Patents

Literature

202results about How to "Solve the gap problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

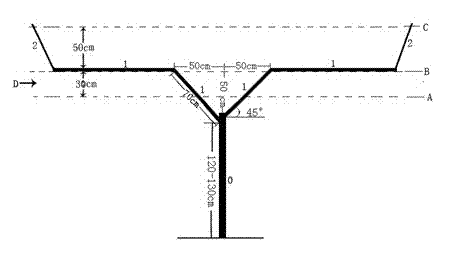

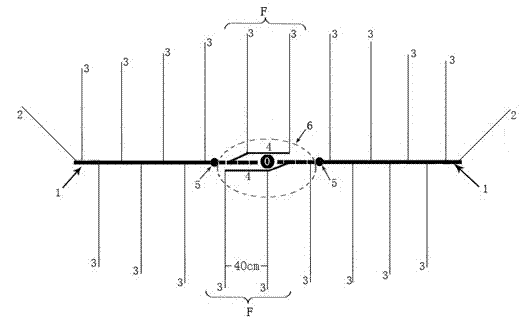

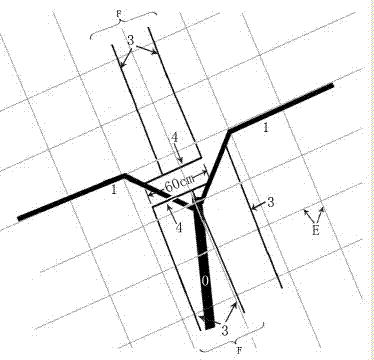

Novel shed frame pear tree shape and reshaping method thereof

ActiveCN103081770AAchieve standardizationSimple resultCultivating equipmentsHorticulture methodsTree trunkPear tree

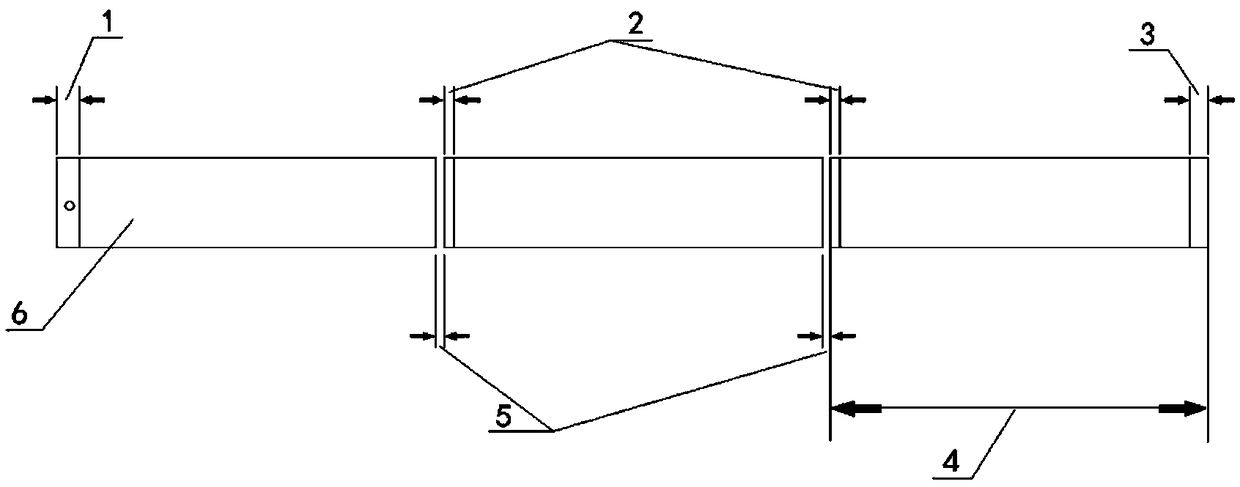

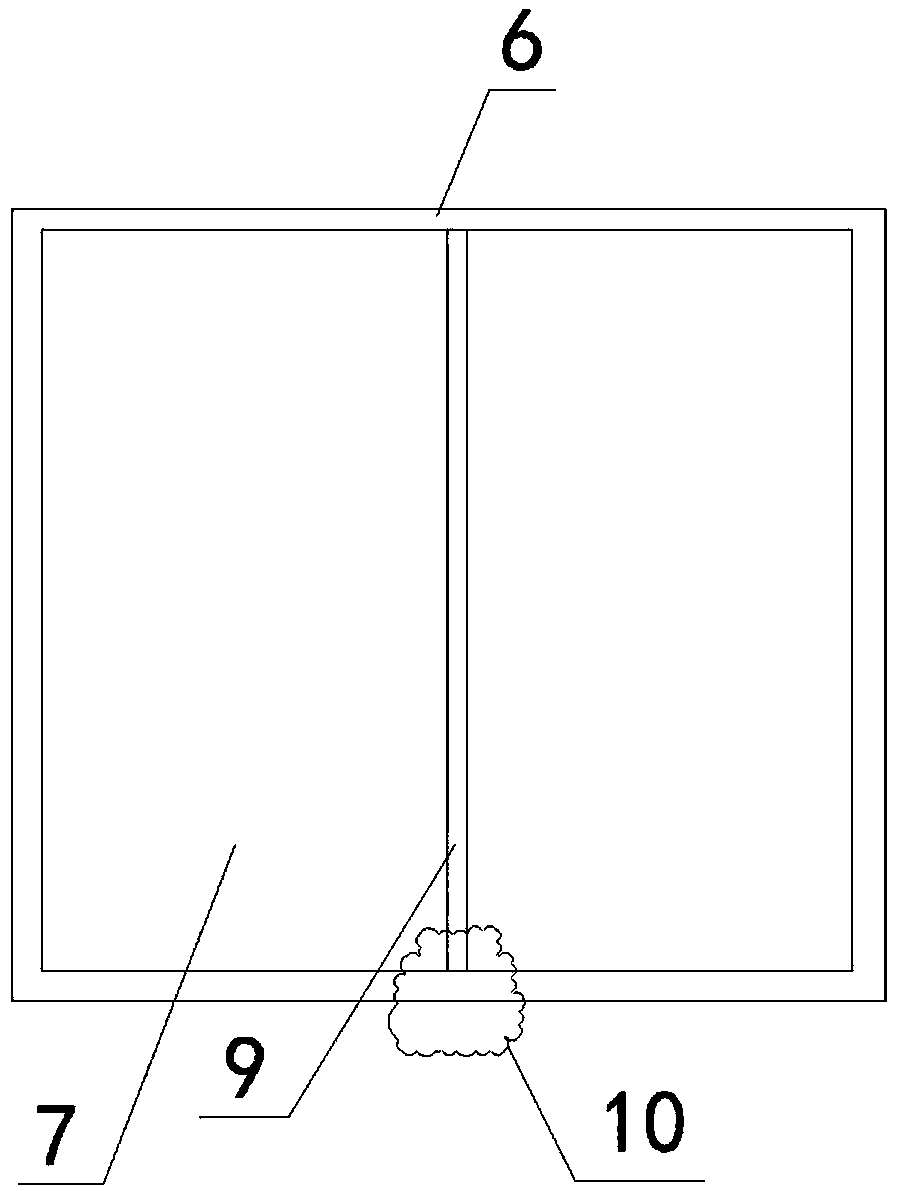

The invention provides a pear tree two-arm direct-motion type shed frame tree shape which comprises a tree trunk. The tree trunk has two boughs which grow in a direct-motion mode, and base angles of the two boughs are 45 degrees. When reaching a frame-climbing point, the boughs are fixed on a horizontal shed frame in a direct-motion mode, and extended long branches of the boughs are guided onto an elevation guide line in a perpendicular mode. The boughs have long placed fruit branches which are arranged in parallel and vertically extend into intervals. Before the two boughs climb a frame, two horizontal robust side position branches which are pulled along the reverse direction to be parallel to the boughs after the horizontal robust side position branches grow upward to the frame face. The side position branches have F-shaped single-shaft long placed type fruit branches which are arranged in parallel and vertically extend to the intervals. The tree shape only has the two boughs, and therefore the problems that an inclined crown appears easily in a three-bough tree shape and the main boughs intersect are solved. The two boughs oppositely extend in a direct-motion mode and do not influence each other. The two-bough tree shape is easy to reshape, and the two boughs are easy to form after the trunk is fixed. The phenomenon of lack of branches appears in a three-bough shed frame due to the fact that sprout force of a pear tree is weak. The three shape has the advantages that cultivation density is high, early-stage output is high, light conditions are good, the branches are easy to arrange in an ordered mode, uniformity of fruit quality is high, and standardization is easy to achieve.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

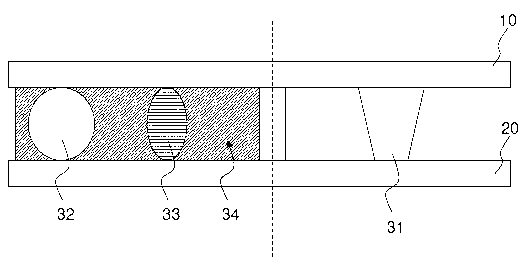

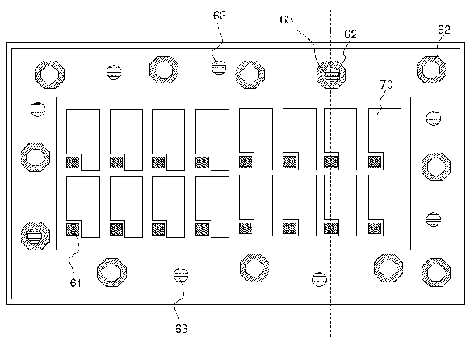

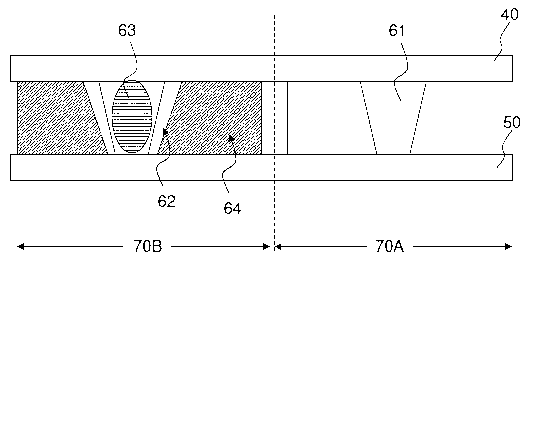

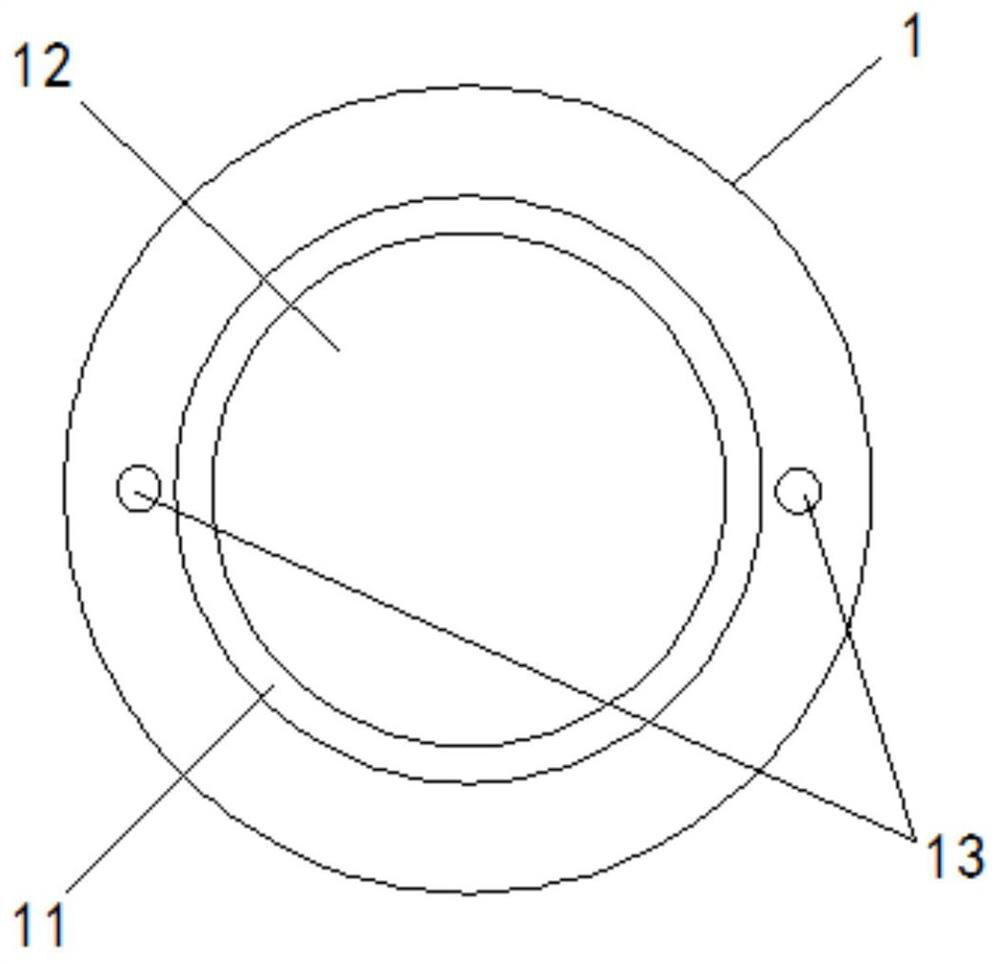

Photo spacer and liquid crystal display panel

The invention provides a photo spacer and a liquid crystal display panel. The photo spacer is used for a display panel, and the display panel comprises an upper substrate, a lower substrate, a plurality of liquid crystal boxes, a plurality of fist photo spacers, a plurality of second photo spacers, a plurality of conducting particles and seal. The first photo spacers are arranged in a first seal area of the display panel and comprise first through holes, the conducting particles are arranged in the seal area corresponding between the upper substrate and the lower substrate, and the second photo spacers are correspondingly arranged in a first active area of the display panel. The seal is filled between the first photo spacers and the conducting particles, and when the conducting particles vertically correspond to the first photo spacers, the conducting particles are embedded in the through holes. The photo spacer can replace a silicon photo spacer, and the problem that spaces of the liquid crystal boxes are influenced due to stacking of the photo spacers and complete cycle conducting golden spacers is solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

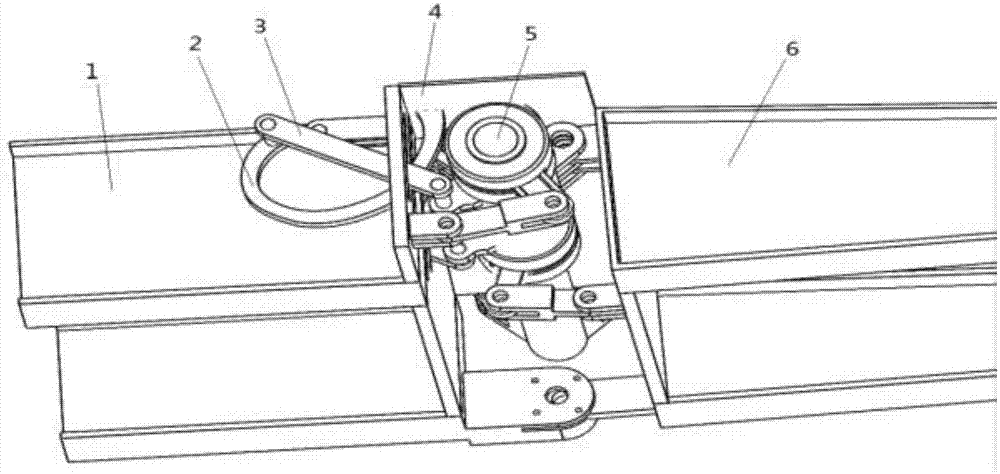

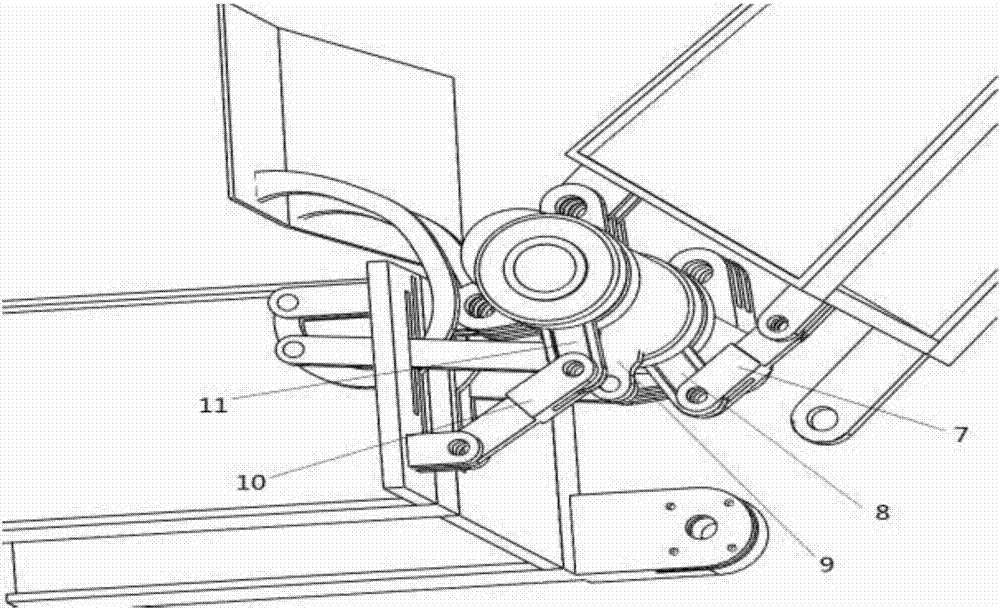

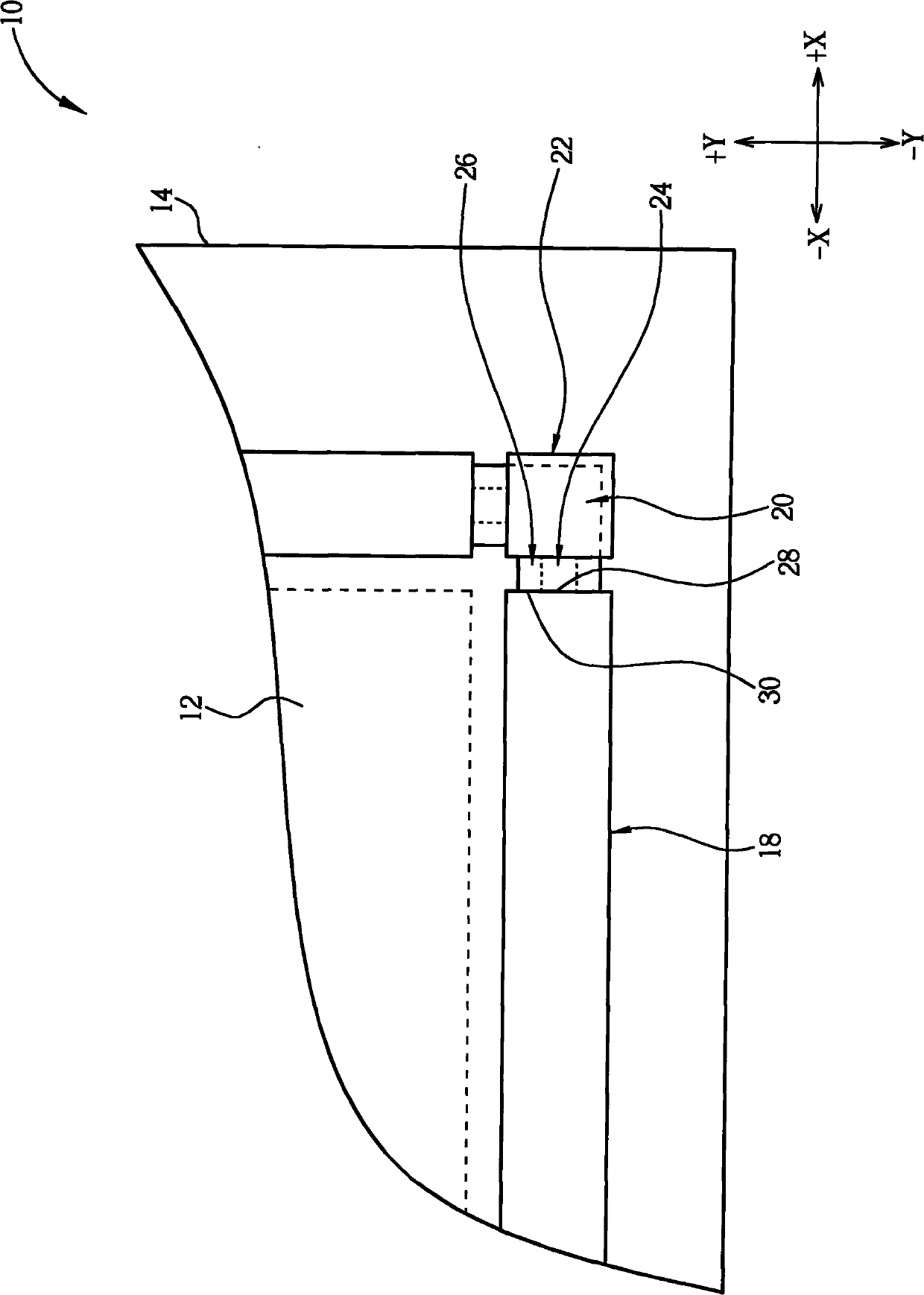

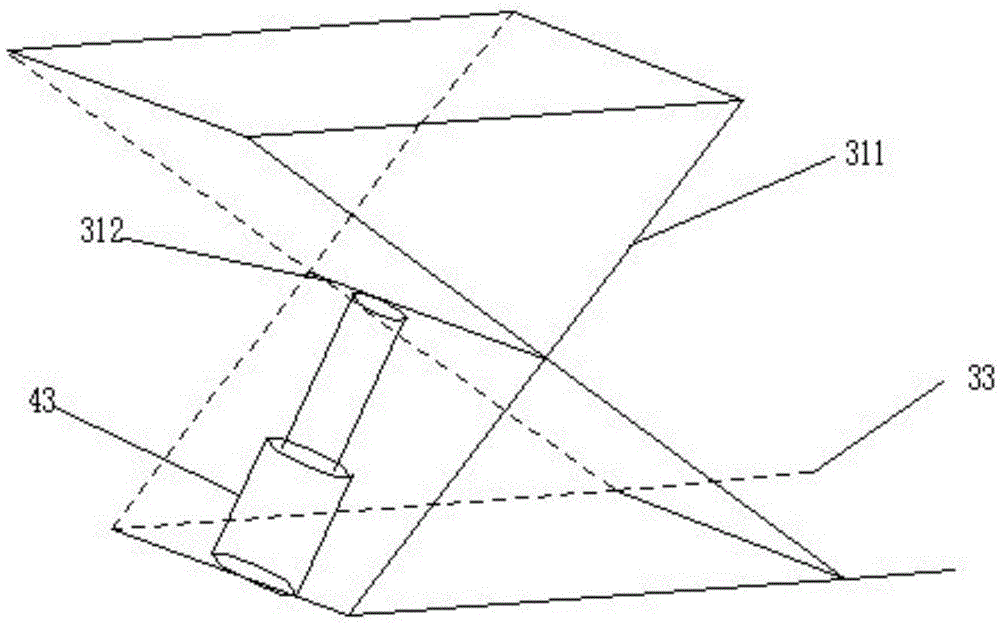

Aircraft wing folding mechanism and covering cap mechanism based on aircraft wing folding mechanism

The invention discloses an aircraft wing folding mechanism and a covering cap mechanism based on the aircraft wing folding mechanism and mainly solves the problems in the prior art of unevenness of wing joint surfaces due to the existing wing folding, absence of a covering cap and complex structure of the covering cap. The aircraft wing folding mechanism comprises an inner wing, an outer wing anda folding actuator, wherein the folding actuator is arranged between the inner wing and the outer wing and is respectively hinged with the upper parts of the end surfaces of the inner wing and the outer wing; the folding actuator is provided with two output ends; and a first stage rotation pair is hinged between one output end and the lower part of the end surface of the inner wing, and a second stage rotation pair is hinged between the other output end and the lower part of the end surface of the outer wing. By virtue of the technical solution, the aircraft wing folding mechanism and the covering cap mechanism based on the folding mechanism achieve the purpose of evenness of the wing joint surfaces and have high practical value and popularization value.

Owner:北京新兴东方航空装备股份有限公司

Formula and production technology of polyurethane low-speed solid tire

The invention relates to a formula and a production technology of a polyurethane low-speed solid tire and belongs to the technical field of high-polymer material products. The formula is characterized by comprising the following raw materials in parts by weight: 0.8-1.5 parts of polyester polyol, 0.15-0.25 parts of toluene diisocyanate, and 0.1-0.15 parts of curing agent component. The production technology is characterized by specifically comprising the following steps: dehydrating the polyester polyol and adding toluene diisocyanate to firstly obtain a prepolymer; and respectively feeding the prepolymer and the curing agent components into tanks A and B of a casting machine, mixing according to the weight parts and casting into a tire casting die, performing casting forming, and performing secondary vulcanization. The integrated solid tire having completely identical internal material, external material and performances is prepared by virtue of the formula technology and the formula, and the technology can be realized by performing primary cast forming through the tire casting die, and the production technology of the tire can be greatly simplified.

Owner:日照悍马轮胎股份有限公司

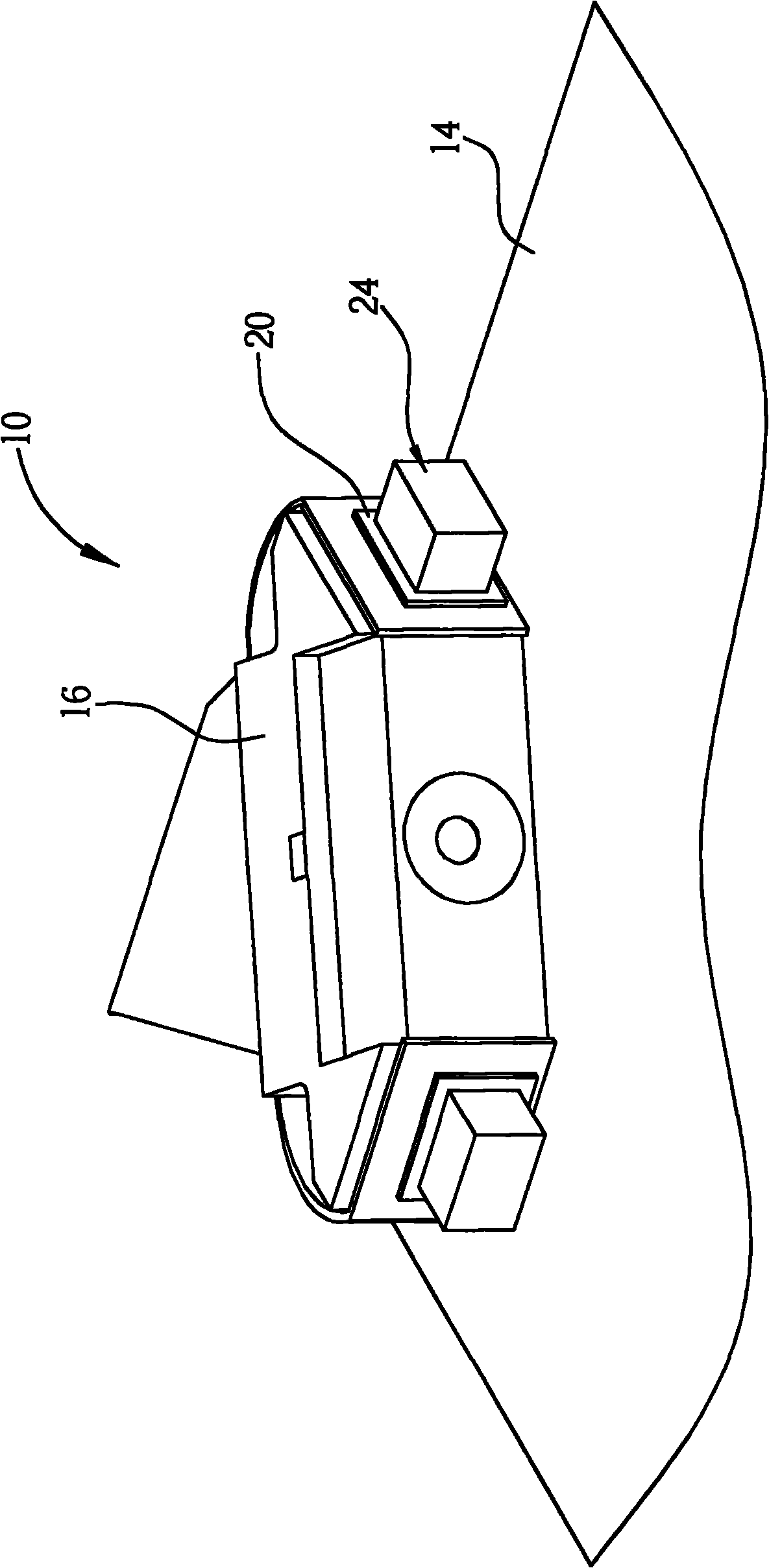

Optical touch module

InactiveCN101907958AAvoid light leakageAnti-blocking of light leakageInput/output processes for data processingLight guideThermal expansion

The invention discloses an optical touch module, comprising a touch surface, a substrate, at least one optical sensor, a light guide structure, an elastic element and a light emitting unit. The touch surface is positioned on the substrate, the optical sensor captures the image of a touch zone towards the touch surface; the light guide structure is arranged along one side of the touch surface to guide light into the touch surface. The elastic element is arranged at one end part of the light guide structure. The light emitting unit is arranged between the light guide structure and the elastic element, and is butted against the elastic element to allow the light exit surface of the light emitting unit to be closely adjacent to the light incoming surface of the light guide structure substantially. Therefore, the optical touch module provided by the invention can solve the problem that gaps appear between the light emitting unit and the light guide structure due to that the light guide structure has structural distortion caused by expansion on heating and contraction on cooling under different use environments, provides good assembling effect and effectively eliminate light leakage problem.

