Patents

Literature

4758results about "Ball bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

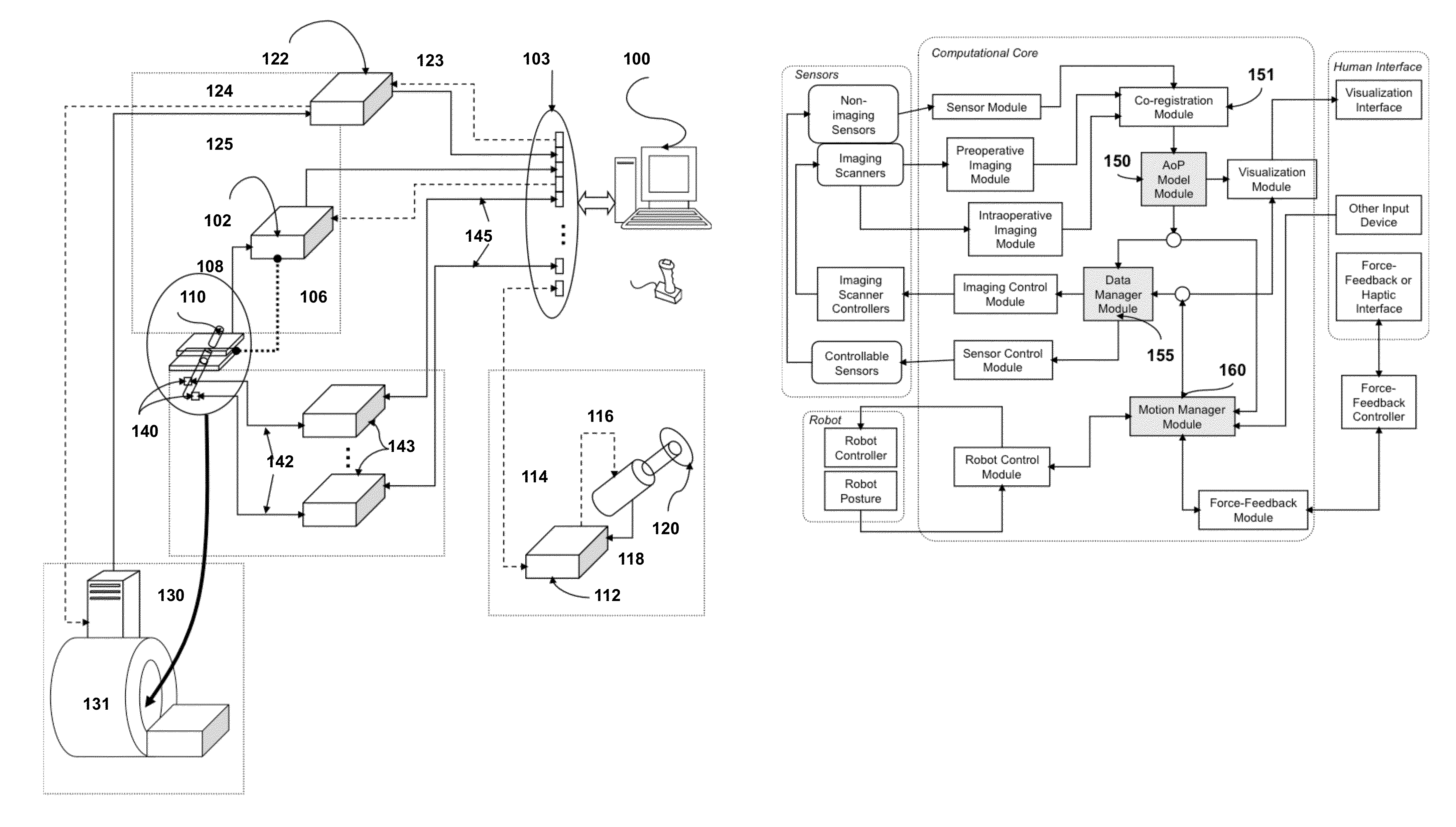

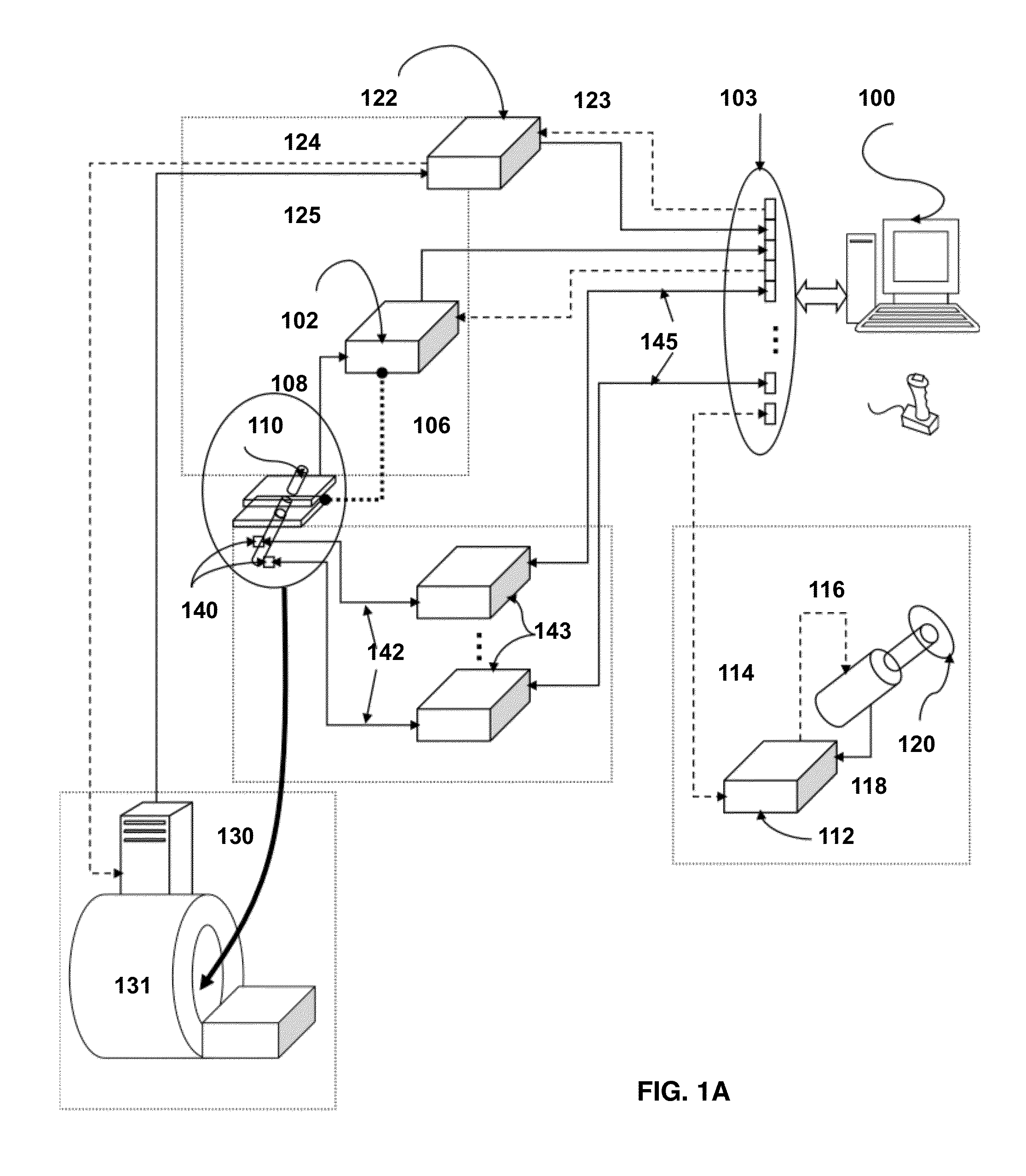

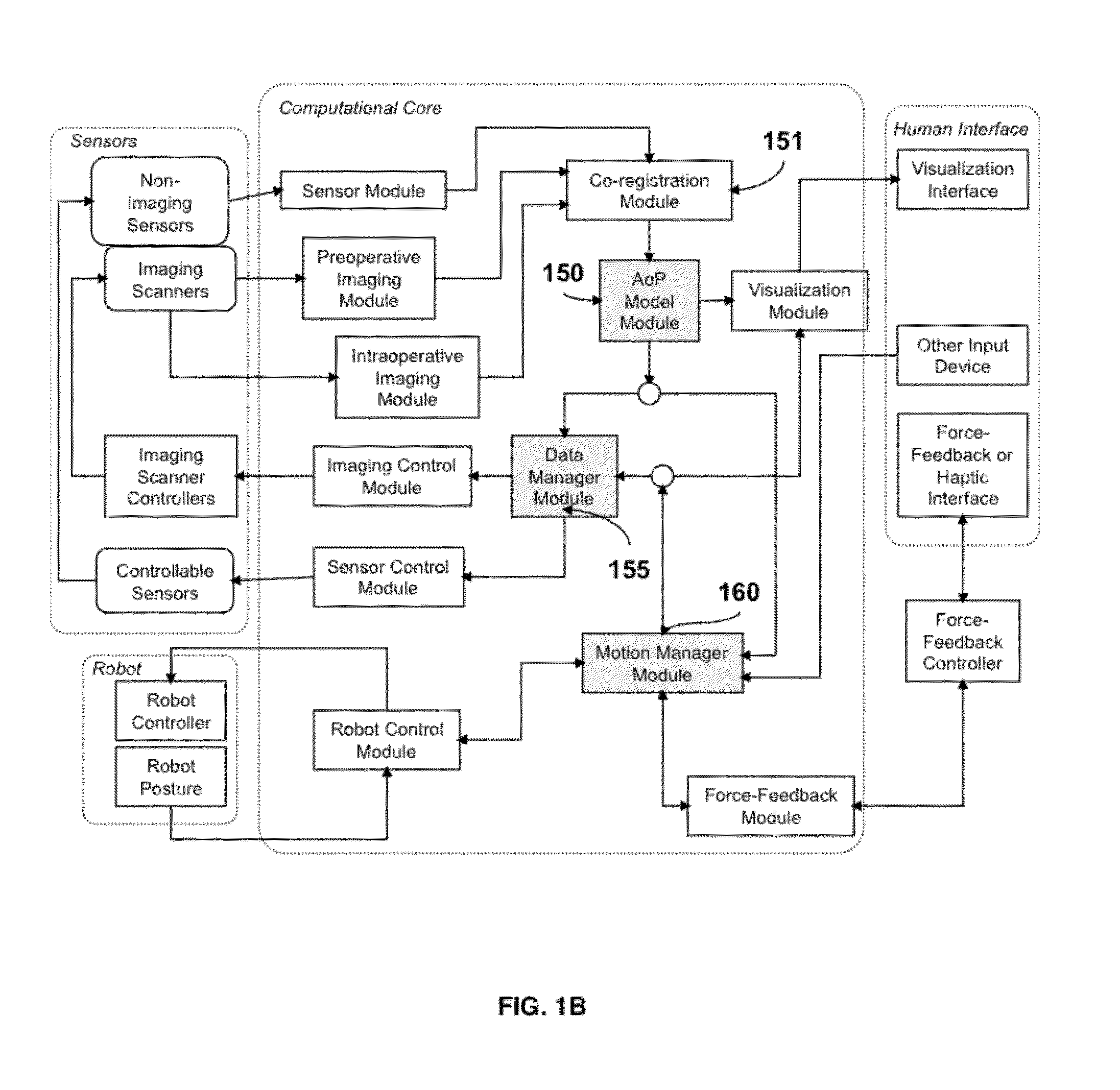

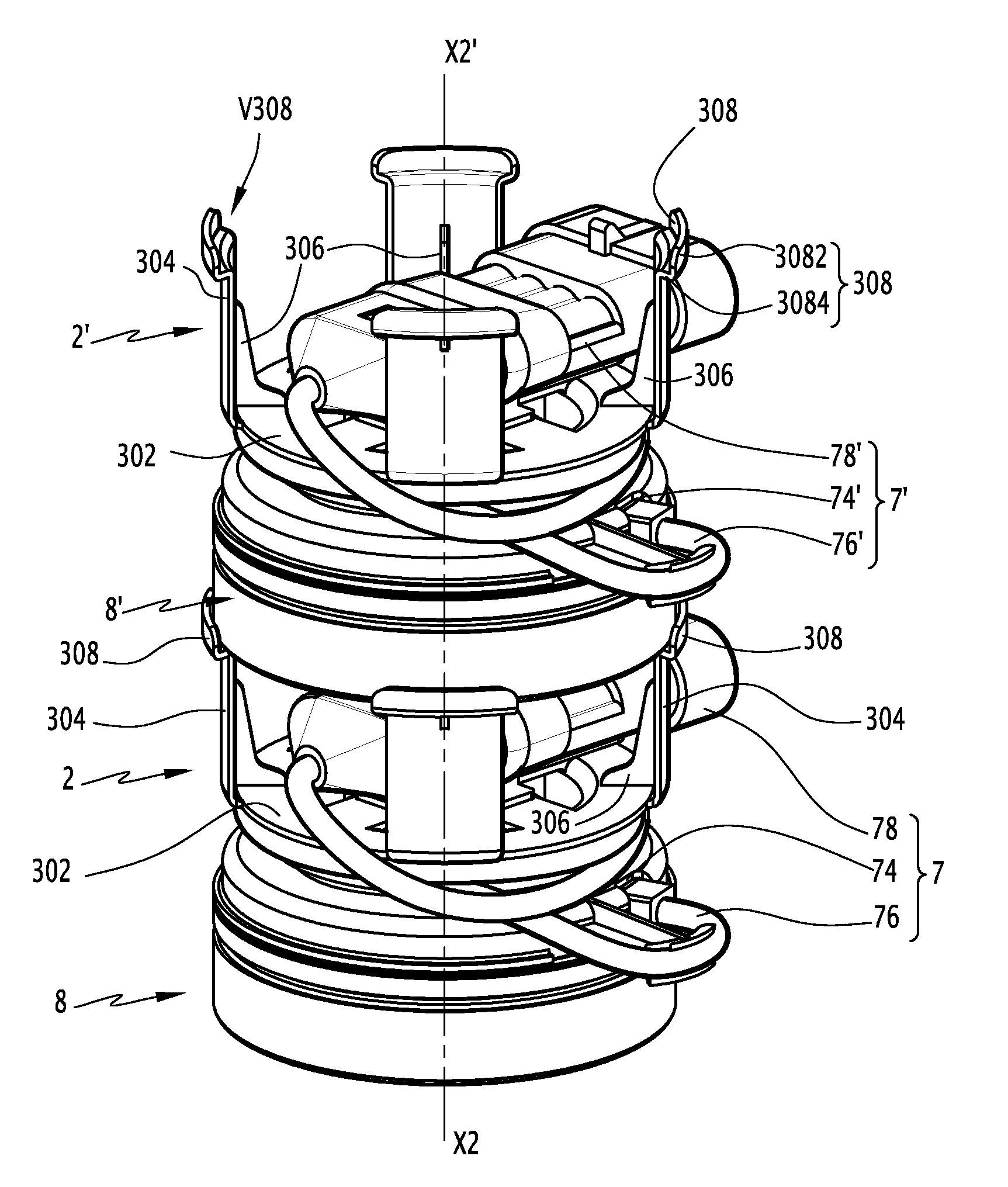

Robotic Device and Systems for Image-Guided and Robot-Assisted Surgery

Provided herein are robotic systems, for example, MRI guided robots, for image-guided robot-assisted surgical procedures and methods for using the same to perform such surgical procedures on a patient. The robotic systems comprise a robotic manipulator device or global positioner, means for actuating the robotic manipulator or global positioner that is mechanically linked thereto and a computer having a memory, a processor and at least one network connection in electronic communication with the robotic system. The actuating means comprises at least one transmission line having a flexible component comprising a displaceable medium, a rigid component comprising rigid pistons or a combination through which actuation is transmitted to the robotic manipulator or global positioner. The computer tangibly stores in memory software modules comprising processor-executable instructions to provide interfaces between the robotic system, an imaging system and an operator and to control operation thereof.

Owner:UNIV HOUSTON SYST

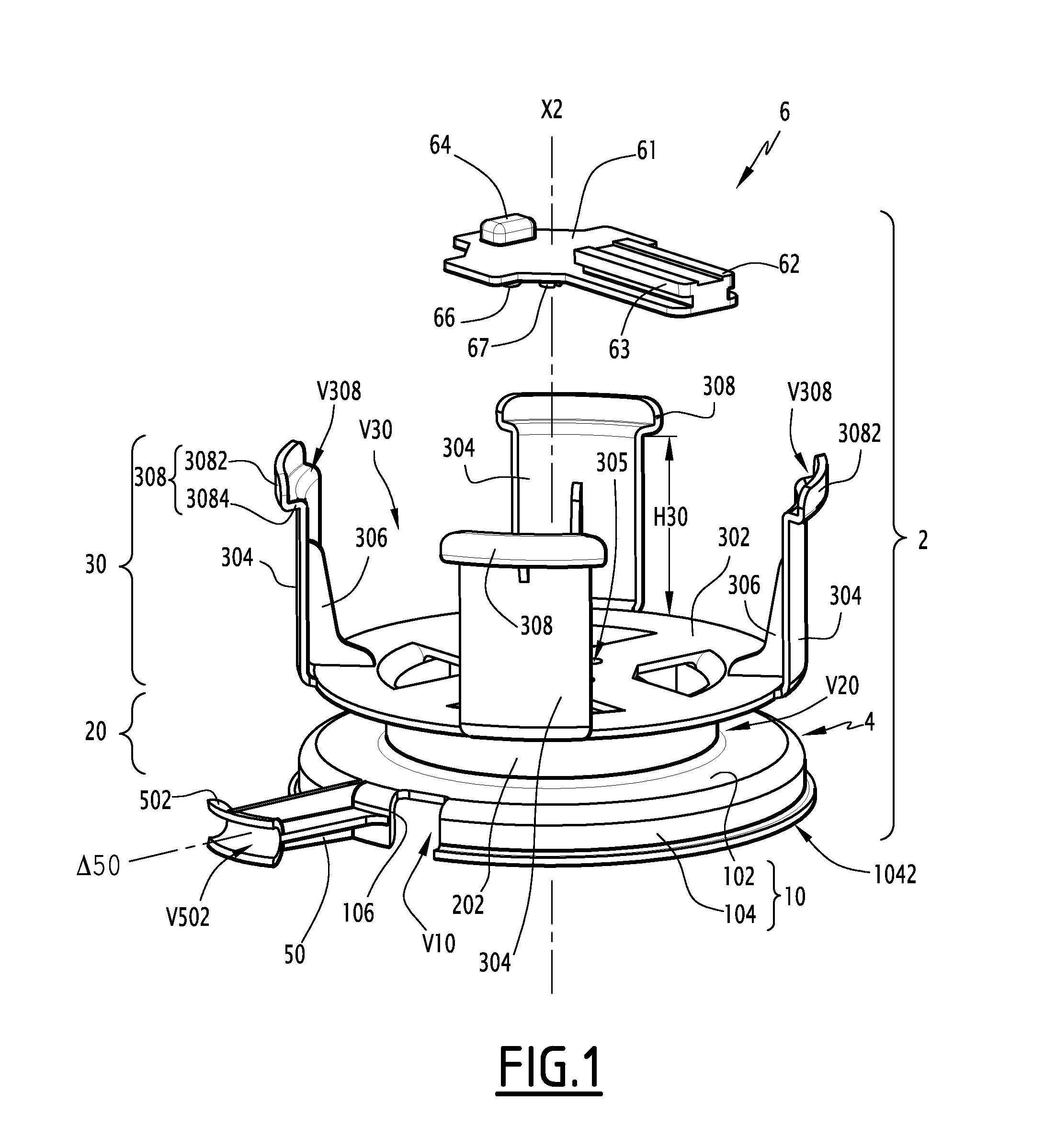

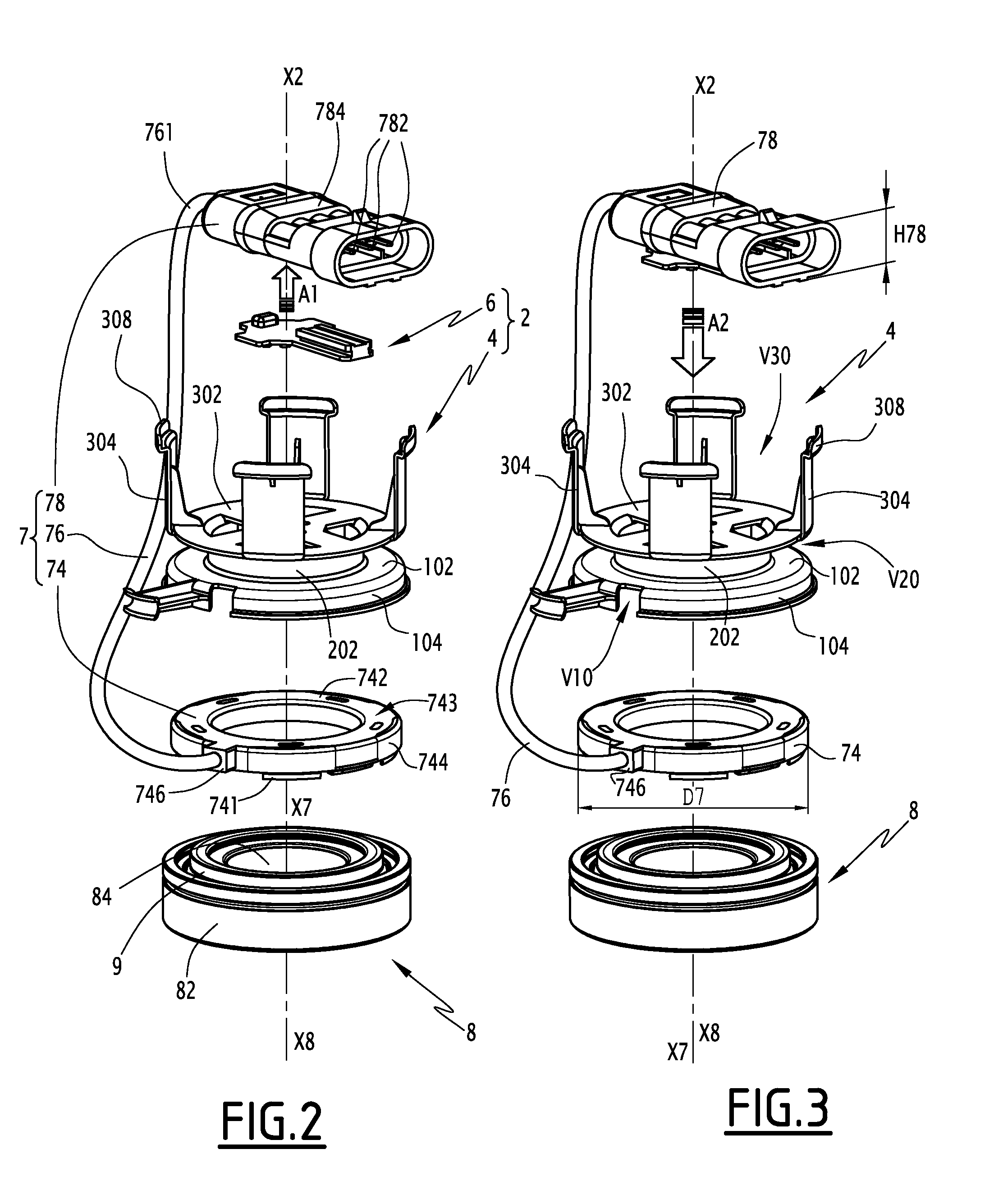

Temporary support member for a sensor unit of a bearing, sensing sub-assembly and bearing assembly comprising such a support member

ActiveUS20130301966A1Improve automationPipe supportsBearing assemblyEngineeringMechanical engineering

This temporary support member for a sensor unit of a bearing assembly is stackable with a similar support member when a sensor unit is mounted on each one of the support member and the similar support member.

