Patents

Literature

48results about How to "Increase the rated load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plunger

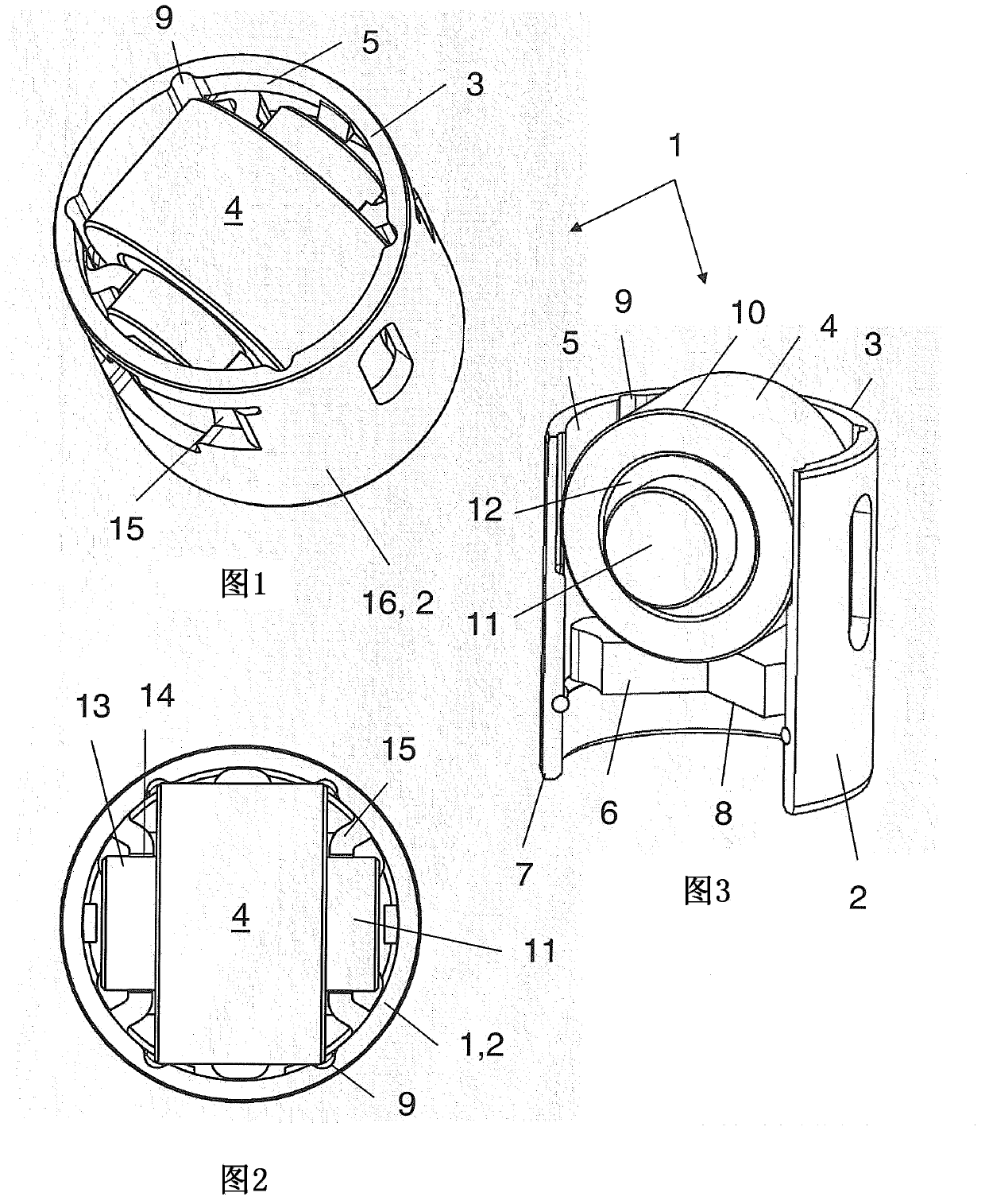

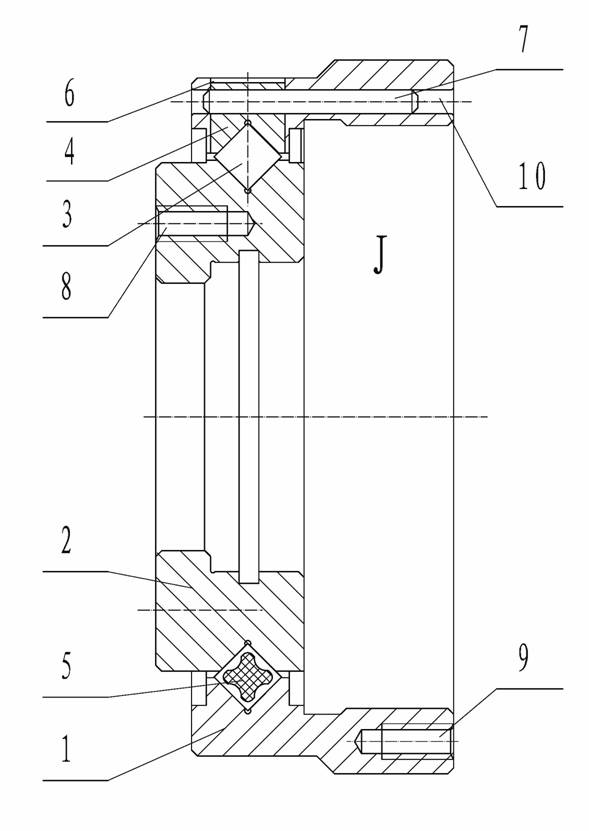

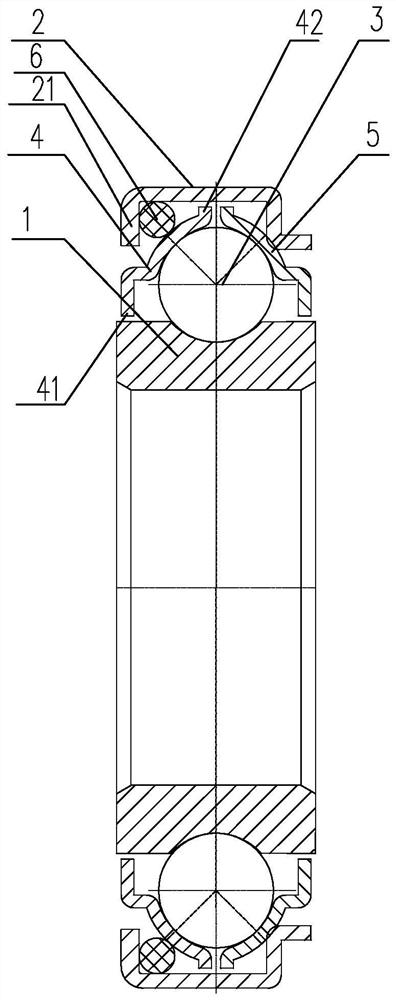

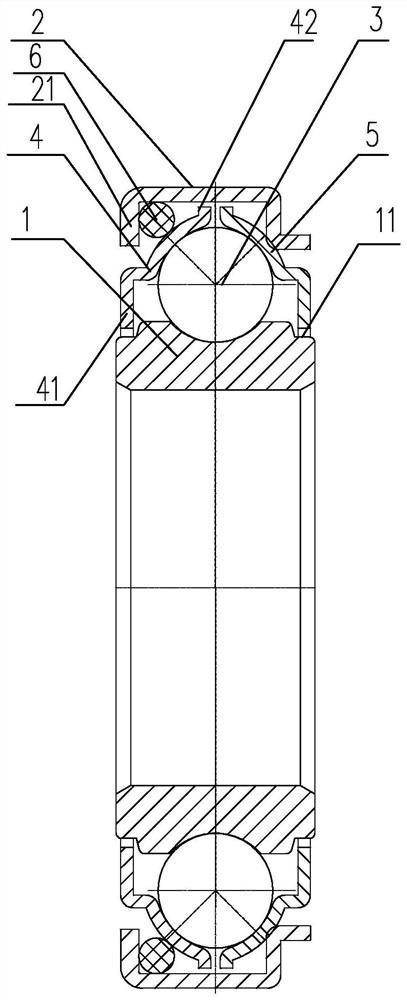

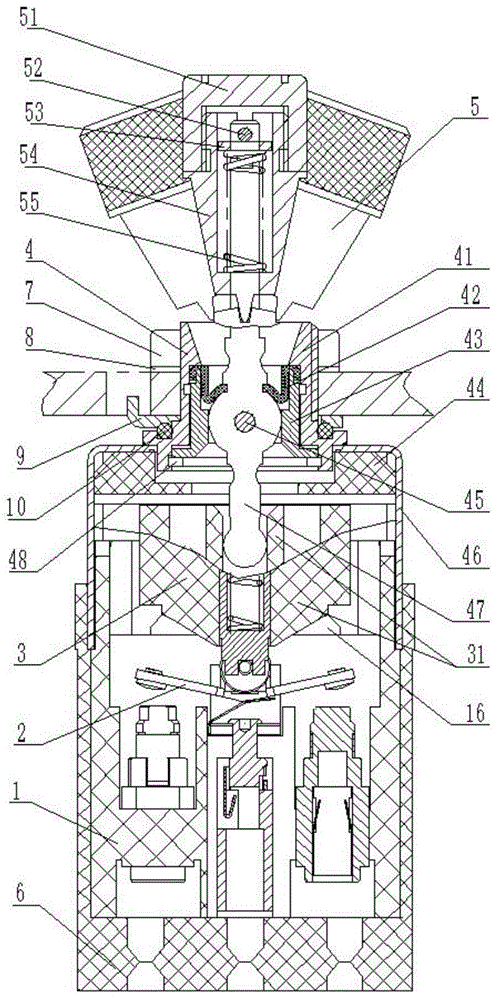

InactiveCN103423119AIncrease loadIncrease the rated loadValve arrangementsFuel injecting pumpsEngineeringCam

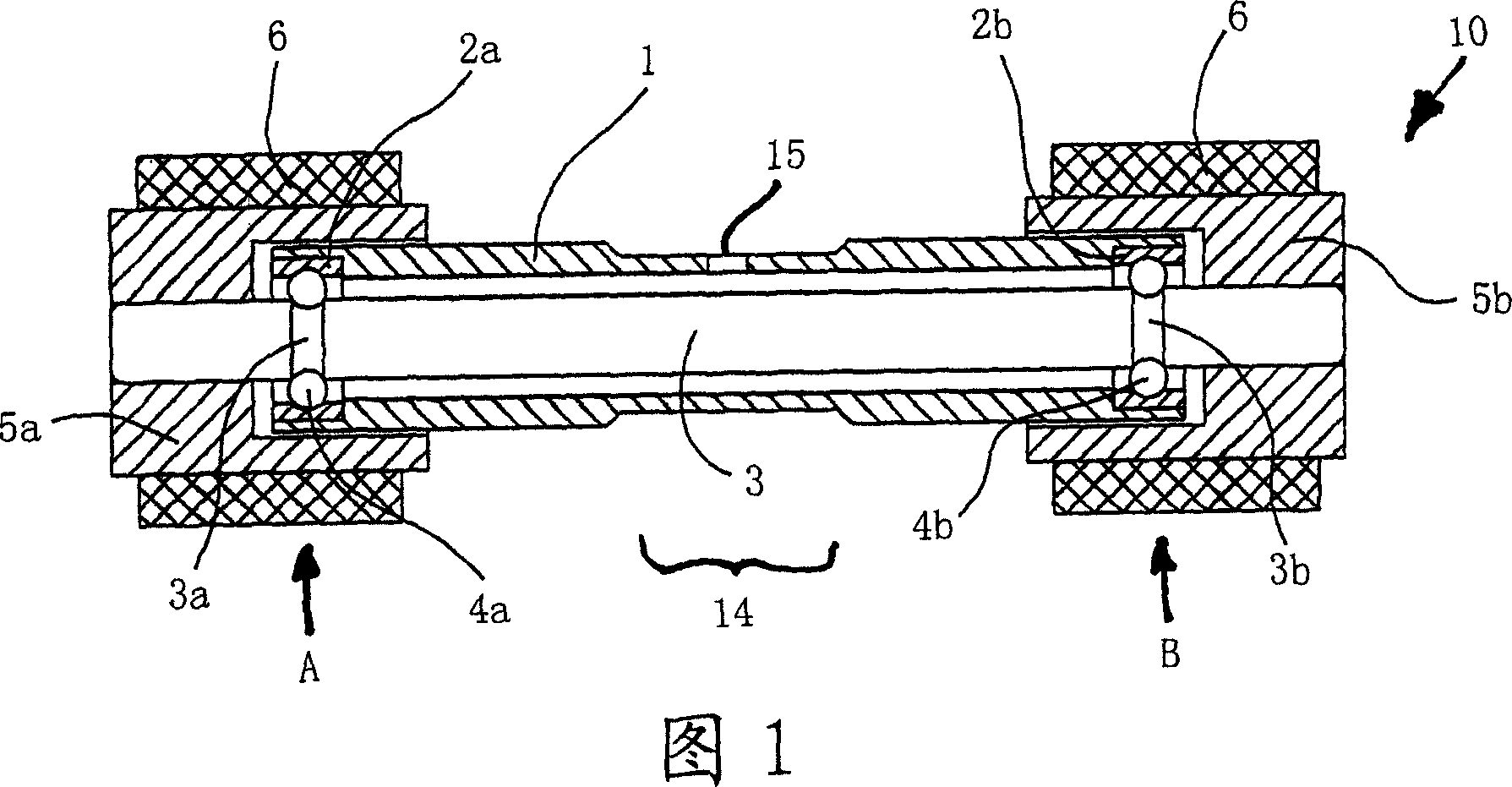

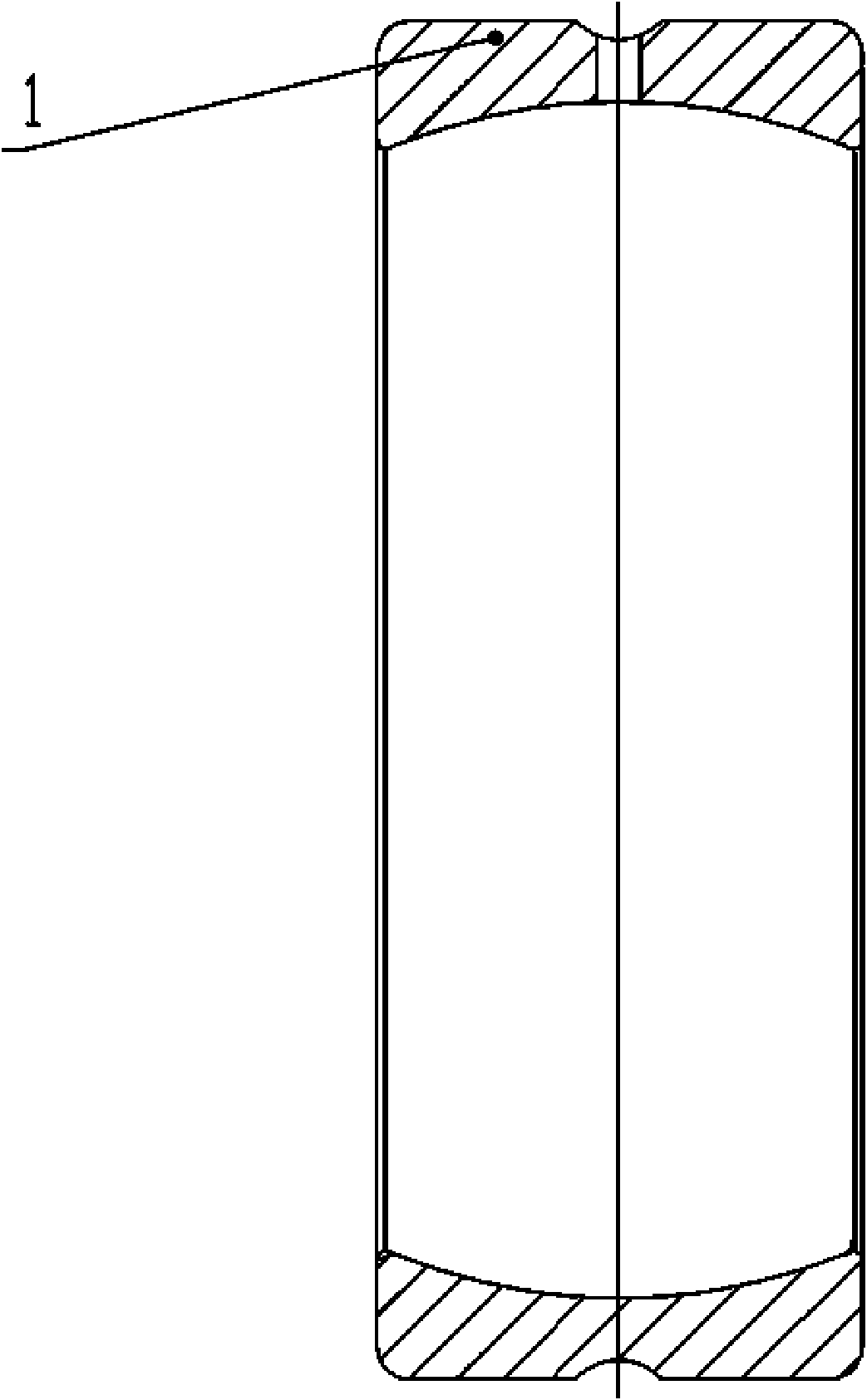

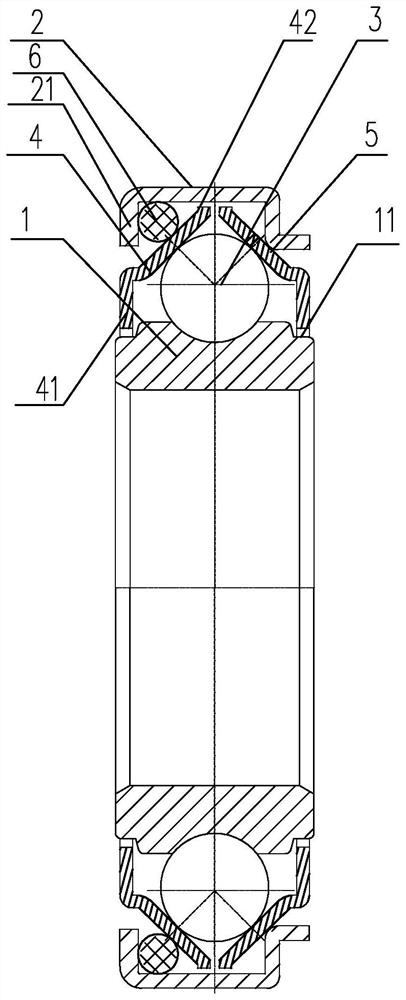

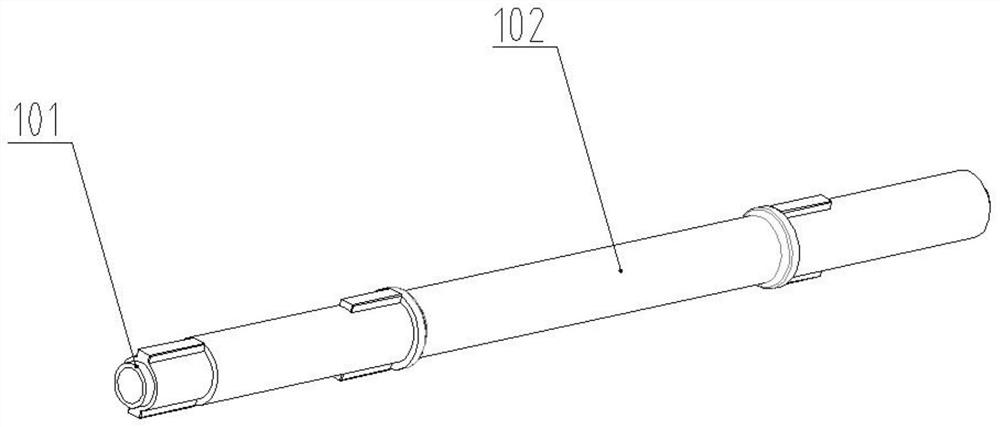

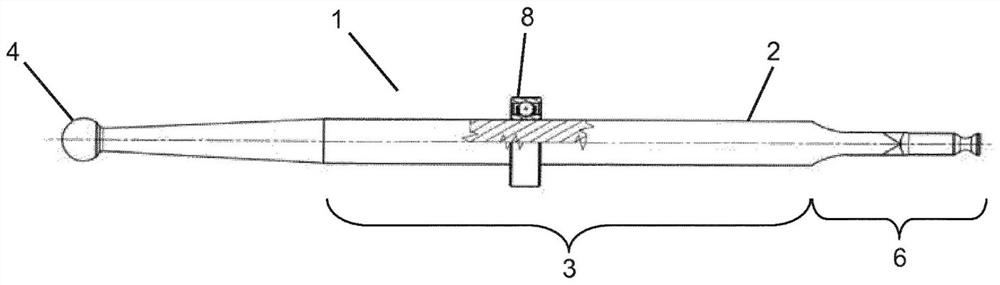

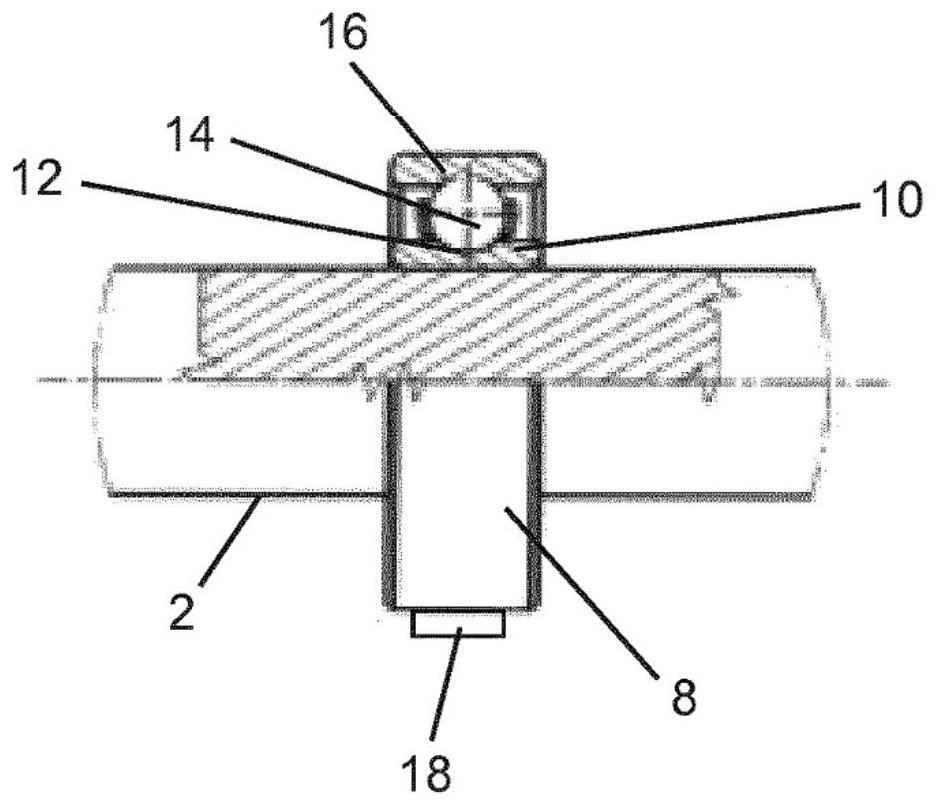

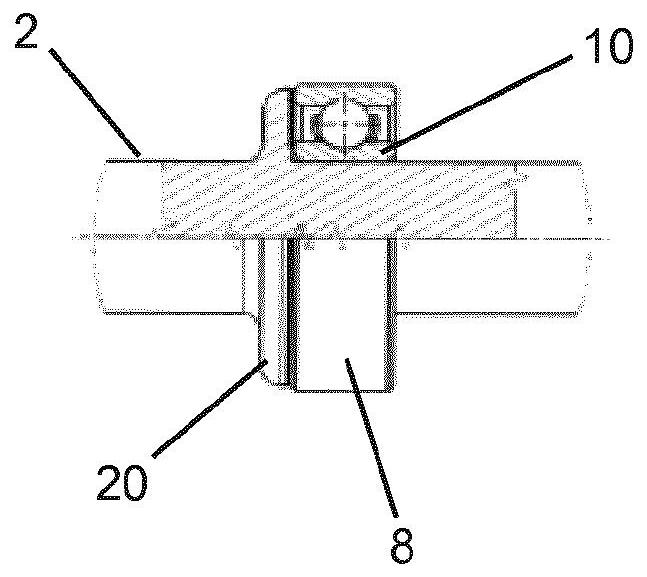

Provided is a plunger (1) particularly used for a fuel injection pump. The pluger has a housing (2) receiving a roller (4) used for being struck by a cam, wherein the roller is in a cylindrical inner circumference side (5) in a region of a first annular end (3), a bridge piece (6) axially projects through the housing (2) below the roller (4), and a bottom side (8) of the bridge piece faces towards a second annular end (7) of the housing, and functions as a system for a plunger follower. Four notch-like discharges (9) extend along the inner circumference side (5) of the housing (2), and the roller (4) with ring edges (10) projects into the discharges.