Owner:QISDA SUZHOU +1

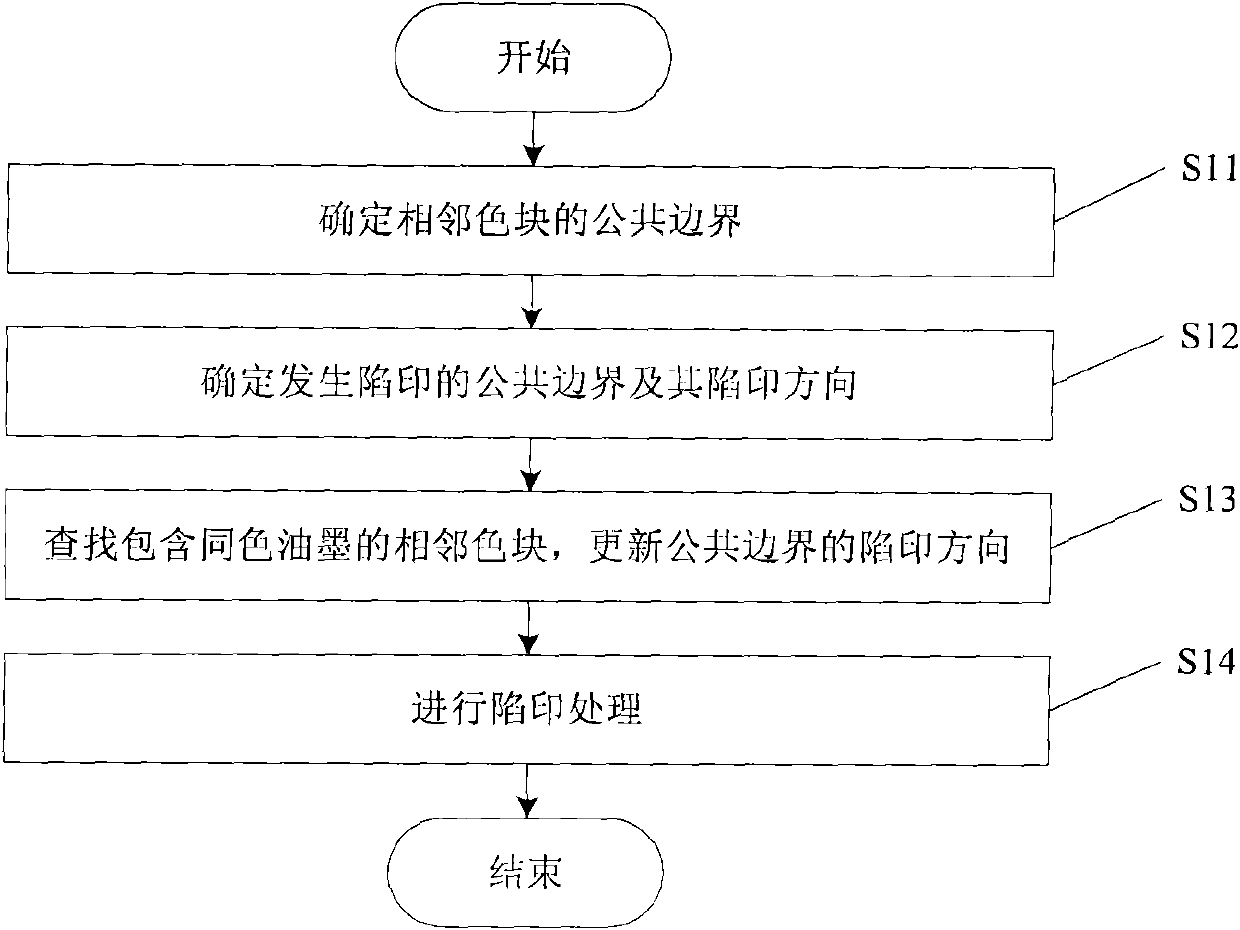

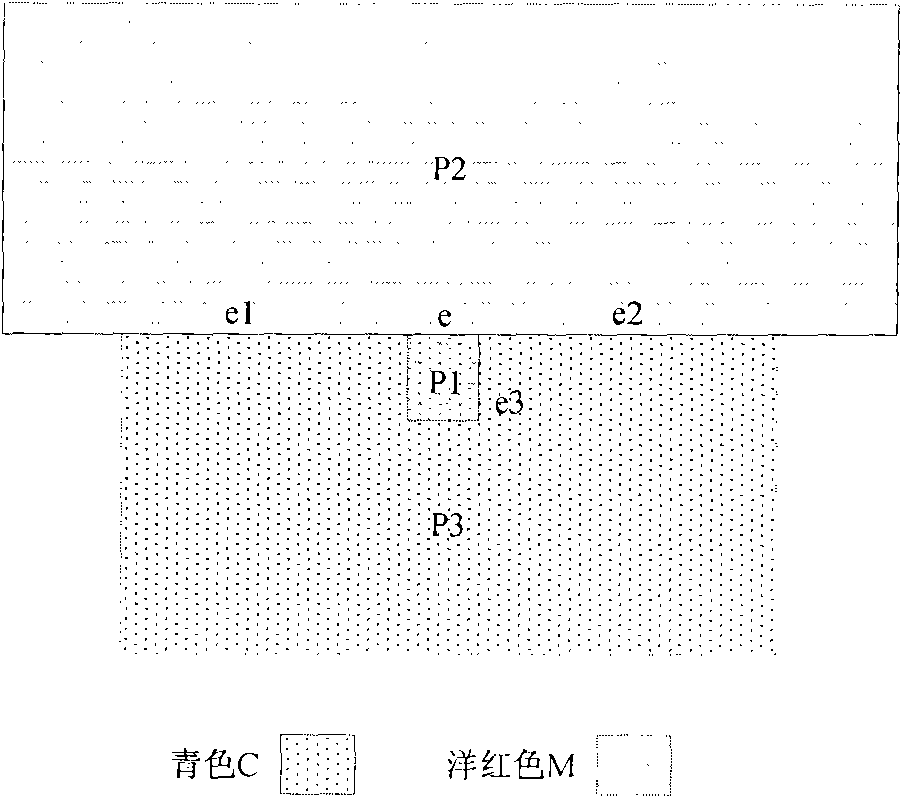

Trapping method and device

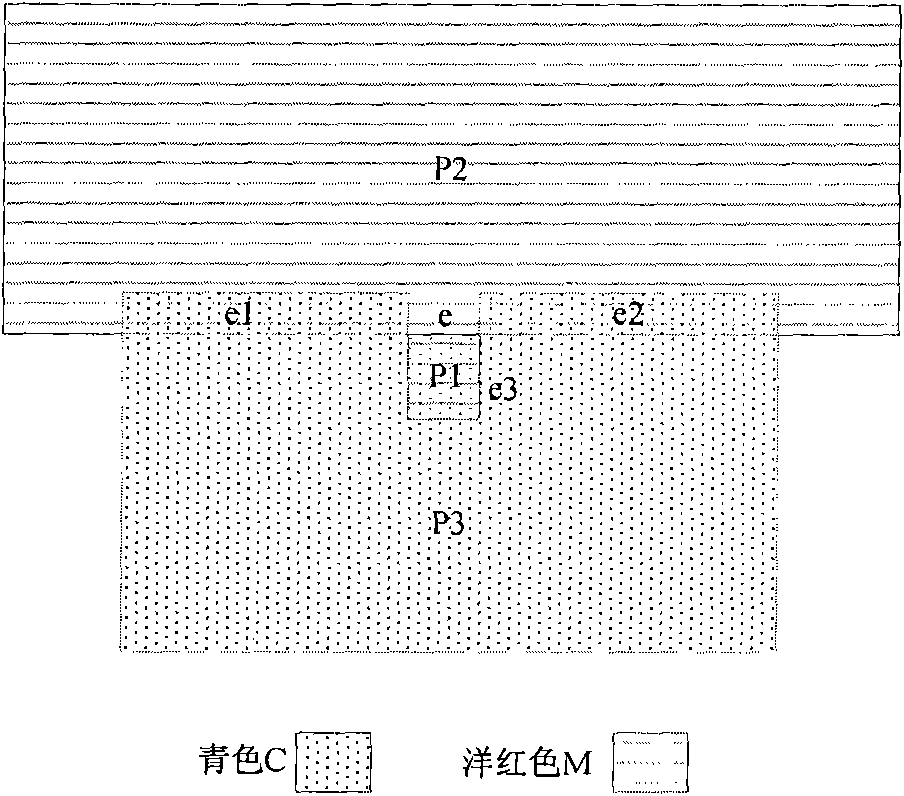

ActiveCN102088540ASolve the gap problemImprove aestheticsPictoral communicationTrapping regionComputer science

The invention discloses a trapping method and device, which belong to the technical field of package printing. The method comprises the following steps of: firstly, determining trapping directions of public boundaries which meet a trapping processing condition; secondly, sequentially judging each non-trapped public boundary, and determining that a public boundary e is trapped in the same trappingdirection as a boundary e1 if oil ink of a color lump P1 on one side of the public boundary e comprises oil ink of a color lump P2 on the other side of the public boundary e and oil ink of an adjacent color lump P3 on the other side of the adjacent boundary e1 on the P2 on the public boundary e is oil ink obtained by subtracting the lump P2 from the color lump P1; and lastly, performing trapping processing in the updated trapping direction. By applying the method and the device, the problem of breaches on trapping regions of adjacent color lumps comprising the same type of oil ink during trapping can be solved, and the appearances of the trapping regions are enhanced.

Owner:PEKING UNIV +1

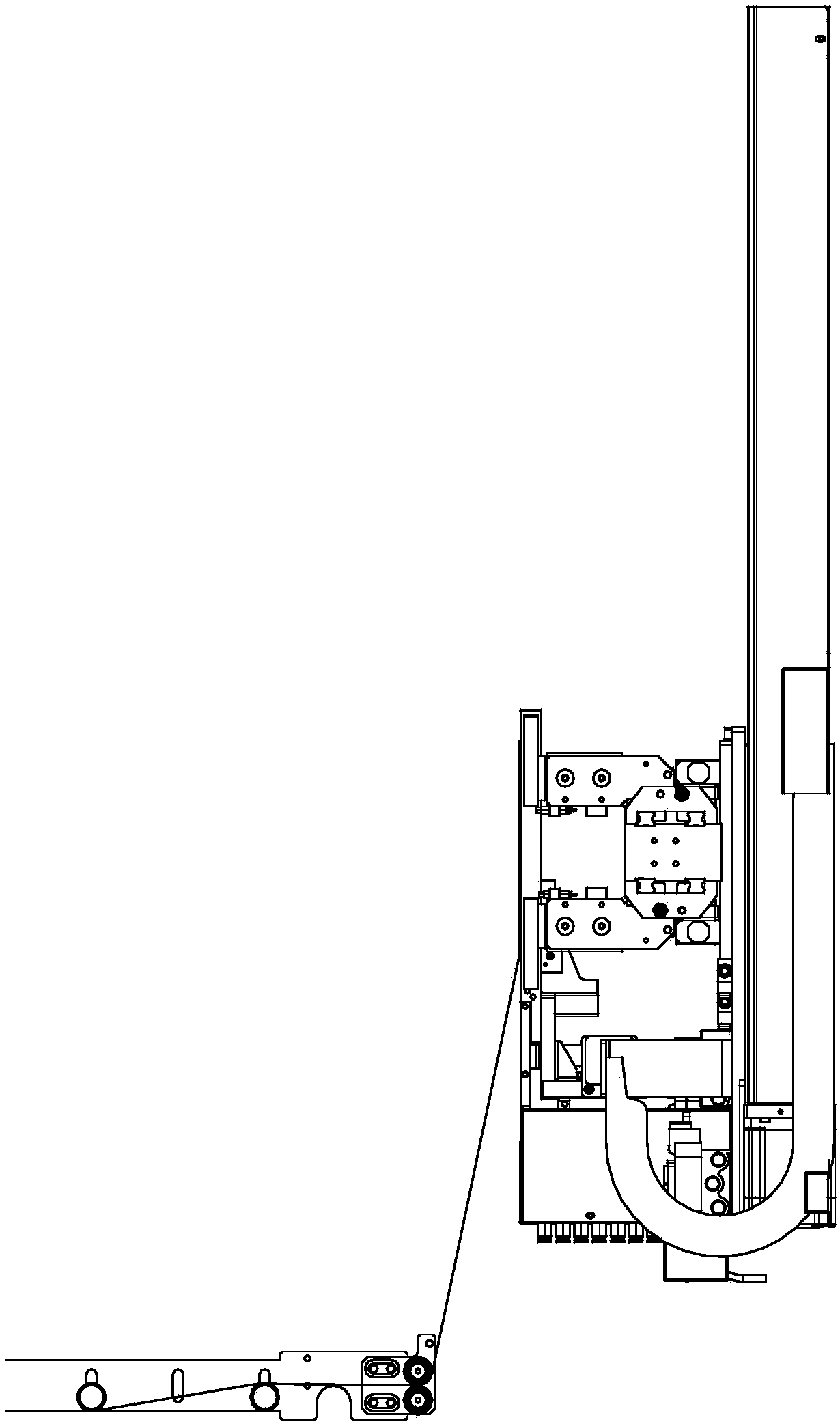

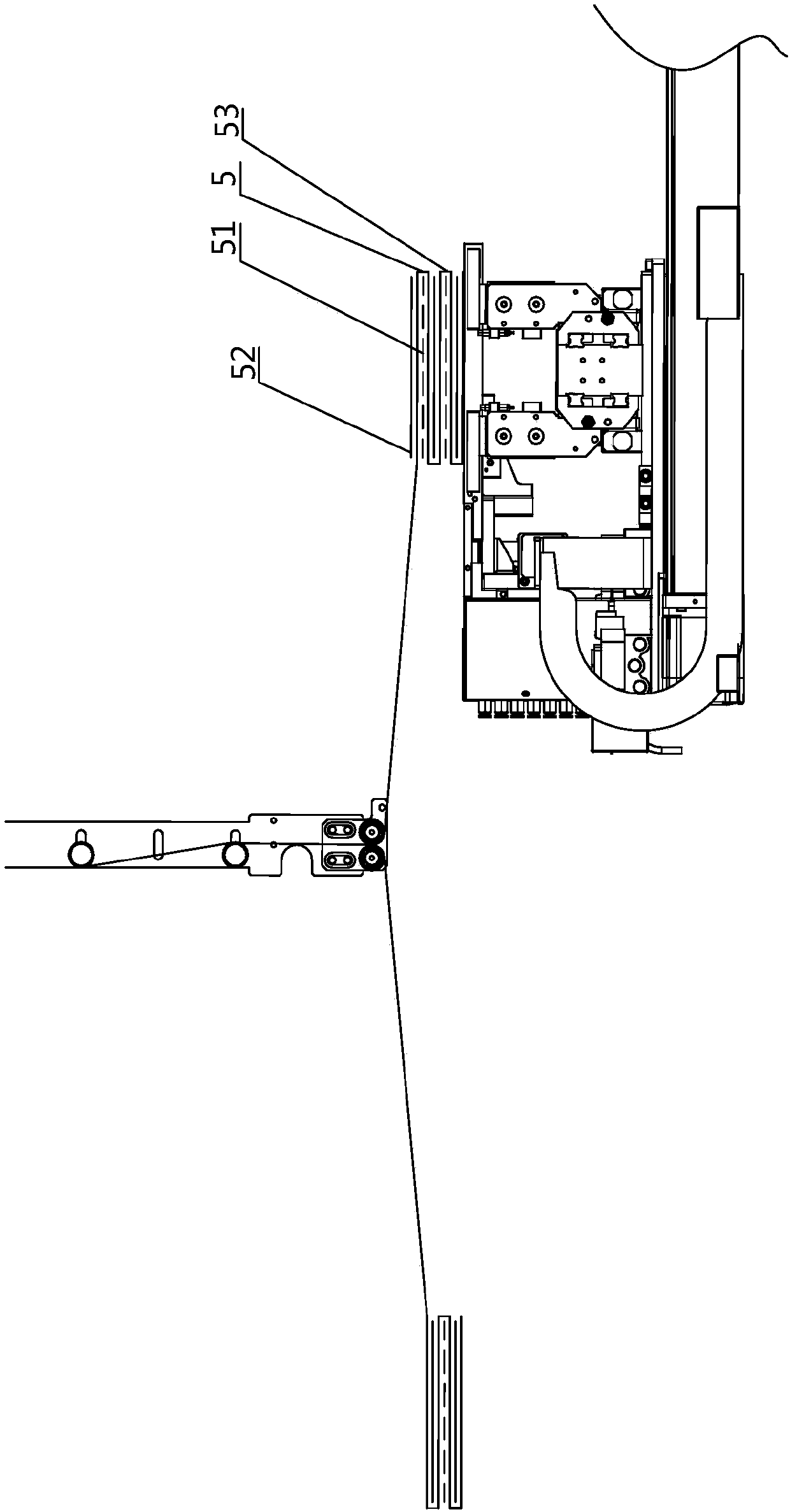

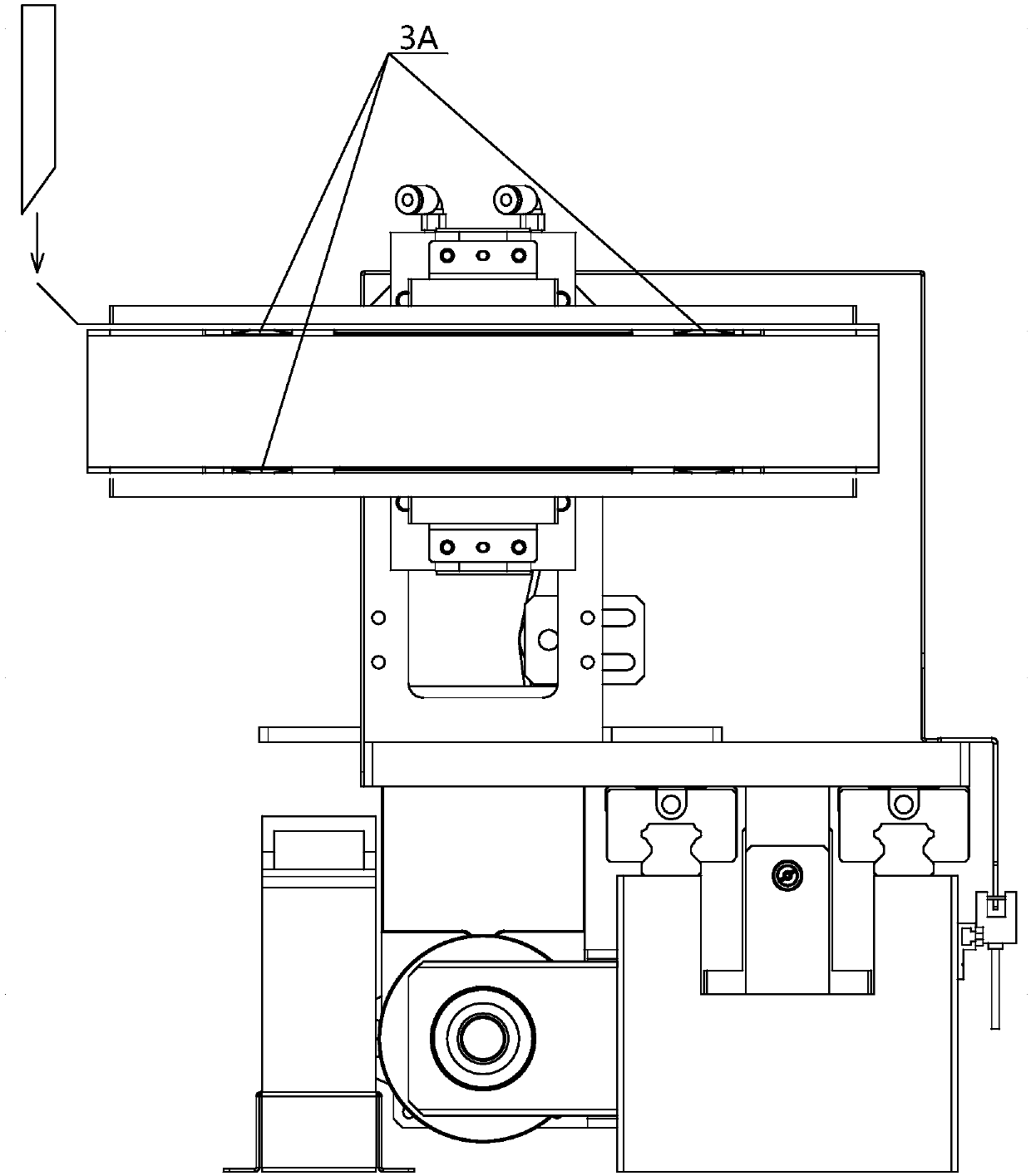

Automatic post-brick-unloading grouping and loading device and technology for baked bricks

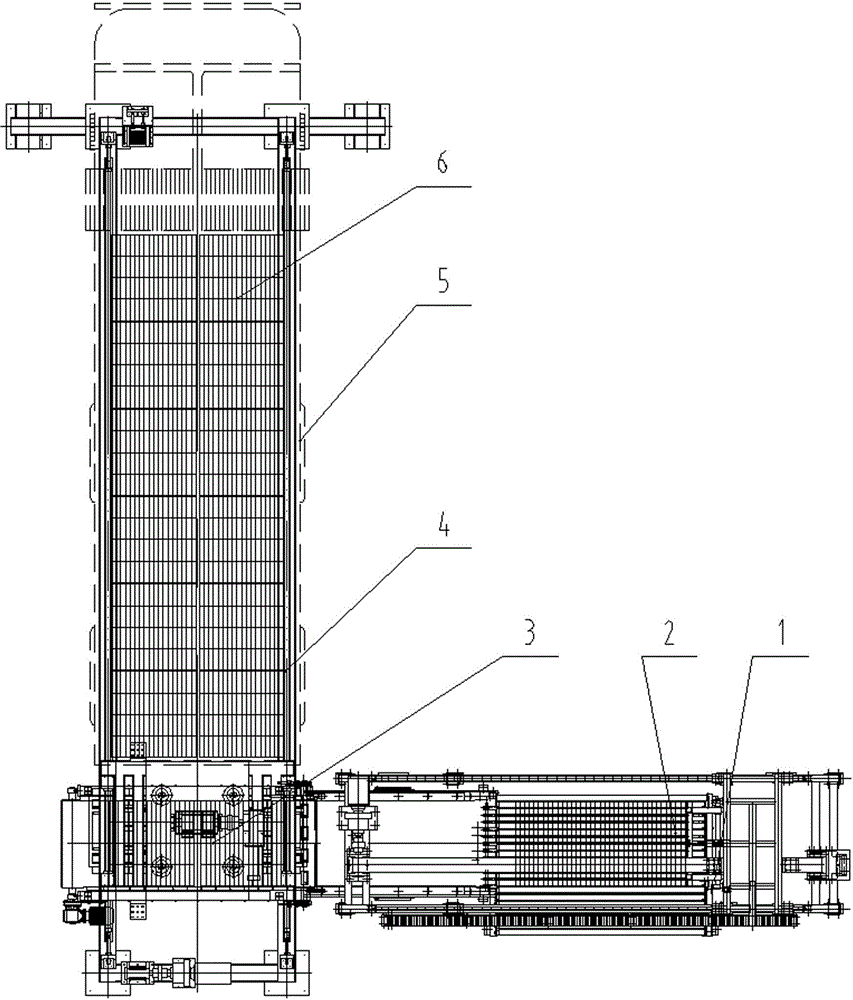

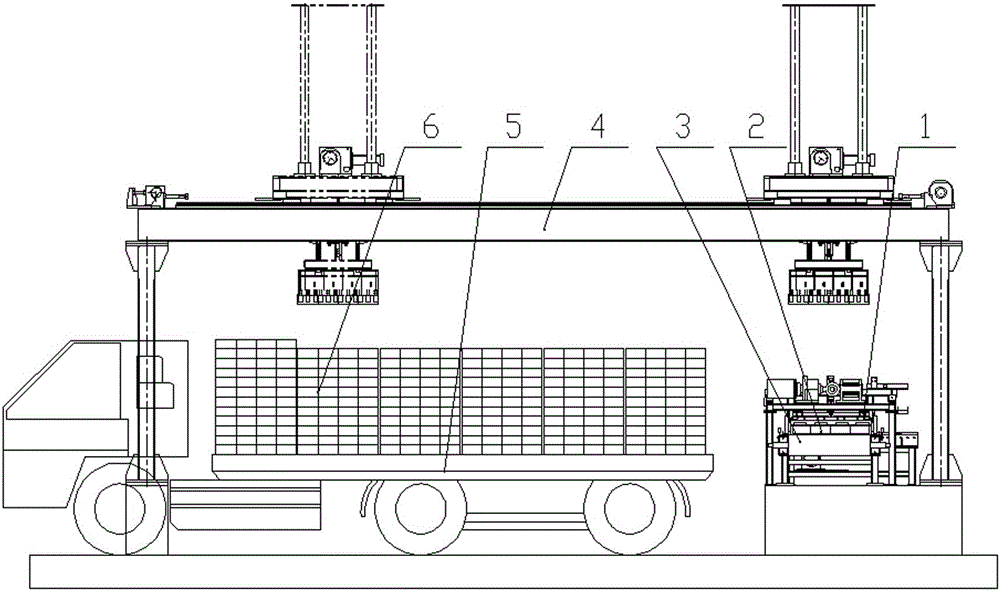

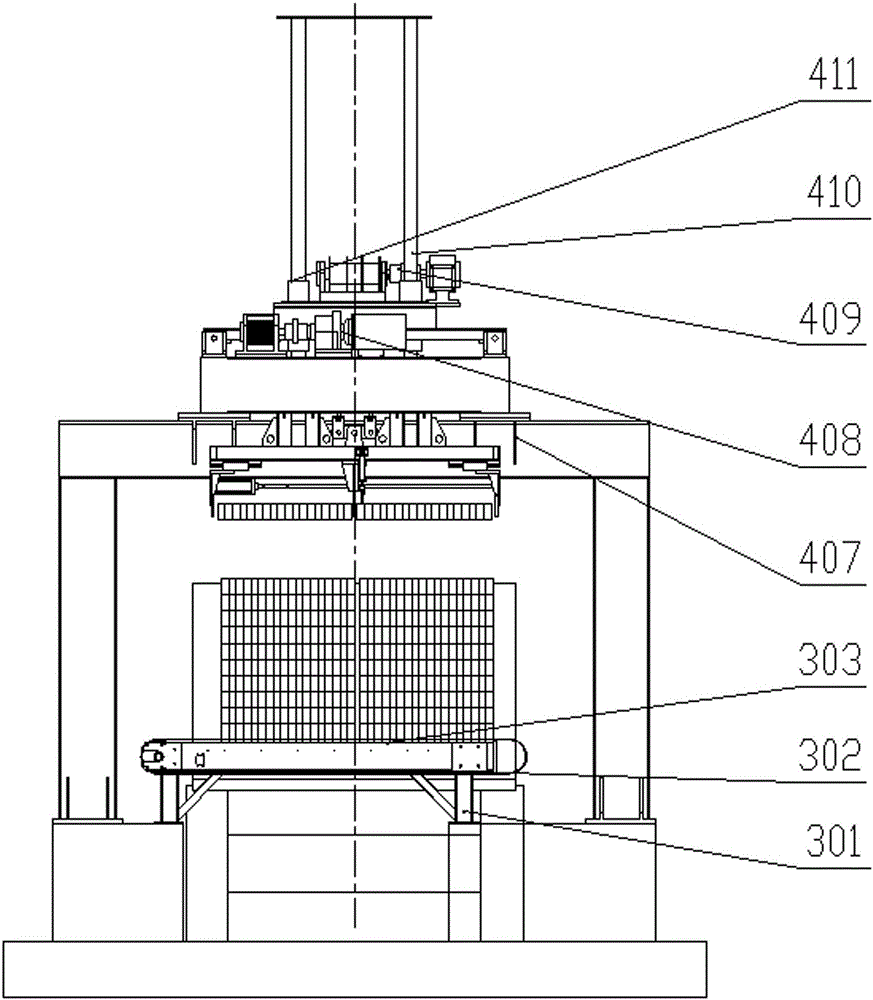

InactiveCN105084042AImprove the full load factorImprove vehicle utilizationLoading/unloadingStack machineBrick clamp