Owner:AB SKF

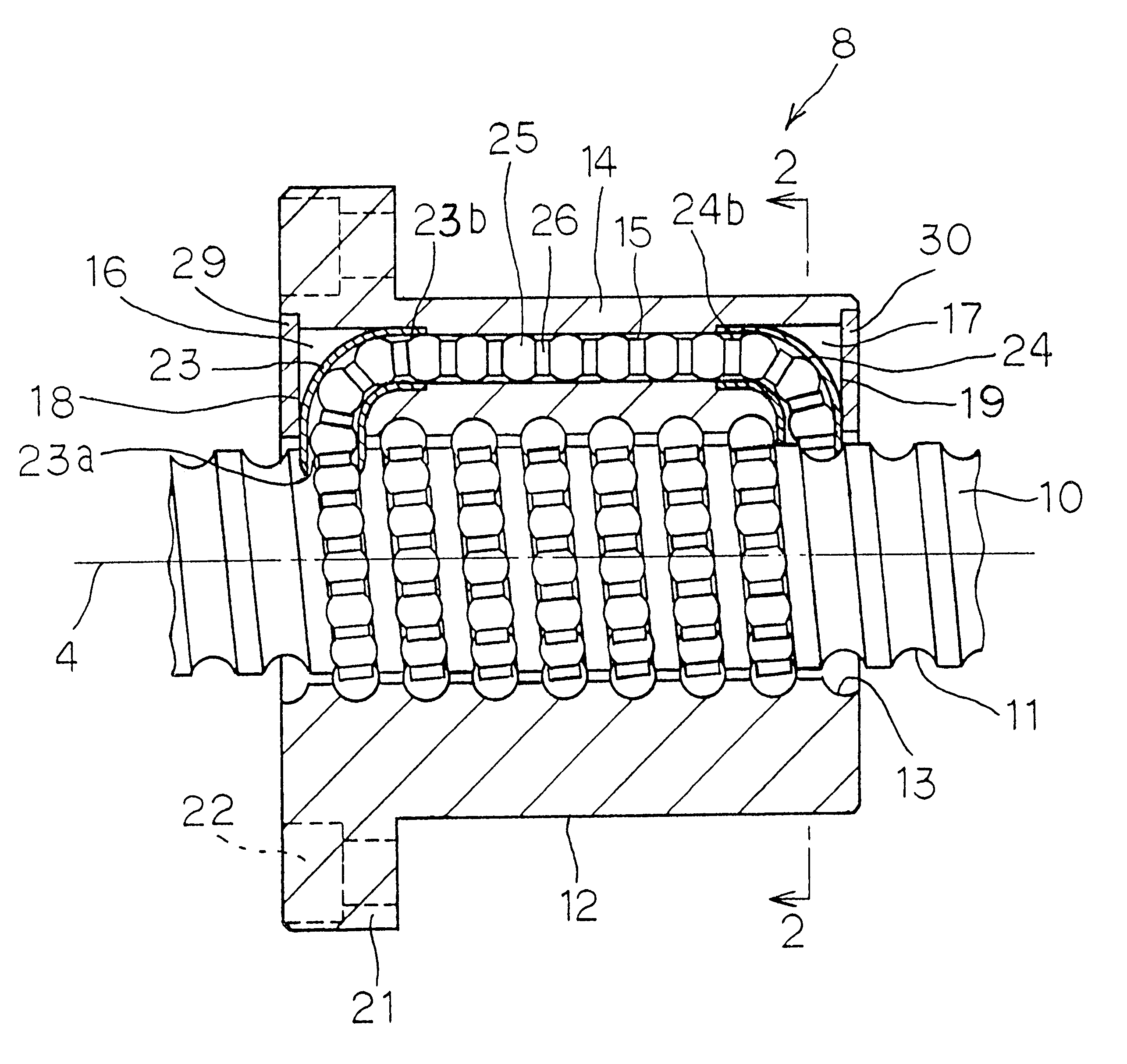

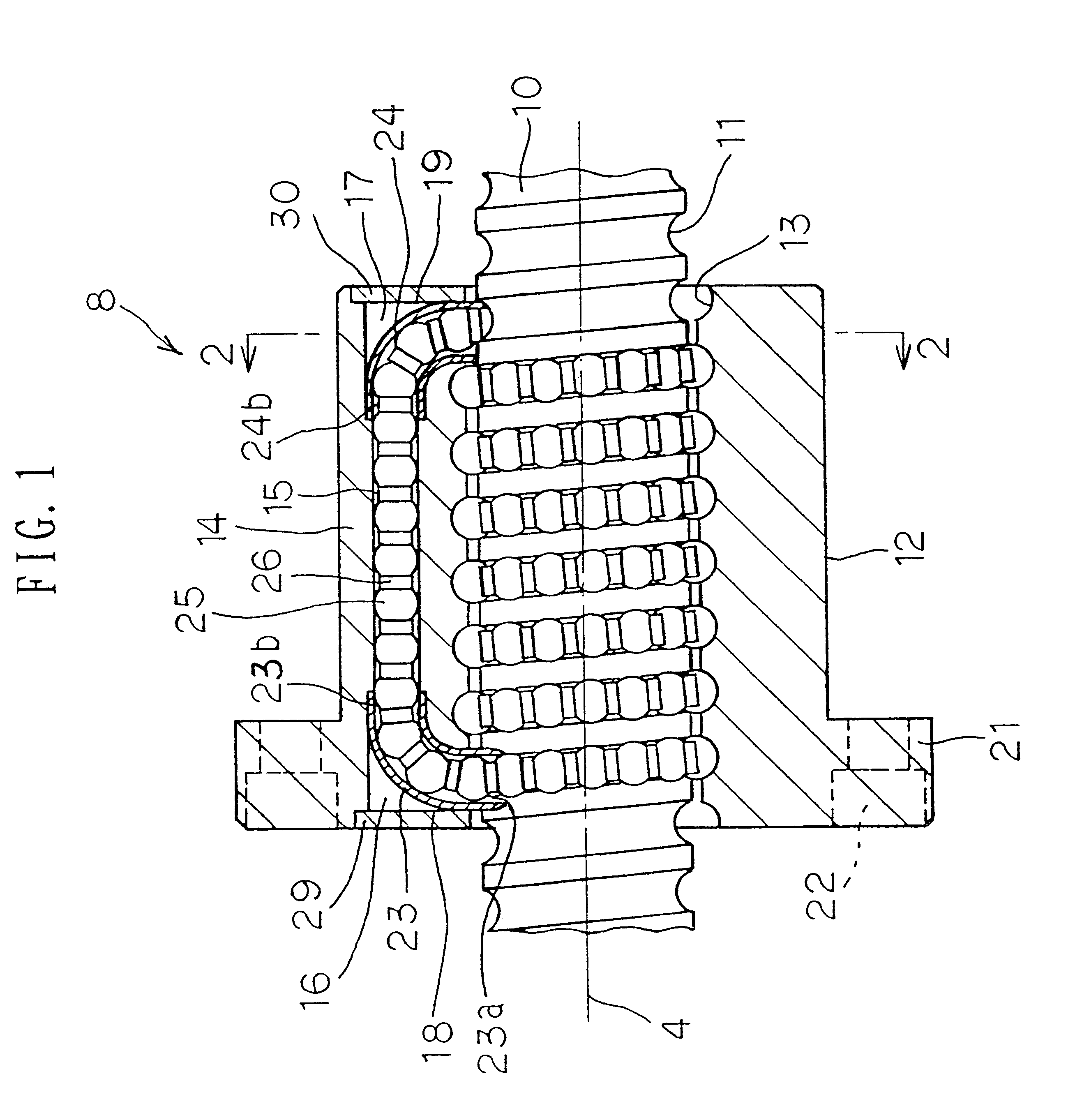

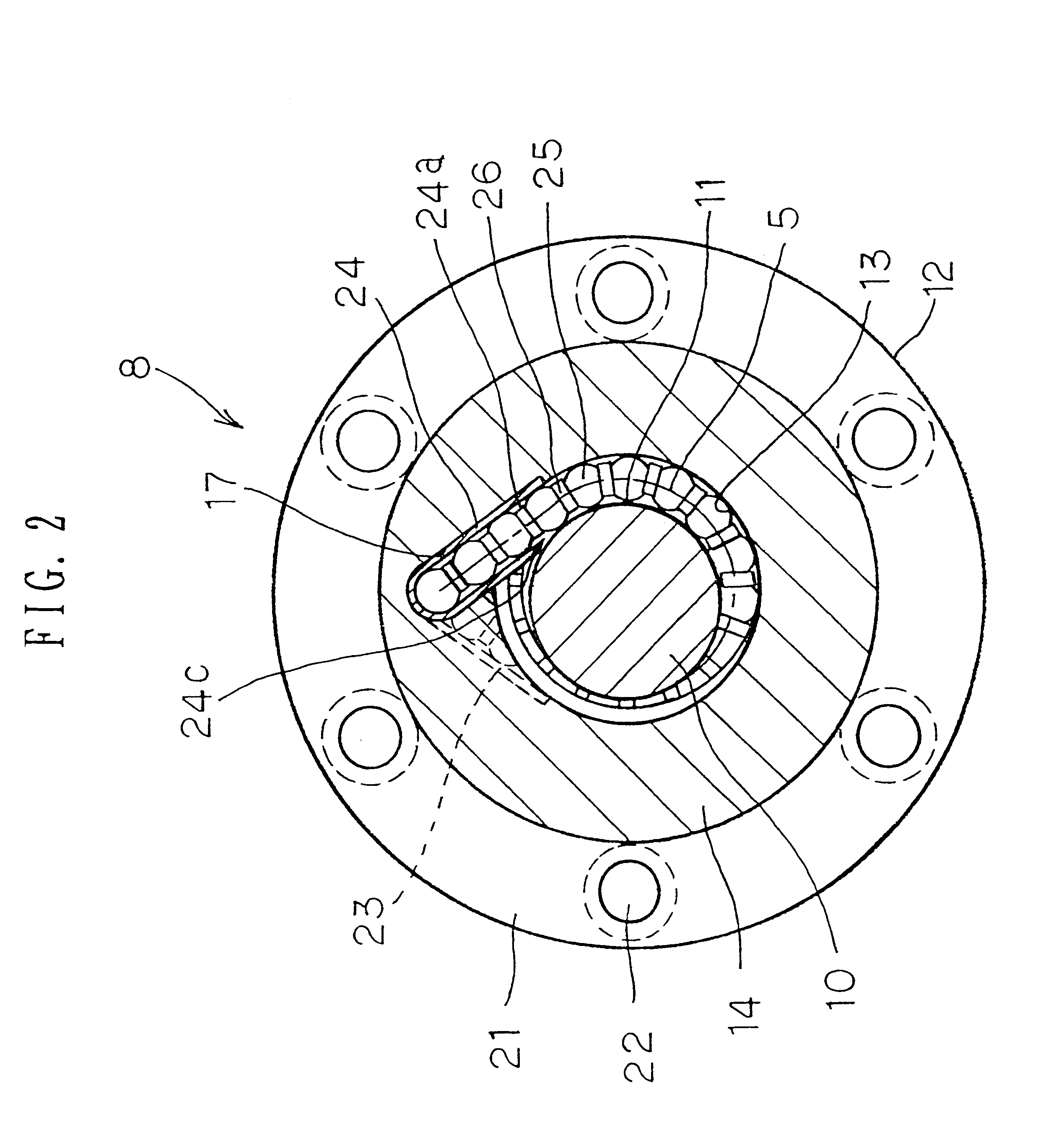

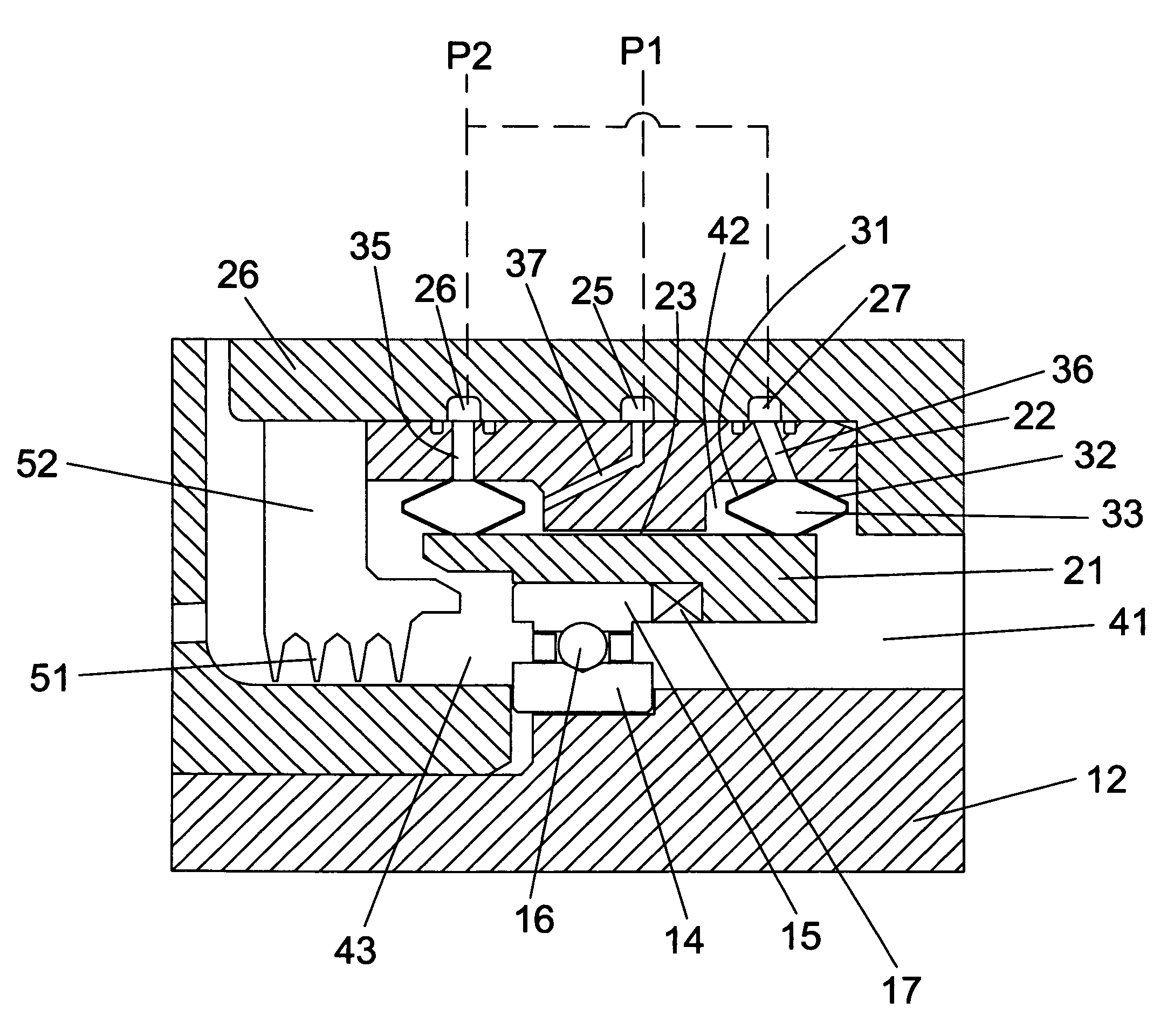

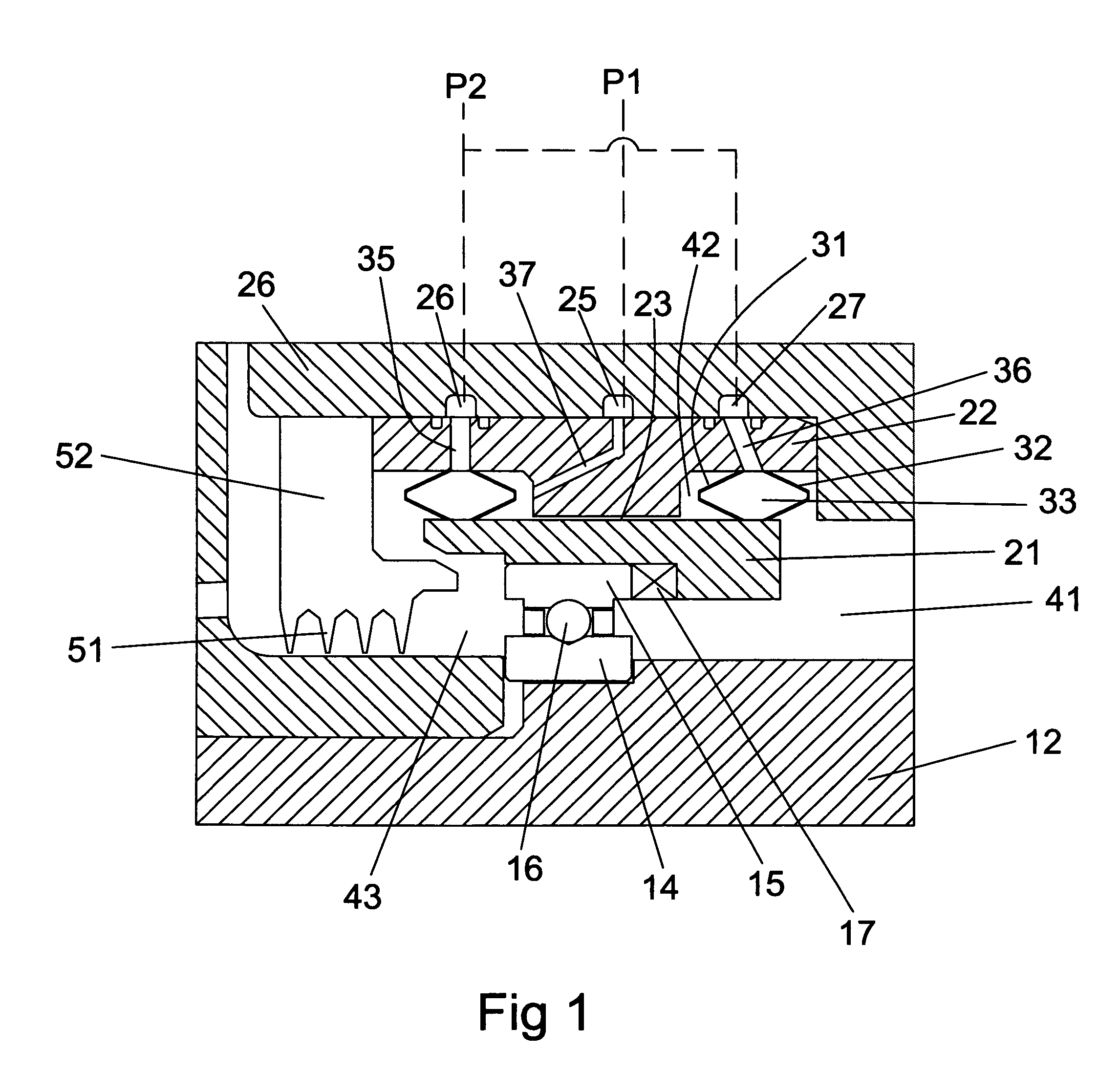

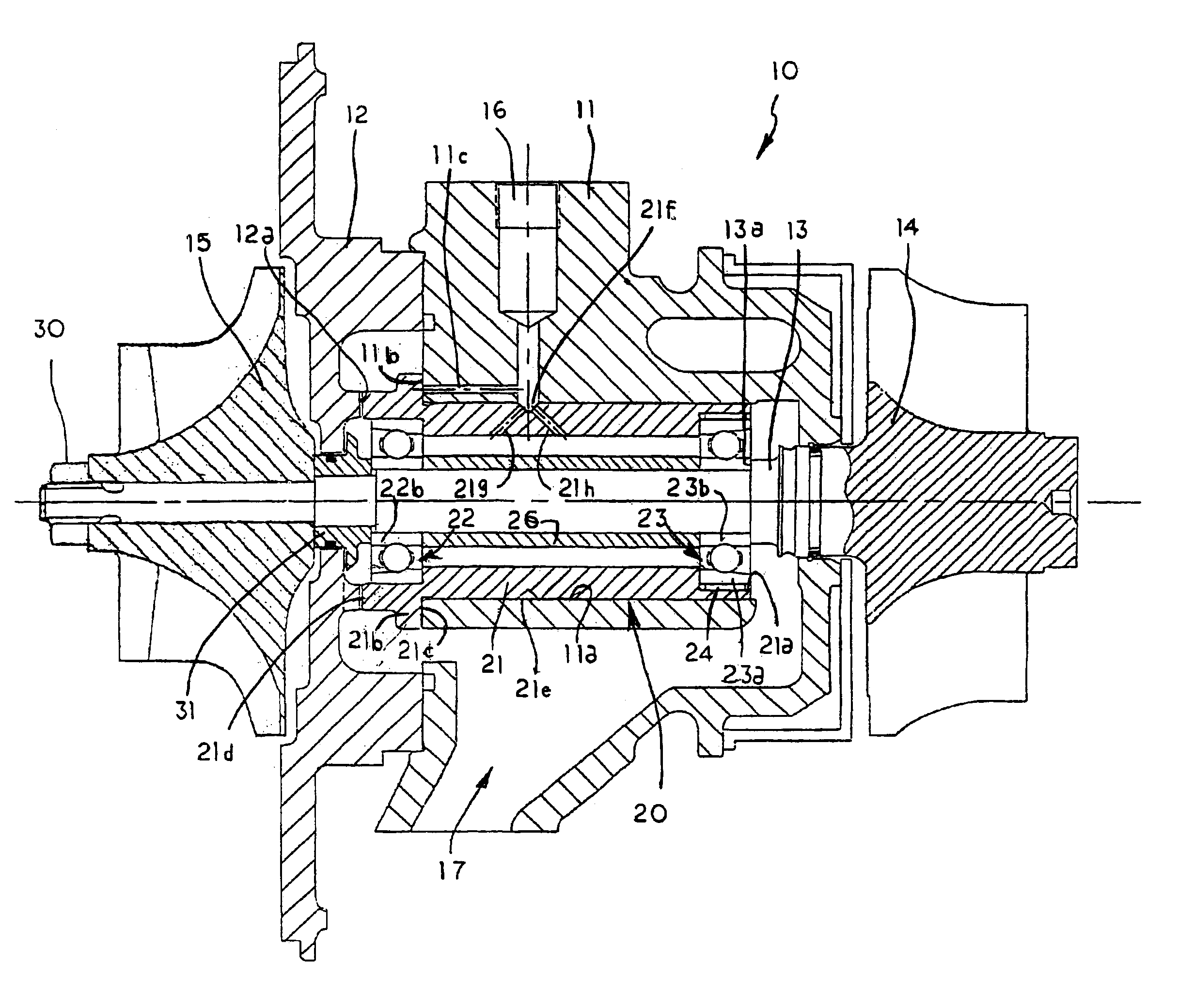

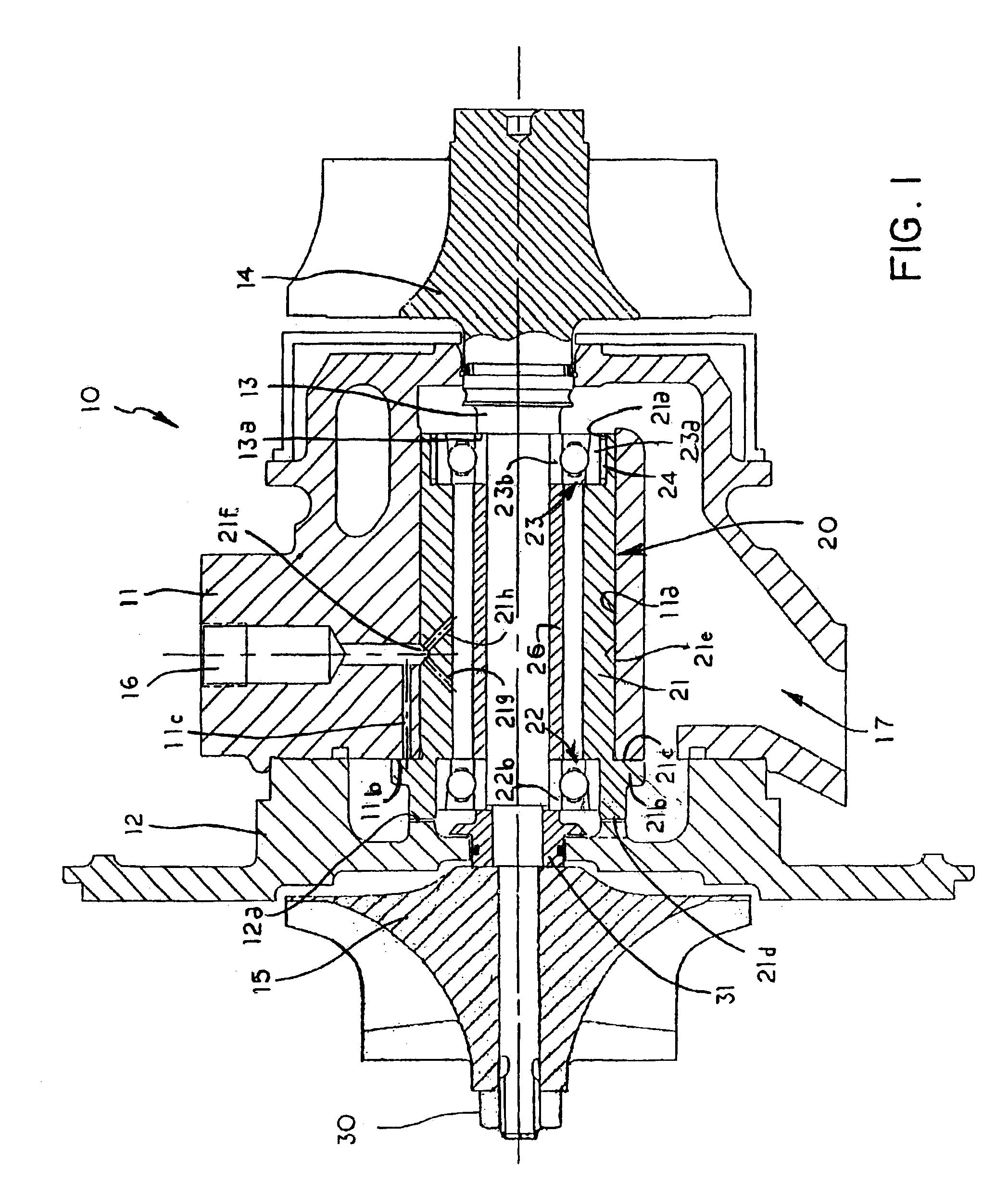

Ball screw having spacers

InactiveUS6176149B1Improve carrying capacityIncrease stiffnessControlling membersLinear bearingsCarrying capacityReciprocating motion

Spacers 26 each of which has a concave surface 27 complementary to the spherical surface of a ball 25 at each end thereof are disposed at areas between the adjacent balls 25, 25. A ball circulation mechanism comprises; a through hole 15 which extends in parallel to an axial line 4 of the ball nut 12 inside a thick wall part 14 of the ball nut 12; and adapters 23, 24 having open ends 23a, 24a provided with tongue portions 23c, 24c for scooping up or returning balls 25 between a ball screw groove 11 of a ball shaft 10 and a ball screw groove 13 of the ball nut 12, and the other open ends 23b, 24b being connected to be in communication with the through hole 15, and each adapter being fitted into recesses 16, 17 provided on both axial ends in the thick wall part 14 of the ball nut 12. Therefore, there is no need of upsizing a ball screw, and thus a compact ball screw which has a high load-carrying capacity and is suitable for a reciprocating movement can be provided.

Owner:TSUBAKI NAKASHIMA

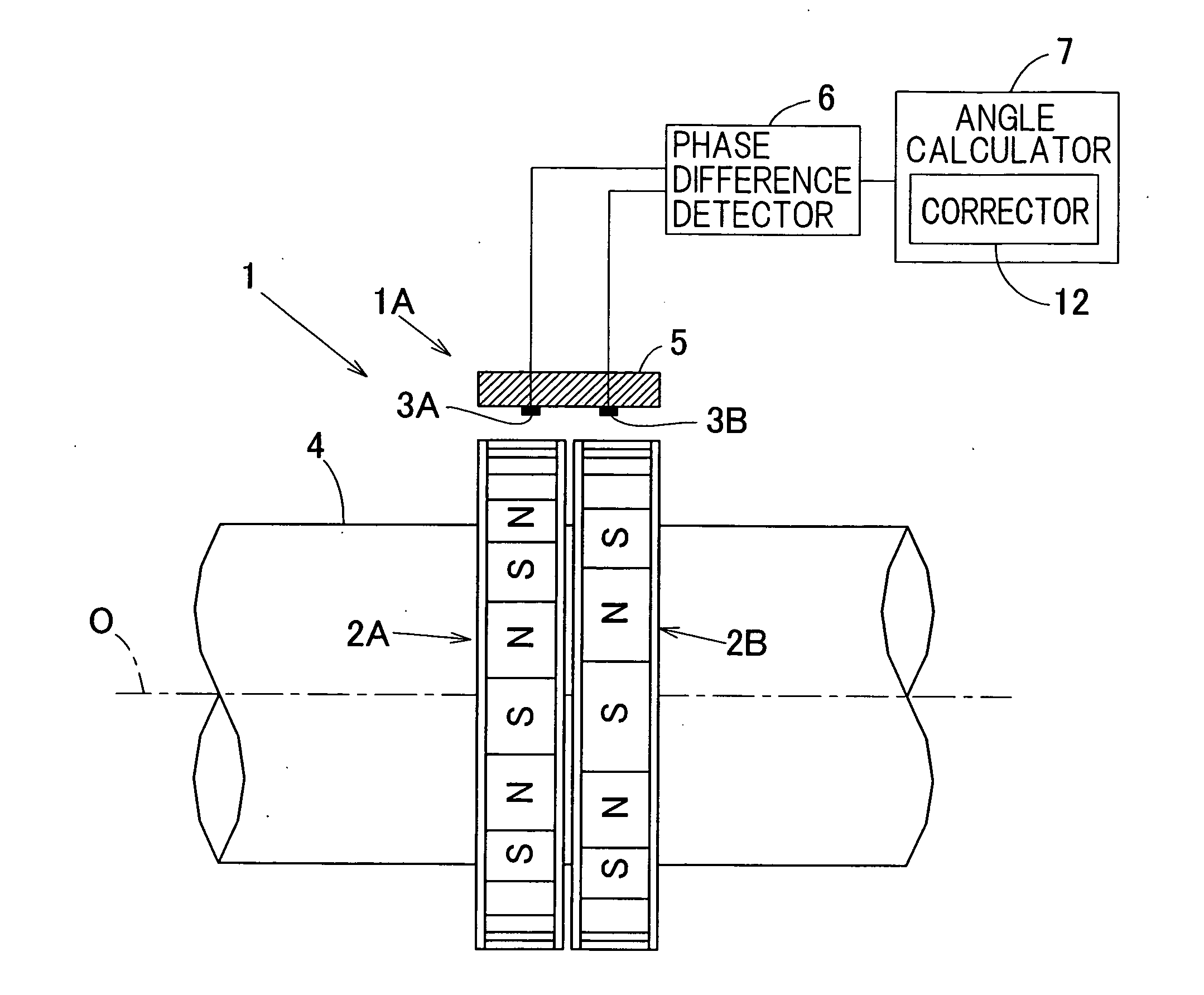

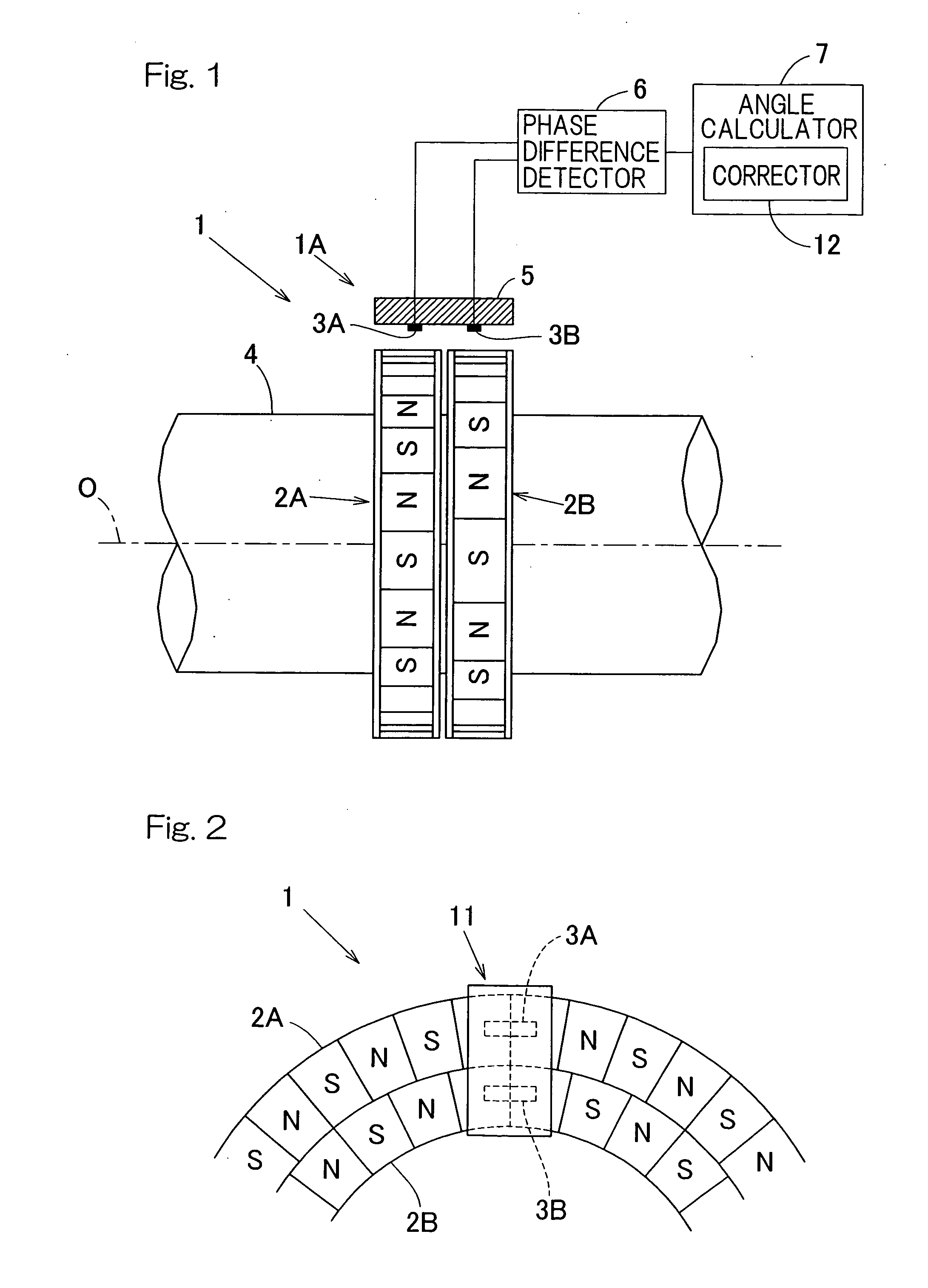

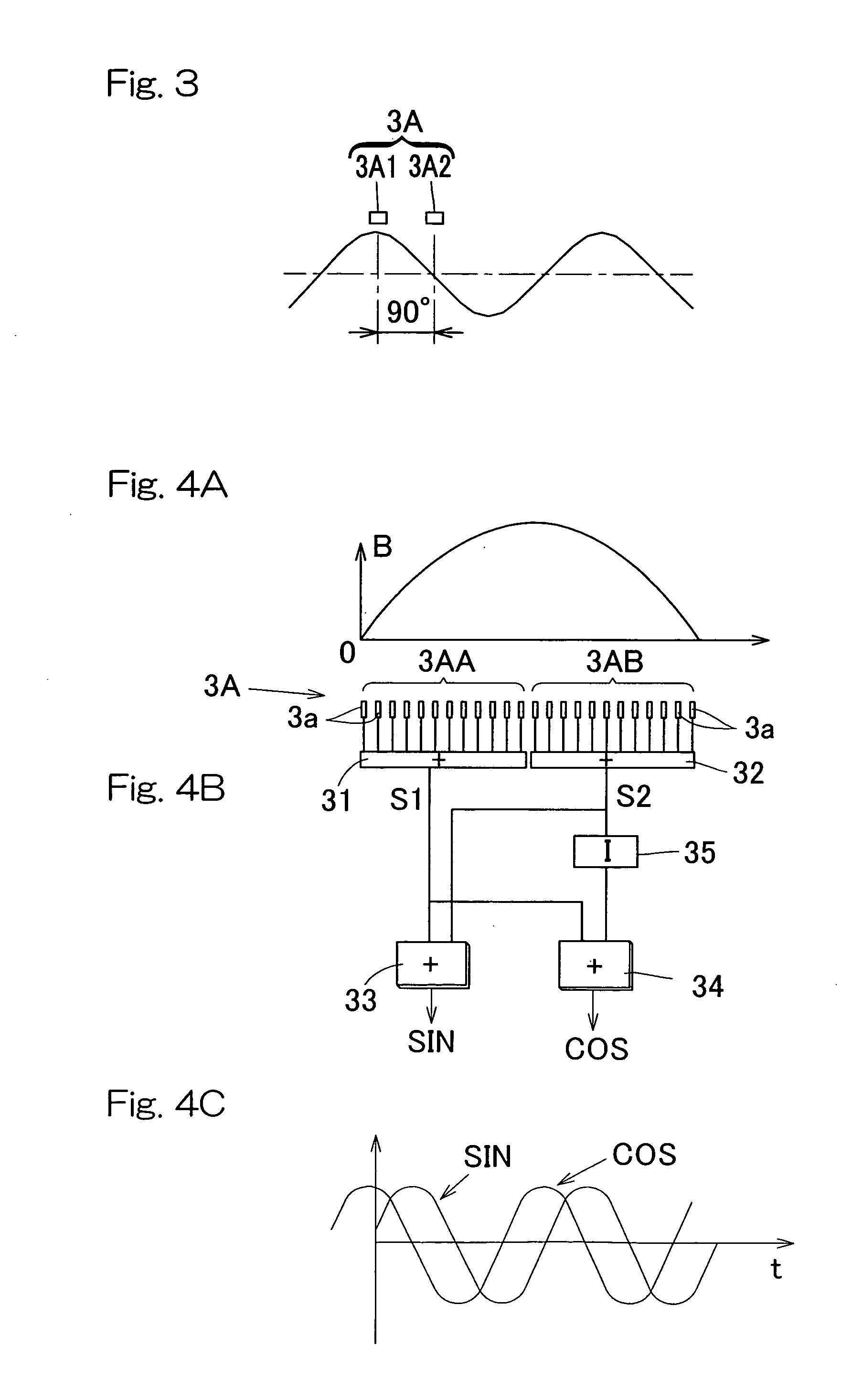

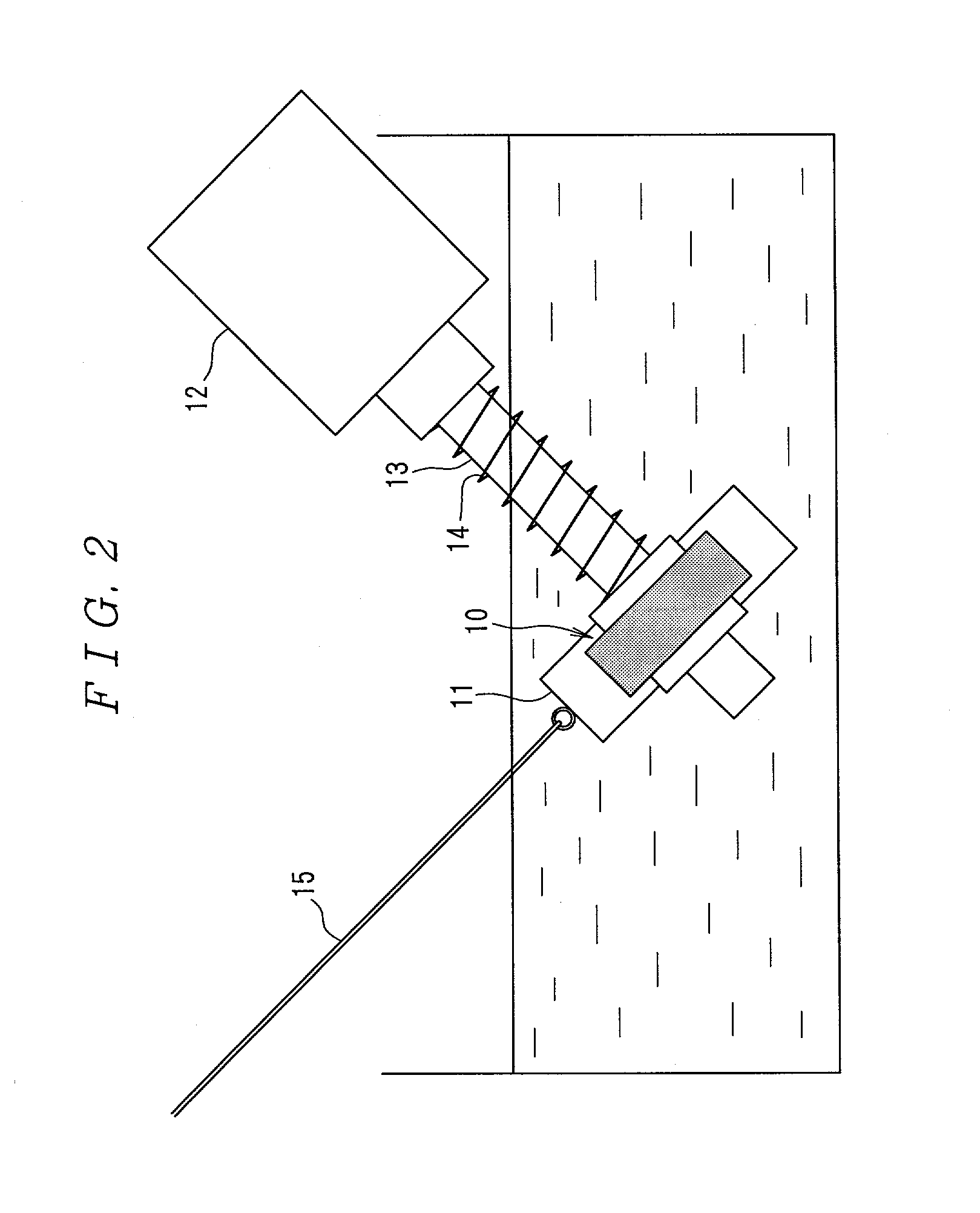

Rotation detection device and rotation detector equipped bearing assembly

ActiveUS20090315544A1Highly vehicle controlEasy to operateBearing assemblyRailway vehiclesAbsolute rotationPhase difference

There is provided a rotation detection device 1 which includes a plurality of magnetic encoders (2A, 2B) of a ring shape arranged coaxially and having different numbers of magnetic poles, a plurality of magnetic sensors (3A, 3B) each operable to detect the magnetic field of the corresponding magnetic encoder and having a function of detecting positional information within a single magnetic pole of the corresponding magnetic encoder, a phase difference detector (6) for determining the phase difference of magnetic field signals detected respectively by the magnetic sensors (3A, 3B), and an angle calculator (7) for calculating an absolute rotation angle of the magnetic encoders based on the detected phase difference.

Owner:NTN CORP

Squeeze film damper with variable support stiffness

A squeeze film damper assembly having a variable stiffness and damping control. The squeeze film damper includes a damper chamber formed by two flexible bellows chambers of the sides. A first pressure source is applied to the damper chamber to regulate the damping. A second pressure source is applied to the flexible bellows chambers to vary the stiffness of the damper. The flexible bellows chambers are secured between an outer member and an inner member of the damper assembly and form the sealed damper chamber. A pressure ratio between the bellows chambers and the damper chamber can vary to control the stiffness of the squeeze film damper.

Owner:FLORIDA TURBINE TECH

Tensioning or deflection pulley for a belt drive

InactiveUS7011593B2Easy to installFirmly connectedGearingBall bearingsRolling-element bearingEngineering

A tensioning or deflection pulley for a belt drive includes a carrier and a track roller comprised of an inner ring, an outer ring, and a connecting assembly, including a wheel disk extending between the inner and outer rings, and a rib assembly disposed in both sides of the disk in circumferential spaced-apart relationship, for interconnecting the inner and outer rings. The track roller is supported on the carrier by a sealed rolling-contact bearing via a fastening screw. A first sealing element is connected to the track roller on a carrier-distal side, and a second cap-shaped sealing element is disposed between the carrier and the track roller and detachably secured to the inner ring of the track roller to thereby seal the track roller on both sides.

Owner:INA SCHAEFFLER KG

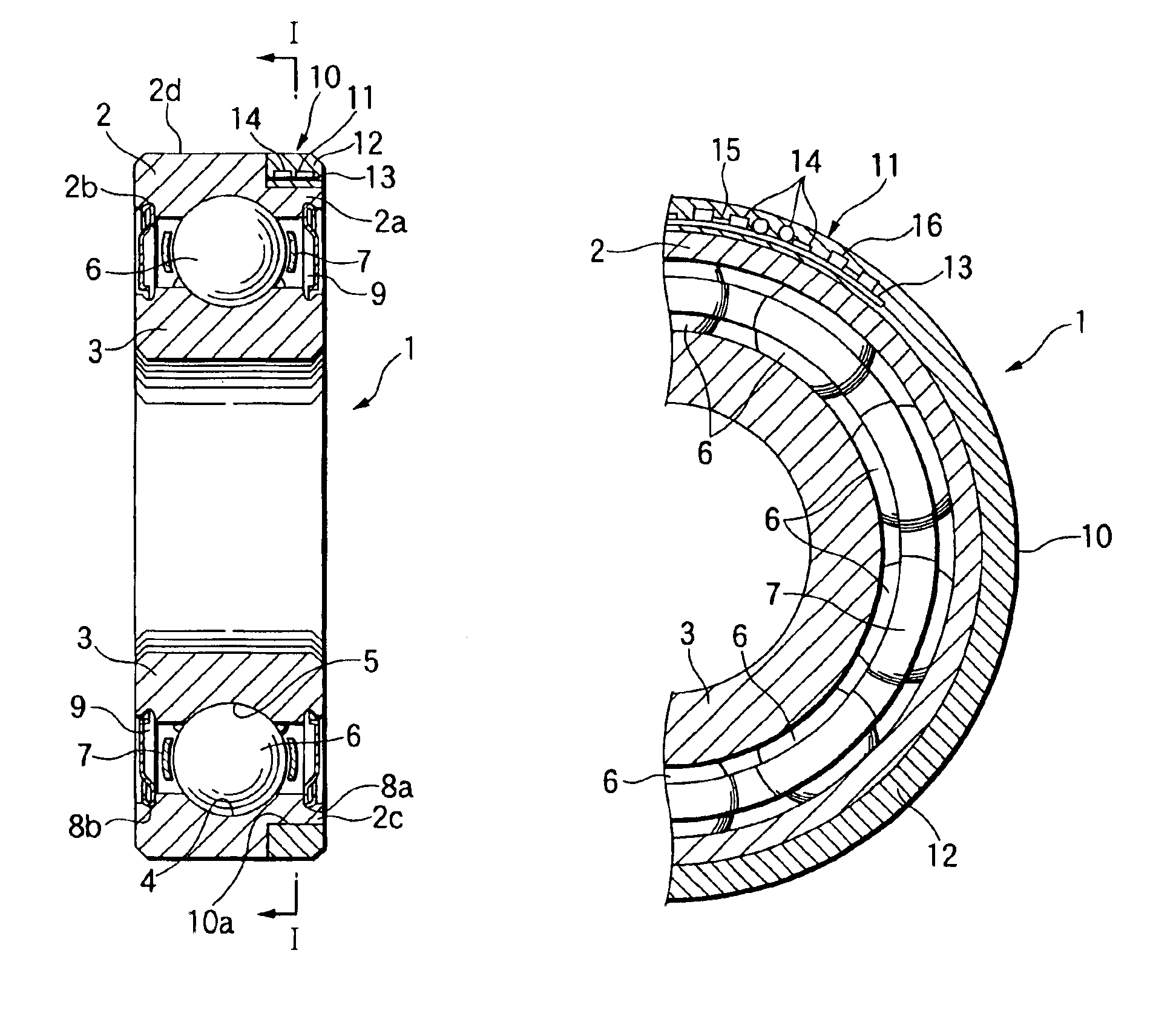

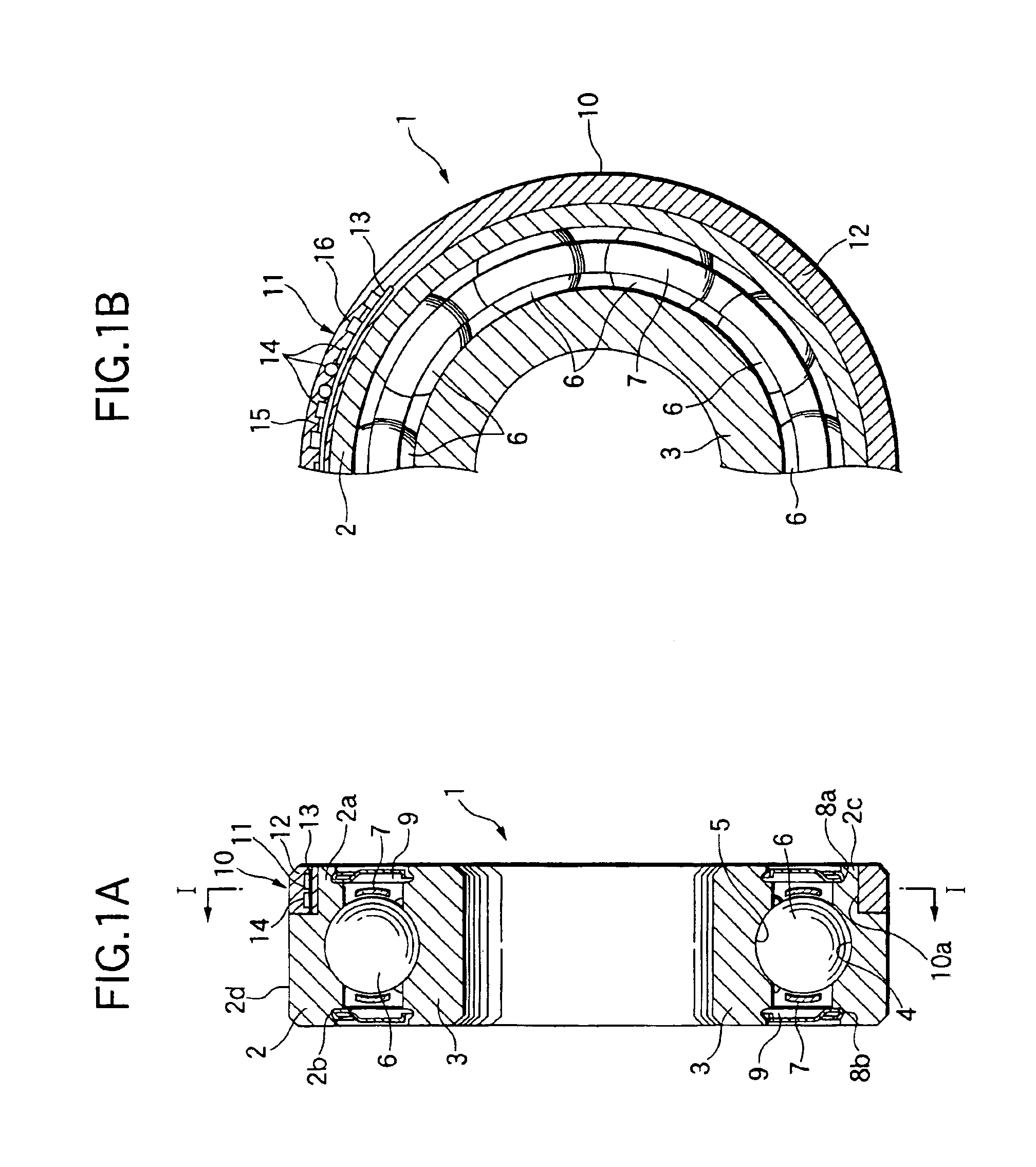

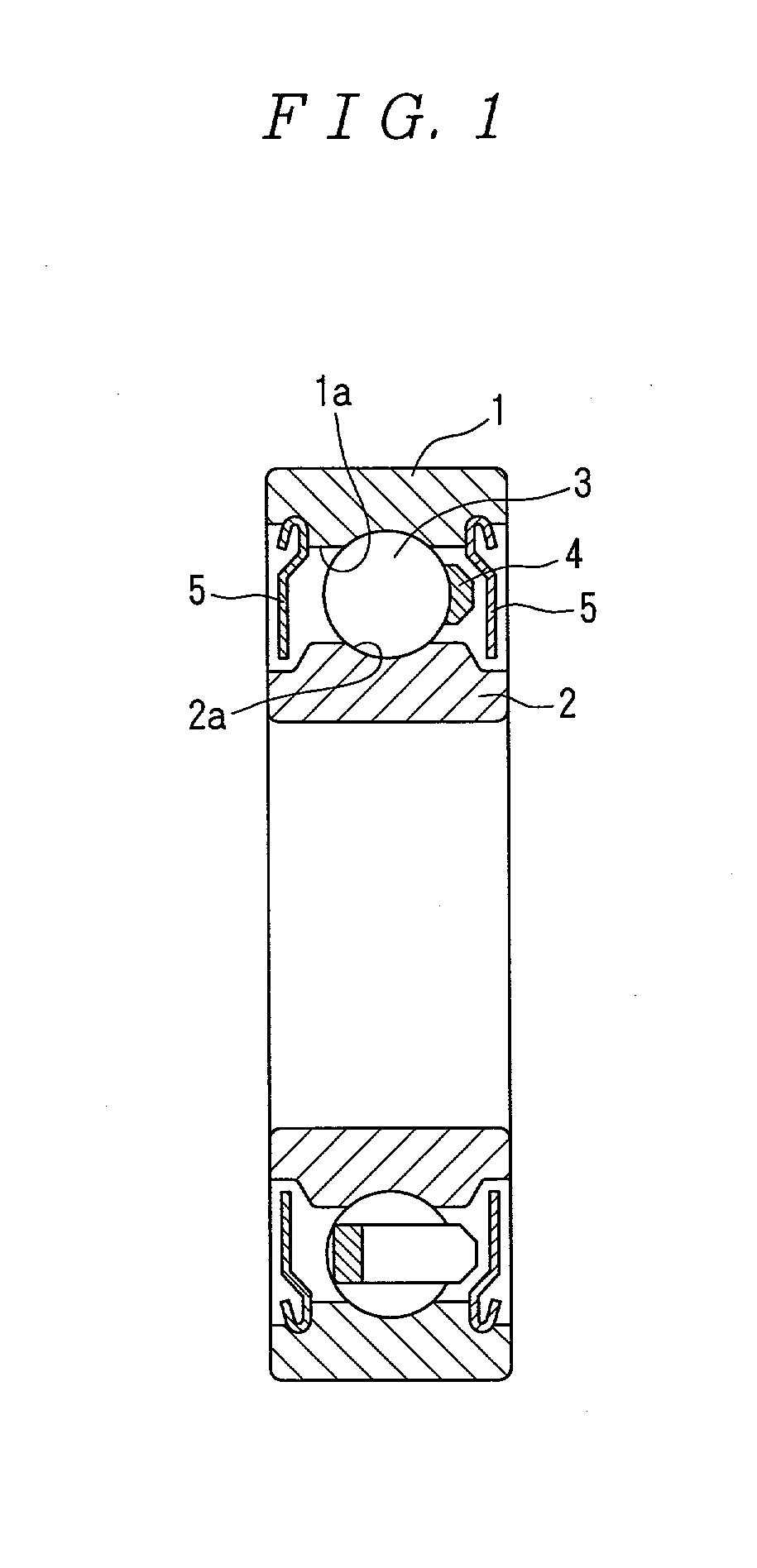

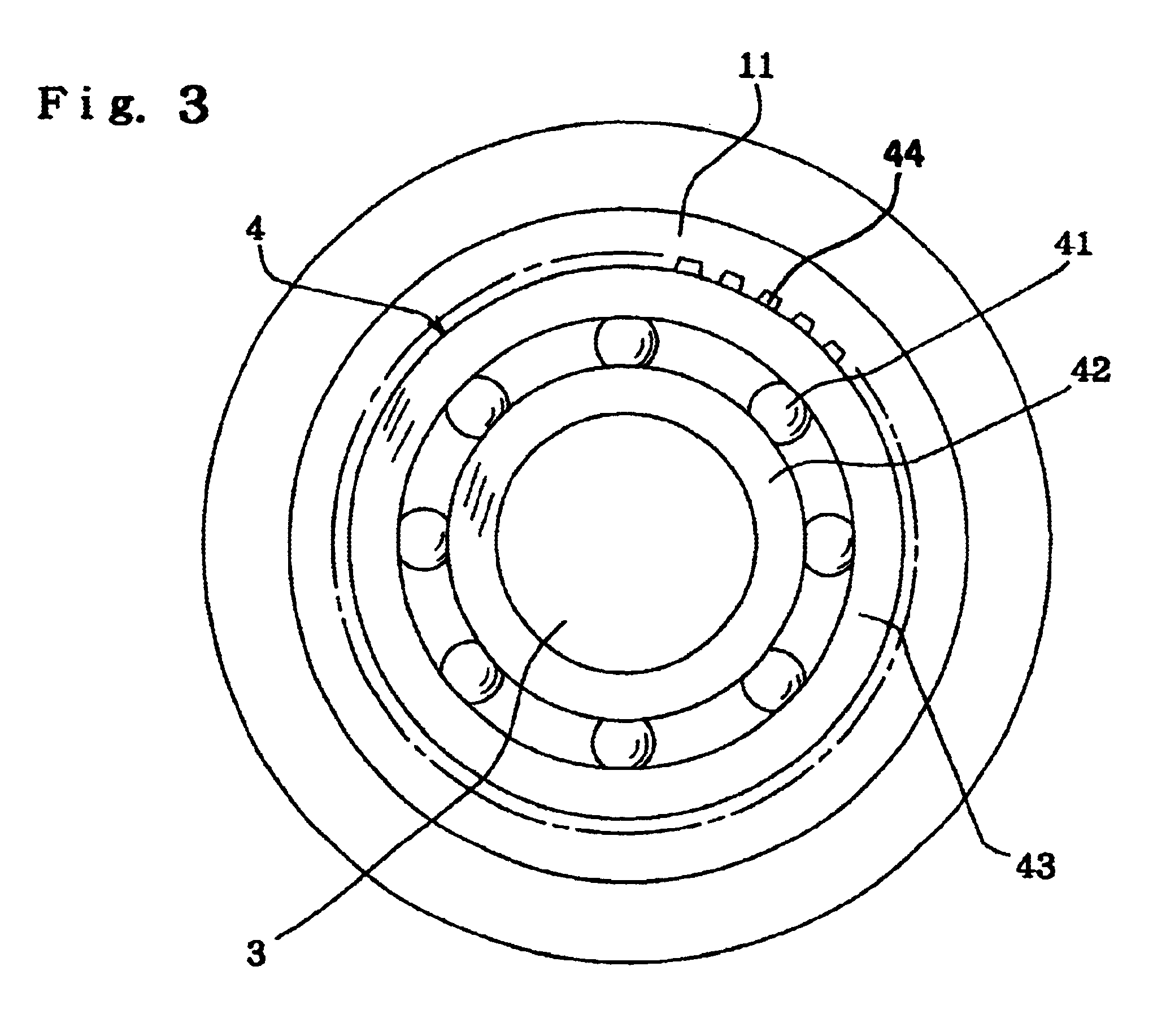

Rolling bearing device and ring with sensor for the rolling bearing device

InactiveUS6948856B2Minimize formationGood adhesionBearing assemblyBall bearingsRolling-element bearingElectrical and Electronics engineering

Owner:NSK LTD

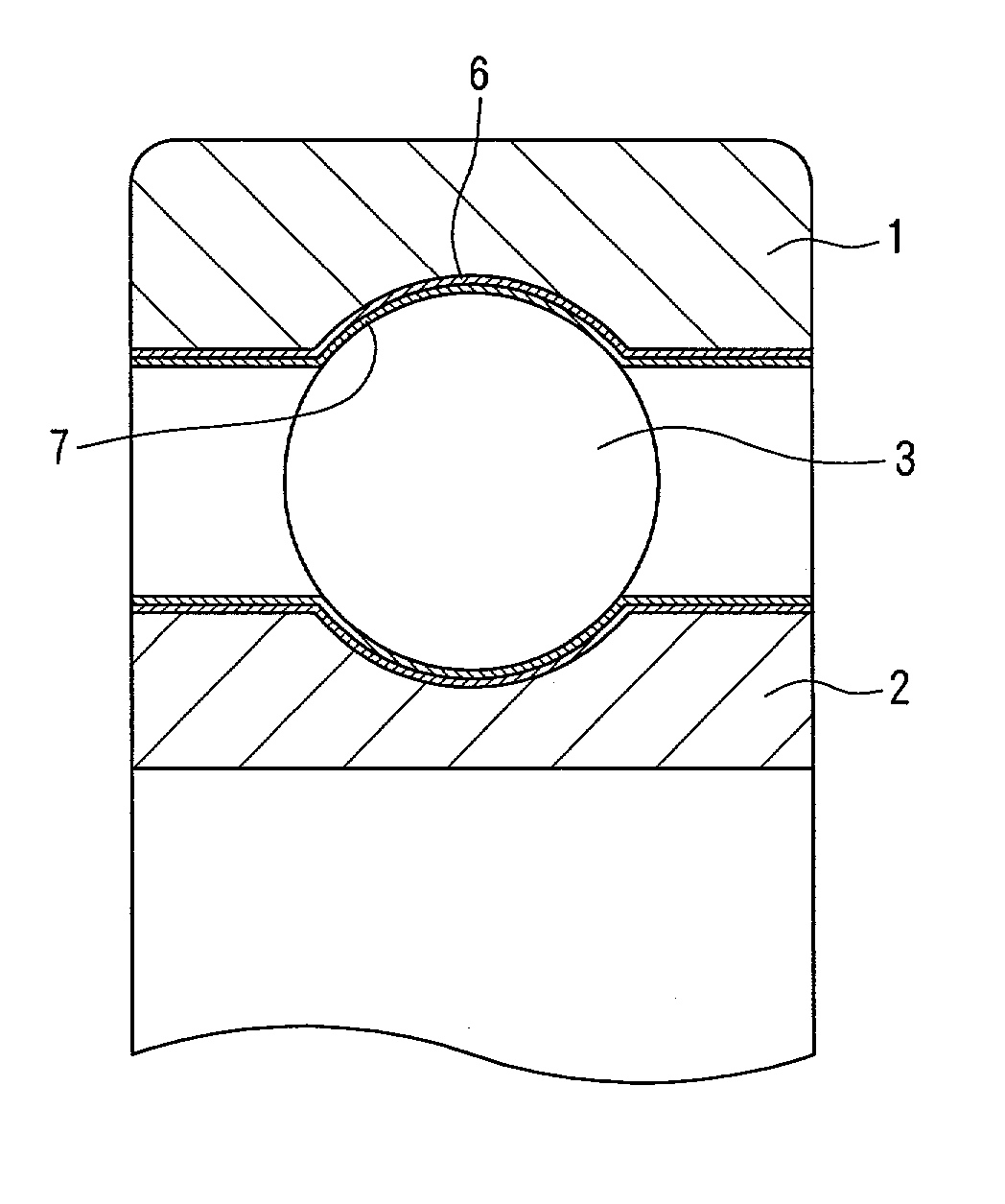

Rolling apparatus

The bearing rings 1 and 2 of a rolling bearing is formed of one kind of titanium alloys of beta type titanium alloys, near beta type titanium alloys and alpha+beta type titanium alloys. The titanium alloy has a surface hardness of Hv 400 or more and less than Hv 600 for increasing the corrosion resistance and wear resistance of the bearing ring. Spherical rolling elements 3 rolling on the raceway surfaces 1a and 2a of the bearing rings 1 and 2 are formed of ceramics such as silicon nitride. When beta type titanium alloys or alpha+beta type titanium alloys after a solution treatment and applied with an oxidation treatment at a low temperature of 400 to 600° C. are used as the material for the bearing ring, a bearing ring made of titanium alloy suitable to use under a circumstance requiring corrosion resistance is obtained.

