Numerical control fly reed mechanism of towel machine

A technology of towel machines and numerical control motors, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of small friction coefficient of warp yarn, large inertia of rotating shaft, low energy consumption of mechanism, etc., and achieve small motion friction coefficient and overall structure The effect of simplicity and stable operation of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

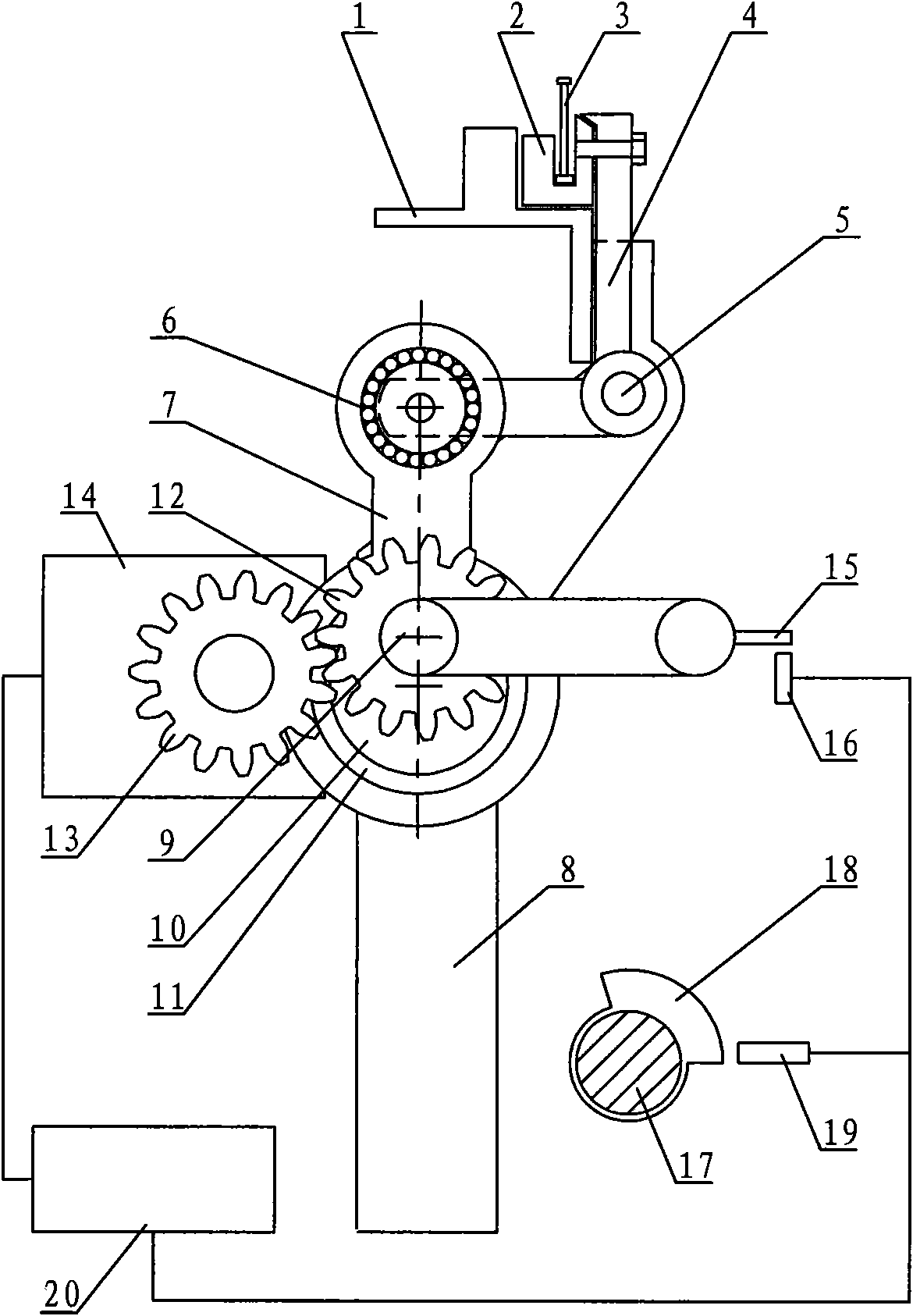

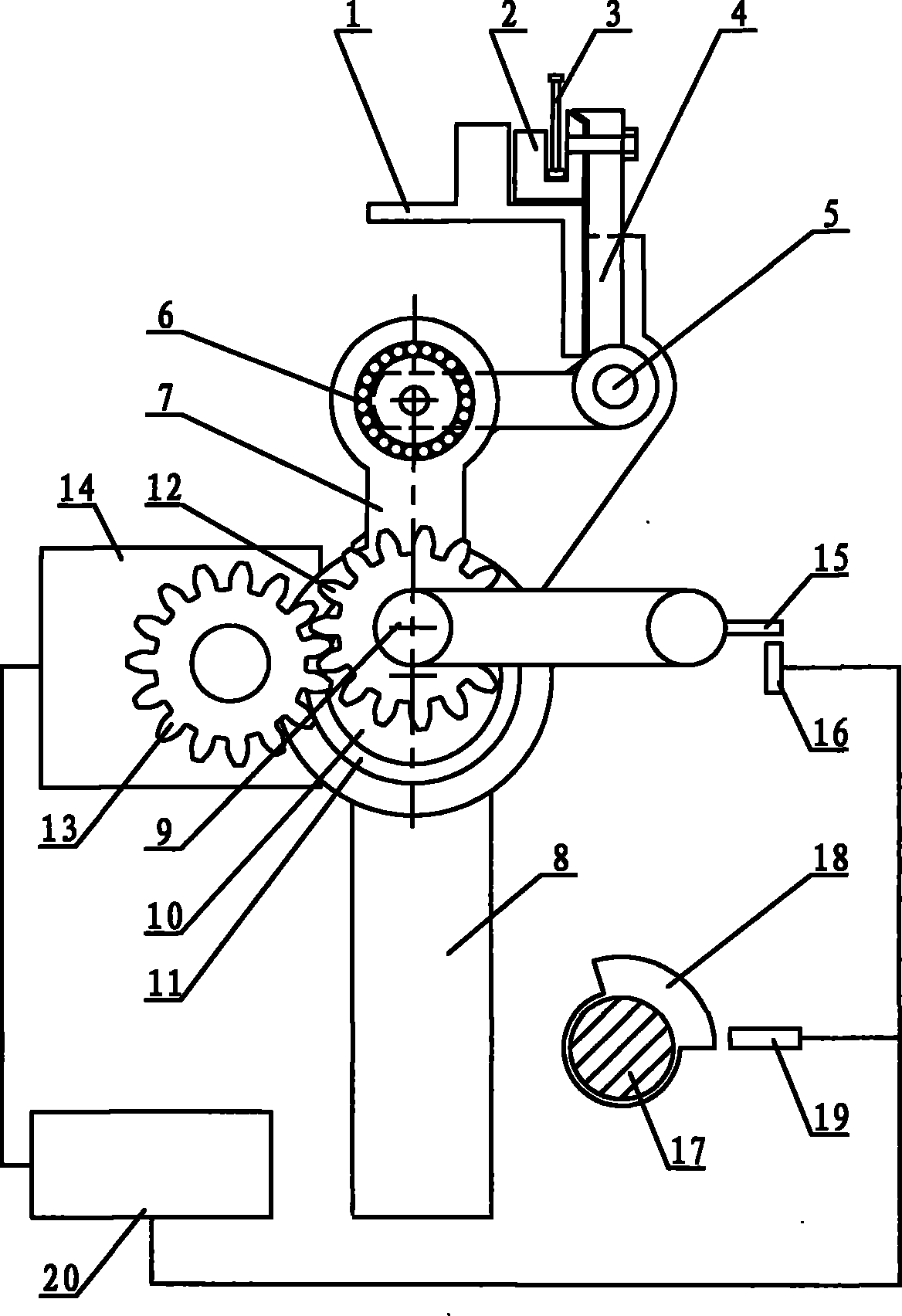

[0016] figure 1 As shown, the CNC movable reed mechanism of towel machine mainly includes main sley 1, movable sley 2, steel reed 3, reversing lever 4, supporting shaft 5, link bearing 6, link 7, sley foot 8, rotating shaft 9. Eccentric cam 10, bearing 11, rotating gear 12, output gear 13, CNC motor 14, origin signal convex 15, origin proximity switch 16, towel machine main shaft 17, main signal convex 18, main proximity switch 19, electric control box 20 . The sley foot 8 of the towel machine frame is provided with a rotating shaft 9, and the rotating shaft 9 is fastened with a rotating gear 12 and an eccentric cam 10. To the lever 4, the eccentric cam 10 is connected to one end of the connecting rod 7 through the bearing 11, the other end of the connecting rod 7 is connected to one end of the reversing lever 4 through the connecting rod bearing 6, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com