The invention relates to an automatic post-brick-unloading grouping and loading device and technology for baked bricks. The device is provided with a grouping belt conveyor, a stacking machine and a brick-unloading unit transferring mechanism. The grouping belt conveyor is arranged at the tail end of the brick-unloading unit transferring mechanism. The baked bricks are gathered together by the brick-unloading unit transferring mechanism, and then grouped and conveyed to the grouping belt conveyor. According to the width of a transport vehicle, the baked bricks are grouped by grouping belt conveyor matched with the brick-unloading unit transferring mechanism. The stacking machine is arranged above the grouping belt conveyor. The grouped baked bricks are clamped and stacked up to the transport vehicle by the stacking machine. According to the device and the technology, direct mechanized automatic grouping and loading of finished bricks can be achieved; the problem that the multiple bricks are not firm to clamp is solved; the method is simple, practical and reliable. The problem of the gaps between brick stacks is solved; the load factor of the bricks and the utilization rate of the vehicle are improved; the damage rate in the transport process is reduced; a great deal of manpower is saved; the production efficiency is improved; the labor intensity of workers is lowered.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

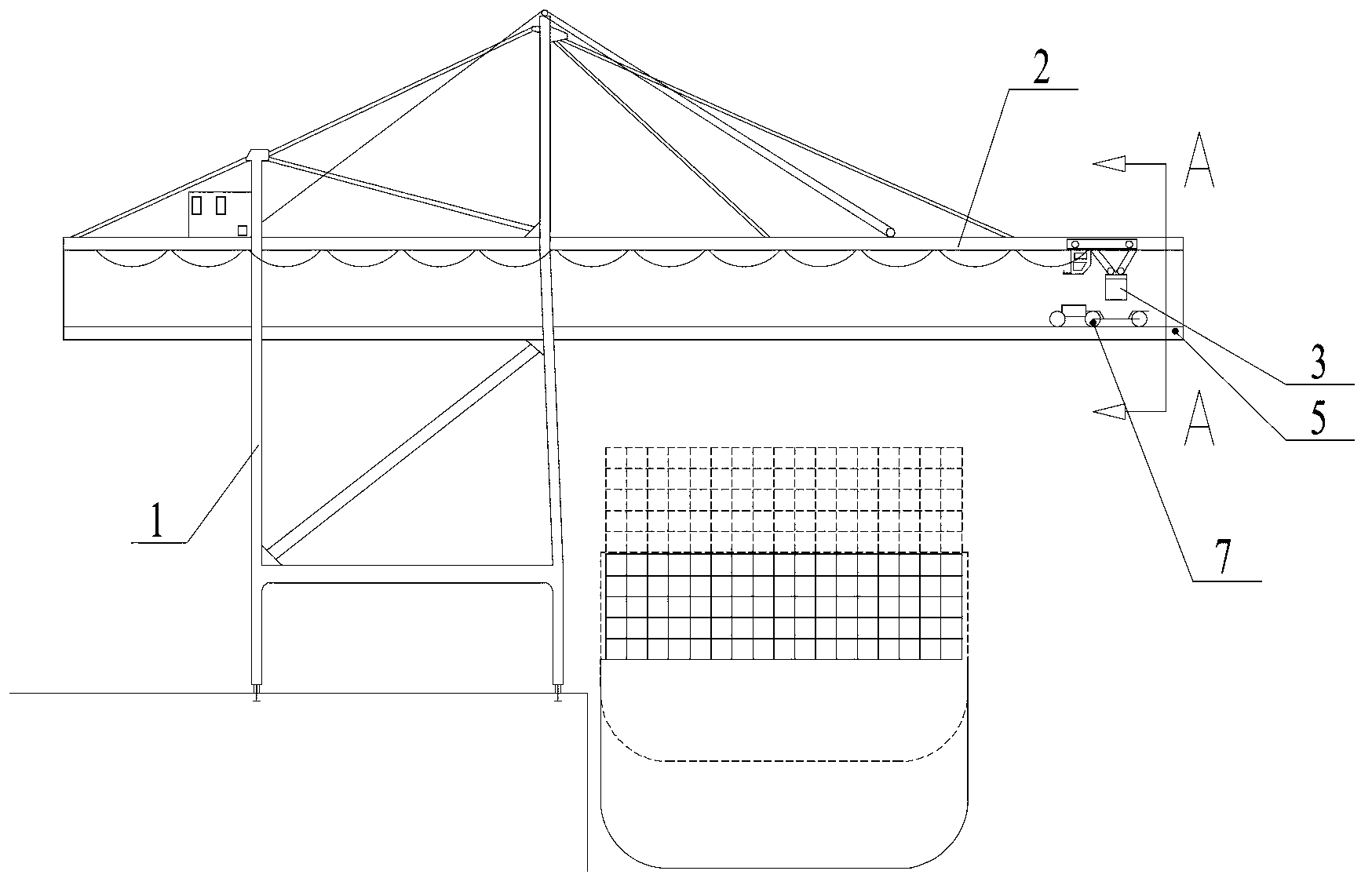

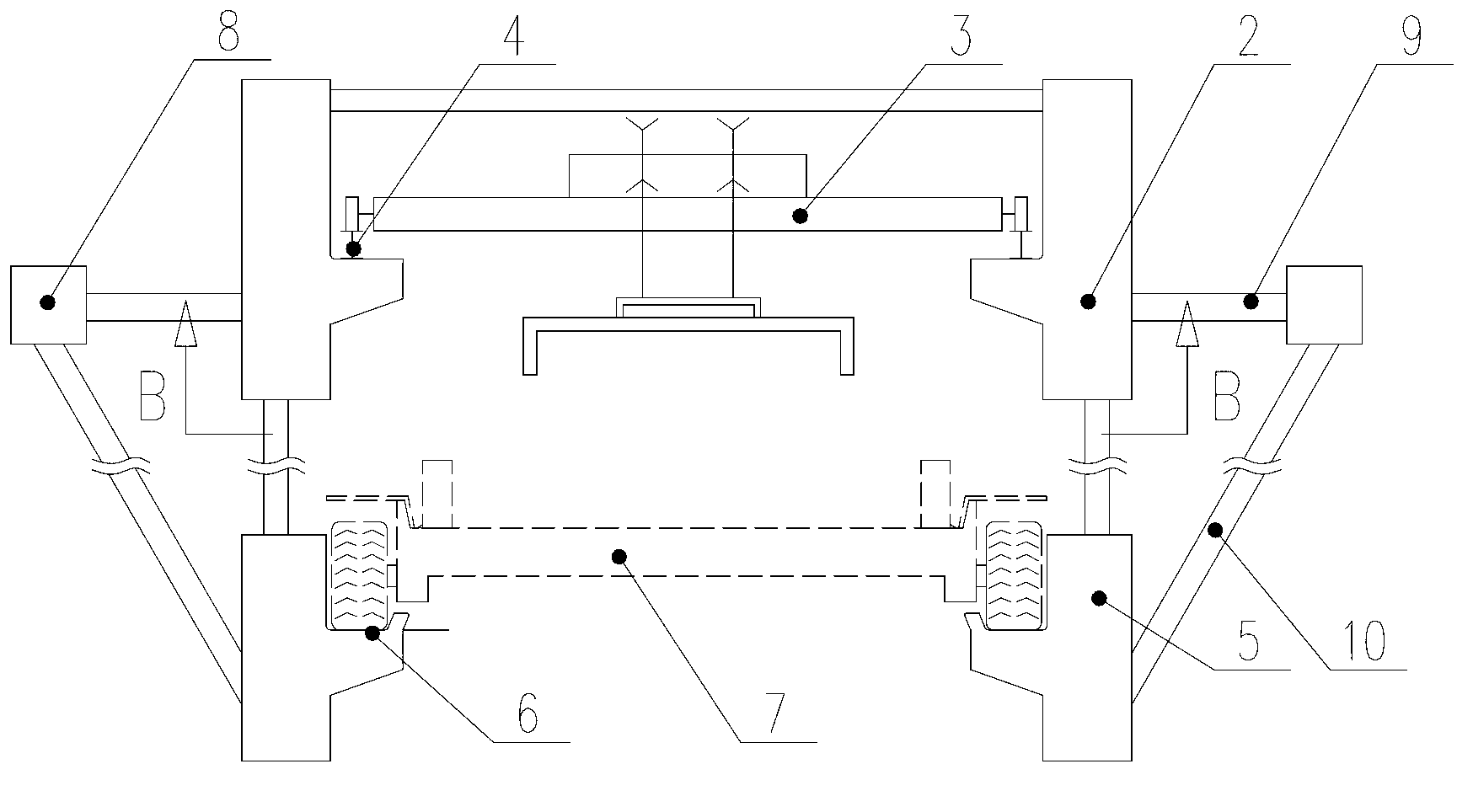

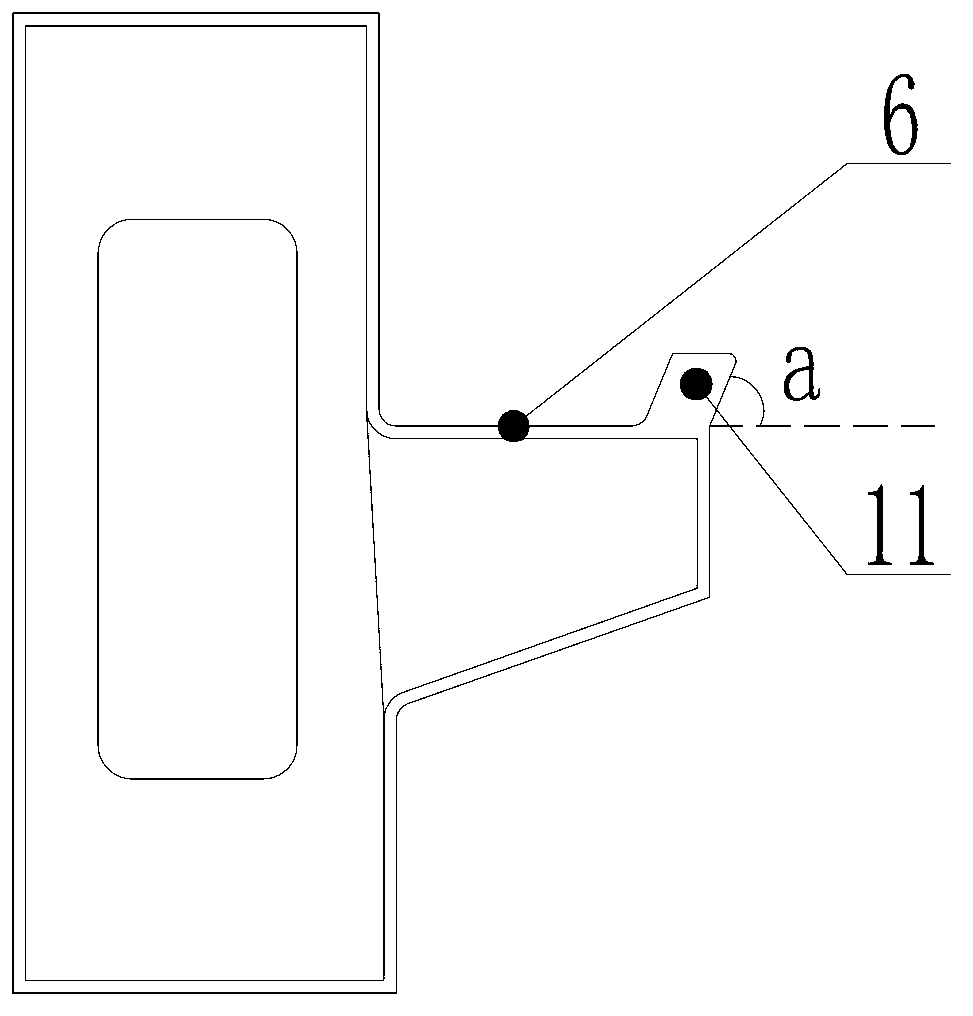

Double-layered quay crane for loading and unloading containers

ActiveCN103303805AImprove loading and unloading efficiencyImprove efficiencyLoad-engaging girdersTravelling cranesEngineeringMechanical engineering

The invention discloses a double-layered quay crane for loading and unloading containers. The double-layered quay crane comprises a portal type supporting leg, main walking girders and a hoisting trolley, wherein the portal type supporting leg is provided with the two main walking girders; a walking rail is arranged on the inner side of each main walking girder; the hoisting trolley is arranged on the walking rails; two transfer vehicle walking girders, which are parallel to the main walking girders, are arranged just below the main walking girders; the inner sides of the two transfer vehicle walking girders are provided with walking rails with baffles; a transfer vehicle is arranged on the walking rails with the baffles. According to the double-layered quay crane disclosed by the invention, the transfer vehicle walking girders are arranged below the main walking girders and the transfer vehicle is arranged on the transfer vehicle walking girders, so that the transfer vehicle is responsible for transferring the containers and the hoisting trolley is only responsible for hoisting the containers; in a process of transferring a container by the transfer vehicle, the hoisting trolley finishes the hoisting work of another container, so that the loading and unloading efficiency of the containers is improved; when the double-layered quay crane is used for loading and unloading the containers, the efficiency is improved by 50% compared with that of traditional quay cranes.

Owner:华电蓝科科技股份有限公司

Pouring sealant for filling gap between warhead charge and shell

InactiveCN103205229AEasy pottingAvoid volume shrinkageNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHydroxyl-terminated polybutadieneChemistry

The invention discloses a pouring sealant for filling a gap between a charge and a shell of a warhead. The pouring sealant comprises hydroxyl-terminated polybutadiene, a curing agent, a plasticizer and a curing catalyst, wherein mol ratio of R=[NCO] in the curing agent to [OH] in the hydroxyl-terminated polybutadiene is 0.8-1.2, content of the plasticizer is 0-1.5 times that of the hydroxyl-terminated polybutadiene, and the content of the curing catalyst is 0-0.01wt% that of the hydroxyl-terminated polybutadiene. The pouring sealant disclosed by the invention can be used for effectively solving the problem of an inherent gap between the charge and the shell of the warhead of the conventional weapon, so that use safety performance of the warhead and penetration stability to a target are greatly improved; and by adopting the pouring sealant disclosed by the invention, fabricated charging can be carried out without prefabricating a grain, so that the warheads in various sizes and shapes are directly poured and moulded, the mass production capability is greatly improved and the charging process cost is greatly reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

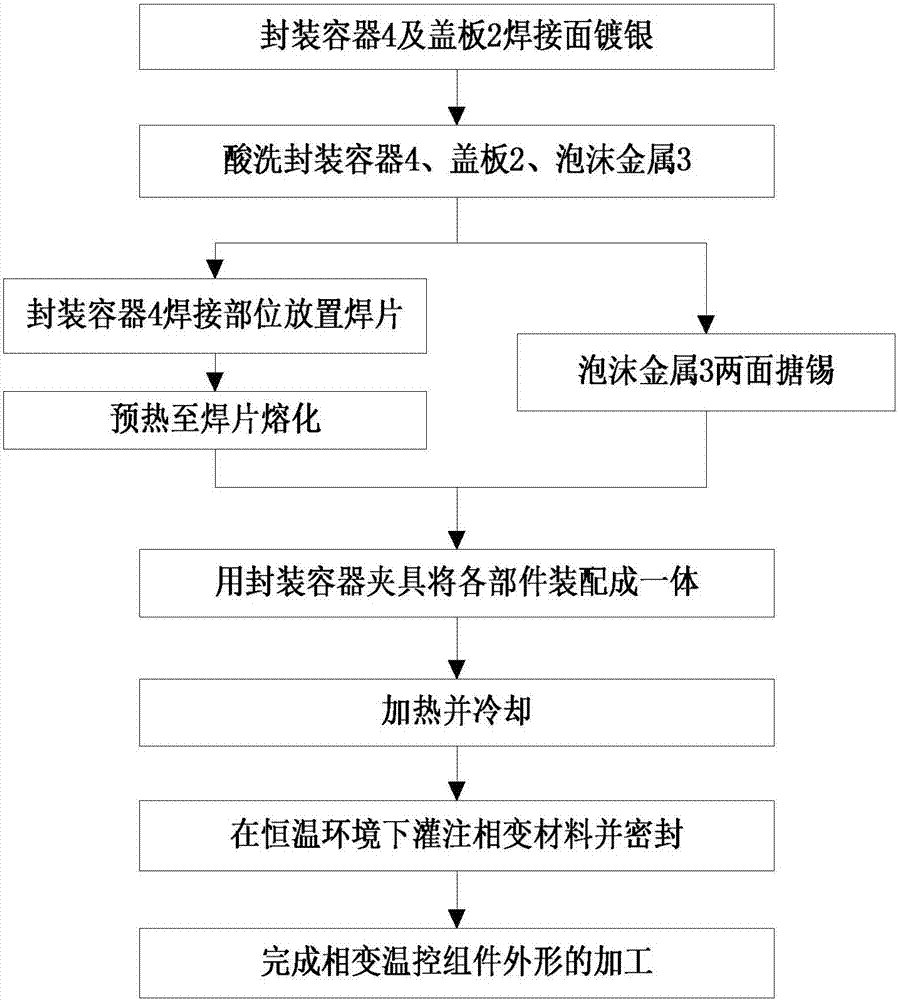

Method for integrated preparing of foam metal phase change temperature control assembly

InactiveCN107116279AOvercome failureImprove the equivalent thermal conductivityHeating appliancesWelding/soldering/cutting articlesTemperature controlEngineering

The invention provides a method for integrated preparing of a foam metal phase change temperature control assembly and aims at providing a technology method for solving the problem that in a phase change temperature control assembly, a gap exists between foam metal and a base body material, and the heat response rate is influenced. The method is achieved through the following technical scheme that according to the boundary dimension of a packaging container, a packaging container clamp is prepared; a cavity used for welding the foam metal is machined in the packaging container in advance, a layer of welding piece is laid on the inner side welding face of the cavity of the packaging container, and the contact interface of the foam metal is subjected to tin lining; the foam metal is compressed to the cavity size; the packaging container, the foam metal and the clamp are assembled into a whole and heated, and after cooling, a formed phase change temperature control assembly blank is taken out of the clamp of the packaging container; in the constant-temperature environment, a liquid phase change material is poured into the phase change temperature control assembly from a pouring port in the bottom of the packaging container; and finally, the pouring port is sealed, and machining of the appearance of the temperature control assembly is finished.

Owner:10TH RES INST OF CETC

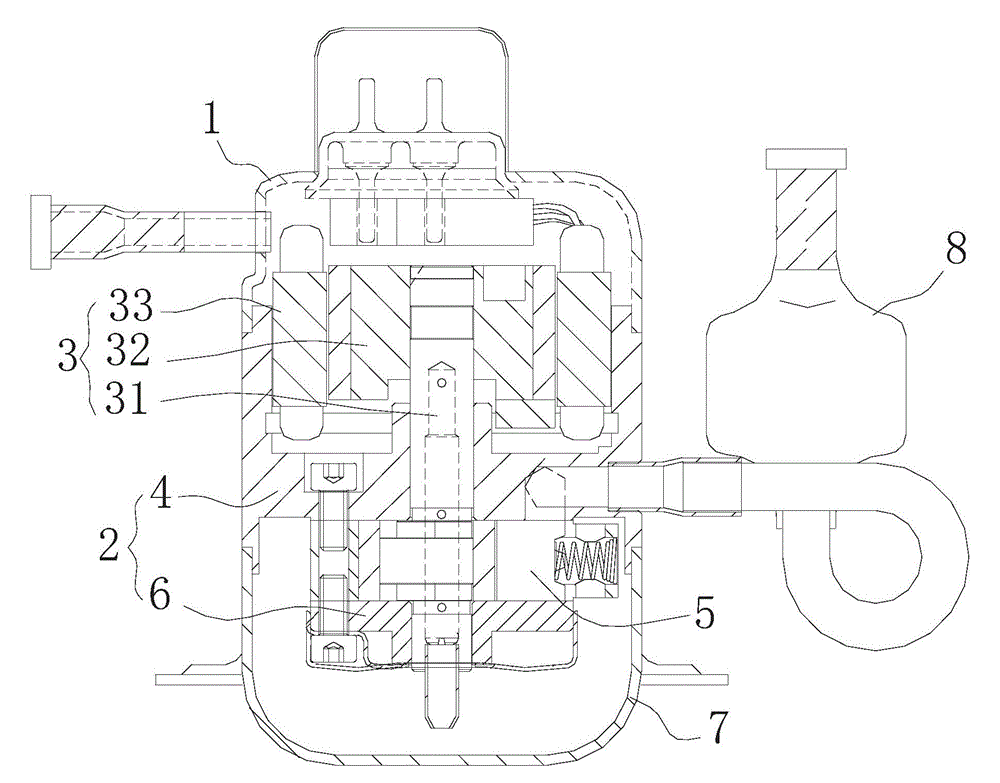

Unfolding method of circular cylinder wall and cylindrical surface during eccentric oblique intersection

InactiveCN103559405APrecise expansionResolve local contactSpecial data processing applicationsTransformerStructural engineering

The invention relates to an unfolding method of a circular cylinder wall and a cylindrical surface during eccentric oblique intersection, and belongs to the technical field of transformer sheet-metal processing. The method adopts the technical scheme that an actual section of the cylinder wall in any unfolding position is a rectangle, and in order to avoid interference of the cylinder wall and the cylindrical surface under ideal assembly, the axial length of the section rectangle of the cylinder wall is required to be reduced, so that the length of the section rectangle is equal to an axial minimum distance from a section coordination edge to a plain end of the cylinder wall. With the adoption of the method, multiple coordinate points can be obtained, and an unfolding curve of coordination ends of the cylinder wall can be drawn by utilizing the obtained points, so that an unfolding diagram of the cylinder wall is drawn. The method has the positive effects that precise unfolding of the circular cylinder wall and the cylindrical surface during the eccentric oblique intersection is realized; the problems that the coordination ends of the cylinder wall are partially contacted during butting, and gaps appear at other parts are solved; welding operation is facilitated; the welding quality is improved; and the actual height of the cylinder wall of an ascending flanged base is ensured.

Owner:BAODING TIANWEI GRP CO LTD

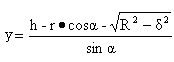

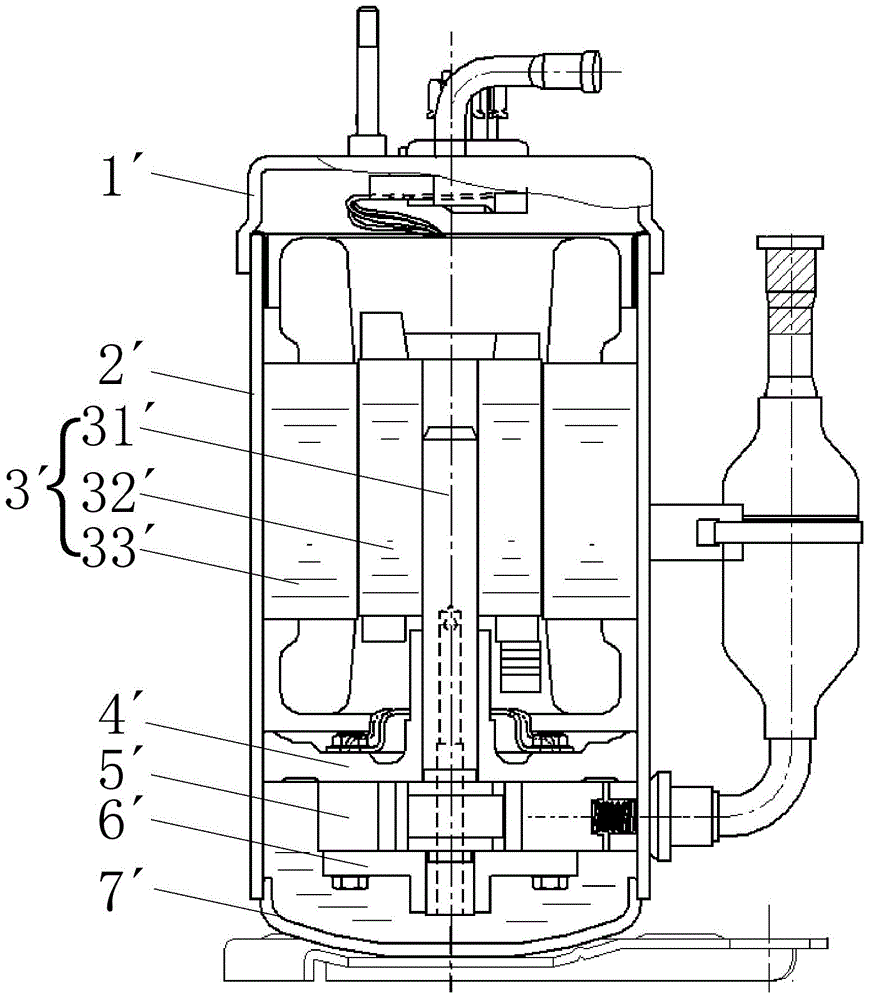

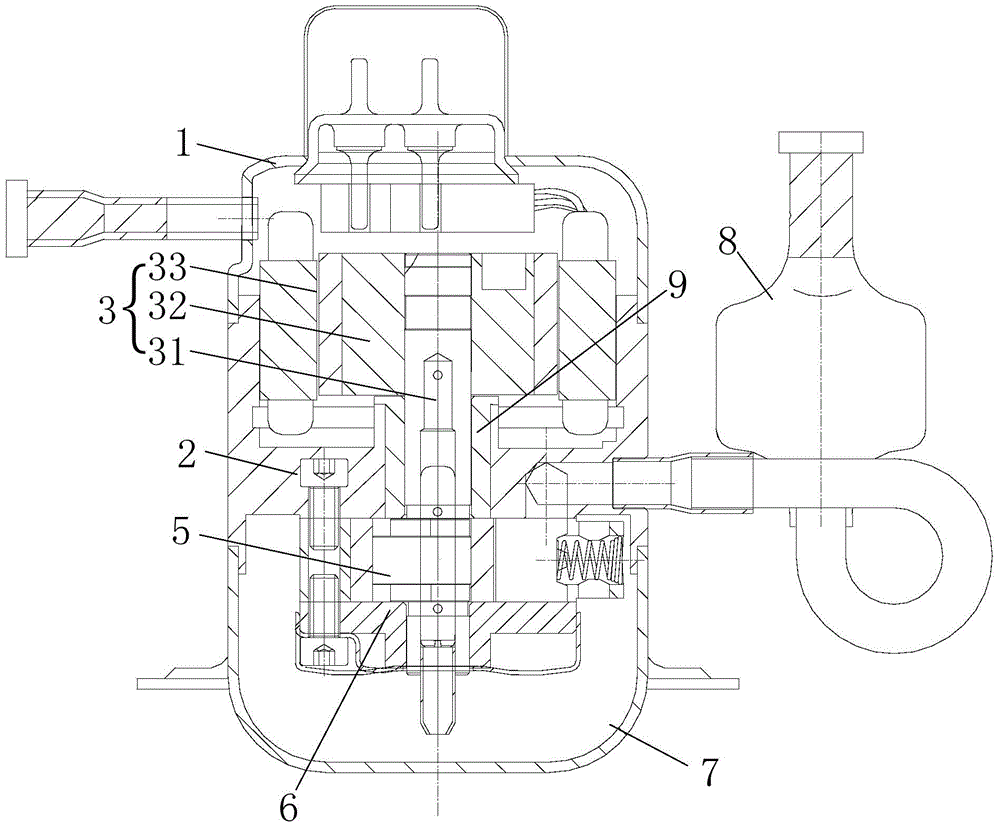

Compressor and manufacturing method thereof

InactiveCN105464980AMeet welding requirementsPrevent thermal deformationRotary/oscillating piston combinations for elastic fluidsIncreasing energy efficiencyInduction hardeningEngineering

The invention provides a compressor and a manufacturing method thereof. The compressor comprises a shell; a motor and a cylinder, which are accommodated in the shell; a crankshaft, which is used for transmitting the rotary force of the motor to the cylinder to compress a refrigerant; and a frame, which is fixedly connected with the shell through welding and comprises a main bearing and an auxiliary bearing, wherein the main bearing and the auxiliary bearing define a compression space together with the cylinder and are both provided with an inner hole for supporting the crankshaft, the main bearing is used as one part of the shell and welded with the other parts of the shell to form one body, and the surface of the inner hole of the main bearing is strengthened through induction hardening.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