Owner:NSK LTD

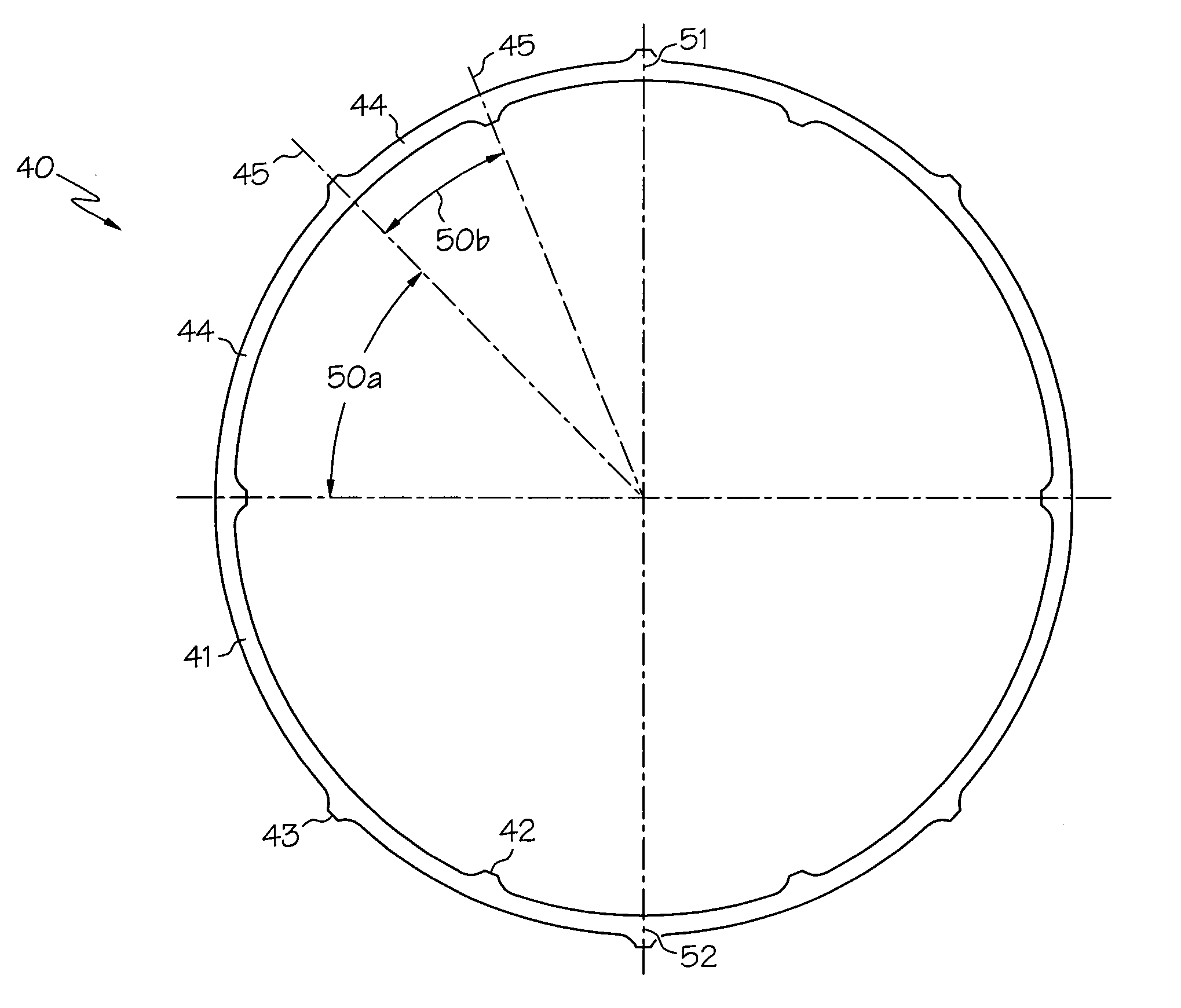

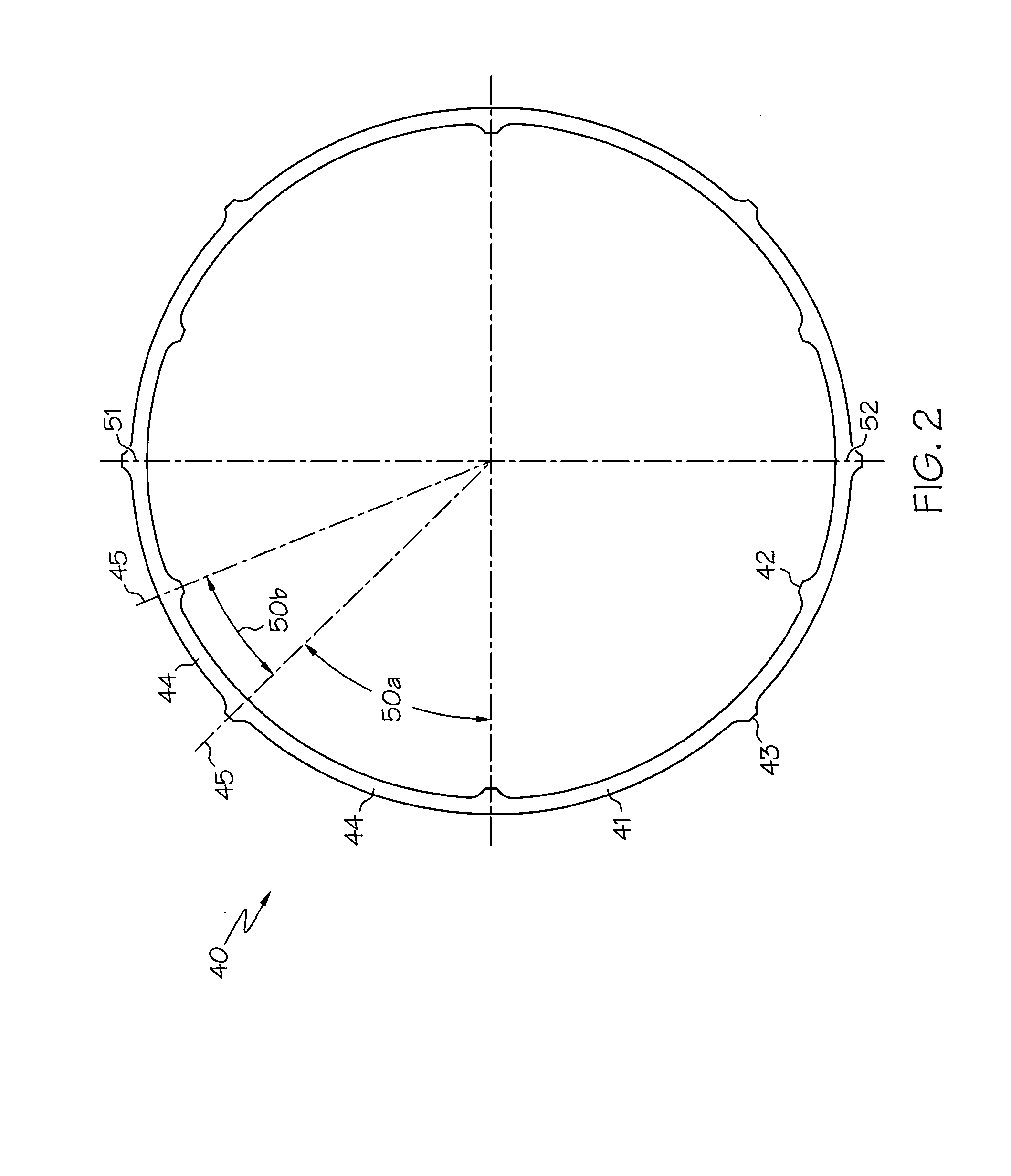

Compact resilient anisotropic support for bearing

InactiveUS20060204153A1Providing some stiffnessEngine manufactureShaftsViscous dampingElastic anisotropy

A support for a bearing comprises a resilient ring having unevenly spaced inner and outer bumpers. The unevenly spaced bumpers provide anisotropy to the rotor to preclude non-synchronous vibration. The inner bumpers can be ground to provide a vertical offset of the rotor centerline to accommodate the deflection due to the rotor weight. A tangential groove in the outer bumper allows oil passage during ring deflection so that oil can be squeezed out under dynamic load, providing additional viscous damping to the rotor.

Owner:HONEYWELL INT INC

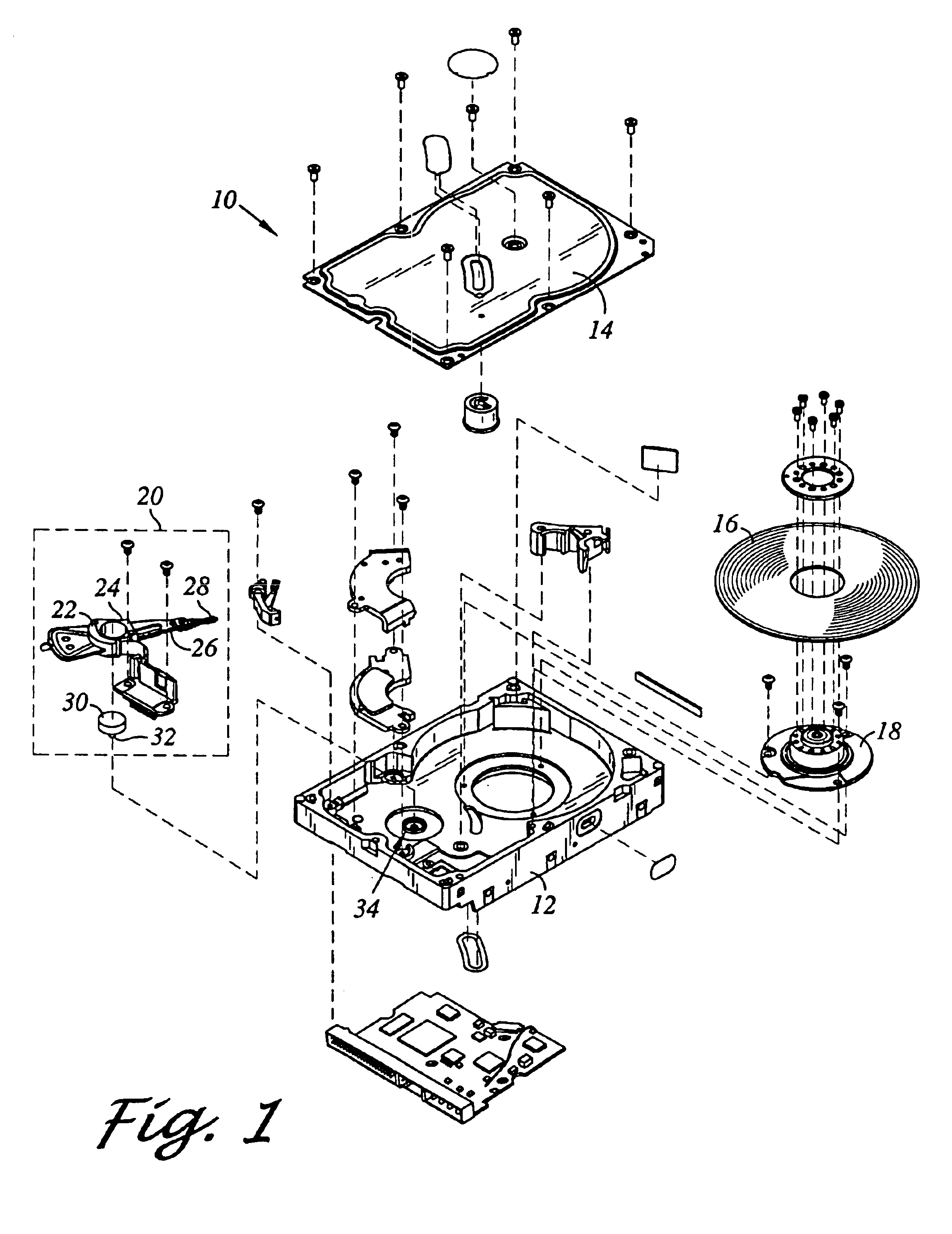

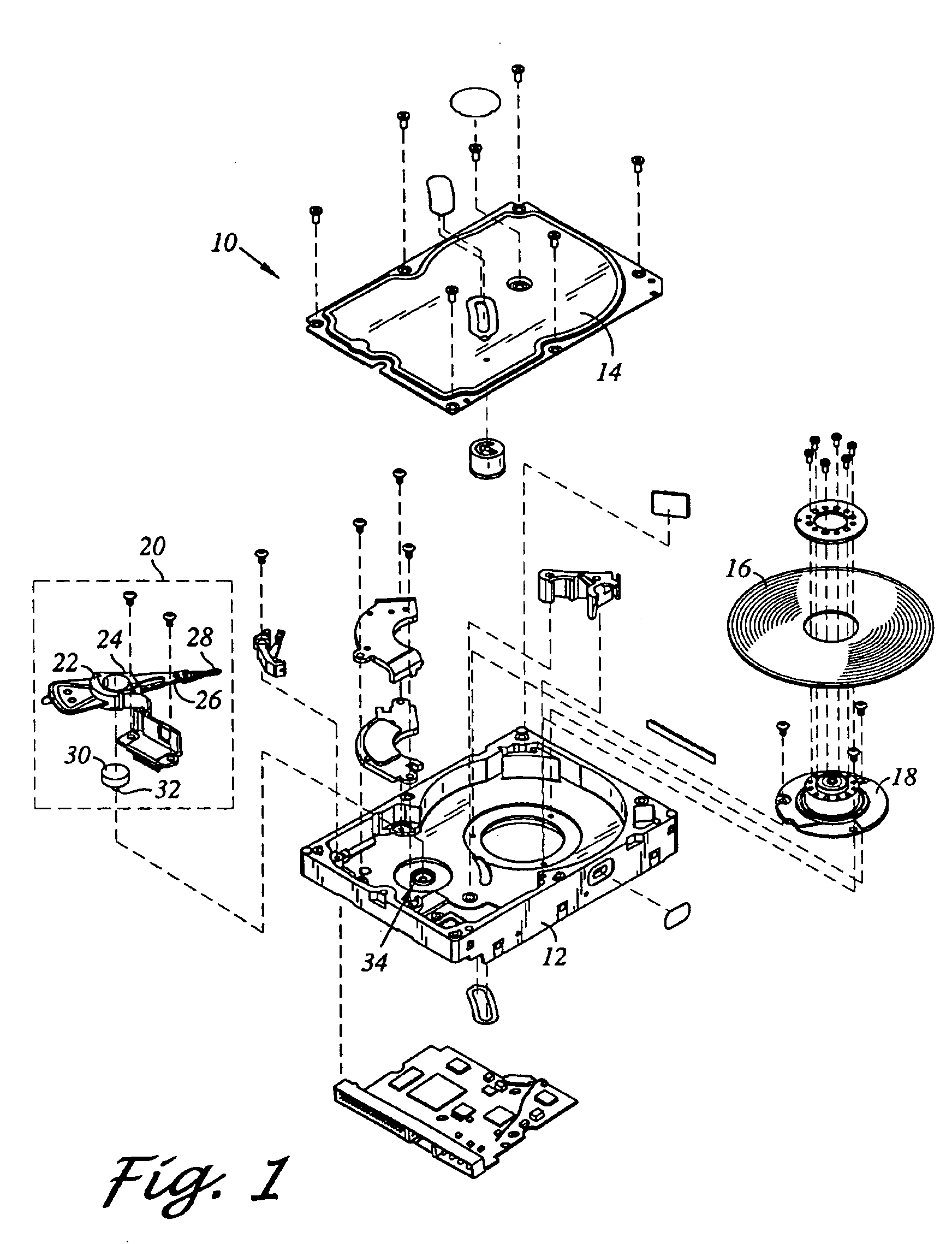

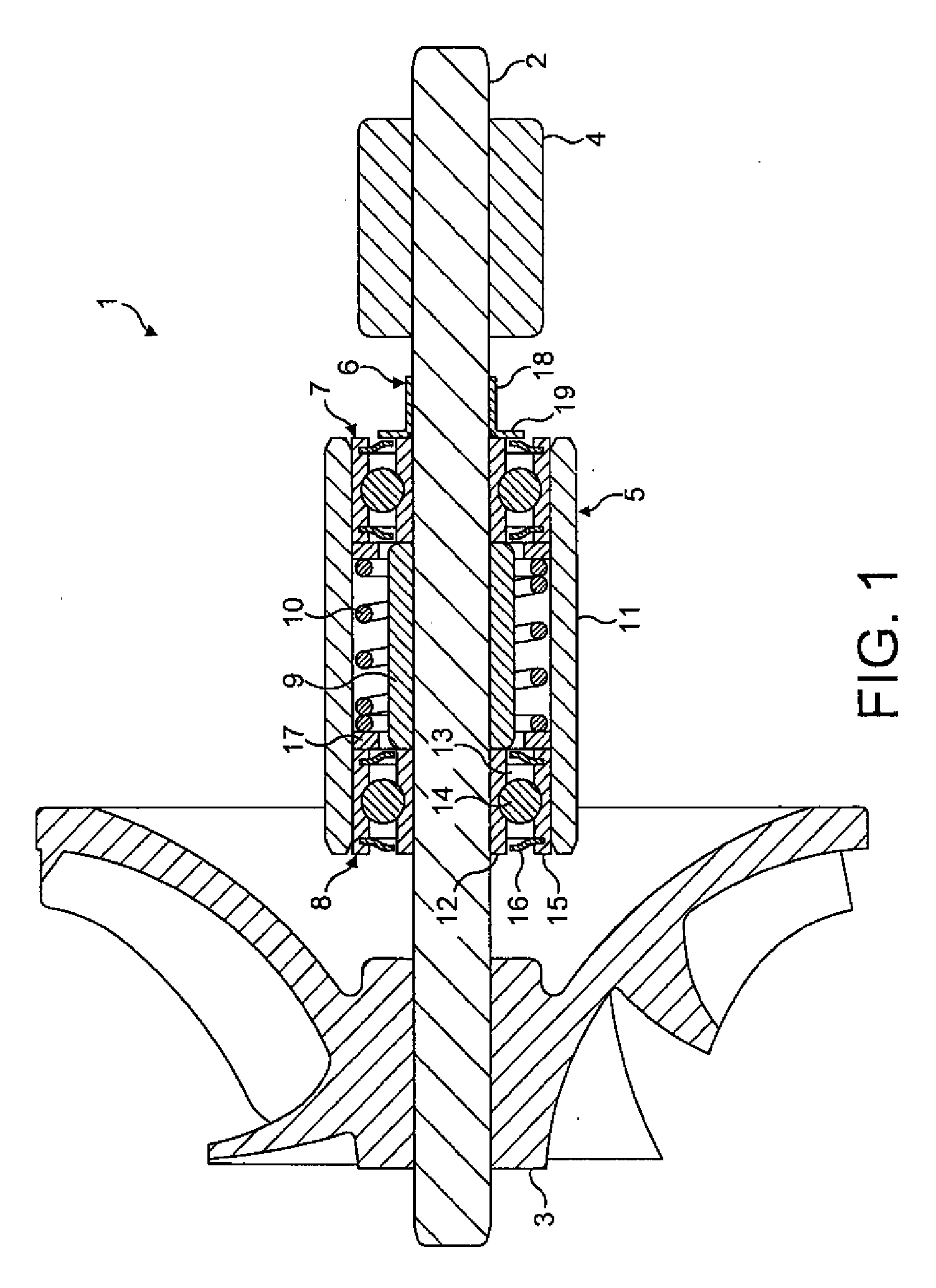

Pivot bearing cartridge including central pivot element and ball bearing set

A pivot bearing cartridge for use in a head stack assembly. The pivot bearing cartridge includes a pivot shaft including a shaft body and a shaft distal end. The pivot bearing cartridge further includes a cap disposed about the pivot shaft. The cap includes a cap annular body and a cap closed end. The pivot bearing cartridge further includes a ball bearing set in mechanical communication with the pivot shaft and the cap annular body. The pivot bearing cartridge further includes a central pivot element disposed between and in mechanical communication with the shaft distal end and the cap closed end for facilitating rotation of the cap relative to the pivot shaft.

Owner:WESTERN DIGITAL TECH INC

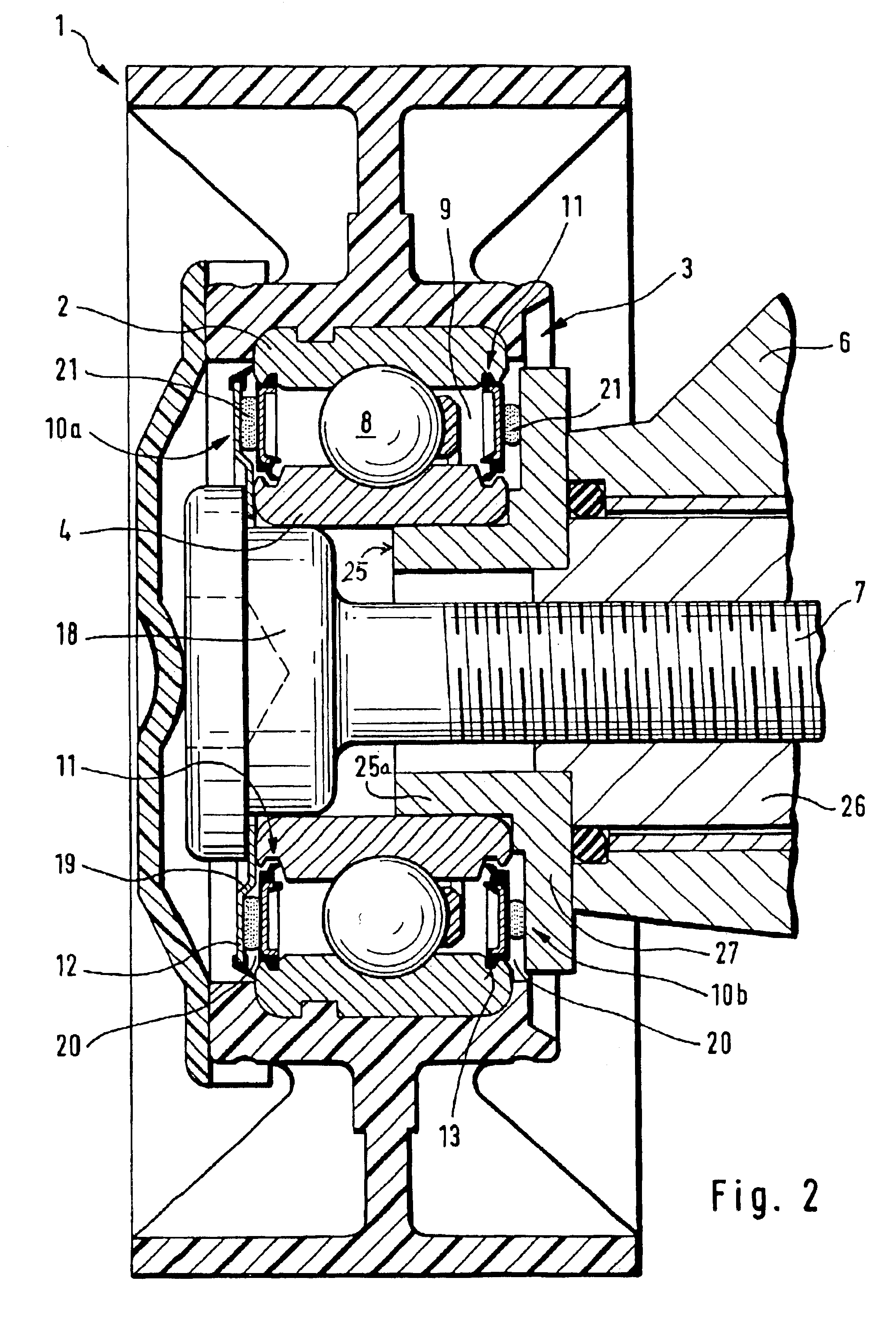

Seal arrangement for an electric motor

A technique is provided for sealing a bearing cavity in a rotating machine such as an electric motor. The bearing cavity is defined by annular elements on either side of an antifriction bearing set. Seals are provided on the sides of the bearing cavity and are secured to a support structure, such as the motor housing, and include elements which ride against the rotating shaft during operation. The seals exert a sealing force against the rotating element which results at least partially from internal pressure within the bearing cavity provided by a pressurized lubricant stream. The lubricant stream is provided in the form of an airborne oil mist.

Owner:RELIANCE ELECTRIC TECH

Pivot bearing cartridge including central pivot element and ball bearing set

A pivot bearing cartridge for use in a head stack assembly. The pivot bearing cartridge includes a pivot shaft including a shaft body and a shaft distal end. The pivot bearing cartridge further includes a cap disposed about the pivot shaft. The cap includes a cap annular body and a cap closed end. The pivot bearing cartridge further includes a ball bearing set in mechanical communication with the pivot shaft and the cap annular body. The pivot bearing cartridge further includes a central pivot element disposed between and in mechanical communication with the shaft distal end and the cap closed end for facilitating rotation of the cap relative to the pivot shaft.

Owner:WESTERN DIGITAL TECH INC

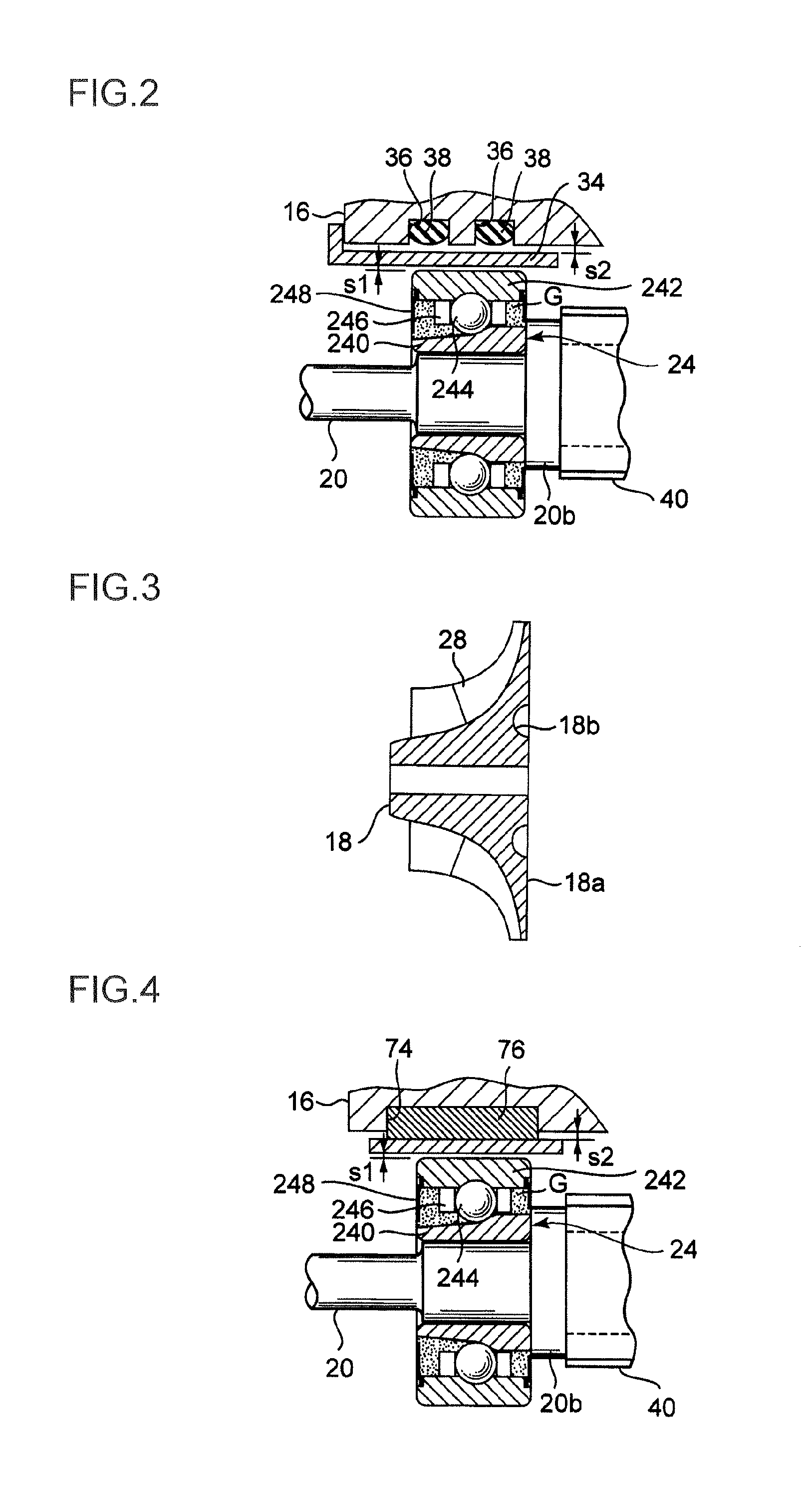

Sealing arrangement for a rolling-contact bearing

InactiveUS6854893B2Improve efficiencyAdded costEngine sealsGearingRolling-element bearingEngineering

A two-stage sealing arrangement for sealing an annular gap between an outer bearing ring and an inner bearing ring of a rolling-contact bearing, includes a first sealing element securely fixed to the outer bearing ring and having at least one sealing lip supported against the inner bearing ring. A second sealing element is disposed at an axial distance to the first sealing element, thereby defining a circular ring shaped sealing gap in a radial direction for accommodating, at least partially, a sealing material.