Owner:SCHAEFFLER TECH AG & CO KG

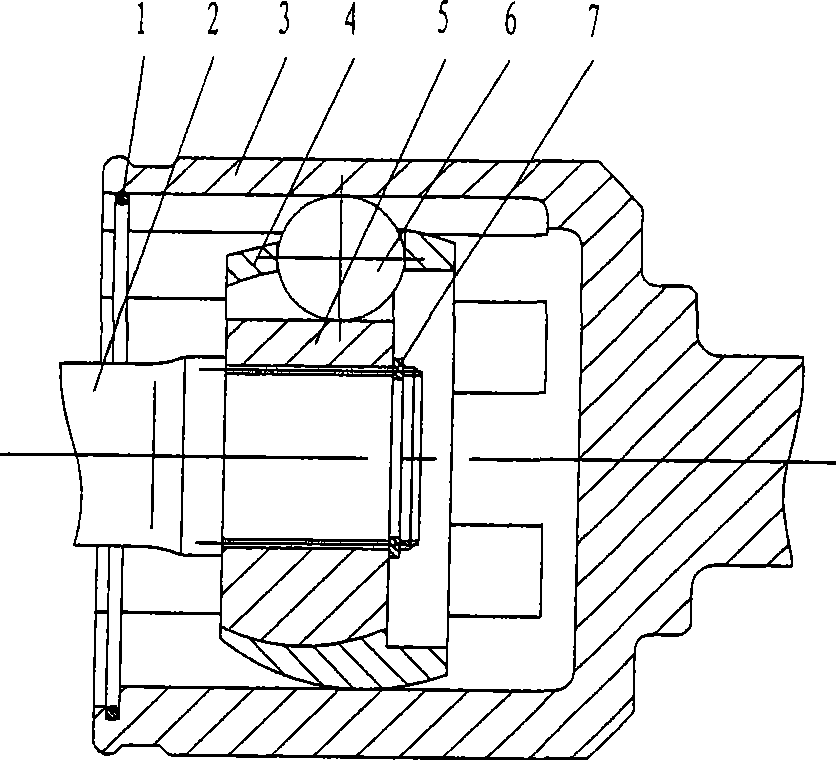

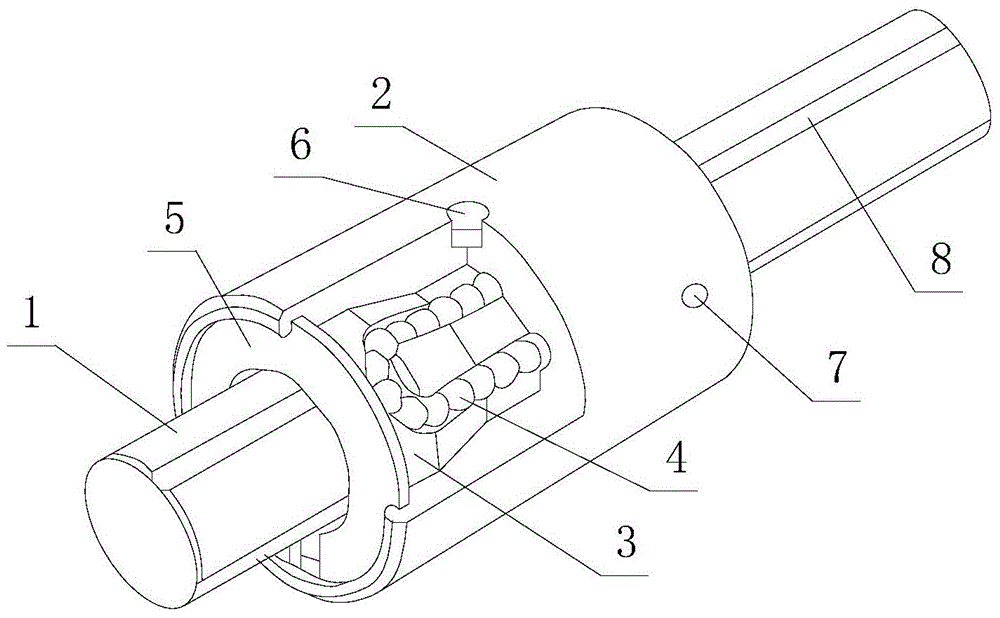

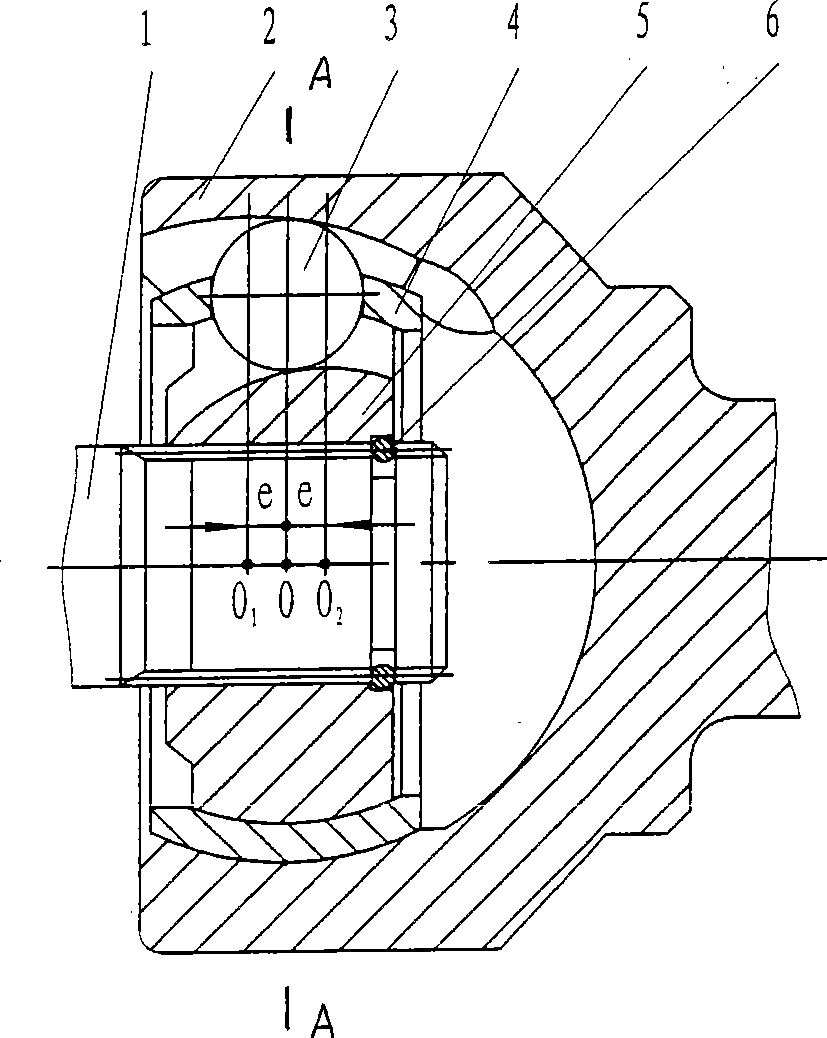

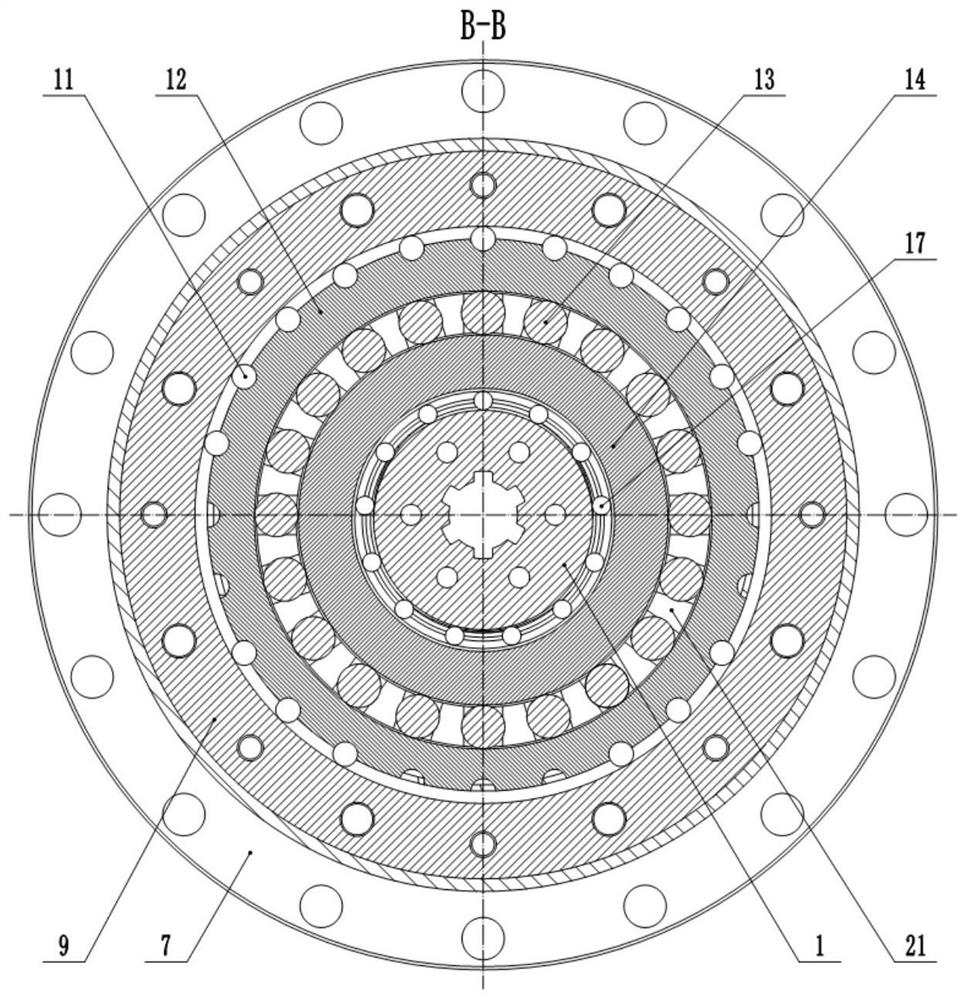

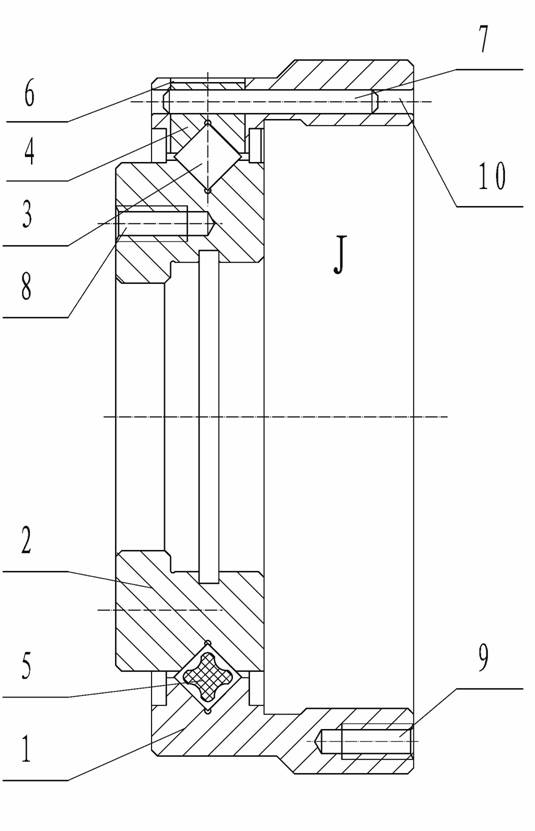

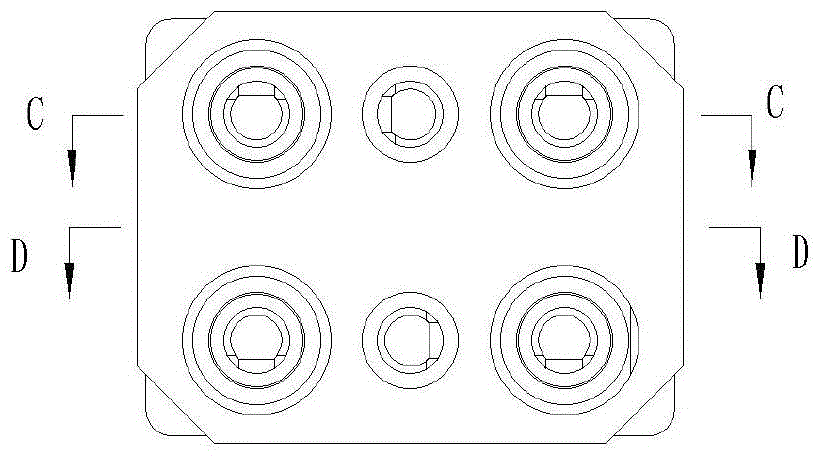

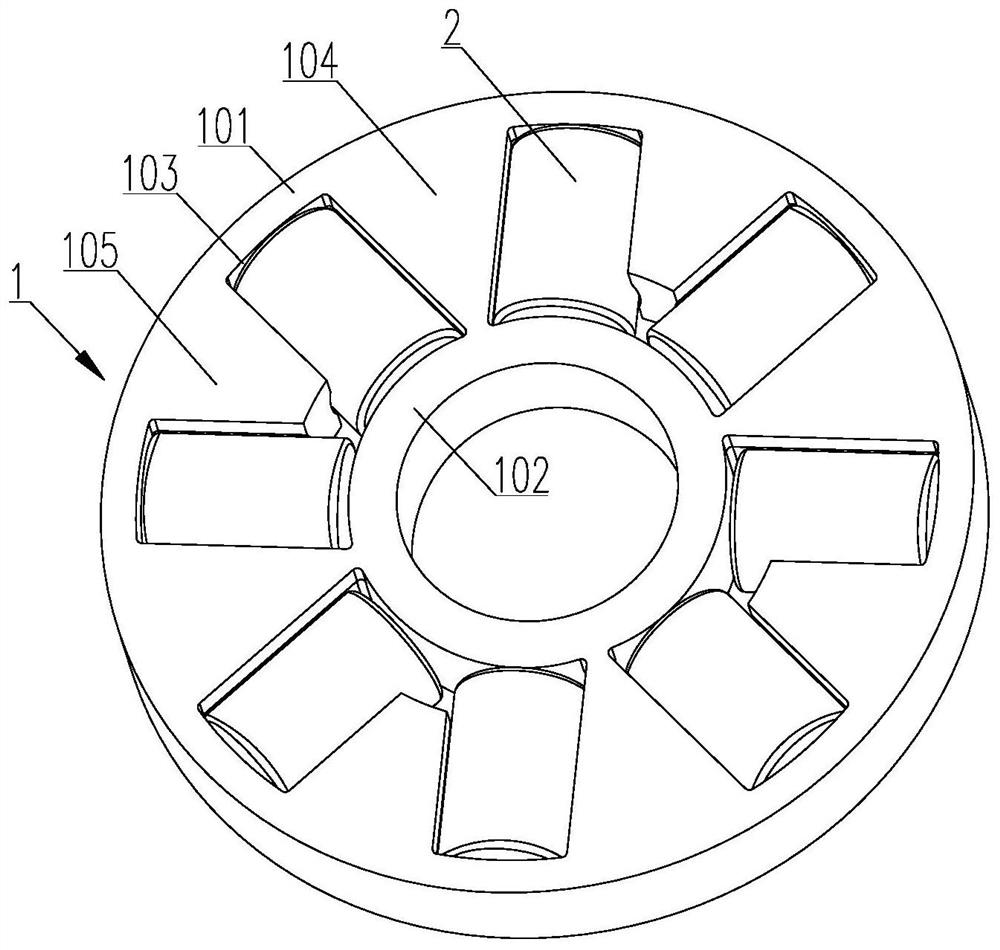

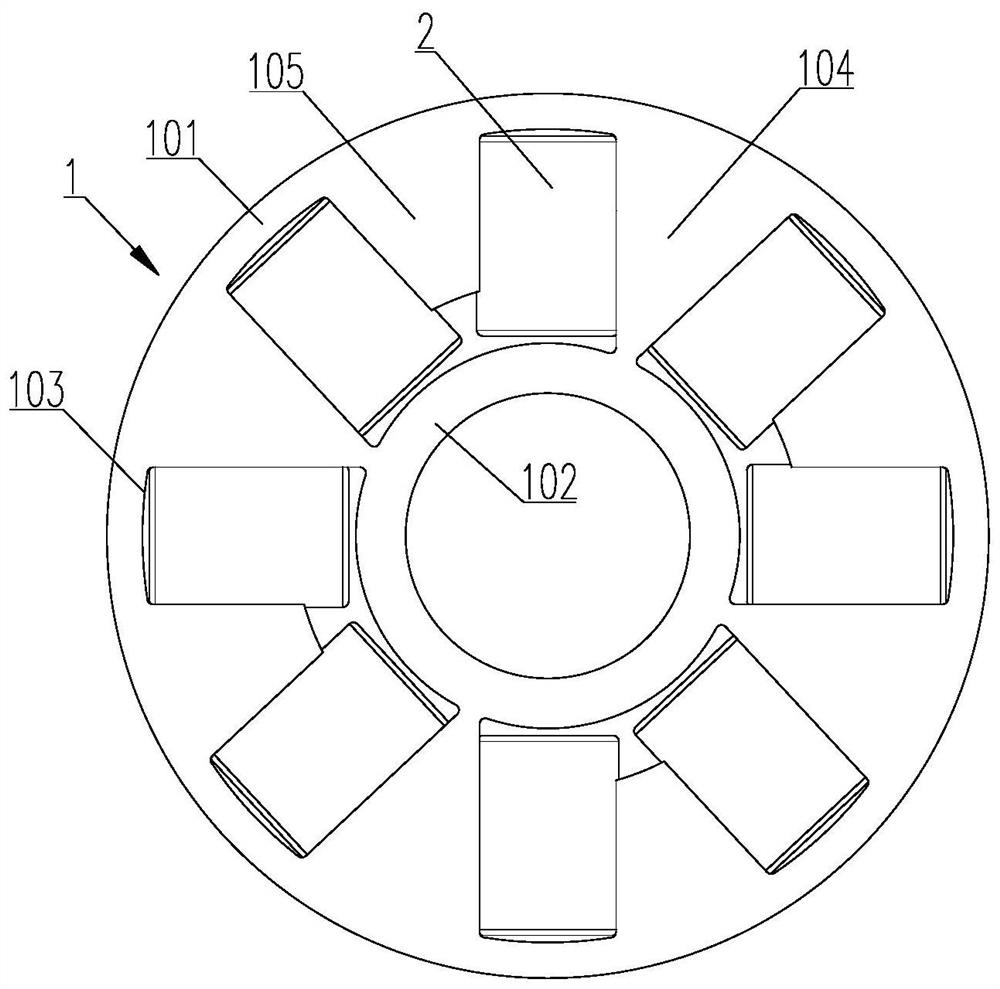

7-channel double offset cardan joint

InactiveCN101363482AAvoid hard-to-arrange phenomenaImprove carrying capacityYielding couplingUniversal jointDrive shaft

The invention relates to a seven-channel double offset type universal joint which consists of a cylindrical shell, a transmission shaft, an eccentric retainer, a plurality of steel balls, an inner race housing, a snap spring and an elastic collar. The number of the steel balls is seven, the number of openings of the eccentric retainer is seven, the number of the corresponding channels of the cylindrical shell and the inner race housing is also seven, the inner race housing is installed in the eccentric retainer, the seven channels of the cylindrical shell and the inner race housing are respectively corresponding to seven openings of the eccentric retainer, the steel balls are positioned in the seven channels of the inner race housing and the cylindrical shell, the inner race housing is installed on the transmission shaft by a spline and is axially positioned by a spring collar, the end edge of an inner bore of the cylindrical shell is provided with a snap spring groove which is internally provided with the snap spring. Compared with a traditional specific offset type universal joint, the carrying capacity of the seven-channel double offset type universal joint disclosed in the invention is increased, and rated load is raised by 16%; meanwhile, the phenomenon that eight steel balls are difficult to arrange can be avoided.

Owner:石宝枢

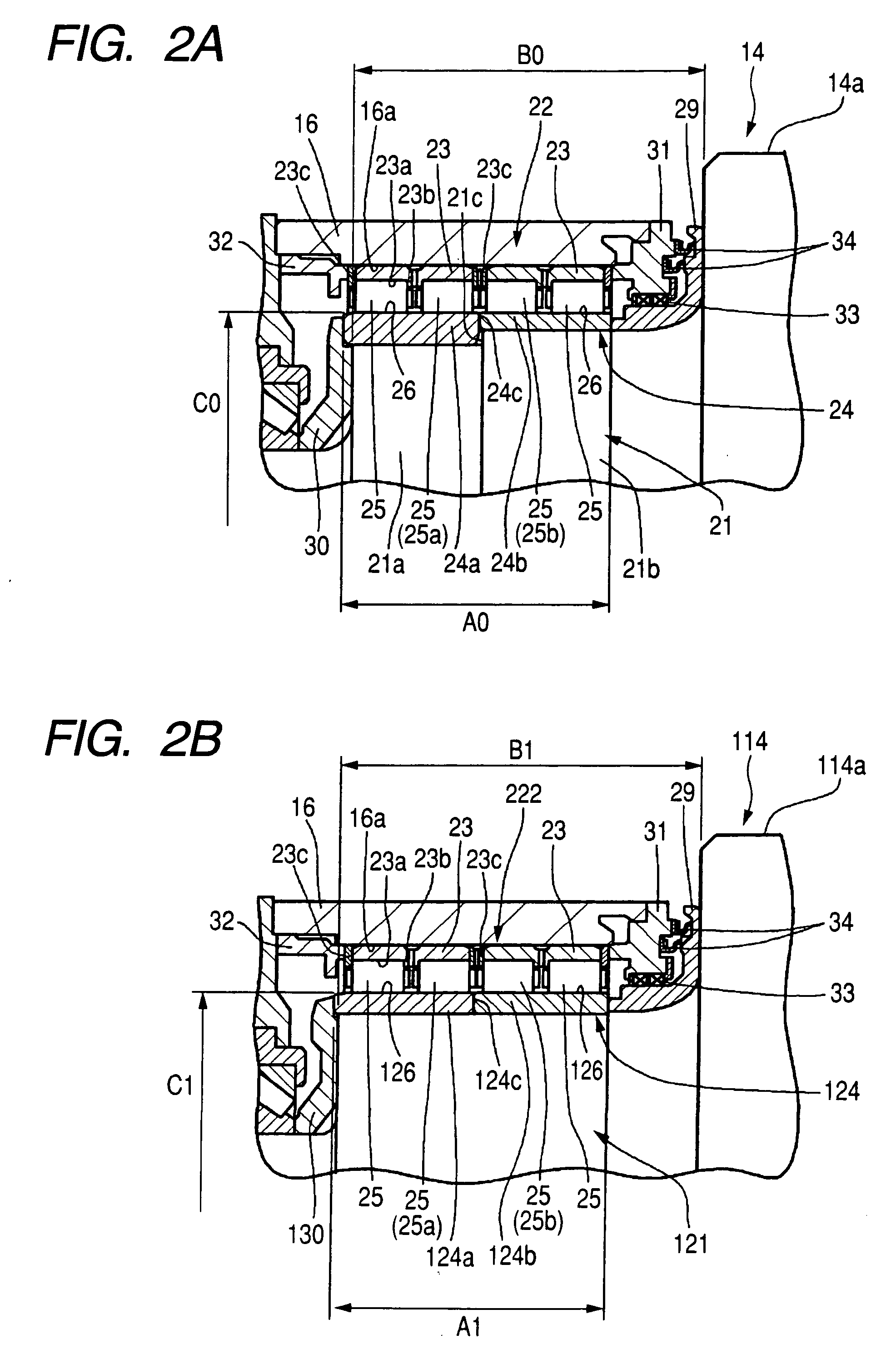

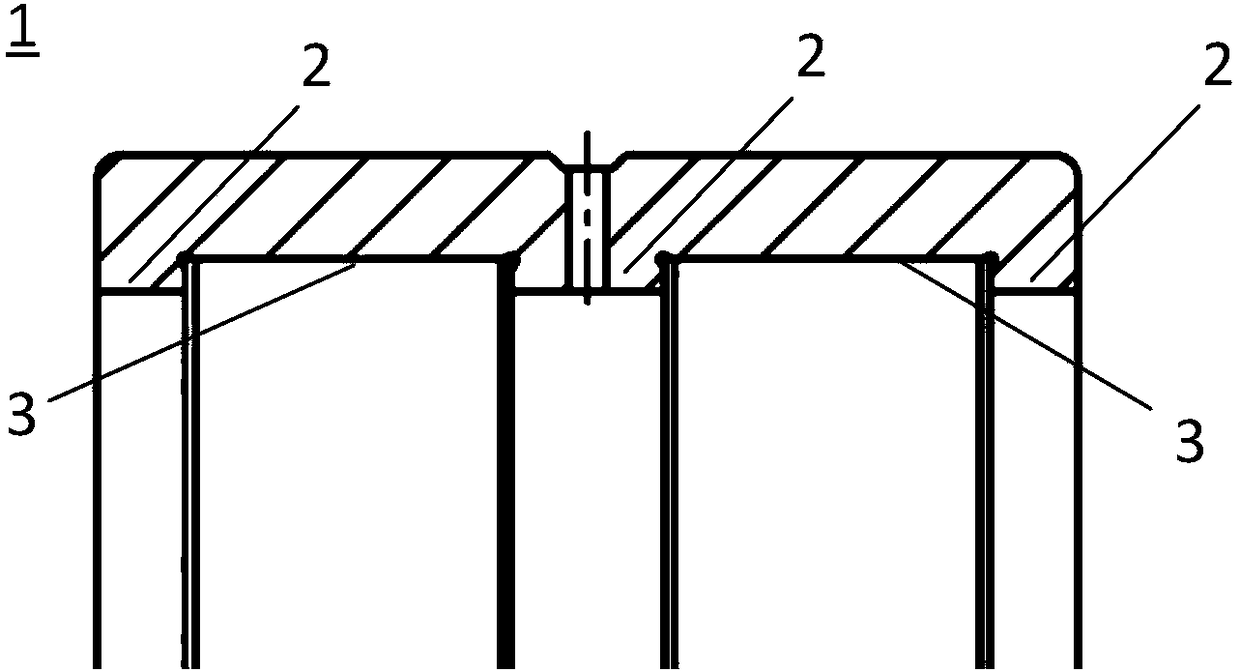

Bearing assembly

InactiveCN1940154AEasy to assembleExtended service lifeTextile treatmentShaftsEngineeringMechanical engineering

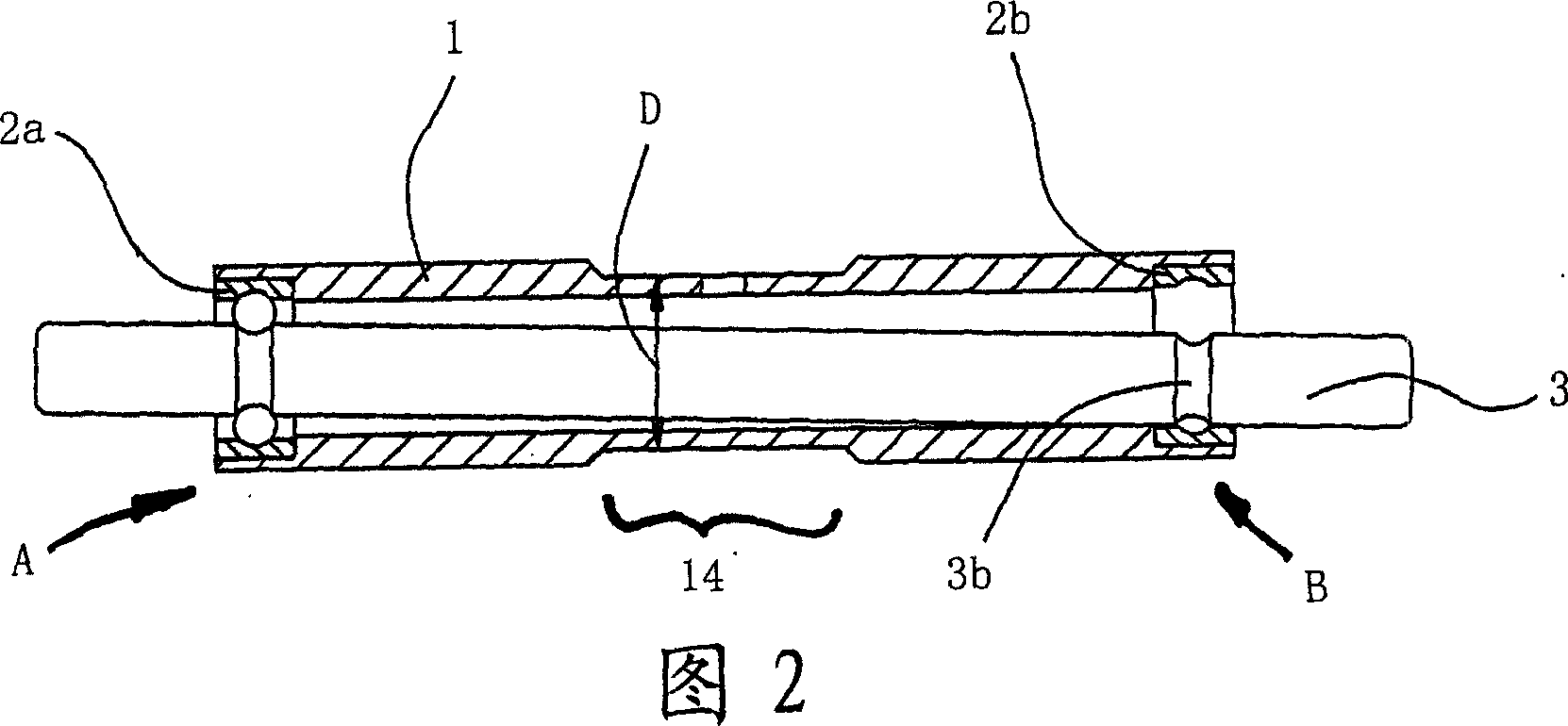

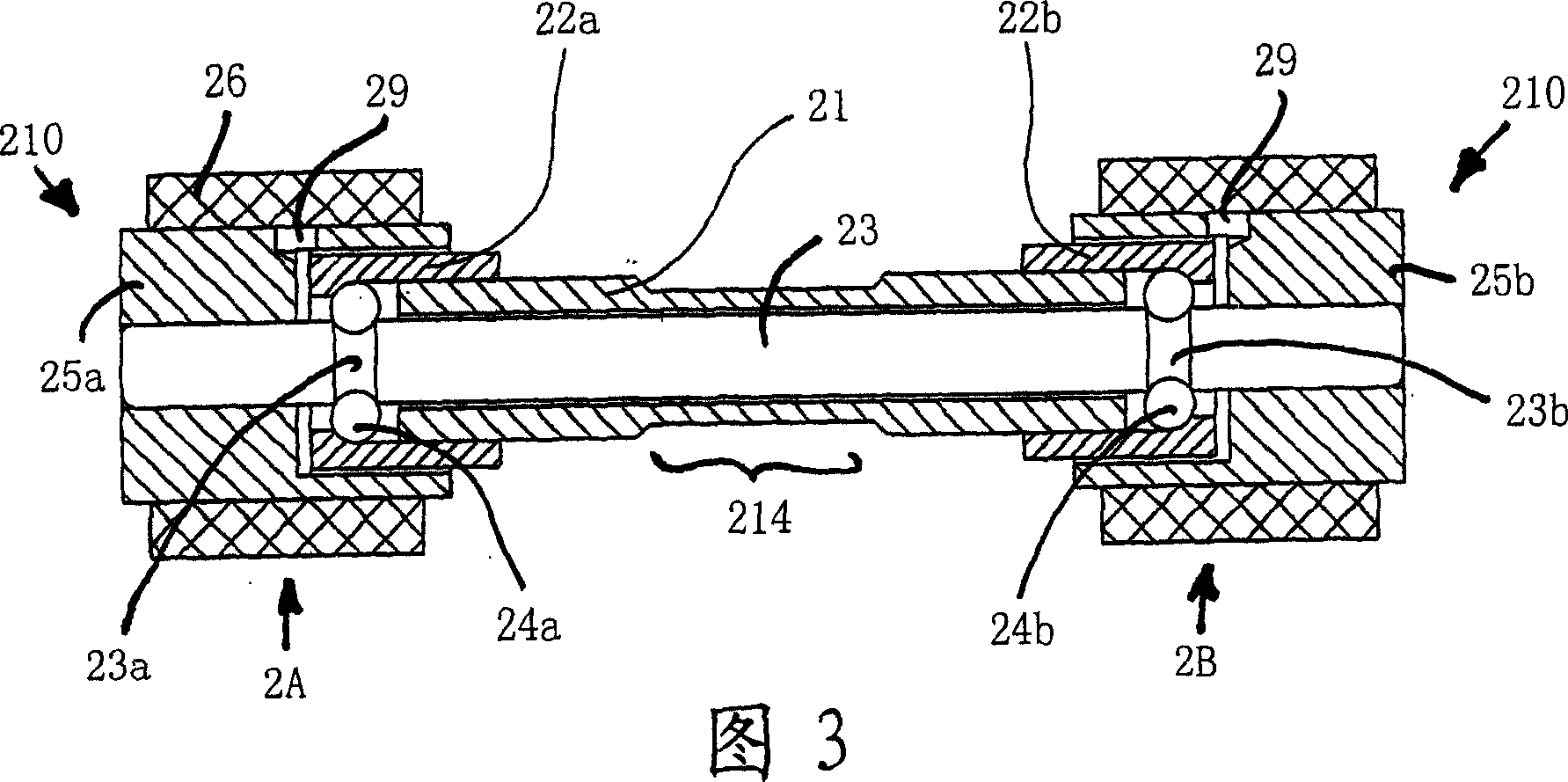

The invention provides a bearing assembly for fixed rollers (210, 310) particularly for a drawing unit of spinning machine. The bearing assembly comprises a shell-like middleware (21, 31) for installing a first bearings (2A, 3A) and a second bearing (2B, 3B). The first bearing (2A, 3A) and second bearing (2B, 3B) is used for the mandrel (23, 33) of the fixed rollers (210, 310). The bearing assembly is characterized in that the outer rings (22a, 22b, 32a, 32b) of the first bearing (2A, 3A) and the second bearing (2B, 3B) are mounted on the outer periphery of the middleware.