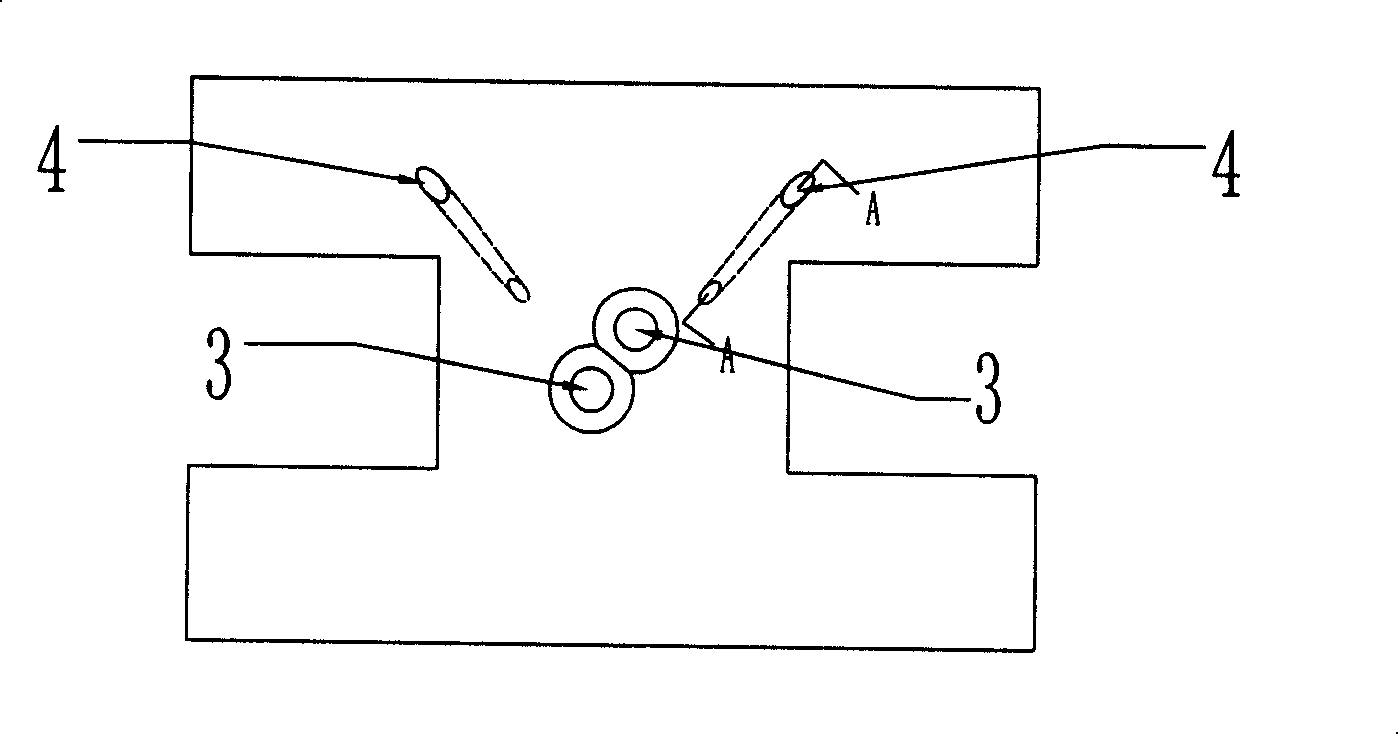

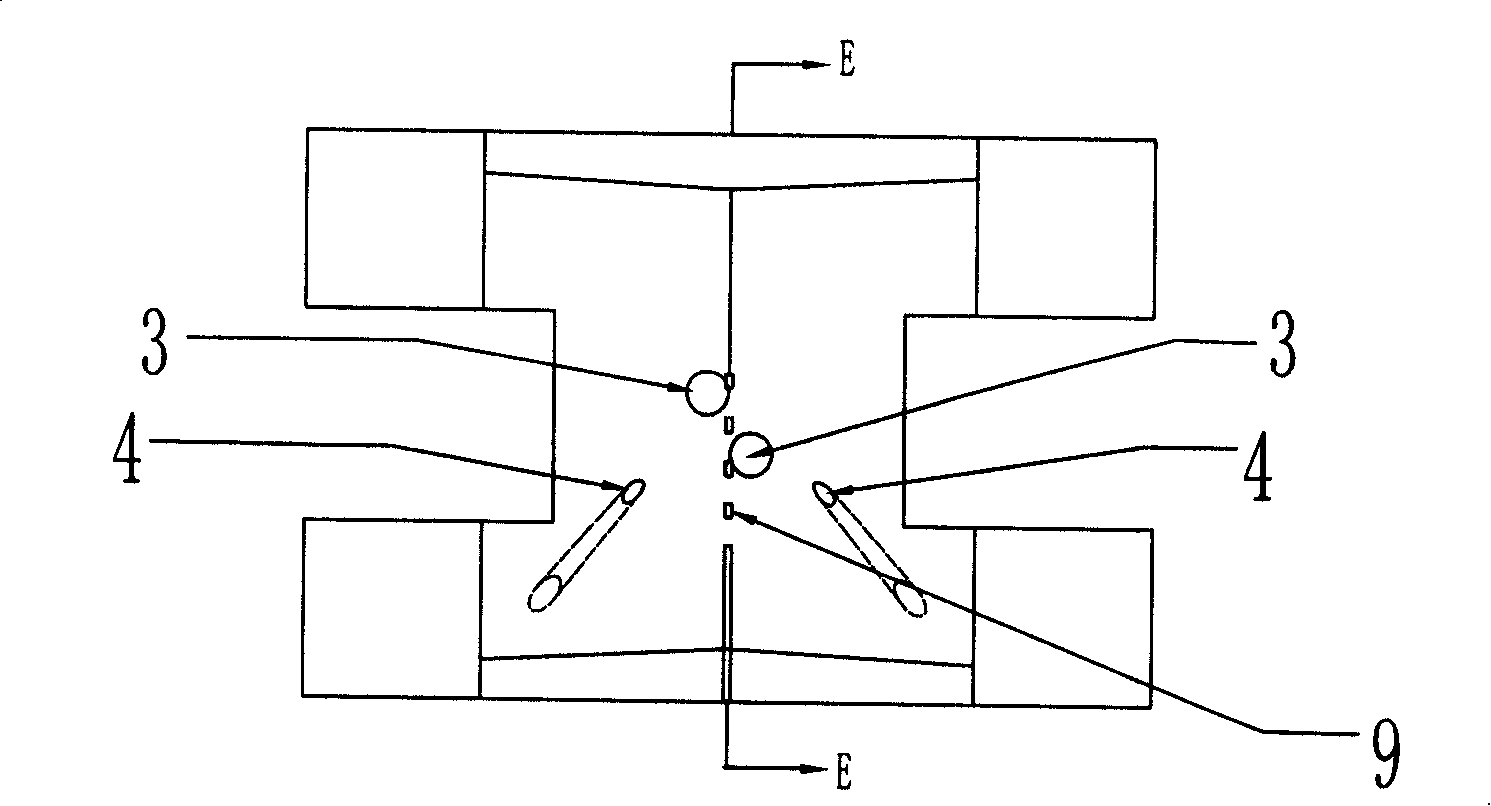

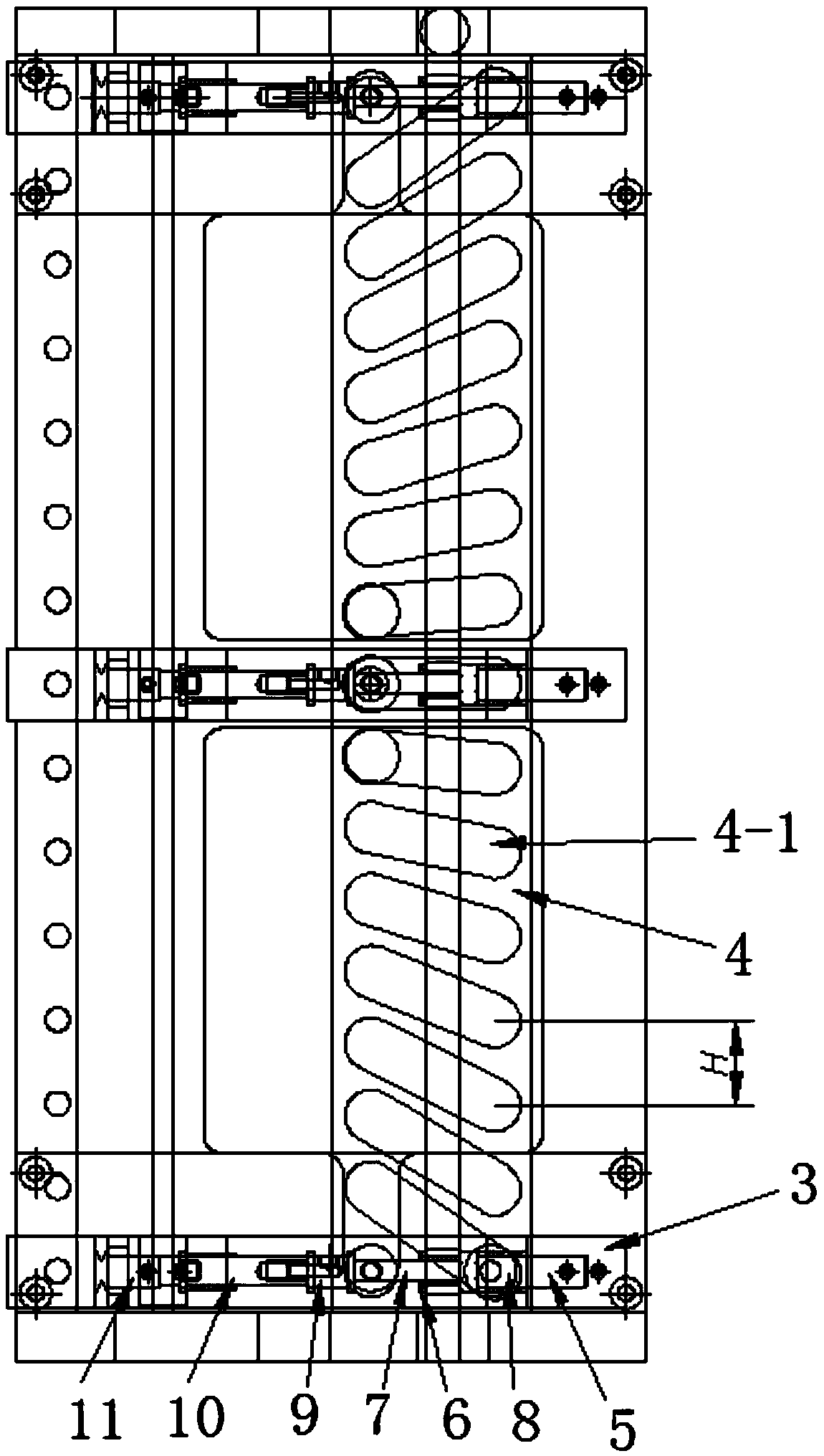

Processing device of waterproof slide fastener

InactiveCN101228982ASolve the gap problemSuture smoothlySlide fastenersWork-feeding meansLeft halfAgricultural engineering

The invention relates to a production and processing device of a waterproof zipper. The invention solves the problem that a gap is generated between a right waterproof glue layer and a left waterproof glue layer of the zipper when processing waterproof zippers in the prior art. The invention adds an opposite slant hole and a blowing pipe to a pressing board structure of a sewing machine in the prior art; according to aerodynamic principle, the cloth ribbons pasted with waterproof glue layer are pushed to middle by the constant air blowed out from the additionally equipped blowing pipe, thus ensuring that the gap between the waterproof glue layer cloth ribbons at the right half side and the left half side of the zipper is close after sewing; at the same time, a spotted fence on the back of an upper pressing board can avoid overlapping sewing caused by excessive squeeze when the cloth ribbons are pushed to the middle by wind blowing. The invention can guarantee the smooth sewing of the waterproof zipper cloth ribbons pasted with waterproof glue layers and compact sewing gap after sewing, thereby resulting in excellent waterproof performance of the product.

Owner:SHANGHAI EASTDRAGON FABRIC & GARMENT

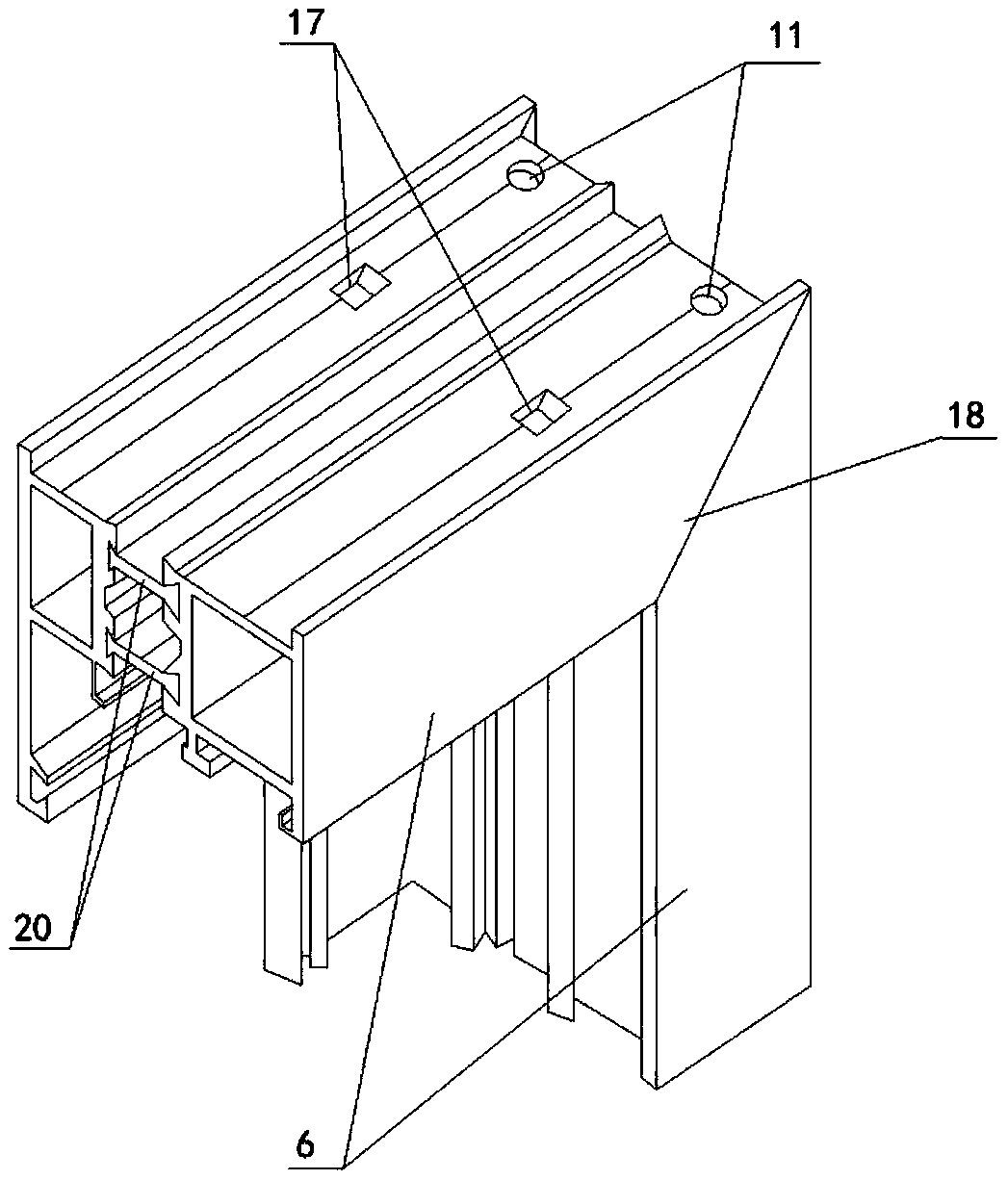

Manufacturing method of strong-connection seamless aluminum alloy window

InactiveCN109396754AHigh bonding strengthSolve the gap problemCorner/edge jointsSealing arrangementsUltimate tensile strengthAluminium alloy

The invention discloses a manufacturing method of a strong-connection seamless aluminum alloy window. The manufacturing method is characterized by comprising the steps of material blanking, milling and finishing, drilling and milling hardware installation holes, rubber penetrating strip, corner assembling, mounting of the hardware assembly and the lock, assembling the glass and the glass is assembled in a combined mode. The method belongs to the manufacturing method of the high-connection seamless aluminum alloy window, and solves the problem of poor strength of the existing window matching and assembling combination, the overall sealing performance is poor, the gap of the assembling joint is large, the waterproof and dustproof performance is poor, the interior of the aluminum alloy section and the contact area of the aluminum alloy section and the glass are easy to leak, so that the service life of the window is greatly shortened, the overall use effect of the window is severely affected, and the manufacturing method are suitable for being widely popularized and used in the process of manufacturing windows.

Owner:HEFEI JIAWEI DECORATION ENG

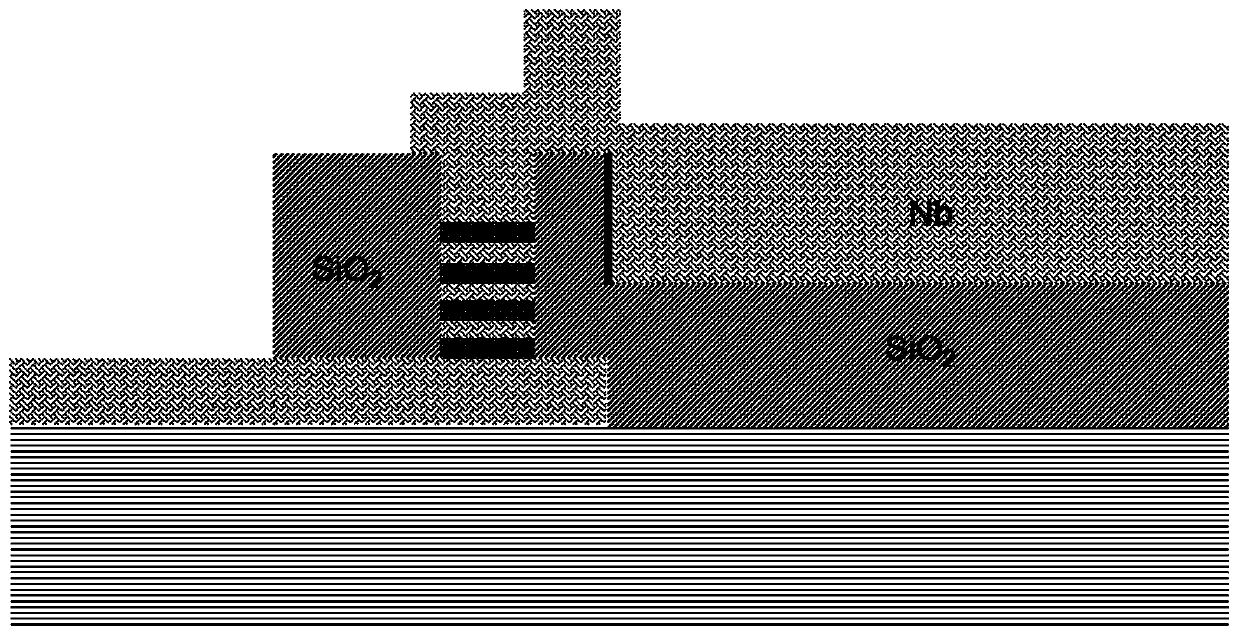

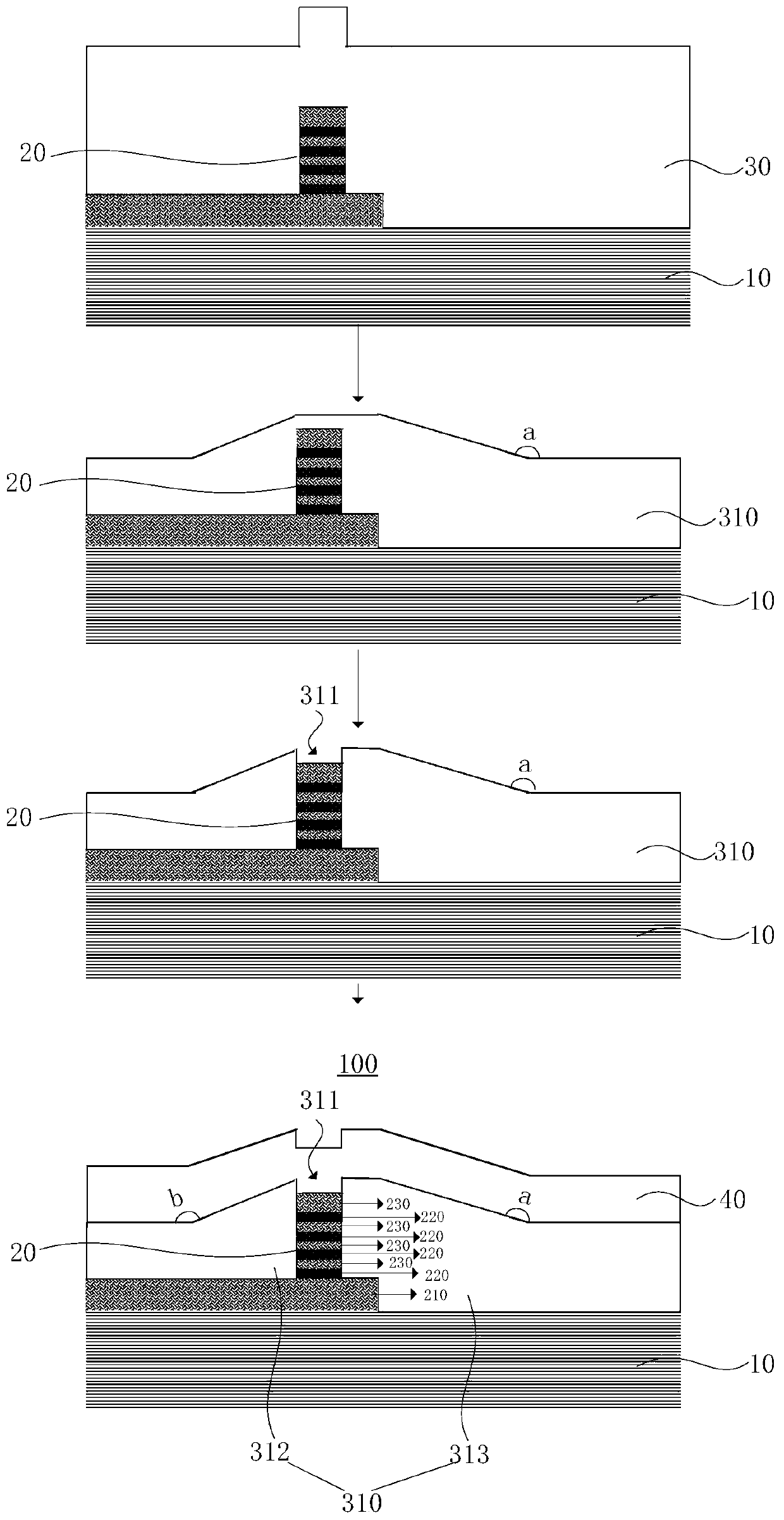

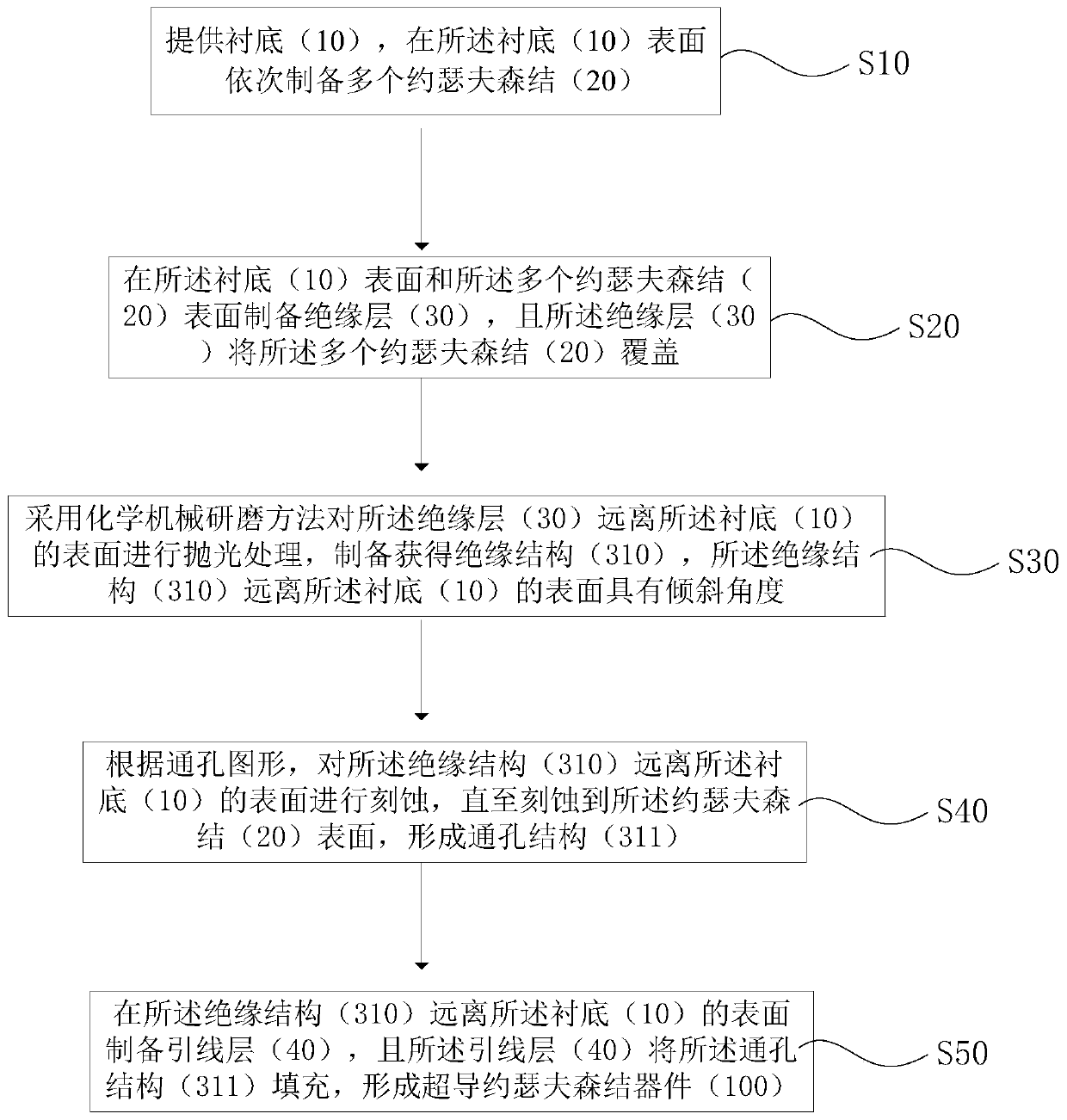

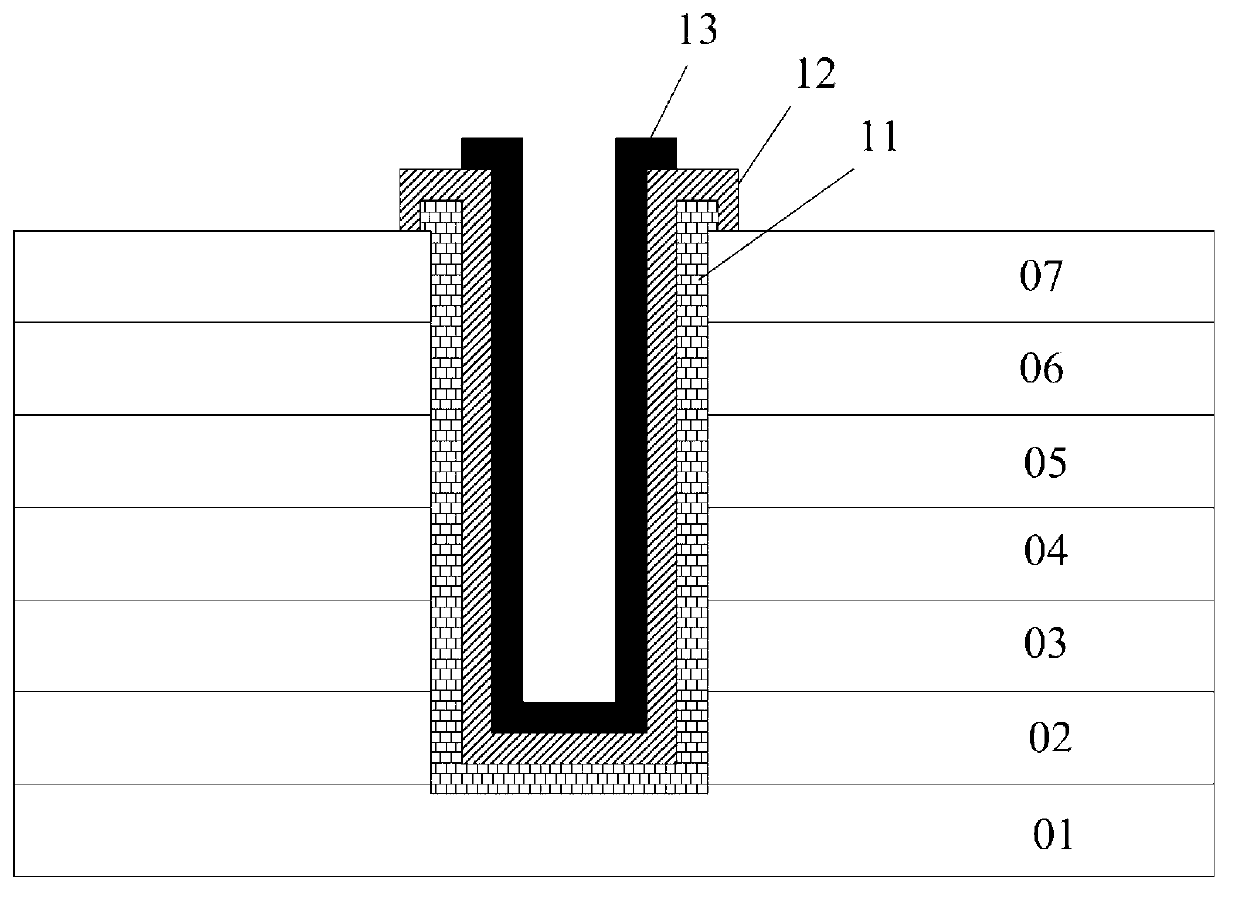

Preparation method of superconducting Josephson junction device and superconducting Josephson junction device

ActiveCN111244260ASolve the gaps that are easy to generateResolve the breakSuperconductor detailsDissimilar materials junction devicesSoftware engineeringMechanical engineering

