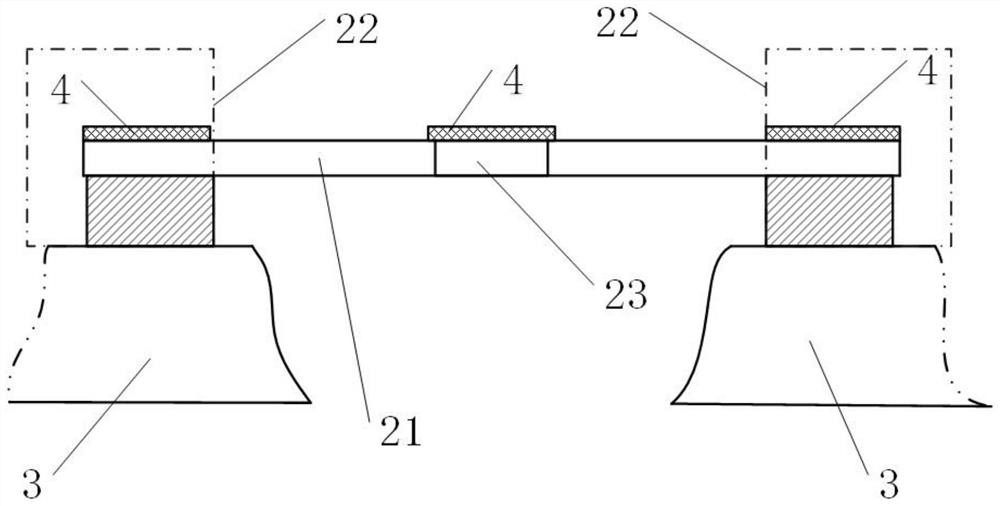

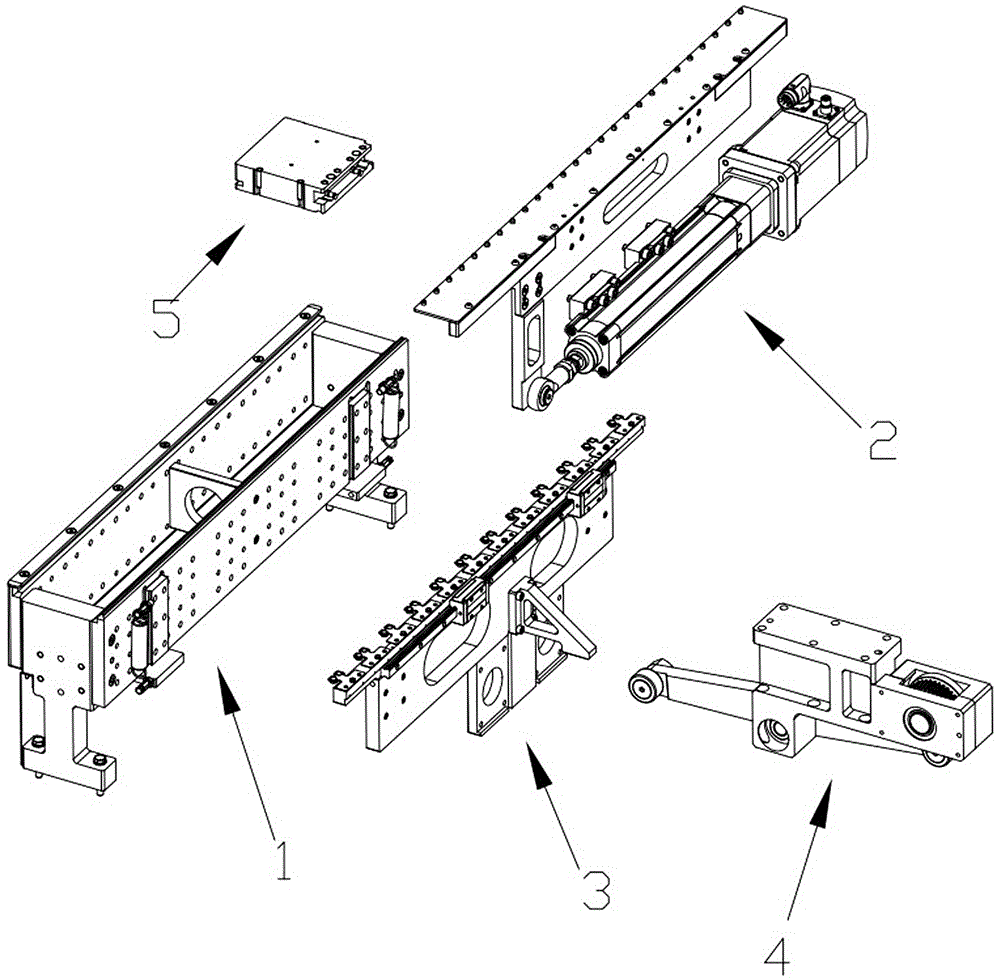

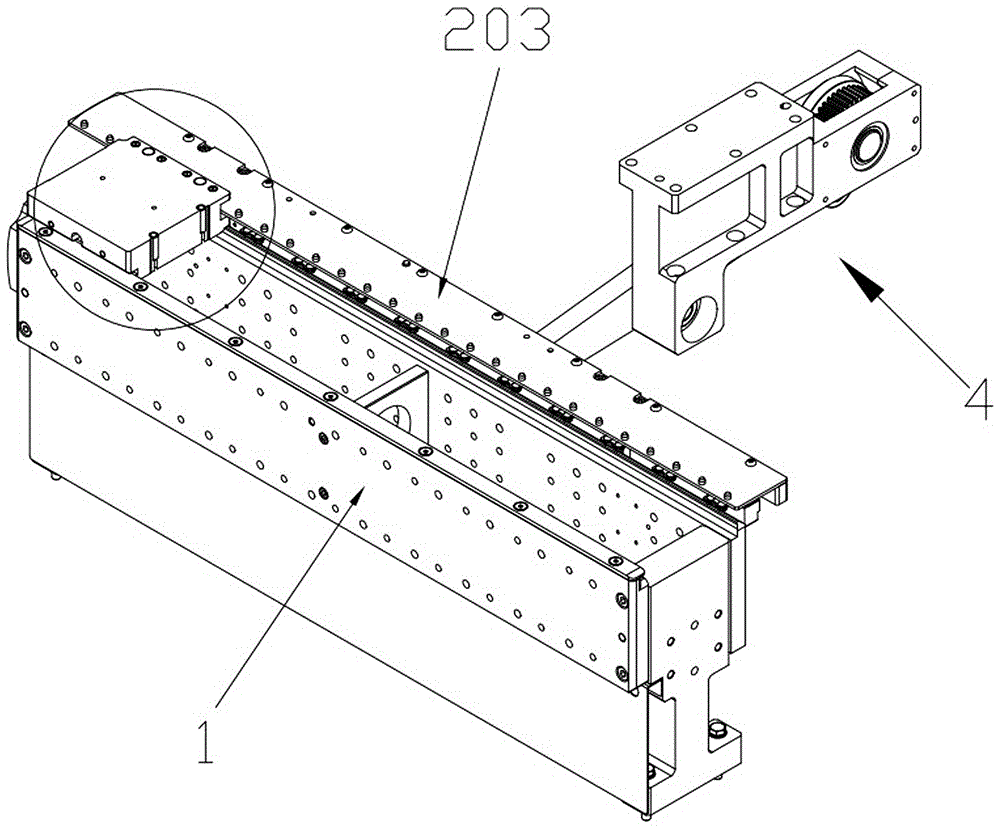

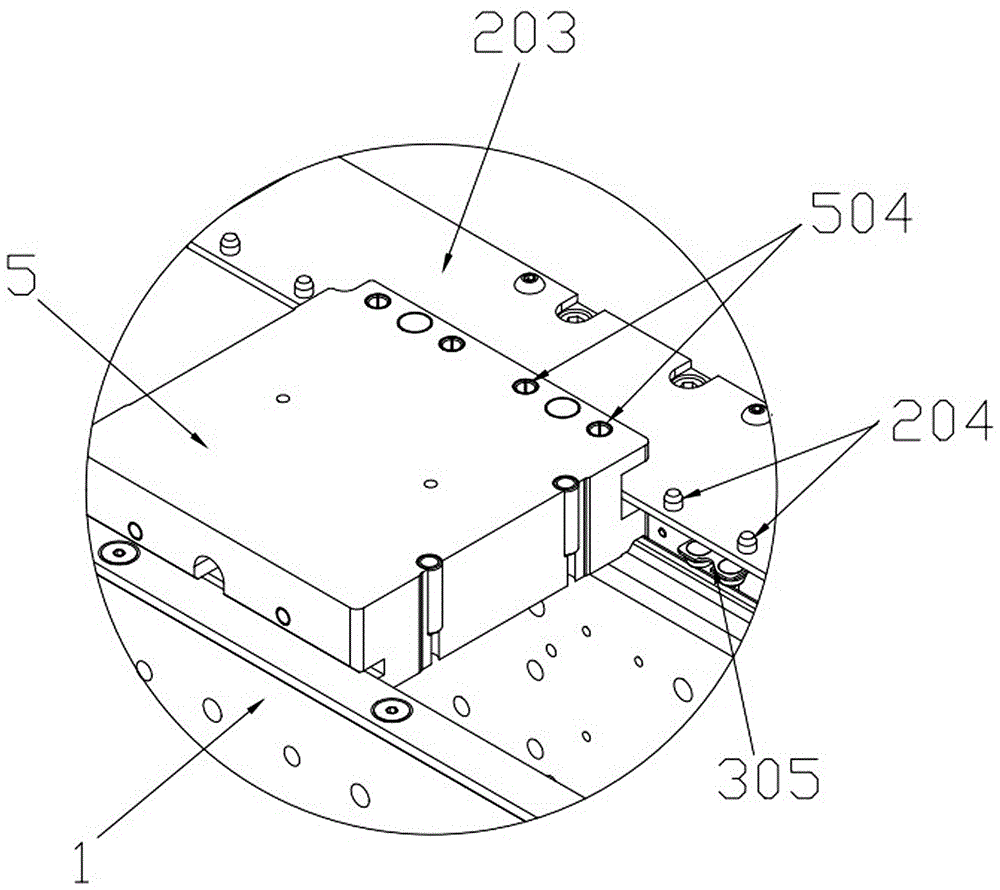

Precise positioning mechanism for driving tray

InactiveCN106586451AHigh precisionGuaranteed success rateMetal working apparatusConveyor partsCamElectric power

The invention relates to the field of mechanical transmission equipment, in particular to a precise positioning mechanism for driving a tray. The precise positioning mechanism comprises a conveying base, a cam transmission assembly, a lifting assembly and a traction assembly. A horizontal sliding rail is arranged on the top of the conveying base. The tray capable of horizontally sliding along the horizontal sliding rail is arranged on the horizontal sliding rail. A first horizontal sliding groove is formed in the left side of the tray. A second horizontal sliding groove is formed in the right side of the tray. Clamping positioning columns are arranged on the inner bottom face of the second horizontal sliding groove. Grabbing positioning columns are arranged above the clamping positioning columns. The lifting assembly comprises a lifting main plate, a horizontal guide rail and multiple positioning plates. The traction assembly comprises an electric power push rod, a traction main plate and a traction pin plate. The traction assembly is used for driving the tray to move horizontally, and the lifting assembly is used for pressing the tray, so that the tray is positioned precisely. The traction assembly and the lifting assembly are both driven by the cam transmission assembly. No electronic control elements are required, no connection with any complex circuit is required, and the manufacturing cost is low.