Owner:SCHAEFFLER TECH AG & CO KG

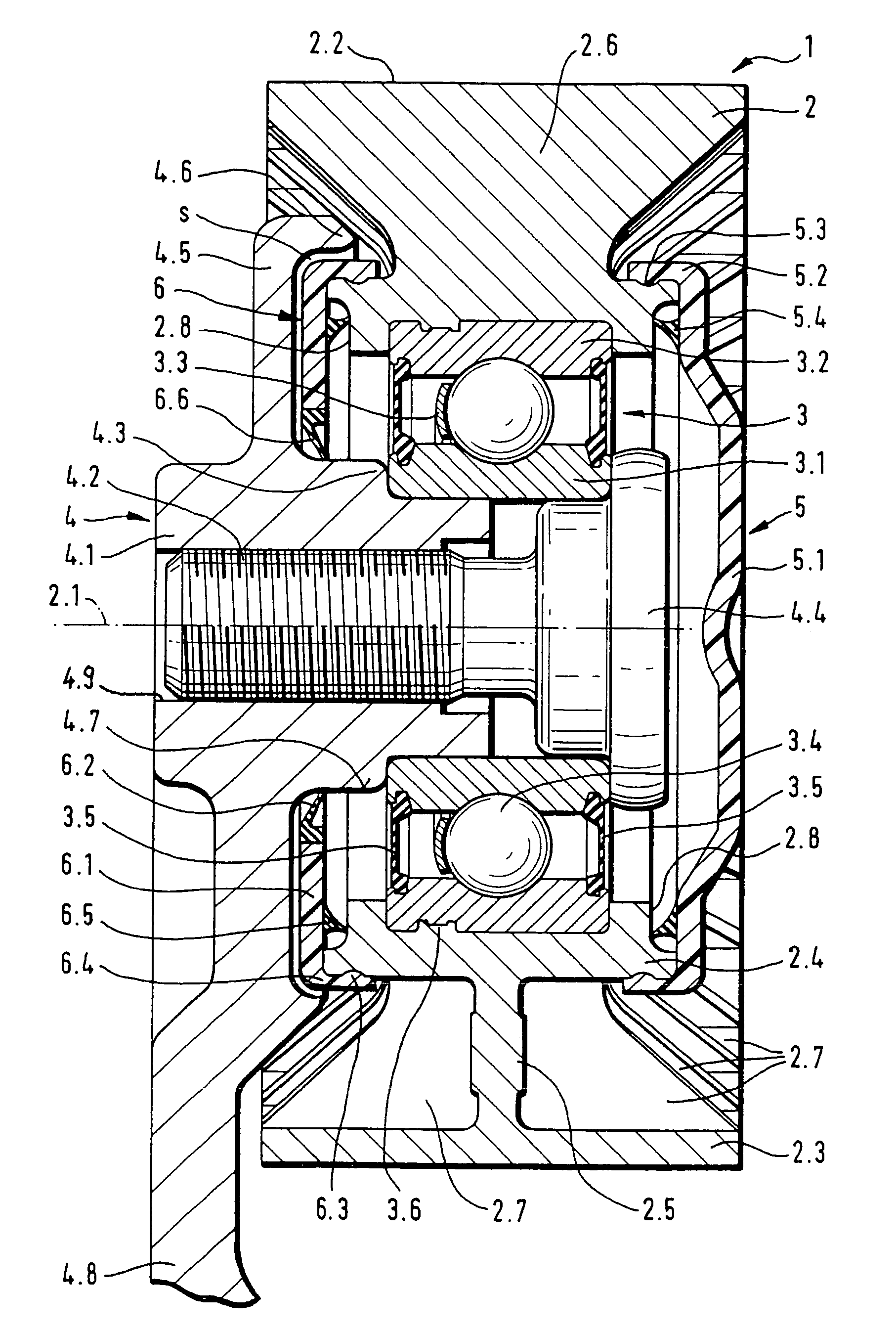

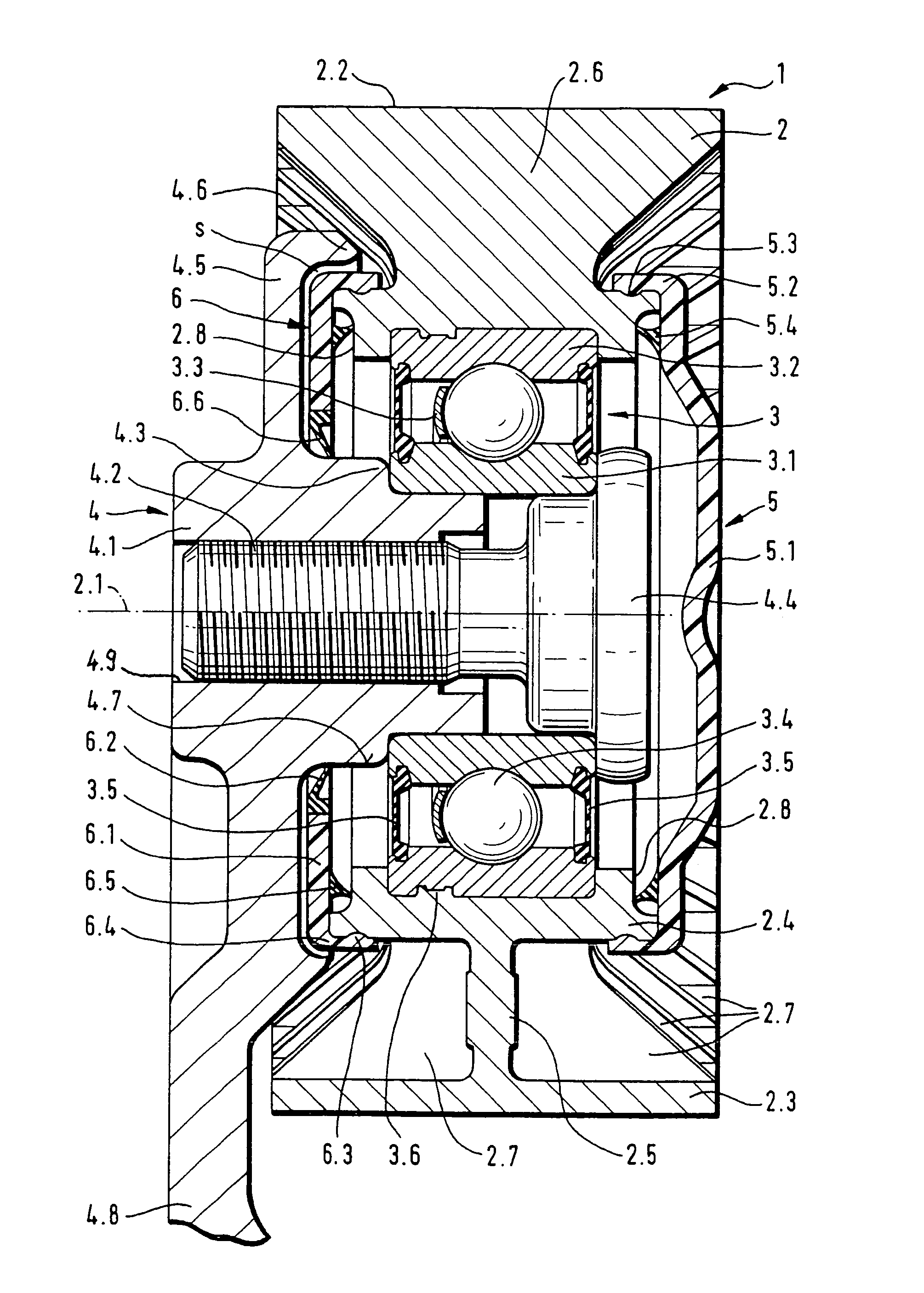

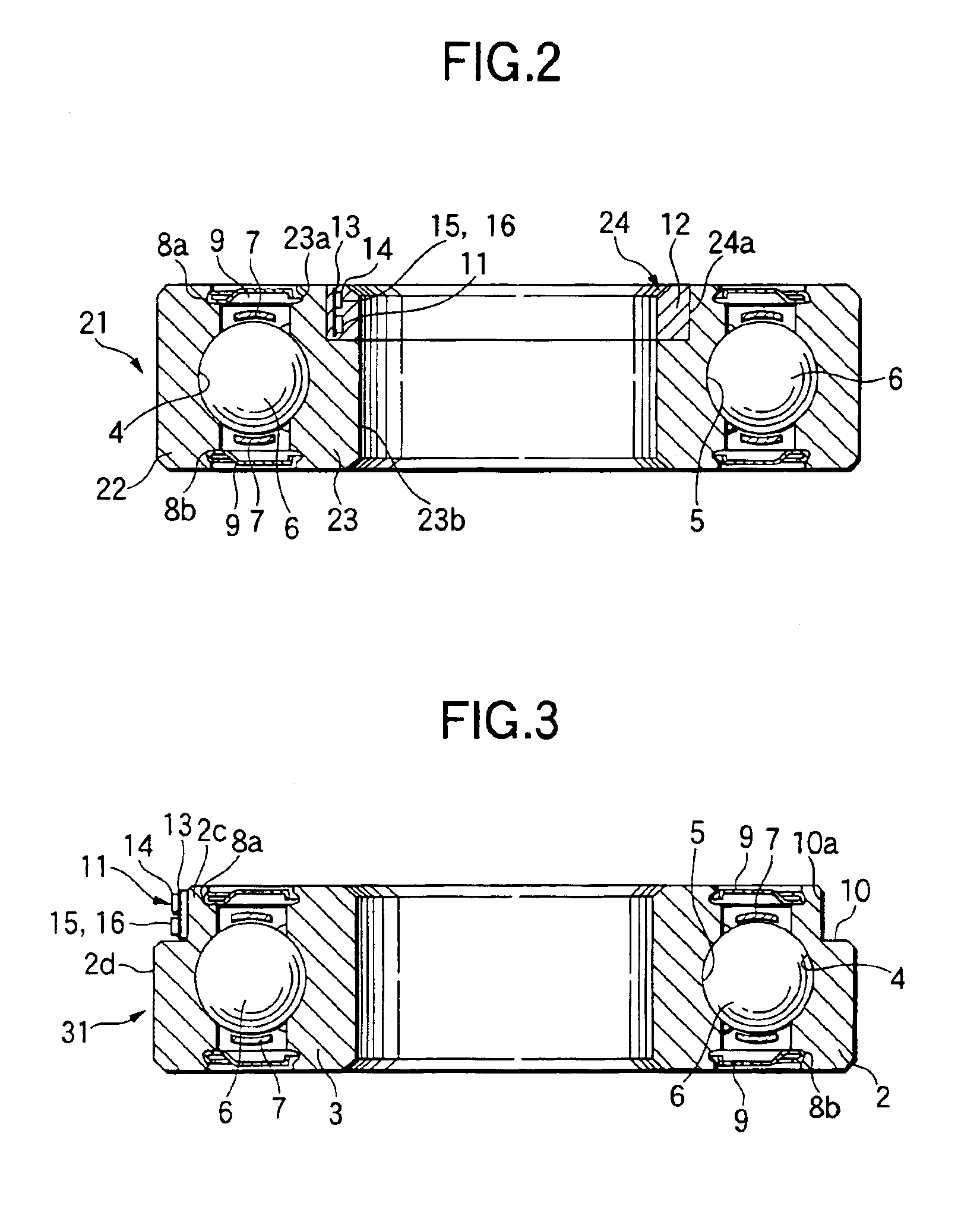

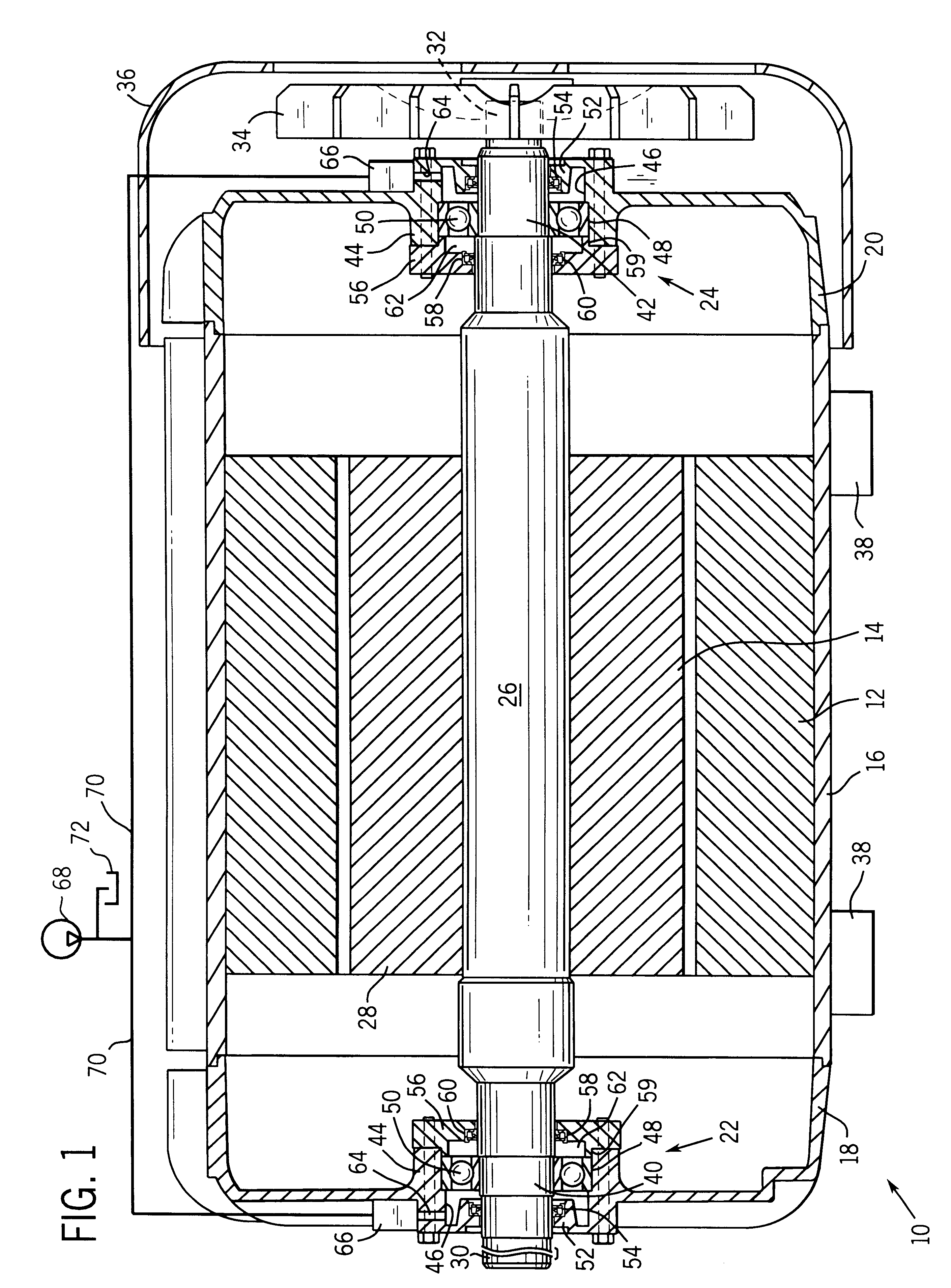

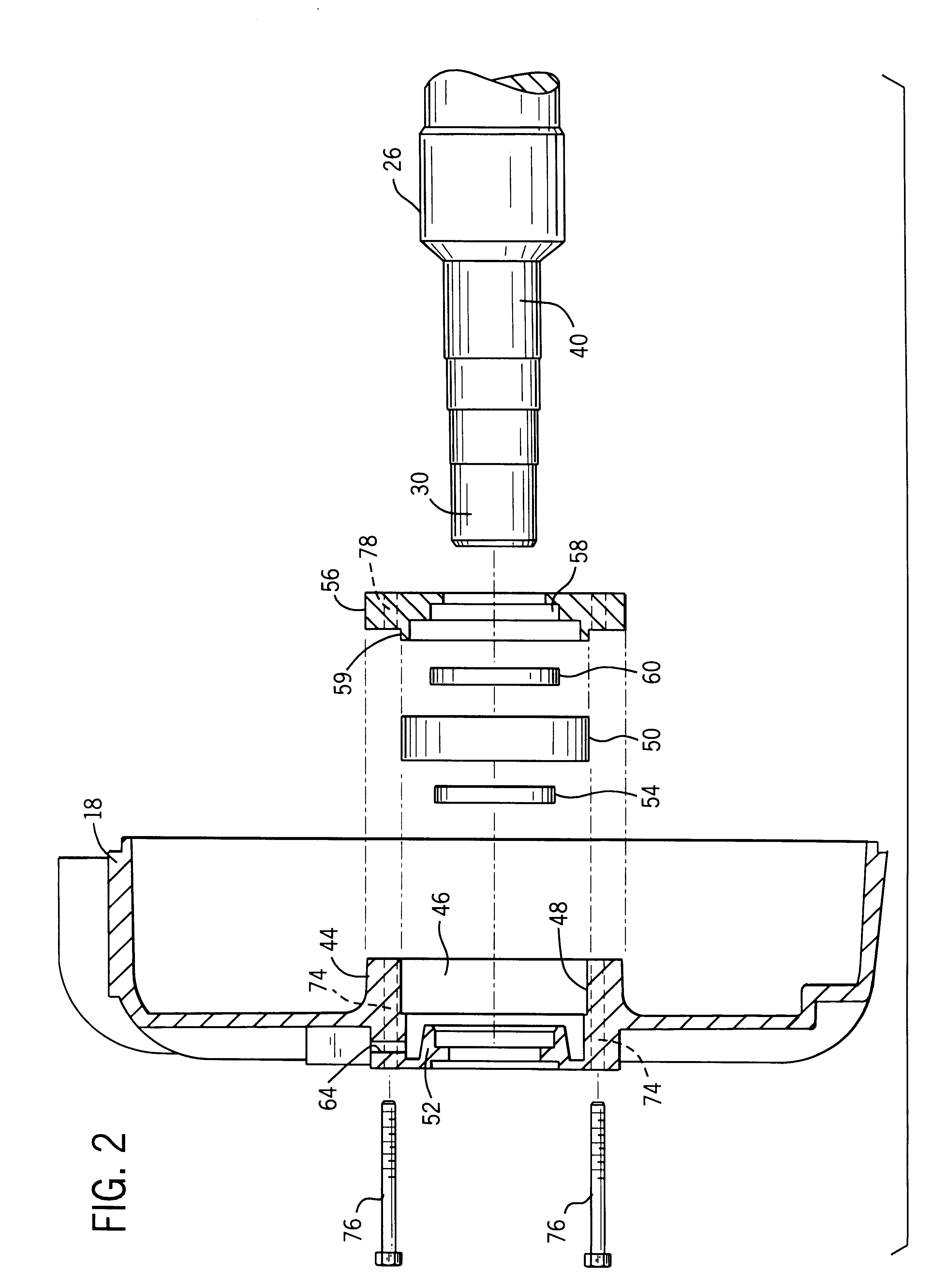

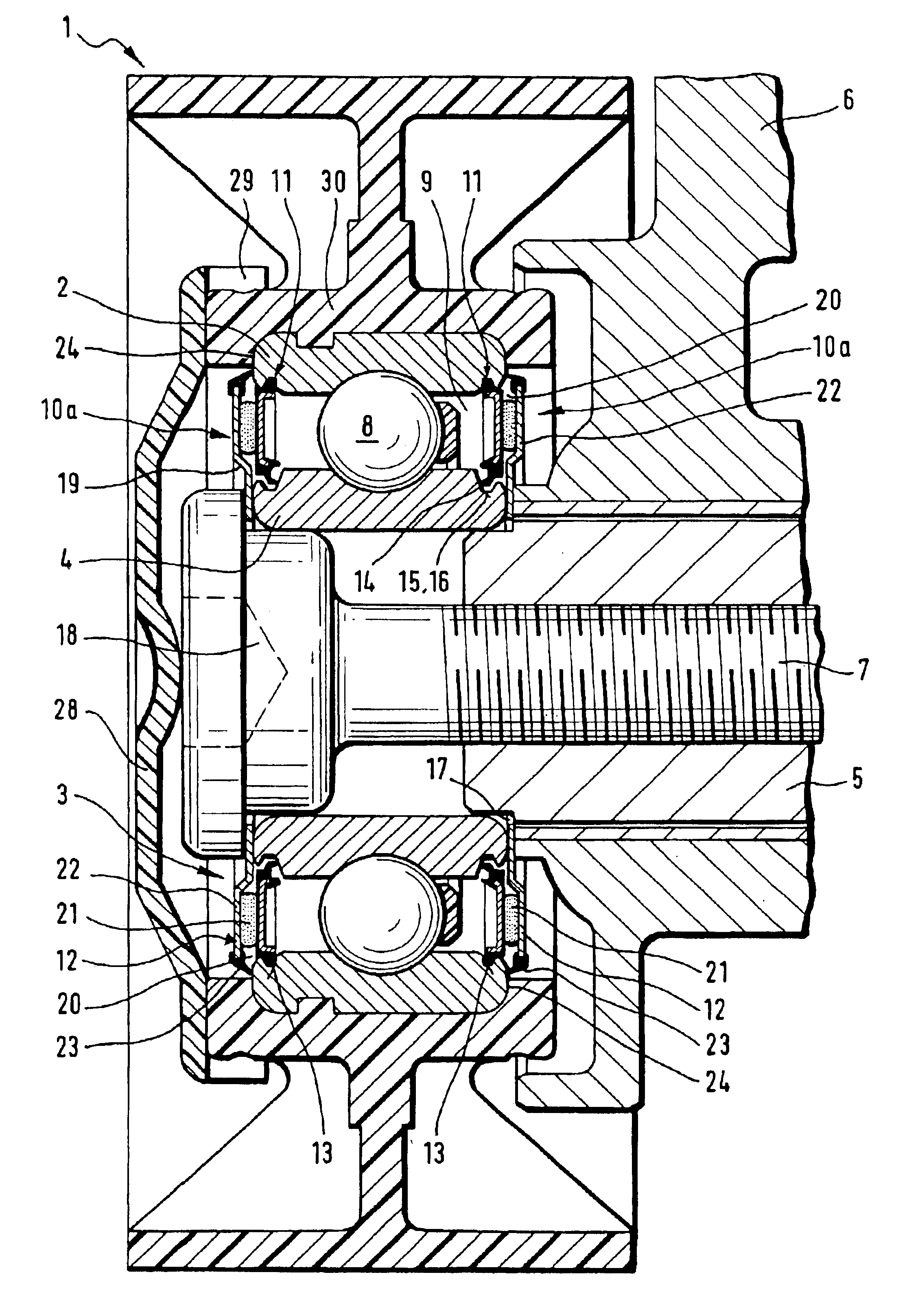

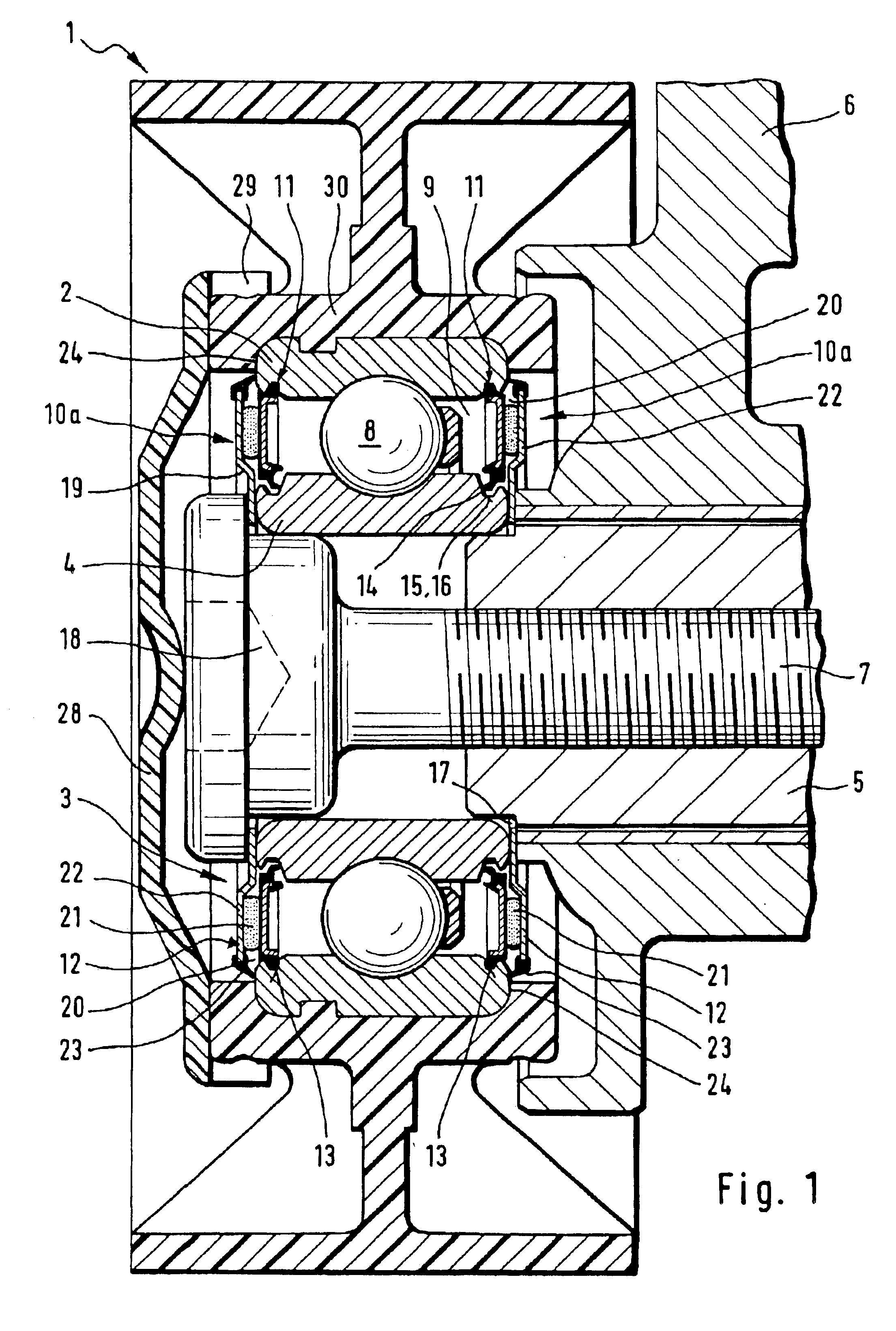

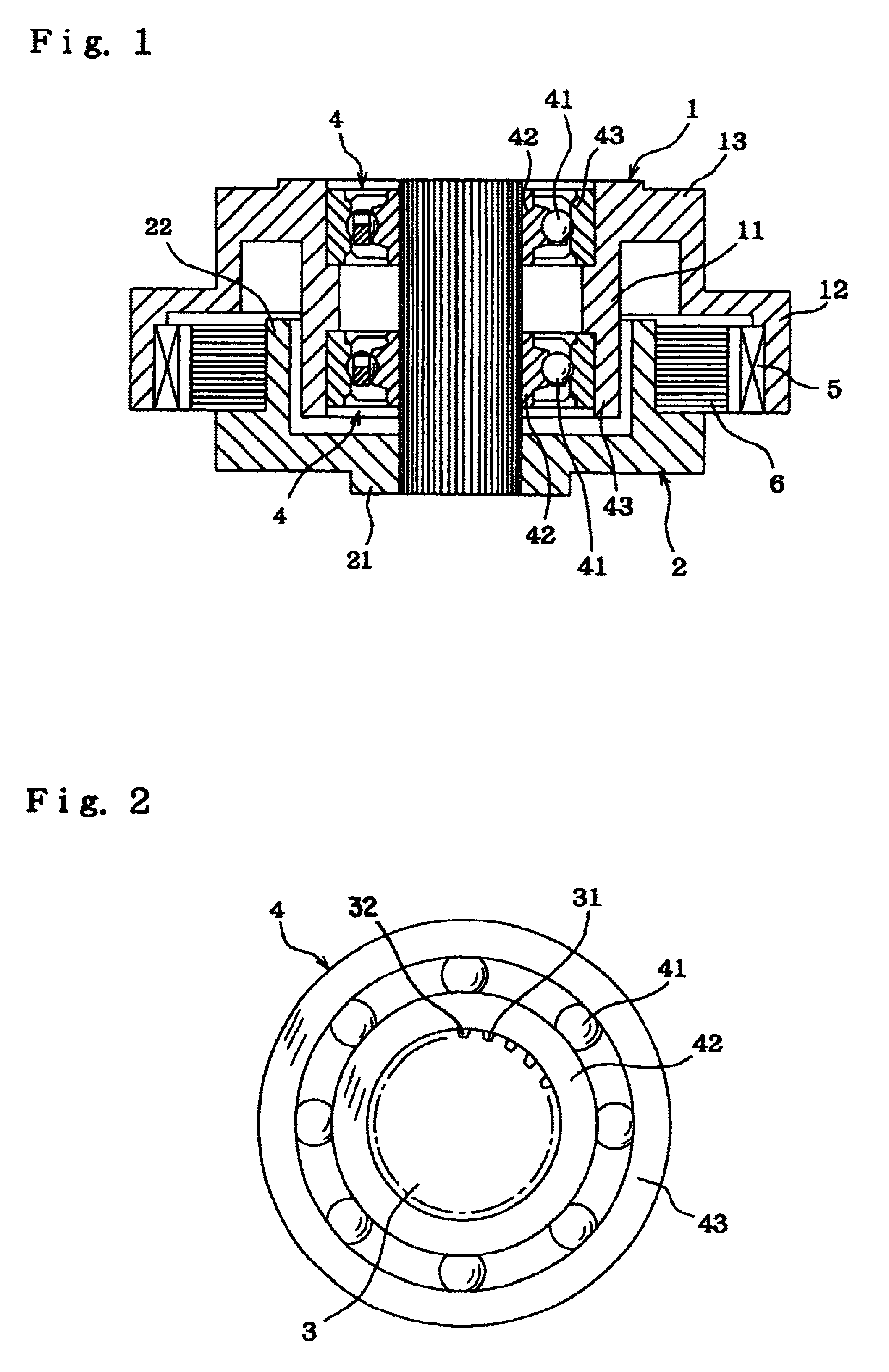

Bearing system for high-speed rotating machinery

InactiveUS6877901B2Reduce manufacturing costImprove efficiencyRotary combination bearingsShaftsBall bearingTurbocharger

A bearing system for a turbocharger shaft includes two angular contact ball bearings mounted in the opposite ends of a lubricated rotatable elongated cylinder, which includes a radially extending flange at one end that cooperates with stationary housing portions and carries the thrust load of the rotor in both directions. The angular contact ball bearing on the turbine end (hot end) of the machine is provided with a radial spring between the outside of its outer race and the elongated cylinder, which prevents rotation of the outer race, but still allows axial movement of the outer race in the elongated cylinder due to axial expansion of the shaft when exposed to high temperature. The inner races of the ball bearings are separated by a spacer, which is clamped in place between the bearings when the rotor assembly lock nut is tightened. Thus, the inner race of the bearings and spacer rotate with the shaft as part of the rotating assembly.

Owner:WOLLENWEBER WILLIAM E

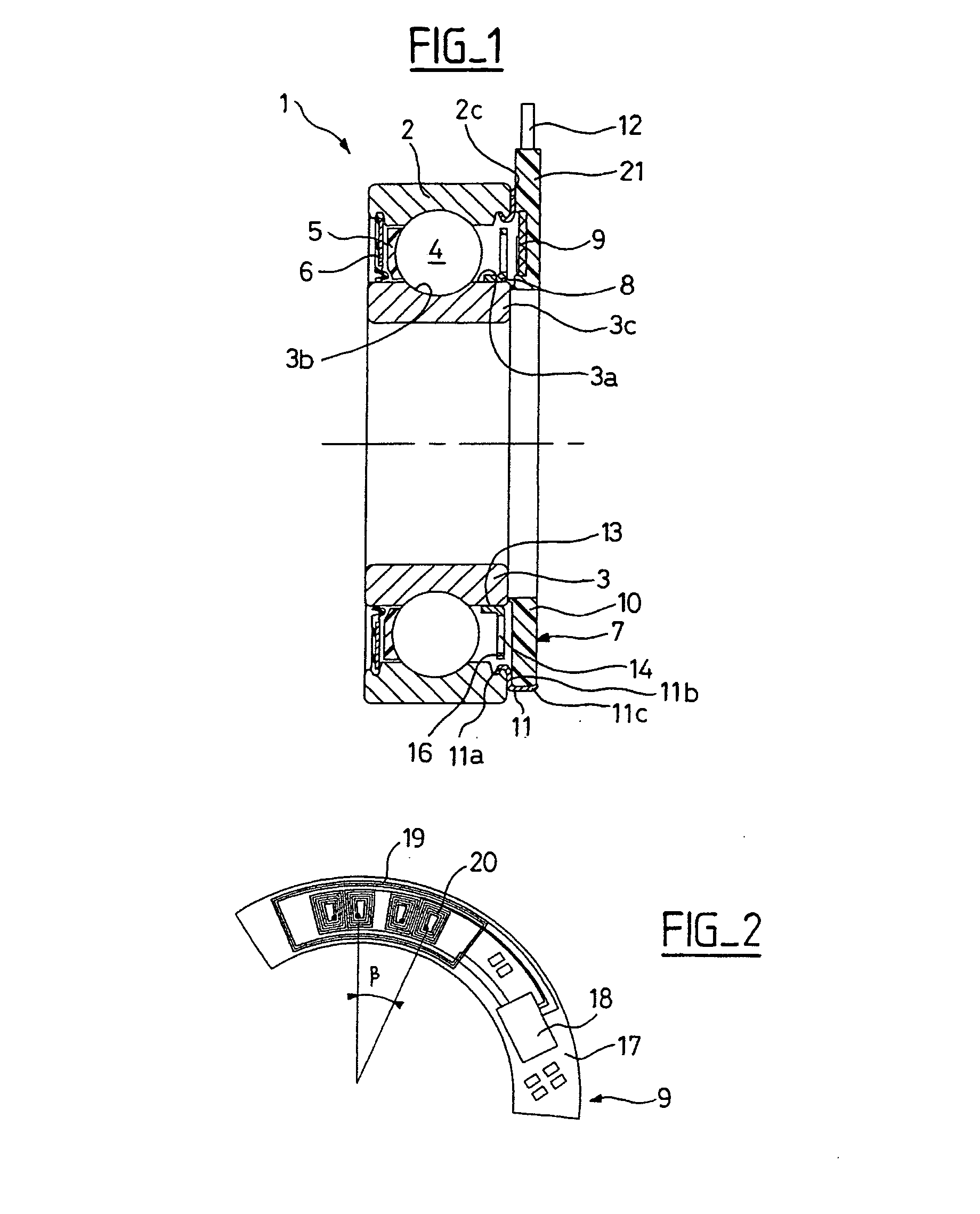

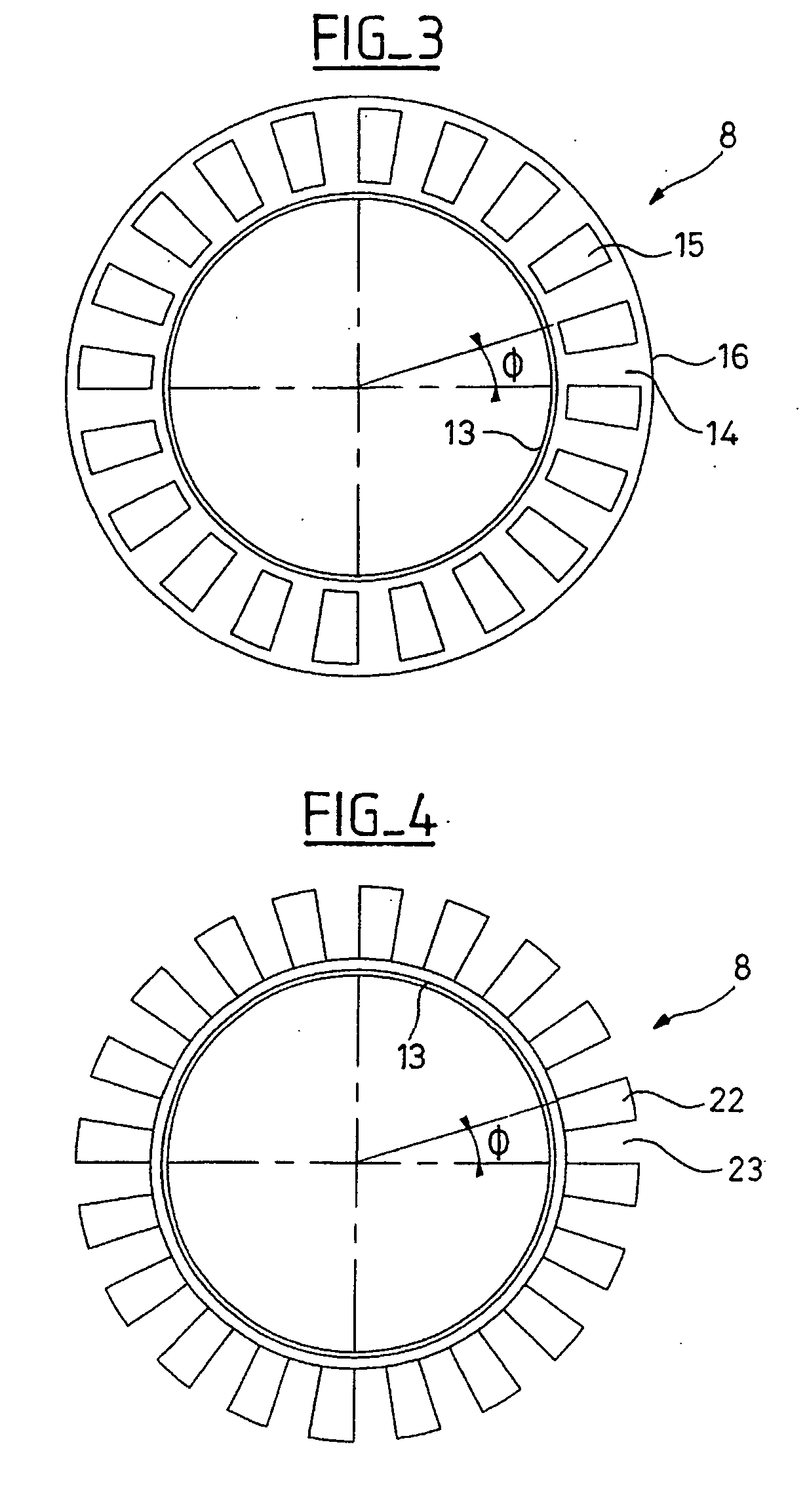

Instrumented antifriction bearing and electrical motor equipped therewith

InactiveUS20060104558A1Satisfactory axial compactnessAccurate detectionBearing assemblyShaftsBall bearingRolling-element bearing

An instrumented ball-bearing may include a rotating part, a non-rotating part, and an assembly for detecting rotation parameters. The assembly for detecting rotation parameters may include an encoder and a sensor. The sensor may be integrated with the non-rotating part. The sensor may include a sensor unit and at least a microcoil. The microcoil may have a substantially planar winding. The microcoil may be positioned in the sensor unit of the non-rotating part such that the microcoil may be positioned axially opposite the encoder.

Owner:AB SKF

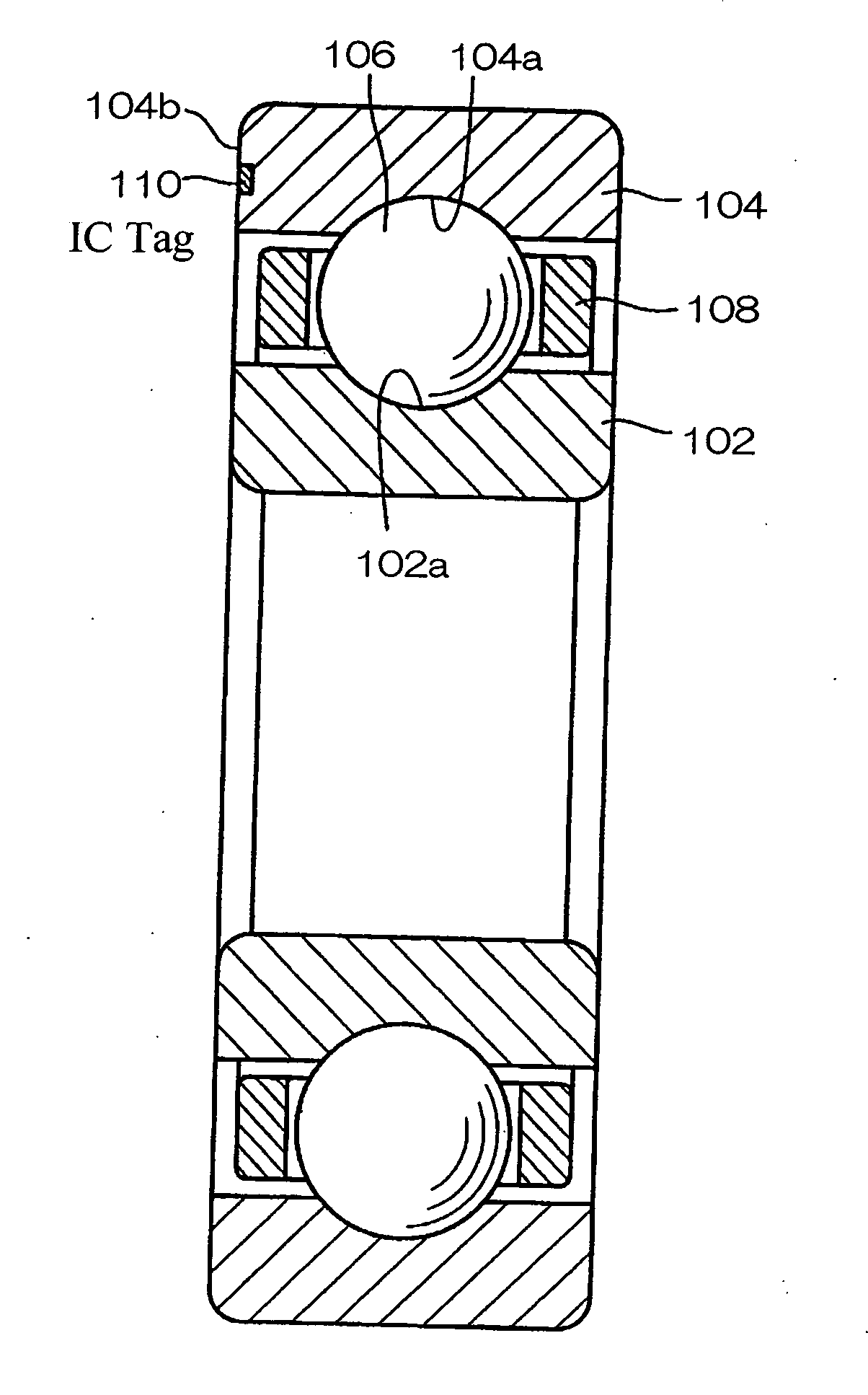

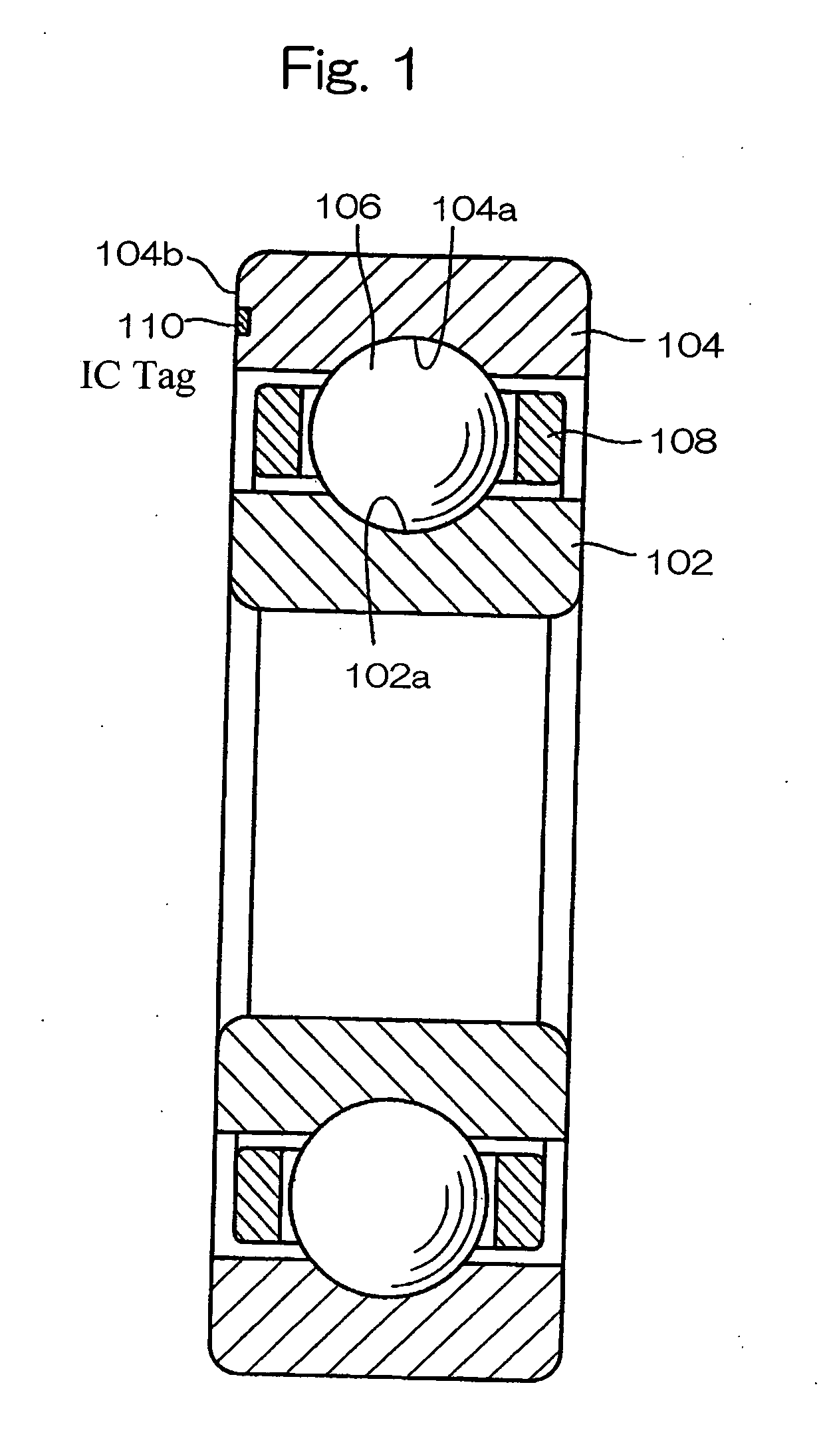

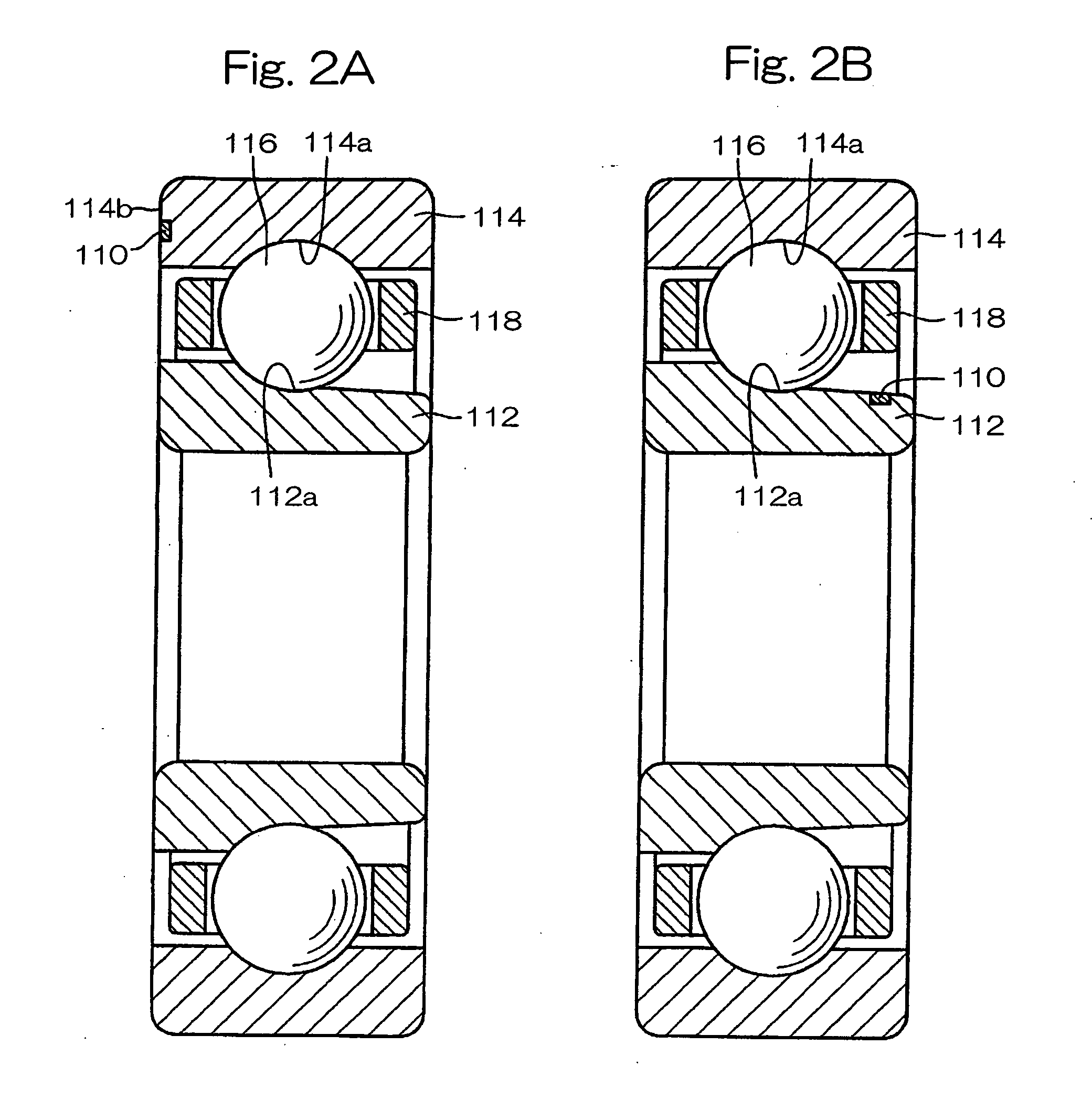

Machine component using ic tag and its method for controll quality and system for inspecting abnormality

InactiveUS20060170551A1Consistent controlAchieve traceabilityBearing assemblyRailway vehiclesElectricityQuality of control

There is provided a machine component having an IC tag attached thereto, which can be controlled consistently from manufacture to disposal without the IC tag missed on the way. The machine component is embedded with the IC tag (110) made up of an IC chip having recorded thereon information unique to the relevant machine component and an antenna connected electrically with the IC chip.