Owner:NAT INST OF METROLOGY CHINA

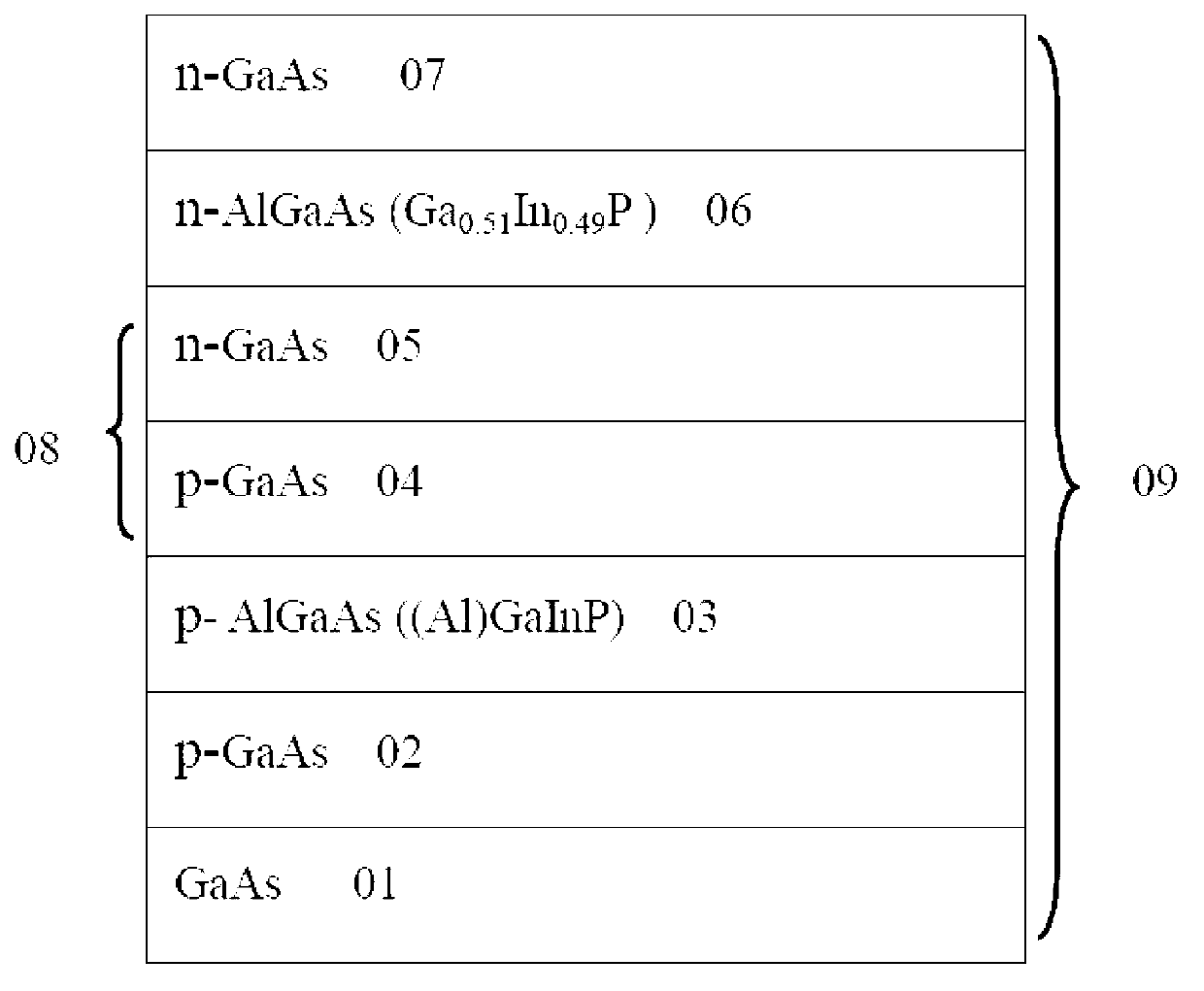

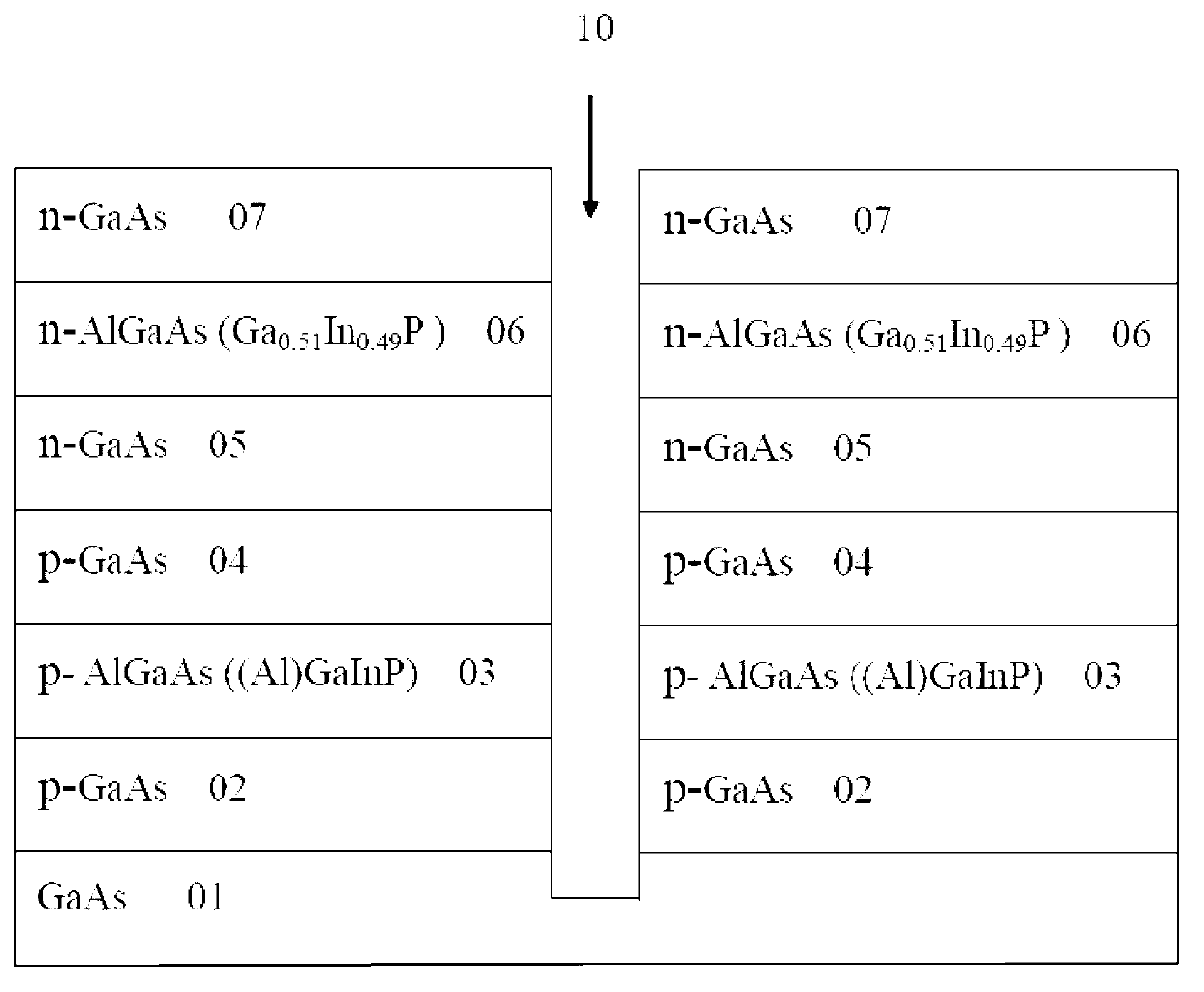

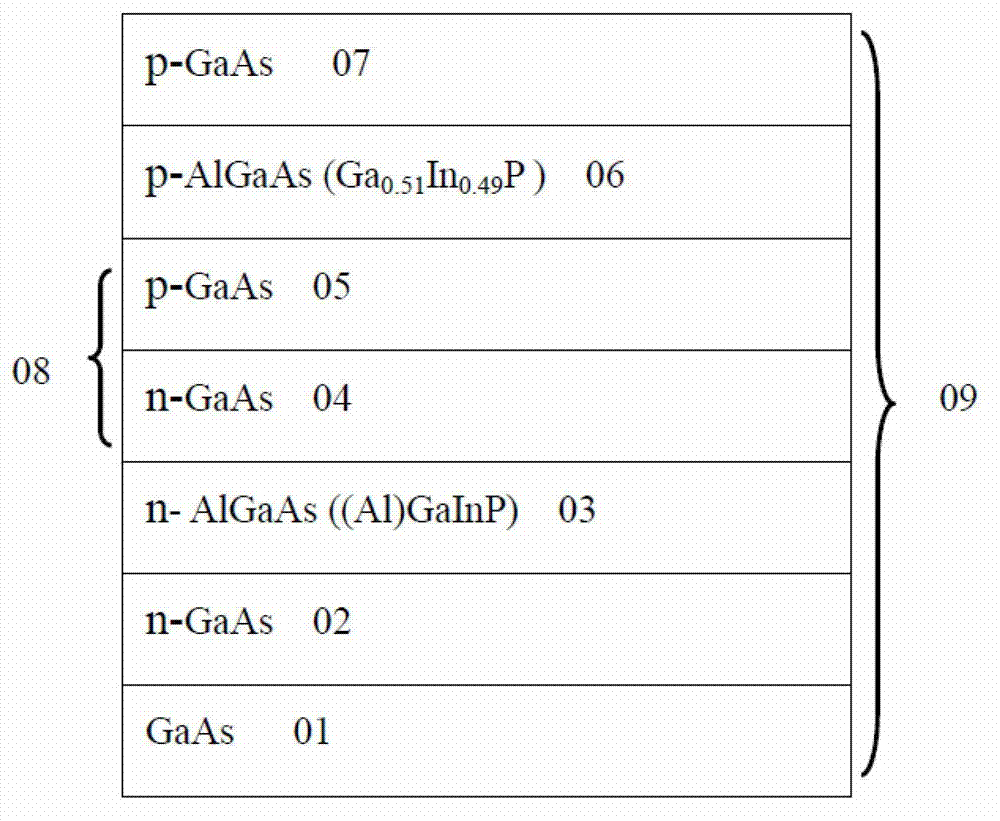

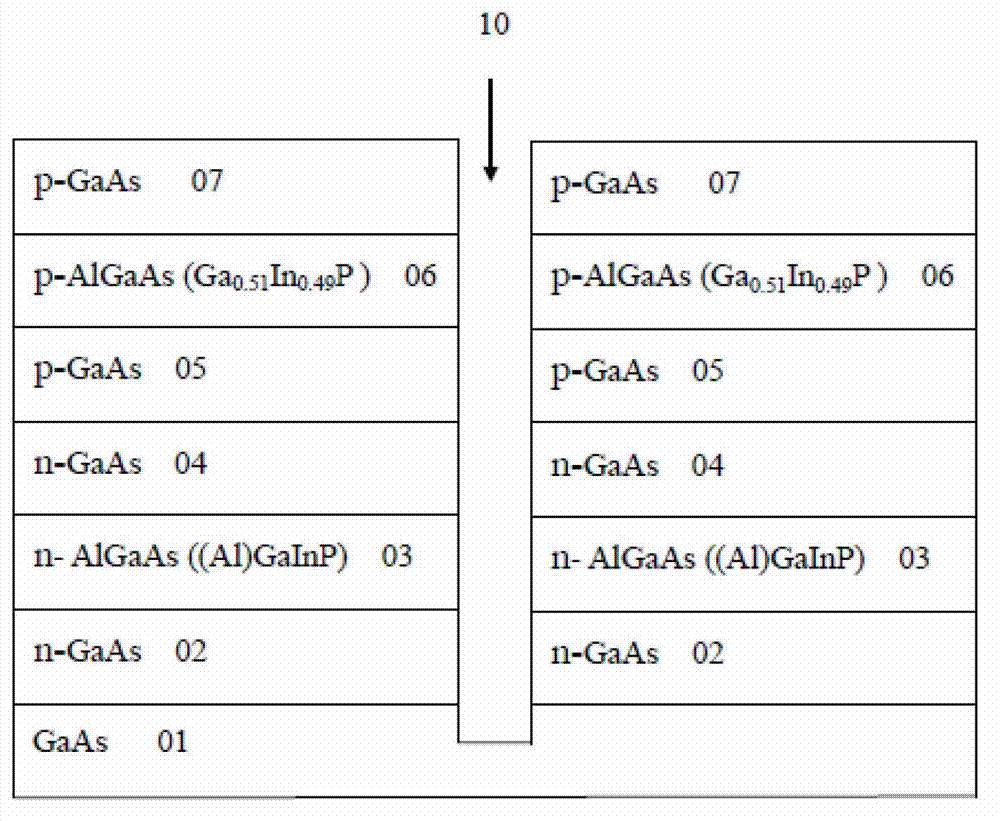

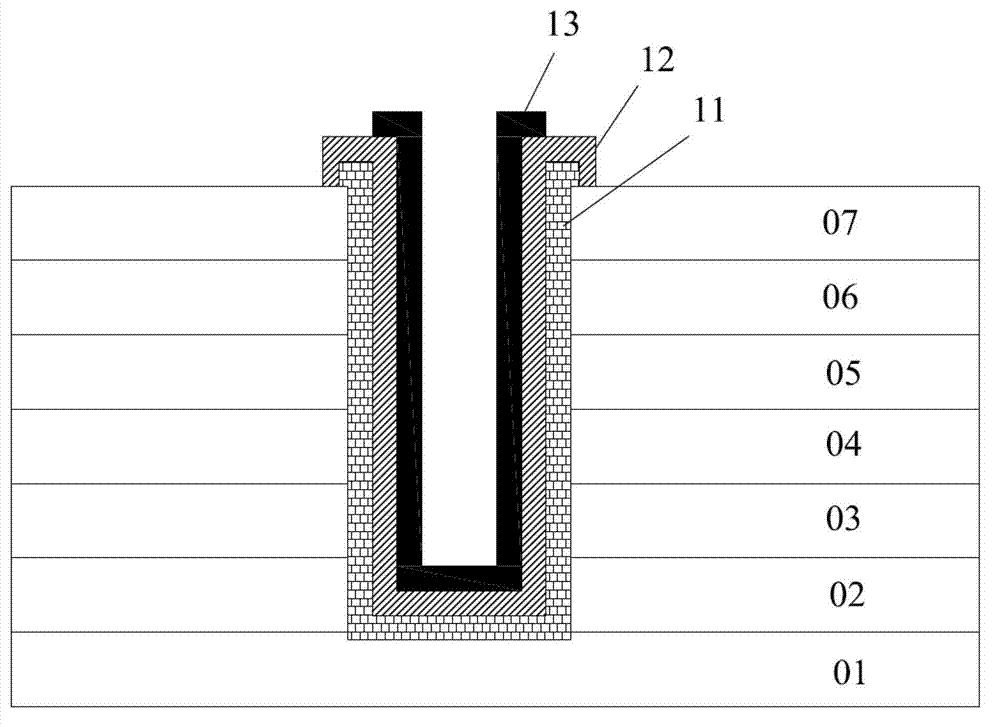

Laser photovoltaic cell and manufacturing method thereof

ActiveCN103123923ASolve substrate leakageImprove performanceFinal product manufactureDiodeSemi insulatingElectricity

The invention discloses a laser photovoltaic cell which includes an isolation tank. The isolation tank is used for dividing the laser photovoltaic cell into a plurality of battery units. The battery units are connected in series. A polyimide layer, a dielectric film layer and a metal shading layer are formed in sequence on the surface of inwall of the isolation tank. The invention also discloses a manufacturing method thereof. According to the invention, electricity leakage problem due to semi-insulating substrate illumination is solved. The manufactured photovoltaic cell has the advantages of high parallel resistance, small electricity leakage and the high conversion efficiency.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