Owner:HUNAN SUPER INFORMATION

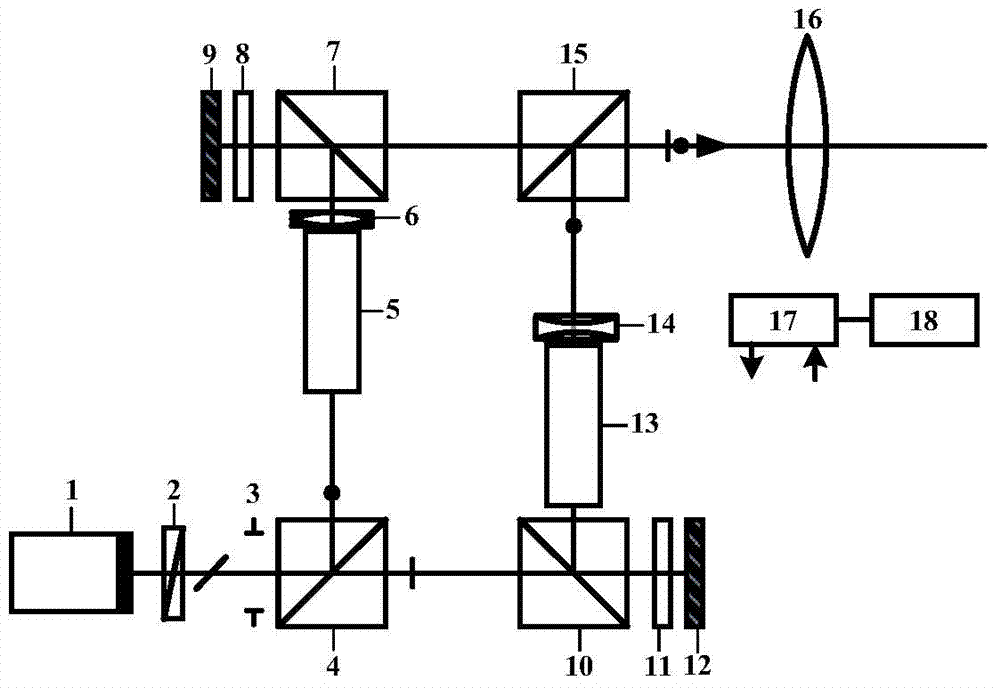

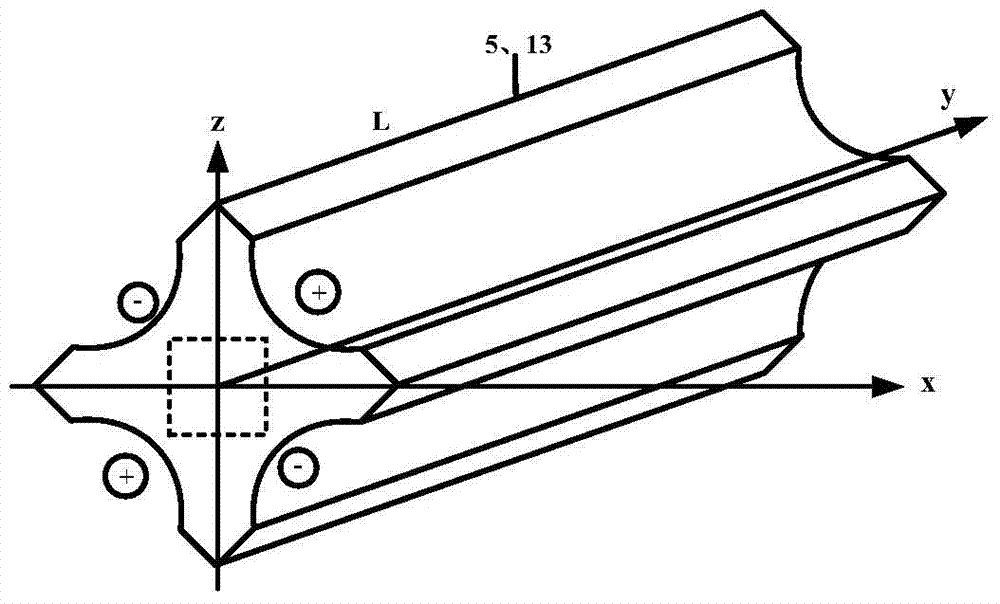

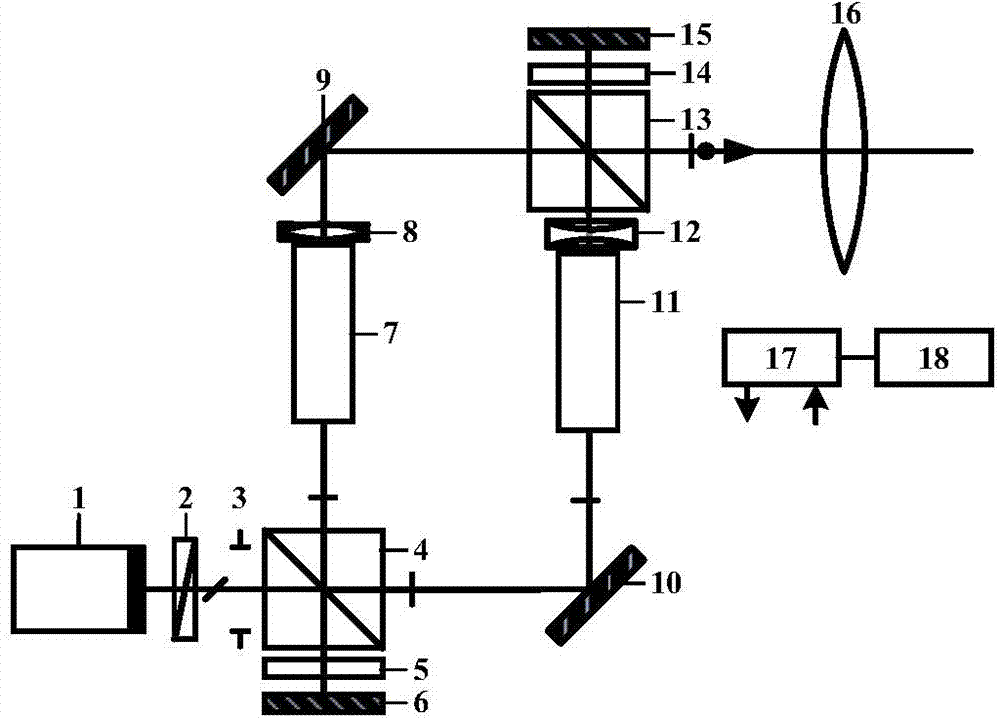

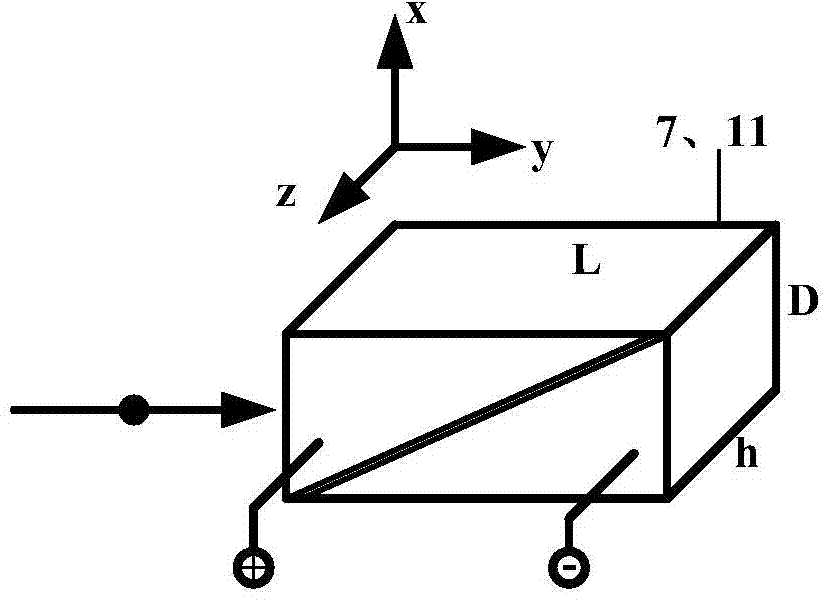

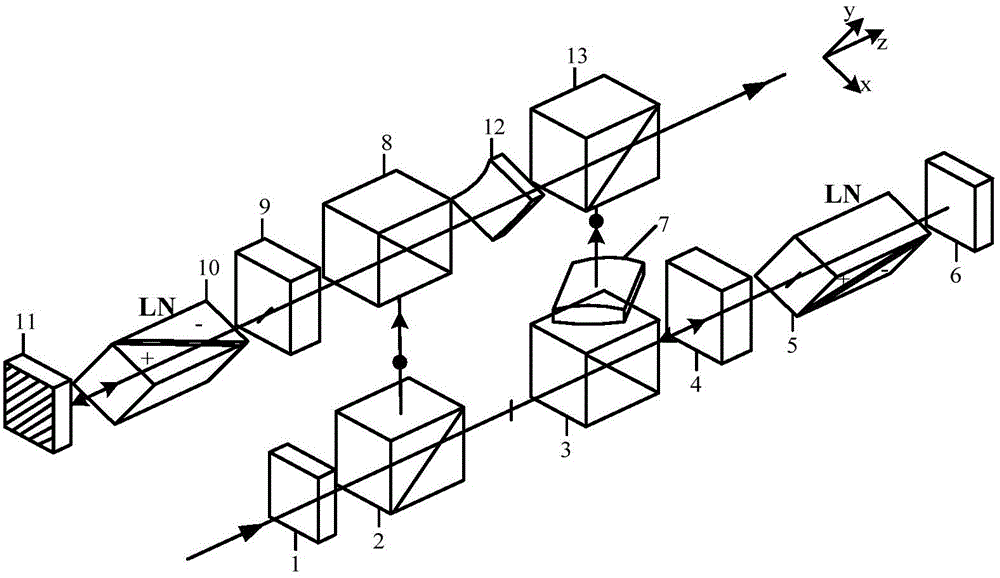

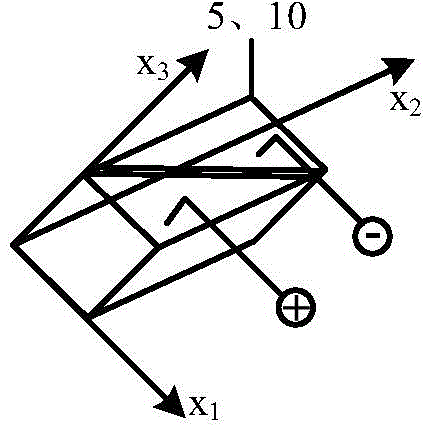

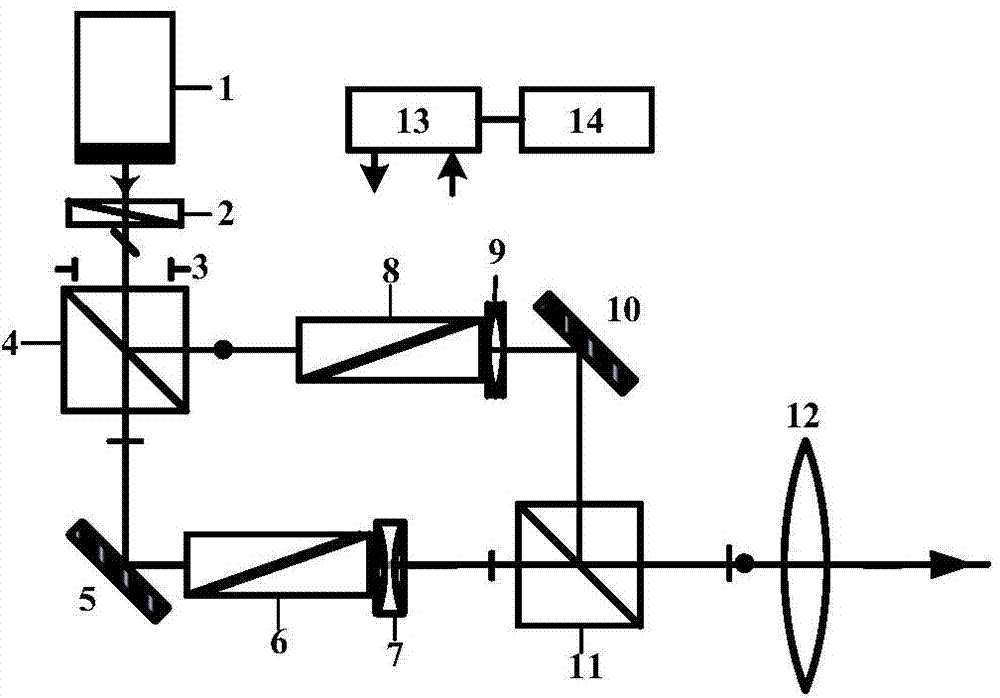

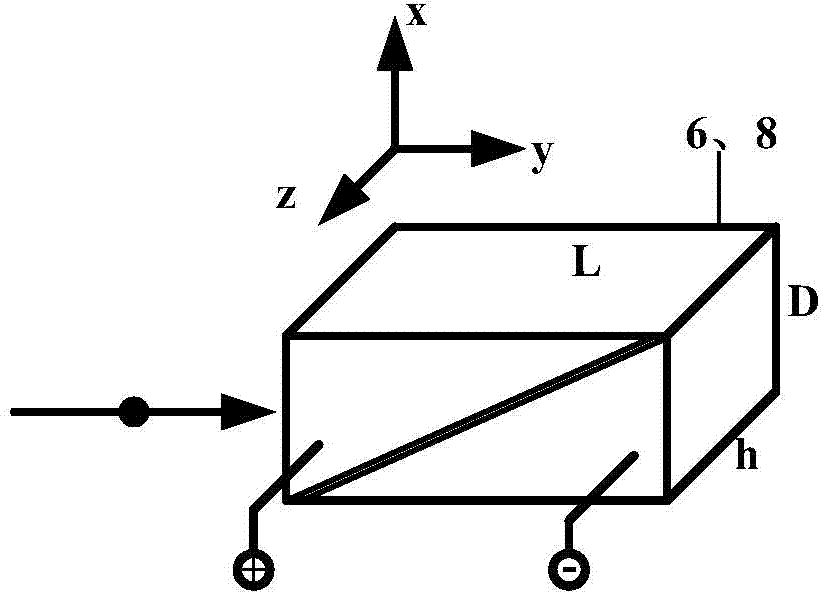

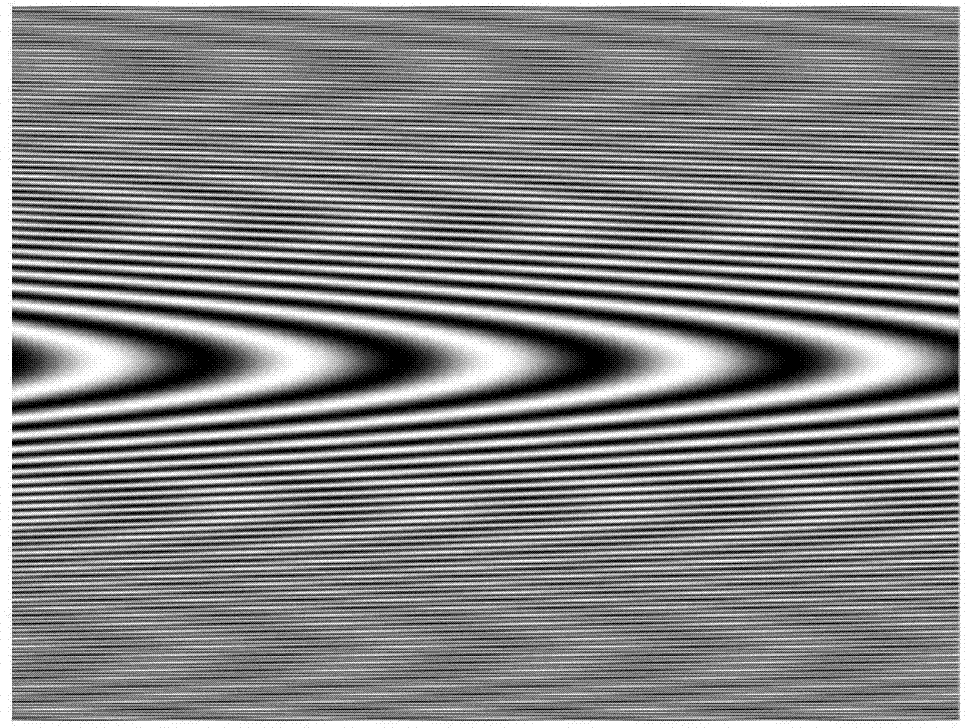

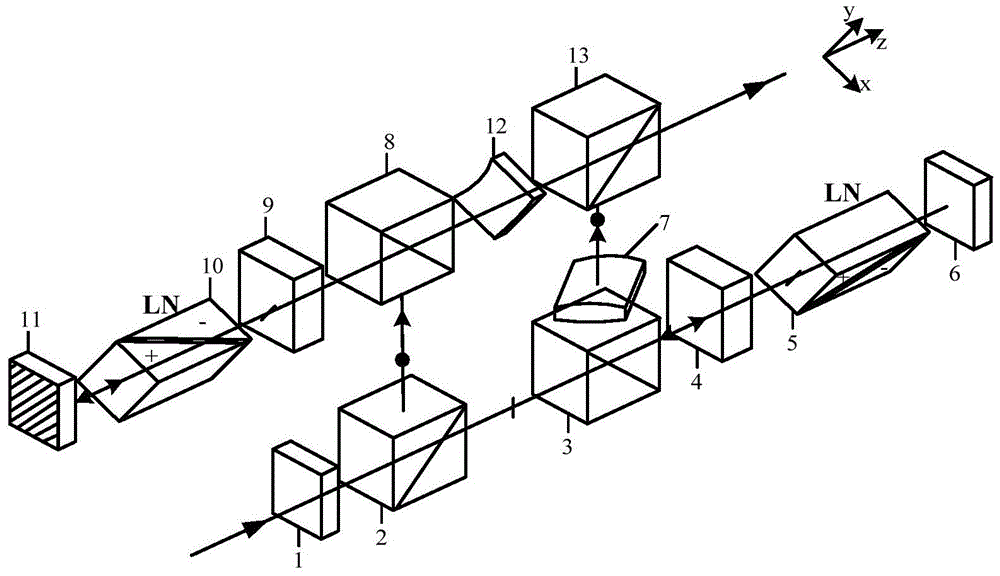

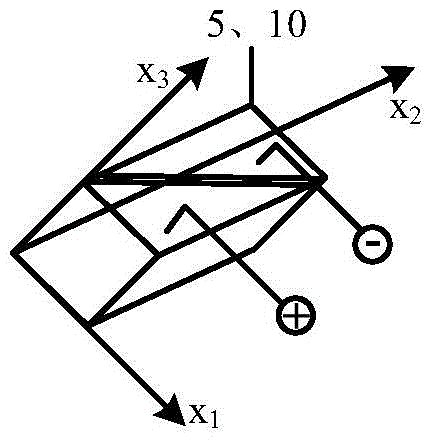

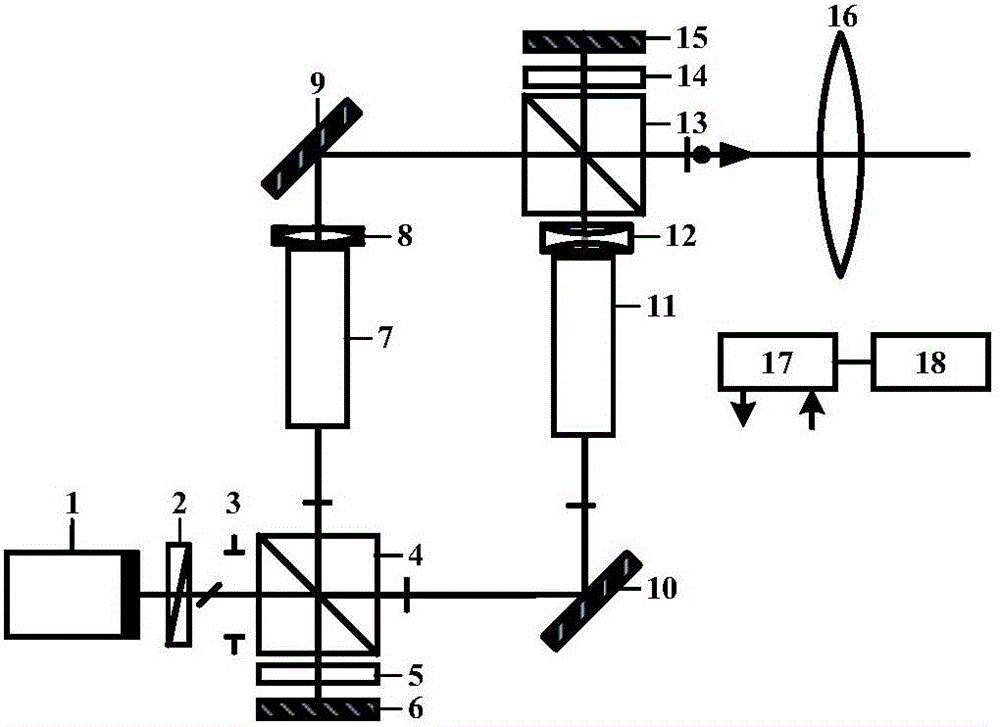

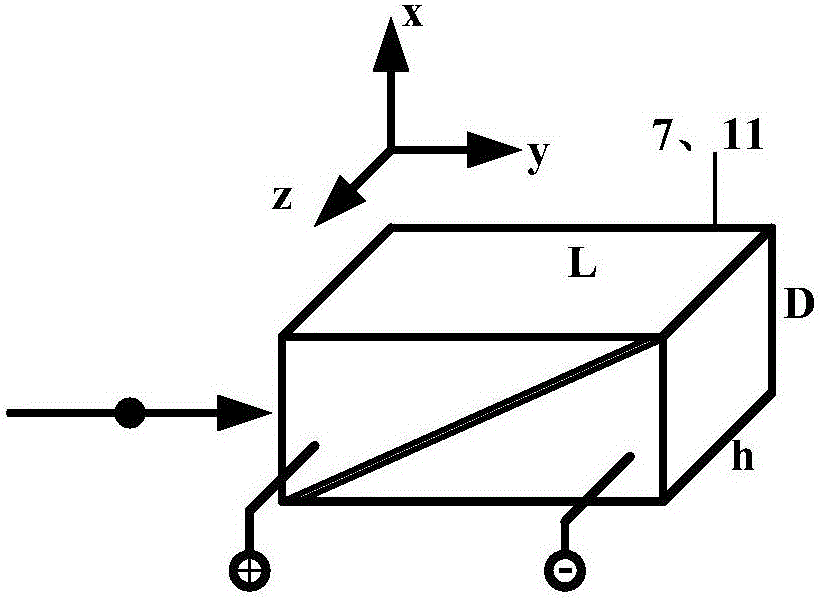

Bi-channel electrooptical scanning laser imaging radar transmitting system for down-looking synthetic aperture

ActiveCN103543443ADevice compactReduce complexityElectromagnetic wave reradiationSatellitePhase modulation