Owner:NTN CORP

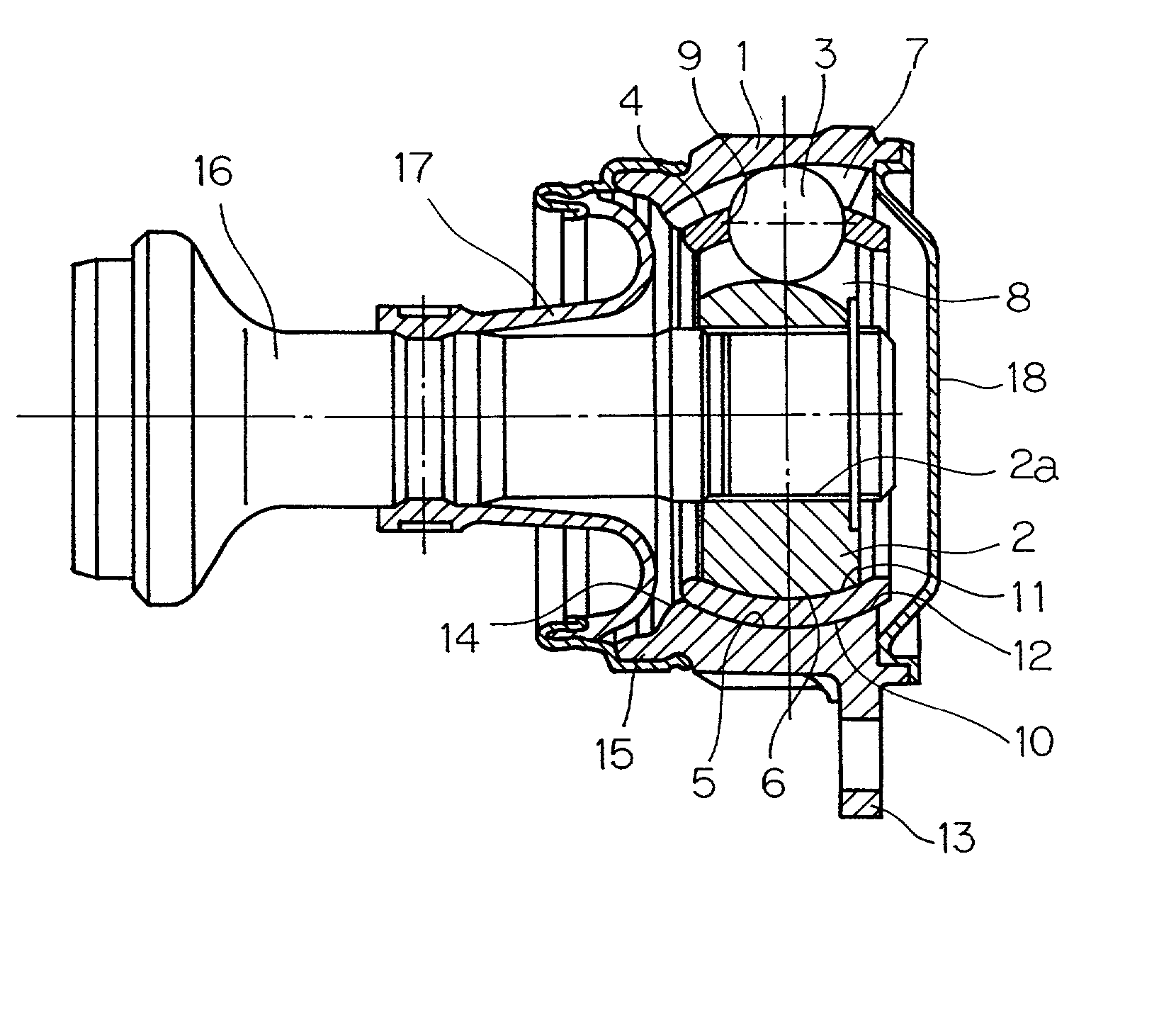

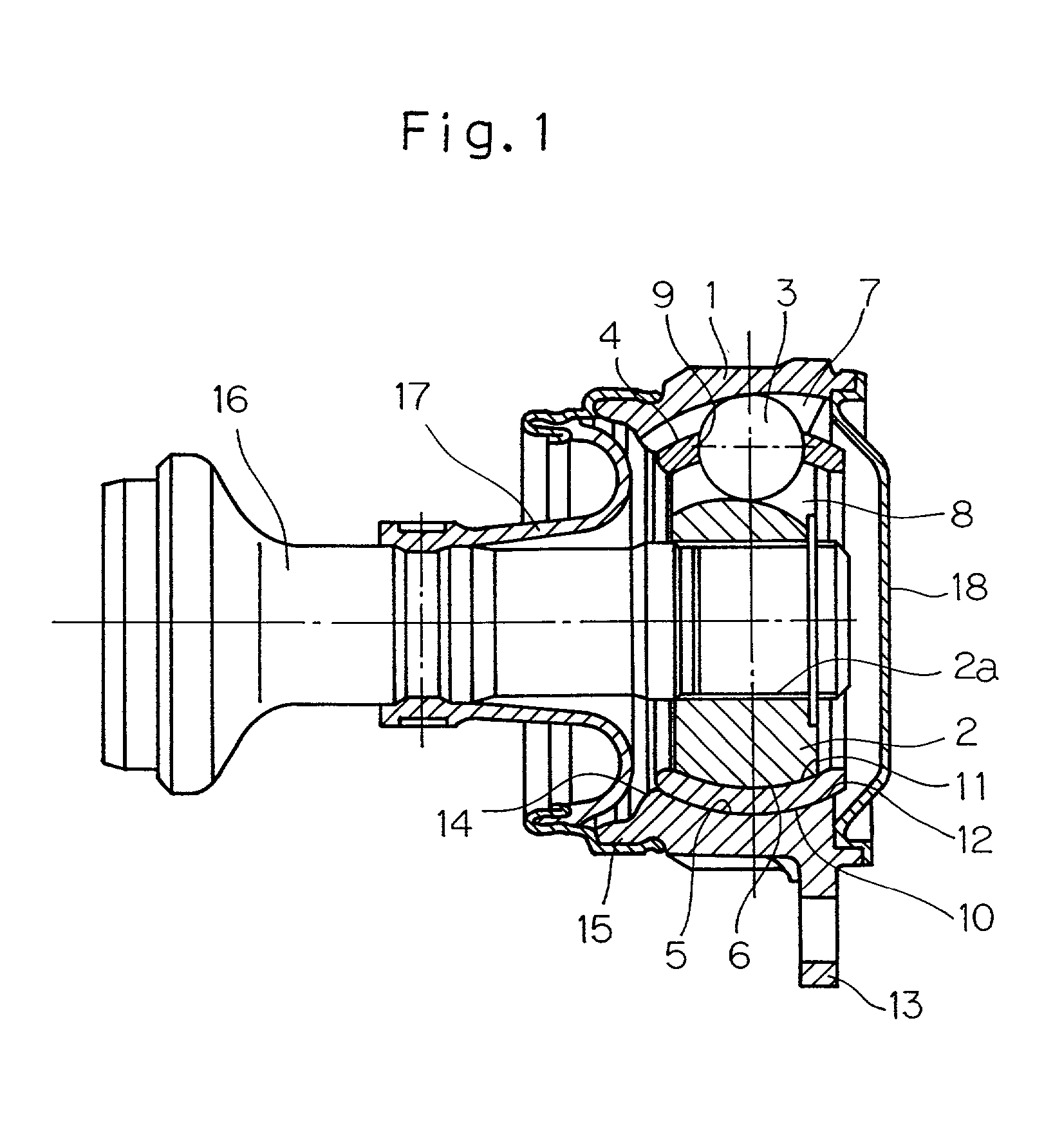

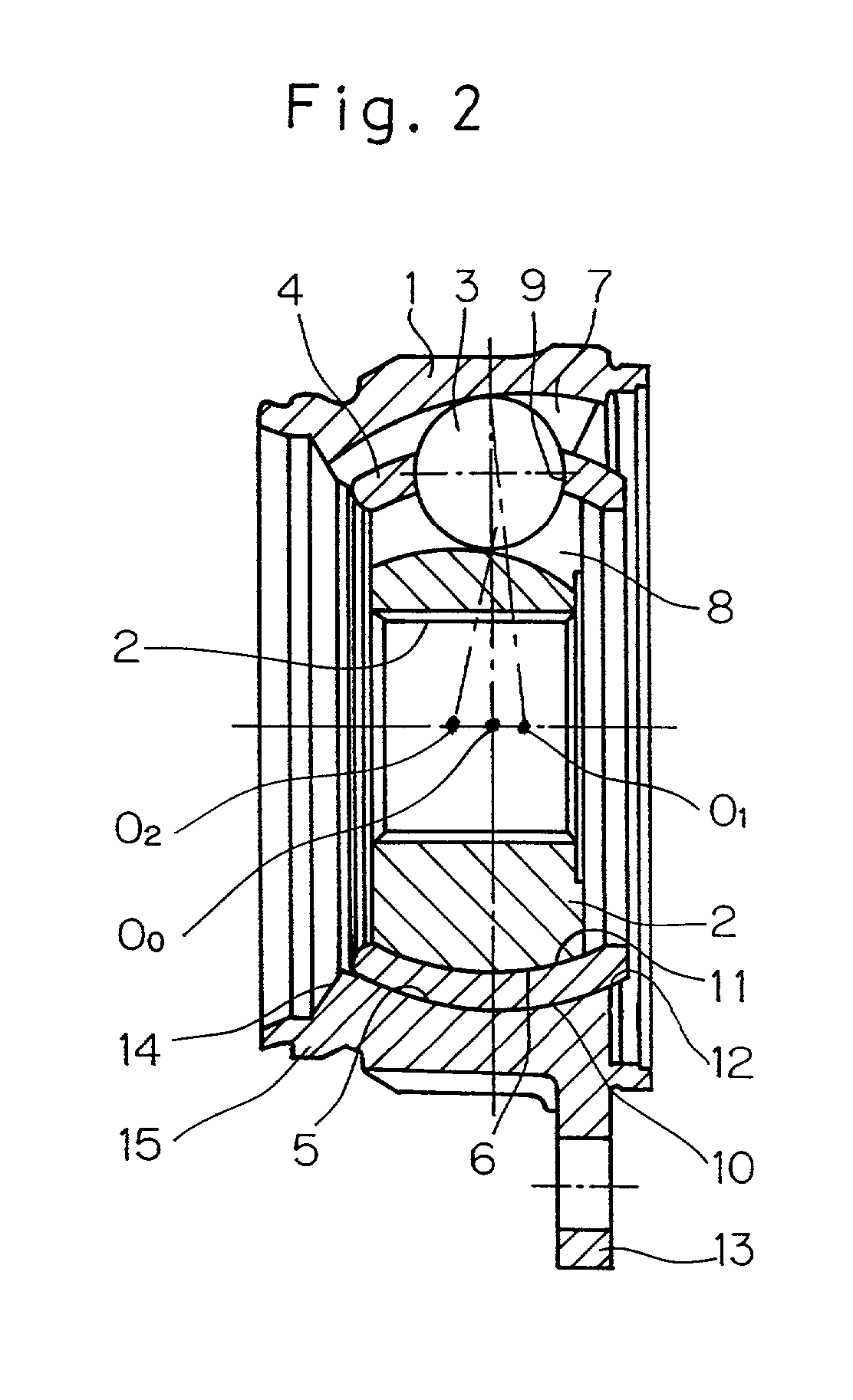

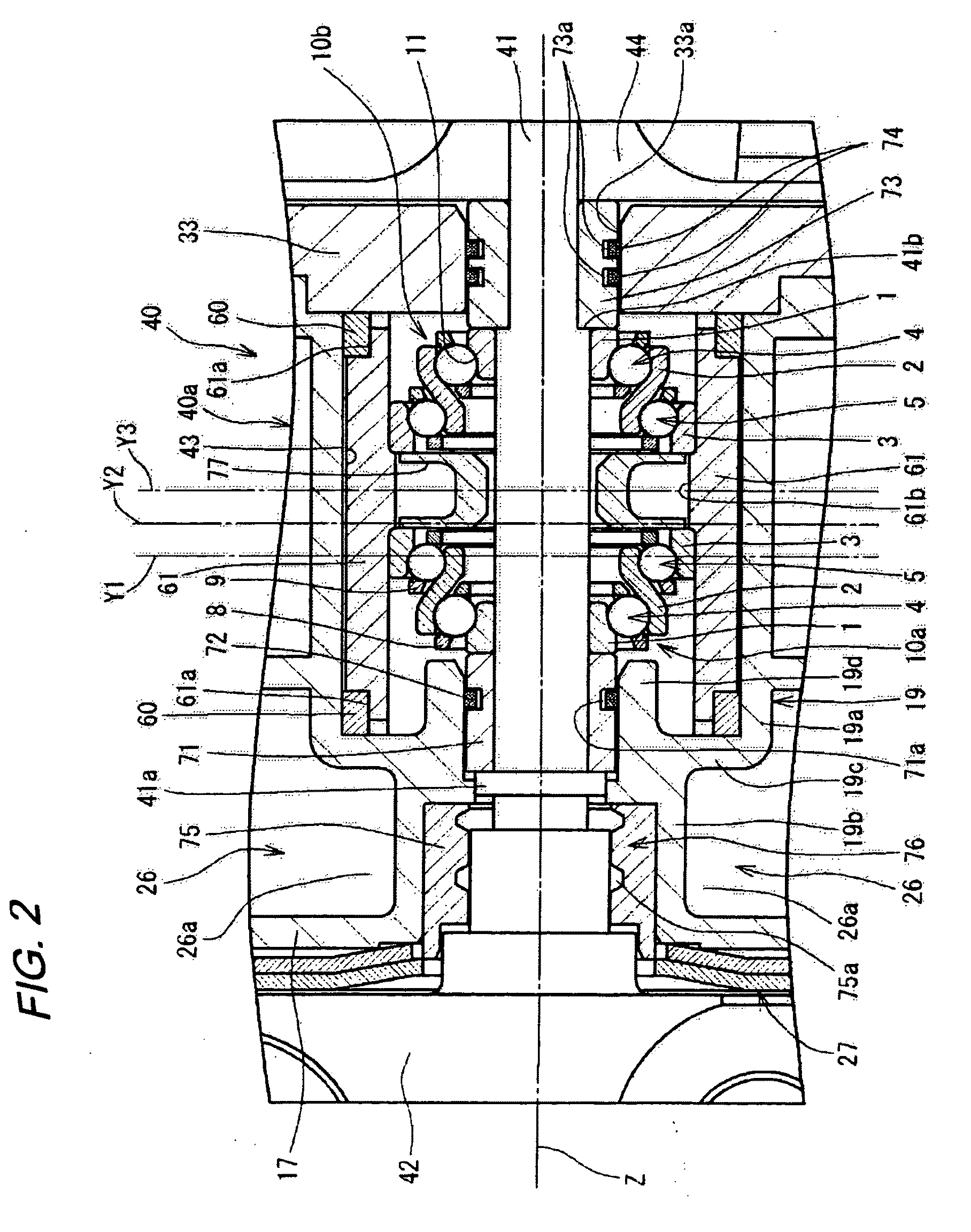

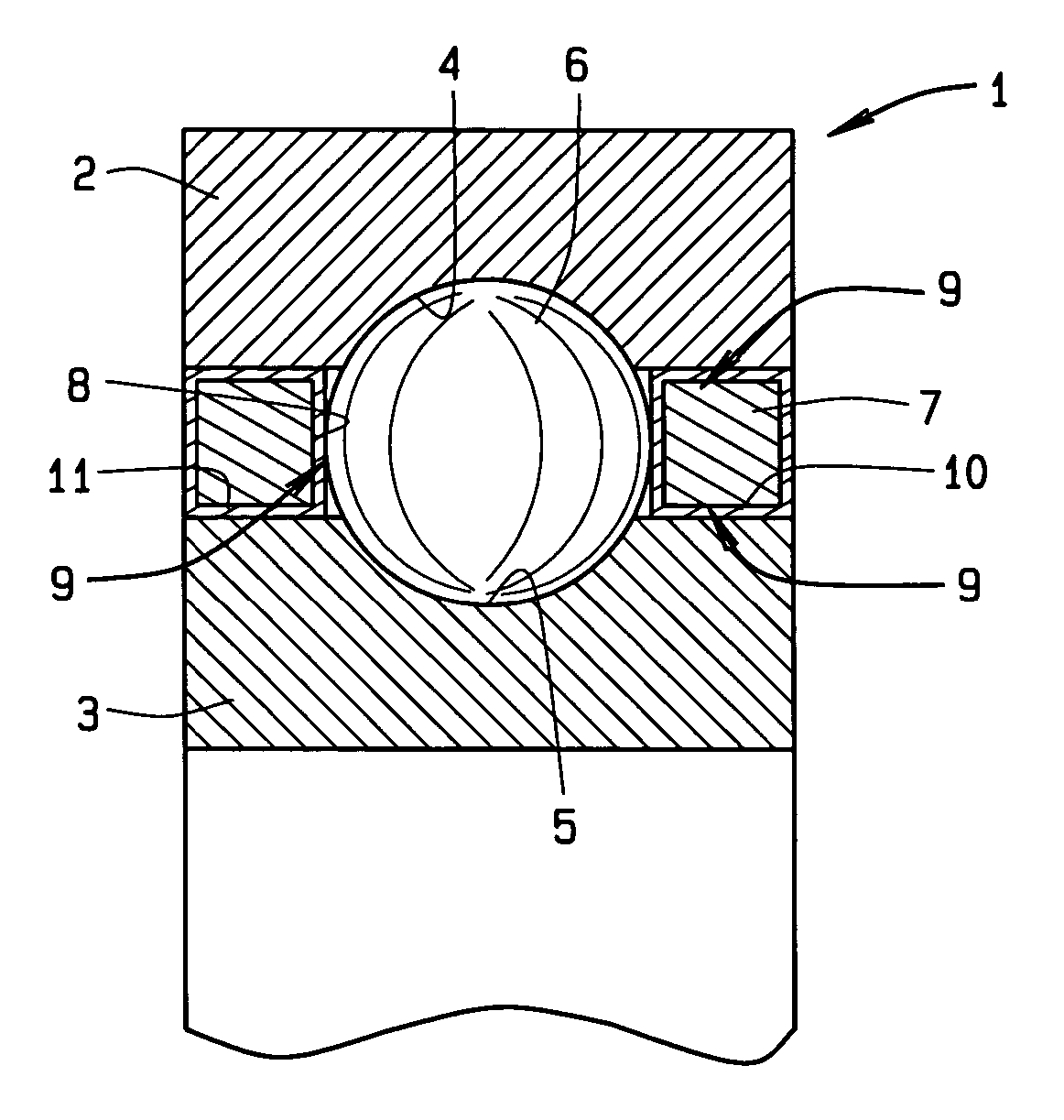

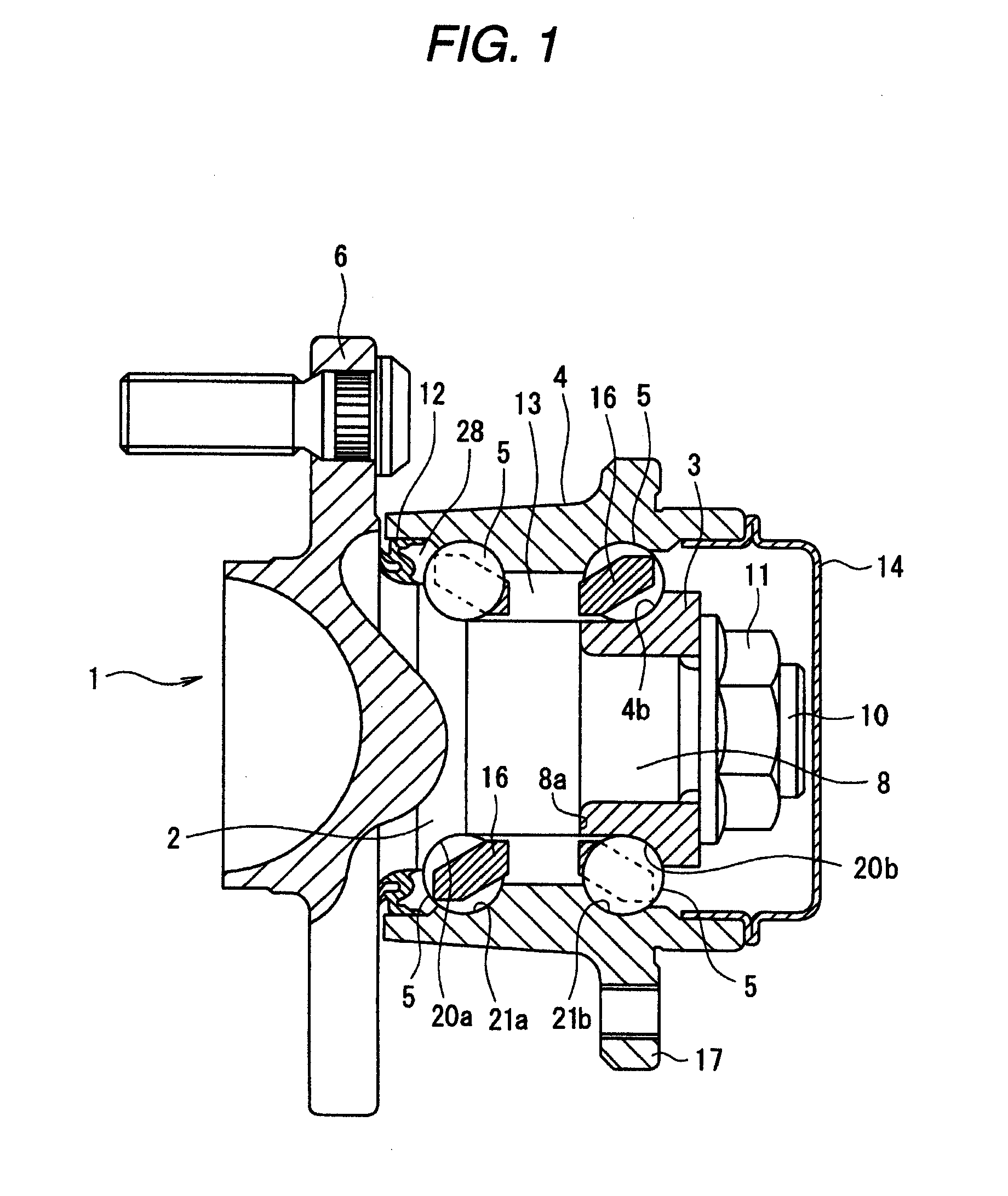

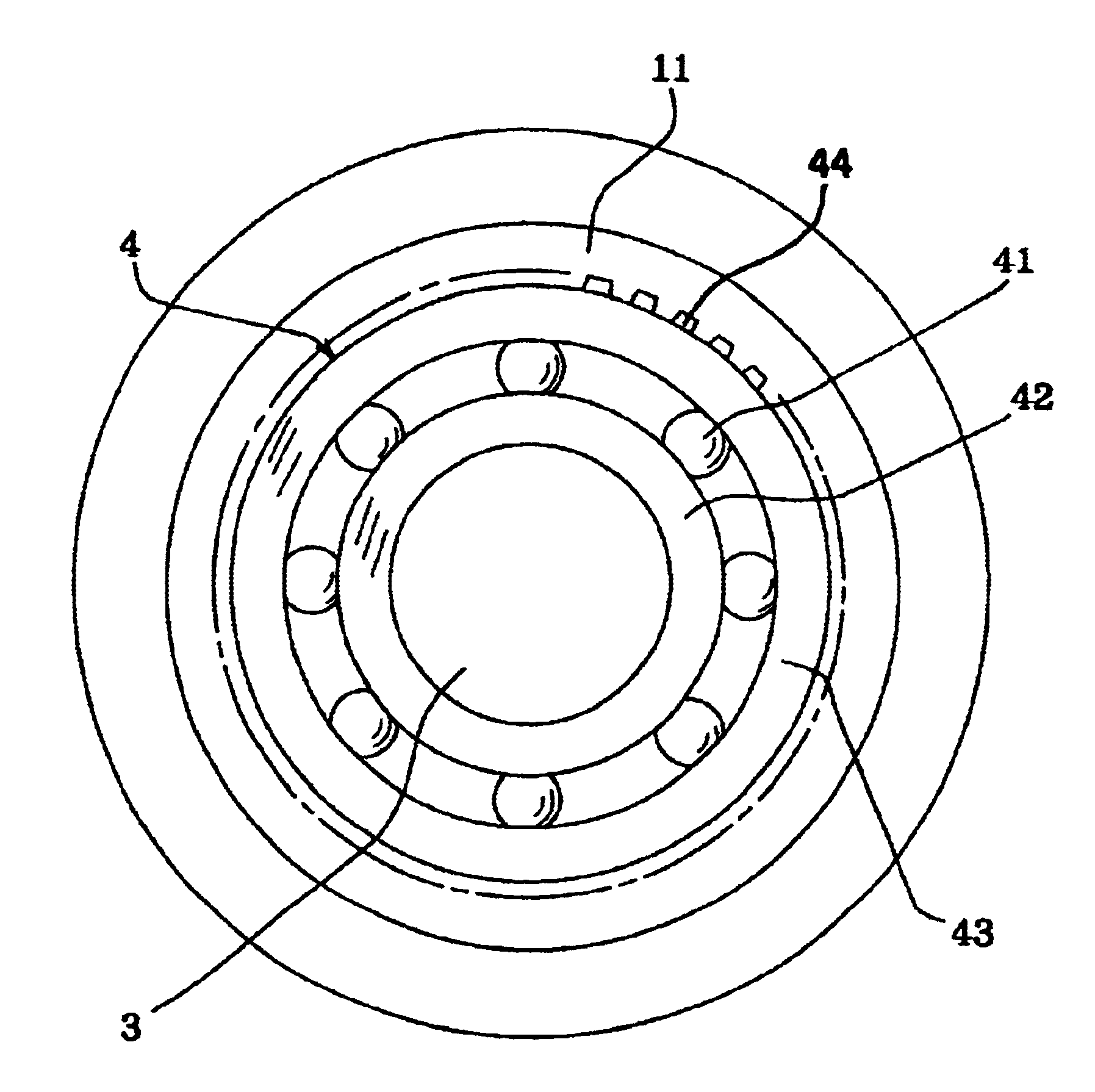

Constant velocity universal joint

InactiveUS20020077186A1Required machining timeMinimizing heat generationClutchesYielding couplingUniversal jointEngineering

A spherical inner surface 5 of the outer race 1 and track grooves in the outer race 1 are each defined by a post-hardening cut surface. A spherical outer surface 6 of the inner race 2 and track grooves in the inner race 2 are also each defined by a post-hardening cut surface. A retainer 4 has a spherical outer surface 10, a spherical inner surface 11 and inner surfaces of the pockets 9, all of which are defined by a post-hardening cut surface. Respective surfaces of the retainer 4, the outer race 1 and the inner race 2 which contact with each other are formed with a surface treatment layer for reducing a frictional resistance.