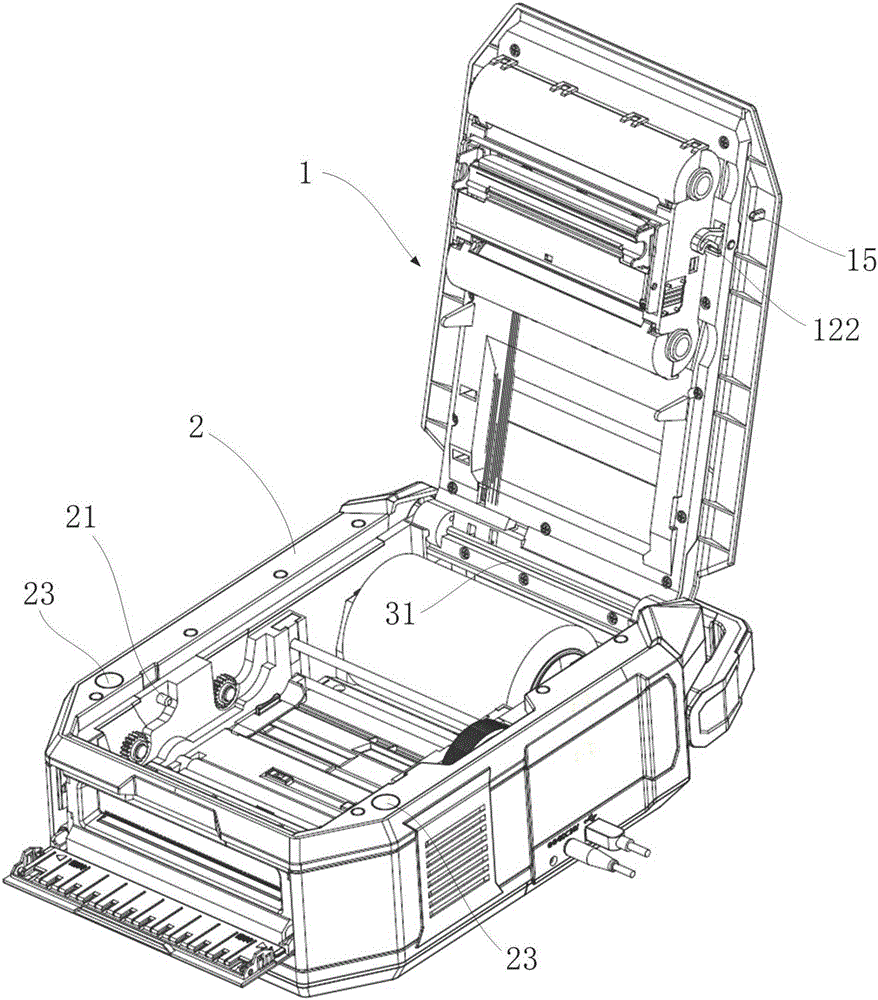

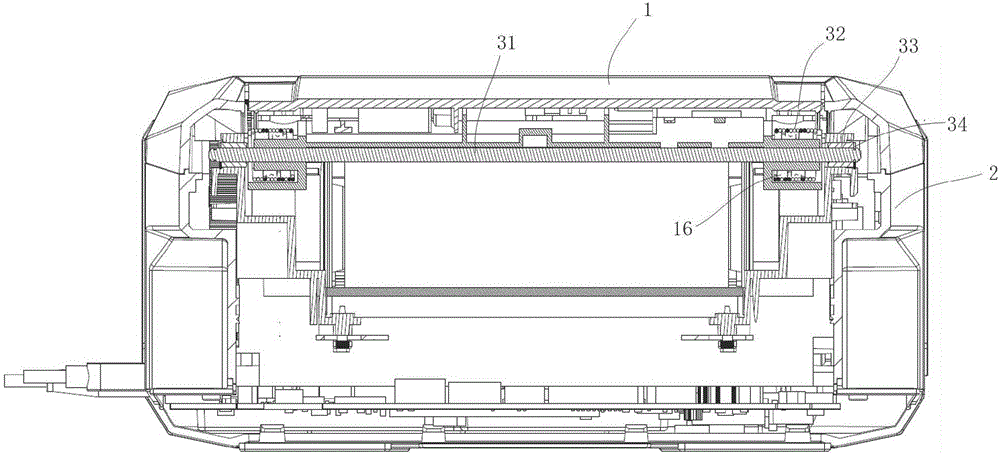

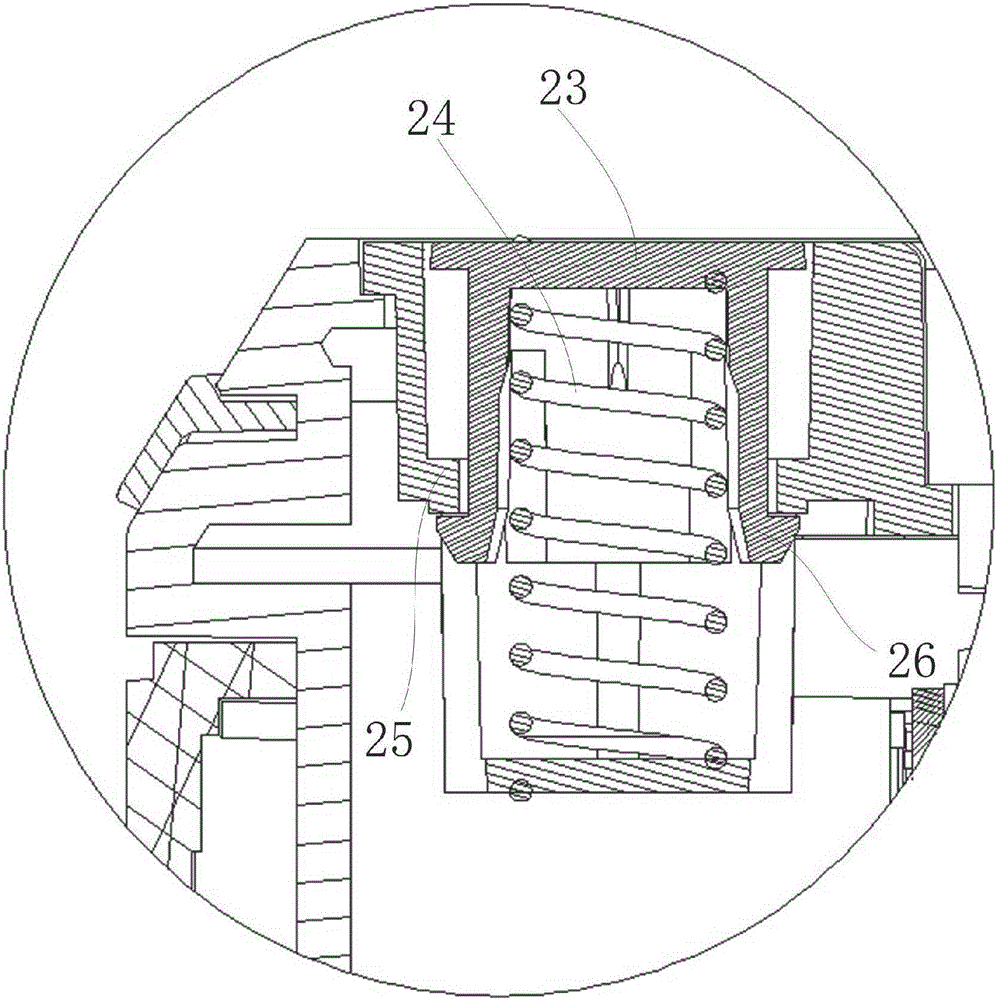

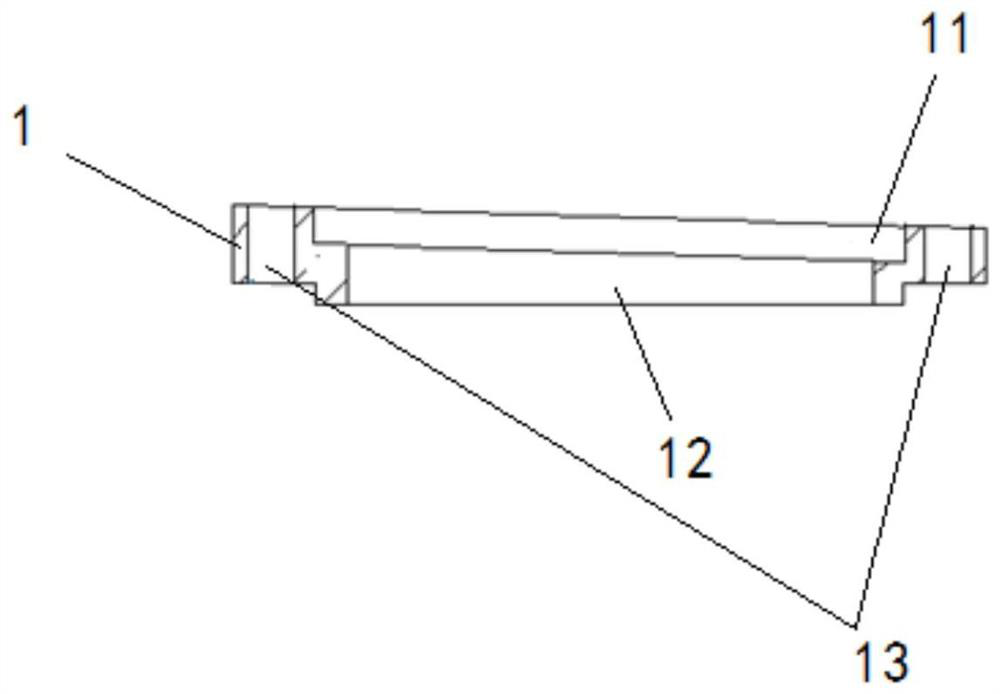

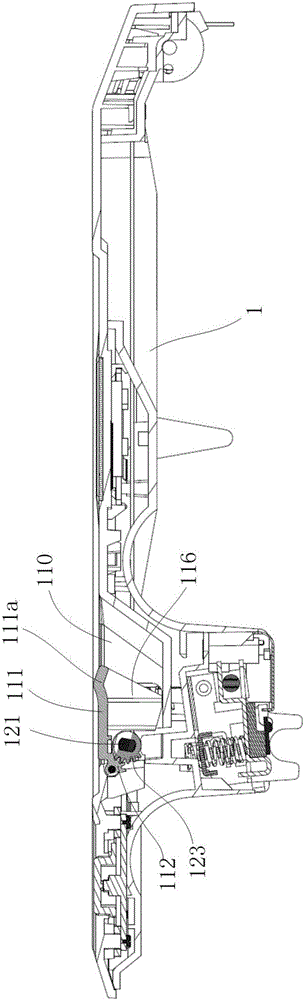

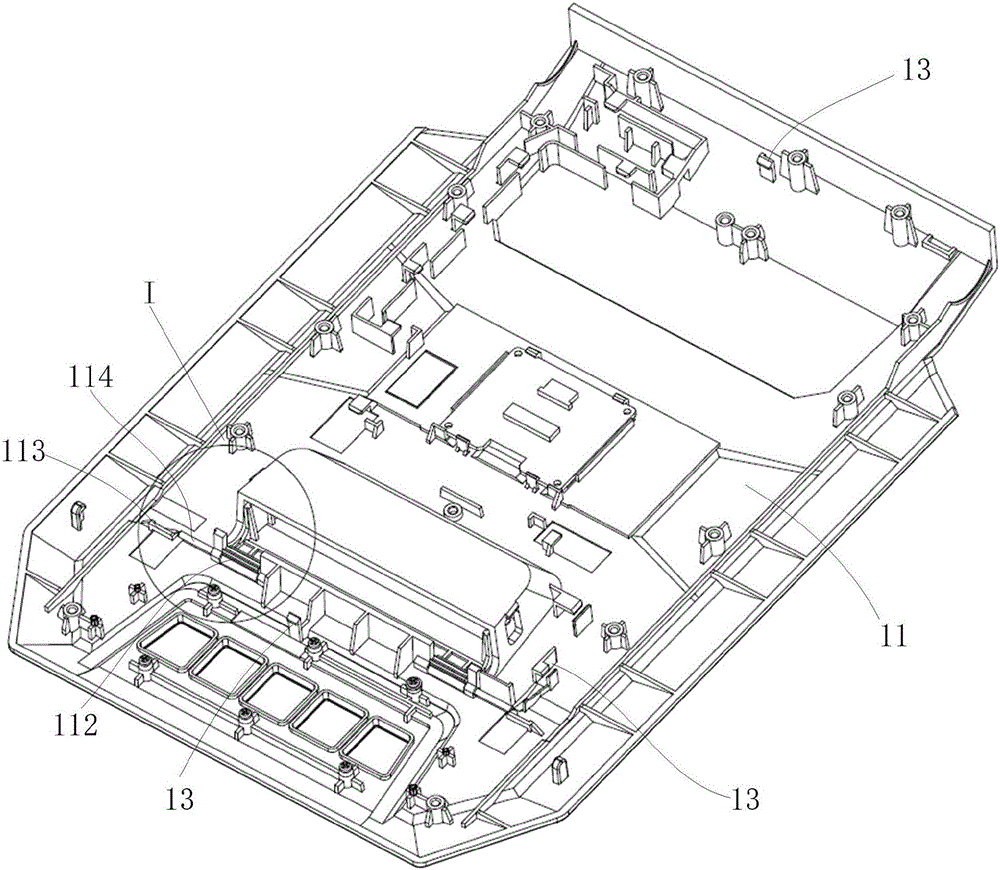

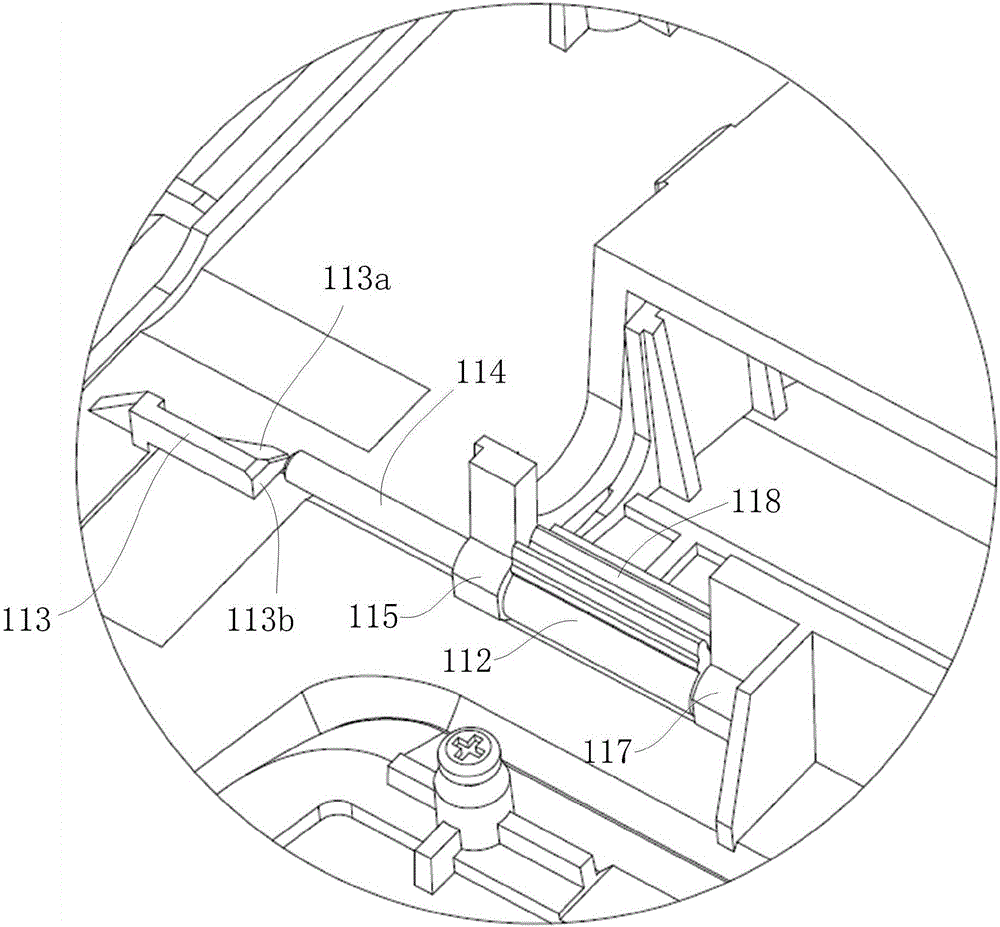

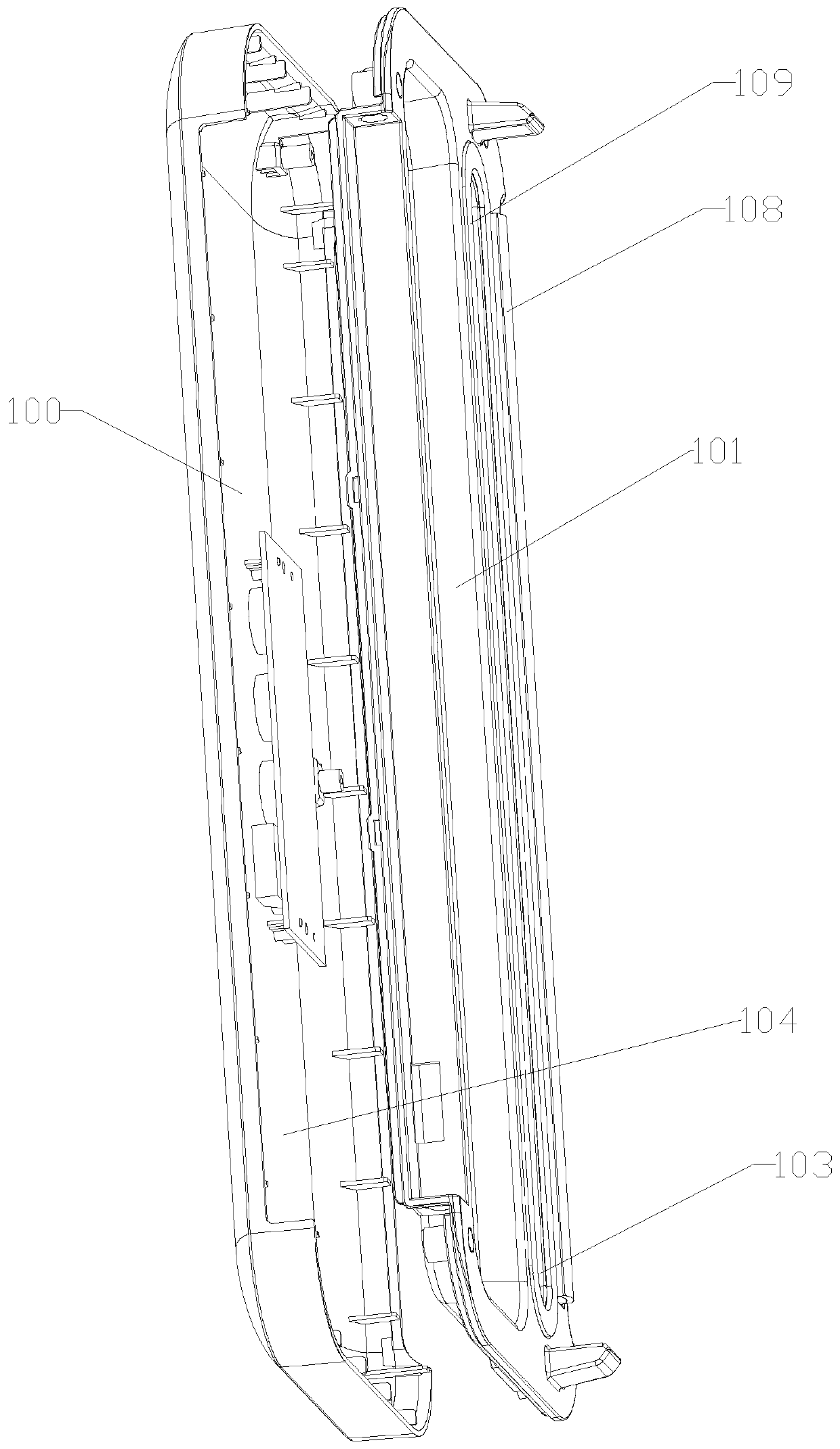

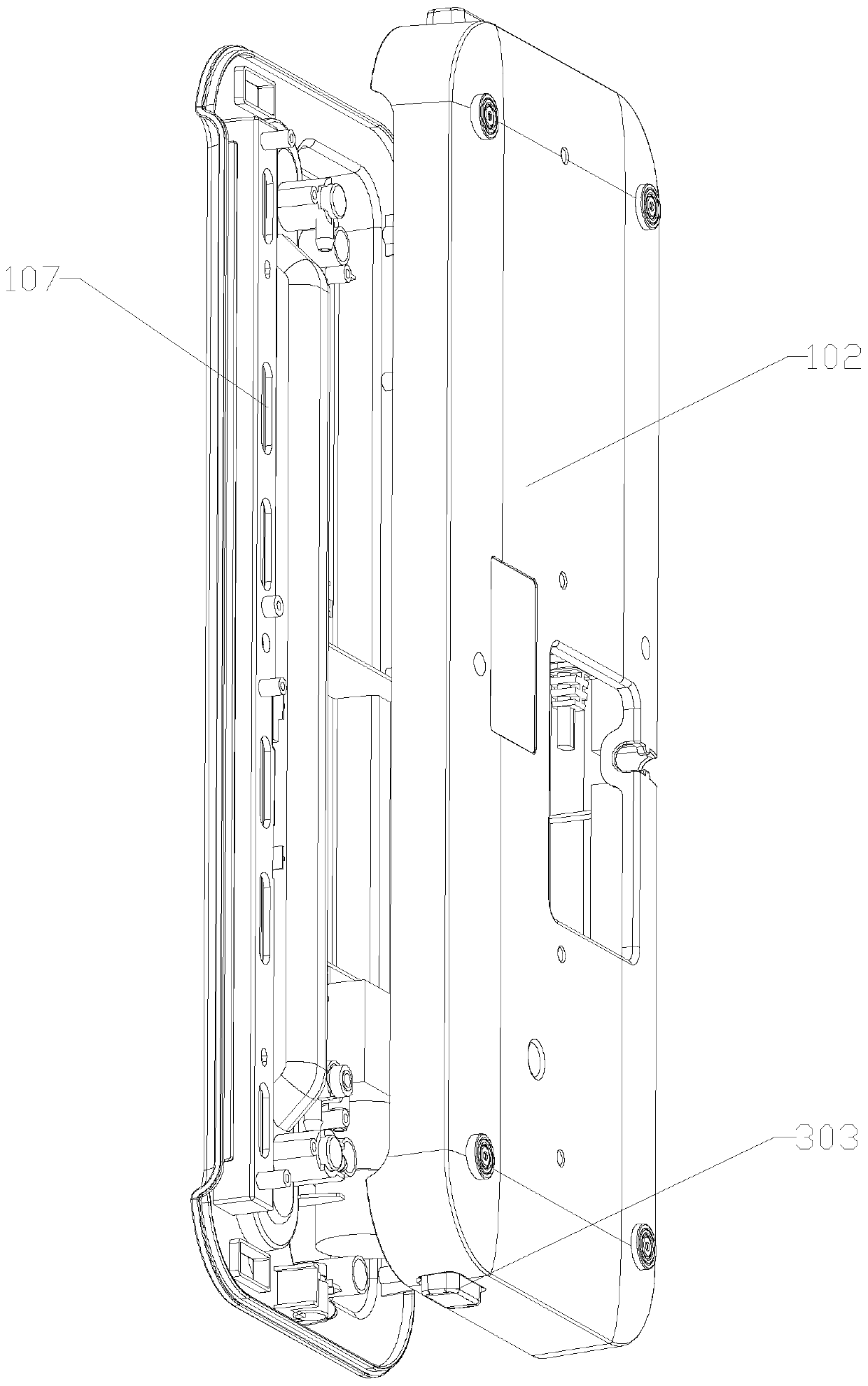

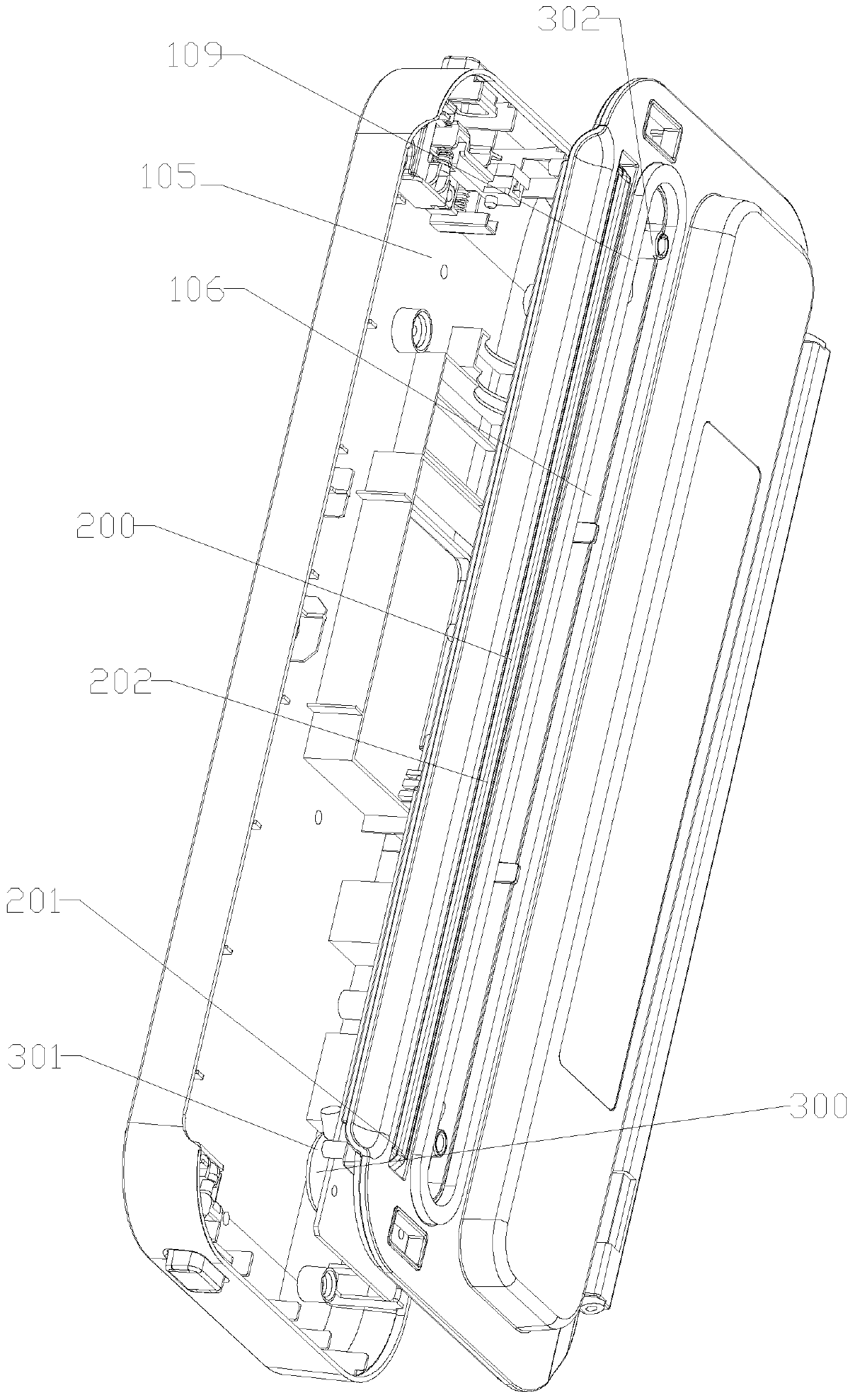

Upper and lower shell connecting structure and printer comprising same

ActiveCN106626823ASolve the gap problemEliminates the problem of not locking in placeOther printing apparatusLocking mechanismEngineering

The invention provides an upper and lower shell connecting structure and a printer comprising the same. The upper and lower shell connecting structure comprises an upper shell component and a lower shell component which are connected rotationally. A cover locking mechanism is arranged between the upper shell component and the lower shell component. An auxiliary push-out mechanism is also arranged between the upper shell component and the lower shell component. When a cover is being opened, the auxiliary push-out mechanism pushes the upper shell component out so there is a gap between the upper shell component and the lower shell component. The back ends of the upper shell component and the lower shell component are connected rotationally through a torsion spring and a rotating shaft. The cover locking mechanism is disposed in the front part of the upper shell component and the lower shell component. The auxiliary push-out mechanism is close to the cover locking mechanism. After the cover locking mechanism is opened, the auxiliary push-out mechanism pushes out the end of the upper shell component away from the hinge joint to separate the upper shell component from the lower shell component so that an operator can extend a finger in to open the upper shell component for carbon ribbon or label installation. Through the torsion spring and the auxiliary push-out mechanism, the problem that a printer may be damaged or an operator may be injured when the torsion of the torsion spring is too big or small is avoided.

Owner:CHONGQING PINSHENG TECH CO LTD

Laser photovoltaic cell and production method thereof

ActiveCN103117286AEasy to coverSolve the gap problemFinal product manufactureDiodeSemi insulatingLaser

The invention discloses a laser photovoltaic cell which comprises an isolation groove. The isolation groove divides the photovoltaic cell into a plurality of cell units which are in series connection, and a polyimide layer, a dielectric film layer and a metal shading layer are sequentially formed on the surface of the inner wall of the isolation groove. The invention further discloses a production method of the laser photovoltaic cell. By the laser photovoltaic cell and the production method thereof, the problem of electric leakage due to the fact that a semi-insulating substrate exposes to light is effectively solved. Besides, the produced photovoltaic cell has the advantages of high parallel resistance, small electric leakage and high conversion efficiency.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

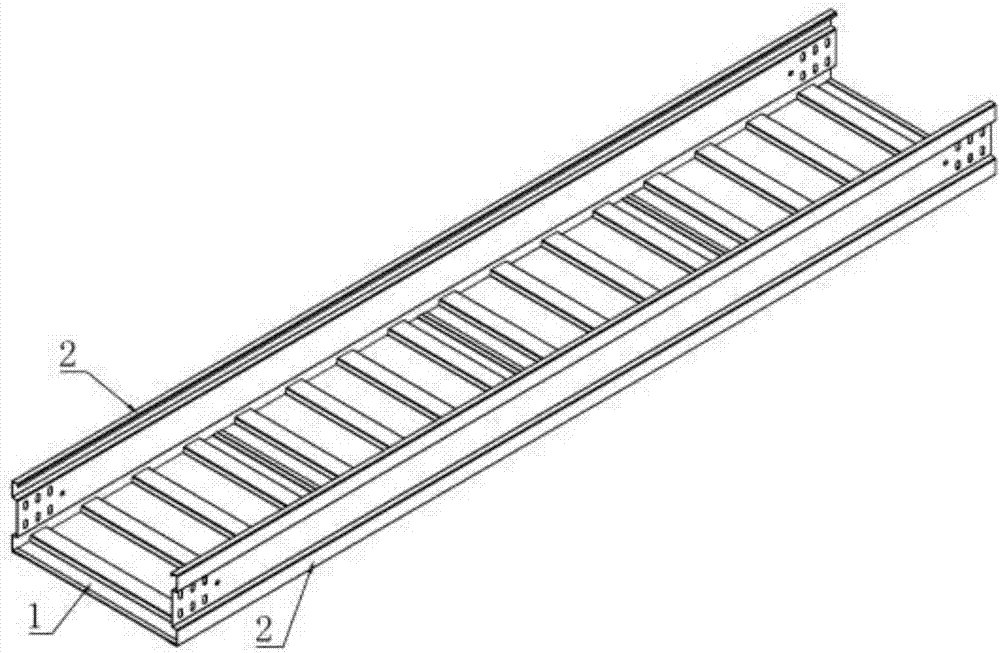

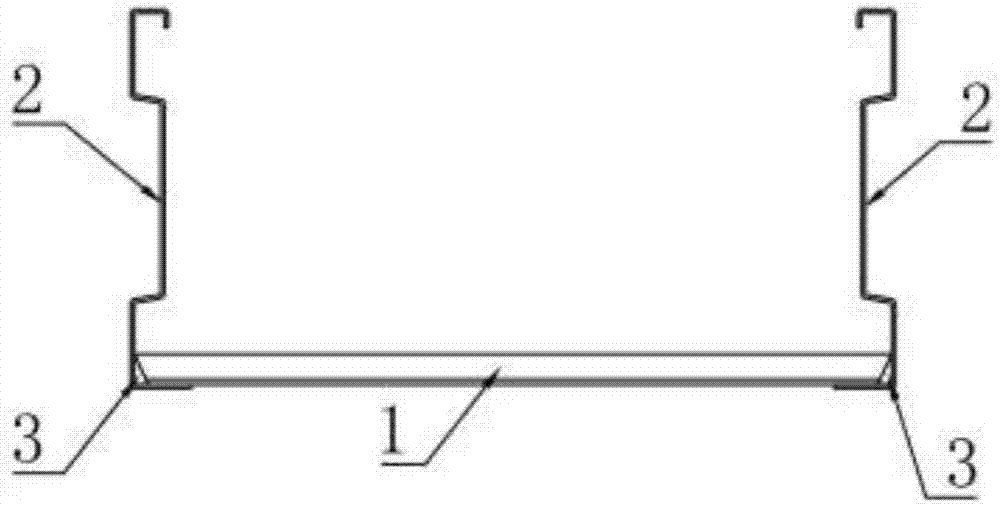

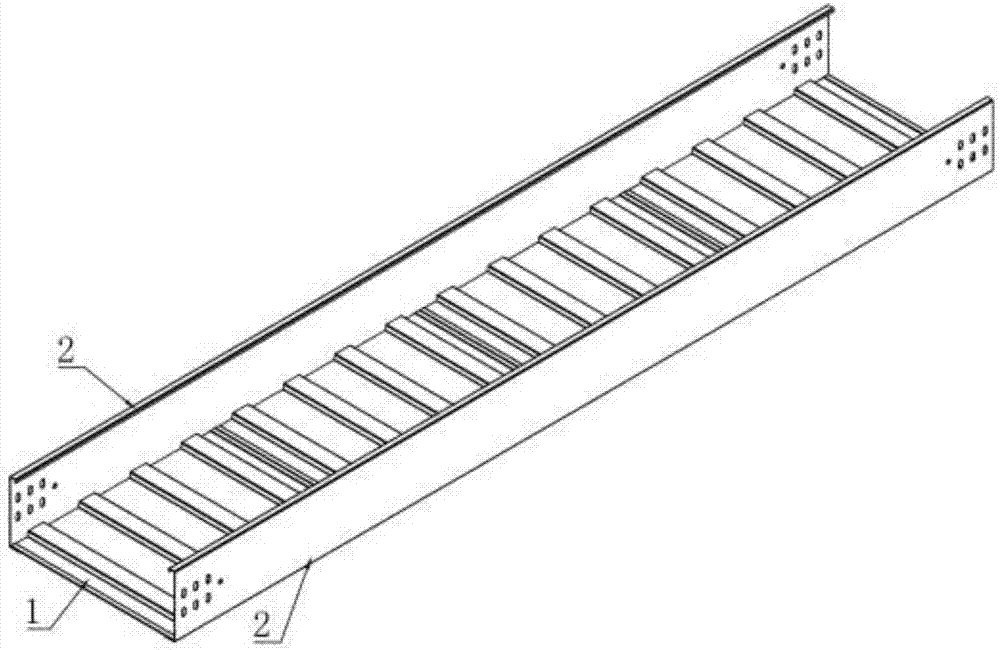

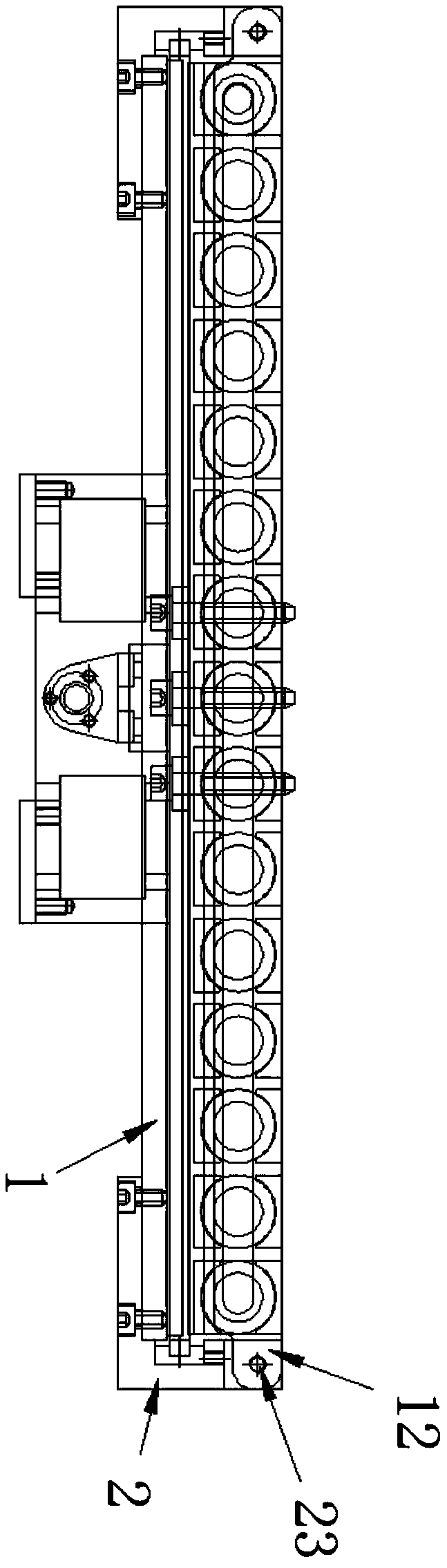

Light enhanced tray type bridge stand

InactiveCN106972429AHigh strengthGuaranteed assembly accuracyElectrical apparatusResource utilizationStructural engineering

The invention provides a light enhanced tray type bridge stand. The bridge stand is composed of two side plates (2) and multiple baseplates (1). The baseplates (1) are arranged between the two side plates (2), and multiple baseplates (1) are continuously spliced along the length direction of the internal side of the side plates (2) to form the bridge stand. The width of the baseplates (1) is cut according to the specification of the bridge stand. The cutting angle of the baseplates (1) is inclined, i.e. the width of the transverse upper plane of the baseplates (1) is greater than the width of the lower plane so that the transverse width of bottom grooves (12) is enabled to be less than the width of protrusions (11), a certain gap (3) can be reserved between the bottom connecting part of the baseplates (1) and the side plates (2) and finally the baseplates (1) and the side plates (2) are spliced and welded into an organic whole. Compared with the bridge stands in the prior art, the bridge stand is low in weight, high in strength and easy to process, the cumulative error is eliminated and the splicing part is not liable to deform so that the problem of zinc liquid deposition in the baseplate grooves in hot-dip galvanizing can be solved, water accumulation of the bottom part is not liable to occur and the resource utilization rate is high.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

Method and device for improving metal coverage of DFB laser

PendingCN112481587ASolve the gap problemVacuum evaporation coatingSputtering coatingMetal coatingPhysical chemistry

The invention provides a method and device for improving metal coverage of a DFB laser. A clamp which can be placed in a coating machine and enables a coated sheet to be placed at a certain inclination angle is provided, the clamp is matched with a planetary turntable to perform electron beam evaporation, and thus the problem that cracks occur due to the influence of film material accumulation rate and direction in horizontal and vertical coating processes is solved. The device is simple in structure, solves the problem of the step coverage rate of the metal coating process on a non-planar structure, increases the production yield, and is suitable for popularization.

Owner:全磊光电股份有限公司

Printer uncovering structure

ActiveCN106183476ASolve the gap problemEliminates the problem of not locking in placeOther printing apparatusEngineeringMechanical engineering

The invention provides a printer uncovering structure. The printer uncovering structure comprises an upper shell assembly. An uncovering poking block and an uncovering rotary shaft are rotationally installed on the upper shell assembly. A latch hook is installed on the uncovering rotary shaft. The uncovering rotary shaft and the uncovering poking block are provided with meshed clamping teeth. When poked, the uncovering poking block drives the uncovering rotary shaft to rotate through the clamping teeth, so that the latch hook is opened. The upper shell assembly is further provided with a reset mechanism. The uncovering poking block of the printer uncovering structure conducts meshing steering during opening rotation through the clamping teeth of the uncovering poking block and the clamping teeth of the uncovering rotary shaft. Assembly of the uncovering structure in a small space is achieved in a clamping tooth mashing mode, so that a product is smaller and more portable.