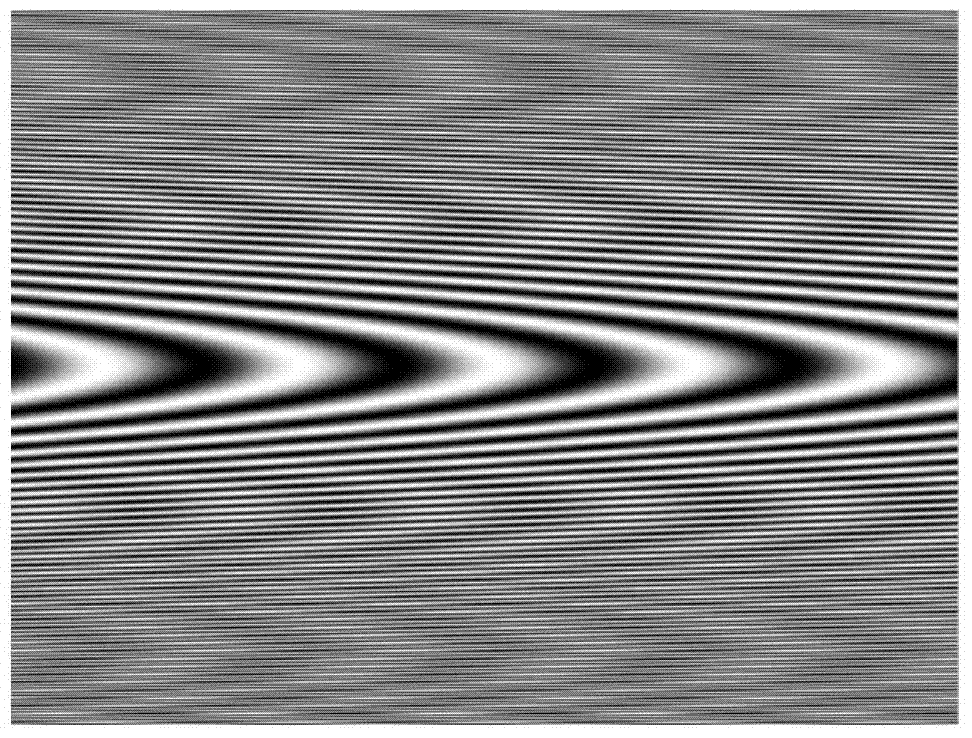

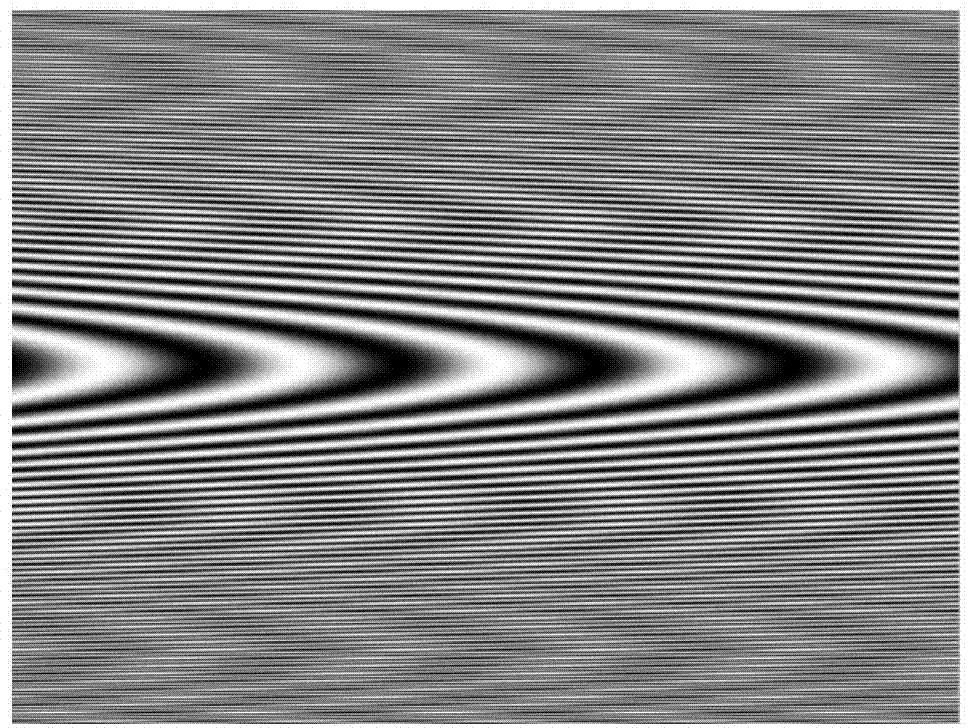

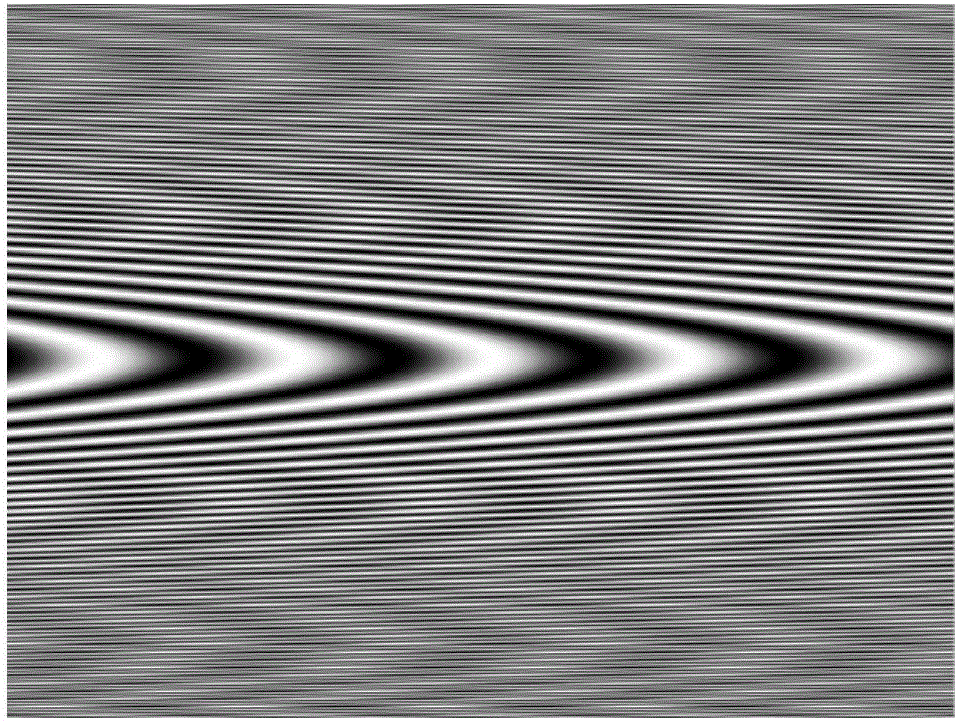

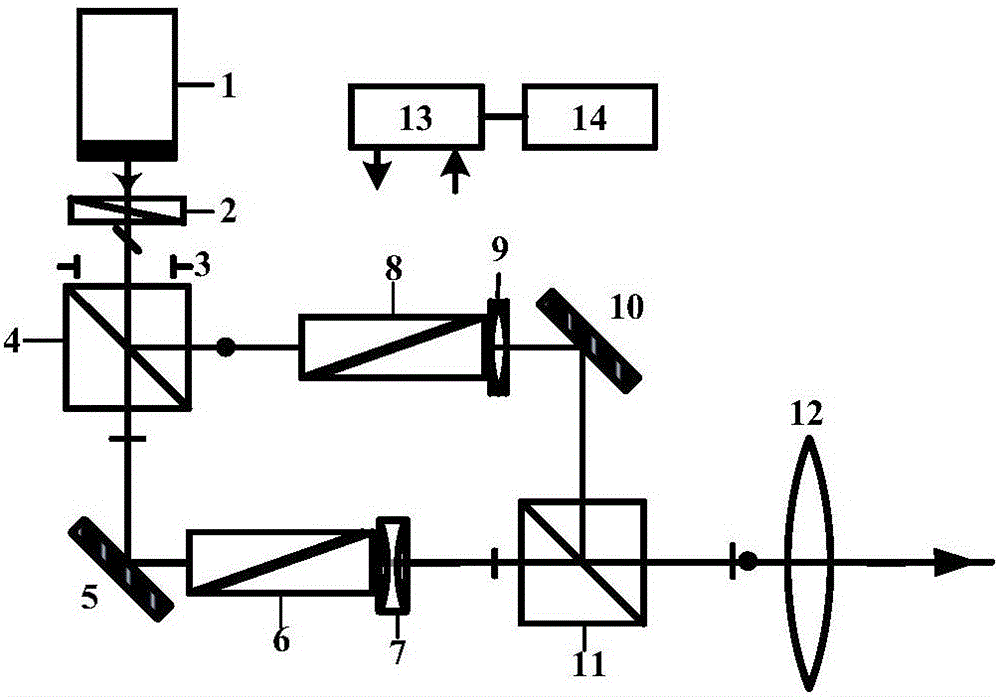

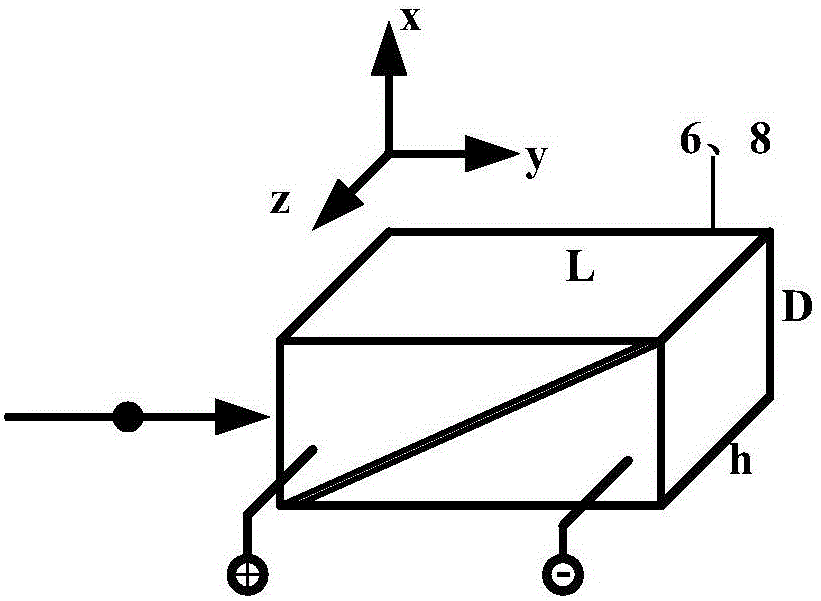

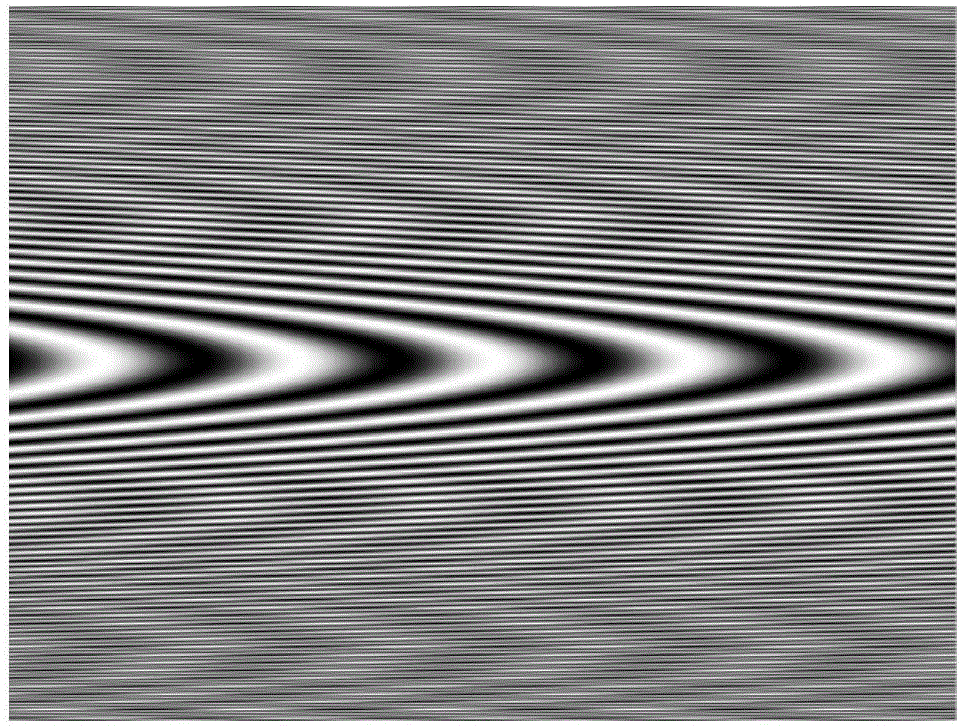

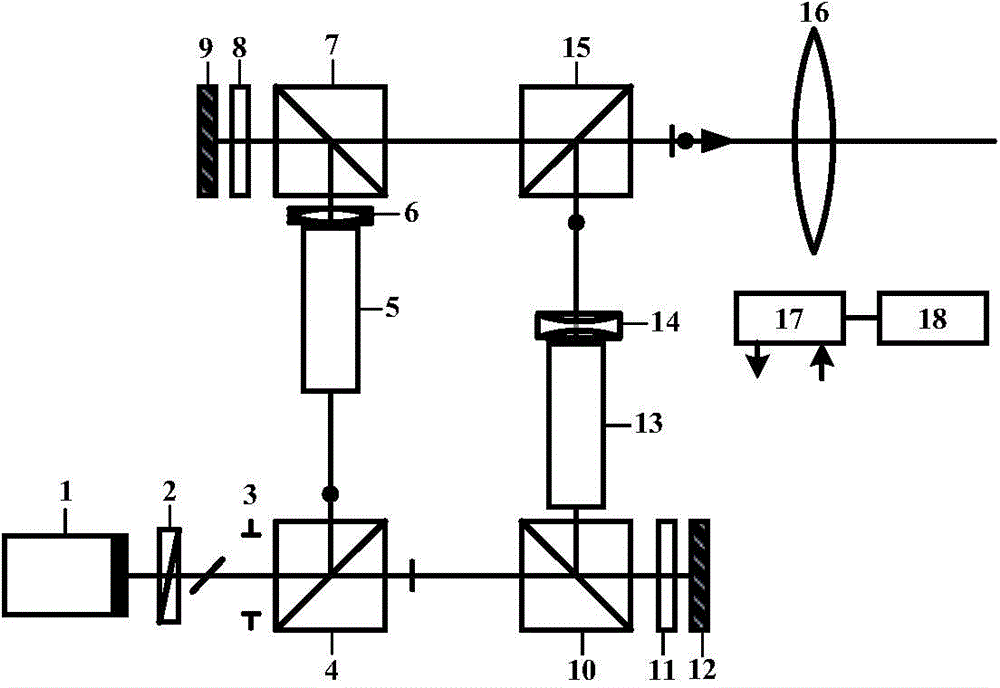

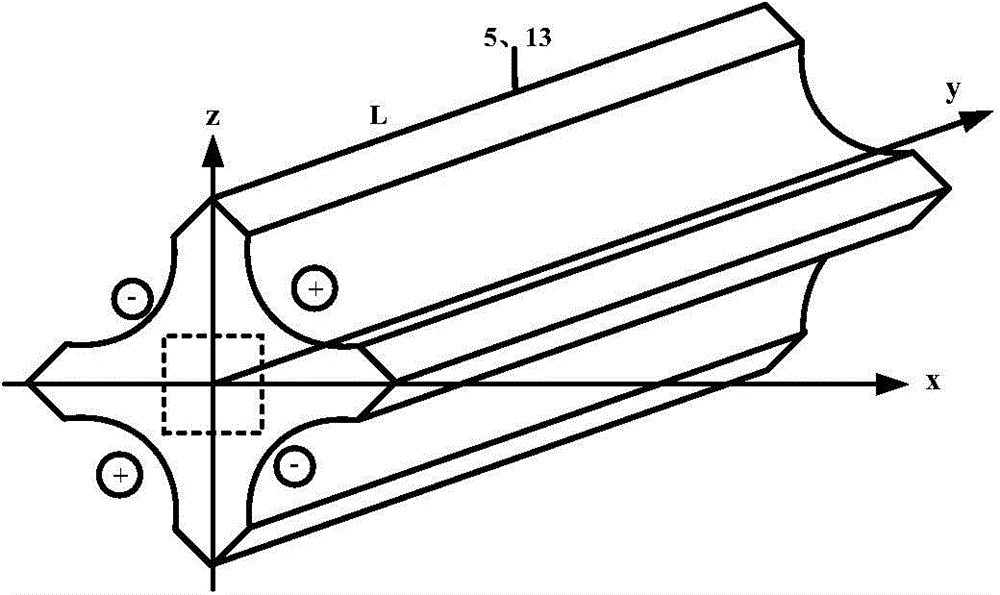

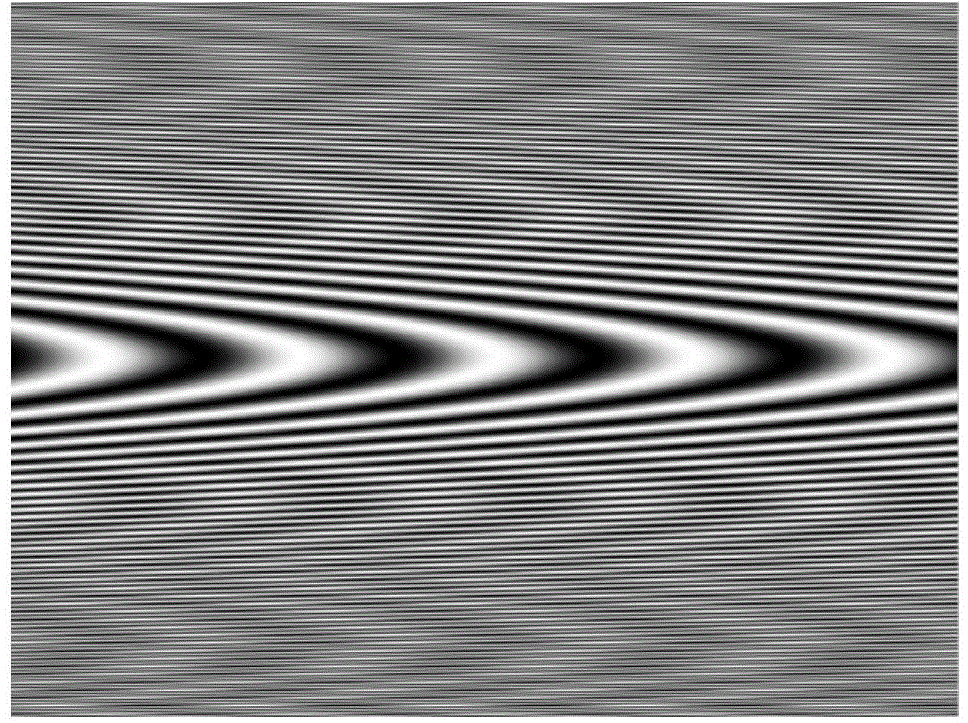

A bi-channel electrooptical scanning laser imaging radar transmitting system for down-looking synthetic aperture comprises a laser, a half wave plate, an aperture diaphragm, a first polarization beam splitter, a first electrooptical scanner, a first cylindrical mirror, a second polarization beam splitter, a first 1 / 4 wave plate, a first reflection mirror, a third polarization beam splitter, a second 1 / 4 wave plate, a second reflection mirror, a second electrooptical scanner, a second cylindrical mirror, a fourth polarization beam splitter, a transmitter-telescope primary mirror, a high-voltage power source and a signal generator. The bi-channel electrooptical scanning laser imaging radar transmitting system is capable of electro-optically scanning two channels of light beams and ultimately realizing parabolic equipotential line difference of two polarization orthogonal light beams at a far-field target, is used for scanning targets, simple in structure, free of mechanical scanning, small in size, light in weight, and particularly suitable for onboard or satellite-borne high-speed operating carrying platforms, and response speed for electrooptical phase modulation wave surfaces is fast and up to nanosecond level.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Same-polarization electrooptical-scanning laser imaging radar transmitting system for down-looking synthetic aperture

ActiveCN103543444AReduce complexityLarge linear modulation rangeElectromagnetic wave reradiationSynthetic aperture radarOptoelectronics

A same-polarization electrooptical-scanning laser imaging radar transmitting system for down-looking synthetic aperture comprises a laser, a half wave plate, an aperture diaphragm, a first polarization beam splitter, a first 1 / 4 wave plate, a first reflection mirror, a first electrooptical scanner, a first cylindrical mirror, a second reflection mirror, a third reflection mirror, a second electrooptical scanner, a second cylindrical mirror, a second polarization beam splitter, a second 1 / 4 wave plate, a fourth reflection mirror, a transmitter-telescope primary mirror, a high-voltage power source and a signal generator. The same-polarization electrooptical-scanning laser imaging radar transmitting system is capable of electro-optically scanning cross rails of the same polarization state and ultimately realizing parabolic equipotential line difference of two polarization orthogonal light beams at a far-field target, is used for scanning targets, simple in structure, free of mechanical scanning, small in size, light in weight, and particularly suitable for onboard or satellite-borne high-speed operating carrying platforms, and response speed for electrooptical phase modulation wave surfaces is fast and up to nanosecond level.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