Owner:汉斯·沙赫勒克尔

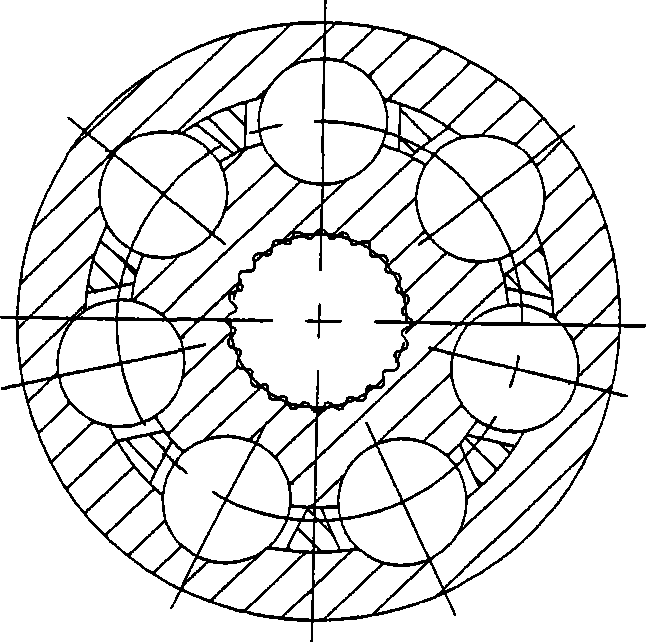

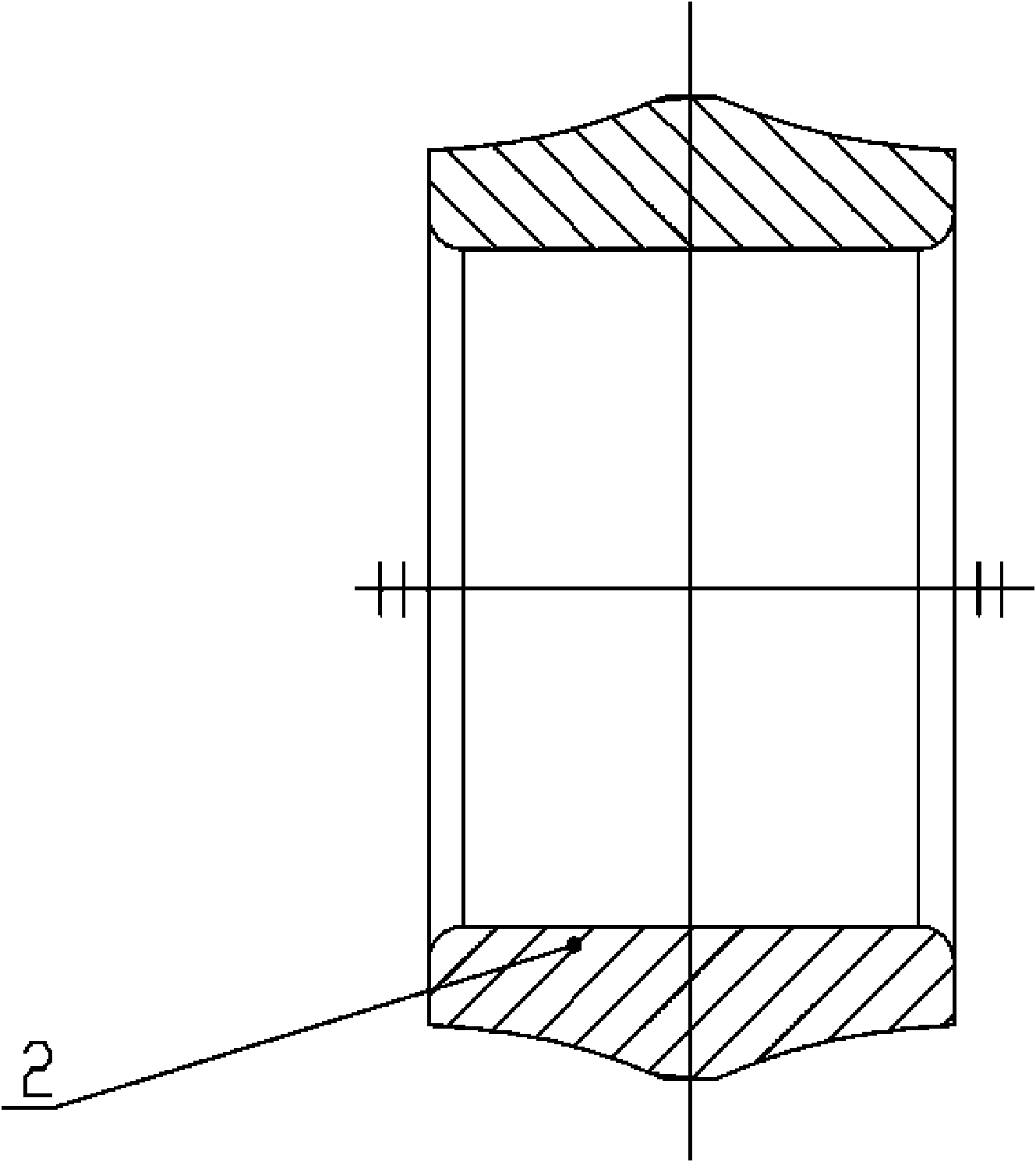

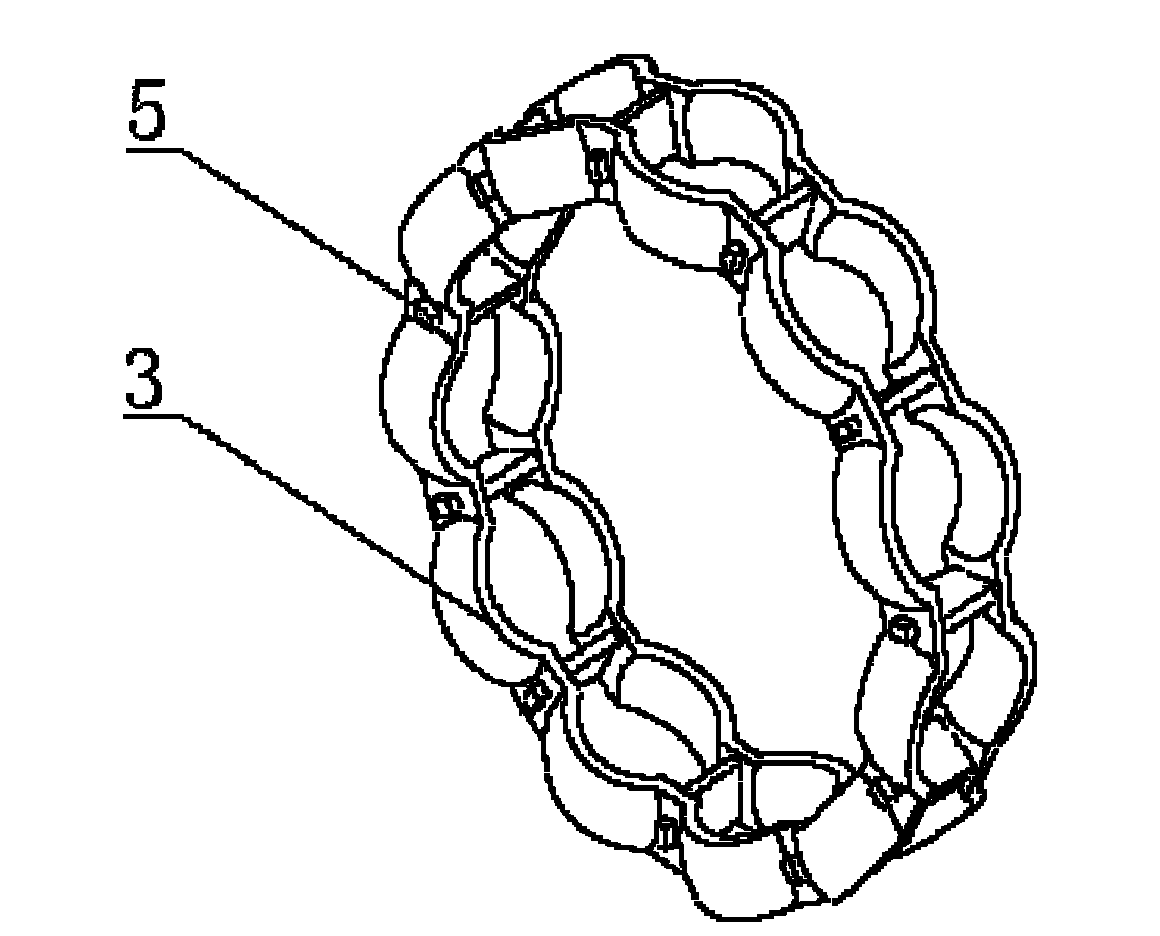

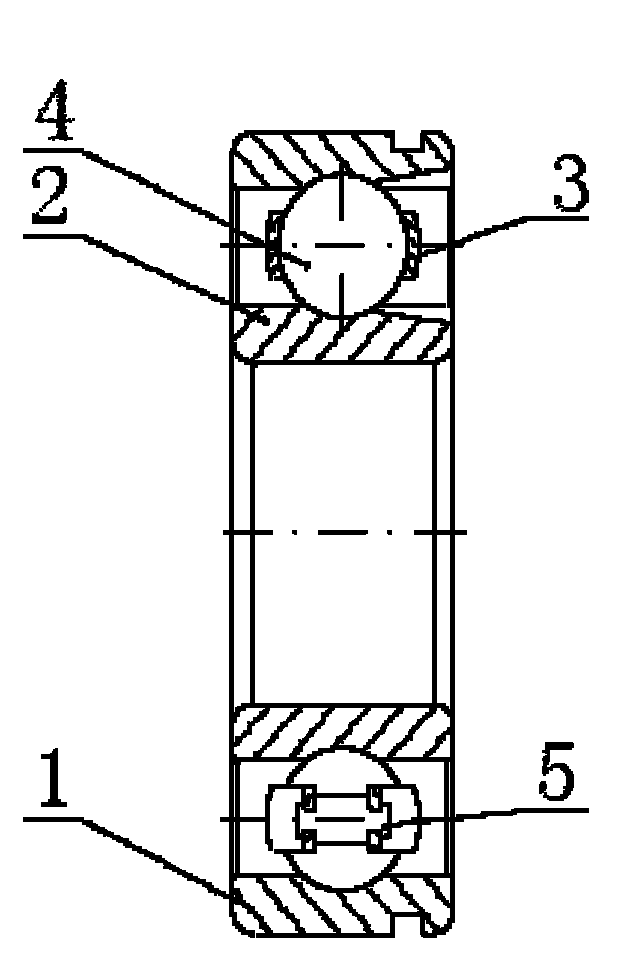

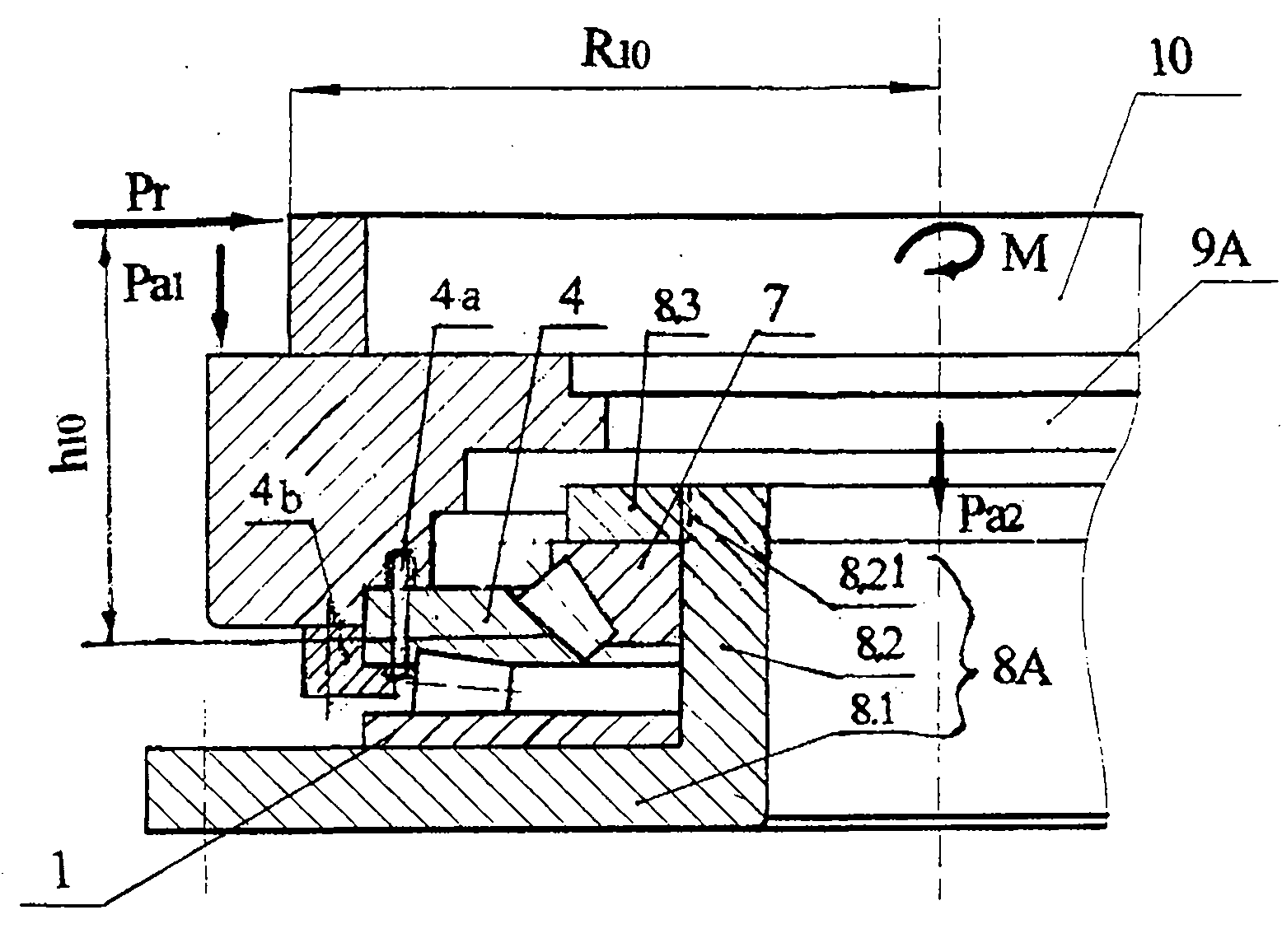

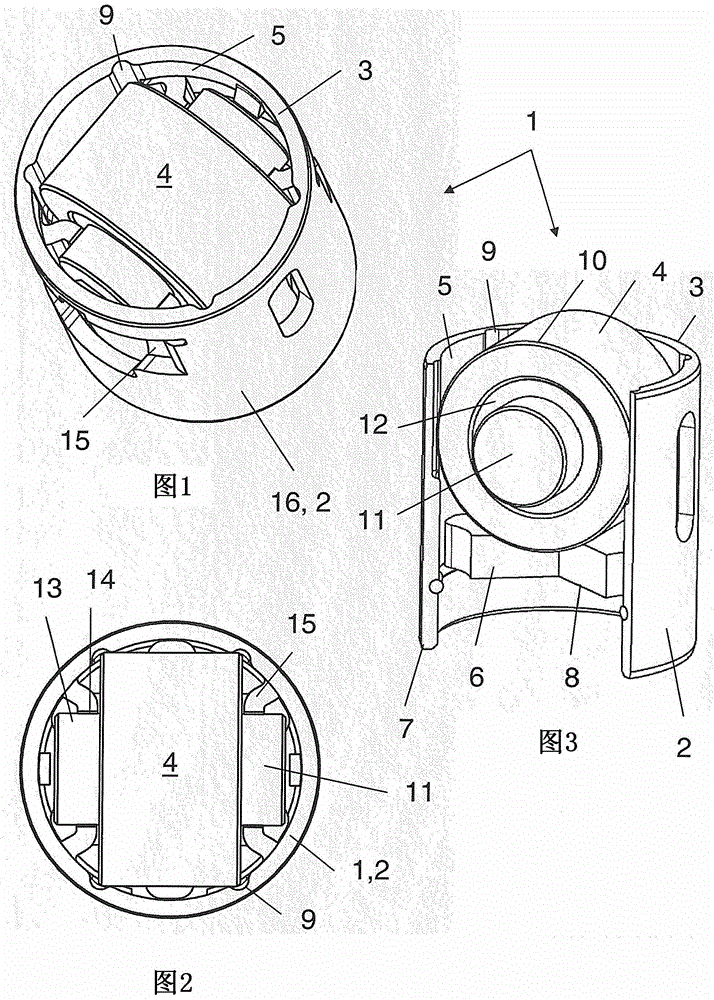

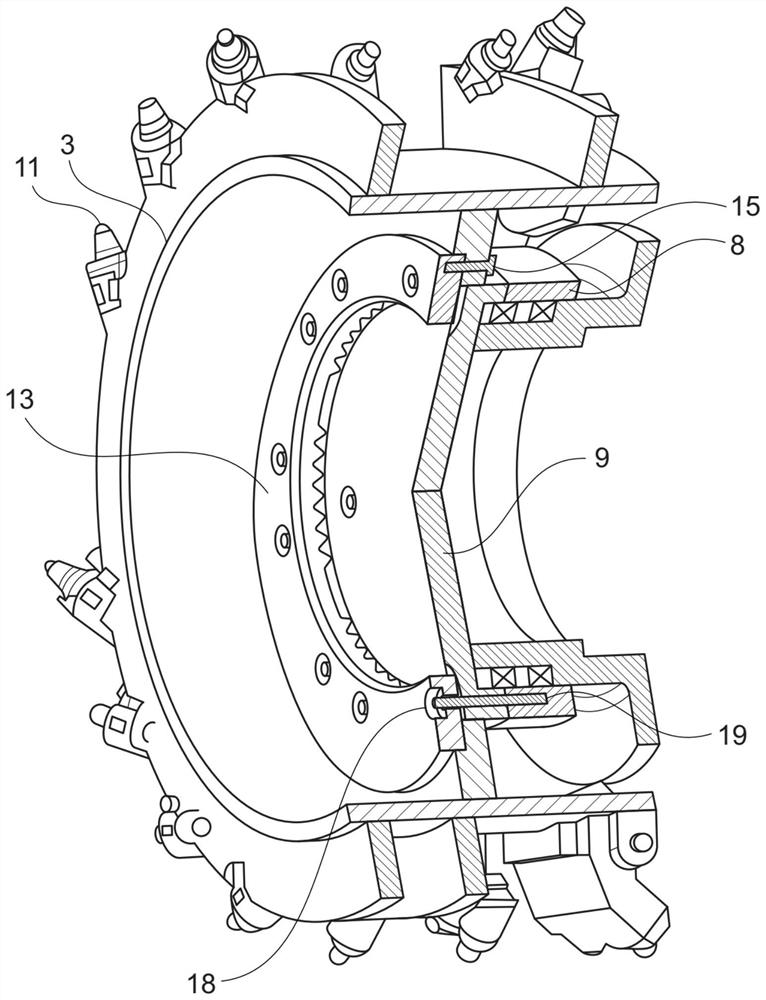

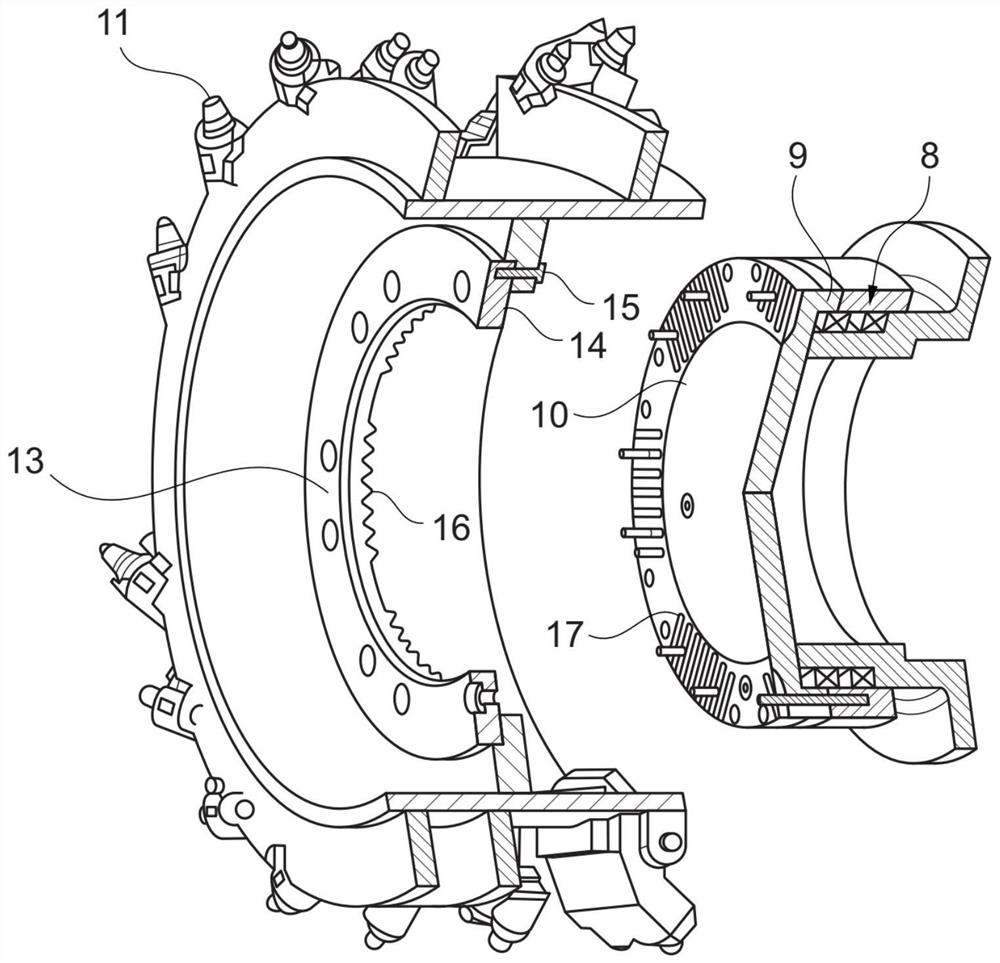

Oversize self-aligning roller bearing

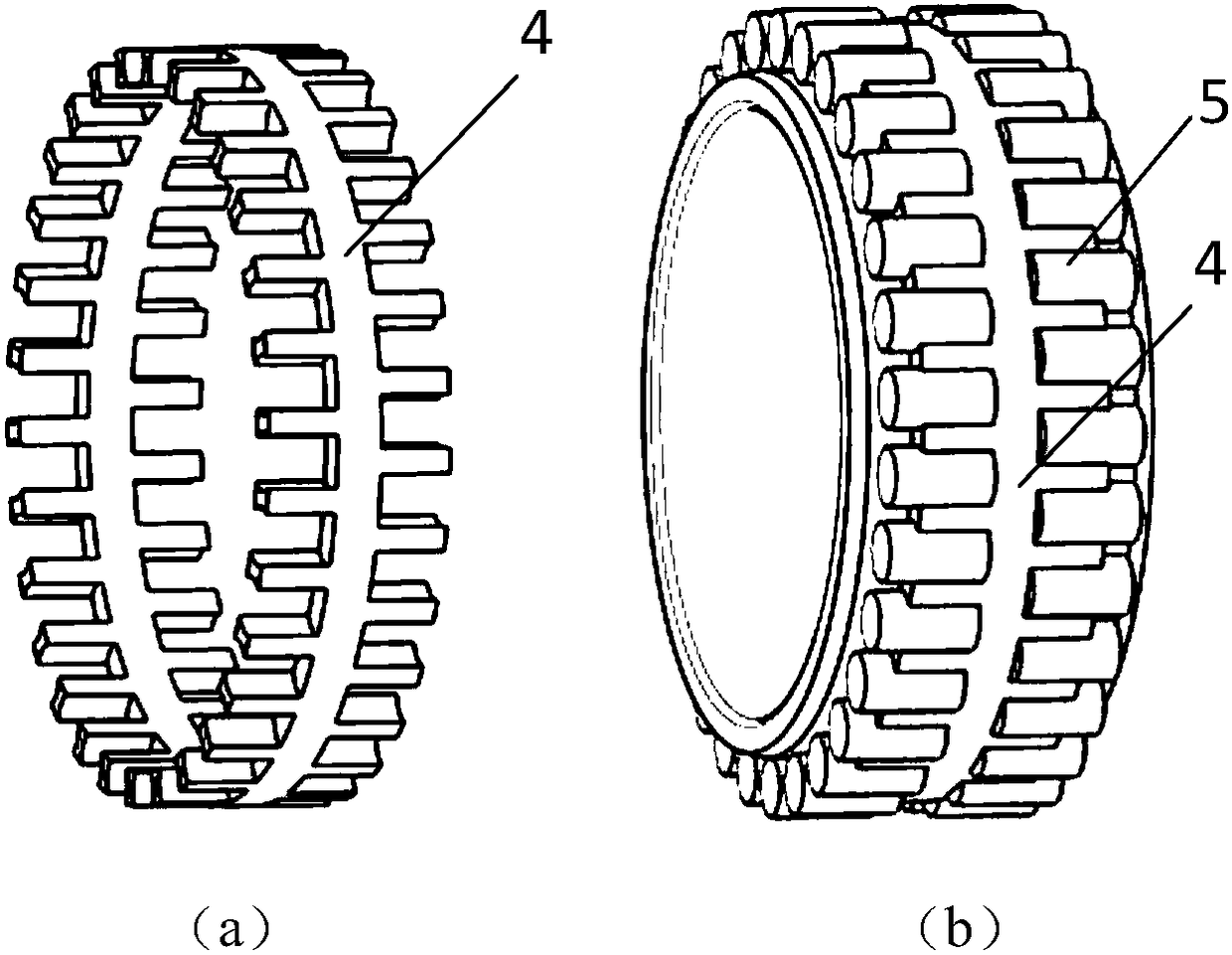

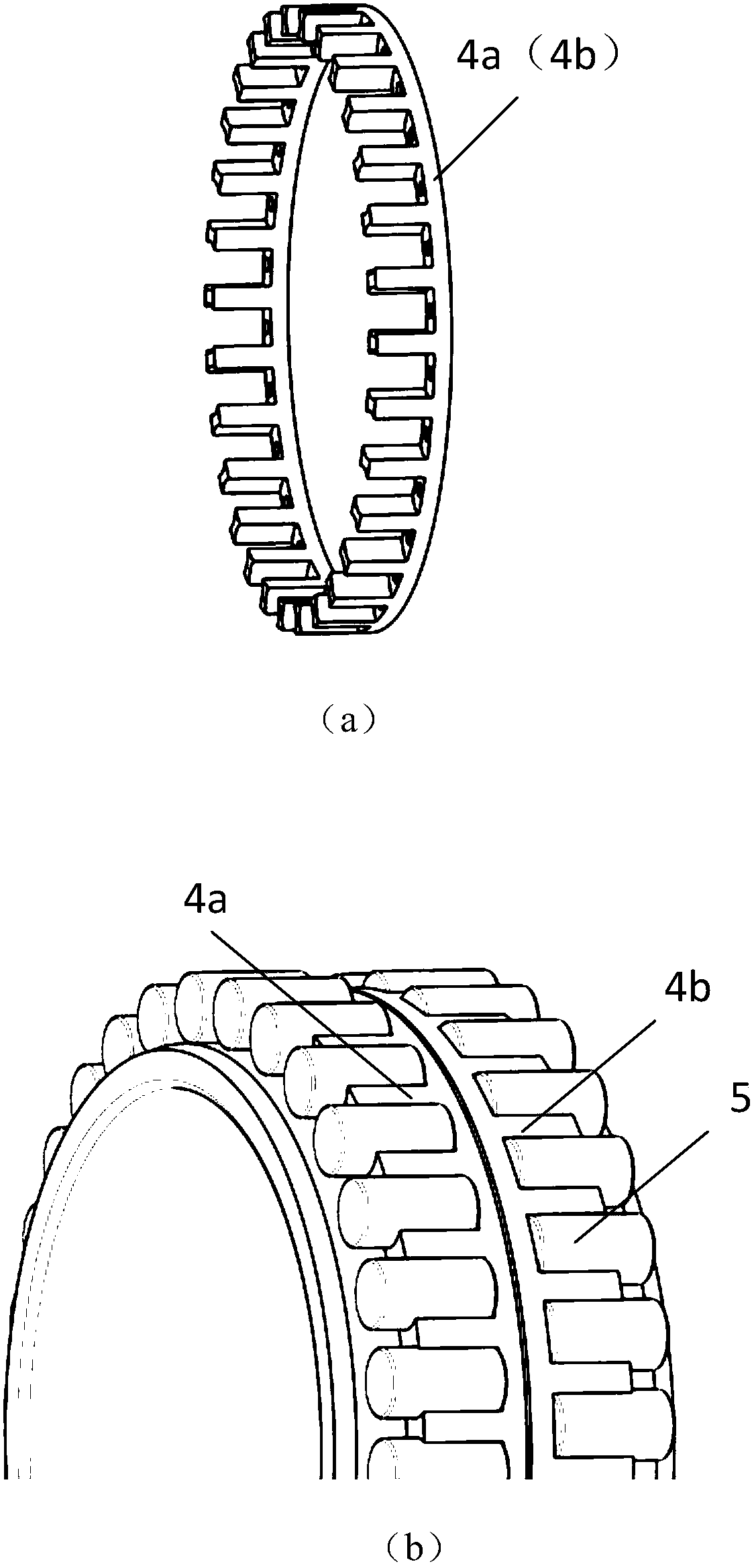

InactiveCN101586620AEasy to processAssembly accuracy is lowRolling contact bearingsBearing componentsEngineeringMechanical engineering

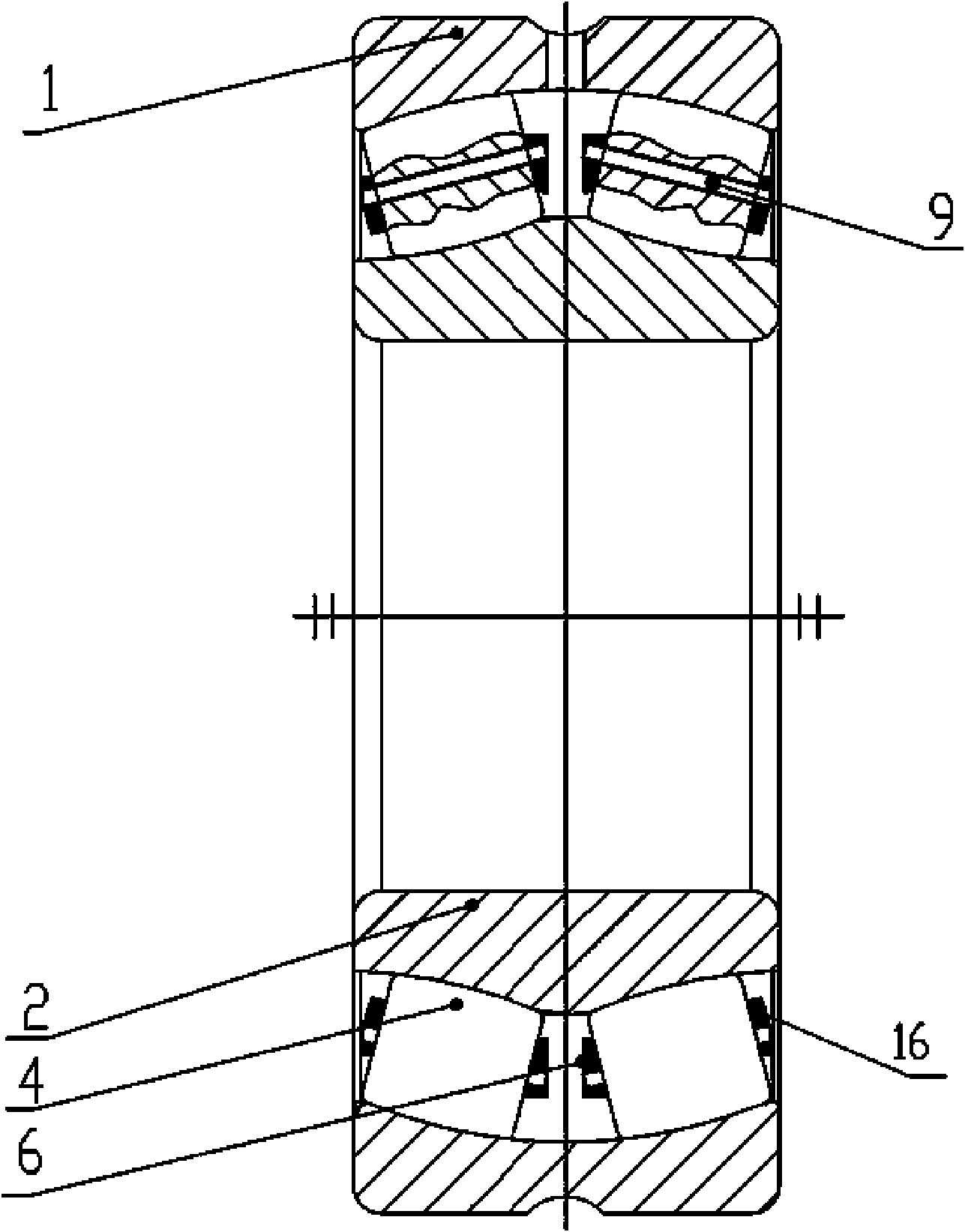

The invention discloses an oversize self-aligning roller bearing, which is provided with an outer ring (1) and an inner ring (2). A retainer is arranged between the outer ring (1) and the inner ring (2), and two groups of spherical rollers (4) are arranged in the retainer. The oversize self-aligning roller bearing is characterized in that: the rotation center of each spherical roller (4) is provided with a through hole; and the retainer consists of a pin shaft (9), and an inner plate annular retainer (6) and an outer plate annular retainer (16) at two ends of the pin shaft (9), wherein the pin shaft (9) runs through the through hole at the rotation center of the spherical roller (4), and the inner plate annular retainer and the outer plate annular retainer are arranged at two end faces of the spherical roller (4). The retainer is not integrated, but assembled, so the requirement of assembly precision between the retainer and the spherical rollers is reduced, and the retainer is easy to process and reduces the manufacturing cost. Moreover, the bearing can increase the number of the rollers as much as possible, and improves the rated load.

Owner:瓦房店第一轧机轴承制造有限公司

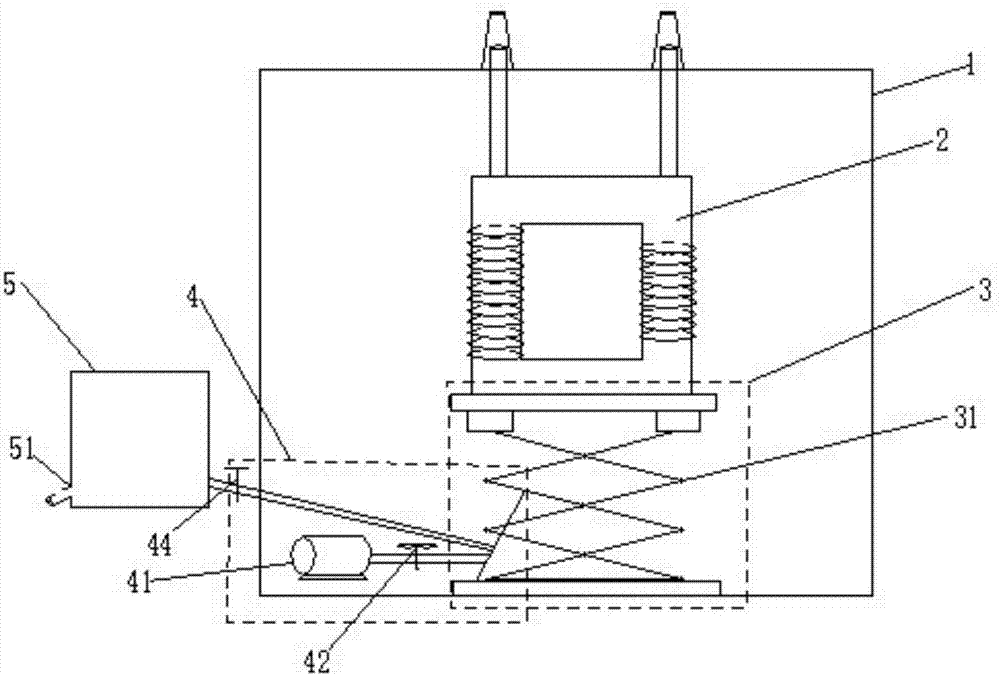

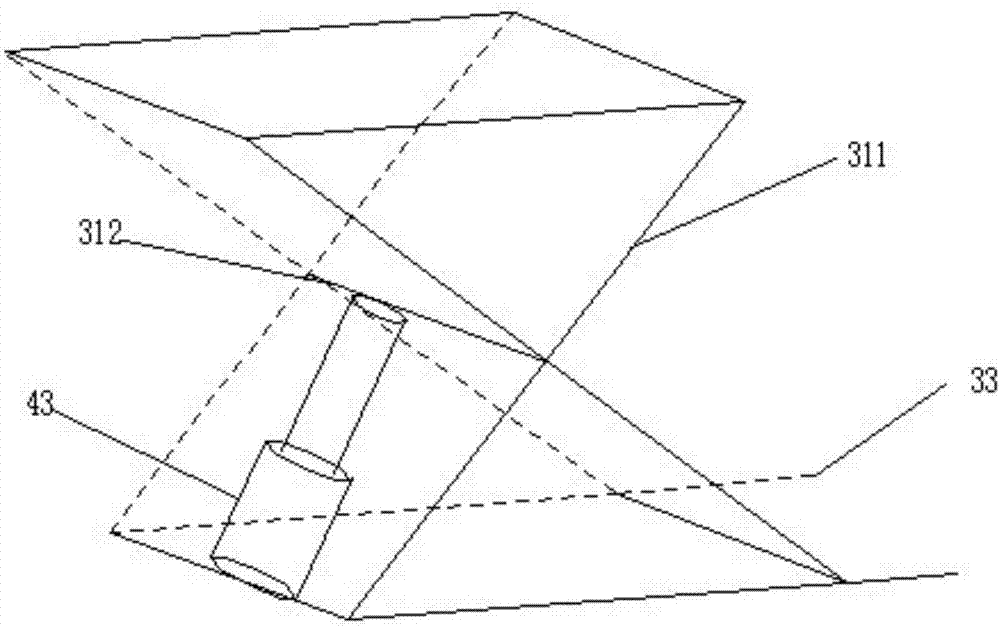