Owner:CHONGQING PINSHENG TECH CO LTD

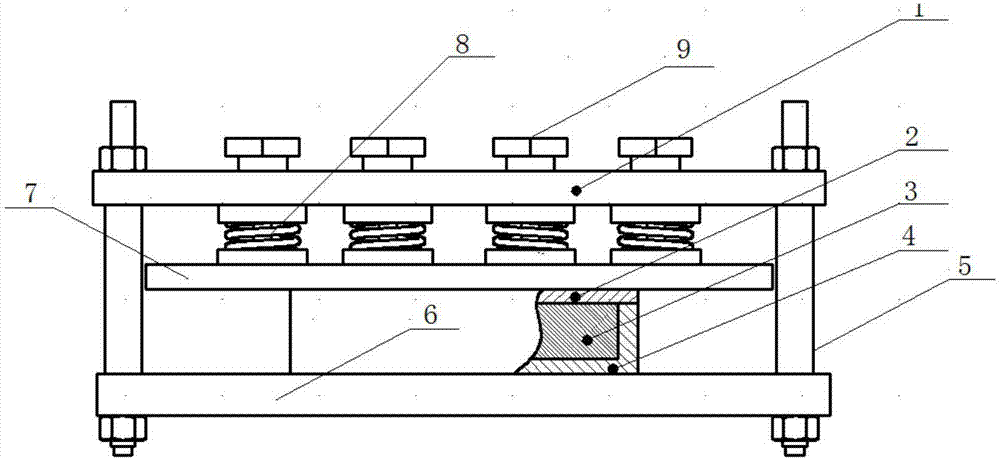

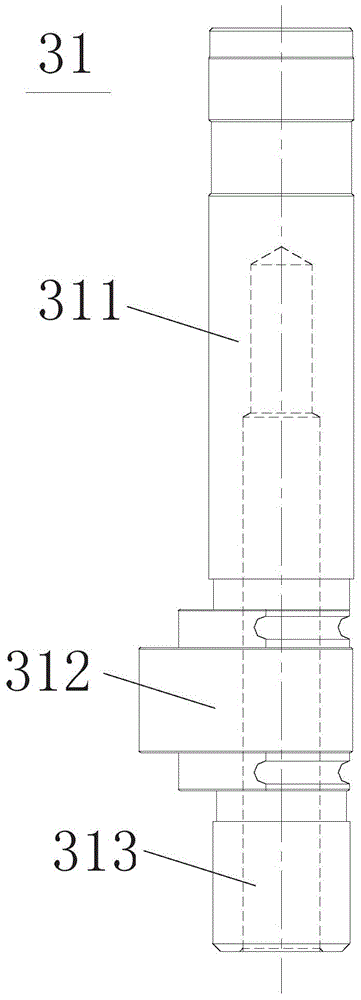

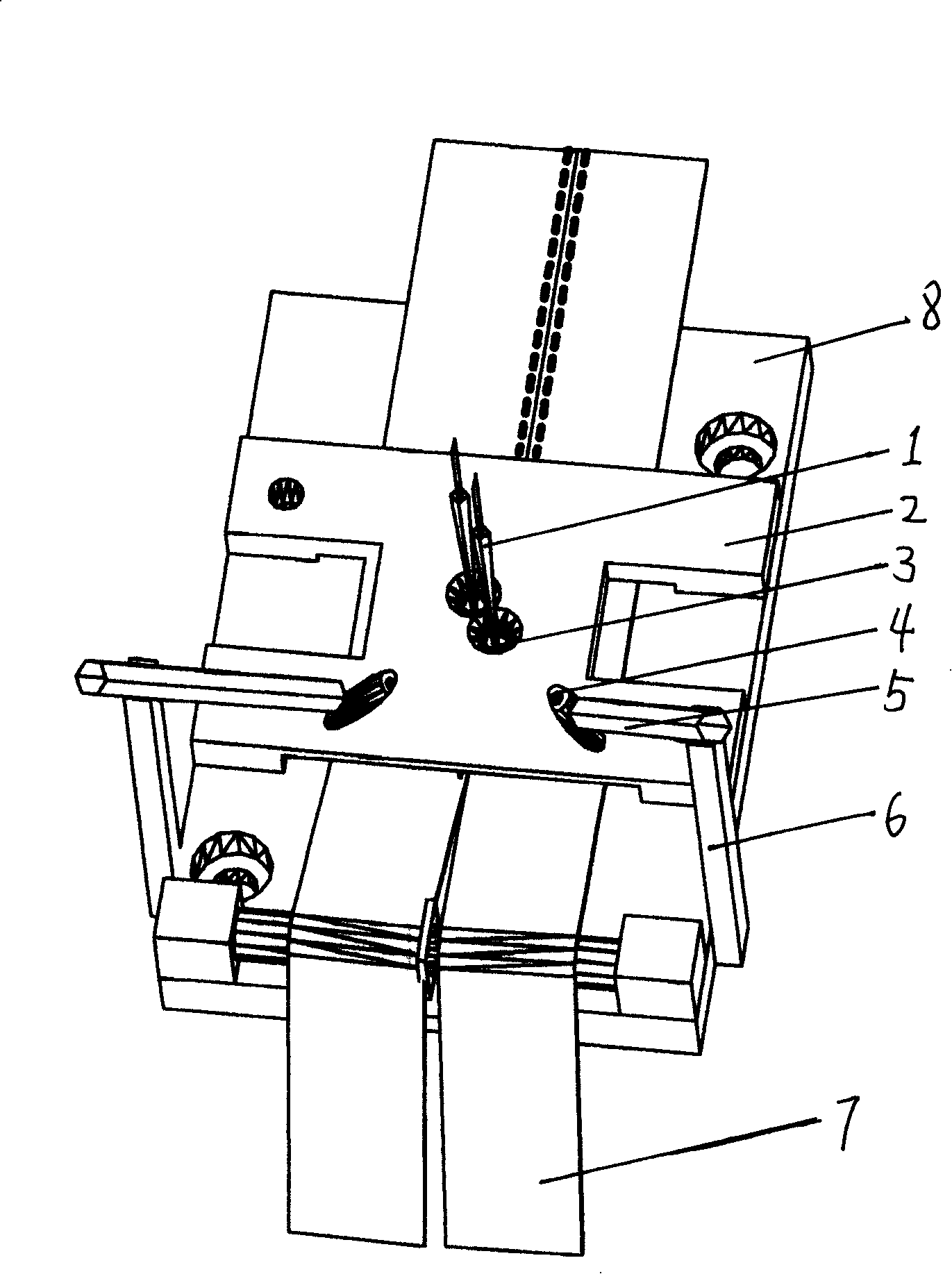

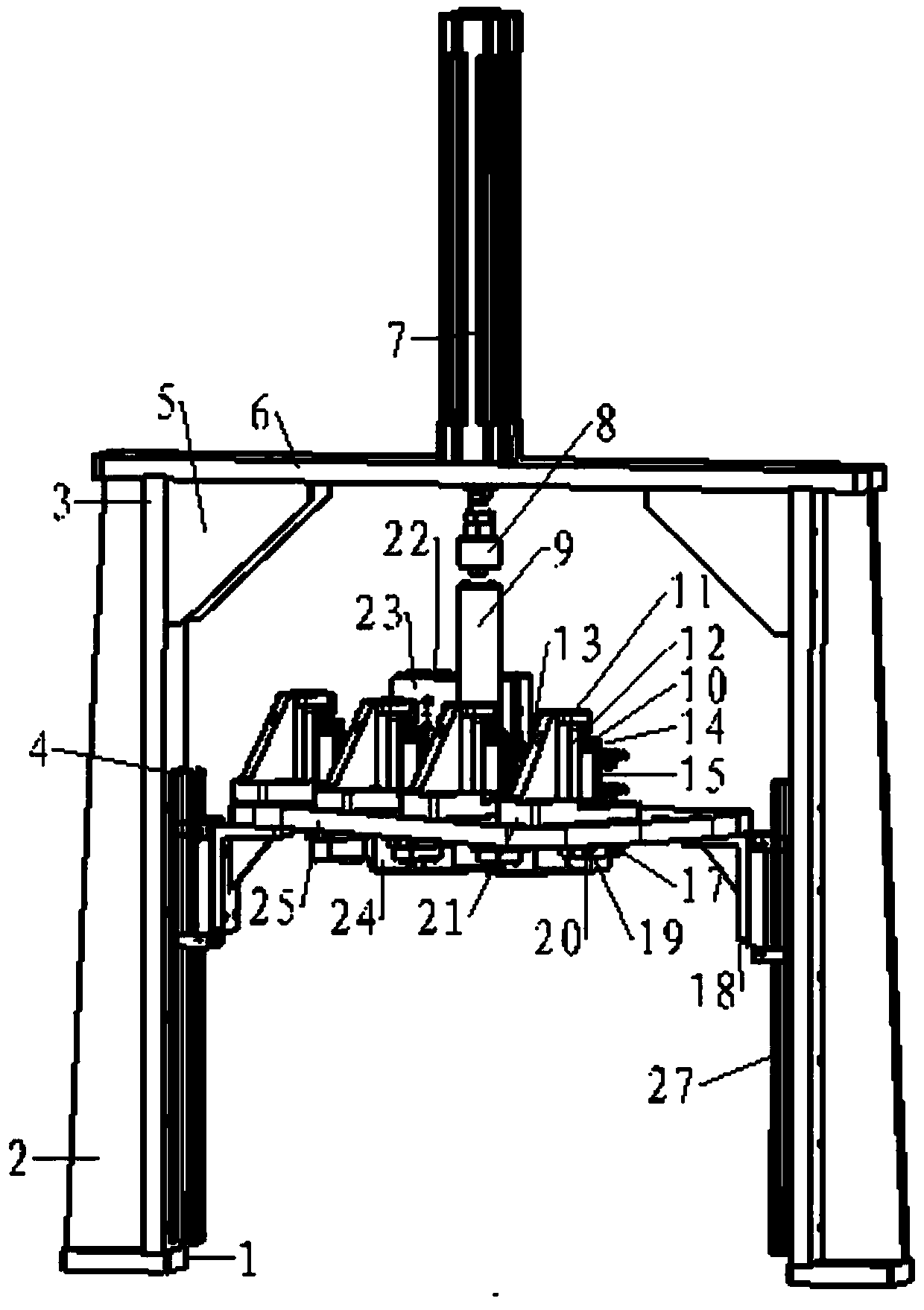

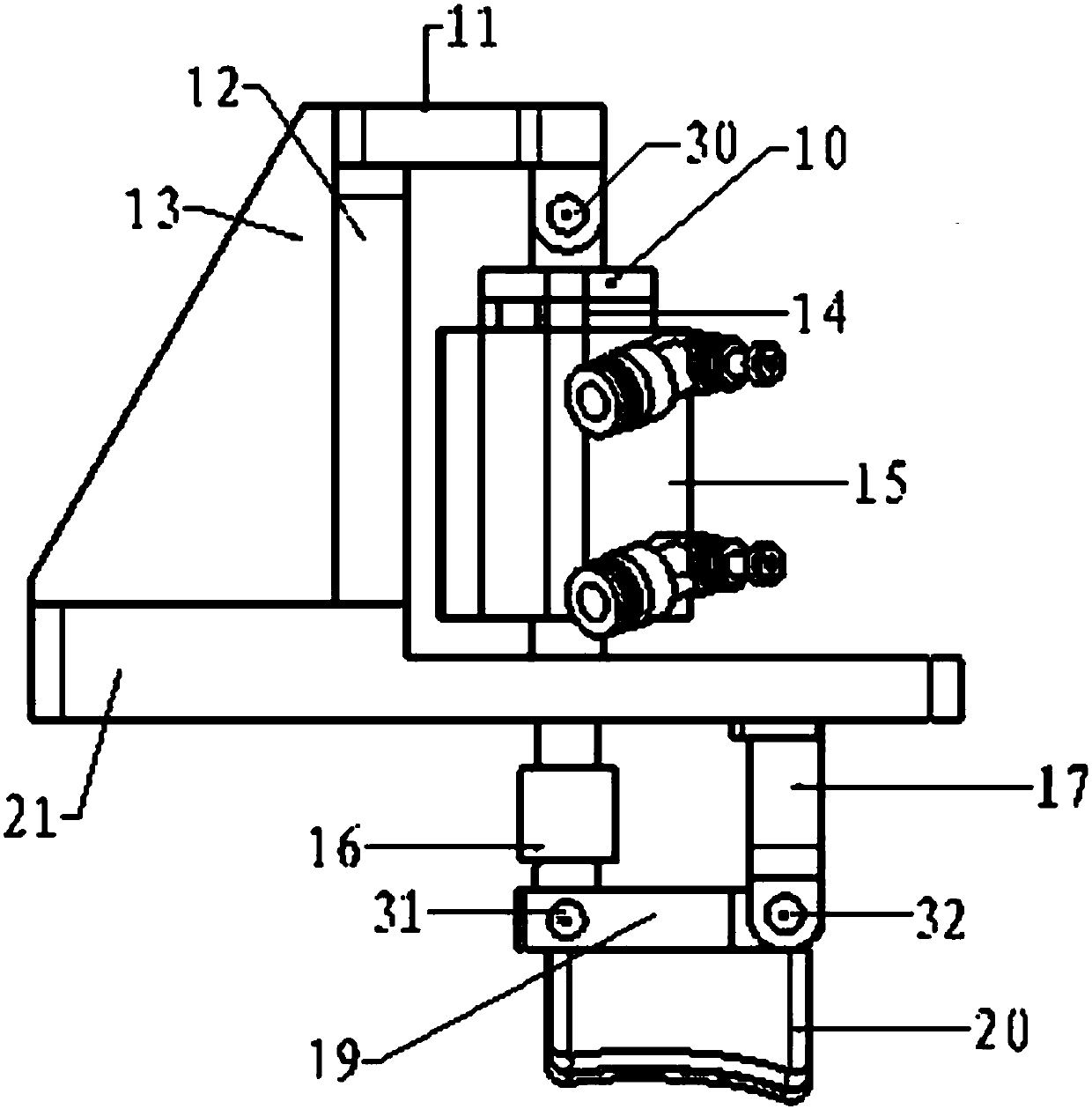

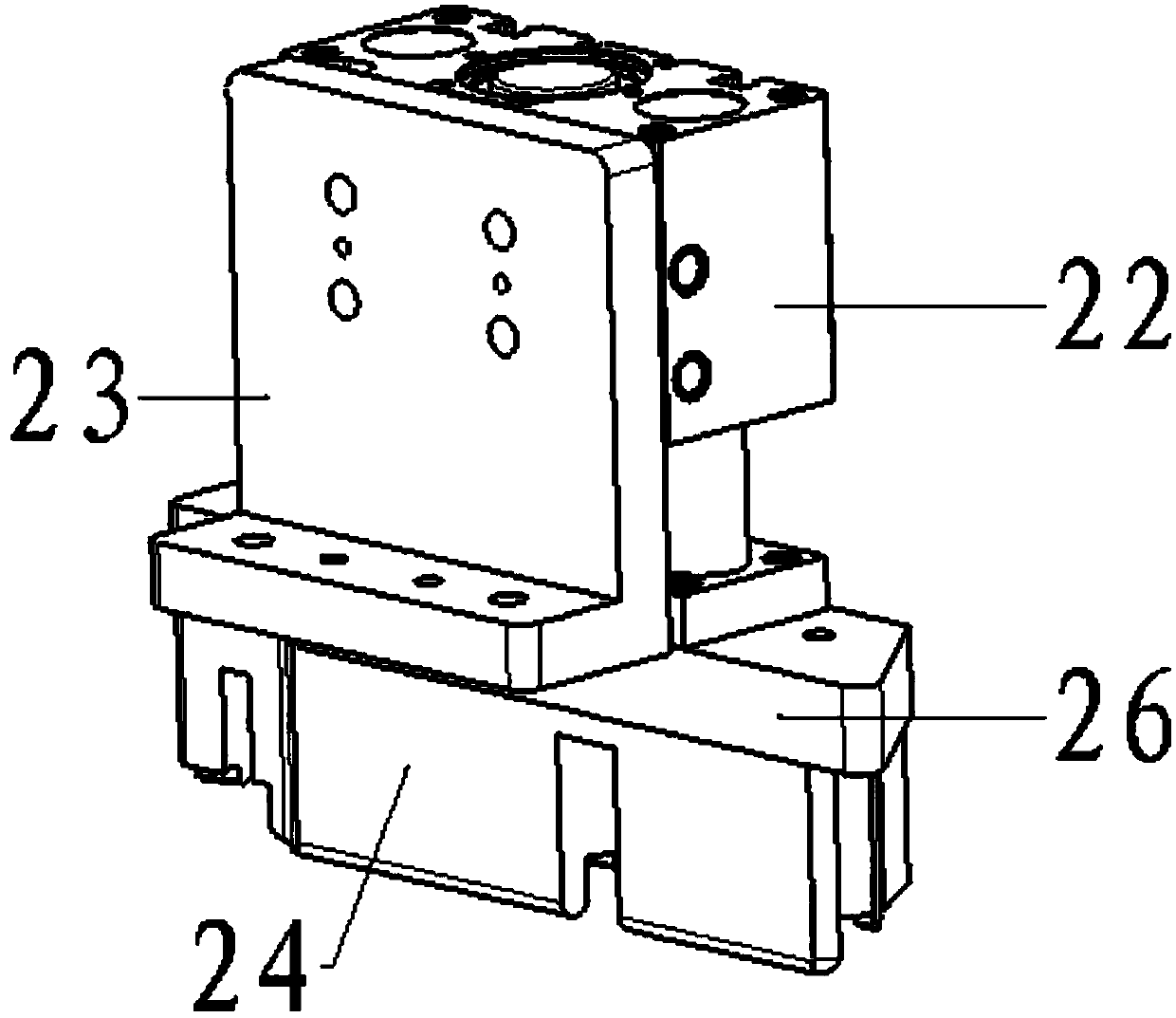

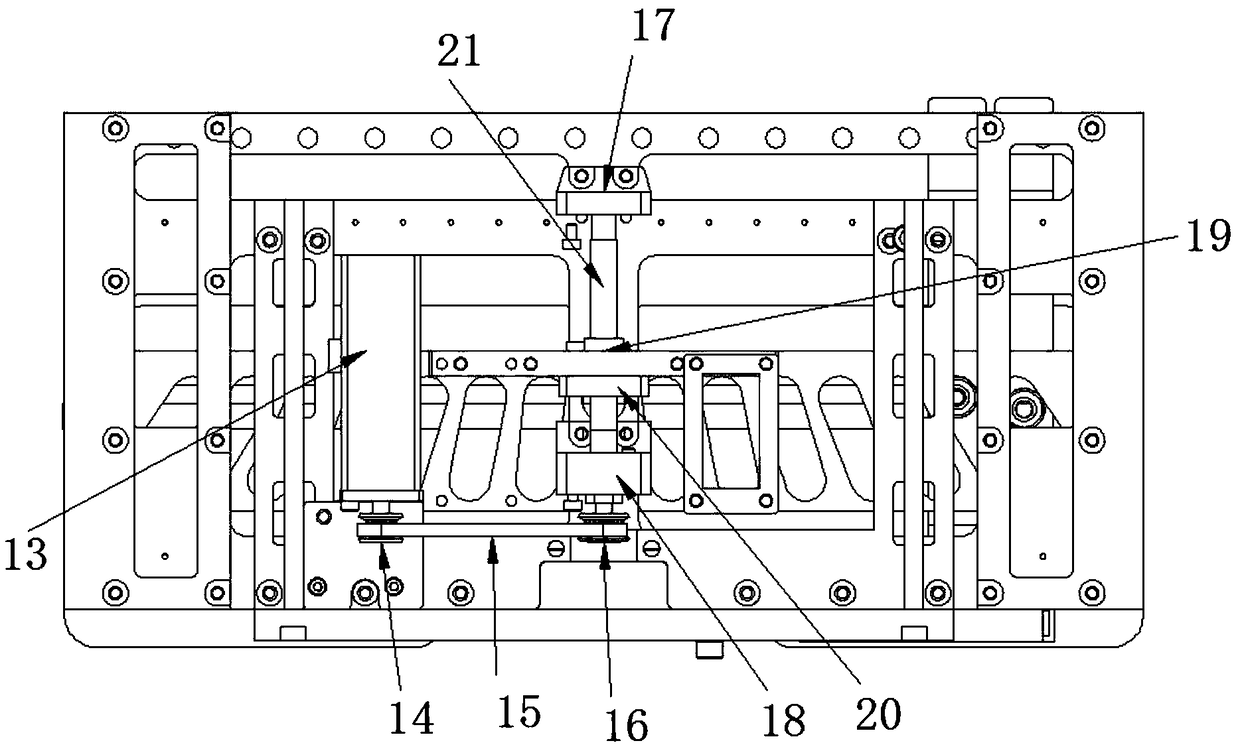

Rotary pressure welding mechanism used for automatically mounting automobile rear quarter window glass bright molding

ActiveCN107813257AAvoid damageSolve the photopolar changeMetal-working hand toolsRear quarterInterference fit

The invention discloses a rotary pressure welding mechanism used for automatically mounting an automobile rear quarter window glass bright molding, and belongs to the technical field of industrial automation. The rotary pressure welding mechanism comprises a portal supporting base, a portal supporting vertical plate, a guide rail, a portal cross beam, a lifting air cylinder, a floating connector,a connecting column, a rotary pressure welding mechanism body, a sliding block fixing plate, a straight-sided mechanism, a main fixing plate and a sliding block. The rotary pressure welding mechanismis mainly formed by combing an air cylinder with the rotary pressure welding mechanism body for achieving the mounting function, and is manufactured by completely copying the shape of the bright molding, the effects that one side of a bright molding buckle is buckled into a glass buckle and then the other side of the bright molding buckle is buckled in can be achieved, the bright molding can be mounted in place only with few effort, and the bright molding can be prevented from being damaged. The problem that optical distortion, tearing cracks, deformation, scratches and flushness of the brightmolding are caused when the bright molding is mounted through snap fasteners in an interference fit mode is effectively solved, and the production efficiency is improved.

Owner:长春吉田快速成型科技有限公司

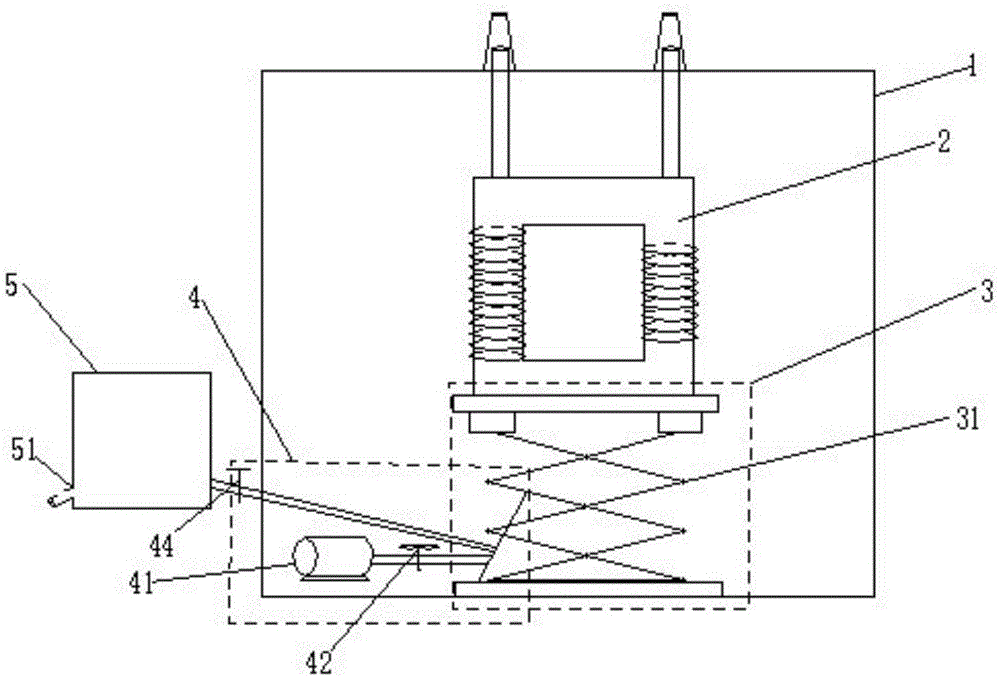

Single-phase oil-immersed transformer and special iron core therefor

ActiveCN105469945ASolve the gap problemGuaranteed uptimeTransformers/inductances coolingTransformers/inductances magnetic coresTransformerLow voltage

The invention provides a single-phase oil-immersed transformer and a special iron core therefor. The single-phase oil-immersed transformer comprises a box body with a box cover, an iron core, a radiating pipe, an oil conservator, a lifting mechanism, a power mechanism and an oil tank, wherein the iron core is a single-frame dual-core column with a groove, is arranged at the center of the box body and is immersed by an oil body; a coil is led out of the box cover; a high-voltage insulating sleeve and a low-voltage insulating sleeve respectively sleeve a lead; the radiating pipe is arranged on the side wall of the box body; the oil conservator is arranged at the upper end of one side of the box body; the lifting mechanism is arranged below the iron core; the bottom end of the lifting mechanism is fixedly connected with the box body; the power mechanism is connected with the lifting mechanism; the oil tank is connected with the power mechanism; and the oil tank is arranged outside the box body. The single-phase oil-immersed transformer can drive the lifting mechanism to take out the iron core by taking the oil in the box body as a power source through the power mechanism and stores the oil in the box body into the oil tank, so that maintenance of the iron core and oil-change operation are facilitated; the cost is saved; and the maintenance efficiency is also improved.