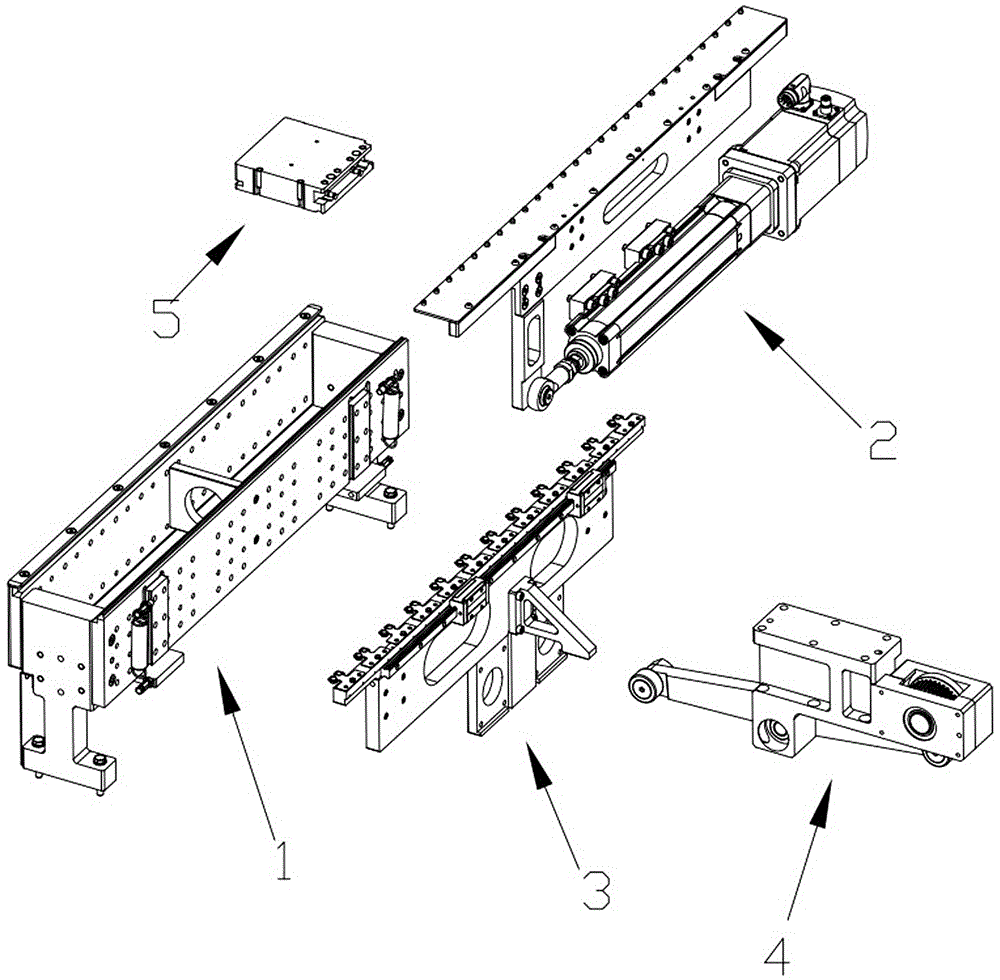

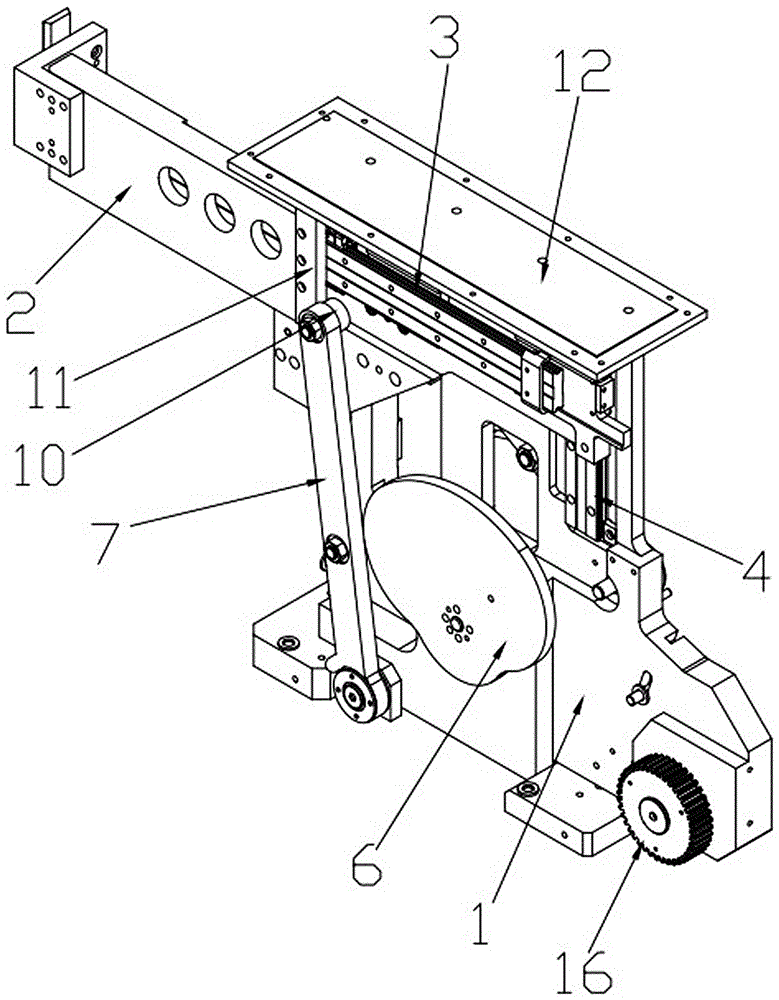

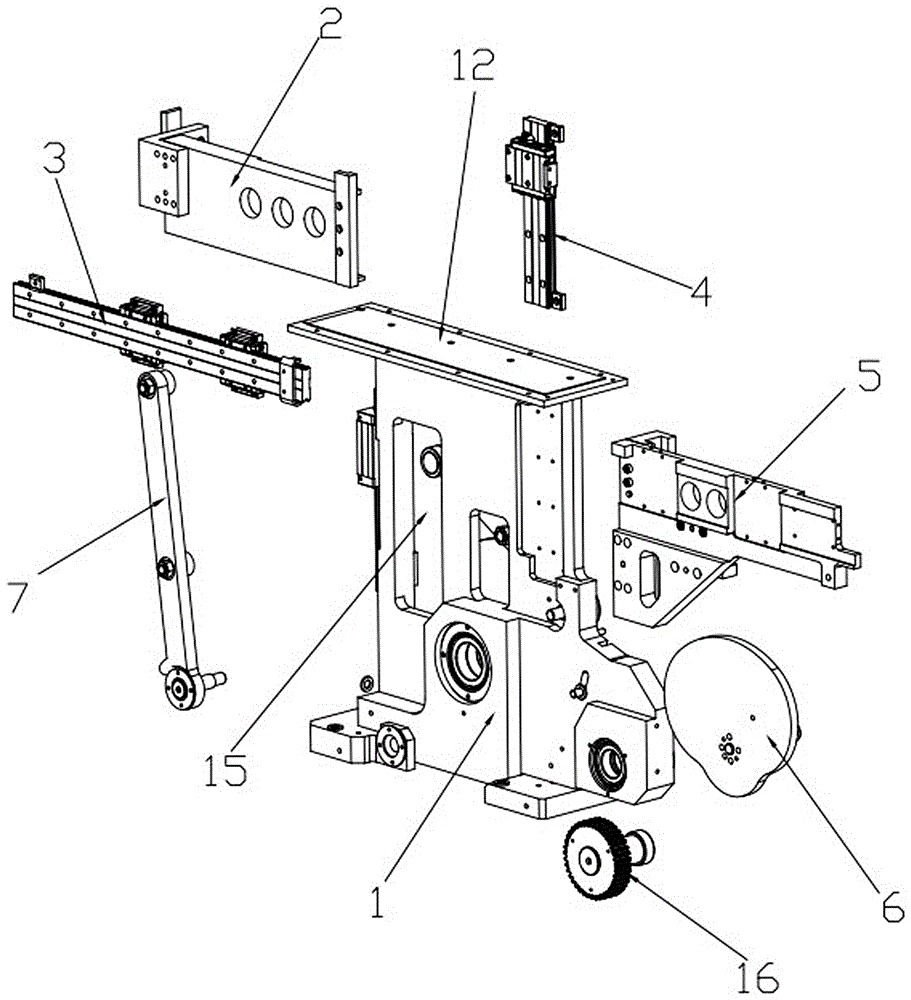

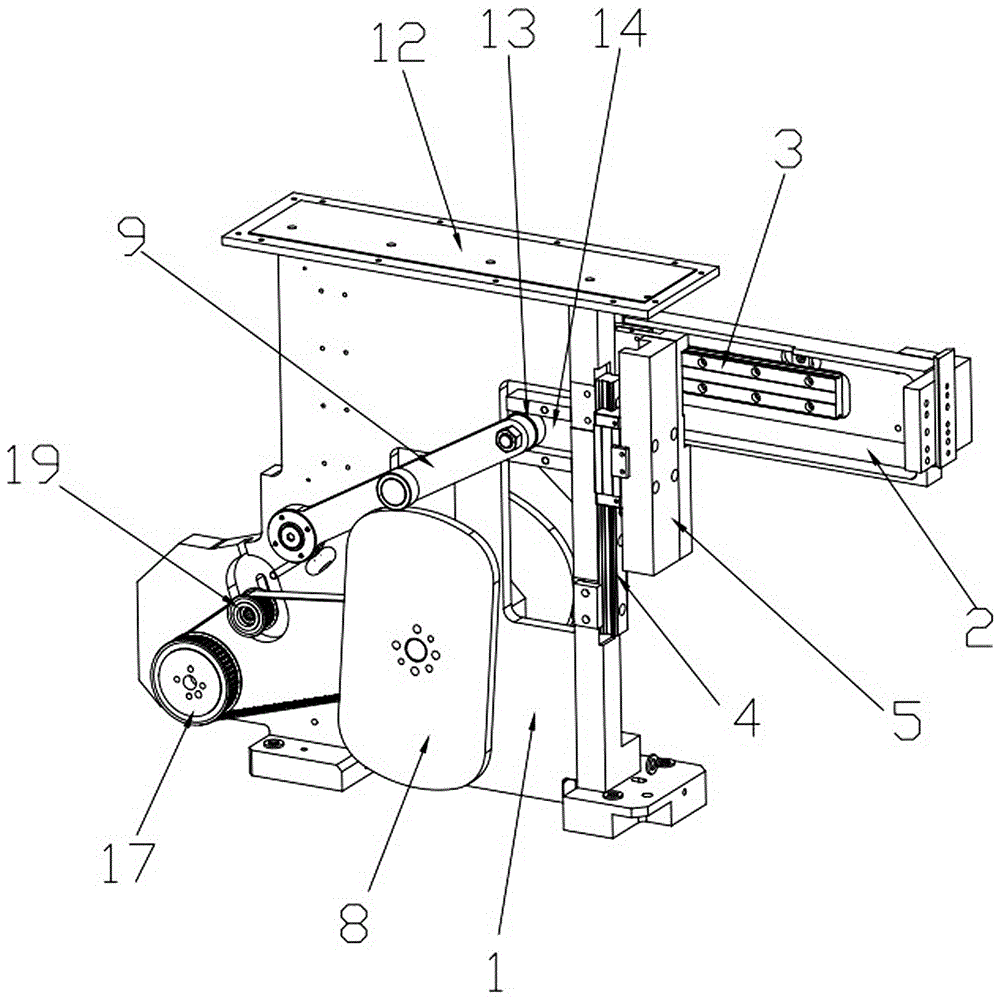

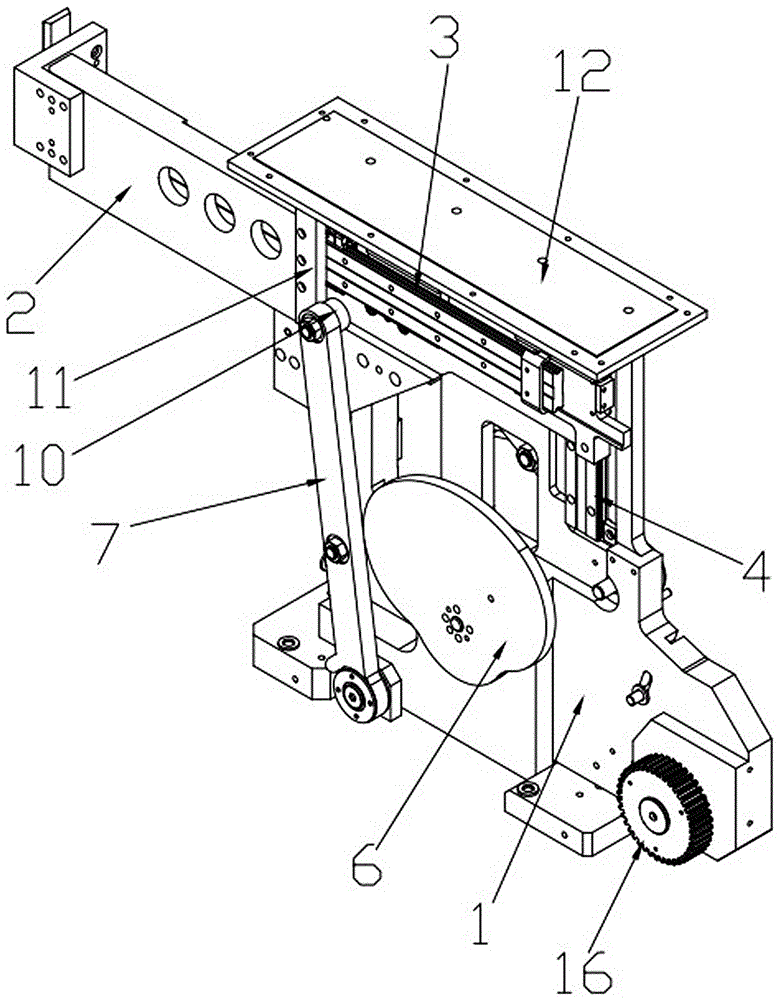

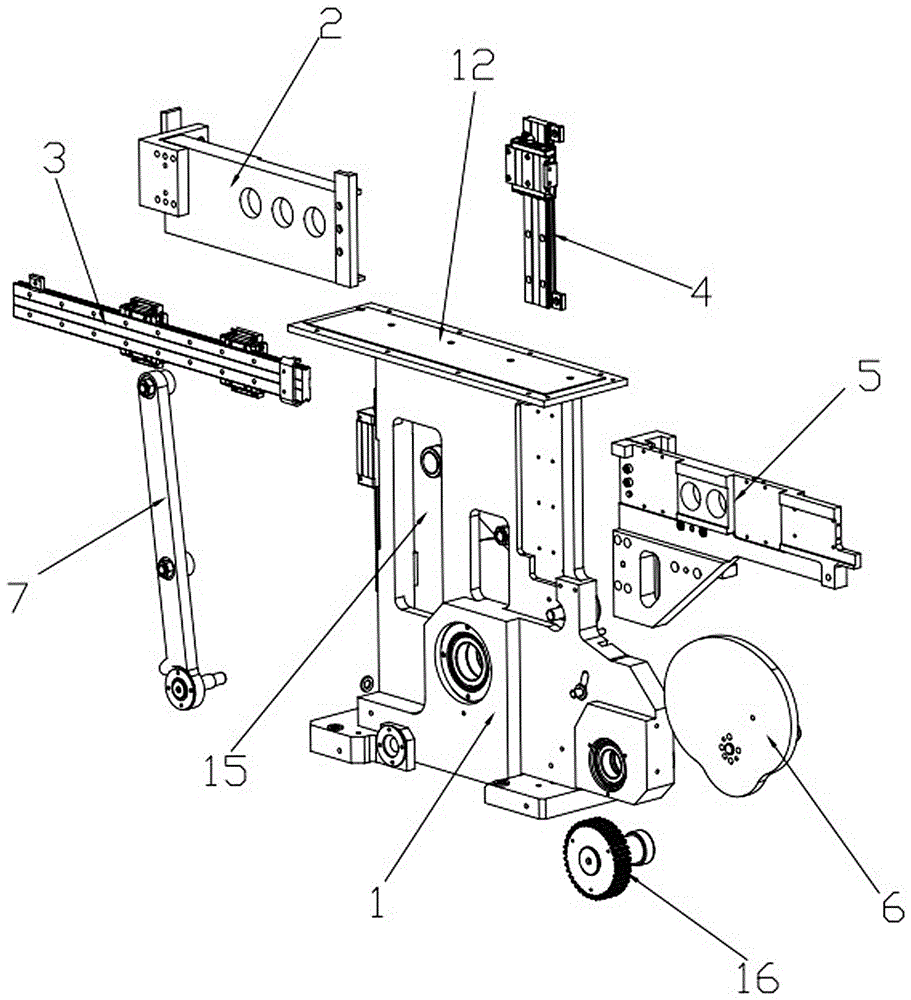

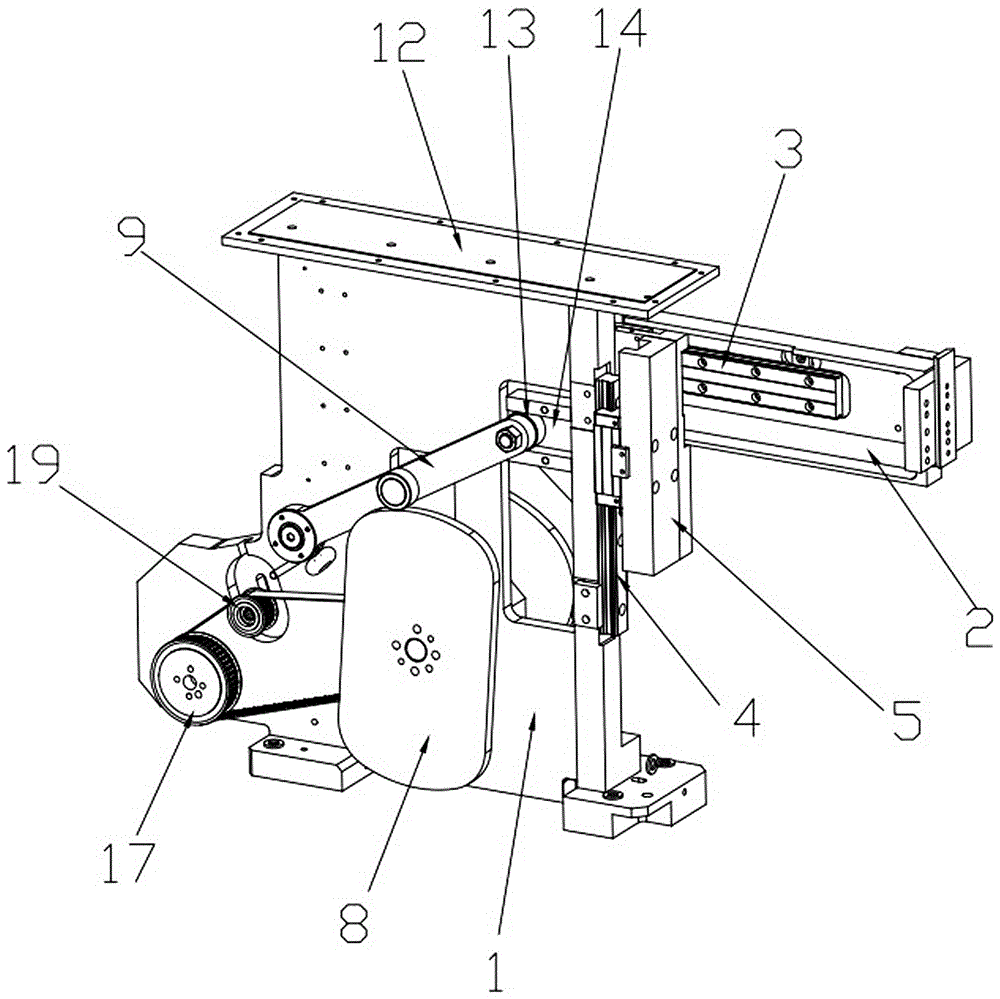

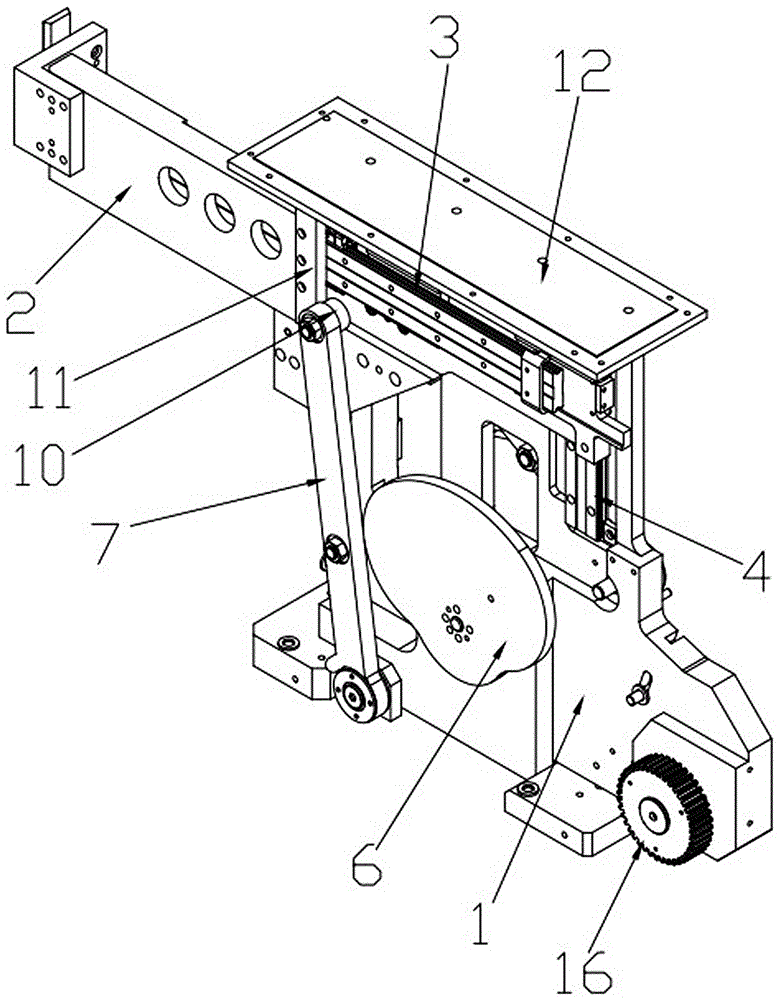

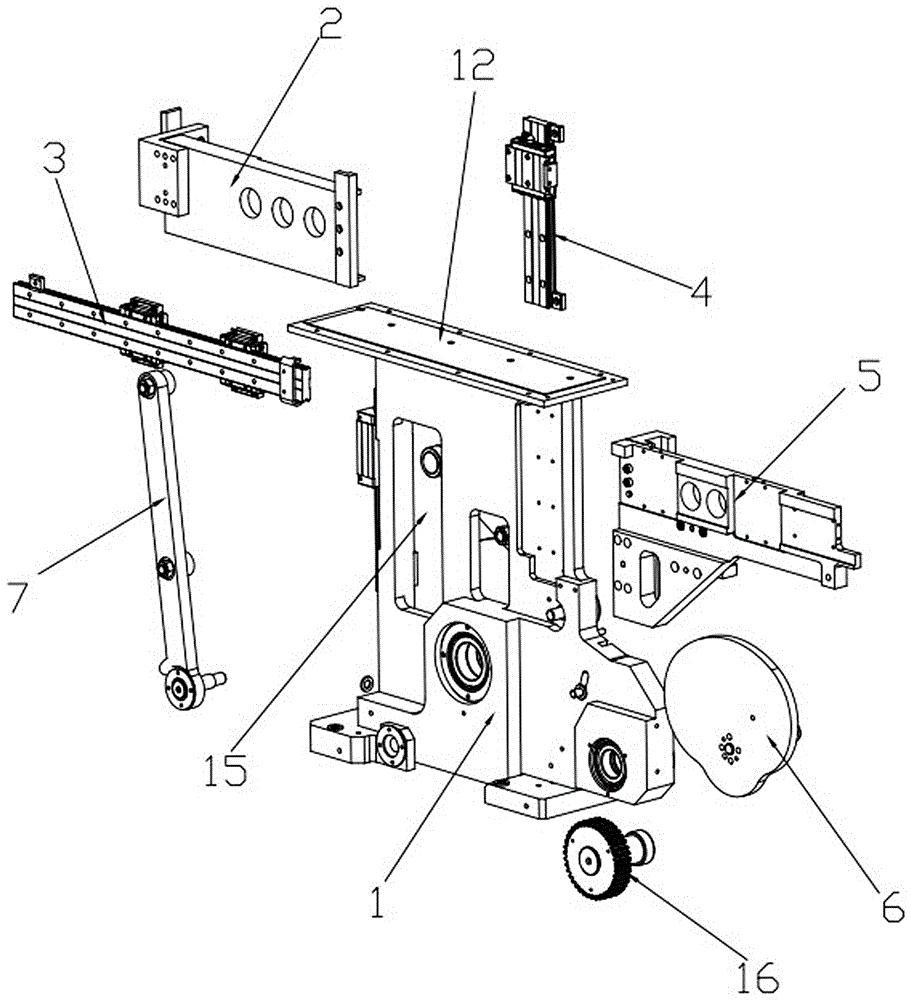

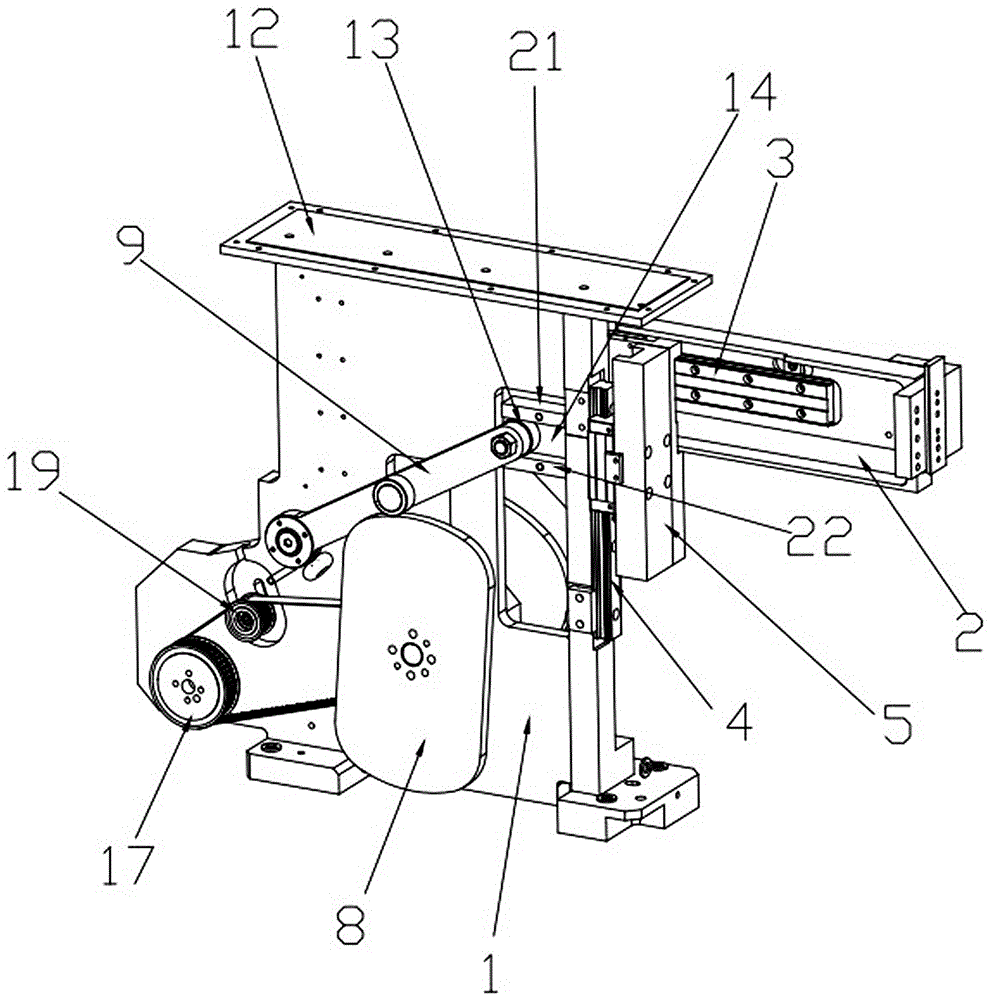

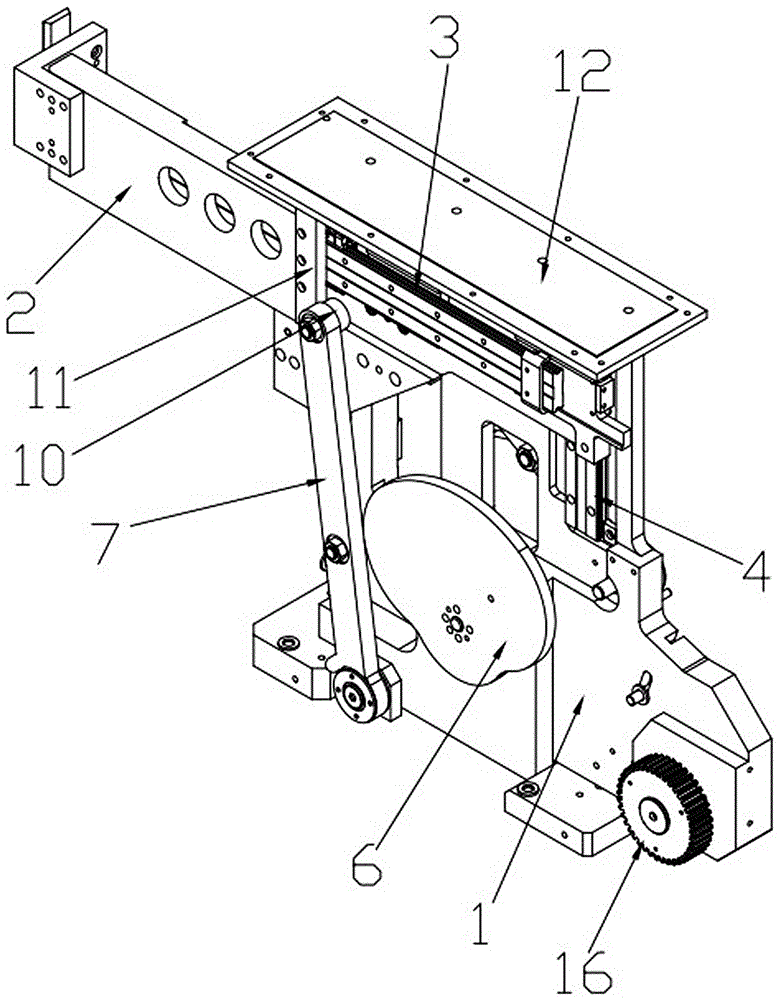

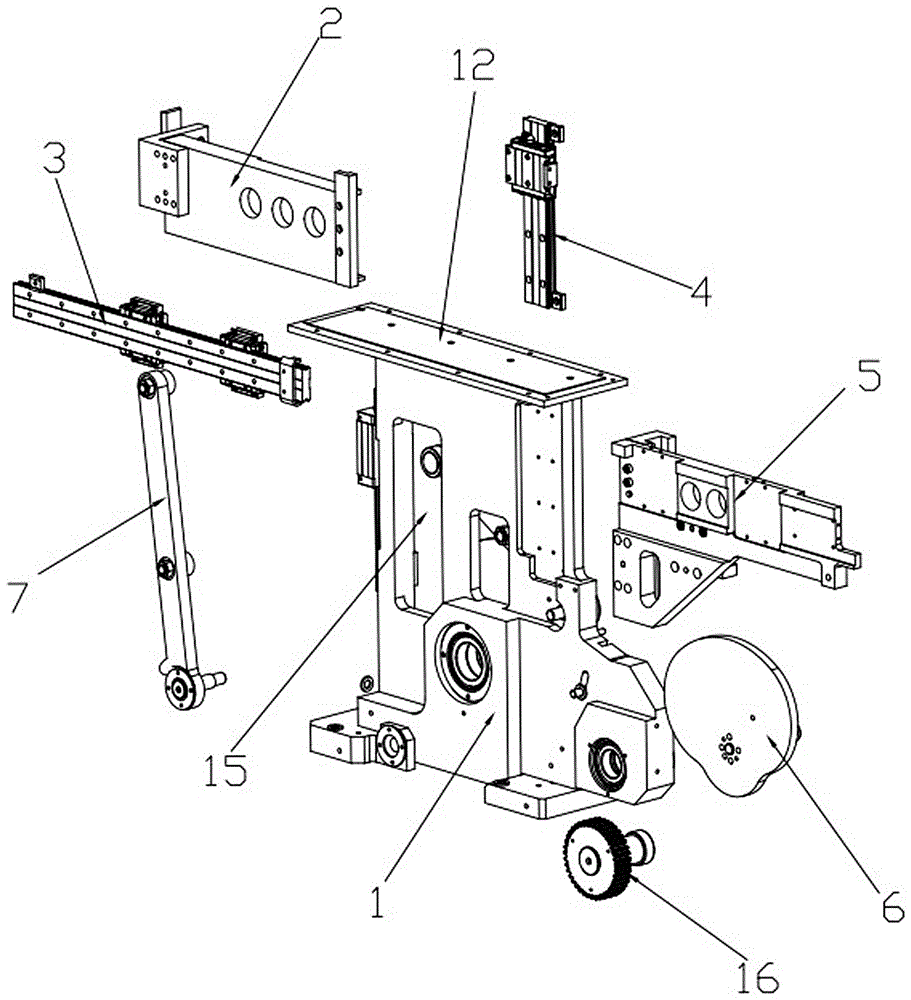

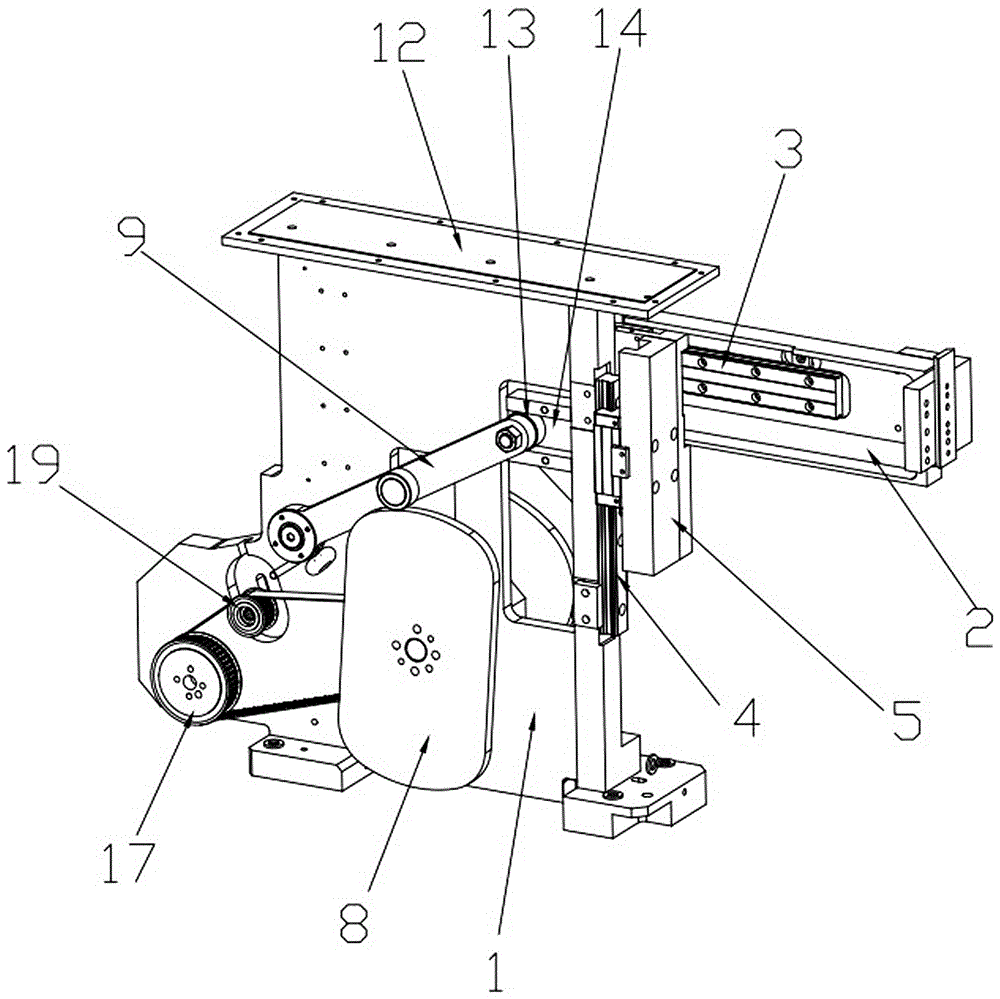

Cam driven mechanical hand

The invention relates to a cam driven mechanical hand and belongs to the field of mechanical transmission equipment. The cam driven mechanical hand comprises a main plate, a guide rail assembly, a horizontal support and a synchronous drive assembly. A first cam drive assembly is arranged on the left side of the main plate. A second cam drive assembly is arranged on the right side of the main plate. The first cam drive assembly is composed of a horizontal cam and a first rocking rod. The second cam drive assembly is composed of a vertical cam and a second rocking rod. The horizontal cam and the vertical cam are jointly driven by the synchronous drive assembly to achieve synchronous rotation. The whole mechanical hand can be manufactured to be of a flat small structure and is extremely small in occupied space. The first cam drive assembly and the second cam drive assembly are combined so as to drive the horizontal support to achieve an arc movement locus, the mechanical hand can precisely move to any point through the arc locus, it is ensured that overall operation of the mechanical hand is stable, no vibration is produced so as to ensure assembly stability, and the cam drive structure is high in precision and particularly applicable to automatic machining or assembly with high requirements for precision.

Owner:HUNAN SUPER INFORMATION

Manipulator capable of moving along arc-shaped track

The invention relates to a manipulator capable of moving along an arc-shaped track, and belongs to the field of mechanical transmission equipment. The manipulator capable of moving along the arc-shaped track comprises a main board, a guide rail assembly, a horizontal bracket and a synchronous transmission assembly, wherein a first cam transmission assembly is arranged at the left side of the main board, and a second cam transmission assembly is arranged at the right side of the main board; the first cam transmission assembly comprises a horizontal cam and a first rocker rod; the second cam transmission assembly comprises a vertical cam and a second rocker