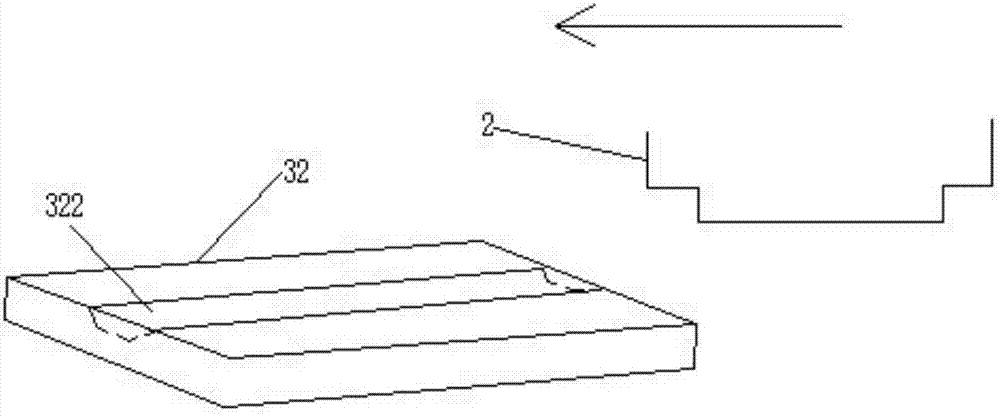

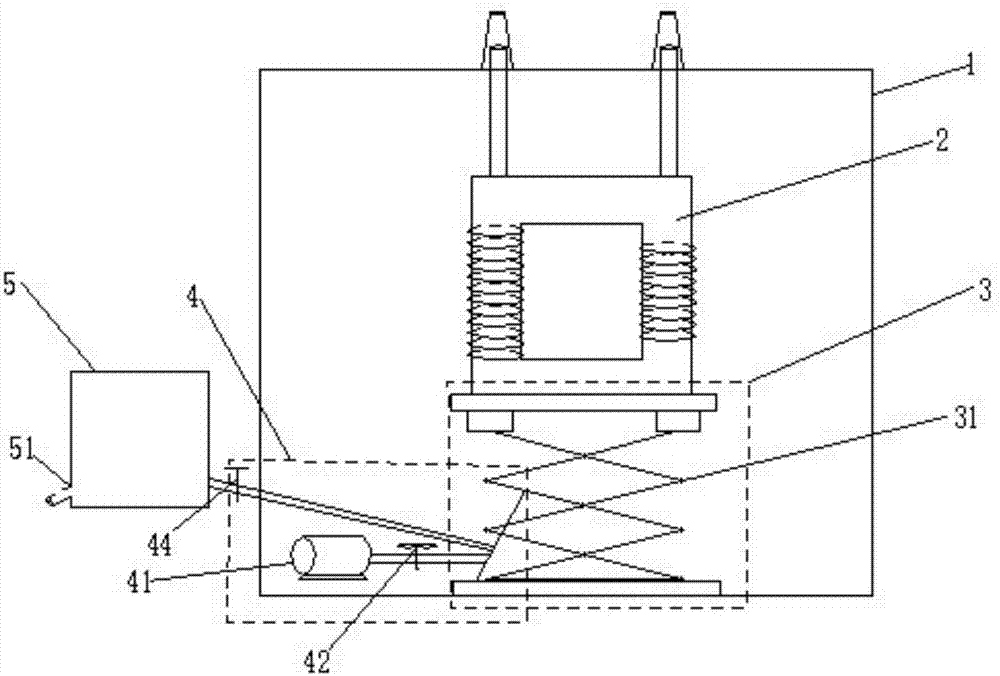

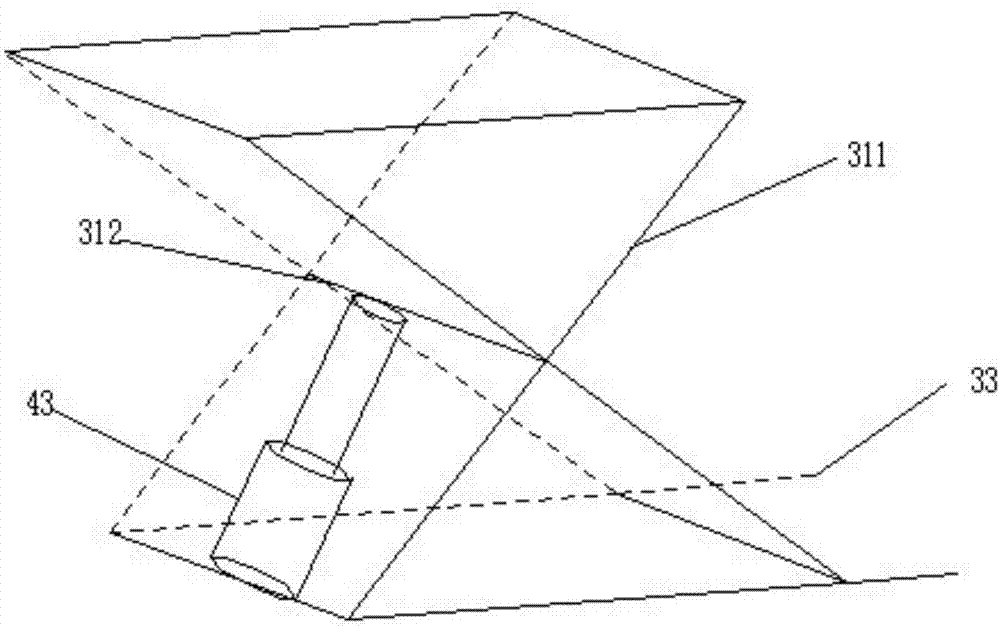

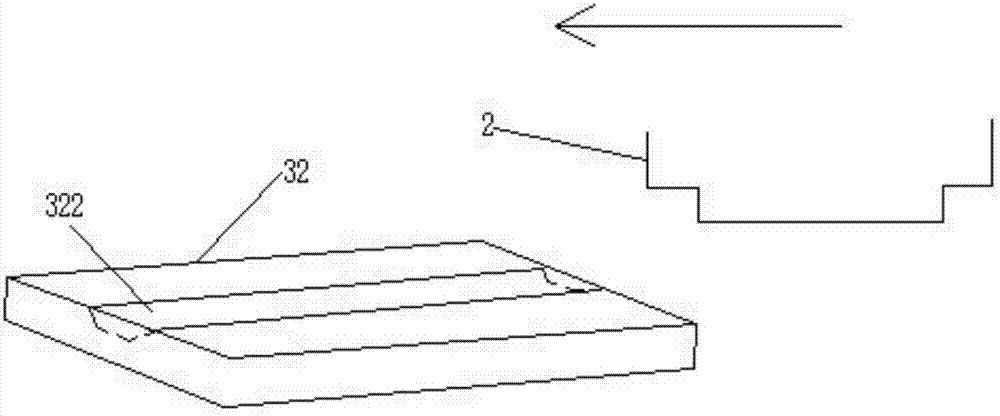

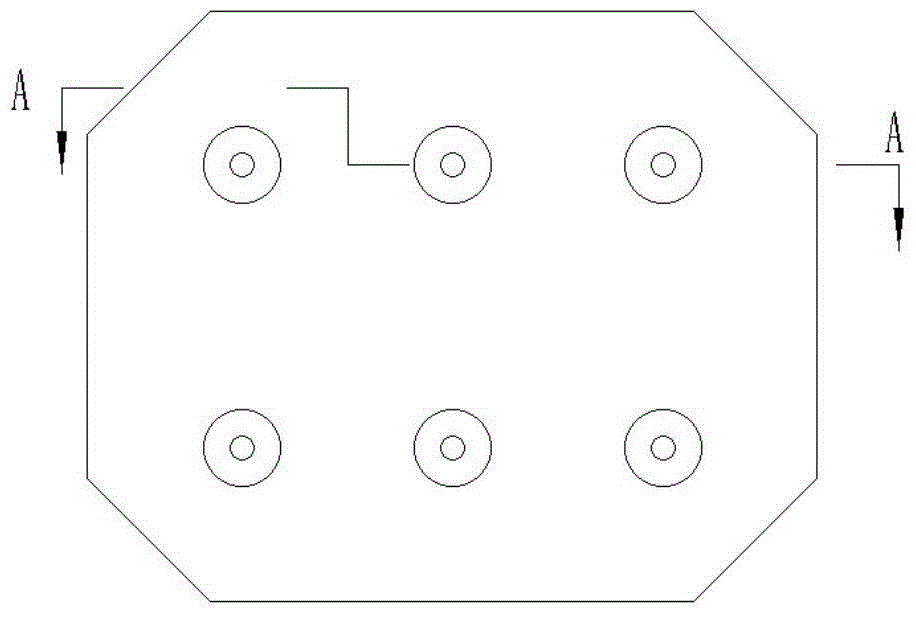

Single-phase oil-immersed transformer and special iron core therefor

ActiveCN105469945ASolve the gap problemGuaranteed uptimeTransformers/inductances coolingTransformers/inductances magnetic coresTransformerLow voltage

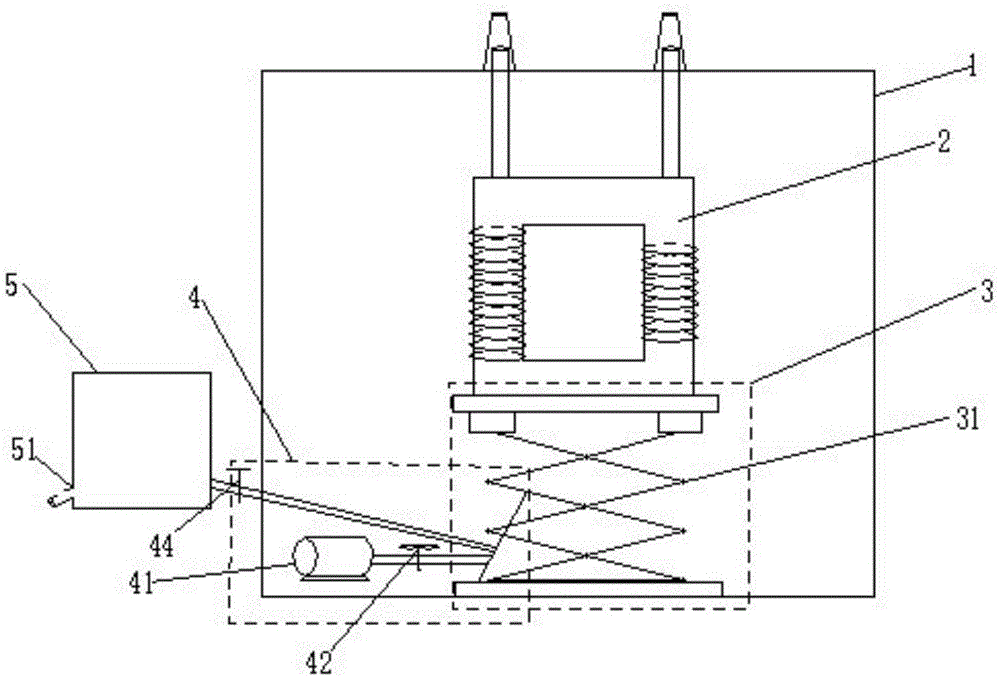

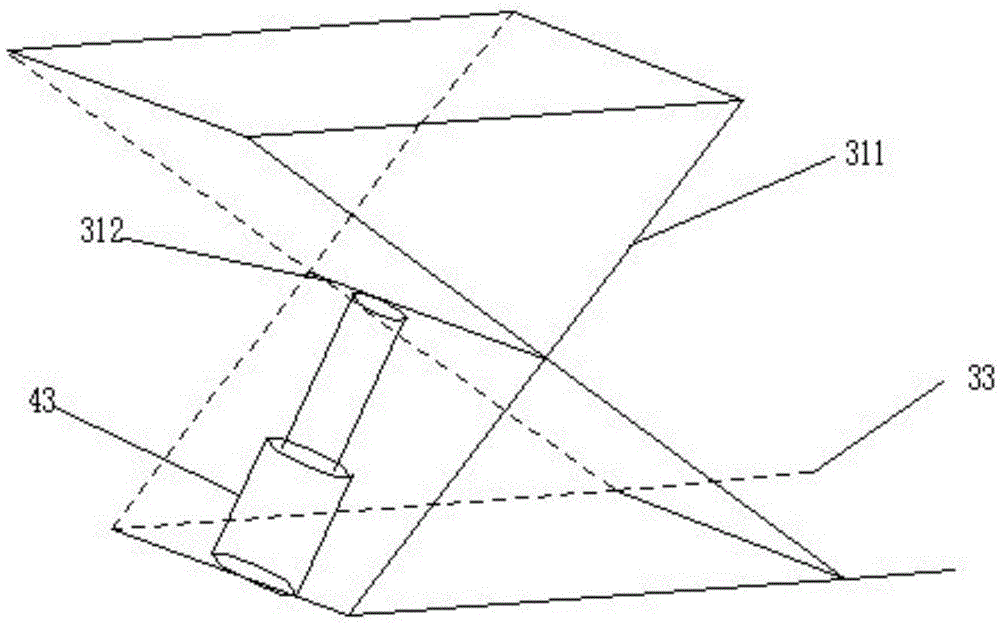

The invention provides a single-phase oil-immersed transformer and a special iron core therefor. The single-phase oil-immersed transformer comprises a box body with a box cover, an iron core, a radiating pipe, an oil conservator, a lifting mechanism, a power mechanism and an oil tank, wherein the iron core is a single-frame dual-core column with a groove, is arranged at the center of the box body and is immersed by an oil body; a coil is led out of the box cover; a high-voltage insulating sleeve and a low-voltage insulating sleeve respectively sleeve a lead; the radiating pipe is arranged on the side wall of the box body; the oil conservator is arranged at the upper end of one side of the box body; the lifting mechanism is arranged below the iron core; the bottom end of the lifting mechanism is fixedly connected with the box body; the power mechanism is connected with the lifting mechanism; the oil tank is connected with the power mechanism; and the oil tank is arranged outside the box body. The single-phase oil-immersed transformer can drive the lifting mechanism to take out the iron core by taking the oil in the box body as a power source through the power mechanism and stores the oil in the box body into the oil tank, so that maintenance of the iron core and oil-change operation are facilitated; the cost is saved; and the maintenance efficiency is also improved.