Owner:NTN CORP

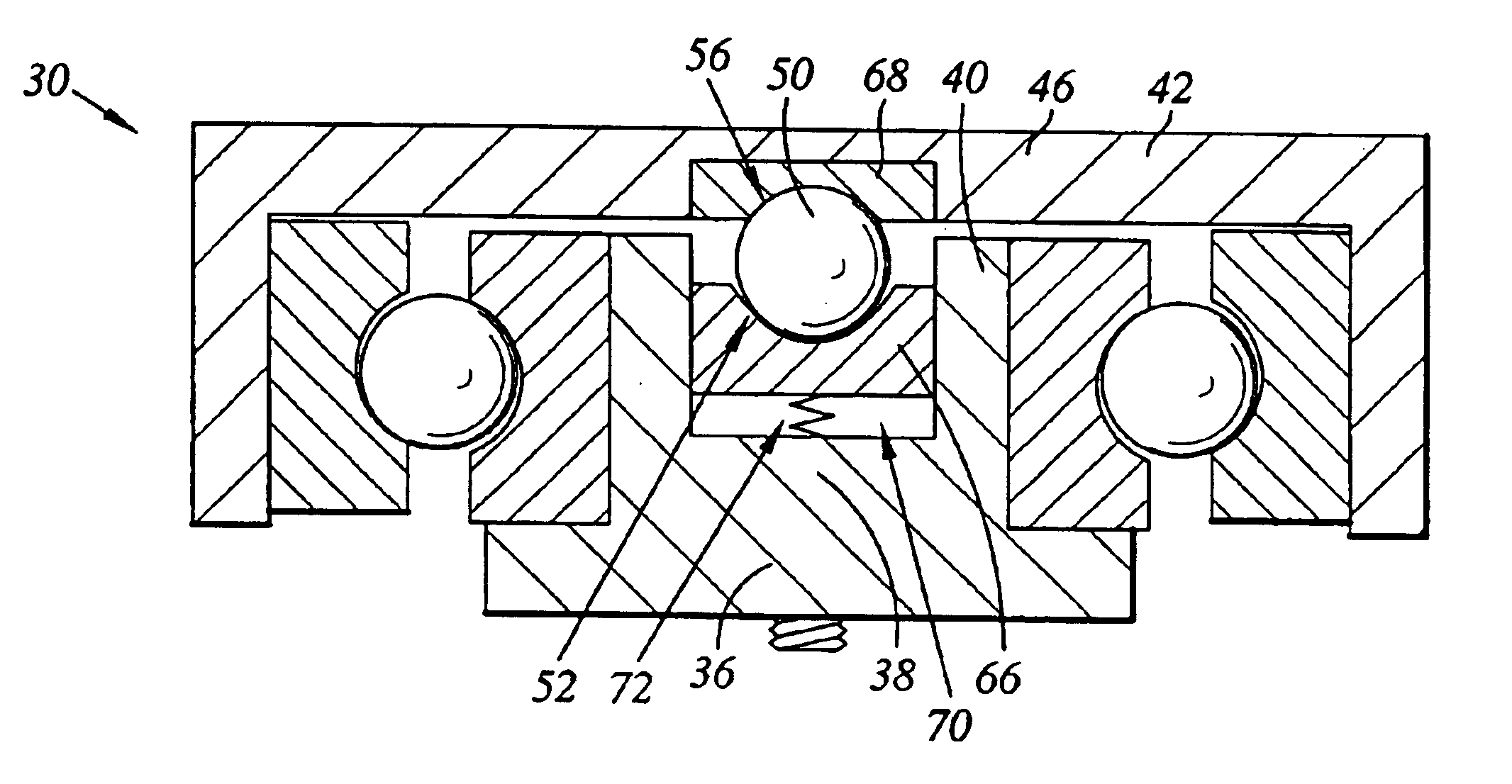

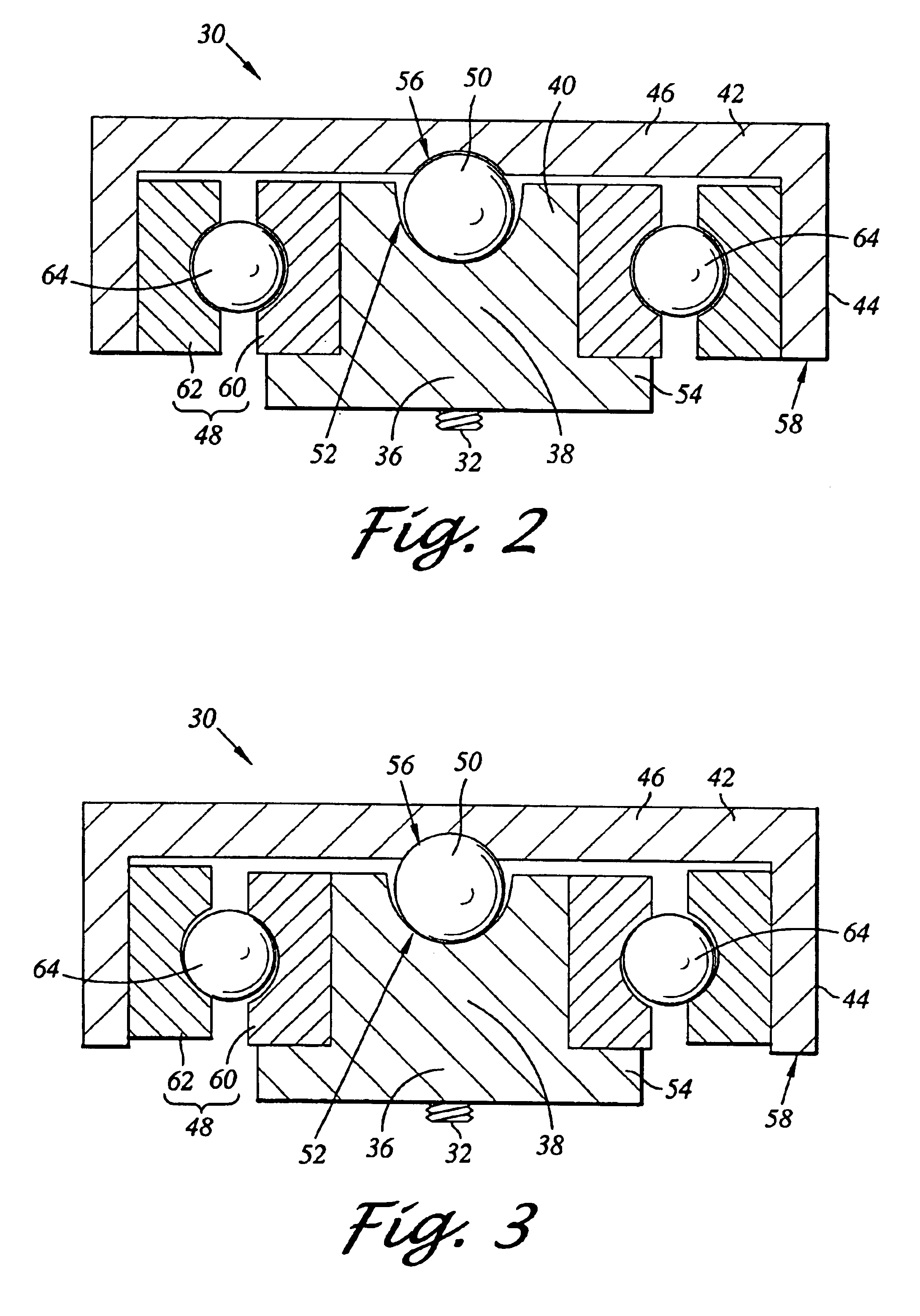

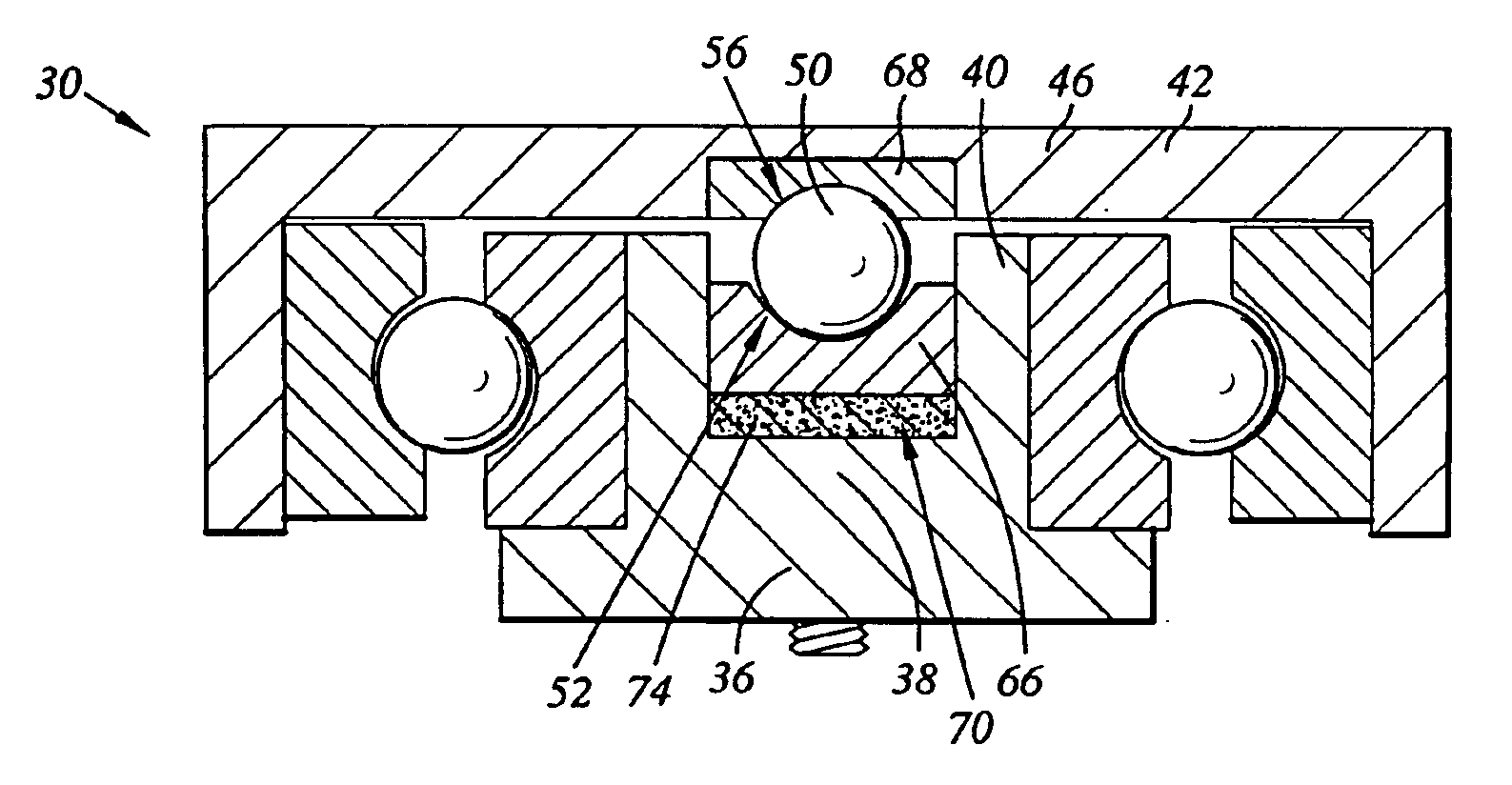

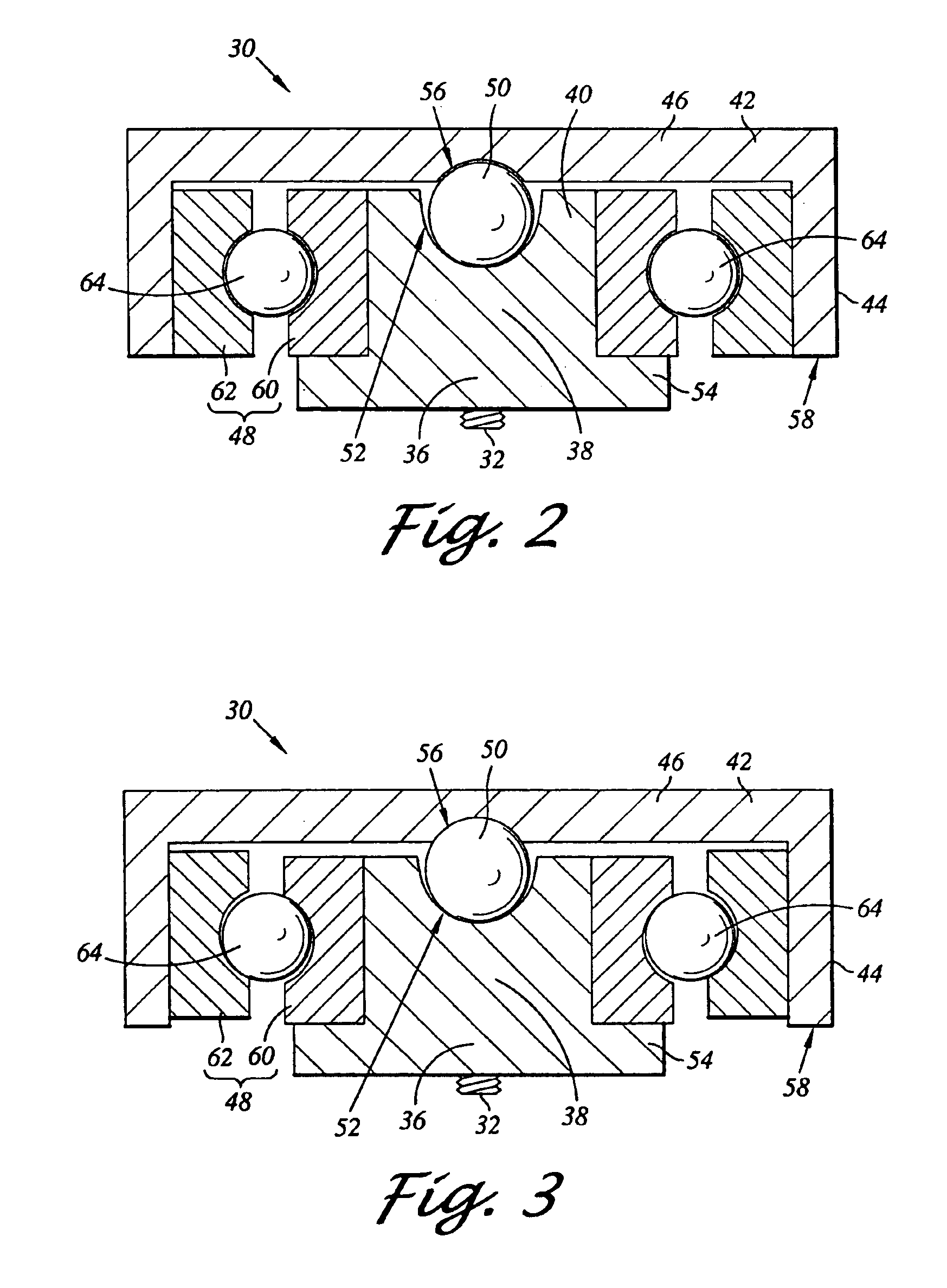

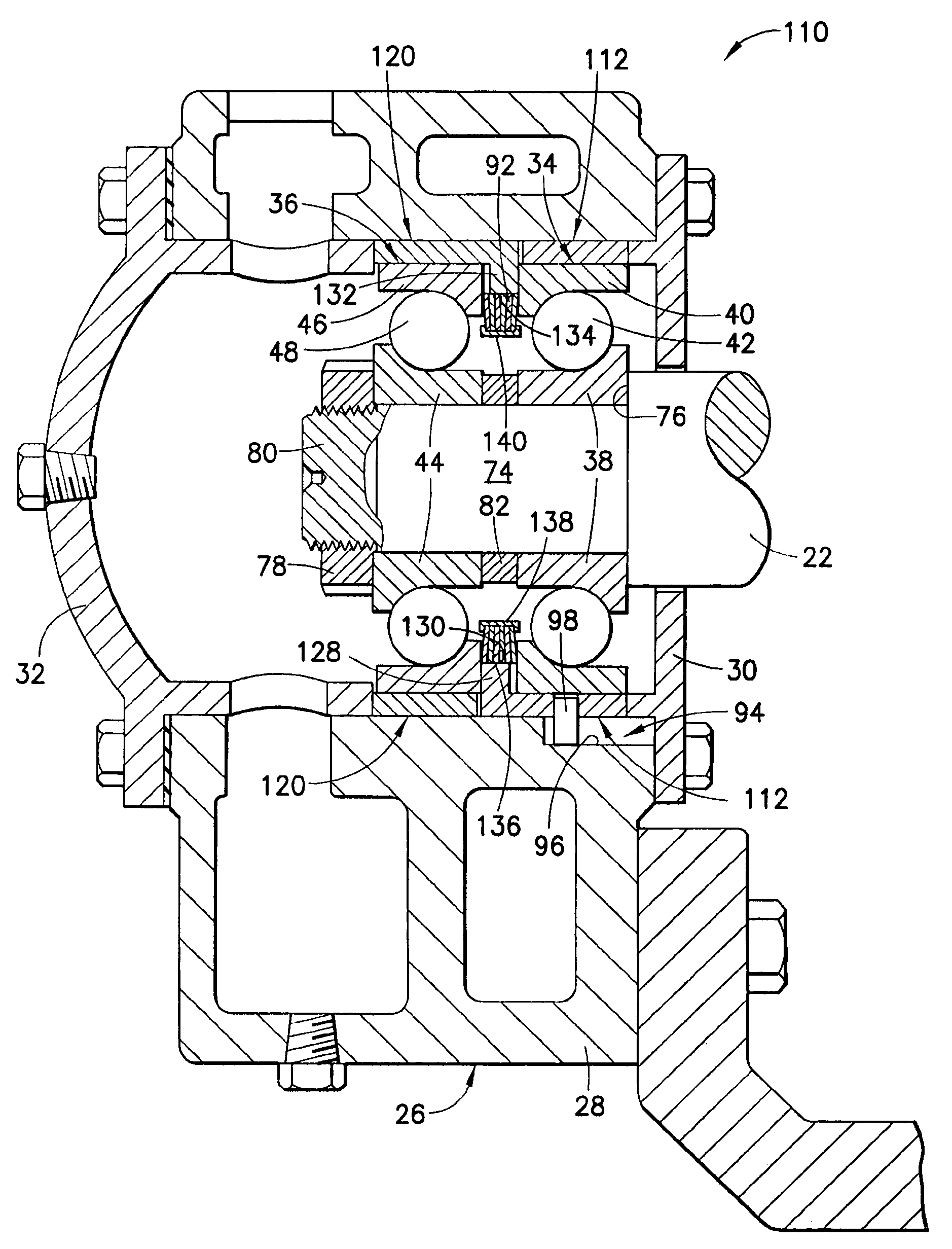

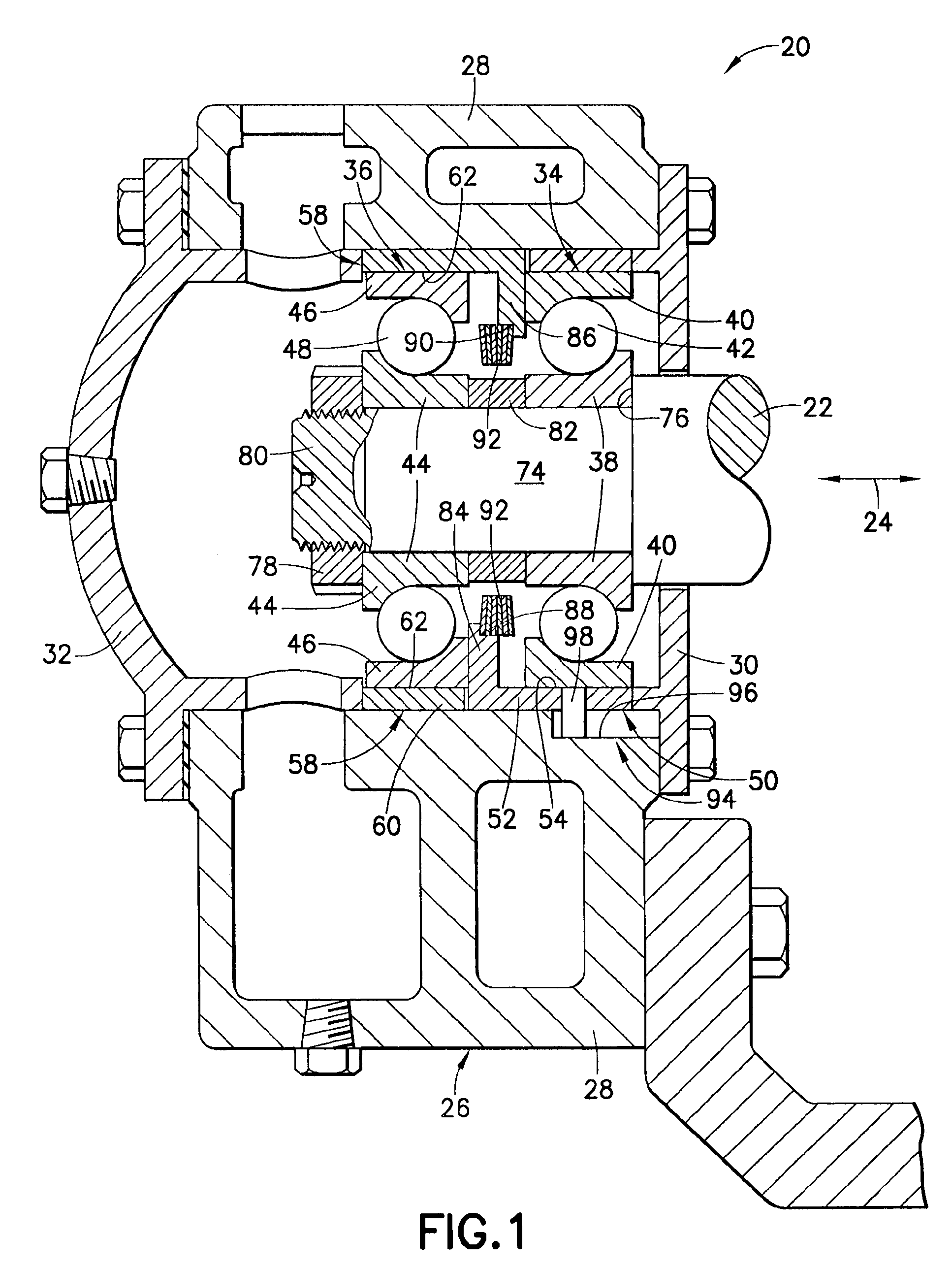

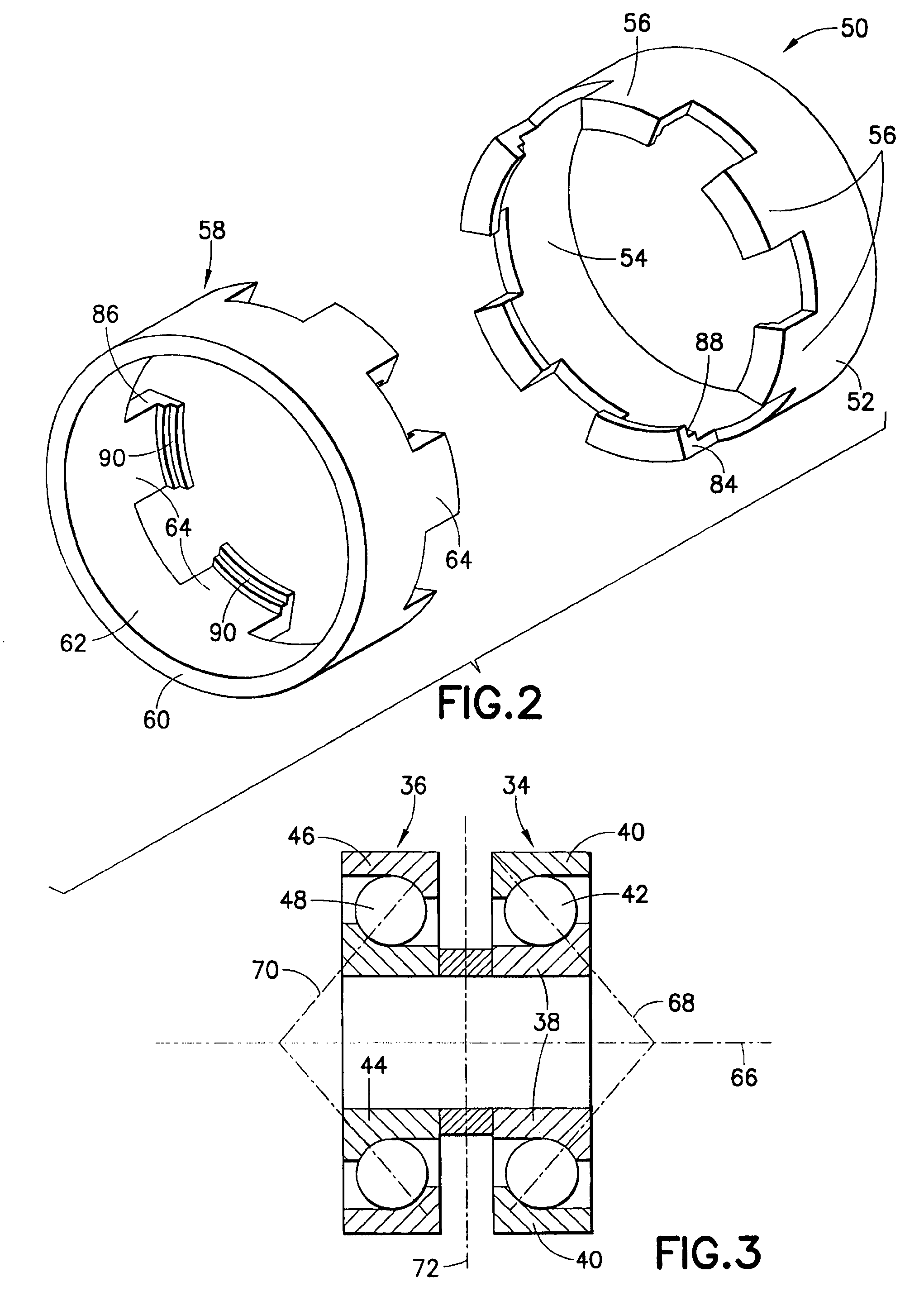

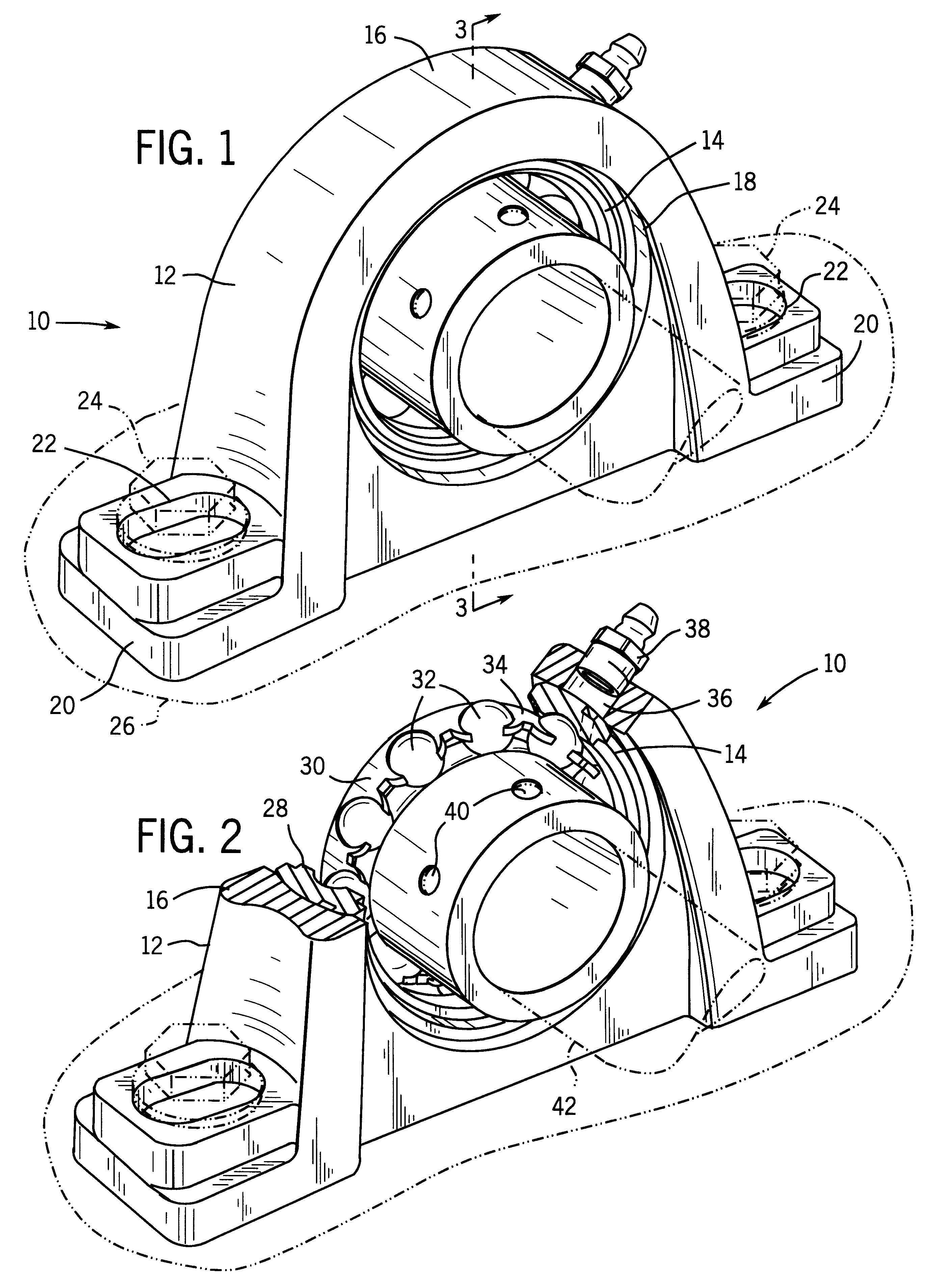

Bearing preload cage assembly

InactiveUS6971802B2Easy to adjustEasy to assembleBall bearingsBearing unit rigid supportEngineeringMechanical engineering

A bearing preload cage assembly for rotatably supporting an axially loaded shaft includes a bearing housing including stationary axially opposed supporting members, first and second axially spaced bearings, each including inner and outer races and rolling elements, first and second cylindrical cage segments coaxial with the shaft, each including a sleeve and circumferentially spaced axially protruding castellations, the outer races engageably received on an internal surface of their associated sleeve, the castellations of each cage segment proximate to and engageable with the outer race of the adjacent bearing, the supporting members proximate to and engageable with an adjacent cage segment, a resilient member biasing at least one of the outer races into full engagement with its rolling elements and, in turn, its rolling elements into full engagement with their inner race whereby the rolling elements of both bearings are maintained in full engagement with their inner and outer races continuously during shaft rotation.

Owner:VEZINA MARTIN J

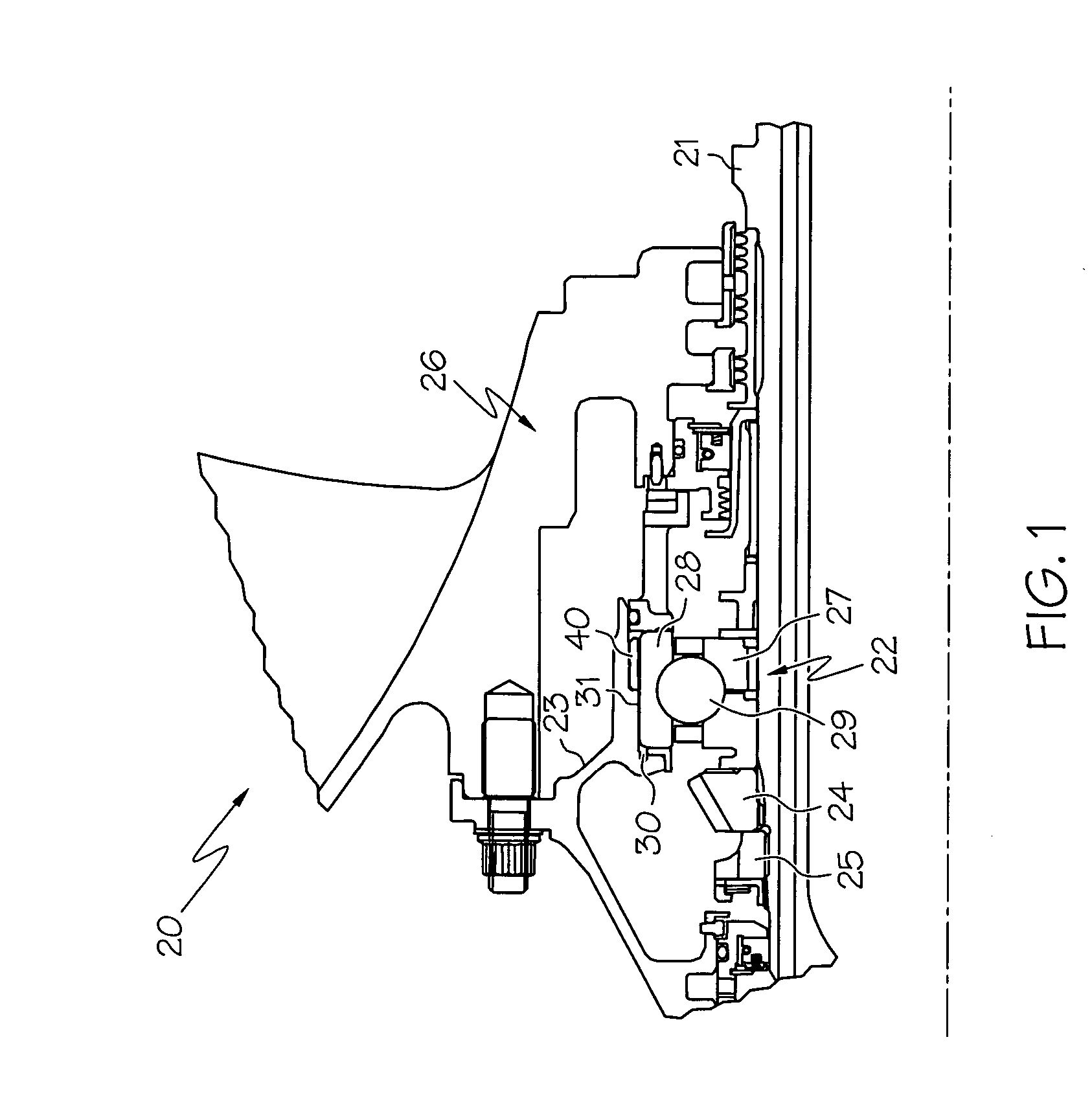

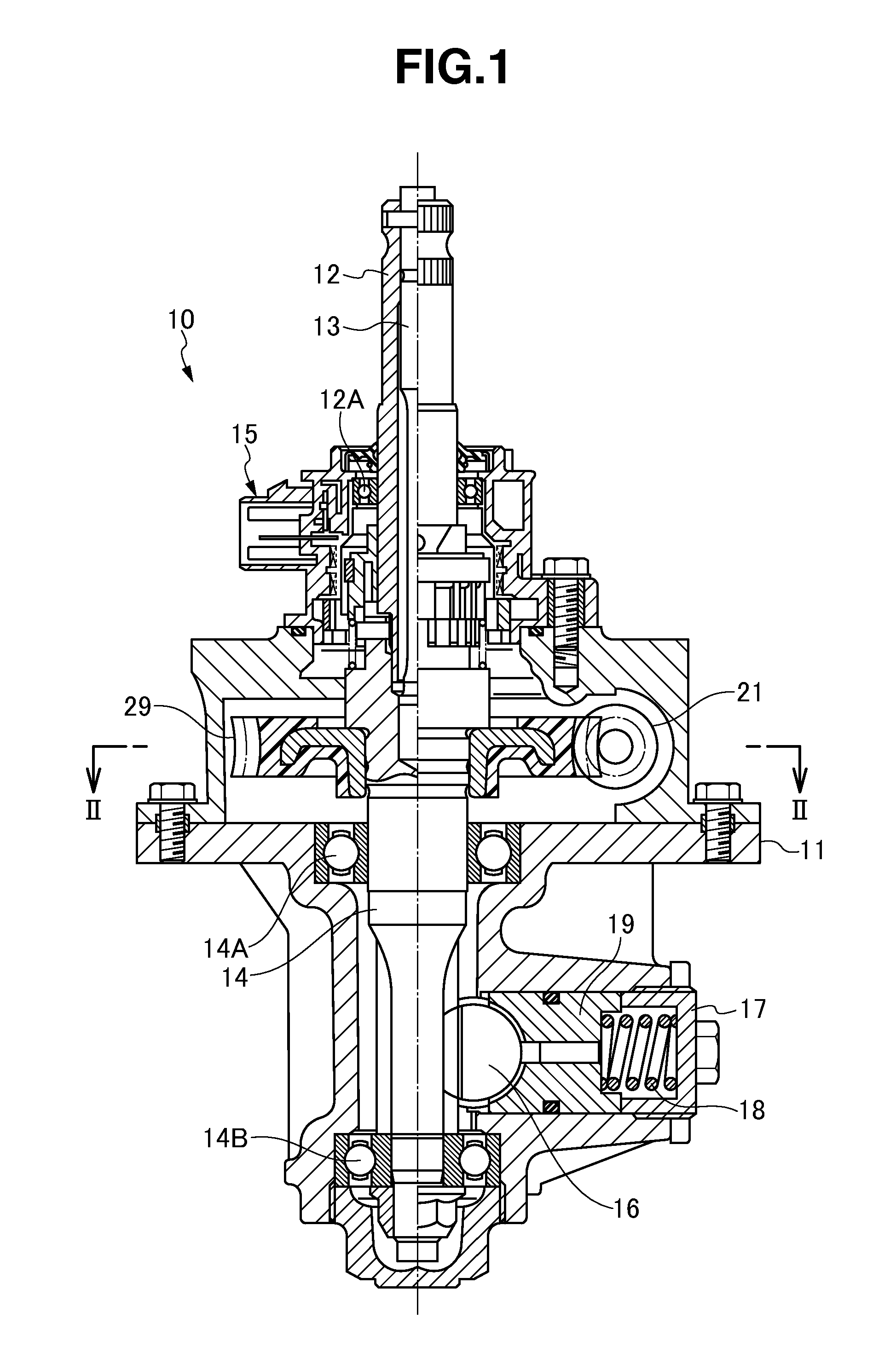

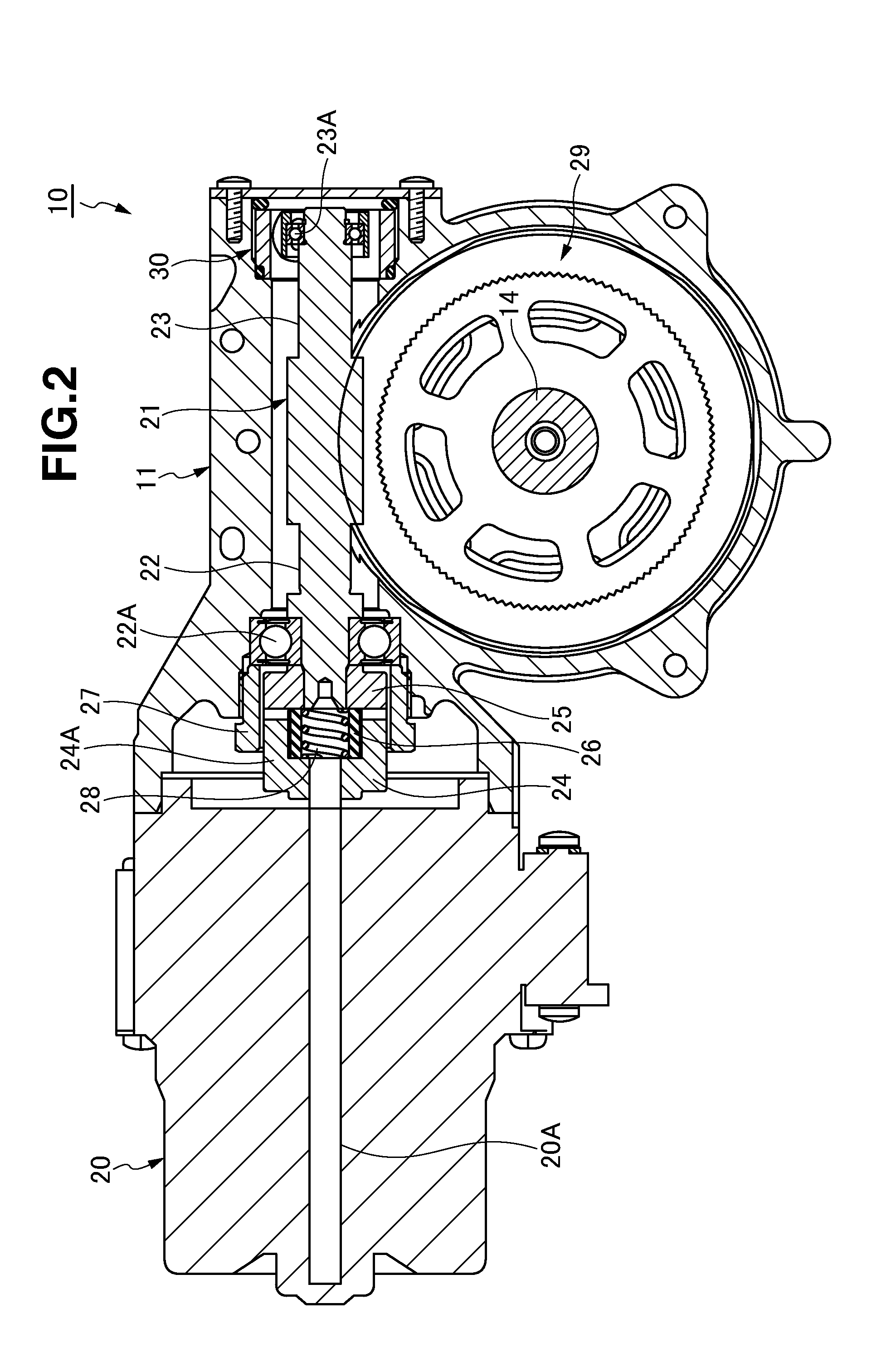

Motor-driven power steering apparatus

InactiveUS20130075189A1Easy to assembleBall bearingsElectrical steeringElectric power steeringMotor drive

In a motor-driven power steering apparatus having a preload means which energizes a bearing of a worm gear in a predetermined preload direction, the preload means has a guide case as well as having a bearing case, and the guide case accommodating the bearing case in which the bearing and a spring are accommodated is attached to an attaching portion which is provided in a gear housing.