rod; the horizontal cam and the vertical cam are driven by the synchronous transmission assembly together to rotate synchronously. The whole manipulator can be manufactured into a small flat structure which needs an extremely small space; the first cam transmission assembly and the second cam transmission assembly can be combined to drive the horizontal bracket to move along the arc-shaped moving track and can accurately move to any point through the arc-shaped track, so that the whole manipulator can stably urn without any vibration, and as a result, the assembling stability can be ensured; the manipulator adopting a cam transmission structure is high in accuracy and particularly applicable to high-accuracy automatic processing or assembling.

Owner:HUNAN SUPER INFORMATION

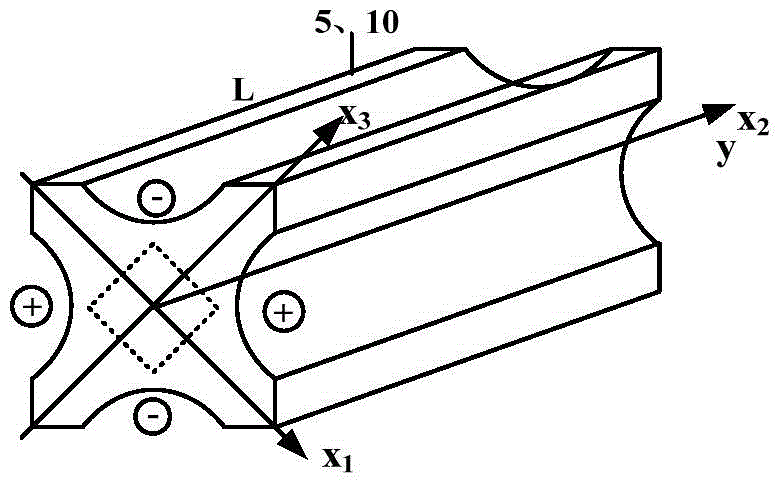

Reflection-type electro-optical scanning device of down-looking synthetic aperture laser imaging radar

ActiveCN103954954AReduce complexityLarge electro-optic modulation rangeElectromagnetic wave reradiationOptical scannersHalf wave

A reflection-type electro-optical scanning device of down-looking synthetic aperture laser imaging radar is placed between a laser source and a primary emitting mirror and comprises a half wave plate, a first polarization beam splitter, a second polarization beam splitter, a first Faraday rotator, a first electro-optical scanner, a second reflector, a first cylindrical mirror, a third polarization beam splitter, a second Faraday rotator, a second electro-optical scanner, a second emitting mirror, a second cylindrical mirror and a fourth polarization beam splitter. According to the reflection-type electro-optical scanning device of the down-looking synthetic aperture laser imaging radar, an electro-optical linear scanning range twice as large as that generated through a transmission-type electro-optical scanning device can be generated through the reflection-type electro-optical scanning device, wave surface phase difference distribution of a parabolic equipotential line at the far field target position of two polarization orthogonal beams is finally achieved, the reflection-type electro-optical scanning device is used for scanning a target, the structure is simple, mechanical scanning is avoided, the response speed of the electro-optical phase modulation wave surface is high, the size is small, the weight is low, and the reflection-type electro-optical scanning device is suitable for an emitting system of the down-looking synthetic aperture laser imaging radar on an onboard rapidly-operating carrying platform and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