Owner:JIANGSU MINGAN ELECTRIC

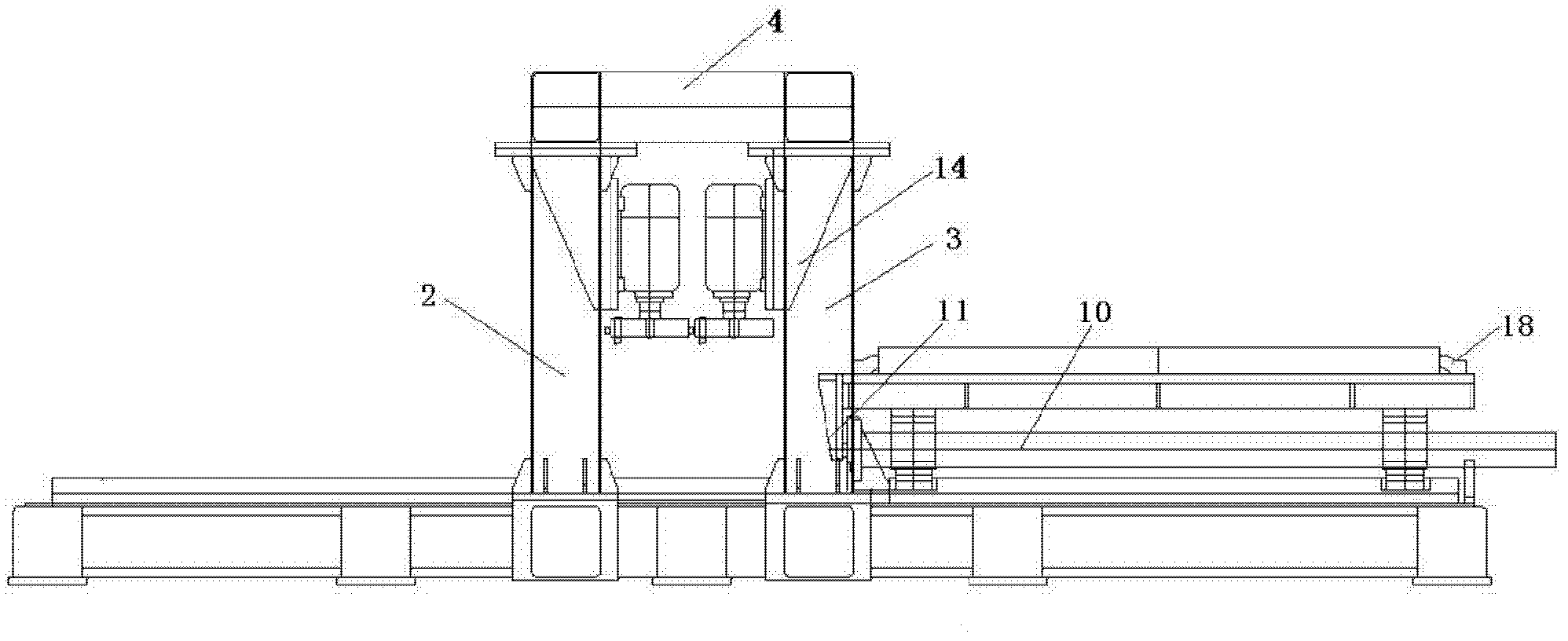

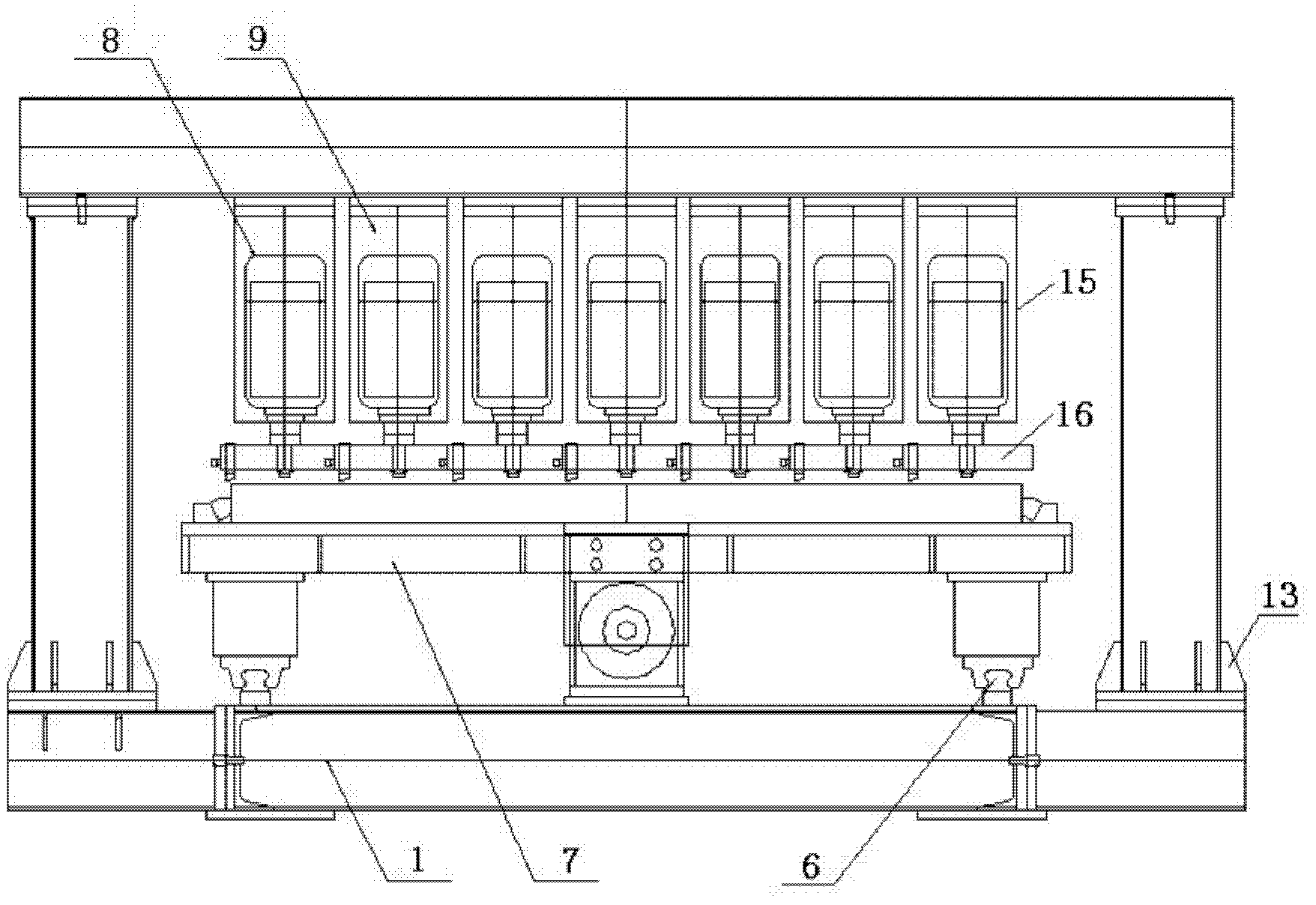

Multi-milling head gantry milling machine

InactiveCN102274999ARealize stepless speed regulationSimple structureFeeding apparatusMilling equipment detailsElectricityElectrical control

The invention relates to a milling machine, in particular to a gantry milling machine with multiple milling heads, which includes a bed, left and right columns, beams, and an electrical control cabinet. The workbench is provided with fixtures, the left and right columns are fixed on the bed, the beam is installed on the left and right columns to form a gantry frame, and the first milling head assembly is installed on the beam. The above-mentioned first milling head assembly is electrically connected with the electrical control cabinet, and a plurality of second milling head assemblies are installed on the beam, and a pushing mechanism for pushing the workbench is arranged on the bed, and the device also It includes an independent driving device that provides power for the pushing mechanism, and the second milling head assembly is electrically connected with the driving device and the electrical control cabinet. The invention can adjust the length of the processing surface according to the size of the product, and also has the advantages of simple structure, low equipment investment, stepless speed regulation, and improved production efficiency.

Owner:杭州宏邦压滤机制造有限公司

Method of replacing supporting bearing for rolling roll

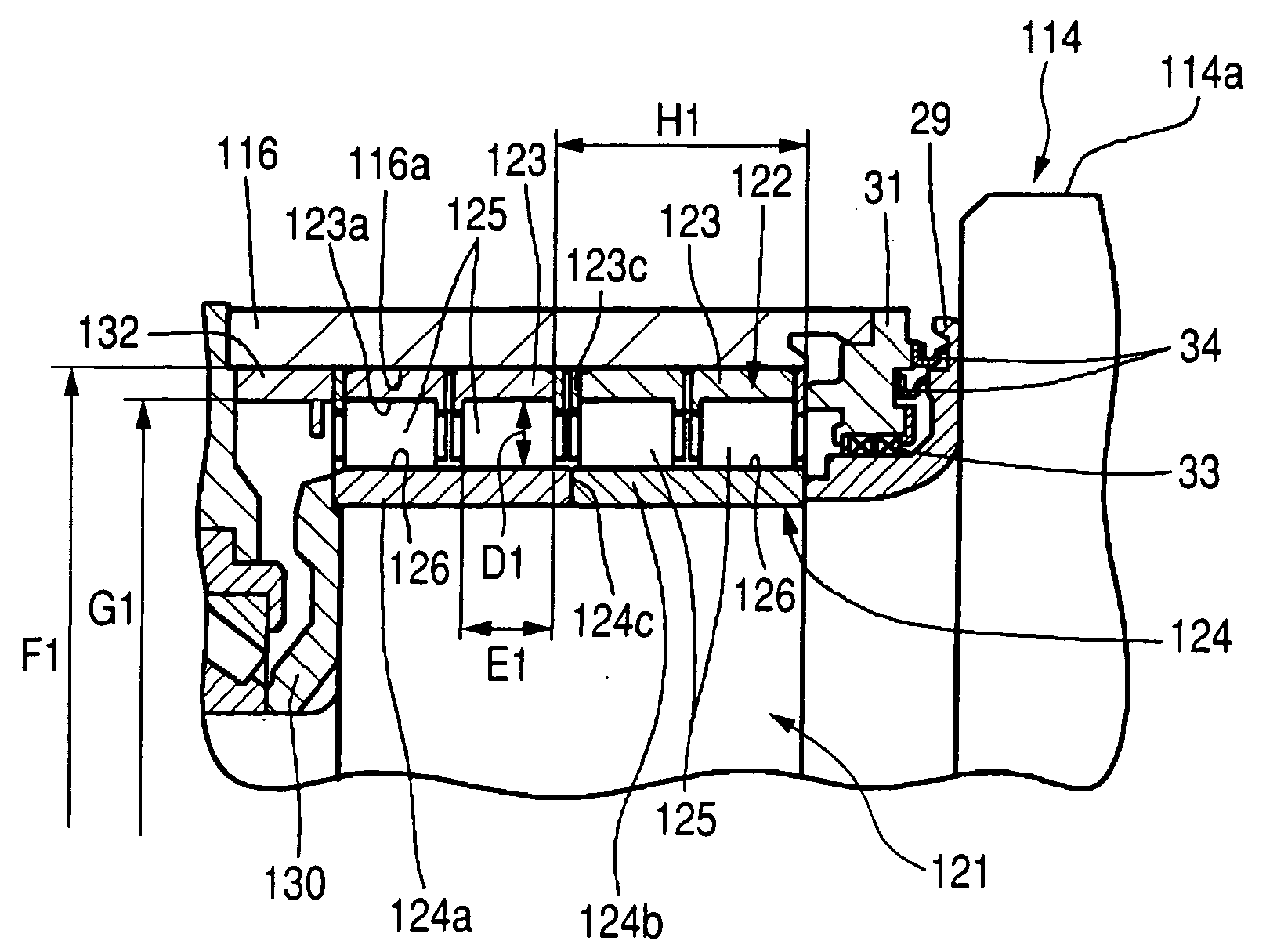

InactiveUS20090094835A1Shorten the overall cycleIncrease the rated loadRoller bearingsMetal rolling stand detailsEngineeringAxial length

A supporting bearing is replaced with a new supporting bearing by conducting a first step and a second step. In the first step., an old inner ring before replacement is replaced with a new inner ring having an inner ring raceway diameter same as the old inner ring, and an axial length of an inner ring raceway face longer than the old inner ring so that a rolling roll is supported by this new inner ring in combination with an old outer ring and old cylindrical rollers. Thereafter, in the second step, the old cylindrical rollers are replaced with new cylindrical rollers having an axial length longer than the old cylindrical rollers, and simultaneously, the old outer ring is replaced with a new outer ring having an axial length of an outer ring raceway face longer than the old outer ring.

Owner:JTEKT CORP

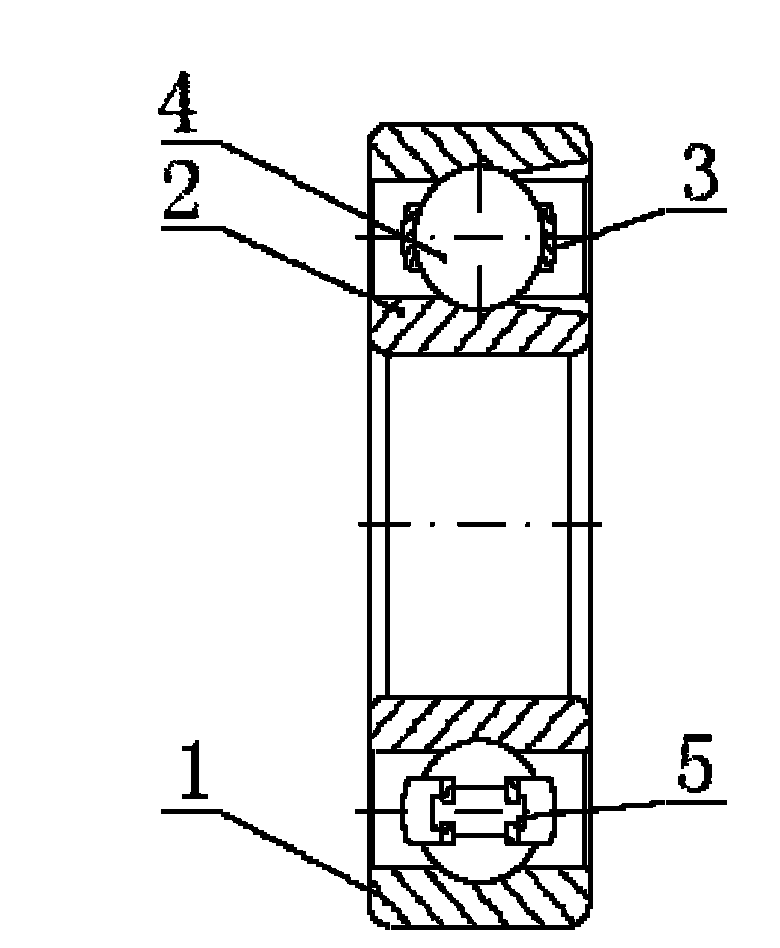

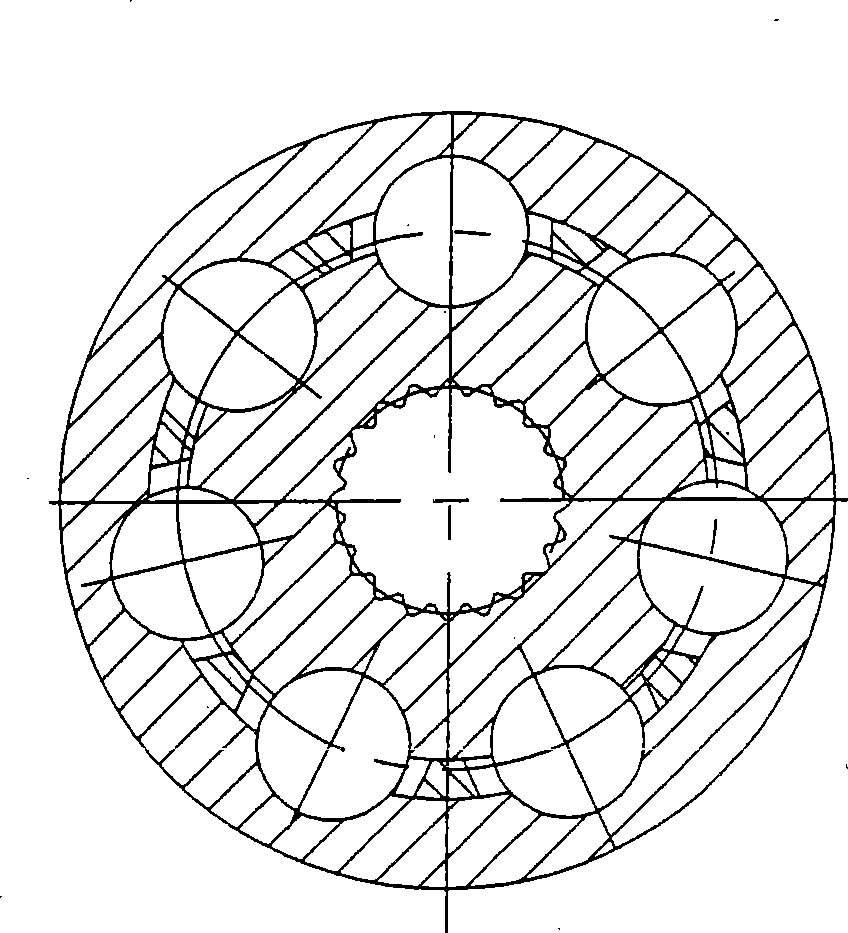

Enhanced heavy-duty deep groove ball bearing

InactiveCN102080686AIncrease the number ofIncrease the rated loadBall bearingsBearing componentsInterior spaceBall bearing

The invention provides an enhanced heavy-duty deep groove ball bearing. The bearing comprises an outer ring, an inner ring, rolling bodies and retainers, wherein the rolling bodies are arranged in a spherical pocket hole formed by two retainers; the inner ring and the outer ring are respectively arranged on the inner and outer sides of an annular body formed by the rolling bodies and the retainers; and a roller way of the inner ring and a roller way of the outer ring are respectively contacted with the rolling bodies. Platy rivets are adopted, and the two ribbon retainers are not directly contacted during riveting, so that inner space is increased; the enhanced heavy-duty deep groove ball bearing is provided with two to three more rolling bodies than the conventional deep groove ball bearing, and the diameter of the rolling bodies is one to two times larger than that of the rolling bodies of the conventional deep groove ball bearing, so that the bearing capacity of the bearing is 20 to 30 percent higher than that of the deep groove ball bearing of the same overall dimension, and the rated load of the bearing is equivalent to that of a cylindrical roller bearing of the same overall dimension; meanwhile, the limit rotating speed of the bearing is improved, and the rotating speed of the series bearing is 20 to 30 percent higher than that of the cylindrical roller bearing.

Owner:HARBIN BEARING GROUP CORP

Linear ball guide sleeve

The invention relates to the technical field of linear guide rail accessories, in particular to a linear ball guide sleeve which is widely applied to sliding parts of a lathe, a grinder and other mechanical devices. The linear ball guide sleeve comprises a rotating shaft and a bearing sleeve, wherein the outside of the rotating shaft is sleeved with the bearing sleeve. The bearing sleeve comprises a holding frame and a bearing sleeve shell. Balls are arranged between the holding frame and the bearing sleeve shell. Stop rings are arranged at the two ends of the bearing sleeve. A pin hole is formed in the outside of the bearing sleeve shell. A pin is inserted into the pin hole to connect the holding frame with the bearing sleeve shell. The rotating shaft is provided with a plurality of circular arc-shaped rolling channels. According to the linear ball guide sleeve, the design is reasonable; the rotating shaft is provided with the multiple circular arc-shaped rolling channels so that the rated load can be improved; an oil injection hole is formed so that the lubrication performance of the linear ball guide sleeve can be improved; the abrasion resistance of the linear ball guide sleeve is improved and the service life is prolonged; the stop rings are arranged at the two ends of the bearing sleeve, and thus the linear ball guide sleeve has the advantage of dust prevention.

Owner:陆如东

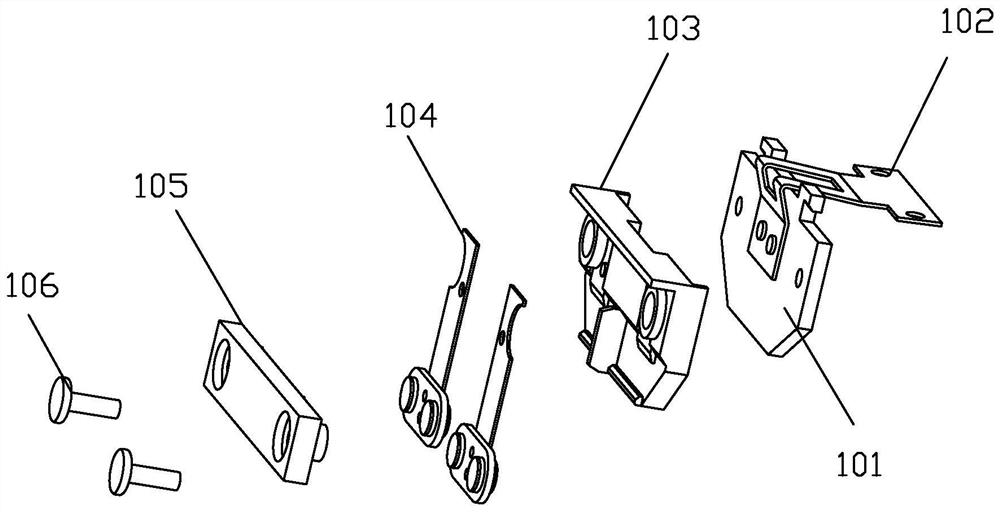

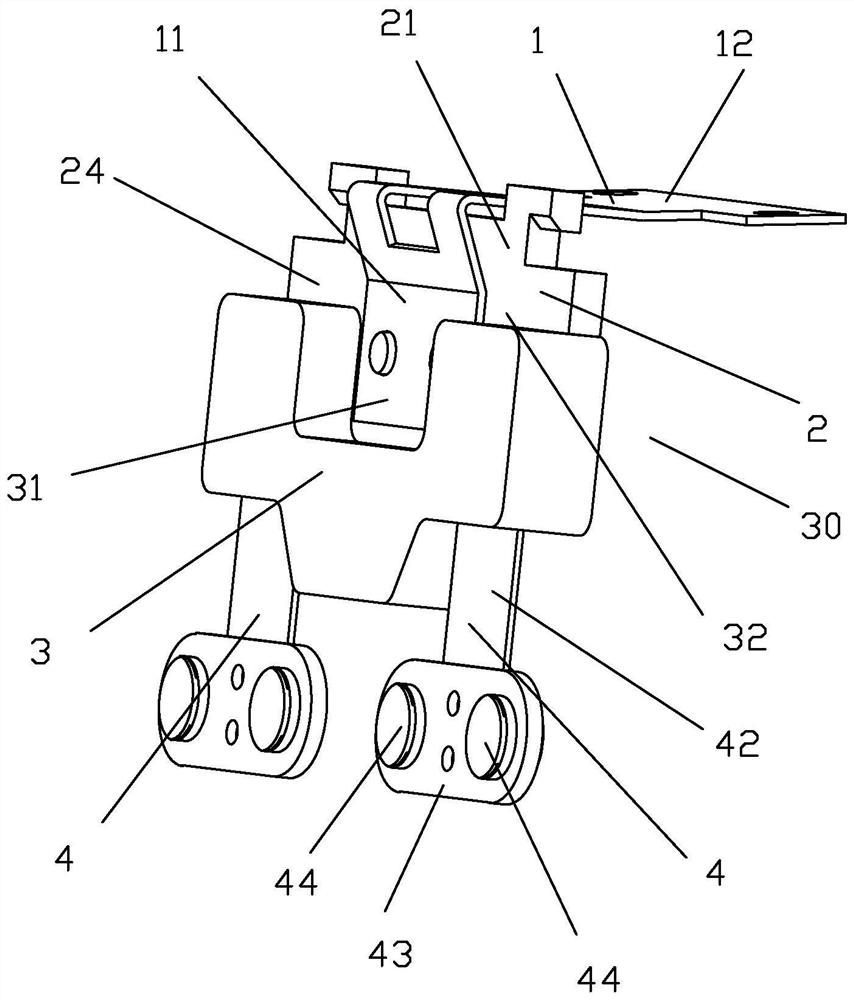

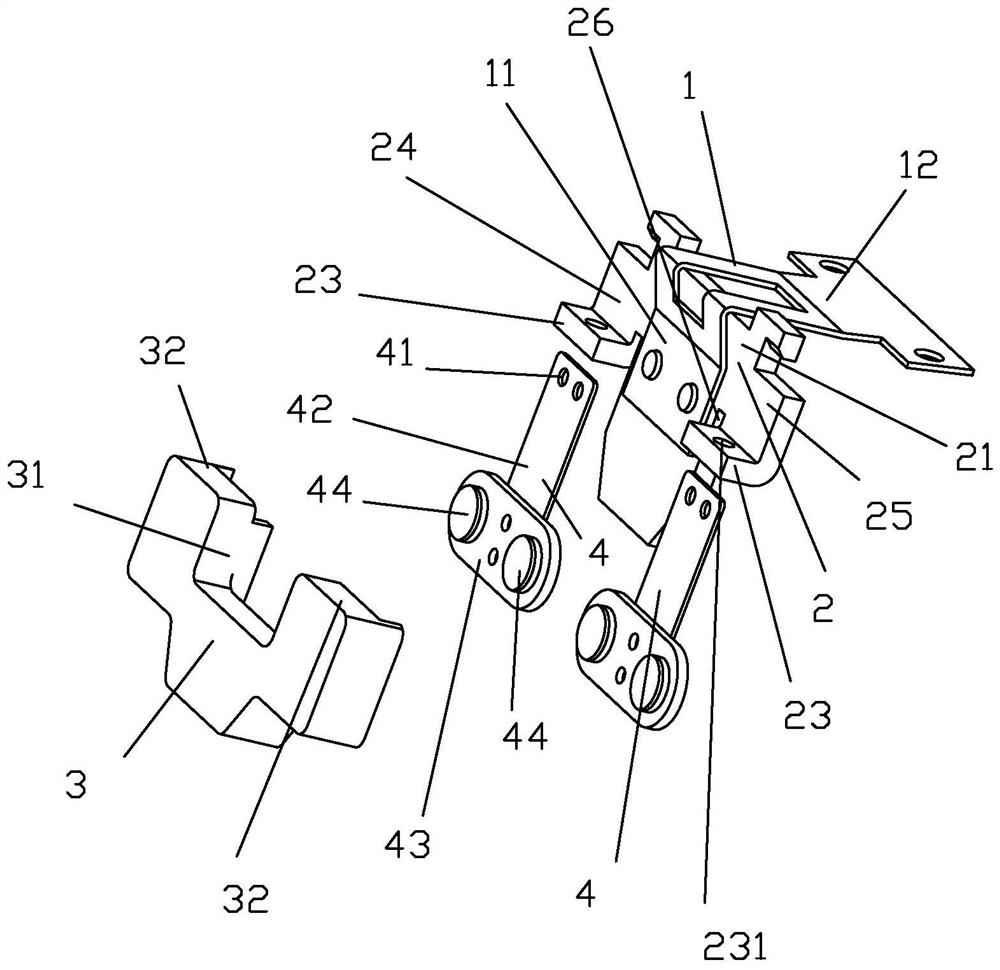

Movable spring armature component and clapper relay thereof

PendingCN112086316ATo achieve voltage isolationParts are smallElectromagnetic relay detailsBatch productionElectrical and Electronics engineering

The invention discloses a movable spring armature component and a clapper relay thereof. The movable spring armature component comprises an armature, an injection molding part and a movable spring, wherein an upper part of the armature is provided with a matching part which is matched with a knife edge of a yoke of a magnetic circuit part of the relay, and one surface of the armature can be matched with a pole surface of an iron core of the magnetic circuit part of the relay through matching with the yoke; two sides of the armature are respectively provided with a bending part which is bent towards the direction deviating from one surface of the armature, and the injection molding piece is coated on the other surface and the side surface of the armature and completely coated on the bendingparts so as to be stably combined with the armature. The movable spring armature component provided by the invention has the characteristics of small component size, simple production and assembly, convenient realization of automatic production, small influence of accumulated assembly tolerance among multiple groups of movable springs, and good parameter consistency of batch production of finished relays.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS

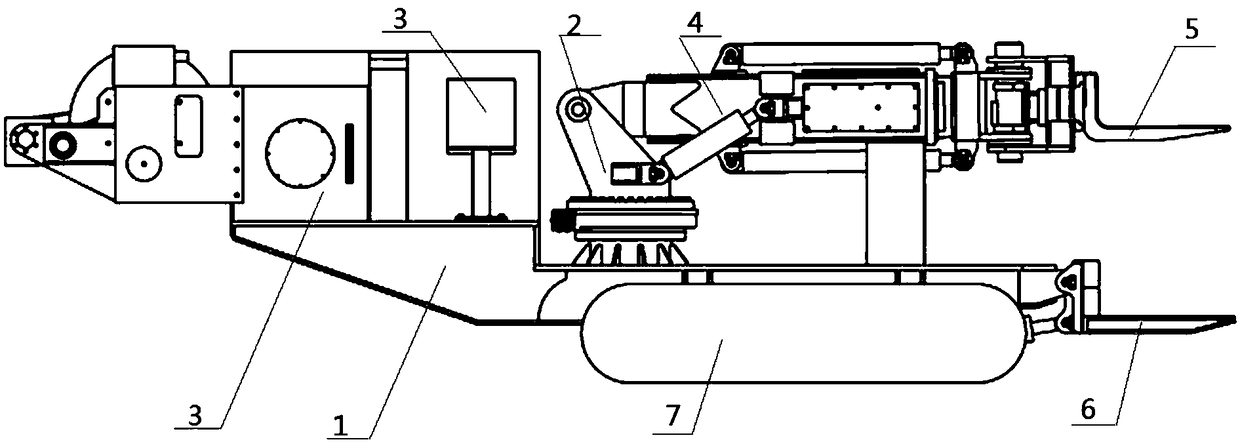

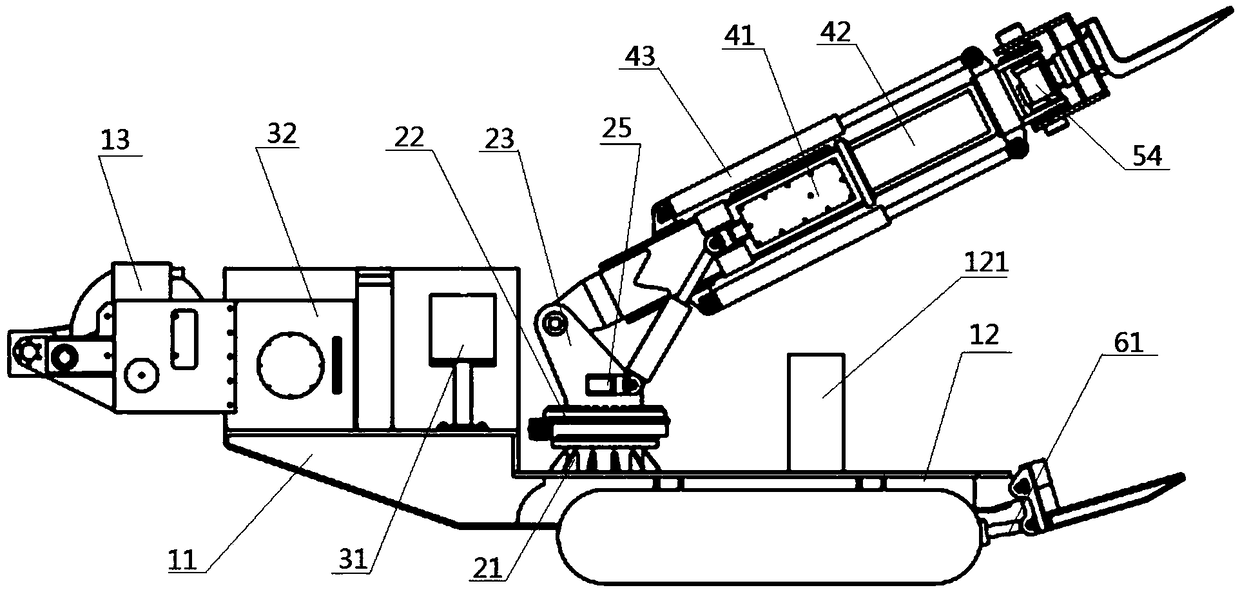

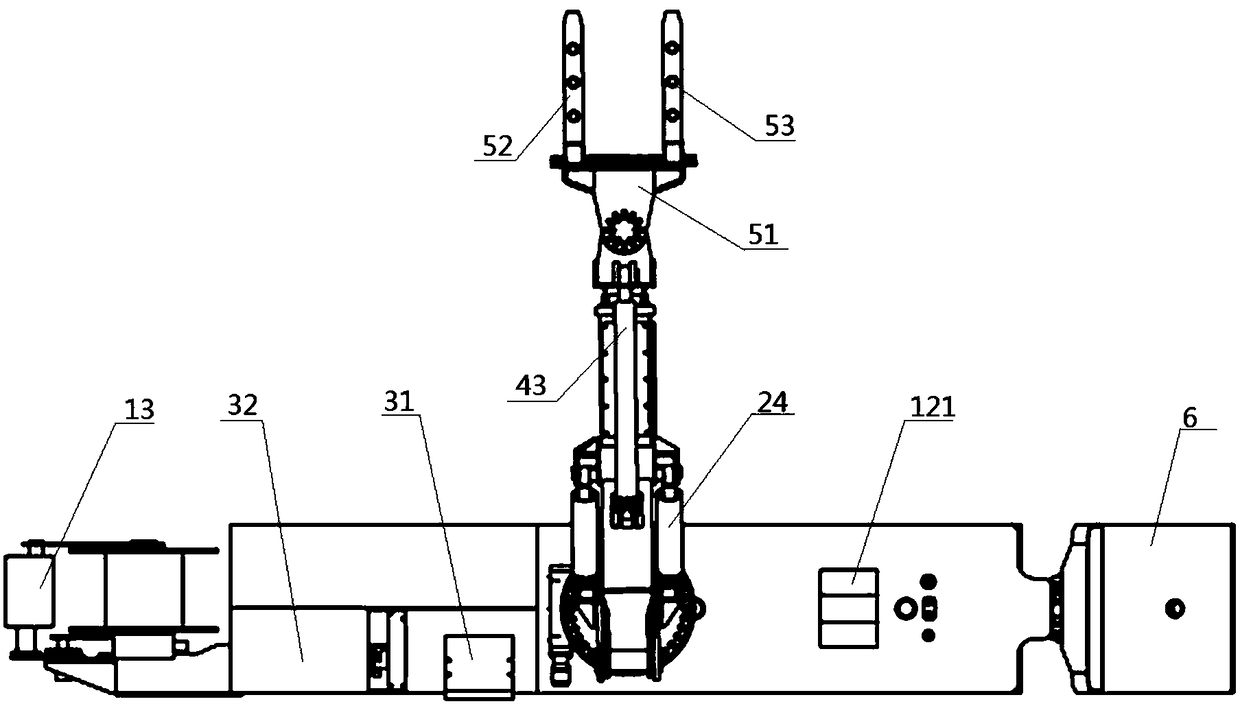

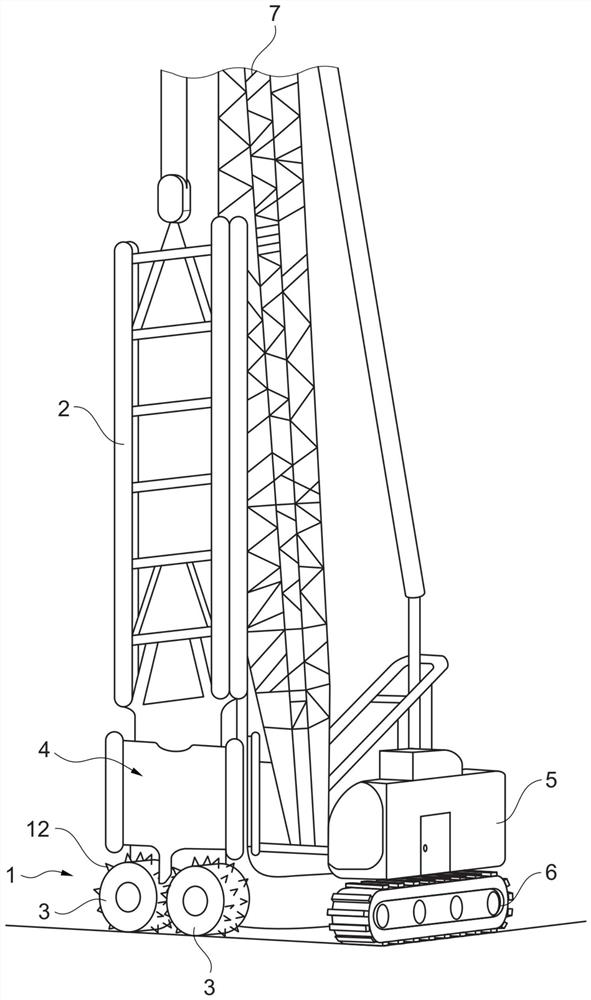

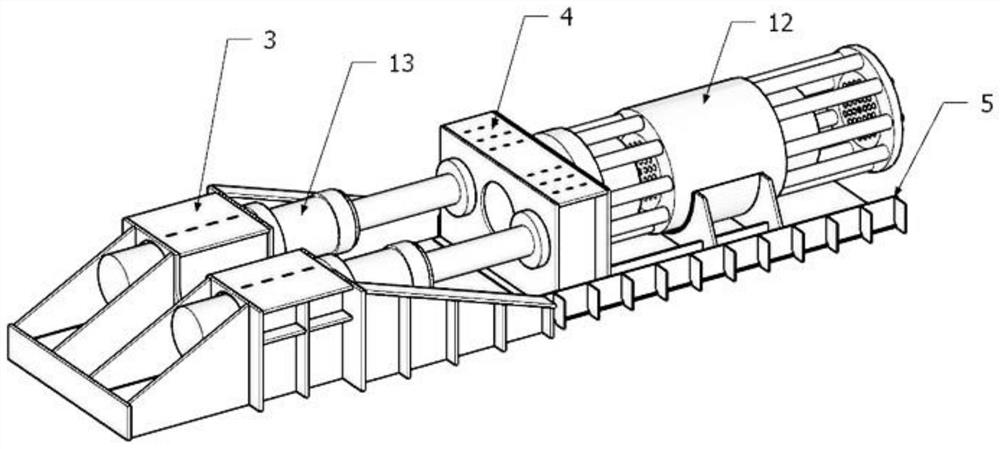

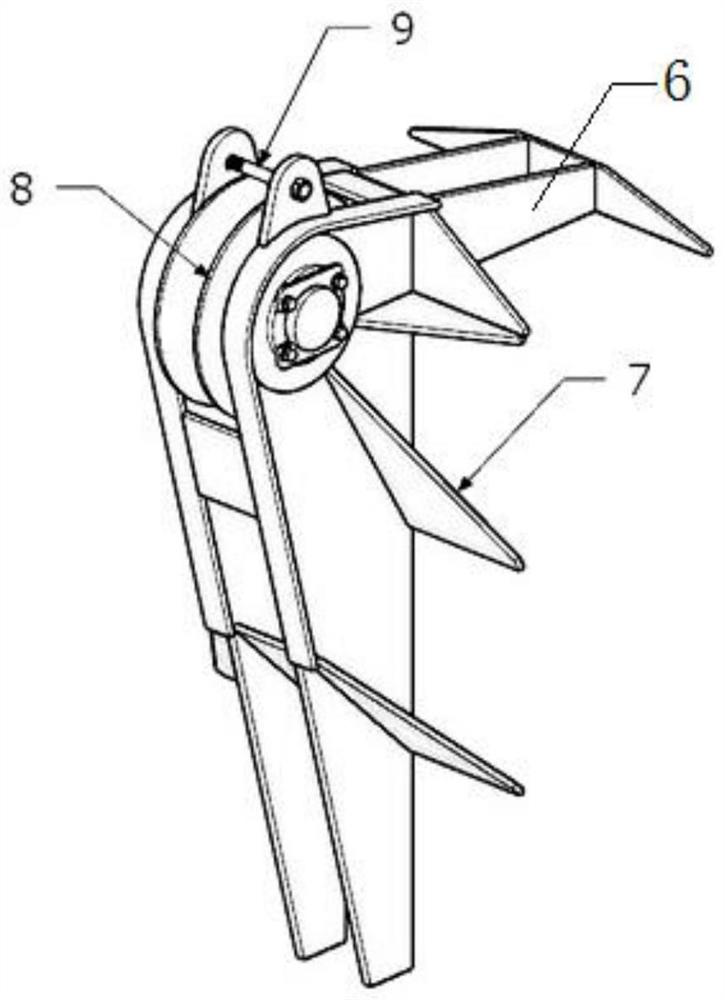

Unit support carrying machine for coal mine

PendingCN109502262AIncrease the rated loadImprove transfer work efficiencyMechanical conveyorsEngineeringCoal

The invention discloses a unit support carrying machine for coal mine. The unit support carrying machine for coal mine comprises a base, a rotary assembly, a control assembly, a large arm assembly, shovel forks, shovel plates and a travelling assembly, wherein the rotary assembly is arranged at the middle part of the base; the control assembly is arranged at the left side of the base; the large arm assembly comprises a swing arm barrel and a telescopic arm, the bottom end of the swing arm barrel is hinged to the rotary assembly, so that the left-right rotation and up-down swing movement of theswing arm barrel is completed through the rotary assembly, the telescopic arm is inserted into the top end of the swing arm barrel, and the telescopic arm is capable of carrying out telescopic actionrelative to the swing arm barrel; the shovel forks are hinged to the upper end and the lower end of the telescopic arm and capable of carrying out left-right swing movement, each shovel fork comprises a swing seat and one shovel plate, and a plurality of hoisting holes which are longitudinally and uniformly arranged are formed in each shovel fork; the shovel plates are hinged to the front top surface of the base and capable of carrying out up-down swing; and the travelling assembly is arranged on the bottom surface of the base to drive the carrying machine to move. The carrying machine has the advantages of being capable of saving manpower resource, high in safety, wide in working range and high in carrying efficiency.

Owner:BEIJING XINNENG YATE TECH DEV CO LTD

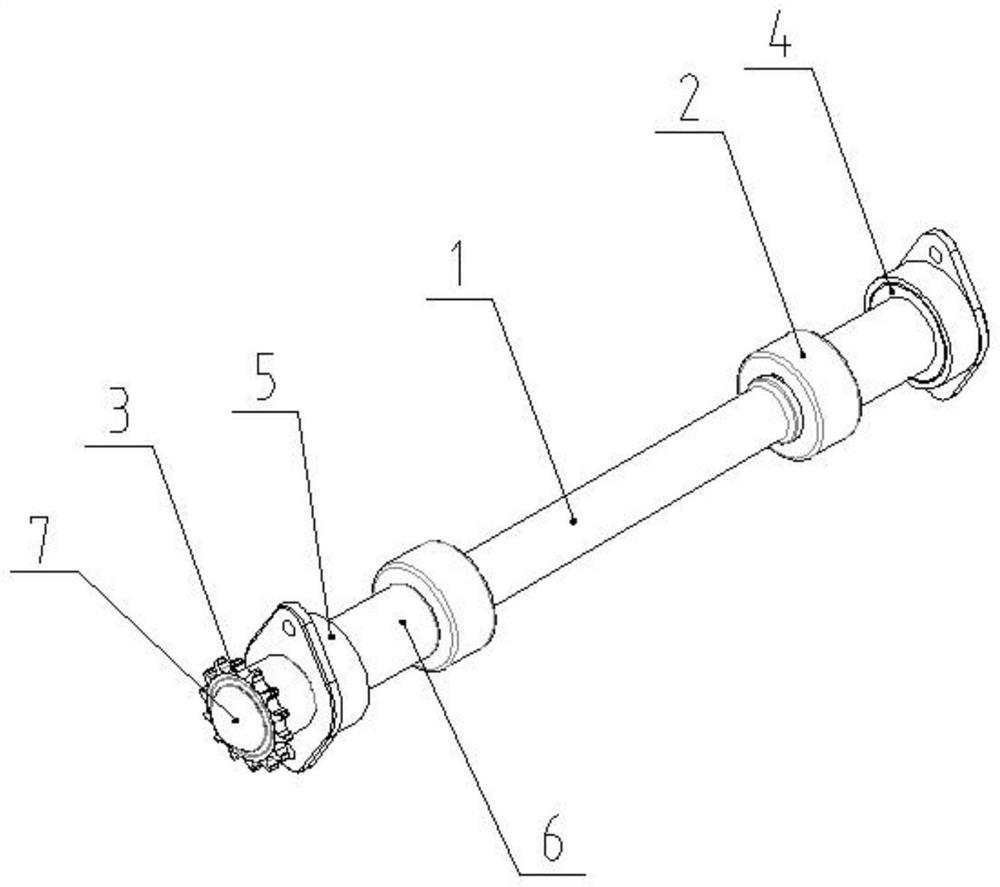

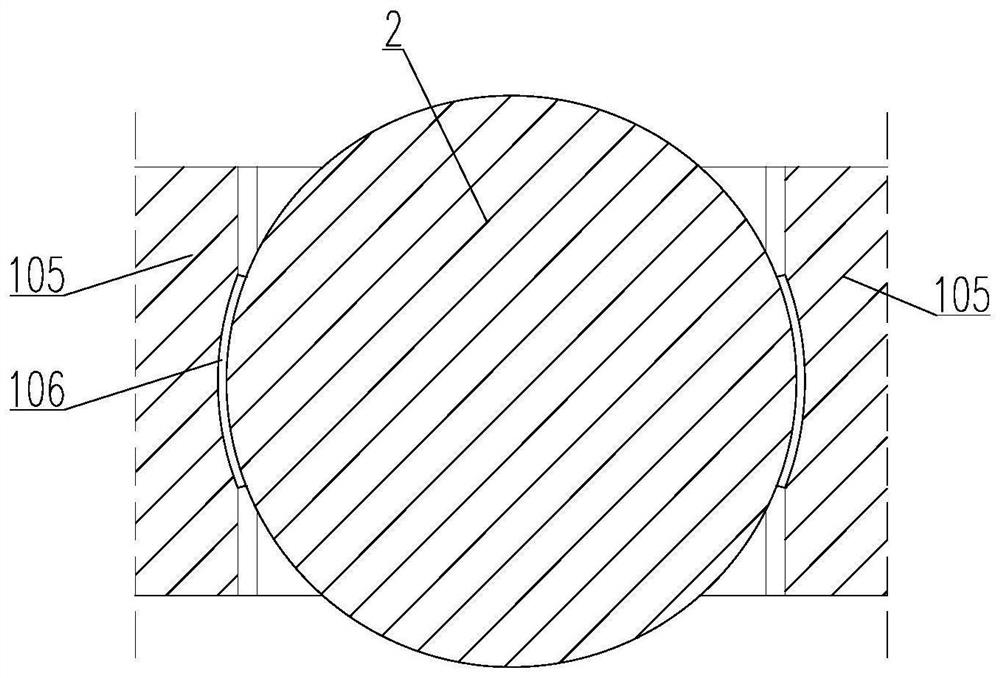

Seven channel ball cage type universal joint

InactiveCN101398035AImprove carrying capacityIncrease the rated loadYielding couplingDrive shaftUniversal joint

The invention relates to a hepta-channel ball-basket universal joint. The universal joint comprises a bell shell, a drive shaft, a cage, a plurality of steel balls, a star-shaped sleeve, a snap spring and the like. The number of steel balls is seven; the number of holes on the cage is seven; and the number of corresponding channels of the bell shell and the star-shaped sleeve are also seven. The star-shaped sleeve is arranged in the interior of the cage; the seven channels of the bell shells and the star-shaped sleeve are corresponding to the seven holes on the cage; the steel balls are arranged in the seven channels of the bell shells and the star-shaped sleeve; and the star-shaped sleeve is arranged on the drive shaft by a spline and axially oriented by a clip ring. Compared with the prior art, as the hepta-channel ball-basket universal joint is adopted, the ball-basket universal joint increases bearing capacity of the traditional ball-basket universal joint and increases rated load by 16 percent; simultaneously, the difficulty in the arrangement of eight steel balls is avoided.

Owner:石宝枢

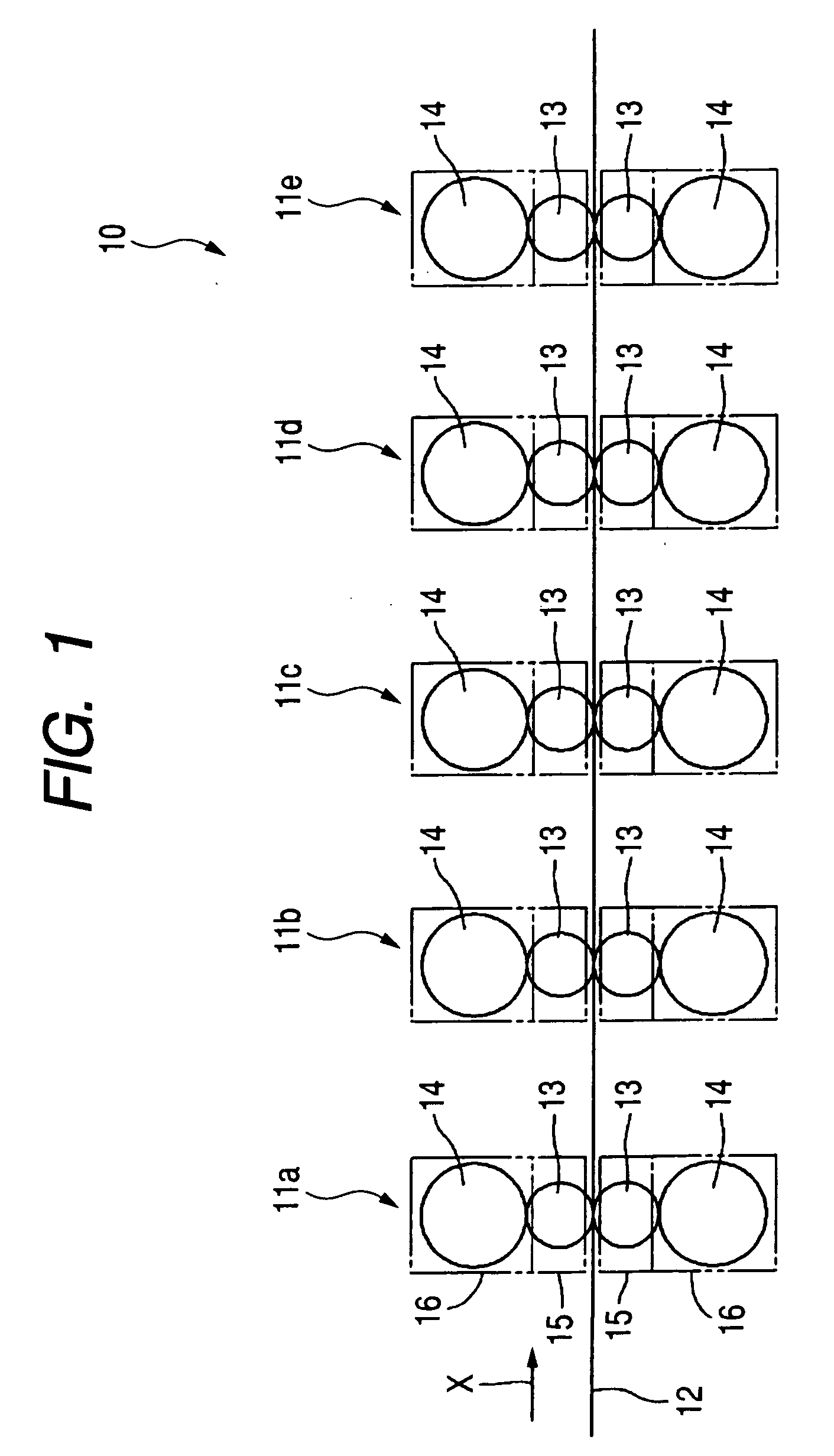

A cage and a double row or multiple row cylinder roller bearing with the cage

The invention provides a cage with low cost and simple processing and used for a double row or multiple row cylinder roller bearing and the double row or multiple row cylinder roller bearing with thecage. The cage includes an annular main part and a plurality of fork parts. Each of the multiple fork parts extends from the axial end face of the main part to the axial outside. The multiple fork parts are arranged spaced apart from each other along a circumferential direction of the main part. Each of the multiple fork parts can be inserted into a hollow part of a corresponding roller so as to enable the cage to be guided by the rollers while holding the rollers.