Owner:SHOWA CORP

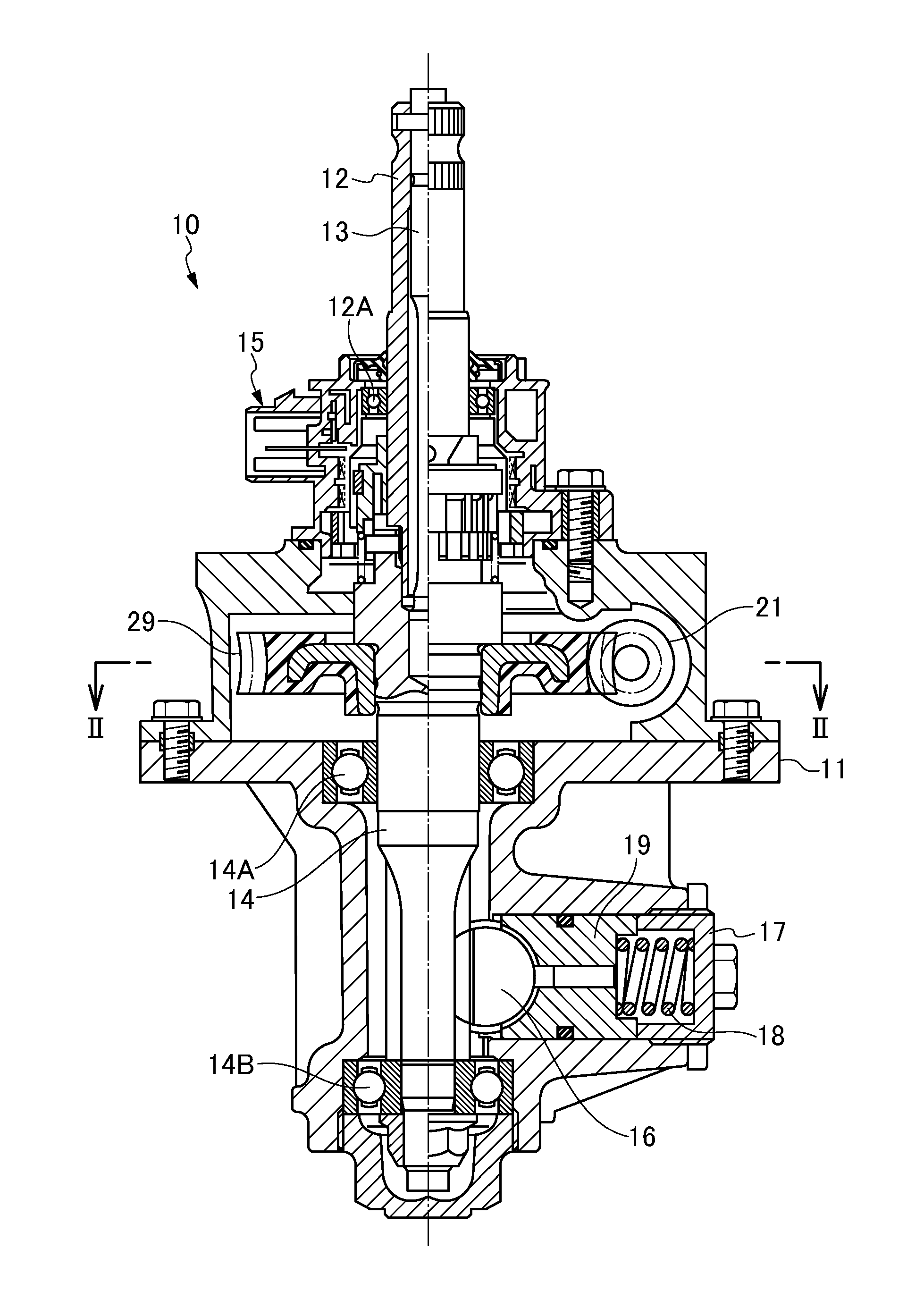

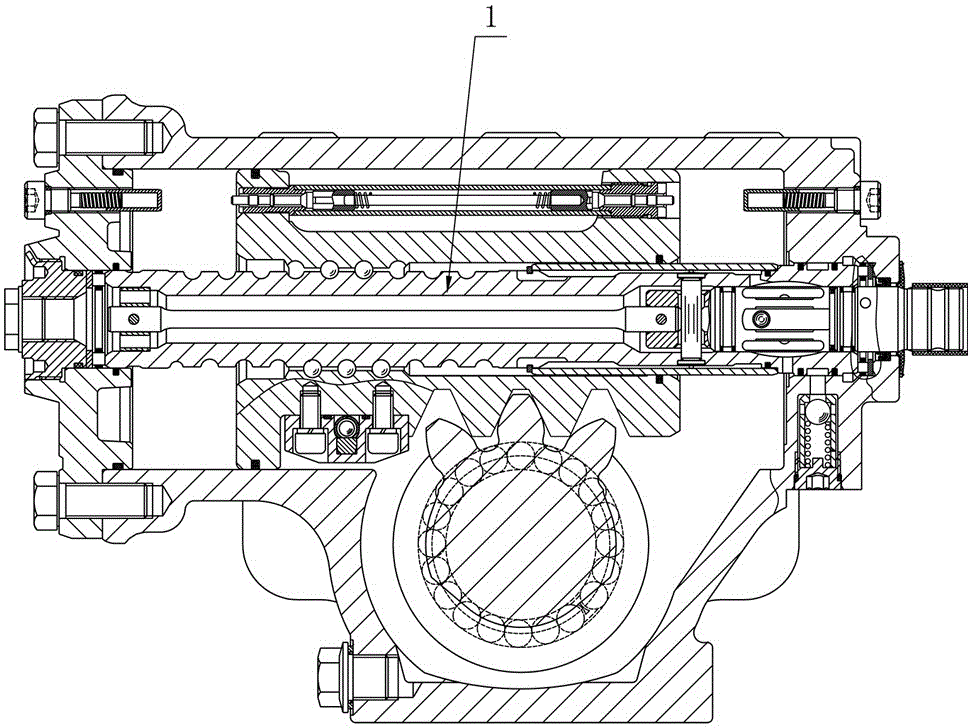

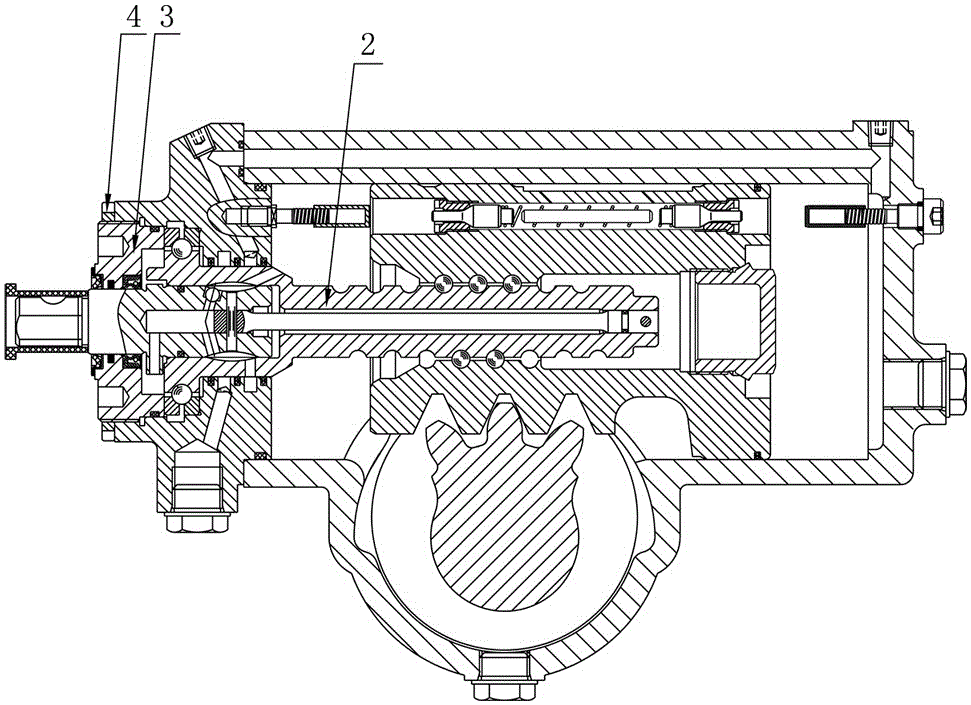

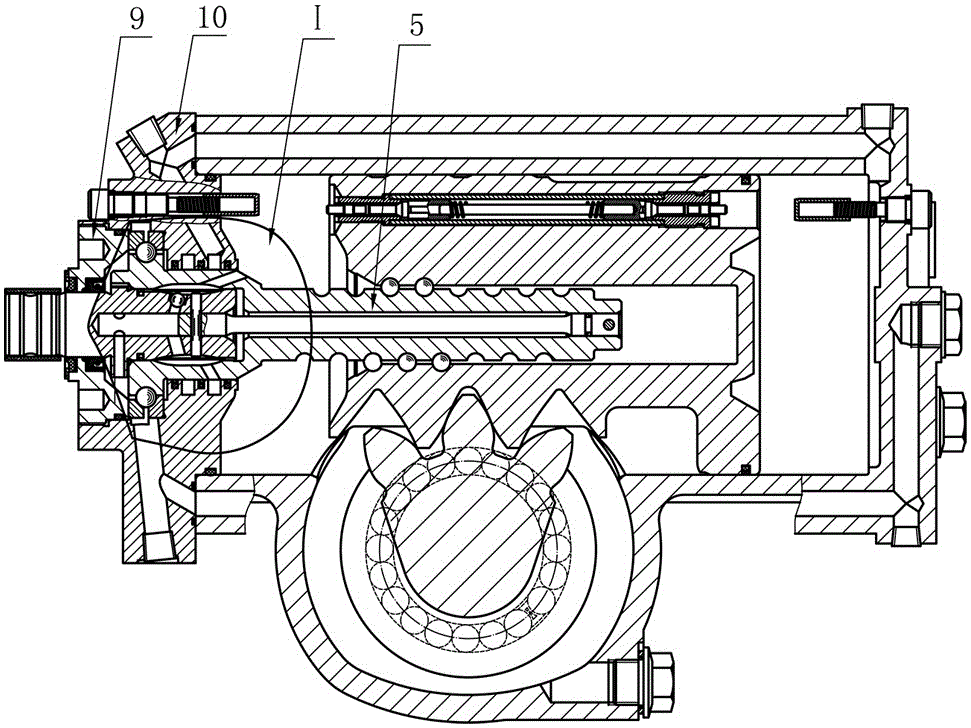

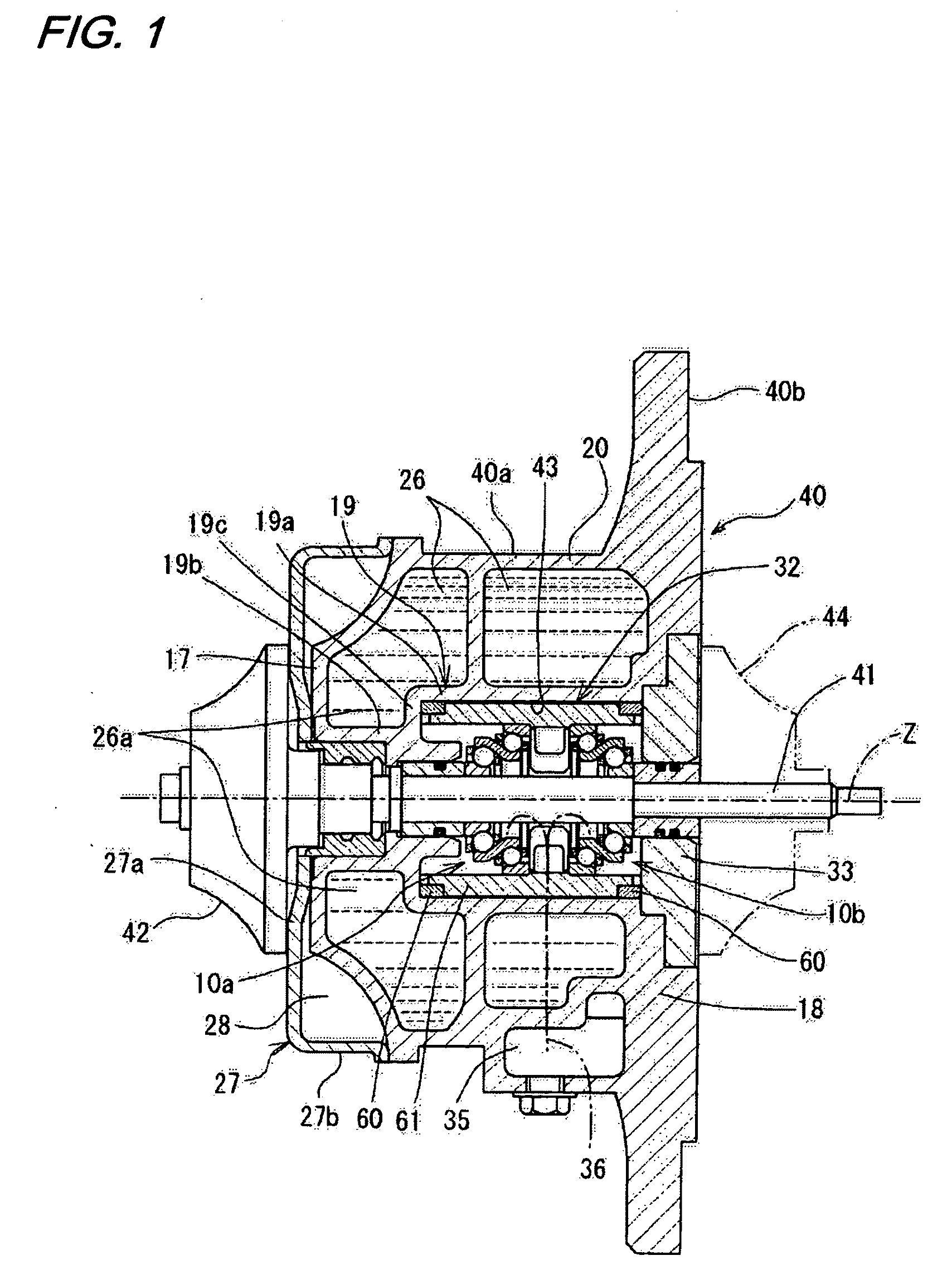

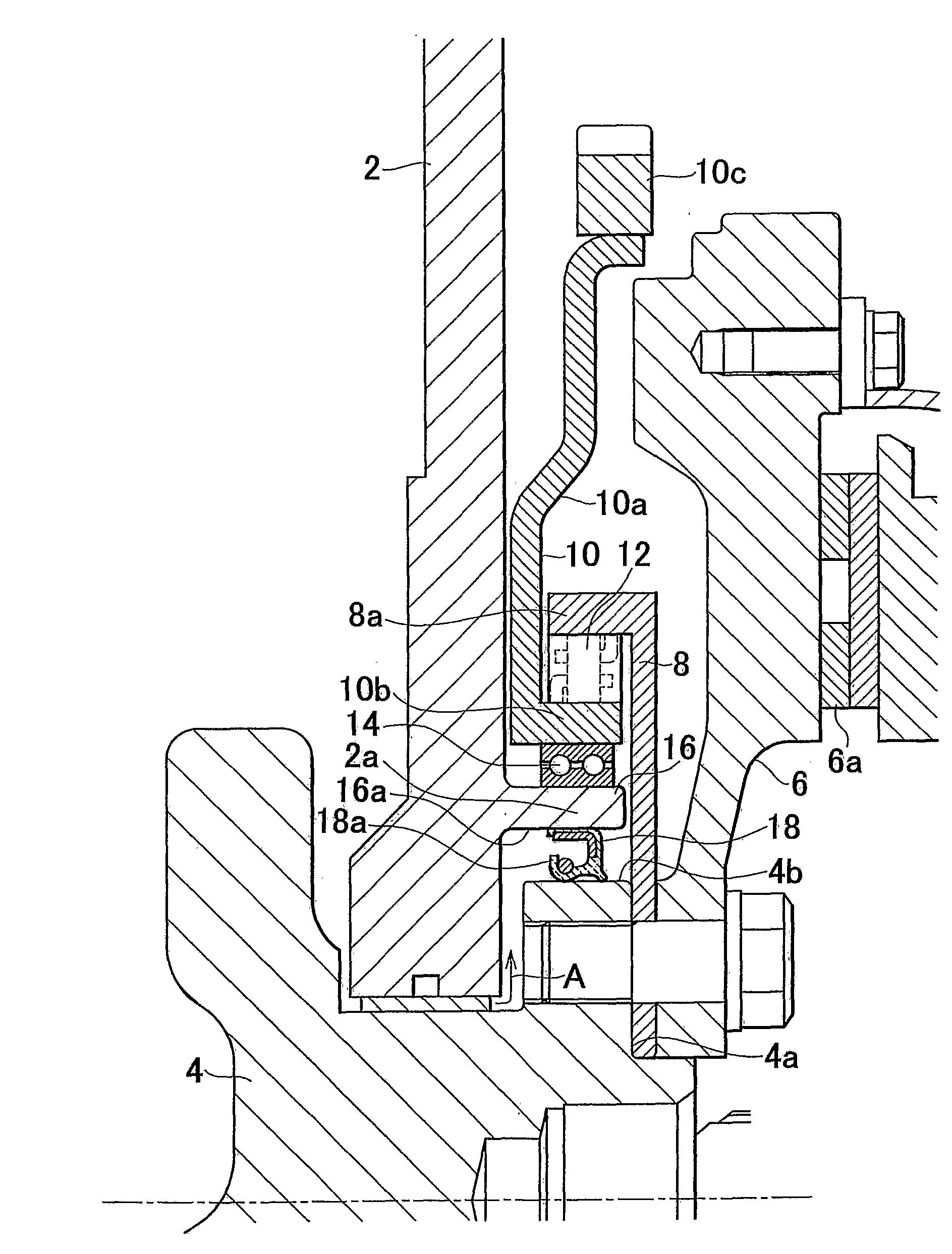

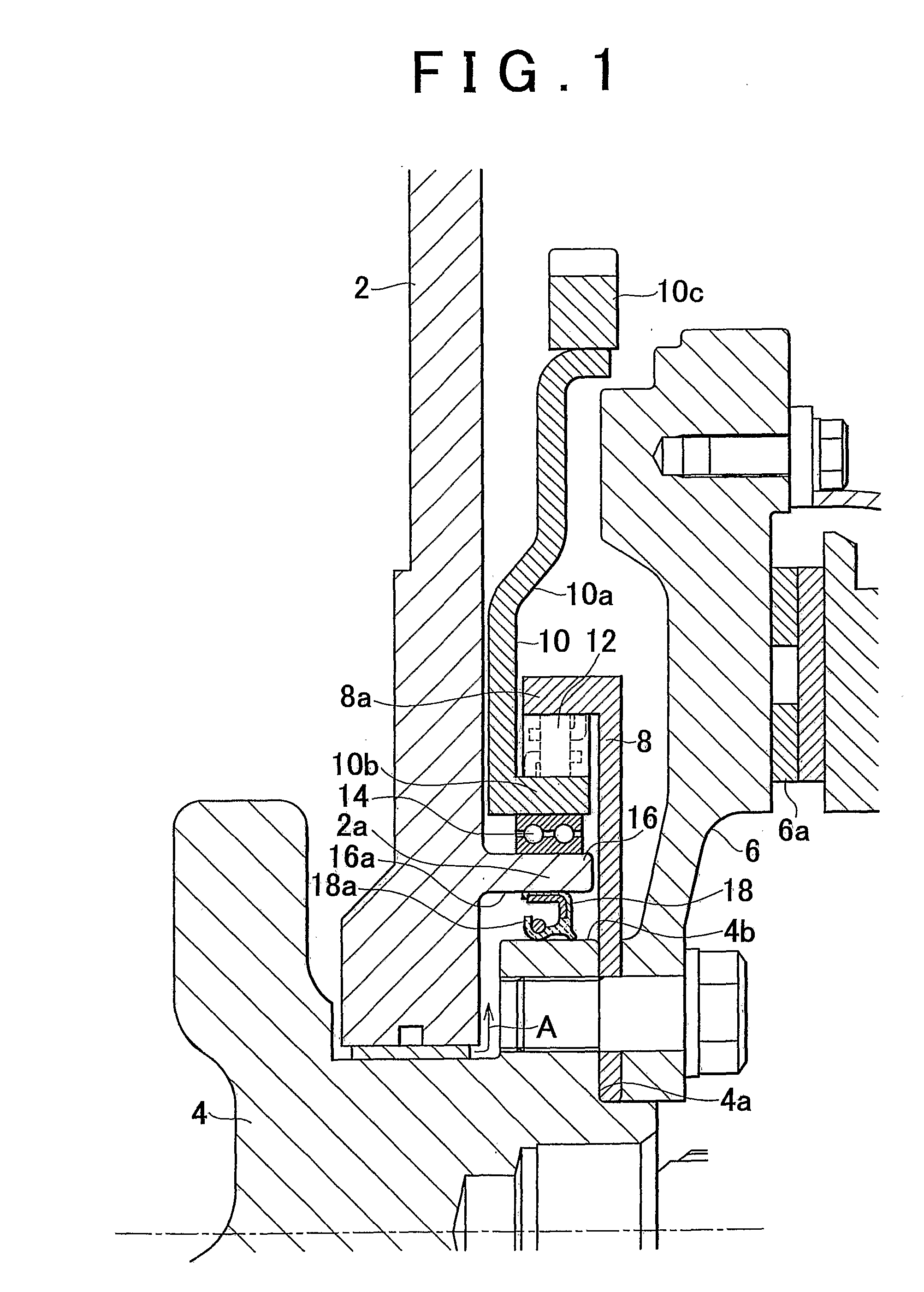

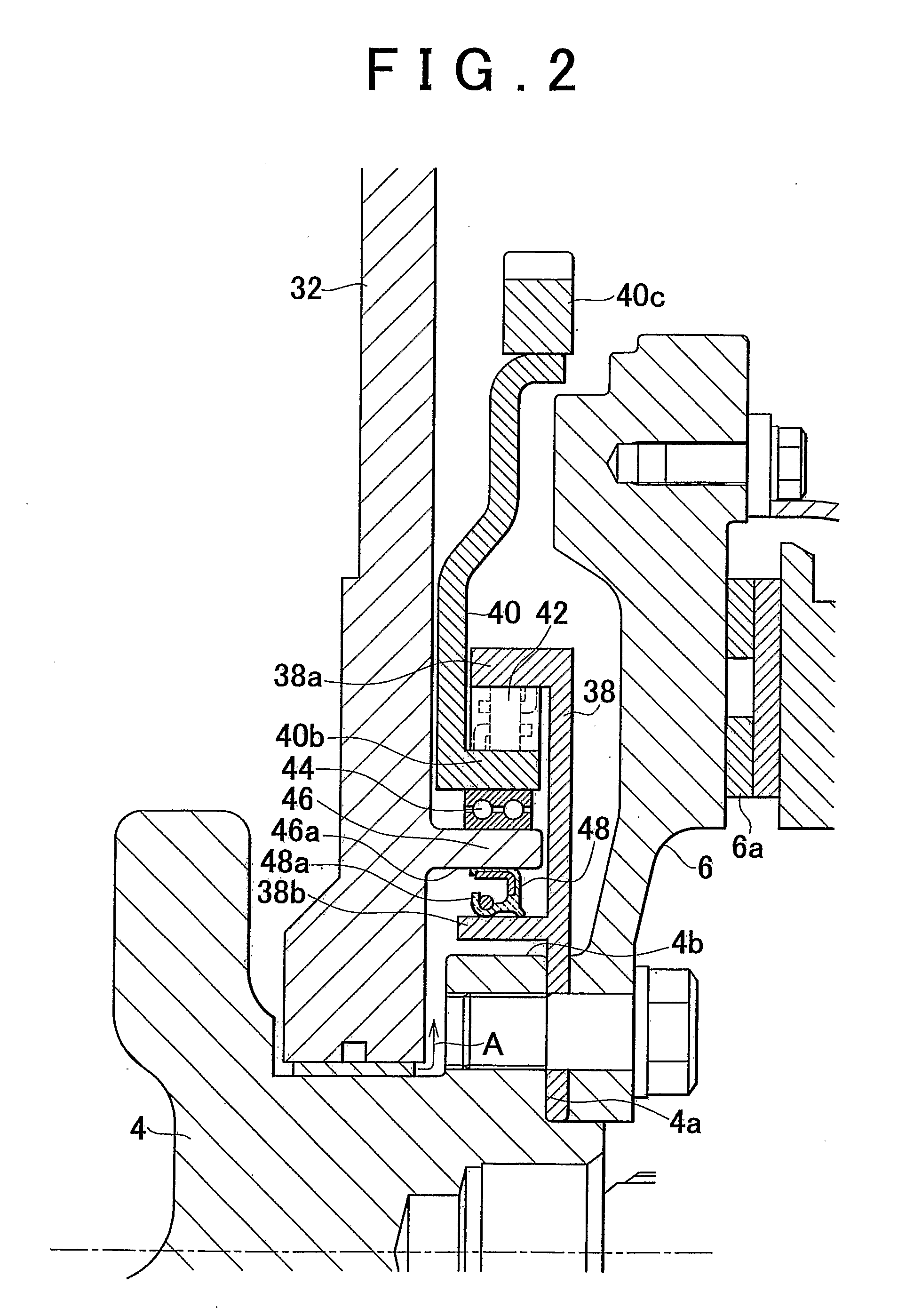

Electric supercharger, assembling method of the same, and internal combustion engine

ActiveUS20140090626A1Reduce vibrationSuppress reduction in output of rotationPump componentsBall bearingsBall bearingExternal combustion engine

It is intended to implement an electric supercharger that has a simplified architecture, is easy to assemble, produces reduced vibration and noise, and has a motor inverter, making it possible to minimize losses in motor output and rotary-shaft output. The electric supercharger is provided with the following: an integrated housing with a built-in electric motor and motor inverter; and a ball bearing and damper-sleeve structure arranged on both sides of the electric motor. The damper-sleeve structure comprises a large-diameter sleeve, a spring guide, a coil spring, and a ball bearing. A gap is formed between the ball bearings and a sleeve and the large-diameter sleeve. The inner ring or outer ring of the ball bearings are supported by various support members disposed on both sides. An elastic O-ring that elastically supports the sleeve and large-diameter sleeve is provided on the outside of the sleeves.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Thrust bearing for screw of ball-nut type steering gear

InactiveCN106481655AExtended service lifeSave assembly spaceBall bearingsMechanical steering gearsBall bearingPunching

The invention provides a thrust bearing for the screw of a ball-nut type steering gear. The thrust bearing comprises a screw. A thrust ball type thrust bearing is arranged on screw. The thrust ball type thrust bearing comprises a steel ball and a ring. The ring is composed of a left semi-ring and a right semi-ring. The cross section of the thrust ball type thrust bearing raceway is a four point contact type. The left semi-ring and the right semi-ring are both provided with a corresponding arc outer raceway. Two arc inner raceways are arranged on the screw. The radius of two inner raceways is the same as that of two outer raceways. The centers of four arc raceways are in a same circumference, but four arc raceways are non-concentric. The steel ball is arranged between the screw and the ring. Four contact points are formed between the steel ball and two outer raceways and two inner raceways, and thus a four point contact type thrust ball bearing is formed. In assembly, a punching-riveting anti-loosening structure is adopted between an adjusting nut and a valve body. For the bearing, a screw is used to replace a shaft washer, a holder is not needed any more, and the installation becomes convenient. The inner raceway and outer raceway are both composed of two arcs, a four point contact ball bearing is formed and is capable of bearing a large axial / radial force, the wear is reduced, and the service life is prolonged.

Owner:DONGFENG MOTOR PARTS & COMPONENTS GROUP

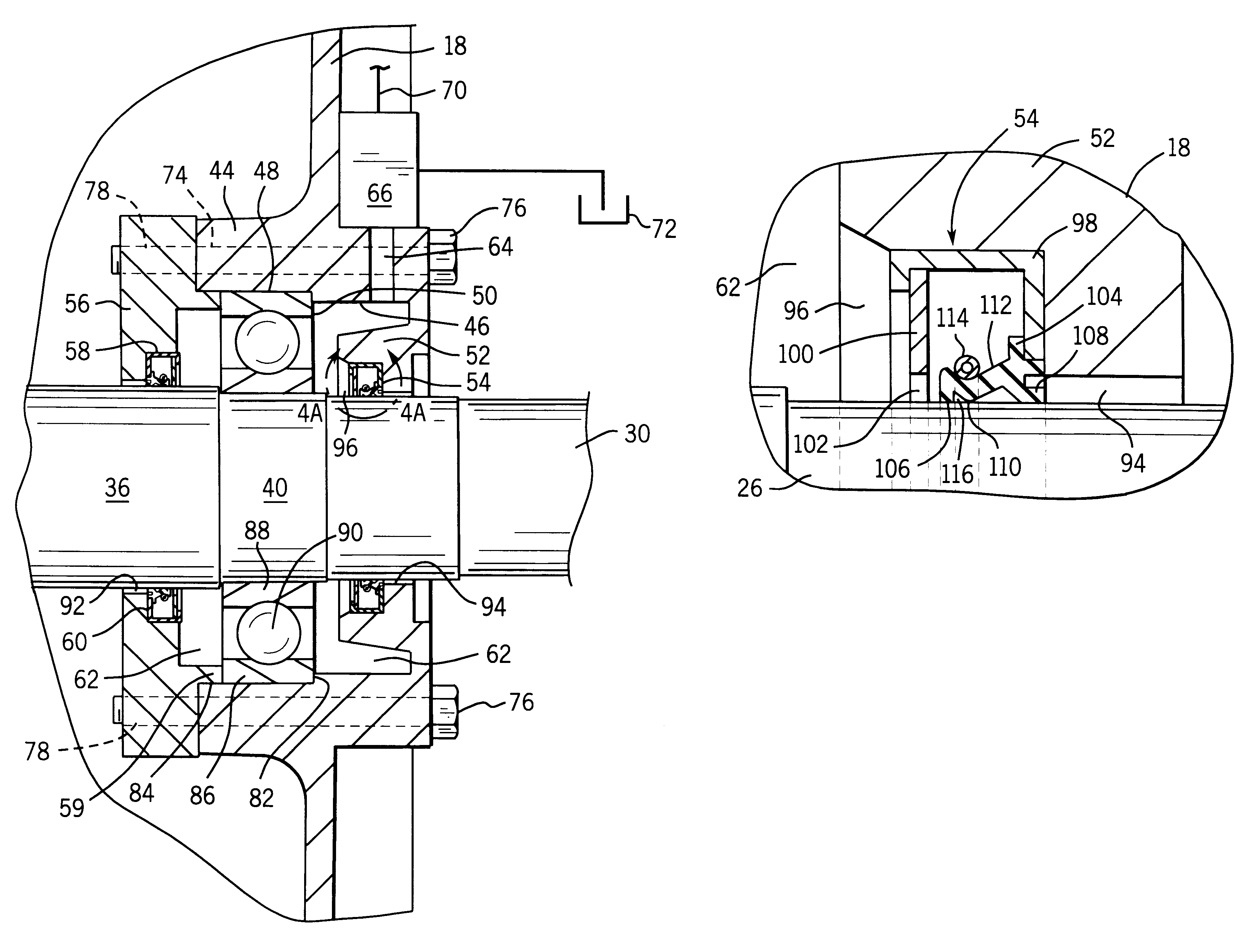

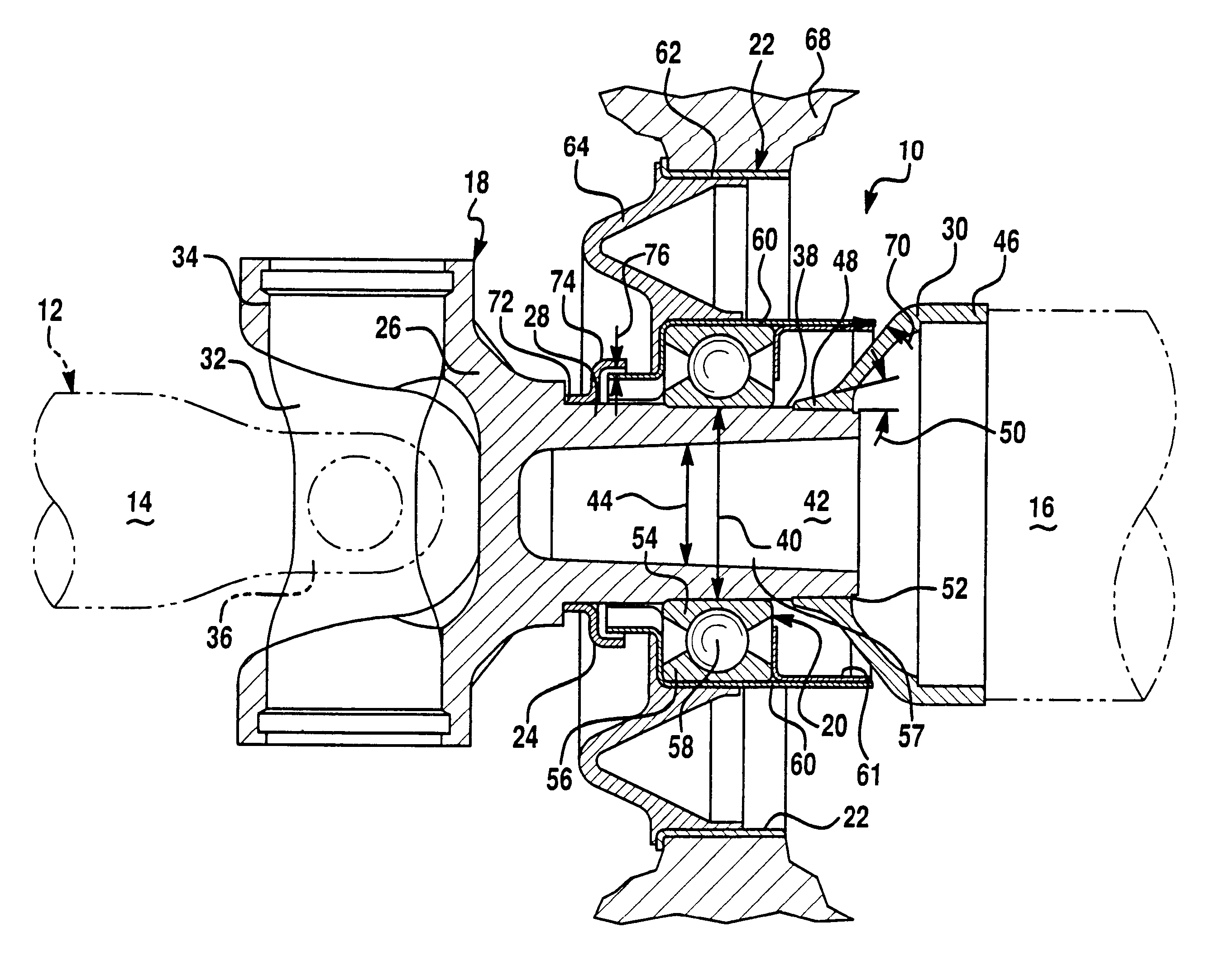

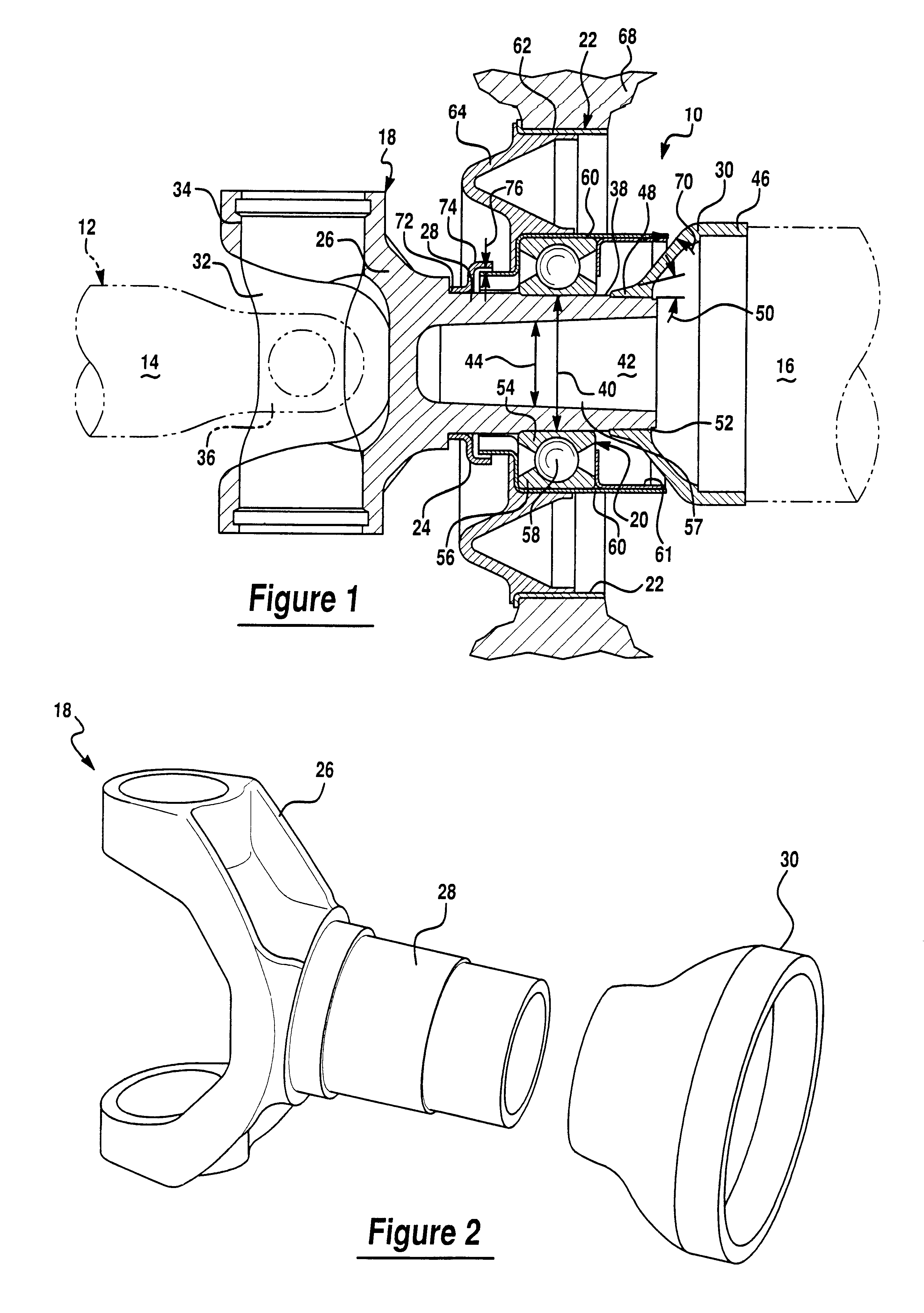

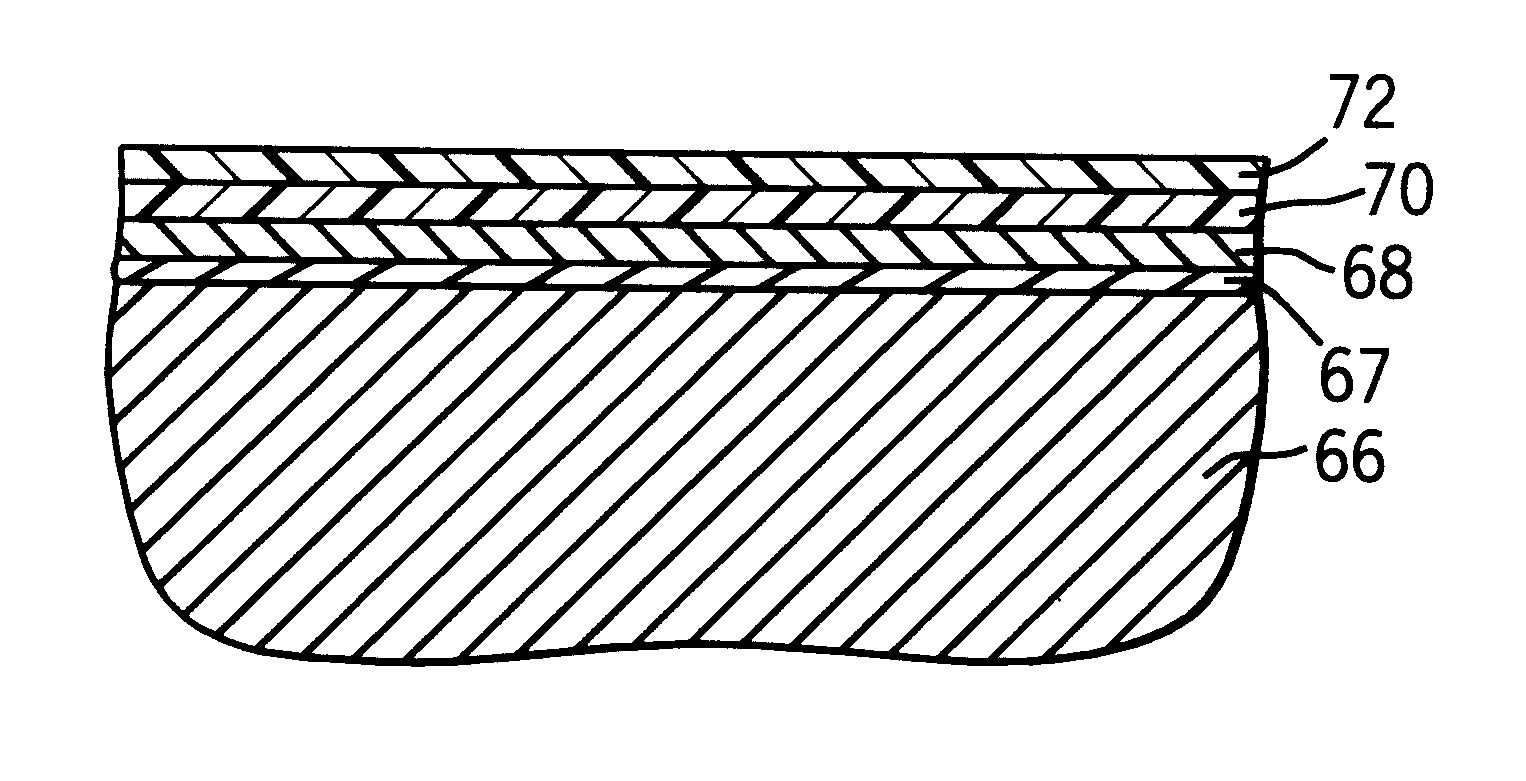

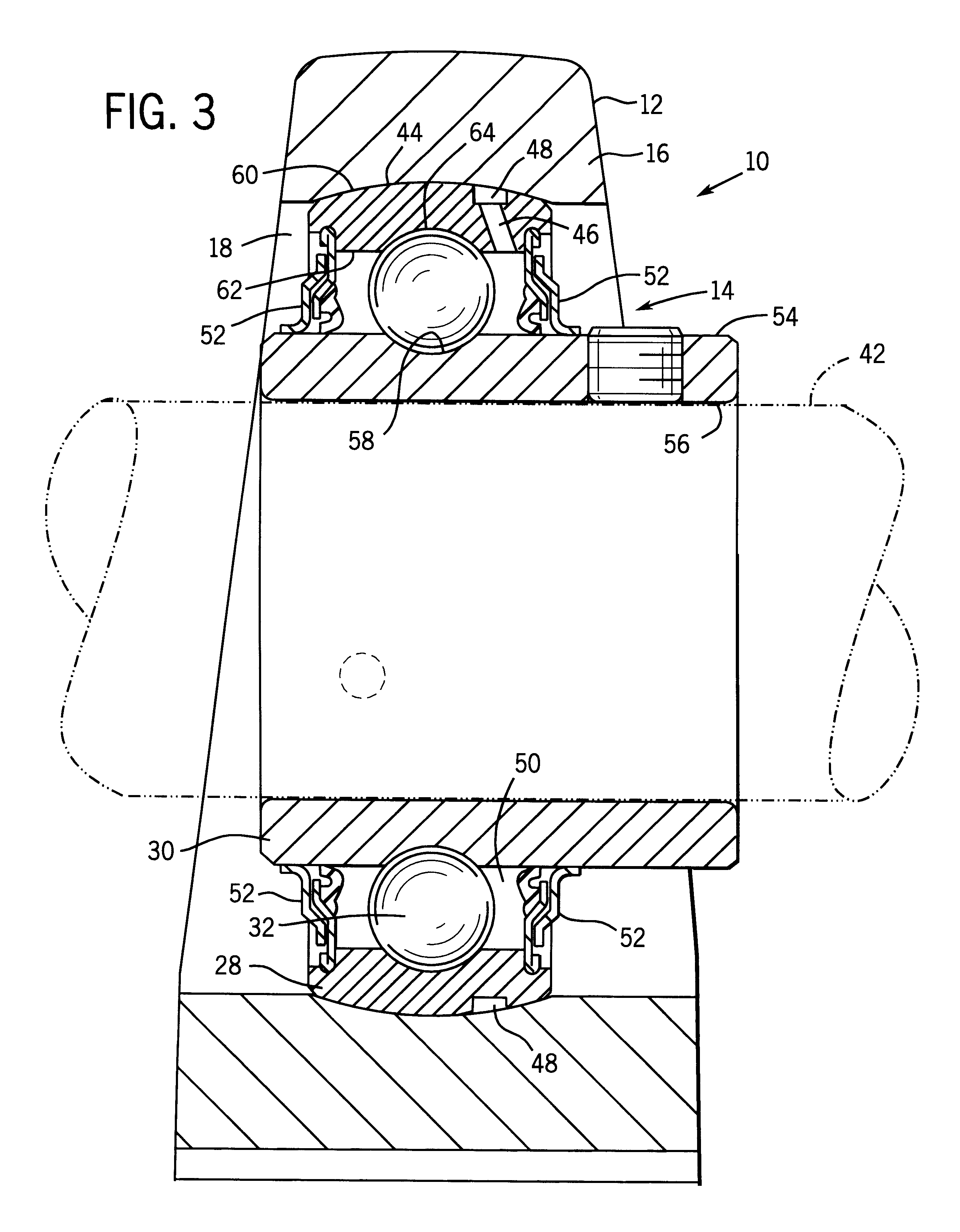

Driveshaft bearing assembly

InactiveUS6422947B1Need for servicingEliminates need for service and replacementYielding couplingBall bearingsDrive shaftClassical mechanics

A driveshaft bearing assembly 10 including a driveshaft connecting rod or member 18, a generally circular or ring-shaped bearing member, assembly or apparatus 20, a bracket assembly 22 and a protective cover or shield member 24. Bearing assembly 10 selectively connects and rotatably supports two members 14, 16 of a multi-piece driveshaft 12.