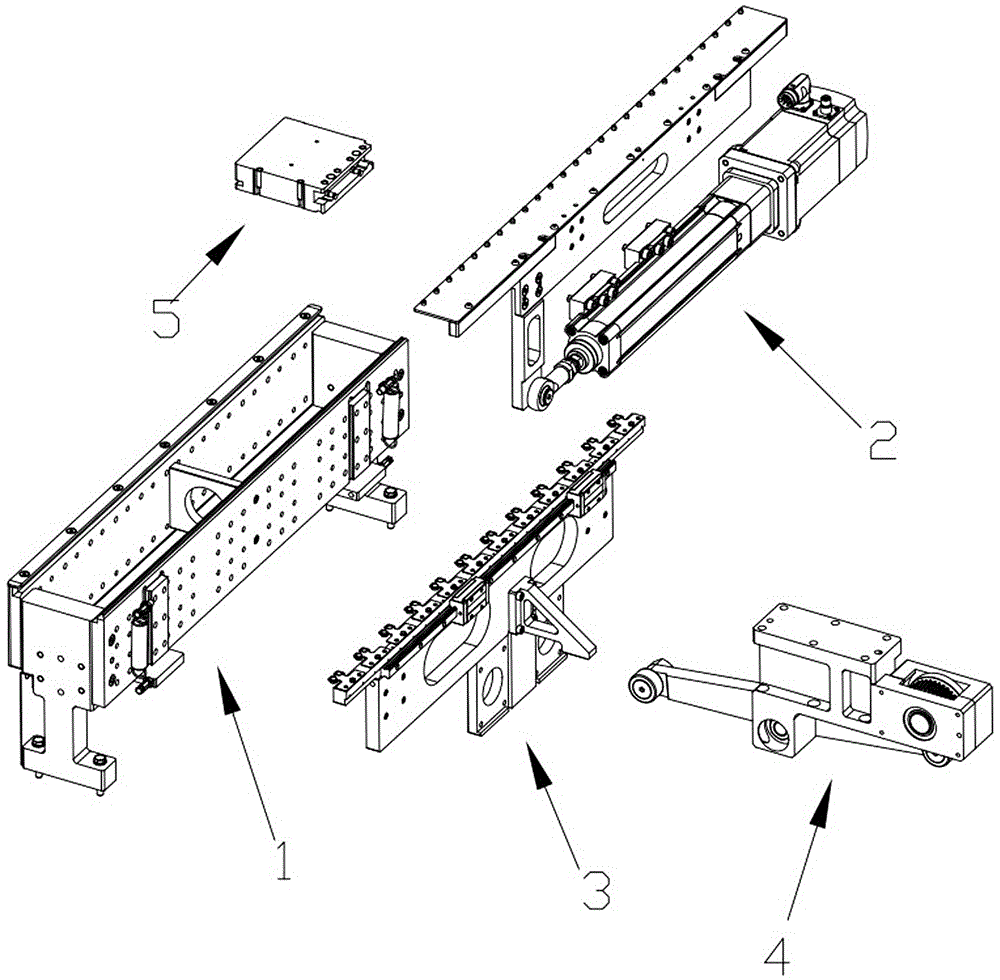

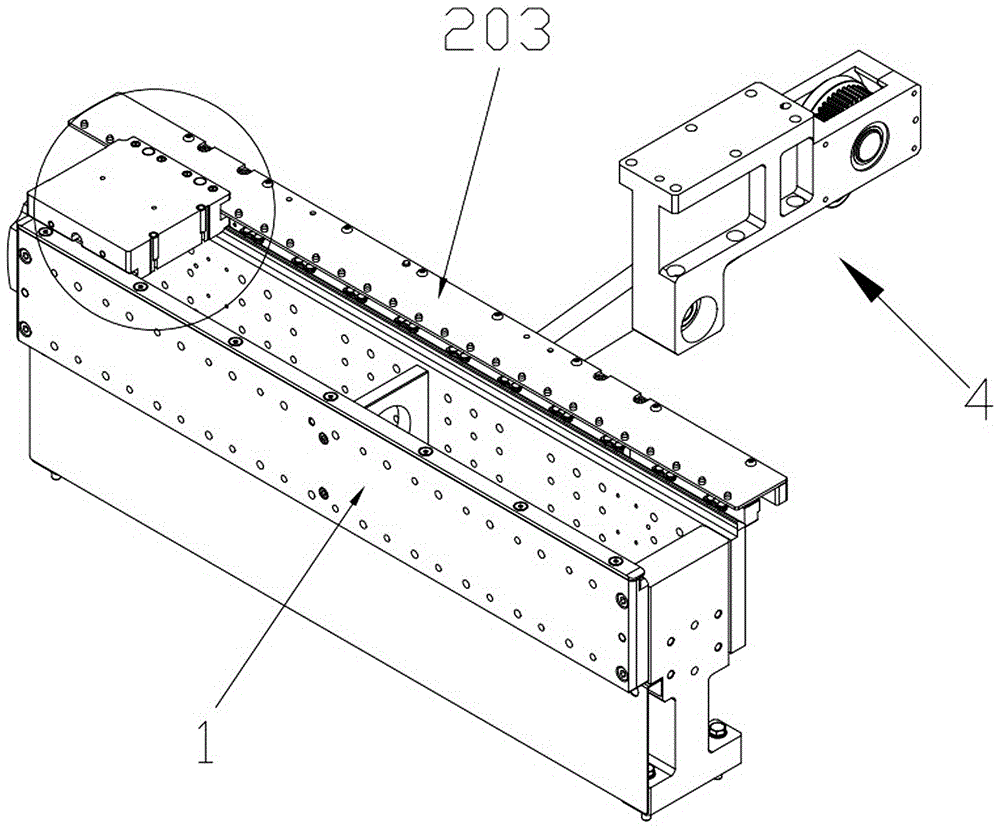

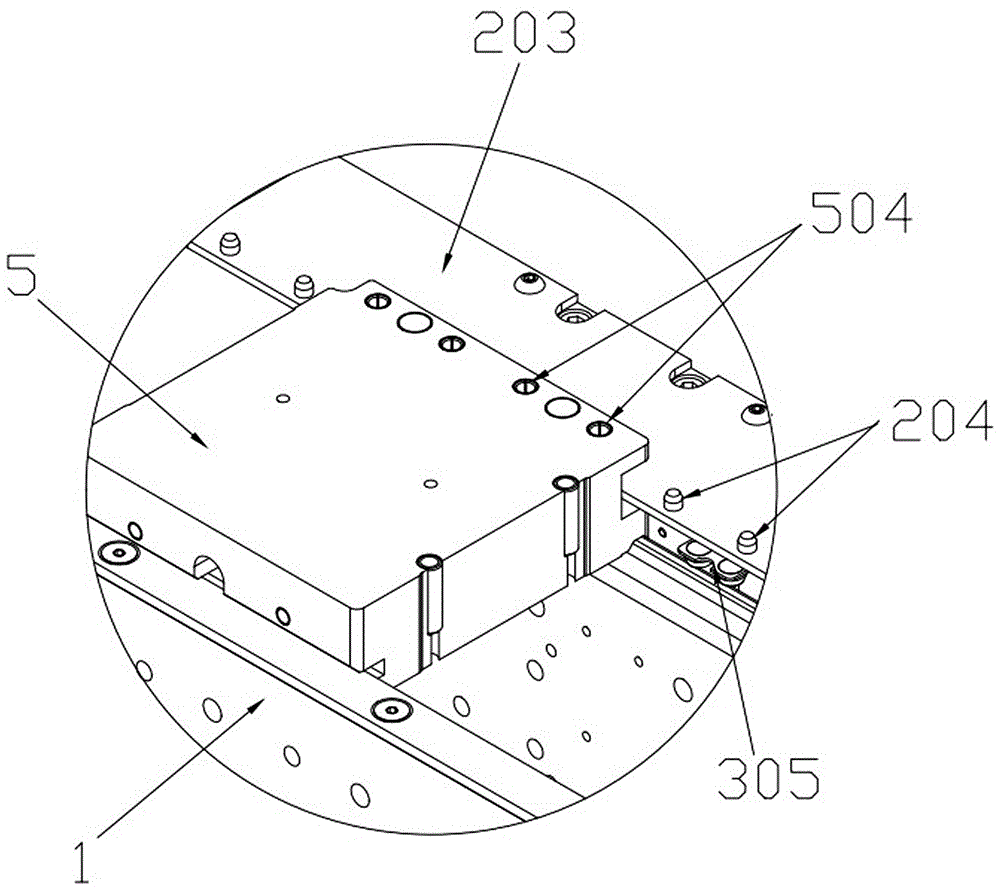

Accurate traction mechanism for driving tray

The invention relates to the field of mechanical transmission, in particular to an accurate traction mechanism for driving a tray. The accurate traction mechanism for driving the tray comprises a conveying base, a cam transmission assembly, a lifting assembly and a traction assembly. A horizontal sliding rail is installed at the top of the conveying base, and the tray which can horizontally slide along the horizontal sliding rail is installed on the horizontal sliding rail; a first horizontal sliding groove is formed in the left side of the tray, a second sliding groove is formed in the right side of the tray, and a clamping positioning pillar is installed on the inner bottom face of the second horizontal sliding groove; and a grabbing positioning pillar is installed above the clamping positioning pillar. The lifting assembly comprises a lifting main plate, a horizontal guide rail and a plurality of positioning plates. The traction assembly comprises an electric pushing rod, a traction main plate and a traction pin plate. The traction assembly is used for driving the tray to move horizontally, the lifting assembly is used for pressing the tray tightly so as to accurately position the tray, the traction assembly and the lifting assembly are both driven by the cam transmission assembly, and the driving mode is easy; any electronic control unit does not need to be adopted, any complex circuit does not need to be connected, and manufacturing cost is low.

Owner:HUNAN SUPER INFORMATION

M-Z (Mach-Zehnder) electrooptical-scanning orthophoria synthetic aperture laser imaging radar transmitting system

ActiveCN103543442AReduce complexityEasy to controlElectromagnetic wave reradiationHigh pressureHalf wave

An M-Z (Mach-Zehnder) electrooptical-scanning orthophoria synthetic aperture laser imaging radar transmitting system comprises a laser, a half wave plate, an aperture diaphragm, a first polarization beam splitter, a first reflection plate, a first electrooptical scanner, a first cylindrical mirror, a second reflection plate, a second electrooptical scanner, a second cylindrical mirror, a second polarization beam splitter, a transmitter-telescope primary mirror, a high-voltage power source and a control computer, wherein the first polarization beam splitter, the second polarization beam splitter, the first reflection plate and the second reflection plate are mutually parallelly arranged to form a Mach-Zehnder structure. The laser imaging radar transmitting system is capable of realizing parabolic equipotential line difference of two polarization orthogonal light beams at a far-field target, is used for scanning targets, simple in structure, free of mechanical scanning, small in size, light in weight, and particularly suitable for onboard or satellite-borne high-speed operating carrying platforms, and response speed for electrooptical phase modulation wave surfaces is fast and up to nanosecond level.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Intelligent positioning and transferring mechanism

InactiveCN106586432APrecise positioningGuaranteed accuracyMetal working apparatusMechanical conveyorsEngineeringElectric control

The invention relates to an intelligent positioning and transferring mechanism and belongs to the field of mechanical transmission equipment. The intelligent positioning and transferring mechanism comprises a transmission base, a cam transmission assembly, a lifting assembly and a traction assembly. Horizontal slide rails are arranged at the top of the transmission base and provided with pellets which can horizontally slide along the horizontal slide rails. First horizontal slide grooves are formed in the left sides of the pellets. Second horizontal slide grooves are formed in the right sides of the pellets. Clamping and positioning columns are arranged on the inner bottom faces of the second horizontal slide grooves. Grabbing and positioning columns are arranged above the clamping and positioning columns. The lifting assembly comprises a lifting main plate, a horizontal guide rail and a plurality of positioning plates. The traction assembly comprises an electric push rod, a traction main plate and a traction pin plate, and is used for driving the pellets to horizontally move. The lifting assembly is used for pressing the pellets to precisely position the pellets. The traction assembly and the lifting assembly are both driven by the cam transmission assembly. The intelligent positioning and transferring mechanism is simple in structure and driving mode, no electric control element is needed, no complex circuit needs to be connected, and the manufacturing cost is low.

Owner:HUNAN SUPER INFORMATION

Efficient and precise manipulator

The invention relates to the field of mechanical transmission equipment, in particular to an efficient and precise manipulator comprising a main plate, a guide rail assembly, a horizontal support and a synchronous transmission assembly. A first cam transmission assembly is arranged on the left side of the main plate, a second cam transmission assembly is arranged on the right side of the main plate, the first cam transmission assembly is composed of a horizontal cam and a first rocker, the second cam transmission assembly is composed of a vertical cam and a second rocker, and the horizontal cam and the vertical cam are jointly driven by the synchronous transmission assembly to synchronously rotate. The whole manipulator can be of a small flat structure, the occupied space is quite small, the first cam transmission assembly and the second cam transmission assembly are combined to drive the horizontal support to move in an arc track, and the horizontal support can move to any point precisely through the arc track, so that overall stable operation of the manipulator is ensured, shock is avoided, and assembling stability is guaranteed; and the precision is high by adopting the cam transmission structure, and the manipulator is especially suitable for automatic machining or assembling with the high precision requirement.

Owner:HUNAN SUPER INFORMATION

Manually operated miller for notched screw surface inside hole

InactiveCN100453224CAchieve finishingNo vibrationMilling machinesMilling equipment detailsAxial displacementMilling cutter

The manually operated miller for notched screw surface inside hole has one sleeve with limiting steps, outer screw section and axially extending notch in the back section wall, screw matched locating disc and milling cutter location regulator in the outer screw section; one inner screw tube inside the sleeve; one cutter rod with screw section for fitting the inner screw tube and front conic front part to match the front hole of the sleeve; one milling cutter extending axially from the front end of the cutter rod; and one manually operated rotation mechanism fixed to the tail of the cutter rod. The present invention operates the cutter rod manually for rotation machining, and has accurate locating, no vibration and no inertia.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

Direct-looking synthetic aperture laser imaging radar reflective electro-optical scanning device

ActiveCN103954954BReduce complexityLarge electro-optic modulation rangeElectromagnetic wave reradiationOptical scannersHalf wave

A reflection-type electro-optical scanning device of down-looking synthetic aperture laser imaging radar is placed between a laser source and a primary emitting mirror and comprises a half wave plate, a first polarization beam splitter, a second polarization beam splitter, a first Faraday rotator, a first electro-optical scanner, a second reflector, a first cylindrical mirror, a third polarization beam splitter, a second Faraday rotator, a second electro-optical scanner, a second emitting mirror, a second cylindrical mirror and a fourth polarization beam splitter. According to the reflection-type electro-optical scanning device of the down-looking synthetic aperture laser imaging radar, an electro-optical linear scanning range twice as large as that generated through a transmission-type electro-optical scanning device can be generated through the reflection-type electro-optical scanning device, wave surface phase difference distribution of a parabolic equipotential line at the far field target position of two polarization orthogonal beams is finally achieved, the reflection-type electro-optical scanning device is used for scanning a target, the structure is simple, mechanical scanning is avoided, the response speed of the electro-optical phase modulation wave surface is high, the size is small, the weight is low, and the reflection-type electro-optical scanning device is suitable for an emitting system of the down-looking synthetic aperture laser imaging radar on an onboard rapidly-operating carrying platform and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

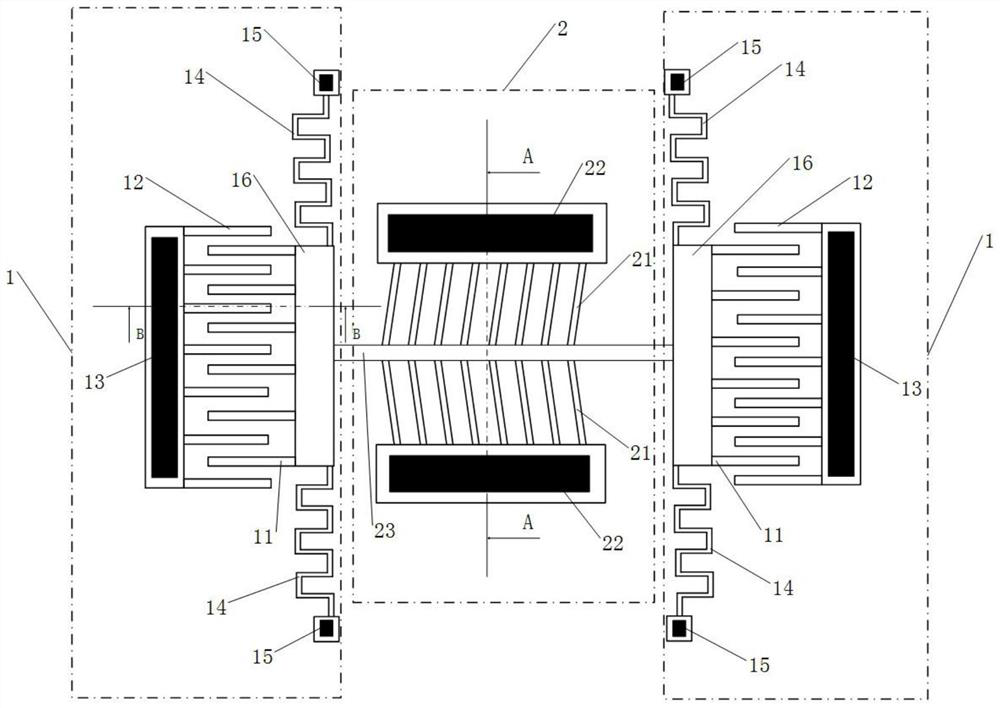

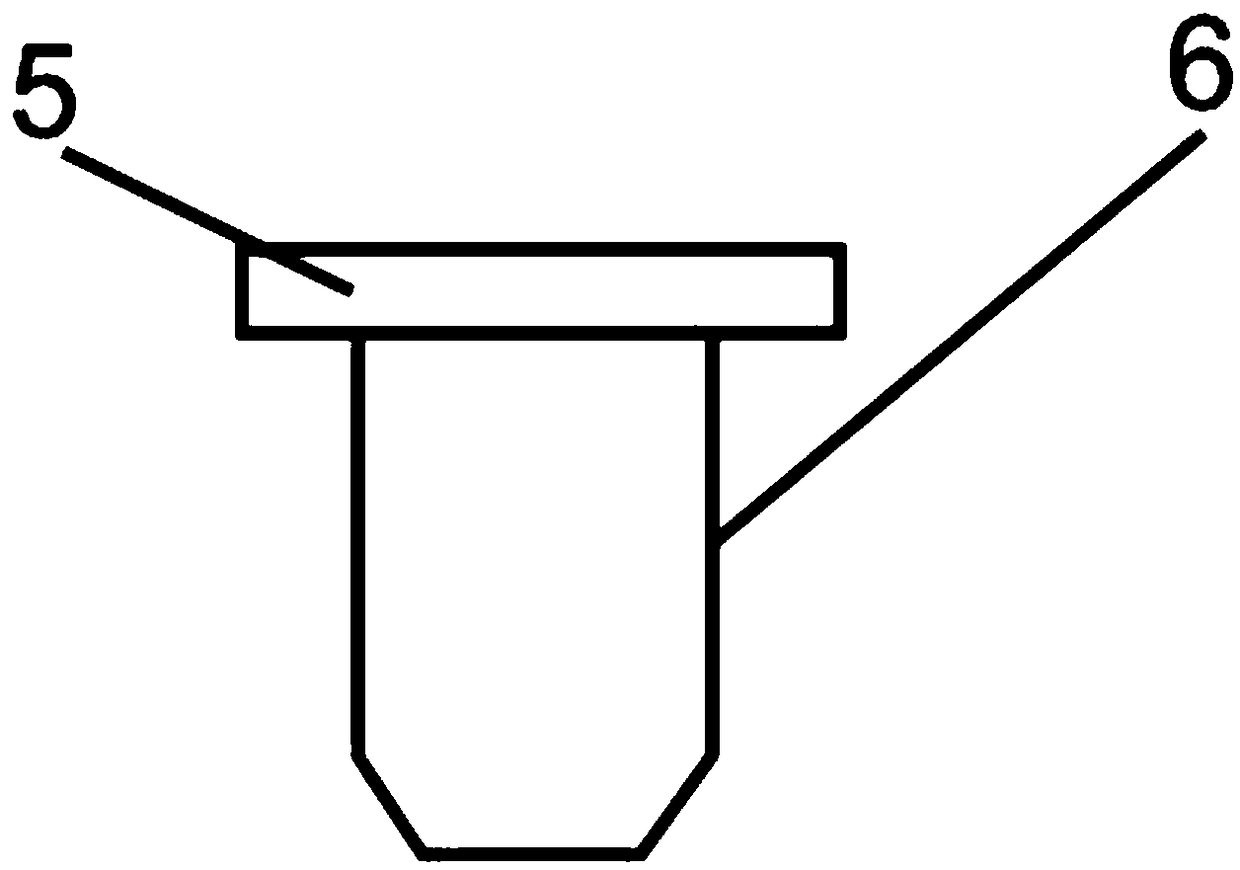

A capacitive mems gas sensor

The invention relates to a capacitance type MEMS (micro-electro-mechanical system) gas sensor. The capacitance type MEMS gas sensor is particularly suitable for coal mine safety monitoring as well asdetection on methane gas in the air in production and living, can be applied to detection on the gases such as helium, carbon dioxide and argon in special environments, and comprises a thermal actuator and two comb capacitors, wherein the thermal actuator comprises a plurality pairs of silicon beams, a micro-spindle and an anchor area; and each group of comb capacitor comprises a movable comb, onegroup of folding structure spring, a fixed comb and an anchor area. The sensor can detect the concentration of the methane gas, adopts thermal deformation of the silicon beams to drive the capacitance change of the comb capacitors according to the principle that the resistance of a semiconductor material is changed along with the change of the methane content of the peripheral gas under a certaincurrent, and measures the methane concentration of the air according to the capacitance change. The capacitance type MEMS gas sensor has the following advantages of simple structure, high adaptability, no poisoning influence, no abrasion and no inertness due to capacitance type measurement, high temperature and precision stability, high electromagnetic interference resistance and high dynamic response speed.