Owner:SCHAEFFLER TECH AG & CO KG

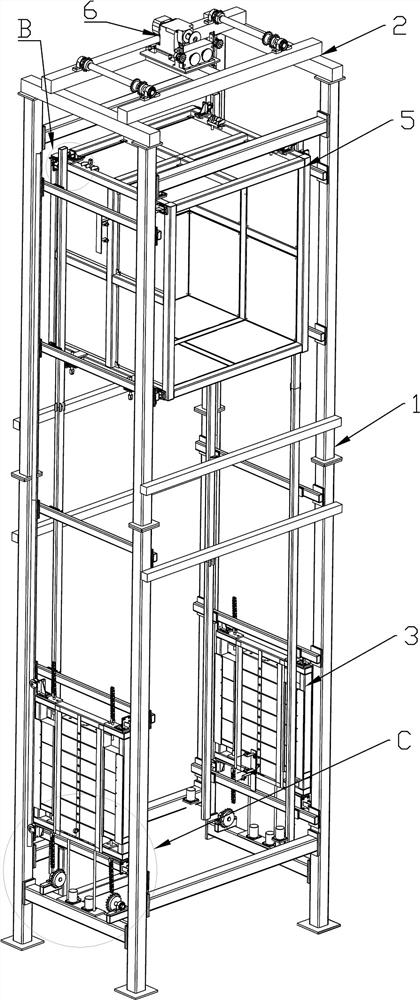

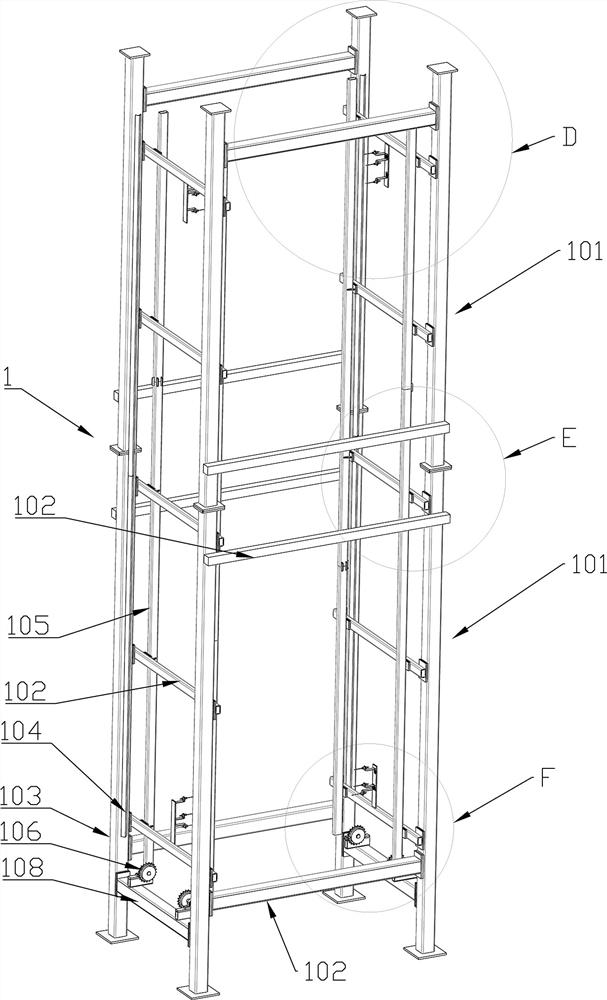

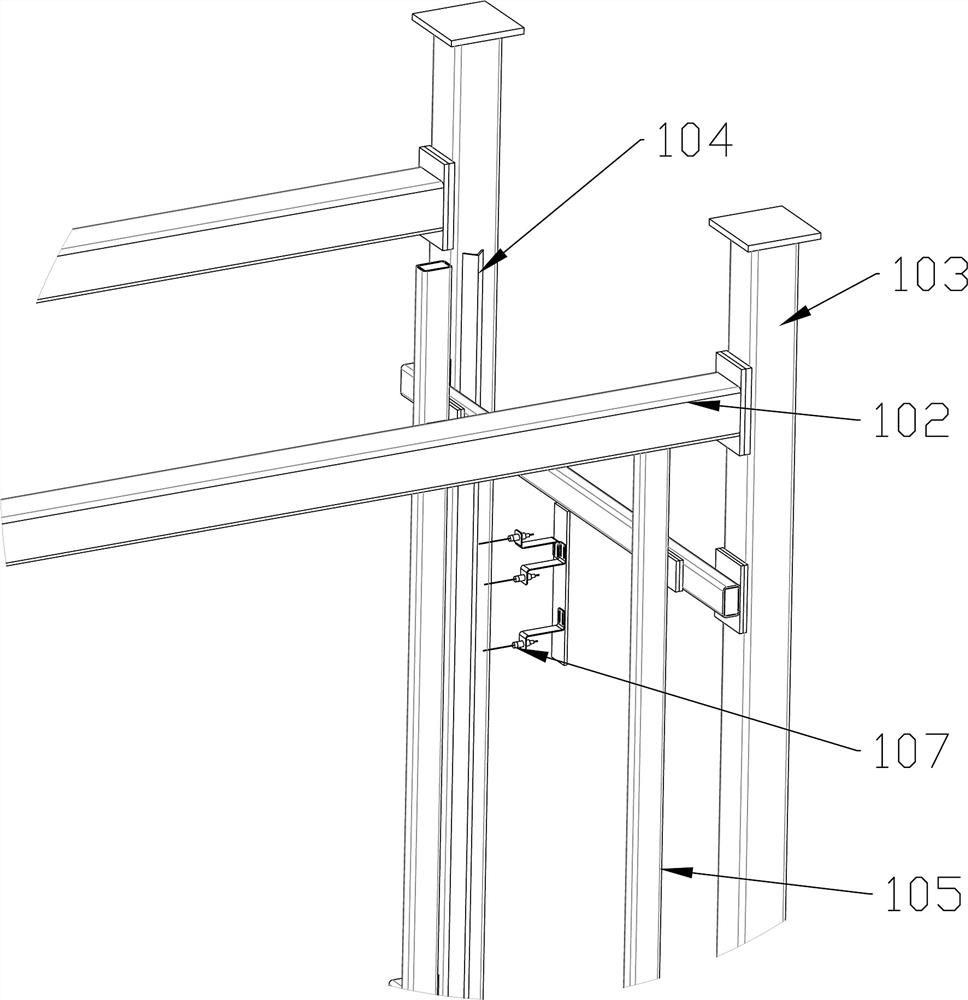

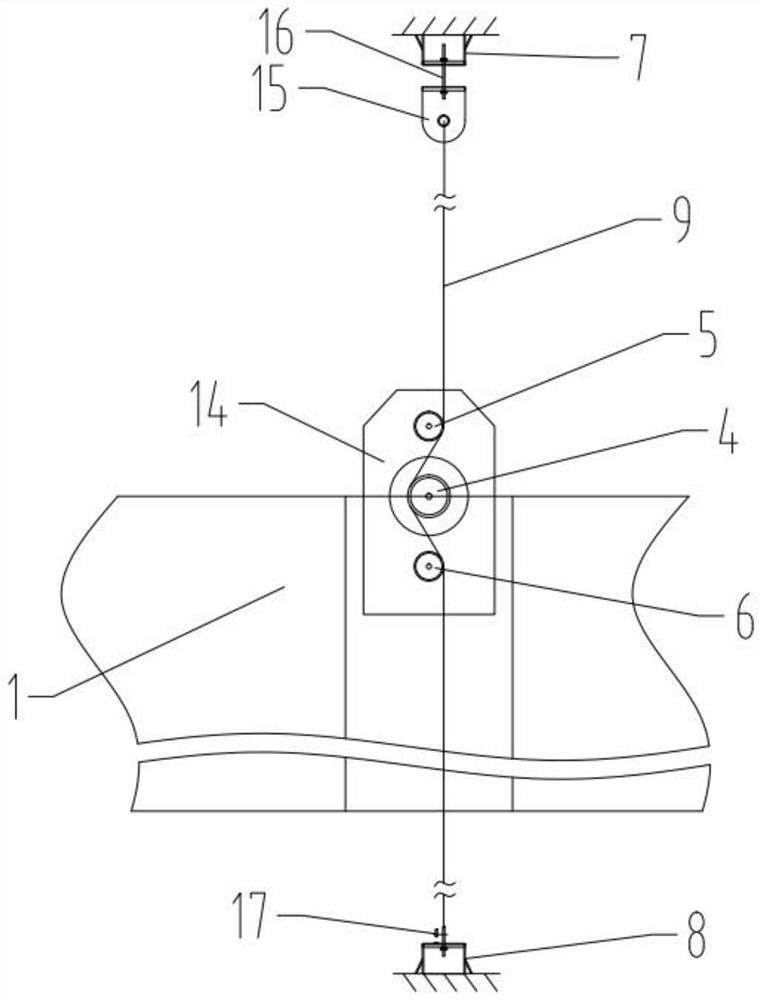

Spliced variable-load hoisting mechanism

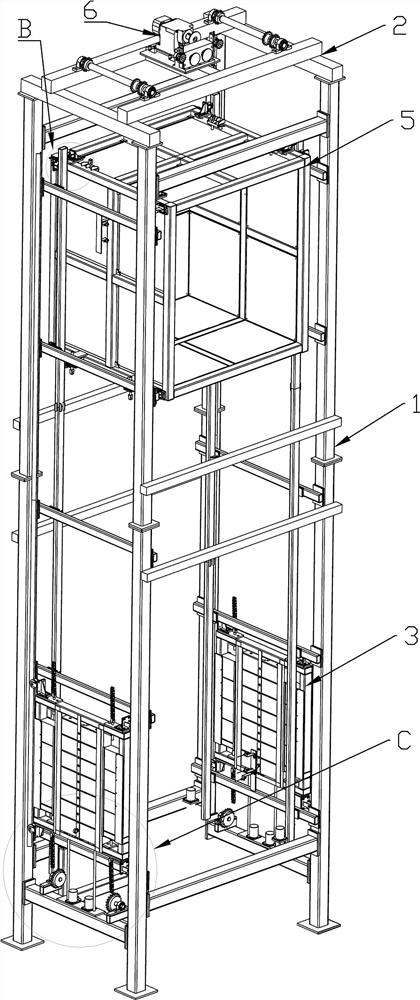

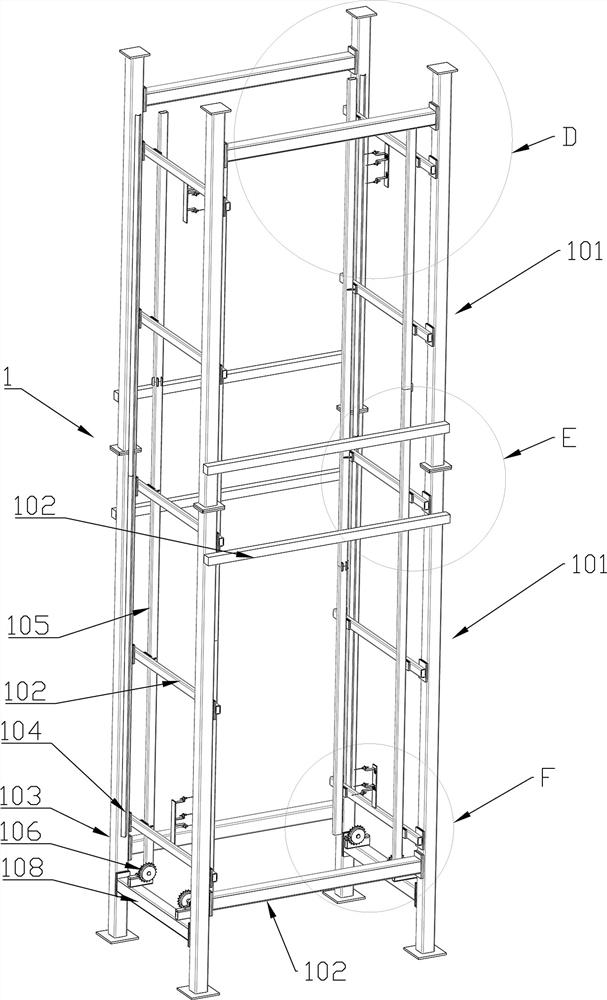

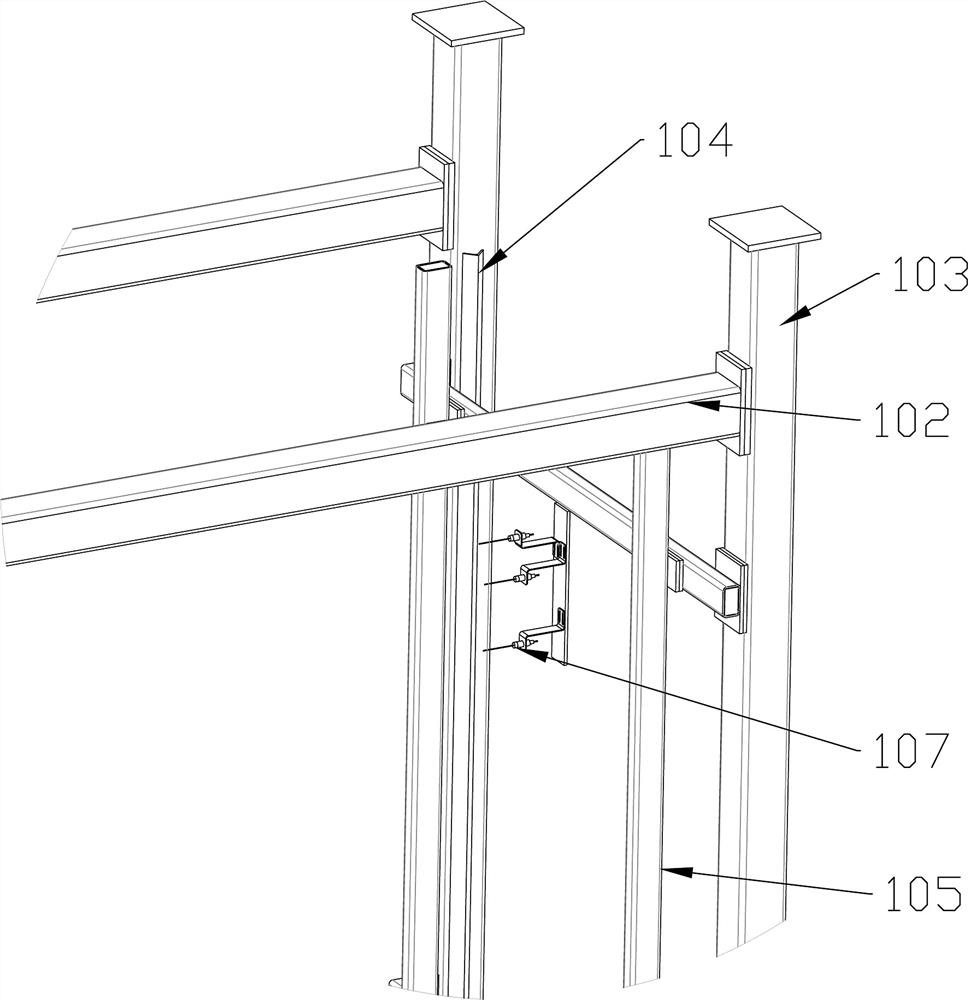

ActiveCN112607556AReduce distortionReduce loadElevatorsBuilding liftsElectric machineryStructural engineering

The invention provides a spliced variable-load hoisting mechanism which comprises a vertical outer frame. The vertical outer frame comprises a plurality of element frames spliced up and down, a driving assembly is arranged at the top end of the vertical outer frame, a lift car assembly is arranged in the vertical outer frame, the lift car assembly is slidably connected with the vertical outer frame, and the driving assembly drives the lift car assembly to move up and down. Counterweight mechanisms are arranged on the two sides of the vertical outer frame, connected with the vertical outer frame in a sliding mode, connected with the lift car assembly and opposite to the lift car assembly in sliding direction, the weight of a lift car is balanced through the counterweight mechanisms, motor loads are reduced, and energy consumption is reduced. The rated load of the lift car can be increased by increasing the number of counterweights of the counterweight mechanism, and a high-power motor is not needed. The lift car adopts lifting points and a plurality of guide wheels, so that the lift car does not incline when goods enter and exit, and the safety is high.

Owner:亿涛建设集团有限公司

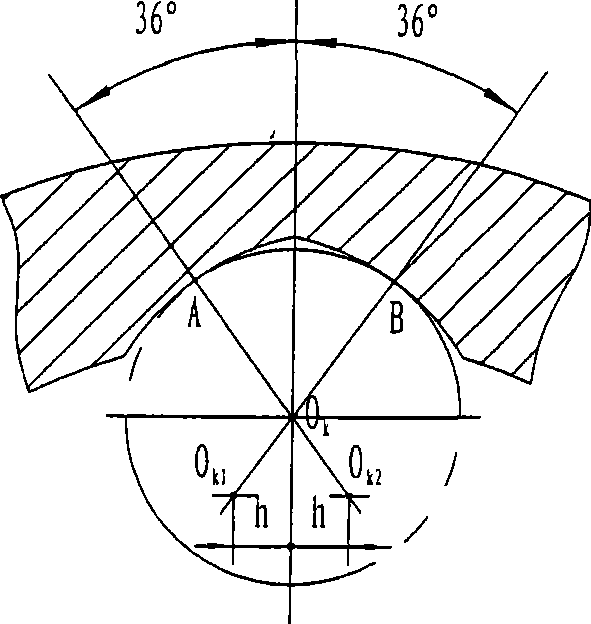

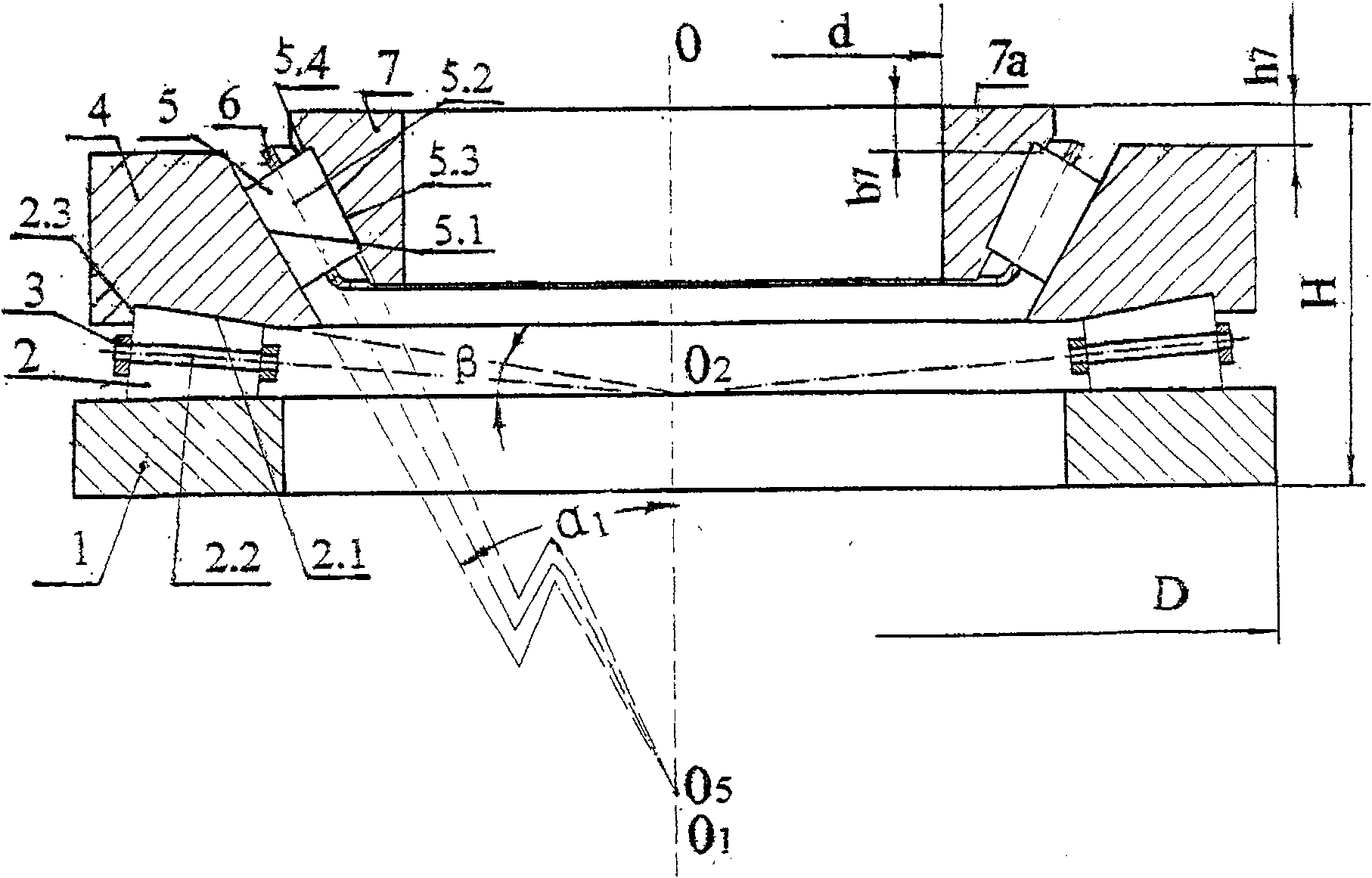

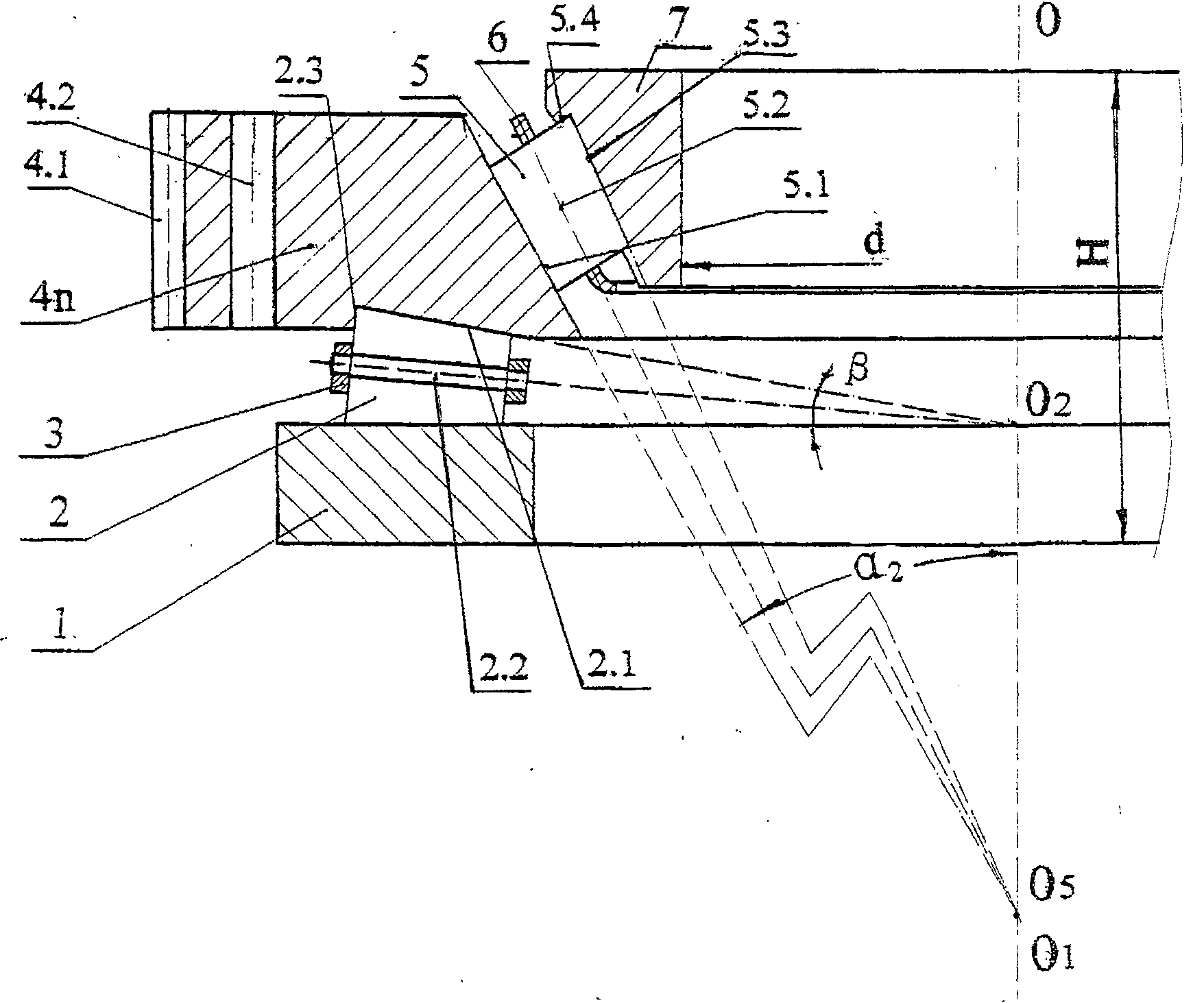

High precision thrust force centripetal combined conical roller bearing

ActiveCN101328933BCompact structureSmall sizeRoller bearingsBearing componentsNumerical controlRadar

The invention relates to a high-precision thrust centripetal combined tapered roller bearing, which is provided with a thrust block seat ring and a movable ring; a thrust tapered roller and a retaining frame are arranged between the thrust block seat ring and the movable ring; a centripetal thrust tapered roller and a retaining frame are arranged between a static inner ring and a movable ring, thereby combining a thrust tapered roller bearing for bearing axial load and a centripetal thrust tapered roller bearing for bearing radial load into a whole. The high-precision thrust centripetal combined tapered roller bearing realizes a capacity of bearing large thrust and large centripetal load; and a pressure adjusting ring is arranged to produce zero or negative clearance to meets the requirements that a numerical control vertical lathe has high precision, high rigidity and a rotating floor with a high rotational speed. Compared with the prior good three-row puncheon bearing of the INA corporation, the weight of the high-precision thrust centripetal combined tapered roller bearing is only 89.7 percent; but the axial load and the radial movable load are respectively 3.7 times and 2.1 times; and the axial static load and the radial static load are respectively 2.864 times and 1.54 times. As a raceway and a block side generatrix use special design, the tapered roller bearing removes the skid of the roller and has low operating temperature and high limit speed. The structure is used to process an inside diameter, the raceway, the block sides, etc. by once positioning and clamping and has high rotating precision; the radial jumping kinetic energy and the axial jumping kinetic energy can reach less than or equal to 3 mu m. The high-precision thrust centripetal combined tapered roller bearing can be used for a high-precision numerical control vertical lathe, a vertical milling and rotating floor, a radar rotating floor, etc.

Owner:成都科华重型轴承有限公司

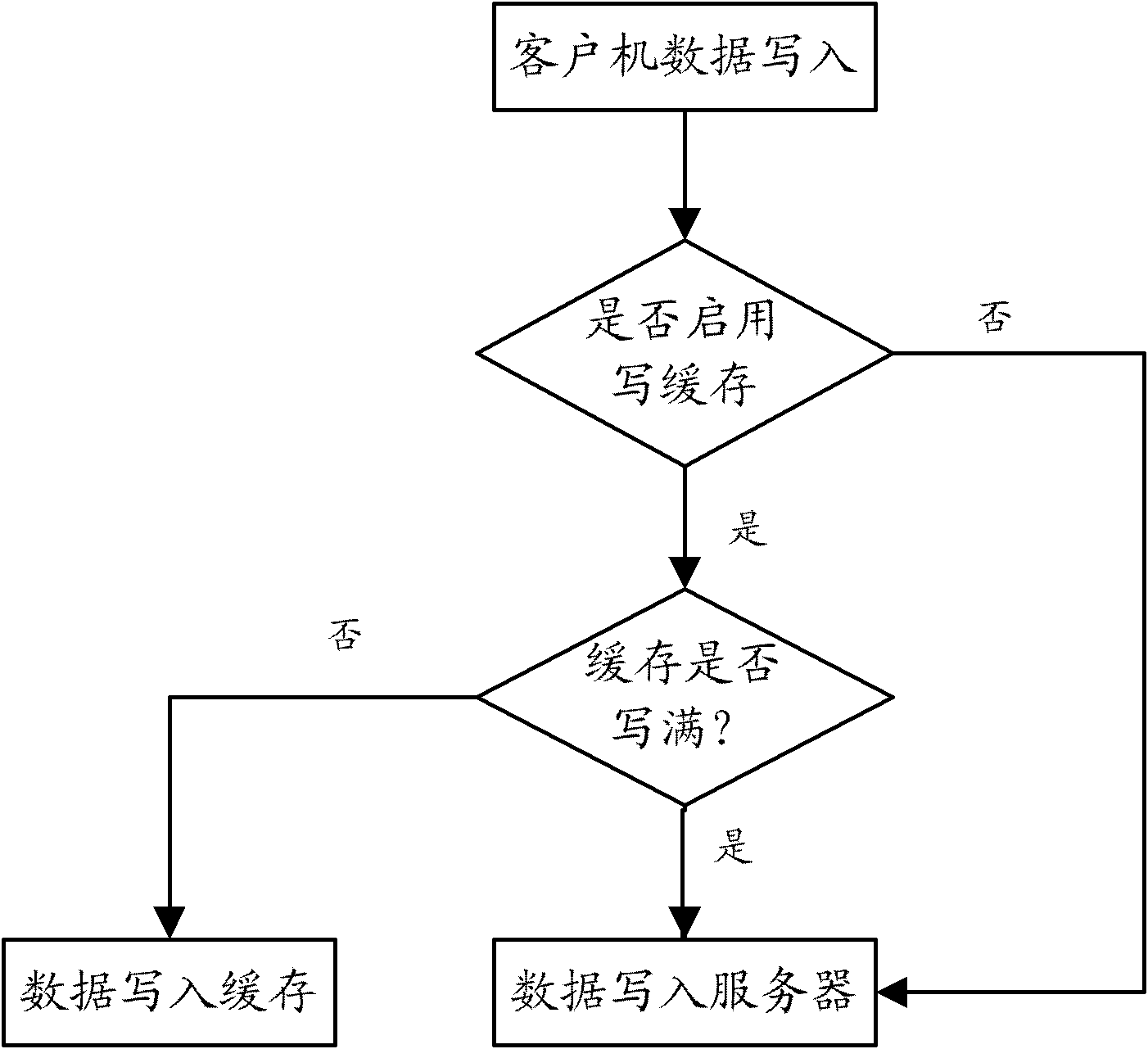

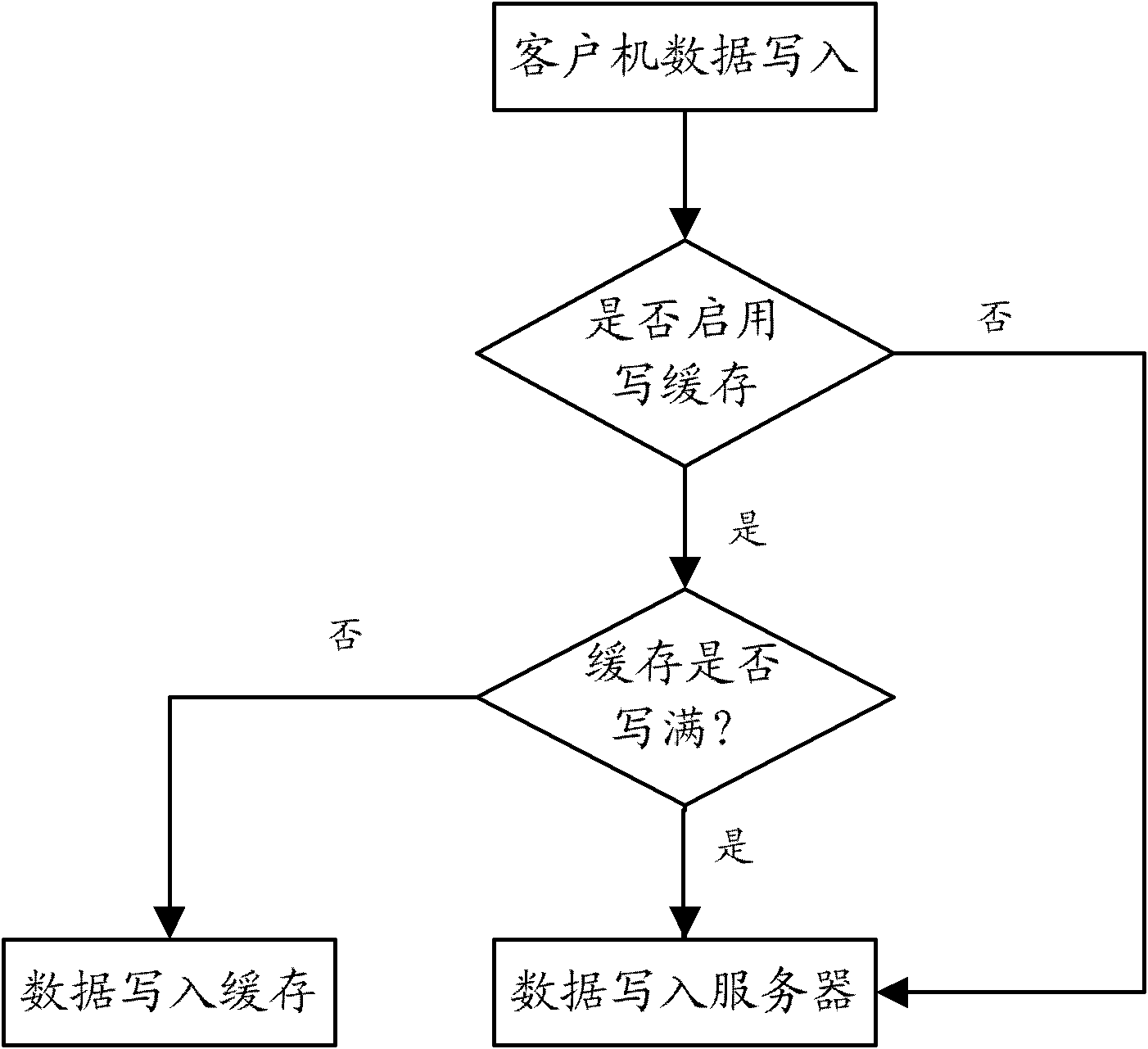

Method for realizing network disc local write cache control in disk-free system

InactiveCN102054031AReduce write pressureIncrease loadTransmissionSpecial data processing applicationsWork performanceClient-side

The invention relates to a method for realizing network disc local write cache control in a disk-free system, comprising: a client executes write cache configuration operation in a memory of a native machine according to parameters set by a server; and the client receives input data according to the input operation of a user, judges whether the native machine enables a write cache function or not, writes the input data into a remote server according to the judging result or judges whether the write cache region of the native machine is filled with data, and writes the input data into the remote server or directly writes the input data into the write cache region of the native machine according the judging result. By adopting the method for realizing network disk local write cache control in the disk-free system, the write pressure of the client to the server is reduced, the rated capacities of the server and the network are obviously expanded, the write pressure of the server is reduced to about one fifth of the original write pressure, the capacity of the server is improved by more than three times, the working performance is stable and reliable, and the application range is wider.

