A three-degree-of-freedom support ball bearing

A technology of degrees of freedom and supporting balls, which is applied in the direction of ball bearings, supporting machines, machine tables/brackets, etc., can solve the problem that the height and dimension of the attitude adjustment platform cannot be further improved, and achieve small friction coefficient, large load capacity, and reduced Effect of height dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

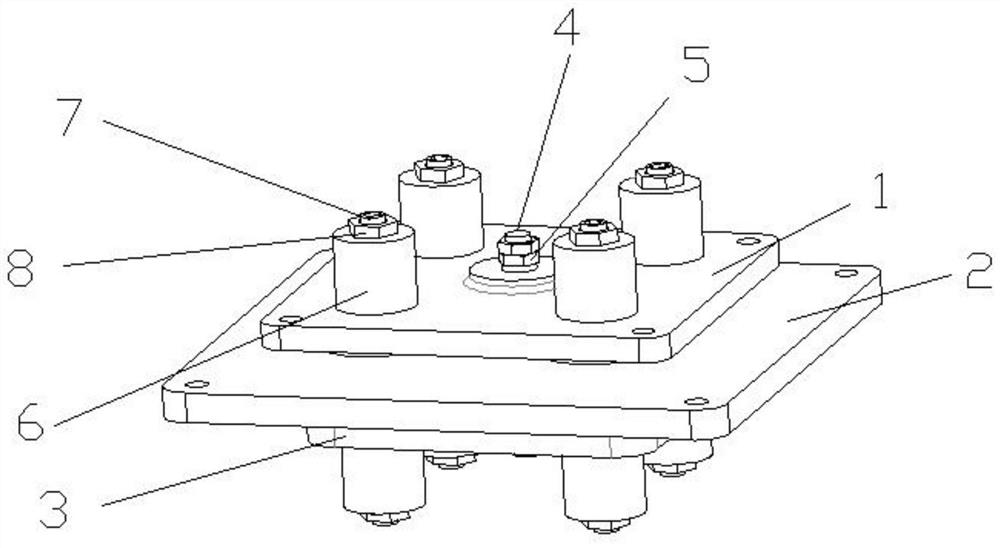

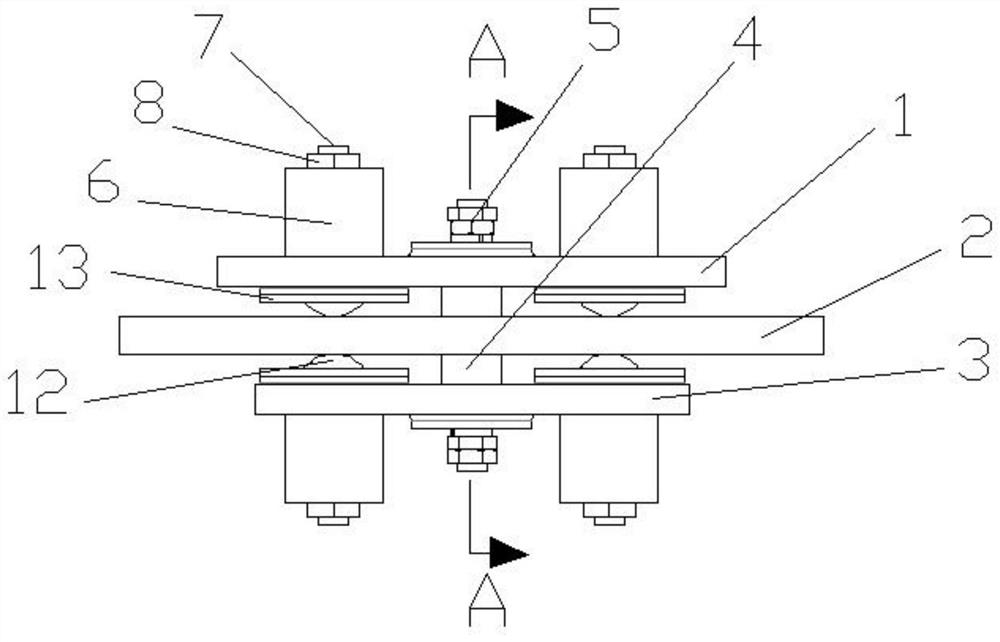

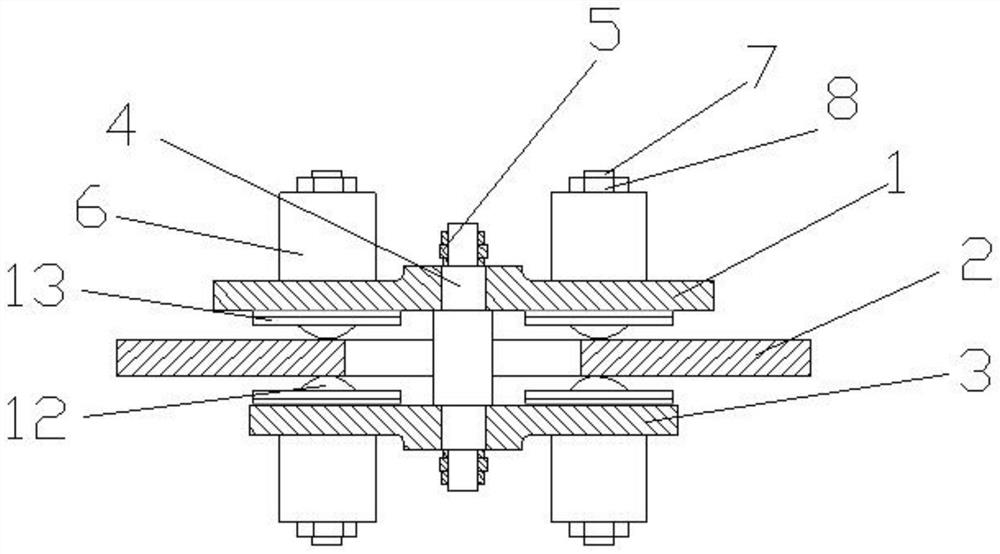

[0019] exist Figure 1 to Figure 4 In the schematic diagram of the present invention shown, the middle part of the middle plate 2, the lower plate 3 and the upper plate 1 is provided with a through hole, the middle connecting shaft 4 passes through the through hole of the middle plate, and the two ends of the middle connecting shaft pass through respectively. The through holes in the middle of the lower plate 3 and the upper plate 1 extend to the outside of the lower plate and the upper plate, and are fixed by connecting shaft nuts 5 . The outer diameter of the intermediate connecting shaft is smaller than the inner diameter of the through hole in the middle part of the intermediate plate. Four concave holes are respectively arranged on the upper surface and the lower surface of the intermediate plate, and the positions of the four concave holes on the upper and lower surfaces of the intermediate plate correspond to each other. Four through holes are respectively arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com