Owner:NEAPCO INTPROP HLDG LLC

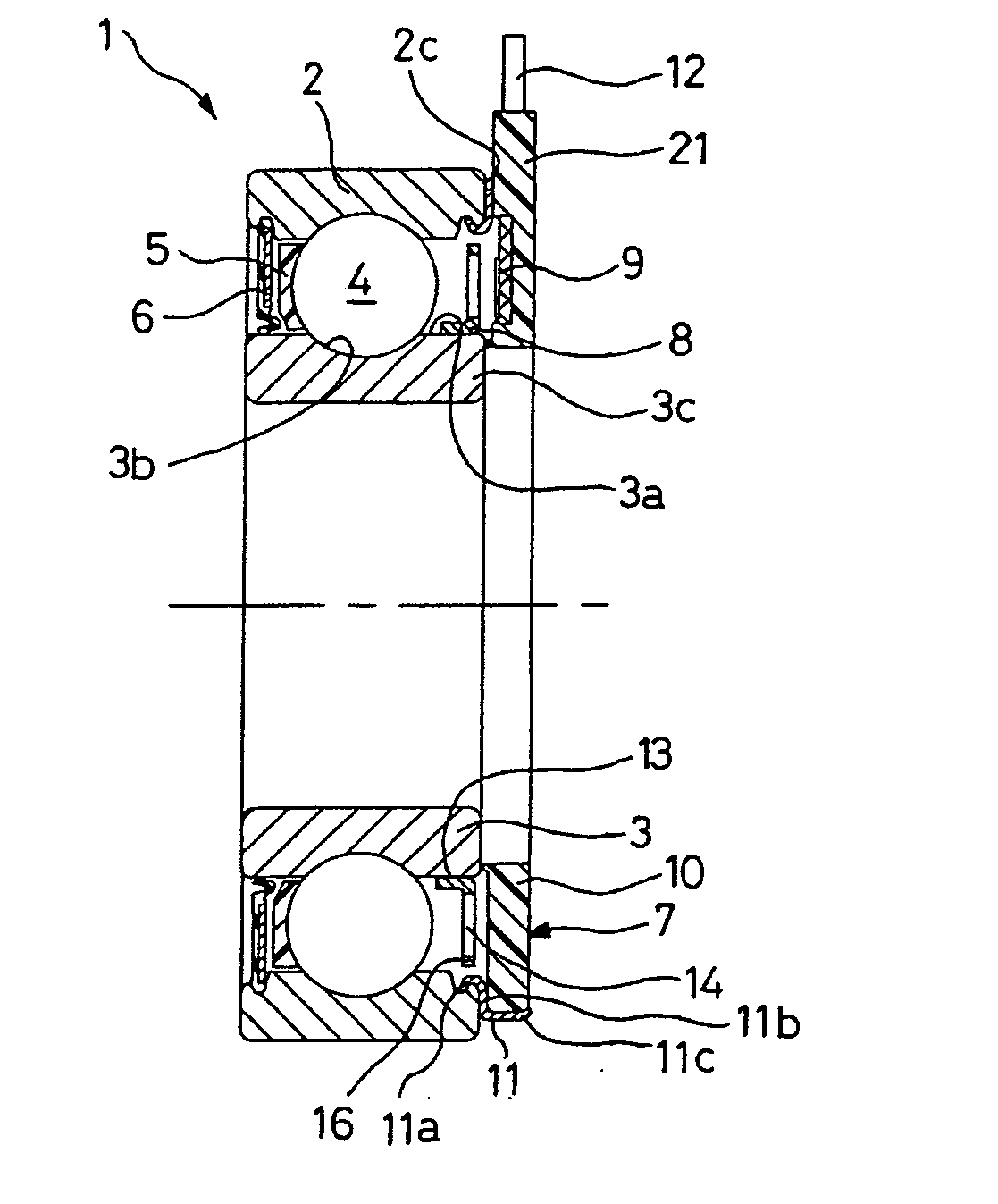

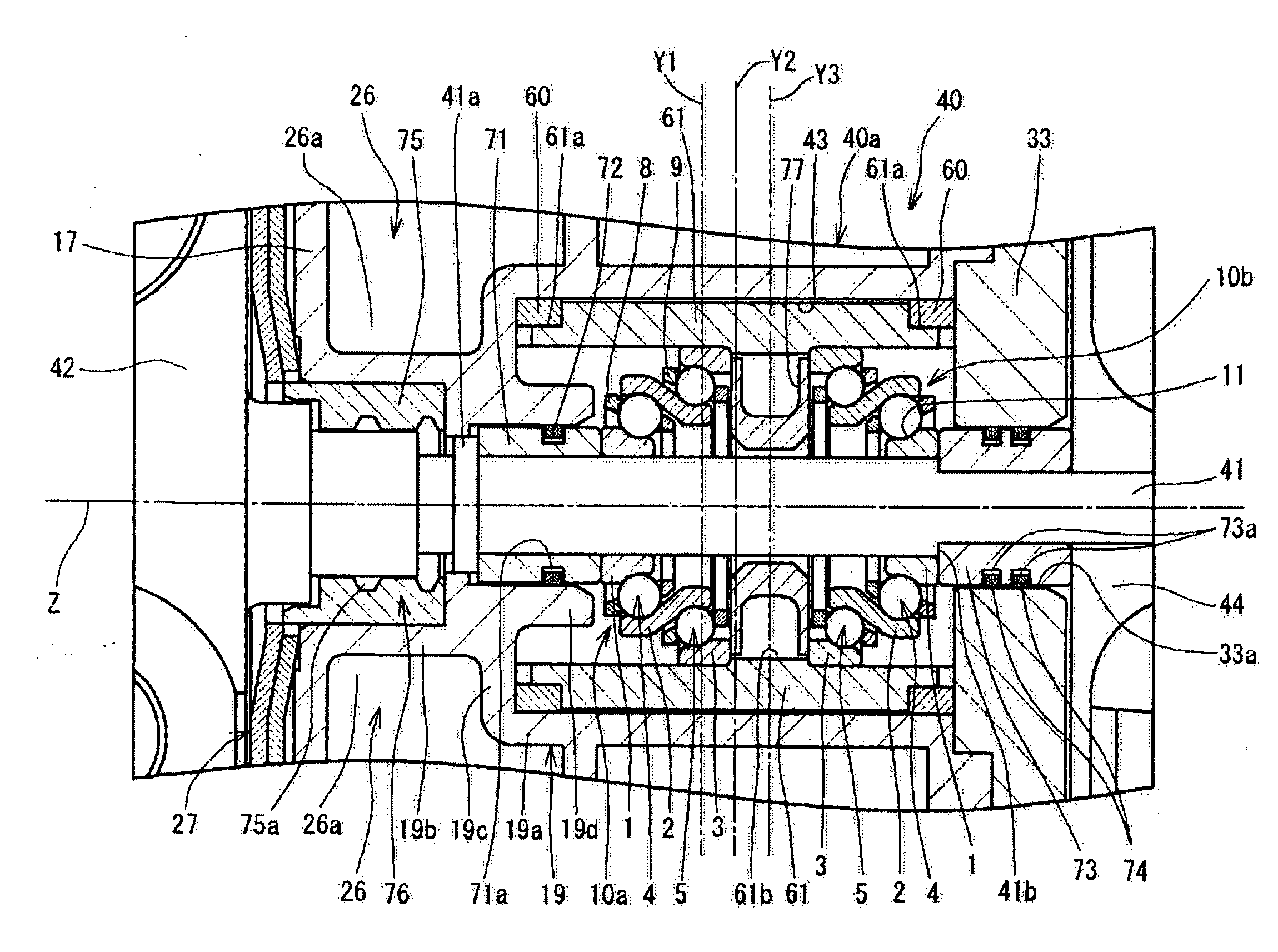

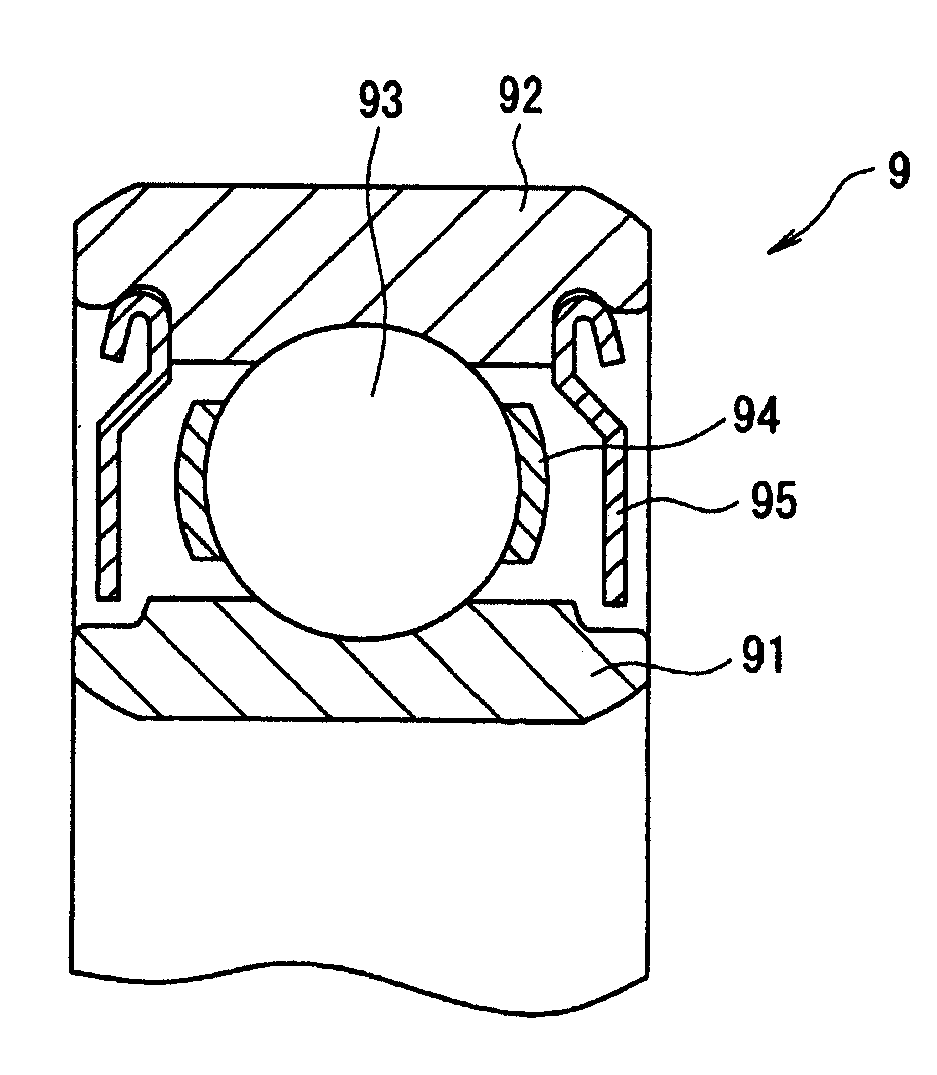

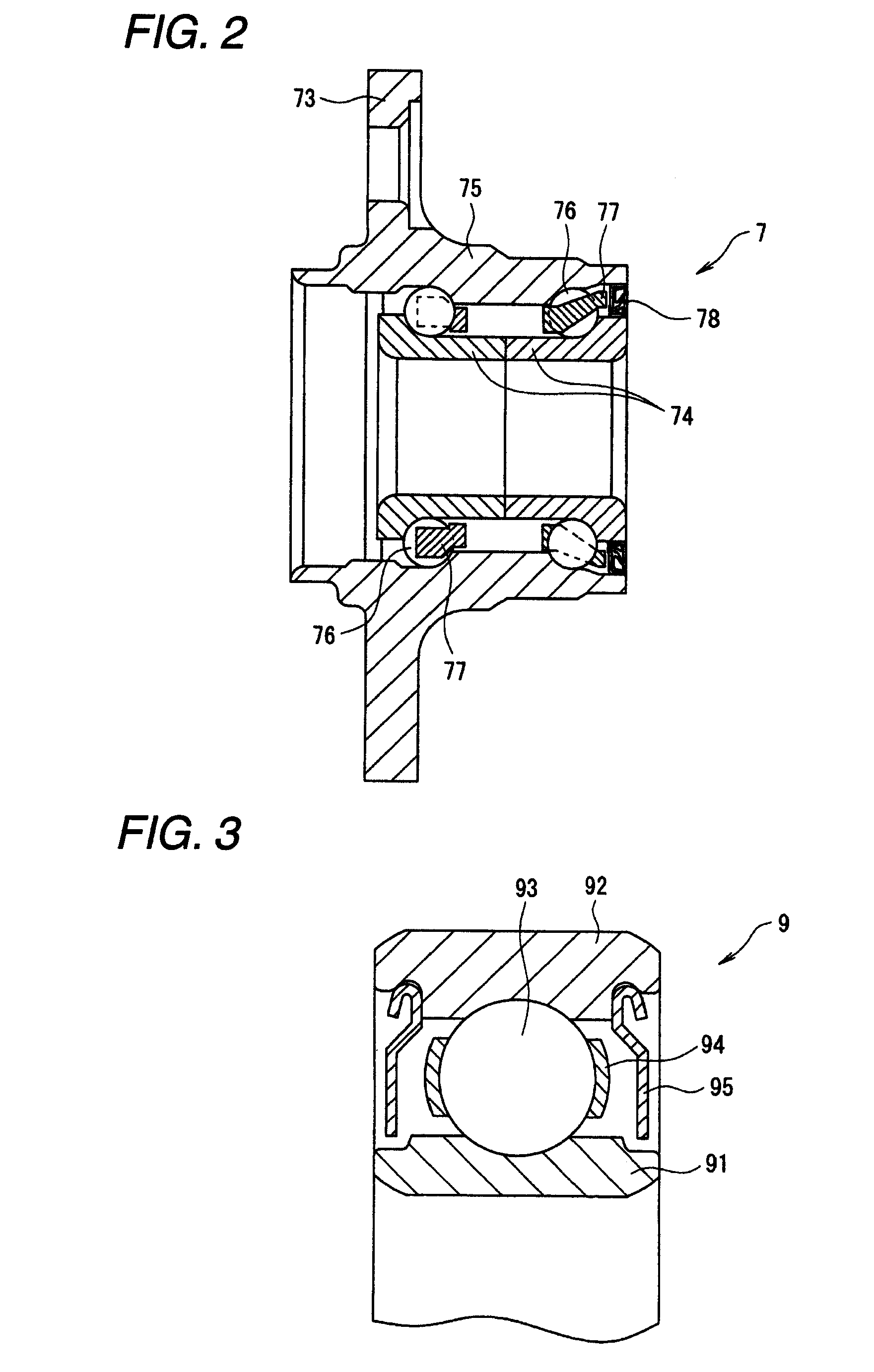

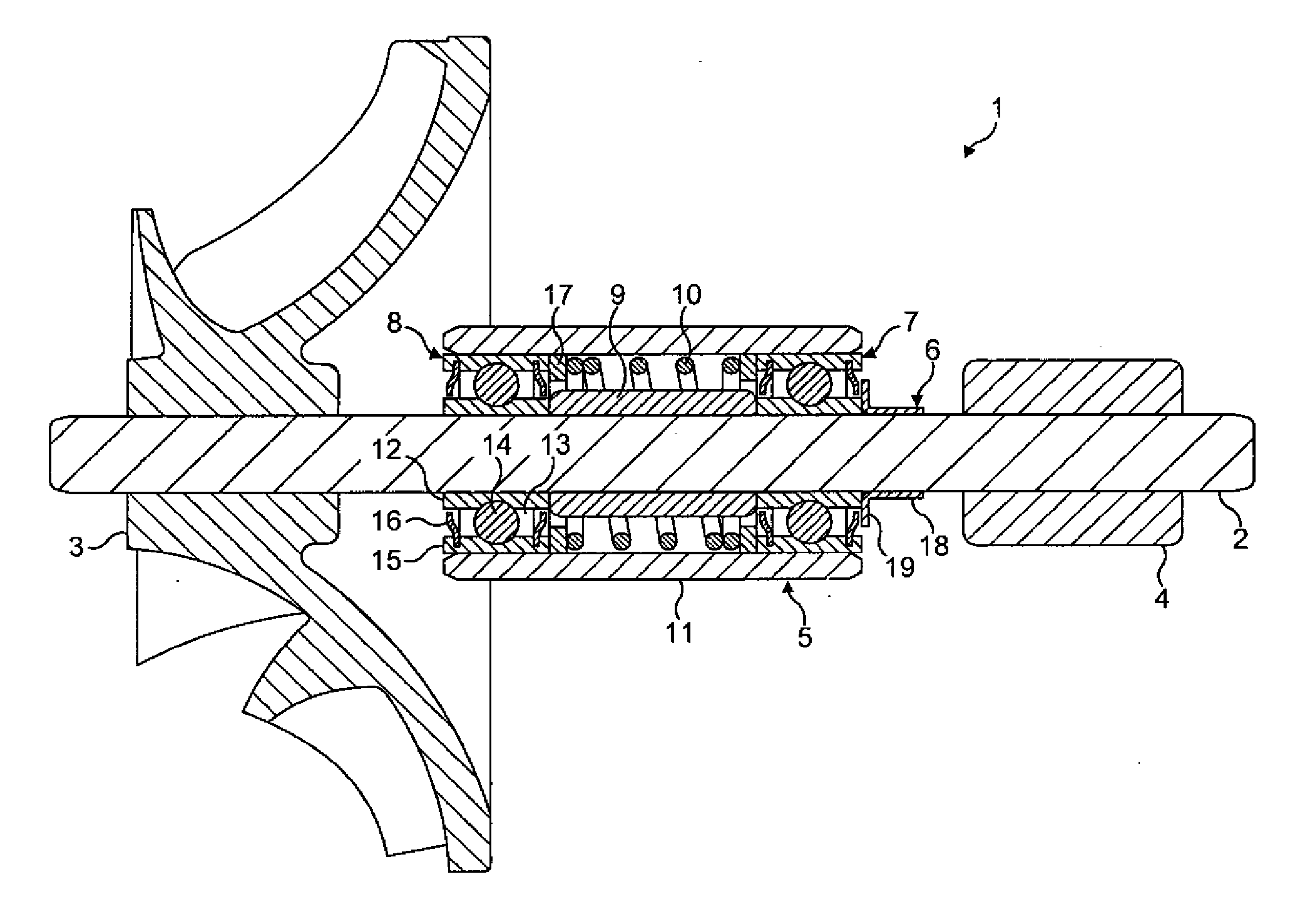

Rolling bearing device and turbocharger incorporating same

InactiveUS20090081040A1Heating effectReduce vibrationPump componentsShaftsRolling-element bearingTurbocharger

A rolling bearing device includes a bearing housing supported on a casing of a turbocharger, and a pair of rolling bearings mounted within the bearing housing and rotatably supporting a turbine shaft. A middle position between the pair of rolling bearings in an axial direction and a central portion of the bearing housing in the axial direction are offset from each other in the axial direction. Each of the rolling bearings includes an inner ring, an outer ring, an intermediate ring interposed between the inner and outer rings, a row of rolling elements rollably interposed between the inner ring and the intermediate ring, and a row of rolling elements rollably interposed between the intermediate ring and the outer ring. The intermediate ring has a damper function to be very slightly displaced or very slightly deformed elastically so as to damp vibration produced during rotation of the turbine shaft.

Owner:JTEKT CORP

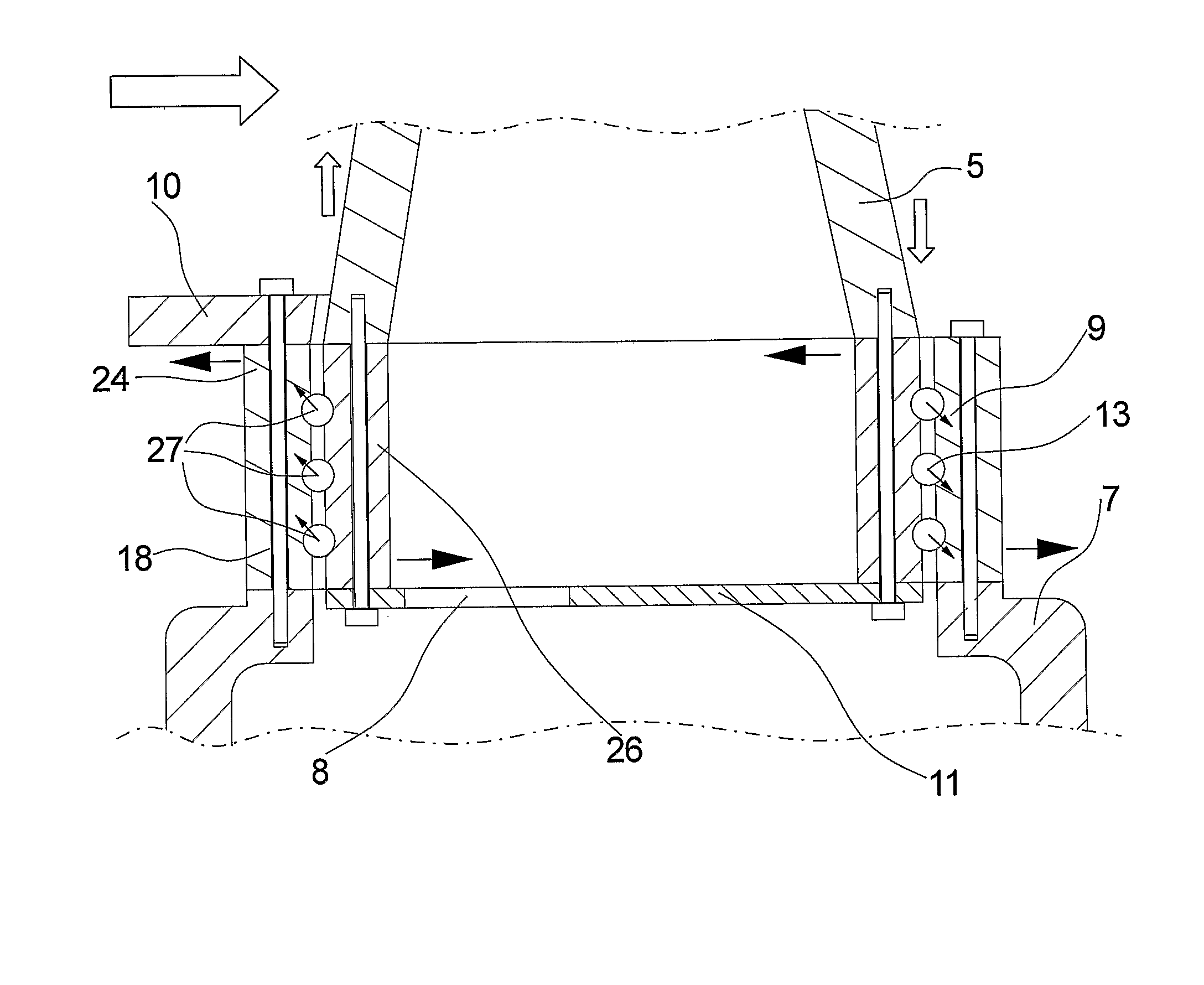

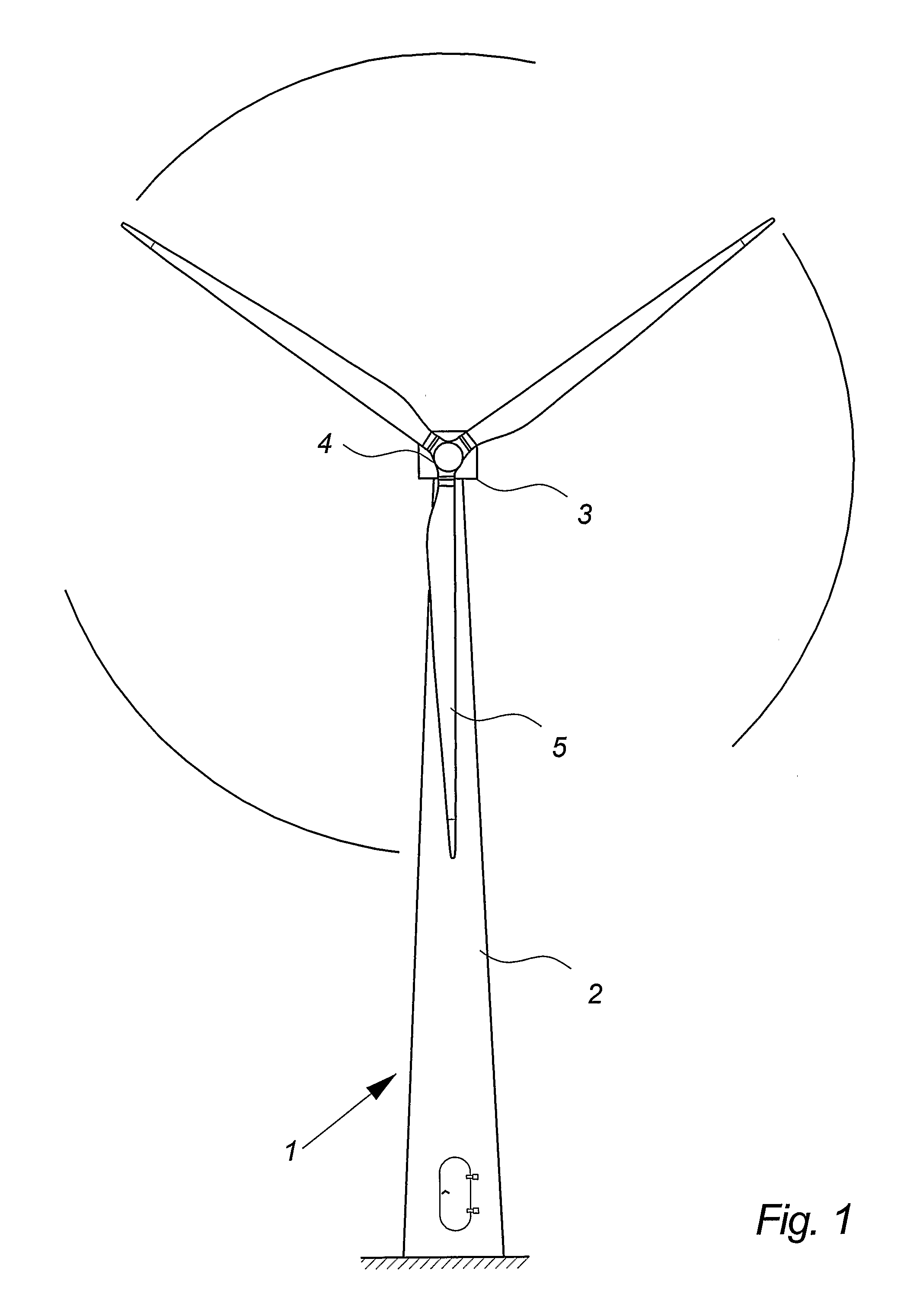

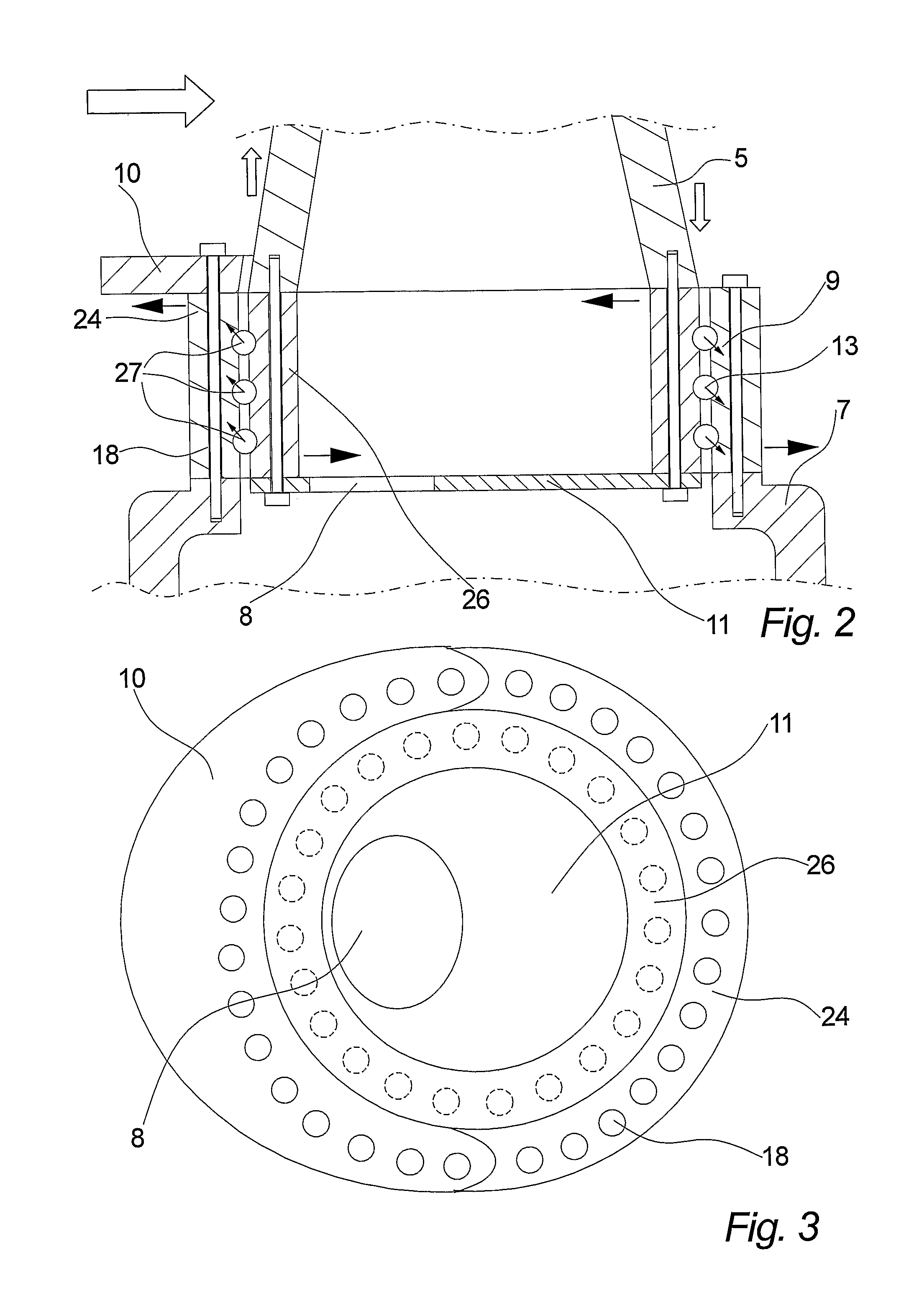

Wind Turbine Pitch Bearing, and Use Hereof

ActiveUS20080213095A1Excessive distortionWithout reducing bearing durability and functionalityPropellersRoller bearingsTurbine bladeBlade pitch

The invention relates to a wind turbine including at least two pitch controlled wind turbine blades. Each blade has pitch bearings including two or more bearing rings, and pitch controlling means for pitching the blades by means of the bearings. The blades are mounted on a hubs via the pitch bearings and the pitch bearings include separate flexibility enhancing means for controlling loads in the bearings.

Owner:VESTAS WIND SYST AS

Coated rolling element bearing cages

ActiveUS6994475B2Eliminate wear and tearShaftsBall bearingsRolling-element bearingMechanical engineering

A rolling element bearing comprises an inner ring (3) and an outer ring (2) each provided with a raceway (4, 5), said rings having land regions (10, 11) on opposite sides of their raceways, and a series of rolling elements (6) which are in rolling contact with the raceways and which are mutually spaced by a cage (7), said cage (7) engaging the land regions (10, 11) of said ring, said cage (7) being coated with a wear and friction reducing coating over its full surface.

Owner:THE TIMKEN CO

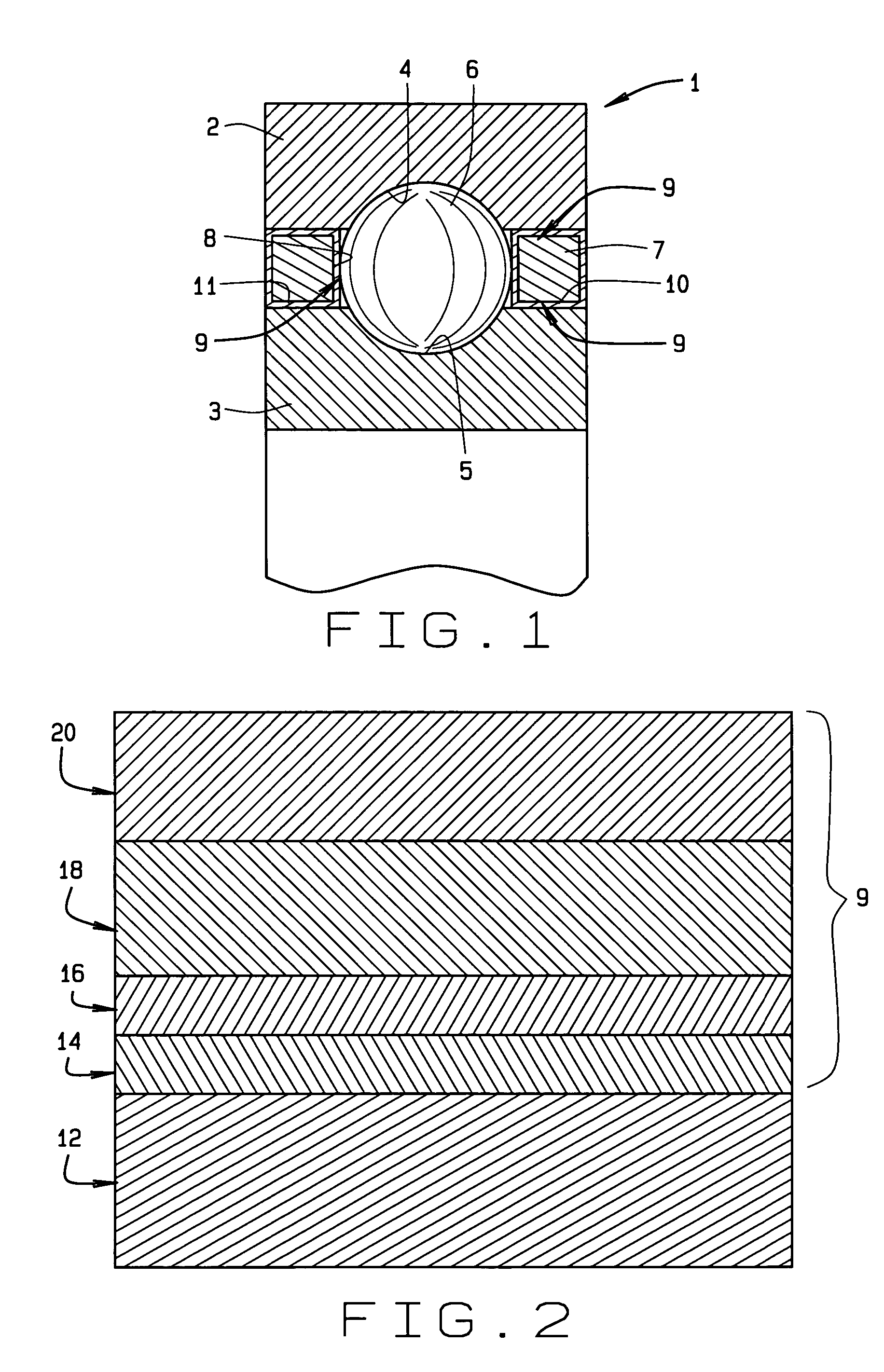

Corrosion-resistant bearing and method for making same

InactiveUS6318898B1Improve corrosion resistanceMore cost-effectiveBall bearingsBearing componentsAlloyProtection system

A corrosion-resistant antifriction bearing is disclosed that includes a multi-layer corrosion protection system over a metallic substrate. The corrosion-resistant system may be applied to a single or multiple components of the bearing, including inner and outer rings, bearing elements, collars, and so forth. The system includes a nickel-phosphorous alloy plating layer applied by an autocatalytic process after surface preparation of the protected component. The surface preparation aids in adherence of the nickel-phosphorous alloy plating layer to the substrate. The preparation may include the application of rust inhibitors, liquid vapor honing, acid neutralizing, and so forth. Additional topcoat layers may be applied to the nickel-phosphorous alloy plating layer. These may include a chromate conversion coating and a polymeric topcoat layer. The polymeric topcoat layer, such as polytetrafluoroethylene, may include a UV marker to enable identification of the bearing when placed in service and throughout its useful life.

Owner:BALDOR ELECTRIC COMPANY

Grease Composition For Hub Unit Bearing, And Hub Unit Bearing For Vehicle

InactiveUS20090003742A1Improve peeling resistanceImprove the lubrication effectOrganic chemistryHubsRolling-element bearingAdditive ingredient

An object of the invention is to provide a grease composition capable of keeping a good lubrication condition for a long period of time even when water has mixed therein, thereby inhibiting white structure flaking and corrosion. Another object is to provide a vehicular hub unit bearing which hardly suffers from white structure flaking and corrosion even when used in an environment where water may penetrate into it and which therefore has a long life.The invention provides a rolling bearing with, sealed up therein, a grease composition containing a waterproof film-forming additive added thereto; a grease composition for hub unit bearings, containing a base oil that comprises at least one of mineral oil and synthetic oil as the main ingredient thereof, and a thickener and a flaking inhibitor; and a vehicular hub unit bearing with the grease composition sealed up therein.

Owner:NSK LTD +1

Motor with a stationary shaft with formed knurled grooves on shaft and/or housing

InactiveUS6630758B2Prevent occurrence of abnormalityAvoid it happening againBearing assemblyBall bearingsRolling-element bearingEngineering

A motor comprises a rotor, a stator, and a shaft wherein one of the stator and the rotor is provided with a housing, a rolling bearing is provided between the housing and the shaft and having an inner race and outer race, the inner race is fixed to the shaft through adhesion between the outer peripheral surface of the shaft and the inner peripheral surface of the inner race, the outer race is fixed to the housing through press-fitting, and the outer peripheral surface of the shaft is formed with knurled grooves, where the number (P) of the knurled grooves in the circumferential direction and the number (Z) of the rolling members in the rolling bearing are in the relations of P≢n Z and P≢nZ±1 where n is a positive integer.

Owner:NSK LTD

Rotor assembly

A rotor assembly that includes a shaft to which are mounted an impeller, a rotor core and a bearing cartridge. The bearing cartridge is mounted between the impeller and the rotor core and comprises a pair of bearings, a spring that applies a preload to each of the bearings, and a sleeve that surrounds the bearings.

Owner:DYSON TECH LTD

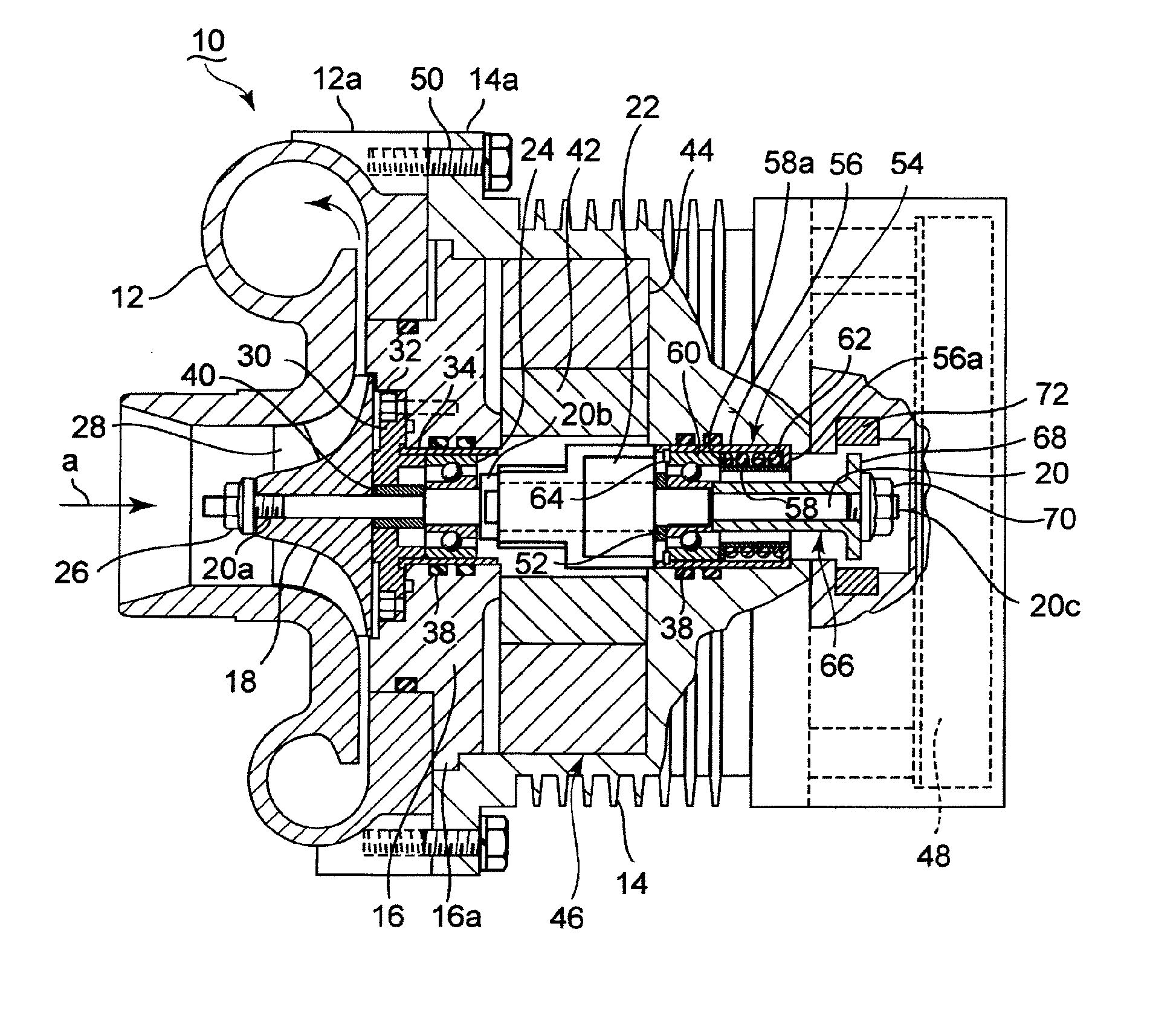

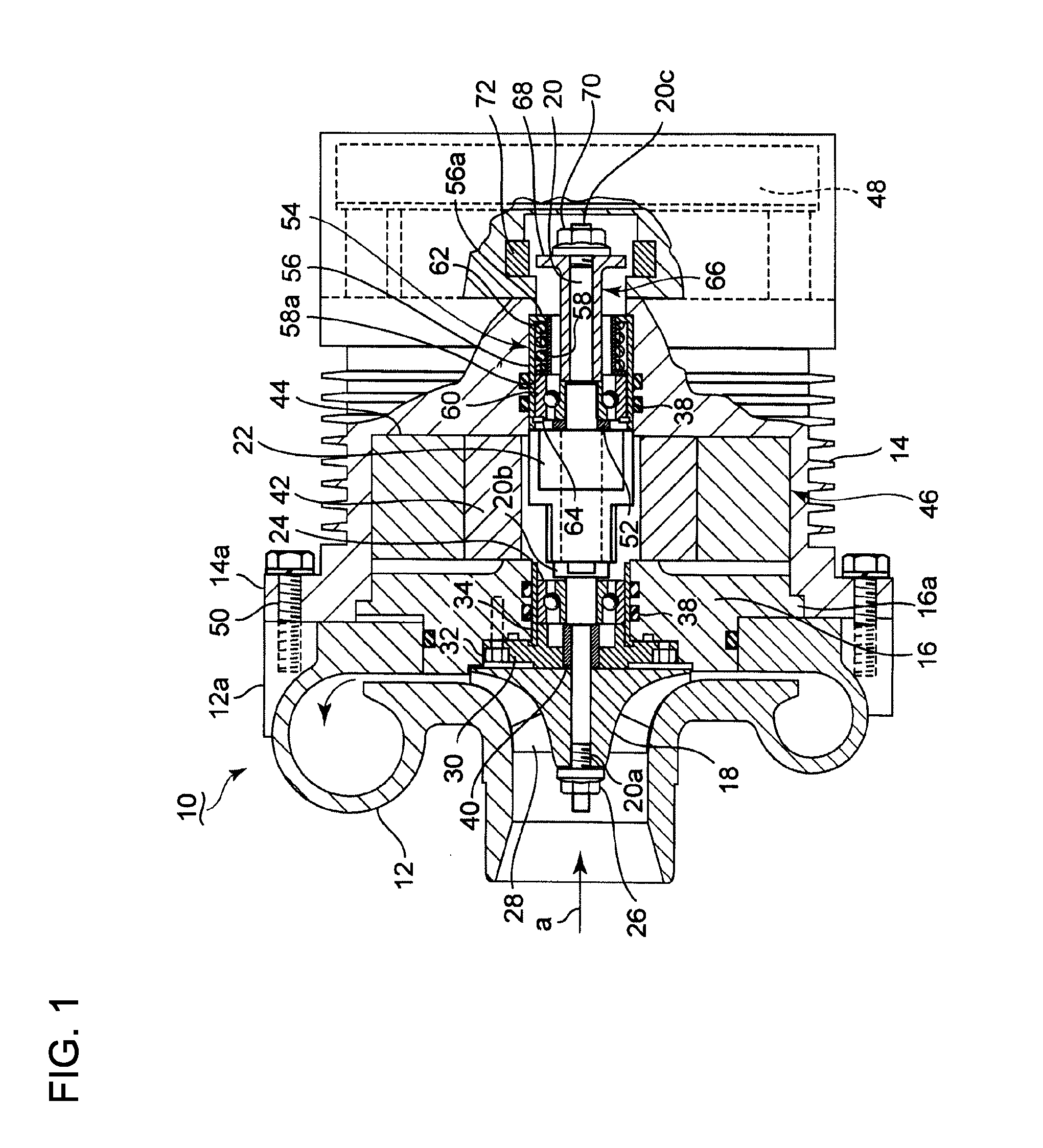

Startup Torque Transmitting Mechanism of an Internal Combustion Engine

InactiveUS20080163843A1Avoid oilAvoid enteringPower operated startersBall bearingsHigh rateExternal combustion engine

A one-way clutch and a bearing are both grease-filled so even if an oil seal member prevents engine oil from flowing thereto, it will cause no problems in terms of lubrication of the one-way clutch and the bearing. Therefore, the oil seal member 18 need only seal between a main body side of an internal combustion engine and a crankshaft and so does not need to have a large diameter. As a result, even when the crankshaft rotates while the internal combustion engine is operating, the small diameter oil seal member will not slide at a high rate of speed against an outer peripheral surface of the crankshaft and so will not degrade quickly.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com