Owner:上海锐起信息技术有限公司

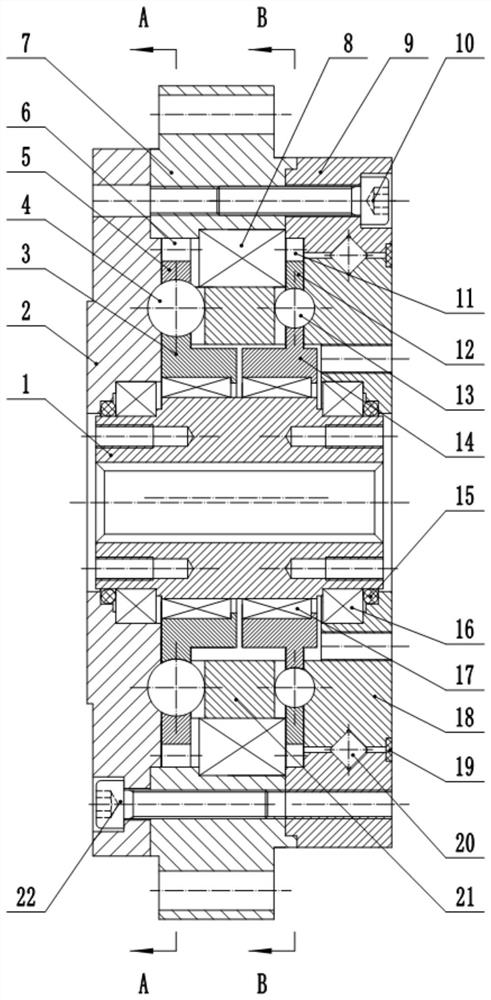

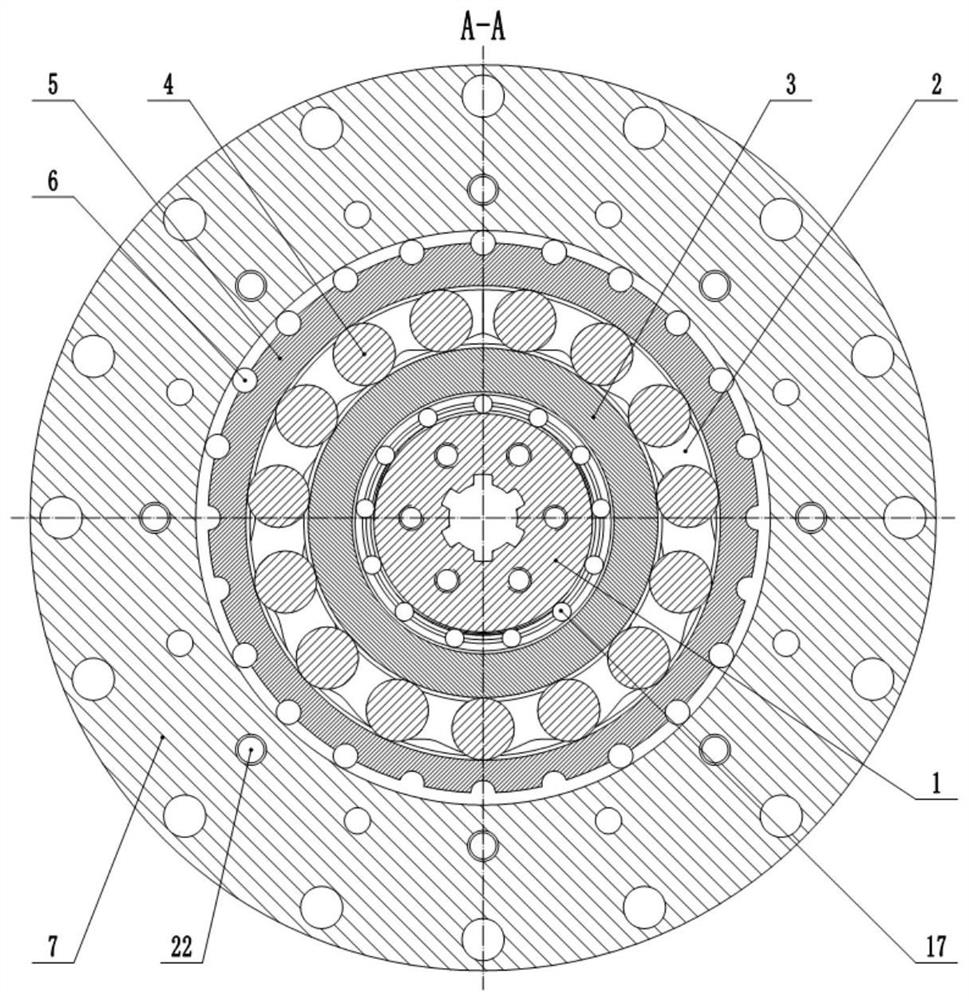

A self-balancing double-shock wave cam double-stage parallel planar movable gear reducer

ActiveCN112096825BWide reduction ratio rangeHigh torque/volume ratioGearingGearing detailsReduction driveReducer

The invention provides a self-balancing double-shock wave cam double-stage parallel planar movable gear reducer, which includes an input shaft, a first center wheel, a first inner shock cam, a first movable tooth, a first outer shock cam, a first Roller, second roller, second outer shock cam, second movable tooth, second inner shock cam, second center wheel, third center wheel, etc. Its transmission mechanism adopts double-stage parallel connection, and the calculation method of reduction ratio is more complicated, but it has a wider range of reduction ratio. At the same time, under the same reduction ratio, this configuration has more movable teeth, and the rated The load and impact resistance have been significantly improved; the form of double shock cams is adopted, that is, the movable teeth mesh with the inner and outer shock cams at the same time, thereby realizing the effect of full tooth meshing force transmission; the outer shock cams are opened outside A circle of roller grooves is used to place the roller counterweight, thereby reducing the eccentric mass of the entire mechanism. At the same time, the rollers provide the function of bearings and increase the stability of the transmission mechanism.

Owner:YANSHAN UNIV

A single-phase oil-immersed transformer

ActiveCN105513755BTo achieve the effect of oil changeSimple design and operation principleTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerEngineering

The invention provides a single-phase oil-immersed transformer which comprises a box body with a box cover, an iron core, coils, radiating tubes and an oil conservator. The iron core is a single-frame double-core column and is arranged at the center of the box body and immersed in oil, the single-frame double-core column is wounded with the coils respectively, the coils are led out of the box cover, leads are respectively sleeved with a high-pressure insulation sleeve and a low-pressure insulation sleeve, the radiating tubes are arranged on the side wall of the box body, and the oil conservator is arranged at the upper end of one side of the box body. The single-phase oil-immersed transformer further comprises a lifting mechanism, a power mechanism and an oil tank, wherein the oil tank is connected with the power mechanism and is arranged outside the box body. The single-phase oil-immersed transformer uses the oil in the box body as a power source through the power mechanism, drives the lifting mechanism to take out the iron core, stores the oil in the box body to the oil tank, facilitates iron core maintenance and oil change operation, saves the cost and also improves the overhaul efficiency.

Owner:JIANGSU MINGAN ELECTRIC

Method for filling and sealing rollers of integrated special-shaped crossed roller bearing

InactiveCN102425610ASolve fill methodSmall sizeBearing componentsClassical mechanicsStructural engineering

The invention relates to the technical field of bearings, and discloses a method for filling and sealing rollers of an integrated special-shaped crossed roller bearing. The method comprises the following steps of: forming a roller filling hole on a bearing outer ring (1) which corresponds to a roller path of a bearing inner ring (2) and is connected with a reduction box; filling the rollers into the roller filling hole (6) and then allowing the rollers to sequentially enter a roller path which is formed by combining the bearing outer ring and the bearing inner ring; and after the rollers are distributed on the roller path which is formed by combining the bearing outer ring and the bearing inner ring, inserting a spring pin (7) into a spring pin hole (10) on the end face of the bearing outer ring to ensure that a plunger (4) is integrated with the bearing outer ring so as to finish sealing. The manufactured integrated crossed roller bearing with large contour dimension for a micro reduction box can replace a separate crossed roller bearing, the filling problems of the rollers of the integrated crossed roller bearing, and an isolated block are solved, the rated load, rigidity and intensity of the bearing are increased, and bearing capacity and rotation speed of the whole reduction box can be improved.

Owner:LUOYANG JUCHUANG BEARING TECH

tappet

The plunger (1) has a cylindrical housing (2) receiving a roller (4) for starting a periodic stroke generator within a cylindrical inner casing (5) in a region of an upper annular end (3). A bridge piece (6) axially projects through the housing below the roller. A lower side (8) of the bridge piece faces towards a lower annular end (7) of the housing, and indirectly functions as a system for a plunger follower. Four notch-like discharges (9) longitudinally extend at the casing. The roller with ring edges (10) projects into the discharges.

Owner:SCHAEFFLER TECH AG & CO KG

Groove cutter drive with split inner wheel/integrated bearing

ActiveCN114787451ASave installation spaceLow costMechanical machines/dredgersExcavationsGear wheelRolling-element bearing

The invention relates to a drive device for a construction machine, in particular for a groove cutting machine, comprising a connecting support and a wheel support, which is rotatably supported on the connecting support via at least one rolling bearing and which can be rotatably driven relative to the connecting support by means of a drive motor via at least one gear stage, a gear of the gear stage is supported in a non-rotatable manner on the connecting bracket and / or on a bearing guard rigidly connected to the connecting bracket by means of a flexible and / or movable bearing element in a radially displaceable and / or tiltable manner relative to the connecting bracket, the gear is disposed within the connecting bracket and is in rolling engagement and / or meshing with at least one other gear.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

Conductive semi-rigid bearing

ActiveCN114542602AImprove conductivityLower resistanceRolling contact bearingsBearing assemblyElectrical resistance and conductanceRubber ring

The invention discloses a conductive semi-rigid bearing which comprises an inner ring, a roller path is arranged on the outer wall of the inner ring, a roller is arranged on the roller path, the conductive semi-rigid bearing further comprises an outer ring, a first roller path ring and a second roller path ring are arranged between the outer ring and the roller, and the first roller path ring and the second roller path ring are arranged on the two sides of the roller respectively. Each of the first roller path ring and the second roller path ring comprises a fitting part used for abutting against the peripheral surface of a roller, an elastic rubber ring is arranged between one end of the outer ring and the first roller path ring in an abutting manner, an abutting part is formed on the outer ring corresponding to the position of the second roller path ring, and the abutting part abuts against the second roller path ring. The bearing is simple in structure, reasonable in layout and convenient to process, and can meet the use requirements of lower electric conduction or resistance of the bearing.

Owner:C&U CO LTD +2

Splicing variable load lifting mechanism

ActiveCN112607556BReduce distortionReduce loadElevatorsBuilding liftsElectric machineryStructural engineering

The invention provides a splicing type variable load lifting mechanism, which includes a vertical outer frame, the vertical outer frame includes a plurality of meta-frames spliced up and down, the top of the vertical outer frame is provided with a drive assembly, and the vertical outer frame is equipped with a car Car assembly, the car assembly is slidingly connected with the vertical outer frame, the drive assembly drives the car assembly to move up and down, there are counterweight mechanisms on both sides of the vertical outer frame, the counterweight mechanism is slidingly connected with the vertical outer frame, and the counterweight mechanism is connected to the vertical outer frame. The car components are connected, and the sliding direction of the counterweight mechanism is opposite to that of the car components. The weight of the car is balanced by the counterweight mechanism, which reduces the load on the motor and reduces energy consumption; the rated load of the car can be increased by increasing the number of counterweights in the counterweight mechanism. , no need to replace the high-power motor; the car adopts lifting points and multiple guide wheels, the car will not tilt when the goods enter and exit, and the safety is high.

Owner:亿涛建设集团有限公司

A single-phase oil-immersed transformer and its special iron core

ActiveCN105469945BSolve the gap problemGuaranteed uptimeTransformers/inductances coolingTransformers/inductances magnetic coresDual coreTransformer

The invention provides a single-phase oil-immersed transformer and a special iron core therefor. The single-phase oil-immersed transformer comprises a box body with a box cover, an iron core, a radiating pipe, an oil conservator, a lifting mechanism, a power mechanism and an oil tank, wherein the iron core is a single-frame dual-core column with a groove, is arranged at the center of the box body and is immersed by an oil body; a coil is led out of the box cover; a high-voltage insulating sleeve and a low-voltage insulating sleeve respectively sleeve a lead; the radiating pipe is arranged on the side wall of the box body; the oil conservator is arranged at the upper end of one side of the box body; the lifting mechanism is arranged below the iron core; the bottom end of the lifting mechanism is fixedly connected with the box body; the power mechanism is connected with the lifting mechanism; the oil tank is connected with the power mechanism; and the oil tank is arranged outside the box body. The single-phase oil-immersed transformer can drive the lifting mechanism to take out the iron core by taking the oil in the box body as a power source through the power mechanism and stores the oil in the box body into the oil tank, so that maintenance of the iron core and oil-change operation are facilitated; the cost is saved; and the maintenance efficiency is also improved.

Owner:JIANGSU MINGAN ELECTRIC

A roller type slide button switch

ActiveCN105097349BNot easy to wearImprove the feel of the wrenchTumbler/rocker switch detailsToggle switchEngineering

The invention provides a roller-type slider toggle switch. A movable contact assembly is arranged on a base of a base assembly through a support, a toggle assembly is movably arranged in a metal housing of a reversing device, the lower end of a handle of the reversing device is inserted into a toggle groove of the toggle assembly, and a latch handle assembly is fixedly arranged at the upper end of the handle; a toggle of the toggle assembly is matched with a limiting block of the base assembly through saw teeth, a roller is arranged on a movable contact of the movable contact assembly, and the base assembly is fixedly connected with the metal housing through the base. The roller-type slider structure is made of stainless steel, so as to solve the problems that the slider of the conventional toggle switch, which is made of hemispherical plastic, is easy to abrade and high in requirements for finish and machining precision; the slider is unlikely to abrade, so that the pull handfeel of the toggle switch is greatly improved, meanwhile, the rated load of the switch is also improved, the toggle switch can bear high current but the slider part is not burnt or deformed.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

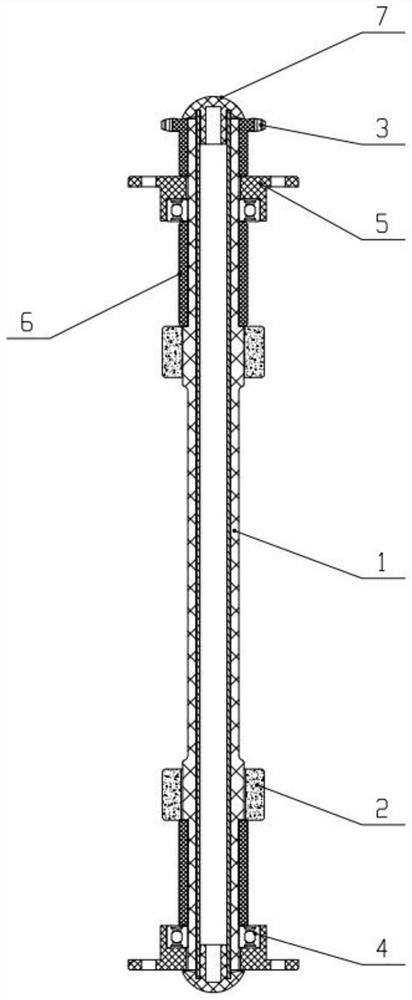

Shaft assembly for lithium battery material production and combination method thereof

PendingCN113895900AReduce security risksAvoid pollutionCouplings for rigid shaftsRollersMechanical engineeringBattery cell

The invention discloses a shaft assembly for lithium battery material production. The shaft assembly comprises a conveyance shaft, wherein the conveyance shaft comprises a hollow supporting shaft and a wrapping layer wrapping the outer surface of the supporting shaft, the conveyance shaft is sleeved with two rollers, one end of the conveyance shaft is sleeved with a transmission wheel, bearings are arranged between the transmission wheel and the rollers, and bearing seats matched with the bearings are arranged outside the bearings. The shaft assembly for lithium battery material production can meet the use requirement of customized conveyance in special industries and the special requirement of multi-product production, and reduce the potential safety hazard of the use environment; in the production process of the lithium battery material, the low-zinc, low-copper and high-temperature-resistant conveyance requirements can be met, pollution from external metal elements in the raw material conveyance process is avoided, the sintering quality of the raw materials is guaranteed, and the potential safety hazard of battery discharge caused by raw material pollution in the production process is reduced; and the rated conveyance load can be increased only by adjusting the thickness of the coating layer according to the mass of conveyed products, machining of a metal piece is avoided, and the production cost is saved.

Owner:NANJING PANDA ELECTRONICS +1

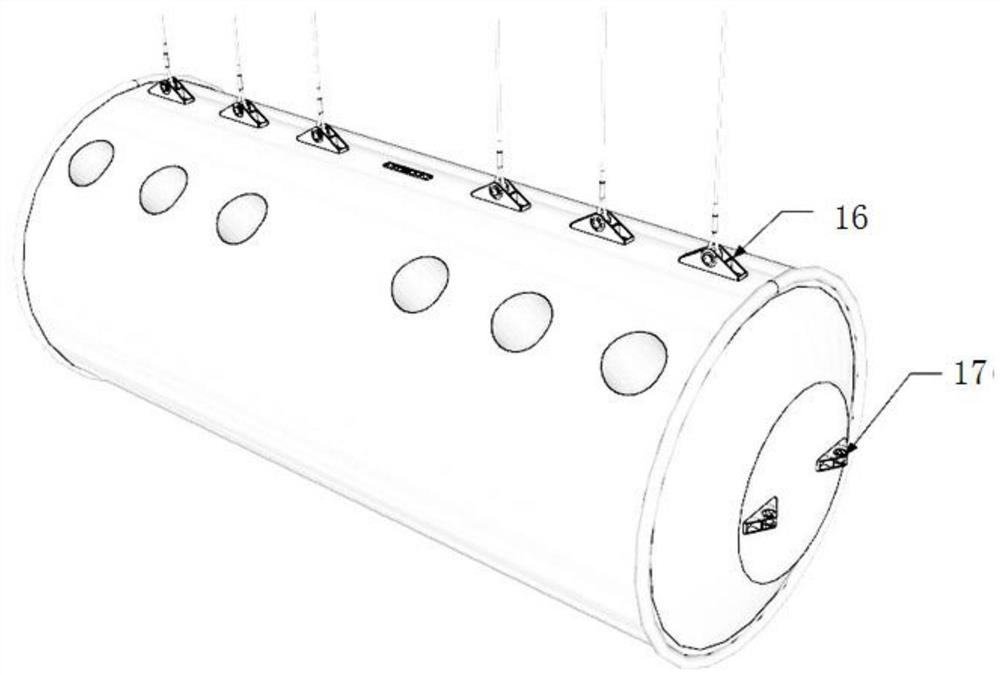

Offshore test platform of large-tonnage sunken ship salvage hydraulic buffering synchronous lifting system

The invention discloses a large-tonnage sunken ship salvage hydraulic buffering synchronous lifting system offshore test platform, which belongs to the technical field of salvage, and comprises a barge, a plurality of groups of synchronous lifting devices, a sunken ship simulator and a monitoring system, the synchronous lifting device is connected with the shipwreck simulator through a steel wire rope. According to the offshore test platform of the large-tonnage sunken ship salvage hydraulic buffering synchronous lifting system, the offshore test platform is provided, reasonable simplification treatment is carried out by adopting a sunken ship overall salvage scheme of the hydraulic buffering synchronous lifting system, and an offshore simulation test of sunken ship overall salvage is carried out; key performance indexes such as rated load, lifting and descending speed, buffer compensation performance and synchronization precision of the whole hydraulic buffer synchronous lifting system are tested and verified more systematically and accurately, and a more accurate and reliable technical basis is provided for scheme design of formal salvage engineering.

Owner:交通运输部上海打捞局

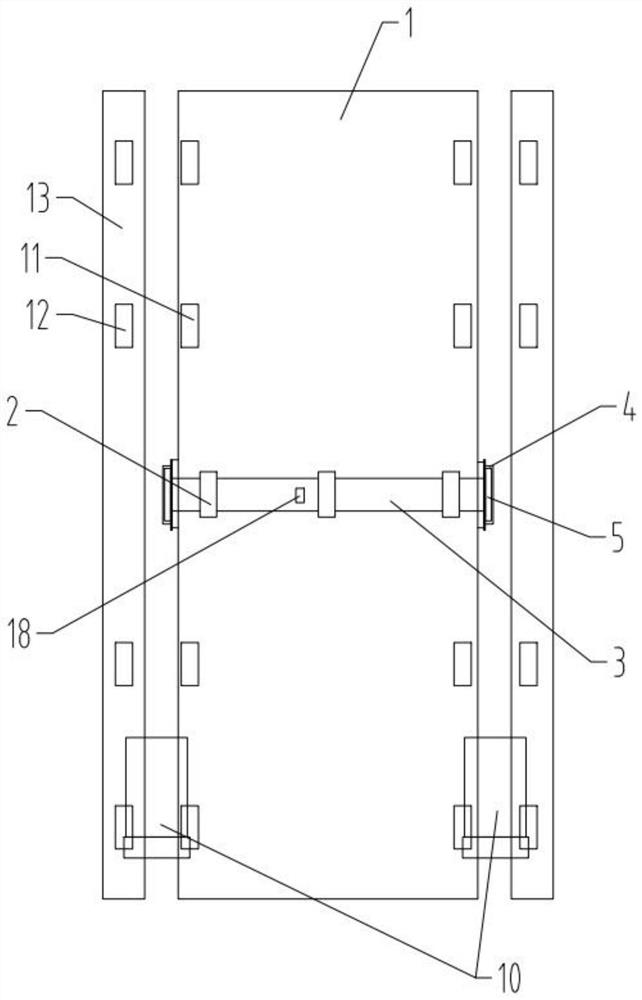

Surgical instrument comprising bearing

PendingCN112512443AImprove usabilityImprove reliabilityTurning machine accessoriesSurgeryEngineeringReoperative surgery

Provided is a surgical instrument (1), in particular a surgical milling or drilling instrument, comprising an instrument shank (2) having an effector (4) at its distal end portion and a coupling structure (6) at its proximal end portion. The coupling structure is designed to be selectively coupled, is axially fixedly and for conjoint rotation, to a drive received in a housing, preferably a handpiece, in order to thereby transmit a rotation of the drive to the instrument shank (2), so that at least one rotary bearing (8) for rotatably supporting the instrument shank (2) on the housing, preferably handpiece, is located between the instrument shank (2) and the housing, preferably handpiece. The rotary bearing (8) and the instrument shank (2) are combined in a unit which, for coupling to the drive can be introduced into the housing, and for uncoupling from the drive can be withdrawn from the housing, as a single unit.

Owner:AESCULAP AG

Large-load freight elevator

PendingCN114803794AGuaranteed uptimeImprove synchronicityElevatorsBuilding liftsReciprocating motionElectric machinery

The heavy-load freight elevator comprises a lift car, a bearing seat and a synchronizing shaft rotationally connected with the bearing seat are arranged at the top of the lift car, the synchronizing shaft extends to the two sides of the lift car, chain wheels are arranged at the two ends of the synchronizing shaft correspondingly, upper tensioning wheels are arranged above the chain wheels, and lower tensioning wheels are arranged above the chain wheels. A lower tensioning wheel is arranged below the chain wheel; an upper chain fixing device corresponding to the chain wheel is arranged at the top of the elevator shaft, a lower chain fixing device corresponding to the chain wheel is arranged at the bottom of the elevator shaft, a chain is arranged between the upper chain fixing device and the lower chain fixing device, and the chain is sequentially meshed with the upper tensioning wheel, the chain wheel and the lower tensioning wheel. Traction main machines are arranged on the two sides of the lift car correspondingly, and the traction main machines drive the lift car to reciprocate up and down along the chain. The double-motor driving and chain wheel and chain meshing structure improves the operation synchronism of the two sides of the lift car, the symmetrical structure on the two sides enables the lift car to operate more stably, and the load capacity of an elevator is improved.

Owner:CANNY ELEVATOR

Thrust roller bearing

PendingCN113374793ATake up a lot of spaceIncrease the rated loadRoller bearingsBearing componentsEngineeringStructural engineering

The invention relates to the technical field of bearings, in particular to a thrust roller bearing which comprises a retainer and a plurality of rollers, wherein the retainer comprises an annular outer diameter check ring and an annular inner diameter check ring, a plurality of connecting beams with large outer ends and small inner ends are distributed between the outer diameter check ring and the inner diameter check ring in the circumferential direction at unequal intervals, and a window used for containing the rollers is formed between every two adjacent connecting beams; at least two of the connecting beams are main beams, and the other connecting beams are auxiliary beams. The design that the main beams are combined with the auxiliary beams is adopted, the occupied space of the main beams is increased by reducing the occupied space of the auxiliary beams, and the rollers are distributed between the outer diameter check ring and the inner diameter check ring in the circumferential direction in a non-equal-interval mode, so that the number of the rollers is increased in a limited space, the rated load of the bearing is improved, the service life of the bearing is prolonged, the application range of the bearing is widened, meanwhile, the main beams can be connected between the outer diameter check ring and the inner diameter check ring in a large size, and the overall strength of the retainer is guaranteed.

Owner:JIANG SU NAN FANG BEARING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com