Owner:JIANGSU MINGAN ELECTRIC

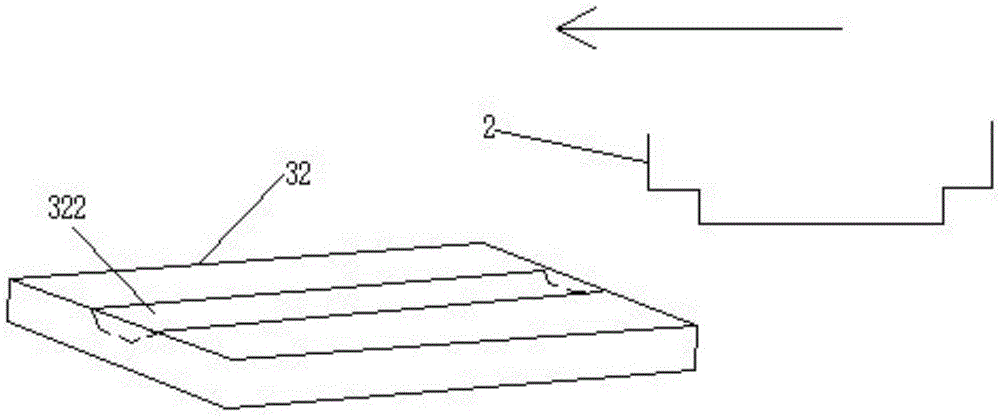

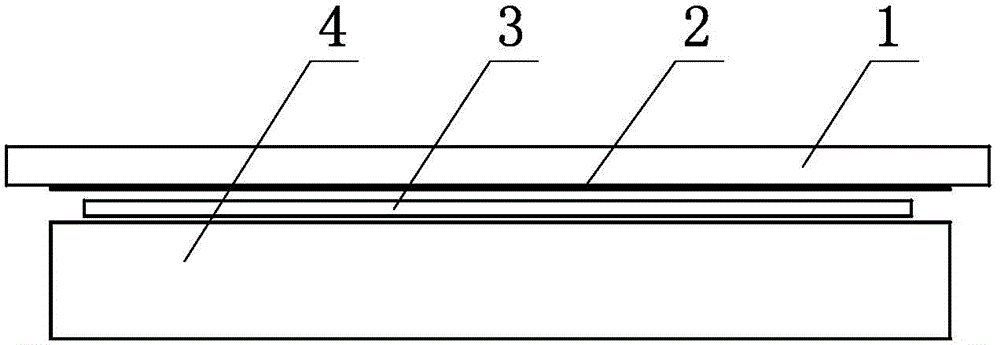

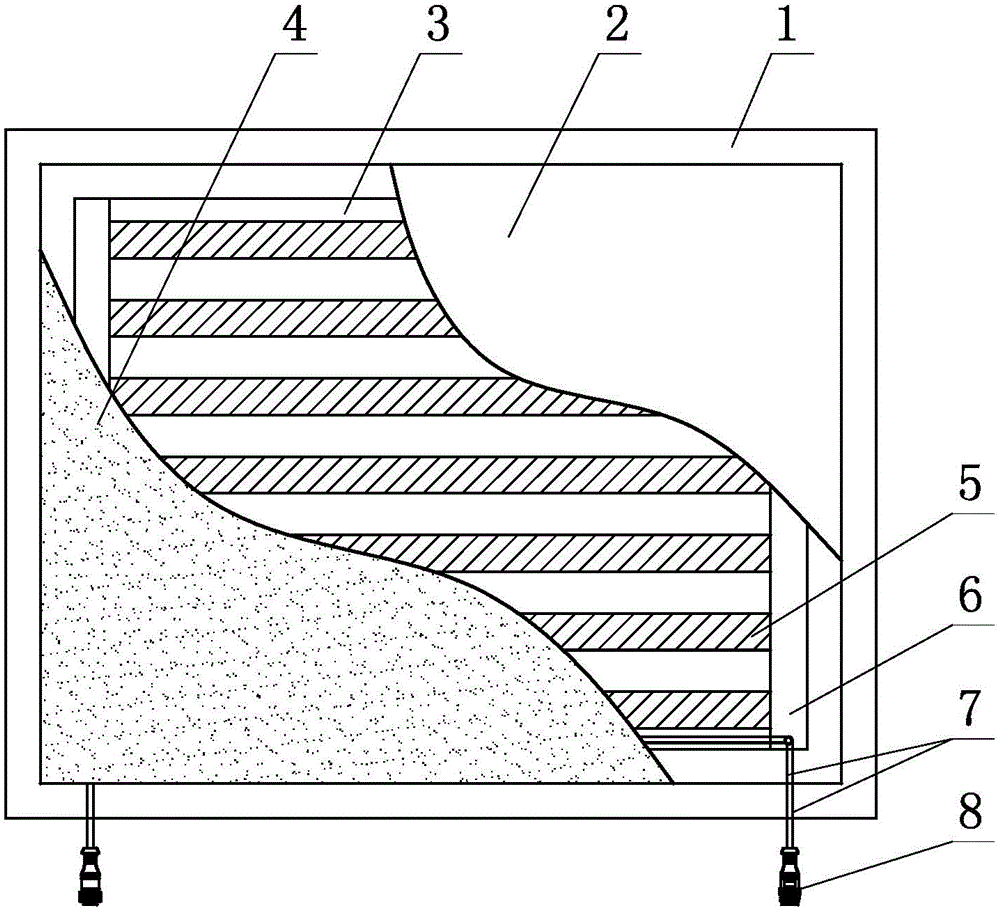

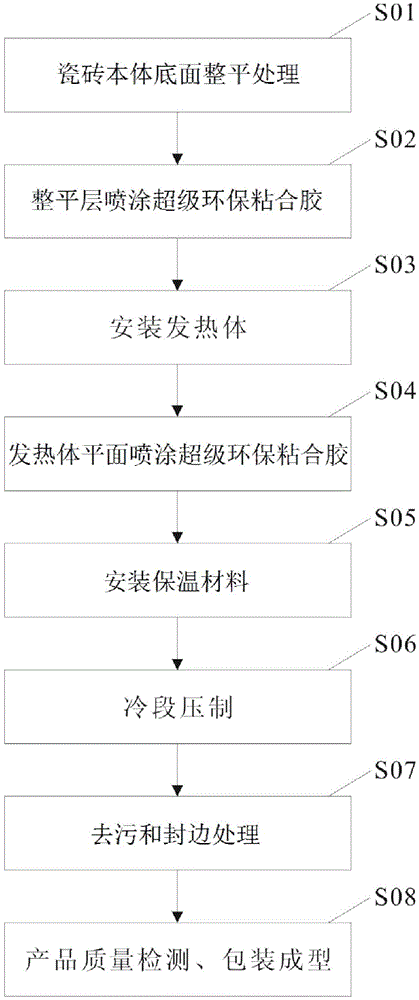

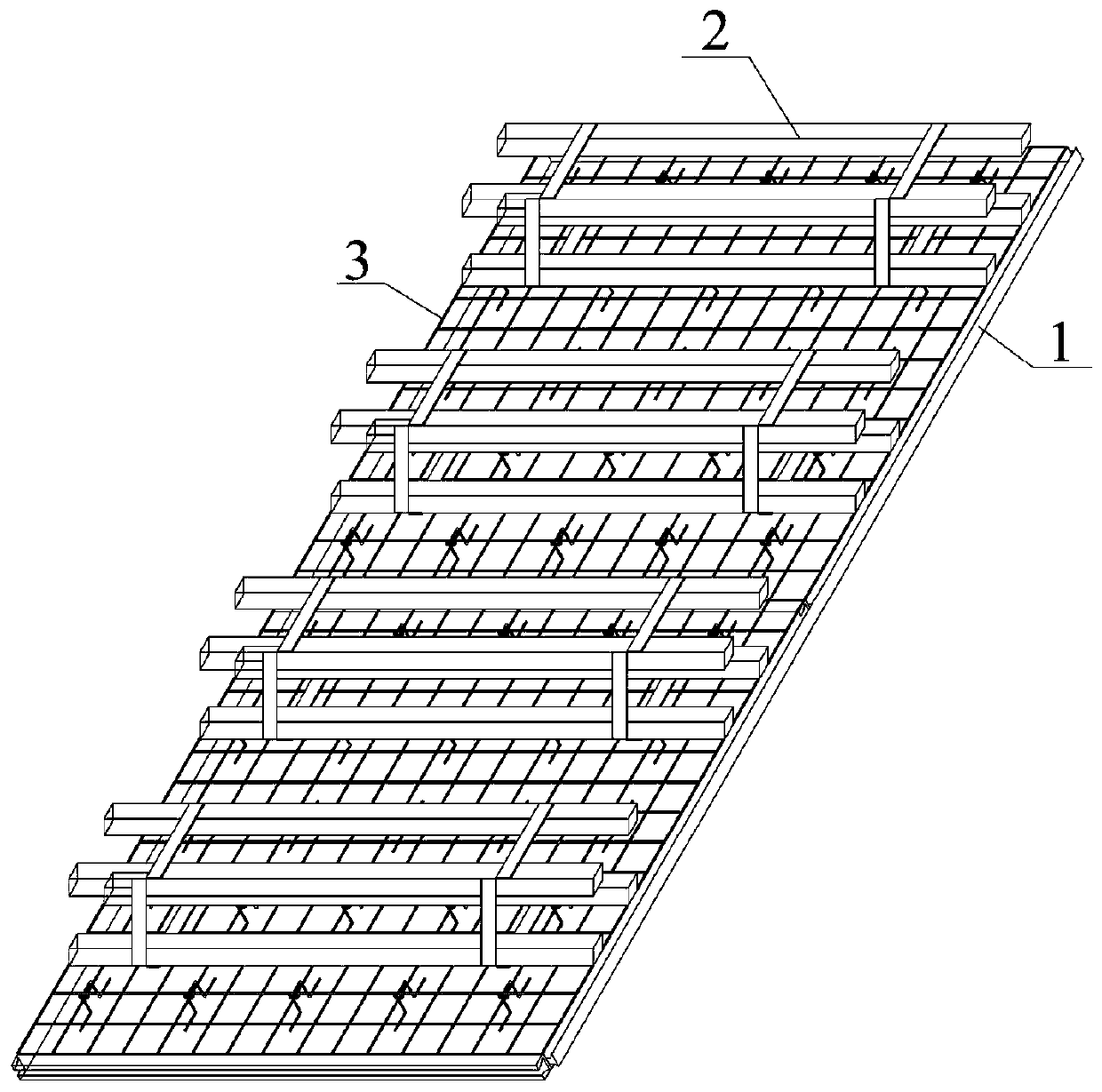

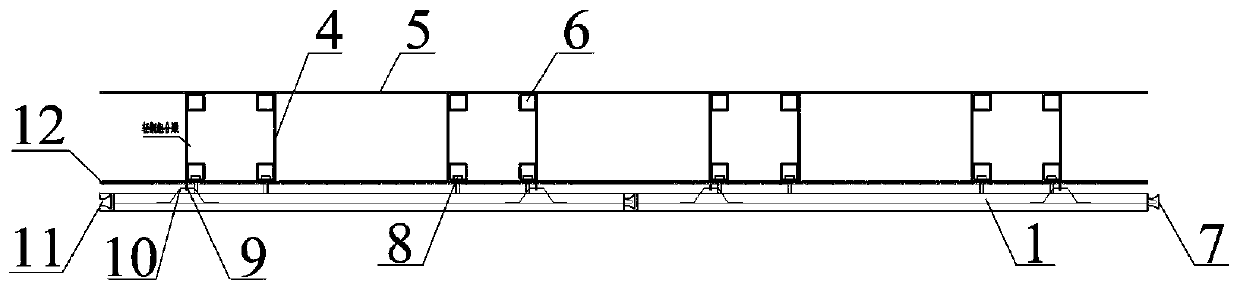

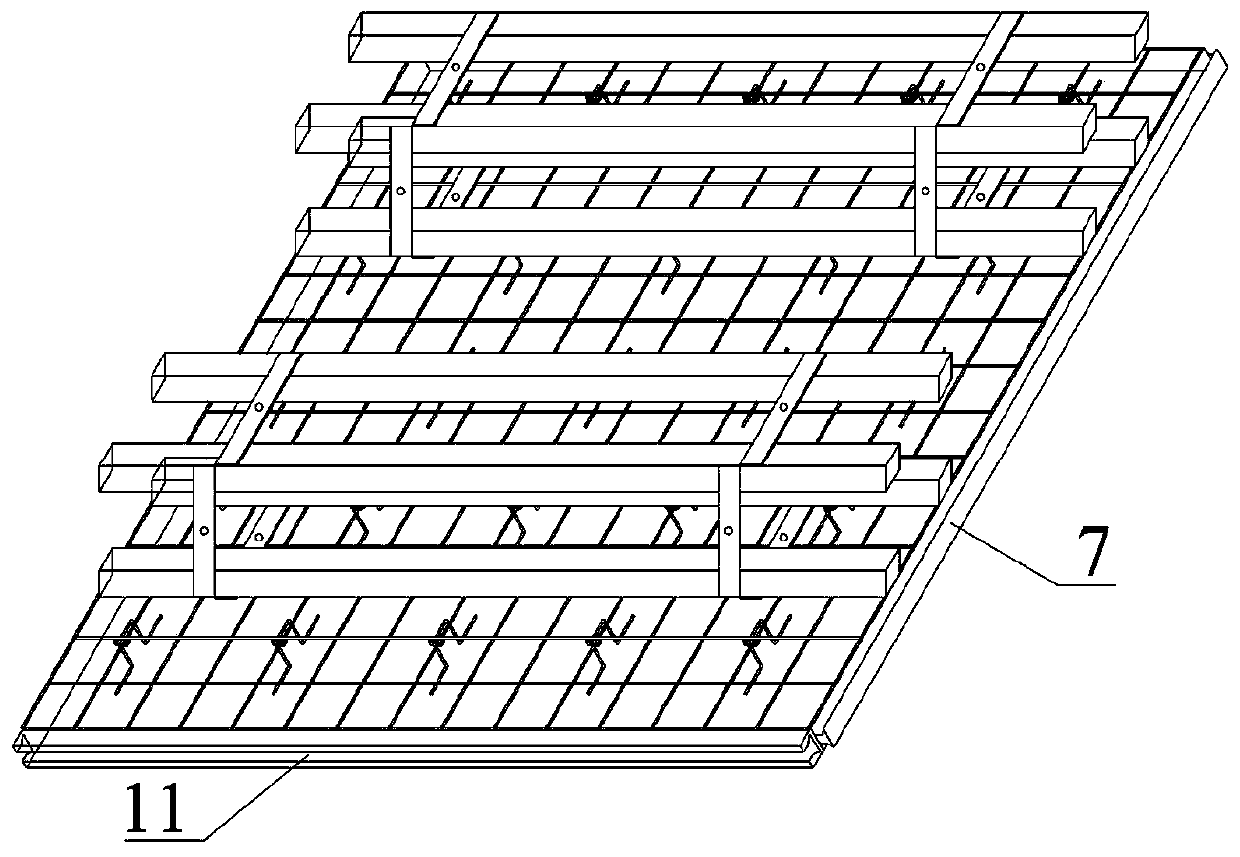

Integral heat generation ceramic tile and manufacturing technique thereof

InactiveCN104019489AUniform conductionSolve the gap problemCovering/liningsLighting and heating apparatusEpoxyHeat conservation

The invention discloses an integral heat generation ceramic tile and a manufacturing technique thereof. The integral heat generation ceramic tile is characterized by comprising a ceramic tile body, a heat generation body and a thermal insulating base plate, wherein the heat generation body is an epoxy resin heat generation body formed by combining multiple transversely arranged heat generation sheets; two conductive plates are arranged at two ends of the heat generation sheets in parallel; a connecting wire led out from a lead connecting end at one end part of the conductive plates is connected with a waterproof connector; and a leveling layer is arranged between the bottom surface of the ceramic tile body and the heat generation body. The machining steps comprise: leveling the bottom surface of the ceramic tile body; spraying a super environment-friendly bonding glue on the leveling layer; installing the heat generation body; spraying the super environment-friendly bonding glue on the surface of the heat generation body; installing a thermal insulating material; pressing cold section; removing dirt and sealing edges; testing product quality; and packing and forming. The integral heat generation ceramic tile has the advantages of being simple and reasonable in structure design, strong in integrity, firm in electric connection, good in electric conductivity, safe, reliable, uniform in heat generation, simple in manufacture technique, long in service life and convenient and rapid to install, use, maintain and replace.

Owner:王超

Buckle type non-dismantling mold floor slab

PendingCN109930727ALarge area of actionExtend your lifeFloorsBuilding reinforcementsFloor slabOmega

The invention discloses a buckle type non-dismantling mold floor slab. The non-dismantling mold floor slab comprises non-dismantling templates, steel wire nets, light steel stand columns and steel braces, wherein one side of each non-dismantling template is a smooth plane and a plurality of pre-embedded omega-shaped parts and a plurality of T-shaped buckles are arranged at the other side of each non-dismantling template; a plurality of male connector grooves and a plurality of female connector grooves are formed in four edges of each non-dismantling template; each steel wire net is provided with a plurality of hanging buckles; each light steel stand column is provided with a plurality of T-shaped grooves; the pre-embedded omega-shaped parts and the steel wire nets are fixedly connected through a first buckle manner; bottom surfaces of the light steel stand columns and the non-dismantling templates are fixedly connected through a second buckle manner; the non-dismantling templates are fixedly connected with each other through a third buckle manner; the non-dismantling templates are rapidly mounted on the light steel stand columns through the connection of a first buckle, a second buckle and a third buckle. The buckle type non-dismantling mold floor slab disclosed by the invention has the advantages that the installation is rapid, the installation is firmer, the construction period is greatly shortened and construction steps of the floor slab are shortened, and the non-dismantling mold floor slab is suitable for being popularized and applied in a large range.

Owner:GUANGZHOU CITY LUBAN CONSTR

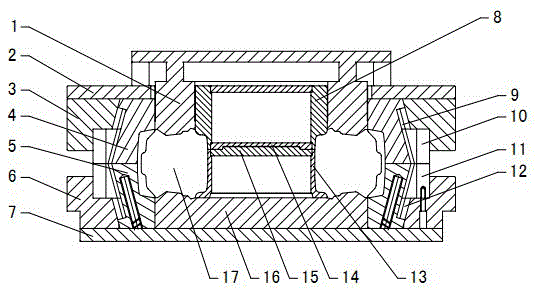

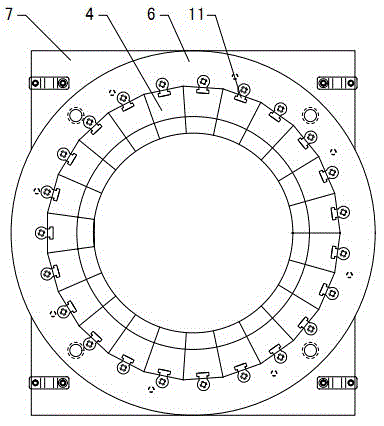

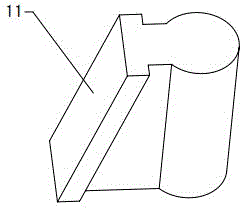

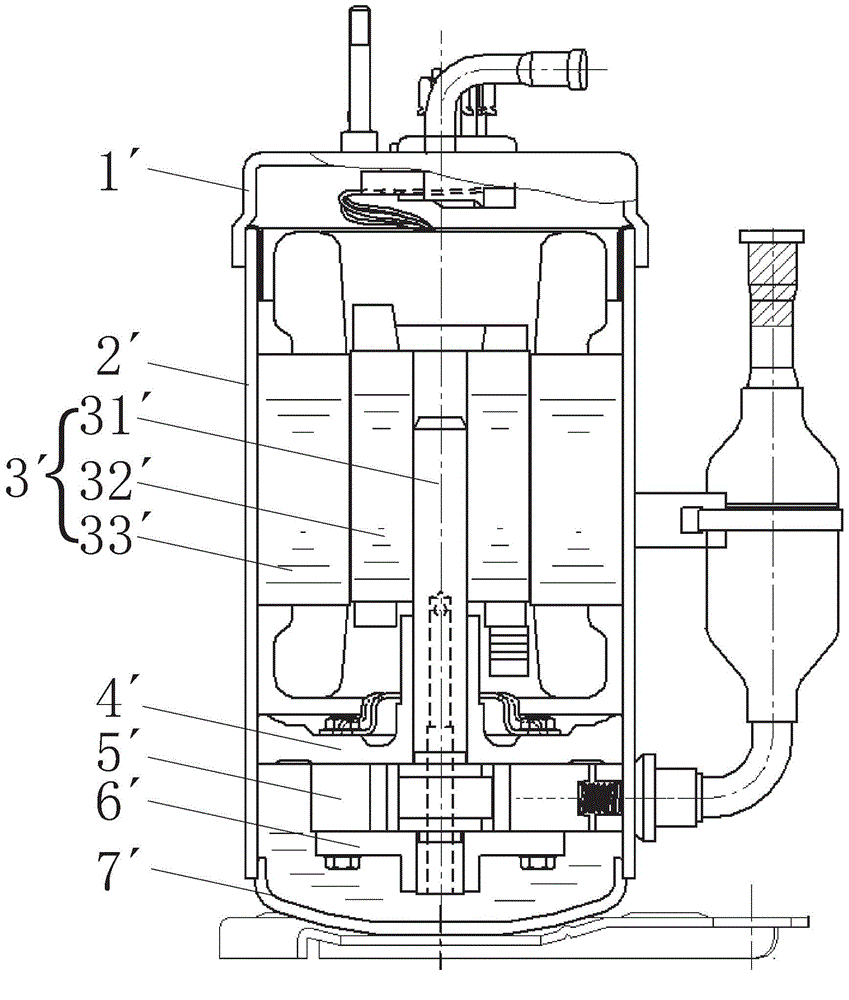

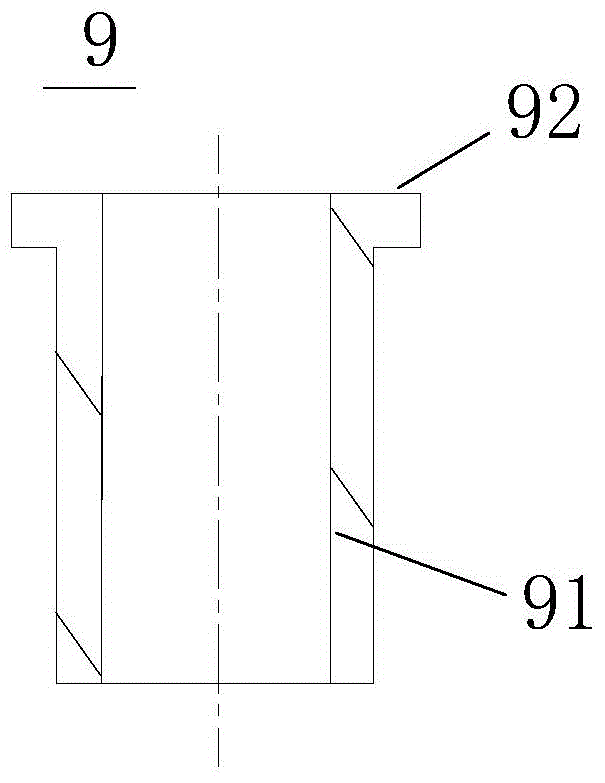

Compressor

ActiveCN105370577AMeet wear requirementsMeet welding requirementsRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigerantCrankshaft

The invention provides a compressor. A motor and an air cylinder are contained in a shell. A bent axle is provided with a long axle part, an eccentric part and a short axle part. The bent axle transmits rotation force of the motor to the air cylinder to compress refrigerant. Compression space is jointly defined by a first bearing assembly, a second bearing assembly and the air cylinder, and the bent axle is supported. The first bearing assembly comprises a main bearing located between the motor and the air cylinder, and a thrust bush. The main bearing is provided with a disc part with a through hole and an inner edge part protruding upwards from the inner circumference of the disc part. The material of the thrust bush is more resistant to abrasion than the material of the main bearing. The thrust bush is provided with a bent axle supporting part and a thrust part bearing the bent axle. The bent axle supporting part is located in the through hole of the main bearing and provided with an inner hole supporting the bent axle so as to be arranged on the long axle part of the bent axle in a sleeving manner. The thrust bush is additionally arranged at the main bearing of the compressor, and the problem of friction abrasion of two friction faces can be solved at a time through one-time pressing.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Lithium battery lamination method and adopted separator membrane turn-over system

PendingCN107591558ASolve the gap problemRealize lamination processFinal product manufactureElectrolyte accumulators manufactureEngineeringMembrane configuration

The invention relates to a lithium battery lamination method and an adopted separator membrane turn-over system. The method comprises vertically arranging a membrane placing apparatus above a lamination table, and making a separator membrane transferred from the membrane placing apparatus and adsorbed on an upper surface of the lamination table; making the lamination table located at the left sideof the membrane placing apparatus, successively completing coating of a plurality of positive and negative pieces, and maintaining the topmost coated piece of the lamination to be a negative piece after the coating is completed; and allowing a membrane cutter to fall and cutting the separator membrane, aerating an airblow pipe, blowing the cut end of the separator membrane from the right side ofthe membrane placing apparatus to the lamination table, and performing rectification, adsorption and positioning. The adopted separator membrane turn-over system includes the lamination table, and a separator membrane turn-over mechanism includes a guide roll and the airblow pipe fixed at two ends of the guide roll. According to the method and system, problems that gaps exist in battery cores andbattery cores are loosen in the prior art are solved. The method and system are beneficial for automatic rectification after a separator membrane is turned over, and the lamination process of tail-free rolling of battery cores is achieved. The separator membrane consumption is saved, and the yield is improved.

Owner:东莞市联德企业管理有限公司

An automatic spacing mechanism for cylindrical batteries

PendingCN108987784ASave spaceImprove processing efficiencyAssembling battery machinesFinal product manufactureAgricultural engineeringNozzle

The invention relates to a cylindrical battery automatic spacing mechanism, which relates to the technical field of electronic product processing equipment. Supporting vertical plates are bolted and fixed on the left and right sides of the supporting bottom plate, a cylinder downward pressing guide plate is movably arranged between the supporting vertical plates on the left and right sides througha guide shaft, the middle slot of the cylinder downward pressing guide plate is sleeved on the outer wall of the lower pressing shaft sleeve, and the upper and lower edges of the slot are arranged incontact with the inner side of the outer edge of the lower pressing shaft sleeve; The lower pressure shaft is sleeved and fixed on the support shaft, one end of the support shaft is screwed and fixedin the inside of the connection shaft, the other end of the support shaft is connected with an air inlet connection shaft, the other end of the air inlet connection shaft is connected with a suctionnozzle connection shaft, and the outer end of the suction nozzle connection shaft is connected with a suction nozzle. The utility model saves space, can solve the problem of cell skipping, and has theadvantages of high processing efficiency, simple operation and stronger practicability.

Owner:李峰

Sealing method for performing single sealing on packaging bag by using vacuum sealing machine

ActiveCN111439412APrevent extractionImprove fitPackaging under vacuum/special atmosphereWrapper twisting/gatheringEngineeringPumping vacuum

The invention provides a sealing method for performing single sealing on a packaging bag by using a vacuum sealing machine. The vacuum sealing machine comprises a cover plate assembly, wherein the cover plate assembly is provided with a control panel, a heat sealing device and a vacuumizing device, the heat sealing device and the vacuumizing device are electrically connected with the control panel, the cover plate assembly comprises an upper cover assembly and a lower cover assembly, and the upper cover assembly covers the lower cover assembly and is movably connected with the lower cover assembly. The sealing method at least comprises the steps that a sealing step is carried out, specifically, the control panel controls the heat sealing device to be started to seal the packaging bag; a pre-tightening step is carried out, specifically, the control panel controls the vacuumizing device to be started to perform a vacuumizing action so as to pre-tighten the cover plate assembly and the packaging bag; the execution time of the pre-tightening step is not longer than the execution time of the sealing step, so that the fitting degree of a film at the sealing position is greatly improved,and the sealing position is tightly sealed.

Owner:杭州青晓白科技有限公司

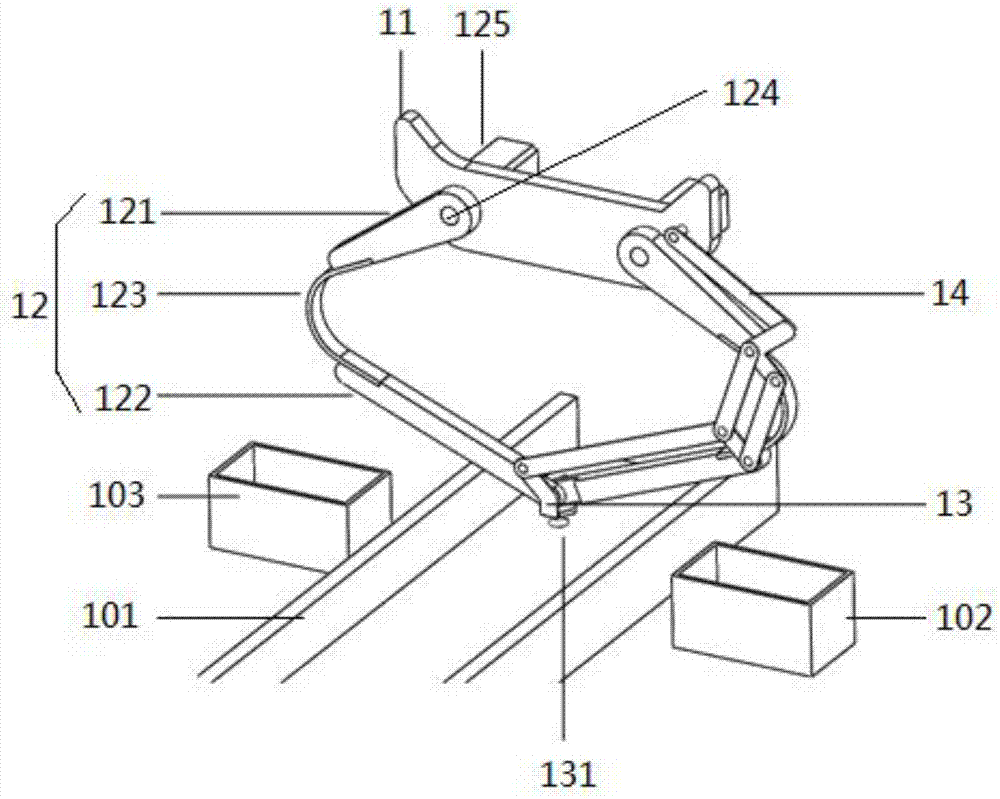

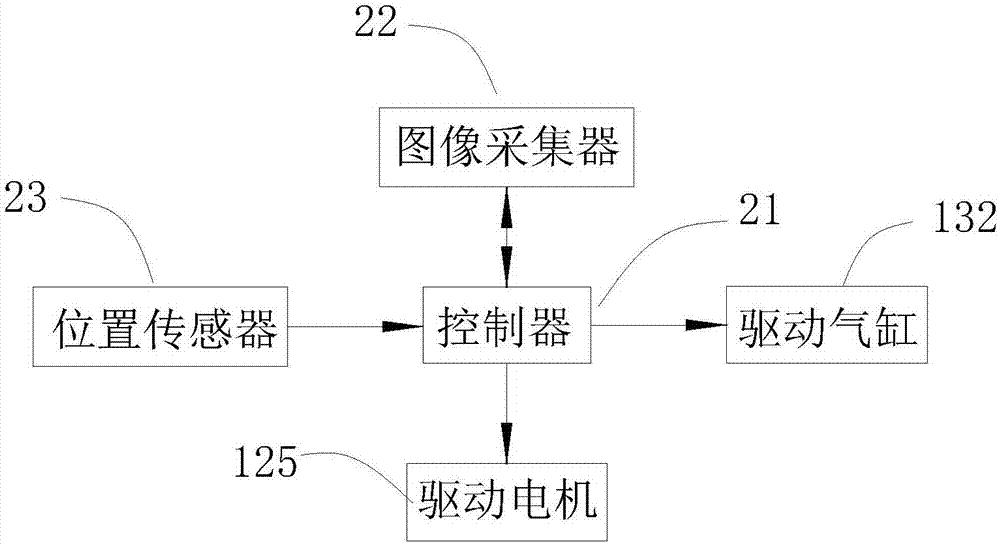

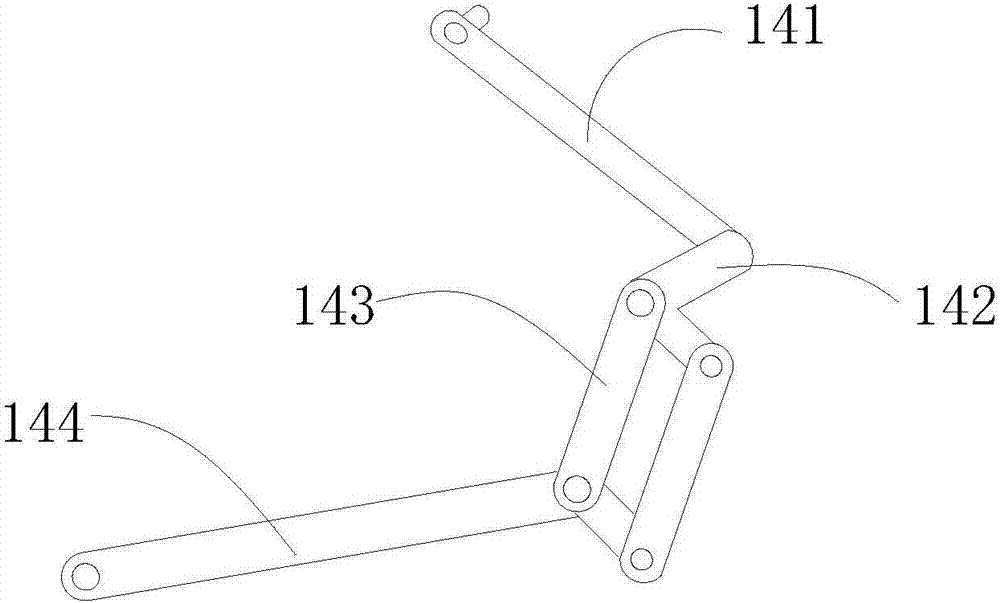

Glass bottle sorting parallel robot with flexible structure

PendingCN107953339AEasy to useGuaranteed horizontal movement without inclinationProgramme-controlled manipulatorControl systemDrive motor

The invention discloses a glass bottle sorting parallel robot with a flexible structure. The glass bottle sorting parallel robot is crossed over a conveying bench, and comprises a sorting mechanism and a control system. The sorting mechanism comprises a stationary platform, mechanical arms, a moving platform and a linkage mechanism. The mechanical arms comprise two sets which can be relatively arranged in a rhombus shape, the mechanical arms comprise flexible joints, and each mechanical arm can rotate in the plane via a driving motor. The moving platform is vertically arranged and hinged to free ends of the two mechanical arms, and the bottom of a grabbing platform is provided with a pneumatic sucker connected with a driving cylinder. The linkage mechanism is disposed at an outer side of any one mechanical arm and linked to the moving platform for driving the moving platform to maintain a vertical state. The control system is used for controlling the robot to carry out sorting work. The gap, friction and impact problems caused by a traditional kinematic pair are solved, horizontal aclinal movement of the moving platform is always ensured, grabbing and disposing are stationary, therobot is suitable for sorting fragile products, and working efficiency is improved.

Owner:INST OF APPLIED MATHEMATICS HEBEI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com