Owner:CHINA UNIV OF MINING & TECH

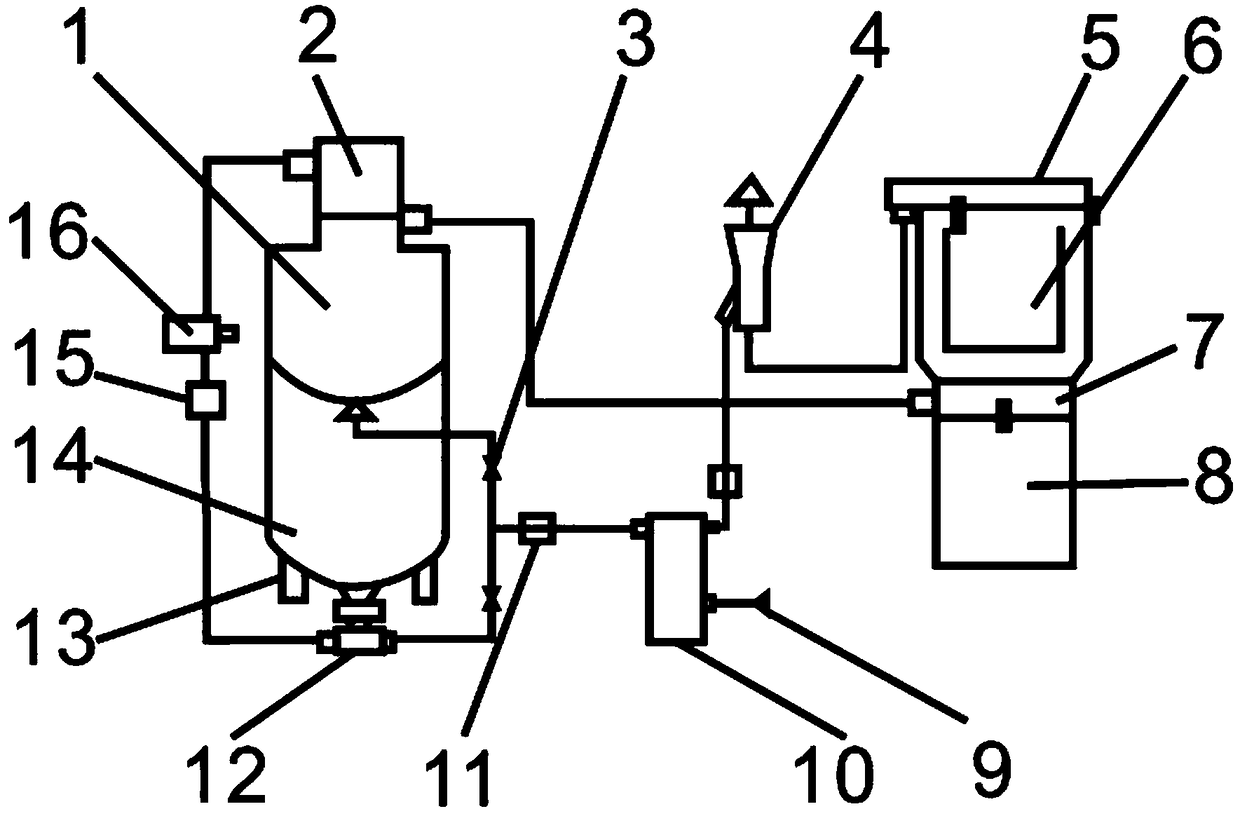

Energy-saving full-automatic incense making machine

The invention discloses an energy-saving full-automatic incense making machine. The machine comprises a feeding chamber, a feeding port, a filter and a hydraulic cylinder, wherein the feeding chamberand the feeding port are directly connected into an integrated structure, the filter is arranged below the feeding port, and a stepping motor driver is arranged above a material scraping mechanism, the scraping mechanism is directly connected with a stepping motor, and a pressure reducing valve is arranged on the left side of the stepping motor; the pressure reducing valve is arranged on the rightside of an electric appliance control screen, a photoelectric switch is arranged on the right left side of the electric appliance control screen; a digital variable-frequency hydraulic control is adopted, the electricity is saved, the efficiency is high, the speed of incense discharging and the transmission speed of the stepping motor are stable and controllable, the adjusting range is wide, moreover, a digital display screen is provided, and the machine can work for a long time; and the energy-saving full-automatic incense making machine has the advantages of being advanced and practical indesign, the labor productivity is greatly improved, and the producing incense can realize large-scale industrial production, the design is simple, cost is low, and the machine can be widely popularized and used.

Owner:朗瀚智能装备(江苏)有限公司

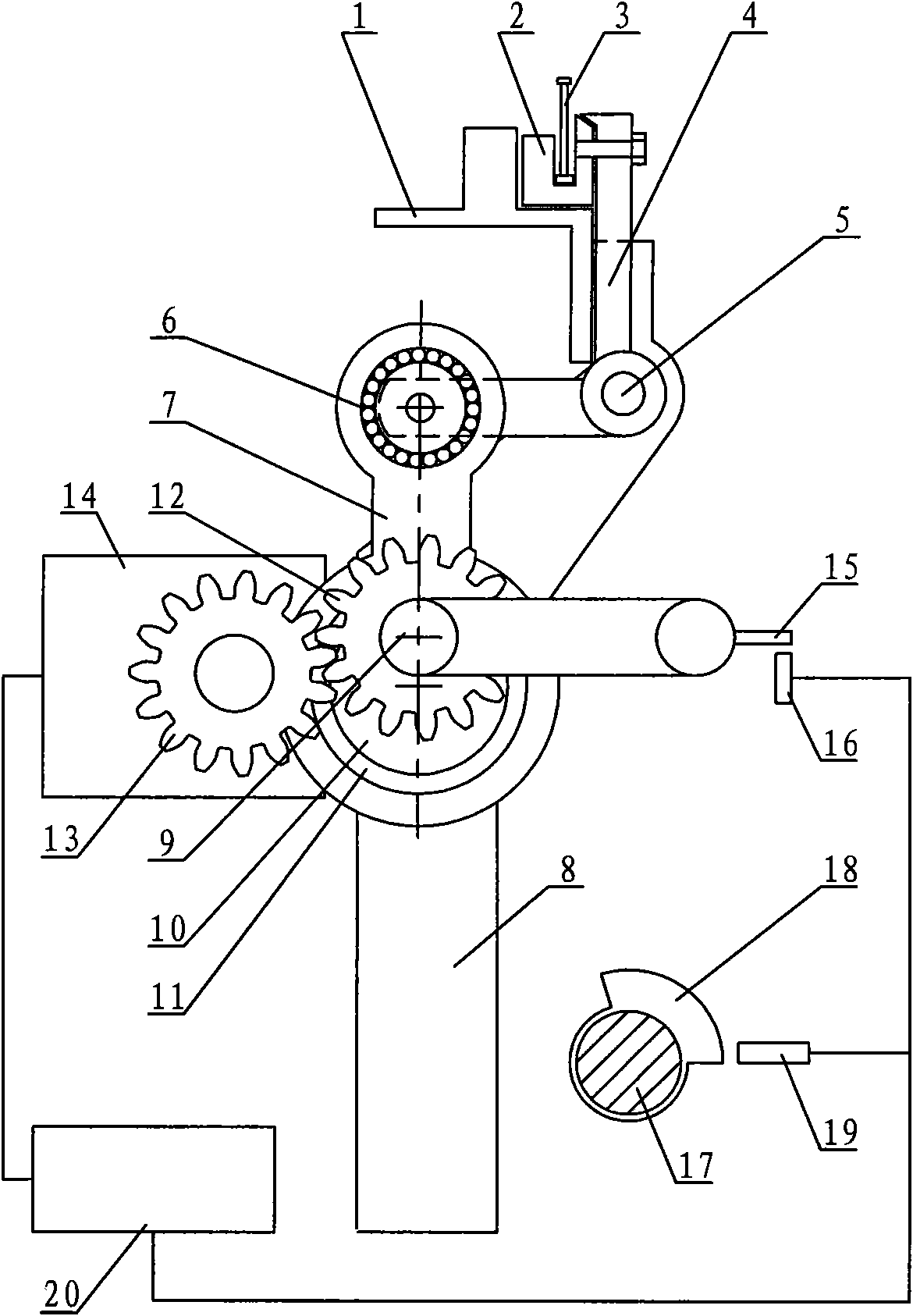

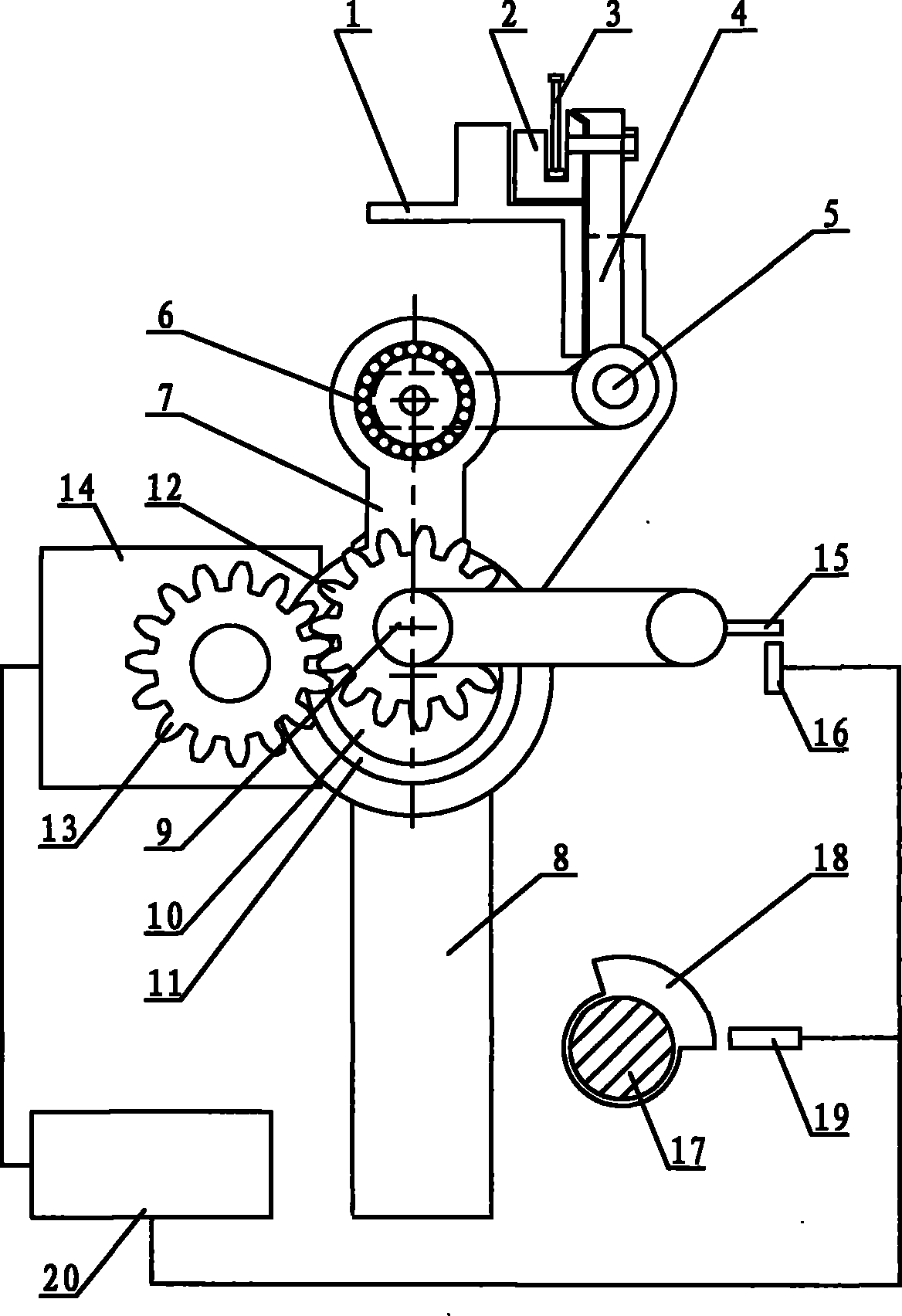

An electric operating mechanism for a high-voltage isolating switch and an earthing switch

InactiveCN102280276ARealize electric operationLow spindle speedContact driving mechanismsSwitch power arrangementsLow speedElectric machine

An electric operating mechanism for a high-voltage isolating switch and a grounding switch relates to the technical field of electric operating mechanisms for switches. Including the fixed frame, the motor is fixedly connected to the lower part of the fixed frame, the gear box is connected to the output end of the motor, the driving pinion is connected to the output shaft of the gear box, the main shaft of the operating mechanism is set on the upper part of the fixed frame, and the main shaft of the operating mechanism A driven bull gear cooperating with the driving pinion is arranged on the top, a shift fork device is arranged on the output shaft of the reduction box, and the driving pinion is arranged in the shift fork device. The spindle has low speed, no inertia, no buffer device, simple structure and more reliable action. Compared with the original electric mechanism, the power required to operate the same isolating switch is greatly reduced.

Owner:沈国祥

Mechanical arm capable of moving smoothly

The invention relates to a mechanical arm capable of moving smoothly in the field of mechanical transmission equipment. The mechanical arm comprises a main plate, a guide rail assembly, a horizontal support and a synchronous transmission assembly; a first cam transmission assembly is arranged on the left side of the main plate, a second cam transmission assembly is arranged on the right side of the main plate, the first cam transmission assembly is composed of a horizontal cam and a first rocking rod, the second cam transmission assembly is composed of a vertical cam and a second rocking rod, and the horizontal cam and the vertical cam are jointly driven by the synchronous transmission assembly to achieve synchronous rotation. The whole mechanical arm can be made to be of the flat small structure, the occupied space is very small, the first cam transmission assembly and the second cam transmission assembly are jointly combined to drive the horizontal support to achieve the arc motion trajectory, the mechanical arm can precisely move to any point position through the arc trajectory, the whole stable motion of the mechanical arm is ensured, no vibration is generated, and therefore assembling stability is ensured; due to adoption of the cam transmission structure, precision is high, and the mechanical arm is particularly suitable for automatic machining or assembling with high requirement for precision.

Owner:HUNAN SUPER INFORMATION

Electro-optical Scanning Direct-Looking Synthetic Aperture Imaging Lidar Transmitting System with the Same Polarization

ActiveCN103543444BReduce complexityLarge linear modulation rangeElectromagnetic wave reradiationSynthetic aperture radarOptoelectronics

A same-polarization electrooptical-scanning laser imaging radar transmitting system for down-looking synthetic aperture comprises a laser, a half wave plate, an aperture diaphragm, a first polarization beam splitter, a first 1 / 4 wave plate, a first reflection mirror, a first electrooptical scanner, a first cylindrical mirror, a second reflection mirror, a third reflection mirror, a second electrooptical scanner, a second cylindrical mirror, a second polarization beam splitter, a second 1 / 4 wave plate, a fourth reflection mirror, a transmitter-telescope primary mirror, a high-voltage power source and a signal generator. The same-polarization electrooptical-scanning laser imaging radar transmitting system is capable of electro-optically scanning cross rails of the same polarization state and ultimately realizing parabolic equipotential line difference of two polarization orthogonal light beams at a far-field target, is used for scanning targets, simple in structure, free of mechanical scanning, small in size, light in weight, and particularly suitable for onboard or satellite-borne high-speed operating carrying platforms, and response speed for electrooptical phase modulation wave surfaces is fast and up to nanosecond level.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

m-z type electro-optical scanning direct-looking synthetic aperture laser imaging radar launch system

ActiveCN103543442BReduce complexityEasy to controlElectromagnetic wave reradiationOptoelectronicsHigh pressure

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

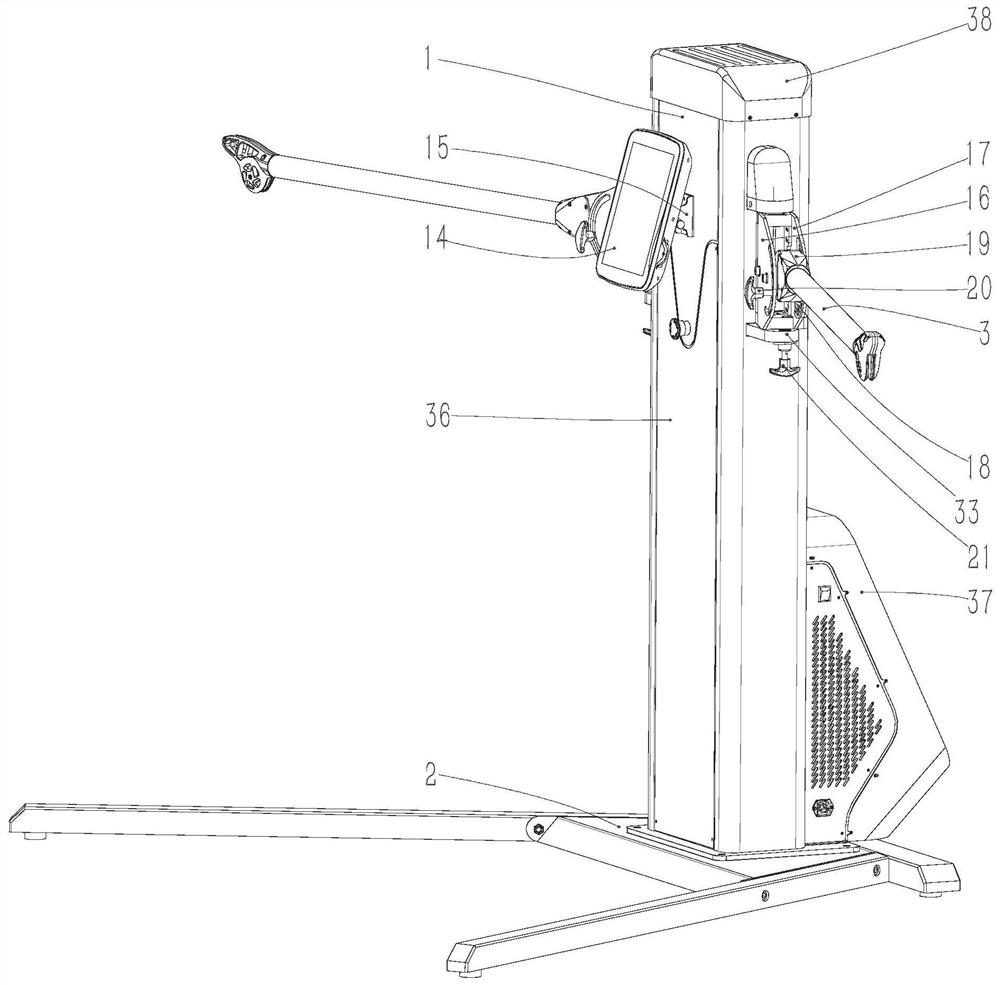

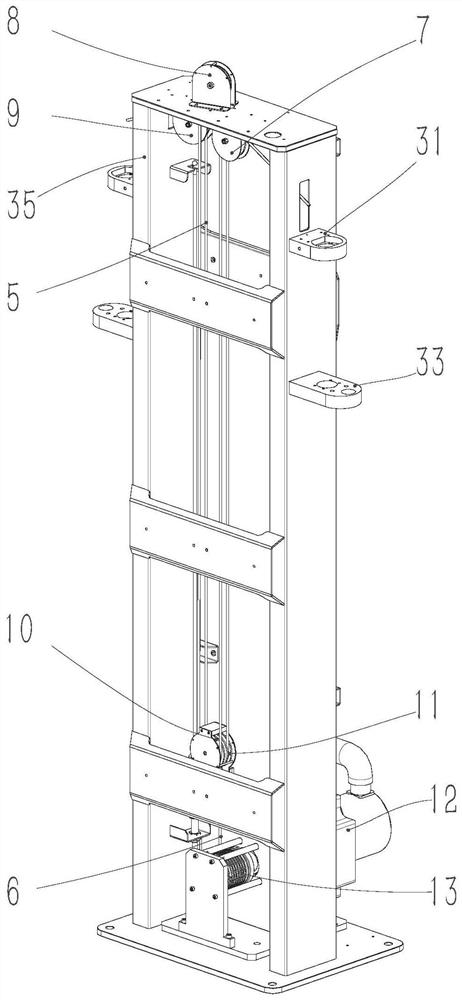

Rope movement training equipment

PendingCN112090023ANo impact noiseImpact noise is absentResilient force resistorsServoPersonalization

The invention discloses rope movement training equipment. The rope movement training equipment comprises a main body assembly, a base, a left arm, a right arm, a pulley block, a pull rope, a power source assembly, an input module and a controller, wherein the power source assembly comprises a servo motor driver, a servo motor and a winding reel; the servo motor driver is connected with the servo motor; a steel wire rope is wound on the winding reel; one end of the steel wire rope is fixedly arranged; the other end of the steel wire rope is connected with the pulley block; the input module comprises an input panel and a mobile phone APP; the mobile phone APP is connected with the controller through Bluetooth; the controller is connected with the servo motor driver; seven movement modes arestored in the controller; and a torque control signal of the servo motor in each movement mode and a reference rotating speed range of the servo motor in each movement mode are stored in the controller. The rope movement training equipment has the advantages that a personalized, diversified and digital training scheme can be realized, the power source assembly does not have impact noise or movement inertia, and the risk of strain in a training process is greatly reduced.

