Thrust bearing for screw of ball-nut type steering gear

A technology of thrust bearing and steering gear, applied in the field of thrust bearing, can solve the problems of large wear of three oil seals, increase of steering gear return torque and input torque, heavy steering, etc., so as to improve impact resistance, increase The effect of reducing the rated load and assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

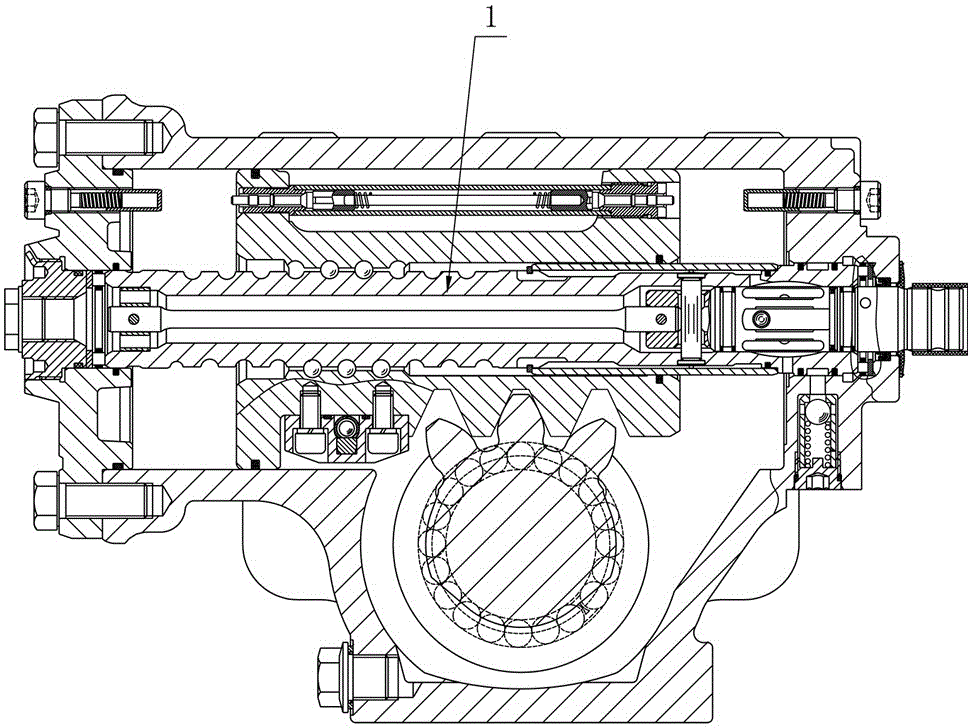

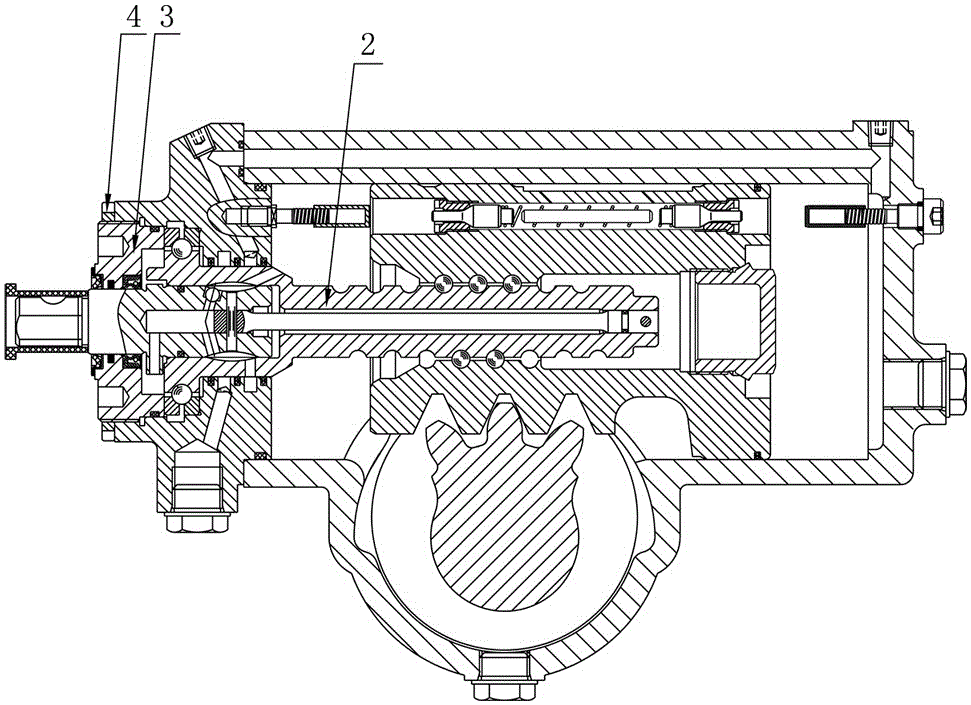

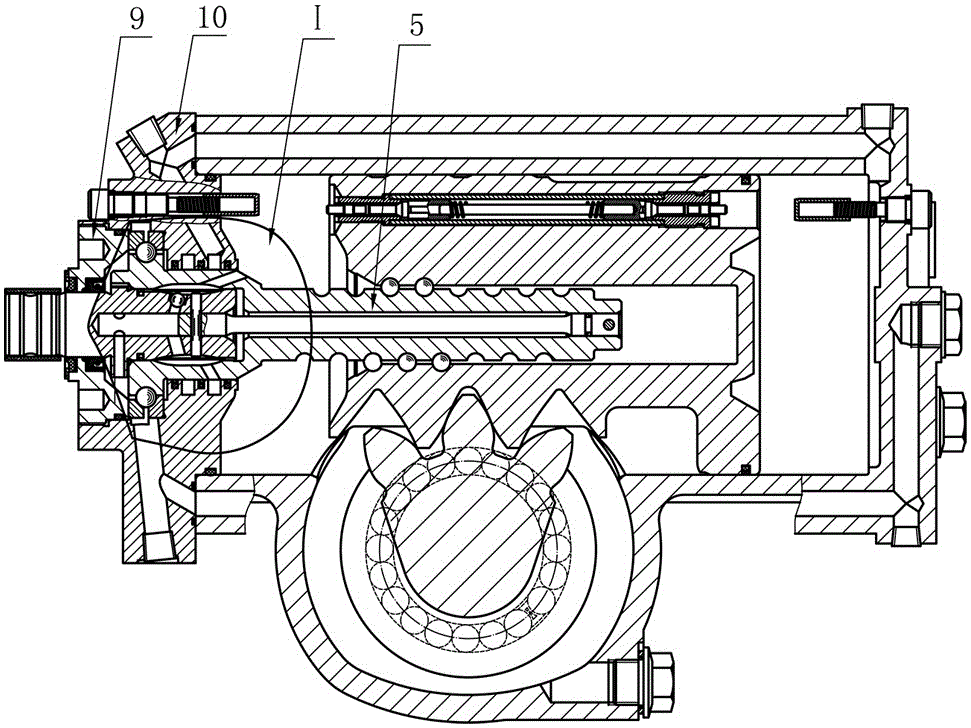

[0018] Such as image 3 , Figure 4 , Figure 5 As shown, a thrust bearing for a recirculating ball steering gear screw includes a screw 5, on which a thrust ball thrust bearing is provided; the thrust ball thrust bearing includes a steel ball 8 and a seat ring, and the seat The ring is assembled by the left half seat ring 6 and the right half seat ring 7. The raceway section of the thrust ball thrust bearing adopts a four-point contact type, and the left half seat ring 6 and the right half seat ring 7 have One section of arc outer raceway, the radius R1 of the two sections of arc outer raceway is the same; on the screw 5, there are two sections of arc inner raceway, the radius of the two sections of arc inner raceway is the same, and is the same as that of the arc The radius R1 of the outer raceway is the same, and the centers of the two sections of the arc outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com