Owner:宁波伊士通技术股份有限公司

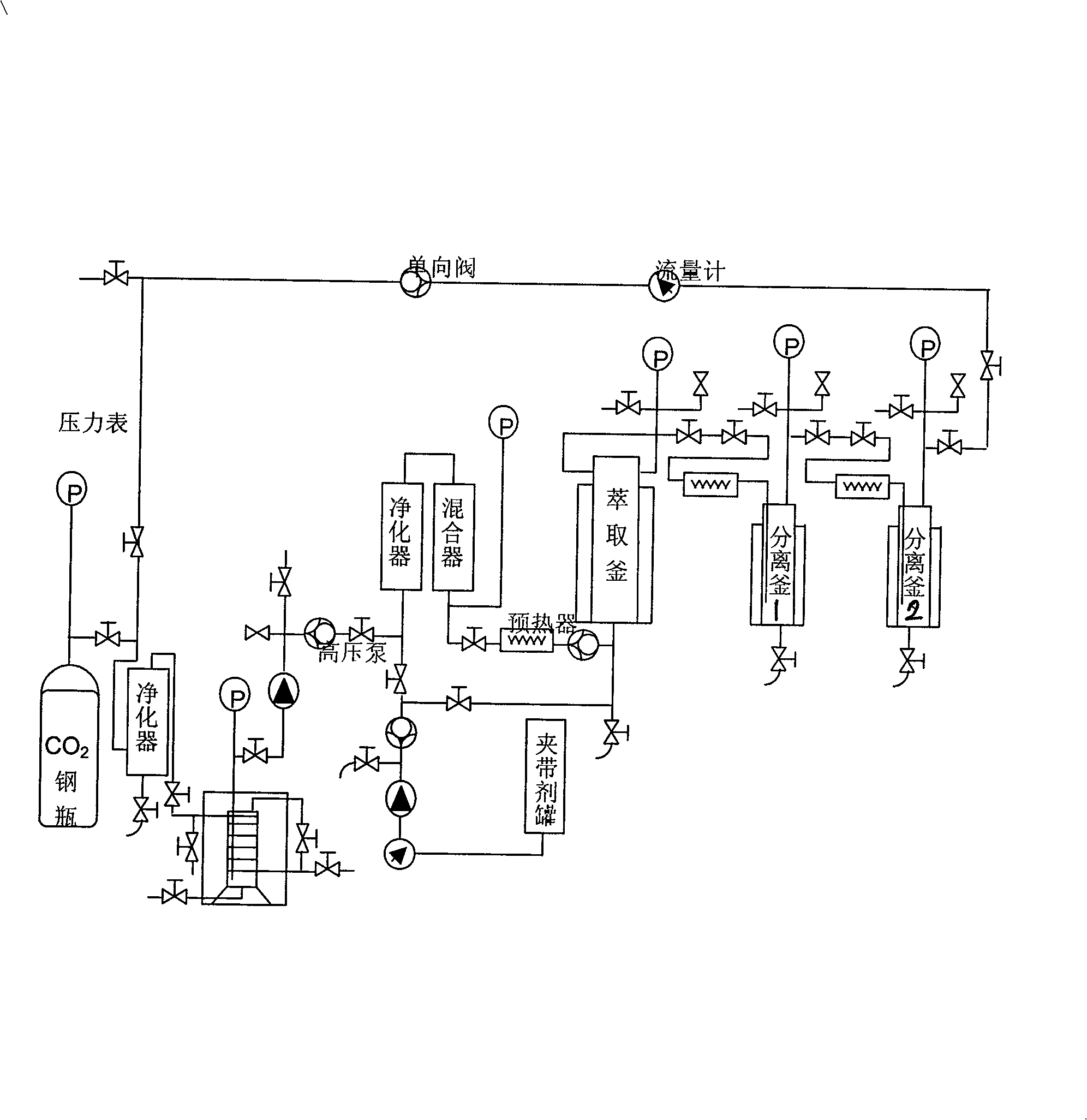

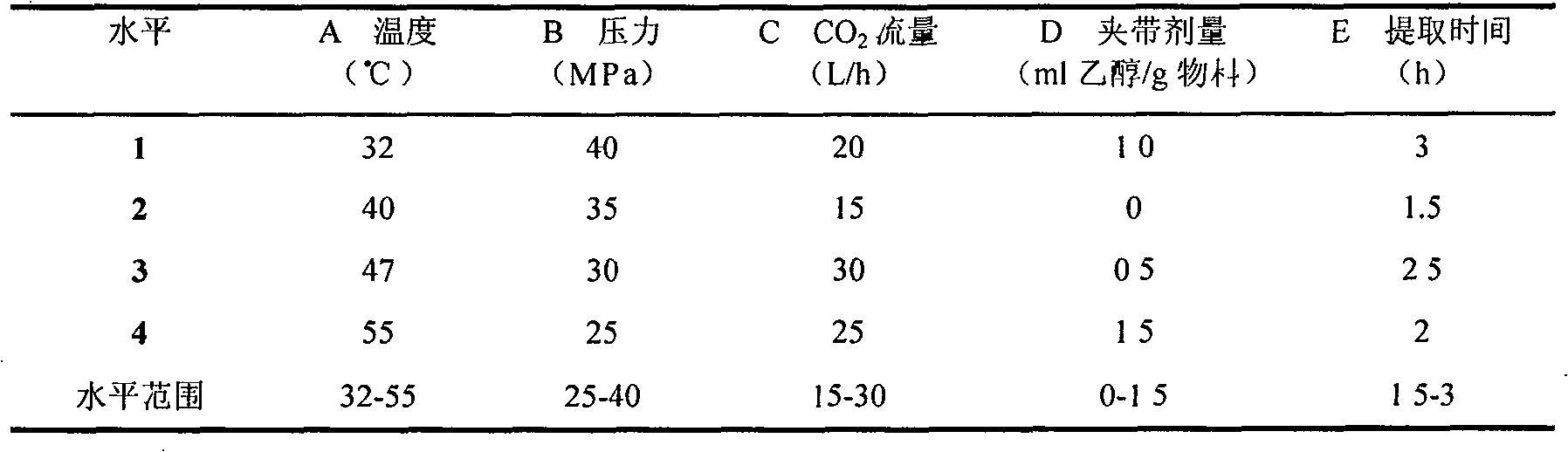

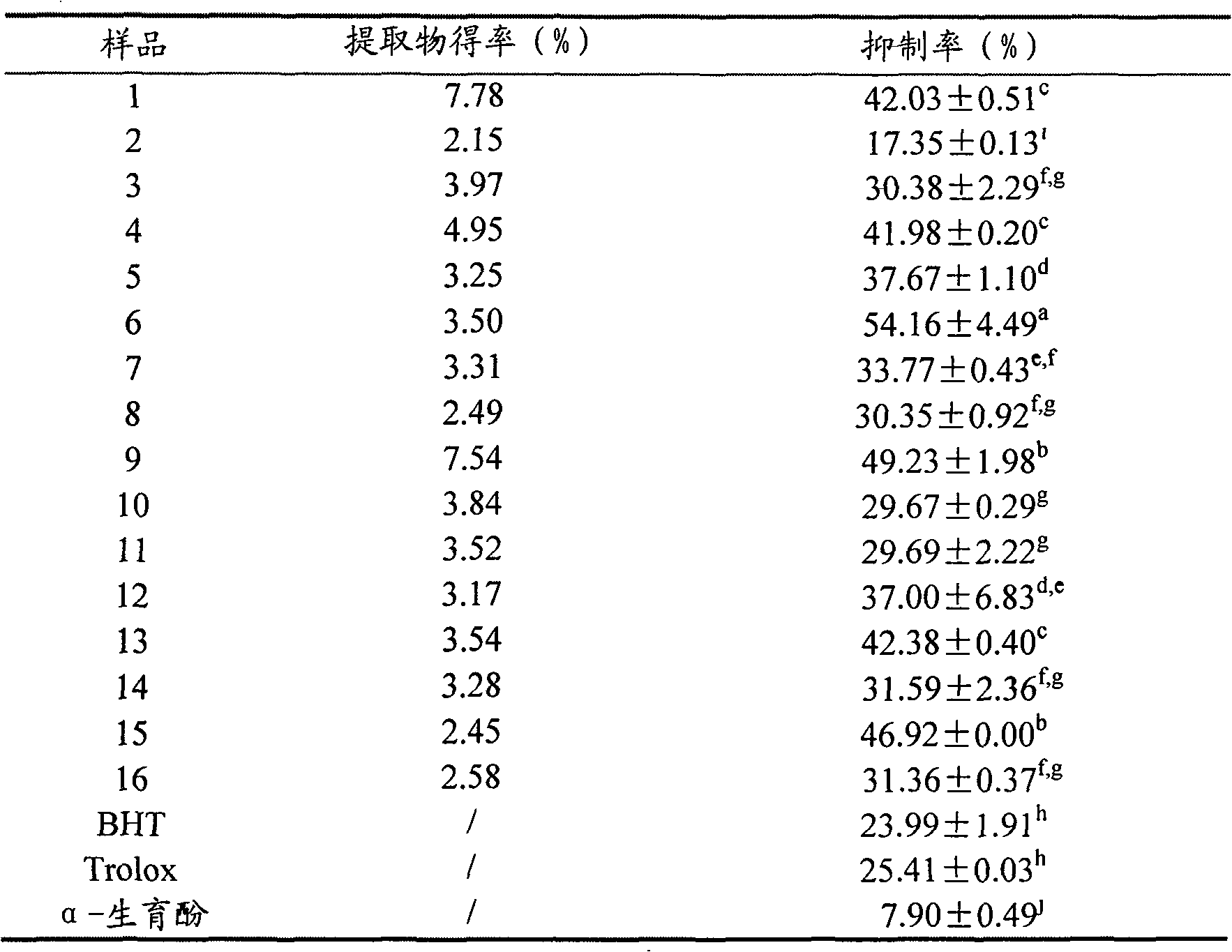

Preparation method of seaweed antioxidation active component

InactiveCN100415335CLow costAntioxidantAlgae medical ingredientsAntinoxious agentsDiseaseActive component

A process for preparing the active antioxidizing component from seaweeds features that the active antioxidizing component is extracted from chlorella by supercritical CO2 at 32-47 deg.C under 35-40 MPa for 1.5-2.5 hr. Its produce can be used for improving immunity, delaying sanility and preventing cardiovascular and cerebrovascular diseases.

Owner:NANJING AGRICULTURAL UNIVERSITY

Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

InactiveCN103552448BSmall sizeFlexible and convenient layoutSpeed controllerElectric propulsion mountingBrushless motorsElectric machine

The invention discloses a motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and a motor and AMT integration-based electric vehicle driving method. The driving system comprises a driving motor, a motor controller, a transmission drive assembly, a gear selection and shifting execution mechanism and a controller for the gear selection and shifting execution mechanism, wherein the transmission drive assembly comprises driving and driven gears of four gears, two splined hubs, two jointing sleeves and an output sensor; the driving motor is a direct current brushless motor; an output shaft of the driving motor is provided with an internal spline; a shell of the driving motor is integrally and directly connected with a transmission case through fine thread screws after being positioned through fixing pins; the output shaft, with the internal spline, of the motor is positioned in the motor; an input shaft of a transmission is directly inserted into the motor to be connected with the output shaft, with the internal spline, of the motor. According to the system, a clutch is eliminated, so that power interruption time during gear shifting is reduced, and the cost is also lowered; the jointing sleeves and the gears of a target gear can be synchronized during gear shifting by actively regulating the speed of the driving motor, and a synchronizer with high requirements on materials is eliminated from the transmission, so that the cost is further lowered.

Owner:张利鹏 +1

Intelligent assembling traction mechanism

The invention relates to the field of mechanical transmission equipment, in particular to an intelligent assembling traction mechanism. The intelligent assembling traction mechanism comprises a transmission base, a cam transmission assembly, a lifting assembly and a traction assembly. A horizontal sliding rail is arranged at the top of the transmission base. A pallet capable of sliding horizontally along the horizontal sliding rail is arranged on the horizontal sliding rail. A first horizontal sliding groove is formed in the left side of the pallet. A second horizontal sliding groove is formed in the right side of the pallet. A clamping positioning column is arranged on the inner bottom face of the second horizontal sliding groove. A grabbing positioning column is arranged on the clamping positioning column. The lifting assembly comprises a main lifting plate, a horizontal guide rail and a plurality of positioning plates. The traction assembly comprises an electric push rod, a main traction plate and a traction pin plate and is used for driving the pallet to move horizontally. The lifting assembly is used for pressing the pallet so that the pallet can be accurately positioned. The traction assembly and the lifting assembly are both driven by the cam transmission assembly. The structure and the driving mode are simple, no electronic control element needs to be adopted, no complex circuit needs to be connected, and the manufacturing cost is low.

Owner:HUNAN SUPER INFORMATION

A metallurgical equipment that is convenient for transportation

Owner:内蒙古包钢西创铁鑫磁材科技有限公司

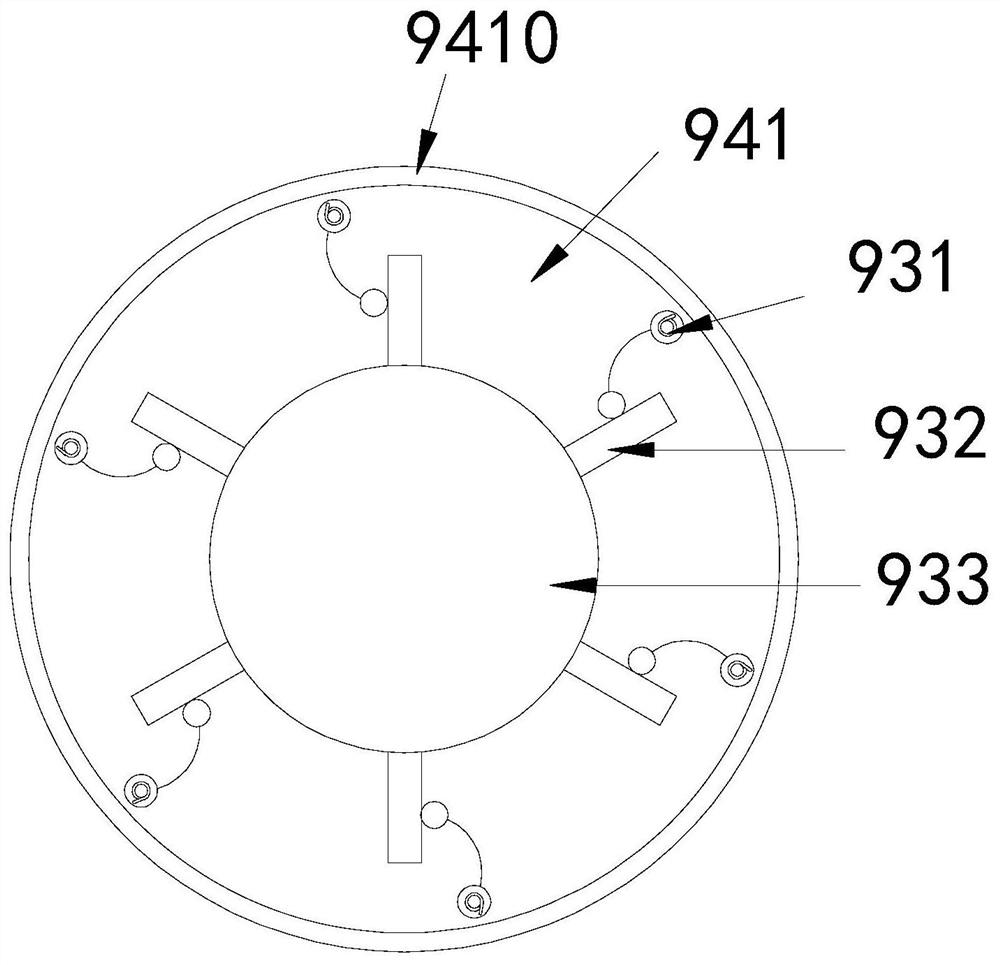

Automatic detection device and control method of rutting tester

ActiveCN108120651BAvoid interactionNo frictionAdaptive controlStrength propertiesCircular discNerve network

The invention discloses a wheel tracking tester automatic detection device which comprises a square base, a turbo-worm reducer, a hollow disc-shaped support part, a butterfly force value sensor and aplurality of linear temperature and humidity sensors, wherein a columnar groove is formed in the upper surface of the square base coaxially, a plurality of columnar guide pillars are uniformly arranged in the groove, close to the periphery; the turbo-worm reducer is fixedly arranged in the middle of the groove, an encoder is arranged at the center of the upper surface of the turbo-worm reducer; the hollow disc shaped support part is provided with columnar through holes matched with the guide pillars, is coaxial with the base and is sleeved on the guide pillars in a vertically moving way; the butterfly force value sensor is fixedly arranged above the encoder by a thread bushing; the lower ends of the linear temperature and humidity sensors are arranged at four opposite angles of the base. The invention also provides a control method of the wheel tracking tester automatic detection device, which adjusts trial wheel displacement and voltage of a detection circuit based on the BP neural network in wheel tracking tester automatic detection. According to the invention, integrated automatic detection is realized; and meanwhile, the accuracy of the test system in a common test environmentis increased.

Owner:白山市盛源工程试验检测有限公司

Dual-channel electro-optical scanning direct-looking synthetic aperture imaging lidar launch system

ActiveCN103543443BReduce complexityEasy to controlElectromagnetic wave reradiationSynthetic aperture radarOptoelectronics

A bi-channel electrooptical scanning laser imaging radar transmitting system for down-looking synthetic aperture comprises a laser, a half wave plate, an aperture diaphragm, a first polarization beam splitter, a first electrooptical scanner, a first cylindrical mirror, a second polarization beam splitter, a first 1 / 4 wave plate, a first reflection mirror, a third polarization beam splitter, a second 1 / 4 wave plate, a second reflection mirror, a second electrooptical scanner, a second cylindrical mirror, a fourth polarization beam splitter, a transmitter-telescope primary mirror, a high-voltage power source and a signal generator. The bi-channel electrooptical scanning laser imaging radar transmitting system is capable of electro-optically scanning two channels of light beams and ultimately realizing parabolic equipotential line difference of two polarization orthogonal light beams at a far-field target, is used for scanning targets, simple in structure, free of mechanical scanning, small in size, light in weight, and particularly suitable for onboard or satellite-borne high-speed operating carrying platforms, and response speed for electrooptical phase modulation wave surfaces is fast and up to nanosecond level.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com